Page 1

SERVICE MANUAL

No. S5407XLHF102B

HI FI COMPONENT SYSTEM

XL-HF102B

XL-HF102B Hi Fi Component System consisting of

XL-HF102B (main unit) and CP-HF102 (speaker system).

In the interests of user-safety (Required by safety regulations

in some countries) the set should be restored to its original

condition and only parts identical to those specified be used.

This audio system supports devices with Android 4.1, Jelly Bean and higher.

For device with a lower Android version, refer the operation manual of the device for recommended app (application).

XL-HF102B

MODEL

CONTENTS

PRECAUTIONS FOR USING LEAD-FREE SOLDER

CHAPTER 1. GENERAL DESCRIPTION

[1] Safety Precaution For Service Manual ........ 1-1

[2] Important Service Notes (for U.S.A only) .... 1-1

[3] AC Power Supply Cord ................................ 1-1

[4] Specifications .............................................. 1-2

[5] Names Of Parts ........................................... 1-3

CHAPTER 2. ADJUSTMENTS

[1] CD Section .................................................. 2-1

[2] Version Check ............................................. 2-1

CHAPTER 3. MECHANICAL DESCRIPTION

[1] Disassembly ................................................ 3-1

CHAPTER 4. FLOWCHART

[1] Troubleshooting ........................................... 4-1

CHAPTER 5. MAJOR PART DRAWING

[1] Function Table Of IC.................................... 5-1

[2] FL Display.................................................. 5-13

CHAPTER 6. CIRCUIT DESCRIPTION

[1] Waveforms Of Servo Circuit ........................ 6-1

[2] Voltage......................................................... 6-2

CHAPTER 7. DIAGRAM

[1] Block Diagram ............................................. 7-1

CHAPTER 8. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] Notes On Schematic Diagram ..................... 8-1

[2] Type Of Transistor And LED ........................ 8-1

[3] Schematic Diagram ..................................... 8-2

[4] Chart Of Connecting Wires ......................... 8-7

[5] Wiring Side Of PWB .................................... 8-8

PARTS GUIDE

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

!

SHARP CORPORATION

– 1

This document has been published to be used for

after sales service only. The contents are subject to

change without notice.

Page 2

XL-HF102B

PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

“MAIN, DISPLAY and SMPS PWB” of this model employs lead-free solder.

The LF symbol indicates lead-free solder, and is attached on the PWB and service manuals. The alphabetical

character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks. As the melting point of lead-free solder (Sn-Ag-Cu) is

higher than the lead wire solder by 40 C, we recommend you to use a dedicated soldering bit, if you are not familiar

with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

o

3. Soldering

As the melting point

o

C, and as it has poor solder wet ability, you may be apt to keep the soldering bit in contact with the PWB for

by 40

of lead-free solder (Sn-Ag-Cu) is about 220

o

C which is higher than the conventional lead solder

extended period of time. However, since the land may be peeled off or the maximum heat-resistance temperature of

parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corrected. Make sure to turn on and

off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Ref No.

PWB-A

PWB-B

*NOTE: Please refer to Parts Guide for PWB Service Category

Parts No.

92LPWB9056MANS

RUiTZ90566AW01

MAIN (A1) / DISPLAY (A2)

SMPS

Description

i

Page 3

CHAPTER 1. GENERAL DESCRIPTION

XL-HF102B

1 – 1

– 3

Page 4

XL-HF102B

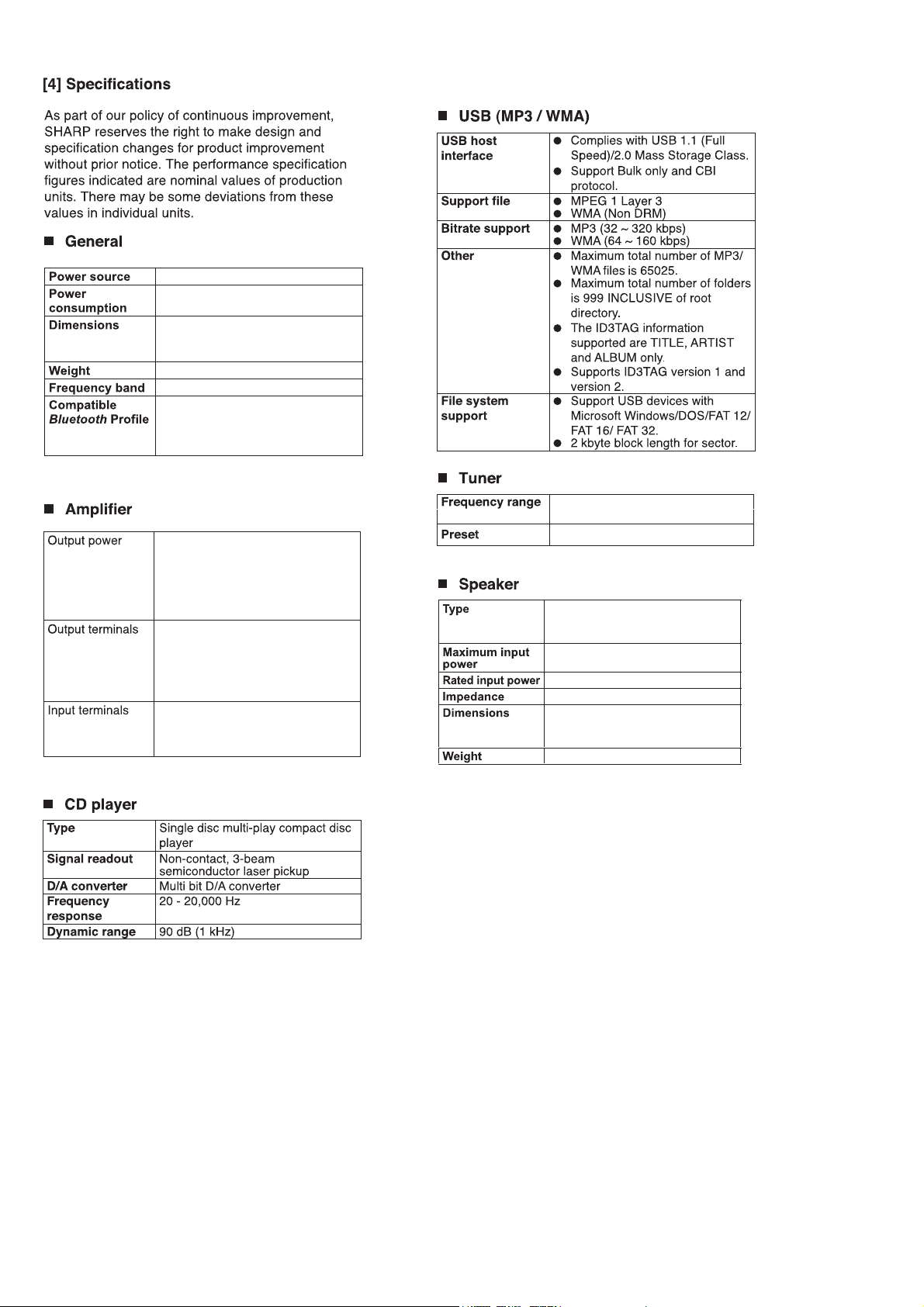

AC 100 - 240 V ~ 50/60 Hz

Power on: 22 W

Width: 8 - 1/2” (216 mm)

Height: 3 - 4/5” (96 mm)

Depth: 11 - 1/4” (285 mm)

4.6 lbs. (2.1 kg)

2.400GHz - 2.480GHz

A2DP (Advanced Audio Distribution

Profile), AVRCP (Audio/Video

Remote Control Profile)

Bluetooth 2.1 +EDR

RMS:

Total 50 W (25 W per

channel into 6 ohms at 1

kHz, 10% T.H.D.)

FTC:

19 W minimum RMS per

channel into 6 ohms from

20 Hz to 20 kHz, 1% T.H.D.

Speakers: 6 ohms

20Hz - 20kHz

Subwoofer Pre-out (audio signal):

200 mV/10 k ohms at 70 Hz

Headphones: 16 - 50 ohms

(recommended: 32 ohms)

Audio In (audio signal):

500 mV/47 k ohms

Line in (Analogue input):

500 mV/47 k ohms

FM: 87.5 - 108.0 MHz

AM: 530 - 1,710 kHz

40 (FM and AM station)

2-way type speaker system

2” (5 cm) tweeter

4” (10 cm) woofer

50 W

25 W

6 ohms

Width: 5-1/2” (139 mm)

Height: 10-3/8” (264 mm)

Depth: 6-1/6” (154 mm)

