Page 1

SERVICE MANUAL

S25A5SE55APRR

SHARP CORPORATION

REFRIGERATOR-FREEZER

SJ-48G-GY/BE/BL

SJ-D48G-GY/BE/BL

SJ-51G-GY/BE/BL

SJ-D51G-GY/BE/BL

SJ-55G-GY/BE/BL

SJ-D55G-GY/BE/BL

TABLE OF CONTENTS

page

OUTLINE OF PRODUCT.......................................................................................................................................2

SPECIFICATIONS .................................................................................................................................................3

DESIGNATION OF VARIOUS PARTS ..................................................................................................................5

LIST OF ELECTRICAL PARTS ............................................................................................................................. 6

WIRING DIAGRAM................................................................................................................................................ 9

FUNCTIONS ........................................................................................................................................................12

ASSEMBLING PROCEDURES OF MAIN PARTS AND CAUTIONS ..................................................................15

COOLING UNIT ...................................................................................................................................................21

REPLACEMENT PARTS LIST ............................................................................................................................22

Refrigerant; HFC-134a

Refer to "HFC-134a COOLING UNIT" Service Manual for handling this refrigerant.

In the interests of user-safety (Required by safety regulations in some

countries) the set should be restored to its original condition and only

parts identical to those specified should be used.

MODELS

DESTINATION ............................. R, M, H, Y, T, Z

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

1

Page 2

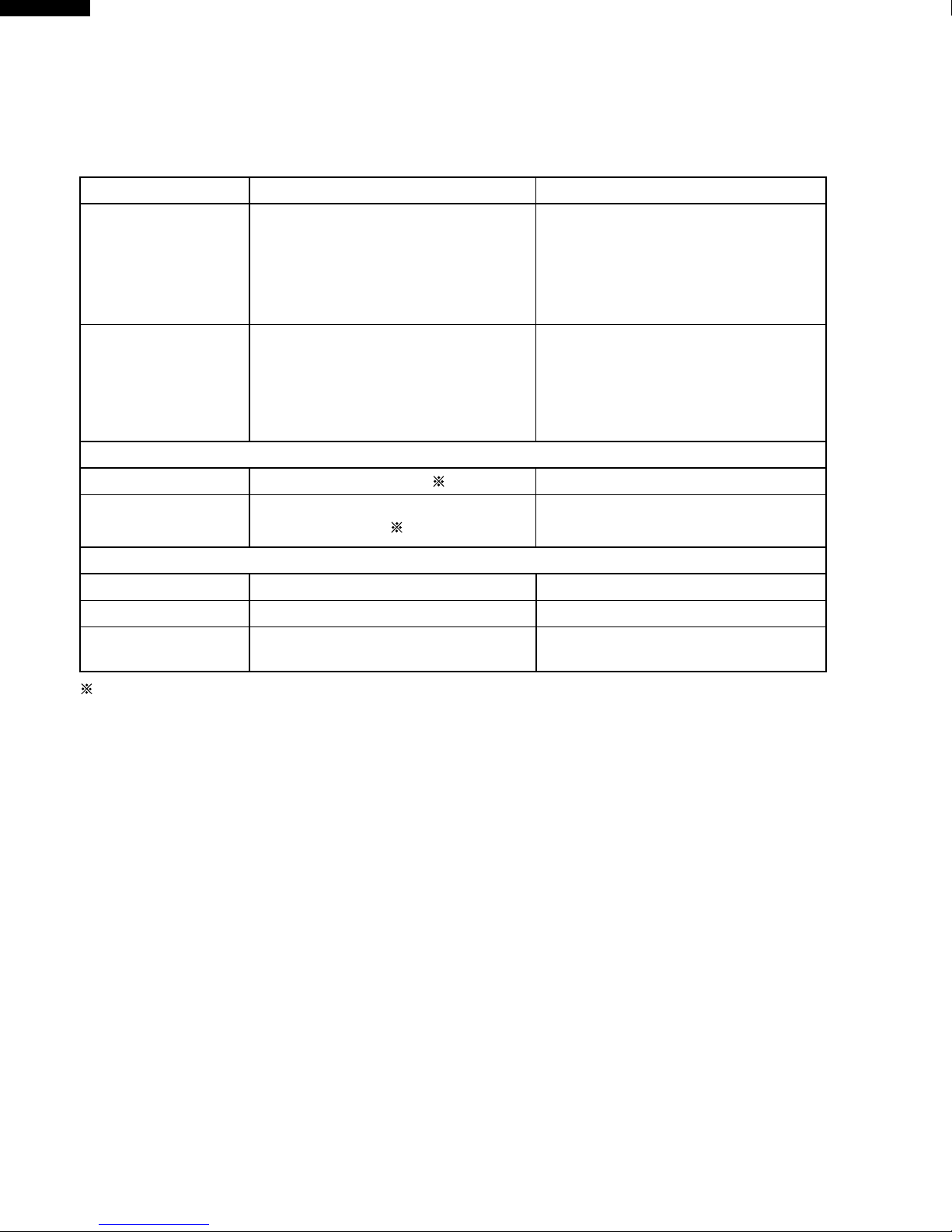

SJ-48G/D48G

G type E type

Cooling Unit

Refrigerant CFC-12

Outer dimensions

(Height~ Width~ Depth)

Heat insulator

48G@ 1620~ 735~ 700(mm)

@@@ (63.8"~ 28.9"~ 27.6")

51G@ 1700~ 735~ 700(mm)

@@@ (66.9"~ 28.9"~ 27.6")

55G@ 1820~ 735~ 700(mm)

@@@ (71.7"~ 28.9"~ 27.6")

42E@ 1620~ 715~ 690(mm)

@@@ (63.8"~ 28.1"~ 27.2")

45E@ 1735~ 715~ 690(mm)

@@@ (68.3"~ 28.1"~ 27.2")

50E@ 1825~ 715~ 690(mm)

@@@ (71.9"~ 28.1"~ 27.2")

Rated storage volume

48G@ 443 liter(15.6cu.ft.)

@@@ F:139(4.9) R:304(10.7)

51G@ 483 liter(17.1cu.ft.)

@@@ F:139(4.9) R:334(11.8)

55G@ 521 liter(18.4cu.ft.)

@@@ F:139(4.9) R:382(13.5)

42E@ 400 liter(14.2cu.ft.)

@@ F:98(3.5) R:302(10.7)

45E@ 430 liter(15.2cu.ft.)

@@ F:128(4.5) R:302(10.7)

50E@ 470 liter(16.6cu.ft.)

@@ F:162(5.7) R:308(10.9)

Specifications of interior

Fresh case 0 2

Chilled case

1 0

Three position

adjustable shelf

1

0

Polyurethane foam that uses

CFC-11

Conforms to the Regulations for Specific CFCs that will take effect in 1996.

HFC-134a

Polyurethane foam that uses

cyclopentane

SJ-51G/D51G

SJ-55G/D55G

OUTLINE OF PRODUCT

(Comparison between Type G and Type E)

2

Page 3

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

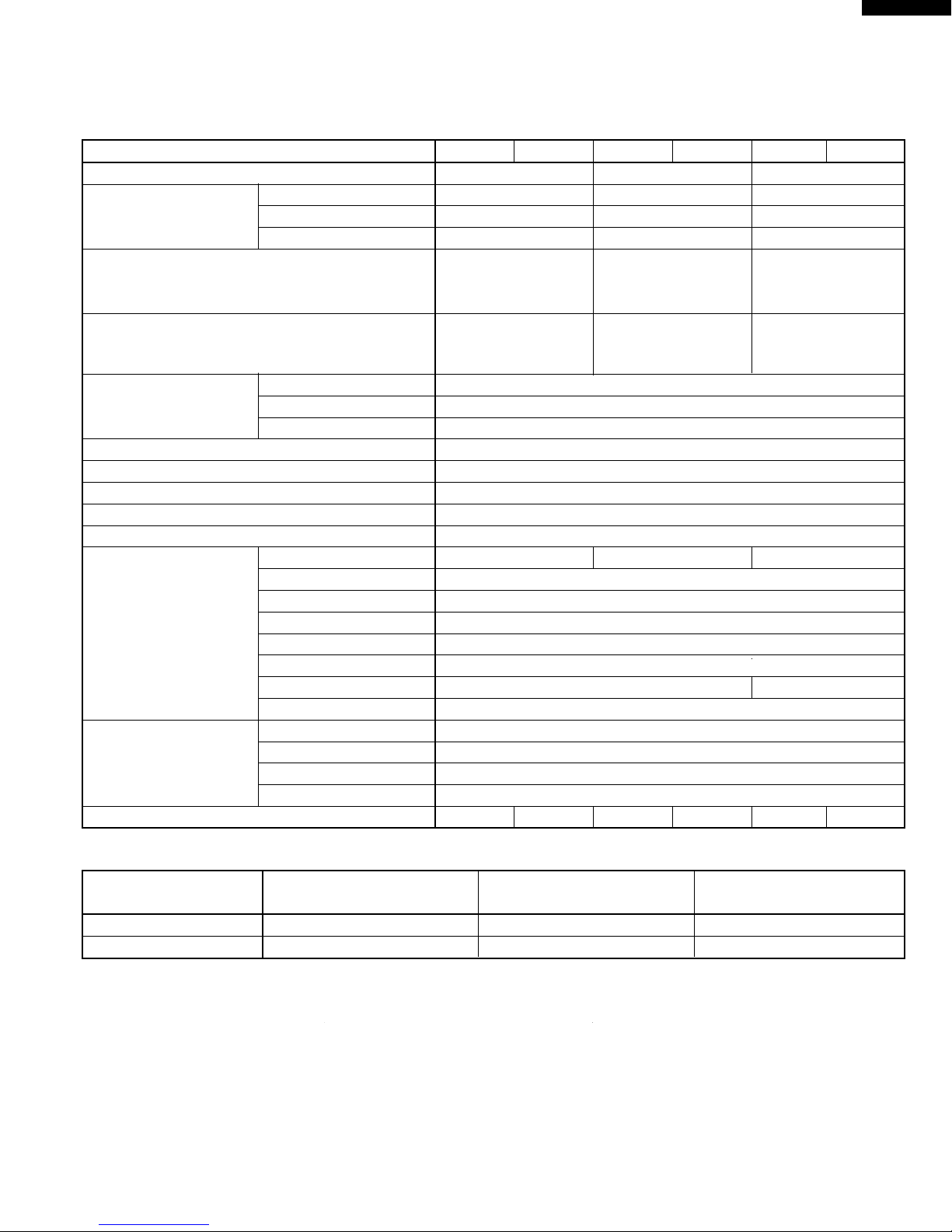

SPECIFICATIONS

Items SJ-48G SJ-D48G SJ-51G SJ-D51G SJ-55G SJ-D55G

Type 2-Door 2-Door 2-Door

Outer dimensions Height 1620mm(63.8") 1700mm(66.9") 1820mm(71.7")

Width 735mm(28.9") 735mm(28.9") 735mm(28.9")

Depth 700mm(27.6") 700mm(27.6") 700mm(27.6")

Rated storage volume 443 liter(15.6 cu.ft) 473 liter(16.7 cu.ft) 521 liter(18.4 cu.ft)

F: 139 liter(4.9 cu.ft) F: 139 liter(4.9 cu.ft) F: 139 liter(4.9 cu.ft)

R: 304 liter(10.7 cu.ft) R: 334 liter(11.8 cu.ft) R: 382 liter

Rated gross volume 475 liter(16.8cu.ft) 505 liter(17.8 cu.ft) 550 liter(19.4 cu.ft)

F: 163 liter(5.8 cu.ft) F: 163 liter(5.8 cu.ft) F: 163 liter(5.8 cu.ft)

R: 312 liter(11.0cu.ft) R: 342 liter(12.0cu.ft) R: 387 liter(13.6cu.ft)

Defrosting System Heater system

Start Automatic

Finish Automatic

Temperature control Automatic (Adjustable)

No-frost freezer Yes

Interior lamp 1

Caster 4

Evaporating pan 1

Refrigerator Refrigerator shelf 1 2 3

Compartment Glass shelf 1

Fruit and Vegetable crisper

1

Egg pocket 1

Egg holder 2

Bottle pocket 2

Free pocket 1 2

Chilled case 1

Freezer Freezer shelf L 1

Compartment Freezer shelf S 1

Ice cube maker Twin ice cube maker

Ice cube box 1

Deodorizing system NO YES NO YES NO YES

(13.5 cu.ft)

COLOR

Items

SJ-48G-GY, SJ-51G-GY, SJ-55G-GY SJ-48G-BE, SJ-51G-BE, SJ-55G-BE SJ-48G-BL, SJ-51G-BL, SJ-55G-BL

SJ-D48G-GY, SJ-D51G-GY, SJ-D55G-GY SJ-D48G-BE, SJ-D51G-BE, SJ-D55G-BE SJ-D48G-BL, SJ-D51G-BL, SJ-D55G-BL

Outside color Gray Beige Blue

Inside color White White White

3

Page 4

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

SOURCE AND COMP. AND NET WEIGHT

DESTINATION: R, M,Y, T

Items SJ-48G, SJ-D48G SJ-51G, SJ-D51G SJ-55G, SJ-D55G

Rated voltage (V) 220/230/240

Rated frequency (Hz) 50

Classification T

Rated input (W) 172/178/184 182/186/190

Rated input of heating elements (W) 137/150/163

Refrigerant (Charging quantity) HFC-134a(125g) HFC-134a(130g)

Net weight (kg) 79 84 88

DESTINATION: H

Items SJ-48G, SJ-D48G SJ-51G, SJ-D51G SJ-55G, SJ-D55G

Rated voltage (V) 200/220

Rated frequency (Hz) 50

Classification ST

Rated input (W) 175/195 180/200 185/205

Rated input of heating elements (W) 136/165

Refrigerant (Charging quantity) HFC-134a(125g) HFC-134a(130g)

Net weight (kg) 79 84 88

DESTINATION: Z

Items SJ-48G, SJ-D48G SJ-51G, SJ-D51G SJ-55G, SJ-D55G

Rated voltage (V) 220

Rated frequency (Hz) 50/60

Classification T

Rated input (W) 195/190 200/195 205/200

Rated input of heating elements (W) 137/137

Refrigerant (Charging quantity) HFC-134a(125g) HFC-134a(130g)

