Page 1

SERVICE MANUAL

CODE: 00ZSF2118SMRE

MODEL SF-2116

MODEL SF-2118

SF-2116

SF-2118

CONTENTS

[ 1 ] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 – 1

[ 2 ] PRODUCT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 – 1

[ 3 ] PRODUCT VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 – 1

[ 4 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 1

[ 5 ] DESCRIPTION ON EACH SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 1

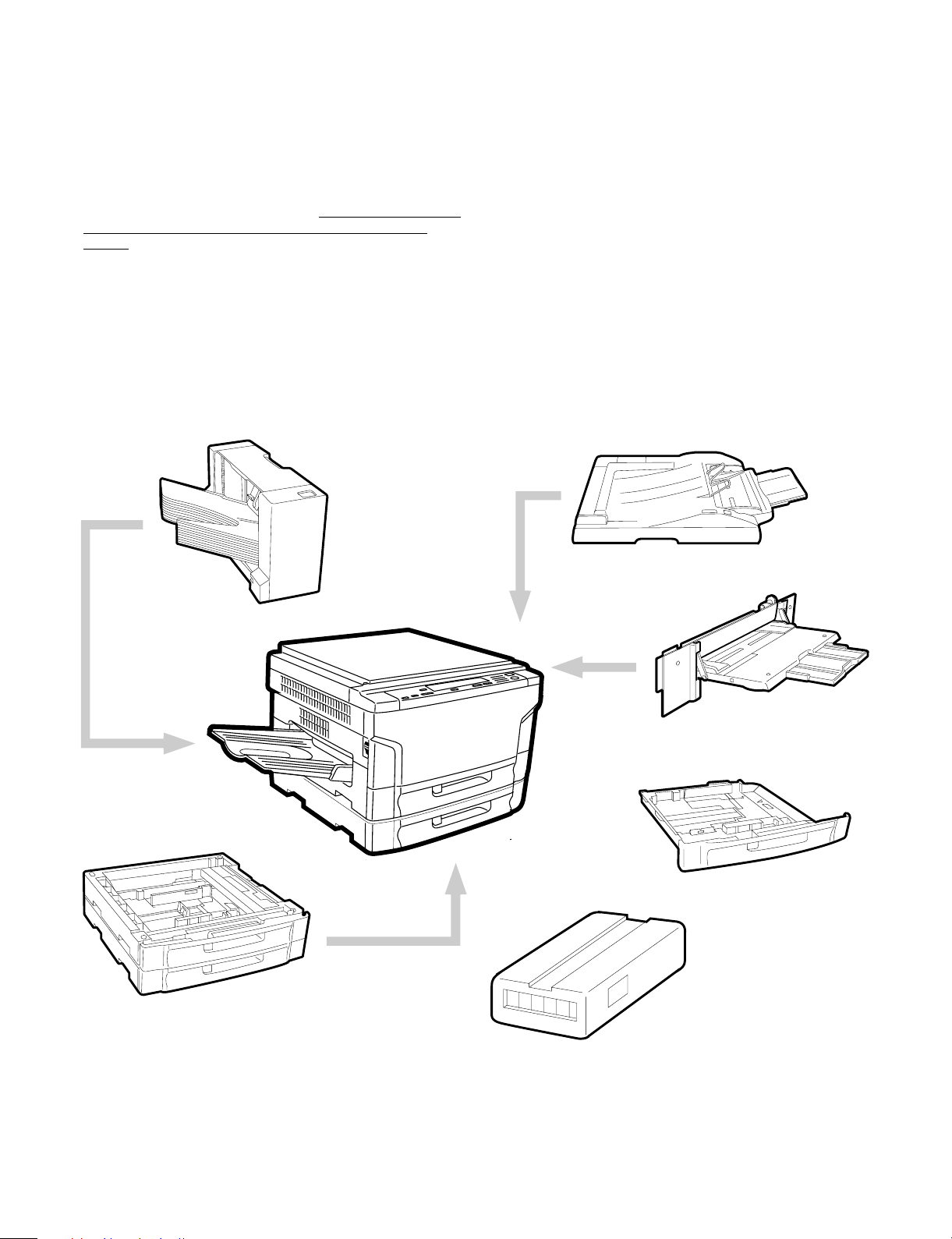

Option • Paper tray (SF-UB15)

• Multi paper feed unit (SF-MF15)

• Two-step paper feed unit

(SF-CM15)

• Personal counter (SF-71A/71B)

• 10-bin sorter (SF-S17) @

• Reverse document feeder

(SF-A15) @

@For the options, refer to their service

manuals.

[ 6 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 – 1

[ 7 ] ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 – 1

[ 8 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 – 1

[ 9 ] SELF DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 – 1

[10] MEMORY TROUBLES, FLOWCHART FOR REPLACEMENT OF

MAIN CONTROL PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 – 1

[11] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 – 1

[12] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 – 1

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

[1] PRODUCT OUTLINE

1. Product features

(1) Compact body

• Compact body size

The body width of 600mm is the smallest in the class.

• The employment of the front loading tray and the folding-type multi

manual paper feed cassette realizes the small occupying area.

(Option)

2. System configuration (options)

(2) Clean copy gentle to the environment

• Silent design of 46dB,

• Low level of ozone, use of recyclable materials

• The energy-saving mode reduces the power consumption.

(3) High capacity of copying

• Warm-up time is less than 35 sec. The first copy of 5.3 sec is the

fastest in the class.

(4) Fully expandable system. (Refer to "2. System configuration.")

Reverse document feeder SF-A15

10-bin sorter SF-S 17

Two-step paper feed unit SF-CM15

(Option for SF-211 8 onl y)

99

Multi paper feed unit SF-MF-15

Tray (reserve) SF-UB15

9

9

9

0

1 – 1

Personal counter

Page 3

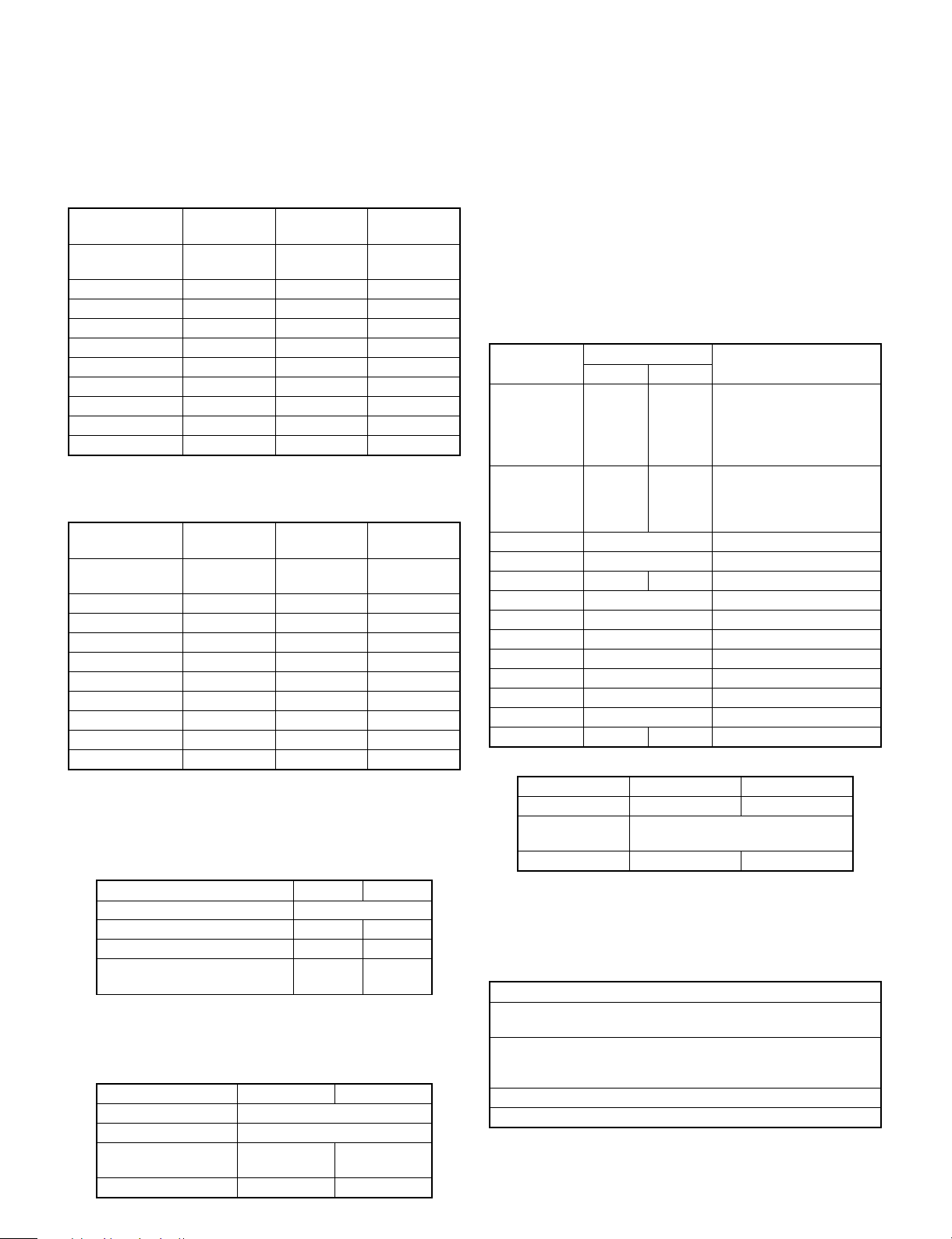

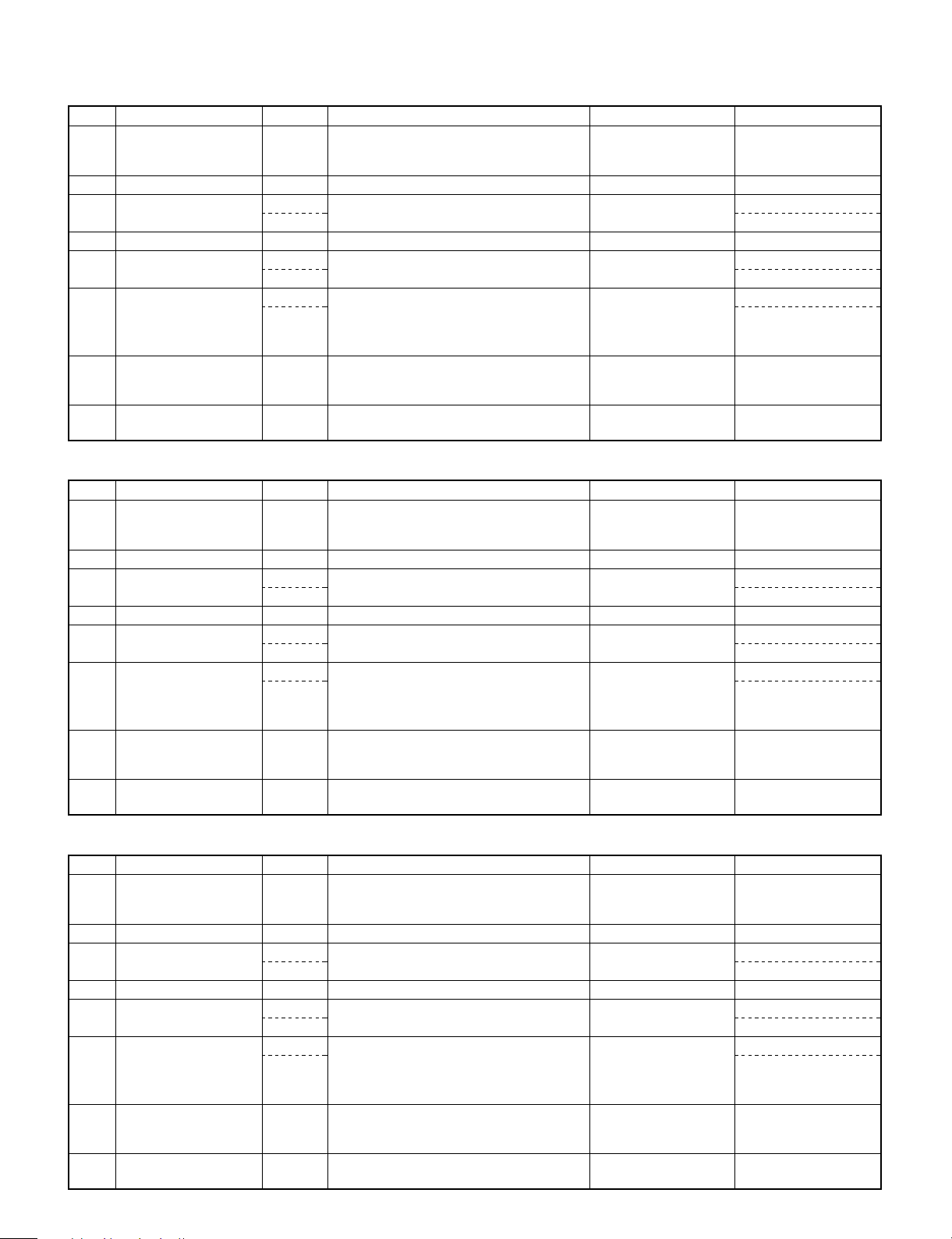

[2] PRODUCT SPECIFICATIONS

1. Basic specifications

(1) Type: Table top

(2) Copy speed:

<SF-2116>

Normal

A3 9 sheets/min 9 sheets/min

B4 11 sheets/min 11 sheets/min 11 sheets/min

A4 (Portrait) 16 sheets/min 13 sheets/min 13 sheets/min

A4 (Landscape) 13 sheets/min 13 sheets/min 13 sheets/min

B5 (Portrait) 16 sheets/min 13 sheets/min 13 sheets/min

B5 (Landscape) 13 sheets/min 13 sheets/min 13 sheets/min

W letter 9 sheets/min 9 sheets/min 9 sheets/min

Legal 11 sheets/min 11 sheets/min 11 sheets/min

Letter (Portrait) 16 sheets/min 13 sheets/min 13 sheets/min

Letter (Landscape) 13 sheets/min 13 sheets/min 13 sheets/min

(Note) The copy speeds for enlargement and reduction are the lowest

ones.

<SF-2118>

Normal

A3 10 sheets/min 10 sheets/min

B4 12 sheets/min 12 sheets/min 12 sheets/min

A4 (Portrait) 18 sheets/min 14 sheets/min 14 sheets/min

A4 (Landscape) 14 sheets/min 14 sheets/min 14 sheets/min

B5 (Portrait) 18 sheets/min 14 sheets/min 14 sheets/min

B5 (Landscape) 14 sheets/min 14 sheets/min 14 sheets/min

W letter 10 sheets/min 10 sheets/min 10 sheets/min

Legal 12 sheets/min 12 sheets/min 12 sheets/min

Letter (Portrait) 18 sheets/min 14 sheets/min 14 sheets/min

Letter (Landscape) 14 sheets/min 14 sheets/min 14 sheets/min

(Note) The copy speeds for enlargement and reduction are the lowest

ones.

(3) Warm up time: 35 sec or less

(4) First copy time: 5.3 sec (Paper feed port: Upper tray)

First copy time from each paper feed port

Paper feed port SF-2116 SF-2118

Body tray upper stage 5.3 sec

Body tray lower stage NO 5.8 sec

Option paper feed unit first step NO 6.1 sec

Option paper feed unit second

step

(5) Jam recovery time: 8 sec (Conditions: After leaving the door

open for 60 sec, the standard conditions)

(6) Multi copy Max. 99 sheets

(7) Original

Max. original size A3/W letter

Reference original size Left side/Center

Original sensing

Sensing size — A3 ∼ B5R

Enlargement

(Magnification)

(200%)

Enlargement

(Magnification)

(200%)

NO 6.4 sec

SF-2116 SF-2118

NO

Reduction

(Magnification)

9 sheets/min

(50%)

Reduction

(Magnification)

10 sheets/min

(50%)

YES

(Japan only)

(8) Copy magnification ratio

Fixed magnification: 200, 141, 122, 115, 100, 86, 81, 70, 50% (9

steps)

Zoom range: 50% ∼ 200% (151 steps by the increment of 1%)

(9) Exposure

Exposure mode: Auto/Manual/Photo

No. of manual steps: 9 steps

(10) Void width

Void area: Lead edge/rear edge: 3mm or less

Image loss Normal: 4mm or less

(11) Paper exit/finishing

Paper exit tray capacity: 250 sheets

Finishing: option 10-bin sorter

(12) Additional functions

Function

SF-2116 SF-228

Auto Paper

Selection

× F

Auto

Magnification

ratio Selection

Shift ×

1-set 2-copy F Enlargement is impossible.

Edge erase × F

Trimming ×

Masking ×

Centering ×

Move image ×

Covers/inserts ×

Overlay ×

Job memory ×

Monochrome × F (Red, Blue)

(13) External dimensions

W x D x H mm 600 x 585 x 375 600 x 585 x 460

Occupying area

(W x D)

Weight 43.5Kg 49.5Kg

(14) Power source

Voltage: 100V 50/60Hz, 110V 50/60Hz, 120V 60Hz, 127V 60Hz,

Frequency: 50/60Hz common

(15) Power consumption

Max. power consumption 1.5kw

Stand-by power

consumption

Average power

consumption during

operation

Preheating 70W

Auto power shut off 15W

2 – 1

× F

SF-2116 SF-2118

220 ∼ 230V 50/60Hz, 240V 50Hz

18W (Heater lamp OFF)

1kW (Heater lamp ON)

1320W

For the SF-2118 (outside

Japan version), original

sensing is possible when

the ADF (option) is

installed.

Inhibited in mixed size

paper feed. For outside

Japan version, the original

size is entered.

