Page 1

SERVICE

MANUAL

TV/VCR COMBINATION

VIDEO TV

Chassis No.

VP-3

VT-3428X

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be

restored to its original condition and only parts identical to those specified should be used.

FEATURES

n

W

TV/VCR Integration for Easy Operation

W

Single Built-in Tuner for Simple Operation

n

Timer Programme Setting by the On-Screen

Display

W

Auto Tracking Control

n

Full

Auto Head Cleaning System

n

On-screen Display with Menu Screen Guidance

H

Wake-Up/Sleep Timer

n

NTSC

Simple Playback

r

CONTENTS

2-way Child-Proof Lock

@To

Lock Operation Mode

@To

Lock the Power Off.

n

Ret Index with DPSS (Digital Programme Search

System)

n

Full Auto Play Function

n

Auto Repeat Playback

n

Front input terminals Audio/Video

VT-5128X

\

l

SPECIFICATIONS

l

IMPORTANT SERVICE NOTES

. LOCATION OF USER’S CONTROL

. DISASSEMBLY AND REASSEMBLY

. ADJUSTMENT OF THE TV ELECTRICAL

CIRCUITRY

. PRECAUTIONS IN REASSEMBLING

. FUNCTION OF MAJOR

. ADJUSTMENT, REPLACEMENTAND

ASSEMBLY OF MECHANICAL PARTS

ADJUSTMENT OF THE VCR ELECTRICAL..

.

CIRCUITRY

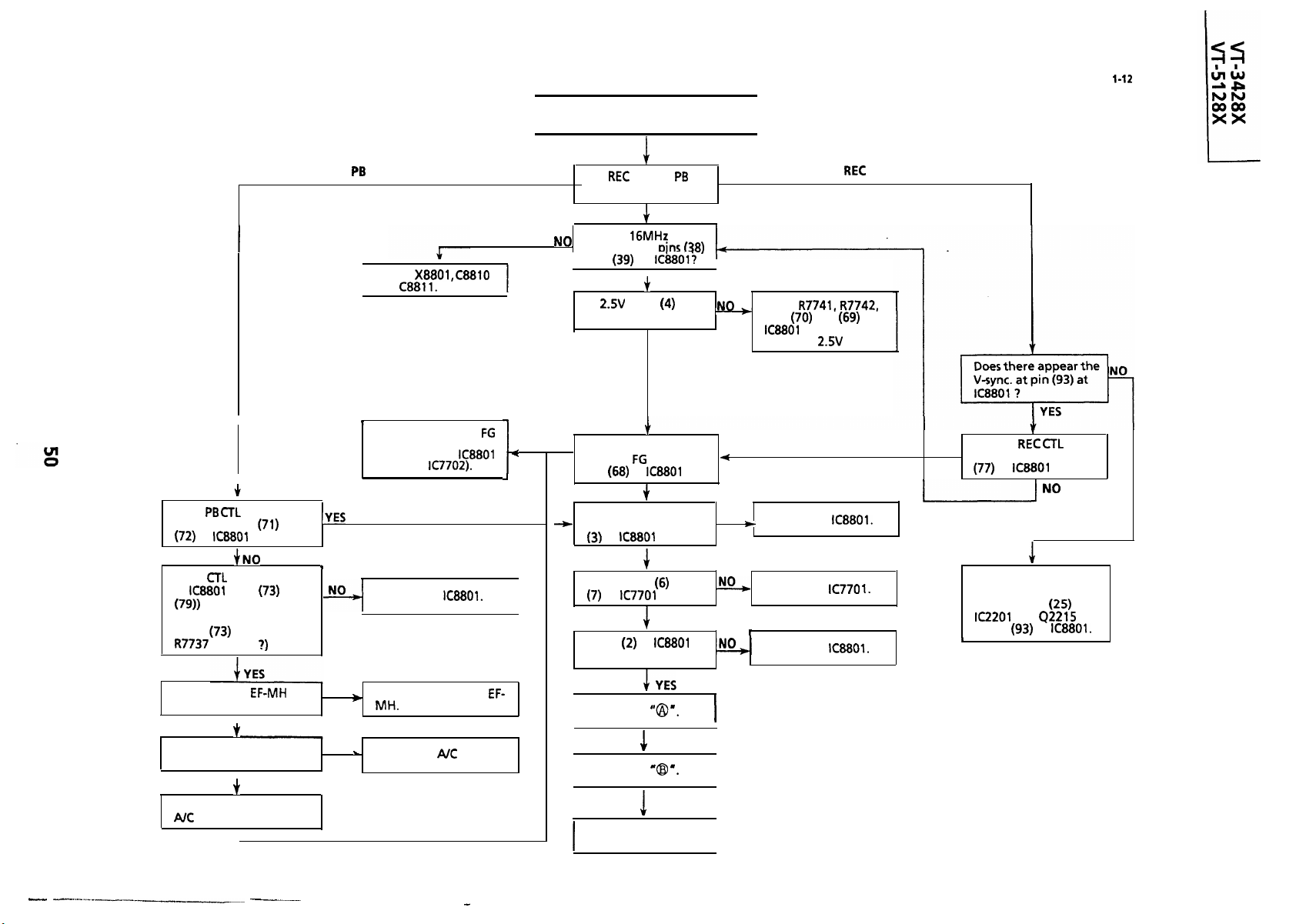

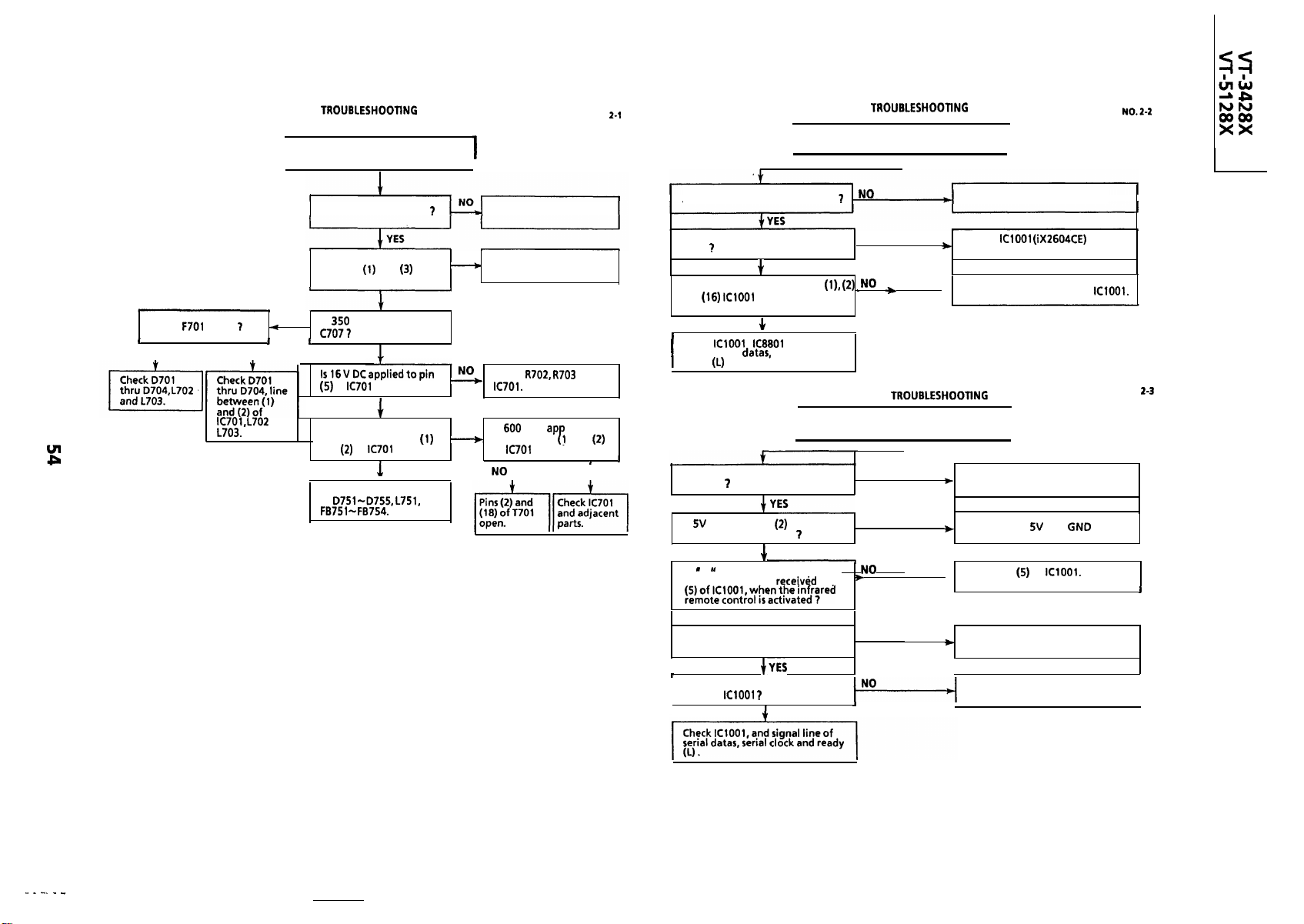

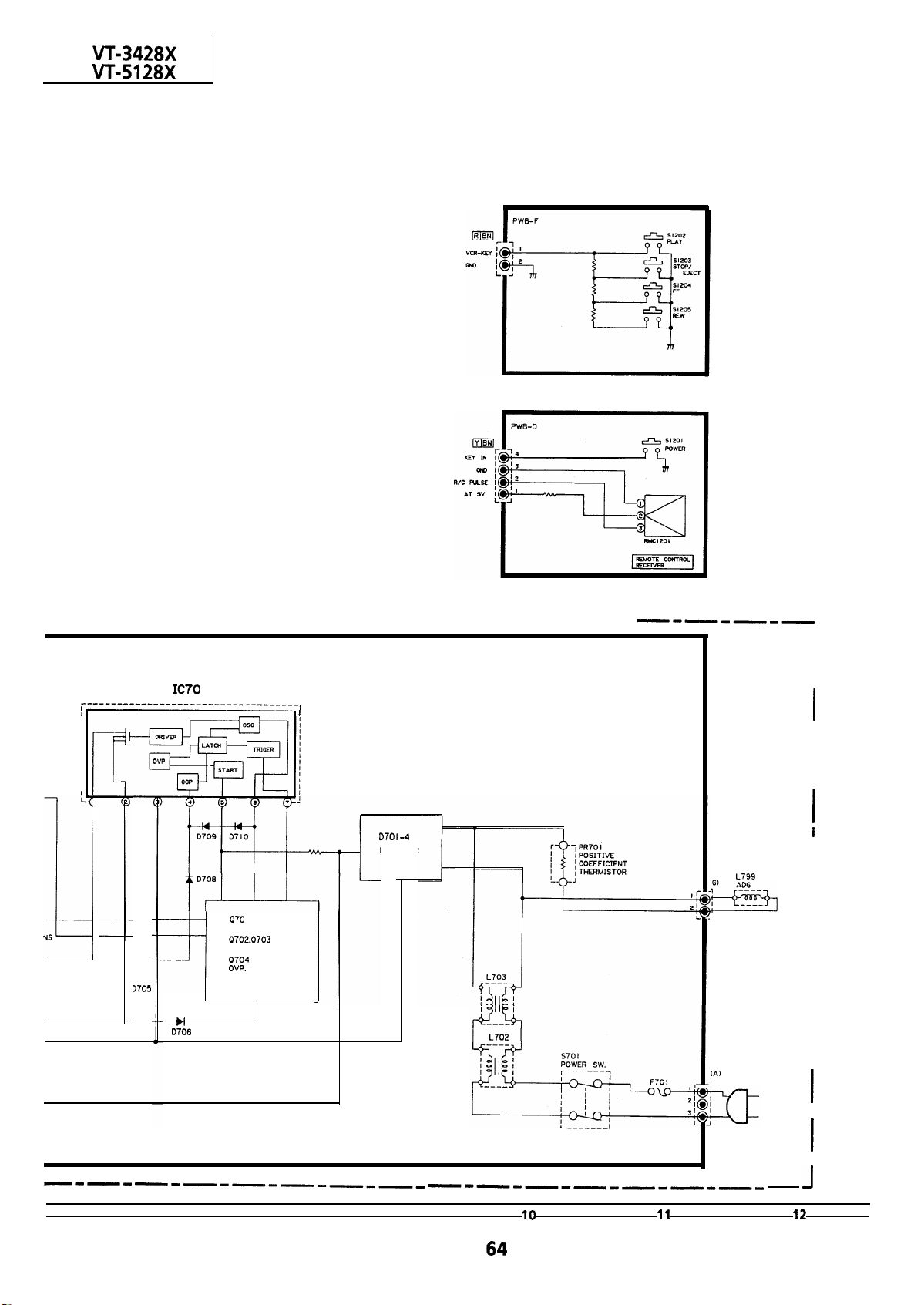

. TROUBLESHOOTING

........................

.............

.........

.............................

MECHANICALaPARTS

............................

...................

........

.

.......

..

Page

2

3

4

6

8

15

16

18

42

45

l

OVERALL SCHEMATIC DIAGRAM

l

CHASSIS LAYOUT OF TV SECTION

.

BLOCK DIAGRAM OF TV SECTION

.

DESCRIPTION OF TV SECTION

SCHEMATIC DIAGRAM

.

CHASSIS LAYOUT OF VCR SECTION

l

BLOCK DIAGRAM OF

. DESCRIPTION OF VCR SECTION

SCHEMATIC DIAGRAM

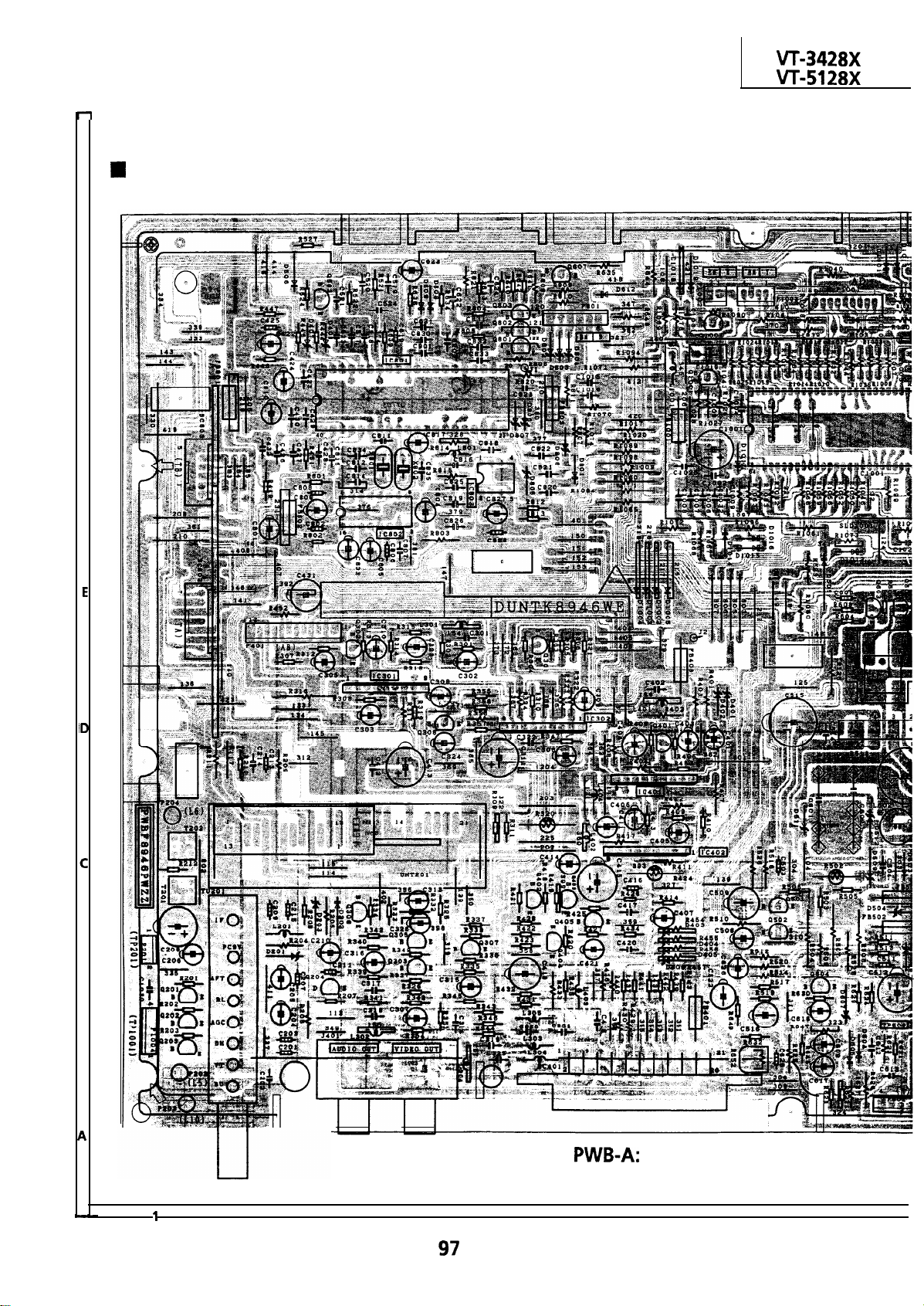

. PRINTED WIRING BOARD ASSEMBLIES

. REPlACEMENT PARTS LIST

.

PACKINGOFTHESET

.................

VCRSECTION

.................

.................

........

.......

.......

............

......

......

...

Page

57

59

61

65

79

81

91

97

105

134

WARNING

The chassis in this receiver is partially hot. Use an isolation transformer between the line cord plug and

power receptacle, when servicing this chassis.

To prevent electric shock, do not remove cover. No user

qualified service personnel.

-

serviceable parts inside. Refer servicing to

SHARP CORPORATION

/

Page 2

W-3428X

VT-51 28X

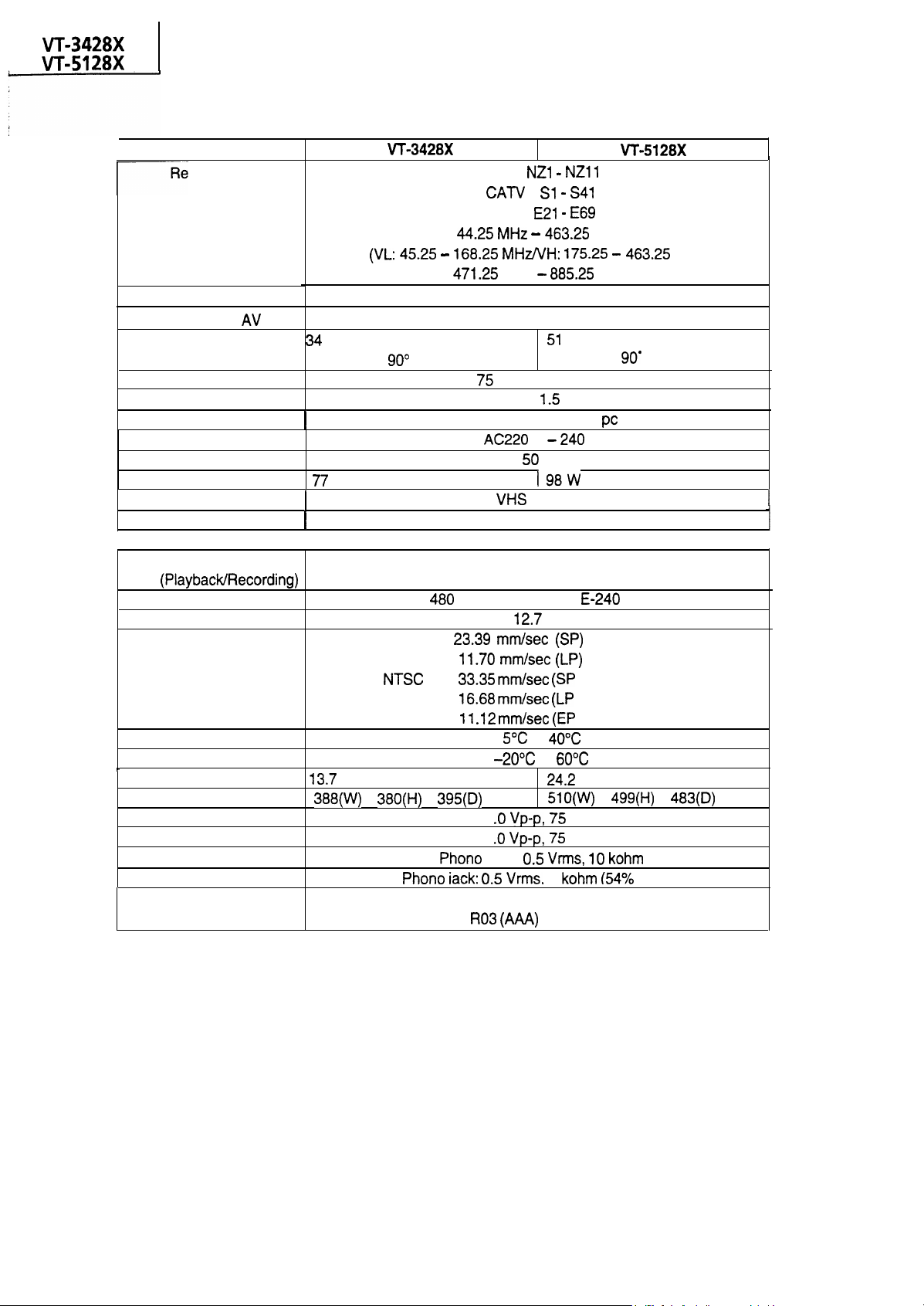

SPECIFICATIONS

I

Model

Reception channels

I-

VHF band

UHF band

Receiving System

AV Input

Screen 34 cm “Viewable” measured

diagonally,

Antenna input

Audio output

Speaker

Rated voltage

Rated frequency

Power consumption 77 W

Video cassette format

I

Video recording system

I

Number of Video Heads I

Video signal

(PlaybacWRecording)

Recording/playing time

Tape width

Tape speed

Operating temperature

I

Storage temperature

Weight

Dimensions

Video input

Audio input

Supplied accessories Operation manual, wireless remote control unit,

output

output

I

1

1

I

1

13.7

388(W)

kg

VT-3428X

VHF :

NZl - NZll

CATV

: Sl -

UHF :

44.25 MHz - 463.25

(VL: 45.25 - 168.25 MHz/VH: 175.25 - 463.25

471.25

MHz -

PAL B/G

90”

deflection

75

ohm unbalanced

Max.