Net weight (kg) 79 84 88

4

Page 5

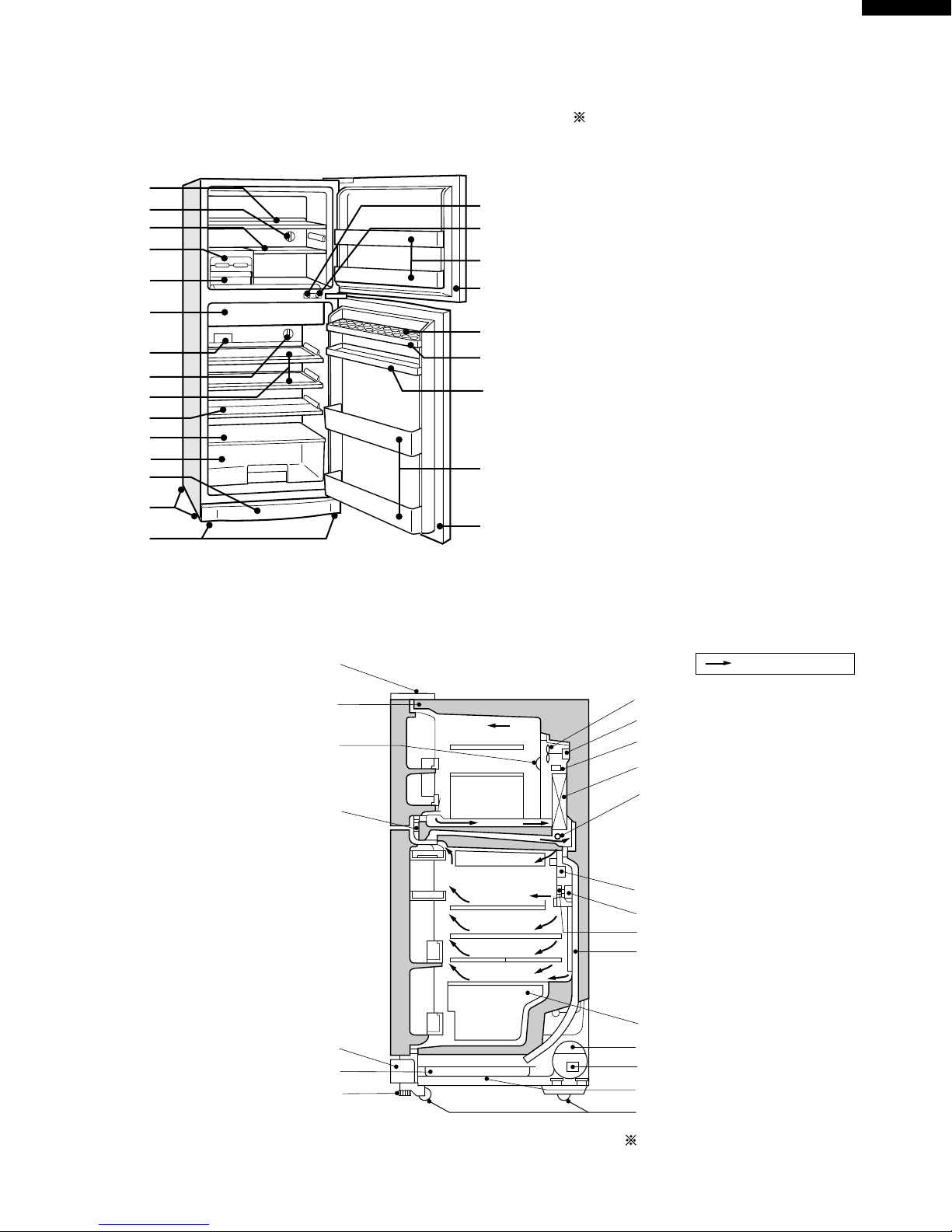

DESIGNATION OF VARIOUS PARTS

1

2

3

4

5

6

7

8

9

10

11

12

13

15

16

17

18

19

20

21

22

23

19

14

Upper hinge cover

Hot pipe

Freezer temp. control knob

Hot pipe

Evaporating pan cover

(Ventilating grille)

Evaporating pan

Adjustable feet

(Adjustable leg)

Fan motor

Propeller fan

Defrost thermostat

Evaporator

Defrost heater

Damper thermostat

Refrigerator temp. control knob

Drain pipe

Vegetable case

Compressor

Starting relay, Overload relay(Protector)

Caster

Sub condenser

Freezer

compartment

Refrigerator

compartment

Mark: Cold air flow

Timer

This figure shows SJ-51G.

Figure D-1. External Description

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

The names in parenthesis are the

denominations used in the REPLACEMENT

PARTS LIST.

1. Freezer shelf (L) (Freezer tray L silk)

2. Freezer temp. control knob

3. Freezer shelf (S) (Freezer tray S silk)

4. Ice cube maker

5. Ice cube box (Ice storage box)

6. Chilled case

7. Light (Lamp)

8. Refrigerator temp. control knob

9. Refrigerator shelf(Ref. tray silk)

(SJ-48G type 1, SJ-51G type 2, SJ-55G type 3)

10. Three position adjustable shelf (Free set shelf)

11. Glass shelf

12. Fruit and Vegetable crisper (Vegetable case)

13. Evaporating pan & Cover

14. Caster

15. Adjustable feet (Adjustable leg)

16. Fan switch

17. Fan & light switch

18. Freezer pocket (F door pocket HS)

19. Magnetic door seal (Door packing)

20. Egg holder (Egg tray)

21. Egg pocket (Egg pocket HS)

22. Free pocket (Utility pocket HS)

(SJ-48G type 1, SJ-51G type 1, SJ-55G type 2)

23. Bottle pocket (Bottle pocket HS)

Figure D-2. Constructions

5

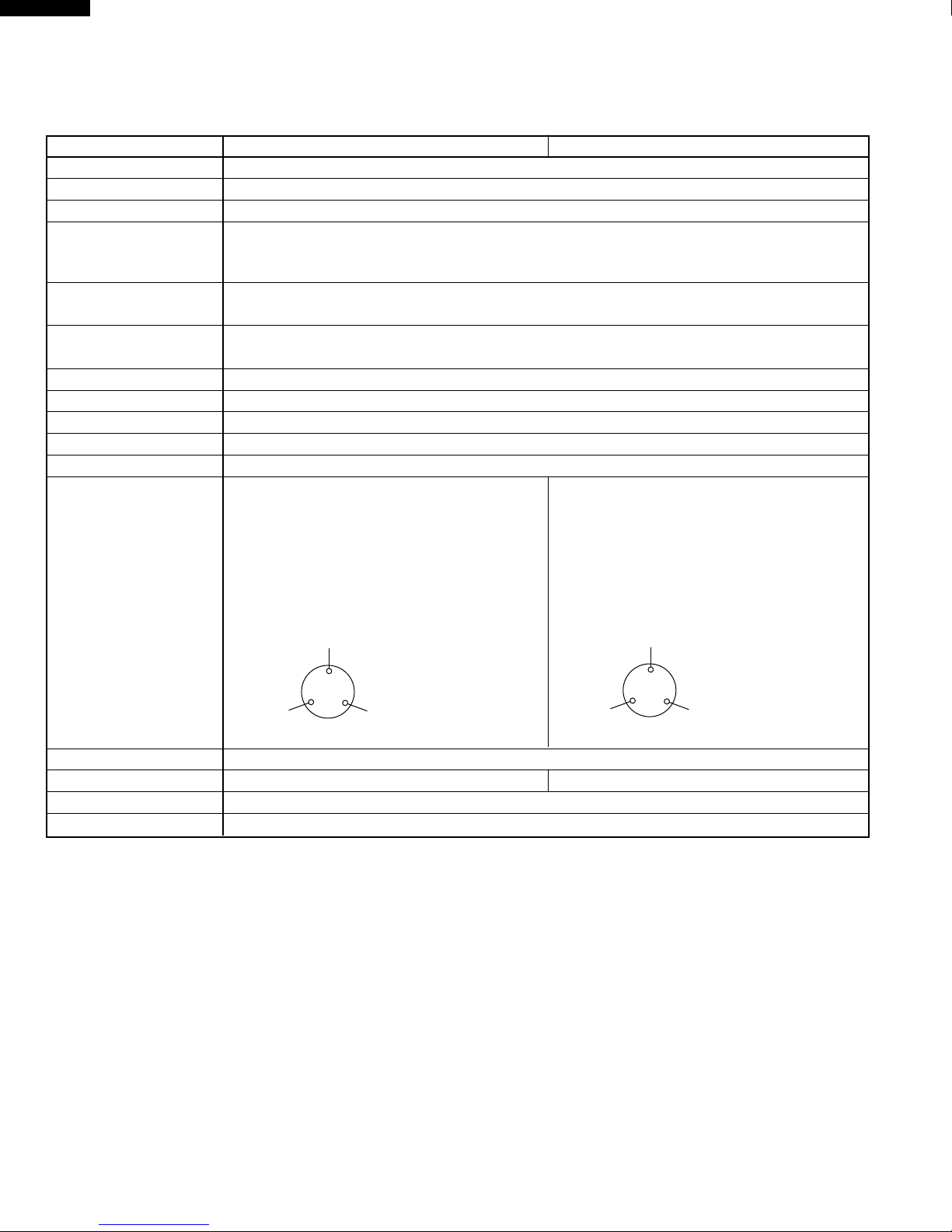

Page 6

SJ-48G/D48G

Aux. coil

Common

Main coil

Aux. coil

Common

Main coil

SJ-51G/D51G

SJ-55G/D55G

LIST OF ELECTRICAL PARTS

DESTINATION: R,M,Y,T

Items SJ-48G, SJ-D48G SJ-51G, SJ-D51G, SJ-55G, SJ-D55G

Source 220/230/240V 50Hz

Climate class T, ST

Thermostat Type: MM1-8025 ON: –17±5˚C OFF: –22±1.5˚C(at normal notch)

Damper thermostat Type: MM1-6129

Baffle opened 1.5˚C(at normal notch)

Baffle closed –3±1.5˚C

Timer Type: TMDF904FD2, Integration type

Cycle 10hours 50 min., Working time about 4min. 20sec. 50Hz

Fuse ass'y Thermo. fuse Type: SF70E 250V 10A Working temp. 70±2˚C

or MTG4A50072 250V 10A Working temp. 72±2˚C

Defrost thermostat Type: US602S 250V 8A OPEN 10±3˚C CLOSE 1±3˚C

Door switch 3 terminals push-button 250V 0.25A

Lamp socket 250V 1A E-12(HARD PLASTIC BODY TYPE)

Lamp 240V 10W E-12

Fan motor Type: MH15SAF-TJA7 200/240V 50Hz

Compressor Type: GL-90BH Type: GL-99BH

50Hz(OIL COOLING) 50Hz(OIL COOLING)

Cooling capacity 223W Cooling capacity 244W

Main coil 8.8Ω Main coil 8.5Ω

Aux. coil 17.7Ω(at 20˚C) Aux. coil 15Ω(at 20˚C)

Terminal Terminal

Starting relay PTC/UH-3003 14Ω 350V

Overload relay

(Protector)

4TM276NFBYY OFF 120˚C ON 61˚C 4TM308NFBYY OFF 120˚C ON 61˚C

Running capacitor 6µF / 400V

Defrost heater 220V 137.1W / 230V 150W / 240V 164.9W 353Ω

6

Page 7

DESTINATION: H

Aux. coil

Common

Main coil

Items SJ-48G, SJ-D48G SJ-51G, SJ-D51G, SJ-55G, SJ-D55G

Source 200/220V 50Hz

Climate class ST

Thermostat Type: MM1-8025 ON: –17±5˚C OFF: –22±1.5˚C(at normal notch)

Damper thermostat Type: MM1-6129

Baffle opened 1.5˚C(at normal notch)

Baffle closed –3±1.5˚C

Timer Type: TMDF904FD2, Integration type

Cycle 10hours 50 min., Working time about 4min. 20sec. 50Hz

Fuse ass'y Thermo. fuse Type: SF70E 250V 10A Working temp. 70±2˚C

or MTG4A50072 250V 10A Working temp. 72±2˚C

Defrost thermostat Type: US602S 250V 8A OPEN 10±3˚C CLOSE 1±3˚C

Door switch 3 terminals push-button 250V 0.25A

Lamp socket 250V 1A E-12(HARD PLASTIC BODY TYPE)

Lamp 240V 10W E-12

Fan motor Type: MH15SAF-TJA7 200/240V 50Hz 0.8W

Compressor Type: GL-99BL

200/220V 50Hz, 220V 60Hz(OIL COOLING)

Cooling capacity 244W/279W

Main coil 6.68Ω

Aux. coil 9.30Ω(at 20˚C)

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

Terminal

Starting relay PTC/UH-3003 14Ω 350V

Overload relay

(Protector)

4TM306NFBYY OFF 120˚C ON 61˚C

Running capacitor 6µF / 400V

Defrost heater 200V 136W / 220V 165W 294Ω

7

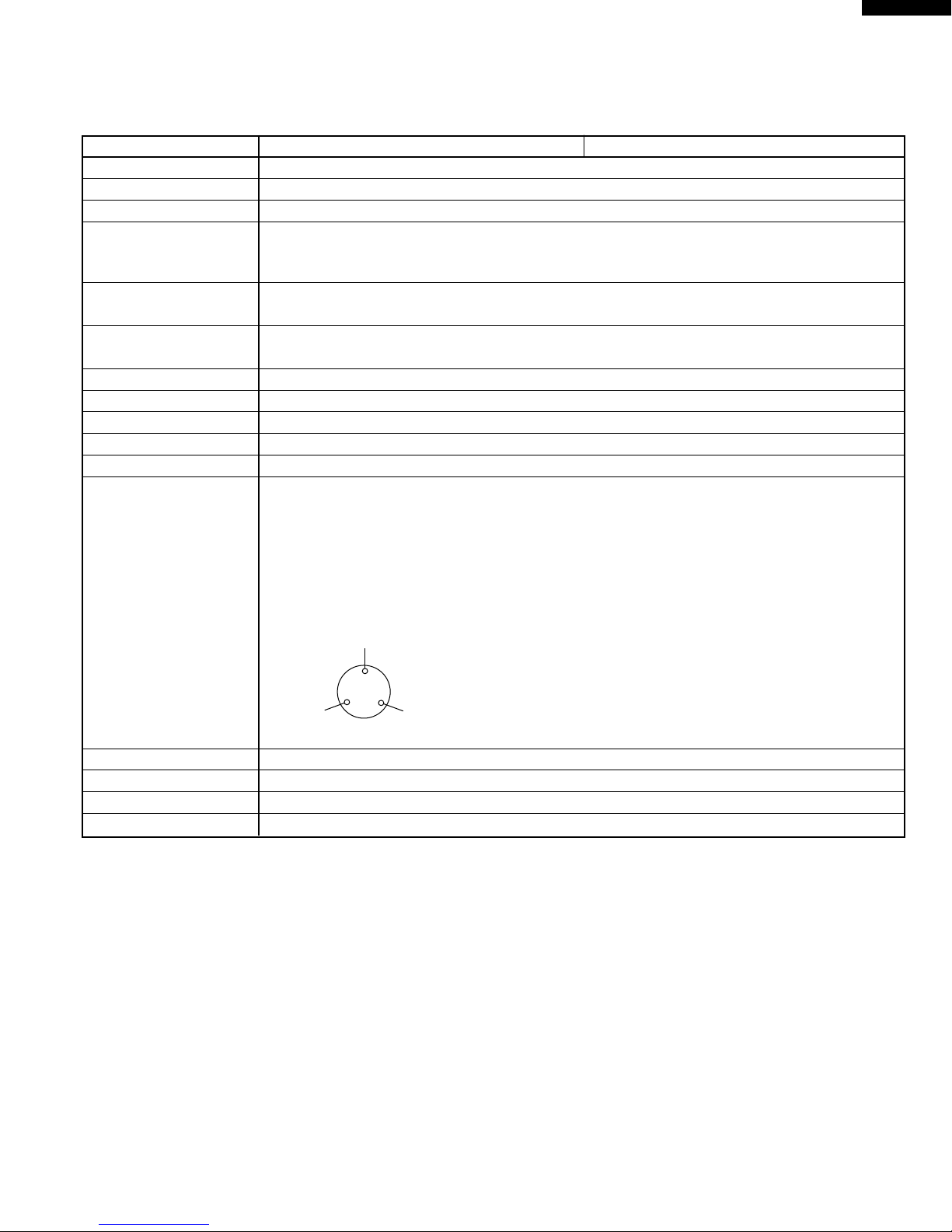

Page 8

SJ-48G/D48G

Aux. coil

Common

Main coil

SJ-51G/D51G

SJ-55G/D55G

DESTINATION: Z

Items SJ-48G, SJ-D48G SJ-51G, SJ-D51G, SJ-55G, SJ-D55G

Source 220V 50/60Hz

Climate class T

Thermostat Type: MM1-8025 ON: –17±5˚C OFF: –22±1.5˚C(at normal notch)

