Page 1

Induction Cooktop: SDH3042DB, SDH3652DB

INSTALLATION MANUAL

SPECIAL WARNING

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE this installation manual FOR LOCAL ELECTRICAL INSPECTOR’S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

IMPORTANT NOTES TO THE INSTALLER

• Read all of the Installation Manual before installing the Induction

cooktop.

• Remove all packing material before connecting the electrical

supply.

• Observe all governing codes and ordinances.

• Be sure to leave these instructions with the consumer.

• All cooktops must be hard wired (direct wired) into an approved

junction box. A “plug and receptacle” is not permitted on these

products.

IMPORTANT SAFETY INSTRUCTIONS

If the information in this manual is not followed

exactly, a re or electrical shock may result that could cause

property damage, personal injury or death.

Never leave children alone or unattended in

the area where a cooktop is in use.

Stepping, leaning or sitting on the cooktop

may result in serious injuries and can also cause damage to

the cooktop.

• For Your Safety: Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any other appliance.

To eliminate the risk of burns or re due to overheating, cabinets

located above the induction unit should be avoided. If cabinet

space is available, the risk can be reduced by installing a range

hood that protects horizontally at a minimum of 5 inches below

the bottom of the cabinets

• To prevent accidents and achieve optimal ventilation, allow for

sufcient space around the cooking area.

• Your cooktop can be installed into a countertop by itself or above

a gas or electric wall oven.

• All electric cooktops run off a single phase, three-wire cable,

240V/60Hz AC only electrical supply with ground. Minimum

distance between cooktop and overhead cabinetry is 3

0".

BEFORE INSTALLING THE COOKTOP

1. Visually inspect the cooktop for damage. Also make sure all

cooktop screws are on tight.

2. Record the model and serial number as found on the bottom of

your cooktop. When ordering parts for or making inquiries about

your cooktop, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate on your

cooktop.

3. Prepare the cutout dimensions of the countertop.

4. Make sure the wall coverings, countertop and cabinets around

the cooktop can withstand heat (up to 200°F) generated by the

cooktop.

5. Gently lower the cooktop into the countertop cutout.

NOTE: Do not seal the cooktop to the countertop, the cooktop must

be removable if service is necessary. The cooktops include spacers

on bo t h sides to ensure prop e r ai row onc e in s t a l l e d. Do not remove

the spacers. See Figure 6.

ELECTRICAL CONNECTION

The Induction Cooktops must connect to a separate, single phase,

AC Only electrical supply with their own circuit breaker. These

appliances must be installed in accordance with National Electrical

Codes, as well as all state, municipal and local codes. This appliance must be supplied with the proper voltage and frequency and

amperage, which is protected by a properly sized circuit breaker or

time delay fuse.

IMPORTANT INSTALLATION INFORMATION

• Dimensions that are shown in Figures 3 & 7 must be used. Given

dimensions provide minimum clearance.

• Contact surface must be solid and level.

• Check location where the cooktop will be installed for proper

electrical supply. Approximate location of junction box, min 12"

(304.8mm) below the cooktop. See Figure 4.

TINSEB569MRR0

1

1

Page 2

The cable from the appliance is equipped with

3-wire.

IMPORTANT: Use the 3-wire cable from Home Power Supply

where local codes permit a 3-wire connection.

Use the 4-wire cable from Home Power Supply where local codes

do not allow grounding through neutral.

