Sharp VNEZ-1 Service manual

SHARI= SERVICE MANUAL

S6919VN-EZI U/

MPEG-4 DIGITAL RECORDER

VN-EZI U

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified

be used.

1

CONTENTS

IMPORTANT SERVICE NOTES

1.

SPECIFICATIONS

2.

3.

PART NAMES ..................................................................................................................................

4.

DISASSEMBLY OF THE SET .........................................................................................................

.

TEST MODE ....................................................................................................................................

5.

BLOCK DIAGRAM ...........................................................................................................................

6.

OSCILLATOR, DIVIDING AND MULTIPLY MAP/8. POWER CONTROL FLOW

7.

TROUBLESHOOTHING ..................................................................................................................

9.

1 O.IC FUNCTION LIST .......................................................................................................................

11 .SEMICONDUCTOR LEAD IDENTIFICATION

12.WIRING DIAGRAM ........................................................................................................................

13.SCHEMATlC DIAGRAMS .............................................................................................................

14.PRINTED WIRING BOARD ASSEMBLIES

15.REPLACEMENT PARTS LIST

16,PACKING OF THE SET .................................................................................................................

...........................................................................................................................

......................................................................................................

...........................

...............................................................................

...................................................................................

.......................................................................................................

Page

l-l

2-l

3-l

4-l

5-l

6-l

7-l

9-I

10-l

1 l-l

12-I

13-l

14-I

15-1

16-I

SHARP CORPORATlON

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

VN-EZl U

1. IMPORTANT SERVICE NOTES

BEFORE RETURNING THE VIDEO CAMERA

RECORDER

Before returning the video camera recorder to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the video camera

recorder.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields, isolation resistor/capacitor networks, mechanical insulators etc.

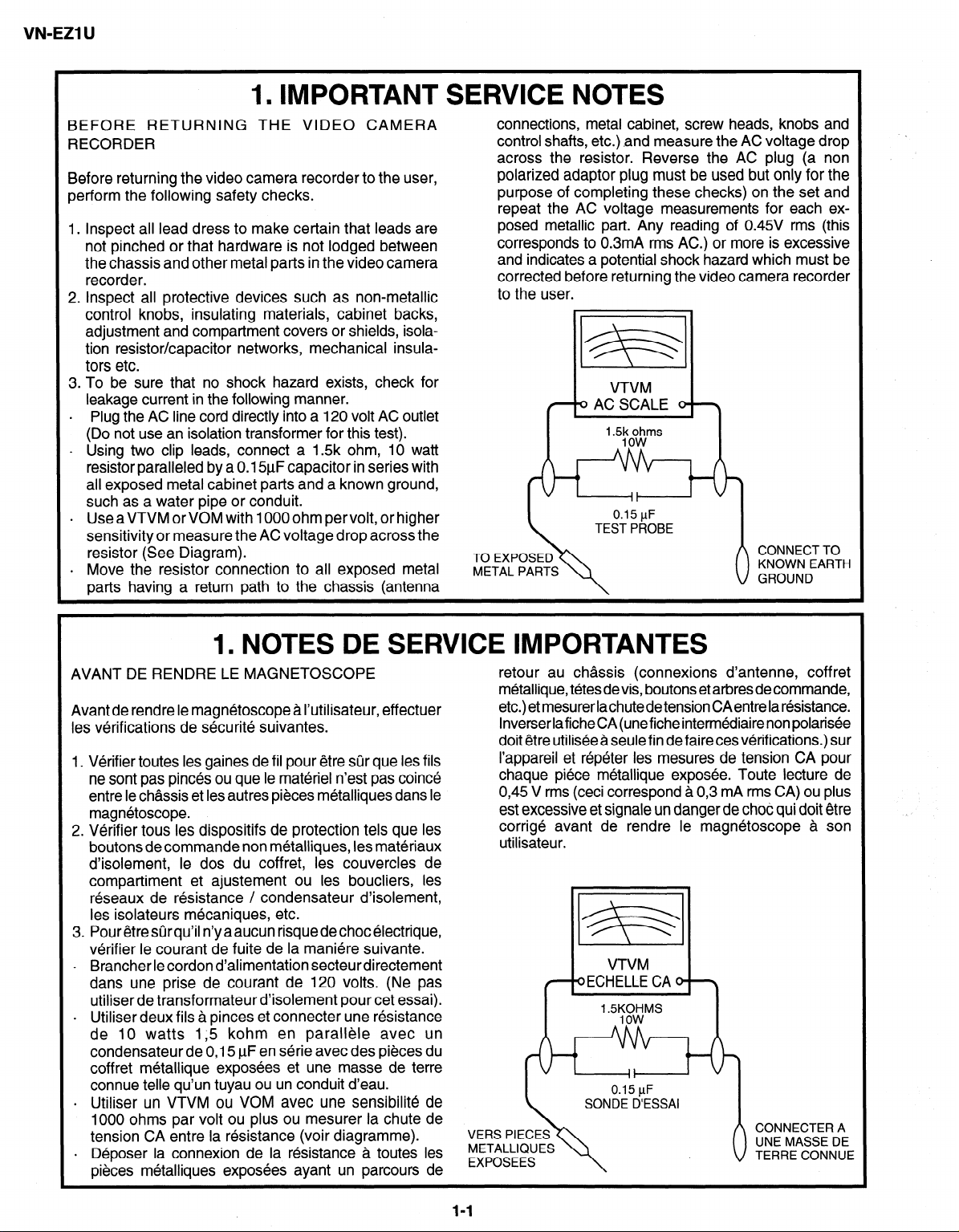

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

l Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

. Using two clip leads, connect a 1.5k ohm, IO watt

resistor paralleled by a 0.1 $LF capacitor in series with

all exposed metal cabinet parts and a known ground,

such as a water pipe or conduit.

. Use a VTVM or VOM with 1000 ohm per volt, or higher

sensitivity or measure the AC voltage drop across the

resistor (See Diagram).

. Move the resistor connection to all exposed metal

parts having a return path to the chassis (antenna

connections, metal cabinet, screw heads, knobs and

control shafts, etc.) ,and measure the AC voltage drop

across the resistor. Reverse the AC plug (a non

polarized adaptor plug must be used but only for the

purpose of completing these checks) on the set and

repeat the AC voltage measurements for each ex-

posed metallic part. Any reading of 0.45V rms (this

corresponds to 0.3mA rms AC.) or more is excessive

and indicates a potential shock hazard which must be

corrected before returning the video camera recorder

to the user.

VTVM

( 0 AC SCALE 0 >

’ -5kims

METAL PARTS

1. NOTES DE SERVICE IMPORTANTES

AVANT DE RENDRE LE MAGNETOSCOPE

Avant de rendre le magnetoscope a I’utilisateur, eff ectuer

les verifications de securite suivantes.

1. Verifier toutes les gaines de fil pour etre sur que les fils

ne sont pas pin&s ou que le materiel nest pas coin&

entre le chassis et les autres pieces metalliques dans le

magnetoscope.

2. Verifier tous les dispositifs de protection tels que les

boutons de commande non metalliques, les materiaux

d’isolement, le dos du coffret, les couvercles de

compartiment et ajustement ou les boucliers, les

reseaux de resistance / condensateur d’isolement,

les isolateurs mecaniques, etc.

3. Pour etre stir qu’il n’y a aucun risque de choc electrique,

verifier le courant de fuite de la maniere suivante.

. Brancher le cordon d’alimentation secteurdirectement VTVM

dans une prise de courant de 120 volts. (Ne pas

utiliser de transformateur d’isolement pour cet essai).

. Utiliser deux fils a pinces et connecter une resistance

de IO watts I;5 kohm en parallele avec un

condensateur de 0,15 PF en serie avec des pieces du

coffret metallique exposees et une masse de terre

connue telle qu’un tuyau ou un conduit d’eau.

. Utiliser un VTVM ou VOM avec une sensibilite de

1000 ohms par volt ou plus ou mesurer la chute de

tension CA entre la resistance (voir diagramme).

. Dbposer la connexion de la rbsistance a toutes les

pieces metalliques exposees ayant un parcours de

retour au chassis (connexions d’antenne, coffret

metallique, t&es de vis, boutons et arbres de commande,

etc.) et mesurer lachute de tension CA entre la resistance.

lnverser lafiche CA (une fiche intermediaire non polarisee

doit etre utilisee a seule fin de faire ces verifications.) sur

I’appareil et repeter les mesures de tension CA pour

chaque piece metallique exposee. Toute lecture de

0,45 V rms (ceci correspond a 0,3 mA rms CA) ou plus

est excessive et signale un danger de choc qui doit etre

corrige avant de rendre le magnetoscope a son

utilisateur.

c oECHELLECAo 3

VERS PIECES

METALLIQUES

I

1-I

VN-EZI U

WARNING :TO REDUCETHE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE

THIS APPLIANCE TO WET LOCATIONS.

/&/AA

CAUTION: TO REDUCE THE RISK OF ELECTRIC

SHOCK. DO NOT REMOVE COVER. NO

USERSERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

This symbol warns the user of uninsulated

voltage within the unit that can cause danger-

A

1

0

n

ATTENTION: POUR REDUIRE LES RESQUES D’INCENDIE OU DE CHOC ELECTRIQUE,

ous electric shocks.

This symbol alerts the user that there are

important operating and maintenance instructions in the literature accompanying this unit.

NE PAS EXPOSER CET APPAREIL A LA PLUIE OU A L’HUMIDITE.

CAUTION

This symbol mark means following.

For continued protection against fire haz-

ard, replace only with same type fuse.

(F901; 1.75A 24V, F902; 1.75A 24V,

F903; 1 A 24V, F904; IA 24V, F905; IA

24V)

ATTENTION:

A

1

0

n

RISQUE DE CHOC ELECTRIQUE

Ce symbole signale a I’utilisateur la presence

d’une tension non isoleea I’interieurde I’appareil

qui peut etre la cause de secousses electriques

dangereuses.

Ce symbole avertit I’utilisateur que des instructions importantes relatives a I’utilisation

et al’entretien se trouvent dans le manuel

accompagnant I’appareil.

NE PAS OUVRIR

AFIN DE REDUIRE LES RISQUES DE

CHOC ELECTRIQUE, NE PAS RETIRER LE

COUVERCLE, AUCUN ORGANE INTERNE

NE PEUT ETRE REPARE PAR

L’UTIUSATEUR, CONFIER L’APPAREIL A

UN DEPANNEUR QUALIFIE.

1

0

n

ATTENTION

Ce symbole signifie que I’on devra utiliser un fusible de meme type (F901;

1.75A 24V, F902; 1.75A 24V, F903; IA

24V, F904; 1 A 24V, F905; IA 24V) pour

assurer la securite.

