Page 1

SF-2314

SERVICE MANUAL

CODE: 00ZSF2314SM1E

Copier

SF-2414

MODEL SF-2314

MODEL SF-2414

MODEL SF-2514

SF-2514

CONTENTS

[ 1 ] GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] PRODUCT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

[ 3 ] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[ 5 ] GENERAL DESCRIPTIONS OF EACH SECTION . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] SELF DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] SERVICE AT MEMORY TROUBLE AND

[10] MAIN CONTROL PWB REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10- 1

[11] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

[ 1 ] GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . 1-1

1. Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Target users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

3. System outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] PRODUCT SPECIFICATIONS . . . . . . . . . . . . . . . 2-1

1. Basic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Details of each section . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

[ 3 ] EXTERNAL VIEW AND INTERNAL

STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1. External view and internal structure

(SF-2514 as the example model) . . . . . . . . . . . . . . . . . 3-1

2. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3. Cross section (SF-2514 as the example model) . . . . . . 3-3

4. Switches, sensors, detectors

(The SF-2514 as the typical example) . . . . . . . . . . . . . 3-4

5. Clutches, solenoids

(The SF-2514 as the typical example) . . . . . . . . . . . . . 3-5

6. Motors (The SF-2514 as the typical example) . . . . . . . 3-6

7. PWBs (The SF-2514 as the typical example) . . . . . . . . 3-7

[ 4 ] UNPACKING AND INSTALLATION . . . . . . . . . 4-1

1. Packing drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

(1) Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

(2) Space around the machine . . . . . . . . . . . . . . . . . . . 4-2

(3) Installing table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

(4) Power source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

(5) Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

3. Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

(1) Optical system unlocking . . . . . . . . . . . . . . . . . . . . . 4-3

(2) Cassette setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

(3) Developer setting . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

(4) Toner supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

(5) Toner density sensor level check . . . . . . . . . . . . . . 4-5

(6) Accessory attachment . . . . . . . . . . . . . . . . . . . . . . . 4-6

4. Locking procedure for transit or repacking . . . . . . . . . . 4-6

(1) No.2/No.3 mirror unit (Mirror base B) lock . . . . . . . 4-6

(2) No.4/no.5 mirror unit (Mirror base C) lock . . . . . . . 4-6

5. Optional paper feed unit (SF-CM14),

Installation Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

(1) Set the main copier unit on the paper feed unit. . . . 4-7

(2) Remove the paper tray from the main copier unit. . . 4-7

(3) Open the upper unit of the main copier unit. . . . . . . 4-7

(4) Connect the main copier unit and

the paper feed unit. . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

6. Optional multi bypass feeder unit Installation Manual . . 4-8

(1) Open the upper unit of the main copier unit. . . . . . . 4-8

(2) Release the lock for the manual bypass unit and

remove the manual bypass unit. . . . . . . . . . . . . . . . 4-8

(3) Mount the multi bypass feeder unit onto

the main copier unit. . . . . . . . . . . . . . . . . . . . . . . . . 4-9

[ 5 ] GENERAL DESCRIPTIONS OF

EACH SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1. Paper feed section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. Separation, transport section . . . . . . . . . . . . . . . . . . . . 5-2

3. Fuser, paper exit section . . . . . . . . . . . . . . . . . . . . . . . 5-2

4. Developer section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5. Optical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-1. General descriptions . . . . . . . . . . . . . . . . . . . . . . . .5-3

(1) Original table . . . . . . . . . . . . . . . . . . . . . . . . .5-3

(2) Copy lamp . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

(3) Mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

(4) Lens (Fixed focus lens) . . . . . . . . . . . . . . . . .5-3

(5) Lens home position sensor (LHPS) . . . . . . . .5-3

(6) Lens base . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

(7) Lens drive shaft . . . . . . . . . . . . . . . . . . . . . . .5-4

(8) Lens drive wire . . . . . . . . . . . . . . . . . . . . . . . .5-4

(9) No. 4/5 mirror base . . . . . . . . . . . . . . . . . . . .5-4

(10) Mirror motor . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

(11) Mirror home position sensor (MHPS) . . . . . . .5-4

(12) No. 2/3 mirror base . . . . . . . . . . . . . . . . . . . .5-4

(13) Copy lamp unit . . . . . . . . . . . . . . . . . . . . . . .5-4

(14) Thermal fuse . . . . . . . . . . . . . . . . . . . . . . . . .5-4

(15) Reflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

(16) Exposure adjustment plates . . . . . . . . . . . . . .5-4

(17) Mirror base drive wire . . . . . . . . . . . . . . . . . . .5-4

(18) Lens drive motor . . . . . . . . . . . . . . . . . . . . . .5-4

(19) AE sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5-2. Basic operations . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

6. Copy process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

(1) Photoconductor . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

(2) Process diagram . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

(3) Actual process . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

(4) Transit of photoconductor drum surface

potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

(5) Process correction system . . . . . . . . . . . . . . . . . .5-12

1) Outline of the correction system . . . . . . . . . . .5-12

2) Correction operation . . . . . . . . . . . . . . . . . . . .5-12

7. SPF section (SF-2514 only) . . . . . . . . . . . . . . . . . . . . .5-14

1. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

[ 6 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . 6-1

1. Paper feed section, paper transport section,

power section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

1-1. Paper feed unit . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

1-2. Paper feed roller ass’y removal . . . . . . . . . . . . . .6-1

1-3. Separation roller . . . . . . . . . . . . . . . . . . . . . . . . .6-2

1-4. Takeup roller, paper feed roller . . . . . . . . . . . . . .6-2

1-5. Resist roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

1-6. Transport belt . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

1-7. Socket holder unit . . . . . . . . . . . . . . . . . . . . . . . . .6-4

1-8. Lower unit PWB . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

1-9. Cassette paper empty detector (CPED1) . . . . . . .6-4

1-10. Power unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

2. Manual paper feed section . . . . . . . . . . . . . . . . . . . . . . .6-5

2-1. Manual paper feed roller, manual takeup roller . . .6-5

2-2. Reverse rotation roller ass’y . . . . . . . . . . . . . . . . . .6-5

3. Fuser section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

3-1. Fuser unit removal . . . . . . . . . . . . . . . . . . . . . . . . .6-6

3-2. Heater lamp replacement . . . . . . . . . . . . . . . . . . . .6-6

3-3. Upper heat roller ass’y removal . . . . . . . . . . . . . . .6-7

3-4. Upper separation pawl replacement . . . . . . . . . . . .6-7

3-5. Lower cleaning roller and

lower heat roller replacement . . . . . . . . . . . . . . . . .6-7

3-6. Scraper replacement . . . . . . . . . . . . . . . . . . . . . . .6-8

3-7. Thermistor/thermostat removal . . . . . . . . . . . . . . . .6-8

4. Optical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

4-1. Copy lamp replacement . . . . . . . . . . . . . . . . . . . . .6-9

I

Page 3

4-2. Copy lamp unit replacement . . . . . . . . . . . . . . . . . 6-9

4-3. Mirror base drive wire replacement . . . . . . . . . . . . 6-9

4-4. Lens and lens drive wire replacement

(Only the zoom function model) . . . . . . . . . . . . . 6-10

4-5. No. 4/5 mirror unit and

peripheral parts replacement . . . . . . . . . . . . . . . 6-11

4-6. Optical unit removal . . . . . . . . . . . . . . . . . . . . . . 6-11

4-7. Other parts in the optical system . . . . . . . . . . . . . 6-11

4-8. Light adjustment plate/temperature fuse

removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

5. SPF section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

5-1. SPF mechanism removal . . . . . . . . . . . . . . . . . . 6-13

5-2. Paper feed roller/takeup roller replacement . . . . 6-14

5-3. Reverse roller (ass’y) replacement . . . . . . . . . . . 6-14

5-4. SPF control PWB replacement . . . . . . . . . . . . . . 6-15

5-5. Clutch/solenoid removal . . . . . . . . . . . . . . . . . . . 6-15

5-6. Sensor removal . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6. Drum section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6-1. Drum unit removal . . . . . . . . . . . . . . . . . . . . . . . . 6-16

