Page 1

SW-100T

Instruction Manual

Version 1 20171114

Page 2

Page 3

Make sure your work area is cleared of uninvited people and obstacles every

time before you start operating the machine.

Never step or stand on the roller table. Your foot may slip or trip on the rollers

and you will fall.

Never wear gloves or loose clothing when operating the machine. It may lead

to serious injury if they are caught in the running machine. Wrap or cover

long hair.

Never touch the running saw blade with gloves or not. It is dangerous if your

hands, clothing or gloves are caught by the running blade.

Make sure any use of fire is prohibited in the shop and install a fire

extinguisher or other fire control device near the machine when cutting

titanium, magnesium, or any other material that produces flammable chips.

Never leave the machine unattended when cutting flammable materials.

Use a water-soluble cutting fluid on this machine. Oil-based cutting fluids

may emit smoke or catch fire, depending on how they are used.

Never cut carbon or any other material that may produce and disperse

explosive dust. It is possible that sparks from motors and other machine parts

will ignite and explode the air-borne dust.

Page 4

Never adjust the wire brush or remove chips while the saw blade is still

running. It is extremely dangerous if hands or clothing are caught by the

running blade.

Stop the saw blade before you clean the machine. It is dangerous if hands or

clothing are caught by the running blade.

Never start the saw blade unless the workpiece has been clamped firmly. If

the workpiece is not securely clamped, it will be forced out of the vise during

cutting.

Take preventive measures when cutting thin or short pieces from the work to

keep them from falling. It is dangerous if the cut pieces fall.

Use roller tables at the front and rear sides of the machine when cutting long

work. It is dangerous if the work piece falls off the machine.

Turn off the shop circuit breaker switch before performing maintenance on

the machine. Post a sign indicating the machine is under maintenance.

Page 5

Section 1 – Safety Information

1-1

Safety Instructions ……………………………………………………………………………………………………...

1-1 Safeguard Devices ……………………………………………………………………………………………………….

1-3 Emergency Stop ………………………………………………………………………………………………………….

1-4

Illustration: Emergency Stop ………………………………………………………………………………………

1-5 Safety Labels ……………………………………………………………………………………………………………….

1-6

Illustration: Safety Labels ………………………………………………………………………………………..…

1-9 Hearing Protection ………………………………………………………………………………………………………

1-10

CE Compliance …………………………………………………………………………………………………………….

1-10

Risk Assessment ………………………………………………………………………………………………………….

1-10

Section 2 – General Information

2-1

Specification ……………………………………..………………………………………………………………………..

2-2 Machine Parts Identification ……………………………………………………………………………………….

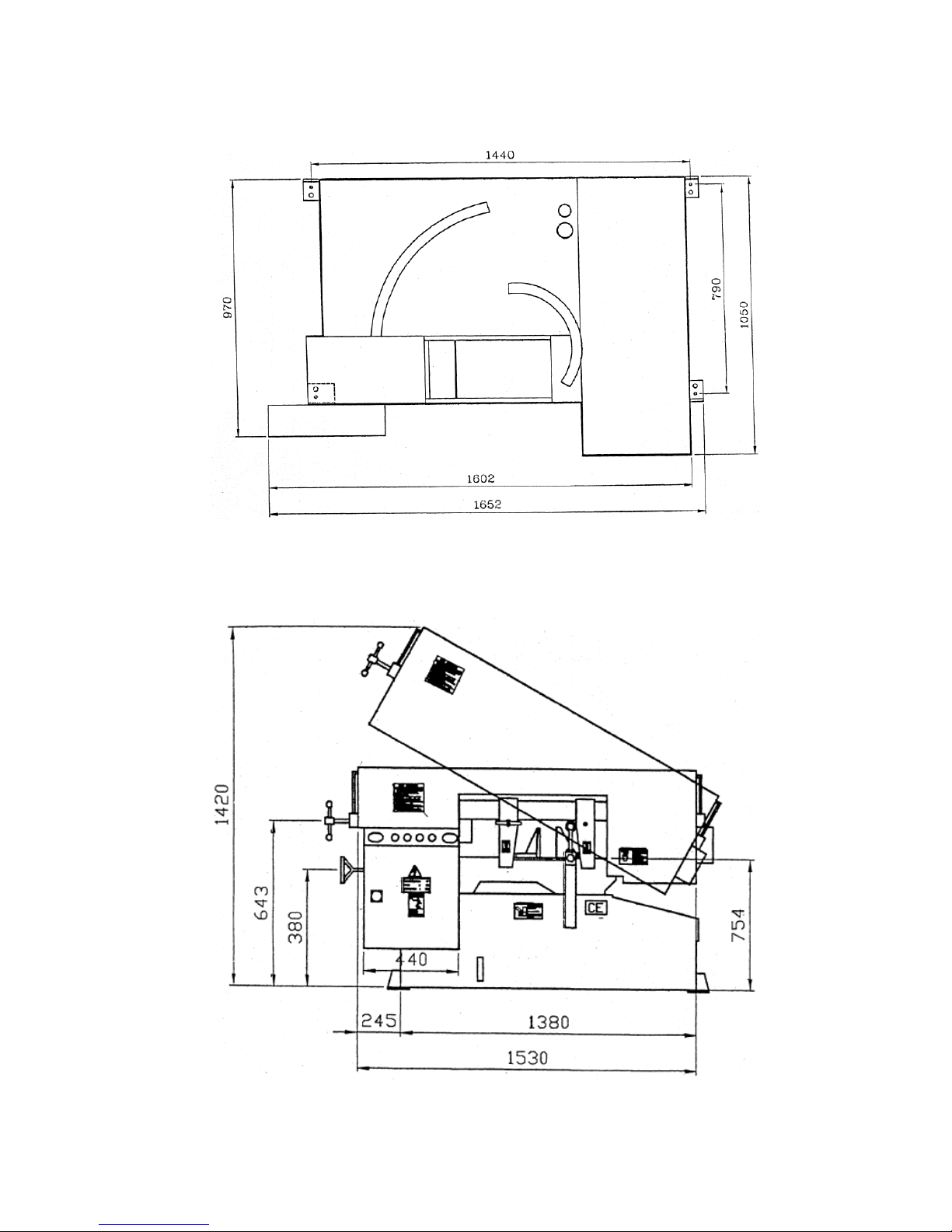

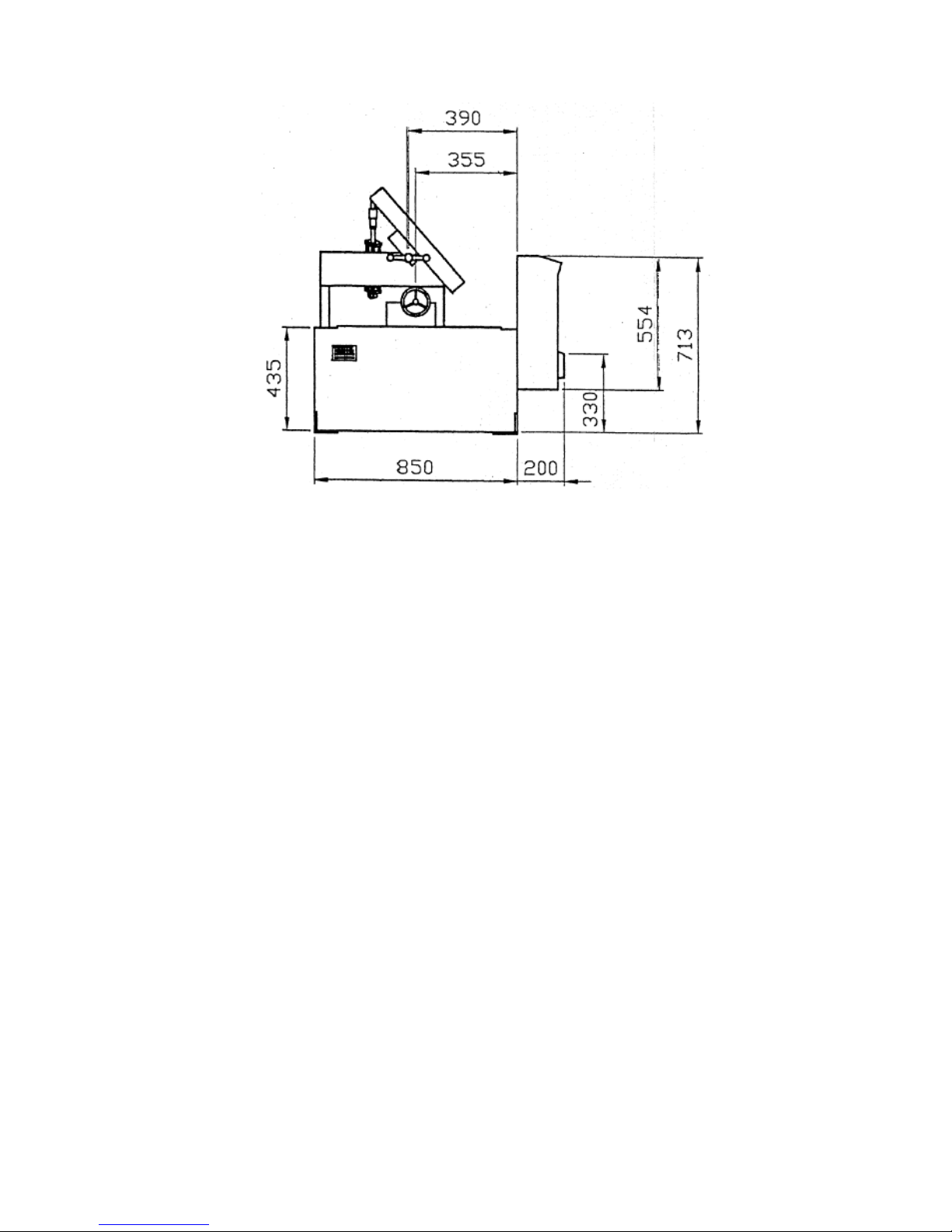

2-3 Floor Plan …………………………………………………………………………………………………..……………….

2-4

Section 3 – Moving & Installation

3-1

Location & Environment ………………………………..……………………………………………………………

3-1

Unpacking & Inspecting ……..……………………………………………………………………………………….

3-2 Lifting …………………………………………..………………………………………………………………….………….

3-3

Illustration: Lifting Points ………………………………………………………….……………………….

3-5 Removing Shipping Bracket …………………………..……………………………………………….……………

3-6 Cleaning …………………………………………..…………………………………………………………….……………

3-6 Installing …………………………...………………………………………………………………………….…………….

3-6

Supplying Hydraulic Oil …………………………………………………………………….…………….

3-6

Supplying Coolant ………..………………………………………………………………….……………..

3-7

Connecting Electric Power ……………………………………………………………….……………..

3-7

Leveling & Anchoring …………………………………………………………………….……………….

3-8

Installing Roller Table (Optional) ………………………………………………….………………….

3-9

Installing Fire Control Device……………………………………………………………………………

3-9 Relocating ………………………...…………………………………………………………………….………………….

3-9

Page 6

Section 4 – Operating Instructions

4-1

Safety Precautions …………………..…………………..……………………………………….…………………….

4-2 Before Operating …………………………..…………………………………………………………………………….

4-3 Control Panel ……..……………………………………..………………………………………….…………………….

4-4

Control Panel ………………….………………………………………………………………………..…….

4-4

Control Buttons ……………………………………………………………………………………….……..

4-4 Cutting Operation ………..………..……………………………………………..…………………………………….

4-5

Selecting Blade Speed …………………………………………………………………………………….

4-5

Changing Blade Speed – 4 Speed Step Pulley ………………………………………………….

4-5

Selecting Blade ……………………………………………………………………………………………….

4-6

Adjusting Feed Rate (Cutting Pressure) ……………………………………………………………

4-6

Adjusting Vise …………………………………………………………………………………………………

4-7

Angle Cutting ………………………………………………………………………………………………….

