Page 1

VL-Z7U/Z75U/Z8U

SERVICE MANUAL

S43Z2VL-Z7U//

LIQUID CRYSTAL DISPLAY CAMCORDER NTSC

VL-Z7U

VL-Z75U

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified

be used.

VL-Z8U

CONTENTS

Page

1. IMPORTANT SERVICE NOTES ........................................................................................................ 2

2. SPECIFICATIONS .............................................................................................................................. 6

3. PART NAMES .................................................................................................................................... 7

4. DISASSEMBLY OF THE SET ............................................................................................................ 8

5. MECHANISM ADJUSTMENT JIGS AND PARTS ............................................................................ 12

6. INSPECTION AND MAINTENANCE

ITEMS AND INTERVALS ................................................................................................................. 13

7. ADJUSTING AND CHECKING OF MECHANISM ........................................................................... 14

8. ADJUSTMENT OF RUNNING SYSTEM .......................................................................................... 17

9. ASSEMBLING OF MECHANISM SECTION AND PART REPLACEMENT

(DISASSEMBLING AND ASSEMBLING) ........................................................................................... 19

10.METHOD OF ADJUSTING THE ELECTRIC CIRCUIT .................................................................... 29

11.USEFUL TIPS ................................................................................................................................... 48

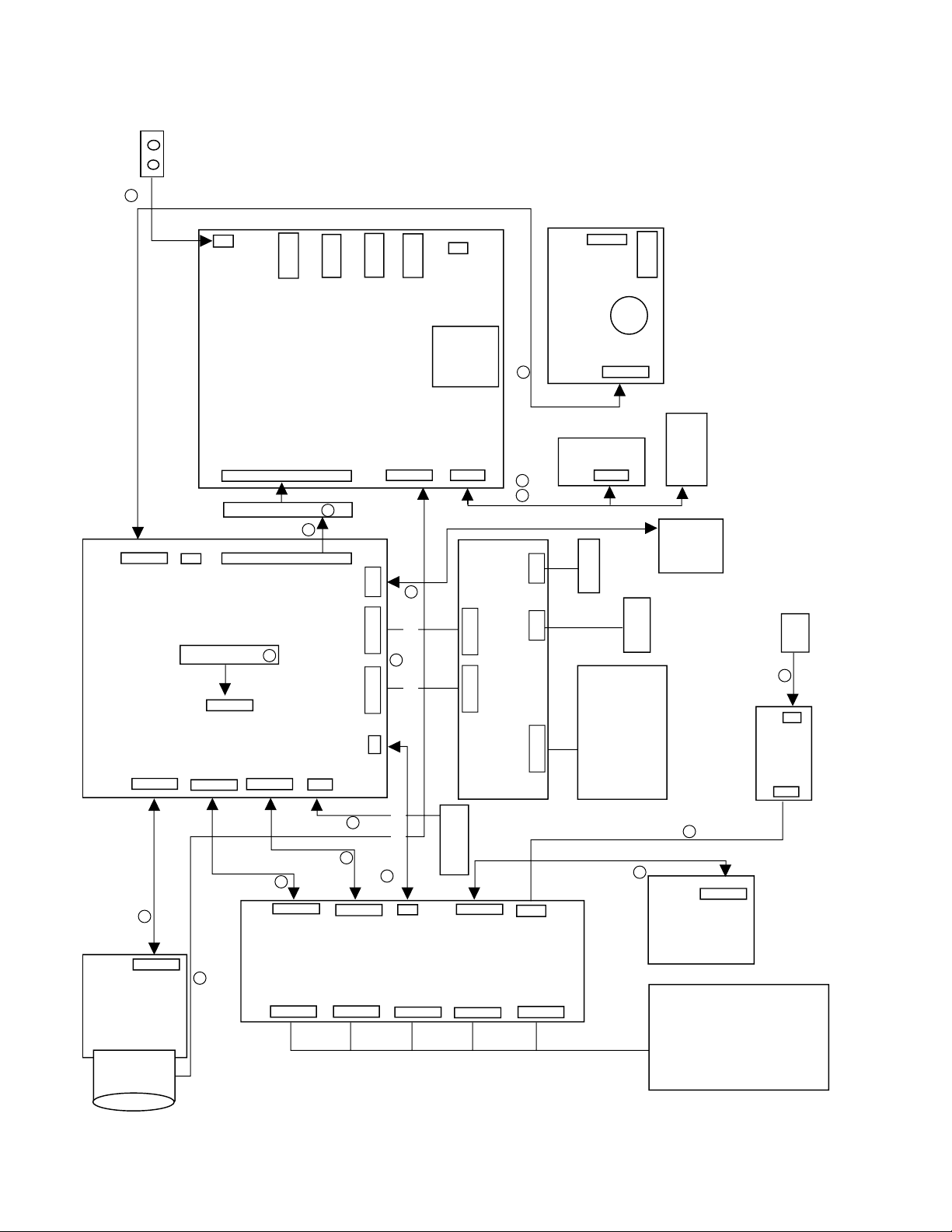

12.SIGNAL FLOW DIAGRAMS ............................................................................................................. 49

13.BLOCK DIAGRAMS ......................................................................................................................... 52

14.SCHEMATIC DIAGRAMS ................................................................................................................ 58

15.SEMICONDUCTOR LEAD IDENTIFICATION ............................................................................... 122

16.PRINTED WIRING BOARD ASSEMBLIES .................................................................................... 124

17.REPLACEMENT PARTS LIST ....................................................................................................... 141

18.PACKING OF THE SET ................................................................................................................. 163

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

VL-Z7U/Z75U/Z8U

1. IMPORTANT SERVICE NOTES

BEFORE RETURNING THE VIDEO CAMERA

RECORDER

Before returning the video camera recorder to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the video camera

recorder.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields, isolation resistor/capacitor networks, mechanical insulators etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

· Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

· Using two clip leads, connect a l.5k ohm, 10 watt resistor

paralleled by a 0.15µF capacitor in series with all

exposed metal cabinet parts and a known ground,

such as a water pipe or conduit.

· Use a VTVM or VOM with 1000 ohm per volt, or higher

sensitivity or measure the AC voltage drop across the

resistor (See Diagram).

· Move the resistor connection to all exposed metal

parts having a return path to the chassis (antenna

connections, metal cabinet, screw heads, knobs and

control shafts, etc.) and measure the AC voltage drop

across the resistor. Reverse the AC plug (a non

polarized adaptor plug must be used but only for the

purpose of completing these checks) on the set and

repeat the AC voltage measurements for each exposed metallic part. Any reading of 0.45V rms (this

corresponds to 0.3mA rms AC.) or more is excessive

and indicates a potential shock hazard which must be

corrected before returning the video camera recorder

to the user.

VTVM

AC SCALE

1.5k ohms

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

1. NOTES DE SERVICE IMPORTANTES

AVANT DE RENDRE LE MAGNETOSCOPE

Avant de rendre le magnétoscope à l’utilisateur, effectuer

les vérifications de sécurité suivantes.

1. Vérifier toutes les gaines de fil pour être sûr que les fils

ne sont pas pincés ou que le matériel n’est pas coincé

entre le châssis et les autres pièces métalliques dans le

magnétoscope.

2. Vérifier tous les dispositifs de protection tels que les

boutons de commande non métalliques, les matériaux

d’isolement, le dos du coffret, les couvercles de

compartiment et ajustement ou les boucliers, les

réseaux de résistance / condensateur d’isolement,

Ies isolateurs mécaniques, etc.

3. Pour être sûr qu’il n’y a aucun risque de choc électrique,

vérifier le courant de fuite de la maniére suivante.

· Brancher le cordon d’alimentation secteur directement

dans une prise de courant de 120 volts. (Ne pas

utiliser de transformateur d’isolement pour cet essai).

· Utiliser deux fils à pinces et connecter une résistance

de 10 watts 1,5 kohm en parallèle avec un

condensateur de 0,15 µF en série avec des pièces du

coffret métallique exposées et une masse de terre

connue telle qu’un tuyau ou un conduit d’eau.

· Utiliser un VTVM ou VOM avec une sensibilité de

1000 ohms par volt ou plus ou mesurer la chute de

tension CA entre la résistance (voir diagramme).

· Déposer la connexion de la résistance à toutes les

pièces métalliques exposées ayant un parcours de

retour au châssis (connexions d’antenne, coffret

métallique, tétes de vis, boutons et arbres de commande,

etc.) et mesurer la chute de tension CA entre la résistance.

Inverser la fiche CA (une fiche intermédiaire non polarisée

doit être utilisée à seule fin de faire ces vérifications.) sur

l’appareil et répéter les mesures de tension CA pour

chaque piéce métallique exposée. Toute lecture de

0,45 V rms (ceci correspond à 0,3 mA rms CA) ou plus

est excessive et signale un danger de choc qui doit être

corrigé avant de rendre le magnétoscope à son

utilisateur.

VTVM

ECHELLE CA

1.5KOHMS

10W

0.15 µF

SONDE D'ESSAI

VERS PIECES

METALLIQUES

EXPOSEES

CONNECTER A

UNE MASSE DE

TERRE CONNUE

2

Page 3

VL-Z7U/Z75U/Z8U

WARNING :TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE

THIS APPLIANCE TO WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC

SHOCK. DO NOT REMOVE COVER. NO

USER·SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

This symbol warns the user of uninsulated

voltage within the unit that can cause dangerous electric shocks.

This symbol alerts the user that there are

important operating and maintenance instructions in the literature accompanying this unit.

CAUTION

This symbol mark means following.

For continued protection against fire hazard, replace only with same type fuse.

(CP1; 0.75A 24V, CP2; 1.25A 24V, CP3;

1.25A 24V)

Camcorder

only

ATTENTION:POUR REDUIRE LES RESQUES D'INCENDIE OU DE CHOC ELECTRIQUE,

NE PAS EXPOSER CET APPAREIL A LA PLUIE OU A L'HUMIDITE.

ATTENTION

RISQUE DE CHOC ELECTRIQUE

NE PAS OUVRIR

ATTENTION: AFIN DE REDUIRE LES RISQUES DE

CHOC ELECTRIQUE, NE PAS RETIRER LE

COUVERCLE, AUCUN ORGANE INTERNE

NE PEUT ETRE REPARE PAR

L'UTIUSATEUR, CONFIER L'APPAREIL A

UN DEPANNEUR QUALIFIE.

Ce symbole signale à l'utilisateur la présence

d'une tension non isolée à l'intérieur de l'appareil

qui peut être la cause de secousses électriques

dangereuses.

Ce symbole avertit l'utilisateur que des instructions importantes relatives à l'utilisation

et àl'entretien se trouvent dans le manuel

accompagnant l'appareil.

ATTENTION

Ce symbole signifie que l'on devra utiliser un fusible de même type (CP1;

0,75A 24V, CP2; 1,25A 24V, CP3; 1,25A

24V) pour assurer la sécurité.

