Page 1

SHARP SERVICE MANUAL

_A

S58P5VL-SWSOU

LIQUID CRYSTAL CAMCORDER q NTSC

MODEL vL-sw5ou

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified

be used.

VL-swsou

CONTENTS

Page

1.

IMPORTANT SERVICE NOTES

.

2

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

3

PART NAMES AND FUNCTION

4:

DISASSEMBLY OF THE SET

.

5

MECHANISM ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~..........................

.

6

ADJUSTMENT OF VCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

7

SYSTEM BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

8

SCHEMATIC DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 .

SEMICONDUCTOR LEAD IDENTIFICATION

lO.PRINTED WIRING BOARD ASSEMBLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~.................. 10-l

11 .REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~......... 11-l

12,PACKING OF THE SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.AC ADAPTER

SHARP CORPORATlON

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .......

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..*............ l-l

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~.....................

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

2-l

3-1

4-l

5-1

6-l

7-l

8-1

9-l

12-1

13-1

Page 2

VL-sw5ou

1. IMPORTANT SERVICE NOTES

BEFORE RETURNING THE VIDEO CAMERA

RECORDER

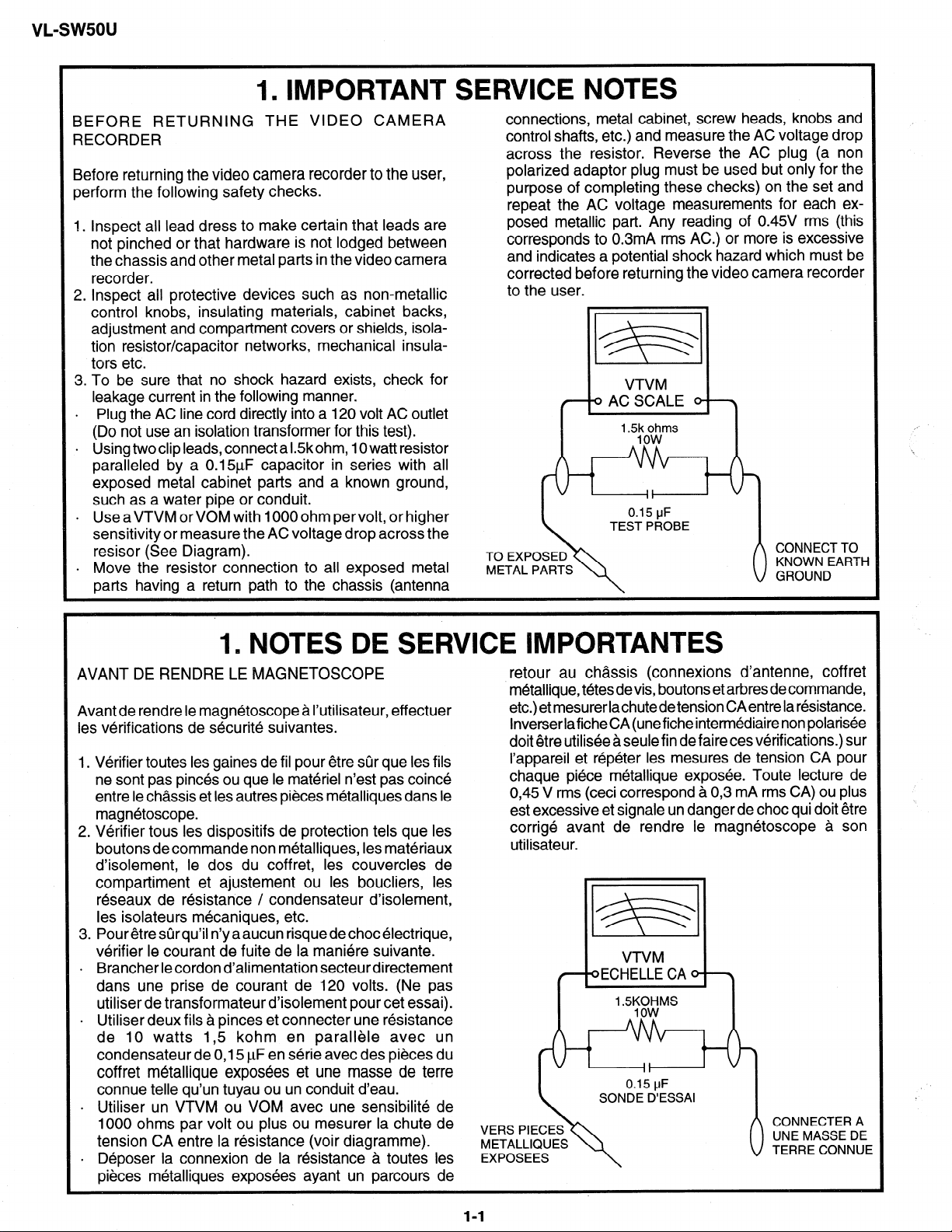

Before returning the video camera recorder to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the video camera

recorder.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields, isolation resistor/capacitor networks, mechanical insulators etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

. Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

l Using two clip leads, connect a Kkohm, 10 watt resistor

paralleled by a 0.15pF capacitor in series with all

exposed metal cabinet parts and a known ground,

such as a water pipe or conduit.

. Use aVTVM or VOM with 1000 ohm pervolt, or higher

sensitivity or measure the AC voltage drop across the

resisor (See Diagram).

. Move the resistor connection to all exposed metal

parts having a return path to the chassis (antenna

connections, metal cabinet, screw heads, knobs and

control shafts, etc.) and measure the AC voltage drop

across the resistor. Reverse the AC plug (a non

polarized adaptor plug must be used but only for the

purpose of completing these checks) on the set and

repeat the AC voltage measurements for each exposed metallic part. Any reading of 0.45V rms (this

corresponds to 0.3mA rms AC.) or more is excessive

and indicates a potential shock hazard which must be

corrected before returning the video camera recorder

to the user.

TO EXP

METAL

CONNECT TO

KNOWN EARTH

GROUND

1. NOTES DE S RVICE IMPORTAhlTES

AVANT DE RENDRE LE MAGNETOSCOPE

Avant de rendre le magnetoscope a I’utilisateur, effectuer

les verifications de securite suivantes.

1. Verifier toutes les gaines de fil pour etre sur que les fils

ne sont pas pin&s ou que le materiel n’est pas coin&

entre le chassis et les autres pieces metalliques dans le

magnetoscope.

2. Verifier tous les dispositifs de protection tels que les

boutons de commande non metalliques, les materiaux

d’isolement, le dos du coffret, les couvercles de

compartiment et ajustement ou les boucliers, les

reseaux de resistance / condensateur d’isolement,

les isolateurs mecaniques, etc.

3. Pour etre sur qu’il n’y aaucun risque de choc electrique,

verifier le courant de fuite de la maniere suivante.

. Brancher lecordon d’alimentation secteurdirectement

dans une prise de courant de 120 volts. (Ne pas

utiliser de transformateur d’isolement pour cet essai).

. Utiliser deux fils a pinces et connecter une resistance

de IO watts I,5 kohm en parallele avec un

condensateur de 0,15 I_LF en serie avec des pieces du

coffret metallique exposees et une masse de terre

connue telle qu’un tuyau ou un conduit d’eau.

. Utiliser un VTVM ou VOM avec une sensibilite de

1000 ohms par volt ou plus ou mesurer la chute de

tension CA entre la resistance (voir diagramme).

. Deposer la connexion de la resistance a toutes les

pieces metalliques exposees ayant un parcours de

retour au chassis (connexions d’antenne, coffret

metallique, t&es devis, boutons et arbres decommande,

etc.) et mesurer lachute de tension CAentre la resistance.

Inverserlafiche CA (unefiche intermediaire non polarisee

doit etre utiliseeaseulefin defairecesverifications.) sur

I’appareil et repeter les mesures de tension CA pour

chaque piece metallique exposee. Toute lecture de

0,45 V rms (ceci correspond a 0,3 mA rms CA) ou plus

est excessive et signale un danger de choc qui doit etre

corrige avant de rendre le magnetoscope a son

utilisateur.

VERS PIECES

METALLIQUES

1-l

Page 3

vL-sw5ou

WARNING :TO REDUCETHE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE

THIS APPLIANCE TO WET LOCATIONS.

1

A

AA

RISK OF ELECTRIC SHOCK

CAUTION: TO REDUCE THE RISK OF ELECTRIC

SHOCK. DO NOT REMOVE COVER. NO

USERSERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

This symbol warns the user of uninsulated

voltage within the unit that can cause danger-

A

ous electric shocks.

This symbol alerts the user that there are

important operating and maintenance instruc-

tions in the literature accompanying this unit.

DO NOT OPEN

l

CAUTION

This symbol mark means following.

For continued protection against fire haz-

ard, replace only with same type fuse.

(CP901; 2.5A 72V, CP902; 2A 72V)

CAUTION

This symbol mark means following.

For continued protection against fire haz-

ard, replace only with same type fuse.

(Fl; 1.5A 250V)

Camcorder

only

AC Adapter

only

A

AmENTION: POUR REDUIRE LES RESQUES D’INCENDIE OU DE CHOC ELECTRIQUE,

NE PAS EXPOSER CET APPAREIL A LA PLUIE OU A L’HUMIDITE.

RISQUE DE CHOC ELECTRIQUE

ATTENTION: AFIN DE REDUIRE LES RISQUES DE

Ce symbole signale a I’utilisateur la presence

d’une tension non isolee a I’interieur de I’appareil

qui peut etre la cause de secousses electriques

dangereuses.

Ce symbole avertit I’utilisateur que des in-

I

0

n

structions importantes relatives a I’utilisation

et al’entretien se trouvent dans le manuel

accompagnant I’appareil.

NE PAS OUVRIR

CHOC ELECTRIQUE, NE PAS RETIRER LE

COUVERCLE, AUCUN ORGANE INTERNE

NE PEUT ETRE REPARE PAR

L’UTIUSATEUR, CONFIER L’APPAREIL A

UN DEPANNEUR QUALIFIE.

ATTENTION

Ce symbole signifie que t’on devra uti-

liser un fusible de meme type (CP901; seulement

2.5A 72V, CP902; 2A 72V) pour assurer

la securite.

Camcorder

n

AmENTION

Ce symbole signifie que I’on devra uti- Adapt&ur CA

liser un fusible de meme type (Fl; 1.5A,

25OV) pour assurer la securite.

seulement

12

I

Page 4

A CAUTION

BEFORE BATTERY DESTROY

NICKEL-CADMIUM BATTERY

The following program is available in the United States. Please consult local environmental

authorities concerning the availability of this or other programs in your area.

The RBRCTM Seal

SHARP participates in the RBRCTM* Nickel-Cadmium Battery Recycling Program in the United

States. The RBRCTM Seal on our battery pack contained in our product indicates that SHARP is

voluntarily participating in an industry program to collect and recycle these batteries. The RBRCTM

program provides you with a convenient alternative to placing spent Nickel-Cadmium battery packs into

the trash or municipal waste stream, which is illegal in some areas. At the end of their useful life, the

Nickel-Cadmium battery can be dropped off at the nearest collection center for recycling. For information

on the nearest collection center, call I-800,8-BATTERY or your local recycling center. If you are located

outside the United States, contact your local authorities for information concerning proper disposal and/

or recycling of this battery. SHARP’s involvement in this program is part of our commitment to protecting

our environment and conserving natural resources.

[Footnote] *RBRCTM is trademark of the Rechargeable Battery Recycling Corporation.

NICKEL-METAL HYDRIDE BATTERY

LITHIUM or LITHIUM-ION BAlTERY

SEALED LEAD BATTERY

Battery disposal

Contains the above (Rechargeable) Battery. must be recycled or disposed of properly.

Remove the Battery from the products and contact Federal or State Environmental Agencies for

information on recycling and disposal options.

1-3

Page 5

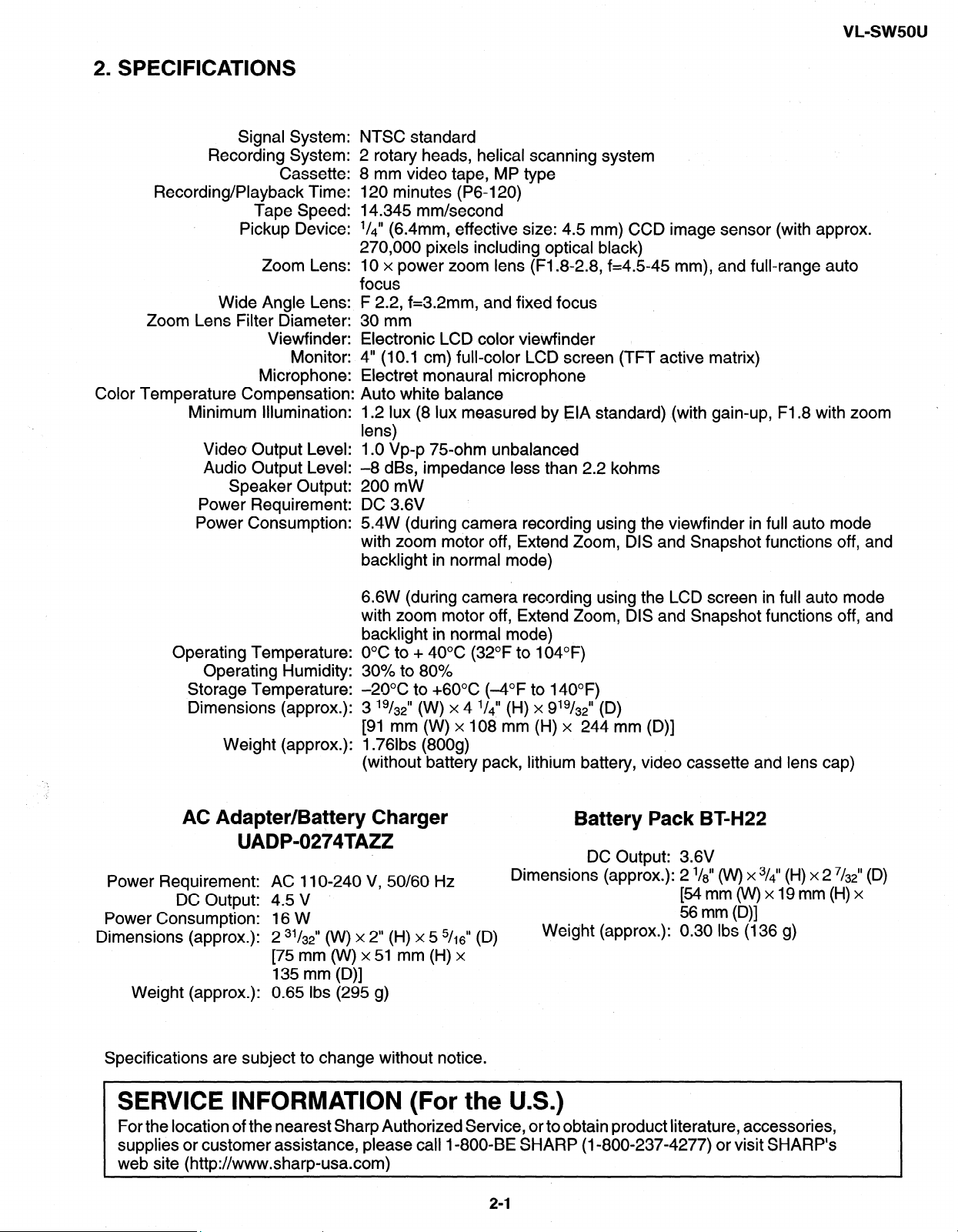

2. SPECIFICATIONS

VL-sw5ou

Signal System:

Recording System:

Cassette:

Recording/Playback Time:

Tape Speed:

Pickup Device:

Zoom Lens:

Wide Angle Lens:

Zoom Lens Filter Diameter:

Viewfinder:

Monitor:

Microphone:

Color Temperature Compensation:

Minimum Illumination:

Video Output Level:

Audio Output Level:

Speaker Output:

Power Requirement:

Power Consumption:

NTSC standard

2 rotary heads, helical scanning system

8 mm video tape, MP type

120 minutes (P6-120)

14.345 mm/second

l/d” (6 4mm effective size: 4.5 mm) CCD image sensor (with approx.

270,060 pixels including optical black)

10 x power zoom lens (Fl.8.2.8, f=4.5-45 mm), and full-range auto

focus

F 2.2, f=3.2mm, and fixed focus

,30mm

Electronic LCD color viewfinder

4” (10.1 cm) full-color LCD screen (TFT active matrix)

Electret monaural microphone

Auto white balance

1.2 lux (8 lux measured by EIA standard) (with gain-up, Fl.8 with zoom

lens)

1 .O Vp-p 75.ohm unbalanced

-8 dBs, impedance less than 2.2 kohms

200 mW

DC 3.6V

5.4W (during camera recording using the viewfinder in full auto mode

with zoom motor off, Extend Zoom, DIS and Snapshot functions off, and

backlight in normal mode)

6.6W (during camera recording using the LCD screen in full auto mode

with zoom motor off, Extend Zoom, DIS and Snapshot functions off, and

backlight in normal mode)

Operating Temperature:

Operating Humidity:

Storage Temperature:

Dimensions (approx.):

Weight (approx.):

O°C to + 40°C (32°F to 104°F)

30% to 80%

-2OOC to +6O”C (-4°F to 140°F)

3 ‘g/32” (W) x 4 ‘/41’ (H) x 9’9/32” (D)

191 mm (W) x 108 mm (H) x 244 mm (D)]

1.76lbs (800g)

(without battery pack, lithium battery, video cassette and lens cap)

AC Adapter/Battery Charger

UADP-0274TAZZ

Power Requirement: AC 1 IO-240 V, 50/60 Hz

DC Output: 4.5 V

Power Consumption: 16 W

Dimensions (approx.):

Weight (approx.): 0.65 Ibs (295 g)

2 31/3$’ (W) x 2” (H) x 5 5/16” (D)

[75 mm o(v) x 51 mm (H) x

135 mm (D)]

Battery Pack BT-H22

DC Output: 3.6V

Dimensions (approx.): 2 l/d’ o(v) x 3/<’ (H) x 2 7/&’ (D)

[54mm(W)xl9mm(H)x

56 mm (D)]

Weight (approx.): 0.30 Ibs (136 g)

Specifications are subject to change without notice.

SERVICE INFORMATION (For the U.S.)

For the location of the nearest Sharp Authorized Service, or to obtain product literature, accessories,

supplies or customer assistance, please call I-800-BE SHARP (I-800-237-4277) or visit SHARP’s

web site (http://www.sharp-usa.com)

2-1

Page 6

lSW5OU

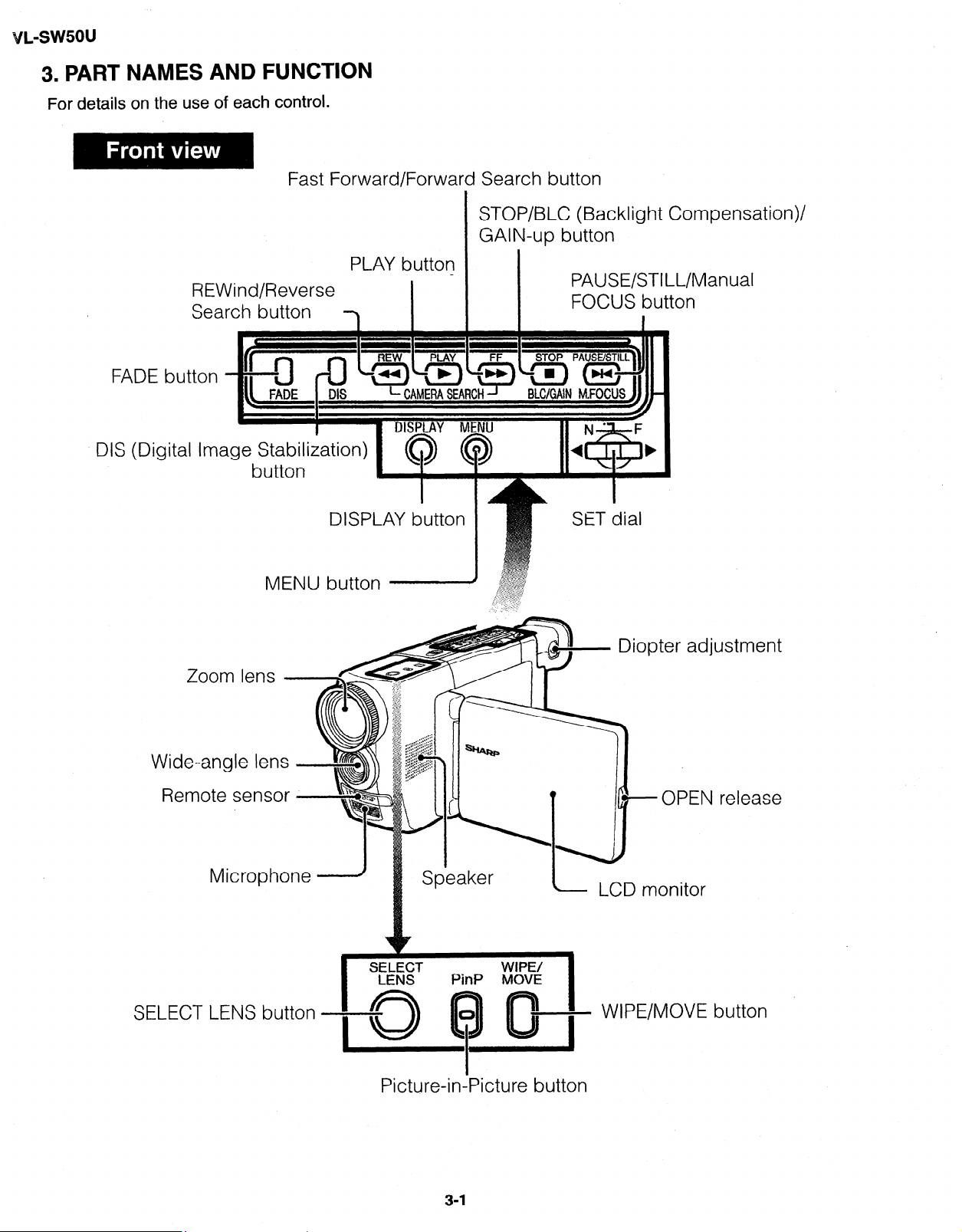

3. PART NAMES AND FUNCTION

For details on the use of each control.