850 x 585

Remark

Page 4

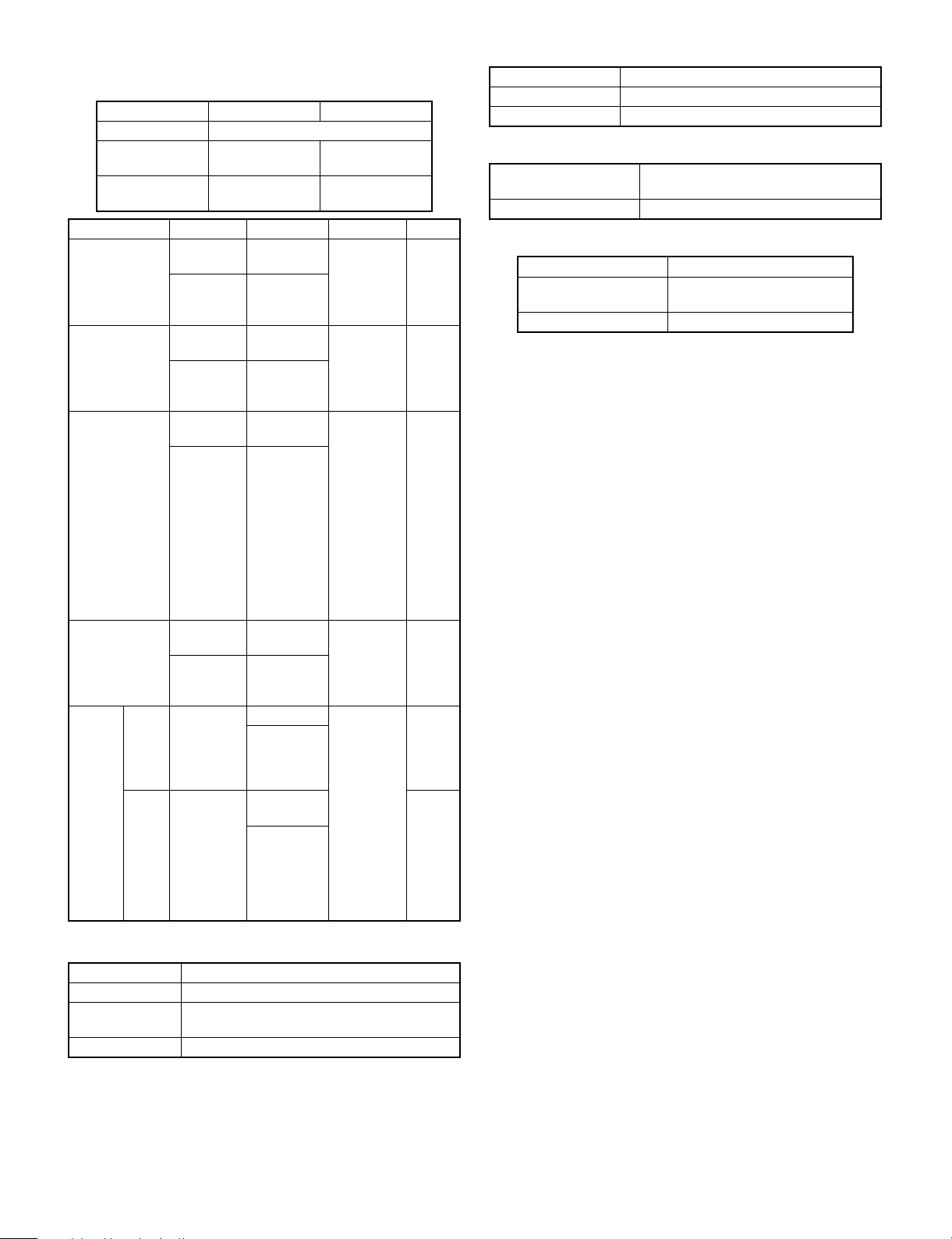

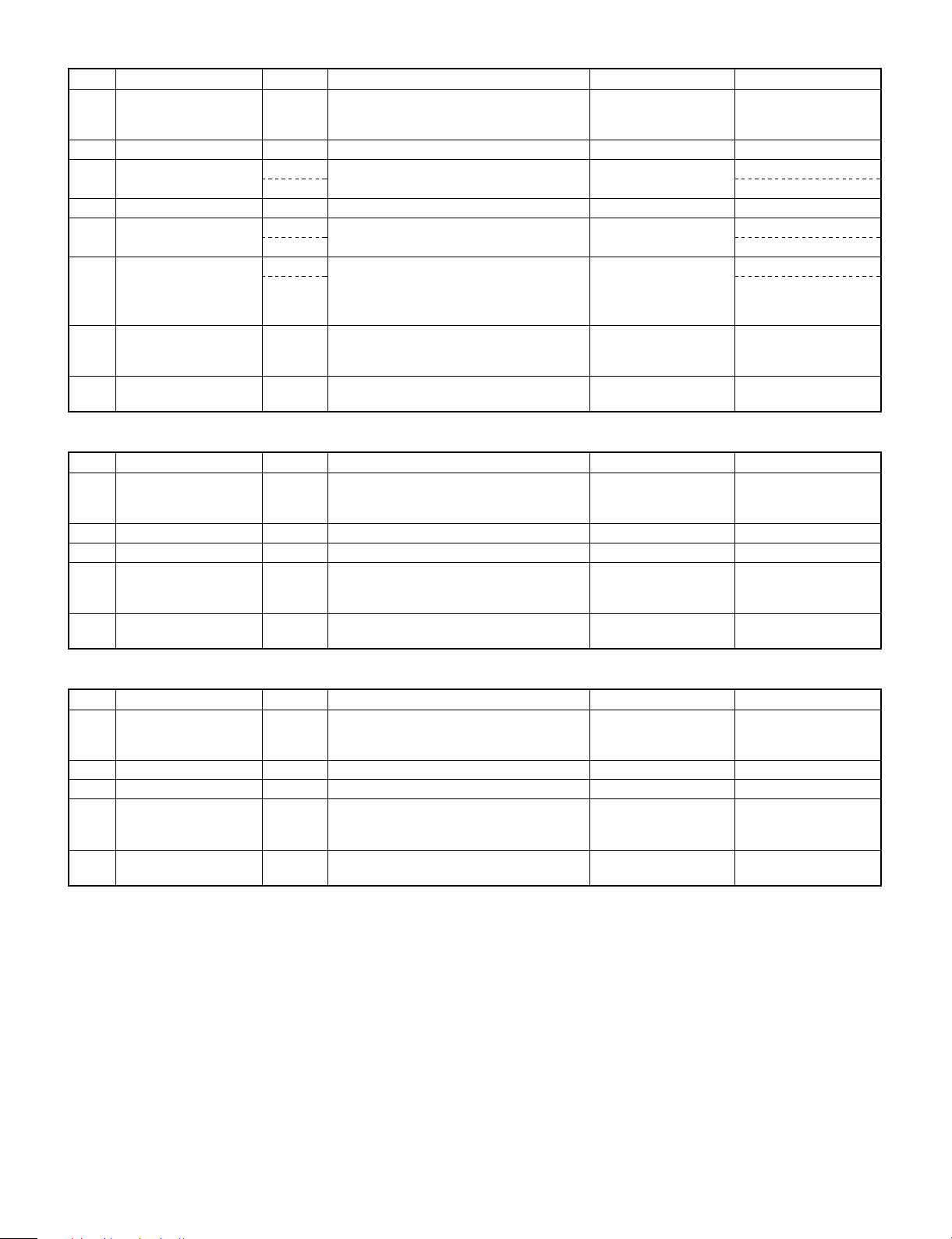

2. Description of each section

(1) Paper feed section

SF-2116 SF-2118

Copying size A3 ∼ A6/W letter ∼ Invoice

Paper feed

system

Paper feed

capacity

Cassette Paper size Paper weight Paper kind Remark

Body tray

upper stage

Body tray lower

stage

Manual feed

Two-step paper

feed unit

(Option)

Multi

Multi

manual

paper

feed

(Option)

Single

1 tray + Single

manual feed

AB series:

A3 ∼ A5

Inch series:

W letter ∼

Invoice

AB series:

A3 ∼ A5

Inch series:

W letter ∼

Invoice

AB series:

A3 ∼ A6R

Inch series:

W letter ∼

Invoice

AB series:

A3 ∼ A5

Inch series:

W letter ∼

Invoice

AB series:

A3 ∼ A6R

Inch series:

W letter ∼

Invoice

AB series:

A3 ∼ A6R

Inch series:

W letter ∼

Invoice

2 trays ∼ Single

manual feed

250 sheets 250 x 2 sheets

56 ∼ 80g/m

2

Standard

paper,

2

recycled

paper

Standard

15 ∼ 20 lbs

56 ∼ 80g/m

paper,

15 ∼ 20 lbs

52 ∼

128g/m

recycled

paper

Standard

2

paper,

specified

paper,

special

paper,

OHP film,

14 ∼ 34 lbs

Second

original

paper,

postcards

(without

folding)

56 ∼ 80g/m

2

Standard

paper,

15 ∼ 20 lbs

recycled

paper

56 ∼ 80g/m2Standard

paper,

15 ∼ 20 lbs

specified

paper,

special

52 ∼

128g/m

paper,

OHP film,

2

Second

original

paper,

14 ∼ 34 lbs

postcards

(without

folding)

SF-2118

only

(3) Process

Charging system (–) DC saw teeth electrode system

Transfer system (–) tungsten system

Separation system (AC) separation tungsten system

(4) Developing section

Developing system Dry, two-component magnetic brush

development (developer replacement)

Developing bias voltage DC–200V ±5V

(5) Fusing section

Fusing system Heat roller system

Upper heat roller

surface temperature

190 degrees

Heater lamp Halogen lamp 1000W × 1

(2) Optical section

Light source Halogen lamp

Exposure system Slit exposure by moving the light source

Zooming system By changing the lens positions and the scan

speed.

Lens Fixed focus lens

2 – 2

Page 5

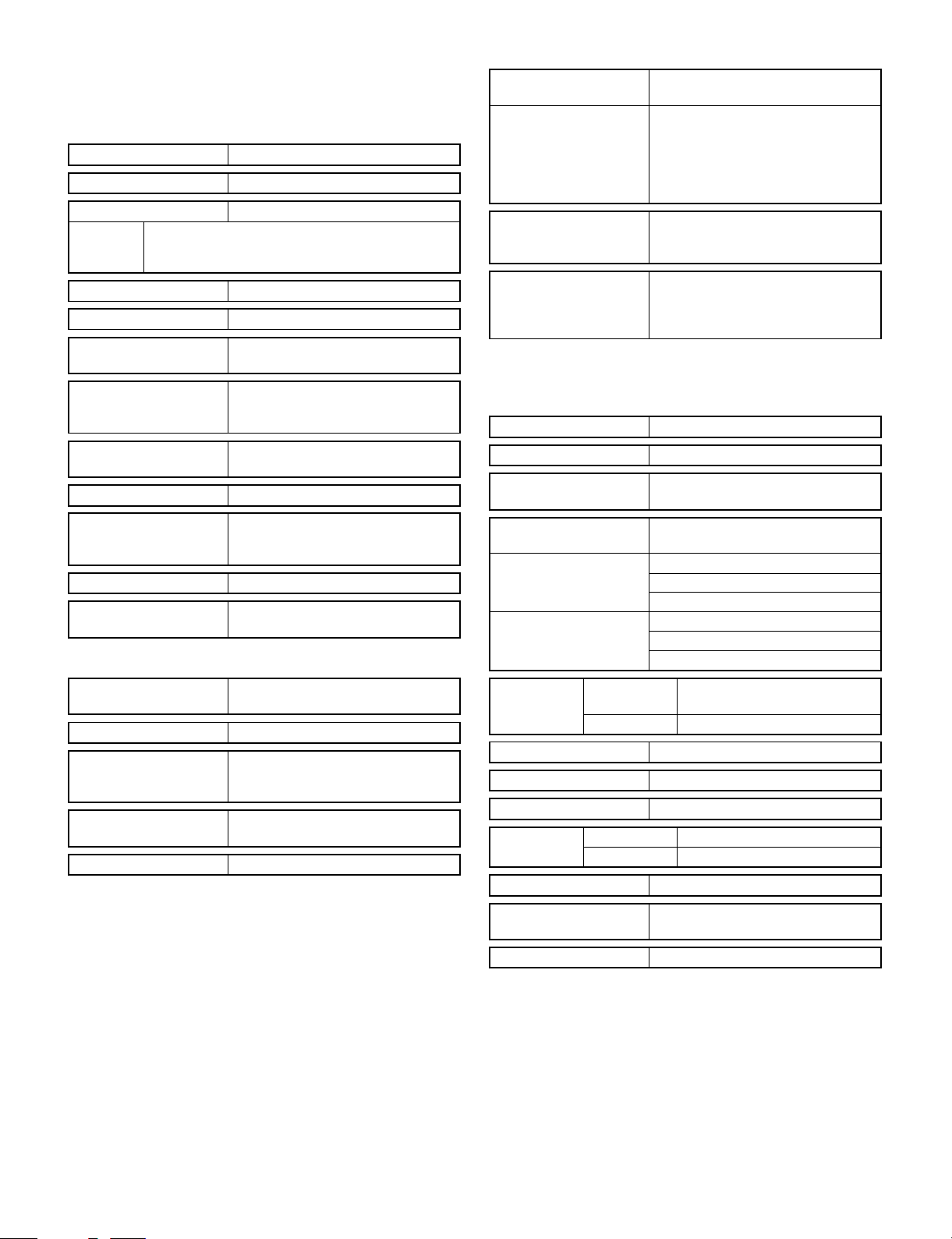

3. Supply parts

U.S.A., Canada

Name Content Life Product name

1 Photoconductor kit Photoconductor drum x 1

Cleaner blade x 1

Drum separation pawl x 2

2 Black developer Black Black developer (530g) x 10 50K x 10 SF-216MD1

3 Color developer Red Color developer (550g) x 10 10K x 10 SF-780MD2

Blue SF-780MD3

4 Black toner Black Black toner cartridge (210g) x 10 5K x 10 SF-216MT1

5 Color toner Red Color toner cartridge (210g) x 10 5K x 10 SF-216MT2

Blue SF-216MT3

6 Color developing unit

kit

7 Upper heat roller kit Upper heat roller x 1

8 Lower heat roller kit Lower heat roller x 1

Red Developing unit x 1

Blue SF-216NK3

Color developer (550g) x 1

Color toner cartridge (210g) x 1

Storage case x 1

Upper fusing separation pawl x 4

Fusing bearing (F) x 1

Lower fusing separation pawl x 2

Europe/U.K.

Name Content Life Product name

1 Photoconductor kit Photoconductor drum x 1

Cleaner blade x 1

Drum separation pawl x 2

2 Black developer Black Black developer (530g) x 10 50K x 10 SF-216LD1

3 Color developer Red Color developer (550g) x 1 10K SF-780DV2

Blue SF-780DV3

4 Black toner Black Black toner cartridge (210g) x 10 5K x 10 SF-216LT1

5 Color toner Red Color toner cartridge (210g) x 1 5K SF-216T2

Blue SF-216T3

6 Color developing unit

kit

7 Upper heat roller kit Upper heat roller x 1

8 Lower heat roller kit Lower heat roller x 1

Red Developing unit x 1

Blue SF-216K3

Color developer (550g) x 1

Color toner cartridge (210g) x 1

Storage case x 1

Upper fusing separation pawl x 4

Fusing bearing (F) x 1

Lower fusing separation pawl x 2

50K SF-216DR

SF-216NK2

100K SF-216UH

50K SF-216LH

50K SF-216DM

SF-216K2

100K SF-216UH

50K SF-216LH

Australia/New Zealand

Name Content Life Product name

1 Photoconductor kit Photoconductor drum x 1

Cleaner blade x 1

Drum separation pawl x 2

2 Black developer Black Black developer (530g) x 10 50K x 10 SF-216LD1

3 Color developer Red Color developer (550g) x 10 10K x 10 SF-780LD2

Blue SF-780LD3

4 Black toner Black Black toner cartridge (210g) x 10 5K x 10 SF-216LT1

5 Color toner Red Color toner cartridge (210g) x 10 5K x 10 SF-216LT2

Blue SF-216LT3

6 Color developing unit

kit

7 Upper heat roller kit Upper heat roller x 1

8 Lower heat roller kit Lower heat roller x 1

Red Developing unit x 1

Blue SF-216K3

Color developer (550g) x 1

Color toner cartridge (210g) x 1

Storage case x 1

Upper fusing separation pawl x 4

Fusing bearing (F) x 1

Lower fusing separation pawl x 2

2 – 3

50K SF-216DM

SF-216K2

100K SF-216UH

50K SF-216LH

Page 6

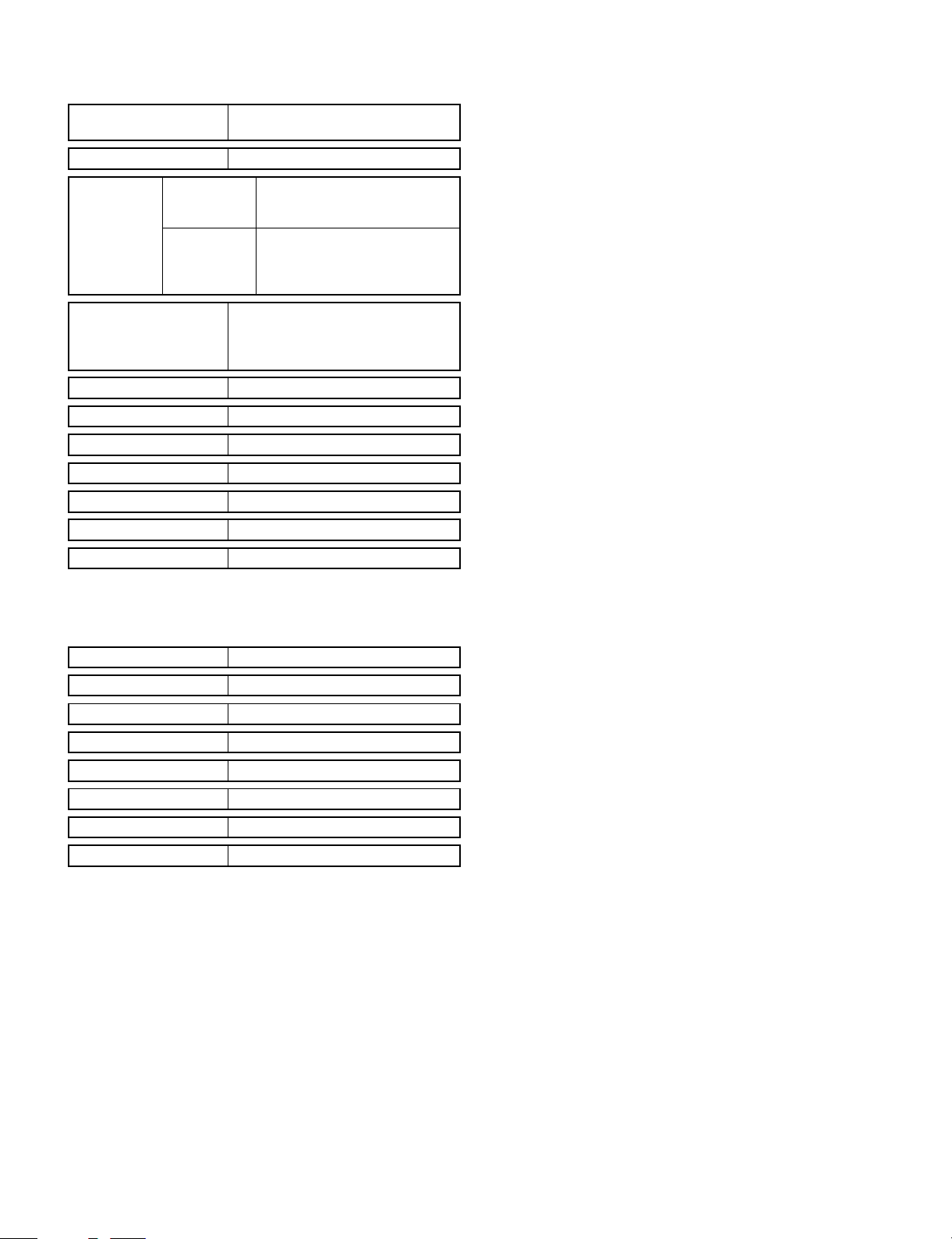

Middle and South America/Asia

Name Content Life Product name

1 Photoconductor kit Photoconductor drum x 1

2 Black developer Black Black developer (530g) x 10 50K x 10 SF-216CD1

3 Color developer Red Color developer (550g) x 10 10K x 10 SF-780LD2

Blue SF-780LD3

4 Black toner Black Black toner cartridge (210g) x 10 5K x 10 SF-216CT1

5 Color toner Red Color toner cartridge (210g) x 10 5K x 10 SF-216CT2

Blue SF-216CT3

6 Color developing unit

kit

7 Upper heat roller kit Upper heat roller x 1

8 Lower heat roller kit Lower heat roller x 1

Red Developing unit x 1

Blue SF-216SK3

Cleaner blade x 1

Drum separation pawl x 2

Color developer (550g) x 1

Color toner cartridge (210g) x 1

Storage case x 1

Upper fusing separation pawl x 4

Fusing bearing (F) x 1

Lower fusing separation pawl x 2

50K SF-216DR

SF-216SK2

100K SF-216UH

50K SF-216LH

Middle East/Africa (excluding Russia)

Name Content Life Product name

1 Photoconductor kit Photoconductor drum x 1

Cleaner bladex 1

Drum separation pawl x 2

2 Black developer Black Black developer x 10 50K x 10 A3SF216LD1

3 Black toner Black Black toner bottle (250g) x 10 6K x 10 A3SF116LT

4 Upper heat roller kit Upper heat roller x 1

Upper fusing separation pawl x 4

Fusing bearing (F) x 1

5 Lower heat roller kit Lower heat roller x 1

Lower fusing separation pawl x 2

50K A3SF216DM

100K A3SF216UH

50K A3SF216LH

Asia (Excluding Taiwan(AURORA)/Hong Kong (SRH))

Name Content Life Product name

1 Photoconductor kit Photoconductor drum x 1

2 Black developer Black Black developer x 10 50K x 10 A3SF216CD1

3 Black toner Black Black toner bottle (250g) x 10 6K x 10 A3SF116CT

4 Upper heat roller kit Upper heat roller x 1

Lower heat roller kit Lower heat roller x 1

5

Cleaner bladex 1

Drum separation pawl x 2

Upper fusing separation pawl x 4

Fusing bearing (F) x 1

Lower fusing separation pawl x 2

50K A3SF216DR

100K A3SF216UH

50K

A3SF216LH

2 – 4

Page 7

4. Optional specifications

(1) Automatic document feeder (ADF)

<SF-A15>

Original set direction Face down

Original set position Center reference

Original transport system Belt (half size) system

Remark For an original of A4 or greater, it is once transported

to the paper exit section and switched back to set the

next original.

Original feed sequence Top taking (Face up exit)

Original size A3 ∼ A5/11" x 17" ∼ 8 1/2" x 5 1/2"

Original change speed

(S → S)

Original weight 35 ∼ 128g/m

Original set quantity 50 sheets, 80 ~ 128 g/cm2,

Original stop system Stopper system

Dimensions 586 (W) x 525 (D) x 99 (H) (mm)

Weight About 11kg

Power source AC100V ∼ 200V supplied from the

Functions

Original sensing on the

tray

Tray form Slide system

Sensing size Inch series: 11" x 17", 8 1/2" x 14", 8

Original mixture Allowed (However, no linkage with the

Original reverse NO

16 sheets/min (SF-2116), 18

sheets/min (SF-2118)

2

Thin paper mode (35 ∼ 50g/m2)

Standard mode (50 ∼ 128g/m2)

thickness max. 5 mm

(Width: when the tray is installed.

Height: Excluding the auxiliary guide.)

copier’s power section.

YES (Scanning read for uncertain size

originals.)

1/2" x 11", 8 1/2" x 11"R, 8 1/2" x 5 1/2"

AB series: A3, B4, A4, A4R, A5

AMS)

Display section

1 Original feed display

section

2 Original remaining

display

SDF mode Selection between the SDF mode and

Thin paper mode Selection between the thin paper

ADF shows the operation valid state.

Lighted when an original is set.

When the original transport cover is

used as the original cover, the LED

lights up on completion of the final

exposure.

When the transport cover is opened,

the LED goes off.

the ADF mode is possible. (Selectable

with the user program.)

mode and the standard mode is

possible. (Selectable with the user

program.)

(2) 10-bin sorter

<Model name: SF-S17>

Type Copier installation type/Hanging type

Distribution system Bin shift by lead screw

No. of bins 10 bins (The top bin is used also for

non-sort.)

Capacity 30 sheets/bin (L4/letter size), 100

Sorting 30 sheets (A4/letter)

Grouping 20 sheets (A4/letter)

Paper size (Non-sort) A3 ∼ A6 (Postcard)R/11" x 17" ∼

(Sort/group) A3 ∼ A5/11" x 17" ∼ 8 1/2" x 11"

Process capacity 16/18 sheets/min

Paper transport Center reference

Paper reception Face up

Paper weight (Non-sort) 52 ∼ 128g/m2 (14 ∼ 34lbs)

(Sort/group) 56 ∼ 80g/m2 (15 ∼ 21lbs)

Power source Supplied from the copier.

sheets for the top bin only.

15 sheets (B4/legal)

15 sheets (A3/W letter)

15 sheets (B4/legal)

15 sheets (A3/W letter)

8 1/2" x 5 1/2"

Dimensions 335 (W) x 493 (D) x 298 (H)

Weight 7kg

2 – 5

(Width: Including the tray.)

Page 8

(3) Multi manual feed unit

<Model name: SF-MF15>

Paper size A3 ∼ A6 (Postcard) R

11" x 17" ∼ 8 1/2" x 5 1/2"

Paper weight 52 ∼ 128g/m2, (14 ∼ 34lbs)

Paper feed

capacity

Paper kind Standard paper, specified paper,

Paper empty sense NO

Manual feed size sense NO

Paper feed tray Folding type

Paper set Same size only

Power source Supplied from the copier.

