Page 1

XL-DV60

SERVICE MANUAL

No. S2517XLDV60//

DVD MICRO SYSTEM

CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

[1] PRECAUTION FOR USING LEAD-FREE

SOLDER .........................................................1-1

[2] IMPORTANT SERVICE NOTES (FOR

U.S.A. ONLY)..................................................1-2

[3] SPECIFICATIONS ..........................................1-3

[4] NAMES OF PARTS ........................................1-4

CHAPTER 2. ADJUSTMENTS

[1] ADJUSTMENT................................................2-1

[2] TEST MODE...................................................2-2

CHAPTER 3. MECHANICAL DESCRIPTION

[1] REMOVING AND REINSTALLING THE

MAIN PARTS ..................................................3-1

[2] DISASSEMBLY...............................................3-2

CHAPTER 4. DIAGRAMS

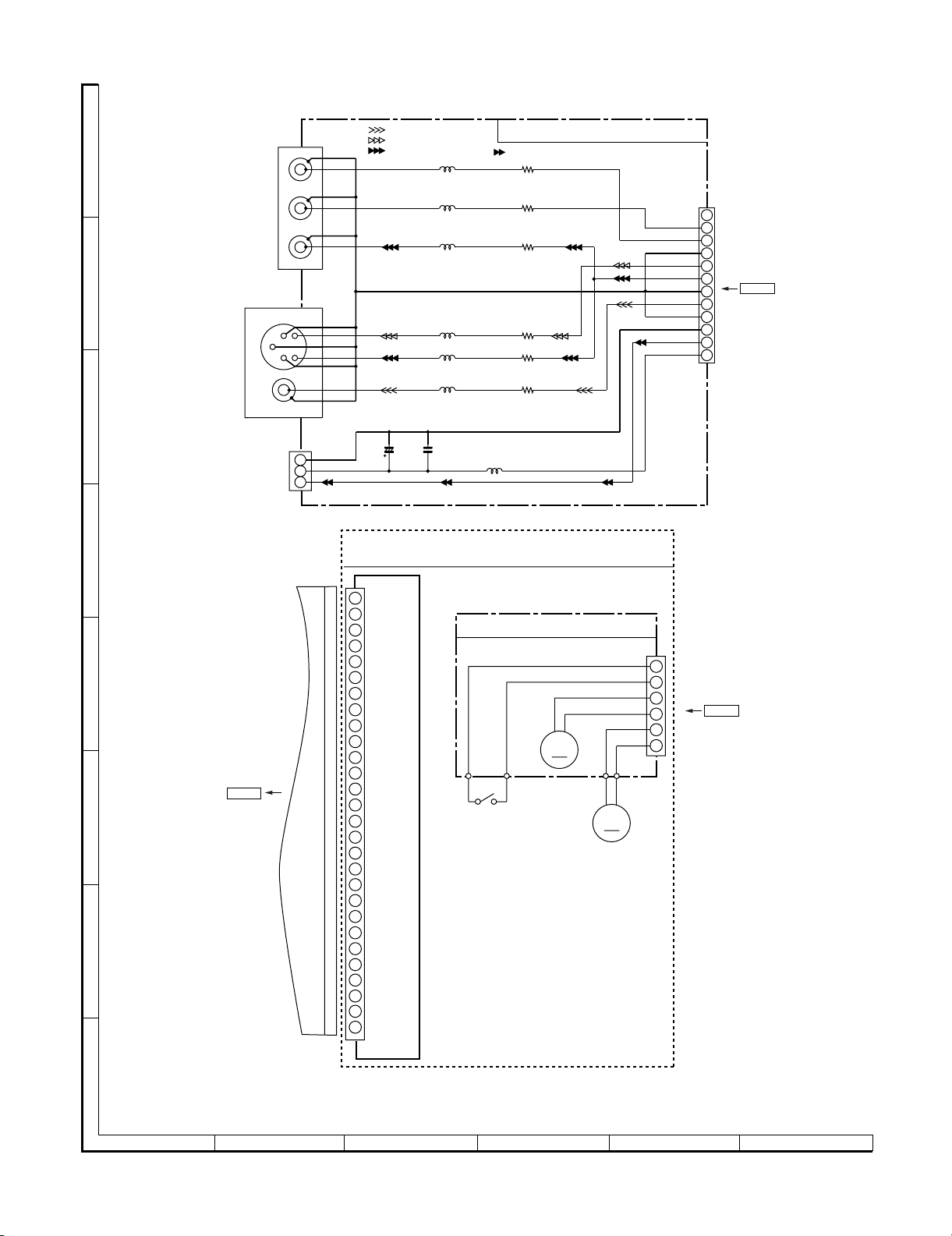

[1] BLOCK DIAGRAM MAIN ................................4-1

[2] BLOCK DIAGRAM TUNER/DISPLAY ............4-3

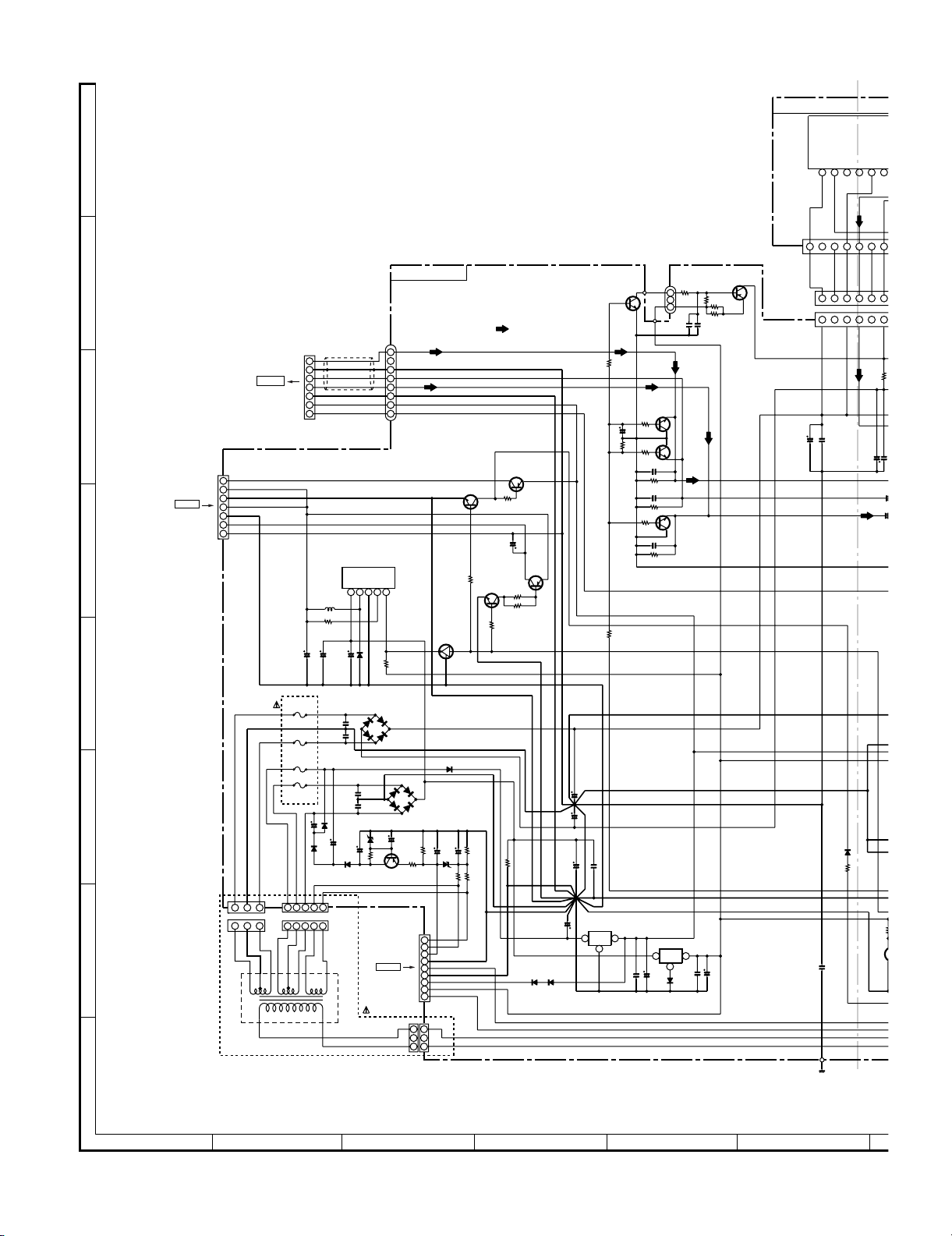

[3] BLOCK DIAGRAM DVD .................................4-5

MODEL

XL-DV60 DVD Micro System consisting of XL-DV60 (main

unit), CP-DV60F (front speakers) and CP-DV60SW(subwoofer).

• In the interests of user-safety the set should be restored to its original condition and only parts identical to those specified be used.

[4] SCHEMATIC DIAGRAM MAIN/POWER

AMP............................................................... 6-3

[5] SCHEMATIC DIAGRAM TUNER .................. 6-5

[6] SCHEMATIC DIAGRAM DISPLAY................ 6-7

[7] SCHEMATIC DIAGRAM DVD1/3 .................. 6-9

[8] SCHEMATIC DIAGRAM DVD2/3 ................ 6-11

[9] SCHEMATIC DIAGRAM DVD3/3 ................ 6-13

[10] WIRING SIDE OF PWB ............................. 6-15

[11] WIRING SIDE OF PWB MAIN TOP/POW-

ER AMP./JACK............................................ 6-17

[12] WIRING SIDE OF PWB MAIN BOTTOM...... 6-19

[13] WIRING SIDE OF PWB TUNER ................. 6-21

[14] WIRING SIDE OF PWB DISPLAY/

SWITCH ...................................................... 6-23

[15] WIRING SIDE OF PWB DVD TOP ............. 6-25

[16] WIRING SIDE OF PWB DVD BOTTOM...... 6-27

[17] WIRING SIDE OF PWB VIDEO TERMI-

NAL ............................................................. 6-29

CHAPTER 7. FLOWCHART

[1] TROUBLESHOOTING .................................. 7-1

XL-DV60

CHAPTER 5. CIRCUIT DESCRIPTION

[1] VOLTAGE .......................................................5-1

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

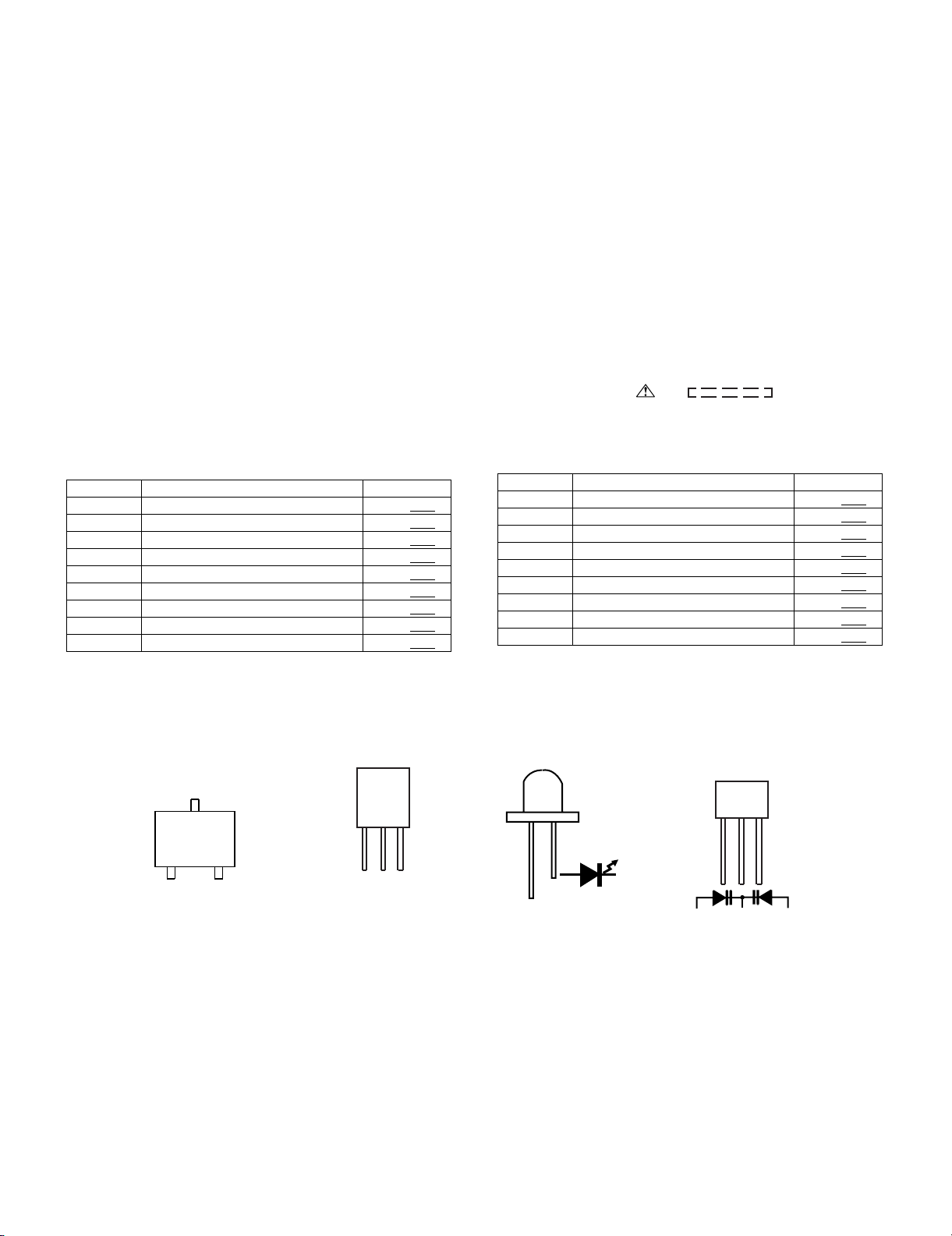

[1] NOTES ON SCHEMATIC DIAGRAM .............6-1

[2] TYPES OF TRANSISTOR AND LED .............6-1

[3] SCHEMATIC DIAGRAM VIDEO TERMI-

NAL.................................................................6-2

SHARP CORPORATION

CHAPTER 8. OTHERS

[1] FUNCTION TABLE OF IC............................. 8-1

[2] FL DISPLAY .................................................. 8-5

Parts Guide

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

XL-DV60

Home StereoXL-DV60Service ManualXLDV60 Service ManualMarketE

CHAPTER 1. GENERAL DESCRIPTION

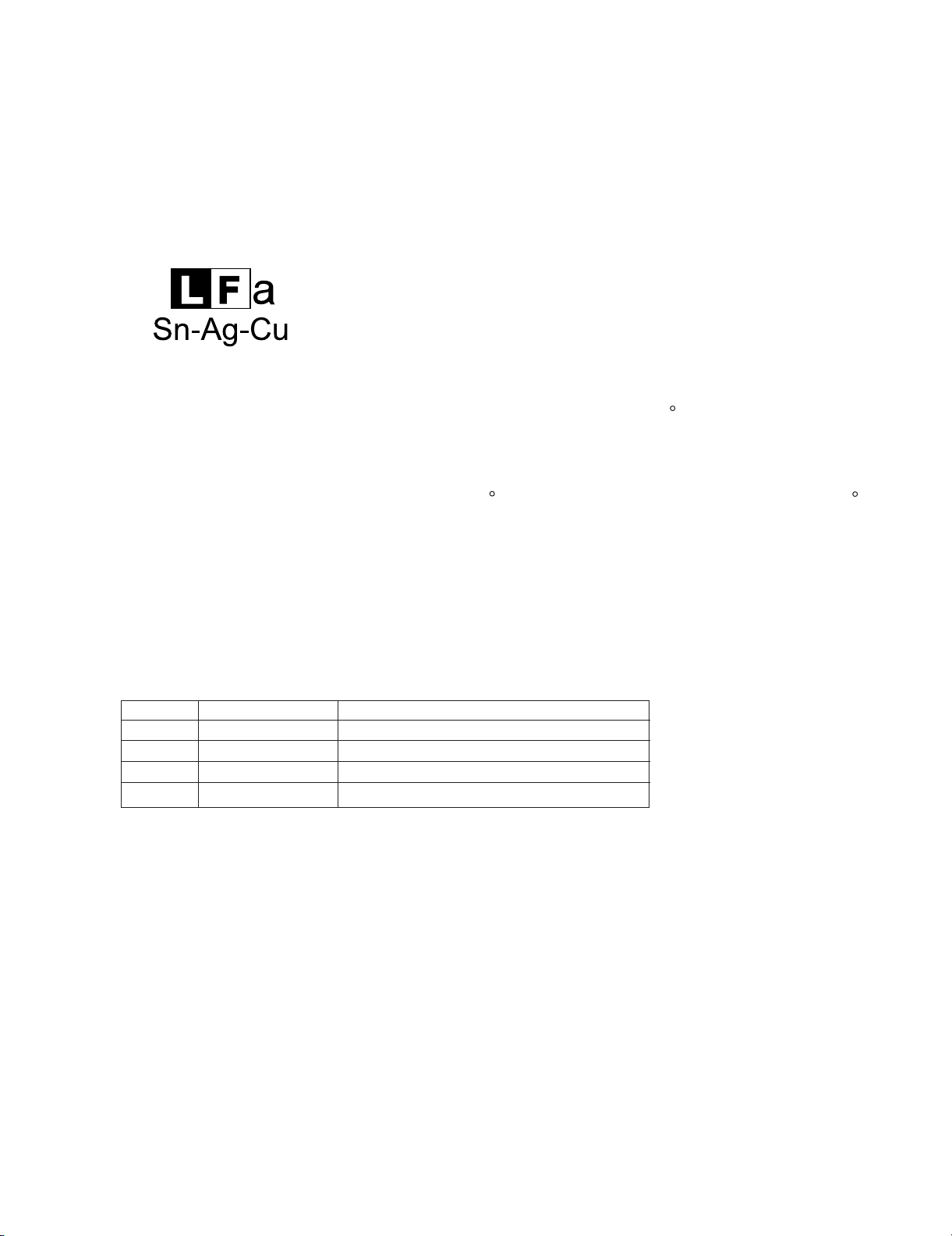

[1] PRECAUTION FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder (From Serial No. 503040001)

"MAIN,TUNER,DISPLAY,

The LF symbol indicates lead-free solder, and is attached on the PWB and service manuals. The alphabetical character

following LF shows the type of lead-free solder.

Example:

2. Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder

may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 C, we recommend you to use a

dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station

or service branch in your area.

3. Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 C which is higher than the conventional lead solder by 40 C,

and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of

time. However, Since the land may be peeled off or the maximum heat-resistance temperature of parts may be exceeded,

remove the bit from the PWB as soon as you confirm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corrected. Make sure to turn on and off the

power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use

of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

VIDEO TERMINAL

Indicates lead-free solder of tin, silver and copper.

,JACK,

SWITCH,DVD,POWER AMP.

,PWB" of this model employs lead-free solder.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Ref No.

PWB-A DCEKKV521SJ03

PWB-B DCEKNV521SJ03

PWB-C DCEKDV521SJ03

PWB-D DCEKSV521SJ03

Parts No.

Main(A1)/Tuner(A2)

DISPLAY(B1)/Video Terminal(B2)/Jack(B3)/Switch(B4)

DVD

Power Amp.