8 cm round type x 1

AC220

50

VHS

Two rotary heads, helical scan

480

minutes max. with

12.7

x

PAL

NTSC

380(H)

:

23.39 mm/set (SP)

11.70 mm/set (LP)

:

33.35 mm/set (SP

16.68 mm/set (LP

11 .12 mm/set (EP

5°C

-20°C to

x

395(D)

mm

Vp-p,

1

.O

1.OVp-p,75ohm

Phono

jack:

0.5 Vrms, 10 kohm

Phono iack: 0.5 Vrms.

R03 (AAA)

S41

E21 - E69

MHz

885.25

MHz

PAL

51

cm “Viewable” measured

diagonally, 90’ deflection

1.5

W

pc

V -

240

V

Hz

I98W

standard

2

PAL

E-240

mm

playback only)

playback only)

playback only)

to

40°C

60°C

24.2

kg

510(W)

x

499(H)

75 ohm

1

kohm (54%

battery x 2

VT-51

tape

MOD)

28X

MHz)

x

483(D)

I

I

mm

*Design and specifications are subject to change without notice.

2

Page 3

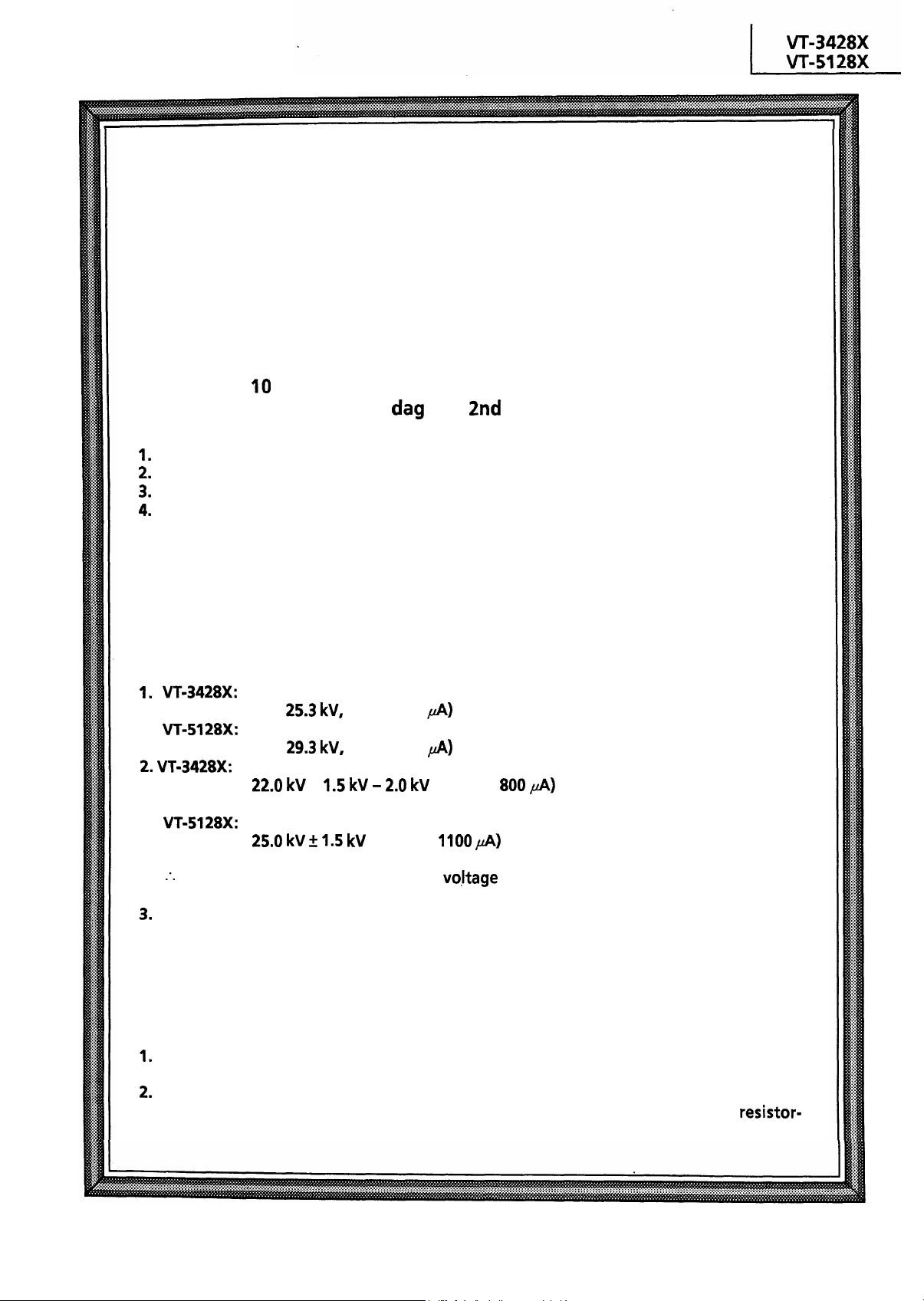

IMPORTANT SERVICE NOTES

Maintenance and repair of this receiver should be done by

qualified service personnel only.

SERVICING OF HIGH VOLTAGE SYSTEM AND

PICTURE TUBE

When servicing the high voltage system,

remove static charge from it by

connecting a 10 k ohm Resistor in series with an insulated wire (such as a test

probe) between picture tube

dag

and

2nd

anode lead. (AC line cord should

be disconnected from AC outlet.)

1.

Picture tube in this receiver employs integral implosion protection.

2.

Replace with tube of the same type number for continued safety.

3.

Do not lift picture tube by the neck.

4.

Handle the picture tube only when wearing shatterproof goggles and after discharging

the high voltage completely.

X-RAY

This receiver is designed so that any X-Ray radiation is kept to an absolute

minimum. Since certain malfunctions or servicing may produce potentially

hazardous radiation with prolonged exposure at close range, the following

precautions should be observed:

1. VT-3428X: When repairing the circuit, be sure not to increase the high voltage to more

than

25.3 kV,

VT-5128X: When repairing the circuit, be sure not to increase the high voltage to more

than

29.3 kV,

2.

m-3428X: To keep the set in a normal operation, be sure to make it function on

22.0 kV

been factory

VT-5128X:

mm-

If there-is a possibility that the high

forget to check for such high voltage after the work.

3.

DO not substitute a picture tube with unauthorized types and/or brands which may cause

excess X-ray radiation.

To keep the set in a normal operation, be sure to make it function on

25.0 kV ,+ 1.5 kV

factory

(at beam 0

(at beam 0 4) for the set.

+

1.5 kV - 2.0 kv

-Adjusted to the above-mentioned high voltage.

(at beam

-Adjusted to the above-mentioned high voltage.

,A)

for the set.

(at beam

1100

,A)

vo,ltage

800 fi)

in the case of the set. The set has been

fluctuates as a result of the repairs, never

in the case of the set. The set has

BEFORE RETURNING THE RECEIVER

Before returning the receiver to the user, perform the following safety

checks.

1.

Inspect all lead dress to make certain that leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in the receiver.

2.

Inspect all protective devices such as non-metallic control knobs, insulating fishpapers,

cabinet backs, adjustment and compartment covers or shields, isolation

capacity networks, mechanical insulators etc.

3

resistor-

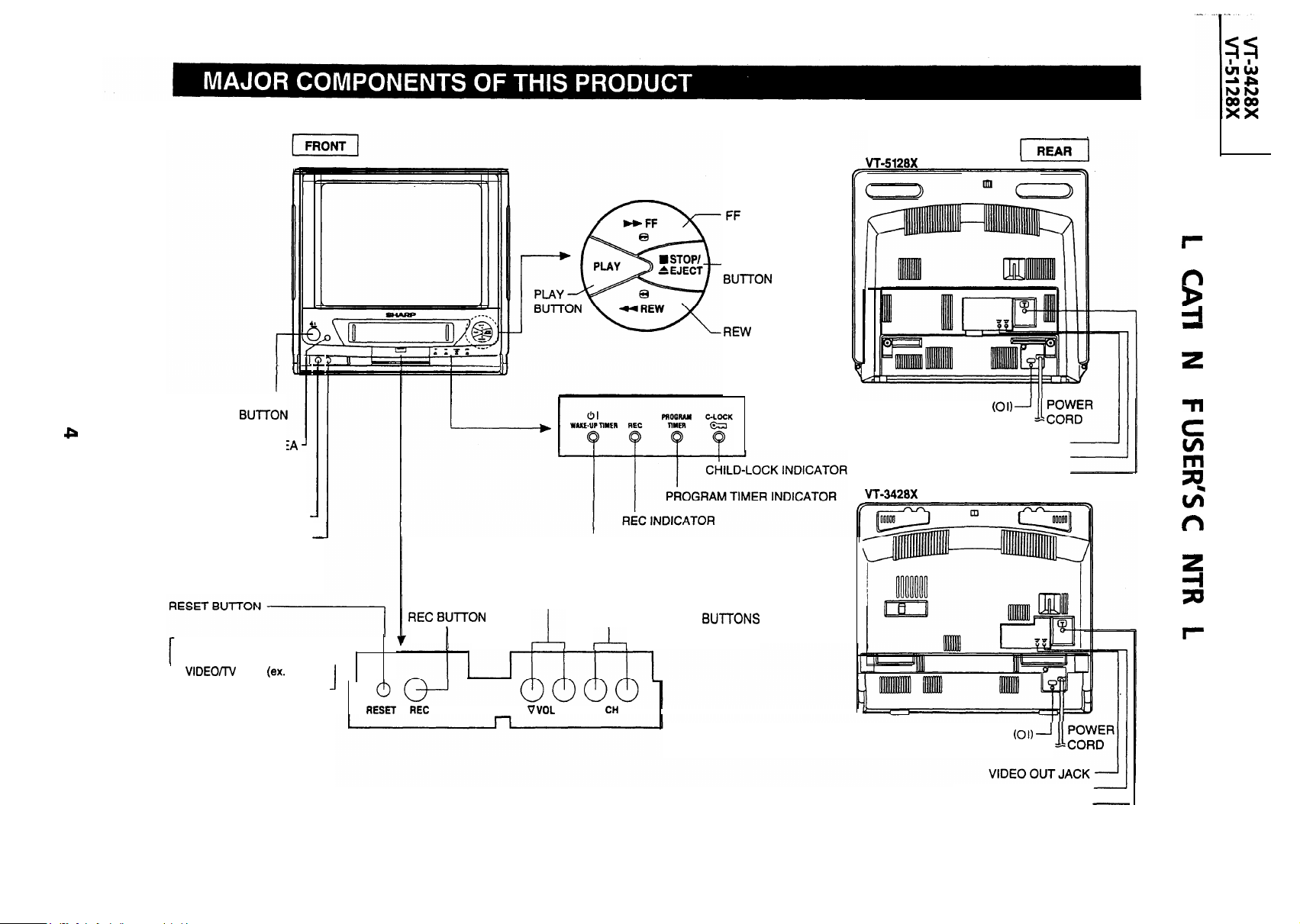

Page 4

(REARI

I

0

n

FF

(Forward video

search) BUTTON

STOP/EJECT

BUlTON

VT-51

28X

2,

-I

REW

(Reverse video

i

. .

: :

POWER

BUTTON

P

SENSOR ARE

FOR REMOTE

CONTROL

VIDEO INPUT JACK

AUDIO INPUT JACK

NOTES:

l Use the RESET button if the

VIDEOAV

Timer, etc.) cannot be operated.

1

mode (ex.

EA ’

Program

-

-

REC

BUlTON

I

POWER/WAKE-UP

TIMER INDICATOR

VOLUME UP/DOWN BUTTONS

CHANNEL UP/DOWN BUl-t-ONS

f-4

1

J

AESR

l REC

VVOL

A V

CH

A

search) BUTTON

MAIN POWER SWITCH

VIDEO OUT JACK

AUDIO OUT JACK

ANTENNA IN TERMINAL

VT-3428X

MAIN POWER SWITCH

(01) _J

(01)--l

0

2

0

In

c

K

51c1

vi

(1

0

z

-I

510

0

I

AUDIO OUT JACK

ANTENNA IN TERMINAL

-

Page 5

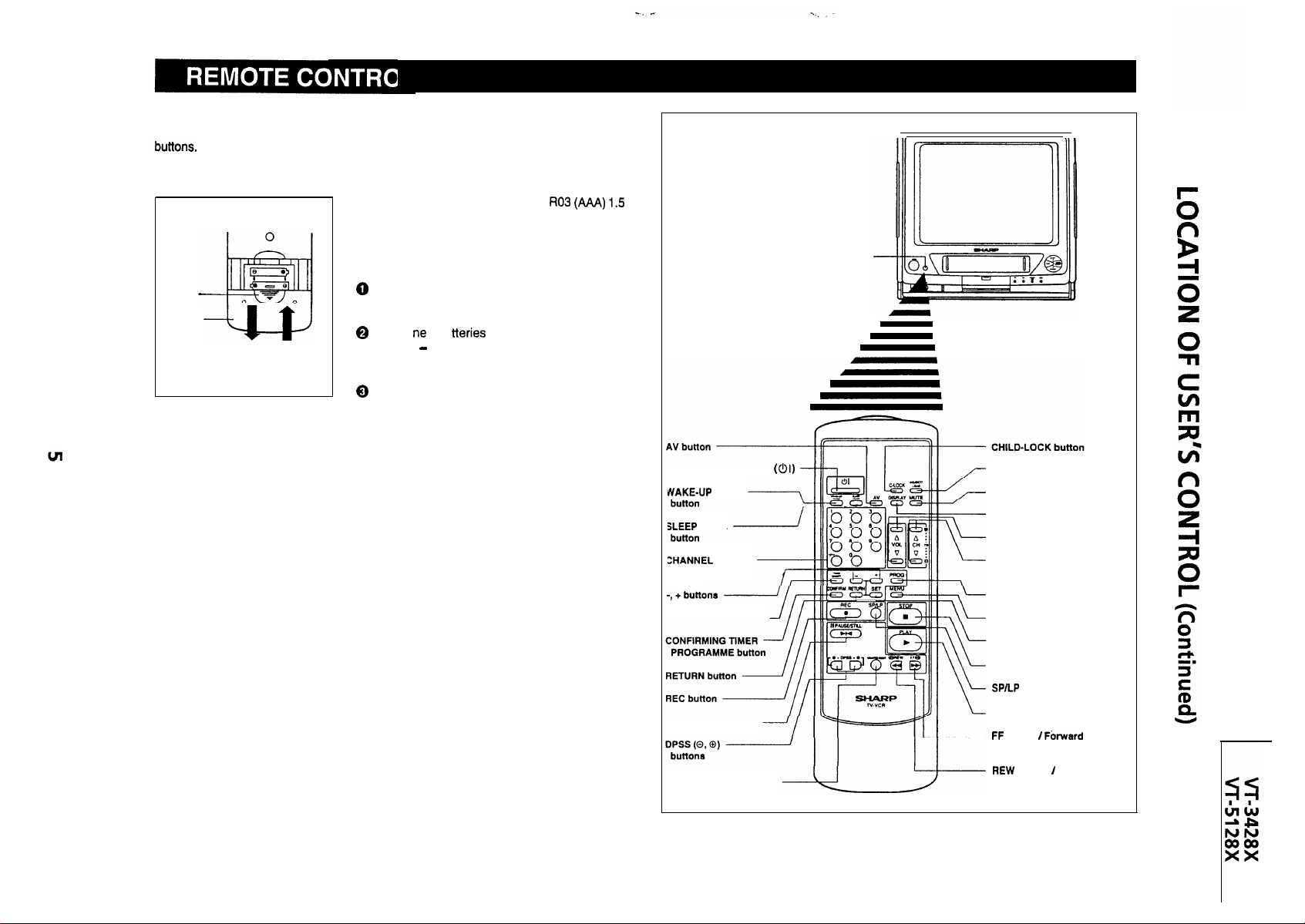

The remote control lets you operate this product at a distance. Just aim the front of the remote

control at the photoreceptor window situated on the front panel and press the appropriate

Inserting the Batteries

The remote control operates on two

volt batteries (included). If the remote control does

‘not operate or fails to function normally due to weak

batteries, new batteries can be purchased at electronics or camera stores.

Press

Down

-

Battery

Cover

-4-P

Slide off

l You can set clock and timer recordings using the remote control.

Slide on

0

Open the battery cover. (Remove any old

batteries that may be in the remote control.)

@

Insert

w ab tteries and match their polarities

ne

( + and - ) with the markings inside the compartment.

0

Replace the cover.

R03 (AAA) 1.5

SENSOR AREA

FOR REMOTE CONTROL

Clock setting:

see SETTING THE CLOCK

Timer recording: see RECORDING WITH THE TIMER

NOTES:

l Do not subject the remote control to impact, water or excessive humidity.

l

The remote control may not function if the photoreceptor window of this product is in direct

sunlight or any other strong light. If so, move the product or alter the lighting.

l Incorrect use of batteries may cause them to leak or burst.

l Do not mix old and new batteries, or mix the brands used.

l

Both rechargeable and disposable batteries are available. Read the battery warnings and

do not try to recharge disposable batteries.

l Remove the batteries if the remote control will not be used for a long time.

POWER ON/OFF button (0

WAKE-UP TIMER

SLEEP

TIMER

XIANNEL

SELECT

buttons

TIMER ON/OFF button

PAUSE/STILL button

COUNTER RESET button

I)

EJECT/LOAD button

MUTE button

DISPLAY button

VOLUME ADJUSTMENT buttons

CHANNEL UP/DOWN buttons

(TRACKING buttons)

PROGRAMME button

MENU button

SET button

STOP button

SPILP button

PLAY button

FF

button I

Video Search

REW button I Reverse

Video Search

F&ward

Page 6

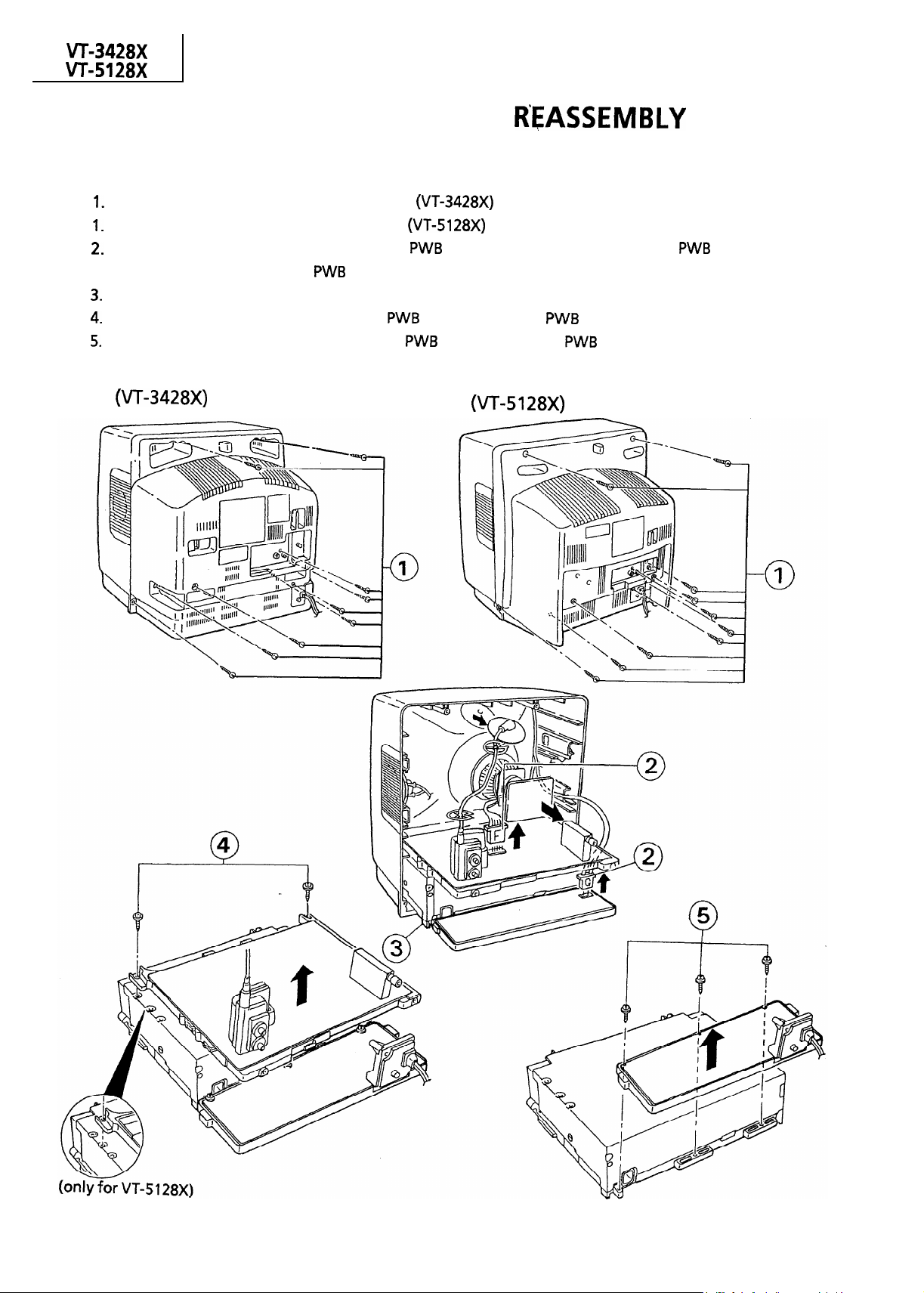

U--3428X

VT-51 28X

DISASSEMBLY AND

n

TV SECTION

1.

Remove the nine screws off the rear cover.

1.

Remove the ten screws off the rear cover. (VT-51 28X)

2.

Disconnect the F connector from the main

the anode cap and the CRT PWB unit from the CRT.

3.

After disconnect the coating earth from the CRT unit and take out the unit.

4.

Remove the two screws from the main PWB and separate the

5.

Remove the three screws from the power

(VT-3428X)

(VT-3428X)

PWB

and G connector from the power

PWB

and separate the

R’EASSEMBLY

PWB

from the video unit.

PWB

(VT-51 28X)

PWB

and disconnect

from the video unit.

