Page 1

SERVICE MANUAL

CODE: 00ZSD2260SME1

COPIER

(DUPLICATOR)

MODEL SD-2260

CONTENTS

[ 1 ] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 – 1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 – 1

[ 3 ] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 – 1

[ 4 ] SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 – 1

[ 5 ] EXTERNAL VIEWS AND INTERNAL STRUCTURE . . . . . . . . . . . . . .5 – 1

[ 6 ] SETTING AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 – 1

[ 7 ] SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 – 1

[ 8 ] RADF UNIT TEST FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 – 1

[ 9 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 – 1

[10] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 – 1

[11] KEY OPERATOR PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 – 1

[12] SETTING/ADJUSTMENT VALUES RECORDING SHEET . . . . . . . .12 – 1

[13] OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 – 1

Parts marked with "! " is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

Contents

[ 1 ] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . 1-1

1. System configura tion . . . . . . . . . . . . . . . . . . . . . 1-1

2. Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . 2-1

1. Basic specification s . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Copy perfor m ance . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. Operational (hardware) specifica tions . . . . . . . . 2-2

4. Option spec ificat i ons . . . . . . . . . . . . . . . . . . . . . 2-5

[ 3 ] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . 3-1

1. OPC drum, develope r, t oner, maintenance kit . 3-1

2. Copy paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3. Environment conditions . . . . . . . . . . . . . . . . . . . 3-7

4. Producti on number identification . . . . . . . . . . . . 3-7

[ 4 ] SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1. Installation (use) environment checking . . . . . . 4-3

2. Transp or t an d in st al la tion . . . . . . . . . . . . . . . . . 4-4

3. Unpacki ng . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4. Lock release . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

5. Parts setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

6. Option instal lation . . . . . . . . . . . . . . . . . . . . . . 4-10

7. Consumabl e parts setup . . . . . . . . . . . . . . . . . 4-11

8. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

9. Operat ional specification setup . . . . . . . . . . . . 4-14

10. Image correction function setup and check . . 4-14

11. Image density sensor, photoconductor

drum mark sensor operation check . . . . . . . . 4-14

12. Image correction execution . . . . . . . . . . . . . . . 4-15

13. Copy density check . . . . . . . . . . . . . . . . . . . . . 4-15

14. Focus (resolution), copy magnification

ratio check (adjustment) . . . . . . . . . . . . . . . . . 4-15

15. Operation check . . . . . . . . . . . . . . . . . . . . . . . 4-16

16. Copy image center shift check . . . . . . . . . . . . 4-16

17. Image loss, void area check (adjustment) . . . . 4-16

18. Recording of adjustment/setting values,

ROM version . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

19. Explanation for user operation . . . . . . . . . . . . 4-16

20. Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

[ 5 ] EXTERNAL VIEWS AND INTERNAL

STRUCTURE

1. External views . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. Intern al oper ation parts . . . . . . . . . . . . . . . . . . . 5-2

3. Operati on panel . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

4. Internal par ts . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5. Sensors and detectors . . . . . . . . . . . . . . . . . . . 5-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6. Solenoids and clutches . . . . . . . . . . . . . . . . . . . 5-9

7. Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

8. PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

9. Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

[ 6 ] SETTING AND ADJUSTMENTS . . . . . . . . 6-1

1. Specificat i on setting . . . . . . . . . . . . . . . . . . . . . 6-6

2. Paper f eed, paper transport section . . . . . . . . . 6-9

3. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

4. Image f or m ing secti on . . . . . . . . . . . . . . . . . . . 6-39

5. Fusing /paper exit section . . . . . . . . . . . . . . . . 6-46

6. Switchback section . . . . . . . . . . . . . . . . . . . . . 6-48

7. Duplex sectio n . . . . . . . . . . . . . . . . . . . . . . . . 6-49

8. RADF section . . . . . . . . . . . . . . . . . . . . . . . . . 6-51

9. Original table section (Japan only) . . . . . . . . . 6-57

10. Picture quality correction system setting

and adjustment . . . . . . . . . . . . . . . . . . . . . . . . 6-59

11. Copy density adjustment . . . . . . . . . . . . . . . . . 6-63

[ 7 ] SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

3. Operati ng procedure . . . . . . . . . . . . . . . . . . . . . 7-1

4. Simulation list . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

5. Details of simulati ons . . . . . . . . . . . . . . . . . . . . 7-6

[ 8 ] RADF UNIT TEST FUNCTIONS . . . . . . . . . 8-1

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Test mode operating procedure . . . . . . . . . . . . 8-1

3. Operati on panel . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

4. Test mode list . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

5. Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

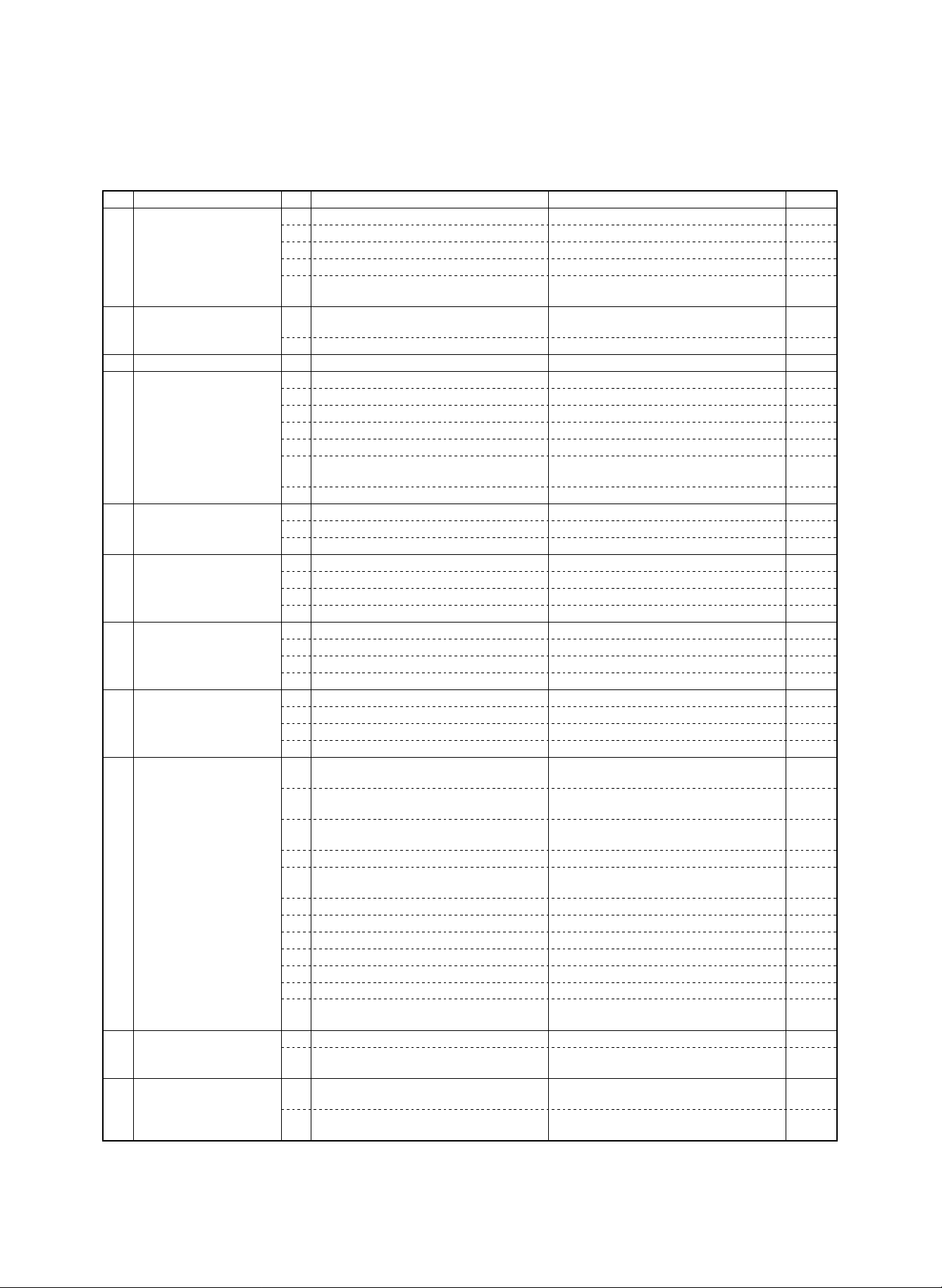

[ 9 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . 9-1

1. Maintenance timing and item s . . . . . . . . . . . . . 9-1

2. Parts replacement, cleaning, lubrication,

grease up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

[10] TROUBLESHOOTING . . . . . . . . . . . . . . . . . 10-1

1. Self diag nosti cs . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. Memor y related troubl es and servicing

for main control troubles . . . . . . . . . . . . . . . . 10-21

3. Paper jam , misfeed table . . . . . . . . . . . . . . . 10-25

[11] KEY OPERATOR PROGRAM . . . . . . . . . . 11-1

[12] SETTING/ADJUSTMENT VALUES

RECORDING SHEET

. . . . . . . . . . . . . . . . . . 12-1

[13] OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Page 3

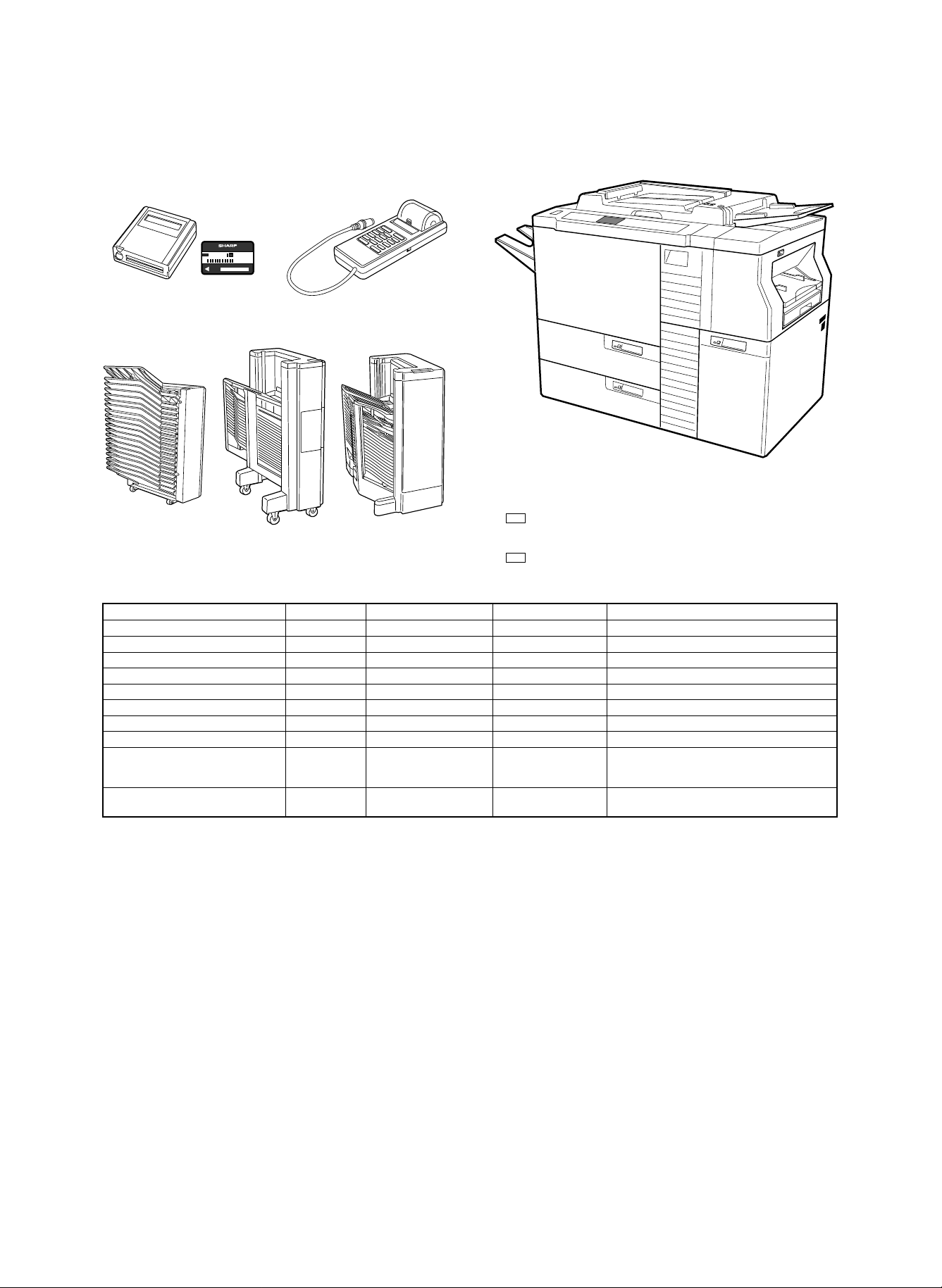

[1] PRODUCT OUTLINE

1. System configuration

COPY CARD

001

Card type auditor Commander

SF-EA11 SF-EA13

20-bin sorter 20-bin staple sorter 20-bin staple sorter

SF-S16 SF-S53 SF-S55

SD-2260 main body

Expansion RAM (2600 dept) (For internal auditor)

* DKIT-0321FCZZ

Communication interface board

* CPLTM4130FC53

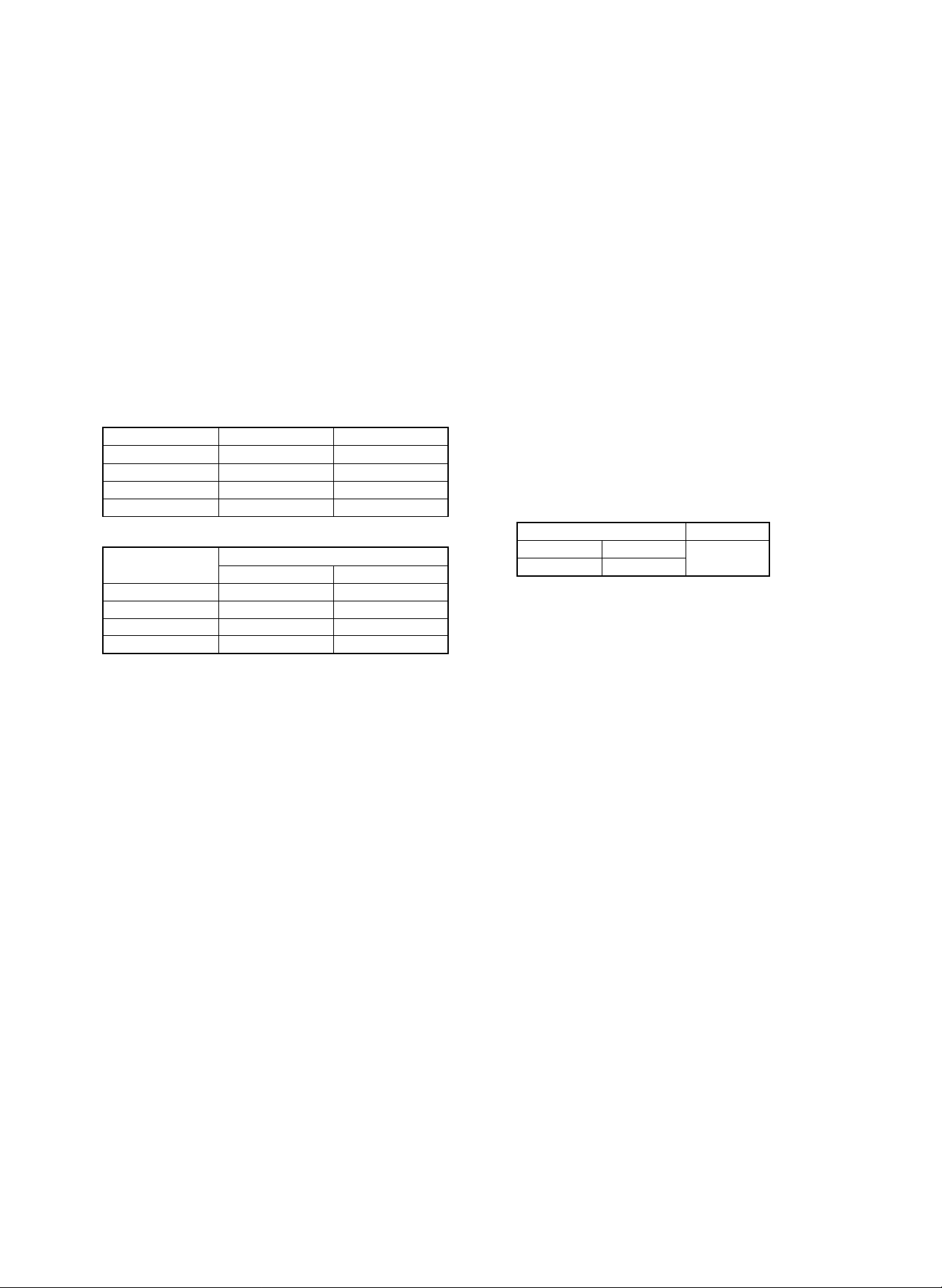

Part name Model Common use model Power source Note

Copier body SD-2260

RADF (New) * Standard (New) Supplied from the copier.

20-bin sorter * SF-S16 SF-2050, SD-2060, etc. Supplied from the copier.

20-bin staple sorter * SF-S53 SF-2050, SD-2060, etc. Supplied from the copier.

20-bin staple sorter * SF-S55 (New) Supplied from the copier. Can be used only in SD-2260.

Card type department control counter * SF-EA11 SF-2050, SD-2060, etc. Supplied from the copier.

Commander * SF-EA13 SF-2050, SD-2060/3062, etc. Supplied from the copier.

Paper exit tray LSOU-0054FCG4 SF-2050, SD-2060, etc. Treated as a service part.

Expansion RAM for internal auditor * DKIT-0321FCZZ SD-2060/3062/2160 The standard capacity of the internal auditor is 500

Communication I/F board * CPLTM4130FC53 SD-2060/3062/2160 Treated as a service part with the frame. The part

departments. By installing this expansion RAM, 2600

departments are added to be 3100 departments in total.

without the frame (PWB unit) is CPLTM4132FC55.

* : Option

1 – 1

Page 4

2. Features

(1) High productivity

1 Large capacity tray, cassette

Air paper feed tray (3,300 sheets) × 1

Air paper feed tray (1,000 sheets) × 1

Paper cassette (250 sheets) × 1

Manual paper feed tray (100 sheets) × 1

2 RADF is equipped with the large capacity tray (100 sheets,

80g/m2).

3 Duplex copying of max. 100 sheets is possible. (The duplex tray

capacity: 100 sheets, 80g/m2) 50 sheets for A3 (11″ × 17″).

4 Large capacity toner hopper (Equivalent to 56K)

5 RADF realizes 100% efficiency of single copy from single docu-

ments.

6 The staple sorter of 50-sheets allows automatic after-process

(with the option sorter installed).

7 Unit structure

The employment of the unit structure allows quick recovery by

replacement of the unit in case of a trouble, shortening the recovery time.

8 Automatic copy density adjustment

This feature automatically adjusts the copy lamp voltage in each

copy mode depending on the copier conditions, eliminating the

need for copy density adjustment by the simulation.

(4) High picture quality

1 AICS (Active Image Control System)

The Sharp’s unique AICS (Active Image Control System) allows to

check toner concentration on the photoconductor drum by the

copier itself, correcting a change in density due to deterioration

automatically. This maintains high quality copies for a long period.

(2) High reliability

1 Air feed system

The air feed system allows smooth paper feed. It utilizes air pressure to separate paper without contact, stabilizing the paper transport force, reducing double feed and paper jam.

2 Auto recovery

In case of a paper jam, the trouble may be canceled by removing

the minimum number of paper. (The drive section of the copier is

divided into several sections, which are driven separately. In case

of a paper jam, transport is continued or stopped depending on

the jam position. By removing paper from the sections which are

not related to the paper jam, the trouble is canceled, reducing

paper jam treatment.)

3 Communication feature

Communication between the copier and the service center is possible through the telephone line. The serviceman can identify the

trouble position in advance to servicing, shortening the recovery

time. (Option)

4 Full frame structure

The frame of the machine is made of a strong structure, enabling

long-period use that is highly durable.

(3) The LCD screen with the backlight allows each

operations.

1 Key operator program

Use of the key operator program allows setting and adjustment of

the operation mode according to the office needs. The department

control counter is a standard provision.

1 – 2

Page 5

[2] SPECIFICA TIONS

1. Basic specifica tio ns

1) Type

Console

2) Copy system

Static electricity transfer, dry copier

3) Class

Segment 4

4) Target users

The target users of this model are high copy volume users such

as general offices and copy centers.