Camcorder

seulement

3

Page 4

VL-Z7U/Z75U/Z8U

NICKEL-CADMIUM BATTERY

The following program is available in the United States. Please consult local environmental

authorities concerning the availability of this or other programs in your area.

The RBRCTM Seal

SHARP participates in the RBRC

States. The RBRC

voluntarily participating in an industry program to collect and recycle these batteries. The RBRC

program provides you with a convenient alternative to placing spent Nickel-Cadmium battery packs into

the trash or municipal waste stream, which is illegal in some areas. At the end of their useful life, the

Nickel-Cadmium battery can be dropped off at the nearest collection center for recycling. For information

on the nearest collection center, call 1-800-8-BATTERY or your local recycling center. If you are located

outside the United States, contact your local authorities for information concerning proper disposal and/

or recycling of this battery. SHARP’s involvement in this program is part of our commitment to protecting

our environment and conserving natural resources.

[Footnote] *RBRCTM is trademark of the Rechargeable Battery Recycling Corporation.

CAUTION

BEFORE BATTERY DESTROY

TM* Nickel-Cadmium Battery Recycling Program in the United

TM Seal on our battery pack contained in our product indicates that SHARP is

TM

NICKEL-METAL HYDRIDE BATTERY

LITHIUM or LITHIUM-ION BATTERY

SEALED LEAD BATTERY

Battery disposal

Contains the above (Rechargeable) Battery. must be recycled or disposed of properly.

Remove the Battery from the products and contact Federal or State Environmental Agencies for

information on recycling and disposal options.

4

Page 5

VL-Z7U/Z75U/Z8U

■ PRECAUTIONS FOR USING LEAD-FREE SOLDER

1) Employing lead-free solder

"Main PWB", "CCD PWB", "Sub PWB", "LCD PWB", "Head amp PWB", "Lithium PWB", "Operation PWB", "VCR

Operation PWB", "Zoom SW PWB", "Mecha Reversion detection PWB", of this model employs lead-free solder. The

LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The alphabetical character

following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper

2) Using lead-free solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead

wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend you to

use a dedicated soldering bit. If you are not familiar with how to obtain lead-free solder or soldering bit, contact our

service station or service ranch in your area.

3) Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is 220°C which is higher than the conventional lead solder by 40°C,

and as it has poor solderability, you may be apt to keep the soldering bit in contact with the PWB for extended period

of time. However, since the land may be peeled off or the maximum heat-resistance temperature of parts may be

exceeded, remove the bit from the PWB as soon as you confirm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and

off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every

use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Lead-free wire solder for servicing

Part No. ★ Description Price Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

5

Page 6

VL-Z7U/Z75U/Z8U

2. SPECIFICATIONS

Recording/Playback Time: 90 minutes (DVM60, LP mode)

Lens Filter Diameter: 30 mm

Color Temperature Compensation: Auto white balance with white balance lock

Minimum Illumination: 3 lux (15 lux measured by EIA standard)(with gain-up, F1.8)

Still Image Compression System: JPEG base line conformance

Still Image Recording Format: JPEG (Exif2.2)

Still Image Recording Medium: SD Memory Card, MultiMediaCard

Power Requirement: DC 7.4 V

Power Consumption: 4.0 W (during camera recording in Tape Camera mode using the viewfinder in Full

Operating Temperature: 32°F to 104°F (0°C to +40°C)

Storage Temperature: –4°F to 140°F (–20°C to +60°C)

Dimensions (approx.): 3 1/

Signal System: NTSC standard

Recording System: 2 rotary heads, helical scanning system

Cassette: Digital VCR Mini DV video cassette

Tape Speed: SP mode: 18.812 mm/second

LP mode: 12.555 mm/second

Pickup Device:1/4" (6.4 mm, effective size: 4.5 mm) CCD image sensor

(with approx. 1,330,000 pixels including optical black,

effective pixels: 690,000 pixels in Tape Camera mode,

1,250,000 pixels in Card Camera mode)

Lens: 10 × optical zoom lens (F1.8, f=3.8-38.0 mm)

Monitor: 2.5" (6.4 cm) CGSilicon

Built-in Microphone: Electret stereo microphone

Auto mode with the DIS function on)

4.6 W (during camera recording in Tape Camera mode using the LCD monitor in

Full Auto mode with the DIS function on and backlight in normal mode)

Operating Humidity: 30% to 80%

" (W) × 3

4

[82.8 mm (W) × 86.2 mm (H) × 103.5 mm (D)]

Weight (approx.): 1.12 lbs (510 g)(without battery pack, lithium battery, video cassette, lens cap,

and card)

13

/

32

" (H) × 4

1

/16" (D)

AC Adapter (UADP-0339TAZZ)(VL-Z7U/C/Z75U)

AC Adapter (UADP-A015WJZZ)(VL-Z7K/Z8K)

Power Requirement: AC 110-240 V, 50/60 Hz

DC Output: 10 V

Dimensions (approx.): UADP-0339TAZZ: 50 mm (W) × 27.0 mm (H) × 65.5 mm (D)

UADP-A015WJZZ: 49 mm (W) × 27.5 mm (H) × 79 mm (D)

Weight (approx.): UADP-0339TAZZ: 100 g

UADP-A015WJZZ: 105 g

Specifications are subject to change without notice.

SERVICE INFORMATION (For the U.S.)

For the location of the nearest Sharp Authorized Service, or to obtain product literature, accessories,

supplies or customer assistance, please call 1-800-BE SHARP (1-800-237-4277) or visit SHARP's

website (http://www.sharpusa.com)

6

Page 7

3. PART NAMES

Front view

Zoom lens

Zoom microphone

shoe

VL-Z7U/Z75U/Z8U

Operation button

Left view

LCD monitor

USB terminal

Terminal cover

Flash

Stereo microphone

Earphones jack

AV terminal

DV terminal

DC IN jack

Flash sensor

Right view

STANDBY indicator

DISPLAY button

LCD LAMP button

Window cleaning cover

Viewfinder

POWER/CHARGE

(RED) indicator

DC IN jack cover

Start/Stop button

Power switch ( Camera

Recording mode/ Playback

mode select switch)

PHOTO button

Cassette holder

Power Zoom Wide angle/

Telephoto control/

VOLume control

Media Selection

switch ( Tape

mode/ Card

mode selection

switch)

STANDBY button

Speaker

Hand strap

Tripod socket*

Card slot cover

* When attaching a tripod

with a guide pin, do not

attach the pin to the bottom

of the camcorder.

Lithium battery cover

Diopter adjustment dial

Battery release

Cassette compartment

door release

Cassette compartment door

7

Page 8

VL-Z7U/Z75U/Z8U

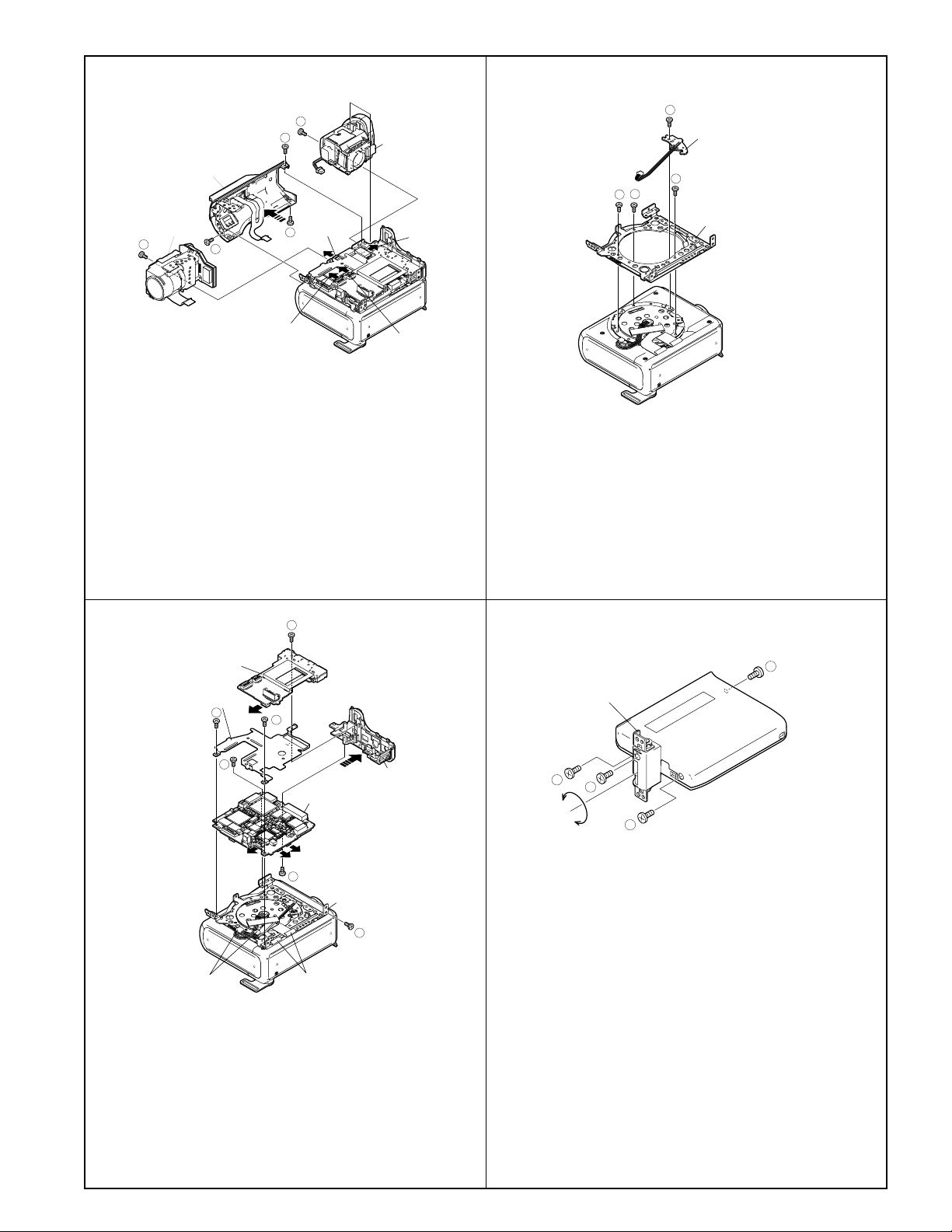

4. DISASSEMBLY OF THE SET

4-1. Procedure for disassembling the cabinet

Note:

Before removing the cabinet, turn OFF the power and make sure that the battery is not connected.

1.

· Remove the screw ((s) XiPSF14P06000).

· Remove the shoe cover by sliding it frontward, remove the screw

((f) XiPSF17P04000) and remove the shoe terminal cover.

· Remove the screw ((b) XiPSN17P03000).

· Open the LCD panel 90 degrees and remove the two screws ((x)LX-

HZ0050TAFN).

· Remove the two screws ((c)XiPSN17P04000) and remove the KS

camera front cover by pulling it frontward.

