Page 1

SERVICE MANUAL

S13V5SX76NF8/

COLOUR TELEVISION

Chassis No. GA-20X

SX76NF8

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

SX76NF8

FEATURE

Ë

Ë

Full Auto Channel Preset and Auto Channel Skip

Ë

100 CH Program Memory

Ë

CATV (Hyper Band) Ready

<Used Frequency Synthesizer Tuner>

Ë

High Contrast Picture

Ë

TELETEXT(10 page)

English / German / French / Spanish / Italian

/ Swedish / Dutch / portuguese

Ë

ON Timer/OFF T imer

Blue Back Noise Mute

Ë

White Temperature Adjustment

Ë

Child Lock

Ë

Auto Sound Limiter

Ë

Headphone Terminal

Ë

Stereo (NICAM / IGR) Decoder

Ë

Rotation adjustment (picture tilt adjustment)

Ë

Component Input Terminal

CONTENTS

Page

» SPECIFICATIONS.............................................2

» IMPORTANT SERVICE NOTES........................2

» ADJUSTMENT PRECAUTIONS........................3

» TROUBLE SHOOTING TABLE ......................... 8

» WAVEFORMS ..................................................12

» CHASSIS LAYOUT ..........................................14

» BLOCK DIAGRAM...........................................16

» DESCRIPTION OF SCHEMATIC DIAGRAM ..18

» SCHEMATIC DIAGRAM

Ë

CRT UNIT.....................................................19

Ë

MAIN UNIT ...................................................20

Ë

CONTROL UNIT .......................................... 26

Ë

DF UNIT .......................................................28

Ë

LED UNIT .....................................................29

Ë

KEY UNIT..................................................... 29

Ë

SUB WOOFER UNIT ...................................30

» PRINTED WIRING BOARD ASSEMBLIES..... 31

» REPLACEMENT PARTS LIST

Ë

ELECTRICAL PARTS

MAIN UNIT ................................................... 38

CRT UNIT.....................................................43

CONTROL UNIT .......................................... 44

DF UNIT .......................................................45

LED UNIT .....................................................45

SUB WOOFER UNIT ...................................45

KEY UNIT..................................................... 45

Ë

MISCELLANEOUS PARTS..........................46

Ë

SUPPLIED ACCESSORIES.........................46

Ë

PACKING PARTS......................................... 46

Ë

CABINET PARTS ......................................... 46

Ë

CABINET PARTS LOCATION...................... 46

» PACKING OF THE SET...................................47

Page

The chassis in this receiver is partially hot. Use an isolation transformer between the line cord plug and power

receptacle, when servicing this chassis. To prevent electric shock, do not remove cover. No user – serviceable

parts inside. Refer servicing to qualified service personnel.

WARNING

SHARP CORPORATION

1

Page 2

SX76NF8

SPECIFICATIONS

Convergence ................................................................. Self Convergence System

Focus ............................................................Electrostatic Focus High Bi-Potential

Sweep Deflection......................................................................................Magnetic

Intermediate Frequencies

Picture IF Carrier .................................................................................. 38.9MHz

Sound IF Carrier Frequency

5.5MHz ..............................................................................................33.4MHz

Colour Sub-Carrier Frequency............................................................34.47MHz

Power Input......................................................................... AC 220 ~ 240V 50 Hz

Power Consumption ...................................................................................... 140W

Audio Power Output Rating ............................................5W + 5W + 10W(at Max.)

Speaker

Size.............................................................................. 11 x 5 cm Elliptic (2 pcs)

10cm Round (1pc)

Voice Coil Impedance..............................................................4 ohm (11 x 5cm)

8 ohm (10cm)

Aerial Input Impedance

VHF/UHF ............................................................................ 75 ohm Unbalanced

Receiving System (PAL-B/G)

VHF.......................................................................................AU 0 thru AU 12 ch

UHF ....................................................................................AU 28 thru AU 69 ch

Receiving Frequency

VHF-Channels ......................................................... 44.25MHz thru 463.25MHz

UHF-Channels....................................................... 471.25MHz thru 863.25MHz

Dimensions................................................................................... Width: 880.0mm

Height: 566.0mm

Depth: 545.0mm

Weight(approx): 54.0 kg

Cabinet material .................................................................................... All Plastics

Specifications are subject to change without prior notice.

IMPORTANT SERVICE NOTES

Maintenance and repairing of this receiver should be done by quali-

fied service personnel only .

SERVICE OF HIGH VOLTAGE SYSTEM AND PIC-

TURE TUBE

When servicing the high voltage system, remove static charge from it by

Connecting a 10K ohm Resistor in series with an insulated wire(such as a

test probe) between picture tube dag and 2nd anode lead. (AC line cord

should be disconnected from AC outlet.)

1. Picture tube in this receiver employs integral implosion protection.

2. Replace with tube of the same type number for continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing shatterproof goggles and after discharging

the high voltage completely.

X-RAY

This receiver is designed so that any X-Ray radiation is kept to an absolute

Minimum. Since certain malfunctions or servicing may produce potentially

hazardous radiation with prolonged exposure at close range, the following

precautions should be observed:

1. When repairing the circuit, be sure not to increase the high voltage to more than 34.5kV(at

beam 0

µ

A) for the set.

2. To keep the set in a normal opeartion , be sure to make it function on 30.5kV

±

1.5kV(at

beam 1800

µ

A) in the case of the set. The set has been factory - Adjusted to the above-

mentioned high voltage.

*If there is a possibility that the high voltage fluctuates as a result of the repairing,

never forget to check for such high voltage after the work.

3. Do not substitute a picture tube with unauthorizerd types and/or brands which may

cause excess X-ray radiation.

BEFORE RETURNING THE RECEIVER

Before returning the receiver to the user, perform the following safety Checks.

1. Inspect all lead dress to make certain that leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in the receiver.

2. Inspect all protective devices such as non-metallic control knobs, insulating fishpapers,

cabinet backs, adjustment and compartment covers or shields, isolation resistor- ca-

pacity networks, mechanical insulators etc.

2-2

2-1

2

Page 3

SX76NF8

ADJUSTMENT PRECAUTIONS

All adjustments to this chassis, except for focus, are carried out in the Service Mode.

Service Mode

The Service Mode is provided to enable the engineer to correctly set up the receiver to the CRT fitted in the set.

Note that these adjustments may vary from one receiver to another.

To enter the Service Mode, carry out the following procedure.

1.Connect a test pattern to the antenna terminal.

2.Tune the receiver to this signal.

3.Turn the receiver off using the mains switch.

4.Press volume down and channel up buttons on the front of

the receiver at the same time.

5.Keeping these buttons pressed, turn the mains on.

6.When the set starts up it will be in Service Mode.

7.Release the two buttons.

» Use the channel up and down buttons to move between the options.

» Use the volume control buttons to change the data.

» To store the data, use the stand-by button on the remote control.

» To exit the Service Mode, turn the receiver off using the mains switch.

When the Service Mode is entered the following On Screen Display appears

SERVICE SOFTWARE

SW on: XXXX SW off: XXXX Hours ON: XXXX

The figures displayed in the XXXX locations are hexadecimal representations of the number of times that particular

function has been executed. For example if the hexadecimal number displayed after SW ON was 0E4A, this would

correspond to the receiver being turned on 3658 times.

Adjustment menu:

The following adjustments can be carried out in the Service Mode.

» Horizontal Shift » Blue Gain

» East West Width » Red Cut Off

» Pin Phase » Green Cut Off

» Pin Amp (Amplitude) » Blue Cut Off

» Corner Amplitude » Alter NVM Pag (Page)

» Corner Symmetry » Alter NVM Pos (Position)

» Vertical Linearity » Alter NVM Val (Value)

» Vertical Angle » Teletext Mix Mode Contrast

» Vertical Bow » Teletext Contrast

» Vertical Amplitude » OSD Contrast

» S Correction » DVCO Adjustment (Only PAL)

» Vertical Shift » DVCO Adjustment (Only NTSC)

» Red Gain » AGC Adjustment

» Green Gain » Rotation Inspection

» INTIAL On/Off

Note that the receiver should be set to FULL MODE before carrying out any geometry adjustments. This can be achieved

by pressing the widescreen mode button on the remote control until FULL MODE appears on the OSD. This can only be

done out of the Service Mode.

Detailed instructions on how to execute these are given on the following pages.

Front

Top of front cabinet

Changing NVM Data

To change the data contained within the Non Volatile Memory, it is necessary to first select the page the data is stored

in, then the position and finally to change the data itself. The procedure below outline this process.

1. Press the channel up/down buttons and ALTER NVM PAG appears, use the volume up/down buttons to change this

data (it is shown in hexadecimal format).

2. Press the channel up button and ALTER NVM POS appears use the volume up/down buttons to change this data (it

is shown in hexadecimal format).

3. Press the channel up button and ALTER NVM VAL appears, use the volume up/down buttons to change this data (it

is shown in hexadecimal format).

4. Once this data has been set, press the stand-by button to store.

5. If another NVM value has to be changed, use the channel down button to select the page or position and repeat as

necessary.

Note: DO NOT change any NVM data, unless you have been adviced to do so by a Sharp representative. If data is

incorrectly changed, serious damage may occur to hte receiver.

3-2

3

3-1

Page 4

SX76NF8

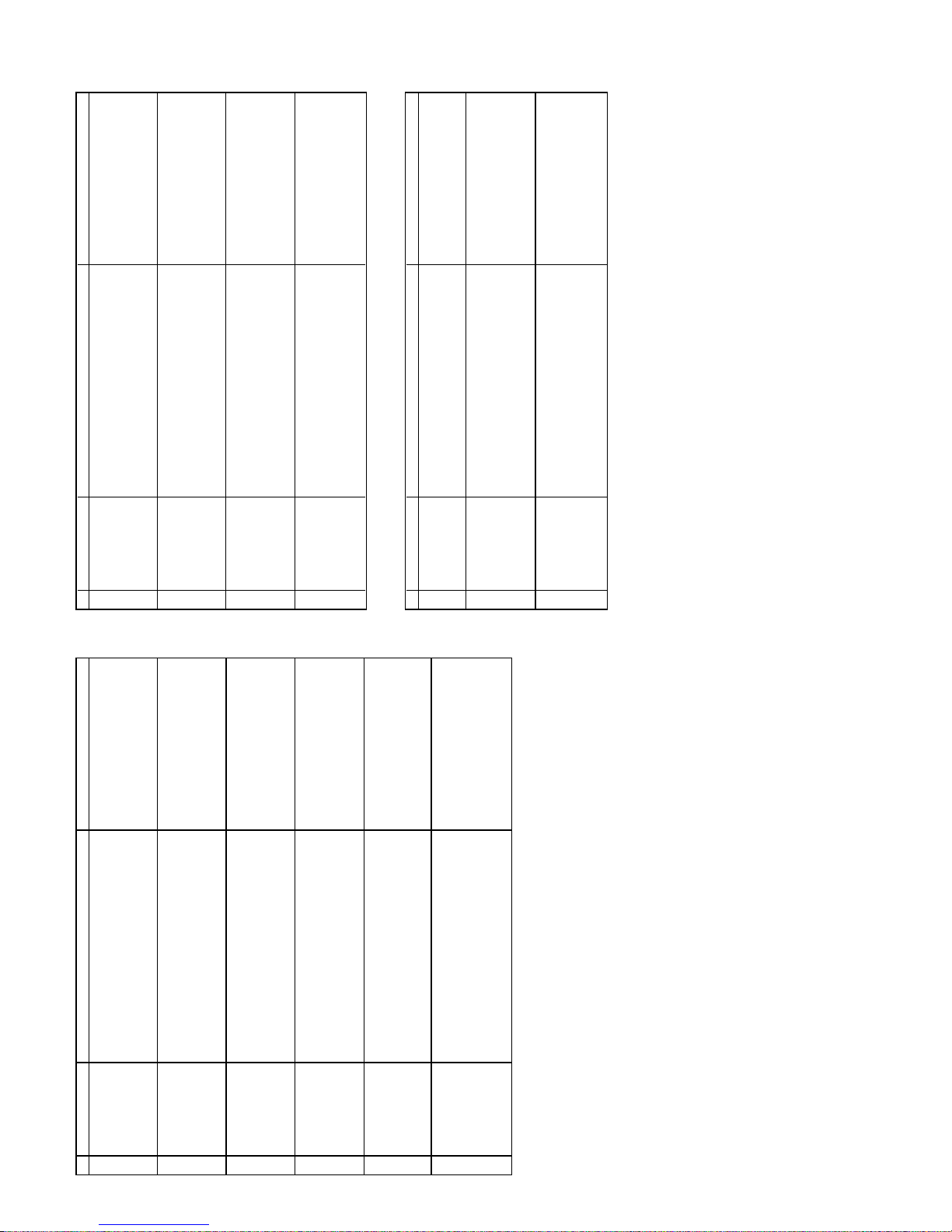

PIF ADJUSTMENT

NO

1

ADJUSTMENT POINT

RF-AGC

ADJUSTMENT

(I2C BUS CONTROL)

ADJUSTMENT CONDITION / PROCEDURE

(1) Receive signal.

E-12cH

Signal strength: 57

± 1dBµV (50 ohm open)

(2) Call "AGC" mode in service mode.

(3) Push "power button", automatically adjust.

WAVEFORM OR OTHERS

Note: For the 50 ohm signal strength gauge,

when not using 50/75 impedance adapter,

signal strength is 57

±1dBµV(50 ohm open),

instead of 59 ±1dBµV(75 ohm open).

precaution: The loss of using impedance

adapter.

CUT OFF, BKGD ADJUSTMENT

NO

1

ADJUSTMENT POINT

AGING

ADJUSTMENT CONDITION / PROCEDURE

(1) Receive PR-99ch (BLUE BACK OFF), "NOISE

PICTURE"

(2) Aging 30 minutes.

WAVEFORM OR OTHERS

1 CRT CUTOFF

ADJUSTMENT

(1) Receive 50Hz Monoscope Pattern Signal.

(2) Set Picture Normal condition.

(3) Select full mode.

(4) Call "RED GAIN" mode in service mode.

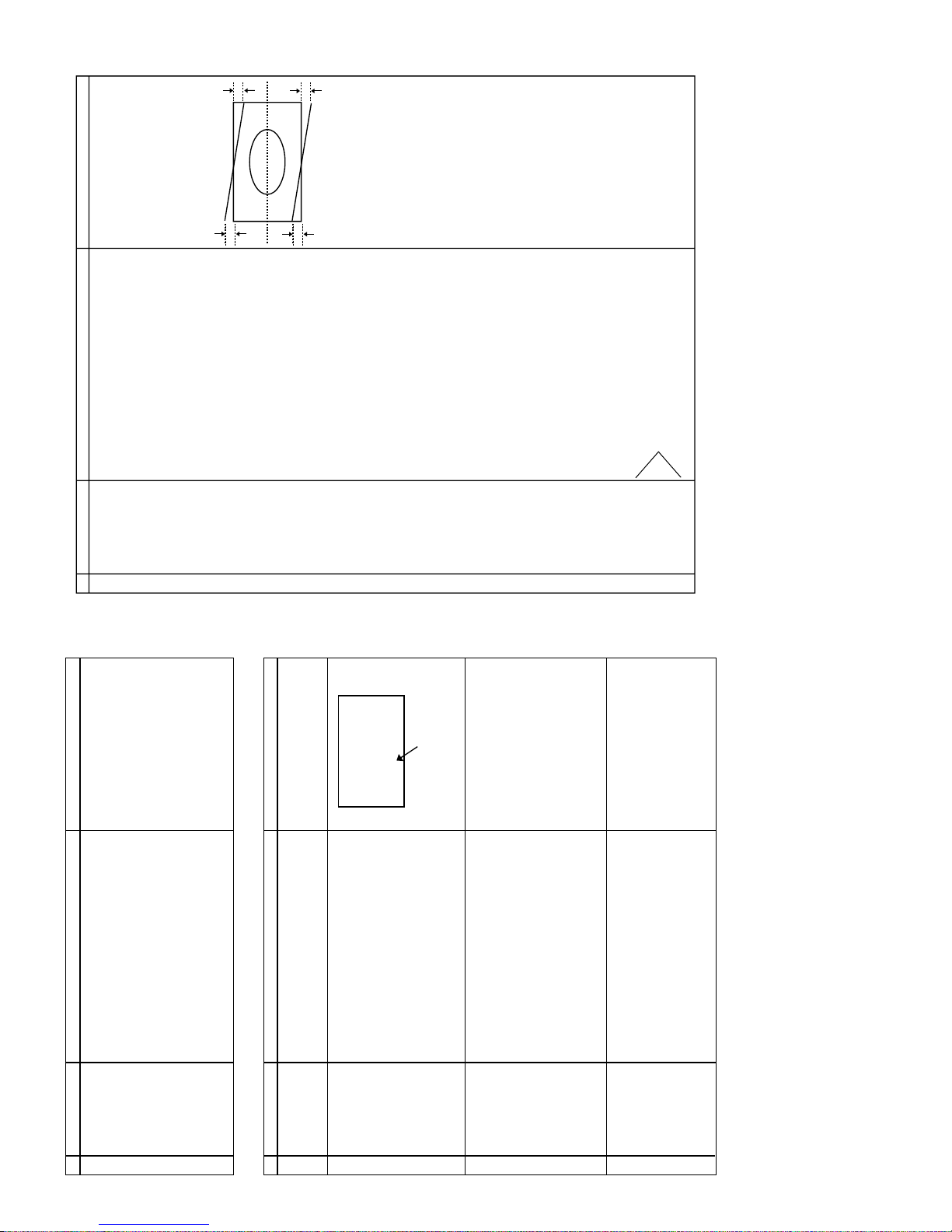

(5) Adjust SCREEN VR, so that the value of OSD reach

50h ± 8h. (Fig.1)

07 52 53 54

13 50 51 52

Fig.1

The value of this point

2

WHITE BALANCE

SERVICE MODE ADJ

(1) Receive the "WHITE/BLACK" Pattern SIGNAL.