Description

1 – 1

Page 3

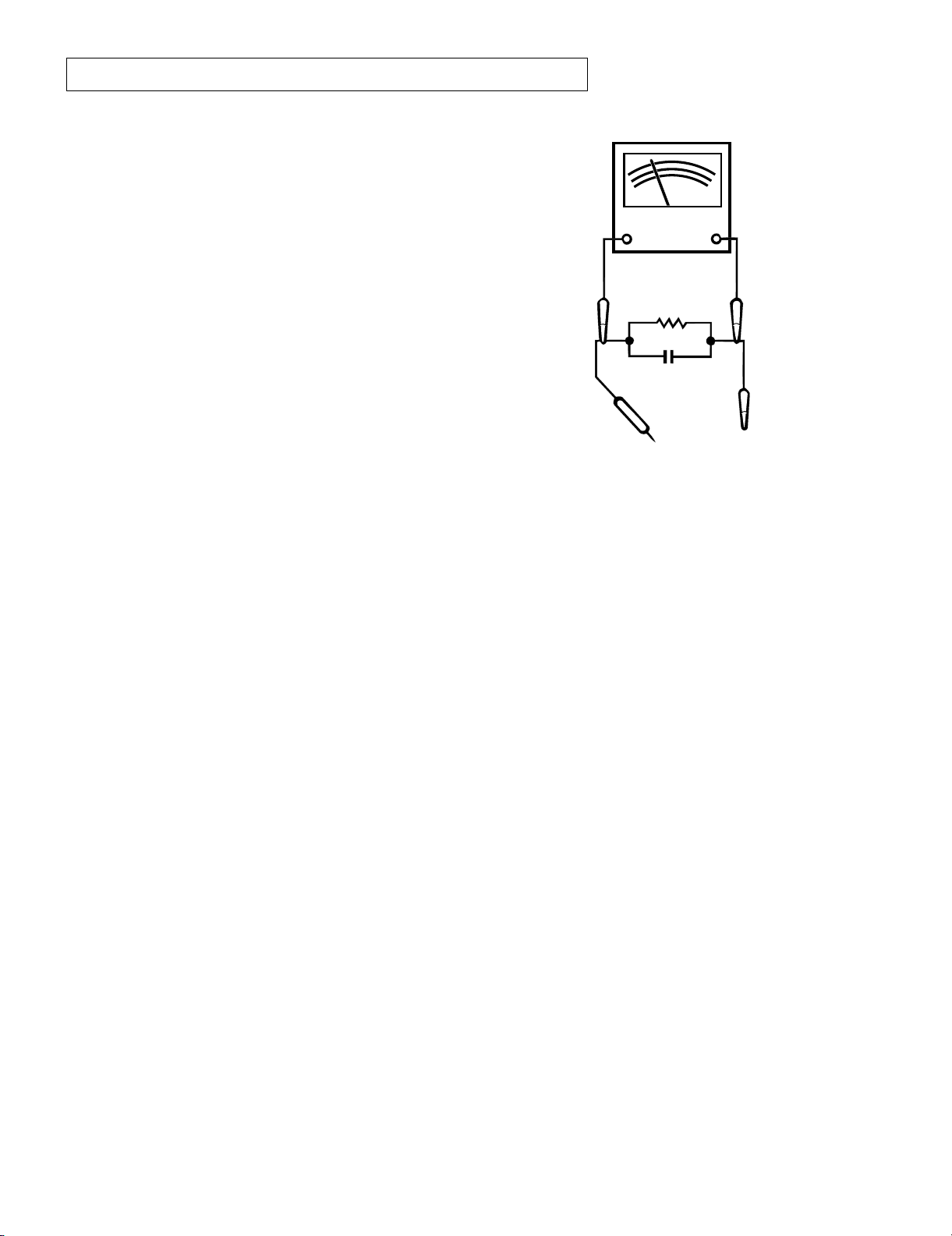

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

[2] IMPORTANT SERVICE NOTES (FOR

U.S.A. ONLY)

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the user, perform the following

safety checks.

1. Inspect all lead dress to make certain that leads are not pinched or

that hardware is not lodged between the chassis and other metal

parts in the audio product.

2. Inspect all protective devices such as insulating materials, cabinet,

terminal board, adjustment and compartment covers or shields,

mechanical insulators etc.

3. To be sure that no shock hazard exists, check for leakage current in

the following manner.

* Plug the AC line cord directly into a 120 volt AC outlet.

* Using two clip leads, connect a 1.5k ohm, 10 watt resistor paral-

leled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as conduit or electrical

ground connected to earth ground.

* Use a VTVM or VOM with 1000 ohm per volt, or higher, sensitivity

to measure the AC voltage drop across the resistor (See diagram).

* Connect the resistor connection to all exposed metal parts having a

return path to the chassis (antenna, metal cabinet, screw heads,

knobs and control shafts, escutcheon, etc.) and measure the AC

voltage drop across the resistor.

TO EXPOSED

METAL PARTS

All check must be repeated with the AC line cord plug connection

reversed.

Any reading of 0.3 volt RMS (this corresponds to 0.2 milliamp. AC.) or

more is excessive and indicates a potential shock hazard which must

be corrected before returning the audio product to the owner.

VTVM

AC SCALE

1.5k ohms

10W

0.15 µ F

TEST PROBE

XL-DV60

CONNECT TO

KNOWN EARTH

GROUND

1 – 2

Page 4

XL-DV60

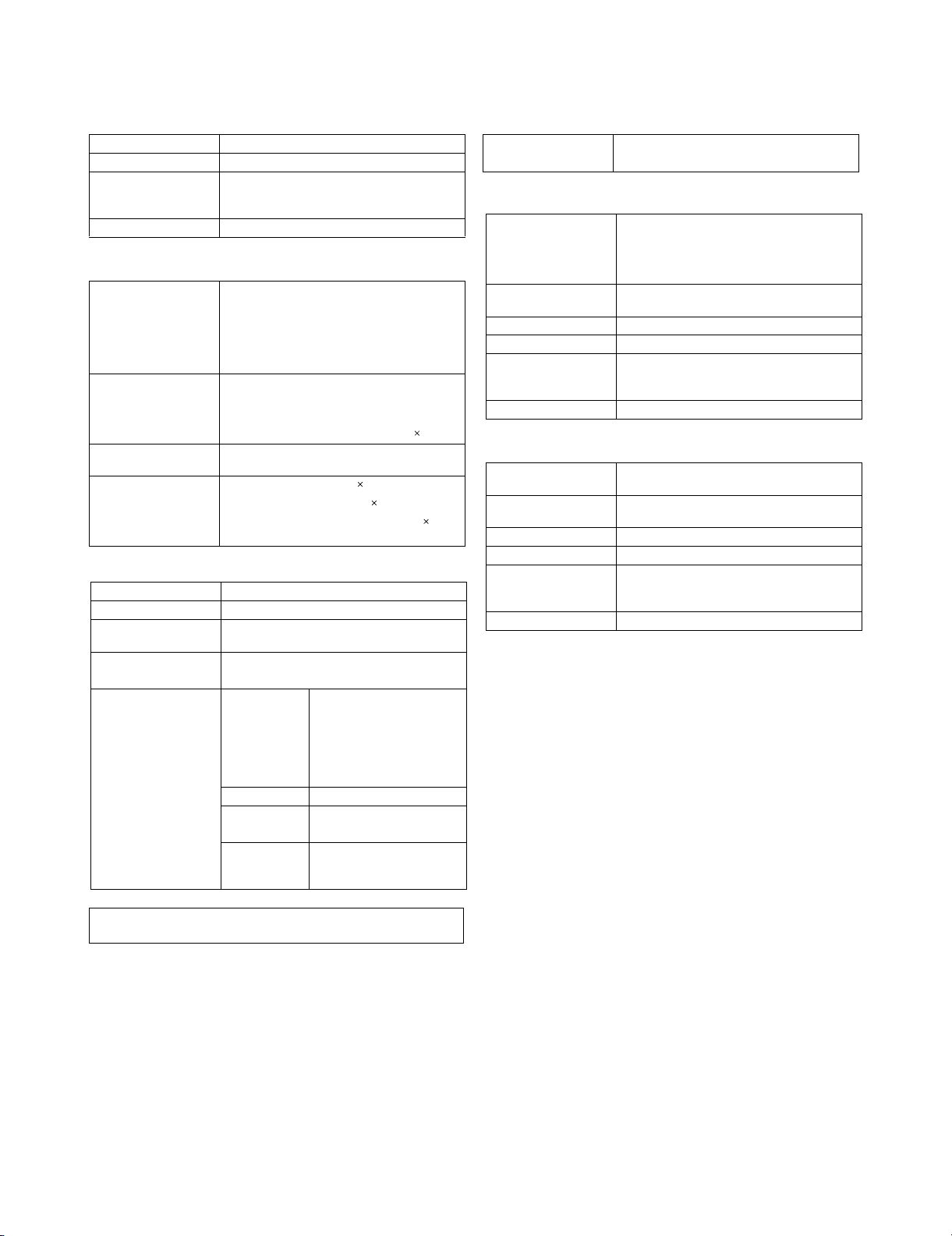

[3] SPECIFICATIONS

■ General

Power source AC 120 V, 60 Hz

Power consumption 116 W

Dimensions Width: 6-5/16" (160 mm)

Weight 12.3 lbs. (5.6 k g)

Height: 9-7/16" (240 mm)

Depth: 12-9/16" (319 mm)

■ Amplifier

Output power Front speakers: 37.5 watts minimum RMS

Audio output

terminals

Audio input

terminals

Video output

terminals

per channel into 6 ohms from 100 Hz to 20

kHz, 10% total harmonic distort ion

Subwoofer: 45 watts minimum RMS into 6

ohms from 70 Hz to 130 Hz, 10% total

harmonic distortion

Front speakers and subwoofer: 6 ohms

Headphones: 16 - 50 ohms

(recommended: 32 ohms)

Optical digital output: Square type 1

Video/Auxiliary (audio signal): 500 mV/47 k

ohms

Video output: RCA type 1

S-video output: S-terminal 1

Component video output: RCA type 3

(Pr/Cr, Pb/Cb, Y)

■ DVD player

Type 5-disc multi-play compact disc player

Signal readout NTSC color

Supported disc

types

Video signal Horizontal resolution: 500 lines

Audio signal Frequency

DVD (region number 1, ALL), video CD,

audio CD, CD-R, CD-RW

S/N ratio: 75 dB

characteristics

S/N ratio CD: 95 dB (1 kHz)

Dynamic

range

Total harmonic distortion ratio

Linear PCM DVD: 30 Hz to

20 k Hz (sampling rate: 48

kHz)

30 H z to 20 kHz

(sampling rate: 96 kHz)

CD: 30 Hz to 20 kHz

Linear PCM DVD: 92 dB

CD: 92 dB

0.14 %

■ Tuner

Frequency range FM:87.5-108MHz

AM: 530 - 1,720 kHz

■ Front speaker

Type 2-way type speaker system

Maximum input

power

Rated input power 37.5 W

Impedance 6 ohm s

Dimensions Width: 6-1/2" (165 mm)

Weight 5.1 lbs. (2.3 kg)/each

(magnetic shield)

1-9/18" (4 cm) semi dome tweeter

4" (10 cm) woofer

75 W

Height: 9- 7/16" (240 mm)

Depth: 9-3/8" (238 mm)

■ Subwoofer

Type Subwoofer system (m agnetic shield)

Maximum input

power

Rated input power 45 W

Impedance 6 ohm s

Dimensions Width: 6-5/16" (160 mm)

Weight 7.3 lbs. (3.3 kg)

5-1/8" (13 cm) woofer

90 W

Height: 9- 7/16" (240 mm)

Depth: 11-1/4" (285 mm)

Specifications for this model are subject to change without prior

notice.

