Page 1

SERVICE MANUAL

CODE: 00ZSF2050TM/E

No.2

MODEL SF-2050

MODEL SF-C52

CONTENTS

[ 1 ] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] PRODUCT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] OPTION SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] PAPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[ 5 ] COMPONENT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] PROCESS SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] DEVELOPING SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] PAPER FEED SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] TRANSPORT/FUSING SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] HIGH VOLTAGE SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[11] OPTICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] ADU UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

[ 1 ] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1. General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Target users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

3. Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

(1) Compact body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

(2) Clean copy production wi th out cont am i nating environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

(3) High copy performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

(4) Adoption of modular st ru ct ur e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

(5) Service, maintenance, and installation enhancement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

4. System outline (options) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] PRODUCT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -1

1. Basic specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

(1) Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

(2) Copy method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

(3) Kinds of originals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

(4) Copy speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

(6) Warmup time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

(7) Multicopy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

(8) Magnification ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

(9) Exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

(10) Paper feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

(11) Developing method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

(12) Charge method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

(13) Transfer method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

(14) Separation method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

(15) Fusing method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

(16) Cleaning method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

(17) Light source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

(18) Blanking areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

(19) Automatic duplex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

(20) Paper eject and finishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

(21) Additional features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

(22) Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

(23) Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

(24) Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

(25) Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

[ 3 ] COMPONENT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1. External view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3. Internal view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

4. Clutches, solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

5. SF-2035 sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

6. Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

7. Board list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

8. Duplex copy tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

9. Desk unit (SF-D20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

10. Desk unit (SF-D21) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Page 3

[ 4 ] PROCESS (Photocondor drum and cleaning unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1. Basic theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

(1) Image forming process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

(2) Photoconductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

(3) Types of photoconductors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

(4) Characteristics of photoconductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2. SF-2035 basic process and structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

(1) Details of image forming process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

(2) Relationship between the OPC drum and light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

(3) Transition of photoconductor surface potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

(4) Photoconductor drum sensitivity correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

(5) Process control function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

3. Basic structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

[ 5 ] DEVELOPING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1. Basic theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

(1) Two-component developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

(2) Two-component magnetic brush development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

(3) Developing bias voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

3. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] PAPER FEED UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

1. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Basic configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

3. Basic operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

(1) Manual paper feed operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

(2) Cassette paper feed operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

[ 7 ] TRANSPORT/FUSING SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Basic composition and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

(1) Transport section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

(2) Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] HIGH VOLTAGE SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Basic composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

(1) Main (charging) corona – H i gh voltage transform er (MHVG ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

(2) Transfer corona – High vo ltage transformer (THVG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

(3) Separation corona – High vol ta ge t ra nsf or m er (SHVG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] OPTICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. Basic composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

(1) Original table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

(2) Copy lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

(3) Mirror1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

(4) Lens (Fixed focus lens) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

(5) Lens home position sensor (LHPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

(6) No. 4, No. 5 mirror base hom e posit i on sensor (MBHPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(7) Lens base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(8) Lens slide shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(9) Lens drive wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Page 4

(10) Mirror base C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(11) Mirror base C (No. 4, No. 5 mirrors) drive wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(12) Mirror motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(13) Mirror home position sensor (MHPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(14) Mirror base B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(15) Copy lamp unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(16) Thermal fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(17) Reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(18) Exposure adjusting plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(19) Mirror base drive wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(20) Mirror base (No. 4, No. 5) drive motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(21) Lens drive motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(22) AE sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(23) Blank lamp operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

(24) Original size detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

3. Basic operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

4. Optical system dirt correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

(1) Setting the reference value for optical system correcti on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

(2) Dirt correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

[10] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

1. System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. Main circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

(1) Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

(2) CPU (IC113) H8/570 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

(3) I/O (IC114) TE7750 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

(4) RAM (IC115) X28C64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

(5) Decoder (IC139, IC138) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

(6) Start/stop control circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

(7) Heater lamp control circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

(8) Driver circuit (Solenoid , magnetic clutch) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-18

(9) Stepping motor drive circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-18

(10) AE (Auto Exposure) sensor circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

(11) Toner supply motor drive circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

3. Operation circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

<Key circuit> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

(1) Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

(2) Key detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

(3) System configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

<Display circuit> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

(1) Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

(2) Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

4. LCD display circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

(1) Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

(2) CPU (IC222) µPD78213G-AB8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

(3) ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-24

(4) Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-24

(5) LCD controller (IC213) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-26

5. DC power circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-27

(1) Noise filter circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-27

(2) Rush current limiting circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-27

(3) Rectifying/smoothing circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

(4) Invertor circuit (Forward-c onvertor system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

(5) Rectifying/smoothing ci r cui t in the secondary side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

Page 5

(6) Control circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-29

(7) Overcurrent protection circui t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-29

(8) Series regulator circuit (–20V syste m ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-29

(9) Chopper regulator ci r cui t (10 V, 5V sy stem) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-29

(10) FW system output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-29

(11) Over voltage protection circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-30

6. Desk circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-36

[11] Function of PPC communication system (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

1. General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

2. System A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

(1) Functions of System A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

3. System B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

(1) Functions and applicati ons of System B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

4. Communication interface PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

Page 6

[1] GENERAL DESCRIPTION

1. The SF-2050 is a high speed copier which allows copying of 50

sheets per minute, and first copy at the at the highest speed in the

class with remarkable copying efficiency.

2. Target users

Average copy volume: 20,000 ∼ 25,00 0 sh ee t s

Scope: 10,000 ∼ 60,000 sheet s

3. Characteristics of the product

(1) Improvements in the basic functions

• First copy: 2.7 sec

• Automatic duplex function (standard)

• Large capacity tray (3 trays + LCC), max. 4,550 sheets

(5,500 sheets in Japan)

Improved efficiency in duplex copy (Single → duplex efficiency 75%)

• RADF and the staple sorter are optionally available to pro-

vide higher copy productivity.

(2) High copy volume

• Console design

• AICS (Active Image Control System) provided.

• Non-stop/non-slow-down copy (Japan)

• Toner supply during copying

• Paper supply to a non-active tray during copying

(3) Measures against environmental problems

• Low noise (Conforming to Blue Angel standards.)

• Low ozone 0.02mg/m or less

• Low power consumption, 15% down from the conventional

model (SF-9400)

(4) Improved manipulation

• Front access structure

• LCD display

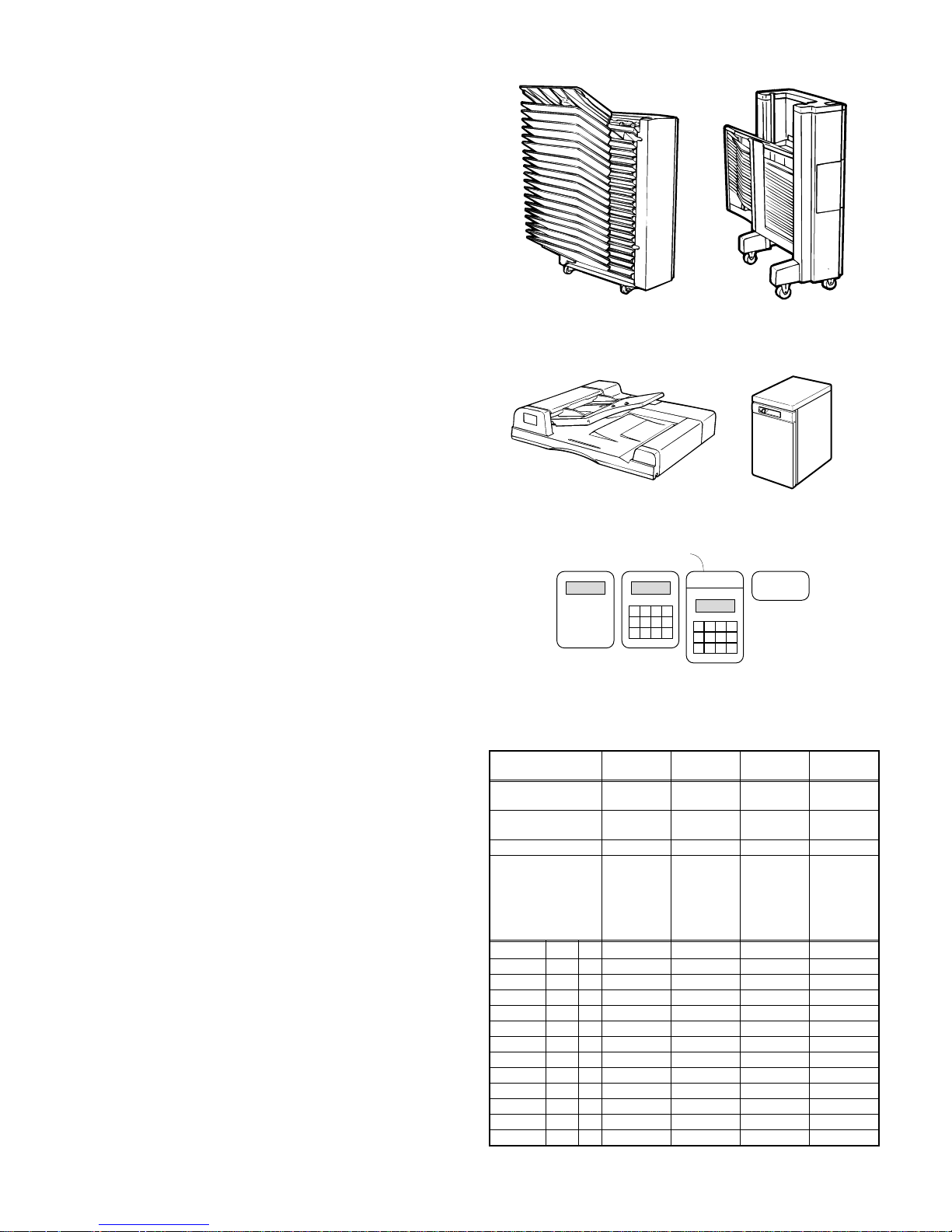

(5) Options

• RADF: SF-A55 (New)

• 20-bin sorter: SF-S16 (Used in the SD-2060)

• 20-bin staple sorter: SF-S53 (Used in the SD-2060/SF-

2035)

• Large capacity tray

(LCC):

• Card type counter: SF-EA11 (Used in the SD-2060/SF-

• Password type

counter:

• Personal counter: SF-71A/B

SF-C52 (New)

2035)

SF-EA12 (Used in the SD-2060/SF-

2035)

20-b in sort er

(SF-S16)

Duplex reversing automatic

document feeder

(SF-A55)

Card type department control counter (SF-EA11)

Password type department control counter (SF-EA12)

Commander (SF-EA13)

Personal counter (SF-71A/B)

SD-2050

Japan

No. of paper feed tray

steps

Platen original size

detection

RADF Option Standard Option Standard

LCC Option (3,300)

Destination

Japan

SEC AU

SECL AL

SEEG GG

SEEG BG

SUK BK

SCA BA

SCNZ BE

SRS BE

SRH BE

STCL BE

Agent AE

Agent BE

4 trays (550) 3 trays (500) 3 trays (500) 3 trays (500)

SF-2050

Standard

(Shipped

separately

from the

20-bin staple sorter

(SF-S53)

Large capacity tray

(SF-C52)

US

✕✕✕

(3,000)

body)

SF-2050

EX1

Option (3,000) Option (3,000)