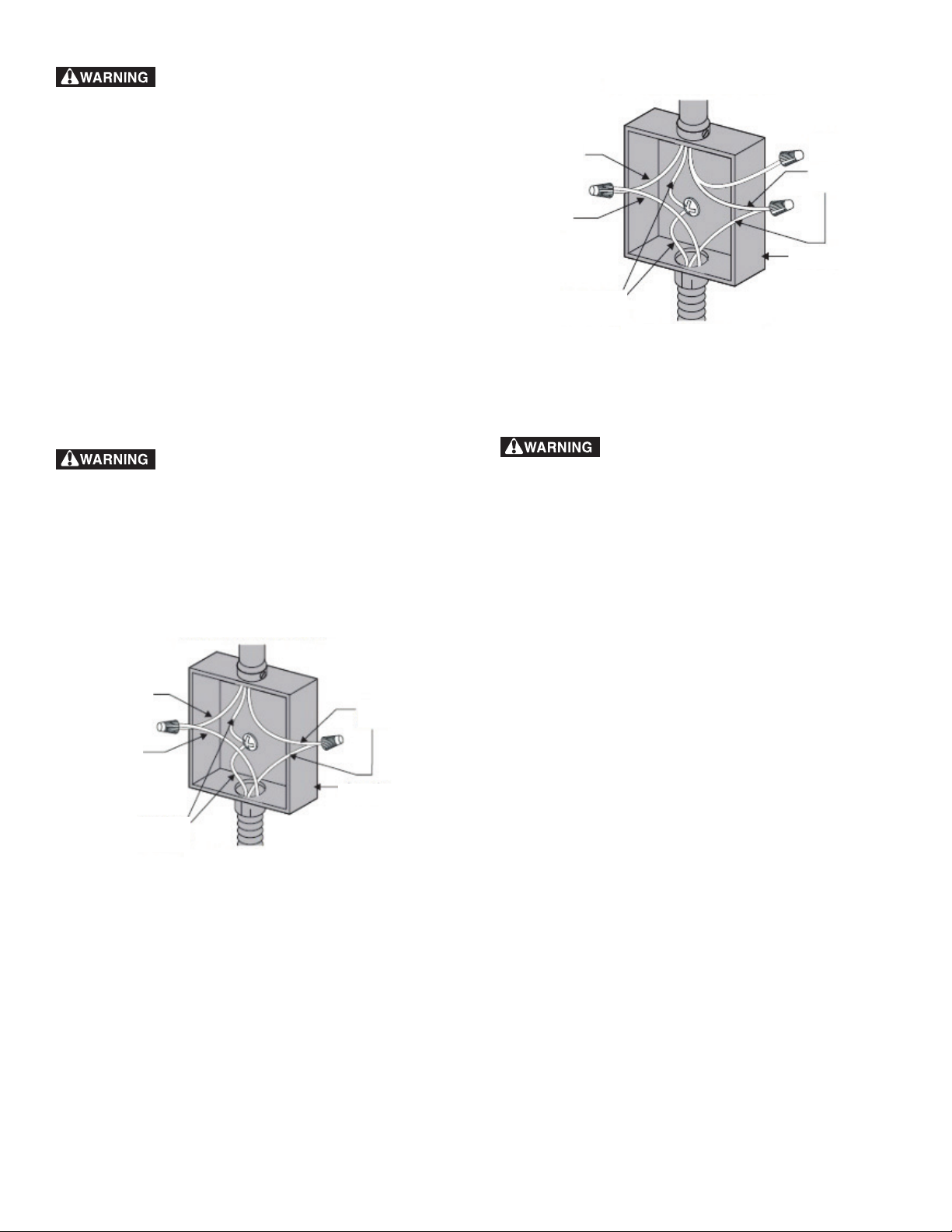

Connecting to a 3-wire power OR 4-wire power supply cable

electrical system

1. Disconnect the power supply.

2. In the circuit breaker, fuse box, or junction box, connect appliance

and power supply cable wires as shown below (3-wire, Figure 1;

4-wire, Figure 2).

3. Circuit breaker fuse rating must be above 40 A, and wire should

be 2/8 or 3/8 copper.

4. Minimum acceptable size of conductors should be no less than

10AWG, copper only, and no less than 167°F.

5. A wire-binding screw or stud used in the wire terminal should

be 10 or larger.

• The electrical power to the cooktop must be shut off while line

connections are being made. Failure to do so could result in

serious injury or death.

• An extension cord must not be used with this appliance. Such

use may result in a re, electrical shock or other personal injury.

Cable from Power Supply

Red Wire

Red Wire

Green Wire

(Grounding)

Cable from Appliance

White Wire

Black Wire

Junction Box

4-Wire Cable from Home Power Supply

Figure 2

The cooktop conduit wiring is approved for cop-

per wire connection only, if you have aluminum house wiring, use

only special connectors which are approved for joining copper and

aluminum wires conform with local codes and ordinances. Follow the

electrical connector manufacturer’s recommended procedure closely.

IMPORTANT - Save for the local electrical inspector's use.

