Page 1

COPIER : SF-2350

Date

:

May. 11, 1999

1. CHANGE IN THE GROUNDING WIRE CARRIED OUT AS A MEASURE TO COMPLY WITH UL

STANDARDS.

2. MEASURE TO PREVENT THE DISCHARGED PAPER FROM FALLING.

3. IN-HOUSE PRODUCTION OF THE OPERATION MANUALS CARRIED OUT AS A MEASURE

TO IMPROVE PRODUCTIVITY.

4. DISCONTINUANCE OF THE REVERSE GUIDE STOPPER SHEET.

No. : SP-2361

1. Change in the grounding wire carried out as a measure to comply with UL

standards.

1.Model Name: SF-2025/2030/2040/2530/2540 (only for machines of the 100 V series.)

2.General: A change has been carried out in the grounding wire used with the AC PWB. The

grounding wire has been changed to a double-colored wire which is green and yellow.

This action has been carried out as a measure to comply with UL standards.

3.Action: *1 Japanese domestic production: From the 1st lot of 1999 March production.

Chinese (SOCC) production: From the 1st lot of 1999 April production.

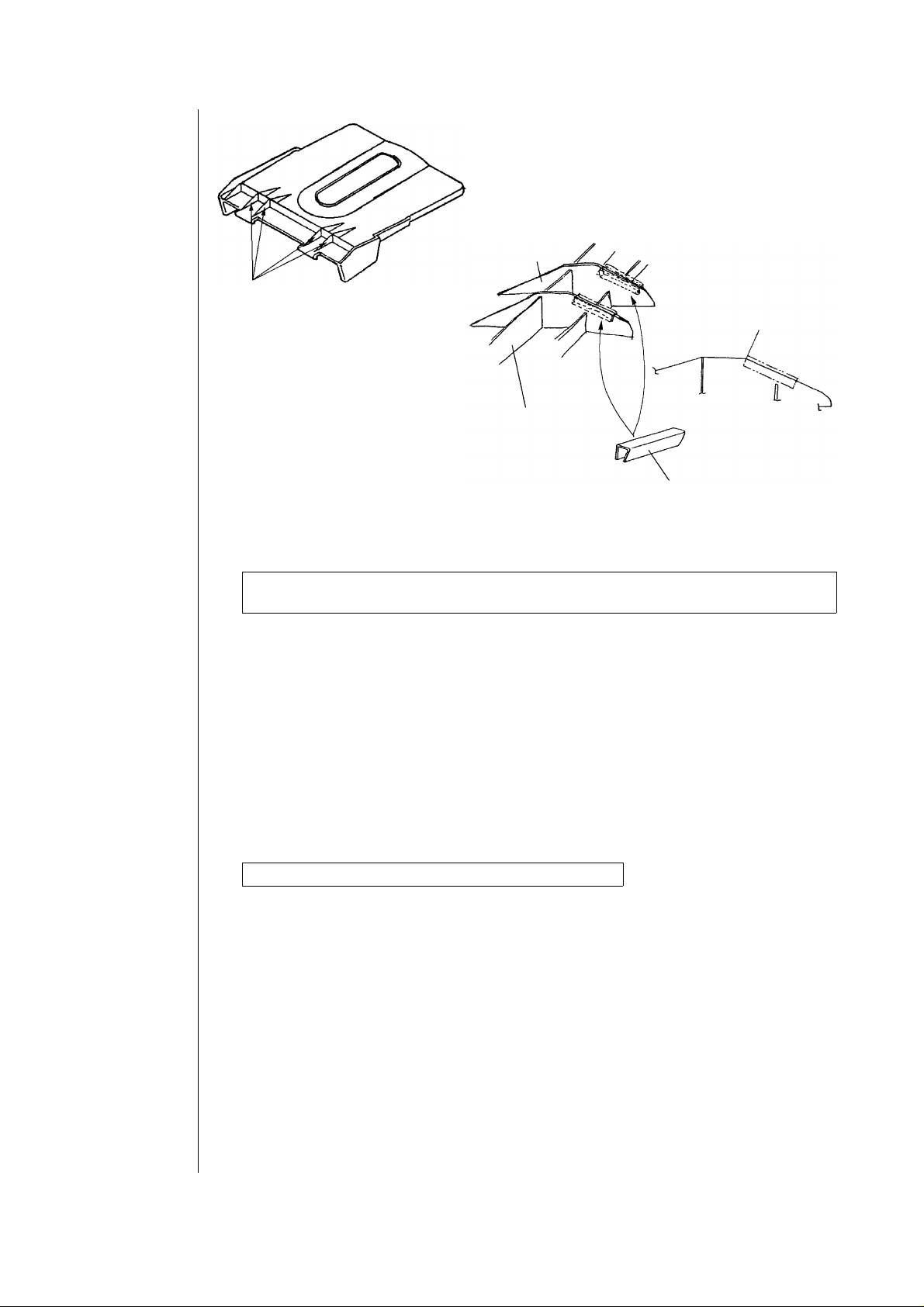

2. Measure to prevent the discharged paper from falling.

1.Model Name: SF-2022/2027/2035/2025/2030/2040

2.General: There was a problem of the copy paper falling from the paper delivery tray during paper

delivery operations of overseas copy paper (IGEPA A3 sized paper). As a measure to

alleviate this problem, the action described below has been carried out.

