Page 1

SERVICE MANUAL

CODE: 00ZSFS15SM//E

MODEL SF-S15

CONTENTS

[ 1 ] BASIC SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

[ 2 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

[ 3 ] COMPONENT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

[ 4 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

[ 5 ] DISASEEMBLY, ASSEMBLY AND ADJUSTMENT . . . . . . . . . . . . . . . . . .9

[ 6 ] ELECTRIC CIRCUITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

[ 7 ] ELECTRICAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

[ 8 ] CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

[ 9 ] PWB LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

PARTS GUIDE

Parts marked with "! " is important for maintaining the safety of the set. Be sure to replace these parts with specified ones for

maintaining the safety and performance of the set.

This document has been published to be used for

SHARP CORPORATION

after sales service only.

The contents are subject to change without notice.

Page 2

[1] BASIC SPECIFICATIONS

Name: SF-S15

Type: Floor type

Paper distribution: Gate switching distribution

No. of bins: 20

No. of sheets accommodated: 50 sheets/bin, except for the top bin

(non-sort tray) which accommodates

100 sheets.

• When sorting: 50 sheets

• When grouping: 30 sheets

Paper size

• Non-sorting: A3~A6/11″×17″~8-1/2″×5-1/2″

• Sorting, grouping: A3~A5/11″×17″~8-1/2″×5-1/2″

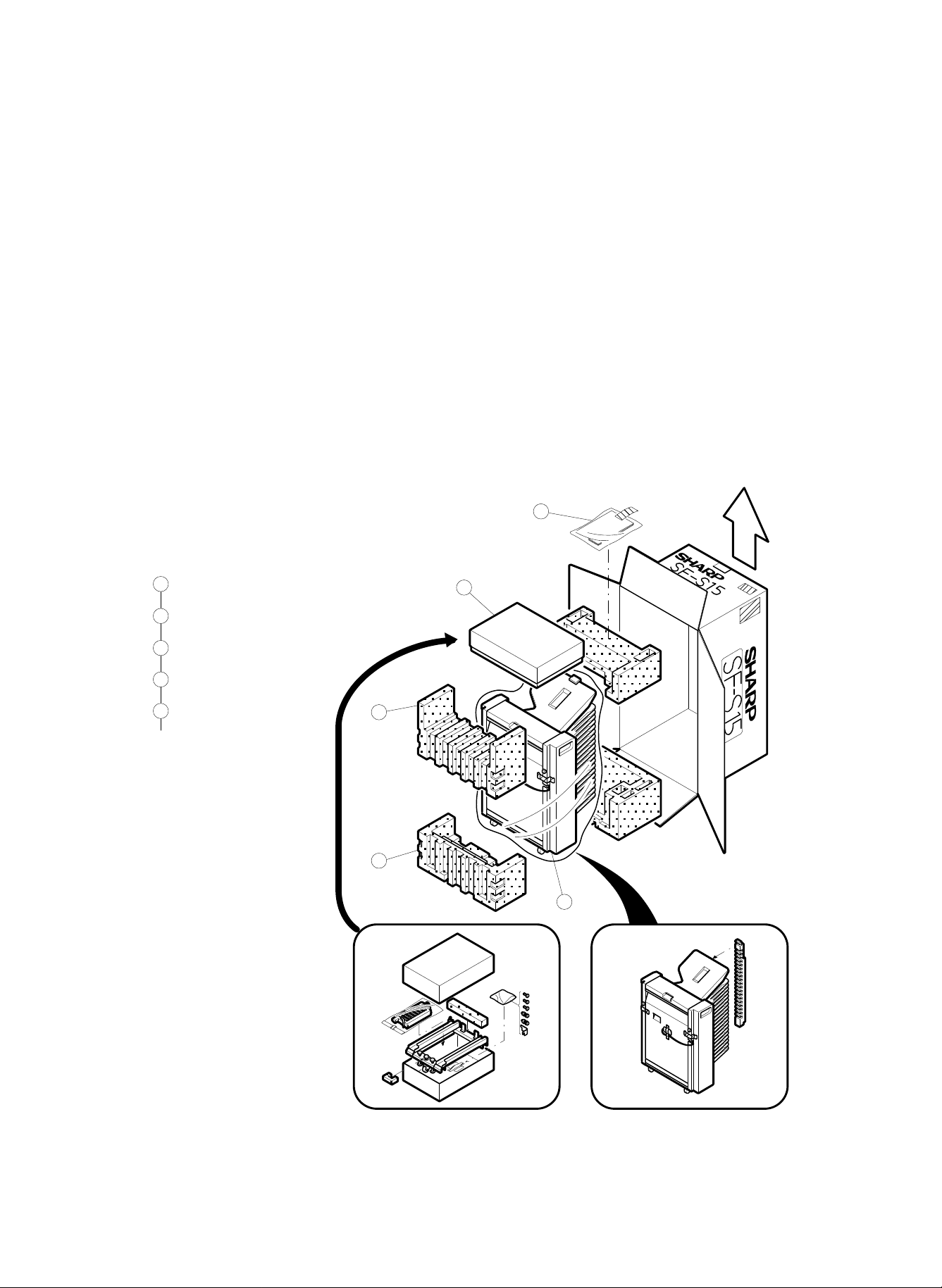

[2] UNP ACKING AND INSTALLATION

1. Unpacking

• Unpack following the flow chart shown below.

Processing capacity: Equivalent to 25 to 60 sheets/min.

Paper transfer: Center reference

Storage: Face up

Paper weight

• Non-sorting: 52~128 g/m

• Sorting, grouping: 56~80 g/m

Power supply: Supplied from copier

Dimensions: 550 (W) x 519 (D) x 924 (H)mm

Weight: 20.3 kg (44.6 pounds)

5

2

(14-31 1bs)

2

(15-21 1bs)

Accessories

1

2

Packing DR

3

Packing DL

4

Sorter

5

Instruction manual set

Subsequent steps omitted.

1

2

3

4

– 1 –

Page 3

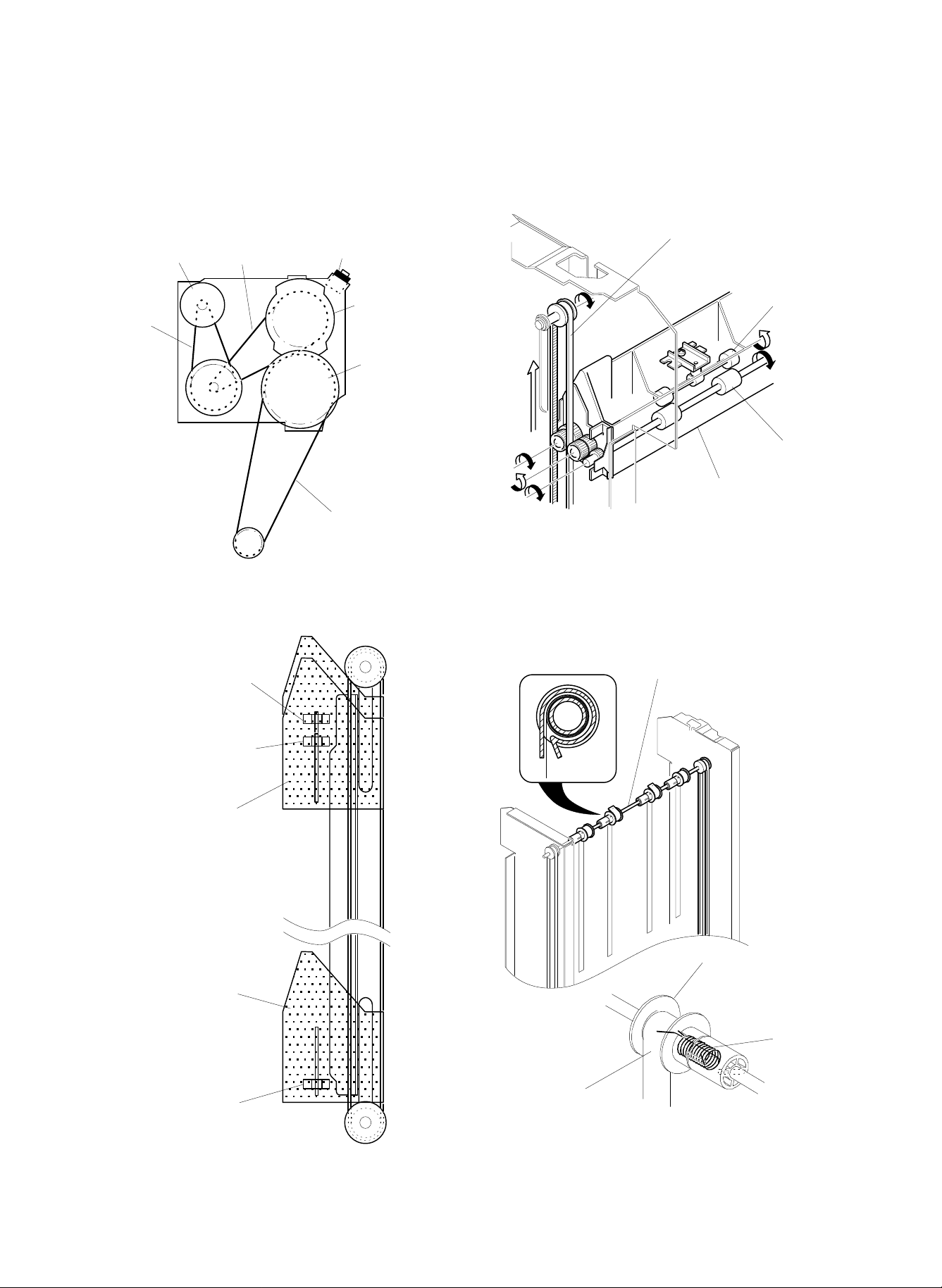

2. Installat ion

• Check the contents of package for specified quantities of the fol-

lowing items.

Accessories

3. Remove the front panel of the sorter.

Loosen the four screws which clamp the front panel of the sorter, and

remove the front panel.

• Install the sorter in the following procedure, after disconnecting the

power cord of the copier.

1. Mount the linkage paper guide.

Mount the linkage paper guide by hooking its two claws in the paper

outlet of the copier as shown below.