Cable from Power Supply

Red Wire

Red Wire

Green Wire

(Grounding)

Cable from Appliance

3-Wire Cable from Home Power Supply

Figure 1

Black Wire

Junction Box

2

Page 3

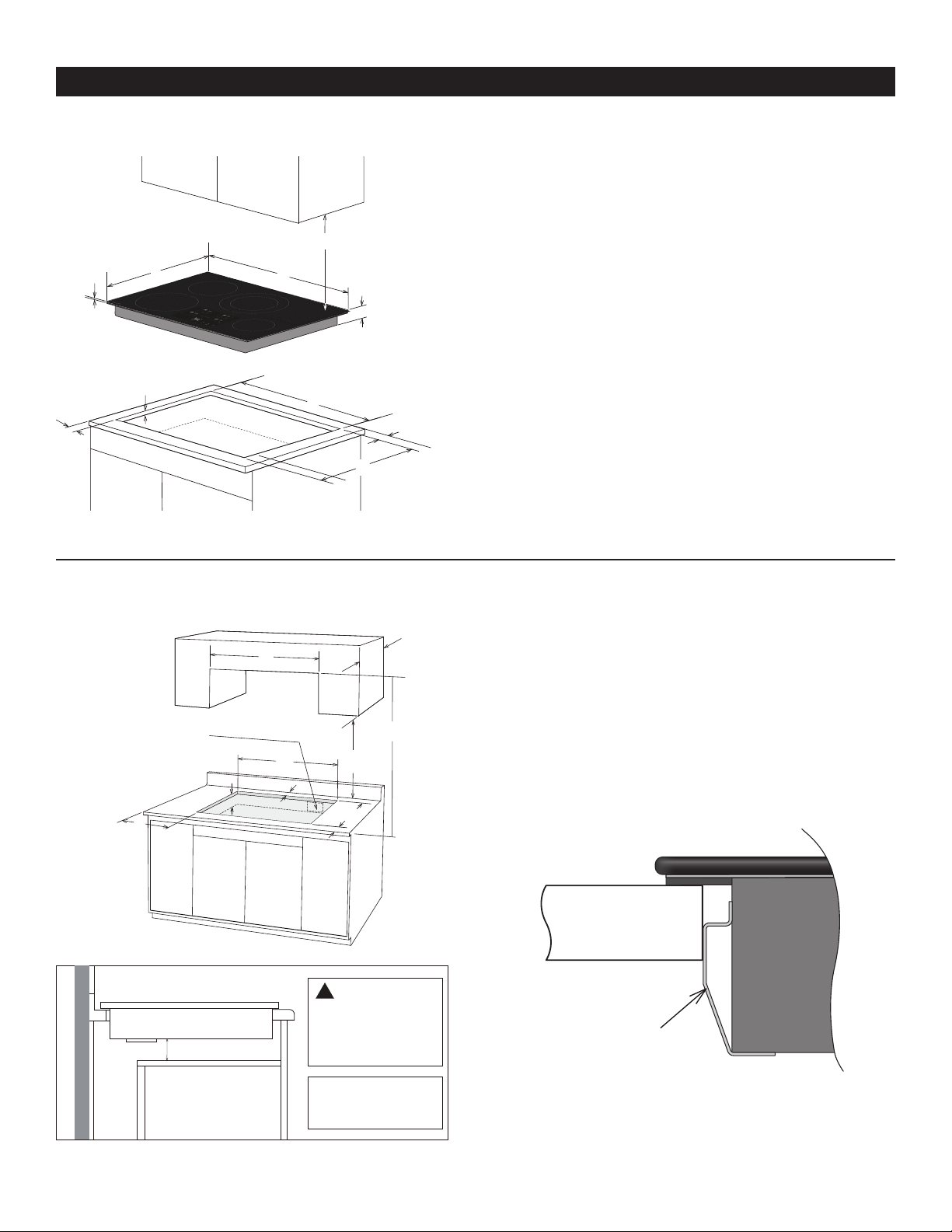

INSTALLATION – 30” MODEL SDH3042DB

B

Spacer Graphic Profile

COOKTOP AND CUTOUT DIMENSIONS (See Figure 3)

30” (76.2 cm) min. for cabinet

I*

* Do not obstruct these areas.