SF-2050

EX2

1 – 1

Page 7

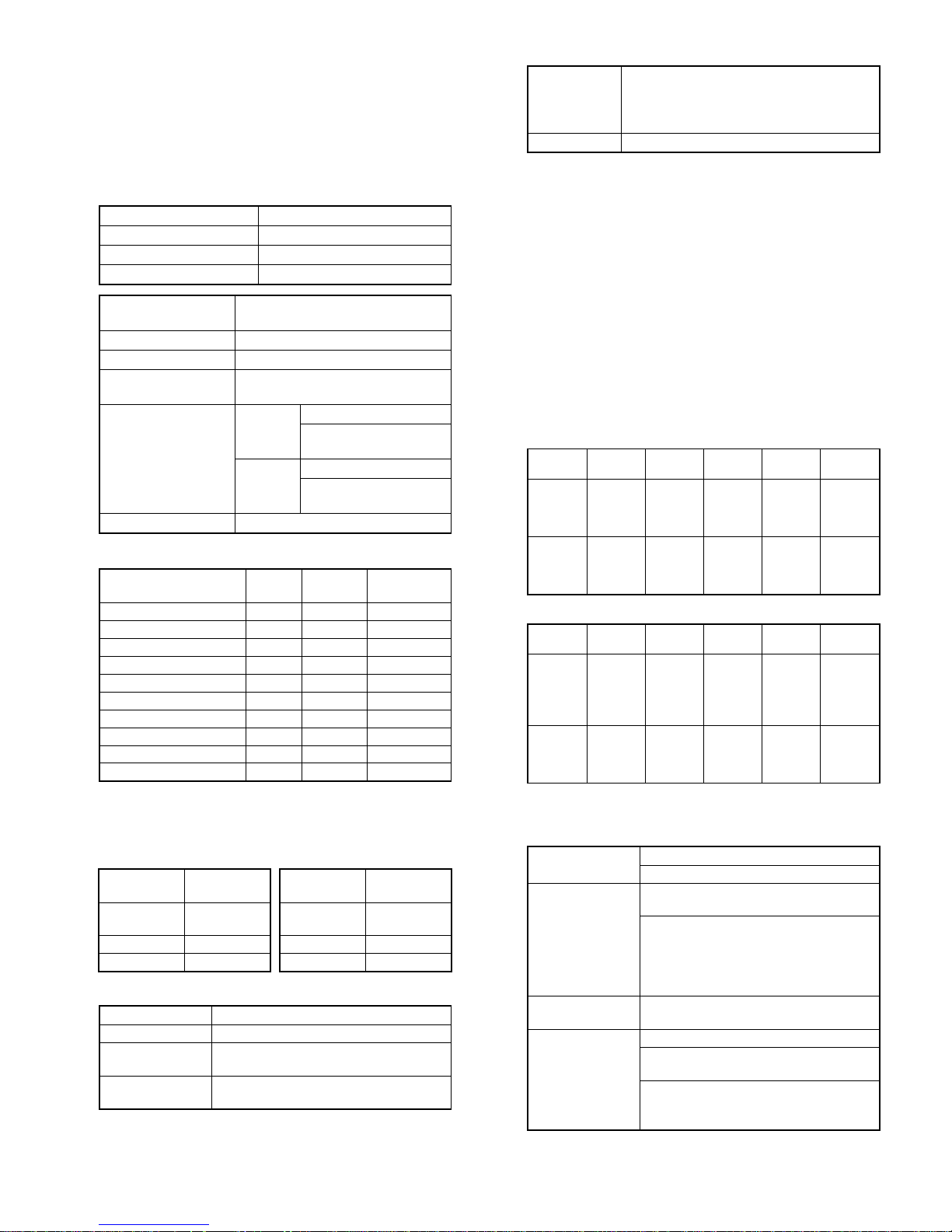

[2] PRODUCT SPECIFICATIONS

1. Basic specifications

(1) Type: Console

(2) Copying system: Dry, electrostatic transfer system

(3) Original Kinds: Sheet, book, cubic

Max. original size A3, 11 × 17

Original reference position Center left

Detection Japan, YES; outside Japan, NO

Detection size A3, B4, A4, A4R, B5, B5R

Option

Original load capacity 50 sheets

Original size A3 ∼ A5, 11 × 17 ∼ 5.5 × 8.5

Original replacement

speed

Original weight

(Excluding special

paper)

Mixed original feed Possible

(4) Copying speed

A3 28 28 27

B4 32 30 31

A4 (Portrait) 50 43 36

A4 (Landscape) 39 37 36

B5 (Portrait) 50 48 36

B5 (Landscape) 39 37 36

11 × 17 28 28 27

8.5 × 14 32 30 31

8.5 × 11 (Portrait) 50 43 36

8.5 × 11 (Landscape) 39 37 36

(Note) The speeds at enlargement/reduction are at the mag-

nification ratio of the lowest speed.

(5) First copy time about 2.7sec (paper feed port: tray 1)

First copy time at each paper feed port (sec)

Paper feed

port

Tray 1 2.7

Tray 2 2.9 Manual feed 2.9

Tray 3 3.1 LCC 2.8

(6) Warm-up time

Japan About 4 min

Outside Japan About 3 min

Pre-heat

Jam recovery

time

(7) Multi copy: max. 999 sheets

RADF (Standard except for

Japan/SEEG/SUK)

50 sheets/min (A4, 8.5 × 11)

Signal

mode

Duplex

mode

Normal

First copy

time

(Japan) 35 ∼ 128 g/cm

(Outside Japan) 50 ∼

128 g/cm

2

(Japan) 50 ∼ 110 g/cm

(Outside Japan) 50 ∼

110 g/cm

2

Reduction

(50%)

Paper feed

port

Tray 4

(Japan only)

YES (Selected by the key operator

program (P31).)

4 sec or less (Jam outside the fusing

section)

Enlargement

First copy

(200%)

time

3.3

(8) Copy magnification ratio

Fixed

magnification

ratio

AB series: 4R+4E: 200, 141, 122, 115,

100, 86, 81, 70, 50 %

Inch series:4R+4E: 200, 141, 129, 121,

100, 95, 77, 64, 50 %

Zoom range 50 ∼ 200% (151 steps in 1% increm ent)

(9) Exposure

(9)-1 Exposure system: Slit exposure by moving the optical

system (Fixed original table)

(9)-2 Exposure mode: Auto/Manual/Photo

(9)-3 Manual steps: 9 steps (Manual/Photo)

(10) Paper feed

(10)-1 Paper feed system: (Japan) 4 trays + multi manual feed

(Outside Japan) 3 trays + multi

manual feed

(For SEC/SECL, LCC is a standard

provision.)

(10)-2 Paper feed

capacity:

2

(10)-3 Details of the paper feed section

(Japan) 550 × 4 + 50

(Outside Japan) 500 × 3 + 50

AB series

2

Paper feed

Tray 2

Tray 1

Tray 3

Tray 4

(Japan only)

port

Paper feed

capacity

500 sheets

(500 sheet

in Japan)

500 sheets

(550

sheets in

Japan)

Paper size

A4, A4R,

B5, B5R,

B4, A3,

(*A5)

A4, A4R,

B5, B5R,

B4, A3

Paper

weight

52 ∼

80g/m

14-21 lbs

52 ∼ 80

2

, 14 ∼

g/m

21 lbs

2

,

Size

selection

Guide

change is

made by a

serviceman.

Guide

change is

made by a

serviceman.

Side/front

Front/

drawer

integrated

Frontdrawer

integrated

Inch series

Paper feed

Tray 2 500 sheets

Tray 1

Tray 3

port

Paper feed

capacity

500 sheets

Paper size

8.5 × 11

8.5 × 11R

8.5 × 14

11 × 17

(*8.5 × 5.5)

8.5 × 11

8.5 × 11R

8.5 × 14

11 × 17

Paper

weight

52-80g/m

14-21 lbs

52-80g/m

14-21 lbs

Guide

2

change is

made by a

serviceman.

Guide

2

change is

made by a

serviceman.

Size

selection

Side/front

Front/

drawer

integrated

Front/

drawer

integrated

* For A5 (8.5" × 5.5"), the rear edge guide is required.

8.8" × 13" is feedable.

Manual feed section

Paper size

AB series: A3 ∼ A6R

Inch series: 11 × 17 ∼ 5.5 × 8.5

Multi paper feed: 56 ∼ 80 g/m2,

15 ∼ 21 lbs

Single paper feed:52 ∼ 128 g/m2,

Paper weight

15 ∼ 21 lbs

(When exceeding

104 g/m2,

A4 or smaller.)

Paper kinds

Standard paper, specified paper, special

paper, OHP film, Postcard, etc,

(Japan) A3, A4, A4R, B4, B5, B5R

(Outside Japan AB series)

Detection size

(Outside Japan inch series)

A3, B4, A4, A4R, A5

11 × 17, 8.5 × 12, 8.5 × 11,

8.5 × 11R, 8.5 × 5.5

2 – 1

Page 8

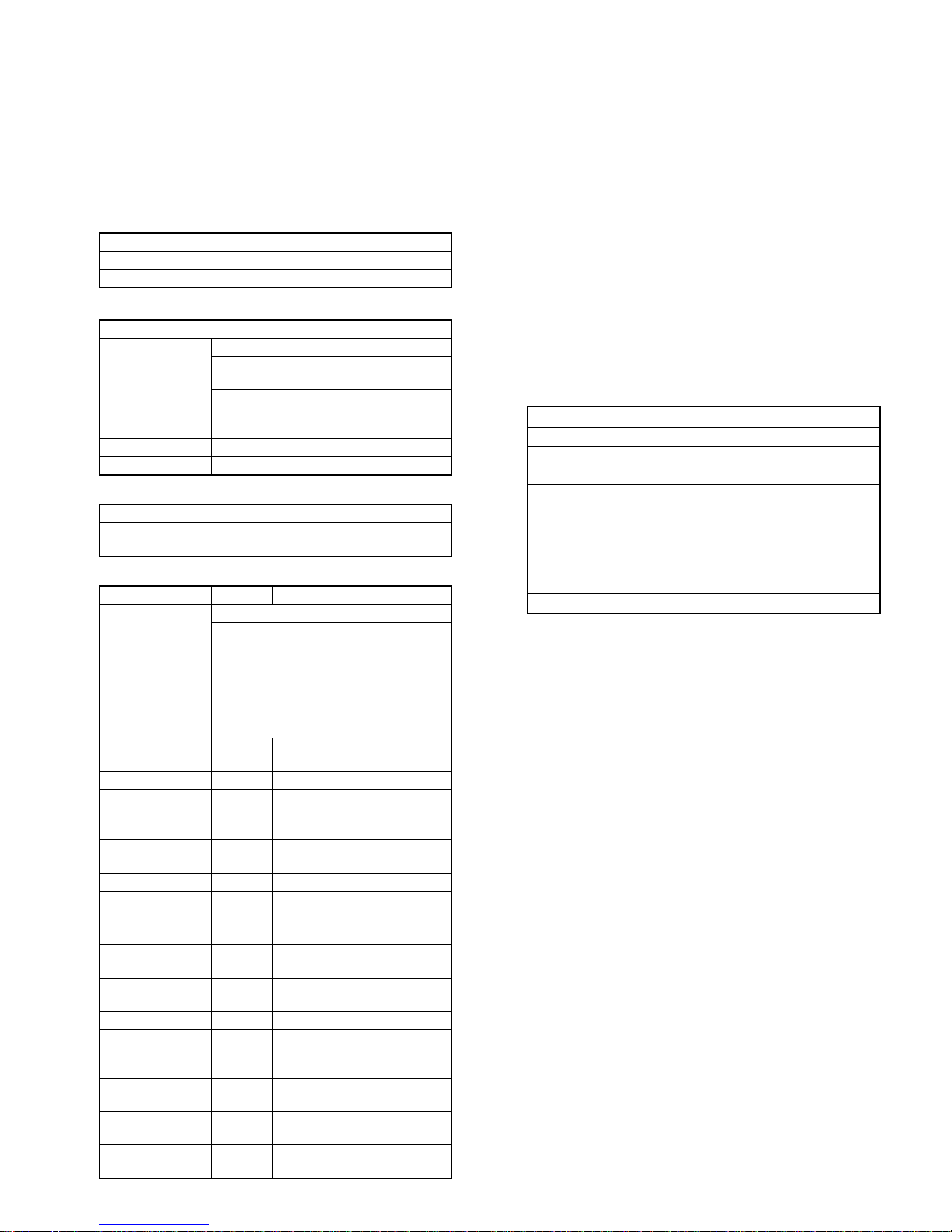

(11) Developing system: Dry, two-component magnetic brush

development

(12) Charging system: (–) DC saw teeth electrode system

(13) Transfer system: (–) DC corotron system

(14) Separation system: (–) AC corotron system

(15) Fusing system: Heat roller system

(16) Cleaning system: Counter blade system

(17) Light source: Halogen lamp

(18) Void width

Void area Lead edge: 3mm or less

BAck surface void area Rear edge: about 3mm

Image loss Normal: 4mm or less

(19) Automatic duplex

Standard

Japan: A3, A4, A4R, B4, B5, B5R

Outside Japan AB series:

Size

Outside Japan inch series:

A3, A4, A4R, B4, B5

11 × 17, 8,5 × 14, 8.5 ×

11, 8.5 × 11R

Capacity 50 sheets (all sizes)

Paper weight 56 ∼ 80 g/m

2

(20) Paper exit/finishing

Paper exit tray capacity 250 sheets

Finishing

Option

20-bin sorter, 20-bin staple sorter

(21) Additional functions

Name Function Content

Automatic paper

selection (APS)

Japan: Yes

Outside Japan: Only with RADF

Japan: Yes

Automatic

magnification

selection (AMS)

Outside Japan: Only with RADF

During used of RADF,

AMS by scanning in

impossible. (PAT

prevention)

Shift copy YES

Shift width 9mm, 1/4 inch

(adjustable)

Dual page copy YES Enlargement is impossible.

Edge erase YES

Edge erase/center

erase/edge and center erase

Center erase YES

Cover copy YES

Covers/back covers/front and

rear covers

Inserts copy YES

OHP inserts copy YES

Job memory YES 9 kinds

Auditor YES 50 departments

Key operator

program

Communication

features

YES

YES

Bi-directional (The I/F PWB is

a service parts.)

Process control YES

For SUK, toner save mode is

Toner save mode YES

not available. For Japan,

serviceman mode selection.

Auto tray

switching

Installed tray

priority selection

Pre-heating YES

YES

YES (PAT. prevention)

Switching by key operator

program

(22) Power source Voltage: 100V, 110V, 120V, 127V,

200V, 220V, 220 ∼ 230V,

240V

Frequency: 50/60 Hz common

(23) Power consumption Max. power consumption:

Japan, 1500W (with options);

Outside Japan, 1920W (with options)

(24) External view W × D × H (mm)

750 × 660 × 950 (Glass top)

750 × 660 × 995 (OC cover top)

750 × 660 × 1137 (RADF top)

Occupying area W × D (mm)

1407 × 660 (with the paper exit tray,

when the manual feed is open.)

Weight:

131 kg (Body only)

145 kg (with RADF)

(25) Accessories

Packed with the main body (supply parts only)

OPC drum (installed to the body) × 1

Developer (1.0kg) × 1

Toner cartridge (0.93kg) × 1

Upper/lower heat roller (installed to the body) each × 1

Upper/lower fusing separation pawl (installed

to the body)

Upper/lower cleaning roller (lower cleaning

roller: installed to the body)

each × 1

each × 1

Cleaner blade (installed to the body) × 1

Waste toner bottle (installed to the body) × 1

2 – 2

Page 9

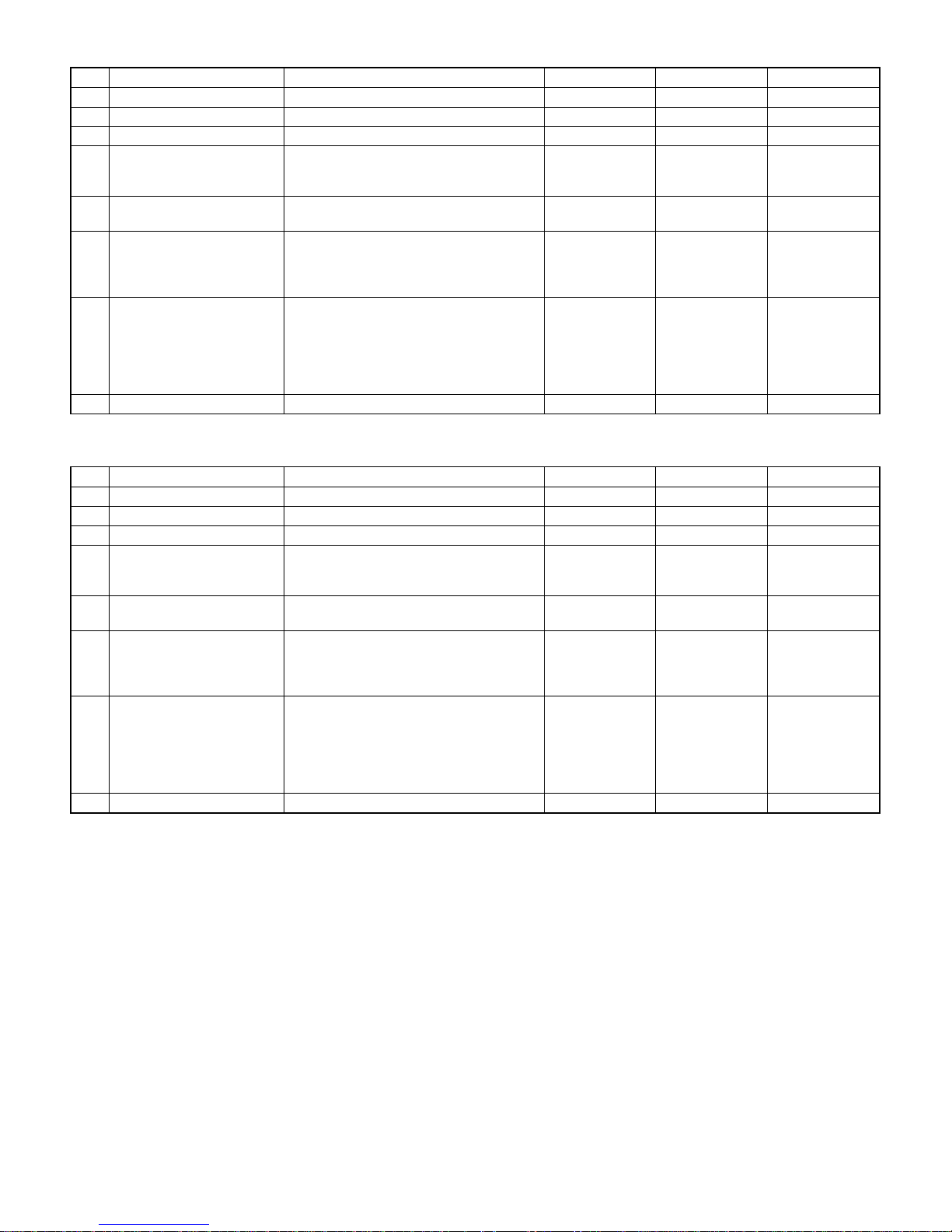

2. Supply parts

1 SEC

No. Name Content Life Product name Packing

1 Drum OPC drum × 1 200K SF-250DR 10

2 Developer (Black) Developer (1.0kg) × 10 100K × 10 SD-360MD 1

3 Toner (Black) Toner cartridge (0.93kg) × 10 28K × 10 SD-360MT 1

4 Upper heat roller kit Upper heat roller × 1

Fusing separation pawl (Upper) × 4

Fusing gear × 1

5 Lower heat roller kit Lower heat roller × 1

Fusing separation pawl (Lower) × 4

6 Cleaner blade Cleaner blade × 10 100K × 10 SD-360CB 1

7 Upper cleaning roller Upper cleaning roller × 10 100K × 10 SF-250UR 1

8 Lower cleaning roller Lower cleaning roller × 10 100K × 10 SF-250LR 1

9 Waster toner bottle Waste toner bottle × 1 100K SF-250TB 5

10 200K maintenance kit SF-250CP × 5

(Drum separation pawl × 2)

(Charging plate unit × 1)

(CL side seal F/R × 1)

(DV side seal F/R × 1)

(Toner reception seal × 1)

11 Staple cartridge Staple cartridge × 5 5000 × 5 SD-LS20 10

The screen grid (200K), the charger wire (200K), the ozone filter (400K), and the toner reception seal (200K) are service parts.

The waste toner bottle (100K), and charging plate unit (200K), and the DV seal (400K) are also available as service parts.

* The developer is in common with the SD-2060/3062. This model uses one bag (100K).

2 SECL

No. Name Content Life Product name Packing

1 Drum OPC drum × 1 200K SF-250DR 10

2 Developer (Black) Developer (1.0kg) × 10 100K × 10 SD-360MD 1

3 Toner (Black) Toner cartridge (0.93kg) × 10 28K × 10 SD-360MT 1

4 Upper heat roller kit Upper heat roller × 1

Fusing separation pawl (Upper) × 4

Fusing gear × 1

5 Lower heat roller kit Lower heat roller × 1

Fusing separation pawl (Lower) × 4

6 100K PM kit Cleaner blade × 1

Waste toner bottle × 1

Upper cleaning roller × 1

Lower cleaning roller × 1

7 200K PM kit Drum separation pawl × 2

Charging plate unit × 1

Screen grid × 1

CL side seal F/R × 1

DV side seal F/R × 1

Toner reception seal × 1

8 Staple cartridge Staple cartridge × 5 5000 × 5 SD-LS20 10

* The developer is in common with the SD-2060/3062. This model uses one bag (100K).