1 – 3

Page 5

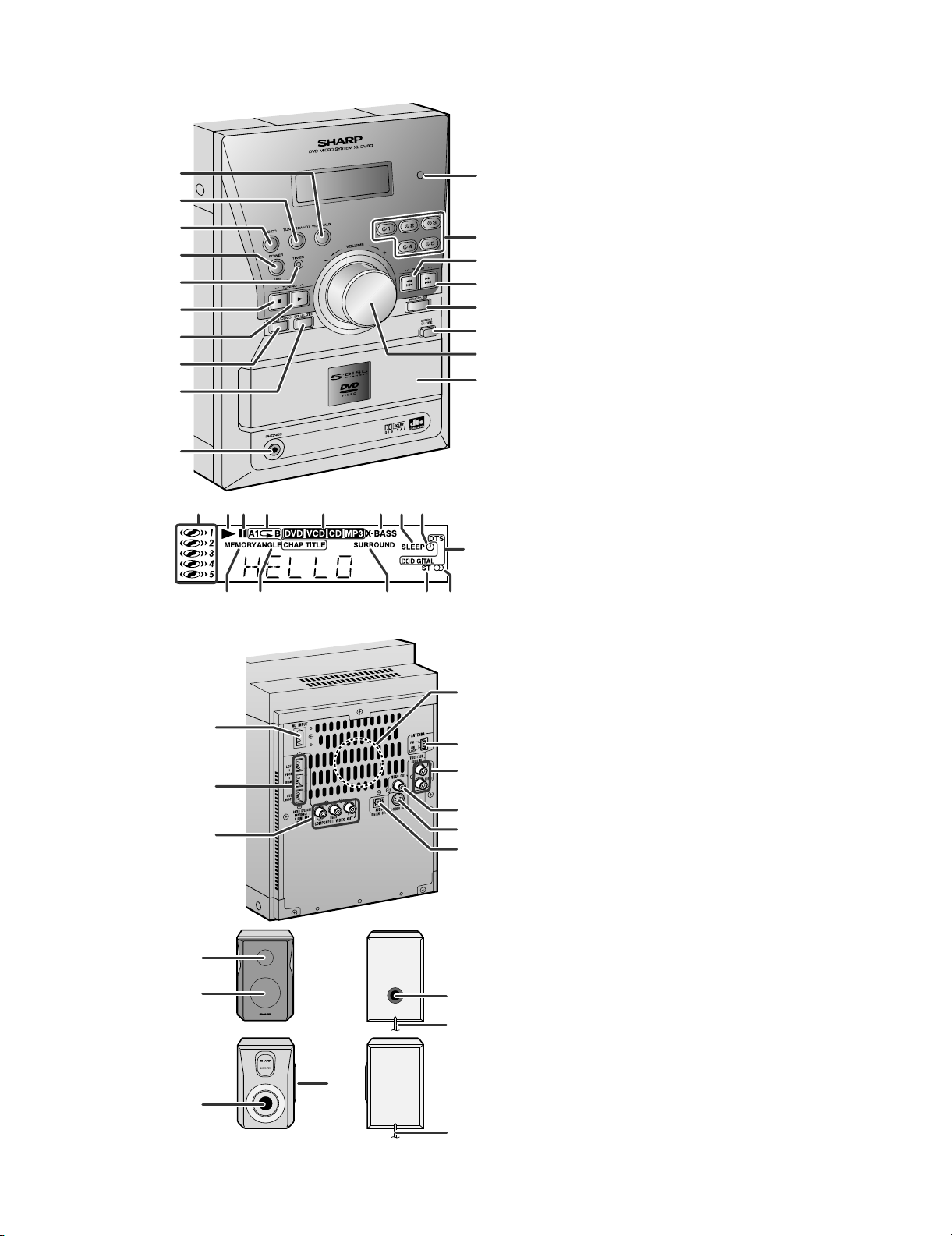

[4] NAMES OF PARTS

1

2

3

4

5

6

7

8

9

10

321 4 5678

XL-DV60

■ Front panel

1. Video/Auxiliary Button

2. Tuner (Band) Button

3. DVD/CD Button

11

12

13

14

15

16

17

18

9

13 1410 11 12

4. Power On/Stand-by Button

5. Timer Indicator

6. Stop or Tuning Down Button

7. Play or Tuning Up Button

8. Extra Bass/Demo Mode Button

9. Equ a lizer Mode S elect Button

10. Head p hon e Jack

11. Remote Sensor

12. Di sc Number Select Buttons

13. Chap ter (Track) Skip Down or Fast Reverse,

Tuner Preset Down Button

14. Chap ter (Track) Skip Up or Fast Forward,

Tuner Preset Up Button

15. Memory/Set Button

16. Disc Compartment Open/Close Button

17. Volume Control

18. Di sc Compartment

■ Display

1. Di sc Number Indicators

2. Play Indicator

3. Pause Indicator

4. Repeat Play Indicators

5. Disc Type Indicators

6. Extra Bass Indicator

7. Sleep Indicator

8. T ime r Play Indicator

9. Sound Mode Indicators

10. Memory Indicator

11. Angle Indicator

12. Surround Mode Indicator

13. FM Stereo Mode Indicator

14. FM Stereo Receiving Indicator

■ Rear panel

1. AC Power Input Jack

2. Speaker Terminals

4

1

5

6

3. Component Video Output Jacks

4. Cooling Fan

5. FM/AM Loop Antenna Jack

6. Video/Auxiliary (Audio Signal) Input Jacks

7. Video Output Jack

8. S-video Output Jack

9. Optical Digital Audio Output Jack

2

7

3

8

9

■ Front speaker

1

2

3

1. Semi Do me Tweeter

2. Woofer

3. Bass Reflex Duct

4. Speaker Wire

4

■ Subwoofer

2

1

1. Sub Duct Pipe

2. Subwoofer

3. Speaker Wire

3

1 – 4

Page 6

XL-DV60

10

11

12

13

14

15

16

17

18

1

2

19

3

20

4

21

5

6

7

8

9

22

23

24

25

26

27

28

29

30

31

32

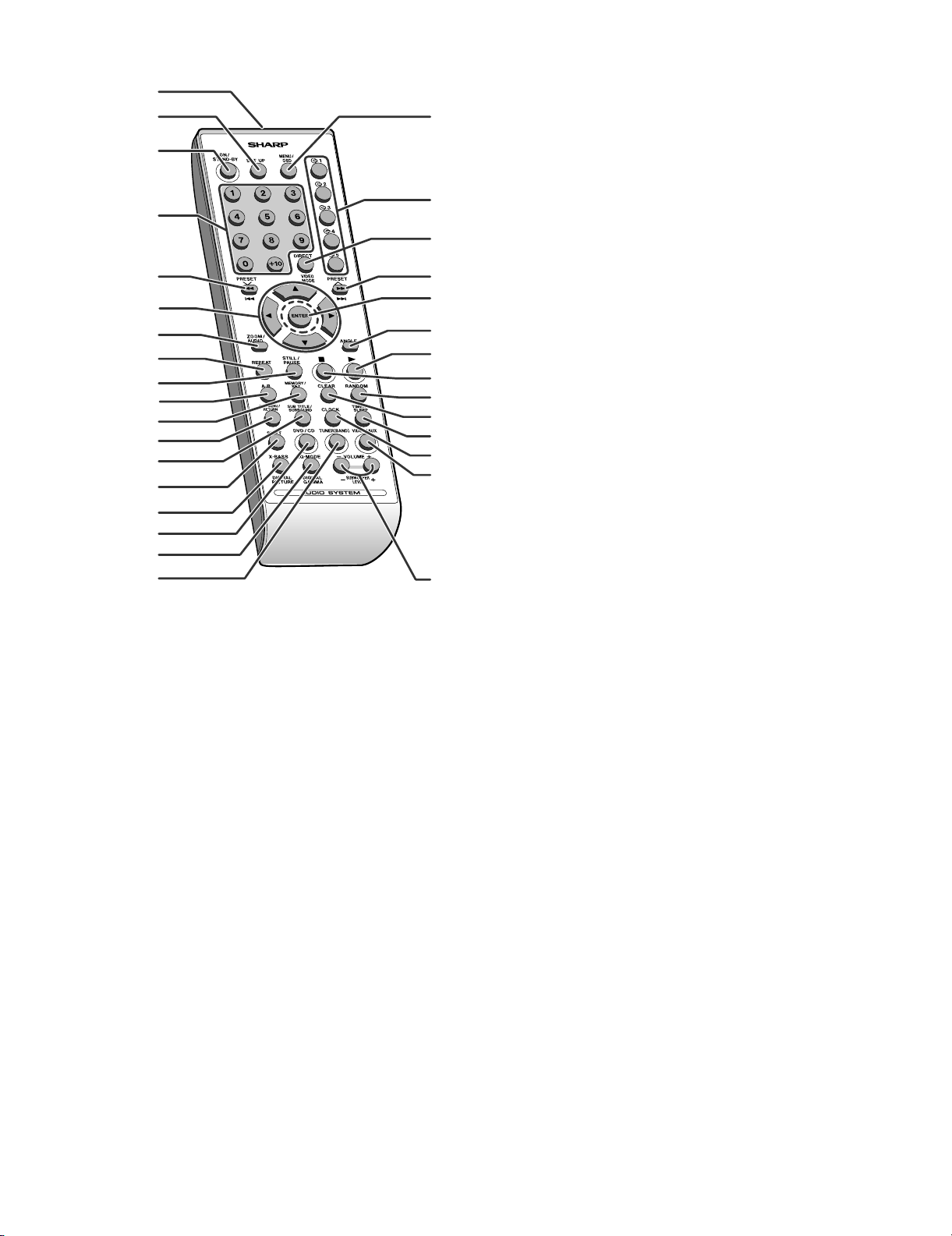

■ Remote control

1. Remote Control Transmitter

2. DVD Setup Button

3. Power On/Stand-by Button

4. Direct Number Buttons

5.Chapter(Track)SkipDownorFastReverse,

Tuner Preset Down, Time Down Button

6. Cursor Buttons

7. Zoom or Audio Select Button

8. Repeat Play Button

9. Frame Advance or Pause Button

10. A - B Repeat Button

11. Memory/Set Button

12.TopMenuorReturnButton

13. Subtitle or Surround Mode Select Button

14. Shift B utton

15. Extra Bass or Digital Picture Select Button

16. DVD/CD Button

17. Equ alizer Mode S elect or Digital Gamma Button

18. Tuner (Band) Button

19. Menu or On Screen Display Select Button

20. Di sc Number Select Buttons

21. Direct or Video M ode Select Button

22. Chap ter (Track) Skip Up or Fast Forward,

Tuner Preset Up, Time Up Button

23. Enter Button

24. An g le Select Button

25. Play Button

26. Stop Button

27. Random Button

28. Clear Button

29. T imer/Sleep Bu tto n

30. C l ock Button

31. Video/Auxiliary Button

32. Volume or Subwoofer Level Up and Down Buttons

1 – 5

Page 7

XL-DV60

CHAPTER 2. ADJUSTMENTS

Service Manual

XL-DV60

TUNER PWB-A2

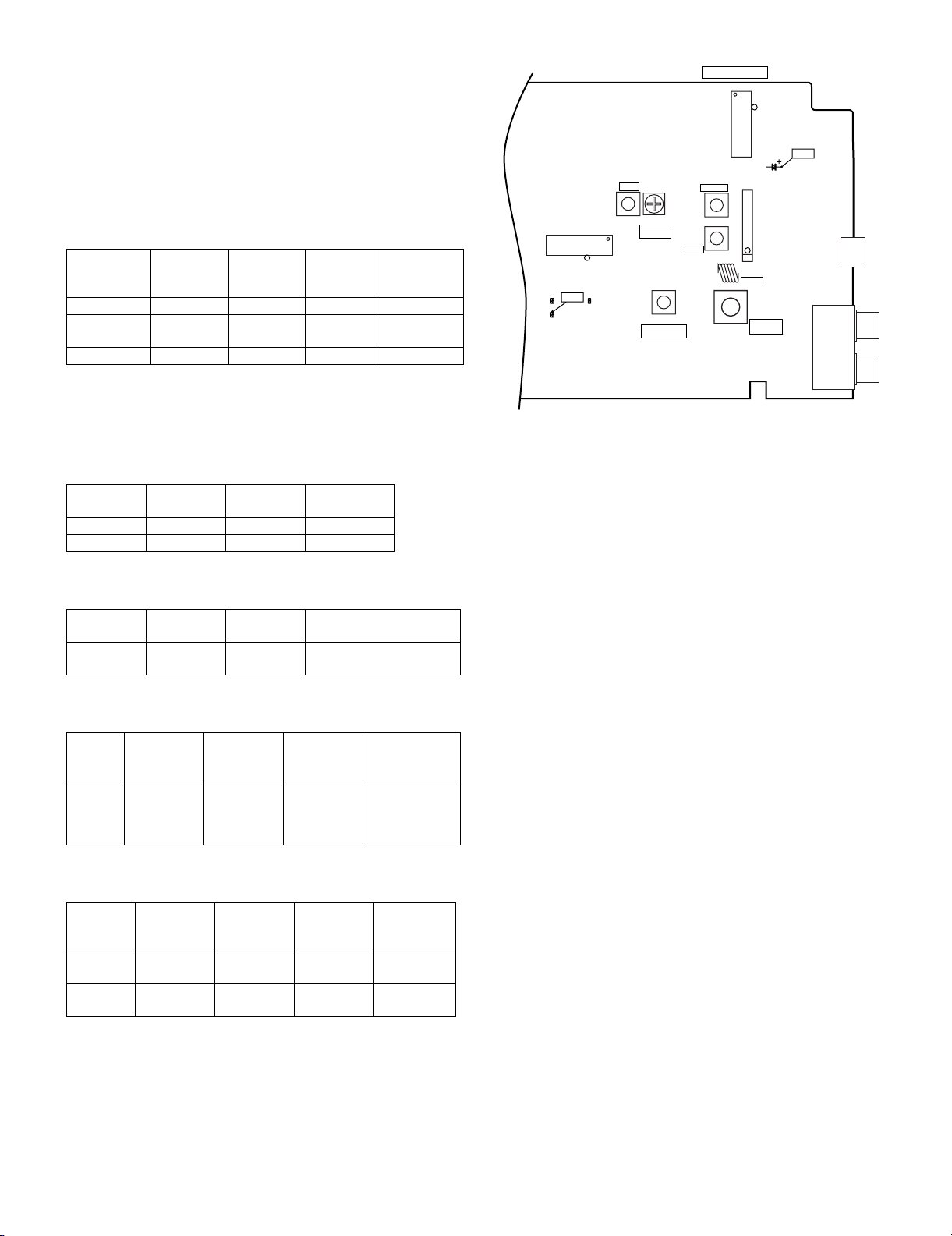

[1] ADJUSTMENT

1. TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

• AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

Test Stage Frequency Frequency

Display

IF 450 kHz 1,602 kHz T351 *1

AM Band

— 530 kHz (fL): T306

Coverage

AM Tracking 990 kHz 990 kHz T302 *3

*1. Input: IC303 21Pin Output: IC303 23Pin

*2. Input: Input is not connected Output: TP-VT(TP301)

*3. Input: Antenna Output:IC303 23Pin

• Check FM VT

Signal generator: 1 kHz, 40 kHz dev., FM modulated

Frequency Display Check

Point

87.5 MHz 87.5 MHz 3.4V ± 1.0V TP301

108 MHz 108 MHz 7.8V ± 1.0V TP301

• FM Mute Level

Signal generator: 1 kHz, 40 kHz dev., FM modulated

Frequency Display Adjusting

Parts

98.00 MHz

98.00 MHz VR351 Input: Antenna

(30 dBµV)

• FM Detection

Signal generator: 10.7 MHz FM sweep generator

Setting/

Adjusting

Connection

Parts

*2

1.1 ± 0.1 V

Instrument

Connection

Instrument

Connection

Output: Speaker Terminal

Instrument

20

IC302

TP301

L302

FM RF

1

T302

C393

IC301

AM

Tracking fL

CNP301

R356

IC303

R357

TP302

T351

AM IF

VR351

FM MUTE

LEVEL

18

R350

T306

AM BAND

COVERAGE fL

T304

FM IF

L303

FM OSC.

Figure 1 ADJUSTMENT POINTS

2. DVD/CD SECTION

• Adjustment

Since this DVD/CD system incorporates the following automatic

adjustment functions, readjustment is not needed when replacing

the pickup. Therefore, different PWBs and pickups can be combined freely.

Each time a disc is changed, these adjustments are performed

automatically. Therefore, playback of each disc can be performed

under optimum conditions.

Test

Stage

Frequency Frequency

Display

Setting/

Adjusting

Instrument

Connection

Parts

FM IF 10.7 MHz 98.00 MHz T304 Input: Pin 1 of

IC301

Output: Pin 18

of IC303

• FM RF

Signal generator: 1 kHz, 75 kHz dev., FM modulated

Test

Stage

Frequency Frequency

Display

Setting/

Adjusting

Instrument

Connection

Parts

FM OSC. — 87.50 MHz (fL): L303

*1

3.4 ± 0.1 V

FM RF 98.00 MHz

98.00 MHz L302 *1

(10 ~ 20dB)

*1. Input: Antenna Output: 18 Pin of IC303

2 – 1

Page 8

XL-DV60

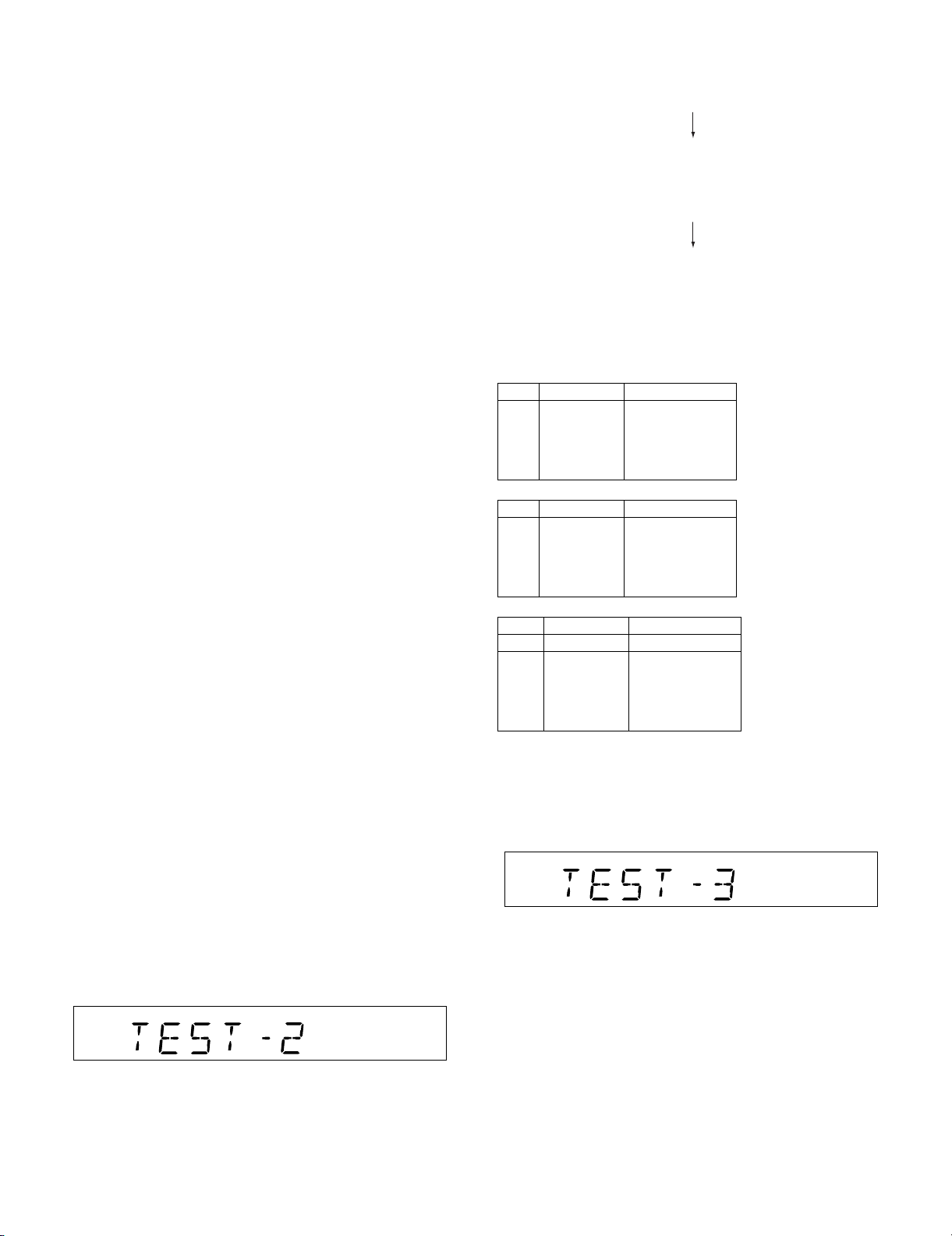

[2] TEST MODE

The test mode applied to this microcomputer has three modes, namely

the ordinary test mode for adjustment or measurement, the aging test

mode, and the self-diagnosis test mode for self-judgment in case of

final product inspection.

• The TUNER TEST 2 mode is obtained with >> + MEMORY/SET +

POWER ON/STAND-BY. ->Turn off AC in the TEST 2 mode to

restore the initial state.

1. Turning on the test mode

For obtaining each test mode, press the Power ON/STAND BY button,

while keeping pressing the following two buttons in the ordinary standby mode (power off). In this case, the main unit buttons are valid.

When turning the POWER on with remote control buttons, test modes

are not obtained.

[Ordinary test mode]

1. Tuner Test Mode (TEST 2).......................................................

TUNER(BAND) + DISC1

2. Electronic Volume Test Mode (TEST 3)...................................

TUNING DOWN + VOLUME UP

3. Timer Test Mode (TEST 4).......................................................

TUNING UP + DISC5

4. FL Test Mode (TEST 5)...........................................................

PRESET DOWN + VOLUME DOWN

5. DVD MECHANISM Aging Test Mode (TEST 8).......................

DVD/CD + Equalizer

[Self-diagnosis Test Mode]

1. Button input diagnosis test mode (TEST 6)..............................

PRESET UP + DISC5

Processes are different depending on destinations at initial settings.

2. Tuner Test Mode (TEST 2)

1. Outline of tuner (radio) test mode

The tuner test mode is intended to store the adjustment and measurement frequencies in the preset memory CH. When adjusting

the tuner section in the production line, adjusting personnel are not

required to set frequency.

2. Details of tuner test mode

Press the "TUNER(BAND)" button and "VOLUME UP" jog in

POWER OFF state and turn on the power by the use of "POWER

ON/STAND BY" button to preset and store frequency for adjustment and measurement of destination specified by the AREA terminal in the preset memory CH. However, Ordinary 1 and Ordinary 2

are stored in the destinations when the test mode is obtained.

(As for frequencies to be preset and stored for each destination, refer

to item 3.)

The tuner test mode is started from preset No.1.

The operations of test mode are identical with the ordinary operations

of TUNER function. FUNCTION switching is invalid.

It is necessary to discard the content of preset memory when the tuner

test mode is ended; be sure to write "0000" or "1111" bits in the memory to be checked for judging memory error at initial setting and to initialize memory.

When the tuner test mode is obtained, the following display lights for

one second.

Turn off POWER to protect the memory of TEST 2 mode.

Turn off POWER again to obtain the ordinary operation while the

data is stored in the memory (besides TUNER).

If AC OFF state is maintained in this state for about 1/2 day, start is

executed in the initial state.

• To clear the whole memory, insert the AC cord, pressing MEMORY/SET + PLAY.

3. Preset frequencies for various destinations

(random preset memory)

CH BAND FM

1

2

FM STEREO

3

4

5

CH BAND FM

6

7

AM

8

9

10

CH BAND FM

16-35 ——————

36

37

FM MONO

38

39

40

• The slant line sections of the table store no memory.

FM 87.5 MHz

FM108.0 MHz

FM 98.0 MHz

FM 90.0 MHz

FM106.0 MHz

AM 530 kHz

AM1720 kHz

AM 990 kHz

AM 600 kHz

AM1400 kHz

FM106.0 MHz

FM 90.0 MHz

FM 98.0 MHz

FM108.0 MHz

FM 87.5 MHz

3. Electronic volume Test Mode (TEST 3)

When this test mode is obtained, the following display lights for one

second.

In this mode, volume is Volume -14 dB (STEP 23), FLAT AND X-BASS

ON, and start-up function to DVD/CD, respectively. The button operations in the test mode are the same as those of ordinary operation

except volume UP/DOWN.

1) The display is the same as that of ordinary operation except test

mode setting.

2) Unlike the ordinary state, the volume is controlled with the volume

UP/DOWN jog in accordance with the following three steps.

Vol ume - ∞ (STEP 0) <-> Volume-14 dB (STEP 23) <-> Volume-0

(STEP 30)

3) X-BASS is switched when button is pressed.

2 – 2

Page 9

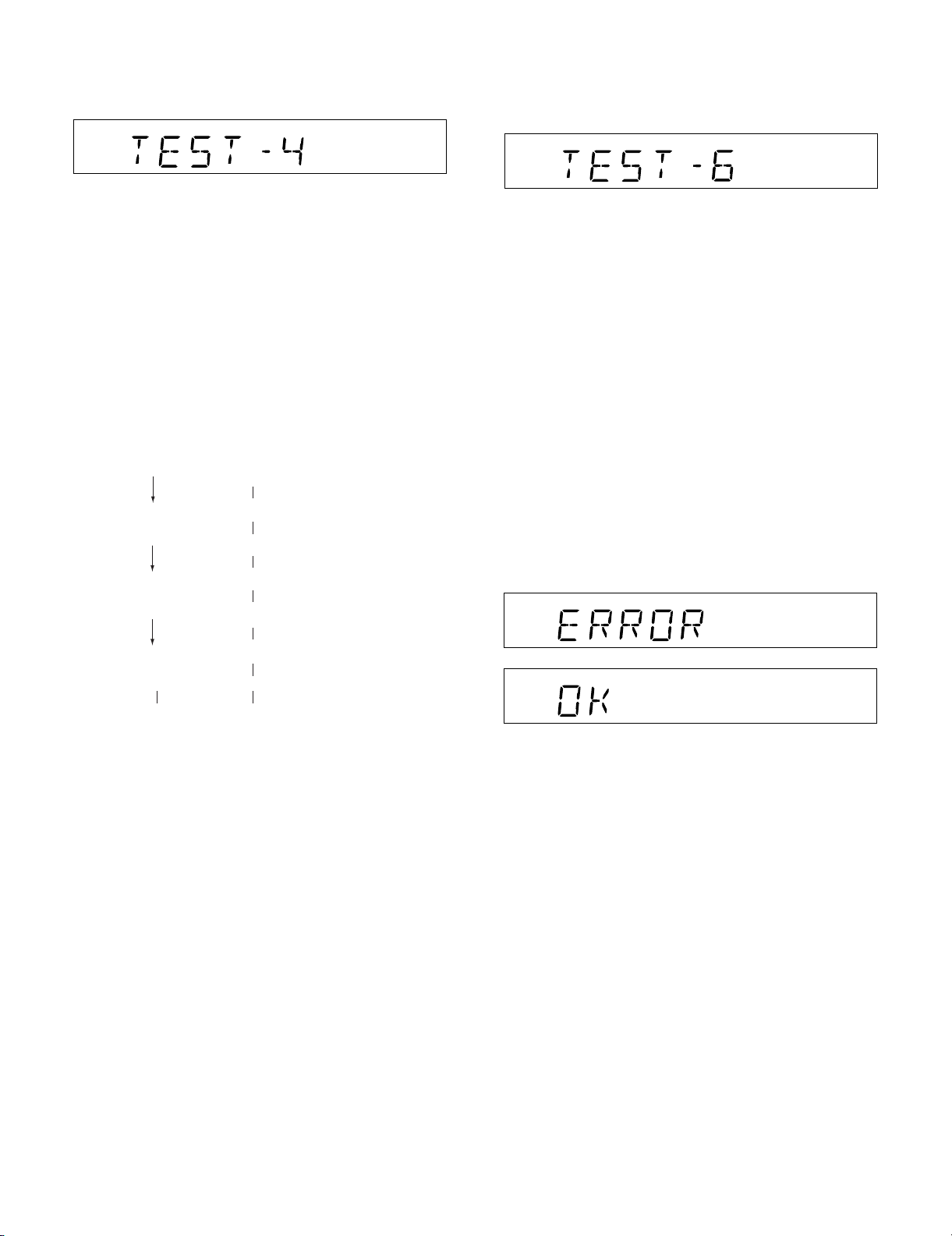

4. Timer test Mode (TEST 4)

When this test mode is obtained, the following display lights for one

second.

Set the current time and timer time according to the following procedure to reproduce the timer.

1. Set the current time to 1:00, the timer to ON time 1:05, the function

to DVD/CD, and volume to STEP 12, respectively. One minute is

counted as one second, and the timer is reproduced. The fade-in

(when playback is started) is executed at a rate of one step for 1

sec. After completion of fade-in, the fade-out is executed at a rate

of one step for 1 sec (WAIT 1 sec inserted).

After completion of fade-out, the power is turned off (after WAIT 1

sec), and the mode is shifted to the standby.

The display during operation is the same as that of ordinary timer

operation.

5. FL Test Mode (TEST 5)

When the FL test mode is obtained, all the FL segments are lighted.

Then pressing the "PLAY" button switches display as below.

————–

Lighting of all segments

XL-DV60

6. Button input diagnosis Test Mode (TEST 6)

When the test mode is obtained, the following is displayed.

(STAND-BY AND DEMO OFF STATUS)

This test mode is intended to check whether all the main unit buttons

can be detected. Accordingly, in this test mode, it is checked whether

the "POWER ON/STAND BY" button was pressed after all the buttons

shown below were pressed. If the result is OK, OK is displayed. If any

one of keys was not pressed, an error is displayed. In both cases of

OK termination or error termination, the mode is shifted to the standby

mode if the "POWER ON/STAND BY" button is pressed subsequently.

All models using this type of microcomputer are not always provided

with the same buttons. Since the buttons used are different depending

on models, types of buttons to be used are determined by whether

SURROUND, and an electric lid are available at the initial setting by

MODEL port.

The order of buttons to be pressed is not determined. Accordingly, it is

checked whether all buttons have been pressed.

1. PU-IN buttons: REW/PRESET DOWN + STOP

Since this model is provided with SURROUND (HAVE OR NOT),

and electric DVD/CD lid, the following 10 buttons are detected as

all buttons.

PLAY, X-BASS/DEMO, FUNCTION, VOLUME UP/DOWN, MEMORY/SET, REW, FF, STOP, DVD/CD-OPEN/CLOSE

The OK/ERROR display of test result is as follows.

