Page 1

SERVICE MANUAL

S9333SE47JPT1

REFRIGERATOR-FREEZER

MODELS

SJ-44L

SJ-48L

SJ-44LSJ-48L-

In the interests of user-safety (Required by safety regulations in some

countries) the set should be restored to its original condition and only

parts identical to those specified should be used.

SJ-44L

Refrigerant; HFC-134a

Refer to "HFC-134a COOLING UNIT" Service Manual for handling this refrigerant.

SJ-48L

DESTINATION ........................1, 2

TABLE OF CONTENTS

WH1/WH2

WH1/WH2

page

CAUTIONS AND INFORMATIONS ..................................................................................................................2

SPECIFICATIONS ............................................................................................................................................3

DESIGNATION OF VARIOUS PARTS .............................................................................................................4

DIMENSIONS ...................................................................................................................................................5

LIST OF ELECTRICAL PARTS ........................................................................................................................7

WIRING DIAGRAM...........................................................................................................................................8

FUNCTIONS ...................................................................................................................................................10

ASSEMBLING PROCEDURES OF MAIN PARTS AND CAUTIONS .............................................................13

COOLING UNIT ..............................................................................................................................................19

REPLACEMENT PARTS LIST .......................................................................................................................21

SHARP CORPORATION

1

Page 2

SJ-44L

SJ-48L

CAUTIONS AND INFORMATIONS

In case of following troubles, the cause is not related with the failure of refrigerator.

Please mention the correct way to the customer for the use of refrigerator when the repairing.

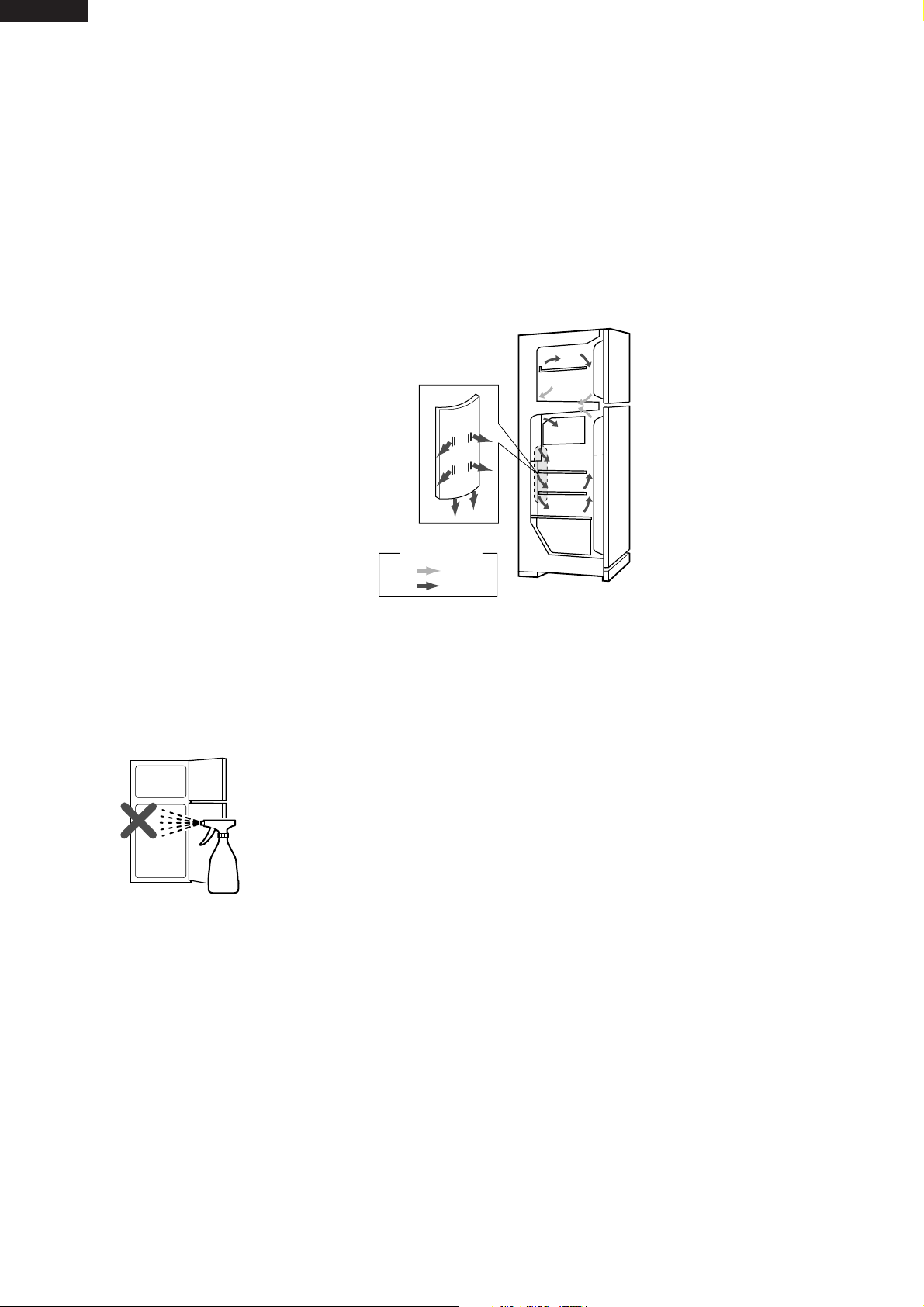

1. Some foods freezed in the refrigerator compartment.

Do not place food directly in front of

cold air outlet.

This may lead to the food freezing.

cold air flow

IN

OUT

2. Some plastic parts were cracked or splitted.

Some household cleaning chemicals may affect the internal

food liner and plastic parts resulting in splitting or cracks

occurring.

When cleaning all plastic parts inside this refrigerator, only

use diluted dishwashing liquid(soapy water). Make sure that

all plastic parts are thoroughly rinsed with water after cleaning.

3. IT IS NORMAL for the refrigerator to produce the following sounds.

Cracking or crunching sound;

Sound produced by expansion and contraction of inner walls and internal parts during cooling.

Squeaking sound;

Sound produced by expansion and contraction of internal parts.

Sound of flowing fluid (gurgling sound, fizzing sound);

Sound of refrigerant flowing in pipes (sound may become louder from time to time).

2

Page 3

SPECIFICATIONS

Items SJ-44L SJ-48L

Type 2-Door 2-Door

Outer dimensions Height 1700mm(66.9") 1820mm(71.7")

Width 680mm(26.8") 680mm(26.8")

Depth 660mm(26.0") 660mm(26.0")

Rated storage volume 347 liter (12.3cu.ft) 384 liter (13.6 cu.ft)

(Rated volume) F: 99liter (3.5 cu.ft) F: 99 liter (3.5 cu.ft)

R: 248 liter(8.8 cu.ft) R: 285 liter(10.1 cu.ft)

Gross volume 370 liter (13.1cu.ft) 407 liter (14.4 cu.ft)

F: 107liter (3.8 cu.ft) F: 107 liter (3.8 cu.ft)

R: 263 liter(9.3 cu.ft) R: 300 liter(10.6 cu.ft)

Defrosting System Heater system

Start Automatic

Finish Automatic

Temperature control Automatic (Adjustable)

No-frost freezer Yes

Interior lamp 1

Caster 2

Evaporating pan 1

Refrigerator Refrigerator tray 2

Compartment Vegetable tray 1

Vegetable case 1

V parting plate 1

R door pocket 1

Egg tray 1

R door pocket S 2

Bottle pocket 1

Bottle stopper 1

Door pocket 1

Fresh case 1

Freezer Freezer tray 1

Compartment Ice cube maker Twin ice cube maker

Ice storage box 1

Door pocket 2

Deodorizing unit 2 ( Honeycomb type)

SJ-44L

SJ-48L

RATING

Items SJ-44L-WH1 SJ-48L-WH1 SJ-44L-WH2 SJ-48L-WH2

Rated voltage 110V~ 220-240V~

Rated frequency 50Hz 50 / 60 Hz

Rated current (A) 2.8 0.93-0.97

Rated input (W) 160 115-120

Rated input of heating systems (W) 128 128-152

Rated voltage 110-120V~

Rated frequency 60Hz

Rated current (A) 2.8-2.9

Rated input (W) 160-165

Rated input of heating systems (W) 128-152

Climate class ST ST

Refrigerant (Charging quantity) HFC-134a(105g) HFC-134a(105g)

