Page 1

SF-2530

CODE: 00ZSF2530FM/E

No.1

MODEL SF-2530

MODEL SF-D23/D24

MODEL SF-DM11

[Note] The SF-2530 is a minor change model of the SF-2030. This Service Manual omits descriptions

common with the SF-2030, and describes onl y the different points of the SF-2530. For the different

points, refer to the list of changes between the SF-2030 and the SF-2530.

CONTENTS

[ 1 ] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] PRODUCT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] OPTIONS SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] COMPONENT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . 4-1

[ 5 ] INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] DISASSEMBLY AND REASSEMBLY . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] SIMULATION AND DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] MAINTENANCE AND OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

SF-2530

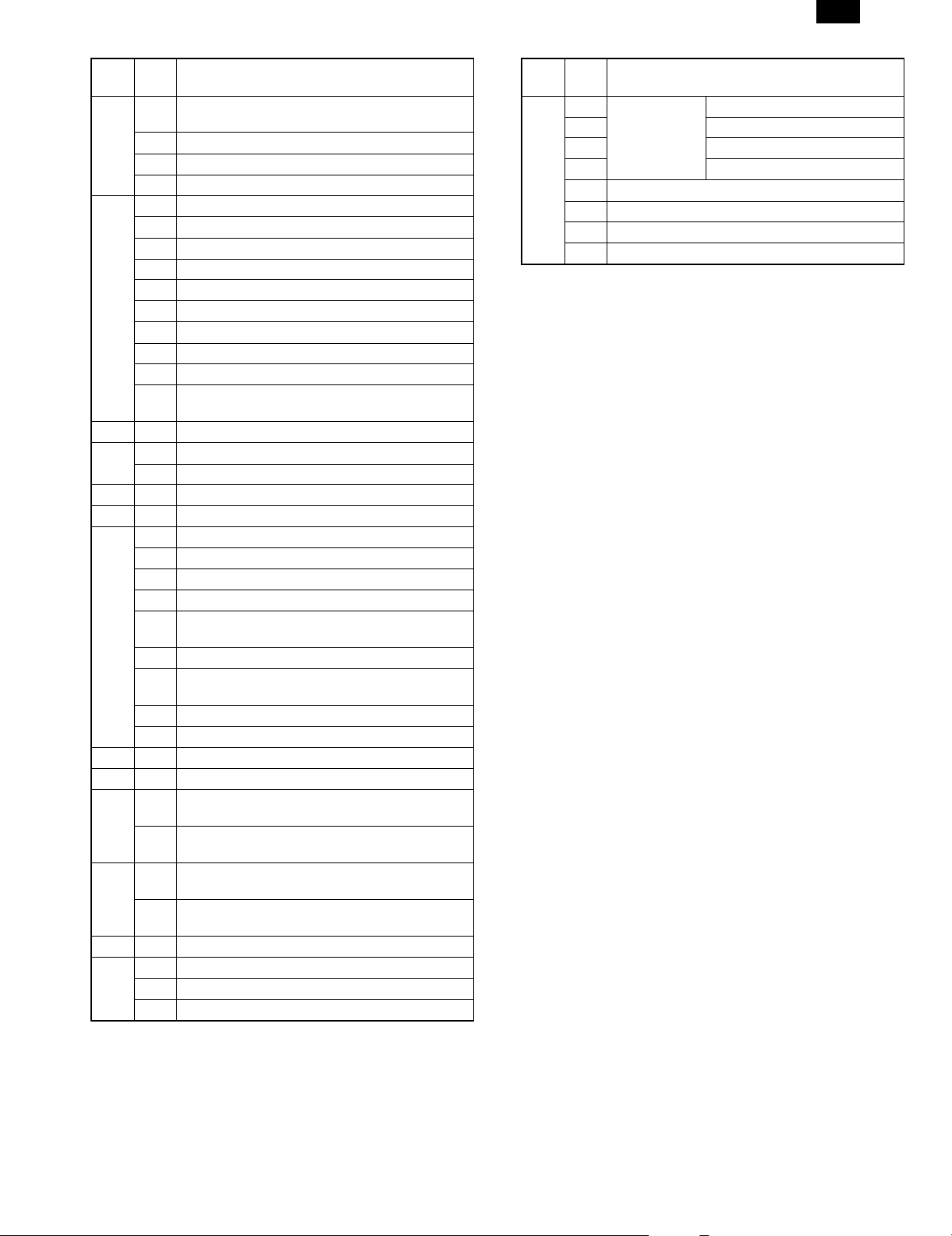

List of changes between SF-2030 and SF-2530

No.

Page Item Content Change

1-1 [1]-1 General description Model name change

[1]-4 System outline Model name change and addition

SF-2030 SF-2530

SF-2030 is changed to SF-2530.

SF-2040 is changed to SF-2540.

20-bin staple sorter: SF-S56 is added.

SF-S56

10-bin staple sorter SF-S54N is added.

SF-S54

Remark

10-bin staple sorter (SF-S52) is deleted.

Desk: SF-DS15 is added.

ADU: SF-DM11 is added.

Card-type department control counter:

SF-EA11 is added.

Password-type department control counter

: AD-EA12 is added.

Commander: SF-EA13 is added.

Personal counter: SF-71A/B is added.

SF-S53 is changed to SF-S53N.

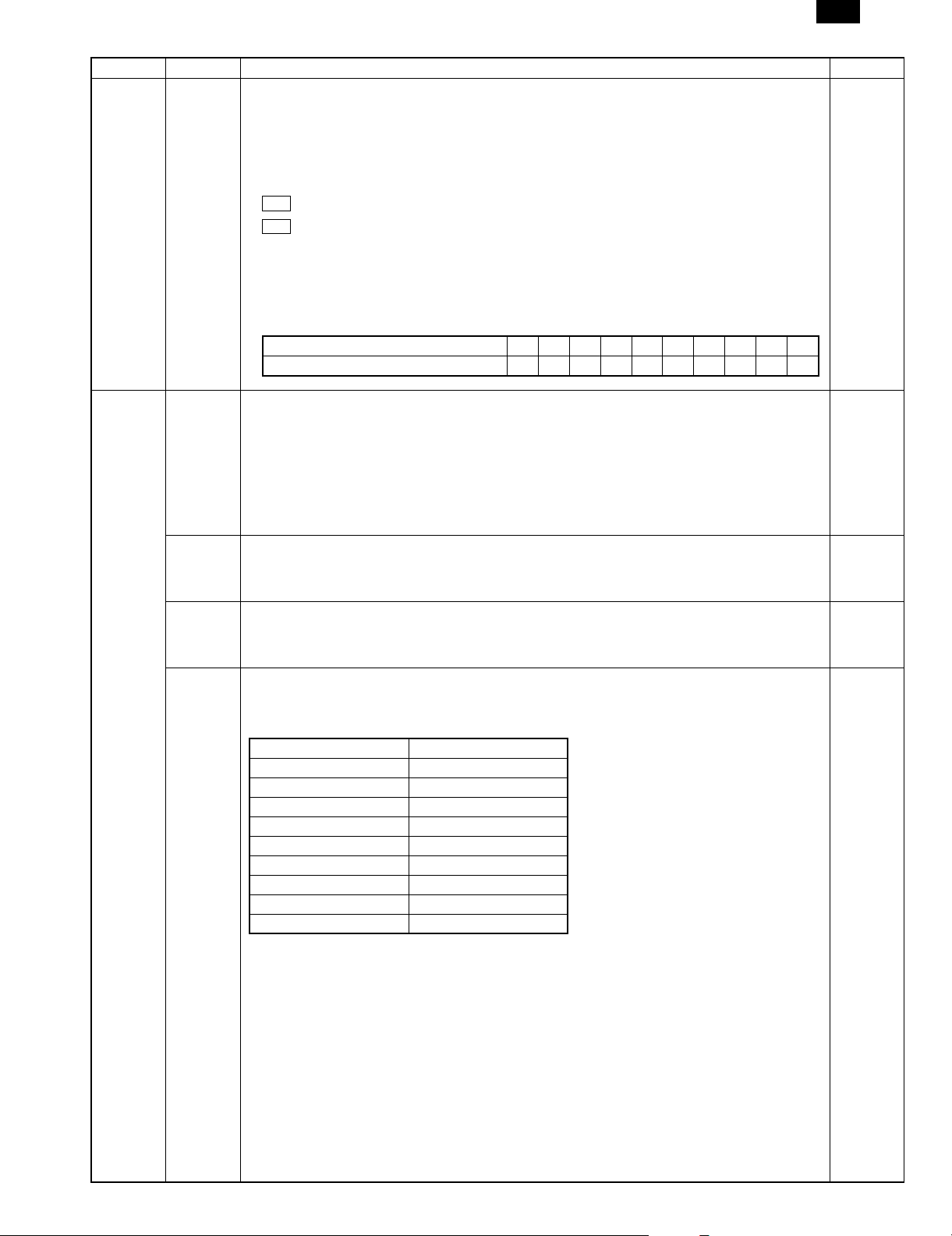

2-1 [2]-1-(6) Warmup time "About 60 sec" is changed to "About ??? sec."

[2]-1-(7) Multicopy 999 sheets is changed to 99 sheets.

2-2 [2]-1-(10) Paper feed Letter size is added to AB series.

A4 size is added to Inch series.

Letter/13" is added to AB series.

13"/A4 is added to Inch series.

AB series

Paper entry Paper size

Upper cassette

(Option)

Lower cassette A5/B5/B5R

Inch series

Paper entry Paper feed size

Upper cassette

(Option)

Lower cassette Letter/Letter R/

B5/B5R

A4/A4R/B4/A3

Letter/13"

A4/A4R/B4/A3

Letter/13"

A5: * With the option ~

Letter/Letter R/

Legal/Ledger

13", A4

Legal/Ledger/

Invoice, 13"/A4

* With the option ~

– 1 –

Page 3

SF-2530

No.