3.71 lbs. (1.7 kg)/each

– 4

1 – 2

Page 5

XL-HF102B

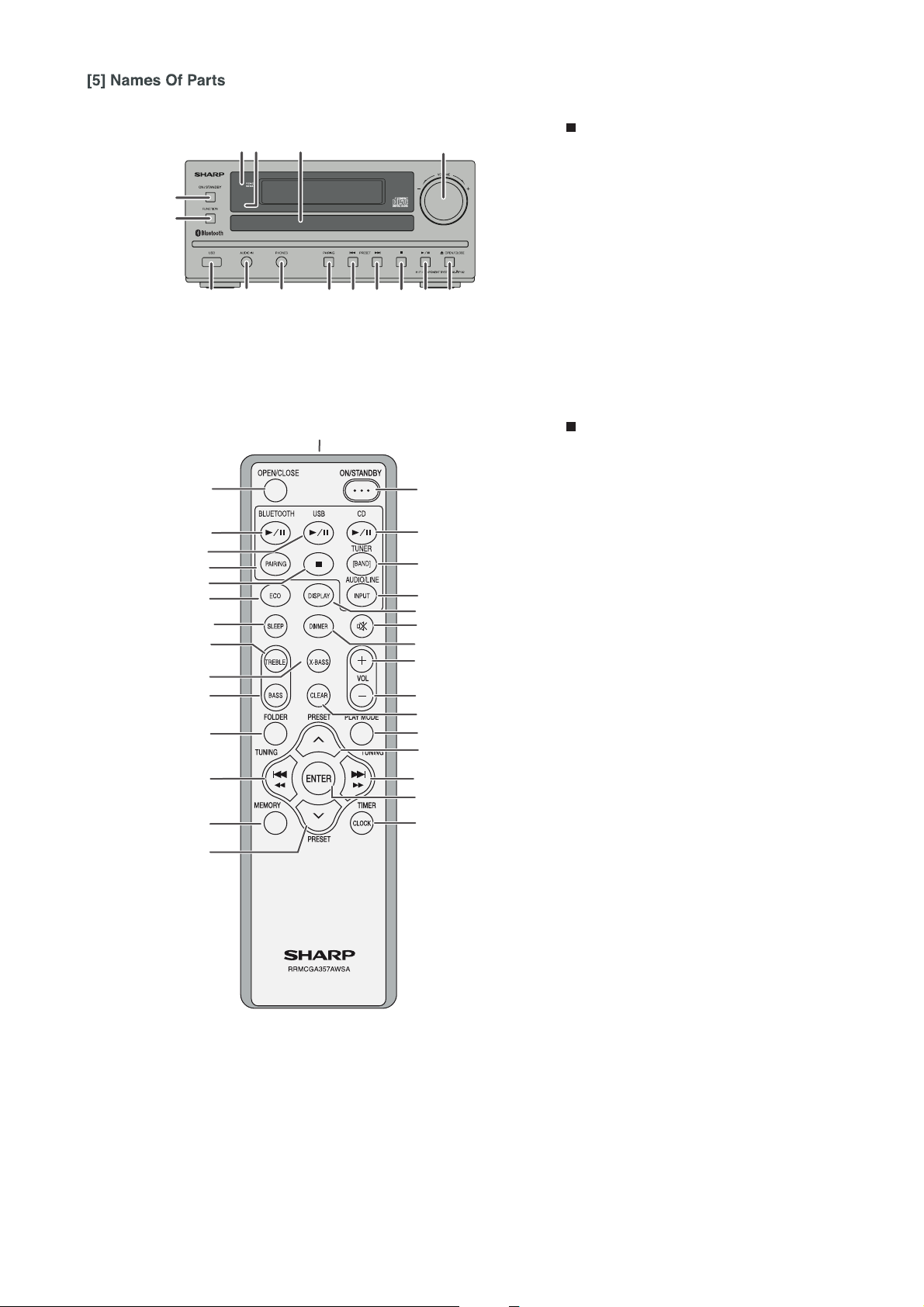

2 3

5

6

9

8

7

1110 12

13

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

4

14 15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1. Remote sensor

2. Timer indicator

3. Disc Tray

4. Volume Control

5. ON/STANDBY Button

6. FUNCTION Button

7. USB Terminal

8. Audio In Jack

9. Headphone Jack

10. Pairing Button

11. Tuner Preset Down, CD/USB Skip Down Button

12. Tuner Preset Up, CD/USB Skip Up Button

13. Disc/USB/Bluetooth Stop Button

14. Disc/USB/Bluetooth Play or Pause Button

15. Disc Tray Open/Close Button

Remote control

1. Remote Control Transmitter

2. Open/Close Button

3. Bluetooth Play / Pause Button

4. USB Play / Pause Button

5. Pairing Button

6. CD/USB/Bluetooth Stop Button

7. Eco Button

8. Sleep Button

9. Treble Button

10. X-Bass Button

11. Bass Button

12. Folder Button

13. Tuning Down, Skip Down, Fast Reverse,

Time Down Button

14. Memory Button

15. Tuner Preset Down Button

16. ON/STANDBY Button

17. CD Play / Pause Button

18. Tuner/Band Button

19. Audio/Line (Input) Button

20. Display Button

21. Mute Button

22. Dimmer Button

23. Volume Up Button

24. Volume Down Button

25. Clear Button

26. Play Mode Button

27. Tuner Preset Up Button

28. Tuning Up, Skip Up, Fast Forward,

Time Up Button

29. Enter Button

30. Clock/Timer Button

1

Front panel

– 5

1 – 3

Page 6

XL-HF102B

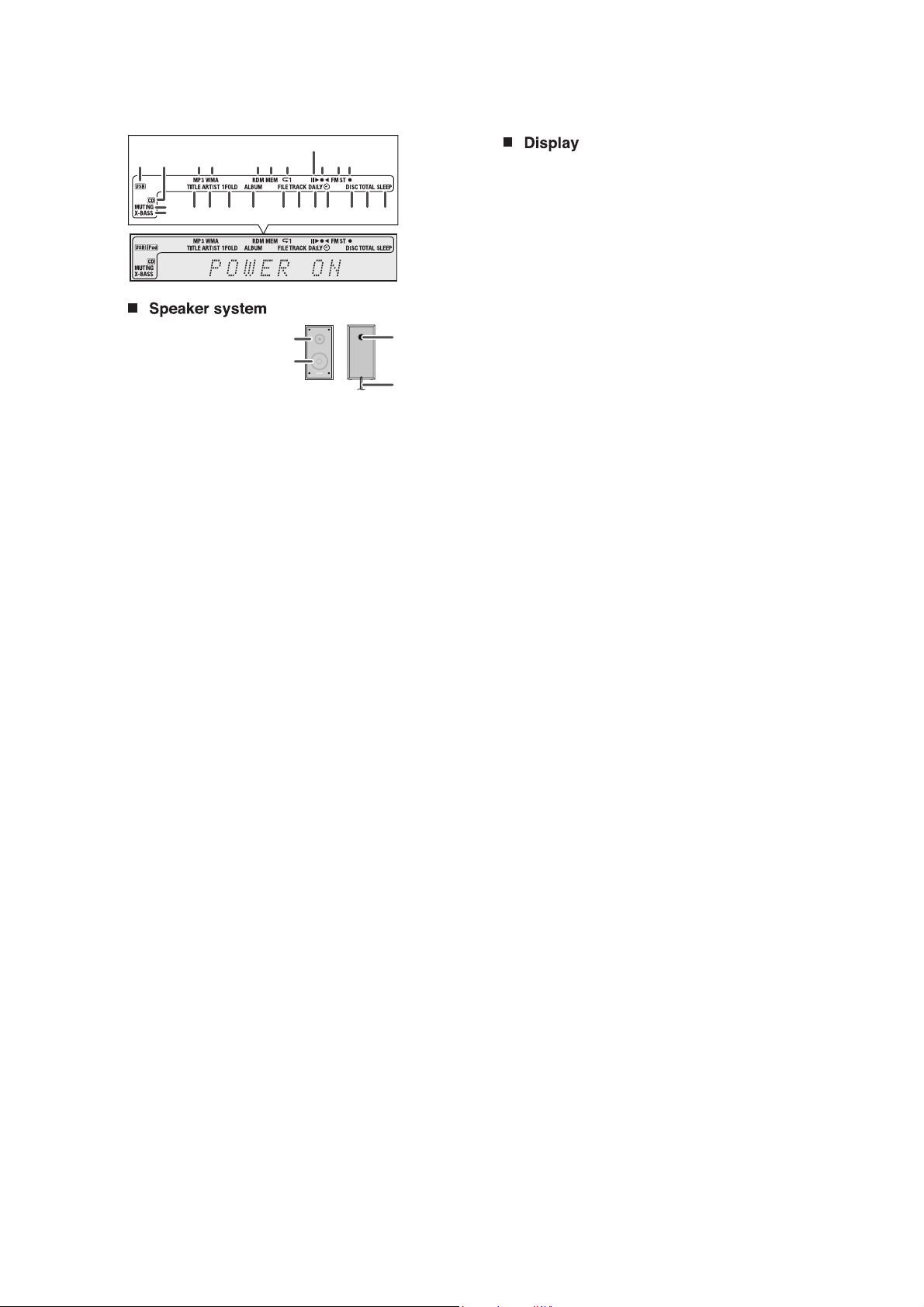

2

1

4

3

1 3 4 5 6

2

12

13

1. Tweeter

2. Woofer

3. Bass Reflex Duct

4. Speaker cable

789 1011

1. USB Indicator

2. CD Indicator

24232220 2119181514 1716

3. MP3 Indicator

4. WMA Indicator

5. RDM (Random) Indicator

6. MEM (Memory) Indicator

7. Repeat Indicator

8. Play/Pause Indicator

9. Tuning FM/Bluetooth status Indicator

10. FM Stereo Mode Indicator

11. Stereo Station Indicator

12. Muting Indicator

13. X-bass Indicator

14. Title Indicator

15. Artist Indicator

16. Folder Indicator

17. Album Indicator

18. File Indicator

19. Track Indicator

20. Daily Timer Indicator

21. Once Timer Indicator

22. Disc Indicator

23. Total Indicator

24. Sleep Indicator

– 6

1 – 4

Page 7

CHAPTER 2. ADJUSTMENTS

[1] CD Section

XL-HF102B

Adjustment

Since this CD system incorporates the following

automatic adjustment functions, readjustment is not

needed when replacing the pickup. Therefore, different

PWBs and pickups can be combined freely.

Each time a disc is changed, these adjustments are

performed automatically. Therefore, playback of each

disc can be performed under optimum conditions.

[2] Version Check

[Version Check Method]

1. During Audio In function, press button (main unit) then press and hold button (main unit) until

software version display appears.

2. Software version displays as below.

Items adjusted automatically

1)

Offset adjustment (The offset voltage between the head

amplifier output and the VREF reference voltage is

compensated inside the IC)

* Focus offset adjustment

* Tracking offset adjustment

2) Tracking balance adjustment

Gain adjustment (The gain is compensated inside the

3)

IC so that the loop gain at the gain crossover frequency

will be 0 dB.)

* Focus gain adjustment

* Tracking gain adjustment

For model XL-HF102B: “ XL-HF102 Vxxx ” Vxxx : Software version

3. [Exiting Version Check]

3.1. While in Version display, press ON / STAND-BY button (main unit).

“RESET” appears at display. The unit will be reset before go to stand-by mode (demo).

3.2.

2 – 1

Page 8

XL-HF102B

CD-ES700/CD-ES77CD-ES700/CD-ES77Service ManualCD-ES700/CD-ES77MarketE

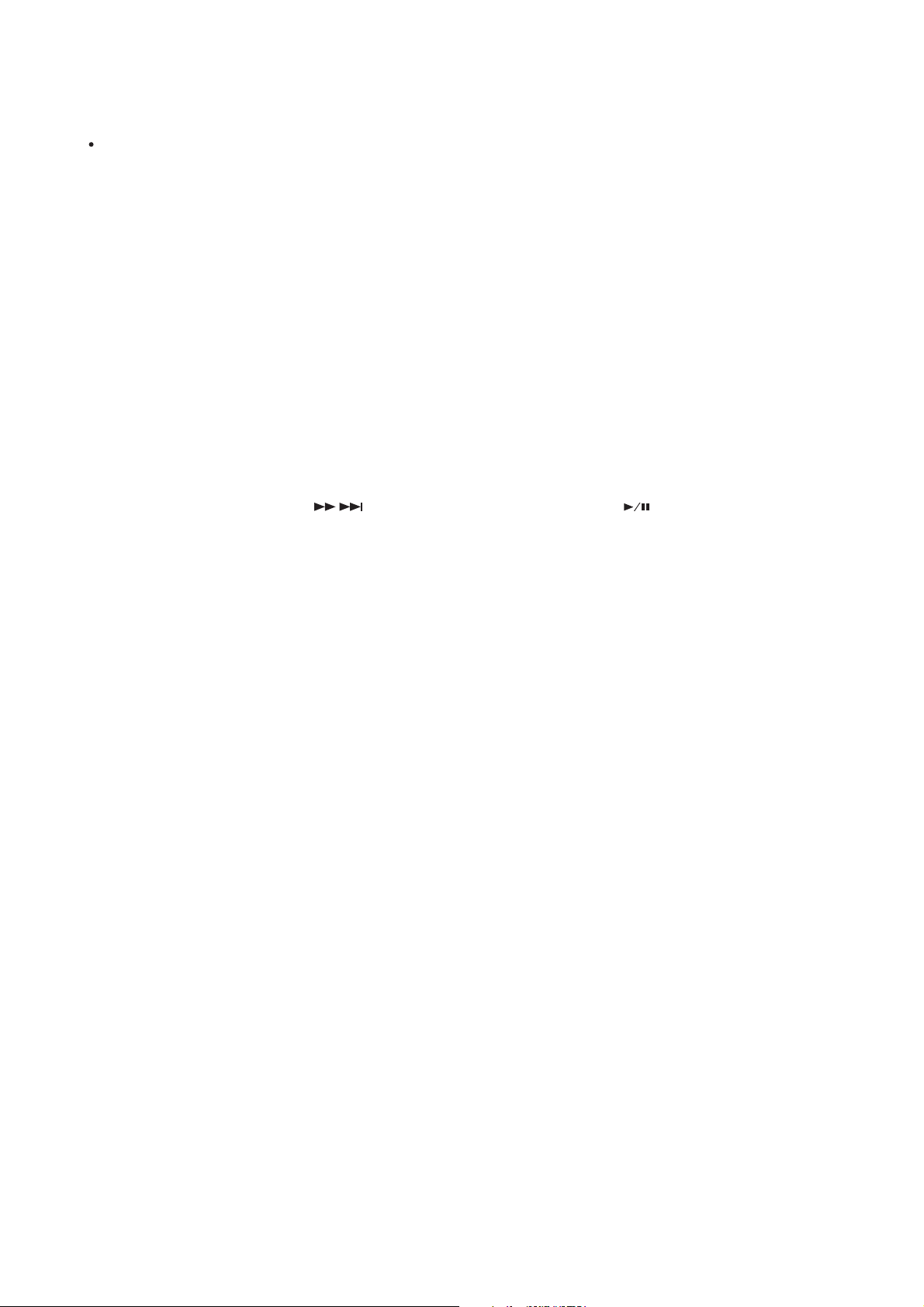

CHAPTER 3. MECHANICAL DESCRIPTION

[1] Disassembly

Caution On Disassembly

Follow the below-mentioned notes when disassembling the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they nee

the unit, be sure to rearrange the leads where they were before disassembling.

