Page 1

CVP09FX

SERVICE MANUAL

S3503CVP09FX/T

PORTABLE AIR CONDITIONER

CONTENTS

CHAPTER 1. PRODUCT SPECIFICATION

[1] SPECIFICATION............................................1-1

[2] ELECTRICAL PARTS .................................... 1-1

[3] WIRING DIAGRAM........................................1-2

[4] EXTERNAL DIMENSION...............................1-2

CHAPTER 2. OPERATION INSTRUCTION

[1] PART NAMES................................................2-1

[2] LOCATION.....................................................2-2

[3] INCLUDED.....................................................2-3

[4] INSTALL WINDOW PANEL ........................... 2-3

[5] INSTALLATION AND REMOVAL OF EX-

HAUST HOSE................................................2-4

[6] PRE-OPERATION CHECKS..........................2-5

[7] OPERATION MODE ...................................... 2-5

[8] DRAINAGE ....................................................2-7

[9] MAINTENANCE.............................................2-7

MODEL

In the interests of user-safety (Required by safety regulations in some countries)

the set should be restored to its original condition and only parts identical to

those specified should be used.

CHAPTER 4. EXPLANATION OF CIRCUIT AND OPERATION

[1] ELECTRONIC CONTROL CIRCUIT DIA-

GRAM............................................................4-1

[2] PRINTED WIRING BOARD...........................4-2

[3] FUNCTION....................................................4-3

[4] PERFORMANCE CURVES...........................4-6

CHAPTER 5. ATTENTION WHEN REPAIRING

[1] HOW TO REPAIR REFRIGERATION ...........5-1

[2] ELECTRICAL COMPONENT TEST..............5-3

CHAPTER 6. TROUBLESHOOTING GUIDE

[1] TROUBLESHOOTING ..................................6-1

REPLACEMENT P ARTS LIST

CV-P09FX

CHAPTER 3. DISASSEMBLING PROCEDURE

[1] PROCEDURE FOR DISASSEMBLY ............. 3-1

[2] DISASSEMBLING THE CONTROL BOX........3-9

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for

maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

CVP09FX

CVP09FX

CHAPTER 1. PRODUCT SPECIFICATION

ServiceManual

[1] SPECIFICATION

Cooling Capacity BTU/h 9000

Moisture Removal Pint/h 2.5

Electrical Data

Phase Single

Rated frequency Hz 60

Rated voltage V 115

Rated current A 9.0

Rated input W 1010

Power factor % 98

EER BTU/Wh 8.9

Compressor

Type (Hermetically sealed rotary type)

Model, Motor Output 44R211AE-AJS (805W)

REFRIGERANT SYSTEM

Evaporator Louver fin, Grooved tube, 7mm, hair pin

Condenser Louver fin, Grooved tube, 7mm, hair pin

Control O.D. x I.D x Length(mm)

(Capillary Tube)

Refrigerant Volume R-22 (OZ)

(Factory Charge)

NET DIMENSIONS

Width Height Depth Inch (mm) 18.5" (470) x 32.3" (820) x 15.1" (383)

Net Weight Lbs 84

GROSS DIMENSIONS

Width Height Depth Inch (mm) 22.1" (561) x 35.8" (910) x 18.3" (465)

Gross Weight Lbs 95

FAN SYSTEM

Indoor side (Evaporator) Centrifugal fan

Outdoor side (Condenser) Centrifugal fan

Air Flow rate (Indoor side) CFM High / Med / Low

OTHERS

Safety devices Compressor : Overload relay

Air filter Polypropylene net

Power cord length ft 4.6

Power plug type NEMA 5-15P

2.7 x 1.4 x 400

12.5

240/190/140

Fan motor (IN/OUT) : Internal thermal fuse / Internal thermal protector

[2] ELECTRICAL PARTS

Running capacitor 250V - 60µF

Fan capacitor (IN/OUT) 250V - 6µF / 250V - 8µF

Thermistor 10kΩ at 77°F (TH1), 4.431kΩ at 77°F (TH2, TH3)

Fan motor (IN) IBH-884-512 (MLB180)

Fan motor (OUT) PFU040ZREA/SHP (MLB178)

Overload relay MRA99239L-9054 or B380-150B-141E

Drain motor ORM-1524K1 (M-A438)

1 – 1

Page 3

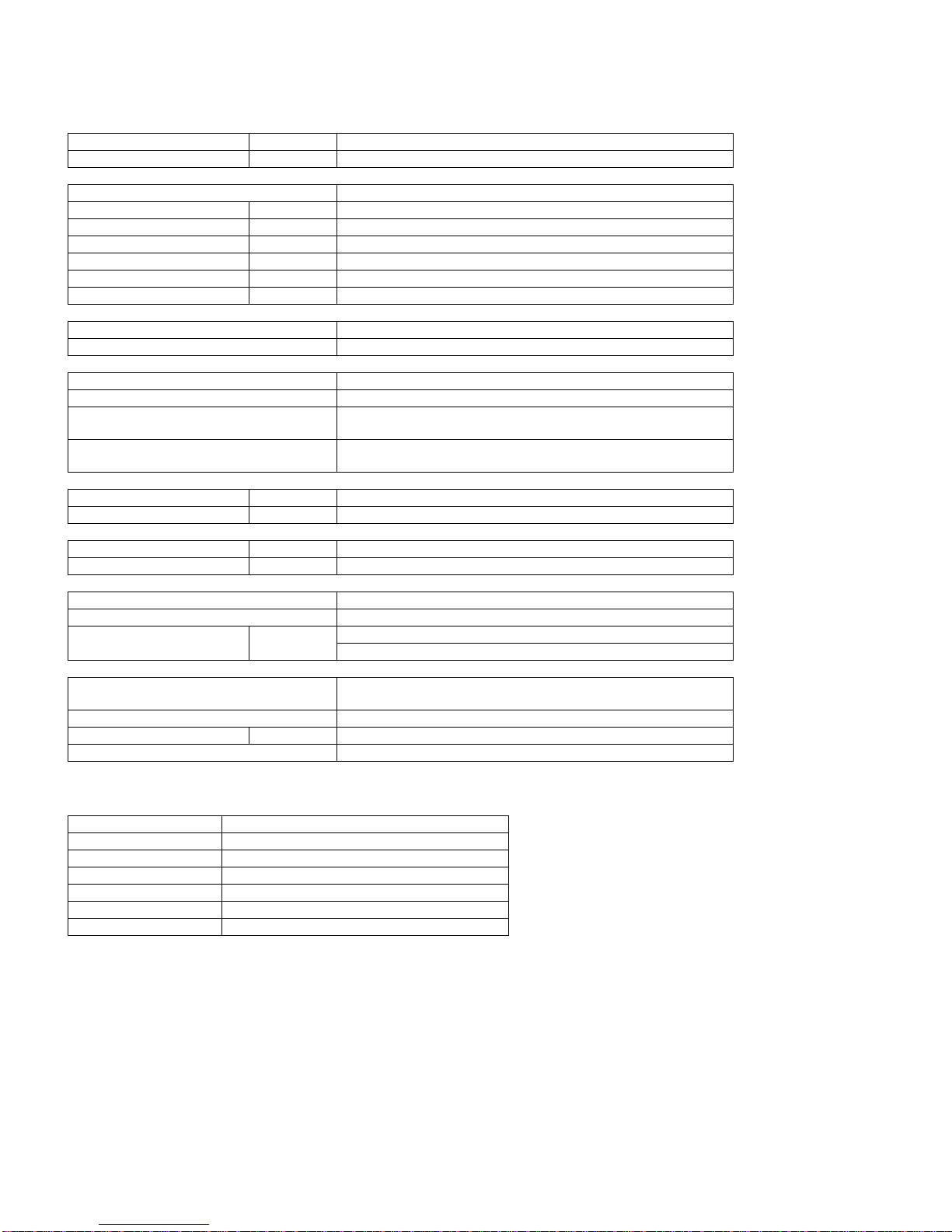

[3] WIRING DIAGRAM

CVP09FX

[4] EXTERNAL DIMENSION

18.5"

M

M

TH2

TH1

TH3

Max. : 59"

32.3"

0.95"

15.1"

16.1"