7. Developer section . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

7-1. Developer unit removal . . . . . . . . . . . . . . . . . . . . 6-16

7-2. Developer cartridge removal . . . . . . . . . . . . . . . 6-16

7-3. Toner motor removal . . . . . . . . . . . . . . . . . . . . . 6-17

7-4. Toner density sensor . . . . . . . . . . . . . . . . . . . . . 6-17

8. Operation panel section/medium cabinet . . . . . . . . . . 6-17

9. Major parts in the frame side . . . . . . . . . . . . . . . . . . . . 6-18

9-1. Ozone filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

9-2. Optical unit/SPF unit cooling fan removal . . . . . . 6-18

9-3. Ventilation fan motor . . . . . . . . . . . . . . . . . . . . . 6-18

9-4. Transport roller clutch . . . . . . . . . . . . . . . . . . . . 6-19

9-5. Paper exit sensor . . . . . . . . . . . . . . . . . . . . . . . . 6-19

[ 7 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

1. Developer section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

(1) MG roller main pole position adjustment . . . . . . . . . 7-1

(2) Adjustment of clearance between DV doctor and MG

roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

2. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

A. Adjustments list . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

B. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

C. Adjustment contents . . . . . . . . . . . . . . . . . . . . . . . . 7-6

(1) Lens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

(2) Mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

(3) Image distortion adjustment . . . . . . . . . . . . . . . 7-8

(4) Copy image center position adjustment . . . . . 7-12

(5) Focus adjustment (R esoluti on adjust m ent) . . . 7-14

(6) Copy magnification ratio adjustment . . . . . . . . 7-15

(7) Uniformity adjustment . . . . . . . . . . . . . . . . . . . 7-18

(8) Image loss/void area adjustment . . . . . . . . . . . 7-19

3. COPY DENSITY ADJUSTMENT . . . . . . . . . . . . . . . . 7-26

(1) Copy density adjustment timing . . . . . . . . . . . . . 7-26

(2) Note for copy density adjustment . . . . . . . . . . . . 7-26

(3) Necessary items for the co py density adjustment 7-26

(4) Copy density adjustment mode . . . . . . . . . . . . . . 7-26

(5) Copy density adjustment procedure . . . . . . . . . . 7-26

A. Test chart (UK0G-0162FCZZ) setting . . . . . . 7-26

B. Normal copy mode (Non-toner-save mode)

copy density adjustment . . . . . . . . . . . . . . . . 7-26

C. Normal copy mode (Toner save mode)

copy density adjustment . . . . . . . . . . . . . . . . 7-27

D. Photo copy mode (Non-toner-save mode)

copy density adjustment . . . . . . . . . . . . . . . . 7-27

E. Auto copy mode (Non-toner-save mode)

copy density adjustment . . . . . . . . . . . . . . . . 7-27

F. Auto copy mode (Toner save mode) copy

density adjustment . . . . . . . . . . . . . . . . . . . . . 7-28

G. Copy density adjustment in the SPF

copy mode . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-28

(6) Copy density adjustment table . . . . . . . . . . . . . . .7-29

4. Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-30

(1) Transfer charger wire installation . . . . . . . . . . . . .7-30

(2) DV bias adjustment . . . . . . . . . . . . . . . . . . . . . . .7-30

(3) Separation charger output adjustment . . . . . . . . .7-30

[ 8 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

1. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

2. Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

3. Operating procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

4. Purpose list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

5. Details of simulations . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

6. User simulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-13

[ 9 ] SELF DIAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

1. Summary/purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

2. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

3. Clearing the self diag display . . . . . . . . . . . . . . . . . . . . .9-1

4. Self diag contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

5. Conditions for the JAM display . . . . . . . . . . . . . . . . . . . .9-7

1) Paper feed section . . . . . . . . . . . . . . . . . . . . . . . . . .9-7

2) Transport section . . . . . . . . . . . . . . . . . . . . . . . . . . .9-7

[10] SERVICING AT MEMORY TROUBLE AND

MAIN CONTROL PWB REPLACEMENT . . . .10-1

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

2. Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

3. Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

4. Set value recording sheet . . . . . . . . . . . . . . . . . . . . . . .10-4

5. Memory simulation list . . . . . . . . . . . . . . . . . . . . . . . . .10-5

[11] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

[12] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . .12-1

1. System block diagram . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

2. System operation at power ON . . . . . . . . . . . . . . . . . . .12-1

3. Main circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-2

(1) Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-2

(2) CPU (IC110) M37702 . . . . . . . . . . . . . . . . . . . . . .12-2

1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-2

2 Pin arrangement . . . . . . . . . . . . . . . . . . . . . . .12-2

3 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . .12-3

4 CPU: M37702 (IC110) pin signals . . . . . . . . . .12-4

(3) Start/stop control circuit . . . . . . . . . . . . . . . . . . . .12-5

(4) Heater lamp control circuit . . . . . . . . . . . . . . . . . .12-6

1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

(5) Driver circuit (Solenoid, magnetic clutch) . . . . . . .12-7

1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-7

2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-7

(6) Stepping motor drive circuit . . . . . . . . . . . . . . . . .12-7

1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-7

(7) AE (Auto Exposure) sensor circuit . . . . . . . . . . . .12-7

(8) Toner supply motor drive circuit . . . . . . . . . . . . . .12-8

(9) Reset IC (IC113) . . . . . . . . . . . . . . . . . . . . . . . . . .12-8

1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-8

2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-8

(10) Copy lamp control section . . . . . . . . . . . . . . . . . .12-9

4. Operating section . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-11

(1) Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-11

(2) Display circuit . . . . . . . . . . . . . . . . . . . . . . . . . . .12-12

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . .12-12

2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . .12-12

(3) LED display . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

5. Power section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

(1) Signal name and output voltage . . . . . . . . . . . . .12-13

II

Page 4

[1] GENERAL DESCRIPTION

1. Features

[Small]

• Compact design

• Small area for operation

[Speedy]

• Warm-u p time 30 se c or less, the fi rst co py 5.9 sec ∼ the fastest in

the class.

• The automatic document feeder (standard provision in the SF-

2514 only) increases copy productivity.

2. Target users

Average copy volume of 2,000 ∼ 3,000 sheets/mon th (max. 10,000

sheets/month)

3. System outli ne

SPF (Standard)

Zooming range

SF-2514

(64 ~ 129%)

250-sheet tray

[Soft]

• The energy save mode reduces the total power consumption.

• Ozone generation is limited.

• Use of materials which can be recycled.

User simulation

The user can select the desired operating conditions easily. Auto

clear time, power save mode time, power save mode warm up time

can be set by the user simulation.

Single manual feed (Standard)

50-sheet multi manual feed unit (SF-MF14)

(Option)

50

(Opti on)

250-sheets paper f eed uni t

(SF-CM14)

250 sheets

250 sheets

No.2 tray unit

(Option)

250-sheets paper tray

(SF-UB14)

SF-2414

SF-2314

Zooming range

(64 ~ 129%)

250-sheet tr ay

Zooming range

(1:1)

250-sheet tr ay

Single manual feed (Standard)

50-sheet multi manual feed unit (SF-MF14)

(Option)

Single manual feed (Standard)

50-sheet multi manual feed unit (SF-MF14)

(Option)

50

50

1 – 1

Page 5

[2] PRODUCT SPECIFICATIONS

(9) Exposure

Exposure mode Auto/Manual/Photo

Manual steps 9 steps

1. Basic specifica tio ns

(1) Type: Table top

(2) Copy speed

• SF-2314

Paper size Normal Enlargement Reduction

B4 11 sheets/min — —

A4 (Landscape) 14 sheets/min — —

B5 (Landscape) 14 sheets/min — —

10″ × 14″ 11 sheets/min — —

Legal 11 sheets/min — —

Letter (Landscape) 14 sheets/min — —

• SF-2414/2514

Paper size Normal Enlargement Reduction

B4 11 sheets/min 10 sheets/min 12 sheets/min

A4 (Landscape) 14 sheets/min 10 sheets/min 12 sheets/min

B5 (Landscape) 14 sheets/min 10 sheets/min 12 sheets/min

10″ × 14″ 11 sheets/min 10 sheets/min 12 sheets/min

Legal 11 sheets/min 10 sheets/min 12 sheets/min

Letter (Landscape) 14 sheets/min 10 sheets/min 12 sheets/min

Note: Copy speeds in the enlargement/reduction copy are the

same in all the rates.

(3) Warm-up time

Normal 30 sec or less (20 ˚C, 65%RH, rated

voltage)

(Preheat YES/NO) 10sec or less (Preheat mode)

Max. 30sec (auto power shut off

mode/auto off mode)

Jam recovery time 8sec (Conditions: Standard condition

after 60sec of leaving after opening

the door.)

(10) Void width

Normal Reduction Enlargement

Lead edge

3.0mm or less

Void area

Image

loss

(11) Paper exit

Paper exit tray capacity 100 sheets

(12) External view

W × D × H (mm)

OC top

W × D × H (mm)

SPF top

Occupying

area

Weight SF-2314

(13) Power source

Voltage 100V, 110V, 120V, 127V, 220V, 220 ∼ 230V, 230 ∼

Frequency 50/60Hz common

Side (front)

3.0mm or less

Rear edge

1mm ∼ 3.0mm

Lead edge

3.0mm max.

Side (front)

3.0mm max.

Rear edge

4.0mm max.

Common in

SF-2314/2414

SF-2514 540 × 502 × 364

W (mm) Common in

SF-2314/2414

S (mm) 502

about

26.8kg

240V, 240V

Lead edge

3.0mm or less

Side (front)

3.0mm or less

Rear edge

1mm ∼ 3.0mm

Lead edge

5.0mm max.

Side (front)

5.0mm max.

Rear edge

6.0mm max.

SF-2414

about 27kg

Lead edge

3.0mm or less

Side (front)

3.0mm or less

Rear edge

1mm ∼ 3.0mm

Lead edge

2.5mm max.

Side (front)

2.5mm max.

Rear edge

3.0mm max.

500 × 502 × 295

500 + 261 (paper

exit tray) + 205

(option Multi

paper feed unit)

SF-2514 about

30.1kg

(4) First copy time

First copy time 5.9sec (Paper feed port: No. 1 tray)

First copy time from

each paper feed port

(5) Jam recovery time: 5 sec (Condition: Jam in a section except

(6) Multi copy

Max. quantity of multi copy 99 sheets

(7) Original

Max. original size B4/10 × 14″

Original reference

position

Detection NO

Detection size AB series

(8) Copy magnification ratio (SF-2414/2514 only)

Fixed

ratio

AB series 3R+3E/129, 122, 115, 81, 70, 64%

Inch series 2R+2E/129, 117, 78, 64%

Zoom width 64 ∼ 129%

No. 2 tray (option): 6.8sec

Manual: 5.9sec

for the fuser section, within 6.0 sec from

door open, standard condition.)

Left side, about 12mm from the rear

Inch series

(14) Power consumption

Max. power consumption 1.4 kW

Average power consumption when

operating (Ref. value)

Power consumption in standby

(Ref. value)

Power consumption in pre-heating

(Ref. value)

Power consumption in auto power

shut off (Ref. value)

Auto OFF mode (Ref. value)

Dry heater connected

Dry heater not connected

Energy consumption efficiency 49.4 Wh

Note: Max. value when an option is installed.

2. Details of each section

(1) Paper feed

Copying size

(Max. ∼ Min.)

Paper feed system 1 tray + single manual feed

Paper feed capacity 250 sheets × 1

AB series B4 ∼ A6 (Postcard)

Inch series 10 × 14 ∼ 5 1/2 × 8 1/2

582.4 Wh

72.5 Wh

47.7 Wh

16.5 Wh (with SPF)

14.8 Wh (without SPF)

9.5 Wh

0 Wh

2 – 1

Page 6

• AB series

Each paper

feed port

No. 1 tray B4 ∼ A5

No. 2 tray

(OP)

Single

manual feed

Paper feed

(Landscape)

B4 ∼ A5

(Landscape)

B4 ∼ A6

postcard

(Portrait)

* For paper of 104 ∼

Multi manual

feed (OP)

• When in

multi

paper feed

• When in

single

paper feed

B4 ∼ A5

(Landscape)

postcard

(Portrait)

B4 ∼ A6

postcard

(Portrait)

* For paper of 104 ∼

size

130g/m2, A4 or smaller.

130g/m2, A4 or smaller.

Paper weight Special paper

56 ∼ 80g/m

56 ∼ 80g/m

52 ∼

2

130g/m

56 ∼ 80g/m

52 ∼

2

130g/m

2

Recommended

recycle paper

2

Recommended

recycle paper

No. 2 original,

OPH, label,

postcard

sheet,

recommended

recycle paper,

postcards

2

Postcards,

recommended

recycle paper

Postcard

sheet,

recommended

recycle paper,

postcards, No.

2 original,

OPH label

Front

Front

(3) Process section

Charging system (–) DC scorotron system

Transfer system (–) DC scorotron system

Separation

system

Main charger

grid voltage

Charge/Transfer

charger applied

voltage

(4) Developer section

Developing system Two-component developing

Toner density detection

system

Toner box capacity Toner 210 ±5g

Developing bias DC–200V±3V

Discharge plate/separation pawl

Copy mode

Standard 8-02 –750V

Photo 8-03 –460V

Toner save 8-04 –634V

Simulations

No.

+5

F–29µA

R–29µA

system

Magnetic sensor system

µA

−3

+5

µA

−3

• Developer

Material Iron powder carrier

Charging system Negatively charged by friction

Grid

voltage

• Inch series

Each paper

feed port

No. 1 tray 10 × 14 ∼

No. 2 tray

(OP)

Single

manual feed

Multi manual

feed (OP)

• When in

multi

paper feed

• When in

single

paper feed

(2) Optical section

Light source Halogen lamp

Exposure system Slit exposure by moving the

Magnification ratio changing

system

Lens Fixed focus lens

Paper feed

size

5 1/2 × 8 1/2

10 × 14 ∼

5 1/2 × 8 1/2

10 × 14 ∼

5 1/2 × 8 1/2

Paper weight Special paper

15 ∼ 21 lbs. Recommended

15 ∼ 21 lbs. Recommended

14 ∼ 34.5 lbs. No. 2 original,

* For paper of 28 ∼ 34.5lbs,

letter size or smaller.