Net Weight (kg) 66 68 66 68

3

Page 4

SJ-44L

SJ-48L

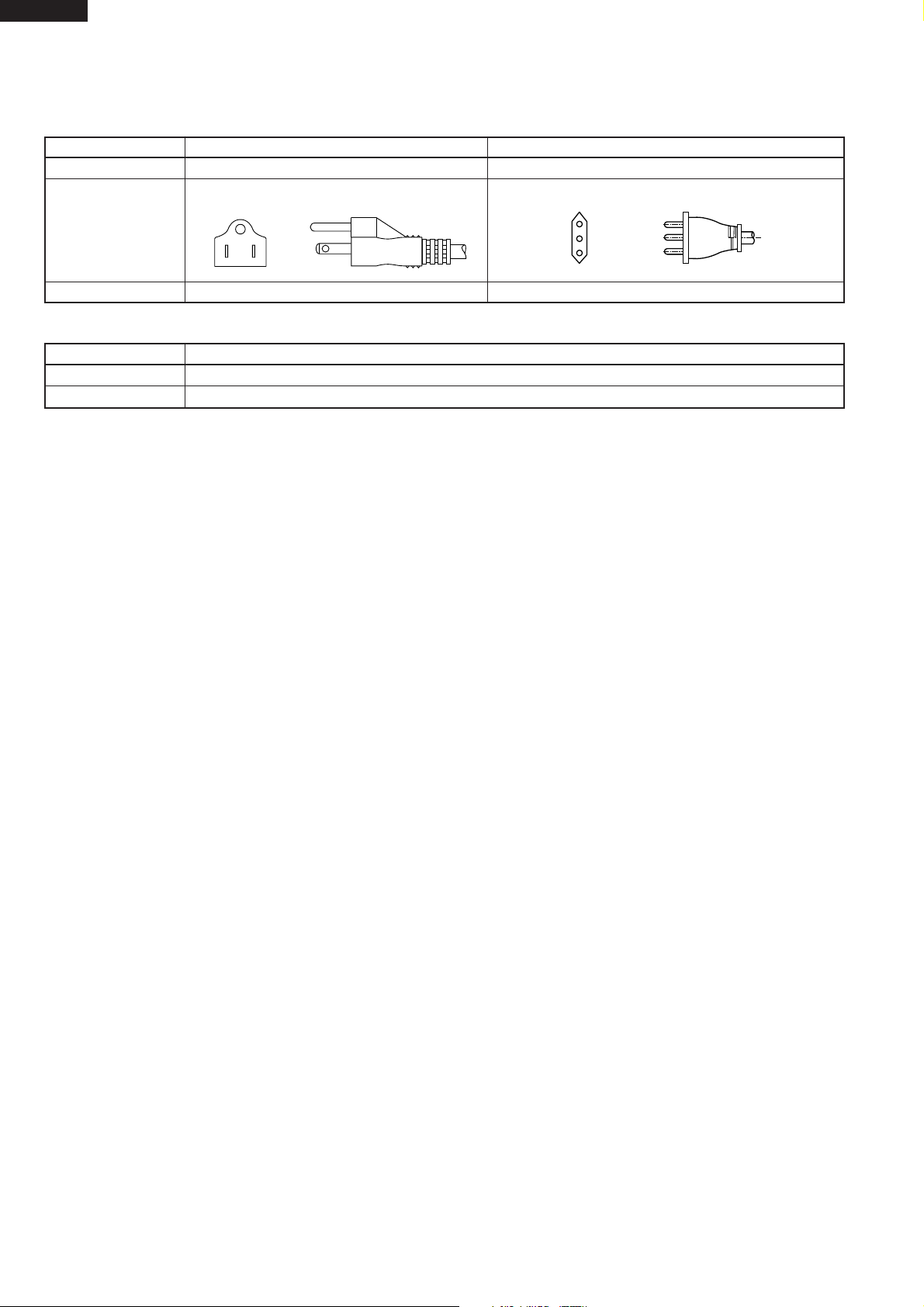

PLUG TYPE

Items SJ-44L-WH1,SJ-48L-WH1 SJ-44L-WH2,SJ-48L-WH2

Plug cord 3 pin 3 pin

Plug type A-2 (UL type) C-1

Destination mark 1 2

COLOR

Items -WH1, -WH2

Outside color White

Inside color White

4

Page 5

)

y)

1

1

1

1

1

1

1

1

1

2

3

4

5

6

7

5

8

9

0

1

2

3

4

5

6

7

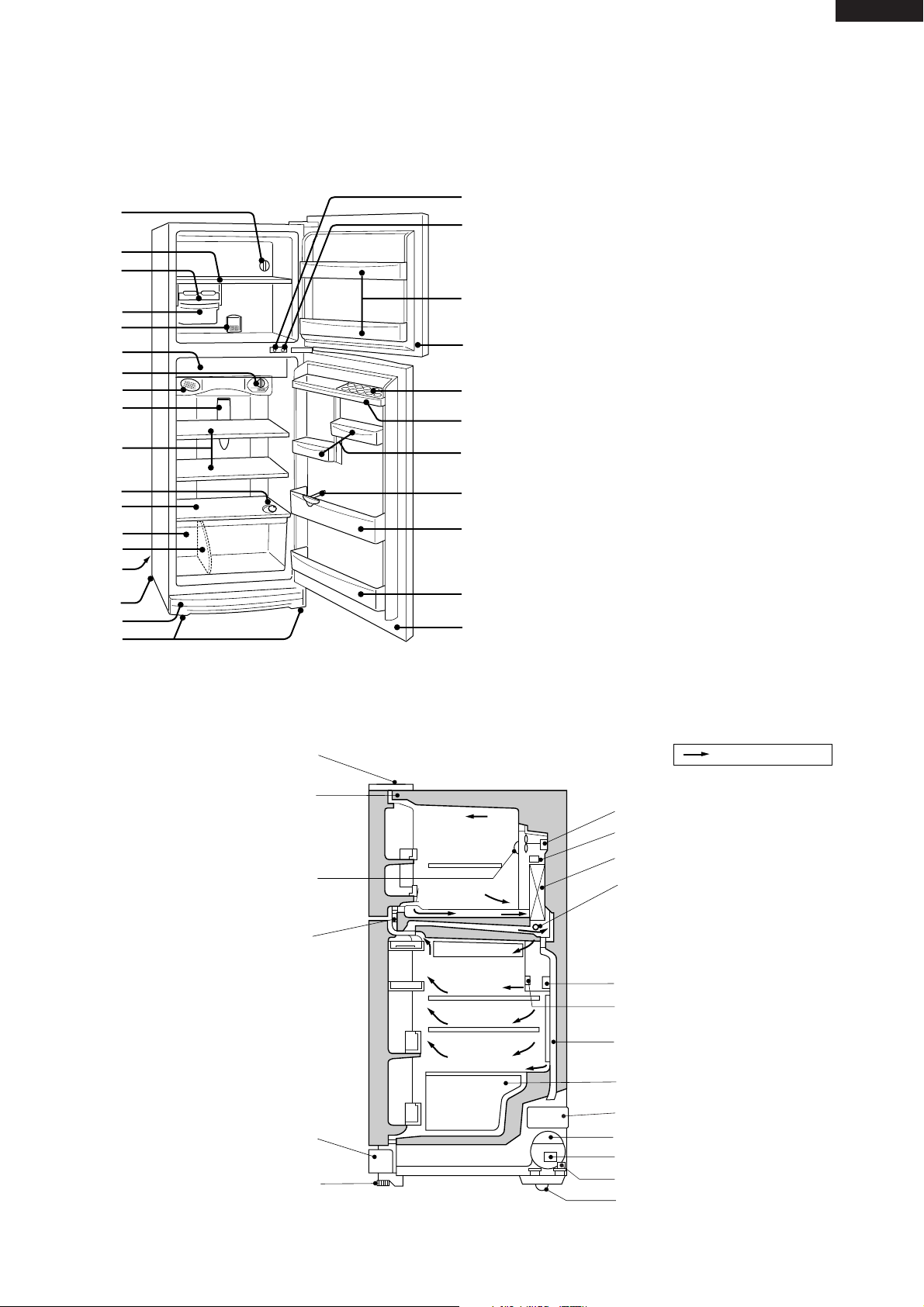

Figure D-1. External Description

DESIGNATION OF VARIOUS PAR TS

The names are the denominations used in the

REPLACEMENT PARTS LIST.

1. Freezer temp. control knob

18

19

20

21

22

23

24

25

26

20

21

2. Freezer shelf(Freezer tray)

3. Ice cube maker

4. Ice cube box(Ice storage box)

5. Deodorizing unit

6. Fresh case

7. Refrigerator temp. control knob

8. Light(Lamp)

9. Refrigerator shelf(Refrigerator tray

10. Lever

11. Shelf(Vegetable tray)

12. Vegetable crisper(Vegetable case)

13. Separator plate(V parting plate)

14. Evaporating pan

15. Casters

16. Ventilating grille

17. Adjustable feet(Adjustable leg ass’

18. Fan switch

19. Fan & light switch

20. Utility pocket(Door pocket)

21. Magnetic door seal(Door packing)

22. Egg holder(Egg tray)

23. Egg pocket(R door pocket)

24. Small pocket(R door pocket S)

25. Bottle guard(Bottle stopper)

26. Bottle pocket

SJ-44L

SJ-48L

Upper hinge cover

Hot pipe

Fan motor

Freezer

compartment

Freezer temp. control knob

Hot pipe

Refrigerator

compartment

Ventilating grille

Adjustable leg ass'y

Defrost thermostat

Evaporator

Defrost heater

Damper thermostat

Refrigerator temp. control knob

Drain pipe

Vegetable case

Evaporating pan

Compressor

Starting relay, Overload relay(Protector)

Defrost timer

Caster

Mark: Cold air flow

Figure D-2. Constructions

5

Page 6

SJ-44L

)

)