(2) Press R/C to set Picture NORMAL condition.

(3) Select full mode.

(4) Call "*** GAIN/***CUT OFF" mode in service mode.

(5) Adjust the "RED GAIN","GREEN GAIN","BLUE

GAIN","GREEN CUT OFF", and "BLUE CUT OFF" data

to have a colour temperature of 12300

°K (white).

3

Max Beam Check (1) Receive 50Hz Monoscope Pattern Signal.

(2) Press R/C to set Picture NORMAL condition.

(3) Select full mode.

(4) Connect the DC miliammeter between R611(10K

Ω)

(Full Scale: 3mA Range)

(5) Beam current must be within 1600

±100µA.

Refer to SHIPPING SETTING & CHECKING.

• 12300°KX : 0.272±0.010

Y : 0.275±0.010

(MINOLTA COLOUR ANALYZER CA-100)

*Note: Above Data can be UP/DOWN by

Volume Key.

HIGH 100cd/m

2

± 10cd/m

2

LOW 10.0cd/m

2

± 1cd/m

2

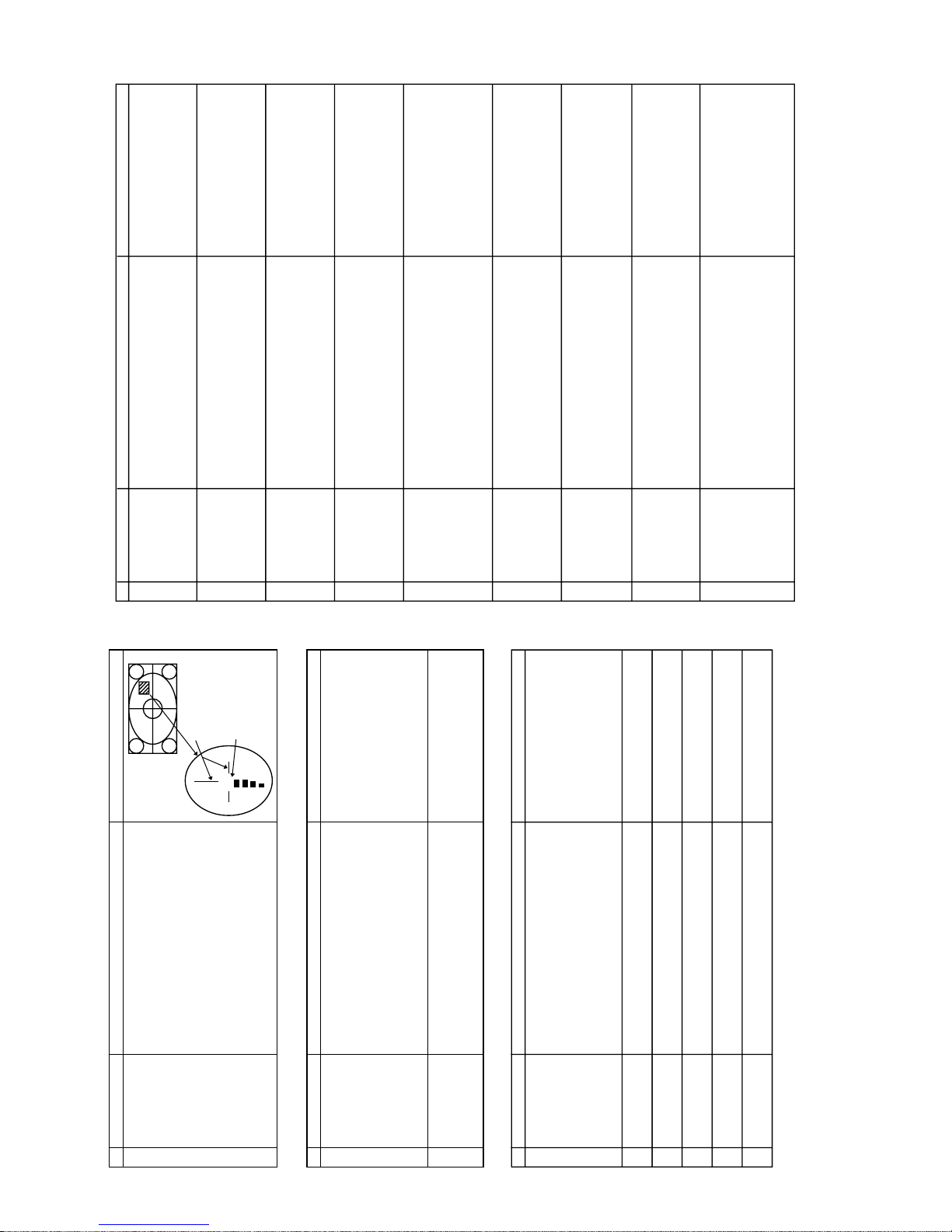

HORIZONTAL, VERTICAL, DEFLECTION LOOP ADJUSTMENT.

NO

1

2

3

4

5

6

7

8

9

10

11

12

ADJUSTMENT POINT

1) 50Hz FULL

V. LINEARITY

(I2C BUS CONTROL)

VERTICAL SHIFT

(I2C BUS CONTROL)

VERTICAL AMP.

(I2C BUS CONTROL)

HORIZONTAL SHIFT

(I2C BUS CONTROL)

EAST -W AST WIDTH

(I2C BUS CONTROL)

PIN PHASE

(I2C BUS CONTROL)

PIN AMP

(I2C BUS CONTROL)

CORNER AMPLITUDE

(I2C BUS CONTROL)

CORNER SYMMETRY

(I2C BUS CONTROL)

VERTICAL ANGLE

(I2C BUS CONTROL)

VERTICAL BOW

(I2C BUS CONTROL)

S CORRECTION

(I2C BUS CONTROL)

2) 50Hz CINEMA

3) 60Hz FULL

4) 60Hz CINEMA

ADJUSTMENT CONDITION / PROCEDURE

(1) Press R/C to set Picture NORMAL condition.

(2) Select full mode.

*Receive 50Hz Monoscope Pattern Signal.

(1) Call the "VERTICAL LINEARITY" mode.

(2) Increase or decrease "VERTICAL LINEARITY" by

Volume key till the horizontal line in the center of

monoscope is just at the position where the blanking

starts.

(1) Call the "VERTICAL SHIFT" mode.

(2) Increase or decrease "VERTICAL SHIFT" by Volume key

till the picture is centered.

(1) Call the "VERTICAL AMPLITUDE" mode.

(2) Increase or decrease "VERTICAL AMPLITUDE" by

Volume key to set overscan of 8% typical.

Adjustment Spec 8% range +1% -1%

(1) Call the "H-CENT" mode.

(2) Increase or decrease "H-CENT" by Volume Key to center

the picture horizontal.

(1) Call the "EAST-WAST WIDTH" mode.

(2) Increase or decrease "EAST-WAST WIDTH" by Volume

key to set overscan of 8% typical.

Adjustment Sepc 8% range +1% -1%

*Receive 50Hz Cross-Hatch Pattern Signal.

(1) Call the "PIN PHASE" mode.

(2) Increase or decrease "PIN PHASE" by Volume key.

(1) Call the "PIN AMP" mode.

(2) Increase or decrease "H-CENT" by Volume key.

(1) Call the "CORNER AMPLITUDE" mode.

(2) Increase or decrease "CORNER AMPLITUDE" by

Volume key.

(1) Call the "CORNER SYMMETRY" mode.

(2) Increase or decrease "CORNER SYMMETRY" by

Volume key.

(1) Call the "VERTICAL ANGLE" mode.

(2) Increase or decrease "VERTICAL ANGLE" by Volume

key.

(1) Call the "VERTICAL BOW" mode.

(2) Increase or decrease "VERTICAL BOW" by Volume key.

(1) Call the "S CORRECTION" mode.

(2) Increase or decrease "S CORRECTION" by Volume key.

Adjust items NO1---NO12, same as 50Hz FULL

In CINEMA mode

V-SIZE Adjustment Spec 25% range +1% -0%

H-SIZE Adjustment Spec 8% range +1% -1%

WAVEFORM OR OTHERS

Note:

V. LINEARITY is the fixation values.

No adjustment.

VERTICAL SHIFT and VERTICAL AMP.

2mm > |A-B| E-5

2mm > |C-D| A face is for south

Adjustment Spec 8.0% range +1% -1%

at the upper side of the geometry center and

the lower side of the geometry center

CORNER SYMMETRY is the fixation values.

No adjustment

VERTICAL ANGLE is the fixation values.

No adjustment

VERTICAL BOW is the fixation values.

No adjustment

Note: Refer to PAGE 9/11

A

B

C

D

4-2

4-1

4

Page 5

SX76NF8

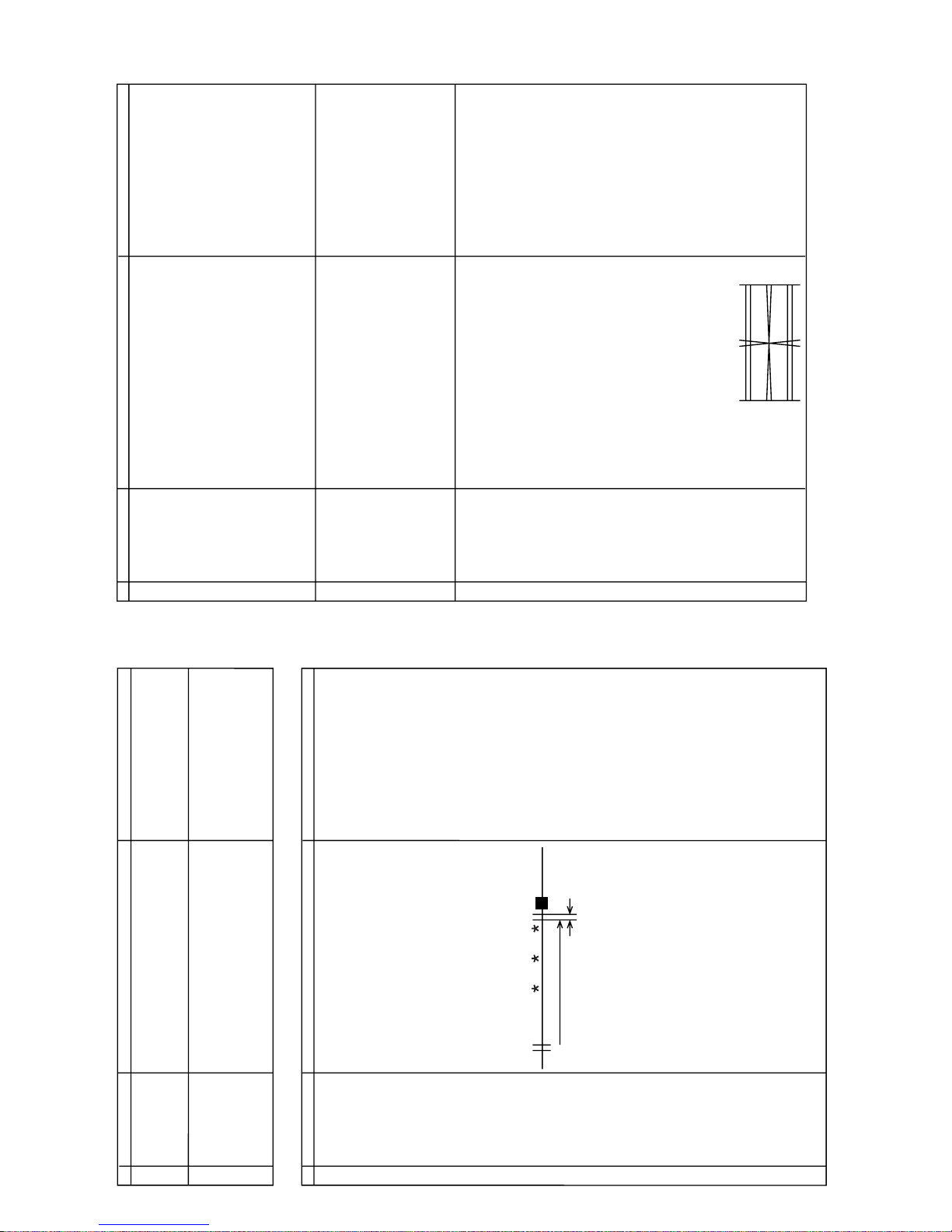

FOCUS ADJUSTMENT

NO

1

ADJUSTMENT POINT

FOCUS

ADJUSTMENT CONDITION / PROCEDURE

(1) Receive the "Monoscope Pattern" signal.

(2) Press R/C to set Picture NORMAL condition.

(3) Select full mode.

(4) Adjust the focus control to get the best focusing.

(Refer to Adjustment Point as right drawing, SX76NF8

and SX66NF8)

WAVEFORM OR OTHERS

(Adjusted point)

PROTECTOR OPERATION CHECKING

NO

1

2

ADJUSTMENT POINT

H•V PROTECTOR

OTHER

PROTECTOR

ADJUSTMENT CONDITION / PROCEDURE

(1) Receive "Monoscope Pattern" signal.

(2) Connect output of Bias Box to D607 cathode

(3) Set voltage of Bias Box to 18V and make sure the

protector is not work.

(4) Set voltage of Bias Box to 27V, and make sure the

protector is work.

(1) Once finish rectified Electrolytic Capacitor short testing

in + B line, check all possible damaged components on

+B line.

(Use random selected set for inspection)

WAVEFORM OR OTHERS

A/V INPUT AND OUTPUT CHECKING

NO

1

2

3

4

5

6

ADJUSTMENT POINT

AV

OUTPUT CHECK

AV-1

INPUT CHECK

AV-2

INPUT CHECK

AV-1

Component

INPUT CHECK

FRONT

INPUT CHECK

FRONT S-Terminal

INPUT CHECK

ADJUSTMENT CONDITION / PROCEDURE

(1) Receive the "PAL Color Bar" signal (100% White Color

Bar, Sound 400Hz 100% Mod)

(2) Terminate the Video output with a 75 ohm impedance.

Make sure the output is as specified (1.0 Vp-p

± 3dB)

(3) Terminate the Audio output with a 10 Kohm impedance.

Make sure the output is as specified (2.61 Vp-p

± 3dB)

Check of AV

Check of AV

Check of AV

Check of AV

Check of AV

WAVEFORM OR OTHERS

50

Adjust these Horizontal

and Vertical lines

(SX76NF8)

Adjust at "50" position

(SX66NF8)

FUNCTION OPERATION CHECKING (1) (VIDEO & AUDIO)

NO

1

2

3

4

5

6

7

8

9

ADJUSTMENT POINT

CONTRAST

COLOUR

BRIGHTNESS

SHARPNESS

TINT

ECO MODE

COMB FILTER

NTSC HUE

NORMAL

ADJUSTMENT CONDITION / PROCEDURE

(1) Receive "Monoscope Pattern" signal.

(2) Set P-Mode to select CONTRAST.

