Page 1

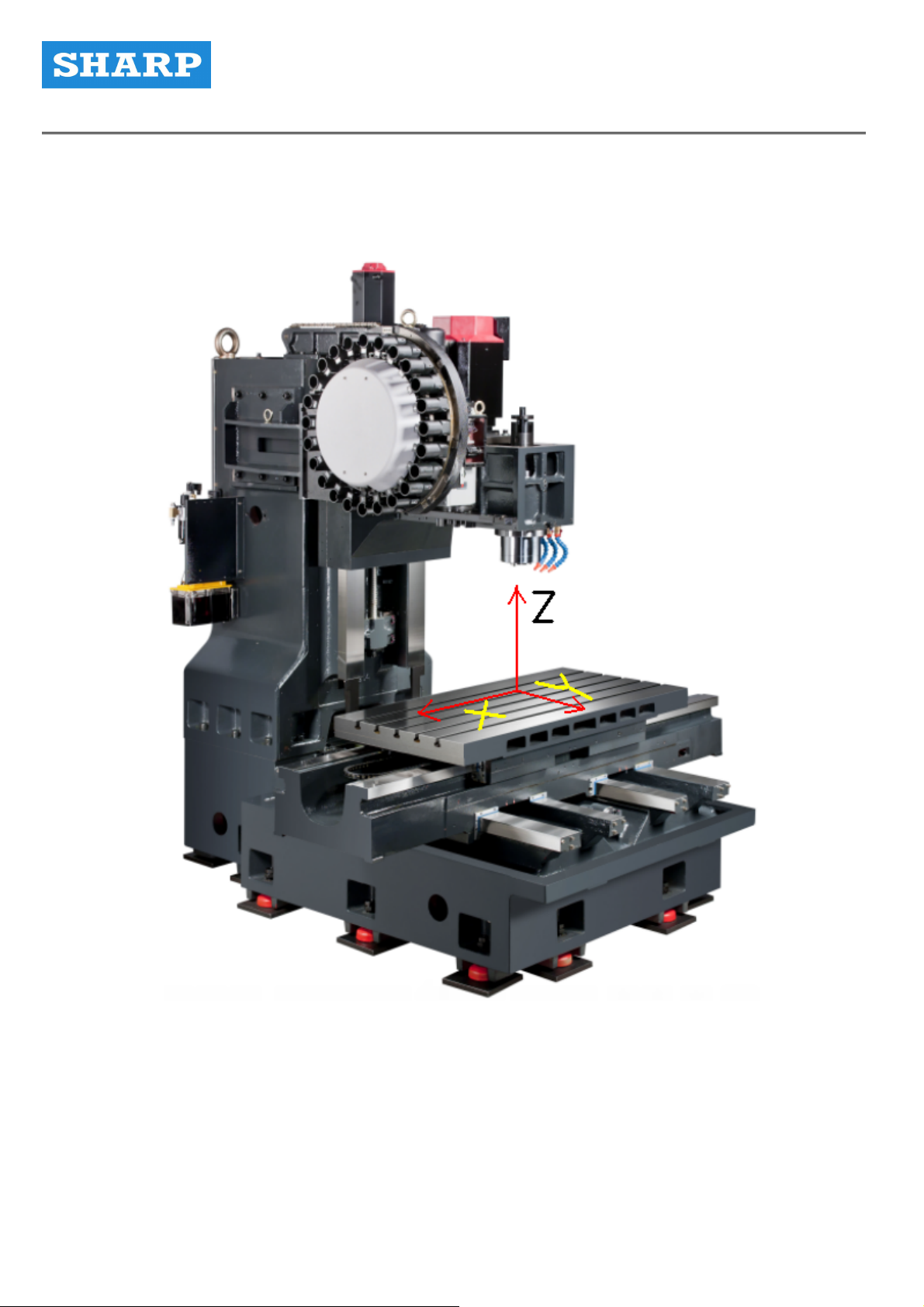

SV-4328ST

VERTICAL MACHINING CENTER

MAINTENANCE MANUAL

Ver 2.1

Page 2

2

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Chapter 1 Routine Maintenance

1-1 Routine Maintenance Checklist 4

1-2 Routine Maintenance Instruction Diagram 5

1-3 Cautions for Machine Maintenance 9

Chapter 2 The Spindle Unit

2-1 Cautions for High Speed Processing 12

2-2 Tool Shank and Broach Bolts 13

2 - 3 S p i n d l e W a r m - u p 1 5

2- 4 Spi n dl e P re - O pe r at i on C h e ck 1 6

2- 5 Spi n dl e A l ar m H an d l in g 17

Chapter 3 The Air Compressor Unit

3-1 Air Comp ressor System Layout 19

3-2 Air Compressor System Circui t 20

3-3 The Air Compressor Unit 20

3-4 Ai r C om pr esso r D eta ile d Spe ci fi c ati o ns an d F un cti o ns 21

3-5 Air Compressor Unit Usage Instr uction 24

3-6 A i r C o m p r e s s o r T r o u b l e s h o o t i n g 2 5

Chapter 4 The Lubrication Unit

4-1 C ent ralize d L ub ric ati on Sys te m Di agram 2 7

4- 2 Spi n dl e B ea ri ng Lu br i ca ti o n 2 9

4 - 3 G u i d e wa y s a n d B a l l S c r e w L u b r i c a t i o n 2 9

4-4 Lubricati on of the Cam Box of Tool Magazine 34

4-5 Counterweight Chain a nd Spro cket Be aring Lubrication 34

4 - 6 C y l i n d e r L u b r i c a t i o n 3 5

4 - 7 L u b r i ca t i o n L o c a t i o n 3 5

Chapter 5 The Spindle Oil Cooling Unit

5-1 Oil Cooling Pipeline Diagram 37

5-2 The Spindle Oil Cooling Unit 38

Chapter 6 The Electrical Unit

6- 1 Th e El e c tr i c al Uni t 4 5

Chapter 7 Appendix

7- 1 Oi l S el e c t i on 4 9

7-2 Calibratio n of Spindl e Tool Change Locati on 50

7-3 Determination of the Z-axis Mechanical Reference Point 52

7 - 4 P r o g r a m a n d S e r v o A l a r ms D e s c r i p t i o n 5 5

7-5 List of the Machine Components 110

Page 3

3

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Chapter 1

Routine Maintenance

Page 4

4

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

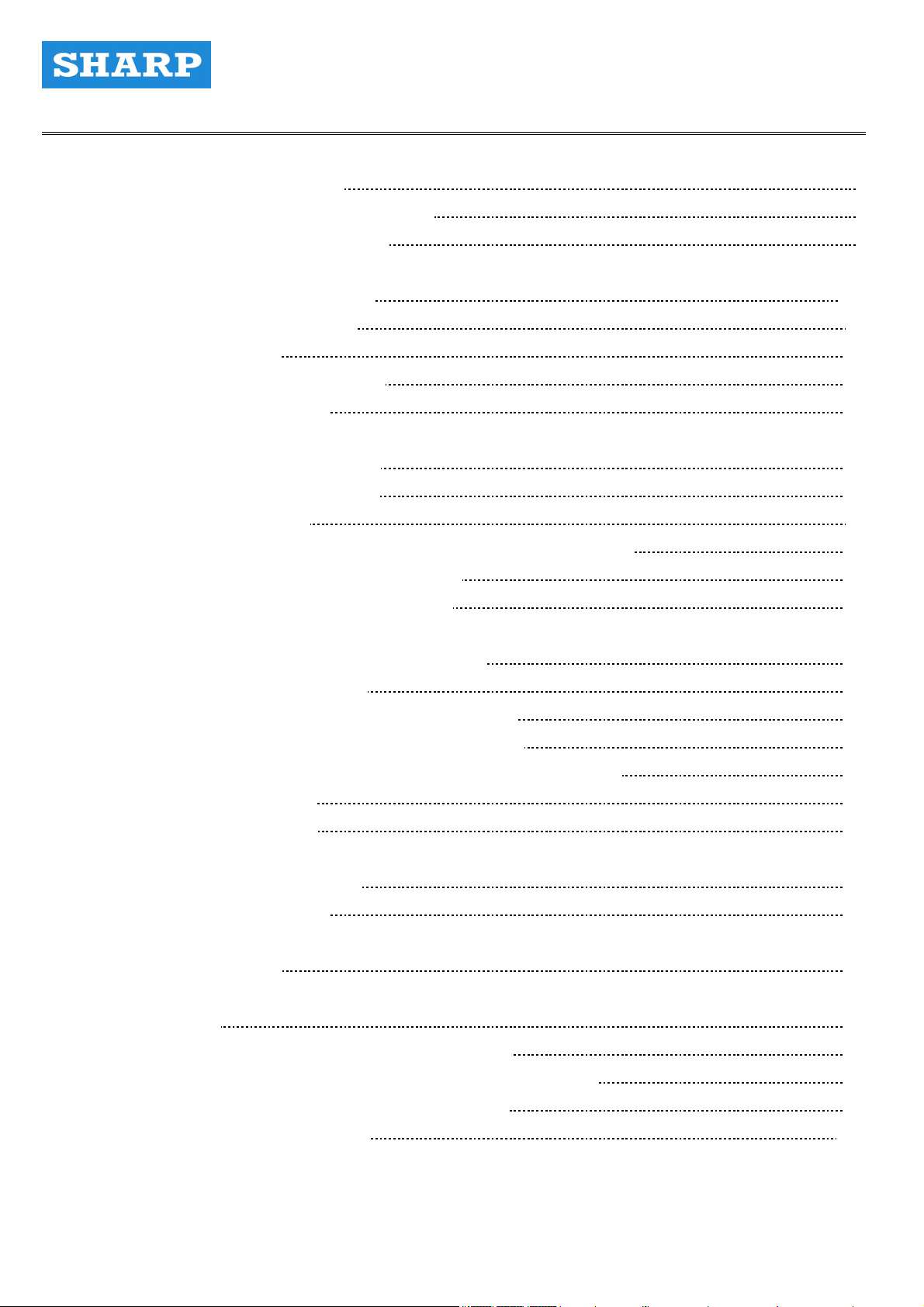

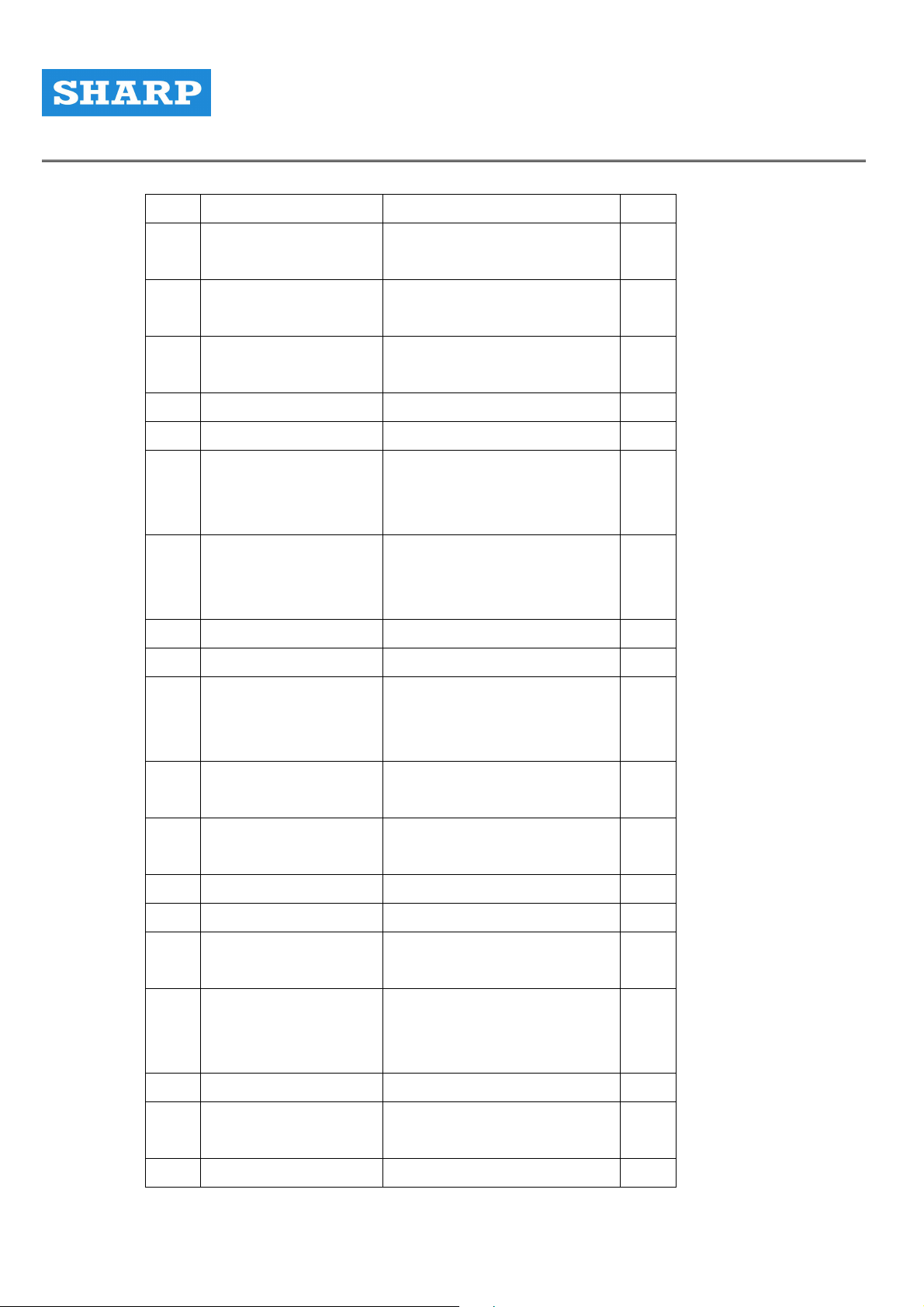

1-1 Routine Maintenance Checklist

Routine maintenance inspection can be classified into daily, weekly, monthly and annually. The

maintenance is given when the machine functions normally The actual frequency and the operation

frequency are different. When operating the both, pay attention to abnormal noises, oil volume, air

pressure and machine abnormalities during the processing.