6

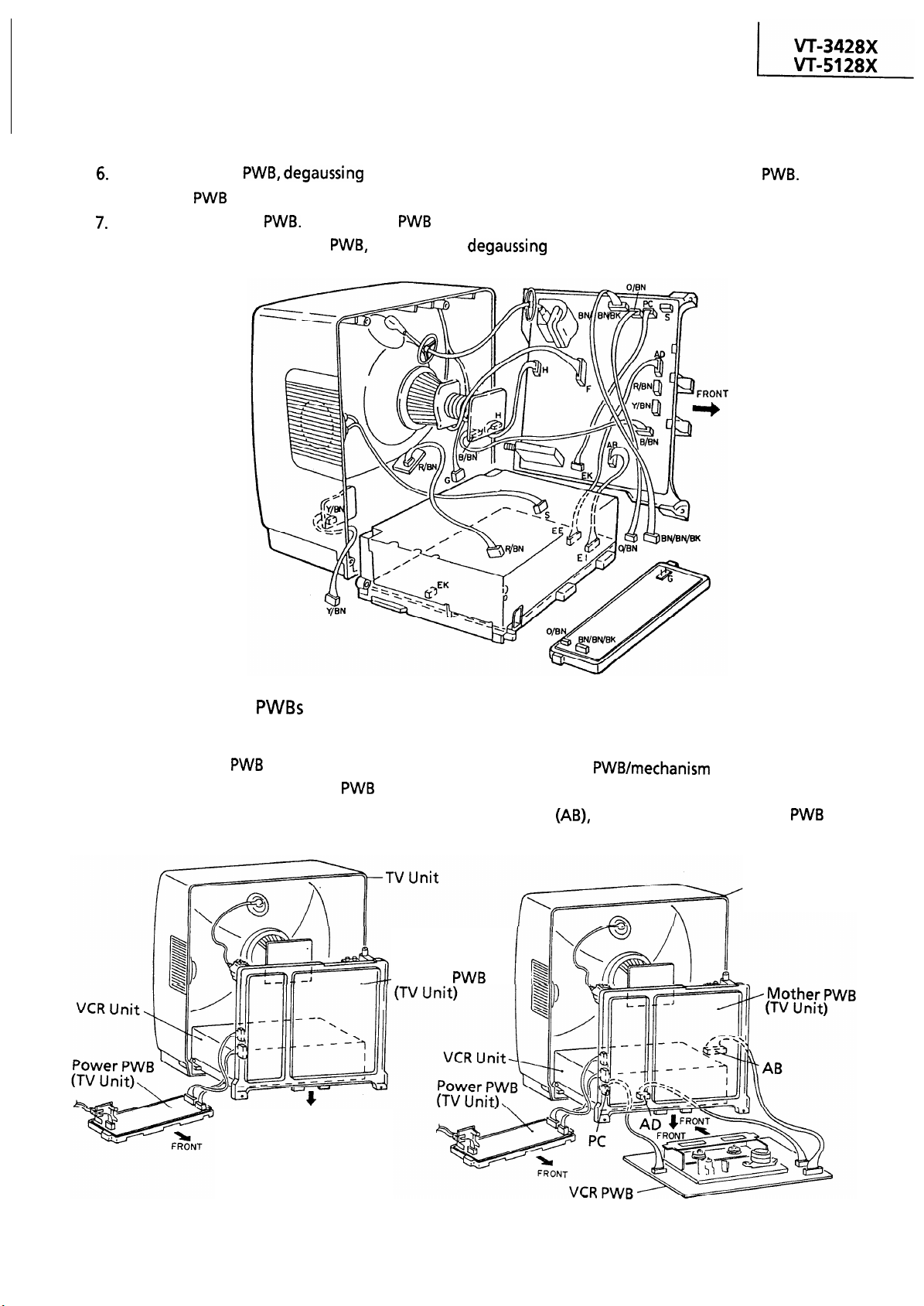

Page 7

DISASSEMBLY AND REASSEMBLY

6.

Remove the CRT PWB,

the main PWB upright.

7.

Reconnect the CRT PWB. Put the main PWB and the VCR unit together as shown below. Keep the front

power switch remote control PWB, speakers and

degaussing

coil connector G and front power switch remote control

degaussing

coil connector G off position.

(Continued)

PWB.

Place

n SERVICING THE

<Repairing the TV unit>

Unhook the power PWB and place it on the left

hand of the set. Set up the mother PWB as shown

below.

PWBs

-Mother

FRONT

PWB

<Repairing the TV and VCR units>

Unhook the

VCR unit, and place it as shown here. Connect the

cables

start repairing.

PWB/mechanism

(AB),

(AD) and (PC) to the mother

assembly from the

TV Unit

PWB

to

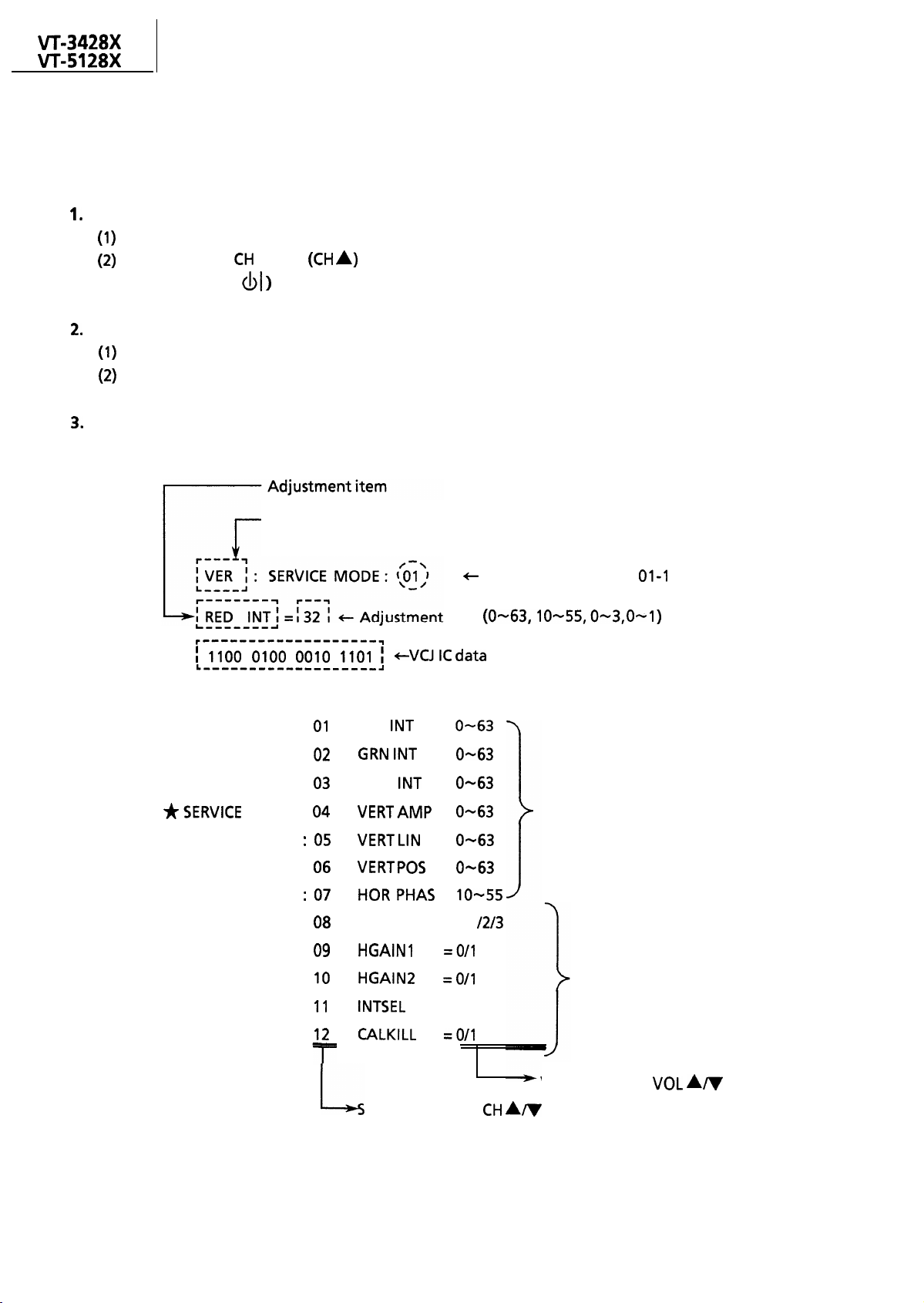

Page 8

W-3428X

VT-51 28X

l PRECAUTIONS

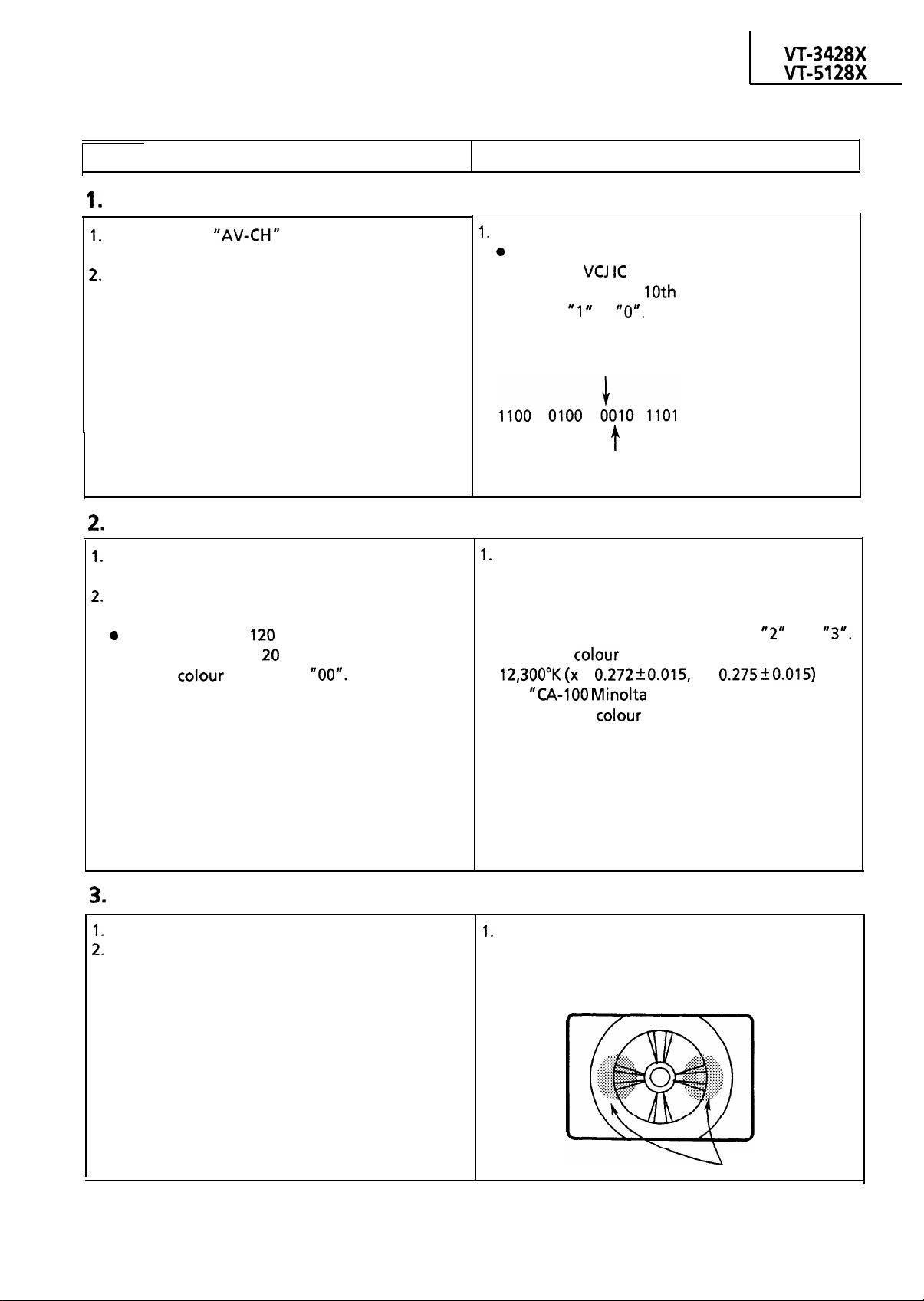

Calling the service mode

I,

(1) Place the set in the stand-by mode.

(2)

Hold down the CH UP key

POWER button ( bl ) of the set. Now the set is in the service mode.

Clearing the service mode

2.

(1)

There are two ways to clear the service mode. Press the MENU key on the remote control gun

(2) Or place the set in the stand-by mode again.

Display in the service mode

3.

ADJUSTMENT OF THE

TV ELECTRICAL CIRCUITRY

(CH A)

of the set for 2 seconds or longer and at the same time press the

ROM No. in the microprocessor

L-------d

r-------------------~

i 1100 0100 0010 1101 I’ +VCJICdata

L---------------,,,,~

*SERVICE MODE :

*SERVICE MODE :

*SERVICE MODE :

*SERVICE

*SERVICE MODE :

*SERVICE MODE :

*SERVICE MODE :

*SERVICE MODE :

*SERVICE MODE :

L---l

MODE :

01

02

03

04

05

06

07

08

09

RED

INT

GRN

INT

BLUE INT

VERTAMP

VERT

LIN

VERT

POS= O-63

HOR PHAS

HI-VI

HGAlNl

+

Adjustment item Nos.

data

=

O-63

=

O-63

=

O-63

= O-63

=

O-63

=

lo-55

= O/l

/2/3

=0/l

01-l

(O-63,1 O-55,0-3, O- 1)

General adjustment items

2

*SERVICE MODE :

*SERVICE MODE :

*SERVICE MODE :

10

HGAlN2

11

INTSEL

12

CALKILL

T-

Ls

electable

=0/l

= O/l

=0/l

by the CH

8

Basically fixed

Variable by the VOL

Aw

key

Aff

key

Page 9

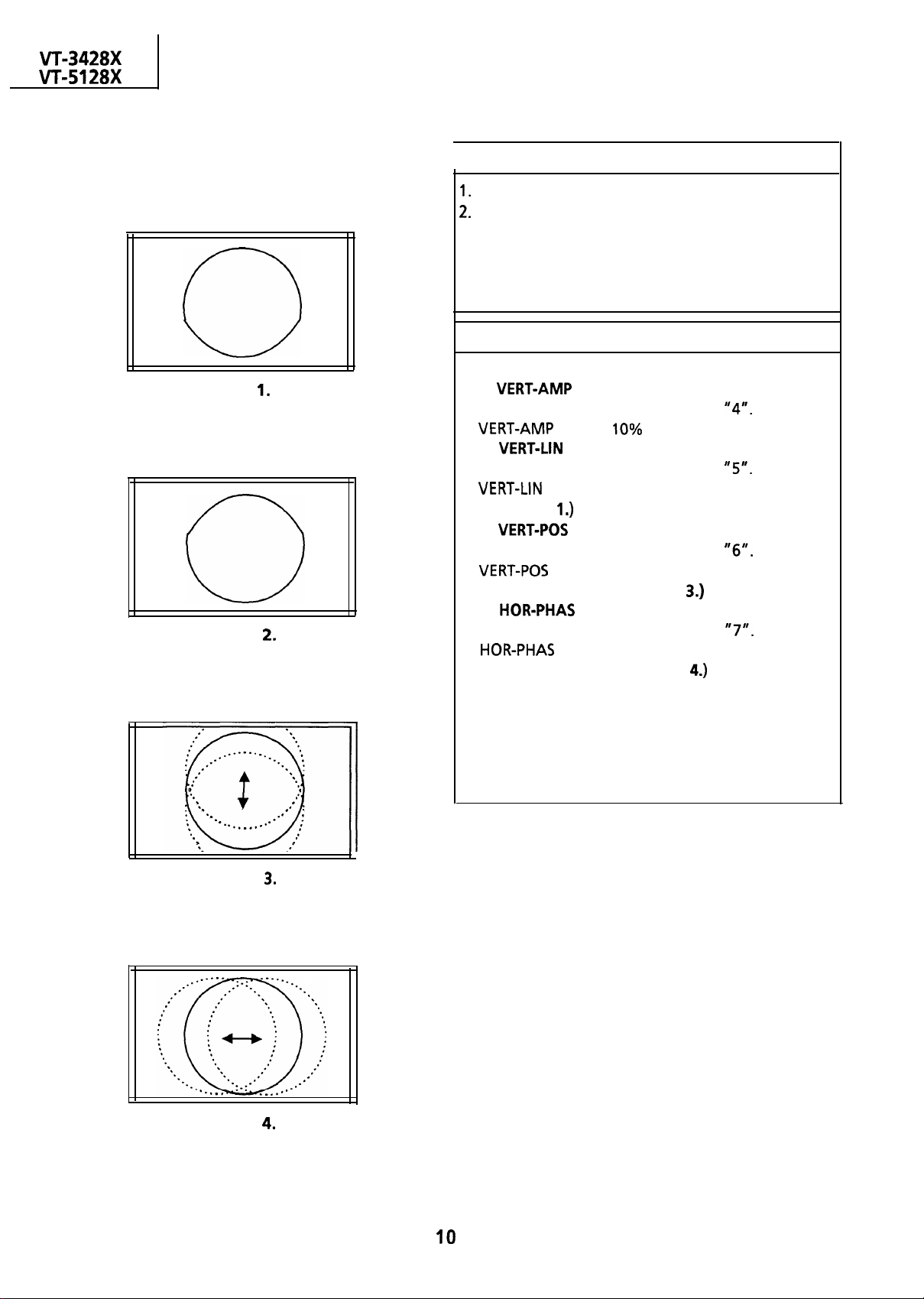

SCREEN/BACKGROUND ADJUSTMENT

i/T-3428X

VT-51 28X

.

1.

Screen Adjustment

1.

Receive the “AV-CH” signal. Keep the blue

background off.

2.

Reset “video adjust” mode.

t

2.

Background Adjustment

1.

Receive

PATTERN” signal.

2.

In the video adjust mode, adjust the brightness

and contrast.

8

Bright portion:

l Dark portion:

Keep the colour adjusted at “00”.

Adjusting Conditions

“WHITE BALANCE ADJUSTMENT

120

nit

20

nit

1.

Call the service mode and take the step below.

0

Screen control:

Look at the

control so that the

turn from “1 II to

1.

Call the service mode and take the step below.

l

Red intensity :

l

Green intensity :

l

Blue intensity :

Pick up the service mode numbers

Adjust the

12,300”K (x

The

“CA-100 Minolta

be used as a colour thermometer.

Adjusting Procedures

VCJ IC

data on the screen. Adjust the

10th

figure from left should

“0”.

To be 0 here too.

f

To turn to 0 here.

colour

temperature as follows.

=

0.272 + 0.015,

y =

CRT Color Analyzer” should

“2”

and

0.275 It 0.015)

“3”.

3.

Focus Adjustment

1.

Receive “monoscope pattern” signal.

2.

Reset the video adjust mode to have the Video

Normal Position.

1.

Adjust the focus control to have the best focus in

the areas between the pattern’s center. and its

both ends.

Adjust point

9

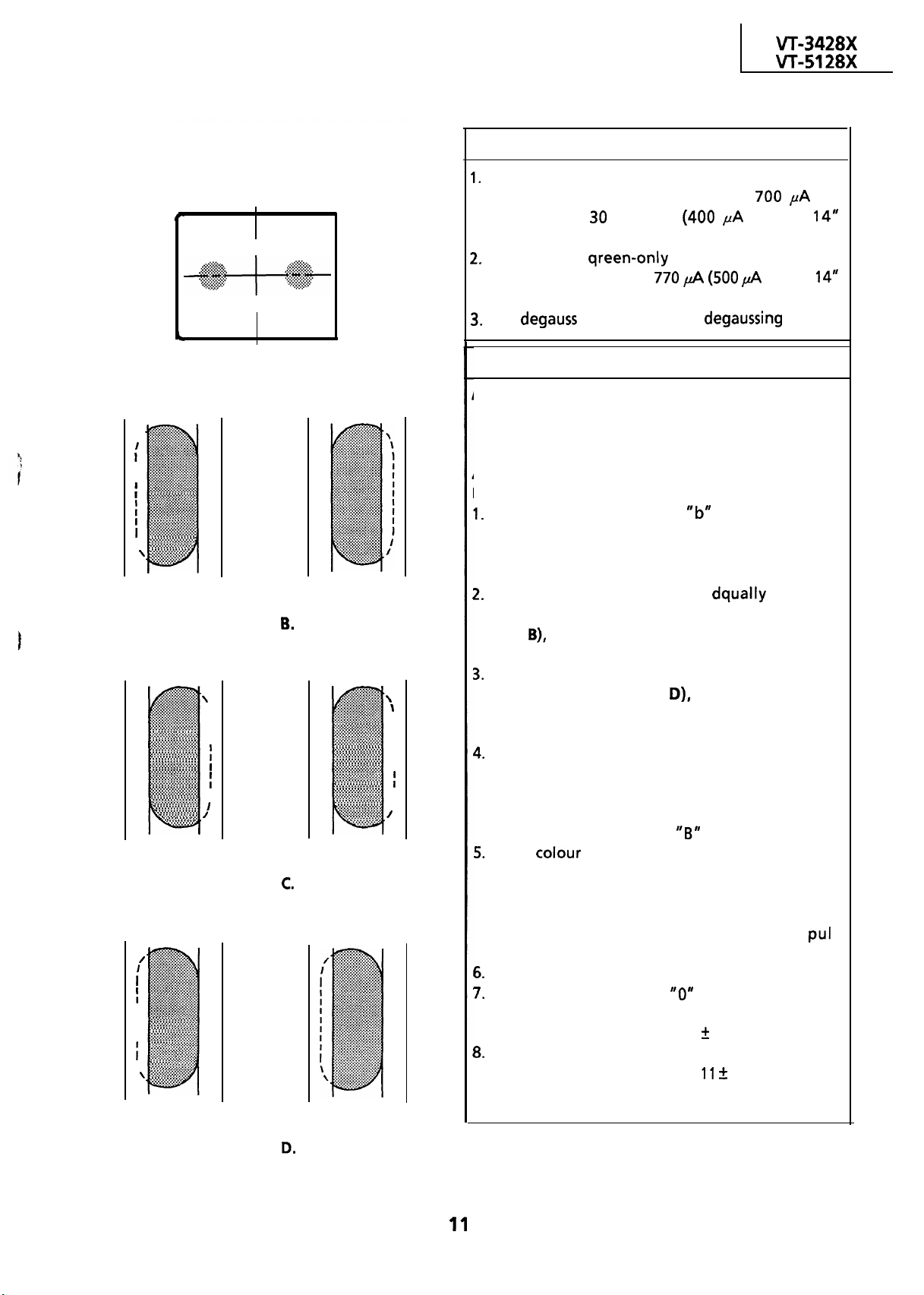

Page 10

W-3428X

VT-5128X

HORIZONTAL/VERTICAL CIRCUIT ADJUSTMENT

0

Figure

0

Figure

1.