SJ-48L

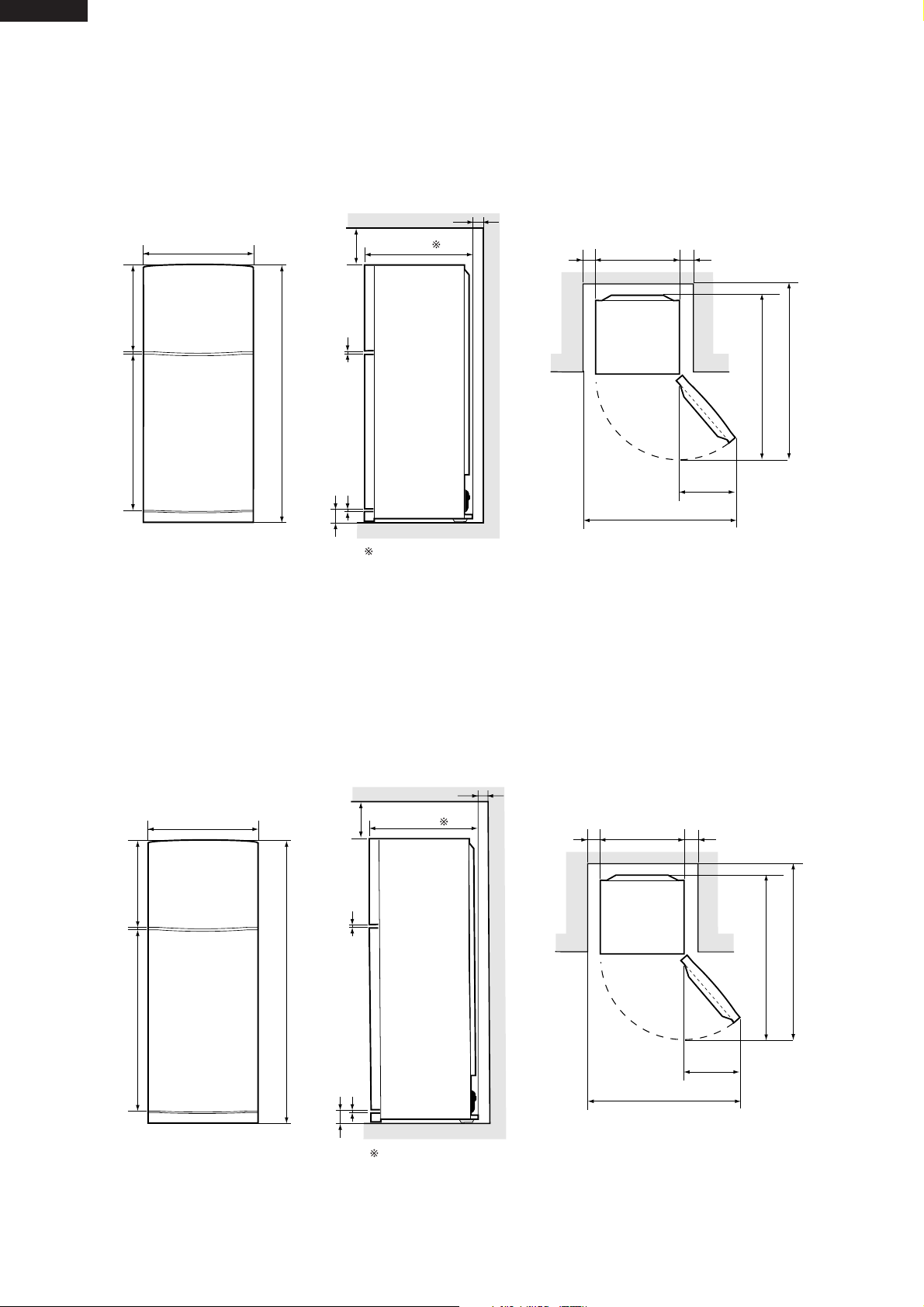

OUTER DIMENSIONS AND CLEARANCE

680

more than

90

5951022.5

1700

DIMENSIONS

more than

60

660

1

more than

60

680

more than

60

1260

1320

5951142.5

680

73

more than

90

16 9.5

1: Include the badge

Not include the handle

Fig. E-1(SJ-44L)

more than

660

1

9.5

60

more than

60

1210

680

470

(Unit : mm

more than

60

1820

16

73

1: Include the badge

Not include the handle

Fig. E-2(SJ-48L)

1260

1320

470

1210

(Unit : mm

6

Page 7

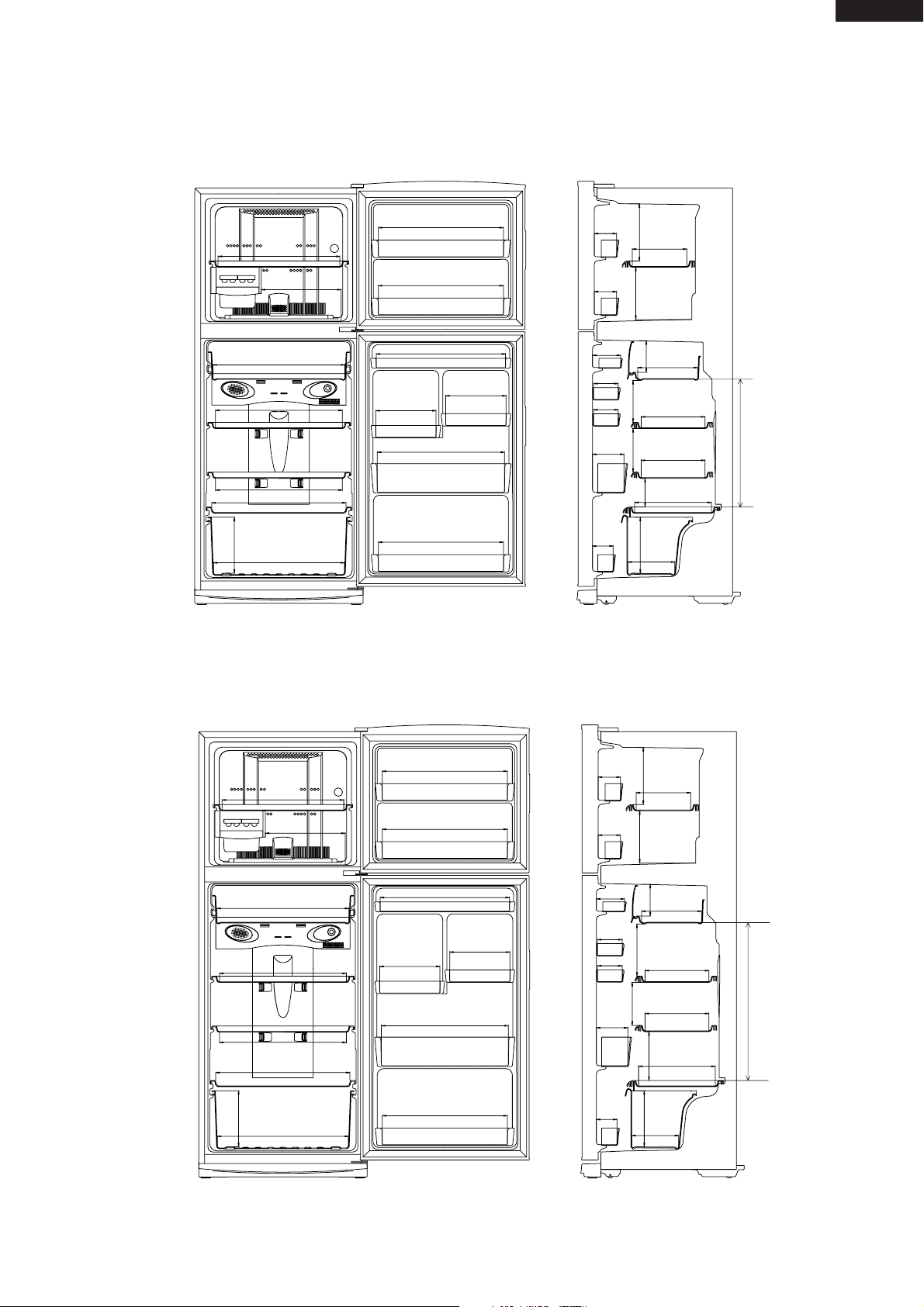

INNER DIMENSIONS

)

)

The dimensions between shelves can be changed by setting the shelves on the other rails.

SJ-44L

SJ-48L

225

502

531

524

524

526

526

321

502

502

518

242

242

510

502

Fig. E-3(SJ-44L)

89

89

112

99

99

126

82

229

210

118

(168.5)

(125)

(165)

226

188

232

246

269

269

320

508.5

(Unit: mm

225

502

531

524

524

526

526

321

502

502

518

242

242

510

502

Fig. E-4(SJ-48L)

112

126

82

89

229

232

89

210

118

246

99

99

(218.5)

269

(175)

(185)