1 – 2

Page 4

CVP09FX

CVP09FX

CHAPTER 2. OPERATION INSTRUCTION

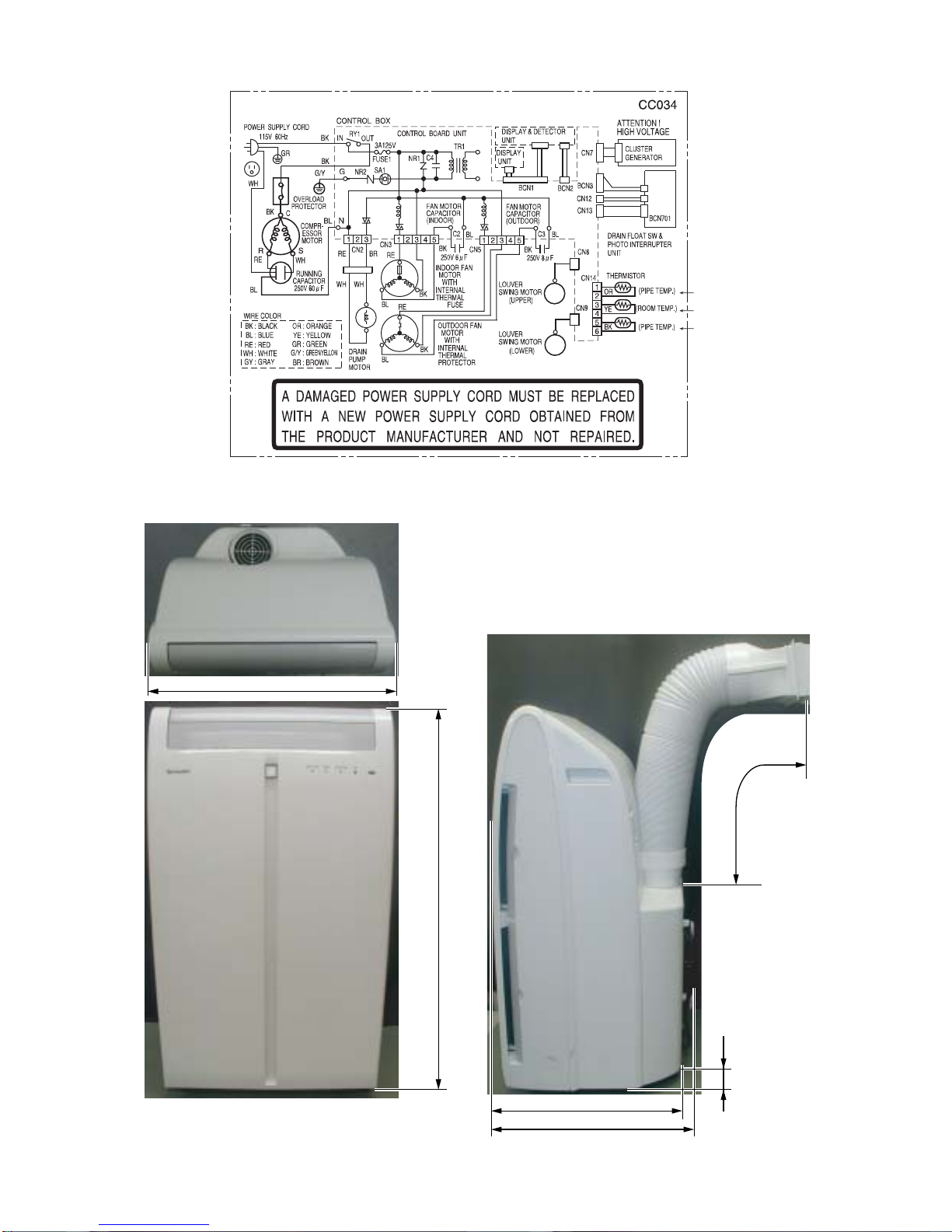

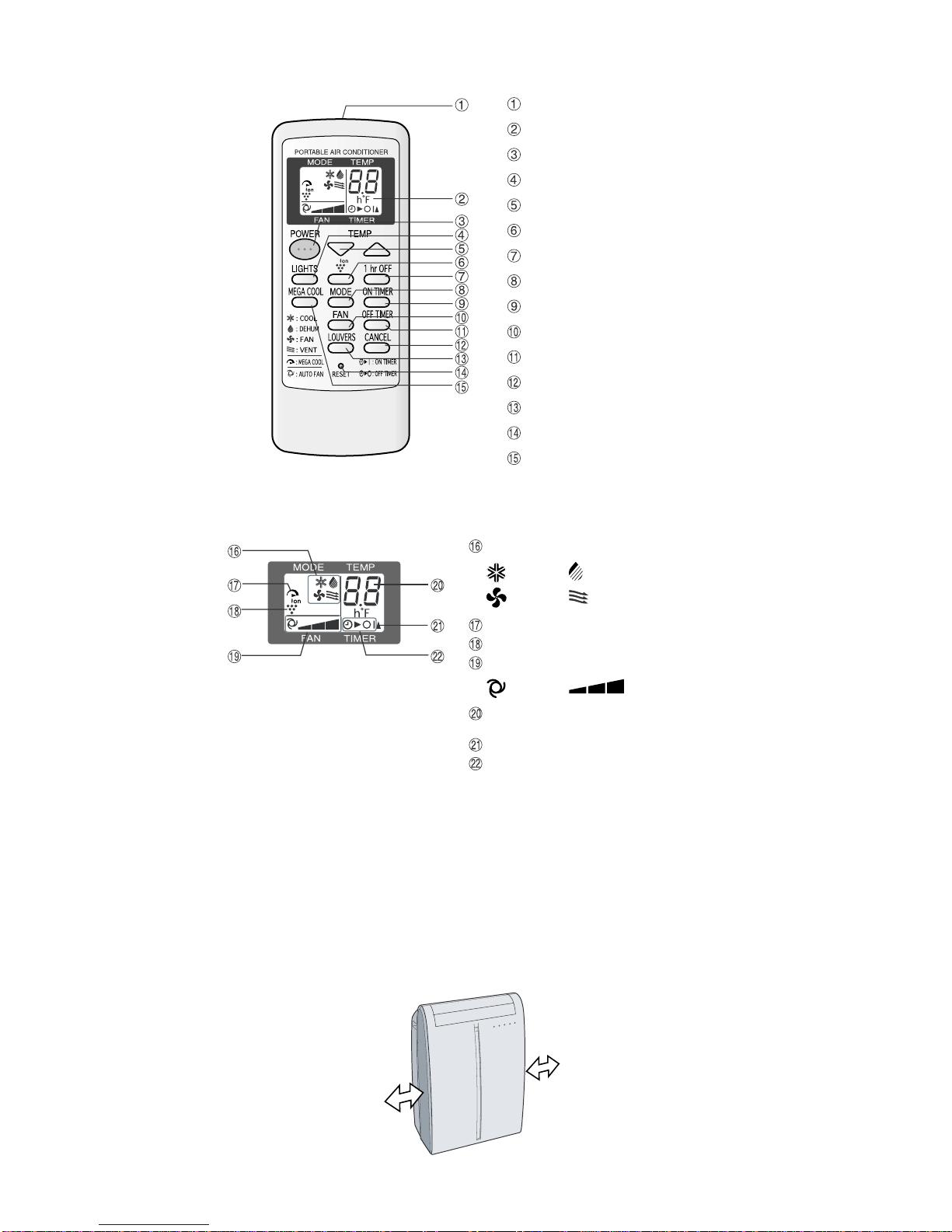

[1] PART NAMES

1. Front view

ServiceManual

Air Outlet

Vertical louvers

Horizontal louvers

PLASMACLUSTER Lamp (blue)

Remote control signal receiver

window

AUX. Button

OPERATION Lamp (red)

TIMER Lamp (orange)

MEGA COOL Lamp (green)

Air inlet

2. Rear view

Exhaust air outlet

Window exhaust adapter

Exhaust hose

Remote control hook

Air filters

Drainage nozzle and stopcock

Power supply cord hooks

Drainpipe nozzle and stopcock

Power supply cord

Power plug

Casters(4)

2 – 1

Page 5

3. Remote control

CVP09FX

Transmitter

Display

POWER Button

LIGHTS Button

TEMPERATURE Button

PLASMACLUSTER Button

1 hr OFF Button

MODE Button

ON TIMER Button

FAN Button

OFF TIMER Button

CANCEL Button

LOUVERS Button

RESET Button

MEGA COOL Button

4. Remote control display

MODE SYMBOLS

: COOL : DEHUMIDIFICATION

: FAN : VENTILATION

MEGA COOL SYMBOL

PLASMACLUSTER SYMBOL

FAN SPEED SYMBOLS

: AUTO : Manual setting

TEMPERATURE AND TIMER COUNT

DOWN INDICATOR

TRANSMITTING SYMBOL

ON TIMER / OFF TIMER SYMBOL

[2] LOCATION

• The air conditioner should be placed on a firm foundation to minimize noise and vibration. For safe and secure positioning, place the unit on a

smooth, level floor strong enough to support the unit.

• The unit has casters to aid placement, but it should only be rolled on smooth, flat surfaces. Use caution when rolling on carpet surfaces. Do not

attempt to roll the unit over objects.

• The unit must be placed within reach of a properly rated grounded socket.

• Never place any obstacles around the air inlet or outlet of the unit.

• Allow at least 12" (30cm) of space from the wall for efficient air-conditioning.