10 × 14 ∼

5 1/2 × 8 1/2

10 × 14 ∼

5 1/2 × 8 1/2

15 ∼ 21 lbs. Recommended

14 ∼ 34.5 lbs. No. 2 original,

* For paper of 28 ∼ 34.5lbs,

letter size or smaller.

light source

By changing the lens

position and scan speed.

recycle paper

recycle paper

OHP.

recommended

recycle paper

recycle paper

OHP, label,

recommended

recycle paper

Front

Front

• Toner

Charging system Positively charged by friction

(5) Fuser section

Fusing system Heat roller system

Upper heat roller surface

temperature

Heater lamp 100V Halogen lamp 1000 W × 1 pc.

110V Halogen lamp 1000 W × 1 pc.

120V Halogen lamp 1000 W × 1 pc.

127V Halogen lamp 1000 W × 1 pc.

220V Halogen lamp 1000 W × 1 pc.

230V Halogen lamp 1000 W × 1 pc.

240V Halogen lamp 1000 W × 1 pc.

(6) Drive section

Main motor

standard

(7) SPF

Standard/option Standard only in the SF-2514

Document load capacity About 20 sheets, max. thickness

Document size A5 ∼ B4, 5 1/2″ × 8 1/2″ ∼ 10″ ×

Document replacement

speed

Document weight 52 ∼ 90 g/m2 (14 ∼ 24 lb s)

Random/mix paper feed Not available

Rating: DC32V, max. 1.32A, 1500 rpm

180˚C

3-phase full wave drive, DC brushless

of 3.0 mm

14″

14 sheets/min

2 – 2

Page 7

3. Supplies

SEC/SECL

No. Name Content Product name

1 OPC drum kit

2 Black developer

3 Black toner

4 Heat roller kit

Middle and South America/Asia

No. Name Content Product name

1 OPC drum kit

2 Black developer

3 Black toner

4 Heat roller kit

OPC drum x 1

Cleaning blade x 1

Black developer (560g) x 10 SF234MD

Black toner cartridge (200g) x 10 SF234MT

Upper heat roller x 1

Upper fusing separation pawl x 3

Fusing bearing x 1

Lower heat roller x 1

Lower fusing separation pawl x 4

OPC drum x 1

Cleaning blade x 1

Black developer (560g) x 10 SF234CD

Black toner cartridge (200g) x 10 SF234CT

Upper heat roller x 1

Upper fusing separation pawl x 3

Fusing bearing x 1

Lower heat roller x 1

Lower fusing separation pawl x 4

SF234DR

(SF234NDx10)

(SF234NTx10)

SF214HR1

SF234DR

(SF234SDx10)

(SF234STx10)

SF214HR

SEEG/SUK/SCA/SCNZ/Europe/Middle and Near East/Africa

No. Name Content Product name

1 OPC drum kit

2 Black developer

3 Black toner

4 Heat roller kit

Note 1: The heat roller kit for this series is common with the previous models SF-2314/2414/2514.

OPC drum x 1

Cleaning blade x 1

Black developer (560g) x 10 SF234LD

Black toner cartridge (200g) x 10 SF234LT

Upper heat roller x 1

Upper fusing separation pawl x 3

Fusing bearing x 1

Lower heat roller x 1

Lower fusing separation pawl x 4

SF234DM

(SF234DVx10)

(SF234Tx10)

SF214HR

2 – 3

Page 8

Environmental conditions

Observe the following environmental conditions to ensure the copy

quality and machine performance.

1 Standard condition

20 ∼ 25 ˚C, 65 ±5% RH

2 Operational condition

(%)RH

85

60

20

10 30 35

(˚C)

3 Shipping condition of copier (within 2 weeks)

(%)RH

90

60

20

-20 30 45

(˚C)

4 Supply storing condition

3 Numeral

The end digit of the year of coating.

4 Numeral or X, Y, Z

Indicates the month of coating.

X means October, Y November, and Z December.

56 Numeral

Indicates the day of coating.

7 Numeral or X, Y, Z

Indicates the month of packing.

X means October, Y November, and Z December.

89 Numeral

Indicates the day of packing.

F Alphabet

Indicates the factory of production. "A" is the code for Nara plant.

B. Developer and toner

The lot number of toner is put on the individual cartridge package and

on the group package, and that of toner is put on the bag and the

group package.

The lot number is of 7 digits, each digit indicating as follows:

1

2 3

4 5 6

7

1 Alphabet

Indicates the factory of production.

2 Numeral

Indicates the end digit of the year of production.

34 Numeral

Indicates the month of production.

56 Numeral

Indicates the day of production.

7 Numeral

Indicates the sub lot number.

Normal C A B

1234

(%)RH

90

10

-5

40

(˚C)

Storage period:

OPC drum Max. 30 months from production

Developer/Toner Max. 24 months from production

5 Identification of production number

A. OPC drum

The lot no. is of 10 digits. Each digit indicates as follows. This number

is printed on the F side flange.

1 2 3

4

5

6

7 8

9

10

1 Numeral

Indicates the OPC drum sensitivity.

2 Alphabet

Indicates the model code. "M" is the code for this model.

When a change is made on the product in the same operation system:

Normal C A B

15263748

A,B,C: Operation system

2 – 4

Page 9

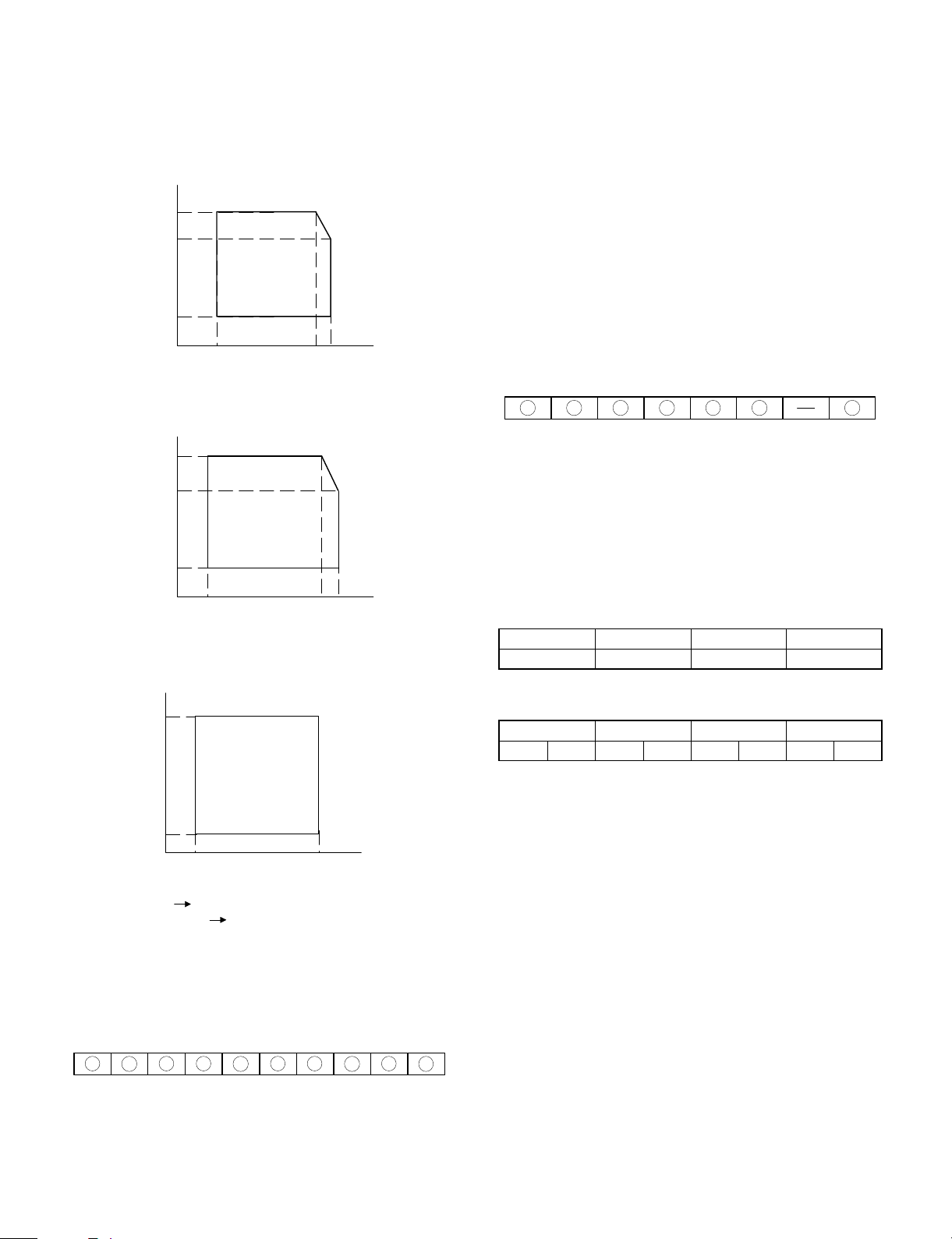

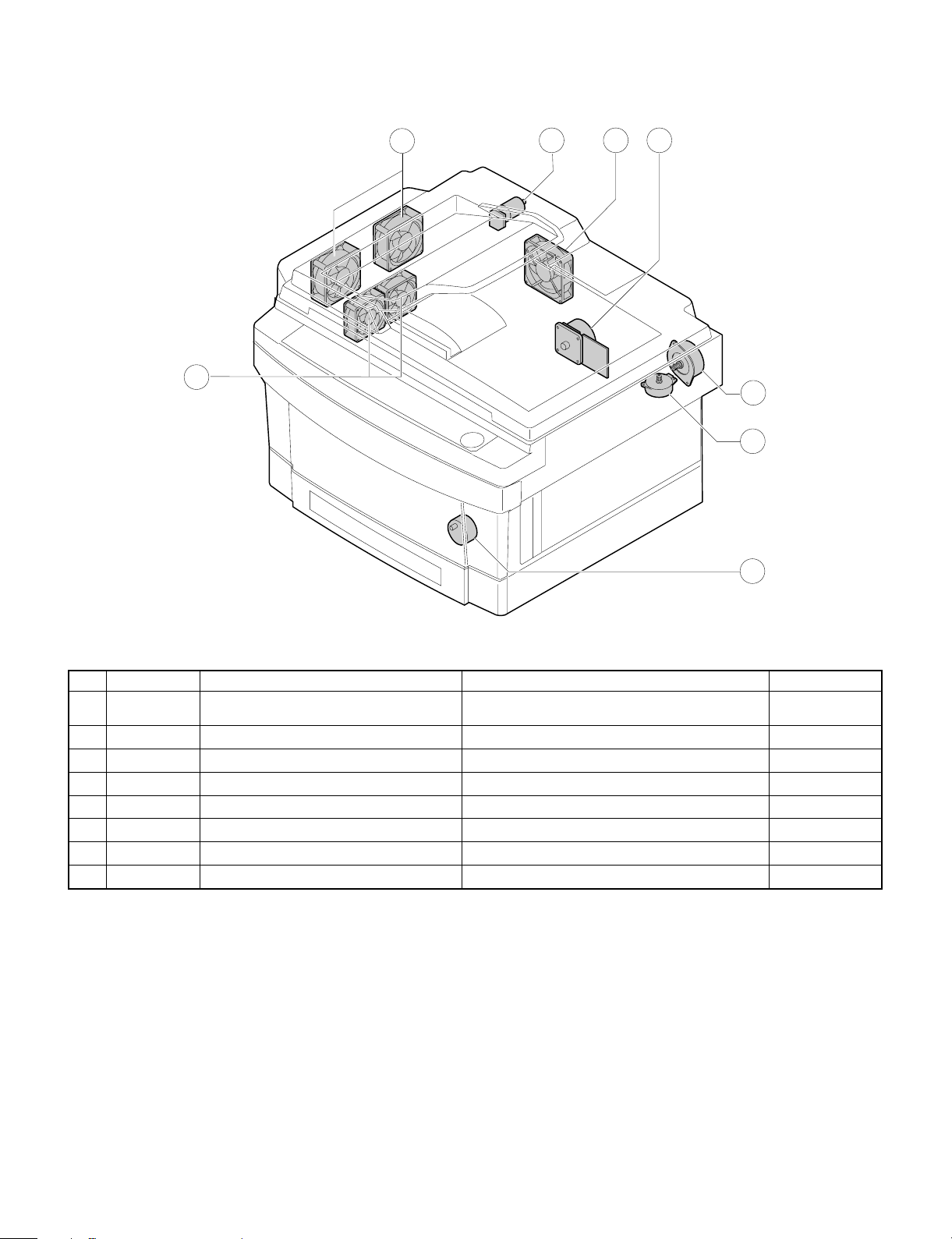

[3] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view and internal structure (SF-2514 as the example model)

1 2 3 4 5 6

7

8

9

12

13

16

15

14

20 19

No. Name No. Name No. Name

Exit tray

1

Document cover

4

Manual bypass guide

7

Paper tray

F

Power switch

I

Toner cartridge

L

Fusing unit (High temperature)

O

SPF exit tray

2

Original guide

5

Manual bypass

8

Front cover

G

Toner cartridge release lever

J

Open/close lever

M

Fusing unit lever

P

11

10

17

18

SPF tray

3

Document table

6

Operation panel

9

Release button

H

Handel

K

Photoconductive drum

N

Upper unit

Lower unit

3 – 1

Page 10

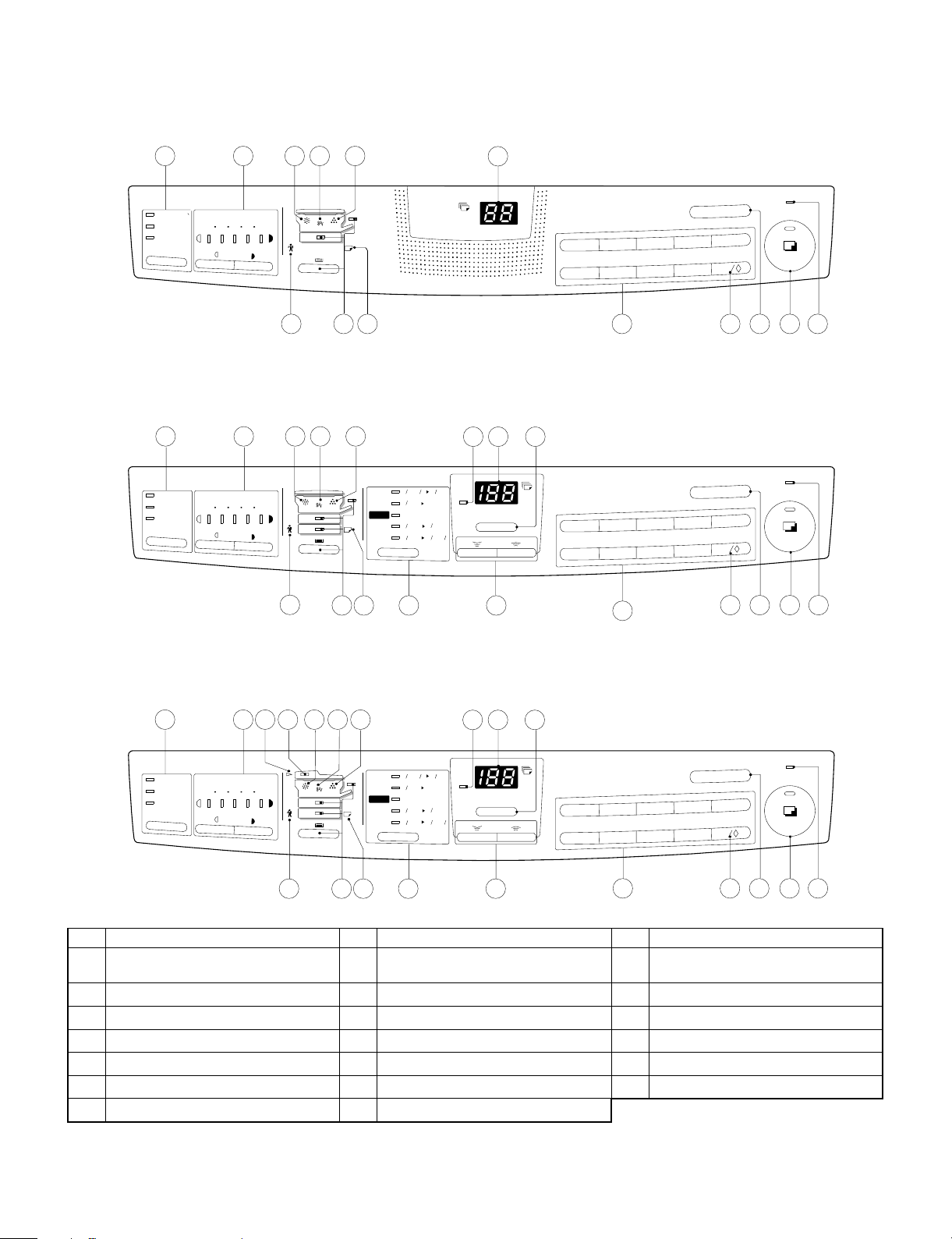

2. Operation panel

SF-2314

1 2 3 4 5

EXPOSURE

AUTO

MANUAL

PHOTO

SF-2414

1 2 3 4 5

EXPOSURE

AUTO

MANUAL

PHOTO

11

TRAY SELECT

C

51234

1

6

3

2

8

7

5

4

0

9

6 7 8 14 15 16 17 18

11

1210

7 8

COPY RATIO

1

1

x

129%

5

8

2

1

x

8

11 10 14

2

117%

100%

1

x

78%

8

14

2

1

64%

x

11 5

8

2

9 13

1

x

8

11

2

2

ZOOM

x

1

x

8

11

2

1

1

x

2

2

8

%

1

6

3

2

8

7

14

C

5

4

0

9

15 16 17 18

TRAY SELECT

51234

6

POWER SAVE

POWER SAVE

SF-2514

1 2 3 4

AUTO

MANUAL

PHOTO

19 20

TRAY SELECTEXPOSURE

51234

6 7 8

No. Name No. Name No Name

Auto/manual/photo key and indicators

1

Misfeed indicator

4

Tray select key and indicators

7

Zoom indicator

F

Zoom keys

I

Clear key

L

SPF misfeed indicator

O

5

COPY RATIO

1

1

1

x

x

2

2

5

1

8

1

8

1

8

8

x

11 10 14

2

x

14

2

x

11 5

2

2

8

11

ZOOM

x

1

x

11

8

2

1

1

x

8

2

2

129%

117%

100%

78%

64%

9 13

Light and dark keys and exposure

2

indicators

Toner required indicator

5

Paper required indicator

8

Copy quantity display

G

10-key pad

J

Print button and ready indicator

M

SPF indicator

P

11

1210

POWER SAVE

C

%

1

6

3

2

8

7

5

4

0

9

14 15 16 17 18

Developer replacement lamp

3

Maintenance required indicator

6

Copy ratio selector key and indicators

9

Copy ratio display key

H

Zero/read-out key

K

Power save indicator

N

3 – 2

Page 11

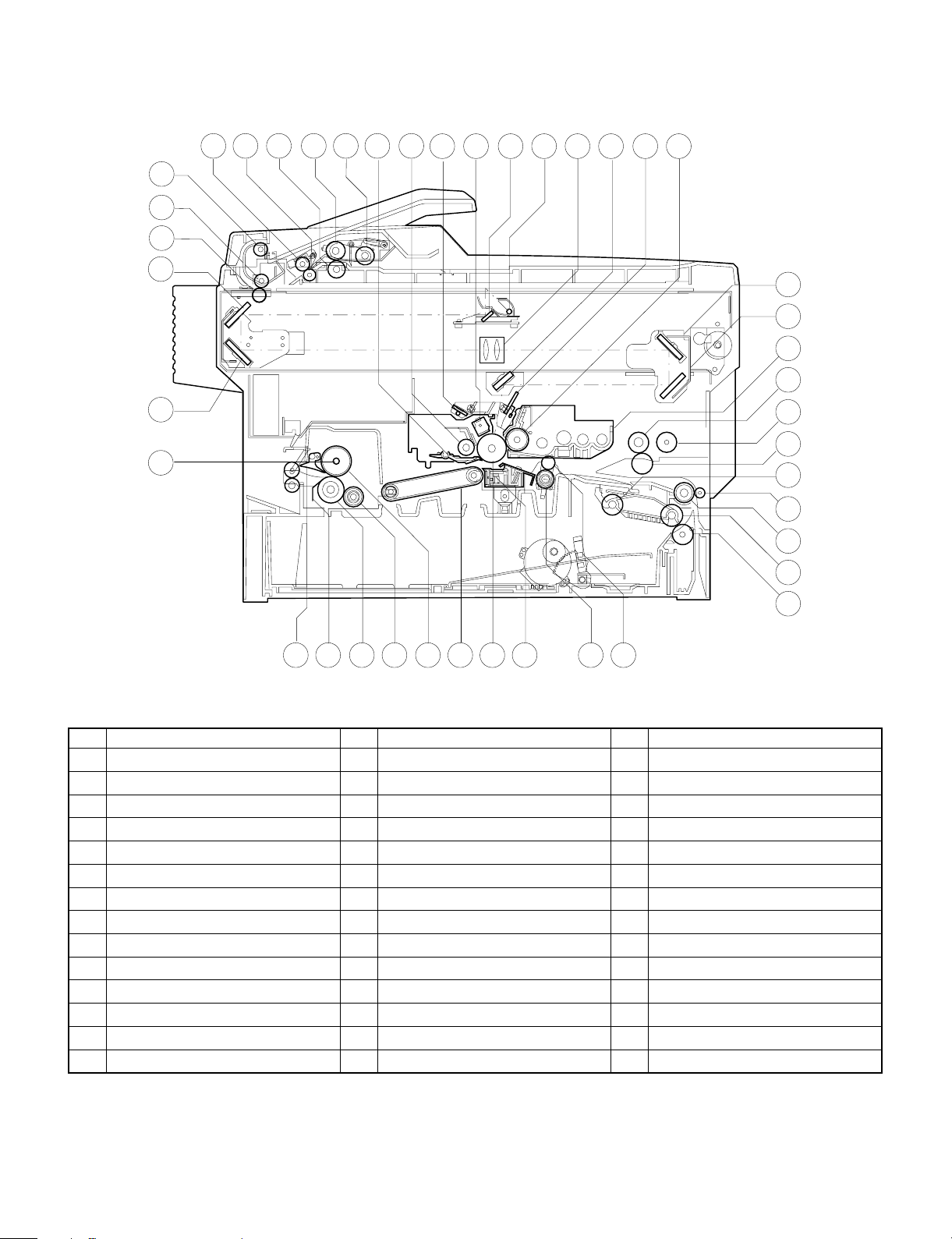

3. Cross section (SF-2514 as the example model)

1

42

6

87

10

9

11 12 13 14 15 16 17 18 19 20

5

4

3

2

21

22

23

24

25

26

27

28

29

30

4041

No. Name No. Name No Name

No.3 mirror

1

SPF transport roller

4

SPF PS roller lower

7

SPF document takeup roller

F

Discharge lamp

I

Copy lamp

L

Blank lamp

O

No.5 mirror

R

Manual feed take-up roller

U

Tray transport follower roller

X

Option tray transport roller

[

Transfer charger

^

Upper heat roller

a

Lower separation pawl

d

2

5

8

G

J

M

P

S

V

Y

\

_

b

e

37

No.2 mirror

SPF document exit roller

SPF document feed reverse roller

Drum separation pawl

Main charger unit

Lens unit

Developer magnet roller

Developer tank

Manual paper feed follower roller

Transport roller (Upper)

