Page 1

SF-7370

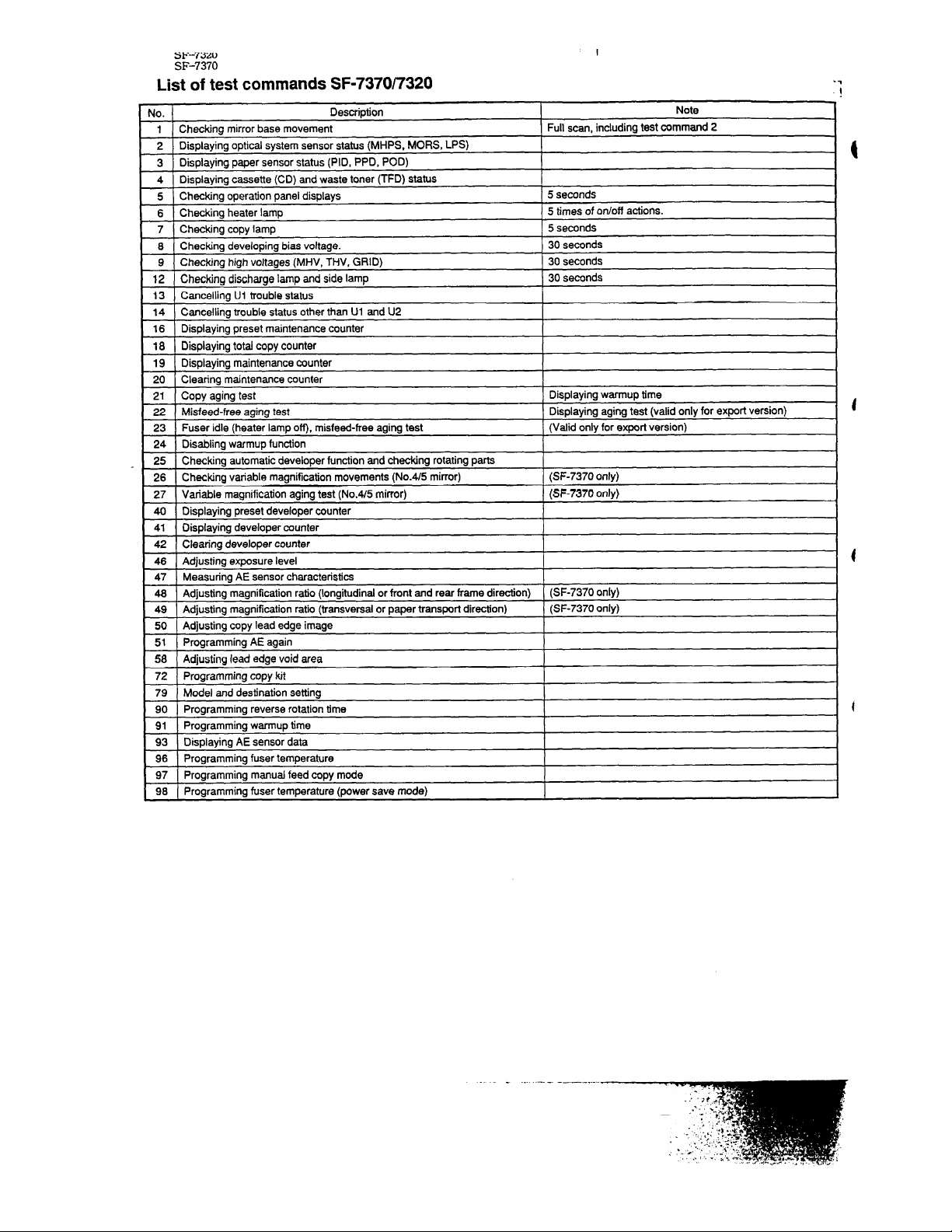

List of test commands SF-7370~320

.7

.!

40.

Description

Note

1

Checkingmirrorbase movement

Full scan, includingtest command2

2

Displayingoptic~ systemsensorstatus(MHPS, MORS, LPS)

3

Displayingpaper sensorstatus(PID, PPD, POD)

4

Displayingcassette(CD) and waste toner (TFD) status

5

Checkingoperationpanel displays

5 seconds

6

Checkingheaterlamp

5 timesof otioff actions.

7

Checkingcopy lamp

5 seconds

8

Checkingdevelopingbias voltage.

30 seconds

9

Checkinghighvoltages(MHV, THV, GRID) 30 seconds

12

Checkingdischargelampand sidelamp

30 seconds

13

Canceling U1 troublestatus

14

Cacelling troublestatusotherthan U1 and U2

16

Displayingpresetm~ntenance counter

18

Displayingtotalcopycounter

19

Displayingmaintenancecounter

20

Clearing maintenancecounter

21

Copy aging test

Displayingwarmuptime

22

Misfeed-freeaging test

Displayingagingtest (valid onlyfor exportversion)

23

Fuser idle (heater lamp o~, miafeed-freeaging test (Valid onlyfor exportversion)

24

Disablingwarmupfunction

25

Checkingautomaticdeveloperfunctionandcheckingrotatingparts

26

Checkingvari~le magnificationmovements(No.415mirror)

(SF-73700nly)

27

Vtiable magnificationagingtest (No.~5 mirror)

(SF-7370 only)

40

Displayingpresetdeveloperwunter

41

Displayingdevelopercounter

42

Clearina develooercounter

4 6

Adjustingex~sure level

47

MeasuringAE sensorcharacteristics

48

Adjustingmagnificationratio(Iongitudindorfront and rear frame direction) (SF-7370 only)

49

Adjustingmagnificationratio(transversalor paper transpotidirection)

(SF-7370 only)

50

Adjustingcopylead edge image

51

ProgrammingAE again

58

Adjustingleadedge voidarea

72

Programmingcopykit

79

Model and destinationsetting

90

Programmingreverserotationtime

91

Programmingwarmuptime

93

DisplayingAE sensordata

96

Programmingfusertemperature

97

Programmingmanualfeed copy mode

98

Programmingfuser temperature(powersave mode)

-. .-—.-.-——----. ..