Monthly copy volume: Average 40,000 ∼ 50,000/month

(Min. 30,000/month, max. 200,000/month)

5) Machine life (Overhaul): 1200K

6) Size

1167 × 762 × 1080mm

1627 × 762mm (Occupying area) (With the paper exit tray and the

paper feed tray installed)

7) Weight

257 kg (567 lbs)

2. Copy performance

A. Original size

(1) Original table mode

Max. original size: A3 (11 × 17")

(2) RADF mode

Original size: A3 ∼ A5 (11 × 17" ∼ 5.5 × 8.5")

B. Copy paper size, weight, kinds

(1) A3 ∼ A5 (11 × 17" ∼ 5.5 × 8.5")

C. Copy mode

Auto mode

Photo mode (Variable in 9 steps)

Manual mode (Variable in 9 steps)

D. Copy magnification ratio

(1) Zoom mode

50 ∼ 200% (Variable in 1% increment )

(2) Fixed magnification ratios

AB series: 200/141/122/115/100/86/81/70/50 [%]

Inch series: 200/141/129/121/100/95/77/64/50 [%]

(Error ±0.9%)

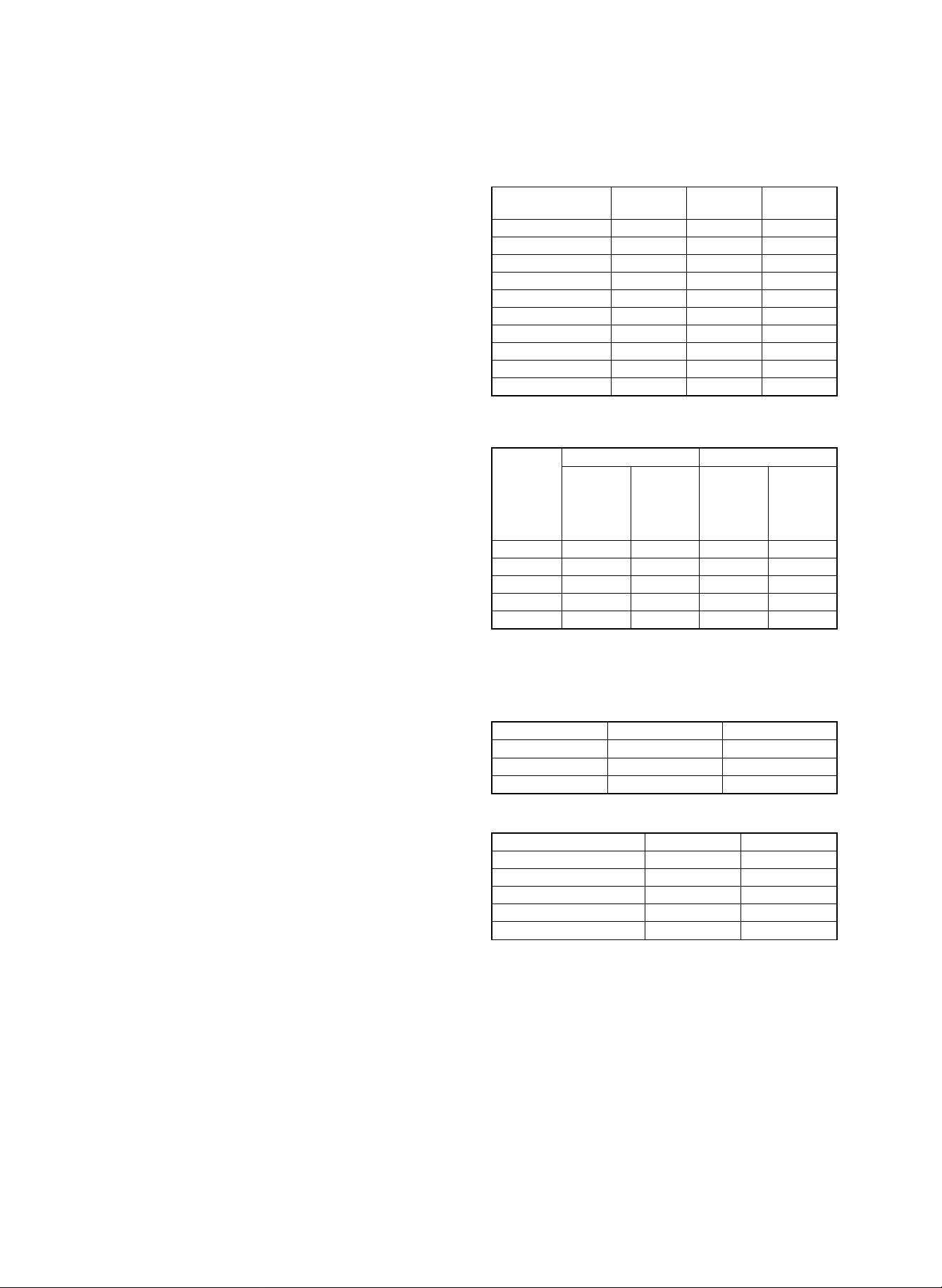

E. Copy speed

(1) Continuous copy speed

Unit (CPM)

Paper size Normal

A3 36 36 36

B4 41 39 41

A4 60 53 44

A4R 46 45 44

B5 60 58 44

B5R 46 45 44

11 × 17 36 36 36

8.5 × 14 41 39 41

8.5 × 11 60 53 44

8.5 × 11R 46 45 44

(2) First copy speed

Unit (sec), 8.5 × 11" or A4 paper

Non-RADF mode RADF mode

With sorter

P.F. unit

TRAY1 4.0 4.3 4.6 4.9

TRAY2 4.7 5.0 4.8 5.1

TRAY3 5.2 5.5 5.3 5.6

M.F TRAY 3.7 4.0 4.7 5.0

Cassette 3.6 3.9 4.7 5.0

Without

sorter

(SF-S55)

installed

(Reference

value)

Reduction

(50%)

Without

sorter

Enlargement

(200%)

With sorter

(SF-S55)

installed

(Reference

value)

F. Max. continuous copy quantity

999 sheets

G. Void area, image loss

Item Lead edge Rear edge

Image loss 1.0 ∼ 4.5 mm —

Void area 1.0 ∼ 3.0 mm 1.0 ∼ 4.0 mm

Image shift for paper 0±1.5 mm —

H. Resolution

Copy magnification ratio Copy center Corners

100% 5.0 lines/mm 4.5 lines/mm

101 ∼ 200% 5.0 lines/mm 4.5 lines/mm

90 ∼ 99% 4.5 lines/mm 4.0 lines/mm

64 ∼ 89% 3.6 lines/mm 3.2 lines/mm

50 ∼ 63% 3.2 lines/mm 2.8 lines/mm

2 – 1

Page 6

I. Center shift

Original table mode

Overall (RADF mode)

Single ±2.0 mm

Duplex ±2.0 mm

Single S → S

D → S

Duplex S → D

D → D

±3.0 mm

±4.0 mm

±3.0 mm

±4.0 mm

J. Skew feed

Copier

(Original table mode)

Overall (RADF mode)

Single 2.0mm or less

Duplex 2.0mm or less

S → S, S → D 3.0mm or less

D → S, D → S 3.0mm or less

K. Duplex multi copy

Max. 100 sheets, however 50 sheets for A3 (11 × 17")

3. Operational (hardware) specifications

A. Paper feed section

(1) Paper feed system

3 paper feed tray (Air paper feed system)

1 paper cassette (Roller paper feed system)

Multi manual paper feed (Roller paper feed system)

(2) Paper capacity, paper weight, paper size, paper kinds

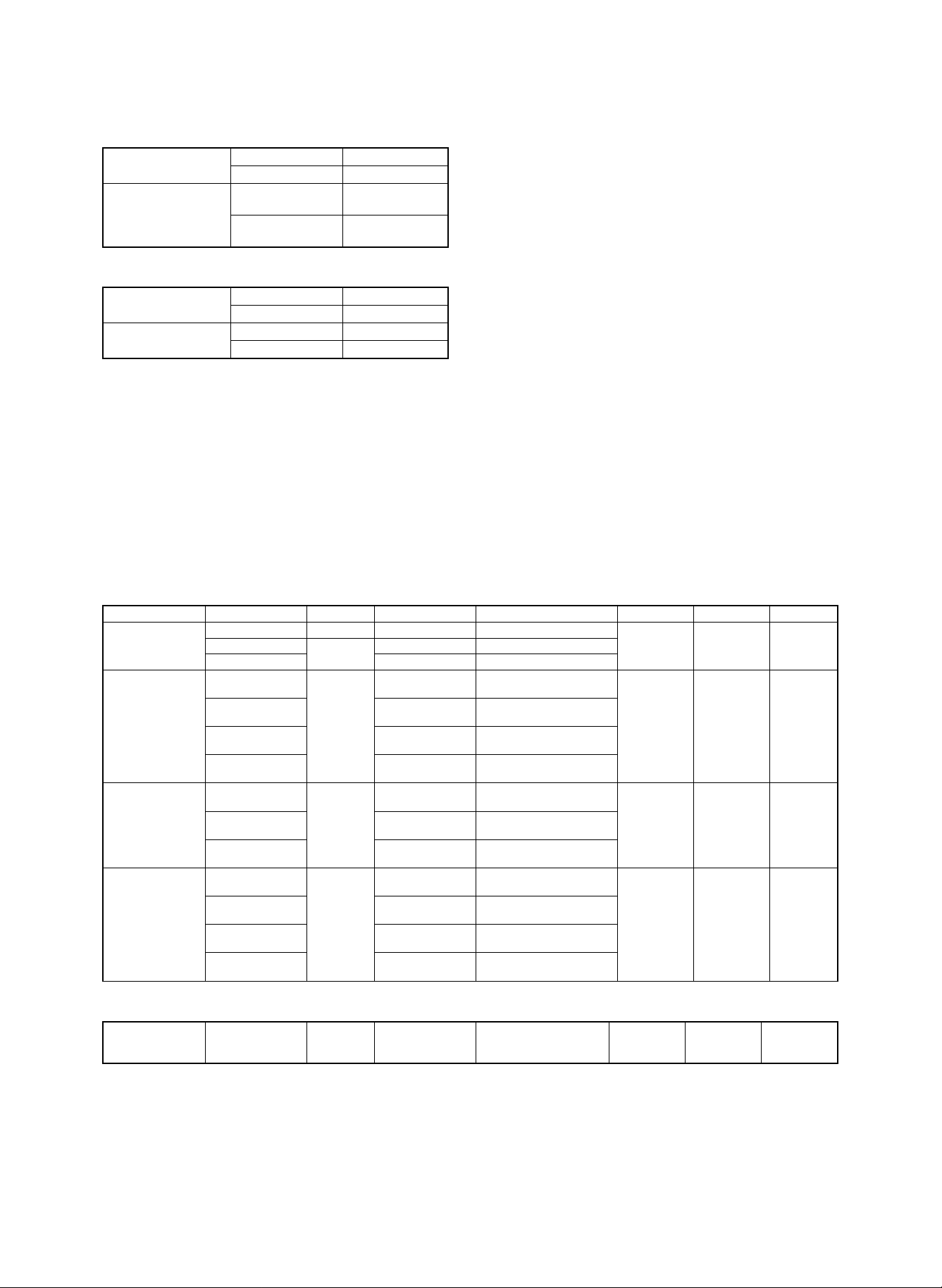

Paper feed section Destination Capacity Paper size Detection size Paper weight Size selection Type

No. 1 paper feed tray

No. 2/3 paper feed tray

Cassette paper feed

Manual paper feed tray

Japan 3,300 sheets A4, B5 A4, B5

EX AB series

Ex Inch series 8.5 × 11 8.5 × 11

Japan

Inch series 11 × 17 ∼ 8.5 × 11

EX other AB series A3 ∼ A4

Australia, New Zealand A3 ∼ A4

Japan

EX AB series A4, A4R, B5, B5R

EX inch series A4, A4R, B5, B5R

Japan

Inch series 8.5 × 5.5 ∼ 11 × 17 11 × 17, 8.5 × 14, 8.5 × 11

EX other AB series A3 ∼ A5 A3, B4, A4, A4R, A5

Australia, New Zealand A3 ∼ A5 A3, B4, A4, A4R, A5

3,000 sheets

1,000 sheets

250 sheets

100 sheets

A4 A4

A3 ∼ B5 A3, B4, A4, B5, A4R, B5R,

A4

8.5 × 14, 8.5 × 11

8.5 × 13, 8.5 × 11

A4, A4R, B5, B5R

8.5 × 11, 8.5 × 11R

8.5 × 11, 8.5 × 11R

8.5 × 11, 8.5 × 11R

A3 ∼ A5 A3, B4, A4, A4R,

8.5 × 11, 8.5 × 14

11 × 17, 8.5 × 14, 8.5 × 11, 8.5

× 11R, A4, (8.5 × 13)

A3, B4, A4, A4R

8.5 × 11, 8.5 × 14

A3, B4, A4, A4R

216 × 279, 216 × 330 (mm)

A4, A4R, B5, B5R

8.5 × 11

A4, A4R

8.5 × 11

A4,

8.5 × 11, 8.5 × 11R

B5R, 8.5 × 11

8.5 × 11R, 8.5 × 5.5, (8.5 × 13)

8.5 × 11

216 × 279, 216 × 330 (mm)

60 ∼ 90 g/m

16 ∼ 24 lbs

60 ∼ 128 g/m

16 ∼ 32 lbs

60 ∼ 128 g/m

16 ∼ 32 lbs

cover paper

(176g)/index

paper (200g)

50 ∼ 128 g/m

13 ∼ 32 lbs

cover paper

(176g)/

index paper

(200g) * 1

2

2

2

2

Guide change

(by serviceman)

Universal

Universal

Universal

*1: Manual tray

Special paper (OHP, etc.)

Duplex unit All destinations 100 sheets,

50 sheets for

A3 (11 × 17")

A3 ∼ B5

(11 × 17 ∼ 8.5 × 11) —

60 ∼ 90 g/m

16 ∼ 24 lbs —

2

Air paper feed

system

Air paper

feed system

Air paper

feed system

Roller paper

feed system

Roller paper

feed system

2 – 2

Page 7

B. Original table section

(1) Max. original size

A3, 11 × 17"

(2) Original reference position

Left center reference

(3) Original size detection

System: Photo transmission sensor system

Detection size:A3, B4, A4, A4R, B5, B5R

C. RADF section

(1) Paper feed system

Roller paper feed system

(2) Transport system

Belt transport system

(3) Reverse system

By the reverse gate and the roller.

(4) Original tray capacity (paper feed, paper exit tray)

Max. 100 sheets (80g/m2)

(5) Original size

A3 ∼ A5 (11 × 17" ∼ 5.5 × 8.5)

(6) Original paper weight

Single mode: Japan - 35 ∼ 128g/m2 (35 ∼ 50g/m2 for thin paper mode)

EX - 50 ∼ 128g/m2, 13 ∼ 32 lbs

Duplex mode: 50 ∼ 128g/m2, 13 ∼ 32 lbs (A5 ∼ A4)

50 ∼ 110g/m2, 13 ∼ 29 lbs (A5 ∼ A3)

(7) Original replacement speed

60 sheets/min (Max.) (A4/8.5 × 11")

(8) Operation mode

• Duplex/single

• Normal paper/thin paper

• Normal/stream mode

(9) Original size detection

1) Original size detection by the original tray

Detection by the detector on the original tray (The paper width is

detected by the analog sensor, and the paper length by the paper

length detector.)

(Detection size)

Japan: A3, B4, A4, B5, A4R, B5R, 8,5 × 11, 8.5 × 14

EX inch series: 11 × 17, 8.5 × 14, 8.5 × 11, 8.5 × 11R, 8.5 × 5.5,

A4 (8.5 × 13 possible by SIM setting)

German/UK: A3, B4, A4, A4R, A5, 8.5 × 11, 8,5 × 14

Australia: A3, B4, A4, A4R, A5, 216 × 179, 216 × 330 (mm)

2) Original size detection by the original transport roller rotation

(Detection size)

Japan: A3, B4, A4, B5, A4R, B5R

EX inch series: 11 × 17, 8.5 × 14, 8.5 × 11, 8.5 × 11R, 8.5 × 5.5

(8.5 × 13 possible by SIM setting)

German: A3, B4, A4, A4R, A5

Australia: A3, B4, A4, A4R, A5, 216 × 330 (mm)

D. Optical section

(1) Exposure system

Exposure section (lamp) scanning slit exposure system

(2) Zooming system

Lens moving system

(3) Lens specifications

Composition: 1-group, 4-lens

Fixed focus lens F: 5.6, f: 220mm

(4) Exposure mode

Auto mode (Synchronized with scanning operation to measure the

center of 100mm wide for automatic adjustment of the copy lamp

voltage.)

Manual mode

Photo mode

(5) Copy lamp specifications

Halogen lamp

(100V system) 85V, 220W

(200V system) 170V, 260W

(6) Correction

Automatic correction of the copy lamp voltage.

E. Image forming section

(1) Photoconductor section

1) Type: OPC

2) Size: 100 ϕ

3) Life: 250K

4) Humidity control by the surface heater

(2) Charger section

1) Main charger

Scorotron system (screen grid, saw tooth electrode)

2) Transfer charger

Corotron system by wire

(3) Separation section

1) System: Separation by the separation charger and the separation

pawl

2) Separation charger

Corotron system by wire

3) Separation pawl life

4) Pre-transfer discharger

Corotron system by wire

(4) Developing section

1) System: Magnetic brush developing system

2) 2-component development (Developer: Positive charging, toner:

negative charging)

3) Developing bias voltage: DC–220V

4) Developer

Capacity: 850g/bag × 2 bags (= 1.7 kg)

Life: 250K

Type: Ferrite type

(5) Toner hopper section

Capacity 930g (Equivalent to 28K with 6% density originals)

2 – 3

Page 8

(6) Cleaning section

Cleaning by the brush and the pressure contact blade system

Cleaning blade life: 125K

(7) Correction

Main charger grid voltage correction

Photoconductor drum OPC membrane wear sensitivity correction

I. Paper exit section

Tray capacity 250 sheets

Full detection feature

J. Waste toner collection section

Capacity: 1750g (125K, with 6% density originals)

F. Fusing section

(1) System

Roller pressure system

(2) Roller type

Teflon roller (heat roller) life

500K

Silicon rubber roller (pressure roller) life

250K

(3) Heater lamp

Destination Main Sub

Japan 15A spec. 750W 660W

Japan 20A spec. 1075W 700W

EX 100V series 1100W 700W

EX 200V series 1150W 650W

(4) Fusing temperature

Destination

Japan 15A spec. 205˚C 205˚C

Japan 20A spec. 200˚C 200˚C

EX inch series 200˚C 180˚C

EX AB series 205˚C 205˚C

Normal Duplex

(5) Separation system

Forced separation by the separation pawl

Upper separation pawl life: 250K

Lower separation pawl life: 250K

(6) Cleaning system

Cleaning by the cleaning roller

Upper cleaning roller life: 125K

Lower cleaning roller life: 125K

Copy mode

K. Jam recovery time

Within 5 sec (When jam canceling is made within 60 sec in case of a

jam outside the fusing section.)

L. Communication function

Remove communication function (RS232C)

M. Warm-up time

Japan: About 10 min (15A specification), about 5 min (20A specifica-

tion)

EX: About 5 min

N. Operating voltage, power consumption

(Power consumption)

Max.

Japan EX

15A 20A

1500W 1800W

Average 1200W (During copying)

Power save mode

(Pre heat mode (Fusing temperature fall)) 236Wh or less

Stand-by mode (Ready state) 332Wh or less

Power shut off (Power switch OFF) 15Wh or less

(Operating power) (Fluctuation)

Within 10% of the rated voltage, within ±2% of the rated r\frequency

1900W

O. Noise

Sound power level Sound pressure level

During copying 75db or less 63db or less

Standby 55db or less 40db or less

G. Switchback section

(1) System

Transport speed variable system by the reverse gate and the stepping motor

H. Duplex section

(1) Paper feed system

Air paper feed system

(2) Paper capacity, paper weight, paper size, paper kinds

(Paper weight, size)

A3 ∼ B5 (11 × 17 ∼ 8.5 × 11) However, f ixed size.

60 ∼ 90g/m

(Paper capacity)

Max. 100 sheets, however 50 sheets for A3 (11 × 17)

2

P. Electromagnetic noise

Japan: Electromagnetic wave regulations VCCI

USA: FCC

Europe/Australia/South Africa: CISPR

2 – 4

Page 9

Q. Additional functions

Japan SEC SECL SEEG SUK SCA Others

Auto paper selection (APS) || (Only when RADF is used)

Auto magnification ratio selection (AMS)

Binding margin Shift width: 9mm, /4 inch (with adjustment function)

1-set 2-copy | (Enlargement impossible)

Edge erase | (Edge erase/center erase/edge + center erase)

Cover insertion | (Cover paper/back cover/ front, back cover (duplex copy possible))

Index insertion | (Duplex copy possible/max. 18 pages insertion possible)

OHP index |

Job memory | (9 ways)

Auditor | (Standard 500 departments. 3,,100 departments when expanded. DKIT-0321FCZZ required.)

