Page 1

SHARP CORPORATION

N.S.W. SEWVIGE

1

HUNTINGWOOD DE;/.

BLACKTOVVEil

N.S.W.

DEPT.

2148

W-341 8X

VT-5118X

SERVICE MANUAL

S94D8VT3418Xi

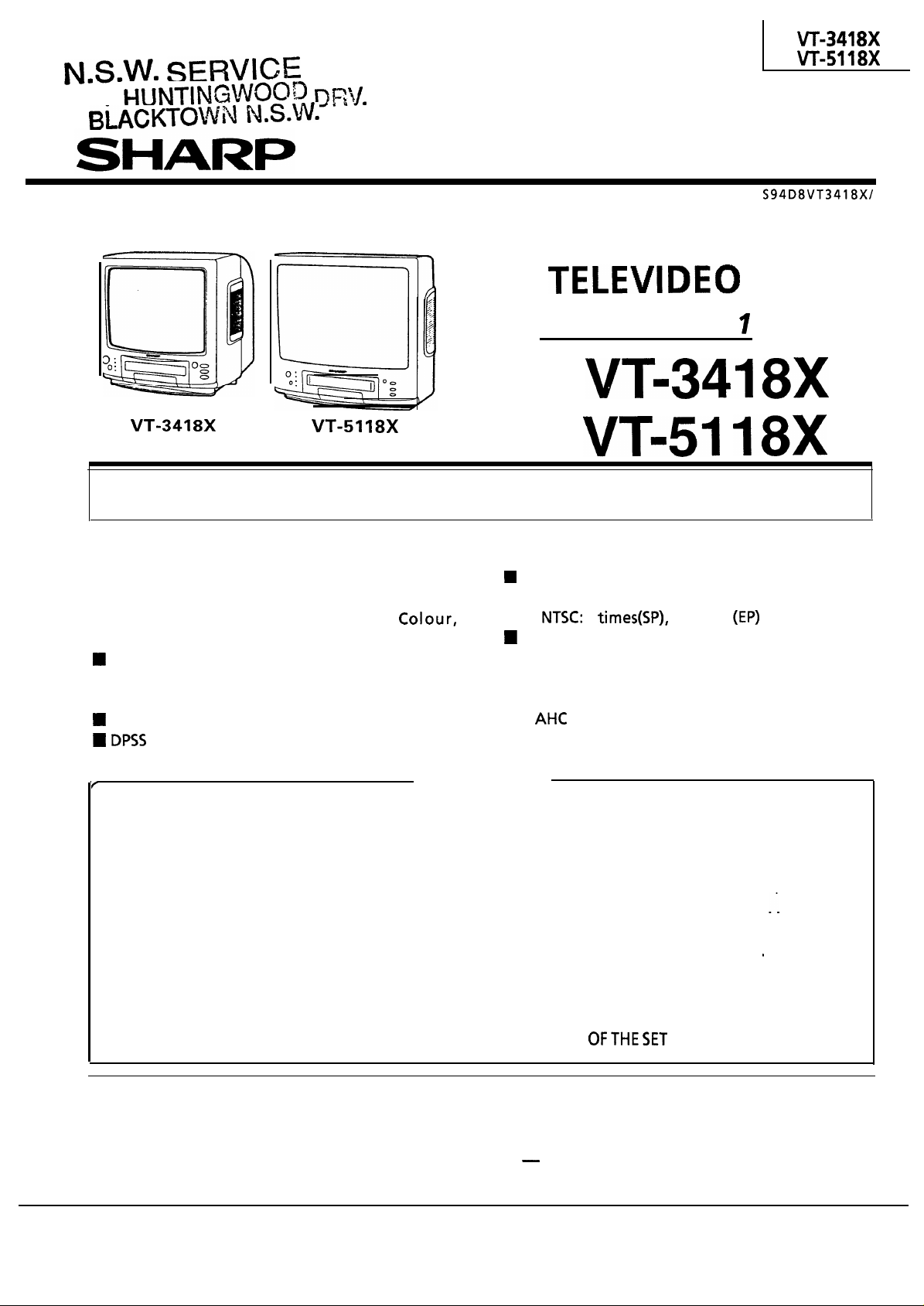

TV/VCR COMBINATION

i==T=D

TELEVIDEO

Chassis No. VP-

7

VT-341 8X

VT-341 8X

In the interests of user-safety (Required by safety regulations in some countries ) the set should be

restored to its original condition and only parts identical to those specified should be used.

FEATURE

n Full Auto Search Tuning System

n

On Screen Digital Channel/Sound Level/

Tuning Display, Control (Contrast,

Brightness, Tint, P-Tone) Symbol and Level

H

Blue Back Off Timer

n

40 Key, Wireless Remote Control Unit

n Channel Skip

H

Dew Warning Indicator

W DPSS

(Digital Program Search System)

VT-51

18X

Colour,

MODELS

H

High Speed Video Search System

l

PAUSECAM: 7 times

l

NTSC:

w

Quick Start Playback with Full Loading System

n

Still/Slow Function with Noiseless Frame Still

n

Digital Automatic Tracking Control

n

Automatic Playback Function

n

AHC

(Automatic Head Cleaning System)

VT-51

5

times(SP),

15 times

18X

(EP)

I

.

SPECIFICATIONS

l

IMPORTANT SERVICE NOTES

l

LOCATION OF USER’S CONTROL

.

DISASSEMBLY AND REASSEMBLY

. ADJUSTMENT OF THE

TV ELECTRICAL CIRCUITRY

.

FUNCTION OF MAJOR MECHANICAL PARTS

. ADJUSTMENT, REPLACEMENTAND

ASSEMBLY OF MECHANICAL UNITS

. ADJUSTMENT OF THE

VCR ELECTRICAL CIRCUITRY

. TROUBLESHOOTING

........................

.............

.........

........

...........

.........

...................

CONTENTS

Page Page

l

2

3

4

7

8

14

..

16

41

47

OVERALL SCHEMATIC DIAGRAM

l

CHASSIS LAYOUT OF TV SECTION

l

BLOCK DIAGRAM OF TV SECTION

.

DESCRIPTION OF TV SECTION

SCHEMATIC DIAGRAM

.

CHASSIS LAYOUT OF VCR SECTION

.

BLOCK DIAGRAM OF VCR SECTION

. DESCRIPTION OF VCR SECTION

SCHEMATIC DIAGRAM

. PRINTED WIRING BOARD ASSEMBLIES . .

.

REPLACEMENT PARTS LIST

.

PACKING OFTHESET

.................

........

.......

.......

........:.....

......

.....

*

.............

............

65

69

73

82

99

101

111

119

129

167

WARNING

The chassis in this receiver is partially hot. Use an isolation transformer between the line cord plug and

power receptacle, when servicing this chassis.

To prevent electric shock, do not remove cover. No user

qualified service personnel.

-

serviceable parts inside. Refer servicing to

SHARP CORPORATION

Page 2

n

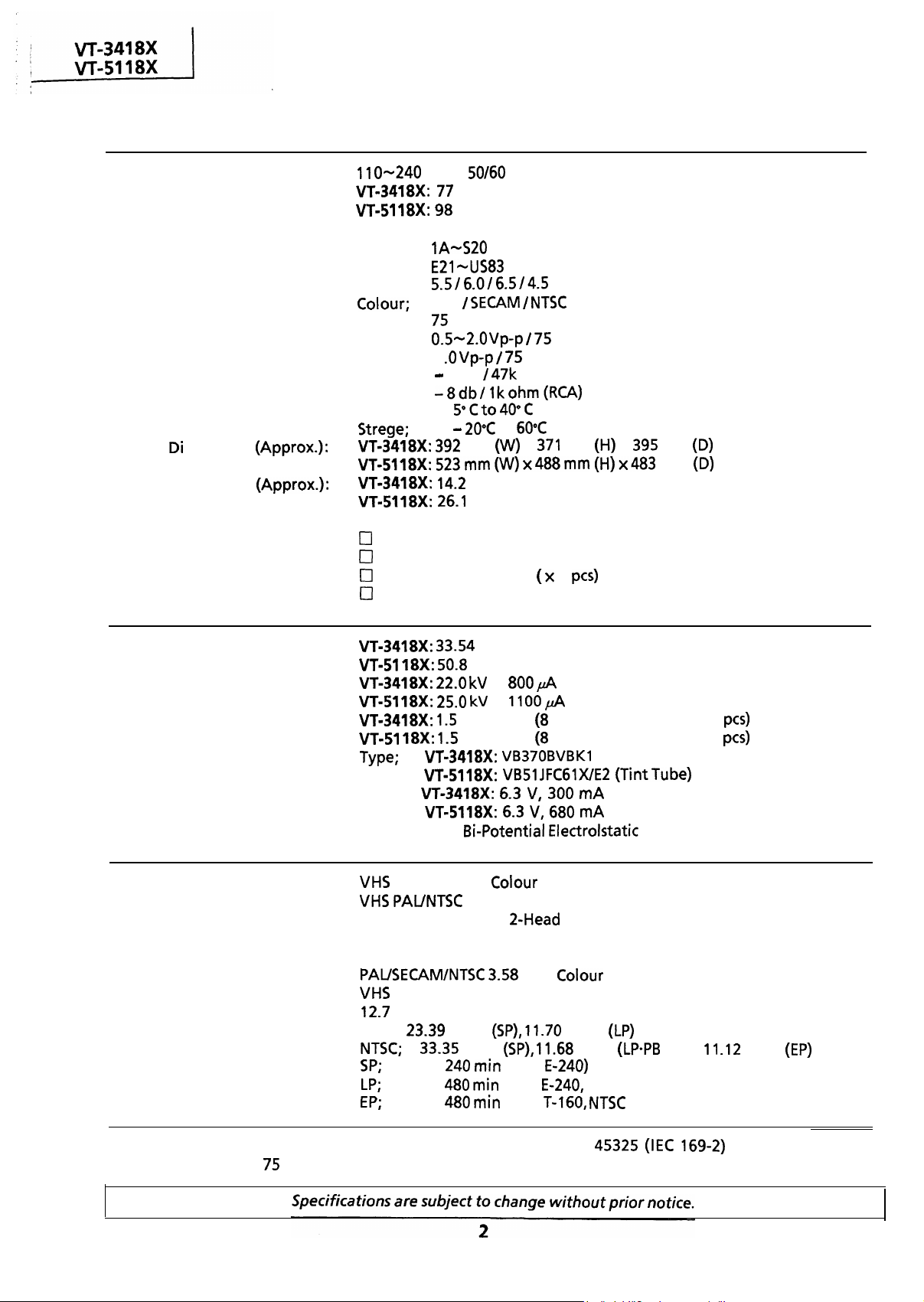

OUTLINE OF THE PRODUCT

Power Source:

Power Consumption:

Receiving Broadcast Standard:

Receiving Channel:

Receiving System:

Antenna Input Impedance:

Video Signal:

Audio Signal:

Temperature:

Di

mentions

n

TV SECTION

n

VCR SECTION

Weight (Approx.):

Cabinet Material:

(Approx.):

Accessories:

Viewing Area:

Picture Power:

Speaker Output:

Picture Tube:

SPECIFICATIONS

11 O-240

VT-3418X: 77

i/T-5118X: 98 W

PAL System B/G, I, D/K, M

VHF;

UHF;

Sound;

Colour;

VHF/UHF;

Input;

output;

Input;

output;

Operation;

Strege;

VT-3418X: 392

VT-5118X: 523mm(W)x488mm (H)x483

VT-3418X: 14.2

VT-5118X: 26.1

Plastic

0

Operation Manual

Cl

Infrared Remote Control Unit

0

Dry Batteries, Type AA (x 2

0

Guarantee Card

VT-3418X: 33.54

VT-51 18X: 50.8

VT-3418X: 22.0 kV

VT-5118X: 25.0 kV

VT-3418X: 1.5

VT-51 18X: 1.5

Type;

Heater;

Focus;

V AC,

VT-3418X: 6.3 V, 300

50/60

Hz

w

lA-S20

E21-US83

5.5/6.0/6.5/4.5

PAL /

SECAM / NTSC

75

ohm Unbalanced (DIN)

O-5-2.0

1 .O

-

-8db/lkohm(RCA)

VT-3418X:

VT-5118X: VB51JFCGlX/E2

VT-5118X: 6.3 V, 680

High

Vp-p / 75 ohm (RCA)

Vp-p /

8 d b /

47k

5”Cto40”C

- 20°C

to

mm

(W)

kg

kg

cm Diagonal Measurement

cm Diagonal Measurement

at

at

W at Max. (8 cm Round Dynamic x 2

W at Max. (8 cm Round Dynamic x 2

Bi-Potential Electrolstatic

MHz

75 ohm (RCA)

ohm (RCA)

60°C

x

371

mm

PCS)

800 ,&

1100 fi

VB370BVBKl

Beam Current

Beam Current

mA

mA

(H)

x

395

U-S (Tint Tube)

(TintTube)

mm

mm

(D)

(D)

PCS)

PCS)

Outline:

Format:

Video Recording System :

Luminance: FM Recording

Chrominance: Low Frequency Converted Direct Recording

Video Signal System: PAUSECAM/NTSC 3.58

Cassette Tape:

Tape Width:

Tape Speed:

Recording/Playback Time:

Note: The antenna must correspond to the new standard DIN 45325

antenna with 75 ohm connector.

VHS

Video System

VHS PAUNTSC

Rotary Slant Azimuth 2-Head Helical Scan System

VHS

Type Video Cassette Tape

12.7

mm

PAL;

NTSC;

SP;

LP;

EP;

23.39

mm/s

33.35 mm/s

Max.

240 min

Max.

480 min

Max.

480 min

Colour

Standard

MHz

(SP), 11.70

(SP),

(with

(with

(with

Video Cassette Recorder

Colour

mm/s

11.68 mm/s

E-240)

E-240,

T-160, NTSC

(LP)

(LP*PB

PAL only)

only)

only), 11

(IEC 169-2)

-12

mm/s

(EP)

for combined UHF

Page 3

IMPORTANT SERVICE NOTES

Maintenance and repair of this receiver should be done by

qualified service personnel only.

SERVICING OF HIGH VOLTAGE SYSTEM AND

PICTURE TUBE

When servicing the high voltage system,

remove static charge from it by

connecting a 10 k ohm Resistor in series with an insulated wire (such as a test

probe) between picture tube

dag

and

2nd

anode lead. (AC line cord should

be disconnected from AC outlet.)

1.

Picture tube in this receiver employs integral implosion protection.

2.

Replace with tube of the same type number for continued safety.

3.

Do not lift picture tube by the neck.

4.

Handle the picture tube only when wearing shatterproof goggles and after discharging

the high voltage completely.

X-RAY

This receiver is designed so that any X-Ray radiation is kept to an absolute

minimum. Since certain malfunctions or servicing may produce potentially

hazardous radiation with prolonged exposure at close range, the following

precautions should be observed:

1. VT-3418X:

VT-5118X:

2. VT-3418X:

VT-5118X:

-‘.

If there is a possibility that the high voltage fluctuates as a result of the repairs, never

forget to check for such high voltage after the work.

3.

DO not substitute a picture tube with unauthorized types and/or brands

excess X-ray radiation.

When repairing the circuit, be sure not toincrease the high voltage to more

than

25.3 kV,

When repairing the circuit, be sure not to increase the high voltage to more

than

29.3 kV,

To keep the set in a normal operation, be sure to make it function on

22.0 kV

been factory

To keep the set in a normal operation,

25.0 kV + 1.5 kV

factory -Adjusted to the above-mentioned high voltage.

(at beam 0 +) for the set.

(at beam 0 +) for the set.

+

1.5 kV - 2.0 kV

-Adjusted to the above-mentioned high voltage.

(at beam

(at beam

1100 ,uA)

800 ,&)

in the case of the set. The set has been

in the case of the set. The set has

be sure to make it function on

which may cause

BEFORE RETURNING THE RECEIVER

Before returning the receiver to the user, perform the following safety

checks.

1.

Inspect all lead dress to make certain that leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in the receiver.

2.

Inspect all protective devices such as non-metallic control knobs, insulating fishpapers,

cabinet backs, adjustment and compartment covers or shields, isolation resistorcapacity networks, mechanical insulators etc.

Page 4

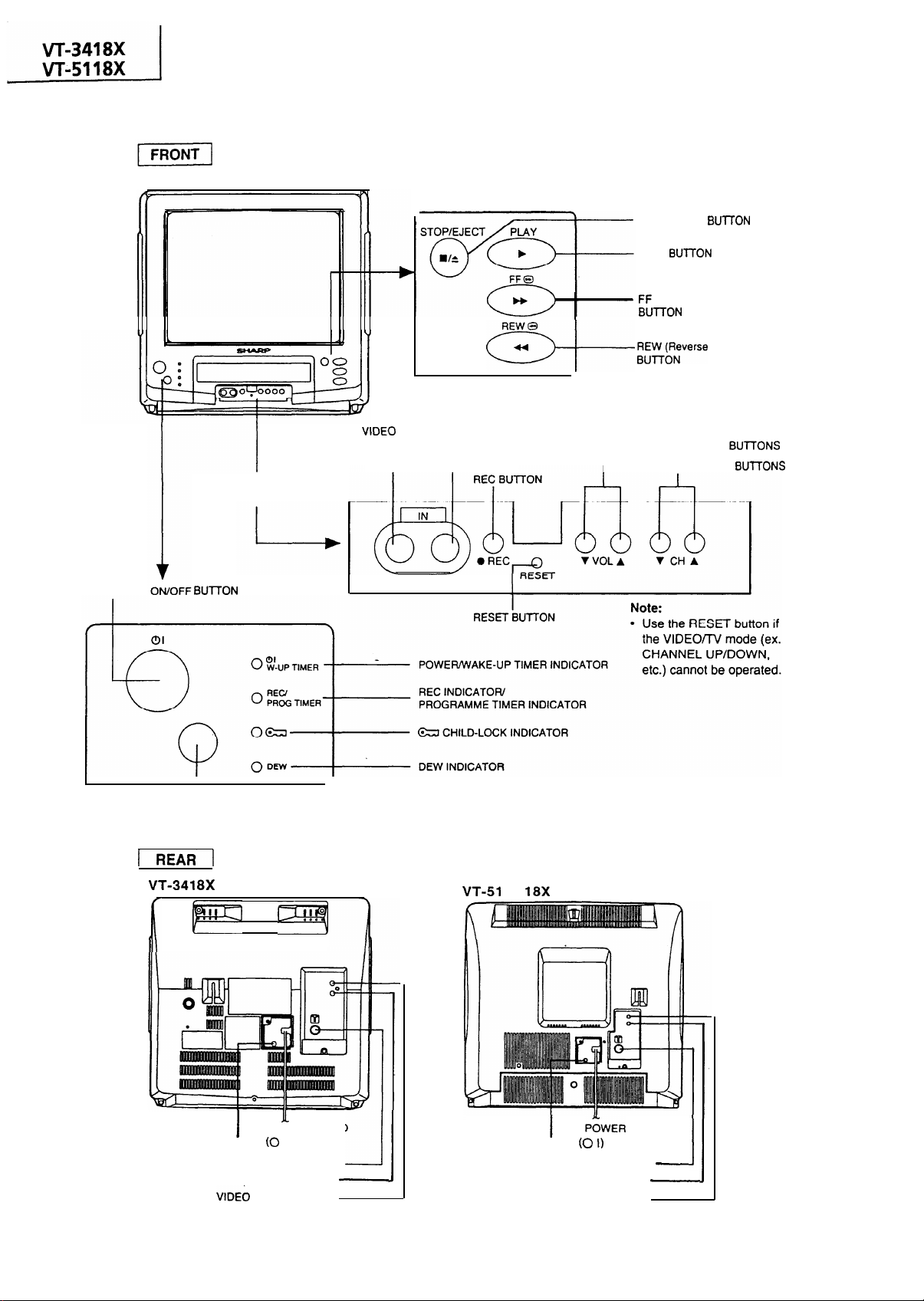

LOCATION OF USER’S CONTROL

CONTROL PANEL

INSIDE THE COVER

POWER BUTTON

\

VlDEO INPUT JACK

AUDIO INPUT JACK

I

VIDEO AUDIO

STOP/EJECT BUlTON

PLAY BlJlTON

FF

(Forward video search)

BUTTON

mh

I

;;;rF$verse

VOLUME UP/DOWN

CHANNEL UP/DOWN

r

video search)

BlJlTONS

BUlTONS

I

SENSOR AREA FOR

REMOTE CONTROL

VT-341 8X

o I

I

p

MAIN POWER SWITCH (0 I)

q

POWER CORD

ANTENNA IN TERMINAL

AUDIO OUT TERMINAL

VIDE;

OUT TERMINAL

I

o

. . .

v

JL

_1

-

VT-51

18X

MAIN POWER SWITCH (0

ANTENNA IN TERMINAL

AUDIO OUT TERMINAL

VIDEO OUT TERMINAL

4

.