Dimensions (W x D x H) 350 (W) x 493 (D) x 185mm (H)

Weight About 2kg

MUlti paper

feed

Single paper

feed

56 ∼ 80g/m2 (15 ∼ 21lbs) (50

sheets)

Postcard (20 sheets)

52 ∼ 128g/m2, (14 ∼ 34lbs) and

special paper (For paper of

105g/m2 (28lbs) or heavier, A4

size or lower.)

special paper, OHP film, Second

original paper, postcards (without

folding)

(4) Two-step paper feed unit (SF-2118 only)

<Model name: SF-CM15>

Paper size A3 ∼ A5

Paper feed capacity 250 sheets x 2 steps

Paper weight 56 ∼ 80g/m2 (15 ∼ 21 lbs)

Paper kind Standard paper, recycled paper

Size selection Tray replacement/user handling

Power source Supplied from the copier.

Dimensions (W x D x H) 570 (W) x 570 (D) x 188mm (H)

Weight About 14kg

2 – 6

Page 9

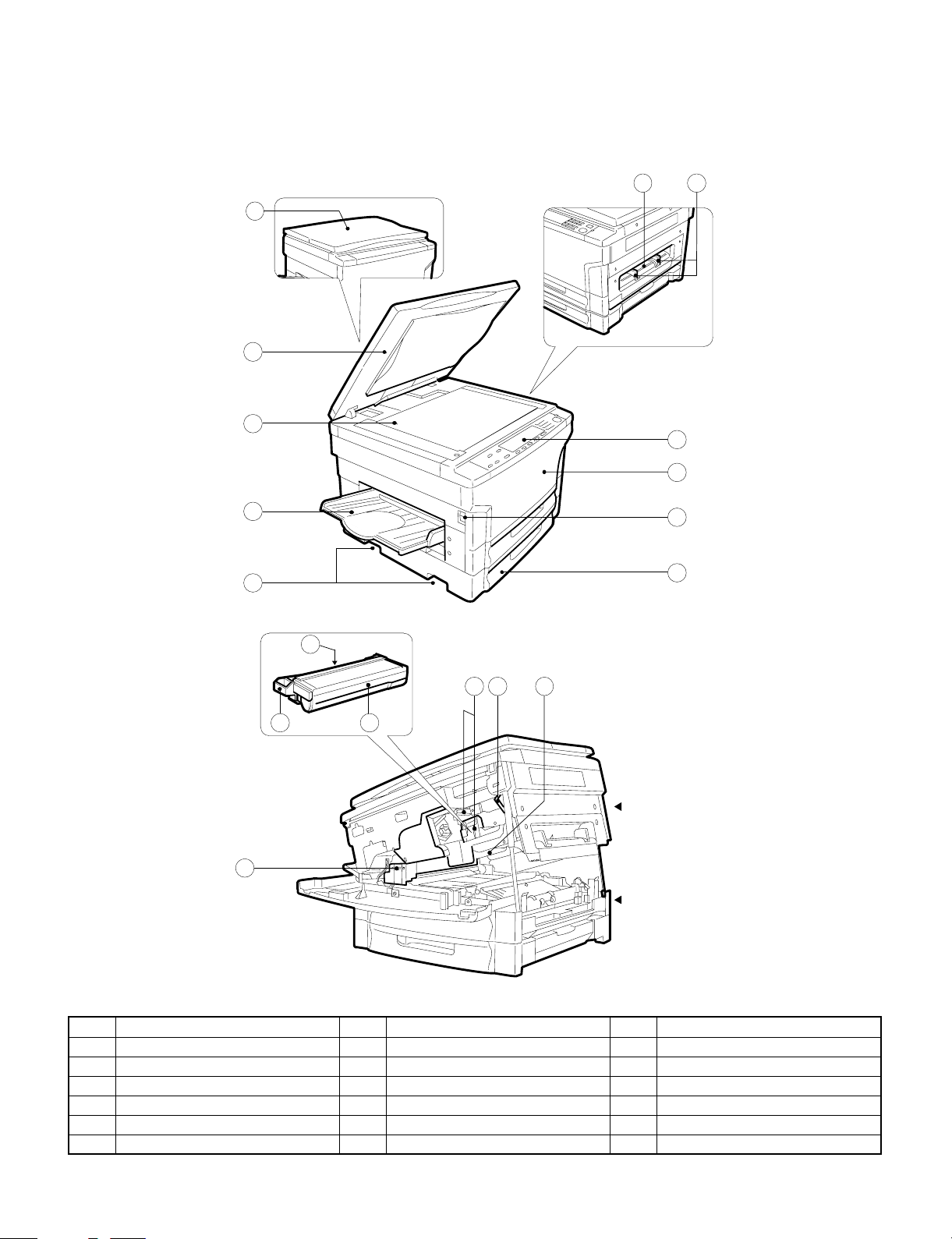

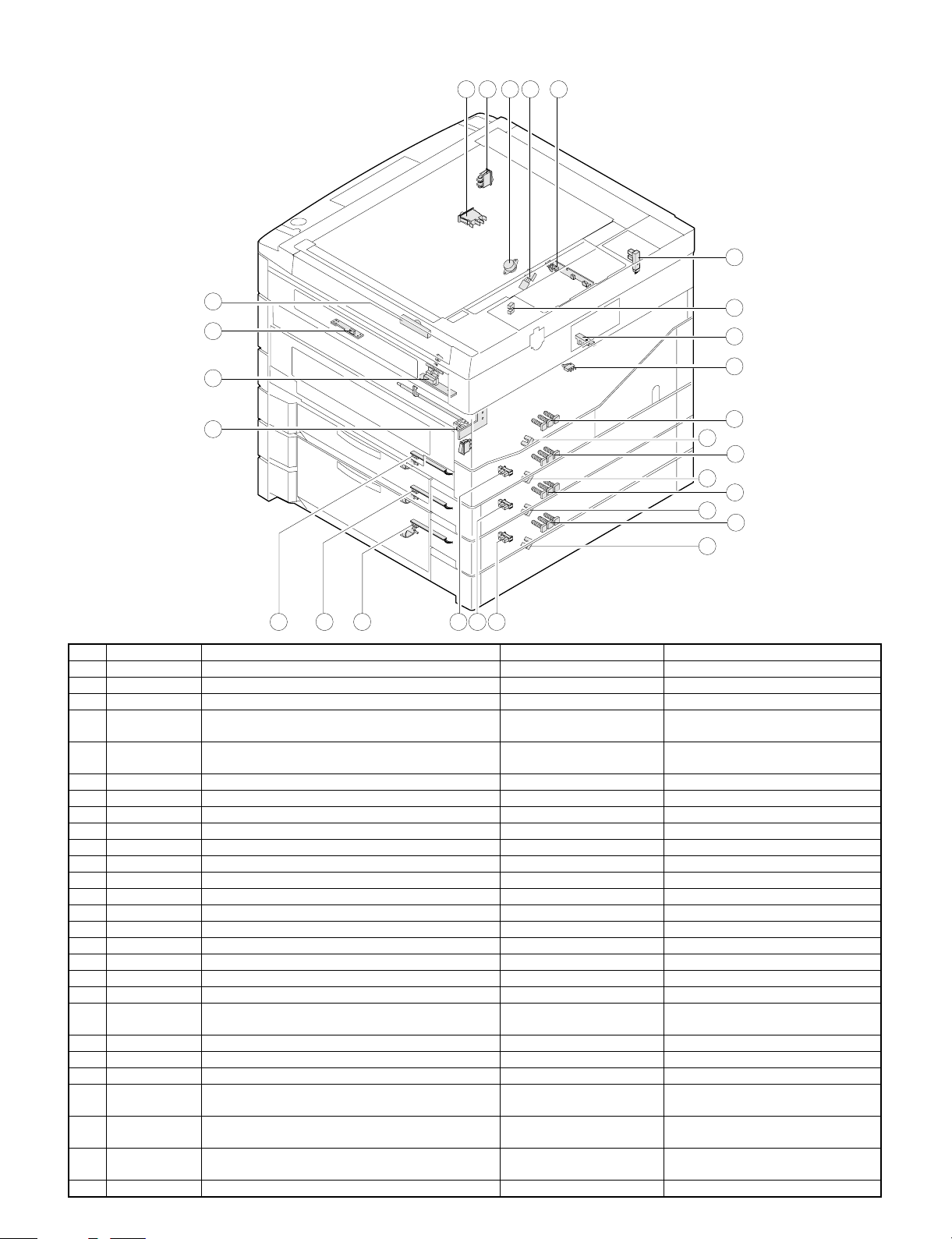

[3] PRODUCT VIEWS

1. External view and internal structure

1

2

3

67

8

9

4

5

12 14

17

10

11

13

15 16 18

Upper unit

Lower unit

No. Name No. Name No. Name

1 Original cover 2 Original table 3 Paper exit tray

4 Grip 5 Manual feed unit 6 Manual feed original guide

7 Operation panel 8 Front cover 9 Power switch

F Paper tray G Developing unit grip H Developing unit strap

I Toner hopper J Developing unit lock lever K Release lever

L Fusing unit M Drum

3 – 1

Page 10

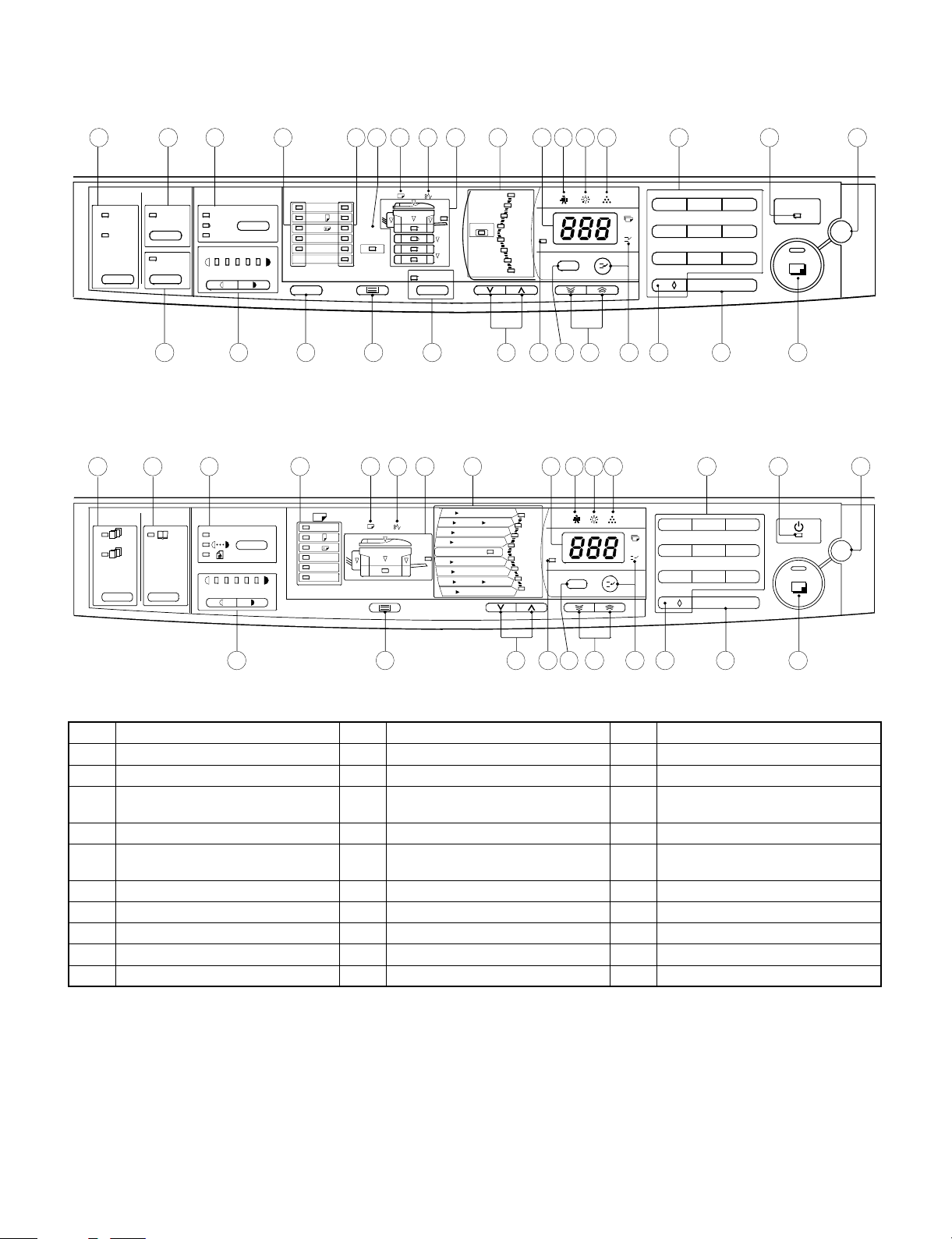

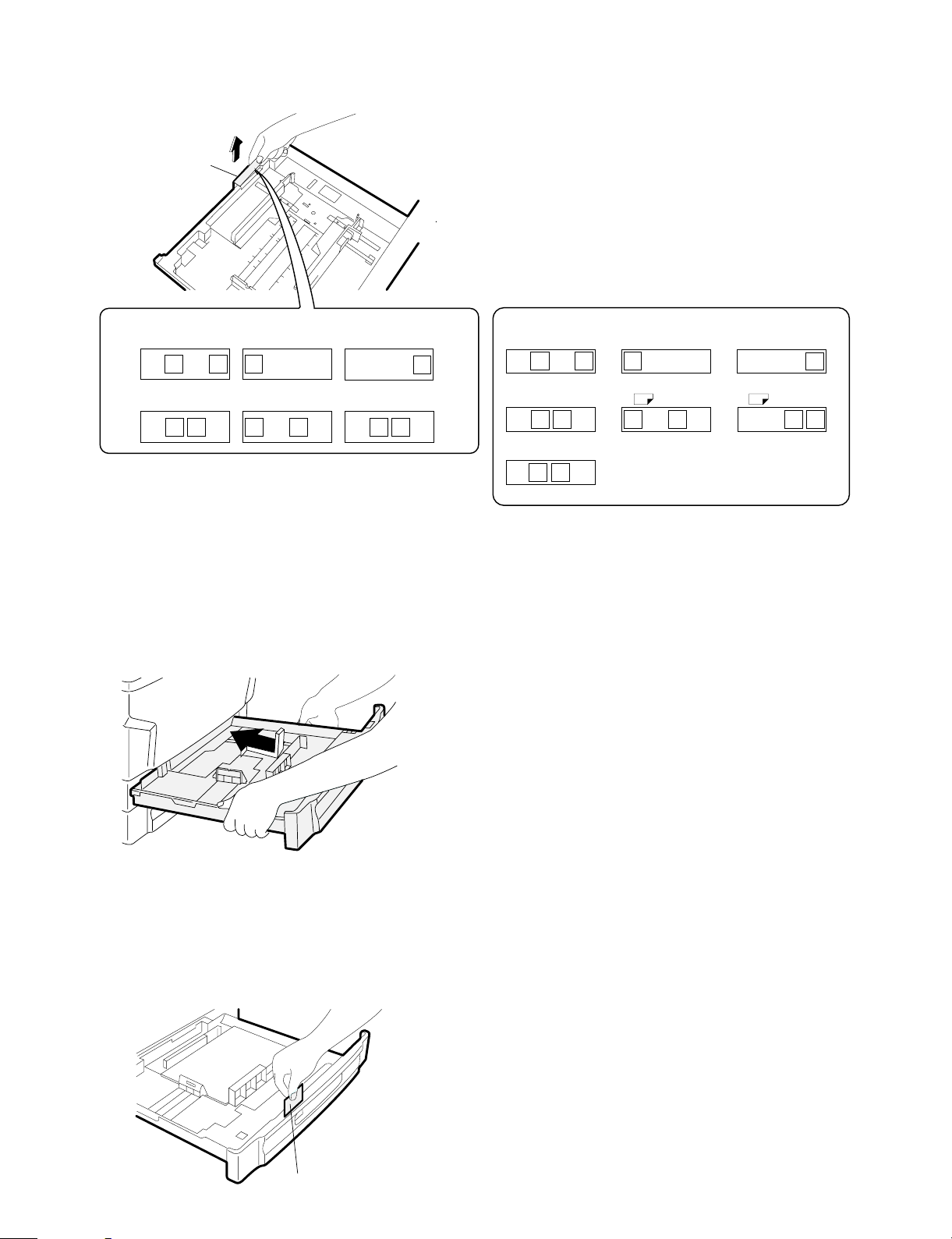

2. Operation panel

SF-2118

1

SORT ER

SORT

GROUP

SF-2116

1

2

DUAL PAGE

COPY

EDGE

ERASE

3 4 5 6 7 8 9 10 11121314 15 16 17

EXPOSURE

AUT O

MANUAL

PHOTO

0 1 2 3 4

. . . .

ORIGI NA L

SIZE

ORIGINAL S IZE

ENTER

EXTRA

PAPER

SIZE

A3

A4

A4

AUTO PAPER

A5

SELEC T

B4

TRAY SELECT

AUTO I MAG E

PRESET

RAT IO

100%

115%

86%

122%

81%

141%

70%

200%

50%

0 1 2

ZOOM

%

3

6 4 8 5 9

//

18 19 2 0 21 22 23 24 25 26 27 28 2 9 30

2

...

0,2,3,

...

0,2,3,

...

1,2,

...

0,1,

357

AUTO

0

1 2 3 4

. . . .

A3

A4

A4

A5

B4

EXTRA

8

910 11121314 15 16 17

A5

A4

A4

B4

A3

B4

A4

A3

A3

A3 A5

B4

A3

100%

B4

A4

A5 A3

200%

A4

141%

122%

115%

ZOOM

86%

81%

70%

A4

A5

%

50%

012

3

64859

// C

POWER SAVE

CA

C

CA

19 21 23 24 26 27 28 29 30

25

No. Name No. Name No. Name

1 Sorter key and indicators 2 Dual page copy key and indicators 3 Auto/Manual/Photo key and indicators

4 Original size indicators 5 Paper size indicators 6 Auto paper select indicators

7 Paper required indicator 8 Misfeed indicator 9 Paper feed location/misfeed location

indicators

F Preset ratio indicators G Copy quantity display H Maintenance required indicator