(3) Press Volume Up/Down key to check whether the

CONTRAST effect is OK or not.

(1) Receive "Color Bar" signal.

(2) Set P-Mode to select COLOUR.

(3) Press Volume Up/Down key to check whether the

COLOUR effect is OK or not.

(1) Receive "Monospcope Pattern" signal.

(2) Set P-Mode to select BRIGHTNESS.

(3) Press Volume Up/Down key to check whether the

BRIGHTNESS effect is OK or not.

(1) Receive "Monoscope Pattern" signal.

(2) Set P-Mode to select SHARPNESS.

(3) Press Volume Up/ Down key to check whether the

SHARPNESS effect is OK or not.

(1) Receive "Monoscope Pattern" signal.

(2) Set PICTURE to TINT select.

(3) Press Volume Up/Down key to check TINT Option,

STANDARD: NORMAL SETTING, WARM for more

REDDISH direction changing, COOL for more BLUISH

direction changing.

(1) Receive "Monoscope Pattern" signal.

(2) Set P-Mode to select ECO MODE.

(3) Press Volume Up/Down key to check whether the ECO

MODE effect is OK or not.

(1) Receive "Color Bar" signal.

(2) Set P-Mode to select COMB FILTER.

(3) Press Volume Up/Down key to check whether the COMB

FILTER effect is OK or not.

(1) INPUT "NTSC Color Bar" signal from AV-input.

(2) Set P-Mode to select NTSC HUE..

(3) Press Volume Up/Down key to check whether the NTSC

HUE effect is OK or not.

(1) In PICTURE Mode, select NORMAL and press menu

button all the settings will be present to normal setting.

(Normal setting value for every mode).

CONTRAST : 80%

COLOUR : 50%

BRIGHTNESS : 50%

SHARPNESS : 50%

TINT : 50%

WAVEFORM OR OTHERS

Notes:

If nothing is display mean contrast, colour,

bright, tint, sharpness are all normal setting.

5-2

5

5-1

Page 6

SX76NF8

CHECKING FUNCTION OPERATION (2) (VIDEO & AUDIO) CONTINUED

NO

10

11

12

13

14

15

ADJUSTMENT POINT

VOLUME

BALANCE

BASS

TREBLE

SOUND IDENT

DYNAMIC BASS

ADJUSTMENT CONDITION / PROCEDURE

(1) Receive "Monoscope Pattern" signal.

(2) Set S-Mode to select VOLUME.

(3) Press Volume Up/Down key to check whether the

VOLUME effect is OK or not.

(1) Receive "Monoscope Pattern" signal.

(2) Set S-Mode to select BALANCE.

(3) Press Volume Up/Down key to check whether the Left-to

-Right BALANCE effect is OK or not.

(1) Receive "Monoscope Pattern" signal.

(2) Set S-Mode to select BASS.

(3) Press Volume Up/Down key to check whether the BASS

effect is OK or not.

(1) Receive "Monoscope Pattern" signal.

(2) Set S-Mode to select TREBLE.

(3) Press Volume Up/ Down key to check whether the

TREBLE effect is OK or not.

(1) Receive "Monoscope Pattern" signal.

(2) Set S-Mode to select SOUND IDENT.

(3) Press Volume Up/Down key to check whether the

SOUND IDENT effect is OK or not.

(1) Receive "Monoscope Pattern" signal.

(2) Set S-Mode to select DYNAMIC BASS.

(3) Press Volume Up/Down key to check whether the

DYNAMIC BASS effect is OK or not.

WAVEFORM OR OTHERS

CHECKING FUNCTION OPERATION (3) (VIDEO & AUDIO) CONTINUED

NO

16

17

18

19

ADJUSTMENT POINT

VOLUME

Headphone

BALANCE

Headphone

BASS

Headphone

TREBLE

Headphone

ADJUSTMENT CONDITION / PROCEDURE

(1) Connect Headphone

(2) Set S-Mode to select VOLUME in headphone mode.

(3) Press Volume Up/Down key to check whether the

VOLUME effect is OK or not.

(1) Connect Headphone.

(2) Set S-Mode to select BALANCE in headphone mode.

(3) Press Volume Up/Down key to check whether the Left-to

-Right BALANCE effect is OK or not.

(1) Connect Headphone.

(2) Set S-Mode to select BASS in headphone mode.

(3) Press Volume Up/Down key to check whether the BASS

effect is OK or not.

(1) connect Headphone.

(2) Set S-Mode to select TREBLE in headphone mode.

(3) Press Volume Up/ Down key to check whether the

TREBLE effect is OK or not.

WAVEFORM OR OTHERS

CHECKING FUNCTION OPERATION (WIDE MODE)

NO

1

2

3

ADJUSTMENT POINT

WIDE MODE

V-SIZE

in wide mode

V-SCROLL

in wide mode

ADJUSTMENT CONDITION / PROCEDURE

(1) Receive "Monoscope Pattern" signal.

(2) Press WIDE key to check change WIDE mode

AUTO/PANORAMA/FULL/NORMAL/ZOOM14:9/CINEMA

(1) Receive "Monoscope Pattern" signal.

(2) Select PANORAMA, ZOOM14:9, and CINEMA mode.

(3) Select V-SIZE, Press Volume Up/Down key to check

whether the V-SIZE effect is OK or not.

(1) Receive "Monoscope Pattern" signal.

(2) Select PANORAMA, ZOOM14:9, and CINEMA mode.

(3) Select V-SCROLL, Press Volume Up/Down key to check

whether the V-SCROLL effect is OK or not.

WAVEFORM OR OTHERS

6-2

6

6-1

Page 7

SX76NF8

CHECKING FUNCTION OPERATION (TEXT MODE)

NO

1

2

ADJUSTMENT POINT

TEXT

TEXT key

ADJUSTMENT CONDITION / PROCEDURE

(1) Receive E-12ch signal.

(2) Press TEXT key to check change TEXT mode /

SPLIT SCREEN mode / TELETEXT mode / MIXED

mode.

(1) Receive E-12ch signal.

(2) Press HALF PAGE, HOLD, REVEAL, CLOCK, CANCEL,

LIST, INDEX, and RESET key to check whether each

effect is OK or not.

(3) Select V-SIZE, Press Volume Up/Down key to check

whether the V-SIZE effect is OK or not.

WAVEFORM OR OTHERS

PURITY AND CONVERGENCE ADJUSTMENT

NO

1

ADJUSTMENT POINT

DY location (YPB)

adjustment procedure

ADJUSTMENT CONDITION / PROCEDURE

(1) Turn on the set to make coarse adjustments to the CRT

cut-off, white balance, etc. as well as the purity static

convergence.

(2) To improve the purity adjustment accuracy, perform

coarse adjustments to the H-SIZE/center, V-SIZE/LIN

and side pin.

(3) Enter the video mode to set the beam current to the

standard value below using the screen VR. (Or it is

possible to use the noise signal of an empty channel.)

Age the set for more than 30 minutes with the following

current.

Standard value of beam current: 1000

µA ± 200µA

(4) Receive the monoscope signal to adjust the cut-off

voltage.

Consequently, adjust the contrast, color level and then

set the beam current to the above standard value.

Age the set for more than 2 minutes.

Note: If other adjustments between step 3 and 4 (the

area marked by *) affect the conditions of the beam

current, complete the adjustment for each point within 2

minutes, which is not included in the aging time).

* Perform the adjustments in an earth magnetism room

with Bh and Bv set to 0.20G and -0.50G respectively.

(5) Under the above conditions, move DY and the purity

magnet to make the following adjustments.

- 1. Set YPB of DY to 2.5 mm temporarily.

- 2. Adjust the center to A rank by moving the purity

magnet.

- 3. Insert a temporary wedge to balance DY vertically.

- 4. Move DY back and forth to set L and R to the

standard value below. (Apply to the purity correction

magnet if L and R are imbalanced.)

- 5. Correct the center to "AB rank" if the L and R are

imbalanced.

- 6. After making sure the landing is properly positioned,

fix DY.

Note: Preliminary adjustments are made to set L and R

to the standard value after convergence adjustment.

Standard value: -25

µm ± 5 µm at the 90 mm point

WAVEFORM OR OTHERS

Purity adjustment

Aging for more

than 2 minutes

Aging for more than 30 minutes

Raster

output

PURITY AND CONVERGENCE ADJUSTMENT (Continued)

NO

2

ADJUSTMENT POINT

Peripheral landing

correction

ADJUSTMENT CONDITION / PROCEDURE

(1) Place the set in a magnetic room with the horizontal line

and vertical line set to 0G and - 0.5G respectively, and

receive red monochrome.

(2) After a complete external; demagnetization, generate a

horizontal magnetic field of

±10000nT (0.1G) and apply

the purity correction magnet to the multi-colored areas.

Check blue monochrome equally.

(3) Return the magnetic field to zero and perform a

complete demagnetization.

(4) Generate a reverse horizontal magnetic field, check red

and blue monochrome and apply the magnet to multi-

colored areas.

(5) After correcting the magnet in step 4, check the reverse

magnetic field again.

3 Directional tolerance

check

(1) Place the set in a magnetic room the horizontal line and

vertical line set to 0.2G and - 0.5G respectively, and

receive red monochrome.

(2) Move the set from side to side at the four points of the

compass to check the status of the multiple colors and

ensure L and R are well-balanced.

(3) Apply to the purity correction magnet if L and R are

imbalanced.

(4) If the magnet was applied in step 3, check from other

directions equally.

WAVEFORM OR OTHERS

4 Convergence

adjustment procedure

(1) Set the video adjustment level to normal, and receive a

crosshatch pattern.

(2) Center convergence adjustment

Superimpose RGB of the screen center area for

optimization, by using the 4 pole and 6 pole of the purity

magnet. Superimpose the red and blue by the 4 pole

magnet, the green and magenta by the 6 pole magnet.

As for vertical lines, avoid setting the red line to the left,

blue to the right.

(3) Peripheral convergence adjustment

Combine the following item with the ferrite sheet to make

optimal adjustments.

1.XV cross

Rotate the variable coil on the DY PWB for

optimization.

2.YH cross

Adjust with the volume on the DY PWB.

If peripheral PQH is oversized, correct with the ferrite

sheet or by shaking slightly.

3.XH, YV

Use the dedicated correction strip to correct them.

YH

YV

XV

7-2

7

7-1

Page 8

SX76NF8

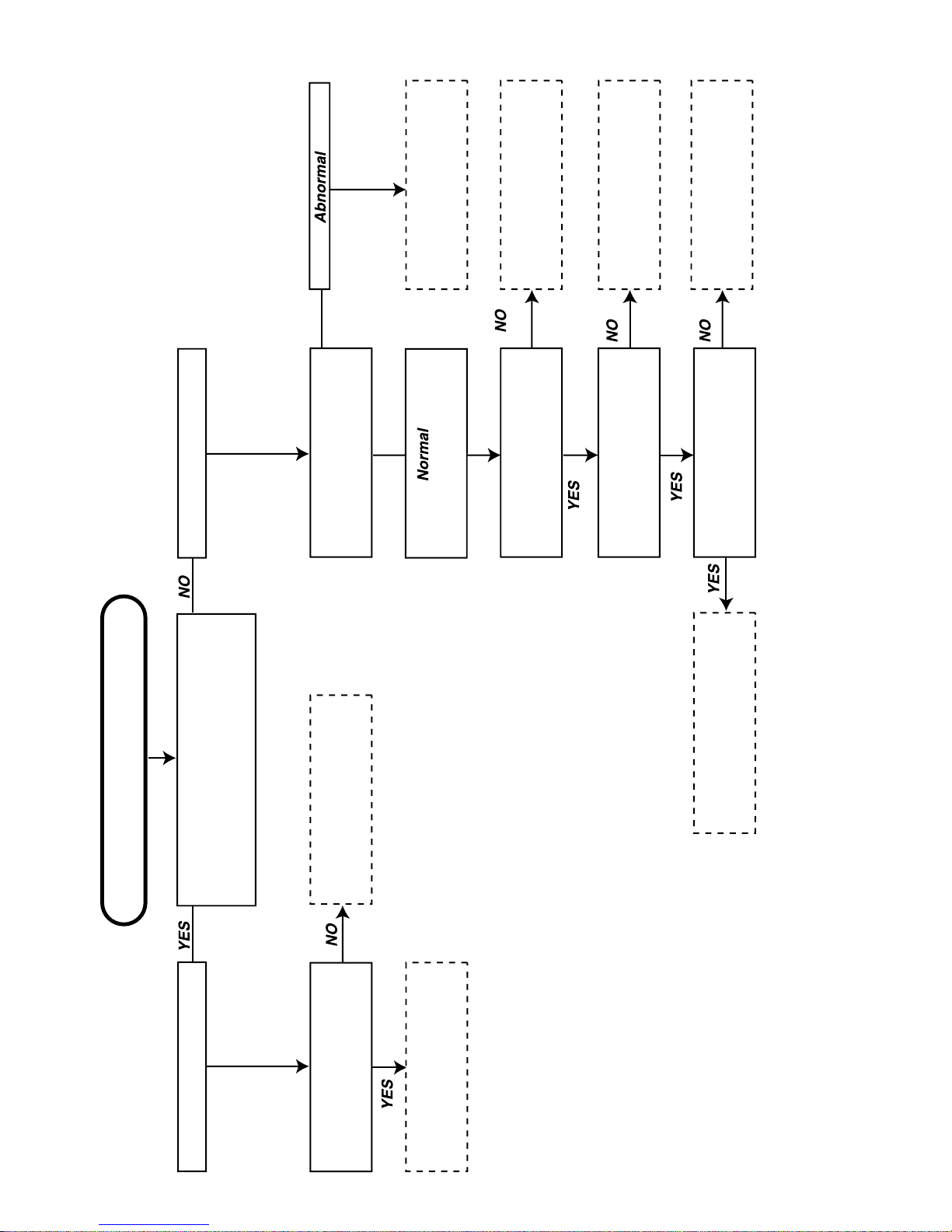

TROUBLE SHOOTING TABLE

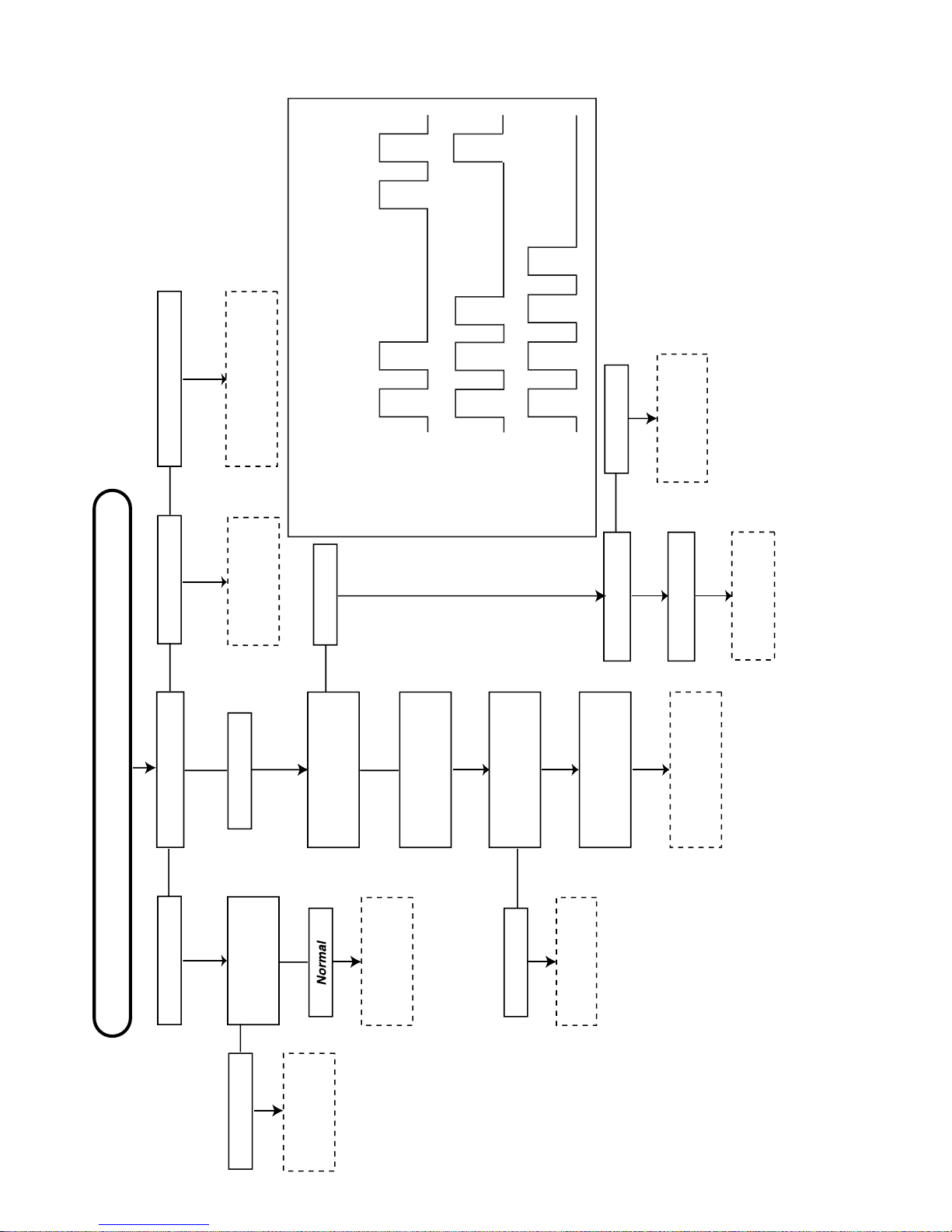

NO PICTURE

Does the snow noise appear on

the CRT at max contrast and

brightness control?