4-7 Adjusting Coolant Flow ………..………..…………………………………………………………………..……….

4-9

Installing Material Stop Bracket …………………………………………………………………………………..

4-10

Unrolling & Installing the Blade …………………………………………………………………….…………….

4-11

Adjusting Blade Tension ………..………..…………………………………………………………………………..

4-12

Adjusting Wire Brush ………..……………………………………………………………………….……………….

4-12

Adjusting Saw Arm……………..……………………………………………………………………….………………

4-12

Adjusting Horizontal Stop Spring Cushion ……………………………………………………………………

4-13

Section 5 – Electrical System

5-1

Electrical Circuit Diagrams ……….…………………..……………………………………………………………..

5-1

Section 6 – Hydraulic System

6-1

Hydraulic Diagrams ……….…………………..………………………………………………………………………..

6-1

Section 7 – Bandsaw Cutting: A Practical Guide

7-1

Introduction ……………………….…….…………………..…………………………………………………………….

7-2 Saw Blade Selection ………………….…………………..……………………………………………………………

7-2

VISE LOADING …………….…………………..………………………………………….………………………………

7-3

BladeBreak -In …………………………………………………………………………………….……………………..

7-4

Section 8 – Maintenance & Service

8-1

Introduction ……………………….…….…………………..…………………………………………………………….

8-1

Basic Maintenance ………………….…………………..…………………………………………….……………….

8-1

Maintenance Schedule …………….…………………..…………………………………………………………….

8-2

Before Beginning a Day’s Work ……………………………………………………………………….

8-2

After Ending a Day’s Work …………………………………………………….………………………..

8-2

Page 7

Every 2 weeks …………………………………………………………………….……………………….

8-2

First 600hrs for new machine,then every 1200h…………………….……………………….

8-2

Every Six Months ……………….………………………………………………….……………………….

8-3 Storage Conditions …………………………....………..……………………………………………………………..

8-3 Terminating the Use of Machine ……..…………..……………………………………………………………..

8-3 Oil Recommendation for Maintenance ……………………………………………………………………….

8-4

Section 9 – Troubleshooting

9-1

Introduction ……………………….…….…………………..…………………………………………………………….

9-1 Precautions ………………….…………………..…………………………………………………………………….....

9-2 General Troubles & Solutions ………………………..…………………………………………………………….

9-2 Minor Troubles & Solutions ………………………..………………………………………………..…………….

9-3 Motor Troubles & Solutions ………………………..…………………………………………………..………….

9-3 Blade Troubles & Solutions ………………………..………………………………………………………………..

9-4 Sawing Problems & Solutions ………………………..……………………………………………………………

9-5

Re-Adjusting the Roller Table ………………………..…………………………………………………………….

9-12

Section 10 – Parts

10-1

Spare Parts Recommendations …………………..……………………………………………………………….

10-1

Part List …………………..………………………………………………………………………………………………….

10-2

Page 8

Section 1

SAFETY

INFORMATION

SAFETY INSTRUCTIONS

SAFEGUARD DEVICES

EMERGENCY STOP

SAFETY LABELS

HEARING PROTECTION

CE COMPLIANCE

RISK ASSESSMENT

Safety is a combination of a well-designed machine, operator’s knowledge about the machine and

alertness at all times. This band machine has incorporated many safety measures during the design

process and used protective devices to prevent personal injuries and potential risks. Warning labels also

serve as a reminder to the operator.

Throughout this manual, you will also see various safety-related symbols indicating important

information that you should take note of prior to use of the machine or part of its functions. These

important safety instructions do not cover all possible situations that might occur. It is your responsibility

to take caution and follow procedures stated in this manual when installing, maintaining and operating

your machine.

SAFETY INSTRUCTIONS

What the icons and signs in this user manual mean:

This icon marks WARNING; hazards or unsafe practices that may result in

personal injury or damage to the machine.

Supplementary information to the procedures described in this manual.

Call your local agent or our service center for help.

Page 9

This manual has important safety

information. Read through it carefully

before operating this machine to prevent

personal injury or machine damage.

Learn the operation, limitation and the

specific potential hazards peculiar to this

band saw. All users must read it before

performing any activity on the machine,

such as replacing the saw band or doing

regular maintenance.

Do not operate this machine unless it is

completely assembled.

Keep all guards and shields in place

before installing or starting up the

machine.

Keep blade protection cover and wheel

covers in place and in working order.

Make sure the power switch is off before

plugging in power cord.

Disconnect the power cord before

making adjustment, maintenance or

blade changes.

Always remember to switch off the

machine when the work is completed.

Keep unauthorized personnel away.

Use recommended accessories.

Improper accessories may be hazardous.

Never hold the material by hand for

cutting. Always use the vise and make

sure the material is clamped securely

before cutting.

When a workpiece is too long or heavy,

make sure it is supported with a roller

table (recommended).

Do not use the machine to cut explosive

material or high pressure vessels as it

will generate great amount of heat

during the sawing process and may

Wear proper apparel during operation

and when servicing the machine. Some

personal protective equipment is

required for the safe use of the machine,

e.g. protection goggles.

Never operate while under the influence

of drugs, alcohol or medication.

Do not reach over or stand on any part

of the machine.

It is dangerous to operate the machine

when the floor is slippery. Keep the floor

clean and dry. Check for ice, moisture, or

grease before entering.

Keep the work environment safe. Do not

use band saw in a damp or wet location.

Keep your work area clean. Cluttered

and slippery floors invite accidents.

Keep your work area well illuminated at

minimum 500 lumen.

Remove adjusting keys, wrenches or any

loose parts or items from the machine

before turning on power.

Moving parts should be kept in proper

alignment and connection with the

machine. Check for breakage, mounting

and any other conditions that may

affect its operation. Any damaged part or

guard should be properly repaired or

replaced.

Use a sharp saw blade and keep the

machine in its best and safest

performance by following a periodical

maintenance schedule.

Page 10

ignite an explosion.

SAFEGUARD DEVICES

The safeguard devices incorporated in this machine include the following two main parts:

1. Protection covers & guards

2. Safety-related switches

Protection Covers & Guards

1. Idle wheel housing cover

2. Drive wheel housing cover

3. Gear reducer cover

4. Wire brush belt cover

5. Blade guard cover (left & right)

The protection devices should always be mounted on the machine whenever the machine is running.

Do not remove any of these safeguard devices under any circumstances except when servicing the

machine. Even skilled service technicians should still take cautions when performing repairs or service on

the machine with any of these protectors removed. It is the responsibility of the user to make sure all

these elements are not lost and damaged.

Take note of the following main moving parts on the machine prior to and during machine operation:

Saw bow assembly

Drive and idle wheels

Blade guide arm

Saw blade guide rollers

Quick approach device (optional)

Wire brush

Chip conveyor (optional)

Workpiece clamping vises

Shuttle vises and workbed rollers

Top clamps (optional)

Gear reducer

Page 11

Safety Related Switches

To protect the operator, the following safety related switches on the machine are actuated when the

machine is in operation.

Wheel motion detector

This is a proximity sensor used to detect the motion

of the drive wheel. Once the saw blade is broken or

as soon as it starts slipping, the sensor will detect

and stop the drive wheel and the machine.

Power switch

Located on the cover of electrical cabinet, the power

switch controls the main power of the machine. Up

to your company’s internal rules, this power switch

can be locked with a padlock or a luggage lock to

protect the operator and the machine.

Emergency stop button

Located on the control panel, the button when

pressed will stop the machine completely.

Vise clamp switch

This switch assures firm clamping of the workpiece. If

the workpiece is not clamped properly, the saw blade

is not allowed to run.

Wheel cover interlock switches

(CE model only)

Located on the two wheel housings, these switches

are used to assure that the machine will stop

whenever the wheel covers are open. This device is

to protect users from being cut by the running saw

blades.

Among all these safety switches, some of them are used to protect the users and some of them are used

to prevent damage to saw blades, the workpiece and the machine itself, etc. We have taken every

precaution to prevent injury or damage and to provide safe and economical operation of the machine.

EMERGENCY STOP

Designed to be easily accessible, the emergency stop button is located on the left bottom corner on the

control panel and is made in red color and rubber material. For CE models, supplementary emergency

stop button may be available at other area(s) of the machine depending on machine type. Please refer

to Illustration: Emergency Stop.

When you press the button, the machine will immediately come to a full stop to avoid injury or damage

when an accident occurs. The button will be locked when you press it. To unlock it, turn the button

clockwise.

You should press it immediately without any hesitation when observing:

An emergency situation that would cause any injury or damage

An abnormal situation or problem such as fire, smoke, abnormal noise and etc.