2. Install the sorter mount base on the desk.

Cut two notches into the left panel of the desk. Screw two clamp

screws of the sorter mount base into the desk. Hook the sorter mount

base on the two clamp screws A as shown in the figure.

Also attach the sorter clamp fixture on the sorter mount base and

clamp it with a clamp screw B.

4. Mount the sorter on the sorter mount base.

Lift the sorter using the handles, and place the sorter on the mounting

base with the rollers riding along the guide rails. Slide the sorter

gently to the end. Be sure the roller grooves of the sorter are all riding

on the guide rails as shown in the detail drawing below.

– 2 –

Page 4

5. Remove the rear panel of the copier and cut a

notch in the left panel.

Unscrew four clamp screws of the copier’s rear panel and remove the

rear panel. Then cut a notch in the left panel.

7. Replace the rear panel.

Install the rear panel removed in step 5 to its place, and fasten it with

four clamp screws.

8. Install the front panel of the sorter.

Install the front panel removed in step 3 to its place, and fasten it with

four clamp screws.

6. Connect the sorter connector.

Temporarily fix one of the two bracket clamp screws, which are

packed together with the sorter, into the threaded hole shown below.

Hook the lower notch of the bracket on the screw and clamp it on the

upper notch with another clamp screw. Tighten the temporarily fixed

clamp screw. Connect the 6P and 10P connectors of the sorter with

their counterparts of the copier. Fasten the lead wires with twist

bands.

9. Adjust the clearance between sorter and copier.

Press the sorter against the left panel of the copier gently. Adjust the

clearance between the sorter and the copier by turning the adjust

knobs provided on the sorter mount base, using as reference the gap

spacer which is attached on the back of the sorter.

After adjustment, remove the gap spacer.

– 3 –

Page 5

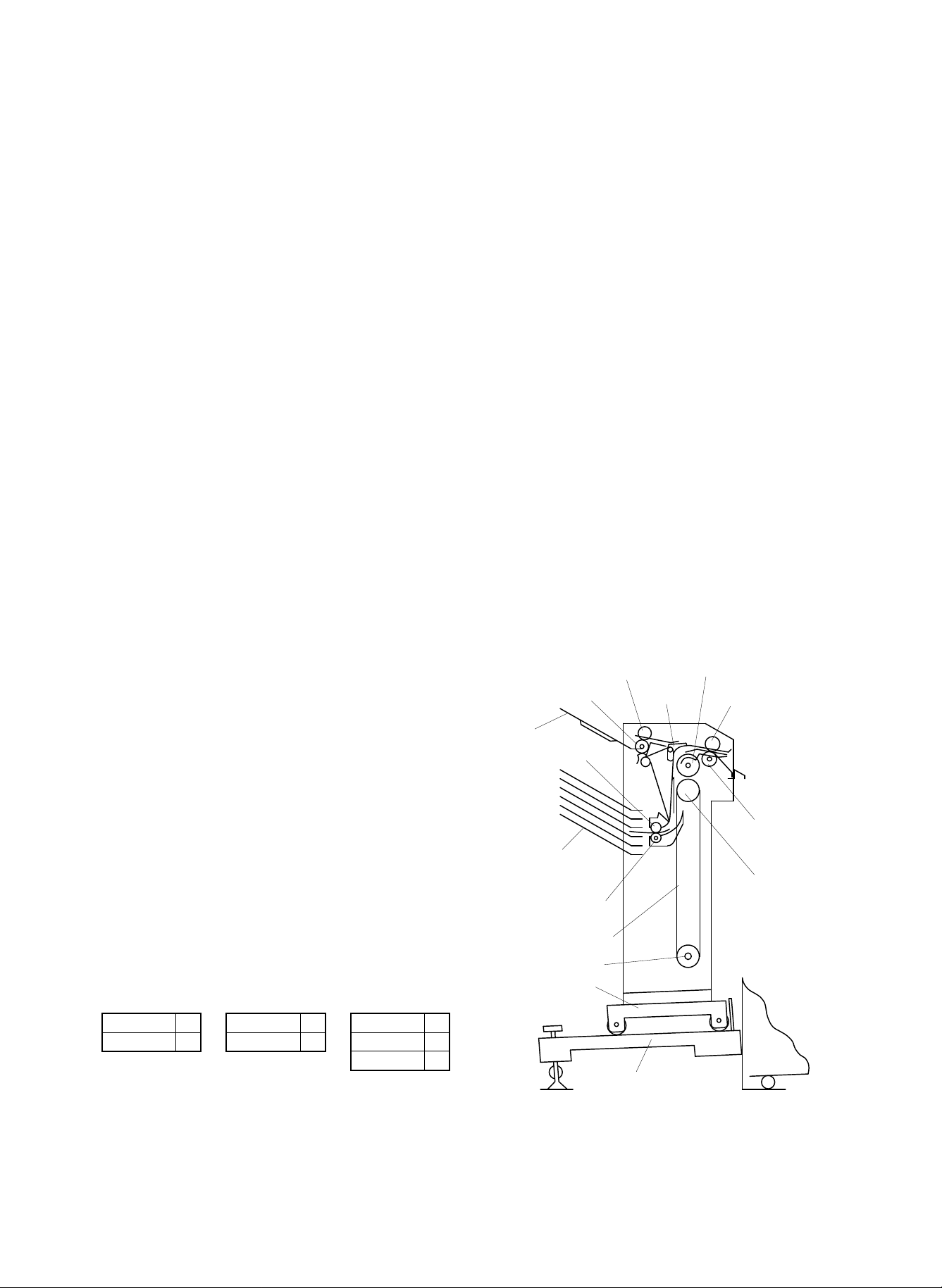

10. Set the option mode.

Discharge roller

Discharge roller

Top bin

Separator

claw

Idle roller

Feed roller

Discharge roller

Belt-driven roller

Sort bin

Eject roller

Suction belt

Belt-drive roller

Carrier rail

Sorter mount base

• Set the option mode by the keypad on the copier.

[3] CONPONENT IDENTIFICATION

1. External view

The above operation makes the current setting displayed.

• If SF-S15 only is to be set, the above operation should be followed

by the following key operation to set the mode.

• If mode setting is to be done in combination with other option, add

the values which correspond to the peripheral devices to be set

and enter the sum.

ex. To set SF-S15 and SF-A54, key in as follows since the value

corresponding to the peripherals to be set is 1 + 10 = 11.

2. Internal structure

SF-A54 1 SF-D20 4 SF-S14 10

SF-A14 1 SD-D21 4 SF-S15 10

SF-S52 10

– 4 –

Page 6

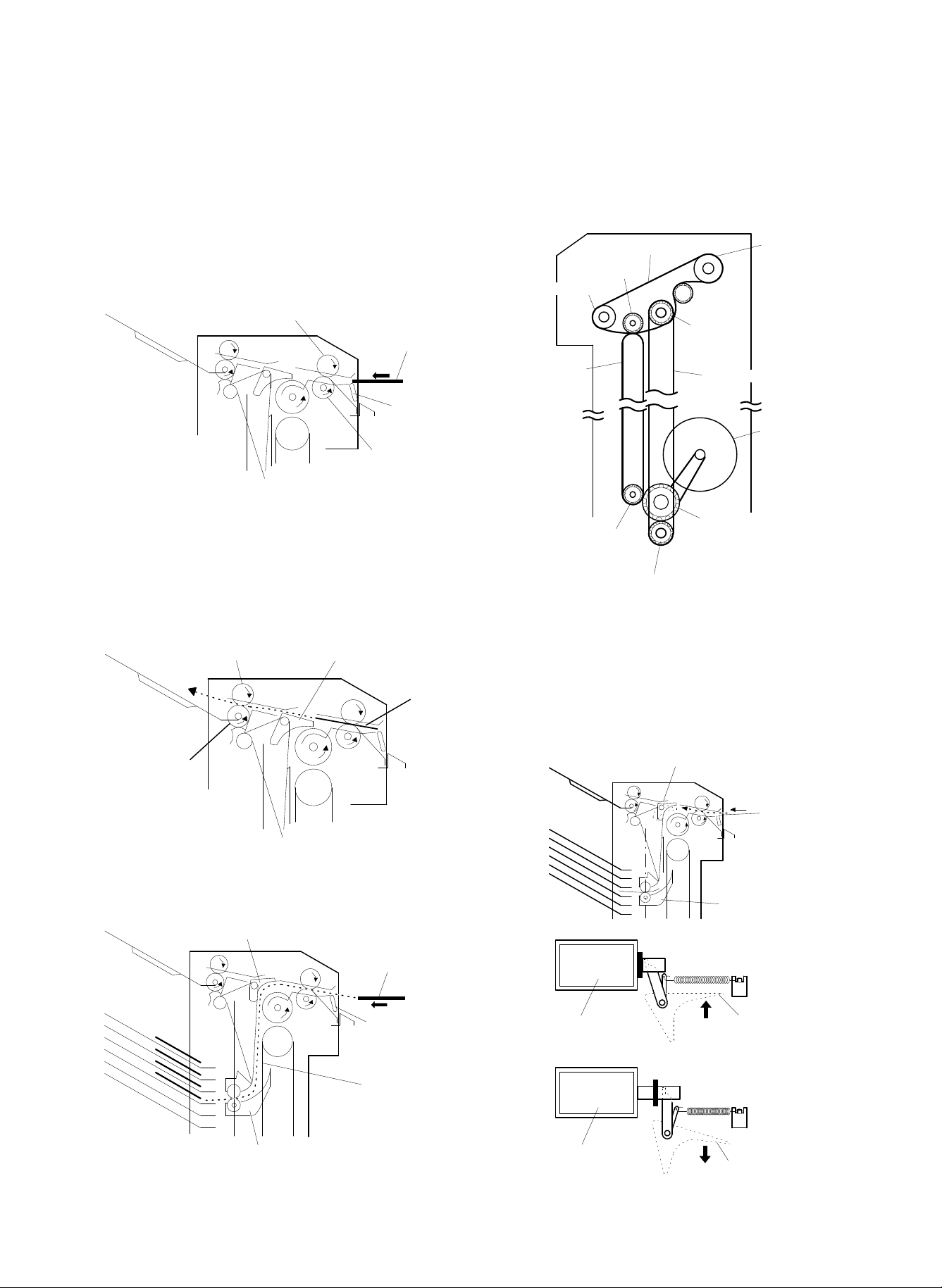

[4] OPERATIONAL DESCRIPTIONS

Timing belt

Pulley 23T

Pulley 23T

Paper feed

roller

Suction belt

Gear 23T

Gear 24T

High trail pulley

Transfer motor

Exit roller

Pulley 20T

Pulley 24T

Transfer belt

Separator claw

Indxer

Solenoid

Separator claw

Solenoid

Separator claw

Solenoid ON (When sorting or grouping)