Lighting of odd segments

Lighting of even segments

__________

2 – 3

Page 10

XL-DV60

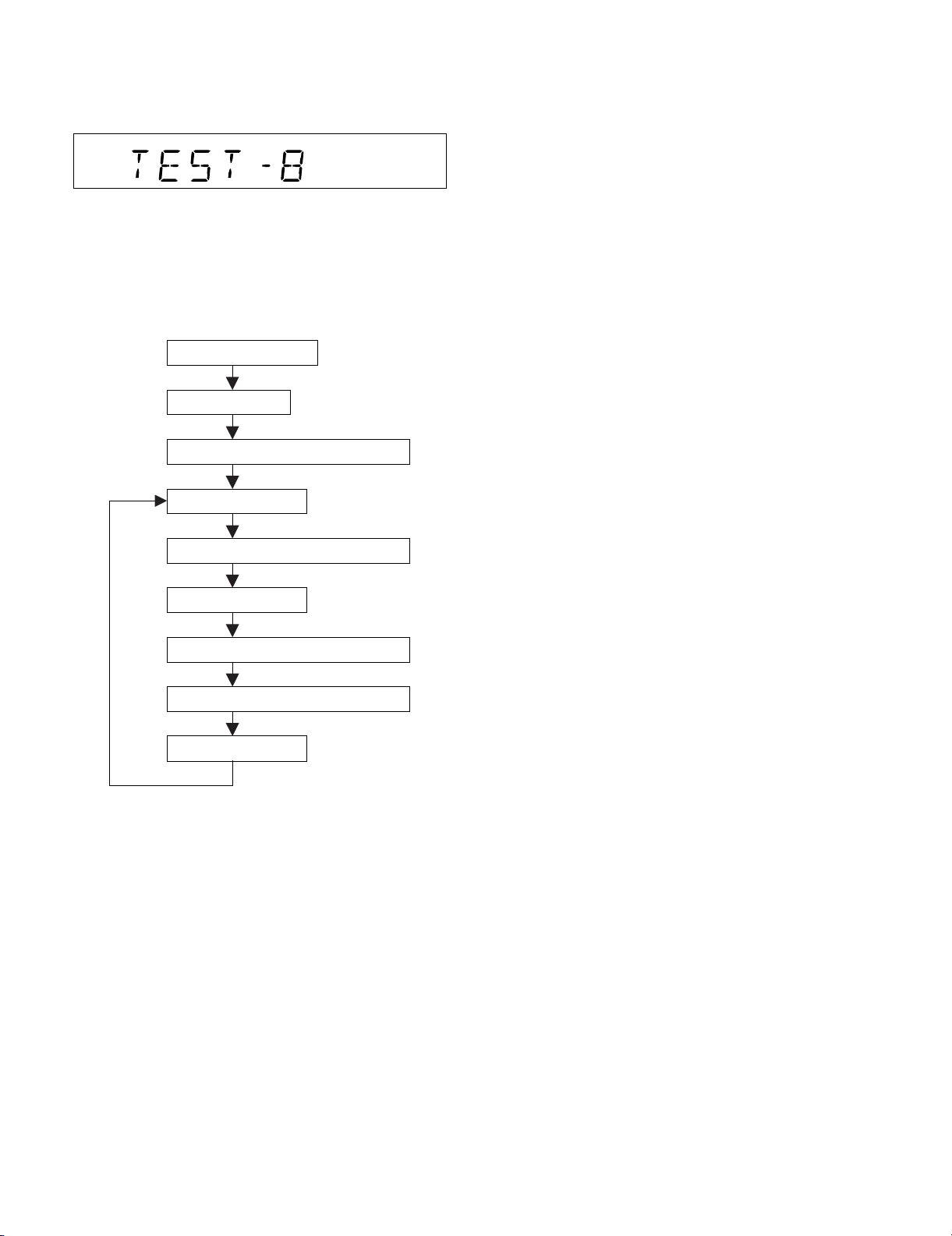

7. DVD MECHANISM Aging Test Mode (TEST 8)

OPEN/CLOSE & 5 DISC CHANGER aging test.

DISPLAY:

FUNCTION:

Enter the TEST MODE 8, MCU control the 5 DISC CHANGER OPEN/

CLOSE. After open finished, tray rotate 1 circle (360 degree). Then

close, After close finished, tray rotate 1 circle (360 degree) again.

Request:

Every period include 4 operation. Below is TIMING:

Enter test mode

CHANGER

Find the disc 1 position

open

delay 3S after open finish

rotate 1 circle

close

delay 3S after close finish

rotate 1 circle

2 – 4

Page 11

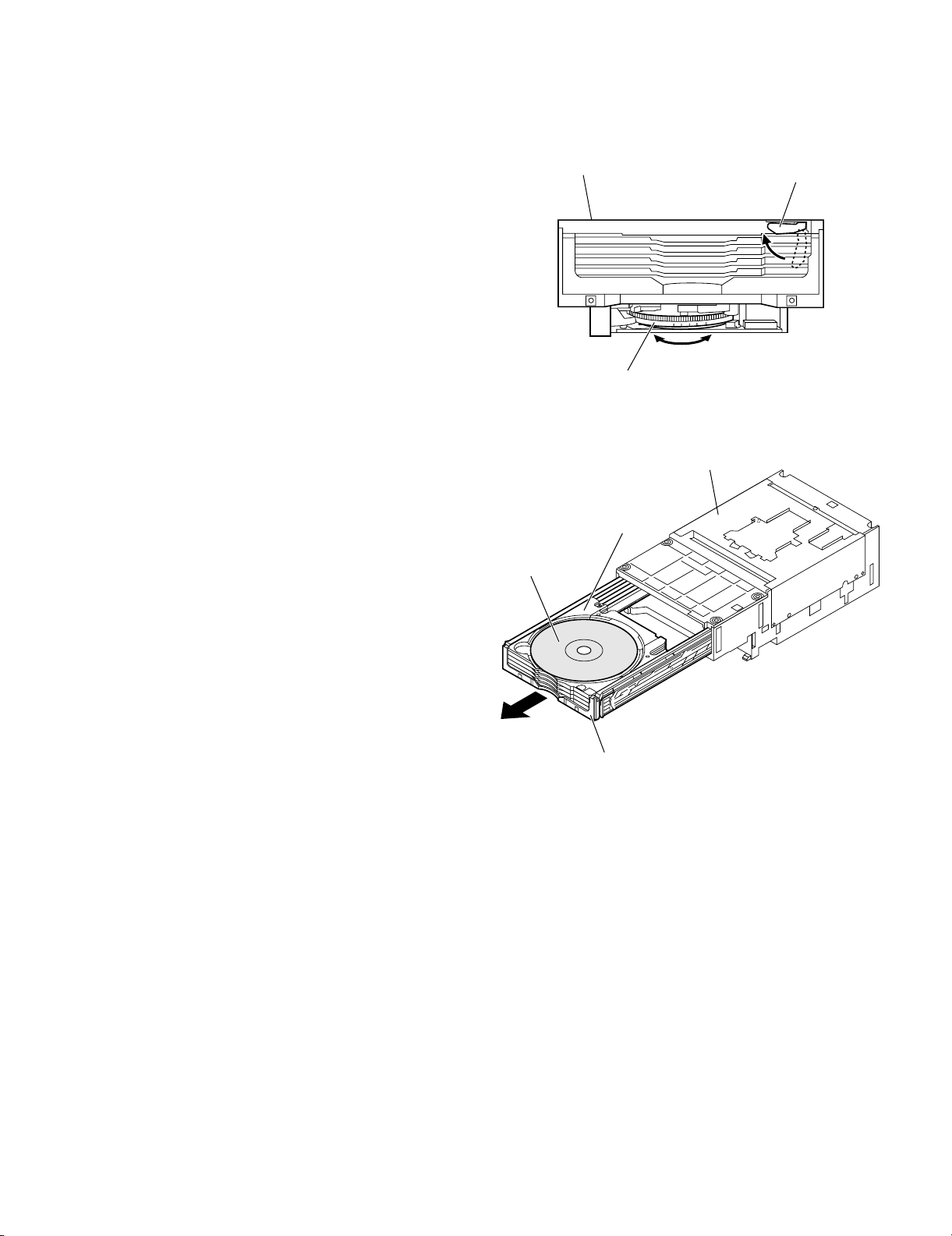

DVD Changer

Unit

DVD/CD Disc

Carriage

Drawer

Home StereoXL-DV60Service ManualXLDV60 Service ManualMarketE

CHAPTER 3. MECHANICAL DESCRIPTION

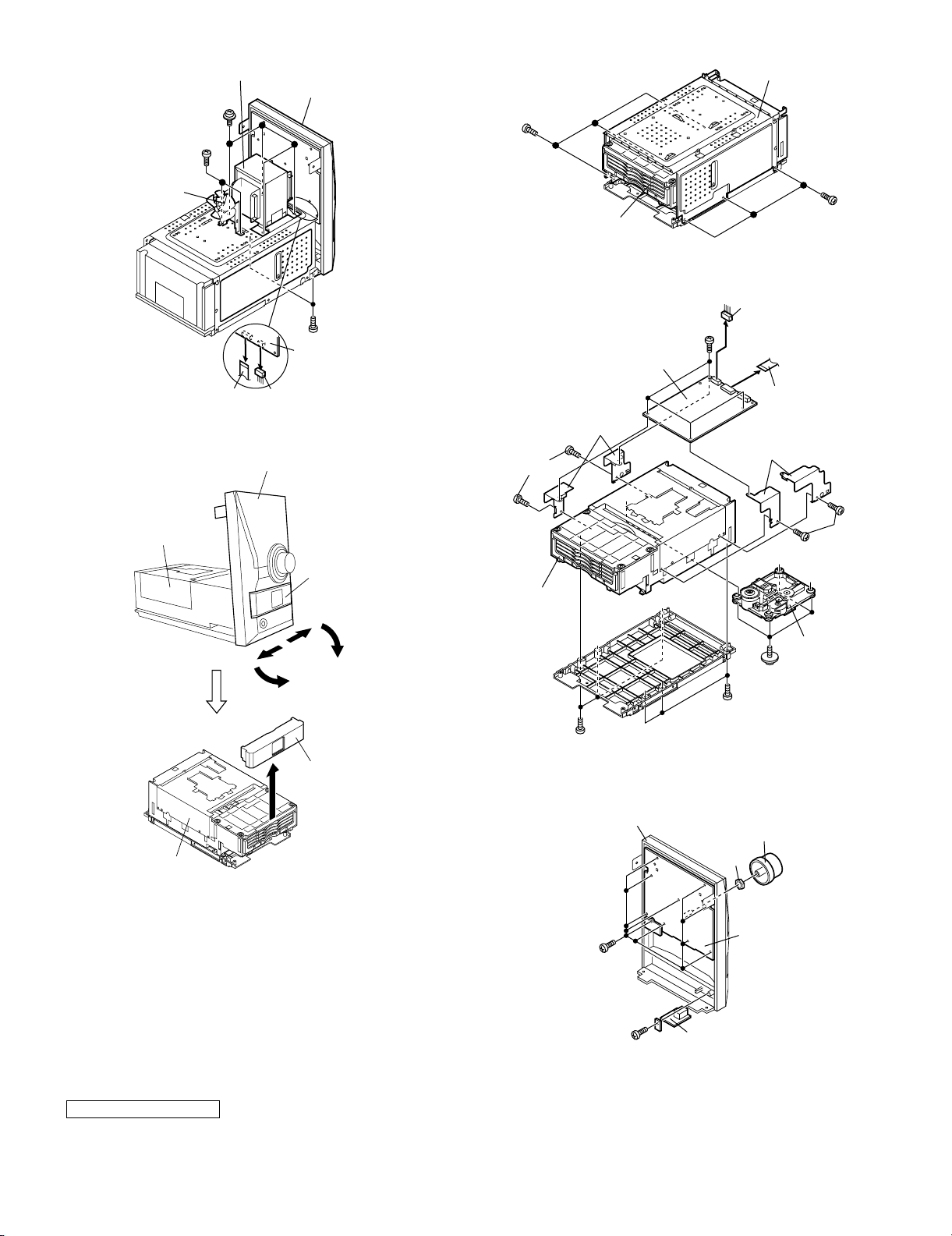

[1] REMOVING AND REINSTALLING THE MAIN PARTS

1. How to remove DVD/CD Disc manually (See Fig.

1,2)

Perform steps 1 to 9 of the disassembly method to remove the DVD

Changer unit.(see page 3-2,3-3)

1. Rotate the gear cam until the arm switch C becomes the position of

the Figure 1.

2. Pull the drawer to the front like the Figure 2.

And the DVD/CD disc on the carriage is taken out.

DVD Changer

Unit

XL-DV60

Arm switch C

Gear cam

Figure 1

Figure 2

3 – 1

Page 12

XL-DV60

(A1) x2

ø3x8mm

(A1) x2

ø3x8mm

(B1) x2

ø3x8mm

(B1) x2

ø3x12mm

(B1) x2

ø3x10mm

(B1) x2

ø3x8mm

(A1) x1

ø3x8mm

Top Cabinet

Side Panel

(Left)

Side Panel

(Right)

Rear

Panel

(E1) x1

ø3x12mm

(F1) x1

ø3x6mm

(E1) x2

ø3x6mm

(E2) x2

(E2) x1

(E2) x1

Main PWB

Power Amp.

PWB

(E2) x1

(E2) x3

(E2) x2

Front Panel

(F1) x3

ø3x6mm

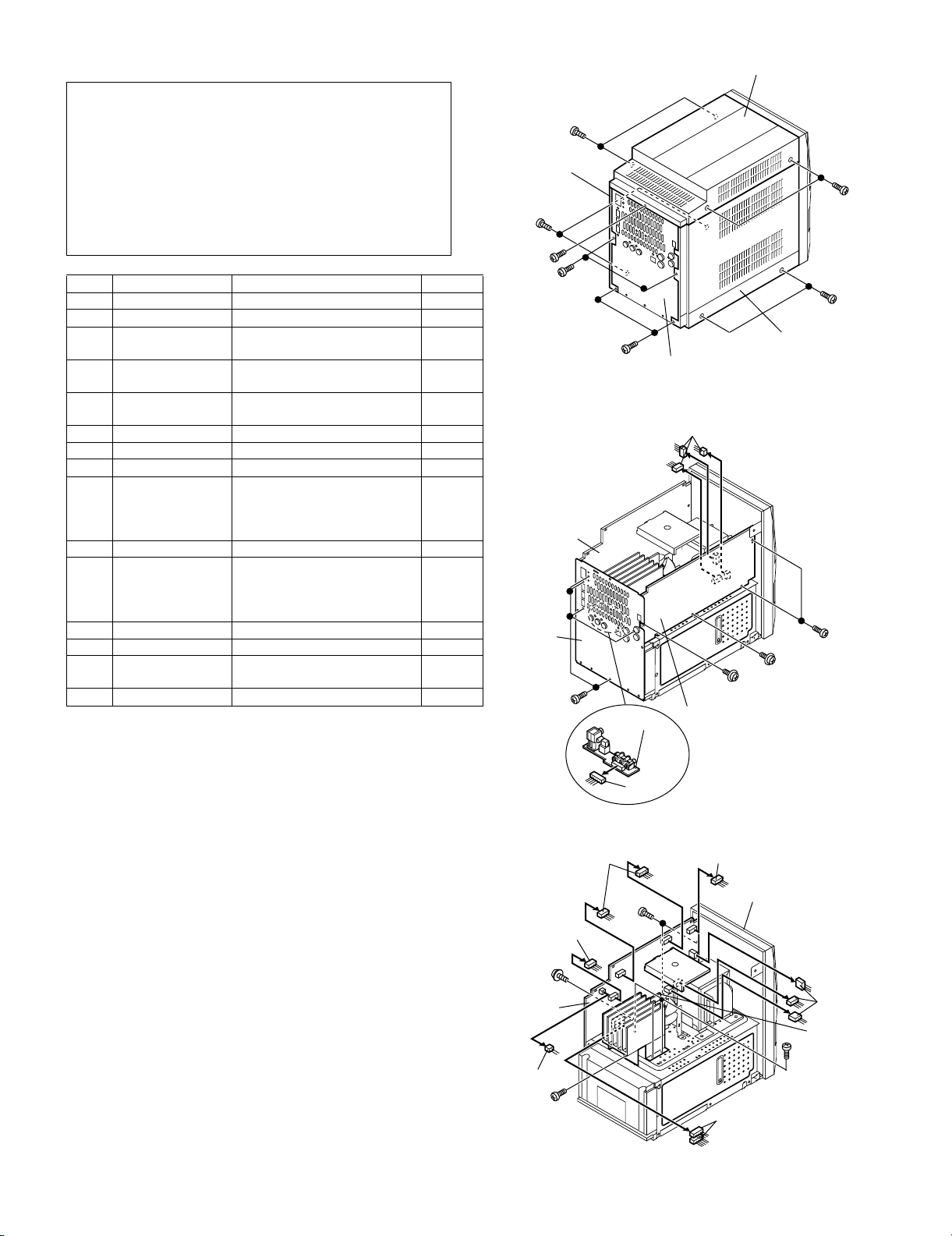

[2] DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling the unit and

reassembling it, to keep it safe and ensure excellent performance:

1) Be sure to remove the power supply plug from the wall outlet

before starting to disassemble the unit.

2) Take off nylon bands or wire holders where they need to be

removed when disassembling the unit. After servicing the unit,

be sure to rearrange the leads where they were before disassembling.

3) Take sufficient care on static electricity of integrated circuits and

other circuits when servicing.

STEP REMOVAL PROCEDURE FIGURE

1 Top Cabinet 1. Screw.........................(A1) x 5 1

2 Side Panel 1. Screw.........................(B1) x 8 1

3 Rear Panel 1. Screw........................(C1) x 6

2. Socket.......................(C2) x 1

4 Tuner PWB 1. Screw........................(D1) x 3

2. Socket.......................(D2) x 3

5 Main PWB 1. Screw.........................(E1) x 3

2. Socket.....................(E2) x 10

6 Power Amp.PWB 1. Screw.........................(F1) x 4 3

7 Transformer 1. Screw........................(G1) x 4 4

8 Fan Motor 1. Screw........................(H1) x 2 4

9 Front Panel/DVD

Tray Cover

1. Screw.........................(J1) x 2

2. Flat cable...................(J2) x 1

3. Socket........................(J3) x 1

4. DVD Tray cover..........(J4) x 1

10 Chassis 2. Screw........................(K1) x 6 6

11 DVD PWB

(Note 1)

1. Flat cable...................(L1) x 1

2. Socket........................(L2) x 1

3. Screw.........................(L3) x 4

4. Screw.........................(L4) x 4

12 DVD Changer Unit 1. Screw........................(M1) x 6 7

13 DVD Mechanism 1. Screw........................(N1) x 4 7

14 Display PWB 1. Knob.........................(P1) x 1

2. Screw......................(P2) x 10

15 Jack PWB 1. Screw........................(Q1) x 1 8

Note 1:

After removing the connector for the optical pickup from the connector,

wrap the conductive aluminium foil around the front end of the connector so as to protect the optical pickup from electrostatic damage.

2

2

3

4

5

7

8

Main PWB

Rear

Panel

(C1) x5

ø3x10mm

Video Terminal

PWB

(C2) x1

Figure 1

(D2) x3

(C1) x1

ø3x12mm

Tuner PWB

(D1) x2

ø3x6mm

(D1) x1

ø3x12mm

Figure 2

Figure 3

3 – 2

Page 13

(H1) x2

(K1) x3

ø3x8mm

(K1) x3

ø3x8mm

DVD Changer

Unit

Chassis

(M1) x3

ø3x8mm

(M1) x3

ø3x8mm

(N1) x4

ø2.5x10mm

(L3) x4

ø3x6mm

(L4) x2

ø3x6mm

(L4) x2

ø3x6mm

Bracket

(L1) x1

(L2) x1

DVD Changer

Unit

DVD PWB

DVD Mechanism

Bracket

(P2) x10

ø2.5x8mm

(Q1) x1

ø2.5x8mm

(P1) x1

Nut

Front Panel

Display PWB

Jack PWB

ø3x6mm

Fan Motor

Transformer

(G1) x4

ø4x10mm

(J2) x1 (J3) x1

Figure 4

Front Panel

Front Panel

(J1) x2

ø3x12mm

Display PWB

XL-DV60

Figure 6

DVD Changer

Unit

DVD Changer

Unit

Figure 5

DVD Tray Cover

DVD Tray Cover

(J4) x1

Figure 7

CP-DV60F, CP-DV60SW

These speaker CP-DV60F, CP-DV60SW are available in assembles

only and may not be disassembled.