2.

I

1.

Receive “PAL monoscope pattern” signal.

2.

Reset the video adjust mode to have the Video

Normal position.

I. Call the service mode and take the steps below.

l

VERT-AMP

Select the service mode number

VERT-AMP

l

VERT-LIN

Select the service mode number

VERT-LIN

Figs. 1 and

l

VERT-POS

Select the service mode number “6”. Adjust the

VERT-POS

center of the screen. (See

l

HOR-PHAS

Select the service mode number

HOR-PHAS so that the horizontal center be at the

center of the screen. ( See

Adjusting Conditions

Adjusting Procedures

(vertical size):

“4”.

Adjust the

to have 10% overscan.

(vertical linearity):

‘5’.

Adjust the

to have optimum vertical linearity. (See

1.)

(vertical center):

so that the vertical center be at the

Fig.

3.)

(horizontal center):

“7’.

Adjust the

Fig.

4.)

~~

:

.

.

. . . . . . .

..--

.

:

.’

.*

i

.

‘.

.

$

-.

.

-.

-.

.

-......-

.

‘.

.

Figure

Figure

3.

4.

‘.

:

-.

.

-.

.

.

.

‘.

:

,

a* ;

*.-

,

:

.

.

_

l ‘

,

:

IO

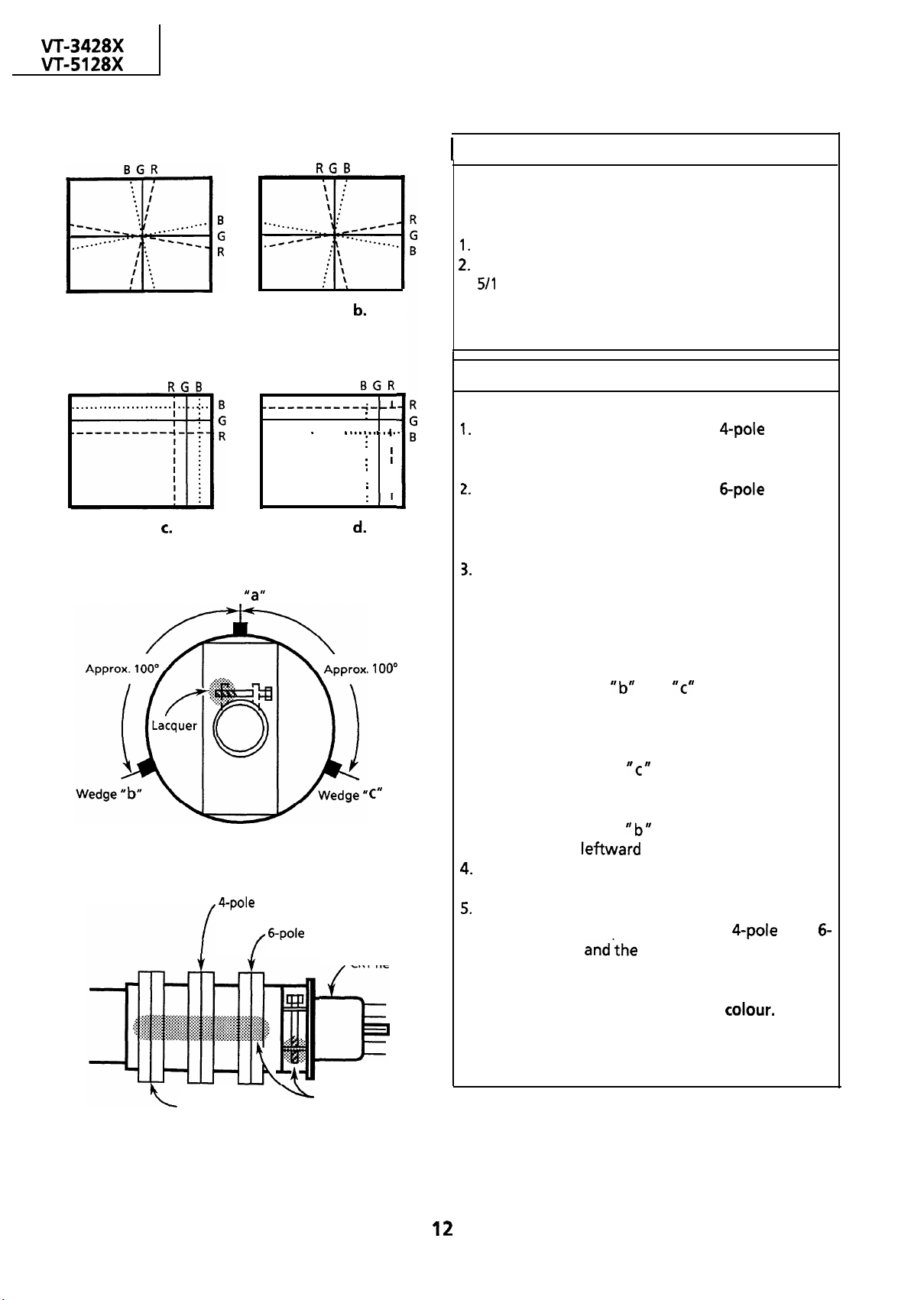

Page 11

W-3428X

VL5128X

PURITY ADJUSTMENT

Adjusting Conditions

1.

Before the purity adjustment, warm up the set

with beam current of more than 700

longer than 30 minutes (400 PA for the

I

a

b

model).

2.

Receive the qreen-only signal and adjust the

beam current to about 770 @I (500 fi for the

model).

3.

Fully

degauss

the CRT with the

degaussing

,uA

coil.

for

14”

14”

Figure A.

Adjusting Procedures

Notes:

Left

.

A..*.-...*.

::::::::::::::::::::~.

,

. . . . . . . . . . . .

:.~:.>:.y*.~;

::::~::::::::::::::::::::

s:~:::::::::::::::::~:::

::::::::::::::::$::::

I

:::::::::~~::::::::::::::::::

. . . . . . . . . . . . . . .

~~~,:.:.:,~.:.:.:.:.:.:.:

I

:::::::~::~~~.:~:::::

I

f

:::::::::::::::::::::::::::::::

:::::::::::~:~:::::::::

I

:::~~.:::::~:::::::::::::::::

:::~.::~.:::::~~::::~.::

~~

. . . . . . . . . . . . . . .

; ~~~~

::::::~::::::::::::::::::::::

\

::::#:::::::x:::$::.

\ :::::::::~.::::::~::::::..

“::::~::~:y$.:.~

~

Beam landing equally outwards.

Figure

B.

t

Left

. . . .

..:.:::::::::::::::::..

.::;~:~:~:; \

..:.:.:.:.:.:.:,~.:.:.:.:.:.

..:.:.:.:.:.:.:.~.:.:.:.:.:

:::::::~:::::::::::::::~~:::

:::::::::::::::::::::::::::::::

:~:::::::::::::::::::::::::::

2.. ..A........ *.5..* ..A..

;y:y$$:::::::y$$$$:

:::::::::::::::::~~::::::::::

:::::::::::::::::::::::::::::

.:.:.:.:.:.:.:.:.:.:.:.~.:.:.

:.:.I:.:.:.:.:.:.:.:.:.:.:.:.:

i.....~......................

:::::::::::::::::::::::::::::::

::::::::::::::::::::::::~:::::

:::::::::~:::::::::::::::::::

:::::::~:::::::::::::::::::::

:::::::~:::::::::~::::~:::

.:.:.ff~:.:.:.:.:.:.~:.:.:.

:.:.:.:.:.:.:.~.:.:.:.:.~

:.:.:.~.:.:.:.:.:.:.~~

:.:.:.:.:.~.:5.:.:,:.:.:.:

..:.:.:.:.:.:.:.:.:.:.:.:

vZ.*.5..~.5V

il

\

I

,

,

i

1

I

I

I

A...

/

*..

s.5.. fS%S. .. . .

.

y.:,:.:.:.*.v

Beam landing shifted to the right.

Figure

C.

Right

Right

.

.v.*.

. .

,::$yjg::>g

..~:.:.:.:.~:.:.:.:.:.:.:

.:.>>>:.:.p:.>~.~. \

..:.:.:.:.:.:.:.:.:.:.:.:.:.:.:

:::::::~~.::::::::::~::

:::::::::::::~:::~.:::.

::~:::::::::::::::~::::::

@Jg$g$~~

g$$J#jgg:$

::::::::~::::::::::::~:::::::

:::::::::::::::::::::::::::::::

:::::::~:::::::::::::::::::::

~~~~.:.

:::::::::::::::::::::~::::~::

.~.:.>‘:.:.~.~.;.~.:.:.~.

:.:.:.:.~.:.:.~.:.:.:.:.:

::::::;::::::::::::::::::::::::

:~:::~:::::~.::::::~.:::::::;

.:.~:,~~:.~..~X.:.:.

s::~::::::::::::::::~::::

13

\

1

I

I

,

I

1

I

::::::y$::::::::::::::::

.7...5......,.....5.,

I

. . . . . . . . . . . .

/

v.;.:.:.~

,

l

Static convergence should be roughly adjusted.

l

The purity magnet should be positioned where

the magnetic field is zero.

Adjustment:

During the adjustment, keep the set facing the east.

1.

Observe the spots “a” and

with a microscope. Adjust the purity magnet to

have these spots at the specified landing

positions.

2.

If the right and left spots are

outwards from their landing positions (shown in

Fig.

B),

push the deflection yoke forwards for

proper positioning.

3.

If both the spots are shifted to the right or left

(shown in Figs. C and

angle of the purity magnet for proper

positioning.

4.

Make sure that the center spot

and left spots are in their specified landing

positions. Check the four corners of the CRT

screen.

See if all the landing positions are

satisfactory with the Rank “B” specifications.

5.

If any

colour

other than green appears, pull the

deflection coil backwards.

Landing too outwards: Deflection yoke to push

“b”

(shown in Fig. A)

dqually

D),

adjust the opening

as

deviated

well as the right

forwards.

Left

.

A55..

.

:::::::::::::~~::::..

/ .5..55............55

.:,:.:.:.:.:.:f.:.:.:.:.~.

~:.v.-.~...*

. . . . . . . . . . . . . .

>:.f:.:*:.:.:.:.>:.~.:.:.