A

1-2

VNkEZlU

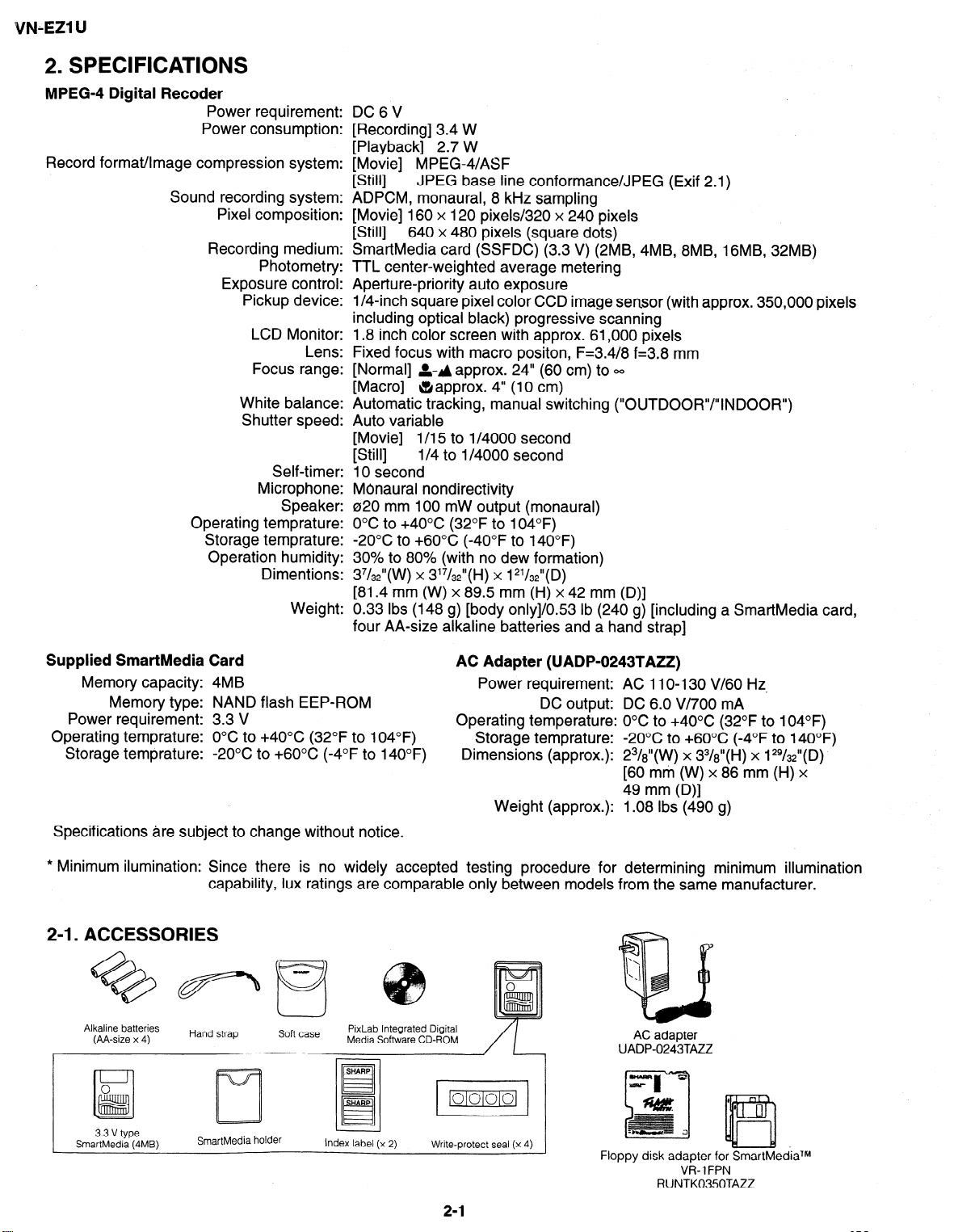

2. SPECIFICATIONS

MPEG-4 Digital Recoder

Power requirement:

Power consumption:

Record format/Image compression system:

Sound recording system:

Pixel composition:

Recording medium:

Photometry:

Exposure control:

Pickup device:

LCD Monitor:

Focus range:

White balance:

Shutter speed:

Microphone:

Operating temprature:

Storage temprature:

Operation humidity:

Dimentions:

Lens:

Self-timer:

Speaker:

Weight:

DC6V

[Recording] 3.4 W

[Playback] 2.7 W

[Movie] MPEG-4/ASF

[Still]

JPEG base line conformance/JPEG (Exif 2.1)

ADPCM, monaural, 8 kHz sampling

[Movie] 160 x 120 pixels/320 x 240 pixels

[Still] 640 x 480 pixels (square dots)

SmartMedia card (SSFDC) (3.3 V) (2MB, 4MB, 8MB, 16MB, 32MB)

TTL center-weighted average metering

Aperture-priority auto exposure

l/4-inch square pixel color CCD image sensor (with approx. 350,000 pixels

including optical black) progressive scanning

1.8 inch color screen with approx. 61,000 pixels

Fixed focus with macro positon, F=3.4/8 f=3.8 mm

[Normal] t-A approx. 24” (60 cm) to 00

[Macro] aapprox. 4” (10 cm)

Automatic tracking, manual switching (“OUTDOOR”/“INDOOR”)

Auto variable

[Movie] l/l 5 to l/4000 second

[Still]

l/4 to l/4000 second

IO second

Monaural nondirectivity

020 mm 100 mW output (monaural)

O°C to +4O”C (32°F to 104°F)

-20°C to +6O”C (-40°F to 140°F)

30% to 80% (with no dew formation)

37/32”(W) x 317l$‘(H) x 1*‘/32”(D)

[81.4 mm (W) x 89.5 mm (H) x 42 mm (D)]

0.33 Ibs (148 g) [body only]/053 lb (240 g) [including a SmartMedia card,

four AA-size alkaline batteries and a hand strap]

Supplied SmartMedia Card

Memory capacity:

Memory type:

Power requirement:

Operating temprature:

Storage temprature:

4MB

NAND flash EEP-ROM

3.3 v

O°C to +4O”C (32°F to 104°F)

-20°C to +6O”C (-4°F to 140°F)

AC Adapter (UADP-0243TAZZ)

Power requirement: AC 11 O-130 V/60 Hz,

DC output: DC 6.0 V/700 mA

Operating temperature: O°C to +40°C (32°F to 104°F)

Storage temprature: -20°C to +6O”C (-4°F to 140°F)

Dimensions (approx.): 23/8”(W) x 33/8”(H) x 1*‘/32”(D)

[60 mm (W) x 86 mm (H) x

49 mm (D)]

Weight (approx.): 1.08 Ibs (490 g)

Specifications are subject to change without notice.

* Minimum ilumination: Since there is no widely accepted testing procedure for determining minimum illumination

capability, lux ratings are comparable only between models from the same manufacturer.

Alkaline batteries

(AA-size x 4)

Hand strap Soft case

PixLab Integrated Digital

Media Software CD-ROM

AC adapter

UADP-0243TAZZ

3.3 V type

SmartMedia (4MB)

SmartMedia holder

Index label (X 2)

Write-protect seal (x 4)

Floppy disk adapter for med’iaTM

VR- 1 FPN

RUNTK0350TAZZ

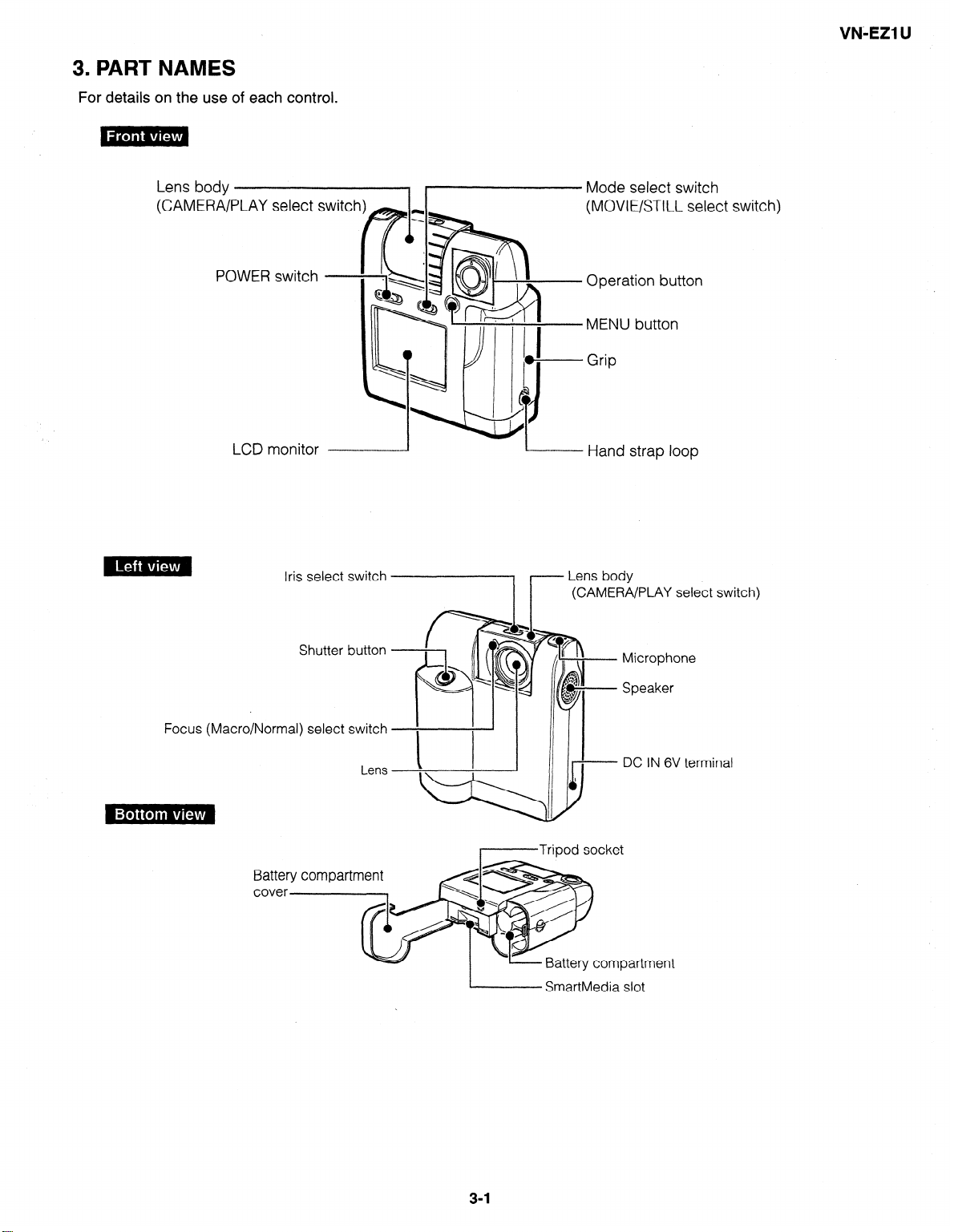

3. PART NAMES

For details on the use of each control.

VN-EZl U

Lens body --i 1

(CAME

RA/PLAY

POWER

LCD monitor

Iris select switch

Shutter button

Mode select switch

(MOVIE/STILL select switch)

Operation button

MENU button

.

Grip

L_.---- Hand strap loop

Lens body

(CAMERA/PLAY select switch)