Fast Forward/Forward Search button

REWind/Reverse

Search button

FADE button

DIS (Digital Image Stabi

buttor

MENU button

PLAY button

I

STOP/BLC (Backlight Corn

GAIN-up button

PAUSE/STILL/M

FOCUS button

Diopter adjustment

lpensation)/

anual

Remote sensor

SELECT LENS button

Speaker

I

I

Picture-in-Picture button

-OPEN release

LCD monitor

WIPE/MOVE button

Page 7

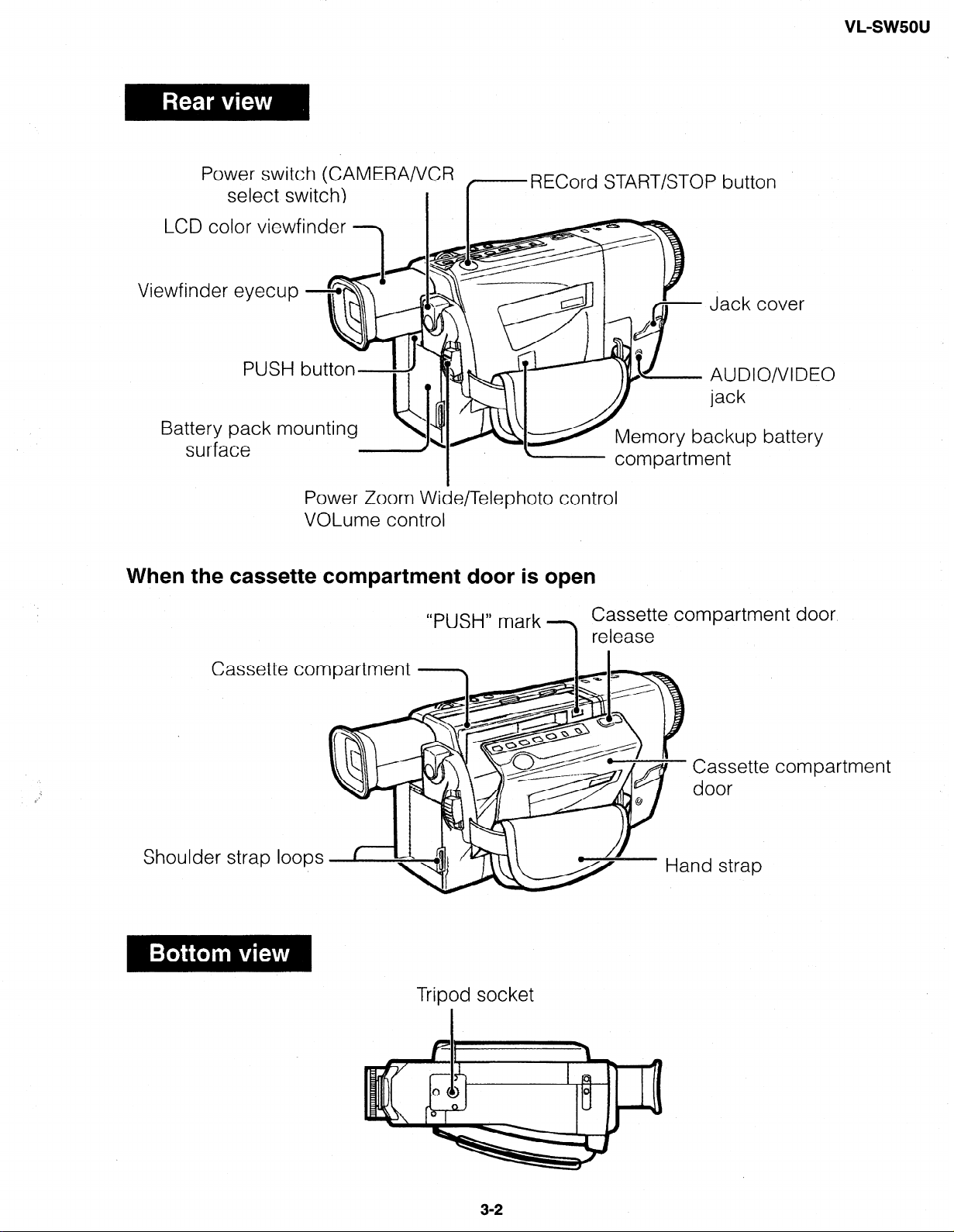

VL-sw5ou

Power switch (CAMERA/VCR

select switch)

LCD color viewfinder h-1

.

VI

ewfind

Batter

When the cassette compartment door is open

er eyecup

y pack mounting

sur

face

t3scx

Power Zoom Wide/Telephoto control

VOLume control

1 I

--

- RECord START/STOP button

l

“PUSH” mark

- compartment

f& Jack cover

O/VIDEO

battery

Cassette compartment door

release

Cassette compartment

Shoulder strap loops

Tripod socket

Cassette

door

nd strap

compartment

3-2

Page 8

VL-swsou

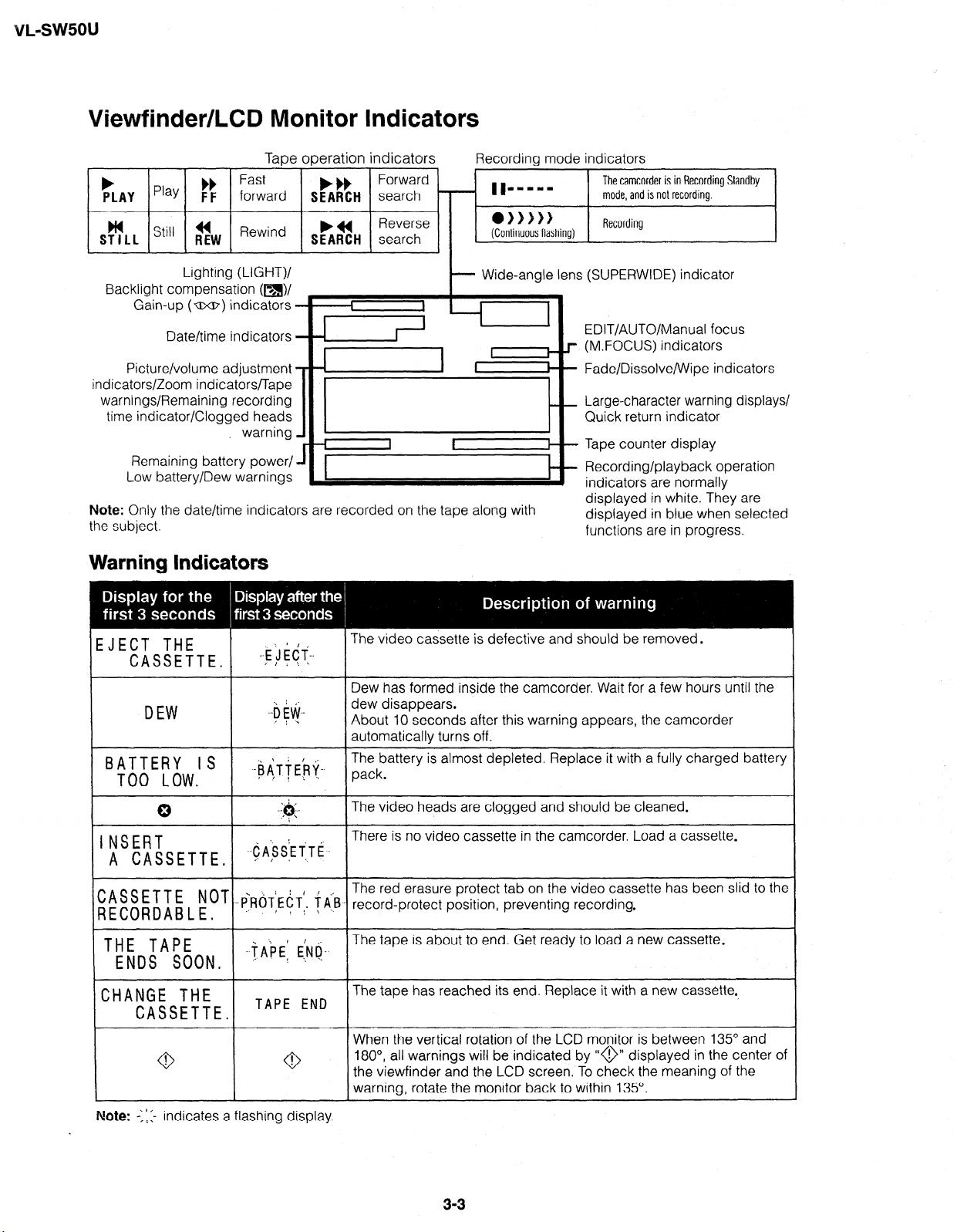

Viewfinder/LCD Monitor Indicators

.

b

PLAY Play F’: !%ard &sH ~~~~hd L ’ ‘lrn w m w w

HI

ST I LL ““’

Backlight compensation (m)/

Gain-up ( UXP) indicators -

Picture/volume adjustment

indicators/Zoom indicators/Tape

warnings/Remaining recording

time indicator/Clogged heads

Remaining battery power/

Low battery/Dew warnings

Note: Only the date/time indicators are recorded on the tape along with

the subject.

44

RE,,,, Rewind b*

I 1

Lighting (LIGHT)/

Date/time indicators

Tape operation indicators Recording mode indicators

l ))W

(Continuous flashing)

I

Wide-angle lens (SUPERWIDE) indicator

t

I

I 1

I I

. warnrng

Reverse

SEARCH search

I 1

I

l-----l -

-

-I_ -

J

_I

I

I

Warning Indicators

The camcorder is in Recording Standby

mode, and is not recording.

Recording

EDIT/AUTO/Manual focus

(M.FOCUS) indicators

r

-

Fade/Dissolve/Wipe indicators

Large-character warning displays/

-

Quick return indicator

-

Tape counter display

I

-

Recording/playback operation

indicators are normally

displayed in white. They are

displayed in blue when selected

functions are in progress.

:JECT THE

CASSETTE.

DEW

BATTERY IS '

T()() L ()W,

0

INSERT

A CASSETTE, ++S~T,TE’-

ZASSETTE NOT . ..PRijf&' ij(B_.

3 E COR DA B L E , a” 1 1 :’ \. .I.

THE TAPE a ' ’ ;

ENDS SOON, jk! E.;NP-’

_.'i j i 6 =f_.

XI t :'

. ..b EW .-

.J 1 i

._bAT&_.

.- / ! 5 ..-

I

: .*

. ...;&;.

i

t

. . ,+

CHANGE THE

The video cassette is defective and should be removed.

Dew has formed inside the camcorder. Wait for a few hours until the

dew disappears.

About IO seconds after this warning appears, the camcorder

automatically turns off.

The battery is almost depleted. Replace it with a fully charged battery

pack.

The video heads are clogged and should be cleaned.

I

There is no video cassette in the camcorder. Load a cassette.

The red erasure protect tab on the video cassette has been slid to the

record-protect position, preventing recording.

The tape is about to end. Get ready to load a new cassette.

The tape has reached its end. Replace it with a new cassette.

CASSETTE, TAPE END

When the vertical rotation of the LCD monitor is between 135” and

0

!

0

!

180°, all warnings will be indicated by ‘@” displayed in the center of

the viewfinder and the LCD screen. To check the meaning of the

warning, rotate the monitor back to within 135”.

I

I

Note: -1: I- indicates a flashing display.

33

I

Page 9

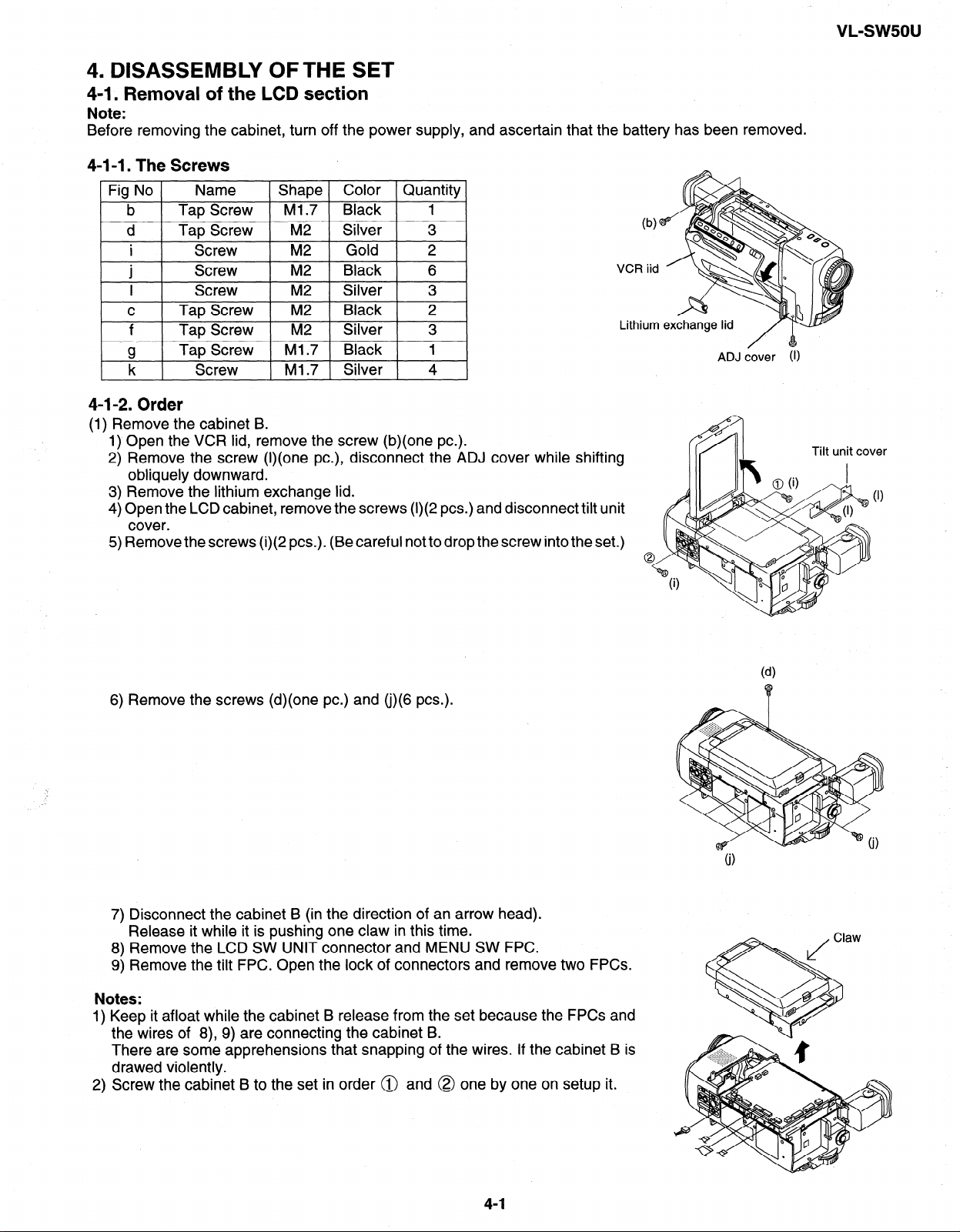

4. DISASSEMBLY OFTHE SET

4-l. Removal of the LCD section

Note:

Before removing the cabinet, turn off the power supply, and ascertain that the battery has been removed.

4-1-1. The Screws

Fig No

b

d Tap Screw M2 Silver 3

I

C

f Tap Screw M2

g

k Screw Ml .7 Silver 4

4-1-2. Order

(1) Remove the cabinet B.

1) Open the VCR lid, remove the screw (b)(one PC.).

2) Remove the screw (I)(one PC.), disconnect the ADJ cover while shifting

obliquely downward.

3) Remove the lithium exchange lid.

4) Open the LCD cabinet, remove the screws (I)(2 PCS.) and disconnect tilt unit

cover.

5) Remove the screws (i)(2 PCS.). (Be careful not to drop the screw into the set.)

Name Shape Color Quantity

Tap Screw Ml.7 Black 1

Screw

Screw

M2

M2

Screw M2

Tap Screw M2

Gold

Black

Silver 3

Black

Silver 3

Tap Screw

Ml .7 Black 1

2

6

VCR iid

2

Lithium exchange lid

ADJ

cover (1)

VL-sw5ou

’ .

Tilt unit cover

6) Remove the screws (d)(one PC.) and (j)(6 PCS.).

7) Disconnect the cabinet B (in the direction of an arrow head).

Release it while it is pushing one claw in this time.

8) Remove the LCD SW UNIT connector and MENU SW FPC.

9) Remove the tilt FPC. Open the lock of connectors and remove two FPCs.

Notes:

1) Keep it afloat while the cabinet B release from the set because the FPCs and

the wires of 8), 9) are connecting the cabinet B.

There are some apprehensions that snapping of the wires. If the cabinet B is

drawed violently.

2) Screw the cabinet B to the set in order @ and @ one by one on setup it.

4-1

Page 10

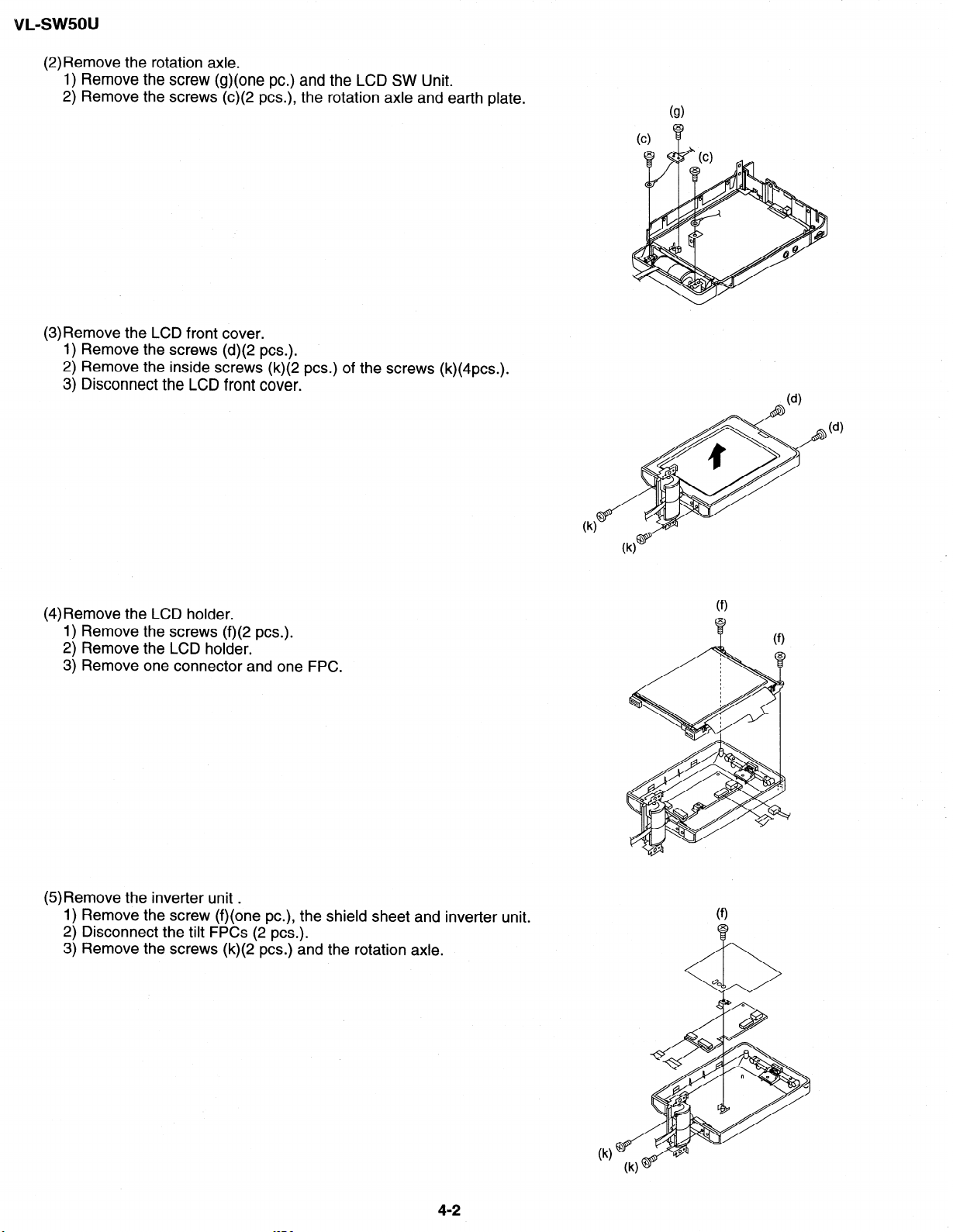

vL-sw5ou

(2) Remove the rotation axle.

