Page 1

SERVICE MANUAL

CODE: 00ZSFS18SM//E

MODEL SF-S18

CONTENTS

[ 1 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

[ 2 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

[ 3 ] PARTS IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

[ 4 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

[ 5 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

[ 6 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

[ 7 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

[ 8 ] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

[ 9 ] ACTUAL WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

[10] CIRCUIT DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

PARTS GUIDE

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

[ 1 ] SPECIFICAT IO N S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

[ 2 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

[ 3 ] PARTS IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1. External fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Mechanism section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Sensors and switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4. Motors and PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

[ 4 ] O PERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1. Paper transport mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2. Bin up-down shift mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. Operation process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

[ 5 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1. External fitting removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2. Paper exit roller removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3. Spiral cam and tray removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4. Discharge brush removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5. Interface cable removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6. Control PWB removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7. Motor bracket removal (Transport motor & bin shift motor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8. Bin shift motor clock sensor and transport motor clock sensor removal . . . . . . . . . . . . . . . . . . . 18

9. Bin home sensor and upper/lower limit sensor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10. One rotation sensor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

11. Take-up position sensor and entry port sensor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

12. Paper empty sensor upper removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

13. Paper empty sensor lower removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

[ 6 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

1. Single unit test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2. Starting the single unit test mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3. Kinds of single unit test modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4. Description on each mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5. Setting of buzzer sound in the take-up mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

[ 7 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

[ 8 ] T ROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

[ 9 ] ACTUAL WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

[10] CIRCUIT DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1. Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Page 3

[1] SPECIFICA TIONS

(1) Type: Installation to a copier (hanging type)

(2) Distribution method: Bin shift by lead screws

(3) No. of bins: 10 bins (The top bin is used also for

non-sort.)

(4) Capacity of sheets: 30 sheets for each bin, (100 sheets for

the top bin)

When sorting A4 / 8-1/2 × 11″ 30 sheets

B4 / 8-1/2 × 14″ 20 sheets

A3 / 11 × 17″ 15 sheets

When grouping A4 / 8-1/2 × 11″ 20 sheets

B4 / 8-1/2 × 14″ 15 sheets

A3 / 11 × 17″ 15 sheets

(5) Paper size

Non-sort A3 ∼ A6 (Postcard) R / 11″ × 17″ ∼ 8-1/2″× 5-1/2″

Sort/group A3 ∼ A5 / 11″ × 17″ ∼ 8-1/2″× 11″

(6) Process capacity: 10 ∼ 30 sheets/min

(7) Paper transport: Center reference

(8) Paper collecting: Face up

(9) Paper weight

Non-sort 52 ∼ 128 g/m2 (14 ∼ 34 lbs)

Sort/group 56 ∼ 80 g/m2 (15 ∼ 21 lbs)

(10) Power source: Supplied from the copier body.

(11) External dimensions: 335 (W) × 493 (D) × 298 (H) mm

(12) Weight: About 7 kg

[2] UNP ACKING AND INSTALLATION

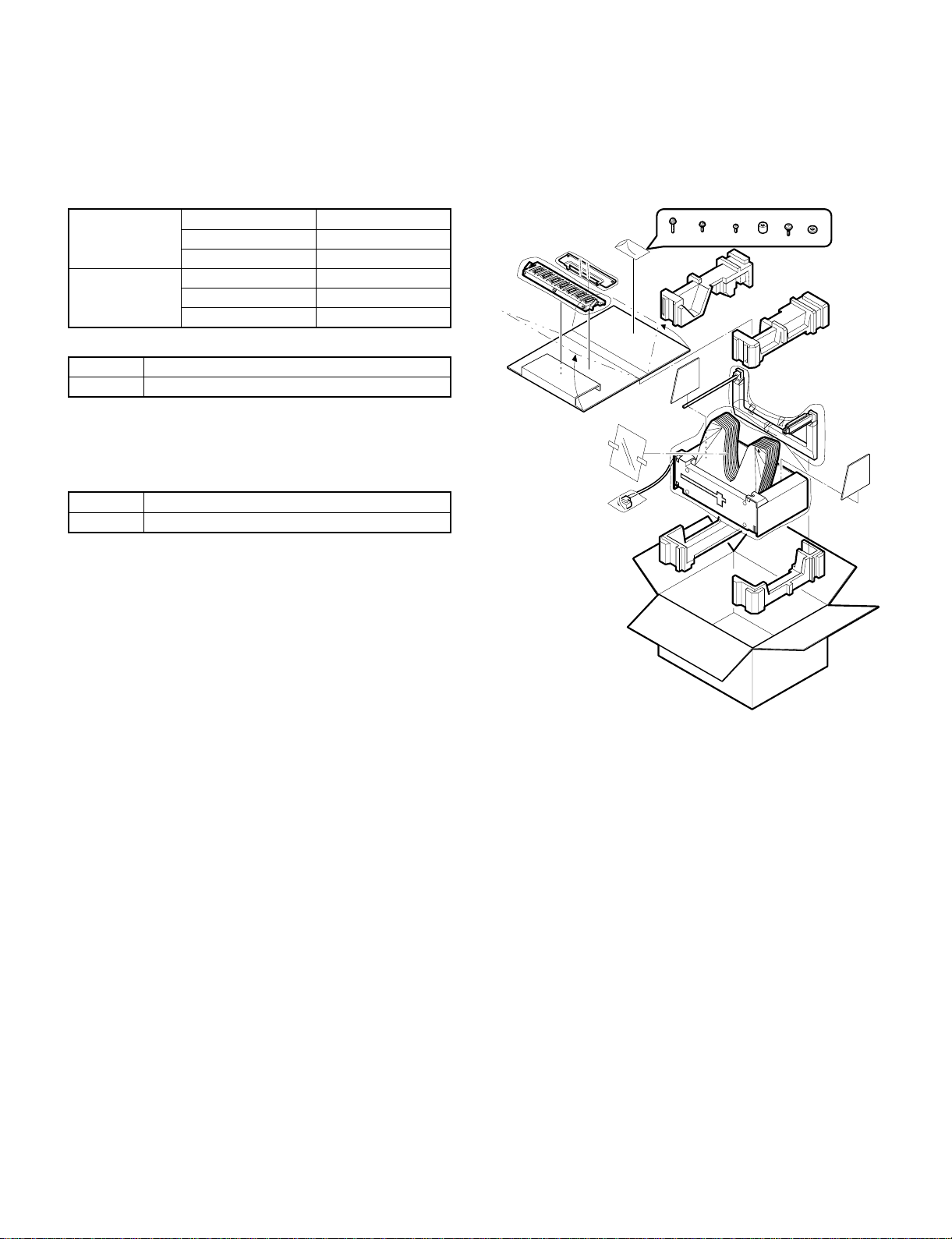

1. Unpacking

When unpacking, refer to the figure below.

– 1 –

Page 4

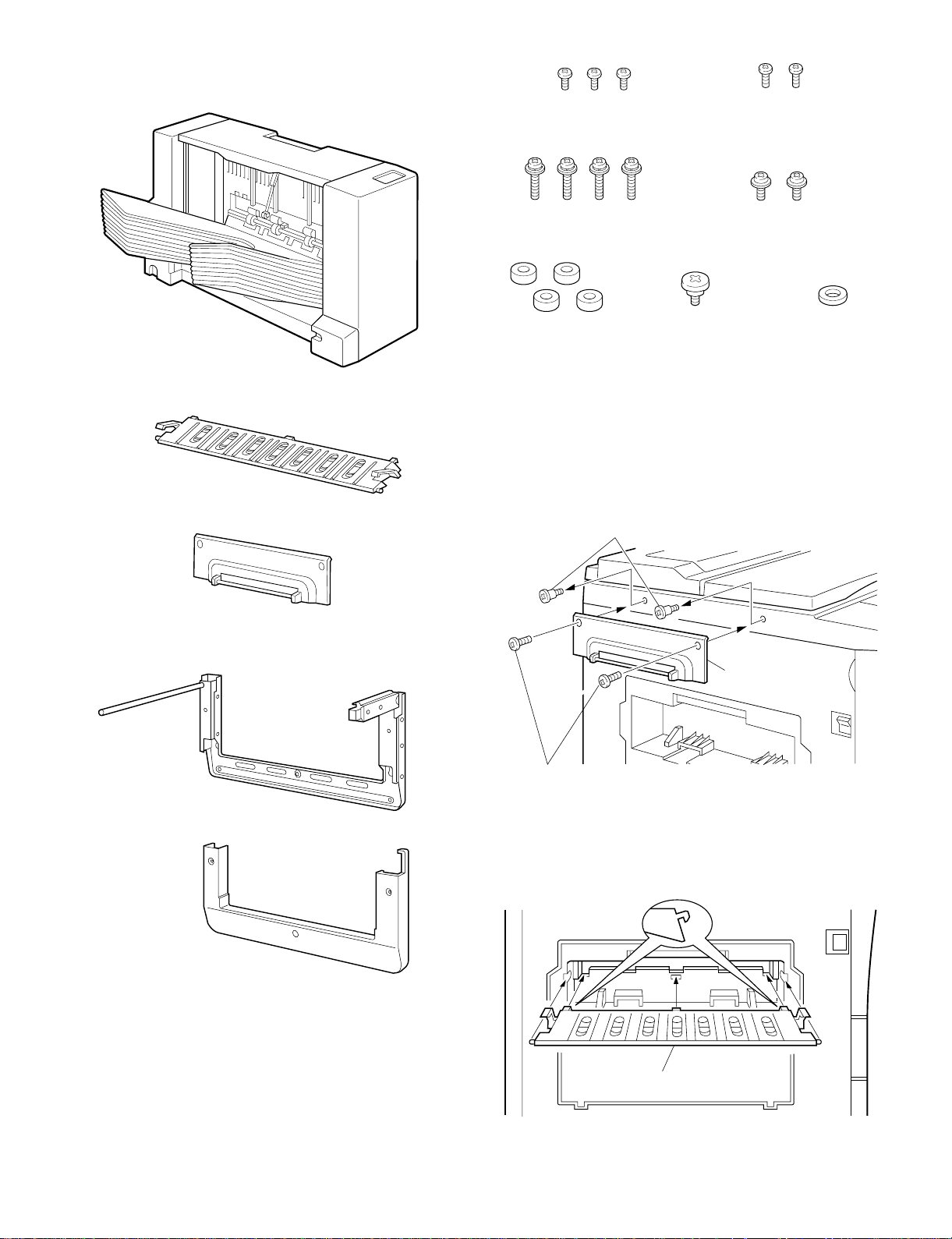

2. Installat ion

(5) SF-S18

Included parts

Support guide

(1 pc.)

Sorter seat cover securing screws

Sorter seat securing screws

(4 pcs.)

Spacers

(4 pcs.)

(3 pcs.)

Stopper screw

Lockplate screws (M4 x 8)

(2 pcs.)

Sorter securing screws (M4 x 8)

(2 pcs.)

Felt washer

(1 pc.)

(1 pc.)

Unplug the copier and follow the procedure below.

1. Mount the lock plate.

Remove the screws (2) from the upper side of the copier’s left cabinet

panel.

Mount the lock plate to the upper side of the copier’s left cabinet

panel and secure it with the M4 x 8 lockplate screws (2).

Upper left cabinet panel screws

Lock plate

(1 pc.)

Sorter seat

(1 pc.)

Sorter seat cover

(1 pc.)

Lock plate

Lock plate screws

2. Mount the support guide.

Hang the two hooks of the support guide on the exit area of the

copier to mount the support guide.