;

~~~~

. . . . . . . . . . . . . . z.

.:e:.:.>:.:.:.:.:.:.:.>:.:.:.

1 .r:‘:‘:‘:‘:‘:‘:‘:‘:‘:‘:’

. . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . .

:.~.:.:.~.:.:.~.:.:.:.:.:

. . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . .

*...*A. ..,.........A.......

I

. . . . . . . . . . . . . . . .

.:.:.:.:.:.:.:.>:.:.:.:.:.:.:.

. . . . . . . . . . . . . . . .

.:.:.:.:.:.:.:.:.:.:.:.>:.:.:.

I

:.~.:.:.>:.:.:.:s.:.~.:.:

. . . . . . . . . . . . . . .

I

:.~:.:.:.:.:.:.:.:.:.:.:.f:.:

.:.:.:.:.:.:.:.:.:.:.:.:.:.:...

I

:.~.:.:.~:.:.:.:.:.:.:.:::

. . . . . . . . . . . . . . .

:*:‘:.:.:.:.:.:.:.:.:.:.:.:.:..

.:.:.:.~.:.:.:.:.:.:.:,p:

. . . . . . . . ...*.....

... .

. . . . .

.

. . . . . . . . . .... . . .

:.x.:.:.>:.

. . . . . . . . . . . . . . .

;

\

\ ::pJ:$.:$#~..*.

[fl

.

.:.:.:.:‘:.:.:.:.~:.:.:.>:

:.~.:.:.:.:.:.:.:.:.:.:.:.:.

::$::::::p+:.:.:.:.:...

.::~~:$::*$.J$.~

. . . . .

Right

Landing too inwards : Deflection coil to

backwards.

6.

Receive the monoscope pattern signal.

7.

Set the raster rotation at

“0”

position with the set

facing the east.

Adjustment error: 0 + 2 mm

8.

Tighten up the deflection coil screws.

Tightening torque:

11 +

2 kg

pul

I

Beam landing shifted to the left.

Figure

D.

11

Page 12

VT-3428X

VT-51 28X

CONVERGENCE ADJUSTMENT

Adjusting Conditions

RGB

This adjustment should be performed after

the purity magnet adjustment.

1.

Receive the crosshatch pattern signal.

2.

Set the brightness and contrast controls to the

5/l 0 and 1 O/l 0 positions, respectively.

Figure a.

RGB

Figure

c.

Wedge

4-pole

w----------~--L

..I.......... * . . . . *

“a”

magnet

6-pole

f

Figure

Figure

magnet

b.

BGR

:

I

I

..I..... .‘.

.

:

I

.

.

: I

’

I

.

.

I

*

-

I

.

*I

d.

,100"

C"

CRT neck

.

I

Adjusting Procedures

STATIC CONVERGENCE

1.

Adjust the opening angle of the

and rotate the magnet to impose the blue line

over the red one.

2.

Adjust the opening angle of the

and rotate the magnet to impose the green line

over the blue one.

4-pole

6-pole

magnet

magnet

DYNAMIC CONVERGENCE

3.

Take the following steps for dynamic

convergence at the edges of the CRT screen.

l

Convergence in Fig a :

Insert the wedge “a”

deflection coil upward for correct convergence.

l

Convergence in Fig b :

Insert the wedges

he deflection coil downward for correct

convergence.

l

Convergence in Fig c :

Insert the wedge

deflection coil rightward for correct convergence.

l

Convergence in Fig d :

insert the wedge

deflection coil

4.

Stick the above wedges on the CRT, and apply

glass tape over them.

5.

Apply lacquer to the deflection yoke screw, the

magnet unit (consisting of purity,

pole magnets)

leftward

and’the

Finally receive the red-only signal to make sure

there is no mixture with any other

same with the blue-only signal.

in position, and tilt the

“b”

and

“c’

in position, and tilt

“c”

deeper, and tilt the

“b”

deeper, and tilt the

for correct convergence.

4-pole

magnet unit screw.

colour.

and

6

Do the

Purity magnet

L

3

Lacquer

12

Page 13

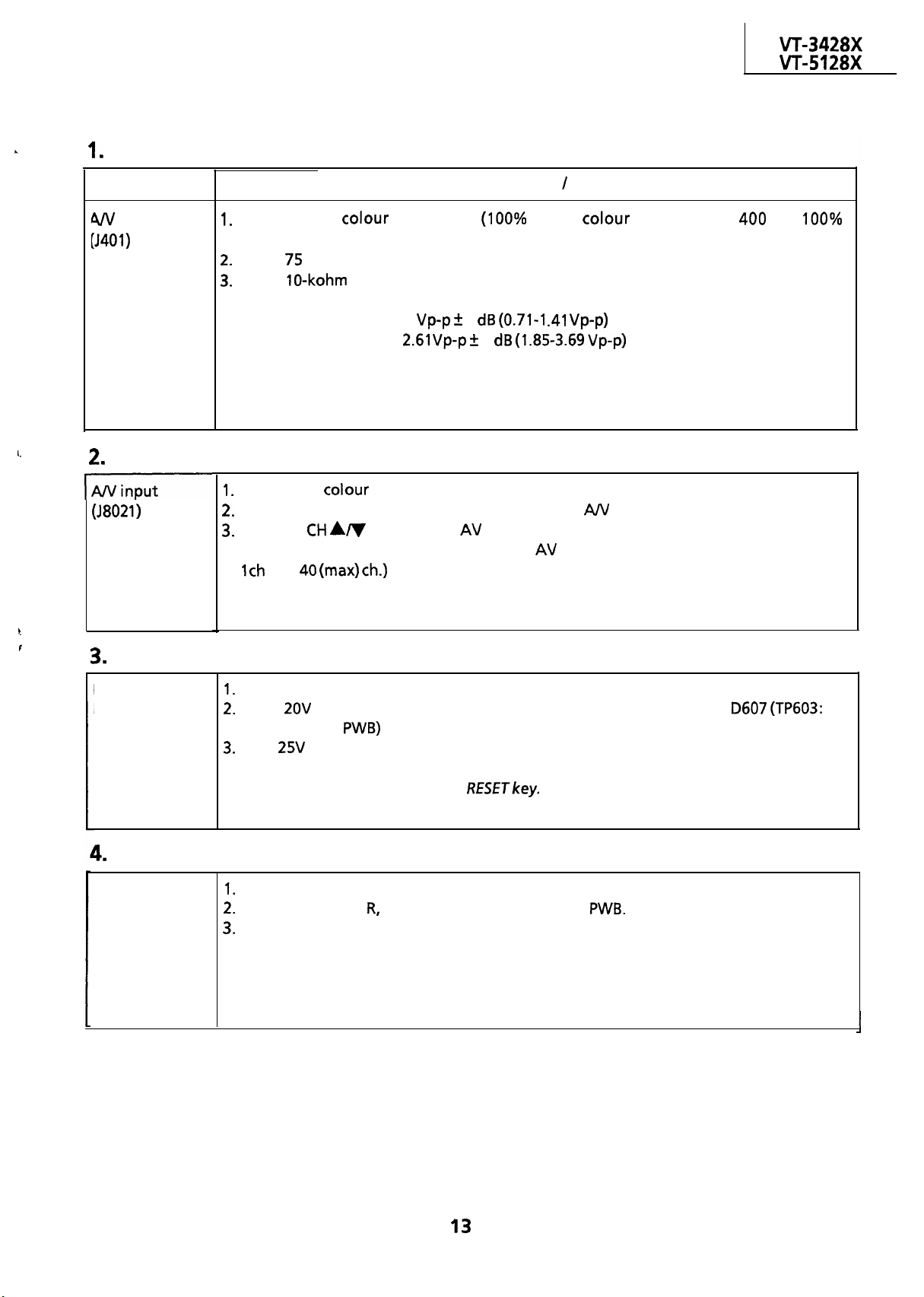

1.

A/V Output Checking

VT-3428X

VT-51 28X

PERFORMANCE CHECK

Adjusting Point

1.

w

output

(J401)

1.

I

2.

A/V Input Checking

lANinput

(J802 1)

Receive the

modulation).

2.

Add a 75 ohm terminal resistor to the video output terminal.

3.

Add a

The output levels are as follows.

Note:

Make sure the video and audio outputs are as specified.

1.

Receive the

2.

Feed the external video and audio signals via the

3.

Using the CH

signals are being properly received. (The AV mode is available somewhere between

lo-kohm

Video output:

Audio output:

lch and 40

colour

terminal resistor to the audio output terminal.

colour

Am

key, call the AV mode and make sure the external video and audio

(max) ch.)

Adjusting Conditions / Procedures

bar signal

1

Vp-p +

2.61Vp-p +

bar signal.

(100%

3 dB

(0.71-l .41 Vp-p)

3 dB

(1.85-3.69 Vp-p)

white

colour

A/V

front jacks.

bar, audio : 400 Hz, 100%

t

f

3.

Protector Performance Checking

Protector

Performance

4.

Beam Protector Performance Checking

Beam

Protector

Performance

1. Receive the monoscope pattern signal.

2.

Apply

3.

Feed 25V in the same way and make sure the protector is activated.

1.

Receive the monoscope pattern signal.

2.

Ground any of the R, G and B cathodes on the CRT PWB.

3.

Make sure the protector is activated immediately.

20V

from the constant-voltage power supply to the cathode of

symbol on the

Note:

To reset the protector, press the

Note:

To reset the beam protector, press the RESET key.

PWB)

and make sure the protector is not activated.

RESETkey.

D607 (TP603:

no

13

Page 14

W-3428X

VT-51 28X

PERFORMANCE CHECK

5.

Blue Background Checking

Adjusting Point

1.

Blue

background

c

6.

Record Index Checking

Record

index

In the SET UP mode, select the BLUE SCREEN function.

2.

Turn on the function. With any signal input,

Make sure also that the audio is mute.

3.

Turn off the function and make sure the blue background disappears.

1.

In the SET UP mode, select the

2.

Turn on the function to make recording. (Make sure the clock has been preset.)

3.

Check the recorded contents.

Note:

Make

sure

the channel and time

(Continued)

Adjusting Conditions / Procedures

make sure the background is blue.

REC

INDEX function.

are

recoded.

14

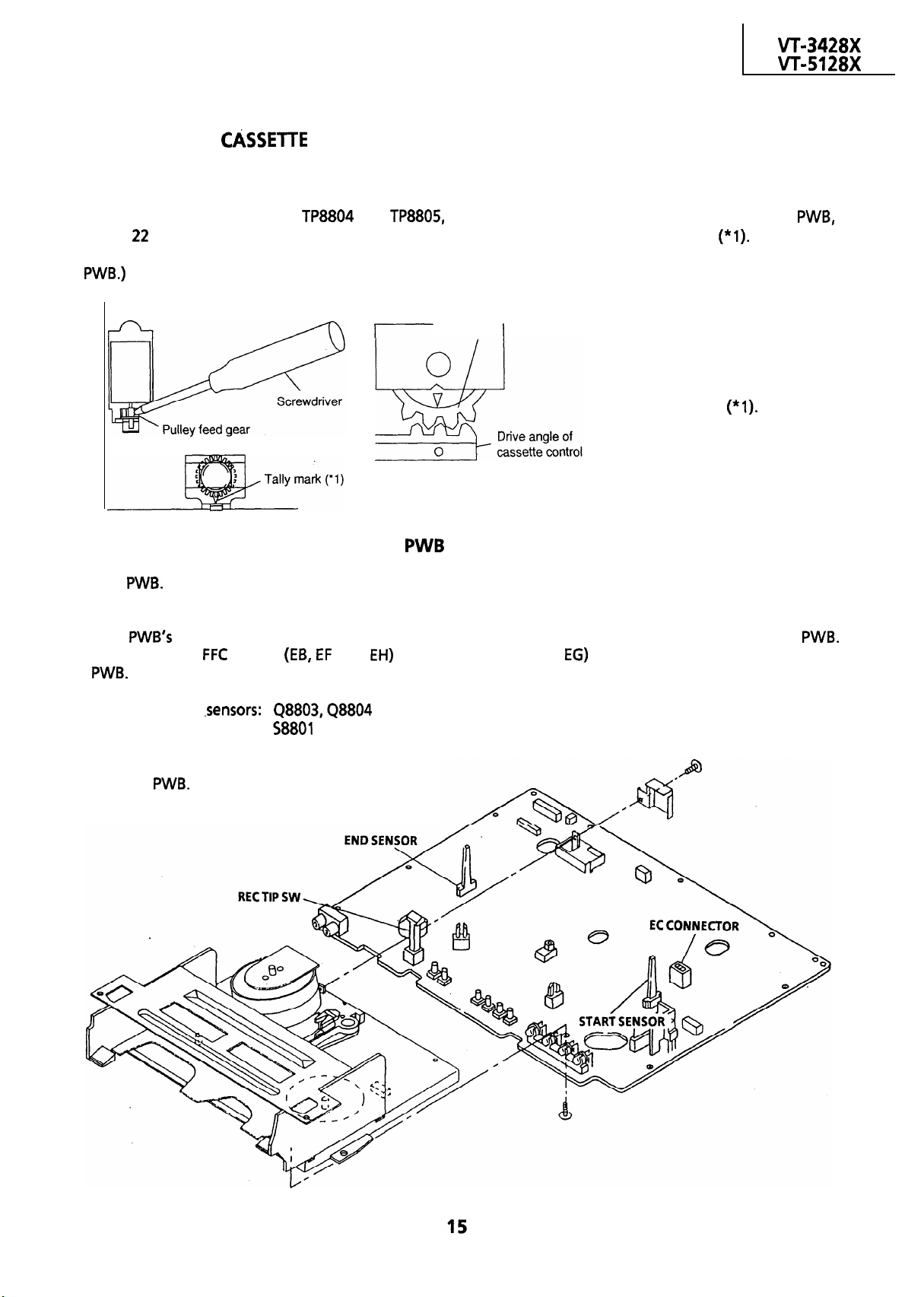

Page 15

PRECAUTIONS IN REASSEMBLING

VT-3428X

VT-51 28X

MOUNTING THE

Initial setting is indispensable

made in two ways; electrical and mechanical.

CASSETTE

before placing the cassette controller in the mechanism. The initial setting is

CONTROLLER

Electrical setting:

Make a short-circuit between TP8804 and TP8805, both located at the center on your side on VCR

with a 22 ohm resistor and be sure that the mechanism is back to its initial setting position

the cassette controller in position. (This method is used when the mechanism has been already set on its

PWB.)

(*l).

Now place

PWB,

Mechanical setting:

Cassette control

r----

COUPLING THE MECHANISM TO THE

Match the mechanism’s projections with the two symbols (round reference and oval sub-reference) on the

VCR PWB. Place the mechanism straight down in position with due care so that the mechanism chassis’s

outer edges should not damage any parts nearby.

Tighten up the two screws (one for fixing the mechanism and the head amplifier shield, the other on the

VCR

PWB’s

soldering side and located near the loading motor) to fix the mechanism and VCR PWB.

Reconnect the

PWB.

FFC

cables

(EB, EF

and EH) and harnesses (ED and

drive gear

Phase matching point

PWB

EG)

between the mechanism and VCR

Turn the loading motor’s

pulley feed gear using a

screwdriver and be sure

that the mechanism is

back to its initial setting

position

the cassette controller in

position. (This method is

applicable for the

mechanism alone.)

(*l).

Now place

Parts to pay attention to:

Start and end

Record tip switch:

Take special care of the MC-EC connector

(board

and VCR

to

PWB.

.sensors:

Q8803,Q8804

58801

board) between

the mechanism

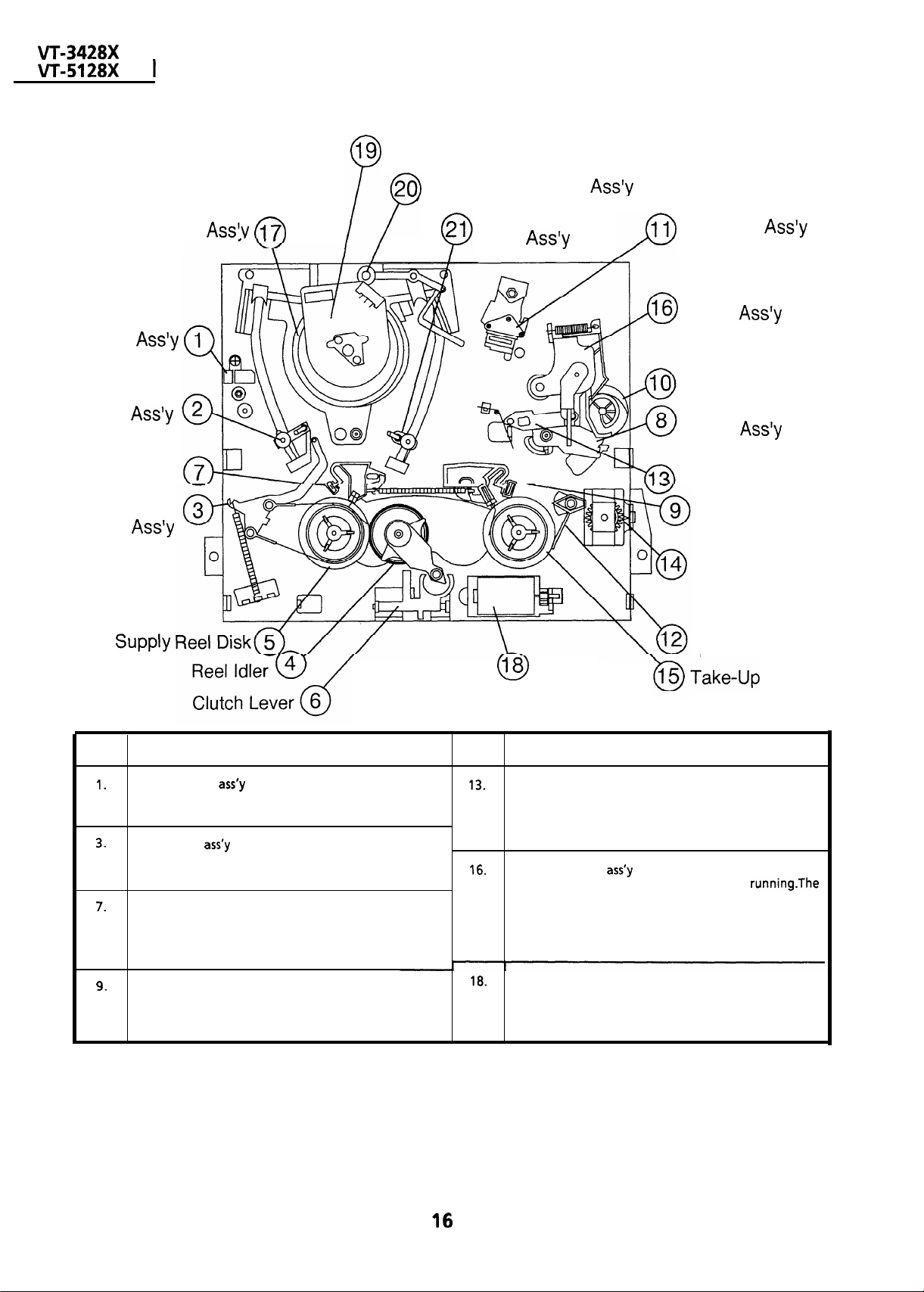

Page 16

W-3428X

VT-5128X

I

t

FUNCTION OF MAJOR MECHANICAL PARTS

19

Drum Motor

20

Drum

Full Erase

Head

Ass’y

Supply Pole

Base

Ass’y

Main Supply

Brake Lever

Tension

Arm

Ass’y

Ass’v m

Auto Head Cleaner

f

P

P

/

Take-Up Pole

Base Ass’y

Ass’y

(TOPVIEW)

A/C Head

Pinch Roller

Lever

Pinch Drive Car

Pinch Drive

Lever

Reverse Guide

Main Take-Up

Brake Lever

Cassette

Housing

Drive Gear

Ass’y

Ass’y

Ass’y

n

SUPPlY

No.

Full erase head

1.

Erase the whole records on the tape in the recording

mode.

3.

Tension arm

Detects the tension of tape while running, and brakes

the supply reel disk via the tension band.

7.

Main supply brake lever

Brakes the supply reel disk to prevent tape slackening

when the unit is stopped in fast forward or rewind

mode.

9. Main take-up brake lever

Brakes the take-up reel disk to prevent tape slackening

when the unit is stopped in fast forward or rewind

mode.

ass’y

Function

ass’y

Take-Up

Lock Lever

@

Loading

Motor

No.

Reverse guide

13.

Pulls out the tape and controls the tape drive train

height with the upper and lower guides.

Pinch roller lever

16.

Press-fits tape to the capstan during tape running-The

right protrusion switches the clutch of the cassette

housing control assembly in “tape eject”, and makes

the mechanism eject tape,

Loading motor

18.

A motive power which drives the mechanism. It

transmits the power to the master cam and cassette

housing control assembly .

Function

ass’y

Reel Disk

16

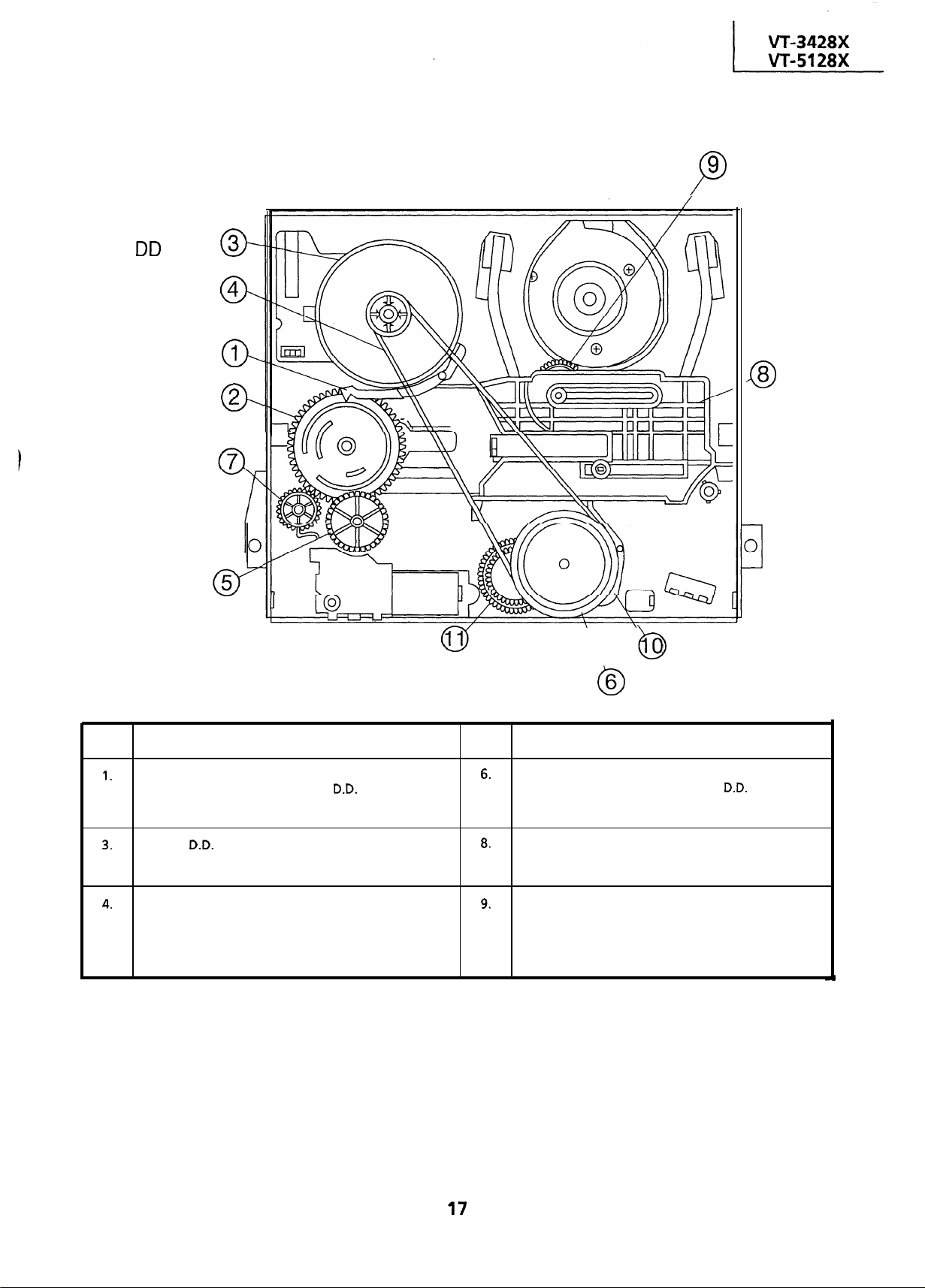

Page 17

FUNCTION OF MAJOR MECHANICAL PARTS

(BOTTOM VIEW)

Capstan

DD

Motor

o-

3

9

Take-up

Loading Gear

P

Reel Belt

Slow

Brake Lever

Master Cam

Cassette Housing

Drive Gear

Connect Gear 5

o++

@,

1

o-

@,

Clutch Gear

@

\

10

0

6

Reel Pulley

0

8

Shifter

0

Clutch Connect Arm

No.

Slow brake lever

1.

Gets in contact with the capstan

the master cam in the slow still mode, and brakes it to a

certain degree.

3.

Capstan

A motive power which runs the tape. It transmits the

power via the reel belt.

4.

Reel belt

Transmits the power to run the tape to the reel pulley.

D.D.

motor

Function

D.D.

motor linking to

No.

6.

Reel pulley

Transmits the power of the capstan

reel disk via the reel idler.

8.

Shifter

Transmits the operation of the master cam to break

and loading gear.

9.

Take-up loading gear

Shifts the take-up pole base and guide roller via the

loading relay gear, and applies the tape around the

drum assembly, as well as transmits the power to the

supply loading gear.

Function

D.D.

motor to the

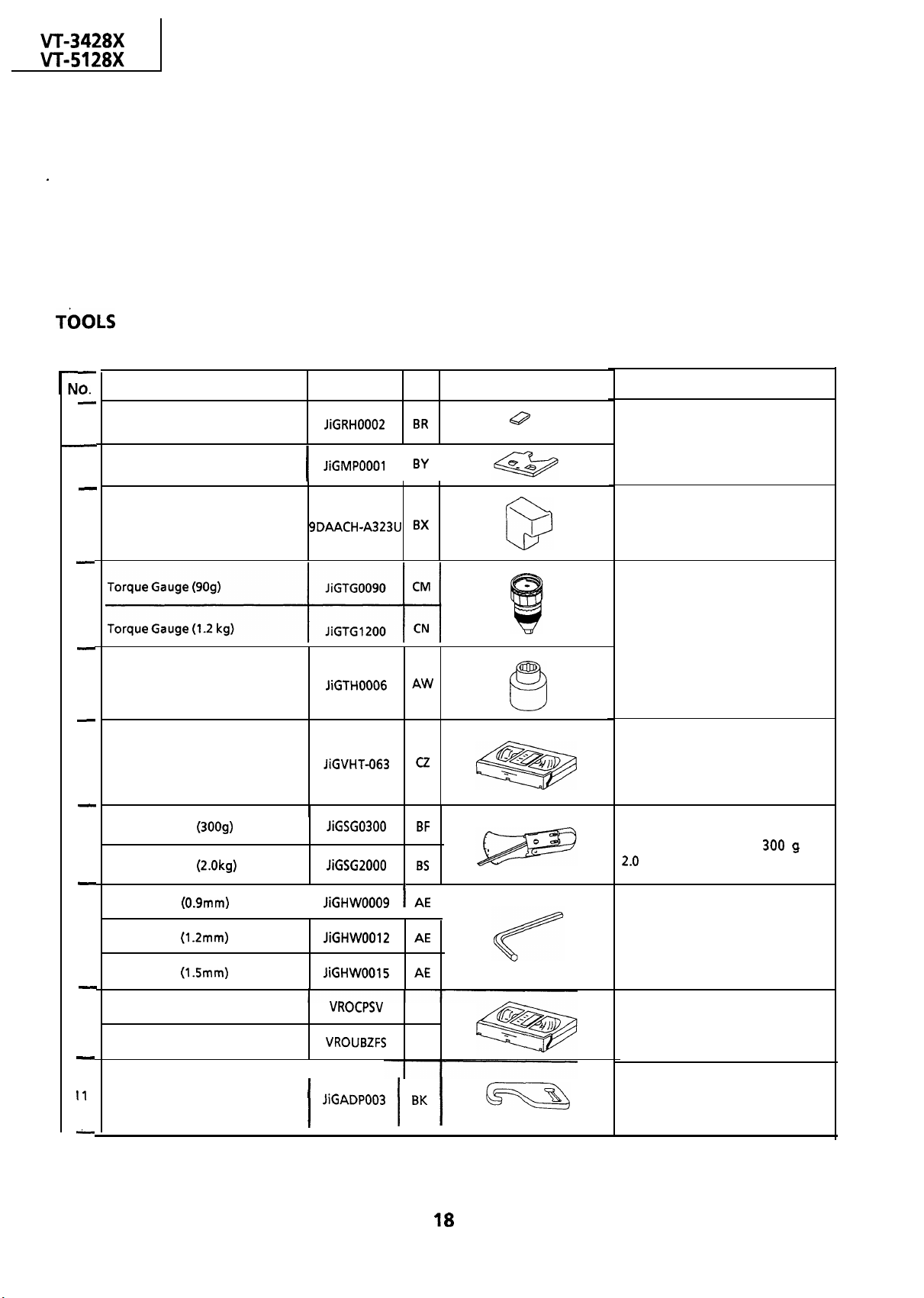

Page 18

VT-3428X

VT-51 28X

ADJUSTMENT, REPLACEMENT AND ASSEMBLY OF

MECHANICAL UNITS

_

Here we will describe a relatively simple service

work in the field, not referring to the more

complicated repairs which would require the use of

special equipment and tools (drum assembly

We are sure that the easy-to-handle tools listed

below would be more than handy for periodical

maintenance to keep the machine in its original

working condition.

replacement, for example).

TbOLS

NECESSARY FOR ADJUSTING THE MECHANICAL UNITS

The following tools are required for proper service and satisfactory repair.

-

0.

-

Reel Disk Height Adjusting Jig

1

-

Master Plane Jig

2

-

3

A/C Head Tilt Adjusting Jig

-

4

-

Jig Item

Part No. Code

JiGRH0002 BR

JiGMPOOOl BY

I

9DAACH-A323U

I I

BX

Configuration

42

acD

Gauge Head

5

-

6

Cassette Torque Meter