Resist roller

Photoconductor drum

Lower cleaning roller

Upper separation pawl

32333435363839

SPF transport follower roller

3

SPF PS roller upper

6

SPF document feed roller

9

Cleaner unit

H

No.1 mirror

K

No.6 mirror

N

No.4 mirror

Q

Manual paper feed roller

T

Tray paper feed takeup roller

W

Tray paper feed roller

Z

Resist roller

]

Suction belt

‘

Lower heat roller

c

Heater lamp

f

31

3 – 3

Page 12

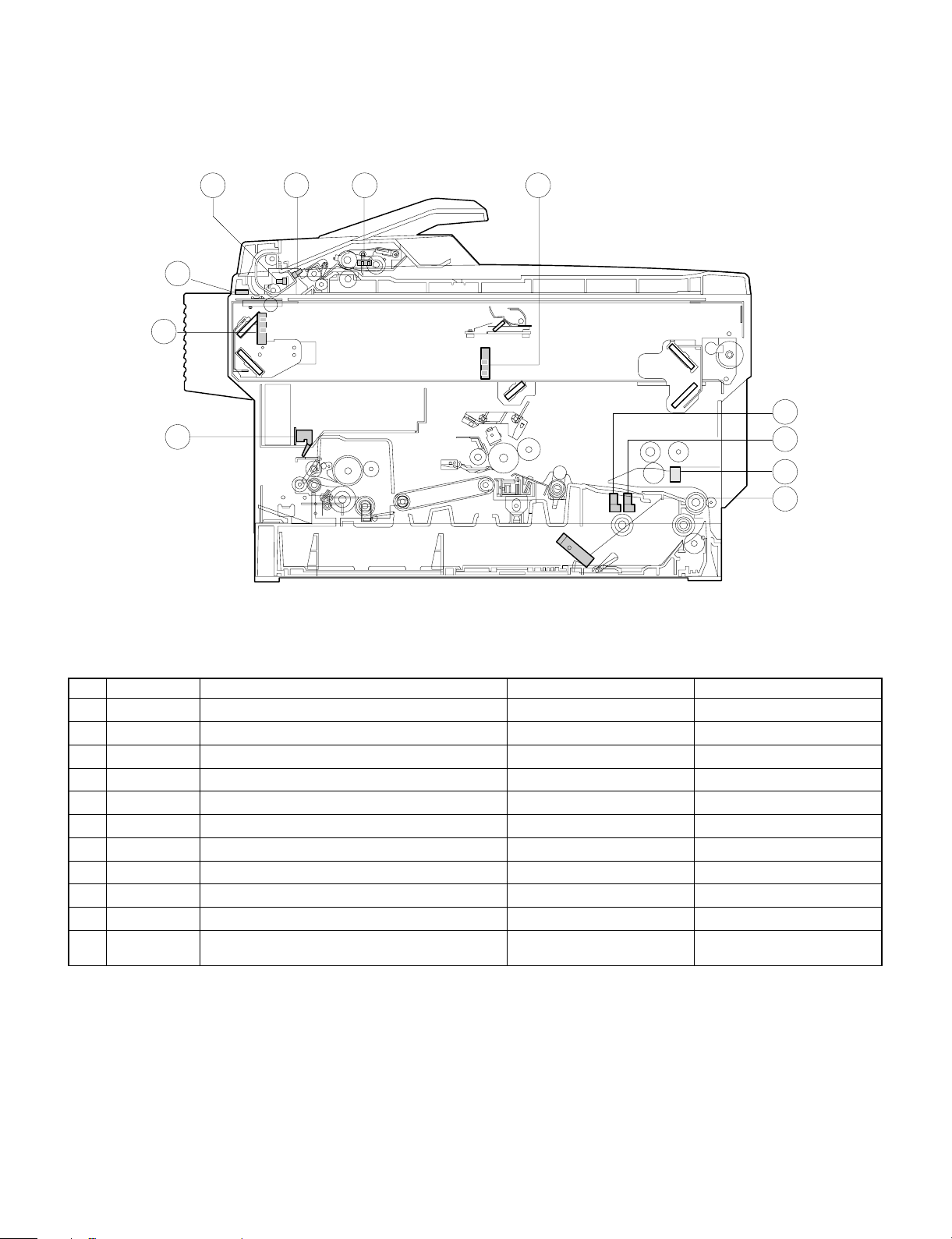

4. Switches, sensors, detectors (The SF-2514 as the typical example)

654

7

3

2

9

1

8

11

10

No. Abbreviation Function Type Operation

POD Paper out sensor Transmission photo sensor H when paper is sensed.

1

MHPS Mirror home position sensor Transmission photo sensor H at the home position.

2

SDSW SPF cover open/close sensor Lead switch H when the cover is open.

3

SPOD SPF document out sensor Transmission photo sensor L when paper is sensed.

4

SPPD SPF document transport sensor Transmission photo sensor H when paper is sensed.

5

SPFD SPF document set sensor Transmission photo sensor L when a document is set.

6

LHPD Lens home position sensor Transmission photo sensor H at the home position.

7

PWD Paper size (large/small) sensor Transmission photo sensor L with the large size.

8

PPD Paper transport sensor Transmission photo sensor L when paper is sensed.

9

CPED1 Tray paper empty sensor Transmission photo sensor H when paper is present.

F

G

PID (MFD1)

Paper sensor for Manual paper feed unit

(only single Manual Paper feed unit)

Transmission photo sensor L when the cover is open.

3 – 4

Page 13

5. Clutches, solenoids (The SF-2514 as the typical example)

1

2

3

4

8

5

7

6

No. Abbreviation Name Function and operation

SRRC SPF resist roller clutch For SPF resist roller rotation

1

SPM SPF document transport clutch For SPF transport roller rotation

2

PSPS Paper separation solenoid For paper separation solenoid drive

3

RRC Resist roller clutch For resist roller rotation

4

TRC Transport roller clutch For transport roller rotation

5

MPFS Manual paper feed solenoid For takeup roller pressing

6

CPFC1 Tray paper feed clutch For paper feed roller rotation

7

SPFM Multi paper feed clutch For multi paper feed roller rotation

8

3 – 5

Page 14

6. Motors (The SF-2514 as the typical example)

8

432

1

6

5

7

No. Abbreviation Name Function Type

VFM Paper exit fan motor

1

SPFM SPF motor For SPF drive DC brushless

2

CFM Cooling fan motor For cooling the optical system DC brushless

3

MM Main motor For the main body drive and the option drive DC brushless

4

LM Lens motor For the optical lens drive DC stepping

5

MRM Mirror motor For the optical mirror base drive DC brushless

6

TM Toner motor For toner supply DC synchronous

7

SPFFM SPF cooling fan motor For cooling the optical system in the SPF mode DC brushless

8

For ventilation of the fuser unit.

For cooling the machine and removing ozone.

DC brushless

3 – 6

Page 15

7. PWBs (The SF-2514 as the typical example)

2

8

1

4

9

3

5

6

7

No. Name Description

AC circuit PWB AC power input

1

Discharge lamp PWB Discharge lamp drive

2

Main PWB Main body control

3

AE PWB Document density auto exposure detection

4

Blank lamp PWB Blank lamp control

5

Lower unit PWB Lower unit parts control

6

High voltage PWB Supply of the process high voltage and the developer bias voltage.

7

Operation PWB Operation input, display control

8

SPF control PWB SPF control

9

3 – 7

Page 16

[4] UNP ACKING AND INSTALLAT ION

1. Packing drawi ng (SF-25 14)

List of packing materials and accessories

Name Q’ty

1 Packing case 1

2 SPF tray 1

4 SPF cover protection material 3

5 Body 1

6 Polyethylene bag for paper exit tray 1

7 Vinyl sheet for body 1

8 Bottom case 1

9 Bottom case pad (L) 1

10 Bottom case pad (R) 1

11 AC cord sleeve 1

12 Paper exit tray 1

14 Instruction Manual unit

Instruction Manual 1

Dust cover (For some agents) 1

Warranty card (For Austraria) 1

Warranty resistration (For U.K.) 1

Installation report (For Europe

except U.K.)

15 Consumable parts kit

Developer 1

Toner for installation 1

1

2. Installat ion

Installation conditions

The following installing conditions must be satisfied to assure the

normal operations of the machine.

(1) Environment

1 Keep the machine away from direct sunlight and avoid instal-

lation near a window or in a bright place.

(Draw the curtain and close the blind shutter completely.)

The plastic parts and the original cover may be deformed by direct

sunlight. Avoid installation near a window even with frosted glass.

4 – 1

Page 17

2 Avoid installation in high temperature or high humitity en-

vironments. Also, avoid installation where temperature or

humidity may change quickly. (e.g., near an air conditioner).

Otherwise copy papers may be dampened and condensation may

be generated in the machine. This may result in paper jams or

poor copy quality.

(Ideal conditions): The best suitable conditions for machine

operation:

20˚C ∼ 25˚C: 65 ±5%RH

(Temperature/humidity range): 15˚C ∼ 30˚C (59˚F ∼ 86˚F),

20% ∼ 85%

65% for 35˚C (95˚F)

% RH

85

65

Humidity

20

˚C

15 30 35

(59˚ ) (86˚) (95˚)

(˚F)

5 Install in a well ventilated place.

6 Avoid installation where there is inflammable gases or am-

monium gases.

Installation near a diazonium copier may degrade copy quality and

cause malfunctions.

3 Avoid installation where there is a lot of dust or vibrations.

If dust enters the machine, it may degrade copy quality and cause

malfunctions.

4 Avoid installation on an unstable surface.

To assure the proper operations, install on a level surface.