226

188

269

320

628.5

(Unit: mm

7

Page 8

SJ-44L

il

A

il

A

SJ-48L

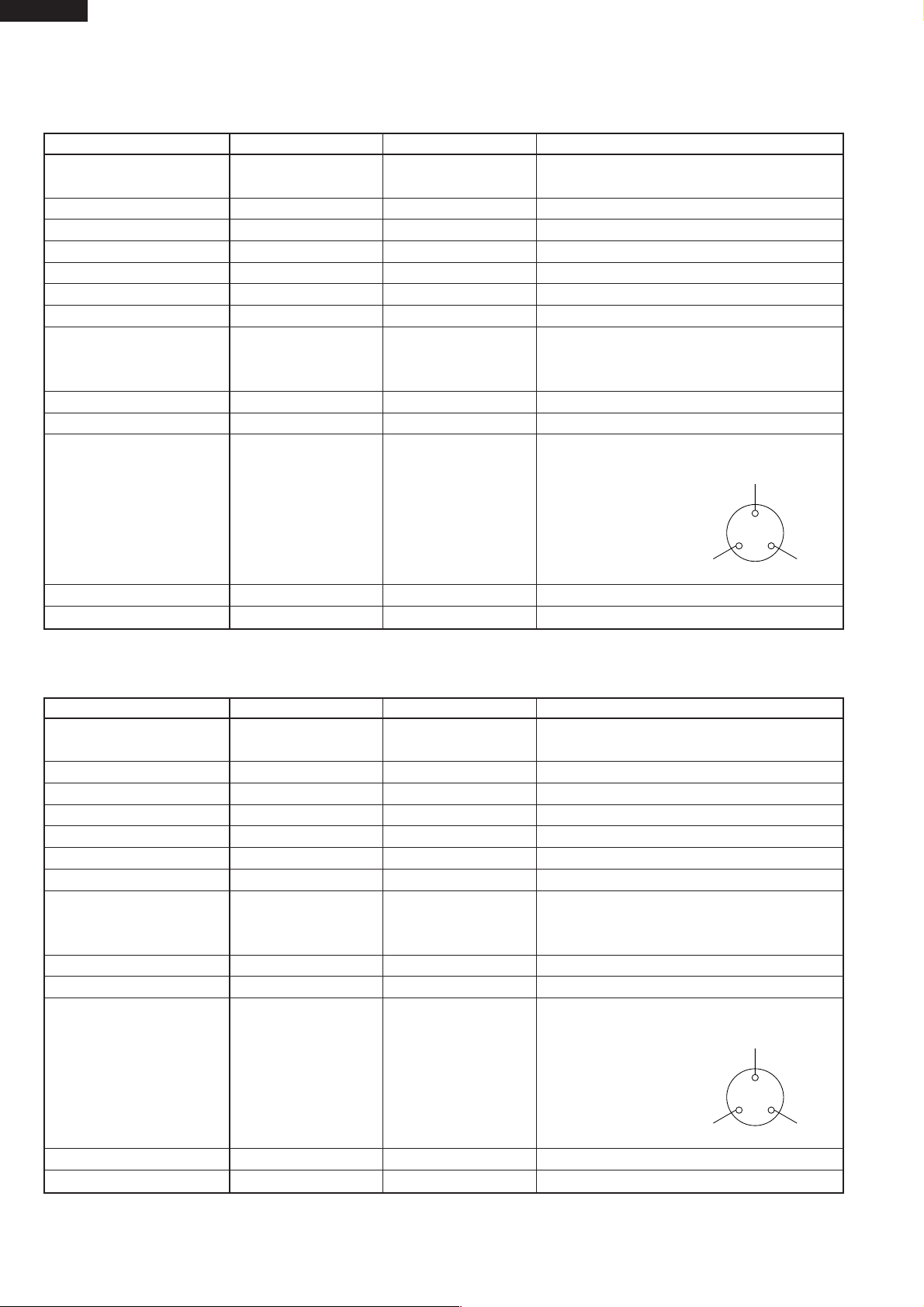

LIST OF ELECTRICAL PARTS

SJ-44L-WH1,SJ-48L-WH1

ITEMS TYPE NAME RATING SPECIFICATIONS

Thermostat MM1-8149 125V 6A (At normal notch)

250V 3A ON/OFF : -20 / -25˚C

Defrost thermostat S101 250V 8A Open/Close : 8 / 1˚C

Thermo. fuse SF70E 250V 10A Working temp. : 70˚C

Fan motor 3R00171 110-120V 60Hz Working with ø100 fan

Defrost heater MM1-4266 120V 94.5Ω 140W at 115V

Door switch DSD-5 125V 0.5A 4 terminals push-button type

Damper thermostat MM1-6173 — Open/Close : 5 / 0˚C

Defrost timer TMDFX04FB2 110-127V Integration type

50/60Hz Cycle time : 12h/10h(50/60Hz)

Delay time : 4m48s/4m(50/60Hz)

Lamp socket — 250V 1A E-12(Hard plastic body type)

Lamp — 130V 15W E-12

Compressor FGI85HAK 115V/60Hz Cooling capacity : 243W

Main coil : 1.78Ω

Aux. coil : 6.8Ω

(at 25˚C)

Common

ux. coil

Starting relay PTH7M4R7MC1 — 4.7 Ω 180V

Overload relay(Protector) 4TM771RFB — Open/ Close : 130/61˚C

SJ-44L-WH2,SJ-48L-WH2

ITEMS TYPE NAME RATING SPECIFICATIONS

Thermostat MM1-8149 125V 6A (At normal notch)

250V 3A ON/OFF : -20 / -25˚C

Defrost thermostat S101 250V 8A Open/Close : 8 / 1˚C

Thermo. fuse SF70E 250V 10A Working temp. : 70˚C

Fan motor 3R00121A 220-240V 50/60Hz Working with ø100 fan

Defrost heater MM6-4264 220-240V 378 Ω 140W at 230V

Door switch DSD-5 250V 0.25A 4 terminals push-button type

Damper thermostat MM1-6173 — Open/Close : 5 / 0˚C

Defrost timer ND1004M2 220-240V Integration type

50/60Hz Cycle time : 10h44m/8h57m(50/60Hz)

Delay time : 4m20s/3m37s(50/60Hz)

Lamp socket — 250V 1A E-12(Hard plastic body type)

Lamp — 240V 15W E-12

Compressor FL1568SD 220-240V/50Hz Cooling capacity : 188W(50Hz)

Main coil : 13.3Ω

Common

Aux. coil : 25.6Ω

(at 25˚C)

Main co

ux. coil

Main co

Starting relay PET0SAT — 22 Ω 300V

Overload relay(Protector) 1.8C36A1 — Open/ Close : 130/60˚C

8

Page 9

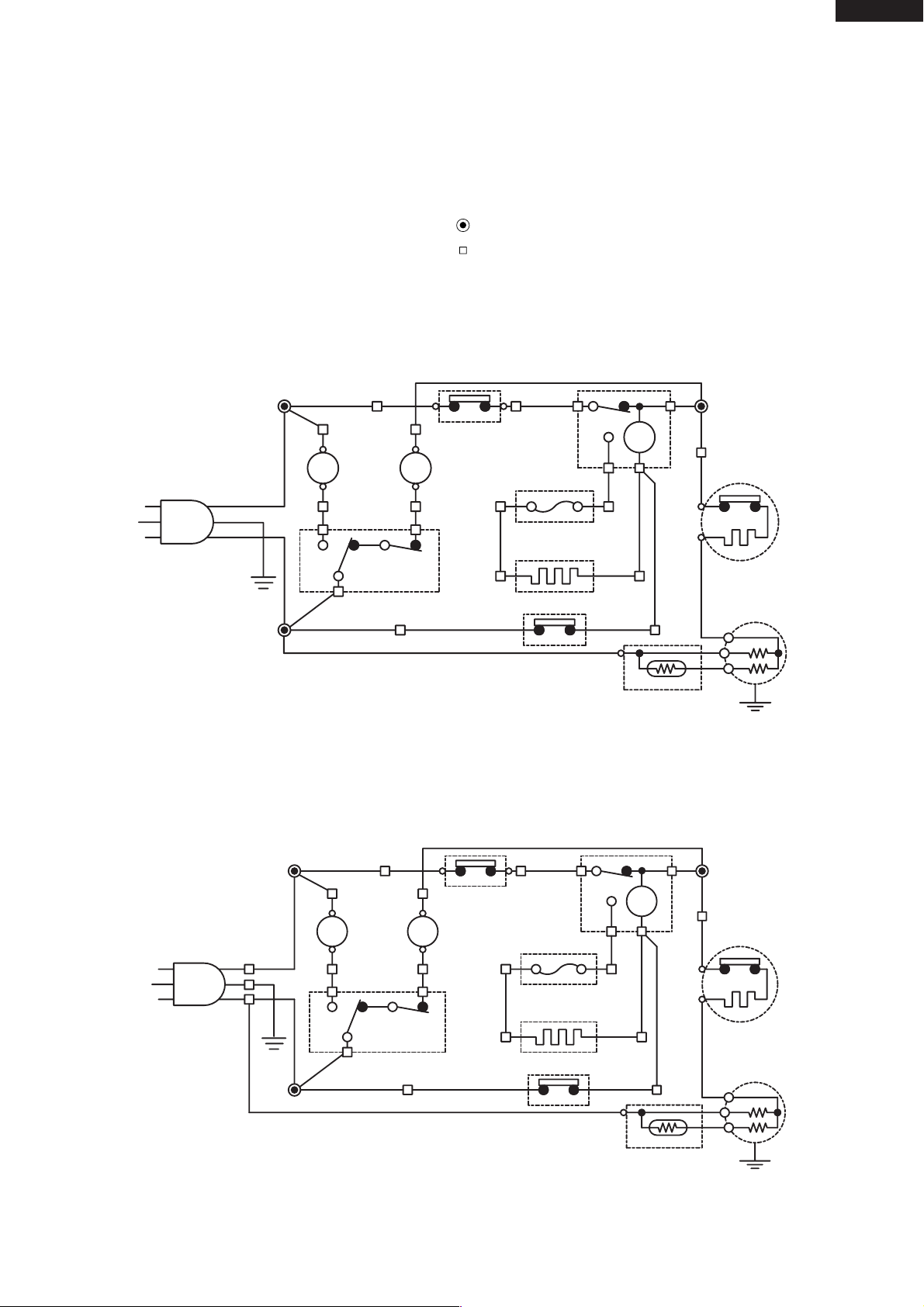

WIRING DIAGRAM

or

or

Be sure to replace the electrical parts with specified ones for maintaining the safety and performance of the set.

GY

: GRAY

BR

: BROWN (live)

OR

: ORANGE

Y

: YELLOW

R

: RED

P

: PINK

BL

: BLUE(neutral)

BK

: BLACK

SB

: SKY-BLUE

G-Y

: GREEN-YELLOW (earth)

W

: WHITE

(BR)

CONNECTED IN TERMINAL BOX

CONNECTOR

Defrost timer

(R)

(GY)

SJ-44L

SJ-48L

Source

Plug

Lamp

L

(SB)

Door switch

(BL)

F-Thermostat

FM

Fan motor

(OR)

(W)

Defrost

thermo.

Thermo.

fuse

Defrost

heater

(BK)

Figure W-1. Wiring Diagram(SJ-44L-WH1,SJ-48L-WH1)

Defrost timer

(BR)

(R)

TM

(Y)

Starting relay

Protector

Compress

C

M

A

(GY)

Source

Plug

Lamp

L

E

(BL)

(SB)

Door switch

F-Thermostat

FM

Fan motor

(OR)

(W)

Defrost

thermo.