Page Item Content Change

SF-2030 SF-2530

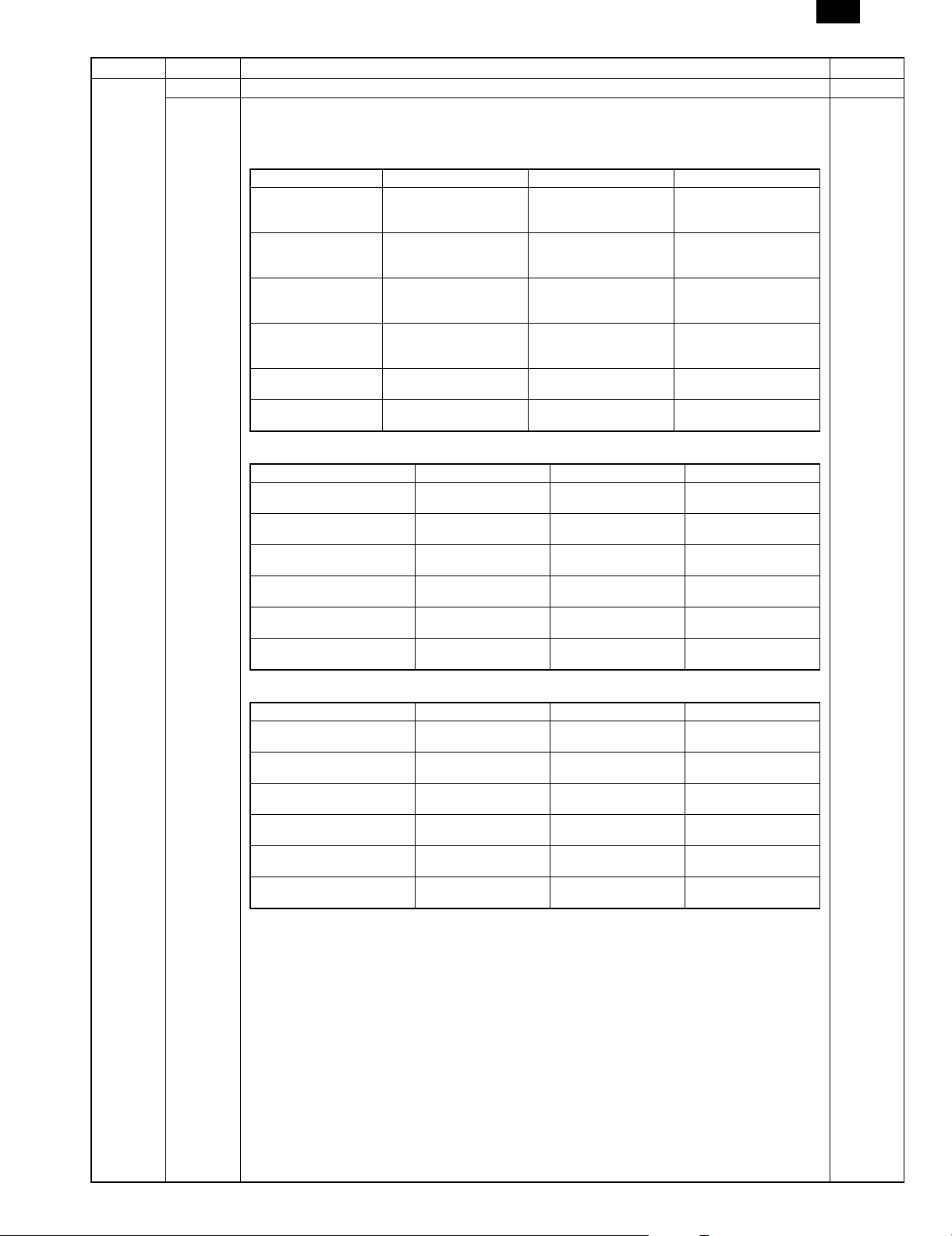

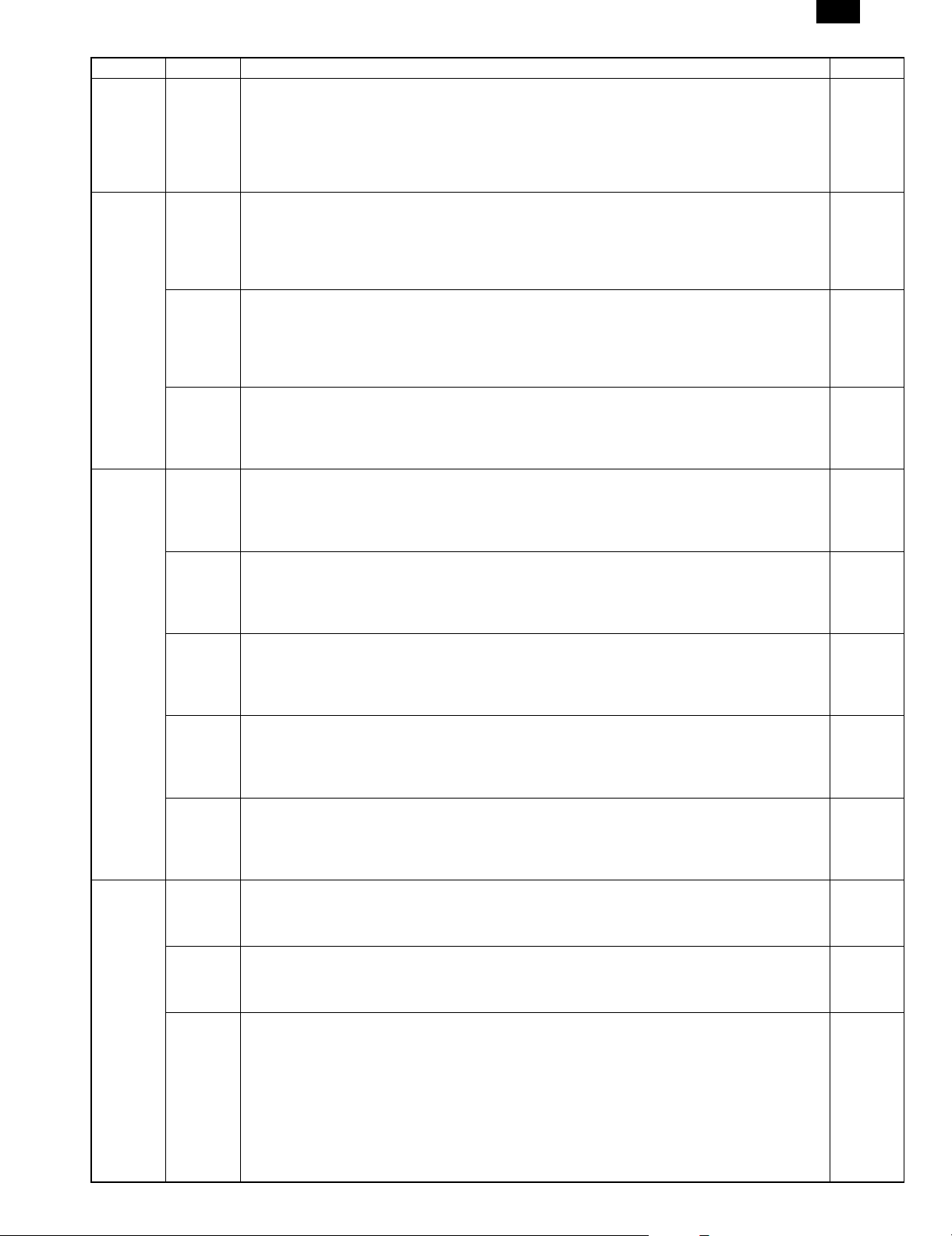

2-3 [2]-1-(20) (20) Paper receive tray and finishing Model name change and delete

SF-S53 is changed to SF-S53N.

SF-S52 is deleted.

Models in the table below are added.

Finishing function

Sort

capacity

Non-sort

capacity

10-bin sorter ??? ???

(SF-S54)

20-bin staple sorter ??? ???

(SF-S56)

Accessory of SF-2530 (Addition and changes in this model are in bold fonts.)

<Note> ROM language is deleted.

(25) Accessories

Destination Japan SEC SECL SEEG SUK SCA AB agent

*2

Drum

Developer (Black) | ✕✕ ✕ ✕✕✕✕

Toner cartridge | ✕✕ ✕ ✕✕✕✕

Original cover Standard

Paper exit tray 1

*1

Original table

Toner collection

container

Operation manual Japanese Exclusive

Dust cover | ✕ | (Part)

Zooming ratio

table

ROM language

Key sheet

Other printed matters

Delivery/installation report (Japan/SEEG), SCA warranty, Warranty registration (SUK), Maintenance card,

Counter contract × 2 (Japan)

*1

: Retractable (Japan), Fixed (Outside Japan)

*2

: For SEEG/SUK, only products of SOCC are installed when shipping.

Installed

when

shipping

provision

Japanese English English

Japanese English

Installed

when

shipping

Option Option Option Option Option

✕ |

English

| ✕

SEL = English/French packed together. SEEG (BG) = Treated in a kit.

Installed

when

shipping

| (4 pcs.) One is installed when shipping.

English/

French

English/

French

Separately

packed

CG:

German/

English

BG: None

GG:

German

BG: None

CG:

German/

English

BG: None

Installed

when

shipping

|

Exclusive

English

English English

English

Installed

shipping

English English/

English

Foolscap

when

+

Installed

when

shipping

LAG is an option.

LAG is an option.

French/

Arabic

Typical

example

English/French/

Spanish depending

on the destination

English,

partly

Spanish

Foolscap

+

Inch

agent

Installed

when

shipping

Standard

✕

English/

Spanish

Typical

example

English,

partly

Spanish

Foolscap

Remark

+

– 2 –

Page 4

SF-2530

No.

Page Item Content Change

SF-2030 SF-2530

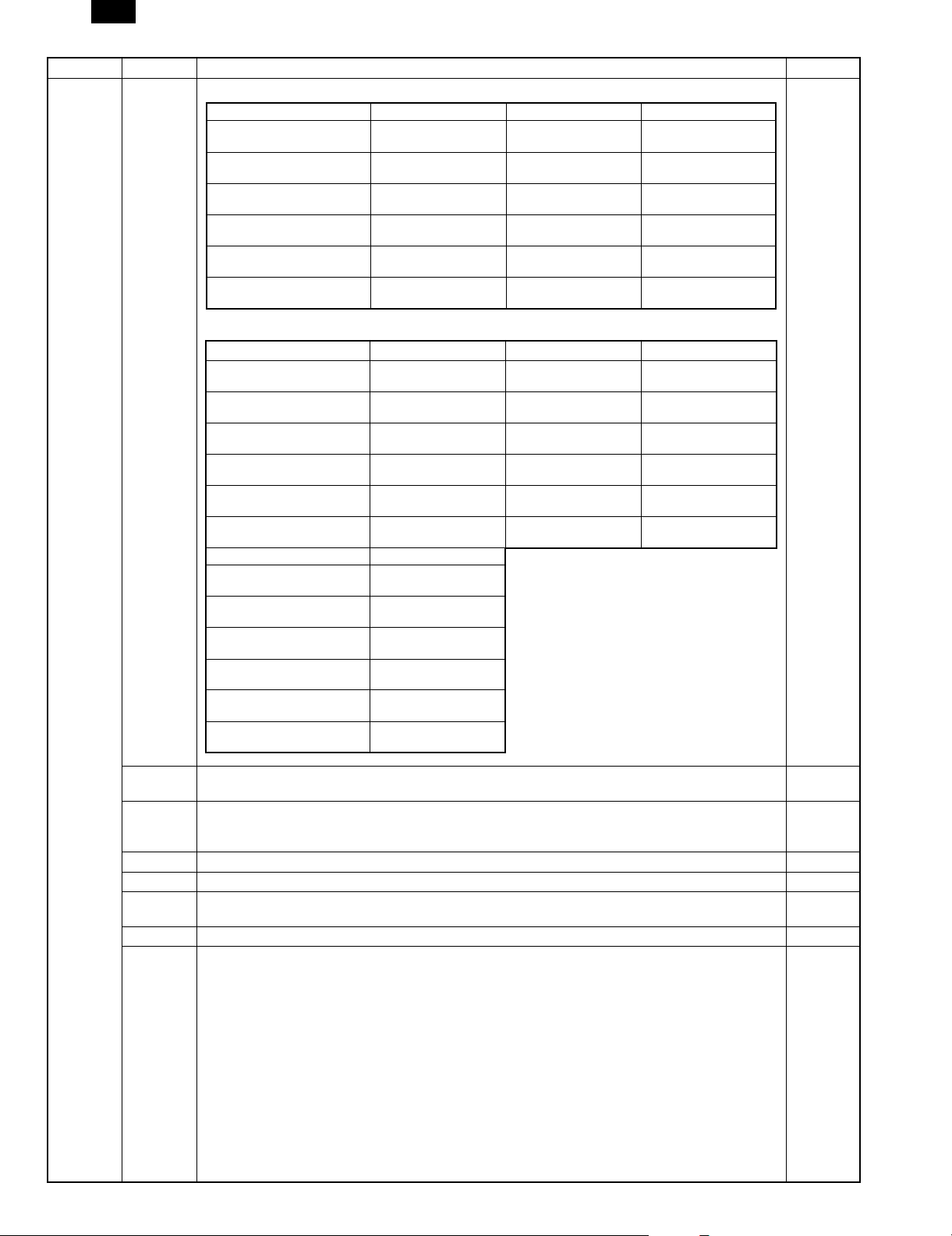

2-5 [2]-2 Consumable change (Refer to the table below.)