1) Remove the screw (g)(one PC.) and the LCD SW Unit.

2) Remove the screws (c)(2 PCS.), the rotation axle and earth plate.

(3)Remove the LCD front cover.

1) Remove the screws (d)(2 PCS.).

2) Remove the inside screws (k)(2 PCS.) of the screws (k)(4pcs.).

3) Disconnect the LCD front cover.

(4)Remove the LCD holder.

1) Remove the screws (f)(2 PCS.).

2) Remove the LCD holder.

3) Remove one connector and one FPC.

(5)Remove the inverter unit .

1) Remove the screw (f)(one PC.), the shield sheet and inverter unit.

2) Disconnect the tilt FPCs (2 PCS.).

3) Remove the screws (k)(2 PCS.) and the rotation axle.

4-2

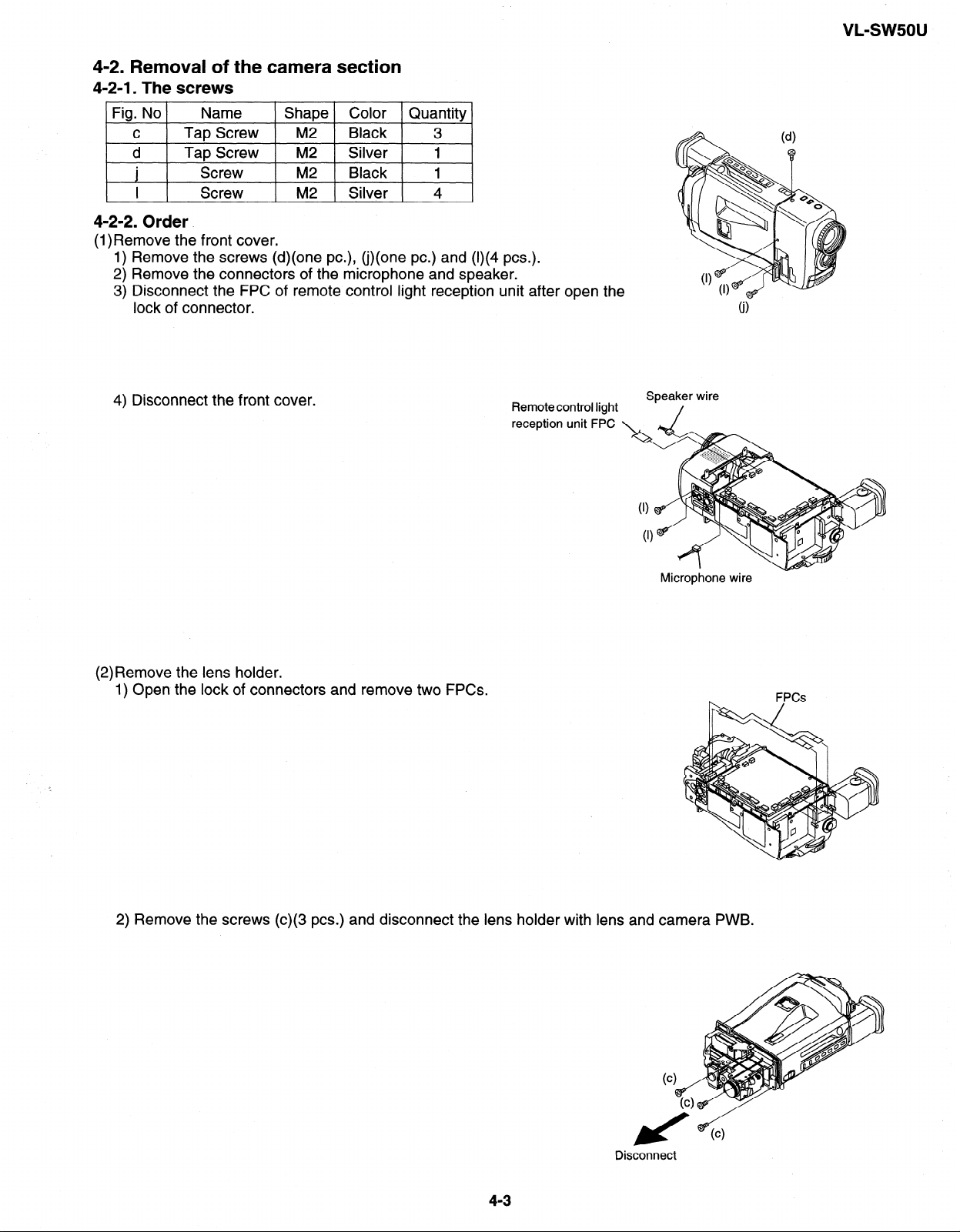

Page 11

VL-SW5OU

Fig. No Name

C

d

.

J

Tap Screw M2

Tap Screw M2

Screw

I Screw

Shape Color Quantity

Black 3

Silver 1

M2

Black 1

_ M2 _ Silver _ 4

4-2-2. Order.

(1)Remove the front cover.

1) Remove the screws (d)(one PC.), (j)(one PC.) and (I)(4 PCS.).

2) Remove the connectors of the microphone and speaker.

3) Disconnect the FPC of remote control light reception unit after open the

lock of connector.

4) Disconnect the front cover.

Remote control light

reception unit FPC

Speaker wire

(2)Remove the lens holder.

1) Open the lock of connectors and remove two FPCs.

2) Remove the screws (c)(3 PCS.) and disconnect the lens holder with lens and camera PWB.

4-3

Disconnect

Page 12

4-3. Removal of the V/F

4-3-1. The screws

Fig. No

g

l

I

4-3-2. Order

(1)Disconnect the zoom switch unit FPC.

(2)Open the lock the connector and remove the V/F FPC.

(3)Remove the screw (j)(one PC.) and disconnect the V/F.

(4)Remove the screws (g)(2 PCS.) and the V/F bottom cabinet.

Name Shape Color Quantity

Tap Screw

Screw

Ml .7 Black 2

M2 Black 1

Zoom switch

FPC

V/F FPC

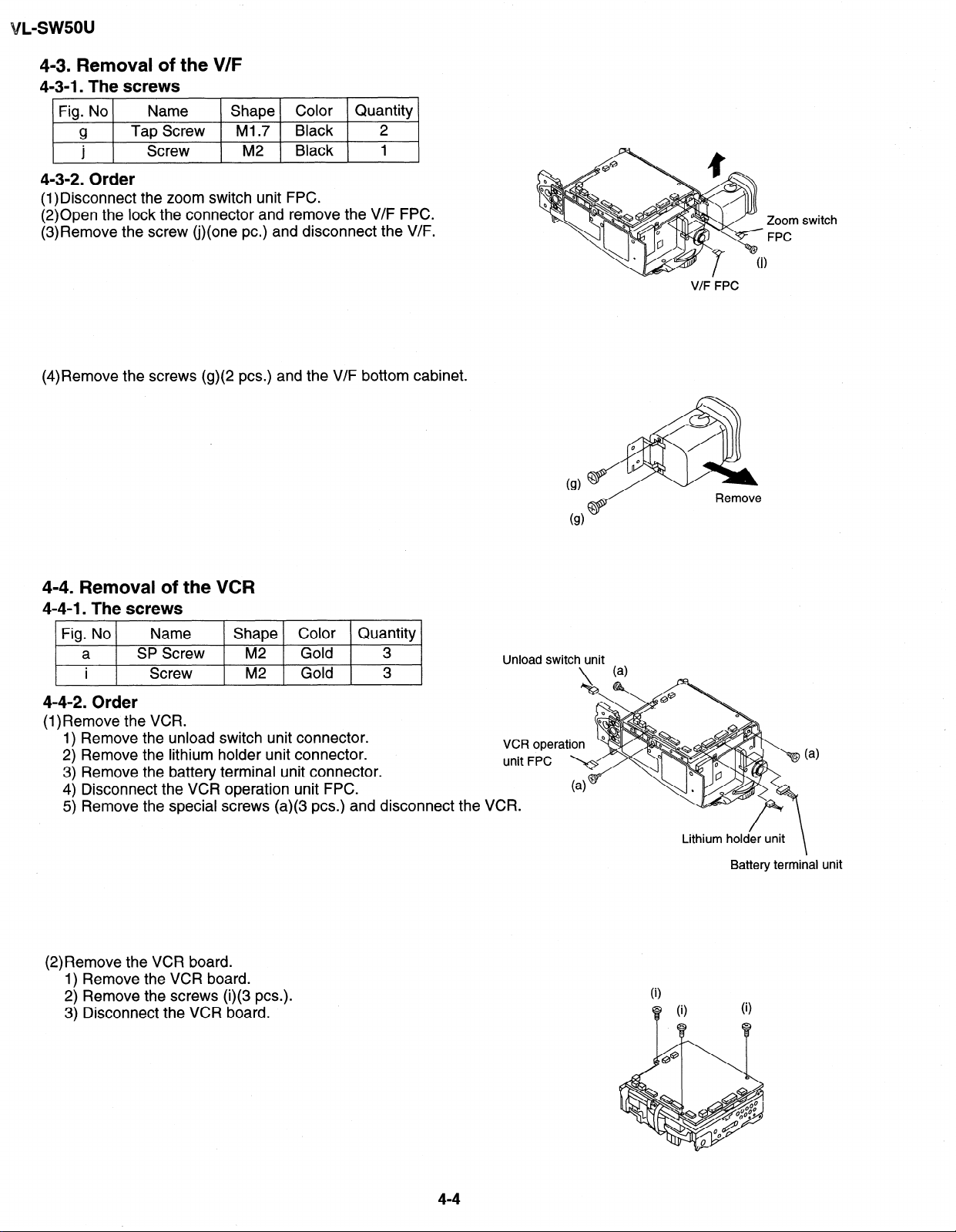

4-4. Removal of the VCR

4-4-l. The screws

Fig. No

a SP Screw M2

i

4-4-2. Order

(l)Remove the VCR.

1) Remove the unload switch unit connector.

2) Remove the lithium holder unit connector.

3) Remove the battery terminal unit connector.

4) Disconnect the VCR operation unit FPC.

5) Remove the special screws (a)(3 PCS.) and discon

(2)Remove the VCR board.

1) Remove the VCR board.

2) Remove the screws (i)(3 PCS.).

3) Disconnect the VCR board.

Name

Shape Color Quantity

Screw M2

Gold

Gold 3

3

nect the V

Lithium holder unit

i

0

a

( 1

Battery terminal unit

\

4-4

Page 13

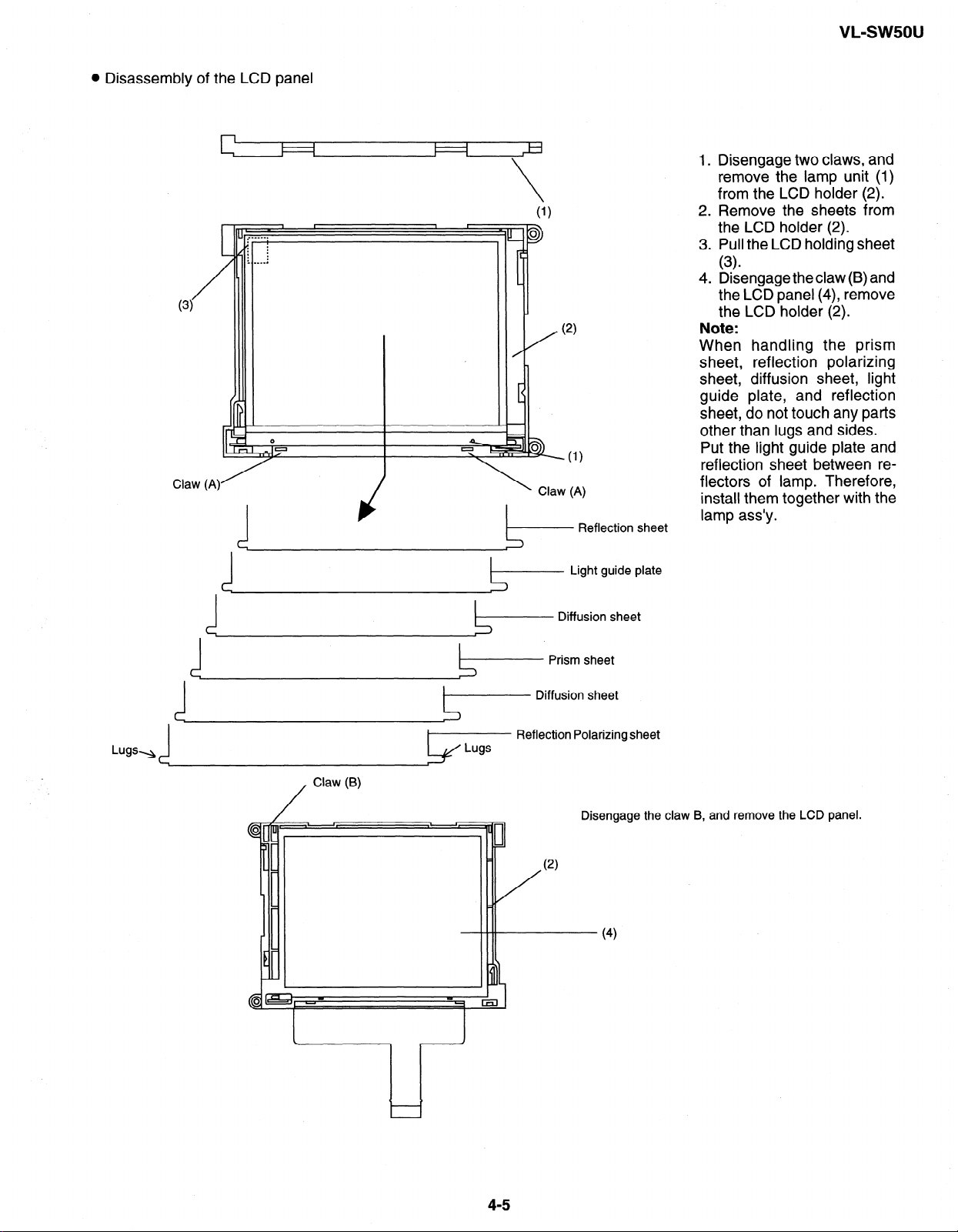

0 Disassembly of the LCD panel

VL-sw5ou

I I

I

I

Claw (A)

(- Reflection sheet

Light guide plate

1 .

Disengage two claws, and

remove the lamp unit (1)

from the LCD holder (2).

.

2

Remove the sheets from

the LCD holder (2).

.

3

Pull the LCD holding sheet

(3)

4.

Disengage the claw (B) and

the LCD panel (4), remove

the LCD holder (2).

Note:

When handling the prism

sheet, reflection polarizing

sheet, diffusion sheet, light

guide plate, and reflection

sheet, do not touch any parts

other than lugs and sides.

Put the light guide plate and

reflection sheet between re-

flectors of lamp. Therefore,

install them together with the

lamp ass’y.

Lugs-

1

/

Diffusion sheet

Prism sheet

Diffusion sheet

Reflection Polarizing sheet

Claw (6)

Disengage the claw B, and remove the LCD panel.

(2)

(4)

4-5

Page 14

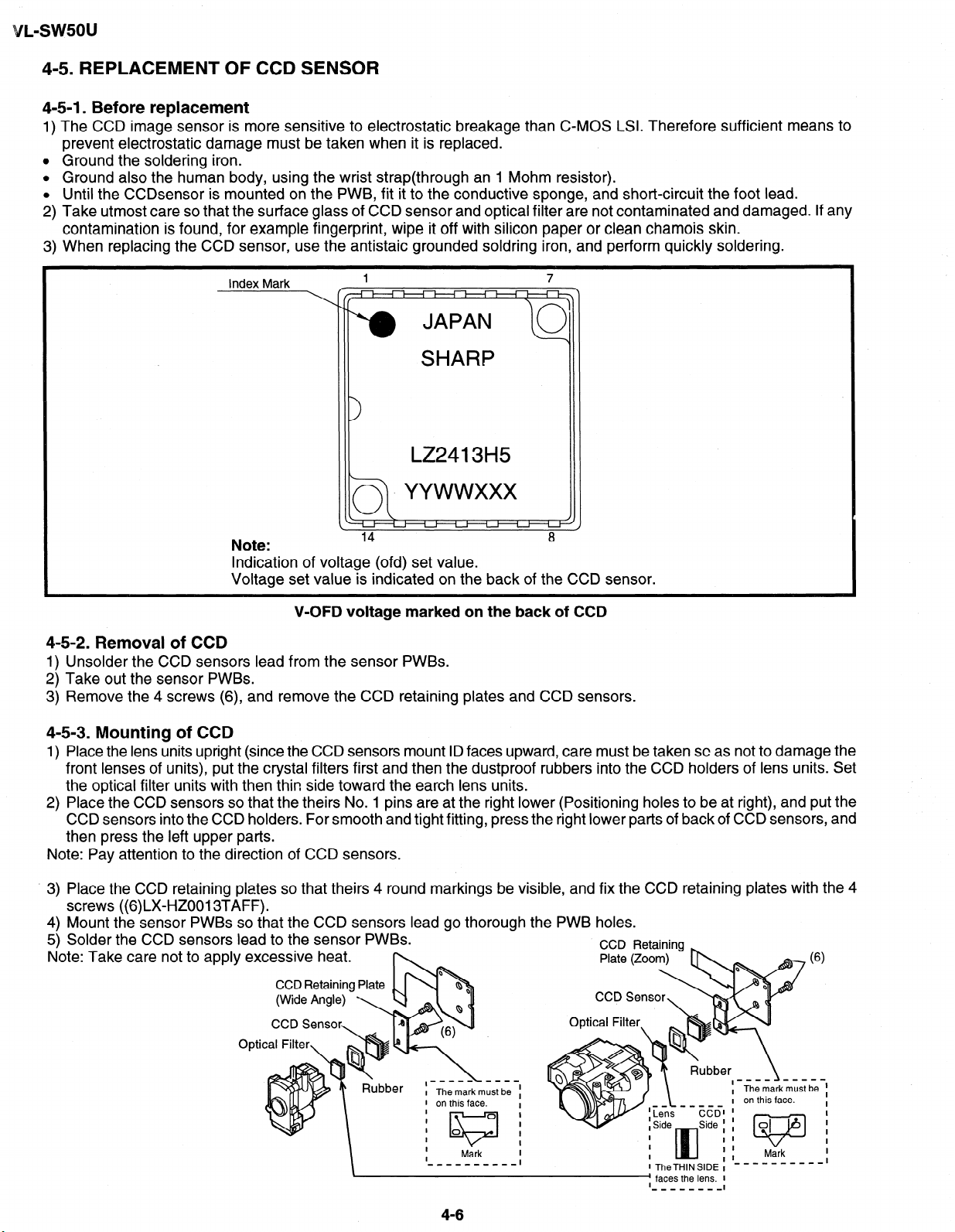

4-5. REPLACEMENT OF CCD SENSOR

4-5-l. Before replacement

The CCD image sensor is more sensitive to electrostatic breakage than CMOS LSI. Therefore sufficient means to

prevent electrostatic damage must be taken when it is replaced.

Ground the soldering iron.

Ground also the human body, using the wrist strap(through an 1 Mohm resistor).

Until the CCDsensor is mounted on the PWB, fit it to the conductive sponge, and short-circuit the foot lead.

Take utmost care so that the surface glass of CCD sensor and optical filter are not contaminated and damaged. If any

contamination is found, for example fingerprint, wipe it off with silicon paper or clean chamois skin.

When replacing the CCD sensor, use the antistaic grounded soldring iron, and perform quickly soldering.

Index Mark

LZ2413H5

L

.ct yywwxxx

Note:

Indication of voltage (ofd) set value.

Voltage set value is indicated on the back of the CCD sensor.

V-OFD voltage marked on the back of CCD

4-5-2. Removal of CCD

1) Unsolder the CCD sensors lead from the sensor PWBs.

2) Take out the sensor PWBs.

3) Remove the 4 screws (6), and remove the CCD retaining plates and CCD sensors.

4-5-3. Mounting of CCD

1) Place the lens units upright (since the CCD sensors mount ID faces upward, care must be taken SC as not to damage the

front lenses of units), put the crystal filters first and then the dustproof rubbers into the CCD holders of lens units. Set

the optical filter units with then thin side toward the earth lens units.

2) Place the CCD sensors so that the theirs No. 1 pins are at the right lower (Positioning holes to be at right), and put the

CCD sensors into the CCD holders. For smooth and tight fitting, press the right lower parts of back of CCD sensors, and

then press the left upper parts.

Note: Pay attention to the direction of CCD sensors.

’ 3) Place the CCD retaining plates so that theirs 4 round markings be visible, and fix the CCD retaining plates with th

screws ((6)LX_HZ0013TAFF).