Damper thermostat Type: MM1-6129

Baffle opened 1.5˚C(at normal notch)

Baffle closed –3±1.5˚C

Timer Type: TMDF904FD2, Integration type

Cycle 10hours 50 min., Working time about 4min. 20sec. 50Hz

Fuse ass'y Thermo. fuse Type: SF70E 250V 10A Working temp. 70±2˚C

or MTG4A50072 250V 10A Working temp. 72±2˚C

Defrost thermostat Type: US602S 250V 8A OPEN 10±3˚C CLOSE 1±3˚C

Door switch 3 terminals push-button 250V 0.25A

Lamp socket 250V 1A E-12(HARD PLASTIC BODY TYPE)

Lamp 240V 10W E-12

Fan motor Type: MH15SAF-TJA7 200/240V 50Hz 0.8W

Compressor Type: GL-99BL

50/60Hz(OIL COOLING)

Cooling capacity 244W/279W

Main coil 6.68Ω

Aux. coil 9.30Ω(at 20˚C)

Terminal

Starting relay PTC/UH-3003 14Ω 350V

Overload relay

(Protector)

4TM306NFBYY OFF 120˚C ON 61˚C

Running capacitor 6µF / 400V

Defrost heater 220V 137W 353Ω

8

Page 9

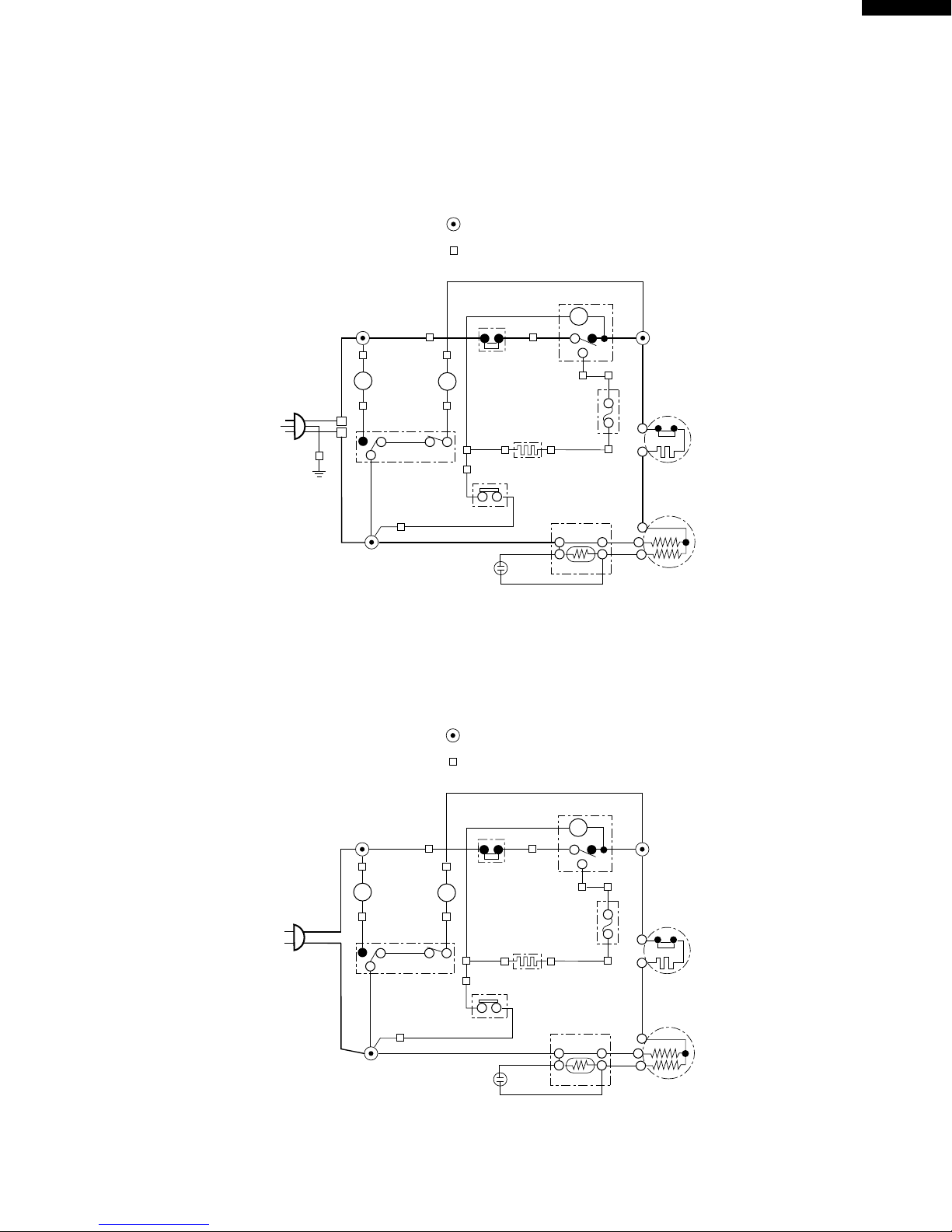

WIRING DIAGRAM

THERMOSTAT

TIMER

(R)

(G)

(Bk)

THERMO.

FUSE

OVERLOAD

RELAY

DEFROST

HEATER

STARTING

RELAY

(P)

(W)

INTERIOR

LIGHT

FAN

MOTOR

(S-B)

(O)

DOOR SWITCH

DEFROST

THERMOSTAT

(Bk)

C

M

A

N

3PIN

PLUG/

CORD

(G-Y)

(B)

COMPRESSOR

L

FM

TM

N

L

(Br)

RUNNING CAPACITOR

CONNECTED IN TERMINAL BOX

CONNECTOR

G

Br

O

Y

R

P

B

Bk

S-B

G-Y

W

: GRAY

: BROWN

: ORANGE

: YELLOW

: RED

: PINK

: BLUE

: BLACK

: SKY-BLUE

: GREEN-YELLOW

: WHITE

THERMOSTAT

TIMER

(R)

(G)

(Bk)

THERMO.

FUSE

OVERLOAD

RELAY

DEFROST

HEATER

STARTING

RELAY

(P)

(W)

INTERIOR

LIGHT

FAN

MOTOR

(S-B)

(O)

DOOR SWITCH

DEFROST

THERMOSTAT

(Bk)

C

M

A

N

2PIN

PLUG/

CORD

(B)

COMPRESSOR

L

FM

TM

(Br)

RUNNING CAPACITOR

CONNECTED IN TERMINAL BOX

CONNECTOR

G

Br

O

Y

R

P

B

Bk

S-B

G-Y

W

: GRAY

: BROWN

: ORANGE

: YELLOW

: RED

: PINK

: BLUE

: BLACK

: SKY-BLUE

: GREEN-YELLOW

: WHITE

Be sure to replace the electrical parts with specified ones for maintaining the safety and performance of the set.

Because these are important for maintaining the safety of the set.

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

Figure W-1. Wiring Diagram(3 pin plug region)

Figure W-2. Wiring Diagram(2 pin plug region)

9

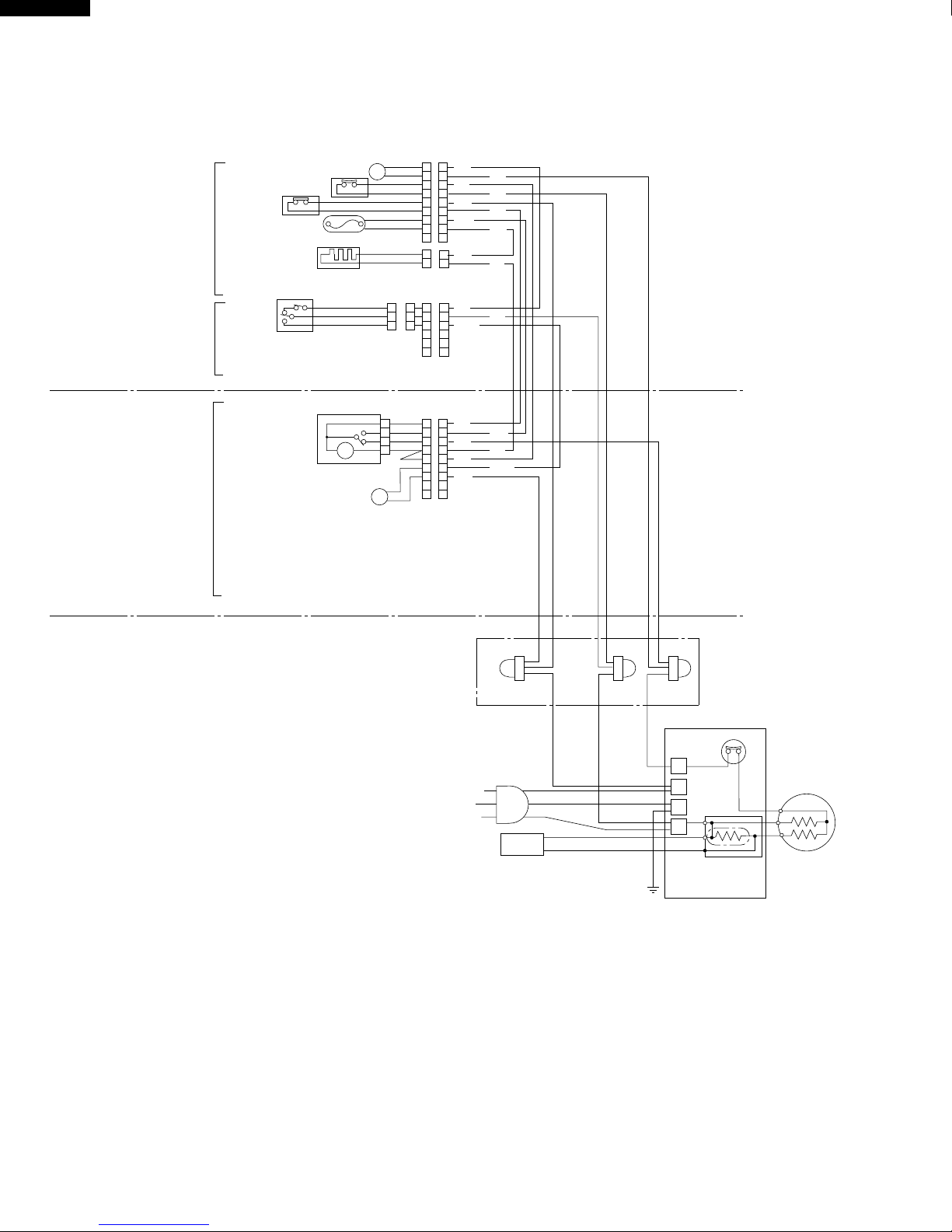

Page 10

SJ-48G/D48G

Fan motor

C1(LR-09-1V)

Defrost thermo.

F-thermostat

Thermo fuse

Defrost heater

Door switch

FREEZER

REFRIGERATOR

(RC-box ass'y)

(C-part. ass'y)

(E.V cov. ass'y)

MACHINE ROOM

Defrost timer

Lamp

C2(ELR-02V)

C3(ELR-06V)

C4(LR-09-1V)

3(Push close)

4(Push open)

(O)

Terminal box

Source plug

Running capacitor

(G-Y)

Overload

relay

Terminal cover

Starting relay

Compressor

CE-2

(Br)

CE-2

(B)

CE-2

(G)

G

Br

O

Y

R

P

B

Bk

S-B

G-Y

: GRAY

: BROWN

: ORANGE

: YELLOW

: RED

: PINK

: BLUE

: BLACK

: SKY-BLUE

: GREEN-YELLOW

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

121

2

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

FM

3

1

4

1

L

3

2

4

1

TM

C

M

A

1

L

N

E

(G)

(P)

(B)

(Br)

(R)

(Bk)

(W)

(W)

(Y)

(O)

(B)

(S-B)

(R)

(Bk)

(G)

(Y)

(S-B)

(P)

(Br)

SJ-51G/D51G

SJ-55G/D55G

Figure W-3. Electric Accessories Layout(3 pin plug region)

10

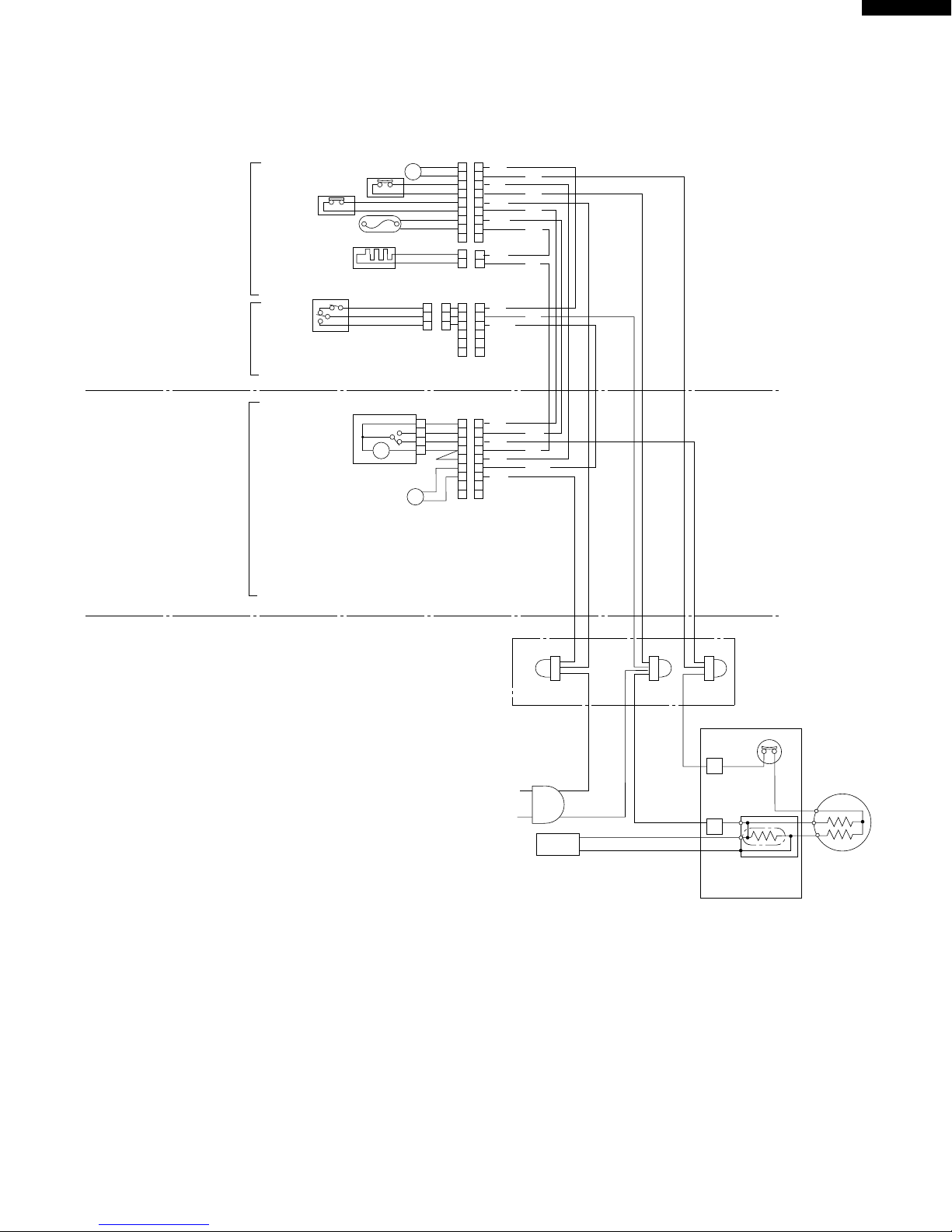

Page 11

SJ-48G/D48G

Fan motor

C1(LR-09-1V)

Defrost thermo.