SEC: SF-2530

No. Name Content Life Product name Packing Remark

1 Upper heat

roller kit

2 Lower heat

roller kit

3 80K

maintenance kit

4 Cleaner blade Cleaner blade × 10 80K (× 10) SF-222CB 1

5 Upper cleaning

roller

6 Lower cleaning

roller

7 Staple cartridge Staple cartridge (3 pcs) × 10 SF-LS51 1 Common with the staple sorter

8 Staple cartridge Staple cartridge × 5 5000 times × 3 SD-LS20 10 Common with the staple sorter

Upper heat roller × 1 160K SF-230UH 5 For replacement of fusing

Fusing separation pawl (Upper) × 4

Fusing gear × 1

Lower heat roller × 1 160K SF-240LH 5 For replacement of fusing

Fusing separation pawl (Lower) × 2

Cleaner blade × 1 80K SF-240KAI 5

Charging plate unit × 1

Drum separation pawl unit × 1

Upper cleaning roller × 10 80K (× 10) SF-240UR 1 (SF-240RU) × 10 = SF-240UR

Lower cleaning roller × 10 80K (× 10) SF-235CR2 1

separation pawl (80K life) at

every 80K, use a service part.

separation pawl (80K life) at

every 80K, use a service part.

(SF-S51)

(SF-SC51) × 10 = SF-LS51

(SF-S53)

(SD-SC20) × 5 = SD-LS20

* For Toner collection container (4 pcs/80K)/Screen grid (80K)/Charger wire (80K)/Ozone filter (80K)/toner

reception seal (160K)/DV seal (160K), use service parts.

Charging plate unit (80K) and drum separation pawl unit (80K) are also supplied as service parts.

Remark

2-6 [2]-2 SECL, Agents: SF-S2530

No. Name Content Life Product name Packing Remark

1 80K

maintenance kit

2 160K

maintenance kit

3 Staple cartridge Staple cartridge (3 pcs) × 1 SF-SC51 10 Common with the staple sorter

4 Staple cartridge Staple cartridge × 5 5000 times SD-LS20 10 Common with the staple sorter

Upper cleaning roller × 1 80K SF-240DKA 1

Lower cleaning roller × 1

Cleaner blade × 1

Toner collection container × 4

Fusing separation pawl (Upper) × 4

Fusing separation pawl (Lower) × 2

Screen grid × 1

Charging plate unit × 1

Drum separation pawl unit × 1

Upper heat roller × 1 160K SF-230KB 1

Lower heat roller × 1

Toner reception seal × 1

DV seal × 1

Fusing gear × 1

(SF-S51)

(SF-S53)

(SD-SC20) × 5 = SD-LS20

– 3 –

Page 5

SF-2530

No.

Page Item Content Change

SF-2030 SF-2530

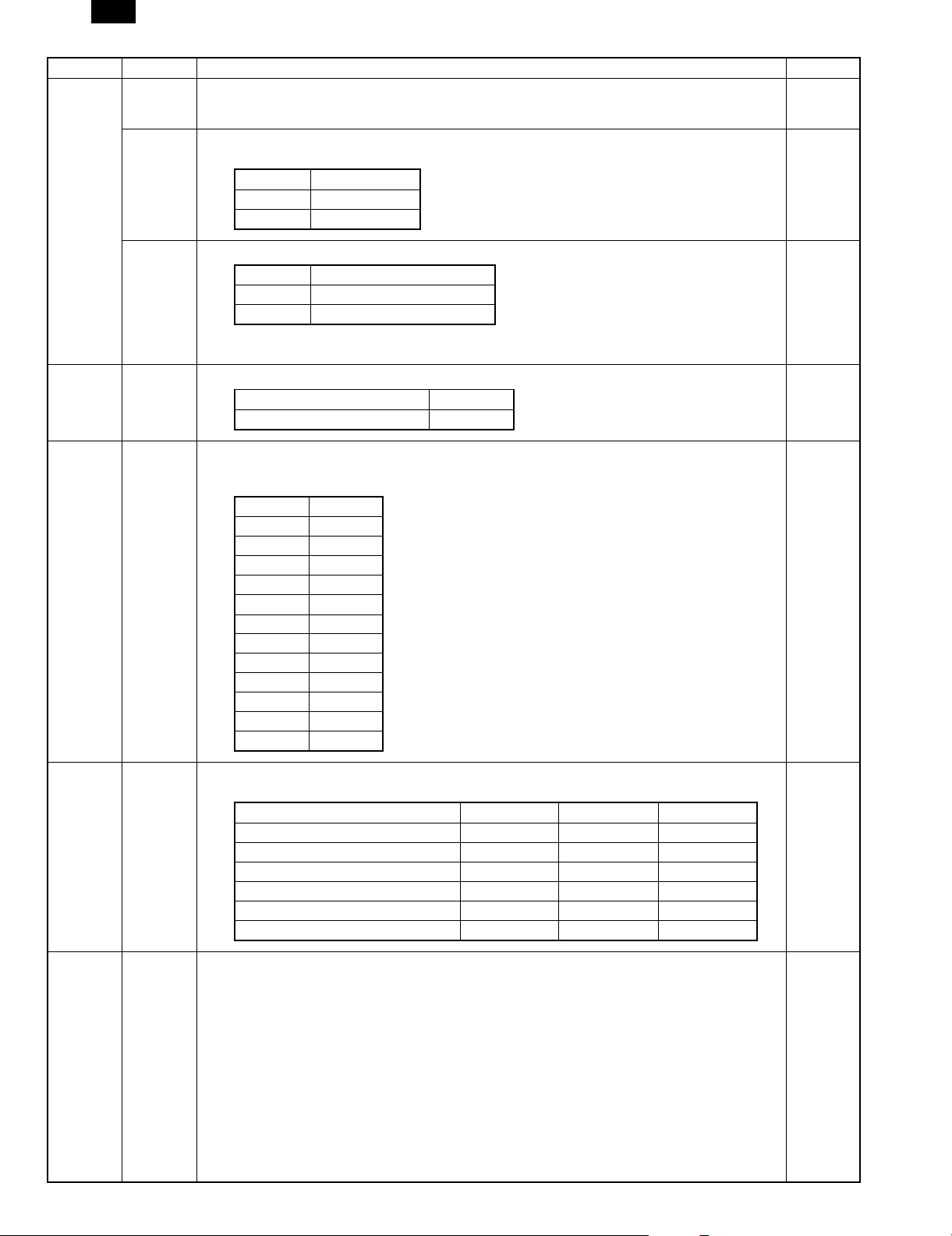

2-7 SEEG, SUK, SCA, SCNZ: SF-2530

No. Name Content Life Product name Packing Remark

1 80K

maintenance kit

2 160K

maintenance kit

3 Staple cartridge Staple cartridge (3 pcs) × 1 SF-SC51 10 Common with the staple sorter

4 Staple cartridge Staple cartridge × 5 5000 times SD-LS20 10 Common with the staple sorter

Upper cleaning roller × 1 80K SF-240KA 1 Distinguished from

Lower cleaning roller × 1

Cleaner blade × 1

Toner collection container × 4

Fusing separation pawl (Upper) × 4

Fusing separation pawl (Lower) × 2

Screen grid × 1

Charging plate unit × 1

Drum separation pawl unit × 1

Upper heat roller × 1 160K SF-230KB 1 Distinguished from

Lower heat roller × 1

Toner reception seal × 1

DV seal × 1

Fusing gear × 1

A3SF240KA for conformity of

EAM code.

A3SF230KB for conformity of

EAM code.

(SF-S51)

(SF-S53)

(SD-SC20) × 5 = SD-LS20

3-1 [3] OPTIONS SPECIFICATIONS Model name change

SF-S53 is changed to SF-S53N.

SF-S54/SF-S56 are added.

SF-S54N

SF-S54N/SF-S56 are added.

Remark

SF-S54N

– 4 –

Page 6

SF-2530

No.

Page Item Content Change

SF-2030 SF-2530

SF-S56

Name Staple sorter

Number of bins 20 bins

Collection system Face up

Capacity per bin Max. 50 sheets per bin (Top bin:

Collatable paper

size/weight

Staplable sheets

of paper

Power source Supplied by the copier.

Dimension 418mm (W) × 594mm (D) ×

Weight About 25kg

100 sheets)

Max.: A3 Min: B5

Normal paper (52 ∼ 80g/m

Thick paper (81 ∼ 200g/m

50 sheets (80g/m2 paper), For

A3/B4, 25 sheets.

624mm (H)

2

)

2

)

Remark

4-1 [4]-1 External view I Front cover shape change

13

4-3 [4]-2 Operation panel Illustration and table change Refer to the

separation

sheet 4-3.

4-8 [4]-7 BOARD LIST Japan in 5 6 is changed to Common.

5 Original sensing light emilting PWB Common

6 Orignal sensor light receve PWB Common

K L illustration and list are added.

5-2 [5]-B Model name change

SF-S2030 is changed to SF-S2530.

K L illustration and list are deleted.

[5]-B B. SF-2030 Model name change

SF-2030 is changed to SF-2530.

– 5 –

Page 7

SF-2530

No.

Page Item Content Change

SF-2030 SF-2530

5-13 [5]-B-(3) (3) SF-S53 Model name change

SF-S53 is changed to SF-S53N.

5-19

[5]-B-(4) (4) SF-S52 • SF-S52 is deleted.

~

5-29

• SF-S56 is added.

(Note) For installation of SF-S56, refer to the

SF-S56 Service Manual.

5-39 [5]-B-(9) (9) SF-DM11 9. The following note is inserted into item B of

"9. To check and adjust the matching

guide."

Enter "0" in SIM 52-3. (All destinations

except for SEC/SECL.)

6-4 [6]-2 Manual feed multicopy unit Illustration change (Refer to the figure below.)

C

6

4

5

8

7

Shift the spring to the position

shown with the arrow.

Remark

6-5 [6]-3 Paper feed unit • PS clutch shape change

PS clutch shape in Fig. A ~ B is changed.

(Refer to the figure below.)

6-6 [6]-4 Transport baseplate unit Paper stop clutch illustration change

6-8 [6]-4 Transport baseplate unit Clutch H shape in Illustration F is changed.

F

12

5

11

Changed to round shape.

– 6 –

Page 8

SF-2530

No.

Page Item Content Change

6-16 [6]-8 8. Operation panel unit and document size

SF-2030 SF-2530

• Flow chart change

sensor board (light receive side)

Procedures 8, 9, F, and G of LCD unit

delete procedures are deleted.