Hooks

– 2 –

Support guide

Page 5

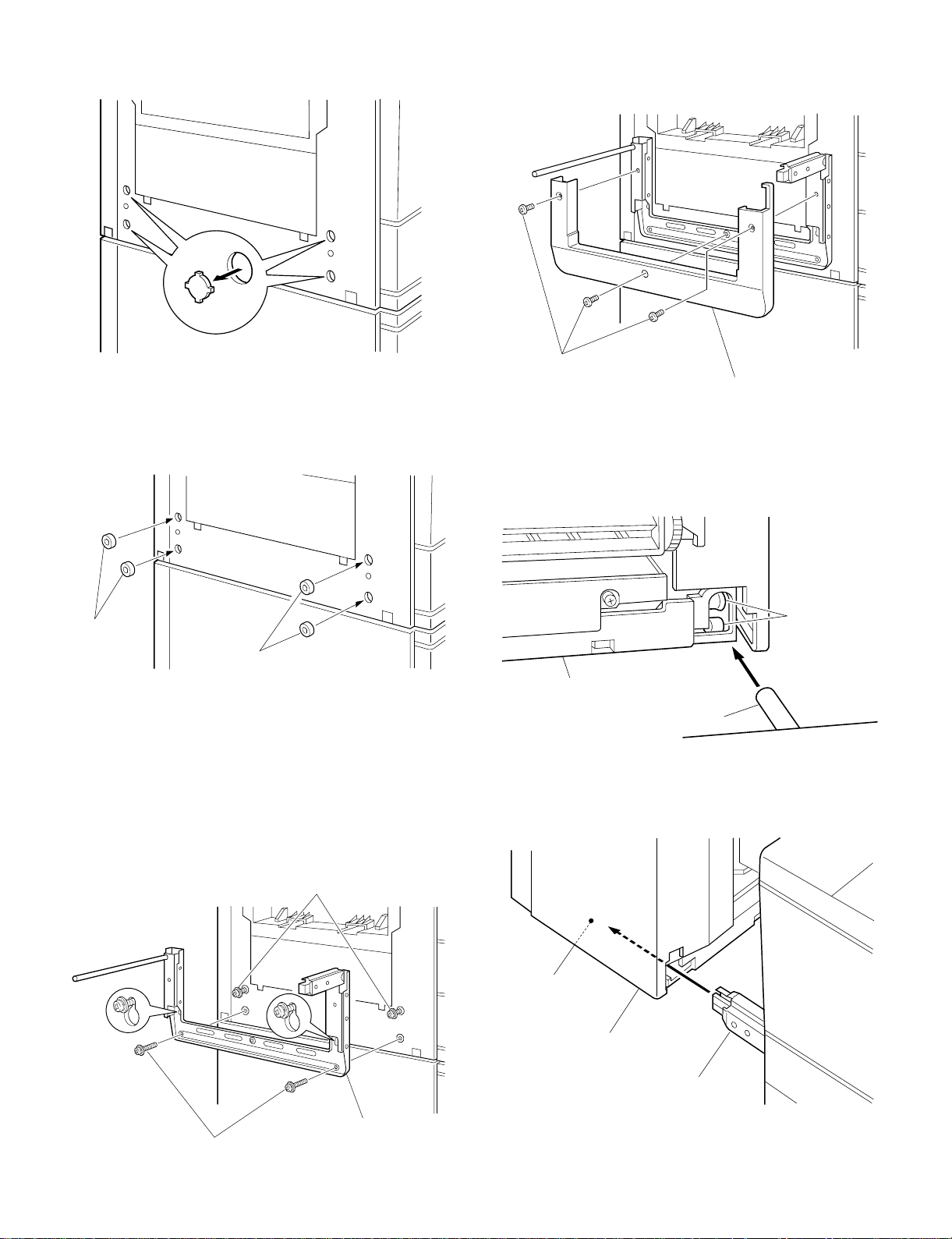

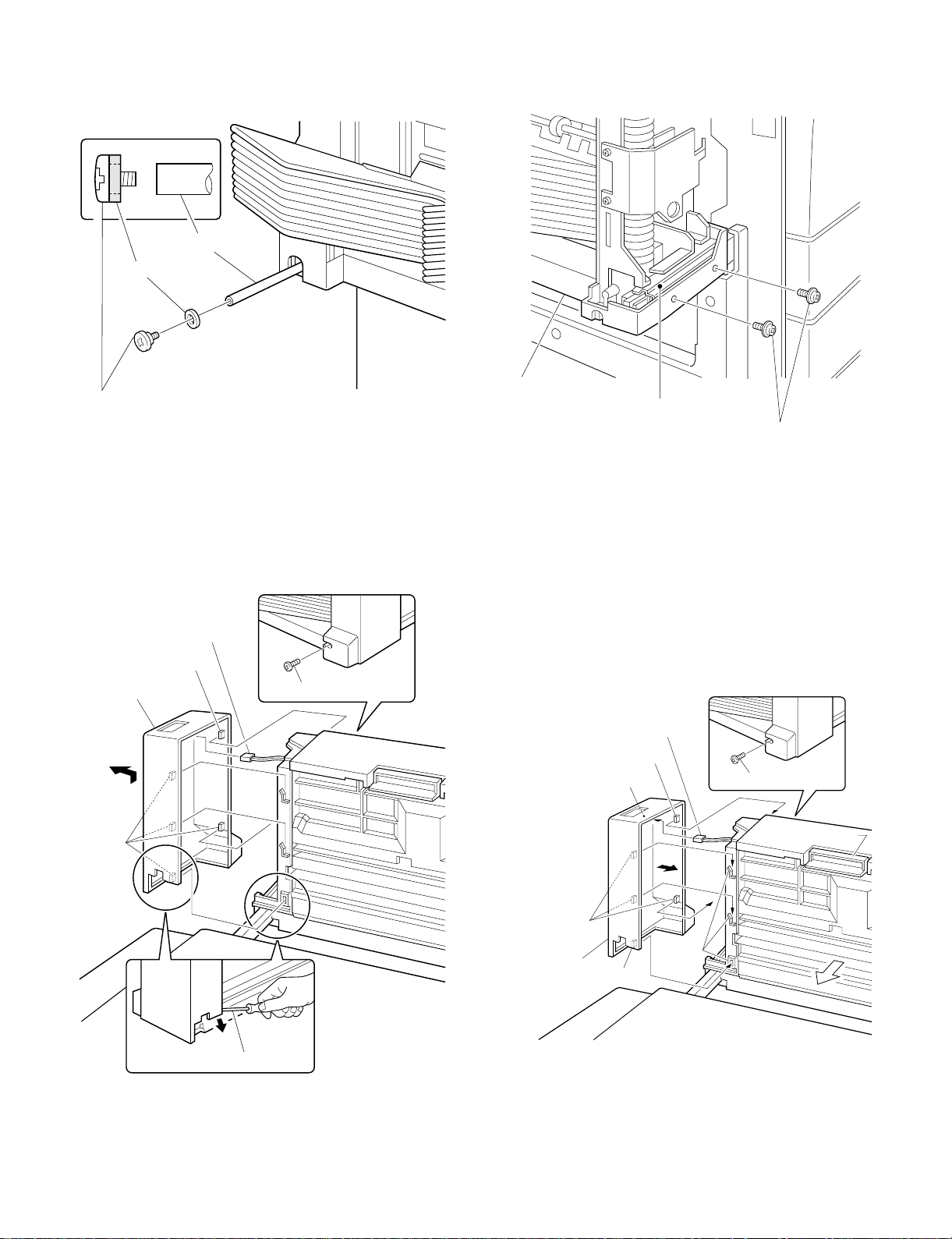

3. Remove the cut-outs.

Remove the four cut-outs from the left cabinet panel of the copier.

Cut-outs

4. Insert the spacers.

Insert the four spacers into the holes which have been made by

removing the cut-outs in step 3.

6. Mount the sorter seat cover.

Mount the sorter seat cover to the sorter seat and secure it using

three sorter seat cover securing screws.

Sorter seat cover securing screws

Sorter seat cover

7. Mount the sorter.

Insert the shaft on the back of the sorter seat between the rollers at

the back of the sorter.

Back side

Spacers

Spacers

5. Mount the sorter seat.

Temporarily secure the sorter seat securing screws to the two upper

spacers which have been mounted in step 4.

Insert these two sorter seat securing screws into the two upper holes

of the sorter seat as shown in the figure.

Secure the lower part of the sorter seat by inserting the two sorter

seat securing screws into the lower two holes of the sorter seat and

tighten the temporarily secured upper screws to secure the sorter

seat.

Sorter seat securing screws

Rollers

Sorter

Sorter seat shaft

Next, insert the slide rail on the front of the sorter seat into the slide

rail mount on the front of the sorter and push the sorter in place.

Front side

Slide rail mount

Sorter

Sorter seat securing screws

Sorter seat

Sorter seat slide rail

NOTE:

Be sure to slide the sorter away from the copier and check that the

sorter is not removed from the slide rail of the sorter seat.

– 3 –

Page 6

8. Mount the stopper.

Mount the felt washer to the stopper screw and secure the screw to

the sorter seat shaft.

Shaft

Felt washer

Stopper screw

9. Remove the sorter’s front cabinet panel.

Remove the front cabinet panel screw.

Next, using a screwdriver, pry open the lower part of the front cabinet

panel to pull the lowest tab from the slot in which it is anchored.

Pull the front cabinet panel slightly up and out to remove it.

Disconnect the connector which is plugged into the front cabinet

panel.

Connector

Tab

Front cabinet panel

Front cabinet panel screw

10. Attach the sorter to the sorter seat.

Install the M4 x 8 sorter securing screws (2 pcs.) in the screw holes

on the sorter to attach the sorter to the sorter seat.

Sorter

Slide rail

Sorter securing screws

(M4 x 8)

11. Mount the sorter’s front cabinet panel.

Plug the connector from the sorter into the circuit board inside the

sorter’s front cabinet panel.

Fit the tabs on the left side of the front cabinet panel behind the ribs

on the sorter, and slide the tabs on the right-hand side of the front

cabinet panel behind the ribs in the sorter.

Check to be sure the tabs are securely positioned behind the ribs and

inserted properly into the slot.

Secure the front cabinet panel using the screw which was removed in

step 9.

Tab

Straight-edge screwdriver

Tab

Front cabinet panel

Circuit board

Tab

Connector

Tab

Front cabinet panel screw

Lock lever

Ribs

– 4 –

Page 7

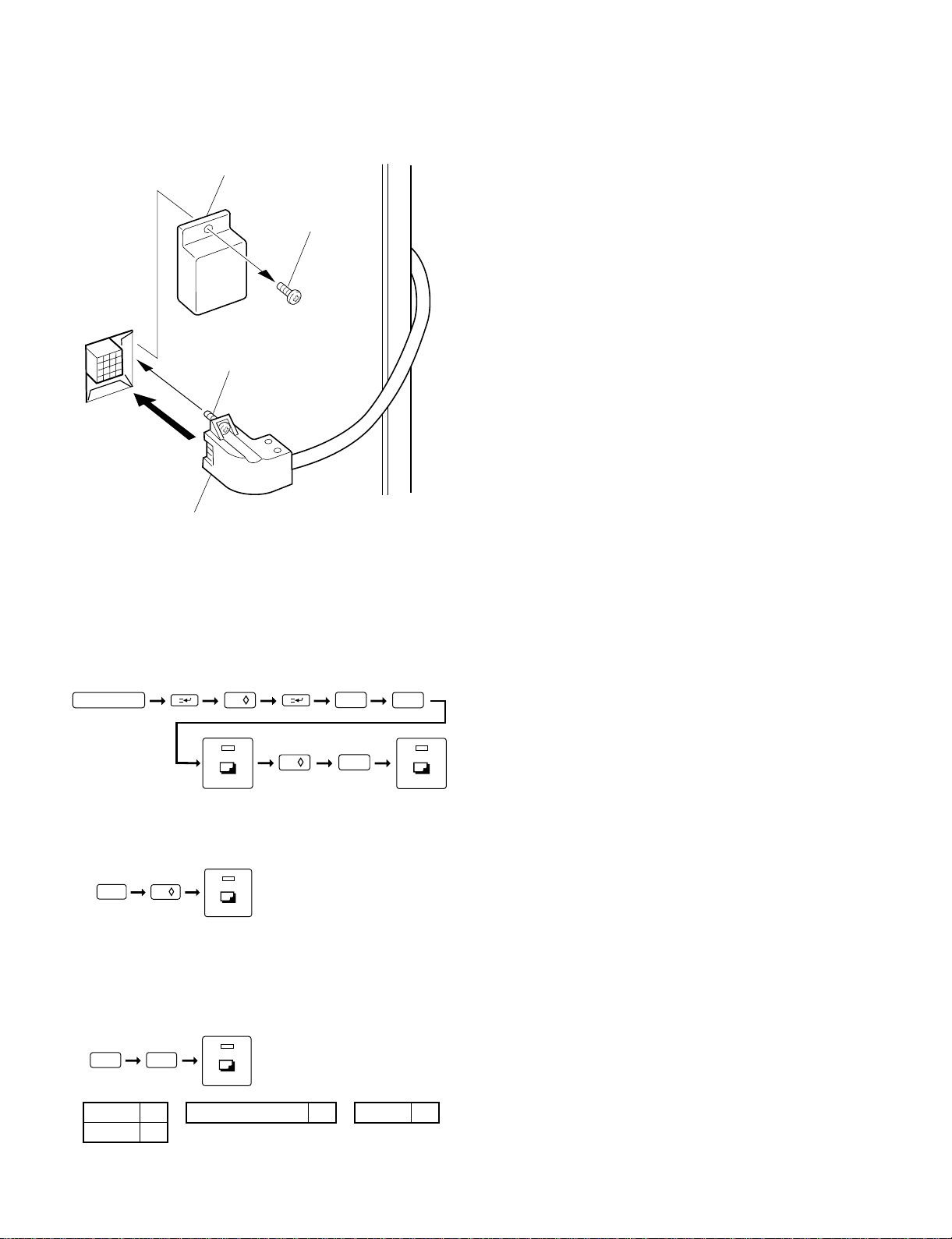

12. Connect the sorter connector.

Remove the sorter connector cover securing screw which is mounted

to the rear cabinet panel of the copier and remove the sorter connector cover.