P;;WER

I)

CORD

I

-

-

Page 5

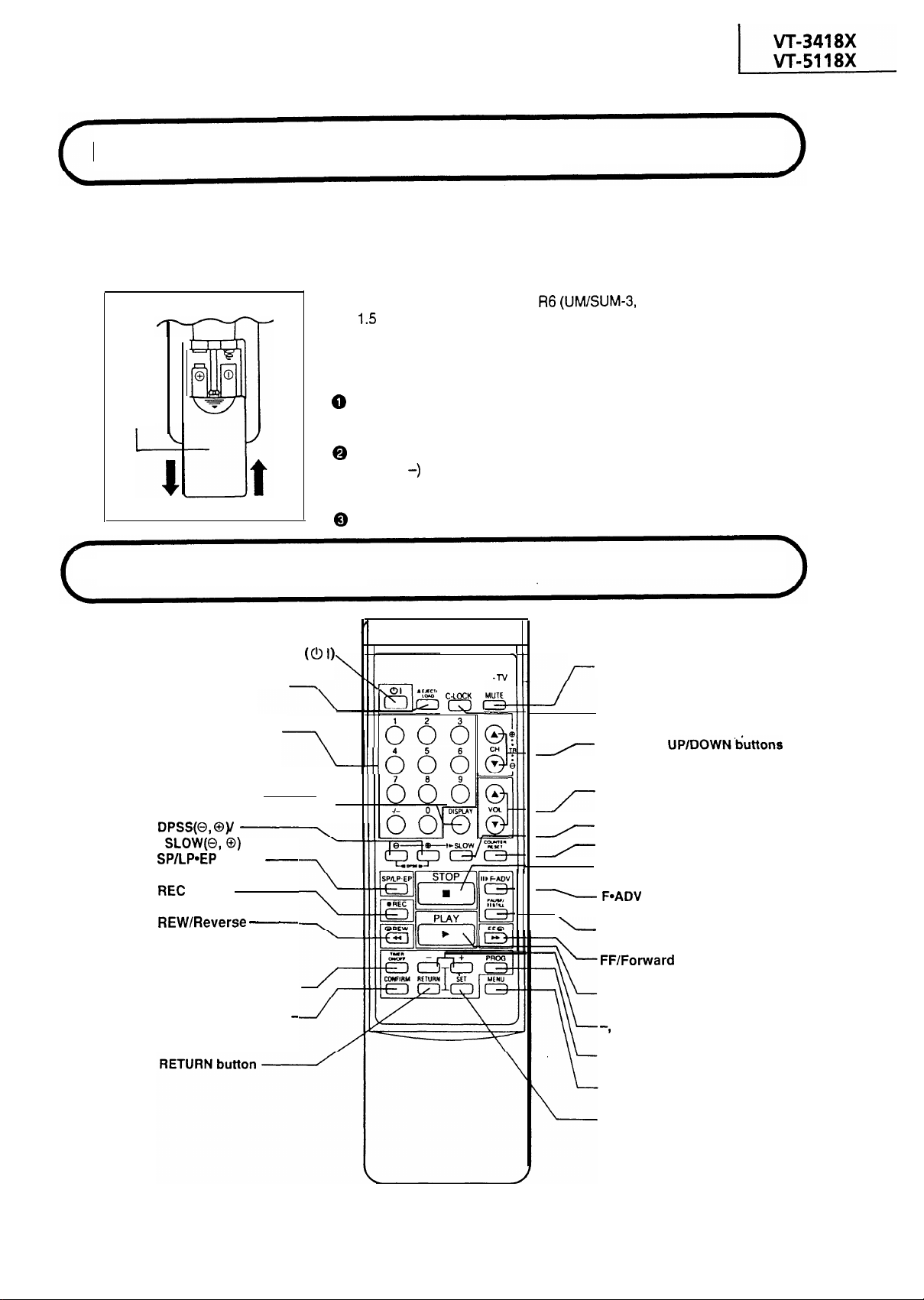

Remote Control Battery Installation

The remote control lets you operate this product at a distance. Just aim the front of the remote

control at the photoreceptor window situated on the front panel and press the appropriate

buttons.

Inserting the Batteries

The remote control operates on two R6 (UM/SUM-3,

AA)

1.5

volt batteries (included). If the remote control

does not operate or fails to function normally due to

weak batteries, new batteries can be purchased at

electronics or camera stores.

Open the battery cover. (Remove any old bat-

Battery

cover

0

teries that may be in the remote control.)

Insert new batteries and match their polarities

@

( + and -) with the markings inside the compartment.

@

Replace the cover.

Location

POWER ON/OFF button (0

EJECT/LOAD button

CHANNEL SELECT

buttons

DISPLAY button

DPSS(O, @)I

SLOW@, 0) buttons

SP/LP*EP

REC

button

REW/Reverse -

Video Search button

TIMER ON/OFF button

CONFIRMING TIMER

PROGRAMME button

of Controls

I)

button

-

-

666

--686

SHARP

VIDEO

-TV

C-COCK

r

I

I

/--

MUTE button

CHILD-LOCK button

r

1

r

r

-

CHANNEL UP/DOWN&&tons

(TRACKING buttons)

VOLUME ADJUSTMENT

buttons

SLOW PLAYBACK button

COUNTER RESET button

STOP button

F*ADV

button

-

PAUSE/STILL button

FF/Forward

Video Search button

PLAY button

-,

+ buttons

PROGRAMME button

MENU button

SET button

5

Page 6

c

VT-341

8X

VT-5118X

n

TV SECTION

DISASSEMBLY AND REASSEMBLY

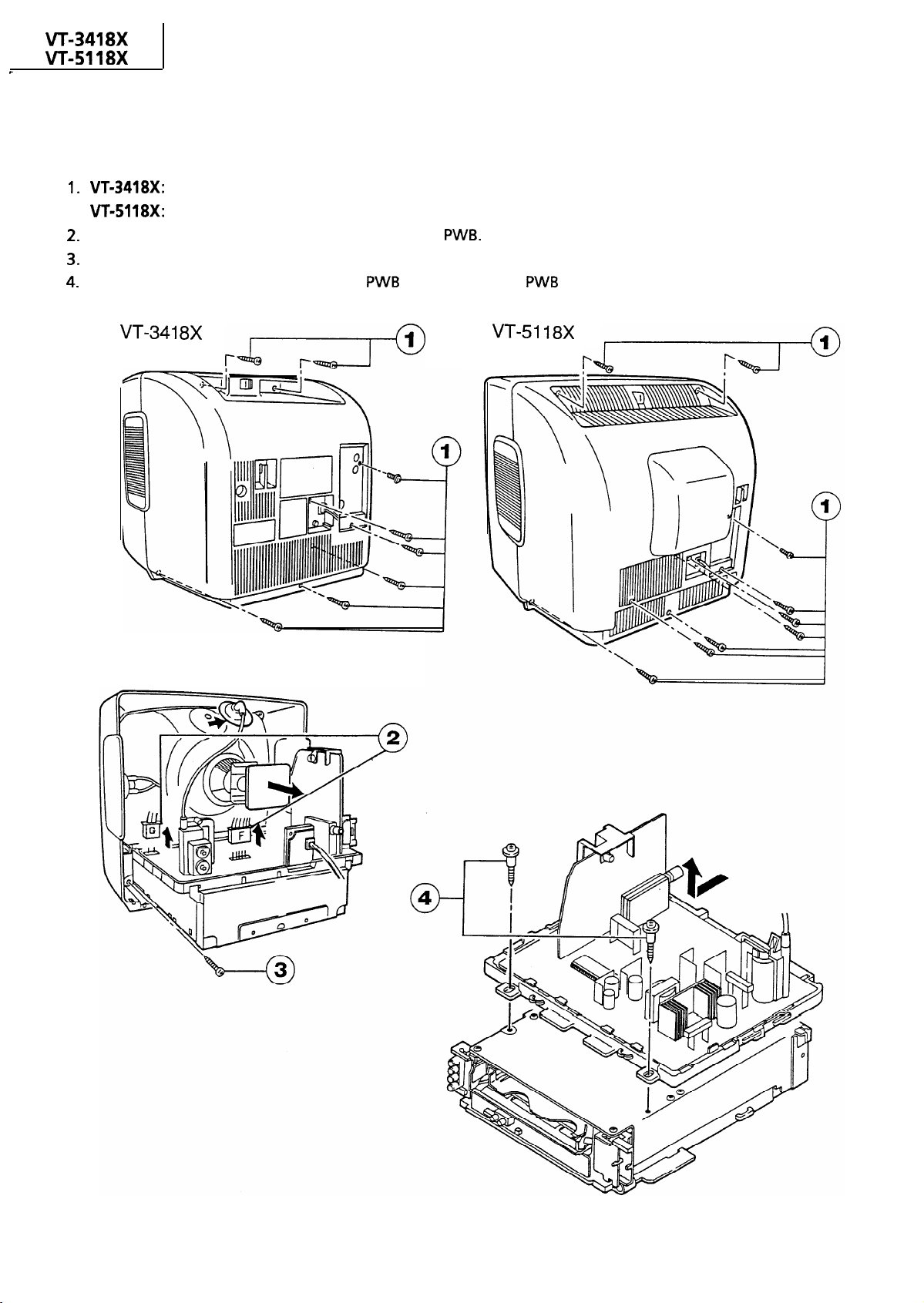

I. VT-3418X:

VT-51

18X: Remove the nine screws off the rear cover.

Disconnect the F and G connectors from the main

2.

3.

Remove the screws off the video unit and take out the unit.

4.

Remove the two screws from the main

VT-341

Remove the eight screws off the rear cover.

PWB.

PWB

and separate the

8X

rr

PWB

from the video unit

VT-51 18X

6

Page 7

n

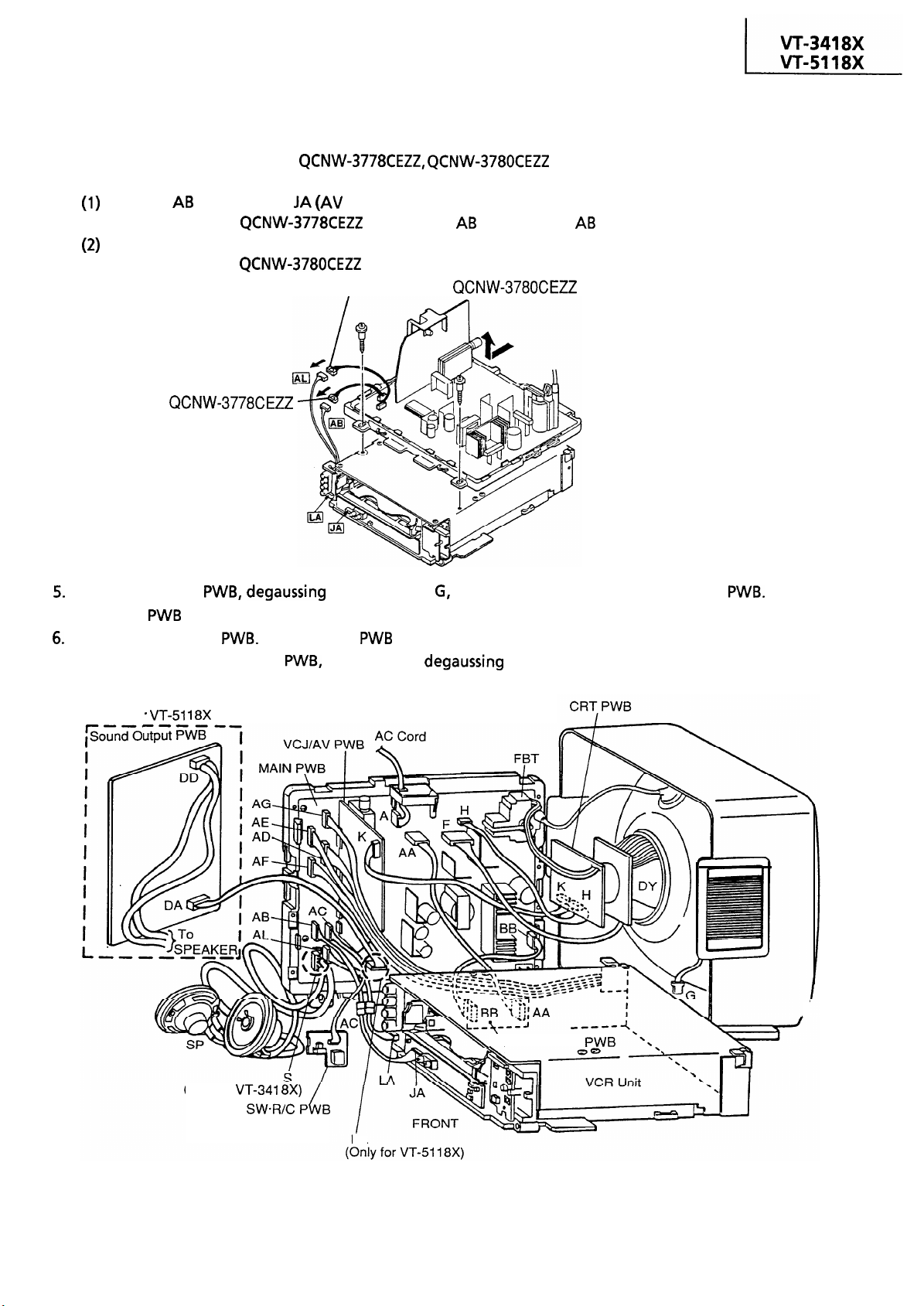

CONNECTIONS FOR SERVICING

Use the following extension cables in servicing the VCR unit taken out of the set.

Extension cables:

l

Connecting the extension cables

(1)

Between AB (TV unit) and JA

Connect the cable

(2)

Between AL (TV unit) and LA (LED unit):

Connect the cable

Part codes

QCNW-3778CEZZ

QCNW-3780CEZZ

QCNW-3778CEZZ, QCNW-3780CEZZ

(AV

jack):

between the AB plug and the AB socket.

between the AL plug and the AL socket.

Extension cable: QCNW-3780CEZZ

Extension

5.

6.

cable: QCNW-3778CEZZ

Remove the CRT

the main

PWB

PWB, degaussing

upright.

Reconnect the CRT

PWB.

power switch remote control

*

VT-51 18X

Only for

~oUnd0

coil connector G, and front power switch remote control

Put the main

PWB,

speakers and

PWB.

PWB

and the VCR unit together as shown below. Keep the front

degaussing

coil connector G off position.

Place

(Only for VT-341 8X)

Power

SW+I/C

/

PWB

DA

\

‘LINE FILTER PWB

,

Page 8

VT-341

8X

VT-5118X

I

I

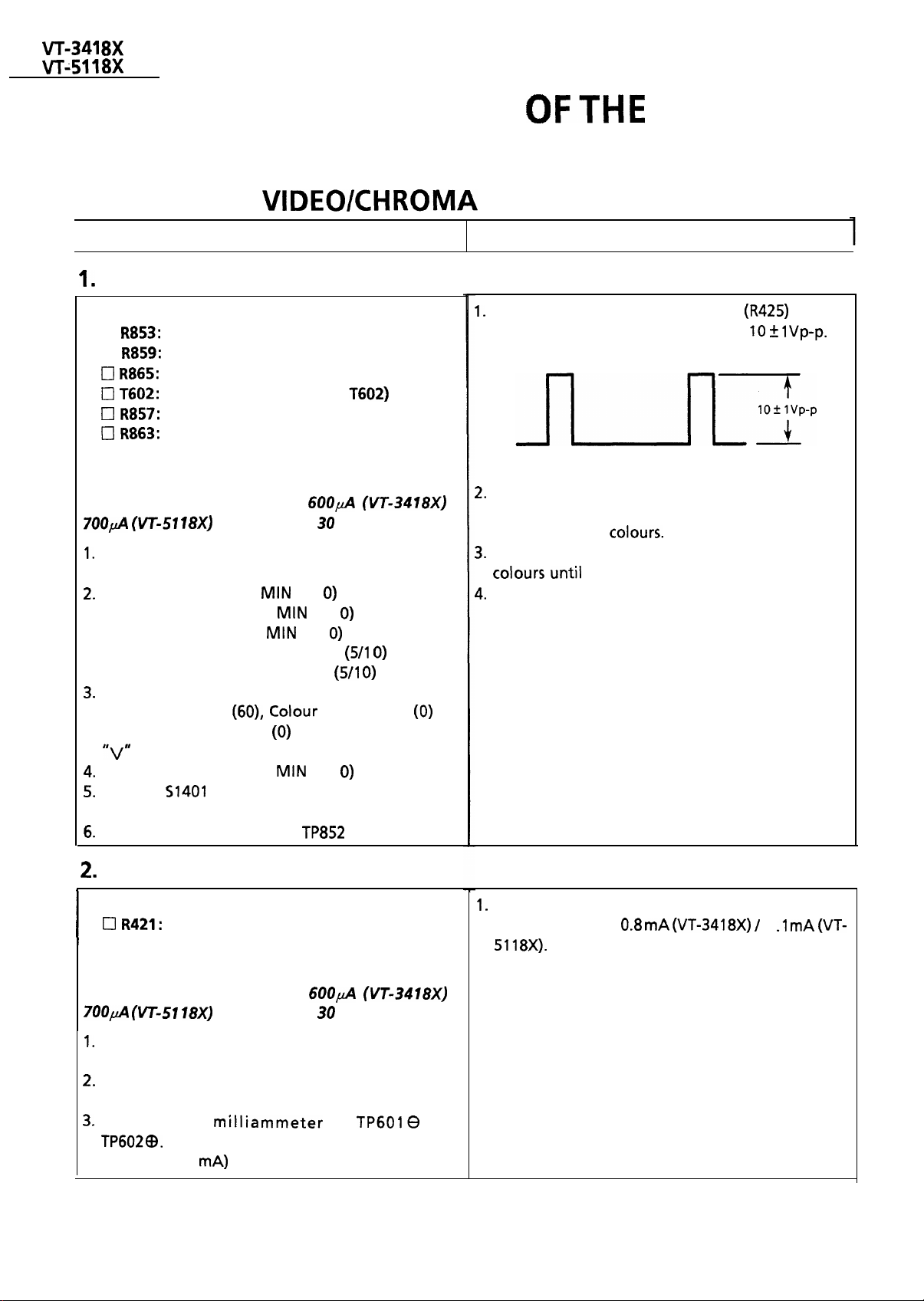

ADJUSTMENT

TV ELECTRICAL CIRCUITRY

VIDEOKHROMA

I

1.

CRT Cut-off Adjustment

Adjusting Point

Cl

R853:

Cl

R859:

Cl R865:

El T602: Screen control (a pat-t of T602)

Cl R857:

!Il

R863:

Note:

Prior to this adjustment, warm up the unit with the

beam current of more than

7004 (VT-51 18X)

1.

Receive “MONOSCOPE PATTERN” signal with

pattern generator.

2.

Set Red bias control at

Set Green bias control at

Set Blue bias control at

Set Green drive control at CENTER

Set Blue drive control at CENTER

3.

Set the control at the “NORMAL” position that

Contrast is MAX

Brightness is CENTER

“v”

keys.

4.

Set the Screen control at

5.

Turn on

line position.

6.

Connect the oscilloscope to

Adjusting Conditions

Red Bias control

Green Bias control

Blue Bias control

Green Drive control

Blue Drive control

for more than 30 minutes.

MIN

(O/l 0) position.

MIN

MIN

(O/l 0) position.

(60), Colour

(0)

using control, “A” and

MIN

51401

(Service switch) at the horizontal

6OOfl (VT-3418X)

(O/l 0) position.

(5/l 0)

position.

(5/l 0)

position.

is CENTER

(O/l 0) position.

TP852

(Red Cathode).

(0)

OFTHE

ADJUSTMENT

1.

Adjust the Sub-Brightness control

the blanking pulse on oscilloscope is 10 +

2.

Slowly turn the Screen control clockwise and stop

I

an

it where the horizontal raster appears slightly, in

one of the three

3.

Carefully adjust the Bias controls of the other two

colours

4.

Turn the Screen control counterclockwise until

the horizontal raster disappears, and stop it.

untii the horizontal raster becomes white.

Adjusting Procedures

colours.

(R425)

so that

lVp-p.

2.

Sub-Contrast Adjustment

Adjusting Point

I

0 R421:

Sub-Contrast control

I

Note:

Prior to this adjustment, warm up the unit with the

beam current of more than

7004 (W-51 18X)

1.

Receive “MONOSCOPE PATTERN” signal with

pattern generator.

2.

Set the Contrast and Brightness controls at MAX

position.

3.

Connect DC

TP602@.

(Full scale: 3

for more than 30 minutes.

milliammeter

mA)

600@ (VT-3418X)

to

TP6019

and

1.

Adjust Sub-Contrast control so that the beam

current becomes

5118X).

I

0.8

mA

(VT-3418X) /

8

1 .l mA

(VT-

Page 9

VT-341

8X

W-5118X

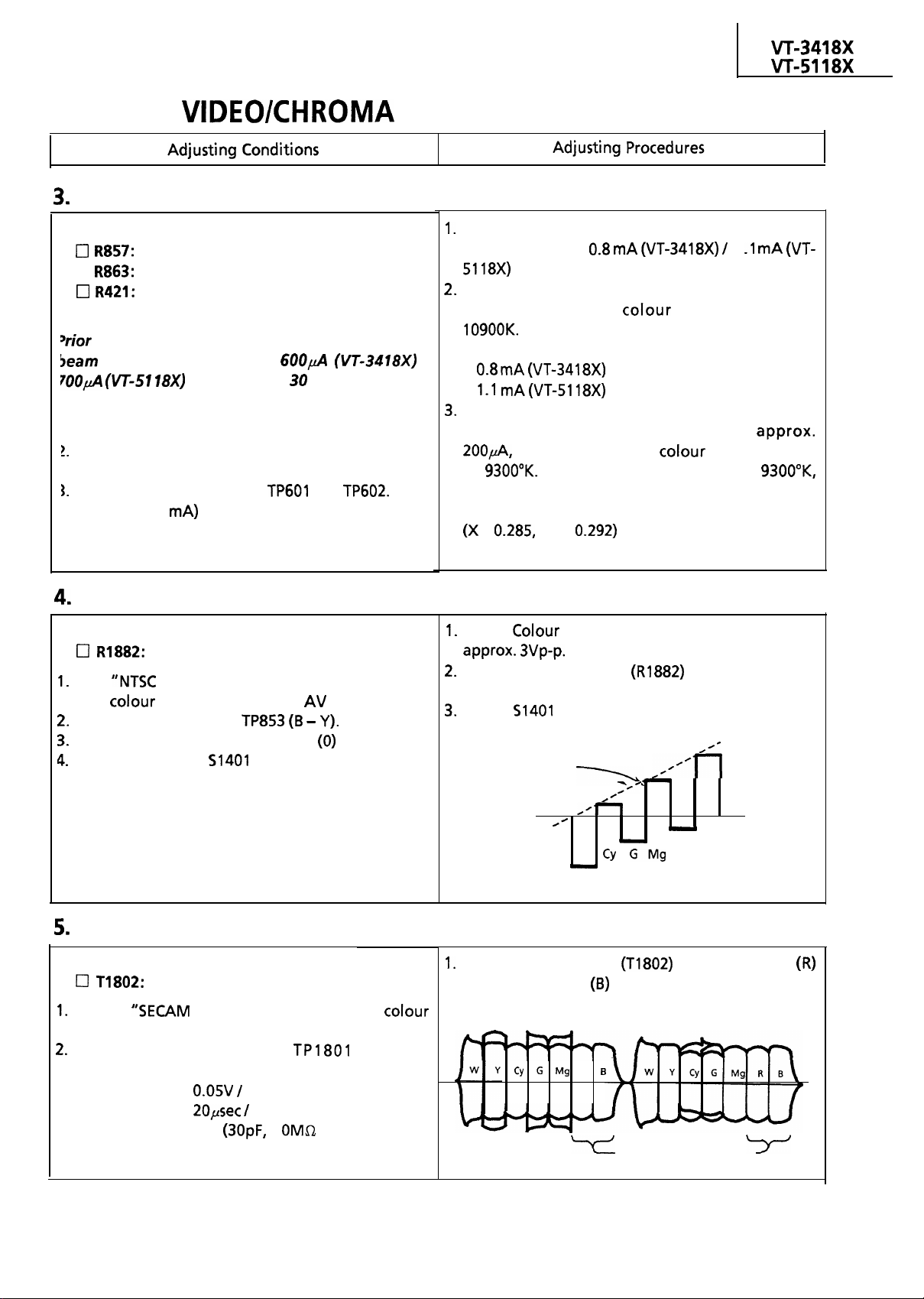

VIDEOICHROMA

3.