MIN.12"

(30cm)

MIN.12"

(30cm)

2 – 2

Page 6

CVP09FX

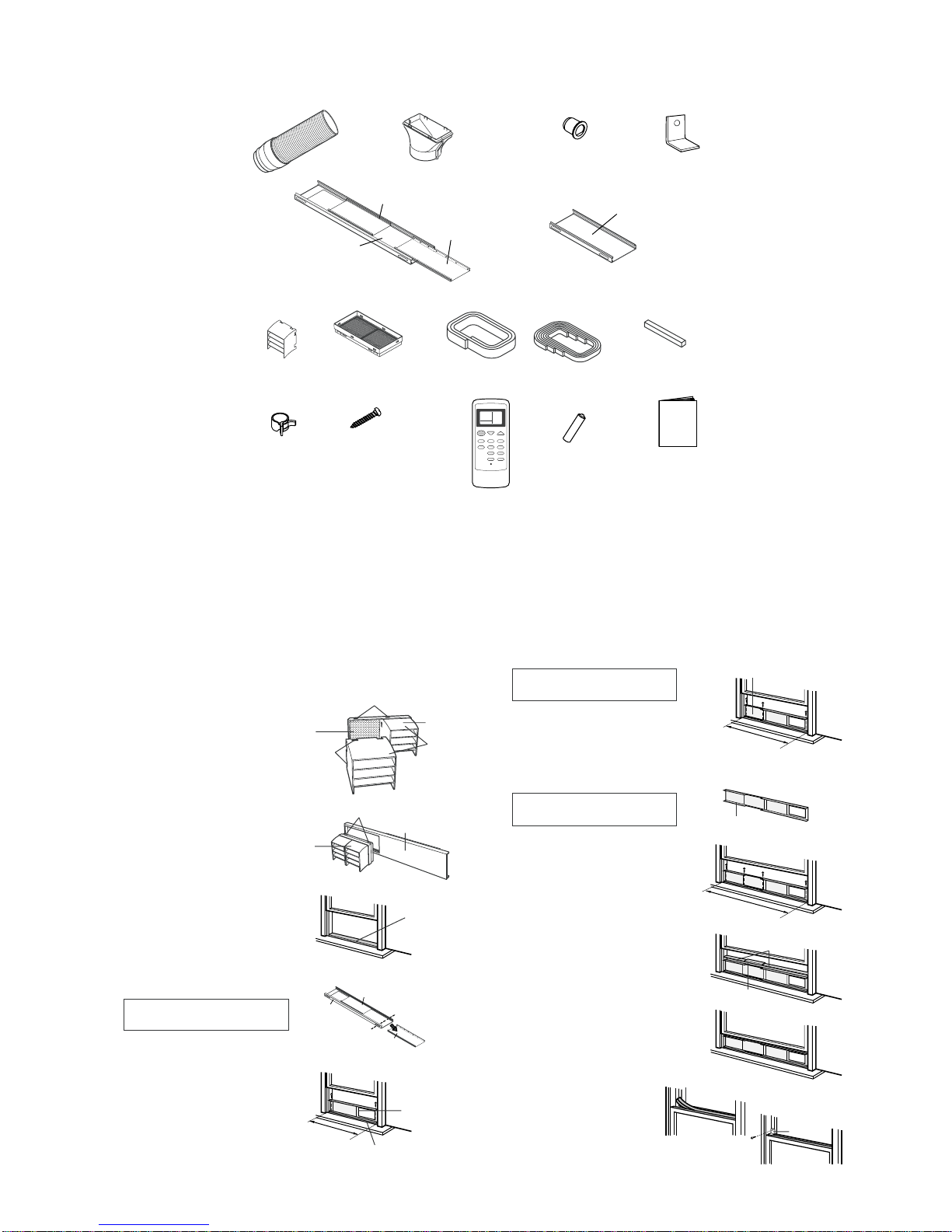

[3] INCLUDED

Exhaust hose (1) Window exhaust adapter (1)

Exhaust cover (1)

Drainage Grommet (1)

Extension panel (1)

Bracket (1)

Adjustment panel (1)

Window panel (1)

Rain guard (2)

Insect guard net (1)

Foam seal (1)

Foam seal (3)

(adhesive type)A

Foam seal (1)

(adhesive type)B

(thickness:1/5") (thickness:2/5")

Hose clamp (1)

Screw (8)

Remote control (1)

Battery (2)

(AAA.R03)

Manual (1)

SUGGESTED TOOLS FOR WINDOW PANEL INSTALLATION

1. Screwdriver(medium size Phillips)

2. Tape measure or ruler

3. Knife or scissors

4. Saw (In the event that the window panel needs to be cut down in size because thewindow is too narrow for direct installation.)

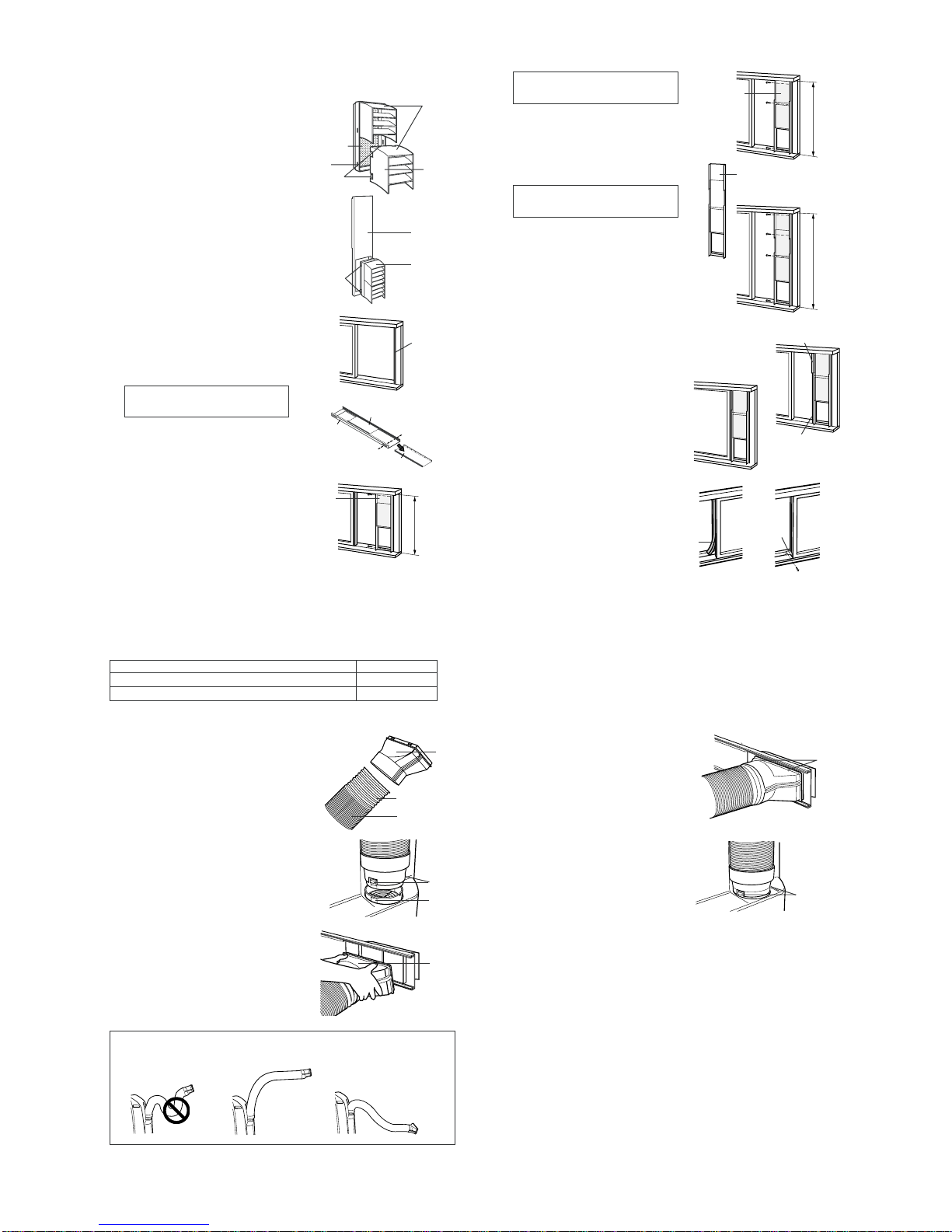

[4] INSTALL WINDOW PANEL

Installation in a double-hung sash window

(See page 14 for installation in a sliding sash window. )

Connect the rain guards to the insect

1

guard net.

Insert all three projections on each rain

guard into the holes in the insect guard net.

Side “A” will now be uppermost, as indicated in the diagram.

Attach the guard combined above to the

2

window panel

Push the insect guard net firmly to ensure

that its four projections fit into the holes in

the window panel.

Side “A” will now be at the top, as indicated

in the diagram.

Cut the foam seal A (adhesive type) to

3

the proper length and attach it to the

window stool.

Attach the window panel to the window

4

stool.

If the inner width of the window is between 22" (559mm) and 24" (609mm)

inclusive.

The window panel cannot be installed in

windows less than 22" (559mm) wide, as

you will be unable to shut the exhaust cover.

(1) Remove the adjustment panel from th e

window panel, and cut the window

panel to the same width as the window.

(2) Open thewindow sash and place the win-

dow panel on the window stool

(3) Secure the window panel to the window

stool with 2 screws.

Insect guard

net

Projection

"A"

Window

panel

22"~ 24"

Hole

Projection

Exhaust cover

Adjustment panel

Window stool

Window panel

Foam seal A

(adhesive type)

Cut

Window panel

Rain guard

"A"

If the inner width of the window is

between 24" (609mm) and 36.8"

(934mm) inclusive.

(1) Open the window sash and place the

window panel on the window stool.

