Page 1

AR-F14

CODE : 00ZARF14//A1E

DIGITAL COPIER

MULTIFUNCTIONAL SYSTEM

OPTIONS

FINISHER

PUNCH UNIT

AR-F14

MODEL

CONTENTS

[1] INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[2] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . 2 - 1

[3] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . 3 - 1

[4] OPERATIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

[5] DISASSEMBLY AND ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . 5 - 1

[6] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

[7] MACHINE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

[8] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

AR-PN1

[9] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

[10] SIMULATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

[11] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 1

Parts marked with “ “ are important for maintaining the safety of the set.

Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used for

SHARP CORPORATION

after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

[1] INTRODUCTION

1. Product outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

3. Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

4. Consumable parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. External view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Internal structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. Finisher and saddle section . . . . . . . . . . . . . . . . . . . . . 2-2

4. Interfac e transport section . . . . . . . . . . . . . . . . . . . . . . 2-3

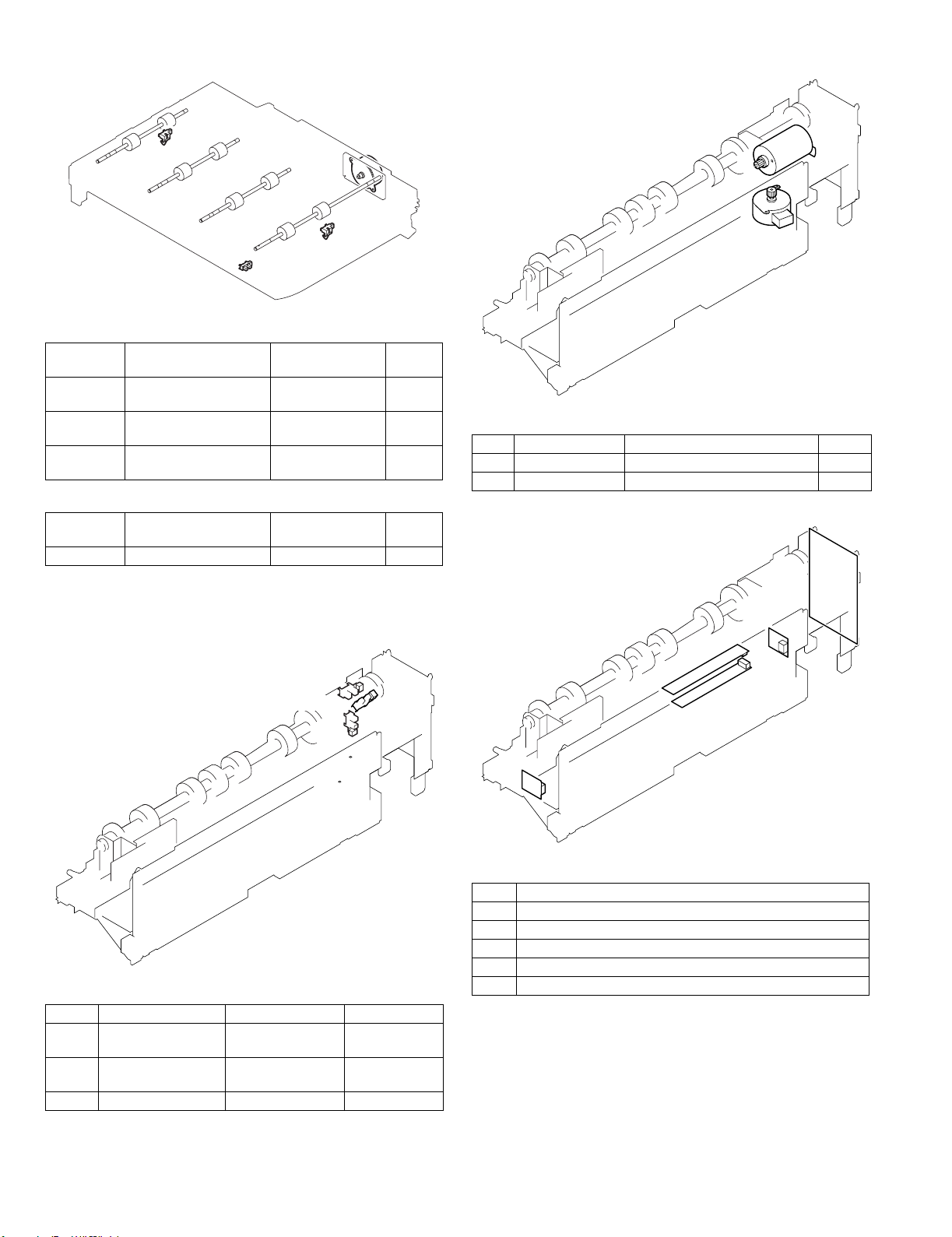

5. Puncher section (AR-PN1). . . . . . . . . . . . . . . . . . . . . . 2-3

[3] UNPACKING AND INSTALLATION

1. AR-F14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2. AR-PN1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

[4] OPERATIONAL DESCRIPTION

1. Basic Operatio n s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Feed/Drive System. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

3. Stapling Operatio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4. Delivery Tray Operation . . . . . . . . . . . . . . . . . . . . . . . . 4-10

5. Saddle Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

6. Puncher Unit (option). . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

7. Detecting Jams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

8. Power Supply System. . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

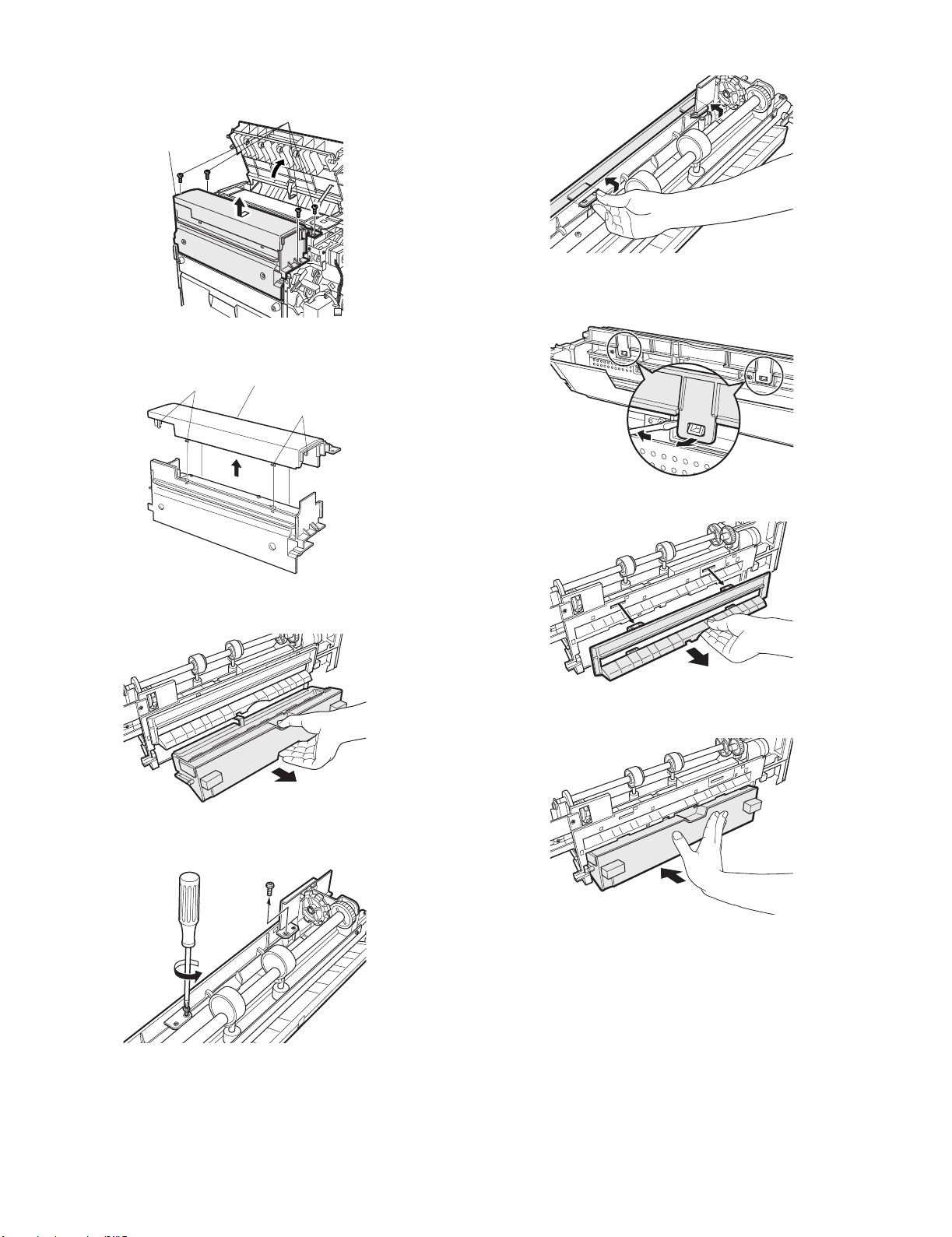

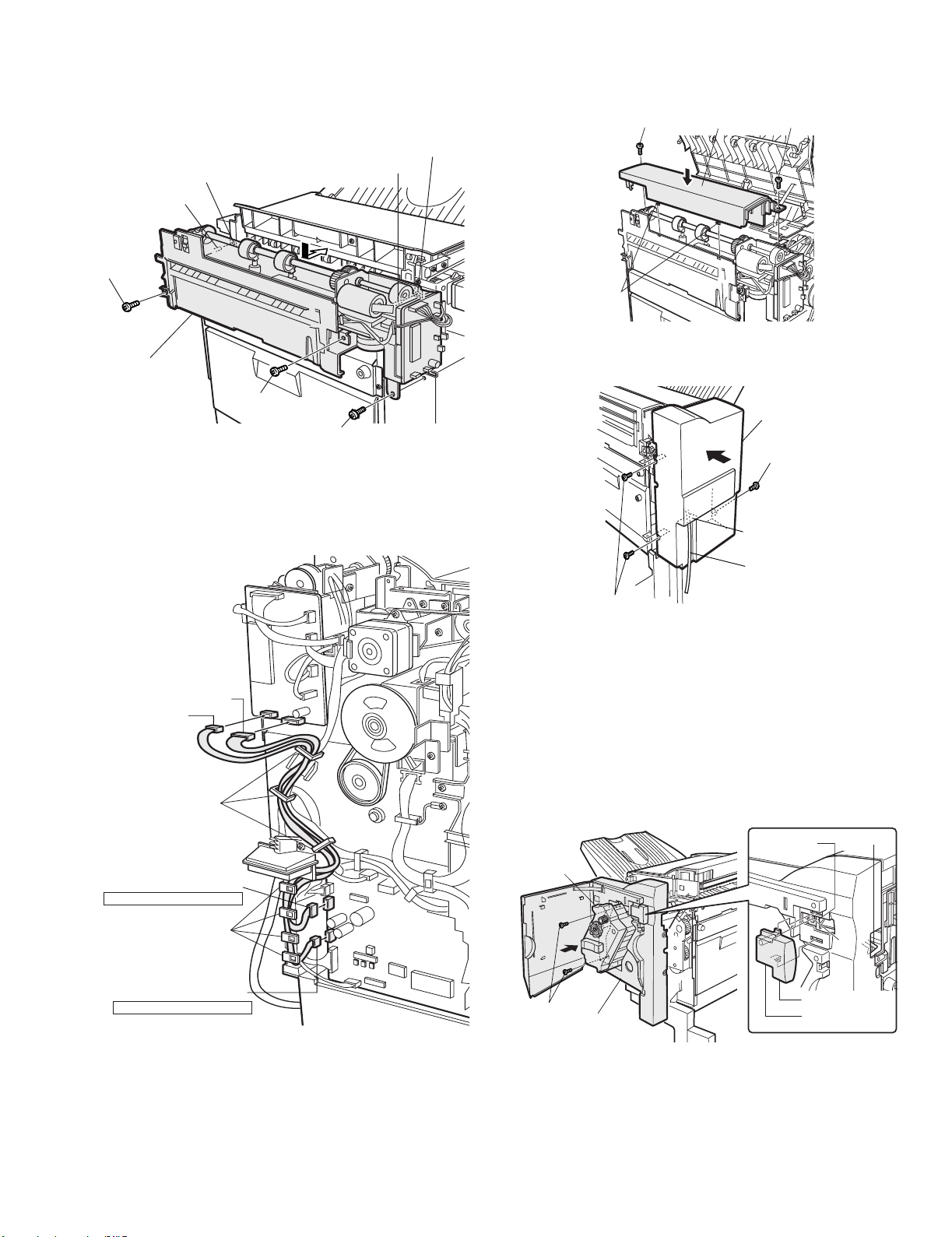

[5] DISASSEMBLY AND ASSEMBLY

1. Finisher Saddle Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. puncher Unit (option) . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

[6] MAINTENANCE

1. Maintenance System Table . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Discarding punch waste

(when a punch unit is installed) . . 6-1

[7] MACHINE OPERATION

1. Staple sort mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Setup by the printer driver. . . . . . . . . . . . . . . . . . . . . . . 7-2

3. Using the saddle stitch finisher functions

in copy mode . . 7-2

[8] ADJUSTMENTS

1. Finisher/saddle unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Puncher unit (option ). . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] TROUBLE SHOOTING

1. Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. Trouble code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

3. Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

[10] SIMULATIONS

1. Finisher/Saddle unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. Puncher unit (option ). . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] ELECTRICAL SECTION

1. LEDs and Ch e ck Pin s by PC B . . . . . . . . . . . . . . . . . . . 11-1

2. Wiring diagram (AR-F14) . . . . . . . . . . . . . . . . . . . . . . . 11-2

3. Wiring diagram (AR-PN1). . . . . . . . . . . . . . . . . . . . . . . 11-4

Page 3

[1] INTRODUCTION

1. Product outline

This unit is installed to the following machines to perform the after-process of output paper from a copier, or a fax machine.

1) Employment of the through-type stapler

Employment of the through-type stapler allows to make saddle stitch by one stapler.

2) 3 kinds of auto staple functions

There are 3 staple positions available. (One position in the front, one position at the back, 2 positions at the center)

3) Saddle stitch function

Up to 10 sheets of paper can be stapled at the center and folded into two and discharged.

4) Punch function (Option)

By installation of a puncher unit, paper can be punched to make holes for a binder. (Applicable for 64 - 128g/m². OHP films cannot be used.)

Applicable models AR-M237 / M277, AR-M236 / M276

2. Configuration

1. When installing this machine, the exclusive-use table (large) or the exclusive-use table (small) + the multi-stage paper feed unit

(AR-D21 or AR-D22) must be attached to in advance.

2. This unit cannot be installed with the following units:

•Finisher (AR-FN5N)

3. Specifications

A. AR-F14

(1) Basic specifications

Type Console type finisher

Transport speed 23/26/27 ppm

Transport reference Center reference

Tray type

(Number of trays)

Paper exit direction Face down

Paper exit paper size A3, B4, A4, A4R, B5, B5R, A5,

Power consumption 60W or below

Power source Supplied from the machine power

External dimensions (W x D x H) 661 x 603 x 1016 (mm)

Occupying dimensions (W x D) 712 x 603 (mm)

Weight About 38kg

Upper tray Lift-up/down offset tray

Lower tray Book tray for saddle stitch

11" x 17", 8.5" x 14", 8.5" x 13",

A5/Invoice R inhibited

A5/Invoice horizontal allowed

8.5" x 11", 8.5" x 11"R,

5.5" x 8.5"

(DC24V, 2.5A)

(2) Finishing section

Capacity of

paper exit and

load

Offset function Provided

Paper size which

can be stapled

Kinds and

weights of paper

to be discharged

Non-staple *1,000 sheets (Small size)

500 sheets (Large size)

Staple sort *30 sheets

* Equivalent to 64g/m² of paper

Max 1,000 sheets (Small size)

500 sheets: (Large size)

Less than 1,000 sheets and less than 30 copies

depending on the use environment and paper curl.

Large size A3, B4,

11" x 17", 8.5" x 14", 8.5" x 13"

Small size A4R , B5, B5R, A5,

8.5" x 11", 8.5" x 11"R, 5.5" x 8.5"R

A3, B4, A4, A4R, B5, B5R,

11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11",

8.5" x 11"R

Normal paper 60 - 128g/m² (16 - 34lbs)

Index paper 176g/m² (47lbs)

Cover paper 200 g/m² (54lbs)

Quantity of paper

to be stapled

(Max.)