• Illustrations A B are changed (Refer to the

figure below.)

A

1

2

B

3

4

Remark

5

Illustration D is added.

D

6-17 [6]-8 Illustration is deleted.

6-21 [6]-9 9. Optical unit The following note is added.

Copy lamp unit installing position * When the copy lamp unit is pressed onto

the optical notch section, there must be a

clearance of 2mm between the optical

notch section and the No. 2/3 mirror base

unit.

6

– 7 –

2mm 2mm

Page 9

SF-2530

No.

Page Item Content Change

SF-2030 SF-2530

No. 2/3 mirror base unit installing position Item 1 is changed to the following content.

1 Manually turn the mirror base drive pulley

to press the copy lamp unit onto the optical

notch section. If the clearance between the

mirror base B and the optical notch section

is 2mm both at the front frame side and at

the rear frame side, the parallelism of mirror base B is proper and there is no need to

adjust. If not, loosen the pulley fixing screw

as shown below and move the pulley to adjust.

7-2 [7]-1-4 (4) Notes on installing various rollers of the

developing unit

• Part code change

φ8 V-ring PRNGP0013FCZZ is changed to

PRNGP0051FCZZ.

φ6 V-ring PRNGP0015FCZZ is changed to

PRNGP0050FCZZ.

• The roller shown below is deleted.

V-ring Φ6

Rear Front

Roller SV (X1 )

V-ring Φ6

• Insert C-ring into the figure of MG roller.

(Refer to the figure below.)

V-ring Φ8

V-ring Φ8

Remark

Rear Front

Magnet roller

• Roller name change

Roller S (x1) is changed to Roller SS (x1).

Roller MX is changed to Roller MXW.

7-2 [7]-1-(5) (5) Notes on applying the developing side

seals (front and rear)

Note for attaching developer side seals F/R Side seal FN, PN shape change

D B

(Rear)

(Front)

7-17 [7]-4-3 3. Procedure for copy density adjustment The following content is deleted.

D B

(Rear)

The following message is displayed on the

LCD.

AUTO EXPOSURE ADJUST.

(Front)

↓

– 8 –

1. 2. 3. STD 4. 5.

← LIGHTER DARKE R →

Page 10

SF-2530

No.

Page Item Content Change

7-18 [7]-4-3 (6) Adjustment of copy density • A. Output value -150V is changed to –215V.

SF-2030 SF-2530

• The following figure of 3 is deleted.

ME1 ME5 TS1 TS5 PE1

PE5 AE1 AE5 AT1 AT5

7-19 [7]-4-3 LCD displays (shown below) are deleted.

ME1 ME5 TS1 TS5 PE1

PE5 AE1 AE5 AT1 AT5

ME1 ME TS1 TS5 PE1

PE5 AE1 AE5 AT1 AT5

ME1 ME5 TS1 TS5 PE1

PE5 AE1 AE5 AT1 AT5

ME1 ME5 TS1 TS5 PE1

PE5 AE1 AE5 AT1 AT5

ME1 ME5 TS1 TS5 PE1

PE5 AE1 AE5 AT1 AT5

Remark

7-21 [7]-5-6 A. Adjustment when installing the machine The following procedures (2) and (3) are

B. Adjustment in maintenace within the life of

supply part

D. Adjustment when replacing the drum

(Photoconductor)

added.

(2) Execution of SIM 44-2.

Drum sensor level adjustment

Standard value: 204 ±10

(3) Execution of SIM 44-3

Image density sensor level adjustment

Standard value: 204 ±10

• The following items in (1) are deleted.

[+10] toner control A correction enable is

deleted.

[37] is changed to [27] and "37" to "27."

• Procedures are changed as follows.

(2) is changed to (3).

(3) is changed to (2),

(4) is changed to (5).

• (4) is added. (Refer to the following

description.)

(4) Execution of SIM 44-3

Image density sensor level adjustment

Standard value: 204 ±10

E. Adjustments when replacing the developer

and the drum (photoconductor)

• Procedures are changed as follows.

(3) is changed to (5).

(4) is changed to (3).

• (4) is added. (Refer to the following

description.)

(4) Execution of SIM 44-3.

Image density sensor level adjustment

Standard value: 204 ±10

7-24 (Trouble codes and countermeasures)

8-1 [8] [8] Simulation and diagnostics Refer to the separate sheet. Refer to the

separate sheet

8-1 to 8-19.

– 9 –

Page 11

SF-2530

No.

Page Item Content Change

9-7 [9]-4-(6) (6) Paper-feed torque limiter 500-sheet

SF-2030 SF-2530

Illustration shape change (Refer to the figure

cassette brake spring

below.)

Remark

Brake spring

Torque limiter

– 10 –

Page 12

CA

SF-2530

2. Operation panel

EDGE ERASE key and indicator

1

AUTO IMAGE key

4

CHECK STAPLER indicator

7

Developer replacement required

F

indicator

Misfeed indicator

I

CLEAR ALL ( ) key

L

ORIGINAL TO COPY key and

O

indicators

Reduction ( ) key

R

ORIGINAL SIZE indicators

U

PAPER SIZE indicators

X

10-key pad

[

START key and indicator

^

2 3

1

EDGE

MARGIN

ERASE

SORTER

SORT

STAPLE

SORT

GROUP

DUAL PAGE

SHIFT

COPY

ORIGIN A L TO COP Y

1

1

(ORIGINALS)

EVEN NUMBER

ODD NUMBER

2

2

PRE-COUNT

ORIGINALS

2

2

11

18 19 20 21 23 25 27

EXPOSURE

AUTO

MANUAL

PHOTO

12345

LIGHT DARK

4

5 7

%

AUTO IMAGE

ZOOM

100%

6

CHECK STAPLER

ORIGINAL

SIZE

11 x 17

8½ x 14

8½ x 11

8½ x 5½

8½ x 11

EXTRA

AUTO PAPER

SELECT

ORIGINAL SIZE ENTER

26

22 24 28

MARGIN SHIFT key and indicator

2

COPY RATIO display

5

Paper required indicator

8

Toner collecting container full indicator

G

Copy quantity display

J

POWER SAVE indicator

M

LIGHT and DARK keys and indicators

P

Enlargement ( ) key

S

ORIGINAL SIZE ENTER key

V

TRAY SELECT key

Y

Zero/readout key

\

101112

98

PAPER

SIZE

TRAY SELE CT

29 31 33 34

123

4

7

0/ C

30

32

14

CLEAR ALL

56

89

DUAL PAGE COPY key and indicator

3

ZOOM keys

6

Maintenance required indicator

9

Toner required indicator

H

INTERRUPT key and indicator

K

SORTER key and indicators

N

EXPOSURE key and indicators

Q

100% key

T

AUTO PAPER SELECT indicator

W

Paper feed location/misfeed location

Z

indicators

Clear (

]

1513

INTERRUPT

CA

POWER SAVE

START

16 17

) key

C

4 – 3

Page 13

*

1

*

1

*

1

YES

YES

NO

NO

NO

YES

1

Press the CLEAR key.

2

Pres s the PAUSE key.

3

Press the 0/

◊ ΚΕΨ.

4

Pres s the PAUSE key.

As the copy number window number

disappears, the control becomes ready

for ent ry of a si mula ti on nu mber .

Enter the re quired

simula tio n num be r on

the keypad.

After entering a two-digit number, t he

simulation number comes displayed

on the copy number window.

Is there

any subsequent

code?

6

Press the PRINT switch.

*

2 Action takes place corresponding

to the given simulation n umbe r.

7

Pres s the PAUSE key.

As the figure in the copy number window

disappears, the control becomes ready

for ent ry of a s im ulation number.

Doing other

simulation?

Press the CLEAR ALL key (*3).

The simulation is canceled and the

contro l returns t o the st ate immediately

after t he switch w as turned on.

6

Press the PRINT switch.

The figure in the copy number window

blinks and becomes ready for entry of

a simulation number.

8

Press the PRINT switch.

*

2 Action takes place corresponding to

the given simulation number.

9

Pres s the PAUSE key.

The figure in the copy number window

blinks and becomes ready for entry of

a simulation number.

Want to

return to the main

command

entry?

Press th e PAUS E k e y.

As the m ain simulat ion code c omes

display ed, the c ontrol becomes ready

for ent ry of the s imulation mai n code.

5

Enter the re quired

simula tio n num be r on

the keypad.

After entering a two-digit number,

the simulation number comes

displayed on the copy number window.

7

SF-2530

[8] Simulation and diagnostics

1. Simulation

(1) Introduction

Simulation are used to do the following:

• To operate any functional block independently to check its func-

tion.

• To adjust the machine.

• To cancel troubles.

• To set up functions.

(2) Purpose

Simulation are used to help repair and adjust the machine.

When the PAUSE key is pressed in a course of a simulation being

executed, the simulation is interrupted with the copy number window

turned off and the copier becomes ready to accept entry of a simulation number.

*1: If the key was pressed for more than five seconds, it may not go

into the simulation mode.

(3) Simulation execution procedure

*2: Further operation may be needed depending on the kind of

simulation.

*3: One of the next methods is required to cancel the simulation as

it varies according to the simulation. The machine then starts

from the state immediately after power on.

— Other than simulation 7

The simulation is canceled when the CLEAR ALL key is pressed.

— Simulation 7

One of the following operation cancels the simulation execution.

1. Power switch off.

2. Press the CLEAR → PAUSE → 0 → PAUSE → CLEAR ALL

keys.

— Simulation 14

The simulation 14 is used to clear the memory contents (H2, H3,

H4) that have been stored. After the simulation 14 has been executed, the diagnostic is automatically terminated.

— Special keys

CLEAR ALL key: Simulation mode → normal mode.

PAUSE key: Execution of simulation is interrupted.

CLEAR key: Clears the copy number window.

— The diagnostic is automatically terminated after the doorswitch

operation "ON → OFF → ON", except "H" and "U2" code.

8 – 1

Page 14

SF-2530

List of the test commands

Sim. NOSim.

SUB

01 Optical system mirror scanning check

02 Optical system sensor state display

01

03 Lens movement operation check

04 Lens aging

01 RADF aging

02 RADF sensor state display

03

04 Motor A reverse rotation

05 Motor B forward rotation

02

03

04

05

06 02 Separation pawl solenoid operation check

RADF

06 Motor B reverse rotation

individual load

operation

07 Belt clutch

check

08 Paper feed solenoid

09 Reverse solenoid

10 Stopper solenoid

11 Brake clutch

01 Sorter state display

02 Sorter sensor state display

03

04 Bin shift motor

Sorter

05 Fan motor (SF-S15 only)

individual load

06 Gate solenoid

operation

08 Staple motor (SF-S53 only)

check

09

10 Guide bar motor (SF-S53 only)

02 Desk sensor state display

03 1st cassette slot, cassette size switch check (Desk)

2nd cassette slot, cassette size switch check

04

(Desk)

05 3rd cassette slot, cassette size switch check (Desk)

06

07 1st cassette slot, lift-up motor

08 2nd cassette slot, lift-up motor

09 3rd cassette slot, lift-up motor

10 Transport clutch

Desk

11

individual load

operation

12

check

13

14

15

16

01 Operation panel display check

02 Fuser lamp check

03 Copy lamp check

04 BL/DL check

Description

Motor A forward rotation

Transport motor

Paper hold solenoid (SF-S53

only)

Transport motor

1st cassette slot, paper feed

solenoid

1st cassette slot, paper feed

clutch

2nd cassette slot, paper feed

solenoid

2nd cassette slot, paper feed

clutch

3rd cassette slot, paper feed

solenoid

3rd cassette slot, paper feed

clutch

Sim. NOSim.