Figure 8

3 – 3

Page 14

XL-DV60

+5V+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B

3.3K

LM2576T

KIA7812API

31

KIA7805API

31

9

POWER TRANSFORMER

(MAIN)

8

7

6

5

4

3

2

1

2

2

+5.6V

+7V

3.15A 125V

GNDA

2A 125V

VCCA

VCC2

GNDRF

GND

VCC1

S12V

+10V

MGND

6.3A 125V

6.3A 125V

VF1

VF2

+B1

-B1

AGND

+B2

DGND

DGND

3.8V

3.8V

-30V

-B

-B

-B

-B

-B

D_GND

+5.6V

P_CON

NC

NC

VEE

VCC

+12V

GND

S/W

R_CH

A_GND

L_CH

1

4

7

3

2

5

6

1

7

5

2

6

4

8

3

2345

1234

5

4

6

2

3

1

7

1

TO TUNER PWB

FROM DVD PWB

FROM

DISPLAY PWB

A GND

A GND

VOLTAGE

REGULATOR

VOLTAGE REGULATOR

CNW602

CNS602

CNP807

R155

IC203

IC201

IC202

CNP101

D205

C211

D201

F201

F202

F204

C212

T201

F203

Q101

Q102

Q117

Q118

Q213

Q214

Q115

Q116

Q201

Q207 Q208

Q203

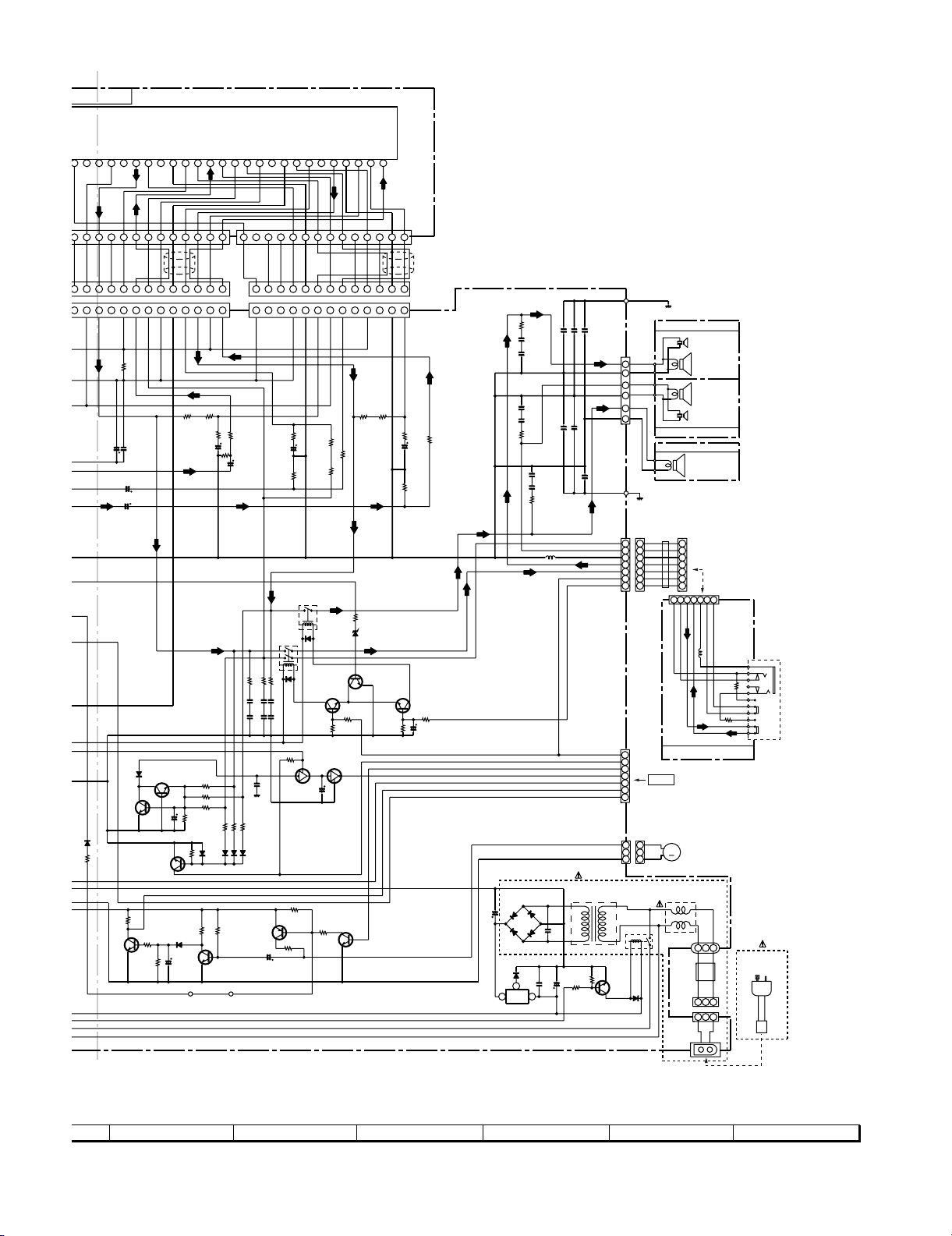

CHAPTER 4. DIAGRAMS

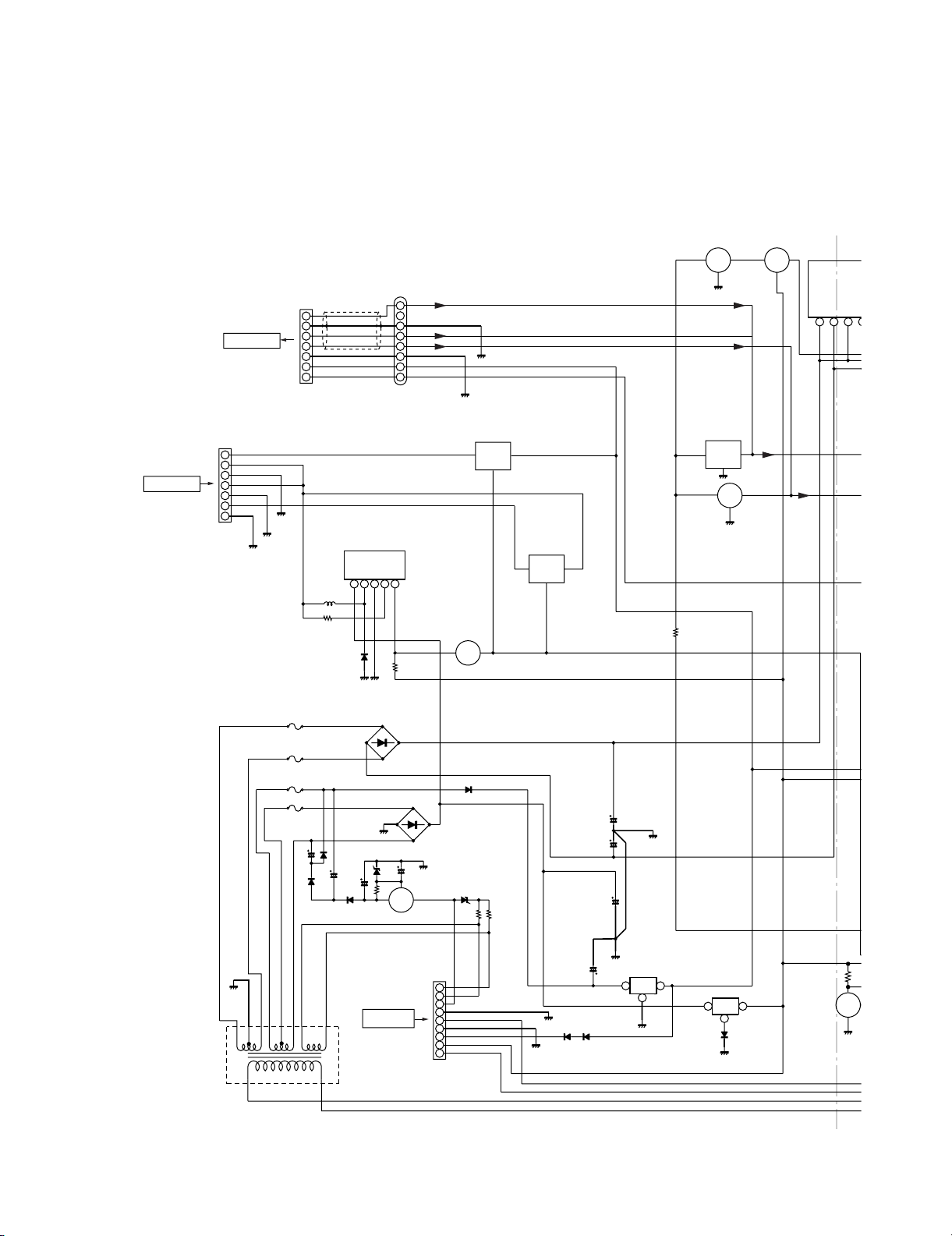

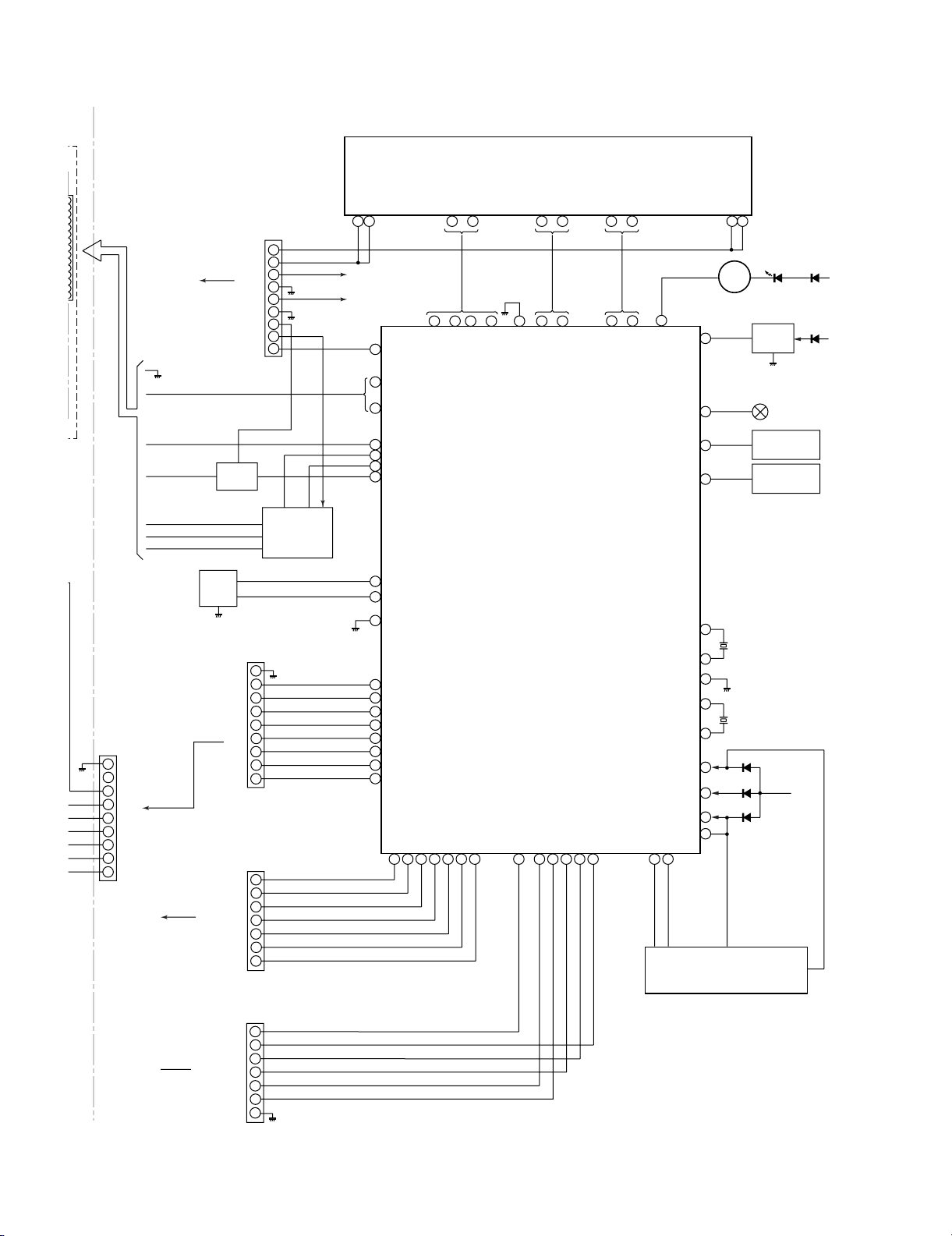

[1] BLOCK DIAGRAM MAIN

Figure 4-1 BLOCK DIAGRAM (1/6)

4 – 1

Page 15

+

IC101

LM4733TA

POWER AMP.

S/W_RF

MUTE3

GND

S/W_OUT

NC

R_RF

MUTE2

GND

NC

VEE

R_IN

R_OUT

L_RF

L_IN

MUTE1

GND

NC

VEE

L_OUT

NC

VCC

NC

NC

VEE

VCC

123456789101112131415161718192021222324252627

B +B

-B

VCC

-B

S/W_IN

+

-

+

-

+

-

SO101

SPEAKER TERMINAL

L-CH

FRONT SPEAKER

R-CH

SUB WOOFER

XL-DV60

RIN

ROUT

A_GND

LOUT

LIN

+B

L

+B

B

-B

Q107

Q108

R

RLY101

R158

Q110

RLY102

+B

Q111

R

L

Q112

Q113

Q114

+B

SUB_RELAY IN

SUB_RELAY OUT

SP_RELAY

SINGAL_LVL

FAN_START

SP_DETECT

P_MUTE

FAN_PRO

CD+B

CNP102

1

2

3

4

5

6

7

FROM DISPLAY PWB

1

3

11

10

2

9

8

7

6

5

4

JK101

HEADPHONES

Q109

T202

+B

+B

D214~217

POWER TRANSFORMER

(SUB)

LF201

LINE FILTER

Q203

M

M201(218-4)

Q205

IC204

AN78L05

CONSTANT VOLTAGE

REGULATOR

+B

31

2

RLY201

SO202

AC

SOCKET

Q206

+B

AC POWER

SUPPLY CODE

AC 120V 60Hz

Q204

Q202

FAN MOTOR

+B

Figure 4-2 BLOCK DIAGRAM (2/6)