400K SF-250UH 5

200K SF-250LH 5

200K SF-250CK 1

400K SF-250UH 5

200K SF-250LH 5

100K SF-250KA 1

200K SF-250KB 5

2 – 3

Page 10

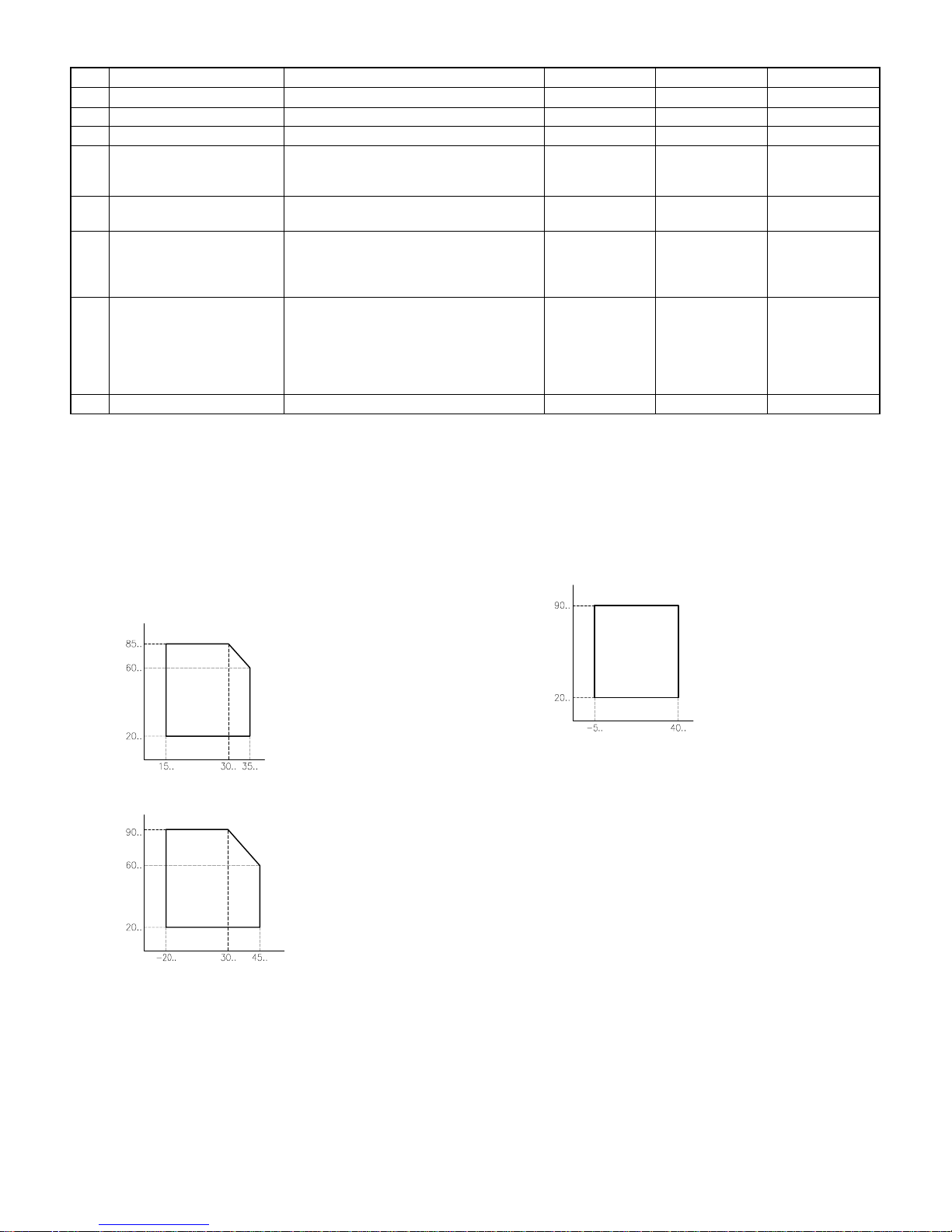

3 SEEG/SUK

No. Name Content Life Product name Packing

1 Drum OPC drum × 1 200K SF-250DM 10

2 Developer (Black) Developer (1.0kg) × 10 100K × 10 SD-360LD 1

3 Toner (Black) Toner cartridge (0.93kg) × 10 28K × 10 SD-360LT 1

4 Upper heat roller kit Upper heat roller × 1

5 Lower heat roller kit Lower heat roller × 1

6 100K PM kit Cleaner blade × 1

7 200K PM kit Drum separation pawl × 2

8 Staple cartridge Staple cartridge × 5 5000 × 5 SD-LS20 10

* The developer is in common with the SD-2060/3062. This model uses one bag (100K).

Fusing separation pawl (Upper) × 4

Fusing gear × 1

Fusing separation pawl (Lower) × 4

Waste toner bottle × 1

Upper cleaning roller × 1

Lower cleaning roller × 1

Charging plate unit × 1

Screen grid × 1

CL side seal F/R × 1

DV side seal F/R × 1

Toner reception seal × 1

400K SF-250UH 5

200K SF-250LH 5

100K SF-250KA 1

200K SF-250KB 5

4 Asia, Middle/South America

No. Name Content Life Product name Packing

1 Drum OPC drum × 1 200K SF-250DR 10

2 Developer (Black) Developer (1.0kg) × 10 100K × 10 SD-360CD 1

3 Toner (Black) Toner cartridge (0.93kg) × 10 28K × 10 SD-360CT 1

4 Upper heat roller kit Upper heat roller × 1

Fusing separation pawl (Upper) × 4

Fusing gear × 1

5 Lower heat roller kit Lower heat roller × 1

Fusing separation pawl (Lower) × 4

6 100K PM kit Cleaner blade × 1

Waste toner bottle × 1

Upper cleaning roller × 1

Lower cleaning roller × 1

7 200K PM kit Drum separation pawl × 2

Charging plate unit × 1

Screen grid × 1

CL side seal F/R × 1

DV side seal F/R × 1

Toner reception seal × 1

8 Staple cartridge Staple cartridge × 5 5000 × 5 SD-LS20 10

* The developer is in common with the SD-2060/3062. This model uses one bag (100K).

400K SF-250UH 5

200K SF-250LH 5

100K SF-250KA 1

200K SF-250KB 5

2 – 4

Page 11

5 SCA, SCNZ, Middle East, Africa

No. Name Content Life Product name Packing

1 Drum OPC drum × 1 200K SF-250DM 10

2 Developer (Black) Developer (1.0kg) × 10 100K × 10 SD-360LD 1

3 Toner (Black) Toner cartridge (0.93kg) × 10 28K × 10 SD-360LT 1

4 Upper heat roller kit Upper heat roller × 1

5 Lower heat roller kit Lower heat roller × 1

6 100K PM kit Cleaner blade × 1

7 200K PM kit Drum separation pawl × 2

8 Staple cartridge Staple cartridge × 5 5000 × 5 SD-LS20 10

* The developer is in common with the SD-2060/3062. This model uses one bag (100K).

Fusing separation pawl (Upper) × 4

Fusing gear × 1

Fusing separation pawl (Lower) × 4

Waste toner bottle × 1

Upper cleaning roller × 1

Lower cleaning roller × 1

Charging plate unit × 1

Screen grid × 1

CL side seal F/R × 1

DV side seal F/R × 1

Toner reception seal × 1

400K SF-250UH 5

200K SF-250LH 5

100K SF-250KA 1

200K SF-250KB 5

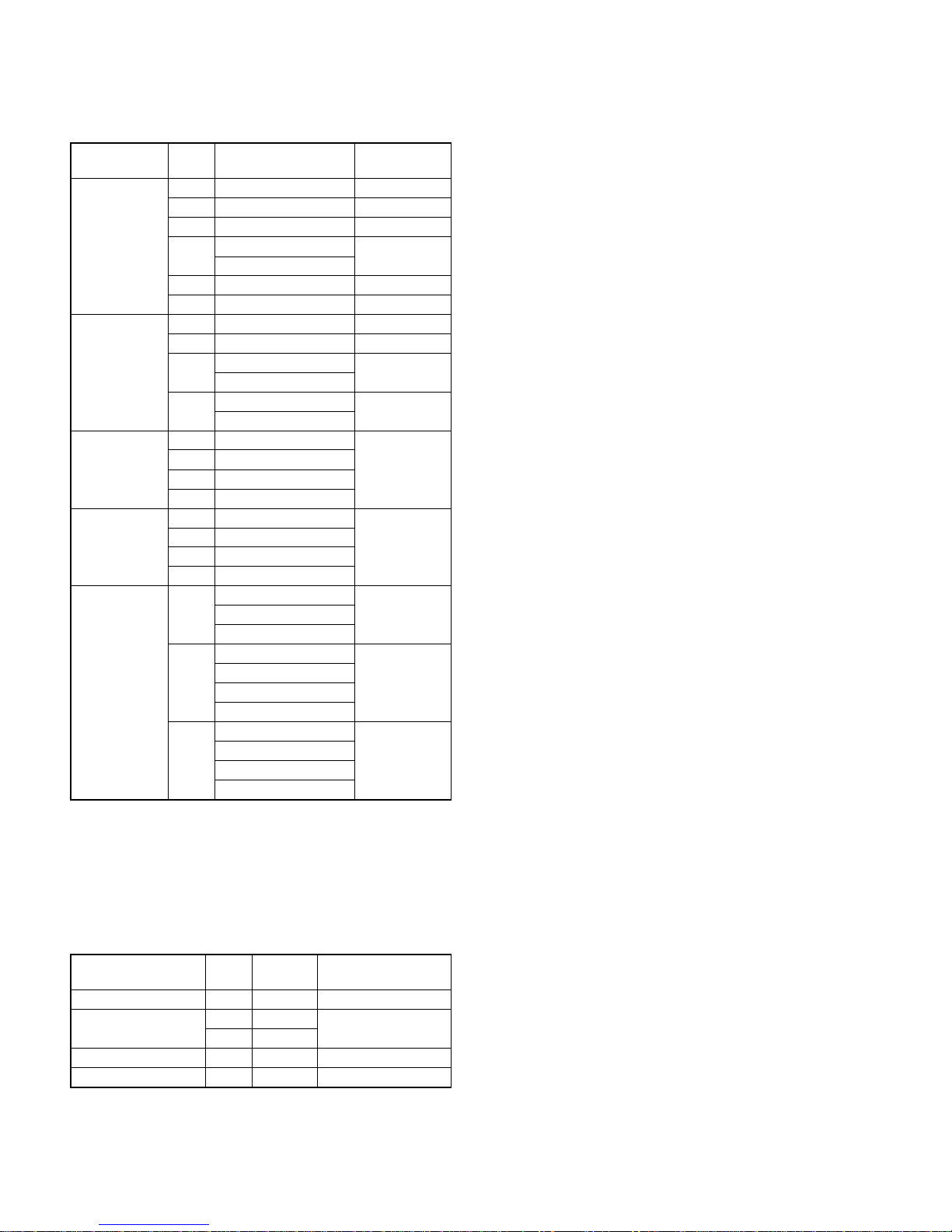

3. Environmental conditions

The following environmental conditions should be preserved for assuring copy quality and proper machine operations.

1 Standard conditions

Temperature, 20 ∼ 25 C; humidity, 65 ±5% RH

2 Operational conditions

Humidity (RH)

3 Transit conditions

Humidity (RH)

4 Supply store conditions

Humidity (RH)