d to be removed when disassembling the unit. After servicing

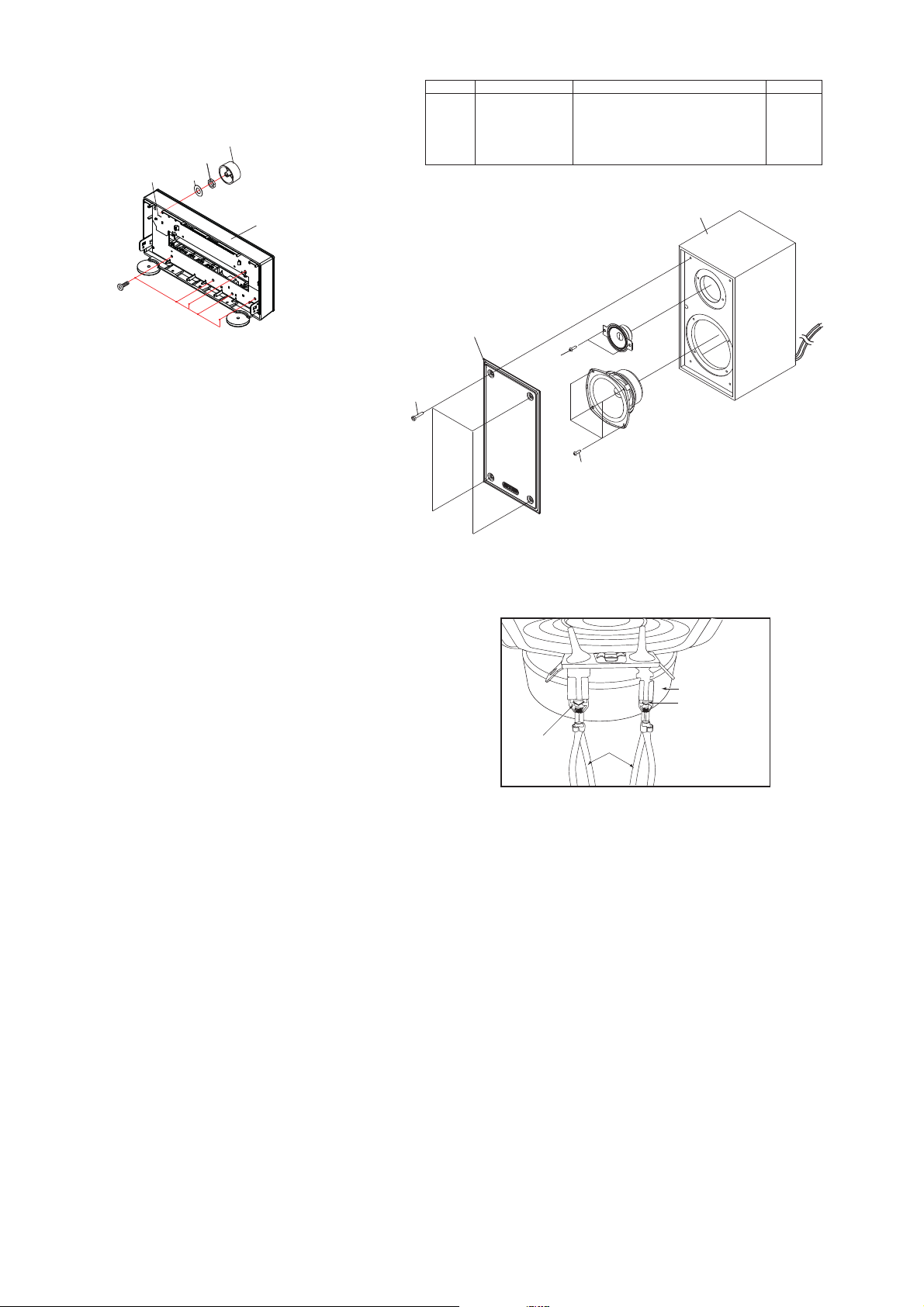

STEP REMOVAL PROCEDURE FIGURE

1 Top Cabinet

1. Screw..................(A1) X 4

1

1. Screw..................(A2) X 1 1

2 Rear Panel

3 Main PWB

4 Front Panel

Assy

5 SMPS PWB

6 CD Mechanism

1. Screw..................(B1) X 8

2. Screw..................(B2) X 1

1. Screw..................(C1) X 1

2. Socket ................(C2) X 2

3. Flat Cable ...........(C3) X 1

4. Socket ................(C4) X 1

1. Screw..................(D1) X 2

2. Screw..................(D2) X 2

3. Screw..................(D3) X 2

4. Screw..................(D4) X 1

5. Socket ................(D5) X 1

6. Flat Cable ...........(D6) X 1

7. Socket ................(D7) X 1

8. Hook ...................(D8) X 2

1. Screw..................(E1) X 2

1. Socket. ................(E2) X 1

1. Screw..................(F1) X 4

1

2

2

2

2

2

2

2

2

2

2

2

2

2

3

2

3

Assy

7 CD Mechanism

1. Screw................. (G1) X 4

4

Unit

8 Display PWB

1. Knob ...................(H1) X 1

5

2. Nut......................(H2) X 1

3. Washer ...............(H3) X 1

4. Screw..................(H4) X 5

(B2)x1

M3x8mm

SMPS PWB

(E2)x1

(C4)x1

(D7)x1

Main

PWB

Hook

(D8)x1

PULL

(D1)x1

M3x6mm

Figure 2

(C1)x1

M3x10mm

(C2)x2

(D6)x1

(C3)x1

(D4)x1

M3x6mm

Front Panel Assy

(D8)x1

(D2)x2

M3x8mm

(D3)x2

M3x6mm

Main PWB

Hook

PULL

M3x6mm

(D1)x1

(D5)x1

M3x8mm

(A1)x2

M3x8mm

Rear Panel

(A1)x1

M3x8mm

(A2)x1

Special

Screw

Top Cabinet

(B1)x7

M3x8mm

(B1)x1

M3x6mm

Figure 1

Front Panel Assy

(A1)x1

M3x8mm

CD Mechanism Assy

CD Mechanism Unit

Special Screw

(F1)x4

CD Mechanism Assy

Figure 3

Figure 4

(G1)x4

Special Screw

SMPS PWB

(E1)x2

M3x8mm

3 – 1

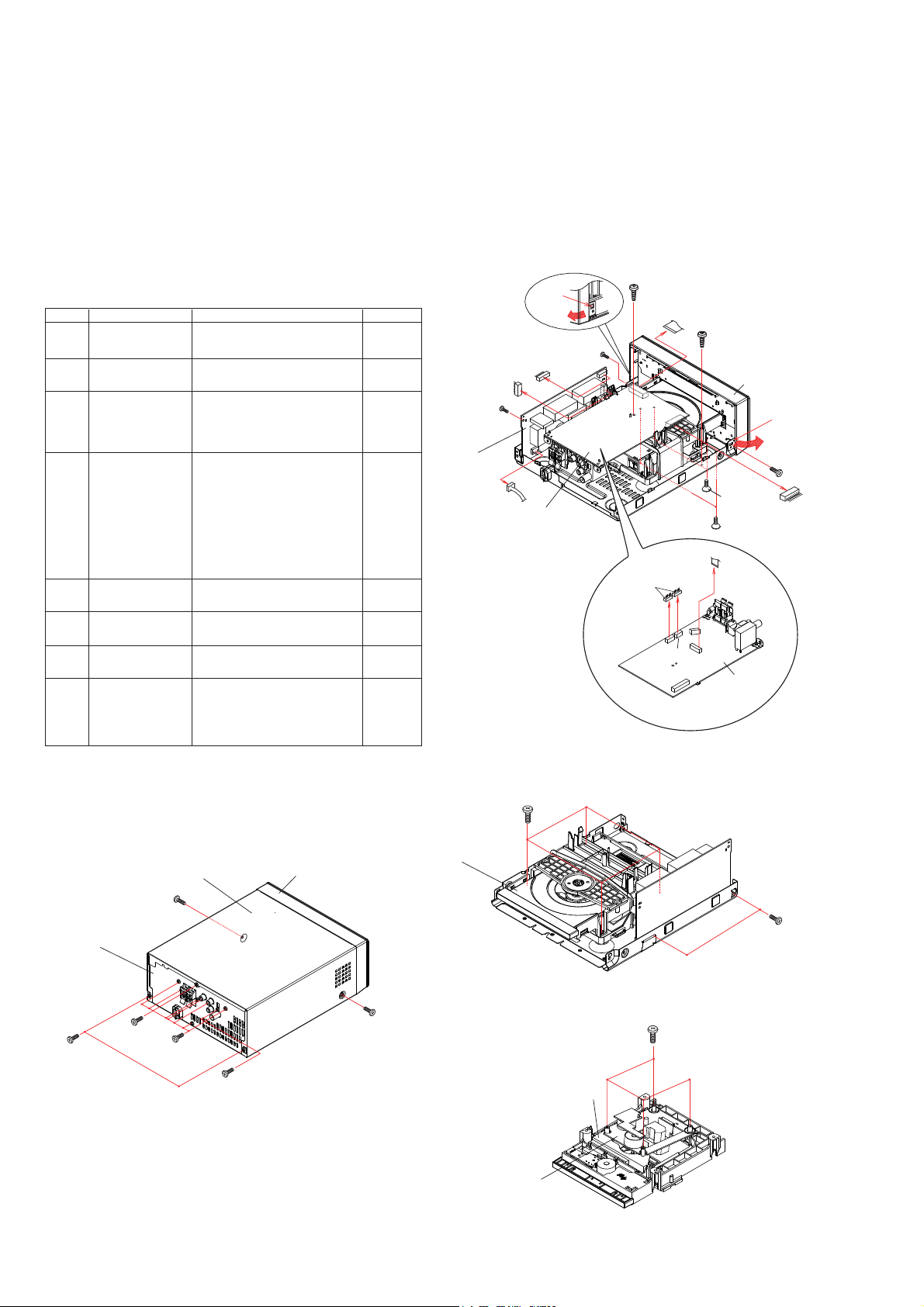

Page 9

Display PWB

(H2)x1

(H3)x1

(H1)x1

XL-HF102B

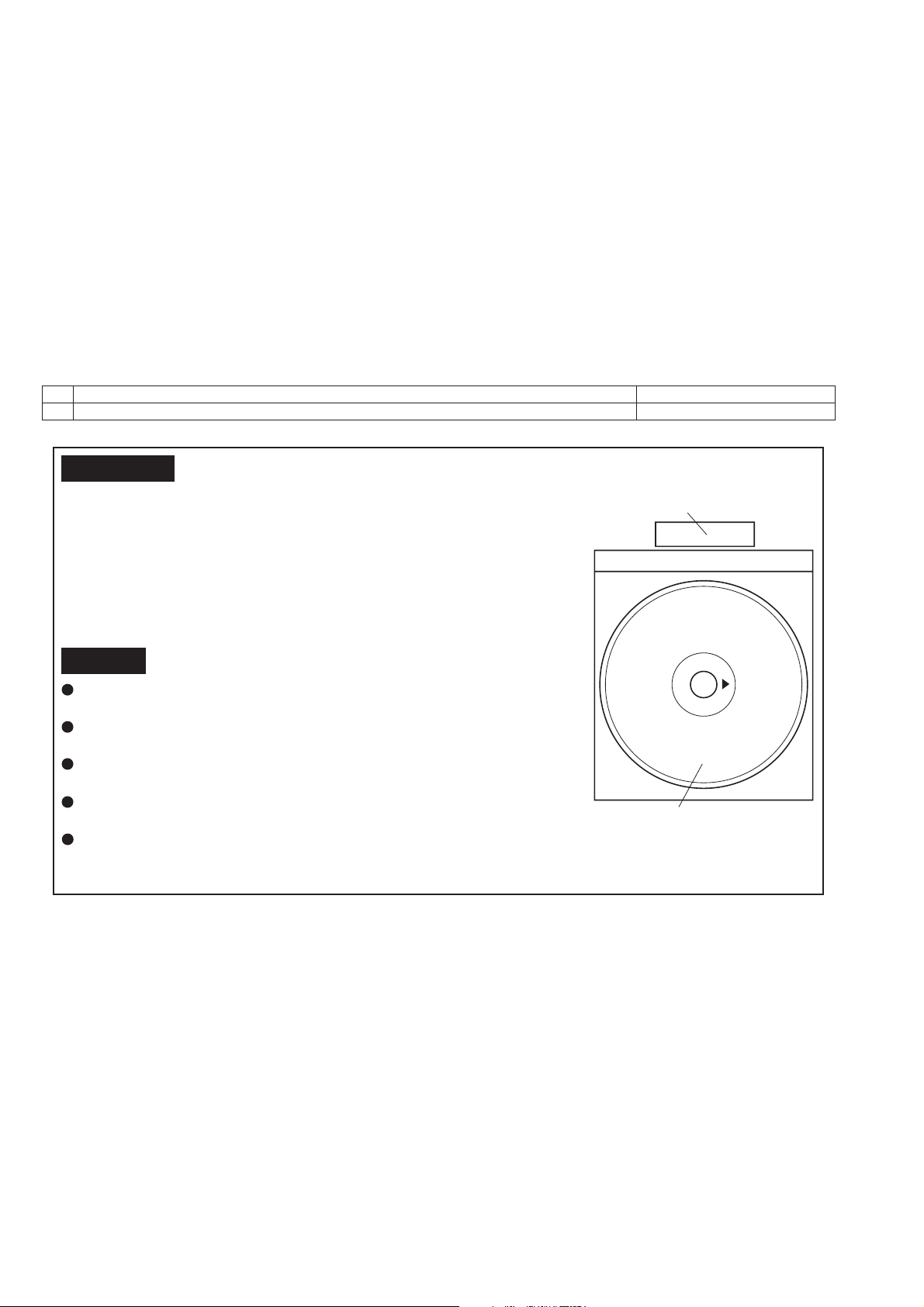

STEP REMOVAL PROCEDURE FIGURE

1 Woofer/Tweeter

1. Screw........................(A1) X 4

2. Net Frame Ass’y.......(A2) X 1

3. Screw........................(A3) X 4

4. Screw........................(A4) X 2

6

6

6

6

(H4)x5

M2.6x8mm

Figure 5

Front Panel Assy

(A1)x4

Special Screw

(A2)x1

Net Frame Ass’y

(A4)x2

M3.5 x 14mm

(A3)x4

M3.5 x 14mm

Speaker Box

Figure 6

SPEAKER UNIT

LOCKING TAB

LOCKING

TAB

CAUTION:

TO REMOVE SPEAKER UNIT, PRESS THESE LOCKING TABS

TO RELEASE SPEAKER WIRES.

SPEAKER

WIRE

3 – 2

Page 10

XL-HF102B

CHAPTER 4. FLOWCHART

[1] Troubleshooting

1. When the CD does not function

The CD section may not operate when the objective lens of the optical pickup is dirty. Clean the objective lens, and

check the playback operation. When this section does not operate even after the above step is taken, check the

following items.

Remove the cabinet and follow the troubleshooting instructions.

“Track skipping and/or no TOC (Table Of Contents) may be caused by build up of dust other foreign matter on the

laser pickup lens. Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned

below.”

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

Parts code

1. CD optical pickup Lens cleaner disc UDSKA0004AFZZ

HOW TO USE

1.

Using the brush in the cleaner cap, apply 1 or 2 drops of the cleaning fluid to the

brush on the CD cleaner disc which has the mark next to it.

2.

Place the CD cleaner disc onto the CD disc tray with the brush side down, then

press the play button.

3.

You will hear music for about 20 seconds and the CD player will automatically stop.

If it still play continuously, press the stop button.

Cleaning fluid

CAUTION

The CD lens cleaner should be effective for 30-50 operations, however if the

brushes become worn out earlier then please replace the cleaner disc.

If the CD cleaner brushes become very wet then wipe off any excess fluid with a soft

cloth.

Do not drink the cleaner fluid or allow it contact with the eyes. In the event of this

happening then drink and / or rinse with clean water and seek medical advice.

The CD cleaner disc must not be used on car CD players or on computer CD-ROM

drives.

All rights reserved. Unauthorized duplicating, broadcasting and renting this product

is prohibited by law.

2. When a CD cannot be played

2.1. Pressing the CD operation key is accepted, but playback does not occur.

1) Focus-HF system check

2) Tracking system check

3) Spin system check

4) PLL system check

Cleaner disc

4 – 1

Page 11

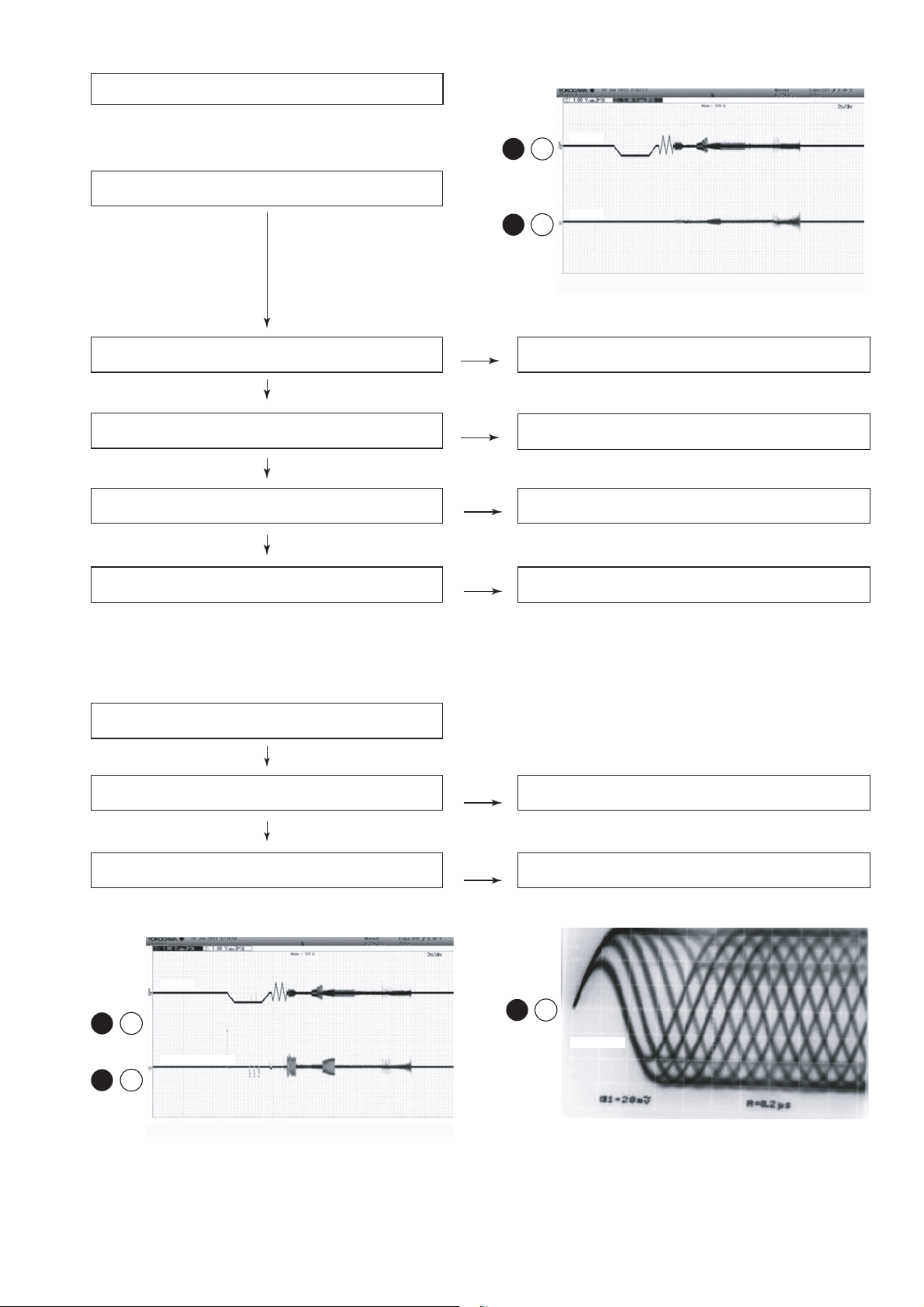

(1) Focus-HF system check.