r

Microphone

Focus (Macro/Normal) select switch

Lens

Speaker

DC IN 6V terminal

-Tripod socket

- SmartMedia slot

3-1

VN-EZl U

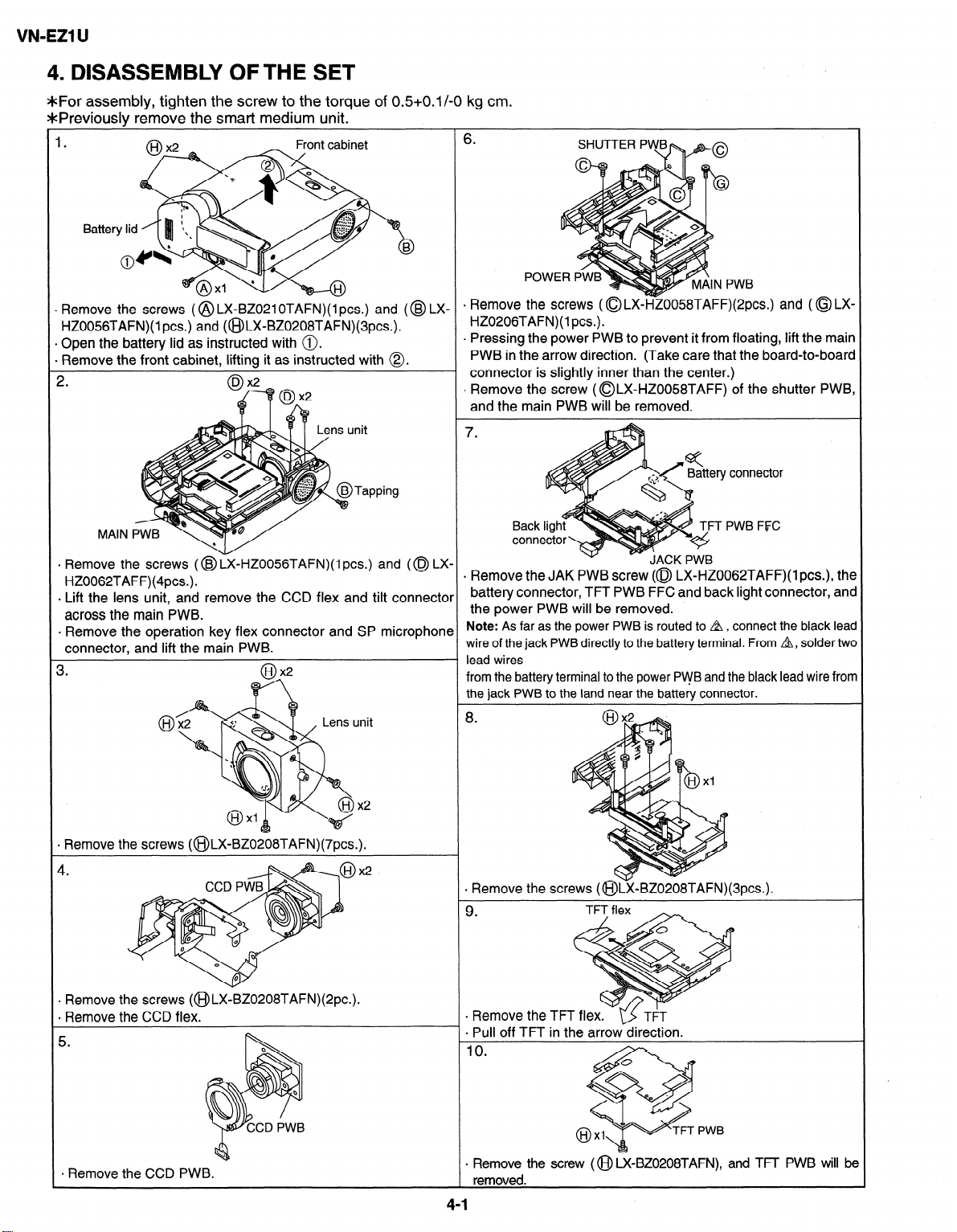

4. DISASSEMBLY OFTHE SET

*For assembly, tighten the screw to the torque of 0.5+0.1/-O kg cm.

*Previouslv remove the smart medium unit.

1.

Batter

B

J

6.

Remove the screws ( @ LX-BZ021 OTAFN)( 1 PCS.) and (@ LX-

HZOQ56TAFN)(l PCS.) and (@LX-BZO208TAFN)(3pcs.).

Open the battery lid as instructed with 0.

Remove the front cabinet, lifting it as instructed with 0.

Is unit

@Tapping

b

.

Remove the screws (@ LX-HZ0056TAFN)(l PCS.) and (@I LXHZ0062TAFF)(4pcs.).

. Lift the lens unit, and remove the CCD flex and tilt connector

across the main PWB.

l Remove the operation key flex connector and SP microphone

connector, and lift the main PWB.

3.

. Remove the screws (

HZ0206TAFN)( 1 PCS.).

8TAFF)(2pcs.) and ( t@ LX-

. Pressing the power PWB to prevent it from floating, lift the main

PWB in the arrow direction. (Take care that the board-to-board

connector is slightly inner than the center.)

.

Remove the screw (OLX-HZ0058TAFF) of the shutter PWB,

and the main PWB will be removed.

7.

ery connector

Back lig

connect

.

Remove the JAK PWB screw (0 LX-HZ0062TAFF)(l PCS.), the

battery connector, TFT PWB FFC and back light connector, and

the power PWB will be removed.

Note: As far as the power PWB is routed to A, connect the black lead

wire of the jack PWB directly to the battery terminal. From A, solder two

lead wires

from the battery terminal to the power PV’!/B and the black lead wire from

the jack PWB to the land near the battery connector.

JACK PWB

PWB FFC

8.

.

Remove the screws (@LX-BZO208TAFN)(7pcs.).

4.

.

Remove the screws (@LX-BZO208TAFN)(2pc.).

. Remove the CCD flex.

5.

G

Q

. Remove the CCD PWB.

.

Remove the screws (@%BZ0208TAFN)(3pcs.).

.

Remove the TFT flex. _ p TUT

. Pull off TFT in the arrow direction.

IO.

PWB

/ . Remove the screw (6 LX-BZ0208TAFN), and TFT PWB will be

1 removed.

4-I

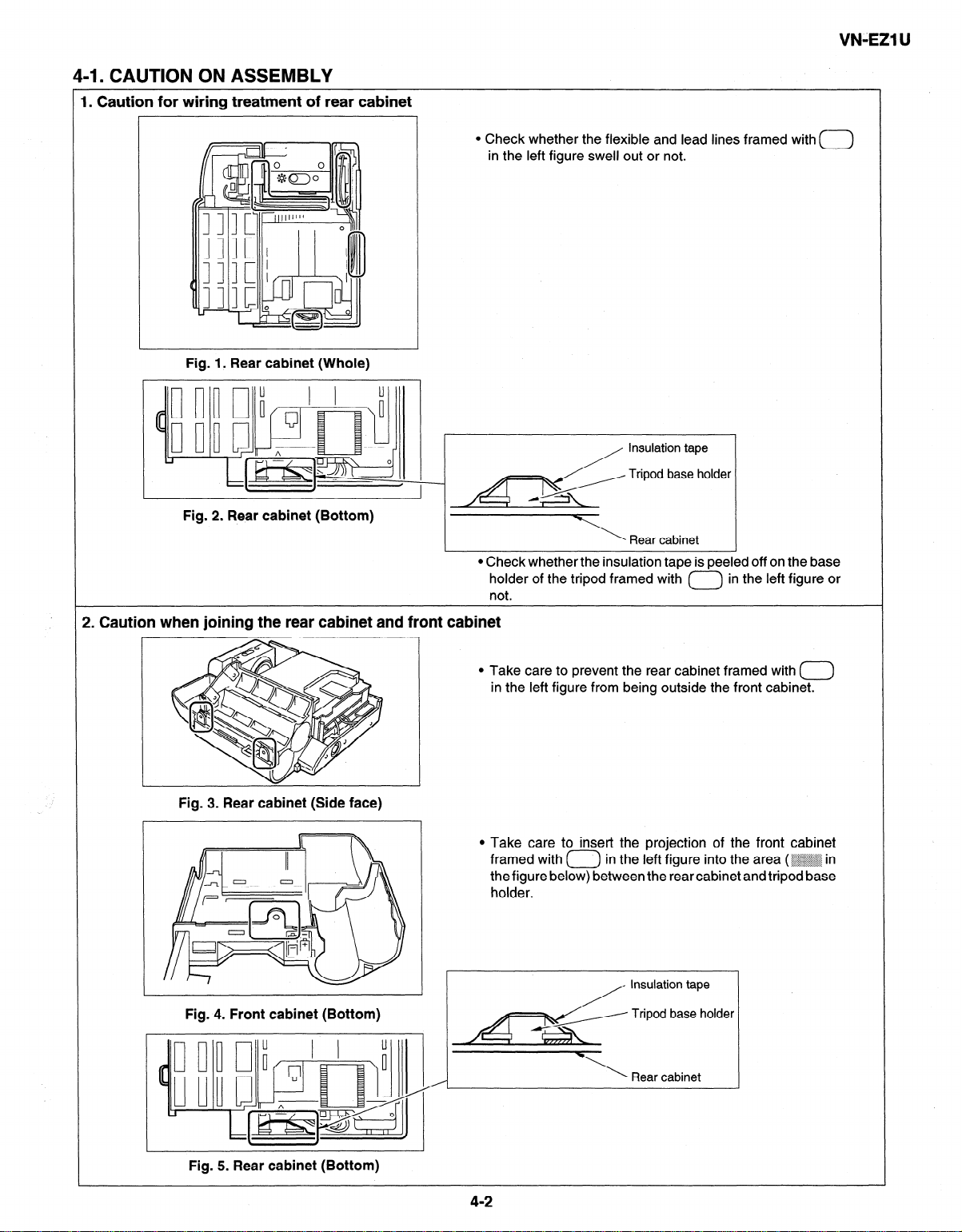

4-1. CAUTION ON ASSEMBLY

I. Caution for wiring treatment of rear cabinet

Fig. 1. Rear cabinet (Whole)

VN-EZl U

l Check whether the flexible and lead lines framed with ()

in the left figure swell out or not.

Tripod base holder

2. Cauti

Fig. 2. Rear cabinet (Bottom)

l Check whether the insulation tape is peeled off on the base

holder of the tripod framed with (-) in the left figure or

not.

l Take care to prevent the rear cabinet framed with ()

in the left figure from being outside the front cabinet.

Fig. 3. Rear cabinet (Side face)

l Take care to insert the projection of the front cabinet

framed with (-) in the left figure into the area (~ in

the figure below) between the rear cabinet and tripod base

holder.

Fig. 5. Rear cabinet (Bottom)

Tripod base holder

4-2

VN-EZl U

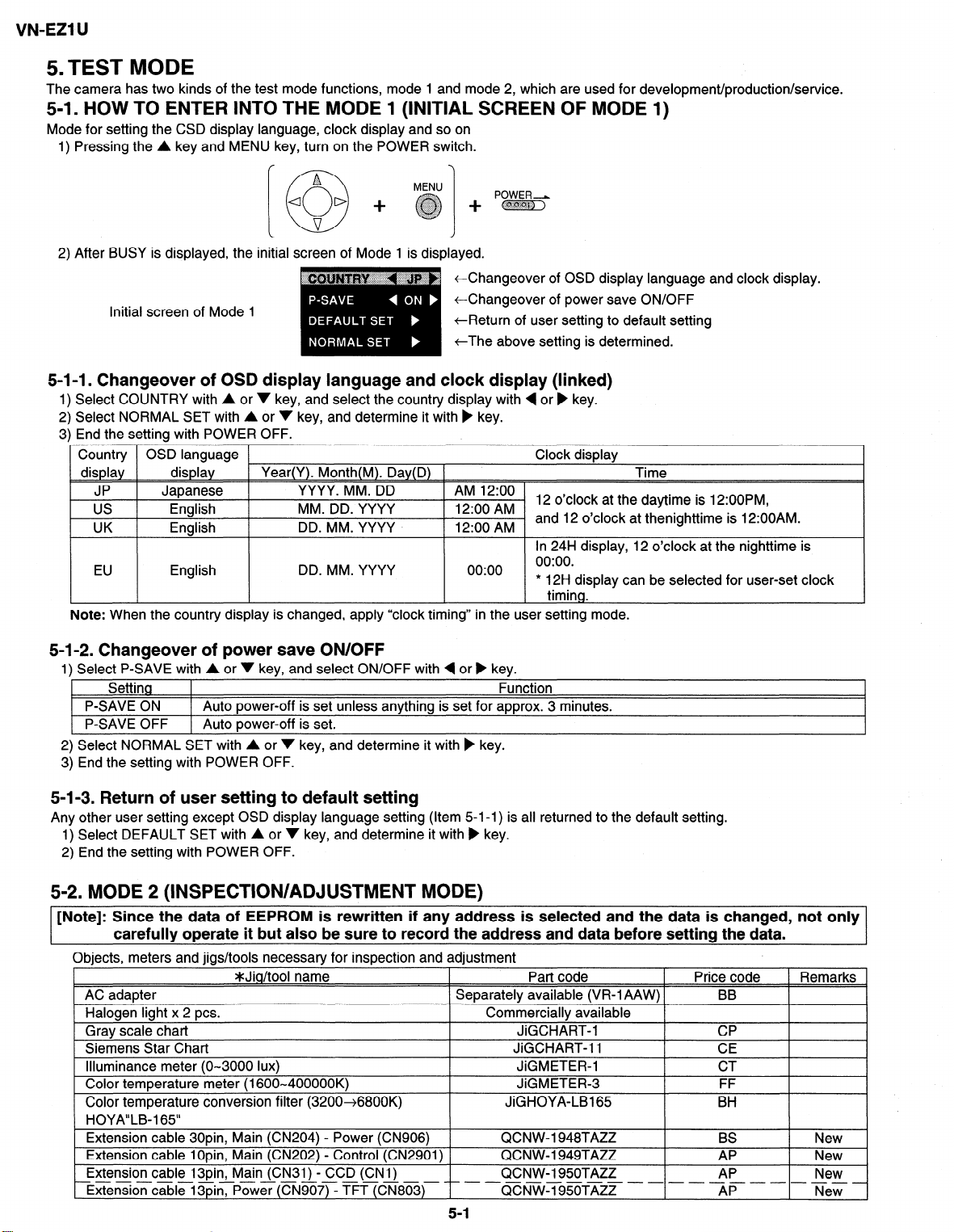

5. TEST MODE

The camera has two kinds of the test mode functions, mode 1 and mode 2, which

5-l. HOW TO ENTER INTO THE MODE 1 (INITIAL SCREEN

Mode for setting the CSD display language, clock display and so on

1) Pressing the A key and MENU key, turn on the POWER switch.

f - ‘I

) c-a_: + ~ I+ pg$T

I

2) After BUSY is displayed, the initial

Initial screen of Mode 1

w

screen of Mode 1 is displayed.