I Developer replacement required

J Toner required indicator K 10-Key pad

indicator

L Power save indicator M Clear all key N Edge erase

O Light and dark keys and indicator P Original size enter key Q Tray select key

R Auto image key and indicator S Copy ratio keys T Zoom indicator

U Copy ratio display key V Zoom keys W Interrupt key and indicator

X Zero/readout key Y Clear key Z Print button and ready indicator

3 – 2

Page 11

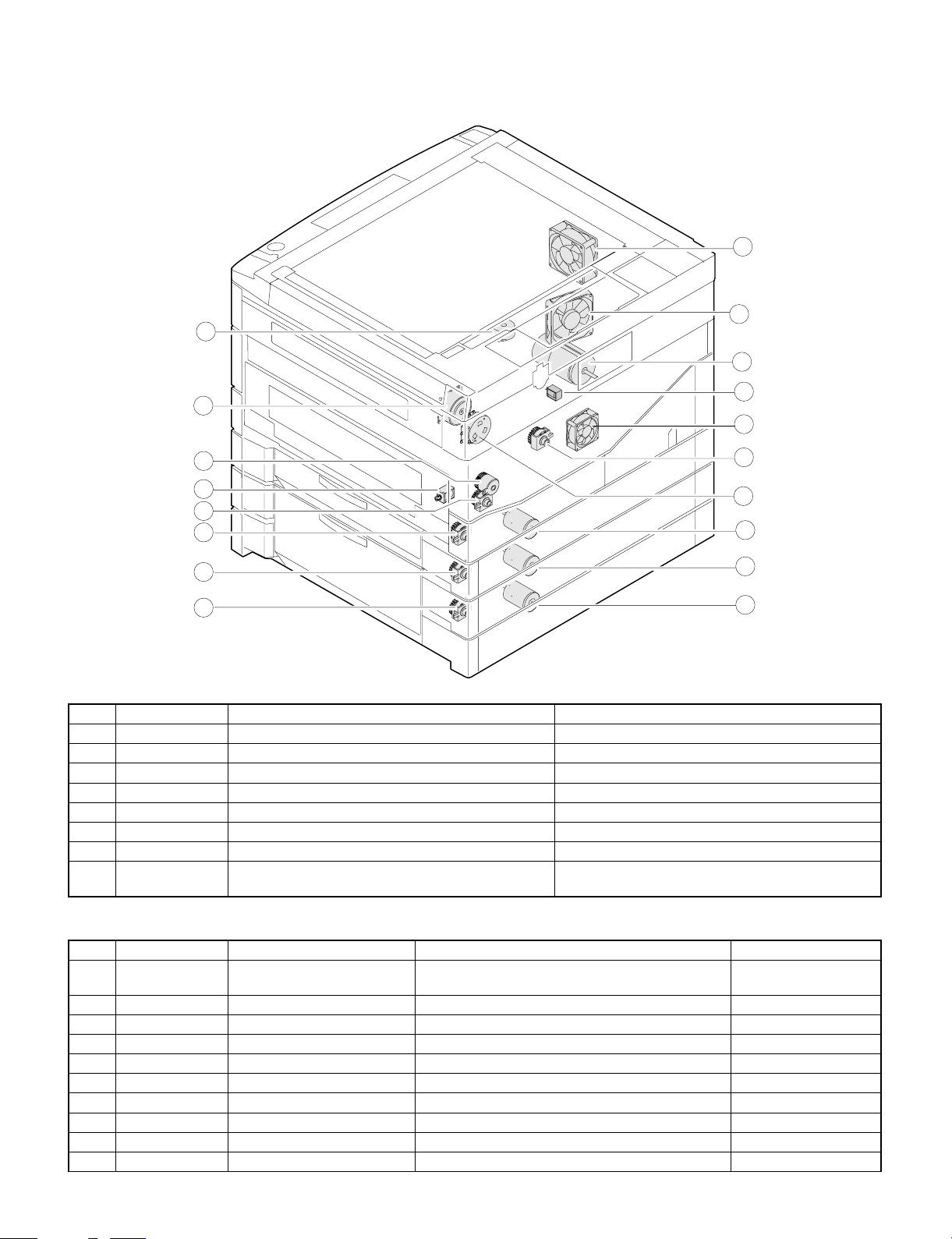

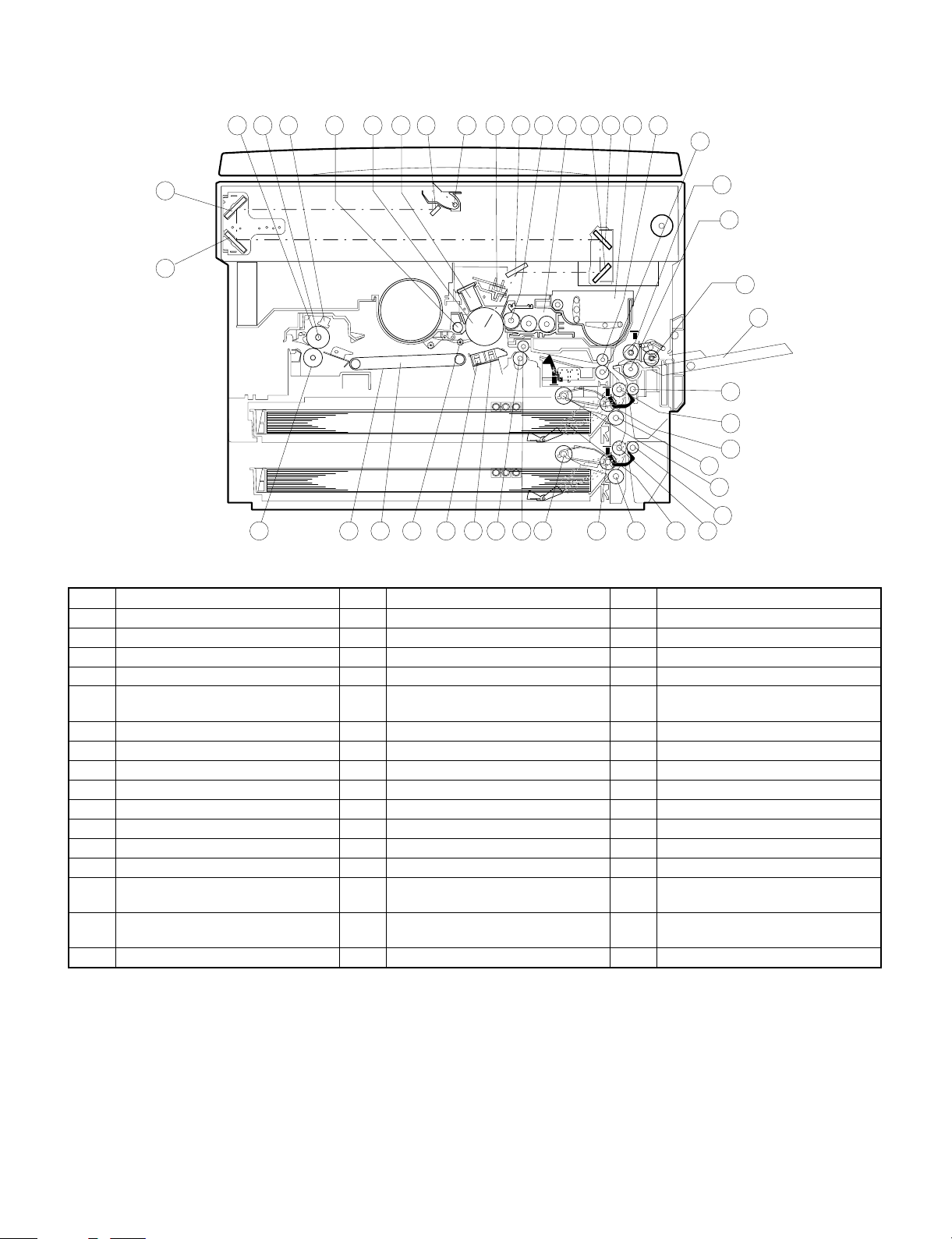

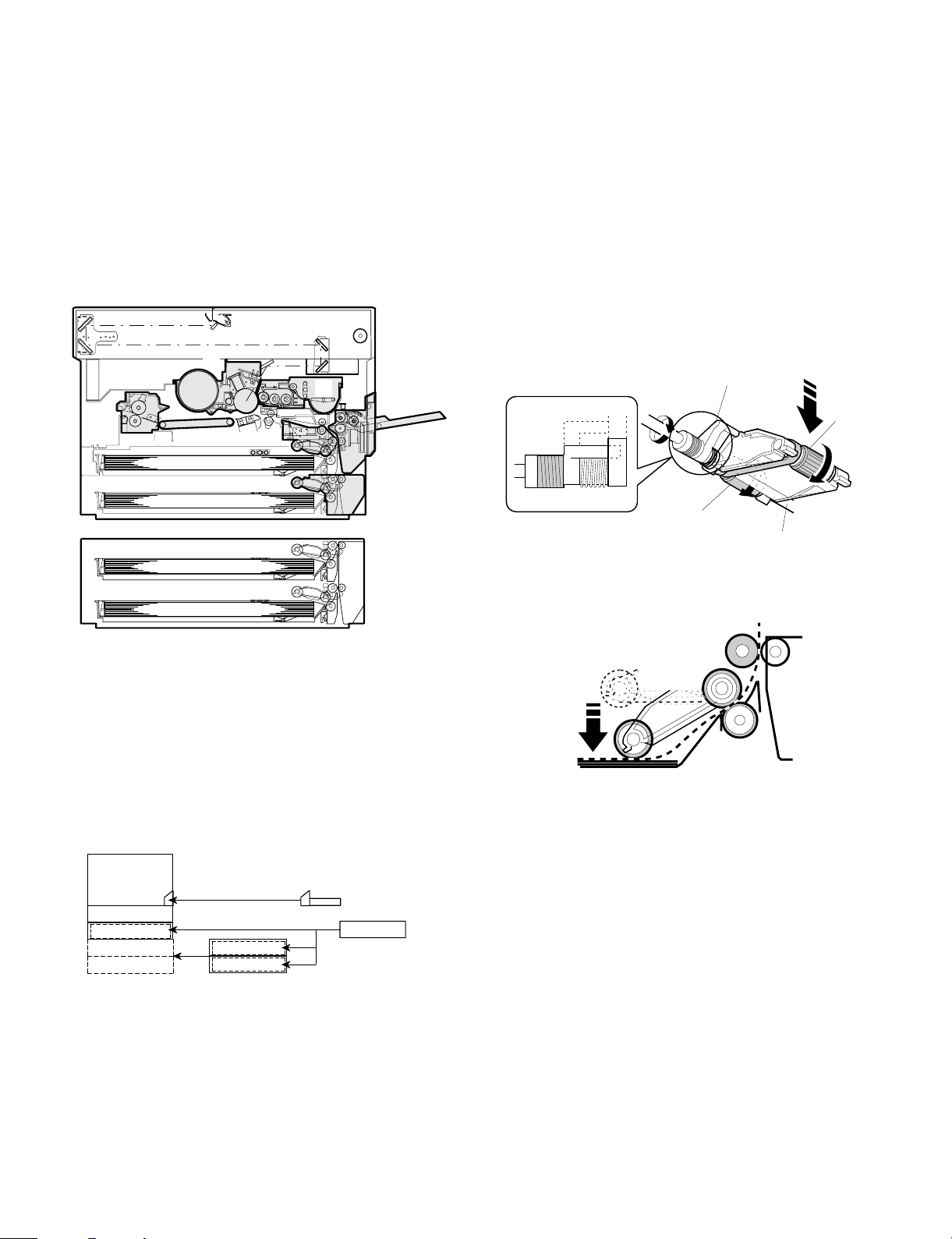

3. Clutches, solenoids, and motors

Clutches and solenoids

12

9

11

10

14

3

8

4

5

6

7

No. Signal name Name Functions, operations

1 PSPS Paper separation solenoid Paper separation solenoid drive

2 RRC Resist roller clutch For resist roller rotation

3 TRC Transport roller clutch For transport roller rotation

4 CPFC1 Tray paper feed clutch For paper feed roller rotation

5 CPFC2 Tray paper feed clutch (SF-2118) For paper feed roller rotation

6 CPFC3 Option tray paper feed clutch For paper feed roller rotation

7 CPFC4 Option tray paper feed clutch For paper feed roller rotation

8 MPFS Manual paper feed solenoid

(Option 2-step paper feed unit: SF-MF15 only)

For pressing take-up roller

1

18

2

13

15

16

17

Motors

No. Signal name Name Functions, operations Type

9 VFM Ventilation fan motor Used to ventilate around the fusing section, cools

down the machine, and remove ozone.

F MM Main motor Used to drive the body. DC brush

G CFM Optical system cooling fan Used to cool and ventilate the optical system. DC brushless

H LM Lens motor Used to move the optical lens. DC stepping

I TM Toner motor Used to stir toner. DC synchronous

J MRM Mirror motor Used to move the mirror base. DC stepping

K CS2M Paper feed motor (SF-2118) Used to drive the paper feed roller. (SF-2118) DC brush

L CS3M Option paper feed motor Used to drive the option paper feed roller. DC brush

M CS4M Option paper feed motor Used to drive the option paper feed roller. DC brush

N SMF Suction fan motor Used to ventilate the suction section. DC brushless

3 – 3

DC brushless

Page 12

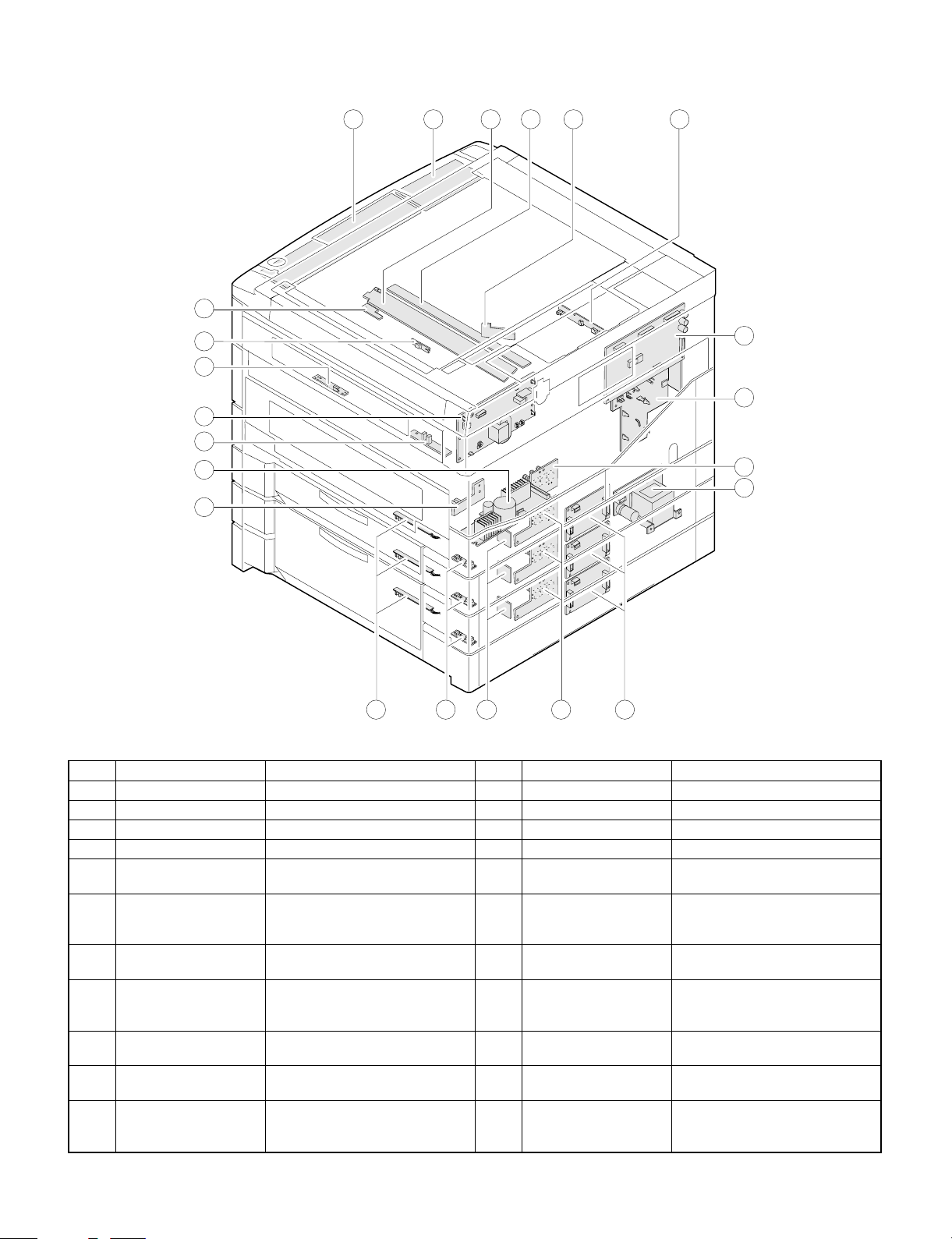

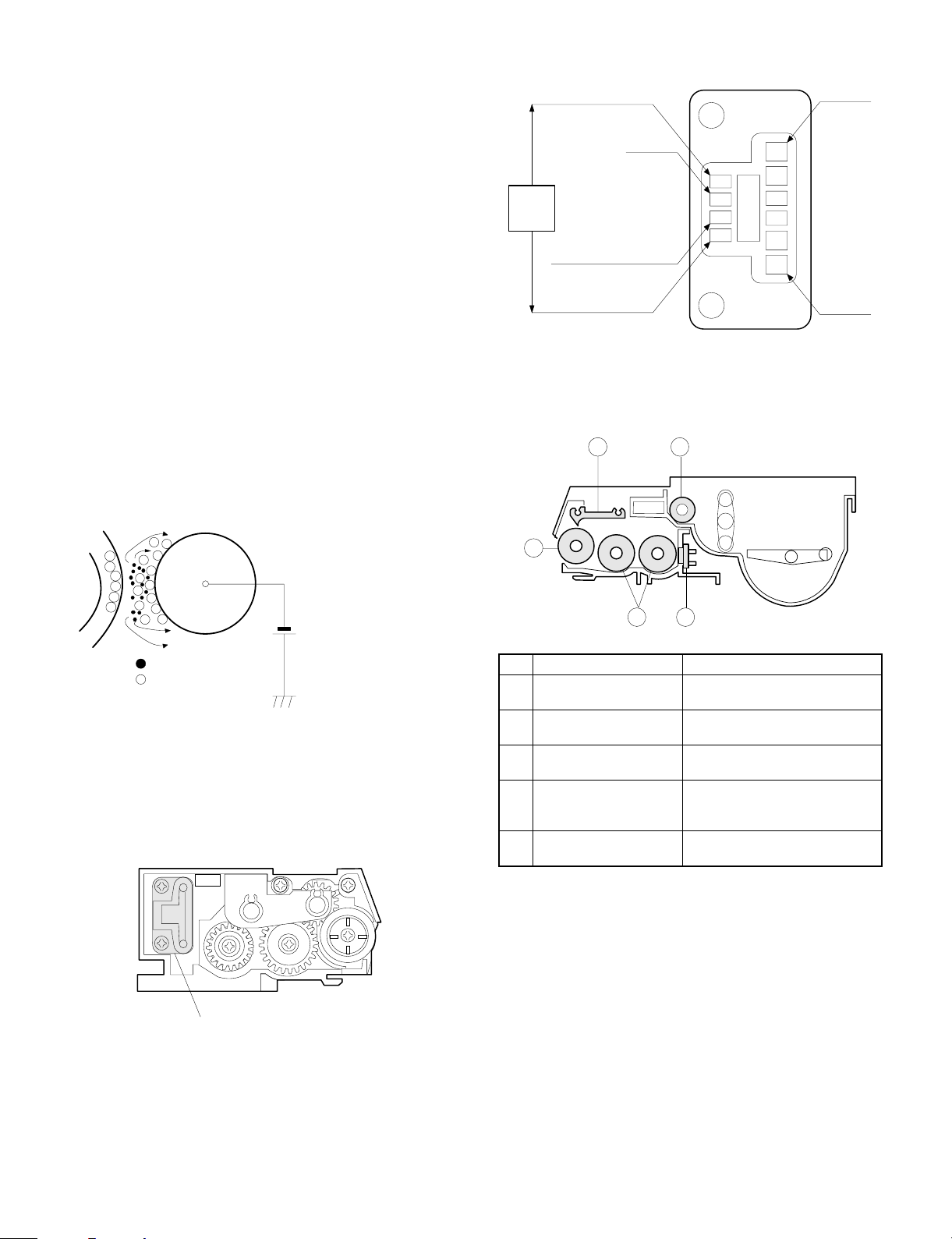

4. PWB

22

18

20

19

10

17

2

6

213 4 51

7

8

9

11

16 1214 1315

No Name Description No Name Description

1 Operation PWB A Operation input, display control 2 Operation PWB B Operation input, display control

3 Blank lamp PWB Used to control the blank lamp. 4 DL PWB Used to drive the discharge lamp.

5 Optical PWB AE sensor and lens motor interface 6 Process control PWB Used to sense the toner density.

7 Main PWB Used to control the body. 8 AC circuit PWB AC power input

9 CSD PWB Used to sense the body cassette

size.

G Paper feed power PWB Used to supply power to drive the

paper feed unit.

I CSD B PWB Used to sense the cassette size of

2nd ∼ 4th tray.

K Tray module PWB Vertical transport of 2nd ∼ 4th

cassette, JAM detection, paper

feed clutch interface

M Paper feed I/F PWB Body paper detection, paper feed

clutch interface

O PPD PWB Body PR roller JAM detection P High voltage PWB Process high voltage, developing

Q PDD PWB Body paper exit section JAM

detection, ventilation fan motor

interface

F DC circuit PWB DC power input

H Motor control PWB Used to drive and control the

paper feed motor and the

transport motor.

J Motor sensor PWB Encoder for 2nd ∼ 4th paper feed

motor

L DPPD PWB Vertical transport of 2nd ∼ 4th tray,

JAM detection and cover open

detection

N PID PWB Manual paper entry detection

bias voltage supply

R Mark sensor PWB Drum marking point detection

3 – 4

Page 13

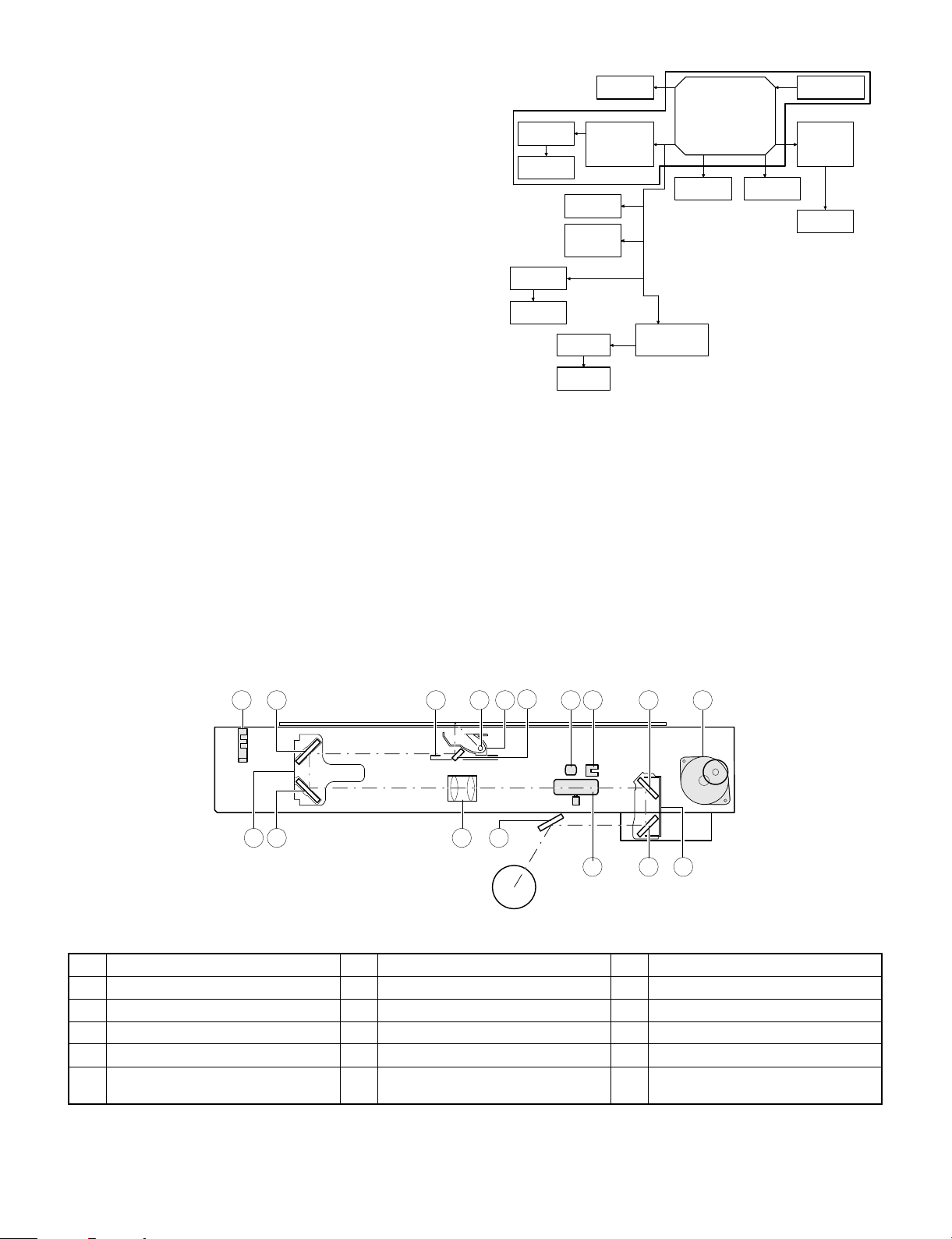

5. Sensors and switches

2 3 5 4 6

7

1

27

11

23

2224 25 26 2120

16

17

18

19

10

8

9

12

13

14

15

No. Signal name Name Type Operation, function

1 TCS Toner density control sensor Transmission sensor HIGH when toner density falls.

2 ILSW Front cabinet open/close switch Interlock switch ON when closed.

3 MSW Power switch Seesaw switch

4 TH Fusing heater thermistor Thermistor Greater resistance at low

temperature

5 TS Fusing heater thermostat Thermostat Contact open at abnormally high

temperature

6 POD Paper exit paper sensor Transmission photo sensor LOW when paper is present.

7 MHPS Mirror home position sensor Transmission photo sensor HIGH when paper is sensed.

8 MMRE Main motor encoder Transmission photo sensor Rotation pulse output

9 TFD Waste toner full switch Lead switch HIGH when sensed.

F LHPS Lens home position sensor Transmission photo sensor LOW when reduction.