2 – 5

Page 12

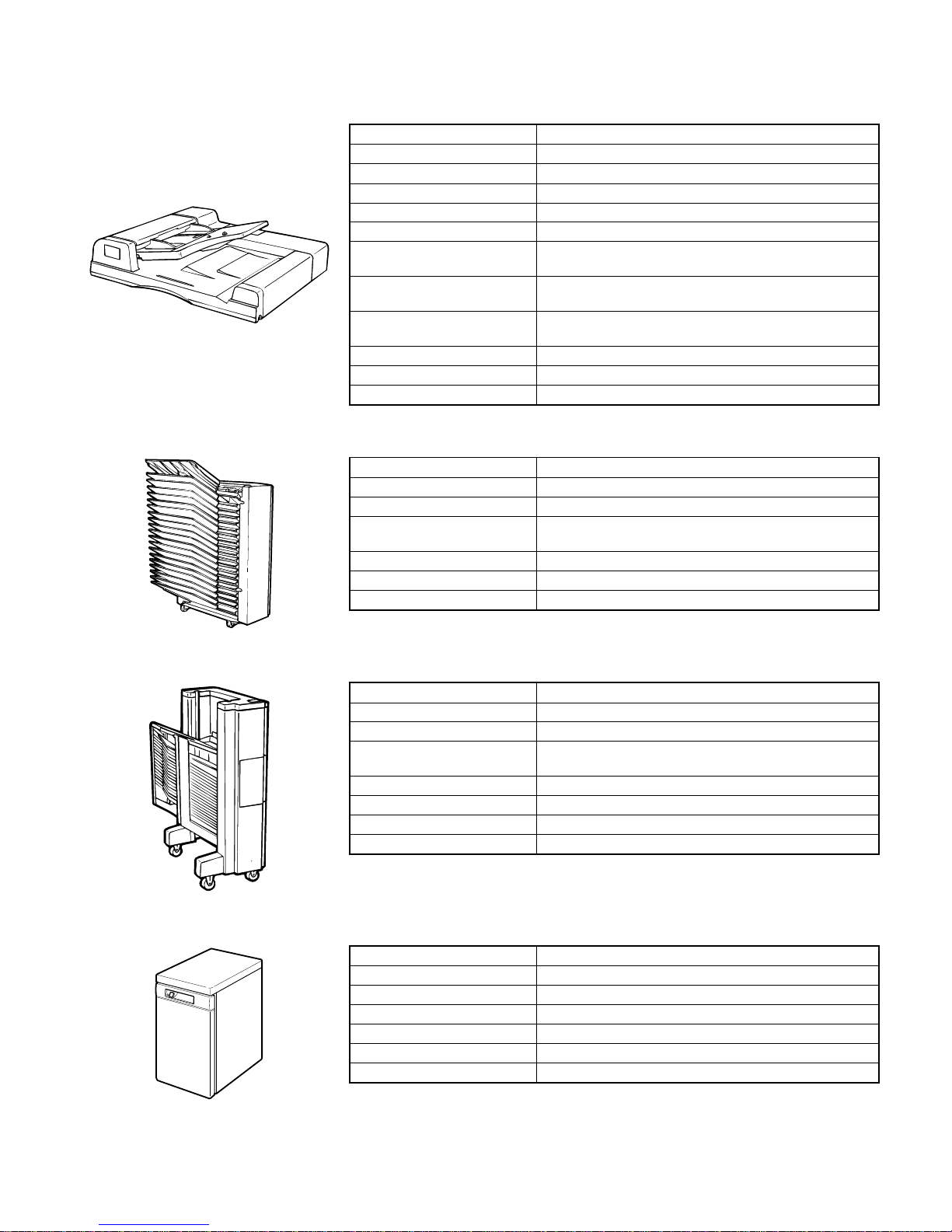

[3] OPTION SPECIFICATIONS

1. SF-A55

Name Duplex reversing automatic document feeder

Document feed system Continuous, automatic feed

Document exit system Face up exit

Document transport system One-belt, (center reference)

Document set direction Face up

Document size A3 ∼ B5

Document weight Thin paper mode, 35 ∼ 50g/m2;

Document set quantity Max. 50 sheets (35 ∼ 80g/m2)

Functions Document reversing (Duplex documents), SDF/ADF mode

Power source Supplied from the copier body.

Dimensions 595mm (W) × 525mm (D) × 130mm (H) (without tray)

Weight About 150 kg

2. SF-S16

Name 20-bin sorter

No. of bins 20 bins

Storing system Copy face up

Storing capacity of each bin Max. 50 sheets (Top bin, 100 sheet) Collatable paper

Power source Supplied from the copier body.

Dimensions 550mm (W) × 519mm (D) × 924m (H)

Weight About 26.5kg

standard mode, 51 ∼ 128g/ m

(Max. 30 for A3 and 11" × 17")

selection, mixed paper feed, random paper feed

size/weight

2

3. SF-S53

4. SF-C52

Name Staple sorter

No. of bins 21 bins

Storing system Face up

Storing capacity of each bin Max. 50 sheets (Top bin, 250 sheet) Collatable paper

size/weight

No. of sheets staplable 50 sheets (80g/m2 paper)

Power source Supplied from the copier body.

Dimensions 475mm (W) × 597mm (D) × 995mm (H)

Weight About 42.1kg

Name Large capacity cassette (LCC)

Paper feed capacity 3,000 sheets

Paper feed size A4/B5

Paper weight 52 ∼ 80g/m

Power source Supplied from the copier body.

Dimensions 294mm (W) × 536mm (D) × 523mm (H)

Weight 26kg

2

3 – 1

Page 13

[4] PAPER

1. Standard paper for tray feed

Name Size Type

A3 SF-3AS2 250 sheets

B4 SF-4BS2 500 sheets

Standard type

General type

paper (thick)

Thick paper

Recycled

paper

Color paper

A4 SF-4AS2 500 sheets

SF-5BS2 (Horizontal)

B5

SF-5Bs3 (Vertical)

A5* SF-5AS2 250 sheets

B6* SF-6BS2 250 sheets

A3 SF-3AM2 250 sheets

B4 SF-4BM3 500 sheets

SF-4AM2 (Horizontal)

A4

SF-4AM3 (Vertical)

SF-5BM2 (Horizontal)

B5

SF-5BM3 (Vertical)

A3 SF-3AH

B4 SF-4BH

A4 SF-4AH

B5 SF-5BH

A3 SF-3AR1

B4 SF-4BR1

A4 SF-4AR1

B5 SF-5BR1

SF-4B1R (Pink)

B4

SF-4B1B (Blue)

SF-4B1G (Green)

SF-4A1R (Pink)

SF-4A1Y (Cream)

A4

SF-4A1B (Blue)

SF-4A1G (Green)

SF-5B1R (Pink)

SF-5B1Y (Cream)

B5

SF-5B1B (Blue)

SF-5B1G (Green)

Quanty in one

bag

500 sheets

each

500 sheets

each

500 sheets

each

250 sheets

each

500 sheets

each

500 sheets

each

500 sheets

each

500 sheets

each

● <Note> ● - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

• Be sure to use the above paper on the tray. For the paper with

mark "*," use in the manual feed mode.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ●