Although a CD is inserted and the CD cover

is closed, “NO DISC” is displayed.

Press the Open / Close switch without inserting a disc, and try

starting the playback operation.

XL-HF102B

IC1

FDOUT

13

1

IC1

TDOUT

14

2

Figure 1

1. Does the pickup move to the PICKUP-IN Switch position ? Sled motor.

No

Yes

2. Does the focus (lens) move up and down ?

(Waveform drawing Figure 1)

No

Check the focus peripheral circuit.

Yes

3. Is the laser lit ?

No

Check the laser diode driver Q5 peripheral circuit.

Yes

4. Is the turntable rotating ?

No

Spindle motor.

When a disc is loaded, start playback operation.

1. Is focus servo activated ?

(Waveform drawing Figure 2)

No

Pins 16, 15, 14, 13 (2, 3, 6, 7, 8, 9) on IC1.

Check the laser diode driver Q5 peripheral circuit.

2. Is the HF waveform normal ?

(Waveform drawing Figure 3)

FDOUT

IC1

13

1

ANA_MONI1 (TE)

IC1

62

4

Yes

Figure 2

4 – 2

No

If the level is not normal.

IC1

63

7

FRI (RFOUT)

Figure 3

Page 12

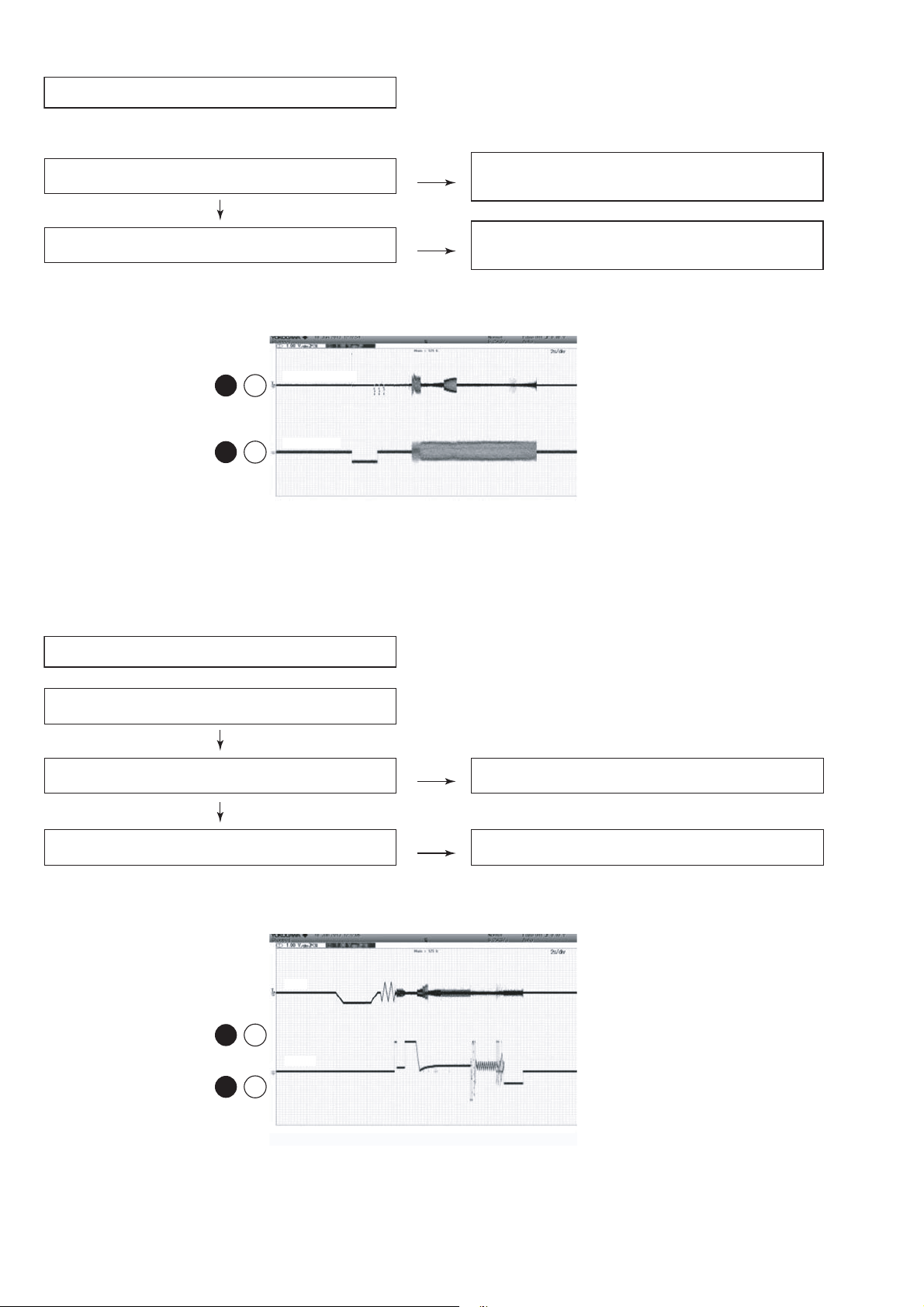

XL-HF102B

(2) Tracking system check.

Check the TE waveform at pin 62 on IC1.

If the waveform shown in Figure 4 appears and soon after NO

DISC appears ?

No

“Initialization” is possible, but play is not possible ?

IC1

ANA_MONI1 (TE)

62

4

IC1

FRI (RFOUT)

63

7

Yes

Yes

Figure 4

The tracking servo is not activated.

Check the peripheral circuits at pins 16, 15, 14, 13 on IC1 and

CNP1.

A normal jump operation cannot be completed or the begining of

the track cannot be found.

Check the around pin 14 on IC1.

(3) Spin system check.

Press the OPEN/CLOSE switch without inserting a disc, and

then try starting the play operation.

1. The turntable rotates a little ?

(Waveform drawing Figure 5)

No

2. The turntable does not rotate.

FDO

IC1

13

1

SPDO

IC1

16

3

Yes

The spin driver circuit is OK.

Check around pin 16 on IC1, pins 5 and 6 on CNP2.

Figure 5

4 – 3

Page 13

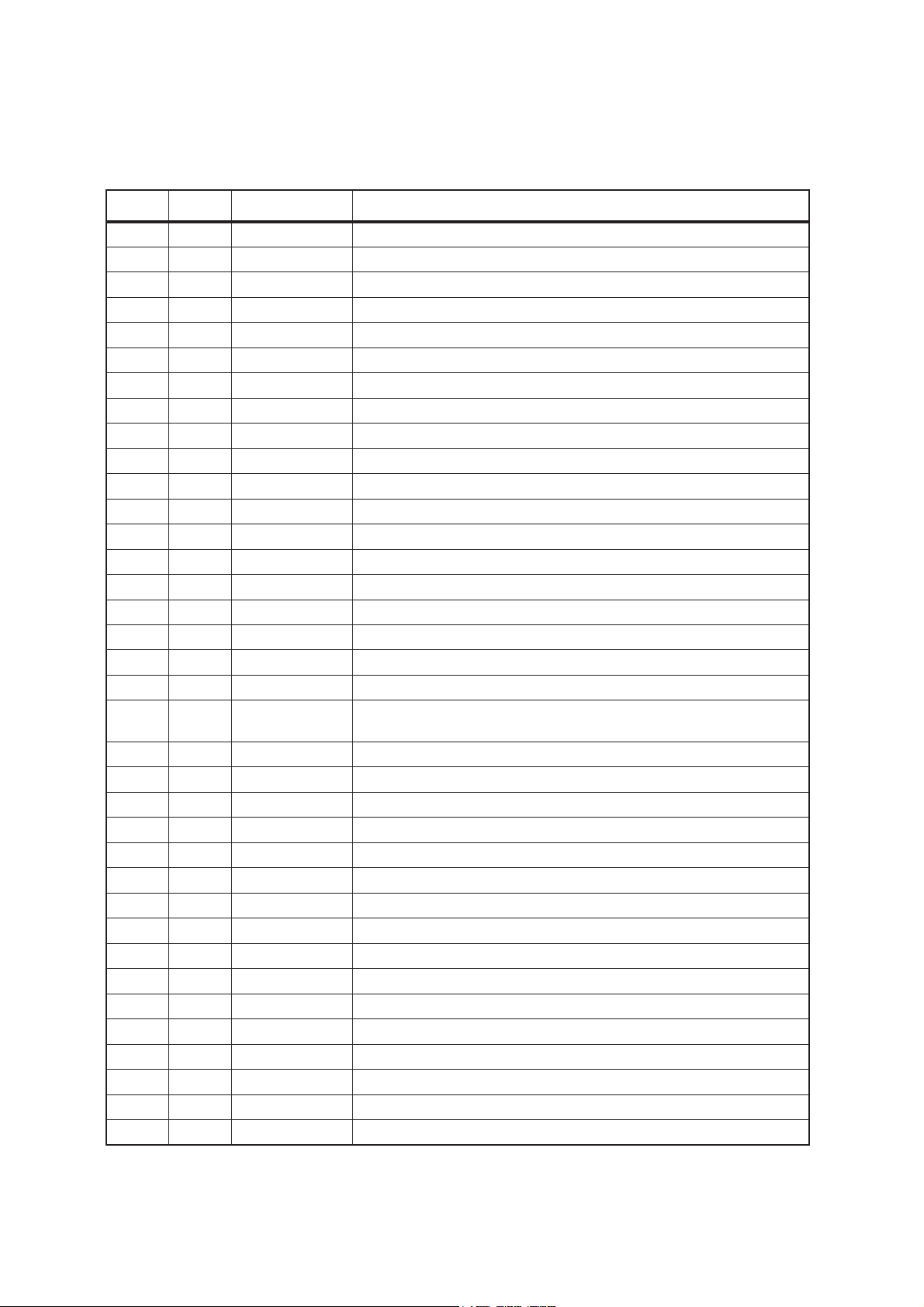

CHAPTER 5. MAJOR PART DRAWING

[1] Function Table Of IC

IC901 VHISTA339BW-1 : POWER AMPLIFIER IC (1/2)

noitpircseDemaNepyTniP

1 GND GND_SUB Substrate ground

2 I SA I

3 I TEST_MODE This pin must be connected to ground (pull-down)

4 I/O VSS Internal reference at V

5 I/O VCC_REG Internal V

6 O OUT2B Output half bridge 2B

7 GND GND2 Power negative supply

8 Power VCC2 Power positive supply

9 O OUT2A Output half bridge 2A

10 O OUT1B Output half bridge 1B

11 Power VCC1 Power positive supply

12 GND GND1 Power negative supply

13 O OUT1A Output half bridge 1A

14 GND GND_REG Internal ground reference

15 Power VDD Internal 3.3 V reference voltage

16 I CONFIG Paralleled mode command

17 O OUT3B / FFX3B PWM out Ch3B / external bridge driver

18 O OUT3A / FFX3A PWM out Ch3A / external bridge driver

19 O EAPD / OUT4B Power down for external bridge / PWM out Ch4B

20 I/O TWARN / OUT4A

21 Power VDD_DIG Digital supply voltage

22 GND GND_DIG Digital ground

23 I PWRDN Power down (pull-up)

24 Power

25 I FILTER_PLL Connection to PLL filter

26 GND GND_PLL Negative supply for PLL

27 I XTI PLL input clock

28 I BICKI I

29 I LRCKI I

30 I SDI I

31 I RESET Reset (pull-up)

32 O INT_LINE Fault interrupt

33 I/O SDA I

34 I SCL I

35 GND GND_DIG Digital ground

36 Power VDD_DIG Digital supply voltage

VDD_PLL Positive supply for PLL

2

C select address (pull-down)

- 3.3 V

CC

reference

CC

Thermal warning from external bridge (pull-up when input)

/ PWM out Ch4A

2

S serial clock

2

S left/right clock

2

S serial data channels 1 and 2

2

C serial data

2

C serial clock

XL-HF102B

Note : I - Input, O - Output

5 – 1

Page 14

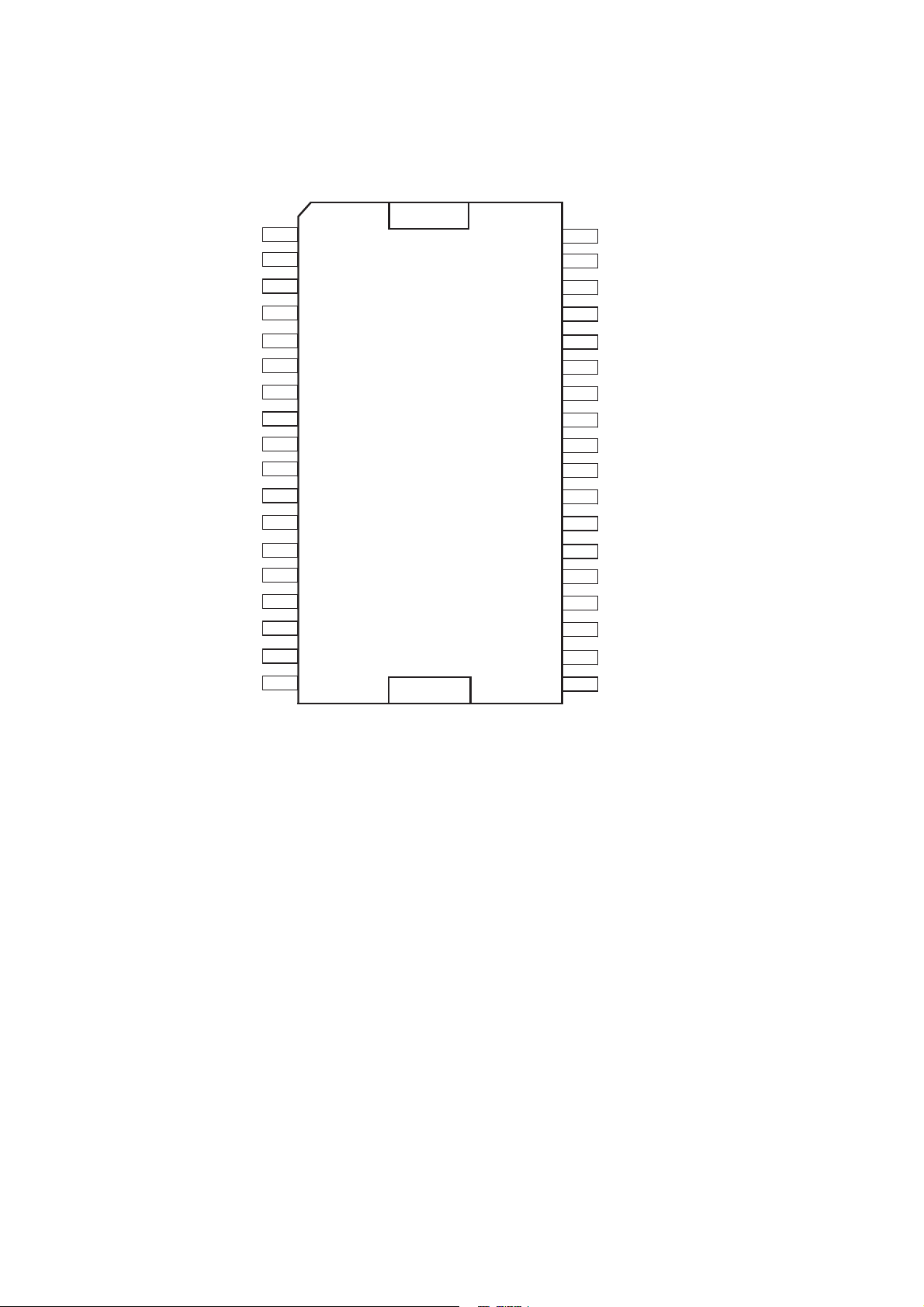

XL-HF102B

IC901 VHISTA339BW-1 : POWER AMPLIFIER IC (2/2)