2.

· Disconnect the connector of the KS camera front cover.

· Disconnect the two LCD tilt FPCs of the liquid crystal panel.

· Remove the two screws ((r) XiPSN20P08000) and remove the LCD

panel.

· Remove the screw ((p) LX-HZ0063TAFN) and screw ((q)

XiPSN17P06000) that hold the camera L cabinet, open the terminal

cover and remove the three screws ((b) XiPSN17P03000).

Shoe cover

Shoe terminal cover

f

s

b

r

LCD panel

c

KS camera front cover

r

LCD panel

q

p

Camera L cabinet

x

x

c

b

3.

· Disconnect the hot shoe FPC of the hot shoe and remove the

camera L cabinet.

· Remove the screw ((c) XiPSN17P04000) and remove the KS

camera bottom cover.

· Disconnect the strobe FPC, remove the two screws ((a)

XiPSN17P02000) and remove the strobe unit.

å Precautions in servicing the strobe unit

Once put in the card mode, the main condenser of the strobe

unit stays still electrically charged. If touching the strobe unit or

its nearby parts, you may get an electric shock.

To avoid this, connect a 7 kΩ resistor (300-V withstand voltage)

across the main condenser for about 10 seconds. The condenser

will be discharged.

a

Strobe unit

b

LCD tilt FPC

KS camera front cover

Hot shoe FPC

a

Strobe FPC

Terminal cover

b

Connector

Camera L cabinet

KS camera bottom cover

c

8

Page 9

VL-Z7U/Z75U/Z8U

4.

b

x

Camera top cover

Camera unit

b

a

p

FPC(2)

Connector

· Remove the screw ((x) LX-HZ0050TAFN), screw ((p) LXHZ0063TAFN) and screw ((a) XiPSN17P02000), disconnect

the FPC (1) and remove the camera top cover.

· Remove the screw ((b) XiPSN17P03000) from the camera

unit, disconnect the FPC (2) and remove the camera unit.

· Remove the screw ((b) XiPSN17P03000), disconnect the

connector and FPC (3) and remove the VF.

VF

FPC(3)

FPC(1)

6.

b

Mechanism reversion detection PWB unit

u

u

u

PWB mounting angle

· Remove the screw ((b) XiPSN17P03000) and remove the

Mechanism reversion detection PWB unit.

· Remove the three screws ((u) LX-BZ0221TAFC) and remove

the PWB mounting angle.

5.

Sub PWB unit

Radiating angle

b

b

Connector

x

b

Terminal cabinet

Main PWB unit

x

PWB mounting angle

x

Tilt FPC

· Disconnect the two connectors of the sub PWB unit and main

PWB unit.

· Remove the two screws ((b) XiPSN17P03000) from the

radiating angle, remove the screw ((b) XiPSN17P03000)

from the PWB unit and remove each unit.

· Disconnect the two FFCs of the main PWB unit.

· Remove the two screws ((x) LX-HZ0050TAFN), remove the

screw ((x) LX-HZ0050TAFN) from the PWB mounting angle

and remove the terminal cabinet.

7.

b

LCD tilt unit assembly

b

a

b

· Turn the LCD tilt unit assembly 90 degrees.

· Remove the three screws ((b) XiPSN17P03000).

· Remove the screw ((a) XiPSN17P02000).

9

Page 10

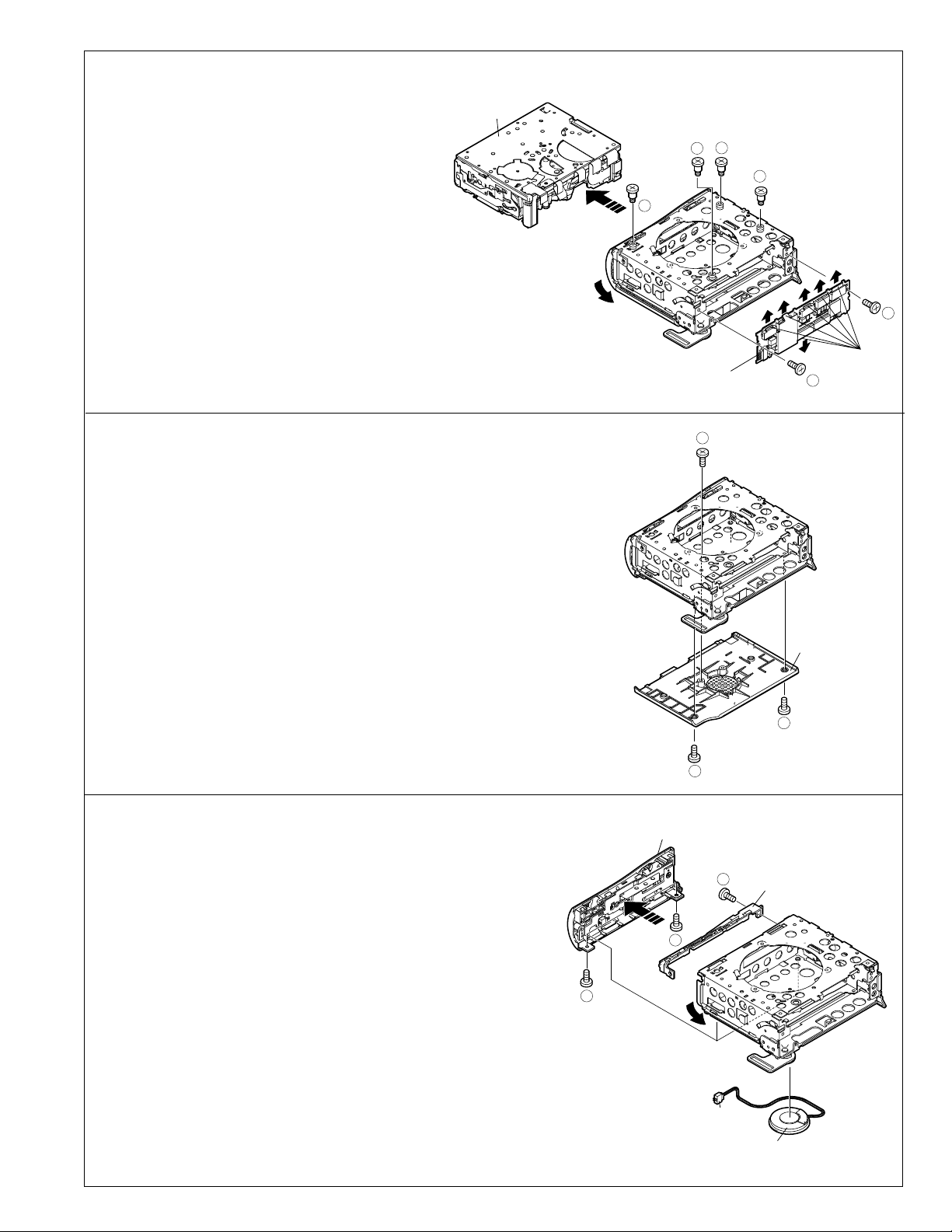

VL-Z7U/Z75U/Z8U

4-2. Procedure for disassembling the cabinet

1.

· Remove the three screws ((e) XiPSF17P03000) remove the screw

((d) XiPSF17P02000) and remove the VCR bottom cover.

2.

· Remove the two screws ((e) XiPSF17P03000) and remove the tilt

cover.

· Remove the VCR front cover with the cassette cover opened.

· Disconnect the connector and two tilt FPCs, remove the three screws

((h) LX-BZ0220TAFC) and remove the KS camera tilt.

e

VCR bottom cover

e

e

d

e

e

Tilt cover

How to remove the VCR front cover

1. Remove the two couplings and turn the VCR front cover about 20 degrees in

the direction indicated by (1).

2. Turn the VCR front while sliding it in the direction indicated by (2) to disengage

the internal lug.

* If the VCR front cover is removed by turning it forcedly in the direction indicated

by (1), the internal lug may be damaged.

1

If the VCR front cover is removed

only by turning it in the direction

indicated

The internal lug

may be damaged

2

3.

· Remove the screw ((f) XiPSF17P04000) with the cassette lid opened,

disconnect the operation PWB FFC and remove the KS VCR operating

cover.

VCR front cover

h

h

KS VCR operating cover

h

KS camera unit

Tilt FPC

Connector

f

10

Operating PWB FFC

Page 11

4.

k

a

a

w

w

w

Mechanism

Head amp PWB unit

FPC

· Disconnect the six FPCs of the head amp circuit board

unit.

· Remove the two screws ((a) XiPSN17P02000) and

remove the head amp PWB unit.

· Remove the three screws ((w) LX-BZA022WJFN) and

remove the screw ((k) LX-BZA023WJFD).

· Remove the mechanism with the cassette lid opened.

VL-Z7U/Z75U/Z8U

5.

· Remove the screw ((x) LX-HZ0050TAFN).

· Remove the two screws ((d) XiPSF17P02000) and remove the cassette

lid.

6.

· Remove the two screws ((d) XiPSF17P02000).

· Disconnect the connector of the speaker while removing the KS upper

lid cover with the cassette control lid opened.

· Remove the screw ((d) XiPSF17P02000) and remove the lock support

cover.

· Remove the speaker.