Thermo.

fuse

Defrost

heater

(BK)

Figure W-2. Wiring Diagram(SJ-44L-WH2,SJ-48L-WH2)

9

TM

(Y)

Starting relay

Protector

Compress

C

M

A

Page 10

SJ-44L

R

or

SJ-48L

E.V. cover ass'y

Fan motor

F-thermostat

Def thermo. ass'y

Fuse ass'y

Def. heater ass'y

Door switch

lamp box ass'y

Lamp 15W

Lead EV-cover ass'y

FM

2 (PUSH OPEN)

1 (NEUTRAL)

3 (PUSH CLOSE)

4 (PUSH OPEN)

L

1

2

3

4

Lamp socket

Terminal box

Defrost timer

TM

1

5

2

6

3

7

4

8

121

121

2

1

5

2

6

3

7

4

8

2

1

2

3

4

BL-2

SB-1

BR-2

GY-1

OR-1

R-1

BR-1

Y-1

BL-1

BK-1

W-1

(W-1)

Y-2

(OR-1)

(SB-1)

1

2

3

4

(Y-1)

(Y-2)

(BK-1)

(R-1)

GY-2

Cabinet ass'y

BROWN

BLUE

GRAY

EARTH

GY

: GRAY

BR

: BROWN (live)

OR

: ORANGE

Y

: YELLOW

R

: RED

P

: PINK

BL

: BLUE (neutral)

BK

: BLACK

SB

: SKY-BLUE

G-Y

: GREEN-YELLOW (earth)

W

: WHITE

Source cord

Protector

Starting

relay

Compress

C

M

A

Figure W-3. Electric Accessories Layout (SJ-44L-WH1,SJ-48L-WH1)

10

Page 11

SJ-44L

Cabinet ass’y

E.V. cover ass’y

Lead EV-cover ass’y

Fan motor

F-thermostat

Def thermo. ass’y

Fuse ass’y

FM

Def. heater ass’y

Door switch

2 (PUSH OPEN)

3 (PUSH CLOSE)

4 (PUSH OPEN)

1 (NEUTRAL)

1

2

121

2

121

2

3

4

1

2

3

4

1

2

3

4

1

L

E

N

1

5

2

6

3

7

4

8

1

5

2

6

3

7

4

8

GY-1

OR-1

R-1

BR-1

Y-1

W-1

BL-1

BL-2

BR-2

SB-1

(SB-1)

BK-1

(W-1)

Y-2

(OR-1)

R lamp box ass’y

Lamp 15W

Lamp socket

L

Terminal box

TM

Defrost timer

(Y-1)

(Y-2)

(R-1)

(BK-1)

GY-2

Terminal block

Protector

Compressor

C

M

A

Starting

relay

Source cord

BROWN

BLUE

GRAY

EARTH

GY

BR

OR

Y

R

P

BL

BK

SB

G-Y

W

: GRAY

: BROWN (live)

: ORANGE

: YELLOW

: RED

: PINK

: BLUE (neutral)

: BLACK

: SKY-BLUE

: GREEN-YELLOW (earth)

: WHITE

SJ-48L

Figure W-4. Electric Accessories Layout (SJ-44L-WH2,SJ-48L-WH2)

11

Page 12

SJ-44L

).

SJ-48L

1. ADJUSTABLE TEMPERATURE CONTROL

(1) Temperature control of freezer

Thermostat (senses freezer temperature) operates on ON/OFF switchover to control the compressor and

cool air circulating fan , and allows the freezer temperature to keep at a suitable temperature.

However adjust the freezer temp. control knob as follows depending upon the storing condition of foods.

FUNCTIONS

KNOB

SETTING

MAX

MED

MIN

Figure F-1.

(2) Temperature control of refrigerator

Damper-thermostat senses temperature of the refrigerator and changes the opening angle of the damper

automatically.

However, as the Damper-thermostat has no function to switch on or off the compressor and fan motor, the

freezer temperature control causes temperature in the refrigerator to vary to some extent.

However, adjust the refrigerator temp. control knob as follows depending upon the cooling condition.

KNOB

SETTING

Coldest

MED

MIN

Figure F-2.

(Coldest)

PURPOSE

For making ice rapidly or fast freezing.

When restocking with fresh food.

For normal freezing.

For storing frozen food for a short period (up to one month

When frozen food or ice cream is not stored.

PURPOSE

For keeping freshness of food longer.

When the refrigerator does not provide sufficient cooling.

For normal operation.

When the refrigerator provides excessive cooling.

NOTE: The refrigerator temperature is affected also by the freezer temperature. If the freezer temp.

control knob is set at the position "MAX", the temperature tends to be lower than the following

values, and if set at near the position "MIN", temperature tends to be higher.

If the refrigerator is operated for a long time with the freezer temperature control sets the "MAX"

position, foods stored in the refrigerator compartment may also freeze.

When refrigerator temperature control sets to the "Coldest", some foods stored may freeze.

In this case adjust control set back to the "MED" position.

When refrigerator temperature control sets to the "Coldest", some foods stored in Fresh case may

also become frozen.

(3) Reference value of temperature

SETTING OF

FREEZER TEMP.

CONTROL KNOB

Freezer

temperature

MAX

(Coldest)

Approx.

-21˚C

MED MIN

Approx.

-18˚C

Approx.

-15˚C

SETTING OF

REFRIGERATOR TEMP.

CONTROL KNOB

Refrigerator

temperature

Fresh case

temperature

Coldest MED MIN

Approx.

0˚c

Approx.

-3˚c

Approx.

3˚c

Approx.

1˚c

Approx.

6˚c

Approx.

4˚c

The values shown above refer to the case where the

freezer temp. control knob is set at "MED".

The values shown above refer to the measurement carried out center area and 1/3 of overall height from the bottom

at each of the refrigerator and the freezer after machine has been operated at an ambient temperature of 30˚C with no

food stored and the door closed until the temperature is stabilized.

The values vary depending upon frequency of opening and closing the door, ambient temperature, amount of stored

foods and manner of storing foods.

12

Page 13

2. DEFROSTING

s

s

t

d

.

.

s

f-

(1) No defrosting operation is necessary

No defrosting operation is necessary.

As this machine is so designed that a built-in

evaporator cools air and a fan circulates cooled

air, neither the freezer nor the refrigerator is

frosted, though the evaporator is frosted.

(2) Where is melted frost brought

1. Melted frost is brought into the evaporating

pan at the back of the set and is evaporated

here by the heat of compressor.

2. Be sure to use Evaporating pan as inserted

so as to be level with the outer case.

The frosted evaporator is defrosted automatically

due to the function of defrosting timer and heater,

requiring no defrosting operation.

(3) The following circuit diagrams in the table show automatic defrosting function of the refrigerator with

timer and defrost thermostat.

Operation Electric diagram Description

1. Cooling

(Normal)

Defrost thermostat ON Compressor running

Timer motor running

Thermostat

Timer contact

The integration timer integrates running

time of the compressor. When it reache

cycle time of defrost timer, the timer

contact is changed to start defrosting.

Thermo. fuse

Defrost heater

TM COMP

SJ-44L

SJ-48L

2. Defrosting

(Time 20 to 30 min.)

3. Drain

(Time approx. 5 min.)

SOURCE

Defrost

thermostat (ON)

Figure F-3.

Defrost thermostat ON Compressor stops

Timer motor stops

Thermostat Timer contact

Thermo. fuse

TM COMP

SOURCE

Defrost heater

Defrost

thermostat (ON)

Figure F-4 .

Defrost thermostat OFF Compressor stops

Timer motor running

Thermostat Timer contact

Thermo. fuse

TM COMP

SOURCE

Defrost heater

Defrost

thermostat (OFF)

Timer motor

Timer motor

Timer motor

Compressor

Compressor

Compressor

The timer contact is changed to star

defrosting, the timer motor stops, an

power is supplied to the defrost heater

It takes about 20 to 30 min. to defrost

When little frosted, the defrosting take

little time. When much frosted, the de

rosting takes much time.

When the defrost thermostat become

OFF, the timer motor starts running.

During the operation time (delay time

of defrost time)

defrosted water is

drained outside the refrigerator.

4. Restart

(Time approx. 5 min.)

Figure F-5.

Defrost thermostat OFF Compressor running

Timer motor stops

Thermostat Timer contact

Thermo. fuse

TM COMP

SOURCE

Defrost heater

Defrost

thermostat (OFF)

Figure F-6.

13

Timer motor

Compressor

Timer contact is changed to cooling

operation and the compressor starts

running and the timer motor stops.

Defrost thermostat contact becomes ON

when it’s cooled. And the timer motor

starts running. (Figure F-3.)

Page 14

SJ-44L

H

SJ-48L

(4) As a reference to determine the causes of trouble, malfunction and phenomena are described below.

Refer to the following when repairing.

1. Disconnection of defrost heater

As off-cycle defrosting is performed, the defrosting time is extremely prolonged. Each time defrosting is

started, the freezer temperature rises and a portion of ice and stored foods are melted.

2. Melted thermo. fuse or opened-circuit due to the defect of defrost thermostat.

When the above mentioned trouble occurs in cooling operation, the timer motor does not run, defrosting

will not take place, and consequently freezing is caused. In the above mentioned condition, when the timer

shaft is turned by hand to defrost, the timer motor runs during the operation time. However, the motor stops

from the time when the contact is changed, and freezing causes.

NOTE:

As the thermo. fuse assembly is intended to prevent dangers, do not use it under shorted condition even

for a short period.

3. DEW PREVENTION

The hot pipe, namely D.P.-condenser, is arranged around the flange part of

cabinet and the C-partition plate, preventing dew from being generated on

the cabinet.

NOTE:

D.P.-condenser pipe may be felt hot if touched by hand while the

compressor is in operation.

If you are asked about this, please explain that the hot pipe serve to

ot pipe

prevent the dew generation.

4. INSPECTION OF INITIAL STARTING

(1) Inspection of cooling unit

1. Set the temperature control knob to "MAX" and check that the compressor starts to operate.

2. Depress the door switch to run the fan and check that cool air is blown out of the cold air outlet of the

freezer and the refrigerator.