F-thermostat

Thermo fuse

Defrost heater

Door switch

FREEZER

REFRIGERATOR

(RC-box ass'y)

(C-part. ass'y)

(E.V cov. ass'y)

MACHINE ROOM

Defrost timer

Lamp

C2(ELR-02V)

C3(ELR-06V)

C4(LR-09-1V)

3(Push close)

4(Push open)

(O)

Terminal box

Source plug

Running capacitor

(G-Y)

Overload

relay

Terminal cover

Starting relay

Compressor

CE-2

(Br)

CE-5

(B)

CE-2

(G)

G

Br

O

Y

R

P

B

Bk

S-B

G-Y

: GRAY

: BROWN

: ORANGE

: YELLOW

: RED

: PINK

: BLUE

: BLACK

: SKY-BLUE

: GREEN-YELLOW

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

121

2

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

FM

3

1

4

1

L

3

2

4

1

TM

C

M

A

1

N

(G)

(P)

(B)

(Br)

(R)

(Bk)

(W)

(W)

(Y)

(O)

(B)

(S-B)

(R)

(Bk)

(G)

(Y)

(S-B)

(P)

(Br)

SJ-51G/D51G

SJ-55G/D55G

Figure W-4. Electric Accessories Layout(2 pin plug region)

11

Page 12

SJ-48G/D48G

MIN

MED

MAX

FREEZER TEMP. CONTROL

Coldest

MIN

MED

CHILLED

ZONE

REFRIGERATOR TEMP. CONTROL

Refrigerator

temperature

Chilled room

temperature

CHILLED

ZONE

(Coldest)

MED MIN

Approx.

0˚c

Approx.

-3˚c

Approx.

3˚c

Approx.

1˚c

Approx.

6˚c

Approx.

4˚c

The values shown above refer to the case where the

freezer temp. control knob is set at "MED".

SETTING OF

FREEZER TEMP.

CONTROL KNOB

Freezer

temperature

MAX

(Coldest)

MED MIN

Approx.

-21˚C

Approx.

-18˚C

Approx.

-15˚C

KNOB

SETTING

MAX

(Coldest)

MIN

PURPOSE

For making ice rapidly or fast freezing.

For storing frozen food for a short period (up to one month).

When frozen food or ice cream is not stored.

For normal freezing.

MED

When restocking with fresh food.

KNOB

SETTING

MED

CHILLED

ZONE

(Coldest)

MIN

PURPOSE

For keeping freshness of food longer.

For normal operation.

When the refrigerator provides excessive cooling.

When the refrigerator does not provide sufficient cooling.

SJ-51G/D51G

SJ-55G/D55G

1. ADJUSTABLE TEMPERATURE CONTROL

(1) Temperature control of freezer

Thermostat (freezer temperature sensing thermostat) operates on ON/OFF switchover to control the compressor

and allows the freezer temperature to keep at a suitable temperature.

However adjust the freezer temp. control knob as follows depending upon the storing condition of foods.

Figure F-1.

(2) Temperature control of refrigerator

Damper-thermostat senses temperature of the refrigerator and changes the opening angle of the damper

automatically.

However, as the Damper-thermostat has no function to switch on or off the compressor and cool air circulating

fan, the freezer temperature control causes temperature in the refrigerator to vary to some extent.

However, adjust the refrigerator temp. control knob as follows depending upon the cooling condition.

FUNCTIONS

Coldest

Figure F-2.

NOTE: The refrigerator temperature is affected also by the freezer temperature. If the freezer temp. control

knob is set at the position "MAX", the temperature tends to be lower than the following values, and if set

at near the position "MIN", temperature tends to be higher.

If the refrigerator is operated for a long time with the freezer temperature control sets the "MAX"

position, foods stored in the refrigerator compartment may also freeze.

When refrigerator temperature control sets to the "CHILLED ZONE", some foods stored may freeze.

In this case adjust control set back to the "MED" position.

When refrigerator temperature control sets to the "CHILLED ZONE", some foods stored in fresh cases

may also become frozen.

(3) Reference value of temperature

SETTING OF

REFRIGERATOR TEMP.

CONTROL KNOB

12

The values tables above refer to the measurement carried out center area and 1/3 of overall height from the bottom at each

of the refrigerator and the freezer after machine has been operated at an ambient temperature of 32˚C with no food stored

and the door closed until the temperature is stabilized.

The values vary depending upon frequency of opening and closing the door, ambient temperature, amount of stored foods

and manner of storing foods.

Page 13

2. DEFROSTING

Operation Electric diagram Description

1. Cooling

(Normal)

2. Defrosting

(Time 20 to 30 min.)

3. Drain

(Time approx. 5 min.)

4. Cooling (start)

(Time approx. 5 min.)

The integration timer integrates running

time of the compressor. When it reaches

10 hours 50 min. at 50Hz, the timer

contact is changed to start defrosting.

When the defrost thermostat becomes

OFF, the timer motor at rest starts running.

During the operation time(4 min. 20 sec.

/50Hz) defrosted water is drained outside

the refrigerator.

Timer contact is changed to cooling

operation and the compressor starts

running and the timer motor stops.

Defrost thermostat contact becomes ON

when it's cooled. (Figure F-3.)

Figure F-3.

Figure F-4 .

Figure F-5.

Figure F-6.

TM COMP

Defrost thermostat ON Compressor running

Timer motor running

Timer contact

Defrost

thermostat (ON)

Defrost heater

Thermo. fuse

Comp ressor

Time r motor

SOUR CE

TM COMP

Defrost thermostat OFF Compressor running

Timer motor stops

Thermostat Timer contact

Defrost

thermostat (OFF)

Defrost heater

Thermo. fuse

Comp ressor

Time r motor

SOUR CE

TM COMP

Defrost thermostat OFF Compressor stops

Timer motor running

Thermostat Timer contact

Defrost

thermostat (OFF)

Defrost heater

Thermo. fuse

Comp ressor

Time r motor

SOUR CE

TM COMP

Defrost thermostat ON Compressor stops

Timer motor stops

Thermostat Timer contact

Defrost

thermostat (ON)

Defrost heater

Thermo. fuse

Comp ressor

Time r motor

SOUR CE

Thermostat

The timer contact is changed to start

defrosting, the timer motor stops, and

power is supplied to the defrost heater.

It takes about 20 to 30 min. to defrost.

When little frosted the defrosting takes

little time.

When much frosted, the

defrosting takes much time.

(1) No defrosting operation is necessary

No defrosting operation is necessary.

As this machine is so designed that a built-in

evaporator cools air and a fan circulates cooled air,

neither the freezer nor the refrigerator is frosted,

though the evaporator is frosted.

(2) Where is melted ice brought

1. Melted ice is brought into the evaporating pan at

the bottom of the set and is evaporated here by

the heat of sub condenser.

2. Be sure to use the evaporating pan as inserted

so as to be level with the outer case.

The frosted evaporator is defrosted automatically

due to the function of defrosting timer and heater,

requiring no defrosting operation.

(3) The following circuit diagrams in the table show automatic defrosting function of the refrigerator with

timer and defrost thermostat.

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

13

Page 14

SJ-48G/D48G

Hot pipe

(1) Inspection of cooling unit

1. Set the temperature control knob to "MAX" and check that the compressor starts to operate.

2. Depress the door switch to run the fan and check that cool air is blown out of the cold air outlet of the freezer and

the refrigerator.

3. When the compressor does not work, check that the timer is not set to "defrost" position.

4 It takes about an hour and a half or two hours to put food in the refrigerator after starting operation.

NOTE:

After return the temperature control knob to "MED" position.

When the refrigerator is operated initially after installed, the compressor may vibrate excessively for 1 to 2 min.

However, vibration becomes normal if it is continuously operated.

(2) Inspection of defrost device

Operate the refrigerator for 20 to 30 min. and then check the defrost device in the following procedures :

Allow 5 min. to restart the compressor since immediate starting after stopping will cause unsmooth operation.

1. Turn the timer shaft clockwise with a screw driver.

At this time, make certains the timer clinks and the compressor stops.

2. After more than 5 min., turn the shaft further to operate.

Make certain cooling operation is started again.

NOTE:

It's not necessary to switch the timer by changing of source frequency (50Hz, 60Hz).

SJ-51G/D51G

SJ-55G/D55G

(4) As a reference to determine the causes of trouble, malfunction and phenomena are described below. Refer

to the following when repairing.

1. Disconnection of defrost heater

As off-cycle defrosting is performed, the defrosting time is extremely prolonged. Each time defrosting is started,

the freezer temperature rises and a portion of ice and stored foods are melted.

2. Melted thermo. fuse or opened-circuit due to the defect of defrost thermostat.

When the above mentioned trouble occurs in cooling operation, the timer motor does not run, defrosting will not

take place, and consequently freezing is caused. In the above mentioned condition, when the timer shaft is

turned by hand to defrost, the timer motor runs during the operation time. However, the motor stops from the

time when the contact is changed, and freezing causes.

NOTE:

As the thermo. fuse assembly is intended to prevent dangers, do not use it under shorted condition even for a

short period.

3. DEW PREVENTION

The hot pipe, namely D.P.-condenser, is arranged around the flange part of

cabinet and the C-partition plate, preventing dew from being generated on the

cabinet.

NOTE:

D.P.-condenser pipe may be felt hot if touched by hand while the compressor

is in operation.

If you are asked about this, please explain that the hot pipe serve to prevent

the dew generation.

4. INSPECTION OF INITIAL STARTING

Figure F-7.

14

Page 15

ASSEMBLING PROCEDURES OF MAIN PARTS AND CAUTIONS

Lamp socket

Lamp

Warning label

R-temp. control knob

R-Cbox cover

Defrost timer

D timer lead ass'y

R-air guider A

RA-insulation

Damper

thermostat

A-sealer thermo. cap

Dial sealer

C-box base

Thermo. cap sealer

R-air guider B

A-sealer air guid. B

A-sealer

RC-box

A-sealer

RC-duct

A-sealer air guid. C

A-sealer air guid. D

A-sealer air guid. D

R-air guider A

A-sealer

thermo. cap

Dial

sealer

Start

Finish

datum

(all round)

RA-insulation

R-air guider A

R-air guider A

AA

SEC. AA

Insert RA-insulation

R-air guider A

A- sealer air guid. C

Start

A-sealer

air guid. B

Overlap

R-air guider B

R-air guider B

A-sealer

air guid. D

CAUTION: DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE ANY REPAIRING.

1. R-CONTROL COV. ASSEMBLY

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

(1) Sticking of SEALER

15

Page 16

SJ-48G/D48G

R-air guider A

Bend the senser

tube of Damper thermostat

Stick thermo.

cap. sealer

Less than 130

Damper

thermostat

3

±1

5

±1

Less than 12

25

±2

NOTE

Minimum bending radius is R5.

There should be no gas leak by reforming of sensor tube.

Paper tape (40 x 100)

Start

A-sealer RC-duct

Overlap

BB

Overlap

C-box

base

A-sealer

RC-box

Start

datum

A-sealer

RC-duct

datum

A-sealer

RC-box

SEC. BB

C-box base

A sealer air guid. C

(The back of C-box base)

Damper thermostat

C-box base

R-air guider B

Screw

Fix with claw

A-sealer air guid. D

SJ-51G/D51G

SJ-55G/D55G

(2) Forming sensor of Damper thermostat

(3) Setting of C-box base, Damper thermostat, R-air guider A and R-air guider B

16

Page 17

(4) Fixing of Lamp socket, Defrost timer

R-C box cover

Claws (2 places)

Claws (2 places)

2

±1

4

±1

WARNING

DISCONNECT AC PLUG

FROM SUPPLY BEFORE

REPLACING THE LAMP

BULB.

LAMP RATING

240V. 10W

Stick Warning label

Set R-temp. control knob

Lamp

socket

Lamp

R-Cbox cover

Connect

D timer

lead ass'y

Screw

SKY-BLUE

Insert Pin No.6

BROWN

Insert Pin No.7

Defrost timer

6

7

(5) Fixing of R-Cbox cover

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

17

Page 18

SJ-48G/D48G

Fuse ass'y

Alminum tape

E.V cover sealer A

Fan motor

Motor cushion

Fan motor cushion B

Fan motor cushion A

Propeller fan 100

Fan clamp

E.V cover sealer D

E.V cover sealer C

E.V cover sealer B

Lead E.V cover ass'y.

F-thermostat

E.V cover sealer E

E.V cover

L-band C

Defrost thermo. ass'y

L-band C

E.V cover

E.V cover sealer AE.V cover sealer B

Overlap 10mm(min.)

E.V cover sealer E E.V cover

A

[Front View]

E.V cover

Along this edge

[View from A direction]

Fix E.V cover sealer E along the edge of E.V cover.

SJ-51G/D51G

SJ-55G/D55G

2. E.V COVER ASSEMBLY

(1) Sticking of sealer to E.V cover

18

Page 19

(2) Fixing of Fan motor and Fan

E.V cover

Motor cushion

Tapping screw

Fan motor cushion B

Fan motor

Fan motor cushion A

Fan clamp

Propeller fan 100

Fan motor

Motor shaft to be flush

with front surface of hub.

B C

D

A

L-band C

Defrost

thermo. ass'y

L-band C

Fuse ass'y

Alminum tape

E.V cover sealer D

Lead wire “WHITE”

Fuse ass'y

Alminum tape

E.V cover

sealer D

DetailA

Bend this pin

DetailB

Fan motor cushion

Lead wires

DetailC

Set Lead wires of Defrost thermo. ass'y as shown.

Cut off to

7mm or shorter

7mm

Thermo. sensing element side

(Silver metal)

Horizontally

DetailD

Fasten Defrost thermo. ass'y's

wires as bellow.

And set it inside of the four pins.

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

(3) Wiring of Lead Wire

19

Page 20

SJ-48G/D48G

Set surely edges of

these two ribs.