(2) Slide the adjustment panel to fit the

window frame width.

(3) Secure the window panel tothe stool with

3 screws.

If the inner width of the window is

between 36.8" (934mm) and 48"

(1219mm) inclusive.

(1) Attach the extension panel to the

adjustment panel.

(2) Open thewindow sash and place the win-

dow panel on the window stool.

(3) Slide the adjustment and extension

panels to fit the window frame width.

(4) Secure the window panel to the window

stool with 4 screws.

Cut the foam seals (adhesive type) A and

5

B to the proper length and attach it to the

window panel.

Attach foam seal A to the window panel and

extension panel, and attach foam seal B to

the adjustment panel.

Close the window sash securely against

6

the Window panel.

Cut the foamseal to an appropriate length

7

and seal the opening between the top of

the inner window sash and the outer window sash.

Attach a bracket with the screw.

8

36.8"~48"

Foam seal

24"~36.8"

Extension panel

Foam seal B

(adhesive type)

Adjustment panel

Foam seal A

(adhesive type)

Bracket

2 – 3

Page 7

CVP09FX

Installation in a sliding sash window

(See page 12 for installation in a double-hung window.)

Connect the rain guards to the insect

1

guard net.

Insert all three projections on each rain

guard into the holes in the insect guard net.

Side “A” will now be uppermost, as

indicated in the diagram.

Attach the guard combined above to the

2

window panel.

Push the insect guard net firmly to ensure

that its four projections fit into the holes in

the window panel.

Side “A” will now be at the top, as indicated

in the diagram, when it is installed in the

window.

Cut the foam seal A (adhesive type) to the

3

proper length and attach it to the window

frame.

Install the window panel into the window

4

frame.

If the inner height of the window is

between 22" (559mm) and 24" (609mm)

inclusive.

The window panel cannot be installed in

windows less than 22" (559mm) high, as

you will be unable to shut the exhaust

cover.

(1) Remove the adjustment panel from the

window panel, andcut the window panel

to the same height as the window.

(2) Open the window sash and place the

window panel on the window frame.

(3) Secure the window panel to the window

frame with 2 screws.

Insect guard net

Hole

Projection

Projection

Window

panel

Window

panel

Exhaust cover

Adjustment panel

"A"

Rain guard

Window panel

"A"

Foam seal A

(adhesive type)

Cut

22"~24"

If the inner height of the window is

between 24" (609mm) and 36.8"

(934mm) inclusive.

(1) Open the window sash and place the

window panel on the window frame.

(2) Slide the adjustment panel to fit the

window frame height.

(3) Secure the window panel to the window

frame with 3 screws.

If the inner height of the window is between 36.8" (934mm) and 48" (1219mm)

inclusive.

(1) Attach the extension panel to the

adjustment panel.

(2) Open the window sash and place the

window panel on the window frame.

(3) Slide the adjustment and extension

panels to fit the window frame height.

(4) Secure the window panel to the window

frame with 4 screws.

Cut the foam seals (adhesibe type) A and

5

B to the proper length and attach them to

the window panel.

Attach foam seal Ato the window panel and

extension panel, and attach foam seal B to

the adjustment panel.

Close the window sash securely against

6

the Window panel.

Cut the foamseal to an appropriate length

7

and seal the opening between the side of

the inner window sash and the outer window sash.

Attach a bracket with the screw.

8

Foam seal

Adjustment

panel

Extension panel

Foam seal B

(adhesive type)

Foam seal A

(adhesive type)

Bracket

24"~36.8"

36.8"~48"

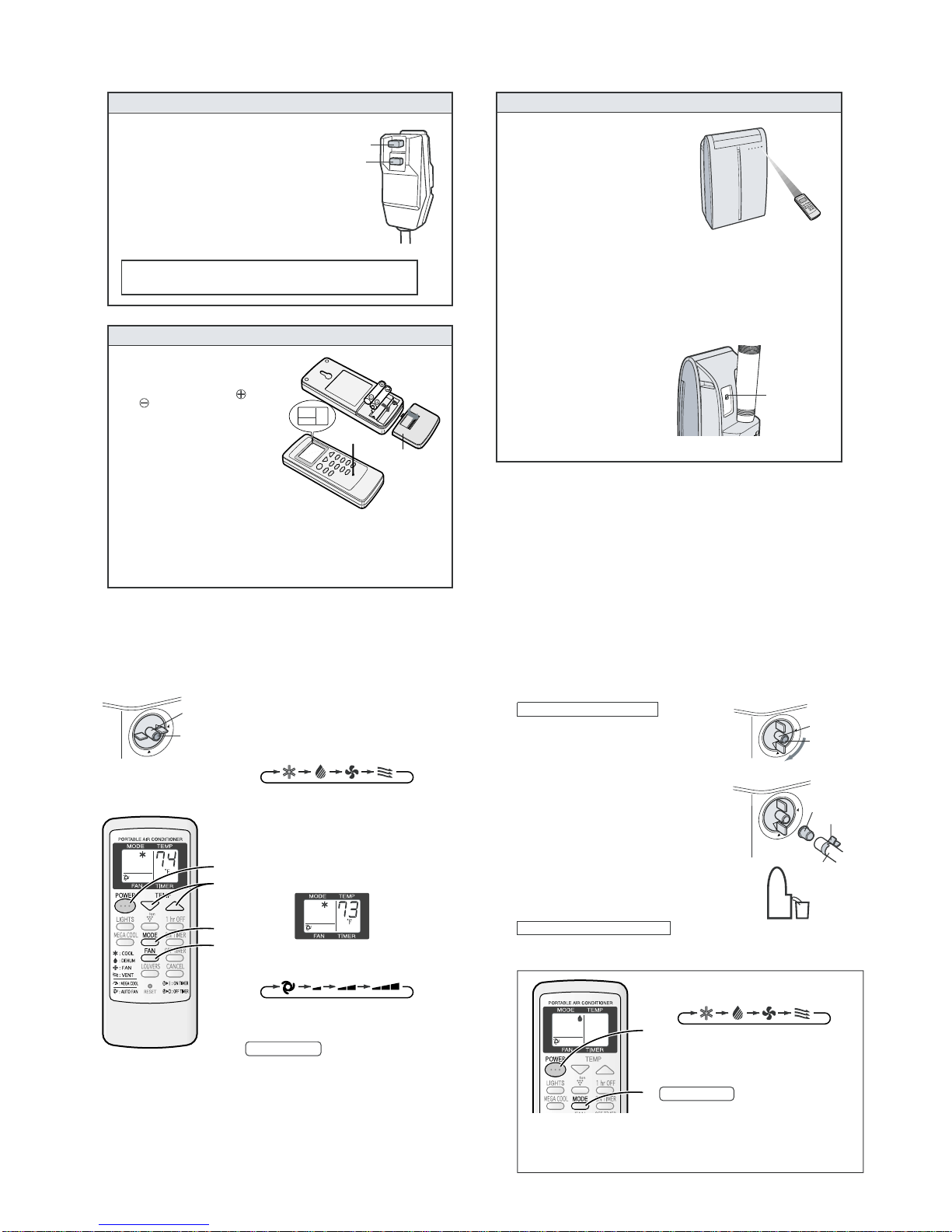

[5] INSTALLATION AND REMOVAL OF EXHAUST HOSE

The exhaust hose must be installed or removed in accordance with the usage mode.

MODE EXHAUST HOSE

COOL, FAN, VENTILATION, DEHUMIDIFICATION with no container Install

DEHUMIDIFICATION with container(minimum capacity 3 gallons) Remove

Installation of the exhaust hose

Attach the window exhaust adapter to

1

the exhaust hose.

Extend one end of the exhaust hose and

insert it into the window exhaust adapter,

and turn it (approx. three times) until it

stops.

Make sure they are securely attached

afterwards.

Attach the exhaust hose adapter to the

2

unit.

Insert the two projections on the exhaust

hose adapter into the two holes on the

unit, and firmly attach them to each

other.

Slide and open the exhaust cover on

3

the window panel, and attach the window exhaust adapter.

Surface of window exhaust adapter

marked "TOP" should be at the top when

it is installed in a double-hung sash

window.

Surface of window exhaust adapter

marked "TOP" should be on the window

frame side when it is installed in a sliding

sash window.

The exhaust hose should be as short as possible for operational efficiency;

however, it must not be twisted or bent.

Unacceptable

Acceptable

Acceptable

Extend

Exhaust hose

Window

exhaust

adapter

Projection

Hole

"TOP"

Removal of the exhaust hose

Remove the window exhaust adapter.

1

Pull out and remove the window exhaust

adapter by pushing down two “PUSH”

markings, and slide and close the exhaust

cover in the window panel.

Remove the exhaust hose adapter from

2

the unit.

Lift up and remove the exhaust hose

adapter from the unit by pushing down on

the two projections.

"PUSH"

Projection

2 – 4

Page 8

CVP09FX

1

Remove the exhaust hose (See Page 17)

2

Turn the drainage nozzle to the OPEN position.

3

Pull the stopcock out from the drainage nozzle.

• When the stopcock is removed, a small amount of water

may be discharged from the drainage nozzle.

• Always perform this procedure with the unit turned off.