○:Check ◎:Add oil ☉:Clean

A:Adjustment F: Function check G: Grease coasting R: Replace when necessary

No.

1

2

3

4

5

6

7

8

Spindle unit

Lubrication

unit

Spindle oil

coolant unit

Maintenance Daily Weekly Monthly Annually Note

Spindle operation

○

warm-up

Spindle nose

Lubrication pump

☉

☉

Depending

on the brand

of the lube oil

Lubrication pump

◎

oil volume

Spindle oil

○

☉

coolant unit

Temperature

○ -1°C

difference setup

Oil coolant unit filter

☉

Air compressor

○ 5.5~7 kgf/cm²

source pressure

Air compressor

9

Air

Compressor

Unit

10

cylinder and filter

drainage

Air compressor

○

◎

unit lube oil

Air leakage of the air

11

○

compressor system

12 Coolant capacity ○

Coolant

13

Coolant box filter

☉

Page 5

5

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

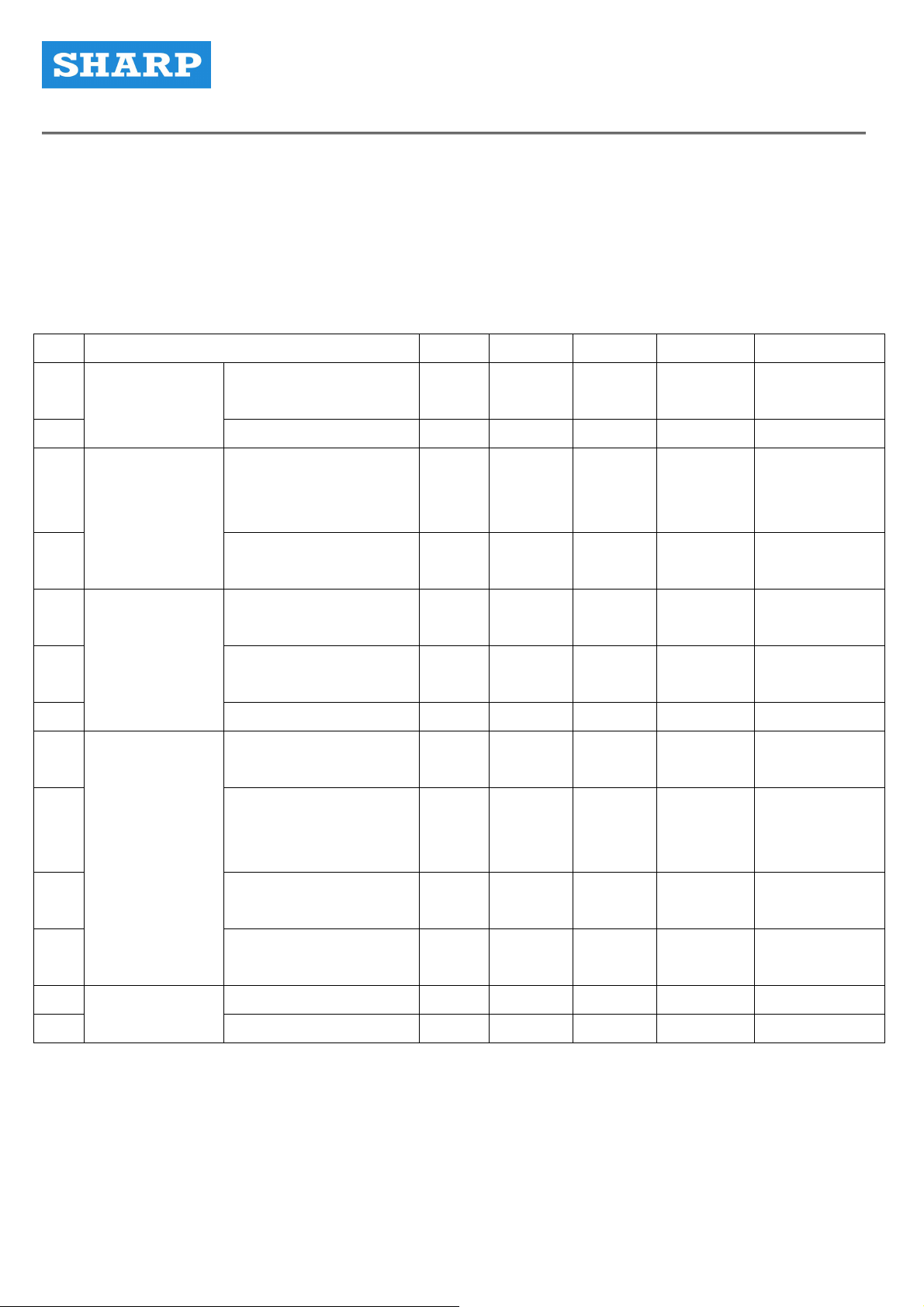

No.

Maintenance Daily Weekly Monthly Annually

Note

Depending

Internal flow of

Tool magazine

14

automatic tool

the tool change

R/

1-year

on the brand

of the lube

machine

change (ATC)

system

15

Tool sleeve and

☉

oil

tool change claw

16 CNC operation

panel

Emergency stop

button

○,F

17 Operation button ○,F

18 Spindle cooling fan

○/☉

Electric box

19

CNC axial battery ○ R

20 Machine static precision check ○,A

21 Machine position precision check ○,A Replace

22 Spindle cooling fan

23 Oil skimmer ○,F

○/☉

☉

Note: The schedule presented in table is for normal operation only. If the environment is not optimal

or if the usage frequency has exceeded the suggested basic standard, you may need to increase the

frequency of maintenance

Note 2: If there is any inconsistency between this table and instruction from elsewhere, use the

information provided on this table.