2. Special paper (Manual feed only)

Name Size Type

Postcards A4 SF-4A5C 100 sheets

Second original

paper

Label paper A4 SF-4A3F 100 sheets

OHP film A4 SF-4A6F 100 sheets

B4 SF-4B2A

A4 SF-4A2A

No. of sheets in one

bag

500 sheets each

4 – 1

Page 14

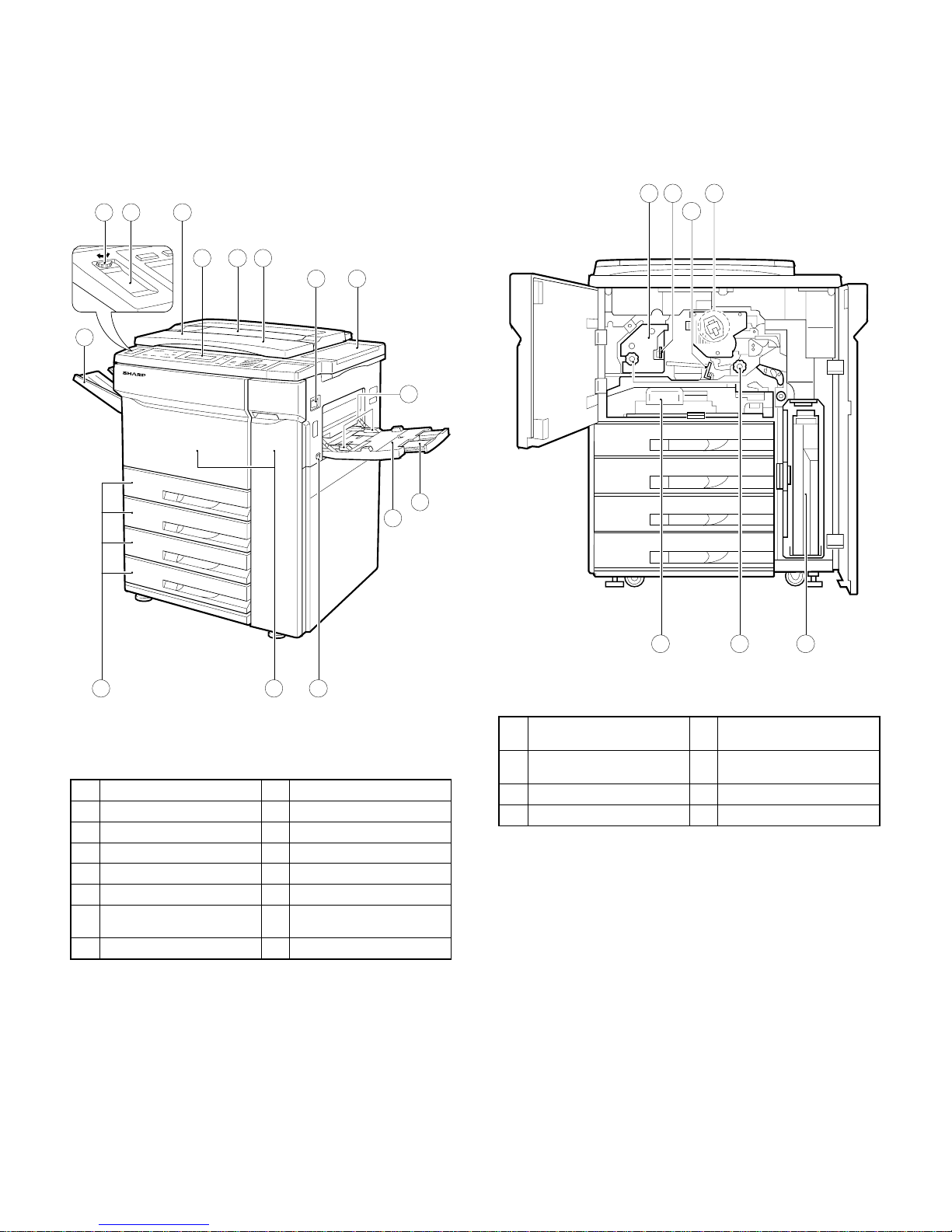

[5] PRODUCT VIEW

1. External view

1011 7

12

1 8

2. Internal view

6 2

9

6

15

3

4

5

7

3

13

Operation panel

1

Manual feed guide

3

Manual feed tray

5

Original cover

7

Original table

9

Contrast adjusting knob

G

Tray

I

Power switch

K

142

Front cover

2

Manual feed additional tray

4

Toner cover

6

Original stocker

8

Clip tray

F

Copy tray

H

Paper feed pressure

J

release button

Roller rotation knob

1

Transport section

3

open/close lever

Waste toner box

5

OPC drum

7

Transport section

2

adjustment knob

Duplex tray

4

Fusing section

6

54 1

5 – 1

Page 15

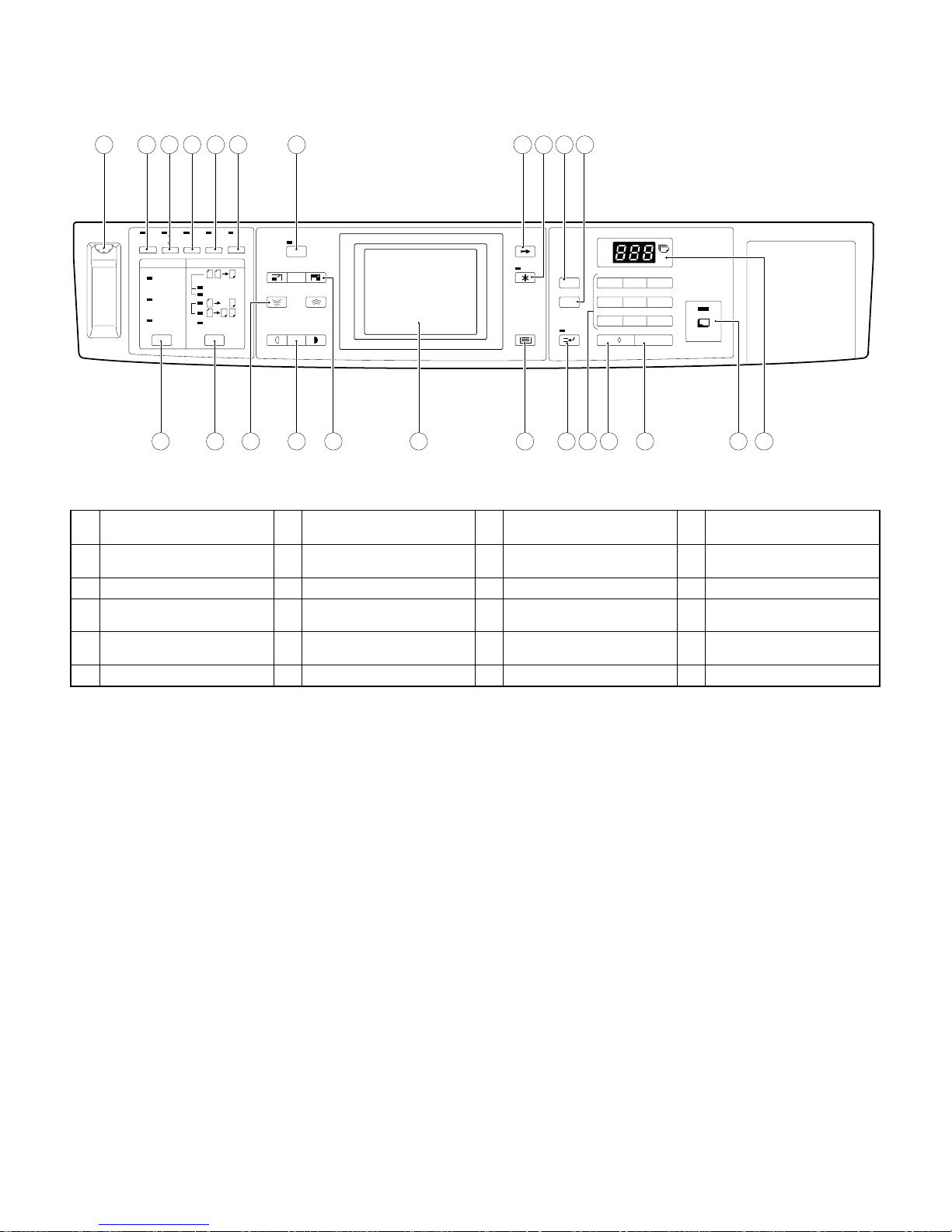

3. Operation panel

1

2

3

4

5

6 7

13 141516

TRAN SPARENCY

INSERTS

SHFT

INSERT S

SORTER ORIGINAL TO COPY

SORT

ATAPLE

SORT

GROUP

MARGIN

COVERS/

89

Contrast adjustment knob

1

Edge erase key/display lamp

5

Duplex key/display lamp

9

Message forward scroll key

I

Tray selection key

M

Clear (C) key

Q

ERASE

1 12

(ORIGINALS)

EVEN NUMBER

ODD NUMBER

2

11

2

PRE-COUNT

ORIGINALS

DUAL PAGE

COPY

2

AUTO IMAGE

REDUCTION

ENLARGEMENT

100%

ZOOM

EXPOSURE

ARTO

MANUAL

DARK

LIGHT

PHOTO

11 17

12

OHP insert paper insertion

2

key/display lamp

Dual paper copy key/display

6

lamp

Zoom key

F

Operation guide key/display

J

lamp

Interruption key/display lamp

N

Start key/Start lamp

R

2410

SCROLL DISPLAY

INFORMATION

TRAY SELECT

PROGRAM

P

CLEAR ALL

CA

INTERRUPT

1

4

7

AUDIT CLEAR

18 19 20 21 22 23

Cover/insert paper insertion

3

key/display lamp

Automatic magnification ratio

7

selection key/display lamp

Copy density key

G

Program key

K

Numeric key

O

Copy quantity display

S

32

START

65

98

0/

C

Shift key/display lamp

4

Sort key/display lamp

8

Reduction

H

All clear key

L

Zero/department count end

P

key

Message screen

T

5 – 2

Page 16

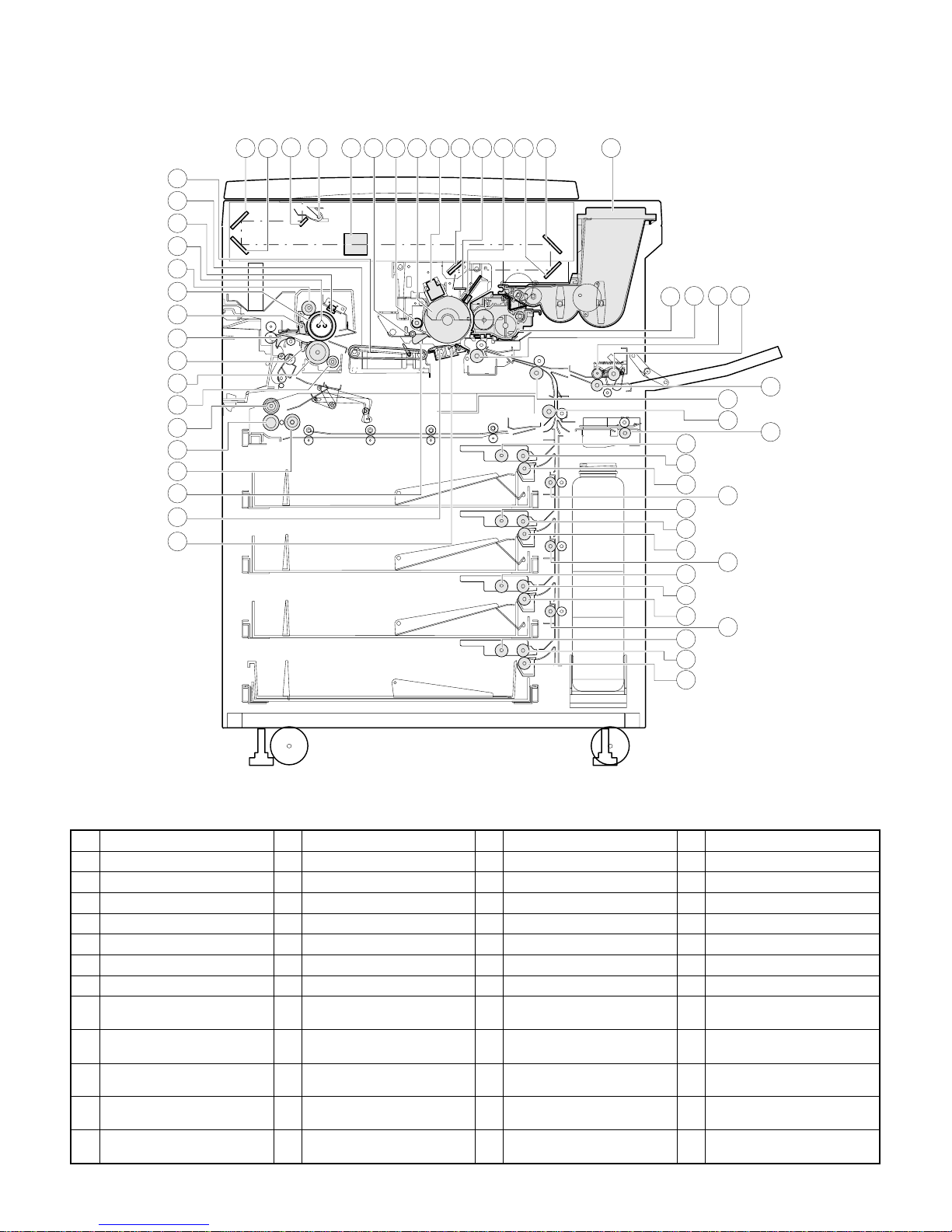

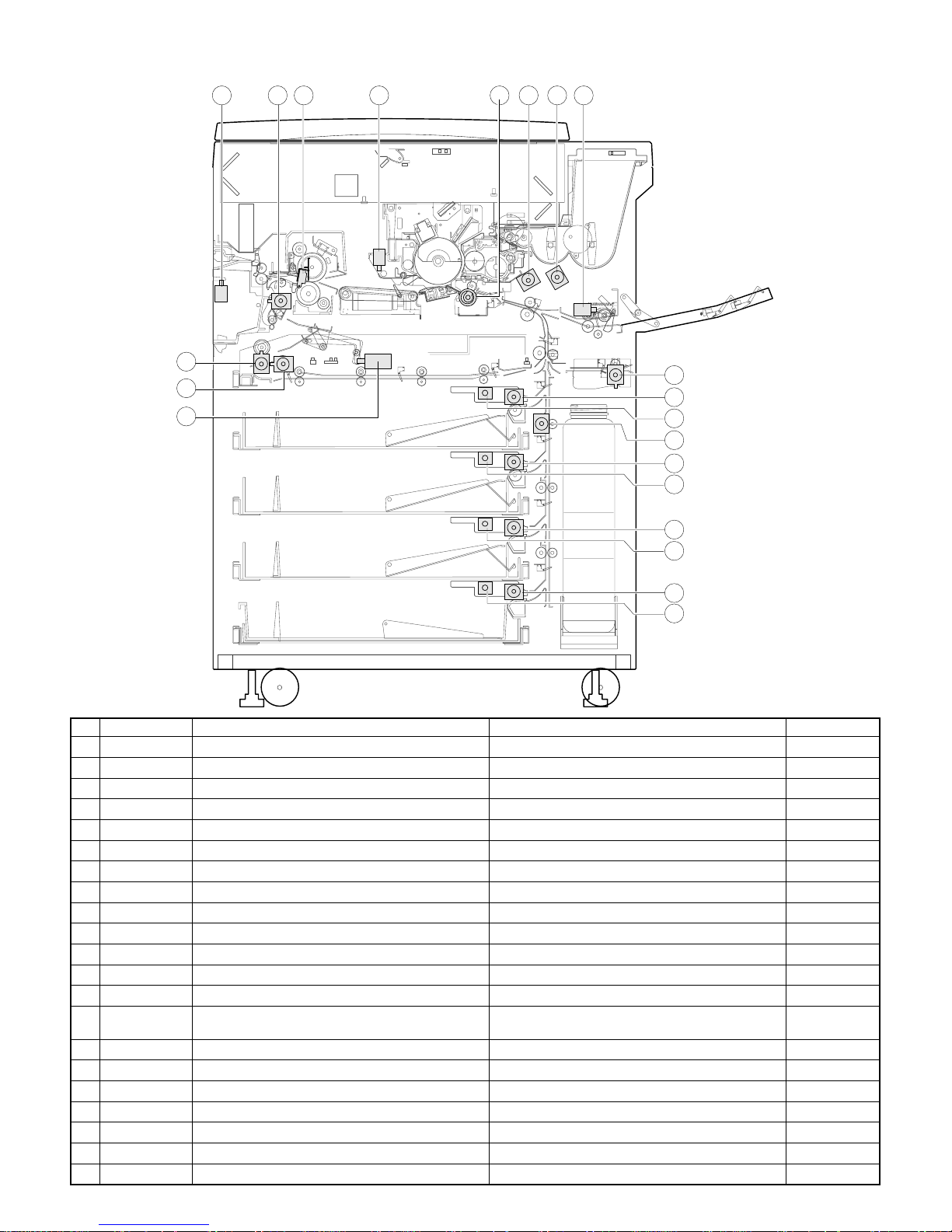

4. Internal structure (Japan model)

19

20

27

23

26

21

25

28

24

22

48

49

50

51

46

16

14

3

2

1

468710911

15

18

175

47

12

34

35

36

37

38

39

40

41

42

43

44

45

32

30

13

32

32

32

32

29

31

33

No. 2 mirror

1

Lens unit

5

No. 4 mirror

9

Transport roller (upper)