G PPD Paper transport sensor Transmission photo sensor LOW when paper is present.

H 1 CSD0 ∼ 2 Body upper tray paper size detection Tact switch Shorted when the switch is turned on.

I 2 CSD0 ∼ 2 Body lower tray paper size detection (SF-2118) Tact switch Shorted when the switch is turned on.

J 3 CSD0 ∼ 2 Option upper tray paper size detection Tact switch Shorted when the switch is turned on.

K 4 CSD0 ∼ 2 Option lower tray paper size detection Tact switch Shorted when the switch is turned on.

L PED1 Body upper tray paper presence detection Transmission photo sensor HIGH when paper is present.

M PED2 Body lower tray paper presence detection (SF-2118) Transmission photo sensor HIGH when paper is present.

N PED3 Option upper tray paper presence detection Transmission photo sensor HIGH when paper is present.

O PED4 Option lower tray paper presence detection Transmission photo sensor HIGH when paper is present.

P Motor sensor 2 Body lower stage paper feed motor encoder sensor

Transmission photo sensor Rotation pulse output

(SF-2118)

Q Motor sensor 3 Option upper paper feed motor encoder sensor Transmission photo sensor Rotation pulse output

R Motor sensor 4 Option lower paper feed motor encoder sensor Transmission photo sensor Rotation pulse output

S DPPD1 Body upper tray paper transport sensor Transmission photo sensor LOW when paper is present.

T DPPD2 Body lower tray paper transport sensor (SF-2118) Transmission photo sensor LOW when the side door is open

and paper is present.

U DPPD3 Option upper tray paper transport sensor Transmission photo sensor LOW when the option door is open

and paper is present.

V DPPD4 Option lower tray paper transport sensor Transmission photo sensor LOW when the option door is open

and paper is present.

W PID Single manual feed paper entry sensor Transmission photo sensor HIGH when paper is present.

3 – 5

Page 14

6. Rollers, mirrors, etc.

30 29 28

20 19 18 3 4 17 7 34 16

6

5 8 14

15

2

12

13

1

11

9

32

33

35

36

37

39

31 27 26 25 24 23 22 21 43 42 41

38 40

No. Name No. Name No. Name

1 No. 3 mirror 2 No. 2 mirror 3 No. 1 mirror

4 Copy lamp 5 No. 4 mirror 6 No. 5 mirror

7 No. 6 mirror 8 Developing unit toner box 9 Manual tray

F — G Take-up roller (SF-MF15 only) H Paper feed roller (SF-MF15 only)

I Reverse roller (SF-MF15 only) J PS front roller follower roll

(SF-MF15 only)

L Developing unit M Blank lamp N Main charger unit

O Photoconductor drum P Cleaner unit Q Resist roller follower roll

R Resist roller S Transfer charger T Separation charger

U Drum separation pawl V Suction unit W Suction belt

X Fusing thermistor Y Heater lamp Z Upper heat roller

[ Lower heat roller \ Transport roller (upper) follower roller ] Transport roller (upper)

^ Developing magnet roller _ Tray paper feed roller ‘ Tray paper feed reverse roller

a Tray paper feed take-up roller b PE actuator c Transport roller (lower) (SF-2118)

d Transport roller (lower) follower roller

(SF-2118)

g Tray paper feed take-up roller

(SF-2118)

@ Since \, ], _ ~ g are the same as in the SF-C M 15 (option), they are omitted.

@ The above figure shows the machine with the SF-MF15 installed.

e Tray paper feed reverse roller

(SF-2118)

K PS front roller (SF-MF15 only)

f Tray paper feed roller (SF-2118)

3 – 6

Page 15

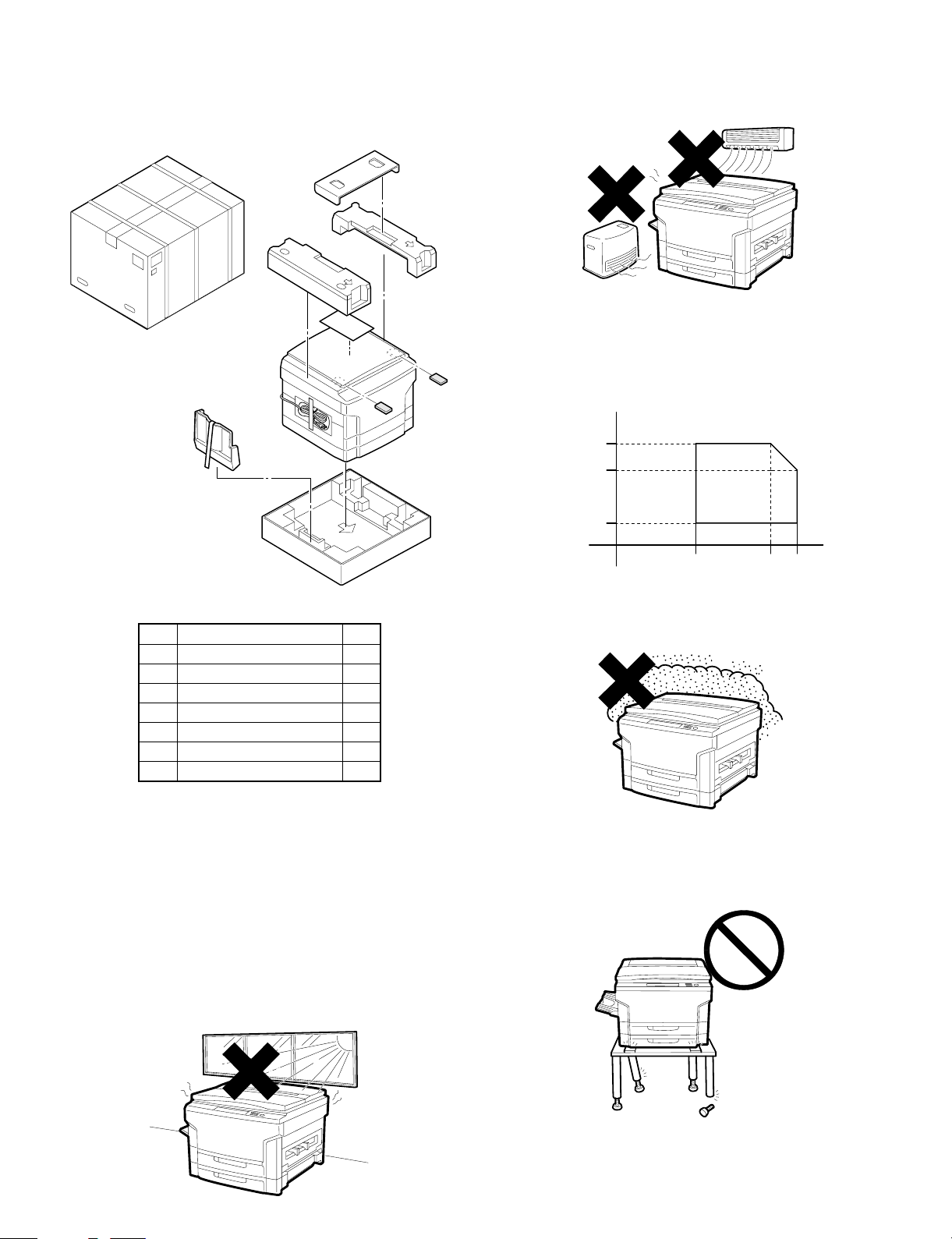

[4] UNP ACKING AND INSTALLATION

1. Unpacking

2 Avoid high temperature and high humidity, and avoid sudden

temperature change. (Avoid installation near a cooler or a heater.)

If not, paper absorbs moisture and dew forms in the machine,

causing paper jam or degraded image quality.

(Standard condition): The best condition to use the machine.

20 ∼ 25 °C, 65±5% RH

(Temperature and humidity): 15 ∼ 30 °C

HR

%

85

65

20% ∼ 85% RH

35 °C for 65%

Humidity

Packing material /accessory list

Name Q’ty

1 Paper exit tray 1

2 Instruction Manual 1

3 Maintenance card 1

4 Dust cover 1

5 Service contract 1

6 Installation manual 1

7 Magnification select label 1

2. Installat ion

Install a ti on c onditions

The surrounding conditions of the machine affect the machine performance gr eatly. U se great care for the following items:

(1) Environm en t

1 Avoid direct sunlight, and avoid installation near the window.

(Curtains or blinds must be shut completely.)

If not, the plastic parts and the original cover may be deformed.

Even if the window is of frosted glass, there is no difference.

20

15 30 35

3 Avoid dusts and vibrations.

If dusts enter the machine, malfunctions may occur.

4 Avoid installation to an unstable place.

Keep the machine in horizontal state to maintain the performances.

˚C

4 – 1

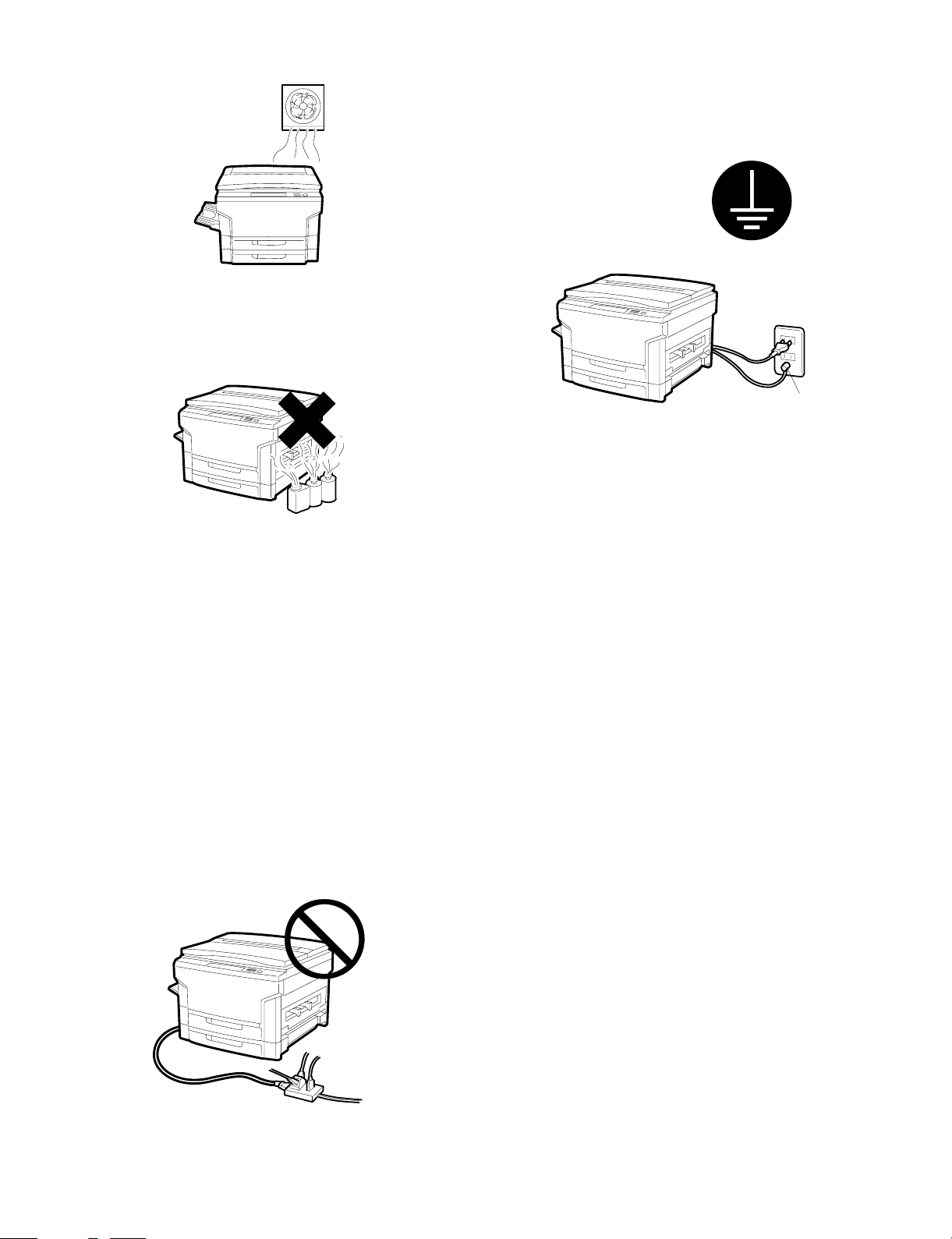

Page 16

5 Avoid installation to a poorly ventilated place.

6 Avoid installation to a place where there are flammable materials

or ammonia gas, etc. If the machine is installed near a diazo

copier, the picture quality may be degraded and malfunctions may

occur.

(5) Grounding wire connection

1 Connect the grounding wire to prevent against a danger.

2 When connecting the grounding wire, connect only to the ground-

ing object (the grounding terminal of the power outlet, etc.) and

never connect to a gas pipe.

Grounding

terminal

7 Install near a power outlet.

(2) Space around the machine

Install the machine with its rear side about 10cm apart from the wall in

order to allow space for ventilation by the cooling fan.

Also allow eno ug h space around th e ma ch ine for proper operation.

(3) Installation base

Set the machine in horizontal position in the following procedure.

Be sure to use a le veling instrumen t (UKOGM0054CSZZ) to install

the machine on a flat, horizontal place.

[Note] If the machine is not in horizontal position, the toner density

control function may not work normally, resulting in degraded

picture quality.

(4) Power sou rc e

1 Use the power source of the rated capacity.

2 Avoid complicated wiring. If not, the breaker or the fuse may be

blown off to cause a fire.

4 – 2

Page 17

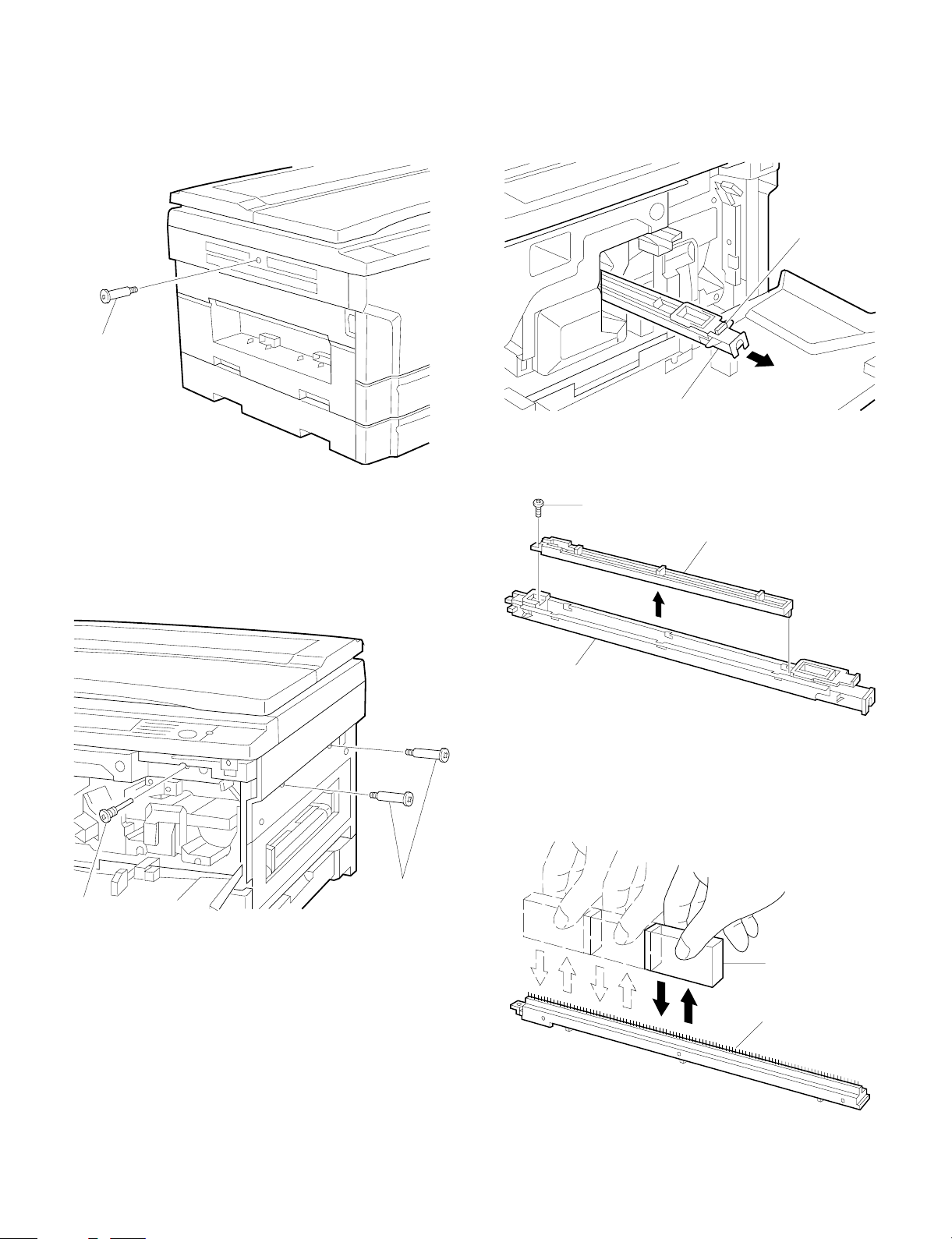

3. Optical system lock release

4. Charger cle ani ng

A. No. 2/3 mirror unit lock release

Remove the one fixing screw of the No. 2/3 mirror unit on the let side

of the copier.

Mirror unit

fixing screw

B. Lens and No. 4/5 mirror unit lock release

Remove two fixing screws of the No. 4/5 mirror unit on the right side

of the copier,

Open the fr ont cabinet and r emove one fixi ng screw of the lens on the

lower side of the operation panel.

A. Main charger unit electrode cleaning

1 Press the hook section of the main charger unit to release lock,

and pull out and remove the main charger unit from the copier.

Hook

Main charger unit

2 Remove one fixing screw of the main charger unit (on the back

side).

Fixing screw

Electrode section

Lens fixing screw

Main charger un i t

3 Press the electrode cleaner onto the tips of the electrode so that

the tips are inserted into the cleaner a few times to clean.

[Note] Do not move the cleaner back and forth with the electrode

tips inserted into it.

Mirror unit

fixing screw

Electrode

cleaner

Electrode

section

4 – 3

Page 18

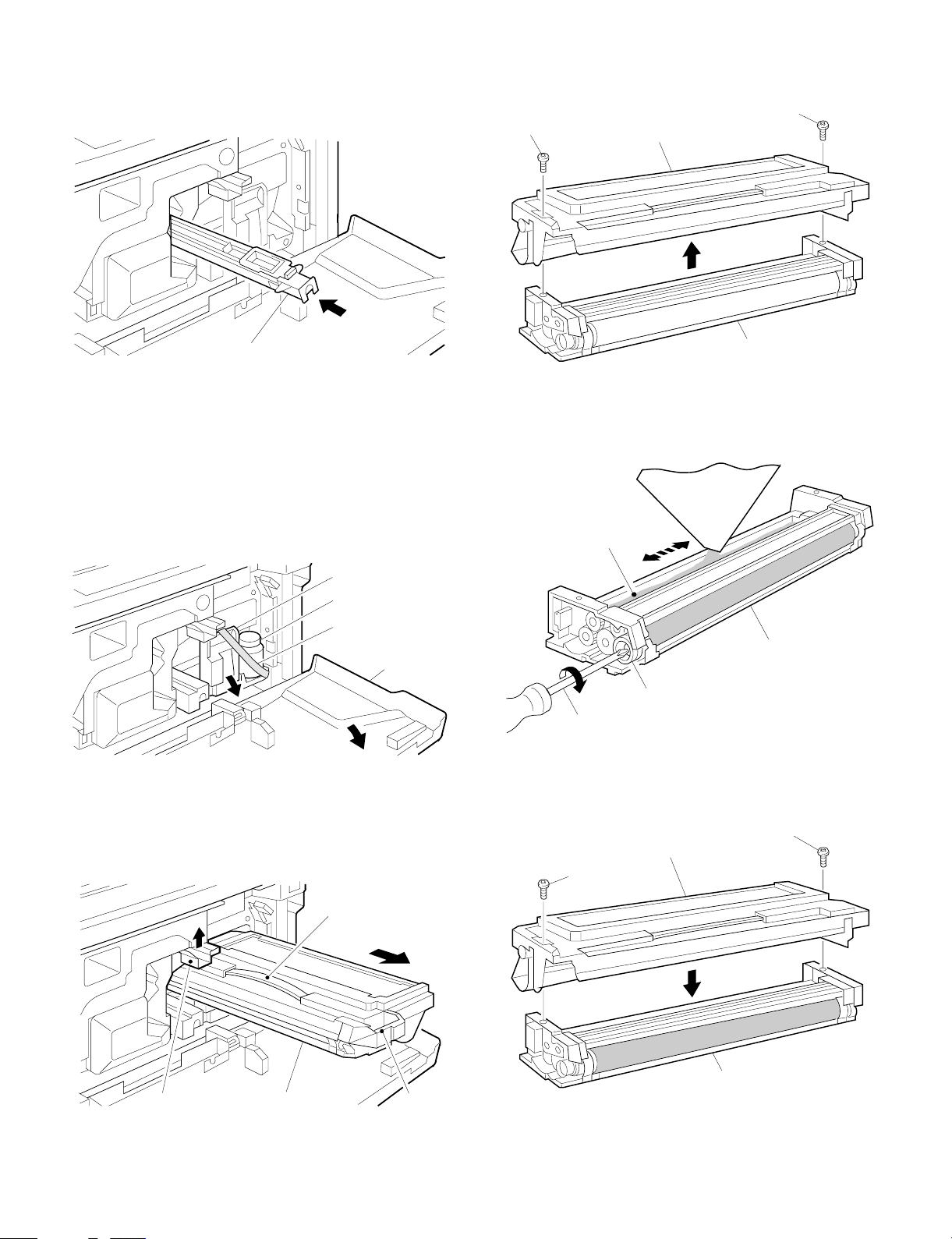

4 Return the electrode section to the original position and fix it with a

screw.