Page 2

SF-7320

SF-7370

Tv~es of test commands and their functions

- , ~ - —- --—- ------.-—..—— —.

Test command

Function

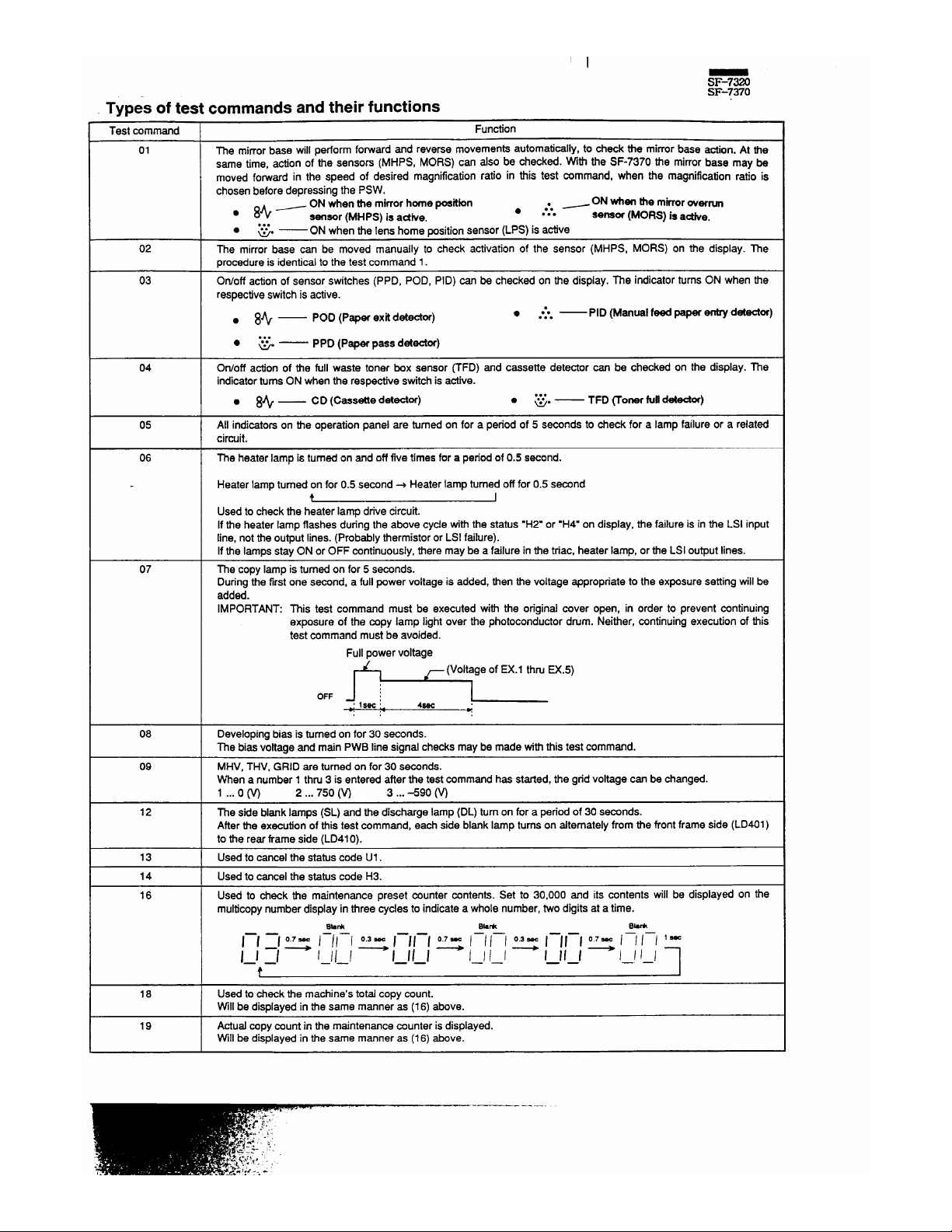

01

The mirrorbase will pedorm fo~ard and reverse movementsautomati~lYt to check tie mimerbase action. At the

same time, actionof the sensom (MHpS, MORS) can also be check~. ~~ the SF-7370 the mirrorbase may be

moved forwardin the speed of desired magnificationratio in tiis test ~mmand, when the magnificationratio is

chosenbeforedepressingthe PSW.

~ ON when the mirrorhome poekbn

~, —ON when the

mirroroverrun

. 8+

●

sensor (MHPS) is adke.

. . .

senam (MORS) is astke.

. . .

●

%“

— ON when tie lens home positionsensor(LPS) is active

02

me mirror base can be moved manually to check activationof the sensor (MHPS, MORS) on the display. The

procedureisidenticaltothe test command 1.

03

Otiotf action of sensorswitches (PPD, POD, PID) can be checked on the display. The indicatorturnsON when the

respectiveswitchisactive.

● 8%—

POD (Paper exti d-or)

● ●*O —

. . .

PID (Manuel feed paper em detester)

. . .

●

=.

— PPD (Paper pass detector)

04 Otioff action of tie full waste toner box sensor ~FD) and cassette detector can be checked on the display. The

indicatorturnsON whenthe respectiveswitchis active.

● 8+ —

CD (Cassette detester)

. . .

●

=.