‘.Z. ::::::::::::: .:::

J

5-l-l. Changeover of OSD display language and clock display (linked)

1) Select COUNTRY with A or ‘I key, and select the country display with 4 or ) key.

2) Select NORMAL SET with A or v key, and determine it with ) key.

3) End the setting with POWER OFF.

Country OSD language Clock display

displav displav Year(Y). Month(M). Dav(D) 1

JP 1 Japanese 1 YYYY. MM. DD 1 AM 12:OO 1

us I Enalish 1 MM. DD. YYYY 1 12:OOAM 1

UK 1

EU

Note: When the country display is changed, apply “clock timing” in the user setting mode.

Enalish 1 DD. MM. YYYY 1 12:OOAM 1

English DD. MM. YYYY 0o:oo

. ..~.Qq$:

are used for development/production/service.

OF MODE 1)

Time

12 o’clock at the daytime is 12:00PM,

and 12 o’clock at thenighttime is 12:OOAM.

In 24H display, 12 o’clock at the nighttime is

0o:oo.

* 12H display can be selected for user-set clock

timina.

5-l-2. Changeover of power save ON/OFF

1) Select P-SAVE with A or v key, and select ON/OFF with 4 or) key.

Setting

P-SAVE ON

P-SAVE OFF

2) Select NORMAL SET with A or v key, and determine it with ) key.

3) End the setting with POWER OFF.

Auto power-off is set unless anything is set for approx. 3 minutes.

Auto power-off is set.

Function

5-l-3. Return of user setting to default setting

Any other user setting except OSD display language setting (Item 5-I -1) is all returned to the default setting.

1) Select DEFAULT SET with A or v key, and determine it with ) key.

2) End the setting with POWER OFF.

5-2. MODE 2 (INSPECTION/ADJUSTMENT MODE)

[Note]: Since the data of EEPROM is rewritten if any address is selected and the data is changed, not only

carefully operate it but also be sure to record the address and data before setting the data.

Objects, meters and jigs/tools necessary for inspection and adjustment

*Jig/tool name

AC adapter

Halogen light x 2 PCS.

Gray scale chart

Siemens Star Chart

llluminance meter (o-3000 lux)

Color temperature meter (1600~400000K)

Color temperature conversion filter (3200+68OOK)

1 HOYA”LB-165”

Extension cable 30pin, Main (CN204) - Power (CN906) QCNW-1948TAZZ

Extension cable lOpin, Main (CN202) - Control (CN2901)

Extension cable 13pin, Main (CN31) - CCD (CNl)

Extensioncable %in~P~~(~%7~ wT(CN803)

Separately available (VR-1 AAW)

I

- - -QCNW_19~TAZ~ - - - - -AK - - - New -

5-I

Part code

Commercially available

JiGCHART-

JiGCHART- 1

JiGMETERJiGMETER-

JiGHOYA-LB165

Price code

I

QCNW-1949TAZZ AP

QCNW-1950TAZZ

Remarks

BB

CP

CE

CT

FF

BH

I

BS New

New

AP New

How to enter into the test mode (initial screen of TEST MODE)

Pressing the V key and MENU key, turn on the POWER switch.

1)

When BUSY is displayed on the screen, release the V key and MENU key, and

2)

the initial screen of the test mode will be displayed. (Refer to the center of the

following figure.)

Shift to each mode with the operation button of the main unit.

3)

After setting is completed, press the MENU key, and it will return to the initial

4)

screen of the test mode. Then turn off the power.

Color bar pattern

W/Y/Cy/GIMglRIBluelBlack

t

/

a

0

0

n

..:‘.

v

‘I>

POWER-

+ m

Screen of EEPROM SET

Version display +

Initial screen

of TEST MODE Initial screen of EEPROM INI

Screen of WB ADJ

5-2-l. Method of displaying the test pattern

To inspect and adjust the liquid crystal the color bar and monochrome pattern can be displayed.

mMethod of displaying the color bar (75% modulated)

1) The initial screen of the test mode is displayed.

2) Press the A key to display the color bar.

3) Press the MENU key, and it will return to the initial screen of the test mode. Then turn off the power.

mMethod of displaying various patterns

1) The initial screen of the test mode is displayed.

2) Press the 4 key to display EEPROM SET screen.

3) Press the 4 key to display Address 1 FE of EEPROM.

4) Press the A key to set 00 as the data of Address 1 FE.

5) Press the A or V key to vary the data, and the patterns in the following table will be displayed.

Address (h)

IFE 1 04

6) Set FF as the data of Address IFE of EEPROM.

7) Press the MENU key, and it will return to the initial screen of the test mode. Then turn off the power.

Data (h)

I

I

i

01

02

03

05

06

07

White signal 40%

I

1 White s&al 100%

1 Black signal

1 Color bar signal

Red signal:The signal level is the same as that of the color bar.

1 Green signaLThe signal level is the same as that of the color bar.

I Blue signal:The signal level is the same as that of the color bar.

Display pattern

I

I

J

I

I

5-2

5-2-2. Method of selecting VALID/INVALID of the battery lid switch

For disassembly and operation, set the switch of the battery lid at VALID.

1) The initial screen of the test mode is displayed.

2) Press the 4 key to display EEPROM SET screen.

3) Select Address 1 FD with 4 or ) key, and set FF as the data with A or v key.

4) Press the MENU key, and it will return to the initial screen of TEST MODE. Then turn off the power to complete the setting.

Since the battery lid switch becomes invalid, it can be disassembled for inspection and repair.

[Note]: After the inspection and repair are completed, be sure to return the data of Address 1 FD to 00 (except FF), and turn the battery

lid switch to VALID.

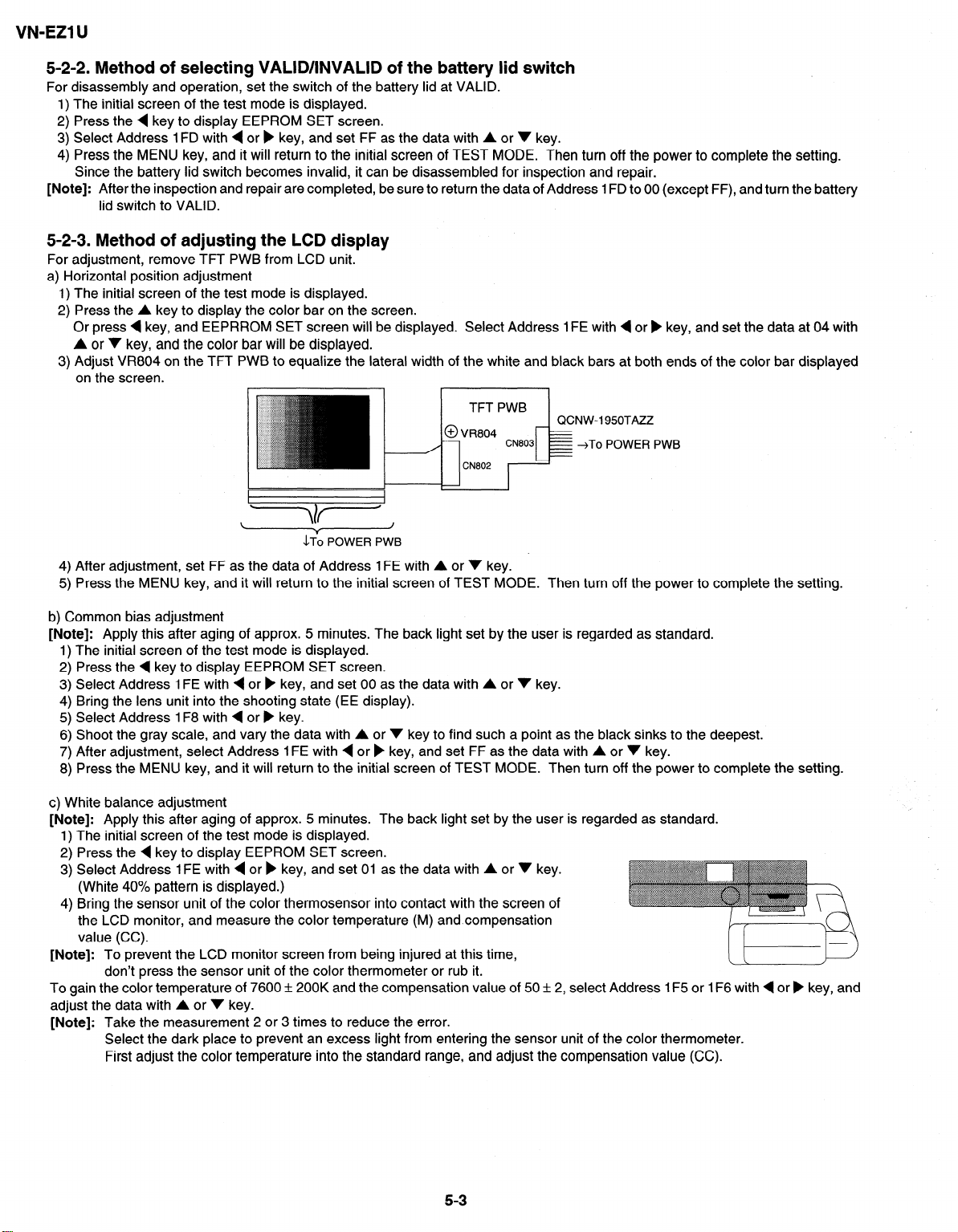

5-2-3. Method of adjusting the LCD display

For adjustment, remove TFT PWB from LCD unit.

a) Horizontal position adjustment

1) The initial screen of the test mode is displayed.

Select

Address 1 FE with

the wh ite and black bars

+To POWER PWB

I I

L-l-,

4) After adjustment, set FF as the data of Address 1 FE with A or v key.

5) Press the MENU key, and it will return to the initial screen of TEST MODE. Then turn off the power to complete the setting.

b) Common bias adjustment

[Note]: Apply this after aging of approx. 5 minutes. The back light set by the user is regarded as standard.

1) The initial screen of the test mode is displayed.

2) Press the 4 key to display EEPROM SET screen.

3) Select Address 1 FE with 4 or ) key, and set 00 as the data with A or v key.

4) Bring the lens unit into the shooting state (EE display).

5) Select Address 1 F8 with 4 or ) key.

6) Shoot the gray scale, and vary the data with A or v key to find such a point as the black sinks to the deepest.

7) After adjustment, select Address 1 FE with 4 or ) key, and set FF as the data with A or v key.

8) Press the MENU key, and it will return to the initial screen of TEST MODE. Then turn off the power to complete the setting.

v

JTo POWER PWB

key, and set the data

4orb

at both ends of the color bar

at 04 with

displayed

c) White balance adjustment

[Note]: Apply this after aging of approx. 5 minutes. The back light set by the user is regarded as standard.

1) The initial screen of the test mode is displayed.

2) Press the 4 key to display EEPROM SET screen.

3) Select Address 1 FE with 4 or ) key, and set 01 as the data with A or v key.

(White 40% pattern is displayed.)