Page 6

6

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

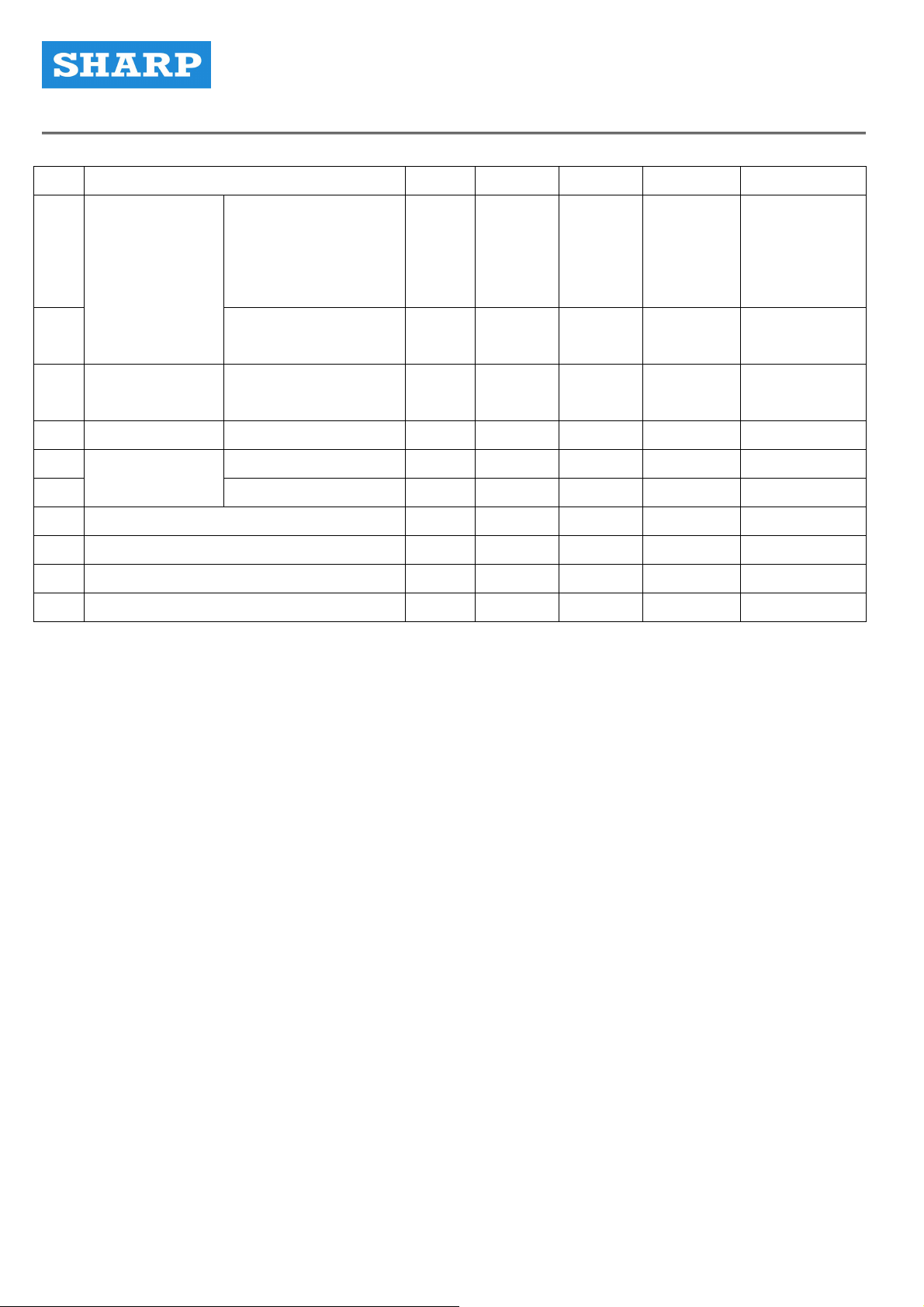

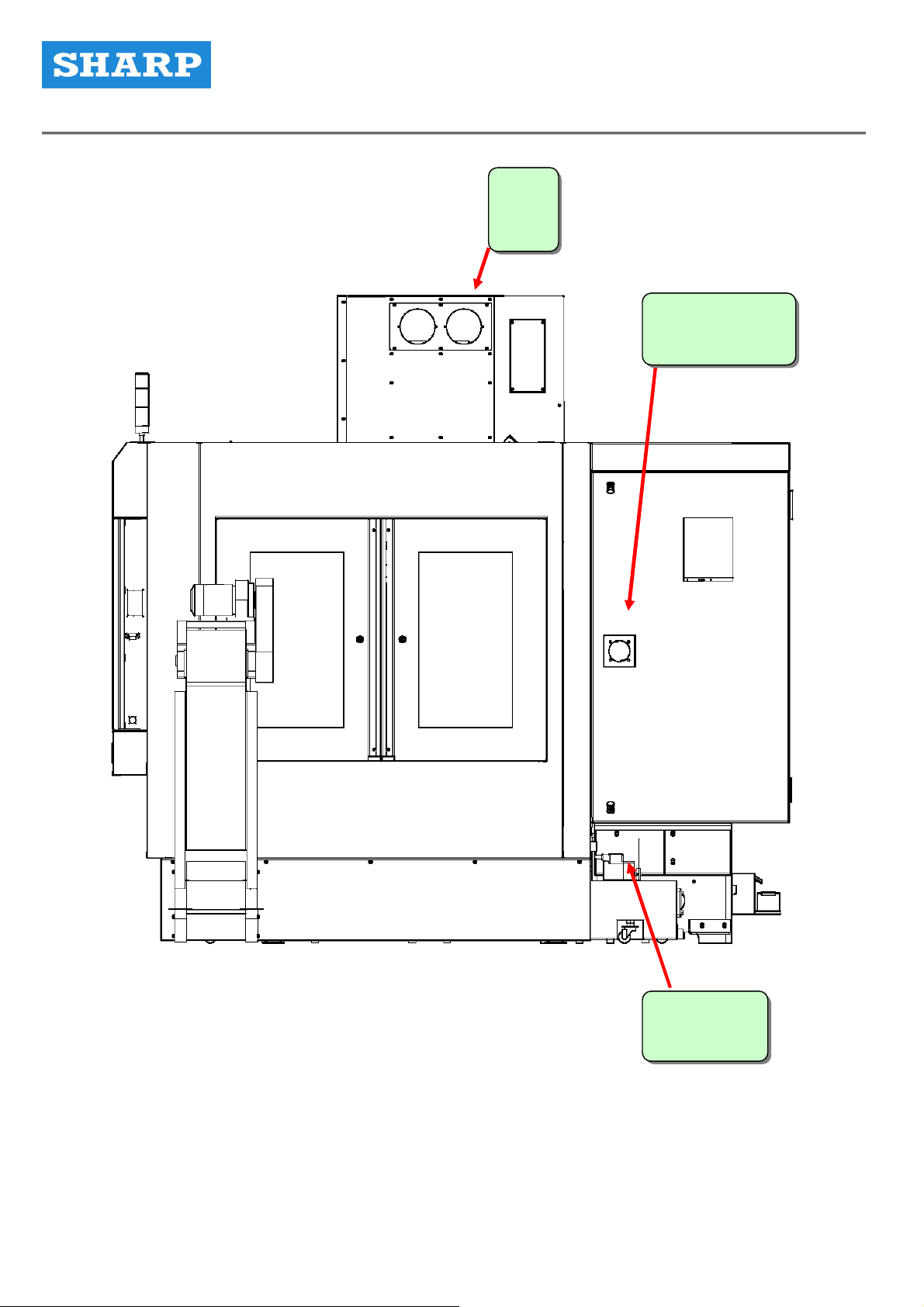

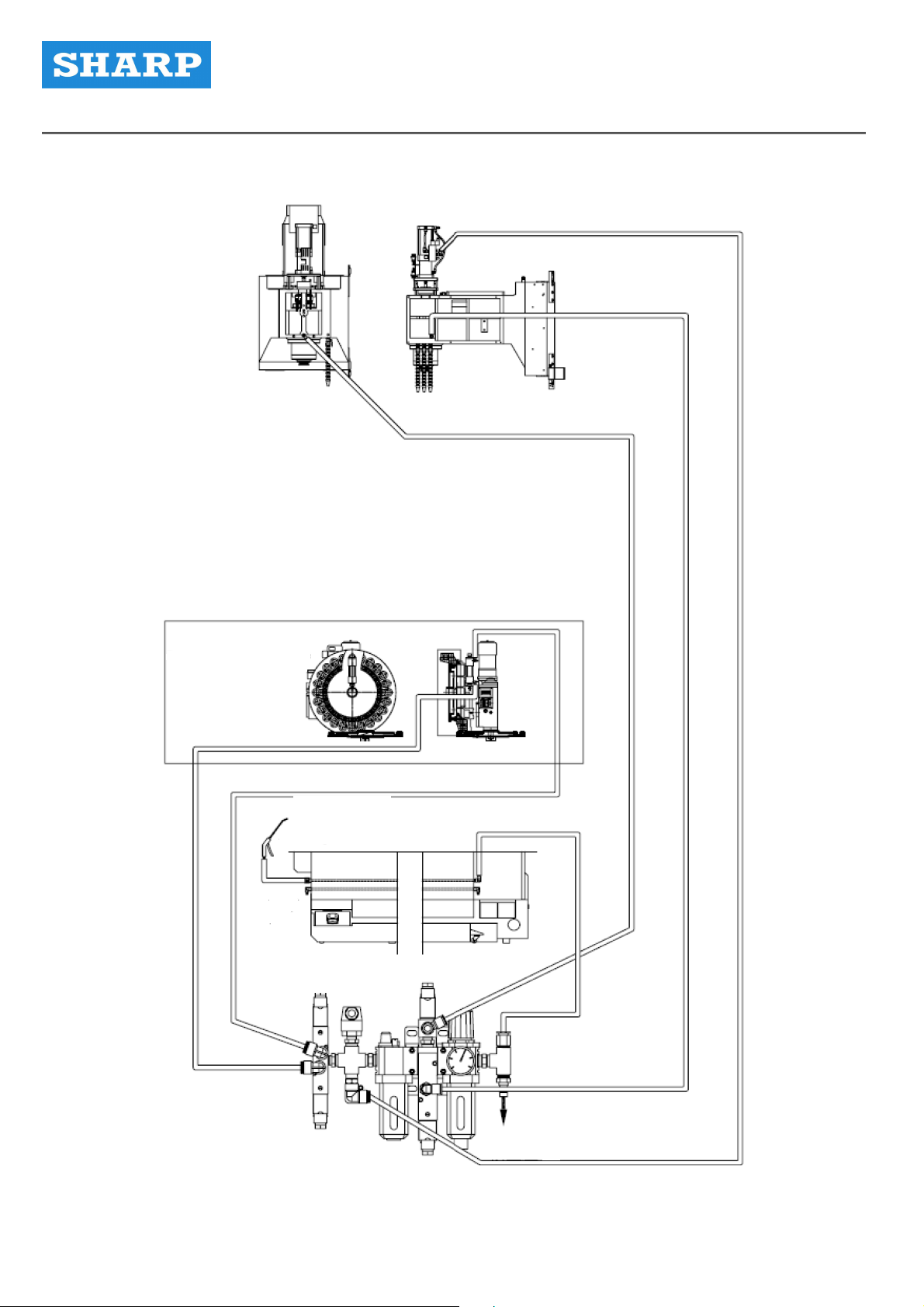

1-2 Routine Maintenance Instruction Diagram

( 14、15 ) Tool magazine / Automatic tool change system

( 1、2 ) Spindle unit

( 17 ) Operation box

( 12、13 ) Coolant

( 16 ) Emergency stop button

Page 7

7

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

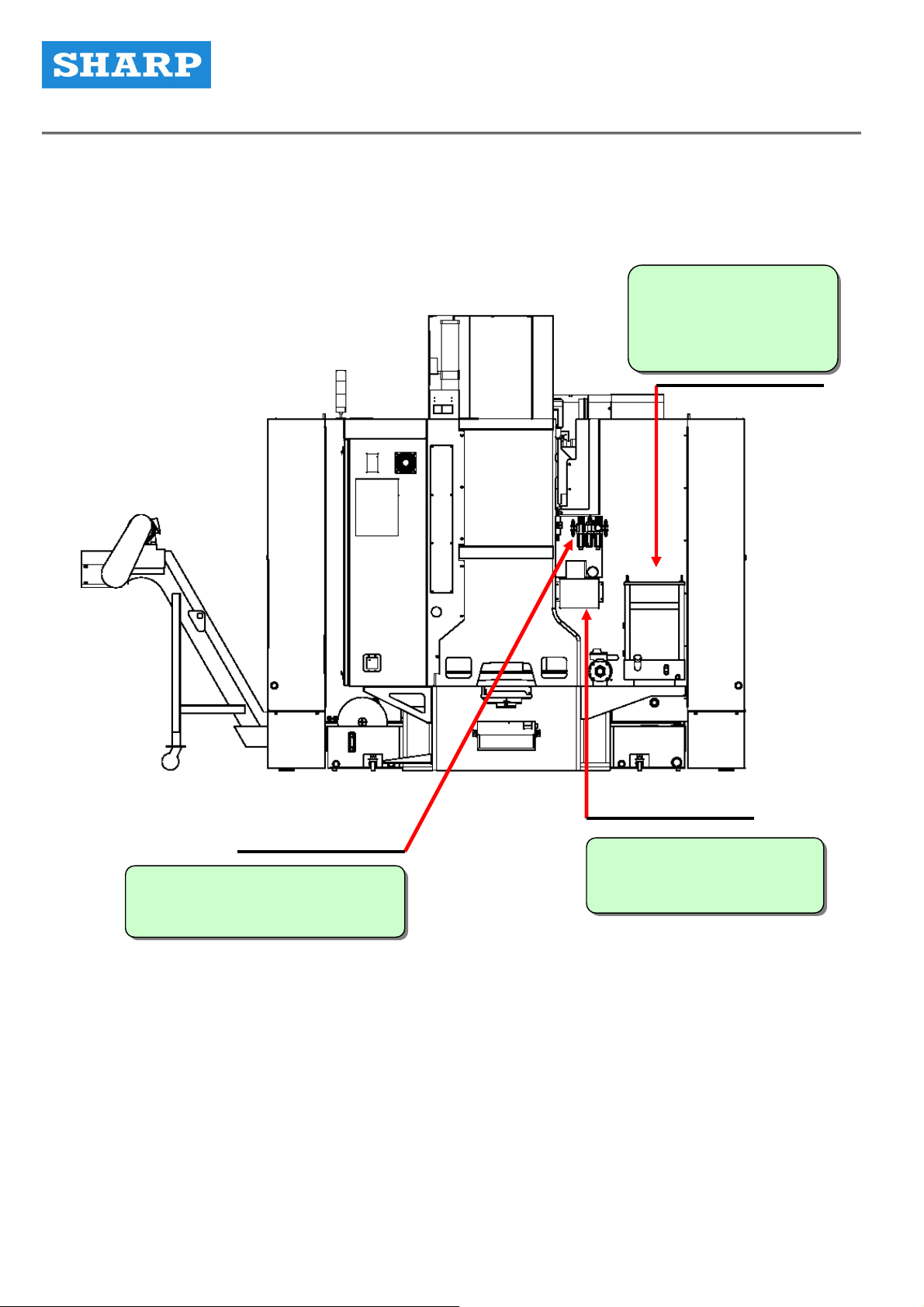

Machine precision check (20 – 21)

Page 8

8

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

( 22 )

Fans

( 18、19 )

Electrical box

( 23 )

Oil skimmer

Page 9

9

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

( 5、6、7 )

Spindle oil temperature

controller

( 8、9、10、11 )

Air compressor preparation unit

( 3、4 )

Central lubrication system

Page 10

10

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

1-3 Cautions for Machine Maintenance

It is important to perform maintenance on each listed items in order to maintain machine precision

and extend machine lifespan.

Erroneous operation may damage the machine or lead to injury of the operator. Be cautious about

the following matters:

Cautions Prevention

To extend the lifespan, follow the instructions given in Section

2-3 for machine warm-up before turning on the machine.

Spindle operation warm-up

Dynamic balance of the cutter

Standard broach bolts

Spindle pre-operation check

Manually loosening the

spindle’s cutter

If the machine has been stopped for a long period, follow the

instructions given in Section 2-3 for machine warm-up before

turning on the machine in order to extend the life span.

To extend the lifespan as well as to increase the precision,

please follow instructions given in Section 2-1 for usage as

well as achieving a dynamic balance for the cutter.

Broach bolt is an important component jointing the spindle and

the tool shank. Using a wrong broach bolt is hazardous for the

operation. Make sure that only the standard one is used.

Check the machine before spindle operation according to

instructions given in Section 2-4 in order to extend the lifespan

of the spindle.

When loosening the cutter of the spindle, make sure that each

step is executed correctly or may lead to personnel injury.

When changing the cutter, be cautious not to drop the cutter,

Manual installing the cutter onto

which may damage the workbench or tools. Manually change

the cutter only if necessary, and the procedures are written on

the spindle

the operation panel at the front. Press and let go of the spindle

cutter loosening button to loosen up or to grasp the cutter.

The tool magazine is controlled by CNC and motor. After

Do not touch the spinning tool

turning on the machine, do not touch the tool magazine or may

magazine

be injured. Turn off the power for changing the cutter.

Page 11

11

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Cautions Prevention

Spindle nose cleaning Keep the taper of spindle nose and cutter shank clean at all

time to prevent dust or iron filings affecting the precision. The

spindle has an automatic dust removal function, but the

operator should wipe the parts with standard air-laid paper for

maintaining spindle precision.

The function pressure of this air compressor is 5kgf/cm²( 71

psi ). Therefore the air pressure source has to be at least 5.5

kgf/cm²( 78 psi ) and stabilized.

This machine has an air filter that eliminates impurities and

Air quality inside the air

compressor

Lube oil from the lubricating

pump (automatic)

Adding oil to the spindle oil

cooler and setting up the

water vapor from the air. Air for the air pressure source has to

be clean and dry. Check the filter constantly to extend the

lifespan of the filter.

To effectively eliminates water vapor by the filter, drain the

water from the air tank of the air compressor. (Water drainage

is more effective in the morning).

Lube oil is released by the lubricating pump to lubricate the

guide ways and the lead screws. Insufficient lubrication may

speed up the abrasion and affect machine precision.

Always make sure that there is enough oil in the tank. If the

amount of oil is below the lower limit of the oil-level gauge, the

operation panel as well as the screen will issue a warning

message. Please add more oil as early as possible.

Oil cooling circulation system was adopted for the spindle to

effectively suppress spindle temperature increase and thus

extend the lifespan of the spindle. Use the correct type of

circulation and add more oil when the level is too low.

temperature difference

The machine adopts synchronous machine temperature

adjustment Temperature difference is set to 0 to prevent big

temperature difference, which can damage spindle bearing.

Do not change the value arbitrarily.

Page 12

12

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Cautions Prevention

Constantly check the guide ways of the three

axes (X, Y & Z). Check whether there are iron

Guide way check

Correctly locking the work pieces

Correctly locking the doors

filings or other types of grains attached to the

guide ways. To extend the lifespan, remove the

dust or they may scratch the slide.

When placing work pieces onto the workbench,

make sure that they are well locked or they may

spin out and cause personnel injury.

Make sure the operation door and the two side

doors are well locked to prevent the cutter from

bursting apart or iron filings from flying out,

which is dangerous.

Page 13

13

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Chapter 2

The Spindle Unit

Page 14

14

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

2-1 Cautions for High Speed Processing

During high-speed processing (S = 8000 rpm or above; F = 300 mm/min or above), the shank and

the style of the cutter has a critical impact on spindle lifespan and processing precision. Matters that

need more attention are:

1). Grasp the cutter before running the spindle to avoid damaging the spindle.

2). During high-speeding chipping (8000rpm or above), use only G2.5 level cutters and shanks that

have been calibrated for dynamic balance. The reason is that vibration generated from centrifugal

force may damage the spindle bearing and rapidly wear out the cutter.

3) Balance tolerance for the shank and the cutter combination is affected by the following three

factors: rotation speed of the cutter, balance tolerance of the spindle, and weight of the shank.

Therefore, using a shorter cutter with a smaller diameter for high-speed chipping is advantageous in

terms of spindle vibration, temperature increase, thermal deformation, and processing precision.

4) The geometric shape of the cutter blade has an effect on cutter abrasion. Increase the angular

backlash of the blade can reduce abrasion due to scratches. Suitable cutter materials can also

minimize abrasion during high-speed processing; for example, cermet, tin or tic coated carbide

cutters have longer lifespan than conventional cutters. Ceramic (Si3N4) cutters are better than cermet

cutters.

5) Perform another dynamic balance calibration after combining the cutter and the shank together.

The dynamic balance standard should be G2.5 or above.