4 – 2

Page 16

XL-DV60

M

C

D

J

D

C

S

F

D

D

S

C

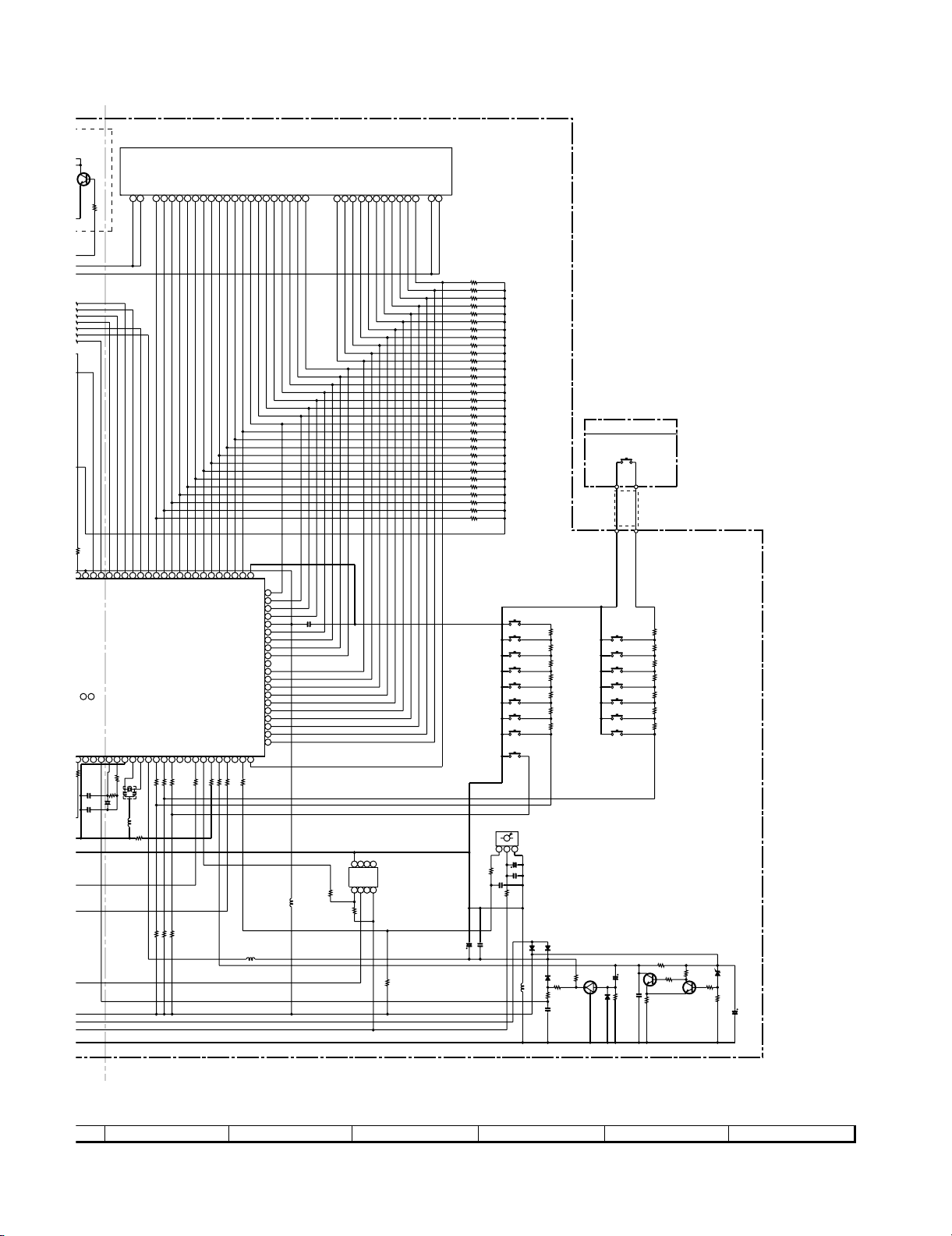

C

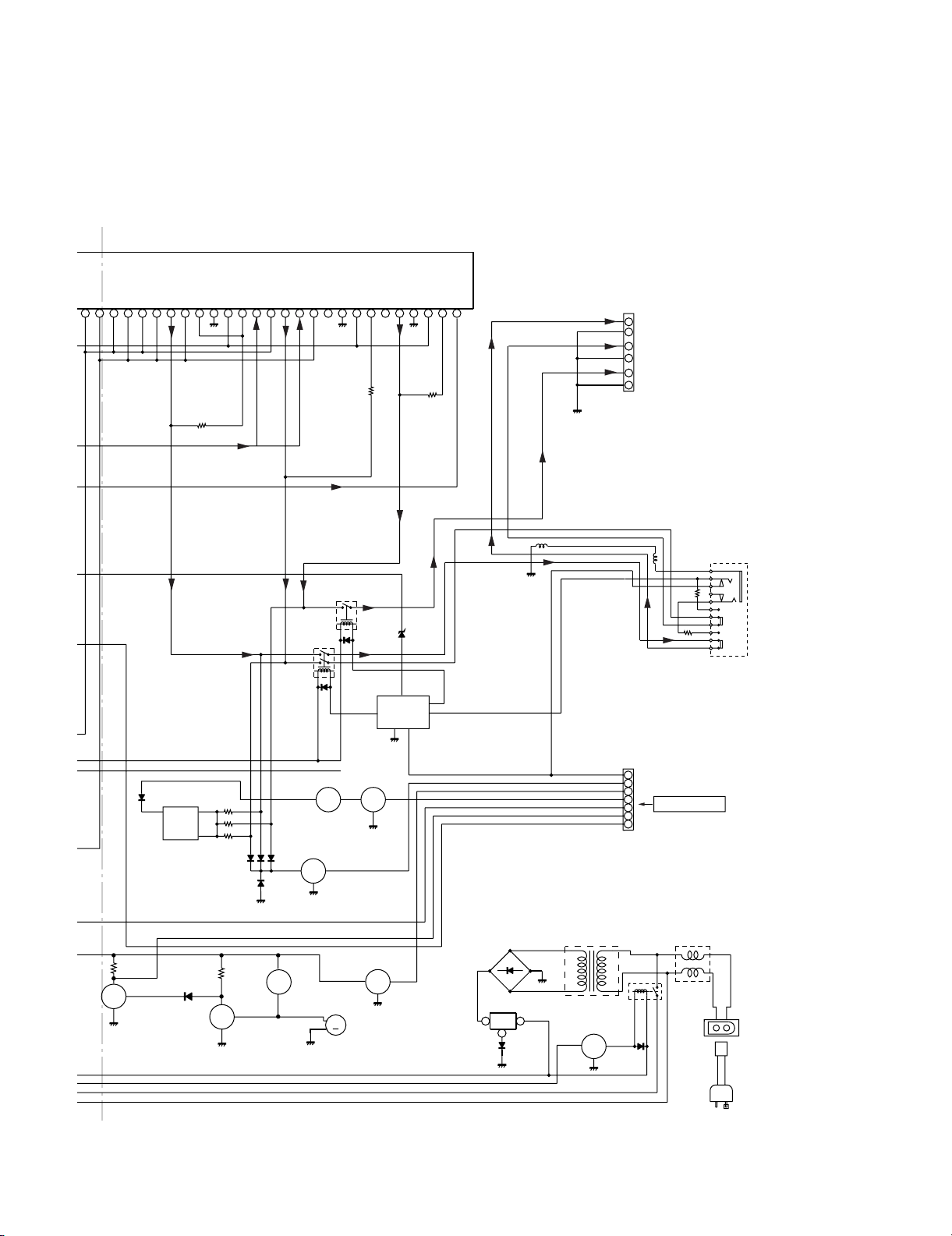

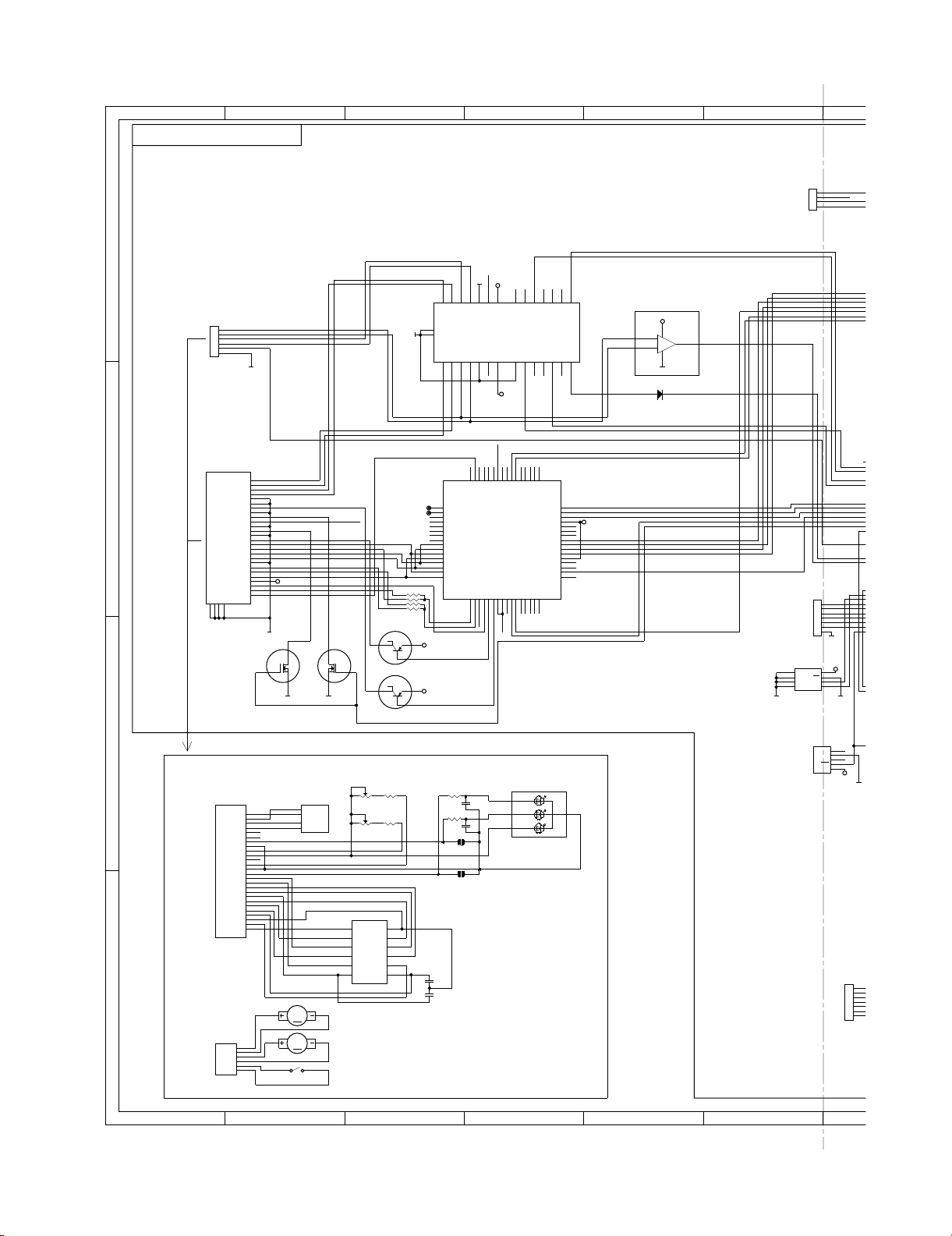

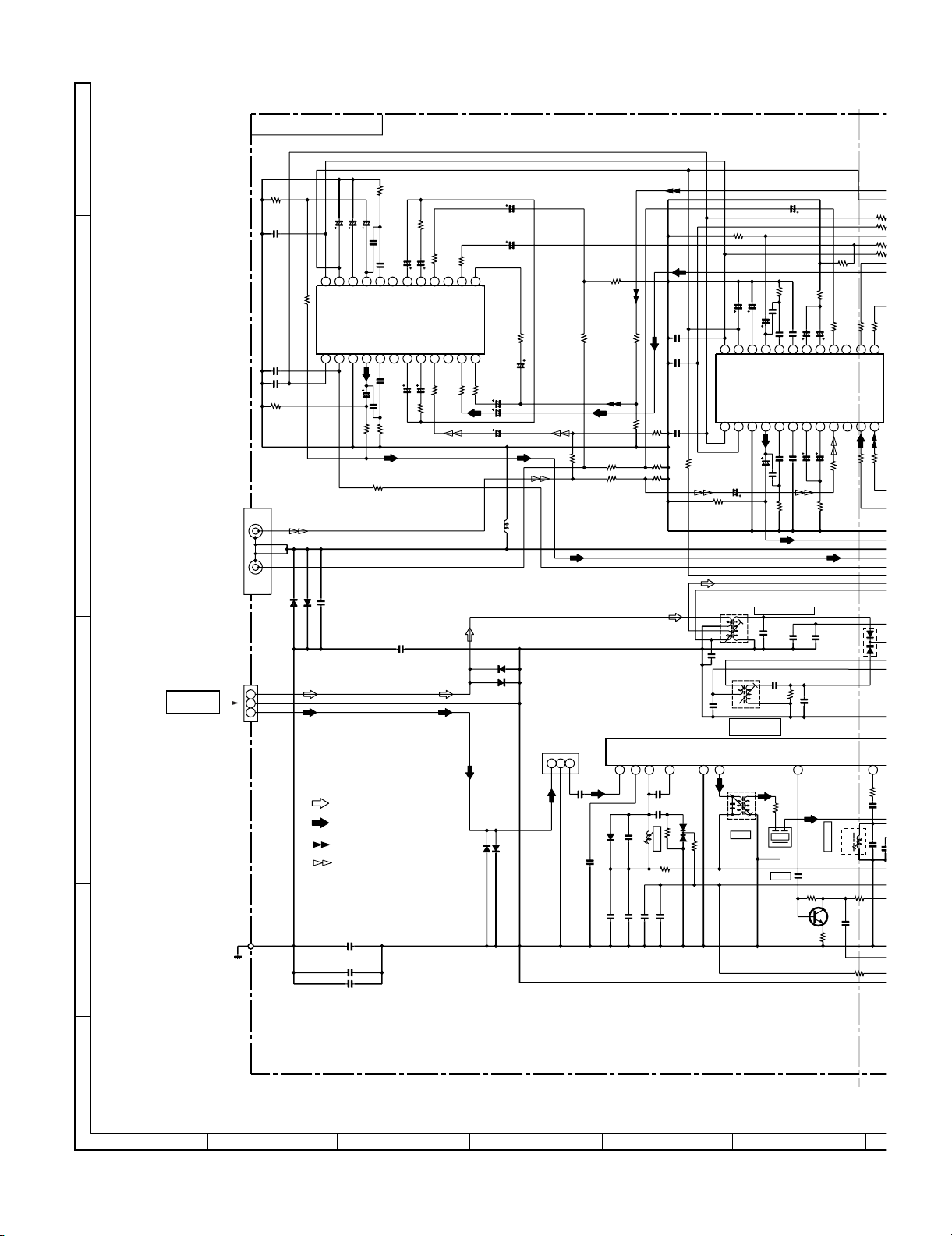

[2] BLOCK DIAGRAM TUNER/DISPLAY

+7V

+12V

D_GND

SW_CH

R-CH

A_GND

L-CH

CNP602

7

6

5

4

3

2

1

SO601

VIDEO/AUX

AUDIO IN

L-CH

R-CH

+B5

SW_CH

A_12V

+B5

8

IC602

1

NJM4558D

BUFFER AMP.

4

+7V

23

VDD

LC75341M

SIGNAL CONTROL

CLDICE

3

L/R OUT

214

IC603

DVD DECODER SECTION

L

R

1624 921

DVD/CD_SUB

1312

R

L

R

L

1411

+7V

24 21

AUX_L/R

L/R OUT

21423

L

R

IC601

VDD

LC75341M

SIGNAL CONTROL

CL

L

CE

TUN_L/R

R

169

DI

DVD/CD_L/R

1312

L

R

33

L

R

1411

MOTOR

SOLENOID

CE_WOOF

DI

CE

CL

CD CHANGER PWB ASS'Y

PHOTO

INTERRUPTER

M

D_GND

SW4

SW3

SW5

SW6

SW2

SW1

SW7

CD_PH2

CD_PH3

MM+

CD_SOL1

MM-

CD_SOL2

SW8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

AM LOOP/FM

ANTENNA

CNP301

14

LA1832S

FM IF DET.

FM MPX./AM IF

DO

CL

DI

CE

A_12V

+B5

IC303

CNP302

1

2

3

4

5

6

7

8

9

TO

TO

IC301

TA7358AP

B.P.F

BF301

FM

3

2

AM

1

FM FRONT END

1

384

L302

FM RF

AM

TRACKING

T302 T306

FM OSC

+B6

7

5

L303

AM BAND

COVERAGE

FM IF

OSC

BUFF

Q302

FM+B

CF303 CF302T304

VT

SWITCHING

Q306

IC302

LC72131

PLL(TUNER)

+B5

Q360

450 kHz

T351

CF352

AM IF

21

OUT

AM MIX

IF OUT

21

10

AM OSC IN

AM OSC OUT

AM RF IN

X352

4.5 MHZ

20 22 11 12

AOUT

21

FM

1615

XIN

7

IF REQ

AM IN

FM IN

XOUT

CLK

DI

CE

FM

5413

6

6

9

7SD6

STEREO

IF IN

DO

4

AM IF

9810

10.7 MHz

CF351

98517

FM

DET

GND

FM+B

VCO

FM/AM

OUT

MPXIN

18

1215162324

Q351

17

MUTE

MO/ST

FM/AM

+B5

ZD351

5.1V

X351

456 kHz

13

L

MO/ST

R

FM/AM

Figure 4-3 BLOCK DIAGRAM (3/6)

4 – 3

Page 17

XL-DV60

0

1

2

3

4

5

VFD701

FL DISPLAY

VF2

CNS101

3.8V

1

VF1

3.8V

VF2

2

-30V

3

P_CON

Q502

Q503

Q511

-B2

D_GND

+5.6V

M_GND

+10V

+5.6V

4

5

6

7

8

9

+5.6V(MOTOR)

TO MAIN PWB

CNP101

D_GND

SW1~8

CD_PH3

CD_SOL1,2

3940

+5.6V(SYSTEM)

P_CON

6

SW1

64

~

~

SW8

71

CD_PH

73

MM+

74

MM-

75

CD_SOL

76

37 22

~

50

63

P20

47

52

~

~

~

~

P8

P9

21 18

~

4551

42

~

~

P5

P4

VP

14 4

~

40 30

~

~

P1

11G

1G

TIMER_LED

POWER_KEY

KEY2

KEY1

IRQ

VF1

112

LED701

Q705

REMOTE

SENSOR

29

20

19

18

RX701

SW709

POWER

ON/STAND-BY

KEY

SW710~SW717

KEY

SW701~SW708

+5.6V

(SYSTEM)

+5.6V

(SYSTEM)

CNP302

1

2

3

4

5

6

7

8

9

TO MAIN PWB

MM-

CD_PH2

MM+

D_GND

SUB_WOOF_SEL

CE_WOOF

SD

FM_ST

DO

CL

CE

DI

CNP102

SW700

VOLUME

JOG

D_GND

SUB_WOOF_SEL

CE_WOOF

FM_ST

SP_RELAY

SIGAL_LVL

FAN_START

SP_DETECT

P_MUTE

FAN_PRO

CD+B

SD

DO

CL

CE

DI

CNS302

1

2

3

4

5

6

7

8

9

CNS102

1

2

3

4

5

6

7

Q504~Q509

CHANGER

MOTOR

DRIVER

IC701

IXA009SJ

JOG_DOWN

77

JOG_UP

78

VSS2

89

2

SUB_WOOF_SEL

100

CE_WOOF

80

SD

79

FM_ST

91

DO

87

CL

85

CE

86

DI

FAN_PRO

FAN_START

SP_DETECT

SP_RELAY

SINGAL_LVL

88 94 927 8 23 83 9527 96 11 2697 98 99

P_MUTE

SYSTEM

MICROCOMPUTER

DVD_STB

CD+B

DVD DI

CF2

16

X702

15

14

13

12

17

90

46

72

RESET

X701

8MHz

32.768 kHz

+B3

CF1

VSS1

XT2

XT1

VDD1

VDD2

VDD3

CLID_OUT

DVD BUSY

DVD CLK

DVD DO

RESET

VDD4

SYS_STOP

Q702,Q703,Q704

TO DVD PWB

J5

DVD_STB

CLID_OUT

DVD BUSY

DVD CLK

DVD DI

DVD DO

D_GND

CNP802

1

2

3

4

5

6

7

Figure 4-4 BLOCK DIAGRAM (4/6)