-

Tension Gauge (3009)

7

Tension Gauge (2.0kg)

-

Hex Wrench (0.9mm)

a

Hex Wrench (1.2mm)

Hex Wrench (1.5mm)

-

Alignment Tape (PAL)

9

Alignment Tape (PAL)

-

JiGTH0006

JiGVHT-063 CZ

JiGSG0300

JiGSG2000

JiGHW0009 AE

I

JiGHWOOl2 AE

JiGHWO015 AE

VROCPSV

VROUBZFS

AW

BF

BS

1

I

f!3

Remarks

These Jigs are used for checking and

adjusting the reel disk height.

This Jig is used for setting the A/C

head tilt.

These Jigs are used for checking and

adjusting the torque of take-up and

supply reel disks.

This cassette torque meter is used

for checking and adjusting the

torque of take-up for measuring

tape back tension-

There

are two gauges used

tension measurements, 300 g and

2.0 kg.

These Jigs are used for loosening or

tightening special hexagon type

screws.

These tapes are especially used for

electrical fine adjustment.

for the

11

Tension Gauge Adapter

b

/ JiGADP003 / BK 1

18

This Jig is used with the tension

gauge. Rotary transformer

clearance adjusting jig.

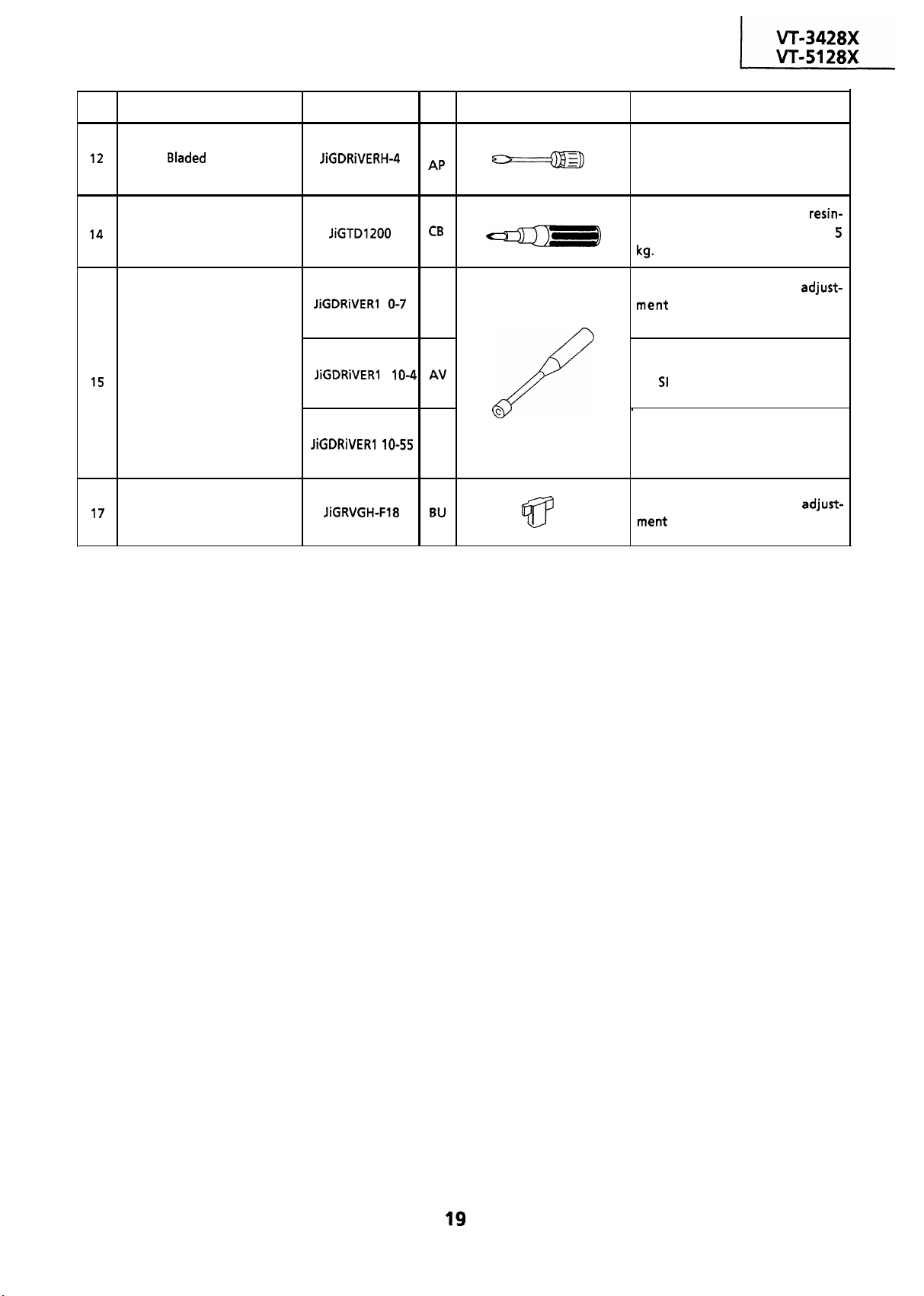

Page 19

No.

Jig Item

Part No. Code

Configuration

Remarks

Special Bladed Screwdriver

12

Torque Driver

14

Box Driver

15

Reverse Guide Height

17

Adjusting Jig

JiGDRiVERH-4 Ap

JiGTDl200

JiGDRiVER

JiGDRiVER 10-4 AV

JiGDRiVER

JiGRVGH-F18

1

lo-55

O-7

AR

CB

AS

BU

This screwdriver is used for adjusting

the guide roller height.

This is used to screw down

made parts: the specified torque is

-

C

/

:

kg-

This Jig is used for height

ment

of the A/C head and X-

position.

This Jig is used for replacement of

the SI roller.

’

This Jig is used for height adjust-

ment of the reverse guide.

This Jig is used for height

ment

of the reverse guide.

resin-

5

adjust-

adjust-

19

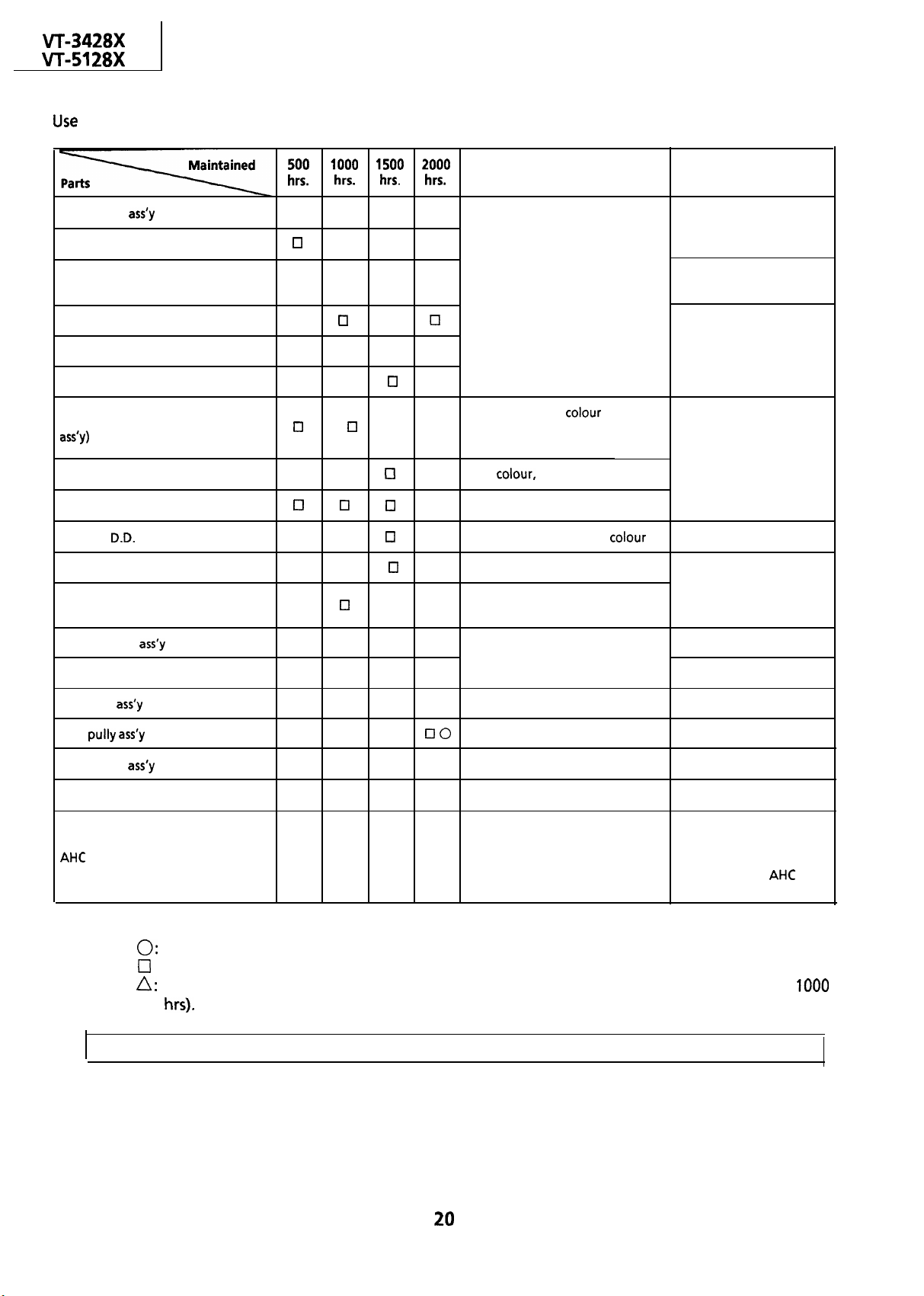

Page 20

W-3428X

W-51 28X

MECHANICAL PARTS REQUIRING PERIODICAL INSPECTION

Use

the following table as a guide to maintain the mechanical parts in good operating condition.

500

1000 1500 2000

hrs. hrs. hrs. hrs.

Possible symptom encountered

Remarks

Guide roller

Supply impedance roller

Supply impedance roller

(inner hole and shaft)

Supply impedance roller flange

Retaining guide

Slant pole

Video head (upper/Lower drum

ass’y)

Full-erase head

A/C head

Capstan

Pinch roller

Reel belt

Tension band

Loading Motor

D.D.

ass’y

Motor

ass’y

q q q 0

Cl

q cl 0

cl

cl cl cl

cl cl cl El

q

Lateral noises

Head occasionally blocked

cl

cl q cl 0

El

q q

Cl

0 cl 0

cl q

0

Cl

0 Cl 0 Cl

0

0

Poor S/N ratio, no

Poor flatness of the envelope with

alignment tape

Poor

0

0

colour,

Sound too small or distorted

No tape running, uneven

colour

beating

cl q cl 0 No tape running, tape slack

III

No tape running, tape slack, no

0

fast forward/rewind motion

0

Cassette not loaded or unloaded

0

Abnormal rotation or

significant vibration

requires replacement.

Clean with pure high

quality isopropyl alcohol.

Clean tape contact part

with the specified cleaning

liquid.

Clean tape contact area

with the specified cleaning

liquid.

colour

Clean rubber and rubber

contact area with the

specified cleaning liquid.

.

Reel idler

Reel

Clutch gear

Main supply/take-up brake levers

AHC

NOTE:

ass’y

pully ass’y

ass’y

(Automatic Head Cleaner)

0:

Part replacement.

q

A

0 0

No tape running

0

00

0

0 Tape slack

Cl :Cleaning (For cleaning, use a lint-free cloth dampened with pure isopropyl alcohol).

A:

Oil refilling (The indicated point should be lubricated with high quality spindle oil every

hrs).

If the reading is out of the specified value, clean or replace the part.

Replace the roller of the

cleaner when it wears

down.

Just change the

assembly for new one.

AHC

roller

1000

,

20

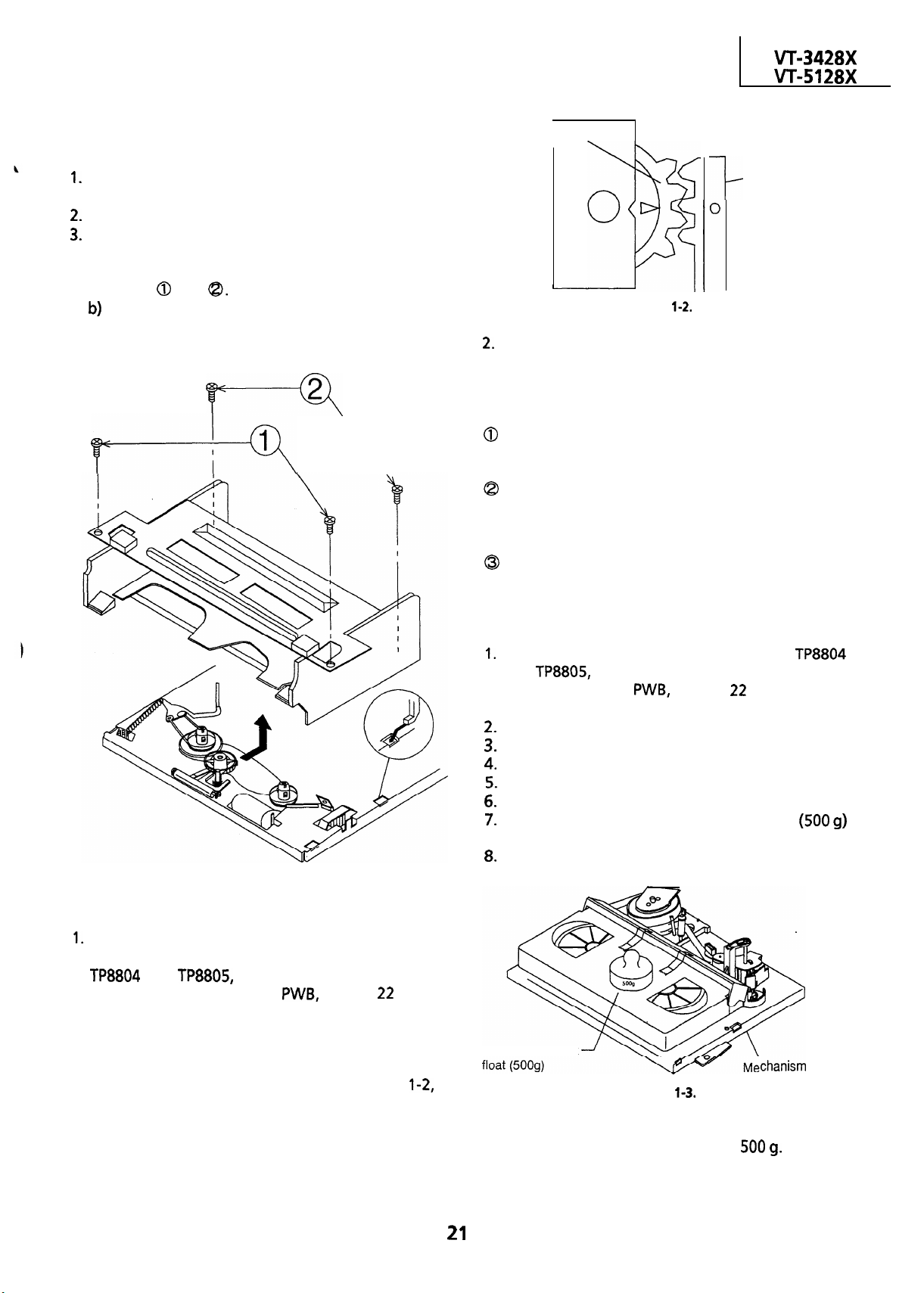

Page 21

VTg3428X

VT-51 28X

REMOVAL AND REASSEMBLY OF

CASSETTE HOUSING CONTROL ASSEMBLY

l

Removal

1.

Set the cassette ejected condition in the cassette

eject mode.

2.

Unplug the recorder from the main source.

3.

Follow the procedures below in the specified

order.

a) Remove the cassette housing installation

screws 0 and

b)

Slide and pull out the cassette housing control

assembly upward.

\

.

a.

m

\

Cassette control

drive gear

2.

Follow the procedures for removal in the reverse

order.

Notes:

0

In using a magnet screw driver, be sure to keep it

away from the A/C head, FE (Full Erase) head, or

the drum.

Q

In removal and reassembly, take care not to hit

the cassette housing control assembly or tools

against the guide pin, drum, or the like

thereabout.

0

Load the cassette once onto the cassette housing

control assembly after reassembly.

I

Drive angle of

cassette control

l-

Figure

l-2.

Figure l-l.

l

Reassembly

1.

Before installation of the cassette housing

control assembly, make a short-circuit between

TP8804 and TP8805, both located at the center

on your side on the VCR

resistor. Plug in the power cord. The cassette

control drive gear starts and stops just when a

tally mark appears in the mechanism chassis

window. Align this tally mark with the cassette

control drive angle’s mark, as shown in Fig.

to position the cassette control on the

mechanism chassis.

PWB,

with a 22 ohm

l-2,

TO RUN A TAPE WITHOUT THE CASSETTE

HOUSING CONTROL ASSEMBLY

1.

Be sure to make a short-circuit between TP8804

and

TP8805,

side on the VCR

before turning on the power.

2.

Plug in the power cord.

3.

Turn on the power switch.

4.

Open the lid of a cassette tape by hand.

5.

Hold the lid with two pieces of vinyl tape.

6.

Set the cassette tape in the mechanism chassis.

7.

Stabilize the cassette tape with a weight

to prevent floating.

8.

Perform running test.

Weight to prevent

Note:

The weight should not be more than

both located at the center on your

PWB,

with a 22 ohm resistor,

(500 g)

chanism chassis

Figure

1-3.

500 g.

21

Page 22

1

W-3428X

VT-51 28X

REPLACEMENT AND HEIGHT CHECKING

AND ADJUSTMENT OF REEL DISKS

l

Removal (Supply and Take-up reel disks)

1.

Remove the cassette housing control assembly.

2.

Pull the tension band out of thetension arm.

3.

Remove the supply main brake and the take-up

main brake.

4.

Open the hook at the top of the reel disk, and

remove the reel disk.

Takeup

Tension Arm Ass’y

Supply reel disk

main brake

Take-up reel disk

Notes:

@Take enough care not to deform the tension

band during installation of the supply reel disk.

@

Be careful not to damage the supply main brake.

l

Reassembly (Take-up reel disk)

1.

Clean the reel disk shaft and apply oil to it.

2.

Install a new take-up reel disk onto the shaft.

3.

Check the reel disk height and reassemble the

take-up main brake.

Note:

Take care not to damage the take-up main brake.

After reassembly, check the video search rewind

back tension (see page

25)‘

and check the brake

torque (see page 28).

Height checking and adjustment

Note :

Place the master plane onto the mechanism unit,

taking care not to hit the drum (see Figure

l-6).

Figure

l-4.

Note:

When the tension band is pressed in the direction

of the arrow for removal, the catch is hard to be

deformed.

Figure

l-5.

l

Reassembly (Supply reel disk)

1.

Clean the reel disk shaft and apply oil to it.

2.

Install a new supply reel disk onto the shaft.

3.

Replace the tension band around the supply reel

disk, and insert it to the hole of the tension arm.

4 Check the reel disk height and reassemble the

supply main brake.

SUI

Set the master plane releasing the

reverse guide by a finger.

Figure

l-6.

22

Page 23

l

l

Check that the reel disk is lower than part A but

higher than

part

If the height is not correct,

B.

readjust the reel disk height by changing the

poly-slider washer under the reel disk.

Note:

Whenever replacing the reel disk, perform the

height checking and adjustment.

Adjustment

1.

If the take-up torque is outside the range, clean

the capstan

pulley with cleaning liquid, then recheck the

torque.

2.

If the take-up torque is still out of range, replace

the reel belt.

D.D.

motor pulley, reel belt and reel

Notes:

Master plane

10 2 0.2mml

.

1

Reel disk

Reel disk height

adjusting jig

J

1

Mechanism chassis

1.

Hold down the torque gauge so that it may not

fly off.

2.

When checking the take-up torque, do not keep

the reel disk locked for a longer time.

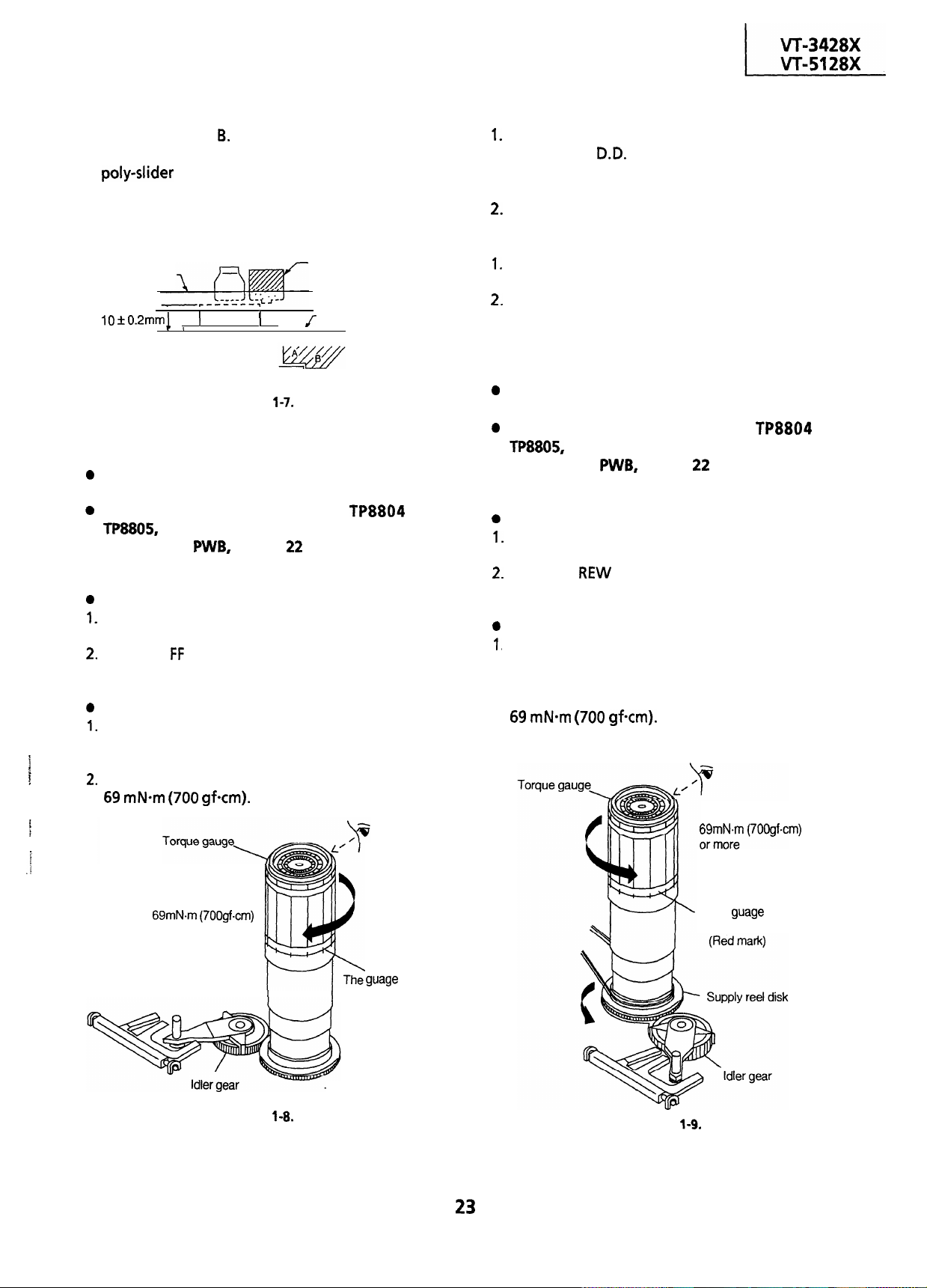

CHECKING AND ADJUSTMENT OF TAKE-UP

Reel disk

Figure

I

l-7.

CHECKING AND ADJUSTMENT OF TAKE-UP

TORQUE IN FAST FORWARD MODE

0

Remove the cassette housing control assembly.

0

Make a short-circuit between

TP8805,

on the VCR

both located at the center on your side

PWB,

with a 22 ohm resistor. Now

turn on the power.

0

Setting

1.

Set a torque gauge to zero on the scale. Place it

on the take-up reel disk.

2.

Press the FF button to set the mechanism to the

fast forward mode.

0

Checking

1.

Turn the torque gauge slowly (one rotation

every 2 to 3 seconds) by hand in the take-up

i

I

direction.

2.

Check to see if the take-up torque is higher than

69 mN-m (700 gfcm).

TP8804

and

TORQUE IN REWIND MODE

0

Remove

0

Make a short-circuit between

TP8805,

on the VCR

turn on the power.

0

Setting

1.

Set a torque gauge to zero on the scale. Place it

on the supply. reel disk.

2.

Press the REW button to set the mechanism to

the rewind mode.

0

Checking

1,

Turn the torque gauge slowly (one rotation

every 2 to 3 seconds) by hand in the take-up

direction.

2

.

Check to see if the take-up torque is higher than

69 mN*m (700 gf-cm).

the

cassette housing control assembly.

TP8804

and

both located at the center on your side

PWB,

with a 22 ohm resistor. Now

f

I

69mN.m (70Ogf.cm)

i

.i

69mN.m (700gf.cm)

or more

Figure

l-8.

guage

1

its maximum value.

(Red mark)

3

Take-up direction

is held at

Figure

The guage is held at

its maximum value.

l-9.

23

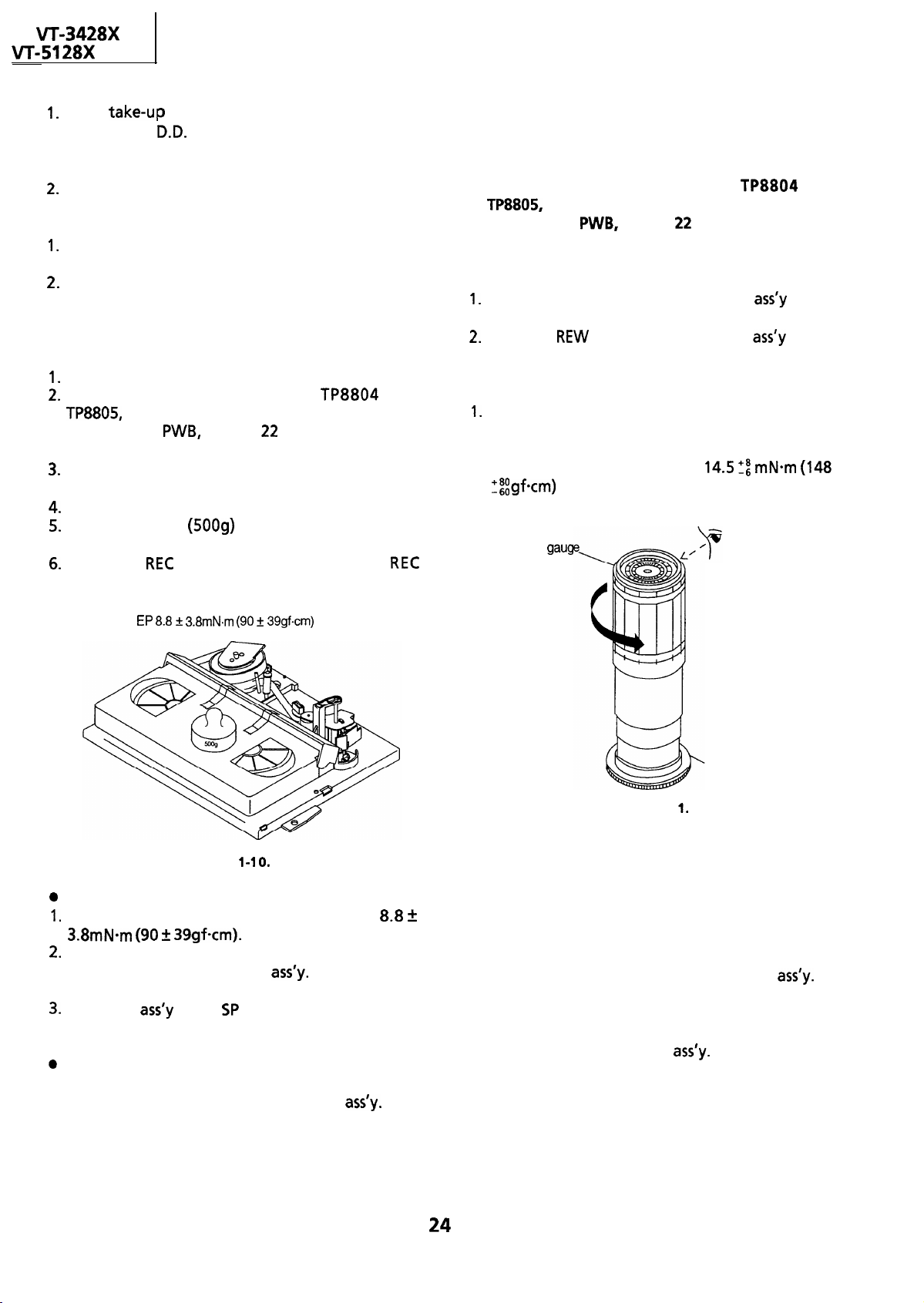

Page 24

VT-3428X

VT-5128X

l

Adjustment

1.

If the

take-u1

the capstan

torque is outside the range, clean

Q

D.D.

motor pulley, reel belt and reel

pulley with-cleaning liquid, then recheck the

torque.

2.

If the take-up torque is still out of range, replace

the reel belt.

Notes:

1.

Hold down the torque gauge so that it may not

fly off.

2.

When checking the take-up torque, do not keep

the reel disk locked for a longer time.

CHECKING AND ADJUSTMENT OF TAKE-UP

TORQUE IN PLAYBACK MODE

Remove the cassette housing control assembly.

1.

2.

Make a short-circuit between

TP8805, both located at the center on your side

on the VCR

PWB,

with a 22 ohm resistor. Now

plug in the power cord and turn on the power.

Open the lid of the cassette torque meter, and