Page 12

Illustration: Emergency Stop

Emergency Stop Button

Page 13

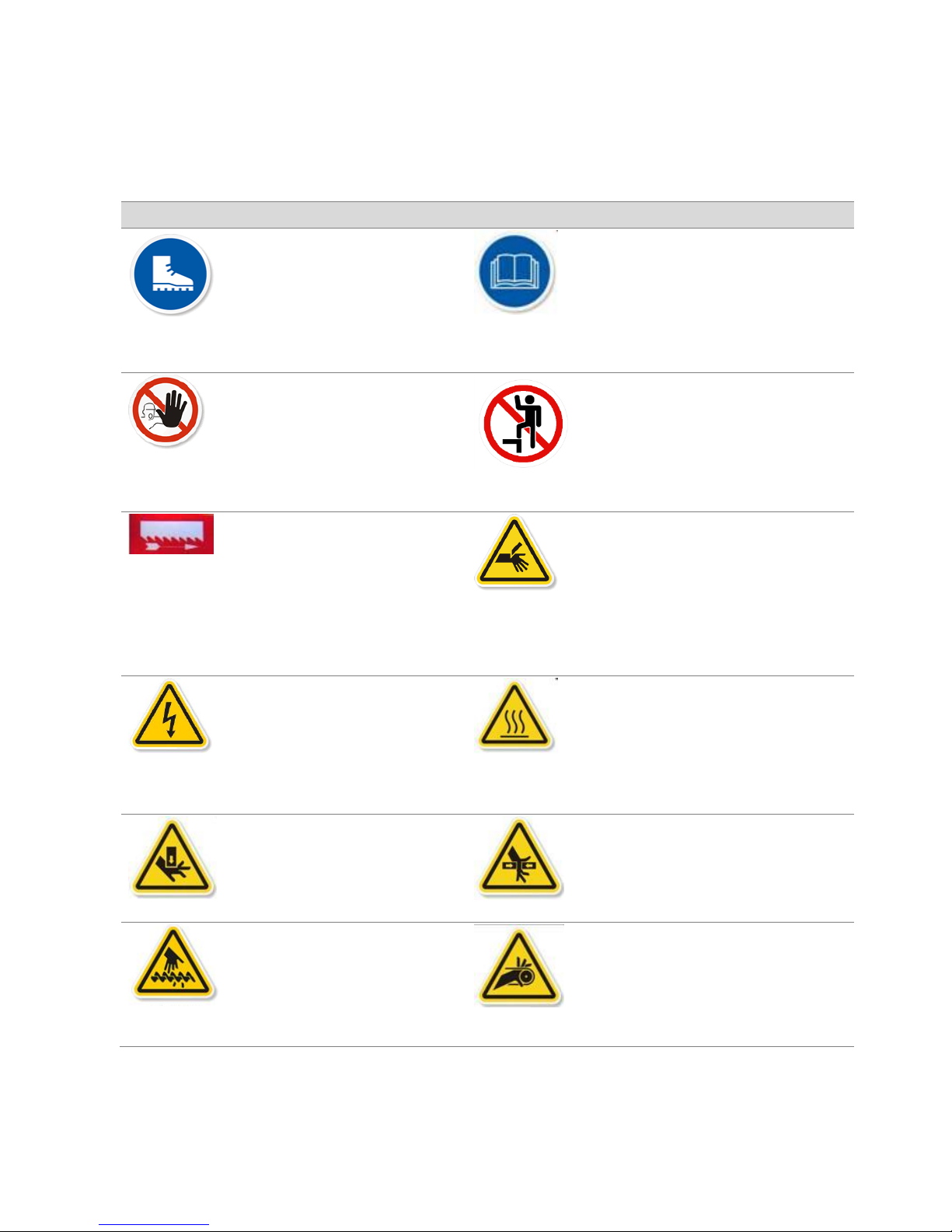

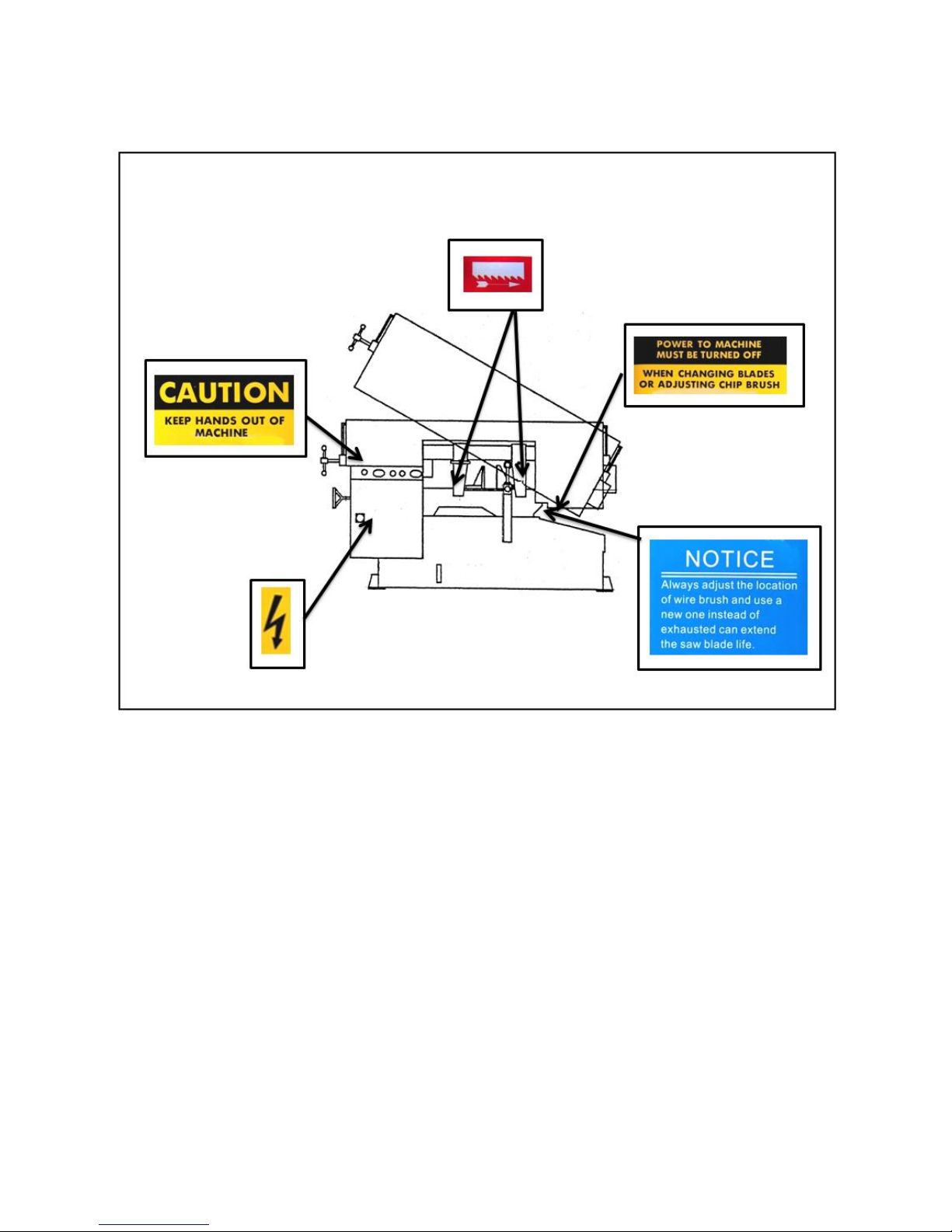

SAFETY LABELS

Please read through and understand them before operating the machine. Refer to Illustration: Safety

Labels.

Label

Meaning

Label

Meaning

Impact Hazard

WEAR SAFETY SHOES. Do

not approach dropping area

during operation.

Read Operator’s Manual

This manual has important safety

information. Read through it

carefully before operating this

machine to prevent personal injury

or machine damage.

Keep Unauthorized

Personnel Away

Do not step.

Do not stand on the machine or on

the accessories!

DANGER: Running Blade

Blade runs through this

area. Keep your hands away

from a running blade to

avoid severe injury. The

arrow indicates direction of

the blade.

Cutting Hazard

KEEP COVER CLOSED / KEEP HAND

OFF while the blade is running. Turn

power off before opening cover.

Failure to follow the warning can

result in severe injury.

Hazardous Voltage

TURN POWER OFF before

servicing. Failure to

following the warning can

result in severe injury.

Burn Hazard/Hot Surface

Hand Crush/Force from

Above

Crush hazard by vise

Loose Hand Hazard

KEEP HAND OFF. Do not

touch chip conveyor. Failure

to follow the warning can

result in severe injury.

Pinch Point/Hand Entanglement

Page 14

Illustration: Safety Labels

SW-100T SafetyLabels

Page 15

HEARING PROTECTION

Always use ear protection!

When your machine is running, noise generated by the machine may come from the following:

Saw blade during cutting or material feed mechanism

Wire brush unit

Chip conveyor unit

Speed reducer

Hydraulic motor/pump

Belt transmissions variable speed motors

Blade motor

Coolant pump

Drive wheel

Parts not assembled tightly causing mechanical vibration

Our products pass noise testing less than 78 dBA. Noise level vary according to working conditions and

we recommend ear plugs or other hearing protection at all time. If your machine produces an

undesirable noise while it is running, you should:

1. Make sure all maintenance tasks have been performed following the prescribed maintenance

schedule (Refer to Section 6).

2. If maintenance does not seem to solve the problem, follow the troubleshooting procedures under

Section 7.

RISK ASSESSMENT

Risk assessment generally takes account of intended use and foreseeable misuse, including process

control and maintenance requirements. We made every effort to avoid any personal injury or equipment

damage during the machine design stage. However, the operator (or other people) still needs to take

precautions when handling any part of the machine that is unfamiliar and anywhere on the machine

that has potential hazards (e.g. the electrical control box).

Page 16

Section 2

GENERAL

INFORMATION

SPECIFICATION

MACHINE PARTS IDENTIFICATION

FLOOR PLAN

This band saw machine is designed by our R&D engineers to provide you the following features and

advantages:

Safety

This machine is designed to fully protect the operator from its moving parts during cutting

operation.

The machine and each compoment has passed strict testing (Council Directive on the

approximation of the laws of the Member States relating to Machinery).

The machine will shut off automatically when the saw blade is broken, protecting both the

operator and the machine.

Convenience & High-Performance

The machine is designed in the way that the operation and adjustment can be easily

performed.

The machine will stop automatically when out of stock.

Dual valve system is designed to achieve optimal cutting performance with the simple setting

of feed rate and perspective cutting pressure for different material.

Durability

The intended life-span of the machine is counted based on regular daily operation. It is

calculated with the life expectancy of 10 years under normal operating condition and exact

attention to the maintenance schedule.

8 hours × 5 days × 52 weeks × 10 years = 20,800 hours

Page 17

SPECIFICATION

Model

SW-100T

Semi-Automatic Horizontal Bandsaw

Capacity

Angle

0°

45°

Round

250 mm (10”)

190 mm (7.5”)

Square

230 mm (9”)

190 mm (7.5”)

Rectangular (H x W)

230 x 400 mm (9” x 15.7”)

190 x 190 mm (7.5” x 7.5”)

Saw Blade

Speed

60Hz

29, 46, 65, 98 m/min (95, 150, 213, 321fpm)

50Hz

24, 38, 53, 81 m/min (78, 124, 173, 265 fpm)

Size

3,350 x 27 x 0.9 mm (132” x 1.06” x 0.035”)

Tension

Hydraulic with automatic blade breakage detection

Guide

Interchangeable tungsten carbide

Cleaning

Steel wire brush with flexible drive shaft driven by main motor

Motor

Output

Saw Blade

2 HP (1.5 kW)

Hydraulic

1/4 HP (0.2 kW)

Coolant Pump

1/8 HP (0.1 kW)

Coolant Tank Capacity

20 L (5.28 gal)

Vise Control Method

Manual

Feeding Mode

Manual

Workbed Height

640 mm (25”)

Weight

Net

540 kg (1,188 lb)

Gross

640 kg (1,408 lb)

Floor Space (W x D x H)

1,700 x 1,100 x 1,400 mm (67” x 43.5” x 55.5”)