5 Insert the main charger unit along the guide groove in the copier

fully to the bottom.

3 Remove three fixing screws of the toner hopper of the developing

unit, and remove the toner hopper.

Fixing screw

Fixing screw

Toner hopper

Main charger unit

5. Developing nit set tin g

A. Developing unit setting

1 Open the front cabinet, remove the installation toner fixed to the

developing unit lever with tape, and pull the developing unit lever

toward you.

Developing unit

lever

Installation toner

Fixing tape

Front cabinet

2 Hold the grip of the developing unit, and slowly pull out the

developing unit until it stops.

Then hold the hand carry strap and press the developing lever,

and remove the developing unit.

Developing unit

4 While supplying developer from the developer supply port of the

developing unit, turn the MG gear clockwise with a screwdriver or

a scale to supply fully in the developing unit.

Developer

Developer

supply port

Developing unit

MG gear

Developing unit

5 Install the toner hopper to the developing unit and fix it with two

screws.

Fixin g scr ew

Toner hopper

Fixing screw

DV lever

Developing unit

Hand carry strap

Developing unit

Grip

4 – 4

Page 19

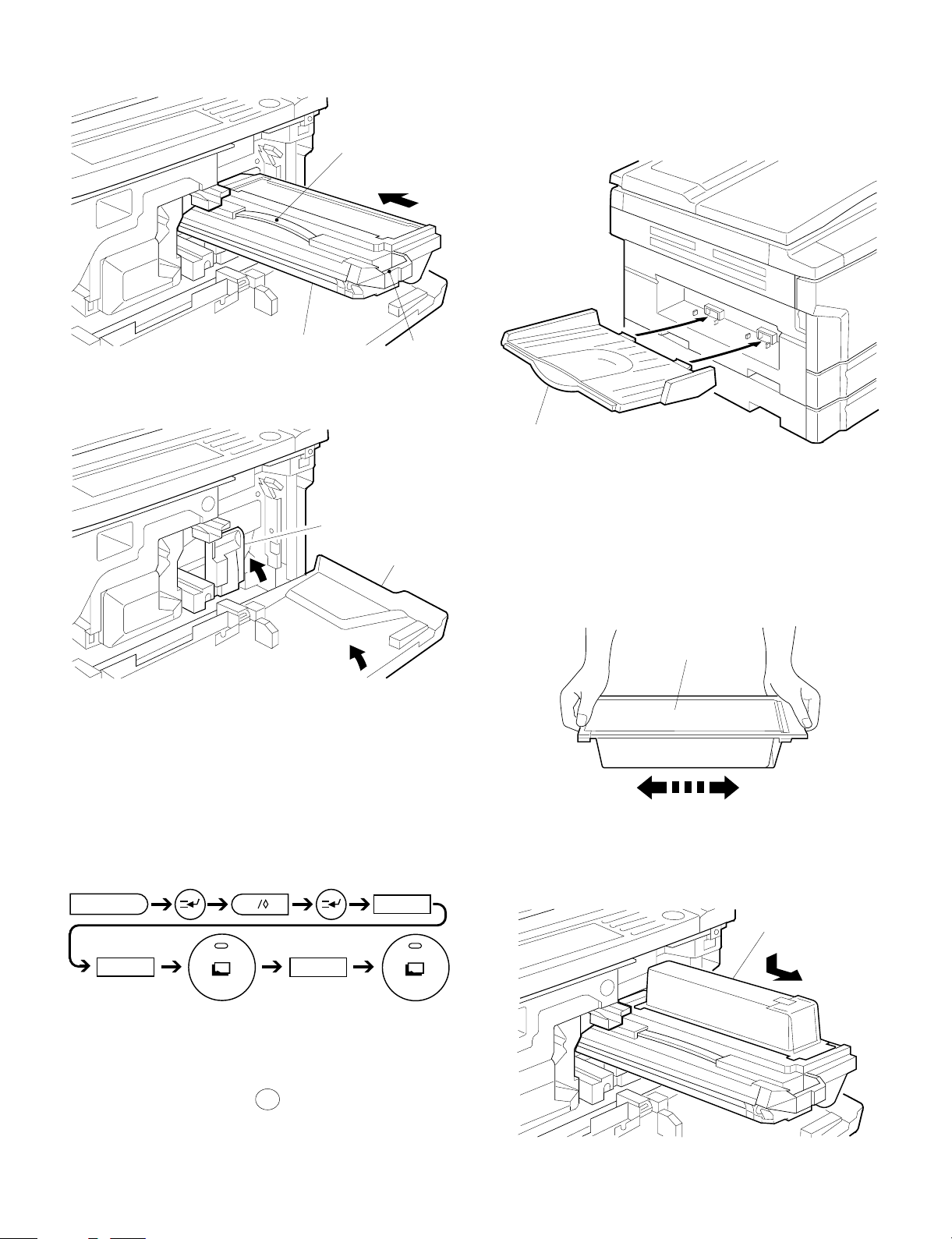

6 Hold the hand carry strap of the developing unit and insert it into

the copier fully to the bottom.

Hand carry strap

7. Accessor y i nst all ation

A. Copy tray installation

Install the copy tray to the paper exit section on the left side of the

copier.

Developing unit

7 Close the developing unit lever and close the front cabinet.

Grip

Developing unit lever

Front cabinet

With the above procedure, setting of the developing unit is completed.

6. Toner density sensor level adjustment

Copy tray

8. Toner supply

Toner cartridge tone r supply

1 With the sheet surface of the toner cartridge facing upward, shake

the cartridge right and left several times.

Sheet surface

Toner cartridge

Turn on the copier power switch.

A. Developing unit level adjustment

1 Execute simulation 25.

C

5

2 After 3 minutes, simulation 25 is completed.

[Note] If the simulation is terminated halfway, automatic reading is

not performed. Do not terminate it halfway.

3 Cancel simulation 25 with the CA key.

0

2

2

2 Install the toner cartridge to the toner hopper of the developing

unit, and slide it toward you until it clicks.

Be careful not to place toner one-sidedely in the toner cartridge.

Toner cartridge

4 – 5

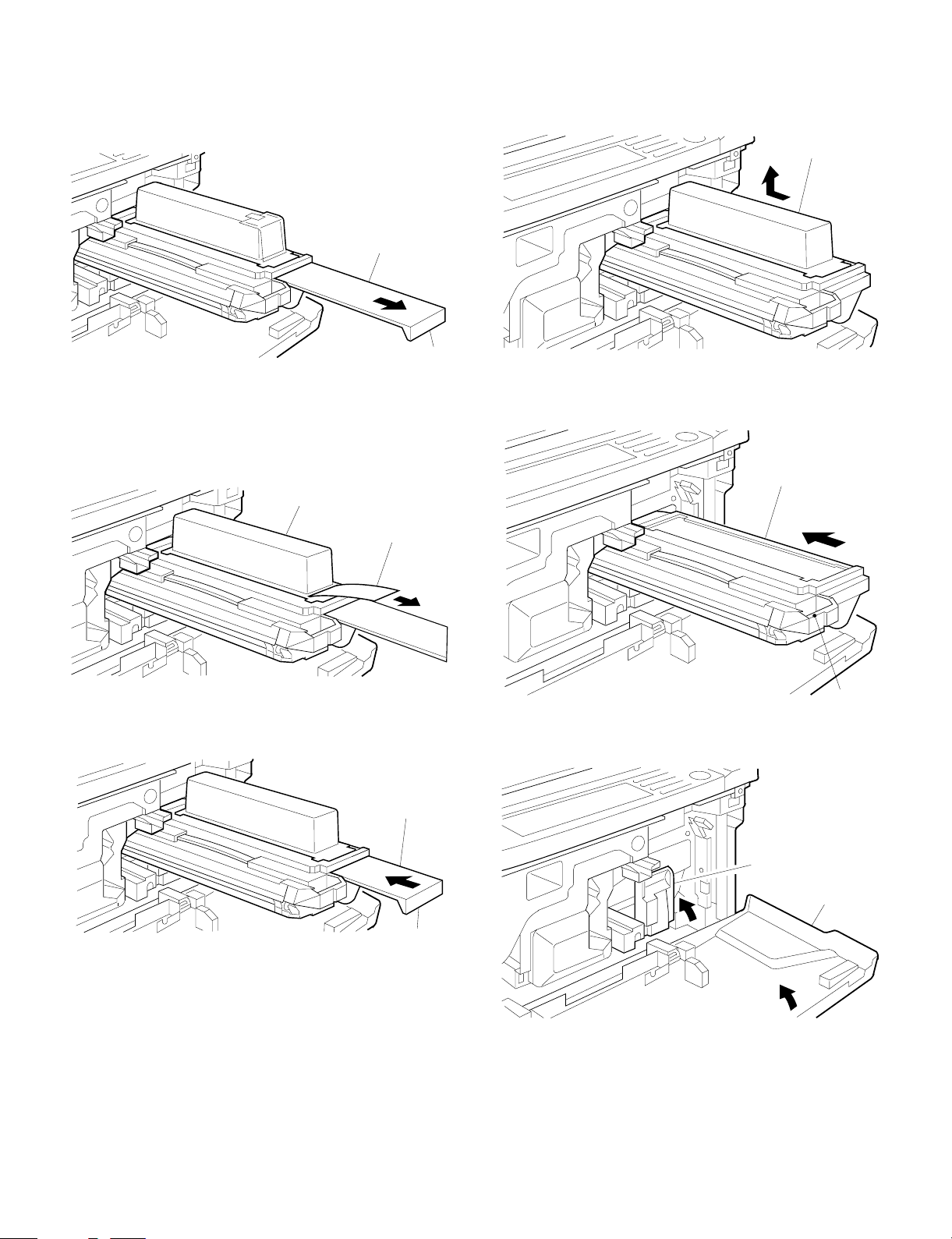

Page 20

3 Hold the grip of the toner hopper shutter, and slowly pull out the

shutter fully toward you.

If the shutter won’t move, the procedure in 2 may have not

performed properly. In that case, slide the toner cartridge again

toward you until it clicks.

Shutter

Grip

6 Slide the toner cartridge to the bottom and remove it slowly.

If the shutter have not been pushed completed in procedure 5,

the toner cartridge cannot be slid. In that case, push the shutter

completely and slide and remove the cartridge.

Toner cartridge

4 While pressing the toner cartridge securely, strongly pull the toner

cartridge sheet toward you. This will supply toner into the toner

hopper. The toner cartridge sheet must be removed completely.

Then tap the top of the toner cartridge several times to feed toner.

Toner cartridge

Sheet

5 Hold the grip of the toner hopper shutter and slowly push the

shutter completely to the bottom.

Shutter

7 Hold the grip of the developing unit, and insert the developing unit

slowly to the bottom.

Developing unit

Grip

8 Close the developing unit lever, and close the front cabinet.

Grip

Developing unit lever

Front cabinet

4 – 6

Page 21

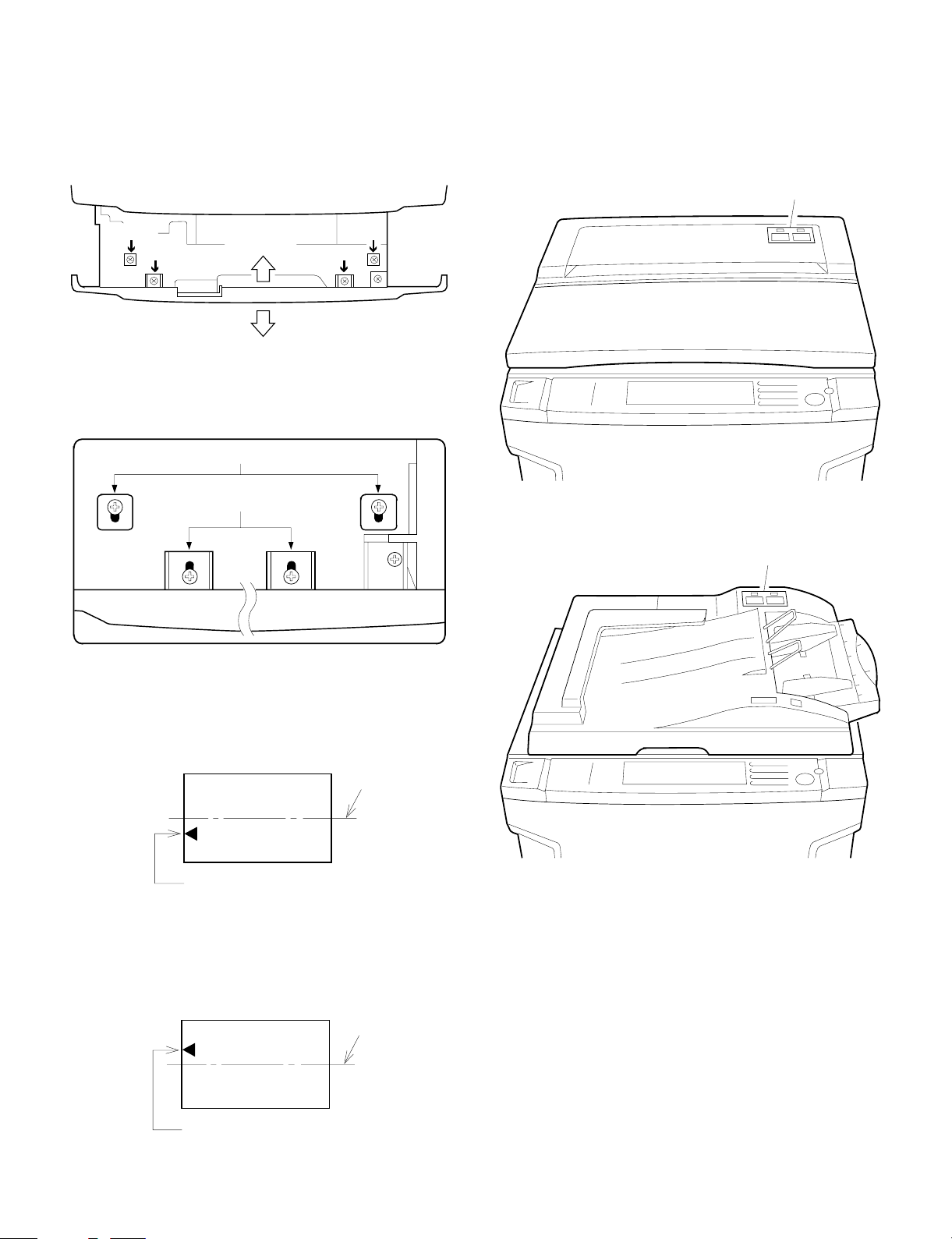

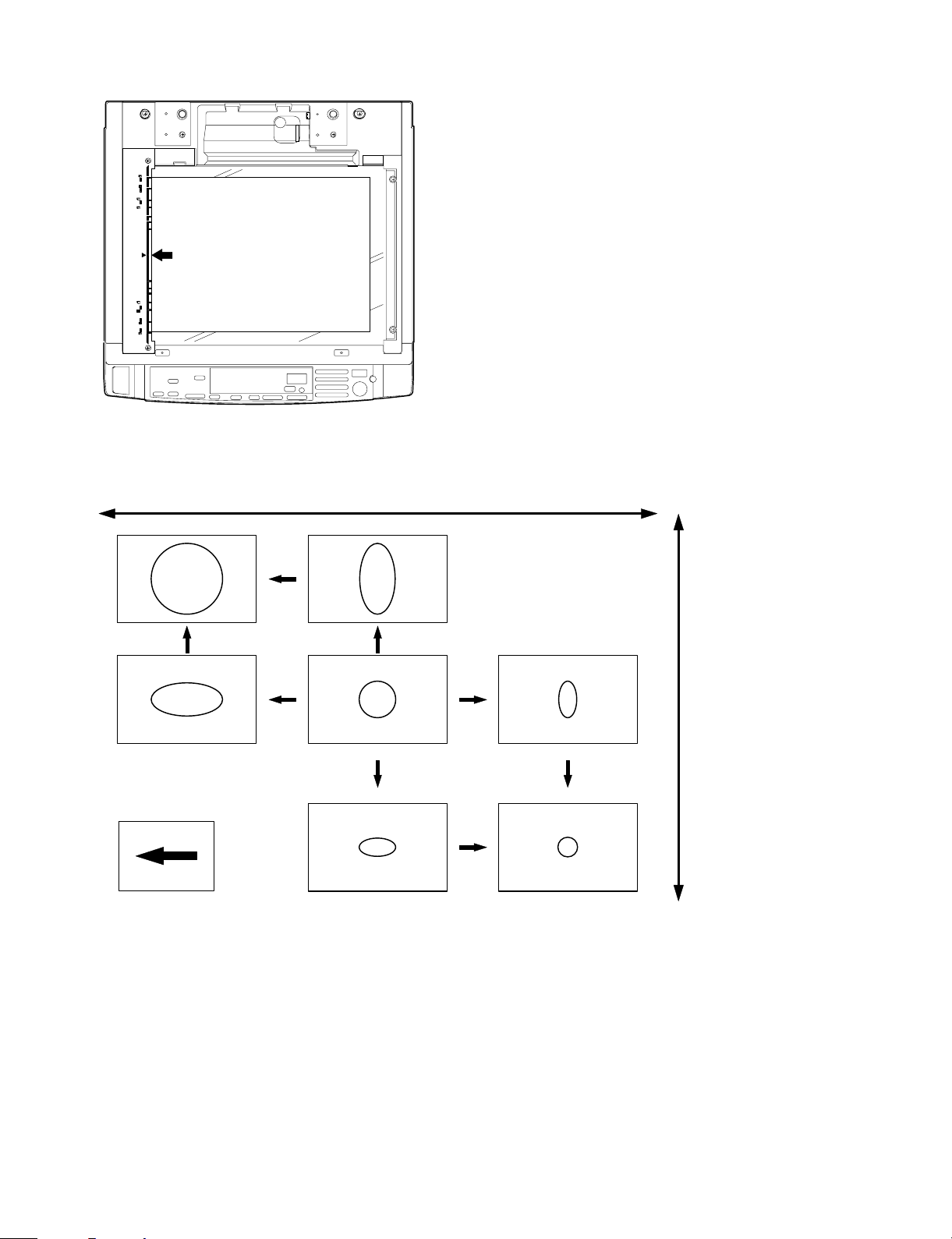

9. Center shift adjustment

10. Label attachment

There is basically no need to perform the center shift adjustment

because it is made when shipping. If the center should be shifted,

adjust in the following procedures.

Make a c opy. If the center is shifted as shown in Fig. 1 or Fig. 2,

loosen the four screws which are fixing the cassette grip cabinet.

Section b

Section a

Direction A

Section b

Section a

Direction B

[Note] When fixing the cassette cabinet, the fixing screws and the

cabinet clearance a and b are in symmetry.

Section b

Section a

A. Label attachment

Attach the magnification select label packed together with the Operation Manual to the position shown in the figure below.

• When attaching the label to the copier with the original cover.

Magnification ratio select label

• When attaching the label to automatic original feeder (SF-A15)

(1) Fig. 1

Move the cassette grip cabinet in direction A, tighten two fixing

screws (a) and two fixing screws (b) in this sequence. Make a copy

again and check the center.

[Fig.1]

Paper

center line

Image center (First image)

(2) Fig. 2

Move the cassette grip cabinet in direction B, tighten two fixing

screws (a) and two fixing screws (b) in this sequence. Make a copy

again and check the center.