50 – 6000 rpm Level G6.3 Balance level

6000 – 18000 rpm Level G2.5

Spindle Rotation Speed (rpm) Cutter Diameter (mm) Cutter Length (mm)

6000 – 8000 125 250

8000 – 10000 100 250

10000 – 12000 80 250

12000 – 15000 65 200

15000 – 18000 50 200

Page 15

15

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

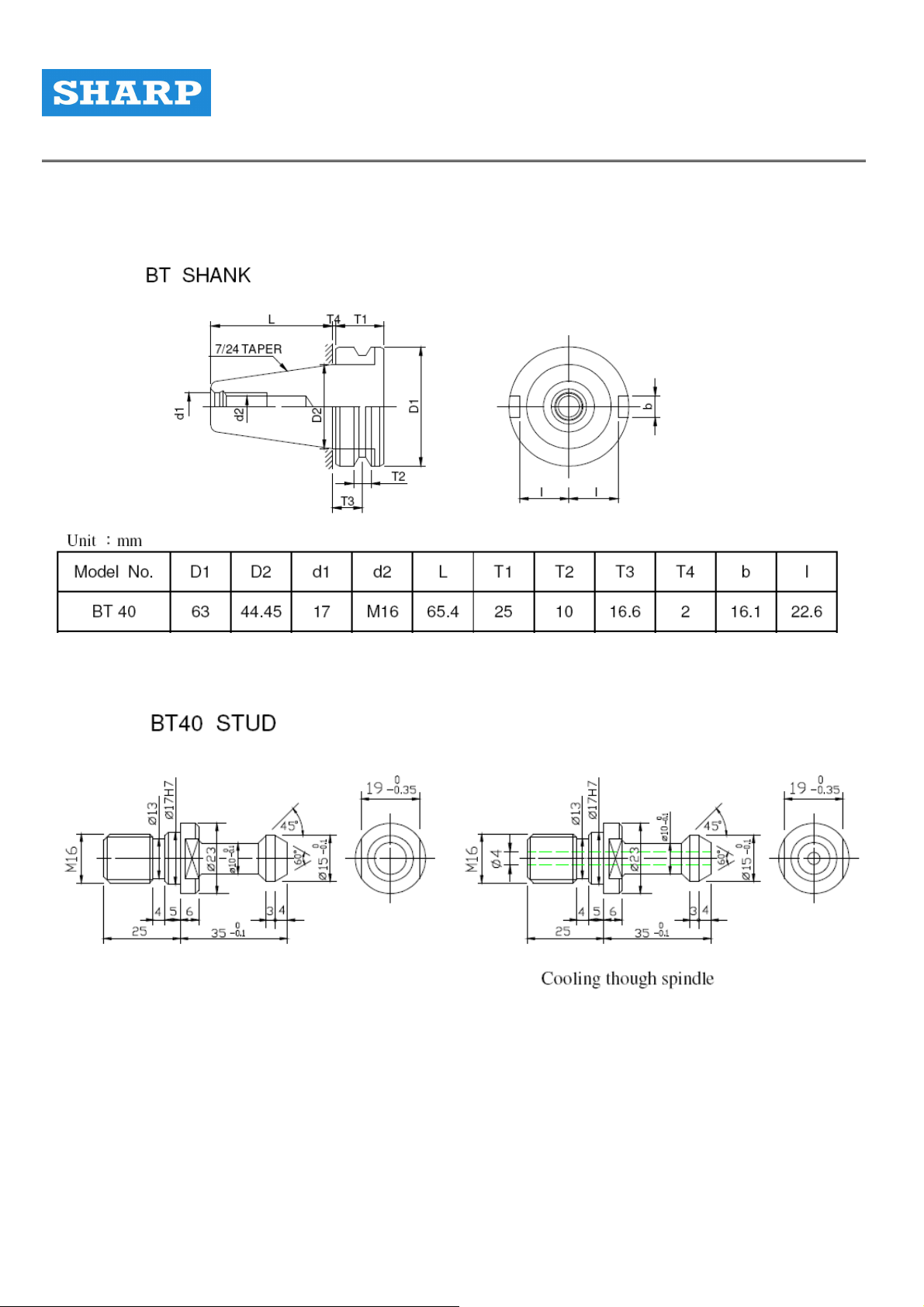

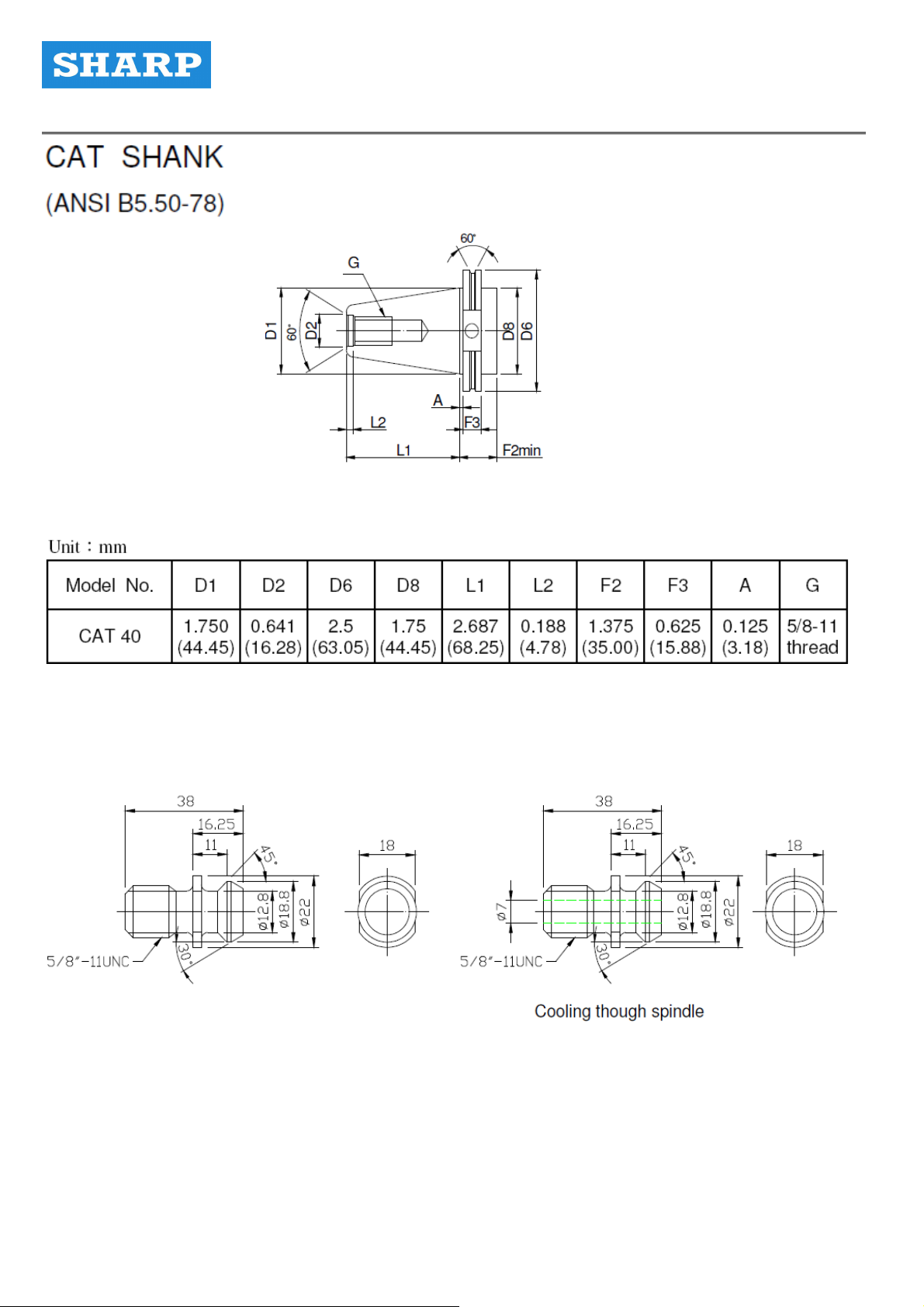

2-2 Tool Shank and Broach Bolts

Page 16

16

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

CAT 40 STUD

Page 17

17

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

2-3 Spindle Warm-up

This is an aerosol lubrication design, and so before turning on the machine, follow the warm-up steps

below to extend the lifespan of the spindle and to avoid damaging the bearing by letting the oil

aerosol getting into the bearing ahead.

Spindle warm-up time

Item

1 Routine operation Max Rpm 20% 10

If the spindle has been

stopped for more than two

2

hours, warm-up is

compulsive.

Spindle stopped for more

3

than 72 hours

Condition

Spindle RPM

(Maximum RPM %)

20% 10

1. 20%

2. 50%

Rotation Time

( min )

Check Contents

1. Less than 10°C

increase of

temperature

2. Shocks

3. Noises

1. Less than 10°C

increase of

temperature

Shocks

2. Noises

1. Less than 10°C

increase of

10

temperature

10

2. Shocks

3. Noises

1. 500 RPM

2. 20%

3. 40%

Spindle stopped for more

4

than 2 weeks

4. 60%

5. 80%

6. Maximum RPM

60

10

10

*10

*10

*10

Less than 10°C

increase of

temperatureShocks

Noises

4. Do not go onto the

next step until the

temperature has

become stable.

Page 18

18

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

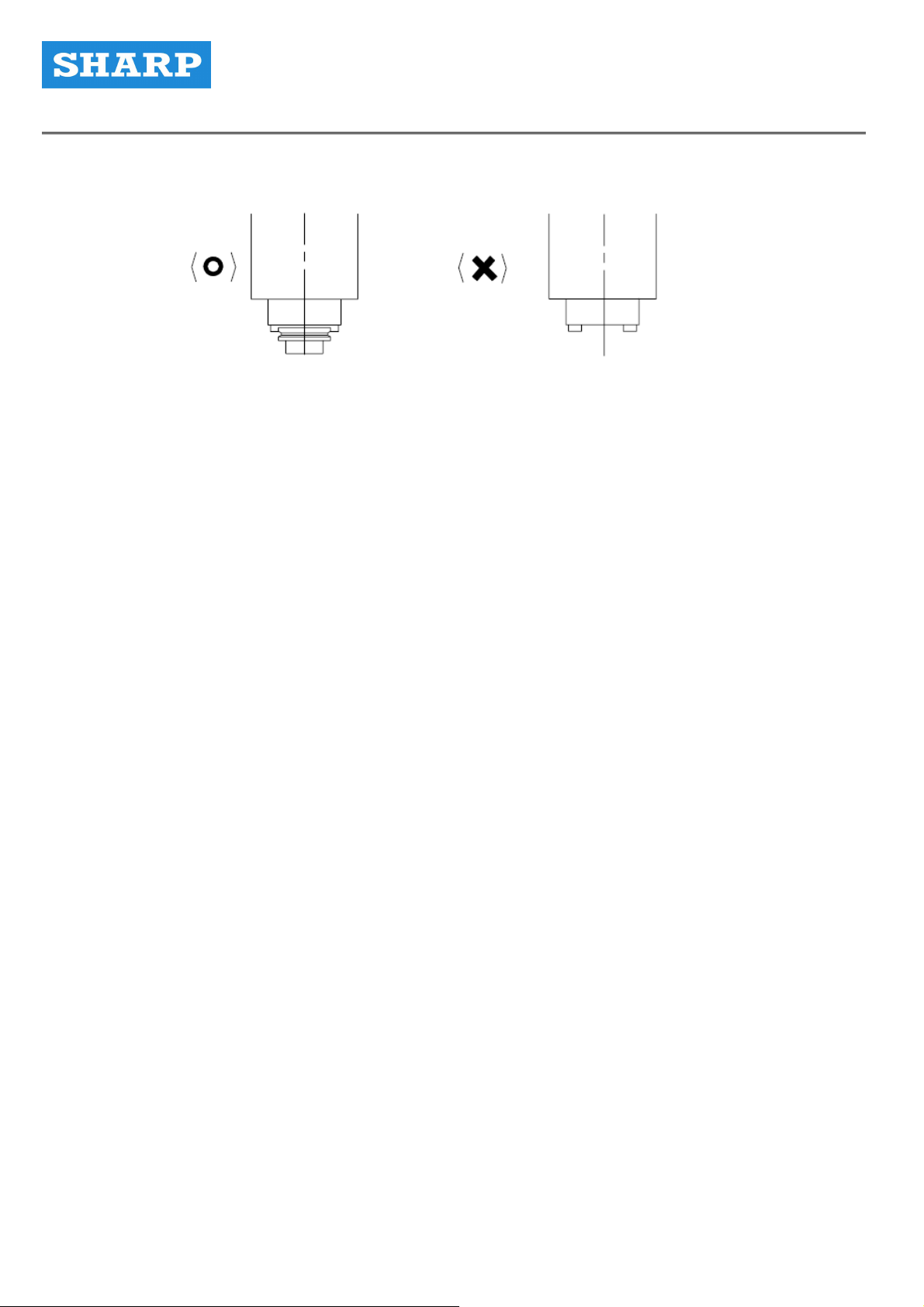

Cautions

1) If the shank is not installed onto the spindle, do not operate the spindle. See the figure below.

If the temperature of the bearing has increased for more than 10%, reduce the rotation speed of the

spindle to 500 and do not carry out the warm-up until the temperature is about 5°C higher than the

room temperature.

Page 19

19

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

2-4 Spindle Pre-Operation Check

1) Check whether the air pressure source is normal.

2) Check No.7 electric oil pump tank (Refer to the diagram in Section 3-1) for whether there is

enough oil.

3) Run the spindle at 100 rpm to check whether the oil pump is functioning normally.

4) If everything is okay, carry out the warm-up according to the spindle warm-up procedures

presented in Section 2-3.

Caution

1. The oil volume and air supply volume of this aerosol lubrication unit has already been set at the

factory. Do not adjust the values arbitrarily.