7 Install near a power outlet.

(2) Space around the machine

Allow a space of about 15 cm (6 inches) between the rear side of the

machine and the wall for ventilation of the cooling fan. Also allow

sufficient space around the machine for operations.

(3) Installing table

Use a level (UKOGM0054CSZZ) to install the machine horizontally.

(Allowable tilt: 5 mm between the front and rear frames)

(Note) If the machine is not installed horizontally, toner density con-

trol may not function properly. This may result in poor copy

quality.

4 – 2

Page 18

(4) Power source

1 The power source should be the rated voltage ±10% with the

capacity corresponding to the max. power consumption.

2 Do not use an extension cord, or operate any other equipment

from the same wall outlet.

(5) Grounding

To avoid electrical hazard, use the properly grounded wall outlet only.

(Carrying the machine)

When carrying the machine, remove the copy tray and hold the dent

portions on the bottom.

[In the case of SF-2314/2414/2514 with SF-MF14 (Optional)

equipped.]

Open the paper feed tray on the right side of the copier.

Remove the No.4/No.5 mirror unit fixing screws (2 pcs.).

Then close the paper feed tray.

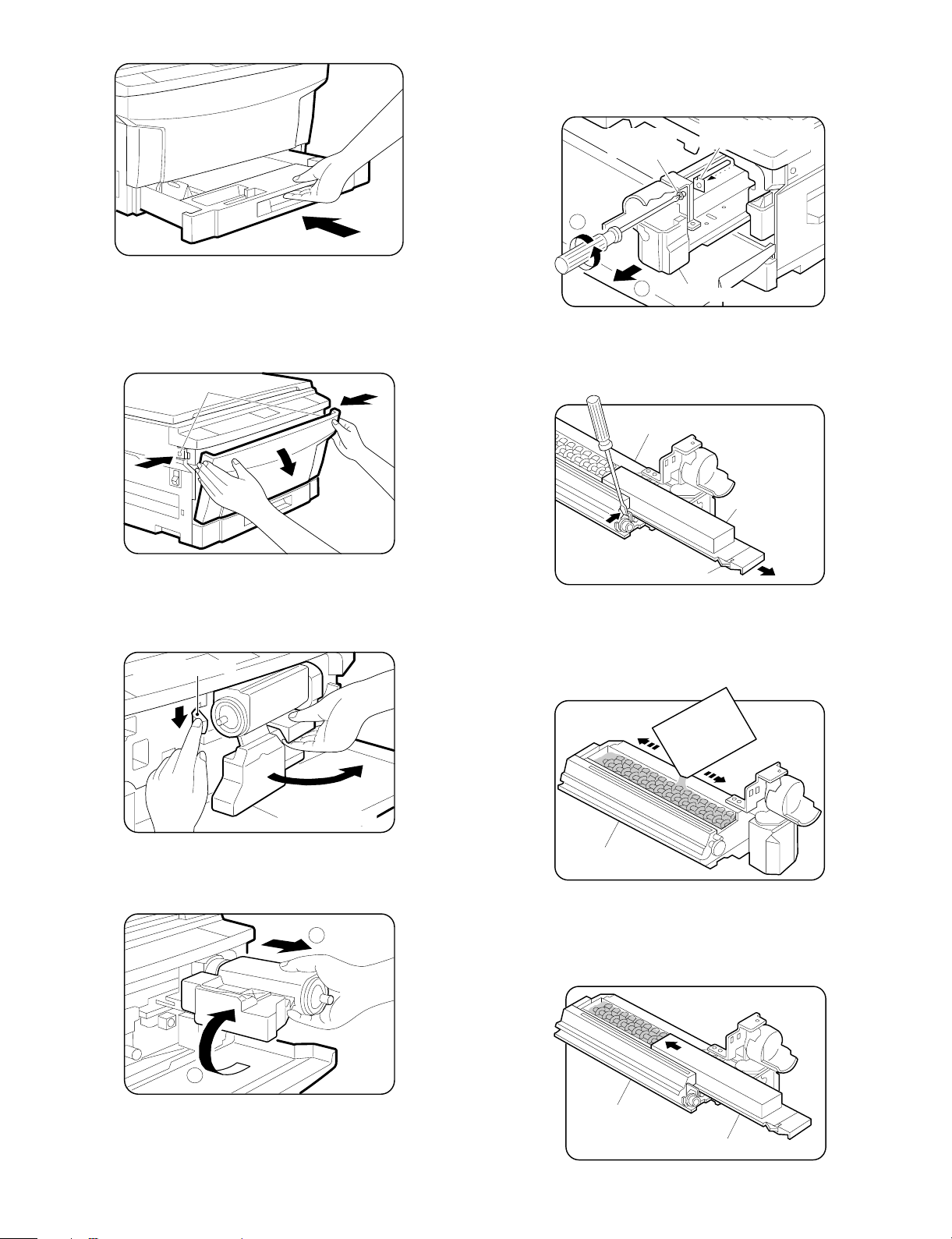

3. Installation procedure

(1) Optical system unlocking

1 Unlock the No.2/No.3 mirror unit.

Remove the No.2/No.3 mirror unit fixing screw (1 pc.) on the left

side of the copier.

Mirror unit fixing screw

2 Unlock the No.4/No.5 mirror unit.

Remove the No.4/No.5 mirror unit fixing screws (2 pcs.) on the

right side of the copier.

Mirror unit fixing screw

(2) Cassette setting

1 Pull out the cassette.

Lift the cassette and slowly pull it out from the copier until it stops.

2 Loading copy paper.

Set the copy papers in the cassette. Do not exceed the limit line

indicator.

Mirror unit fixing screw

4 – 3

Page 19

Gently insert the cassette fully into the copier.

4 Remove the developing unit.

Loosen the fixing screw (step screw) which is fixing the copier and

the developing unit, and slowly pullout the developing unit and

Lenz hold Plate from the copier.

(3) Developer setting

1 Open the front cabinet.

Push the front cabinet open buttons which are on the left and right

sides of the copier, and open the front cabinet.

Front cabinet open button

2 Open the toner cartridge.

While pressing the toner cartridge release lever (B), open the

toner cartridge.

Release lever (B)

Fixing screw

(step screw)

1

2

Lenz hold plate

(SF-2414/2514 only)

Developer unit

5 Remove the developer tank.

Slightly open the pawl which is fixing the developing unit and the

developer tank with a screw driver, and pull out the developer

tank.

Developing unit

Developing

tank

Pawl

6 Supply developer.

Supply a bag of developer to the developer supply port of the

developing unit.

At that time, move the bag of developer to supply developer evenly.

Toner cartridge

3 Remove the toner cartridge.

Slowly turn the toner cartridge clockwise to remove.

2

1

Developing

Developing unit

7 Install the developer tank.

Insert the developer tank to the developing unit along the guide of

the developing unit.

At that time, check that the developer tank is securely fixed in the

developing unit.

Developing unit

Developing tank

4 – 4

Page 20

8 Install the developing unit.

Slowly insert the developing unit into the copier along the guide of

the copier until it stops.

Tighten the fixing screw which was removed in procedure (D), and

fix the developing unit to the copier.

Fixing screw

(step screw)

2

4 Close the front cabinet.

1

Developer unit

(4) Toner supply

1 Shake the toner cartridge up and down.

Shake the toner cartridge up and down 9 to 10 times.

2 Install the toner cartridge.

Install the toner cartridge to the copier along the guide of the

copier.

Turn the toner cartridge counterclockwise to lock.

1

2

(5) Toner density sensor level check

1 Turn on the power switch of the copier.

2 Adjust the developer level.

(a) Perform the key operations of simulation 25 sub 2.

C0 0 C

25 2

With the above key operations, simulation 25 is performed and

the developer is stirred for 3 minutes.

(b) After stirring the developer for 3 minutes, the toner density

level is read by the main PWB.

During stirring, the toner density sensor level is displayed on

the MULTI COPY display. (Range: 1 ∼ 99)

[Note] If the simulation is cancelled during execution, the

automatic reading cannot be performed. Do not cancel

the simulation during execution.

(c) Press the CLEAR key three times to cancel simulation 25.

c c c

3 Supply toner.

Remove the sheet from the toner cartridge and supply toner.

Slowly return the toner cartridge to the original position.

4 – 5

Page 21

(6) Accessory attachment

1 Attach the copy tray.

(2) No.4/no.5 mirror unit (Mirror base C) lock

1 Perform locking with the unit at its home position and with the

external fitting installed.

2 Lock the unit with two mirror unit fixing screws. (The hole in the

right cabinet)

2 Attach the document tray.

[SF-2514 only]

2

1

4. Locking procedure for transit or

repacking

In general, reverse the procedures in "3. Installation procedure." For

the optical system lock, perform the following procedure.

(1) No.2/No.3 mirror unit (Mirror base B) lock

1 Perform locking with the unit at its home position (normal copy

position) with the power ON and with the mirror stopped and with

the external covers installed.

2 Lock the unit with the mirror unit fixing screw. (The hole in the left

cabinet)

Mirror unit fixing screw

[SF-2314/2414/2514 with SF-MF14 (Optional) equipped.]

1 Turn off the power at the 64% position. Perform locking with the

external fitting installed.

Mirror unit fixing screw

Mirror unit fixing screw

2 Open the paper feed tray at the right side of the body, and fix the

unit with two fixing screws. (Two holes in the right cabinet)