SUB

01 Warm-up time display and aging with jam detection

02 Aging without jam

03 Aging without jam without fusing

07

04 Warm-up disabled

06 Intermittent aging

07 Intermittent aging without jam

08 Warm-up time display (without aging)

01 Developer bias check

02

MHV

(Charge), grid

03 Photo

08

09

10 ** Toner motor aging

14 ** Cancel of troubles except U2, H2, H3, H4

16 ** Cancel of U2 trouble code

17 ** PF trouble cancel

20 ** Maintenance counter clear

21

22 01 Maintenance counter display

22

24

check

04 TSM

06 THV (Transfer) check

07 SHV (Separation) check

02 ADU sensor state display

03 ADU trail edge plate aging

04 ADU alignment plate aging

05 Gate solenoid operation check

01 Maintenance cycle setting

02 Mini maintenance cycle setting

02 Maintenance preset counter display

03 Jam memory display

04 Total jam counter display

05 Total counter display

Mini maintenance counter display (Japan),

06

Developer counter display (EX)

Mini maintenance preset (Japan)/Developer preset

07

(EX) counter display

08 RADF counter display

09 ADU counter display

10 Staple counter display

11 Developer adjustment time display

12 Drum adjustment time display

15 Trouble memory display

16 Cassette paper feed counter display

17 Developer counter display (Japan)

18 Developer life preset counter display (EX)

01 Jam memory/total jam counter clear

02 Trouble memory clear

03 Duplex counter clear

04 ADF/RADF counter clear

05 Staple counter clear

06 Developer adjustment time clear

07 Drum adjustment time clear

08 Cassette paper feed counter clear

Description

Standard

8 – 2

Page 15

SF-2530

Sim. NOSim.

SUB

Main motor system ON, toner sensor output

01

display

25

02 Auto developer adjustment

06 Toner control A counter value setting

07 Grid correction setting for toner control A

01 Option setting

03 Coin vendor setting

05 Counter mode setting

06 Destination setting

07 Drum sensitivity setting

26

08 Lens focus setting

09 4/5 mirror characteristics setting

10 AE original density setting

24 Margin position setting

Standard state setting of duplex copy from

25

even-number single copy

27 01 PPC communication trouble

01 Paper sensor state display

30

02 Cassette size switch state display

42 ** Developer counter clear

43 ** Fusing temperature setting

01 Correction mode setting,

02 Drum mark sensor sensitivity adjustment

03 Image density sensor sensitivity adjustment

05 Half tone density correction test mode

44

46 01 Exposure level adjustment

47 ** AE sensor characteristics setting

48

50

51 02 Paper buckle adjustment

52

Half tone density correction compulsory execution

06

mode

07 DM/ID sensor gain select switch

Half tone density correction measurement data

09

display

11 Operation setting at grid bias

12 Copying without half tone density correction

Front/rear magnification ratio adjustment, focus

01

adjustment

Paper transport direction magnification ratio

02

adjustment (scanner speed)

Lead edge image position adjustment, lead edge

01

void adjustment (Calculation)

Lead edge image position adjustment, lead edge

02

void adjustment (Measurement)

01 ADU alignment plate adjustment value setting

02 ADU trail edge plate adjustment value setting

03 ADU drive clutch OFF time setting

Description

Sim. NOSim.

SUB

01

02 Normal paper, Duplex copy

03 Thin paper, Single copy

53

04 Thin paper, Duplex copy

05 RADF resist sensor adjustment

06 RADF timing sensor adjustment

07 RADF repulsion sensor adjustment

08 RADF empty sensor adjustment

RADF stop

position

adjustment

Description

Normal paper, Single copy

8 – 3

Page 16

SF-2530

Main code Sub code Description Ref. Page

01 01 This is the test command used to test the optical system. The mirror base automatically starts to scan.

(1) With depression of the PAUSE key, the control moves from the test command mode to be ready to

execute it. The READY pilot lamp (RPL) comes active with the zoom ratio at 100%. It is possible to

change the zoom mode using the ZOOM key.

(2) When the PRINT key is pressed while the RPL is active, the status lamp turns off and the test

command starts to execute. The mirror base moves to scan in the zoom ratio at that time.

(3) If the door is opened while the operation is in process, the operation is interrupted with status "CH"

prompted. Closing the door will start the operation all over again from its initial step.

02 This is the test command used to test the optical system sensors. When the test command starts and

the sensor turns on and the display reverses, it starts to test the on/off action of a optical system

sensor.

Display Active status lamp

MENTEL (Maintenance lamp) Mirror rotary encoder pulse (RE) input

TNEL (Waste toner full lamp) Mirror home position sensor

DVPL (Developer maintenance lamp) Lens home position sensor

TPL (Toner empty lamp) No.4/5 mirror home position sensor

03 Used to test the zoom lens movement.

• The zoom ratio is displayed on the zoom ratio window.

AB series machine

Inch series machine

100% 50% 70% 81% 86%

115%

122%

200%141%

100% 50% 64% 77% 95%

121%

129%

200%141%

04 Used to test the zoom lens in the aging test mode.

• Test command 01-03 are repeated to test.

02 01 Used to test the action of the RADF. The aging test starts when the document presence sensor is

manually turned on.

02 This is the test command used to test RADF sensors. On/off state of sensor can be manually tested.

03 Used to test the action of RADF (individual load check)

04 Motor A revere rotation

05 Motor B forward rotation

06 Motor B revere rotation

07 Belt clutch (Staple sorter only)

08 Paper feed solenoid (Staple sorter only)

09 Inversion solenoid

10 Stopper solenoid

11 Brake clutch

By pressing 10-key, a desired sensor can be selected.

10-key position 0 1 2

TPL

(Toner empty)

TNFL

(Waste toner full lamp)

DVPL

(Developer

maintenance lamp)

MENTEL

(Maintenance lamp) DTD

JPL

(Jam empty)

PPL

(Paper empty lamp)

Document

presence/empty detection

DSD

Document preliminary

feed detection

DFD

Document exit detection

RDD

Document pass width

detection

DWS

DF section open/close

detection

AUOD

Paper feed section

open/close detection

FGOD

Reverse section

open/close detection

TGOD

Document length detection

DLS3

Empty sensor 1

DED1

Empty sensor 2

DED2

Document width detection

Document width detection

Document width detection

Document width detection

Document length detection

Document length detection

Reverse display: Paper presence/Door open, Normal display: No paper/Door closed

Motor A forward rotation

DWS1

DWS2

DWS3

DWS4

DLS1

DLS2

8 – 4

Page 17

SF-2530

Main code Sub code Description Ref. Page

03 01 Sorter operation check (Only when the SF-S56 is installed)

02 This is the test command used to test the sensors in the sorter.

On/off state of sensors can be manually tested.

By pressing 10-key during execution of this simulation, a desired sensor can be selected.

(When S15 installed)

Position/10-key 0 1 2

TPL

(Toner empty)

TNFL

(Waste toner full lamp)

DVPL

(Developer

maintenance lamp)

MENTEL

(Maintenance lamp) —

JPL

(Jam lamp)

PPL

(Paper empty lamp)

Paper entry detection

(Non sort)

PES

Paper exit detection

PWB-S

———

———

Indexer upper limit

detection

IULS

Indexer lower limit

detection

ILLS

Indexer (bin) home

position detection

IHS

Indexer (bin) fixed position

detection

IPS

Sorter set detection

SJS

Top cover open/close

detection

UCSW

Blower cover open/close

detection

FCSW

—

(When S52 installed)

Position/10-key 0 1 2

TPL

(Toner empty)

TNFL

(Waste toner full lamp)

DVPL

(Developer maintenance lamp)

MENTEL

(Maintenance lamp)

JPL

(Jam lamp)

PPL

(Paper empty lamp)

Pass sensor Jogger sensor Sorter set detection

Bin home sensor Paper edge sensor Top cover open/close

Bin cam sensor Staple cam switch Blower cover open/close

Paper sensor 1 Staple needle sensor

Paper sesnor 2

———

——

detection

detection

—

(When S18 installed)

Position/10-key 0 1 2

TPL

(Toner empty)

TNFL

(Waste toner full lamp)

DVPL

(Developer maintenance lamp)

MENTEL

(Maintenance lamp)

JPL

(Jam lamp)

PPL

(Paper empty lamp)

Entry port sensor

Paper empty sensor

Upper limit sensor

Lower limit sensor

Paper sensor 2

Paper take-out sensor

——

——

——

——

——

——

8 – 5

Page 18

SF-2530

Main code Sub code Description Ref. Page

(When S54 installed)

Position/10-key 0 1 2

TPL

(Toner empty)

TNFL

(Waste toner full lamp)

DVPL

(Developer maintenance lamp)

MENTEL

(Maintenance lamp)

JPL

(Jam lamp)

PPL

(Paper empty lamp)

Entry port sensor Alignment rod home

Paper empty sensor Gripping home sensor

Upper limit sensor Stapler home sensor

Lower limit sensor Stapler paper sensor

Paper sensor Stapler near sensor

Paper take-out sensor

sensor

——

—

—

—

—

—

(When S56 installed)

Position/10-key 0 1

TPL

(Toner empty)

TNFL

(Waste toner full lamp)

DVPL

(Developer maintenance lamp)

MENTEL

(Maintenance lamp)

JPL

(Jam lamp)

PPL

(Paper empty lamp)

Position/10-key 4

TPL

(Toner empty)

TNFL

(Waste toner full lamp)

DVPL

(Developer maintenance lamp)

MENTEL

(Maintenance lamp)

JPL

(Jam lamp)

PPL

(Paper empty lamp)

Staple door switch Lead cam sensor Staple cue sensor

Joint switch Stapler home position Staple sensor

Paper exit sensor 24V sensor Bin upper paper sensor

Stapler oscillation home

position

Alignment rod home

position sensor

Bin unit home position

sensor

DIP switch 04

DIP switch 05

DIP switch 06

Push switch 02

Push switch 03

Staple cartridge sensor DIP switch 01

Staple cartridge sensor DIP switch 02

Stapler foreign material

sensor

2

DIP switch 03

03 Used to test the components of the sorter (individual load check).

Transport motor rotation (When SF-S56 is installed, this simulation is disabled.)

04 Indexer motor rotation (returns to the home position at first, then stops at each bin location Bin 1 to Bin

21, moving up and down. Sorter bin moving. (Bin motor rotation when SF-S54 is installed) (When

SF-S56 is installed, this simulation is disabled.)

05 Fan motor rotation in the case of SF-S54 only (When SF-S56 is installed, this simulation is disabled.)

06 Gate solenoid ON (SF-S15/18 only)

08 Stapler motor rotation (the paper is stapled once when there is a paper in the stapler tray). (SF-S53

only) (When SF-S54 is installed, the gripping motor rotation)

09 Paper holder solenoid operation check (SF-S53 only)

10 Guide motor operation check (SF-S53 only)

8 – 6

Page 19

SF-2530

Main code Sub code Description Ref. Page

04 02 This is the test command used to test sensors in the desk. On/off state of the sensors can be manually

tested.