— TFD ~oner fuUdetector)

05 All indicatorson tie operationpanel are turned on for a period of 5 seconds to check for a lamp failure or a related

circuit.

06

The heaterlampis turnedon and offfive timesfora periodof 0.5 second.

Heater lampturnedon for 0.5 second+ Heaterlampturned offfor0.5 second

t I

Used to checkthe heater lamp drive circuit.

If the heaterlampflashesduringthe above cycletith the status “H2. or .H4” on display,the failureis in the LSI input

line, notthe outputlines.(Probablythermistoror LSI failure).

If the lamps stay ON or OFF continuously,there may be a failurein the triac, heater lamp, or the LSI outputlines.

07 The copy lamp is turnedon for 5 seconds.

Duringthe firstone second, a fullpowervoltage is added,then the voltage appropriateto the ex~sure settingwillbe

added.

IMPORTANT: ~is test command must be executed with the original cover open, in order to prevent continuing

exposure of the copy lamp lightover the photoconductordrum. Neither, continuingexecutionof this

test commandmustbe avoided.

Fullpowervoltage

~ (Voltageof EX.1 thruEX.5)

0-

1

4W

::

*

08 Developingbiasis turnedon for 30 seconds.

The biasvoltage and main PWB line signal checksmaybe made withthis test commend.

09 MHV, THV, GRID are turnedon for 30 seconds.

When a number 1 thm 3 is entered after the testcommand has started,the gridvoltagecan be changed.

1 ...0 m 2,..750 (w 3... +90 (w

12

The side blanklamps (SL) and the discharge lamp (DL) turnon for a periodof 30 seconds.

Afterthe executionof this test command, each side blanklamp turnson dtemately from the frontframeside (LD401)

to the reartiame side (LD41O).

13

Usedto cancelthe statuscode U1.

14

Used to cancel the statuscode H3.

16

Used to check the maintenance preset counter contents. Set to 3 0, 0 00 and its contents will be displayed on the

multicopynumber displayin three cycles to indicatea whole number,two digitsat a time.

Bb*

Bk *

Bhk

——

l—l :1 ~ / // / ~ 1–1 1-1 ~ I / / / ~ I–J I–I ~ / / / / ‘ *

——

——

ill

1–1 1–1 – – – – –.

I I I I

I I I I I I 1 –1

——

——

f

18

Used to checkthe machine’stotal co py count.

VVillbe displayedin the same manneras (16) above.

19

Actualcopycountin the maintenancecounteris displayed.

Will be displayedin the same manneras (16) above.

.-—— -.-.-—

Page 3

5F-7W0

Test command

I

Function

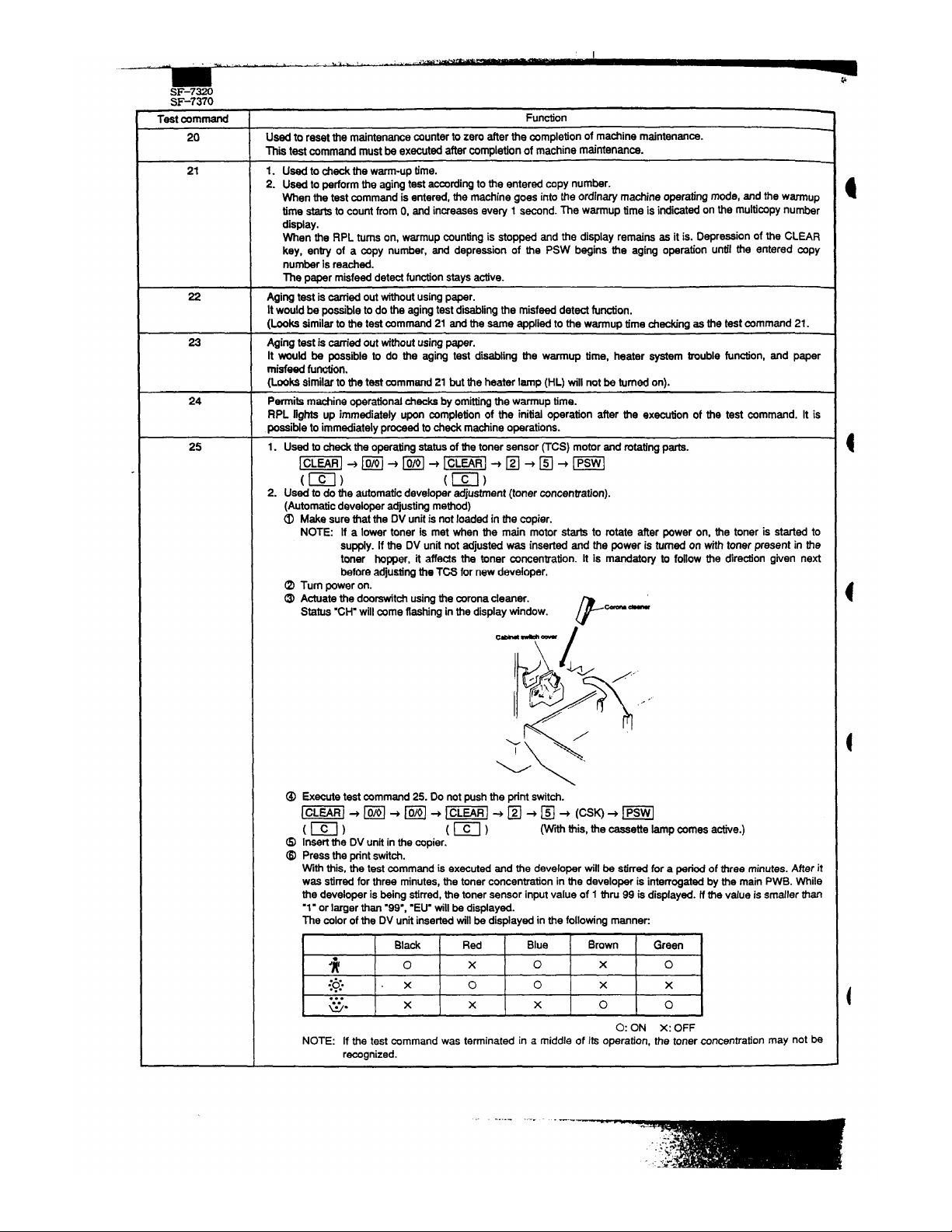

20

Used to resetthe maintenancecounterto zero after the completionof machine maintenance.