Page 18

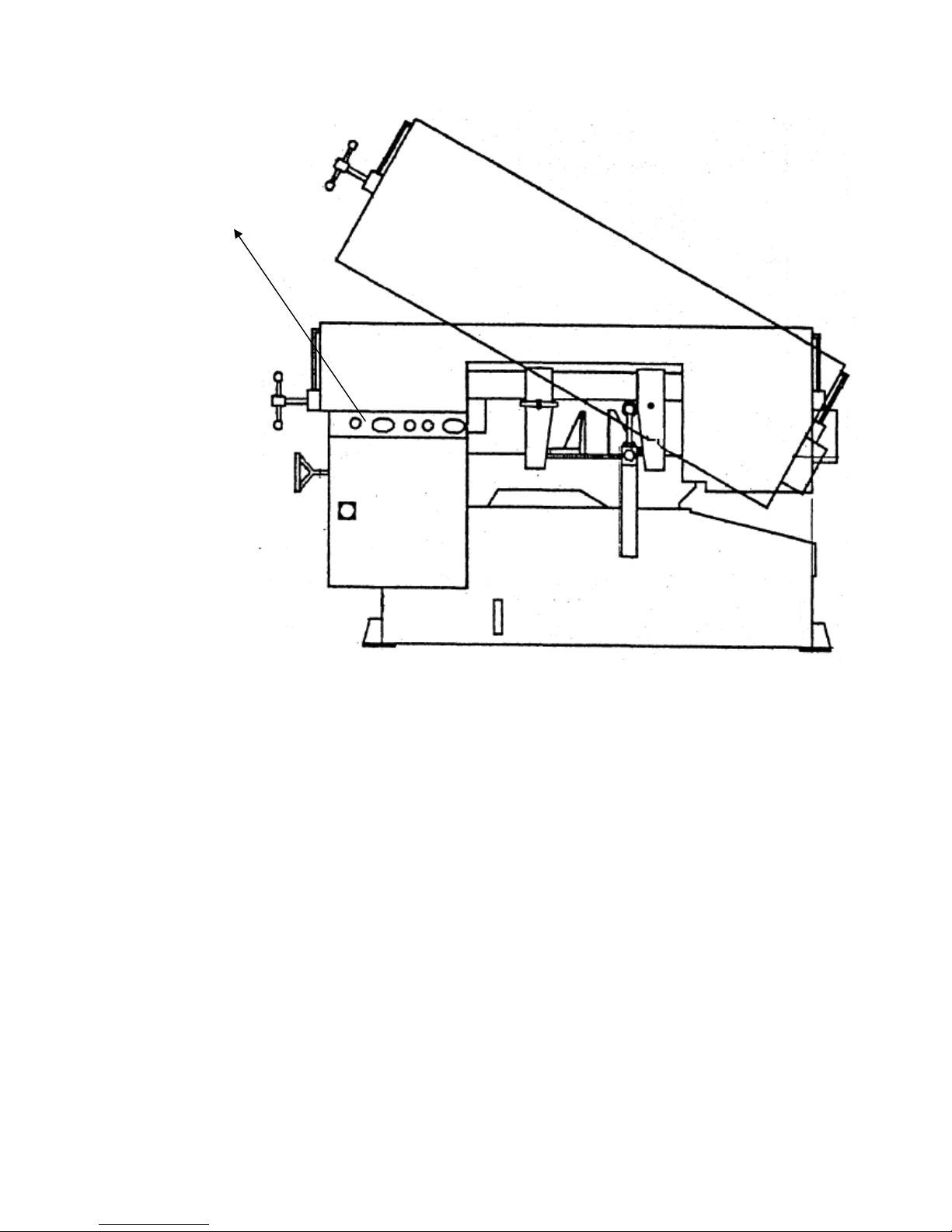

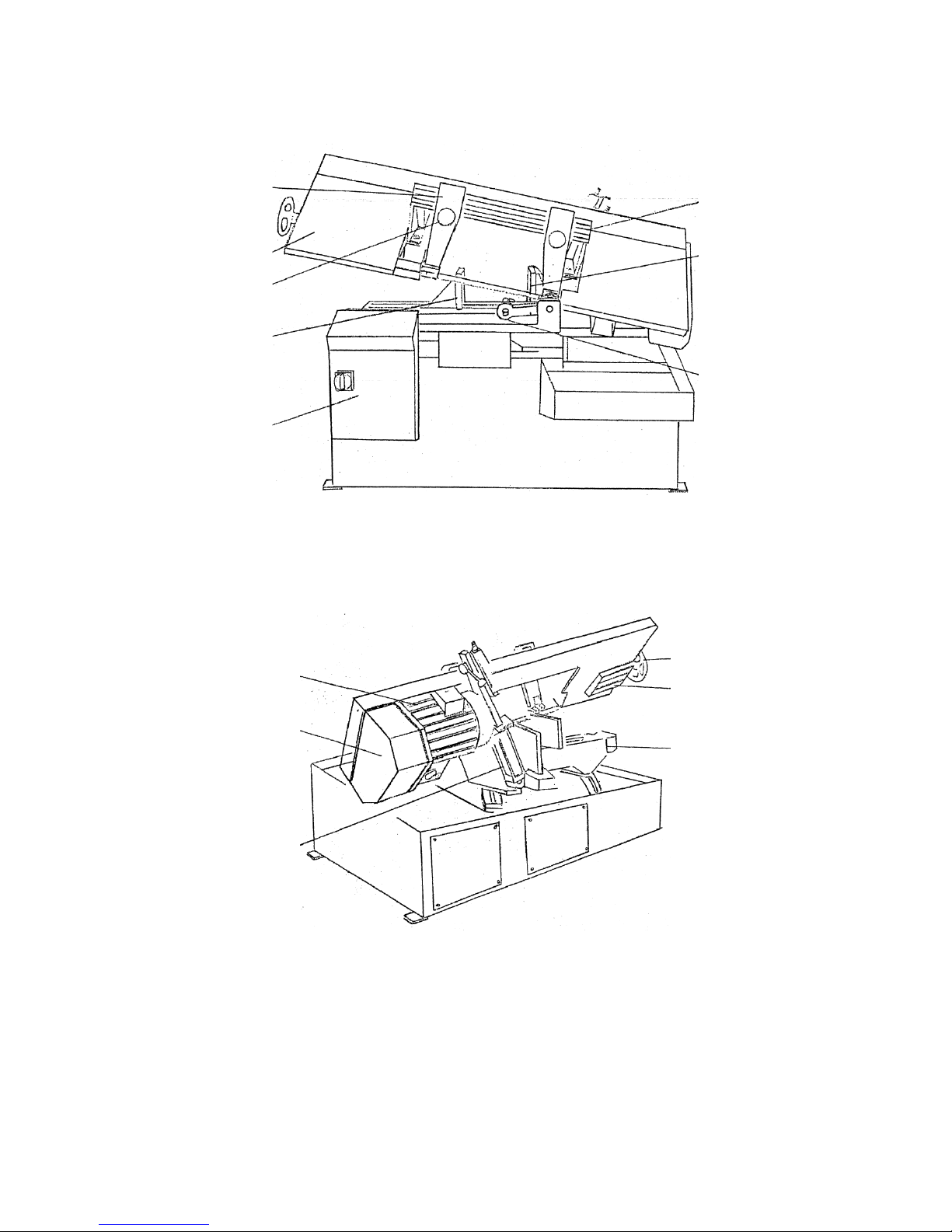

MACHINE PARTS IDENTIFICATION

Fixed vise

Guide arm handle

Dovetail slide guide

Control box

Dovetail gauge plate

Idle wheel cover

Movable vise

Stopper

Motor

Variable blade

speed control

Blae tension handwheel

Blade tension device

Bed

Hydraulic feed

cylinder

Page 19

FLOOR PLAN

Machine top view

Machine front view

Page 20

Machine front view

Page 21

Section 3

MOVING &

INSTALLATION

LOCATION & ENVIRONMENT

UNPACKING & INSPECTING

LIFTING

REMOVING SHIPPING BRACKET

CLEANING

INSTALLING

RELOCATING

LOCATION & ENVIRONMENT

For your safety, please read all information regarding installation before proceeding. Install your machine

in a place satisfying all of the following conditions:

Space:

Leave enough free space around the machine for loading work and unloading cut-off pieces as

well as for maintenance and inspection. Refer to Section 2 General Informattion for machine

dimensions and floor space.

Environment:

Well lighted (500 lumen at minimum).

Floor kept dry at all times in order to prevent operators from slipping.

Away from direct exposure to the sunlight

Room temperature between 5˚C to 40˚C.

Humidity level kept at 30~95%“(without condensation) to avoid dew on electric installation

and machine.

Away from vibration of other machines

Away from powders or dusts emitted from other machines

Avoid uneven ground. Choose a solid level concrete floor which can sustain weight of both

machine and material.

Limit the operation area of the machine to staff only.

Page 22

UNPACKING & INSPECTING

Unpack your machine carefully to avoid damage to machine parts or surfaces.

Upon arrival of your new band saw, please confirm that your machine is the correct model and it

comes in the same specification you ordered by checking the model plate on the machine base.

It is also imperative that a thorough inspection be undertaken to check for any damage that could

have occurred during shipping. Pay special attention to machine surface, equipments furnished and

the electrical and hydraulic systems for damaged cords, hoses and fluid leaks.

In the event of damage caused during shipping, please contact your dealer and consult about filing a

damage claim with the carrier.

Your machine comes in with a set of tools for you to maintain the machine. The accessories

furnished are as follows:

1.

Tool box

1 pc

2.

Grease gun

1 pc

3.

Screwdriver (+, -)

2 pcs

4.

Open-ended spanner

3 pcs

5.

Hexagon wrench

1 set

6.

Chip spade (only for manual models)

1 pc

7.

Operation manual

1 pc

Should you find any missing accessories, please contact your local agent immediately.