4 – 4

Page 18

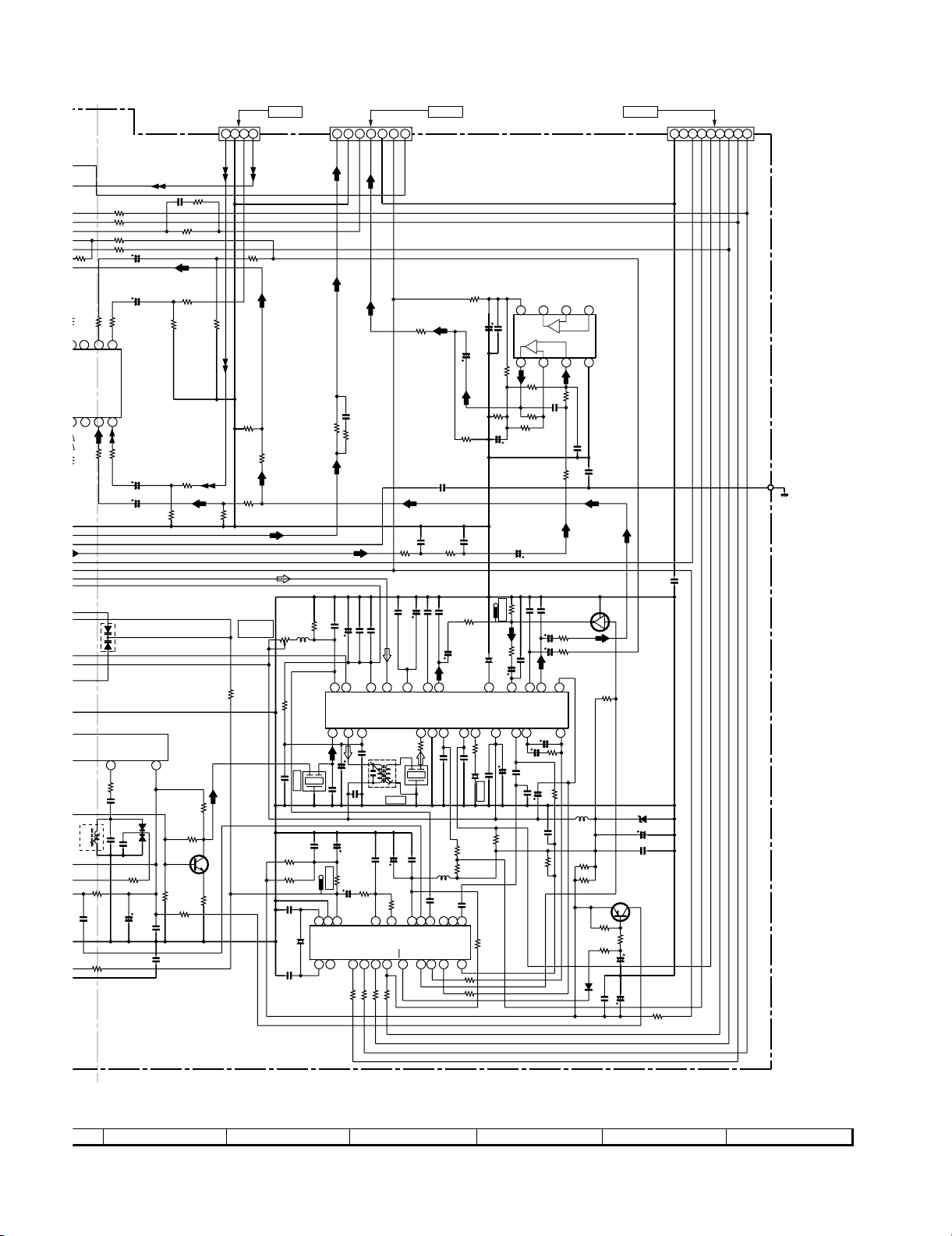

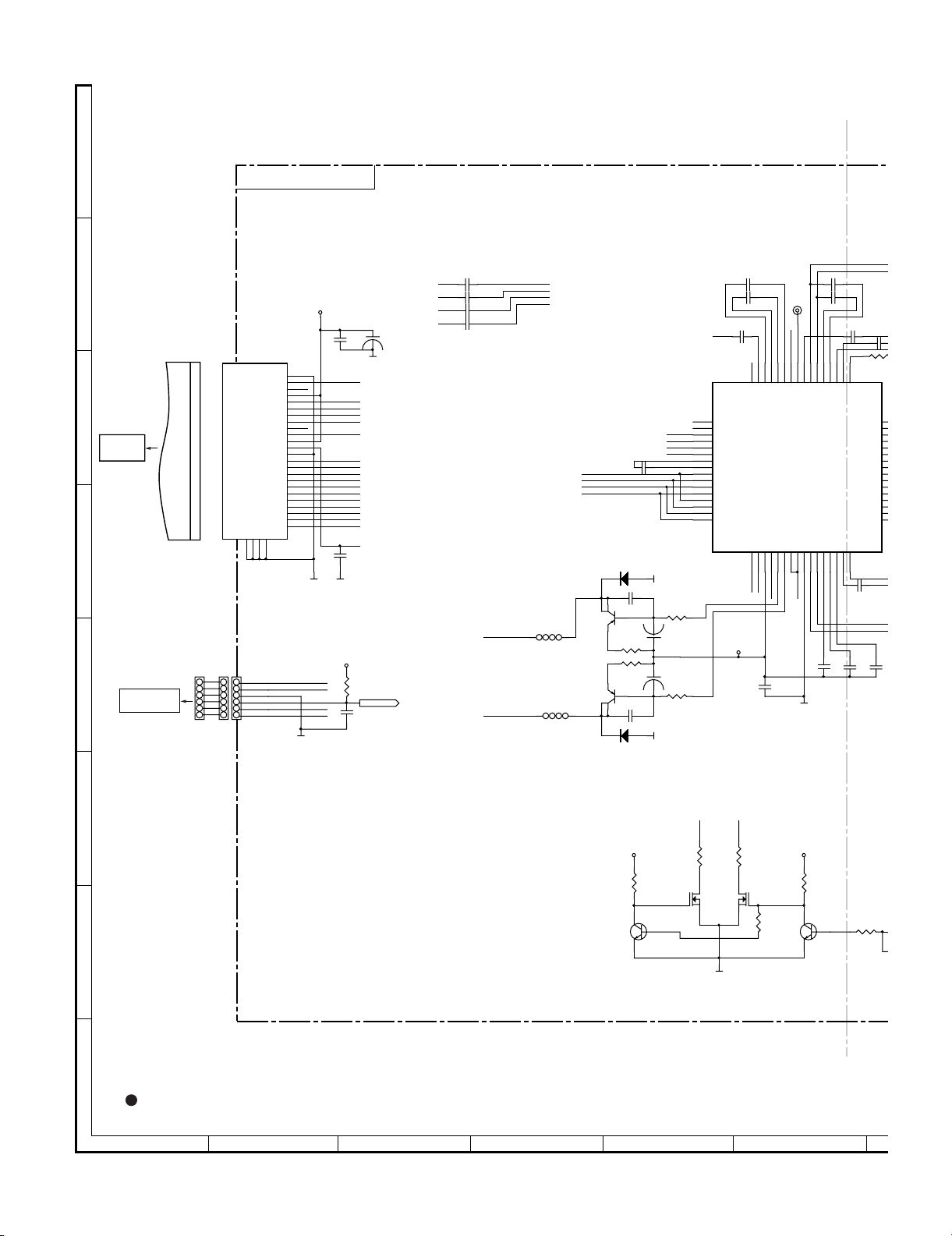

XL-DV60

T

A

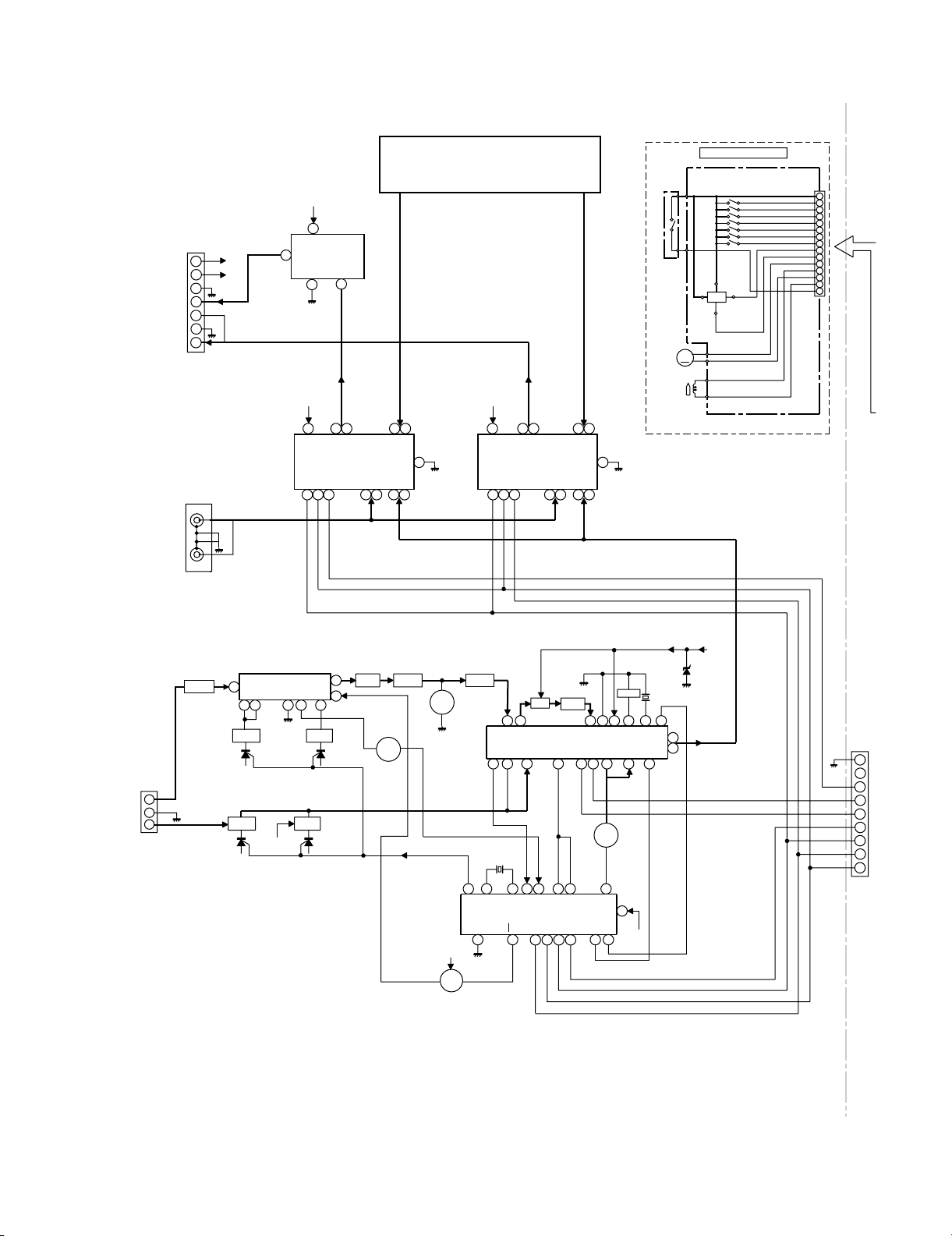

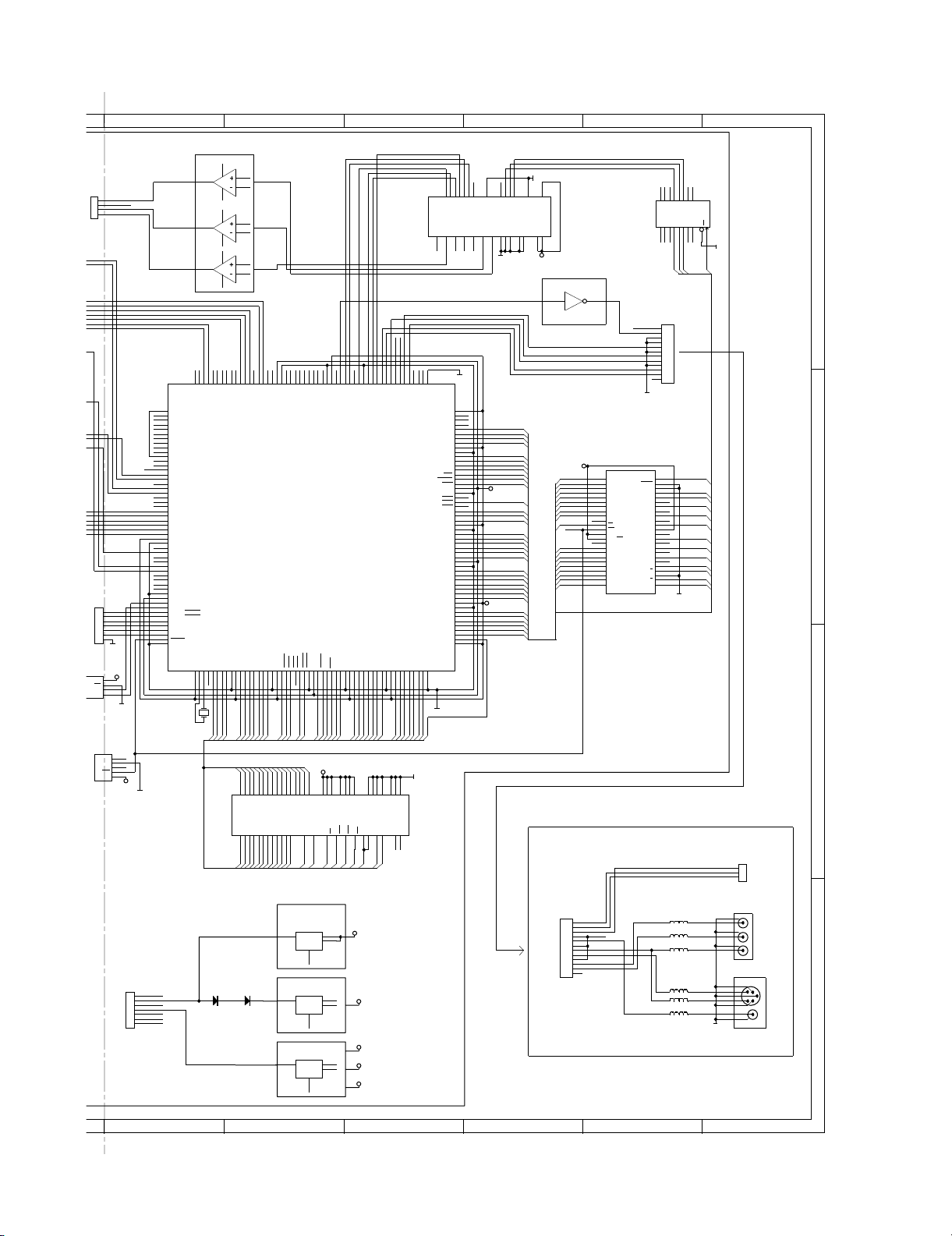

[3] BLOCK DIAGRAM DVD

DECODER SECTION

D

J4

LOAD-/DCMO-

1

LOAD+/DCMO+

2

SLED+

3

SLED-

4

5

6

CON6

MGND

JP1B

C

B

GND(NC)

GND(NC)

LD(CD)

(GND)

VR(CD)

GND(NC)

VR(DVD)

(GND)

LD(DVD)

(GND)

(VCC)

VS(VCC)

GND27GND28GND29GND

RFOUT

30

KHM-280 (JP26-0.5MM)

PICKUP UNIT ASS'Y

TRKTRK+

FCS-

FCS+

LD(780nm)

GND(780nm)

VR(780nm)

VR(650nm)

GND(650nm)

LD(650nm)

GND(PDIC)

VCC

KHM-280CN

A

DVD MECHANISM UNIT ASS'Y

SPINDLE+

SPINDLE-

SLED+

SLEDLIMIT_SW

LIMIT_SW

MOTOR_CN

TRACK-

26

TR-

TRACK+

25

TR+

24

FOCUS-

FO-

FOCUS+

23

FO+

22

21

CDLDO

20

19

VRCD

18

PD

17

PD

16

VRDVD

15

14

DVDLDO

13

12

B

B

11

E

E

10

D

D

9

C

C

8

7

H

6

G

G

A

5

A

4

RF50V

PVC

3

2

F

F

RFOUT

1

RFGND

3

Q12

2SK3018

2

1

RFGND

26

25

24

23

22

NC

21

NC

20

19

18

17

PD

16

NC

15

14

13

12

B

11

E

10

D

9

C

8

7

H

6

G

5

A

4

3

VC

2

F

1

RF

SPINDLE MOTOR

12

12

1

2

3

SLED MOTOR

4

5

6

SW-SPST

RFGND

A

Focus+Tracking tot a

must be 150mA RMS o

1

TRK+

2

TRK-

3

FCS-

4

FCS+

2-AX1S

M

M

R68 1K

R67 1K

R64 1K

R65 1K

Q11

2SB1132

4

3

1

Q13

2SK3018

2

1

Q10

2

2SB1132

4

2

1

0

6.8K

0

2.2K

7

VC6RF

8

9

10

11

12

5

H

G

4

C

B

3

D

A

2

E

F

1

GND

VCC

PH561L

Spindle Motor

Rated Voltage(DC): 3.0V (1.7-6.0);

Rated load: 0.392mN.m;

Current(At rated voltage and load): 105mA or less;

Sled Motor

Rated Voltage(DC): 3.0V (1.6-6.0);

Rated load: 0.392mN.m;

Current(At rated voltage and load): 92mA or less;

MGND

654321

J1

L_OUT

1

GNDA

2

TO TUNER PWB

MVCC

VCC

MGND

14

29

GND

30

GND

VOLD+

VOTK+

VOLD-

VOTK-

17

16

15

LOAD+/DCMO+

TRACK-

TRACK+

RFDC

1

DVDFRP

2

DVDRFN

3

A2

4

B2

5

C2

6

D2

7

CP

8

CN

9

D

10

C

11

B

12

A

13

CD_D

14

CD_C

15

CD_B

16

CD_A

CD_F

3

RF50V

3

RF50V

4.7

4.7

1uF

12

SHORT-LAND

12

SHORT-LAND

PD IC: PH561L

VCC: 4.5V-5.5V

VC: 2.2V-(VCC2

A,B,C,D: Focus Erro

E,F,G,H: Track Erro

RF: RF Output

0.1uF

0.1uF

VCC8PVCC19PGND10VOSL-11VOSL+12VOFC-13VOFC+

PVCC2

VNFTK

PGND

21

20

19

18

LOAD-/DCMO-

MVCC

RF50V

64

63

ATOP62ATON61AIN60AIP59VPA58RFAC57BYP56DIN55DIP54FNP53FNN52VNA

RFSIN

U7

ES6603S

RF AMP.

DVDPD

DVDLD

CDPD

CDLD

CD_E

VNB

VPB

17

18

19VC20

21

22

23

24

25

PD

PVC

CDLD

DVDLD

RF50V

1

1uF

4

SLD6261ALI

7

PREGND

VINLD

22

LDON

MIRR

26

27MP28MB29

LDON

MIRR

DVD_LD

CD_LDPDGND

SLEGN

CTKERR125CTKERR2

24

23

SPINDLE

51

49

MEV50RX

SDATA

MEVO

MLPF

MIN

30

31

32

VLD: 4.75V- 5

MNTR

SDEN

SCLK

FOCUS

MOTOR DRIVER

BA5954FP

2

U8

VINFC1CFCERR1

CFCERR23VINSL+4VINSL-5VOSL6VNFFC

LOAD-/DCMO-

VINTK

26

TRACK

V33

LCP

LCN

CE

FE

TE

PI

V25

V125

TPH

DFT

LINK

LOAD+/DCMO+

STBY

BIAS

28

27

SCSJ

48

47

SDATA

SCLK

46

45

RF33V

44

43

42

41

40

39

38

37

36

35

34

33

23

CEI

FEI

TEI

SBAD

U6A

TL3472

AMP.

MVCC

8

3

+

2

-

4

MGND

D6

RLS4148

1

TO DISPLAY PWB

GND

3

4

CON4

J5

1

2

3

4

5

6

7

CON7

U10

24C02

1

S0

VCC

2

S1

WC

3

S2

SCL

GND4SDA

SERIAL

EEPROM

U12

GND

VDD

V6300

RESET

TO MAIN PWB

NC

NC

RES

R_OUT

SUB_OUT

STB

CLID

BUSY

CLK

DI

DO

GND

VCC

8

7

6

5

GND

XSCSJ

XSDAT

XSCLK

SDEFC

LDON

SPDON

RESET#

1

2

3

4

5

VCC

GND

J2

1

2

3

4

5

6

7

CON7

123 4 5 6

Figure 4-5 BLOCK DIAGRAM (5/6)

4 – 5

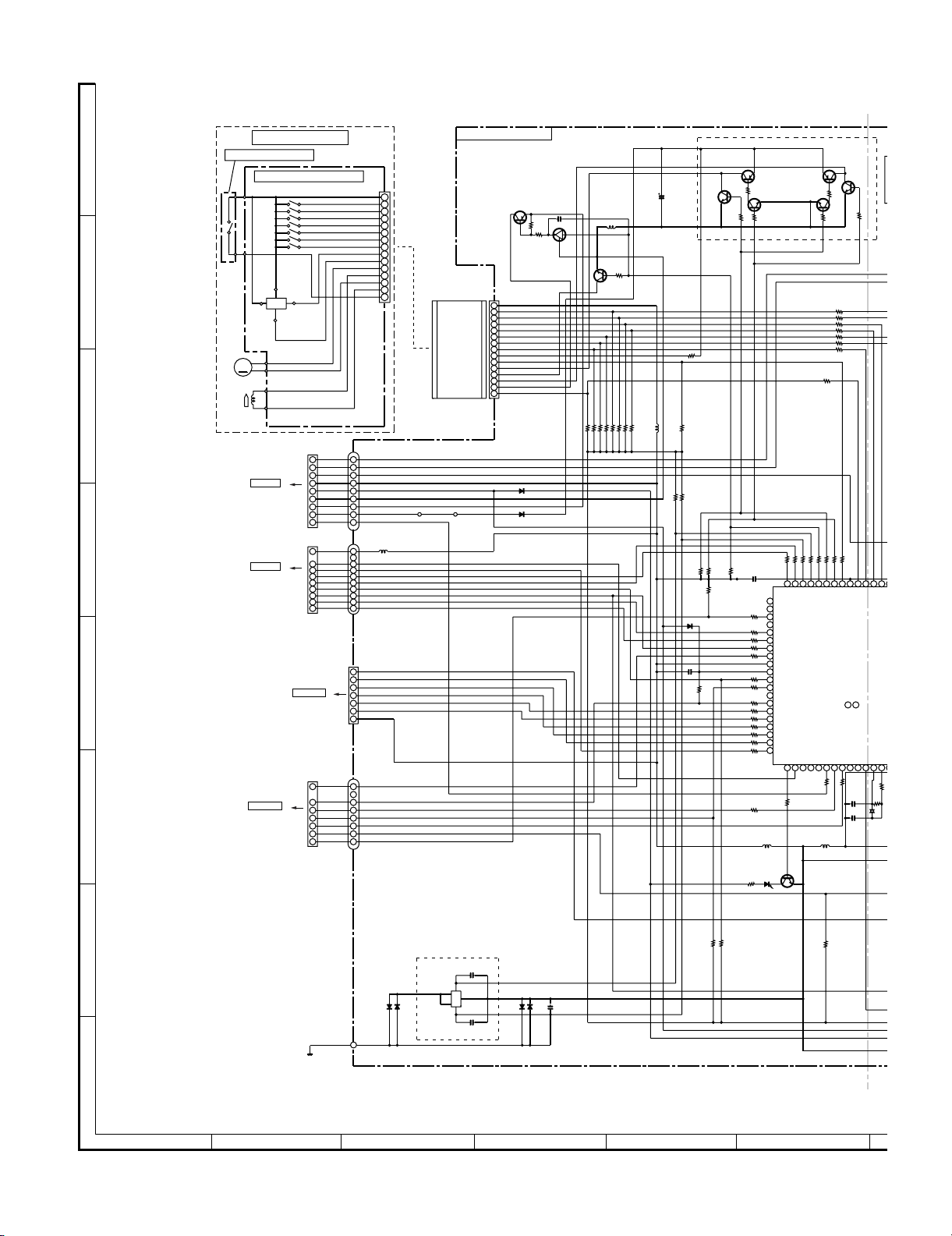

Page 19

XL-DV60

J1

L_OUT

1

GNDA

2

R_OUT

3

SUB_OUT

4

CON4

J5

1

2

3

B

4

5

6

7

CON7

GND

10

C02

VCC

WC

SCL

SDA

IAL

ROM

U12

NC

GND

NC

RES

VDD

V6300

RESET

1110987

U4B

8

4558

V+

AMP.

L_OUT

R_OUT

SUB_OUT

5

7

1

1

L

6

V-

4

U4A

8

4558

V+

AMP.

3

R

2

V4

8

V+

3

SUB

2

U5A

V-

4

4558

AMP.

7

OUT0R

OUT1R

OUT2R

OUT0L

OUT1L

OUT2L

CAP

17

16

19

SUB

GR026GR122GR2

18

27

25

23

21

R

L

GNDA

GND

DVDD1DGND11LATCH/12S12SCLK/IWL13SDIN/DM014MUTE9MODE8LRCLK210MCLK2BCLK3LRCLK4DIN05DIN16DIN2

AGND120AGND2

28

24

VCCA

AUDIO D/A CONVERTER

WM8746

AVDD115AVDD2

U2A

12

U1

7404

TBCK

TSD2

UDAC

SPDIF

MCLK

155

156

152

153

154

XSDSSLV

XSIPIN

XSRFIN

XSRFIP

157

AVSS_DS

158

AVSS_PL

159

XSPDOFTR1

160

XSFDO

161

XSFTROPI

162

AVDD3_PL

163

XSPLLFTR1

164

XSPLLFTR2

165

XSVREF0

166

XSAWRC

167

AVSS_DA

168

XSRFRPCTR

169

XSTRAY

170

AVDD3_DA

171

XSSPINDLE

172

XSFOCUS

173

XSSLEGP

174

XSSLEGN

175

XSTRACK

176

XSTESTDA

177

XSFGIN

178

XSPHOI

XSCSJ

179

SXCSJ

XSDATA

180

XSDATA

XSCLK

181

XSCLK

SDEFCT

182

XSDFCT

LDON

183

XSLDC

SPDON

184

XSSPDON

185

VD33

186

VS33

187

XGPIO[9]

188

XGPIO[8]

189

XGPIO[7]

190

XGPIO[6]

191

XGPIO[5]

192

XGPIO[4]

193

EAUX03

194

EAUX02

195

EAUX01

196

EAUX00

197

VSS

198

VDD

199

AUX0

200

AUX1

201

STB

CLID

BUSY

CLK

DI

DO

VCC

8

7

6

5

GND

1

2

3

4

5

VCC

RESET#

AUX2/ HSYNC

202

AUX3/ VSYNC

203

AUX4

204

AUX5

205

AUX6

206

AUX7

207

RESET

208

VS33

XOUT

DCLK

VD33

XIN

1

2

3

4

G1

27M

GND

149

150

151

XSVREF[09]

XSVREF[15]

XSIREF

AVDD3_DS

DMA05DMA16DMA27DMA3

DMA1

DMA2

DMA0

145

146

147

148

XSRFRP

AVDD3_AD

XSVREF[21]

DMA411DMA512DMA613DMA714DMA815DMA9

VD33

VS33

9

10

8

DMA3

DQ02DQ1

A023A124A225A3

DMA4

DB0

DMA0

144

XSTEI

DB1

4

DMA1

XSCEI

DMA5

DQ25DQ3

141

142

143

XSFEI

AVSS_AD

DMA6

DMA7

DMA8

DB3

DB4

DB2

7

DQ48DQ5

A429A530A631A732A833A9

26

DMA3

DMA2

DMA4

XSSBAD

133

134

135

136

137

138

139

140

XSFLAG[0]

XSFLAG[1]

XSFLAG[2]

XSFLAG[3]