2. During the maintenance, do not disassemble, bend, or flatten the output oil pipe, which may

damage the oil pipe.

3. Timely fill up the oil tank.

4. If the spindle has been stopped for more than 2 hours, run the spindle system, including the

aerosol lubrication system, at a speed that is 20% of the maximum speed.

The machine has to have a forced warm-up for 10 minutes before starting the actual work.

5. Do not adjust the oil/air mixing valve. Use the factory-set default value for lubrication interval.

Do not change the values arbitrarily or the bearing may be damaged.

6. For this unit, if the screen displays “ALARM 1002, 1056, 2004,” check and turn off the alarm

before continuing the operation.

7. Do not turn on and off the spindle repeatedly in a short period of time during the processing.

The inside of the spindle may be over-lubricated, which can cause the spindle overheated.

8. If the spindle alarm went off when starting the operation, it is due to overheated bearing. Stop

the operation. Wait until the temperature returns to normal. Check if there is any problem before

starting the warm-up and the operation.

9. It is normal to have oil dropped onto the workbench or the processing item when running the

machine. This comes from the exhausted oil aerosol. Do not block the outlet or the back pressure

may lead to temperature increase, thereby damaging the spindle bearing.

Page 20

20

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

2-5 Spindle Alarm Handling

1) For this unit, if the screen displays “ALARM 1002, 1056, 2004,” check whether the temperature of

the protective device of the bearing is 50°C. After checking the temperature, check whether the

pipelines are abnormal, squeezed or broken. Check whether the oil cooler and the air compressor

are normal. Wait for the temperature to drop before turning on the spindle for warm-up. This is the

first line of protection for the spindle.

2) The second spindle protection is the oil pump. The oil pump has liquid level detection, and when

the level is too low, ALARM will be issued. If the oil pipeline is blocked, the screen will display

ALARM 1002.

3) The third spindle protection is the pressure switch for air pressure supply. If there is insufficient air

pressure, the mixing valve will be incapable of emitting the oil aerosol. If this ALARM goes off, check

whether the oil pipeline is broken and whether air pressure supply is sufficient.

4) If the clients still cannot turn off the alarm after checking relevant pipelines, contact the service

department of the Company. Do not modify the setting arbitrarily.

5) Messages of the ALARM signals:

1. 1002 LUBE PRESSURE FAULT:Insufficient pressure from the automatic lubrication pump

2. 1056 SPINDLE COOLER ALARM:Abnormal spindle oil cooling function

3. 2004 LUBE LEVEL ALARM:Under the standard liquid level of the oil tank of the automatic

lubrication pump

6) For relevant settings, please refer to the electrical instructions.