3.Cause: The attachment angle of the paper delivery tray was too shallow.

4.Action: The addition of edging has been carried out to the paper delivery tray. As a result of this

change, the attachment angle of the paper delivery tray has been made deeper.

SHARP CORPORATION Document Division I

1/4

Green

C

Page 2

Rib G

(4 locations)

Rib G

Attachment standard

(Rib G)

Paper delivery tray

(LSOU-0090FCZZ)

Edging 25

(LBSHC0113FCZZ)

5.Action: No action has been carried out for production. Action should be carried out in

accordance with necessity.

3. In-house production of the operation manuals carried out as a measure to improve

productivity.

1.Model Name: SF-2530/2540

2.General: The operation manuals were previously produced and supplied by an outside maker,

but now the operation manuals are being produced in-house. (Only for Japanese

domestic production lots.) This action has been carried out as a measure to improve

productivity. In accordance with the action described above, a change has been carried

out in the part codes of each of the operation manuals.

3.Action: From the 1st lot of 1999 January production.

4. Discontinuance of the reverse guide stopper sheet.

1.Model Name: SF-2530/2540 (except for machines bound for the USA (SEC) and Canadian market

destinations.)

2.General: The reverse guide stopper sheet used in the paper delivery reversion unit of machines

bound for market destinations in which a decurler is used in the fusing unit was not

necessary, and for this reason, the reverse guide stopper sheet has been discontinued.

3.Action: *2 Japanese domestic production: From the 1st lot of mass production.

Chinese (SOCC) production: From 1999 February production.

2/4

Page 3

Ref.

Model

No.

name

SF-2025

SF-2030

1

SF-2040 35 -1

Version P/G No.

100V

36 -1

Current parts New parts

Parts code Parts code

DHAI-2487FCZZ DHAI-2737FCZZ AE AC earth harness *1 1

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

SF-2530

SF-2540

SF-2022

SF-2027

SF-2035

2

SF-2025

SF-2030

SF-2040

3 SF-2530

37 -1

All ---- ---- LBSHC0113FCZZ AC Edging 25 ---- 6

U.S.A.

(SEC)

* TINSE1808FCZZ CINSE1808FC51

U.K. TINSE1809FCZZ CINSE1809FC51

German TINSG1810FCZZ CINSG1810FC51

French TINSF1811FCZZ CINSF1811FC51 AY

Spanish TINSS1812FCZZ CINSS1812FC51 BA

Italian TINSI1813FCZZ CINSI1813FC51 AY

Dutch TINSH1814FCZZ CINSH1814FC51

Swedish TINSW1815FCZZ CINSW1815FC51

Arabic TINSZ1816FCZZ CINSZ1816FC51

Russian TINSR1817FCZZ CINSR1817FC51

Hong Kong TINSE1821FCZZ CINSE1821FC51

45 -9

TINSE1807FCZZ CINSE1807FC51

AY

BA

Operation manual

BA

1st lot

’99/1

1

* English text for markets other than the USA and the UK.

3/4

Page 4

Ref.

Model

No.

name

3 SF-2540

SF-2530

4

SF-2540

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with ‘‘ ’’ is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

Version P/G No.

U.S.A.

(SEC)

* TINSE1794FCZZ CINSE1794FC51

U.K. TINSE1795FCZZ CINSE1795FC51

German TINSG1796FCZZ CINSG1796FC51 BB

French TINSF1797FCZZ CINSF1797FC51 AZ

Spanish TINSS1798FCZZ CINSS1798FC51 BB

Italian TINSI1799FCZZ CINSI1799FC51 AZ

Dutch TINSH1800FCZZ CINSH1800FC51

Swedish TINSW1801FCZZ CINSW1801FC51

Arabic TINSZ1802FCZZ CINSZ1802FC51

Russian TINSR1803FCZZ CINSR1803FC51

Hong Kong TINSE1820FCZZ CINSE1820FC51

U.S.A.

(SEC)

Except

U.S.A.

(SEC)

Canada

45 -9

7 -42

Current parts New parts

Parts code Parts code

TINSE1793FCZZ CINSE1793FC51 AY

TINSE1805FCZZ CINSE1805FC51 AQ

PSHEP4107FCZZ Discontinued ---- Guide stopper sheet *2 6 Q’ty: 2

Price

rank

AZ

BB

BA

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Parts name

Operation manual

Operation manual

(Key operation guide)

Effec-

tive

time

1st lot

’99/1

Inter-

change-

ability

1

Note

4/4

* English text for markets other than the USA and the UK.

Loading...

Loading...