GND_SUB

SA

TEST_MODE

VSS

VCC_REG

OUT2B

GND2

VCC2

OUT2A

OUT1B

VCC1

GND1

OUT1A

GND_REG

VDD

CONFIG

OUT3B / FFX3B

OUT3A / FFX3A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

VDD_DIG

GND_DIG

SCL

SDA

INT_LINE

RESET

SDI

LRCKI

BICKI

XTI

GND_PLL

FILTER_PLL

VDD_PLL

PWRDN

GND_DIG

VDD_DIG

TWARN / OUT4A

EAPD / OUT4B

Figure 5-1. Pin connection (top view)

5 – 2

Page 15

CHAPTER 6. CIRCUIT DESCRIPTION

[1] Waveform Of CD Circuit

XL-HF102B

IC1

FDOUT

13

1

1

IC1

TDOUT

14

2

4

Figure 1

IC1

63

7

FRI (RFOUT)

4

7

IC1

13

IC1

62

IC1

62

IC1

63

FDOUT

ANA_MONI1 (TE)

Figure 2

ANA_MONI1 (TE)

FRI (RFOUT)

Figure 3

FDO

IC1

13

1

SPDO

IC1

16

3

Figure 4

Figure 5

6 – 1

Page 16

XL-HF102B

[2] IC Voltage

IC 1

Pin No. Voltage (V) Pin No. Voltage (V)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Pin No. Voltage (V) Pin No. Voltage (V)

1

2

3

4

5

6

7

3.44

1.78

1.78

1.67

32.63m

1.75

1.75

168.29m

2.31

26.78m

1.68

1.72

1.70

1.73

1.73

1.82

1.71

5.20

1.05

1.72

1.24

28.37m

31.04m

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

8

9

10

11

12

13

14

3.38

2.75

2.08

2.89

3.41

1.19

1.23

2.59

2.38

2.01

32.95m

53.34m

2.37

3.17

2.43

33.71m

5.20

29.46m

27.30m

2.68

2.61

92.67m

102.96m

Pin No. Voltage (V) Pin No. Voltage (V)

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

IC 2

Pin No. Voltage (V) Pin No. Voltage (V)

15

16

17

18

19

20

21

3.36

2.36

2.23

2.30

2.01

47.26m

47.58m

49.60m

39.88m

1.72

3.38

2.13

2.49

50.13

3.38

1.67

2.76

2.66

2.96

1.93

5.19

1.08

3.13

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

22

23

24

25

26

27

28

1.82

30.60m

28.63m

3.37

3.38

41.59m

1.69

1.69

1.69

3.37

3.37

1.19

30.68m

49.87m

1.77

2.19

34.69m

1.86

5.16

5.17

1.72

1.72

3.38

Pin No. Voltage (V)

1

2

3

4

5

6

7

8

7.36

7.30

7.11

28.09m

7.11

7.30

7.36

14.47

IC401

Pin No. Voltage (V) Pin No. Voltage (V)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

210.96m

111.47m

55.71m

46.64m

115.07m

27.08m

28.26m

28.43m

14.46

36.67m

97.85m

103.39m

142.87m

72.80m

62.42m

14.49

IC402IC300

1

2

3

4

5

6

7

8

7.47

6.43

6.43

45.94m

5.59

5.59

7.42

14.55

6 – 2

Page 17

SOC IC

IC 600

XL-HF102B

IC 601

Pin No. Voltage (V) Pin No. Voltage (V) Pin No. Voltage (V)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

1.19

2.56

2.85

3.31

3.31

2.71

3.26

3.28

2.42

2.07

1.67

2.48

2.12

2.16

2.33

2.33

3.30

1.30

1.07

3.12

3.24

1.80

1.88

2.75

1.90

49.10m

34.40m

2.13

2.19

2.56

2.89

32.75n

29.03n

2.68

2.50

3.30

50.46n

1.27

1.66

1.52

2.10

1.86

1.04

3.33

3.31

3.30

2.94

3.27

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

31.99m

3.15

3.32

1.12

2.26

2.00

1.28

3.35

45.09m

46.59m

5.19

1.28

44.93m

3.36

1.47

2.62

74.64m

493.60m

31.73

3.30

2.910

2.96

30.31m

3.31

27.28m

3.32

1.72

2.27

56.97m

15.28m

8.58m

8.13m

1.29

3.32

8.23m

7.67m

7.15m

7.22m

7.19m

7.79m

7.80m

7.48m

7.48m

7.21m

7.38m

7.37m

7.38m

27.87m

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

3.31

28.73m

28.29m

28.56m

28.54m

28.50m

28.55m

28.61m

27.58m

9.92m

28.86m

3.31

29.72m

75.76m

2.31

76.37m

21.11m

30.23m

28.53m

28.40m

28.81m

28.90m

28.86m

28.75m

28.67m

1.29m

3.31

27.17m

363.87m

2.17

2.79

1.83

2.35

2.07

3.15

2.74

28.69m

3.30

31.25m

1.70

27.41m

3.33

1.70

31.59m

3.14

1.67

1.68

1.68

Pin No. Voltage (V)

1

2

3

4

5

6

7

8

Pin No. Voltage (V)

1

2

3

4

5

6

7

8

43.83m

44.01m

44.13m

44.67m

2.73

2.62

45.47m

3.32

IC 604

2.49

1.41

1.25

45.50m

1.23

1.92

1.39

3.31

6 – 3

Page 18

XL-HF102B

IC 700

Pin No. Voltage (V) Pin No. Voltage (V)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

32.42

4.17

30.63

32.44

29.85

27.85

25.95

27.77

26.08

25.22

22.49

27.89

27.79

25.22

23.64

28.83

27.72

30.22

27.83

30.34

25.19

22.73

28.22

33.00

30.72

26.82

28.39

25.08

24.30

25.81

26.66

30.81

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

30.86

30.89

30.85

30.92

30.87

30.87

30.87

30.87

30.87

30.88

30.86

30.88

30.87

30.87

30.88

33.20

470.42m

1.48

1.86

3.00

2.99

2.99

481.82m

3.00

490.72m

478.91m

28.46

28.50

28.41

23.07

25.90

25.91

IC 802

Pin No. Voltage (V)

1

2

3

Pin No. Voltage (V)

1

2

3

4

5

Pin No. Voltage (V)

1

2

3

4

5

5.21

3.32

27.44m

IC 804

3.92

46.86m

3.91

38.36m

3.35

IC 805

3.31

27.70m

3.35

42.69m

1.28

IC 803

Pin No. Voltage (V)

1

2

3

4

5

6

7

8

Pin No. Voltage (V)

1

2

3

4

5

11.45

18.07

8.86

98.80m

100.43m

491.49m

9.11

4.86

IC 806

3.92

47.59m

3.90

43.37m

3.32

IC 901

Pin No. Voltage (V) Pin No. Voltage (V)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

28.35m

28.37m

9.69m

14.70

18.02

3.98

33.74m

18.03

4.81

5.10

33.66m

18.04

6.73

47.03m

3.37

18.29

1.34

1.64

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

3.35

3.78

3.35

33.91m

3.30

3.29

512.43m

29.17m

2.29

2.36

2.13

2.40

3.32

3.34

3.24

3.24

30.37m

3.33

Pin No. Voltage (V)

1

2

3

4

5

6

7

8

6 – 4

IC 902

7.47

6.42

6.42

28.75m

5.58

5.58

7.40

14.48

Page 19

CHAPTER 7. DIAGRAM

5

6

2

34

31

30

19

36

35

18

64

63

10

8

11214

5

2

15

10

6

9

10

13

R +

R-CH

L-CH

2

3295

69

70

1

[1] Block Diagram

XL-HF102B

16.9344MHz

PICK UP

AUDIO IN

LINE IN

JACK

L-CHL-CH

TUNER

R-CH

R-CH

PACK

MUX

R-CH

IC

74HC4052

L-CH

EEPROM

45

TUNER RESET

53

SDA

48

49

CD DSP IC

BU9543KV-SE2

z

1

32

16

11

.768kH

32

54

SCL

14

CD DATA

16

CD BCLK

15

CD LRCK

30

CD CLK

21

CD RST

CD SDA

23

CD SCL

24

12

UART_TX

UART_RX

14

16

BT_LDO_EN

11

D +

D -

FLASH DO

FLASH D1

FLASH D2

L-CH

136

FLASH D3

FLASH CS

FLASH CLK

R-CH

139

OPTEK IC

OTK5268

EY 2

K

OWER ON

P

KEY 1

FL RST

FL CS

FL SCK

ST

R

FL

36

4

53

54

28

29

25

75

76

AMP RST

AMP PWRDN

SDA

SCL

LRCK

BCLK

MCLK

24MHz

31

23

33

34

29

28

27

AMP IC

STA339BW

L +

L -

6Ω

25W/CH

FRONT L-CH

6Ω

18

17

20

19

R -

25W/CH

FRONT R-CH

OP-AMP

L +

L -

R -

R +

L DATA

FL SCK

FL CE

F

OP-AMP

L-CH

R-CH

NJM4558

SUB-WOOFER

PRE-OUT

NJM4558

HEADPHONE

USB

TERMINAL

FLASH IC

KEY 1/KEY 2

POWER ON KEY

FL DRIVER IC

ML9208-11

FL DISPLAY

UNIT

OP-AMP

NJM4558

Figure 7-1: BLOCK DIAGRAM

7 – 1

Page 20

XL-HF102B

CHAPTER 8. CIRCUIT SCHEMATICS AND PARTS LAYOUT

[1] Notes On Schematic Diagram

Resistor:

To differentiate the units of resistors, such symbol as

K and M are used: the symbol K means 1000 ohm

and the symbol M means 1000 kohm and the

resistor without any symbol is ohm-type resistor.

Besides, the one with “Fusible” is a fuse type.

Capacitor:

•

To indicate the unit of capacitor, a symbol P is used:

this symbol P means pico-farad and the unit of the

capacitor without such a symbol is microfarad. As to

electrolytic capacitor, the expression “capacitance/

withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): P

olypropylene type

PWB Switch Location

REF. NO DESCRIPTION POSITION

SW701

SW702

SW703

SW704

SW705 FUNCTION

SW706

SW707

VR701

ON/STAND-BY

PLAY / PAUSE

OPEN / CLOSE

STOP

REWIND

FORWARD

VOLUME

ON-OFF

ON-OFF

ON-OFF

ON-OFF

ON-OFF

ON-OFF

ON-OFF

MAX-MIN

Schematic diagram and Wiring Side of P.W.Board

••

for this model are subject to change for

improvement without prior notice.

The indicated voltage in each section is the one

•

measured by Digital Multimeter between such a

section and the chassis with no signal given.

•

Parts marked with “ ” are important for

maintaining the safety of the set. Be sure to replace

these parts with specified ones for maintaining the

safety and performance of the set.

[2] Types Of Transistor And LED

FRONT

VIEW

VDD NC

E C B

(1) (2) (3)

(S) (G)

(D)

KTA1271S

KRC107S

KRC104S

CATHODE

ANODE

VHPM3BR2

1 4

2 3

TOP VIEW

DA1010

GNDOUT

B

(3)

E

(1)

TOP VIEW

EXA701W

EXA720W

EXA726W

TOP

VIEW

KTC3875

C

(2)

B5782CTK7228TSP

8 – 1

Page 21

[3] Schematic Diagram

A

B

C

XL-HF102B

D

E

F

G

H

1

2 3 4 5 6

Figure 8-1: MAIN SCHEMATIC DIAGRAM (1/2)

7

8 9 10 11 12

8 – 2

Page 22

XL-HF102B

A

B

C

D

E

F

G

NOT CONNECTED

H

1

2 3 4 5 6

Figure 8-2: MAIN SCHEMATIC DIAGRAM (2/2)

7

8 9 10 11 12

8 – 3

Page 23

XL-HF102B

A

B

C

D

E

F

G

H

1

2 3 4 5 6

Figure 8-3: MAIN (CD SECTION) SCHEMATIC DIAGRAM

7

8 9 10 11 12

8 – 4

Page 24

XL-HF102B

A

B

C

!