Color: RED Color: BROWN

Under 5mm

10mm over

Standard line

E.V cover

E.V cover sealer C

E.V cover

F-thermostat

Lead E.V cover

ass'y

Through between ribs

Inside of ribs

9 8 7

6 5 4

3 2 1

View from A

A

1. Lead E.V cover ass'y

2. Lead E.V cover ass'y

3. Pink lead of Defrost thermo. ass'y

4. Blue lead of Defrost thermo. ass'y

5. Lead E.V cover ass'y

6. Lead E.V cover ass'y

7. Black lead of Fuse ass'y

8. White lead of Fuse ass'y

9. No connect

SJ-51G/D51G

SJ-55G/D55G

(4) Setting of Lead E.V cover ass'y and F-thermostat

(5) Wiring of Connector

(6) Fixing of E.V cover sealer C

20

Page 21

COOLING UNIT

Hot pipe L

(Side condenser)

Hot pipe

(DP-condenser)

Hot pipe R

(Side condenser)

Evaporator

Suction pipe

Bottom condenser

Compressor

Capillary tube

Dryer

Back condenser

Mark: Refrigerant flow

Mark: Brazing portion

Except for SJ-48G

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

Figure C-1. Cooling unit

21

Page 22

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

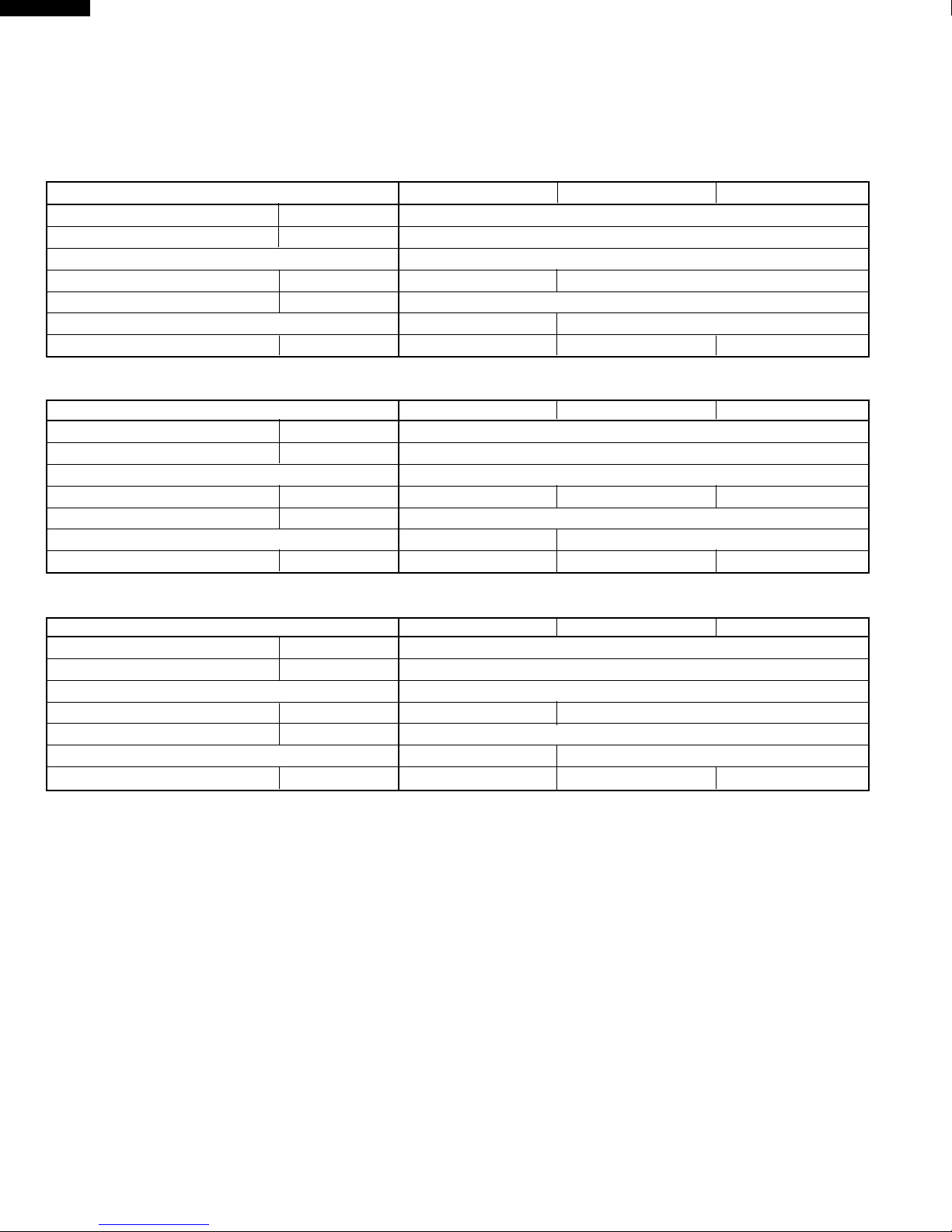

REPLACEMENT PARTS LIST(SJ-48G/SJ-D48G)

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-48G SJ-48G SJ-48G

SJ-D48G SJ-D48G SJ-D48G

-GY -BE -BL

ELECTRIC PARTS

1- 1 RTHM-A057CBE0 F-thermostat 1 1 1 BA

1- 1 RTHM-A063CBE0 F-thermostat(Thailand only) 1 1 1 AX

1- 2 RSTT-A105CBE0 Starting relay

1- 2 RSTT-A110CBE0 Starting relay

(220/230/240V 50Hz region)

(200/220V 50Hz region,220V 60Hz region)

1 1 1 AN

1 - - AN

1- 3 QSWTDA035CBE0 Defrost timer 1 1 1 BB

1- 4 PDMP-A025CBE0 Damper thermostat 1 1 1 AZ

1- 4 PDMP-A028CBE0 Damper thermostat(Thailand only) 1 1 1 AY

1- 5 FTHM-A012CBK0 Defrost thermo.ass’y 1 1 1 AQ

1- 6 RMOTRA030CBE0 Fan motor 1 1 1 AZ

1- 7 QSOCAA037CBE0 Lamp socket 1 1 1 AM

1- 8 RLMP-001ECBE0 Lamp 1 1 1 AH

1- 9 QACC-A096CBE0 Source cord(Plug type BF) 1 1 1 AX

1- 9 QACC-A101CBE0 Source cord(Plug type C-2) 1 1 1 AN

1- 9 QACC-A095CBE0 Source cord(Plug type A-1) 1 1 1 AM

1-10 QSW-PA056CBEA Door switch 1 1 1 AP

1-11 RHOG-A091CBE0 Protector

1-11 RHOG-A092CBE0 Protector

(220/230/240V 50Hz region)

(200/220V 50Hz region,220V 60Hz region)

1 1 1 AN

1 - - AN

1-15 RC-EZA124CBE0 Running capacitor 1 1 1 AX

1-16 FW-VZA108CBE0 Earth wire(For 3P. plug) 1 1 1 AE

1-17 FFS-TA036CBK0 Fuse ass’y 1 1 1 AN

1-19 FW-VZA109CBE0 D timer lead ass’y 1 1 1 AN

1-20 FW-VZA110CBE0 Lead EV-cover ass’y 1 1 1 AP

1-21 FHETBA082CBE0 Def. heater ass’y 1 1 1

(SJ-D48G,220/2330/240V 50Hz region220V 60Hz region)

1-21 FHETBA087CBE0 Def. heater ass’y

(SJ-D48G,200/220V 50Hz region)