When a sensor turns on, the display reverses.

10-key position 0 1 2

TPL

(Toner empty)

TNFL

(Waste toner full lamp)

DVPL

(Developer

maintenance lamp)

MENTEL

(Maintenance lamp)

JPL

(Jam lamp)

PPL

(Paper empty lamp)

Upper paper sensor

DPOD1

Upper paper exit sensor

DPOD2

Lower paper sensor

DPOD3

Door open/close detection

DDOP

Upper cassette lift up

sensor

DLUD1

Medium cassette lift up

sensor

DLUD2

Lower cassette lift up

sensor

DLUD3

Upper cassette paper

detection

DPE1

Medium cassette paper

detection

DPE

Lower cassette paper

detection

DPE3

03 Used to test the on/off state of the first cassette size switch of the desk.

When the switch turns on, the display reverses.

(Cassette size board)

Switch positions when viewed from the front frame

TPL (Toner empty) CSSW1

TNFL (Waste toner full lamp) CSSW2

DVPL (Developer maintenance lamp) CSSW3

MENTEL (Maintenance lamp) CSSW4

CSSW4 CSSW3 CSSW2 CSSW1

Paper exit side

5CN

1

Paper entry side

04 Used to test the on/off state of the second cassette size switch of the desk. Function is identical to the

test command 04-03.

When the switch is turned on, the display reverses.

05 Used to test the on/off state of the third cassette size switch of the desk. Function is identical to the test

command 04-03.

When the switch is turned on, the display reverses.

06 Transport motor rotation. (Desk)

07 Motor turns off when detected the upper limit of the first cassette lift up motor rotation. (Desk).

08 Motor turns off when detected the upper limit of the second cassette lift up motor rotation. (Desk)

09 Motor turns off when detected the upper limit of the third cassette lift up motor rotation. (Desk)

10 Activate transport clutch of the desk

11 Activate first cassette paper feed solenoid of the desk

12 Activate paper feed clutch of the first cassette of the desk

13 Activate second cassette paper feed solenoid of the desk

14 Activate paper feed clutch of the second cassette of the desk

15 Activate third cassette paper feed solenoid of the desk

16 Activate paper feed clutch of the third cassette of the desk

05 01 All LED’s on the operation panel are turned on for one minute. After one minute, the machine automat-

ically goes into the sub code input wait state.

02 This is the test command used to test the heater lamp. Heater lamp turned on and off five times.

ON

PR

ON

OFF

OFF

HL

500msec

The heater turns on and off in the order shown above.

8 – 7

Page 20

SF-2530

Main code Sub code Description Ref. Page

05 03 This is the test command used to test the copy lamp. Copy lamp turned on in the following order.

When the test command starts, the copy lamp turns full power for one second with the manual

exposure setting 3.0 shown, and the copy lamp intensity can be changed to the power set on the

exposure setup key for a period of 6.25 seconds.

ON

PR

Use care not to damage original

cover or RADF belt.

CL

0.5 1

0 6

25

ON

* Refrain from repeating this test command without waiting for lamp and glass to cool.

04 This is the test command used to check activation of the discharge lamp (DL) and the blank lamps (BL).

The discharge lamp (DL) turns on for 30 seconds.

Each blank lamp turns on, from the front frame side to the rear frame side. Finally, all blank lamps turn

on. After lighting, the machine automatically goes into the sub code input wait state.

06 02 Activation of the separation solenoid

Used to test the action of the drum separator pawl solenoid.

07 01 Aging test with alert for paper misfeed

1. Used to check the warmup time.

2. Executes the continuing aging test for the given number of copies.

When the test command is executed. the machine performs its normal action and the warmup time

starts to count from zero and increase count every one second. The count is displayed on the copy

lamp window.

When the RPL is turned on, the addition of the copy number is interrupted with the copy number

remaining on display as it is. When the CLEAR key is pressed, the copy number must be entered on

the keypad, and with depression of the PRINT switch, the given number of copies repeated to

produce. In this case, the paper misfeed function comes alive.

02 Aging without jam

Aging is performed without paper feed.

Similar to SIM 7-1. Aging is performed by disregarding paper jam. (Warm up time check is similar to

SIM 7-1.)

03 Aging without jam without fusing

Similar to SIM 7-1. Aging is performed by saving the warm up time and disregarding the heater system

trouble functions and paper jam. (The heater lamp does not turn on.)

04 Saving warm up

Warm up time is saved to check operations of the machine. When this simulation is executed, RPL

turns on to allow the operation check of the machine. When the heater section is at low temperature,

the heater low temperature may be sensed and H4 may be displayed.

06 Intermittent aging

07 Intermittent aging without jam

08 Warm up time display (without aging)

(Warm up time check is similar to SIm 7-1.)

08 01 Developing bias voltage output. After delivering the output, the machine automatically goes into the sub

code input wait state.

This is the test command used to check the developing bias voltage. The developing bias voltage is

turned on for 30 seconds.

Standard developing bias setting is –215±10V.

02 Main (charge) corona output [ME]. After delivering the output, the machine automatically goes into the

sub code input wait state.

Standard manual exposure mode main corona grid voltage is –650±5V.

This is the test command used to check the main corona variance between the front and rear sides.

The corona output continues for 30 seconds.

• The main corona variance must be within 8µA between the front and the rear.

03 Main corona output [PE]. After delivering the output, the machine automatically goes into the sub code

input wait state.

Standard photographic mode main corona grid voltage is –440±5V.

04 Main corona output [TSM]. After delivering the output, the machine automatically goes into the sub code

input wait state.

Standard TSM main corona grid voltage is –550V±5V.

[7]-2(3)

[7]-5-(D)

[7]-5-(D)

[7]-5-(D)

8 – 8

Page 21

SF-2530

Main code Sub code Description Ref. Page

08 06 Transfer corona output [TSM]. After delivering the output, the machine automatically goes into the sub

[7]-4-(B)

code input wait state.

This is the test command used to check the transfer corona output (THV). The transfer corona output

continues for 30 seconds.

THV

30 sec

Standard transfer corona output is –42±4µA (F/R difference: Max. 5µA).

07 Separation corona output. After delivering the output, the machine automatically goes into the sub code

input wait state.

This is the test command used to check the separation corona output (SHV). The separation corona

output continues for 30 seconds.

SHV

30 sec

Standard separation corona output is 0±10 V.

09 02 ADU sensor check test command ON/OFF state of each sensor can be manually checked.

When the sensor turns on, the display reverses.

Position Sensor Function

TPL (Toner empty) DPPD1 ADU transport sensor 1

TNFL (Waste toner full lamp) DPPD2 ADU transport sensor 2

DVPL (Developer maintenance lamp) DTPID ADU tray sensor

MENTEL (Maintenance lamp) DPFD ADU tray out sensor

JPL (Jam lamp) APHPS1 ADU alignment plate home position sensor

PPL (Paper empty lamp) APHPS2 ADU rear edge plate home position sensor

03 ADU trail edge plate drive motor rotation

• Used to check the trail edge plate movement

(AB series)

HP.A3

B4 A4R B5R A4 B5 A5

[7]-6-(E)

(Inch series)

HP.11" x 17"

11" x 14"

04 ADU alignment plate drive motor rotation

• Used check the alignment plate movement

(AB series)

HP.A3

(Inch series)

HP.11" x 17"

05 Gate solenoid activation

Used to check the gate solenoid operation.

10 — Toner motor activation

Used to check the toner motor activation.

14 — Trouble code cancellation

This is the test command used to cancel other than the "U2" trouble (H2, H3, H4). After the trouble has

been removed, the test command terminates.

16 — U2 trouble code cancellation

This is the test command used to cancel the "U2" trouble code.

After the trouble code has been removed, the test command terminates.

17 — PF trouble cancel

Used to cancel the PF trouble in the machine with PC/Modem when the copy inhibition command from

the host machine is received. After cancelling the trouble, the test command is automatically cancelled.

20 — Maintenance counter clear

1. Clear 2. Not clear

When the main code is entered, the staple check lamp turns on and the machine enter the standby

mode for entry of conditions.Select 1 or 2 with 10-key. After selection, the staple check lamp goes off.

This simulation is used to set the maintenance preset counter to "0" after completion of maintenance.

Be sure to execute this simulation always after completion of maintenance.

B4 A4R B5R A4 B5 A5

11" x 14"

1

x8

" 11"(R) x8

2

1

x8

" 11"(R) x8

2

1

" 11"

2

1

" 11"

2

8 – 9

Page 22

SF-2530

Main code Sub code Description Ref. Page

21 01 Maintenance cycle setting

Used to set the maintenance cycle.

Code Maintenance cycle

0 ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 80,000 sheets

1 ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 5,000 sheets

2 ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 10,000 sheets

3 ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 20,000 sheets

4 ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 40,000 sheets

5 ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ None

The default is 0. The code number is displayed on the copy quantity display.

22 01

Mini maintenance cycle setting (Japan only)

°

Used to set mini maintenance cycle.

Code

0 ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 80,000 sheets

1 ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 5,000 sheets

2 ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 10,000 sheets

The initial value is set as "1."

The code number is displayed on the copy quantity display.

02

Maintenance preset counter display

°

This test command is used to check the contents of the maintenance preset cycle counter.

03

JAM memory display (JAM map display)

°

Displays the causes (positions) of JAM occurred in copy operation.

To check the history of JAM cause, press the message forward feed key.

JAM CODE: XX

1

2

3

4

5

6

7

8

9

A

B SORTER Sorter

C DESK Desk

D Other

E (Reserved)

F (Reserved)

Manual feed PPD2 not

Machine

upper step

(1CS)

Machine

lower step

(2CS)

Machine

paper

Desk top

feed

step (3CS)

Desk

medium

step (4CS)

LCC

Desk lower

step (5CS)

ADU PPD2 not

ON JAM DPPD2 not

Transport

OFF JAM DPPD2 not

ADF Preliminary

Option

Other PPD1 ON

MFT Manual feed

1CS 1 cassette

2CS 2

3CS 3

4CS 4

5CS 5

ADU ADU

ON JAM

OFF JAM

0123456789ABCDEF

reached

PPD2 not

PPD1 not

reached

reached

PPD2 not

PPD1 not

reached

PPD1 not

reached

PPD1 not

reached

PPD1 not

reached

PPD1 not

reached

PID not

reached

PID not

reached

PID not

reached

PID not

reached

DPFD not

reached

reached

DPPD1

remaining

PDD

remaining

PSD

remaining

PPD2

remaining

PPD1

remaining

PID

remaining

reached

and PPD2

OFF before

1CS paper

feed

DPPD1 not

POD not

reached

reached

Paper feed Paper exit Reverse

paper feed

POD ON

DPFO ON

and PPD2

and PPD1

OFF before

ON and

2CS paper

PPD2 OFF

feed

before ADU

paper feed

PSD not

reached

reached

PPD2 not

reached

PPD2 not

reached

PPD2 not

reached

reached

8 – 10

Page 23

SF-2530

Main code Sub code Description Ref. Page

22 04

05

06

07

08

09

10

11

12

15

16

17

18

24 01

02 Trouble memory clear

03

04

05

06

07

08

Total misfeed counter display

°

Total counter display

°

This counter is used to show the total copy number of the machine.

Developer counter display (EX)

°

The contents of the copy number counter of the installed developing unit is displayed.