I

Drum separation pawl

M

Upper heat roller

Q

Upper separation pawl

U

manual take-up roller

Y

Large cassette tray unit paper

]

feed roller

No. 2 tray take-up roller

a

No. 3 tray paper feed roller

e

No. 4 tray paper feed reverse

i

roller

Duplex section paper feed

m

roller

No. 3 mirror

2

Main charger unit

6

No. 5 mirror

F

Transfer charger

J

Cleaner unit

N

Lower heat roller

R

Upper cleaning roller

V

Manual paper feed roller

Z

No. 1 tray take-up roller

^

No. 2 tray paper feed roller

b

No. 3 tray paper feed reverse

f

roller

Process control sensor

j

Duplex section paper feed

n

reverse roller

No. 1 mirror

3

Blank lamp

7

Developing unit toner box

G

Photoconductor drum

K

Suction unit

O

Heater lamp

S

Fusing thermistor

W

Manual separation roller

[

No. 1 tray paper feed roller

_

No. 2 tray paper feed reverse

c

roller

No. 4 tray take-up roller

g

Drum marking sensor

k

Duplex section take-up roller

o

5 – 3

Copy lamp

4

No. 6 mirror

8

Developing unit

H

Separation charger

L

Suction belt

P

Lower separation pawl

T

Paper exit separation gate

X

Resist roller

\

No. 1 tray paper feed reverse

‘

roller

No. 3 tray take-up roller

d

No. 4 tray paper feed roller

h

Lower cleaning roller

l

Page 17

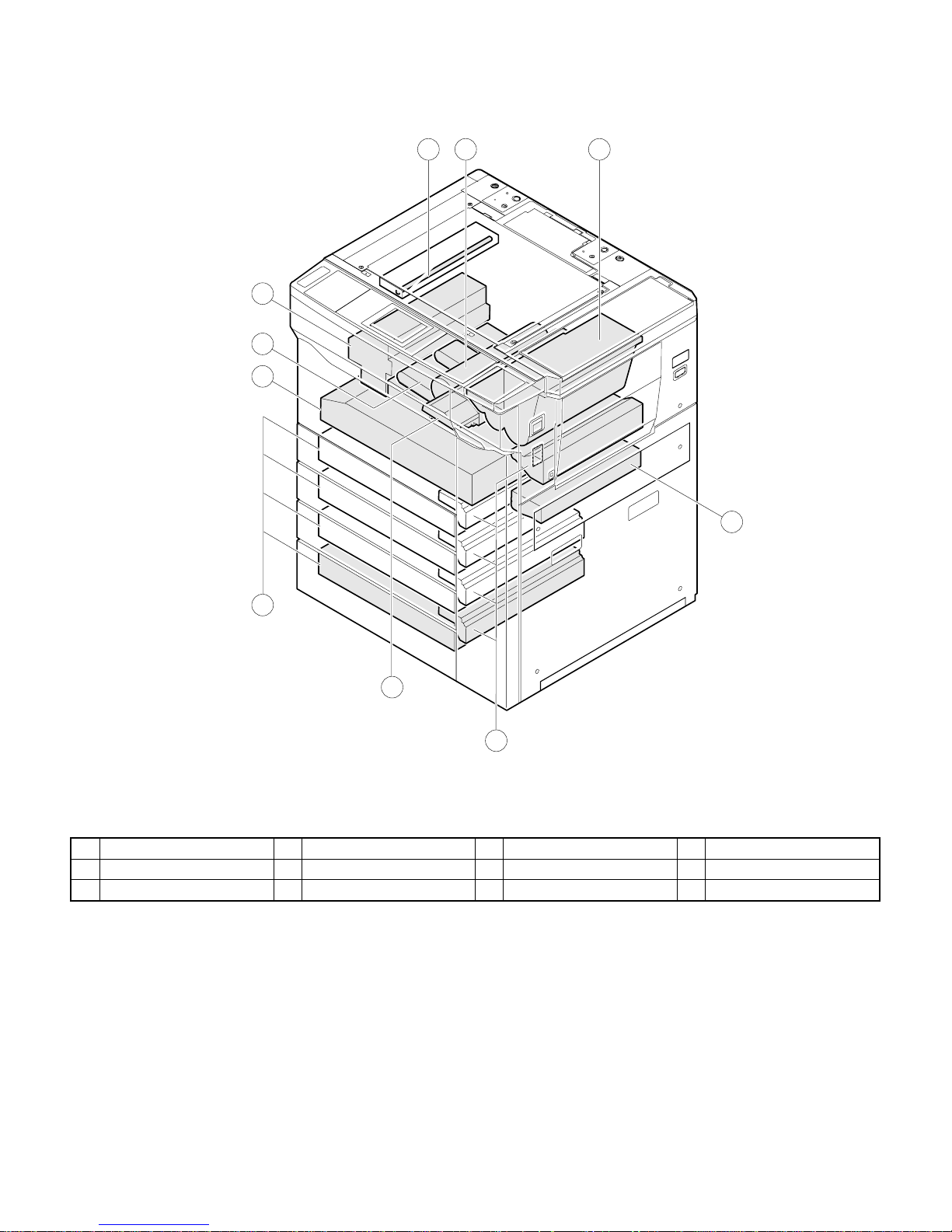

5. Unit

4

1

3

2

6

8

7

Process unit

1

Developing unit

5

500-sheet tray unit

9

9

5

10

Suction frame unit

2

Toner hopper unit

6

Paper feed unit

F

Fusing unit

3

Transport unit

7

Optical unit

4

Center tray unit (ADU)

8

5 – 4

Page 18

6. Clutches and solenoids

1619 21 913 1517 20

11

12

10

Signal name Part name Function and operation Remark

CPFC1 No. 1 cassette paper feed clutch No. 1 tray paper feed roller rotation

1

CPFS1 No. 1 cassette paper feed solenoid No. 1 tray take-up roller rotation

2

CPFC2 No. 2 cassette paper feed clutch No. 2 tray paper feed roller rotation

3

CPFS2 No. 2 cassette paper feed solenoid No. 2 tray take-up roller rotation

4

CPFC3 No. 3 cassette paper feed clutch No. 3 tray paper feed roller rotation

5

CPFS3 No. 3 cassette paper feed solenoid No. 3 tray take-up roller rotation

6

CPFC4 No. 4 cassette paper feed clutch No. 4 tray paper feed roller rotation Japan only

7

CPFS4 No. 4 cassette paper feed solenoid No. 4 tray take-up roller rotation Japan only

8

MPFS Manual feed solenoid Manual feed take-up roller pressing

9

DPFWS DP paper feed weight plate solenoid Duplex paper holding plate driving

F

DPFC Duplex paper feed clutch Duplex paper feed roller rotation

G

DTRC Duplex paper transport clutch Duplex paper transport roller rotation

H

PSPS Separation solenoid Paper separation solenoid driving

I

TRC3 Paper entry roller clutch

J

RRC Resist roller clutch Resist roller driving

K

CURLRC Curl correction clutch Curl correction section driving

L

HRS Heat roller solenoid Heat roller pressing

M

TRC1 Transport clutch 1 Transport roller rotation

N

DGS Duplex gate solenoid Duplex gate ON/OFF

O

TRC2H Transport clutch 2 (High speed) Transport roller rotation

P

TRC2L Transport clutch 2 (Low speed) Transport roller rotation

Q

Paper entry roller driving from large capacity tray

(LCC)

14

1

2

18

3

4

5

6

7

8

5 – 5

Page 19

7. Switches and sensors

14

25

26

16

19

22

18

20

40

43 37 36

46

34

12 1315 2829 27

35

24

45

42

17

21

44

11

9 10

41

23

30

1

2

31

3

4

32

5

6

33

7

8

38

39

Signal name Part name Switch/sensor Function/operation Remark

LUD1 No. 1 cassette upper limit sensor Sensor No. 1 tray upper limit sensing

1

PED1 No. cassette paper sensor Sensor No. 1 tray paper presence sensing

2

LUD2 No. 2 cassette upper limit sensor Sensor No. 2 tray upper limit sensing

3

PED2 No. 2 cassette paper sensor Sensor No. 2 tray paper presence sensing

4

LUD3 No. 3 cassette upper limit sensor Sensor No. 3 tray paper upper limit sensing

5

PED3 No. 3 cassette paper sensor Sensor No. 3 tray paper presence sensing

6

LUD4 No. 4 cassette upper limit sensor Sensor No. 4 tray upper limit sensing Japan only

7

PED4 No. 4 cassette paper sensor Sensor No. 4 tray paper presence sensing Japan only

8

PLS1 Manual feed paper length sensor 1 Sensor Manual feed tray paper length sensing

9

PLS2 Manual feed paper length sensor 2 Sensor Manual feed tray paper length sensing Inch series

F

MPED Manual feed paper sensor Sensor Manual feed tray paper presence sensing

G

OCSW OC cover open/close sensor Sensor OC cover open/close sensing Japan only

H

MBHP Mirror base home position sensor Sensor No. 4, 5 mirror home position sensing

I

MHP Mirror home position sensor Sensor

J

Mirror base (No. 2, 3 mirror) home position

sensing

5 – 6

Page 20

Signal name Part name Switch/sensor Function/operation Remark

LHP Lens home position sensor Sensor Lens home position sensing

K

DPFD ADU paper feed sensor Sensor Duplex section paper feed sensing

L

DTBHPS ADU rear plate home position Sensor

M

DTWHPS ADU alignment plate home position Sensor

N

DPPD1 ADU transport sensor 1 Sensor Duplex section transport sensing

O

DPPD2 ADU transport sensor 2 Sensor Duplex section transport sensing

P

DPPD3 ADU transport sensor 3 Sensor Duplex section transport sensing

Q

DTPD ADU paper sensor Sensor Duplex section paper presence sensing

R

DFDL2 Paper feed sensor 5 Sensor LCC paper feed sensing

S

PPD3 Transport sensor 3 Sensor Paper transport sensing

T

DPID1 ADU paper entry sensor 1 Sensor Duplex section paper entry sensing

U

DPID2 ADU paper entry sensor 2 Sensor Duplex section paper entry sensing

V

TES Toner empty sensor Sensor Toner hopper toner empty sensing

W

TNCTR in Toner cartridge sensor Switch Refill toner cartridge installation sensing

X

TCS Toner density sensor Sensor Developing unit toner density sensing

Y

PFD1 Paper feed sensor 1 Sensor No. 1 tray paper feed sensing

Z

PFD2 Paper feed sensor 2 Sensor No. 2 tray paper feed sensing

[

PFD3 Paper feed sensor 3 Sensor No. 3 tray paper feed sensing

\

PFD4 Paper feed sensor 4 Sensor No. 4 tray paper feed sensing Japan only

]

DSWF1 Front cover switch 1 Switch Front cover open/close sensing 100V system

^

DSWF2 Front cover switch 2 Switch Front cover open/close sensing 100V system

_

TS Thermostat — —

‘

THS Fusing temperature sensor Thermister Fusing section temperature sensing

a

TBBOX Waste toner bottle sensor Sensor Waste toner bottle presence sensing

b

TNF Waste toner full sensor Sensor Waste toner full sensing

c

DSWE Paper exit section open switch Switch Paper exit section open/close sensing 100V system

d

PPD1 Transport sensor 1 Sensor Paper transport sensing

e

PPD2 Transport sensor 2 Sensor Paper transport sensing

f

POD Paper exit sensor Sensor Paper transport sensing

g

DHSW Dehumidifier heater switch Switch Dehumidifier heater ON/OFF Japan only

h

MSW Power switch Switch Power switch ON/OFF Japan only

i

PSD Separation sensor Sensor Paper separation sensing,

j

Duplex section rear plate home position

sensing

Duplex section alignment plate home

position sensing

5 – 7

Page 21

8. Motors

6

4

57

8 1112

1

9

10

3

2

13

14

15

Mirror motor

1

No. 4, 5 mirror base motor

5

Cooling fan motor

9

Suction fan motor

I

Tray lift-up motor 3

M

Main motor

2

Lens motor

6

Ventilation fan motor 1

F

DV fan motor

J

Tray lift-up motor 4

N

Drum motor

3

Duplex motor 1 (for shifting

7

the rear plate)