4) Bring the sensor unit of the color thermosensor into contact with the screen of

the LCD monitor, and measure the color temperature (M) and.compensation

value (CC).

[Note]: To prevent the LCD monitor screen from being injured at this time,

don’t press the sensor unit of the color thermometer or rub it.

To gain the color temperature of 7600 +_ 200K and the compensation value of 50 +_ 2, select Address 1 F5 or 1 F6 with 4 or ) key, and

adjust the data with A or v key.

[Note]: Take the measurement 2 or 3 times to reduce the error.

Select the dark place to prevent an excess light from entering the sensor unit of the color thermometer.

First adjust the color temperature into the standard range, and adjust the compensation value (CC).

5-3

VN-EZl U

Color temperature

Low

High Low Fixed

Low High Fixed

High

Low

High

Within standard

Within standard

Within standard

Compensation value

Low

High

Within standard

Within standard

Low

High

Within standard

Address 1 F5 (B) 4 Address 1 F6 (R) )

‘IDown Fixed

VDown

I AUP I

AUP

VDown

AUP

VDown VDown

AUP

Adjustment end

Fixed

AUP

VDown

AUP

Adjustment end

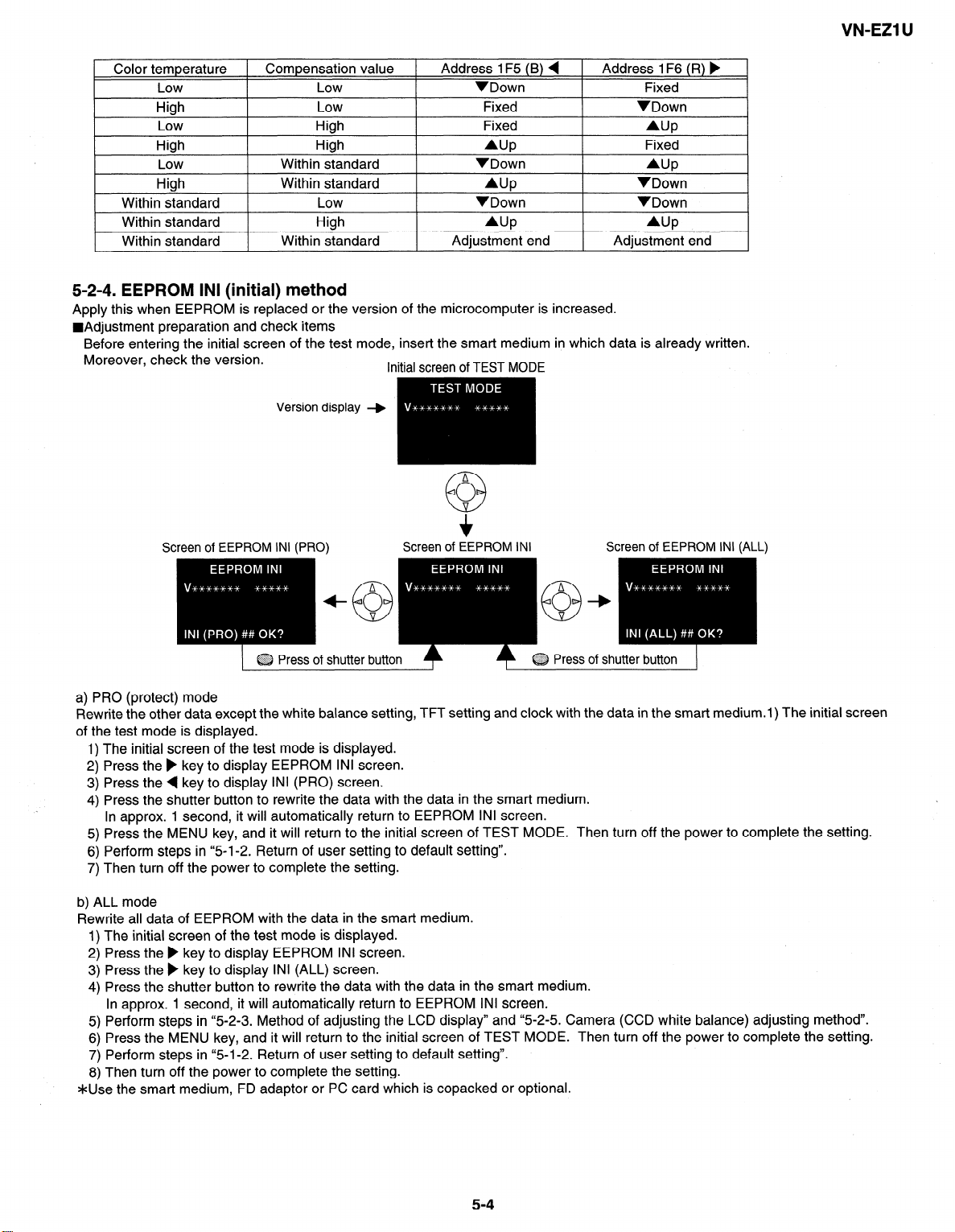

5-2-4. EEPROM INI (initial) method

Apply this when EEPROM is replaced or the version of the microcomputer is increased.

n Adjustment preparation and check items

Before entering the initial screen of the test mode, insert the smart medium in which data is already written.

Moreover, check the version.

Version display +

Initial screen of TEST MODE

Screen of EEPROM INI (PRO) Screen of EEPROM INI Screen of EEPROM INI (ALL)

a) PRO (protect) mode

Rewrite the other data except the white balance setting, TFT setting and clock with the data in the smart medium-l) The initial screen

of the test mode is displayed.

1) The initial screen of the test mode is displayed.

2) Press the ) key to display EEPROM INI screen.

3) Press the 4 key to display INI (PRO) screen.

4) Press the shutter button to rewrite the data with the data in the smart medium.

In approx. 1 second, it will automatically return to EEPROM INI screen.

5) Press the MENU key, and it will return to the initial screen of TEST MODE. Then turn off the power to complete the setting.

6) Perform steps in “5-l-2. Return of user setting to default setting”.

7) Then turn off the power to complete the setting.

b) ALL mode

Rewrite all data of EEPROM with the data in the smart medium.

1) The initial screen of the test mode is displayed.

2) Press the ) key to display EEPROM INI screen.

3) Press the ) key to display INI (ALL) screen.

4) Press the shutter button to rewrite the data with the data in the smart medium.

In approx. 1 second, it will automatically return to EEPROM INI screen.

5) Perform steps in “5-2-3. Method of adjusting the LCD display” and “5-2-5. Camera (CCD white balance) adjusting method”.

6) Press the MENU key, and it will return to the initial screen of TEST MODE. Then turn off the power to complete the setting.

7) Perform steps in “5-l-2. Return of user setting to default setting”.

8) Then turn off the power to complete the setting.

*Use the smart medium, FD adaptor or PC card which is copacked or optional.

5-4

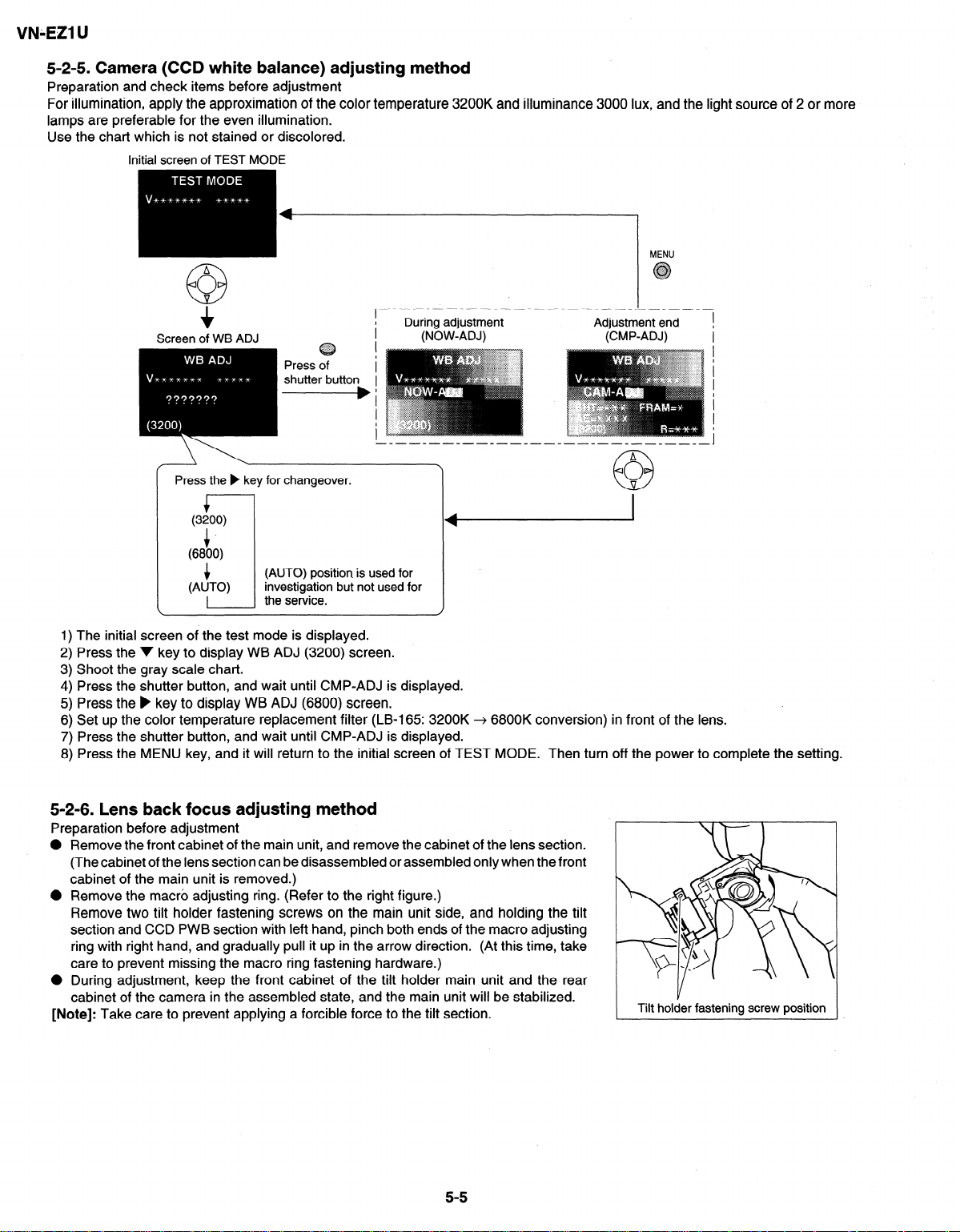

5-2-5. Camera (CCD white balance) adjusting method

Preparation and check items before adjustment

For illumination, apply the approximation of the color temperature 3200K and illuminance 3000 lux, and the light source of 2 or more

lamps are preferable for the even illumination.

Use the chart which is not stained or discolored.

Initial screen of TEST MODE

1 MENU

I

I

Screen of WB ADJ

, During adjustment

Adjustment end I

(CMP-ADJ) 1

I

i

I

i

I

i

Press the ) key for changeover.

(AUTO) position is used for

investigation but not used for

the service.

1) The initial screen of the test mode is displayed.

2) Press the V key to display WB ADJ (3200) screen.

3) Shoot the gray scale chart.

4) Press the shutter button, and wait until CMP-ADJ is displayed.

5) Press the ) key to display WB ADJ (6800) screen.

6) Set up the color temperature replacement filter (LB-165 3200K -+ 6800K conversion) in front of the lens.

7) Press the shutter button, and wait until CMP-ADJ is displayed.

8) Press the MENU key, and it will return to the initial screen of TEST MODE. Then turn off the power to complete the setting.