Does approx.30V appear

at pin (9) of TU201(tuner)

Check L204, D606 and

R618

Check TU201 and their

peripheral parts.

Check pin(1) and (2) of

IC201

Check pin(51) of IC 1001

Does noise or signal

appear?

Check IC1001 RGB output

Normal?

Check pin(1), (2) and (3) of

IC850 Signal or Noise?

Check R616(Heater), Screen

connection and Peripheral

circuits of T602(FBT) and CRT

Check TU201(tuner),

SF202 and Peripheral

parts.

Check IC201, Q201 and

their Peripheral circuits.

Check IC1001 and their

Peripheral circuits.

Check "CJ" connection,

IC850 and their Peripheral

circuits

Snow noise increase

No Snow noise

(Noise or signal appear)

(Noise)

(Signal)

8

Page 9

SX76NF8

TROUBLE SHOOTING TABLE

NO SOUND

Check sound setting by R/C.

Siganl should be received.

Check C1302(C1309) Voltage

Approx. 15(-15V)

Check IC1301, IC1302 and Speaker

0V

Check L1302, L1303

D752 and D753

9

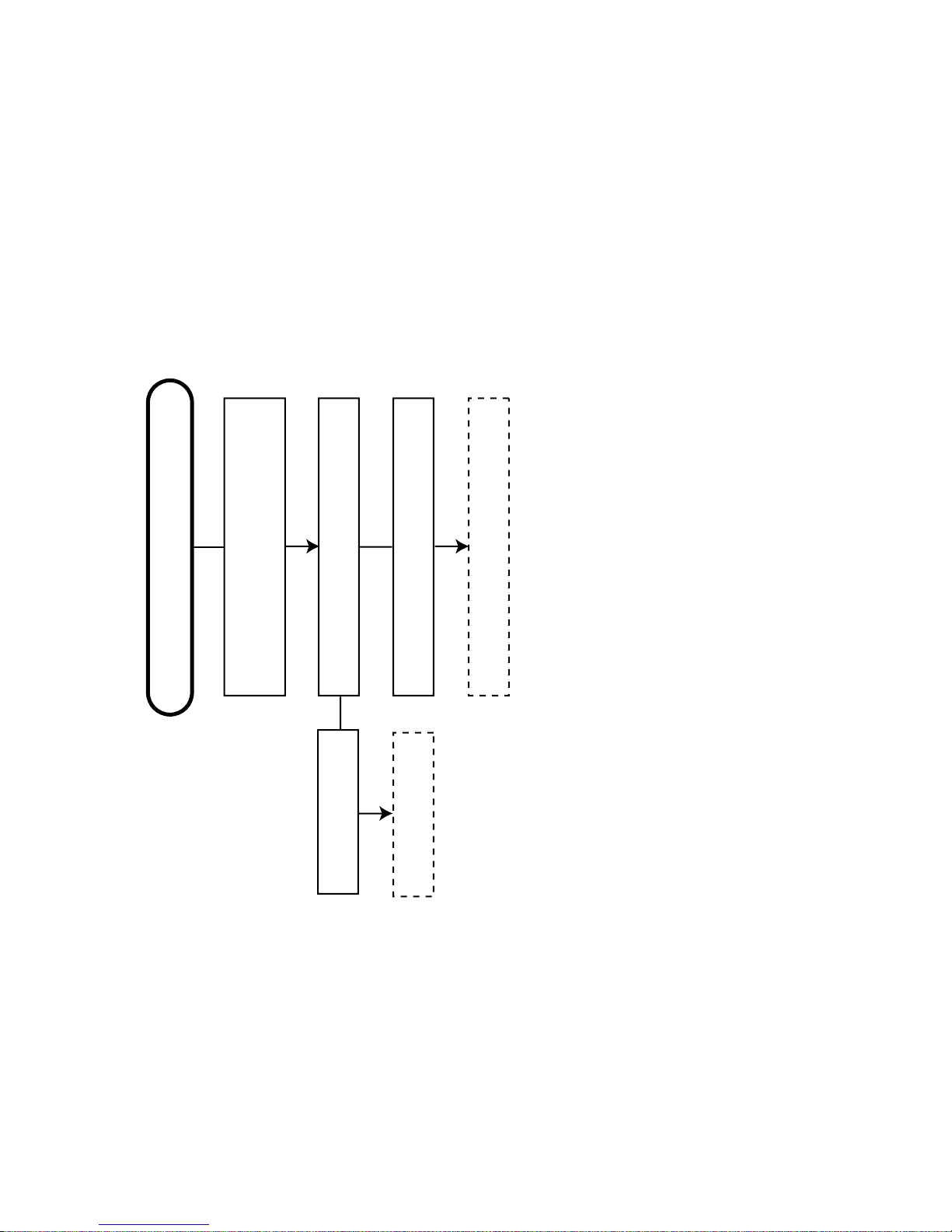

Page 10

SX76NF8

TROUBLE SHOOTING TABLE

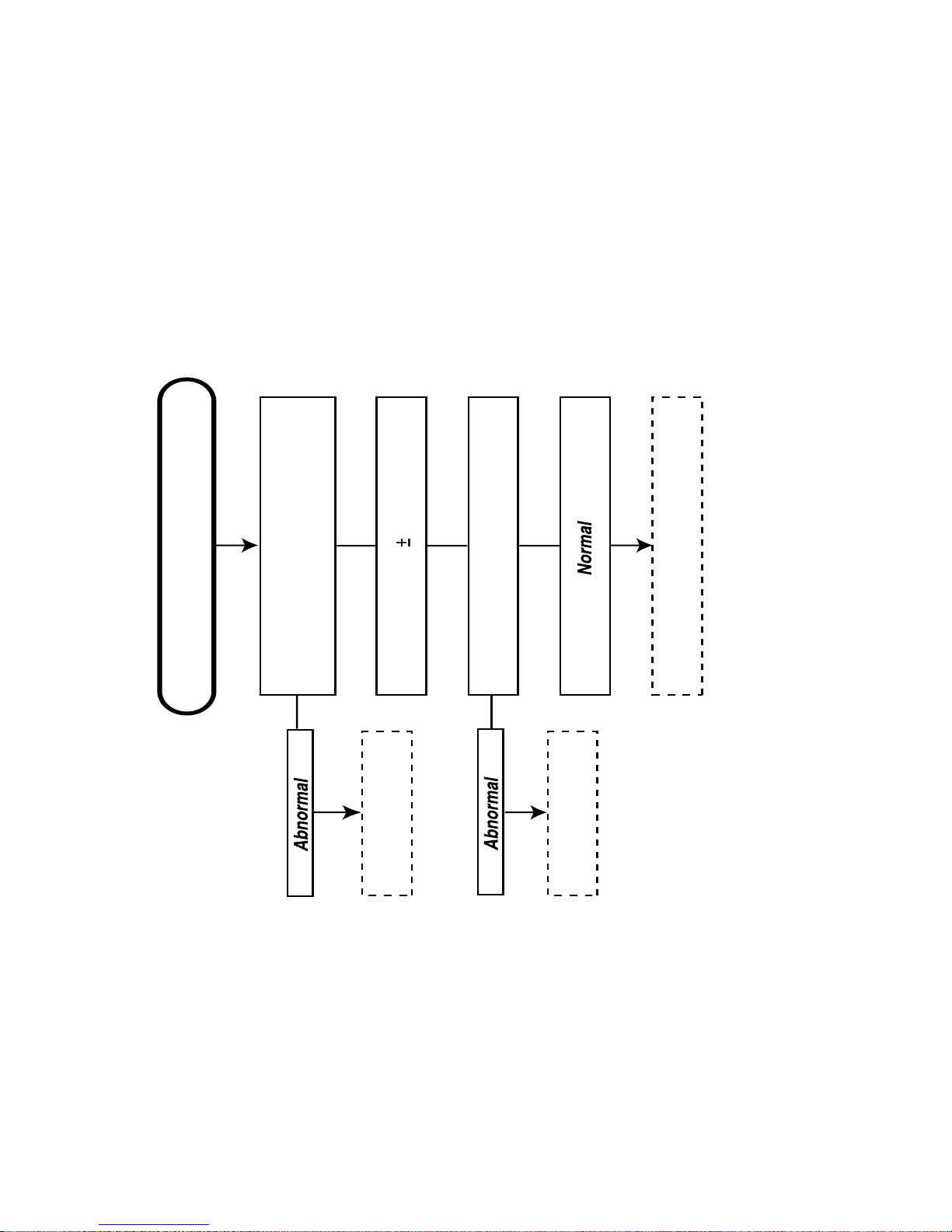

NO FUNCTION (NO SOUND AND NO PICTURE)

Is D2201(LED) on a light?

Check IC 1001

94pin INPUT

Check C755 Voltage

Immediately appear

approx. 145V, and turn

to 0V soon.

Check C752 Voltage

Check C715Voltage

Refer to "No

Picture", trouble

shooting

Check IC701,

Q702 and T703

Check IC1001, IC1003,

IC301, IC201, TU201(Refer

to LED FLASHING CODES)

GREEN RED

Approx. 320V

Completely 0V

No Input Pulse

FLASHIN

Check D754 and

IC751

Check Vertical

Circuit

Check Q1012,

D1016 and SP wire

"SS" connection.

0V

Check R718,

F2001 and "AA"

connection

0V

Green

Green

Green

Red

Red

Red

No Light

Immediately appear

approx. 8V, and turn to

0V soon.

Check D752, D753,

C756, C757 and IC752

LED FLASHING CODES

If the TV set does not work and the power LED is flashing "Red <=>Green",

follow the sequence according to the information below, as a guide to fault

finding.

1.Unable to read or write into NMV;66% Green,33% Red twice and Red for

a second.

2.MSP failure;66% Green,33% Red for three times and Red for a second.

3.VCT failure;66% Green,33% Red for four times and Red for a second.

10

Page 11

SX76NF8

TROUBLE SHOOTING TABLE

NO VERTICAL SCAN

Check the Voltage at pin(15)(1)