Key operator program |

Communication | (I/F PWB is treated as a service part.)

Toner save mode | (Set by the simulation.) |

Auto tray switching |

Installation tray priority selection ✕

Pre-heat function | (Selection by the key operator program)

Auto power shut off (EnergyStar compliance) | (OFF mode available

Power save mode ✕ |

|

Adjustment width: 0, 3, 6, 9, 12, 15mm/0, 1/8, 1/4, 3/8, 1/2, 5/8 inch

Edge erase adjustment width: 0 ∼ 6, 6 ∼ 12, 1 2 ∼ 18mm/ 0 ∼ 1/4, 1/4 ∼ 1/2, 1/2 ∼ 3/4 inc h

Center erase adjustment width: 10, 15, 20mm/2/5, 3/5, 4/5 inch

by the simulation)

| (Only when RADF is used)

AMS is used by document size detector of RADF tray.

✕

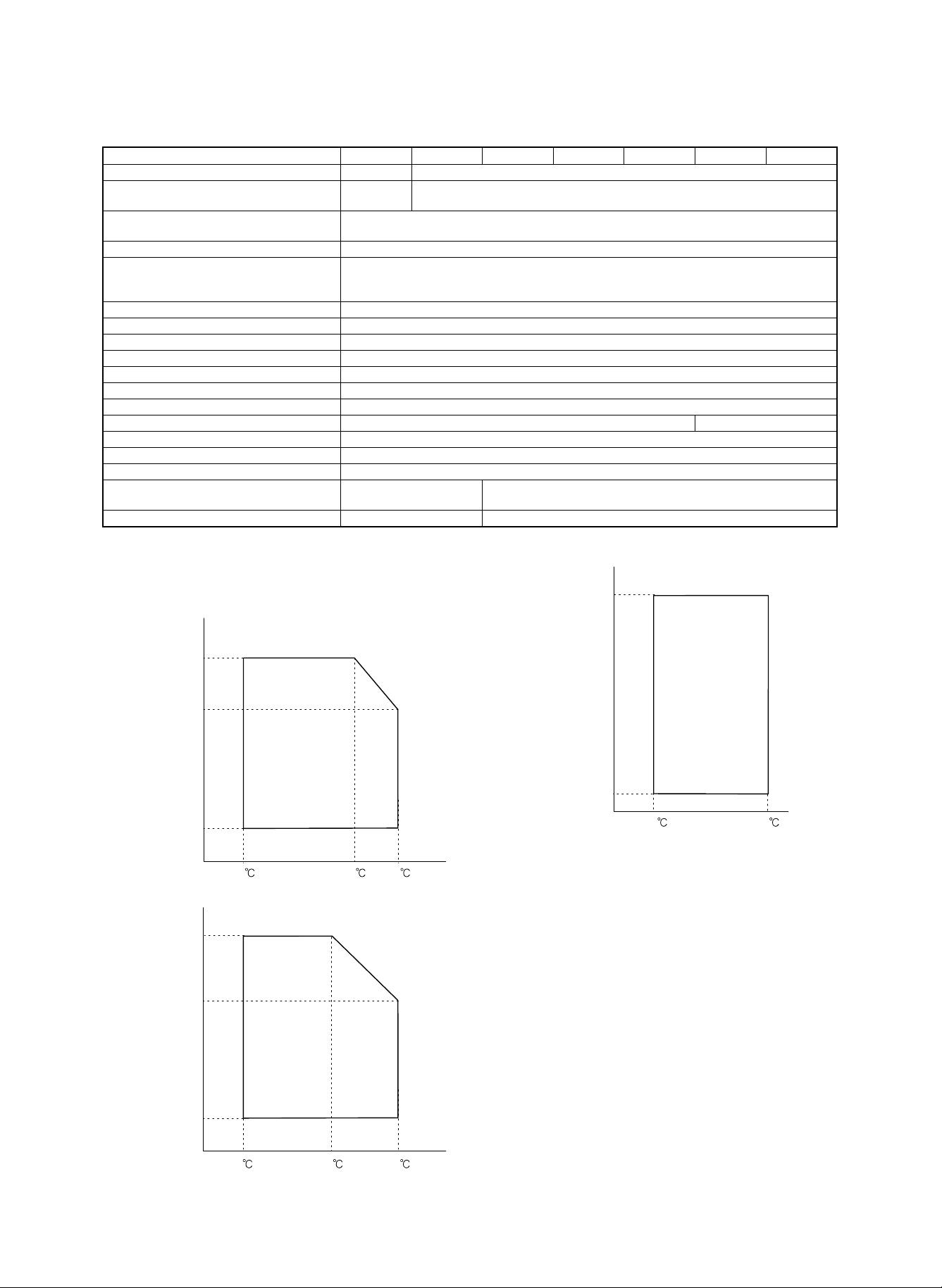

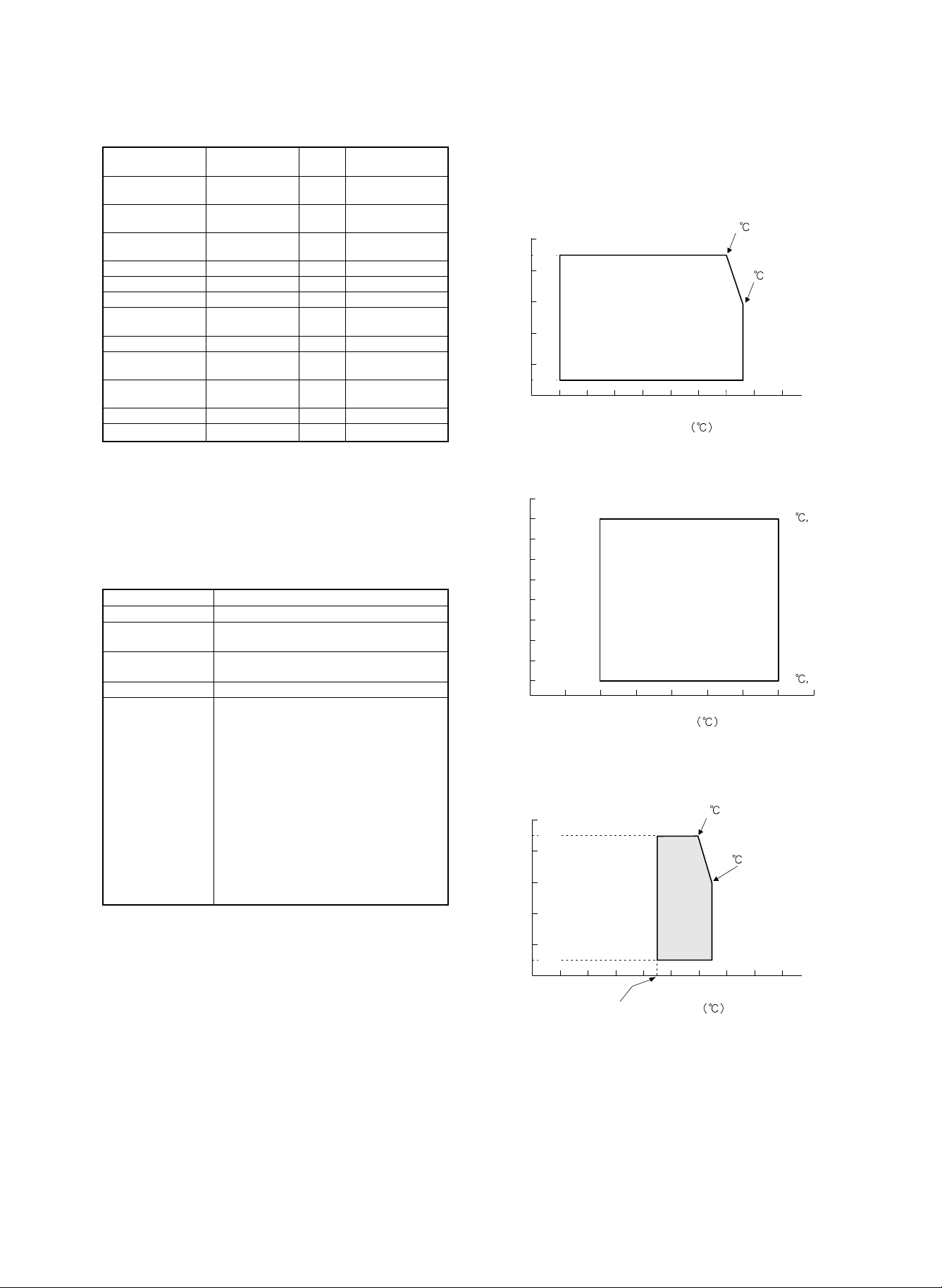

R. Environmental conditions

(Standard conditions)

Temperature: 20 ∼ 25˚C, humidity: 65 ± 5% RH

(Operational condition)

Humidity (RH)

85%

60%

20%

15

(Transport conditions)

Humidity

(RH)

90%

60%

20%

-5

30

30 35

45

(Consumable parts storage conditions )

(Supply storage conditions)

Humidity

(RH)

90%

10%

-10

4. Option specifications

A. Sorter

• 20-bin sorter (SF-S16)

Number of bins: 20 bins

Capacity: Non-sorting 100 sheets

Sorting 50 sheets

Grouping 30 sheets

Sortable size: Japan; all detectable sizes

USA; All detectable size excluding 5.5 ×

8.5

Canada; All detectable size excluding 5.5 ×

8.5

UK: All detectable sizes excluding A5

Europe; All detectable sizes excluding A5

Australia; All detectable sizes excluding A5

2 – 5

40

Page 10

Power: 24V (Supplied from the copier)

Copier weight: 26.5kg

Dimensions: 512 (W) × 520 (D) × 883 (H)mm

• 20-bin staple sorter (SF-S53)

Number of bins: Non-sort bin - 1 bin, sort bin - 20 bins

Capacity: Non-sorting 250 sheets

Sorting: 11 × 17, 8.5 × 14, 8.5 × 13, A3, B4;

25 sheets

8.5 × 11, 8.5 × 11R, A4, A4R, B5;

50 sheets

Grouping: 11 × 17, 8.5 × 14, 8.5 × 13, A3, B4;

25 sheets

8.5 × 11, 8.5 × 11R, A4, A4R, B5;

30 sheets

Sortable size: Japan; All the detectable sizes

USA; All the detectable sizes excluding 5.5

× 8.5"

Canada; All the detectable sizes excluding 5.5

× 8.5"

UK; All the detectable sizes excluding A5

Europe: All the detectable sizes excluding A5

Australia; All the detectable sizes excluding A5

Staple sortable

sizes:

Staple capacity: 50 sheets

Staple position: Left upper corner, slant, one position

Stapler cartridge: 1 cartridge - 5000 staplers

Stapler detection: Available

Alignment: 2.5mm

Bin shift time: About 15 sec (20 bins → Bin home position)

Power source: 24V (Supplied from the copier)

Max. power consumption: 75W or less

Weight: 37kg

Dimensions: 465 (W) × 597 (D) × 926 (H) mm

Japan; All the detectable sizes excluding

B5R

USA; All the detectable sizes excluding 5.5

× 8.5"

Canada; All the detectable sizes excluding 5.5

× 8.5"

UK; All the detectable sizes excluding A5

Europe: All the detectable sizes excluding A5

Australia; All the detectable sizes excluding A5

• 20-bin multi position staple sorter (SF-S55)

Number of bins: Non-sort - 1 bin, sort bin - 20 bins

Capacity: Non-sorting 50 sheets

Sorting: 11 × 17, 8.5 × 14, 8.5 × 13, A3, B4;

25 sheets

8.5 × 11, 8.5 × 11R, A4, A4R, B5, A5;

50 sheets

Grouping: 11 × 17, 8.5 × 14, 8.5 × 13, A3, B4;

25 sheets

8.5 × 11, 8.5 × 11R, A4, A4R, B5;

30 sheets

Sortable size: Japan; All the detectable sizes including A5

USA; All the detectable sizes excluding

Canada; All the detectable sizes

UK; All the detectable sizes

Europe: All the detectable sizes

Australia; All the detectable sizes

Staple sortable Japan; All the detectable sizes

sizes: USA; All the detectable sizes excluding 5.5

× 8.5"

Canada; All the detectable sizes excluding 5.5

× 8.5"

UK; All the detectable sizes excluding A5

Europe: All the detectable sizes excluding A5

Australia; All the detectable sizes excluding A5

Staple capacity: 50 sheets

Staple position: Corner 1 position, 2 positions, 1 position

Stapler cartridge: 1 cartridge - 5000 staplers

Stapler detection: Available

Alignment: 2.5mm

Bin shift time: about 15 sec (20 bins → Bin home position)

Power source: 24V (Supplied from the copier)

Max. power consumption: 100W or less

Weight: 56kg

Dimensions: 564 (W) × 609 (D) × 986 (H) mm

B. Auditor,commander

MODEL DESCRIPTION

CARD COUNTER (Read the department code by

SF-EA11

SF-EA13 COMMANDER (Setting the department)

SF-EA11 YES NO YES NO 200

SF-EA13 NO YES NO YES

Card (Used for SF-EA11)

SF-EA11A 1 to 30 30

SF-EA11B 31 to 100 70

SF-EA11C 101 to 200 100

Combination of use

SF-EA11 and SF-EA13

printed on card and memory of the copy count is

stored to insided memory.)

Memory Printer Display Key

Dept number Number of card

TOTAL 200 200

Maximum number

of department

C. Expansion memory (For the international auditor)

DKIT-0321FCZZ (3100 department expansion)

D. Key sheet and operation manual kits

English SD-260SE

German SD-260SG

French SD-260SF

Dutch SD-260SH

Spanish SD-260SS

Italian SD-260SI

2 – 6

Page 11

1 Two packages are used. (SD-365ND) × 10 = SD-365MD

1 (SD-365NT) × 10 = SD-365MT

(SD-365NT × 10)

(SD-365ND × 10)

(365RU) × 10 = 365UR, order reception as SD=365UR.

(360RL) × 10 = 360LR, order reception as SD-360LR.

No. 6, 8, 9: Common to SD-2060/3062.

1 (360BL) × 10 = 360CB, order reception as SD-360CB.

1

(SD-360BL × 10)

1

(SD-365RU × 10)

10 Use for SF-S53

(SD-360RL × 10)

Common to SD=2060/3062.

1 (365CP) × 5 = 365CK, order reception as SD-365CK.

(SD-SC20 × 5)

(SD-365CP × 5)

[3] CONSUMABLE PARTS

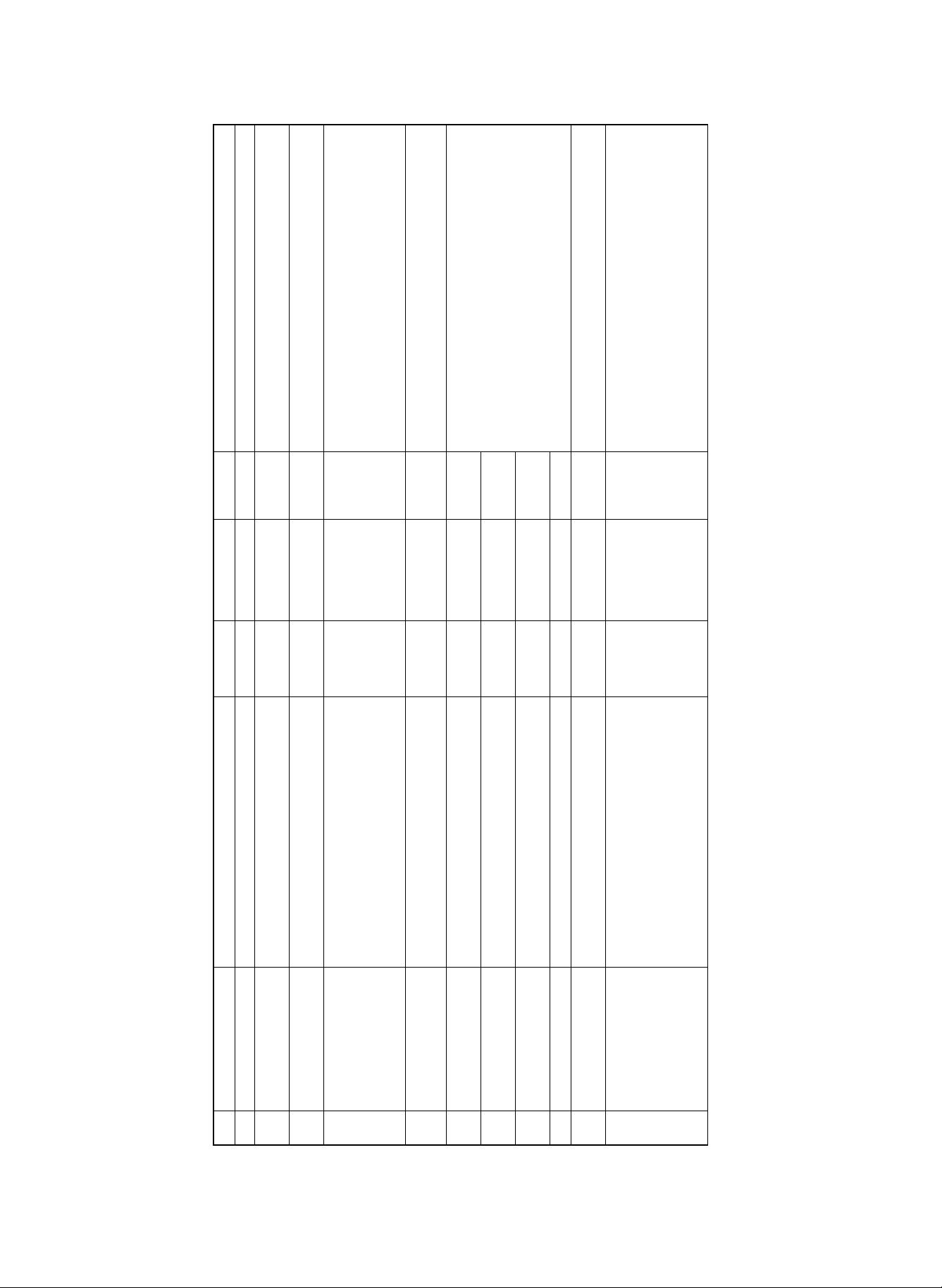

Fusing separation pawl (Upper) × 4

Fusing gear (New) × 1

Heat insulation bush (New) × 2

Fusing separation pawl (Lower) × 4

Developer Developer (New) (0.85Kg) × 10 250K SD-365MD

Toner Toner cartridge (New) (0.93Kg) × 10 28K SD-365MT

1 Drum OPC drum (New) × 1 250K SD-365DR 6 Similar to the drum for SD-2060/3062.

2

3

4 Upper heat roller kit Upper heat roller (New) × 1 500K SD-365UH 5 Similar to the upper heat roller kit for SD-2060/3062.

(USA)

No. Name Content Life Product name Package Remark

1. OPC drum, developer, toner, maintenance kit

5 Lower heat roller kit Lower heat roller × 1 250K SD-360LH 5 Similar to the lower heat roller kit for SD-2060/3062.

6 Cleaner blade Cleaner blade × 10 125K SD-360CB

7 Upper cleaning roller Upper cleaning roller (New) × 10 125K SD-365UR

8 Lower cleaning roller Lower cleaning roller × 10 125K SD-360LR

9 Waste toner bottle Waste toner bottle × 1 125K SD-360TB 5

10 Staple cartridge Cartridge × 5 5000 SD-LS20

3 – 1

(Drum separation pawl × 2)

(Charging blade unit × 1)

11 Convenience parts kit 365CP × 5 250K SD-365CK

(Screen grid (New) × 1)

(Toner reception seal × 1)

Waste toner bottle (125K), screen grid (250K), charging blade unit (250K), drum separation pawl (250K), and toner reception seal (250K) are supplied also as service parts.

* Charger wire (250K), Ozone filter (500K), DV seal (500K), and CL brush roller (500K) are supplied as service parts.