Stapling 3 kinds

Staple supply Staple cartridge replacement

Staple detection Staple empty

50 sheets

(Small size, 128g/m² x 2 + 80g/m² x 48)

25 sheets (Large size, 80g/m² x 25)

Large size A3, B4,

Small size A4 , A4R,

(One in the front, one at the back: two positions)

two positions A3, B4, 11" x 17", 8.5" x 14",

one at the back A3, B4, A4, A4R, B5, B5R

one in the front 11" x 17", 8.5" x 14", 8.5" x 13",

detection

Cartridge

empty

detection

Staple jam

detection

11" x 17", 8.5" x 14", 8.5" x 13"

8.5" x 11", 8.5" x 11"R, B5, B5R

8.5" x 13", A4, 8.5" x 11", B5, B5R

8.5" x 11", 8.5" x 11"R, B5, B5R

Provided

Provided

Provided

(3) Saddle stitch section

Stapling type Center stapling: Center folding

Stapling position 120mm pitch from the paper center

Weight of paper applicable for

saddle stitch

Paper size 64 - 80g/m²

Book tray stacking type Fixed

Quantity of paper to be stapled 10 sets (6 - 10 pages)

A3, A4R, B4,

11" x 17", 8.5" x 11"R

(Cover: 64 - 128g/m²)

20 sets (1 - 5 pages)(80g/m²)

B. AR-PN1

Type Punch unit

No. of punch holes AR-PN1A AR-PN 1B AR-PN1C AR-PN1D

Size of paper

applicable for punching

2 holes 2 / 3holes 4 holes 4 holes

Max. A3, Min. B5R

4. Consumable parts

Name Content Life Product

Staple cartridge Staple cartridge x 3 5000 x 3 AR-SC2

AR-F14/PN1 INTRODUCTION 1-1

Remark

name

Page 4

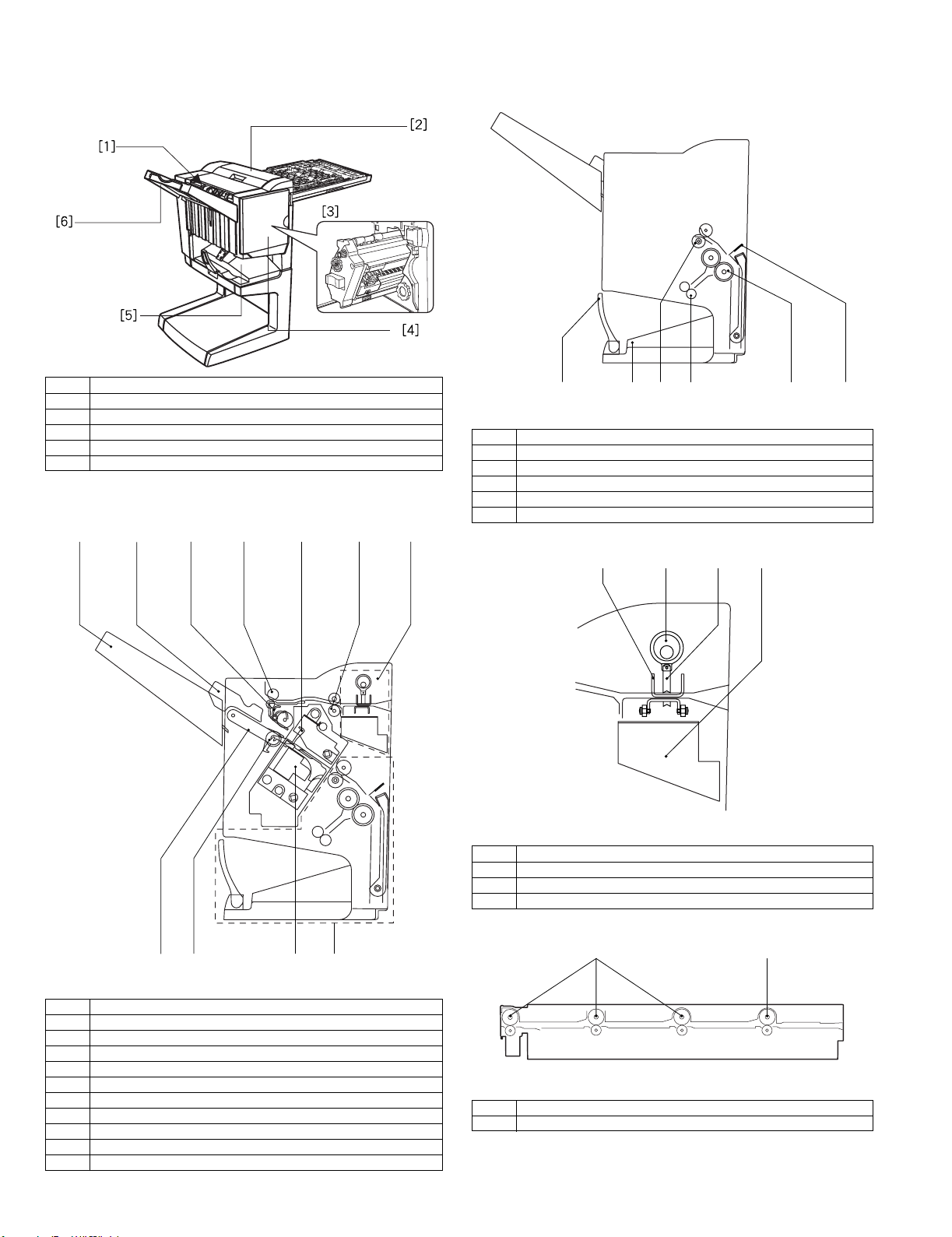

[2] EXTERNAL VIEWS AND INTERNAL STRUCTURES

[1]

[3] [7][5][4] [6]

1. External view

[1] Stapler compiler

[2] Top cover

[3] Stapler section

[4] Front cover

[5] Saddle stitch tray

[6] Offset tray

2. Internal structure

A. Finisher section

[2]

B. Saddle section

[1]

[1] Book making stopper

[2] Book making tray

[3] Bundle transport roller

[4] Book making exit roller

[5] Paper folding roller

[6] Paper pushing plate

[3]

Fig. F01-301-02

C. Puncher section (Option)

[2]

[4][2]

[3][1]

[5]

[4]

[6]

Fig. F01-301-03

[1] Dice

[2] Cam

[3] Punch

[4] Punch dust box

D. Interface transport section

[9]

[8]

Fig. F01-301-01

[1] Paper exit tray

[2] Alignment plate (Front, back)

[3] Paddle

[4] Paper exit roller

[5] Process tray stopper

[6] Transport roller

[7] Puncher section (Option)

[8] Paper exit belt

[9] Bundle exit roller

[10] Stapler

[11] Saddle section

[10]

[11]

Fig. F01-301-04

[1] Interface transport medium roller

[2] Interface transport drive roller

AR-F14/PN1 EXTERNAL VIEWS AND INTERNAL STRUCTURES 2-1

[2][1]

Page 5

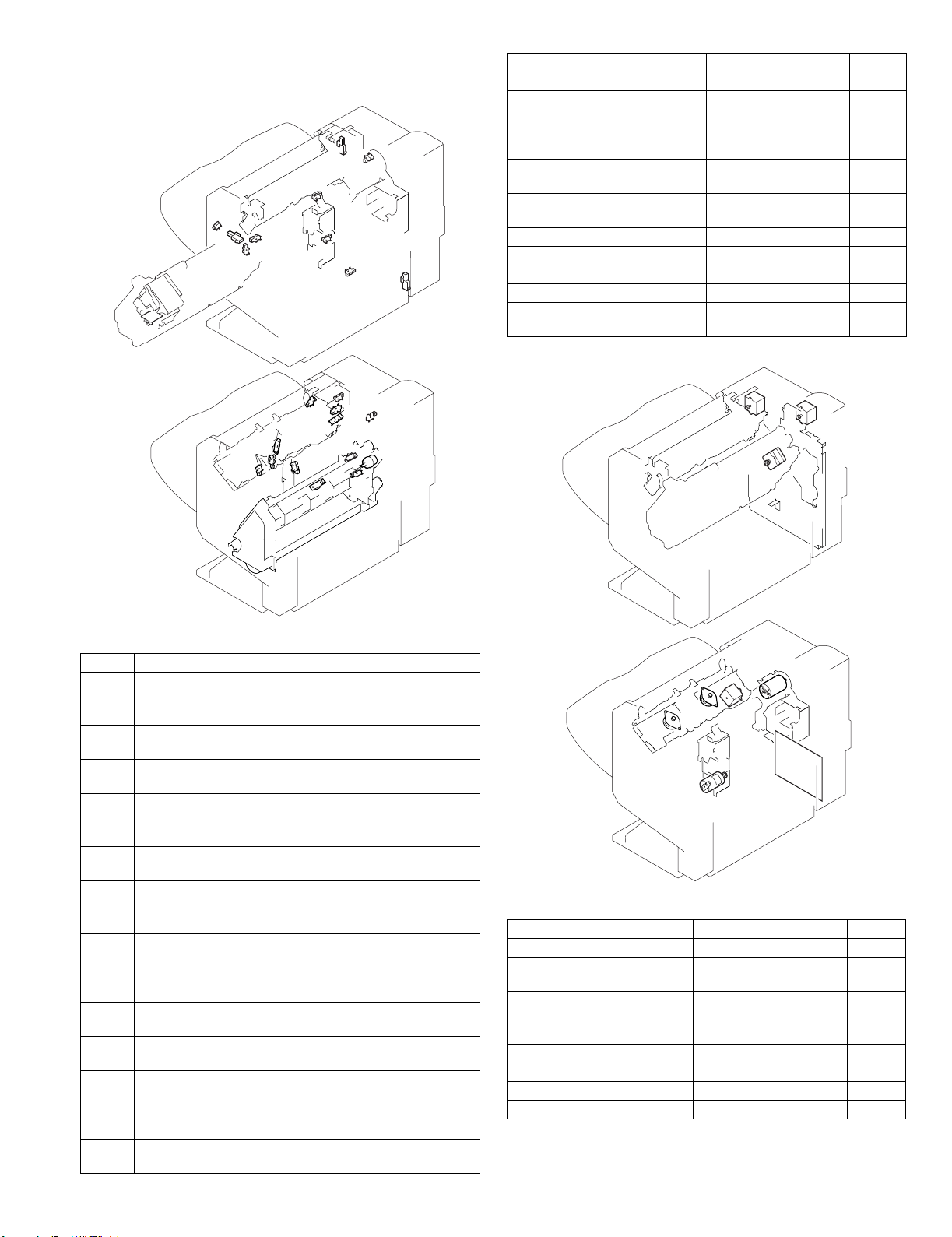

3. Finisher and saddle section

A. Sensor

SSS

LLLS

FJHPS

TCS

FDS

FDSW

STHPS

SPS

SS

SHPS

LE

FES

FE

Code Name Active condition Remark

LE Lift lock sensor

SHPS Slide home position

Stapler HP : "H"

sensor

STHPS Stapler home position

Stapler stapling HP : "L"

sensor

SPS Self prime sensor Cartridge staple

detected : "L"

SS Staple sensor Stapler cartridge

detected : "L"

FDS Front door sensor Front cover open : "H"

TCS Upper cover sensor Upper cover open : "H"

JS

FDSW Front door switch Front door closed : "H"

JS Joint switch Printer connected : "H"

SSS Stapler safety switch Oscillation guide closed :

"H"

B. Motor and PWB

ULS

BES

AS

RJHPS

OBHPS

O

SLS

PHPS

FRHPS

FPS

ARHPS

FHPS

ES

FFC

Fig. F05-201-01

Code Name Active condition Remark

ES Entry sensor Paper detected : "H"

PHPS Paddle home position

Paddle HP : "H"

sensor

ARHPS Bundle roller home

position sensor

FJHPS Alignment home position

sensor (front)

RJHPS Alignment home position

sensor (rear)

Oscillation guide

HP : "H"

Alignment tray (F)

HP : "H"

Alignment tray (R)

HP : "H"

AS Alignment tray sensor P aper detected : "H"

OBHPS Exit belt home position

Paper exit belt HP : "H"

sensor

BES Tray paper sensor Tray paper detected :

"H"

SLS Paper level sensor Paper detected : "H"

FPS Bookbinding position

Paper detected : "L"

sensor

FHPS Bookbinding home

position sensor

FRHPS Bookbinding roller HP

sensor

FES Bookbinding paper

Folding operation

HP : "L"

Bundle transport roller

HP : "H"

Paper detected : "H"

sensor

FE Bookbinding clock

sensor

ULS Lift upper sensor Tray upper limit detected

: "H"

LLLS Lift lower sensor Tray lower limit detected

: "H"

FPM

FFM

FSM

FAM

FRJM

FFJM

FLM

FFSM

[1]

Fig. F05-201-02

Code Name Active condition Remark

FFM Transport motor Paper transport

FPM Paddle motor Oscillation guide drive,

paper exit to offset tray

FAM Bundle exit motor Paper exit operation

FFJM Alignment motor

Alignment plate (F) drive

(front)

FRJM Alignment motor (rear) Alignment plate (R) drive

FLM Shift motor Paper exit tray up/down

FFSM Stapler/Fold motor Stapling/paper folding

FSM Slide motor Staple unit sliding

AR-F14/PN1 EXTERNAL VIEWS AND INTERNAL STRUCTURES 2-2

Page 6

4. Interface transport section

B. Motor

FJOS

FJES

FJCS

A. Sensor

Code /

Brevity Code

FJOS Interface transport unit

paper exit sensor

FJES Interface transport unit

paper entry sensor

FJCS Interface transport unit

cover sensor

Name Acti ve condition Remark

Paper detection: [L]

Paper detection: [L]

Cover open: [L]

B. Motor

Code /

Brevity Code

FJM Interface transport motor Paper transport

Name Acti ve condition Remark

5. Puncher section (AR-PN1)

A. Sensor

FJM

FPNM

FPSM

Fig. F05-202-02

Code Name Active condition Remark

FPNM Punch motor Punch drive

FPSM Punch side motor Punch slide unit transverse move

C. PWB

[1]

[4]

[2]

PE

Punch Home Position

PSHPS

Fig. F05-202-01

Code Name Active condition Remark

Punch home position

sensor

PSHPS Punch side home

position

PE Punch dust sensor In the punch unit

Punch HP

detected:"L"

Punch slide unit HP

detected:"H"

In the punch unit

In the punch unit

[3]

[5]