Drain water will spout out if attempted during operation.

4

I

nsert the hose clamp into a standard commercially-available hose (5/8"inner diameter, 7/8" outer

diameter) and attach the drain grommet to the

hose.

5

Attach the hose to the drainage nozzle, and secure

it with the hose clamp.

• Insert the hose securely into a container with a minimum

capacity of 3 gallons. Be sure to monitor the water levelin

the container and empty as necessary. Do not operate in

dehumidify mode for more than 8 hours at a time. Be sure

to empty the watercontainer wheneverdehumidify modeis

started. Failure to empty the water container can cause

the container to overflow and cause damage to underlying

materials.

• Set the hose sloping downwards for easier drainage.

Moreover, do not bend the hose at any point, nor allow

the end to be submerged in water.

Dehumidification with no container

2

1

In this mode, the air conditioner dehumidifies the room.

CAUTION

When operating dehumidification with container, the unitgenerates heat during dehumidification mode and the room temperature will rise. Operate dehumidification with no container if

you don't want the room temperature to rise. This will help to slightly drop the room

temperature, but dehumidification performance will become less effective than when operating dehumidification with container.

1

Press the MODE button to select DEHUMIDIFICATION mode.

COOL DEHUM FAN VENT

2

Press the power button to start operation.

• The red OPERATION lamp on the unit will light.

• The temperature cannot be set.

• The fan speed is preset to AUTO and cannot be

changed.

TO TURN OFF

Press the POWER button again.

• The red OPERATION lamp on the unit will turn off.

Dehumidification with container

Drainage nozzle

Stopcock

Drain grommet

Hose clamp

Hose

I

f draining of the water is not desirable, install the exhaust hose (See Page 16), turn the drainage nozzle to the

CLOSE position, and check that the drainage nozzle is covered with the stopcock. In this operation, the water

tank inside the unit may be full, the unit stops operating and then the TIMER, OPERATION and MEGA COOL

lamps are blinking, depending on room condition. In this case, drain out the water within the unit (See Page 29).

"OPEN" position

[6] PRE-OPERATION CHECKS

POWER PLUG CHECK

This air conditioner uses a fused power plug.

Always check the power plug before use.

Press the RESET button.

1

Insert the power plug into the wall socket.

2

Press the TEST button.

3

You will hear a CLICK if the circuit breaker is

functioning correctly.

Press the RESET button until you hear another

4

CLICK.

The circuit breaker is activated, power is supplied,

and the air conditioner is now ready for use.

Do not attempt to use the air conditioner if the above procedure is

impossible, as it is malfunctioning.

Disconnect the power plug and request service.

LOADING BATTERIES

Remove the battery cover at the

1

back of the remote control.

Insert batteries into the compart-

2

ment, making sure the

polarities are correctly

aligned.

¥ Lines will appear on the display

when batteries are properly installed.

Reattach the battery cover.

3

Press the RESET button using a

4

thin pointed implement.

NOTES:

¥ The battery should last approximately one year under normal use.

¥ When replacing the batteries, always change both batteries at the same time, and

make sure they are the same type.

¥ If the remote control does not operate normally after replacing the batteries, press

the RESET button using a thin pointed implement.

¥ If you will not be using the unit for a prolonged period, remove the batteries from

the remote control.

Use two AAA (R03) batteries.

and

RESET

TEST

Battery cover

HOW TO USE THE REMOTE CONTROL

Point the remote control towardsthe

units signal receiver window and

press the desired button. A beep

will sound when the unit receives

the signal.

• Make sure nothing, such as curtains,

blocks the signal receiver window.

• The remote control operates up to 23

feet (7 meters) away.

CAUTION

• Do not expose the signal receiver window to direct sunlight. This may adversely

affect its operation. If necessary, close the curtains to block out the sunlight.

• Use of a fluorescent lamp in the same room may interfere with transmission of the

signal.

• The unit may be affected by signals emitted from other remote controllers for

televisions, VCRs or other equipment used in the same room.

• Do not leave the remote control exposed to direct sunlight or near a heater. Protect the remote control from moisture and shock which can discolor or damage it.

To prevent the remote control from

being misplaced, hook it to the unit

when not in use.

When attached, to remove the remote

control from the unit, lift the remote

control up slightly and pull it out.

Remote control hook

[7] OPERATION MODE

1. Cool mode 2. Dehumidification mode

Install the exhaust hose (See Page16), turn

the drainage nozzle to the CLOSE position,

Drainage nozzle

"CLOSE" position

Stopcock

and check the drainage nozzle is covered

with the stopcock.

Press the MODE button to select COOL

1

mode.

COOL DEHUM FAN VENT

Press the POWER button to start op-

2

eration.

• The red OPERATION lamp on the unit will

light.

Press the TEMPERATURE button toset

3

2

3

the desired temperature.

• The temperature can be setwithin the range

of 64°F to 86°F.

1

4

Press the FAN button to set the de-

4

sired fan speed.

AUTO QUIET LOW HIGH

TO TURN OFF

Press the POWER button again.

• The red OPERATION lamp on the unit will turn

off.

2 – 5

Page 9

3. Fan mode

1

Press the PLASMACLUSTER button during

operation.

• The remote control will display “ ”.

• The blue PLASMACLUSTER lamp on the unit will

light.

TO CANCEL

Press the PLASMACLUSTER button again.

• The PLASMACLUSTER lamp on the unit will turn off.

NOTES:

• Use ofthe PLASMACLUSTER function will bememorized and it will be activated the next time you turn on

the air conditioner.

• To turn off the PLASMACLUSTER Lamp, press the

LIGHTS button.

• PLASMACLUSTER operation cannot be set during

VENTILATION mode.

The Plasmacluster ion generator inside the air conditioner will release positive and

negative Plasmacluster ions into the room. Approximately the same numbers of positive and negative ions released into the air.

1

In this mode, the air conditioner simply circulates the air without cooling it.

Install the exhaust hose (See Page16), turn the drainage nozzle to the CLOSE

position, and check the drainage nozzle is covered with the stopcock.

Press the MODE button to select FAN mode.

1

COOL DEHUM FAN VENT

2

Press the POWER button to start operation.

2

• The red OPERATION lamp on the unit will light.

2

5

• The temperature cannot be set.

Press the FAN button to set the desired fan

3

3

speed.

1

3

1

QUIET LOW HIGH

TO TURN OFF

Press the POWER button again.

• The red OPERATION lamp on the unit will turn off.

4. Ventilation mode

CVP09FX

6. Plasmacluster operation

In this mode, the air conditioner ventilates the air to outdoors.

Install the exhaust hose (See Page 16), turn the drainage nozzle to the CLOSE

position, and check the drainage nozzle is covered with the stopcock.

Press the MODE button to select VENT mode.

1

COOL DEHUM FAN VENT

Press the POWER button to start operation.

2

2

2

• The red OPERATION lamp on the unit will light.

• The temperature cannot be set.

5

Press the FAN button to set the desired fan

3

3

speed.

• Although the louvers are closed and no air blows

1

3

out into the room, the external ventilation fan speed

changes.

1

4

QUIET LOW HIGH

TO TURN OFF

Press the POWER button again.

• The red OPERATION lamp on the unit will turn off.

5. To change air flow direction

UP / DOWN AIR FLOW DIRECTION

Press the LOUVERS button on the re-

1

mote control.

• The horizontal louvers will swingcontinuously.

Press the LOUVERS button again when

2

the horizontal louvers are at the desired

1

2

LEFT / RIGHT AIR FLOW DIRECTION

CAUTION

Never attempt to adjust the horizontal louvers manually.

• Manual adjustment of the horizontal louvers can cause the unit to malfunction when the remote

control is used for adjustment.

• When the horizontal louvers are positioned atthe lowest position in the COOL or DEHUMIDIFICATION mode for an extended period of time, condensation may result.

Do not adjust the vertical louvers to the extreme left or right in the COOL mode with the fan

speed set to "QUIET (

Condensation may form on the louvers.

)" for an extended period of time.

position.

• The horizontal louvers will stop moving.

• The adjusted position will be memorized and

the same position will be set automatically

when operated the next time.

NOTE

• During VENTILATION mode, UP/DOWN air flow

direction cannot be changed.

Horizontal louvers

Hold the vertical louver as shown in the diagram and adjust the air flow direction.

Vertical louvers

7. Mega cool operation

In this operation, the air conditioner fan works at extra high speed with a setting

temperature of 59°F.

NOTES:

• You cannot set the temperature or fan speed during MEGACOOL operation.

• The fan returns to the HIGH speed setting after the unit has run for 30 minutes in MEGA

COOL mode.

• The extra high fan speed may automatically slow down to protect the unit.

8. One-hour off timer

When the ONE-HOUR OFF TIMER is set, the unit will automatically turn off after one

hour.

NOTES:

• The ONE-HOUR OFF TIMER operation has priority over ON TIMER and OFF TIMER

operations.

• If the ONE-HOUR OFF TIMER is set while the unit is not operating, the unit will operate for

an hour at the formerly set condition.

• If you wish to operate the unit for another hour before the ONE-HOUR OFF TIMER is

activated, press the 1hr OFF TIMER button again during operation.