d

KS upper lid cover

d

x

Cassette lid

d

d

Lock support cover

11

d

Connector

Speaker

Page 12

VL-Z7U/Z75U/Z8U

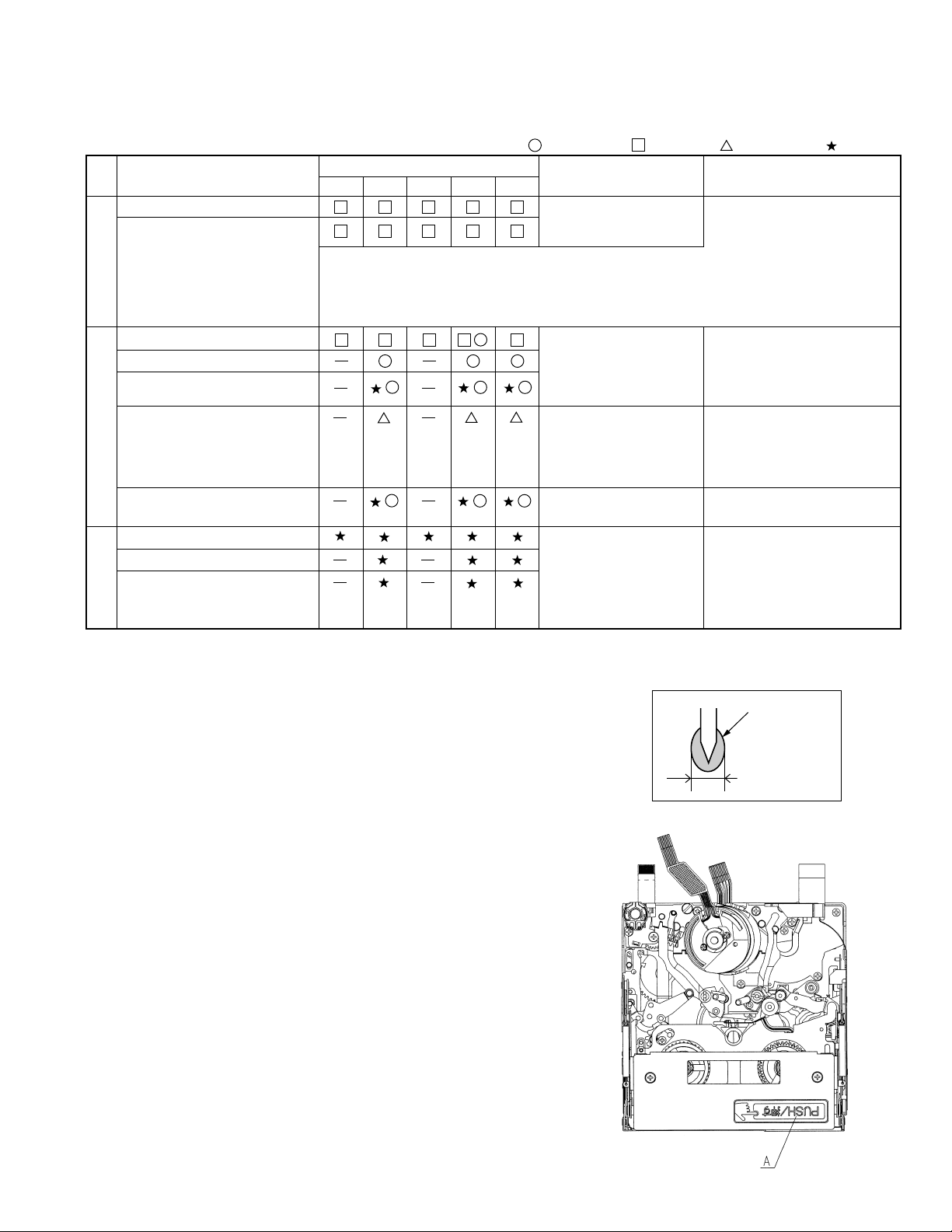

5. MECHANISM ADJUSTING JIGS AND PARTS

5-1. Mechanism checking and adjusting jigs

<Note: Order of descriptions>

Sketch

1. Name

2. Part code

3. Code

* Model number and usage

1. Cassette torque

meter for PB

2. 9DASD-1015

3. DB

* 1mN·m/1.5mN·m

50 or more

ø2

No.0 Phillips bit

No.00 Phillips bit

1. Torque driver

150mN·m

2. JiGTD1500RTDH

3. CB

1. Torque gauge

2. JiGTG0045

3. CN

* For measurement of VS-

REW winding torque

1. Master plane

2. 9EQMP-VLPD1

3. CL

* For checking of

1. Torque gauge head

2. 9EQTGH-DH5000

3. BW

*

For torque gauge shown

left

1. Height adjustment jig

2. 9DAHG-PD1

3. BZ

* For height adjustment

height of reel table

1. Bit for hexagon nut

1. Alignment tape – (I)

2. VR3-GAZXS

3. CF

* Adjustment of running

system

(Linear signal)

1. Alignment tape – (II)

2. VR3-GTZQS

3. CG

* For adjustment of SW

point(Color bar signal)

*

90ADVC-TAPE available

with opposite side

distance of 3 mm

2. 95CM22001

3. BL

* For installation of Tu

guide nut

5-2. Parts for periodic inspection and maintenance

1. Oil

Cosmo Hydro HV22

2. 9EQ-OiL-HV22

3. AE

* Cosmo Oil Co., Ltd.

1. Cleaning paper

2. JiGDUSPER

3. AP

* DUSPER ∑ (SIGMA)

(Ozu Co., LTD.)

<How to make mechanism checking and adjusting jigs>

(1) Reel hub for back tension measurement (Fig.1)

1) Have the reel hub of a commercially available cassette

tape ready.(Disassemble the cassette tape and remove

the tape from the reel hub.)

2) Attach one end of a thread (having a length of about

20cm) to the reel hub using Scotch tape etc.

3)

Attach a weight of about 0.21N to the top face of the reel hub.

(2) Thread for pinch roller press force measurement

1) Have a commercially available thread having a length of

about 20cm ready.

1. Dry grease CFD-409Z

* Sankei Chemical Co., LTD.

1. Grease

Molykote YM-103

2. 99FGREASEYM103

* Dow Corning

2) Tie both ends together to loop the thread.

Thread

1. Tension gauge 4N

2. JiGSG0400

3. BK

* For measurement of

pinch roller press force

1. Driver for height

adjustment

2. 9EQDRiVER-DH5

3. BC

<Miscellaneous>

(1) Vernier calipers

(2) Precision screwdriver

(Phillips head and slot-

ted)

(3) Long-nose pliers

(with thin tips)

(4) Tweezers

<Note: Order of descriptions>

Weight

Fig. 1

1. Dial tension gauge

2. 9DAPTG-10-10W

3. CA

* PTG-10

* For adjustment of guide

roller

* Bit shape

1.4

3

1. Name

2. Part code

3. Code

* Model number and usage

1. Cleaning liquid

Industrial ethyl alcohol

* Commercial item

1. Loctite adhesive (1401B)

* Three Bond

1. Ultrathin cotton swab

* Commercial item

Reel hub

Fig. 2

(see figure below)

Tolerance ± 0.1

2

Tip thickness 0.5

Thread

12

Page 13

VL-Z7U/Z75U/Z8U

6. INSPECTION AND MAINTENANCE ITEMS AND INTERVALS

In order to maintain the quality of the mechanism section, perform the following maintenance and inspection. After repairing the

mechanism section, perform the following maintenance regardless of the number of hours of use by the user.

6-1. Maintenance and inspection list

Inspection and

maintenance location

Tape running section (See 8-3.)

Drum section, Video head

(See 8-3.)

Running system

Pinch roller

Capstan motor (Timing belt)

Swing arm

S reel table, Tu reel table

Center gear boss

Relay pulley shaft

Driving system

Loading motor

Mode SW

Abnormal noise

PB and VS/R winding torque

PB, VS/R and loading back tension

S reel table unloaded torque

Performance check

Number of hours of use (h)

500 1,000 1,500 2,000 3,000

<Rollers>

• Replace if abnormal rotation or swing (large) is found.

<Others>

• Cleans the portions that come in contact with the tape (the lower

drum helical portion in particular). Use the specified cleaning liquid.

• • • Replace. • • • Clean. • • • Lubricate. • • • Check.

Symptoms observed at the

time of maintenance

• Block noise

• Clogging of head

• Damage to tape

• Tape not running

• Tape sagged

• Block noise

• Abnormal noise

• Abnormal noise

• Ejecting cannot be made.

• Mode cannot be set.

• Tape not running

• Tape sagged

• Damage to tape

• Abnomaly in reproduced

picture

[Oil] Cosmo Hydro HV22

[Grease] Molykote YM-103

Sankei Chemical CFD-409Z

Notes and remarks

Note:

If no envelope output is obtained

in spite of the video head being

cleaned, replace the drum

component.

(If the envelope output is normal,

refer to "11. USEFUL TIPS".)

• Replace if any abnormal

condition is found.

• Apply oil.

[Oil]

Cosmo Hydro HV22

Note:

Apply oil to the shaft and

lightly wipe it off with a cloth.

• Replace if any abnormal

condition (noise etc.) is found.

• If a part is out of spec, replace

it.

[Loctite adhesive] Three Bond 1401B

[Cleaning liquid] Industrial ethyl alcohol

6-2. Cautions in handling the mechanism

(1)Cut washers removed at the time of part replacement etc. should be

replaced with new ones without fail.

(2) Because no volume adjustment is available in this mechanism, cleaning or

part replacement should be performed if the setting is not satisfied.

(3) About oil

a) Be sure to use the specified oil. (If any oil other than the specified oil is

used, various troubles will occur.)

b) When lubricating the bearing, be sure to oil free from foreign particles

such as dust. (If oil in which foreign particles such as dust are mixed is

used, it will cause wear and seizure to the bearing.)

c) The term "One drop of oil" here means the amount of oil on the point of

a needle etc. shown in Fig.1.

(4) Repairing of circuits, final adjustment of running system, etc. should be

performed with the cassette controller assembly installed in the mechanism.

(5) When operating the mechanism singly, apply voltage to the loading motor

to drive it. The voltage between the terminals should be 3 to 4V DC. (Do

not apply external voltage to the loading motor with the mechanism

connected with the main circuit board. Doing so could cause a failure.)

(Turning the gears forcedly by hand may cause them to get damaged.)

When placing the mechanism singly, use an appropriate spacer so that the

capstan motor is not rubbed.

(6) When installing the cassette controller, push the portion indicated by "A" in

Fig.2. Do not push other portions.

(7) Take care not to deform the components of the mechanism.

13

Oil

Ø1.5 or less

Fig. 1

Fig. 2

Page 14

VL-Z7U/Z75U/Z8U

7. ADJUSTING AND CHECKING OF MECHANISM

The items described here are relevant to the general on-site servicing (field service). This section does not cover adjustment and

replacement for which sophisticated equipment, jigs and techniques are required.

In order to maintain the initial characteristics of the mechanism, it is necessary to perform maintenance and inspection and also it is

essential not to damage the tape etc. In the case of an adjustment that requires a jig, be sure to use the specified jig.

<Caution>

(1) When adjusting and checking the mechanism, be sure to see that the power supply and the status are as indicated in

Caution on the title.

(2) Do not apply external voltage to the loading motor with the mechanism connected with the main circuit board. (Doing

so could cause a failure.)

(3) When running the tape, be sure to do so with the cassette controller assembly installed.

7-1. Checking of PB (REC) winding torque

AC adapter used, Cassette controller assembly installed

(1) Set the torque cassette with the cassette controller installed in the mechanism. In the SP record mode (or in the PB mode

if signals have been SP-recorded on the tape), check that the winding torque is within spec.

<Spec for PB (REC) winding torque>(If there is a torque ripple, read the center value.)

0.7+0.2/-0.05N·m, Ripple: 0.1mN·m or less

7-2. Checking of VS-REW winding torque

AC adapter used, Cassette controller assembly not installed (Mechanism only)

(1) Remove the cassette controller, turn ON the down SW while referring to 9-3, operate

in the test mode (T01) and select the VS-REW mode.

(2) Set the torque gauge in the S reel table, push the tip of the tension pole with your finger

in the direction shown by Arrow A to release the tension band, and check that the

winding torque is within spec. (Fig.1) (Do not apply the own weight of the torque

gauge or rotate it during measurement.)

<Spec for VS-REW winding torque>

(If there is a torque ripple, read the center value.)

1.5 ± 0.15N·m, Ripple: 0.15mN·m or less

(3) After checking the winding torque, remove the torque gauge and turn OFF the down

SW. The mechanism will automatically go into the standby mode.