1 - - BK

1-21 FHETBA072CBE0 Def. heater ass’y(SJ-48G) 1 1 1 BD

1-22 QCNW-A634CBE0 Relay wire G(For 3P. plug) 1 1 1 AE

1-23 QCNW-A635CBE0 Relay wire B 1 1 1 AE

1-24 QCNW-A636CBE0 Relay wire BR 1 1 1 AE

1-25 QTAN-A032CBE0 Terminal block 1 1 1 AE

MECHANICAL PARTS

2-1 LSTPPA078CBFA Back spacer 1 1 1 AD

2-2 JKNB-A036CBFA F-temp. control knob 1 1 1 AL

2-4 LPLTMA404CBE0 FL plate AL. 1 1 1 AD

2- 7 FLEGPA045CBK0 Leg holder L ass’y 1 1 1 AQ

2- 7-1 FAJS-A009CBK0 Adjustable leg ass’y 2 2 2 AD

2- 7-2 LHLD-A354CBM0 Leg holder L 1 1 1 AE

2- 8 FLEGPA046CBK0 Leg holder R ass’y 1 1 1 AQ

2- 8-2 LHLD-A355CBM0 Leg holder R 1 1 1 AE

2-11 PSPAVA074CBEA Bottom hinge spacer 1 1 1 AD

2-13 DHNG-A274CBM0 Upper hinge ass’y 1 1 1 AK

2-14 DHNG-A275CBM0 Bottom hinge R ass’y 1 1 1 AK

2-15 DHNG-A276CBK0 C-hinge RD ass’y 1 1 1 AN

2-15-1 PSPAVA075CBEA Center hinge spacer 1 1 1 AD

2-16 GCOV-A141CBFA E.V cover 1 1 1 AD

2-17 LCRA-A010CBE0 Fan clamp 1 1 1 AD

2-19 LHLD-A245CBF0 Motor cushion 2 2 2 AF

2-20 NFANPA011CBF0 Propeller fan100 1 1 1 AD

2-21 PSEL-B128CBE0 E.V cover sealer A 1 1 1 AD

2-22 PSEL-B129CBE0 E.V cover sealer B 1 1 1 AD

2-23 PSEL-A415CBE0 E.V cover sealer C 1 1 1 AC

2-24 PCOVPA164CBFA Terminal cover(Singapore, Malaysia) 1 1 1 AE

2-24 PCOVPA175CBFA Terminal cover 1 1 1 AF

2-26 PCOV-A151CBFA Lamp cover 1 1 1 AF

2-27 GCOVPA067CBRA R-Cbox cover 1 1 1 AE

2-28 HGRL-A133CBRA Fan louver 1 1 1 AT

2-29 GCOV-A140CBFA Upper hinge cover 1 - - AE

2-29 GCOV-A140CBFC Upper hinge cover - 1 - AE

2-29 GCOV-A140CBFF Upper hinge cover - - 1 AE

2-31 JKNB-A033CBFA R-temp. control knob 1 1 1 AD

2-33 LRALPA114CBFA C-case rail L 1 1 1 AE

2-34 LRALPA115CBFA C-case rail R 1 1 1 AE

2-36 PCAP-A006CBFK Screw cover - 1 - AD

2-36 PCAP-A006CBFL Screw cover 1 - - AB

2-36 PCAP-A006CBFM Screw cover - - 1 AB

2-38 PGID-A119CBF0 R-air guider A 1 1 1 AH

2-39 LFRM-A202CBFA C-box base 1 1 1 AK

2-40 PFPFPA809CBF0 RA-insulation 1 1 1 AD

22

Page 23

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-48G SJ-48G SJ-48G

SJ-D48G SJ-D48G SJ-D48G

-GY -BE -BL

2-41 PSEL-B244CBE0 Thermo. cap. sealer 1 1 1 AB

2-42 PGID-A118CBF0 R-air guider B 1 1 1 AG

2-49 LSTPPA074CBFA C-stopper 2 2 2 AD

2-55 HGRL-A135CBFA Multi louver 1 1 1 AL

2-56 PFPFPA824CBF0 R-louver insu. 1 1 1 AE

2-57 PSEL-B143CBE0 A-sealer R-louver 2 2 2 AC

2-61 LHLD-A235CBE0 SL-4N clip(For 3P. plug) 1 1 1 AK

2-62 DCOV-A061CBK0 Harness cover ass’y(Singapore, Malaysia) 1 1 1 AK

2-63 LHLD-A302CBF0 Fan motor cushion B 1 1 1 AL

2-64 LHLD-A303CBM0 Fan motor cushion A 1 1 1 AM

2-66 PSHEMA132CBP0 Heater cover AL 1 1 1 AD

2-67 LPLTMA403CBP0 Drain support AL 1 1 1 AL

2-68 PSEL-A562CBE0 Leading wire sealer 2 2 2 AC

2-69 PSEL-B127CBE0 E.V cover sealer D 1 1 1 AC

2-70 PSEL-B167CBE0 E.V cover sealer E 1 1 1 AB

2-71 PSEL-A552CBE0 Dial sealer 1 1 1 AC

2-72 PSEL-B120CBE0 A-sealer RC-box 1 1 1 AB

2-73 PSEL-B121CBE0 A-sealer RC-duct 1 1 1 AD

2-74 PSEL-B122CBE0 A-sealer thermo. cap. 1 1 1 AB

2-75 PSEL-B124CBE0 A-sealer air guid.B 1 1 1 AB

2-76 LHLD-A124CBFB K-frame holder 1 1 1 AH

2-77 LHLD-A359CBFA T-box holder(For 2p. plug) 1 1 1 AE

2-78 LPLTMA399CBP0 Dryer support 1 1 1 AD

2-80 PBOX-A071CBFA Terminal box(Singapore, Malaysia) 1 1 1 AE

2-80 PBOX-A078CBFA Terminal box 1 1 1 AG

2-81 PPIPPA055CBE0 Drain pipe S 1 1 1 AG

2-82 PTUBBA043CBE0 Insulating tube 1 1 1 AG

2-83 PSEL-B242CBE0 A-sealer air guid.C 2 2 2 AC

2-84 PSEL-B243CBE0 A-sealer air guid.D 2 2 2 AD

2-86 LBND-A026CBE0 Nylon band(Singapore only) 1 1 1 AC

DOOR PARTS

3-2 HDECAA053CBEA Handle trim(SJ-D48G) 1 - - AZ

3-2 HDECAA053CBEB Handle trim(SJ-D48G) - 1 - AZ

3-2 HDECAA053CBEC Handle trim(SJ-D48G) - - 1 AZ

3-2 HDECAA056CBEA Handle trim(SJ-48G) - - 1 AX

3-2 HDECAA056CBEB Handle trim(SJ-48G) 1 - - AX

3-2 HDECAA056CBEC Handle trim(SJ-48G) - 1 - AX

3- 5 FDORFA722CBK0 F-door ass’y 1 - - BP

3- 5 FDORFA732CBK0 F-door ass’y - 1 - BP

3- 5 FDORFA737CBK0 F-door ass’y - - 1 BP

3- 5-1 LSTPPA075CBFA F-door stopper 1 1 1 AP

3- 5-2 NBRGPA013CBFB Nylon bearing2 1 1 1 AH

3- 6 FPACGA204CBK0 F-door packing 1 1 1 AZ

3- 9 GLIN-A145CBFA F-door liner 1 1 1 AX

3-10 PFPFPA810CBE0 F-liner plate 2 2 2 AX

3-12 PFPFPA852CBE0 F-liner plate bottom 1 1 1 AD

3-14 PSEL-B126CBE0 F-door sealer 2 2 2 AG

3-15 FDORRA574CBK0 R-door ass’y 1 - - BR

3-15 FDORRA579CBK0 R-door ass’y - 1 - BR

3-15 FDORRA596CBK0 R-door ass’y - - 1 BR

3-15-1 LSTP-A043CBM0 R-door stopper 1 1 1 AH

3-15-2 NBRGPA012CBF0 Nylon bearing R 1 1 1 AE

3-15-3 NBRGPA014CBFB Nylon bearing3 1 1 1 AH

3-16 GLIN-A148CBEA R-door liner 1 1 1 AX

3-17 FPACGA207CBK0 R-door packing 1 1 1 AZ

3-20 PFPFPA822CBE0 R-liner plate 2 2 2 AF

3-25 HBDGDA710CBEA Badge 1 - - AN

3-25 HBDGDA710CBEB Badge - 1 - AN

3-25 HBDGDA710CBEC Badge - - 1 AN

OTHER PARTS

4- 1 LBND-A023CBE0 L-band C 4 4 4 AC

4- 3 LX-VZA003CBE0 Special screw 2 2 2 AB

4- 9 QTAN-A012CBE0 Solderless term. B 3 3 3 AH

4-14 PSPANA002CBF0 Door spacer 1 1 1 AC

4-15 LX-BZA018CBE0 Special screw 1 1 1 AA

4-16 LX-BZA052CBE0 Clamp screw 2 2 2 AB

4-17 LX-WZA003CBE0 Washer 4 4 4 AA

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

23

Page 24

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-48G SJ-48G SJ-48G

SJ-D48G SJ-D48G SJ-D48G

-GY -BE -BL

ATTACHMENT PARTS

5- 1 UPOK-A120CBRA Bottle pocket HS 2 2 2 AQ

5- 2 UPOK-A117CBRA Egg pocket HS 1 1 1 AM

5- 3 UPOK-A119CBRA F door pocket HS 2 2 2 AT

5- 4 UPOK-A118CBRA Utility pocket HS 1 1 1 AM

5- 5 UTNA-A167CBFC Egg tray 2 2 2 AG

5- 6 FSRA-A142CBY0 Ice cube maker 1 1 1 AR

5- 7 LFRM-A200CBFA Ice maker 1 1 1 AR

5- 8 USRA-A174CBRA Ref. tray silk 1 1 1 AX

5- 9 USRA-A176CBRA Freezer tray L silk 1 1 1 AT

5-11 USRA-A175CBRA Freezer tray S silk 1 1 1 AU

5-12 HDECQA360CBEA Glass shelf trim 1 1 1 AK

5-13 HGRL-A132CBFA Ventilating grille 1 - - AN

5-13 HGRL-A132CBFC Ventilating grille - 1 - AN

5-13 HGRL-A132CBFE Ventilating grille - - 1 AN

5-14 USRA-A177CBFA Evaporating pan 1 1 1 AR

5-15 UTNA-A227CBE0 Glass shelf 1 1 1 BB

5-16 UYOK-A180CBFA Vegetable case 1 1 1 AZ

5-17 UYOK-A181CBFA Ice storage box 1 1 1 AH

5-18 UYOK-A179CBFA Chilled case 1 1 1 AS

5-19 GDORPA042CBRA Chilled door HS 1 1 1 AP

5-20 UTNA-A228CBRA F-set shelf F silk 1 1 1 AT

5-21 UTNA-A229CBFA Free set shelf B 1 1 1 AS

CYCLE PARTS

6- 1 PCMPLA134CBE0 Compressor

6- 1 PCMPLA135CBE0 Compressor

6- 2 PSPAGA028CBE0 Rubber grommet 4 4 4 AD

6- 3 FCONSA052CBK0 Sub. condenser ass’y 1 1 1 AR

6- 4 FFRM-A085CBK0 Base frame ass’y 1 1 1 AF

6- 5 PDRY-A005CBE0 Dryer 1 1 1 AP

6- 6 PCLI-A035CBE0 Clip 1 1 1 AC

6- 9 PSPAFA020CBE0 Sleeve 4 4 4 AB

6-11 PPIPCA220CBE0 S.P connector 1 1 1 AH

6-12 LANG-A024CBP0 Absorbent rubber CLM 1 1 1 AC

6-13 LHLD-A061CBF0 Evaporating pan holder 2 2 2 AD

6-14 PGUM-A002CBF0 Absorbent rubber B 1 1 1 AH

6-15 PGUM-A003CBF0 Absorbent rubber B 1 1 1 AH

6-16 PGUM-A004CBF0 Absorbent rubber A 1 1 1 AH

6-18 PPIPCA222CBE0 Charge pipe L 2 2 2 BC

6-19 LHLD-A357CBE0 Clamp supplement 1 1 1 AC

6-20 LHLD-A358CBE0 Cable clamp 2 2 2 AD

6-21 PCOVPA165CBE0 Terminal cover 1 1 1 AF

(220/230/240V 50Hz region)

(200/220V 50Hz region,220V 60Hz region)

1 1 1 BZ

1 - - CA

24

Page 25

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-48G SJ-48G SJ-48G

SJ-D48G SJ-D48G SJ-D48G

-GY -BE -BL

MISCELLANEOUS

90- 1 TINS-A277CBR0 Operation manual(English) 1 1 1 AE

90- 1 TINS-A282CBR0 Operation manual(Thai) 1 1 1 AF

90- 2 TLAB-A153CBR0 Warning label 1 1 1 AD

90- 3 SPAKCG448YDE0 Packing case(Destination mark “ R “) 1 - - BH

90- 3 SPAKCG449YDE0 Packing case(Destination mark “ R “) - 1 - BH

90- 3 SPAKCG458YDE0 Packing case(Destination mark “ R “) - - 1 BH

90- 3 SPAKCG455YDE0 Packing case(Destination mark “ Y “) 1 - - BH

90- 3 SPAKCG456YDE0 Packing case(Destination mark “ Y “) - 1 - BH

90- 3 SPAKCG462YDE0 Packing case(Destination mark “ Y “) - - 1 BH

90- 3 SPAKCG533YDE0 Packing case(Destination mark “ H “) 1 - - BH

90- 3 SPAKCG502YDE0 Packing case(SJ-48G, Destination mark “ T “) 1 - - BF

90- 3 SPAKCG503YDE0 Packing case(SJ-48G, Destination mark “ T “) - 1 - BF

90- 3 SPAKCG504YDE0 Packing case(SJ-48G, Destination mark “ T“) - - 1 BF

90- 3 SPAKCG505YDE0 Packing case(SJ-D48G, Destination mark “ T “)1 - - BF

90- 3 SPAKCG506YDE0 Packing case(SJ-D48G, Destination mark “ T “) - 1 - BH

90- 3 SPAKCG507YDE0 Packing case(SJ-D48G, Destination mark “ T“) - - 1 BF

90- 3 SPAKCG451YDE0 Packing case(Destination mark “ M “) 1 - - BH

90- 3 SPAKCG452YDE0 Packing case(Destination mark “ M “) - 1 - BH

90- 3 SPAKCG460YDE0 Packing case(Destination mark “ M“) - - 1 BH

90- 3 SPAKCG573YDE0 Packing case(Destination mark “ Z “) 1 - - BF

90- 3 SPAKCG574YDE0 Packing case(Destination mark “ Z“) - 1 - BF

90- 6 CPADBA501YDK0 Bottom pad ass’y 1 1 1 AY

90- 7 CPADBA495YDK0 Top pad ass’y 1 1 1 AS

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

HOW TO ORDER REPLACEMENT PARTS

To have your order filled prompty and correctly, please furnish the following information.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

Destination mark

Packing case

25

Page 26

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

REPLACEMENT PARTS LIST(SJ-51G/SJ-D51G)