4) Mount the sensor PWBs so that the CCD sensors lead go thorough the PWB holes.

5) Solder the CCD sensors lead to the sensor PWBs.

Note: Take care not to apply excessive heat.

CCD Retaining Plate

CCD Retainin

e4

\

._-___ ___I

I

I Themarkmust be :

1 on this face.

I

I

I

I

I

I

_1_____1-1

0

0

KJ

M&k

4-6

I

I

I

I

I

I

I

1 TheTHlNSlDE 1

I faces the lens. I

I

__--_-_-

I

Page 15

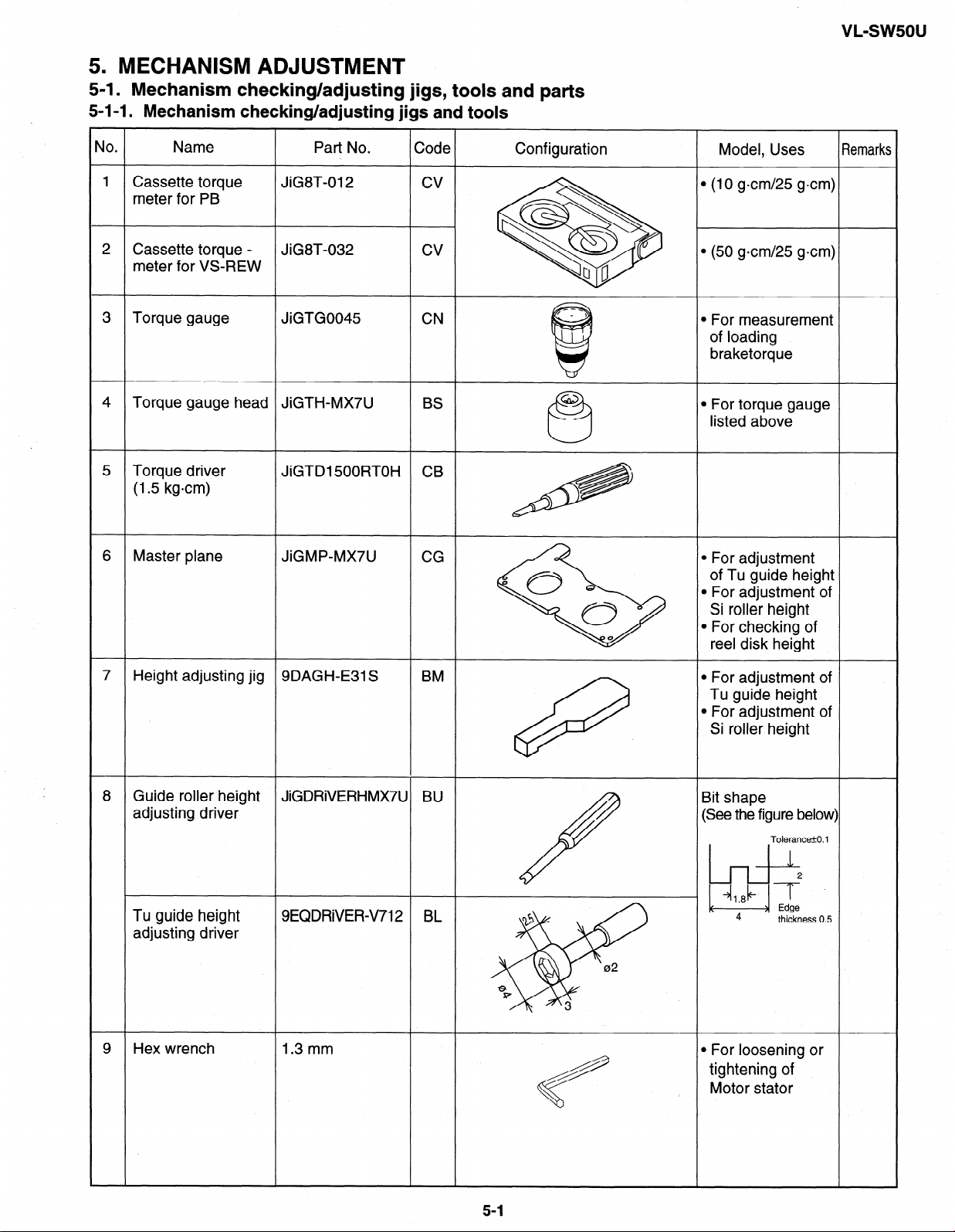

5. MECHANISM ADJUSTMENT

5-l. Mechanism checking/adjusting jigs, tools and parts

5-1-I. Mechanism checking/adjusting jigs and tools

VL=S\NSOU

l (10 g-cm/25 g=cm)

l (50 g-cm/25 g*cm)

l For measurement

Guide roller height

8

JiGDRiVERHMX7U BU

adjusting driver

Tu guide height 9EQDRiVEKV712 BL

adjusting driver

9 Hex wrench

1.3 mm l For loosening or

l For adjustment of

Si roller height

Bit shape

(See the figure below)

Tolerance&O. 1

/

4&b

I++/

15

02

8

17

+

3

2

Edge

thickness 0.5

tightening of

Motor stator

5-l

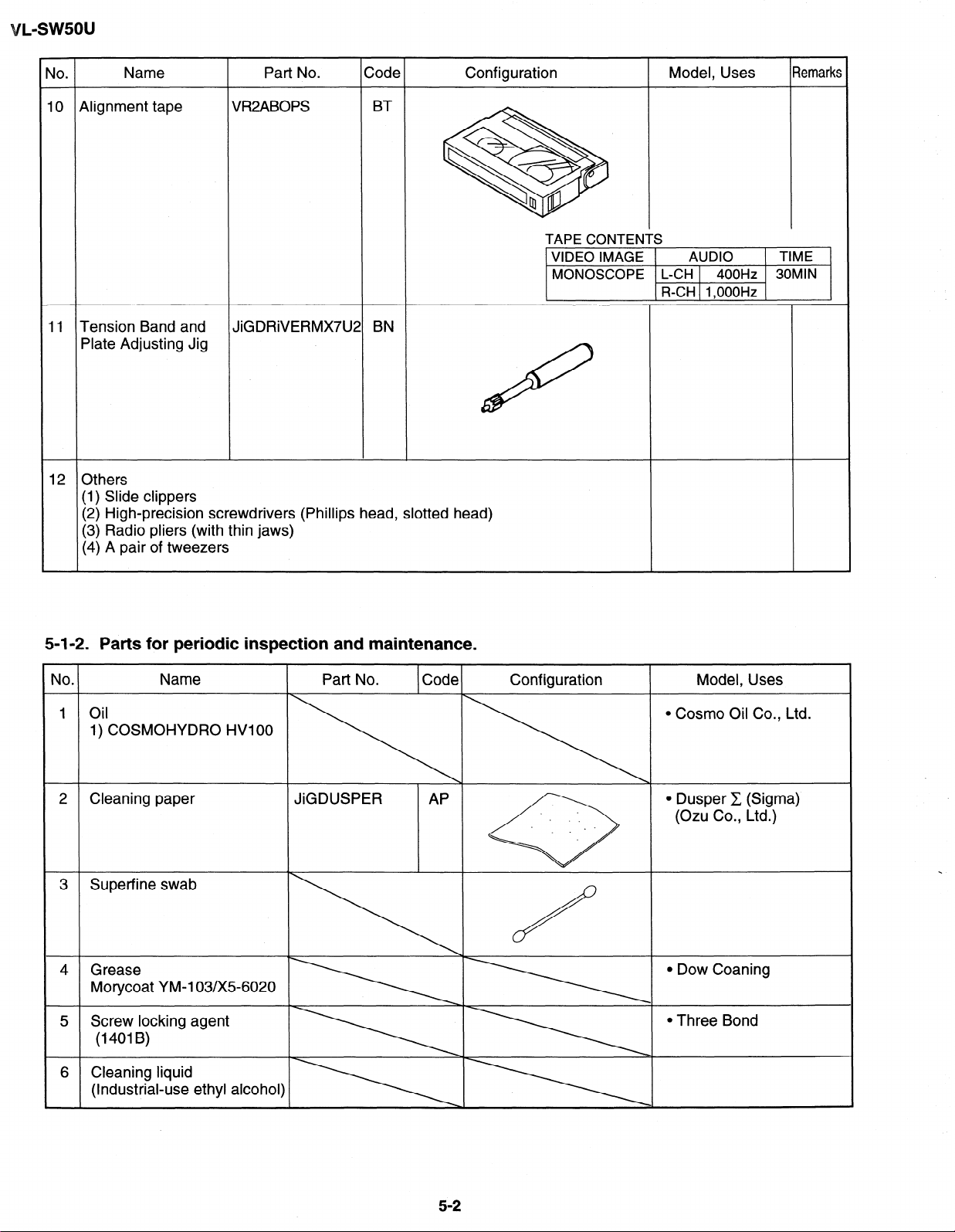

Page 16

Name

Part No.

Code

Configuration

Model, Uses

Remarks

9lignment tape

11 Tension Band and

VR2ABOPS

JiGDRiVERMX7UZ

BT

BN

f

Plate Adjusting Jig

12

Others

(1) Slide clippers

(2) High-precision screwdrivers (Phillips head, slotted head)

(3) Radio pliers (with thin jaws)

(4) A pair of tweezers

TAPE CONTENTS

1 VIDEO IMAGE 1

MONOSCOPE L-CH

R-CH 1,OOOHz

AUDIO

400Hz 30MlN

1 TIME 1

5-1-2. Parts for periodic inspection and maintenance.

No

1

.

.

011

Name

1) COSMOHYDRO HVIOO

Cleaning paper

2

3 Superfine swab

4 Grease

Morycoat YM-103/X5-6020

Screw locking agent

5

(1401B)

6 Cleaning liquid

(Industrial-use ethyl alcohol]

Part No. Code

-\.\.\

I

JiGDUSPER AP

Configuration

Model, Uses

l Cosmo Oil Co., Ltd.

l Dusper C (Sigma)

(Ozu Co., Ltd.)

l Dow Coaning

l Three Bond

5-2

Page 17

VL-SW50U

5-2. Items and timings of inspection and maintenance

.

The mechanism of VCR needs the following periodic inspection and maintenance in order that it maintains its high quality Also,

after the machine is repaired, execute the following maintenance and checks regardless of how long it has been used.

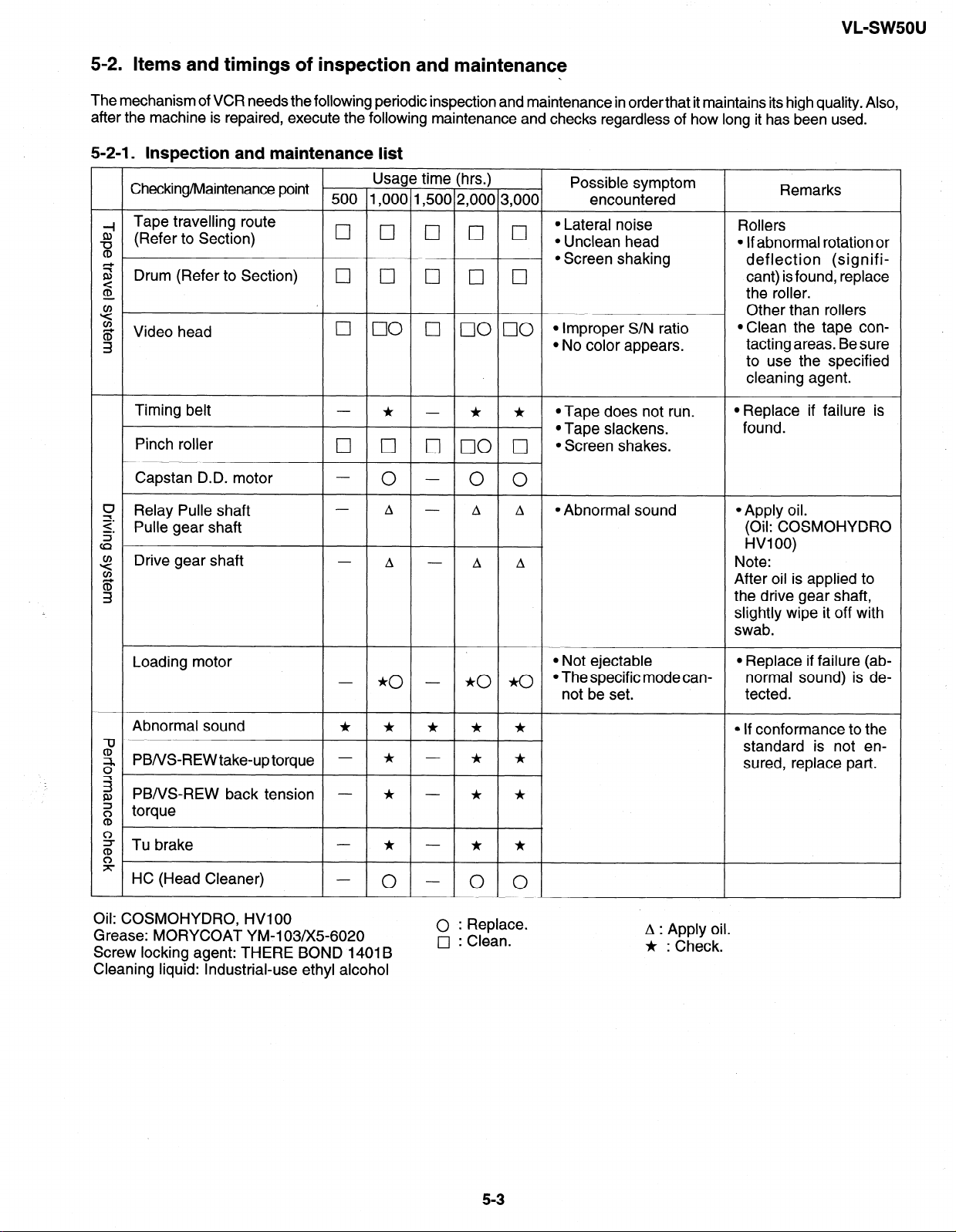

5-2-l. Inspection and maintenance list

Checking/Maintenance point

Tape travelling route

2

(Refer to Section)

CD

s L Drum (Refer to Section)

3

g Video head

3

Timing belt

Pinch roller

Capstan D.D. motor

CJ Relay Pulle shaft

2: Pulle gear shaft

cz

Drive gear shaft

3

il;

3

Usage time (hrs.)

500 1,000 1,500 2,000 3,000

0 0 0 0 0 $;;ran”;g;d

q cl q cl 0

0 00 q 00 00 *Improper S/N ratio

* - * *

0 0 0 00 0 *Screen shakes.

- 0 - () 0

A - A A

A - A A

Possible symptom

encountered

Remarks

Rollers

l If abnormal rotation or

l Screen shaking deflection (signifi-

cant) is found, replace

the roller.

. Other than rollers

*Clean the tape con-

l No color appears.

tatting areas. Be sure

to use the specified

cleaning agent.

*Tape does not run.

*Tape slackens.

@Abnormal sound

l Replace if failure is

found.

l Apply oil.

(Oil: COSMOHYDRO

HVI 00)

Note:

After oil is applied to

the drive gear shaft,

slightly wipe it off with

swab.

Loading motor

*o a

Abnormal sound

- *o -

* * * * *

a

?, PBNS-REWtake-uptorque - * - * *

g

2 PBA/S-REW back tension - * - * *

Z torque

CD

2 Tu brake

* - * *

%

HC (Head Cleaner)

Oil: COSMOHYDRO, HVI 00

Grease: MORYCOAT YM-103/X5-6020

Screw locking agent: THERE BOND 1401 B

0

0 0

0 : Replace.

0 : Clean.

Cleaning liquid: Industrial-use ethyl alcohol

l Not ejectable

l The specific mode can-

not be set.

A : Apply oil.

* : Check.

l Replace if failure (ab-

normal sound) is de-

tected.

* If conformance to the

standard is not ensured, replace part.

5-3

Page 18

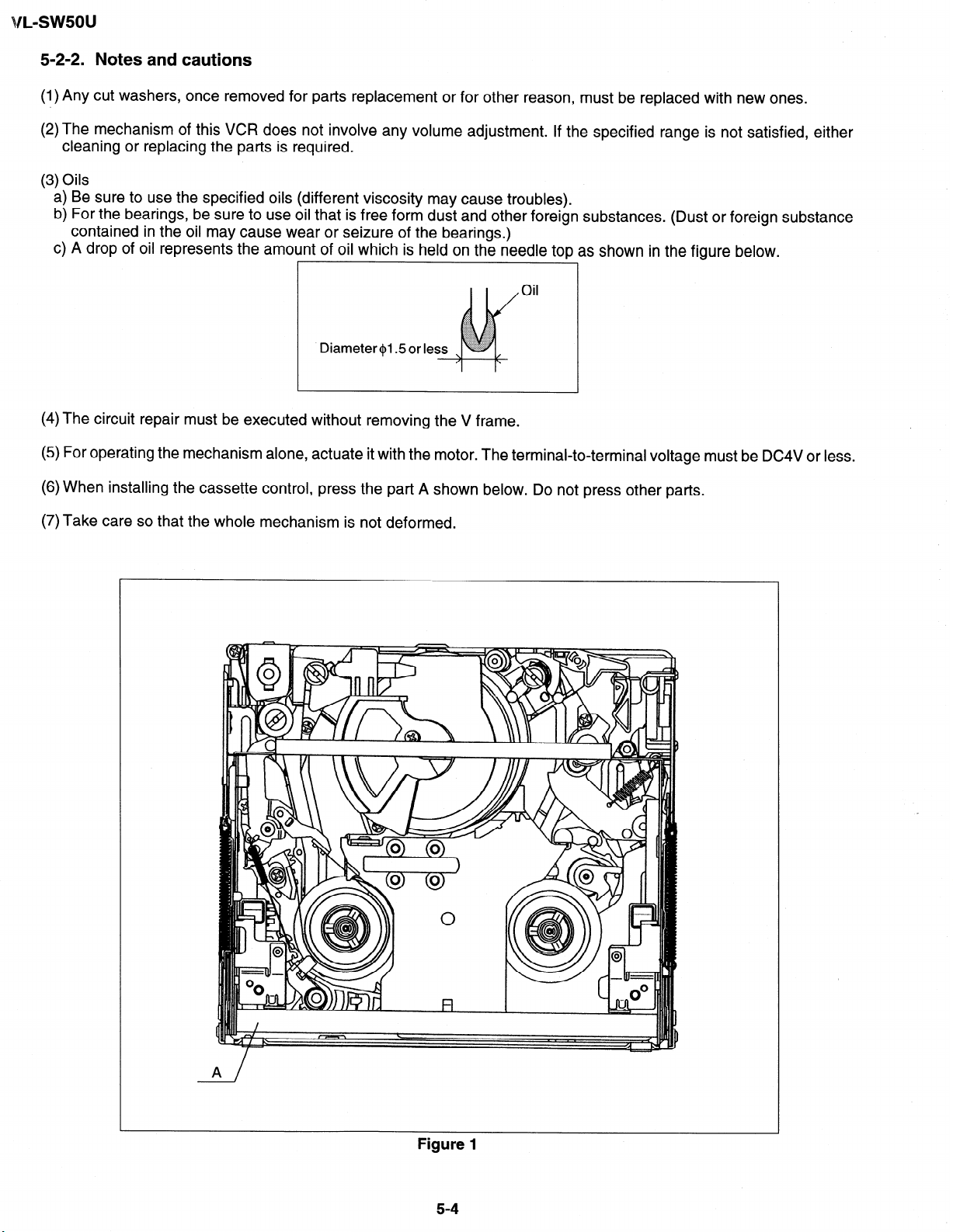

5-2-2. Notes and cautions

(1) Any cut washers, once removed for parts replacement or for other reason, must be replaced with new ones.

(2) The mechanism of this VCR does not involve any volume adjustment. If the specified range is not satisfied, either

cleaning or replacing the parts is required.

(3) Oils

a) Be sure to use the specified oils (different viscosity may cause troubles).

b) For the bearings, be sure to use oil that is free form dust and other foreign substances. (Dust or foreign substance

contained in the oil may cause wear or seizure of the bearings.)

c) A drop of oil represents the amount of oil which is held on the needle top as shown in the figure below.

Oil

(4) The circuit repair must be executed without removing the V frame.

(5) For operating the mechanism alone, actuate it with the motor. The terminal-to-terminal voltage must be DC4V or less.

(6) When installing the cassette control, press the part A shown below. Do not press other parts.

(7) Take care so that the whole mechanism is not deformed.

A /

Figure 1

5-4

Page 19

VL-SWSOU

5-3. Mechanism checks and adjustments

The description given below relates to the general field services, but does not relate to the adjustment and replacement

that require high level equipments, jigs, and technical skills.

In order to maintain the initial characteristics of the machine, it is necessary to execute the maintenance and check and

to prevent damage to tapes and other parts. For adjustments which need jigs, be sure to use the jigs.

Notes and cautions

(1) For mechanism checks and adjustments, be sure to use the AC adapter as the power supply.

(2) For running the tape, be sure to install the cassette control ass’y in advance. (if the cassette control ass’y is to be

removed subsequently after its installation.)