Page 23

LIFTING

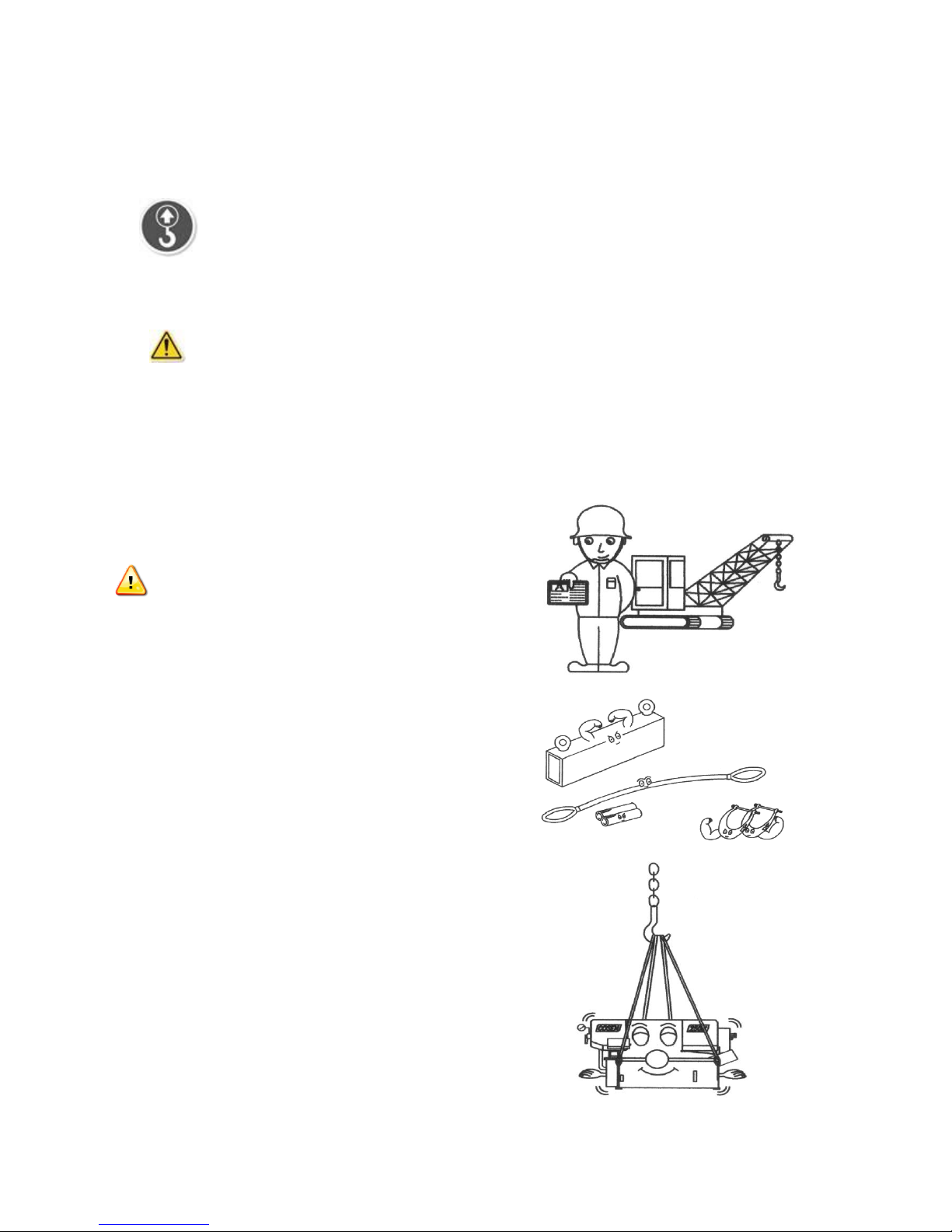

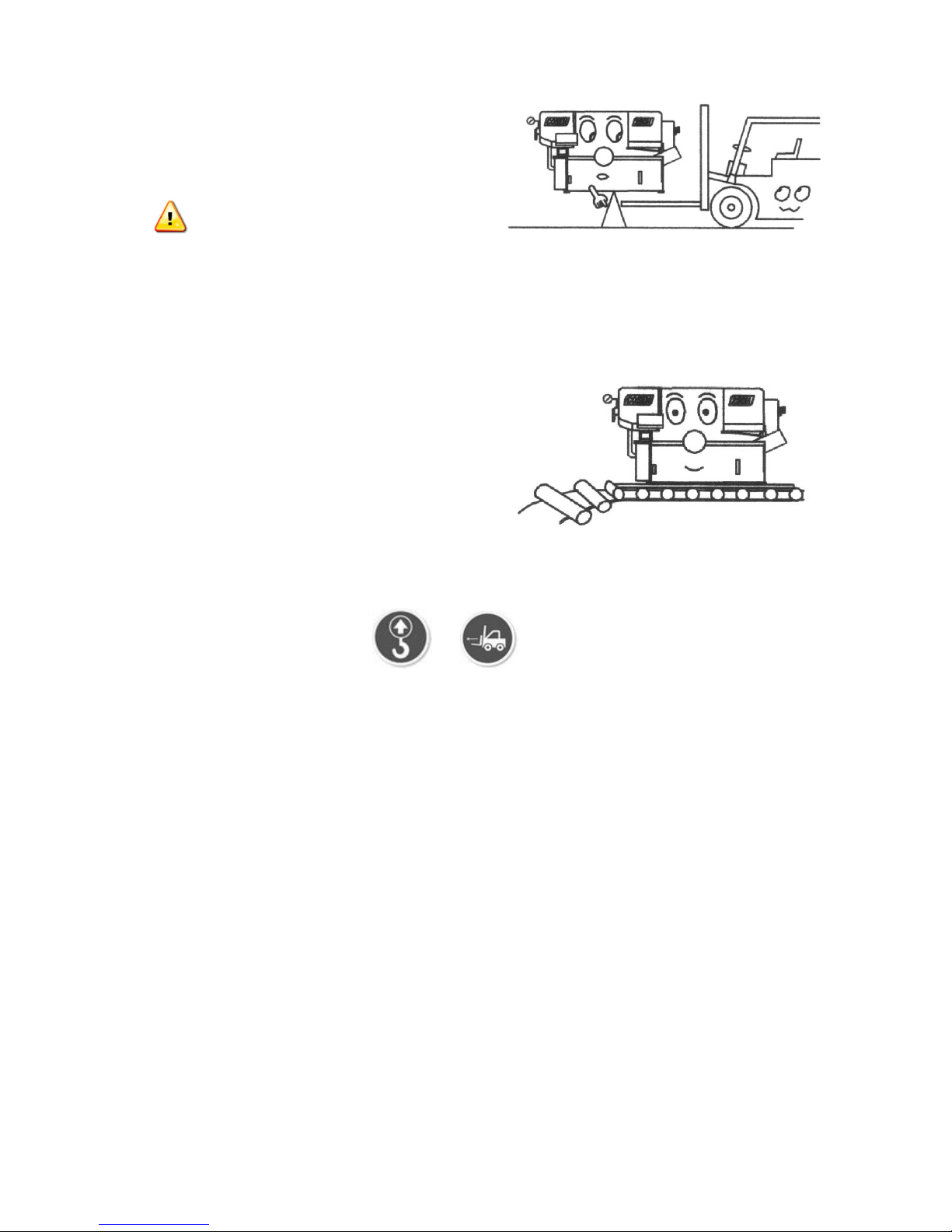

When moving the machine, we strongly suggest you choose any one of the methods described below to

move your machine.

1. (Only applies to the machine with the design of the hanging point.)

Move the machine to its location by using a crane and a wire rope sling that can fully withstand the

weight of the machine (refer to machine specification under Section 2 General Information).

Machine hanging with a crane should be done strictly according to the hanging points

designated by the original manufacturer. If there is any doubt on missing hanging points on your

machine, please consult with the original manufacturer or its qualified agent before hanging the

machine.

Machine lifting is likely to damage the machine

if not performed properly.

Warning: You must have a qualified crane

operator to perform the job.

You must use tools and equipment with the

proper tensile strength and use proper method

when moving your machine.

Apply the wire rope sling to the lifting hooks on

the four ends of the machine. Refer to

Illustration: Lifting Points for exact locations.

Slowly lift the machine. Be sure to protect the

machine from impact or shock during this

procedure. Also watch out your own fingers and

feet to avoid injuries.

Page 24

Keep the machine well balanced during lifting

process and make sure the wire rope does not

interfere with the saw frame.

When you work together with more than two

people, it is best to keep constant verbal

communication with each other.

2. Use a forklift (Only applies to the machine with the design of the lifting point.)

Make sure that the lifting rod can fully withstand the weight of the machine. (Refer to Section 2 –

General Information for Specifications.)

Machine lifting with a forklift should be done strictly according to the lifting points

designated by the original manufacturer. If there is any doubt on missing lifting points on your machine,

please consult with the original manufacturer or its qualified agent before lifting the machine.

Machine lifting is likely to damage the machine

if not performed properly.

You must have a qualified forklift operator

to perform the job.

You must apply proper forklift technique to

avoid damage to the machine.

Make sure the forks are able to reach in

at least 2/3 of the machine depth.

Page 25

You must keep the machine balanced at all

times.

Make sure the forks are centered before

use.

(Illustration only. Please follow user guide of your forklift.)

3. Use rolling cylinders

You can use rolling cylinders to move your machine in a small machine shop environment.

You must use rolling cylinders made in material

of proper compressive strength.

4. Other ways to move

If the machine does not have or stickers, please contact your local agent

immediately.

Page 26

Illustration: Lifting Points

Minimum weight capacity for each wire rope: 1 ton

Total number of wire ropes required: 4

Page 27

REMOVING SHIPPING BRACKET

After the machine has been properly

positioned, remove the shipping bracket that is

used to lock the saw frame and the saw bed.

Retain this bracket so that it can be used again

in the event that your machine must be

relocated.

CLEANING

After the machine has been placed at the designated position, remove the rust-preventive grease with

wiping cloth dampened with cleaning oil or kerosene. Apply machine oil to machine surfaces that are

prone to rust.

Do not remove the rust-preventive grease with a metal scraper and do not wipe the

painted surfaces with solvent as doing so would damage surface paint.

INSTALLING

Our bandsaw machine is relatively easy to install. Follow these six easy steps to install your machine.

Supplying hydraulic oil

Open the filler cap and fill the hydraulic oil tank to

above 2/3 or full level.

Check the sight gauge to make sure the oil level in

the tank.

Refer to specification chart under Section 2

for tank capacity.

Oil tank should be full already if it is a new

machine that operates for the first time.

Supply

cutting fluid

Supply

hydraulic oil

Connect

electric

power

Leveling &

anchoring

Installing roller

table

(Optional)

Page 28

Supplying coolant

Fill the coolant tank to the middle level of the sight

gauge by pouring the coolant from above the chip

conveyor.

Use the sight gauge to check the coolant level

remaining in the tank.

Always check the coolant supply before

starting the machine. If the coolant pump is

started without enough coolant supply in

the tank, the pump and its drive motor may

be damaged.

Refer to specification chart under Section 2

General Information

for tank capacity.

Consult your coolant supplier for bandsaw

use regarding coolant type and mix ratio.

Page 29

Connecting electric power

Have a qualified electrician make the electrical connections.

If the power supply voltage is different from the transformer and motor connection voltage

shown on the label attached to the electrical compartment of the machine, contact us or your agent

immediately.

Connect to power supply independently and directly. Avoid using the same power supply with

electric spark machines such as electric welder. Unstable electric tension may affect your machine’s

electric installation from working properly.

Ground the machine with an independent grounding conductor.

Supply voltage: 90 - 110 of nominal supply voltage.

Source frequency: 99 - 101 of nominal frequency.

Refer to the specification chart under Section 2 for total electric power consumption of the

motors and make sure your shop circuit breaker is capable of this consumption amount. Also use a

power supply cable of proper size to suit the power supply voltage.

1. Turn off the shop circuit breaker.

2. Make sure the machine circuit breaker switch on the

electrical compartment door is turned to OFF.

3. Remove the screw securing the electrical

compartment and then open the door.

4. Pull the power supply cable and grounding conductor

through the power supply inlet into the electrical

compartment. (Shown right)

5. Connect the power supply cable to the circuit breaker

(N.F.B.) to the R, S and T terminals, and connect the

ground cable to the E terminal.

6. Close the compartment door and fasten the screw

back.

7. Turn on the shop circuit breaker and then turn the

machine circuit breaker switch to ON. The Power

Indicator on the control panel will come on.

8. Pull to unlock the Emergency Stop button and press

the hydraulic ON button to start the hydraulic motor.

Power Supply Inlet

Page 30

9. Make sure the sawing area is clear of any objects.

Start the blade and check the blade rotation. If the

electrical connections are made correctly, the blade

should run in a counterclockwise direction. If not,

shut the hydraulics off, turn off the machine as well as

the shop circuit breaker. Then swap the power the

power cable conductors connected to R and T

terminals.

10. Repeat step 6 to 9 to ensure the electrical

connections are in the right order.

Leveling

Place spirit level on the vise slide plates and the work

feed table.

Level the machine in both directions i.e. along and

across the machine. Adjust the level of the machine by

turning the leveling bolts.

Make sure all leveling bolts evenly support the

machine weight.

Anchoring the machine

Normally there is no need to anchor the machine. If the machine is likely to vibrate, fix the machine to

the floor with anchor bolts.

Shock absorption steel plates are provided and can be placed under each leveling bolt to prevent their

sinking into the concrete floor.

Page 31

Installing roller table (optional)

The roller table is used to support long material at

the rear and/or the front of the machine.

If you have ordered the optional roller table for

cutting long material, position it before or behind

the machine.

Level the roller table and the stand with the

machine by adjusting the leveling bolts.

Installing fire control device

Install a fire extinguisher or any other fire control device in the shop in case a fire breaks out.

RELOCATING

We recommend you follow these procedures when relocating or shipping your machine to other place:

1. Descend the saw frame to its lowest position then turn off the power.

2. Fix the saw frame using the shipping bracket that originally came with the machine.

3. If you are shipping the machine, pack the machine carefully with industrial plastic wraps to

protect it from dust.

4. Use a crane or forklift to raise it. If a crane is used to lift the machine, ensure that the lifting cable

is properly attached to the machine.

5. Do not forget to include the equipments originally furnished including the shock absorption steel

plates and the instruction manual.

Adjust bolts

Page 32

Section 4

OPERATING

INSTRUCTIONS

SAFETY PRECAUTIONS

BEFORE OPERATING

CONTROL PANEL

CHECK PRIOR TO OPERATION

CUTTING OPERATIONS

UNROLLING & INSTALLING THE BLADE

ADJUSTING BLADE TENSION

ADJUSTING WIRE BRUSH

ADJUSTING SAW ARM

ADJUSTING HORIZONTAL STOP SPRING CUSHION

Page 33

SAFETY PRECAUTIONS

For your safety, please read and understand the instruction manual before you operate the machine.

The operator should always follow these safety guidelines:

• The machine should only be used for its designated purpose.

•

Do not wear gloves, neckties, jewelry or loose clothing/hair while operating the machine.

•

For eye protection, always wear protective safety glasses.

•

Check the blade tension and adjust blade guides before starting the machine.

•

Use auxiliary clamping or supporting devices to fix material in place before cutting long

workpieces. Always make sure the material is clamped firmly in place before starting to cut.

•

Do not remove jammed or cut-off pieces until the blade has come to a full stop.

•

Keep fingers away from the path of the blade.

•

Protection devices should be in place at all times. For your own safety, never remove these

devices.

•

Disconnect machine from the power source before making repairs or adjustments.

•

Wear protection gloves only when changing the blade.

•

Do not operate the machine while under the influence of drugs, alcohol or medication.

•

Do not take your eyes off the machine while in operation.

•

Do place warning signs to mark out machine work zone and restrict entry to be staff-only.

Page 34

BEFORE OPERATING

Choosing an appropriate saw blade and using the right cutting method is essential to your cutting

efficiency and safety. Select a suitable saw blade and cutting method based on your work material and

job requirements e.g. cutting accuracy, cutting speed, economic concern, and safety control.

Wet cutting

If you choose dry cutting or low-speed cutting, the chips may accumulate in machine parts and may

cause operation failure or insulation malfunction. We suggest you choose wet cutting to avoid machine

damage.

Cutting unknown materials

Before cutting an unknown material, consult the material supplier, burn a small amount of chips from

the material in a safe place, or follow any other procedure to check if the material is flammable.

Never take your eyes off the machine while in operation.