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-51G SJ-51G SJ-51G

SJ-D51G SJ-D51G SJ-D51G

-GY -BE -BL

ELECTRIC PARTS

1- 1 RTHM-A057CBE0 F-thermostat 1 1 1 BA

1- 1 RTHM-A063CBE0 F-thermostat(Thailand only) 1 1 1 AX

1- 2 RSTT-A105CBE0 Starting relay(220/230/240V 50Hz region) 1 1 1 AN

1- 2 RSTT-A110CBE0 Starting relay(220V 60Hz region) 1 1 - AN

1- 3 QSWTDA035CBE0 Defrost timer 1 1 1 BB

1- 4 PDMP-A025CBE0 Damper thermostat 1 1 1 AZ

1- 4 PDMP-A028CBE0 Damper thermostat(Thailand only) 1 1 1 AY

1- 5 FTHM-A012CBK0 Defrost thermo. ass’y 1 1 1 AQ

1- 6 RMOTRA030CBE0 Fan motor 1 1 1 AZ

1- 7 QSOCAA037CBE0 Lamp socket 1 1 1 AM

1- 8 RLMP-001ECBE0 Lamp 1 1 1 AH

1- 9 QACC-A096CBE0 Source cord(Plug type BF) 1 1 1 AX

1- 9 QACC-A095CBE0 Source cord(Plug type A-1) 1 1 1 AN

1- 9 QACC-A101CBE0 Source cord(Plug type C-2) 1 1 1 AN

1-10 QSW-PA056CBEA Door switch 1 1 1 AP

1-11 RHOG-A084CBE0 Protector(220/230/240V 50Hz region) 1 1 1 AN

1-11 RHOG-A092CBE0 Protector(220V 60Hz region) 1 1 - AN

1-15 RC-EZA124CBE0 Running capacitor 1 1 1 AX

1-16 FW-VZA108CBE0 Earth wire(For 3p. plug) 1 1 1 AE

1-17 FFS-TA036CBK0 Fuse ass’y 1 1 1 AN

1-19 FW-VZA109CBE0 D timer lead ass’y 1 1 1 AN

1-20 FW-VZA110CBE0 Lead EV-cover ass’y 1 1 1 AP

1-21 FHETBA082CBE0 Def. heater ass’y(SJ-D51G) 1 1 1

1-21 FHETBA072CBE0 Def. heater ass’y(SJ-51G) 1 1 1 BD

1-22 QCNW-A634CBE0 Relay wire G(For 3p. plug) 1 1 1 AE

1-23 QCNW-A635CBE0 Relay wire B 1 1 1 AE

1-24 QCNW-A636CBE0 Relay wire BR 1 1 1 AE

1-25 QTAN-A032CBE0 Terminal block 1 1 1 AE

MECHANICAL PARTS

2- 1 LSTPPA078CBFA Back spacer 1 1 1 AD

2- 2 JKNB-A036CBFA F-temp. control knob 1 1 1 AL

2- 4 LPLTMA404CBE0 FL plate AL. 1 1 1 AD

2- 7 FLEGPA045CBK0 Leg holder L ass’y 1 1 1 AQ

2- 7- 1 FAJS-A009CBK0 Adjustable leg ass’y 2 2 2 AD

2- 7- 2 LHLD-A354CBM0 Leg holder L 1 1 1 AE

2- 8 FLEGPA046CBK0 Leg holder R ass’y 1 1 1 AQ

2- 8- 2 LHLD-A355CBM0 Leg holder R 1 1 1 AE

2-11 PSPAVA074CBEA Bottom hinge spacer 1 1 1 AD

2-13 DHNG-A274CBM0 Upper hinge ass’y 1 1 1 AK

2-14 DHNG-A275CBM0 Bottom hinge R ass’y 1 1 1 AK

2-15 DHNG-A276CBK0 C-hinge RD ass’y 1 1 1 AN

2-15- 1 PSPAVA075CBEA Center hinge spacer 1 1 1 AD

2-16 GCOV-A141CBFA E.V cover 1 1 1 AU

2-17 LCRA-A010CBE0 Fan clamp 1 1 1 AD

2-19 LHLD-A245CBF0 Motor cushion 2 2 2 AF

2-20 NFANPA011CBF0 Propeller fan 100 1 1 1 AD

2-21 PSEL-B128CBE0 E.V cover sealer A 1 1 1 AD

2-22 PSEL-B129CBE0 E.V cover sealer B 1 1 1 AD

2-23 PSEL-A415CBE0 E.V cover sealer C 1 1 1 AC

2-24 PCOVPA164CBFA Terminal cover(Singapore, Malaysia) 1 1 1 AE

2-24 PCOVPA175CBFA Terminal cover 1 1 1 AF

2-26 PCOV-A151CBFA Lamp cover 1 1 1 AF

2-27 GCOVPA067CBRA R-Cbox cover 1 1 1 AE

2-28 HGRL-A133CBRA Fan louver 1 1 1 AT

2-29 GCOV-A140CBFA Upper hinge cover 1 - - AE

2-29 GCOV-A140CBFC Upper hinge cover - 1 - AE

2-29 GCOV-A140CBFF Upper hinge cover - - 1 AE

2-31 JKNB-A033CBFA R-temp. control knob 1 1 1 AD

2-33 LRALPA114CBFA C-case rail L 1 1 1 AE

2-34 LRALPA115CBFA C-case rail R 1 1 1 AE

2-36 PCAP-A006CBFK Screw cover - 1 - AD

2-36 PCAP-A006CBFL Screw cover 1 - - AB

2-36 PCAP-A006CBFM Screw cover - - 1 AB

2-38 PGID-A119CBF0 R-air guider A 1 1 1 AH

2-39 LFRM-A202CBFA C-box base 1 1 1 AK

2-40 PFPFPA809CBF0 RA-insulation 1 1 1 AD

2-41 PSEL-B244CBE0 Thermo. cap. sealer 1 1 1 AB

2-42 PGID-A118CBF0 R-air guider B 1 1 1 AG

26

Page 27

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-51G SJ-51G SJ-51G

SJ-D51G SJ-D51G SJ-D51G

-GY -BE -BL

2-49 LSTPPA074CBFA C-stopper 2 2 2 AD

2-55 HGRL-A134CBFA Multi louver 1 1 1 AL

2-56 PFPFPA814CBF0 R-louver insu. 1 1 1 AE

2-57 PSEL-B130CBE0 A-sealer R-louver 2 2 2 AB

2-61 LHLD-A235CBE0 SL-4N clip(For 3p. plug) 1 1 1 AK

2-62 DCOV-A061CBK0 Harness cover ass’y(Singapore, Malaysia) 1 1 1 AK

2-63 LHLD-A302CBF0 Fan motor cushion B 1 1 1 AL

2-64 LHLD-A303CBM0 Fan motor cushion A 1 1 1 AM

2-66 PSHEMA132CBP0 Heater cover AL 1 1 1 AD

2-67 LPLTMA403CBP0 Drain support AL 1 1 1 AL

2-68 PSEL-A562CBE0 Leading wire sealer 2 2 2 AC

2-69 PSEL-B127CBE0 E.V cover sealer D 1 1 1 AC

2-70 PSEL-B167CBE0 E.V cover sealer E 1 1 1 AB

2-71 PSEL-A552CBE0 Dial sealer 1 1 1 AC

2-72 PSEL-B120CBE0 A-sealer RC-box 1 1 1 AB

2-73 PSEL-B121CBE0 A-sealer RC-duct 1 1 1 AD

2-74 PSEL-B122CBE0 A-sealer thermo. cap. 1 1 1 AB

2-75 PSEL-B124CBE0 A-sealer air guid. B 1 1 1 AB

2-76 LHLD-A124CBFB K-frame holder 1 1 1 AH

2-77 LHLD-A359CBFA T-box holder(For 2p. plug) 1 1 1 AE

2-78 LPLTMA399CBP0 Dryer support 1 1 1 AD

2-80 PBOX-A071CBFA Terminal box(Singapore, Malaysia) 1 1 1 AE

2-80 PBOX-A078CBFA Terminal box 1 1 1 AE

2-81 PPIPPA055CBE0 Drain pipe S 1 1 1 AG

2-82 PTUBBA043CBE0 Insulating tube 1 1 1 AG

2-83 PSEL-B242CBE0 A-sealer air guid. C 2 2 2 AC

2-84 PSEL-B243CBE0 A-sealer air guid. D 2 2 2 AD

2-86 LBND-A026CBE0 Nylon band(Singapore only) 1 1 1 AC

DOOR PARTS

3- 2 HDECAA053CBEA Handle trim(SJ-D51G) 1 - - AZ

3- 2 HDECAA053CBEB Handle trim(SJ-D51G) - 1 - AZ

3- 2 HDECAA053CBEC Handle trim(SJ-D51G) - - 1 AZ

3- 2 HDECAA056CBEA Handle trim(SJ-51G) - - 1 AX

3- 2 HDECAA056CBEB Handle trim(SJ-51G) 1 - - AX

3- 2 HDECAA056CBEC Handle trim(SJ-51G) - 1 - AX

3- 5 FDORFA722CBK0 F-door ass’y 1 - - BP

3- 5 FDORFA732CBK0 F-door ass’y - 1 - BP

3- 5 FDORFA737CBK0 F-door ass’y - - 1 BP

3- 5- 1 LSTPPA075CBFA F-door stopper 1 1 1 AP

3- 5- 2 NBRGPA013CBFB Nylon bearing 2 1 1 1 AH

3- 6 FPACGA204CBK0 F-door packing 1 1 1 AZ

3- 9 GLIN-A145CBFA F-door liner 1 1 1 AX

3-10 PFPFPA810CBE0 F-liner plate 2 2 2 AD

3-12 PFPFPA852CBE0 F-liner plate bottom 1 1 1 AD

3-14 PSEL-B126CBE0 F-door sealer 2 2 2 AG

3-15 FDORRA569CBK0 R-door ass’y 1 - - BU

3-15 FDORRA577CBK0 R-door ass’y - 1 - BT

3-15 FDORRA584CBK0 R-door ass’y - - 1 BT

3-15- 1 LSTP-A043CBM0 R-door stopper 1 1 1 AH

3-15- 2 NBRGPA012CBF0 Nylon bearing r 1 1 1 AE

3-15- 3 NBRGPA014CBFB Nylon bearing 3 1 1 1 AH

3-16 GLIN-A146CBFA R-door liner 1 1 1 BA

3-17 FPACGA205CBK0 R-door packing 1 1 1 BB

3-20 PFPFPA811CBE0 R-liner plate 2 2 2 AB

3-25 HBDGDA710CBEA Badge 1 - - AN

3-25 HBDGDA710CBEB Badge — 1 - AN

3-25 HBDGDA710CBEC Badge — - 1 AN

OTHER PARTS

4- 1 LBND-A023CBE0 L-band C 4 4 4 AC

4- 3 LX-VZA003CBE0 Special screw 2 2 2 AB

4- 9 QTAN-A012CBE0 Solderless term. B 3 3 3 AH

4-14 PSPANA002CBF0 Door spacer 1 1 1 AC

4-15 LX-BZA018CBE0 Special screw 1 1 1 AA

4-16 LX-BZA052CBE0 Clamp screw 2 2 2 AB

4-17 LX-WZA003CBE0 Washer 4 4 4 AA

27

Page 28

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-51G SJ-51G SJ-51G

SJ-D51G SJ-D51G SJ-D51G

-GY -BE -BL

ATTACHMENT PARTS

5- 1 UPOK-A120CBRA Bottle pocket HS 2 2 2 AQ

5- 2 UPOK-A117CBRA Egg pocket HS 1 1 1 AM

5- 3 UPOK-A119CBRA F door pocket HS 2 2 2 AT

5- 4 UPOK-A118CBRA Utility pocket HS 1 1 1 AM

5- 5 UTNA-A167CBFC Egg tray 2 2 2 AG

5- 6 FSRA-A142CBY0 Ice cube maker 1 1 1 AR

5- 7 LFRM-A200CBFA Ice maker 1 1 1 AR

5- 8 USRA-A174CBRA Ref.tray silk 2 2 2 AX

5- 9 USRA-A176CBRA Freezer tray L silk 1 1 1 AT

5-11 USRA-A175CBRA Freezer tray S silk 1 1 1 AU

5-12 HDECQA360CBEA Glass shelf trim 1 1 1 AK

5-13 HGRL-A132CBFA Ventilating grille 1 - - AN

5-13 HGRL-A132CBFC Ventilating grille - 1 - AN

5-13 HGRL-A132CBFE Ventilating grille - - 1 AN

5-14 USRA-A177CBFA Evaporating pan 1 1 1 BB

5-15 UTNA-A227CBE0 Glass shelf 1 1 1 BB

5-16 UYOK-A180CBFA Vegetable case 1 1 1 AZ

5-17 UYOK-A181CBFA Ice storage box 1 1 1 AH

5-18 UYOK-A179CBFA Chilled case 1 1 1 AS

5-19 GDORPA042CBRA Chilled door HS 1 1 1 AP

5-20 UTNA-A228CBRA F-set shelf F silk 1 1 1 AT

5-21 UTNA-A229CBFA Free set shelf B 1 1 1 AS

CYCLE PARTS

6- 1 PCMPLA130CBE0 Compressor(220/230/240V 50Hz region) 1 1 1 CA

6- 1 PCMPLA135CBE0 Compressor(220V 60Hz region) 1 1 - CA

6- 2 PSPAGA028CBE0 Rubber grommet 4 4 4 AD

6- 3 FCONSA051CBK0 Sub. condenser ass’y 1 1 1 AF

6- 4 FFRM-A085CBK0 Base frame ass’y 1 1 1 AF

6- 5 PDRY-A005CBE0 Dryer 1 1 1 AP

6- 6 PCLI-A035CBE0 Clip 1 1 1 AC

6- 9 PSPAFA020CBE0 Sleeve 4 4 4 AB

6-11 PPIPCA220CBE0 S.P connector 1 1 1 AH

6-12 LANG-A024CBP0 Absorbent rubber CLM 1 1 1 AC

6-13 LHLD-A061CBF0 Evaporating pan holder 2 2 2 AD

6-14 PGUM-A002CBF0 Absorbent rubber B 1 1 1 AH

6-15 PGUM-A003CBF0 Absorbent rubber B 1 1 1 AH

6-16 PGUM-A004CBF0 Absorbent rubber A 1 1 1 AH

6-18 PPIPCA222CBE0 Charge pipe L 2 2 2 BC

6-19 LHLD-A357CBE0 Clamp supplement 1 1 1 AC

6-20 LHLD-A358CBE0 Cable clamp 2 2 2 AD

6-21 PCOVPA165CBE0 Terminal cover 1 1 1 AF

28

Page 29

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-51G SJ-51G SJ-51G

SJ-D51G SJ-D51G SJ-D51G

-GY -BE -BL

MISCELLANEOUS

90- 1 TINS-A277CBR0 Operation manual(English) 1 1 1 AE

90- 1 TINS-A282CBR0 Operation manual(Thai) 1 1 1 AF

90- 2 TLAB-A153CBR0 Warning label 1 1 1 AD

90- 3 SPAKCG340YDE0 Packing case(Destination mark " R ") 1 - - BG

90- 3 SPAKCG341YDE0 Packing case(Destination mark " R ") - 1 - BG

90- 3 SPAKCG342YDE0 Packing case(Destination mark " R ") - - 1 BG

90- 3 SPAKCG325YDE0 Packing case(Destination mark " M ") 1 - - BG

90- 3 SPAKCG326YDE0 Packing case(Destination mark " M ") - 1 - BG

90- 3 SPAKCG327YDE0 Packing case(Destination mark " M ") - - 1 BH

90- 3 SPAKCG490YDE0 Packing case(SJ-51G, Destination mark " T ") 1 - - BG

90- 3 SPAKCG491YDE0 Packing case(SJ-51G, Destination mark " T ") - 1 - BG

90- 3 SPAKCG492YDE0 Packing case(SJ-51G, Destination mark " T ") - - 1 BG

90- 3 SPAKCG493YDE0 Packing case(SJ-D51G, Destination mark " T ") 1 - - BG

90- 3 SPAKCG494YDE0 Packing case(SJ-D51G, Destination mark " T ") - 1 - BG

90- 3 SPAKCG495YDE0 Packing case(SJ-D51G, Destination mark " T ") - - 1 BG

90- 3 SPAKCG425YDE0 Packing case(Destination mark " Z ") 1 - - BG

90- 3 SPAKCG570YDE0 Packing case(Destination mark " Z ") - 1 - BG

90- 3 SPAKCG419YDE0 Packing case(Destination mark " Y ") 1 - - BG

90- 3 SPAKCG422YDE0 Packing case(Destination mark " Y ") - 1 - BG

90- 3 SPAKCG424YDE0 Packing case(Destination mark " Y ") - - 1 BG

90- 6 CPADBA501YDK0 Bottom pad ass’y 1 1 1 AY

90- 7 CPADBA495YDK0 Top pad ass’y 1 1 1 AS

HOW TO ORDER REPLACEMENT PARTS

To have your order filled prompty and correctly, please furnish the following information.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

Destination mark

Packing case

29

Page 30

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G REPLACEMENT PARTS LIST(SJ-55G/SJ-D55G)