4 – 6

Page 22

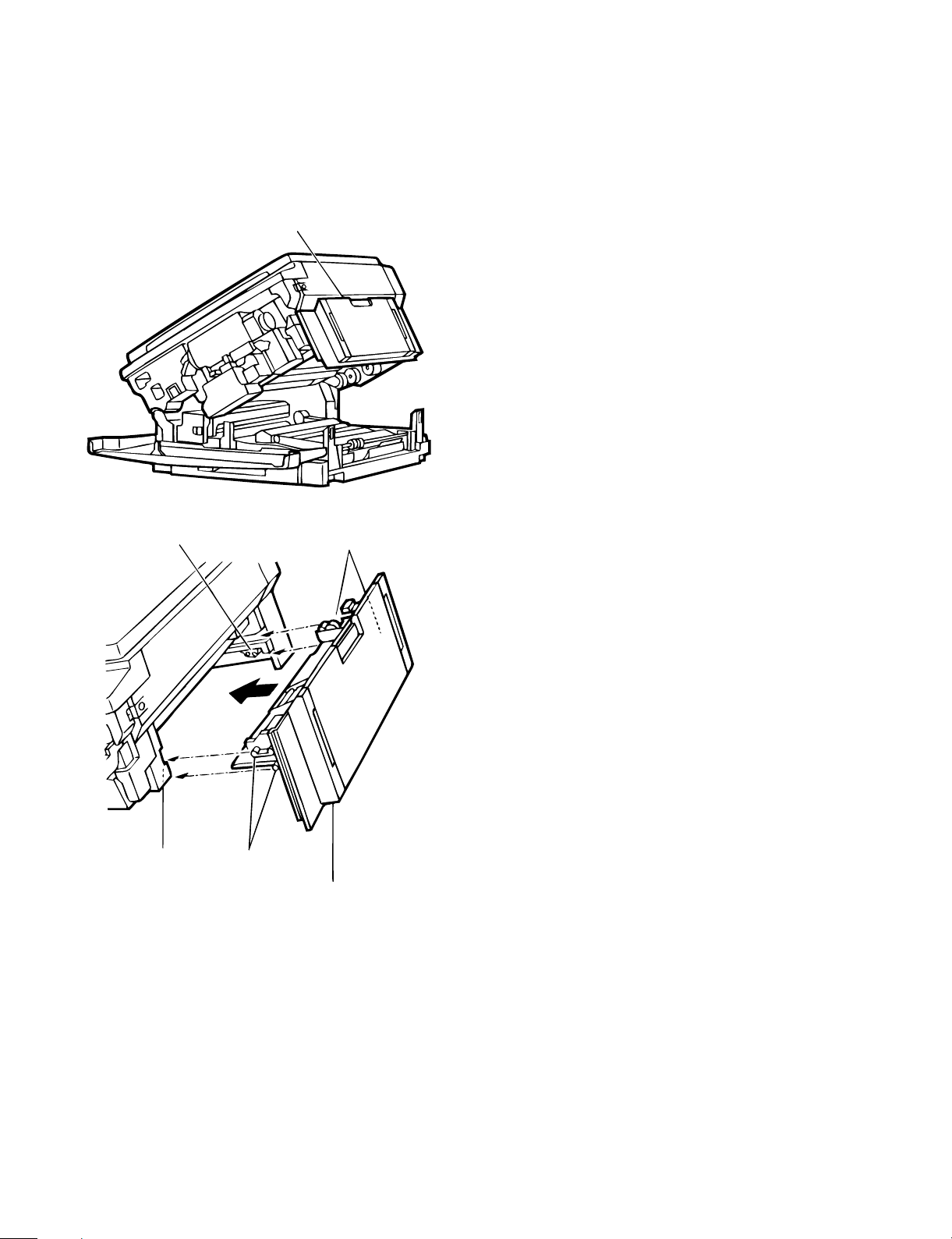

5. Optional paper feed unit (SF-CM14),

Installation Manual

For use with compatible SHARP copies.

See SHARP copier Installation Manual to determine suitability.

Included parts

(2) Remove the paper tray from the main copier

unit.

1 While lifting up slightly, gently pull out on the paper tray until it

stops.

2 Then, lift up on the paper tray with both hands and remove it.

Mounting screw A,

1 pc

[SF-2414/2514 only]

Mounting screw B,

2 pc

(1) Set the main copier unit on the paper feed unit.

1 Lift the main copier unit by the grips, place it upon the paper feed

unit, and slip the positioning holes (3 locations) on the bottom of

the main copier unit over the 3 positioning pins on the paper feed

unit.

[NOTE] This procedure should always be performed by two

people.

Grip

Grip

(3) Open the upper unit of the main copier unit.

1 Press the release buttons on the left and right sides of the main

copier unit’s front cover, then open the front cover.

2 Push the upper half release lever (green) to the right and down,

then gently open the upper unit.

Front cover release buttons

Positioning pin

Positioning pin

Front cover

Upper half

release lever

4 – 7

Page 23

Upper unit

(4) Connect the main copier unit and the paper

feed unit.

1 Secure mounting screw A (1 pc) in the main copier unit (1 loca-

tion).

Mounting

screw A

6. Optional multi bypass feeder unit

Installation Manual

(1) Open the upper unit of the main copier unit.

1 Press the release buttons on the left and right sides of the main

copier unit’s front cover, then open the front cover.

2 Push the upper half release lever (green) to the right and down,

then gently open the upper unit.

(2) Release the lock for the manual bypass unit and

remove the manual bypass unit.

1 Release the manual bypass unit by pressing upward on the rock

claws (green; 2 locations) which lock it in place in the main copier

unit’s upper unit.

The manual bypass unit will come out toward you slighly.

2 Pull out upon the manual bypass unit to remove it from the main

copier unit.

Manual bypass unit

Then, gently close the upper unit and front cover.

2 Connect the paper feed unit and the main copier unit by securing

mounting screw B (2 pcs) in the mounting holes (2 locations)

located in the slot from which the paper tray was removed.

Mounting screw B

After these procedures have been completed, reload the paper

*

tray which was removed in step 2.

3 Insert the paper feed unit connector into the jack on the side of the

main copier unit.

Rock claw (latch)

Rock claw (latch)

Connector

4 – 8

Page 24

(3) Mount the multi bypass feeder unit onto the

main copier unit.

1 Slide the positioning pins which project from the multi bypass

feeder unit in to the grooves in the main copier unit, then push the

multi bypass feeder unit into place to in stall it.

At this time, to be sure that the multi bypass feeder unit is securely

installed, push down once more on the fourcorners of the unit. (If it

has not been securely installed, "CH" may appear in the COPIES

MADE display when the power is turned on.)

Multi bypass feeder unit

Rock claw (latch)

Rock claw

(latch)

2 Close the upper unit of the main copier unit.

Positioning pins

Positioning pins

Multi bypass

feeder unit

4 – 9

Page 25

[5] GENERAL DESCRIPTIONS OF

EACH SECTION

The general descriptions of the following sections are given:

1 Paper feed section

2 Separation, transport section

3 Fuser, paper exit section

4 Developer section

5 Optical system

6 Image forming section

7 SPF section (SF-2514 only)

Internal structure

7

When the CPCF turns off, rotation is stopped, and the takeup roller is

pushed up by the roller release arm spring to the position.

5

3

6

4

2

1

1. Paper feed secti on

The paper feed system is in two ways: the tray feed and the manual

feed. The cassette is of the universal type and has the capacity of

250 sheets. It is attached and detached at the front cabinet, that is,

the front loading system.

The manual paper feed is single for the SF-2314 and multi for the

SF-2414/2514. (The multi paper feed unit (SF-MF14) is an option for

the SF-2314 only.)

In addition to the standard cassette (250 sheets), the optional cassette module (SF-CM14, 250 sheets) can be added.

(Tray paper feed operation)

The cassette paper feed clutch (CPFC) turns on, the paper feed roller

shaft, the paper feed roller, and the takeup roller rotate. At the same

time, the roller release arm is lowered by the limiter spring. As a

result, the takeup roller falls by its own weight to reach the paper

surface, performing the paper feed operation.

(Manual paper feed operation) Multi

When the solenoid B (MPFS) turns on, the takeup roller falls and the

gate rises.

Almost simultaneously the solenoid A (MPFC) turns on and the

takeup roller and the paper feed roller turns to perform the paper feed

operation.

ON

When the PPD turns on, the MPFS turns off and the RRC turns on.

Almost simultaneously the MPFC turns off to return the roller and the

gate to the initial state.

5 – 1

OFF

Page 26

2. Separation, transport section

4. Developer section

After passing the resist roller section, the paper is transported to the

transfer section. After transfer, the paper is separated from the drum

by the separation electrode and the drum separation pawl, then

transported to the fuser section by the transport belt.

3. Fuser, paper exit section

The toner image transferred on the paper is fused by the heat and

pressure of the upper and the lower heat rollers. After fusing, discharge static electricity on the paper with the discharge brush. Then

the paper is discharged to the copy tray.

4-1. General descriptions

(1) Two-component developer

The developer is composed of toner and carrier.

Carrier serves as a medium for attaching toner onto the electrostatic

image on the photoconductor drum.

By stirring toner and carrier, they are rubbed to be charged positive

(+) and negative (–) respectively.

Since developer will deteriorate to degrade copy quality, it should be

replaced regularly.

(2) Two-component magnetic brush development

The rotatable non-magnetic sleeve is provided over the magnet roller

and is rotated.

Carrier forms a magnetic brush on the sleeve surface by magnetic

force to attach toner onto the electrostatic image on the photoconductor drum.

(3) Developing bias

When the photoconductor is charged and exposed to light (exposure), the surface potential (voltage) of the photoconductor will not

be lost completely. (The residual potential remains.)

Toner is attracted to the photoconductor by this residual potential,

dirtying the photoconductor. As a result, a dirty copy of white background is generated.

To prevent against this, a voltage of the same polarity and higher

than the residual potential is applied to the MG roller, preventing toner

from being attached to the photoconductor surface.

• Temperature control

Heat roller surface

temperature detection

The heat roller is heated by the

heater lamp.

(When the heat roller surface

temperature is 180 C˚ or lower,

the heater lamp is actuated)

Contact open (*)

Abnormal high

tem p erature

CPU

(Heater troub l e)

Self diag di spl ay

Thermistor

Heat r olle r

Heater lamp

Thermostat

• Abnormally high temperature (H3)

• Abnormally low temperature (H4)

• Thermistor disconnection (H2)

When the thermostat contact is open, it is required to press the

*

reset button in the upper side of the thermostat. (The contact is not

reset automatically.)

Toner

Carrier

Residual potential < DV BIAS

MG roller

DV BIAS

-200V

Developing bias voltage

5 – 2

Page 27

5. Optical system

5-1. General descriptions

• The optical system is composed of the fixed focus lens and six

mirrors.

Since the fixed focus lens is employed, No.4/No. 5 mirror base is

moved as well as the lens to change the distance between the

document and the drum (OID, Original Image Distance) for reduction and enlargement.

To move the lens and No.4/No. 5 mirror unit, he stepping motor is

driven by the signal from the main control PWB to allow zooming

of 0.70 to 1.22 (inch series: 0.64 ∼ 1.29) with 1% increment. (The

SF-2314 has no zooming function, and its lens and No.4/No.5

mirror base are fixed.)

4

5

10

• Exposure is adjusted by changing the voltage of the copy lamp.

The copy lamp unit is provided with the AE sensor for detection of

the original density to adjust the light quantity of the copy lamp

according to the original density.

• For exposure, the slit exposure system is employed where the light

source is moved. (The original table is fixed.)

12

9

17

615

127

1311316

8 14

1 Copy lamp 2 Reflector 3 No. 1 mirror

4 No. 2 mirror 5 No. 3 mirror 6 Lens

7 No. 4 mirror 8 No. 5 mirror 9 No. 6 mirror

F No. 2/No. 3 mirror base unit G Copy lamp unit H No. 4/No. 5 mirror base unit

I Mirror motor J Lens/No. 4/No.5 mirror base drive motor K Lens home position sensor

L Mirror home position sensor M Auto exposure sensor

(1) Original table

The original table is fixed, and originals are set to the left frame side

as the reference.

(2) Copy lamp

100V s ystem (285W)

200V s ystem (285W)

(3) Mirror

Six mirrors are used.

No. 1 mirror is provided in the copy lamp, No. 2/3 mirrors at the

No.2/3 mirror base, No. 4/5 mirrors at the No. 4/5 mirror base. The

No.2/3 mirror base is scanned during copying. The No.4/5 mirror

base is moved to change the distance between the original and the

photoconductor during zoom copying.

(4) Lens (Fixed focus lens)

• Construction (One group 3 lenses)

• Brightness (F8)

• Focus (175mm)

(5) Lens home position sensor (LHPS)

This sensor is used to sense the lens position. The sensor output

signal serves as the basic signal to control the copy magnification

ratio.