Solenoid OFF (When non-sorting)

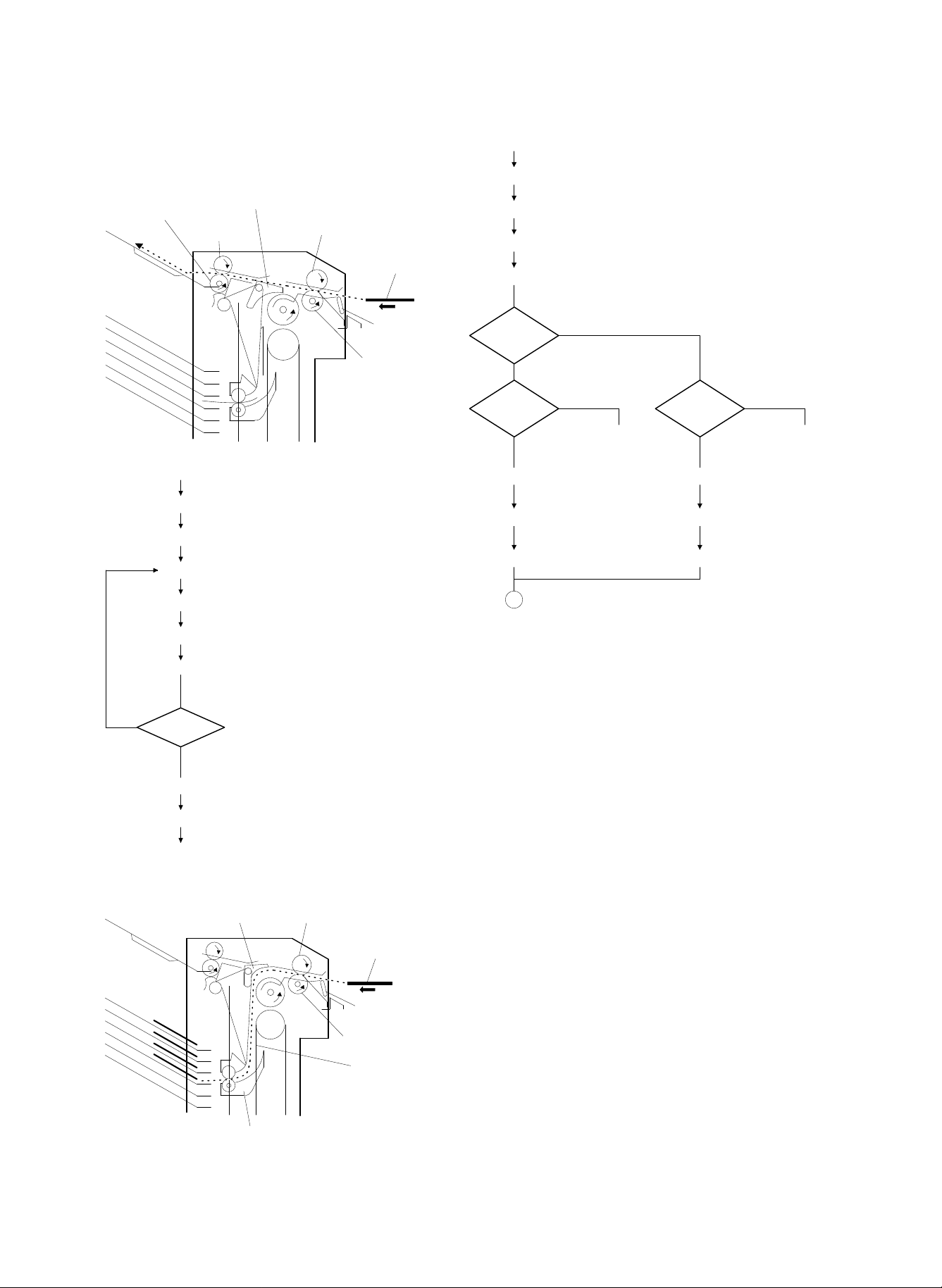

3. Driving mechanism of the transfer

section

1. Feeder section

• Copy paper discharged from the copier is fed along the paper

entry guide.

• A paper entry paper sensor is provided halfway along the paper

entry guide to detect the paper entry of paper.

• Feed rollers catch the paper to send it to the transfer section.

Feed roller

Copy paper

Paper

entry

sensor

Feed roller

2. Transfer section

• The paper passage is switched by a separator claw between one

to the top bin (bin 1) and one to bins 2 through 20.

<Non-sorting operation>

The separator pawl rests on the lower position so that the paper

passes over the pawl to be transferr through the discharge rollers into

the non-sorting bin (top bin).

Discharge roller

Non-sorting bin

(Top bin)

Separator claw

(lowers upon solenoid OFF)

Paper

The feed rollers and the discharge rollers are driven by the transfer

motor via a high trail pulley, gear 24T, transfer belt, pulley 24T and

timing belt.

4. Separator section

• The solenoid-driven separator claw selects the paper passage be-

tween non-sorting and sorting paths.

• When the solenoid is OFF, the separator claw is in the lower

position so that the paper is discharged into the non- sorting bin.

• When the solenoid is ON, the separator claw is in the upper posi-

tion so that the paper is transferred by the suction belt and discharged into bins 2 through 20 by the indexer successively.

Discharge roller

<Sorting operation>

The separator pawl is in the lifted position so that the paper passes

under the pawl and is transferred by the suction belt to the indexer

which discharges the paper.

Indexer (Goes up or down by 1 bin after discharging paper.)

Separator claw (rises upon solenoid ON)

Paper (.. indicates

transfer passage.)

Suction belt

– 5 –

Page 7

5. Indexer sectio n

Drive belt

Discharge roller

Discharge roller

Indexer

Reel shaft

Reel

Reel spring

Riil film

6. Roller driving mechanism in the indexer

• Shifting operation of the indexer is driven by the shift motor.

• Indexing is performed by starting and stopping the shift motor

according to the ON/OFF of the Geneva. The sensor detects cuts

on the circumference of the Geneva gear while the gear rotates. A

half turn of the Geneva gear causes the indexer to make one shift.

Geneva sensor

Geneva gear

Wheel gear

Belt

Belt

Shift motor

Belt

• Rotation of the indexer is controlled from the copier.

Provided at top of the indexing mechanism are home position

sensor and upper limit sensor (over-run protection). Provided at

the bottom is the lower limit sensor.

• The discharge rollers in the indexer are driven by the transfer

motor via the high trail pulley, gear 24T and drive belt.

7. Reel film

• Reel film is stretched between the reel shaft and the indexer.

• The reel film is wound around the reel and is kept tight by a reel

spring.

Home position sensor

Upper limit sensor

Indexer

Indexer

Lower limit sensor

– 6 –

Page 8

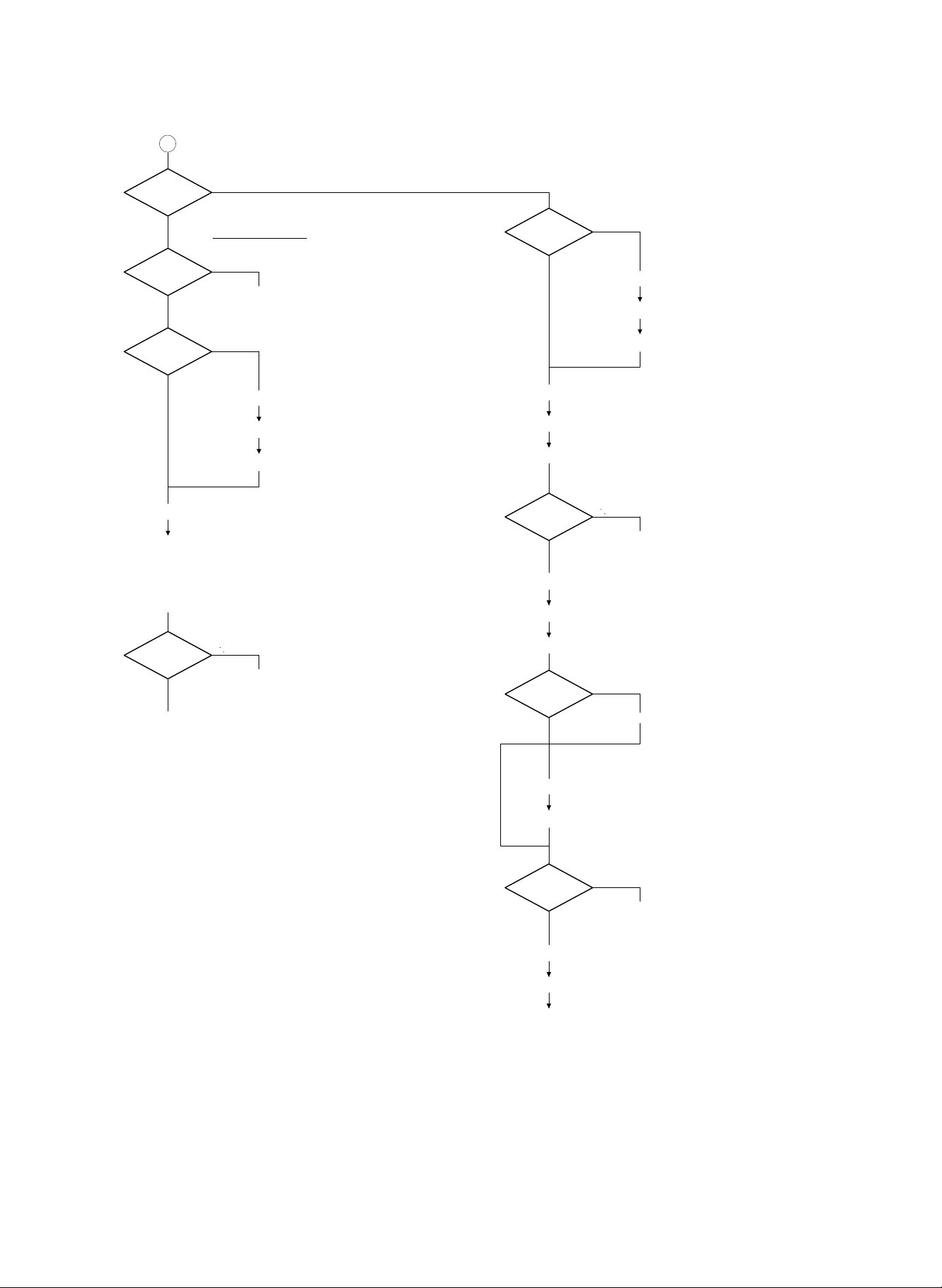

8. Operation seq uen ce

Start

STEP1

STEP2

STEP 3

STEP4

Print SW ON

Sorter fan motor ON

Sorter paper transfer motor ON

(discharge bin information, paper size information

included)

STEP18

STEP19

STEP20

1

Discharge

paper to bin 1?