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-55G SJ-55G SJ-55G

SJ-D55G SJ-D55G SJ-D55G

-GY -BE -BL

ELECTRIC PARTS

1- 1 RTHM-A057CBE0 F-thermostat 1 1 1 BA

1- 1 RTHM-A063CBE0 F-thermostat(Thailand only) 1 1 1 BA

1- 2 RSTT-A105CBE0 Starting relay(220/230/240V 50Hz region) 1 1 1 AN

1- 2 RSTT-A110CBE0 Starting relay(220V 60Hz region) 1 1 - AN

1- 3 QSWTDA035CBE0 Defrost timer 1 1 1 BB

1- 4 PDMP-A025CBE0 Damper thermostat 1 1 1 AZ

1- 4 PDMP-A028CBE0 Damper thermostat(Thailand only) 1 1 1 AZ

1- 5 FTHM-A012CBK0 Defrost thermo.ass’y 1 1 1 AQ

1- 6 RMOTRA030CBE0 Fan motor 1 1 1 AZ

1- 7 QSOCAA037CBE0 Lamp socket 1 1 1 AM

1- 8 RLMP-001ECBE0 Lamp 1 1 1 AH

1- 9 QACC-A096CBE0 Source cord(Plug type BF) 1 1 1 AX

1- 9 QACC-A095CBE0 Source cord(Plug type A-1) 1 1 1 AM

1- 9 QACC-A101CBE0 Source cord(Plug type C-2) 1 1 1 AN

1-10 QSW-PA056CBEA Door switch 1 1 1 AP

1-11 RHOG-A084CBE0 Protector(220/230/240V 50Hz region) 1 1 1 AN

1-11 RHOG-A092CBE0 Protector(220V 60Hz region) 1 1 - AN

1-15 RC-EZA124CBE0 Running capacitor 1 1 1 AX

1-16 FW-VZA108CBE0 Earth wire(For 3p. plug) 1 1 1 AE

1-17 FFS-TA036CBK0 Fuse ass’y 1 1 1 AN

1-19 FW-VZA109CBE0 D timer lead ass’y 1 1 1 AN

1-20 FW-VZA110CBE0 Lead EV-cover ass’y 1 1 1 AP

1-21 FHETBA082CBE0 Def. heater ass’y(SJ-D55G) 1 1 1

1-21 FHETBA072CBE0 Def. heater ass’y(SJ-55G) 1 1 1 BD

1-22 QCNW-A634CBE0 Relay wire G(For 3p. plug) 1 1 1 AE

1-23 QCNW-A635CBE0 Relay wire B 1 1 1 AE

1-24 QCNW-A636CBE0 Relay wire BR 1 1 1 AE

1-25 QTAN-A032CBE0 Terminal block 1 1 1 AE

MECHANICAL PARTS

2- 1 LSTPPA078CBFA Back spacer 1 1 1 AD

2- 2 JKNB-A036CBFA F-temp. control knob 1 1 1 AL

2- 4 LPLTMA404CBE0 FL plate AL. 1 1 1 AD

2- 7 FLEGPA045CBK0 Leg holder L ass’y 1 1 1 AQ

2- 7- 1 FAJS-A009CBK0 Adjustable leg ass’y 2 2 2 AD

2- 7- 2 LHLD-A354CBM0 Leg holder L 1 1 1 AE

2- 8 FLEGPA046CBK0 Leg holder R ass’y 1 1 1 AQ

2- 8- 2 LHLD-A355CBM0 Leg holder R 1 1 1 AE

2-11 PSPAVA074CBEA Bottom hinge spacer 1 1 1 AD

2-13 DHNG-A274CBM0 Upper hinge ass’y 1 1 1 AK

2-14 DHNG-A275CBM0 Bottom hinge R ass’y 1 1 1 AK

2-15 DHNG-A276CBK0 C-hinge RD ass’y 1 1 1 AN

2-15- 1 PSPAVA075CBEA Center hinge spacer 1 1 1 AD

2-16 GCOV-A141CBFA E.V cover 1 1 1 AU

2-17 LCRA-A010CBE0 Fan clamp 1 1 1 AD

2-19 LHLD-A245CBF0 Motor cushion 2 2 2 AF

2-20 NFANPA011CBF0 Propeller fan 100 1 1 1 AD

2-21 PSEL-B128CBE0 E.V cover sealer A 1 1 1 AD

2-22 PSEL-B129CBE0 E.V cover sealer B 1 1 1 AD

2-23 PSEL-A415CBE0 E.V cover sealer C 1 1 1 AC

2-24 PCOVPA164CBFA Terminal cover(Singapore/Malaysia) 1 1 1 AE

2-24 PCOVPA175CBFA Terminal cover 1 1 1 AF

2-26 PCOV-A151CBFA Lamp cover 1 1 1 AF

2-27 GCOVPA067CBRA R-Cbox cover 1 1 1 AE

2-28 HGRL-A133CBRA Fan louver 1 1 1 AT

2-29 GCOV-A140CBFA Upper hinge cover 1 - - AE

2-29 GCOV-A140CBFC Upper hinge cover - 1 - AE

2-29 GCOV-A140CBFF Upper hinge cover - - 1 AE

2-31 JKNB-A033CBFA R-temp. control knob 1 1 1 AD

2-33 LRALPA114CBFA C-case rail L 1 1 1 AE

2-34 LRALPA115CBFA C-case rail R 1 1 1 AE

2-36 PCAP-A006CBFK Screw cover - 1 - AD

2-36 PCAP-A006CBFL Screw cover 1 - - AB

2-36 PCAP-A006CBFM Screw cover - - 1 AB

2-38 PGID-A119CBF0 R-air guider A 1 1 1 AH

2-39 LFRM-A202CBFA C-box base 1 1 1 AK

2-40 PFPFPA809CBF0 RA-insulation 1 1 1 AD

2-41 PSEL-B244CBE0 Thermo. cap. sealer 1 1 1 AB

2-42 PGID-A118CBF0 R-air guider B 1 1 1 AG

30

Page 31

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-55G SJ-55G SJ-55G

SJ-D55G SJ-D55G SJ-D55G

-GY -BE -BL

2-49 LSTPPA074CBFA C-stopper 2 2 2 AD

2-55 HGRL-A134CBFA Multi louver 1 1 1 AL

2-56 PFPFPA814CBF0 R-louver insu. 1 1 1 AE

2-57 PSEL-B130CBE0 A-sealer R-louver 2 2 2 AB

2-61 LHLD-A235CBE0 SL-4N clip(For 3p. plug) 1 1 1 AK

2-62 DCOV-A061CBK0 Harness cover ass’y(Singapore/Malaysia) 1 1 1 AK

2-63 LHLD-A302CBF0 Fan motor cushion B 1 1 1 AL

2-64 LHLD-A303CBM0 Fan motor cushion A 1 1 1 AM

2-66 PSHEMA132CBP0 Heater cover AL 1 1 1 AD

2-67 LPLTMA403CBP0 Drain support AL 1 1 1 AL

2-68 PSEL-A562CBE0 Leading wire sealer 2 2 2 AC

2-69 PSEL-B127CBE0 E.V cover sealer D 1 1 1 AC

2-70 PSEL-B167CBE0 E.V cover sealer E 1 1 1 AB

2-71 PSEL-A552CBE0 Dial sealer 1 1 1 AC

2-72 PSEL-B120CBE0 A-sealer RC-box 1 1 1 AB

2-73 PSEL-B121CBE0 A-sealer RC-duct 1 1 1 AD

2-74 PSEL-B122CBE0 A-sealer thermo. cap. 1 1 1 AB

2-75 PSEL-B124CBE0 A-sealer air guid. B 1 1 1 AB

2-76 LHLD-A124CBFB K-frame holder 1 1 1 AH

2-77 LHLD-A359CBFA T-box holder(For 2p. plug) 1 1 1 AE

2-78 LPLTMA399CBP0 Dryer support 1 1 1 AD

2-80 PBOX-A071CBFA Terminal box(Singapore/Malaysia) 1 1 1 AE

2-80 PBOX-A078CBFA Terminal box 1 1 1 AE

2-81 PPIPPA055CBE0 Drain pipe S 1 1 1 AG

2-82 PTUBBA043CBE0 Insulating tube 1 1 1 AG

2-83 PSEL-B242CBE0 A-sealer air guider C 2 2 2 AC

2-84 PSEL-B243CBE0 A-sealer air guider D 2 2 2 AD

2-86 LBND-A026CBE0 Nylon band(Singapore only) 1 1 1 AC

DOOR PARTS

3- 2 HDECAA053CBEA Handle trim(SJ-D55G) 1 - - AZ

3- 2 HDECAA053CBEB Handle trim(SJ-D55G) - 1 - AZ

3- 2 HDECAA053CBEC Handle trim(SJ-D55G) - - 1 AZ

3- 2 HDECAA056CBEA Handle trim(SJ-55G) - - 1 AX

3- 2 HDECAA056CBEB Handle trim(SJ-55G) 1 - - AX

3- 2 HDECAA056CBEC Handle trim(SJ-55G) - 1 - AX

3- 5 FDORFA722CBK0 F-door ass’y 1 - - BP

3- 5 FDORFA732CBK0 F-door ass’y - 1 - BP

3- 5 FDORFA737CBK0 F-door ass’y - - 1 BP

3- 5- 1 LSTPPA075CBFA F-door stopper 1 1 1 AP

3- 5- 2 NBRGPA013CBFB Nylon bearing 2 1 1 1 AH

3- 6 FPACGA204CBK0 F-door packing 1 1 1 AZ

3- 9 GLIN-A145CBFA F-door liner 1 1 1 AX

3-10 PFPFPA810CBE0 F-liner plate 2 2 2 AD

3-12 PFPFPA852CBE0 F-liner plate bottom 1 1 1 AD

3-14 PSEL-B126CBE0 F-door sealer 2 2 2 AG

3-15 FDORRA573CBK0 R-door ass’y 1 - - BV

3-15 FDORRA578CBK0 R-door ass’y - 1 - BV

3-15 FDORRA585CBK0 R-door ass’y - - 1 BV

3-15- 1 LSTP-A043CBM0 R-door stopper 1 1 1 AH

3-15- 2 NBRGPA012CBF0 Nylon bearing R 1 1 1 AE

3-15- 3 NBRGPA014CBFB Nylon bearing 3 1 1 1 AH

3-16 GLIN-A147CBEA R-door liner 1 1 1 BA

3-17 FPACGA206CBK0 R-door packing 1 1 1 BA

3-20 PFPFPA819CBE0 R-liner plate 2 2 2 AD

3-25 HBDGDA710CBEA Badge 1 - - AN

3-25 HBDGDA710CBEB Badge - 1 - AN

3-25 HBDGDA710CBEC Badge - - 1 AN

OTHER PARTS

4- 1 LBND-A023CBE0 L-band C 4 4 4 AC

4- 3 LX-VZA003CBE0 Special screw 2 2 2 AB

4- 9 QTAN-A012CBE0 Solderless term. B 3 3 3 AH

4-14 PSPANA002CBF0 Door spacer 1 1 1 AC

4-15 LX-BZA018CBE0 Special screw 1 1 1 AA

4-16 LX-BZA052CBE0 Clamp screw 2 2 2 AB

4-17 LX-WZA003CBE0 Washer 4 4 4 AA

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

31

Page 32

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-55G SJ-55G SJ-55G

SJ-D55G SJ-D55G SJ-D55G

-GY -BE -BL

ATTACHMENT PARTS

5- 1 UPOK-A120CBRA Bottle pocket HS 2 2 2 AQ

5- 2 UPOK-A117CBRA Egg pocket HS 1 1 1 AM

5- 3 UPOK-A119CBRA F door pocket HS 2 2 2 AT

5- 4 UPOK-A118CBRA Utility pocket HS 2 2 2 AM

5- 5 UTNA-A167CBFC Egg tray 2 2 2 AG

5- 6 FSRA-A142CBY0 Ice cube maker 1 1 1 AR

5- 7 LFRM-A200CBFA Ice maker 1 1 1 AR

5- 8 USRA-A174CBRA Ref. tray silk 3 3 3 AX

5- 9 USRA-A176CBRA Freezer tray L silk 1 1 1 AT

5-11 USRA-A175CBRA Freezer tray S silk 1 1 1 AU

5-12 HDECQA360CBEA Glass shelf trim 1 1 1 AK

5-13 HGRL-A132CBFA Ventilating grille 1 - - AN

5-13 HGRL-A132CBFC Ventilating grille - 1 - AN

5-13 HGRL-A132CBFE Ventilating grille - - 1 AN

5-14 USRA-A177CBFA Evaporating pan 1 1 1 AR

5-15 UTNA-A227CBE0 Glass shelf 1 1 1 BB

5-16 UYOK-A180CBFA Vegetable case 1 1 1 AZ

5-17 UYOK-A181CBFA Ice storage box 1 1 1 AH

5-18 UYOK-A179CBFA Chilled case 1 1 1 AS

5-19 GDORPA042CBRA Chilled door HS 1 1 1 AP

5-20 UTNA-A228CBRA F-set shelf F silk 1 1 1 AT

5-21 UTNA-A229CBFA Free set shelf B 1 1 1 AS

CYCLE PARTS

6- 1 PCMPLA130CBE0 Compressor(220/230/240V 50Hz region) 1 1 1 CA

6- 1 PCMPLA135CBE0 Compressor(220V 60Hz region) 1 1 1 CA

6- 2 PSPAGA028CBE0 Rubber grommet 4 4 4 AD

6- 3 FCONSA051CBK0 Sub. condenser ass’y 1 1 1 AS

6- 4 FFRM-A085CBK0 Base frame ass’y 1 1 1 AF

6- 5 PDRY-A005CBE0 Dryer 1 1 1 AP

6- 6 PCLI-A035CBE0 Clip 1 1 1 AC

6- 9 PSPAFA020CBE0 Sleeve 4 4 4 AD

6-11 PPIPCA220CBE0 S.P connector 1 1 1 AB

6-12 LANG-A024CBP0 Absorbent rubber CLM 1 1 1 AC

6-13 LHLD-A061CBF0 Evaporating pan holder 2 2 2 AD

6-14 PGUM-A002CBF0 Absorbent rubber B 1 1 1 AH

6-15 PGUM-A003CBF0 Absorbent rubber B 1 1 1 AH

6-16 PGUM-A004CBF0 Absorbent rubber A 1 1 1 AH

6-18 PPIPCA222CBE0 Charge pipe L 2 2 2 BC

6-19 LHLD-A357CBE0 Clamp supplement 1 1 1 AC

6-20 LHLD-A358CBE0 Cable clamp 2 2 2 AD

6-21 PCOVPA165CBE0 Terminal cover 1 1 1 AF

32

Page 33

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-55G SJ-55G SJ-55G

SJ-D55G SJ-D55G SJ-D55G

-GY -BE -BL

MISCELLANEOUS

90- 1 TINS-A277CBR0 Operation manual(English) 1 1 1 AE

90- 1 TINS-A282CBR0 Operation manual(Thai) 1 1 1 AF

90- 2 TLAB-A153CBR0 Warning label 1 1 1 AD

90- 3 SPAKCG435YDE0 Packing case(Destination mark " R ") 1 - - BH

90- 3 SPAKCG436YDE0 Packing case(Destination mark " R ") - 1 - BH

90- 3 SPAKCG438YDE0 Packing case(Destination mark " R ") - - 1 BH

90- 3 SPAKCG330YDE0 Packing case(Destination mark " M ") 1 - - BH

90- 3 SPAKCG331YDE0 Packing case(Destination mark " M ") - 1 - BH

90- 3 SPAKCG332YDE0 Packing case(Destination mark " M ") - - 1 BH

90- 3 SPAKCG496YDE0 Packing case(SJ-55G, Destination mark " T ") 1 - - BH

90- 3 SPAKCG497YDE0 Packing case(SJ-55G, Destination mark " T ") - 1 - BH

90- 3 SPAKCG498YDE0 Packing case(SJ-55G, Destination mark " T ") - - 1 BH

90- 3 SPAKCG499YDE0 Packing case(SJ-D55G, Destination mark " T ") 1 - - BH

90- 3 SPAKCG500YDE0 Packing case(SJ-D55G, Destination mark " T ") - 1 - BH

90- 3 SPAKCG501YDE0 Packing case(SJ-D55G, Destination mark " T ") - - 1 BH

90- 3 SPAKCG572YDE0 Packing case(Destination mark " Z ") 1 - - BH

90- 3 SPAKCG571YDE0 Packing case(Destination mark " Z ") - 1 - BH

90- 3 SPAKCG430YDE0 Packing case(Destination mark " Y ") 1 - - BH

90- 3 SPAKCG432YDE0 Packing case(Destination mark " Y ") - 1 - BH

90- 3 SPAKCG434YDE0 Packing case(Destination mark " Y ") - - 1 BH

90- 6 CPADBA501YDK0 Bottom pad ass’y 1 1 1 AY

90- 7 CPADBA495YDK0 Top pad ass’y 1 1 1 AS

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

HOW TO ORDER REPLACEMENT PARTS

To have your order filled prompty and correctly, please furnish the following information.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

Destination mark

Packing case

33

Page 34

SJ-48G/D48G

6

4 5

1

2

3

6

4 5

1

2

3

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

3-9

3-6

3-10

3-5

3-5-2

3-2

5-3

5-2

5-5

5-4

5-1

3-20

3-5-1

3-15-3

3-16

3-15-2

3-15-1

3-17

3-15

SJ-55G

3-25

3-12

3-10

3-14

3-20

SJ-51G/D51G

SJ-55G/D55G

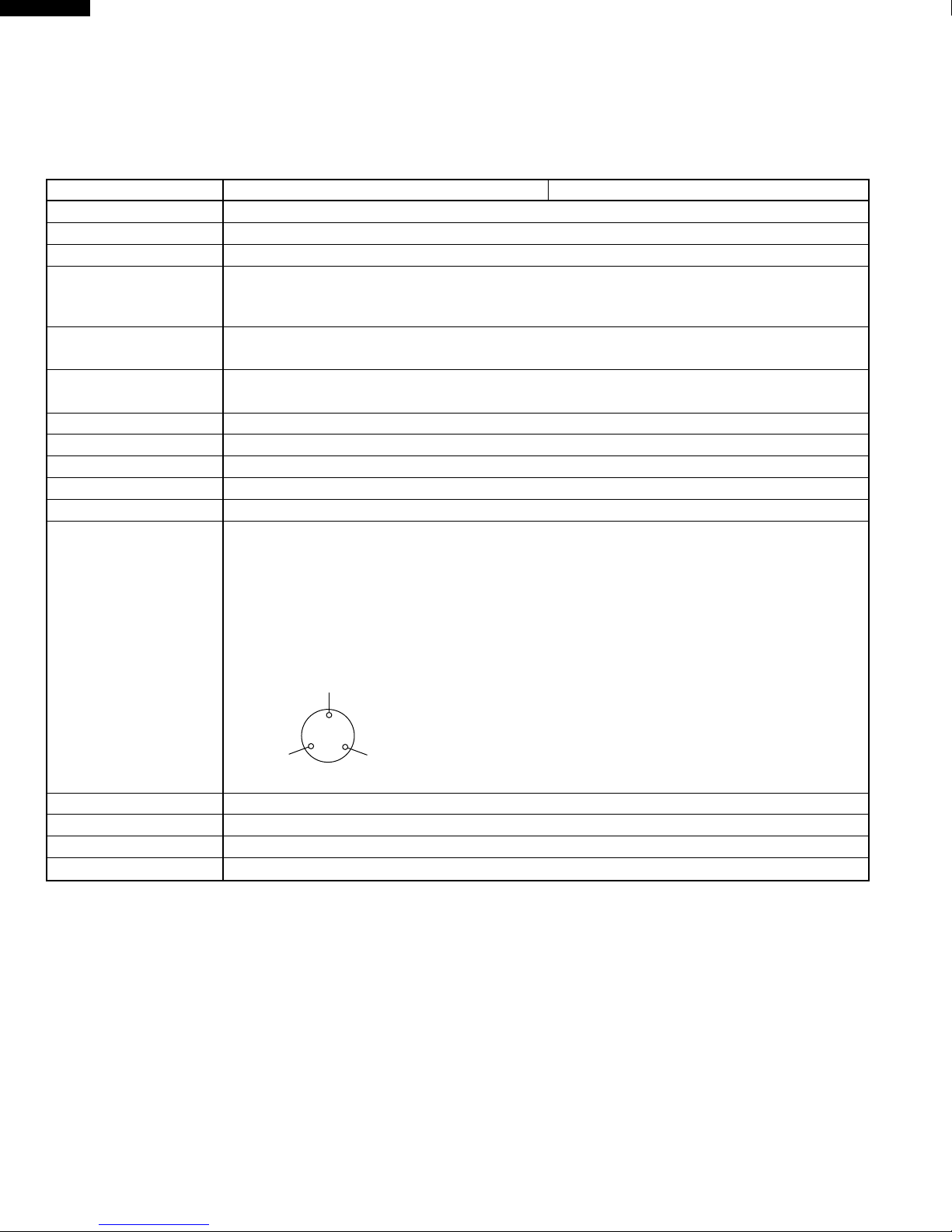

DOOR PARTS

34

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

Page 35

SJ-48G/D48G

6

4 5

1

2

3

6

4 5

1

2

3

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

2-29

2-13

2-7

2-7-2

2-7-1

2-8

2-8-2

2-7-1

6-16

6-14

6-12

6-15

6-1

2-63

1-6

1-20

2-19

2-64

2-20

2-17

4-1

1-5

4-1

2-11

2-14

2-21

1-17

2-22

2-16

2-28

2-2

2-69

1-1

2-23

2-62

5-7

5-6

5-17

5-11

5-9

2-33

2-34

5-18

5-19

2-75

2-72

2-73

2-39

2-42

2-40

1-3

1-19

1-7

1-8

2-71

1-4

2-41

2-26

90-2

2-31

2-74

2-57

2-56

2-55

5-12

5-15

5-16

5-14

6-9

6-2

4-17

6-18

6-6

1-11

4-16

6-20

6-19

1-2

6-21

1-25

6-4

6-13

6-3

2-61

1-22

1-23

1-24

1-16

1-9

2-80

2-24

6-18

6-5

4-9

2-78

2-82

1-10

2-15-1

2-15

4-14

2-36

2-76

2-66

2-68

2-67

2-81

2-1

2-4

5-13

SJ-55G

1-21

4-15

2-27

1-15

2-70

2-38

4-3

2-84

2-84

2-83

6-11

2-86

5-8

5-21

5-20

2-49

SJ-51G/D51G

SJ-55G/D55G

CABINET PARTS

SJ-48G/D48G

SJ-51G/D51G

SJ-55G/D55G

35

Page 36

SJ-48G/D48G

Type Plug

Section of Power

Supply Cord

C-2

A-1

S-C

B

BF

X

S

C-9

SJ-51G/D51G

SJ-55G/D55G

36

'95 SHAP CORP. (2U0.45E) Printed in Japan

Loading...

Loading...