of IC502

Normal approx. 14V

Check IC502 and related circuits

Check D601, D605,

R608 and R614

Check IC1001 and

peripheral parts

Check vertical trigger pulse at

pin(12)(13) of IC502

11

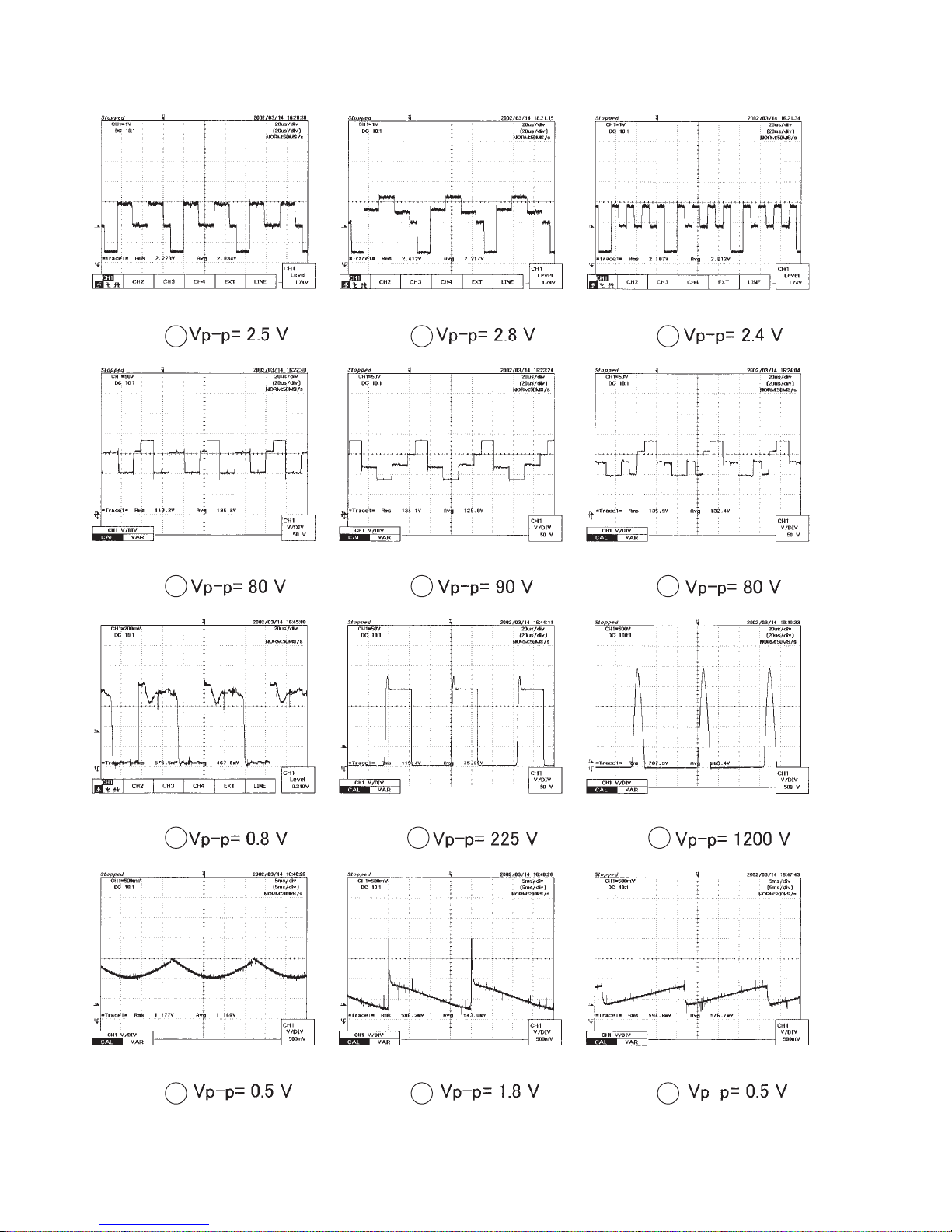

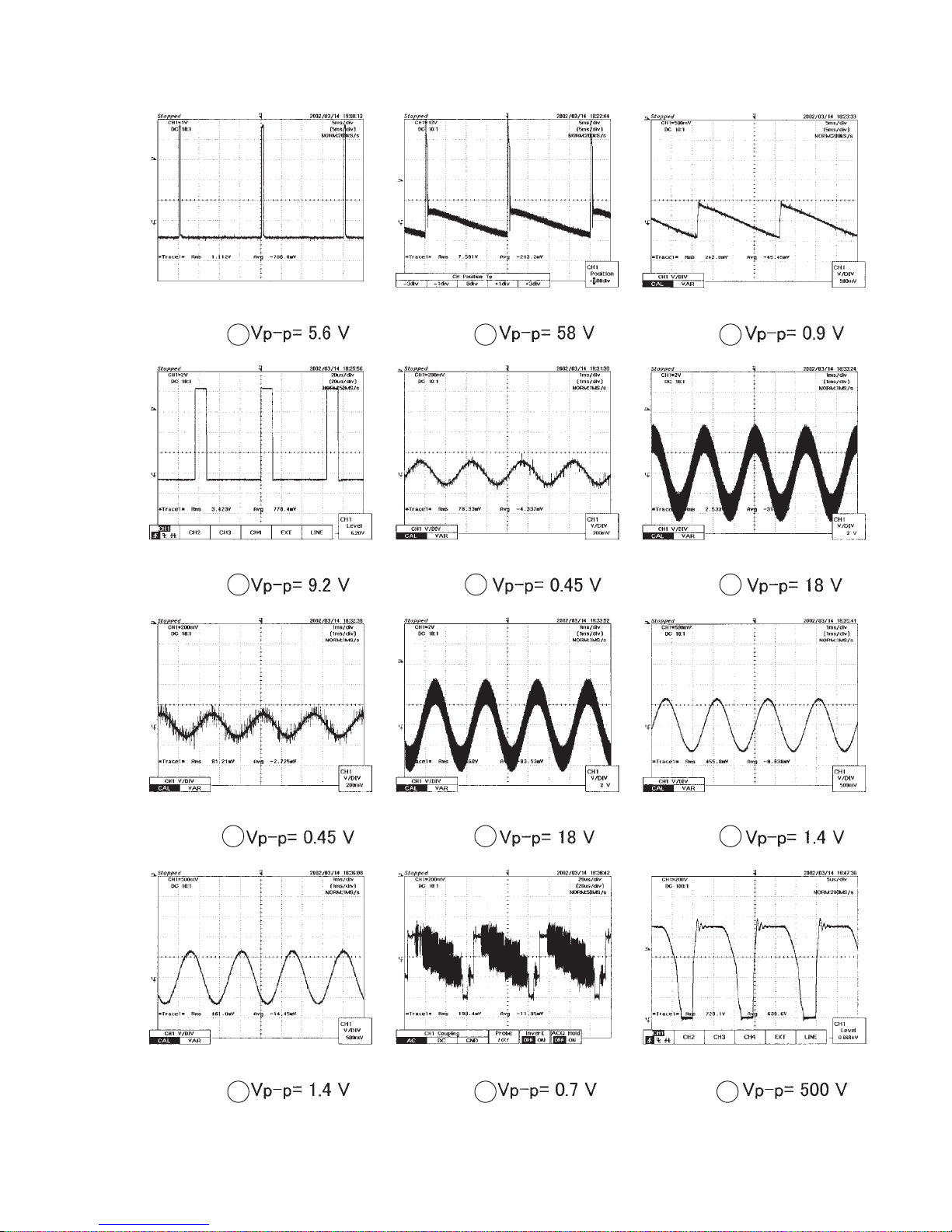

Page 12

SX76NF8

WAVE FORMS

1

4 5 6

2 3

7

10

8

11 12

12

9

Page 13

13 14 15

SX76NF8

16 17 18

19

20 21

22 23 24

13

Page 14

SX76NF8

CHASSIS LAYOUT

14

Page 15

SX76NF8

15

Page 16

SX76NF8

BLOCK DIAGRAM

16

Page 17

SX76NF8

17

Page 18

SX76NF8

DESCRIPTION OF SCHEMATIC DIAGRAM

SAFETY NOTES:

1. DISCONNECT THE AC PLUG FROM THE AC OUTLET BEFORE

REPLACING PARTS.

2. SEMICONDUCTOR HEAT SINKS SHOULD BE REGARDED AS

POTENTIAL SHOCK HAZARDS WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å” ( ) ARE IMPORTANT FOR

MAINTAINING THE SAFETY OF THE SET. BE SURE TO REPLACE THESE PARTS WITH SPECIFIED ONES FOR MAINTAINING THE SAFETY AND PERFORMANCE OF THE SET.

SERVICE PRECAUTION:

THE AREA ENCLOSED BY THIS LINE (

CONNECTED WITH AC MAINS VOLTAGE.

WHEN SERVICING THE AREA, CONNECT AN ISOLATING TRANSFORMER BETWEEN TV RECEIVER AND AC LINE TO ELIMINATE

HAZARD OF ELECTRIC SHOCK.

) IS DIRECTLY

NOTES:

1. The unit of resistance “ohm” is omitted.

(K = 1000 ohms, M = Meg ohm).

2. All resistors are 1/16 watt, unless otherwise noted.

3. All capacitors are µF, unless therwise noted. (P = µµF).

VOLTAGE MEASUREMENT CONDITIONS:

1. Voltage in parenthesis measured with no Signal.

2. Voltages without parenthesis measured with PAL Colour-Signal.

3. All the voltages in each point are measured with high impedence

volt-meter.

WAVEFORM MEASUREMENT CONDITIONS:

1. Colour bar generator signal of 2.0V peak to peak applied at Base

of Video Buffer Amp. Q254.

2. Approximately 4.0 V AGC bias.

18

Page 19

SX76NF8

A

B

C

D

E

F

G

H

I

J

12345678910

SCHEMATIC DIAGRAM

CRT UNIT

19

Page 20

SX76NF8

J

I

H

G

MAIN UNIT-1/3

F

E

D

C

B

A

12345678910

20

Page 21

SX76NF8

10 11 12 13 14 15 16 17 18 19

21

Page 22

SX76NF8

J

I

H

G

MAIN UNIT-2/3

F

E

D

C

B

A

12345678910

22

Page 23

SX76NF8

10 11 12 13 14 15 16 17 18 19

23

Page 24

SX76NF8

J

I

H

G

MAIN UNIT-3/3

F

E

D

C

B

A

12345678910

24

Page 25

SX76NF8

10 11 12 13 14 15 16 17 18 19

25

Page 26

SX76NF8

J

I

H

G

CONTROL UNIT

F

E

D

C

B

A

12345678910

26

Page 27

SX76NF8

10 11 12 13 14 15 16 17 18 19

27

Page 28

SX76NF8

J

I

H

G

DF UNIT

F

E

D

C

B

A

12345678910

28

Page 29

SX76NF8

A

B

C

D

E

F

G

H

I

J

12345678910

LED UNIT

KEY UNIT

29

Page 30

SX76NF8

J

I

H

G

SUB WOOFER UNIT

F

E

D

C

B

A

12345678910

30

Page 31

SX76NF8

A

B

C

D

E

F

G

H

I

J

12345678910

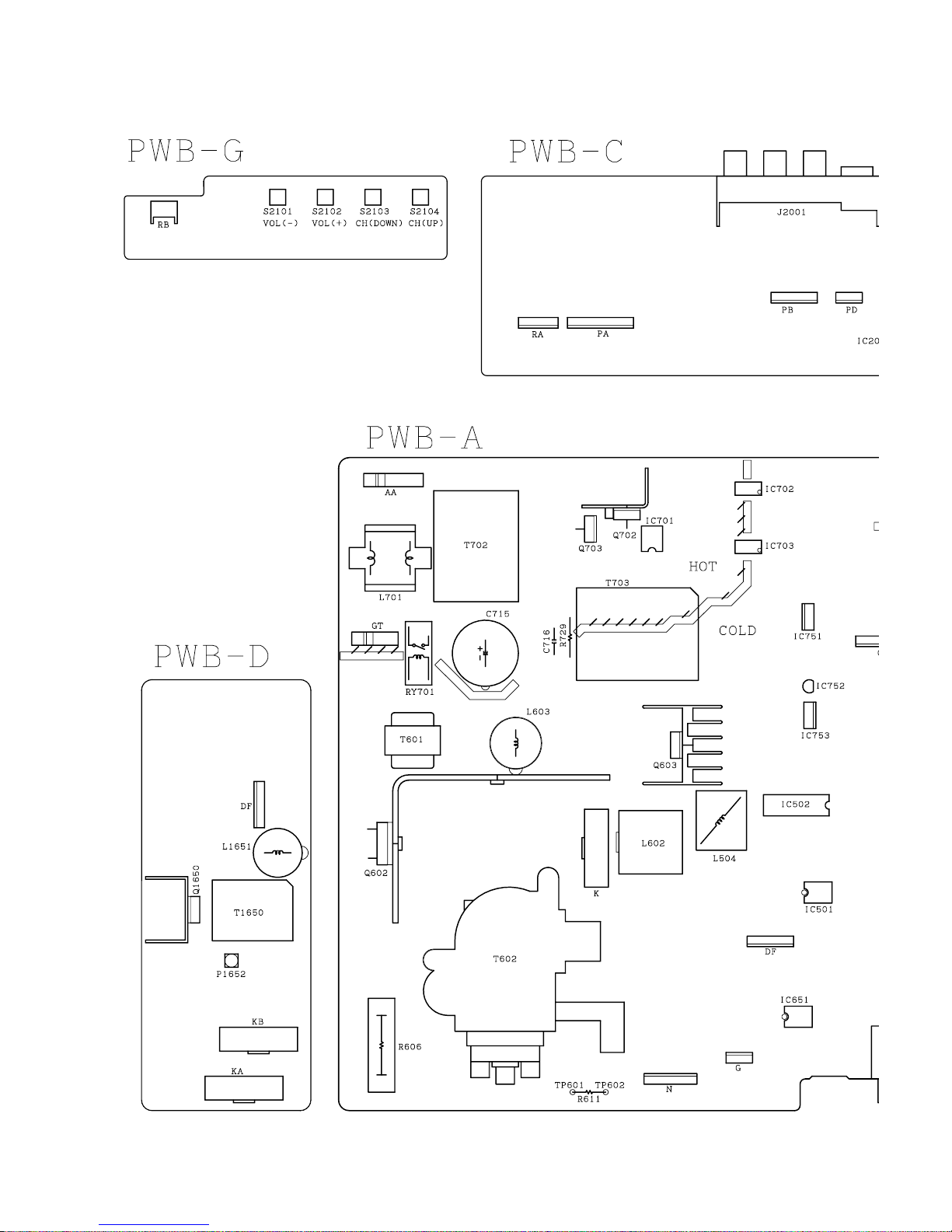

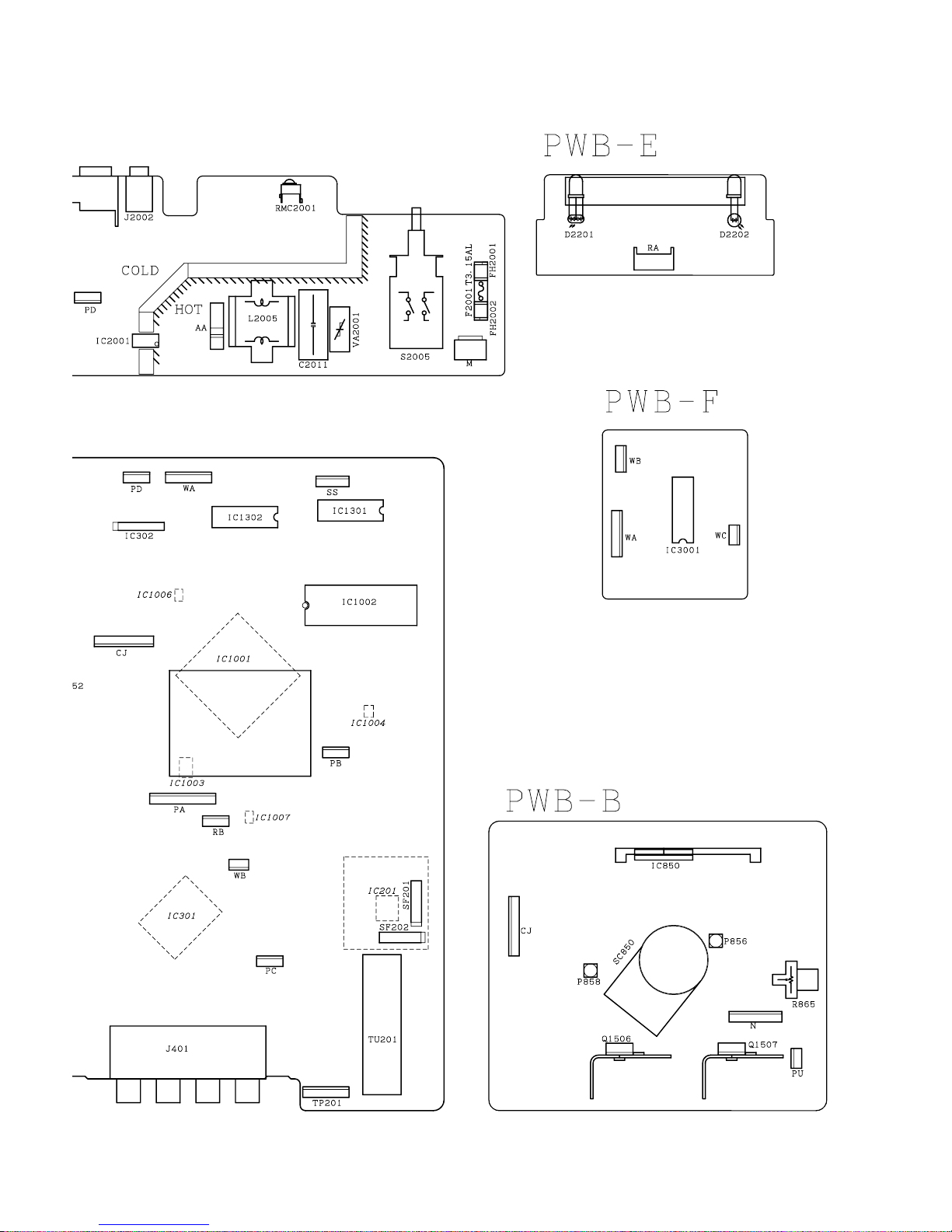

PRINTED WIRING BOARD ASSEMBLIES

PWB-B: CRT UNIT

PWB-D: DF UNIT

31

Page 32

SX76NF8

J

I

H

G

PWB-A: MAIN UNIT (COPPER SIDE)

F

E

D

C

B

A

12345678910

32

Page 33

SX76NF8

10 11 12 13 14 15 16 17 18 19

33

Page 34

SX76NF8

J

I

H

G

PWB-A: MAIN UNIT (Chip Parts Side)

F

E

D

C

B

A

12345678910

34

Page 35

SX76NF8

10 11 12 13 14 15 16 17 18 19

35

Page 36

SX76NF8

J

I

H

G

F

E

D

C

B

A

12345678910

PWB-C: CONTROL UNIT

36

Page 37

SX76NF8

A

B

C

D

E

F

G

H

I

J

12345678910

PWB-E: LED UNIT

PWB-F: SUB WOOFER UNIT

PWB-G: KEY UNIT

37

Page 38

SX76NF8

Ref. No. Part No. ★ Description Code

REPLACEMENT PARTS LIST

PARTS REPLACEMENT

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by "å" in the Replacement Parts Lists.

The use of a substitute replacement part which does not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual may create shock, fire or other hazards.

"HOW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly, please furnish the following

informations.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

MARK : SPARE PARTS-DELIVERY SECTION.

Ref. No. Part No. ★ Description Code

PICTURE TUBE

å VB76LTL352WFS R Picture Tube DV

å L799 RCiLGA035WJZZ R Degaussing Coil AT

PWB-A DUNTKB557WEV0 - MAIN Unit —

PWB-B DUNTKB558WEV0 - CRT Unit —

PWB-C DUNTKB559WEV0 - CONTROL Unit —

PWB-D DUNTKB560WEV0 - DF Unit —

PWB-E DUNTKB563WEV0 - LED Unit —

PWB-F DUNTKB700WEV0 - SUB WOOFER Unit —

PWB-G DUNTKB562WEV0 - KEY Unit —

NOTE: THE PARTS HERES SHOWN ARE SUPPLIED AS AN

å TU201 VTUCTF5511+++ R Tuner AZ

IC201 RH-iX1799BMZZY R I.C. AQ

IC301 RH-iX1853BMZZY R I.C. BE

IC302 VHiM5218AL/-1 R M5218L AD

IC501 VHiUPC358C/-1 R UPC358C AD

IC502 VHiSTV9380+-2 R STV9380 AP

IC651 VHiUPC358C/-1 R UPC358C AD

IC701 VHiTEA1507/-1 R TEA1507P/N1 AL

å IC702 RH-FX0008GEZZ R PC123FY8 AE

å IC703 RH-FX0008GEZZ R PC123FY8 AE

IC751 VHiPQ05RD08-1 R PQ05RD08 AF

IC752 VHiKA78S05P-1+ R KIA78S05P AD

IC753 VHiKA7808AP-1 R KIA7808API AE

IC1001 RH-iXA186WJZZQ R VCT3834A-QH-C4 BM

RCiLG0443CEZZ R Degaussing Coil AL

RCiLHA057WJZZ R Deflection Yoke BT

QEARCA015WJZZ R Grounding Strap AL

PMAGF3087CEZZ R Magnet AL

PMAGG3006CEZZ R Magnet AC

PRINTED WIRING BOARD ASSEMBLIES

(NOT REPLACEMENT ITEM)

DUNTKB557WEV0

PWB-A MAIN UNIT

TUNER

ASSEMBLY NOT INDEPENDENTLY.