White Balance and Back Ground Adjustment

Adjusting Point

El R857:

Cl

Cl R421:

Vote:

srior

5eam

7004 (VT-51 18X)

I. Receive “MONOSCOPE PATTERN” signal with

pattern generator.

!.

Set the Contrast and Brightness controls at MAX

position.

5.

Connect beam ammeter to

(Full scale: 3 mA)

Green Drive control

R863:

to this adjustment, warm up the unit with the

current of more than

Blue Drive control

Sub-Contrast control

6004

for more than 30 minutes.

TP601

(VT-3418X) I

and

TP602.

ADJUSTMENT (Continued)

1.

Adjust the Sub-Contrast control so that the beam

current becomes

5118X) (rough adjustment).

2.

Adjust the Green Drive control and Blue Drive

control so that the colour temperature is at

10900K.

l

High beam:

0.8

mA

1.1

mA(VT-5118X)

3.

Adjust the Contrast control and Brightness

control so that the beam current is

200,&,

at

9300°K.

go back to “CRT CUT-OFF ADJUSTMENT” and

repeat the adjustment.

(X = 0.285,

0.8

mA

(VT-3418X) /

(VT-341 8X)

and check that the

If the temperature is not at

Y = 0.292)

colour

1 .l mA

temperature is

(VT-

approx.

9300”K,

4.

Sub-Tint Adjustment

Adjusting Point

0 R1882:

1.

Feed

with

2.

Connect oscilloscope to

3.

Set the Tint control at the CENTER

4.

Set Service switch

to cut off the Y-signal.

1

j.

Bell Filter Adjustment

Adjusting Point

0 T1802:

1.

Receive

bar generator.

2.

Connect oscilloscope to TP1801 with the

following settings.

l

Range:

l

Sweep Time:

l

Probe:

Sub-Tint control

“NTSC

COLOUR BAR” signal to video in jack

colour

bar generator at the AV mode.

TP853 (B - Y).

51401

at the Video Cut position

Bell Filter

“SECAM

COLOUR BAR” signal with colour

0.05V /

20psec /

l/l 0

div. AC

div.

(3OpF,

1

OMQ

(0)

position.

or more)

1.

Adjust

approx. 3Vp-p.

2.

Adjust Sub-Tint control

waveform is as shown in figure below.

3.

Return

1.

Adjust the Bell Filter

output and blue

amplitude.

Colour

51401

Same

B-Y

CY G Mg

control key to obtain the output of

(R1882)

to CENTER (normal position).

level

y

/’

/-

.)

.

W Y Cy

-

(B)

R

B

‘c_

/@(

-

GMg

(T1802)

output will have the same

Same amplitude

so that the output

_.z_‘-

-

-

R B

so that the red

//-

(R)

r-

9

Page 10

VIDEOICHROMA

ADJUSTMENT (Continued)

Adjusting Conditions

6.

PAL

Adjusting Point

Cl

0 T1801:

Note: Before this adjustment, the

1.

Receive “PAL COLOUR BAR” signal with pattern

generator.

2.

Connect the following resistance matrix to pins 3

and 4 of the connector

oscilloscope is connected.

TP853 (K)+

3.

Set the Service switch

position to cut off the Y-signal.

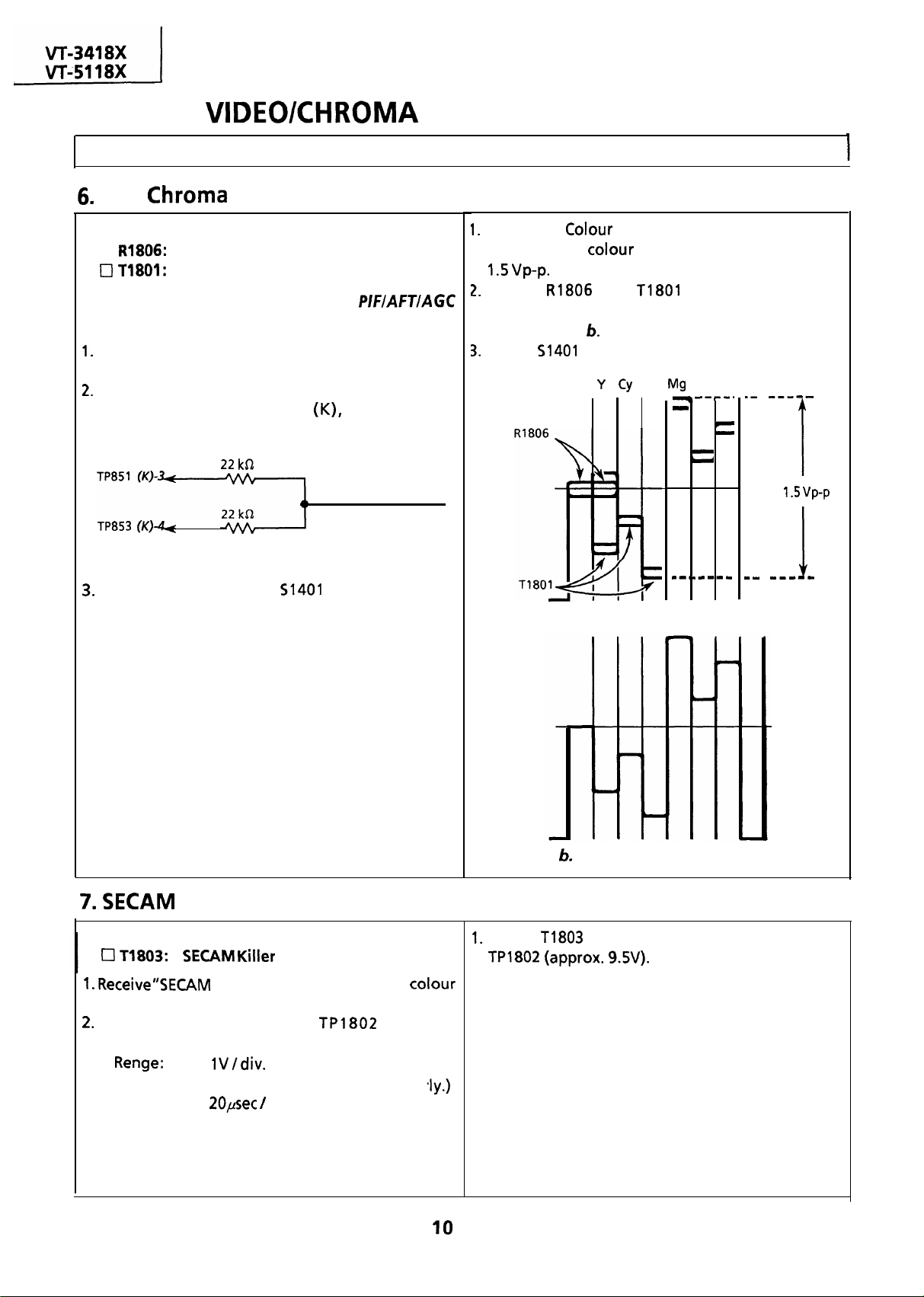

Chroma

R1806:

adjustment must have been completed.

Adjustment

1 H Delay Amp. control

1 H Delay Phase control

(K),

to which an

22 kSZ

To oscilloscope

Resistance Matrix

51401

at the Video Cut

PIFIAFTIAGC

I

1.

Adjust the

waveform of

1.5

vp-p.

2.

Adjust

waveform shown in Fig. a is corrected to that

shown in Fig.

3.

Return

Adjusting Procedures

Colour

control key so that the output

colour

difference signal becomes

R1806

and

T1801

so that the output

6.

51401

to CENTER (normal position).

W Y Cy G Mg R B

--#--.

-

-

u

--*m---w

.-

---m-

r

-

mm --m-w

1

Figure a. Waveform before the adjustment

1

1.5 vp-p

I

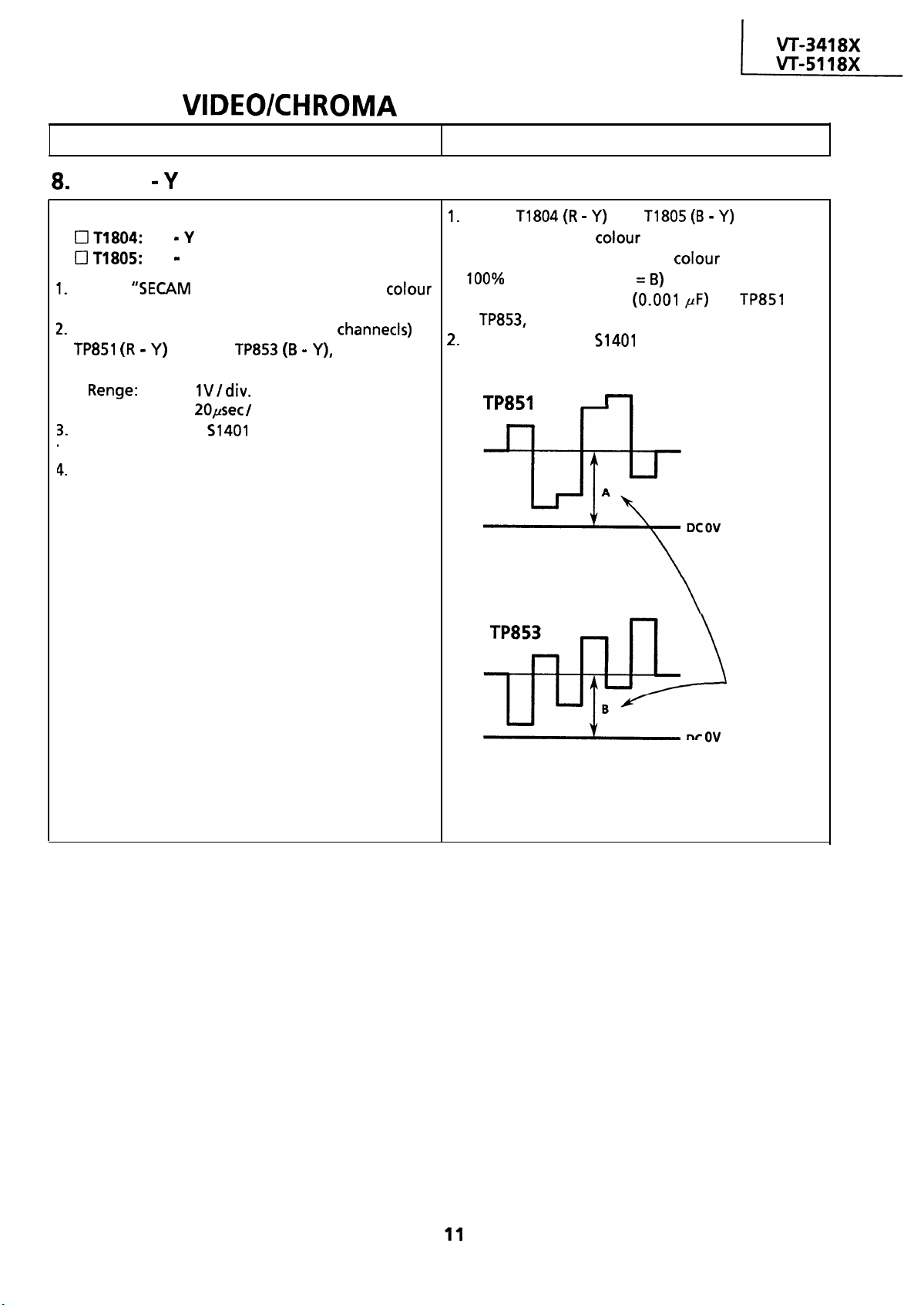

7. SECAM

r

Adjusting Point

0 11803:

1. Receive”SECAM

bar generator.

2.

Connect oscilloscope to

following settings.

l

Renge:

l

Sweep Time:

Killer Adjustment

SECAM Killer

COLOUR BAR” signal with

lV/div.

(Adjust vertical position proper

20psec /

DC

div.

control

TP1802

colour

with the

,lY.)

IO

Figure 6. Waveform after the adjustment

1.

Adjust

TPl802

T1803

to obtain maximum DC voltage at

(approx. 9.5V).

Page 11

VIDEOKHROMA

Adjusting Conditions Adjusting Procedures

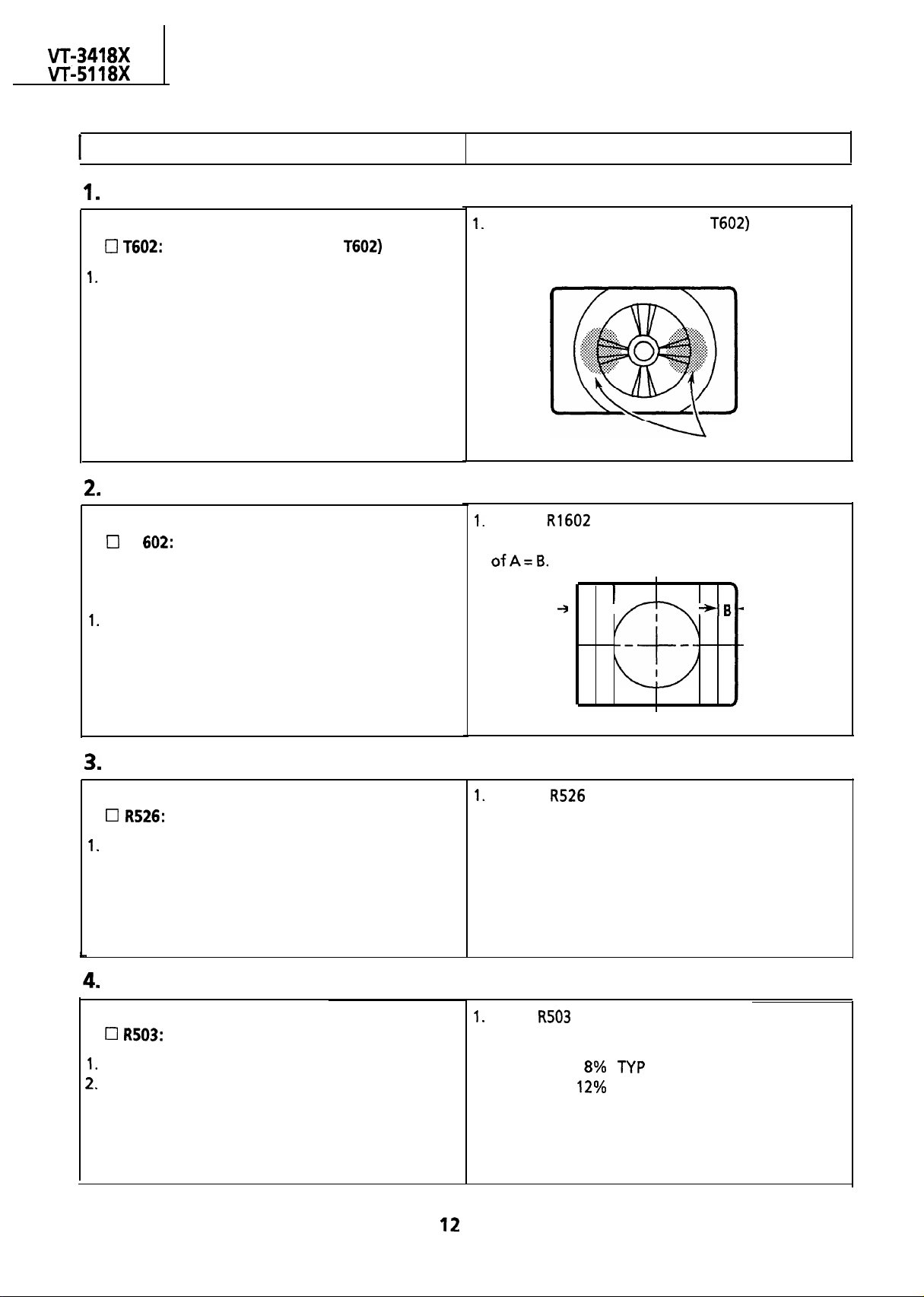

8.

R -Y/B -Y Discriminator Adjustment

Adjusting Point

0 T1804:

0 T1805:

1.

Receive “SECAM COLOUR BAR” signal with colour

bar generator.

2.

Connect the oscilloscope (with two

TP851 (R - Y)

on the CRT Socket Unit of the set.

l

Renge:

l

Sweep Time:

3.

Set service switch

’

to cut-off the Y-signal.

4.

Set both the Contrast and Brightness controls to

their maximum postions.

R - Y Discriminator

B - Y Discriminator

and the

TP853 (B - Y),

lV/div.

20psec /

51401

DC

div.

at the Video Cut position

channecls)

both located

ADJUSTMENT (Continued)

to

1.

Adjust

output level with

will be the same as that with

100%

* Connect capacitor (0.001

2.

Set service switch

T1804 (R - Y)

of saturation. (A =

TP853,

thus to prevent noise interference.

and

colour

51401

TP851

T1805 (B - Y)

control set at minimum

colour

B)

,xF)

to the canter position.

so that DC

control set at

to

TP851

and

TP853

*

Same

B

DC

DC output level

OV

11

Page 12

VT-341 8X

VT-5118X

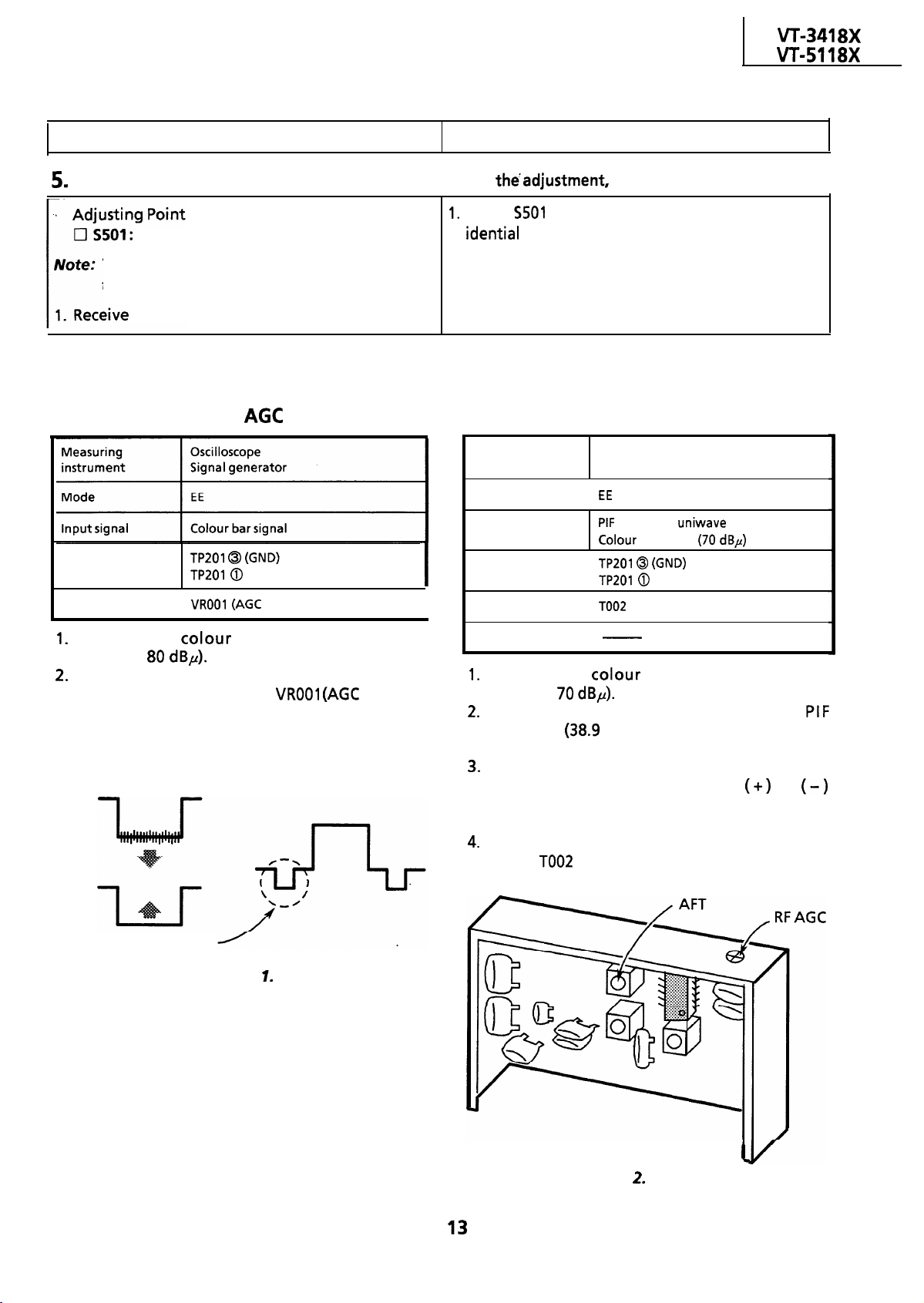

DEFLECTION LOOP ADJUSTMENT

Adjusting Conditions

1.

Focus Adjustment

Adjusting Point

0 T602: Focuscontrol (a part of

1.

Receive “MONOSCOPE PATTERN” signal.

2 Set the Brightness and Contrast controls at

NORMAL position.

2.