Previous

paper passed

inlet sens or ?

Yes

Yes

No

No

Previous

paper passed

inlet sensor?

Yes

No

STEP 5

STEP 6

STEP 7

To STEP7 To STEP7

Solenoid ON timer

starts.

Solenoid ON timer

time-up

Solenoid ON

Solenoid OFF timer

starts.

Solenoid OFF timer

time-up

Solenoid OFF

<Non-sorting mode>

Discharge roller

Start

STEP1

STEP2

STEP3

STEP4

Separator claw

Discharge

roller

Feed roller

Feed roller

∗

··· ··· indicates transfer

passage.

Print SW ON

Sorter fan motor ON

Discharge signal received (discharge bin

information, paper size information included)

Sorter paper tr ansfer motor O N

Paper

Paper entry

sensor

Sorter inlet sensor ON

Sort er in let sensor OFF,

All load OFF timer starts.

All load OFF timer time-up

Fan motor, transfer motor OFF

Present

STEP5

STEP6

Next paper

STEP7

STEP8

End

<Sort/grouping mode>

⋅⋅⋅indicates paper transfer passage.

Separator claw

Indexer

Feed roller

Paper

Paper entry switch

Feed riller

Suction belt

– 7 –

Page 9

1

Discharge bin

information

> current bin position

< = C ur r e nt bin p o s it i o n

Discharge bin

information

= Current bin position

To STEP12

< Current bin position

Is previous paper

accommodated?

No

Yes

STEP24

STEP25

STEP26

STEP21

Indexer motor runs to lift.

STEP22

Indexer position sensor OFF

STEP23

Indexer position sensor ON

Previ ous paper dis c harge sens or OF F

Indexer ON timer starts.

Indexer ON timer tim e-up

Previous paper

accommodated

No

Yes

STEP27

Previous paper discharge

sensor O F F

STEP 8

STEP28

STEP29

Indexer motor runs to lift.

Indexer ON timer starts.

Indexer ON timer time-up

STEP9 Indexer position sensor OFF

STEP10 Indexer position sensor ON

Discharge bin

information

= Current bin position

To STEP8

= Current bin position

To ST EP11

To ST EP12

Indexer motor stops.

Sorter inlet se nsor ON

Discharge bin

information

To ST EP11

= Current bin position

To STEP12

= Current bin position

To ST EP13

Discharge paper

to bin 1?

No

Sorter inlet sensor OFF

Yes

All load OFF timer starts.

STEP14 Sorter discharge sensor ON

STEP15

Sorter discharge sensor OFF,

All load OFF timer st art s.

Next paper

No

STEP 9

STEP10

Present

To STEP3

All load OFF timer time-up

Sorter fan motor, Sorter paper transfer motor,

solenoid OFF

END

– 8 –

Page 10

[5] DISASSEMBLY, ASSEMBLY AND

Tray

Locking claw

Locking

claw

Front cover

Rear cover

Blower cover

Stepped screw

Blower stopper

Screw

Connector

Earth cable

Screw

Blower stopper

ADJUSTMENTS

Note: The sorter is equipped with casters. Ensure the sorter is not

allowed to roll away.

1. External parts

a. Loosen four screws of each of the front and rear covers, located

as indicated by the arrows in the figure below.

Front cover

Rear

cover

Rear

cover

Discharge side

<Precautions on assembly>

• Install the front and rear covers using their top as reference.

• When installing the rear cover, pay attention to the motor and

cables.

b. To remove the top cover, unscrew the two screws indicated by

arrows as shown below.

Feed side

2. Blower sectio n

(1) Blower unit

a. Remove the front and rear covers.

b. Unscrew the six screws shown in the figure below, and remove

the blower cover.

Reassemble

starting from top tray

Remove

starting from

bottom tray

c. Remove the tray, by pulling the tray toward you while pressing

down the lock pieces on both sides.

Note: The non-sorting tray (top bin) can be taken out and mounted

individually, but other trays must be removed in order starting

with the bottom tray, and mounted starting with the top.

c. Disconnect the connector and the earth cable.

d. Unscrew the two stepped screws which clamp the blower unit.

e. Unscrew four screws and remove the two blower stoppers.

– 9 –

Page 11

f. Remove the blower unit, with care not to hit the gear 23T with the

Screws

Screws

Support plate

E ring

Drive gear

Pin

Bearing

E ring

Suction belt roller

Bearing

Support plate

Screws

Fan motor

E ring

Sensor

cover

Screw

Screw

Screw

Magnetic

catches

E ring

Bearing

Screws

Bearing

E ring

Pin

G20T gear

E ring

Timing belt

First loosen this screw

angle.

Blower unit

Gear 23T

[Cautions on assembly]

• Assembly should be done in reverse order of disassembly.

• After setting the blower cover on the blower unit with six screws,

check as follows.

With the blower unit locked on the frame, check the dimension A in

figure below to see if A equals 2

smaller than 2mm, the blower belt may touch the indexer.

+0.5

mm. If this cle ara nce is

–0

(2) Disassembly of blower unit

a. Remove the blower unit from the frame in the procedure shown in

2.(1), a~f.

b. Remove the fan motor by removing cable bands, connectors and

three screws.

c. Unscrew six screws and remove two reinforcement plates.

d. Remove two blower belts.

e. Remove three E rings, drive gear 23T, parallel pin and two bear-

ings, to remove the blower belt roller.

Frame

Screw

Blower unit frame

Locking claw

A

+0.5

2

mm

-0

After adjustment, apply screw locking paint to the screw.

3. Dismount of feed roller

a. Remove the front and rear covers, to open the top cover.

b. Unscrew the clamp screw of the tension pulley and remove the

timing belt.

c. Unscrew four screws and remove the two magnet catches.

d. Remove the three E rings which fasten the feed roller, gear 24T,

parallel pin and two bearings.

e. Among three screws fastening the right and left, each, of each of

the upper and lower paper entry guides, unscrew two and loosen

one.

– 10 –

Page 12

f. Lower the lower paper entry guide in the direction indicated by

Remove screw

Solenoid

Top cover

Non-sort tray

E ring

Parallel pin

E ring

Timing belt

Bearing

Discharge roller

Bearing

E ring

Drive gear

A

2±0.3mm

Top guide

Separator claw

Guide roller

Solenoid

E ring

Within 8.0mm

Rubber washer

arrow in figure, lift the upper paper entry guide, and take out the

feed roller from the frame.

Note: Exercise care when pulling out the feed roller so as not to

damage the paper entry switch.

Paper entry switch

Upper entry

guide

Lower entry

guide

4. Dismounting of discharge roller

a. Remove the front and rear covers, to open the top cover.

b. Unscrew the clamp screw of the tension pulley and remove the

timing belt.

c. Remove the non-sorting tray.

d. Unscrew two screws and remove the solenoid.

e. Remove the three E rings, two bearings, parallel pin and the drive

gear.

Note: Be careful not to lose the parallel pin.

f. Remove the discharge roller.

Paper entry rollers

[Cautions on assembly]

• When setting the magnet catch for the clamping of the top cover,

clamp it with two screws while pressing the bend-up of the top

guide against the paper entry guide. Apply screw locking agent to

the screws after the adjustment described below.

<Adjustment>

1 Clearance between the bend-up and the paper entry guide

must be within 0.5mm when attracted by the magnet.

2 When the top cover is released at a position where its front

edge is 5mm high, it must be attracted by the magnet.

Top cover

Entry guide

GAP within 0.5mm

<Cautions on assembly>

• When setting the solenoid, exercise the following caution.

1 The solenoid must be set so that when it is pulling the clear-

ance between the separator claw and the guide roller is

2±0.3mm. The stroke of solenoid actuation should be within

8.0mm.

Note: When measuring the solenoid stroke, press the plunger in the

direction of arrow to remove play.

– 11 –

Page 13

2 After adjustment, apply screw locking paint to the two screws

Reel film

Transfer timing belt

Drive

timing belt

Slide

washer

Screw

Screw

Indexer

gear plate

Indexer

Screw

AB

Indexer

Fixed

screws

Loosen

screws

to adjust

Frame slit for bin fixing plate

which clamp the solenoid.

• When setting the timing belt and clamping the tension pulley parts,

check the following.

Loosen the W sems and check the tension pulley assembly to see

if it moves up and down smoothly. Then tighten the W sems to

clamp the tension pulley assembly.

This is because loosening of the W sems makes the tension spring

pull the tension pulley assembly upward resulting in proper tension

in the timing belt.

W sems

Tension spring

Timing belt

Tension pulley assembly

5. Dismounting the indexer

a. Remove the front and rear covers.

b. Remove the blower unit from the frame in the procedure de-

scribed in 2 (1), a~f.

c. Lower the indexer to a position around bin 13 where access with a

screwdriver is obtained.

Note: The indexer can be moved up or down by turning the gear

of the indexer drive motor by hand.

Indexer drive

motor gear

e. Unscrew the screws and remove the indexer gear and the slide

washer.

f. Remove the transfer timing belt from the indexer gear.

g. Unscrew four screws and remove the indexer from the drive tim-

ing belt.

<Cautions on assembly>

• Assembly should be done in reverse order to the disassembly.

• Set the indexer on the drive timing belt with four screws, with

care to keep the indexer horizontal (within 0.5mm of accuracy).