This test command mustbe executedaftercompletionof machinem~ntenanCS.

21

1. Used to checkthe warm-uptime.

2. Used to performthe agingtest -rding to the entered copy number.

When the test mmmand is entered, the machinegoes intothe ordinw machine operatingmode, and the wmup

time startsto countfrom O, and increasesevew 1

second.The warmup time is indiated on the muMmPYnumber

dis~ay.

When the RPL turnson, warmupcountingis stopped and the display

remainsasit is. Depressionof the CLEAR

key, entry of a copy number, and depression of the PSW begins the aging operation until the enteredcopy

numberis reached.

The paper misfeeddetectfunctionstaysactive.

22

Agingtestis~ed outtihout usingpqer.

It wouldbe poasi~etodothe agingtestdisablingthe misfeeddetectfu~on.

(tike similarto tie test command21 and the same applied to the warmuptime checkingas the teat mmmand 21.

a

Agingtest is ~.ed out withoutusingpaper.

It WOUMbe possible to do the aging test di~ing the warmup time, heater system trouble funtion, and paper

misfeedfuncdon.

(Lookssimilarto thetestmmmand21 but the heater lamp (HL) wtllnot be turnedon).

24 Pemifs machine operationalti~ks by omitdngthe warmuptime.

RPL nghta up immediately upon completionof the initial operation after the execution of the test command. It is

possibleto immediatelyproceed to check machineoperations.

25

1. Used to checkthe operatingstatusof the toner sensor ~CS) motor and rotatingparts.

%)+~+~+m+D

“D+m

2. Used to do the automaticdeveloperadjustment(tonerconcentration).

(Automaticdeveloperadjustingmethod)

O

Makesurethatthe DVunitis not loaded in the copier.

NOTE: If a lower toner is met when tie main motorstarts to rotate after poweron, the toneris startedto

supply.If the DV unit not adjustedwas insertedand the power is turned on withtonerpresentin the

toner hopper, it affeds the toner concentration. It is mandatory to follow the dire~on given next

beforeadjustingthe TCS fornew developer.

~ Turn poweron.

O Actuatethe doorewitchusingthe coronacleaner.

Status“CH.willcome flashingin the displaytindow.

F

~-

cM --

/

P>\

&J

~,

/,.

‘<

.. ,“’

/

/’

~\

\

~ ~=utetestmmmsnd 25. Do not pushthe printswitch.

w, ~ B + ~ ~ m ~

❑ ~ E ~ (CSW~ m

(Wh this,the cassette lampames a*e.)

0 Insertthe DVunitinthecopier.

@ Presstheprintswitch.

Wth this,

the test command is executedand the developerwill be stirred for a periodof three minutes.After it

was stirredforthree minutes,the toner concentrationin the developeris interrogatedbythe main PWB. While

the developer is being stirred,the toner sensorinputvalue of 1 tiru 99 is displayed.Wme value is smaller than

.1. or lager than “99’, .EU9willbe displayed.

The colorof the DV unitinsetiedwill be displayedinthe followingmanner:

?

Black

Red Blue Brown

Green

*

o

x

o

x

o

:+;.

,x

o 0

x

x

. . .

G.

x x

x

o

0

O: ON X: OFF

NOTE: If the test command was terminated in a middle of its operation,the toner concentrationmay not be

recognized.