Magnification ratio select label

[Fig.2]

Paper

center line

Image center (First image)

4 – 7

Page 22

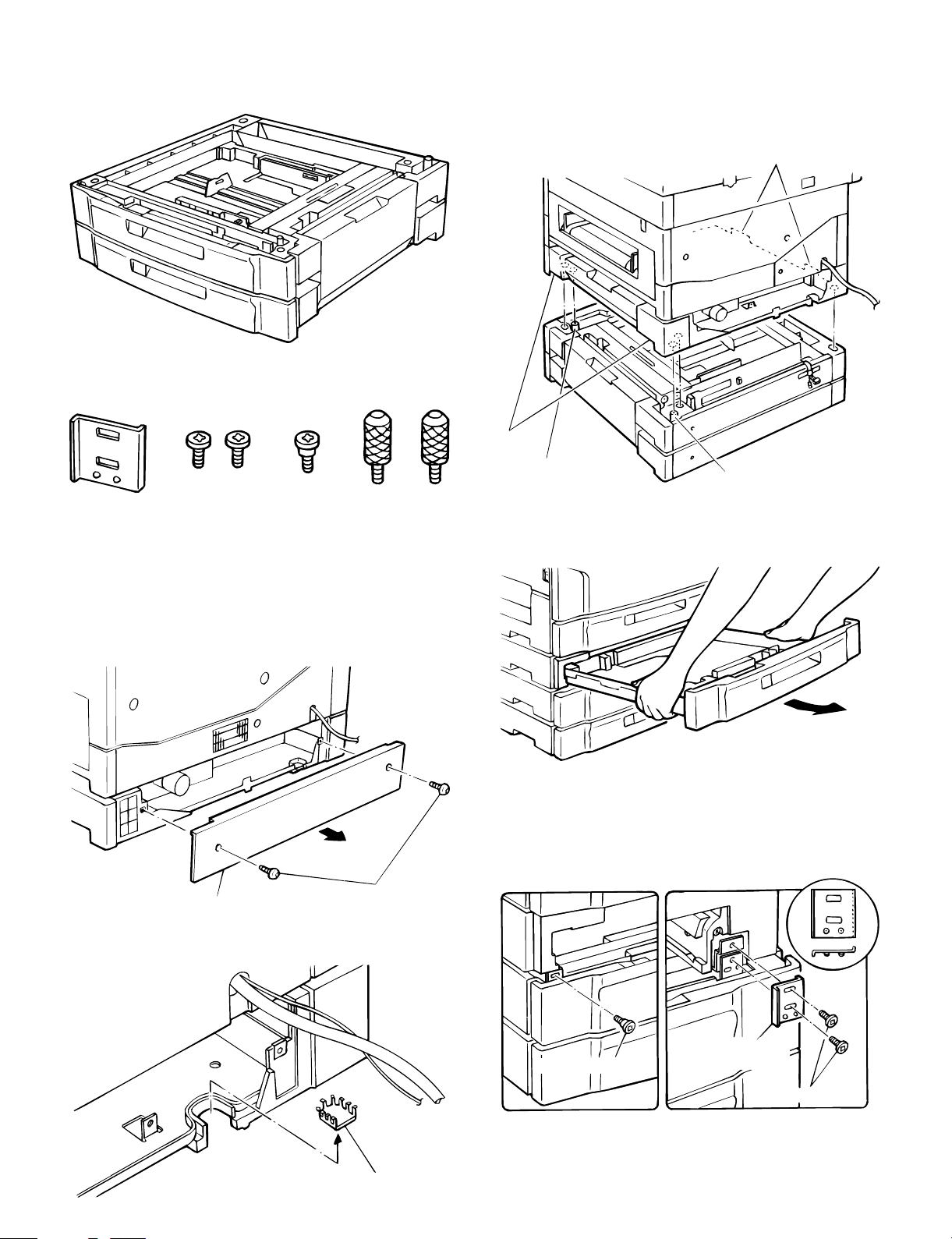

11. Optional two- stage paper feed unit

(SF-CM15) installation

Parts packed together

3 The following procedure must be performed by two persons.

Hold the grips of the copier, and insert the positioning bosses (2

positions) of the two-stage paper feed unit into the positioning

holes (2 positions) on the bottom of the copier. Then put the four

legs of the copier on the two-stage paper feed unit.

Grip

Grip

Connec tion

adjustment plate

x 1 pc.

Connection

screw A

x 2 pcs.

Connection

screw B

x 1 pc.

Connection

screw C

x 2 pcs.

Disconnect the power plug of the copier and

perform the following procedures.

1 Remove two screws which are fixing the rear cabinet on the lower

stage of the copier, and remove the rear cabinet.

Rear cabinet

Fixin g scr ew

Positioning boss

4 While lifting the lower stage tray slightly, pull it out until it stops.

Then hold the both sides of the tray and lift and remove it.

5 Attach the connection adjustment plate as shown in the figure and

fix it with two screws A. Then fix the left side with screw B.

Install the paper tray which was removed in procedure 4 to the

copier.

Positioning boss

2 Remove the notched section of the lower stage of the copier.

Notched section

4 – 8

Connection screw B

Connection

adjustment plate

Connection screw A

Page 23

Connect the rear side of the copier with two connection screws C.

Connection screw C

Connection screw C

6 Remove the connecter which is fixed to the rear cabinet of the

two-stage paper feed unit with tape. Connect the 4P connector

and 10P connector with the 4P connector and 16P connector of

the copier.

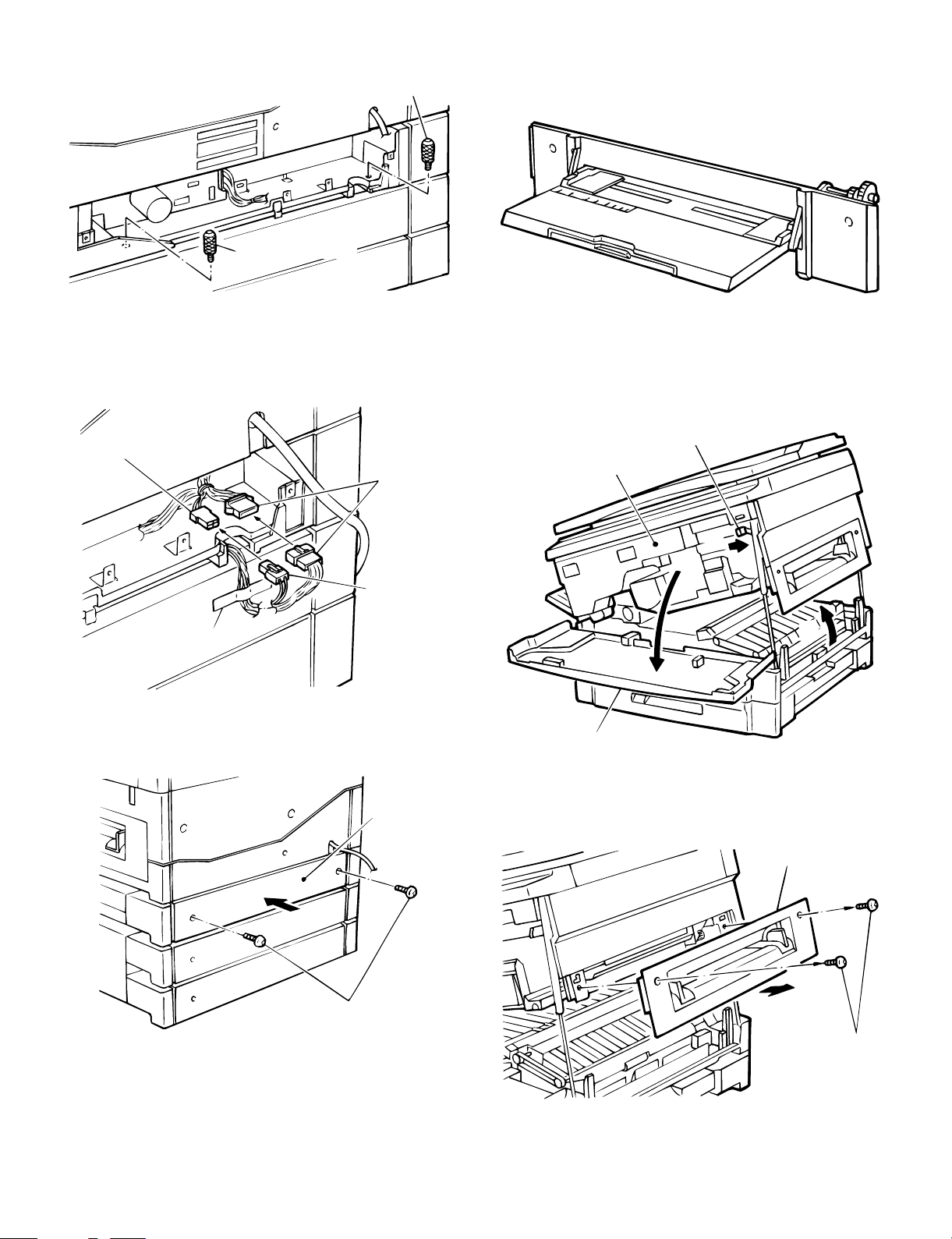

12. Optional multi paper feed unit

(SF0MF15) installation

Disconnect the power plug of the copier and

perform the following procedures.

1 Open the front cabinet of the copier and lift the upper unit slowly

with the open/close lever.

4P connector

16P

connector

4P

connector

Fixing tape

7 Install the rear cabinet which was removed in procedure 1 to the

original postilion, and fix it with two screws.

Rear

cabinet

Body open/close lever

Upper unit

Front cabinet

2 Remove two fixing screws of the right cabinet, and remove the

right cabinet. The two removed screws are used for installation of

the multi paper feed unit to the copier.

Right cabinet lower

Fixing screw

8 Adjust according to "9. Center shift adjustment" in [4] UNPACK-

ING AND INSTALLATION.

Fixing screw

* Keep the right cabinet, which is required when the multi paper feed

unit is removed.

4 – 9

Page 24

3 Insert the positioning pins of the multi paper feed unit into the

installation holes of the copier.

At that time, first insert the rear pins, then insert the front pins.

(Check that the multi paper feed unit connecting pins are properly

connected.)

Then fix the multi paper feed unit with the two screws which were

removed in procedure (2).

Rear side

Positioning pin

Installation holes

Fixing screw

Fixing screw

Multi paper feed unit

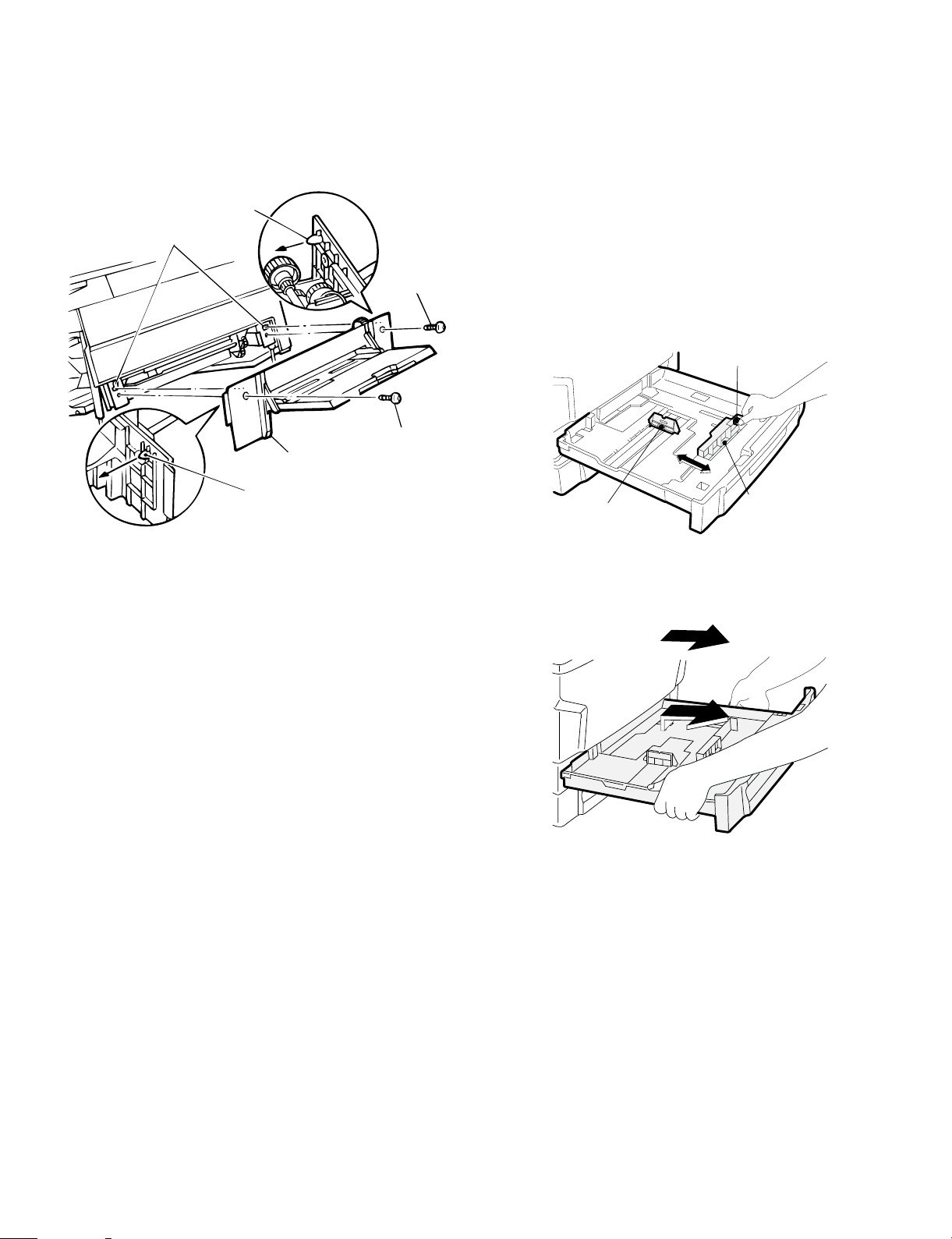

13. Tray paper size selection (Explained

with the SF-2118.)

Either of the upper and lower trays allows setting of the paper size as

shown in t he fi gu re. To select the d esi red s ize, fol low the proc ed ures

below.

(A5 size is handled as the special size. The factory setting is

A3: 11″ × 17″ size.)

1. Fit partitioning plates A and B in the tray to the

vertical and horizontal sizes according to the

paper s i ze .

Fit the plates to the scales of the paper size.

Partitioning plate A is of slide ty pe. Hold the fixing knob a nd slide

partitioning plate A to the sc ale.

Partiti oning plat e B is of in sertion type . Remove it and ins ert to the

scale po sit i on .

Lever

Positioning pin

Front side

4 With the above procedure, the multi paper feed unit installation is

completed.

* Clo se th e uppe r uni t slow ly and c lose t he fr ont cab inet. The mul ti

paper feed unit mode is automatically set.

Left guide

Front guide

2. Remove the tray.

Pull out the tray fully toward you, and tilt it upward to remove.

4 – 10

Page 25

3. Remove the size block upward, and attach it to

the selected size.

Attach the size block according to the selected size as shown below:

Paper size

block

(Inch series) (AB series)

11" x 17"

x 11R

8-1/2

8-1/2" x 5-1/2"

EXTRA

Top view from front side

11x17

8-1/2

x 5-1/2

8-1/ 2" x 14 " 8- 1/ 2" x 11 "

x 11

8-1/ 2

8-1/2

x 14

8-1/2" x 11"R

8-1/2

A3

x 11R

x 14

8-1/2

EXTRA

x 5-1/2

8-1/2

8-1/2

x 11

EXTRA

(Note)

• When the tray paper size is changed, be sure to adjust the size

block. If not, the paper size display remains unchanged. (The previous size is displayed.)

4. Attach the tray.

Reverse the removing procedure. That is, tilt the tray upward and

insert into the body. Then push it in horizontally.

A3

B5

Extra

A3 B4

A4R

EXTRA

B5

EXTRA

B4 A4

A4

B5 A4R

A4

R R

A3

B5

A4

B4

B5R

A3

5. Set the papers on the tray, and select the display

of the paper size display slit.

Remove the paper size display plate, and insert it according to the

selected paper size so that the paper size indication can be seen

from the display slit.

When A5 size is selected, display "Special."

Paper size plate

4 – 11

Page 26

[5] DESCRIPTIONS OF EACH

SECTION

Descri ptions are made on the following sections:

1 Paper feed section

2 Developing section

3 Optical section

4 Process section

5 Separation/transport section

6 Fusing/paper exit section

7 High voltage section

3

4

6

5

2

1

In the case of SF-2118:

The SF-2118 is provid ed with the thr ee-way pa per fe ed syst em. Th e

tray is of the universal t y pe an d has cap ac it y o f 2 50 sheets. Th e front

loading system allows the tray to be loaded from the lower side of the

front cabinet.

(The SF-2116 ha s the two-way pape r feed system with one 250-sheet

tray and ma nual feed.)

Manual pa per feed is in the sin gle mode. The mu lti paper feed un it

(SF-MF15) is an option.

The tray has the capacity of 500 sheets (250 sheets for the SF-2116).

In addi tion to that, th e option al paper feed uni t allows loading o f 500

sheets more.

2) Basic operati ons

(Tray paper feed operat ion)

When the CPFC (Cassette paper feed clutch) turn on, the paper feed

roller shaft, t he paper fe ed roller, and the ta ke-up roller rotat e in the

direction of A. At the same time, the limiter spring moves down the

roller release arm. As a result, the take-up roller falls by its own

weight onto the paper su rface, starting paper feed .

Roll er r elease arm

Take-up

roller

1. Paper feed secti on

1) General descriptions

To r ealize th e compact design, t he front l oading system and the fo ldable multi paper feed unit (option) are employed.

Use of t he optional tw o- s ate paper fee d un it and the spar e tr ay allo w s

a varie ty of sy st e m co nf i gu r ations.

(System configuration) Example with the SF-2118:

SF-2118

Sheet

250 sheets

250 sheets

250 sheets

250 sheets

SF-CM15

(Two-step paper feed unit)

50 sheets

SF-MF15(Multi paper feed unit)

250 sheets

SF-UB15

(Spare tray)

Paper f eed ro l l er

Paper feed roller shaft

When the CPFC turns off, rotation stops and the take-up roller is

pushed up to the original position by the roller release arm spring.

(Single manual paper feed operation)

There is no special mechanism for manual paper feed other than the

manual feed paper sensing actuator and the paper guide.

(Multi manual paper feed operation)

When the MPFS (multi paper feed solenoid) turns on, the spring

clutch rotates to pr ess the take- up roller on t he paper, feeding the

paper.

5 – 1

Page 27

2. Developing secti on

1) General descriptions

(1) Two-component developer

The developer is composed of toner and carrier.

Carrier serves as a me dium for attachi ng ton er onto the ele ctrostat ic

image on the photoconductor drum.

By stirring toner and carrier, they are rubbed to be charged positive

(+) and negative (–) respectively.

Since deve loper will deter iorate to degra de copy quality, it shou ld be

replaced regularly.

(2) Two-component magnetic brush development

The rotatable non-magnetic sleeve is provided over the magnet roller

and is rotated.

Carrier forms a magnetic b rush on the sleev e surface by magn etic

force to attach toner onto the electrostatic image on the photoconductor drum.

(3) Developing bias

When the photoconductor is charged and exposed to light (exposure ), th e surfac e poten tia l (volt ag e) of the p ho tocon duct or w ill no t

be lost completely. (The residual potential remains.)

Toner is attracted to the photoconductor by this residual potential,

dirty ing the phot oconductor. As a r esult, a dirt y copy of whi te background is generated.

To prevent ag ainst this, a voltage of the same polarity and higher than

the residual potential is applied to the MG roller, preventing toner from

being attached to the photocondu ctor surface .

(Detail s of DV harness co nnect or)

For color identification

GND

Resistor

*For toner density sensor

GND

*Resistance value is identified by color

2) Basic composition

2

For bias

VB

4

Residual potent i al < D V B IAS

MG rolle r

DV BIAS

Toner

Carrier

Devel opi ng bia s v olt age

-200V

(4) DV harness

The toner density sensor, the developing bias, and the developing

unit identification resistance harness.

(For details, refer to [6] DISASSEMBL Y AND ASSEMBLY.)

(View ed fr om th e rear of devel oi ng uni t )

1

3 5

No. Name

Magnet roller Forms a magnetic brush of carrier

1

Developing doctor blade Limits the height of the magnetic

2

Developing MIX roller Stirs carrier in the developing unit

3

Toner transport roller Transport toner sent from the

4

Toner density sensor Senses toner density in

5

by magnetic force.

brush.

and distributes toner evenly.

toner hopper unit to the stirring

section.

developer.

DV har ness c onnec t or

5 – 2

Page 28

3) Basic operations

(Cassette paper feed)

When t he CPFC (cassette paper feed clutch) is turned on, the paper

feed roller shaft, the paper feed roller, and the take-up roller rotates in

the dire ction of A, an d the r oller re lease arm is moved downwa rd by

the limiter spring. As a result, the take-up roller falls by its weight to

reach the paper surface, feeding the paper. When the CPFC is turned

off, the take-up roller is pushed up to the position by the roller release

arm spring.

(3) Optical section

Stirring roll er

MG roller

Transport

roller(upper)

Transport

roller(lower)

DV drive unit

PS roller

Multi manual

insertion paper

feed unit

(Option)

Paper fe ed

unit

Paper fe ed

unit

Proccess

unit

Paper feed

rive unit

Main drive unit

Cleaner

unit

Transport

unit

Main motor

Fuser unit

Paper ex it

roller

1. General description

• The optical section of this model is composed of the fixed focus

lens and six mirrors. Since the fixed focus lens is used, No. 4/5

mirror base is shifted according to the shift of the lens to change

the distance between the original and the drum (OID, Original

Image Distance) in reduction or enlargement copy.

The lens and No. 4/5 mirror unit are shifted by driving the stepping

motor with the signals from the main control PWB, allowing zooming of 151 steps in 1% increment in the range of 0.50 to 2.00.

5 6 910

• Exposure is adjusted by changing the copy lamp voltage. The AE

sensor is provided in the zoom base to sense the density of the

original.

The copy lamp light is reflected by the original to the AE sensor,

which senses the density of the original and adjust the copy lamp

light quantity according to the density.

• The exposure system is the slit exposure system by moving light

source.

3

17

151 2

14 8 12

711 1316 4

Copy lamp

1

No. 2 mirror

4

No. 4 mirror

7

No. 2/3 mirror base unit

F

Mirror motor

I

Mirror home position sensor

L

Reflector

2

No. 3 mirror

5

No. 5 mirror

8

Copy lamp unit

G

Lens/No. 4/5 mirror base drive motor

J

Automatic exposure (AE) sensor/

M

Optical system dirt sensor

5 – 3

No. 1 mirror

3

Lens

6

No. 6 mirror

9

No. 4/5 mirror base unit

H

Lens home position sensor

K

Page 29

(1) Original table

The original table is fixed. The original is set in the left center position.

Mirror base sc an spe ed is chang ed f o r zoomi ng

Enlargment

(2) Copy lamp

100V s eries: 85V, 275W

200V series: 170V, 310W

(3) Mirror

This model uses six mirrors.

No. 1 mirror is attached to the copy lamp unit, No. 2/3 mirrors are

attached to No. 2/3 mirror base, No. 4/5 mirrors are attached to No.