Connect the sorter connector to the connector on the copier and

secure it using the sorter connector securing screw.

Sorter connector cover

Securing screw

Securing screw

Sorter connector

Plug the copier into a grounded outlet and turn the

power switch on.

Then, follow the procedure below.

13. Set the mode.

• Operate the copier keys to set the mode.

C

0/

0/

The above key operation will display the currently set mode.

2

6

1

• When only the SF-S18 is to be set, immediately after the above

key operation, operate the keys as follows:

1

0/

• If the mode is to be set in combination with other options, use the

table shown below to add up the total of the setting values for all

the peripheral devices to be set, and set that total value.

For example, if the SF-S18 and RADF are to be set, the total setting

value is 1 + 10 = 11.

Operate the keys as follows:

1

RADF 1 Stand/paper drawer 4 SF-S18 10

ADF 1

1

– 5 –

Page 8

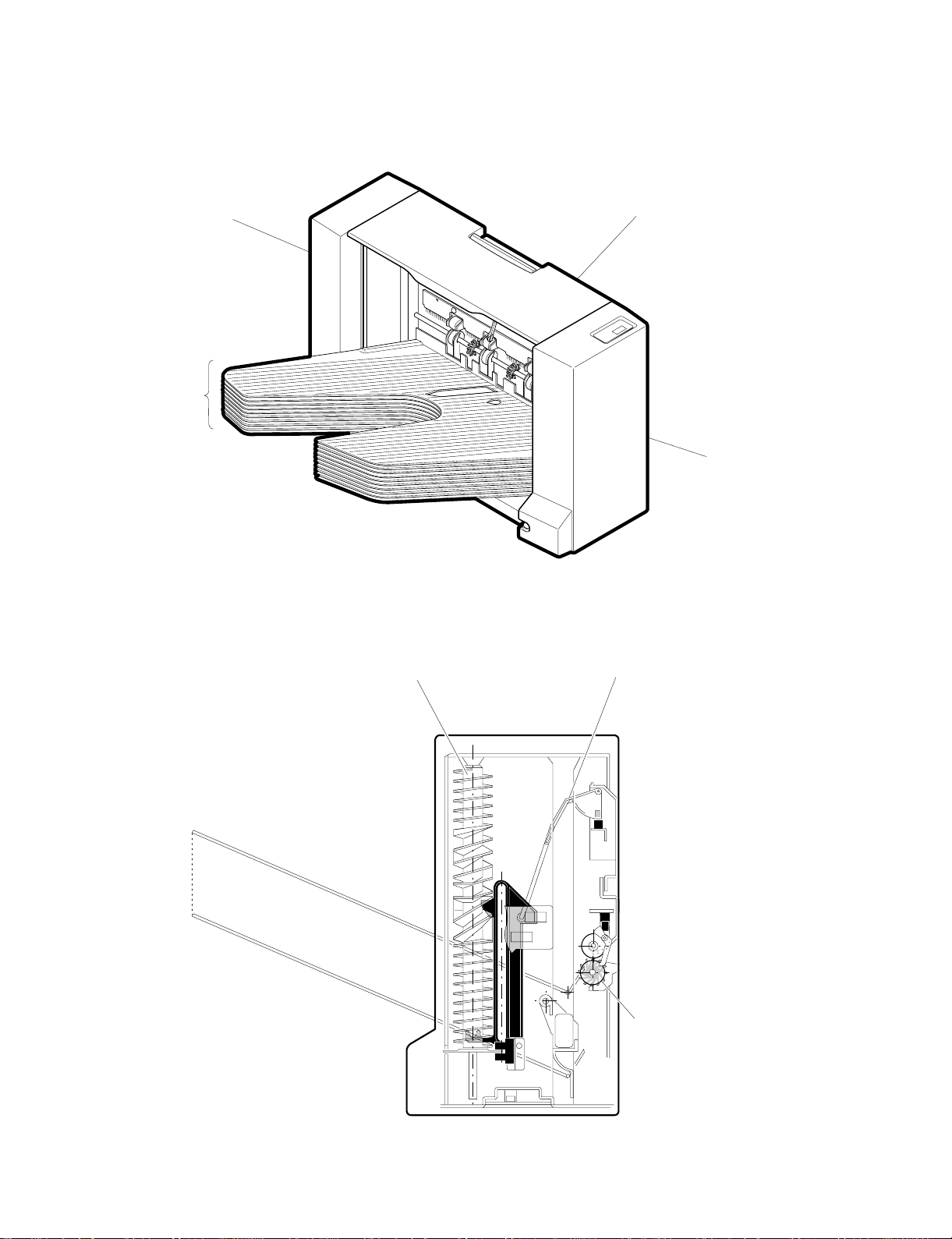

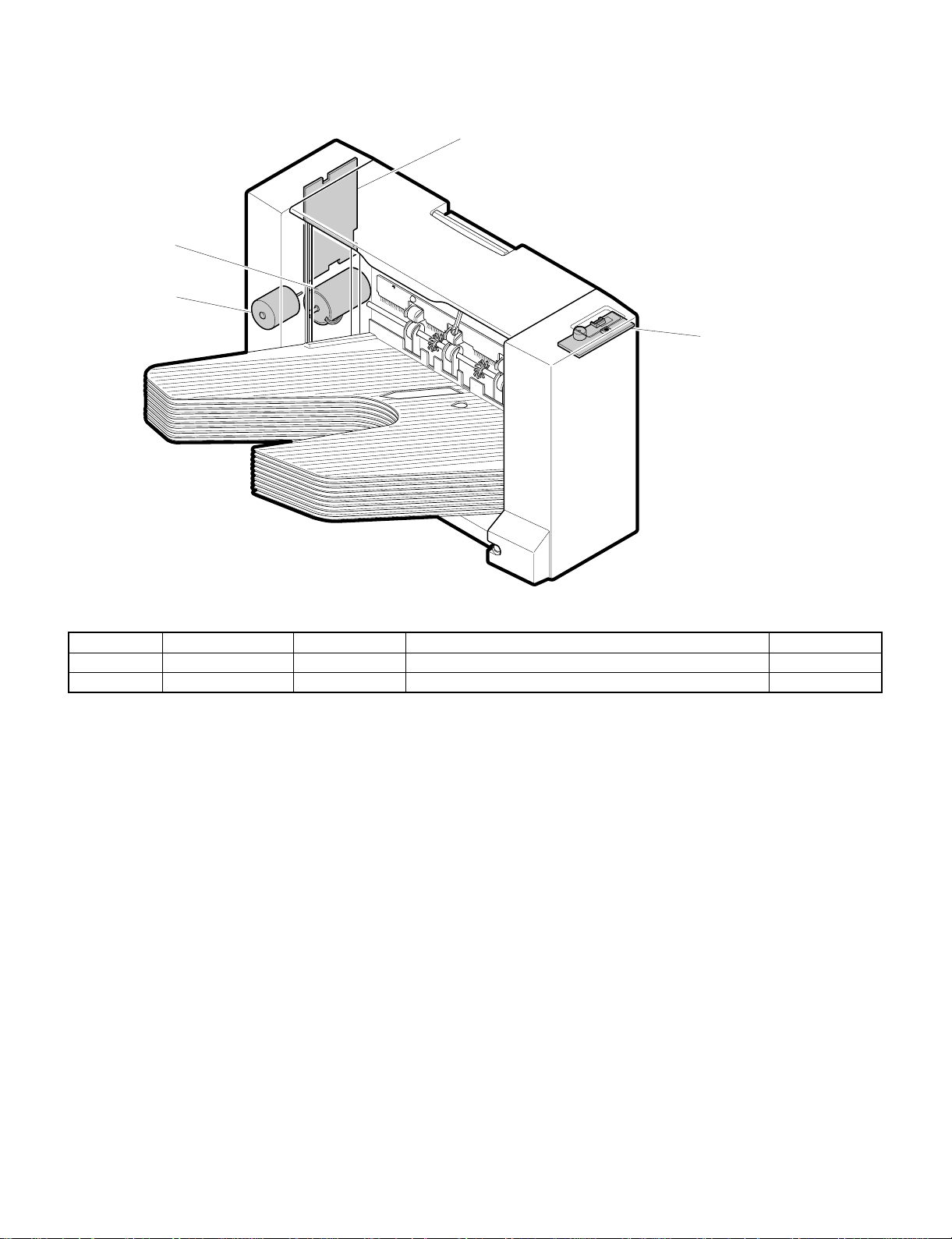

[3] PARTS IDENTIFICATION

1. External fittings

Rear cover

Trays

2. Mechanism section

Top cover

Fro nt co ve r

Spiral cam

Take-up SEN lever

Paper exit roller

– 6 –

Page 9

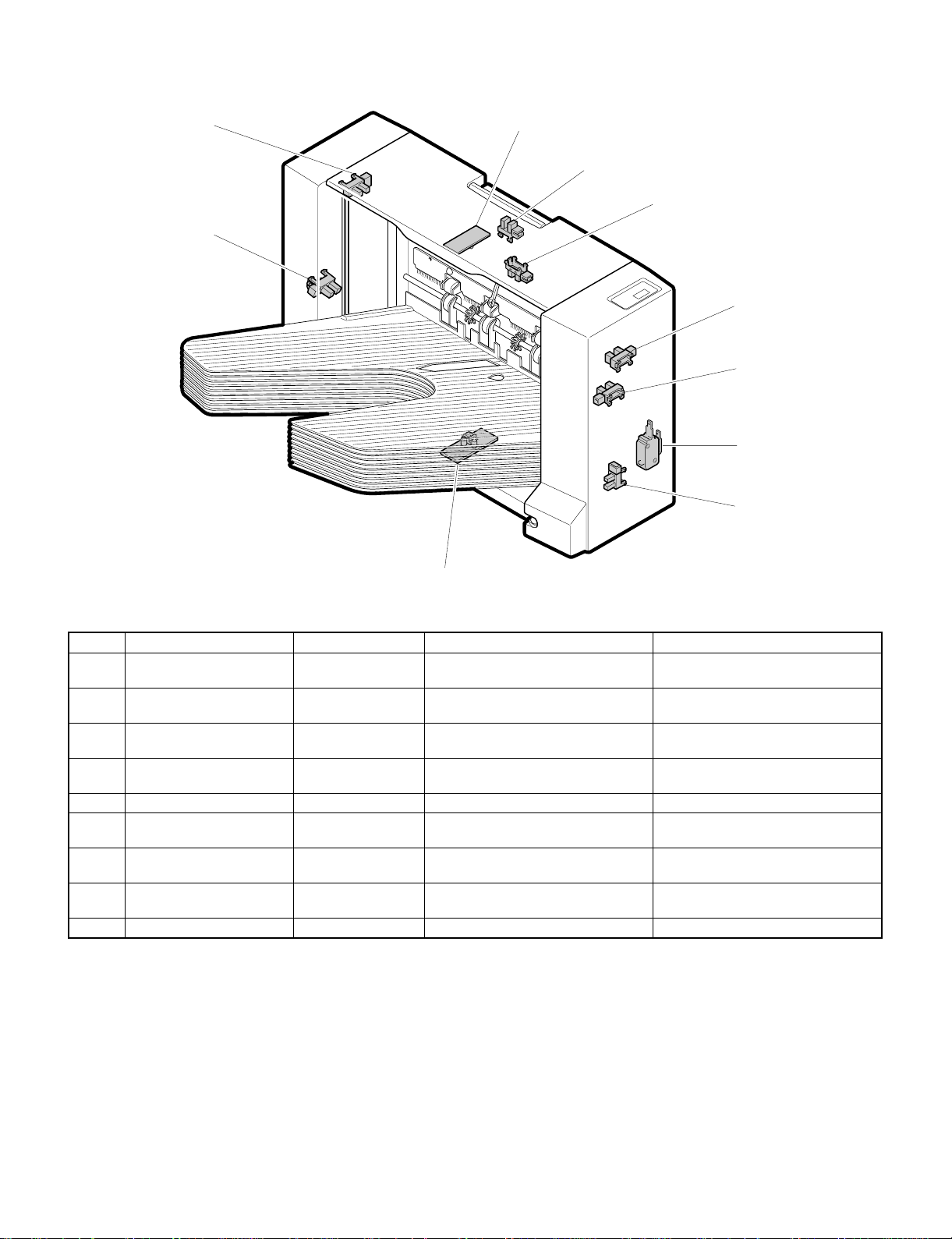

3. Sensors and switches

SEN7

SEN6

SEN5 (Light emitting)

SEN4

SEN1

SEN2

SEN8

SW1

SEN3

SEN5 (Light receiving)

Code Name Type Operation, function Contact, output

SEN1 Entry port sensor Photo interrupter Turns HIGH when the paper lead edge

reaches the transport roller.