VSS

VDD

XSTEXI

XSTESTAD

ES6629F

DECODER

DMA11

DMA10

DCAS

DCS022DCS1

VD33

VS33

17

18

19

20

21

23

16

DMA10

CAS#

CS0#

DMA11

DMA9

DB6

DB12

DB10

DB5

DB11

DB9

DB8

DB7

10

13

44

47

DQ611DQ7

DQ842DQ9

DQ1045DQ11

DQ1248DQ13

A1135A10

22

34

DMA6

DMA10

DMA5

DMA11

DMA9

DMA7

DMA8

132

DRAS0

24

RAS0#

DB13

50

CLK

131

XSIP2

XSIP1

U9

DBANK0/ DRAS1

VSS

25

RAS1#

DB14

DQ1451DQ15

38

DSCK

130

XSLG

VDD

26

DB15

53

CKE

124

125

126

127

128

129

SPDIFIN

VD33

VS33

XSWBLCLK

XSWBL

DCKE/DOE/TDMTSC

DBANK1/ DRAS2

DWE

DB031DB132DB2

28

29

30

27

DB1

DB0

DOE#

RAS2#

DWE#

VCC33

1

27

14

VCC

VCCQ

VCC

VCC

18CS19

37

RAS0#

DOE#

CS0#

119

120

121

122

123

VS33

TSD2

TSD3

MCLK

TBCK

SPDIF/SEL_PLL3

VD33

VS33

DB336DB437DB538DB639DB7

33

34

35

DB3

DB4

DB2

3

9

43

49

VCCQ

VCCQ

VCCQ

DQML

CAS17RAS

DWE#

CAS#

TSD0

TSD1

TWS

114

115

116

117

118

YUV2/CDAC

YUV0/UDAC

TWS/SEL_PLL2

TSD0/SEL_PLL0

TSD1/SEL_PLL1

DB1541DB14

VS33

40

42

DB15

DB6

DB5

DB14

DB7

6

12

46

52

VSSQ

VSSQ

VSSQ

VSSQ

DQMH

BA1

BA0

20

21

15WE16

39NC40

RAS1#

RAS2#

DQM

GNDV

CDAC

YDAC

111

112

113

VD33_DA

VS33_DA

YUV5/YDAC

VD3344DB1345DB1246DB1147DB10

43

DB13

28

41

VSS

VSS

NC

36

FDAC

VDAC

VCC33V

108

109

110

YUV4/RSET

YUV7/FDAC

YUV6/VDAC

DB949DB8

48

DB10

DB12

DB11

54

VSS

105

106

107

VS33_PL

YUV1/VREF

YUV3/COMP

VD33_PLL

RWS/TDMFS

RBCK/TDMCLK

RSD/TDMDR

LWRLL

DSCK

VS33

52

50

51

GND

DSCK

DQM

DB8

DB9

GND

64M SDRAM

3664164T

U13

GND

104

103

102

101

100

LD7

LD6

LD5

LD4

VD33

VS33

LD3

LD2

LD1

LD0

LOE

LCS3

VDD

VSS

LCS2

LCS1

LCS0

LA0

LA1

LA2

VD33

VS33

LA3

LA4

LA5

LA6

LA7

LA8

VDD

VSS

LA9

LA10

LA11

LA12

LA13

LA14

LA15

VD33

VS33

LA16

LA17

LA18

LA19

LA20

LA21

DQM

VD33

LD7

99

LD6

98

LD5

97

LD4

96

95

94

LD3

93

LD2

92

LD1

91

LD0

90

LOE#

89

WRLL#

88

LCS3#

87

VCC20

86

85

84

LCS1#

83

82

LA0

81

LA1

80

LA2

79

78

LA3

77

76

LA4

75

LA5

74

LA6

73

LA7

LA8

72

71

70

69

LA9

68

LA10

67

LA11

66

LA12

65

LA13

LA14

64

LA15

63

62

VCC33

61

LA16

60

LA17

59

LA18

58

LA19

57

LA20

56

LA21

55

54

53

LOGIC

VCC33

LA16

LA15

LA14

LA13

LA12

LA11

LA10

LA9

LA20

WRLL#

RESET#

LA19

LA18

LA8

LA7

LA6

LA5

LA4

LA3

LA2

XL-DV60U

OUTPUT SECTION

U15

1

A15

2

A14

3

A13

4

A12

5

A11

6

A10

7

A9

8

A8

9

NC

10

NC

11

W

12

RP

13

VPP

14

DU/WP

15

NC

16

NC

17

A17

18

A7

19

A6

20

A5

21

A4

22

A3

23

A2

24

A1

IXA024SJ

FLASH ROM

+5V

VDAC

YDAC

FDAC

UDAC

CDAC

GNDV

BYTE

DQ15/A_1

DAC_MD

DAC_MC

ML1196

8D TRIGGER

12

15

16

19

9

6

5

2

Q4

Q5

Q6

Q7

Q3

Q2

Q1

Q0

CLK

OE

D4

D5

D6

D7

D3

D2

D1

D0

13

14

17

18

11

1

8

7

4

3

LD5

LD4

LD3

LCS1#

J3

12

11

10

9

8

7

6

5

4

3

2

1

CON12

LA17

48

A16

47

46

GND

LA0

45

LD7

44

DQ7

43

DQ14

LD6

42

DQ6

41

DQ13

LD5

40

DQ5

39

DQ12

LD4

38

DQ4

37

VCC

36

DQ11

LD3

35

DQ3

34

DQ10

LD2

33

DQ2

32

DQ9

LD1

31

DQ1

30

DQ8

LD0

29

DQ0

28

LOE#

G

27

GND

LCS3#

26

E

LA1

25

A0

GND

74HC374

U3

GND

S903

GND

1

VCC

2

OPTICAL

3

PLT130/T2

12

D

C

B

TO MAIN PWB

S901

V(Cr/Pr)

U(Cb/Pb)

Y(UV)

C

Y(C)

CVBS1

GNDV

R

1

2

B

3

4

(U ONLY)

G

5

6

RCA-314

S902

2

4

1

5

3

6

7

SAV-21E

CON12

CNP904A

12

11

10

9

8

7

6

5

4

3

2

1

VCC

OPTICAL

GND

GNDV

VDAC

YDAC

FDAC

UDAC

CDAC

Q3

AMS1117

3.3V REGULATOR

IN3OUT

J2

+12V

1

VCC

2

GND

3

SVCC

4

RFGND

5

VCCA

6

GNDA1

7

CON7

789101112

D4

D3

1N4001

K

K

1N4001

AA

AMS1117

IN3OUT

AMS1117

IN3OUT

VCC33

2

ADJ

4

OUT

1

(EZ1085)

Q1

VCC20

2

ADJ

4

OUT

1

Q2

1

VD33D

PLL33V

2

ADJ

4

OUT

RF33V

L905 FB

L906 FB

L904 FB

L907 FB

L902

L903

FB

FB

Figure 4-6 BLOCK DIAGRAM (6/6)

4 – 6

A

Page 20

XL-DV60

Home StereoXL-DV60Service ManualXLDV60 Service ManualMarketE

CHAPTER 5. CIRCUIT DESCRIPTION

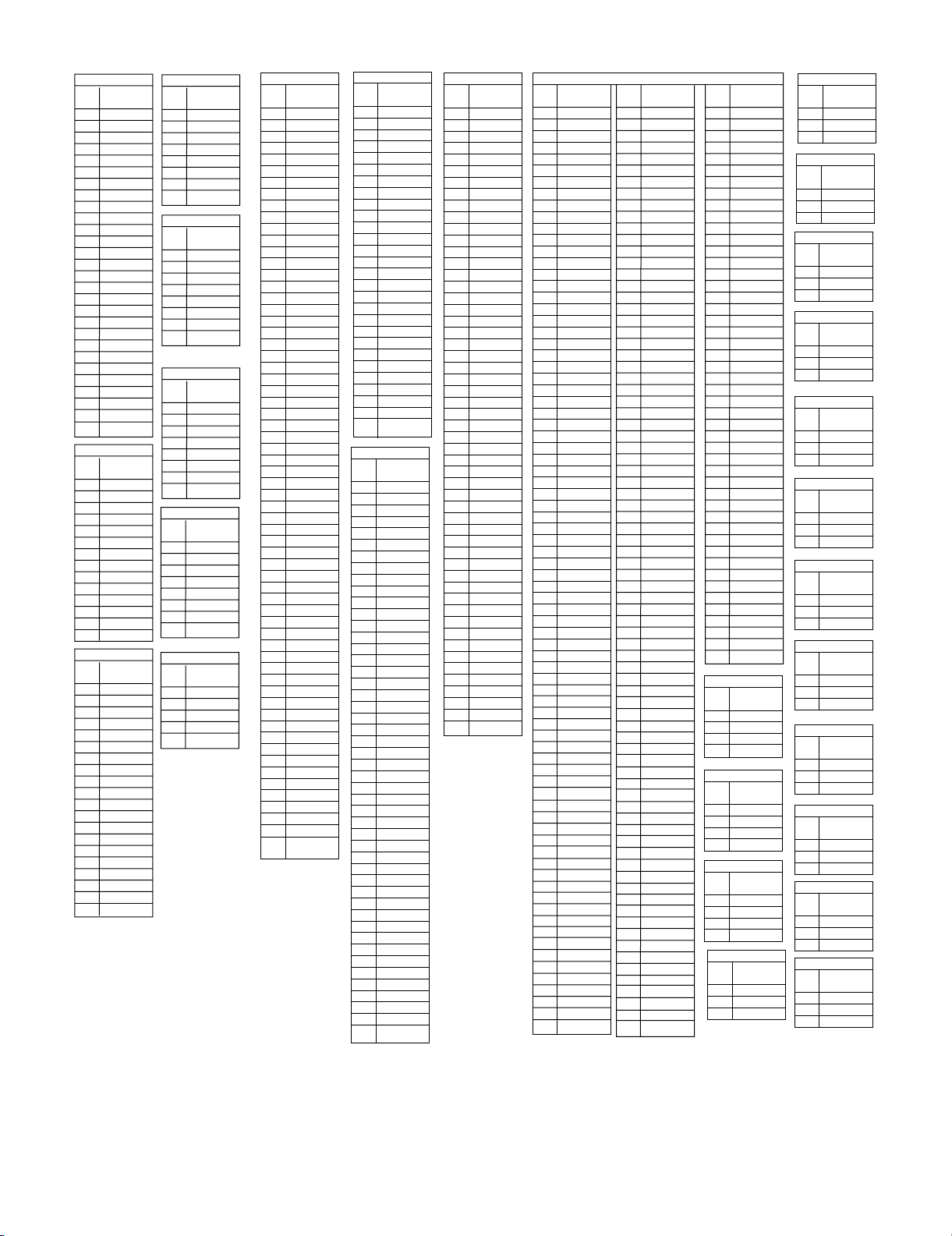

[1] VOLTAGE

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

1

2

3

4

5

6

7

8

9

1

2

3

1

2

3

1

2

3

4

5

1

2

3

1

2

3

4

5

6

7

8

IC101

VOLTAGE

30 V

-30 V

-

30 V

0V

-30 V

0V

-4 V

0V

0V

30 V

0V

0V

-30 V

-

-

-4 V

0V

0V

0V

-4 V

0V

0V

IC201

VOLTAGE

14 V

0.7 V

5.6 V

IC202

VOLTAGE

23 V

0V

12 V

IC203

VOLTAGE

14 V

5 (0) V

0V

5 (0) V

5 (0) V

IC204

VOLTAGE

9V

0.7 V

5.6 V

IC702

VOLTAGE

0V

0V

0V

0V

5V

5V

0V

5V

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PIN

NO.

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

IC601

VOLTAGE

3.5 V

3.5 V

0V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

7V

3.5 V

IC602

VOLTAGE

6V

6V

6V

6V

6V

6V

6V

12 V

IC603

VOLTAGE

3.5 V

3.5 V

0V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

3.5 V

7V

3.5 V

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

E

C

B

E

C

B

E

C

B

E

C

B

VOLTAGE

5(0) V

5(0) V

-

-

-

5(0) V

5(0) V

5(0) V

-

5V

0V

0V

0V

0V

0V

5V

5V

5V

5V

-

-

5 V

0V

5V

-

5V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

-

-27 V

-27 V

-27 V

-27 V

5V

-27 V

-27 V

-27 V

-27 V

Q101

VOLTAGE

0V

0V

0.7(0) V

Q102

VOLTAGE

0V

0V

0.7(0) V

Q107

VOLTAGE

0V

5V

0V

Q108

VOLTAGE

0V

5V

0V

IC701

PIN

NO.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

PIN

NO.

C

PIN

NO.

PIN

NO.

PIN

NO.

C

VOLTAGE

0V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

-27 V

5(0) V

5(0) V

5(0) V

5(0) V

5(0) V

5(0) V

5(0) V

5(0) V

5 V

5(0) V

5(0) V

5(0) V

5(0) V

5(0) V

5(0) V

5(0) V

5(0) V

-

-

5(0) V

5V

5V

5 V

5(0) V

0V

5V

5V

5V

5V

5V

5V

5V

5V

5V

5V

Q109

VOLTAGE

0V

E

5V

0V

B

Q110

VOLTAGE

5V

1

5V

2

0V

3

Q111

VOLTAGE

0V

1

5V

2

0V

3

Q112

VOLTAGE

0V

E

0V

0.7 V

B

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

Q113

VOLTAGE

0V

0V

0.7 V

Q114

VOLTAGE

0V

0V

0.7 V

Q115

VOLTAGE

0V

0V

0.7(0) V

Q116

VOLTAGE

0V

0V

3.5 V

Q117

VOLTAGE

12 V

12 V

0V

Q118

VOLTAGE

0V

0V

0.7 V

Q201

VOLTAGE

-30 V

-40 V

-30 V

Q202

VOLTAGE

0V

0V

0.7 V

Q203

VOLTAGE

0V

6V

0V

Q204

VOLTAGE

5.6 V

5.6 V

0.7 V

Q205

VOLTAGE

0V

0V

0.7 V

Q206

VOLTAGE

0V

0V

0.7 V

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

Q207

VOLTAGE

0V

0V

0.7 V

Q208

VOLTAGE

0V

0V

0V

Q213

VOLTAGE

5V

5V

0V

Q214

VOLTAGE

0V

0V

0.7 V

Q302

VOLTAGE

0V

5V

0V

Q306

VOLTAGE

0V

5V

0V

Q502

VOLTAGE

0V

0V

5V

Q503

VOLTAGE

10 V

9V

9V

Q504

VOLTAGE

0V

0V

0.7 V

Q505

VOLTAGE

5V

5V

4V

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

E

C

B

E

C

B

E

C

B

E

C

B

E

C

B

1

2

3

E

C

B

E

C

B

E

C

B

Q506

VOLTAGE

0V

0V

0.7 V

Q507

VOLTAGE

0V

0V

0.7 V

Q508

VOLTAGE

5V

5V

4V

Q509

VOLTAGE

0V

0V

0.7 V

Q511

VOLTAGE

0V

0V

0.7 V

Q702

VOLTAGE

0.7 V

0V

0V

Q703

VOLTAGE

0V

4V

0V

Q704

VOLTAGE

0V

0V

0.7 V

Q705

VOLTAGE

0V

0V

0.7 V

5 – 1

Page 21

XL-DV60

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

PIN

NO.

10

11

12

13

14

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

U1

VOLTAGE

4.78 V

0V

0V

0V

0V

0V

0V

0V

NC

NC

0V

0V

0V

0V

4.8 V

2.4 V

2.4 V

0V

2.4 V

0V

2.4 V

0V

2.4 V

0V

2.4 V

0V

2.4 V

4.8 V

U2

VOLTAGE

2.5 V

2.5 V

2.5 V

2.5 V

2.5 V

2.5 V

0V

2.47 V

2.47 V

2.48 V

2.48 V

2.48 V

2.48 V

15 V

U3

VOLTAGE

0V

0V

1.4 V

0.12 V

4.97 V

4.97 V

0.23 V

0.80 V

0V

0V

4.97 V

0V

1.2 V

1.83 V

0V

4.97 V

0.28 V

0.28 V

4.97 V

4.97 V

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

U4

VOLTAGE

5.9 V

5.9 V

5.87 V

0V

5.87 V

5.9 V

5.9 V

11.77 V

U5

VOLTAGE

5.9 V

5.9 V

5.87 V

0V

1.4 V

1.47 V

11.24 V

11.77 V

U6

VOLTAGE

3.6 V

1.3 V

2.08 V

0V

1.84 V

1.65 V

4.42 V

4.98 V

U10

VOLTAGE

0V

0V

0V

0V

4.8 V

4.8 V

0V

4.96 V

U12

VOLTAGE

NC

0V

NC

4.96 V

4.96 V

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

1

2

3

4

5

6

7

8

9

U7

VOLTAGE

NC

NC

2.46 V

2.46 V

2.46 V

2.46 V

3.55 V

3.55 V

2.56 V

2.56 V

2.56 V

2.57 V

2.56 V

2.56 V

2.56 V

2.54 V

2.54 V

2.54 V

4.93 V

2.47 V

4.9 V

3.2 V

0.15 V

0V

3.29 V

0V

2.39 V

2.39 V

2.1 V

2.1 V

0V

0V

2.53 V

0V

3.56 V

1.52 V

3.3 V

1.9 V

1.50 V

1.42 V

1.58 V

1.9 V

3.94 V

3.98 V

3.3 V

3.3 V

2.2 V

0V

1.47 V

0V

0V

2.25 V

2.37 V

3.3 V

3.3 V

3.2 V

2.2 V

4.93 V

4.1 V

4.1 V

2.91 V

2.94 V

3.27 V

2.87 V

PIN

NO.

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

1

2

3

4

5

6

7

8

9

U8

VOLTAGE

1.43 V

2.43V

2.33 V

1.42 V

1.40 V

1.41 V

2.28 V

4.76 V

4.78 V

0V

2.29 V

2.34 V

2.27 V

2.95 V

2.47 V

2.48 V

1.87 V

2.97 V

0V

2.36 V

4.78 V

0V

1.22 V

2.57 V

2.36 V

1.4 V

1.4 V

3.23 V

U15

VOLTAGE

0V

0V

0V

0V

0V

0V

0V

0V

0V

NC

0V

0V

3.3 V

3.3 V

NC

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

NC

0V

NC

0V

NC

0V

NC

3.3 V

0V

NC

0V

NC

0V

NC

0V

0V

0V

0V

0V

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

1

2

3

4

5

6

7

8

9

U13

VOLTAGE

3.2 V

0V

3.2 V

0V

0V

0V

0V

0V

3.2 V

0V

0V

0V

0V

3.2 V

0.1 V

3.1 V

3.1 V

3V

3V

0.04 V

0V

0V

0V

0V

0V

0V

3.2 V

0V

0V

0V

0V

0V

0V

0V

0V

NC

0V

CLK

0V

NC

0V

0V

3.2 V

0V

0V

0V

0V

0V

3.2 V

0V

0V

0V

0V

0V

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

1

2

3

4

5

6

7

8

9

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

VOLTAGE

3.16 V

1.7 V

1.7 V

1.7 V

0V

0V

0V

0V

0V

3.16 V

0V

0V

0V

0V

0V

0V

0V

0V

3.16 V

0V

0V

0V

NC

0V

0V

0V

1.87 V

0V

0V

0V

0V

0V

0V

0V

3.16 V

0V

0V

0V

0V

0V

0V

0V

0V

3.16 V

0V

0V

0V

0V

0V

0V

0V

0V

3.16 V

0V

0V

0V

0V

0V

0V

0V

0V

3.16 V

0V

0V

0V

0V

0V

0V

0V

0V

1.87 V

0V

0V

0V

0V

0V

0V

0V

3.16 V

0V

PIN

NO.

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

U9

VOLTAGE

0V

0V

NC

0V

0V

0V

1.87 V

0V

0V

0V

0V

0V

0V

0V

0V

3.16 V

0V

0V

0V

0V

3.24 V

0V

0V

0V

0V

0V

0V

0V

0V

0V

NC

0V

0V

0V

0V

3.76V

0V

NC

NC

NC

0V

0V

NC

NC

NC

NC

0V

1.87 V

0V

0V

0V

0V

0V

0V

0V

0V

3.3 V

0V

0V

0V

0V

3.3 V

1.5 V

0V

0V

1.5 V

0V

0V

1.5 V

1.5 V

1.5 V

0V

NC

1.75 V

1.5 V

1.66 V

0V

0V

0V

0V

PIN

NO.

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

PIN

NO.

PIN

NO.

PIN

NO.

PIN

NO.

1

2

3

4

1

2

3

4

1

2

3

4

E

C

B

VOLTAGE

0V

3.24 V

0V

0V

0V

0V

0V

0V

0V

3.3 V

0V

0V

NC

0V

0V

0V

NC

NC

0V

0V

0V

0V

0V

0V

3.16 V

0V

0V

2.2 V

0V

0V

4.4 V

3.6 V

0V

0V

0V

0V

0V

1.87 V

0V

0V

0V

0V

0V

0V

0V

0V

5V

0V

Q1

VOLTAGE

0.8 V

2.0 V

3.3 V

2.0 V

Q2

VOLTAGE

2.0 V

3.2 V

4.86 V

3.2 V

Q3

VOLTAGE