D

701

E

F

TO

(CNP750)

MAIN PWB

G

H

1

2 3 4 5 6

7

HEADPHONE

8 9 10 11 12

Figure 8-4: DISPLAY SCHEMATIC DIAGRAM

8 – 5

Page 25

[4] Chart Of Connecting Wires

XL-HF102B

A

B

TUN401

ANTENNA IN

LINE IN

C

SUBWOOFER

PRE-OUT

L-CH (+/-)

D

SPEAKER JACK

(TERMINAL)

R-CH (+/-)

SO901

JK300 JK401

1

2 3 4 5

BI800

6

8

7

MAIN PWB-A1

CNP1

CNP4

5 4 3 2 1

CNP2

1 2 3 4 5 6

11

CNP750

1

4 3 2 1

CNP350

1

CNP701A

21

11

1

FFC701

RD

YL

GY

WH

BK

RD

BK

WH

RD

BK

WH

BL

TO

CN3

SMPS PWB-B

FFC701

RD

BL

BK

BL

12345

1

2

3

45

1

CNP701B

21

Bi702

DISPLAY PWB-A2

CNS4

E

FROM

DISPLAY PWB-A2

BI702

BLBKBL

RD

CNS702

4 3 2 1

5 4 3 2 1

GY

CD TRAY MOTOR

SECTION

1 2 3 4 5 6

RD

GYWHWH

RDBLWH

TO

CD MOTOR

SECTION

CNS2

WH

WH

BL

TO

CD MECHANISM

SECTION

CNS1

TO

CR2

(RING CORE WITH

1 TURN)

BL

WH

BK

RD

WH

BK

RD

(SHIELD WIRE)

1

BI750

BK

WH

GY

YL

RD

LUG75

JK702

HEADPHONE

JK701

AUDIO IN

F

CN1

N L

WH

BL

BK

RD

G

Y CORD

WER SUPP

O

C P

A

, 60Hz

V

H

120

L

RD

BK

BK

7

7654321

6

5

43

21

CN2

4 3 2 1

CN3

(This PWB is not serviceable item)

SMPS PWB-B

CR1

(RING TYPE WITH

2 TURNS)

BK

WH

BK

JK700

USB

BK

CHASSIS

1

2 3 4 5 6

7

8 9 10 11 12

Figure 8-5: CHART OF CONNECTING WIRES

8 – 6

Page 26

XL-HF102B

[5] Wiring Side Of PWB

A

B

C

D

MAIN PWB-A1

E

F

G

TOP VIEW

Lead-free solder indication

H

Lead-free solder is used in the MAIN PWB.

Refer to “Precautions for handling lead-free solder” for instructions

and precautions.

1

2 3 4 5 6

Figure 8-6: WIRING SIDE OF MAIN PWB (TOP VIEW)

7

8 9 10 11 12

8 – 7

Page 27

XL-HF102B

A

B

C

D

MAIN PWB-A1

E

F

G

BOTTOM VIEW

Lead-free solder indication

H

Lead-free solder is used in the MAIN PWB.

Refer to “Precautions for handling lead-free solder” for instructions

and precautions.

1

2 3 4 5 6

Figure 8-7: WIRING SIDE OF MAIN PWB (BOTTOM VIEW)

7

8 9 10 11 12

8 – 8

Page 28

XL-HF102B

A

B

C

DISPLAY PWB-A2

TOP VIEW

D

E

F

G

Lead-free solder indication

Lead-free solder is used in the DISPLAY PWB.

H

Refer to “Precautions for handling lead-free solder” for instructions

and precautions.

BOTTOM VIEW

1

2 3 4 5 6

Figure 8-8: WIRING SIDE OF DISPLAY PWB (TOP & BOTTOM VIEW)

7

8 9 10 11 12

8 – 9

Page 29

PARTS GUIDE

HI FI COMPONENT SYSTEM

XL-HF102B

CONTENTS

[1] INTEGRATED CIRCUITS

[2] TRANSISTORS

[3] DIODES

[4] COILS

[5] CRYSTALS / VIBRATORS

[6] CAPACITORS

[7] RESISTORS

Explanation of capacitors/resistors parts codes

MODEL

XL-HF102B

[8] OTHER CIRCUITRY PARTS

[9] CABINET PARTS / CD MECHANISM

PARTS

[10] SPEAKER BOX PARTS

[11] ACCESSORIES / PACKING PARTS

[12] P.W.B. ASSEMBLY

[13] OTHER SERVICE PARTS

Capacitors

VCC ....................... Ceramic type

VCK ........................ Ceramic type

VCT ........................ Semiconductor type

VC • • MF ............... Cylindrical type (without lead wire)

VC • • MN ............... Cylindrical type (without lead wire)

VC • • TV ................ Square type (without lead wire)

VC • • TQ ............... Square type (without lead wire)

VC • • CY ............... Square type (without lead wire)

VC • • CZ ............... Square type (without lead wire)

VC • • • • • • • • • J .. The 13th character represents capacity difference.

("J" ±5%, "K" ±10%, "M" ±20%, "N" ±30%,

"C" ±0.25 pF, "D" ±0.5 pF, "Z" +80-20%.)

If there are no indications for the electrolytic capacitors, error is ±20%.

Resistors

VRD ....................... Carbon-film type

VRS ........................ Carbon-film type

VRN ....................... Metal-film type

VR • • MF ............... Cylindrical type (without lead wire)

VR • • MN ............... Cylindrical type (without lead wire)

VR • • TV ................ Square type (without lead wire)

VR • • TQ ............... Square type (without lead wire)

VR • • CY ............... Square type (without lead wire)

VR • • CZ ............... Square type (without lead wire)

VR • • • • • • • • • J .. The 13th character represents error.

("J" ±5%, "F" ±1%, "D" ±0.5%.)

If there are no indications for other parts, the resistors are ±5%

carbon-film type.

Explanation of PWB Assembly parts code category

S Category -- Repair ( Component parts of PWB can be replace and repair, PWB no supply )

X Category -- Replacement ( PWB can not be repair. Component parts no supply )

S.X Category -- Repair and Replacement ( PWB can repair and replace )

KG Category -- Revolve repair by Business Center ( Return to Business Center and repair by manufacturer. Component parts no supply )

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with specified ones

for maintaining the safety and performance of the set.

!

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 30

XL-HF102B

NO. PARTS CODE

[1] INTEGRATED CIRCUITS

IC 1

VH IB U95 43 KV -1

IC 2

IC 30 0

IC 40 1

IC 40 2

IC 60 0

IC 60 1

IC 60 3

IC 60 4

IC 70 0

IC 80 2

IC 80 3

IC 80 5

IC 80 6

IC 90 1

IC 90 2

[2] TRANSISTORS

Q3 00

Q3 01

Q3 04

Q4 04

Q4 05

Q4 70

Q4 71

Q4 72

Q4 73

Q4 74

Q4 77

Q6 01

Q7 00

Q7 01

Q7 02

Q7 03

Q7 04

Q8 00

Q8 01

Q8 02

Q8 04

QA 61 0

QA 61 1

QA 62 0

QA 62 2

QA 62 3

[3] DIODES

D3 00

D3 01

D4 00

D4 01

D4 06

D4 07

D7 03

D7 04

D7 05

D7 06

D8 00

D8 01

D8 02

D8 03

D8 09

D8 10

D8 11

D8 12

D8 13

DA 61 0

DA 61 1

DA 61 2

DA 62 0

DZ 80 0

DZ 80 1

DZ 80 2

DZ 80 3

[4] COILS

FB 10 0

FB 10 1

FB 40 1

FB 40 2

FB 70 4

FB 70 5

VH IS A58 88 TR -1

VH IU TC4 58 0E -1

VH IC D40 52 BM -1

VH IU TC4 58 0E -1

VH IO TK5 26 8/ -1

VH IB R24 T0 8F -1

VH IP ST8 22 7U -1

RH -I XA3 89 AW 00

VH IL 920 8A 11 -1

VH IU TC1 11 7Y 33

VH IU P17 07 S+ -1

VH IT CR2 EF 13 -1

VH IB U33 TD 3W G1

VH IS TA3 39 BW -1

VH IU TC4 58 0E -1

Q1

VS KR C10 7S // -1

Q2

VS KT A12 71 Y/ -1

Q5

VS 2S A11 62 GR -1

VS KT C38 75 GR -1

VS KT C38 75 GR -1

VS KR A10 2S // -1

VS KT C38 75 GR -1

VS KT C38 75 GR -1

VS KR C10 4S // -1

VS KT C38 75 GR -1

VS KT C38 75 GR -1

VS KT C38 75 GR -1

VS KT C38 75 GR -1

VS KR A10 2S // -1

VS KR C10 7S // -1

VS KR C10 7S // -1

VS KR A10 7S // -1

VS 2S C27 12 Y/ -1

VS KT C38 75 GR -1

VS KT C38 75 GR -1

VS 2S C27 12 Y/ -1

VS 2S A11 62 GR -1

VS KR C10 4S // -1

VS 2S C22 35 O/ -1

VS KR C10 4S // -1

VS KR C10 4S // -1

VS KR A10 7S // -1

VS KT C28 75 B/ -1

VS KT C28 75 B/ -1

VH DD A10 10 ++ -1

D1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DD A10 10 ++ -1

VH DG S1G LT P+ -1

RH -E XA7 01 WJ QZ

RH -E XA7 01 WJ QZ

RH -E XA7 20 WJ QZ

RH -E XA7 26 WJ QZ

CR 1

RC OR FA0 26 AW ZZ

CR 2

RC OR FA0 15 AW ZZ

RB LN -00 67 TA ZZ

RB LN -00 67 TA ZZ

RB LN -00 70 TA ZZ

RB LN -00 70 TA ZZ

RB LN -02 54 TA ZZ

RB LN -02 54 TA ZZ

PRICE

RANK

AR

AG

AC

AE

AC

BA

AD

AC

AN

AD

AE

AC

AC

AP

AC

AB

AC

AD

AB

AB

AB

AB

AB

AC

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AD

AC

AD

AC

AC

AB

AC

AC

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AG

AD

AA

AA

AA

AA

AB

AB

NEW

MARK

PART

RANK

DESCRIPTION

CD D SP IC

CD D riv er I C

Du al Op er at io nal A mp li fie r IC

An al og Mu lt i / D em ul ti ple xe r IC

Du al Op er at io nal A mp li fie r IC

So C IC, 1 44 P

EE PR OM IC

Re se t I C 2. 7V

Fl as h I C

FL D isp la y Dr ive r IC

Lo w Dro p Re gu lat or I C, 3. 3V 1 A

DC -D C I C, 5 V 3A (M ax . Inp ut V ol tag e= 26 Volts .)

LD O Reg ul at or IC , 1. 3V

CM OS Re gu la to r I C

Po we r A mp li fi er IC

Du al Op er at io nal A mp li fie r IC

NP N Tra ns is to r K RC 10 7S

PN P Tra ns is to r K TA 12 71 Y

Tr an sis to r 2S A11 62 -G R

NP N Tra ns is to r K TC 38 75 GR

NP N Tra ns is to r K TC 38 75 GR

PN P Tra ns is to r K RA 10 2S

NP N Tra ns is to r K TC 38 75 GR

NP N Tra ns is to r K TC 38 75 GR

NP N Tra ns is to r K RC 10 4S

NP N Tra ns is to r K TC 38 75 GR

NP N Tra ns is to r K TC 38 75 GR

NP N Tra ns is to r K TC 38 75 GR

NP N Tra ns is to r K TC 38 75 GR

PN P Tra ns is to r K RA 10 2S

NP N Tra ns is to r K RC 10 7S

NP N Tra ns is to r K RC 10 7S

NP N Tra ns is to r K RC 10 7S

NP N Tra ns is to r 2 SC 27 12

NP N Tra ns is to r K TC 38 75 GR

NP N Tra ns is to r K TC 38 75 GR

NP N Tra ns is to r 2 SC 27 12

Tr an sis to r 2S A11 62 -G R

NP N Tra ns is to r K RC 10 4S

Sw it chi ng P ow er Tr an si sto r 2S C2 235 -0

NP N Tra ns is to r K RC 10 4S

NP N Tra ns is to r K RC 10 4S

PN P Tra ns is to r K RA 10 7S

NP N Tra ns is to r K TC 28 75 GB

NP N Tra ns is to r K TC 28 75 GB

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Si li con D io de , D A1 01 0