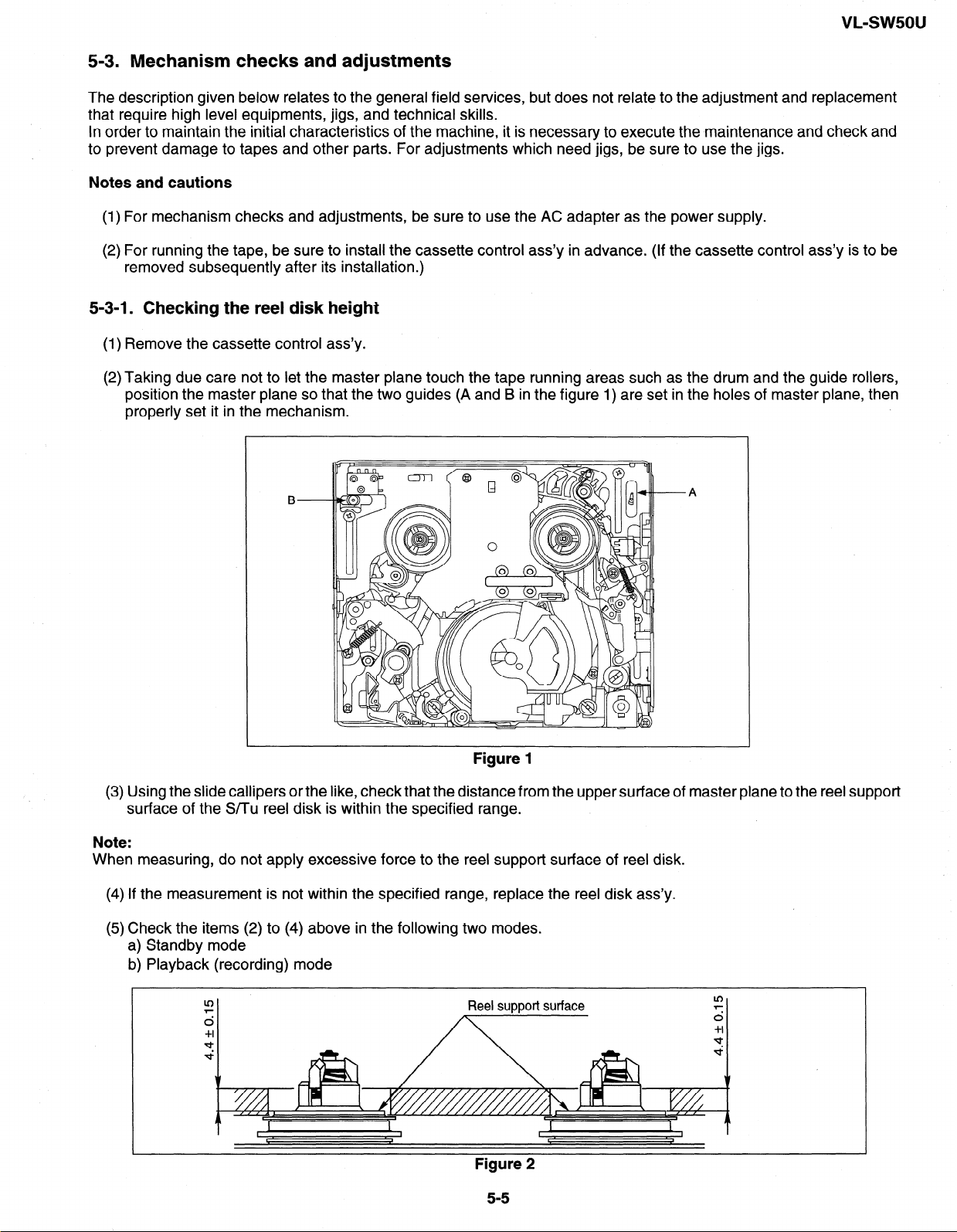

5-3-l. Checking the reel disk height

(1) Remove the cassette control ass’y.

(2) Taking due care not to let the master plane touch the tape running areas such as the drum and the guide rollers,

position the master plane so that the two guides (A and B in the figure 1) are set in the holes of master plane, then

properly set it in the mechanism.

B

Figure 1

(3) Using the slide callipers or the like, check that the distance from the upper surface of master plane to the reel support

surface of the Smu reel disk is within the specified range.

Note:

When measuring, do not apply excessive force to the reel support surface of reel disk.

(4) If the measurement is not within the specified range, replace the reel disk ass’y.

(5) Check the items (2) to (4) above in the following two modes.

a) Standby mode

b) Playback (recording) mode

A

Figure 2

Page 20

vL-sw5ou

5-3-2. Checking the take-up torque for playback (recording)

(1) Set the torque cassette (8T-012) in position, and check in the SP-mode recording mode (tape recorded in SP mode)

that the torque at the tape taking-up side is within the standard range.

Standard of take-up torque for SP-mode recording (playback)

9 +, 3 gem with ripples less than 4 gem

(If the torque ripples appear, read the center value of torque between the ripples.)

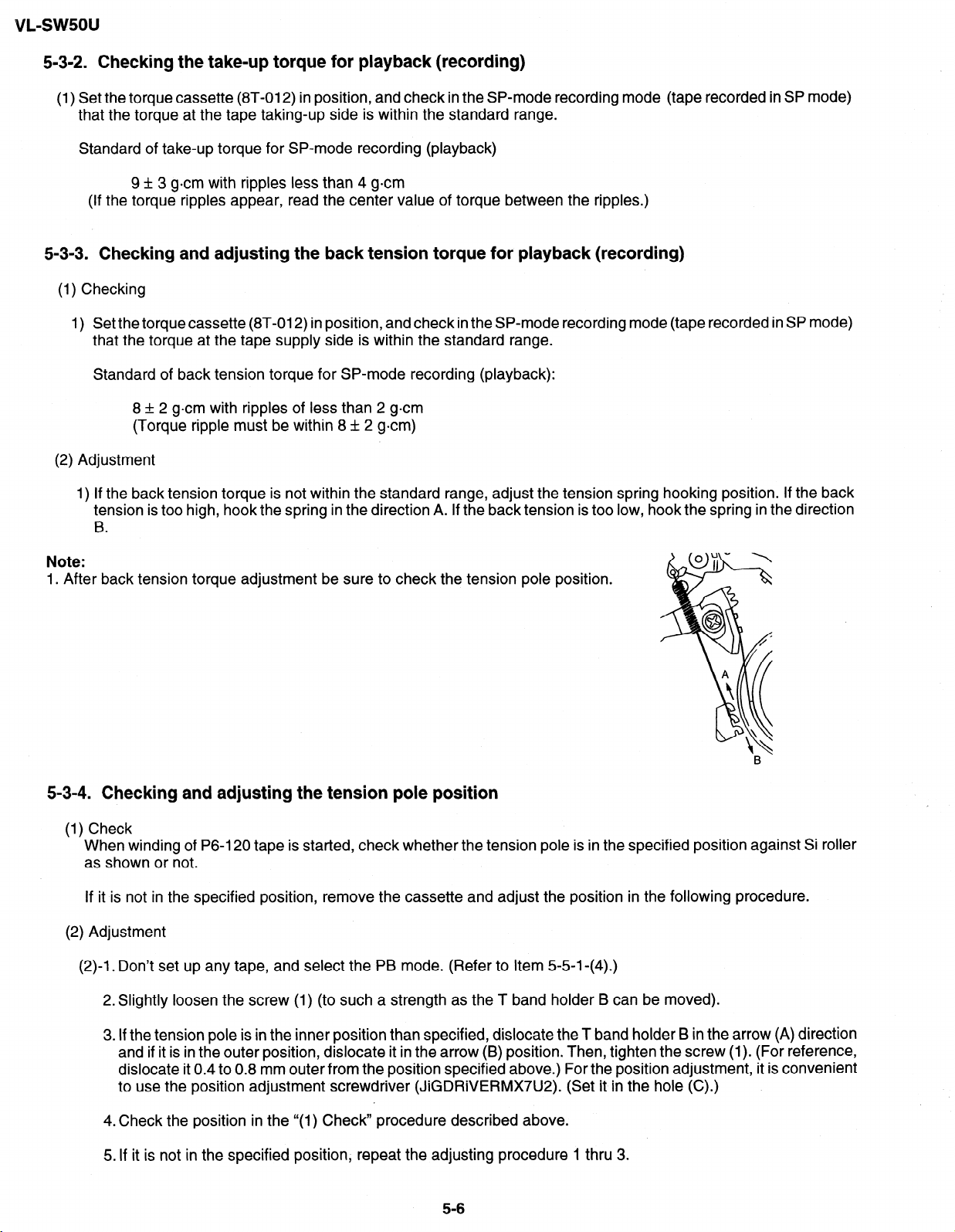

5-3-3. Checking and adjusting the back tension torque for playback (recording)

(1) Checking

1) Set the torque cassette (8T-012) in position, and check in the SP-mode recording mode (tape recorded in SP mode)

that the torque at the tape supply side is within the standard range.

Standard of back tension torque for SP-mode recording (playback):

8 & 2 gem with ripples of less than 2 gem

(Torque ripple must be within 8 + 2 gem)

(2) Adjustment

1) If the back tension torque is not within the standard range, adjust the tension spring hooking position. If the back

tension is too high, hook the spring in the direction A. If the back tension is too low, hook the spring in the direction

.

B

Note:

1. After back tension torque adjustment be sure to check the tension pole position.

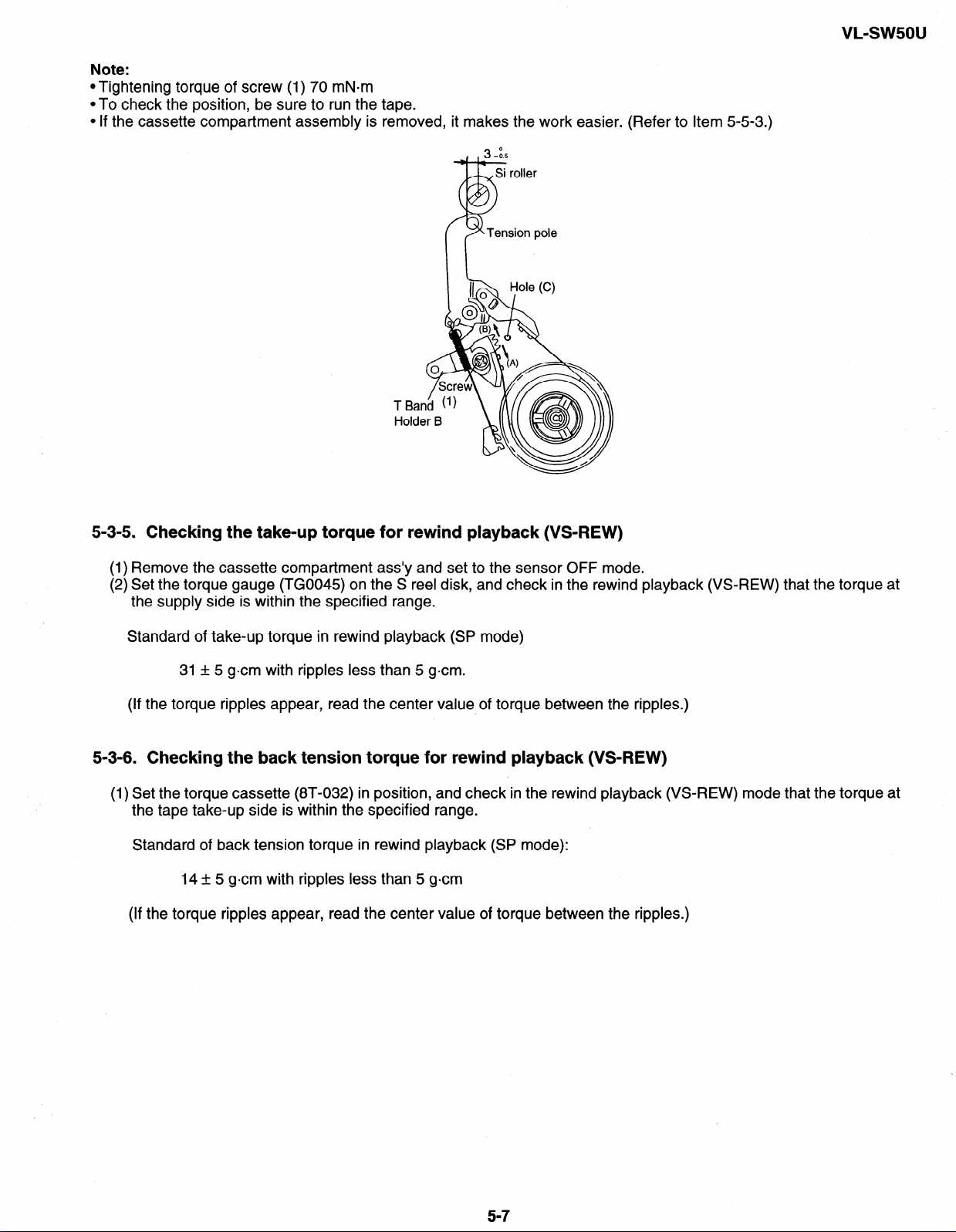

5-3-4. Checking and adjusting the tension pole position

(1) Check

When winding of P6-120 tape is started, check whether the tension pole is in the specified position against Si roller

as shown or not.

If it is not in the specified position, remove the cassette and adjust the position in the following procedure.

(2) Adjustment

(2)-l. Don’t set up any tape, and select the PB mode. (Refer to Item 5-5-l-(4).)

2. Slightly loosen the screw (1) (to such a strength as the T band holder B can be moved).

3. If the tension pole is in the inner position than specified, dislocate the T band holder B in the arrow (A) direction

and if it is in the outer position, dislocate it in the arrow (B) position. Then, tighten the screw (1). (For reference,

dislocate it 0.4 to 0.8 mm outer from the position specified above.) For the position adjustment, it is convenient

to use the position adjustment screwdriver (JiGDRiVERMX7U2). (Set it in the hole (C).)

4.Check the position in the “(1) Check” procedure described above.

5. If it is not in the specified position, repeat the adjusting procedure 1 thru 3.

5-6

Page 21

Note:

*Tightening torque of screw (1) 70 mN-m

*To check the position, be sure to run the tape.

l If the cassette compartment assembly is removed, it makes the work easier. (Refer to Item 5-5-3.)

VL-sw5ou

5-3-5. Checking the take-up torque for rewind playback (VS-REW)

(1) Remove the cassette compartment ass’y and set to the sensor OFF mode.

(2) Set the torque gauge (TG0045) on the S reel disk, and check in the rewind playback (VS-REW) that the torque at

the supply side is within the specified range.

Standard of take-up torque in rewind playback (SP mode)

31 & 5 gem with ripples less than 5 gem.

(If the torque ripples appear, read the center value of torque between the ripples.)

5-3-6. Checking the back tension torque for rewind playback (VS-REW)

(1) Set the torque cassette (8T-032) in position, and check in the rewind playback (VS-REW) mode that the torque at

the tape take-up side is within the specified range.

Standard of back tension torque in rewind playback (SP mode):

14 + 5 gem with ripples less than 5 gem

(If the torque ripples appear, read the center value of torque between the ripples.)

5-7

Page 22

VL-swsou

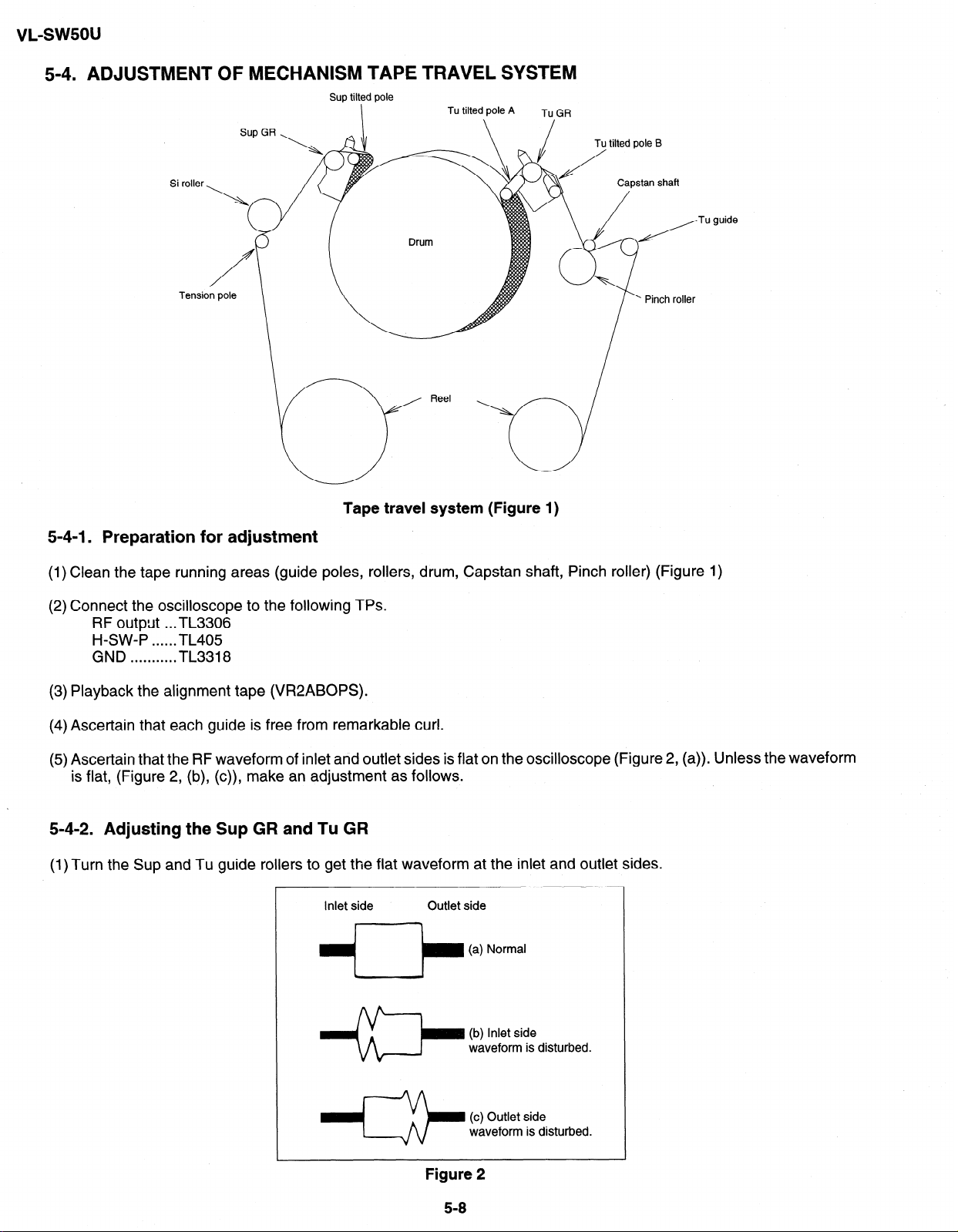

5-4. ADJUSTMENT OF MECHANISM TAPE TRAVEL SYSTEM

Sup tilted pole

Tu guide

Tape travel system (Figure 1)

5-4-l. Preparation for adjustment

(1) Clean the tape running areas (guide poles, rollers, drum, Capstan shaft, Pinch roller) (Figure 1)

(2) Connect the oscilloscope to the following TPs.

RF output . ..TL3306

H-SW-P . . . . ..TL405

GND . . . . . . . . . . . TL3318

(3) Playback the alignment tape (VR2ABOPS).

(4) Ascertain that each guide is free from remarkable curl.

(5) Ascertain that the RF waveform of inlet and outlet sides is flat on the oscilloscope (Figure 2, (a)). Unless the waveform

is flat, (Figure 2, (b), (c)), make an adjustment as follows.

5-4-2. Adjusting the Sup GR and Tu GR

(1) Turn the Sup and Tu guide rollers to get the flat waveform at the inlet and outlet sides.