2 – 6

Press the MEGA COOL button during cooling

1

mode.

• The remote control will display " ".

• The temperature display will go off.

• The green MEGA COOL lamp on the unit will light.

TO CANCEL

Press the MEGA COOL button again.

• MEGA COOL operation is also cancelled when the

1

mode is changed, or when the unit is turned off.

• The green MEGA COOL lamp onthe unit will turn off.

Press the 1hr OFF button.

1

• The remote control displays “ ”.

• The orange TIMER lamp on the unit will light.

• The unit will stop operating after one hour.

TO CANCEL

Press the CANCEL button.

• The orange TIMER lamp on the unit will turn off.

1

Alernatively, turn the unit off by pressing the

POWER button.

• The red OPERATION lamp and the orange TIMER

lamp on the unit will turn off.

CANCEL

Page 10

CVP09FX

CLEANING THE UNIT AND THE REMOTE CONTROL

Wipe them with a soft, dry cloth or with a cloth moistened with a mild soap. Carefully remove

any residue by wiping with a damp cloth and dry completely.

Avoid splashing water onto the unit. Water can dangerously damage the electrical insulation.

Never use harsh chemicals or abrasive cleanerson anypart ofthe unit. To avoid damaging the

unit, do not use hot water (120°F/50°C or hotter) when cleaning.

1

Perform drainage to drain out water within the unit. (See Page 29 "When the unit is not

used for a long time").

2

Operate the unit the FAN or VENTILATION mode for about half a day to thoroughy dry

inside the unit.

3

Clean the filters, then reinstall them.

CLEANING THE INSECT GUARD NET

The cooling performance may be reduced or stop

completely if the insect guard net becomes clogged

with dust.

Periodically remove the window exhaust adapter from

the window panel and clean the insect guard net with a

vacuum cleaner or suchlike.

Filters

Be sure to disconnect the power from the wall socket before performing any maintenance.

CLEANING THE FILTERS

If the filter is clogged with dust, the airflow will be reduced, resulting in poor cooling performance. The filter should be cleaned every two weeks.

1

REMOVE THE FILTERS

• Gently pull the filter handle to the right and slide

the filter out of the unit.

2

CLEAN THE FILTERS

• Use a vacuum cleaner to remove any dust. If the

filters are very dirty, wash themwith detergentand

rinse carefully with clean water. Dry the filters in

the shade before reinstalling them.

3

REINSTALL THE FILTERS

• Hold thefilter handleand gentlypush thefilter back

into place.

Never operate the unit without the filter. Doing so

may result in serious damage to the unit.

MAINTENANCE AFTER AIR CONDITIONER SEASON

Insect guard net

9. Timer operation

[8] DRAINAGE

9.1. Off timer

The unit will turn off automatically according to your setting.

Timer duration can be set from a minimum of half an hour (30 minutes) to a

maximum of 12 hours.

Up to 9.5 hours, you can set in half-hour (30-minutes) increments and from 10 to 12

hours, in 1-hour increments.

Display shown when you

set the unit to turn off 2.5

hours later.

NOTES ON TIMER SETTING AND OPERATION

• The latest time setting will be memorized and will appear on the remote control display the next

time you set the OFF TIMER or ON TIMER.

• The OFF TIMER and ON TIMER can not be set together.

Only the most recent TIMER setting will be valid.

• While the ONE-HOUR OFF TIMER is set, the OFF TIMER and ON TIMER is settings are

unavailable.

• If the ONE-HOUR OFF TIMER is set while the OFF TIMER or ON TIMER activated, the ON

TIMER or OFF TIMER setting will be cancelled.

• If a power failure occurs while the OFF TIMER or ON TIMER is set, the TIMER setting will be

cancelled and will not be retrieved even after the power is restored.

Point the remote control at the signal receiver window on the unit.

Press the OFF TIMER button and set the time

1

as desired.

• The time setting will change as you press the

button as follows.

0.5h 1.0h 1.5h 10h 11h 12h

Hold the button down to speed through the settings.

• The orange TIMER lamp on the unit will light.

• The unit will emit a beep when it receives the

1

signal.

• The time setting will count down to show the remaining time.

TO CANCEL TIMER

Press the CANCEL button.

• The orange TIMER lamp on the unit will turn off.

9.2. On timer

The unit will turn on automatically according to your setting.

Timer duration can be set from a minimum of half an hour (30 minutes) to a

maximum of 12 hours.

Up to 9.5 hours, you can set in half-hour (30-minute) increments and from 10 to 12

hours, in 1-hour increments.

Display shown when you set

the unit to turn on 6.5 hours

later.

Point the remote control at the signal receiver window on the unit.

Press the ON TIMER button.

1

• The time setting will change as you press the button

as follows.

0.5h 1.0h 1.5h 10h 11h 12h

Hold the button down to speed through the settings.

• The orange TIMER lamp on the unit will light.

• The unit will emit a beep when it receives the signal.

1

• The time setting will count down to show the remaining time.

Select the mode, temperature, fan speed setting

and PLASMACLUSTER operation as desired.

• When the temperature is set with the ON TIMER,

the temperature will show in the display for 5 seconds and then return to the time display.

• If you do not change the setting, the unit will operate

using the most recent setting.

TO CANCEL TIMER

Press the CANCEL button.

• The orange TIMER lamp on the unit will turn off.

Prepare for drainage and drain out water within the unit in the following cases.

If the unit stops operating and the TIMER, OPERATION and MEGA COOL lamps are

blinking. (This indicates that the water tank inside the unit is full.)

Make sure to turn the unit off.

1

Turn the drainage nozzle to the OPEN

2

position.

Pull the stopcock out from the drainage

3

nozzle.

• When the stopcock is removed, a small amount of

water may be discharged from the drainage nozzle.

Insert the hose clamp into a standard

4

commercially available hose (5/8" inner

diameter, 7/8" outer diameter) and attach

the drain gromment to the hose.

Attach the hose to the drainage nozzle, and

5

secure it with the hose clamp.

• Prepare for draining, as drain water will come out

through the hose during operation.

Press the AUX. button on the unit twice.

6

• The water will drain out through the drainage hose.

Maximum amount of water that may be drained

out is approximately 4

• The OPERATION, TIMER and MEGA COOL

lamps will be blinking.

When drainage water stops running out from the hose, turn the unit off by

7

pressing AUX. button.

• This would take about one minute.

Remove the hose from the drainage nozzle, and replace the stopcock.

8

• Keep the hose clamp and drain grommet in case of re-used.

Turn the drainage nozzle to the CLOSE position.

9

Whenever the unit is moved (to provent water within the unit from spilling).

When the unit is not used for a long time.

Carry out the above procedures from 1 to 5.

1

Press the AUX. button on the unit.

2

• The water will drain out through the drainage hose.

Maximum amount of water that may be drained out is approximately 4

• The OPERATION lamps will light.

When drainage water stops running out from the hose, turn the unit off by

3

pressing AUX. button.

• This would take about one minute.

Remove the hose from the drainage nozzle, and replace the stopcock.

4

• Keep the hose clamp and drain grommet in case of re-used.

Turn the drainage nozzle to the CLOSE position.

5

Remove the stopcock from the drainpipe nozzle, and completely drain any

6

water within the unit.

• Always prepare a receptacle to collect the water

before draining. Maximum amount of water that

may be drained out is approximately

Replace the stopcock to the drainpipe nozzle.

7

1

/5 pints.

2

/5 pints.

"OPEN" position

[9] MAINTENANCE

Drainage

nozzle

Stopcock

Drain grommet

Hose clamp

Hose

1

/5 pints.

Stopcock

Drainpipe nozzle

10. Auxiliary mode

Use this mode when the remote control is not available.

NOTES:

• If the AUX. button is pressed during normal operation, the unit will turn off.

• Upon starting AUXILIARY operation, the drainage pump inside the unit runs for

about a minute, which may produce an audible gurgling sound.

Press the AUX. button on the unit.

1

• The red OPERATION lamp on the unit will

light and the unit will start operating in COOL

1

mode.

• The fan speed is set to AUTO.

• The temperature setting is automatically set

according to the room temperature.

TO TURN OFF

Press the AUX. button again.

• The red OPERATION lamp on the unit will turn off.