Page 4

Test commend

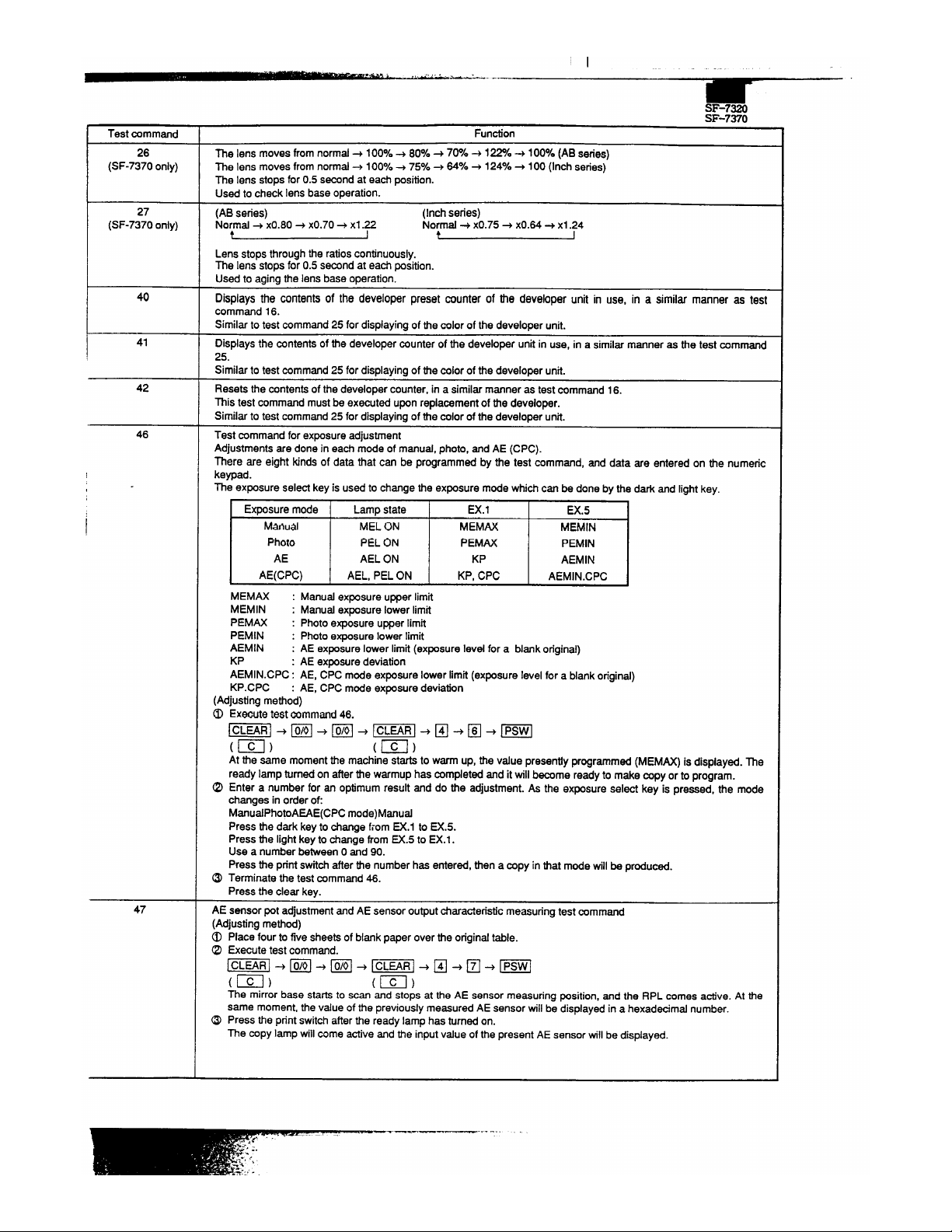

26

(SF-737Oonly)

(SF-7~~0 only)

40

41

—

42

4 6

I

47

SF-737O

Fundon

The lens moves fromnormal+ IOOY~+ 80Y0+ 7W14+ l~o + IOOYO(ABseries)

The lens moves fromnorm~ + 100% + 75Y0+ ~VO + 124V0+ 100 (lnChseries)

The lens stopsfor 0.5 secondat each position.

Used to check lens base operation.

(ABseries)

(Inchseries)

No\md + xO.80 + xO.70+ xl.7

Normal+ xO.75+ xO.64+ xl .24

Lens stopsthroughthe ratioscontinuously.

The lens stopsfor 0.5 secondat each position.

Used to aging the

lensbaseoperation.

Displaysthe contentsof the developerpresetcounter of the developerunit in use, in a similar manner as test

command16.

Similarto test command25 for displayingof the colorof the developerunit.

Displaysthe ~ntents of the developercounterof the developer unit in use, in a similarmanner as the test command

25.

Similarto test command25 for displayingofthe colorof the developerunk.

Resets the contentsof the developercounter,in a simila manner as testcommand16.

This test commandmustbe executed uponreplacementof tie developer.

Similarto test command25 for displayingofthe colorof the developerunit.

Testmmmand for exposureadjustment

Adjustmentsare done in each mode of menuaf,photo,and AE (CPC).

Thereare eightkindsof data that can be programmedby the test command,and data are enteredon the numeric

keypad.

Theexposureselect key is usedto changethe exposuremode whiti can be done by the dark and lightkey.

I

Ex~sure mode Lampstate EX.1

Mmual

MEL ON MEMAX

Photo

PEL ON

PEMAX

AE AEL ON KP

[

AE(CPC)

AEL, PEL ON

KP, CPC

EX.5

MEMIN

PEMIN

AEMIN

AEMIN.CPC

MEMN : Manual exposureupper limit

MEMIN : Manual ex~sure lower limit

PEMAX : Photoe~osure upperlimit

PEMIN : Photoexposurelower limit

AEMIN

: AE ex~sure lower limit(ex~sure level for a blank original)

KP : AE exposuredeviation

AEMIN.CPC: AE, CPC mode exposurelowerlimit(exposurelevel for a blankoriginal)

KP.CPC

: AE, CPC mode exposuredeviation

(Adjustingmethod)

Exeotitetest &mmand 46.

M)+m+ m+ w)+ ❑ +E ~m

At the same momentthe machine startsto warm up, the value presentiyprogrammed(MEMAX) is displayed.The

ready lamp turnedonafterthe warmuphascompletedandit will bme readyto makecopyor to program.

Entera numberfor en optimumresultand do the adjustment.As the exposure select key is pressed, the mode

changes in orderof:

M~udPhotoAEAE(CPC mode)Menud

Press the dark key to change from EX.1 to EX.5.

Pressthe lightkey to changefrom EX.5 to EX.1.

Use a number betweenO and 90.

Press the printswitchafter the number has entered, then a copyinthat modewillbe produced.

Terminatethe test command46.

Pressthe clear key.

AE sensorpot adjustmentandAE

sensoroutputcharacteri~.cmeasuringtest command

(Adjustingmethod)

o Place fourto five sheetsof blankpaper over the originaltable.

~

Executetestcommand.

The mirrorbase startsto scan and stopsat the AE sensormeasuringposition,and the RPL comes adve. At the

same moment,the value of the previouslyme~ured AE sensorwillbe displayedin a hexadecimalnumber.

@ Press the printswitchafter the ready lamp has turnedon.