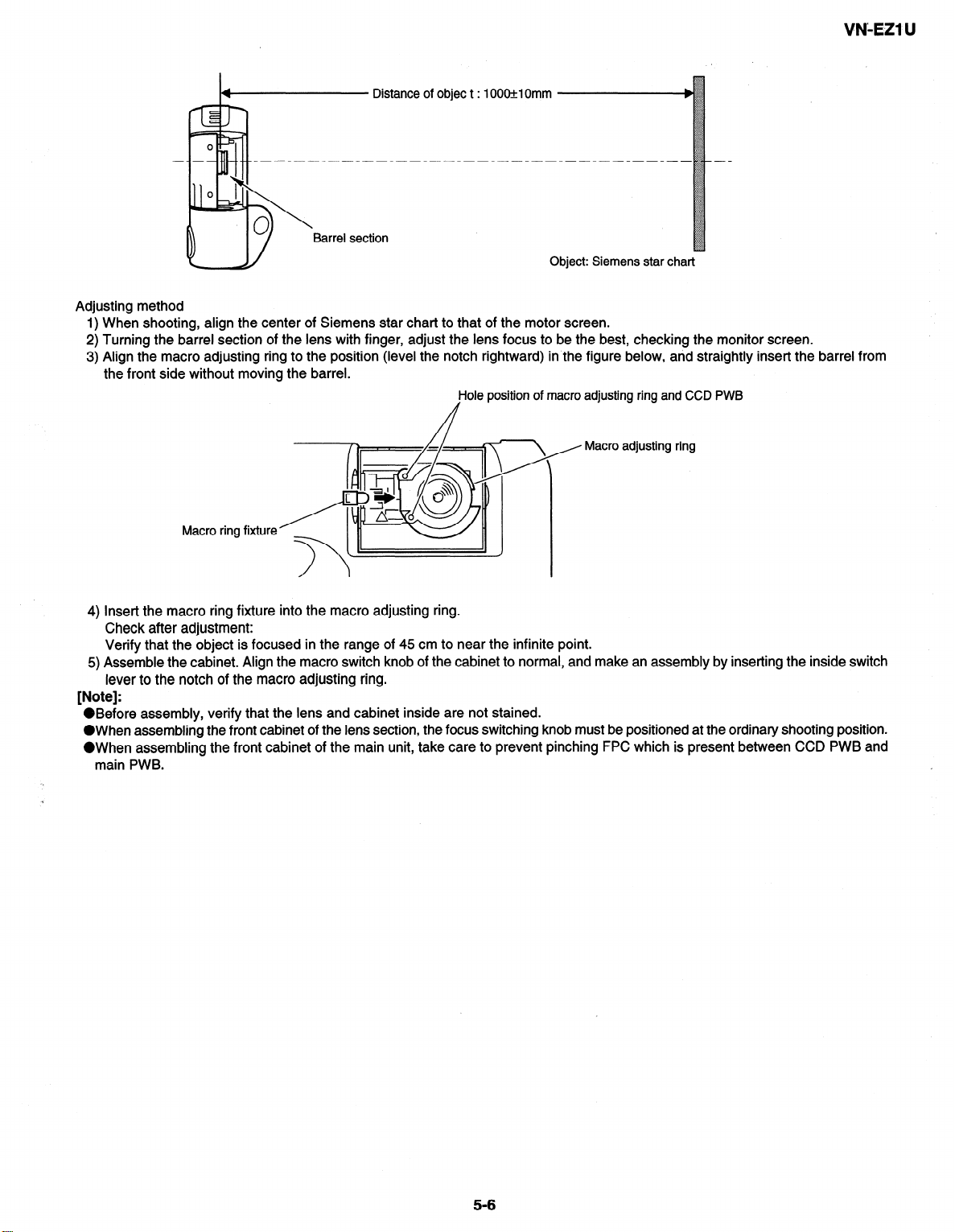

5-2-6. Lens back focus adjusting method

Preparation before adjustment

Remove the front cabinet of the main unit, and remove the cabinet of the lens section.

(The cabinet of the lens section can be disassembled or assembled only when the front

cabinet of the main unit is removed.)

Remove the macro adjusting ring. (Refer to the right figure.)

Remove two tilt holder fastening screws on the main unit side, and holding the tilt

section and CCD PWB section with left hand, pinch both ends of the macro adjusting

ring with right hand, and gradually pull it up in the arrow direction. (At this time, take

care to prevent missing the macro ring fastening hardware.)

During adjustment, keep the front cabinet of the tilt holder main unit and the rear

cabinet of the camera in the assembled state, and the main unit will be stabilized.

[Note]: Take care to prevent applying a forcible force to the tilt section.

Tilt holder fastening screw position

I

5-5

I_L Distance of objet t : 1000&l

Barrel section

Adjusting method

1) When shooting, align the center of Siemens star chart to that of the motor screen.

2) Turning the barrel section of the lens with finger, adjust the lens focus to be the best, checking the monitor screen.

3) Align the macro adjusting ring to the position (level the notch rightward) in the figure below, and straightly insert the barrel from

the front side without moving the barrel.

Hole Dosition of macro adjusting ring and CCD PWB

y Macro adjusting ring

Macro ring fixture

4) Insert the macro ring fixture into the macro adjusting ring.

Check after adjustment:

Verify that the object is focused in the range of 45 cm to near the infinite point.

5) Assemble the cabinet. Align the macro switch knob of the cabinet to normal, and make an assembly by inserting the inside switch

lever to the notch of the macro adjusting ring.

[Note]:

@Before assembly, verify that the lens and cabinet inside are not stained.

l When assembling the front cabinet of the lens section, the focus switching knob must be positioned at the ordinary shooting position.

l When assembling the front cabinet of the main unit, take care to prevent pinching FPC which is present between CCD PWB and

main PWB.

5-6

VN-EZl,U

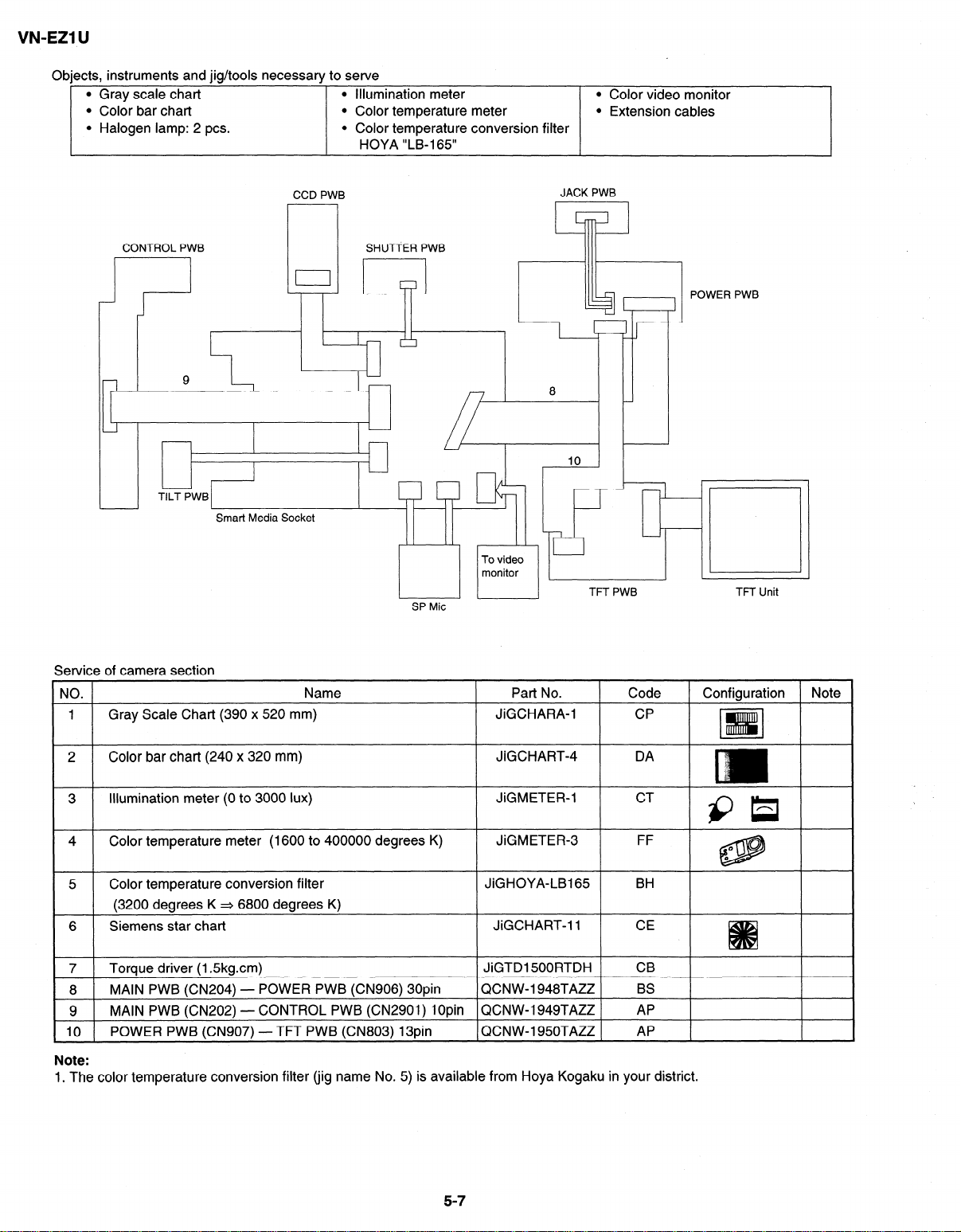

Objects, instruments and jig/tools necessary to serve

l Gray scale chart

l Color bar chart

l Halogen lamp: 2 PCS.

l Illumination meter

l Color temperature meter

l Color temperature conversion filter

HOYA “LB-1 65”

l Color video monitor

l Extension cables

CONTROL PWB

lrl

L

TILT PWB

CCD PWB

Smart Media Socket

SHUTTER PWB

fY

SP Mic

To video

monitor

JACK PWB

POWER PWB

8

IO

I1 jIl.

TFT PWB TFT Unit

Service of camera section

.

NO 1

1 Gray Scale Chart (390 x 520 mm)

2 Color bar chart (240 x 320 mm)

Illumination meter (0 to 3000 lux)

3

Color temperature conversion filter

5

(3200 degrees K a 6800 degrees K)

Siemens star chart

6

Torque driver (1.5kg.cm)

7

MAIN PWB (CN204)

8

MAIN PWB (CN202) -

9

IO 1 POWER PWB (CN907) - TFT PWB (CN803) 13pin

Note:

1. The color temperature conversion filter (jig name No. 5) is available from Hoya Kogaku in your district.

- POWER PWB (CN906) 30pin QCNW-1948TAZZ BS

Name

(1600 to 400000 degrees K)