Page 12

1 Two packages are used. (SD-365ND) × 10 = SD-365MD

1 (SD-365NT ) × 10 = SD-365MT

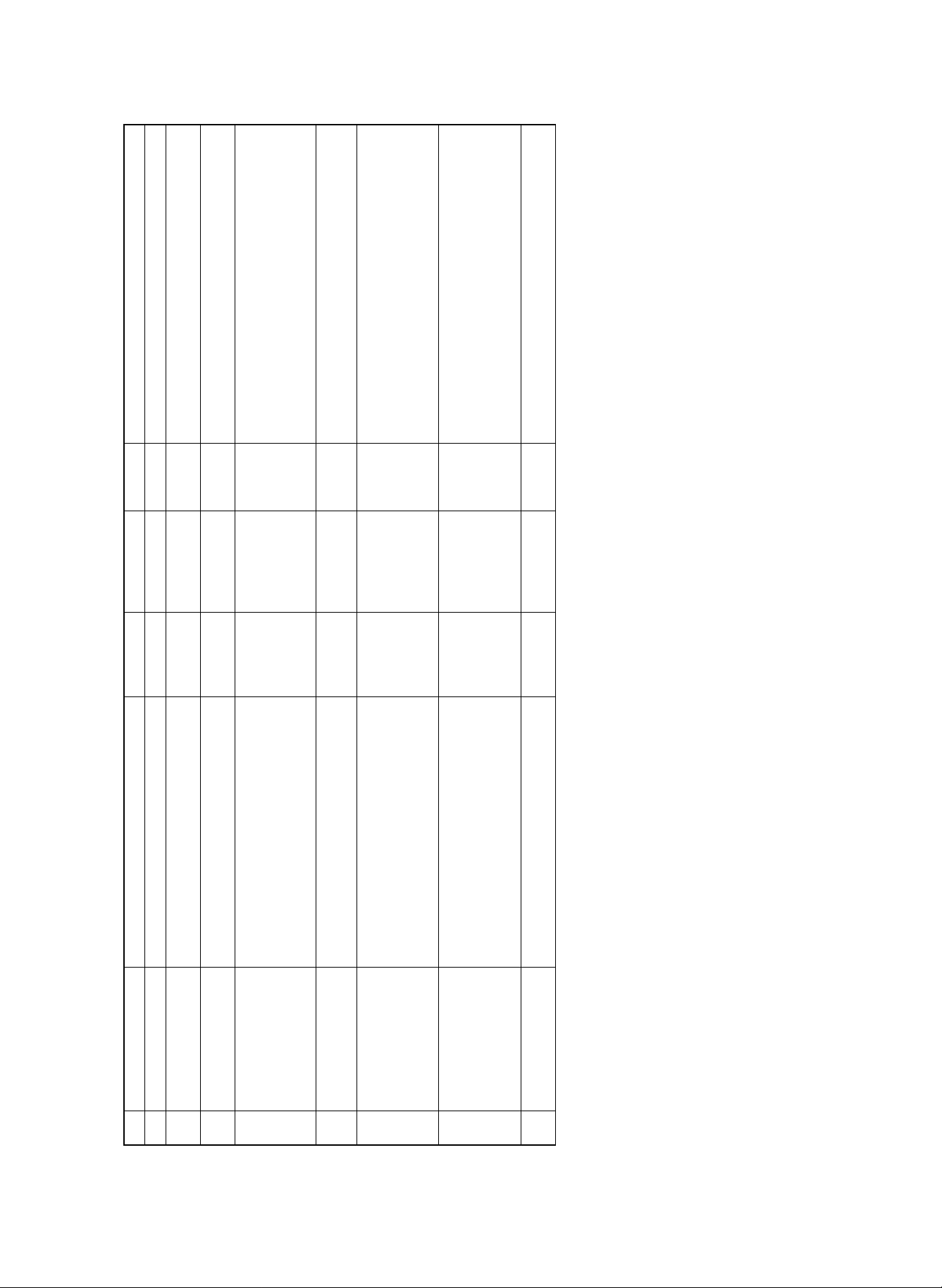

10 Use for SF-S55

(SD-365ND × 10)

(SD-365NT × 10)

(SD-SC20 × 5)

Fusing separation pawl (Upper) × 4

Fusing gear (New) × 1

Heat insulation bush (New) × 2

Fusing separation pawl (Lower) × 4

Waste toner bottle × 1

Upper cleaning roller (New) × 1

Lower cleaning roller × 1

Charging blade unit × 1

Toner reception seal × 1

Screen grid (New) × 1

No. Name Content Life Product name Package Remark

(Canada)

Developer Developer (New) (0.85Kg) × 10 250K (× 5) SD-365MD

Toner Toner cartridge (New) (0.93Kg) × 10 28K (× 10) SD-365MT

1 Drum OPC drum (New) × 1 250K SD-365DR 6 Similar to the drum for SD-2060/3062.

2

3

4 Upper heat roller kit Upper heat roller (New) × 1 500K SD-365UH 5 Similar to the upper heat roller kit for SD-2060/3062.

5 Lower heat roller kit Lower heat roller × 1 250K SD-360LH 5 Similar to the lower heat roller kit for SD-2060/3062.

6 125KPM kit Cleaner blade × 1 125K SD-365KA 5

7 250KPM kit Drum separation pawl × 2 250K SD-365KB 5 Common to 250KPM kit for SD-2060/3062.

3 – 2

8 Staple cartridge Cartridge × 5 5000 SD-LS20

Page 13

SD-2060/3062.

(SD-365DV) × 10 = SD-365LD

1 Two packages are used.

1 (SD-365T) × 10 = SD-365LT

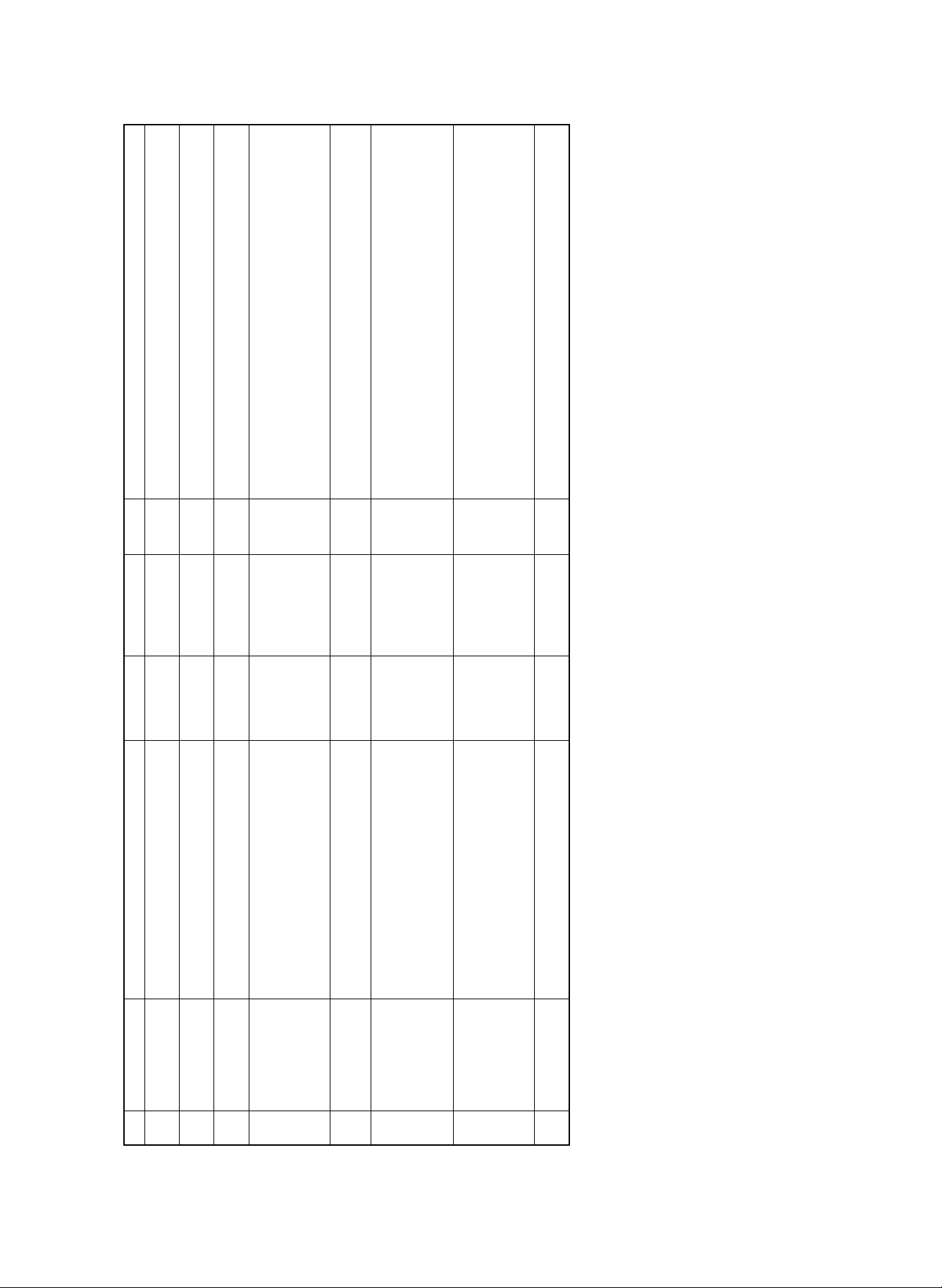

10 Use for SF-S55

(SD-365DV × 10)

(SD-365T × 10)

(SD-SC20 × 5)

Fusing separation pawl (Upper) × 4

Fusing gear (New) × 1

Heat insulation bush (New) × 2

Fusing separation pawl (Lower) × 4

Waste toner bottle × 1

Upper cleaning roller (New) × 1

Lower cleaning roller × 1

Charging blade unit × 1

Toner reception seal × 1

Screen grid (New) × 1

1 Drum OPC drum (New) × 1 250K SD-365DM 6 Similar to the drum for

No. Name Content Life Product name Package Remark

(Europe) SEEG, SUK

2 Developer Developer (New) (0.85Kg) × 10 250K (× 5) SD-365LD

3 Toner Toner cartridge (New) (0.93Kg) × 10 28K (× 10) SD-365LT

4 Upper heat roller kit Upper heat roller (New) × 1 500K SD-365UH 5 Similar to SD-2060/3062.

5 Lower heat roller kit Lower heat roller × 1 250K SD-360LH 5 Similar to the lower heat roller kit for SD-2060/3062.

6 125KPM kit Cleaner blade × 1 125K SD-365KA 5

7 250KPM kit Drum separation pawl × 2 250K SD-365KB 5

3 – 3

8 Staple cartridge Cartridge × 5 5000 SD-LS20

Page 14

1 Two packages are used. (SD-365SD) × 10 = SD=365CD

1 (SD-365SI) × 10 = SD-365CI

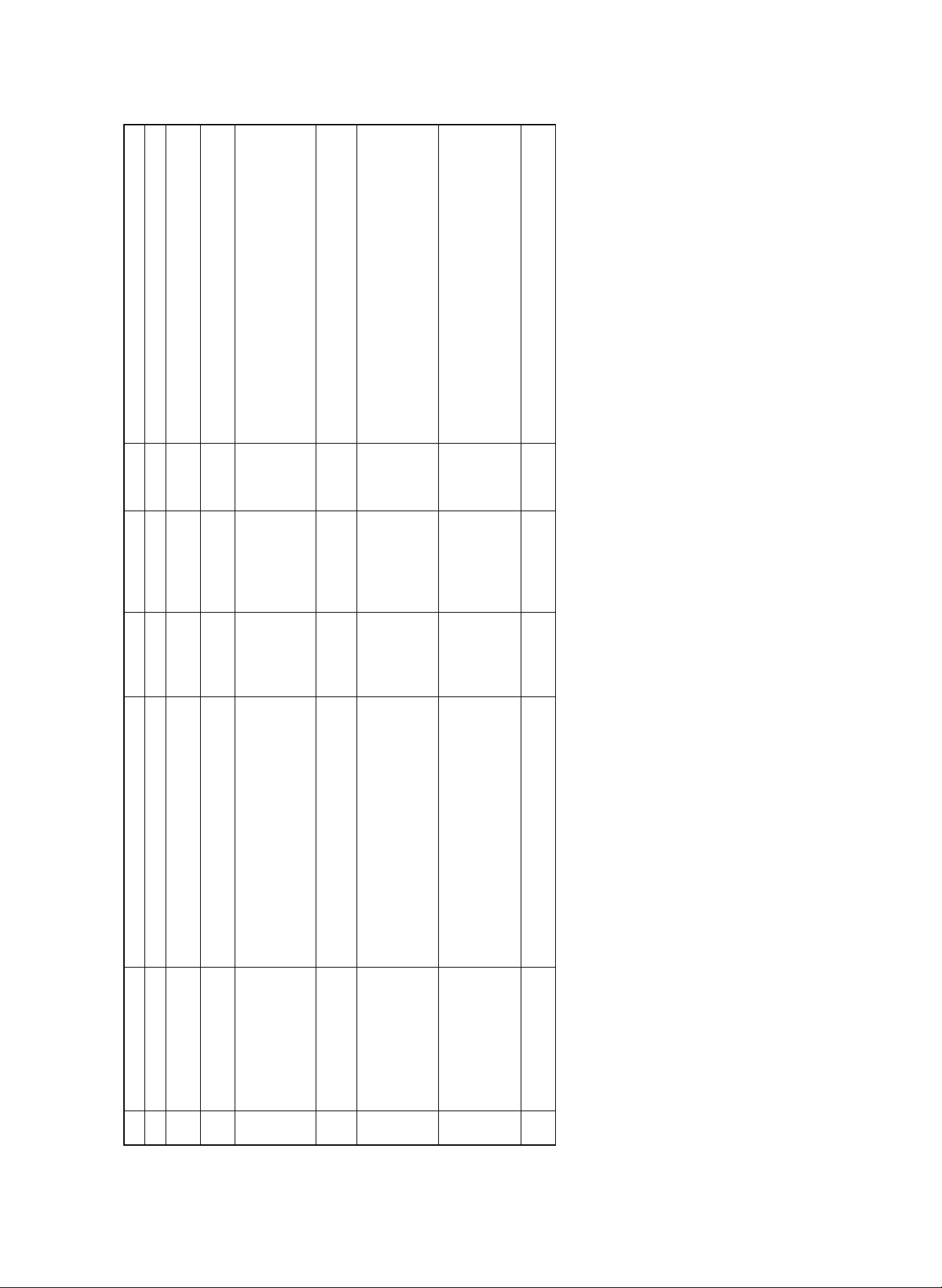

10 Use for SF-S55

(SD-365SD × 10)

(SD-365ST × 10)

(SD-SC20 × 5)

Fusing separation pawl (Upper) × 4

Fusing gear (New) × 1

Heat insulation bush (New) × 2

Fusing separation pawl (Lower) × 4

Waste toner bottle × 1

Upper cleaning roller (New) × 1

Lower cleaning roller × 1

Charging blade unit × 1

Toner reception seal × 1

Screen grid (New) × 1

Developer Developer (New) (0.85Kg) × 10 250K (× 5) SD-365CD

Toner Toner cartridge (New) (0.93Kg) × 10 28K (× 10) SD-365CT

1 Drum OPC drum (New) × 1 250K SD-365DR 6 Similar to the drum for SD-2060/3062.

2

3

No. Name Content Life Product name Package Remark

(Asia, Middle & South America)

4 Upper heat roller kit Upper heat roller (New) × 1 500K SD-365UH 5 Similar to the upper heat roller kit for SD-2060/3062.

5 Lower heat roller kit Lower heat roller × 1 250K SD-360LH 5 Similar to the lower heat roller kit for SD-2060/3062.

6 125KPM kit Cleaner blade × 1 125K SD-365KA 5

7 250KPM kit Drum separation pawl × 2 250K SD-365KB 5 Similar to 250KPM kit for SD-2060/3062.

3 – 4

8 Staple cartridge Cartridge × 5 5000 SD-LS20

Page 15

1 Two packages are used. (SD-365DV) × 10 = SD=365LD

1 (SD-365T) × 10 = SD-365LT

10 Use for SF-S55

(SD-365DV × 10)

(SD-365T × 10)

(SD-SC20 × 5)

Fusing separation pawl (Upper) × 4

Fusing gear (New) × 1

Heat insulation bush (New) × 2

Fusing separation pawl (Lower) × 4

Developer Developer (New) (0.85Kg) × 10 250K (× 5) SD-365LD

Toner Toner cartridge (New) (0.93Kg) × 10 28K (× 10) SD-365LT

1 Drum OPC drum (New) × 1 250K SD-365DM 6 Similar to the drum for SD-2060/3062.

2

3

No. Name Content Life Product name Package Remark

(Australia, New Zealand, Middle East, Africa)

4 Upper heat roller kit Upper heat roller (New) × 1 500K SD-365UH 5 Similar to the upper heat roller kit for SD-2060/3062.

5 Lower heat roller kit Lower heat roller × 1 250K SD-360LH 5 Similar to the lower heat roller kit for SD-2060/3062.

Waste toner bottle × 1

Upper cleaning roller (New) × 1

Lower cleaning roller × 1

Charging blade unit × 1

Toner reception seal × 1

Screen grid (New) × 1

6 125KPM kit Cleaner blade × 1 125K SD-365KA 5

7 250KPM kit Drum separation pawl × 2 250K SD-365KB 5 Similar to 250KPM kit for SD-2060/3062.

3 – 5

8 Staple cartridge Cartridge × 5 5000 SD-LS20

Page 16

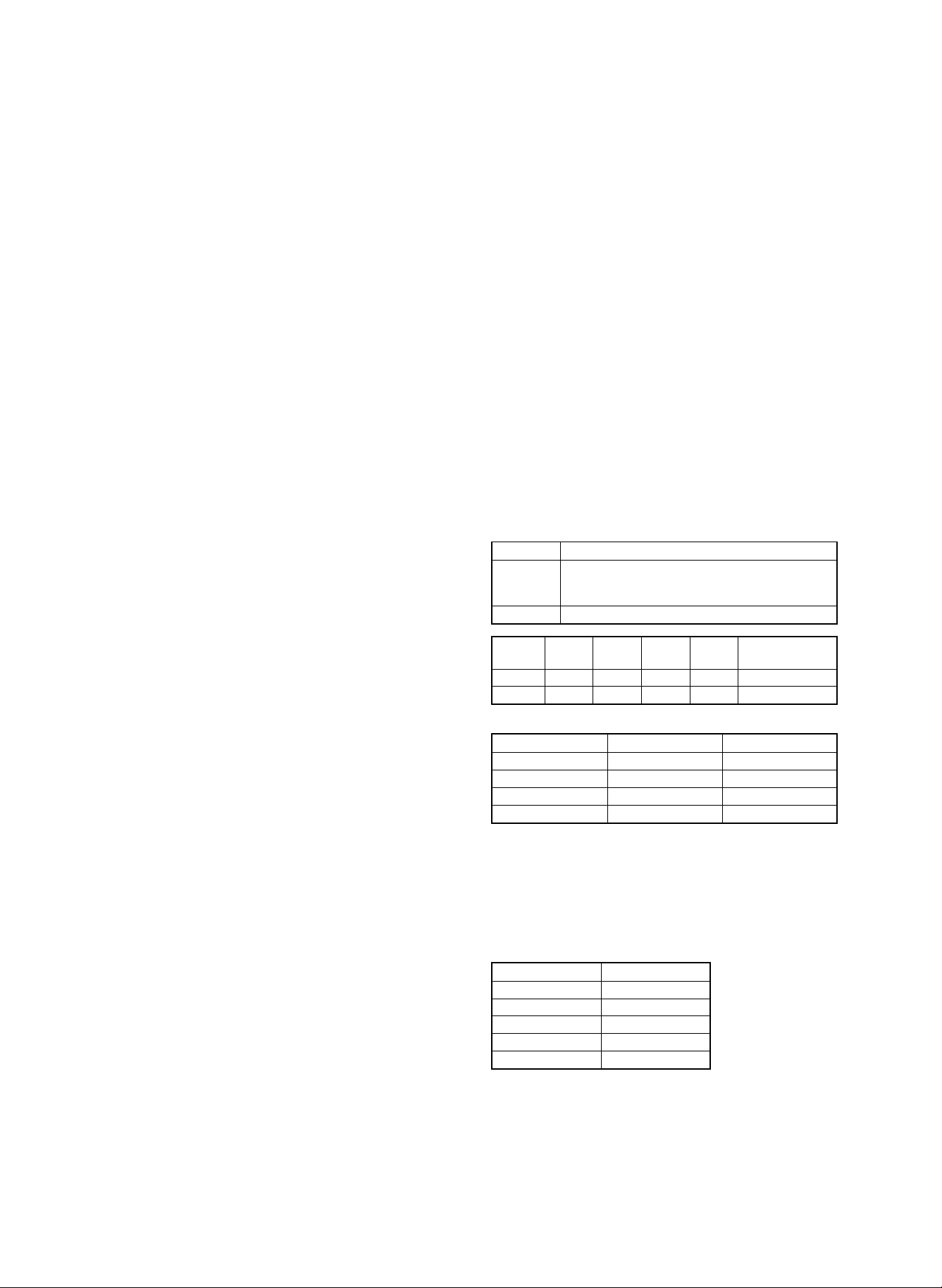

Compatibility with SD-2260/3062/2060/2160

Compatibility with

SD-2260/3062/2060

Photoconductor drum New

Developer New 0.85kg Two packs are used

Toner New 930g Two packs can be

Upper heat roller New

Lower heat roller Available

Cleaner blade Available

Upper/lower cleaning

roller

Drum separation pawl Available

Upper fusing

separation pawl

Lower fusing

separation pawl

Charging blade unit Available

Waste toner bottle

*

New Lower cleaning roller

Available

Available

Available

* : One for SD-2260 (New) is applicable to SD-3062/2060/2160.