Fig. F05-202-03

Code Name

[1] Punch driver PWB

[2] Side resist photo sensor PWB

[3] Side resist LED PWB

[4] Dust full photo sensor PWB

[5] Dust full LED PWB

AR-F14/PN1 EXTERNAL VIEWS AND INTERNAL STRUCTURES 2-3

Page 7

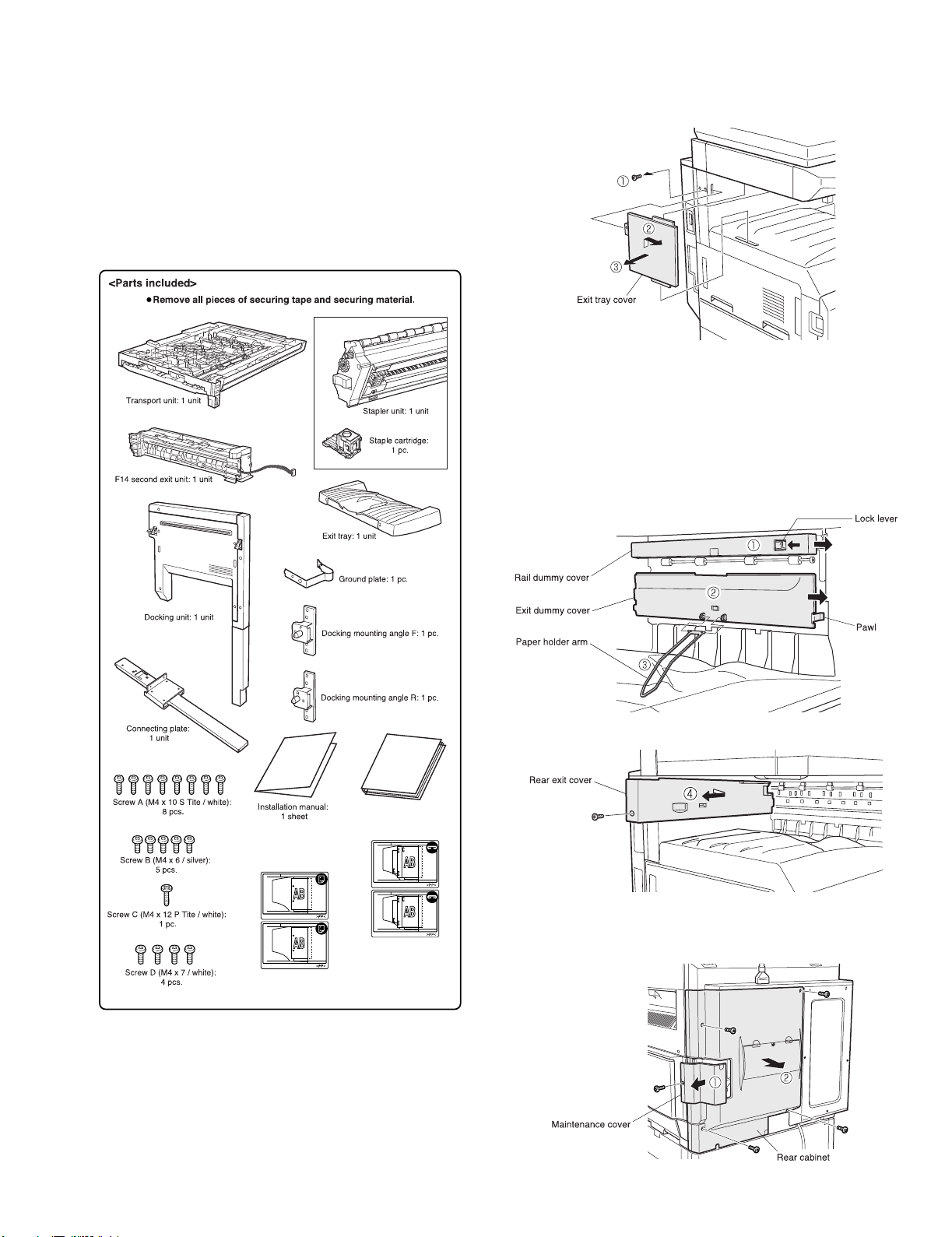

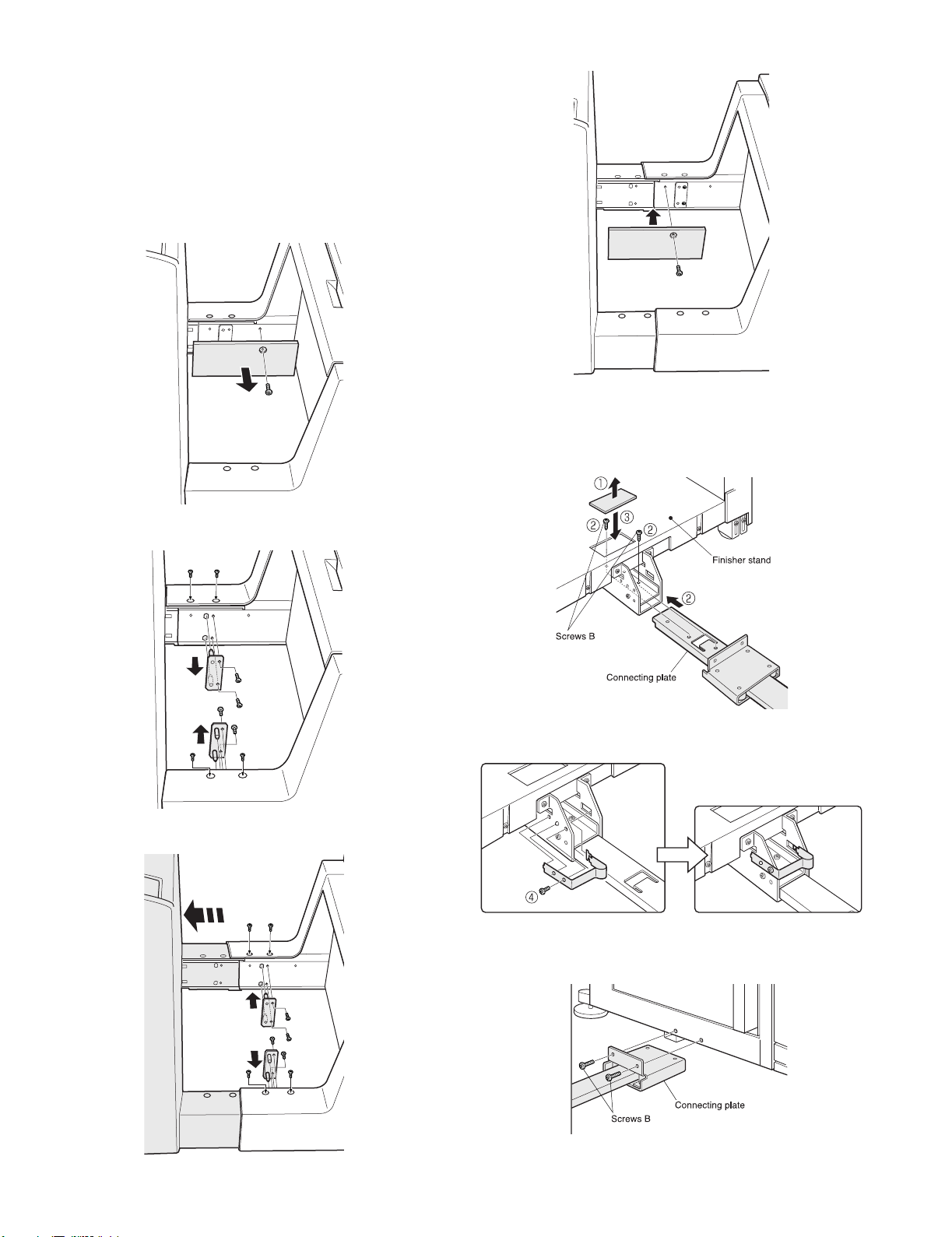

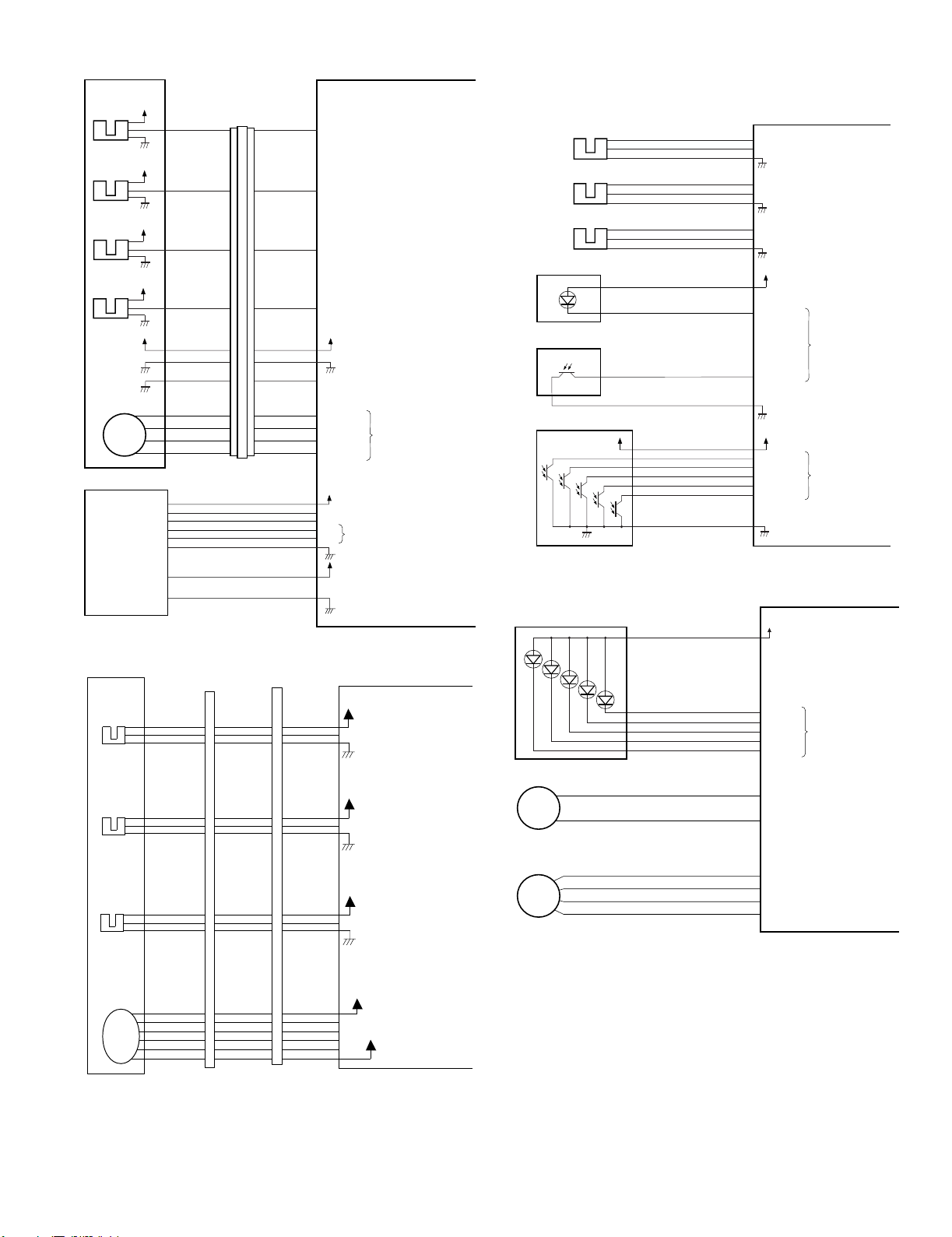

[3] UNPACKING AND INSTALLATION

1.AR-F14

<Before installation>

•For installation of AR-F14, an optional stand (small stand or large stand)

must have been installed.

•When adjusting the height of the finisher, be sure to perfor m step15)

with the finisher placed on the packing box.

•For improvement of workabillity, part of the description in this manual

may be modified without prior notice. In this case, refer to the ser vice

manual.

1) Remove the exit tray cover.

•If the copier is equipped with an exit tray cover:

Remove the screw and then remove the exit tray cove r as shown in the

illustration.

2) Remove the internal cabinet and the paper holder arm from the

copier.

<1>Pull the lock lever to the left and pull out the rail dummy cover to

the front.

(If the second exit tray is pro vided, remove it together with the rail

dummy cover.)

<2>Unlatch the pawls of the exit dummy cover and remove the exit

dummy cover.

<3>Remove the paper holder arm from the exit dummy cover.

Saddle finisher

instruction manual:

1 copy

Stapling position label:

2 sheets

Punch position label:

2 sheets

Turn off the main switch of the copier and then remove the power plug

from the outlet.

<4>Remove the screw and then remove the rear exit cover.

3) Remove the rear cabinet.

<1>Remove the screw and then remove the maintenance cover.

<2>Remove the four screws and then remove the rear cabinet.

AR-F14/PN1 UNPACKING AND INSTALLATION 3-1

Page 8

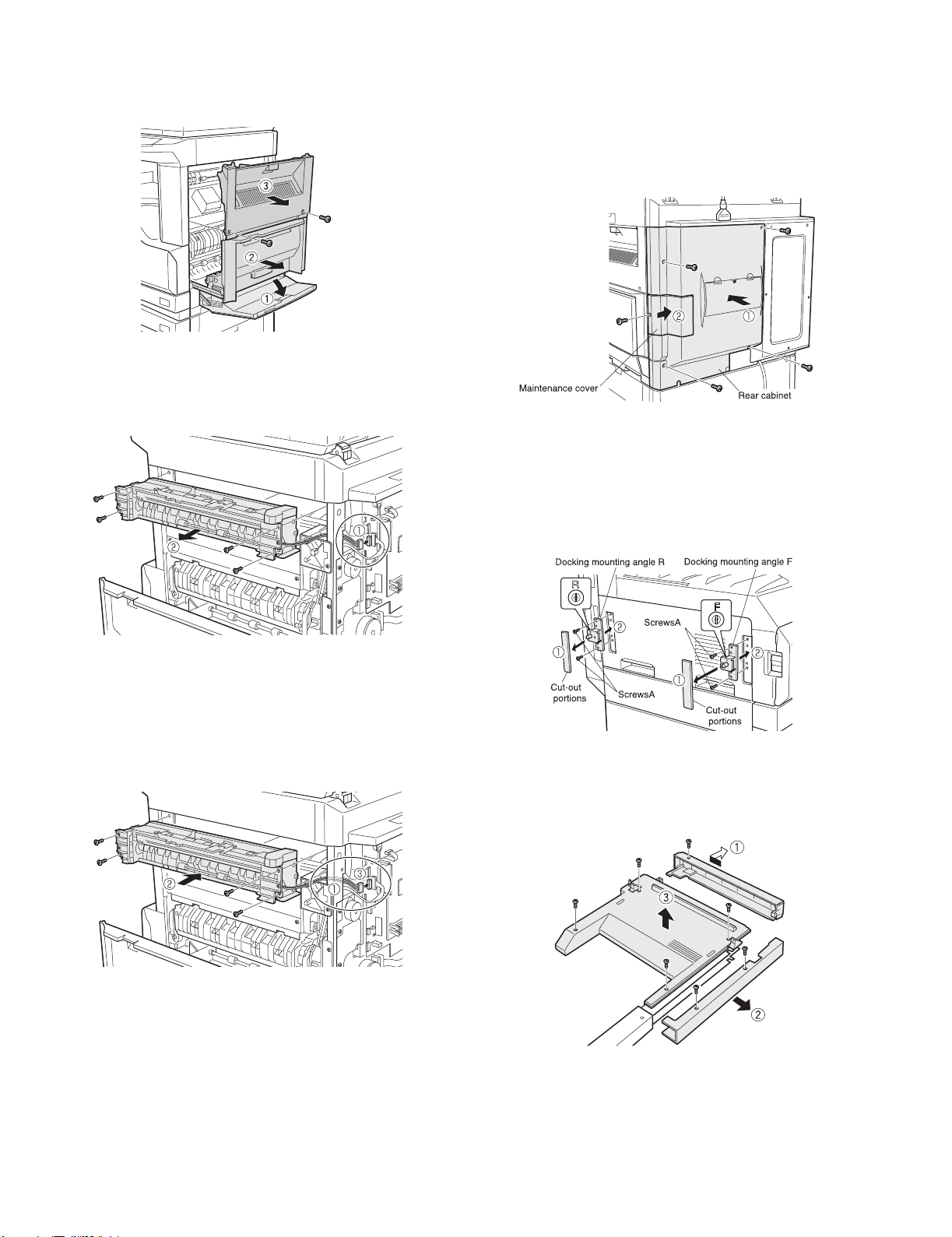

4) Remove the right cabinet.

<1>Open the bypass tray.

<2>Open the right door.

<3>Remove the two screws and then remove the right cabinet.

5) Remove the copier second exit unit.

<1>Remove the connector of the copier second exit unit from the

copier.

<2>Remove the four screws and then remove the copier second exit

unit.

7) Attach the rear cabinet.

<1>Reattach the rear cabinet to its original position and secure it

with the four screws.

<2>Reattach the maintenance cover to its original position and

secure it with the screw.

<3>Reattach the right cabinet that has been removed in step4) to its

original position and secure it with the two screws.

<4>Close the right door and the bypass tray.

8) Attach the docking mounting angles.

<1>Cut out the two cut-out portions on the left cabinet of the copier

using nippers or the like.

(Be careful about the orientation of the nippers so that the cross

section is flat.)

<2>Secure the docking mounting angle F and docking mounting

angle R with two screws A (M4 x 10) each.

(F/R is indicated with marking.)

6) Attach the supplied F14 second exit unit.

<1>Arrange the connector harness of the supplied F14 second exit

unit as shown in the illustration.

<2>Attach the F14 second exit unit to the copier and secure it with

the four screws.

At this time, take care so that the harness is not caught between

the copier and the second exit unit.

<3>Connect the connector to the copier.

9) Remove the covers from the docking unit.

<1>Remove the screw and slide the top cover in the direction of the

arrow to remove it.

<2>Remove the two screws and then remove the front cover.

<3>Remove the four screws and then remove the left cover.

AR-F14/PN1 UNPACKING AND INSTALLATION 3-2

Page 9

10) Attach the docking unit.

Insert docking mounting angel F and docking mounting angel R that

have been attached to the copier, into the holes of the docking unit.

13) Attach the transport unit.

<1>Place the rail of the transport unit on the guide of the copier and

gently push it in.

<2>Connect the connector of the docking unit and then push the

transport unit in until it stops.

11) Secure the docking unit.

<1>Use two screws A (M4 x 10) to secure the unit to the copier.

<2>Then use the screw that has been remove in step2) to secure the

docking unit.

12) Attach the paper holder arm to the transport unit.

Attach the paper holder arm that has been rem oved in step2) to the

lower part of the transport unit.

<3>Open the cover of the transport unit.

<4>Secure the unit with two screws A (M4 x 10).

<5>Close the cover of the transport unit.

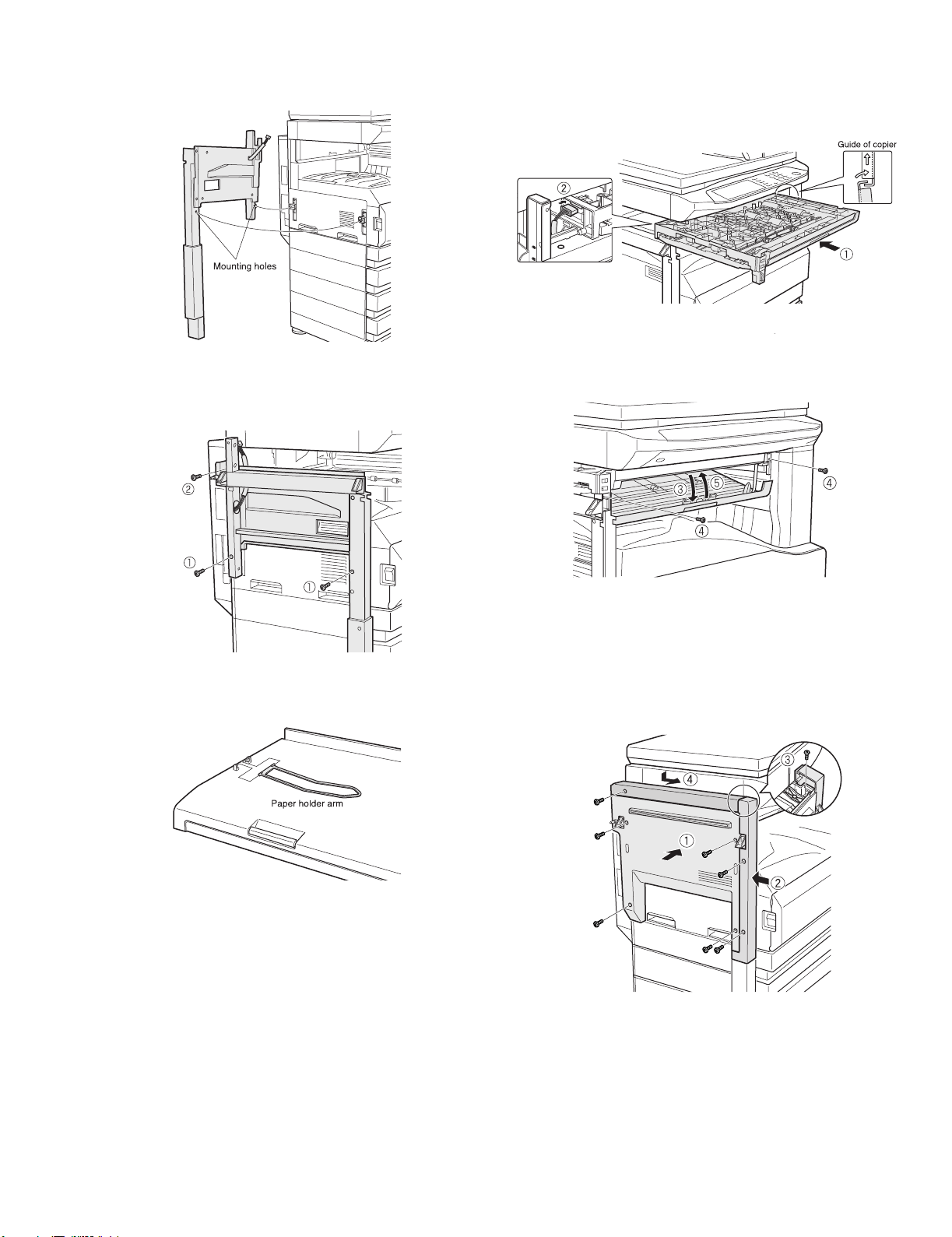

14) Attach the covers of the docking unit.