3. When the compressor does not work, check that the timer is not set to "defrost" position.

4 It takes about an hour and a half or two hours to put food in the refrigerator after starting operation.

NOTE:

After return the temperature control knob to "MED" position.

When the refrigerator is operated initially after installed, the compressor may vibrate excessively for 1 to 2

min. However, vibration becomes normal if it is continuously operated.

(2) Inspection of defrost device

Operate the refrigerator for 20 to 30 min. and then check the defrost device in the following procedures :

Allow 5 min. to restart the compressor since immediate starting after stopping will cause unsmooth operation.

1. Turn the timer shaft clockwise with a screw driver.

At this time, make certains the timer clinks and the compressor stops.

2. After more than 5 min., turn the shaft further to operate.

Make certain cooling operation is started again.

Figure F-7

14

Page 15

ASSEMBLING PROCEDURES OF MAIN PARTS AND CAUTIONS

er

R

CAUTION: DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE ANY REPAIRING.

SJ-44L

SJ-48L

1. R-AIR GUIDER ASSEMBLY

A-sealer ag1

air guider S

(1) Forming sensor of Damper thermo.

R air guider

Figure A-1

Damper thermo.

Thermo. cap. seal

A-sealer ag3

A-sealer ag2

Dial sealer

Damper

thermostat

mm

1

++

5

mm

1

8

After forming, fix it to the refrigerator.

Less than 12 mm

(2) Setting R air guider S and sticking sealers to R air guider.

R air guider S

Masking tape

R air guider

Less than 160 mm

+

10 2 mm

NOTE

Minimum bending radius is R5mm.

There should be no gas leak by reforming of sensor tube.

Stick thermo.

cap. sealer

Figure A-2

R air guider

DATUM

OVERLAP 8mm

OVERLAP AREA

OVERLAP 15mm

DATUM

A-sealer ag1A-sealer ag1

OVERLAP 15mm

DATUM

A-sealer ag1

A-sealer ag1

A-sealer ag2A-sealer ag2

Dial sealer

A-sealer ag3

Figure A-3

15

Page 16

SJ-44L

F

B

Fan motor holder A

U-sealer handle

U-sealer handle

7 2mm

+

+

0 1mm

C

C

SEC. C-C

SJ-48L

2. FAN LOUVER AND E.V COVER ASSEMBLY

2-1. How to remove the Fan louver

(1) Take out 2 screws.

(2) Insert the screwdriver into the air hole of the Fan

louver.

(3) Press the Fan louver to the left side with the

screwdriver,and pull it toward yourself to take off the

Fan louver.

2-2. E.v cover assembly

E.v cover sealer C

Defrost thermo.

ass’y

E.v cover

L-band C

Propeller fan

100

Fan clamp

E.v cover

sealer G

Fan motor

holder A

Fan louver

Claw

(1)

Screw

Motor cushion

U-sealer

handle

Lead EV-cover

ass’y

Claw

(3)

(2)

Figure A-4

Fan motor holder

Fan motor

Claw

(1)

Screw

Claw

-thermostat

E.v cover sealer D

(1) Sticking of Sealers to E.V cover

E.v cover sealer A

E.v cover sealer C

STICK START

E.v cover

E.v cover sealer E

E.v cover

sealer C

Fuse ass’y

Figure A-5

E.v cover

sealer A

E.v cover

sealer B

(2) Fixing of Fan motor and Fan

L-band C

(2)-1 Stick U-sealer handle to Fan motor holder A.

E.v cover sealer B

STICK START

STICK START

Figure A-6

E.v cover sealer G

[back side]

Figure A-7

16

Page 17

SJ-44L

Fan clamp

Propeller

fan 100

Fan clamp

Slit

Slit of each Fan clamp

and Propeller fan

should not be at same position.

Shaft

4 0.5mm

+

Detail of D

D

Note

Propeller fan should not be

taken out from shaft when

pulled by 3 kgf.

SJ-48L

(2)-2 Insert the terminals of Lead EV-cover ass'y to

Fan motor.

(2)-4 Set Fan clamp to Propeller fan 100 and insert

it to the shaft of Fan motor.

(2)-3 Fix two Motor cushions to Fan motor, and set it

at Fan motor holder A and B.

Then fix with Tapping screw.

Fan motor

holder B

Motor cushion

Fan motor

holder A

Tapping

screw

Fan motor

Lead EV-cover ass’y

BROWN

RED

Figure A-8

(3) Setting of Fan motor ass'y , Defrost thermo. ass'y and Fuse ass'y.

Figure A-9

Lead e.v cover

ass’y

E.v cover sealer C

Take out lead wire

from square hole to

front and fix with

L-band C, then seal

with E.v cover sealer C

Aluminum tape

Turn up lead wire

Detail of G

ATTENTION

E.v cover

L-band C

Fuse ass’y

Tapping screw

Tapping screw

Set metal side below

H

H

[back side]

Fuse ass’y

E.v cover

sealer E

SEC. H H

Aluminum tape

L-band C

F

F

Defrost thermo.

ass’y

G

Aluminum tape

Aluminum tape

more than 3.5mm more than 3.5mm

[front side]

CUT

Defrost thermo.

ass’y

L-band C

Not come out of claw.

SEC. F F

+

10 5mm

E.v cover sealer E

[Front side]

Figure A-10

17

Page 18

SJ-44L

F-thermostat

SEC. B B

B

B

E.v cover sealer D

SJ-48L

(4) Inserting of pins

Fan motor 1 , 5

WIRE COLOR FOR FAN MOTOR

100-110V : WHITE

127V : YELLOW

220-240V : BLUE

1234

5678

F-thermostat 6

(BROWN, inserted)

Note Pins should be inserted surely,

and check by pulling it.

Figure A-11

(5) Setting of F-thermostat

(5)-1 Form capillary tube of F-thermostat.

F-thermostat 2

(RED, inserted)

Defrost thermo. 3 (PINK)

Fuse 8 (WHITE)

Fuse 8 (BLACK)

Defrost thermo. 7 (BLUE)

(5)-3 Set to E.V cover.

After inserting, fix with vinyl tape.

Vinyl tape

Figure A-12

Stick E.v cover sealer D.

21mm

R10mm

R10mm

Note

• Bending radius of

capillary tube should be

8.5mm

50mm

from R5mm to R10mm.

Figure A-13

(5)-2 Insert terminal of Lead EV-cover ass'y.

RED

(front side)

BROWN

(back side)

Figure A-15

Figure A-14

18

Page 19

SJ-44L

Screw

Drain support al

Drain support al

Heater cover

Protrusion parts

Protrusion part of Drain support al(2 pcs.)

Heater cover

Def. heater ass’y

Fixed parts

Drain support al

Def.heater ass’y

SJ-48L

3. DEFROST HEATER

(1) Taking-out Evaporator

(1)-1. Take out E.v cover ass'y (Fig. A-16).

Evaporator

Food liner convex part

Fig. A-16

(1)-2. As shown in Fig. A-17, pull the upper part of

Evaporator toward you, pull it diagonally so that

the pipe of Evaporator does not contact the convex

part of food liner.

Food liner convex part

(2) Replacement of Def. heater ass'y.

(2)-1 Remove the center screw of Drain support al

to take it off from the food liner.

Fig. A-19

(2)-2 Raise the protrusion part of Drain support al.

Then remove Heater cover.

(1)-3. As shown in Fig. A-18, bend the removed

Evaporator

Pipe

Fig. A-17

Evaporator horizontally so that Defrost heater can

be replaced easily.

NOTE: When pulling Evaporator and bending the

pipes, pay attention so as not to break and

deform the pipes. Still, take care not to hurt

yourself by fin of Evaporator.

Evaporator

Fig. A-20

(2)-3 Open Def.heater fixed part of Drain support al to

the right and left, then remove Def.heater ass'y.

Fig. A-18

Fig. A-21

19

Page 20

SJ-44L

Glass cloth tape

Glass cloth tape

Glass cloth tape

Glass cloth tape

aluminum tape

(more than 2 turns)

[back side]

[bottom side]

A

A

Sec. AA

(W25 X L40)

top edge

Drain support al

Heater cover

Heater cover

Def.heater ass’y

Def.heater ass’y

c

d

Sec. BB

B

B

Drain support al

Heater cover

Def.heater ass’y

190 20

+

Leading wire sealer

SJ-48L

(2)-4. Replace Def. heater ass'y with new one. (2)-7. Stick the longer wire to the Drain support by

aluminum tape (2 pieces), and wind vinyl tape

(2 pieces) to lead wires of Def. heater ass'y by

Heater cover

aluminum tape as shownin Fig. A-25.

Note: Glass cloth tape part shall be both side of Drain

support to protect the lead wire from damaged.

Def.heater ass’y

Drain support al

Fig. A-22

(2)-5. Wind the Glass cloth tape (3M: No. 27) to lead wire

of Def. heater ass'y. (2 places)

Def. heater ass’y

(40)50

+

360

+

5

5

(40)

Glass cloth tape

(W40 x L25)

Lead wire

Glass cloth tape

Wind the Glass cloth tape

more than 2 turns.

Fig. A-23

(2)-6. Bend a and b of Drain support al to right angle

(90˚) to set Def. heater ass'y. (Fig. A-24)

This side is longer wire

Fig. A-25

(2)-8. Set Heater cover on Drain support, and bend top

edge c and d to outside as shown in Fig. A-26.

Fig. A-26

(2)-9. Wind up Leading wire sealer as shown in Fig. A-27

a

Drain support al

Def.heater ass’y

Fig. A-24

This side is shorter wire

b

20

Fig. A-27

(2)-10

. Set the assembly above on the food liner by fixing

a screw.