Horizontal Center Adjustment

Adjusting Point

Cl

RI

602: Horizontal Center control

Note: This adjustment should be performed after

the purity and convergence adjustments.

1.

Receive “MONOSCOPE PATTERN” signal.

T602)

Adjusting Procedures

l

During the adjustment, keep the unit facing the east.

1.

Adjust Focus control (a part of

focus at the central area of CRT.

l

During the adjustment, keep the unit facing the east.

1.

Adjust

picture is at the position which gives the relation

ofA=B.

R1602

so that the horizontal center of

+

I

A-

l

T602)

Adjust point

-)B

to have best

4

3.

Vertical Linearity Adjustment

Adjusting Point

Cl R526:

1.

Receive “MONOSCOPE PATTERN” signal.

4.

Vertical Size Adjustment

Adjusting Point

Cl R503:

1.

Receive “MONOSCOPE PATTERN” signal.

2.

Set the Brightness and Contrast controls at MAX

position.

Vertical Linearity control

Vertical Size control

(+=

I

I

l

During the adjustment, keep the unit facing the east.

1.

Adjust

picture is at best point.

l

During the adjustment, keep the unit facing the east.

1.

Adjust

the same size as horizontal size.

. V-SIZE

R526

so that the vertical linearity of

R503

so that the vertical size of picture is at

8%

TYP

12% MAX

12

Page 13

DEFLECTION LOOP ADJUSTMENT (Continued)

VT-341 8X

VT-5118X

Adjusting Conditions

5.

Vertical Centering Adjustment

Vertical Center Adjust switch

This adjustment should be performed after

the purity and convergence adjustments.

“MONOSCOPE PATTERN” signal.

ADJUSTMENT OF THE IF CIRCUIT

Adjustment of the RF

Test point

Adjusting point

TP201 @I (GND)

TP201 0

VROOl (AGC

I

AGC

(Video Output)

control)

Adjusting Procedures

l

During

the’adjustment,

1.

Adjust

idential to CRT geometrical vertical center.

5501

so that the picture’s vertical center is

keep the unit facing the east.

Adjustment of the AFT

Measuring

instrument Signal generator

Mode

Input signal

Test point

I

Adjusting point

Oscilloscope

EE

I

PIF

frequency

Colour bar signal

TP201 @ (GND)

TP201 @

I

TOO2

I

(Video Output)

(AFT coil)

uniwave

(70

dBp)

1.

Receive the

strength: 80

2.

Observe the video output terminal waveform

on the oscilloscope. Adjust

in the IF pack until the noise disappears from

the oscilloscope screen and the waveform

nearly comes into sync.

Just before shrinking

colour

dBp).

bar signal (input field

Figure

VROOl (AGC

1.

control)

Specification

1.

Receive the colour bar signal (input field

strength: 70

2.

Using the signal generator, feed the

frequency

tuner IF output terminal.

3.

Set the tuning switch to the VHF or UHF

position. Keep the tuning button

depressed until the beating on the oscilloscope

screen be minimum.

4.

Set the tuning switch on the normal position.

Adjust

oscilloscope screen be minimum.

TOO2

-

I

dBp).

(38.9

MHz) signal (sinewave) to the

(+)

or

(AFT coil) so that beating on the

PIF

(-)

13

I

Figure 2. IF Pack

Page 14

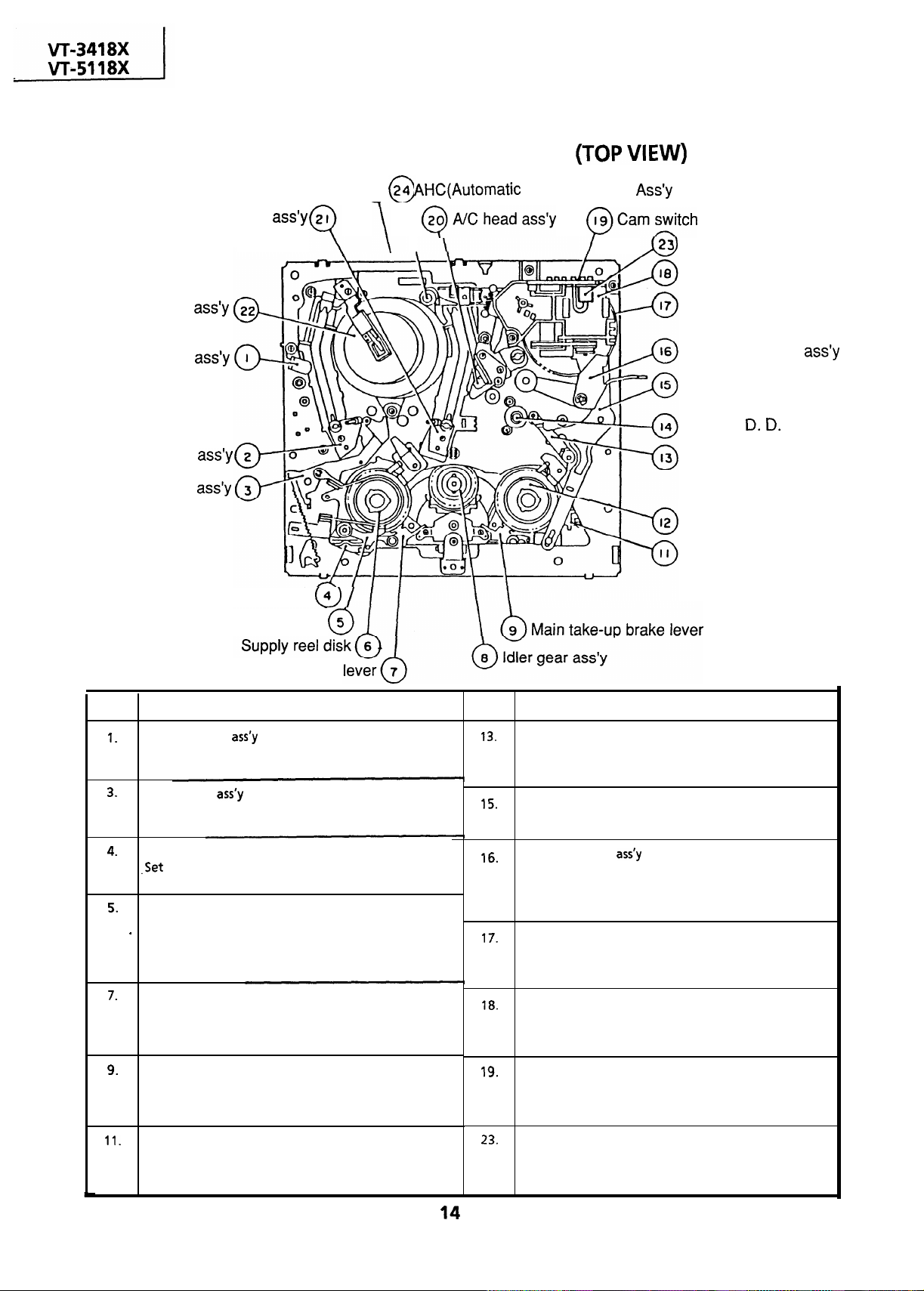

FUNCTION OF MAJOR

Take-up pole

Drum

Full erase head

Supply pole base

Tension arm

MECHANICAL PARTS

base

ass’y 2

ass’y

ass’y

I

ass’y

ass’y

Brake shifter w

I

Q,

\

24 AHC(Automatic

0

@/Cheadass’y

/

Head Cleaner)

(TOPVIEW)

@Camztch

h

Ass’y

23

Dew sensor

AJ

Loading motor

Master cam

Pinch roller lever

Relay shifter lever

Capstan D. D. motor

Reverse guide

Take-up reel disk

Video

lever

ass’y

search brake

Back tension lever

Main supply brake

No.

Full erase head

1.

Erase the whole records on the tape in the recording

mode.

3.

Tension arm

Detects the tension of tape while running, and brakes

the supply reel disk via the tension band.

4.

Brake shifter

,Set the position of brake or the like in accordance with

the modes such as stop and playback.

5.

Back tension lever

Brakes the supply reel disk to a certain degree to .

’

prevent tape slackening during “half-loading”,

“loading” and “shifting from playback to video search

rewind”.

7.

Main supply brake lever

Brakes the supply reel disk to prevent tape slackening

when the unit is stopped in fast forward or rewind

mode.

ass’y

Function

ass’y

No.

Reverse guide

13.

Pulls out the tape in the video search rewind mode,

and controls the tape drive train height with the upper

and lower guides.

Relay shifter lever

T5.

Transmits the operation of the master cam to the

brake shifter, and operates the reverse guide.

Pinch roller lever

16.

Press-fits the tape to the capstan during tape running.

The right protrusion switches the clutch of the cassette

housing control assembly in “tape eject”, and makes

the mechanism eject the tape.

Master cam

17.

Turns clockwise during loading, and counterclockwise

during unloading, and moves the shifter or the like in

accordance with each mode.

Loading motor

18.

A motive power which drives the mechanism. It

transmits the power to the master cam and cassette

housing control assembly via the belt.

Function

ass’y

9.

Main take-up brake lever

Brakes the take-up reel disk to prevent tape slackening Rotates synchronously with the master cam, and

when the unit is stopped in fast forward or rewind detects the position of each mode by means of the

mode.

11.

Video search brake lever

It is in contact with the take-up reel disk normally, and

brakes it to a certain degree. It applies larger brake in unit. This element is activated, when it senses

the video search rewind mode.

Cam switch

19.

internal switch.

Dew sensor

23.

An element which detects condensation inside the

condensation, to interrupt the mechanism.

14

Page 15

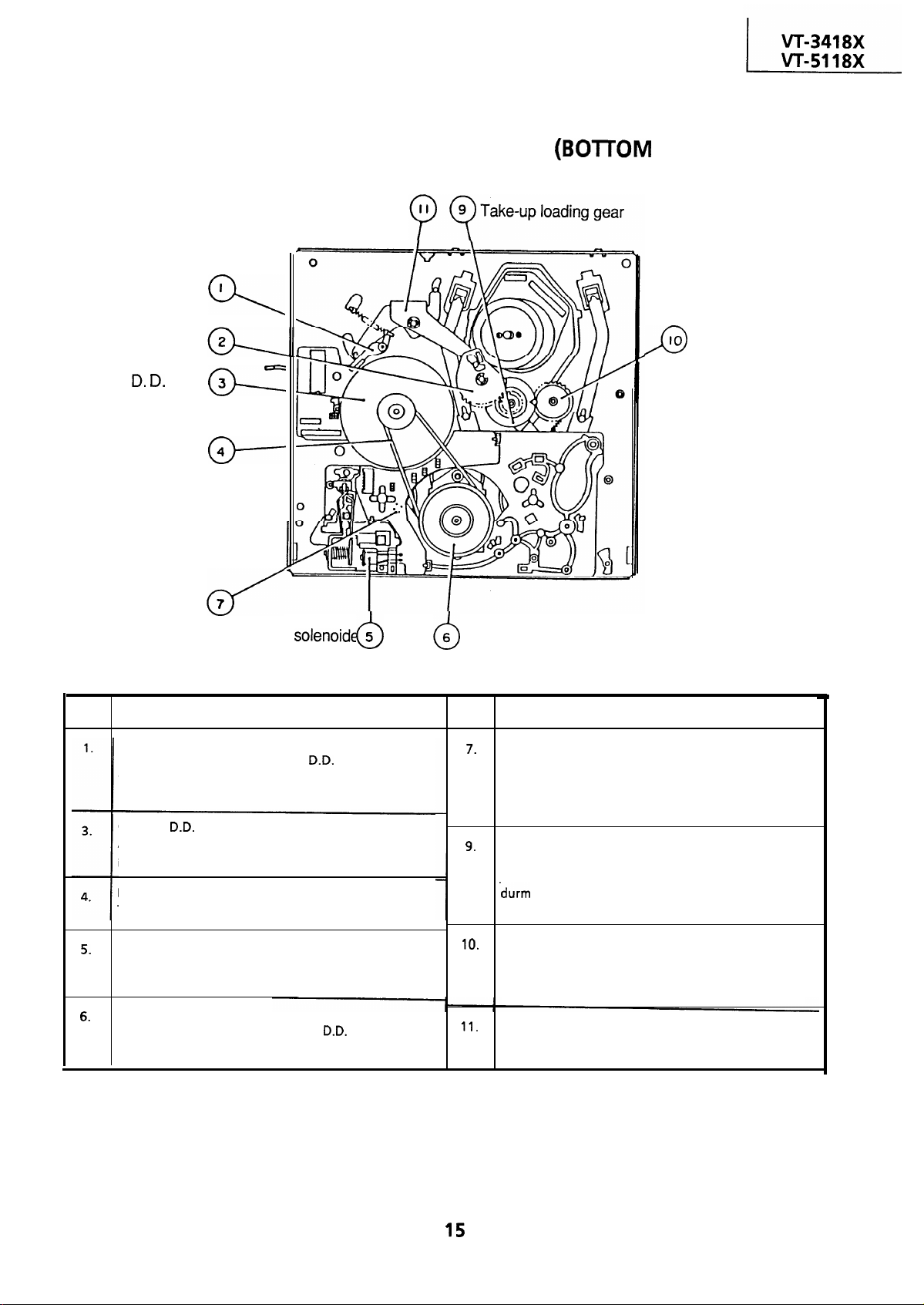

FUNCTION OF MAJOR

MECHANICAL PARTS

Slow brake lever

Loading relay gear

Capstan D. D. motor

Reel belt

Relay gear drive lever

I

x

3

o=

@-

(BOmOM

VIEW)

IO

Supply loading gear

/o

Reel sensor

No.

Slow brake lever

Gets in contact with the capstan

the master cam in the slow still mode, and brakes it to a

certain degree.

Capstan

A motive power which runs the tape. It transmits the

power via the reel belt.

Reel belt

Transmits the power to run the tape to the reel pulley.

Brake solenoid

5.

Adsorbs and holds the brake shifter in the fast forward

and rewind modes, and releases it in the stop mode.

Reel pulley

6.

Transmits the power of the capstan

reel disk via the reel idler.

D-D.

7

d

motor

Brake

Function

solenoide

D.D.

motor linking to

D.D.

5

()

motor to the

d

Reel pulley

No.

7.

9.

10.

.

11.

Function

Reel sensor

An element which sheds the light onto the reflection

plate affixed to the bottom side of the reel disk, and

detects the rotation of the reel disk through receiving

the reflected light.

Take-up loading gear

Shifts the take-up pole base and guide roller via the

loading relay gear, and applies the tape around the

durm

assembly, as well as transmits the power to the

supply loading gear.

Supply loading gear

Shifts the supply pole base and guide roller via the

take-up loading gear, and applies the tape around the

drum assembly.

Relay gear drive lever

Transmits the movement of the master cam to the

take-up loading gear via the loading relay gear.

15

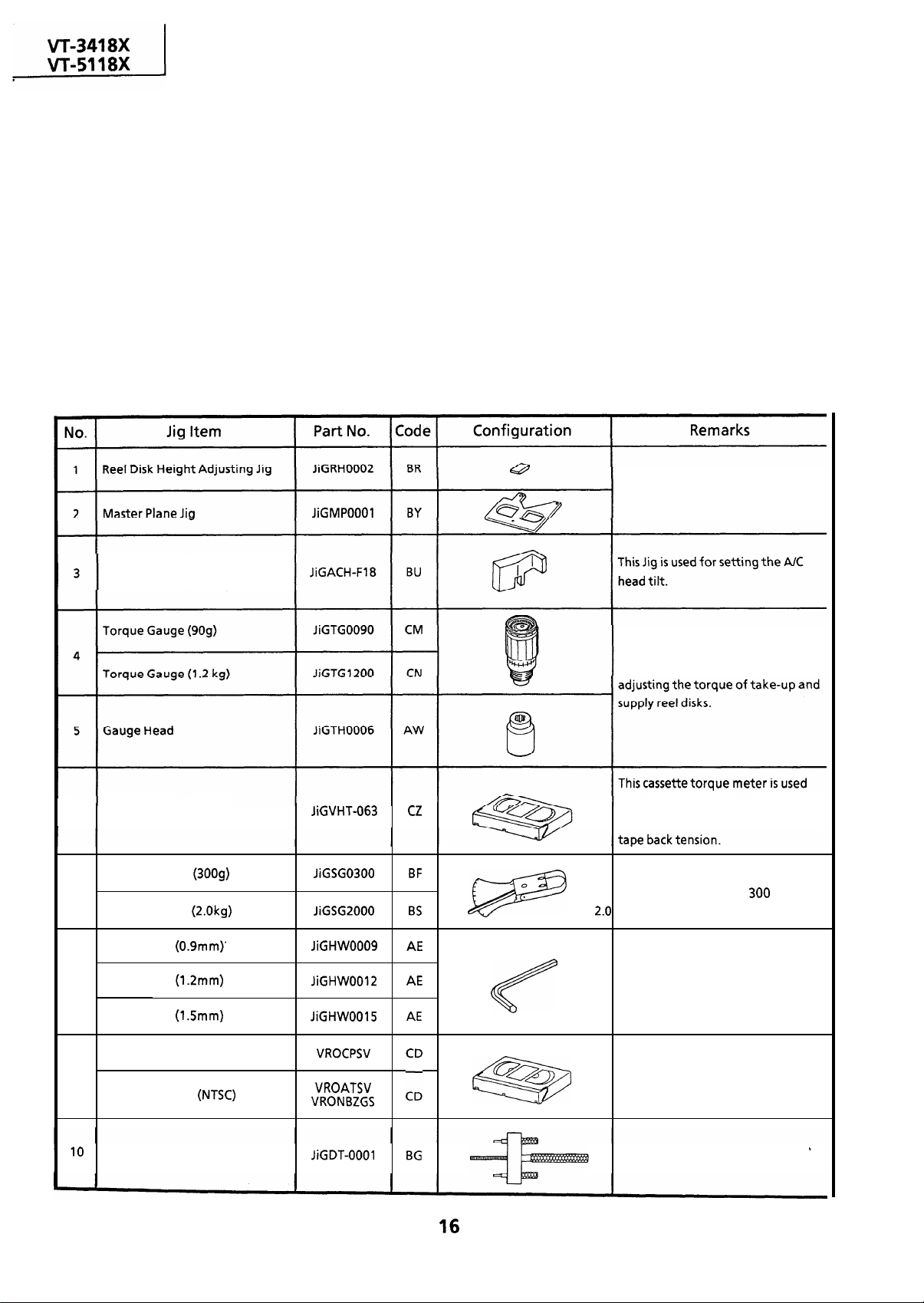

Page 16

ADJUSTMENT, REPLACEMENTAND

ASSEMBLY OF MECHANICAL UNITS

Here we will describe a relatively simple service

work in the field, not referring to the more

complicated repairs which would require the use of

special equipment and tools (drum assembly

We are sure that the easy-to-handle tools listed

below would be more than handy for periodical

maintenance to keep the machine in its original

working condition.

replacement, for example).

TOOLS NECESSARY FOR ADJUSTING THE MECHANICAL UNITS

The following tools are required for proper service and satisfactory repair.

These Jigs are used for checking and

adjusting the reel disk height

A/C Head Tilt Adjusting Jig

6

Cassette Torque Meter

Tension Gauge (3009) .

7

Tension Gauge

Hex Wrench (0.9mm)’

Hex Wrench (1.2mm)

8

Hex Wrench (1.5mm)

Alignment Tape (PAL)

9

Alignment Tape

JiGVHT-063

JiGSG0300

(2.Okg) JiGSG2000

JiGHW0009 AE

JiGHW0012

JiGHW0015

VROCPSV

(NTSC)

VROATSV

VRONBZGS

CZ

BF

BS.

AE

AE

11

w

<

f4sz$zg

These Jigs are used for checking and

for checking and adjusting the

torque of take-up for measuring

There are two gauges used for the

tension measurements, 300 g and

2.0

kg.

These Jigs are used for loosening or

tightening special hexagon type

screws.

This tape is especially used for

electrical fine adjustment.

10

Drum Replacing Jig

JiGDT-0001

BG

This is used for replacement of the

VCR’s upper drum.

16

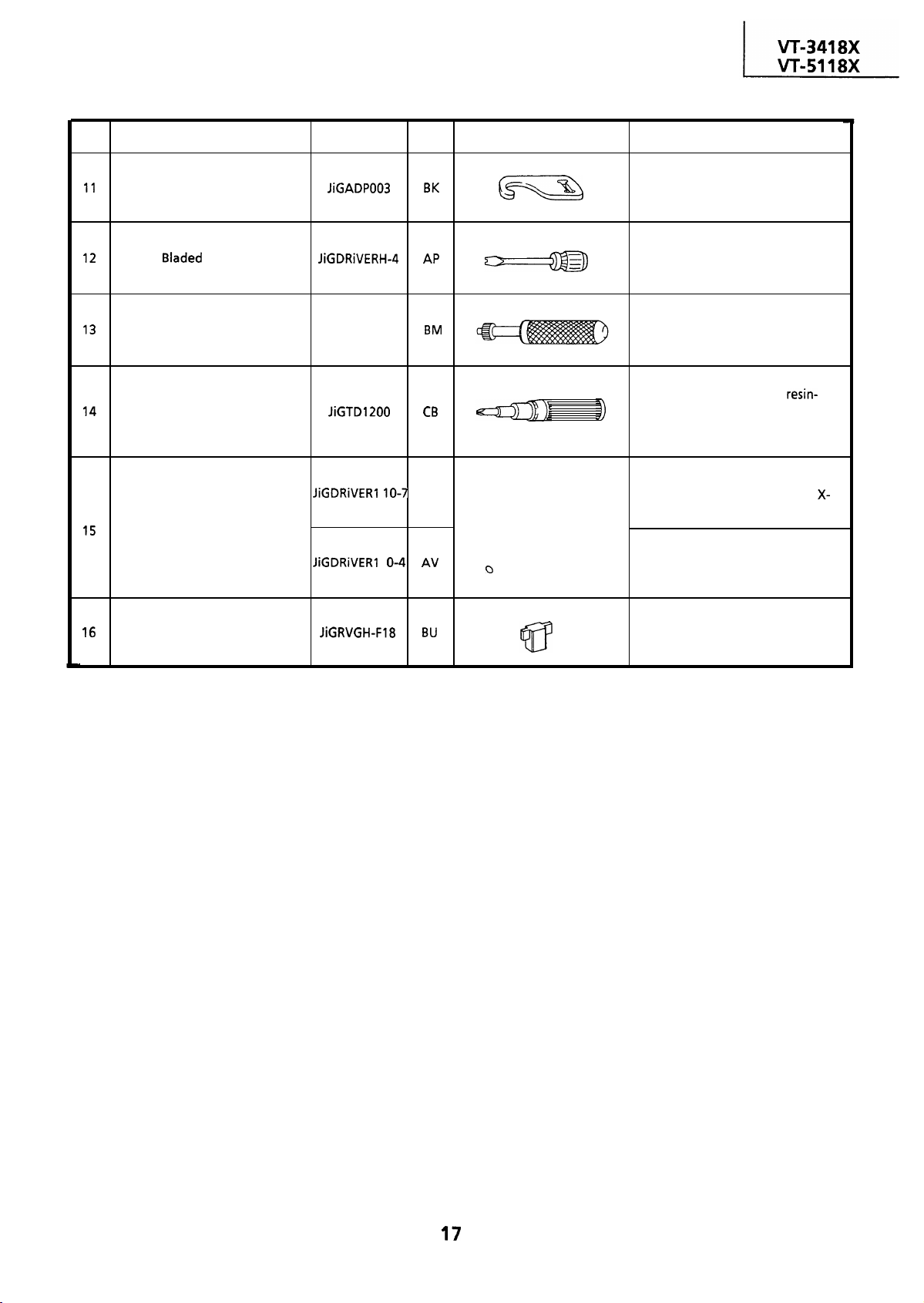

Page 17

No.