One for SD-3062/2060/2160 is not applicable to SD-2260.

Capacity Remark

for once.

supplied for once.

(compatible)

2. Copy paper

The following conditions for copy quality and transportability of PPC

paper must be satisfied. The values are at temperature of 20 ±1˚C

and 65 ±2% RH.

Item Standard

Weight 56 ∼ 80g/ m

Smoothness Face: 20 sec or above (BEKK method)

Back: 20 sec or above (BEKK method)

Rigidness Length 17cm or above, width 13cm or

above (CLARK method)

Thickness 75 ∼ 110µ

Dimensions Standard dimensions ± 1mm (5/128")

B4 (257 ±1 × 364±1mm)

B5 (182 ±1 × 257±1mm)

B6 (128 ±1 × 182±1mm)

A3 (297 ±1 × 420±1mm)

A4 (210 ±1 × 297±1mm)

A5 (148 ±1 × 210±1mm)

A6 (105 ±1 × 148±1mm)

11" ±5/128 × 17" ±5/128 inch

8.5" ±5/128 × 14" ±5/128 inch

8.5" ±5/128 × 11" ±5/128 inch

5.5" ±5/128 × 8.5" ±5/128 inch

8.5" ±5/128 × 13" ±5/128 inch

2

3. Environment conditions

A. Transport conditions

1) Transport condition

(%)

100

90%

80

60

40

Humidity

20

10%

0

-30 -20 -10 0 20 30 40 50 60

10

Temperature

2) Storage condition (packed conditions)

100

90

80

70

(%)

60

50

40

Humidity

30

20

10

Temperature

B. Use conditions

(%)

100

90%

80

60

Use envi-

40

Humidity

20

10%

0

-30 -20 -10 0 20 30 40 50 60

15

ronment

conditions

10

Temperature

30

40

85%

35

45

60%

90%

60%

40 90%

40

10%

50403020100-10-20

3 – 6

Page 17

C. Life (packed conditions)

Photoconductor drum (36 months from the production month)

Developer, toner (24 months from the production month)

B. Developer, toner

1 2 3 4 5 6-7

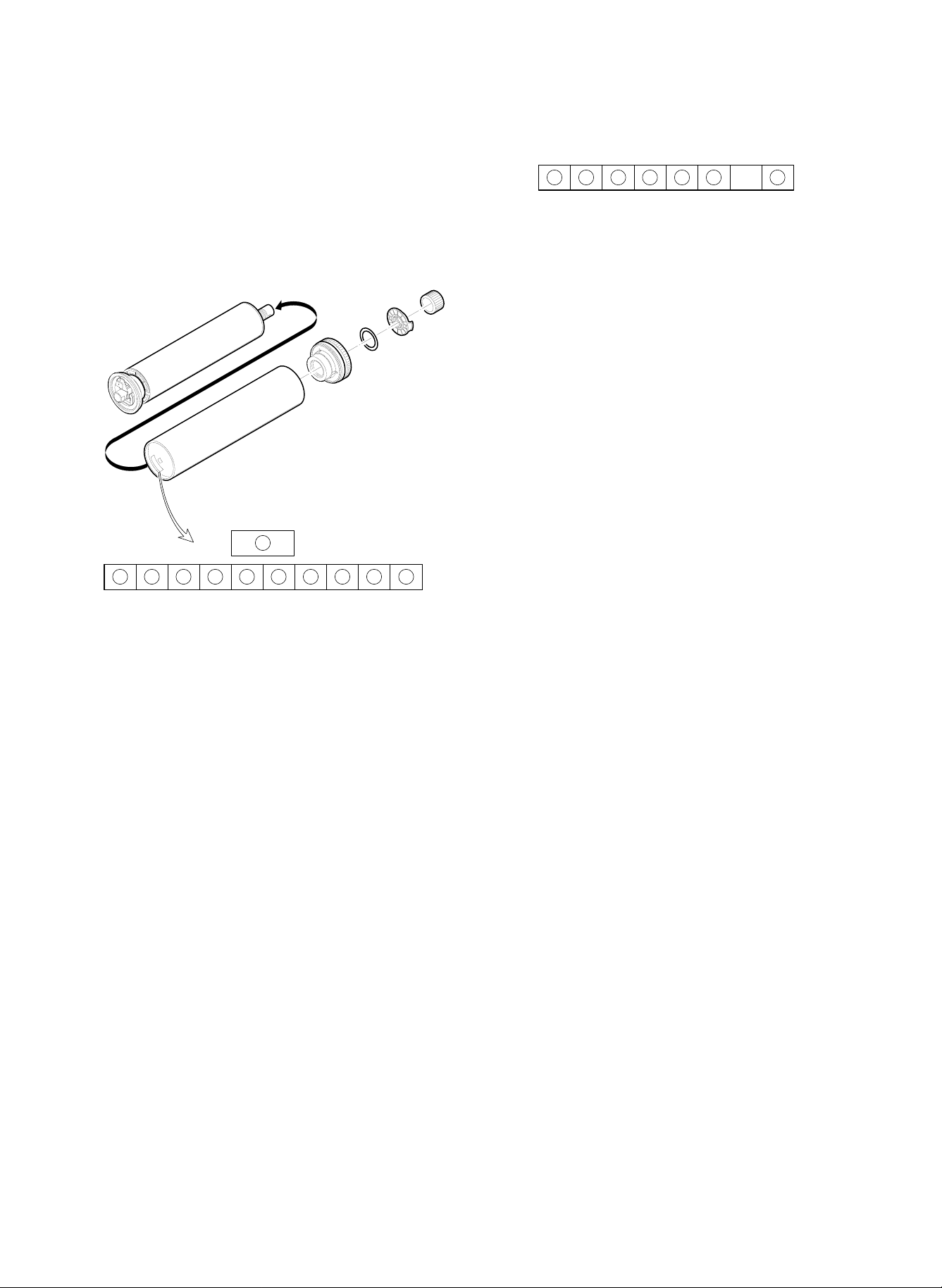

4. Production number identification

A. Photoconductor drum

11

1 2 3 4 5 6 7 8 9 10

1 Numeral

Shows the sensitivity of the photoconductor.

2 3 Alphabet

Shows the applicable model. AF for this model.

4 Numeral

Shows the end digit of the production year.

5 Numeral or X, Y, Z

Shows the production month.

X stands for October, Y November, and Z December.

6 Numeral

Shows the production lot.

7 Numeral

Shows the distinction of sub lot.

8 Numeral or X, Y, Z

Shows the packing month.

X stands for October, Y November, and Z December.

9 F Numeral

Shows the packing day.

G Numeral or alphabet

Shows the product name of the drum.

1 , 2 Alphabet

SF stands for toner, and SH for developer.

3 Numeral, alphabet

Shows the production month. O stands for October, Y November, and Z December.

4 , 5 Numeral

Shows the production day.

6 Numeral

Shows the end digit of the production year.

7 Alphabet

Shows the production batch.

Though the shapes of the photoconductor drum, developer, toner,

and the fusing section cleaning roller are similar to those of the SD2060, they are not compatible with each other.

The differences are as follows:

1) Photoconductor drum

If installed erroneously, the error code F2 is displayed.

2) Toner

The port shape of the toner bottle differs to prevent against erro-

neous installation.

The characteristics of toner differ from each other. The proper

toner must be used to obtain stable picture quality at proper density.

3) Developer

Proper developer must be used to obtain stable picture quality at

proper density.

4) Fusing section cleaning roller

(Upper cleaning roller)

(Lower cleaning roller)

3 – 7

Page 18

[4] SETUP

Setup list

No. Item No. Content Method Check

1 Installation environment

check

2 Delivery 1 Facility, equipment, man power Use a fork lift. (If a fork lift is not used, 6 men

3 Unpacking Remove the protection material.

4 Lock release 1 Scanner unit

5 Parts setup 1 Cleaning roller (2 pcs.) (Fusing unit)

6 Option setup 1 Sorter (SF-S55/53/16)

7 Consumable parts setup 1 Photoconductor drum (Europe only)

8 Cleaning 1 Main charger unit

9 Operation setting 1 Separation charger voltage setting

10 Image correction

setting/check

11 Image density sensor,

photoconductor drum mark

sensor check (adjustment)

1 Delivery space

2 Installation space

3 Power (Capacity, fluctuation, safety)

4 Floor strength

5 Direct sunlight, dust, temperature, humidity,

gases, chemicals

power is required.)

2 Delivery form Transported in packed condition.

2 No. 4/5 mirror unit

3 Lens unit

4 Paper feed tray (No. 1, 2, 3)

5 Paper feed cassette

6 Photoconductor drum protection sheet

(excluding Europe countries)

7 Paper exit guide (Fusing unit)

2 Fusing roller pressure set

3 Cleaning blade set

2 Staple cartridge

3 Auditor (SF-EA11)

4 Internal auditor expansion memory

2 Developer set

3 Toner concentration control level setting Set with SIM 25-2.

4 Toner set

2 Pre-transfer charger unit

3 Transfer/separation charger unit

4 Original table glass

Change connection of the high voltage PWB

(According to the altitude)

2 No. 1 paper feed tray paper size setting

(Hardware)

3 No. 1 paper feed tray paper size setting

(Software)

4 Option setting (Software) Set with SIM 26-1.

5 Expansion memory initializing (only when an

expansion memory is installed)

6 Auditor operation mode setting Set with SIM 26-3.

7 Count mode setting Set with SIM 26-5.

8 Destination specification setting Set with SIM 26-6.

9 Maintenance cycle setting Set with SIM 21-1.

10 Toner save mode YES/NO setting Set with SIM 26-18.

11 Power shut off operation mode setting Set with SIM 26-26.

12 Display language setting Replace the data ROM on the operation

1 Image correction valid setting Set SIM 44-1 to (127).

2 Main charger correction reference density

setting

1 Photoconductor drum mark sensor sensitivity

check (adjustment)

2 Image density sensor sensitivity check

(adjustment)

connector CN2.

Refer to [6] 2-C.

Set with SIM 26-2.

Set with SIM 26-3.

control PWB.

Set SIM 44-4 to 75.

Check with SIM 44-2. (adjustment)

Check with SIM 44-3. (adjustment)

4 – 1

Page 19

No. Item No. Content Method Check

12 Image correction execution

(Main charger grid voltage)

(Optical dirt correction)

(Auto copy exposure)

13 Copy exposure check

(adjustment)

14 Focus (resolution), copy

magnification ratio check

(adjustment)

15 Functional operation check 1 Paper size detection (manual paper feed tray)

16 Copy image center shift

check (adjustment)

17 Image loss, void area

check (adjustment)

18 Adjustment, set value,

ROM version recording

19 Explanation on user

operations

20 Others 1 Fixing support setting

1 Manual copy mode (non-toner-save mode) Automatic adjustment

2 Photo copy mode (non-toner-save mode) Set the key operator program 20 (copy

3 Auto copy mode (non-toner-save mode)

4 Manual copy mode (toner save mode)

5 Auto copy mode (toner save mode)

1 Focus (resolution) (Normal, 50%, 200%) Adjust with SIM 48-1 (A/B/C).

2 Vertical copy magnification ratio

(normal, 50%, 200%)

3 Horizontal copy magnification ratio (normal) Adjust with SIM 48-1.

2 Paper size detection (No. 2/3 paper feed tray)

3 Paper size detection (original table)

(Japan only)

4 Original size detection

(RADF original feed tray)

5 (Manual paper feed tray, No. 1, 2, 3 paper

feed tray cassette) copying

6 RADF copying (S-S mode)

7 RADF copying (S-D mode)

8 RADF copying (D-D mode)

9 RADF copying (D-S mode)

10 Zoom copying (enlargement, reduction)

11 Sort mode copy (with SF-S16/53/55 installed)

12 Group mode copying

(with SF-S16/53/55 installed)

13 Sort staple mode copying

(with SF-S16/53/55 installed)

1 Original table copy mode (surface) (Manual

paper feed tray, No. 1, 2, 3 paper feed tray,

paper feed cassette)

2 Original table copy mode (back) (No. 1, 2, 3

paper feed tray, paper feed cassette)

3 RADF copy mode Adjust by changing the RADF paper feed

1 Original table copy mode (lead edge image

loss, void area) (rear edge void area)

2 RADF copying (S-S mode) (Lead edge

image loss, void area)

3 RADF copying (D-D mode) (Lead edge

image loss, void area, rear edge void area)

4 RADF thin film copy mode (Lead edge image

loss, void area, rear edge void area)

5 RADF step copy mode (Lead edge image

loss, void area, rear edge void area)

1 Simulation set value, adjustment value Use the commander SF-EA13 with SIM 28-4

2 Key operator program set value Use the commander SF-EA13 with SIM 28-3

3 ROM version Use the commander SF-EA13 with SIM 28-5

Power OFF → ON (Automatic adjustment

during warming up.)

density level) to 3.

Adjust with SIM 48-1 (D/E/F).

Adjust by changing positions of the paper

feed tray, paper feed cassette, and manual

paper feed tray.

Adjust by changing the duplex tray position.

tray position.

Adjust with SIM 50-1.

In the RADF copy mode, the adjustment

value of SIM 53-1 must be also checked.

to print out the list. (The set values and

adjustment values are checked in each

simulation mode.)

to print out the list.

to print out the list.

(Checking is possible with SIM 22-5.)

4 – 2

Page 20

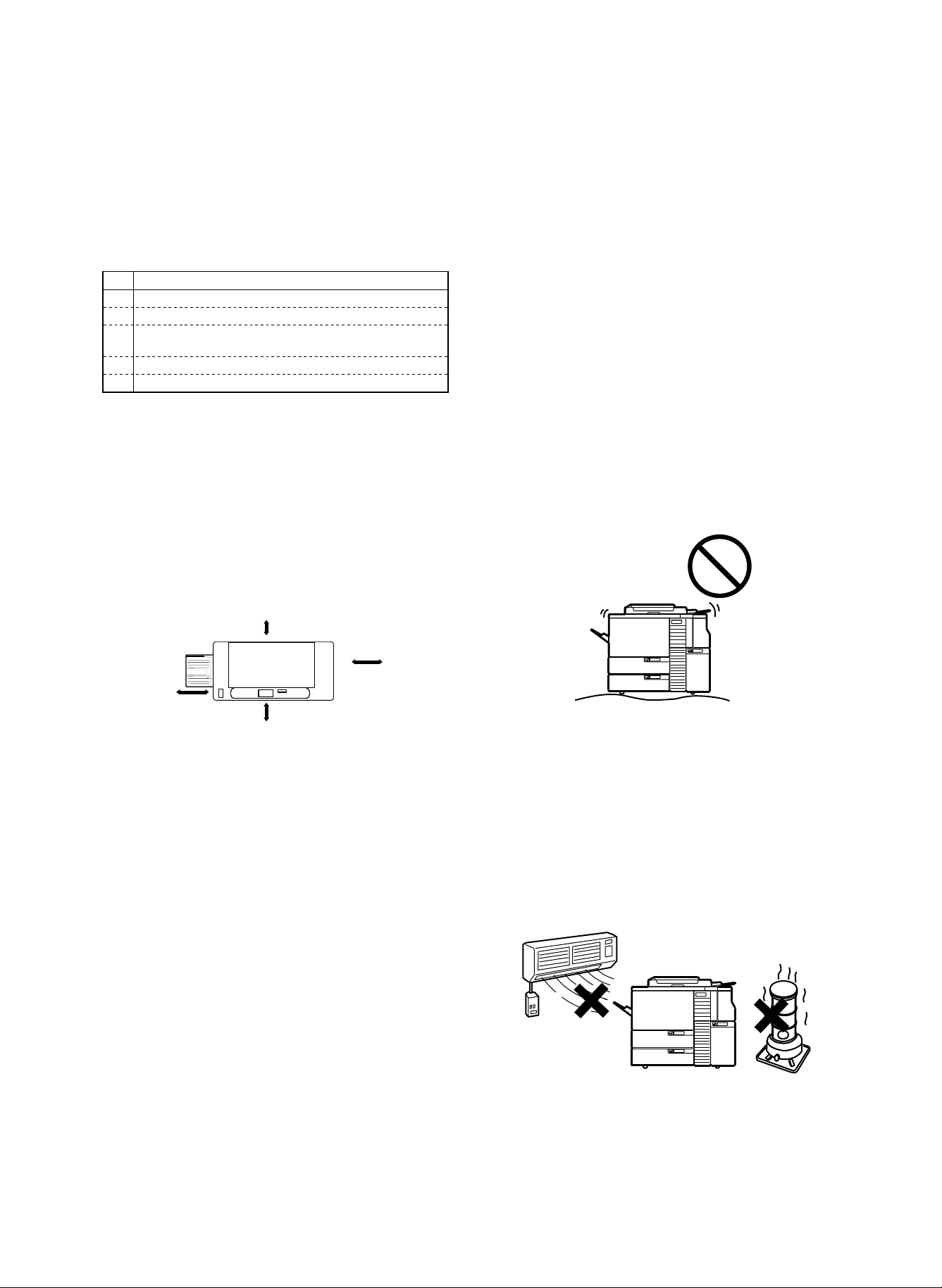

1. Installation (use) environment checking

Before delivery and installation of the machine, check the following

conditions of the environment.

If the following conditions of installation (use) are not satisfied, the

machine may not display full performances and may cause dangerous troubles.

Be sure to satisfy the installation (use) conditions in advance to installation and use.

No. Content

1 Delivery space

2 Installation space

3 Power

(capacity, fluctuation, safety)

4 Floor strength

5 Direct sunlight, dust, temperature, humidity, gases, chemicals

2) Power voltage

Measure the power voltage during copying to check that it is

within the range of the rated voltage ±10%.

If the voltage is not within the above range, use wider wires to

reduce impedance. (An electrical work is required.)

There is a method to use a step-up transformer. In this case, use

the transformer of greater capacity than the machine’s max.

power consumption.

3) Power frequency, waveform

The frequency must be the specified level ±2%. If the frequency is

distorted, a trouble may be caused.

4) Safety

Be sure to ground the machine.

5) Power plug

Check the shape of the power plug, Do not use a plug of different

shape.

(1) Delivery space

Check the door sizes to allow delivery of the machine in advance.

(2) Installation space

Allow the following installation space around the machine for proper

operations and performances.

The space for options must be also considered.

Especially allow enough space at the back of the machine. If the back

space is insufficient, heat radiation and the dust proof function are

prevented, suppressing the machine performances and causing troubles.

30cm

60cm

80cm

120cm

(3) Power source (capacity, voltage, frequency,

safety, plug)

If the power source requirements are not satisfied, the machine cannot display full performances, and may cause dangerous troubles.

BE sure to follow the following instructions:

1) Power source capacity

Check that the power capacity is enough as specified below. If it is

insufficient, it must be corrected.

Current capacity (Japan 15A specification) 15 A or above

Japan 20A specification machine: 20 A or above

EX 100V series: 16 A or above

EX 200V series: 9 A or above

(4) Floor strength and level

The machine is heavy, and options add further weight. Be sure to

check the floor strength for safety.

If the machine is not leveled properly, the toner concentration control

is not performed properly, affecting copy quality adversely.

(5) Direct sunlight, dust, temperature, humidity,

gases, chemicals, vibrations

1) Temperature, humidity

The storage and operation of this copier is assured under the

following conditions. If the following conditions are exceeded, the

copier may not display full performances, causing troubles.

Especially when the humidity is too high, paper absorbs moisture

to cause paper jams and dirty copy.

4 – 3

Page 21

Humidity (RH)

85%

60%

20%

5) Vibrations

Do not install machines which produce vibrations around the cop-

ier. If vibrations are applied to the copier, copies may be blurred

and troubles may be caused.

15°C

Temperature (°C)

Do not install t he copie r near a he ater, a cooler, or a hum idifier. If

installed, the copier may form dew and cause troubles. Be careful

of ventilation, too.

2) Dust

If dust enters the copier, it may cause dirty copy, paper jams, and

short lifetime.

3) Direct sunlight

If the copier is exposed to direct sunlight, the external section may

be discolored, causing poor copy quality.