Page 21

21

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Chapter 3

The Air Compressor Unit

Page 22

22

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

3-1 Air Compressor System Layout

ATC

Rotary disk type tool magazine

Air gun

Machine front

Air pressure source

Page 23

23

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

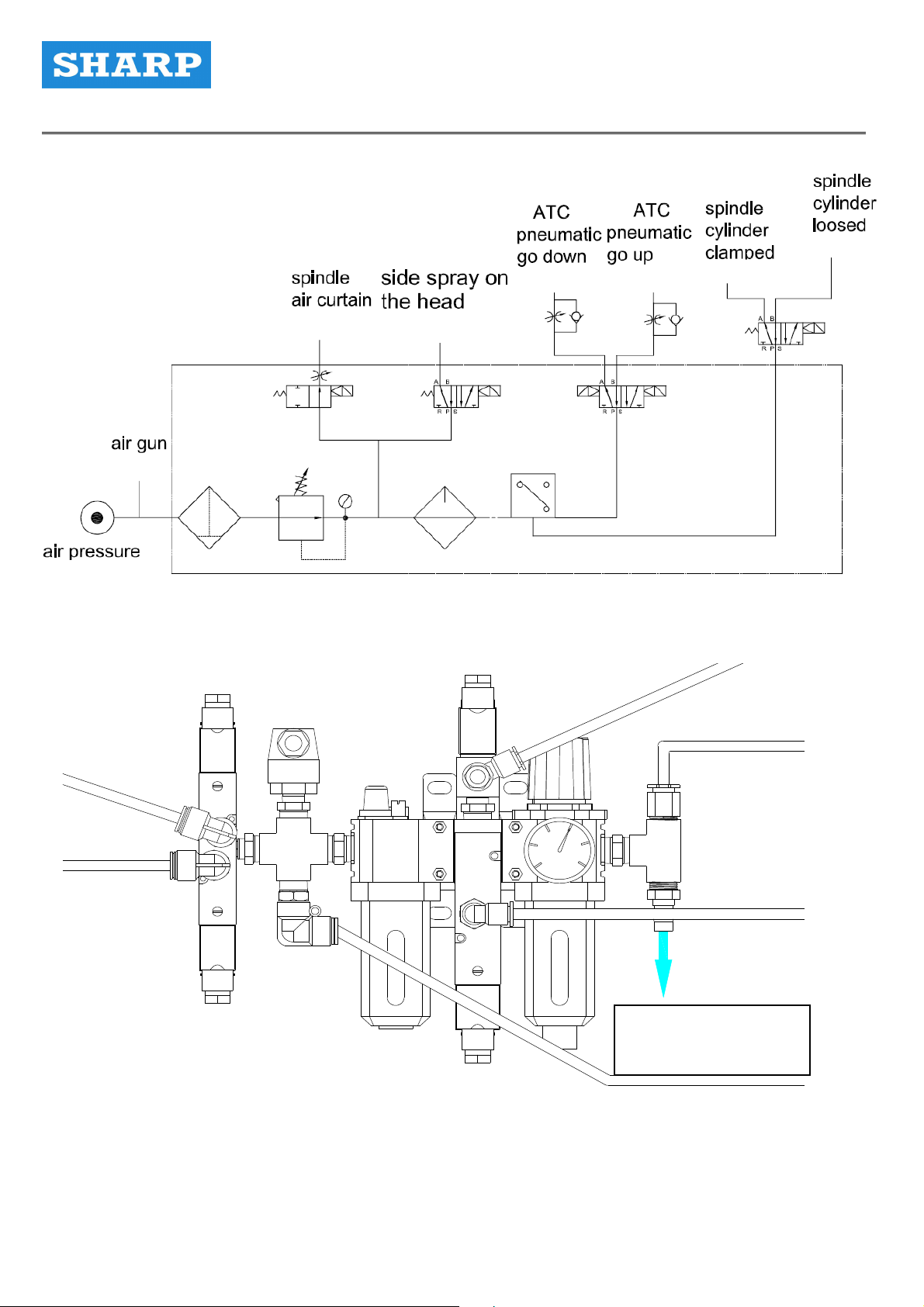

3-2 Air Compressor System Circuit Diagram

3-3 Air Compressor Unit

Connect to the air

pressure source

Page 24

24

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

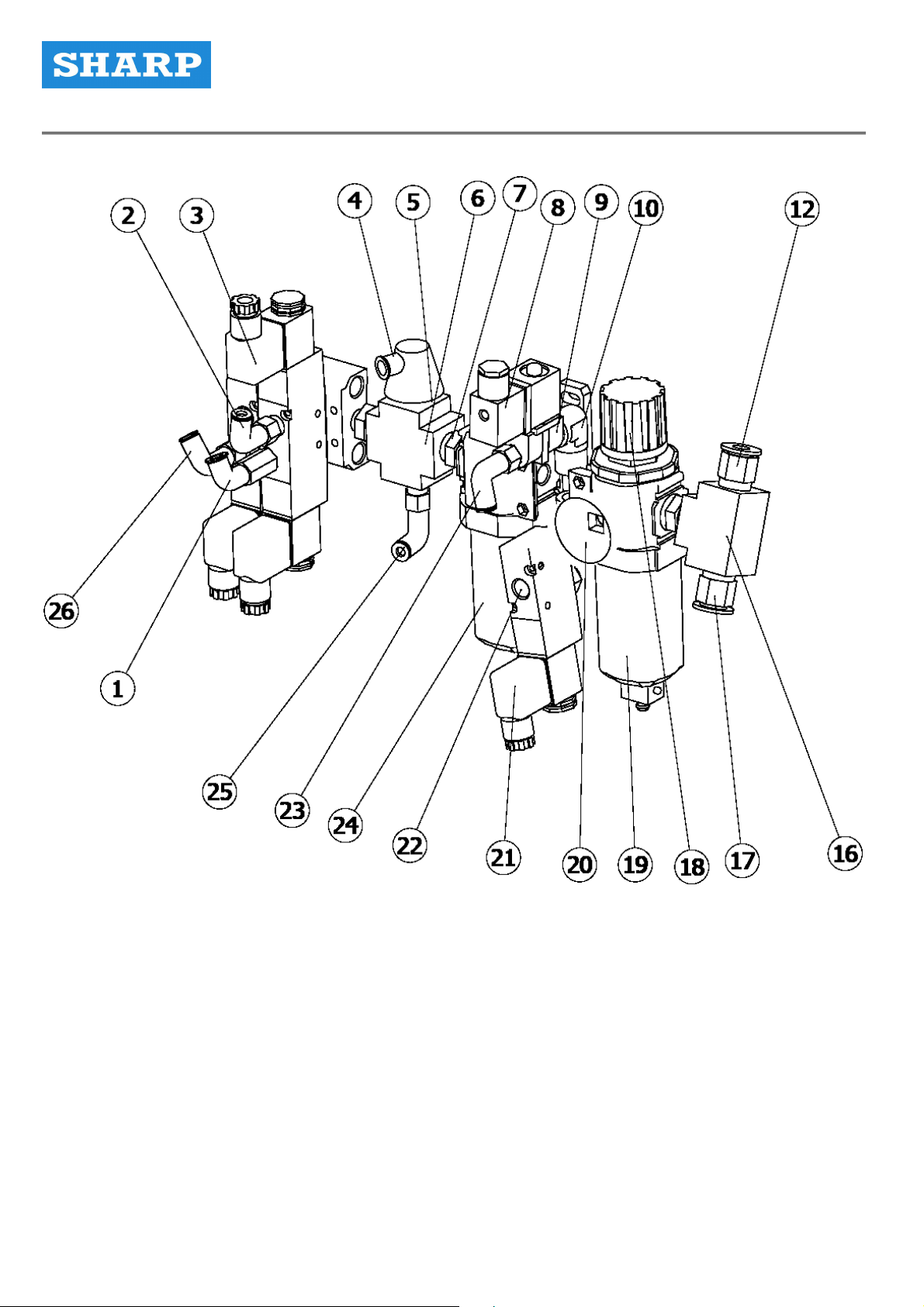

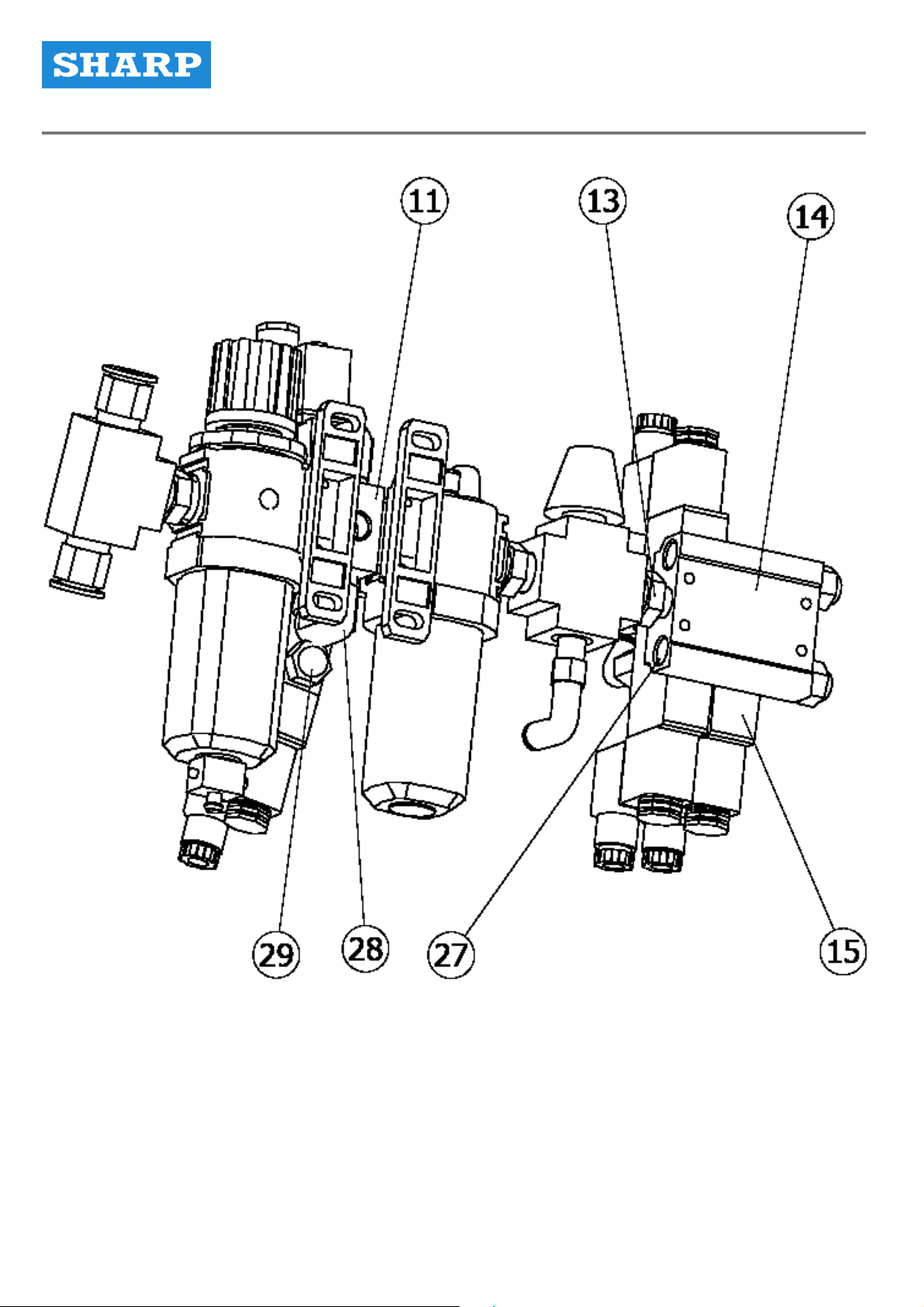

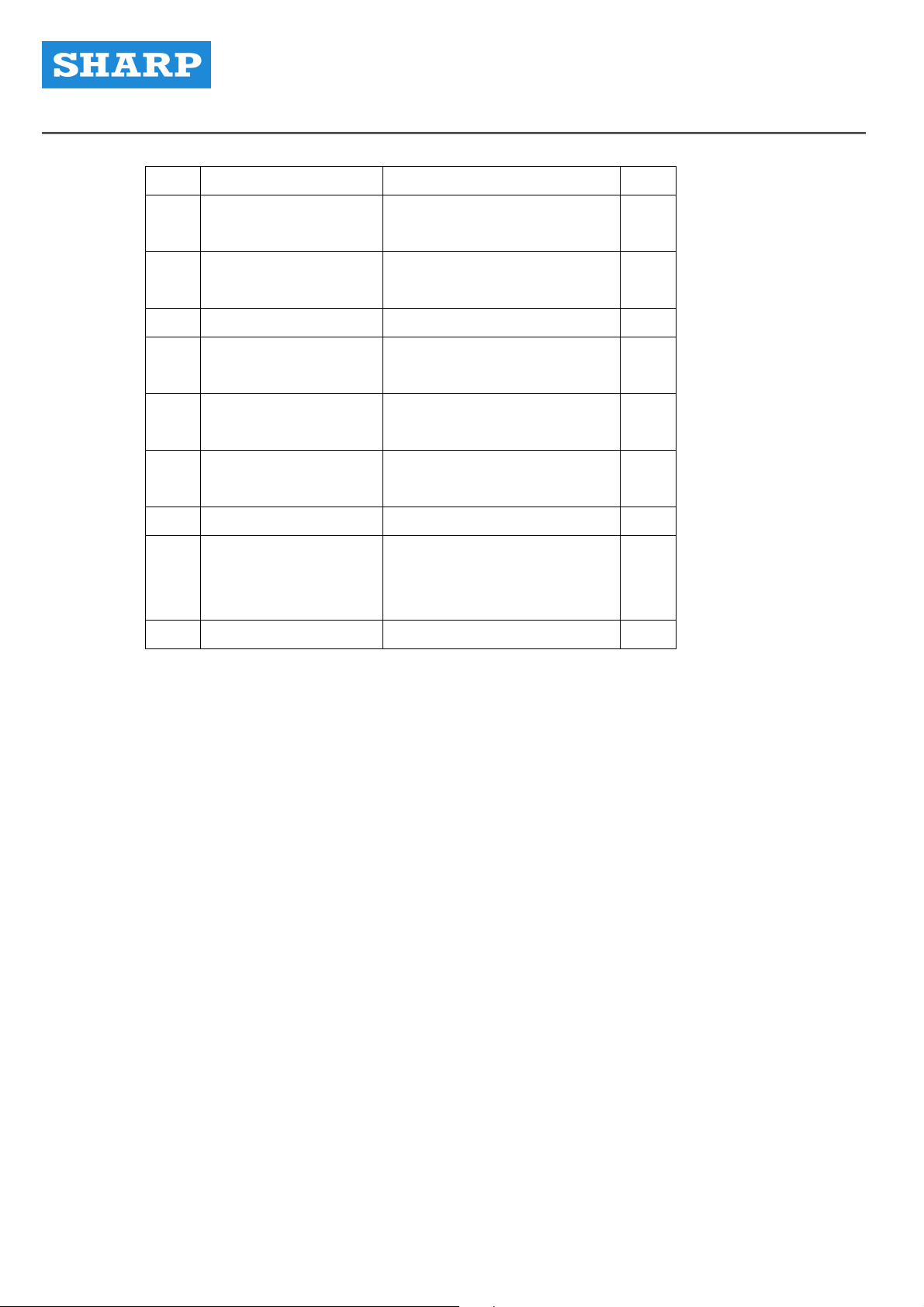

3-4 Air Compressor Detailed Specifications and Functions

Page 25

25

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 26

26

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Item

Name Size Qty.

L-shape extended

1

10mm_1/4" 1

brass connector

L-shape brass

2

10mm_1/4" 1

connector

1/4" 5/2-way_double

3 Solenoid valve

solenoid operated

4 Pressure detector 1/4" 1

5 Brass bushing 1/4"x3/8" 3

Copper female

6

thread four-way

3/8" 1

connector

Copper double

7

male thread

3/8" 1

connector

8 Solenoid valve 1/4" 2/2-way 1

1

9 Copper street elbow 1/4" 1

0

1/4" 2

10

Copper 90

double-male thread

connector

MACP300 T10

11 Connecting block

1

Quick straight

12

10mm_3/8" 1

connector

13 Straight connector 1/4"T*3/8"T 1

14 Air distribution block 1/4” * 2 1

MUSC-220-4E1-DC24

15 Solenoid valve

1

with lamp

Copper female

16

thread four-way

3/8" 1

connector

17 Quick connector 12mm_3/8" 1

Pressure regulating

18

MACP300-12A 1

valve

19 Water filtering cup MACP300-12A 1

Page 27

27

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

20 Pressure gauge 1.5" 10KG/PSI 1

21 Solenoid valve

1

solenoid operated

L-shape

3/8" 3/2-way_single

22

8mm_3/8" 1

compressor fitting

23 Throttle valve 8mm_1/4" 1

Lubrication pump oil

24

55cc MACP300-12A 1

cup

L-shape

25

10mm_3/8" 1

compressor fitting

Quick nylon-tube

26

10mm_1/4"*90° 1

connector

27 Hex head plug 1/4" 4

0

3/8" 1

28

Copper 90

double-male thread

connector

29 Muffler (flat) 1/4" 3

Page 28

28

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

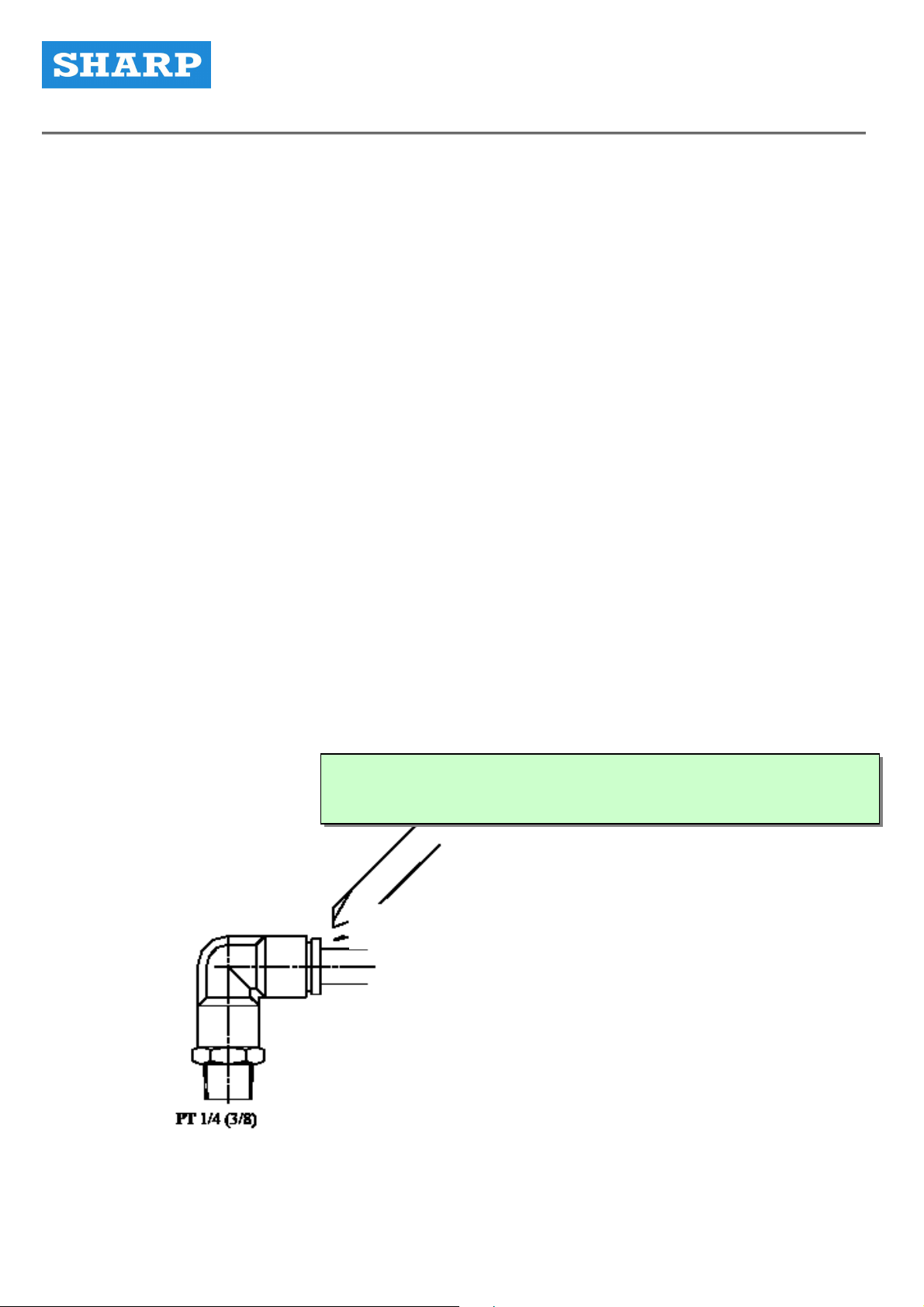

3-5 Air Compressor Unit Usage Instruction

1) The pressure source of this machine’s pressure pipeline goes through the air pressure preparation

unit, and the pressure is set to 6kg/cm2. When the pressure source is less than 5kg/cm2, and the

duration lasts more than 2 – 3 sec, NC will turn on the alarm, and CRT will display 1011 AIR

PRESSURE LOW. In this case, check the pressure source and then press the RESET button to

continue the operation.

2) Maximum pressure: 10kgf/cm²

3) Adjustment range: 0.5 ~8.7 Kg f/ cm²

4 ) Filter size:5μ

5 ) Recommended lube oil:ISO VG32

6) The pressure source should not be lower than: 5.5kgf/cm²

7) Although the air compressor preparation unit of the water filter has an automatically water

drainage, the machine operator should check whether there is any water accumulation at the shift or

at the end of the day. If the water drainage function is abnormal, water vapor may get into the air

compressor component, thereby reducing the lifespan. For the water drainage function of the filter to

be more effective, water in the air tank of the air compressor should fully drained out. It is also

recommended to install a dehumidifier at the pressure source to make sure that the air is dry.

8) The machine operator should pay attention to whether the pressure pipeline is making a bz kind of

noise. This may be due to gas leakage at the connector. Check the machine by tracing the noise.

The pipeline of this machine is connected by connectors, and the disassembling method is

described below: The nylon tube can be directly inserted into the connector. Use the finger or a flat

screw driver to secure the connector when pulling out the nylon tube.

Use a screwdriver or fingers to press down the fixing ring.

Fixing ring

tube

Page 29

29

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

3-6 Air Compressor Unit Troubleshooting

Problem Cause Correction

Reduced pressure source

output

Gas leakage

Disfunctional pressure

regulator

Output side air pressure low

Gas leakage at the screw cap

No oil dripped from the oil cup

The oil volume cannot be

adjusted

Oil leadkage at the adjustment

needle

Blocked filter Clean the filter

1. Loosened nut

2. Broken O-ring

3. Broken tube

Broken pressure regulator

1. Broken spring of the

pressure regulator

2. Broken spring of the valve

3. Dust or dirts on the base of

the valve

1. Tighten the nut

2. Replace the o-ring

3. Replace the tube

1. Replace the spring

2. Replace the spring

3. Clean the valve and the

base

4. Replace the valve

5. Replace the film

4. Broken lining of the valve

5. Broken film

1. Dust on the valve base

2. Broken inner lining rubber

3. Broken valve spring

1. Clean the valve and the

valve base

2. Replace the valve

3. Replace the spring

1. Loosened cap nut

2. Broken film

1. The adjusting needle being

too tight

2. The adjusting needle

cannot be closed or there

are dirts on the needle. The

adjustment needle cannot

bear the pressure

3. Broken or damaged

adjusting needle or needle

1. Tighten the cap nut

2. Replace the film

1. Loosen up the needle

2. Reduce the oil volume until

the level reaches the

maximum oil level

3. Add more oil until the level

reaches between the

maximum and the

minimum level

4. Clean up the blockage

base

1. The adjustment needle is

too loose

2. The adjustment needle

cannot be closed or dirt on

the needle. The adjusting

1. Tighteen the needle and

gradually loosen it for

adjustment

2. Remove the dirt

3. Partial replacement

needle cannot bear the

pressure

3. Broken or damaged

adjustment needle or

needle base

1. The needle is too loose

2. Broken O-ring

1. Tighten up the adjustment

needle

2. Replace the O-ring

Page 30

30

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Chapter 4

The Lubrication Unit

Page 31

31

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

4-1 Centralized Lubrication System Diagram

1) Components of the lubrication oil pump

( a ) Flow rate:300cc / min

( b ) Voltage:220V ( 50 / 60 HZ )

( c ) Power:150W( d ) Maximum output pressure:15kg/cm²

( e ) Oil tank capacity:6L

Connections:

1、3:Electric source

2、3:Manual oil injection

4、5:Floating switch

6、7:Pressure in section

Page 32

32

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

2) Lubrication System Diagram

Number Model Name Quantity

1. PA6 Pipe cape 3

2. PB6 Pipe 3

3. PKD6 3-way pipe 1

4. PH601 Right angle connector 2

caution:

1) Value of the input source current has to be the same as the one on the plague.