(6) Lens base

The lens is mounted to this lens base. It is moved in the paper feed

direction in reduction copying, and in the paper exit direction in enlargement copying.

5 – 3

Page 28

(7) Lens drive shaft

This shaft is to control the optical axis of the lens in zoom copying.

The lens follows on the slide base shaft.

(8) Lens drive wire

The wire is used to drive the lens base and the 4/5 mirror base.

(9) No. 4/5 mirror base

The No. 4/5 mirror is installed to this base. It is moved in zoom

copying in order to fit the distance between the original and the

photoconductor.

(10) Mirror motor

The mirror motor is a stepping motor, and used to move the copy

lamp unit and the No. 2/3 mirror base in order to obtain the rpm

corresponding to each magnification ratio.

(11) Mirror home position sensor (MHPS)

Used to sense the home position of the copy lamp unit. This sensor is

a photo transmission type sensor.

(12) No. 2/3 mirror base

The No. 2/3 mirrors are attached to this base. The mirror base is

scanned by the mirror motor.

(13) Copy lamp unit

This is composed of No. 1 mirror, the thermal fuse, the copy lamp,

the exposure adjustment plate, and the reflector, and is scanned by

the mirror motor.

5-2. Basic operati on s

(Relationship among the original, the lens and the image in each

magnification ratio)

Normal copy: The distance between the surface of original on the

table glass and the lens is made equal to the distance

between the lens and the exposure surface of the

photoconductor to make the original and the image

equal to each other.

Enlargement copy: The lens is nearer to the original when compared

with the normal copy to shorten the distance between the original surface and the lens.

The No. 4/5 mirror base is positioned further

away from the lens to increase the distance between the lens and the exposure surface of the

photoconductor.

The distance between the original and the exposure surface of the photoconductor is greater

than that in the normal copy.

(14) Thermal fuse

The thermal fuse is closely attached to the reflector in order to

prevent against abnormal temperature rise in the optical system. In

case of abnormal temperature rise, the power for the copy lamp is

turned off.

100V system

200V system

(117˚C)

(117˚C)

(15) Reflector

Light from the copy lamp is reflected onto the original.

(16) Exposure adjustment plates

Three exposure adjustment plates are attached to the copy lamp unit

to adjust the exposure balance in the front and the rear frame direction.

(17) Mirror base drive wire

This wire is used to transmit the drive power of the mirror motor to the

copy lamp unit and the No. 2/3 mirror base to scan the mirror base.

(18) Lens drive motor

This is a stepping motor, which is used to move the lens and the No.

4/5 mirror base.

(19) AE sensor

The original density is detected with the intensity of the copy lamp

light reflected from the original. The measurement area is the mirror

base scan area of about 100mm at the center.

The element is a photo diode.

Reduction copy: When compared with the normal copy, the lens

comes closer to the photoconductor to increase the

distance between the original and the lens. The

distance between the lens and the exposure surface of the photoconductor is decreased.

The No. 4/5 mirror base is positioned further away

from the lens.

The distance between the original and the exposure

surface of the photoconductor is longer than that in

the normal copy.

5 – 4

Page 29

The mirror base scan speed (mirror motor rpm)

is changed t o z oom.

The lens and the mirror are

Copy paper

feed direction

The mirr or sc an speed is c hanged to zoom .

Mirror scan speed Drum rotating speed < Mirror scan speed

Enlargement

moved to zoom.

(Optical system dirt correction)

The SF-2314/2414 perform dirt correction by changing the copy lamp

intensity according to the dirt degree in the optical system (the copy

lamp unit, No. 1 mirror, No.2 mirror, No.3 mirror) to prevent against

remarkable degrading of copy quality.

The reference value is the AE sensor output value which is obtained

when the reference plate is exposed with the copy lamp voltage of

67.7V (135.4V) at power ON.

This value is checked with sim 44-02.

Reference plate (Glass holder)

Table glass

Copy lamp light quantity "UP"

Original

(Copy lamp control in each copy density)

80

70

CLV

(Copy lamp

application

voltage)

60

50

40

(V)

Reduction

[MAX. 85V(170V)]

[MIN. 40V(80V)]

The lens

and the

mirror are

move to

zoom.

Automatic exposure

sensor

CPU

Reference value

> Measured value

Correction data output

EX1

234

EX5

5 – 5

Page 30

6. Copy process

(1) Photoconductor

• This model uses OPC (organic photoconductor) as photoconduc-

tive material.

OPC layer CTL (Electric charge moving layer)

CGL (Electric charge generating layer)

Aluminum layer

(2) Process diagram

Original

Copy lampMirror lens

High voltage unit

Exposure

Transfer

Exposure

Development

Drum up per

ima ge/paper

synchronization

Resist roller

Discharge lamp

Cleaning bl ade

Waste toner collection

Paper exit

Main corona unit

Cleaning

Separ a tion

Fusing

Charging

Discharging

Separation

Blank lamp

Toner

Developer

High voltage unit

Paper feed roller

Transportroller

Manual paper feed

Pape r ca sse tte

Discharge lamp

Cleaning bl ade

Seper ati on pa w l

Heat r olle r

Heater lamp

Separation cor ona unit

High voltage unit

Main corona unit

Seperation corona unit

Transfer charger

High voltage unit

Blank lamp

Devel oper u nit

MG roller

Resist roller

Transfer corona unit

Image forming process

Paper transport path

5 – 6

Page 31

(3) Actual process

Step 1 (charging)

The OPC drum is negatively charged by corona discharge of the

transfer charger . Positive charges are generated in the aluminum

layer.

Aluminum layer

OPC drum

CGL

CTL

Seperation pawl

Transfer corona unit

High voltage unit

Step 2 (Discharging)

When the OPC drum is exposed to the discharge lamp light, positive

and negative charges are generated in the OPC drum CGL. The

negative charges move to the positive charges generated in the

aluminum layer in step 1, and the positive charges move to the

negative charges on the OPC drum surface charged in step 1. The

positive charges and the negative charges are neutralized each other

in the aluminum layer and on the OPC drum surface. As a result, the

OPC dru m surface potential becomes 20V ∼ 30V.

Discharge lamp

Cleaning blade

Main corona unit

Seperation corona unit

Blank lamp

Devel oper u nit

MG roller

Resist roller

Transfer corona unit

Discharge lamp

Light

OPC drum

CTL

CGL

Aluminum layer

By performing step 1 (Charging) and step 2 (Discharging), the

photoconductor itself is initialized to stabilize the drum surface potential.

Discharge lamp

Cleaning blade

Seper ati on pa w l

Main corona unit

Seperation corona unit

Blank lamp

Devel oper u nit

MG roller

Resist roller

Transfer corona unit

5 – 7

Page 32

Step 3 (Main Charging)

By negative discharging of the main charger, uniform negative charges are applied to the OPC drum surface.

The OPC drum surface potential is controlled by the screen grid

voltage to maintain the grid voltage at a constant level.

• When the drum surface potential is lower than the grid voltage,

electric charges generated by discharging of the charger go

through the screen grid to charge the drum surface potential until it

becomes equal to the grid voltage.

• When the drum surface potential virtually reaches the grid potential

level, electric charges generated by discharging of the charger

flows through the electrode of the screen grid to the high voltage

unit grid voltage output circuit, thus always maintaining the drum

surface potential at a level virtually equal to the grid voltage.

• The main corona unit employs the scorotron system to charge the

photoconductor surface to a certain level uniformly.

In addition, the conventional corona wire is replaced with the

corona charging mechanism by saw-teeth plate (stainless steel

plate of 0.1 mm thick). In corona discharge, oxygen molecules in

the air are ionized to generate ozone (O3). The mechanism restrict

the generation of ozone.

Main corona unit

Main corona unit

Blank lamp

High voltage unit

Screen grid

CTL

CGL

OPC drum

Aluminum

layer

Step 4 (Exposure)

Light from the copy lamp is radiated on the document, and the optical

image of the document is reflected by the mirrors and projected

through the lens to the OPC drum.

The lighter portion of the document reflects more light (high intensity)

to the OPC drum, and the darker portion of the document reflect less

light (low intensity) to the OPC drum. Positive or negative charges are

generated in the CGL of the OPC drum where lights are radiated.

Negative charges generated in the CGL move towards the positive

charges in the aluminum layer generated in step 3. While the positive

charges in the CGL move towards the negative charges on the CPU

drum surface generated in step 3. Therefore, positive charges and

negative charges are neutralized in the aluminum layer and the OPC

drum surface at the light radiating position, decreasing the OPC drum

surface potential. The CGL electric charge generating amount increases in proportion to the document density, that is, reflected light

intensity (the OPC drum surface intensity). Therefore, electric charges are generated less in the CGL layer corresponding to the lighter

density of document (higher intensity of the OPC drum surface), and

a greater quantity of the negative charges on the OPC drum surface

is neutralized, decreasing the OPC drum surface potential more.

Discharge lamp

Cleaning blade

Seperation pawl

Seperation corona unit

On the contrary, electric charges are generated more in the CGL

layer corresponding to the darker density of document (lower intensity

of the OPC drum surface), and less quantity of the negative charges

on the CPU drum surface is neutralized, decreasing the OPC drum

surface less. Therefore, the OPC drum surface potential corresponding to the lighter portion of the document is lower, and that corresponding to the darker portion of the document is higher. Latent

static-electricity images are formed in the above manner.

Transfer corona unit

Developer unit

MG roller

Resist roller

5 – 8

Page 33

CTL

CGL

Low intensity in

the area corresponding to the

darker density

portion of the

document

Medium intensity

in the area corresponding to the

medium density

portion of the

document

HIgh intensity in

the area corresponding to the

lighter density of

the document

Aluminum

layer

OPC drum

Surface potential

(High)

CTL

CGL

Surface

potential

(Medium)

Surface

potential

(Low)

Aluminum

layer

OPC drum

Step 5 (Development)

Toner is attached to the latent static-electricity images on the drum

surface to change them to visible images. The two-component magnetic brush development system charges toner positively by friction

with carriers, and toner is attached to negative charges on the drum

surface. The potential in the darker document projecting area (low

intensity) is high (much negative charges) and attracts more toner.

The potential in the lighter document projecting portion (high intensity) is low (less negative charges), and attracts less toner.

Discharge lamp

Cleaning blade

Seperation pawl

Main corona unit

Seperation corona unit

Blank lamp

Developer unit

MG roller

Resist roller

Transfer corona unit

OPC drum

CGL

Aluminum layer

Higher surface

potential

(Much negative

(charges)

Medium surface

potential

(Less negative

(charges)

Lower surface

potential

(No negative

(charges)

CTL

MG roller

-200V

High voltage unit

bias voltage

At that time, a bias of –200V is applied to the MG roller (magnet

roller), which is provided for preventing toner from being attracted by

the residual voltage (about –80V to –100V) in the lighter portion after

exposure.

Discharge lamp

Cleaning blade

Seperation pawl

5 – 9

Main corona unit

Seperation corona unit

Blank lamp

Developer unit

MG roller

Resist roller

Transfer corona unit

Page 34

Step 6 (Transfer)

g

The transfer paper is charged higher than the OPC drum surface

potential by strong negative discharge of the transfer charger, making

the binding force between the transfer paper and toner stronger than