Fig.1 How to release the tension

band when measuring the

VS-REW winding torque

7-3. Checking of height of reel table

3 to 4V DC, Cassette controller assembly not installed (Mechanism only)

(1) Remove the cassette controller. (Refer to 9-2.)

(2) Apply 3 to 4V DC to the loading motor while referring to 9-1 and select the

PB mode.

(3) Fit the holes of the master plane to the two guides (portions A and B) shown

in the Fig.2, taking great care not to allow master plane to strike the running

parts such as the drum and guide roller or the MIC contact.

(4) Using a pair of vernier calipers etc., measure the heights of the reel-supporting

faces of the S reel table and Tu reel table from the top face of the master plane

and check that the measured heights satisfy the set values. (Fig.3)

When measuring the height of the S reel table, push the tip of the tension

pole with your finger in the direction shown by Arrow A to release the tension

band. (Fig.1)

(5) If the measured height does not satisfy the set value, replace the reel table

and make checking again.

<Note> After replacement, select the L start mode (see 9-1) and check that the

reel table rotates smoothly.

Reel-supporting face

2.4±0.1

Set value of height

of reel table

(3)

Fig.3

A

MIC contact

Fig.2 Checking of reel table

2.4±0.1

Set value of height

of reel table

B

14

Page 15

VL-Z7U/Z75U/Z8U

7-4. Checking and adjusting of tension pole position during

REC (PB)

3 to 4V DC, Cassette controller assembly not installed (Mechanism only)

(1) Checking

Check that the tension pole is located in the prescribed position as shown in Fig.4

at the start of a 60-minute tape.

If the tension pole is not located in the prescribed position, take out the tape and

make adjustment according to the procedure shown below.

(2) Adjusting (See Fig.4.)

1. Select the PB mode without setting a tape.

2. Slightly loosen the screw 1 (to such an extent that the T band adjustment base

2 can be moved.)

3. If the tension pole is dislocated inward from the prescribed position, shift the

T band adjustment base 2 in the direction shown by Arrow (A). If it is dislocated

outward from the prescribed position, shift the T band adjustment base 2 in the

direction shown by Arrow (B). Then fix the T band adjustment base 2 with the

screw 1.

(For how much the T band adjustment base is to be shifted, refer to Fig.4.)

4. Check the tension pole position as described in "(1) Checking" above.

5. If out of position, make readjustment.

7-5. Checking and adjusting of REC (PB) back tension

torque

AC adapter used, Cassette controller assembly installed

(1) Checking

Set the torque cassette (SD-1015). In the SP record mode (or in the PB mode if

signals have been SP-recorded on the tape), check that the feed-side torque is

within the following spec.

<Spec>(If there is a torque ripple, read the center value.)

0.55 ± 0.05N·m

(2) Adjusting (See Fig.5.)

If the measured back tension torque is out of spec, make adjustment according

to the following procedure.

1. Slightly loosen the screw 3.

2. If the back tension is higher, shift the T-SPR adjustment ANG in the direction

shown by Arrow (D). If it is lower, shift the T-SPR adjustment ANG in the

direction shown by Arrow (C).

3. After adjusting the back tension torque, fix the T-SPR adjustment ANG with the

screw 3. Apply loctite adhesive to screw 3.

<Reference>

Screw tightening torque: 0.04 N·m

Apply loctite

adhesive.

Tension pole position

(Based on drum base outside shape)

0±0.3

Fig.4 Adjusting of position (tape exists)

Fig.5 Checking (tape exists)

Drum base

T pole

T band adjustment

base 2

Screw 1

Screw 3

T-SPR adjustment ANG4

7-6. Checking of S reel table unloaded torque

3 to 4V DC, Cassette controller assembly not installed (Mechanism only)

(1) Remove the cassette controller assembly, apply 3 to 4V DC to the loading motor

and select the L start mode. (See 9-1.)

(2) Move the swing arm to the Tu reel table side. At this time, take care not to damage

the gears etc. (See Fig.6.)

(3) Set the reel hub for back tension measurement on the S reel table.

(4) Using the dial tension gauge, pull the thread of the reel hub in the direction shown

by Arrow A and check that the tension is within spec.

<Spec>

(If the tension fluctuates, read the center value.)

10mN or less

Fig.6 How to measure the S reel table unloaded torque

15

Move the swing arm to

A

the Tu reel table side.

Page 16

VL-Z7U/Z75U/Z8U

7-7. Checking of loading back tension

3 to 4V DC, Cassette controller assembly not installed (Mechanism only)

(1) Apply 3 to 4V DC to the loading motor and select the L start mode. (See 9-1.)

(2) Move the swing arm to the S reel table side. At this time, take care not to damage

the gears etc. (See Fig.7.)

(3) Set the reel hub for back tension measurement on the Tu reel table.

(4) Using the dial tension gauge, pull the thread of the reel hub in the direction shown

by Arrow A and check that the tension is within spec.

<Spec>

(If the tension fluctuates, read the center value.)

27.5 ± 7.5mN

7-8. Checking of VS-REW back tension

3 to 4V DC, Cassette controller assembly not installed (Mechanism only)

(1) Apply 3 to 4V DC to the loading motor and select the VS-REW mode. (See 9-1.)

(2) Move the swing arm to the S reel table side. At this time, take care not to damage

the gears etc.

(3) Set the torque gauge in the Tu reel table.

(4) While turning the torque gauge counterclockwise (one turn in three seconds),

check that the torque is within spec.

<Spec>

(If the tension fluctuates, read the center value.)

0.8+0.2/-0.05mN·m

Move the swing arm

to the S reel table

side.

Fig.7 How to measure the loading back tension

A

7-9. Checking of pinch roller press force

3V DC, Cassette controller assembly not installed (Mechanism only)

(1) Hook the thread for pinch roller press force measurement over the pinch lever (position A in Fig.8).

(2) Put the mechanism into the PB mode to press the pinch roller against the capstan shaft.

(3) Hook the thread for pinch roller press force measurement over the tension gauge and pull the tension gauge in the direction shown

by Arrow B in Fig.10 so that the pinch roller is slightly separated from the capstan shaft.

(4) Return the pinch roller gradually and read the value indicated when the pinch roller comes in parallel contact with the capstan shaft

(see Fig.9). Check that the read value is within the following spec.

<Spec>

1.8+0.4/-0.4N

<Note> After measuring the press force of the pinch roller, promptly exit from the PB mode to separate the pinch roller from the capstan

shaft. (If the pinch roller is left pressed against the capstan shaft for a long time, the pinch roller will be deformed.)

Capstan shaft

Pinch roller

B

Fig.8

A

OK

Fig.9

NG

16

Right guide

Fig.10

Page 17

VL-Z7U/Z75U/Z8U

8. ADJUSTMENT OF RUNNING SYSTEM

8-1. Outline of adjustment of running system

(Replacement parts)

· Tu guide and arm

· Slide chassis

(Replacement parts other

than above)

· Pole base

· Guide roller

· Drum assembly

· Cap motor, etc.

8-2. Adjustment of height of running system

· After replacement of the Tu guide and slide chassis, adjust the height of the Tu guide using the height adjustment jig.

· If wrinkles are found in the tape, turn the Tu guide to remove them.

(For further details, refer to "Coarse adjustment of running system".)

· After adjusting the Tu guide height, apply screw loctite at the tip of the shaft.

Readjustment of height

Presetting of height not

necessary

Tu guide

Installation of

cassette controller

View A

Preparations for

adjustment of

Running system

Adjusting

procedure(8-3)

Height

adjustment jig

Coarse adjustment

of Running system

Adjusting

procedure(8-4)

Final adjustment

of Running system

Adjusting

procedure(8-5)

Bottom edge

Apply it in this direction.

Master plane

Height

adjustment jig

View A

Align the top face of the lower flange of the Tu

guide with the bottom edge of the height

adjustment jig.

After adjusting the height, turn the head

clockwise 180 degrees.

Master plane

8-3. Preparations for adjustment of running system

Measuring instrument and Jig : Oscilloscope, Adjustment remote control, Height adjustment screwdriver, Alignment tapes (for

adjustment of running system and adjustment of SW point), Master plane, Height adjustment jig

<Method and description>

(1) Clean the surfaces that come in contact with the tape. (Clean

well the drum surface and the lower drum helical surface in

particular.)

(2) Install the cassette controller.

(3) Connect the oscilloscope to each TP of the joint circuit board.

(4) Turn ON the power of the AC adapter.

(5) Select TEST mode T-05 with the adjustment remote control.

(6) Play back the alignment tape for running system adjustment

and check that the tape is moving in the SP mode.

(7) While observing the PB envelope on the oscilloscope, adjust

the running system so that the envelope becomes flat in

states of [+1/4 shift] and [-1/4 shift].

(Each time the PB key is pressed, the shift amount changes

as shown below.)

+1/4 shift - Normal - -1/4 shift - Normal

S guide

Tension pole

Sup guide roller

Drum

Tu guide roller

Tu guide

Capstan shaft

Pinch roller

Reel

17

Page 18

VL-Z7U/Z75U/Z8U

8-4. Coarse adjustment of running system

(Cassette controller installed)

1. Adjustment of height of Su and Tu guide rollers

<Method and description>

(1)Play back the alignment tape for running system

adjustment and make adjustment so that the inlet

and outlet sides of the envelope become flat.

(2)In states of [+1/4 shift] and [-1/4 shift], make

adjustment in the same manner as described in (1)

above.

2. Checking of V/SR envelope waveform

<Method and description>

(1) In the V/SR mode, check that the envelope waveform

is shaped uniformly.

(2) If the envelope waveform is not shaped uniformly,

fine-adjust the guide roller and Tu guide.

NG

±1/4 shift

Inlet side Outlet side

Normal

A

Make adjustment so that A B.

B

NG

±1/4 shift

3. Checking for wrinkles in tape

<Method and description>

(1) In the PB mode and V/SR mode, check the tape for

distortion between the Tu guide and the pinch roller.

- If wrinkles are found, make adjustment within a

range of ±180 degrees.

Pinch roller

Wrinkle

Tu guide

Distortion

Distortion

- After making adjustment, apply loctite adhesive to

the tip of the shaft.

4. Checking of envelope waveform rise time

<Method and description>

(1) Check the envelope waveform rise time in switching from the V/SR mode to the PB mode. - 5 seconds or less

(2) Check the envelope waveform rise time in switching from the STOP mode to the PB mode. - 5 seconds or less

8-5. Final adjustment of running system

(Cassette controller installed)

1. Adjustment of height of Sup and Tu guide rollers

<Method and description>

(1) If the ratio of MIN to MAN of the envelope waveform is less

than 60%, adjust the height of the guide roller again. (See

Fig.1.)

(2) Perform unloading and then loading again, select the PB

mode and check that there are no significant changes in

the envelope waveform.

Fig.1

2. Adjustment of PB SWP

<Method and description>

(1) Play back the alignment tape for SW point adjustment.