Figure 2

5-8

Page 23

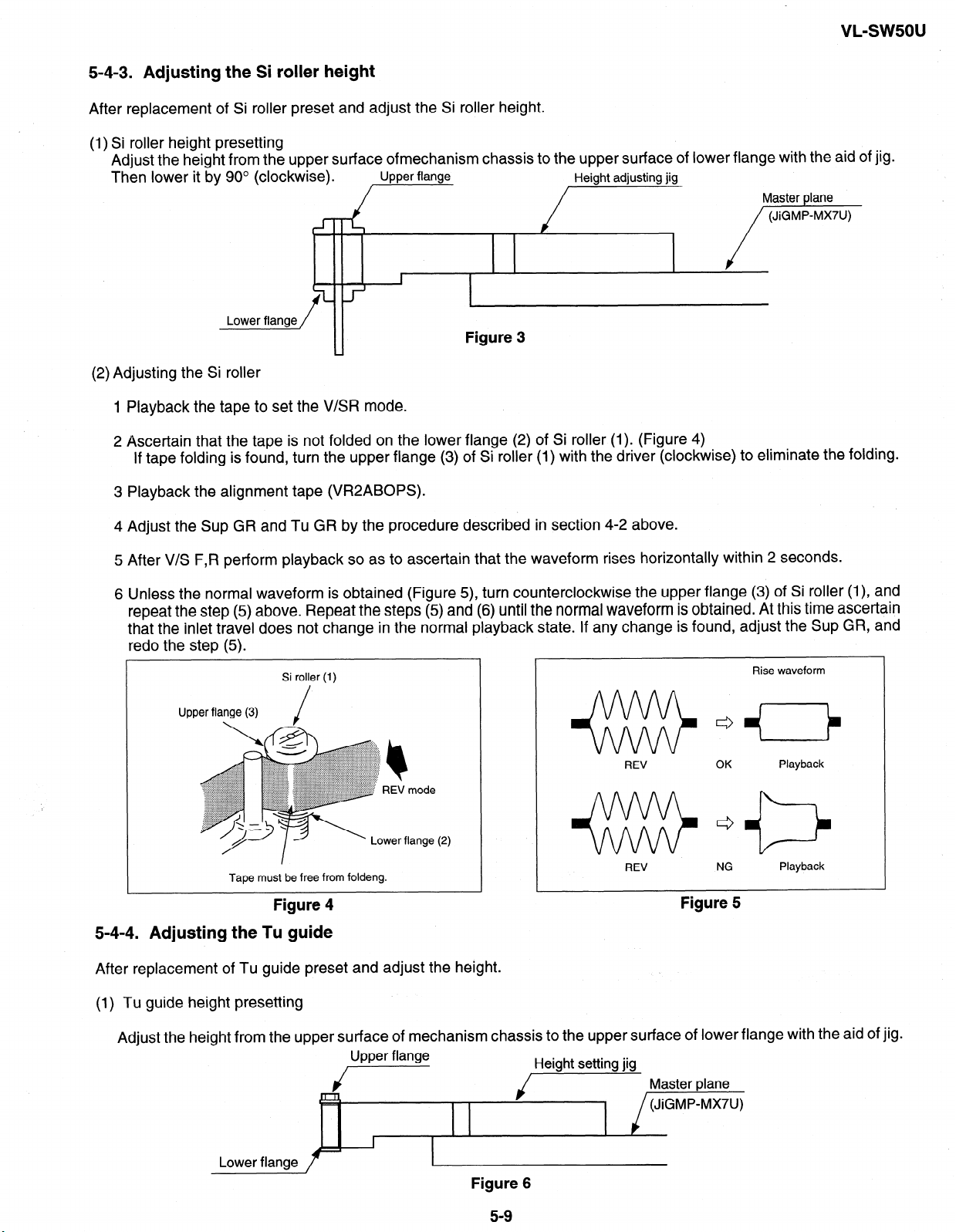

5-4-3. Adjusting the Si roller height

After replacement of Si roller preset and adjust the Si roller height.

(1) Si roller height presetting

Adjust the height from the upper surface ofmechanism chassis to the upper surface of lower flange with the aid of jig.

Then lower it by 90’ (clockwise).

Upper flange

Figure 3

(2) Adjusting the Si roller

1 Playback the tape to set the V/SR mode.

2 Ascertain that the tape is not folded on the lower flange (2) of Si roller (1). (Figure 4)

If tape folding is found, turn the upper flange (3) of Si roller (1) with the driver (clockwise) to eliminate the folding.

Height adjusting jig

Master plane

/w

VL-sw5ou

3 Playback the alignment tape (VR2ABOPS).

4 Adjust the Sup GR and Tu GR by the procedure described in section 4-2 above.

5 After V/S F,R perform playback so as to ascertain that the waveform rises horizontally within 2 seconds.

6 Unless the normal waveform is obtained (Figure 5), turn counterclockwise the upper flange (3) of Si roller (I), and

repeat the step (5) above. Repeat the steps (5) and (6) until the normal waveform is obtained. At this time ascertain

that the inlet travel does not change in the normal playback state. If any change is found, adjust the Sup GR, and

redo the step (5).

NG

Rise waveform

Playback

Upper flange (3)

. /

Tape must be free from foldeng.

Si roller (1)

Figure 4

REV

+%%I&

REV

Figure 5

5-4-4. Adjusting the Tu guide

After replacement of Tu guide preset and adjust the height.

(1) Tu guide height presetting

Adjust the height from the upper surface of mechanism chassis to the upper surface of lower flange with the aid of jig.

Upper flange

i---

jHeight setWI its Master p,ane

(JiGMP-MX7U)

I

Lower flange

Figure 6

5-9

Page 24

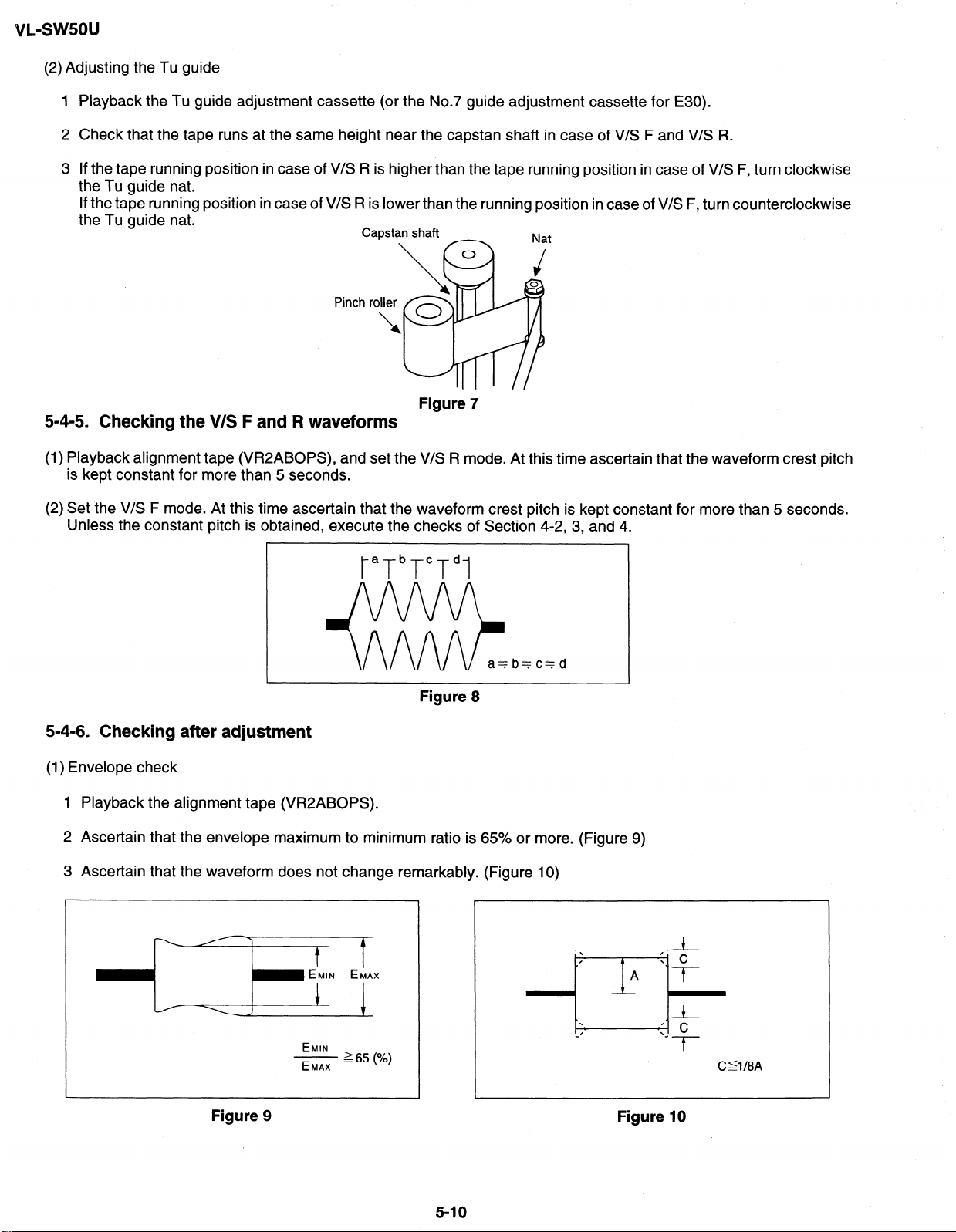

VL-sw5ou

(2) Adjusting the Tu guide

1 Playback the Tu guide adjustment cassette (or the No.7 guide adjustment cassette for E30).

2 Check that the tape runs at the same height near the capstan shaft in case of V/S F and V/S R.

3 If the tape running position in case of V/S R is higher than the tape running position in case of V/S F, turn clockwise

the Tu guide nat.

If the tape running position in case of V/S R is lower than the running position in case of V/S F, turn counterclockwise

the Tu guide nat.

Pinch roller

I

Figure 7

5-4-5. Checking the V/S F and R waveforms

(1) Playback alignment tape (VR2ABOPS), and set the V/S R mode. At this time ascertain that the waveform crest pitch

is kept constant for more than 5 seconds.

(2) Set the V/S F mode. At this time ascertain that the waveform crest pitch is kept constant for more than 5 seconds.

Unless the constant pitch is obtained, execute the checks of Section 4-2, 3, and 4.

taTbTcTdl

Figure 8

5-4-6. Checking after adjustment

(1) Envelope check

1 Playback the alignment tape (VR2ABOPS).

2 Ascertain that the envelope maximum to minimum ratio is 65% or more. (Figure 9)

3 Ascertain that the waveform does not chanae remarkably. (Figure 10)

- EMIN EMAX

EMIN

- 2 65 (%)

EMAX

Figure 10 Figure 9

5-l 0

Page 25

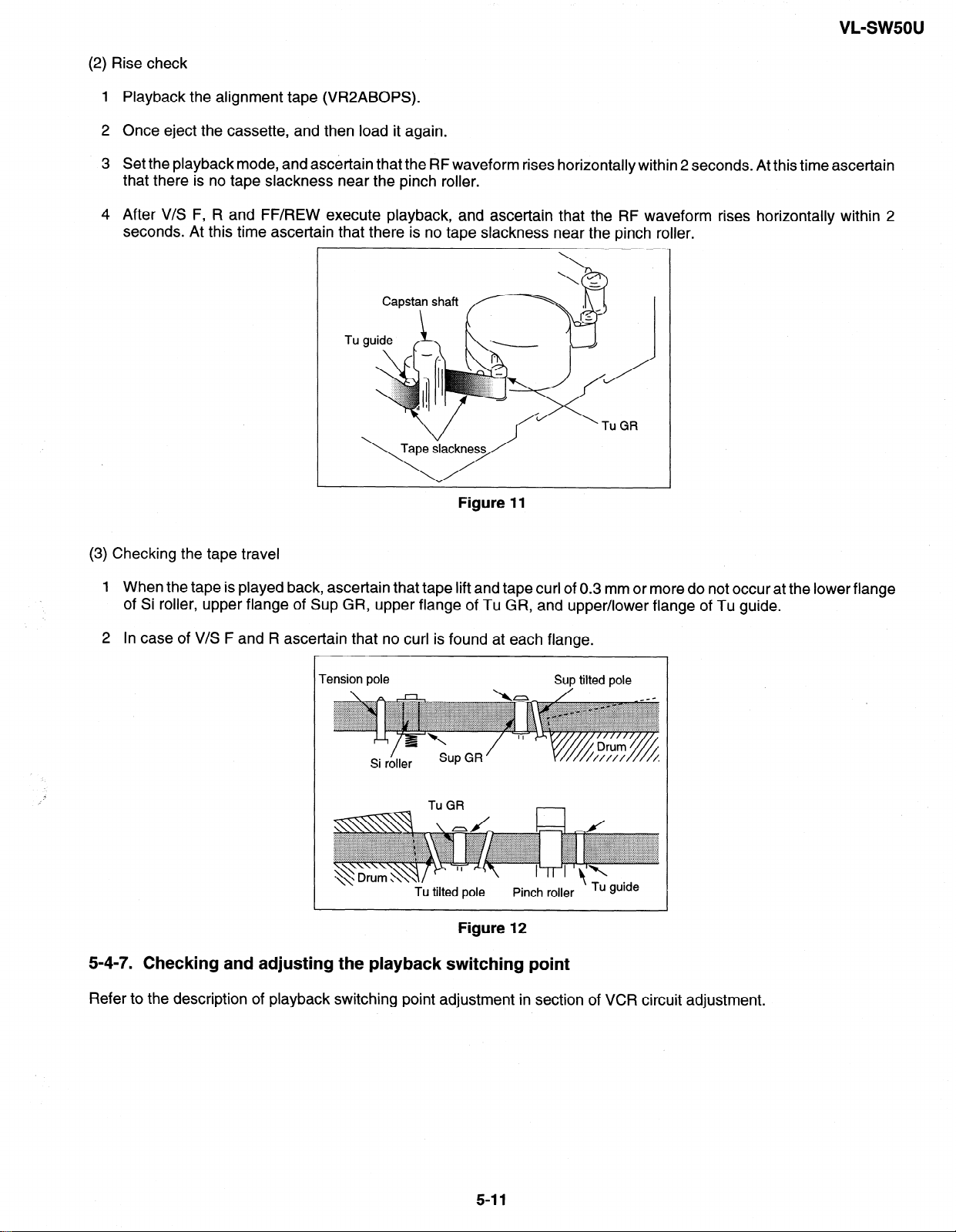

(2) Rise check

Playback the alignment tape (VR2ABOPS).

Once eject the cassette, and then load it again.

Set the playback mode, and ascertain that the RF waveform rises horizontally within 2 seconds. At this time ascertain

that there is no tape slackness near the pinch roller.

After V/S F, R and FF/REW execute playback, and ascertain that the RF waveform rises horizontally within 2

seconds. At this time ascertain that there is no tape slackness near the pinch roller.

Tu

cl’

/

GR

VL-swsou

Figure 11

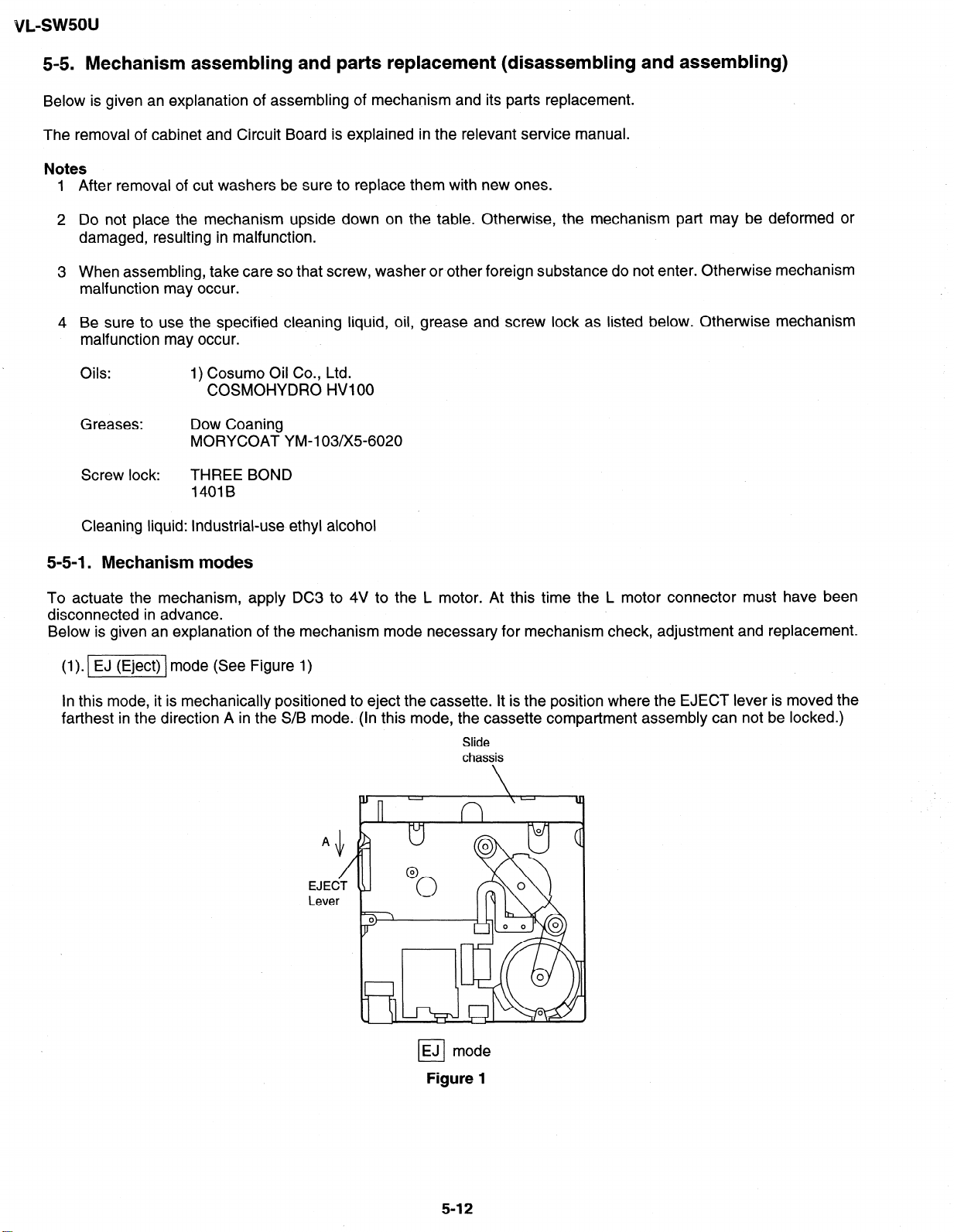

(3) Checking the tape travel

1 When the tape is played back, ascertain that tape lift and tape curl of 0.3 mm or more do not occur at the lower flange

of Si roller, upper flange of Sup GR, upper flange of Tu GR, and upper/lower flange of Tu guide.

2 In case of V/S F and R ascertain that no curl is found at each flange.

Tension pole

Tu tilted pole

Sup tilted pole

Pinch roller

’

Tu guide

Figure 12

5-4-7. Checking and adjusting the playback switching point

Refer to the description of playback switching point adjustment in section of VCR circuit adjustment.

5-l 1

Page 26

vL-sw5ou

5-5. Mechanism assembling and parts replacement (disassembling and assembling)

Below is given an explanation of assembling of mechanism and its parts replacement.

The removal of cabinet and Circuit Board is explained in the relevant service manual.

After removal of cut washers be sure to replace them with new ones.

Do not place the mechanism upside down on the table. Otherwise, the mechanism part may be deformed or

damaged, resulting in malfunction.

When assembling, take care so that screw, washer or other foreign substance do not enter. Otherwise mechanism

malfunction may occur.

Be sure to use the specified cleaning liquid, oil, grease and screw lock as listed below. Otherwise mechanism

malfunction may occur.

Oils: 1) Cosumo Oil Co., Ltd.

COSMOHYDRO HVlOO

Greases: Dow Coaning

MORYCOAT YM-103/X5-6020

Screw lock:

Cleaning liquid: Industrial-use ethyl alcohol

THREE BOND

14018

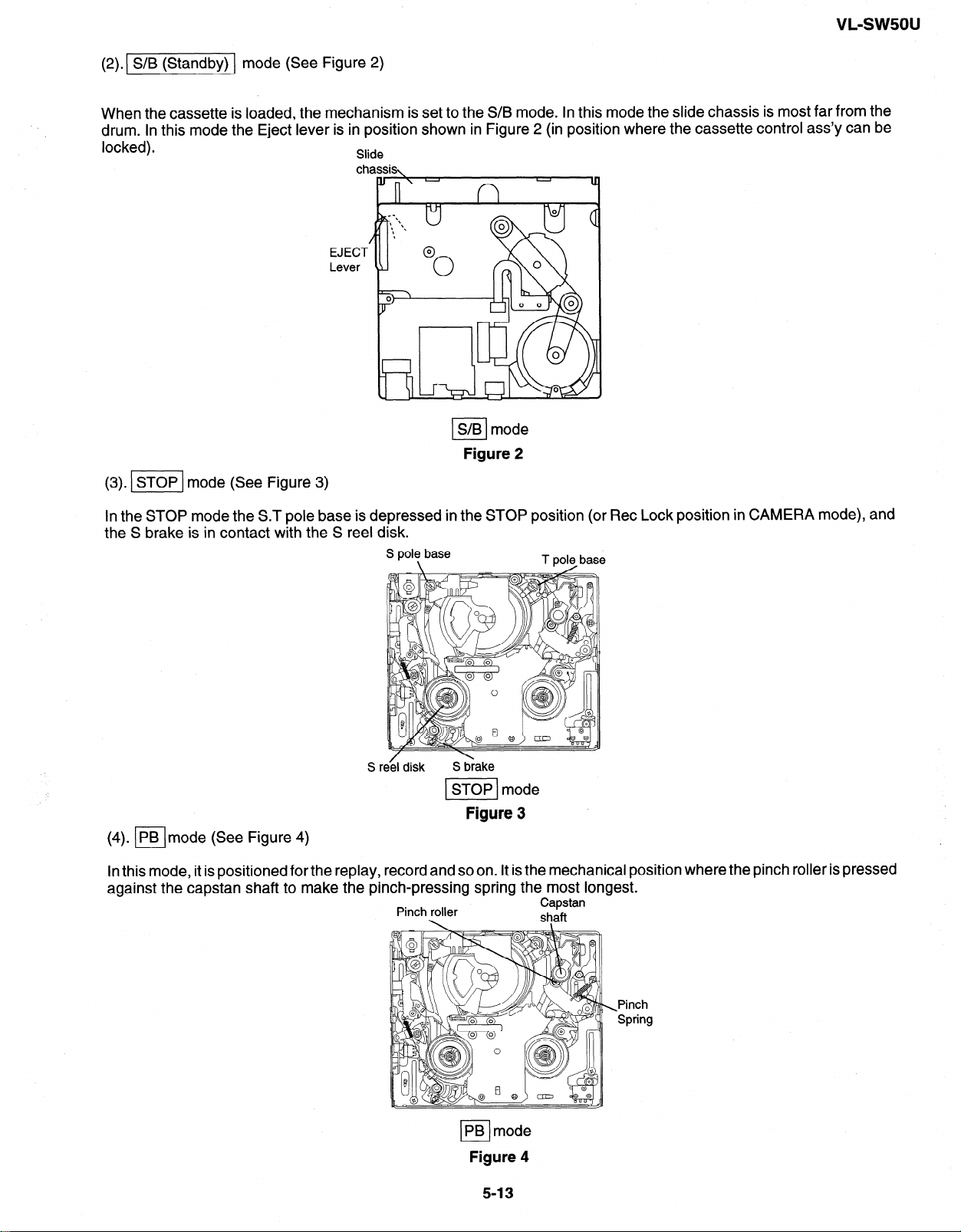

5-5-l. Mechanism modes

To actuate the mechanism, apply DC3 to 4V to the L motor. At this time the L motor connector must have been

disconnected in advance.