Su rf ace M ou nt Re ct if ie r

Ch ip Ze ne r Di ode , 6. 8V 5. 0m A

Ch ip Ze ne r Di ode , 6. 8V 5. 0m A

Ch ip Ze ne r Di ode

Ch ip Ze ne r Di ode

Fe rr ite C or e, Ri ng

Fe rr ite C or e, Ri ng

Fe rr ite B ea d BAL UN

Fe rr ite B ea d BAL UN

Ch ip Co il , Ch oke

Ch ip Co il , Ch oke

Ch ip Co il

Ch ip Co il

1

Page 31

NO. PARTS CODE

[4] COILS

L2

RB LN -01 09 TA ZZ

L1 05

RC OR FA0 40 AW ZZ

L4 00

RB LN -00 77 TA ZZ

L7 00

RB LN -A0 04 AW ZZ

L7 02

RB LN -A0 04 AW ZZ

L8 05

RC IL ZA0 83 AW ZZ

L8 10

RC OR FA0 40 AW ZZ

L9 01

RB LN -00 61 TA ZZ

L9 03

RC IL PA7 60 WJ QZ

L9 04

RC IL PA7 60 WJ QZ

L9 05

RC IL PA7 60 WJ QZ

L9 06

R6 20

R6 21

R6 22

R6 27

R6 34

R6 35

R6 36

R6 37

R6 38

R6 39

R6 50

R7 09

R7 64

R7 65

R7 66

R7 67

R9 02

R9 05

R9 06

R9 07

R9 08

R9 25

R9 26

RC IL PA7 60 WJ QZ

RB LN -A0 16 AW ZZ

RB LN -A0 16 AW ZZ

RB LN -A0 33 AW ZZ

RF IL NA0 29 AF ZZ

RF IL NA0 26 AF ZZ

RF IL NA0 26 AF ZZ

RF IL NA0 26 AF ZZ

RF IL NA0 26 AF ZZ

RF IL NA0 26 AF ZZ

RF IL NA0 26 AF ZZ

RB LN -A0 16 AW ZZ

RF IL NA0 07 AW ZZ

RB LN -00 70 TA ZZ

RB LN -00 70 TA ZZ

RB LN -00 70 TA ZZ

RB LN -00 70 TA ZZ

RB LN -A0 11 AW ZZ

RB LN -A0 11 AW ZZ

RB LN -01 10 TA ZZ

RB LN -A0 11 AW ZZ

RB LN -A0 11 AW ZZ

RF IL NA0 23 AF ZZ

RF IL NA0 23 AF ZZ

[5] CRYSTALS / VIBRATORS

RC RS PA0 40 AW ZZ

X1

X6 01

X6 02

RC RS PA0 37 AW ZZ

RC RS PA0 46 AW ZZ

[6] CAPACITORS

C1

VC KY CZ1 EF 10 4Z

C2

VC KY CZ1 EB 56 2K

C3

VC KY CY1 HB 18 2K

C4

VC KY CY1 HB 10 4K

C5

VC KY CY1 HF 22 4Z

C6

VC KY CZ1 EF 10 4Z

C7

VC KY CZ1 EF 10 4Z

C8

VC KY CZ1 EF 10 4Z

C9

VC KY CZ1 EF 10 4Z

C1 0

VC KY CZ1 EF 10 4Z

C1 1

VC KY CZ1 EF 10 4Z

C1 2

VC KY CY1 HB 10 4K

C1 3

VC KY CY1 HB 10 4K

C1 4

VC KY CZ1 EF 10 4Z

C1 5

VC CC CZ1 HH 22 0J

C1 6

VC CC CZ1 HH 22 0J

C1 7

VC KY CZ1 EF 10 4Z

C1 8

VC KY CZ1 EF 10 4Z

C1 9

VC KY CZ1 EF 10 4Z

C2 0

VC KY CZ1 HB 68 1K

C2 1

VC KY CY1 HB 10 4K

C2 3

VC KY CY1 HB 10 4K

C2 6

VC KY CY1 HB 10 4K

C2 9

VC KY CY1 HB 10 4K

C3 0

VC KY CY1 HB 10 4K

C3 1

VC KY CY1 HB 10 4K

C3 2

VC KY CY1 HB 10 4K

C3 4

VC KY CY1 HB 10 4K

C3 5

VC KY CY1 HB 10 4K

C3 6

VC KY CY1 HB 10 4K

C3 7

VC CC CY1 HH 47 0J

C3 9

VC KY CY1 HB 10 4K

C4 0

C1 07

C1 08

C3 00

C3 02

C3 03

C3 04

C3 05

C3 06

C3 07

C3 08

C3 09

C3 10

C3 13

VC KY CY1 HB 10 4K

VC KY CY1 HB 22 3K

VC KY CY1 HB 10 4K

VC KY CY1 HB 47 3K

VC KY CY1 HB 10 4K

VC KY CZ1 HB 10 2K

VC KY CZ1 HB 10 2K

VC CC CZ1 HH 10 1J

VC CC CZ1 HH 10 1J

VC KY CY1 CB 12 4K

VC CC CZ1 HH 10 1J

VC KY CZ1 HB 22 2K

VC KY CZ1 HB 22 2K

VC KY CY1 EB 10 5K

PRICE

RANK

AA

AC

AB

AB

AB

AF

AC

AB

AA

AA

AB

AB

AB

AB

AB

AB

AB

AB

AA

AA

AA

AA

AA

AA

AB

AB

AA

AB

AB

AB

AB

AD

AD

AD

AA

AA

AA

AD

AB

AA

AA

AA

AA

AA

AA

AD

AD

AA

AA

AA

AA

AA

AA

AB

AD

AD

AD

AD

AD

AD

AD

AD

AD

AD

AA

AD

AD

AA

AD

AB

AD

AB

AB

AB

AB

AB

AB

AB

AB

AB

NEW

MARK

PART

RANK

Fe rr ite B ea d

Fe rr ite J um pe r

Ch ip Fe rr it e Bea d, B AL UN

Co il 47 uH 9 00 mA

Co il 47 uH 9 00 mA

In du cto r 15 uH 3A

Fe rr ite J um pe r

Ch ip Fe rr it e bea d

Co il

Co il

Co il

Co il

Fe rr ite B ea d

Fe rr ite B ea d

Fe rr ite B ea d

Fe rr ite B ea d BAL UN

Ch ip Fe rr it e Bea d, F il ter

Ch ip Fe rr it e Bea d, F il ter

Ch ip Fe rr it e Bea d, F il ter

Ch ip Fe rr it e Bea d, F il ter

Ch ip Fe rr it e Bea d, F il ter

Ch ip Fe rr it e Bea d, F il ter

Fe rr ite B ea d

Fe rr ite B ea d

Ch ip Co il , Ch oke

Ch ip Co il , Ch oke

Ch ip Co il , Ch oke

Ch ip Co il , Ch oke

Ch ip Fe rr it e Bea d

Ch ip Fe rr it e Bea d

Fe rr ite B ea d BAL UN

Ch ip Fe rr it e Bea d

Ch ip Fe rr it e Bea d

Ch ip Fe rr it e Bea d

Ch ip Fe rr it e Bea d

Cr ys tal 1 6. 93 4MH z

Cr ys tal 3 2. 76 8KH z

Cr ys tal 2 4M Hz

0. 1 µF, 25 V

56 00 pF ,2 5V

18 00 pF ,5 0V

0. 1 µF, 50 V

0. 22 µF ,5 0V

0. 1 µF, 25 V

0. 1 µF, 25 V

0. 1 µF, 25 V

0. 1 µF, 25 V

0. 1 µF, 25 V

0. 1 µF, 25 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 25 V

22 p F,5 0V

22 p F,5 0V

0. 1 µF, 25 V

0. 1 µF, 25 V

0. 1 µF, 25 V

68 0 pF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

47 p F,5 0V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 02 2 µ F, 50 V

0. 1 µF, 50 V

0. 04 7 µ F, 50 V

0. 1 µF, 50 V

10 00 pF ,5 0V

10 00 pF ,5 0V

10 0 pF, 50 V

10 0 pF, 50 V

0. 12 µF ,1 6V

10 0 pF, 50 V

22 00 pF ,5 0V

22 00 pF ,5 0V

1 µF ,25 V

2

XL-HF102B

DESCRIPTION

Page 32

XL-HF102B

NO. PARTS CODE

[6] CAPACITORS

C3 14

C4 00

C4 01

C4 03

C4 04

C4 05

C4 13

C4 14

C4 16

C4 17

C4 21

C4 22

C4 23

C4 24

C4 25

C4 26

C4 27

C4 28

C4 29

C4 30

C4 31

C4 32

C4 33

C4 34

C4 35

C4 40

C4 42

C4 48

C4 70

C4 71

C4 72

C4 73

C4 74

C4 75

C4 76

C4 77

C4 78

C4 79

C4 80

C4 85

C4 86

C6 04

C6 05

C6 08

C6 09

C6 10

C6 11

C6 12

C6 13

C6 14

C6 15

C6 16

C6 17

C6 18

C6 19

C6 20

C6 21

C6 22

C6 23

C6 24

C6 25

C6 26

C6 28

C6 30

C6 31

C6 33

C6 36

C6 37

C6 40

C6 41

C6 42

C6 43

C7 00

C7 01

C7 04

C7 05

C7 06

C7 07

C7 08

C7 09

C7 10

C7 12

C7 13

C7 16

C7 21

C7 22

C7 23

C7 25

C7 26

VC KY CY1 EB 10 5K

VC KY CY1 HB 12 2K

VC KY CY1 HB 12 2K

VC KY CY1 HB 10 2K

VC CC CY1 HH 18 1J

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC CC CY1 HH 18 1J

VC CC CY1 HH 18 1J

VC CC CY1 HH 18 1J

VC KY CZ1 HB 10 2K

VC KY CZ1 HB 10 2K

VC CC CZ1 HH 33 0J

VC CC CZ1 HH 33 0J

VC CC CZ1 HH 33 0J

VC CC CZ1 HH 33 0J

VC CC CZ1 HH 33 0J

VC KY CY1 EB 10 5K

VC KY CY1 EB 10 5K

VC KY CY1 EB 10 5K

VC KY CY1 EB 10 5K

VC KY CY1 EB 10 5K

VC KY CY1 EB 10 5K

VC KY CY1 EB 10 5K

VC KY CY1 EB 10 5K

VC KY CY1 EB 10 5K

VC KY CY1 EB 10 5K

VC KY CZ1 EF 10 4Z

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 2K

VC KY CY1 HB 10 2K

VC KY CZ1 HB 10 2K

VC KY CZ1 HB 10 2K

VC KY CZ1 HB 10 2K

VC KY CZ1 HB 10 2K

VC CC CZ1 HH 10 1J

VC CC CZ1 HH 10 1J

VC CC CZ1 HH 10 1J

VC CC CZ1 HH 10 1J

VC KY CY1 EB 10 5K

VC KY CY1 EB 10 5K

VC KY CZ1 EF 10 4Z

VC KY CZ1 EF 10 4Z

VC CC CZ1 HH 47 0J

VC CC CZ1 HH 47 0J

VC CC CY1 HH 18 0J

VC CC CY1 HH 18 0J

VC CC CZ1 HH 33 0J

VC KY CY1 AB 22 5K

VC KY CY1 HB 10 4K

VC KY CZ1 EF 10 4Z

VC KY CZ1 EF 10 4Z

VC KY CZ1 EF 10 4Z

VC CC CZ1 HH 18 0J

VC CC CZ1 HH 18 0J

VC KY CZ1 EF 10 4Z

VC KY CZ1 EF 10 4Z

VC KY CZ1 EF 10 4Z

VC KY CZ1 EF 10 4Z

VC KY CZ1 EF 10 4Z

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 EB 10 5K

VC KY CY1 HB 10 4K

VC KY CY1 EB 10 5K

VC KY CZ1 EF 10 4Z

VC CC CY1 HH 47 0J

VC KY CY0 JB 10 6K

VC KY CZ1 EF 10 4Z

VC KY CZ1 EF 10 4Z

VC KY CY1 HB 10 4K

VC TY PA1 HF 10 4Z

VC KY CY1 HB 22 3K

VC KY CY1 HB 22 3K

VC CC CZ1 HH 39 0J

VC KY CZ1 EF 10 4Z

VC CC CZ1 HH 10 1J

VC CC CZ1 HH 10 1J

VC CC CZ1 HH 10 1J

VC KY CY1 EB 10 5K

VC KY CY1 HB 10 2K

VC KY CY1 HB 22 3K

VC KY CY1 HB 10 2K

VC KY CY1 HB 22 3K

VC KY CZ1 EF 10 4Z

VC KY TV1 HB 10 5K

VC KY TV1 HB 10 5K

VC KY CY1 HB 10 4K

VC CC CY1 HH 33 0J

PRICE

RANK

AB

AA

AA

AA

AA

AD

AD

AA

AA

AA

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AA

AD

AA

AA

AB

AB

AB

AB

AB

AB

AB

AB

AB

AB

AA

AA

AB

AB

AA

AA

AB

AB

AD

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AD

AD

AB

AD

AB

AA

AA

AB

AA

AA

AD

AB

AA

AA

AB

AA

AB

AB

AB

AB

AA

AA

AA

AA

AA

AC

AC

AD

AA

NEW

MARK

PART

RANK

1 µF ,25 V

12 00 pF ,5 0V

12 00 pF ,5 0V

10 00 pF ,5 0V

18 0 pF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

18 0 pF, 50 V

18 0 pF, 50 V

18 0 pF, 50 V

10 00 pF ,5 0V

10 00 pF ,5 0V

33 p F,5 0V

33 p F,5 0V

33 p F,5 0V

33 p F,5 0V

33 p F,5 0V

1 µF ,25 V

1 µF ,25 V

1 µF ,25 V

1 µF ,25 V

1 µF ,25 V

1 µF ,25 V

1 µF ,25 V

1 µF ,25 V

1 µF ,25 V

1 µF ,25 V

0. 1 µF, 25 V

0. 1 µF, 50 V

10 00 pF ,5 0V

10 00 pF ,5 0V

10 00 pF ,5 0V

10 00 pF ,5 0V

10 00 pF ,5 0V

10 00 pF ,5 0V

10 0 pF, 50 V

10 0 pF, 50 V

10 0 pF, 50 V

10 0 pF, 50 V

1 µF ,25 V

1 µF ,25 V

0. 1 µF, 25 V

0. 1 µF, 25 V

47 p F,5 0V

47 p F,5 0V

18 p F,5 0V

18 p F,5 0V

33 p F,5 0V

2. 2 µF, 10 V

0. 1 µF, 50 V

0. 1 µF, 25 V

0. 1 µF, 25 V

0. 1 µF, 25 V

18 p F,5 0V

18 p F,5 0V

0. 1 µF, 25 V

0. 1 µF, 25 V

0. 1 µF, 25 V

0. 1 µF, 25 V

0. 1 µF, 25 V

0. 1 µF, 50 V

0. 1 µF, 50 V

1 µF ,25 V

0. 1 µF, 50 V

1 µF ,25 V

0. 1 µF, 25 V

47 p F,5 0V

10 µ F,6 .3 V

0. 1 µF, 25 V

0. 1 µF, 25 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 02 2 µ F, 50 V

0. 02 2 µ F, 50 V

39 p F,5 0V

0. 1 µF, 25 V

10 0 pF, 50 V

10 0 pF, 50 V

10 0 pF, 50 V

1 µF ,25 V

10 00 pF ,5 0V

0. 02 2 µ F, 50 V

10 00 pF ,5 0V

0. 02 2 µ F, 50 V

0. 1 µF, 25 V

1 µF ,50 V

1 µF ,50 V

0. 1 µF, 50 V

33 p F,5 0V

3

DESCRIPTION

Page 33

NO. PARTS CODE

[6] CAPACITORS

C7 27

C7 28

C7 29

C7 32

C7 33

C7 34

C7 36

C7 40

C7 45

C7 47

C7 50

C7 51

C7 54

C7 56

C7 57

C8 00

C8 01

C8 02

C8 03

C8 04

C8 05

C8 06

C8 07

C8 08

C8 09

C8 10

C8 14

C8 30

C8 32

C8 33

C8 36

C8 37

C8 39

C8 40

C8 51

C8 52

C8 53

C8 54

C8 55

C8 56

C8 57

C8 58

C8 59

C8 60

C8 61

C8 62

C8 63

C8 64

C8 65

C8 66

C8 67

C8 68

C8 69

C9 01

C9 02

C9 03

C9 05

C9 06

C9 07

C9 10

C9 11

C9 12

C9 13

C9 14

C9 15

C9 16

C9 17

C9 18

C9 19

C9 20

C9 21

C9 22

C9 23

C9 24

C9 25

C9 26

C9 27

C9 28

C9 29

C9 30

C9 31

C9 32

C9 33

C9 34

C9 40

C9 41

C9 42

C9 43

C9 46

VC CC CY1 HH 33 0J

VC KY CY1 HB 10 4K

VC KY TV1 EB 10 6K

VC KY CY1 HB 22 3K

VC KY CY1 HB 10 4K

VC CC CY1 HH 47 0J

VC CC CY1 HH 47 0J

VC KY CY1 EB 10 5K

VC KY CY1 HB 10 4K

VC KY CY1 HB 22 3K

VC KY CY1 HB 22 3K

VC KY CY1 HB 22 3K

VC KY CY1 HB 22 3K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY TV1 EB 10 6K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 3K

VC KY CY1 HB 39 2K

VC KY CY1 HB 10 4K

RC -K ZA8 15 WJ QZ

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC CC CY1 HH 22 0J

VC CC CY1 HH 22 0J

VC KY TV1 EB 10 6K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY TV1 EB 10 6K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY TV1 EB 10 6K