(2) Using the adjustment remote control, make SWP automatic adjustment.

(3) Check that an OK is given as a result of self-judgment. In the case of a NG, adjust the GR height again.

* After replacement of the mechanism and drum, adjust the phase and equalizer using the adjustment remote control.

(Refer to "10. ADJUSTING THE ELECTRICAL CIRCUITS".)

18

Page 19

VL-Z7U/Z75U/Z8U

9. ASSEMBLING OF MECHANISM SECTION AND PART REPLACEMENT

(DISASSEMBLING AND ASSEMBLING)

This section describes the method of assembling the mechanism section and the method of part replacement.

For how to remove the cabinet etc., refer to " 4. DISASSEMBLY OF THE SET".

<Cautions>

1. Cut washers removed at the time of part replacement etc. should be replaced with new ones without fail.

2. When assembling the mechanism, take care to prevent screws, washers and foreign matter from getting into it. If such things

get into the mechanism, it will cause the mechanism to malfunction.

3. Be sure to use the specified cleaning liquid, oil, grease and loctite adhesive shown below. Failure to do so will cause the

mechanism to malfunction.

Oil: Cosmo Hydro HV22 (Cosmo Oil) Loctite adhesive: 1401B (Three Bond)

Grease: Molykote YM-103 (Dow Corning), Suncall CFD-409Z (Sankei Chemical Co., LTD.)

Cleaning liquid: Industrial ethyl alcohol

9-1. Mechanism mode

To operate the mechanism singly, apply 3 to 4V DC to the loading motor.

(Do not apply external voltage to the loading motor with the mechanism connected with the main circuit board. Doing so could cause a failure.)

(1) Ejection mode

This mode is used to take out a cassette. In this mode, the

ejection lever is shifted farthest in the direction shown by

Arrow A. (In this mode, the cassette controller assembly

cannot be locked.)

(2) Standby mode

This mode is used to set a cassette. In this mode, the slide

chassis is farthest away from the drum and the ejection lever

is turned (the cassette controller assembly can be locked).

(The tip of the ejection lever is hidden behind the main chassis

and the moving part of the down SW is visible.)

Ejection lever

A

Back view

Main chassis

EJECTION MODE

(3) L start mode

This mode is used for the Tu reel hub to take up the tape

of a cassette whose leader tape is visible. (In this

mode, the S main brake is located away from the S reel

table.)

Down SW

(moving part)

Ejection lever

Main chassis

STANDBY MODE

(4) Stop mode

This mode is used for stopping (camera mode:

RecLock). In this mode, the S and T pole bases are

pressed against the drum base and the S main brake

is engaged with the S reel table. However the pinch

roller and capstan shaft are separated.

S pole base

Drum base

T pole base

Capstan shaft

Back view

Pinch roller

S reel table

S main brake

L START MODE

S reel table

S main brake

STOP MODE

19

Page 20

VL-Z7U/Z75U/Z8U

(5)PB (Record, Fast forward, Fast rewind, VSF and VSR)

mode

This mode is used for playback, recording, fast-forwarding,

fast -rewinding, VSF and VSR. In this mode, the pinch roller

is pressed against the capstan shaft and the S main brake

is located away from the S reel table.

Capstan shaft

Pinch roller

S reel table

S main brake

PB (RECORD, FAST FORWARD,

FAST REWIND, VSF AND VSR) MODE

9-2. Cassette controller assembly

<Procedure for removing the cassette controller> (The cassette controller can be installed and removed without removing the cover.)

(1) Apply 3 to 4V DC to the loading motor to establish the standby mode. When removing the cover from the cassette controller, remove

the tow screws (A). (See Fig.1.)

(2) Push the lock lever in the direction shown by the arrow and move up the cassette controller. (See Fig.2.)

(3) Remove the two screws (C) and remove the down guide (D) in the direction shown by the arrow (E). (See Fig.3 and Fig.4.)

(4) Shift the cassette controller in the direction shown by the arrow (F), remove the inner arm guide shaft L and the groove of the inner

arm R toward the inside of the mechanism, and turn the cassette controller. (See Fig.5 and Fig.6.)

(5) Turn the cassette controller in the direction shown by the arrow (H) and shift it in the direction shown by the arrow (I) to remove it

from the slide chassis. (See Fig.7.)

(A)

At this position, remove the inner arm guide

shaft L toward the inside of the mechanism.

Fig.1 Fig.2

(C)

(C)

(D)Down guide

E

Fig.3

(F)

Fig.5 Fig.6

E

Fig.4

(F)

(B)

At this position, remove the groove of the inner arm

R toward the inside of the mechanism.

20

Page 21

VL-Z7U/Z75U/Z8U

H

II

Fig.7

H

Fig.8

9-3. Method of operating on the circuit board with the cassette controller assembly removed

If this method is performed improperly, the tape may be damaged. Therefore do not use this method except in special cases

such as measuring the VSR torque. Be sure to follow the cautions shown in this manual.

(1) Apply 3 to 4V DC to the loading motor to establish the standby mode.

(2 Insert a sheet of thick paper folded in two as shown in Fig.9 into the position shown in Fig.10 to turn OFF the down SW.

(Pass the paper along the heavy line in the figure.)

Note) To go into the REC mode, press the pin of the recognition SW.

(3 Selecting the test mode (T-01) with the adjustment remote control without setting a tape will make it possible to operate

the mechanism with the mode keys.

(4) For ejecting, remove the paper inserted in step (2) above.

Pass the folded paper between

the slide chassis and the lock cam

to press the moving part of the

down SW.

34~36

5

Fold a sheet of paper

in two.

Fig.9

Recognition SW pin

Fig.10

Press

Moving part of

down SW

21

Page 22

VL-Z7U/Z75U/Z8U

9-4. Phase-adjust

Phase-adjust the following parts.

(1) Mode SW

(2) Main cam

(3) Sub cam (The main cam and sub cam should be also phase-adjusted for the chassis.)

(4) S loading arm

(5) Tu loading arm

(6) Loading drive gear (main cam, sub cam, S loading gear)

Note) Check the marker position carefully before disassembling.

Note) When installing the loading drive gear, check that the main cam, sub cam, S loading gear are all phase-adjusted.

(5)Tu loading arm ass'y(4)S Loading arm ass'y

(1)Mode SW

Phase adjustment

Phase adjustment

mark

hole (for chassis)

(3)Sub cam

Phase adjustment

(gear section)

Phase adjustment

hole (for chassis)

(2)Main cam

Phase adjustment

mark

(4)S loading arm ass'y

Phase adjustment

mark

Phase adjustment hole

(for chassis)

(6)Loading gear drive gear

Fig.1

(5)Tu loading arm ass'y

Fig.2

22

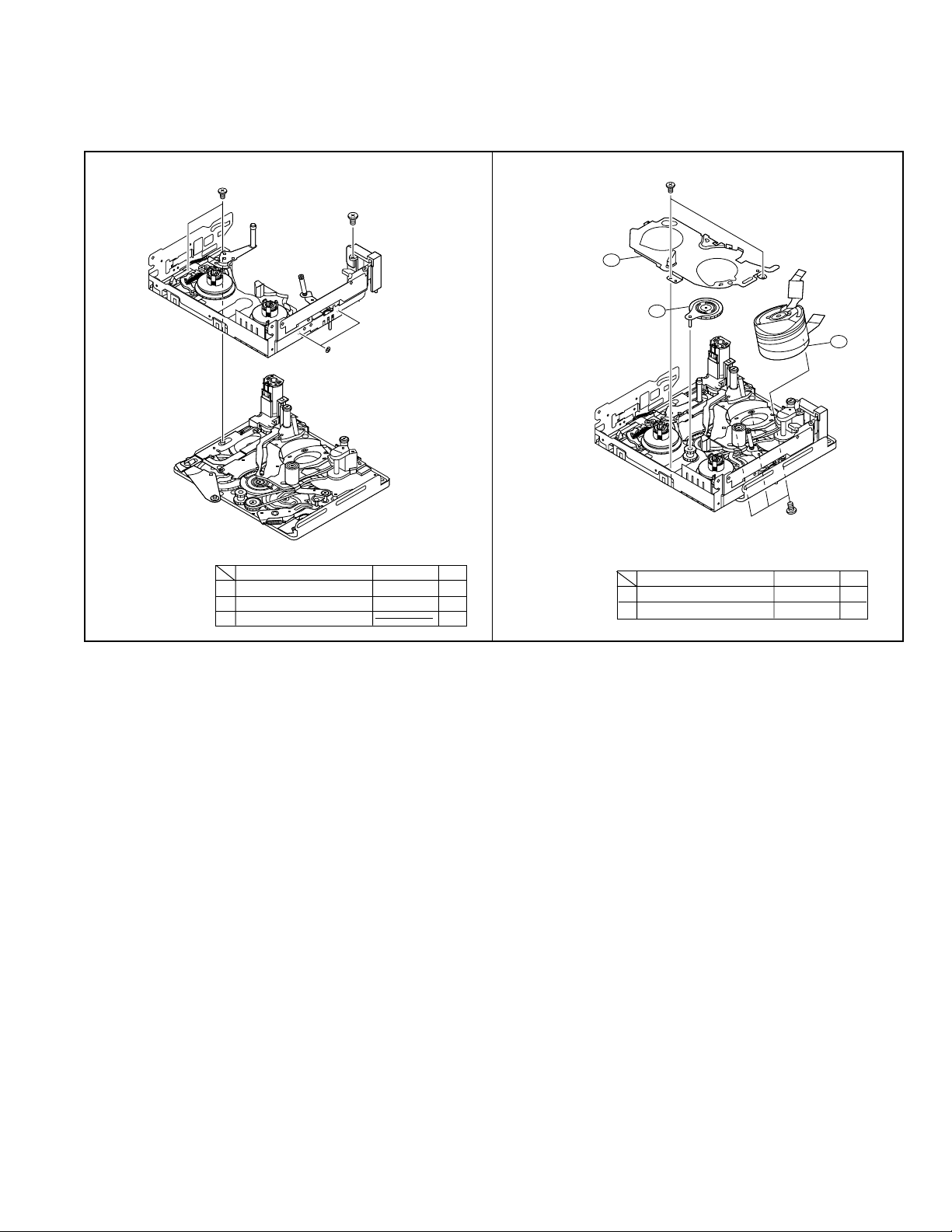

Page 23

9-5. Assembling method

9-5-1. Method of assembling the main chassis assembly

Note) For reference, numbers are prefixed to parts names to show the sequence of assembly.

(For the greasing/oiling and cleaning locations, refer to the diagram of greasing/oiling locations.)

VL-Z7U/Z75U/Z8U

1.

2.

302

(1)Mode SW

304

(3)Main cam

(4)T arm operating lever

(3)S brake operating

lever

308

307

(2)SL drive lever

A

303

(2)LM/Mode FPC

305

(4)Ejection lever

Type

Tightening torque

A M1.4xL1.6(Special screw) 0.4mN·m2

H

309

B

306

(1)Sub cam

Q'ty

4.