Mini maintenance counter display (Japan only)

Developer preset cycle counter display (EX)

°

Number of developer replacements and the reset counter contents of the installed developing unit are

displayed.

Mini maintenance preset counter display (Japan only)

RADF counter display

°

Used to check the number of originals fed through the RADF.

Duplex counter display

°

Used to check the number of sheets fed through the duplex unit.

Staple counter display

°

Used to check the number of use of the staple unit.

Developer adjustment time display

°

Used to check the correction level according to the developer rotating time.

Drum adjustment time display

°

Used to check the correction level according to the drum rotating time.

Trouble memory display

°

When the sub code is entered, the latest trouble main code is displayed on the copy quantity display.

Press the Enter key to display the previous ones. When the PSW is pressed with the trouble main

code displayed, the trouble code corresponding to that main code is displayed.

When the sorter key is kept pressing for 3 sec or more, the trouble counter value is displayed on the

copy quantity display.

Cassette paper feed counter display

°

Select the paper feed destination with the tray select key, and the counter value corresponding to the

selected paper feed destination is displayed by 2 digits on the copy quantity display.

Developer counter display (Japan only)

°

The content of the copy quantity counter of the DV unit installed is displayed.

Developer life preset counter (Japan only)

°

The content of the developer replacement quantity preset counter of the DV unit installed is displayed.

Misfeed map memory and total misfeed counter clear

°

Duplex counter clear

°

The contents of the copy number counter is reset to the duplex unit.

It is mandatory to clear the memory contents after the maintenance is completed.

RADF counter clear

°

The contents of the copy number counter is reset for the RADF.

It is mandatory to clear the memory contents after the maintenance is completed.

Staple counter clear

°

The staple unit using counter is cleared to zero.

Developer adjustment time clear

°

The developer adjustment time is cleared to zero.

Drum adjustment time clear

°

The drum adjustment time is cleared to zero.

Tray paper feed counter clear

°

Delete by entering the code.

1 Manual feed counter delete

2 1CS counter delete

3 2CS counter delete

4 3CS counter delete

5 4CS counter delete

6 5CS counter delete

7 AX counter delete

25 01 Main motor activation

• Used to check malfunction in the main motor drive train. (Rotates for 3 min.)

• Also, monitors the toner density sensor. (Sensor output value display)

C → =↵ → 0 → =↵ → 2 → 5 → PSW → 1 → PSW

8 – 11

Page 24

SF-2530

Main code Sub code Description Ref. Page

25 02 Automatic developer adjustment

• This is the test command used to monitor the toner sensor and to automatically set the developer.

• For automatically setting developer, the developing tank is stirred and the toner sensor output is

monitored. The sensor is monitored 16 times in 3 minutes after the stirring started and the mean

value is stored in the memory as the toner density referance value. (See the area marked with an

asterisk in the figure below.) ( Afterwards, referance changes as copies are made to maintain

density.)

MM

DVBIAS

THV

DL

100m

sec

3min

900msec

C → =↵ → 0 → =↵ → 2 → 5 → PSW → 2 → PSW

06 Toner control A count number setting

Used to set the max. number of toner control corrections.

07 Grid correction amount setting for toner control A

Used to set the absolute value of the toner control reference value.

26 01 Option unit setup

• Used to set up option unit.

1 When the test command is executed, the presently stored machine setup code is displayed with the

READY lamp turned on.

2 After the READY lamp has turned on, enter an appropriate setup code on the keypad and press the

PRINT switch. Then, the date is stored in the memory and the READY lamp turns off.

Code Option

+1 RADF

+2 ADU [Auto setting]

+4 Desk

+10 Sorter

No need to set "+2 (ADU)". If the ADU is installed, "2" is automatically added.

°

Used to set the code that corresponds to an option unit.

°

(EX): To set the RADF and desk together with ADU, enter 1+2+4=7, or 1+4=5.

NOTES:

(1) Be sure to enter the code that corresponds to the installed option unit.

(2) If option setup is incorrect, a trouble code is displayed. See the trouble code chart.

03 Coin vendor setting

0: Cancel, 1: Setting

(Note ) When a coin ve ndor is installe d, selec t "1. Setting."

05 Counter mode setup

1 When the test command is executed, the code of the presently stored mode is displayed with the

READY lamp turned on.

2 After the READY lamp has turned on, enter an appropriate setup code on the keypad and press the

PRINT switch. Then, the code is stored in the memory and the READY lamp turns off.

Code Total counter Maintenance counter

0 Double count Double count

1 Single count Double count

2 Double count Single count

3 Single count Single count

8 – 12

Page 25

SF-2530

Main code Sub code Description Ref. Page

26 06 Destination setup

Used to set the destination setting.

1 When the test command is executed, the presently stored model number and the destination code

are displayed (see table below) and the READY lamp turns on.

2 After the READY lamp has turned on, enter the model number and the destination code on the

keypad and press the PRINT switch to store the setting in the memory. The READY lamp then

turns off.

Code Destination AB/Inch

0 SEC (ES) America

1 SEC America

2 SECL Canada

3 Other

4 Japan

5 Other

6 SEEG German

7 SUK U.K.

8 SCA Australia

9 Other

10 BW-UT1 Taiwan

07 Drum sensitivity setup

1 When the test command is executed, the number stored in the memory is recalled and the READY

lamp turns on.

2 A number 1 to 3 may be entered on the keypad while the RPL is active.

3 Press the PRINT switch after the number has been entered. With this, the READY lamp turns off

and the test command number is displayed.

Drum

°

Keypad entry 1 2 3

Sensitivity 1 2 3

(Inch)

(AB Japan)

(AB Export)

08 Lens characteristics entry (at a time of lens replacement)

Because each lens has a variance in focal distance, the lens moving distance in any zoom mode must

correspond with the focal distance of the lens. The zoom ratio varies proportionate to the variance of

the lens focal distance.

To avoid focus problem, the class of the lens focal distance (refer to chart on page 7-11) is stored in the

memory using the test command. In a variable zoom mode, the lens moving distance that corresponds

to the lens focal distance is obtained on the basis of the data so as to produce the accurate zoom copy.

Setup method (26-08)

1 When the test command is executed, the presently stored preset code is displayed and the READY

lamp turns on.

2 After the READY lamp turned on, enter the lens number shown on the top of lens area and press

the PRINT switch to store the value in the memory. The READY lamp now turns off.

C → =↵ → 0/◊ → =↵ → 2 → 6 → PSW → 8 → PSW → 1

→ 4 → PSW

09 4/5 mirror characteristics entry (at a time of lens replacement)

(Setup method (26-09)

1 Set the correction value for lens marked value based on "lens value vs. test command input."

Press C → =↵ → 0/◊ → =↵ → 2 → 6 → PSW → 9 → PSW keys to execute

the test command 26-09.

As the READY lamp turns on, the previously set value 1 to 21) is shown.

2 Enter the new value on the keypad.

EX: If the value shown on the lens is +1, 2, pick up "14."

Press the 1 → 4 → PSW keys.

A figure 0 to L is shown on the lens value label.

[7]-10-(6)

[7]-10-(6)

82525

No. 114191

O-L

+1.2

8 – 13

Page 26

SF-2530

Main code Sub code Description Ref. Page

26 10 AE original density setting

Used to set the original density. (Set value: 1 ∼ 9)

Default: 2 Set to 9 if the density is extremely low.

24 Margin position setting

This simulation is used to set the margin position when margin copy is executed.

Set value Content

0 Left margin

1 Right margin

25 Standard state setting from even-number single copy to duplex copy

Set value Content

0 From single to duplex

1 Even-number single to duplex

The duplex mode when the poser is turned on or when the CA (auto clear) key is pressed is set from

even-number single to duplex copy.

27 01 PPC communication trouble (EX only)

0: PPC communication trouble No display

1: PPC communication trouble Displayed

30 01 Monitoring main unit paper sensor

Copier paper sensor ON/OFF can be checked with the paper jam lamp and paper feed position lamp.

(Lighted at ON)

1 JL1 PID

2 JL2 PPD1

3 JL3 PPD2

4 JL4 PSD

5 JL5 POD

6 JL6 TFD

7 JL7 —

8 JL8 —

9 CSL1 PED1

F CSL2 PED2

G CSL3 PED3

H JPL LUD1

I PPL LUD2

30 02 Monitoring paper cassette size

Use the cassette select key to select the tray.

Cassette position Manual Upper cassette Lower cassette

TPL (Toner empty) PWS1 UCSS1 LCSS1

TNFL (Waste toner full lamp) 2 UCSS2 LCSS2

DVPL (Developer maintenance lamp) 3 UCSS3 LCSS3

MENTL (Maintenance lamp) 4 UCSS4 LCSS4

JPL (Jam lamp) PLS1 — —

PPL (Paper empty lamp) PLS2 — —

42 *

Developer counter data clear (Japan only)

°

1. Mini maintenance counter data clear

2. Cancel

3. Developer counter clear

When the main code is entered, the staple check lamp lights up to allow to enter the conditions.

Select among 1 - 3 with 10-key. After entering the code, the staple check lamp goes off. Execution is

immediately performed on entering with 10-key.

Developer count data clear (EX only)

°

1. Clear

2. Not clear

The copy quantity counter of the DV unit installed is cleared.

When the main code is entered, the staple check lamp lights up to allow to enter the conditions.

Select between 1 and 2 with 10-key. After entering the code, the staple check lamp goes off.

Execution is immediately performed on entering with 10-key.

8 – 14

Page 27

SF-2530

Main code Sub code Description Ref. Page

43 *

44 01 Correction mode setting

02 Drum mark sensor sensitivity adjustment : 0 ~ 255 (5V)

03 Image density sensor sensitivity adjustment : 0 ~ 255 (5V)

05 Half tone density correction test mode

Fusing temperature setting

°

Used to set the fusing temperature.

When this simulation is executed, the currently set fusing temperature is displayed. Under this state,

press 10-key, and the number is displayed on the copy magnification ratio display, and the fusing

temperature corresponding to the number is displayed on the coy quantity display by 2 digits.

Selection of single/duplex copy

Press the sorter key to switch between the single copy and duplex copy temperature setting.

P lamp OFF: Single copy temperature setting

P lamp ON: Duplex copy temperature setting

display method of the copy quantity display

A number of one or two digits is displayed normally.

For a number of three or more digits, the upper two digits are displayed after a long blank (time

interval), then the lower two digits are displayed after a short blank (time interval).

(3 or more digits) kk → FF → k → FF

Long blank Upper 2 digits Short blank Lower 2 d igits

Number on the magnification ratio display 1234567890

Number on the copy quantity display 160 165 170 175 180 185 190 195 200 205

[+ 1] Process control correction enable

[+ 2] Optical dirt correction enable

[+ 4] Drum layer wear correction enable

[+10] Toner control A correction valid

[+20] Toner control B correction valid

Note: When all are "Enable," set to 07.

The corrections, except for the process control correction mode, can be disabled in the normal

copy mode. When "0" is inputted, "1" (Process control correction) is enabled. (Automatic setting)

For the drum mark sensor gain rank, [2] is selected.

The main motor rotates and the drum mark sensor sensing level is displayed on the magnification ratio

display. Adjust VR1 in the process unit to obtain [204±10].

For the image density sensor gain rank, [2] is selected.