4/5 mirror base.

The copy lamp unit and th e No. 2/3 mir ror base unit are scanne d in

copying. The No. 4/5 mirror base is shifted in zoom copying to

change the distance between ten original and the drum.

(4) Lens (fixed focus lens)

• Construction (1 group 3 lenses)

• Brightness (F8.5)

• Focus: (195mm ±1%)

(5) Lens home position sensor (LHPS)

This sens or sen ses the le ns home position . The out put sign al of thi s

sensor is the basic signal to control the copy magnification ratio.

(6) Lens base

The lens is mounted to the lens base, which is shifted toward the

paper feed direction in reduction copy or toward the paper exit direction in enlargement copy by the lens drive motor.

Copy direction

Normal

Zooming b y c hangi ng th e le ns

and mirror positi on

Original

Reduct i o n

5 – 4

Page 30

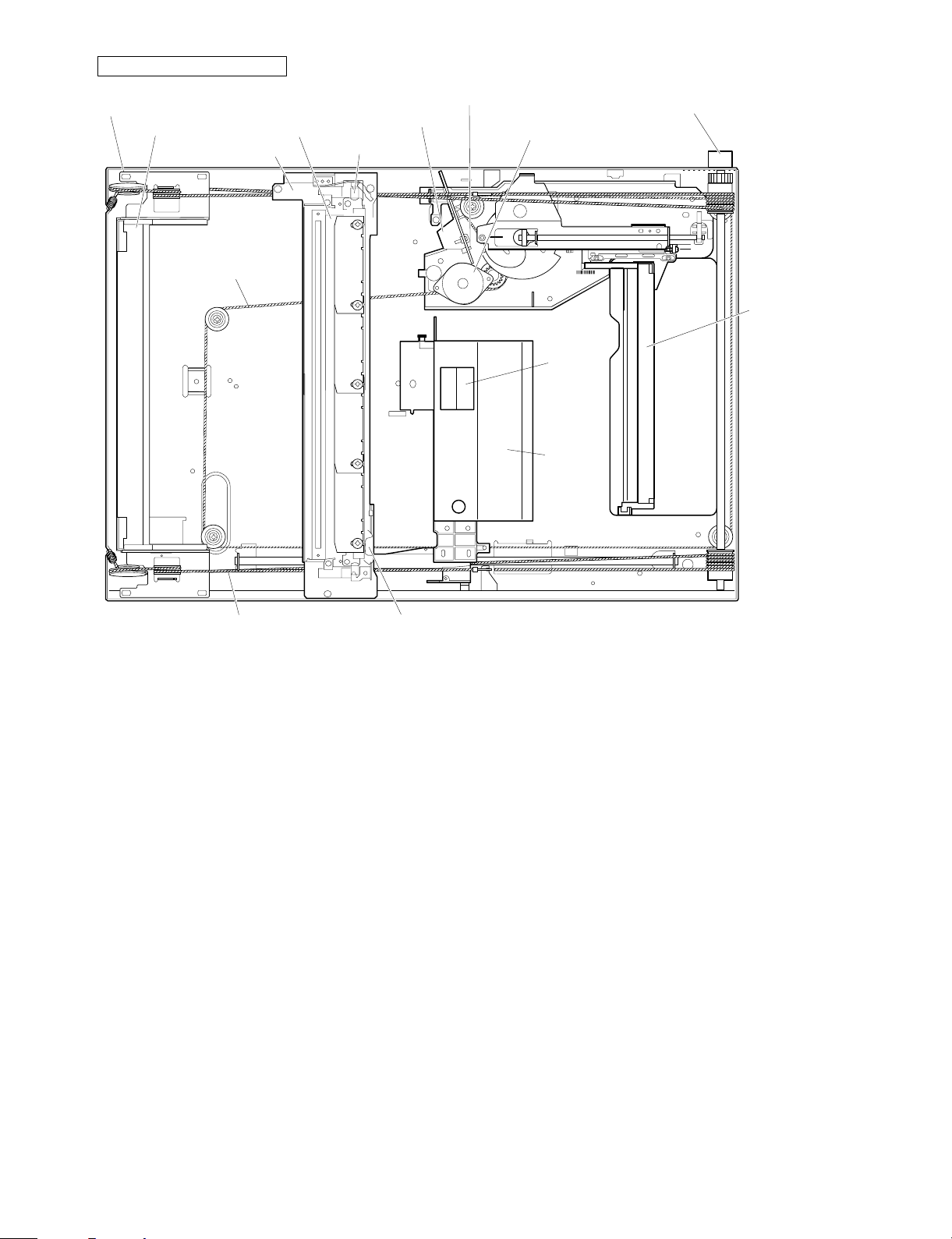

Parts identification and functions

Mirror home position sensor

No. 2/3 mirror un it

Copy lamp unit

Lens drive wire

Reflector

Copy lamp

Lens home position sensor

AE sensor

Lens No. 4/5 mi rr or uni t

drive motor

Mirror motor

No. 4/5 mirr or uni t

Lens

Lens

unit

Mirror base wire Tempera t ure fuse

(7) Lens drive shaft

This shaft controls the optical axis of the lens in zoom copy. The lens

follows along the slide base shaft.

(8) Lens drive wire

This is to shift the lens unit and the No. 4/5 mirror base.

(9) No. 4/5 mirror unit

No. 4/ 5 mirro rs a re a ttach ed t o this unit. It is shif ted by the le ns driv e

motor to change the distance between the original and the drum

according to the zooming ratio.

(10) Mirror m otor

This st epping motor shifts the co py lamp unit and the No. 2 /3 mir ror

base. It is rotated at the rpm according to each zooming ratio.

(11) M irror home position sensor (MHPS)

This sensor senses the home position of the copy lamp unit. It is of

light t r ansmission ty pe.

(12) No. 2/3 mirror unit

No. 2/3 mirrors are attached to th is unit. It is scann ed by the mirror

motor.

(13) Copy lamp unit

This is composed of No. 1 mirror, the temperature fuse, the copy

lamp, the exposure adjustment plate, and the reflector, and scanned

by the mirror motor.

(14) Temperature fuse

This is attached closely to the reflector to prevent against abnormal

temperature rise in th e optic al syste m. If the temperatu re ri ses a bnormally, it turns off the copy lamp power directly.

100V s eries (117°C)

200V s eries (117°C)

(15) Reflector

Light from the copy lamp is reflected by the reflector to the original.

(16) Exposure adj ustment plate

Four exp osure adjust ment plat es are attac hed to the copy lamp unit

to adjust exposure balance in back and forth direction of the frame.

(17) Mirror base drive wire

This wire transmits the m irror motor p ower to th e copy lamp unit and

the No. 2/3 mirror base to scan the mirror base.

(18) Lens drive m ot or

This stepping motor drives the lens and the No. 4/5 mirror base.

(19) AE sensor

This AE sensor senses the original density by the light emitted from

the copy l am p a nd r ef lec te d by the orig ina l, c on tr o llin g the develop ing

bias. The photometric area is about 100m width at the center and in

the mirr or base scannin g direction.

The element is photo diodes.

5 – 5

Page 31

(20) Original size sensing

g

g

The origin al siz e is sensed by the orig in al interrupti on system.

The LED in the rear frame side emits light to the table glass surface.

The original interrupts this light, and its size is detected.

Light emit

Li

ht receivin

Table glass

2. Basic operations

(Positions of the o riginal, the lens, and the image in each magnification ratio)

Normal: The distance between the original set on the table glass and

the lens is equal to the distance between the lens and the

drum, resulting in the equal size of the original and the

image.

Mirror base scan speed

Lens and mirror positions

are changed to adjust the

Copy paper

magnif ic ati o n ra t io

feed derection

Mirror scan speed is cahnged to adjust the magnification ratio

Mirror scan sp eed Drum rotation speed <Mirror scan speed

Enlargement

Original

Reduction

Enlargement: Compared to the normal copy, the lens is nearer to the

original and the distance between the original and the

lens is shorter.

The distance between the No. 4/5 mirror unit and the

lens is greater, and the distance between the lens and

the drum is also greater.

The distance between the original and the exposure

surface of the drum is greater than that in the normal

copy.

Reduction: Compared to the normal copy, the lens is nearer to the

drum, and the distance between the original surface and

the lens is longer.

The distance between the lens and the exposure surface

of the drum is shorter.

The distance between the No. 4/5 mirror unit and the

lens is greater.

The distance between the original and the exposure surface of the drum is greater than that in the normal copy.

(Copy lamp control in each copy density)

[MAX. 83V(166V) ]

80

70

CLV

(Copy lamp

application

voltage)

Execute Sim 46-01 to de termine the copy lamp applicatio n voltage

(CLV) in EX1 and EX5.

Then divide the difference between the voltages of EX1.0 and EX5.0

into nine.

The application vol tage of the copy lamp in each expo sure level is

determined by varying the ON timer duty of the copy lamp ON control

signal.

(V)

60

50

40

EX1

23

[MIN. 45V(90V)]

EX5

4

• Photo density copy mode

Make the same control procedures as the manual density copy

mode.

The image density is controlled by lowering the grid bias voltage of

the charging charger. To maintain the reproduction quality in half

tone, the ON time duty of the copy lamp ON signal is made shorter

than in the manual density copy mode. (The application voltage is

lower.)

5 – 6

Page 32

(Optical system dirt correction)

This mo del pe rform dirt correc tion by cha nging t he cop y lamp intensity a ccord ing t o the d irt degr ee in th e optic al s ystem (t he co py la mp

unit, No. 1 mirror, No.2 mirror, No.3 mirror) to prevent against remarkable de grading of copy quality.

The reference value is the AE sensor output value which is obtained

when th e reference plate is e xposed with th e copy lamp voltage of

67.0V (134.0V) at power ON.

This value is checked with sim 44-08, 09.

CLV

Sim46

Reference plate (Glass holder)

CPU

Reference value

>Measured value

Correction data output

Table glass

Copy lamp light quantity "UP"

Automatic exposu re

sensor

100 200 300 400 79.8K 80K

CLV + (0.7)

(1) Setting the reference value for optical system correction.

Reference plate (Glass holder)

CPU reference value

setting

1 Clean the optical system at every maintenance.

2 Perform Simulation 46-1.

(The previous data are cleared.)

3 After completion of Simulation 46-1, when performing the first

mirror initialization, measure light quantity of the copy lamp.

Obtain the average value from the four measurement values and

use the average value as the reference value for correction.

800ms

Table glass

Automatic exposu re

sensor

1234

(2) Dirt corr ection

Reference plate (Glass holder)

CPU

Referenc e v a lue

>Measured value

Correction data output

1 Measure light quantity when performing mirror initialization.

2 Store the correction data into memory.

3 Reset the register inside the CPU.

Table glass

Copy lamp light quantity "UP"

Automatic exposu re

sensor

CL

Light quan t i t y

measurement

Obtain the average value of four AE sensor values, and store it.

5 – 7

Page 33

(4) Copy process

This model basic process and structure

• The Scorotron method is used to evenly charge the photoconduc-

tor surface to the given potential in the charge process. The

corona wire regularly used is now replaced with a new corona

charge mechanism that employs the 0.1mm thick stainless steel

saw teeth plate, in order to suppress ozone generated when the

oxide molecule in air is ionized.

• Considering the service efficiency, the process separation

mechanism is adopted.

• To prevent high voltage leakage by the loose corona charge unit, a

one-touch stopper mechanism is adopted.

Stirring roll er

MG roller

Transport

roller(upper)

Transport

roller(lower)

DV drive unit

PS roller

Multi manual

insertion paper

feed unit

(Option)

Paper fe ed

unit

Paper fe ed

unit

Proccess

unit

Paper feed

rive unit

Main drive unit

Cleaner

unit

Transport

unit

Main motor

Fuser unit

Paper exit

roller

(1) Photoconductor

• This model uses OPC (organic photoconductor) as photoconduc-

tive material. (φ50 mm)

OPC la ye r CTL (Ele ctr ic char g e moving layer)

CGL (Electric charge gener ating layer)

Aluminum layer

5 – 8

Page 34

(2) Process diagram

High voltage unit

Original

Copy lampMirror lens

Cleani n g bl ad e

Waste toner collection

Paper exit

Discharge lamp

Main corona unit

Discharge lamp

Fusing

Heat r olle r

Heater lamp

Main corona unit

Discharging

Cleaning

Separ at ion

Separation corona unit

High voltage unit

Charging

Separation

Blank lamp

Exposure

Transfer

Transfer charger

High voltage unit

Discharge

Development

Drum u ppe r

image /paper

synchronization

Blank lamp

Developer

Resist roller

Toner

Paper feed roller

Transportroller

Image forming process

Paper transport path

High voltage unit

Manual paper feed

Paper cassette

Cleaning blade

Seper ati on pa w l

Seperation corona unit

Developer unit

MG roller

Resist roller

Transfer corona unit

5 – 9

Page 35

(1) Details of image forming process

Step 1 (Main Char gi ng)

By negative discharging of the main charger, uniform negative charges are applied to the O PC drum surface.

The OPC drum surface potential is controlled by the screen grid

voltage to maintain the grid voltage at a constant level.

• When the drum surface potential is lower than the grid voltage,

electric charges generated by discharging of the charger go

through the screen grid to charge the drum surface potential until it

becomes equal to the grid voltage.

• When the drum surface potential virtually reaches the grid potential

level, electric charges generated by discharging of the charger

flows through the electrode of the screen grid to the high voltage

unit grid voltage output circuit, thus always maintaining the drum

surface potential at a level virtually equal to the grid voltage.

• The main corona unit employs the scorotron system to charge the

photoconductor surface to a certain level uniformly.

In addition, the conventional corona wire is replaced with the

corona charging mechanism by saw-teeth plate (stainless steel

plate of 0.1 mm thick). In corona discharge, oxygen molecules in

the air are ionized to generate ozone (O3). The mechanism restrict

the generation of ozone.

Main corona unit

Main corona unit

Blank lamp

High voltage unit

Screen grid

CTL

CGL

OPC drum

Aluminum

layer

Step 2 (Exposure)

Light from the copy lamp is radiated on the document, and the optical

image of the document is reflected by the mirrors and projected

through the lens to the OPC drum.

The ligh ter p orti on of th e docu men t refl ec ts more light ( high int ensit y)

to the OPC drum , an d the d ark er por tion o f the docu ment ref lect les s

light (l ow intensity) to the OPC drum. Positive or ne ga ti v e ch ar g es ar e

generated in the CGL of the OPC dr um where lights are radiated.

Negative charges generated in the CGL move towards the positive

charges in the aluminum layer generated in step 3. While the positive

charges in the CGL move towards the negative charges on the CPU

drum surface generated in step 3. Therefore, positive charges and

negati ve ch arg es a re n eutr aliz ed in the alum inum laye r an d th e OPC

drum surface at the light radiating position, decreasing the OPC drum

surface potential. The CGL electric charge generating amount increase s in proport ion to the d ocument density, that is, refl ected ligh t

intens ity (the OPC drum surfac e intensity). Ther efore, electric ch arges are gener ated les s in th e CGL layer cor respon ding to the lig hter

density of document (higher intensity of the OPC drum surface), and

a greater quantity of the negative charges on the OPC drum surface

is neutralized, decreasing the O PC drum surf ace potentia l more.

Discharge lamp

Cleani n g bl ad e

Seperation pawl

Seperation corona unit

On the contrary, electric charges are generated more in the CGL

layer corresponding to the darker density of document (lower intensity

of the OPC drum surface), and less quantity of the negative charges

on the CPU drum surface is neutralized, decreasing the OPC drum

surface less. Therefore, the OPC drum surface potential corresponding to the lighter portion of the document is lower, and that corresponding to the darker portion of the document is higher. Latent

static-electric ity images ar e formed in the above manner.

Transfer corona unit

Developer unit

MG roller

Resist roller

5 – 10

Page 36

CTL

CGL

Low intensi ty in

the area corresponding to the

darker density

portion of the

document

Medium intensity

in the area cor responding to the

medium dens it y

portion of the

document

HIgh intensity in

the area corresponding to the

lighter density of

the document

Aluminum

layer

OPC drum

Surface pot e nt i al

(High)

CTL

CGL

Surface

potential

(Medium)

Surf ace

potenti al

(Low)

Aluminum

layer

OPC drum

Step 3 (Develop me nt )

Ton er is atta ched to t he latent static-elec tricity ima ges on th e drum

surface to change them to visible images. The two-component magnetic brush development system charges toner positively by friction

with car riers , and toner is attac hed t o nega tive cha rges on the d rum

surface. The potential in the darker document projecting area (low

intens ity) is high (m uch negative c harges) and a ttracts more toner.

The potential in the lighter document projecting portion (high intensity)

is low (less negativ e charges), an d attracts less toner.

Discharge lamp

Cleaning bl ade

Seper ati on pa w l

Main corona unit

Seperation corona unit

Blank lamp

Devel oper u nit

MG roller

Resist roller

Transfer corona uni t

OPC drum

CGL

Aluminum layer

Higher surface

potential

(Much negative

(charges)

Medium surface

potential

(Less negative

(charges)

Lower surface

potential

(No negative

(charges)

CTL

MG roller

-200V

High v ol t age u ni t

bias volt ag e

At that time, a bias of –200V is applied to the MG roller (magnet

roller), which is provided for preventing toner from being attracted by

the resi du al vol tag e (abo ut –80V t o –1 00V ) in the ligh te r port ion aft er

exposure.

Discharge lamp

Cleani n g bl ad e

Seperation pawl

Main corona unit

Seperation corona unit

Blank lamp

Developer unit

MG roller

Resist roller

Transfer corona unit

5 – 11

Page 37

Step 4 (Transfer)

The transfer paper is charged higher than the OPC drum surface

potential by s tr on g negati ve discharge of the tran sf er c harger, makin g

the binding force between the transfer paper and toner stronger than

that between the drum and toner, attracting toner to the transfer

paper.

Aluminum

layer

CGL

CTL

Transfer corona unit

High voltage unit

OPC drum

Toner

Transfer paper

Seperation pawl

Step 5 (Separati on)

After transfer, the copy paper and the drum are negatively charged.

Since, however, the negative potential of the copy paper is higher

than tha t of the drum, a attract ion for ce is appl ied betw een the dr um

and the copy paper. To avoid this, AC corona is applied to the copy

paper by the separation charger to decrease the copy paper potential

to the same level as the drum surface potential. The attraction between t he copy pape r and the drum is weakened by this, a llowing

separation of the copy paper by its own extending force. If the copy

paper is not separated by the separation charger, it is separated by

the separation pawl mechanically.

Discharge lamp

Cleani n g bl ad e

Main corona unit

Seperation corona unit

Blank lamp

Developer unit

MG roller

Resist roller

Transfer corona uni t

Aluminum

layer

CGL

CTL

High voltage unit

Seperation corona unit

OPC drum

Toner

Transfer paper

Discharge lamp

Cleaning bl ade

Seper ati on pa w l

Main corona unit

Seperation corona unit

Blank lamp

Developer unit

MG roller

Resist roller

Transfer corona unit

5 – 12

Page 38

Step 6 (Cleaning)

Residual toner on the drum is removed by the cleaning blade. The

removed toner is sent to the waste toner container by the waste toner

transp ort screw.

CGL

Blade Aluminum layer

CTL

Discharge lamp

Main corona unit

Blank lamp

Residual toner

OPC drum

Step 7 (Dischargi ng)

When the OPC drum is exposed to the discharge lamp light, positive

and negative charges are generated in the OPC drum CGL. The

negati ve charges ge nerated in th e CGL move towards the residual

positiv e char ges in the alu minum layer, wh ile the posit ive cha rges i n

the CGL move towards the residual negative charges on the OPC

drum s urface. The refore, t he positi ve and the ne gative cha rges are

neutralized in the aluminum layer and on the OPC drum surface,

removing the residual charges on the OPC drum surface. As a result,

the OPC drum surface potential becomes 20V ∼ 30V.

Dis charge lam p

Cleaning bl ade

Seperation pawl

Seperation corona unit

Main corona unit

Developer unit

MG roller

Resist roller

Transfer corona unit

Blank lamp

Resi dual charge

CTL

CGL

Aluminum layer

OPC drum

Resi dual charge

Discharge lamp

Cleani n g bl ad e

Seper ati on pa w l

Seperation corona unit

Devel oper u nit

MG roller

Resist roller

Transfer corona unit

5 – 13

Page 39

(4) Transition of photoconductor surface potential

Develop

Charge Exposure

BL

-730V

Dark area

-215V

Devel opi ng bia s v olt age

Light area

(5) Photoco nduc t or drum s e nsitivity correc t ion

In this mod el, f all i n sen sitiv ity due to long use o f th e pho tocon du ctor

drum is co rrected by th e copy lamp lig ht intensi ty to preven t against

considerable change in copy quality.

The photocondu ctor drum se nsitivity fall co rrection is per formed as

follows:

Cleaner

OPC drum

Develop

Change the tickness of the carrier transport layer (CTL).

By the developper.

By the cleaner blade.

Residual po tentia l

(NEW)

Transfer Separate

Clean

(USED)

DL

CLV

CLV + 2 counts

(Sim46)

CL(V) + (0.33V x 2)

Sim46

(6) Process control function

[Summary]

The process control function detects the density of the standard toner

image formed on the photoconductor, the density of the initial image

and controls the charging grid voltage so that the same level as the

initial imag e den si t y is pro vid ed .

That is, the process conditions are established and the high voltage

output and exposure level are controlled to stabilize the toner density.

In this model, the density sensing level is automatically set.

CTL

CGL

5K0 10K 15K 20K 25K 70K 75K 80K

CTL

CGL

F

R

MAin control PWB

CPU density

judgement

Drum c ounter

5 – 14

I/O MC grid

output selecti on

High voltage PWB

MC grid bias

output (density

correction)

in each mode

(Light quan tity

correction)

Page 40

Process control

1 Toner patch images are formed on the photoconductor surface

under the three process conditions (MC grid bias voltage).