<1>Reattach the left cover to its original position and secure it with

the four screws.

<2>Secure the front cover with the two screws.

<3>Secure the front cover to the docking unit using screw C from

above the front cover.

<4>Slide the upper cover to attach as shown in the illustration and

secure it with the screw.

AR-F14/PN1 UNPACKING AND INSTALLATION 3-3

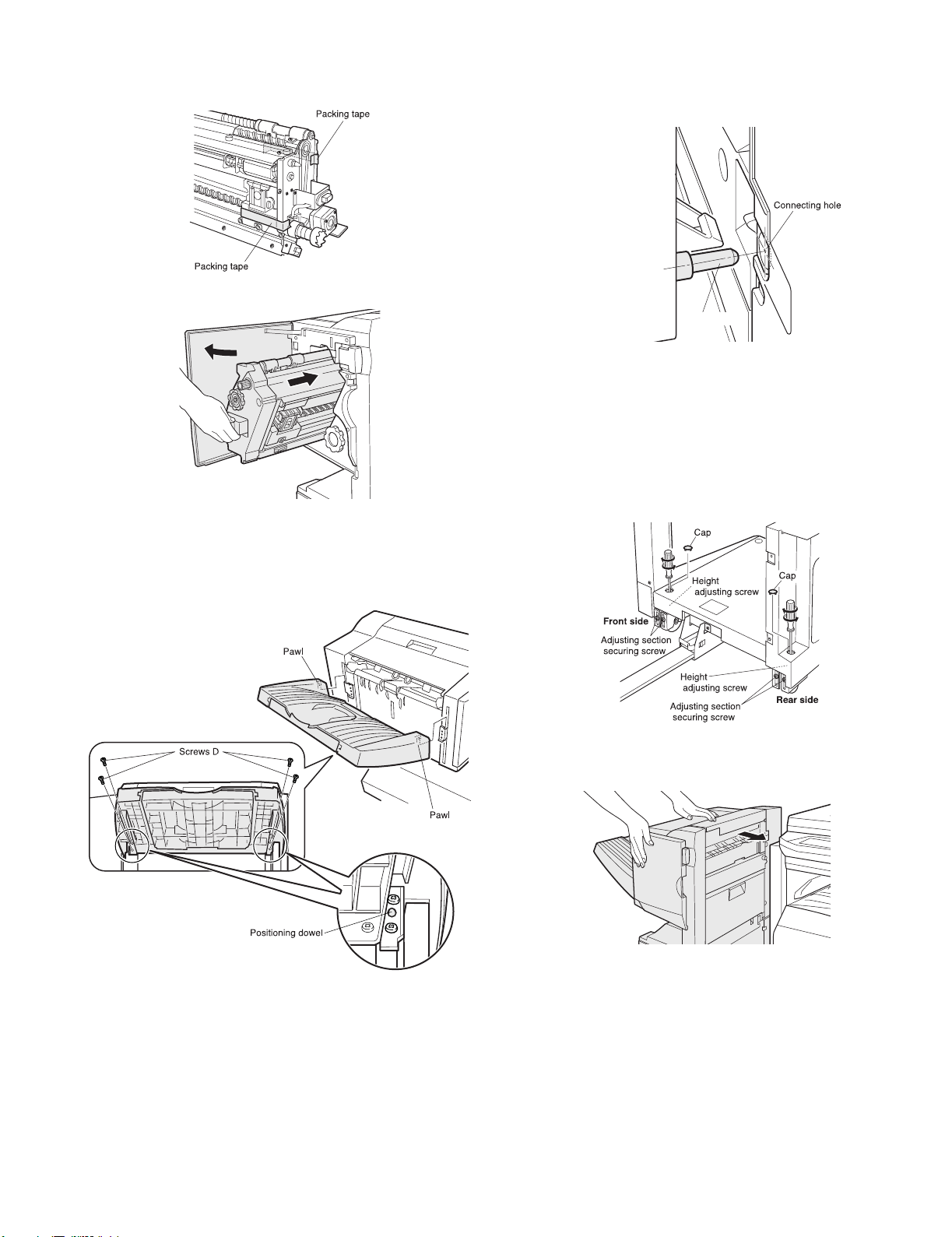

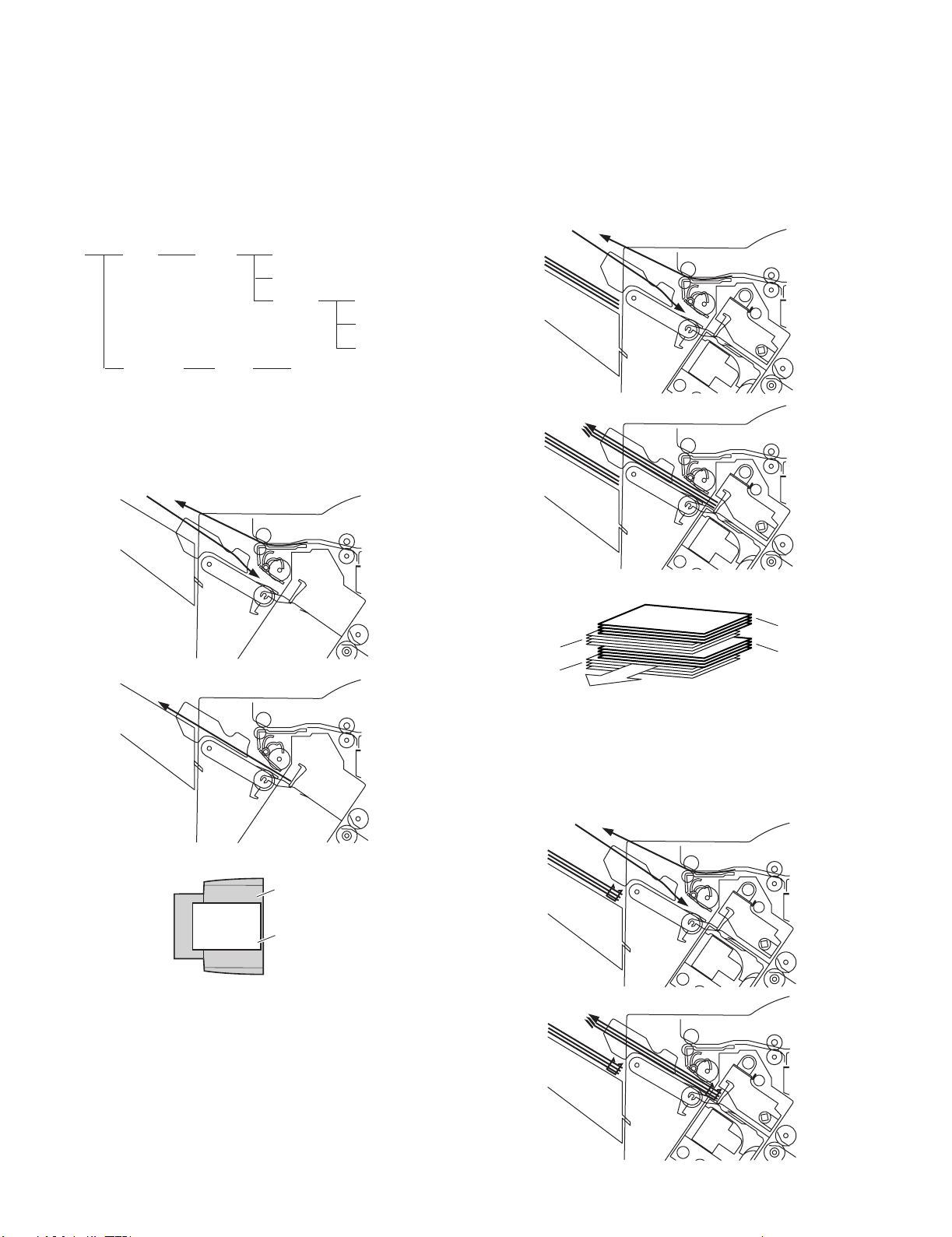

Page 10

•If the copier is equipped with a small stand and three paper drawers,

proceed to step16).

•If the copier is equipped with a large stand and two paper drawers or a

small stand and four paper drawers, you must change the height of the

finisher. In this case, be sure to perform step15) with the finisher placed

on the packing box.

15) Change the height of the finisher

(if the copier is equipped with a large stand and two paper drawers or

a small stand and four paper drawers)

<1>Remove the screw and then remove the cover.

<4>Reattach the cover and secure it with the screw.

16) Connect the finisher to the stand / paper drawers.

<1>Remove the cover from the finisher stand.

<2>Inser t the connecting plate into the connecting plate mounting

section and attach it with two screws B.

<3>Reattach the cover to its original position.

<2>Remove the four screws that secure the fittings of the front side

and rear side respectively and then remove the two fittings.

<3>Extend the finisher stand, reattach the two fittings that have been

removed in <2>, and secure them with four sc rews for each.

<4>Attach the ground plate as shown in the illustration and secure it

with screw B.

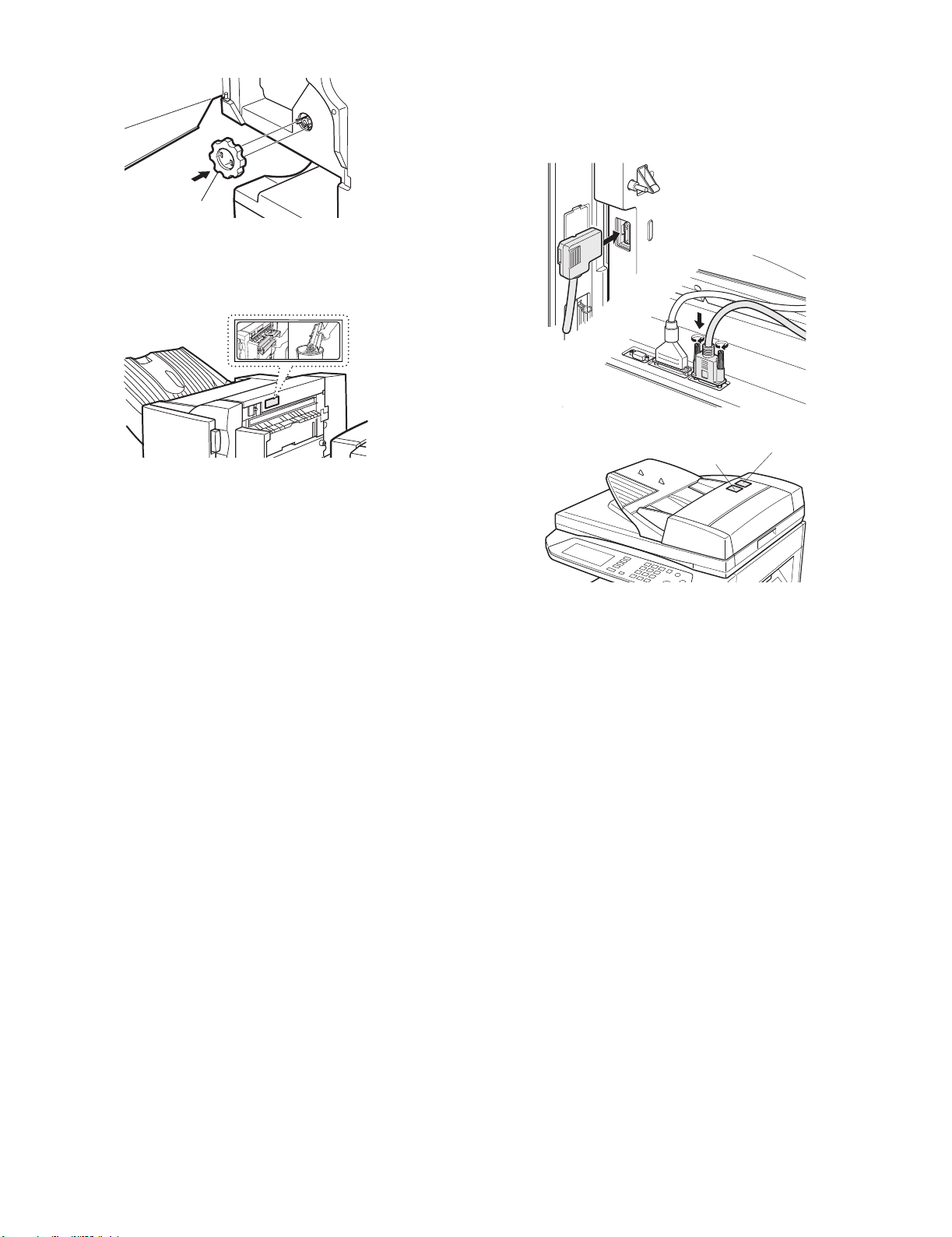

17) Secure the connecting plate to the stand / paper drawers.

Secure the finisher connecting plate to the stand / paper drawers

with two screws B (M4 x 6).

AR-F14/PN1 UNPACKING AND INSTALLATION 3-4

Page 11

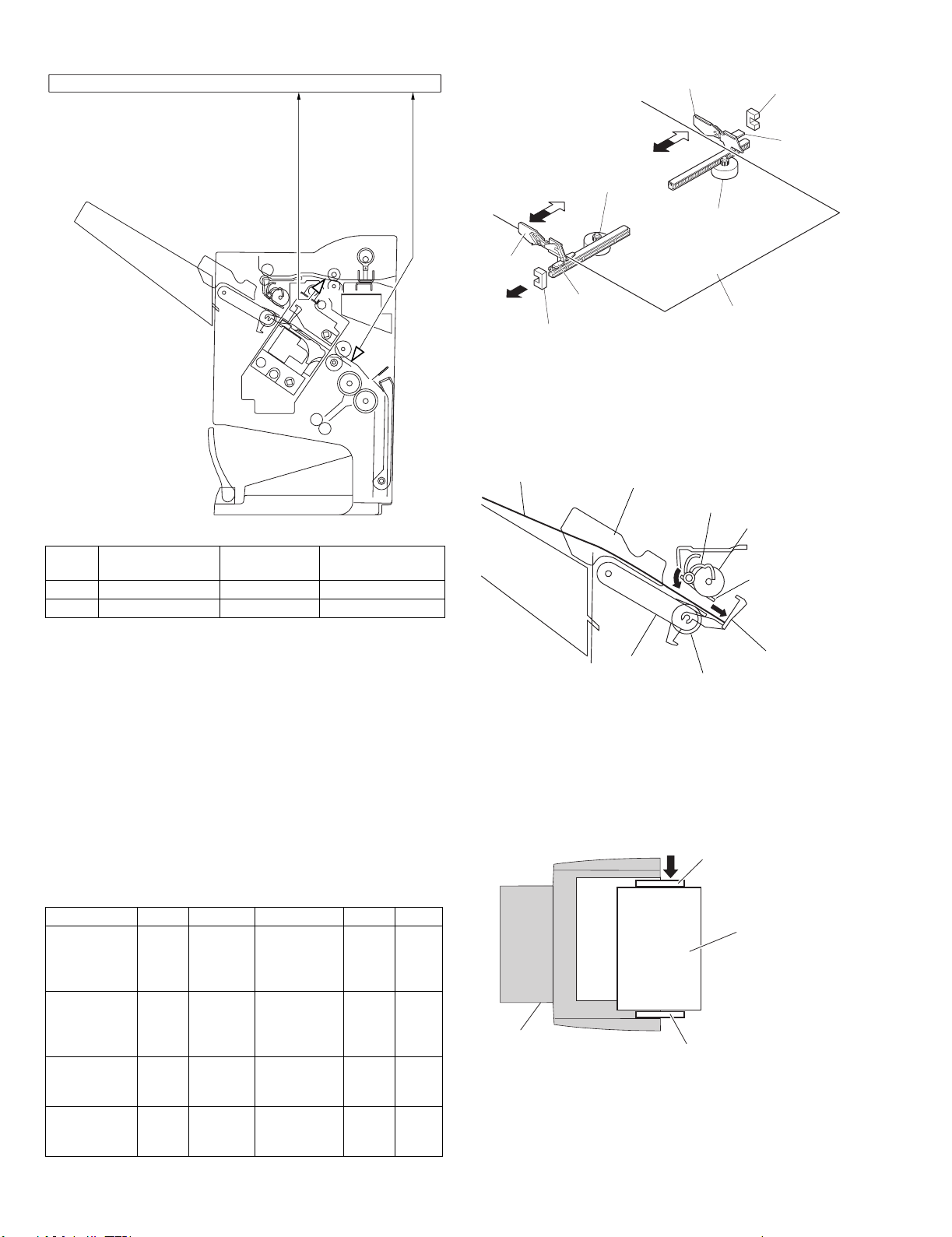

18) Install the stapler unit into the finisher.