Page 21

er

(3) Installing of Evaporator

(3)-1. Install Evaporator as shown in Fig. A-16 in the

reverse order of Fig. A-17.

(3)-2. Correct the deformed fin.

NOTE

1. When installing Evaporator, take care not to

deform significantly and break the pipes.

2. Take care not to damage the lead wires and hurt

yourself by the fin of Evaporator.

COOLING UNIT

SJ-44L

SJ-48L

Mark: Refrigerant flow

Mark: Brazing portion

Hot pipe L

(Side condenser)

Hot pipe

(DP-condenser)

Hot pipe R

(Side condenser)

Evaporator

Suction pipe

Eva-pan pipe

Back condens

Compressor

Figure C-1. Cooling unit

21

Capillary tube

Dryer

Page 22

SJ-44L

e

F

t

e

E

e

F

t

SJ-48L

vaporator

Suction pipe

rom Back condenser out

o Hot pipe

Capillary tube

Charge pipe

S.P. connector

Figure C-2. Location

From Eva-pan pipe ass'y

to Back condenser In

From Compressor

to Discharge p connector

Dryer

Compressor

Charge pipe

Eva-pan pipe

Hot pip

Back condenser

From Suction pipe

to SP connector

From Hot pipe

to Dryer

From Dryer

to Capillary tub

From Compressor

to Charge pipe

From SP connector

to Compressor

From Discharge p connector

to Eva-pan pipe ass'y

Figure C-3. Location (SJ-44L-WH1,SJ-48L-WH1)

From Eva-pan pipe ass’y

to Back condenser In

rom Back condenser out

o Hot pipe

From Compressor

to Discharge p connector

From Suction pipe

to SP connector

From Hot pipe

to Dryer

From Dryer

to Capillary tub

From SP connector

to Compressor

From Compressor

to Charge pipe

From Discharge p connector

to Eva-pan pipe ass’y

Figure C-4. Location (SJ-44L-WH2,SJ-48L-WH2)

22

Page 23

SJ-44L

SJ-48L

REPLACEMENT PARTS LIST(SJ-44L/48L-WH1/WH2)