(Measurement and adjustment)

1. Set the indexer on the drive timing belt with four screws.

2. Measure the distance between the bottom frame of the indexer and the slit of the bin mounting frame. Finely adjust

the vertical position by means of the two screws on the left

shown in the figure below, so that the errors of A and B fall

within 0.5mm. In this case, the dimensions should be measured with the indexer lifted upwards.

A = B = 13mm

d. Unscrew four screws and remove the four reel films.

Note: Disengage the reel films while holding the films tight. Let

the reel film wind up to a position where the spring force is

balanced, and then release the films.

– 12 –

• When setting the reel films, be sure that the inner two reel

films are hooked on the shafts of the separator claws.

Page 14

6. Indexer unit

Inner ribbons fit to

rollers on diverter

guide shaft

a. When taking out and setting the indexer unit, see the instructions

given in paragraph 5.

b. When disassembling or assembling the indexer unit, refer to the

figure below.

c. When replacing the anti-static brush, refer to the figure below.

Align anti-static

brush with

A

Align anti-static brush guide

A

Earthing plate

Anti-static brush

side view

– 13 –

Page 15

7. Transfer timing belt

Reel retainer

Reel film

Indexer

Reel film

Reel film (Stuck with

double sided tape)

Reel

a. Remove the rear cover.

b. Remove the timing belt.

c. Remove the timing belt and remove the transfer timing belt from

the indexer gear.

d. Remove the two E rings, gear, parallel pin and two screws, and

remove the pulley assembly (w/transfer timing belt).

e. Unscrew four screws and remove the four reel films from the

indexer.

Note: Even when only one reel film is to be replaced, remove all

four reel films as in order to perform the adjustment.

f. Remove four reel retainers.

Pulley assembly

Transfer timing belt

Side frame

A

Screw

E ring

Gear

E ring

Screw

Parallel pin

<Cautions on assembly>

• Adjust the tension of the transfer timing belt in the following proce-

dure.

1 Set the transfer timing belt on the upper and lower pulleys, and

set the upper pulley assembly on the side plate.

2 While pressing the part A of the pulley assembly against the

upper side of notch in the side plate, raise the pulley assembly

(w/transfer timing belt) and clamp it with two screws.

3 After adjustment, apply screw locking paint to the two screws.

8. Replacemen t of reel fil ms

a. Remove the front and rear covers.

b. Remove the blower unit.

c. Remove the discharge roller and discharge guide.

d. Lower the indexer to the bottom bin.

Note: The indexer can be moved by turning the gear of the in-

dexer drive motor by hand.

g. Stick the double-side adhesive tape part of the reel film to be

replaced on the reel.

h. Wind up only the double-side adhesive tape section for all the four

reel films.

i. Clamp the four reel films on the indexer with four screws.

Note 1: Be sure that the indexer is positioned at the bottom bin.

2: The inner two reel films must be fastened to the indexer

after hooking on the shafts of the separator claws.

– 14 –

Page 16

j. While sliding the reel adjust upper in the direction of arrow in the

Bearing

Spring

E ring

Drive

timing

belt

E ring

Bearing

Slit in frame

Drive shaft

Reel shaft

Spring

Bearing

E ring

Bearing

E ring

Pulley

E ring

Slit in frame

figure below, turn the reel shaft CCW 8.5 turns with a flat tip

screwdriver, then slide back the reel adjust upper and lock the

reel.

Note 1: Be sure never to turn the reel shaft more than 8.5 turns.

2: Be sure that the reel films are not damaged by any

nearby surface, while turning them.

Reel

Reel

shaft

Front frame

k. After setting the reel films on the reels, set the reel retainers.

l. The rest of the assembly operation should be done in the reverse

order of the disassembly.

Reel adjust upper

Reel film

Drive belt

9. Replacement of drive timing belt

a. Remove the front and rear covers.

b. Remove the blower unit.

c. Remove the discharge roller and the discharge guide.

d. Remove the indexer in the procedure of 5, c~g.

e. Lower the indexer belt holder of the drive timing belt to the bottom

position. The belt can be moved by turning the gear of the drive

motor by ha nd.

Reel shaft

f. Remove the two E rings, two tension spring and two bearings.

Then tilt the drive shaft along the front side slit and remove the

two drive timing belts.

Indexer belt holder

(Lower to the bottom.)

Drive shaft

h. Set the indexer belt holder on the belt to be replaced.

i. Set two drive timing belt on the drive shaft, and set the drive shaft

on the frame.

j. Set two drive timing belt on the reel shaft, and set the reel shaft on

the frame.

Note: Both indexer belt holders, right and left, of the two drive

timing belt must be set at the same height. Set the drive

timing belt in the following procedure.

1 Set the two timing belts on the reel shaft.

Lower the two indexer belt holders of the belt to the

2

bottom position (see the detail drawing).

Set the reel shaft (with the drive timing belt

3

attached) on the frame. Be careful not to allow the

holder to move while setting.

After setting, turn the gear of the drive motor to

4

raise the indexer belt holder, and measure the

difference in the height of both holders.

Yes

5 Is the height difference within 2mm?

No

Remove the reel shaft from the frame and repeat

6

the above operation starting with step 2.

Proceed to process K.

– 15 –

Page 17

Reel shaft

10. Dismounting the indexer drive motor

unit

a. Remove the rear cover.

b. Remove the transfer motor assembly.

c. Remove the connector, cable holder and three screws, and re-

move the indexer drive motor unit.

Drive shaft

Indexer belt

holder should

Indexer

belt holder

Drive

shaft

k. Set the indexer in the indexer belt holder. For the cautions on

installation and adjustment of the indexer, refer to <Cautions on

assembly> in [5], 5. Dismounting the indexer.

l. For the procedure of setting the reel films, refer to steps i through l

in [5] 8. Replacement of reel films.

m. The rest of the assembly operation should be done in reverse

order to the disassembly.

touch pulley

d. For the disassembly an assembly of the indexer drive motor unit,

refer to the figure.

<Cautions on assembly>

• Before setting the indexer drive motor unit on the frame, check the

belts of the unit to see if they are properly set on the pulleys.

– 16 –

Page 18

11. Discharge section

4

4

±

1m

m

Discharge

brush

Tray fixing

angle

Discharge brush

Home position sensor

Red connector

White connector

Upper limit sensor

Sensor protection angle

Screw

Screw

(1) Replacement of discharge brush

a. Remove the non-sorting tray and 19 sorting trays.

b. Unscrew four screws and remove the top cover.

Top cover

Screw

(2) Replacement of tray brush

a. Remove the front and rear covers.

b. Remove the non-sorting tray and the sorting trays.

c. Remove the tray brush.

d. Wipe the sticking surface of the tray brush to remove oil.

e. Stick the tray brush with reference to the figure below.

Note: When sticking the tray brush, the brush must be pressed

against the angle.

c. Unscrew two screws and replace the discharge brush.

Feed brush

Screw

12. Dismounting the home position sensor

and upper limit sensor

a. Remove the front cover.

b. Unscrew two screws and remove the sensor protection angle.

c. Unscrew one screw each to remove the home position sensor and

the upper limit sensor.

Screw

<Cautions on assembly>

• Identical sensors are used in home position detection and upper

limit detection. Never confuse the wires when connecting. Be sure

to connect the red connector to the home position sensor.

– 17 –

Page 19

13. Arrangement of wiring

a. Arrangement of the wiring for the paper entry switch section and

the discharge sensor section is as shown in the figure below.

Keep the wiring from contacting the roller.

Paper entry switch section

Harness

Discharge sensor section

Harness

14. Adjustment of discharge sensor

a. Set the elements of SW2 as 1: ON, 2:ON, 3:OFF, to open all

doors. Then turn on the power while pressing SW1.

b. Insert a sheet of tracing paper into the opening of bin 20.

c. Turn VR1 slowly to turn off the LED. Then VR1 again until LED1

lights, which completes the adjustment.

– 18 –

Page 20

[6] ELECTRICAL CIRCUITS

1. General

The electric circuit controls the motions of taking in the sheets of

paper discharged from the copier and distributing them into bins 1

through 20. These motions are controlled by the control signals delivered from the control circuit board based on the sensor outputs. The

circuit consists of the sensor input circuit which receives signals from

the sensors and sends them to the CPU and a circuit which drives the

motor and solenoid.

2. Block diagra m

DTR

DSR

TXD

RXD

RES

+5V

System

reset

Inverter

(IC9)

AND gate

(IC7)

+5V

+5V

(IC2)

(IC12)

IC1

+5V

PWB-S

PWB-L

ILLS

IPS

IULS

IHS

PES

UCSW

FCSW

SJS

+5V

+5V

+5V

+24V

+5V

+24V

+5V

PGND

AGND

(IC10)

(IC10 )

(IC10)

(IC10)

(IC10)

(IC10)

(IC10)

TrQ1

TrQ2

(IC9)

+24V

Driver

(IC4)

IM direction control circuit

+24V

+5V

Gate

(IC3)

Driver

(IC5)

SW1

SW2

PVF

GS

IM

+24V

PFM

Oscillator circuit

11.0592MHz

– 19 –

Page 21

3. Communication circuit

+5V

+5V

3

2

RA3

10K

RA2

47K

2

C6

1000000P

R1

7.5

IC8

13

4

C13

1000P

IC10

11

10

VR1

100

TD62305F

HD74HC14FP

T-PT7

CN5-1

CN5-2 PWB-S

SEN2+5V

CN5-3

CN5-4

SENGND

CN6-1

CN6-2 PWB-L

LED2+5V

SENVOL

PWB-S 1

PWB-S 2

PWB-S 3

PWB-S 4

PWB-L 1

PWB-L 2

PWB-S

PWB-L

13

PB4

1

IC1

10K

Ω

8

1

5

6

SEN2+5V

PWB-S (OUT )