30°C 35°C

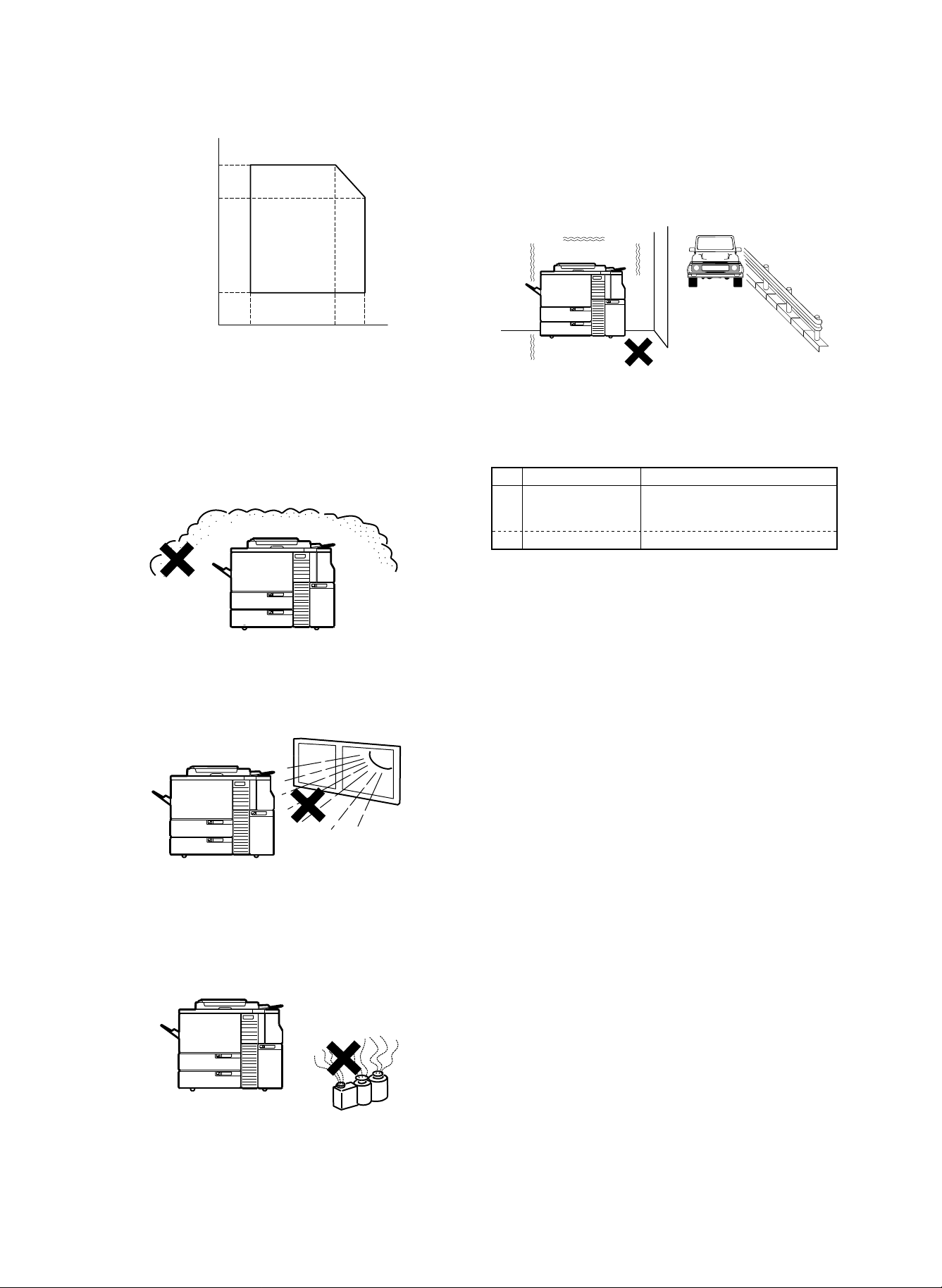

2. Transport and installation

No. Content Method

1 Facility, equipment,

man power

2 Delivery form Transported in packed conditions.

(1) Equipment, facility, man power

It is advisable to use a fork lift for efficiency and safety. If a fork lift is

not available, six men are required to move the machine. The copier

is very heavy. Consider for safety in delivery and installation work.

Transport of the copier must be made in the packed conditions to the

installing place (building).

(2) Delivery form

Remove the copier from the packing case outside the installing building, then carry it inside the building.

Use a fork lift.

(If a fork lift is not used, 6 men power

is required.)

4) Gases and chemicals

Do not install the copier near gases and chemicals. Especially be

careful of a diazo-type copier, which may produce ammonium

gas. The copy quality may be adversely affected, causing troubles.

4 – 4

Page 22

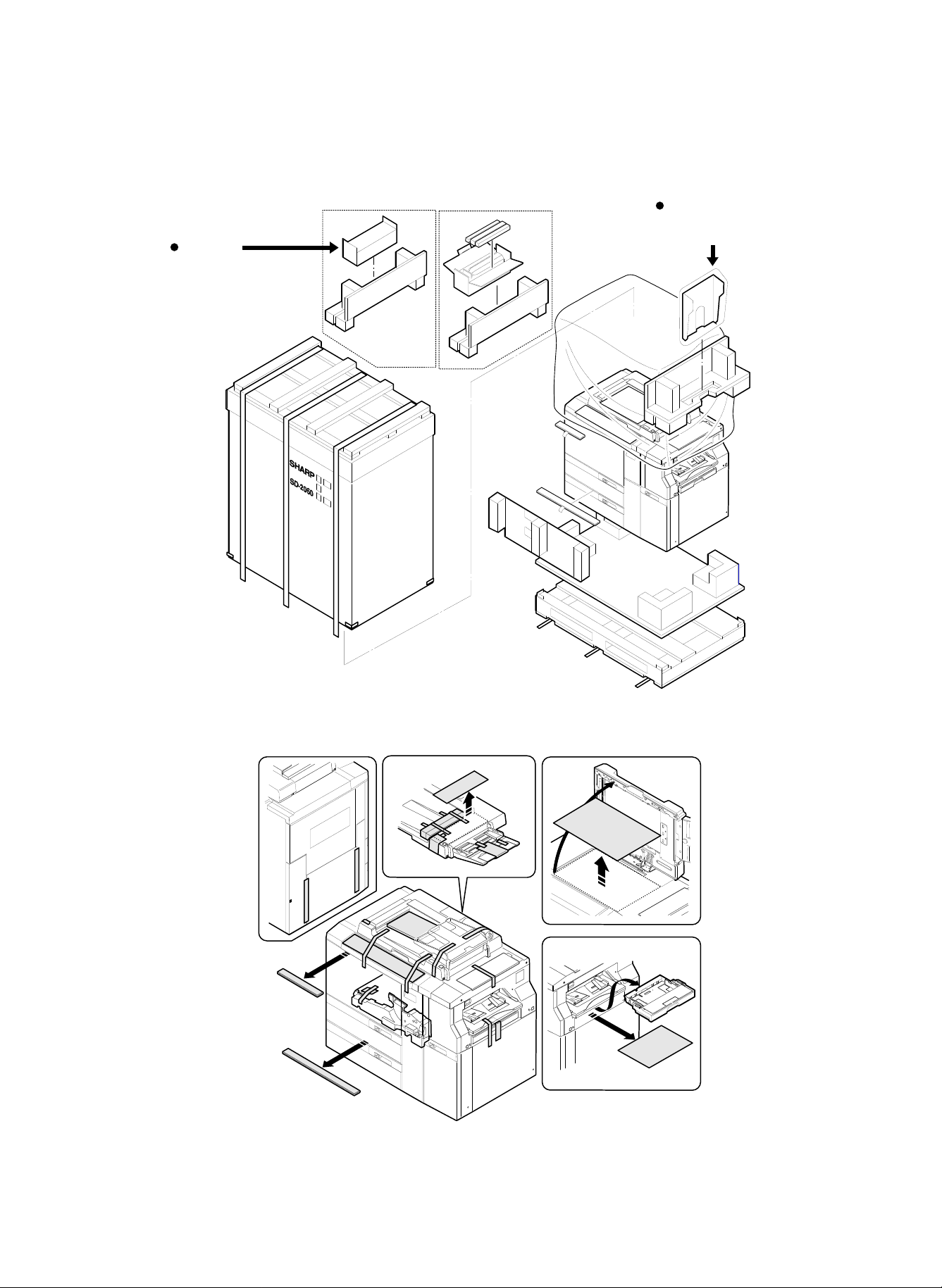

3. Unpacking

1) Remove the copier from the packing case as shown below:

Japan only

Upper cleaning roller unit

Lower cleaning roller unit

Oil application roller unit

Consumable parts unit

DNNT-6891FCZZ

Japan

Export

Japan only

Paper exit tray ass'y

LSOU-0054FCG4

2) Remove the fixing tapes and protection materials.

4 – 5

Page 23

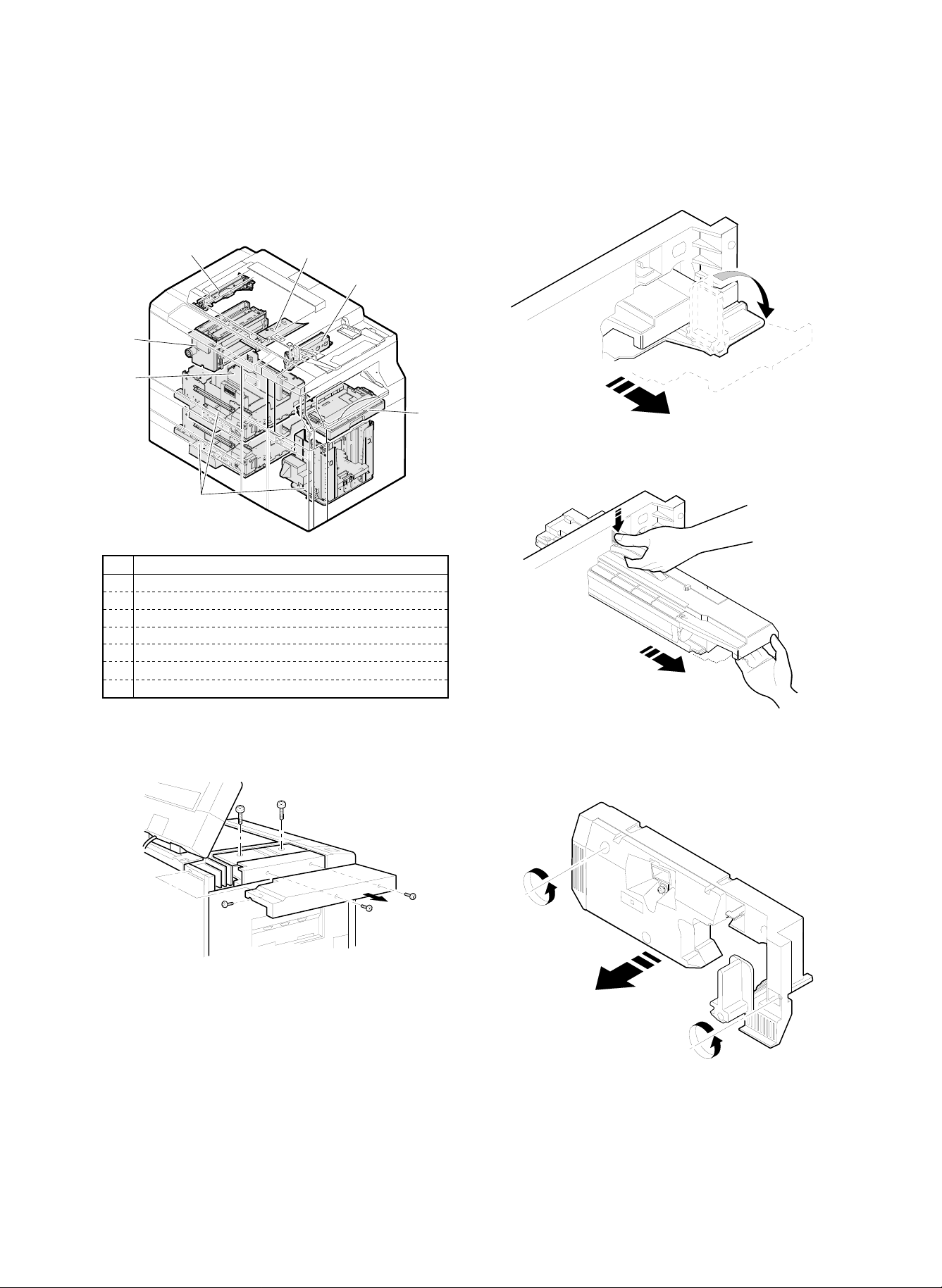

4. Lock release

To prevent against dropping or damage of parts during transit, some

parts are locked.

Before use, those parts must be released.

Be sure to lock them again when transporting or moving the copier.

(2) No. 4/5 mirror unit lock release

1) Open the front cabinet and pull out the developing unit.

1

3

2

7

6

4

No. Content

1 Scanner unit

2 No. 4/5 mirror unit

3 Lens unit

4 Paper feed tray (No. 1, 2, 3)

5 Paper feed cassette

6 Photoconductor drum protection sheet (Except for Europe)

7 Paper exit guide (Fusing unit)

5

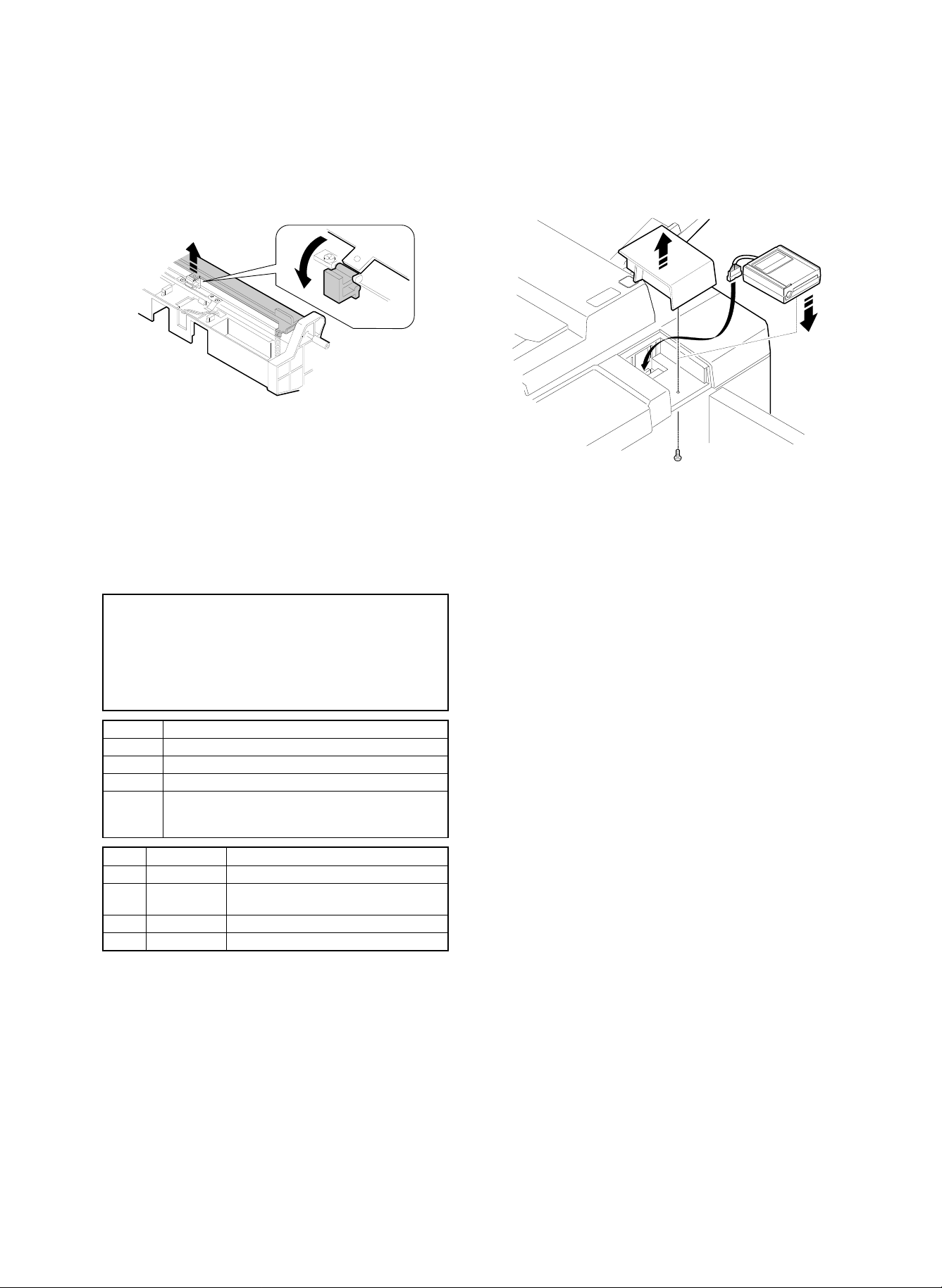

(1) Scanner unit lock release

Remove the cabinet, and remove the lock screw of the scanner unit.

(Locking method)

1) Manually move the scanner unit to the lock position and lock it

with the lock screw.

2) Pull out the process unit.

4 – 6

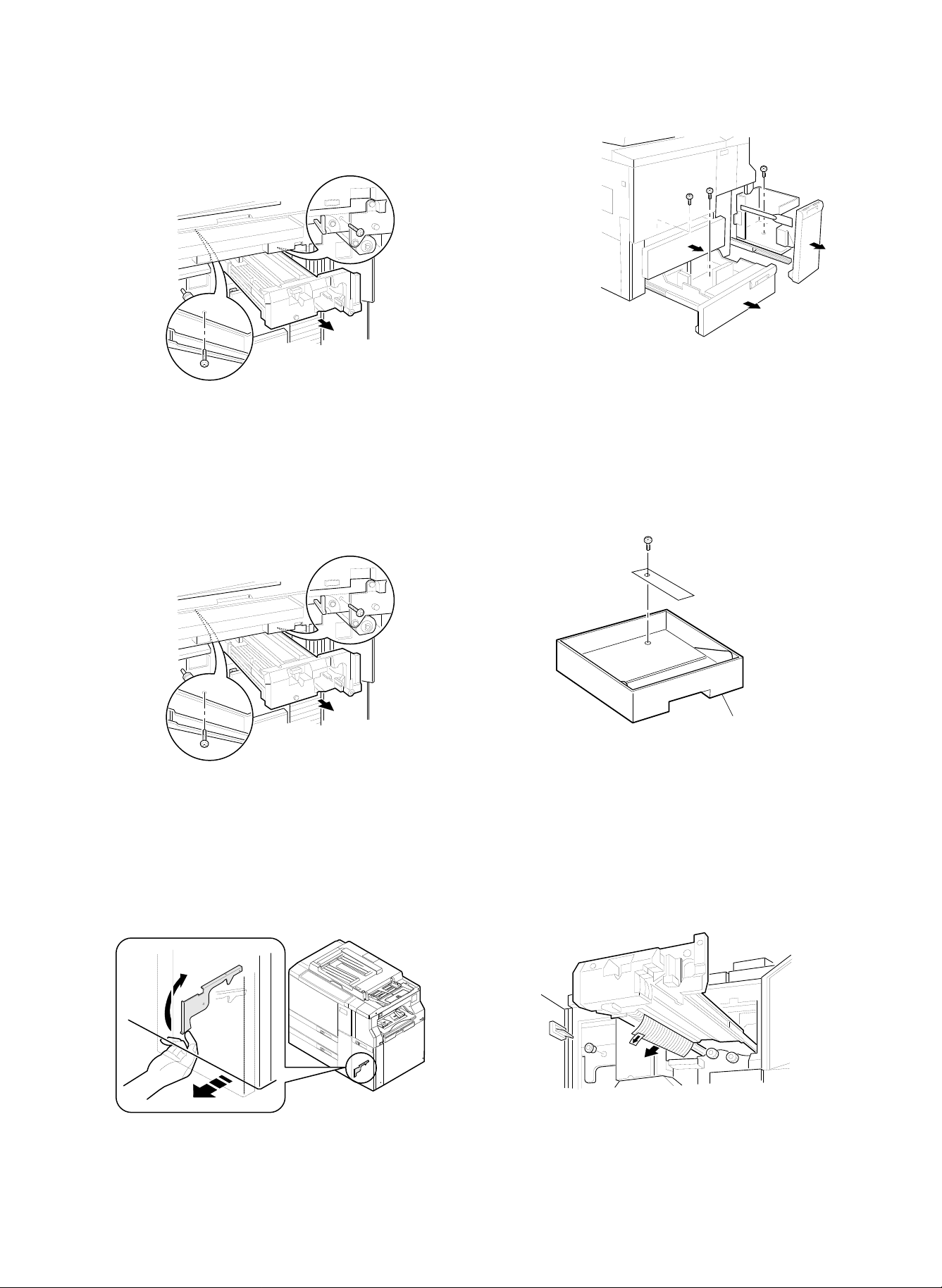

Page 24

3) Remove the lock screw of No. 4/5 mirror unit.

(Locking method)

1) With the power ON, set the magnification ratio to normal. (The No.

4/5 mirror unit is fixed to the normal position.)

2) Turn off the power, and lock with the lock screw.

(3) Lens unit lock release

Remove the lock screw of the lens unit.