Cutting fluid

For cooling and lubrication purpose, we recommend you use water-soluble cutting fluids. The following

table lists out its pros and cons for your reference.

Pro

Con

Have a high cooling effect

Not flammable

Economical

Does not require cleaning of the cut

products

Remove machine paint

Lose its rust protection effect if

deteriorated

Tend to create foam

Subject to decay

Decline in performance, depending on

the quality of the water used for

dilution

Never use water as your coolant.

Always add coolant into water for better mix result.

Consult your coolant supplier for bandsaw use regarding coolant type and mix ratio.

Before starting a cutting job, make sure there is sufficient amount of coolant in the tank. Check

the fluid level through the sight gauge. Please refer to machine specifications in this manual

(Section 2) for tank capacity.

Page 35

CONTROL PANEL

The control panel is located on the top of the electrical box. It includes the following function: power

system and cooling system. The operator must fully understand the function of each switch and button

before operating the machine.

Control Buttons

1. Blade start button

Press this button to start the blade.

2. Emergency stop button

Press this button to stop the machine in an emergency. When the button is pressed, it brings the

machine to a full stop. The button locks when pressed. In order to unlock it, please turn the button

clockwise.

3. Saw bow up button

When this button is pressed, the saw bow rises until the operator lets go of the button.

4. Saw bow down button

When this button is pressed, the saw bow descends.

5. Flow control valve

This valve is used to adjust the descend speed of the saw blade.

Turning the valve clockwise increases the blade descend speed.

Blade descend speed is a determining factor to a good cutting time and quality cutoff surface.

Page 36

CUTTING OPERATIONS

Do not connect power cord to power source until the following instructions are clearly

understood and followed.

Selecting Blade Speed

Blade speed selection should be made according to the material being cut. The following chart provides

information on blade speed and is used for reference only.

Material

Speed

Pulley Groove Used

50 Hz

60 Hz

Motor pulley

Saw Pulley

High speed alloy, stainless and

heavy cross section material

57

68

Smallest

Large

Tool, stainless and alloy steel,

bearing bronze

100

120

Small

Medium

Cast iron, mild steel, hard brass,

bronze

164

196

Medium

Small

Plastic, copper, soft brass,

aluminum, other light materials

277

330

Large

Smallest

Some materials due to manufacturing processes such as certain types of cast iron pipe or

materials containing certain types of welds cannot be cut on the machine.

Changing Blade Speed – 4 Speed Step Pulley

(Fig 1)

Step 1 - Remove pulley cover.

Step 2 - Loosen lock handle.

Step 3 - Position belt in proper grooves

according to below speed selection chart

attached on the pulley cover.

Step 4 - Make sure the belt is tightly and

securely positioned in the groove and

tighten lock handle.

Step 5 - Install pulley cover back in place.

Page 37

Speed Selection Chart

Selecting Blade

For best results, the correct number of teeth on

the workpiece is important. For mild materials,

the 3-6-12-24 rule applies. For hard materials,

the 6-12-24-48 rule applies.

At least two teeth must be in cutting area at all

times. A finer blade tooth is used when cutting

thin sections and harder materials. Coarse teeth

are for sawing large work and tough gummy

metals.

Page 38

Adjusting Feed Rate (Cutting Pressure)

To obtain desired feed rate (cutting pressure), the “hydraulic cylinder” (Fig 3, #4) and “feed tension

spring” (Fig 3, #6) are to be adjusted together.

(Fig 3)

1. Saw bow

2. By-pass valve (Do not make

adjustment here.)

3. Workbed

4. Hydraulic cylinder

5. Bracket

6. Feed tension spring

7. Lock nut

8. Adjustment screw

9. Wire rope guide wheel

10. Lock screw

11. Gearbox

12. Screw bow bracket

Feed pressure is the amount of pressure forcing the blade downward into the material.

Proper feed pressure is important. Excessive pressure can break the blade or stall the saw.

Insufficient pressure rapidly dulls the blade.

The hydraulic cylinder regulates the rate at which the blade is lowered into the material being cut.

Adjusting the blade descend speed control knob provides an infinite choice for feed rate.

When cutting workpiece of 2 mm thick or below, please adjust the blade descend speed control

knob to between “1~2” gradually; when cutting workpiece of 3 mm and above, to “3~4” gradually.

The by-pass valve (Fig 3, #2) has been factory adjusted and should not be altered.

Using blade descend speed control knob while repositioning your workpiece: When repositioning

your workpiece, raise the saw head halfway up and turn the blade descend speed control knob

clockwise all the way pass “0” to hold the saw head in position.

Adjusting Vise

Always use the vise to clamp the work. Never hand-hold the work for cutting.

Clamp material securely by turning the vise handwheel clockwise.

Vise handwheel

Page 39

Angle Cutting

The vise offers the user great flexibility in angle cutting from 0° (Position 1) to 45° (Position 2).

Page 40

Cutting at 45°

Step 1 - Move the right guide arm to the end of the dovetail guide.

Step 2 - Lift the saw bow up to the highest position.

Step 3 - Loosen the two lock bolts (Fig 5, #2 and #3) of the fixed vise jaw (Fig 5, #1). Then adjust the fixed

vise jaw until it is 45° to saw blade with an accurate protractor. (See Fig 6 below). Tighten the

two lock bolts.

Step 4 - Clamp the workpiece with the movable vise jaw. (Fig 4, #4)

Step 5 - When repositioning the vise for 90° cutting, make sure it is square with an accurate square

instrument.

Page 41

When cutting irregularly-shaped material, if possible, avoid positioning the work in the way that the cut

would be started on a sharp corner. Arrange your workpiece in the way that as many teeth as possible

will be applied to the work at one time.

Adjusting Coolant Flow

Step 1 – Press the power on button to start the saw blade drive motor.

Step 2 – Lower the saw bow.

Step 3 – Use the flow control valve (shown below) to adjust the amount of fluid flowing to the cutting

area.

Adjust the flow amount if you observe the following changes to the chips generated from cutting.

If the chips are sharp and curved, increase the coolant

flow amount.

If the chips are granulated, decrease the coolant flow

amount.

Page 42

Installing Material Stop Bracket

Step 1 - Install the depth bar (Fig 9, #2) and

tighten the set screw (Fig 9, #1). (The

depth bar is taken off from the

machine base during transit for safety

reason.

Step 2 - Lift the saw bow and clamp material

securely with vise.

Step 3 - Lower the saw bow to allow about 1

mm clearance between saw blade

teeth edge and the top of the

material. Then measure your desired

cutoff length.

Step 4 - Loosen the fastening bolt (Fig 9, #3)

Step 5 - Slide and position the stopper (Fig 9,

#6) so that the end of stopper faces

the direction of the front end of the

material. Then tighten the stopper

handle (Fig 9, #5) to fix the stopper in

the bracket (Fig 9, #4).

Step 6 - Move the stopper bracket (Fig 9, #4)

toward the workpiece so the stopper

end just touches the front of the

material, then tighten the fastening

bolt (Fig 9, #3).

Page 43

UNROLLING & INSTALLING THE BLADE

Always wear leather gloves and protection glasses when handling a blade.

Unrolling the blade

Please follow the procedures illustrated below.

Unroll and roll the blade

Installing a new blade

Make sure the power cord is disconnected from power source.

Step 1 - Elevate the saw bow until it is positioned vertically.

Step 2 - Open the idle and drive wheel covers.

Step 3 - Release blade tension by turning the blade tension handle lever counterclockwise (see below

“Adjusting Blade Tension”) and remove the blade.

Step 4 - Install the new blade with teeth pointing downward and place the blade around the wheel

consecutively following the direction of the teeth.

Step 5 - Make sure the back of the blade is also pressed against the flange of the wheels.

Page 44

Step 6 - Apply tension by turning the blade tension handle lever clockwise. Make sure you have proper

blade tension. Proper tension exists when the blade does not slip on the drive wheel when

cutting.

ADJUSTING BLADE TENSION

Turn blade tension handle lever clockwise to increase blade tension; counterclockwise to decrease

blade tension. Tension should be enough that the blade does not slip on drive wheel while cutting.

Do not apply excessive tension.

ADJUSTING WIRE BRUSH

Follow these steps to adjust wire brush to appropriate position:

Step 1 - Open the drive wheel cover.

Step 2 - Adjust the screw to make brush move up / down until it makes proper contact with the saw

blade (see below illustration).

Step 3 - Close the drive wheel cover.

Proper

Improper

ADJUSTING SAW ARM

Adjust the blade guide (guide arm) position based on the size of your workpiece:

Step 1 – Loosen the blade guide locking handle. Then adjust the guide arm to a position suitable for your

workpiece size.

Blade Tension Handle Lever

Blade Tension Device

Page 45

Step 2 – After adjustment is made, tighten the blade guide locking handle.

ADJUSTING HORIZONTAL STOP SPRING CUSHION

Always make sure the power cord is disconnected from power source when making adjustments.

Complete Cut – Adjusting Horizontal Stop Spring Cushion

The workpiece should be able to cut through completely. If it does not, please follow these steps to adjust

the horizontal stop spring cushion.

Step 1 - Place a level on the workbed (Fig 10, #4)

to make sure the bed is level.

Step 2 - Loosen the lock nut (Fig 10, #3) and

lower down the saw bow. Place the

level on top of the saw blade (Fig 10-A)

to check its leveling against the bed

horizontal line. Adjust the screw (Fig 10,

#2) until the blade is level.

Step 3 - Tighten the lock nut (Fig 10, #3) when

leveling is obtained.

If the saw blade top line is not leveled

against the bed horizontal line, the workpiece

will not be able to cut off completely.

Locking Handle

Page 46

Automatic Shut-Off – Adjusting Horizontal Stop Spring Cushion

The motor should shut off immediately after the blade has cut through the material and right before the

head comes to rest on the horizontal stop spring cushion. If it does not, the spring cushion must be

adjusted.

1. Check the horizontal stop spring cushion. Refer to “Complete Cut – Adjusting Horizontal Stop

Spring Cushion.”

2. Raise the saw head and press the power on button to ON. Lower the saw head slowly and observe

the switch mechanism.

Page 47

Section 5

ELECTRICAL

SYSTEM

ELECTRICAL CIRCUIT DIAGRAMS

Page 48

Page 49

Section 6

HYDRAULIC

SYSTEM

HYDRAULIC CIRCUIT DIAGRAM

Page 50

Page 51

Section 7

BANDSAW CUTTING:

A PRACTICAL GUIDE

INTRODUCTION

SAW BLADE SELECTION

VISE LOADING

BladeBreak -In

SOLUTIONS TO SAWING PROBLEMS

Page 52

INTRODUCTION

1. TPI: The number of teeth per inch as measured from gullet to gullet.

2. Tooth Rake Angle: The angle of the tooth face measured with respect to a line perpendicular to the cutting

direction of the saw.

3.Tooth Pitch: Tooth pitch refers to the number of teeth per inch (tpi). 1 inch equates to 25.4 mm.

A distinction is made between constant tooth pitches with a uniform tooth distance, 2 tpi for example, and

variable tooth pitches with different tooth distances within one toothing interval.

Variable tooth pitches, for instance 2-3 tpi, can be characterized by two measures: 2 tpi stands for the

maximum tooth distance and 3 tpi stands for the minimum tooth distance in the toothing interval.

Constant Variable

Min. Max

4. Set: The bending of teeth to right or left to allow clearance of the back of the blade through the cut.

5. Width: The nominal dimension of a saw blade as measured from the tip of the tooth to the back of the

band.

6. Thickness: The dimension from side to side on the blade.

7. Gullet: The curved area at the base of the tooth. The tooth tip to the bottom of the gullet is the gullet

depth.

SAW BLADE SELECTION

1. Band length

The dimensions of the band will depend on the band saw machine that has been installed.

Please refer to Section 2 – General Information

2. Band width

Band width: the wider the band saw blade, the more stability it will have.