<1>Remove the packing the tape (two pieces) from the locations

shown in the illustration.

<2>Open the finisher front cover and insert the stapler unit.

19) Attach the exit tray to the finisher.

<1>Hang the two pawls of the exit tray on the finisher.

<2>Use the four screws D to secure the exit tray.

At this time, check that the positioning dowel is securely

inserted.

20) Check and adjust the height of the finisher.

Bring the finisher close to the copier and check that the guide pin is

inserted smoothly into the connecting hole of the finisher.

If the guide pin should not be inserted smoothly, adjust as follows.

Guide pin

a. If the guide pin is deviated from the finisher connecting hole:

<1>Loosen the adjustment section securing screw on the rear side.

<2>Remove the cap with a flat-blade screwdriver or the like and use

the height adjusting screw to adjust the position so that the guide

pin matches the center of the finisher connecting hole.

<3>Loosen the adjustment section securing screw on the front side.

<4>If the guide pin can be inserted smoothly, tighten the adjusting

section securing screws on the front side and the rear side and

attach the cap.

b. If the guide pin matches the finisher connecting hole:

<1>Push the finisher into the copier.

AR-F14/PN1 UNPACKING AND INSTALLATION 3-5

Page 12

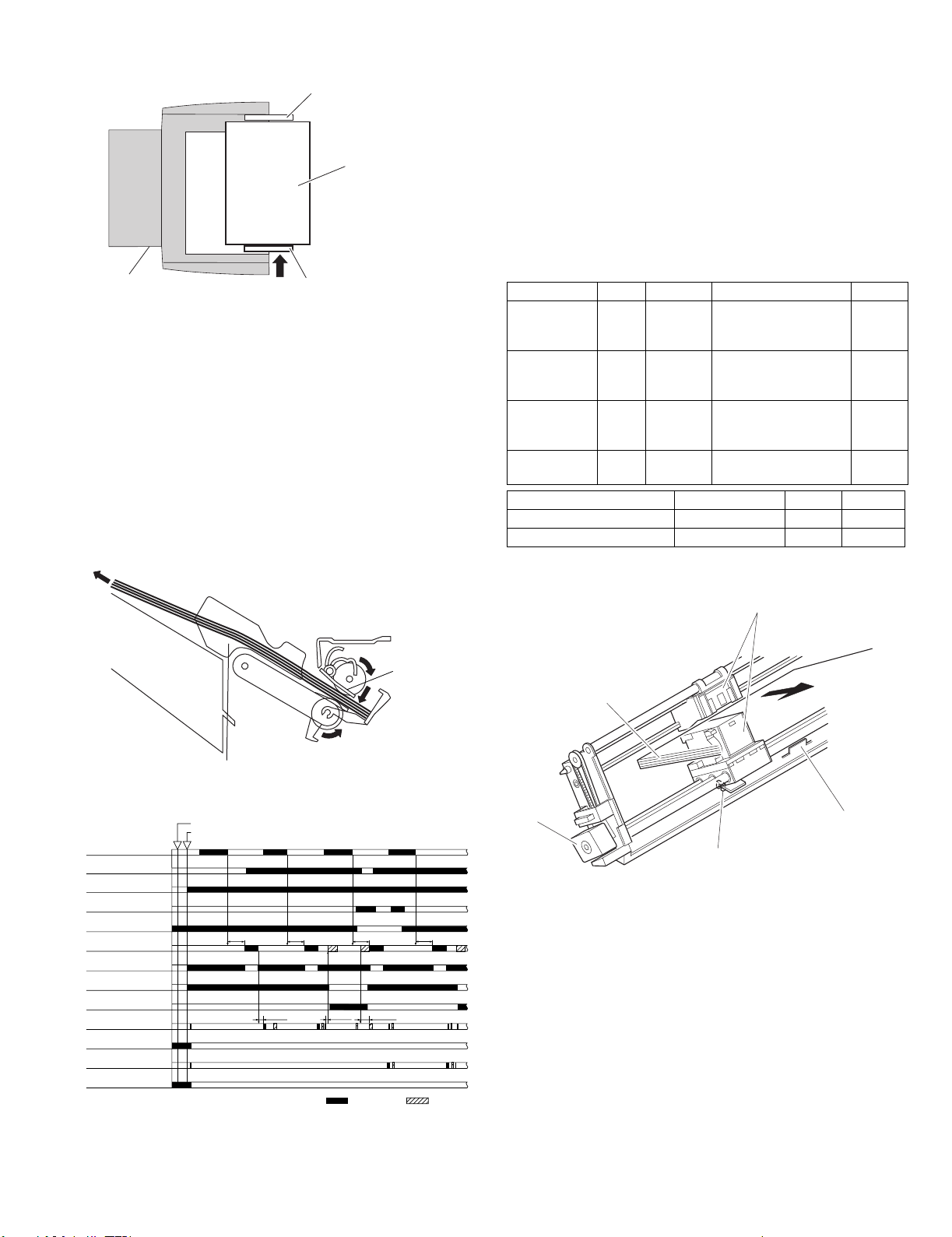

<2>If the gap between the copier and the finisher is not uniform at

the upper and lower parts, remove the caps from the front side

and the rear side of the finisher stand with a flat-blade

screwdriver or the like.

Then, remove the screws of the front and rear subcovers (one

screw for each) and then remove the subcovers.

<3>Loosen the four adjustment section securing screws located at

the positions shown in the illustration and then rotate the front

and rear height adjusting screws so that the gap becomes

uniform.

Gap

Gap

<4>If the gap becomes uniform, tighten the adjustment section

securing screws and reattach the caps and the subcovers.

22) Set the staple cartridge in the stapler unit.

<1>Open the finisher front cover and pull out the stapler unit.

<2>Turn the roller rotating knob unit the triangle mark is aligned with

the index.

<3>Inser t the staple cartr idge securely into the staple section unit it

clicks.

21) Connect the connector of the finisher.

Connect the connector of the finisher to the connector of the docking

unit.

Connect the connector of the finisher to the connector of the copier

and then tighten the screws.

Note:Check also that the right and left parts of the staple

cartridge do not float.

<4>Insert the staple section and close the finisher front cover.

23) Paste the stapling position label.

Paste the stapling position label to the document feeder.

Staple position label

Insert the power plug of the copier to the outlet and turn on the main

switch of the copier.

AR-F14/PN1 UNPACKING AND INSTALLATION 3-6

Page 13

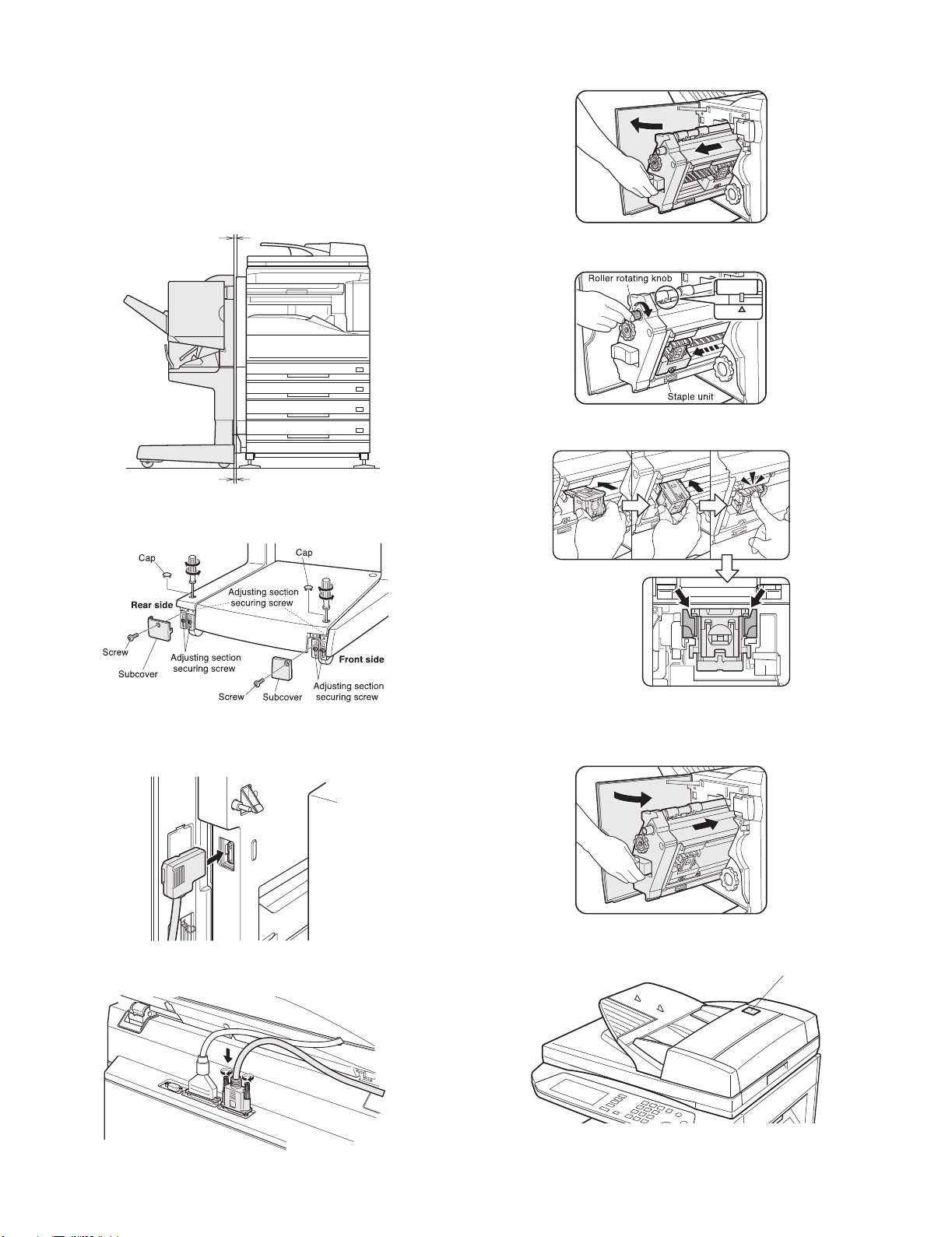

2. AR-PN1

<Before installation>

For installation of AR-PN1A/PN1B/PN1C/PN1D, a saddle stitch finisher

(AR-F14) must have been installed.

<1> Then remove the power plug of the main unit from the outlet.

<2> Remove the connector of the finisher.

2) Remove the front cabinet and the rear cabinet from the finisher.

<1> Open the front door of the finisher and remove the jam handling dial.

Parts included

Harness A (purple): 1 pc.

Screw

(M4 x 6 with rosette)

: 1 pc.

Dust box label:

1 sheet

Harness B (orange): 1 pc.

1) Turn off the main switch of the main unit.

OFF

Hole punch position label*:

2 sheets

* Will not be used.

Use the hole punch

position labels packed

in AR-F14

Jam handling dial

<2> Remove the two front cabinet securing screws, pull out the staple

unit until it stops, then remove the pawl of the front cabinet in the

direction indicated by the arrow and remove the front cabinet..

Pawl

Staple unit

Screws

Front cabinet

<3> Remove the three rear cabinet securing screws, remove the pawl in

the direction indicated by the arrow, and remove the rear cabinet.

At this time, remove the relay harness through the opening of the

rear cabinet.

Pawl

Screw

AR-F14/PN1 UNPACKING AND INSTALLATION 3-7

Rear

cabinet

Screw

Opening for

relay harness

Relay harness

Page 14

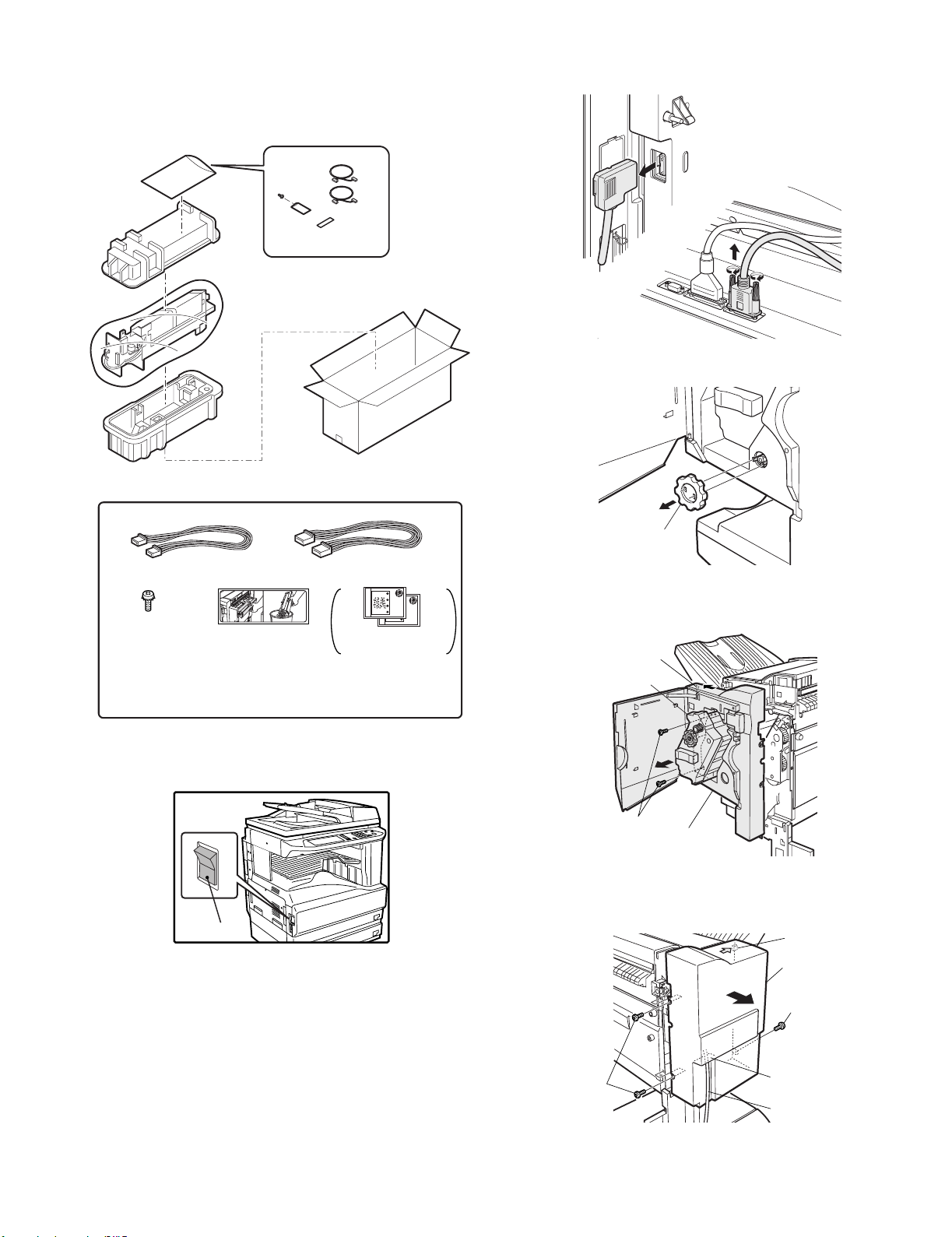

3) Remove the top cover.

<1> Remove the four top cover securing screws and remove the top

cover.

Screw

Top cover

<2> Remove the four pawls from the top cover and separate the cove r

into the upper and lower portions. Reuse the upper portion.

Top cover

Pawl

Pawl

<3> Remove the boss on the upper side of the paper entry PG.

<4> Remove the boss on the lower side of the paper entry PG with a

straight-slot screwdriver.

<5> Remove the beak PG (paper entry PG).

4) Remove the paper entry PG.

<1> Remove the dust box.

1

<2> Remove the screws (2 pcs.) which are fixing the beak PG

(paper entry PG).

<6> Replace the dust box to the original position.

AR-F14/PN1 UNPACKING AND INSTALLATION 3-8

Page 15

5) Attach the punch module.

<1>Insert the two bosses of the punch unit into the boss holes of the

finisher and fix the punch module using three screws.

Note:For the screws, use a supplied screw and the two screws that have

been removed in step 4).

Boss hole

Boss hole

Boss

Screw

Boss

7) Reattach the covers that have been removed.

<1>Hang the two pawls of the top cover and secure them using the

two screws.

Screw ScrewTop cover

Pawl

Punch module

Screw

Screw (with rosette)

(supplied with this unit)

6) Connect the harness of the punch module to the PWB of the finisher.

<1>Remove the clamps that fix the harness, handle the wiring of

harness A (pur ple) and harness B (orange), and fix them with

the clamps.

Harness B (orange)

Harness A (purple)

Clamps

<2>Pass the relay harness to the rear cabinet and secure the rear

cabinet using the three screws.

Rear cabinet

Screw

Opening for

relay harness

Relay harness

Screws

<3>Remove the lock release lever that has been attached to the

front cabinet.

Reattach the front cabinet to its original position, push in the

staple unit, and attach it using the two screws.

Insert the protrus ion (B) of the lock release lever that has been

removed before to the hole (C) of the latch arm.

After attaching it, move the lever to check that it moves smoothly.

If the lever does not move smoothly, remove the lock release

lever by releasing the pawl at the lower part of the lock release

lever using a flat-blade screwdriver or the like and then insert it

again.

Harness B (orange)

Connect to CN14 on PWB

Clamps

Harness A (purple)

Connect to CN12 on PWB

Staple unit

Screws

Front cabinet

AR-F14/PN1 UNPACKING AND INSTALLATION 3-9

Latch arm

Lock release lever (A)

Projection (B)

Pawl (D)

(C)

Page 16

<4>Reattach the jam handling dial and close the front cover.