SEN2 Bin home sensor Photo interrupter Used to sense the tray home position. HIGH when the home position is

SEN3 One rotation sensor Photo interrupter Used to sense the tray stop position. HIGH when the stop position is

SEN4 Take-up position sensor Photo interrupter Used to sense the paper take-up

position.

SEN5 Paper empty sensor Transmission sensor Used to sense the paper on the tray. LOW when the paper is sensed.

SEN6 Bin shift motor clock sensor Photo interrupter Used to sense rotation of the bin shift

motor.

SEN7 Transport motor clock

sensor

SEN8 Upper/lower limit sensor Photo interrupter Used to sense the tray limit position. HIGH when the limit position is

SW1 Sorter set switch Micro switch Used to sense the sorter installation LOW when the sorter is installed.

Photo interrupter Used to sense rotation of the transport

motor.

HIGH when paper is sensed.

sensed.

sensed.

LOW when the take-up position is

sensed.

Pulse output

Pulse output

sensed.

– 7 –

Page 10

4. Motors and PWB

M2

M1

Control PWB

Display PW B

Code Name Type Operation, function Contact, output

M1 Transport motor DC motor Used to shift the transport roller.

M2 Bin shift motor DC motor Used to drive the spiral cam for moving the tray up and down.

– 8 –

Page 11

[4] OPERATIONAL DESCRIPTIONS

1. Paper transport mechanism

The transport motor power is transmitted to the paper exit roller and

the paper feed roller.

Paper feed

direction

Paper exit roller

Paper feed roller

Transport motor

2. Bin up-down shift mechanism

The bin shift motor power is transmitted to the spiral cam 1 (R side)

by the timing belt and the gear, and to the spiral cam 2 (F side) at

the same time by the drive shaft.

The bin is shifted up or down by forword or reverse rotation of the

motor. The bin is stopped at the stop position by the one rotation

sensor attached to the spiral cam 2.

Down

Up

Spiral cam

2

Bin shaft

motor

Up

Down

Down

Up

Spiral cam

One rotation sensor

1

Paper exit

direction

Drive shaft

– 9 –

Page 12

3. Operatio n pr ocess

(Normal copy mode (Non-sort/sort/group))

START

STEP01

STEP02

First

paper exit bin

position

Curre nt bin position

≠

First

paper exit bin

position

> Current bin position

STEP03

STEP04

STEP05

STEP06

STEP07

First

paper exit bin

position

= Current bin position

STEP08

STEP09

STEP10

Copier START k ey ON

The operation mode (mo de, firs t paper

exit bin position) is received.

Transport motor ON

= Current bin position

→

to

1

< Current bin position

→

To STEP 11

Bin motor lowering rotation

One rotation sensor OFF

One rotation sensor ON

One rotation sensor OFF

One rotation sensor ON

> Current bin position

To STEP 04

→

Bin stop position correction pulse set

Bin stop position correction pulse up

Bin motor stop

<Operation mode reception, transport motor ON,

paper exit roller rotation>

Bin

Follower roller

Paper exit roller

One rotation sensor

to 1

STEP11

STEP12

STEP13

STEP14

STEP15

First

paper exit bin

position

= Current bin position

To STEP 08

Bin motor lifting rotation

One rotation sensor OFF

One rotation sensor ON

One rotation sensor OFF

One rotation sensor ON

< Current bin position

→

To STEP 12

– 10 –

Page 13

1

Group mode

No

Sort mode

No (Non-sort mode)

STEP 1 6

STEP 17

STEP 1 8

Next paper

No

To STEP 42

STEP 1 9

STEP 2 0

STEP 2 1

To 2

2

YES

→

To STEP 31

YES

→

To STEP 19

Copier paper exit comman d rec ept i on

Sorter entry p o rt sensor O N

Sorter entr y port sens or O F F

YES

→

To STEP 16

Copier paper exit comman d rec ept i on

Sorter entry p o rt sensor O N

Sorter entry port sensor OFF

<Copy paper entry sensor passing, sensor ON>

Bin

Entry port

sensor ON

Copy paper

Paper exit roller

Next paper

YES

Folding

command

NO

Sorting

directi o n

Reverse sorting

STEP 2 2

STEP 23

STEP 2 4

STEP 25

STEP 2 6

STEP 27

STEP 2 8

STEP 2 9

To STEP 19

STEP 3 0

NO

→

To ST EP 4 2

YES

To ST EP 1 9

→

Normal sorting

→

To ST EP 3 0

Bin motor lifting rotation

One rotation sensor OFF

One rotation sensor ON

One rotation sensor OFF

One rotation sensor ON

Bin stop position correction pulse set

Bin stop posi tion c or recti on pu lse up

Bin motor stop

Bin motor lower i ng r otat ion

<Copy paper entry port sensor passing, sensor OFF>

Bin

Copy

paper

Entry port

sensor OFF

Paper exit

roller

To STEP 23

STEP 3 1

STEP 3 2

STEP 3 3

Next paper

YES

To 3

Copier paper exit comman d rec ept i on

Sorter entry p o rt sensor O N

Sorter entr y port sens or O F F

NO

→

To ST EP 4 2

– 11 –

Page 14

3

Bin shift

command

NO

→

YES

STEP 34

STEP 35

STEP 36

STEP 37

STEP 38

STEP 39

STEP 40

STEP 41

Bin lowering rotation

One rotation sensor OFF

One rotation sensor ON

One rotation sensor OFF

One rotation sensor ON

Bin stop position correction pulse set

Bin stop posi t i on corre cti on pul se up

Bin motor stop

To STEP 31

STEP 42

Transport motor stop

END

(Take-up mode)

START

STEP 01

Paper

present on

Take-up mode start command reception

Paper empt y

tray

→

Paper present

To STEP 31

STEP 21

<Paper exit completion - transport motor stop -

paper exit roller stop>

Copy paper

<Take-up mode reception - take-up home position>

Current

bin position

< Take-up home position

STEP 02

STEP 03

STEP 04

Current

bin position

1

Take-up

sensor

Bin lifting rotation

One rotation sensor OFF

One rotation sensor ON

= Take -up home po si tion

OFF

STEP 05

STEP 06

STEP 07

STEP 08

One rotation sensor OFF

One rotation sensor ON

One rotation sensor OFF

One rotation sensor ON

To 1

STEP 09

STEP 10

STEP 11

STEP 12

Bin stop position correction pulse set

Bin stop posi t i on corre cti on pul se up

Bin motor stop

Tray pape r tak e- up

> Take-up ho me p osition

→

STEP 14

> Take-up ho me p osition

→

STEP 03

> Take-up ho me p osition

→

STEP 9

To 2

– 12 –

Page 15

2

Take-up

sensor

ON

→

OFF

Tray paper

present

Paper empty

→

Paper present

STEP 13

Bin motor lifting rotation

To STEP 05

STEP 14

STEP 15

STEP 16

Current

bin posi tion

Bin motor l owe ri ng rotation

One rotation sensor OFF

One rotation sensor ON

Take-up home po s it i on

→

= Take -up home po si tion

STEP 17

STEP 18

STEP 19

STEP 20

Bin stop position correction pulse set

Bin stop posi t i on corre cti on pul se up

Bin motor stop

Tray pape r tak e- up

To 2

To STEP 12

To STEP 21

To STEP 15

<Take-up mode completion - bin home position>

STEP 21

STEP 22

STEP 23

STEP 24

STEP 25

STEP 26

END

Bin motor l owe ri ng rotation

Bin home sens or ON

One rotation sensor ON

Bin stop position correction pulse set

Bin stop posi t i on corre cti on pul se up

Bin motor stop

– 13 –

Page 16

[5] DISASSEMBLY AND ASSEMBLY

No. Item

1 External fitting removal 13

2 Paper exit roller removal 14

3 Spiral cam and tray removal 14

4 Discharge brush removal 16

5 Interface cable removal 16

6 Control PWB removal 17

Motor bracket unit removal

7

(Transport motor and bin shift motor)

Bin shift motor clock sensor and transport motor

8

clock sensor removal

Bin home sensor and upper/lower limit sensor

9

removal

10 One rotation sensor removal 18

Take-out position sensor and entry port sensor

11

removal

12 Paper empty sensor upper removal 19

13 Paper empty sensor lower removal 19

Ref.

page

17

18

18

18

1. External fitting removal

(1) Remove screw A and connector B, and remove front cover C.

(In the sequence of 1, 2, 3 and 4.)

(2) Remove screw D, and remove rear cover E. (In the sequence

of 1, 2, 3, and 4.)

(3) Remove connector F, and remove top cover G.

(4) Remove screw H and remove harness cover I in the se-

quence of 1, 2, 3.

G

D

E

F

B

4

A

4

C

2

1

2

3

Screwdriver

3

– 14 –

Page 17

Rear side

(2) Remove take-up SEN lever A.

1

2

3

Front

side

H

2. Paper ex it roller removal

(1) Remove the harness cover. (Refer to procedure 1 - (4).)

(2) Remove connection cover A.

(3) Remove paper exit roller B.

I

A

(3) Remove lever B from tray collar 2 C.