3.

hold it with two pieces of vinyl tapes.

Load the cassette torque meter into the unit.

4.

Put the weight (5009) on the cassette torque

5.

meter.

6.

Press the

REC

button to put the unit in

mode.

TP8804

and

REC

CHECKING AND ADJUSTMENT OF TAKE-UP

TORQUE IN VIDEO SEARCH REVERSE

MODE

l

Remove the cassette housing control assembly.

l Make a short-circuit between

TP8805,

on the VCR

both located at the center on your side

PWB,

with a 22 ohm resistor. Now

turn on the power.

l

Setting

1.

Push the PLAY button to place the

playback mode.

2.

Push the

video search reverse mode.

l

Checking

1.

Place the torque gauge on the supply reel disk,

and turn it counterclockwise very slowly (one

rotation every 1 to

torque is within the set value

Tii

gfcm)

Torque

REW

button to place the

2 seconds) and

gaug

TP8804

ass’y

ass’y

and

in the

in the

check that the

14.5 Ti mN*m (148

Set value EP

0

Checking

1.

Check that the torque is in the range of 8.8

3.8mNmm (90 +

2.

The torque fluctuates due to the rotational

deviation of the reel pulley

8.8 + 3.8mN.m (90 f 39gf-cm)

Figure

l-1

0.

39gfcm).

ass’y.

Use the center

of the fluctuation as the value.

3.

Place the

ass’y

in the SP record mode, and check

that the take-up torque is within the range.

0

Adjustment

If

the take-up torque in the playback mode is

outside the range, replace the reel pulley

ass’y.

Note:

Stabilize the cassette torque meter to prevent

floating.

Supply reel disk

Figure l-l

1.

Note:

Set the torque gauge securely on the supply reel

disk. If it is not secure, the measurement will be

incorrect.

+

l

Adjustment

If the take-up torque

is outside the range, replace the reel pulley

in video search reverse mode

ass’y.

Note:

The torque fluctuates due to the rotational

deviation of the reel pulley

the fluctuation at the value.

ass’y.

Use the center of

24

Page 25

CHECKING THE FAST FORWARD BACK

TENSION

l

Remove the cassette housing control assembly.

l Make a short-circuit between

TP8805,

on the VCR

both located at the center on your side

PWB,

with a 22 ohm resistor. Now

turn on the power.

l

Checking

I. Push the FF button to place the

fast forward mode.

2.

Place the torque gauge on the supply reel

disk, and turn it clockwise very slowly (one

rotation every 2 to 3 seconds) and check that

the torque is I .5 *

Torque gauge

Supply reel disk

0.9mN.m

Figure

l-1

2.

Note:

0

Set the torque gauge securely on the supply reel

disk. If the torque gauge is not securely set on

the reel disk, measurement will be incorrect.

QMeasure the torque with the torque gauge’s

weight exerted on the reel disk.

(I 5 +

TP8804

ass’y

9gfcm).

and

in the

/

KZ::

2.

Place the torque gauge on the take-up reel

disk, and turn it counterclockwise very slowly

(one rotation every 2 to 3 seconds) and check

that the torque is I .3 2

gfcm).

Note:

@Set the torque gauge securely on the take-up

reel disk. If it is not secure, the measurement will

be incorrect.

QMeasure the torque with the torque gauge’s

weight exerted on the reel disk.

0.8mNem

(I 3 + 8

CHECKING THE VIDEO SEARCH REVERSE

BACK TENSION

Remove the cassette housing control assembly.

Make a short-circuit between

TP8805,

on the VCR

both located at the center on your side

PWB,

with a 22 ohm resistor. Now

turn on the power.

Checking

Push the PLAY button to place the

playback mode.

Push the rewind button to place the

video search reverse mode.

Place the torque gauge on the take-up reel disk,

and turn it counterclockwise very slowly (one

rotation every 2 to 3 seconds) and check that the

torque is within the set value 4 f

(41 f 17gfcm).

-

Torque gauge

TP8804

\-

,

,

‘f’

and

ass’y

in the

ass’y

in the

1.7mNam

.

CHECKING THE REWIND BACK TENSION

l

Remove the cassette housing control assembly.

l Make a short-circuit between

TP8805,

on the VCR

both located at the center on your side

PWB,

with a 22 ohm resistor. Now

turn on the power.

l

Checking

I. Push the REW

rewind mode.

buton

to place the

Torque gauge

Take-up reel disk

Figure

l-l

3.

TP8804

ki

,

/

ass’y

and

in the

Take-up reel disk

Figure-l-14.

Note:

0

Set the t

reel disk. If it is not secure, the measurement will

be incorrect.

QMeasure the torque with the torque gauge’s

weight not exerted on the reel disk.

orque

gauge securely on the take-up

CHECKING THE PINCH ROLLER PRESSURE

l

Remove the cassette housing control assembly.

l Make a short-circuit between

TP8805,

on the VCR

both located at the center on your side

PWB,

with a 22 ohm resistor. Now

turn on the power.

l

Checking

Push the PLAY button to place the

playback mode.

TP8804

ass’y

and

in the

25

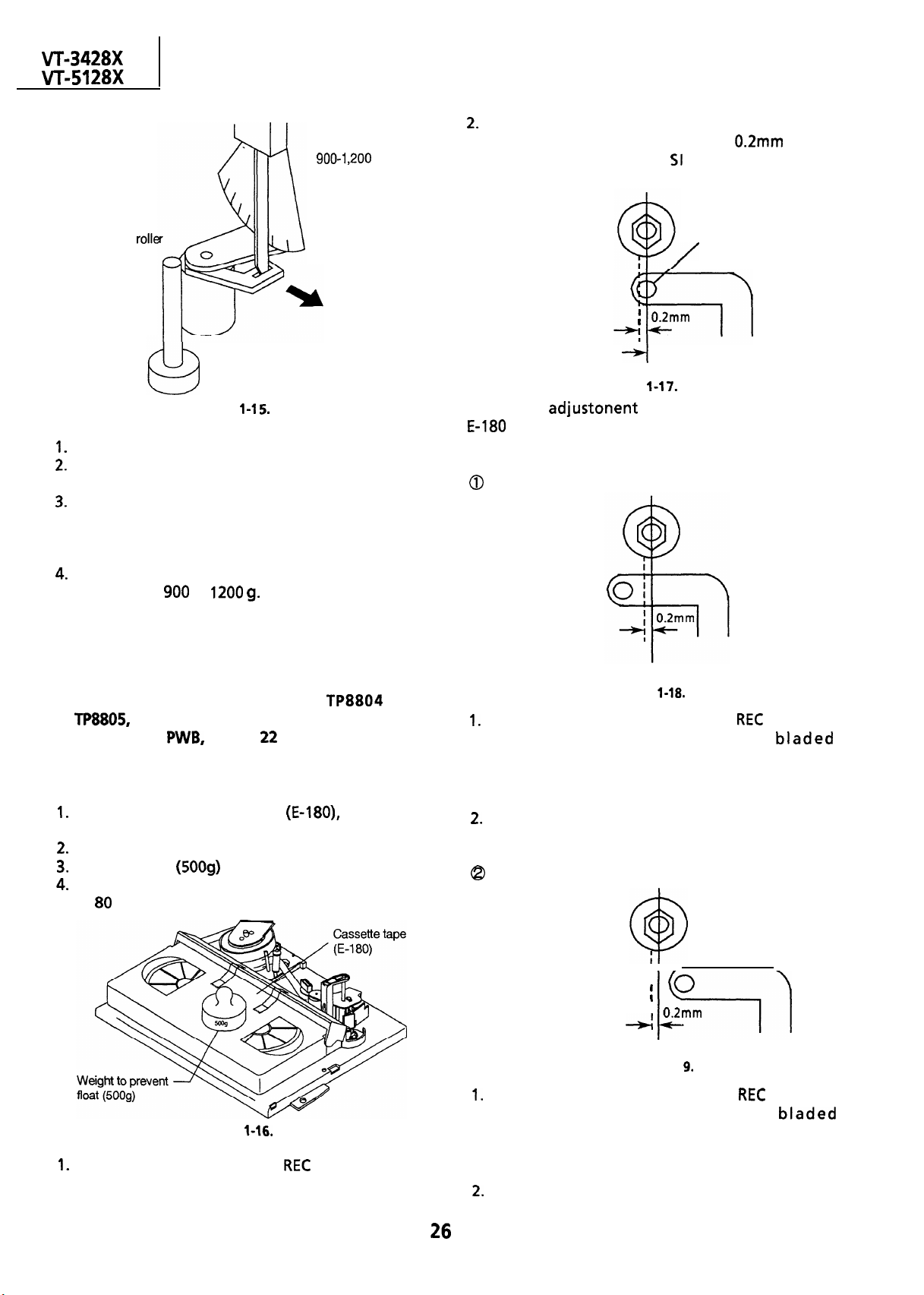

Page 26

m-3428X

VT-51 28X

Tension gauge

900-l

,200 g

2.

Visually check to see if the left end of the tension

pole is in alignment with the line

the center line of the SI roller. Readjust as

required in the following steps.

0.2mm

left of

Pinch rolle

Capstan shaft

1.

Detach the pinch roller from the capstan shaft.

2.

Set the tension gauge by hooking the tension

gauge adapter onto the pinch roller shaft.

3.

Gradually release the pressure to allow the pinch

roller to touch the capstan shaft. When the

pinch roller just touches the capstan shaft, read

the indication on the gauge.

4.

Check that the reading of the tension gauge is in

the range of 900 to

Tension gauge adapter

Figure

l-1 5.

1200 g.

CHECKING AND ADJUSTMENT OF TENSION

POLE POSITION

l

Remove the cassette housing control assembly.

Tension/pole

I

0.2mm

I

Center line

Make the adjustonent with the beginning of a

E-180

tape.

0

If the end is at the left from the center line:

+fw

-+

Figure

l-1 7.

l Make a short-circuit between

TP8805,

on the VCR

turn on the power.

l

Setting

1.

Open the lid of cassette tape (E-180), and hold it

with two pieces of vinyl tapes.

2.

Load the cassette tape into the unit.

3.

Put the weight

4.

Make the adjustment with the beginning of a

E-l 80 tape.

l

Checking

1.

Set a cassette tape, press the

the tape loaded. Now check the tension pole

position.

both located at the center on your side

PWB,

with a 22 ohm resistor. Now

(500g)

on the cassette tape.

Figure

l-16.

TP8804

REC

button and get

and

26

Figure

l-18.

1.

Remove the cassette and press the

make an empty loading. Put a bladed

screwdriver into the tension band positioning

cam and turn it clockwise.

2.

Place the cassette in position and check the

tension pole position.

@

If the end is at the right from the dotted line:

I

@

4

Figure l-l

1.

Remove the cassette and press the

make an empty loading. Put a bladed

screwdriver into the tension band positioning

cam to turn it counterclockwise.

2.

Place the cassette in position and check the

tension pole position.

.

i

I

0

1

I

0.2mm

I

L-1

9.

REC

button to

REC

button to

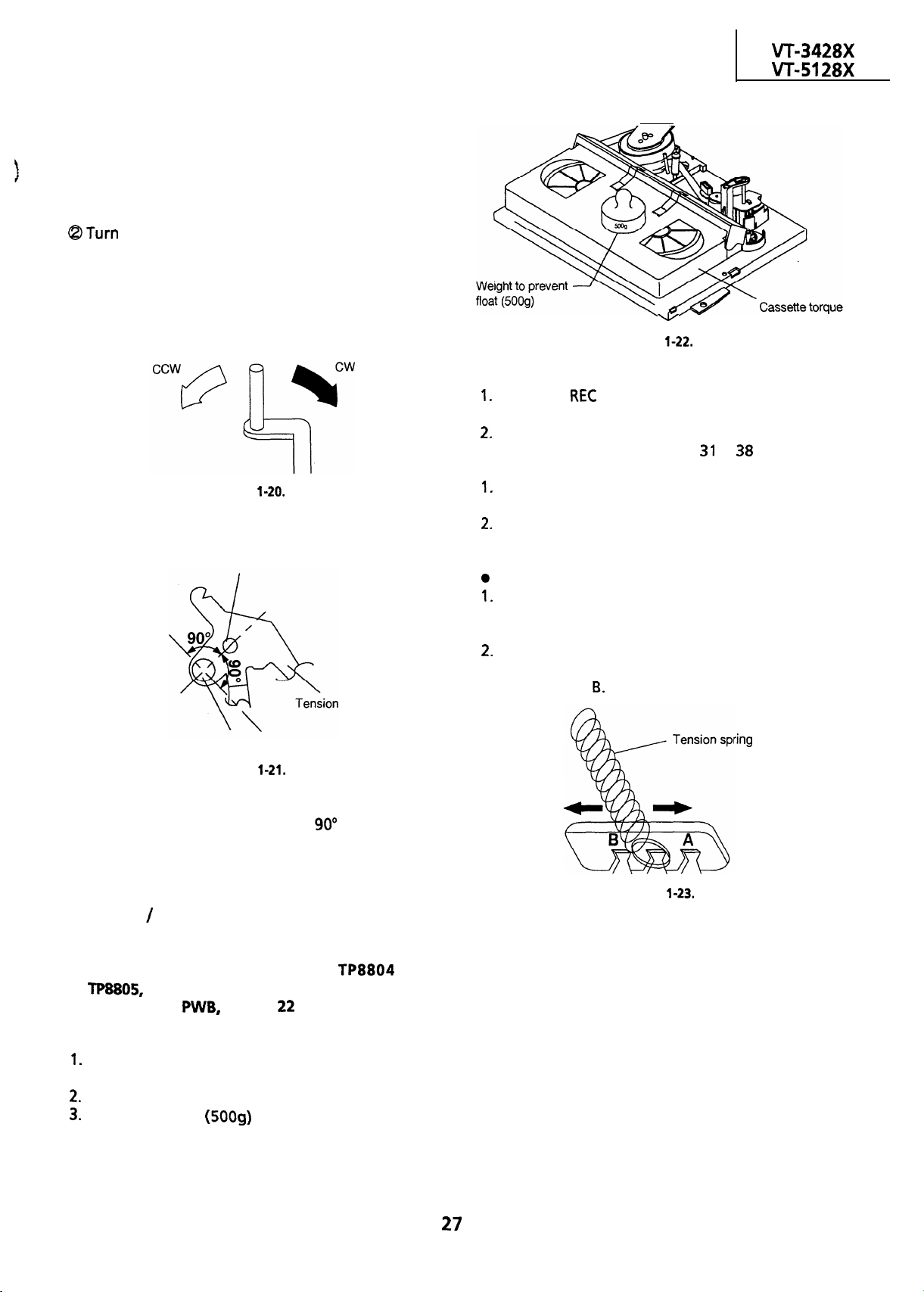

Page 27

Note:

@The tension band positioning cam cannot be

adjusted with a cassette in place because the cam

will be located below the cassette. Repeat a

series of steps; empty loading, adjustment,

cassette placement and position checking.

aTurn

@Adjustable range of the tension pole positioning

the positioning cam clockwise to move the

tension pole to the right (in the black-arrow

direction). Turn it counterclockwise to move the

tension pole to the left (in the white-arrow

direction).

Figure

l-20.

cam.

Tension arm shaft

\

arm

VT-3428X

VT-51 28X

w

Figure

l-22.

l

Checking

1.

Push the

REC

button to place the unit in the

record mode.

2.

Check that the back tension indicated by the

gauge is within the set range 31 to 38 g-cm.

Notes:

1.

Make sure that the video cassette tape is over

the retaining guide.

2.

Make sure that the tape is not slack nor

damaged at either end.

0

Adjustment

1.

If the reading of the cassette torque meter is less

than specified, move the tension spring hook

toward A.

2.

If the reading of the cassette torque meter is

more than specified, move the tension spring

hook toward

B.

meter

Tension pole adjusting cam

Figure

l-21.

Adjust the tension pole positioning cam so that the

arrow mark on the cam be within

90”

left and right

from the tension arm shaft’s center.

CHECKING AND ADJUSTMENT OF

RECORD / PLAYBACK BACK TENSION

l

Remove the cassette housing control assembly.

l Make a short-circuit between

TP8805,

on the VCR

both located at the center on your side

PWB,

with a 22 ohm resistor. NOW

turn on the power.

l

Setting

1.

Open the lid of the cassette torque meter, and

hold it with two pieces of vinyl tapes.

2.

Load the cassette torque meter into the unit.

3.

Put the weight (5009) on the cassette torque

meter.

TP8804

and

Figure

ping

l-23.

27

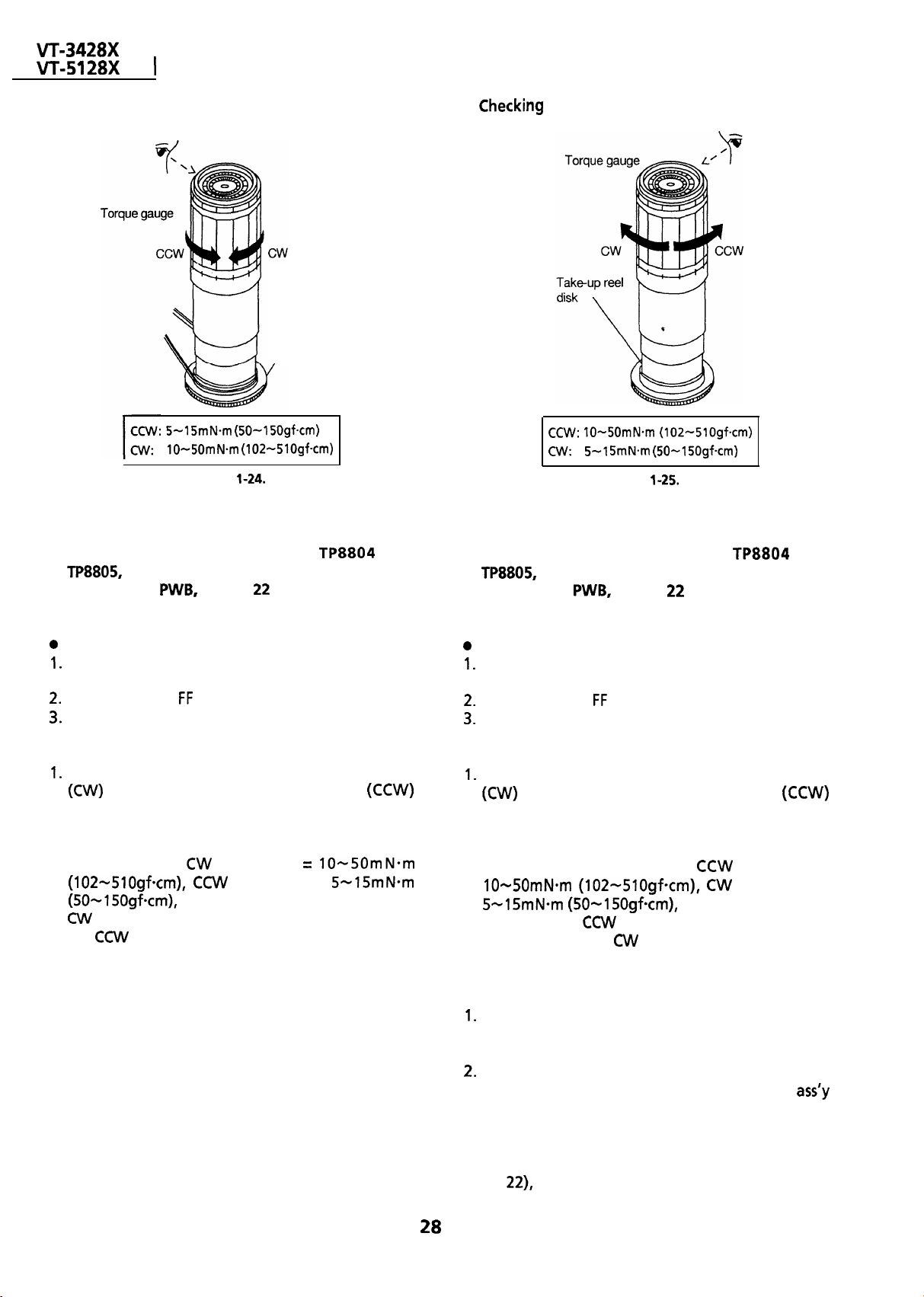

Page 28

m-3428X

VT-5128X

I

1

CHECKING THE BRAKE TORQUE

l

Checking the brake torque at the supply side

,

Supply reel disk

5-l

5mN.m (SO-1

lo-50mN.m (102-SlOgf-cm)

Figure

l

Remove the cassette housing control assembly.

SOgf-cm)

l-24.

l

Checki4the brake torque at the take-up

CCW: lo-50mN.m (102-510gfxm)

CW:

5-l

5mN.m (SO-1

Figure

l

Remove the cassette housing control assembly.

SOgf-cm)

l-25.

side

l Make a short-circuit between

TP8805,

on the VCR

both located at the center on your side

PWB,

with a 22 ohm resistor. Now

TP8804

and

turn on the power.

0

Setting

1.

Set a torque

on the supply reel disk.

2.

Switch from the FF mode to the STOP mode.

3.

Disconnect the AC power plug.

l

Checking

1.

Slowly rotate the torque gauge in the clockwise

(CW)

direction and counterclockwise

direction of the supply brake so that the reel disk

and the indicator of the torque gauge rotate at

an equal rate. Check that the values are within

the range of CW direction =

(102-510gfcm), CCW

(50450gfcm),

CW

direction is at least twice as high as that in

the

CCW

gauge to zero on the scale. Place it

IO-50mN.m

direction =

and that the brake torque in the

direction.

545mN*m

(CCW)

l Make a short-circuit between

TP8805,

on the VCR

both located at the center on your side

PWB,

with a 22 ohm resistor. Now

TP8804

and

turn on the power.

0

Setting

1.

Set a torque gauge to zero on the scale. Place it

on the take-up reel disk.

2.

Switch from the FF mode to the STOP mode.

3.

Disconnect the AC power plug.

l

Checking

1.

Slowly rotate the torque gauge in the clockwise

(CW)

direction and counterclockwise

direction of the take-up brake so that the reel

disk and the indicator of the torque gauge

rotate at an equal rate. Check that the values

are within the range of

IO-50mN.m

545mN*m (50450gfcm),