INTEGRATED CIRCUITS

Ref. No. Part No. ★ Description Code

IC1002 RH-iXA424WJZZ R I.C. AW

IC1003 VHiBR24C64F-1Y R BR24C64F-E2 AL

IC1004 VHiMM1503XN-1Y R MM1503XNRE AE

IC1006 VHiBA033LBS-1Y R BA033LBSG-TR AF

IC1007 VHiBA033LBS-1Y R BA033LBSG-TR AF

IC1301 VHiTDA7480/-1 R I.C. AM

IC1302 VHiTDA7480/-1 R I.C. AM

TRANSISTORS

Q201 VS2SA1037KQ-1Y R 2SA1037KQ AA

Q206 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q301 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q302 VS2SA1037KQ-1Y R 2SA1037KQ AA

Q305 VSDTC314TK/-1Y R DTC314TK AC

Q306 VSDTC314TK/-1Y R DTC314TK AC

Q601 VS2SC2482//-1+ R 2SC2482 AD

Q602 VS2SC5450//1E R 2SC5450 AL

Q603 VS2SD1830//1E R 2SD1830 AF

Q604 VS2SA1246//1E+ R 2SA1246 AE

Q651 VS2SC3228Y/-1+ R 2SC3228Y AD

Q652 VS2SA1275Y/-1+ R 2SA1275Y AD

Q701 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q702 VSSPA07N60C-1 R SPA07N60C AN

Q703 VSSTP4NC80Z1E R STP4NC80Z1E AK

Q704 VS2SC3198-G-1+ R 2SC3198-G AA

Q751 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q752 VS2SA1037KQ-1Y R 2SA1037KQ AA

Q753 VS2SA1037KQ-1Y R 2SA1037KQ AA

Q754 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q755 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q756 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q757 VS2SA1037KQ-1Y R 2SA1037KQ AA

Q759 VS2SA1037KQ-1Y R 2SA1037KQ AA

Q762 VS2SC3198-G-1+ R 2SC3198-G AA

Q1006 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q1007 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q1008 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q1011 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q1012 VS2SA1037KQ-1Y R 2SA1037KQ AA

Q1013 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q1301 VS2SA1037KQ-1Y R 2SA1037KQ AA

Q1302 VS2SA1037KQ-1Y R 2SA1037KQ AA

Q1303 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q1304 VS2SC2412KQ-1Y R 2SC2412KQ AA

Q1305 VS2SC2412KQ-1Y R 2SC2412KQ AA

DIODES AND LED’S

D202 RH-EX1394CEZZY R Zener Diode 5.73V AB

D203 RH-EX1394CEZZY R Zener Diode 5.73V AB

D303 RH-EX1398CEZZY R Zener Diode 8.36V AB

D304 RH-EX1398CEZZY R Zener Diode 8.36V AB

D305 RH-EX1398CEZZY R Zener Diode 8.36V AB

D306 RH-EX1398CEZZY R Zener Diode 8.36V AB

D308 RH-EX1398CEZZY R Zener Diode 8.36V AB

D309 RH-EX1398CEZZY R Zener Diode 8.36V AB

D310 RH-EX1398CEZZY R Zener Diode 8.36V AB

D312 RH-EX1394CEZZY R Zener Diode 5.73V AB

D313 RH-EX1394CEZZY R Zener Diode 5.73V AB

D314 RH-EX1398CEZZY R Zener Diode 8.36V AB

D315 RH-EX1398CEZZY R Zener Diode 8.36V AB

D401 RH-EX1397CEZZY R Zener Diode 7.6V AB

D402 RH-EX1397CEZZY R Zener Diode 7.6V AB

D403 RH-EX1397CEZZY R Zener Diode 7.6V AB

D404 RH-EX1397CEZZY R Zener Diode 7.6V AB

D405 RH-EX1397CEZZY R Zener Diode 7.6V AB

D406 RH-EX1397CEZZY R Zener Diode 7.6V AB

D501 VHDHSU119//-1Y R HSU119 AB

D502 VHDHSU119//-1Y R HSU119 AB

D503 RH-DX0487CEZZY R Diode AC

D756 VHiMM1431AT-1+ R MM1431ATT AD

D601 RH-DX0295CEZZ R Diode AD

D602 RH-DX0514CEZZ R Diode AF

D603 RH-DX0229CEZZ R Diode AF

D604 RH-DX0302CEZZY R Diode AC

D605 RH-DX0295CEZZ R Diode AD

D606 RH-EX0673GEZZY R Zener Diode 30.51V AB

38

Page 39

SX76NF8

Ref. No. Part No. ★ Description Code

D607 RH-DX0487CEZZY R Diode AC

D608 RH-EX0630GEZZY R Zener Diode 9.01V AA

D651 RH-EX0718GEZZY R Zener Diode 2.63V AB

D701 VHDHSU119//-1Y R HSU119 AB

D703 RH-DX0279CEZZY R Diode AB

D704 RH-DX0279CEZZY R Diode AB

D705 RH-DX0321CEZZY R Diode AC

D706 VHSSF0R5G43-1+ R SI.Control Rectifier AE

D707 RH-DX0321CEZZY R Diode AC

D708 VHD1SS244//-1Y R 1SS244 AB

D709 RH-DX0279CEZZY R Diode AB

D710 RH-EX0645GEZZY R Zener Diode 14.13V AB

D711 RH-DX0279CEZZY R Diode AB

D712 VHDHSU119//-1Y R HSU119 AB

D751 RH-EX0655GEZZY R Zener Diode 19.59V AB

D752 RH-DX0460CEZZ R Diode AF

D753 RH-DX0460CEZZ R Diode AF

D754 RH-DX0406CEZZY R Diode AD

D755 RH-DX0461CEZZ R Diode AG

D758 VHDHSU119//-1Y R HSU119 AB

D759 VHDHSU119//-1Y R HSU119 AB

D760 VHDHSU119//-1Y R HSU119 AB

D761 VHDHSU119//-1Y R HSU119 AB

D763 VHDHSU119//-1Y R HSU119 AB

D764 RH-EX1274CEZZY R Zener Diode 13.49V AB

D765 VHD1SS119//1EY R 1SS119 AA

D766 VHDHSU119//-1Y R HSU119 AB

D767 RH-EX0641GEZZY R Zener Diode 12.35V AA

D768 VHDHSU119//-1Y R HSU119 AB

D770 VHDHSU119//-1Y R HSU119 AB

D773 VHDHSU119//-1Y R HSU119 AB

D774 VHDHSU119//-1Y R HSU119 AB

D775 VHDHSU119//-1Y R HSU119 AB

D776 VHD1SS119//1EY R 1SS119 AA

D780 VHDHSU119//-1Y R HSU119 AB

D783 VHDHSU119//-1Y R HSU119 AB

D784 VHDHSU119//-1Y R HSU119 AB

D785 RH-EX0619GEZZY R Zener Diode 6.44V AA

D786 VHDHSU119//-1Y R HSU119 AB

D1002 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1003 VHDHSU119//-1Y R HSU119 AB

D1004 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1005 RH-EX1241CEZZY R Zener Diode 4.75V AB

D1006 VHDHSU119//-1Y R HSU119 AB

D1007 VHDHSU119//-1Y R HSU119 AB

D1009 RH-EX1241CEZZY R Zener Diode 4.75V AB

D1010 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1011 RH-EX1393CEZZY R Zener Diode 5.2V AB

D1012 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1013 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1014 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1016 VHDHSU119//-1Y R HSU119 AB

D1017 VHDHSU119//-1Y R HSU119 AB

D1018 VHDHSU119//-1Y R HSU119 AB

D1019 VHDHSU119//-1Y R HSU119 AB

D1020 VHD1SS119//1EY R 1SS119 AA

D1021 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1022 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1023 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1024 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1025 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1026 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1027 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1028 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1030 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1031 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1032 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1033 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1034 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1301 VHDHSU119//-1Y R HSU119 AB