B

C

A

B

Radio nipp ers

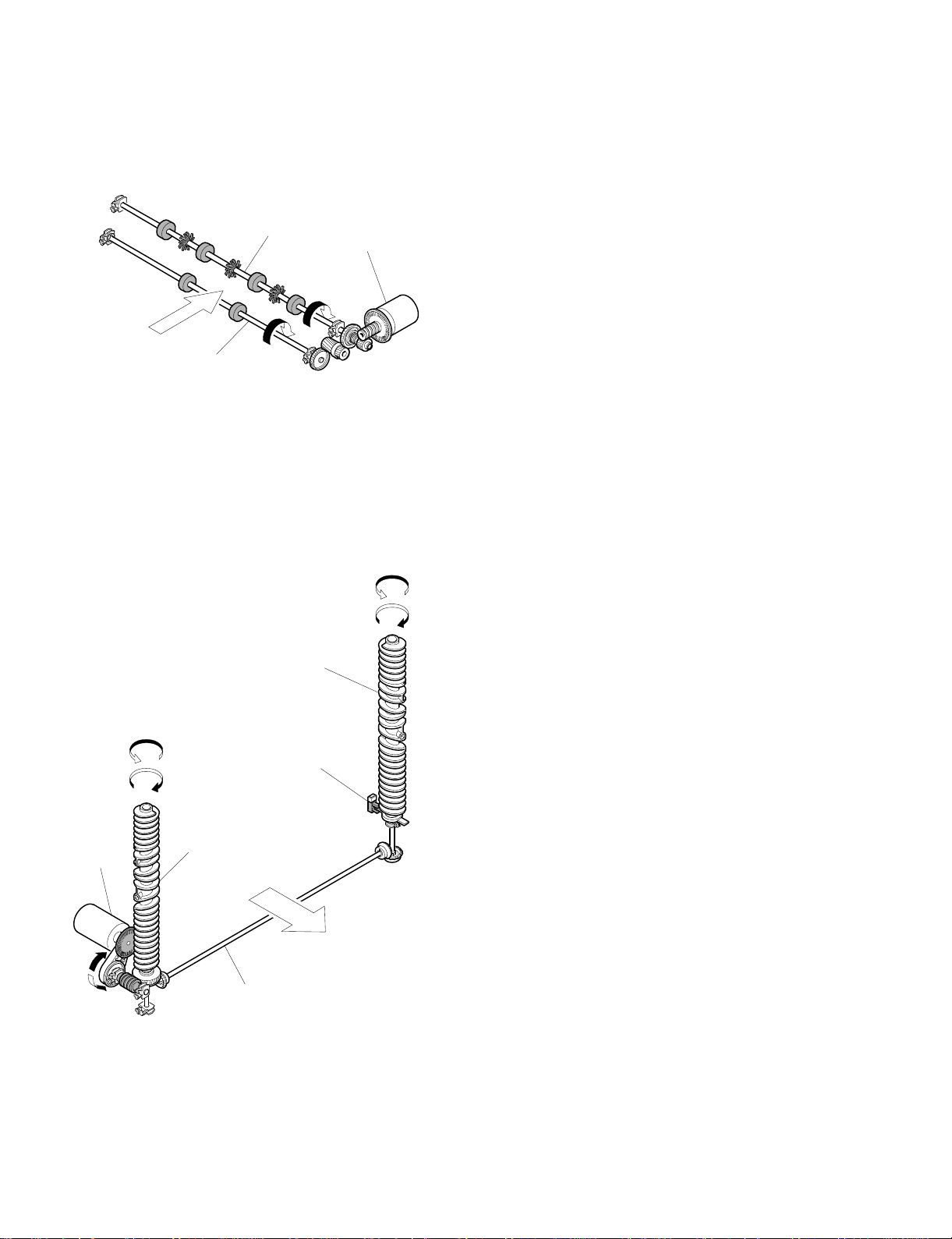

3. Spiral cam and tray remo val

(1) Remove the front cover, the rear cover, and the top cover.

(Refer to procedure 1.)

(4) Remove timing belt D and worm support frame E, and remove

worm gear F.

(5) Manually turn the spiral cam to lower the tray to the bottom.

(Lower than the the home position.)

Loosen the screw.

Tensioner

Timing belt

– 15 –

Page 18

(6) Remove cam bush G, and remove spiral cam H and I.

(7) Remove the tray.

E

Rear side

I

D

F

G

(Assembly)

(8) Assemble spiral cams H and I. Be sure to fit the phases of

both cams.

To fit the phases, use the hole at the center of each spiral

°

cam. Set so that the same shape (round or square) faces

towards you. Look into the front hole through the rear hole,

and set spiral ass’y F.

Front side

G

Front side Rear side

* Be sure to check that the shapes of the holes at the centers

of spiral cams H and I are the same.

• Check that you can see thorough the front hole and the

rear hole.

(9) Turn spiral cam H or I to lower the tray, and insert trays one

by one.

* Be careful not to skip any bin position.

H

– 16 –

Page 19

(10) When the tray reaches the home position, attach the lever which

was removed in procedure (3) to the tray collar.

(11) For the assembly hereinafter, reverse the disassembly proce-

dures. ((5) (4) (3) (2) (1))

4. Discharge bru sh re moval

(1) Remove the timing belt, turn the spiral cam manually to put the

tray at the bottom. (Refer to procedure 4.)

(2) Remove screw A, and remove discharge brush B.

6. Control PWB removal

(1) Remove the rear cover. (Refer to procedure 1.)

(2) Remove the interface cable. (Refer to procedure 6.)

(3) Remove screw A and all connectors from control PWB B, and

remove control PWB B.

B

A

A

A

B

5. Interface cable removal

(1) Remove the rear cover. (Refer to procedure 1.)

(2) Remove connectors A and B, screw C, and grounding screw

D, and remove the interface cable E.

B

A

* When removing connectors of the PWB, be sure to turn off the

power in advance.

7. Motor bracket removal (Transport

motor & bin shift motor)

(1) Remove the rear cover. (Refer to procedure 1.)

(2) Remove the interface cable. (Refer to procedure 6.)

(3) Remove screw A and connectors, and remove harness bracket

B.

(4) Remove timing belt C and screw D, and remove motor bracket

unit E.

D

C

E

– 17 –

Page 20

8. Bin shift motor clock sensor and

transpor t moto r clock sen sor rem o val

(1) Remove the rear cover. (Refer to procedure 1.)

(2) Remove screw A (commonly tighten with the grounding ter-

minal) and connector B, and remove bin shift motor clock sen-

sor C.

(3) Remove screw D and connector E, and remove transport

motor clock sensor F.

E

D

C

* When removing the timing belt, loosen the screw shown

below and loosen the tensioner.

A

A

B

Loosen the screw.

Tensioner

Timing belt

F

D

A

E

C

B

9. Bin home sensor and upper/lower limit

sensor removal

(1) Remove the font cover. (Refer to procedure 1.)

(2) Remove screw A, and remove harness bracket B.

(3) Remove screw C and remove HP-LIM sensor bracket D.

(4) Remove bin home sensor E (white connector) and upper/lower

limit sensor F (black connector).

A

– 18 –

B

A

E

F

C

C

* Be careful not to mistake the bin home sensor for the

upper/lower limit sensor. The connectors are different from

each other to prevent mistaken connection.

D

Page 21

10. One rotation sensor removal

12. Paper empty sensor upper removal

(1) Remove the front cover. (Refer to procedure 1.)

(2) Remove screw A and connector B, and remove one rotation

sensor C.

B

C

A

11. Take-up position sensor and entry

port sensor removal

(1) Remove the harness cover. (Refer to procedure 1.)

(2) Remove screw A, and remove take-up position sensor B.

(3) Remove connection cover C.

(4) Remove entry port sensor D.

(1) Remove the top cover. (Procedure 1.)

(2) Removes crew A, and remove cover B.

C

B

A

A

(3) Remove paper empty sensor upper C (transmission sensor).

13. Paper empty sensor lower removal

(1) Put the sorter on the side.

(2) Remove screw A, and remove cover B.

(3) Remove paper empty sensor lower C (transmission sensor).

D

C

* Be careful not to mistake the take-up position sensor and the

entry port sensor. The connectors are different from each

other to prevent mistaken connection.

Rear side

B

Connctor

Front side

A

C

B

A

– 19 –

Page 22

[6] ADJUSTMENTS

1. Single unit test mode

To enter the single unit test mode, keep the push switch on the

control WPB pressed and supply the power. After entering the single

unit test mode, select the kind of single unit tests with the DIP switch.

Selection of the kind of single unit tests is made by turning on/off the

sorter joint switch.

Setting of buzzer sound in the take-up mode

Use the DIP switch on the control PWB to set the buzzer sound.

Push switch DIP switch

ON

DIP

DIP

DIP

DIP

SW2

SW1

DIP SW4 Operation

ON Buzzer sound ON

OFF Buzzer sound OFF

* DIP SW1 ∼ 3 and the pu sh switch ar e used in the in dividual un it

test mode. For details, refer to [6] ADJUSTMENTS.

2. Starting the single unit test mode

After entering the single unit test mode, push the push switch on the

control PWB to start the test.

To finish the pa per feed m ode, push the switch.

3. Kinds of single unit test modes

Mode DIPSW3 DIPSW2

(1) Non-sort paper feed mode OFF OFF OFF

(2) Sort paper feed mode OFF OFF ON

(3) Group paper feed mode OFF ON OFF

(4) Load operation mode OFF ON ON

(5) Sensor check mode ON OFF OFF

(6) No paper aging mode ON OFF ON

No paper aging mode

(7)

(without speed control)

ON ON OFF

SW3

SW4

DIPSW1

(3) Group paper feed mode

Press the push switch on the control PWB to start. (The transport

motor is turned on.)

After the transport motor is activated, press the push switch on the

display PWB to set the number of groups. (Pressing the push switch

shifts the number from 5, 10, 15, and 20 in this sequence.)

Press the push switch on the control PWB again to finish the operation.

(4) Load operation mode

Used to check each load output. Press the push switch on the control

PWB to start and select each output step in the following sequence.

Turning on/off the joint switch finishes the operation.

1 Transport motor ON

2 Transport motor OFF

3 Bin motor forward rotation (shift bin up)

4 Bin motor OFF

5 Bin motor reverse rotation (shift bin down)

6 Bin motor OFF

7 Buzzer ON

(5) Sensor check mode

Each sensor operation can be checked with the buzzer sounds.

Press the push switch on the display PWB to check each sensor in

the following sequence. The buzzer is turned OFF when the sensor

senses.

1 Bin home sensor

2 Entry port sensor

3 Take-out position sensor

4 Paper empty sensor

5 One rotation sensor

6 Upper/Lower limit sensor

(6) No paper aging mode

The sort mode operations from No. 1 bin to No. 10 bin are performed

in a certain tim ing.

Press the push switch on the control PWB to start and finish the

operation.

(7) No paper aging mode (without speed control)

The operation of the no paper aging mode is performed without

speed control of the motors (at full speeds).

4. Description on each mode

(1) Non-sort paper feed mode

Press the push switch on the control WPB to start. (The transport

motor ON.)

When paper is loaded, it is dischar ged onto the first bin.

Press the push switch again to finish the operation.

(2) Sort paper feed mode

Press the push switch on the control PWB to start. (The transport

motor is turned ON.)

After the transport motor is activated, press the push switch on the

display PWB to set the number of bins for sorting. (The number of

bins can be checked with the buzzer sounds.)

Press the push switch on the control PWB again to finish the operation.

5. Setting of buzzer sound in the take-u p

mode

Set the DIP switch 4 as follows:

DIP SW4 Operation

ON Buzzer sound ON

OFF Buzzer sound OFF

– 20 –

Page 23

[7] MAINTENANCE

[Note] ★ Lubricate, | Clean, ∆ Adjust, ▲ Replace,

✕ = Check. (Clean, replace, adjust as necessary.)

Part name 50K 100K 150K 200K Same cycle afterward

Feed roller H (Paper exit roller) ||||

Sensors ||||

Worm gear (for shifting bin) Grease Grease

Worm gear (for transport) Grease Grease

Timing belt ||||

Transport motor

Bin motor

Replace at 500K.

[8] TROUBLESHOOTING

[A] The sorter does not operate. (Except

for pape r jam)

A

Is the interface

cable pro perl y

connected?

YES

Is DC5V

applied between

CN2,3 p in &

4 pin?

YES

Is DC24V

applied between

CN2,1 p in &

2 pin?

YES

Does the

transport motor

rotate normally?

NO

NO

NO

NO

Connect the inte r face

cabl e properly

Is DC24V

applied between

CN2,1 p in &

2 pin?

NO

Replace t he

interfac e cable

[C] Transport motor check

YES

Check the

copier power

source

[B] Transport motor error

B

Is the load

of the motor shaft

mormal?

YES

Is the motor

winding shorted?

NO

Is DC24V

applied Between

CN7,1 pin &

2 pin?

YES

Is the

harness prope rly

connect ed?

YES

Adjust the mechanism loads and the driv e

NO

system, and remove foreign materials

YES

NO

NO

Replace the mot or

Check or replace

the control PWB

harness prope rly

Connect the

YES

Does the

bin shift m oor

rotate mormally?

YES

Check or r eplace

the contr ol P WB

NO

[C] Bin shift motor check

– 21 –

Is the motor

clock sensor

output normal?

YES

Check or replace the

control PWB

NO

Check the motor clock s ensor

output or replace it

Page 24

[C] Bin shift motor error [D] Communication error

C

Is the load of

the motor shaft

normal?

YES

Is the motor

winding shorted?

NO

Is DC24V

applied between

CN8,1 pin and

2 pin?

YES

Is the harness

connected

properly?

YES

Is the motor

clock sensor

outpu t n orm al?

Adjust the mechanism loads and the driv e

NO

syatem, and remove foreign materials

YES

NO

NO

NO

Replace the mot or

Check or replace

the control PWB

Connect the

harness prope rly

Check the motor clock s ensor

output, or replace it

D

Is the

interfac e cable

normal?