Jam handling dial

8) Paste the dust box label to the top cover.

<1> Paste the supplied dust box label to the location indicated in the

illustration.

9) Connect the connector to the stand/paper drawer and connect the

AC cord of the power supply unit to the main unit of the printer.

<1>Connect the connector of t he relay harness of the finisher to the

stand/paper drawer and tighten the screws of the connector.10)

Paste the label.

(Paste it only if the scanner module is installed.)

<1>Paste the label to the position shown in the illustration.

Punch position label

Staple position label

AR-F14/PN1 UNPACKING AND INSTALLATION 3-10

Page 17

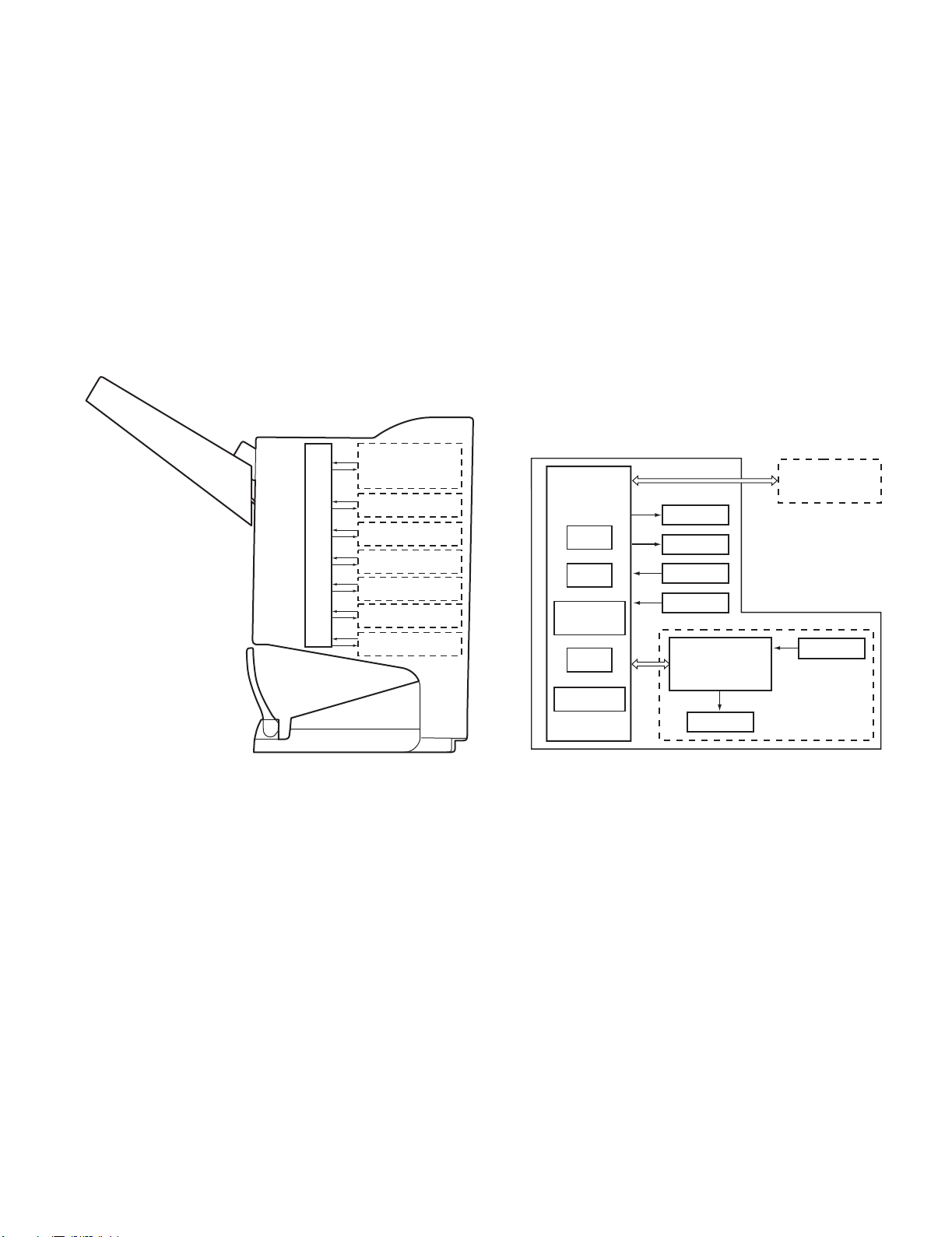

[4] OPERATIONAL DESCRIPTION

1. Basic Operations

A. Specifications

The finisher serves to deliver sheets coming from its host machine. The

mode of delivery may be non-sort stack, job offset*, or staple delivery.

The saddle unit built into the finisher is used to fold a stack of sheets

coming from the finisher unit in half for delivery.

All these operations are controlled by various commands sent by the

host machine in addition to the commands from the finisher cont roller

PCB.

The puncher unit (option) is designed for installation to the pickup

assembly of the finisher, and is used to punch holes in sheets coming

from the host machine.

The above operations are controlled with various commands from the

finisher controller PCB as well as the commands from the punch

controller PCB.

Puncher unit drive

system (puncher unit;

option)

Alignment drive system

Stapler drive system

Delivery drive system

Control system

Feed drive system

Tray drive system

Saddle unit

drive system

B. Outline of the Electrical Circuitry

The sequence of finisher operations is controlled by the finisher

controller PCB. The finisher controller PCB is a 16-bit microprocessor

(CPU), and is also used for combination with the host machine (serial).

The finisher controller PCB drive motors and other loads in response to

the various commands from the host machine. It also communicates

such data as on the states of various sensors and switches to the host

machine by way of the serial communication line.

The ICs mounted to the finisher controller PCB have the following

functions:

•IC13 (CPU)

Controls sequence of operations.

•IC12 (EEP-ROM)

Backs up adjustment settings.

•IC6 (EP-ROM)

Stores sequence programs.

•IC11 (communication IC)

Communicates with the host machine.

•IC1 (regulator IC)

Generates 5 V.

F02-102-01 shows the flow of signals between finisher and options

controller:

Finisher unit

Host machine DC

Finisher

controller

PCB

IC13

CPU

IC12

EEP-ROM

IC11

Communica-

tion IC

IC6

EP-ROM

IC1

Regulator IC

Motor

Clutch

Switch

Sensor

Puncher unit (option)

Punch controller

PCB

Motor

controller PCB

CPU

Sensor

Fig.F02-101-01

NOTE:The position of deliv ery is shifted to the front/rear for each stack to

assist sorting.

AR-F14/PN1 OPERATIO NAL D E SC RI PT IO N 4-1

Fig.F02-102-01

Page 18

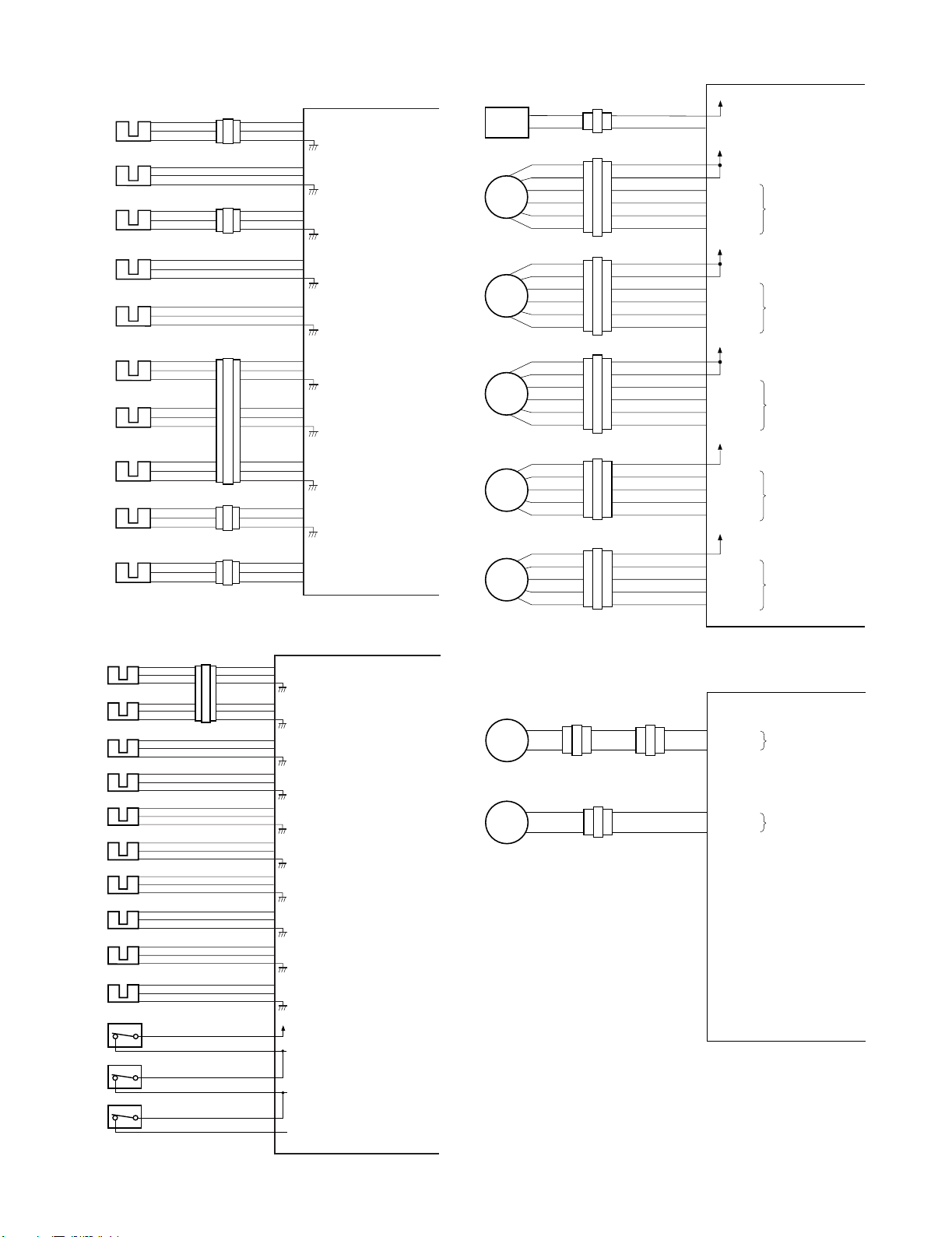

C. Inputs to and Outputs from the Finisher Controller PCB

•Inputs to the Finisher Controller PCB (1/2)

ES

CN44-3

Inlet sensor

Paddle home

position sensor

Swing guide

home position

sensor

Aligning plate

home position

sensor (front)

Aligning plate

home position

sensor (rear)

Processing

tray sensor

Delivery belt

home position

sensor

Tray paper sensor

Paper surface

sensor

Folding position

sensor

PHPS

ARHPS

FJHPS

RJHPS

AS

OBHPS

BES

SLS

FPS

CN51-1

CN55-3

CN23-3

CN36-3

CN30-3

CN31-3

CN32-3

CN35-3

CN39-3

CN43-1

-1

-2

-3

-2

CN54-1

-1

-2

-1

-2

-1

-2

CN29-1

-1

-2

-1

-2

-1

-2

CN34-1

-1

-2

CN38-1

-2

-1

CN42-3

-3

-2

-3

-2

-3

-2

-4

-6

-5

-7

-9

-8

-3

-2

-2

-3

CN53-3

CN28-9

CN33-3

CN37-9

-1

-2

-1

-2

-7

-8

-6

-4

-5

-3

-1

-2

-1

-2

-8

-7

Fig.F02-103-01

•Inputs to the Finisher Controller PCB (2/2)

FHPS

Folding home

position sensor

Stack feed roller

(upper) home

position sensor

Bind tray sensor

Staple/fold motor

clock sensor

Shift upper limit

sensor

Shift lower limit

sensor

Shift motor clock

sensor

Front door sensor

Upper cover sensor

Full stack sensor

Joint switch

Front door switch

Stapler safety

switch

FRHPS

FES

FE

ULS

LLLS

LE

FDS

TCS

XXXX

JS

N. O.

FDSW

N. O.

SSS

N. O.

CN40-3

CN41-3

CN47-3

CN52-1

CN50-3

CN49-3

CN48-3

CN25-3

CN24-3

CN73-3

CN69-2

CN68-2

CN66-2

-1

-2

-1

-2

-1

-2

-2

-3

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

-1

-1

-1

CN38-4

-6

-5

-7

-9

-8

CN37-6

-4

-5

-3

-1

-2

CN15-10

CN16-4

CN15-1

CN9-6

CN15-7

CN15-4

CN4-7

CN4-4

CN19-1

CN8-6

CN8-4

CN8-2

-6

-5

-7

-9

-8

-3

-2

-5

-4

-12

-11

-9

-8

-6

-5

-9

-8

-6

-5

-3

-2

-5

-3

-1

Finisher controller PCB

CN16-10

+5 V

-12

ENT_S

-11

CN9-1

+5 V

-3

PDL_HP

-2

CN9-7

+5 V

-9

BDL_ROL_HP

-8

CN4

+5 V

-3

F JOG_HP

-2

CN5-13

+5 V

-15

R JOG_HP

-14

CN5-1

+5 V

-3

ADJ_TRAY_S

-2

-4

+5 V

-6

EJCT_BLT_HP

-5

-7

+5 V

-9

TRY_EMPS

-8

CN5-10

+5 V

-12

LVL_S

-11

CN16-1

+5 V

-2

BIND_P

-3

BIND_L

Finisher controller PCB

+5 V

BIND_HP

+5 V

BIND_ROL_HP

+5 V

BIND_EMPS

+5 V

BIND_CLK

+5 V

SIFT_UPLMT

+5 V

SIFT_DNLMT

+5 V

SIFT_CLK

+5 V

FDOOR_S

+5 V

TOPCOV_S

+5 V

PAPER_F

+24 VP

JOINT SW

FRONT SW

STPLSAFE SW

When the sensor

detects paper, ‘1’ .

When the paddle is at

home position, ‘1’.

When the swing guide

is at home position, ‘1’.

When the aligning

plate (front) is at

home position, ‘1’.

When the aligning

plate (rear) is at

home position, ‘1’.

When the sensor

detects paper, ‘1’.

When the delivery belt

is at home position, ‘1’.

When paper is present

on the tray, ‘1’.

When the paper

surface is detected,

‘1’.

When paper is

detected, ‘0’.

When LED is lit, ‘1’.

When at folding home position, ‘0’.

When the stack feed roller

(upper) is at home position, ‘1’.

When the sensor

detects paper, ‘1’.

When the staple/fold motor is

rotating, alternates between

‘1’ and ‘0’.

When the tray is at the

upper limit, ‘1’.

When the tray is at the

lower limit, ‘1’.

While the shift motor

is rotating, alternates

between ‘1’ and ‘0’.

When the front door

is open, ‘1’.

When the upper cover

is open, ‘1’.

When the paper is

full, ‘1’.

When connected to

the host machine, ‘1’.

When the front

door is closed, ‘1’.

When the swing

guide is closed, ‘1’.

•Outputs from the Finisher Controller PCB (1/2)

Binding clutch

FFC

Feed motor

FFM

Paddle motor

FPM

Delivery motor

FAM

Alignment motor

(front)

FFJM

Alignment motor

(rear)

FRJM

CN63-1

CN65-1

-1

-2

-2

-1

CN72

-6

-1

-5

-2

-4

-3

-3

-4

CN56

-2

-5

-1

-6

-6

-1

-5

-2

-4

-3

-3

-4

CN57

-2

-5

-1

-6

-6

-1

-5

-2

-4

-3

-3

-4

CN59

-2

-5

-1

-6

CN62-5

-2

-3

-4

-5

CN64-5

-2

-3

-4

-5

CN18-1

-2

B_CLU

CN10-1

-2

-3

FEEDMTR_A

-4

FEEDMTR_*A

-5

FEEDMTR_B

-6

FEEDMTR_*B

CN10-7

-8

-9

PDLMTR_A

-10

PDLMTR_*A

-11

PDLMTR_B

-12

PDLMTR_*B

CN13-1

-2

-3

EJCTMTR_A

-4

EJCTMTR_*A

-5

EJCTMTR_B

-6

EJCTMTR_*B

CN3-1

-4

-3

-2

-1

-2

FJOGMTR_A

-3

FJOGMTR_*A

-4

FJOGMTR_B

-5

FJOGMTR_*B

CN3-6

-4

-3

-2

-1

-7

RJOGMTR_A

-8

RJOGMTR_*A

-9

RJOGMTR_B

-10

RJOGMTR_*B

Fig.F02-103-03

•Outputs from the Finisher Controller PCB (2/2)

Shift motor

FLM

Staple/fold motor

FFSM

-2

-2

-2

-1

-1

-1

CN70

-2

-2

CN71

-1

-1

CN70

CN6-1

-2

SIFTMTR_1

-2

-1

SIFTMTR_0

CN6-3

BINDMTR_1

-4

BINDMTR_0

Fig.F02-103-04

Finisher controller PCB

+24 V

When the drive is transmitted,

‘1’.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

Finisher controller PCB

Switches between ‘+’ and

‘–’ according to the

direction of motor rotation.

Switches between ‘+’ and

‘–’ according to the

direction of motor rotation.