D1302 VHDHSU119//-1Y R HSU119 AB

D1303 VHDHSU119//-1Y R HSU119 AB

D1304 RH-EX1394CEZZY R Zener Diode 5.73V AB

D1305 VHDHSU119//-1Y R HSU119 AB

D1306 VHDHSU119//-1Y R HSU119 AB

Ref. No. Part No. ★ Description Code

PACKAGED CIRCUITS

PR701 RMPTP0102CEZZ R Packaged Circuit AG

X201 RCRSAA029WJZZ R Crystal, 4MHz AF

X301 RCRSB0249GEZZ+ R Crystal, 18.432MHz AF

X1001 RCRSAA030WJZZ R Crystal, 20.25MHz AH

COILS AND TRANSFORMERS

L201 VP-DF6R8K0000Y R Peaking 6.8µHAB

L202 VP-DF120K0000Y R Peaking 12µHAB

L203 VP-DF100K0000Y R Peaking 10µHAB

L204 VP-DF3R3K0000Y R Peaking 3.3µHAE

L301 VP-XF100K0000Y R Peaking 10µHAB

L302 VP-DF120K0000Y R Peaking 12µHAB

L303 VP-XF100K0000Y R Peaking 10µHAB

L501 VP-XF8R2K0000Y R Peaking 8.2µHAB

L504 RCiLP0271BMZZ R Coil AH

L602 RCiLZ1043CEZZ R Coil AM

L603 RCiLZ1053CEZZ R Coil AG

å L701 RCiLF0108BMZZ R Coil AK

L751 RCiLP0212CEZZ+ R Coil AE

L752 VP-CF3R3K0000Y R Peaking 3.3µHAC

L1002 VP-XF1R0M0000Y R Peaking 1µHAB

L1003 VP-XF1R0M0000Y R Peaking 1µHAB

L1004 VP-XF1R0M0000Y R Peaking 1µHAB

L1005 VP-DF1R0M0000Y R Peaking 1µHAB

L1006 VP-XF1R0M0000Y R Peaking 1µHAB

L1007 VP-DF1R0M0000Y R Peaking 1µHAB

L1008 VP-DF3R3K0000Y R Peaking 3.3µHAB

L1009 VP-XF1R0M0000Y R Peaking 1µHAB

L1010 VP-DF1R0M0000Y R Peaking 1µHAB

L1011 VP-DF1R0M0000Y R Peaking 1µHAB

L1012 VP-XF1R0M0000Y R Peaking 1µHAB

L1301 RCiLP0195CEZZ+ R Coil AB

L1302 VP-CF3R3K0000Y R Peaking 3.3µHAC

L1303 VP-CF3R3K0000Y R Peaking 3.3µHAC

L1304 VP-CF3R3K0000Y R Peaking 3.3µHAC

L1305 VP-CF3R3K0000Y R Peaking 3.3µHAC

L1306 RCiLP0195CEZZ+ R Coil AB

SF201 RFiLC0286BMZZ R Filter AH

SF202 RFiLC0278BMZZ R Filter AM

T601 RTRNZ0731CEZZ R Transformer AG

å T602 RTRNFA045WJZZ R H-Volt Transformer AK

å T702 RTRNCA003WJZZ R Choke Transformer AQ

å T703 RTRNWA079WJZZ R Transformer AQ

CAPACITORS

C201

C202

C203

C204

C205

C206

C207

C209

C210

C211

C212 VCFYFA1HA474J+ R 0.47 50V Mylar AC

C213 VCFYFA1HA684J+ R 0.68 50V Mylar AC

C214

C215 VCFYFA1HA224J+ R 0.22 50V Mylar AB

C216

C217

C218

C219

C220

C221

C223

C225

C229

C230

C301

C302

C303

C304

C305

C306

VCEA0A1CW336M+

VCCCCY1HH220JY

VCCCCY1HH270JY

VCEA0A0JW477M+

VCKYCY1CF334ZY

VCEA0A0JW107M+

VCCCCY1HH100DY

VCKYCY1HB103KY

VCCCCY1HH391JY

VCKYCY1HB103KY

VCEA0A0JW227M+

VCKYCY1HB152KY

VCEA0A0JW107M+

VCKYCY1HF223ZY

VCKYCY1EF104ZY

VCCCCY1HH100DY

VCCCCY1HH100DY

VCKYCY1HF103ZY

VCEA0A1CW106M+

VCEA0A1HW106M+

VCKYCY1HB102KY

VCKYCY1EF104ZY

VCKYCY1EF473ZY

VCKYCY1HB102KY

VCKYCY1HB102KY

VCKYCY1HB102KY

VCKYCY1HB681KY

R 33 16V Electrolytic AB

R 22p 50V Ceramic AA

R 27p 50V Ceramic AA

R 470 6.3V Electrolytic AC

R 0.33 16V Ceramic AB

R 100 6.3V Electrolytic AB

R 10p 50V Ceramic AA

R 0.01 50V Ceramic AA

R 390p 50V Ceramic AB

R 0.01 50V Ceramic AA

R 220 6.3V Electrolytic AB

R 1500p 50V Ceramic AA

R 100 6.3V Electrolytic AB

R 0.022 50V Ceramic AB

R 0.1 25V Ceramic AA

R 10p 50V Ceramic AA

R 10p 50V Ceramic AA

R 0.01 50V Ceramic AA

R 10 16V Electrolytic AB

R 10 50V Electrolytic AB

R 1000p 50V Ceramic AA

R 0.1 25V Ceramic AA

R 0.047 25V Ceramic AA

R 1000p 50V Ceramic AA

R 1000p 50V Ceramic AA

R 1000p 50V Ceramic AA

R 680p 50V Ceramic AA

39

Page 40

SX76NF8

Ref. No. Part No. ★ Description Code

C307

C308

C309

C310

C311

C312

C313

C314

C315

C317 VCFYFA1HA334J+ R 0.33 50V Mylar AB

C318 VCFYFA1HA334J+ R 0.33 50V Mylar AB

C319 VCFYFA1HA334J+ R 0.33 50V Mylar AB

C320 VCFYFA1HA334J+ R 0.33 50V Mylar AB

C321

C322

C323

C324

C325

C326

C327

C328

C329

C330

C337

C338

C343 VCFYFA1HA334J+ R 0.33 50V Mylar AB

C344 VCFYFA1HA334J+ R 0.33 50V Mylar AB

C345

C346

C347

C348

C349

C350

C353

C354

C355

C367

C368

C401 VCFYFA1HA684J+ R 0.68 50V Mylar AC

C402 VCFYFA1HA684J+ R 0.68 50V Mylar AC

C404 VCFYFA1HA684J+ R 0.68 50V Mylar AC

C405 VCFYFA1HA684J+ R 0.68 50V Mylar AC

C406 VCFYFA1HA684J+ R 0.68 50V Mylar AC

C501

C502

C503 VCFYAA2EA104J+ R 0.1 250V Mylar AD

C504

C505

C506

C507

C508

C509

C510

C511

C512

C513

C514

C515

C516

C517 VCFYFA1HA224J+ R 0.22 50V Mylar AB

C518

C520 VCFYAH2AA474K R 0.47 100V Mylar AE

C521

C526

C527

C529

C530

C601

C602

C603

C604

C605

C606 RC-KZ0033CEZZ R 150p 2kV Ceramic AB

C607 VCFYAA2EA104J+ R 0.1 250V Mylar AD

C608 VCFPGU2EC244J R 0.24 250V M.Polypro AF

C609 VCFPVC3ZA123H R 0.012 1.8kVM.Polypro AD

C611 VCQPPC2JB333J R 0.033 630V Mylar AC

VCKYCY1HB681KY

VCEA0A1CW106M+

VCEA0A1CW106M+

VCKYCY1EF104ZY

VCEA0A1CW337M+

VCEA0A1CW106M+

VCEA0A1CW106M+

VCEA0A1HW335M+

VCKYCY1EF104ZY

VCEA0A1CW106M+

VCKYCY1EF104ZY

VCKYCY1EF104ZY

VCCCCY1HH470JY

VCCCCY1HH470JY

VCCCCY1HH5R0CY

VCCCCY1HH470JY

VCCCCY1HH5R0CY

VCKYCY1EF104ZY

VCEA0A0JW227M+

VCKYCY1HB681KY

VCKYCY1HB681KY

VCEA0A1EW107M+

VCEA0A1EW107M+

VCKYCY1CF224ZY

VCKYCY1CF224ZY

VCKYCY1HB102KY

VCKYCY1HB102KY

VCKYCY1HB102KY

VCKYCY1HB102KY

VCEA0A0JW227M+

VCEA0A1CW106M+

VCEA0A1CW106M+

VCKYPA1HB391K+

VCEA0A1VW227M+

VCE9EA1HW335M+

VCKYPA1HB391K+

VCKYPA2HB102K+

VCEA0A1VW106M+

VCKYPA2HB102K+

VCEA0A1EW477M

VCQYTA1HM104J+

VCQYTA1HM104J+

VCEA0A1EW477M

VCEA0A1VW107M+

VCKYPA1HB471K+

VCKYPA1HB472K+

VCQYTA1HM104J+

VCQYTA1HM104J+

VCCCCY1HH471JY

VCQYTA1HM683J+

VCQYTA1HM683J+

VCE9GA1CW106M+

VCEA0A1HW107M+

VCKYPA1HB102K+

VCKYPA2HB561K+

VCKYPA2HB102K+

VCEA0A1EW108M

VCKYPA1HB472K+

R 680p 50V Ceramic AA

R 10 16V Electrolytic AB

R 10 16V Electrolytic AB

R 0.1 25V Ceramic AA

R 330 16V Electrolytic AC

R 10 16V Electrolytic AB

R 10 16V Electrolytic AB

R 3.3 50V Electrolytic AB

R 0.1 25V Ceramic AA

R 10 16V Electrolytic AB

R 0.1 25V Ceramic AA

R 0.1 25V Ceramic AA

R 47p 50V Ceramic AA

R 47p 50V Ceramic AA

R 5.0p 50V Ceramic AA

R 47p 50V Ceramic AA

R 5.0p 50V Ceramic AA

R 0.1 25V Ceramic AA

R 220 6.3V Electrolytic AB

R 680p 50V Ceramic AA

R 680p 50V Ceramic AA

R 100 25V Electrolytic AC

R 100 25V Electrolytic AC

R 0.22 16V Ceramic AB

R 0.22 16V Ceramic AB

R 1000p 50V Ceramic AA

R 1000p 50V Ceramic AA

R 1000p 50V Ceramic AA

R 1000p 50V Ceramic AA

R 220 6.3V Electrolytic AB

R 10 16V Electrolytic AB

R 10 16V Electrolytic AB

R 390p 50V Ceramic AA

R 220 35V Electrolytic AC

R 3.3 50V Elect.(N,P) AB

R 390p 50V Ceramic AA

R 1000p 500V Ceramic AA

R 10 35V Electrolytic AB

R 1000p 500V Ceramic AA

R 470 25V Electrolytic AD

R 0.1 50V Mylar AB

R 0.1 50V Mylar AB

R 470 25V Electrolytic AD

R 100 35V Electrolytic AC

R 470p 50V Ceramic AA

R 4700p 50V Ceramic AB

R 0.1 50V Mylar AB

R 0.1 50V Mylar AB

R 470p 50V Ceramic AA

R 0.068 50V Mylar AB

R 0.068 50V Mylar AB

R 10 16V Elect.(N,P) AB

R 100 50V Electrolytic AB

R 1000p 50V Ceramic AA

R 560p 500V Ceramic AA

R 1000p 500V Ceramic AA

R 1000 25V Electrolytic AD

R 4700p 50V Ceramic AB

Ref. No. Part No. ★ Description Code

C613 RC-KZ0036CEZZ R 330p 2kV Ceramic AB

C615

C616

C617 RC-FZ0377CEZZ R 4.7 100V Mylar AF

C618

C619

C620 VCEA0A1EW108M R 1000 25V Electrolytic AD

C621

C622 VCFPVC2DB224J R 0.22 200V M.Polypro AE

C651

C652

C653

C701 RC-KZ0029CEZZ+ R 0.01 250V Ceramic AC

C702 RC-KZ0029CEZZ+ R 0.01 250V Ceramic AC

C704

C705

C706

C707 RC-KZ0029CEZZ+ R 0.01 250V Ceramic AC

C708

C709 RC-KZ0296CEZZ+ R 470p 2kV Ceramic AC

C710 VCFPVC3CA822H R 8200p 1.6kV M.Polypro AE

C712 RC-KZ0038CEZZ R 470p 2kV Ceramic AB

C713 VCQPPC2JB333K R 0.033 630V Mylar AC

C714

C715 RC-EZ1046CEZZ R 220 400V Electrolytic AN

å C716 RC-KZ0106GEZZ R 3300p 4kV Ceramic AG

C717 RC-KZ0038CEZZ R 470p 2kV Ceramic AB

C718 RC-KZ0038CEZZ R 470p 2kV Ceramic AB

C751

C752 VCEA0A1CW108M R 1000 16V Electrolytic AD

C753

C754 RC-EZA035WJZZ R 100 200V Electrolytic AH

C755 RC-EZA035WJZZ R 100 200V Electrolytic AH

C756 VCEA0A1EW108M R 1000 25V Electrolytic AD

C757 VCEA0A1EW108M R 1000 25V Electrolytic AD

C758

C760

C764

C766

C767

C768

C769

C770

C771

C772

C773

C774

C775

C776

C777

C780

C1001

C1002

C1003

C1004

C1005

C1006

C1007

C1008

C1009

C1010

C1011

C1012

C1013

C1014

C1015

C1016

C1017

C1019

C1020

C1021

C1022

C1023

C1024

C1025

C1026

C1027

VCKYPA2HB102K+

VCEA0A2EW106M

VCKYPA2HB102K+

VCEA0A1HW106M+

VCEA0A1VW107M+

VCEA0A1VW106M+

VCEA0A1VW106M+

VCEA0A1VW106M+

VCKYPA1HB102K+

VCEA0A1EW226M+

VCQYTA1HM473J+

VCQYTA1HM104J+

VCEA0A1HW226M+

VCEA0A2AW105M+

VCQYTA1HM273J+

VCQYTA1HM104J+

VCEA0A1CW106M+

VCEA0A1CW476M+

VCEA0A1EW476M+

VCKYCY1HB103KY

VCEA0A1CW476M+

VCEA0A1HW106M+

VCEA0A1CW106M+

VCEA0A1EW227M+

VCEA0A1CW476M+

VCEA0A1HW225M+

VCE9EA1HW105M+

VCEA0A1HW106M+

VCKYCY1EF104ZY

VCKYCY1EF104ZY

VCKYCY1HF103ZY

VCKYCY1EF104ZY

VCKYCY1HB103KY

VCEA0A1CW106M+

VCEA0A1CW227M+

VCKYCY1EF104ZY

VCKYCY1EF104ZY

VCKYCY1HB222KY

VCKYCY1EF104ZY

VCKYCY1EF473ZY

VCEA0A1HW106M+

VCKYCY1HB271KY

VCKYCY1HB222KY

VCKYCY1CF474ZY

VCEA0A1CW476M+

VCCCCY1HH101JY

VCCCCY1HH101JY

VCCCCY1HH101JY

VCKYCY1HB222KY

VCEA0A0JW477M+

VCKYCY1HB222KY

VCKYCY1EF104ZY

VCEA0A1CW476M+

VCEA0A0JW477M+

VCKYCY1HB222KY

VCKYCY1EF104ZY

VCKYCY1EF104ZY

R 1000p 500V Ceramic AA

R 10 250V Electrolytic AD

R 1000p 500V Ceramic AA

R 10 50V Electrolytic AB

R 100 35V Electrolytic AC

R 10 35V Electrolytic AB

R 10 35V Electrolytic AB

R 10 35V Electrolytic AB

R 1000p 50V Ceramic AA

R 22 25V Electrolytic AB

R 0.047 50V Mylar AB

R 0.1 50V Mylar AB

R 22 50V Electrolytic AB

R 1 100V Electrolytic AB

R 0.027 50V Mylar AB

R 0.1 50V Mylar AB

R 10 16V Electrolytic AB

R 47 16V Electrolytic AB

R 47 25V Electrolytic AB

R 0.01 50V Ceramic AA

R 47 16V Electrolytic AB

R 10 50V Electrolytic AB

R 10 16V Electrolytic AB

R 47 25V Electrolytic AB

R 47 16V Electrolytic AB

R 1 50V Electrolytic AB

R 1 50V Elect.(N,P) AC

R 10 50V Electrolytic AB

R 0.1 25V Ceramic AA

R 0.1 25V Ceramic AA

R 0.01 50V Ceramic AA

R 0.1 25V Ceramic AA

R 0.01 50V Ceramic AA

R 10 16V Electrolytic AB

R 220 16V Electrolytic AC

R 0.1 25V Ceramic AA

R 0.1 25V Ceramic AA

R 2200p 50V Ceramic AA

R 0.1 25V Ceramic AA

R 0.047 25V Ceramic AA

R 10 50V Electrolytic AB

R 270p 50V Ceramic AA

R 2200p 50V Ceramic AA

R 0.47 16V Ceramic AB

R 47 16V Electrolytic AB

R 100p 50V Ceramic AA

R 100p 50V Ceramic AA

R 100p 50V Ceramic AA

R 2200p 50V Ceramic AA

R 470 6.3V Electrolytic AC

R 2200p 50V Ceramic AA

R 0.1 25V Ceramic AA

R 47 16V Electrolytic AB

R 470 6.3V Electrolytic AC

R 2200p 50V Ceramic AA

R 0.1 25V Ceramic AA

R 0.1 25V Ceramic AA

40

Page 41

SX76NF8

Ref. No. Part No. ★ Description Code

C1031

C1032

C1034

C1035

C1036

C1037

C1038

C1039

C1040

C1041

C1042

C1043 VCFYFA1HA684J+ R 0.68 50V Mylar AC

C1044

C1045

C1047

C1048

C1050

C1057

C1058

C1059

C1060

C1061

C1065

C1067

C1068

C1074

C1301

C1302

C1303

C1304

C1305

C1306

C1307 VCFYFA1HA474J+ R 0.47 50V Mylar AC

C1308

C1309

C1310

C1311

C1312

C1313

C1314

C1315

C1320

C1321

C1322

C1323

C1324

C1325

C1326

C1327

C1328

C1329

C1330

C1331

C1332

C1333

C1334

VCKYCY1HB103KY

VCKYCY1HB102KY

VCKYCY1HB103KY

VCEA0A1CW477M+

VCKYCY1EF104ZY

VCEA0A1HW335M+

VCKYCY1EF104ZY

VCCCCY1HH3R0CY

VCCCCY1HH3R0CY

VCKYCY1CF474ZY

VCKYCY1EF104ZY

VCKYCY1EF104ZY

VCE9EA1CW106M+

VCKYCY1HB103KY

VCKYCY1HB103KY

VCKYCY1HB103KY

VCEA0A1CW476M+

VCKYCY1HB103KY

VCEA0A1AW477M+

VCKYCY1HB103KY

VCKYCY1CF224ZY

VCKYCY1HF103ZY

VCKYCY1HF103ZY

VCKYTV1HF103ZY

VCKYPA1HF103Z+

VCCCCY1HH101JY

VCEA0A1EW227M+

VCKYCY1EF104ZY

VCKYTV1HF104ZY

VCKYCY1HB561KY

VCKYCY1HB472KY

VCKYCY1EF104ZY

VCEA0A1EW227M+

VCKYTV1HF104ZY

VCKYCY1HB102KY

VCKYCY1CF334ZY

VCEA0A1HW475M+

VCEA0A0JW337M+

VCKYTV1HF104ZY

VCCCCY1HH101JY

VCEA0A1EW227M+

VCKYCY1EF104ZY

VCEA0A1HW105M+

VCKYTV1HF104ZY

VCKYCY1HB561KY

VCFYFA1HA474J+

VCKYCY1HB472KY

VCKYCY1EF104ZY

VCEA0A1EW227M+

VCKYTV1HF104ZY

VCEA0A1HW475M+

VCKYCY1HB102KY

VCKYCY1CF334ZY

VCKYTV1HF104ZY

R 0.01 50V Ceramic AA

R 1000p 50V Ceramic AA

R 0.01 50V Ceramic AA

R 470 16V Electrolytic AC

R 0.1 25V Ceramic AA

R 3.3 50V Electrolytic AB

R 0.1 25V Ceramic AA

R 3.0p 50V Ceramic AA

R 3.0p 50V Ceramic AA

R 0.47 16V Ceramic AB

R 0.1 25V Ceramic AA

R 0.1 25V Ceramic AA

R 10 16V Elect.(N,P) AC

R 0.01 50V Ceramic AA

R 0.01 50V Ceramic AA

R 0.01 50V Ceramic AA

R 47 16V Electrolytic AB

R 0.01 50V Ceramic AA

R 470 10V Electrolytic AC

R 0.01 50V Ceramic AA

R 0.22 16V Ceramic AB

R 0.01 50V Ceramic AA

R 0.01 50V Ceramic AA

R 0.01 50V Ceramic AA

R 0.01 50V Ceramic AA

R 100p 50V Ceramic AA

R 220 25V Electrolytic AB

R 0.1 25V Ceramic AA

R 0.1 50V Ceramic AB

R 560p 50V Ceramic AA

R 4700p 50V Ceramic AA

R 0.1 25V Ceramic AA

R 220 25V Electrolytic AB

R 0.1 50V Ceramic AB

R 1000p 50V Ceramic AA

R 0.33 16V Ceramic AB

R 4.7 50V Electrolytic AB

R 330 6.3V Electrolytic AC

R 0.1 50V Ceramic AB

R 100p 50V Ceramic AA

R 220 25V Electrolytic AB

R 0.1 25V Ceramic AA

R 1 50V Electrolytic AB

R 0.1 50V Ceramic AB

R 560p 50V Ceramic AA

R 0.47 50V Mylar AC

R 4700p 50V Ceramic AA

R 0.1 25V Ceramic AA

R 220 25V Electrolytic AB

R 0.1 50V Ceramic AB

R 4.7 50V Electrolytic AB

R 1000p 50V Ceramic AA

R 0.33 16V Ceramic AB

R 0.1 50V Ceramic AB

RESISTORS

RJ2 VRS-CY1JF000JY R 0 1/16W Metal Oxide AA

RJ3 VRS-CY1JF000JY R 0 1/16W Metal Oxide AA

RJ4 VRS-CY1JF000JY R 0 1/16W Metal Oxide AA

RJ5 VRS-CY1JF000JY R 0 1/16W Metal Oxide AA

RJ6 VRS-CY1JF000JY R 0 1/16W Metal Oxide AA

RJ8 VRS-CY1JF000JY R 0 1/16W Metal Oxide AA

RJ9 VRS-CY1JF000JY R 0 1/16W Metal Oxide AA

RJ10 VRS-CY1JF000JY R 0 1/16W Metal Oxide AA

R202 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R203 VRS-CY1JF681JY R 680 1/16W Metal Oxide AA

R204 VRS-CY1JF473JY R 47k 1/16W Metal Oxide AA

R205 VRS-CY1JF823JY R 82k 1/16W Metal Oxide AA

R206 VRD-RA2BE271JY R 270 1/8W Carbon AA

R207 VRD-RA2BE271JY R 270 1/8W Carbon AA

R208 VRD-RA2BE123JY R 12k 1/8W Carbon AA

R209 VRS-CY1JF562JY R 5.6k 1/16W Metal Oxide AA

R210 VRD-RA2BE101JY R 100 1/8W Carbon AA

R211 VRD-RA2BE101JY R 100 1/8W Carbon AA

Ref. No. Part No. ★ Description Code

R212 VRS-CY1JF221JY R 220 1/16W Metal Oxide AA

R213 VRS-CY1JF221JY R 220 1/16W Metal Oxide AA

R215 VRS-CY1JF331JY R 330 1/16W Metal Oxide AA

R216 VRD-RM2HD330JY R 33 1/2W Carbon AA

R217 VRS-CY1JF223JY R 22k 1/16W Metal Oxide AA

R218 VRS-CY1JF223JY R 22k 1/16W Metal Oxide AA

R238 VRS-CY1JF392JY R 3.9k 1/16W Metal Oxide AA

R239 VRS-CY1JF331JY R 330 1/16W Metal Oxide AA

R240 VRS-CY1JF151JY R 150 1/16W Metal Oxide AA

R241 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R301 VRD-RA2BE101JY R 100 1/8W Carbon AA