Ventilation fan motor 2

G

Tray lift-up motor 1

K

16

17

18

Toner motor

4

Duplex motor 2 (for shifting

8

the alignment plate)

Ventilation fan motor 3

H

Tray lift-up motor 2

L

5 – 8

Page 22

9. PWB unit list

13

17

20

6

105 7 9 8

15

16

14

11

12

2

1

19

18

DC power PWB

1

Operation control PWB

5

LCD invertor PWB

9

Sensor volume PWB

I

Light quantity correction PWB

M

High voltage PWB

2

Operation PWB 1

6

LCD unit

F

Original sensor light emitting

J

PWB (Japan only)

Lift-up motor PWB

N

AC circuit PWB

3

Operation PWB 2

7

DL PWB

G

Original sensor light receiving

K

PWB (Japan only)

Cassette paper size sensor

O

PWB

3

4

Main control PWB

4

Operation PWB 3

8

BL PWB

H

AE sensor PWB

L

Manual feed paper size

P

sensor PWB

5 – 9

Page 23

10. Large capacity cassette unit (LCC)

8

9

6

4

10

1

3 711

5

2

Signal name Part name Switch/sensor Function/operation Remark

TLMD Tray upper limit sensor Sensor Tray upper limit sensing

1

TLD Tray lower limit sensor Sensor Tray lower limit sensing

2

TUD Tray paper upper section sensor Sensor

3

TPTD Tray shift quantity sensing PT sensor Sensor Remaining paper quantity sensing

4

TCD

5

— Tray lift motor — Tray up down

6

LPFS Paper feed solenoid — Paper feed roller pressing

7

LPFC Paper feed clutch — Paper feed roller rotation

8

LPFC2 Paper feed reverse clutch — Double feed preventing clutch

9

— Fuse PWB unit — —

F

— Upper lock SW Switch

G

Door open

Tray SW PWB

— Door (tray) open/close sensing

Tray paper upper section and paper

presence sensing

Upper limit lock sensing (Cutting the motor

power for safety.)

5 – 10

Page 24

[6] PROCESS SECTION

(Photocondor drum and cleaning

unit)

Dark area Dark area

HV

CTL

Light

1. Basic theory

With the indirect static copier, a plain paper is used for the copy

paper. As a latent static image is formed on the surface of the

photoconductor, the image is then developed into visible (toned)

image using the toner. Then the toner is transferred onto the copy

paper.

The plain paper copier (PPC) has six basic processing steps of

corona charge, exposure, development, transfer, discharge, and

cleaning. The cleaning step prepares the photoconductor surface for

repeated use.

(1) Image forming process

Charging

1

Exposure

Transfer

2

3

Development

Discharge

Cleani ng

1 Corona charges the photoconductor.

2 The photoconductor is exposed to light to form a static latent

image.

3 Toner is attracted to the static latent image.

4 The toner on the drum is transferred onto the copy paper.

5 Toner remaining on the photoconductor (residual toner) is

removed.

6 The charge remaining on the photoconductor surface (residual

charge) is removed.

6

Photoconductor

5

4

(2) Photoconductor

While some materials conduct electricity, others do not. Materials,

therefore, can be put into three categories of conductor, semiconductor, and insulator.

These categories are conceptual, distinct classification is difficult.

Generally, the following is applied.

Material whose specific resistance is over 103Ωcm is called a insulator and under 10–3Ωcm is called a conductor.

Those which exist between the two normally called semiconductor.

Conductor in the category always has the electrical conductivity, while

semiconductor does not. But, it may become conductor under certain

conditions.

The photoconductor used by the copier is an insulator when not

exposed to light, but its electrical resistance abates when exposed to

light. When exposed to light, the photoconductor surface becomes

conductive. Material having the property to become conductive in

light (photo conductive phenomenon) is a photoconductor or

photosemiconductor.

CGL

Base

Theory of photoconduction

(3) Types of photoconductors

The principal materials of a photoconductor are zinc oxide (ZnO),

amorphous selenium (amorphous Se), selenium alloy, cadmium sulfide (CdS), amorphous silicon (amorphous Si), and organic photoconductor (OPC).

Amorphous selenium(amorphousSe)

Selenium alloy

Inorganic photoconductor

Organic photoconductor

Described next are structures of the photoconductors we have used

up to now.

Zinc oxide (ZnO) master

Cadmium sulfide (CdS) drum

Organic photoconductor (OPC) master and dr um

Selenium (Se) drum

Zinc oxide(ZnO)

Cadmium sulfide(CdS)

Amorphous silicon( am or phous Si)

Organi c pho toc onduc t or (O PC)

Photoconductive l ayer (zinc oxide layer)

Intermediate layer

Paper

Back coatin g pa per

PET layer

Micro space layer

Photoconductive layer (C dS layer)

Aluminum layer

Charge traffic layer

Charge generation layer

Alum i n um layer

Photoconducti ve layer

Alum i n um la y e r

(selenium layer)

Base paper

Optical

conductive

layer

(OPC layer)

6 – 1

Page 25

Zn0 OPC CdS Se

Photoconductor

sensitivity

Photoconductor

strength

Photoconductor

life

4321

4321

Several hundred

cycles

Several ten

thousand cycles

Several ten

thousand cycles

Several hundred

thousand cycles

Photoconductor characteristics

1 > 2 > 3 > 4

Characteristics of organic photoconductors

• Permits a variety of structures (drum, sheet, belt)

• Higher insulation in dark area (charge acceptability and retentivity)

• Permits a variety of molecular structure (allows a variety of

molecular design)

• Light weight

• Stable against humidity and temperature

• Safe for environment (non-pollution, unrestrained disposal)

• Not strong in anti-wear property

• Not strong against light and ozone.

(4) Characteristics of photoconductor

Mentioned next is the general characteristics important to use for the

photoconductive material.

1. Photo-sensitivity 2. Spectrum characteristics

3. Acceptor potential 4. Charge retentivity

5. Residual potential 6. Fatigue

[Photo-sensitivity]

This is dependent on the attenuation speed of the potential when the

photoconductor is exposed to light.

[Spectrum characteristics]

Wave length of the light differs by the kind of the photoconductor.

[Acceptor potential]

The resistance in the dark area of the photoconductor decreased as

the electric field increases among layers.

As the electric field is formed to a higher value as the photoconductor

is charged, the resistance in the related layer decreases and the rate

of charge retained in the photoconductor is restricted. The potential of

the photoconductor in this instance is called acceptor potential which

is an important factor to determine the potential contrast. To avoid

giving electrical distortion in the photoconductor, charge is normally

made to a level slightly lower than the acceptor potential.

[Charge retentivity]

The time that the static latent image is held by the photoconductor

depends on the speed at which the potential decreases in the dark

area. For this, measure the time that the photoconductor potential

abates to half of the starting value in the dark area. This charge

retentivity may cause a problem when the time from the exposure to

the development is long. But, it may not be a problem with the

machine where a series of operations from charge, exposure, and

development are automated and time between processes is shorter.

[Residual potential]

When the charged photoconductor is exposed to light, the potential

abruptly diminishes at first, then begins decaying relatively slowly.

The potential of the photoconductor where slow decay starts is called

residual potential. A less residual potential produces a large potential

contrast, low residual charge is preferable.

The value of the residual potential affects largely the development of

gradual tone.

[Fatigue]

If charge and exposure are repeated, the phenomenon called

photoconductor fatigue occurs. In other words, it appears as an increase of the decay speed of the photoconductor potential or a

decrease in the charge retentivity.

Now, we have learned about the characteristics required for charging

of the photoconductor. If charge is repeated from the corona unit in

the actual operation, the corona wire is likely to be contaminated with

dust, stain, and scattered toner, causing uneven corona charge. To

avoid this, the corona wire needs to be cleaned well.

1.0

0.8

0.6

0.4

0.2

Spectrum sensitivity (relative value)

400

Se:Te

OPC

500 600 700 800

Wavelength

Spectrum sensitivity

Amorphous sil ic on

Relationship between color and wave length

Light having wave length of 380nm through 780nm can be recognized by human eyes, which is called visible light. Wave length

shorter than that is called ultraviolet light and the longer than that is

called infrared light. Figure below shows the relationship between the

wave length of light and color.

Blue green

Blue

Violet

350 400 450 500 550 600 650 700 750 800

Yellow

Green

Orange

Red Inf ra re dUltraviolet

6 – 2

Page 26

2. SF-2050 basic process and

structure

• The Scorotron method is used to evenly charge the photoconduc-

tor surface to the given potential in the charge process. The

corona wire regularly used is now replaced with a new corona

charge mechanism that employs the 0.1mm thick stainless steel

saw teeth plate, in order to suppress ozone which is generated

when the oxide molecule in air is ionized.

• Considering the service efficiency, the process separation

mechanism is adopted.

(1) Details of image forming process

STEP 1. Charging

The main corona discharges negative corona to give negative charges to the OPC drum surface evenly.

The surface potential of the OPC drum is controlled by the screen

grid voltage to maintain at the potential equal to the grid voltage.

• When the drum surface voltage is lower than the screen grid volt-

age, electric charges from the main corona pass through the

screen grid to reach the drum surface and charge it until the drum

surface voltage becomes equal to the grid voltage.

• When the drum surface voltage reaches almost the same level as

the grid voltage, electric charges from the main corona flow

through the electrode of the screen grid to the high voltage unit

grid voltage output circuit, thus maintaining the drum surface voltage at the same level as the grid voltage.

Exposure

Exposure

(Copy lamp)

OPC layer

Pigment layer

Aluminum

(Drum)

Dark area

Light area

Dark area

Light area

STEP 3. Development (Bias –200V)

The electrostatic latent image on the drum surface is formed into a

visible image by the toner. This copier employs the two-component

magnetic brush development system, where a bias voltage of –200V

is applied to the carrier (MG roller) and the toner is charged positively

by friction with the rotating carrier.

Carrier

Toner

Screen grid

Main corona

output section

Grid voltage

output section

High voltage

unit

STEP 2. Exposure (Copy lamp, mirror, lens)

The optical image of an original is projected through the mirrors and

lenses onto the OPC drum surfac e b y the copy lam p . Th e r e sis t a nc e

of the OPC layer reduces in the bright area (light area on the original)

to discharge negative charge, forming an electrostatic latent image on

the drum surface.

In reduction copy, the non-image area of the image is discharged by

the BL (blank lamp) after exposure.

S

N

N

N

S

-200V

STEP 4. Transfer

The visible image on the drum surface is transferred on to the copy

paper. A negative charge of the transfer corona is applied to the rear

surface of the copy paper to transfer the toner on the drum surface to

the copy paper.

Toner

Paper guide

Copy paper

High voltage uni t

6 – 3

Page 27

STEP 5. Separation

Though the copy paper and the drum are both negatively charged

after transfer, the negative potential on the drum is higher than that

on the copy paper, generating an attraction force between the drum

and the copy paper. To remove the attraction force, AC corona is

applied to the copy paper by the separation corona to raise the

potential on the copy paper to the same level as the drum surface

potential. Resultantly the attraction force is eliminated and the copy

paper is separated from the drum. If the paper is not separated from

the drum, the separation pawl works to separate it mechanically.

Separation

pawl

Copy paper

Separation corona

output section

High voltage unit

STEP 6. Cleaning

Residual toner on the drum is collected by the cleaning blade.

Photo mode

The photo mode is provided to make clear half-tone copy of the photo

originals.