Fig.F02-103-02

AR-F14/PN1 OPERATIO NAL D E SC RI PT IO N 4-2

Page 19

•Inputs to and Outputs from the Finisher Controller (1/2)

Stapler unit

Slide home

position sensor

SHPS

Staple home

position sensor

STHPS

Staple empty

sensor

SPS

Staple top

position sensor

SS

Slide motor

FSM

Host

machine

+5 V

+5 V

+5 V

+5 V

+5 V

CN72-5

CN72-4

CN72-3

CN72-2

CN72-6

CN72-1

CN72-7

CN72-10

CN72-11

CN72-12

CN72-13

CN72A-5

CN72A-4

CN72A-3

CN72A-2

CN72A-6

CN72A-1

CN72A-7

CN72B-5

CN72B-4

CN72B-3

CN72B-2

CN72A-5

CN72A-4

CN72A-3

CN72A-2

CN72A-6

CN72A-1

CN72A-7

CN72B-5

CN72B-4

CN72B-3

CN72B-2

CN11-3

CN11-4

CN11-5

CN11-6

CN11-2

CN11-7

CN11-1

CN7-3

CN7-4

CN7-5

CN7-6

CN2-1

CN1-1

SLID_HP

STPL_HP

HOOK_S

SELF_P

+5 V

STPL_CNCT

SLIDMTR_A

SLIDMTR_*A

SLIDMTR_B

SLIDMTR_*B

+24 V

-3

GND

-4

GND

-5

TXD

-7

RXD

-6

+24 V

-2

Finisher controller PCB

When the stapler is at home

position, ‘1’.

When the stapler is at

stapling home position, ‘0’.

When the cartridge has

staples, ‘0’.

When the staple is at top

the stapler, ‘0’.

When the stapler is

connected, ‘0’.

Communication line

Fig.F02-103-05

•Inputs to and Outputs from the Finisher Controller (2/2)

-5

-6

-8

-9

Finisher control PWB

+5V

LVL_E_S

+5V

LVL_P_S

+5V

LVL_C_S

Interface

transport

paper entry

sensor

FJES

Interface

transport

paper exit

sensor

FJOS

Interface

transport

cover sensor

FJCS

CNFJ2-1

-3

-2

CNFJ3-1

-3

-2

CNFJ4-3

-2

-1

CNFJ1-

-17

-16

CNFJ1-

-14

-13

CNFJ1-

-11

-10

CNFJ1-

-17

-16

CNFJ1-

-14

-13

CNFJ1-

-11

-10

CN73C-1

-2

-3

CN73C-4

-5

-6

CN73C-7

CN73D-2

CN73A-8

CN21-

-2

-7

-6

-3

CN73A-5

CN21-4

-4

-3

CN73A-2

CN21-7

-1

-8

CN73B-8

Switches between ‘1’ and

‘0’ according to the direction

of motor rotation.

"0" when paper is detected.

"0" when paper is detected.

"0" when the interface

transport cover is open.

D. Inputs to and Outputs from the Punch Controller

PCB(option)

•Inputs to and Outputs from the Punch Controller PCB

Punch home

position sensor

Horizontal

registration

home position

sensor

Punch motor

clock sensor

Waste full photosensor PCB

PSHPS

Waste full LED PCB

LED121

PT131

Photosensor PCB

PT1

PT2

PT3

J2008-3

-1

-2

J2007-3

-1

-2

PE

J2009-3

-1

-2

+5 V

PT4

PT5

J1006-4

J1006-1

J1006-7

J1005-1

J1005-3

J1007-12

-6

-5

-3

-2

-9

-8

-2

4

-11

-10

-9

-8

-7

-13

XXXX

Fig.F02-104-01

•Outputs from the Punch Controller PCB

LED5

Punch motor

FPNM

Horizontal

registration

motor

FPSM

LED PCB

LED4

LED3

LED2

LED1

J1007-6

J1002-1

J1001-1

-1

-5

-4

-3

-2

-2

-2

-3

-4

Fig.F02-104-02

+5 V

PUNCH

+5 V

SLIDE

+5 V

CLOCK

+5V

DUSTLED

DUSTPTR

+5 V

SREG1*

SREG2*

SREG3*

SREG4*

PAEND*

+5V

LEDON5

LEDON4

LEDON3

LEDON2

LEDON1

A

B

A*

B*

Punch controller PCB

When the hole puncher is

at home position, ‘0’.

When the punch slide

unit is at home position,

‘1’.

While the punch motor

is rotating, alternates

between ‘0’ and ‘1’.

When the light is

blocked, ‘0’.

When paper is

detected, ‘0’.

Punch controller PCB

When ‘1’, LED goes ON.

Switches between ‘+’

and ‘–’ according to

the direction of motor

rotation.

Switches the pulse

signals according to

the rotation of the motor.

Interface

transport

motor

FJM

CNFJ5

-4

-3

-1

-2

-5

CNFJ1-2

-7

-6

-5

-4

-3

CNFJ1-2

-7

-6

-5

-4

-3

CN73D-9

-4

-5

-6

-7

-8

CN73B-

-6

-5

-4

-3

-2

CN19-

+24V

-2

A

-3

*A

-4

B

-5

*B

-6

The pulse signal is

switched depending

on the motor RPM.

+24V

AR-F14/PN1 OPERATIO NAL D E SC RI PT IO N 4-3

Page 20

2. Feed/Drive System

A. Outline

The machine performs the following in response to the commands

coming from its host machine on the sheets arriving from the host

machine for delivery: simple stacking, job offset, and stapling or folding

(in two).

If a punch unit (option) is installed, the sheets are pouched and delivered

to the delivery tray.

Sheets may be delivered in either of five ways (including one for the

puncher unit):

Delivery

method

delivery

(1)Normal Delivery

a.Simple Stacking

The machine pulls in the sheet once to the processing tray and then

delivers it to the delivery tray.

PunchingNormal

StitchingSaddle delivery

Fig.F02-201-01

Simple stacking

Job offset

Stapling Front 1-point stapling

Rear 1-point stapling

Middle 2-point stapling

Middle 2-point stapling

b.Job Offset

The machine pulls the sheet once to the proc essing tray. It then moves

the sheet to the front or the rear using the aligning plate. When it has

deposited a specific number of sheets, it delivers them in the form of a

aligning plane. When the number of sheets stacked on the processing

tray reaches a specified value, the sheets are delivered in a form of a

stack. Even if the specified value is not reached, stacked sheets are

temporarily delivered when 10 sheets of large-size paper (300 mm or

longer) or 30 sheets of small-size paper (299 mm or shor ter) have been

stacked. (5- and STMT-sizes: 10 sheets)

Tr ay

Fig.F02-201-02

Paper

Results of offset delivery (4 jobs)

4th set

3rd set

1st set

(direction of delivery)

2nd set

Fig.F02-201-03

c.Stapling

The machine stacks sheets coming from its host machine on the

processing tray. When the number of sheets stacked on the processing

tray reaches a specified value, the finisher staples them delivers the

stapled stack to the delivery tray.

AR-F14/PN1 OPERATIO NAL D E SC RI PT IO N 4-4

Fig.F02-201-04

Page 21

d.Saddle Delivery

The machine deposits a stack of sheets on the processing tray, staples it

(middle 2-point), and then moves it to the saddle unit. The saddle unit

folds the stack in two, and delivers it to the bind tray.

Notation Name Description Connector on finisher

controller PCB

FFM Feed motor Stepping motor CN10

FPM Paddle motor Stepping motor CN10

F A M Delivery motor Stepping motor CN13

FFJM Alignment plate

Stepping motor CN3

motor (front)

FRJM Alignment plate

Stepping motor CN3

motor (rear)

FFSM Staple/fold motor Brush DC motor CN6

Table.T02-202-01

Finisher controller PCB (1/2)

Paddle motor

Alignment plate motor

Alignment plate motor

FFJM

(rear) drive signal RJOGMTR

(front) drive signal FJOGMTR

FRJM

drive signal PDLMTR

FPM

Feed motor

drive signal FEEDMTR

Bind clutch drive signal B_CLU

FFM

Fig.F02-201-05

B.Feed/Delivery

(1)Outline

The machine forwards the sheets coming from its host machine to the

delivery tray, processing tray, or saddle unit according to the type of

delivery used. The sheets forwarded to the processing tray or the saddle

unit are offset, stapled, or folded.

F02-202-01 shows the motors that are associated with moving and

aligning sheets. These motors are controlled (rotated clockwise or

counterclockwise) by the microprocessor (CPU) on the finisher controller

PCB.

The paper path is equipped with the sensors shown in T02-202-02 used

to monitor the arrival or passage of sheets.

If a sheet fails to arrive at or move past a specific sensor within a specific

period of time, the finisher controller will assume a jam, and stops the

ongoing operation and, at the same time, communicates the presence of

a jam to the host machine.

FAM

FLM

Shift motor drive signal SIFTMTR

FSM

Delivery motor drive signal EJCTMTR

Slide motor drive signal SLIDMTR

Finisher controller PCB (2/2)

Fig.F02-202-01

FFC

PI14

FFSM

Staple/fold motor drive signal BINDMTR

Staple/fold motor clock detect signal

BIND_CLK

AR-F14/PN1 OPERATIO NAL D E SC RI PT IO N 4-5

Page 22

Finisher controller PCB

Inlet paper detect signal ENT_P

Fold position paper detect signal BIND_P

ES

FPS

Fig.F02-202-02

Notation Name Description Connector on finisher

controller PCB

ES Inlet sensor Photointerrupter CN16

FPS Fold position sensor Photointerrupter CN16

Table.T02-202-02

C.Job Offset

(1)Outline

"Job offset" refers to the operation by which t he machine delivers a set of

sheets with them pulled forward or backward for sorting.

Switching between the forward and backward directions is made using

an aligning plate (front) and an aligning plate (rear).

The sheet coming between the delivery rollers is fed onto the processing

tray and then fed toward the stopper by the paddle.

A swing guide is at the up position while a sheet is being pulled onto the

processing tray or during alignment. It is at the down position du ring

stack feeding, stack delivery, or stapling.

At power-on, the finisher controller PCB drives the aligning plate (front)

motor (FFJM) and the aligning plate (rear) motor (FRJM) to return the

two aligning plates to their home positions.

Sensor Symbol Connector Function Motor Symbol

Aligning plate

(front) home

position sensor

Aligning plate

(rear) home

position sensor

Swing guide

home position

sensor

Paddle home

position sensor

FJHPS CN4-3 Drives the

aligning plate

(front)

RJHPS CN5-15 Drives the

aligning plate

(rear)

ARHPS CN9-9 Drives the

swing guide

drive.

PHPS CN9-3 Drives the

paddle

(feeds paper).

Table.T02-203-01

Aligning

plate

(front)

motor

Aligning

plate

(rear)

motor

Paddle

motor

Paddle

motor

FFJM

FRJM

FPM

FPM

Aligning plate (rear)

Alignment plate (front)

motor (FFJM)

Aligning plate

(front)

(Front)

Aligning plate (front) home position sensor (FJHPS)

Light-shielding plate

Alignment plate (rear)

motor (FRJM)

Aligning plate (rear)

home position sensor (RJHPS)

Light-shielding plate

Paper

Fig.F02-203-01

(2)Processing Tray Paper Stacking Operation

A sheet coming between the delivery rollers is fed onto the processing

tray.Then, the paddle taps on the sheet surface twice (once for the

second and subsequent sheets) to locate the sheet against the

processing tray stopper.

Paper

Aligning plate

Delivery belt

Paddle

Stack delivery roller (upper)

Swing guide

Processing tray stopper

Stack delivery roller (lower)

Fig.F02-203-02

(3)Offset Operation

Each sheet is pulled forward or backward using the aligning plate (front)

and the aligning plate (rear).

The offset operation is performed each time a sheet is pulled onto the

processing tray.

Offsetting in the forward direction

Aligning plate (rear)

Sheet to be offset

Tr ay

Aligning plate (front)

Fig.F02-203-03

AR-F14/PN1 OPERATIO NAL D E SC RI PT IO N 4-6

Page 23

Offsetting in the backward direction

Aligning plate (rear)

Sheet to be offset

Tr ay

Aligning plate (front)

Fig.F02-203-04

(4)Stack Delivery Operatio n

Stack delivery takes place when 10 sheets of large-size paper or 30

sheets of small-size paper (A5- and STMT-sizes: 10 sheets) have been

stacked on the processing tray with them offset in either direction.

The paddle motor rotates and the swing guide descends to hold the

paper stack between the upper and lower stack delivery rollers. The

delivery motor rotates in the forward direction to rotate the delivery

rollers, feeding the paper stack in the delivery direction. The delivery belt

home position sensor is turned OFF. The delivery motor is driven a

specified number of pulses, causing the swing guide to ascend. Next,

the paper delivery motor is driven. Next, the delivery motor is driven to

deliver the paper stack with the nails of the deliver y belt that rotates in

sync with the stack delivery rollers.

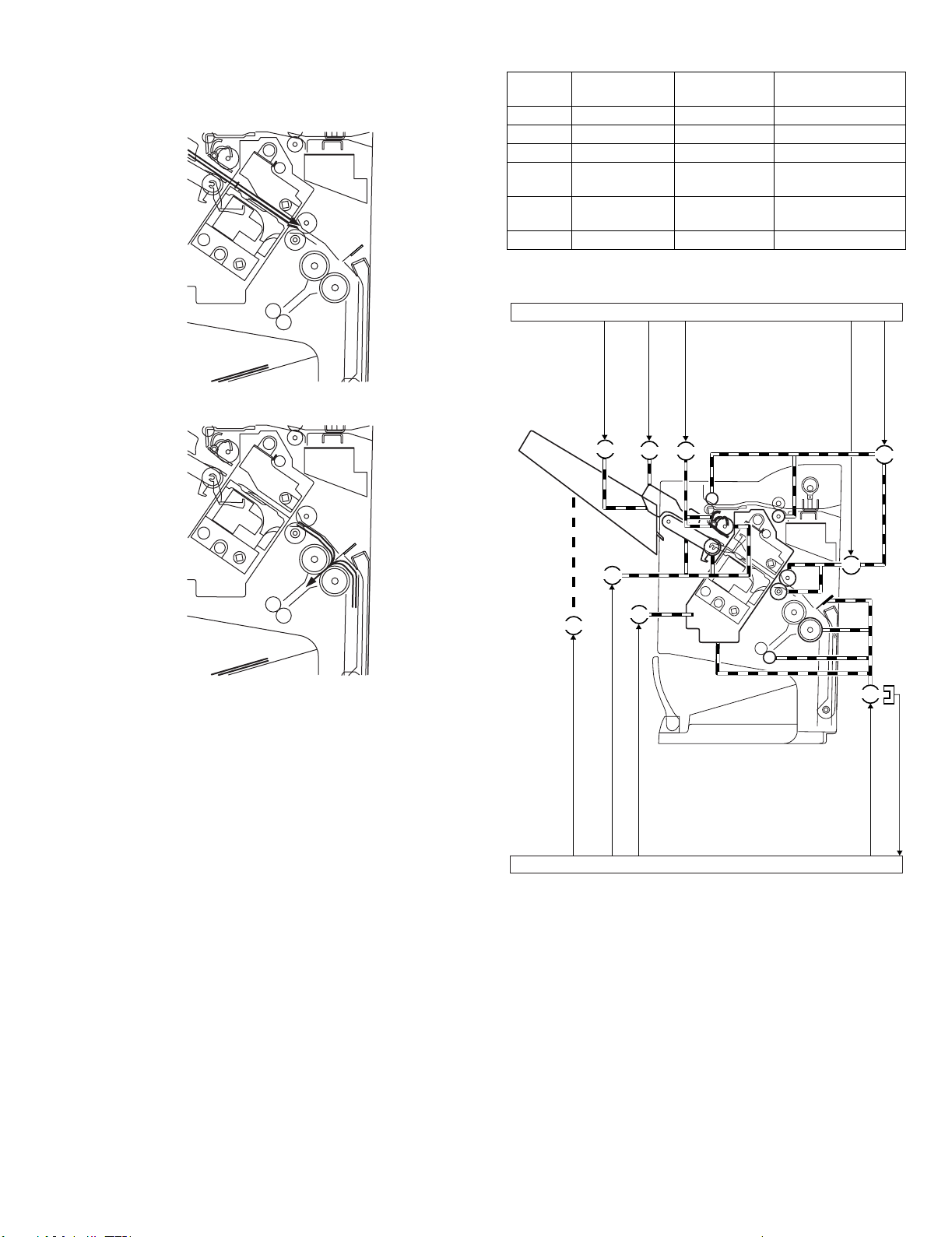

3. Stapling Operation

A.Outline

Staple operation is performed to staple a specified sheets of paper using

a stapler unit.

The stapling position depends on the staple mode and paper size.

When the machine starts immediately after power-on, the finisher

controller PCB drives the slide motor (FSM) to return the stapler unit to

the home position. The stapler unit starts moving toward the front of the

stapler frame. It stops when the slide home position sensor (SHPS) on

the slide PCB located under the stapler unit. Next, the slide motor is

driven a specified number of pulses. The stapler unit moves to rear

standby position at the back of the machine, entering the standby state.

Sensor Symbol Connector Function Remarks

Slide home

position sensor

Staple home

position sensor

Staple empty

sensor

Staple top

position sensor

Moves the stapler . Slide motor FSM Performs stapling operation. Staple/fold motor F F SM -

SHPS CN11-3 Detects the home

position for the stapler

moving back and forth.

STHPS CN11-4 Detects the home

position for the stapling

In the

stapler

operation

SPS CN11-5 Detects presence or

absence of staples in

In the

stapler

the cartridge.

SS CN11-6 Detects the staple top

position.