5.

321

(4)S pole base loading

arm ass'y

322

(6)S Loading gear

324

(2)Loading drive

gear

E

(1)T pole base loading arm

(5)S press SPR

323

ass'y

320

319

(3)Tu loading

gear

Type

318

(2)Tu press SPR

D

(7)S loading arm

sub ass'y

Phase adjustment

Tightening torque

D S Tight M1.4xL3.0 0.4mN·m3

E M1.4xL2.0

B

(t0.2 special screw)

G

F

325

(1)Guide rail

0.4mN·m1

Q'ty

In alignment with

chassis hole

BCWø1.2-ø3.0t-0.25 1

Type

Tightening torque

Q'ty

Phase adjustment (back)

HCWø0.7-ø1.8-t0.2 1

In alignment with

3.

C

B

316

(7)Relay pulley

314

(1)SLA support

310

C

Type

(4)TLA support

(3)DEW sensor

312

311

(2)L Motor ass'y

D

(5)Center gear

C

315

(7)Capstan motor

ass'y

313

(6)CAP FPC protection tape

Tightening torque

6.

Q'ty

chassis hole

(1)Pinch press

lever ass'y

(2)Pinch press SPR

C S Tight M1.4xL2.0 0.4mN·m5

D S Tight M1.4xL3.0 0.4mN·m1

BCWø1.2-ø3.0t-0.25 1

Phase adjustment (front)

F M1.4xL1.5

Type

(t0.2 special screw)

Tightening torque

Q'ty

0.4mN·m1

G M1.2xL4.6 0.4mN·m1

(t0.2 particularly special screw)

BCWø1.2-ø3.0t-0.25 1

326

327

329

(3)Pinch lever

ass'y

Type

H

328

(4)Pinch lever return SPR

Tightening torque

HCWø0.7-ø1.8-t0.2 1

Q'ty

23

Page 24

VL-Z7U/Z75U/Z8U

9-5-2. Method of assembling the slide chassis assembly

1.

3.

(2)T-SPR adjustment

ANG

343

I

(19)T arm SPR

(8)Guide nut

349

(6)Tu guide flange

347

(7)Tu guide

Type

348

(6)Tu guide flange

347

(5)Guide adjustment SPR

346

(4)Tu guide arm

ass'y

345

344

Tightening torque

I

(1)Slide adjustment

ANG

342

(3)Tu guide arm SPR

I Precision type 2·M1.4xL1.0 0.4mN·m2

359

357

C

(17)Tension arm ass'y

Q'ty

2.

(15)S main brake

355

(13)S reel table ass'y

(16)S brake SPR

356

(14)Tu reel table ass'y

353

354

(11)T main brake

352

351

(10)T brake gear

350

(9)VSR brake lever

(18)Tension band ass'y

358

H

Type

Tightening torque

Q'ty

C S Tight M1.4xL2.0 0.4mN·m1

(Tightening fully)

0.05mN·m

(Tightening temporarily)

HCWø0.7-ø1.8-t0.2 1

24

Page 25

VL-Z7U/Z75U/Z8U

377

(22)Drum ass'y

371

(20)Swing arm ass'y

372

(21)Reel cover ass'y

D

I

9-5-3. Method of combining the main chassis assembly and the slide chassis assembly

(1) Position the assemblies as shown in the figure below (the pole base is slightly protruded).

(2) Insert the operation pins (tension arm, Tu guide arm) of the slide chassis assembly into the locations of the main chassis assembly

shown in the figure below, fit the SL drive lever pin of the main chassis assembly into the groove of the slide chassis (the groove

of the slide adjustment ANG), and then fix with the two screws.

1.

C

D

J

Type

C S Tight M1.4xL2.0 0.4mN·m2

D S Tight M1.4xL3.0 0.4mN·m1

JWø2.1-ø4-t0.25 2

Tightening torque

Q'ty

2.

Type

D S Tight M1.4xL3.0 0.4mN·m1

I Precision type 2·M1.4xL1.0 0.4mN·m2

Tightening torque

Q'ty

25

Page 26

VL-Z7U/Z75U/Z8U

9-5-4. Diagram of greasing/oiling locations

26

Page 27

9-6. Method of installing the cassette controller

(2)Completed cassette

controller

1

VL-Z7U/Z75U/Z8U

2

3

Left side view Right side view

Left side view

B-1 B-2

Left side view Right side view

(3)Down guide

(1)Main slide

ass'y

A-1

A-2

Right side view

B-1、2

4

Mechanism viewed from above

A Ml1.4xL2.0(Precision type 2) 0.4mN·m2

Type

B M1.7x2.5(Precision type 2) 2

Tightening torque

Q'ty

(4)Cassette cover

Right side view

5

Right side view

C: Move down the cassette controller by pushing this

portion. When the cassette controller is locked,

attach the cassette cover.

27

Page 28

VL-Z7U/Z75U/Z8U

9-7. Method of taking out the cassette with the mechanism operating singly

(1) Apply 3 to 4V DC to the loading motor for slight unloading.

(2) If the tape is slack, turn the rotor (mechanism backside) of the capstan motor by hand to take up the slack in the tape.

(3) Repeat steps (1) and (2) above. When the pole base is completely unloaded, check that the tape is not slack.

(4) Then apply 3 to 4V DC to the loading motor again. The cassette controller will move up.

(5) Take out the cassette.

Note) When applying 3 to 4V DC to the loading motor for unloading, do so as shown in Fig.1.

Direction of rotation of the rotor

of the capstan motor (from

mechanism backside)

Loading motor

pole

+○

pole

−○

Fig.1

28

Page 29

VL-Z7U/Z75U/Z8U

10. METHOD OF ADJUSTING THE ELECTRIC CIRCUIT

-Before making adjustment-

· It seems that, in most cases, this adjusting method is used when it becomes necessary to adjust the electric circuit as a result of

replacement of worn mechanism parts or the video head. When adjusting the electric circuit, check that the mechanism operates

properly (the mechanism is adjusted completely). If a failure occurs in the electric circuit, be sure to locate the fault using a

measuring instrument and then perform repairing, replacement and adjustment, as described in this adjusting method.

Avoid performing undue adjustments etc. without using proper measuring instruments.

· The electric circuit components in the circuit board unit of this product are densely-packed into packages. Most of them are surfacemounted for downsizing.

When replacing components in servicing the product, perform replacement work swiftly with a soldering iron.

In general, surface-mounted components are inferior in heat resistance to large-sized discrete components used in TV sets,

stationary decks, etc. Heating the electrode of a surface-mounted component with a soldering iron for a long time needlessly will

therefore lead to a failure. Take great care not to do so.

Take special care in this respect when replacing chip multilayer capacitors in particular.

We recommend you to use a ceramic soldering iron (Tip temperature: 250°C, Contact time: 5 seconds or less).

10-1. Adjustment of liquid crystal video section

List of measuring jigs

・ColormonitorTV

・Digitalvoltmeter

・DCpowersource

・Audiogenerator

(CRoscillator)

・Frequencycounter

・ACadapter

・StereoAVoutputcable(supplied)

・Adjustmentremotecontrol

(RRMCG0033TASA)

・Signalgenerator

(NTSCpatterngeneratorLCG-401/

401YC:ManufacturedbyLeader)

・Oscilloscope

・Vectorscope

・Tapeforrecording

・DCcable(suppliedwithACadapter)

・Extensionwireofvideosection

・Alignmenttape

・

Errorrateadjustmenttape(referencetape)

90ADDVC-TAPE(colorbar)

RTPEVA001WJZZ

VL-Z7U/Z75U/Z8U

No. Connection section Connector REF. No.

Specifications of service jigs

No. of pins

New/

Parts cord

Cont. code

1 H/A PWB — MAIN PWB1 SC307—SC3302 33P N QCNW-B315WJZZ AN

2 H/A PWB — MAIN PWB2 SC308—SC3301 33P N QCNW-B315WJZZ AN

4 MAIN — LITHIUM PWB SC8800—SC5800 27P-25P QPWBHB742WJZZ Product FPC used AE

5 MAIN — RUNTA005WJZZ SC1201 80P C QCNW-1373TAZZ BQ

6 RUNTA005WJZZ — SUB P2901 80P N RUNTZA005WJZZ AX

7 Hot shoe — SUB —SC501 15P QPWBHB739WJZZ Product FPC used AH

8 Menu key — SUB SC2002—SC501 9P-15P QPWBHB739WJZZ Product FPC used AH

9 H/A PWB — MAIN PWB P301—P3301 5P QCNW-B171WJZZ Product wire used AF

10

TP jig for envelope checking

11 Power supply SC310—SC2101 12P QCNW-B167WJZZ Product FFC used AC

12 ZOOM SC311—SC2201 10P C QCNW-1769TAZZ BF

13 CCD PWB — MAIN SC1001—SC1202 33P QPWBHB738WJZZ Product FPC used AD

14 Lens unit — SUB SC551 25P CLNS-A005RMA5 Product unit used BQ

15 MIC — SUB P3602 4P RMiCC0108TAZZ Product unit used AP

16 FLASH — MAIN —SC1204 12P QPWBHB740WJZZ Product FFC used AD

17 MECHA TURN — MAIN P1201 2P DUNTKB732PM00 Product unit used AG

19 SPEAKER — ZOOM P2201 2P VSP0020P-B2WN Product unit used AK

20 LCD UNIT — MAIN SC1800/SC1801 18Px2 QPWBHB736WJZZ Product FPC used AR

P3303 30B-B N RUNTZA004WJZZ AW

Price

29

Page 30

VL-Z7U/Z75U/Z8U

Lens

CCD PWB

QPWBHB738WJZZ

HEAD AMP PWB

SC303

SC307

SC301 SC308

SC304

SC310

SC306

SC311

SC305

P301

10

10

7

27

QCNW-B171WJZZ

LCD

LAMP

FLASH

ZOOM PWB

P2201

SC2201

SPEAKER

HOT Shoe

SC2002

MENU

SC5800

SC5801

USB

BAT

P900

SC1501

SD

SC501

J600

J7401

J1401

J2900

P3602

SUB PWB

P2901

SC1201

W8089

P3303

SC3302

SC3301

P1201

P3301

SC1801

SC1800

SC1204

MAIN PWB

SC8800

VF_IF

VF_IF

P8800

RMiCC0108WJZZ

POWER SW

QMPWCB734WJZZ

SC802

LCD PWB

SC801 SC800

SC803

SC9800

18 18

15

25

3

22

25

9

80

4

SC551

80

12

1818

30

2

27

SC1202

33

33

33

33

33

12

2

5

MECHA TURN

24

6

10

SC2101

12

10

10

2

21

*1

*2

QPWBHB740WJZZ

QCNW-1373TAZZ

RUNTXA005WJZZ

RUNTZA004WJZZ

SC1001

5

AV

DV

HP

DC

QPWBHB742WJZZ

QPWBHB739WJZZ

QCNW-B315WJZZ

QCNW-B315WJZZ

QCNW-B167WJZZ

QCNW-1769TAZZ

LI

13

14

9

17

20

16

19

4

7

8

15

1

2

10

5

6

11

12

QPWBHB736WJZZ

Mechanism

*1: Under surface contact

*2: Top surface contact

Caution: Don't make a mistake in putting in SC3301 and SC3302.