11

Tension Gauge Adapter

Jig Item

Part No.

JiGADP003

Code

BK

Configuration

ecih

Remarks

This Jig is used with the tension

gauge. Rotary transformer

clearance adjusting jig.

Special Bladed Screwdriver

12

Tension Band and Plate

13

Adjusting Jig

14

Torque Driver JiGTDl200

Box Driver

15

Reverse Guide Height Adjusting

16

Jig

JiGDRiVERH-4 AP

JiGDRiVER-

JiGDRiVER

JiGDRiVER

JIGRVGH-F18 BU

1

10-7

O-4

BM

CB

AS

AV

This screwdriver is used for adjusting

the guide roller height.

This Jig is used for adjusting the

tension band and tension plate.

This is used to screw down resin-

made parts: the specified torque is 5

kg-

This Jig is used for height

adjustment of the A/C head and X-

position.

0

&@

This Jig is used for height

adjustment of the retaining guide.

This Jig is used for height

adjustment of the reverse guide.

17

Page 18

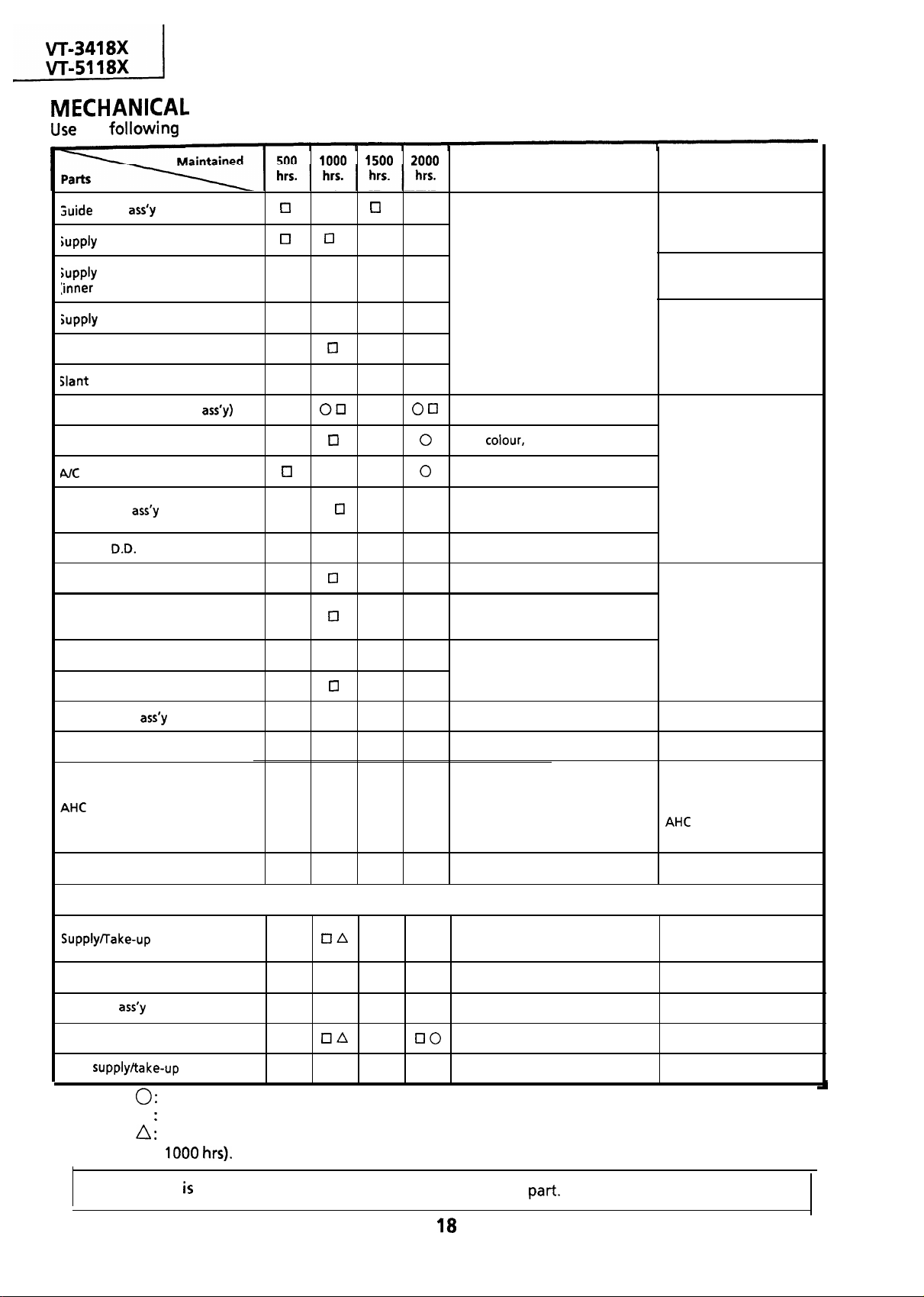

MECHANICAL PARTS REQUIRING PERIODICAL INSPECTION

Use

the

following

table as a guide to maintain the mechanical parts in good operating condition.

;uide

roller

ass’y

;upply

impedance roller

;upply

impedance roller

)nner

hole and shaft)

;upply

impedance roller flange

Retaining guide

slant

pole

Video head (upper drum

Full-erase head

AIC

head

Lower drum

Capstan

Pinch roller

D.D.

ass’y

Motor

ass’y)

1000 1500 2000

Cl

q 0 0

0

0 q 0

q

q q q q

q 0 q q

q q q 0

q

00

q

0 Cl

q 0 q

cl

q q

cl cl q 0

q cl q 0

q Cl q 0

Possible symptom encountered Remarks

Abnormal rotation or

significant vibration

requires replacement.

q

Lateral noises

. Head occasionally blocked

Poor S/N ratio, no color

0

Poor colour, beating

0

Sound too small or distorted

Poor flatness of the envelope with

alignment tape

No tape running, uneven color

No tape running, tape slack

Clean with pure high

quality isopropyl alcohol.

Clean tape contact part

with the specified cleaning

liquid.

Clean tape contact area

with the specified cleaning

liquid.

Reel belt

Loading belt

Cassette loading belt

Tension band

Loading Motor 0

AHC

(Automatic Head Cleaner)

Reel block*

* See the table below for servicing the reel block parts.

SupplyTTake-up reel disks

Video search brake lever

Idler gear

Reel Pulley

ass’y

ass’y

cl

q

cl 0

0 0

IJA

CIA

A 0 No tape running, tape slack

No tape running, tape slack, no

0

fast forward/rewind motion

0

Cassette not loaded or unloaded

Lateral image swing

0

Cassette not loaded or unloaded

See the chart below.

0

No tape running

0

00

Clean rubber and rubber

contact area with the

specified cleaning liquid.

Replace the roller of the

cleaner when it wears

down. Just change the

AHC

roller assembly for

new one.

Clean with pure high

quality isopropyl alcohol.

Main

supplyfiake-up

NOTE:

brake levers

0:

Part replacement.

0 Tape slack

Cl :Cleaning (For cleaning, use a lint-free cloth dampened with pure isopropyl alcohol).

A:

Oil refilling (The indicated point should be lubricated with high quality spindle oil every

1000 hrs).

If the reading is out of the specified value, clean or replace the

18

par-t.

Page 19

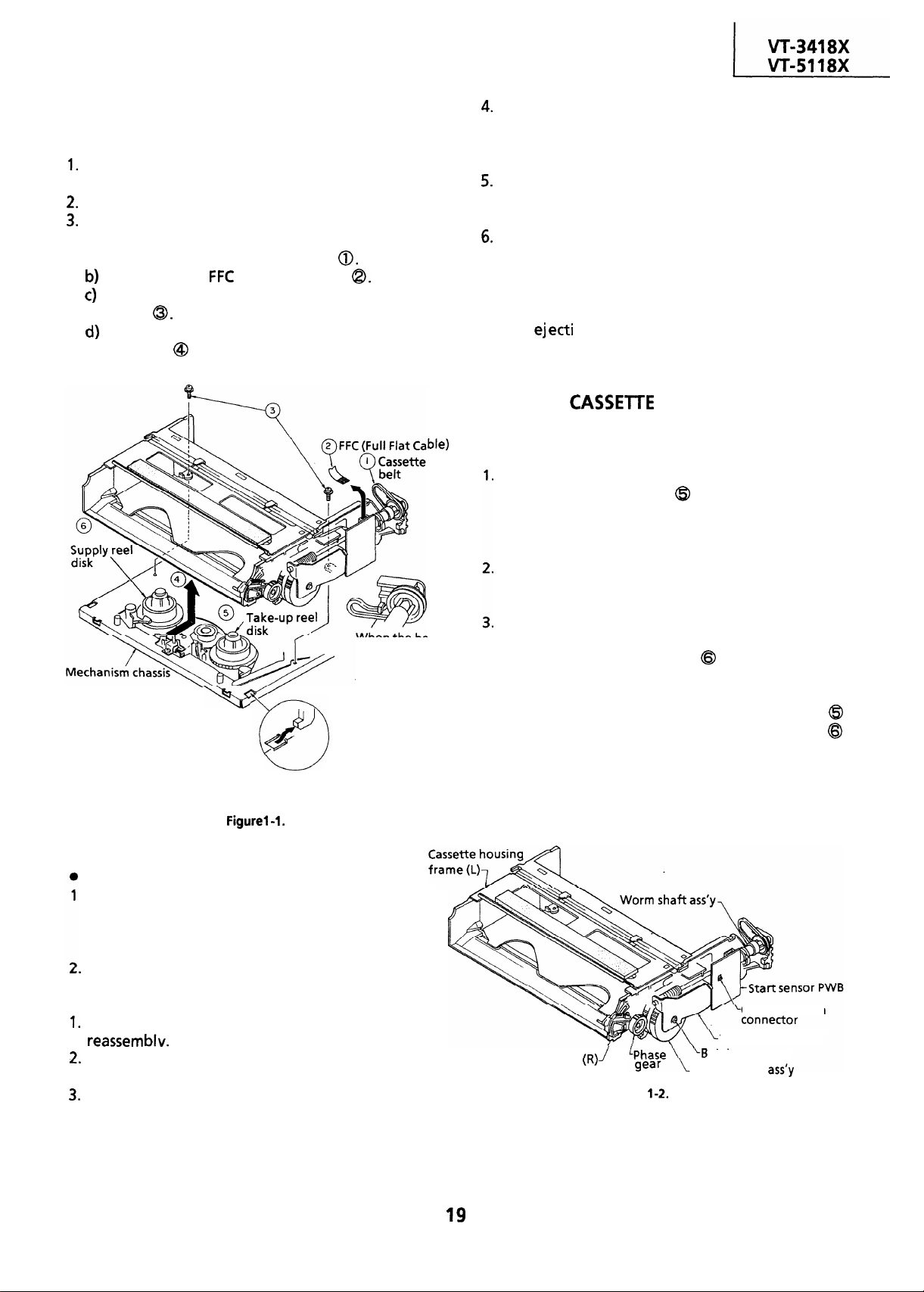

REMOVAL AND REASSEMBLY OF

CASSETTE HOUSING CONTROL ASSEMBLY

l

Removal

1.

Set the cassette ejected condition in the cassette

eject mode.

2.

Unplug the recorder from the main source.

3.

Follow the procedures below in the specified

order.

a) Remove the cassette loading belt

b)

Disconnect the

c)

Remove the cassette housing installation

screws

d)

Slide and pull out the cassette housing control

assembly @ upward.

0.

FFC

(Full Flat Cable)

w

49

4

n

0.

a.

When the

detached, tuck it

as in the figure so

that it is kept free

from grease.

ble)

loading Note the

belt is

4.

In removal and reassembly, take care not to hit

the cassette housing control assembly or tools

against the guide pin, drum, or the like

thereabout.

5.

Place the unit in the eject mode in removal or

reassembly of the cassette housing control

assembly.

6.

Load the cassette once onto the cassette housing

control assembly after reassembly. (If the

cassette housing control assembly normally

operates after this, the phases of mechanism and

the cassette controller are accurately adjusted

after ej

ecti

on.)

MECHANICAL OPERATION CHECK

WITHOUT

When power is on, the general operations of the

mechanism can be checked without a cassette.

Check video search rewind and rewind, rotating

the take-up reel disk @ by hand (in either

normal or reverse direction). If it is not rotated,

the reel sensor works to shift the mechanism to

the eject mode.

When the stop button is pressed, the mechanism

does not stop at a normal stop position. It shifts

to the eject mode and stops.

When the stop button is pressed in the playback,

video search rewind, and video search forward

modes, the supply reel disk 8 keeps on rotating

for several seconds for elimination of tape slack

in the course of shifting to the eject mode. In

such a case, rotate the take-up reel disk

somewhat by hand, and the supply reel disk

stops, which can reduce the working time.

CASSElTE

following points.

@

@

insert the tab of

the Cassette housing

Figure1 -1.

Reassembly

.

Before installation of the cassette housing

control assembly, place the unit in the stop mode

with the power on, then unplug the power cord.

(The main body is placed in the eject mode.)

&.

Follow the procedures for removal in the reverse

order.

Notes:

1.

Be sure to unplug the power cord in removal and

reassem blv.

2.

Keep the cassette loading belt free from grease.

In case of its adhesion, clean the belt.

3.

In using a magnet screw driver, be sure to keep it

away from the A/C head, FE (Full Erase) head, or

the drum.

control assembly to

the mechanism chassis.

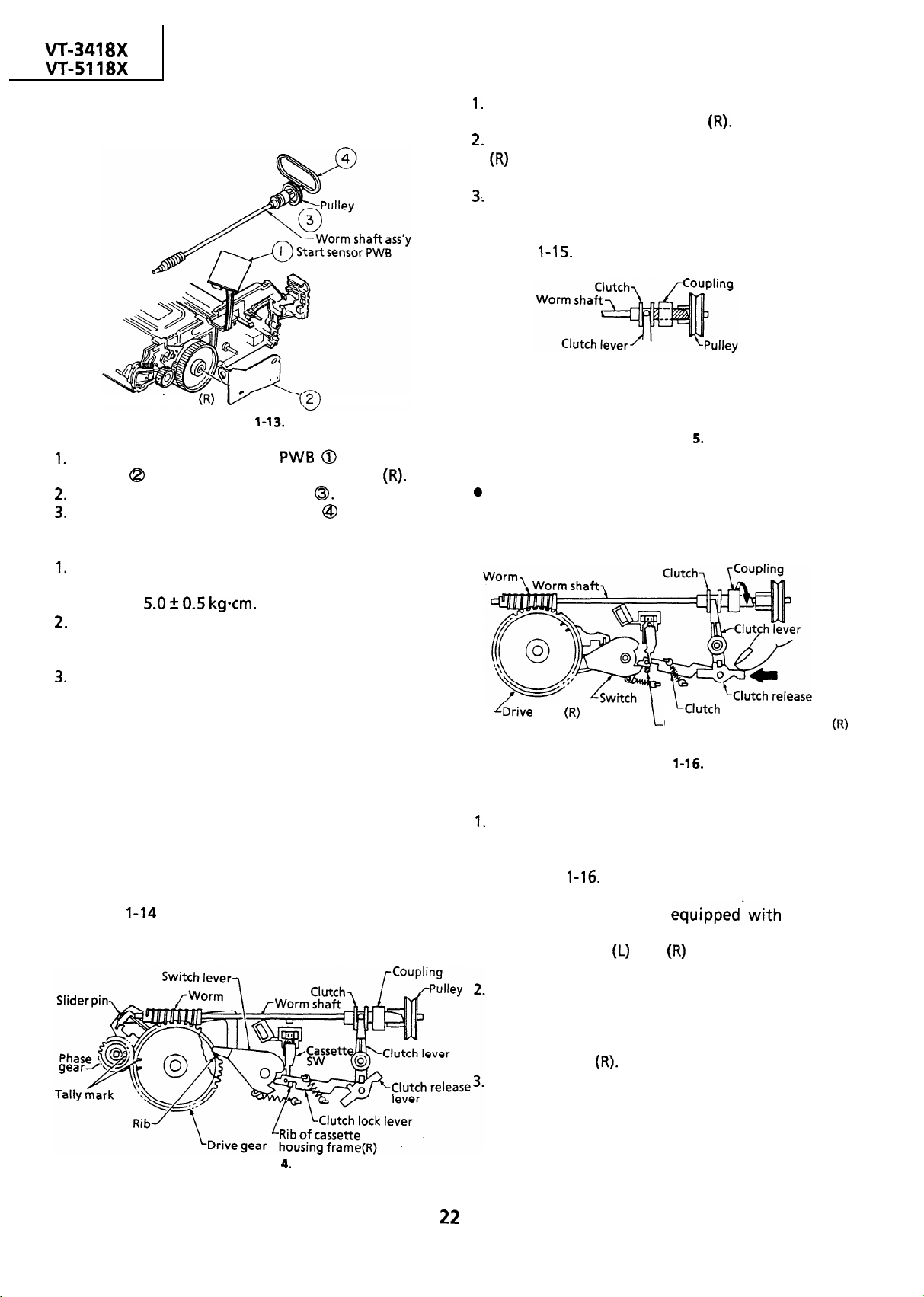

REPLACEMENT OF WORM WHEEL

ASSEMBLY

Cassette housing frame

FO

/

Figure

Worm wheel

l-2.

Cassette switch

Worm bracket

tight screw

ass’y

19

Page 20

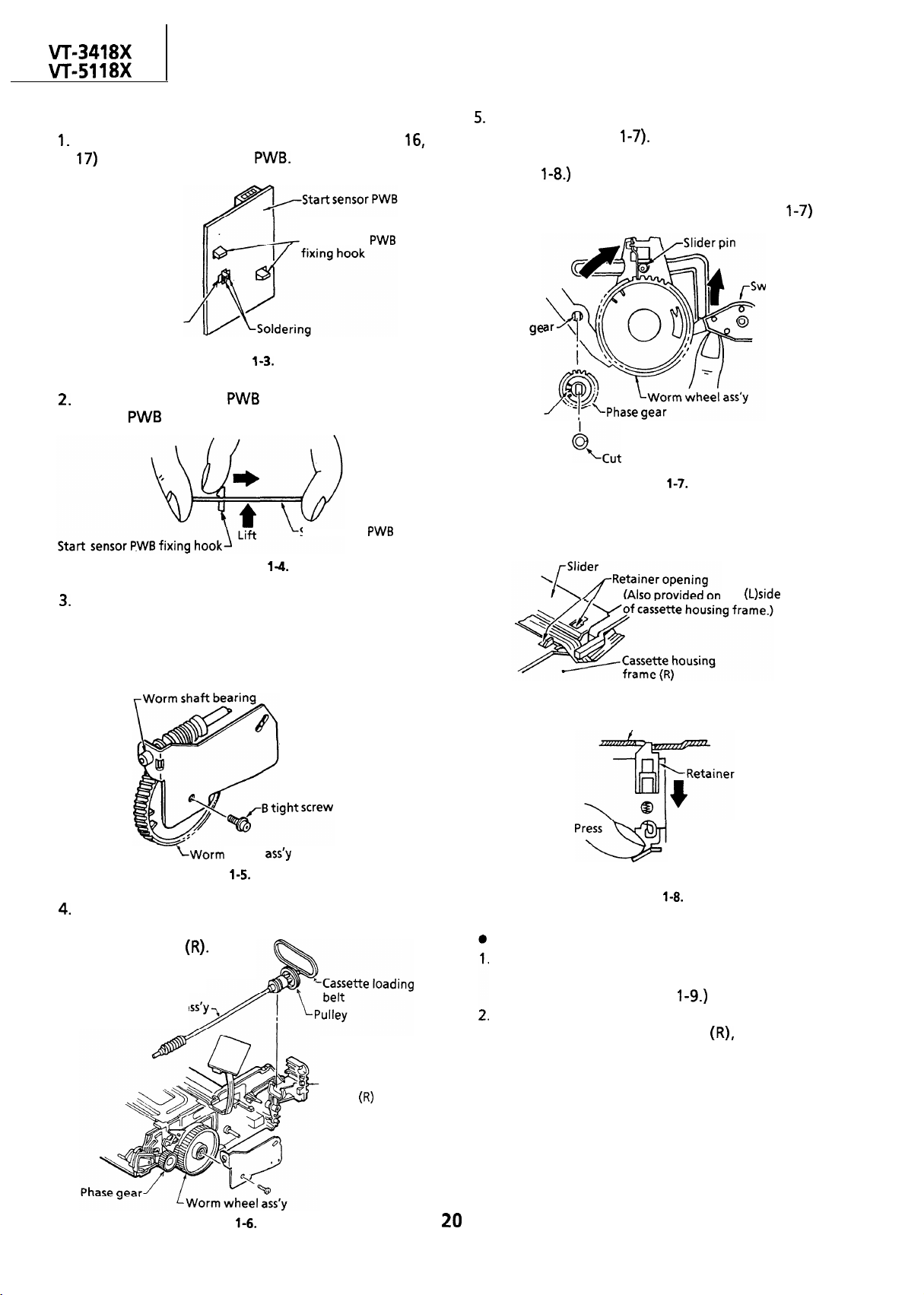

VT-341

W-51

18X

8X

l

Removal

1.