3. Cutting edge material

The machinability of the material to be cut determines what cutting material you should choose.

7

Page 53

4. Tooth pitch

The main factor here is the contact length of the blade in the workpiece.

If it is 4P, 25.4 ÷ 4 P = 6.35 mm, that is, one tooth is 6.35 mm.

If it is 3P, 25.4 ÷ 3 P = 8.46 mm If the number is small, it means that the tooth is large.

What is written as 3/4 is that it is a variable pitch of large (3) / small (4).

The saw blade must contact the cutting material at least two pitches. In the case of a thickness of 15 mm,

4P = OK, 3P = NG.

The surface conditions will also affect the cutting rate. If there are places on the surface on the

material which are hard, a slower blade speed will be required or blade damage may result.

It will be slower to cut tubing than to cut solids, because the blade must enter the material

twice, and because coolant will not follow the blade as well.

Tough or abrasive materials are much harder to cut than their machinability rating would

indicate.

Tooth spacing is determined by the hardness of the material and its thickness in cross section.

Tooth set prevents the blade from binding in the cut. It may be either a "regular set" (also

called a "raker set" ) or a "wavy set".

The regular or raker set is most common and consists of a pattern of one tooth to the left, one

tooth to the right, and one which is straight, or unset. This type of set is generally used where

the material to be cut is uniform in size and for contour cutting.

Wavy set has groups of teeth set alternately to right and left, forming a wave-like pattern. This

reduces the stress on each individual tooth, making it suitable for cutting thin material or a

variety of materials where blade changing is impractical. Wavy set is often used where tooth

breakage is a problem. This is shown in Fig. 7.2 as follows:

Right

Straight

Left

Regular (raker) Set

Wavy Set

Fig. 7.2 The Saw Set

VISE LOADING

The position in which material is placed in the vise can have a significant impact on the cost per cut.

Often, loading smaller bundles can mean greater sawing efficiency.

When it comes to cutting odd-shaped material, such as angles, I-beams,

channel, and tubing, the main point is to arrange the materials in such a way

that the blade cuts through as uniform a width as possible throughout the

entire distance of cut.

Page 54

The following diagrams suggest some costeffective ways of loading and fixturing. Be sure, regardless of the

arrangement selected, that the work can be firmly secured to avoid damage to the machine or injury to the

operator.

BladeBreak -In

Completing a proper break-in on a new band saw blade will dramatically increase its life.

1. Select the proper band speed for the material to be cut.

2. Reduce the feed force/rate to achieve a cutting rate 20% to 50% of normal (soft materials require a larger

feed rate reduction than harder materials).

3.Begin the first cut at the reduced rate. Make sure the teeth are forming a chip. Small adjustments to the

band speed may be made in the event of excessive noise/vibration. During the first cut, increase feed

rate/force slightly once the blade fully enters the workpiece.With each following cut, gradually increase feed

rate/force until normal cutting rate is reached.

Page 55

Section 8

MAINTENANCE &

SERVICE

INTRODUCTION

BASIC MAINTENANCE

MAINTENANCE SCHEDULE

BEFORE BEGINNING A DAY’S WORK

AFTER ENDING A DAY’S WORK

Every 2 weeks

First 600hrs for new machine,then every 1200hrs

EVERY SIX MONTHS

STORAGE CONDITIONS

TERMINATING THE USE OF MACHINE

OIL RECOMMENDATION FOR MAINTENANCE

INTRODUCTION

For the best performance and longer life of the band saw machine, a maintenance schedule is necessary.

Some of the daily maintenance usually takes just a little time but will give remarkable results for the

efficient and proper operation of cutting.

BASIC MAINTENANCE

It is always easy and takes just a little effort to do the basic maintenance. But it always turns out to be a

very essential process to assure the long life and efficient operation of the machine. Most of the basic

maintenance requires the operator to perform it regularly.

Page 56

MAINTENANCE SCHEDULE

We suggest you do the maintenance on schedule.

Before beginning a day’s work

1. Please check the hydraulic oil level. If oil level volume is below 1/2, please add oil as necessary.(Filling

up to 2/3 level is better for system operation.)

2. Please check the cutting fluid level, adding fluid as necessary. If the fluid appears contaminated

or deteriorated, drain and replace it.

3. Please check the saw blade to ensure that it is properly positioned on both the drive and idle

wheels.

4. Please make sure that the saw blade is properly clamped by the left and right inserts.

5. Please check the wire brush for proper contact with the saw blade. Replace the wire brush if it is

worn out.

After ending a day’s work

Please remove saw chips and clean the machine with discharging the cutting fluid when work has been

completed.

Do not discharge cutting fluid while the saw blade is operating because it will cause severe injury on

operator’s hand.

Be sure the saw blade is fully stop, it will be performed after working inspection.

Every 2 weeks

Please apply grease to the following points:

1. Idle wheel

2. Drive wheel

3. Blade tension device

Recommended Grease:

Shell Alvania EP Grease 2

Mobil Mobilplex 48

First 600hrs for new machine,then every 1200hrs

Replace the transmission oil after operating for first 600hrs for new machine,then every 1200hrs

Recommended gear oil

Shell Omala oil HD220

Page 57

Mobil gear 630

Recommended hydraulic oil

ShellTellus 32

Mobil DTE Oil Light Hydraulic 28

Every six months

1.Clean the filter of the cutting fluid.

2.Replace the transmission oil for every half of a year(or 1200 hours).

Check the sight gauge to ascertain the transmission level.

Recommended TRANSMISSION OIL

Omala oil HD220

Mobil comp 632 600W Cylinder oil

3.Replace the hydraulic oil.

Recommended HYDRAULIC OIL

Shell Tellus 27

Mobil DTE OIL light Hydraulic28

STORAGE CONDITIONS

Generally, this machine will be stored on the following conditions in future:

(1) Turn off the power.

(2) Ambient temperature: 5℃ ~ 40℃

(3) Relative humidity: 30%~95% (without condensation)

(4) Atmosphere: use a plastic canvas to cover machine to avoid excessive dust, acid fume,

corrosive gases and salt.

(5) Avoid exposing to direct sunlight or heat rays which can change the environmental

temperature.

(6) Avoid exposing to abnormal vibration.

(7) Must be connected to earth.

TERMINATING THE USE OF THE MACHINE

Waste disposal:

When your machine can not work anymore, you should leak out the oil from machine body. Please storage

the oil in safe place with bottom. Ask a environment specialist to handle the oil. It can avoid soil pollution.

The oil list in machine:

•

Hydraulic oil

•

Cutting fluid

•

Drive wheel gear oil

Page 58

OIL RECOMMENDATION FOR MAINTENANCE

Item

Method

Revolution

Suggest oil

Dovetail guide

Keep grease covered. Antirust.

Daily

Shell R2

Roller bearing

Sweep clean and oil with lubricant.

Daily

SEA #10

Bed roller / surface

Sweep clean and oil with lubricant.

Daily

SEA #10

Nipples of bearing

Use grease gun, but not excess.

Monthly

Shell R2

Blade tension device

Use grease gun, but not excess.

Monthly

Shell Alvania EP

Grease 2,

Mobil Mobilplex

48

Reducer

Inspect once a week. Change oil of 600 hours of

using. Change it every year.

Regularly

Omala oil HD220

Mobil Gear 630

Hydraulic system

Inspect half a year. Change oil every year.

Regularly

Shell Tellus 32

Mobil DTE oil

Light Hydraulic 24

Bearing

Inserts

Oil with lubricant, but not excess.

Daily

Shell R2

Band wheel

Oil with lubricant, but not excess.

Weekly

Cylinder

Oil with lubricant, but not excess.

6 Monthly

Wire brush

Oil with lubricant, but not excess.

6 Monthly

1. Turn off the stop circuit breaker switch before servicing the machine.

2. Then post a sign to inform people that the machine is under maintenance.

3. Drain all of the cutting fluid and oil off and carefully treat them to avoid pollution.

Page 59

Section 9

TROUBLESHOOTING

INTRODUCTION

PRECAUTIONS

GENERAL TROUBLES & SOLUTIONS

MINOR TROUBLES & SOLUTIONS

MOTOR TROUBLES & SOLUTIONS

BLADE TROUBLES & SOLUTIONS

SAWING PROBLEMS & SOLUTIONS

RE-ADJUSTING THE ROLLER TABLE

INTRODUCTION

All the machines manufactured by us pass a 48 hours continuously running test before shipping out and

we are responsible for the after sales service problems during the warranty period if the machines are

used normally. However, there still exist the some unpredictable problems which may disable the

machine from operating.

Generally speaking, the system troubles in this machine model can be classified into three types, namely

GENERAL TROUBLES, MOTOR TROUBLES and BLADE TROUBLES. Although you may have other troubles

which can not be recognized in advance, such as malfunctions due to the limited life-span of mechanical,

electric or hydraulic parts of the machine.

We have accumulated enough experiences and technical data to handle all of the regular system

troubles. Meanwhile, our engineering department had been continuously improving the machines to

prevent all possible troubles.

It is hoped that you will give us your maintenance experience and ideas so that both sides can achieve

the best performance.

PRECAUTIONS

When an abnormality occurs in the machine during operation, you can do it yourself safely. If you have

to stop machine motion immediately for parts exchanging, you should do so according to the following

procedures:

•

Press HYDRAULIC MOTOR OFF button or EMERGENCY STOP button.

•

Open the electrical enclosure door.

•

Turn off breaker.

Page 60

BEFORE ANY ADJUSTMENT OR MAINTENANCE OF THE MACHINE, PLEASE MAKE SURE TO

TURN OFF THE MACHINE AND DISCONNECT THE POWER SUPPLY.

GENERAL TROUBLES AND SOLUTIONS

DISCONNECT POWER CORD TO MOTOR BEFORE ATTEMPTING ANY REPAIR OR INSPECTION.

TROUBLE

PROBABLE CAUSE

SUGGESTED REMEDY

Motor stalls

Excessive belt tension

Adjust belt tension so that belt does not slip on drive

pulley while cutting ( 1/2“ Min. deflection of belt under

moderate pressure.)

Excessive head pressure

Reduce head pressure. Refer to Operating Instructions

“Adjusting Feed”.

Excessive blade speed

Refer to Operating Instructions “Speed Selection”.

Improper blade

selection

Refer to Operating Instructions “Blade Selection”.

Cannot make

square cut

Dull blade

Replace blade.

Guide rollers not

adjusted properly

Refer to Adjustments.

Rear vise jaw not

adjusted properly

Set fixed vise jaw 90 to blade.

Excessive head pressure

Reduce head pressure. Refer to operating instructions

“Adjusting Feed.”

Increased cutting

time

Dull blade

Replace blade

Insufficient head

pressure

Increase head pressure. Refer to Operating

Instructions “Adjusting Feed.”

Reduce blade speed

Refer to Operating Instructions “Speed Selection.”

Will not cut

Motor running in wrong

direction

Reverse rotation of motor. (Motor rotation C.C.W. pulley

end.)

Blade teeth pointing in

wrong direction

Remove blade, turn blade inside out.

Re-install blade. (Teeth must point in direction of

travel. )

Hardened material

Use special alloy blades. (Consult your

industrial distributor for recommendation on type of

blade required.)

Page 61

MINOR TROUBLES & SOLUTIONS

TROUBLE

PROBABLE CAUSE

SUGGESTED REMEDY

Saw blade motor does not run

even though blade drive button

is pressed.

Overload relay activated

Reset

Saw blade is not at forward

limit position.

Press SAW FRAME

FORWARD button

MOTOR TROUBLES & SOLUTIONS

TROUBLE

PROBABLE CAUSE

SUGGESTED REMEDY

Motor will not start

Magnetic switch open, or

protector open.

Reset protector by pushing red button (inside

electric box.)

Low voltage

Check power line for proper voltage.