R302 VRS-CY1JF332JY R 3.3k 1/16W Metal Oxide AA

R303 VRS-TQ2BD220JY R 22 1/8W Metal Oxide AA

R304 VRS-CY1JF102JY R 1k 1/16W Metal Oxide AA

R305 VRS-CY1JF102JY R 1k 1/16W Metal Oxide AA

R306 VRS-CY1JF332JY R 3.3k 1/16W Metal Oxide AA

R307 VRD-RA2BE101JY R 100 1/8W Carbon AA

R308 VRS-CY1JF472JY R 4.7k 1/16W Metal Oxide AA

R311 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R312 VRS-CY1JF472JY R 4.7k 1/16W Metal Oxide AA

R313 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R314 VRS-CY1JF472JY R 4.7k 1/16W Metal Oxide AA

R317 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R318 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R319 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R320 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R325 VRD-RA2BE221JY R 220 1/8W Carbon AA

R326 VRD-RA2BE221JY R 220 1/8W Carbon AA

R330 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R331 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R332 VRD-RA2BE221JY R 220 1/8W Carbon AA

R333 VRD-RA2BE221JY R 220 1/8W Carbon AA

R340 VRD-RM2HD151JY R 150 1/2W Carbon AA

R341 VRS-CY1JF272JY R 2.7k 1/16W Metal Oxide AA

R342 VRD-RM2HD151JY R 150 1/2W Carbon AA

R343 VRS-CY1JF272JY R 2.7k 1/16W Metal Oxide AA

R344 VRS-CY1JF102JY R 1k 1/16W Metal Oxide AA

R345 VRS-CY1JF102JY R 1k 1/16W Metal Oxide AA

R346 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R347 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R348 VRS-VV3AB271J R 270 1W Metal Oxide AA

R349 VRS-VV3AB271J R 270 1W Metal Oxide AA

R352 VRS-CY1JF561JY R 560 1/16W Metal Oxide AA

R353 VRS-CY1JF561JY R 560 1/16W Metal Oxide AA

R356 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R357 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R358 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R359 VRD-RA2BE101JY R 100 1/8W Carbon AA

R360 VRS-CY1JF000JY R 0 1/16W Metal Oxide AA

R401 VRS-TV1JD750JY R 75 1/16W Metal Oxide AA

R403 VRS-TV1JD104JY R 75 1/16W Metal Oxide AA

R404 VRS-TQ2BD750JY R 75 1/8W Metal Oxide AA

R405 VRS-TV1JD750JY R 75 1/16W Metal Oxide AA

R406 VRS-TV1JD750JY R 75 1/16W Metal Oxide AA

R407 VRS-TV1JD750JY R 75 1/16W Metal Oxide AA

R408 VRD-RA2EE220JY R 22 1/4W Carbon AA

R409 VRD-RA2EE220JY R 22 1/4W Carbon AA

R410 VRD-RA2EE220JY R 22 1/4W Carbon AA

R415 VRS-TV1JD750JY R 75 1/16W Metal Oxide AA

R424 VRD-RA2EE220JY R 22 1/4W Carbon AA

R425 VRD-RA2EE220JY R 22 1/4W Carbon AA

R501 VRS-CY1JF822JY R 8.2k 1/16W Metal Oxide AA

R502 VRS-CY1JF823JY R 82k 1/16W Metal Oxide AA

R503 VRD-RA2BE102JY R 1k 1/8W Carbon AA

R504 VRS-CY1JF473JY R 47k 1/16W Metal Oxide AA

R505 VRS-CY1JF683JY R 68k 1/16W Metal Oxide AA

R506 VRS-CY1JF124JY R 120k 1/16W Metal Oxide AA

R507 VRS-CY1JF000JY R 0 1/16W Metal Oxide AA

R508 VRS-CY1JF394JY R 390k 1/16W Metal Oxide AA

R509 VRN-GA2EB1R0JY R 1 1/4W Metal Film AA

R510 VRS-CY1JF224JY R 220k 1/16W Metal Oxide AA

R511 VRS-CY1JF562JY R 5.6k 1/16W Metal Oxide AA

R512 VRD-RA2BE102JY R 1k 1/8W Carbon AA

R514 VRD-RA2BE102JY R 1k 1/8W Carbon AA

R515 VRD-RA2BE683JY R 68k 1/8W Carbon AA

R516 VRS-CY1JF473JY R 47k 1/16W Metal Oxide AA

41

Page 42

SX76NF8

Ref. No. Part No. ★ Description Code

R517 VRD-RA2BE683JY R 68k 1/8W Carbon AA

R518 VRN-RA2BK473FY R 47k 1/8W Metal Film AB

R519 VRS-CY1JF334JY R 330k 1/16W Metal Oxide AA

R520 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R523 VRN-VV3ABR82J R 0.82 1W Metal Film AA

R524 VRS-VV3DB151J R 150 2W Metal Oxide AA

R525 VRS-VV3DB221J R 220 2W Metal Oxide AA

R526 VRS-CY1JF682JY R 6.8k 1/16W Metal Oxide AA

R527 VRS-CY1JF682JY R 6.8k 1/16W Metal Oxide AA

R528 VRS-CY1JF123JY R 12k 1/16W Metal Oxide AA

R529 VRS-CY1JF332JY R 3.3k 1/16W Metal Oxide AA

R601 VRD-RA2BE151JY R 150 1/8W Carbon AA

R602 VRD-RA2BE221JY R 220 1/8W Carbon AA

R604 VRS-KA3HG332J R 3.3k 5W Metal Oxide AD

R605 VRS-VV3AB562J R 5.6k 1W Metal Oxide AA

R606 VRW-KQ3NC3R3K R 3.3 7W Cement AE

R607 VRD-RM2HD150JY R 15 1/2W Carbon AA

R608 VRN-VV3ABR22J R 0.22 1W Metal Film AA

R609 VRN-VV3AB5R6J R 5.6 1W Metal Film AA

R610 VRS-KT3LB122J R 1.2k 3W Metal Oxide AC

R611 VRS-VV3AB103J R 10k 1W Metal Oxide AA

R612 VRN-GA2EB1R0JY R 1 1/4W Metal Film AA

R614 VRN-SV2HCR22J R 0.22 1/2W Metal Film AB

R616 VRN-VV3DB1R8J R 1.8 2W Metal Film AB

R617 VRN-VV3LBR27J R 0.27 3W Metal Film AC

R618 VRS-VV3DB473J R 47k 2W Metal Oxide AB

R621 VRD-RM2HD182JY R 1.8k 1/2W Carbon AA

R622 VRD-RM2HD392JY R 3.9k 1/2W Carbon AA

R623 VRD-RA2BE472JY R 4.7k 1/8W Carbon AA

R624 VRD-RA2BE103JY R 10k 1/8W Carbon AA

R625 VRD-RM2HD822JY R 8.2k 1/2W Carbon AA

R626 VRD-RA2BE102JY R 1k 1/8W Carbon AA

R627 VRD-RA2EE104JY R 100k 1/4W Carbon AA

R651 VRD-RA2BE123JY R 12k 1/8W Carbon AA

R652 VRD-RA2BE223JY R 100k 1/8W Carbon AA

R653 VRD-RA2BE562JY R 5.6k 1/8W Carbon AA

R654 VRD-RA2BE101JY R 100 1/8W Carbon AA

R655 VRS-VV3AB560J R 56 1W Metal Oxide AA

R656 VRS-VV3AB560J R 56 1W Metal Oxide AA

R703 VRD-RM2HD154JY R 150k 1/2W Carbon AA

R706 VRS-CY1JF124JY R 120k 1/16W Metal Oxide AA

R707 VRD-RM2HD154JY R 150k 1/2W Carbon AA

R708 VRD-RM2HD270JY R 27 1/2W Carbon AA

R709 VRS-CY1JF184JY R 180k 1/16W Metal Oxide AA

R710 VRD-RA2BE155JY R 1.5M 1/8W Carbon AA

R711 VRD-RA2BE102JY R 1k 1/8W Carbon AA

R712 VRD-RM2HD102JY R 1k 1/2W Carbon AA

R713 VRD-RA2BE333JY R 33k 1/8W Carbon AA

R714 VRD-RA2BE155JY R 1.5M 1/8W Carbon AA

R715 VRN-VV3DBR10J R 0.1 2W Metal Film AB

R716 VRD-RM2HD122JY R 1.2k 1/2W Carbon AA

R717 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R718 VRW-KQ3HCR47K R 0.47 5W Cement AD

R719 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R720 VRD-RM2HD103JY R 10k 1/2W Carbon AA

R721 VRD-RM2HD102JY R 1k 1/2W Carbon AA

R722 VRS-KT3LB473J R 47k 3W Metal Oxide AE

R723 VRS-CY1JF222JY R 2.2k 1/16W Metal Oxide AA

R724 VRD-RA2BE100JY R 10 1/8W Carbon AA

R725 VRD-RM2HD272JY R 2.7k 1/2W Carbon AA

å R729 RR-HZ0014GEZZY R 12M 1/2W AE

R742 VRD-RM2HD470JY R 47 1/2W Carbon AA

R743 VRS-CY1JF472JY R 4.7k 1/16W Metal Oxide AA

R744 VRD-RA2EE102JY R 1k 1/4W Carbon AA

R746 VRS-CY1JF472JY R 4.7k 1/16W Metal Oxide AA

R747 VRS-CY1JF222JY R 2.2k 1/16W Metal Oxide AA

R748 VRS-CY1JF334JY R 330k 1/16W Metal Oxide AA

R749 VRS-CY1JF222JY R 2.2k 1/16W Metal Oxide AA

R750 VRS-TQ2BD124FY R 120k 1/8W Metal Oxide AA

R751 VRS-TQ2BD124FY R 120k 1/8W Metal Oxide AA

R752 VRS-TQ2BD472FY R 4.7k 1/8W Metal Oxide AA

R753 VRS-CY1JF124JY R 120k 1/16W Metal Oxide AA

R754 VRS-CY1JF183JY R 18k 1/16W Metal Oxide AA

R755 VRS-CY1JF332JY R 3.3k 1/16W Metal Oxide AA

R756 VRS-CY1JF123JY R 12k 1/16W Metal Oxide AA

R757 VRS-CY1JF473JY R 47k 1/16W Metal Oxide AA

R758 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

Ref. No. Part No. ★ Description Code

R759 VRS-CY1JF102JY R 1k 1/16W Metal Oxide AA

R760 VRS-CY1JF473JY R 47k 1/16W Metal Oxide AA

R761 VRS-CY1JF122JY R 1.2k 1/16W Metal Oxide AA

R762 VRD-RA2EE680JY R 68 1/4W Carbon AA

R763 VRD-RM2HD102JY R 1k 1/2W Carbon AA

R764 VRS-CY1JF822JY R 8.2k 1/16W Metal Oxide AA

R765 VRS-CY1JF152JY R 1k 1/16W Metal Oxide AA

R766 VRS-CY1JF102JY R 1k 1/16W Metal Oxide AA

R767 VRS-CY1JF682JY R 6.8k 1/16W Metal Oxide AA

R768 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R769 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R770 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R771 VRD-RA2BE153JY R 15k 1/8W Carbon AA

R772 VRS-CY1JF393JY R 39k 1/16W Metal Oxide AA

R773 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R774 VRD-RA2BE102JY R 1k 1/8W Carbon AA

R775 VRS-VV3DB100J R 10 2W Metal Oxide AA

R776 VRD-RA2BE102JY R 1k 1/8W Carbon AA

R778 VRS-CY1JF332JY R 3.3k 1/16W Metal Oxide AA

R781 VRS-CY1JF102JY R 1k 1/16W Metal Oxide AA

R783 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R785 VRS-CY1JF123JY R 12k 1/16W Metal Oxide AA

R791 VRD-RA2BE101JY R 100 1/8W Carbon AA

R792 VRD-RM2HD101JY R 100 1/2W Carbon AA

R793 VRS-CY1JF393JY R 39k 1/16W Metal Oxide AA

R794 VRD-RA2BE102JY R 1k 1/8W Carbon AA

R795 VRS-CY1JF393JY R 39k 1/16W Metal Oxide AA

R866 RR-DZ0053CEZZY R 8.2M 1/2W Carbon AC

R1001 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1003 VRS-CY1JF102JY R 1k 1/16W Metal Oxide AA

R1004 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1005 VRD-RA2BE101JY R 100 1/8W Carbon AA

R1006 VRD-RA2BE101JY R 100 1/8W Carbon AA

R1007 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1008 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1009 VRD-RA2BE101JY R 100 1/8W Carbon AA

R1010 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1011 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1012 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1013 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1014 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1015 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1016 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1017 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1018 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1019 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1020 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1021 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1022 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1023 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1024 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1025 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1026 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1027 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1028 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1029 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1030 VRS-CY1JF221JY R 220 1/16W Metal Oxide AA

R1031 VRS-CY1JF273JY R 27k 1/16W Metal Oxide AA

R1032 VRD-RA2BE103JY R 10k 1/8W Carbon AA

R1033 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R1034 VRS-CY1JF332JY R 3.3k 1/16W Metal Oxide AA

R1035 VRS-CY1JF332JY R 3.3k 1/16W Metal Oxide AA

R1036 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1037 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1038 VRS-CY1JF102JY R 1k 1/16W Metal Oxide AA

R1039 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R1040 VRD-RA2BE332JY R 3.3k 1/8W Carbon AA

R1041 VRS-CY1JF102JY R 1k 1/16W Metal Oxide AA

R1043 VRD-RM2HD680JY R 68 1/2W Carbon AA

R1044 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R1045 VRS-CY1JF222JY R 2.2k 1/16W Metal Oxide AA

R1046 VRS-CY1JF472JY R 4.7k 1/16W Metal Oxide AA

R1047 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R1049 VRD-RA2BE102JY R 1 k 1/8W Carbon AA

R1050 VRS-CY1JF225JY R 2.2M 1/16W Metal Oxide AA

R1052 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R1053 VRS-CY1JF222JY R 2.2k 1/16W Metal Oxide AA

42

Page 43

SX76NF8

Ref. No. Part No. ★ Description Code

R1054 VRS-CY1JF122JY R 1.2k 1/16W Metal Oxide AA

R1055 VRS-CY1JF271JY R 270 1/16W Metal Oxide AA

R1056 VRS-CY1JF222JY R 2.2k 1/16W Metal Oxide AA

R1057 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R1058 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1059 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1060 VRD-RA2BE103JY R 10k 1/8W Carbon AA

R1061 VRD-RA2BE102JY R 1 k 1/8W Carbon AA

R1062 VRS-CY1JF100JY R 10 1/16W Metal Oxide AA

R1063 VRS-CY1JF100JY R 10 1/16W Metal Oxide AA

R1065 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1067 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1068 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1069 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1070 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1071 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1076 VRS-CY1JF000JY R 0 1/16W Metal Oxide AA

R1077 VRS-CY1JF822JY R 8.2k 1/16W Metal Oxide AA

R1078 VRS-CY1JF102JY R 1k 1/16W Metal Oxide AA

R1082 VRS-CY1JF123JY R 12k 1/16W Metal Oxide AA

R1083 VRS-CY1JF123JY R 12k 1/16W Metal Oxide AA

R1085 VRD-RA2BE100JY R 1 0 1/8W Carbon AA

R1087 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1088 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1089 VRD-RA2BE101JY R 100 1/8W Carbon AA

R1090 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1091 VRS-CY1JF101JY R 100 1/16W Metal Oxide AA

R1099 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R1301 VRS-CY1JF123JY R 12k 1/16W Metal Oxide AA

R1302 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R1303 VRS-CY1JF183JY R 15k 1/16W Metal Oxide AA

R1304 VRS-CY1JF472JY R 4.7k 1/16W Metal Oxide AA

R1305 VRD-RA2BE153JY R 12k 1/8W Carbon AA

R1306 VRS-CY1JF151JY R 150 1/16W Metal Oxide AA

R1307 VRS-CY1JF273JY R 27k 1/16W Metal Oxide AA

R1308 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R1309 VRS-CY1JF123JY R 12k 1/16W Metal Oxide AA

R1310 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R1311 VRS-CY1JF103JY R 10k 1/16W Metal Oxide AA

R1312 VRS-CY1JF472JY R 4.7k 1/16W Metal Oxide AA

R1313 VRS-CY1JF104JY R 100k 1/16W Metal Oxide AA

R1314 VRS-CY1JF151JY R 150 1/16W Metal Oxide AA

R1315 VRS-CY1JF183JY R 15k 1/16W Metal Oxide AA

R1316 VRS-CY1JF273JY R 27k 1/16W Metal Oxide AA

R1317 VRD-RA2BE223JY R 22k 1/8W Carbon AA