SEN GND

SEN VOL

Comparator

Voltage

regulator circuit

Amplifier

Oscillator

Synchronization

sensing

circuit

Demodulator

circuit

5V

0V

tw

tp

tw 8µS

tp 130µS

+5V

98

423

1

C15

1000P

C14

1000P

IC10

HD74HC14FP

12

13 12

T-PT8

T-PT9

RA3

10K

CN4-1

CN4-2

CN4-3

CN4-4

CN4-5

+5V

ILLS

IPS

NC

GND

ILLS 3

ILLS 2

ILLS 1

IPS 3

IPS 2

IPS 1

ILLS

IPS

10

12

PB1

PB3

RA4

47K

IC10

HD74HC14FP

IC1

To IC7-12P

5. Sensor input circuit

+5V

RA5

CN1-1

CN1-2

CN1-3

CN1-4

CN1-5

CN1-6

CN1-7

CN1-8

CN1-9

CN1-10

CN1-11

DTR

GND

DSR

GND

TXD

GND

RXD

GND

RES

GND

JNT

4.7K

8

79

5

R13

100

R12

100

IC11

43

74LS06FP

R11

100

T-PT1

C23

100P

T-PT2

C22

100P

T-PT3

C21

0.1µ

IC9

98

HD74HC14FP

IC11

65

74LS06FP

IC9

11 10

HD74HC14FP

IC11

21

74LS06FP

26

20

23

18

17

INT1

PC3/INT2

PC6/CO0

PC1/RXD

PC0/TXD

This circuit communicates with the copier. Input and output signals

handled are as follows.

a. DTR CN1-1P

Input from the copier, meaning that the copier has the right of

transmission when IC1-20P is at L level (0V).

b. DSR CN1-3P

Output from the sorter, meaning that the sorter has the right of

transmission during a period since IC1-20P changes from L level

(0V) to H level (+5V) until it returns to L level, when IC1-23P is at

H level (+5V).

c. TXD CN1-5P

Input signal from the copier. Data is received when ICI-18P

changes from H level (+5V) to L level.

d. RXD CN1-7P

Output signal from the sorter. Data is transmitted when ICI- 17P

changes from H level (+5V) to L level.

e. RES CN1-9P

Reset signal from the copier. CPU (IC1) is reset when CN1-9P is

H level (+5V).

a. Paper discharge sensor

This circuit monitors the presence of paper on the indexer and determines whether paper is discharged onto the tray. CN6 is connected

to an infrared emitting LED and CN5 is connected to a light receptor

which receives the light from the LED.

Internal circuit of the light receptor is shown in the figure below.

The oscillator of the light receptor sends the output signal shown

below to the connector CN5-4P and SENVOL.

This signal is used to drive the LED to light in pulses, and the light is

sensed by the receptor where the synchronization monitor circuit incorporated in it determines whether the light pulses are synchronized

with the VOL outputs.

4. Reset circuit

IC9

+5V

R4

10K

C5

1000P

13 12

4

5

74HC08FP

HD74HC14FP

T-PT3

6

IC7

IC1

15

PB6

28

RST

+5V

R8

10K

25

NMI

Copier reset

D8

T-PT17

DSA010

2

+5V

RES

3

5

VCC

CK

T-PT5

4

T-PT6

GND

VS

*RES

VREF

7

C4

470P

8

1

CT

6

+

C1

1µ/50V

C7

0.1µ

IC6

MB3773FP

When the power is turned on, IC6-8P in the figure turns from L level

(0V) to H level (+5V) in about 100ms, to complete the resetting operation.

The reset circuit produces logical sum of the output from IC6-8P and

the reset signal from the copier. Reset is effected at the same time

the reset signal is received from the copier.

IC6 functions in such a manner, when the program stored in the

sorter starts to run upon completion of the resetting operation, if

IC6-3P receives clock signals at specified intervals (10ms) and the

CPU (IC1) and the program normally operate, the output of IC6-8P

goes to H level (+5V).

If a failure occurs such as panic run of the program to interrupt the

clock input, the system is reset within the monitor period of the watch

dog timer (about 100ms) determined by C1 (1µF), while the output of

IC6-8P remains at L level (0V). It, however, turns HIGH when a clock

input is applied within 100ms.

If no synchronization is observed, it means that paper is present

between the light emitter and the receptor.

Synchronization is determined to be lost when three pulses are not

synchronized.

When paper is present, output signal at H level (+5V) is fed to IC1011P, and inverted L level (0V) is fed to IC1-13P.

Light intensity is adjusted with VR1 to optimize for the receptor.

b. Indexer lower limit sensor (ILLS) circuit,

Indexer position sensor (IPS) circuit

1 The indexer lower limit sensor (ILLS) circuit is to sense when the

indexer overruns bin 20 to reach the lower limit, due to overrun of

the indexer motor (IM) or a panic run.

ILLS is a sensor of transparent type which comprises a LED and a

photo-diode, where light is normally transmitted. Normal output

level is H (+5V), while the photodiode gives L level (0V) output

when the indexer reaches the lower limit to interrupt the LED light.

– 20 –

Page 22

Consequently, L level output is fed to IC1-1P while inverted H

38

AN4

SJS

SJS 3

SJS 2

SJS 1

+5V

C25

1000P

R16

47K

R9

10K

CN2-1

CN2-2

CN2-3

+5V

SJS

GND

3

4

IC9

HD74HC14FP

T-PT13

IC1

1

16

2

15

3

14

IC8

IC8

IC8

TD62305F

x3

LED2

LED3

LED1

R7

R6

R5

220

x3

GL3PR8

x3

+5V

+5V

3,4

1,2

2678

RA7

10K

SW1

SKHHAM

1

2

3

4

8

7

6

5

SW2

DSS704

6

7

8

PA5

PA6

PA7

34

35

36

19

AN0

AN1

AN2

PC2

IC1

level (+5V) is fed to IC1- 10P.

2 The indexer position sensor (IPS) circuit senses the indexer posi-

tion to see if it is in a position appropriate for discharge.

Operation after sensing is similar to that of ILLS, and output is fed

to IC1-12P.

c. Indexer upper limit sensor (IULS) circuit

Indexer home sensor (IHS) circuit

Paper entrance sensor (PES) circuit

+5V

T-PT10

IULS

IHS

PES

IULS 3

IULS 2

IULS 1

IHS 3

IHS 2

IHS 1

PES 3

PES 2

PES 1

CN3-1

CN3-2

CN3-3

CN3-4

CN3-5

CN3-6

+5V

IULS

IHS

PES

NC

GND

1 The indexer upper limit sensor (IULS) circuit is to sense when the

indexer overruns the indexer home sensor (IHS) to reach the

upper limit, due to overrun of the indexer motor (IM) or a panic

run.

IULS is a sensor of transparent type which comprises a LED and

a photodiode, where light is normally transmitted. Normal output

level is H (+5V), while the photodiode gives L level (0V) output

when the indexer reaches the upper limit to interrupt the LED light.

Consequently, L level output is fed to IC10-3P while inverted H

level (+5V) is fed to IC1- 9P.

2 The indexer home sensor (IHS) circuit senses the indexer position

to see if it is in the discharge position of bin 2.

Operation after sensing is similar to that of IULS, and output is fed

to IC1-11P.

3 The paper entrance sensor (PES) circuit senses the paper dis-

charged from the PPC when it enters the entrance of the sorter.

Operation after sensing is similar to that of IULS, and output is fed

to IC1-14P.

RA3

10K

IC10

54

6

7

8

5

6

3

4

RA2

C16

47K

34

T-PT11

T-PT12

C12

C11

1000P x3

IC10

56

98

IC10

HD74HC14FP

x3

9

11

14

To IC7-9P

e. Sorter joint sensor (SJS) circuit

The sorter joint sensor (SJS) circuit checks to see if the sorter is

securely connected to the copier.

SJS is a sensor of transparent type which comprises a LED and a

photodiode, where light is normally transmitted. Normal output level is

IC1

PB0

PB2

PB5

H (+5V), while the photodiode gives L level (0V) output when the

sorter is connected to the copier causing the LED light to be interrupted. Consequently, L level output is fed to IC9-3P while inverted H

level (+5V) is fed to IC1-38P.

6. Power circuit

FUSE2

DC+24V

PG

DC+5V

SG

UL-TSC3^15A-N1

CN10-1

CN10-2

CN10-3

CN10-4

This circuit receives DC power from the copier. C3 and C2 are capacitors to filter out noise and smooth the +24V and +5V voltages, respectively. D7 and D3 are protective diodes which protect the ICs

from over voltage generated when connecting or disconnecting the

connector CN10.

C3

100µ/50V

C2

33µ/16V

TP3

TP4

TP1

TP2

+5V

+5V

D7

GP10-4003

PGND

ZD3

RD6^2FB

+

+

7. LED ligh tin g cir cu it

d. Upper cover switch (UCSW) circuit

Fan cover switch (FCSW) circuit

E

E

Q2

FA1L3N

C

+5V

R2

R3

10K

10K

IC1

40

AN6

39

AN5

UCSW

FCSW

CN11-3

CN11-2

CN11-1

UCSW

FCSW

DC24VDOR

+24V

ZD1

RD12MB2

ZD2

RD12MB2

T-PT15

T-PT16

Q1

FA1L3N

BC

B

DC +24V

These circuits monitor the upper cover and the fan cover while they

open or close. Two switches are connected in series, and turn on

when the cover is closed and turn off the cover is open. Closing of the

upper cover causes the switch contact to close, pulling up the base

voltage of Q1 to H level and pulling down the collector voltage of Q1

to L level (0V), feeding it to IC1-40P.

Operation of the fan cover switch (FCSW) is similar to the above.

Truth table for cover switch open/close

UCSW FCSW IC1-40P IC1-39P

Open Open H H

Close Open H H

Open Close H L

Close Close L L

General

The LED lighting circuit is used in test mode. LED1, LED2 and LED3

indicate the status of the sorter, and SW2 and SW1 are used in

setting the operation mode.

a. LED lighting circuit

The LED lighting circuit drives LED1 indicating the operating status of

the CPU (IC1), LED2 indicating the jam and alarm information and

LED3 indicating the open/closed status of the fan cover switch

(FCSW) and the upper cover switch (UCSW).

The LEDs are lighted by driving IC1-6P, 7P and 8P LOW. Status of

the LEDs show the status of the sorter as shown in the table below.