torque in the

high as that in the

l

Adjustment of the brake torque at the supply

(102~510gfcm), CW

CCW

direction is at least twice as

CVV

direction.

CCW

direction=

direction =

and that the brake

(CCW)

side and the take-up side

1.

If the supply or take-up brake torque is outside

the range, clean the supply or take-up reel disk

break lever pad, then recheck the torque.

2.

If the supply or take-up brake torque is still

outside the range, replace the main brake

or the main brake spring.

Note:

When the main brake is replaced, perform the

height checking and adjustment of reel disks (see

page

22),

and the brake torque checking.

ass’y

28

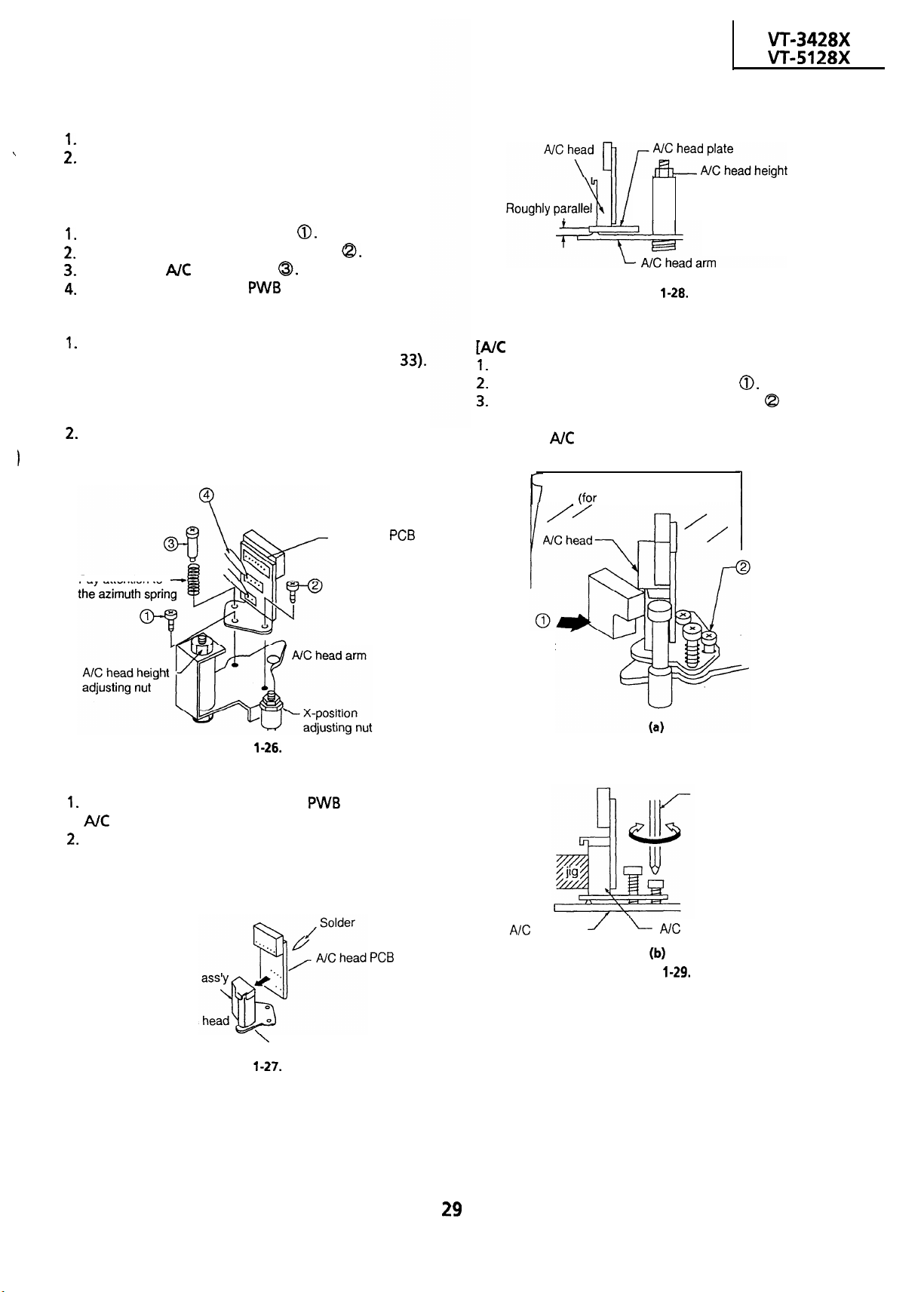

Page 29

VT-3428X

VT-51 28X

REPLACEMENT OF A/C (Audio/Control)

HEAD

1.

Remove the cassette housing control assembly.

2.

Place the unit in the unloading mode, and

unplug the power cord.

l

Removal

1.

Loosen the tilt adjusting screw

2.

Remove the azimuth adjusting screw

3.

Remove the AK head screw

4.

Unsolder the A/C head PWB soldered to the A/C

0.

a.

0.

Figure

head assembly.

Notes:

1.

After replacement, be sure to perform the

adjustment of the tape drive train (see page

33).

Under any circumstances, avoid touching the

head. Clean the head, if touched with your

finger, with alcohol.

2.

Take care that the azimuth spring does not fly

1

off when removing the A/C head screw.

l

Adjustment

[A/C

head tilt angle]

1.

Set the mechanism to the loading mode.

2.

Place the A/C head tilt adjusting Jig

3.

Slowly turn the tilt adjusting screw Q with a

screw driver until there is no gap between the Jig

and the AK head.

A piece of white paper

_

(fqr

visuality of a gap)

adjusting nut

l-28.

0.

A/C head

Pay attention to

l

Replacement

1.

Solder the removed A/C head

AK

head assembly.

2.

The A/C head assembly is attached so that the

-

Figure

l-26.

PWB

onto a new

PCB

A/C head arm and A/C head plate are roughly

parallel to each other.

PCB

A/C head

New

A/C head tilt

adjusting jig

AK

head arm

Tilt adjusting

screw

Screw driver

A/C

J

Figure

head

(W

l-29.

Never

touch the

Figure

\

A/C head plate

l-27.

29

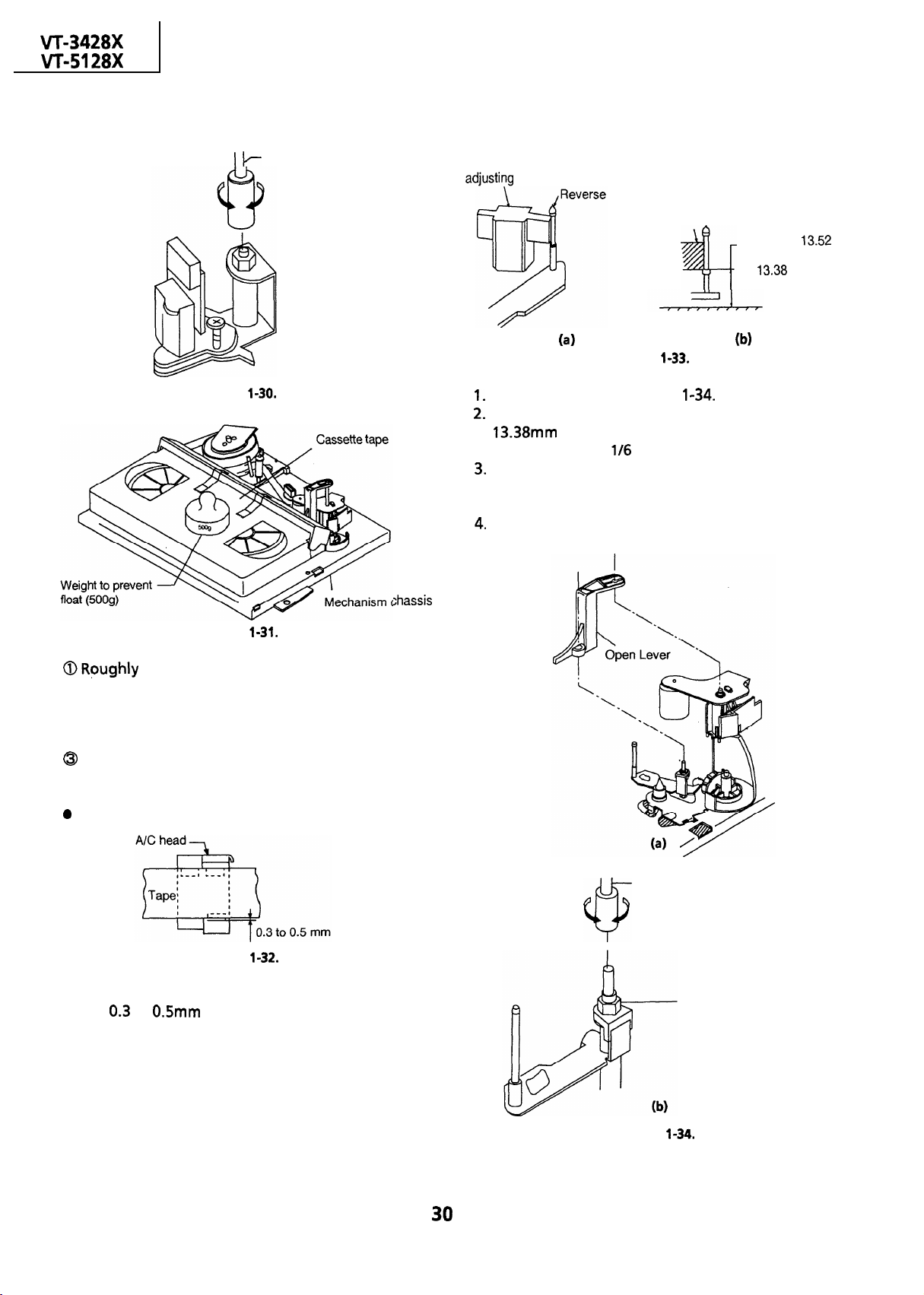

Page 30

VT-3428X

VT-51 28X

[A/C head height rough adjustment]

l

Setting

1 k

Box driver

Figure

l-30.

HEIGHT ADJUSTMENT OF REVERSE GUIDE

[Height adjustment of reverse guide]

Reverse guide height

adjusti?g jig

guide

Reverse guide height

adjusting jig

Go-end is

mm. Not go-end

is

13.38

13.52

mm

4-f

(a)

Figure

l-33.

1.

Remove open lever (Figure

In the tape load mode, make adjustment at the

2.

13.38mm

adjusting nut by

Actually load the unit with a tape, put it in the

3.

play mode, and make sure the tape is free from

wrinkles near the reverse guide.

4.

Use a commercially available box driver to turn

the height adjusting nut.

side first and then rotate the height

l/6

turn counterclockwise.

l-34.

W

(a))

:hassis

Figure

l-31.

aRoughly

turning the A/C head adjusting hexagon nut

with the specialized box driver until the tape is in

the position shown below.

@Set the cassette tape to the mechanism chassis.

@ Press the PLAY button to the put the unit in the

playback

0

Adjustment

Adjust the nut visually so that the control head is

visible

adjust the height of the A/C head by

mode.

Figure

l-32.

0.3

to

0.5mm

below the bottom of the tape.

Box driver

Q

Height adjusting nut

30

Figure

l-34.

Page 31

m-3428X

V-T-5128X

ADJUSTMENT OF TAPE DRIVE TRAIN

1.

Remove the cassette housing control assembly.

Make a short-circuit between

2.

t

TP8805, both located at the center on your side

on the VCR

turn on the power.

Check and adjust the position of the tension

3.

pole. (See page 26.)

4.

Check and adjust the video search rewind back

tension. (See page

5.

Set the tilt angle of the A/C head. (See page

Rough adjustment of tape drive train.

6.

a) Connect the oscilloscope to the test point for

PB CHROMA

the synchronism of the oscilloscope to EXT.

The PB

the head switching pulse

b)

Loosen the setscrew at the lower part of the

guide roller, and adjust it with an adjusting

screw driver

roller turns smoothly. (Do not overloosen the

setscrew, which causes insecurity of the guide

roller.) (See Figure

c)

Set the alignment tape (monoscope pattern)

on the reel disk, and place the unit in the

playback mode.

(Place a

prevent floating of the cassette tape.)

Guide roller

PWB,

with a 22 ohm resister. Now

25.)

envelope output (TP2203). Set

CHROMA

500

signal is to be triggered by

(TP2204).

(JiGDRIVERH-4)

l-35.)

g weight on the cassette tape to

TP8804

so that the guide

and

29.)

z

Wrinkles at upper flange

(a)

Wrinkles at lower flange Counterclockwise

0.4

Figure

l-37.

Notes:

1.

Place the tracking control in the center position,

and adjust the X-position adjusting nut so that

the PB

easier rough adjustment of the tape drive train.

2.

In the rough adjustment, pay particular

attention to the outlet side.

CHROMA

envelop becomes maximum for

Clockwise

Figure

l-35.

d)

In the X value adjustment mode (see the

Electrical Adjustment), change the envelope

waveform from MAX to

by pushing the ( + ) or

check a flat response is obtained on the

waveform.

e)

If a flat response cannot be obtained, roughly

adjust the guide rollers on the supply side and

take-up side using an adjusting screw driver

until a flat response can be obtained.

f)

Turn the A/C head tilt adjusting screw with a

screwdriver to prevent the tape from

wrinkling at the upper and lower flanges of

the fixed guide.

1)

Wrinkles at the upper flange : Turn the

above adjusting screw clockwise, as shown

in Figure

2)

Wrinkles at the lower flange : Turn the

above adjusting screw counterclockwise, as

shown in Figure

1-37

(a).

1-37 (b).

Figure

l-36.

MIN,

and

MIN

to MAX

(-)

tracking button, and

Loosen the setscrew

31

Figure

8

l-38.

Figure

X-position

adjusting nut

l-39.

Page 32

m-3428X

W-5128X

PB CHROMA

-.;i&;

Head switching pulse

7.

Adjustment of A/C head height and azimuth

Connect an oscilloscope to the audio output

a)

envelope

Figure

(TP201)

(TP202)

l-40.

terminal.

Use the alignment tape and play back its

b)

audio 6

kHz

signal (monoscope pattern for

video signal). Adjust the azimuth adjusting

screw to obtain the maximum audio output

on an oscilloscope. (See Figure

Use the alignment tape and play back its

d

audio 1

kHz

signal (colour bar for video signal)

1-41.)

and slowly rotate the A/C head height

adjusting nut with the special box driver to

obtain the maximum audio output.

Perform the adjustment in b) again.

d)

After this adjustment, apply

e)

glyptal

screws and nuts to fix them.

to the

Box driver

Azimuth adjusting

screw

Figure

l-41.

.

Adjustment of tape (VROUBZFS) drive train and

8

Figure

A/C head height

adjusting screw

nut

l-42.

X-Position.

Connect the oscilloscope to the test points

a)

(TP2203)

for PB

CHROMA

envelope output.

Set the synchronism of the oscilloscope to EXT.

The PB

the head switching pulse

Play back the tape drive train alignment tape.

b)

Push the

d

CHROMA

(+)

or

signal is to be triggered by

(TP2204).

(-)

button to change the

envelope waveform from MAX to MIN, and

MIN

to MAX. Adjust the guide roller’s height

on the supply and take-up sides with an

adjusting screw driver, to obtain an envelop

waveform that is as flat as possible.

If the tape is above or below the helical lead,

d)

the PB

shown in Figure

Adjust for maximum flatness of the envelope

d

CHROMA

waveform will take the shape

l-43.

as the step 6, e) in page 31.

~?I~qyTyTpq

.

Adjustment

When the tape is above the helical lead. When the tape is below the helical lead.

Supply side

p-,

Supply side guide

roller rotated in

clockwise direction

(lowers guide roller) to

flatten envelope.

Take-up side

Take-up side guide

roller rotated in

clockwise direction

(lowers guide roller) to

flatten envelope.

Figure

-;y$-Ja

l-43.

Supply side

Supply side guide

roller rotated in

counterclockwise

direction (raises guide

roller) to make the

tape float above the

helical lead. The supply

side guide roller is

then rotated in the

clockwise direction to

flatten the envelope.

Take-up side

Take-up side guide

roller rotated in

counterclockwise

direction (raises guide

roller) to make the

tape float above the

helical lead.

The take-up side guide

roller is then rotated in

the clockwise direction

to flatten the

envelope.

32

Page 33

f)

Push the

(+)

or (-) tracking button to check

that a flat response is obtained on the

envelope waveform.

g)Secure the guide roller by tightening the

guide roller setscrew in the unloading mode.

h)

Play back the tape drive train alignment tape

to check that the envelope waveform does

not change.

9.

Adjustment of A/C head X-position.

a) In the X value adjustment mode (see the

Electrical Adjustment), make a short circuit

between

the on your side on the VCR

TP8804

and

TP8805,

both located at

PWB,

with a

ohm resistor to center the tracking.

b)

Rotate the X-position adjusting nut with an

adjusting box driver, and adjust the A/C head

position for maximum head switching pulse

low side envelope.

c)

Adjust the playback switching point.

d)

Check the flatness of the envelope waveform

and sound by playing back a recorded tape.

X-position adjusting nut

l-

2mm

Main chassis

Figure

l-44.

REPLACEMENT OF THE CAPSTAN D.D.

(DIRECT DRIVE) MOTOR

0

Remove the cassette housing control assembly.

0

Removal (Follow the order of indicated

numbers.)

1.

Disconnect from the board-to-board connector

on the VCR PWB.

2.

Remove the reel belt

3.

Remove the screws

0.

@.

22

l

Reassembly

1.

Mount the capstan motor on the mechanism

chassis making sure not to allow the capstan

shaft to hit the mechanism chassis, and attach it

with the three screws.

2.

Attach the reel belt. Reconnect to the board-to

board connector on the VCR

PWB.

Notes :

1.

After installing the capstan

to rotate the capstan

D.D.

motor, be sure

D.D.

motor and check the

movement.

2.

Check the servo circuit.

REPLACEMENT OF D.D. MOTOR

1.

Put the unit in the cassette eject position.

2.

Unplug the power cord.

l

Removal (Reverse the order in reassembly.)

1.

Disconnect the

2.

Unscrew the stator assembly fixing screws

3.

Take out the stator assembly

4.

Unscrew the rotor assembly fixing screws

5.

Take out the rotor assembly

Notes:

1.

In removing the stator assembly, part of the

drum earth spring pops out of the

collar.

Be careful not to lose it.

2.

Secure the rotor assembly so that the

installation positioning holes in the rotor