Unsolder the cassette switch connectors (No.

17)

from the start sensor

Cassette switch

connector

2.

Lift the start sensor

sensor

PWB

fixing hooks inward.

PWB.

Start sensor

Figure

l-3.

PWB

pressing the two start

Start sensor

PWB

PWB

16,

5.6Place the slider pin just above the worm wheel

assembly (Figure l-7). (The retainer of the slider

is locked at two positions. So unlock it as in the

Figure

1-8.)

Pull out the worm wheel assembly toward you

pressing the switch lever upward. (Figure

Phase

ge

shaft

Tally mark

‘%ut

washer

Figure

l-7.

l-7)

itch lever

Figure

l-4.

3.

Unscrew one B tight screw to detach the worm

bracket.

Note:

The worm shaft bearing can easily come-out of

position. So be careful not to lose it.

-Worm bracket

LWorm

4.

Remove the worm shaft assembly, pulley, and

Figure

wheel

l-5.

ass’y

cassette loading belt all from the cassette

housing frame

Worm shaft a

(R).

Cassette housing

frame

(R)

the

(L)side

/-Slider

Cassette housing frame

(R)/(L) side

Figure

l-8.

Reassembly

Turn the phase gear clockwise until the slider

comes to a halt in the cassette insertion

direction. (See the Figure

l-9.)

Insert the set up worm wheel gear assembly into

the cassette housing frame

(R),

matching the

mark on the phase gear with the mark on the

worm wheel gear. Detach the cut washer on the

phase gear assembly and the phase gear for

easier installation of worm wheel assembly.

Note:

Make sure that the slider pin is in the groove of

the drive gear arm.

Figure

l-6.

20

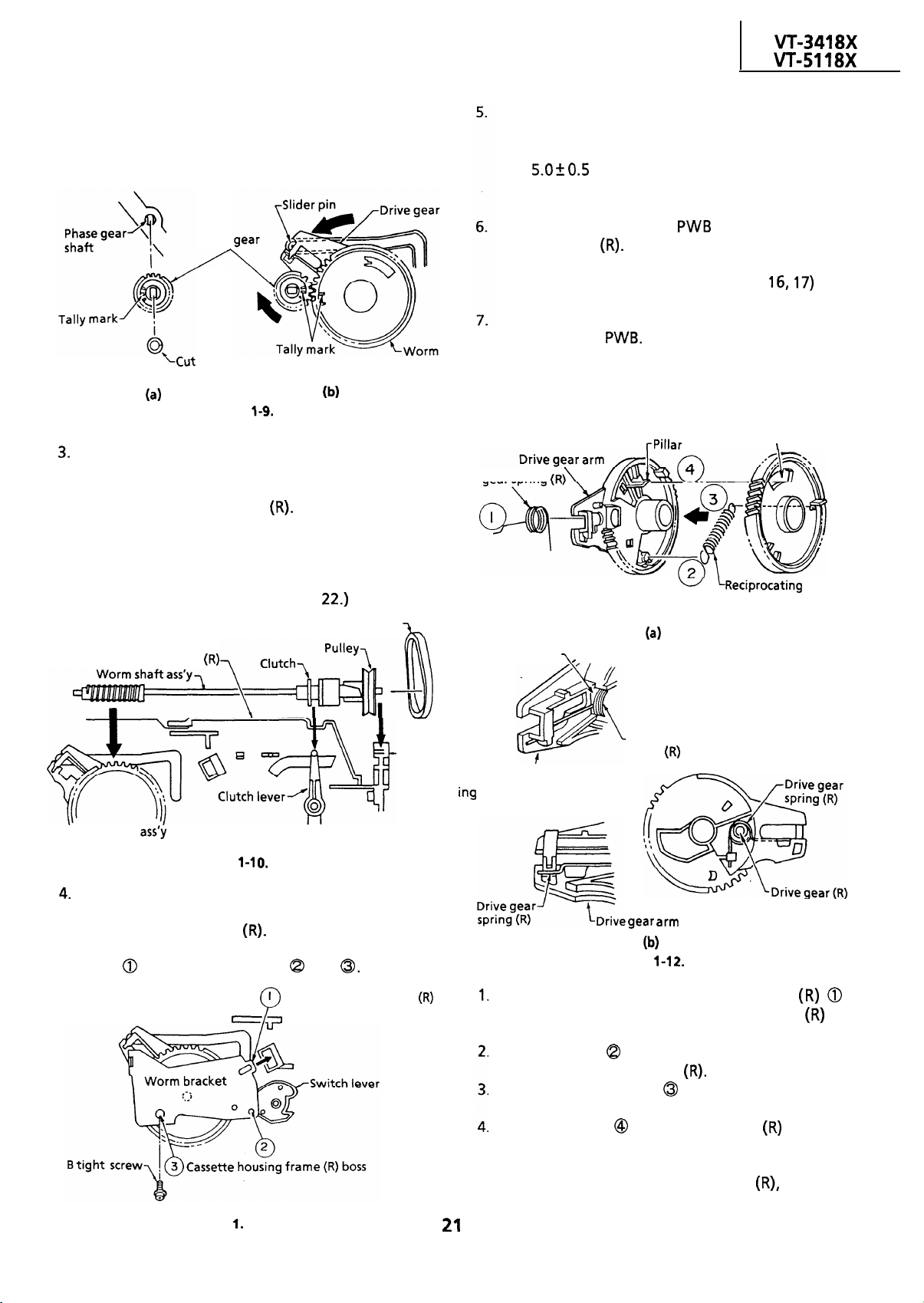

Page 21

Xut

Phase

/

washer

wheel

arm

VT-341 8X

VT-5118X

Tighten one B tight screw.

Note:

Do not over-tighten the B tight screw (no more

than

5.0 +, 0.5

of the screw hole at the resin-made boss can be

broken.

Place the start sensor

housing frame

Note:

Check that the switch connectors (No.

in the cassette switch mounting hole.

Finally resolder the cassette switch connector to

the start sensor

kg-cm), because the lower threads

PWB

on the cassette

(R).

16, 17)

are

PWB.

(a)

Install the pulley and the cassette loading belt on

3.

Figure

l-9.

b)

the worm shaft assembly. Couple the clutch to

the clutch lever. And mount them together in

the cassette housing frame

(R).

Note:

Keep in mind that the clutch switching lever

should be in the correct position.

mechanism might malfunction if the lever is

slightly out of position. (See page

Cassette housing frame

Worm wheel

ass’y

(R)

22.)

Cassette loading belt

The

k

-Cassette

housing

frame(R)

shaft bear

REASSEMBLY OF DRIVE GEAR

rPillar

Drive gear spring

Drive gear arm

ing

(R

,,

1

Drive gear arm

(4

Drive gear

spring

(R)

0

Worm wheel

square hole

I

LReciprocating spring

Figure

l-1 0.

4.

Attach the worm bracket to the worm shaft

assembly. Place them onto the boss on the

cassette housing frame

Note:

Insert 0 before screwing into Q and

Figure l-l

(R).

1

Cassette housing frame

P

r-3

1.

0.

(R)

21

spring-shaft

gear arm

(Drive gear bottom view)

(W

Figure

l-1 2.

1.

Pass the tip of the drive gear spring

(R) 0

through the square hole of the drive gear

hook the spring in position.

Hook one end Q of the reciprocating spring to

the catch of the drive gear

(R).

Hook the other end 0 of the reciprocating

spring to the catch of the worm wheel.

Insert the pillar @ of the drive gear

(R)

into the

square hole of the worm wheel. Turn the worm

wheel somewhat counterclockwise for insertion

of the worm wheel to the drive gear

(R),

because

the reciprocating spring is at work.

(R)

to

Page 22

VT-341

8X

W-5118X

REPLACEMENT OF CASSETTE LOADING

BELT

Cassette

1.

Remove the start sensor

2.

Remove the worm shaft assembly

3.

Replace the cassette loading belt @ with a new

Notes:

1.

2.

3.

housing frame

bracket 0 from the cassette housing frame

(R)

Figure

l-1 3.

PWB @

Worm bracket

and worm

(R).

0.

one.

Do not over-tighten the B tight screw which holds

the worm bracket in position. The specified

torque is

5.0 2

0.5

kgcm.

Make sure that the cassette loading belt is free

from grease.

If stained with grease, clean the

belt with the cleaning liquid.

Perform checking of the clutch switch lever for

proper action.

CHECKING THE CLUTCH SWITCH LEVER

l

Checking

Place the mechanism in the cassette eject mode

when removing and attaching the cassette

housing from and to the mechanism chassis.

Make sure enough that each part in the cassette

housing such as the clutch switch lever is in

position. If not, it causes malfunction.

Note:

Figure

the cassette eject mode.

l-14

shows the position of each part in

Figure l-l

4.

1.

First make sure that the tip of the switch lever is

held at the rib of the drive gear

2.

Check that the rib of the cassette housing frame

(R)

and the concavity of the clutch lock lever are

(R).

engaged.

Finally be sure that the relationship between the

3.

clutch lever and the clutch, as well as between

the clutch and the pulley, are correct as in the

Figure l-1

5.

.

Check that the clutch is engaged

with the pulley through the coupling.

0

Resetting

Figure l-l

5.

Take the following steps to reset the clutch if it is

unlocked or if the switch lever and the clutch

lock lever are unlocked.

LDrive

gear

Shift the slider by turning the coupling in the

1.

(R)

lever

LClutch

l-1

lock lever

6.

Rib of cassette housing frame

Figure

arrow direction (clockwise) until the slider pin is

at the bottom of the slider groove as shown in

the Figure l-16. (The loading mode)

Note:

Note that the slider is

mechanism.

housing frames

Unlock the locks on cassette

(L)

equipped’with

and

(R)

a lock

side before shifting

the slider.

When the position is set as shown in the Figure 4-

16, push the clutch release lever in the direction

of the arrow by hand until the clutch lock lever

becomes tightly locked by the rib of the cassette

housing frame

(R).

Then turn the coupling counterclockwise until

the slider reaches the cassette insertion opening

and the reciprocating spring is activated.

Note:

There is no need to unlock the slider when

shifting the slider to the cassette insertion

opening. Just keep shifting the slider.

lever

(R)

22

Page 23

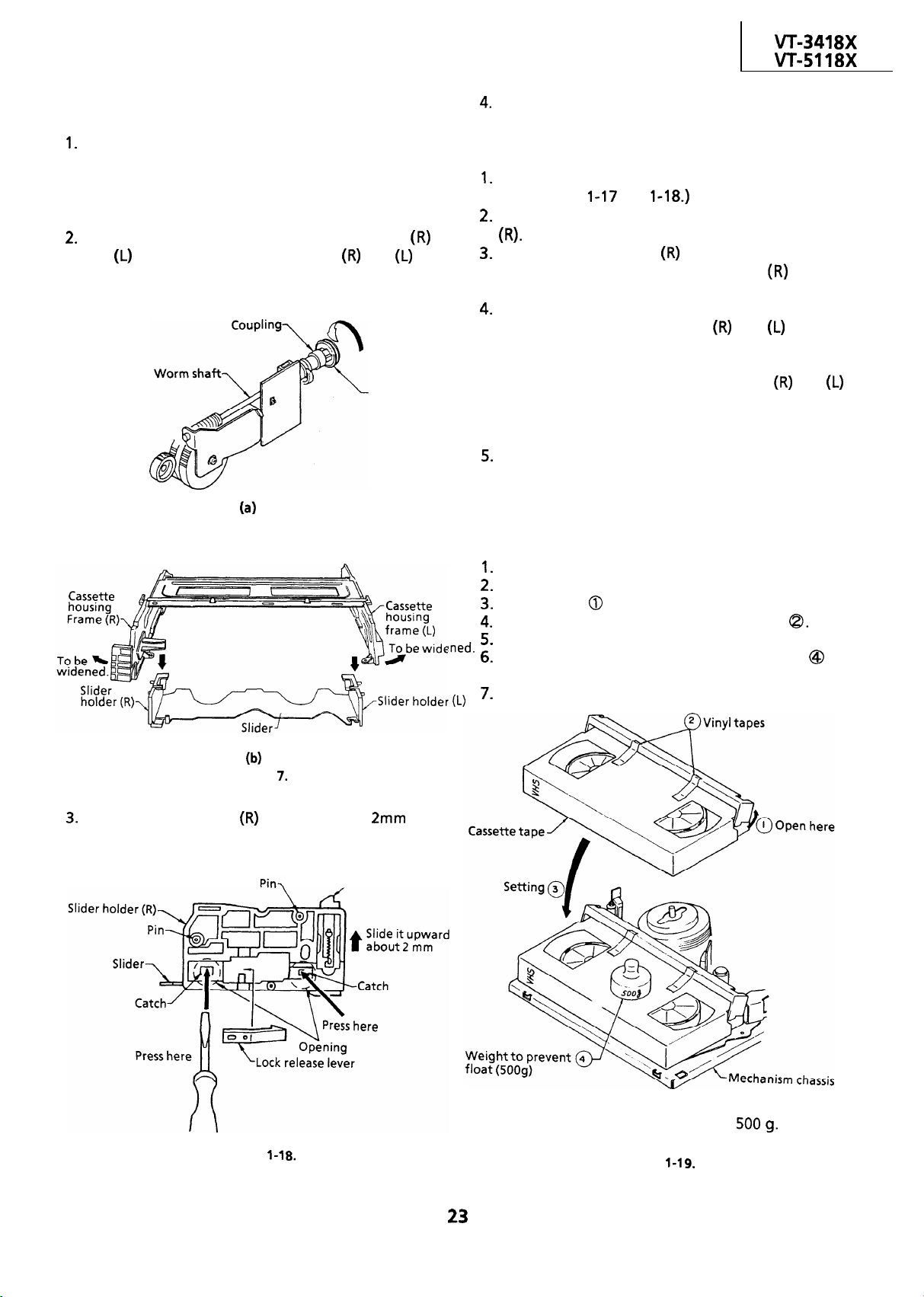

REPLACEMENT OF LOCK RELEASE LEVER

l

Removal

1.

Place the slider in the cassette down position.

(Turn the coupling on the worm shaft clockwise

until the slider is in the cassette down position.)

Note:

Before shifting, unlock the slider.

2.

Slightly widen the cassette housing frames

and

(L)

to unhook the slider holders

(R)

and

the slider assembly off the grooves of the

cassette housing frames.

Pulley

(L)

(R)

of

VT-341 8X

VT-5118X

4.

Remove the lock release lever from the slider

holder(R)

l

Reassembly

1.

Follow the steps for removal in the reverse order.

(See Figures

2.

Attach the lock release lever to the slider holder

00.

3.

Slide the slider holder

two catches of the slider holder

opening of the slider.

4.

Slightly widen the cassette housing frames, and

set the pins of slider holders

grooves of the cassette housing frames.

Note:

Check if the pins of the slider holders

fit the grooves of the cassette housing frames,

and if the drive gear arm is sufficiently engaged

with the slider holders.

5.

Turn the coupling counterclockwise until the

slider is at the cassette insertion opening.

l-17

and

l-18.)

(R)

downward so that the

(R)

(R)

and

(L)

(R)

fit the

into the

and

(L)

(4

(b)

3.

Lift the slider holder

Figure l-l

7.

(R)

upward about

2mm

the slider by pressing two catches with a thin tip

screw driver.

catches.

Take care not to damage the

/-Slide

off

lock catch

TO RUN A TAPE WITHOUT THE CASSETTE

HOUSING CONTROL ASSEMBLY

1.

Plug in the power cord.

2.

Turn on the power switch.

3.

Open the lid @ of a cassette tape by hand.

4.

Hold the lid with two pieces of vinyl tape

5

Ined. We

0.) 7-

Set the cassette tape in the mechanism chassis.

6.

Stabilize the cassette tape with a weight @ to

prevent floating.

Perform running test.

Q.

Figure

l-1 8.

Note:

The weight should not be more than

Figure

l-1 9.

23

500 g.

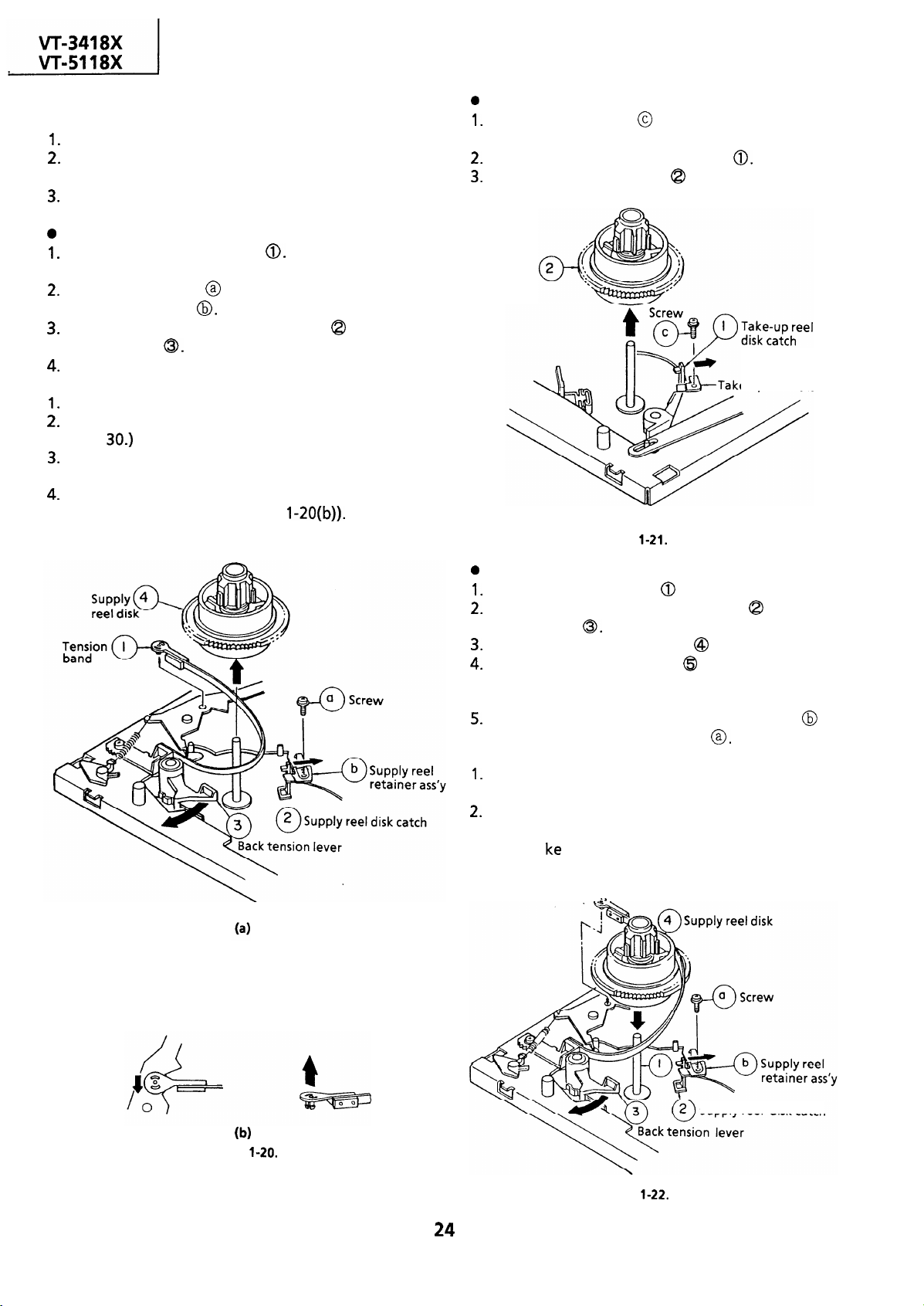

Page 24

REPLACEMENT AND HEIGHT CHECKING

AND ADJUSTMENT OF REEL DISKS

Remove the cassette housing control assembly.

1.

Set the mechanism in the playback mode with no

2.

cassette tape in place. Unplug the power cord.

Set the idler gear in the center (neutral).

3.

a

Removal (Supply reel disk)

Remove the tension band 0. (Take care not to

1.

deform it.)

Unscrew the screw @ and remove the supply reel

2.

retainer assembly

Release the supply reel disk catch @ and back

3.

tension lever

4.

Pull the supply reel disk upward.

Notes:

1.

Take care not to deform the tension band.

2.

Check and adjust the tension pole position. (See

page 30.)

3.

Be careful not to damage the gear and the idler

gear on the supply reel disk.

4.

Press the tension band in the direction of the

arrow for removal (See Figure

8.

0.

1-20(b)).

0

Removal (Take-up reel disk)

1.

Unscrew the screw

@

and remove the take-up

reel retainer.

2.

Release the take-up reel disk catch

3.

Pull the take-up reel disk @ upward.

Take-up

reel disk

Figure

l-21.

0.

e-up reel

retainer

Note:

When the tension band is pressed in the direction

of the arrow for removal, the catch is hard to be

deformed.

0

Reassembly (Supply reel disk)

1.

Clean the reel disk shaft 0 and apply oil to it.

2.

Release the supply reel disk catch Q and back

tension lever

3.

Install a new supply reel disk @ onto the shaft.

4.

Replace the tension band

0.

($9

around the supply

reel disk, and insert it to the hole of the tension

arm.

5.

Replace the supply reel retainer assembly @ in

place, and tighten up the screw

@.

Notes:

1.

Take enough care not to deform the tension

band during installation of the supply reel disk.

2.

Be careful not to damage the supply reel disk

gear, back tension lever, supply reel disk catch,

or the Ii ke with tools.

5 Tension band

Q

-.

(b)

Figure

l-20.

24

Figure

l-22.