HOLE SENSOR

VL-Z7U/Z75U/Z8U Service jig configuration

30

Page 31

[TEST POINT]

TL7824(VF_G_OUT)

VF_DAC full scale

TL6807(G_OUT)

DAC full scale

2

TL1431

R717 R728 C713

C711

R743

R714

TL701

TL3303

R744

C731

R709

R702

C703

R742

R712 C716

R723

R705

R724

R732

P3301

C1809

R1824

R1823

C1810

SC1800

C1439

C1438R1442

(Wiring board diagram: Main Side A)

TL3304

TL3302

SC3301

TL3310

X702

R756 R760 R764

R761 R765 R766

R745 R722 R762

C719

R746

R748

C720

C709

IC706

R754

C728

R751 R753 C726

C725 R752 C723

C737

R750

R757

C730

IC701

R707 R715 C735

R729

R759

C710

R741

C733

C708

R736

R737

R763

R738

Q704

R1802

R718

R1801

R771

Q705

C1802

R1805

R772

C704

R1800

R1818

R747

R1422

R1402

R1419

Q1402

C1406

C1407

R1406

C1416

R1405

C1402

IC1401

C1410

C1441 L1404

C1408

IC1431

L1431

Q1431 L1802

C1431

R1437

C1435

R1436 C1801

Q1433

C1434R1432

R1434

R1433

R1435

R755

R758

Q1800

R1803

R1804

R1806

R1413

C1418

C1409

C1437

R1440

R1441

C1440

C1432

R1431

Q1432

C1433

Q1802

R735

R725

R720

C1805

R1814

R1813

Q1801

R1817

R1808C1803

C1806

R1820

C1804

R1811

R1807

R1810

R1816

R1819

C1800

C1411

C1412

R1414

Q1403

Q1404

R1423

R6802

R1462

R1461

R1424

R6816

R6817

R6803

Q1405

C6800

R6805

TL6804

TL6803

C1419

R1421

Q6801

R6806

R1404

C6802

R6804

R6813

C6801

C6807

R6810

R6800R1403C1417

R6807

R6812

R1439

C6804

R1438

R6809

Q1434

C1436

C4481

L4406

R4489

Q4483

L4404

Q4481

R4471

C4404

C4483 R1809

R4472

SC3302

TL913

R3321

C3321

R3320

C3320

C724R1932

Q703

R768

R749

C712

R779

R716

C722

R703

R704

R713

C707

R721

Q701 Q702

R734 R731 C729 R719

R711

C732

R782

C727

R730

R726

R727

C715

R708

R710

R706

X701

TL8803

C705

R1815

R1812

C1815

R1827

Q1803

R4402

R4401

C4402

C4401 L1800

C4405

IC6801

C6814

TL6807

R6819C6815

C6813

R6820R6818

C6816 FB4405

TL6809

TL7819

C6811

C6812

TL6801

TL6802

R6808

R6811

D6800

L6800

C6805

C4406

C4416

C4419R4494C6806 C6810

R4485

C4420

C4485

Q4482

C4409

R4486

C4407

C4482

R4488

R4487

IC704

C714

IC703

C7802

C7800

L7800

C4408

R4404

Q3320

L701

R701

C7806

C7804

TL7824

R7828R7831

IC4401

C4421

C4410

R932

C706

D701 C3716

R739

C734

R780 C702

L3405

C701

L3404

C1911

R1925

R1928

L8800

C8805 L8801

C8800

C7825

R7830

IC7802

R7827

C7803 Q1913

R7826

R7829

R4436

R4437

C4413

Q4432

R4435

VL-Z7U/Z75U/Z8U

Q908

C980

C955

C960

Q909 C953

L908

C939

FB3701

C3713

C3707

L918

L915

R982

C938

C1901

C3705

C3712

IC3701

R3709

R3712

R3708

R3738

R8842

Q3701

C982

TL902

C981

Q1991

R1991

TL901

L900

R1992

R1990

Q1990

C931

C930

C1990

Q903

Q900

C932 R970

TL8801(VF_COM)

VF_COM

L901

C934

Q1901

TL910

C3708

TL908

Q1905

R1941

TL8804(VF_VG)

VF_WB

FB8800

C1904

TL8805

TL8804

C3702 L3702

TL8806

C3709

R3710

R3718R3739

R8836

TL3701

R8834

R8835

C3701 L3701 L903 C933 L902 C936

C3703

R3737

C3711

C3706

TL3702

R3740

TL8805(VF_VR)

VF_WB

TL8806(VF_VB)

VF_WB

L917

C974

Q911

L923

C992

C991

R951

C3436

C3473

C978

Q1912

TL903

D960

R1926

R1924

TL904

R1927

Q8800

C8804

R8800

IC8800

C7805R8802 R8801

C4427

C7808

C7809

C7807

R4403

C7801

TL4439

TL4438

C4422C4414

C4436C4415

C4435

L916

C973

Q907

C975

L911

C990

C956

C962

D916

C929

R8804

C8801

C4403

C6803

L7810

R7811

C7810

R7812

R7800

C4428

R4415

C4418

C4417

R4495

TL4440

C4426

R4414

R4454

R4456

C4454 R7820R7832

X4451

R4451

C4451

C4462

C4424

C4423

R4462

R4461

R4460

C4465

C4463

Q906

R990

C972

R987 C970

R988 C971

Q904

C954

Q910

R983

L931

Q905

TL8801

C8806

R8805

Q8801

C8807

C8809

C7828

C7829

R7819R7833

R7838 C7812

D4452

L4451

D4451

FB4461

R4466

IC4461

L907

R8806

R8807

C8802

TL911

TL907

C8803

R8809

R8808R8817

C8813

R8814

R8828

R8819

R8820

C3710

R8827

TL8802

C8814

C7822

R7825

R7810

IC3702

R7824

R7840

D7810

C7830

R7836

R7834

C3704

R3705

R3717

Q7800

C7827

R7837 C8808

R7839

FL3702

R3706R3707

R4453

R3701

R3713

R3711

TL1801

R4463

C3714

C1811

TL3703

TH1800

Q4461

R1826

C4461

Q8804

C8822

R8840

R8839

R8841 Q8802

(Envelope checkup TP jig)

31

PCO D/A-Y

PCO D/A-C

Page 32

VL-Z7U/Z75U/Z8U

R824

C9805

SC803

TL852

C820

D801

TL870

(Wiring board diagram: LCD Side A)

TL803

TL9801

TL9802

TL9800

T9800

SC9800

R9810

R9801

C9804

TL853

IC9800

C9806

C9800

L9800

R9800

TL832

TL831

R9811

R9802

C9802

TL830

R9808

R9807

C9807

TL828

TL829

R9804

TL9805

TL9804

TL9803

R9805

R9812

Q9801

R9803

R9809

R9806

Q9802

TL826

D9800

TL825

R810

R811

Q801

Q800

R813

C815

R809

C816

R815

R814

C814

C805

C800

TL820

TL819

TL869

TL827

TL801

R802

TL811

TL812

C801

R800

L801

L800

IC800

TL823

TL821

TL824

TL822

C802

TL805

C808

R805

R801

TL843

IC801

C803

C804

TL813

TL807

TL809

TL806

TL808

TL810

R826

R827

R812

TL835

R825

C818

C813

C821

C809

R816

TL816

R803

R804

TL818

TL851

TL834

TL815

TL817

TL814

Q9800 C9801

C9803

SC801

2

SC800

TL800

TL847

TL848

D800

C817

TL850

TL849

C810

TL845

TL802

R806

TL846

R808

R807

TL844

C811

C812

TL838

R817

TL837

SC802

TL846(LCD_VG)

LCD_contrast

TL842

IC802

R819

IC804

IC803

C807

Q802

(Wiring board diagram: Sub Side A) (Wiring board diagram: Sub Side B)

TL1472

Checking of EE level

Checking of f characteristics

TL601

FB600

TL600

C602

VA603

VA602

TL602

C601

R652

VA600

C600

R600

VA601

R603

TL603

R7427

R7429

R7428

R7426

R2915

R604

C1501R1501

C1503R1502

C1502C1508

C1504R1503

C2904C1509

C1505R1504

C1506R1505

C1507R1506

R1510

R524

R1513R1512

TL510

TL508

TL506TL501

TL551

TL553TL557TL559TL561TL563TL567

TL568

TL571

R2914

C2906

D7402

D7401

C1510

C1513

R1507

R1508

R1509

Q1502

Q1501

R1511

D3601

C523

C525

D3600

C521

TL511

VA501

TL509

C522

TL507

SC501

TL505

TL502

TL504

R3635

FB3601

TL556

TL503

R3602

C3600

TL555

TL552

TL554

TL558

TL562TL560

SC551

TL564

TL566

TL569

TL570

TL1470

Checking of EE level

Checking of f characteristics

TL1476

TL1470

TL1473

TL1472

TL1471

L2901

C2905

TL3603

C524

Q2903

C526

TL565

D551

R2523R2530

R2520

R2527

R2526

R2528

R2525R2531

C2520C2521

R578

R582

IC2502

Q552

C528

R527

R581

C2517 C2515R2515

R2512 R2533R2516

C2514

R2511

R2510

C2519

R2514C2518

R2509R2513 R2912

C2516

R2508

R2901 R1480

C2902

CP3

CP2

CP1

TL1477

SC1501

R2919

R2911

D2904

IC2901

Q2906

R2913

D2906

D2905

Q2902

C2903 R2907

R2909

R2908

C553

C554

C556

C558

C559

C561

R552

R553

R555

R559

1

R2556

R2555

Q2551

R2552

R2560

R2559

C3605

R3607

Q3600

R3605

R3603

C3601

C3602R3604

R3606C3603

R3611R3612

IC3600

L601

Q600

C507

R2905

Q2901

R2917

R2906

Q2905

R2904

Q2904

R2918

R2903

D2902

TL903

TL904

P900

TL902

C2910

TL901

R2910

TL900

C2901

R2916

L501

C503

C502

2

J600

TL3601(INT MIC L)

Checking of EE level

Checking of f characteristics

C3624

C573

C574

R551

C555

C557

IC551

R554

C552

R557

C560

R2557

R2558

R2553

Q2552

Q2554

R3601

R3600 C621 R626

R630

R625

R629

R634

R636

C3604

C604

C603

Q605

Q2553

R623

R2551R2554

R661

R613

R615 Q3604

R620

C648

C606

R617

C618

R606