LED Blink ON OFF

CPU normally

1

running

2 Jamming Alarm issued Normally operating

3 ————— Door released Normally operating

CPU panic CPU panic

– 21 –

Page 23

b. DIP switch circuit

D5

GP10-4003

D6

GP10-4003

CN8-1

CN8-2

CN8-3

CN12-3

+24V

PVF

NC

+24V

GS

NC

NC

CN12-4

CN12-1

CN12-2

PVF 1

PVF 2

GS 1

GS 2

3

6

1

7

2

8

IN1

IN2

OUT1

OUT2

DRV

CLM

IC4

M5261L

R10

51

+5V

+5V

RA6

10K

43

PVF

GS

1

2

PA0

PA1

PGND

IC1

6K

10K

1K

5K

2K

DRIVE

CLM

OUT

GND

VCC

Active = Low

input IN

Unit:

Ω

The DIP switch circuit is used to set the operation mode when operating the sorter individually. Turning ON 1-4P of SW2 sets the signals

at IC1-19P, 34P, 35P and 36P to L level, respectively. The operation

modes are selected by the setting of the switch as shown below.

SW2-1 -2 -3 -4 Mode

1 OFF OFF OFF —

2 OFF OFF OFF —

Non-sorting paper-feed test

mode

Grouping paper-feed test

mode

*1

*2

3 ON OFF OFF — Sorting paper-feed test mode

4 ON ON OFF —

Discharge sensor adjust

mode

5 *2 *2 ON — Sorting no-paper test mode

*1 In the group paper presence test mode, the indexer shifts when

the SW1 (push switch) was pressed in selecting the paper presence test mode.

*2 The sorting no-paper test mode is selected only by setting SW2-3

to ON regardless of the setting of SW2-1 and -2.

8. Explanation of the operation (circuit)

1 Non-sorting paper-feed test mode

Set the DIP switch as 1:OFF, 2:OFF, 3:OFF, close all doors and turn

on the power while pressing SW1. Pressing SW1 in about one second causes the fan motor to turn on and the test mode to start.

In this test mode, when the inlet sensor detects paper, the transfer

motor turns on to discharge the paper into the non- sorting bin (bin 1).

About seven seconds after the tail edge of the last sheet passed the

inlet sensor, the transfer motor stops.

Pressing Sw1 after the transfer motor has stopped causes the fan

motor to stop to exit from the test mode. If SW1 is pressed again, the

fan motor turns on and test mode restarts.

Pressing SW1 after the transfer motor has stopped causes the fan

motor to stop to exit from the test mode. If SW1 is pressed again, the

fan motor turns on and test mode restarts.

4 Sorting no-paper test mode

Set the DIP switch as 3:OFF (1 and 2 may be in any position), close

all doors and turn on the power while pressing SW1. After initialization of the indexer, the transfer motor and the fan motor turn on and

the test mode starts. Pressing SW1 again ends the test mode.

5 Loaded operation mode (test with

commu nic a t ion with copie r )

The sorter is switched to loaded operation mode by a command from

the copier. Then a signal (22H 01H DATA1) which requests individual

loading operation sent from the master to the slave starts the individual loading operation.

Remedy for jam

(1) When paper jams, LED2 blinks and all loads are turned off. Open

the door and take out the jamming paper, and close the door.

LED2 will turn off indicating the jam is removed. Then pressing

SW1 brings the machine into the state similar to that after ending

the test mode.

Canceling alarm

(1) In case of alarm, LED2 blinks and all loads are turned off. The

alarm can be canceled by power ON reset.

9. Paper vacuum fan (PVF) circuit a. Paper

vacuum fan (PVF) circuit

Gate solenoid (GS) circuit

2 Grouping paper-feed test mode

Set the DIP switch as 1:OFF, 2:OFF, 3:OFF, close all doors and turn

on the power while pressing SW1. Pressing SW1 in about one second causes the fan motor to turn on and the test mode to start.

In this test mode, when the inlet sensor detects paper, the transfer

motor turns on to discharge the paper into the non- sorting bin (bin 1).

If SW1 is pressed when the transfer motor is ON after the transfer of

paper, the indexer is lowered by one level when the next sheet of

paper turns on the inlet sensor. Pressing SW1 twice (* ) causes the

If IC1-1P becomes L level (0V), IC4-7P becomes L level (0V) with GS

turning on, and the inlet gate opens to discharge paper into bin 2 and

the subsequent bins.

Circuit diagram

indexer to lower by two levels. Once the indexer reaches bin 20,

subsequent sheets are all transferred into bin 20 even if SW1 is

pressed.

About seven seconds after the tail edge of the last sheet passed the

discharge sensor of the sorter, the transfer motor stops.

Pressing SW1 after the transfer motor has stopped causes the fan

motor to stop to exit from the test mode. If SW1 is pressed again, the

fan motor turns on and test mode restarts.

3 Sorting paper-feed test mode

Set the DIP switch as 1:ON, 2:OFF, 3:OFF, close all doors and turn

on the power while pressing SW1. Pressing SW1 in about one second causes the fan motor to turn on and the test mode to start.

In this test mode, when the inlet sensor detects paper, the transfer

motor turns on to transfer the paper. Then every time the next paper

activates the inlet sensor, the indexer moves to the next bin. Upon

completion of paper transfer into bin 1 or 20, the indexer reverses its

moving direction.

About seven seconds after the tail edge of the last sheet passed the

– 22 –

discharge sensor of the sorter, the transfer motor stops.

Output-function

Input Output

L L (ON)

H H (OFF)

Page 24

10. Indexer (IM) circuit

IM

+24V

6P

2P

IC5

ON

OFF

ON

OFF

8P

4P

9, 5P

7, 3P

IM

+24V

6P

2P

IC5

ON

OFFON

OFF

8P

4P

9, 5P

7, 3P

20K x210000P x2

R19

R18

2

A

4

B

6

C

8

D

R20

R22

10K x2

R21

680

C30

100000P

C32

+5V

R17

680

C31

100000 P

PA2

PA3

PC4/TO

+5V

RA7

10K

12

43

3

13

4

10

74HC08FP

21

9

IC7

IC7

3

CUR

5

11

MODE1

7

MODE2

8

9

PWM

LSI-N9101MTD

IC3

IULS (Upper limit signal)

ILLS (Lower limit signal)

This circuit drives the indexer motor CW or CCW and move the

indexer up or down to discharge paper into bins 2 through 20.

GP10-400 3 x4

FUSE1

6

B

8

B

IC5

MP4005

2

B

4

B

D3D2

10

W

7

C

9

C

3

D4

C

PGND

5

C

W

1

PGND

UL-TSC1^25A-N1

CN9-1

IM

CN9-2

IM

C34

10000P

D1

+24V

IM 1

IM 2

IM

C33

a. CW rotation (down motion)

When IC1-3P output is H level (+5V) and IC1-4P is L level (0V),

IC3-2P and 6P are L level (0V) and 4P and 8P are H level (4P: +24V,

8P: +24V). Consequently, IC5-2P and 6P become L level (0V) and 4P

and 8P become H level (4P: +5V, 8P: +5V), causing the indexer

motor (IM) to rotate CW.

The motor can be turned ON/OFF with IC3-9P; stop at L level (0V),

rotatable at H level (+5V).

In case the lower limit sensor (ILLS) is activated due to software

panic or other reason, hardware protection is provided which stops

the motor using ILLS signal to prevent the motor from locking while

being kept ON.

When the motor is running CW, current flows as shown below.

Truth table for CW rotation

ILLS IM

H

(ON)

L

(OFF)

OFFLHLLHLHHLHHHLH

OFF

ONHHLHHLLHLHLHLH

IC1 IC3 input IC3 output IC5 input

213495724686824

L

HH

HL

L

LLHHHHHHHH

*If pins 5 and 7 of IC3 are both either H or L, brake mode is

effected driving all inputs of IC3 and IC5 to H level regardless of

the above table.

b. CCW rotation (moving up)

When IC1-3P output is L level (0V) and IC1-4P is H level (+5V),

IC3-2P and 6P are H level (2P: +5V, 6P: +24V) and 4P and 8P are L

level (0V). Consequently, IC5-2P and 6P become H level (2P: +5V,

6P: +24V), and 4P and 8P become L level (0V), causing the indexer

motor (IM) to rotate CCW.

The motor can be turned ON/OFF with IC3-9P similarly to the case of

CW rotation; stop at L level (0V), rotatable at H level (+5V).

In case the upper limit sensor (IULS) is activated due to software

panic or other reason, hardware protection is provided which stops

the motor using IULS signal to prevent the motor from locking while

being kept ON.

Current flows as shown below when running CCW.

– 23 –

Page 25

Truth table for CCW rotation

28 27 26 25 24 23 22 21 20 19 18 17 16 15

1 2 3 4 5 6 7 8 9 10 11 12 13 14

IC1

R17

C12

R3

C3

R2

C4

+

R4 R9

R10

C11 C10

R13

H1 H2 H3

R11

LD READY

GND

R16

R15

C9 C8

C5

R7

C6

R8

C2

D1, 2, 3

R1

D4, 5, 6

R12

R5

Q1

Q2

+

C13

R14

R6

C7

C1

+

VCC

+24V

P/S

ON/OFF

IULS IM

H

(ON)

L

(OFF)

ONHLHHLHHLHLHLHL

OFFL LHL LHHHHLHHHL

OFF

IC1 IC3 input IC3 output IC5 input

213495724686824

L

HH

LH

L

LLHHHHHHHH

11. Paper transfer motor (PFM) circuit

IC1

PA4

PB7

+5V

RA6

TD62305F

10K

IC8

2

5

16

5

HD74HC14FP

12

T-PT14

1

2

IC9

This circuit controls the transfer of paper discharged from the copier

into the sorter. PFM starts to run when IC1-5P output is made to L

level (0V). When the motor has stabilized at low speed running, PFM

delivers L level (0V) READY signal. This signal is fed to IC9-1P where

it is inverted to H level (+5V) and is fed to IC1-16P.

When the motor is locked, a protection circuit provided in the PFM

shuts off current flowing in the motor within 5 sec. This protective

action is reset by restoring IC1-5P from H level to L level.