YES

Check or r eplace

tne contr ol P WB

Is it OK?

YES

Check or r eplace

the contr ol P WB

NO

NO

Replace t he

interfac e cable

Check or replace the

main body PPC PWB

YES

Is the bin at the

upper or lower

limit posit ion?

YES

Are the

home senso r ou tpu t

and the limit sensor

output nor ma l?

YES

Check or replace

the control PWB

Manually move the bin from

NO

the limi t position

NO

Check or replace the home

sensor and the limit sensor

– 22 –

Page 25

[9] ACTUAL WIRING DIAGRAMS

Take-up position sens or

(SEN4)

Entry port

sensor

(SEN1)

AIM main harness

ass'y

Transpor t moto r

(SEN7)

Transp o r t mo tor

clock sensor

(SEN5)

Bin shift m ot or (M 2)

Control PWB

(PBA-CONTROL)

AIM-INT

harness

Bin shift

motor clock

sensor

(SEN6)

AIM-CN008 ass'y

Display PWB

(PBA-OPPANEL)

Upper/lower

limi t sens or

(SEN8)

One rota tion sensor

(SEN3)

Bin home sensor

(SEN2)

Sorter set SW

(SW1)

Paper empty

sensor PWB

(PBA-PT43)

AIM-CN005 ass'y

Paper empty

sensor PWB (LED)

(PBA-LR43)

AIM-CN005 ass'y

– 23 –

Page 26

[10] CIRCUIT DESCRIPTIONS

1. Summary

This control circuit is used to pick up the paper discharged from the main body and distribute to one of trays 1 ∼ 10. It is c omposed of sensors ,

switches, the circuit which processes inputs from the PPC, the circuit which drives the motors, the CPU, and its peripheral circuits.

2. Block diagra m

Control PWB

Copier bo dy

interface section

Entry port sensor

Bin home sensor

One rotation s e nsor

Take out position

sensor

Paper empty LED

Paper empty sensor

Bin shift moto r clock

sensor

Transport motor clock

sens or

Upper/Lower limit

sensor

SEN1

SEN2

SEN3

SEN4

SEN5CLK

SEN5

SEN6

SEN7

SEN8

Serial interface

section

Entrance sensor

input section

Bin home sensor

input section

One rotation s e nsor

input section

Take out position sensor

input section

Paper empty LED CLK

output sec t i on

Paper empty sensor

input section

Bin shift motor clock senso r

CLK input section

Transport motor clock sensor

CLK input sec t ion

Upper/Lower limit sensor

input section

SEN1

SEN2

SEN3

SEN4

SEN5CLK

SEN5

SEN6

SEN7

SEN8

System reset

section

CPU

LATCH

Display section LOGIC

Transpor t motor (M1)

control se ct ion

Bin shift motor (M2)

control section

ROM

256K

Display

PWB

M1

Transpor t motor (M1)

M2

Bin shift motor (M2)

Sorter set switch

Main body power

source

SW1

DC24V

DC5V

System cl oc k

secti on

Sorter set swit ch

input section

Power input section

SW1

– 24 –

Page 27

3. Operation

A. Communication circuit

This circuit is used to communicate with the copier body.

+5V

+5V

R8

R6

470

JINT

4

3

1

2

5

6

7

8

CN1,4 TXD

CN1,3 RXD

CN1,1 DTR

CN1,2 DSR

CN1,5 RESET

CN1,6 SGND

CN1,7

CN1,8 N.C

The input and the output of each signal are as follows:

[a] DTR CN1-1 pin

The input from the main body. When LOW (0V) at IC11-4 pin, it means the main body has the control to transmit.

[b] DSR CN1-2 pin

The output in the sorter side. When HIGH (+5V) at IC11-3 pin, IC11-4 pin turns from LOW (0V) to HIGH (+5V) then to LOW again. During that

period, the sorter has the control to transmit.

[c] TXD CN1-4 pin

The input from the main body. When IC11-79 pin turns from HIGH (+5V) to LOW, data reception is started.

[d] RXD CN1-3 pin

The output in the sorter side. When IC11-80 pin turns from HIGH (+5V) to LOW, data transmission is started.

[e] RESET CN1-5 pin

The reset signal from the main body. When CN1-5 pin is HIGH (+5V), the CPU (IC11) is reset.

R7

4.7K

R64

100

R63

100

R62

100

SGND SGND

C20

100PF

C16

100PF

Test pat30

C2

0.10µF

Test pat23

Test pat29

IC2.2

34

HD74HC14FP

IC2.3

HD74LS06FP

6

5

HD74HC14FP

HD74HC14FP

4

IC2.1

12

IC6.1

12

IC6.2

3

HD74LS06FP

Test pat31

Test pat24

VCC-+5V

GND-SGND

11 10

HD74LS06FP

IC6.5

R59

4.7K

IC6.3

6

HD74LS06FP

Test pat25

+5V

R74

10K

5

Test pat26

Test pat27

Test pat28

Test pat35

IC11

79

80

4

3

Main body reset

B. Reset circuit

This circuit is the reset circuit.

D1

RES

VS

SGND

2

7

DSA010

*RES

VREF

C22

470PF

CK

CT

C23

0.10µF

+5V

5

VCC

4

GND

IC5

MB3773 FP

This circuit is used to generate the CPU reset signal, and is composed of IC5 and its peripheral circuits.

+5V

KA

R72

10K

3

8

C17

1µF

Test pat33

1

6

19

HD74LS06FP

+

IC6.4

+5V

R75

10K

8

Test pat64

2

IC7.1Y

3

HD74HC02FP

VCC-+5V

GND-SGND

Main body reset

6

IC11

1

7

– 25 –

Page 28

IC5 has integrated reset functions including the power on reset, the +5V abnormal fall reset, and the watch dog timer function.

When the power line reaches about 0.8V by turning on, IC5 starts operation and IC5 8 pin becomes LOW to reset the CPU. The reset state is

maintained until a certain time is passed after power line’s reaching about 4.3V. The reset maintaining time id determined by the capacity of C17. It

is about 100msec for this circuit. After passing the reset time, IC5 8 pin turns to HIGH to cancel reset, and the CPU resumes operation.

When the power line voltage falls to about 4.2V, IC5 8 pin turns to LOW to issue the reset signal, and the reset state is maintained as far as the

power voltage is lower than about 4.3V. After about 100msec from when the power voltage reaches about 4.3V, reset is cancelled.

IC5 3 pin is the watch dog timer clock sinal input pin, and the output signal from the CPU 6 pin is used as the clock. When the CPU normally

operates, the clock is regular pulse signal of 50% duty and 5msec frequency. When the CPU is hung up or in an abnormal state, the clock is not

supplied. IC5 normally monitors this clock. When the clock supply is stopped, after a ceratin time, IC5 drives 8 pin to LOW to supply the reset signal.

The monitoring time of clock is determined by the capacity of C17, and is about 100msec for this circuit.

Hard reset is also applied from the PPC through the communication cable. In this case, CN1-5 pin is driven to HIGH or opened to reset.

C. Sensor input circuit

[a] Tray paper empty sensor (SEN5) circuit

Test pat14

Paper empty sensor

LED(SEN5)

Paper empty sensor

PHTr(SEN5)

Light

receiving

circuit

Light

emitting

circuit

CN4,2

CN4,1

SEN5_CLK

CN5,1

CN5,2

CN5,3

+5V

+5V

SEN5

SGND

2

1

+5V

1

2

3

SGND

+5V

2.0K

+5V

R58

200K

C6

0.10µF

2SC2712

Test pat22

C

E

SGND

+5VR50

R51

100K

BQ2

R67

4.7K

R31

10K

Test pat21

Test pat15

+5V

Test pat63

R52

3.6K

R53

12K

SGND

R56

4.7K

3

+

2

-

µPC393G2

VCC-+5V

GND-SGND

Test pat16

R54

56K

1

IC9.1

IC12.5

10

HD74HC14FP

Test pat17

+5V

R40

4.7K

Test pat20

11

+5V

+5V

IC3.1

4

*PR

3

CLK

2

D

1

*CLR

HD74HC74FP

VDD-+5V

GND-SGND

R71

10K

5

IC11

5

Q

6

*Q

62

Test pat18

This circuit is used to sense the presence of paper on the tray. CN4 is connected to the light emitting PWB, and CN5 is connected to the light

receiving PWB.

1. Light emitting circuit

The signal outputted from the CPU (IC11-5 pin) at a certain frequency is inputted to IC12-11 pin, and the reversed output is inputted to the base of

Q2. Consequently Q2 turns on to light the LED.

2. Light receiving circuit

(1) Light receiving PWB circuit

1

VCC

C

PT1

ST-1KL3A(CD)

E

Q2

2SC2712GRBL

C

B

E

R3

1.0K

R1

10K

C1

0.01µF

16K

2

C4

0.47µF

3

GND

C

Q1

B

2SC2712

E

R2

0.010µF

R4

4.7K

R7

100K

R6

390

B

C

Q3

2SC2712GRBL

E

C3

10µF

C2

R5

16K

VOUT

GND

CN1,1

CN1,2

CN1,3

The photoelectric current flowing through PT1 becomes the base current of Q1 and operates Q1 and is converted into the output voltage by R4. Part

of current flowing through Q1 is integrated by R2 and C1 and is passed to the base of Q2 to set the operating point of Q1 with Q2, PT1, and R3.

(The collector potential of Q2 is set to about 1.2V)

When disturbance lights (DC light, fluorescent light, etc.) enters the light receiving element, the DC current in PT1 and Q1 tries to increase according

to the disturbance lights. However, this current is passed through R2 to the base of Q2, conducting Q2. Therefore, the photoelectric current

generated by disturbance lights becomes the collector current of Q2, and does not flow to the base of Q1 which has a higher impedance. In this

manner, an increase in the Q2 collector current is suppressed, and the operation is controlled. (When disturbance light increases, the Q2 emitter

voltage increases by R3, therefore the limit of voltage for normal operations is about 2.5V or less. If there is no disturbance light, it is set to about

0V.)

When the signal light becomes too intense, the same control is performed.

R2 and C1 forms the low pass filter which allows the fluorescent light completely to pass and does not allow modulated light to pass.

– 26 –

Page 29

3. Control PWB light receiving circuit

+5V

R71

CN5,1

CN5,2

CN5,3

+5V

SEN5

SGND

1

2

3

SGND

+5V

2.0K

+5V

C6

0.10µF

Test pat22

10K

Test pat17

+5V

R40

4.7K

1

Test pat20

+5V

4

3

2

1

HD74HC74FP

VDD-+5V

GND-SGND

IC3.1

*PR

CLK

D

*CLR

5

Q

6

*Q

+5VR50

R51

100K

R67

4.7K

R52

3.6K

Test pat21

+5V

SGND

Test pat63

R53

12K

R54

56K

3

+

2

-

IC9.1

µPC393G2

VCC-+5V

GND-SGND

5

IC11

62

Test pat18

The signal outputted from the light receiving PWB is DC-cut by C6 and modulated by the comparator (IC9). (It is digitally converted by the

comparator, and the threshold value of the comparator is about 3.8V.)

The digital signal outputted from the comparator is latched by the flip-flop (IC3).

When D (2 pin) is HIGH at the rising edge of CLK (3 pin) of the flip-flop (IC3), it is judged as "no paper" and the output Q (5 pin) becomes HIGH.

When D (2 pin) is LOW (0V), it is judges as "paper present" and the output Q (5 pin) becomes LOW.

[b] Bin home sensor (SEN2) circuit

Entry port sensor (SEM1) circuit

One rotation sensor (SEN3) circuit

Take-out position sensor (SEN4) circuit

Upper/lower limit sensor (SEN8) circuit

1) The bin home sensor (SEN2) circuit is used to sense that the tray is at the paper exit position of the first bin.

The sensor is of the photo transmission type (photo interrupter), and includes the LED and the photo transistor. The output level is normally LOW

(0V) because of light transmission.

When the tray reaches the paper exit position of the first bin,the LED light is interrupted and the output of the photo transistor becomes HIGH

(+5V).

Then the HIGH output is inputted to CN10-10 pin, and the converted LOW output (0V) is inputted to IC11-59 pin.

2) The Entry port sensor (SEM1) circuit is used to sense that the paper discharged from the PPC enters the sorter entrance .

After sensing, it operates in the same manner as the home sensor. The signal is inputted to IC11-60 pin.