VC KY CY1 HB 10 4K

VC CC CZ1 HH 10 1J

VC CC CY1 HH 56 1J

VC KY CZ1 EF 10 4Z

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC CC CZ1 HH 33 0J

VC CC CY1 HH 47 0J

VC CC CY1 HH 47 0J

VC KY CY1 HB 10 3K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY TQ1 HB 10 4K

VC KY CY1 HB 22 3K

VC KY TQ1 HB 10 4K

VC CC CY1 HH 22 0J

VC KY CY0 JB 10 6K

VC KY CZ1 EF 10 4Z

VC KY CZ1 HB 47 2K

VC KY CZ1 HB 68 1K

VC KY CZ1 HB 10 2K

VC KY CZ1 EF 10 4Z

VC KY CY1 HF 22 4Z

RC -K ZA2 15 WJ ZZ

RC -K ZA2 15 WJ ZZ

VC KY CY1 HF 22 4Z

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CZ1 EF 10 4Z

VC KY CY1 HB 33 1K

VC KY CY1 HB 33 1K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

RC -E Z32 13 AW ZZ

RC -E Z32 13 AW ZZ

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 2K

VC KY CY1 HB 10 2K

VC CC CZ1 HH 27 1J

VC CC CZ1 HH 22 1J

VC CC CZ1 HH 27 1J

VC CC CZ1 HH 22 1J

VC CC CZ1 HH 15 0J

PRICE

RANK

AA

AD

AC

AA

AD

AA

AA

AB

AD

AA

AA

AA

AA

AD

AD

AC

AD

AA

AA

AD

AD

AD

AD

AA

AA

AC

AD

AD

AD

AC

AD

AD

AD

AC

AD

AB

AB

AA

AD

AD

AD

AD

AB

AA

AA

AA

AD

AD

AD

AB

AA

AB

AA

AB

AA

AC

AB

AB

AA

AB

AC

AC

AB

AD

AD

AA

AA

AA

AD

AD

AD

AD

AD

AD

AD

AD

AD

AD

AD

AD

AD

AD

AA

AA

AB

AB

AB

AB

AA

NEW

MARK

PART

RANK

33 p F,5 0V

0. 1 µF, 50 V

10 µ F,2 5V

0. 02 2 µ F, 50 V

0. 1 µF, 50 V

47 p F,5 0V

47 p F,5 0V

1 µF ,25 V

0. 1 µF, 50 V

0. 02 2 µ F, 50 V

0. 02 2 µ F, 50 V

0. 02 2 µ F, 50 V

0. 02 2 µ F, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

10 µ F,2 5V

0. 1 µF, 50 V

0. 01 µF ,5 0V

39 00 pF ,5 0V

0. 1 µF, 50 V

4. 7 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

22 p F,5 0V

22 p F,5 0V

10 µ F,2 5V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

10 µ F,2 5V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

10 µ F,2 5V

0. 1 µF, 50 V

10 0 pF, 50 V

56 0 pF, 50 V

0. 1 µF, 25 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

33 p F,5 0V

47 p F,5 0V

47 p F,5 0V

0. 01 µF ,5 0V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 02 2 µ F, 50 V

0. 1 µF, 50 V

22 p F,5 0V

10 µ F,6 .3 V

0. 1 µF, 25 V

47 00 pF ,5 0V

68 0 pF, 50 V

10 00 pF ,5 0V

0. 1 µF, 25 V

0. 22 µF ,5 0V

1 µF ,50 V

1 µF ,50 V

0. 22 µF ,5 0V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 25 V

33 0 pF, 50 V

33 0 pF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 47 µF ,6 3V

0. 47 µF ,6 3V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

10 00 pF ,5 0V

10 00 pF ,5 0V

27 0 pF, 50 V

22 0 pF, 50 V

27 0 pF, 50 V

22 0 pF, 50 V

15 p F,5 0V

4

XL-HF102B

DESCRIPTION

Page 34

XL-HF102B

NO. PARTS CODE

[6] CAPACITORS

C9 47

C9 48

C9 52

C9 53

C9 54

C9 55

C9 56

CA 60 2

CA 60 4

CA 61 0

CA 61 1

CA 61 3

CA 62 0

E1 02

E3 00

E3 02

E3 04

E3 05

E3 07

E3 08

E4 04

E4 70

E4 71

E4 72

E4 73

E4 74

E4 78

E4 79

E6 01

E6 03

E6 04

E6 05

E6 06

E7 02

E7 03

E7 04

E8 01

E8 02

E8 05

E8 06

E8 07

E8 08

E8 09

E9 00

E9 03

[7] RESISTORS

FB 60 1

FB 60 2

FB 70 0

FB 70 1

FB 70 2

GN D0

GN D1

GN D2

GN D3

GN D4

GN D5

GN D6

GN D7

GN D8

GN D1 1

GN D1 3

GN D1 4

JP 80 1

JP 80 2

VC CC CZ1 HH 33 0J

VC CC CZ1 HH 33 0J

VC CC CZ1 HH 22 1J

VC CC CZ1 HH 22 1J

VC CC CZ1 HH 22 1J

VC CC CZ1 HH 22 1J

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CY1 HB 10 4K

VC KY CZ1 EF 10 4Z

VC KY CZ1 EB 10 3K

VC KY CZ1 EB 10 3K

VC KY CY1 HB 10 4K

E1

VC EA ZA1 HW 33 5M

E2

VC EA ZA1 CW 47 6M

E3

VC EA ZA1 AW 47 7M

E4

VC EA ZA1 CW 22 7M

E5

VC EA ZA1 CW 22 7M

E6

VC EA ZA1 CW 47 6M

E7

VC EA ZA1 CW 47 6M

E8

RC -E ZD4 76 AF 1C

E9

RC -E ZD1 07 AF 1C

E1 0

VC EA ZA1 CW 10 7M

VC EA ZA1 CW 10 7M

VC EA ZA1 HW 68 4M

VC EA ZA1 HW 47 5M

VC EA ZA1 HW 10 6M

VC EA ZA1 HW 10 6M

VC EA ZA1 CW 10 7M

VC EA ZA1 CW 10 7M

VC EA ZA1 CW 10 7M

VC EA ZA1 CW 10 7M

VC EA ZA1 CW 22 7M

VC EA ZA1 HW 10 6M

VC EA ZA1 CW 10 7M

VC EA ZA1 HW 10 6M

VC EA ZA1 CW 10 7M

VC EA ZA1 CW 10 7M

RC -E Z31 93 AW ZZ

VC EA ZA1 AW 47 7M

VC EA ZA1 CW 22 7M

VC EA ZA1 HW 10 6M

VC EA ZA1 HW 47 5M

RC -E ZD2 27 AF 1C

RC -E ZD4 76 AF 1E

RC -E ZD2 27 AF 1C

VC EA ZA1 HW 10 6M

VC EA ZA1 EW 47 7M

VC EA ZA1 HW 10 6M

VC EA ZA1 EW 47 7M

RC -E ZD2 27 AF 1E

VC EA ZA1 AW 47 7M

VC EA ZA1 EW 22 7M

VC EA ZA1 EW 10 8M

VC EA ZA1 HW 22 6M

VR S- CY1 JF 00 0J

VR S- CY1 JF 00 0J

VR S- CY1 JF 00 0J

VR S- CY1 JF 00 0J

VR S- CY1 JF 00 0J

VR S- TQ2 BB 00 0J

VR S- TQ2 BB 00 0J

VR S- TQ2 BB 00 0J

VR S- CY1 JF 00 0J

VR S- TQ2 BB 00 0J

VR S- TV2 AB 00 0J

VR S- TQ2 BB 00 0J

VR S- TQ2 BB 00 0J

VR S- TQ2 BB 00 0J

VR S- TV2 AB 00 0J

VR S- TQ2 BB 00 0J

VR S- TQ2 BB 00 0J

VR S- CZ1 JF 10 5J

JP 1

VR S- CZ1 JF 22 1J

VR S- CZ1 JF 33 2J

VR S- CZ1 JF 12 2J

L1

VR S- CZ1 JF 75 2J

L7 01

VR S- CZ1 JF 00 0J

L8 00

VR S- CZ1 JF 56 3J

L8 02

VR S- CZ1 JF 82 3J

L8 03

VR S- CZ1 JF 00 0J

L8 04

VR S- CY1 JF 00 0J

L9 02

VR S- CY1 JF 00 0J

R1

VR S- CY1 JF 18 2J

R2

VR S- CY1 JF 18 2J

R3

VR S- CY1 JF 10 3J

R4

PRICE

RANK

AB

AB

AB

AB

AB

AB

AD

AD

AD

AA

AA

AA

AD

AB

AB

AC

AC

AC

AB

AB

AC

AC

AC

AC

AB

AB

AB

AB

AC

AC

AC

AC

AC

AB

AC

AB

AC

AC

AD

AC

AC

AB

AB

AB

AC

AB

AB

AD

AB

AD

AC

AC

AC

AE

AB

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

NEW

MARK

PART

RANK

DESCRIPTION

33 p F,5 0V

33 p F,5 0V

22 0 pF, 50 V

22 0 pF, 50 V

22 0 pF, 50 V

22 0 pF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 50 V

0. 1 µF, 25 V

0. 01 µF ,2 5V

0. 01 µF ,2 5V

0. 1 µF, 50 V

3. 3 µF, 50 V

47 µ F,1 6V

47 0 µF, 10 V

22 0 µF, 16 V

22 0 µF, 16 V

47 µ F,1 6V

47 µ F,1 6V

47 µ F,1 6V

10 0 µF, 16 V

10 0 µF, 16 V

10 0 µF, 16 V

0. 68 µF ,5 0V

4. 7 µF, 50 V

10 µ F,5 0V

10 µ F,5 0V

10 0 µF, 16 V

10 0 µF, 16 V

10 0 µF, 16 V

10 0 µF, 16 V

22 0 µF, 16 V

10 µ F,5 0V

10 0 µF, 16 V

10 µ F,5 0V

10 0 µF, 16 V

10 0 µF, 16 V

10 00 µF ,6 .3 V

47 0 µF, 10 V

22 0 µF, 16 V

10 µ F,5 0V

4. 7 µF, 50 V

22 0 µF, 16 V

47 µ F,2 5V

22 0 µF, 16 V

10 µ F,5 0V

47 0 µF, 25 V

10 µ F,5 0V

47 0 µF, 25 V

22 0 µF, 25 V

47 0 µF, 10 V

22 0 µF, 25 V

10 00 µF ,2 5V

22 µ F,5 0V

0 oh m, Ju mp er ,1/ 16 W

0 oh m, Ju mp er ,1/ 16 W

0 oh m, Ju mp er ,1/ 16 W

0 oh m, Ju mp er ,1/ 16 W

0 oh m, Ju mp er ,1/ 16 W

0 oh m, Ju mp er ,1/ 8 W

0 oh m, Ju mp er ,1/ 8 W

0 oh m, Ju mp er ,1/ 8 W

0 oh m, Ju mp er ,1/ 8 W

0 oh m, Ju mp er ,1/ 8 W

0 oh m, Ju mp er ,1/ 8 W

0 oh m, Ju mp er ,1/ 16 W

0 oh m, Ju mp er ,1/ 8 W

0 oh m, Ju mp er ,1/ 10 W

0 oh m, Ju mp er ,1/ 8 W

0 oh m, Ju mp er ,1/ 8 W

0 oh m, Ju mp er ,1/ 8 W

0 oh m, Ju mp er ,1/ 10 W

0 oh m, Ju mp er ,1/ 8 W

0 oh m, Ju mp er ,1/ 8 W

0 oh m, Ju mp er ,1/ 10 W

0 oh m, Ju mp er ,1/ 10 W

0 oh m, Ju mp er ,1/ 16 W

0 oh m, Ju mp er ,1/ 16 W

0 oh m, Ju mp er ,1/ 16 W

0 oh m, Ju mp er ,1/ 16 W

0 oh m, Ju mp er ,1/ 16 W

15 k ohm ,1 /1 6 W

15 k ohm ,1 /1 6 W

15 k ohm ,1 /1 6 W

15 k ohm ,1 /1 6 W

5

Page 35

NO. PARTS CODE

[7] RESISTORS

VR S- CY1 JF 10 3J

R5

VR S- CY1 JF 33 2J

R6

VR S- CY1 JF 82 2J

R7

VR S- CY1 JF 82 2J

R8

VR S- TV2 AB 00 0J

R9

VR S- TV2 AB 00 0J

R1 0

VR S- CZ1 JF 10 3J

R1 1

VR S- CY1 JF 00 0J

R1 2

VR S- TQ2 EF 22 0J

R1 3

VR S- TV2 AB 00 0J

R1 4

VR S- CZ1 JF 10 3J

R1 5

VR S- CZ1 JF 10 3J

R1 6

VR S- CY1 JF 00 0J

R1 7

VR S- CY1 JF 00 0J

R1 8

VR S- CZ1 JF 22 2J

R1 9

VR S- CZ1 JF 22 2J

R2 1

VR S- CZ1 JF 12 1J

R2 2

VR S- CZ1 JF 12 1J

R2 3

VR S- CZ1 JF 22 2J

R2 4

VR S- CZ1 JF 22 2J

R2 6

VR S- CZ1 JF 22 1J

R2 7

VR S- CZ1 JF 22 1J

R2 8

VR S- CZ1 JB 39 2J

R2 9

VR S- CZ1 JB 39 2J

R3 0

VR S- CZ1 JF 10 3J

R3 1

VR S- CZ1 JF 10 4J

R3 2

VR S- CZ1 JB 27 2J

R3 3

VR S- CZ1 JB 27 2J

R3 5

VR S- CZ1 JF 10 4J

R3 8

VR S- CZ1 JF 10 3J

R3 9

VR S- CZ1 JF 33 2J

R4 0

VR S- CZ1 JF 33 2J

R4 1

VR S- CZ1 JF 10 2J

R4 3

VR S- CZ1 JF 10 2J

R4 4

VR S- TQ2 EF 22 0J

R4 6

VR S- CZ1 JB 51 5J

R4 7

VR S- CZ1 JF 10 1J

R4 8

VR S- CZ1 JF 10 1J

R4 9

VR S- CZ1 JF 10 1J

R5 0

R3 00

R3 01

R3 03

R3 04

R3 05

R3 07

R3 08

R3 09

R3 10

R3 11

R3 12

R3 13

R3 14

R3 15

R3 16

R3 17

R3 18

R3 19

R3 22

R3 23

R3 25

R3 26

R4 00

R4 01

R4 02

R4 03

R4 04

R4 05

R4 06

R4 08

R4 09

R4 10

R4 13

R4 14

R4 29

R4 30

R4 31

R4 35

R4 36

R4 37

R4 38

R4 39

R4 70

R4 71

R4 72

R4 73

R4 74

R4 75

R4 76

R4 77