Below is given an explanation of the mechanism mode necessary for mechanism check, adjustment and replacement.

(1). I] mode (See Figure 1)

In this mode, it is mechanically positioned to eject the cassette. It is the position where the EJECT lever is moved the

farthest in the direction A in the S/B mode. (In this mode, the cassette compartment assembly can not be locked.)

Slide

chassis

EJ mode

cl

Figure 1

5-12

Page 27

VL-SW5OU

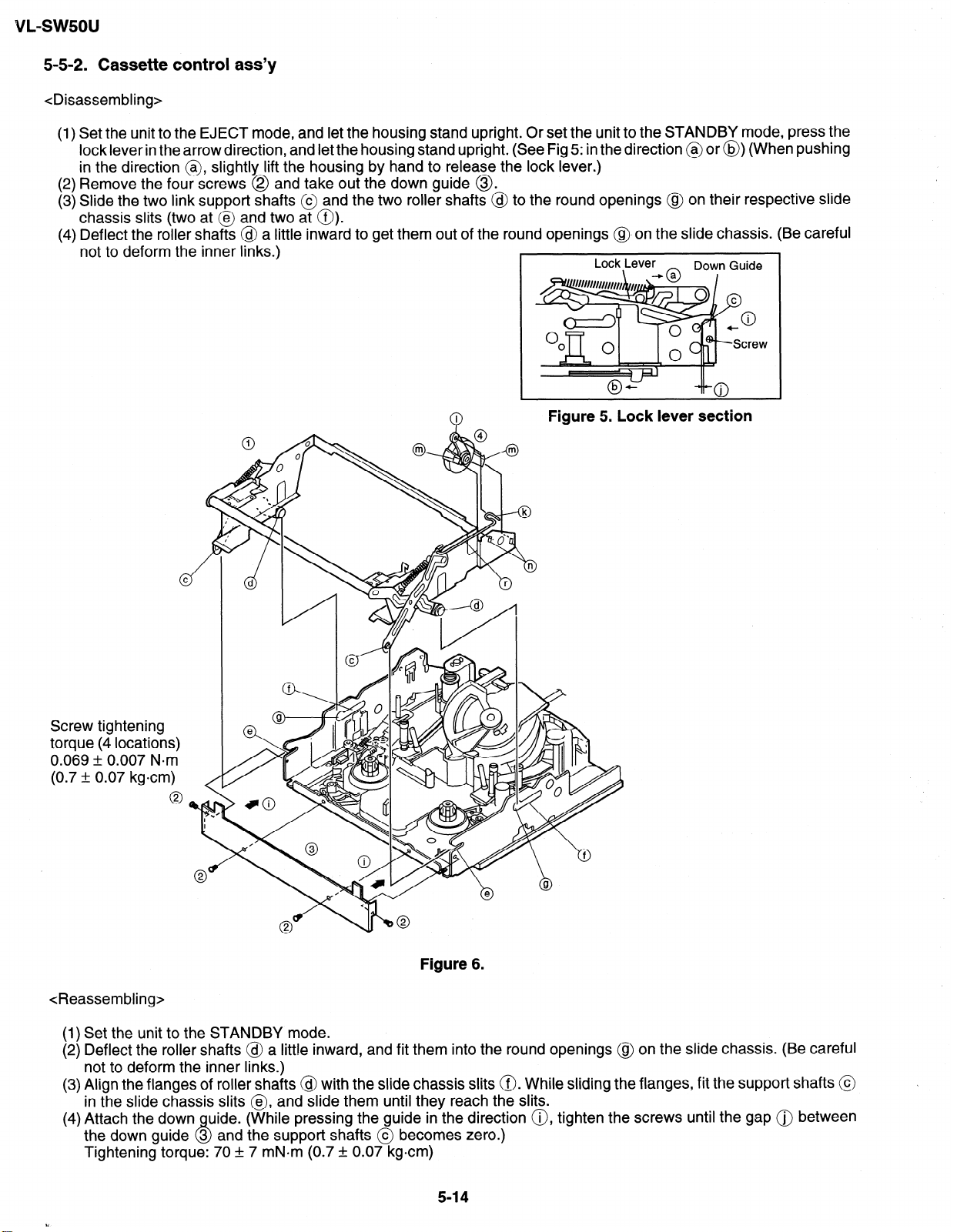

(2).( S/B (Standby)

When the cassette is loaded, the mechanism is set to the S/B mode. In this mode the slide chassis is most far from the

drum. In this mode the Eject lever is in position shown in Figure 2 (in position where the cassette control ass’y can be

locked).

(3). ml mode (See Figure 3)

mode (See Figure 2)

Slide

EJECT

Lever

S/B mode

I

Figure 2

In the STOP mode the ST pole base is depressed in the STOP position (or Ret Lock position in CAMERA mode), and

the S brake is in contact with the S reel disk.

Sr

STOP mode

Figure 3

(4). (PBlmode (See Figure 4)

In this mode, it is pos

against the capstan

itioned for the replay,

shaft to make the pi

record and so on. It is the mechanical position

rich-pressing spring the most longest.

Pinch roller

Capstan

shaft

where the pinch roller is pressed

PB mode

L-l

Figure 4

5-13

-Pinch

Spring

Page 28

VL-swsou

5-5-2. Cassette control ass’y

<Disassembling>

(1) Set the unit to the EJECT mode, and let the housing stand upright. Or set the unit to the STANDBY mode, press the

lock lever in the arrow direction, and let the housing stand upright. (See Fig 5: in the direction @ or @) (When pushing

in the direction @, slightly lift the housing by hand to release the lock lever.)

(2) Remove the four screws @ and take out the down guide @.

(3) Slide the two link support shafts @ and the two roller shafts @ to the round openings @ on their respective slide

chassis slits (two at @ and two at 0).

(4) Deflect the roller shafts @ a little inward to get them out of the round openings (@on the slide chassis. (Be careful

not to deform the inner links.)

Lock Lever

Down Guide

Screw tightening

torque (4 locations)

0.069 & 0.007 Nom

(0.7 1: 0.07 kgcm)

Q

I

Figure 5. Lock lever section

Figure 6.

<Reassembling>

(1) Set the unit to the STANDBY mode.

(2) Deflect the roller shafts @ a little inward, and fit them into the round openings @ on the slide chassis. (Be careful

not to deform the inner links.)

(3) Align the flanges of roller shafts @ with the slide chassis slits 0. While sliding the flanges, fit the support shafts @

in the slide chassis slits @, and slide them until they reach the slits.

(4) Attach the down

the down guide 3 and the support shafts @ becomes zero.)

uide. (While pressing the guide in the direction 0, tighten the screws until the gap 0 between

P,

Tightening torque: 70 + 7 mN*m (0.7 * 0.07 kgcm)

5-14

Page 29

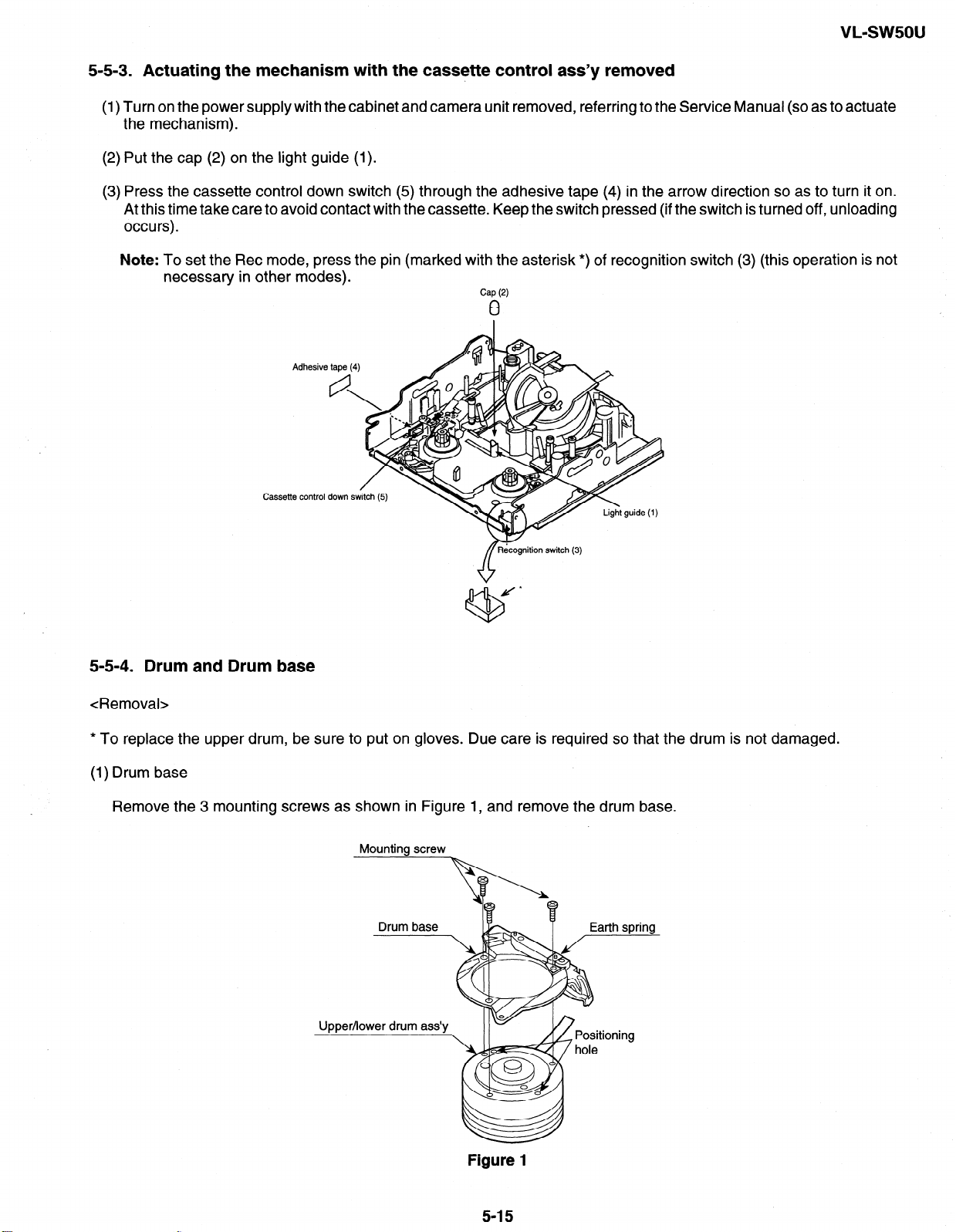

5-5-3. Actuating the mechanism with the cassette control ass’y removed

(1) Turn on the power supply with the cabinet and camera unit removed, referring to the Service Manual (so as to actuate

the mechanism).

(2) Put the cap (2) on the light guide (1).

(3) Press the cassette control down switch (5) through the adhesive tape (4) in the arrow direction so as to turn it on.

At this time take care to avoid contact with the cassette. Keep the switch pressed (if the switch is turned off, unloading

occurs).

Note: To set the Ret mode, press the pin (marked with the asterisk *) of recognition switch (3) (this operation is not

necessary in other modes).

Cassette control

Cap (2)

0

5-5-4. Drum and Drum base

<Removal>

* To replace the upper drum, be sure to put on gloves. Due care is required so that the drum is not damaged.

(1) Drum base

Remove the 3 mounting screws as shown in Figure 1, and remove the drum base.

Mounting screw

Figure 1

5-l 5

Page 30

VL-SWSOU

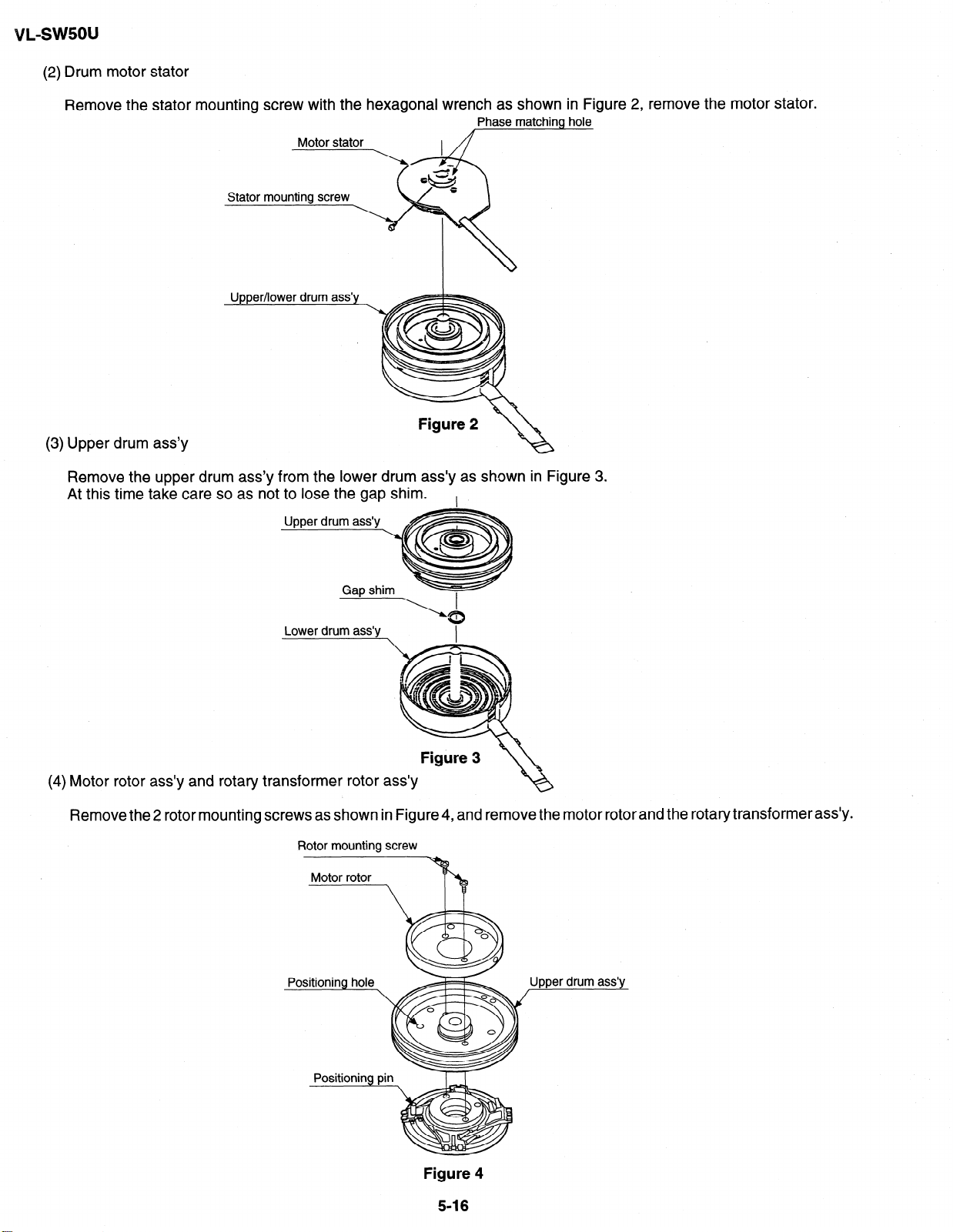

(2) Drum motor stator

Remove the stator mounting

screw with the hexagonal wrench as shown

Stator

Upper/lower drum ass’y

Figure 2

(3) Upper drum ass’y

Remove the upper drum ass’y from the lower drum ass’y as shown

At this time take care so as not to lose the gap shim.

I

Phase matching

\

in Figure 3.

in Figure

hole

2, remove the motor stator.

Lower drum ass’y

\

I

Figure 3

Motor rotor ass’y and rotary transformer rotor ass’y

Remove the 2 rotor mounting screws as shown in Figure 4, and remove the motor rotor and the rotary transformer ass’y.

Rotor mounting screw

I

drum ass’v

Figure 4

5-16

Page 31

(5) Balancer

Remove the balancer mounting screw as shown in Figure 5, and remove the balancer.

BTancer mounting screw ~ /Ba,ancer

Upper drum ass’y

Figure 5

(6) Lower drum ass’y

Remove the FPC mounting screw from the lower drum ass’y as shown in Figure 6.

FPC mounting screw

Lower drum ass’y

VL-swsou

Figure 6

<Installation>

Install the upper drum in the reverse order of removal.

(1) Balancer

Mount the balancer to the upper drum ass’y with the balancer mounting screw. The screw tightening torque must be

0.1 N-m (tighting torque 1 kgcm). (Figure 5)

(2) Motor rotor, rotary transformer rotor ass’y

Clean the contact surfaces of rotor ass’y holder and upper drum ass’y, and ascertain that there are no contamination

and flaws.

Next, adjust the phase so that the positioning pin of rotor ass’y is inserted into the positioning hole of upper drum, and

tight fit the rotor ass’y to the lower surface of upper drum ass’y (Figure 7).

Mounting screw hole

Rotary transformer

Rotor ass’y

Rotary transformer

rotor

with

position pin.

Figure 7

5-17

Page 32

In this state put the motor rotor on the upper surface of upper drum ass’y, and tighten the mounting screw. At this time

make sure that the head screw in the three places is visible through the motor rotor hole (Figure 8). The screw tightening

torque must be 0.1 Nom (1 kgcm).

Rotor mounting screw

Motor rotor

f/

L ch

Upper drum ass’y

Rotary transformer

rotor ass’v

Head mounting

Figure 8

(3) Lower drum ass’y

Tighten the FPC mounting screw to the lower drum ass’y. The screw tightening torque must be 0.08 N-m (tighting torque

0.8 kgcm). (Figure 6)

(4) Upper drum ass’y

After fitting the gap shim which was removed when the upper drum ass’y was dismantled to the shaft of lower drum

ass’y, fit the upper drum ass’y. (Figure 3)

At this time slightly turn the upper drum ass’y by hand to ascertain that RTr does not scrape. If scrape is found, replace

the gap shim with the gap shim packaged together with the replacement upper drum ass’y.

(5) Drum motor stator

Fit the motor stator to the shaft. Then, apply the preliminary pressure 0.07 N-m (0.7 kg) to the motor stator, tighten the

stator mounting screw. The tightening torque must be 0.15 Nom (1.5 kgcm).

Install the stator so that the chassis line is nearly parallel with the motor stator straight section when it is installed on

the chassis. (Figure 9)

(6) Drum base

Align the positioning pin, and tighten the screws (3 PCS.).

Motor stator

Stator set

screw

Chassis line

FPC /

Arrange parallel.

circuit board

Figure 9

5-l 8

Page 33

(7) Drum ass’y

Install the drum ass’y on the main chassis, and tighten the screws (3 PCS.).

(8) Tape guide

Align the positioning pin, and tighten the screw (one PC.).

5-5-5. Phase matching

The phase of the following parts must be matched as shown in the figure below.

(Ascertain that the A marks and round holes align.)

VL-sw5ou

(1) Lo relay gear (2) Main cam (3) Sub-cam

Lo relay gear

(4) Mode switch

Phase alignment mark

(AMaW

Phase alignment mark

(Round hole)

Mode switch

5-6. MECHANISM ASSEMBLING METHOD

(1) Adjust the phase of each part.

(2) Install screws and washers.

(3) Install the segment gear, T arm guide and the M-function lever. Install the eject lever.

B

Item

a S Tight Ml .4 x 3 70 mN*m (0.7 kgfcm)

B 00.8,03.0-to.2

a

claw

t- side.

Tiqhteninq torque

c3

M

rear side&v

Quantity

1

I

5-19

Page 34

VL-sw5ou

(4) Install the loading block assembly and the capstan motor.

(5) Install the drive gear. At this time, pay attention to the direction of gear. (The small gear must be located in the chassis

side.)

Item Tightening torque Quantity

A S Tight Ml .4 x 2.5 70 mN=m

a S Tight Ml .4 x 3 70 mN=m

1

4

a

&?

, Install the

motor under

this plate.