In the

stapler

Function Motor Symbol Remarks

Table.T02-301-01

Job offset sequence

Inlet sensor (ES)

Processing tray sensor

(AS)

Feed motor (FFM)

Delivery motor (FAM)

Delivery belt home

position sensor (OBHPS)

Paddle motor (FPM)

Paddle home position

sensor (PHPS)

Swing guide home

position sensor (ARHPS)

Stapler safety switch

(SSS)

Alignment motor (front)

(FFJM)

Aligning plate home position

sensor (front) (FJHPS)

Alignment motor (rear)

(FRJM)

Aligning plate home position

sensor (rear) (RJHPS)

Fig.F02-203-05

Start signal

Host machine delivery signal

360msec

360msec 360msec

60msec

Swing guide

360msec

30msec

220msec

CW rotation CCW rotation

Slide motor

(FSM)

Paper stack

Stapler

(Deliver direction)

Light-shielding plate

Slide home position sensor (SHPS)

Fig.F02-301-01

Fig.F02-203-06

AR-F14/PN1 OPERATIO NAL D E SC RI PT IO N 4-7

Page 24

B.Stapling Operation

When stacking and alignment of paper on the processing tray are

complete, the finisher controller PCB drives the paddle motor (FPM) in

the reverse direction and lowers the swing guide. When the swing guide

descends, the paper stack is sandwiched between the upper and lower

stack delivery rollers.

The finisher controller PCB moves the stapler for stapling according to

the specified stapling position (when rear 1-point stapling is specified,

the stapler does not move but it staples at the standby position). As the

stapler moves forward, the processing tray stopper is folded forward.

Paper stack

Swing guide

Stack delivery roller (upper)

Processing tray stopper

Delivery tray

Stack

delivery

roller

(lower)

Fig.F02-302-01

Stapler

C.Delivery Operation after Stapling

When stapling is complete, the finisher controller PCB drives the deliver

motor in the forward direction to feed the paper stack (sandwiched

between the stack delivery rollers) in the delivery direction. The delivery

belt home position sensor is turned OFF. The delivery motor is driven a

specified number of pulses, causing the swing guide to ascend. At the

same time, the slide motor is driven to return the stapler back to the

standby position, followed by driving of the delivery motor. Then, the

paper stack is delivered with the nails of the delivery belt that rotates in

sync with the stack delivery rollers.

Paper stack

Swing guide

Delivery tray

Delivery belt

Stack delivery

roller (lower)

Stapler

Paddle motor (FPM)

Staple safety switch

(SSS)

Swing guide

Stack delivery roller

Stack delivery roller

(lower)

(upper)

Fig.F02-302-02

Swing guide home

position sensor (ARHPS)

Light-shielding plate

Paddle motor (FPM)

Staple safety switch

(SSS)

Swing guide

Stack delivery roller

Stack delivery roller

(lower)

(upper)

Fig.F02-303-01

Swing guide home

position sensor (ARHPS)

Light-shielding plate

AR-F14/PN1 OPERATIO NAL D E SC RI PT IO N 4-8

Fig.F02-303-02

Page 25

D.Stapler Unit

The staple/fold motor (FFSM) is used to perform stapling operation. This

motor rotates the cam one turn for stapling. The home position of this

cam is detected by the staple home position sensor (STHPS).

The staple/fold motor is rotated in the forward or reverse direction under

the control of the macro computer (IC13) on the finisher controller PCB.

When the staple home position sensor is OFF, the finisher controller PCB

rotates the staple/fold motor in the forward direction until the sensor turns

ON, allowing the staple cam to the original position.

The staple empty sensor (SPS) is used to detect presence/absence of a

staple cartridge in the machine and presence/ absence of staples in the

cartridge.

The stale top position sensor (SS) is used to determine whether staples

are pushed up to the top of the staple cartridge.

The finisher controller circuit does not drive the staple/fold motor (FFSM)

unless the staple safety switch (SSS) is ON (the swing guide is close).

This assures safety in case where you happen to put your finger in the

stapler.

Fig.F02-304-01

(1)Stapler Movement Controller

The stapler unit is moved by the slide motor (FSM). Its home position is

detected by the slide home position sensor (SHPS). The stapler waits at

the back irrespective of the staple mode and paper size. After paper has

been stacked on the processing tra y, the stapler is moved to the specified

stapling position in response to the stapling command from the host

machine.

F02-304-03 shows the standby position of the stapler and the stapling

position depending on the staple mode.

a.Front 1-point stapling

The stapler waits at the back. The stapler moves to and returns from the

stapling position for each stapling operation.

Standby position

Stapler

Feed direction

Stopper

Stapling position

Fig.F02-304-03

b.Rear 1-point stapling

The stapler waits at the back. The stapling position is the same as the

standby position.

Staple top position detect signal

Staple empty detect signal

Staple home position detect signal

Finisher controller PCB

Fig.F02-304-02

M7

Staple/hold motor drive signal

Standby position

Stabling position

Stapler

Feed direction

Stopper

Fig.F02-304-04

c.Middle 2-point stapling

The stapler waits at the back. The stapler moves to and returns from the

stapling position for each stapling operation. The stapler first staples a

paper stack at the rear stapling position and then staples it at the front

stapling position.

Standby position

Stapler

Stapling position

Stopper

Feed direction

Stapling position

AR-F14/PN1 OPERATIO NAL D E SC RI PT IO N 4-9

Fig.F02-304-05

Page 26

d.Middle 2-point stapling (bind mode)

The stapler waits at the back. The stapler moves to and returns from the

stapling position for each stapling operation. The stapler first staples a

paper stack at the rear stapling position and then staples it at the front

stapling position.

Standby position

Stapler

Stapling position

Stopper

Feed direction

Stapling position

Fig.F02-304-06

Stapling Operation Seque nce

Rear 1-point Stapling of 2 Sheets

Start signal

Inlet sensor (ES)

Processing tray sensor

(AS)

Feed motor (FFM)

Delivery motor (FAM)

Delivery belt home

position sensor (OBHPS)

Paddle motor (FPM)

Paddle home position

sensor (PHPS)

Swing guide home

position sensor (ARHPS)

Stapler safety switch

(SSS)

Alignment motor (front)

(FFJM)

Aligning plate home position

sensor (front) (FJHPS)

Staple/fold motor

(FFSM)

Staple home position

sensor (STHPS)

Host machine delivery signal

360msec

360msec

20msec

CW rotation CCW rotation

Staple

Stack delivery

10msec

Fig.F02-304-07

4. Delivery Tray Operation

A.Outline

The machine has a delivery tray in the finisher unit and a bind tray in the

saddle unit.

The bind tray in the saddle unit is of the fixed type and all the folded

paper stacks are delivered to this tray. This tray has a bind tray sensor

(FES) to detect presence/absence of paper.

The delivery tray in the finisher unit is moved up and down using a shift

motor (FLM).

The finisher has a tray paper sensor (BES) to detect presence/absence

of paper on the stack tray.

The home position sensor of the delivery tray is detected by the paper

surface sensor (STHPS). When paper has already been stacked on the

delivery tray, the home position is on the top surface of the stacked

paper. When paper has not yet been stacked on the delivery tray, the

home position is at the position where the edge of the delivery tray is

detected. At power-on, the finisher controller PCB drives the shift motor

(FLM) to return the delivery tray to the home position.

When the paper coming from the processing tray is stacked on the

delivery tray, the shift motor is driven a specified number of pulses,

causing the delivery tray to descend. Clock pulses are detected by the

shift motor clock sensor (LE). Then, the delivery tray returns to the home

position for the next stacking operation.

The upper limit of the delivery tray is detected by the shift upper limit

sensor (ULS). When the shift upper limit sensor (ULS) is turned ON, the

finisher controller PCB stops the shift motor (FLM) that is ascending.

The lower limit of the delivery tray is detected by the shift lower limit

sensor (LLLS). When the shift lower limit sensor (LLLS ) is turned ON,

the finisher controller PCB stops the shift motor (FLM) that is

descending.

The finisher unit has a full stack sensor (PI24) to det ect overstacking of

large-size or mixed paper according to the stack height.

Shift upper limit sensor

Shift lower limit sensor

Shift motor clock sensor

(ULS)

(LLLS)

(LE)

Tray paper sensor (BES)

Paper surface sensor (SLS)

Edge

Delivery tray

Full stack sensor (XXXX)

Shift motor (FLM)

Fig.F02-401-01

AR-F14/PN1 OPERATIONAL DESCRIPTION 4-10

Page 27

5. Saddle Unit

A.Basic Operations

(1)Outline

The machine stitches a stack of sheets (middle 2-point), then folds the

stack in two in the finisher. These operations are controlled by the

finisher controller PCB.

The finisher controller PCB is controlled by the commands from the host

machine.

B.Feed/Drive System

(1)Outline

This machine stitches the paper stack coming from the finisher, folds it,

and delivers it to the bind tray in the saddle unit in response to the

commands from the host machine.

That is, the machine performs the following operations:

a) Paper feed-in

b) Stitching

c) Stack feed

d) Folding/delivery

b.Stitching

When the center of the paper stack (stitching position) reaches the

stapler's staple position, the stapler stitches the paper stack.

When only one sheet is fed from the host machine, the next step (stack

feed) is performed without performing the stitching operation.

Staple

Stapler (lower)

Stapler (upper)

a) Paper feed-in

d) Folding/delivery

b) Stitching

c) Stack feed

Fig.F02-502-01

a.Paper feed-in

After being aligned on the processing tray, a stack of sheets is

sandwiched between the stack delivery rollers. As the stack delivery

rollers rotate, the stack is fed toward the saddle unit.

Stack delivery roller (upper)

Paper stack

Stack delivery roller

(lower)

Fig.F02-502-03

c.Stack feed

The stack feed rollers feed the paper stack to the stack folding/delivery

position where the center of the stack (stitched position) is level with the

paper pushing plate and paper folding roller's nip part.

Stack feed roller (upper)

Paper pushing plate

Stack feed roller (lower)

Paper fold roller

Fig.F02-502-04

Fig.F02-502-02

AR-F14/PN1 OPERATIONAL DESCRIPTION 4-11

Page 28

d.Folding/delivery

The paper pushing plate pushes in the center of the paper stack to feed it

toward the paper fold rollers. Then, the paper fold rollers and bind

delivery rollers deliver the paper stack to the bind tray.

Bind delivery rollers

Paper fold rollers

Fig.F02-502-05

C.Pa per Feed System

(1)Outline

The paper feed system feeds a stack of sheets (coming from the finisher)

to the position where the center of the paper stack (stitching position) is

aligned to the stapler's staple, allowing the next step (stitching and

folding) to be performed.

When sheets of paper have been stacked and aligned on the processing

tray, the paddle motor (FPM) rotates in the reverse direction, causing the

swing guide to descend. As the swing guide descends, the paper stack

is sandwiched between the upper and lower stack delivery rollers. The

delivery motor (FAM) rotates in the revers e direction, feeding the paper

stack toward the saddle unit. When the leading edge of the paper stack

reaches the folding position sensor (FPS), the finisher controller PCB

drives the delivery motor a specified number of motor pulses to stop the

center of the paper stack (stitching position) at the stapler's staple

position. Before the paper stack passes through the stack feed rollers,

the feed motor (FFM) is driven to rotate the stack feed roller (lower) so

that the leading edge of the paper stack is not bent.

Stack delivery roller (upper)

Paper stack

Fold position sensor

Stack delivery roller

(lower)

D.Stack Feed System

(1)Outline

The stack feed system feeds the stitched paper stack to the folding

position.

When stitching is complete, the feed motor (FFM) rotates, causing the

stack feed roller (upper) to descend. The paper stack is sandwiched

between the stack feed rollers. Then, the bind clutch (FFC) is turned ON

to rotate the feed motor (FFM) in the forward direction, thus feeding the

paper stack to the folding position. The feed amount is equivalent to the

number of pulses used to drive the feed motor (FFM) until the paper

stack reaches the folding position.

Stack feed roller (upper)

Feed amount

Stack feed roller (lower)

Fig.F02-504-01

E.Fold/Delivery System

(1)Outline

The paper fold mechanism consists of a guide plate, paper fold rollers,

and a paper pushing plate.

The guide plate, paper fold rollers, and paper pushing plate are driven by

the staple/fold motor (FFSM). The drive force is transferred with a

combination of gears and cams. Motor operation is monitored by the

staple/fold motor lock sensor (FE).

Until the paper stack reaches the folding position, the guide plate covers

the paper fold rollers to act as a paper path through which a paper stack

is fed to the saddle unit and to prevent a paper stack from touching the

rollers.

A folding home position sensor (FHPS) is provided to detect the

positions of the paper fold rollers and paper pushing plate.

The paper stack folded in two by the paper fold rollers is delivered by

bind delivery rollers.

The bind delivery rollers are also driven by the staple/fold motor (FFSM).

A bind tray sensor (FES) is provided on the bind tray to detect presence/

absence of a paper stack; however, it is not used to detect a jam.

Fig.F02-503-01

Stack feed roller (lower)

AR-F14/PN1 OPERATIONAL DESCRIPTION 4-12

Page 29

(2)Paper Folding

Paper is folded using paper fold rollers and a paper pushing plate.

Almost concurrently with the star t of roller rotation, the paper pushing

plate starts operating to push the paper stack into the gap between the

paper fold rollers. When the paper stack is fed about 10 mm with the

rotation of the paper fold rollers, the paper pushing plate returns to the

home position. Then, the paper stack is delivered to the bind tray using

the paper fold rollers and bind delivery rollers.

Half the entire surface of each paper fold roller is uncovered excluding

the central area and the area at the left and right ends. The uncovered

surface of the upper paper fold roller comes in touch with the uncovered

surface of the lower paper fold roller only at the center and left and right

ends, allowing a paper stack to be fed without causing creases. The

other half of the upper paper fold roller that is covered comes in touch

with the other half of the lower paper fold roller that is also covered,

allowing a paper stack to be folded while being fed.

Sensor flag

Folding home position sensor (FHPS)

Came

Paper stack

Paper fold roller (upper)

Staple/fold

motor

FFSM

Paper fold roller (lower)

Fig.F02-505-01

Paper pushing plate

Folding

home position sensor (FHPS)

Paper pushing plate

[Paper folding start position]

Outlet

Feed motor (FFM)

Delivery motor (FAM)

Paddle motor (FPM)

Paddle home position

sensor (PHPS)

Swing guide home

position sensor (ARHPS)

Stapler safety switch

(SSS)

Slide motor (FSM)

Staple/fold motor (FFSM)

Staple home position

sensor (STHPS)

Folding position sensor

(FPS)

Stack feed roller (upper)

home position sensor (FRHPS)

Binding clutch (FFC)

Folding home position

sensor (FHPS)

Bind tray sensor (FES)

Staple

Paper stack

Inlet

Paper push plate

Folds/feeds a paper stack.

Feeds a paper stack.

Fig.F02-505-03

Fold, Delivery

13571msec

50msec

Paper fold roller (upper)

Staple/fold

motor

Paper fold roller (lower)

FFSM

Paper stack

CW rotation CCW rotation

Fig.F02-505-04

Fig.F02-505-02

AR-F14/PN1 OPERATIONAL DESCRIPTION 4-13

Page 30

6. Puncher Unit (option)

A. Basic Operations

(1)Outline

The puncher unit is an option, and is designed for installation to the

pickup assembly of the finisher. The puncher unit is not equipped with a

paper feeding mechanism, and the sheets from the host mach ine move

through the puncher unit and then the feed system of the finisher.

When the trailing edge of a sheet from the host machine reaches the

puncher unit, the sheet is stopped once, and the punch shaft is rotated to

punch a hole along the trailing edge. These operations are controlled

with various commands from the finisher controller PCB as well as the

commands from the punch controller PCB.

The punch motor and horizontal registration motor are controlled with

various commands from the finisher controller PCB as well as the

commands from the punch controller PCB.

The waste paper occurring as the result of punching is collected in the

waste paper case. The case is monitored by the LED121 on the waste

full LED PCB and PT131 on the waste full photosensor PCB.

Punch controller PCB (1/2)

Punch drive system

Horizontal registration

drive system

Punch controller PCB

Finisher unit control system

Fig.F02-601-01

B.Punching Operation

(1)Outline

The puncher unit is located in the pickup assembly of the finisher, and is

used to punch holes in sheets that have been sent from the host

machine and stopped inside it. When the trailing edge of a sheet reaches

the puncher unit, the inlet roller of the finisher assembly stops the sheet

to punch a hole along the trailing edge of the sheet.

The punch unit consists of a die and hole puncher (punch blade).

The hole puncher is driven by the punch motor (FPNM). It is attached to

the eccentric cam of the punch shaft, and the rotation of the punch shaft

is converted into reciprocating motion for punching operation.

The punch motor (FPNM) is a DC motor. The home position of the punch

shaft is detected by the punch home position sensor (PI1P). To m ake

sure that the punch motor, which is a DC motor, stops exactly at its home

position, the punch motor is stopped in relation to the count of the clock

pulses kept by the punch motor clock sensor (PE).

A single punching operation is executed by rotating the punch shaft 180×

from its home position.

As many as five light-receiving transistors (photosensor PCB) are

mounted over the inlet paper path of the puncher unit; on the other hand,

as many as five LEDs (LED PCB) are mounted under the path, together

serving as five sensors. The frontmost sensor (LE D5, PT5) is used to

detect the training edge of sheets, and the remaining four (LED1 through

LED4, PT1 through PT4) are used as horizontal registration sensors to

detect the rear position of sheets when punching holes.

The punch motor, punch unit, and sensors make up the punch slide unit,