(Locking method)

1) Remove paper on the paper feed tray.

2) Turn on the power and wait until the paper feed tray falls to the

lowest position. (When the paper feed tray falls to the lowest

position, it stops.)

3) Turn off the power, pull out the paper feed tray, and lock it with the

lock screw.

(5) Paper feed cassette lock release

Remove the paper feed cassette lock screw.

(Locking method)

1) With the power ON, set the magnification ratio to normal. (The

lens unit is fixed to the normal position.)

2) Turn off the power, and lock with the lock screw.

(4) Paper feed tray lock release

Manually pull out No. 1, 2, and 3 paper feed trays, and remove the

lock screws.

Paper feed cassette

(6) Photoconductor drum protection sheet (Except

for Europe)

Remove the photoconductor drum protection sheet.

(Note) Do not remove white powder (starting powder) on the pho-

toconductor drum, which is to reduce friction between the

cleaning blade and the photoconductor drum.

If this powder is removed, friction between the cleaning blade

and the photoconductor drum is increased to reverse the

cleaning blade, damaging the photoconductor drum.

4 – 7

Page 25

(7) Paper exit guide lock release (Fusing unit)

1) Pull out the fusing unit.

2) Remove the paper exit guide lock plate.

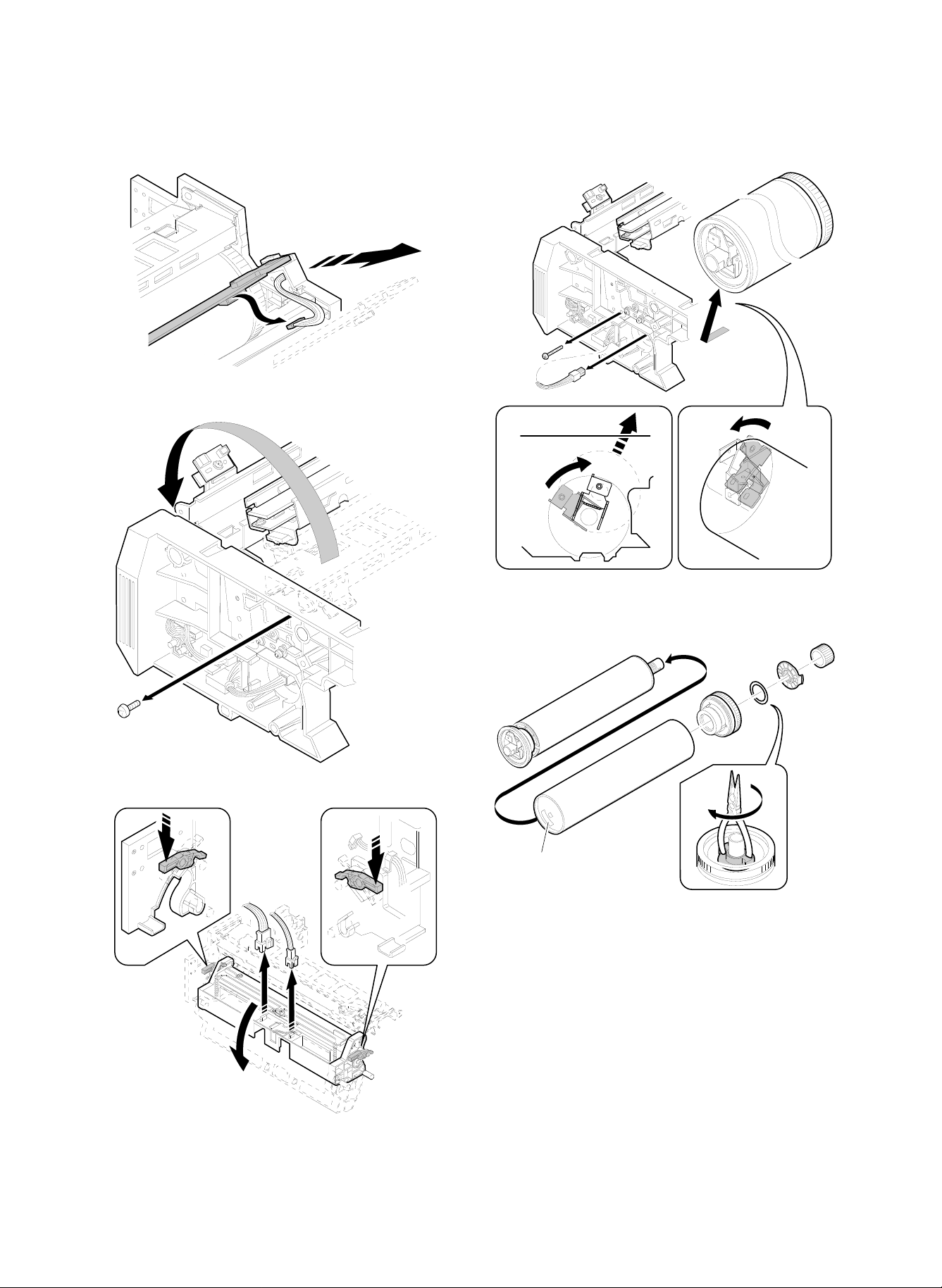

(1) Cleaning roller setup

1) Pull out the fusing unit.

2) Install two cleaning rollers for the upper fusing roller and install

one cleaning roller for the lower fusing roller.

(Japan only)

When installing, check that the tension spring applies

tension to the bearing of the cleaning roller.

5. Parts setup

1, 2

No. Content

1 Cleaning roller (2 pcs.) (Fusing unit)

2 Fusing roller pressure setup

3 Cleaning blade setup

3

4 – 8

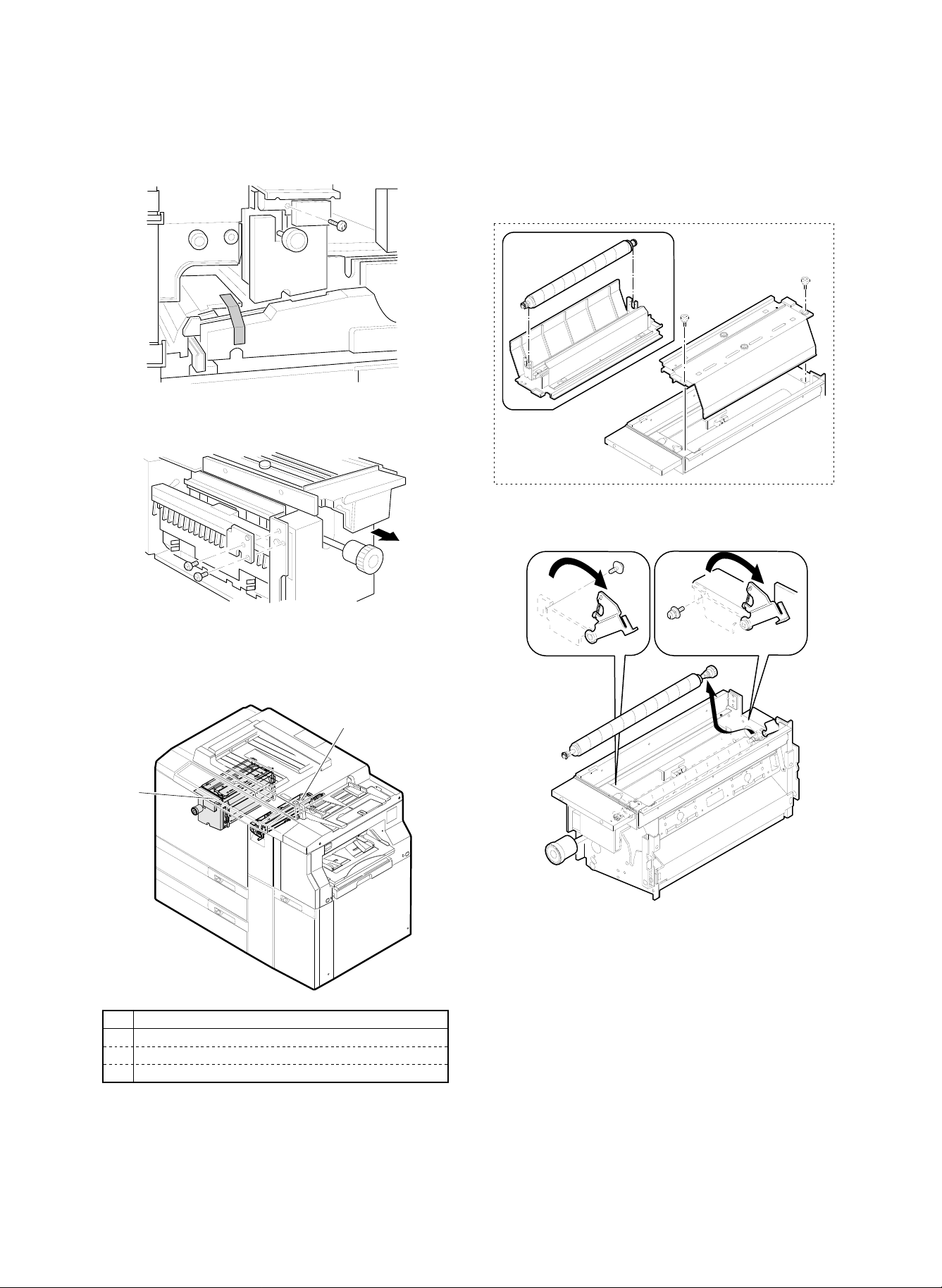

Page 26

(Note) For installation of the fusing guide, put it in close contact with

the fusing guide positioning plate and secure it.

(2) Fusing roller pressure setup

1) Remove the fusing cover, and put down the pressure lever.

2) Remove the lock nut, and turn and fix the pressure adjustment nut

(blue) tightly.

(Tighten the nut until the collar clearance is eliminated.)

Positioning plate

Lock nut

Nut (Blue)

3) Install the lock nut.

4) Set the pressure lever and fix it.

4 – 9

Page 27

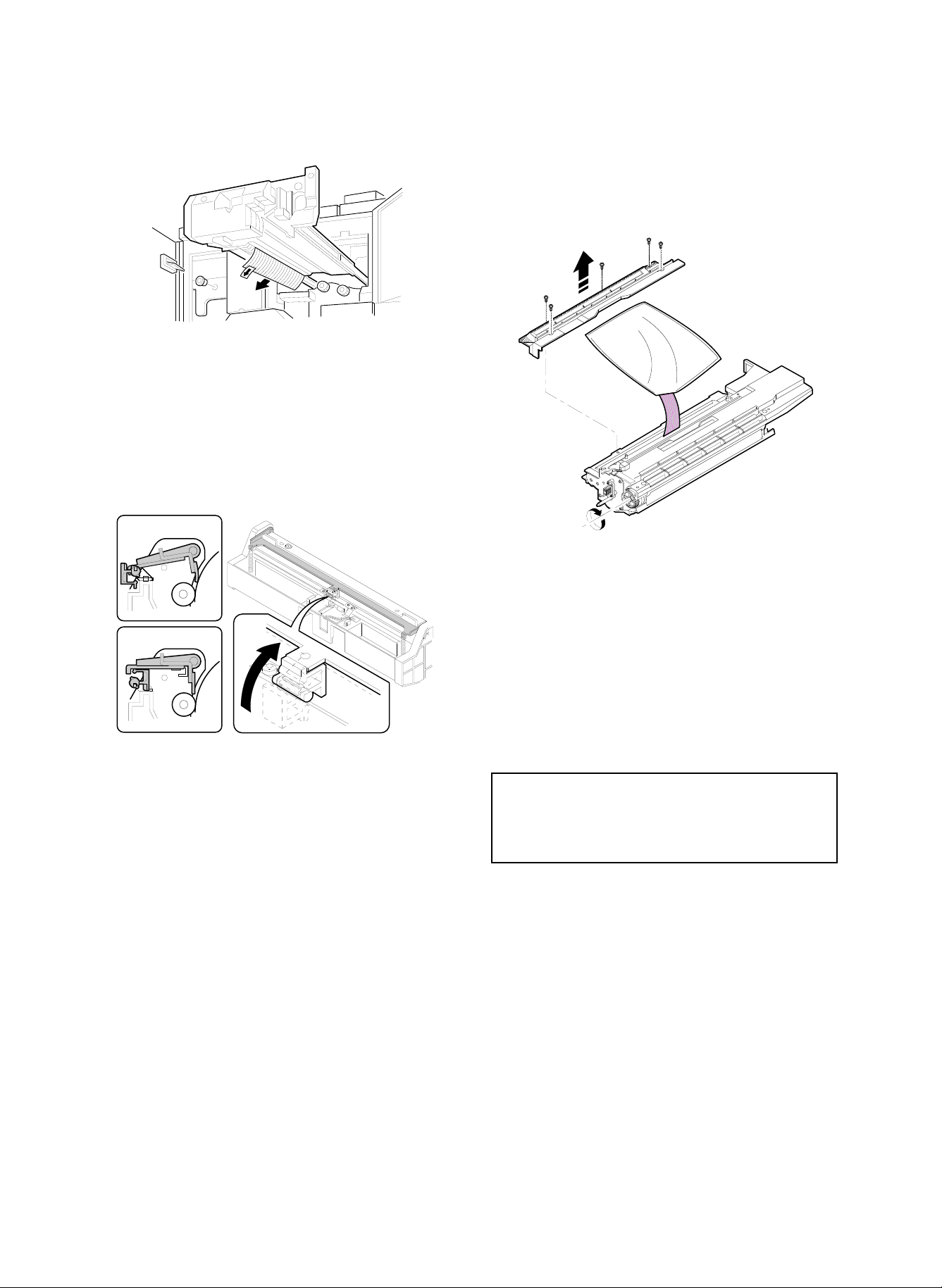

(3) Cleaning blade setup

1) Pull out the process unit and set the cleaning blade.

(Release the release block, and press the cleaning blade onto the

photoconductor drum surface.)

(Note) When the copier is not used for a long time, release the

cleaning blade pressure.

(3) Auditor (SF-EA11) installation

1) Remove the auditor installing section cover, and fix the auditor

(SF-EA11) with the screw.

6. Option installation

When an option is installed, option setting (registration) must be performed with SIM 26-1 and 26-3.

Also when an option is removed, option setting (registration) must be

canceled with SIM 26-1 and 26-3.

SIMULATION NO.26-1

SORTER/STAPLE SORTER SETTING?

0.NO SORTER

1.SF-S55

2.SF-S53/S16

3.SF-S55(DISABLE AUTO FRONT ACCESS

WHEN FEEDING FROM BYPASS-TRAY.)

Set value Content

0 Without sorter

1 With SF-S55 installed

2 With SF-S53 or SF-S16 installed

3 With SF-S55 installed (to inhibit automatic front

take-up of paper in manual paper feed [useful to load

thin films on the manual feed tray])

Code Name Content

1 P10 (500) Internal auditor mode (500 dept.)

P10 (3100) Internal auditor mode (500 dept.)

2

3 SF-EA11/12 Card counter mode (SF-EA11)

4 OTHER Others

+ expansion RAM mode (2600 dept.)

When using the auditor (SF-EA11), SIM 26-3 must be set for use of

the auditor (SF-EA11).

The external auditor (SF-EA11) and the internal auditor (in the main

control PWB) cannot be used together. Either of them must be selected with SIM 26-3.

(1) Sorter (SF-S55/53/16) installation

(2) Staple cartridge setup

For setup of a staple cartridge, refer to the Service Manual of each

model.

4 – 10

Page 28

(4) Expansion memory for the internal auditor

The internal auditor (in the main control PWB) has the capacity of

controlling 500 departments. By adding expansion memory on the

main control PWB, additional 2,600 departments can be controlled, in

total 3,100 departments.

(Note) When an expansion memory is installed, it must be initialized

with SIM 26-3.

Expansion memory (with frame) PARTS CODE

1) Install an expansion memory on the main control PWB.

DKIT-0321FCZZ

Install the expansion memory to connector CN115.

7. Consumable parts setup

(When replacing the consumable parts, follow these procedures.)

No. Content Method

1 Photoconductor drum (Europe only)

2 Developer setup

3 Toner concentration control level setting Set with SIM 25-2.

4 Toner setup

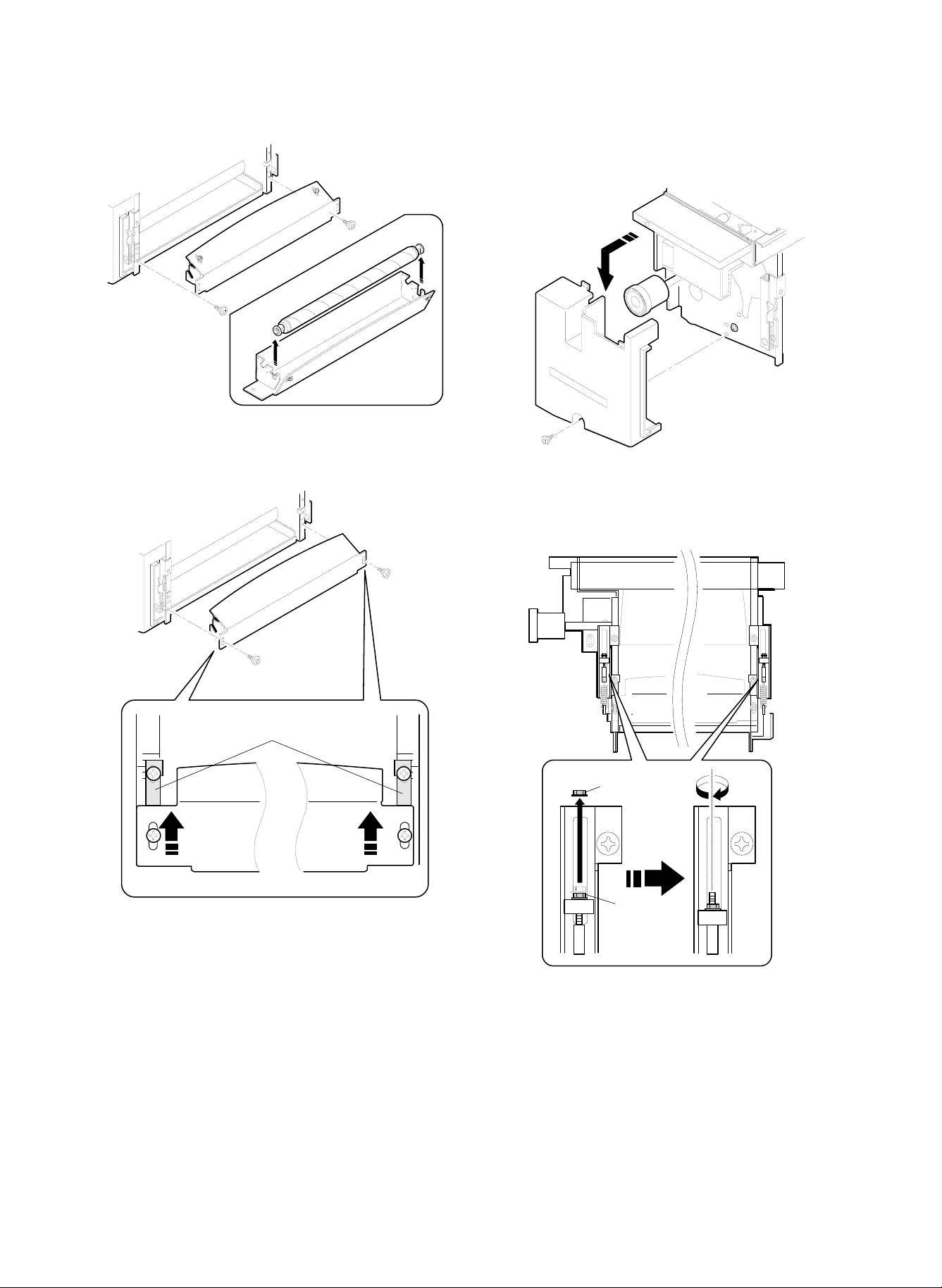

(1) Photoconductor drum setup (Europe only)

Since, in Europe, the photoconductor is not installed to the copier

body, this procedure must be performed.

1) Pull out the process unit, and remove the main charger unit and

the process unit cover.

4 – 11

Page 29

2) Remove the blank lamp unit and the cleaner unit, and open the

main charger holder.

3) Remove the photoconductor drum shaft and the flange unit.

4) Record the serial No. inside the photoconductor drum.

Label

5) Install the photoconductor drum to the flange unit.

(Do not remove the protection sheet.)

6) Install the photoconductor drum to the process unit.

7) Replace the parts to the process unit.

4 – 12

Page 30

8) Remove the photoconductor drum protection sheet.

(Note) Do not remove white powder (starting powder) on the pho-

toconductor drum, which is to reduce friction between the

cleaning blade and the photoconductor drum.

If this powder is removed, friction between the cleaning blade

and the photoconductor drum is increased to reverse the

cleaning blade, damaging the photoconductor drum.