Open circuit in motor or loose

connections.

Inspect all lead terminations on motor for loose

or open connections.

Motor will not start,

fuse or circuit

breakers “blow”.

Short circuit in line, cord or

plug.

Inspect line, cord and plug for damaged

insulation and shorted wire.

Short circuit in motor or loose

connections

Inspect all lead terminations on motor for loose

or shorted terminals or worn insulation on

wires.

Incorrect fuses or circuit

breakers in power line.

Install correct fuses or circuit breakers.

Motor fail to develop

full power. (Power

output of motor

decreases rapidly

with decrease in

voltage at motor

terminals.)

Power line overloaded with

lights, appliances and other

motors.

Reduce the load on the power line.

Undersize wires or circuit too

long.

Increase wire sizes, or reduce length of wiring

General overloading of power

company‘s facilities.

Request a voltage check from the power

company

Motor overheat

Motor overloaded.

Reduce load on motor

Air circulation through the

motor restricted.

Clean out motor to provide normal air

circulation through motor.

Motor stalls

(Resulting in blown

fuses or tripped

circuit breakers)

Short circuit in motor or loose

connections.

Inspect terminals in motor for loose or shorted

terminals or worn insulation on lead wires.

Low voltage

Correct the low line voltage conditions.

Incorrect fuses or circuit

breakers in power line.

Install correct fuses circuit breakers.

Page 62

Motor overloaded

Reduce motor load.

Frequent opening of

fuses or circuit

breakers.

Motor overloaded

Reduce motor load

Incorrect fuses or circuit

breakers.

Install correct fuses or circuit breakers.

BLADE TROUBLES AND SOLUTIONS

DISCONNECT POWER CORD TO MOTOR BEFORE ATTEMPTING ANY REPAIR OR INSPECTION.

TROUBLE

PROBABLE CAUSE

SUGGESTED REMEDY

Teeth

strippage

Too few teeth per inch

Use finer tooth blade

Loading of gullets

Use coarse tooth blade or cutting lubricant.

Excessive feed

Decrease feed

Work not secured in vise

Clamp material securely

Blade

breakage

Teeth too coarse

Use a finer tooth blade

Misalignment of guides

Adjust saw guides

Dry cutting

Use cutting lubricant

Excessive speed

Lower speed. See Operating Instructions “Speed

selection.”

Excessive speed

Reduce feed pressure. Refer to Operating Instructions

“Adjusting Feed.”

Excessive tension

Tension blade to prevent slippage on drive wheel while

cutting.

Wheels out of line

Adjust wheels

Blade line

Run-out or

Run-in

Guides out of line

For a straight and true cut, realign guides, check

bearings for wear.

Excessive pressure

Conservative pressure assures long blade life and clean

straight cuts.

Support of blade insufficient

Move saw guides as close to work as possible.

Material not properly secured

in vise

Clamp material in vise, level and securely.

Blade tension improper

Loosen or tighten tension on blade.

Blade

twisting

Blade not in line with guide

bearings

Check bearings for wear and alignment.

Excessive blade pressure

Decrease pressure and blade tension

Page 63

Blade binding in cut

Decrease feed pressure

Premature

tooth wear

Dry cutting

Use lubricant on all materials, except cast iron

Blade too coarse

Use finer tooth blade

Not enough feed

Increase feed so that blade does not ride in cut

Excessive speed

Decrease speed

Page 64

SAWING PROBLEMS AND SOLUTIONS

Other than this manual, the manufacturer also provides some related technical documents listed as

follows:

Sawing Problems and Solutions

Vibration during cutting

Failure to cut

Short life of saw blade

Curved cutting

Broken blade

✓

✓

✓

✓

✓

Use of blade with incorrect pitch

Use blade with correct pitch suited

to workpiece width

✓

✓

✓

✓

✓

Failure to break-in saw blade

Perform break-in operation

✓

✓

✓

Excessive saw blade speed

Reduce speed

✓

✓

Insufficient saw blade speed

Increase speed

✓

✓

✓

✓

Excessive saw head descending speed

Reduce speed

✓

✓

✓

Insufficient saw head descending speed

Increase speed

✓

✓

Insufficient saw blade tension

Increase tension

✓

✓

✓

✓

Wire brush improperly positioned

Relocate

✓

✓

✓

Blade improperly clamped by insert

Check and correct

✓

✓

✓

✓

✓

Improperly clamped workpiece

Check and correct

✓

✓

✓

Excessively hard material surface

Soften material surface

✓

✓

✓

Excessive cutting rate

Reduce cutting rate

✓

✓

Non-annealed workpiece

Replace with suitable workpiece

✓

✓

✓

✓

Insufficient or lean cutting fluid

Add fluid or replace

✓

✓

✓

✓

Vibration near machine

Relocate machine

✓

✓

Non-water soluble cutting fluid used

Replace

✓

✓

✓

Air in cylinder

Bleed air

✓

✓

✓

Broken back-up roller

Replace

✓

✓

✓

✓

✓

Use of non-specified saw blade

Replace

✓

✓

✓

✓

✓

Fluctuation of line voltage

Stabilize

✓

✓

✓

Adjustable blade guide too far from

workpiece

Bring blade guide close to

workpiece

✓

✓

✓

✓

Loose blade guide

Tighten

✓

✓

Blue or purple saw chips

Reduce cutting rate

✓

✓

✓

Accumulation of chips at inserts

Clean

✓

Reverse positioning of blade on machine

Reinstall

✓

✓

✓

Workpieces are not bundled properly

Re-bundle

Page 65

✓

✓

✓

Back edge of blade touching wheel

flange

Adjust wheel to obtain clearance

✓

✓

✓

Workpiece of insufficient diameter

Use other machine, suited for

diameter of workpiece Replace

✓

✓

✓

Saw blade teeth worn

Replace

SOLUTIONS TO SAWING PROBLEMS

Table Of Contents

#1. Heavy Even Wear On Tips and Corners Of Teeth

#11. Uneven Wear Or Scoring On The Sides Of Band

#2. Wear On Both Sides Of Teeth

#12. Heavy Wear And/Or Swagging On Back Edge

#3. Wear On One Side Of Teeth

#13. Butt Weld Breakage

#4. Chipped Or Broken Teeth

#14. Heavy Wear In Only The Smallest Gullets

#5. Body Breakage Or Cracks From Back Edge

#15. Body Breaking – Fracture Traveling In An Angular

Direction

#6. Tooth Strippage

#16. Body Breakage Or Cracks From Gullets

#7. Chips Welded To Tooth Tips

#17. Band is Twisted Into A Figure "8" Configuration

#8. Gullets Loading Up With Material

#18. Used Band Is "Long" On The Tooth Edge

#9. Discolored Tips Of Teeth Due To

Excessive Frictional Heat

#19. Used Band Is "Short" On The Tooth Edge

#10. Heavy Wear On Both Sides Of Band

#20. Broken Band Shows A Twist In Band Length.

Page 66

#1. Heavy Even Wear On Tips and Corners Of Teeth

Probable Cause :

A. Improper break-in procedure.

B. Excessive band speed for the type of material being

cut. This generates a high tooth tip temperature

resulting in accelerated tooth wear.

C. Low feed rate causes teeth to rub instead of

penetrate. This is most common on work hardened

materials such as stainless and toolsteels.

D. Hard materials being cut such as "Flame Cut Edge"

or abrasive materials such as " Fiber Reinforced

Composites".

E. Insufficient sawing fluid due to inadequate supply,

improper ratio, and/or improper application

#2. Wear On Both Sides Of Teeth

Probable Cause :

A. Broken, worn or missing back-up guides allowing

teeth to contact side guides.

B. Improper side guides for band width.

C. Backing the band out of an incomplete cut.

#3. Wear On One Side Of Teeth

Probable Cause :

A. Worn wheel flange, allowing side of teeth to contact

wheel surface or improper tracking on flangeless

wheel.

B. Loose or improperly positioned side guides.

C. Blade not perpendicular to cut.

D. Blade rubbing against cut surface on return stroke

of machine head.

E. The teeth rubbing against a part of machine such as

chip brush assembly, guards, etc.

Page 67

#4. Chipped Or Broken Teeth

Probable Cause :

A. Improper break-in procedure.

B. Improper blade selection for application.

C. Handling damage due to improper opening of

folded band.

D. Improper positioning or clamping of material.

E. Excessive feeding rate or feed pressure.

F. Hitting hard spots or hard scale in material

#5. Body Breakage Or Cracks From Back Edge

Probable Cause :

A. Excessive back-up guide "preload" will cause back

edge to work harden which results in cracking.

B. Excessive feed rate.

C. Improper band tracking – back edge rubbing heavy

on wheel flange.

D. Worn or defective back-up guides.

E. Improper band tension.

F. Notches in back edge from handling damage

#6. Tooth Strippage

Probable Cause :

A. Improper or lack of break-in procedure.

B. Worn, missing or improperly positioned chip brush.

C. Excessive feeding rate or feed pressure.

D. Movement or vibration of material being cut.

E. Improper tooth pitch for cross sectional size of

material being cut.

F. Improper positioning of material being cut.

G. Insufficient sawing fluid due to inadequate

supply,improper ratio and/or improper application.

H. Hard spots in material being cut.

I. Band speed too slow for grade of material being

cut.

Page 68

#7. Chips Welded To Tooth Tips

Probable Cause :

A. Insufficient sawing fluid due to inadequate supply,

improper ratio and/or improper application.

B. Worn, missing or improperly positioned chip brush.

C. Improper band speed.

D. Improper feeding rate.

#8. Gullets Loading Up With Material

Probable Cause :

A. Too fine of a tooth pitch – insufficient gullet capacity.

B. Excessive feeding rate producing too large of a chip.

C. Worn, missing or improperly positioned chip brush.

D. Insufficient sawing fluid due to inadequate supply,

improper ratio and/or improper application.

#9. Discolored Tips Of Teeth Due To Excessive Frictional Heat

Probable Cause :

A. Insufficient sawing fluid due to inadequate supply,

improper ratio and/or improper application.

B. Excessive band speed.

C. Improper feeding rate.

D. Band installed backwards.

Page 69

10. Heavy Wear On Both Sides Of Band

Probable Cause :

A. Chipped or broken side guides.

B. Side guide adjustment may be too tight.

C. Insufficient flow of sawing fluid through the

side guides.

D. Insufficient sawing fluid due to inadequate supply,

improper ratio and/or improper application.

#11. Uneven Wear Or Scoring On The Sides Of Band

Probable Cause :

A. Loose side guides.

B. Chipped, worn or defective side guides.

C. Band is rubbing on part of the machine.

D. Guide arms spread to maximum capacity.

E. Accumulation of chips in side guides.

#12. Heavy Wear And/Or Swagging On Back

Edge

Probable Cause :

A. Excessive feed rate.

B. Excessive back-up guide "preload".

C. Improper band tracking – back edge rubbing

heavy on wheel flange.

D. Worn or defective back-up guides.

Page 70

#13. Butt Weld Breakage

Probable Cause :

A. Any of the factors that cause body breaks can also

cause butt weld breaks.

(See Observations #5, #15 and #16)

#14. Heavy Wear In Only The Smallest Gullets

Probable Cause :

A. Excessive feeding rate.

B. Too slow of band speed.

C. Using too fine of a tooth pitch for the size of material

being cut.

#15. Body Breaking – Fracture Traveling In An Angular Direction

Probable Cause :

A. An excessive twist type of stress existed.

B. Guide arms spread to capacity causing

excessive twist from band wheel to guides.

C. Guide arms spread too wide while cutting small

cross sections.

D. Excessive back-up guide "preload".

#16. Body Breakage Or Cracks From Gullets

Probable Cause :

A. Excessive back-up guide "preload".

B. Improper band tension.

C. Guide arms spread to maximum capacity.

D. Improper beam bar alignment.

E. Side guide adjustment is too tight.