CONTROL PWB (CN2901) IOpin QCNW-1949TAZZ

Part No. 1 Code 1 Configuration 1 Note

I

JiGCHARA-1

JiGCHART-

JiGMETER-

JiGMETER-

JiGHOYA-LB165 BH

JiGCHART- 1 CE

JiGTD1500RTDH CB

IQCNW-1950TAZZ 1 AP 1

CP

DA

AP

I

5-7

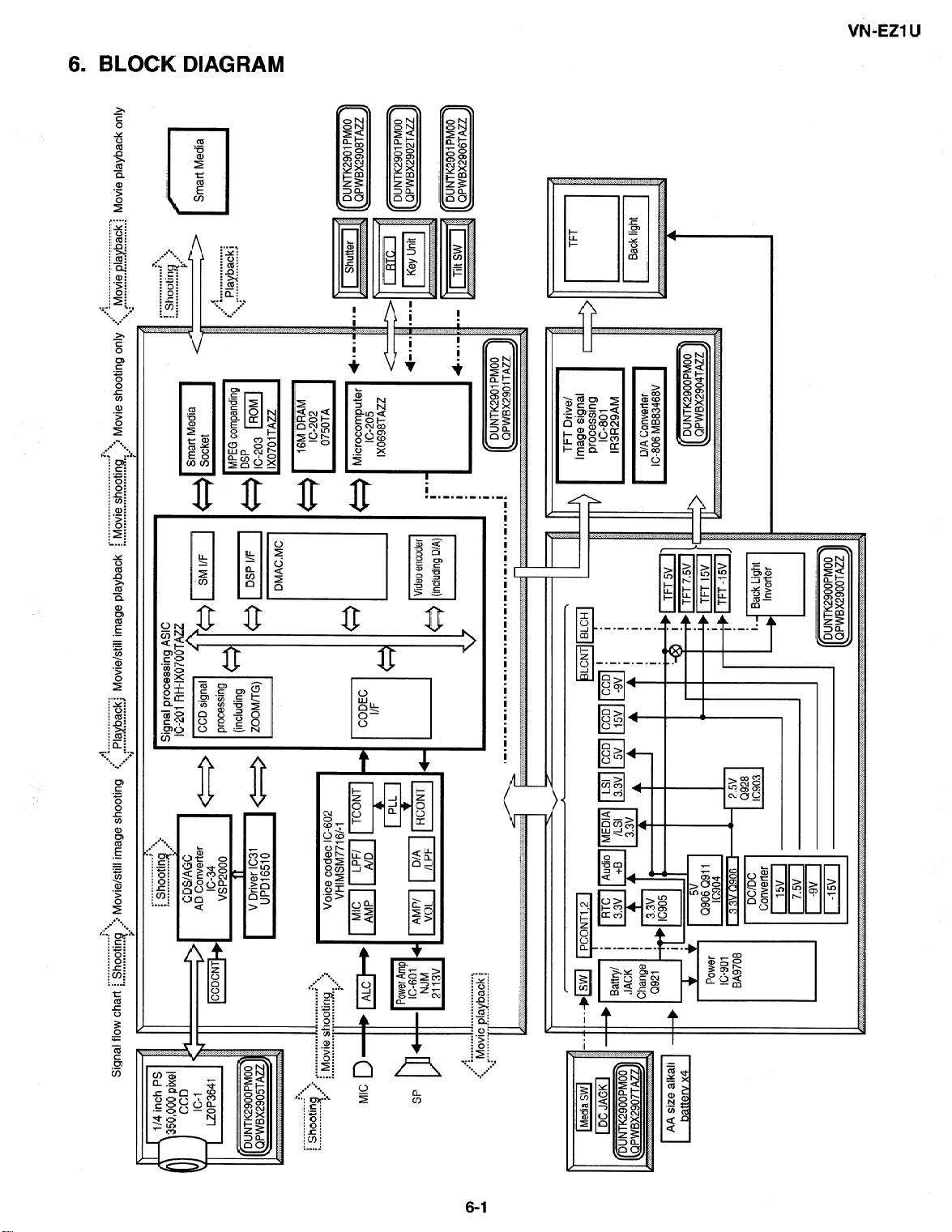

. I(luo 6u!~ooys a!/\oyy 2:;

f

.*

‘0:

t:

:.

,...........................A

tju!~ooys a!AOw I

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

yxqhld a6txu! ~pgs/a!~oyy fjiiiii;i&.jg’ )

.-1;

1.1. .I._

I, ~._rnl,

IL

:.:

:::

.:_

:::

:::

:.:

>

;_

wvtiaw91

VlO%LO

zoz-31

:i::

b

~a~ndumom!w

ZZVl869OXI

soz-31

..I.

i

::::

::::

;:;:

i

. . . .

is

.:.:

I:!:

:::: w

. . . .

i

i

i

I

.:.:

::::

::::

::::

>;.

ii;

.i.

::::

$

. . . .

. . . .

ig

$5

::.

/wa IJL

1’11

\

Ma 6u!pni~u!)

J8pOXl~ Oap!/\

I

1

Ja&laAu(

L

31s~ 6u!ssaaoJd p~6~s

ZZbOOLOXI-Htl 101-31

ieu6!s a33

. . . . . . . . . . . . . . . . . . . 8

5.

. .

v

6u!9ooys a6eu4 ~lgs/a!~op,j (?%~i6ii~~mi j.~eya MO14 IT&!S

l .;

. . . . . . . . . . . . . . . . . .

twwooz

6uqsaaoJd

Gu!pnpu!)

tl

ma03

Ii/l

z09-3l=Po~ =!oA

l-/9lLLWSWIHA

-a 31w

I . . . . . . . . . . . . ,

Y

JaMOd

J

80L6W

LO6-31

k I I I

I

Jaj_4aAuoz

3ana

I I I

rl

.m

. : .

VN-EZl U

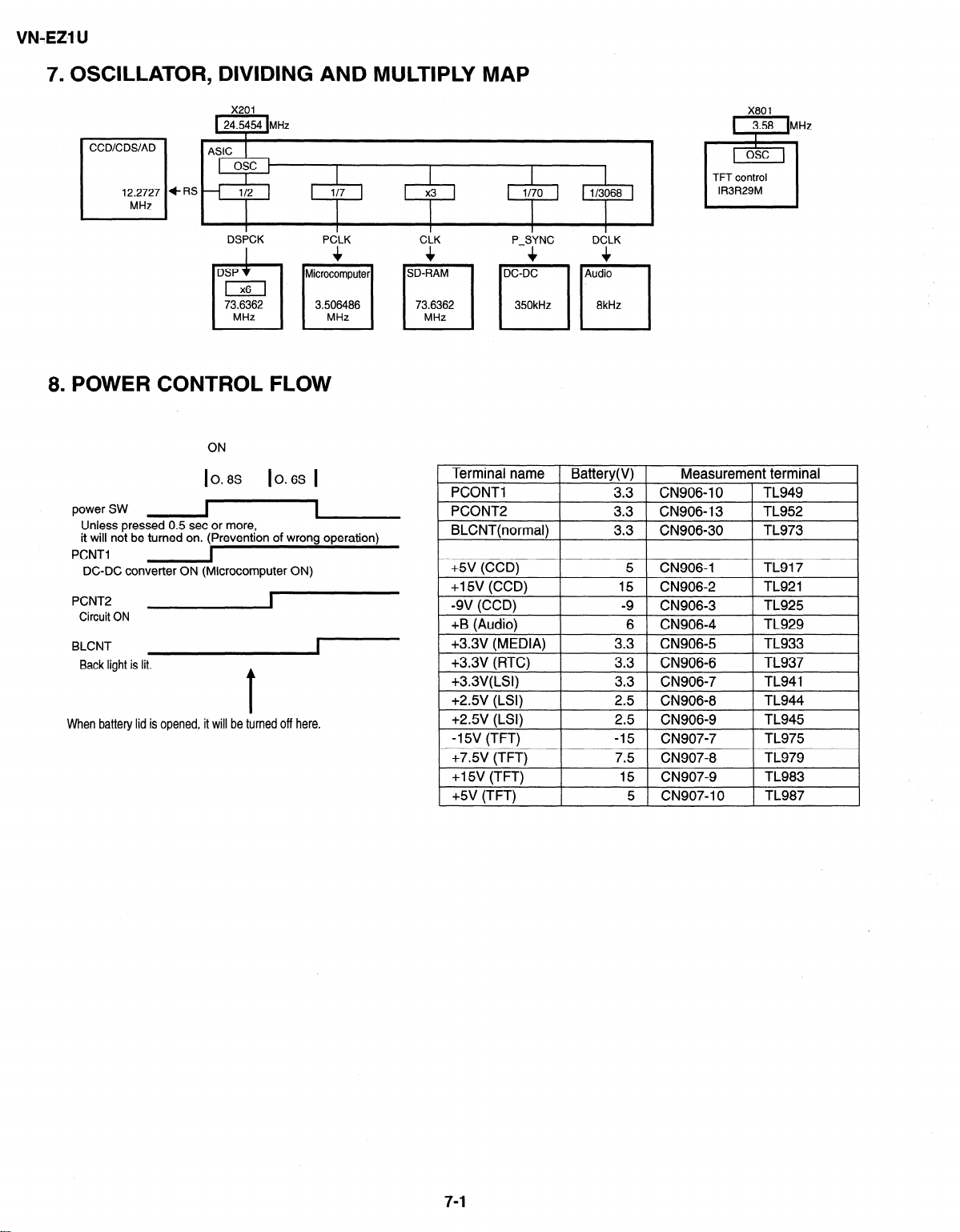

7. OSCILLATOR, DIVIDING AND MULTIPLY MAP

X801

CCDICDSIAD

ASIC

[ 0sE-j

12.2727

MHz

443s -f

I

l/2 l/7

D&K

I

DSP ‘t

I

73.6362

MHz

Microcomputel

3.506486

8. POWER CONTROL FLOW

ON

0.8s 10.6s 1

I

power SW

Unless pressed 0.5 see or more,

it will not be turned on. (Prevention of wrong operation)

PCNTl

DC-DC converter ON (Microcomputer ON)

PCNT2

Circuit ON

BLCNT

Back light is lit.

When battery lid is opened, it will be turned off here.

I

I

I

I

P&K

MHz

I

+

I

x3

CL

4

SD-RAM

73.6362

I

l/70

P_SCNC

4

DC-DC

350kHz

I I

Terminal name

PCONTI

PCONT2

BLCNT(normal)

+5V (CCD)

+I 5V (CCD)

-9V (CCD)

+B (Audio)

+3.3V (MEDIA)

+3.3V (RTC)

+3.3V(LSI)

+2.5V (LSI)

+2.5V (LSI)

-15V (TFT)

+7.5V (TFT)

+I 5V (TFT)

+5V (TFT)

l/3068

D&K

+

Battery(V)