Supply reel

disk catch

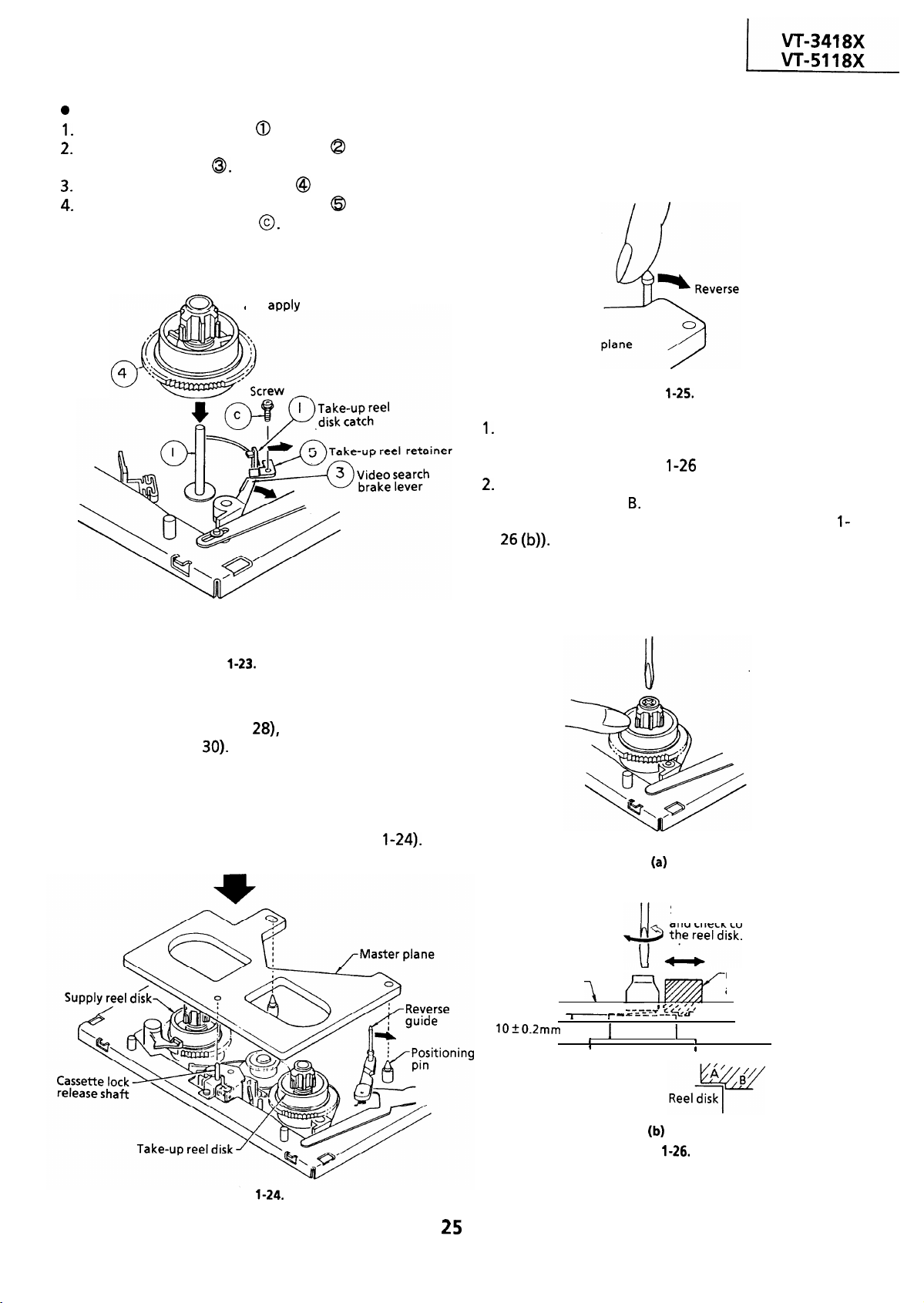

Page 25

0

Reassembly (Take-up reel disk)

Clean the reel disk shaft 0 and apply oil to it.

1.

Release the take-up reel catch @ and video

2.

search brake lever

Install a new take-up reel disk @ onto the shaft.

3.

Replace the take-up reel retainer @ in position

4.

and tighten up the screw

0.

0.

Note:

Take care not to damage the video search brake

lever.

Take-up

reel disk

Apply a thin tip driver to the arrow position in

releasing for easier setting of the take-up reel disk.

Clean the reel disk shaft well,

and

aoolv

oil to it.

Set the master plane releasing

the reverse guide by a finger.

guide

Master

Figure

l-25.

1.

For height adjustment, press the reel disk with a

finger, and turn it right and left with a

screwdriver (see Figure

2.

Check that the reel disk is lower than part A but

1-26

(a)).

higher than part B. If the height is not correct,

adjust the height adjusting screw (see Figure

26 (W.

Note:

Whenever replacing the reel disk, perform the

height checking and adjustment.

l-

Figure

l-23.

* After reassembly, check the video search rewind

back tension (see page

torque (see page

l

Height checking and adjustment

30).

28),

and check the brake

Note:

Place the master plane onto the mechanism unit,

taking care not to hit the drum (see Figure

Setting

l-24).

Master plane

lOfO.Zmm

-

r -

1

Reel disk

I

9

(4

Slide it right and left,

and check contact with

”

I f

’ y, ‘,‘, ,

L

c-c=~Z “fc &I-

‘-

]

I

0

Reel disk height

adjusting jig

/Mechanism chassis

Figure

l-24.

25

(b)

Figure

l-26.

Page 26

VT-341 8X

VT-5118X

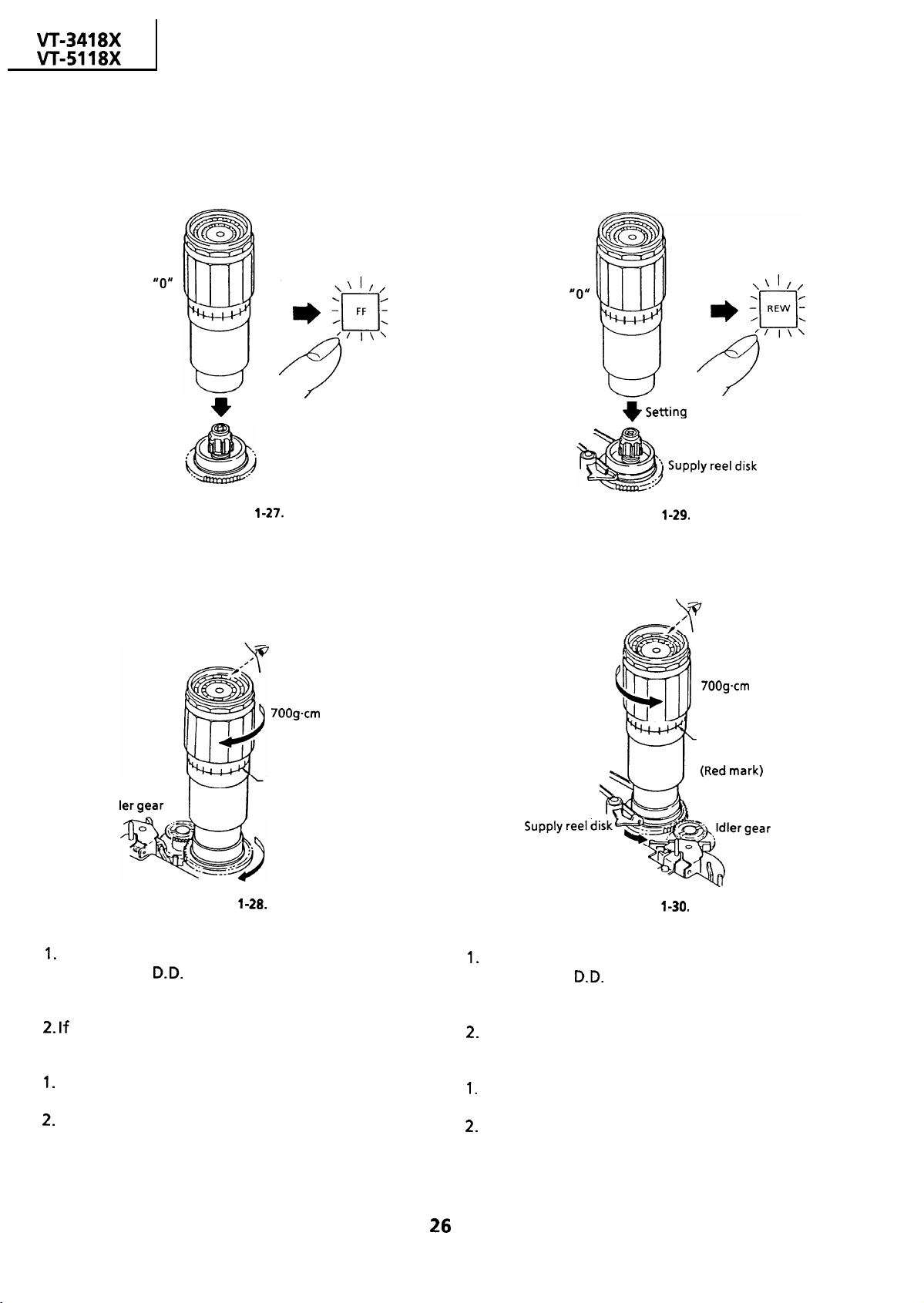

CHECKING AND ADJUSTMENT OF TAKE-UP

TORQUE IN FAST FORWARD MODE

l

Remove the cassette housing control assembly.

l

Setting

Torque gauge

Set the scale to

“0”

Setting

+

Figure

/

Take-up reel disk

l-27.

CHECKING AND ADJUSTMENT OF TAKE-UP

TORQUE IN REWIND MODE

l

Remove the cassette housing control assembly.

l

Setting

Torque gauge

Set the scale to

“0”

Figure

l-29.

l

Checking

Turn the torque gauge slowly

(one rotation every 2 to 3

seconds) by hand in the

take-up direction

700gcm

The gauge is held at

Id

Figure

l Adjustment

1.

If the take-up torque is outside the range, clean

the capstan

D.D.

motor pulley, reel belt and reel

its maximum value.

(Red mark)

Take-up direction

l-28.

or more

pulley with cleaning liquid, then recheck the

torque.

2.

If the take-up torque is still out of range, replace

the reel belt.

Notes:

1.

Hold down the torque gauge so that it may not

fly off.

2.

When checking the take-up torque, do not keep

the reel disk locked for a longer time.

l

Checking

Turn the torque gauge slowly

(one rotation every 2 to 3

seconds) by hand in the

take-up direction

700gcm

The gauge is held at

its maximum value.

Figure

l-30.

l

Adjustment

1.

If the take-up torque is outside the range, clean

the capstan

D.D.

motor pulley, reel belt and reel

or more

pulley with cleaning liquid, then recheck the

torque.

2.

If the take-up torque is still out of range, replace

the reel belt.

Notes :

1.

Hold down the torque gauge so that it may not

fly off.

2.

When checking the take-up torque, do not keep

the reel disk locked for a longer time.

26

Page 27

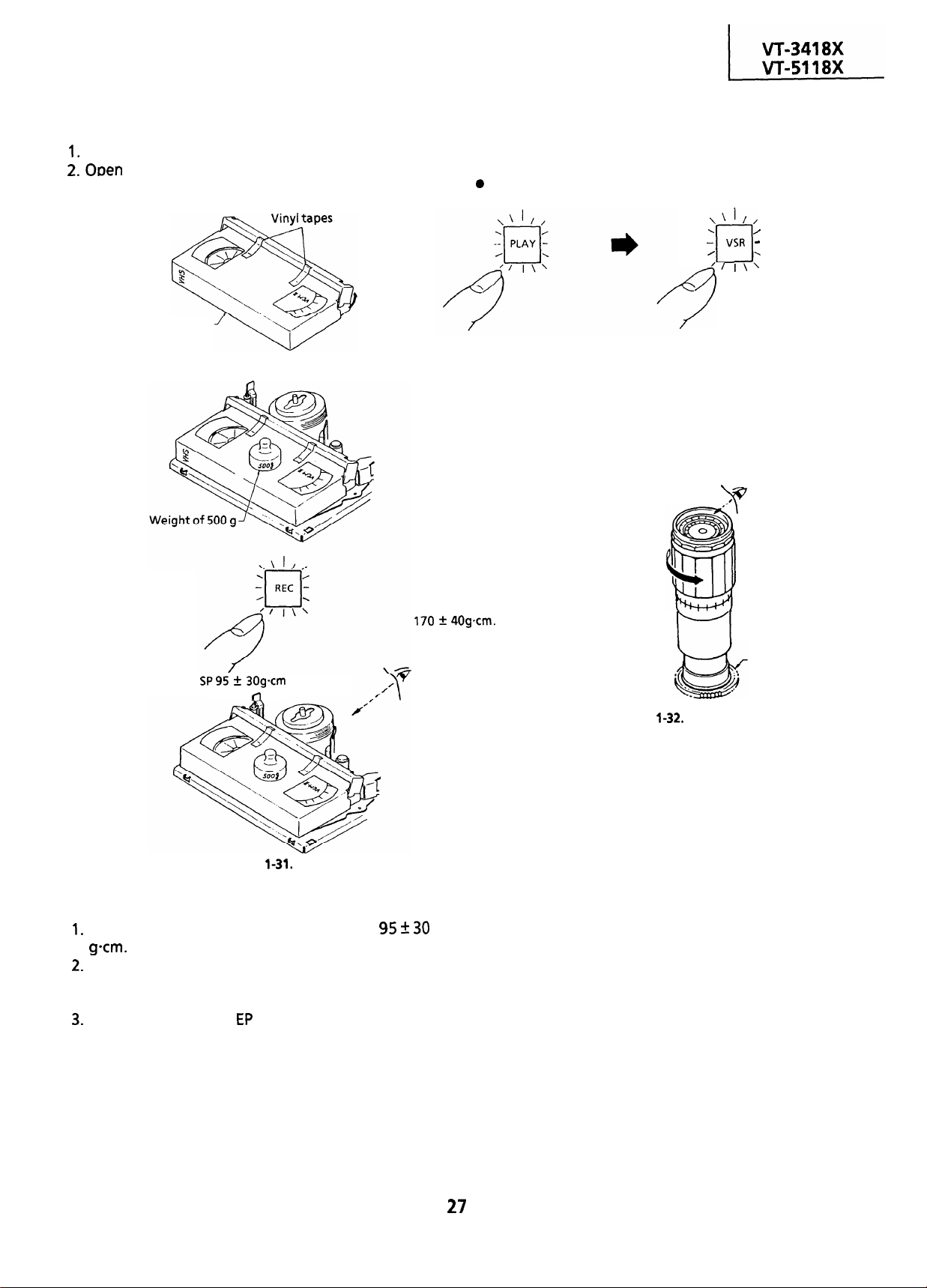

CHECKING AND ADJUSTMENT OF TAKE-UP

TORQUE IN PLAYBACK MODE

1.

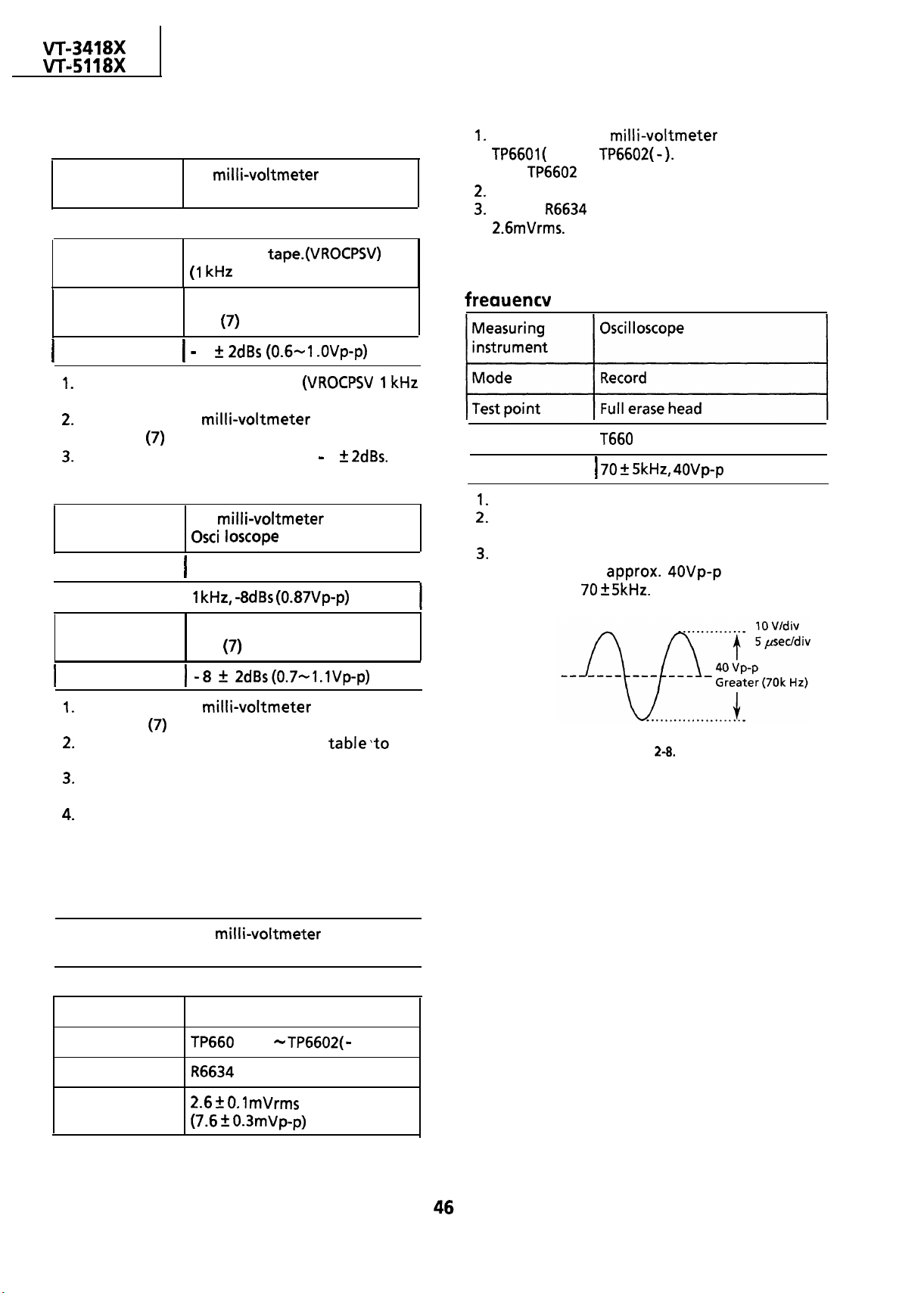

Remove the cassette housing control assembly.

2. Ooen

the lid of the cassette torque meter, and

hold it with two pieces of vinyl tapes.

Open here

Cassette torque meter

Load a cassette torque meter into the unit.

CHECKING AND ADJUSTMENT OF TAKE-UP

TORQUE IN VIDEO SEARCH REWIND MODE

l

Remove the cassette housing control assembly.

a

Checking

\‘I//

VSR -

0

‘/ ,,:

/

1

/

?

Push the play button to place

the unit in the playback mode.

Push video search rewind

button to place the unit in the

video search rewind mode.

Set value

l

Checking

1.

Check that the torque is in the range of 95 2

SP95 + 30gcm

n

Figure

l-31.

g-cm.

2.

The torque fluctuates due to the rotational

deviation of the reel drive unit. Use the center of

the fluctuation as the value.

3.

Place the unit in the EP record mode, and check

that the take-up torque is within the range.

Torque gauge

Place the torque gauge on the supply reel

disk, and turn it counterclockwise very slowly

(one rotation every 2 to 3 seconds) and check

that the torque is within the set value

170 f: 40gcm.

Figure

Note:

Set the torque gauge securely on the supply reel

disk. If it is not secure, the measurement will be

incorrect.

l

Adjustment

If the take-up torque in video search rewind mode

is outside the range, replace the supply reel disk.

30

Note:

The torque fluctuates due to the rotational

deviation of the supply reel disk. Use the center of

the fluctuation at the value.

l-32.

v

.N

I7

Supply reel disk

l

Adjustment

If the take-up torque in the playback mode is

outside the range, replace the take-up reel disk.

Note:

Stabilize the cassette torque meter to prevent

floating.

27

Page 28

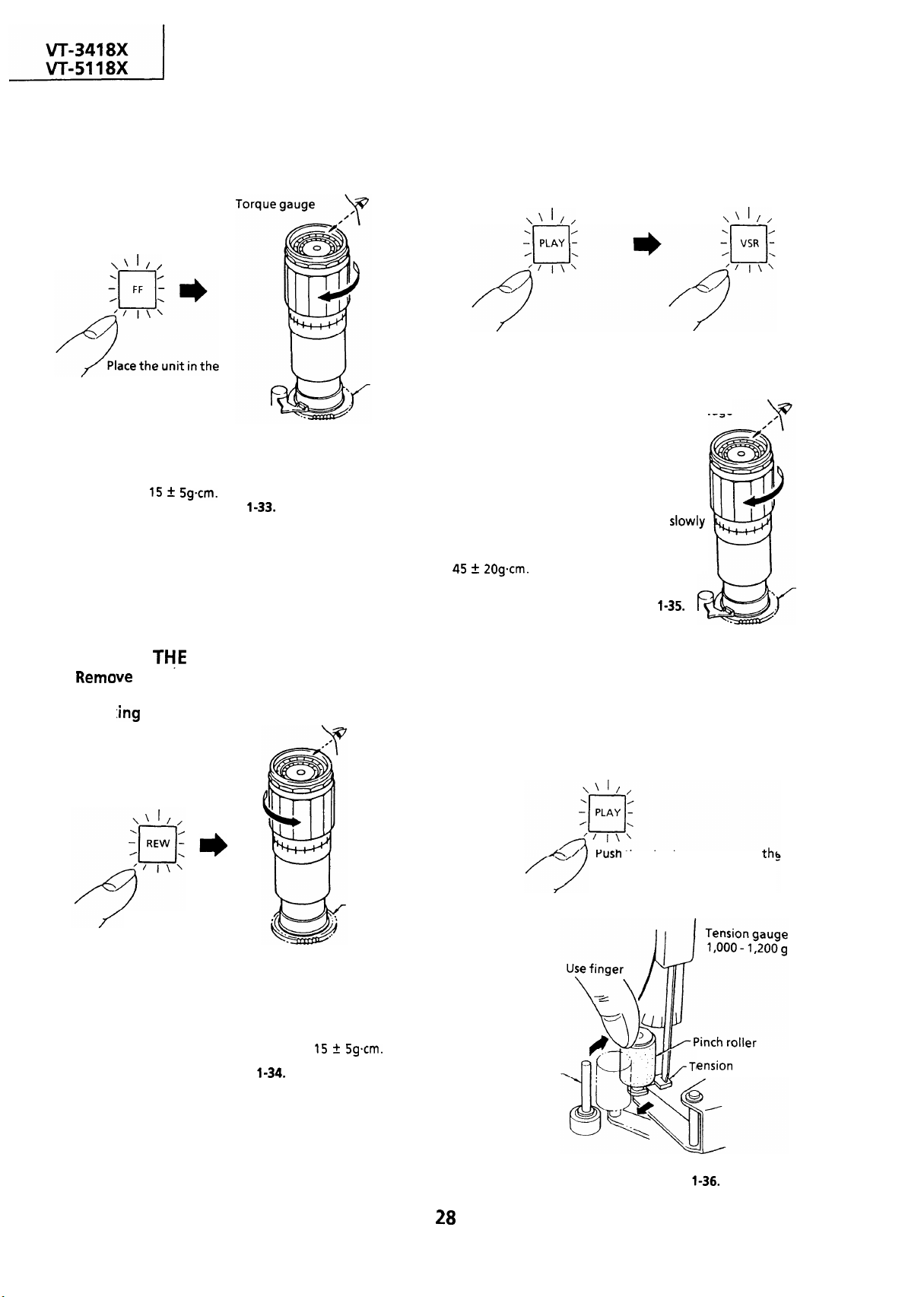

CHECKING THE FAST FORWARD BACK

TENSION

l

Remove the cassette housing control assembly.

l

Checking

CHECKING THE VIDEO SEARCH REWIND

BACK TENSION

Remove the cassette

l

l

Checking

housing control assembly.