2) The wiring has to follow the instructions on the plaque to avoid damaging the oil pump.

3) Ground the ground wire.

4) A filter is installed on the inlet of the oil tank. Do not contaminate the manifold block

components.

5) Wash the filter whenever it is contaminated to maintain its function.

6) Do not drop oil, water or other onto the control circuit, or the control circuit may be

damaged.

7) Pay attention to the oil level when filling up the oil.

Page 33

33

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

4-2 Spindle Bearing Lubrication

High quality lube oil is used for the spindle bearing, and it is good for high temperature and high

speed conditions. Its lubricating effect on the bearing is long-lasting without being too oily, and

therefore there is no need to add or to change the lube oil for a while. It is therefore cost-saving.

4-3 Guide way and Ball Screw Lubrication

The linear guide way of X, Y and Z axes and the ball screws are lubricated by a centralized

lubrication system which lubricates according to the set schedule.Machine operators must ensure

that the oiling machine has enough oil, as well as whether there is any abnormality.

1) Lead Screw Lubrication

The bearing of the lead screw can be divided into the motor end and the housing end. Lube oil is

applied onto both ends for oil sealing. If the oil goes bad, dissemble these parts to wash the bearing

and reassembling them. Please contact the Company to have professionals checkup and

modification for you.

Page 34

34

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

2) Guide way Lubrication

Guide ways of the workbench (X-axis), the saddle (Y-axis), the head (Z-axis), ball screws of the three

axes (X, Y and Z axes) and the nuts are lubricated by the automatic centralized lubrication system in

which an oil pump is located at the back of the machine.

If the machine has not been operated for a long time, less lube oil will be available in the oil tube. For

the following cases:

1) A machine installed for the first time;

2) A machine has not been operated for a long time;

3) Before operating a machine (daily);

You should manually lubricate to ensure that sufficient lube oil has circulated the entire guide way.

Press the red button on the lube oil pump for about 40 sec before releasing the button. Wait for 10

sec to repeat the above procedure. Repeat this process until lube oil has leaked out from the guide

way.

Cautions:

The oil tank has a 6-L capacity. Add oil from the oil inlet each week (or when necessary). If the oil

level reaches the minimum oil level, the operation panel will issue an alarm message informing the

risk.

1) Add clean lube oil specified for the guide way through the oil inlet. Do not use other types of lube

oil.

The recommended oils are:

Mobil VACTRA 1

Shell TONNA T32

2) Lube oil level:

The level should be maintained between the maximum and the minimum oil level marked on the oil

tank. Once the level drops below the midpoint, add oil as soon as possible. Do not add oil only after

the alarm goes off, which can affect the operation of the machine.

Page 35

35

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

SPINDLE HEAD UNIT

Number Model Name Quantity

1. PA6 Pipe cape 1

2. PB6 Pipe 1

3. PQ101 Connector 1

4. PH601 Straight angle connector 1

5. HBL-3 Volume-based distributor 1

6. PAN4 nut 7

7. PB4 Pipe 14

8. PA4 Pipe cape 7

9. PH4-1 Straight angle flat

connector

10. PG01 Sealing plug 1

7

Page 36

36

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

WORK TABLE UNIT

Item Name Item Name

H Left front guide way surface A Right front guide way surface

G

E

F Left rear guide way surface D Right rear guide way surface

Left front reference surface

B

and pressure plate

Left rear reference surface

C

and pressure plate

Right front reference surface

and pressure plate

Right front reference surface

and pressure plate

Page 37

37

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Number

10. PA4 Pipe cape 9

11. PD401 Connector 8

12. HBL-5 Volume-based distributor 1

Saddle unit

Model Name Quantity

1. PH4-1 Flat and straight-angle connector 1

2. PB6 Pipe 7

3. JD6 Fixed dual connector 1

4. PH601 Straight-angle connector 3

5. PKD6 3-way pipe 1

6. HBL-4 Volume-based distributor 1

7. PQ01 Sealing plug 2

8. PAN4 nut 9

9. PB4 Pipe 18

Page 38

38

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Item

Name Item

A Left front embedded pressure plate I Right front embedded pressure plate

B Front left-right reference surface J Front right-right reference surface

C Front left-left reference surface K Front right-left reference surface

D Left front guide way surface L Right front guide way surface

E Left rear guide way surface M Right rear guide way surface

F Rear left-left reference surface N Rear right-left reference surface

G Rear left-right reference surface O Rear right-right reference surface

H Left front embedded pressure plate P Right front embedded pressure plate

Number Model Name Quantity

1. PKD6 3-way pipe 2

2. PB6 Pipe 8

3. PA6 Pipe cape 8

4. HBL-4 Volume-based distributor 1

Name

5. HBL-5 Volume-based distributor 2

6. PAN4 Nut 17

7. PB4 Pipe 34

8. PA4 Pipe cape 17

9. PH4-1 Flat and straight-angle connector

17

10. PH601 Straight-angle connector 2

11. HBL-3 Volume-based distributor 1

12. PQ101 Connector 2

13 PG01 Sealing plug 1

Page 39

39

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

4-4 Lubrication of the Cam Box of Tool Magazine

Tool magazine’s rotation is driven by ACT cam box. To ensure a smooth rotation of the cam box, it

has to be routinely checked on whether there is enough oil for the oil lens. If not, add oil. After 2,400

hour of operation, replace the circulating oil in the cam box.

Oil inlet

Oil lens

4-5 Counterweight Chain and Sprocket Bearing Lubrication

Apply lube oil onto the sprocket of the counterweight chain. There is an oil inlet at the center of the

sprocket bearing. Add oil at least once a year. Lubricate the counterweight chain, too.

入油口

(oil in)

Page 40

40

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

4-6 Cylinder Lubrication

1. Normally, oil in the oil cup will be depleted eventually. The oil will be used up after about 500,000

times.

2. Normally, it is recommended to remove the remaining oil from the oil cup each year and add new

one when doing the machine maintenance (dot not disassemble the oil cup, or it may be

damaged).

3. The color of the oil will be darkened if it has not been replaced for a long time. It will affect the air

pressure and lifespan of the machine. Check it routinely or monthly.

4. It is abnormal is the oil is depleted within 2 to 3 days. Check whether there is leakage at the oil cup

or the cup is broken. If so, replace the oil cup. If the depletion is abnormal, the boosting cylinder

may need to be replaced immediately to protect the spindle.

4-7 Lubrication Location

Page 41

41

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Chapter 5

The Spindle Oil Cooling Unit

Page 42

42

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

5-1 Oil Cooling Pipeline Diagram

Page 43

43

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

5-2 Spindle Oil Cooling Unit

a) Add the correct type of oil according to the instructions presented on the plaque.

b) The air filter of the cooling unit should be kept clean. It can be taken out for cleaning.

c) The cooling unit also has a oil filter, which has to be cleaned routinely.

Names and operation of functions on the small panel

Page 44

44

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

The spindle has already been appropriately adjusted prior to the installation. It is normal to have a

slight increase of temperature. Spindle oil temperature is supplementary only; do not set the

temperature too high or too low. The temperature control mechanism for the cooler is base on

tracking temperature differences between the oil temperature and the room temperature (or the

machine temperature) to make sure that the difference is well maintained.

The cooling unit is turn on and off automatically based on the temperature of the machine. The

control key of the oil temperature is on the control panel of the cooling unit. When the SV is set to 0℃,

the oil temperature and the machine temperature are the same. When the SV is set to +℃,

temperature of the oil will be greater than of machine. When the SV is set to -℃, temperature of the

oil will be less than of the machine. In general, these two temperatures are set to be equal. If the oil

temperature is set to be lower than the machine temperature, temperature of the oil tank will be

smaller than that of the machine. In this case, condensation may occur, which could contaminate the

oil. Moreover, the external guide way of the bearing may shrink during the operation because the

level of fraction and temperature will be increased, which can damage the spindle.

Do not arbitrarily modify the default value.

Note: This machine has automatic fault detection. When any fault detected, the panel will flash and

display the fault signal. Troubleshooting is required. Then, turn off the machine for at least 10 sec

before turning it on again. For operation quality, double-check that all the problems have been

resolved and the system is at a good condition.

Page 45

45

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 46

46

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

The oil filter shall be installed at the return oil ( inlet ) of the cooler to filter impurity efficiently and

protect the spindle.

Oil cooler uses hydraulic oil and lubrication oil. The directed oil for WEXTEN cooler is 2-300 CST.

The oil below are prohibited.

(1 ) Hydraulic oil of phosphoric ester and chlorinated hydrocarbon types, water, water/ glycol

hydraulic oil

( 2 ) Cutting oil, grinding oil and water-soluble liquid.

( 3 ) Medicine and corrosion liquid.

( 4 ) Gasoline , kerosene and EDM oil.

Check points before operation

1. When the power source is turned on, check to see if power lamp is lighted up.( see figure 1 )

2. Check that electrical resistance of compressor and pump is above 500 ohms.

3. Check that the oil level is at least at 80% level of the oil tank ( see figure 2 )

4. Check that the outlet of the oil tank is tightly secured.

5. Check that the overload switch is at “on “position.

6. Check that value is set at 5 kg/cm² for the pump pressure ( 5kg/cm² indicates 12 L/min, 20L/min,

30l/min pump adjust pressure; .5 kg / cm² indicates 4.5L/min, 7.5L/min, pump adjust pressure )

7. Check the high pressure switch of cooler of capacity 3000 kcal/hr is adjusted at 23 kg/cm² and

28 kg/ cm² for cooler of capacity above 6000 kcal/hr. ( see figure 3 )

8. Check if the oil inlet is fitted with an oil filter. ( see figure 4 )

9. Check cooling medium high/low pressure, if the indication needle position is as same as the

testing report

Page 47

47

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 48

48

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

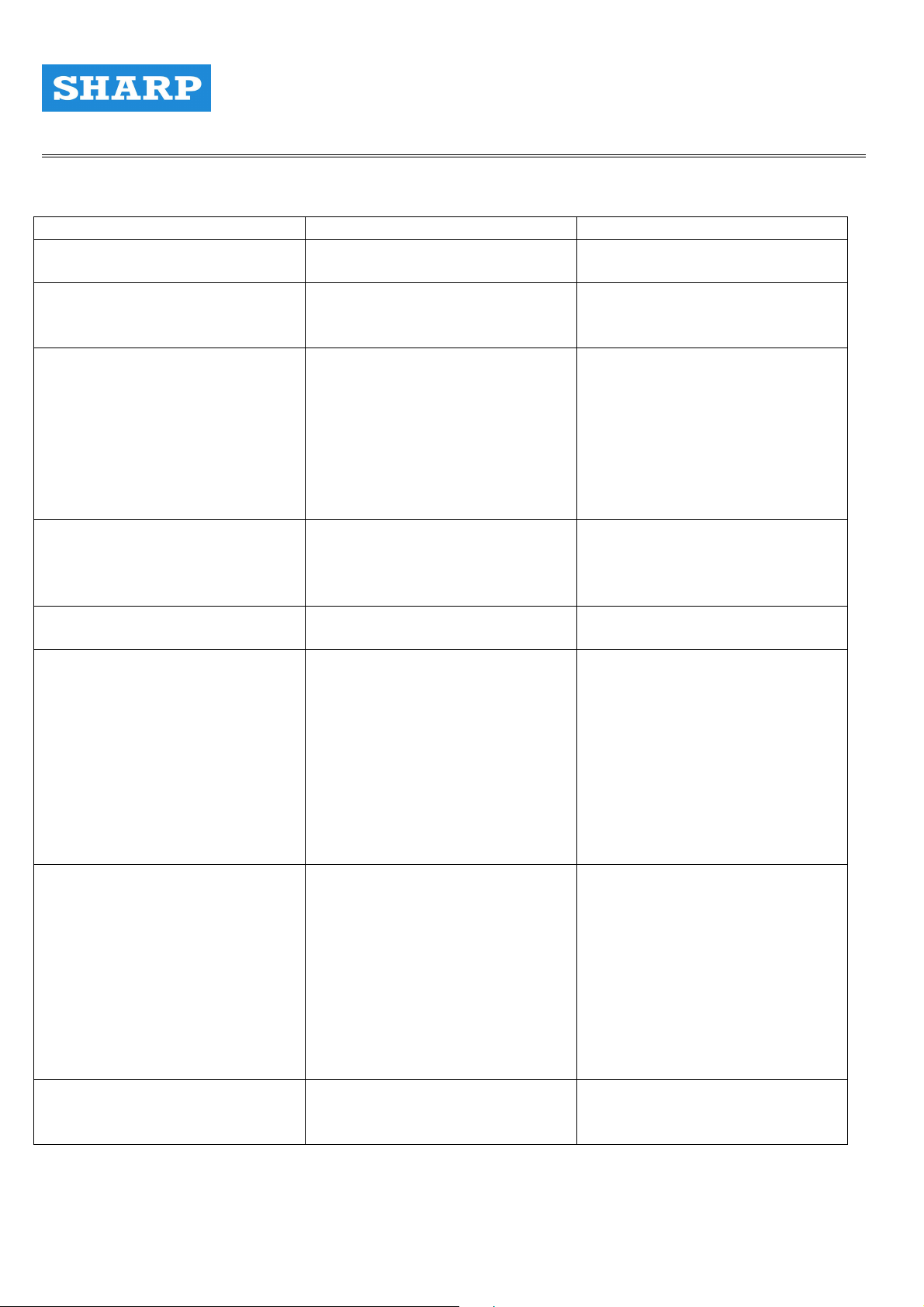

Troubleshooting

Possible Causes and Remedial Action

1. For any alarm signals, please refer to the following recommended remedial action.

If problems cannot be solved, please contact us or our nearest agent. Checking the cooler model,

sear number and the particular alarm sign show on control panel.