R14

10K

C24

1000P

R15

10K

+5V

+24V

PGND

PFM+24V

ON/OFF

READY

READYGND

NC

CN7-1

CN7-2

CN7-3

CN7-4

CN7-5

PFM 1

PFM 3

PFM 4

PFM 2

PFM

Internal circuit of transfer motor

IC1-5P

output

L (0V)

PFM CN7-2P

input

IC1-16P

input

L H Rotating

L L Rotating under overload

H (+5V) H L Not rotating

Remark

– 24 –

Page 26

[7] ELECTRICAL COMPONENTS

PWB-L

UCSW

FCSW

IPS

SJS

PWB-S

ILLS

PES

IHS

IULS

1. Sensors, switches

Sensors, switches

Name Type Function Contact, output

PWB-L Light transmission sensor, emitter Emitter of discharge sensor, pulse lighting H level when detecting paper

PWB-S Light transmission sensor, receptor H level when paper passes discharge section

PES Light transmission sensor L level when paper is fed L level when detecting paper

IPS Light transmission sensor H level when discharge position of indexer is detected H level when detecting the position

IHS Light transmission sensor L level when home position of indexer is detected L level when detecting

IULS Light transmission sensor L level when indexer reaches upper limit L level when detecting

ILLS Light transmission sensor L level when indexer reaches lower limit L level when detecting

SJS Light transmission sensor L level when sorter is connected to copier L level when detecting

UCSW Micro SW Senses open/close of upper cover. ON when closed ON when closed

FCSW Micro SW Senses open/close of fan cover. ON when closed ON when closed

– 25 –

Page 27

2. Solenoids, motor s

GS

PVF

Solenoids

Name Type Function

GS Solenoid Paper is discharged to bin 2 and subsequent

Motor

Name Type Function

PFM Brushless motor Paper transfer motor

PVF Brushless motor Paper suction fan

IM DC motor Indexer drive motor

IM

PFM

bins upon gate solenoid, solenoid ON.

– 26 –

Page 28

6

5

4

3

2

1

3

2

1

IC7

74HC08FP

8

9

IC11

74LS06FP

710

IC8

TD62305F

+5V

1

VPP

*OE

A14

222726

53525150494847

PF6

10

12

11

13

6

11

6

5

IC9

HD74HC 14F P

20

*CE

A13

22321242510 9

PF5

IC2

A12

A11

A10A9A8

*OC

1

11

PF4

PF3

PF2

PF1

PF0

+5V

28 14 9 20 114 14 14

IC2 IC7 IC8 IC9 IC10 IC11 IC12 IC3

11121315161718

O0O1O2O3O4O5O6

A1A2A3A4A5A6A7

A0

8

7

6

2569121516

1Q

2Q

3Q4Q5Q6Q7Q

G

2D

1D3D4D5D6D7D8D

813141718

7

4

3

565758596061624644

55

PD0

PD1

PD2

PD3

PD4

10

GS

PVF

PVF 1

PVF 2

GS 1

GS 2

0.1µ x8

77 710

8

14 7

C27 C8 C17 C18 C19 C26 C29 C28

19

O7

M27C256B -15 F 1

5

4

3

19

8Q

IC12

74HC373F P

RD

PD5

PD6

PD7

ALE

876

5

SW2

123

4

1,2

+5V

78

SW1

6

3,4

2

RA7

10K

+5V

R7

R5

R6

220

x3

LED2

LED3

LED1

GL3PR8

x3

14

IC8

IC8

IC8

116

6

PA5

215

7

PA6

3

8

PA7

x3

TD62305F

343536

AN0

CN8-1

CN8-2

CN8-3

CN12-3

CN12-4

CN12-1

DSS704

+24V

PVFNC+24VGSNC

SKHHAM

D5

GP10-4003

1

CLM

28

DRV

3

R10

51

+5V

+5V

RA6

10K

43

19

1

AN1

AN2

PC2

CN12-2

NC

D6

GP10-4003

7

PGND

OUT1

OUT2

IC4

M5261L

IN2

IN1

6

RA7

+5V

2

PA0

PA1

IM

IM 1

IM 2

CN9-1

CN9-2

+24V

IM

IM

FUSE1

D2

D3

GP10-4003 x4

C33

R18

C32

20K x2 10000P x2

R19

+5V

10K

5

37

AN3

UL-TSC1^25A-N1

10

IC3

7

C

W

B

6

8

R20

R22

246

ABC

CUR

357

11

12

RA7

10K

9

B

MODE1

IC7

13

43

3

C34

10000P

D1

PGND

D4

3

5

C

C

C

PGND

1

W

B

B

IC5

MP4005

2

4

C31

+5V

10K x2

MODE2

8

9

PA2

100000P

R17

680

R21

680

C30

100000P

8

D

PWM

9

LSI-N9101M TD

IC7

10

4

RA1

10K

+5V

74HC08FP

212241

PA3

PC4/TO

+24V

+5V

+5V

934

PC5/CI

PFM

PFM 3

PFM 4

PFM 2

PFM 1

CN7-1

CN7-2

CN7-3

CN7-4

CN7-5

PFM+24V

ON/OFF

READY

READYGND

NC

PGND

R15

10K

R14

10K

C24

1000P

T-PT14

1

IC9

12

2

HD74HC 14F P

IC8

TD62305F

5

2

RA6

10K

RA1

10K

+5V

576

8

5

16

45

WR

PA4

AN7

PB7

245427

PC7/CO 1

29

PF7

MODE1

MODE0

EFGHI

INT1

PC3/INT2

262023

HD74HC14FP

IC9

98

T-PT1

C23

R13

8

+5V

79

5

RA5

4.7K

DTR

CN1-1

BCDEFGHI

A

[8] Circuit diagram

[8] CIRCUIT DIAGRAM

6

PC6/CO0

74LS06FP

IC9

IC11

65

T-PT2

100P

R12

100

100

GND

DSR

GND

CN1-2

CN1-3

CN1-4

PC1/RXD

18

10

HD74HC14FP

11

C22

TXD

GND

CN1-5

CN1-6

PC0/TXD

17

+5V

74LS06FP

IC9

IC11

13 12

21

T-PT3

100P

IC11

74LS06FP

43

RXD

GND

CN1-7

CN1-8

5

IC1

CMP730

AVDD

PB6

VAREF

42

43

C20

HD74HC14FP

C21

0.1µ

R11

100

RES

GND

CN1-9

CN1-10

RST

15

28

0.1µ

6

IC7

T-PT3

5

4

C5

R4

10K

+5V

T-PT5

381

D8

DSA010

T-PT17

JNT

CN1-11

6

CT

CK

2

*RES

RES

VCC

GND

5

4

+5V

C7

0.1µ

NMI

25

13

+5V

R8

10K

10

IC10

11

HD74HC14FP

74HC08FP

1000P

C1

+

7

VREF

VS

IC6

MB3773FP

T-PT7

2

1

RA3

10K

+5V

2

1µ/50V

3

C4

470P

T-PT6

SEN2+5V

CN5-1

µPD78C10AGQ

PB4

+5V

C13

1000P

RA2

47K

7.5

R1

C6

1000000P

SENGND

SENVOL

CN5-2 PWB-S

CN5-3

CN5-4

PB1

PB3

10

12

IC10

13 12

HD74HC14FP

VR1

100

12

IC10

T-PT9

4

13

IC8

RA3

+5V

LED2+5V

CN6-1

CN6-2 PWB-L

C15

T-PT8

2

4

TD62305F

C14

RA4

47K

3

1

10K

98

+5V

ILLS

IPSNCGND

CN4-1

CN4-2

CN4-3

CN4-4

PB0

PB2

PB5

91114

6

98

IC10

IC10

HD74HC14FP

HD74HC14FP

1000P

CN4-5

5

T-PT11

T-PT12

C12

IC10

1000P

34

T-PT10

864

RA3

10K

753

+5V

RA2

54

6

+5V

IULS

IHS

PESNCGND

CN3-1

CN3-2

CN3-3

CN3-4

CN3-5

AN6

AN5

AN4

X1

X2

Q2

E

ZD2

RD12MB2

UCSW

CN11-3

FA1L3N

C

B

FCSW

CN11-2

E

T-PT16

DC24VDOR

CN11-1

30

31

X1

HC49U

4

IC9

3

HD74HC14FP

C25

T-PT13

R16

47K

R9

10K

+5V

+5V

SJS

GND

CN2-1

CN2-2

CN2-3

403938

x3

R3

10K

+5V

R2

10K

1000P x3

C11

Q1

FA1L3N

BC

C16

47K

CN3-6

T-PT15

ZD1

RD12MB2

+24V

VSS

VASS

32

33

C9

33P

C10

33P

D7

GP10-4003

PGND

+5V

1000P

TP3

FUSE2

UL-TSC3^15A-N1

ZD3

RD6^2FB

+5V

TP2

TP4

TP1

+

+

C2

C3

100µ/50V

PG

DC+5V

DC+24V

CN10-3

CN10-1

CN10-2

CD

33µ/16V

SG

CN10-4

B

ILLS 3

ILLS 2

ILLS 1

IPS 3

IPS 2

IPS 1

IULS 3

IULS 2

IULS 1

IHS 3

IHS 2

IHS 1

PES 3

PES 2

PWB-S 1

PWB-S 2

PWB-S 3

PWB-S 4

PWB-L 1

PWB-L 2

ILLS

IPS

IULS

PWB-L

PWB-S

4

3

IHS

PES 1

UCSW

PES

2

SJS 3

SJS 2

SJS 1

FCSW

SJS

A

1

– 27 –

Page 29

[9] COMPONENT LAYOUT DRA WING

Control circuit board (Component side) 125V

Control circuit board (Component side) 250V

Control circuit board ( Solder side)

MEMO

MEMO

– 28 –

Page 30

A E

B

C

D

F

8

+5V

DTR

DSR

TXD

RXD

7

+5V

System

reset

6

PWB-S

PWB-L

ILLS

IPS

5

IULS

IHS

PES

4

UCSW

FCSW

SJS

RES

Inverter

+5V

+5V

+5V

+24V

+5V

(IC9)

IC1

AND gate

(IC7)

(IC10)

(IC10)

(IC10)

(IC10)

(IC10)

(IC10)

(IC10)

TrQ1

TrQ2

(IC9)

+5V

(IC12)

IM direction control circuit

+5V

Gate

(IC3)

(IC2)

+24V

Driver

(IC4)

+24V

Driver

(IC5)

+5V

SW1

SW2

PVF

GS

IM

8

7

6

5

4

+24V

3

+24V

+5V

PGND

AGND

PFM

2

Oscillator circuit

11.0592MHz

1

A E

B

C

D

F

3

2

1

– 29 –

Loading...

Loading...