The copylampwill come active and the inputvalue ofthe presentAE sensorwillbe displayed.

Page 5

-w=”” “““ “’””””“---”

SF-7320

‘1

1

S-7 370

T.. *

-mm.nd

I Function

,=S, -,. ... !-.”

O Adjustthe AE sensoradjustingpoton the main PWB.

Afler me ~py lamp has turned on, adjust the input value between EOH and FOHusin9 me As sensor adjusting

pot. Clockwiseturnof the pot increasesthe inputnumberand vise versa. When the inPutv~ue 1swi~in tie limits,

the cassette lampwill come active.

After the AE sen=r adjustment has complet~. press the print stitch to tian9e to the AE se~or output

characteflsticsmeasurin9mode. If the print switch W* not pressed witiin ten minutesafier tie coPYlamP h=

turnedon, it will automatic~ly change to the AE sensor outputcharacteristicsmeasurin9mode. In the AE sensor

outputcharacteristicsmeasuringmode. the COPYlamp drive voltage automaticallyshiftsand the AE sensor output

characteristicsof thattime is automati~lY measured and stored in the memory.

If the adjustmentwas not finished within ten seconds, press the print switch once again after the ready lamp

turnedon and make adjustment.

Q Terminate tie test command47.

CLEAR key (twice)

Vertid (towardsfrontand rear frame sides) magnificationratioadjustingtestcommand

(SF-73$0 only)

me magnificationratiotowardsthe vertid

CO PYdirection(frontframeandrearframe)canbe adjustedbyvaryingthe

lens stopposition.(SF-7370 only)

(Adjustingmethod)

a Place the scale on the originaltable alongthe frontand rear frame sides.

a

Execute testcommmd 43.

1~~ + ~ + ~ + %; + ❑ + ❑ + m

At the same moment the machine starts to warm up, the present value between 2 and 9 will be displayed. After

the warmuphas completed,the ready lamp turns on

andCOPYbe~mes enal~.

~ Make a normal(xI.0) copy on an A4 (814”x 11.) paper.

~ comp~e the size of the sde image on the copy with the astual scale size and obtain the vetial magnification

ratiousingthefollowingformula.

Verticaldirectionmagnificationratiocompensationrate [O/.]=

(size of original) - (size of scale on the copy) ~ ,00

(size of original)

o Use the followingformulato obtain the vedcd magnificationratio preset value.

Vertid magnificationratiopresetvalue = previousvalue (the number shownin (2) above) + verticalmagnification

ratiocompensationratex 10

Q Programthe presetvalue.

m+m

When the presetvalue is changed by “ln, the magnificationratiochanged0.170.

~ Make a normal (x1.0) copy end compare the scafe image withthe scale size.

~ Adjustmentwillbe satisfacto~ ifthe size of the de image on the copy is withinM.8% with respectto the actual

size of tie s~e, if not, repeat the Xove procedures~ thm 0 to adjustit once a9~n.

If the inputnumberwas smaller than .2. or larger th~ “9”,

it may not entile to corr~ the magnificationratiowith

this test command.In suchevent, move the slit plate on the lens

basetowardsthe paperentrysideif smallerMm

‘2”, or, move it towardsthe paper exit side if largerthan “9”.Then, do the adjustmental over again.

~ Terminate the test command43.

CLEAR

Horizontaldirection(towardspapertransportdirection)magnificationratioadjustingtestcommand

(SF-7~~0 only)

me horizontal(papertrans~rt direction)magnificationratiocan be adjustedby varyingthe mirrorbase scan speed.

(SF-7370 only)

(Adjustingmethod)

~ Place the scale over the originaltable along the paper movingdirection.

Q Executetestcommand49.

m)+~ ~ ~+ %)+ E ~~+

m

At the same moment, the machine starts to warm up, tie presentiy programmednumber between 1 ad 99 will

come displayed.The ready lamp comes active after the warmup has completedand it becomes ready to make

a fi”~~ea normal(x1.0) copyon the A4 (81/2”x 11=)paper.

O Compare the size of the sc~e image on the copywiththe actual scale size and obtainthe horfzontd magnification

ratiousingthefollowingformula.

Horizontaldirectionmagnificationratio= J

size of original)- (size of scale on the coPY)~ ,00

compensationrate

IYO] (size of original)

a Use the followingformulato obtainthe Horizontalmagnificationratio presetvalue.

Horizontalmagnificationratiopreset v~ue = previous value (the number shown in ~ ~ove) + horizontal magnificationratiocompensationrate x 10

~ Programthe presetvalue.

n + ~ + Psw

When the

pre se t v ~ue i s changedby “l”, the magnificationratiowillbe changed O.lYO.

a Make a normal(x1.0) copy and compare the scale image with the scale size.

@ Adjustmentwillbe satisfactoryif the size of the scale image on the copy is withinM.8Y0 with respectto the aCtu4

size of the scale. If not, repeat the above procedures~ thruO to adjustit once a9ain.

-—.

Page 6

I

I

SF-73 2 0

Test mmmartd

50

SF-7370

Function

Q Terminate the test command 49.

CL~R

Copy lead edge image positionadjustingtest commend

Adjustmentis done by changingthe RRS on timing so that the image of the originalmaybe copied ontoappropriate

Iooationof the copypaper.

Before startingthe test mmmad 50, be sure to check tie hoflzontd magnification

ratioif appropriate.If not, do the

test command49 to adjustthe magnificationratio.

There are some differencesin the adjustmentproceduresbetweenthe SF-7320 ad the SF-7370.

(Adjustingmethod)

(SF-7320)

O

placethescaleovertheodgind tablealongthepaper movingdirection.

@ Executetestcommmd 50.