Lack of cooling medium

The following condition is caused by lack of cooling medium:

No alarm information but the motors keep running, cooler can not reach to the setting temperature

and working machine’s spindle is hot.

If the above situation occurred, please call professional technical staff to dispose or contact us

directly.

Oil tank and filter

1. Oil level in tank should be ay least at the 80% level mark to prevent the air into the pump. At the

same time, maintain the oil is clean.

2. The oil filter must be replaced or cleaned periodically, in order to prevent accumulating iron

powder to reduce the discharge rate of pump and cause noisy.

Note: Machine damaged due to not on a regular basis cleaned filter or unrelated return oil filter is

caused by human error, which is not covered by the warranty.

Page 49

49

t run or blades fall.

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Condition Cause Remedy

Power lamp is off

REV is lighted

OPS is lighted

1. LED burnt

2. PC board fuse blown

3. Transformer burnt

4. Wire 18,19 loose connection

1. 3 phase power reverse value 3 phase

is above ±10%

2. Pressure reduction and differential

1. Inlet oil pipe is clogged or loosened

2. Inlet & outlet are reversed

3. Pump motor runs reverse

4. Pump can not run

5. Circulation oil is not enough

6. Oil filter is dirty

7. Oil pressure switch breakdown

1. Overload relay is off

1. Replace PC board

2. Replace fuse

3. Replace transformer

4. Reconnect wire 18,19

1. Switch any 2 of the R.S.T wires

2. Stability power source

1. Check, clean and lock pipe

2. Correct position of in/outlet

3. Check over-relay of 51p red

and white lines.

4. Replace oil pump

5. Supply circulation oil

6. Replace new filter

7. Adjust oil pressure switch DIFF,

0.3 kgf/cm² range 0.8~0.8 cmHg

1. Reset switch

PUMP is lighted

2. Pump switch is off

3. Inlet pipe is clogged

1. Overload relay off

2. Reset pump switch

Clean pipe and replace oil filter

1. Reset switch

COM is lighted

2. Compressor breakdown

1. Condenser is too dirty

2. Air filter is not clean

3. Cooling fan doesn’

4. Cooling medium pressure switch

2. Replace compressor

1. Use compress air to clean fins

and restart cooler.

2. Clean filter.

3. Lock fan blades tightly or replace

HP is lighted

breakdown.

5. Cooling medium is leaking

fan motor.

4. Replace cooling medium

pressure switch.

5. Irrigate cooling medium.

RA is lighted 1. Room temp. sensor breakdown 1. Replace RA sensor

RO is lighted 1. Oil temp. sensor breakdown 1. Replace RO sensor

1. Oil temp. is to high

2. Temp. sensor blown

1. Stop running cooler until oil temp.

returns to normal range start again

OT is lighted

3. Check cooling medium is enough or

2. Replace temp sensor.

not.

3. Supply cooling.

Page 50

50

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Chapter 6The Electrical Unit

Page 51

51

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

6-1 The Electrical Unit

1. Check the connectors of the electrical lines to prevent from detachment.

2. Make sure that the battery is replaced once a year to prevent parameter deletion, unstable

parameters or unstable three-axis positioning precision.

3. The dust cover of the electrical box and the filter of the thermal heat exchanger have to be kept

clean.

4. Operation environment conditions:

Low temperature

Good air circulation

Dry floor

Remote from electromagnetic disturbance

Stable electricity

5. Basic safe operation conditions: (See the following page)

Please follow the five basic rules below:

1. Only people know about this machine and have qualification as well as permission can operate

the machine or performance the maintenance. Those competent individuals have to receive

appropriate training to understand the safety and protective measures as well as machine

maintenance work. These individuals have to be approved for their safety control ability.

Especially those performing the electrical maintenance, they have to be experienced and can

recognize the safety standard and official regulations.

2. Before operating the machine, make sure that the safety instruction part as well as descriptions

on the operation, programs and maintenance in the user’s manual has been well read.

3. Individuals who need to operate the machine or give maintenance should know the emergency

stop button and the function.

Page 52

52

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

1) Operation box

Note:

(a) Please well guard the relevant keys.

(b) The dust pan has two security keys.

To prevent the memory to be modified arbitrarily, use the function showed on the right figure.

Emergency stop:

Press this button to halt

the operation

immediately.

Memory edit lock:

This key is used to prevent unauthorized or

arbitrarily changing of the processing procedure.

Page 53

53

turn of this switch.

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

2) Electrical box

(a) Please well guard the relevant keys.

(b) The machine has two security keys to prevent the electrical box from being opened arbitrarily.

The functions are presented on the right figure.

(c) Keep the user’s manual at an easily accessed location. If the manual word can’t read, please call

the agent and confirm the model as well as the model number of the machine.

Locked electrical box:

The box cannot be opened by

unauthorized personnel.

Main power switch:

Before performing and maintenance,

repair or for any emergency condition,

Page 54

54

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Chapter 7

Appendix

Page 55

55

less deterioration

Recommended

(3)CASTROL HYSPIN

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

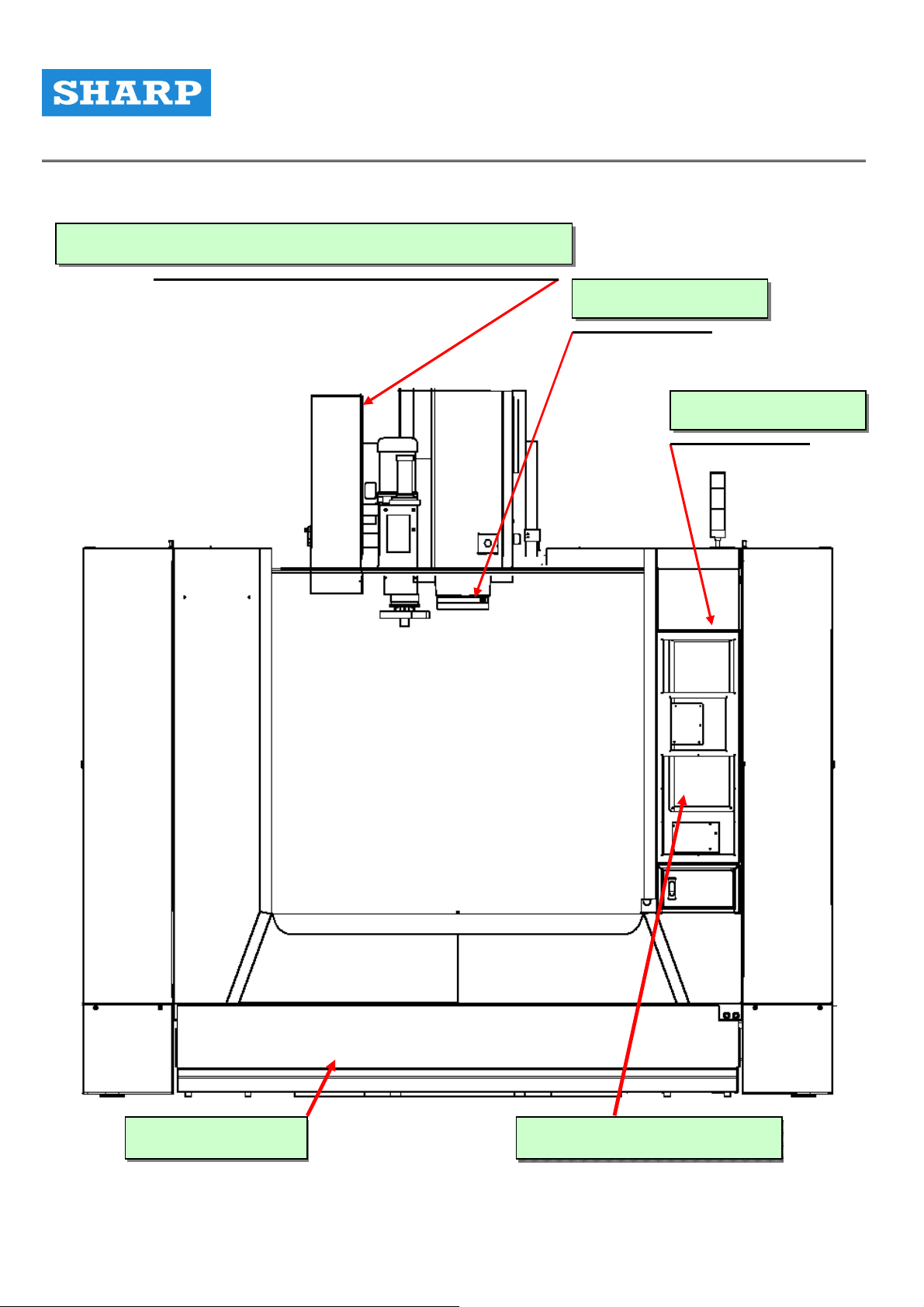

7-1 Oil Selection

Lubrication

Location

Characteristics

of the oil

Lubrication

Methods

Oil

Air Compressor

Preparation Unit

(1) Viscosity ISO

VG32

(2) Anti rust,

foam, oxidation,

etc.

(3) Good stability;

Guide ways and balls

screw

(1) ISO VG32

(2) High oil film

intensity

(3) Low abrasion

(4) High abrasion

resistance

Cylinder Coolant

(1) Viscosity ISO

VG68

(2) Anti rust,

foam, oxidation,

and

emulsification

(5) High thermal

stability

(6) High corrosion

resistance

(7) High rust

resistance

Oil feeder Automatic centralized

Circulation

lubrication

When needed When needed Add more when

(1) High thermal

conduction

2) Good lubrication

When needed

replacement

interval

needed; replace

the oil every

year.

Tank capacity 55CC 3L 270L

Brands

(1)MOBIL

RARUS 424

(2)ESSO

TERESSO S32

(3)CASTROL

HYSPIN VG32

(4)SHELL

TONNA S32

(1)MOBIL VACTRA 1

(2)ESSO FEBIS K32

(3)CASTROL MAGNA

GC32

(4)Shell TONNA T32

(1)MOBIL

RARUS 424

(2)ESSO

TERESSO S32

(3)CASTROL

HYSPIN VG32

(4)SHELL

TONNA S32

(1)MOBIL RARUS

(2)ESSO TERESSO

(4)SHELL TONNA

424

S32

VG32

S32

Page 56

56

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

7-2 Spindle Tool Change Position Calibration

1) Check whether the origin offset of the Z-axis is zero. Change the positive and negative move

distance of the Z-axis to 99999999 and -99999999. Afterward, return the Z-axis to zero position .

Put a cutter on the spindle. Measure 0.6~ 0.8 mm the distance of tool unclamp .

Then, remove the cutter.

2) Lock the tool calibration magazine module onto the body of the tool magazine

Tool magazine calibration

module

(Adjustment block)

Page 57

57

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

3) Take out a modular concentricity test gauge and a dial indicator. Separate the three sections and

place them on the inner hole of the spindle and gripper.

Dial indicator

Gripper

Arm

Modular concentricity test gauge

4) Use the dial indicator to measure the position of the arm of the cutter.

The X-axis deviation should not exceed 0.1mm.

5) Fasten the screws (circled by a red line) according to the ISO standard.

6) Hammer the tool magazine into the fixing pin (circled by a yellow line

Fixing pin for the tool magazine

Fixing screw for the tool magazine

Fixing screw for the tool magazine

Page 58

58

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

7-3 Determination of the Z-Axis Coordinate Origin

Shift the Z-axis from the nose end of the spindle to a position that is 130mm above the workbench.

See the figure below.

Nose end of the spindle

130mm

2.

1) Treat this position as the origin. Zero the value corresponded to the Z-axis on the screen.

2) Shift the Z-axis to a position where the corresponding position on the screen is

740mm.

Page 59

59

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

4. At this point, the relative distance between the spindle nose end and the workbench is 740mm.

See the figure below.

740 mm

Page 60

60

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

4. Enter the parameter setup mode and look for 1815. Change the APZ of the Z-axis to 0 before

turning on the machine.

5. After turning on the machine, enter Parameter 1815 to change APZ of Z-axis to 1. Turn on the

machine again (At this point, the position of the Z-axis will be treated as the machine reference

point).

Page 61

61

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

7-4 Descriptions on Program and Servo Alarms

Page 62

62

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 63

63

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 64

64

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 65

65

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 66

66

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 67

67

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 68

68

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 69

69

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 70

70

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 71

71

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 72

72

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 73

73

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 74

74

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 75

75

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 76

76

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 77

77

PRECISION MACHINE TOOLS Ver 2 Maintenance Manual

Page 78

78

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 79

79

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 80

80

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 81

81

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 82

82

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 83

83

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 84

84

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 85

85

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 86

86

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 87

87

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 88

88

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 89

89

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 90

90

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 91

91

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 92

92

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 93

93

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 94

94

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 95

95

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 96

96

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 97

97

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 98

98

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 99

99

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Page 100

100

PRECISION MACHINE TOOLS Ver2.1 Maintenance Manual

Loading...

Loading...