B

C

G

H

Figure 3

A

D

E

J

F

A. 30” (762 mm)

B. 21” (533 mm)

C. 5/32” (4 mm)

D. 2-5/32” (55 mm)

E. 29-5/8” (753 mm)

F. 19-7/8” (505 mm)

G. Minimum: 13/32” (10 mm)

Maximum: 25/32" (20mm)

H. Minimum: 2” (51 mm)

I. Minimum: 30” (762 mm)

J. Minimum: 2” (51 mm)

COOKTOP CUTOUT OPENING DIMENSIONS (See Figure 4)

A

Approximate location

of junction box,

min. 12" (304.8 mm)

below cooktop

H

Figure 4

G

2-1/2” (63.5 mm)

OVEN

E

I

CAUTION

!

It is very important to

keep 2-1/2” (63.5 mm)

distance between the

cooktop and the oven.

Note: do not put a

divider between the

oven and cooktop

C

D

F

A. 30” (762 mm)

B. 13” (330 mm)

C. 30” (762 mm) min to unprotected wood

D. 18” (457 mm)

E. 29-5/8” (753 mm)

F. 19-7/8” (505 mm)

G. 4-1/2 (114mm)

H. Minimum: 2” (51 mm)

I. Minimum: 2” (51 mm)

Countertop

Do not remove spacer

Figure 6

NOTE: The cooktops include spacers on both sides to ensure proper

airow once installed. Do not remove the spacers. See Figure 6 above.

Figure 5

3

Page 4

INSTALLATION – 36” MODEL SDH3652DB

B

COOKTOP AND CUTOUT DIMENSIONS (See Figure 7)

30” (76.2 cm) min. for cabinet

I*

B

A

C

G

H

E

* Do not obstruct these areas.

D

J

F

A. 36” (914 mm)

B. 21” (533 mm)

C. 5/32” (4 mm)

D. 2-5/32” (55 mm)

E. 35-3/8” (899 mm)

F. 19-7/8” (505 mm)

G. Minimum: 13/32” (10 mm) Maximum: 25/32"

(20mm)

H. Minimum: 2” (51 mm)

I. Minimum: 30” (762 mm)

J. Minimum: 2” (51 mm)

Figure 7

COOKTOP CUTOUT OPENING DIMENSIONS (See Figure 8)

A

Approximate location

of junction box,

min. 12" (304.8 mm)

below cooktop

H

E

G

I

C

D

F

A. 36” (914 mm)

B. 13” (330 mm)

C. 30” (762 mm) min to unprocted wood

D. 18” (457 mm)

E. 35-5/8” (899 mm)

F. 19-7/8” (505 mm)

G. 4-1/2" min (114 mm)

H. Minimum: 2" (51 mm)

I. Minimum: 2” (51 mm)

Figure 8

4

Page 5

AFTER INSTALLATION

1. Remove all the stickers and items from the top of the cooktop

surface.

2. Clean cooktop before use. Dry with a soft cloth. See “Cleaning

Your Cooktop” in the operation manual for reference.

3. Read “Using the Cooktop” in the operation manual.

4. Turn on the power to the cooktop.

5. Verify all functions operate properly.

NOTE: If the cooktop does not work, or you nd any problem

in your operation, please check that the circuit breaker has not

tripped, or a fuse has not blown. For more information, please

See Troubleshooting Guide in the operation manual. If you do

not solve the problem by yourself, please contact us for assistance

or service

FCC STATEMENT

This device complies with Part 18 of the FCC Rules. NOTE:

This equipment has been tested and found to comply with the

limits for a Consumer ISM equipment, pursuant to Part 18 of

the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference

will not occur in a particular installation.

Please note that changes or modications of this product is not

expressly approved by the party responsible for compliance could

void the user's authority to operate the equipment.

If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

5

Page 6

NOTES

Page 7

NOTES

Page 8

SHARP ELECTRONICS CORPORATION • 100 Paragon Drive • Montvale, New Jersey 07645 • USA

SHARP ELECTRONICS OF CANADA LTD • 335 Britannia Road East • Mississauga, Ontario • L4Z 1W9 • Canada

Loading...

Loading...