2 – 7

Page 11

A

㪈㩹

CVP09FX

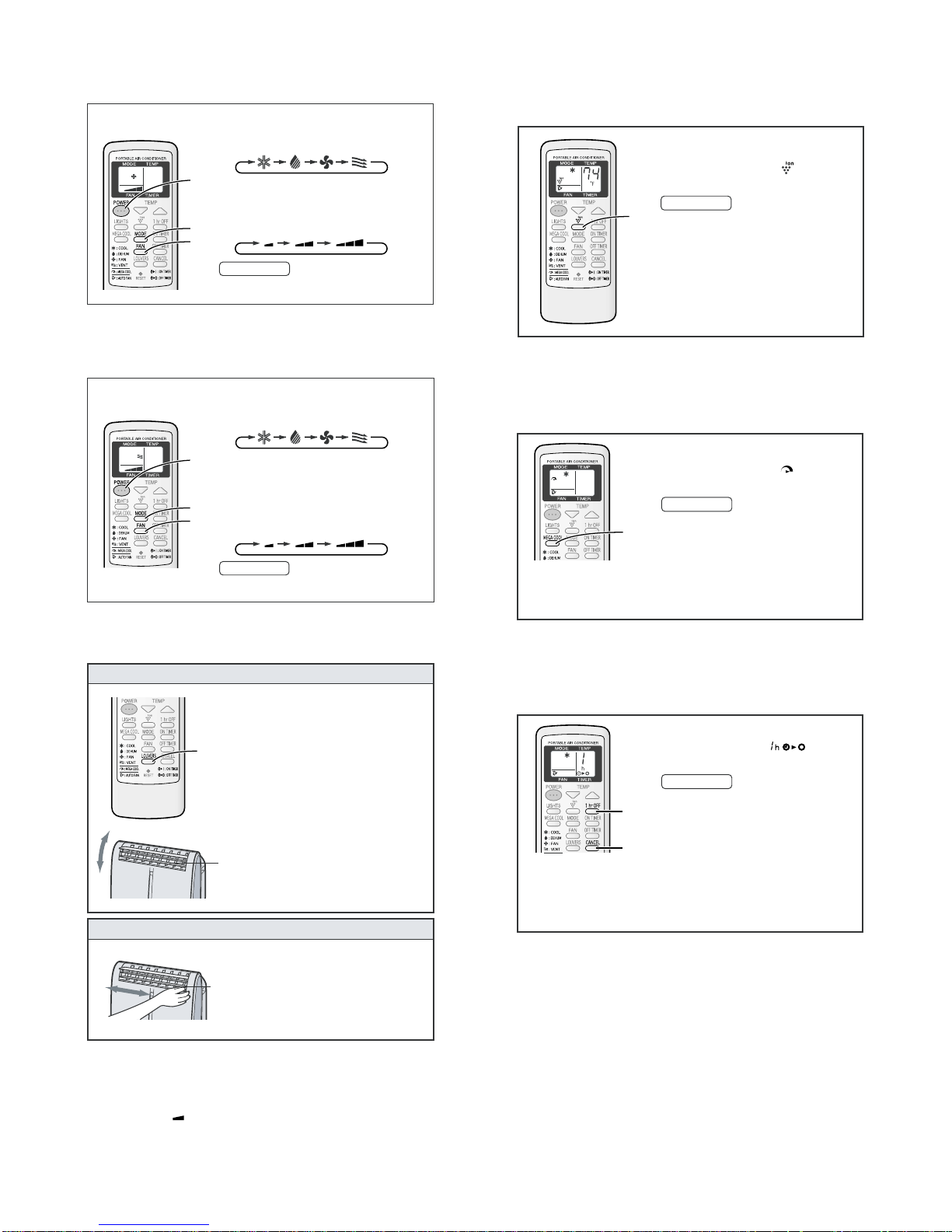

CHAPTER 3. DISASSEMBLING PROCEDURE

ServiceManual

[1] PROCEDURE FOR DISASSEMBLY

"ACTUAL UNITS MAY VARY SLIGHTLY FROM THOSE PICTURES BELOW"

CAUTION:• DISCONNECT THE PORTABLE TYPE ROOM AIR CONDITIONER

1. Unscrew 2 screws holding the front panel on lower both ends.

2. Remove two air filters.

1) Insert flathead screw driver into the position shown in below fig-

CVP09FX

• DISCONNECT THE EXHAUST HOSE FROM THE UNIT BEFORE

• DRAINAGE SHOULD BE PERFORMED BEFORE ANY SERVICE.

(SEE "WHENEVER THE UNIT IS MOVED" OF PAGE 2-7)

ure. Then gently pry the driver to the arrow mark direction, to

unhook the lower hooks (both sides).

3. Open horizontal louvers, as shown in below figure.

4. Unhook 6 hooks of the front panel which is at both sides in an order

from the lower position using flathead screw driver. <6 parts>

2) Insert flathead screw driver into the position shown in below figure. Then gently pry the driver to the arrow mark direction, to

unhook the middle hooks (both sides).

3) Insert flathead screw driver into the position shown in below figure. Then gently pry the driver to the arrow mark direction, to

unhook the upper hooks (both sides).

3 – 1

Page 12

CVP09FX

㪊㩹

㪊㩹

5. Push down the orifice (at position of illustration), as shown in below

figure, to unhook 2 hooks of front panel.

6. Remove the front panel by pulling it at the lower corner toward you

as shown in a figure, and next lift it up and pull it toward you.

7. Unscrew 6 screws holding the side panel L and R.

Remove side panel L and R.

8. Remove the stopcock from the drainpipe nozzle.

* Drain stopcock replacement

• Please check that the stopcock is fully inserted into the

drainage nozzle and drainpipe nozzle when operating at

cooling mode, and after drainage.

• Applying small amount of soapsuds to the stopcock will help

it make easier, if it is difficult to fully insert the stopcock.

9. Unscrew 12 screws holding the cabinet.

6 screws are on each sides.

6 screws are on back side of unit.

3 – 2

Page 13

10.Remove the cabinet by lifting it up and pulling toward you as shown

in below figure.

11.Unscrew 4 screws holding the control bo x cover.

CVP09FX

13.Unscrew 2 screws holding the float switch ass’y.

Then move the float switch a little from bulkhead L.

12.Remove the control box cover, as shown in below figure.

CAUTION:DISCHARGE THE FAN MOTOR CAPACITOR AND RUN-

NING CAPACITOR BEFORE TOUCHING THESE CAP ACITORS OR OTHER COMPONENTS OR WIRING.

14.Unscrew 6 screws holding the bulkhead L.

Remove the wire from wire holder.(2 parts)

Then remove the bulkhead L by pulling it toward the arrow mark in

below figure and next lift it up toward you.

3 – 3

Page 14

CVP09FX

15.Unscrew 7 screws holding the stay angle L.

Remove the stay angle L.

16.Unscrew 3 screws holding the led guide.

Remove the led guide.

19.Remove the plasmacluster unit and cluster cover.

Disconnect the connector of plasmacluster unit.

20.Unscrew 5 screws holding the top duct

Remove the top duct

17.Disconnect two louver motor connectors.

CAUTION:CONNECT THE CONNECTOR OF LOUVER MOTOR

CORRECTLY WHEN RE-ASSEMBLYING.

White connector : Upper louver motor

Black connector : Lower louver motor

18.Unscrew 2 screws holding the cluster holder.

Remove the cluster holder.

21.Cut the fixing band holding the wire and tape. Then remove the

tape.

CAUTION:KEEP THE TAPE IN CASE OF RE-ASSEMBLYING.

3 – 4

Page 15

22.Cut the fixing band holding the wires.(7 parts)

Disconnect 8 connectors.

CAUTION:CONNECT THE CONNECTORS OF FAN MOTOR ETC.

CORRECTLY WHEN RE-ASSEMBLYING.

CN6 : OUTDOOR FAN MOTOR(BLACK AND SMALL)

CN4 : INDOOR FAN MOTOR(WHITE AND SMALL)

CN3 : INDOOR FAN MOTOR(WHITE AND LARGE)

CN5 : OUTDOOR FAN MOTOR(BLACK AND LARGE)

CN13 : LEAD WIRE FOR FLOAT SWITCH ASS'Y(4P)

CVP09FX

24.Cut the fixing band holding the wire and tape.

Then remove the tape.

CAUTION:KEEP THE TAPE IN CASE OF RE-ASSEMBLYING.

Then cut the fixing band holding the wires.

25.Disconnect the micro switch connector.

*Lower micro switch only.

23.Cut the fixing band holding the wires.(1 part)

26.Unscrew 3 screws holding the wire holders.

27.Remove wiring connectors of the compressor cord by using longnose pliers.(3 parts)

CAUTION:DISCHARGE THE FAN MOTOR CAPACITOR AND RUN-

NING CAPACITOR BEFORE TOUCHING THESE CAPACITORS OR OTHER COMPONENTS OR WIRING.

3 – 5

Page 16

CVP09FX

28.Unscrew 2 screws holding the control box.

Remove the control box from the unit.

31.Move the band to the direction shown in below figure (approx.11/

16").

Then removed the drain hose B.

29.Unscrew 6 screws holding the casing cover.

Remove the casing cover from the unit.

30.Unscrew 4 screws holding the orifice.

Remove the orifice from the unit.

32.Unscrew the screw holding the lead wire.

33.Turn the band, as shown in below figure.

CAUTION:RETURN THE BAND TO THE ORIGINAL DIRECTION

WHEN RE-ASSEBLYING.

Move the band to the direction of the arrow(approx.11/16"), and

removed the drain hose A.

Then turn the band to the direction, as shown in below figure.

CAUTION:RETURN THE BAND TO THE ORIGINAL DIRECTION

WHEN RE-ASSEMBLYING.

3 – 6

Page 17

34.Unscrew 4 screws holding the half plate.

CVP09FX

36.Unscrew 6 screws holding the stay angle R.

Remove the stay angle R from the unit.

37.Unscrew 3 screws holding the drain pump ass’y.

Remove the drain pump ass’y from the unit.

Then remove the half plate by lifting it up and pulling toward you as

shown in below figure.