%)+ ~ ~ B ~=, ~ R + ~ ~ m

At the same momentthe machinestartsto warm up, the presentlyprogrammednumberbetweenO and 99 will

be displayed.

Descriptionof RRS-a: After completionof the warmup,the ready lamp till come active and become ready to

make a copy.

~ Programthe RRS-ato .O=.

~+~

o Pressthe printswitchand make a copy.

6 Measurethedistancebetweenthe leadedgeof the paper and the lead edge of fhe image onthe copy.

O Obt~n the value of RRS-a.

If the value measuredin~ is assumedto be L1;

RRS-a = 2.778 x L1 + 6.944

Unitin mm, rounded.

a Enterthe value of RRS-a obtained in ~.

0+0

~ Make a copy end make sure that the lead edge image loss is withinthe limits of -2.5+1 .5mm. If not, change

the value of RRS-a and do adjustmentsothat it maybe withinthe limits.

o Terminate the test command 50.

CLEAR

(SF-7370)

~ Place the sde over the

origin~tablealongthepaper movingdirection.

Q Executetest command50.

%)+ m ~m” =, ~ E ~ m ~m

At the same momentthe machinestarts to warm up, the presentlyprogrammednumber betweenOand 99 will

be displayed.

Descriptionof RRS-a: After completionof the warmup,the ready lamp willcome active and become ready to

make a copy.

~ Programthe RRS-ato “O”.

~.~

O Turn the paper selecf key on.

The cassette lamp turned active changes to blink and the presentiy programmednumber between O and 99

will

bedisplayed.

Descriptionof RRS-b

Q Programthe RRS-b to “On.

~+~

@ Make one each of CO PY in the norm~ (xI.0) and reductionmode (xO.64),and measure the distancebetween

the copy lead edge and the sde image lead edge.

Obtainvalues for RRS-a and RRS-b.

L1 = distance between the copy paper lead edge and tie scale image lead edge in the normal(x1.0) mode.

L2 = distance between the copy paper lead edge and the scale image lead edge in the reducdon (xO.64)

mode.

Substitutethe values of L1 and W into the followingformulateto obtain RRS-a and RRS-b.

RRS-a = 7.716 x (Ll - L2)

RRS-b = ((11.574X

L2) - (7.407X Ll)) + 60.417

Unit in mm, rounded.

Turn the paper select key on. The blinkingcassettelamp changes to permanenton.

Programthe value of RRS-a that obtainedina.

O+n

Programthe value of RRS-b thatobtainedin a.

Paper select key (cassettelampon $ blink) m + m

Make a copy in the normal (xl .0) mode and make sure that the lead edge image

IOSS is within -2.5*1 .5mm. If

not, change the value of RRS-b and do adjustmentso that it may be withinthe limits.

Terminate the test command 50.

CLEAR

Page 7

,. . .- +- ~.&H.LL . .

SF-7320

SF-7370

58

72

79

.—-u.:, ’ ‘“ “’.”’

1

1

Function

Copy lead edge void area adjustingtest rwmmand

ne void ~ea width at the copylead edge is adjustedby varyingthe GRID on timin9.

This test commandmust be executed atier the COPYlead edge IOcatiOnhas been COmPletti usingthe teStcommand

50.

(Adjustingmethod)

O Place the sde and a blarrkpaper on the originaltable.

I

,

@

u:

Sde

.........

........

Executetest command 58.

,W)+E+ ❑ +m

At tie same moment the machinestartsto warm up, the presentiyprogrammednumberbetween 1 ~d gg willbe

disnlaved.ne readv lamp comes active after the warmuphas compiet~ ~d ~omes ready to m~e a ~PY.

O ihe~ normal (x1.6) copy withme oflginalcover Ieti open.

o Entera number and make adjustment.

Increasingthe numbermakes the voidarea wider and tice versa.

By changingthe numberby “1”willchange the void area by about0.12mm.

Q Terminatethe test command

58.

CLEAR

Copy tit programmingtest command

(Prooramminamethod)

6 ~xecute t~stcommand 72.

=~+m+~+=;+~+

E+m

At the same moment the ready lamp comes active, tie presently programmednumber between 1 and 4 will be

displayed.

Entera numberto select the copy kitoutofthe table below.

=.B

Wth this,the numberis storedin the memoryand the readylampturnsoff.

Parameter

Developerlamp DML active after

Maintenancelamp DRL active afier

Black

Color

Mini-maintenance

Norrnd maintenance

1

30000 copies

5000 copies

10000 copies

30000 copies

2

30000 copies

5000 wpies

15000 wpies

30000 mpies

3

30000 copies

5000 copies

30000 wpies

30000 copies

4

Does not turn on

5000 copies

Does notturnon

Does not turnon

~ Terminatetie test command 72.

CLEAR CLEAR

Programmingmodeland destination

(Programmingmethod)

~ Executet~st command79.

l=!+ ~ ~ ~ ~

I=;~❑ +❑ +m

At the same timethe ready lamp turnsactive,the presentlyprogrammd numbertill be displayed.

~ Select and enter a number appropriatetothe modeland destinationfromthe table below.

U+m

Pressthe pdntswitchto storethe numberin the memow. The ready lampturnsoff.

SUK

AB series

SEC

Inchseries

Indonesia

exceptSUK

exceptSEC

SF-7320

1

5

6

7

25

SF-7370

11

15

18

17

35

0 Terminatethe test command79.

CLEAR CLEAR

.

Page 8

——— ‘

SF- 78 2 0

SF- 7W0

T.. + - m m . &

I Funcdon

,g-! . . . . . . .. .

90

used to programthe drumcleaning rode. (Main motor reverse rotationperiodprogrammingafterthe completionof

copyoperation)

Afterthe testcommandhas executed,“109till

be displayti for tie lo-smnd modeor ’60=forthe60-second mode.