The main motor rotates and the image density sensor sensing level is displayed on the magnification

ratio display. Adjust VR2 in the process unit to obtain [204±10].

The main motor is rotated, and toner patches are formed in 8 steps by setting the grid bias to 450 850V (50V step). The patch section level and the image density sensor level at the surface are

displayed.

Magnification ratio display Copy quantity display The value corresponding to the number

0 450VP/450VB

1 500VP/500VB

2 550VP/550VB

3 600VP/600VB

4 650VP/650VB

5 700VP/700VB

6 750VP/750VB

7 800VP/800VB

8 850VP/850VB

which is displayed on the magnification

ratio display by the sorter key is displayed

on the copy quantity display by 2 digits.

8 – 15

Page 28

SF-2530

Main code Sub code Description Ref. Page

44 06 Compulsory execution of half-tone density correction

NORM NORMAL : Standard mode grid bias (450 ∼ 1250V)

T/S T/S : Toner save mode grid bias (450 ∼ 1250V)

PHOT PHOTO : Photo mode grid bias (450 ∼ 1250V)

GB_A GB ADJUST : Grid bias correction value after measurement (±0 ∼ 999V)

TARG TARGET : Patch/foundation, standard patch value when foundation is

ID_G ID GAIN : Image density sensor gain rank in execution (1 ∼ 7)

MARK MARK : Drum mark sensor mark level in execution (0 ∼ 255, 255=5V)

MARB MARK B : Drum mark sensor surface level in execution (0 ∼ 255, 255=5V)

DM_G DM GAIN : Drum mark sensor gain rank in execution (1 ∼ 7)

l*m*nl*m*n : Vc1 correction coefficient

BAS1, 2, 3 BASE1, 2, 3 : Drum surface image density sensor level in execution (0 ∼

PAT1, 2, 3 PATCH1, 2, 3 : Toner patch image density sensor level in execution (0 ∼ 255,

l l : Vg correction coefficient

m m : Dirt correction coefficient

n n : Film wear correction coefficient

M1 M1 : Dirt correction coefficient (M1)

M2 M2 : Dirt correction coefficient (M2)

* Display of (–) indicates PAUSE lamp ON.

255 (255= foundation)

255, 255=5V)

255=5V)

The value corresponding to the number which is displayed on the magnification ratio display by the

sorter key is displayed on the copy quantity display by 2 digits.

Magnification ratio display Copy quantity display

0 MORMAL

1 T/S

2 PHOTO

3 GB ADJUST

4 TARGET

5 ID GAIN

6 MARK

7 MARK B

8 DM GAIN

9l*m*n

10 PATCH1

11 BASE1

12 PATCH2

13 BASE2

14 PATCH3

15 BASE3

16 I

17 m

18 n

19 M1

20 M2

8 – 16

Page 29

SF-2530

Main code Sub code Description Ref. Page

44 07 Drum mark sensor/image density sensor gain select check

The value corresponding to the number which is displayed on the magnification ratio display by the

sorter key is displayed on the copy quantity display by 2 digits.

Magnification ratio display Copy quantity display Magnification ratio display Copy quantity display

0 DM7 7 ID7

1 DM6 8 ID6

2 DM5 9 ID5

3 DM4 10 ID4

4 DM3 11 ID3

5 DM2 12 ID2

6 DM1 13 ID1

09 Half tone density correction measurement data display

The display is similar to SIM 44-6. However, entry of values cannot be made, and only display is shown.

11 Operation and setting at grid bias

Select the code with "→" key, press PSW key, and the set value is stored and aging is performed.

The value corresponding to the number which is displayed on the magnification ratio display by the

sorter key is displayed on the copy quantity display by 2 digits.

For 0, 1, 2, and 3, only the display is made. For 4, 5, 6, and 7, the value can be changed.

Magnification ratio display Copy quantity display

0 GB_250V

1 GB_850V

2 GB_1000V

3 GB_1050V

4 PATCH

5 NORMAL

6 T/S

7 PHOTO

12 Copying is made without process control operation. This simulation is used to know whether the trouble

46 01

47 *

is in the process section or in the other section when F2 trouble occurs.

Exposure level adjustment

°

Used to adjust the copy density and the copy density select level.

The value corresponding to the number which is displayed on the magnification ratio display by the

sorter key is displayed on the copy quantity display by 2 digits.

Magnification ratio display 0 1 2 3 4 5 6 7 8 9

Copy quantity display ME1 ME5 TS1 TS5 PE1 PE5 AE1 AE5 AE1 (TS) AE5 (TS)

AE sensor characteristics measurement

°

AE sensor output characteristics memory

(1) AE sensor output characteristics input

Press the C → =↵ → 0 → =↵ → 4 → 7 → PSW keys. The mirror base is initialized, scans about 10cm, then stops.

The READY lamp turns on now and becomes ready to measure.

Press the PRINT switch. The copy lamp driving voltage changes in increments of 10V (20V)

each from 80V (160V) to 30V (60V), and the AE sensor output characteristics are stored in the

memory. The values are used as referances.

NOTE: Shown in parenthesis is for the 200V series machine.

1 Execute SIM 47. (The mirror base scans and stops at the AE sensor level measurement

position.)

2 Put 4 or 5 sheets of white paper (A3 or 11" × 17") on the document table.

3 Press PSW key again, and the AE sensor output level with the white paper document is

displayed. This output level is stored.

[7]-20-(3)

8 – 17

Page 30

SF-2530

Main code Sub code Description Ref. Page

48 01 Front/rear direction zoom ratio adjustment (refer to [7]-3-(6)-9 for the lens type value.

Used to set the No.4/5 mirror home position (focal adjustment) and to adjust the zoom ratio of the copy

in the vertical direction (from front to rear).

There are two kinds of test command 48-01 of which are described as follows.

1-1. Horizontal copy zoom ratio standard value input method (at a time the lens or main PWB

replacement)

Press the C → =↵ → 0 → =↵ → 4 → 8 → PSW → ➡ keys. The already

set value or "40" is displayed.

Substitute the value of "O.L" shown on the label attached to the lens with the formula value.

40 – [(value of O.L.) x 5] = standard value of correction

Ex: 40 – (+1.2 x 5) = 34

1-2. Use this test command to adjust the horizontal zoom ratio. Change the value entered in "1-1" to

change.

2-1. No.4/4 mirror home position standard value input (at a time of lens or main PWB replacement).

Press the C → =↵ → 0 → =↵ → 4 → 8 → PSW 1 → PSW keys. The already stored value or "50" is displayed.

Substitute the value of "O.L" shown on the label attached to the lens with the formula value.

42 – [(O.L value) x 10] = standard value of correction

Ex: 50 – (+1.2 x 10) = 38

2-2. To adjust the resolution, change the value entered at "2-1" using this test command.

When the No. 4/5 mirror reference value is "+" from the center value "50", the mirror is shifted

away from the lens to lengthen the light path. When it is "–", the mirror is shifted to the lens to

shorten the light path. The value is calculated in this manner.

9 0 1 0 2 4 Manufacturing date

O. L + 1. 2

(O-L) O. i + 2. 4 Preset value

P. NO 12

(O-i) TOPCON

[7]-8-(1)

[8]-3-(3)

[7]-8-(2)

[7]-9-(4)

Label content

Magnification ratio display 0 1

Copy quantity display 45MB LENS

The value corresponding to the number which is displayed on the magnification ratio display by

the sorter key is displayed on the copy quantity display by 2 digits.

02

50 01 Used to adjust the copy lead edge image loss and void areas. For more information, refer to the optical

02 The function of this test command is similar to the test command 50-01.

51 02

Paper moving direction zoom adjustment

°

Used to adjust the zoom ratio in the landscape mode.

Varying the mirror base moving speed adjusts the zoom factor in the landscape direction of the copy

(paper moving direction).

1 Place a scale over the original table in the direction the paper moves. Make a copy in the 100%

zoom mode and obtain the copy zoom ratio correction factor.

Copy zoom correction factor = (original size) −

2 As the READY lamp turns on, the previously set figure between 15 and 35 is displayed. Change

it with the copy zoom factor correction factor obtained in 1.

(Input value) = (previously stored value) + copy zoom ratio correction factor [%] × 10

Press the PRINT switch after entering the input value. With this, the input value is stored in the

memory and the READY lamp turns off.

system copy lead edge adjustment procedure.

The test command 50-02 allows easier lead edge adjustment using the values of L1 and L2.

For more information, refer to the optical system copy lead edge adjustment procedure.

Resist amount adjustment [7]-15-(11)

°

Magnification ratio display 0 1 2

Copy quantity display Manual Cassette ADU

(copy image siz e)

(original siz e)

× 100%

[7]-10-(5)

[7]-15-(11)

[7]-15-(11)

The value corresponding to the number which is displayed on the magnification ratio display by the

sorter key is displayed on the copy quantity display by 2 digits.

At the same time, the corresponding paper feed port is selected with the tray select key.

Reference value: 40, 45, 50

8 – 18

Page 31

SF-2530

Main code Sub code Description Ref. Page

51 05

Frame delete rate adjustment (copy moving direction only)

°

Used to set the frame delete rate.

• When the test command is executed, the READY lamp turns on, and the figure previously stored is

displayed on the copy number window.

Now, it becomes ready to accept a number between 1 and 19 on the keypad. When the PRINT

switch is pressed after the entry, the number is stored in the memory and the READY lamp turns

off. A single rate deletes the frame of about 1.0mm. The standard value has been set to "6."

52 01

02

03 ADU drive clutch off time setup (1 step = 1ms)

53 01

02

03

04

05

53 06

07

08

ADU alignment plate adjust value setup

°

Used to adjust the home position of the ADU alignment plate.

When the test command is executed, the READY lamp turns on. Enter a new value as the previously

set value came displayed, and press the PRINT switch to stored it in the memory. It can be

adjustable from 1 to 99. The default is 7.

Setting a smaller value increases the width of the alignment plate and vice versa.

ADU rear plate adjust value setup

°

Used to adjust the home position of the ADU rear plate.

When the test command is executed, the READY lamp turns on. Enter a new value as the previously

set value came displayed, and press the PRINT switch to stored it in the memory. It can be

adjustable from 0 to 99. The default is 0. Setting a smaller value increases the width of the rear plate

and vice versa.

Can be set to any number between 0 and 99 (Standard: 18).

1 = 1ms, 18 = 18ms, 99 = 99ms

Setting a smaller value shortens the ADU clutch off timings and decreases the enforced curling rate of

paper.

RADF and ADF stop position adjustment value (normal paper, single copy) setting

°

Used to adjust the RADF stop position in single copy with normal paper.

When this simulation is executed, the ready lamp lights up and the currently set adjustment value is

displayed. Enter the new adjustment value and press the PRINT switch to store it in the memory. The

adjustment value should be in the range of 0 to 15.

RADF/ADF stop position adjustment value (normal paper, duplex copy) setting

°

Used to adjust the RADF/ADF stop position in duplex copy with normal paper.

When this simulation is executed, the ready lamp lights up and the currently set adjustment value is

displayed. Enter the new adjustment value and press the PRINT switch to store it in the memory. The

adjustment value should be in the range of 0 to 15.

RADF and ADF stop position adjustment value (thin paper, single copy) setting

°

Used to adjust the RADF stop position in single copy with thin paper.

When this simulation is executed, the ready lamp lights up and the currently set adjustment value is