3) The one rotation sensor (SEN3) circ uit is used to sense that the tray is at a position suitable for paper exit or take-up.

The sensor is of the photo transmission type (photo interrupter), and includes the LED and the photo transistor. The output level is normally LOW

(0V) because of light transmission.

When the lead cam reaches the stop position, the LED light is interrupted and the photo transistor output becomes HIGH (+5V).

Therefore the HIGH level output is inputted to CN10-13 pin, and its signal is inputted to IC11-72 pin.

4) The take-out position sensor (SEN4) circuit is used to sense that the paper on the tray is at the take-up position in take-up mode.

The sensor is of the photo transmission type (photo interrupter), and includes the LED and the photo transistor. The output level is normally LOW

(0V) because of light interruption.

When the paper reaches the take-up position, the LED lights in interrupted, and the photo transistor output becomes HIGh (+5V).

Therefore the HIGH level output is inputted to CN10-3 pin, and the converted LOW signal is inputted to IC11-61 pin.

It is about 1.2V by monitoring through connection between CN10-1 pin and IC11-63 pin, but becomes HIGH (+5V) when open.

– 27 –

Page 30

5) Upper/lower limit sensor (SEN8) circuit is used to sense that the bin reaches the upper or lower limit by an overrun or an abnormal operation.

The sensor is of the photo transmission type (photo interrupter), and includes the LED and the photo transistor. The output level is normally LOW

(0V) because of light interruption.

When the bin reaches the upper or lower limit, the LED transmits light and the photo transistor output becomes HIGH (+5V).

Therefore the HIGH level output is inputted to CN9-2 pin and the converted LOW output (by IC12 is inputted to IC11-56 pin.

3

VCC

Bin home sensor

(SEN2)

S2

GP1S74P

Entry port sensor

(SEN1)

S1

GP1S74P

Take-out position

sensor (SEN4)

S4

GP1S74P

One rotation

sensor (SEN3)

S3

GP1S74P

Upper/lower limit

sensor (SEN8)

S8

LG203D-3

VOUT

GND

VCC

VOUT

GND

VCC

VOUT

GND

VCC

VOUT

GND

VCC

VOUT

GND

1

2

3

1

2

3

1

2

3

1

2

1

2

3

CN10,7

CN10,8

CN10,10

CN10,9

CN10,4

CN10,6

CN10,5

CN10,1

CN10,3

CN10,2

CN10,11

CN10,13

CN10,12

CN3,1

CN3,2

CN3,3

N.C

SEN2AN

SEN2

SGND

SEN1AN

SEN1

SGND

SEN4AN

SEN4

SGND

SEN3AN

SEN3

SGND

+5V

SEN8

SGND

+5V

430 x 4

7

R34

8

R68

10

9

4

6

5

1

3

2

11

13

12

1

2

3

SGND

+5V

30K x 4

10K

Test pat1

R16

R61

R69

R43

SEN4AN

R28

R42

R41

R29

10K

Test pat2

R39

10K

Test pat3

R38

10K

Test pat4

R37

10K

Test pat7

R15

10K

C3 C7 C12 C1 C5

SGND

0.010µF

x 5

IC12.1

HD74HC14FP

IC12.2

HD74HC14FP

IC12.3

HD74HC14FP

R19

10K

IC12.4

8

HD74HC14FP

VCC-+5V

GND-SGND

*SEN2

2

*SEN1

4

*SEN4

1

3

56

9

SEN3

Test pat8

Test pat9

Test pat10

Test pat11

Test pat58

59

60

61

72

56

IC11

[c] Transport motor clock sensor (SEN7), bin shift motor clock sensor (SEN6) input circuit

+5V

10K

Transport motor

clock sensor

(SEN7)

S6

LG203D-3

Bin shift motor

clock sensor

(SEN6)

S7

LG203D-3

VCC

VOUT

GND

VCC

VOUT

GND

1

2

3

1

2

3

CN3,7

CN3,8

CN3,9

CN3,4

CN3,5

CN3,6

+5V

SEN7

SGND

+5V

SEN6

SGND

7

8

9

4

5

6

SGND

x 2

R57

R65

R36

10K

R35

10K

C9

SGND

C8

Test pat5

Test pat6

1000PF

x 2

R18

10K

R17

10K

SEN7

SEN6

Test pat12

Test pat13

73

IC11

74

75

The bin shift motor clock sensor and the transport motor clock sensor are composed of the photo interrupter with built-in amplifier and the slit disc

attached to the motor shaft to obtain pulse signals according to motor rotation. The motor rotation speed is detected by the frequency of the pulse

signals, and by counting the number of pulses, the rotation amount of the motor is detected. The circuit composition of the input section in the two

sensors are the same, and it forms a noise filter composed of R35 (R36) and C9 (C8).

[d] Sorter set switch (SW1) input circuit

+5V

R30

10K

IC11

58

Sorter s et SW

(SW1)

CN9,2 +24V

CN9,1 SW1

2

1

+24V

+24V I/L

ZD1

K

RD12EB1

12V

Test pat59

A

4.7K

B

Test pat60

R5

C

E

SGND

Q1

FA1L3N

This circuit is used to sense the sorter set state, and is connected with the microswitch. When the sorter is installed to the main body, the contact is

closed. The microswitch is connected in series to +24V, and directly switches the power to each drive section. That is, each drive section is not

operated if the switch is open.

When the sorter set switch is on, +24V is applied to the cathode of ZD1, and a current flows through the base of Q1, turning on Q1 to input to IC11

59 pin.

– 28 –

Page 31

C. Motor control circuit

[a] Transport motor drive circuit

This circuit is used to drive the motor which takes paper discharged from the main body into the sorter. The drive signal (ON at LOW) outputted from

the CPU is passed through the invertor (IC12.6) and the HIGH output is inputted to the MOSFET (Q5) gate, turning on Q5. As a result, a current

flows through +24I/L → the motor → Q5 → PGROUND to rotate the motor counterclockwise.

+24V I/L

D2

+5V

IC11

Test pat54 Tes t pat53

47

R32

10K

IC12.6

13

HD74HC14FP

[b] Bin shift motor (M2) drive circuit

VCC-+5V

GND-SGND

Limit sensor signal

Bin home sensor signal

IC11

19

18

48

5

6

HD74H C02F P

IC7.2Y

4

Test pat37

12

13

HD74HC32FP

M2 CW/*CCW

M2 *ON/OFF

M2 PWM

9

10

HD74H C32F P

IC4.4Y

IC4.3Y

Test pat39

11

8

11

HD74HC14FP

VCC-+5V

GND-SGND

Test pat49

Test pat41

Test pat38

IC2.5

12

+5V

10

R14

R23

Test pat67

10K

R22

x 3

8

9

HD74HC02FP

VCC-+5V

GND-SGND

11

12

HD74HC02FP

IC7.3Y

IC7.4Y

R10

1.5K

Test pat48

10

HD74H C 08F P

VCC-+5V

GND-SGND

Test pat40

13

Test pat42

9

IC10.3 Y

10

12

IC10.4 Y

13

HD74H C08F P

D

G

S

PGND

1

IC10.1 Y

2

HD74HC08FP

4

IC10.2 Y

5

HD74HC08FP

VCC-+5V

GND-SGND

Test pat47

8

11

Q5

2SK1283

IC2.4

9

HD74HC14FP

Test

3

pat44

Test pat45

6

Test pat43

HRP22

A

Test pat46

B

B

K

8

HD74HC14FP

Test pat52

C

C

IC2.6

13

Q4

FC146

E

12

R1

1.5K

R55

1.0K

SGND

R4

1.5K

1

2

M1

G

C13

1000PF

Test pat50

S

D

D

G

S

Test pat51

CN7,1+24V

CN7,2

R60

1.0K

+24V I/L

Q7

2SJ263

Q6

2SJ263

Q9

2SK1895

Q8

2SK1895

PGND

M1

Transpor t motor

R3

S

G

1.5K

D

D

S

C14

1000PF

R2

1.5K

2

M2_A CN8,2

1

CN8,1

M2_B

G

M2

Bin shi f t mot or

This circuit is used to control rotation, stop and rotating direction of the bin shift motor, and is composed of the logic IC and the pow er M O SFE T (Q 6

∼ Q9).

The rotation, stop and rotating direction of the motor are controlled by the combination of output logics of CPU 18 pin and 19 pin. The CPU 48 pin is

the PWM output pin for speed control.

First, in the normal rotation of the motor, the CPU 18 pin is LOW, 19 pin is HIGH, 48 pin is HIGH, IC10 p pin and 12 pin are HIGH. Then IC10 6 pin

becomes HIGH, IC2 8 pin becomes HIGH, conducting Q7 and Q8. On the other hand, since IC10 3 pin is LOW and IC2 12 pin is LOW, Q6 and Q8

is shut off. Therefore, a current flows through +24VI/L → Q7 → CN8.1 → Motor → CN8.2 → Q8 → PGROUND to rotate the motor clockwise (when

viewed from the output shaft).

Under this state, when the CPU 48 pin (PWM signal) is drive to LOW, IC10 6 pin becomes LOW to turn off Q7, interrupting power supply from +24V.

However, a regenerative current generated by the motor coil inductance flows through PGROUND → Q8 flywheel diode → CN8.2 → motor →

CN8.1 → Q9 → PGROUND. In this case, the motor rotates in reduced speeds. The motor speed is controlled by controlling the pulse of the power

applied to the motor by adjusting the H/L duty of the PWM signal.

Next, in the reverse rotation, the CPU 18 pin is driven to LOW, 19 pin LOW, and IC10 9 pin and 12 pin HIGH, IC10 3 pin becomes HIGH and IC12

12 pin becomes LOW to turn on Q6 and Q9 and turn off Q7 and Q8. As a result, a current flows through +24V → Q6 → CN8.2 → motor → CN8.1 →

Q9 → PGROUND in the reverse direction of the normal rotation, rotating the motor counterclockwise. The speed control is performed in the same

manner as the normal rotation.

To stop the motor, the CPU 18 pin is driven to HIGH, IC10 3 pin and 6 pin become LOW, IC2 8 pin and 12 pin become HIGH, Q6 and Q7 are turned

off, Q8 and Q9 are turned on, and the both terminals of the motor are shorted to apply the brake. In the brake mode, a strong braking torque is

generated to stop the motor.

When the bin reaches the limit position, the limit sensor signal and the bin home sensor signal are combined to control the stop signal of the motor.

At the upper limit, only the limit sensor senses the signal, and the limit sensor signal becomes LOW and the home sensor signal becomes HIGH.

Therefore IC4 8 pin becomes LOW, IC4 11 pin becomes HIGH, and Q7 is turned off to stop the motor.

At the lower limit, both of the limit sensor and the bin home sensor sense signals, the limit sensor signal is LOW, and the home sensor signal is

LOW. Therefore IC4 11 pin is LOW and IC4 8 pin is HIGH, and Q6 is turned off to stop the motor.

– 29 –

Page 32

D. Other circuits

[a] Display panel OPPANEL) drive circuit

This circuit is used for operation of the operator.

IC11

+5V

SW1.4

KSD04

49

57

Test pat55

R73

10K

45

C21

1µF

B

R20

10

+5V

E

C

+5V

Q3

FN1L3N

R21

10K

Test pat56

R76

2

75

3

1

4

SGND

N.C

BUZ

CN6,2

CN6,3

CN6,1PSW2

CN6,4SGND

Alarm buzzer

(BZ1)

Take-out switch

(PSW2)

1) Take-out switch input circuit

This switch sensor circuit is used to enter the take out mode. When the switch is on, the LOW signal is inputted to the CPU 57 pin. R20 and C10

form a noise filter.

2) Take-out buzzer output circuit

This circuit is used to control the alarm buzzer in the take-out mode. When the CPU 49 pin is driven to LOW, the collector of Q3 becomes HIGH

to sound the buzzer. If the 4th setting notch of SW1 on the control PWB is set to OFF, the buzzer will not sound.

[b] DIP switch circu it

This circuit is used to set the operation mode for single operation of the sorter.

+5V

10K

x 4

R27

R24

R25

R26

IC11

51

52

53

54

SGND

KSD04

8

7

6

3

4

SKHHPK

SW1.1

1

SW1.2

2

3

SW1.3

1

PSW1

2

FG-SGND

When SW1 1 ∼ 1.4 are set to O N, IC11 51, 52, 53, 54 pins ar e driven to LOW.