\‘I//

fast forward mode.

Place the torque gauge on the supply

reel disk, and turn it clockwise very

slowly (one rotation every 2 to 3 seconds)

and check that the torque is within

15 f 5gcm.

Figure

l-33.

Supply reel disk

Note :

Set the torque gauge securely on the supply reel

If the torque gauge is not securely set on the

disk.

reel disk, measurement will be incorrect.

CHECKING

l

Remo

THE

REWIND BACK TENSION

ve the cassette housing control assembly.

\‘I//

Push the play button to place

the unit in the playback mode. button to place the unit in the

Place the torque gauge on the take-up reel

disk, and turn it counterclockwise very

(one rotation every 2 to 3 seconds) and check

that the torque is within the set value

45

5 2Ogcm.

Push the video search rewind

videosearch rewind mode.

Torque gauge

s10wly

Figure

l-35.

\\I//

Note :

Set the torque gauge securely on the take-up reel

disk. If it is not secure, the measurement will be

incorrect.

Take-up

reel disk

Check

:ing

Place the unit in the

rewind mode.

Take-up reel disk

Place the torque gauge on the

take-up reel disk, and turn it

counterclockwise very slowly

(one rotation every 2 to 3

seconds) and check that the

torque is within 15 t

Figure

l-34.

5gcm.

l

Note:

Set the torque gauge securely on the take-up reel

disk. If it is not secure, the measurement will be

incorrect.

CHECKING THE PINCH ROLLER PRESSURE

Remove the cassette housing control assembly.

l

Capstan shaft

rusn the play button to place

unit in the playback mode.

ension gauge adaptor

the

28

Figure

l-36.

Page 29

I.

Detach the pinch roller from the capstan shaft.

2.

Set the tension gauge by hooking the tension

gauge adapter onto the pinch roller shaft.

3.

Gradually release the pressure to allow the pinch

roller to touch the capstan shaft. When the

pinch roller just touches the capstan shaft, read

the indication on the gauge.

4.

Check that the reading of the tension gauge is in

the range of

1000

to

1200 g.

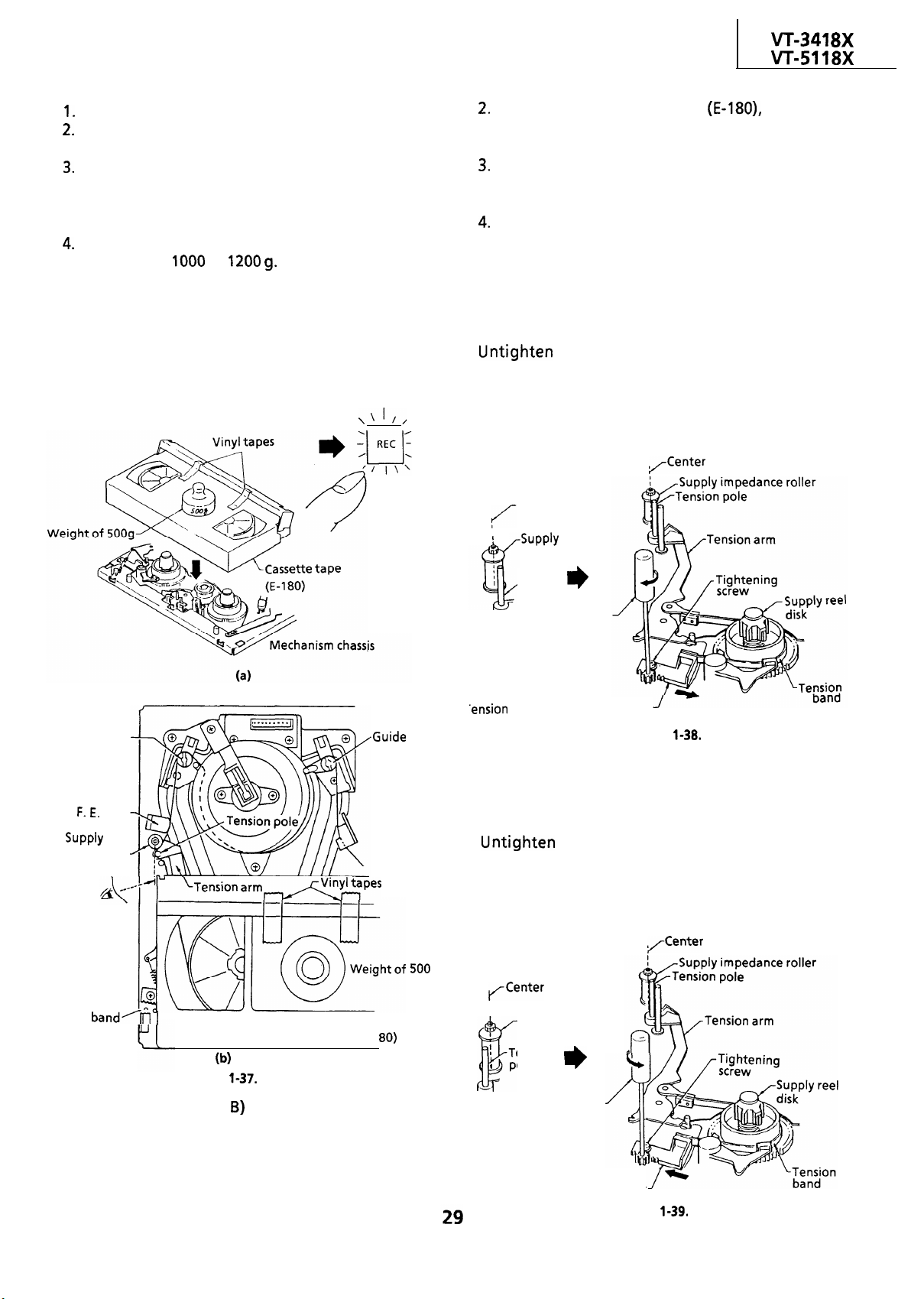

CHECKING AND ADJUSTMENT OF TENSION

POLE POSITION

l

Remove the cassette housing control assembly.

l

Setting

\‘I//

VT-341

8X

VT-5118X

2.

At the beginning of the tape

the tension pole’s left side is aligned with the

supply impedance roller’s center by sight.

3.

Check that the end of the tape is neither curled

against the flange of the supply impedance

roller nor over it.

4.

During the video search rewind mode with no

cassette tape in place, check that the supply reel

disk is free from the tension band.

l

Position adjustment (record mode)

When the tension pole is at the right of the supply

impedance roller’s center:

Untighten the tightening screw, and shift the

tension band adjustment bracket in the direction of

the arrow using a tension band and plate adjusting

Jig until it is in the set value range (center). Then

secure it with the tightening screw.

(Center

(E-180),

check that

Guide roller A

F. E.

head

SUPPlY

impedance.

roller

Check the left

side position

(by sight).

g-&n arm&YkPes

Place the unit in

the record mode.

roller B

.Guide

Center

I

/-SUPPlY

:

impedance

roller

Tension

pole

‘ension band adjustment bracket

T

l

Position adjustment (record mode)

I)

Tension band

and plate

adjusting jig

Figure

l-38.

When the tension pole is at the left of the supply

impedance roller’s center:

Untighten the tightening screw, and shift the

tension band adjustment bracket in the direction of

the arrow using a tension band and plate adjusting

Jig until it is in the set value range (center). Then

secure it with the tightening screw.

/enter

Tension

and plate

adjusting jig

setting hole

band’m

l

Checking

1

Video Cassette tape (E-l

b)

Figure

l-37.

I. The guide rollers (A, B) operate to bring the tape

outside the cassette tape and simultaneously the

tension pole moves to the left, loading the tape.

At that time (loading completed), check the

position of the tension pole.

80)

500

g

<Center

I

I

Supply impedance

roller

!

Tension

a

pole

lir

Tension band adjustment bracket

I)

Tension band

and plate

adjusting jig

Figure

l-39.

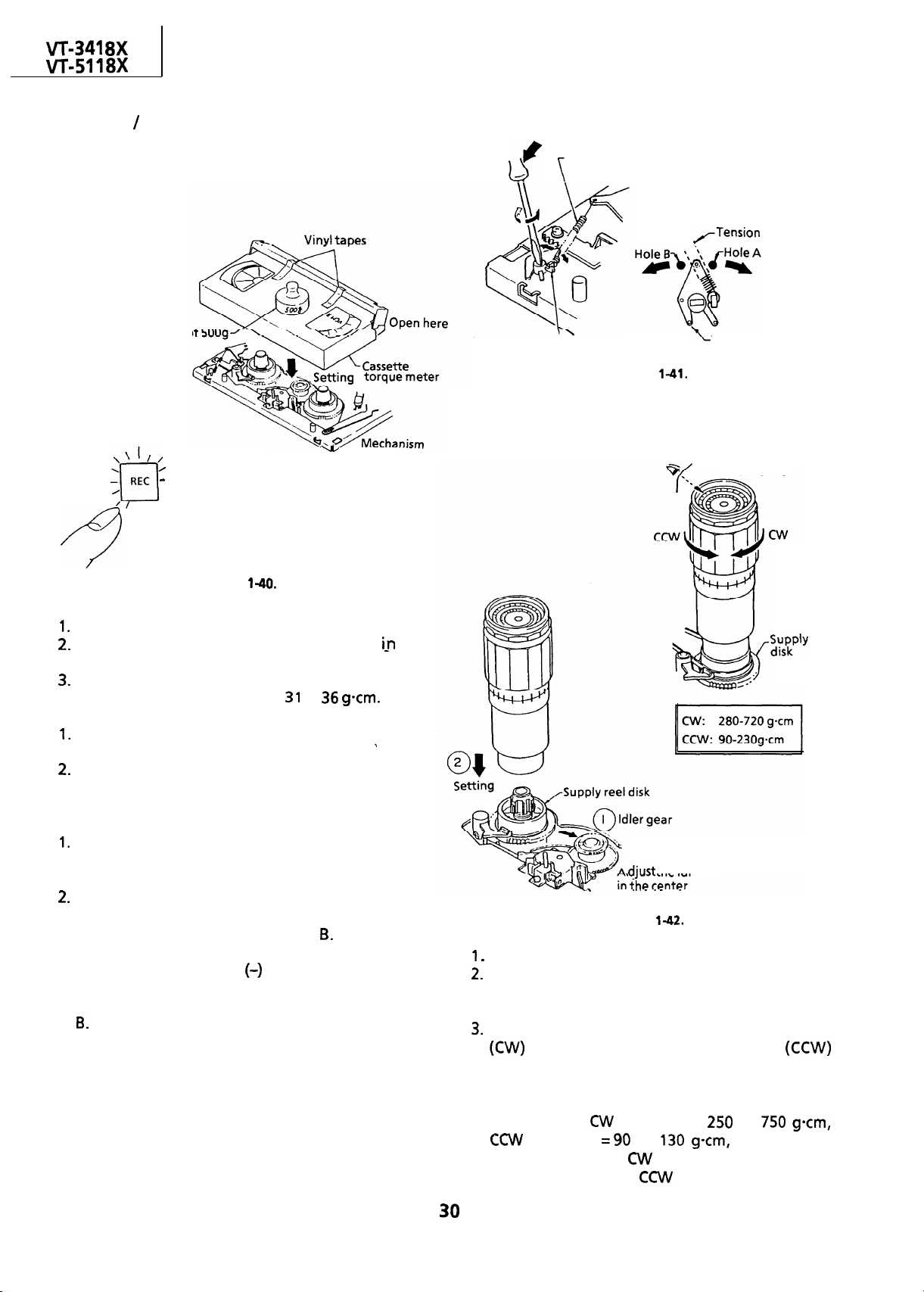

Page 30

VT-341 8X

VT-5118X

CHECKING AND ADJUSTMENT OF

RECORD / PLAYBACK BACK TENSION

l

Remove the cassette housing control assembly.

l

Checking

Tension spring

cf*

\

Weight a

VI

\\‘I/

_‘

9

I.

Put a cassette torque meter into the unit.

2.

Push the record button to place the unit

record mode.

3.

Check that the back tension indicated by the

gauge is within the set range 31 to 36

Notes:

1.

Make sure that the video cassette tape is over

the retaining guide.

2.

Make sure that the tape is not slack nor

damaged at either end.

/

REC -

/

.

Cl

‘1

I\’

Push the record button

to place the unit

in the record mode.

Figure

l-40.

chassis

i-n

g-cm.

\

the

Tension spring hook plate

Figure

/Tension

Tension spring

hook plate

l-41.

spring

CHECKING THE BRAKE TORQUE

l

Checking the brake torque at the supply side

Torque gauge

‘,ysply

reel

l Adjustment

1.

If the reading of the cassette torque meter is less

than specified, move the tip of the tension spring

hook plate toward the hole A.

2.

If the reading of the cassette torque meter is

more than specified, move the tip of the tension

spring hook plate toward the hole

Note:

Put a thin screw driver

it toward you, and turn it for easier shift of the

tension spring hook plate in the direction of A or

B.

(-)

in the shaft hole, lean

B.

l-42.

130 g-cm,

CCW

direction.

idler gear

250

to

and that the

djust the

Mechanism chassis

1 I

Remove the cassette housing control assembly.

2.

Place the mechanism in the stop mode by

unplugging the power cord in the fast forward

or rewind mode.

3.

Slowly rotate the torque gauge in the clockwise

(CW)

direction and counterclockwise

direction of the supply brake so that the reel disk

and the indicator of the torque gauge rotate at

an equal rate. Check that the values are within

the range of CW direction =

CCW

direction

brake torque in the CW direction is at least twice

as high as that in the

m

Figure

=90

to

30

(CCW)

750 gem,

Page 31

j

KZ::

l Checking the brake torque at the take-up side

wchanism

chassis

-upreel

REPLACEMENT OF MAIN BRAKE

1.

Remove the reel belt and the reel block

Flat Cable).

2.

Remove the cut washer @ off the brake shifter.

3.

Unscrew the four screws Q and then the

up reel retainer.

4.

Remove the reel block assembly @ downward.

5.

Remove the cut washer 0 first and then the reel

pulley.

6.

Unscrew the two screws @ and detach the idler

assembly.

7.

Unhook the back tension lever spring @ and

remove the back tension lever Q. (Undo the

hook under the reel chassis.)

8.

Open the shifter latch 8 and remove the brake

shifter assembly

9.

Release the reel disk catchesand @ then remove

the left and right reel disk assemblies 8 and

10.

Finally remove the main brake levers

main brake spring @ .

@I.

FFC

0

and the

(Full

take-

0.

Figure

l-43.

1.

Remove the cassette housing control assembly.

2.

Slowly rotate the torque gauge in the clockwise

(CW)

direction and counterclockwise

direction of the take-up brake so that the reel

disk and the indicator of the torque gauge

rotate at an equal rate. Check that the values

are within the range of

750 gem, CW

that the brake torque in the

least twice as high as that in the CW direction.

0

Adjustment of the brake torque at the supply

side and the take-up side

1.

If the supply or take-up brake torque is outside

the range, clean the supply or take-up reel disk

break lever felt, then recheck the torque.

2.

If the supply or take-up brake torque is still

outside the range, replace the main brake or the

main brake spring.

direction = 90 to

CCW

direction =

CCW

130 g-cm,

direction is at

(CCW)

250

to

and

Figure

l-44.

Note:

When the main brake is replaced, perform the

height checking and adjustment (see page

the brake torque checking (see page

30).

31

25),

and

Page 32

VT-341 8X

W-5118X

REPLACEMENT OF A/C (Audio/Control)

HEAD

1.

Remove the cassette housing control assembly.

2.

Place the unit in the unloading mode, and

unplug the power cord.

l

Removal

I.

Loosen the tilt adjusting screw

2.

Remove the azimuth adjusting screw

3.

Remove the A/C head screw

4.

Unsolder the A/C head

head assembly.

Notes:

1.

After replacement, be sure to perform the

adjustment of the tape drive train (see page

Under any circumstances, avoid touching the

head. Clean the head, if touched with your

finger, with alcohol.

2.

Take care that the azimuth spring does not fly

off when removing the A/C head screw.

4

n

PWB

0.

Q.

0.

soldered to the

A/C

33).

Figure

l-47.

l

Adjustment

[A/C head tilt angle]

l_

Set the mechanism to the loading mode.

2.

Place the A/C head tilt adjusting Jig

3 Slowly turn the tilt adjusting screw Q with a

screw driver until there is no gap between the Jig

and the A/C head.

0.

Pay attention to

Figure

l-45.

l

Replacement

1.

Solder the removed A/C head

A/C head assembly.

2.

The A/C head assembly is attached so that the

A/C head arm and

parallel to each other.

A/C

head plate are roughly

PWB

onto a new

Solder

/

LR

PWB

h

A piece of white paper

1

usting

Screw driver

New AK head

Never touch the head

ass’y

Fiaure 146.

32

AK

head arm

f

b)

Figure 1-48.

Page 33

[A/C head height rough adjustment]

AK

head

adjusting

Weight

Roughly adjust the height

of the AK head by turning

the AK head adjusting

hexagon nut with the

specialized box drive until

the tape is in the position

shown

below.Weight

Reverse guide

adjusting jig

of 5009

ism

chassis

HEIGHT ADJUSTMENT OF REVERSE GUIDE

Note:

Before the rough adjustment of the tape drive

train, check that the retaining guide height is

within the value in Figure

Jigs.

height-\

To readjust the height, remove

the cut washer from behind,

take out the spring, lift the

reverse guide and add a

washer.

(a)

.

-Reverse guide

Reverse guide

height

l-50

by using the special

7

(b)

Reverse guide

AK

head

Adjust the nut visually so that

.

the control head is visible

to

0.5

mm below the bottom

of the tape.

Figure

l-49.

0.3

Adjust the height using

-

Spring

*

.-Spring

El

@Washer

@Cut

bination

O-5,0.4,0.25 and 0.13.

Mechanism chassis

(iron flat)

washer

2.1-5-O-5

of washers

(4

Figure

l-50.

f

33

Page 34

VT-341

8X

i/T-5118X

ADJUSTMENT OF TAPE DRIVE TRAIN

1.

Remove the cassette housing control assembly.

2.

Check and adjust the position of the tension

pole. (See page

3.

Check and adjust the video search rewind back

tension. (See page 28.)

4.

Set the tilt angle of the A/C head. (See page

5.

Rough adjustment of tape drive train.

Connect the oscilloscope to the test point for

a)

PB CHROMA

the synchronism of the oscilloscope to EXT.

The PB

the head switching pulse

Loosen the setscrew at the lower part of the

b)

guide roller, and adjust it with an adjusting

screw driver

roller turns smoothly. (Do not overloosen the

setscrew, which causes insecurity of the guide

roller.) (See Figure

Set the alignment tape (monoscope pattern)

d

on the reel disk, and place the unit in the

playback mode.

(Place a

prevent floating of the cassette tape.)

29.)

envelope output

CHROMA

500

signal is to be triggered by

(TP2202).

(JIGDRIVERH-4)

1-51.)

g weight on the cassette tape to

(TP2201).

so that the guide

32.)

Set

.;w;;

Wrinkles at upper flange

(a)

Wrinkles at lower flange

Clockwise

Counterclockwise

Guide roller

Hexagon

Figure

Figure

l-51.

Change the envelope waveform from MAX to

d)

MIN, and MIN to MAX by pushing the

(-) tracking button, and check a flat response

is obtained on the waveform.

If a flat response cannot be obtained, roughly

e)

adjust the guide rollers on the supply side and

take-up side using an adjusting screw driver

until a flat response can be obtained.

Turn the

screwdriver to prevent the tape from

wrinkling at the upper and lower flanges of

the fixed guide.

1)

Wrinkles at the upper flange : Turn the

above adjusting screw clockwise, as shown

in Figure

2)

Wrinkles at the lower flange : Turn the

above adjusting screw counterclockwise, as

shown in Figure

A/C

head tilt adjusting screw with a

l-53

(a).

l-53 (b).

l-52.

(+)

or

b)

Figure

l-53.

Notes:

Place the tracking control in the center position,

and adjust the X-position adjusting nut so that

the PB

easier rough adjustment of the tape drive train.

In the rough adjustment, pay particular

attention to the outlet side.

Loosen the setscrew o

CHROMA

0

w

R#

Figure 1-54.

envelop becomes maximum for

. .

X-position

adjusting nut

Figure

l-55.