3.3 CN906-10 TL949

3.3

CN906-13

3.3

CN906-30 TL973

5

CN906-1

15

CN906-2

-9

CN906-3

6

CN906-4 TL929

3.3 CN906-5 TL933

3.3

CN906-6

3.3

CN906-7

2.5 CN906-8 TL944

2.5

CN906-9

CN907-7

-15

7.5 CN907-8 TL979

15

CN907-9

5 CN907-IO TL987

TFT control

IR3R29M

I

Measurement terminal

TL952

TL917

TL921

TL925

TL937

TL941

TL945

TL975

TL983

7-1

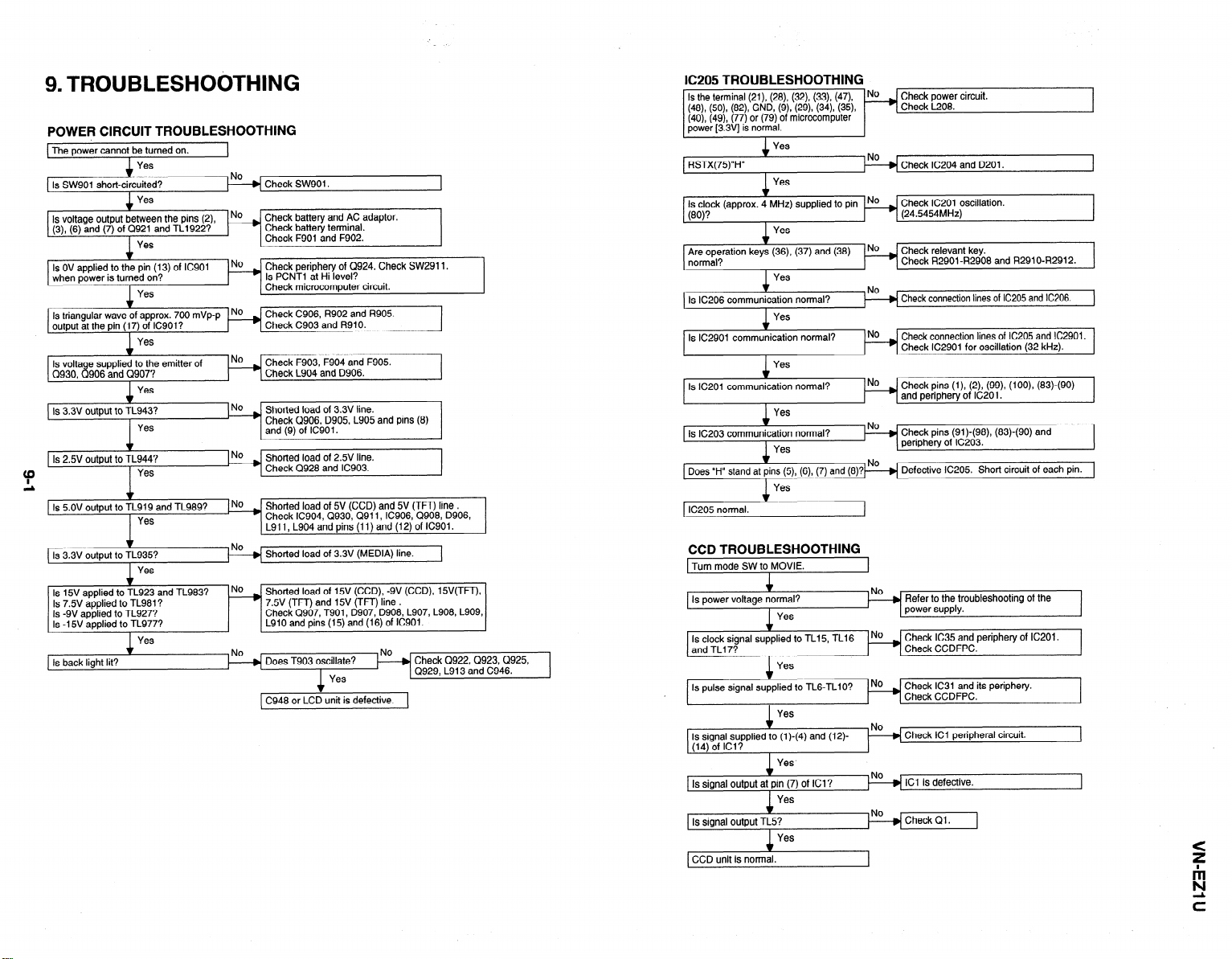

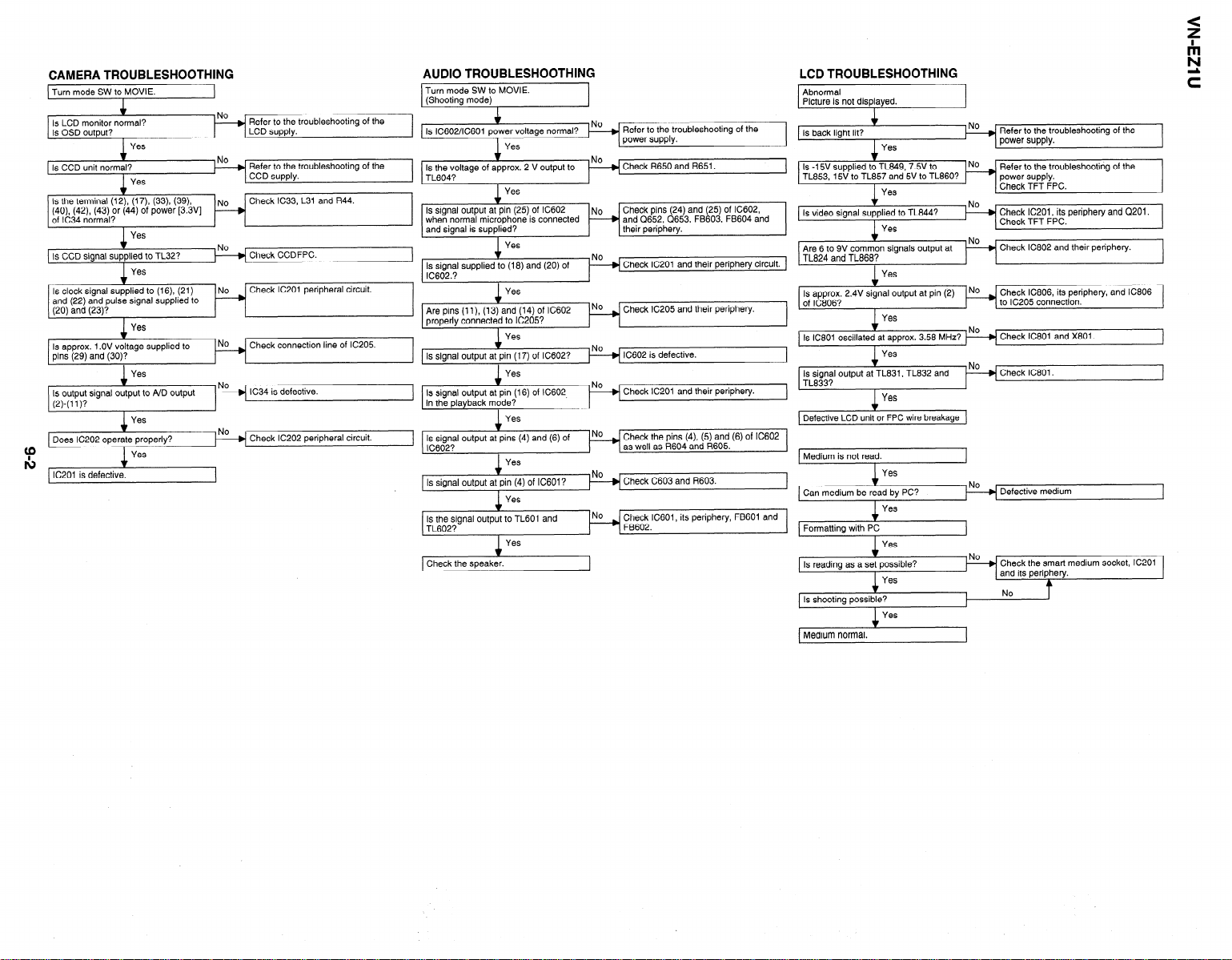

9. TROUBLESHOOTHING

POWER CIRCUIT TROUBLESHOOTHING

The power cannot be turned on.

Is voltage output between the pins (2),

(3) (6) and (7) of Q921 and TL1922?

Is OV applied to the pin (13) of IC901

when power is turned on?

Is triangular wave of approx. 700 mVp-p

output at the pin (17) of IC901?

Is voltage supplied to the emitter of

Q930, Q906 and Q907?

Is 3.3V output to TL943?

Is 2.5V output to TL944?

a

L

Is 5.OV output to TL919 and TL989?

Is 15V applied to TL923 and TL983?

Is 7.5V applied to TL981?

Is -9V applied to TL927?

Is -15V applied to TL977?

Is back light lit?

Yes

Yes

Yes

Yes

Yes

v

Yes

l

Yes

No

No B

No l

‘No

No

No

No l Shorted load of 15V (CCD), -9V (CCD), lSV(TFT),

Check SW901.

l Check battery and AC adaptor.

Check battery terminal.

Check F901 and F902.

Check periphery of Q924. Check SW291 1.

Is PCNTl at Hi level?

Check microcomputer circuit.

Check C906, R902 and R905.

Check C903 and R910.

Check F903, F904 and F905.

l Check L904 and D906.

Shorted load of 3.3V line.

l Check Q906, D905, L905 and pins (8)

and (9) of IC901.

Shorted load of 2.5V line.

l Check Q928 and IC903.

Shorted load of 5V (CCD) and 5V (TFT) line.

Check IC904, Q930, Q911, IC906, Q908, D906,

L911, L904 and pins (11) and (12) of IC901.

Shorted load of 3.3V (MEDIA) line.

7.5V (TFT) and 15V (TFT) line .

Check Q907, T901, 0907,0908, L907, L908, L909,

L910 and pins (15) and (16) of IC901.

No

Does T903 oscillate?

I Yes

b48 or LCD unit is defective.

+ Check Q922, Q923, Q925,

Q929, L913 and C946.

1

IC205 TROUBLESHOOTHING

Check power circuit.

Is the terminal (21), (28), (32) (33) (47)

(48) (50) (82)s GND, (9), (29) (34) (35)

(40) (49) (77) or (79) of microcomputer

power [3.3V] is normal.

RSTX(75)“H”

No -,

Check L208.

Check IC204 and D201.

I

Check IC201 oscillation.

Is clock (approx. 4 MHz) supplied to pin

(80)?

&eoi;ration keys (36) (37) and (38)

Is IC2901 communication normal?

I

1

Is IC201 communication normal?

1 IC205 normal.

I Yes

l

I Yes

*

I Yes

l

I Yes

Yes

CCD TROUBLESHOOTHING

1 Turn mode SW to MOVIE.

1 Is power voltage no-1

I .

Is clock signal supplied to TL15, TL16 No l

1

and TL17?

Is pulse signal supplied to TLG-TLlO?

Is signal supplied to (l)-(4)

(141 of Cl?

I Yes

+

I

Yes

Yes

and (12)-

No b

(24.5454MHz)

No b Check relevant key.

Check R2901 -R2908 and R291 O-R291 2.

Check connection lines of IC205 and lC206.

No

Check connection lines of lC205 and lC2901.

l Check IC2901 for oscillation (32 kHz).

I I -

No

b Check pins (l), (2), (99) (loo), (83)-(90)

and periphery of IC201.

No

+ Check pins (91)-(98), (83)-(90) and

periphery of IC203.

Defective IC205. Short circuit of each pin.

No

d Refer to the troubleshooting of the

I

1 power supply.

Check IC35 and periphery of IC201.

Check CCDFPC.

Check IC31 and its periphery.

No b

Check CCDFPC.

Check ICl peripheral circuit.

r

.

I

I

I

CCD unit is normal.

ICl is defective.

Check Ql.

CAMERA TROUBLESHOOTHING

1 Turn mode SW to MOVIE.

Is LCD monitor normal?

Is OSD output?

Is the terminal (12) (17), (33), (39), No Check IC33, L31 and R44.

(40) (42), (43) or (44) of power [3.3V] b

of IC34 normal?

Is clock signal supplied to (16), (21) No

and (22) and pulse signal supplied to

(20) and (23)?

Is approx. 1 .OV voltage supplied to b

Is output signal output to A/D output

(2)-( 1 1 )?

1 IC201 is defective.

LNo _

I

Yes

-No

Yes

-b Refer to the troubleshooting of the

LCD supply.

No r

l Refer to the troubleshooting of the

CCD supply.

Check CCDFPC.

Check IC201 peripheral circuit.

Check connection line of IC205.

IC34 is defective.

1

AUDIO TROUBLESHOOTHING

Turn mode SW to MOVIE.

(Shooting mode)

b Refer to the troubleshooting of the

power supply.

Is the voltage of approx. 2 V output to

TL604?

Is signal output at pin (25) of IC602

when normal microphone is connected

and signal is supplied? their periphery.

Is signal supplied to (18) and (20) of

IC602.?

Are pins (1 l), (13) and (14) of IC602

properly connected to IC205?

Is signal output at pins (4) and (6) of No b Check the pins (4) (5) and (6) of fC602

IC602? ,

Is the signal output to TL601 and

TL602?

1 Check the speaker.

I Yes

v

I Yes

Yes

Check R650 and R651.

No Check pins (24) and (25) of IC602,

l and Q652, Q653, FB603, FB604 and

Check IC201 and their periphery circuit.

No b Check IC205 and their periphery.

IC602 is defective.

Check IC201 and their periphery.

as well as R604 and R605.

Check C603 and R603.

No

Check IC601, its periphery, FB601 and

i

’ FB602.

LCD TROUBLESHOOTHING

Abnormal

Picture is not displayed.

Is back light lit?

Is -15V supplied to TL849, 7.5V to

TL853,15V to TL857 and 5V to TL860?

IS video signal suppm1

Are 6 to 9V common signals output at

TL824 and TL868?

Is approx. 2.4V signal output at pin (2)

of IC806?

1 IS IC801 oscillated at

I

I Yes

+

I Yes

+-No

I

Yes

Yes

I Yes

Is signal output at TL831, TL832 and

TL833?

1

1 Defective LCD unit or FPC wire breakaae I

Medium is not read.

Formatting with PC

1

I Yes

1

I Yes

Yes

Yes

7

Refer to the troubleshooting of the

power supply.

No

Refer to the troubleshooting of the

b power supply.

Check TFT FPC.

No

+ Check IC201, its periphery and Q201.

Check TFT FPC.

b Check IC802 and their periphery.

Check IC806, its periphery, and IC806

No +

to IC205 connection.

No

d Check lC801 and X801.

Check IC801.

Defective medium

No

+ Check the smart medium socket, lC201

and its periphery.

No

1

I

Medium normal.

Loading...

Loading...