E. Power circuit

This circuit is used to supply DC power from the main body.

(+24V)

TP1

TP2

+24V

(PGND)

(+5V)

(SGND)

TP4

K

A

D3

P10-4002

C18

100µF

PGND

+5V

C15

0.10µF

TP3

SGND

+

C19

47µF

CN2,3 +5V

CN2,4 SGND

CN2,1 +24V

CN2,2 PGND

3

K

ZD2

RD6^2FB

6.2V

A

4

1

C4

0.010µF

2

+

C15 and C18 are capacitors for removing +5V noises and smoothing, and C4 and C19 are capacitors for removing +27V noises and smoothing.

ZD2 and ZD3 are provided for protect the IC’s on the PWB from an overvoltage when connecting or disconnecting the connector (CN2) for power

supply.

– 30 –

Page 33

AB C

CIRCUIT DIAGRAM

D

E

F

G

H

I

6

+5V

N.C

SEN2AN

SEN2

SGND

SEN1AN

SEN1

SGND

SEN4AN

SEN4

SGND

SEN3AN

SEN3

SGND

+5V

SEN7

SGND

+5V

SEN6

SGND

+5V

SEN8

SGND

SEN5_CLK

+5V

+5V

SEN5

SGND

+5V

20

IC1

10

SGND

7

8

10

9

4

6

5

1

3

2

11

13

12

7

8

9

4

5

6

1

2

3

2

1

1

2

3

4

3

1

2

5

6

7

8

2

1

3

4

1

2

SGND

+5V

SGND

+24V I/L

+5V

R6

470

+24V

K

A

C24

0.10µF

+5V

R34

200K

R50

2.0K

R8

ZD1

KA

RD12EB1

12V

ZD2

RD6^2FB

6.2V

C4

0.010µF

R68

R61

R69

R58

+5V

C6

0.10µF

R7

4.7K

SGND

+

CN10,7

CN10,8

CN10,10

CN10,9

CN10,4

CN10,6

CN10,5

CN10,1

CN10,3

CN10,2

CN10,11

5

CN10,13

CN10,12

CN3,7

CN3,8

CN3,9

CN3,4

CN3,5

CN3,6

CN3,1

CN3,2

CN3,3

CN4,2

4

3

2

CN4,1

CN5,1

CN5,2

CN5,3

CN1,4 TXD

CN1,3 RXD

CN1,1 DTR

CN1,2 DSR

CN1,5 RESET

CN1,6 SGND

CN1,7 JINT

CN1,8 N.C

CN9,2 +24V

CN9,1 SW1

CN2,3 +5V

CN2,4 SGND

CN2,1 +24V

CN2,2 PGND

1

430 x 4

SEN4AN

Q2

2SC2712

R64

R63

R62

R5

4.7K

C18

100µF

PGND

Test pat14

Test pat22

100

100

100

Test pat60

+

C19

47µF

+5V

14

IC2

7

SGND

C

E

SGND

SGND

SGND

+5V

10K

x 3

R16

R57

R65

R35

10K

R15

10K

B

R31

10K

+5V

R51

100K

R67

4.7K

Test pat23

C20

100PF

Test pat29

C16

100PF

Test pat60

C2

0.10µF

B

C15

0.10µF

TP3

C25

0.10µF

(+24V)

TP1 (+5V)

+24V

+5V

R43

R42

R41

Test pat15

R52

3.6K

Test pat21

34

56

IC2.1

12

Test pat59

C

Q1

FA1L3N

E

SGND

TP2

(SGND)

TP4

(PGND)

30K x 4

R29

R36

10K

+5V

SGND

IC2.3

K

A

+5V

IC3

SGND

Test pat1

R28

10K

Test pat2

R39

10K

Test pat3

R38

10K

Test pat4

R37

10K

Test pat5

Test pat6

Test pat7

C9 C8 C3 C7 C12 C1 C5

1000PF

x 2

SGND

Test pat16

1

Test pat24

12

34

10 11

HD74HC14FP

+5V

R40

4.7K

VCC-+5V

GND-SGND

C23

0.10µF

Test pat31

IC12.5

Test pat17

Test pat20

+5V

R56

4.7K

Test pat63

R53

12K

IC2.2

HD74HC14FP

HD74HC14FP

HD74HC14FP

+5V

R30

10K

D3

P10-4002

+5V

SGND

14

7

R54

56K

3

+

IC9.1

2

-

µPC393G2

VCC-+5V

GND-SGND

IC6.1

HD74LS06FP

IC6.2

HD74LS06FP

SW1

C21

1µF

C26

0.10µF

SEN4AN

+5V

4

3

2

1

VDD-+5V

GND-SGND

*SET

R59

4.7K

Test pat25

IC6.3

65

+5V

5

VCC

4

GND

+5V

14

IC4

7

SGND

IC12.1

12

HD74HC14FP

IC12.2

34

HD74HC14FP

IC12.3

56

HD74HC14FP

R19

10K

R18

SEN7

10K

R17

SEN6

10K

VCC-+5V

IC12.4

GND-SGND

98

HD74HC14FP

0.010µF

x 5

R70

1.0K

+5V

R71

10K

IC3.1

Test pat18

5

*PR

Q

CLK

6

D

*Q

*CLR

HD74HC74FP

R46

1.0K

DI

Test pat27

Test pat28

Test pat32

RES

IC5

MB3773FP

VS

SGND

C27

0.10µF

Test pat26

2

CK

*RES

CT

VREF

7

C22

470PF

HD74LS06FP

*SEN2

*SEN1

*SEN4

SEN3

Test pat13

LIMIT

Test pat62

*SEN5_CLK

+5V

R13

10K

R9

1.0K

DTR

DSR

D1

DSA010

KA

3

8

1

6

11 10

Test pat10

Test pat11

Test pat12

Test pat61

SCK

D0

+5V

R72

10K

W_DOGCLK

Test pat33

C17

1µF

IC6.5

HD74LS06FP

SGND

Test pat9

Test pat19

+5V

14

IC6

7

Test pat8

SEN5

SGND

RXD

TXD

R48

1.0K

19 8

HD74LS06FP

+

+5V

R74

10K

+5V

Test pat66

R47

1.0K

+5V

IC6.4

Test pat35

C28

0.10µF

*SEN2

SGND

LIMIT

*PSW2

SW1

VDD-+5V

VSS-SGND

61

P75/ANI5

62

P76/ANI6

63

P77/ANI7

64

AVdd

65

AVref1

66

AVss

67

ANO0

68

ANO1

69

AVref2

70

AVref3

71

P20/NMI

72

P21/INTP0

73

P22/INTP1

74

P23/INTP2/CI

75

P24/INTP3

76

P25/INTP4/ASCK

77

P26/INTP5

78

P27/SI

79

P30/RXD

80

P31/TXD

R75

10K

Test pat64

KSD04

8

7

6

3

4

SKHHPK

6059585756

P74/ANI4

P32/SCK

P33/SO/SB0

P34/TO0

1234567

Test pat65

*SEN5_CLK

W_DOGCLK

2

IC7.1Y

3

HD74HC02FP

VCC-+5V

GND-SGND

LIMIT

*SEN2

+5V

14

IC7

7

SGND

1

SW1.1

2

SW1.2

3

SW1.3

1

PSW1

FG-SGND

2

Test pat50

P73/ANI3

P35/TO1

P36/TO2

Test pat36

+5V

10K

x 4

R27

R24

R25

R26

*BUZ

Test pat57

54535251504948474644434241

P17

P16

P15

P14

P13

P72/ANI2

P71/ANI1

P37/TO3

1

C29

0.10µF

P70/ANI0

IC11

µPD78233GC-3B9

RESET

X2X1PO0

9

2

SGND

5

IC7.2Y

6

HD74HC02FP

P12

PO1

PO2

10

Test pat34

PO3

121314151617181920

13

OSC1

CST9^83MTW

R33

10K

C11

1000PF

12

13

10

4

Test pat37

+5V

14

IC8

28

SGND

R12

1.0K

+5V

P11/P WM1

P10/P WM0

PO4

+5V

SGND

*CWSTOP

VCC-+5V

GND-SGND

HD74HC32FP

9

HD74HC32FP

MODE

PO5

PO6

M2 *ON/OFF

*M2_PWM

IC4.4Y

IC4.3Y

C30

0.10µF

ASTB

PO7

*CCWSTOP

SW1.4

KSD04

CS

*BUZ

*M2_PWM

*M1

P40/AD0

P41/AD1

P67/REF RQ

M2 CW/*CCW

11

8

45

*PSW2

P42/AD2

P43/AD3

P44/AD4

P45/AD5

P46/AD6

P47/AD7

P50/A8

P51/A9

P52/A10

P53/A11

P54/A12

P55/A13

P56/A14

P57/A15

P60/A16

P61/A17

P62/A18

P63/A19

P64/RD

P65/WR

P66/WAIT

Test pat39

Test pat49

Test pat41

Test pat38

IC2.5

11 10

HD74HC14FP

*CCWSTOP

VCC-+5V

GND-SGND

*CWSTOP

+5V

+5V

IC9

SGND

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

R14

+5V

R73

10K

Test pat55

AD(8)

AD(9)

AD(10)

AD(11)

AD(12)

AD(13)

AD(14)

AD(15)

R23

Test pat67

8

4

+5V

E

Test pat48

10

HD74HC08FP

VCC-+5V

GND-SGND

Test pat40

13

Test pat42

1

IC4.1Y

2

HD74HC32FP

VCC-+5V

GND-SGND

C

R20

10K

RA1 10K

+5V

9

10

12

13

Q3

FN1L3N

11

SGND

R32

10K

IC10.3Y

IC10.4Y

HD74HC08FP

VCC-+5V

GND-SGND

3

+5V

IC10

SGND

1

3

4

7

8

13

14

17

18

13 12

1

2

4

5

28

14

B

C10

1000PF

RA2 10K

SGND

+5V

AD(0)

AD(1)

AD(2)

AD(3)

AD(4)

AD(5)

AD(6)

AD(7)

Test pat54 Test pat53

*M1

R22

10K

x 3

8

IC7.3Y

9

HD74HC02FP

VCC-+5V

GND-SGND

11

IC7.4Y

12

HD74HC02FP

SGND

C31

0.10µF

Test pat56

*0C

G

IC1

1D

2D

3D

4D

5D

6D

7D

8D

HD74HC373FP

VCC-+5V

GND-SGND

AD(0;7)

A(8;15)

IC12.6

HD74HC14FP

Test pat47

8

IC10.1Y

HD74HC08FP

IC10.2Y

HD74HC08FP

11

HD74LS06FP

SGND

R76

75

+5V

R21

10K

RA2 10K

+5V

2

1Q

5

2Q

6

3Q

9

4Q

12

5Q

15

6Q

16

7Q

19

8Q

AD(8)

AD(9)

AD(10)

R10

1.5K

Test pat52

C

C

IC2.6

13 12

HD74HC14FP

5

+

IC9.2

6

-

µPC393G2

+5V

IC11

SGND

Q4

FC146

E

8,55

11,45

R1

1.5K

R55

1.0K

SGND

7

IC2.4

98

Test pat46

HD74HC14FP

Test

3

pat44

B

Test pat45

B

6

Test pat43

IC6.6

1213

SGND SGND SGND

C32

0.10µF

RA1 10K

AD(11)

R4

1.5K

DI

SCK

DO

CS

AD(12)

AD(13)

G

Test pat50

10

11

12

13

HD74HC74FP

C33

AD(14)

PGND

D

S

G

C13

1000PF

*PR

CLK

D

*CLR

+5V

SGND

AD(15)

Q5

2SK1283

G

Test pat51

IC3.2

Q

*Q

C34

0.10µF x 2

20

22

10

25

24

21

23

26

27

S

D

D

9

9

8

7

6

5

4

3

2

8

D2

HRP22

Q6

2SJ263

Q8

2SK1895

R60

1.0K

R66

R49

R45

IC8

*CE

*OE

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

LE27C256F-12Y1

+24V I/L

KA

+24V I/L

Q7

2SJ263

Q9

2SK1895

PGND

4

IC4.2Y

5

HD74HC32FP

R44

R2

1.5K

1.0M

x 4

SGND

O0

O1

O2

O3

O4

O5

O6

O7

SGND

VCC-+5V

VPP-+5V

GND-SGND

11

12

13

15

16

17

18