Position the small gear of the drive towards

the chassis.

a

(6) Install the guide rail assembly.

insert the

and slide

Make sure not to

deform the arm.

1 part in the rail

it down.

5-20

Page 35

(7) Install the guide rail assembly taking care to position it correctly.

VL-swsou

Item

A S Tight Ml .4 x 2.5 70

B S Tight Ml .4 x 4

C 00.8-03.0-to.2

D 02.1 -&LO-to.25

a S Tight Ml .4 x 3 70

Make sure not deform the arm.

Align the marks on the parts.

Tightening torque

mN*m 2

40 mN*m

mN*m 1

Quantity

1

1

1

5-21

Segment gear

Assly

Page 36

VL-swsou

(8) Install the drum assembly in the chassis.

(9) Install the tape guide in the drum assembly.

(10) Install the Si roller.

Item

A S tight Ml .7 x L5.3

B S tight Ml .7 x L2.5

Tightening torque

100 mN*m

60 mN-m

Si roller

9

4 Rolle

@

r spring

Quantity

3

1

A

Tape guide

Drum assembly

/

Chassis drawing

Page 37

(11) Install the slide chassis.

T arm guide

VL-sw5ou

Item Tightening torque Quantity

/I Ml .4

6 Ml .4 x 1.5 03.5

x 1.5 04.0 40 mN-m

40 mN-m

1

3

\/

Main cam pin

\

Slide this part towards the T arm.

Place the slide chassis

on the guide rail.

1

L---- Sup reel base

I

’ Insert the main cam pin into the hole of

cam of slide chassis.

5-23

Page 38

i/L-SWSOU

(12) Install in the following order: T guide lever spring, T guide lever, pinch lever.

(13) Install the swing arm.

(14) Install the right guide holder.

A S tight Ml .4 x 2.5

B

r

00.8-03.0-to.2

CW

Item

Tightening torque

70 mN*m

70 mN*m

Pinch lever

&jad / Attach to hook

Quantity

1

1

.

Swing arm

Take care of position.

Pinch lever

The pinch lever

is positioned on

the stopper.

@B

Secure on back side

Take

care not to bend the tension band

during assembly or disassembly.

5-24

Page 39

VL-sw5ou

6. ADJUSTMENT OF VCR

6-I w ADJUSTMENT OF VCR SECTION 6-1-1 n Before starting the electric circuit adjustment

l Electric circuit adjustment becomes necessary, in most cases, when any of the wear mechanical parts or the video head

has been replaced. Before starting the electric circuit adjustment, be sure to check that the mechanical parts work well

(i.e., the mechanical parts have all been perfectly adjusted). In case a trouble or troubles are found in the electric

circuitry, be sure to pinpoint the cause(s) by using the measuring instruments described below. After locating the trouble

spot(s), then proceed to repair, replacement or adjustment. Do not change the positions of the controls when adequate

measuring instruments are not available.

l In order to implement a higher-density, smaller machine, most of the electric circuit parts used on the Circuit Boards

are of small-sized, surface-mounted type. For replacing part(s) as after-sales service, work with a soldering iron as

speedily as possible. The heat resistance of the surface-mounted components is poor, when compared with the largersized discrete parts used for television sets and stationary decks, owning to their small sizes. Therefore, exercise due

care to avoid long-time exposure of the pins of these parts to the heat of the soldering iron which may possibly damage

them. Such care should be exercised especially for chip-layer capacitor replacement. It is advisable to use a

temperature-controlled ceramic soldering iron (temperature at the tip: 250°C, contacting time: less than 5 seconds).

< Adjusting the video/LCD section >

l Measuring instruments:

*Color monitor TV set

*Oscilloscope

*Vector scope

*Digital voltmeter

*Frequency counter

*DC power supply

*Signal generator (NTSC pattern generator LCG-401/401 YC: Leader-made)

*Audio generator (CR oscillator)

*Video recording tape (For Y/C, audio and servo adjustments)

*Alignment tapes (JiGWR2-1 NP, VR2-ATOC, JiGWRS-5NSP)

*AC adapter

*DC cable (AC adapter accessory)

*AV output cable (accessory)

*Video extension cables

6-l-2. Initial setting of E*PROM IC

6-1-2-l. E*PROM data alterable ways

1) Set the switch of main body to VCR, and use the remote control (RRMCG0033TASA) for adjustment to turn on the

adjustment mode.

2) VCR adjustment address setting.

V ADJ

00

After an objective address was established, play key is pushed and set.

In addition, numerical change uses a “REW” or “FF” key.

3) VCR adjustment data setting.

V ADJ

00 ##

After an objective data was established, “PLAY” key is pushed and set.

4) When data of other address are changed successively, push “STOP” key, and please repeat operation to 4) from 2).

5) When SW of the substance is turned into off, data are written to E*PROM from systematic microcomputer.

“00” is blinking

Value of “##” differs by an address.

6-l

Page 40

vL-sw5ou

6-1-2-2. IC702 (E*PROM)

When the IC702 has been replaced, make the following settings and adjustments.

e System code setting

* Set the test mode to the VCR adjustment mode. Take the following steps.

1) Destination code Write the destination data (model numbers) to the addresses 02.

Destination 02

U 01

For calling the addresses and writing the data, refer to the VCR adjustment mode.

2) Specification switching code

Address Data

3) Menu selection code

4) Softwere selection code

5) Dew selection code

6) Function code

*After setting the above codes, clear the VCR adjustment mode and turn off the power.

Notes: Cope with only the following case (A), according as the following [Procedure].

(A) The case with the exception of “O”, the superior bite [ ** h ] of date [Address : 021

(B) [Procedure]

@ Set up “0” from the superior bite of date [Address : 021 : [ 0 *h 1.

@ Press “CONTINUE” key and set out the adjustment mode.

@ Disconnect the only battery of electric power on “switch-on”.

Adjustments to follow

Make the system controller servo, VCR, and LCD adjustments according to their respective instructions.

Address Data

04

Address Data

05 00

Address Data

3c cc

Address Data

03 F8

00

-L

Superior bite

Y- Set up “0”

6-1-2-3. Camera adjustment

All the camera adjustment data are written in the E2PROM provided on the lens unit. Therefore, when the lens is replaced,

the camera must be adjusted again according to the camera adjusting procedure.

6-l-3. Adjusting the Y/C, audio and LCD circuits on models without AA/ in mode

(A/V in mode SET-UP produce)

Set the switch of main body to VCR, and use the remote control (RRMCG0033TASA) for adjustment to turn on the

1)

adjustment mode.

Set up the adjustment address (example : EEmode adjustment address 14). Once this address has been set up, the A/V

2)

IN mode (test mode) is automatically brought and the images appear on the LCD display.

Now make the adjustments referring to the instruotions in the manual.

3)

Page 41

6-l-4. Servicing the VCR section Adjustment 6-1-4-l. Typical connections

Extension Cable etc.

NO .

1

4

5

6

7

8

9

Extension Cable Inverter-VCR (7pin)

Extension Cable MECHA-VCR (70pin) QCNW-1534TAZi

Connector fitting and withdrawing

extractor

Connector fitting and withdrawing

tweezers

Service remote control

Operation Unit

LCD SW Unit

NAME

PART NO.

QCNW-1265TAZi

SEQPiNSETOGGE

RRMCGOO33TASP

QSW-20293TAZZ

QSW-Z0289TAZZ

Code 1 CONFIGURATION 1

AX

a

REMARKS

I

VL-swsou

I

10

11

Extens 1Om cable zoom camera

SW-VCR (6pin)

Extens IOm cable LCD-VCR (24pin)

CAMERA

CABINET

I’4702

,_____.

P3301

SC4701 SC4702

L---u

- L-J VCR UNIT

QCNW-154OTAZZ

QCNW4382TAZZ

I

SC804 SC&

I

BD

W-l

540TAZZ

L-----u I I lJNIT I&

QSW-Z0289TAZZ

QCNW-1265TAZZ

QCNW-1382TAZZ

(00ooooa1

QSW-Z0293TAZZ

6-3

Page 42

l Types of test modes

1 TEST No. 1 Title

Sensors off

I

Contents

All sensors but the cassette controller switch, dew sensor

1 Sensor on/off 1

and battery sensor stay off.

Automatic battery sensor Battery sensor’s input voltage put in memory.

adjustment

Battery adjustment error Battery sensor’s adjustment errors are displayed at the

display

right of the “past errors” area.

All sensors on

All but sensors

on

’ 5 PASS mode

6 Camera adjustment mode Camera adjustment mode

Track shift mode (l/4 shift) All sensors on

[VCR

interrupted]

7

8

VCR adjustment mode VCR adjustment mode

Automatic switching point Play standard tape and call this mode. Switching point is

adjustment (STOP ADJ)

automatically adjusted.

@ When the battery adjustment mode is selected from the camera adjustment mode with a cassette with the erase

protection tab, the VCR is automatically put in the REC mode.

l Below discussed are these seven test modes.

@ [TEST No. I] Sensors off mode

All the sensors, except for the cassette controller switch, dew sensor and battery sensor, stay off. This

enables to bring the VCR in the loading mode without tape. The VCR/camera performance can now

be checked with no tape inside.

@ [TEST No. 31 Automatic battery alarm adjustment

Used to automatically adjust the voltage level which makes the “battery” appear on the LCD display.

@ [TEST No. 41 Battery alarm check/error display

l The difference between the preset battery alarm voltage and the current supply voltage is displayed

as follows.

l A past error is displayed at the right of the current battery alarm error.

@ [TEST No. 51 PASS mode

Used to adjust the tape travelling condition. The tracking is shifted by l/4 from the center to make the

tape running-related RF envelope fluctuations easier to observe.

@ VEST No. 61

Camera adjustment mode

Used to adjust the camera section. (For details, see Servicing the Camera Section.)

@ [TEST No. 71

VCR adjustment mode

Used to adjust the VCR section. (For details, see Servicing the VCR Section.)

0 [TEST No. 81

Automatic switching point adjustment

Used to automatically adjust the playback switching point. (For details, see Automatic Adjustment of

the Playback Switching Point.)

6-l-4-2. Setting up the VCR section adjustment mode (camera section adjustment)

e Select adjustment items by using addresses. Rewrite the adjustment data to change the settings.

Below shown the adjustment procedures and on-screen display.

---‘--------________,

Enlarged view

(CAM ADJ) camera

V ADJ+VCR,?=bD

00

(Address) (Data)

00

;VADJi

100 [

___________________a

-----

T-07

64

I

Page 43

VL-sw5ou

Procedural steps

@ Turn up or down the flashing hexadecimal number with the FF or REW key to select the

address of a desired adjustment item. (Initial address: OOH)

Note: The addresses change as follows. 7E - 7F - 00 - 01 - 02

@ Press the PB key to read the data of the selected address. V ADJ

@ Turn up or down the data setting with the FF or REW key. The data display starts flashing. V ADJ

@ Press the PB key again to write the data setting into the selected address. V ADJ

@ Press the STOP key in the above step @ or @, and the screen returns back to the step 0.

When the FF or REW key is held down for 0.3 second or longer, the address selection is repeated in cycles of 100 msec.

The data setting changes by + 4 by holding the key down for 2 seconds or longer.

Display

( : flashing)

V ADJ

2C A3

2c

2C 72

V ADJ

6-l-4-3. Battery shut-off voltage adjusting method

Supply power to the main unit, using the variable-voltage DC power supply (range of 2.5V to 5V).

1)

Set the CAM/OFF/VCR SW to CAM to switch to the camera mode.

2)

Load a recordable tape and set the main unit to CAM REC. PAUSE.

3)

Set the main unit to TEST mode No. 3, and start recording.

4)

Measure voltage between TL901(+) and TL903(GND), and adjust the supply voltage to 3.OV.

5)

The adjustment is complete if “BATTERY” is displayed on the monitor screen for a second when the PLAY key of

6)

operation unit is pressed.

The adjustment is regarded as proper if the auto shut-off is actuated after the warning is displayed when the TEST mode

7)

is cancelled.

*

In case of automatic adjustment of shut-off voltage, adjustment is impossible if voltage is above 3.OV & 0.2V.

If the adjustment is made at 2.9V or below, the low-voltage operation may become unstable.

0 Types of test modes

Any of the eight test modes can be set up by changing the input voltage at pin (54) of IC703. During any test mode, the

REC Start/Stop corn mands are not accepted.

5v

I I

1.2k 1.5k 2.2k 3.3k 5.6k 10k 33k

Use the SW2 thru SW9 switches on the adjustment tool to select the following test modes.

1 SW No. 1 Title

2

3

4

5

6 1 PASS mode

I

7 Camera adjustment mode Camera adjustment mode

8

9

Sensors off All sensors but the cassette controller switch, dew sensor and battery

Mechanism adjustment mode @ Automatic SP/LP detection prohibited

Automatic battery sensor

adjustment

Error display

~a~ad~tmenterror~~y_Ba~rye~o~ ajui’rnxt?%rs are ~p~yeda~h~ight ofihe -

VCR adjustment mode VCR adjustment mode

Automatic switching point Play standard tape and call this mode. Switching point is automatically

adjustment (STOP ADJ)

I

sensor stay off.

@ Different-mode detection prohibited

@ ATF sampling limited to center

Battery sensor’s input voltage put in memory.

Past errors appear on the counter display of the viewfinder.

“past errors” area.

1 Track shift mode (l/4 shift)

adjusted.

Adjustment tool

Contents

I

-

I

Sensor on/off

All sensors on

All sensors on

All but sensors

on

All sensors on

[VCR

interrupted]

@ When the battery adjustment mode is selected from the camera adjustment mode with a cassette with the erase

protection tab, the VCR is automatically put in the REC mode.

I

65

Page 44

VL-swsou

6-1-5. Adjusting the VCR circuit

l Test Points on the Video Circuit Board

o_TL709

o+=TL713

o-TL716

ovTL8825

o_TL8827

TL8810-==--%

TL8819-Qo

TL8812===+o Qo

TL8817_

co pig

0 ZGWO

2 z 44&j o-Jm*

GC 0

1 P1 0 1

TL1925-00 QQ

TL8807-o ~~$26

TL609=

o_TL701

QhTL9706Q-TL706 o_TLg40

o-TL3723

OohTL3719

-TL3722

o0

TL9703

In

O*

c-0

mr,

acr,

*iI

+

TL47

TL47

o-TL9705o+=-TLg46

owTL9704

0

z oe===-TL941

0

PC

cu

TL947-o

Q-

T

L905

TL913-QQ

TL925-0 ," 2

CW==-TL932

cnw

-0

03W

4Ll

+I+

ul.

00

0

l/S

*O-l

:% TL91 TL802

TL9715- f =

TL910-ogc+;b;;;6 m

TL931 2

TL927y

TL903-+oo+TL904

TLg12-ooe=-TL926

TL909-o

m

*

cT) J ;b;;t(==+Q$o+-TL"":

F

II

8

t t

TF

iz

o_TL943

oQ-TL911

iz

TL803-o

Q+--TL801

Q+=TL8

Q_TL8

g-TL8

8‘

4

6-1-5-l. Adjusting the power circuit

POWER CIRCUIT ADJUSTMENT PROCEDURE

Turn on power (camera).

1. Adjust to LCD-1 5.W.

2. Check P-CON 4.9V.

3. Check CAM 4.9V.

4. Check CAM 2.9V.

6-6

I

5. Check LCD 13.5V.

6. Check LCD 7V.

7. Check CAM 15V.

8. Check LCD -7V.

0 Turn off power.

Page 45

POWER CIRCUIT ADJUSTMENT METHOD

0 Input 6V from the battery terminal, and set the power switch to the camera side.

1. Adjustment to LCD-15.5V

1) Make an adjustment so that the digital voltmeter indicates -15.5V + 0.05V.

2. Checking of P-CON 4.9V

1) Check that the digital voltmeter indicates 4.9V + O.lV.

3. Checking of CAM 4.9V

1) Ascertain that the digital voltmeter indicates 4.9V + O.lV. -

4. Checking of CAM 2.9V

1) Ascertain that the digital voltmeter indicates 2.9V& O.lV.

5. Checking of LCD 13SV

1) Ascertain that the digital voltmeter indicates 13.5V +, 0.3V.

Measuring instrument

Measuring terminal

Adjustment address

1 Standard I -15.5v + 0.05v I

Measuring instrument Digital voltmeter

Measuring terminal TL905

Adjustment address

Standard 4.9v + O.lV ‘,

Measuring instrument Digital voltmeter

Measuring terminal

Adjustment address

Standard 4.9v +, O.lV

Measuring instrument Digital voltmeter

Measuring terminal TL93l

Adjustment address

Standard

Measuring instrument

Measuring terminal

Adjustment address

Standard

Digital voltmeter

TL909

20H

-

TL906

2.9v + O.lV

Digital voltmeter

TL913

13.5v + 0.3v

-

6. Checking of LCD 7V

1) Ascertain that the digital voltmeter indicates 7V + 0.25V.

7. Checking of CAM 15V

1) Ascertain that the digital voltmeter indicates 15V - 0.2V / +

0.25V.

8. Checking of LCD -7V

1) Ascertain that the digital voltmeter indicates -7V + 0.5V.

0 Turn off power supply.

.

1 Standard r 15V-0.2V/+O.25V 1

1 Standard

6-l-6. Adjustment of system controller and servo circuit 6-1-6-l. Adjustment of playback switching point

Play back the alignment tape (JiGWRS-5NSP)

1)

Press the “CONTINUOUS PUSH” and “TEST MODE

2)

SELECTION” of adjustment remote controller to set the

test mode.

At this time the numeral of “TESTOI” blinks.)

Using the “FF” and “REW” keys, select “TESTO8”, and pr

3)

After a while the adjustment is completed, and operation

4)

In case of adjustment failure the tape is ejected automati

1 Measuring instrument I Oscilloscope

Mode

Adjustment address

Tape

‘ess the playback key to set the SW-P adjustment mode.

stops automatically.

tally.

Measuring instrument

Measuring terminal TL914

Adjustment address

Standard

Measuring instrument

Measuring terminal

Adjustment address

Measuring instrument

Measuring terminal

Adjustment address

Playback

30 h

Alignment tape (JiGWRS-SNSP)

Digital voltmeter

7V I!Z 0.25V

Digital voltmeter

TL910

Digital voltmeter

TL911

6-7

Page 46

!/L=SW5OU

Only in the case when the satisfactory result was not obtained by the adjusting method described above, perform the

following adjustment.

1)Connect each signal to the oscilloscope.

1 ch: Video output . . . TL801

2ch: H-SW-P . . . . . . . . . . TL405

GND: GND . . . . . . . . . . . . . . . TL802

2) Play back the alignment tape (JiGWRS-5NSP)

3) Press the “CONTINUOUS PUSH”and “VCR ADJUSTMENT” of adjustment remote controller to set the VCR adjustment

mode.

Select the address 30h, set the sync slope of oscilloscope to (-), adjust the data with “REW” and “FF” so that

the interval between the trigger point and the V sync

signal is set to 6H, and fix the data with the “PLAY” button.

(See Figure 6.1 .I .)

------A

3H-4

I

I

I

I

I

i V sync signal

*-

‘k-3H~3H+

6H+

Then, set the sync slope to (+), and ascertain that the

interval between the trigger point and the V sync signal

has been set to 6H. (See Fiqure 6.2.2.)

_

6)Keep the STOP key pressedfor about 3 seconds to exit

I;M,

I

lMl-i_

Figure 6.1 .l Figure 6.2.2

from the adjustment mode.

6-l-7. Y/C circuit adjustment method

Input signal conditions

Video signals generated by a pattern generator are used to make electric adjustments in a Y/C circuit. Thus this signal

must conform to the standards prescribed for adjustment signals.

Use an oscilloscope to check that the video signal is terminated with a 75 &2 resistor, the amplitude of the sync signal

component, video component and burst signal are approx. 0.3 Vp-p, 0.7 Vp-p and 0.3 Vp-p, respectively and that they

are flat. The relative level of the burst signal and the red signal shall be 0.30:0.66.

The color bar used in an electrical adjustment is shown in Figure A.

White (approx. 100%)

r-

I-- Burst signal

Approx. 0.7 VP+

I

L-

Red (approx. 0.6 VP-P)

- Horizontal sync signal

Figure A Color bar signal produced by a pattern generator

* When a pattern generator is not used

Shoot a color bar chart (JiGCHART-4) using a perfectly adjusted video camera.

A signal from a perfectly adjusted video camera shooting a color bar chart (JiGCHART-4) can be used as an adjusting

signal if the lighting can be set to meet the following conditions: output (75 IR terminated), the amplitude of the sync signal

component, video component and burst signal are approx. 0.3 Vp-p, 0.7 Vp-p and 0.3 Vp-p, respectively. The relative

level of the burst signal and the red signal shall be 0.30:0.66. This is shown in Figure B.

White (approx. 100%)

Approx. 0.7 Vp-p

L---

Red (approx. 0.6 VP-P)

- Horizontal sync signal

Figure B Color bar signal produced by a video camera

6-8

Page 47

1. Adjustment of fixed data writing

ADD

DATA

23

25

26 DO

00

00

(l)Before starting Y/C adjustment, be sure to write the

specific data in the addresses listed left.

If the data listed left is written after Y/C adjustment,

adjusting values may deviate.

Before starting Y/C adjustment, write 00 to the address

31

*