Press the paper select key to change it from 10 to 60 men to 10 a9ain, which will bS displayedin the multicopy

window.To select the mode, press the printswitch.

91 Usedto programtie warmupmode. (Man motorrotationm~e pqr~ming duringthe heat rollerwarmup)

Aftertie test commandhas executed,the presentlyprogrammedwarmupmodeis displayedin the multicopytindow

intermsof a number.

Select the mode numberto be used usingthe 1,0 key and press the printstitch to set tie mode.

Number

Warmup mode

o

Norm4 mode

1

Man motorrotationsbeforethe heater warmupterminates.

96

Used for seting the tising temperature.

, ; <-. ; ~ :

When this commandis executed,the lowertwo digitsof the currenttyset fusingtemperatureare displayd. (=ample:

75= means 175

degreesCentigrade.)

Underfhh state, push the paper select key, and the fusing temperature will be changed by 5 degrees. Repeat

pushinguntilthe desiredtemperatureis obtained.

97 Used to selectwhetherthe manualcopymodeis startedautomatidly or by pushingthe PSW.

Method:

1) When this test command is executed, the cumentiystored msnu~ copy mode parameter (see table below) is

displayedand the readylamp turnson.

2) Afterthe ready lamp turnson, enter the parameter using

a figureOor 1 forthe mode to be set. Depress the PSW

and tie parameter is men storedinthe memow and me ready lamp goes out.

Parameter

MarruAcopy mode

● Invalid when the multi-bypassstatier is

o

Autostartmode

instiled. (Copy starts after depressionof

1 PSW

startmode

the PSW, when the multi-bypassstacker

is installed.)

98

Used for settingthe fusingtemperaturein the power saving mode.

When this command is ex~uted, the lower two digits of the currentiyset fusingtemperaturein the power saving

mode are displayed.

Under this state, push the paper select key, and the fusing temperature will be changed by 5 degrees. Repeat

pushinguntilthe desiredtemperatureis obtained.

/ 5-0 — ‘ ~~

Page 9

5F-7370

4. Self-diagnostic functions

When the copiermdfundions, operationswe suspendedimmediatelyand a statusmde is indicated on the multimpynumber display,Statuscodes

are representedas an alphanumericmmbinationof figures.

t

t

1

#

I

I

1

‘ “ ” ’ ” -)I‘-, –

I

I

L

{L

~a y~e ddw

*

-----------------------

I

Smh t=hnkian shouM m~e tie sw& 41 wti Hssary

seMm pm on the beebrof the !rouMestatusreportedby the user.

(2) Status code

Status

males willbe displayed on the copy numberdisplaywindowin

the manner shown.

~ CH, L1, L3, L5, H2, H3, H4, Ul, U2, U3, EE

When one of the test status-s L1, L3, L5, H2, or H4 is

indbtad, it maybe cleared by turningthe power off.

When statusU1 is irrdtited, it maybe ckarad by test

timmand 13.

When statusde CH or PC is indhted, it maybe cleard

automa*l& uponmm~tion of troubkshootiq, wthout

entting a test Hind.

When statusde H3 is indkted, h maybe ckared by test

mmmand 14.

@ PC, P flum on), EL, EU

——

Ahaysdi~layedas: f–’;

Bh*

l-if -l ~ /–J /–/ 0 .5 s-

1—1 1—1

1–1 1–

I

9-10

.-.-,-----———

.--..----—.--—-..”---

—-

Page 10

I

SF- 73 2 0

SF- 73 7 0

status

TroublesyMPtOM

[ Mirrorbase feed trouble

● If the mirrorhome ~sition sensor (MHPS) did not

turn off within one second after the start of the

mirror.

L1

I

● If the mirror base forward movement was not

completedwithinten secondsafter the start of the

I mirrorbase.

I

Q[f the mirror base was not on the MHPS position

when the mirror base staded to move forward

duringcopying.

~Mirrorbase returntrouble

L3

● If the MHPS did notturn on withinsix seconds after

the mirrorbase startedto return.

Magnificationratedtrouble(lens, No.4J5mirror)

L5

● If it did not move to the given locationwithinfifteen

secondsafterthe lens motorstartedto operate.

HZ

Open heat rollerthermistor

H3 Heat rollerirregularlyhightemperature

Heat rollerirregularlylowtemperature

“

If tie heat roller temperature did not reach the

H4

prescribedtemperature within the given time after

the start of the heat rollerwarmupoperation.

I

● If an irregularly low temperature was met afier

reachingthe prescribedtemperature.

U1

I Low memo~ backup batteryvoltage

U2

Backupmemorycountersumcheckerror

AE sensortrouble

U3

- If the AE sensor output voltage did not change in

regard to the wpy lamp voltage in test command

4?.

I TCS (Toner controlsensor)inputtrouble

EE

I

● The TCS level was obtained and stored in the RAM

by the test command 25, but the value obtained is

o~t of the limits.

EU

If the TCS input voltage by test command 25 is

above the limit.

-. If the TCS input voltage by test command 25 is

EL

CH

Pc

P (blink)

underthelimit;

DVunitnot installedor poorconnectorinsertion.

Person4 counter not installed for the machine

programmedforthe personal@unter.

During the time cassette feed or multi-bypass

stacker is used, if the PPD (paper entry sensor)

failed to turn on (paper empty or misfeed)withinthe

given time after the paper feed solenoid (CPFS,

MPFS) have turned on.

P

I If the cassettewas notinstalledon itsgiven location.

------- . .

. ---- .-

-. -.: ‘-.,-2-

““”

Loading...

Loading...