9) Set the cleaning blade.

(Release the release block, and press the cleaning blade onto the

photoconductor drum surface.)

(2) Developer setup

1) Remove the developing unit cover, and pour developer into the

developing unit.

Manually turn the developing roller drive gear, and supply two

packs of developer (1kg × 2).

(Note) When the copier is not used for a long time, release the

cleaning blade pressure.

(Note) Developer for the SD-2060 cannot be used for the SD-2260.

(3) Toner concentration control level setting

Virgin developer has been adjusted to the specified toner concentration. This density is detected by the sensor and stored. After that, the

toner concentration level is used as the reference level, and developer is controlled to provide the level same as the virgin developer.

The above operation is performed with SIM 25-2.

When developer is replaced, this procedure must be performed.

1) With the front cabinet open (with the front cabinet open/close

detection switch OFF), turn on the power to enter the SIM 25-2

mode.

SIMULATION NO. 25

INPUT 1 ∼ 2

1. Toner concentration SENSOR MONITOR

2. AUTO DV DENSITY

(Note) Do not turn on the power with the front cabinet closed (with

the front cabinet open/close detection switch ON). Toner

would be supplied to the developing unit and the toner concentration of the virgin developer may not be the reference

level.

2) Close the front cabinet. (The front cabinet open/close detection

switch is turned ON.)

3) Press the START button.

Developer is stirred for 3 minutes, and the reference toner con-

centration level is memorized.

Be sure not to cancel SIM 25-2 until stirring of developer is com-

pleted in 3 minutes.

If EU trouble or EL trouble occurs midway, check for abnormality

in the developing unit.

4 – 13

Page 31

(Note) In case of memory trouble, if the main control PWB is re-

placed, the stored reference toner concentration level is

cleared.

For countermeasures against this, there are two ways as

shown below. Use one of them according to the situation.

* When the toner concentration level is normal (presump-

tion):

(Countermeasure) Execute SIM 25-2 to set the reference

toner concentration again.

* When the toner concentration is not normal:

Replace the developer with new one, and execute SIM252 to set the reference toner concentration level.

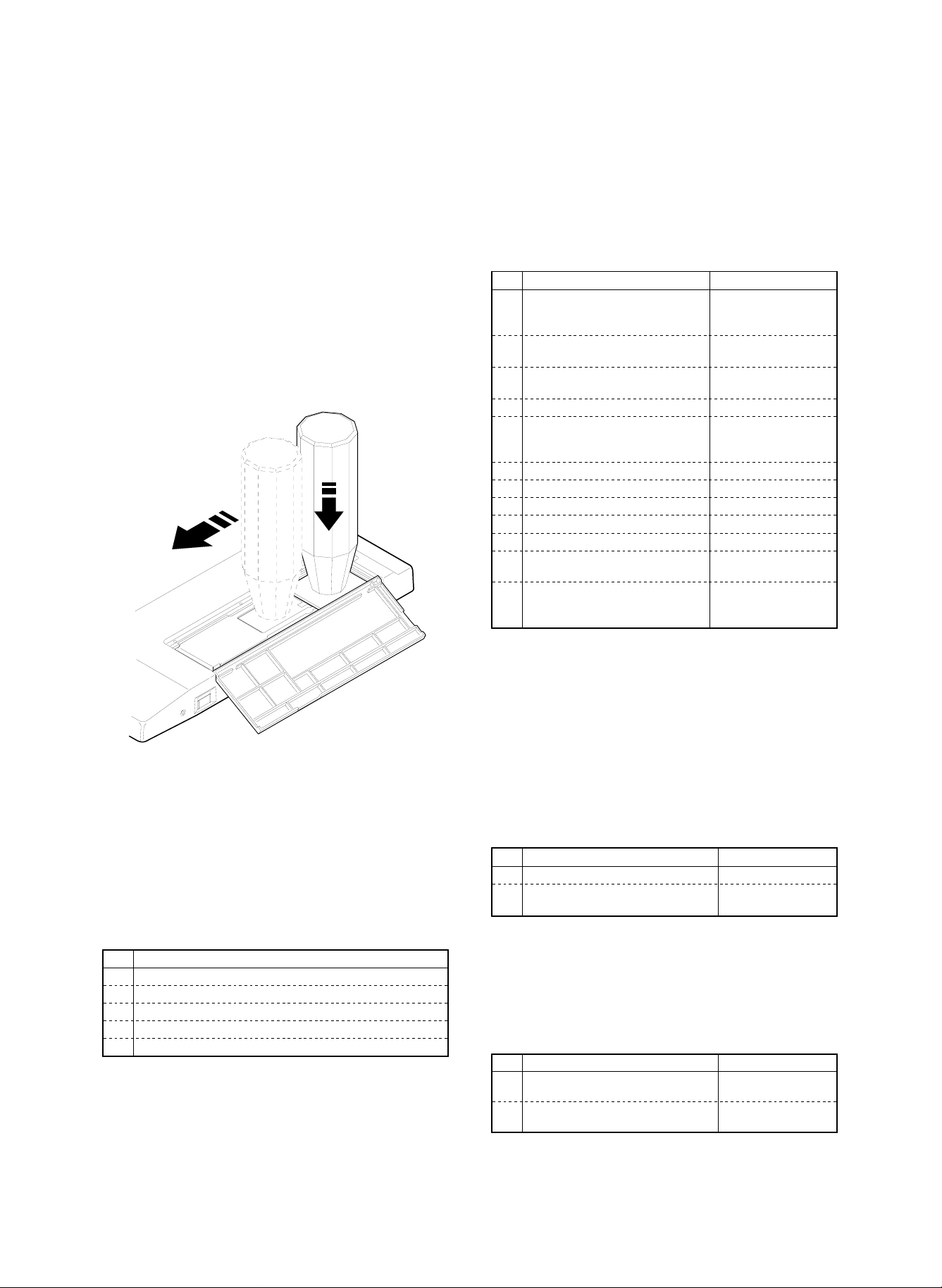

(4) Toner setup

Fit the toner bottle to the toner supply port, and slide it.

Confirm that all toner falls, and remove the toner bottle from the toner

supply port.

5) Others (cabinet, etc.)

9. Operational specification setup

The operational specifications of the copier must be set according to

the user’s necessity.

For setting with software, refer to the sections shown in the table

below.

No. Content Method

1 Separation charger voltage setting

(according to the altitude)

2 No. 1 paper feed tray paper size

setting (hardware)

3 No. 1 paper feed tray paper size

setting (software)

4 Option setting (Software) Set with SIM 26-1.

5 Expansion memory initializing (only

when an expansion memory is

installed)

6 Auditor operation mode setting Set with SIM 26-3.

7 Count mode setting Set with SIM 26-5.

8 Destination specification setting Set with SIM 26-6.

9 Maintenance cycle setting Set with SIM 21-1.

10 Toner save mode YES/NO setting Set with SIM 26-18.

11 Power shut off operation mode

setting

12 Display language setting Replace the data ROM

Check the high voltage

PWB connector CN2

connection.

Refer to [6]-2-C.

Set with SIM 26-2.

Set with SIM 26-3.

Set with SIM 26-26.

on the operation

control PWB.

(Note) Do not supply two or more bottles at one time. If two or more

toner is supplied at one time, toner jam may occur in the

toner hopper. Supply toner only when "SUPPLY TONER" display is made on the LCD.

8. Cleaning

Clean the following units.

For copiers which have been stored for a long time, some sections

other than the following units may be dirtied. Clean them according to

necessity.

No. Content

1 Main charger unit

2 Pre-transfer charger unit

3 Transfer/separation charger unit

4 Original table glass

Others (cabinet, etc.)

1) Main charger unit (screen grid, saw teeth section)

2) Pre-transfer charger unit (charger wire)

3) Transfer/separation charger unit (charger wire)

4) Original table glass

10. Image correction function setup and

check

Image correction function is set up when shipping. Check it before

use.

For correct performance of image correction (main charger, copy

lamp, copy density control correction), the operational setting of

image correction must be made.

The operational setting of image correction is made with simulations.

For the setting procedure, refer to the sections listed in the table

below.

No. Content Method

1 Image correction function setting Set SIM 44-1 to 127.

2 Main charger correction reference

density setting

Set SIM 44-4 to 75.

1 1. Image density sensor, photoconductor

drum mark sensor operation check

These sensors are to control image correction, and must be adjusted

to the proper sensitivity.

They are adjusted when shipping. Check it before use.

No. Content Method

1 Photoconductor drum mark sensor

sensitivity check (adjustment)

2 Image density sensor sensitivity

check (adjustment)

Check with SIM 44-2.

(adjustment)

Check with SIM 44-3.

(adjustment)

4 – 14

Page 32

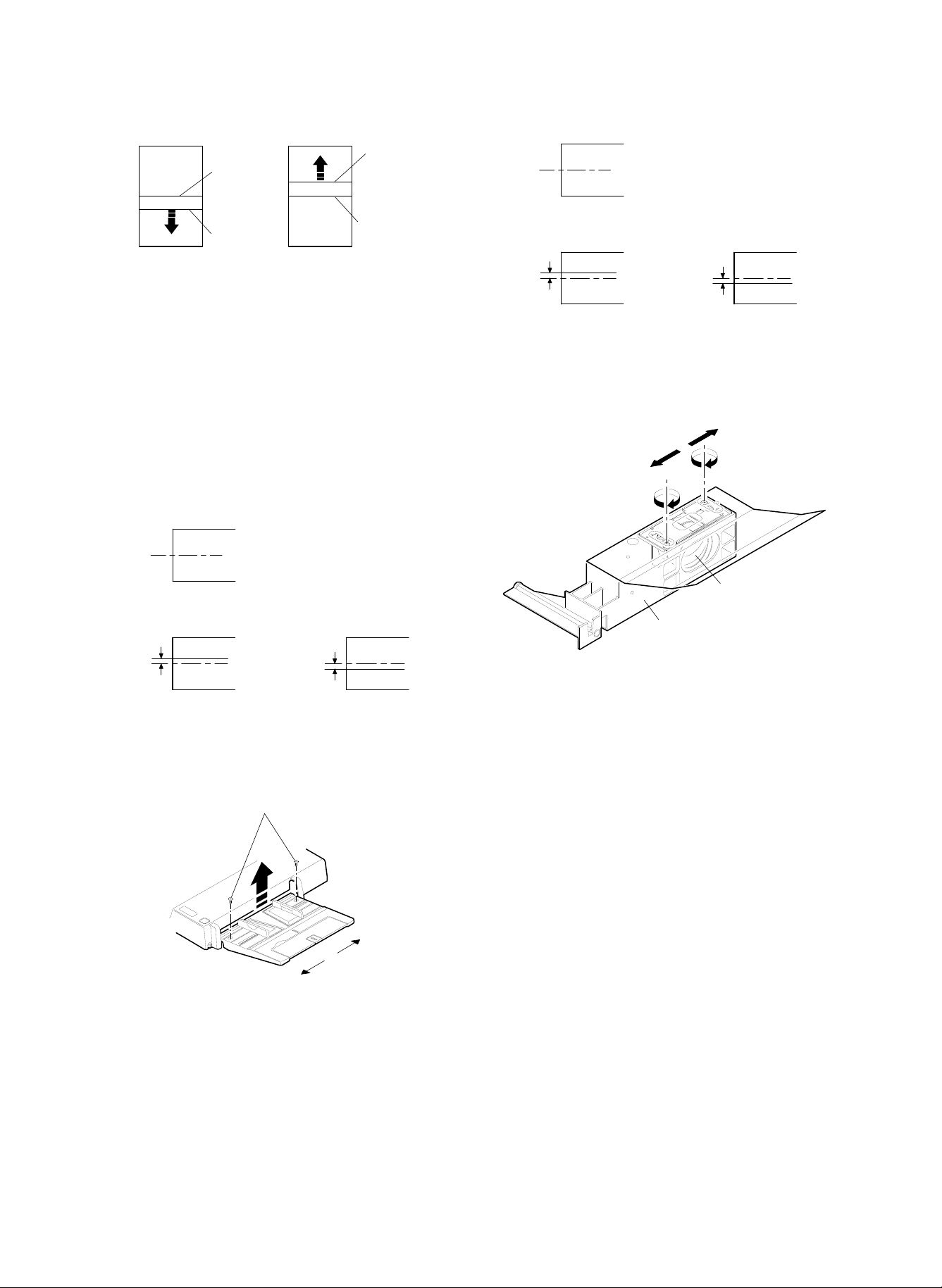

12. Image correction execution

13. Copy density check

When the power is supplied, warming up is started. During warm up,

the following corrections are performed to adjust the copy density

automatically.

1) Main charger grid voltage correction

2) Optical dirt correction (copy lamp voltage)

3) Auto copy density adjustment (copy lamp voltage)

Copy density adjustment reference

Copy mode

(1) Non-toner save

mode

(2) Toner save mode

(Set by key operator

program P20)

a Manual copy mode copy density

adjustment

b Photo copy mode copy density

adjustment

c Auto copy mode copy density adjustment 3 4 3 2

a Manual copy mode copy density

adjustment

c Auto copy mode copy density adjustment 3 4 3 2

Make a copy in each copy mode, and check that the copy density is

within the level in the table below.

Before checking the copy density, be sure to check that the key

operator program 20 copy density level is set to 3.

Selection between the toner save mode and the non-toner-save

mode is made with the key operator pr o gr a m 22 .

(Test chart compatibility table)

1 10

23456789

UKOG-0162FCZZ

Density No.

UKOG-0089CSZZ

Density No.

KODAK

gray scale

Operation panel

density setting

13765

531 W

13765

531 W

13765

531 W

12345678910W

0.1 0.2 0.3 0.5 1.9 0

123419A

Density level UKOG-0162FCZZ gray scale

Key operator

P20 setting

Copied

Slightly

copied

W

Not

copied

14. Focus (resolution), copy magnification

ratio check (adjustment)

Make a copy in each copy mode, and check that the focus (resolution) and the copy magnification ratio are in the range shown in table

below.

For the adjustment and checking procedures, refer to the sections

shown in the table.

Copy magnification ratio Copy center Corners

100% 5.0 lines/mm 4.5 lines/mm

101 ∼ 200% 5.0 lines/mm 4.5 lines/mm

90 ∼ 99% 4.5 lines/mm 4.0 lines/mm

64 ∼ 89% 3.6 lines/mm 3.2 lines/mm

50 ∼ 63% 3.2 lines/mm 2.8 lines/mm

No. Content Method

1 Focus (resolution)

(Normal, 50%, 200%)

2 Vertical copy magnification ration

(normal, 50%, 200%)

3 Horizontal copy magnification ration

(normal)

Adjust with SIM 48-1

(A/B/C).

Adjust with SIM 48-1

(D/E/F).

Adjust with SIM 48-1.

4 – 15

Page 33

15. Operation check

Make a copy in each copy mode listed below, and check that the

operation is normal.

No. Content

1 Paper size detection (manual paper feed tray)

2 Paper size detection (No. 2, 3 paper feed tray)

3 Original size detection (Original table)

4 Original size detection (RADF original feed tray)

5 (Manual paper feed tray, No. 1, 2, 3 paper feed tray,

cassette) copying

6 RADF copying (S-S mode)

7 RADF copying (S-D mode)

8 RADF copying (D-D mode)

9 RADF copying (D-S mode)

10 Zoom copying (enlargement, reduction)

11 Sort mode copying (with SF-S16/53/55 installed)

12 Group mode copying (with SF-S16/53/55 installed)

13 Sort staple mode copy (with SF-S16/53/55 installed)

16. Copy image center shift check

Make a copy in each copy mode listed below, and check that the

copy image center shift is within the allowable range.

For the adjustment and checking procedures, refer to the sections

shown in the table.

Original table mode Single ±2.0 mm

Duplex ±2.0 mm

Overall (RADF) mode Single S → S ±3.0 mm

D → S ±4.0 mm

Duplex S → D ±3.0 mm

D → D ±4.0 mm

No. Content Method

1 Original table copy mode

(front) (Manual paper feed

tray, No. 1, 2, 3 paper fe ed

tray, paper feed cassette)

2 Original table copy mode

(back) (No. 1, 2, 3 paper

feed tray, paper feed

cassette)

3 RADF copy mode Adjust by changing the

Adjust by changing the

positions of the paper feed

tray, the paper feed cassette,

and the manual paper feed

tray.

Adjust by changing the

position of the duplex tray.

position of the RADF paper

feed tray.

No. Content Method

1 Original table copy mode (lead

edge image loss, void area) (rear

edge void area)

2 RADF copy mode (S-S mode)

(lead edge image loss, void area)

3 RADF copy mode (D-D mode)

(lead edge image loss, void area,

rear edge void area)

4 RADF thin film copy mode (lead

edge image loss, void area, rear

edge void area)

5 RADF stepping copy mode (lead

edge image loss, void area, rear

edge void area)

Adjust with SIM 50-1.

In the RADF copy mode,

the adjustment value of

SIM 53-1 must be also

checked.

18. Recording of adjustment/setting

values, ROM version

It is advisable to record the adjustment and setting values as well as

the ROM version. If they are not recorded, all the adjustments must

be executed again from the beginning when a memory trouble occurs, or when the main control PWB is replaced, or memory on the

main control PWB is replaced.

If, however, the adjustment values are recorded, it is only required to

enter the values with the corresponding simulations. This greatly increases the efficiency in servicing.

By use of the commander (SF-EA13), all the adjustment and setting

values and the ROM version are printed.

If the commander (SF-EA13) is not available, execute each simulation related to each adjustment and setting, and read the adjustment

and setting values and record them.

For the concrete procedures, refer to the sections listed in the table

below.

19. Explana tio n fo r use r oper ations

20. Others

(1) Fixing adjuster setup

Turn the adjuster to fix the copier.

17. Image loss, void area check

(adjustment)

Make a copy in each copy mode listed below, and check that the

image loss and void area are within the allowable range.

For the adjustment and checking procedures, refer to the sections

shown in the table.

Item Lead edge Rear edge

Image loss 1.0 ∼ 4.5 mm —

Voide area 1.0 ∼ 3.0 mm 1.0 ∼ 4.0 mm

Image shift for the paper 0±1.5 mm —

4 – 16

Lock

Adjuster

Release

Page 34

[5] EXTERNAL VIEWS AND INTERNAL STRUCTURE

1. External views

1 2 3 4 5 6 7

8109

11

12

13

14

15

16

17

18

Copy tray

1

Document exit section cover

4

Document table

7

Document guide

F

Power switch

I

Manual feed guide tray

L

Front cover

O

Tray falling button/lamp

R

19

2120 22 23

Clip tray

2

Document exit section

5

Document feed lamp, document

8

remaining lamp

Document set table

G

Manual paper feed guide

J

Heater switch

M

No. 3 paper feed tray

P

No. 1 paper feed tray

S

5 – 1

Operation panel

3

Reversing automatic document feeder

6

(RADF) unit

Paper feed pressure release button

9

Toner box cover

H

Manual paper feed tray

K

Paper cassette

N

No. 2 paper feed tray

Q

Page 35

2. Internal operation parts

27262524

28 29 3130

Operation Manual storing section

T

OPC drum

W

Duplex unit

Z

Roller rotating knob

U

Toner collection container storing

X

section cover

Transport section open/close lever

[

Fusing section lock lever

V

Left side cover

Y

5 – 2

Page 36

18

17

16

INSERTS

TRANSPARENCY

COVERS/INSERTS

DUAL PAGE COPY

11 12 13 14 15

SPECIAL MODES

COPIES MADE

COPIES SELECTED

SCROLL DISPLAY

MARGIN SHIFT

PROGRAM

INFORMATION

3

2

1

P

ERASE

START

6

5

4

CA

CLEAR ALL

CHANGE

9

CLEAR/STOP

8

7

INTERRUPT

TRAY SELECT

282625242322

27

C/

AUDIT

CLEAR

0/

Sort/group key/display lamp

Reduction/normal/enlargement key

Operation guide key/display lamp

COPIES SELECTED display

Binding margin key/display lamp

OHP insert paper insert key/display lamp

Message screen

10-key pad

3

6

9

H

K

N

Q

T

Start key/start lamp

W

31

2 4 5 6 7 8 9 10

AUTO IMAGE

1

ORIGINAL TO COPY

SORT

SORTER

21

Staple sort key/display lamp

Magnification ratio auto select key

Message forward scroll key

All clear key

Frame erase/display lamp

Cover/index paper insert key/display lamp

Copy exposure key

Interruption key/display lamp

Clear/stop key

2

5

8

G

J

M

P

S

V

DARK

AUTO

MANUAL

ZOOM

REDUCTION ENLARGEMENT

2

221

1

1

1

EVEN NUMBER

ODD NUMBER

(ORIGINALS)

GROUP

STAPLE

SORT

PHOTO

EXPOSURE

LIGHT

1

2

PRE-COUNT

ORIGINALS

CHANGE

20

19