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-44L SJ-44L SJ-48L SJ-48L

-WH1 -WH2 -WH1 -WH2

ELECTRIC PARTS

1-1 RTHM-A103CBZZ F-themostat 1 1 1 1 AV

1-2 RSTT-A134CBE0 Starting relay - 1 - 1 AS

1-2 RSTT-A137CBE0 Starting relay 1 - 1 - AL

1-3 QSWTDA025CBE0 Defrost timer 1 - 1 - AW

1-3 QSWTDA047CBZZ Defrost timer - 1 - 1 AZ

1-4 PDMP-A050CBEZ Damper thermo 1 1 1 1 AW

1-5 FTHM-A039CBKZ Defrost thermo.ass'y 1 1 1 1 AM

1-6 RMOTRA046CBE0 Fan motor - 1 - 1 AZ

1-6 RMOTRA071CBZZ Fan motor 1 - 1 - AY

1-7 QSOCAA084CBEZ Lamp socket 1 1 1 1 AL

1-8 RLMP-A029CBEZ Lamp15w - 1 - 1 AH

1-8 RLMP-A030CBEZ Lamp15w 1 - 1 - AH

1-9 QACC-A114CBE0 Source cord - 1 - 1 AW

1-9 QACC-A134CBE0 Source cord 1 - 1 - AP

1-10 QSW-PA090CBZA Door switch 1 1 1 1 AS

1-11 RHOG-A150CBEZ Protector 1 - 1 - AN

1-11 RHOG-A161CBZZ Protector - 1 - 1 AX

1-17 FFS-TA061CBKZ Fuse ass'y 1 1 1 1 AM

1-20 FW-VZA146CBEZ Lead ev-cover ass'y - 1 - 1 AL

1-20 FW-VZA148CBEZ Lead ev-cover ass'y 1 - 1 - AL

1-21 FHETBA161CBEZ Def.heater ass'y - 1 - 1 AY

1-21 FHETBA164CBEZ Def.heater ass'y 1 - 1 - AX

1-22 FCNW-A691CBKZ Relay cord s ass'y 1 - 1 - AN

1-22 FCNW-A732CBKZ Relay wire ass'y - 1 - 1 AN

1-33 QCNW-A886CBE0 Olr cord - 1 - 1 AE

MECHANICAL PARTS

2-2 JKNB-A036CBFC F-temp. control knob 1 1 1 1 AC

2-4 LANG-A059CBPZ Eva holder 47 2 2 2 2 AC

2-7 FLEGPA083CBKZ Leg holder l ass'y 1 1 1 1 AF

2-7-1 FAJS-A015CBKZ Adjustable leg ass'y 2 2 2 2 AE

2-7-2 LHLD-A533CBPZ Leg holder l 1 1 1 1 AL

2-8 FLEGPA084CBKZ Leg holder r ass'y 1 1 1 1 AF

2-8-2 LHLD-A534CBPZ Leg holder r 1 1 1 1 AP

2-13 DHNG-A417CBMZ Upper hinge ass'y 1 1 1 1 AE

2-14 DHNG-A419CBMZ Bottom hinge r ass'y 1 1 1 1 AD

2-15 DHNG-A418CBMZ Center hinge r ass'y 1 1 1 1 AE

2-16 GCOV-A210CBFZ E.v cover 1 1 1 1 AR

2-17 LCRA-A010CBE0 Fan clamp 1 1 1 1 AD

2-19 LHLD-A389CBF0 Motor cushion 2 2 2 2 AF

2-20 NFANPA011CBF0 Propeller fan 100 1 1 1 1 AD

2-21 PSEL-C067CBEZ E.v cover sealer a 1 1 1 1 AA

2-22 PSEL-C068CBEZ E.v cover sealer b 1 1 1 1 AA

2-23 PSEL-C066CBEZ E.v cover sealer c 1 1 1 1 AC

2-24 PCOVPA308CBFA Terminal cover 1 1 1 1 AE

2-26 PCOV-A277CBFA R lamp cover 1 1 1 1 AE

2-27 GCOVPA142CBRA R-c box cover 1 1 1 1 AQ

2-28 HGRL-A206CBRA Fan louver 1 1 1 1 AS

2-29 GCOV-A209CBFC Upper hinge cover 1 1 1 1 AC

2-31 JKNB-A033CBFC R-temp.control knob 1 1 1 1 AC

2-32 JKNB-A063CBFA V-tray control knob 1 1 1 1 AC

2-36 PCAP-A006CBFW Screw cover 2 2 2 2 AB

2-38 PGID-A161CBFZ R-air guider 1 1 1 1 AG

2-39 PGID-A162CBFZ R-air guider s 1 1 1 1 AC

2-41 PSEL-B848CBEZ A-sealer thermo.cap 1 1 1 1 AC

2-44 HGRL-A203CBRA F deodo.louver 1 1 1 1 AF

2-45 HGRL-A204CBFA R deodo.louver 1 1 1 1 AE

2-46 PFIL-A047CBEZ Deodorizer 2 2 2 2 AC

2-49 LSTPPA108CBFA Chilled stopper 2 2 2 2 AC

2-50 LSTPPA118CBFA Case stopper v 2 2 2 2 AC

2-55 HGRL-A205CBFA Multi louver l - - 1 1 AM

2-55 HGRL-A209CBFA Multi louver s 1 1 - - AM

2-56 PFPFPB334CBFZ R-louver insu.l - - 1 1 AE

2-56 PFPFPB345CBFZ R-louver insu.s 1 1 - - AE

2-57 PSEL-C085CBEZ A-sealer r-louver - - 2 2 AC

2-57 PSEL-C095CBEZ A-sealer r-louver 2 2 - - AB

2-63 LHLD-A484CBFA Fan motor holder b 1 1 1 1 AH

2-64 LHLD-A485CBFA Fan motor holder a 1 1 1 1 AH

2-65 PSEL-B209CBE0 U-sealer handle 2 2 2 2 AB

2-66 PSHEMA225CBPZ Heater cover 1 1 1 1 AC

2-67 LPLTMA633CBPZ Drain support al 1 1 1 1 AF

2-68 PSEL-A415CBE0 E.v cover sealer c 1 1 1 1 AC

2-69 PSEL-C069CBEZ E.v cover sealer d 1 1 1 1 AA

23

Page 24

SJ-44L

SJ-48L

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-44L SJ-44L SJ-48L SJ-48L

-WH1 -WH2 -WH1 -WH2

2-70 PSEL-C135CBEZ E.v cover sealer e 1 1 1 1 AC

2-71 PSEL-A552CBE0 Dial sealer 1 1 1 1 AC

2-72 PSEL-C078CBEZ A-sealer ag1 2 2 2 2 AC

2-73 PSEL-C079CBEZ A-sealer ag2 1 1 1 1 AB

2-77 LHLD-A359CBFA T-box holder 1 - 1 - AE

2-78 LPLTMA399CBP0 Dryer support 1 1 1 1 AD

2-79 LBND-A019CBE0 Nylon band 1 1 1 1 AB

2-80 PBOX-A132CBFA Terminal box 1 1 1 1 AF

2-83 PSEL-C080CBEZ A-sealer ag3 1 1 1 1 AA

2-84 PSEL-C081CBEZ A-sealer ag4 2 2 2 2 AA

2-87 LBND-A018CBE0 Fastening band a 1 1 1 1 AP

2-91 HGRL-A202CBFA F return cover 1 1 1 1 AF

2-93 PCAP-A068CBFA C sliding cap a 4 4 4 4 AC

2-98 LHLD-A391CBE0 Sl-5n clip 1 1 1 1 AD

2-99 PSEL-A562CBE0 Leading wire sealer 1 1 1 1 AC

2-100 PSEL-C138CBEZ E.v cover sealer g 1 1 1 1 AA

2-101 PSEL-C139CBEZ Ev-insulation 47 2 2 2 2 AC

DOOR PARTS

3-5 FDORFB519CBKZ F-door s ass'y 1 1 1 1 BL

3-5-1 LSTPPA082CBFA Fd-stopper spring r 1 1 1 1 AD

3-5-2 NBRGPA013CBFB Nylon bearing 2 1 1 1 1 AH

3-5-3 LSTPMA008CBM0 F-door stopper r 1 1 1 1 AD

3-5-4 GDAI-A059CBMZ Badge base 1 1 1 1 AK

3-5-5 HBDGDA922CBEA Badge 1 1 1 1 AP

3-6 FPACGA346CBKZ F-door packing 1 1 1 1 AT

3-8 FHNDPA064CBKZ Door handle fl ass'y 1 1 1 1 AU

3-10 LPLTPA286CBFC Handle base fl 1 1 1 1 AK

3-15 FDORRB328CBKZ R-door ass'y - - 1 1 BR

3-15 FDORRB332CBKZ R-door ass'y 1 1 - - BS

3-15-1 LSTPPA084CBFA Rd-stopper spring r 1 1 1 1 AD

3-15-2 NBRGPA022CBFA Nylon bearing 3s 1 1 1 1 AC

3-15-3 LSTP-A058CBM0 R-door stopper r 1 1 1 1 AF

3-17 FPACGA347CBKZ R-door packing - - 1 1 AV

3-17 FPACGA348CBKZ R-door packing 1 1 - - AV

3-19 FHNDPA072CBKZ Door handle rl ass'y 1 1 1 1 AU

3-21 LPLTPA287CBFC Handle base rl 1 1 1 1 AK

OTHER PARTS

4-1 LBND-A023CBE0 L-band c 4 4 4 4 AC

4-3 LX-VZA003CBE0 Special screw 2 2 2 2 AB

4-11 QTAN-A012CBE0 Solderless term. b 2 3 2 3 AH

4-12 QTAN-A013CBE0 Solderless term. a 1 - 1 - AH

4-15 LX-BZA018CBE0 Special screw 2 2 2 2 AA

4-17 LX-WZA003CBE0 Washer 4 4 4 4 AA

ATTACHMENT PARTS

5-1 UPOK-A180CBRA Bottle pocket 1 1 1 1 AR

5-2 UPOKPA268CBFA R door pocket s 2 2 2 2 AH

5-3 UPOK-A179CBRA Door pocket 3 3 3 3 AM

5-4 UPOK-A181CBRA R door pocket 1 1 1 1 AL

5-5 UTNA-A282CBFA Egg tray 1 1 1 1 AH

5-6 FSRA-A193CBYZ Ice cube maker 1 1 1 1 AS

5-9 USRA-A270CBFA Freezer tray 1 1 1 1 AT

5-13 HGRL-A201CBFC Ventilating grille 1 1 1 1 AM

5-14 USRA-A268CBFA Evaporating pan 1 1 1 1 AM

5-15 GGAD-A032CBFA V parting plate 1 1 1 1 AG

5-16 UYOK-A401CBFA Vegetable case 1 1 1 1 AX

5-17 UYOK-A399CBFA Ice storage box 1 1 1 1 AL

5-18 UYOK-A400CBFA Fresh case 1 1 1 1 AV

5-19 GDORPA072CBRA Fresh door hs 1 1 1 1 AN

5-24 USRA-A272CBFA Refrigerator tray 2 2 2 2 AU

5-25 USRA-A271CBFA Vegetable tray 1 1 1 1 AW

5-31 LRALPA136CBFA Ice tray holder l 1 1 1 1 AG

5-32 LRALPA137CBFA Ice tray holder r 1 1 1 1 AG

5-35 UPOKPA269CBFA Bottle stopper 1 1 1 1 AC

CYCLE PARTS

6-1 PCMPLA201CBEZ Compressor 1 - 1 - BX

6-1 PCMPLA215CBEZ Compressor - 1 - 1 BW

6-2 PSPAGA042CBE0 Rubber grommet - 4 - 4 AE

6-2 PSPAGA054CBEZ Rubber grommet 4 - 4 - AH

6-4 FFRM-A120CBKZ Base frame ass'y 1 1 1 1 AG

6-5 FDRY-A006CBK0 Dryer ass'y 1 1 1 1 AX

6-6 LHLD-A465CBE0 Cord clip 1 - 1 - AG

6-6 PCLI-A050CBE0 Clip - 1 - 1 AD

24

Page 25

SJ-44L

SJ-48L

REF. NO. PART NO. DESCRIPTION Q'TY CODE

SJ-44L SJ-44L SJ-48L SJ-48L

-WH1 -WH2 -WH1 -WH2

6-9 PSPAFA034CBE0 Sleeve - 4 - 4 AD

6-9 PSPAFA047CBEZ Sleeve 4 - 4 - AE

6-11 PPIPCA386CBEZ S.p connector - 1 - 1 AF

6-11 PPIPCA400CBEZ S.p connector 1 - 1 - AF

6-18 PPIPCA252CBE0 Charge pipe 2 2 2 2 AD

6-19 FPIPCA172CBKZ Discharge p. ass'y - 1 - 1 AM

6-19 PPIPCA399CBEZ Discharge p.conecter 1 - 1 - AG

6-21 PCOVPA246CBE0 Terminal cover - 1 - 1 AL

6-21 PCOVPA271CBEZ Terminal cover 1 - 1 - AH

6-24 PGUM-A004CBF0 Absorbent rubber a 1 2 1 2 AH

6-25 QTAN-A045CBE0 Terminal block - 1 - 1 AQ

6-26 FPIPCA162CBKZ Eva pan pipe s ass'y 1 1 1 1 AS

6-28 LANG-A058CBPZ Absorbent rubber clm 2 2 2 2 AC

6-29 PGUM-A003CBF0 Absorbent rubber b 2 2 2 2 AH

MISCELLANEOUS

90-1 TINS-A599CBRZ Operation manual 1 1 1 1 AE

90-2 TLAB-A876CBRZ Warning label - 1 - 1 AC

90-2 TLAB-A894CBRZ Warning label 1 - 1 - AC

90-3 SPAKCJ425YDEZ Packing case 48l - - 1 1 BB

90-3 SPAKCJ426YDEZ Packing case 44l 1 1 - - BB

90-5 TLAB-B163CBEZ Case label wh1 4 - 4 - AC

90-5 TLAB-B164CBEZ Case label wh2 - 4 - 4 AC

90-6 CPADBA799YDKZ Bottom pad ass'y 1 1 1 1 AV

90-7 CPADBA798YDKZ Top pad ass'y 1 1 1 1 AQ

90-8 SPADBC439YDEZ Corner post fl 1 1 1 1 AK

90-9 SPADBC440YDEZ Corner post fr 1 1 1 1 AK

90-10 SPADBC435YDEZ Corner post bl 1 1 1 1 AG

90-11 SPADBC436YDEZ Corner post br 1 1 1 1 AG

90-15 TLAB-B055CBEZ R-door pocket label - - 1 1 AC

90-21 TLAB-A939CBRZ Caution label rof 1 1 1 1 AD

HOW TO ORDER REPLACEMENT PARTS

To have your order filled promptly and correctly, please furnish the following information.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

25

Page 26

SJ-44L

A

B

C

D

E

F

G

H

-3

3

3

3

SJ-48L

123456

A

DOOR PARTS

3-6

3-5

3-10

B

-7

3-9

3-8

3-12

3-5-2

C

3-10

5-4

5-2

5

3-7

3-11

3-9

3-15

D

3-10

-7

3-9

E

-19

3-11

3-5-5

3-5-4

3-5-3

3-5-1

3-15-2

5-5

90-15

5-2

5-35

3-9

3-10

3-11

3-17

5-3

5-1

F

3-7

G

3-15-3

3-15-1

SJ-44L

H

SJ-48L

123456

26

Page 27

A

B

C

D

E

F

G

H

123456

5

CABINET PARTS

A

B

SJ-44L

SJ-48L

5-9

-31

5-6

C

5-17

2-93

5-32

5-18

2-36

2-29

2-13

2-91

D

5-24

2-93

2-49

4-3

1-10

2-15

2-36

2-49

5-19

E

5-25

F

5-15

2-32

2-14

2-8

2-93

5-16

G

2-93

5-13

2-7

2-7-2

2-7-1

2-8-2

2-7-1

H

SJ-44L

SJ-48L

123456

27

Page 28

SJ-44L

A

B

C

D

E

F

G

H

2

9

SJ-48L

A

123456

CABINET PARTS

2-19

2-16

1-5

4-1

2-23

2-17

2-100

2-64

2-19

2-20

1-6

2-65

4-1

2-63

1-20

2-68

1-17

2-50

1-7

1-8

2-46

2-84

2-39

2-31

2-28

2-2

2-72

2-27

1-1

2-70

2-69

1-4

2-41

2-83

2-73

2-71

2-38

B

2-44

C

D

2-46

-45

2-84

E

90-2

2-21

2-22

2-67

2-101

2-4

2-99

6-26

2-66

1-21

2-78

1-22

6-18

6-5

2-80

6-29

4-11(4-12)

2-79

1-3

2-77

2-87

6-28

1-9

2-24

(only for " -WH1")

2-98

6-24

5-14

F

G

H

123456

43JPT1/ 43JPT2 / 47JPT1/ 47JPT2

2-26

2-55

2-57

2-56

28

6-2

6-9

6-11

6-1

4-17

6-18

6-1

1-11

4-15

6-4

6-21

1-2

(for " -WH1")

1-11

1-2

(for " -WH2")

6-21

1-33

1-25

6-6

6-6

SJ-44L

SJ-48L

2003 SHARP CORP. (09i0.01E) Printed in Japan

Loading...

Loading...