35.Unscrew 6 screws holding the out casing.

Remove the out casing from the unit.

38.Unfasten and remove the nut holding the terminal cover at the top

of compressor.

Then remove the wiring connector of the compressor cord.

39.Unscrew the screw holding the centrifugal fan.

Remove the centrifugal fan.

3 – 7

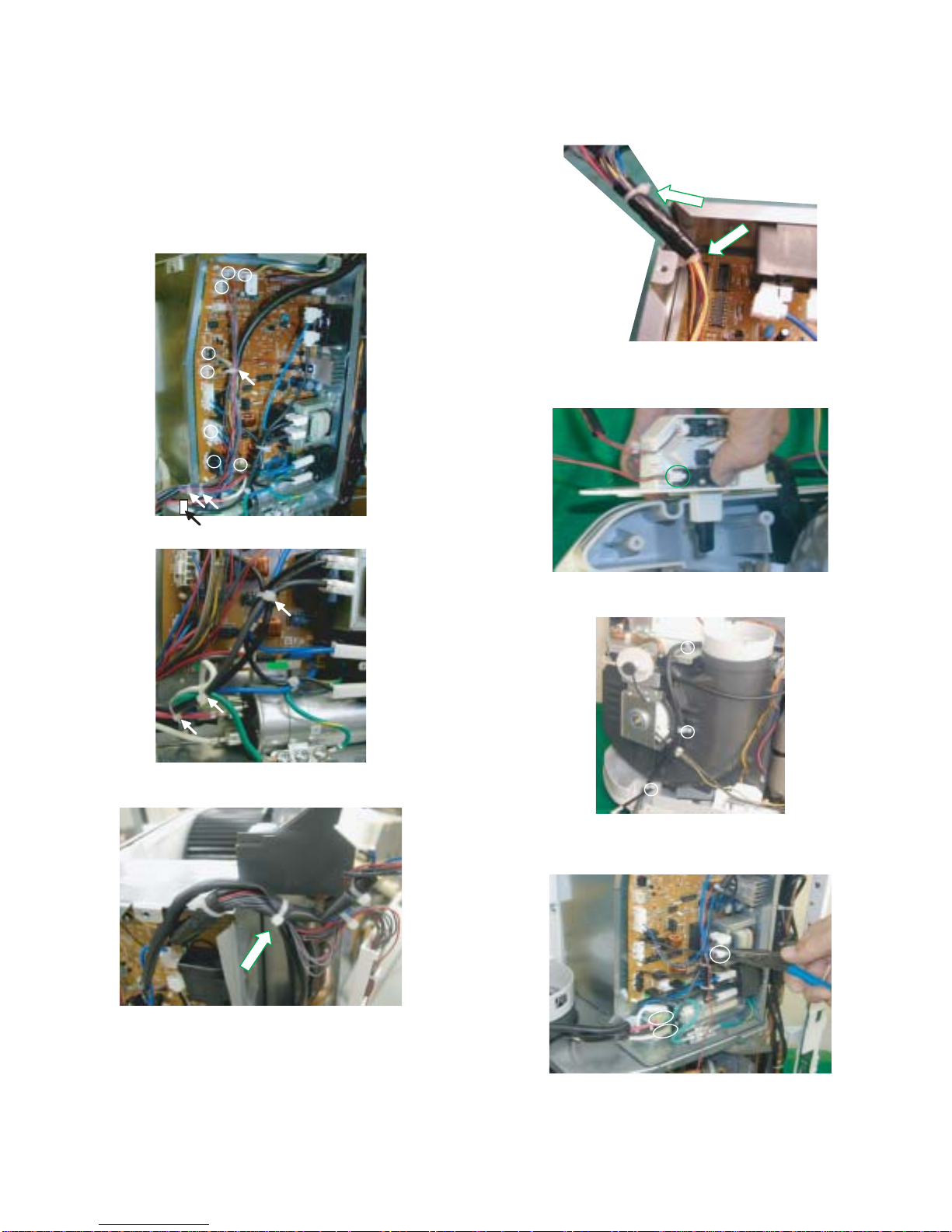

Page 18

CVP09FX

40.Unscrew 4 screws holding the motor cover and wire hold e r.

Remove the motor cover.

Then remove the fan motor.

41.Unscrew the screw holding the centrifugal fan.

43.Remove the 2 motor cushions on each side.

44.Loosen 2 screws holding the motor cover B.

* Do not remove 2 screws and 2 nuts.

45.Remove the motor cover A.

42.Unscrew 5 screws holding the motor cover and wire hold e r.

Remove the motor cover.

Then remove the fan motor.

46.Slide and remove motor cover B, C and D, as shown in b elow figure.

3 – 8

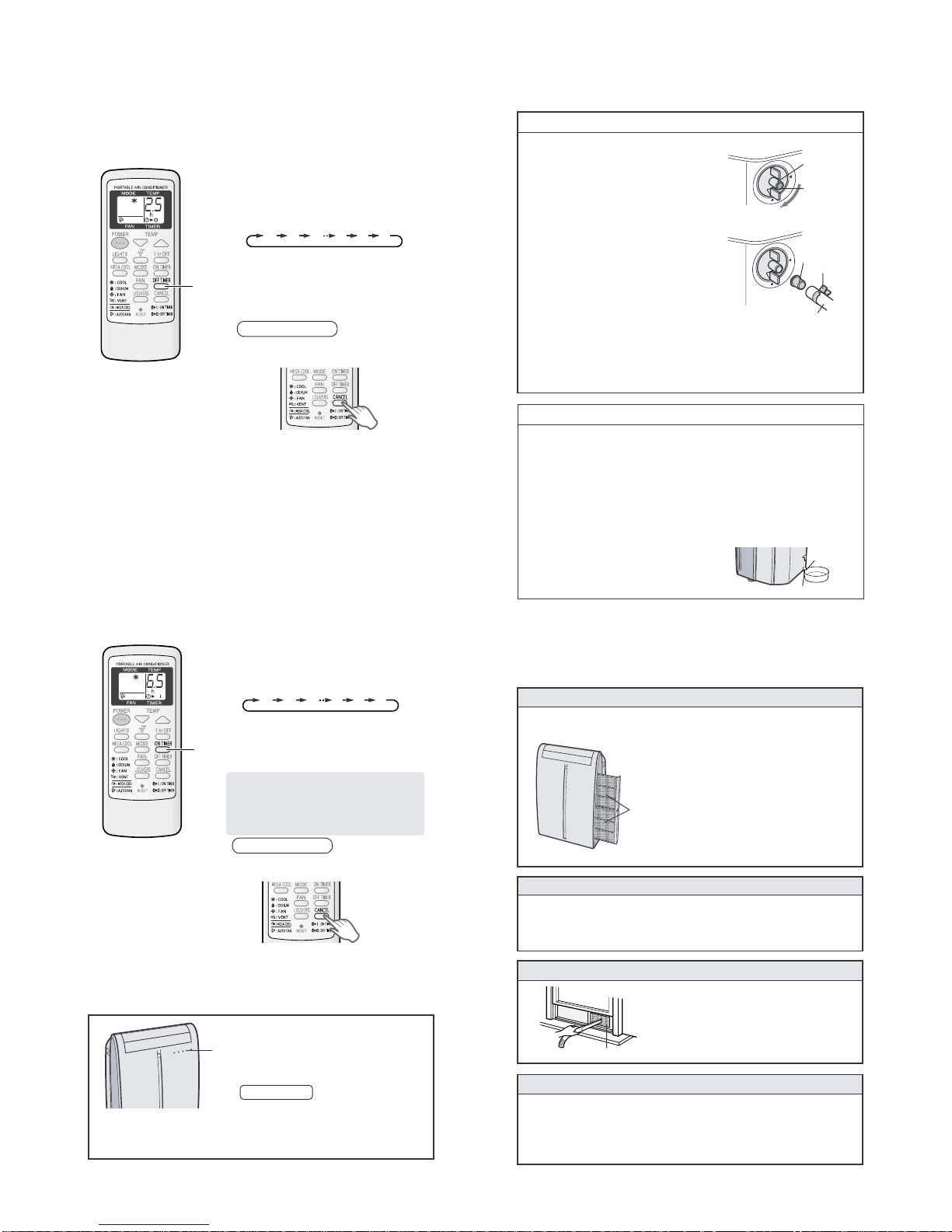

Page 19

CVP09FX

[2] DISASSEMBLING THE CONTROL BOX

CAUTION:DISCHARGE THE FAN MOTOR CAPACITOR AND RUNNING CAPACITOR BEFORE TOUCHING THESE CAPACITORS OR OTHER

COMPONENTS OR WIRING.

1. Cut fixing bands holding the wires.(2 parts)

2. Remove 2 P.W.B.

3. Cut fixing bands holding the wires.(2 parts)

Disconnect 6 connectors.

4. Unscrew 5 screws holding fan motor capacitor, transformer and

lead wire (earth).

5. Remove the control board by unhooking 3 spacers.

3 – 9

Page 20

CVP09FX

CVP09FX

CHAPTER 4. EXPLANATION OF CIRCUIT AND OPERATION

ServiceManual

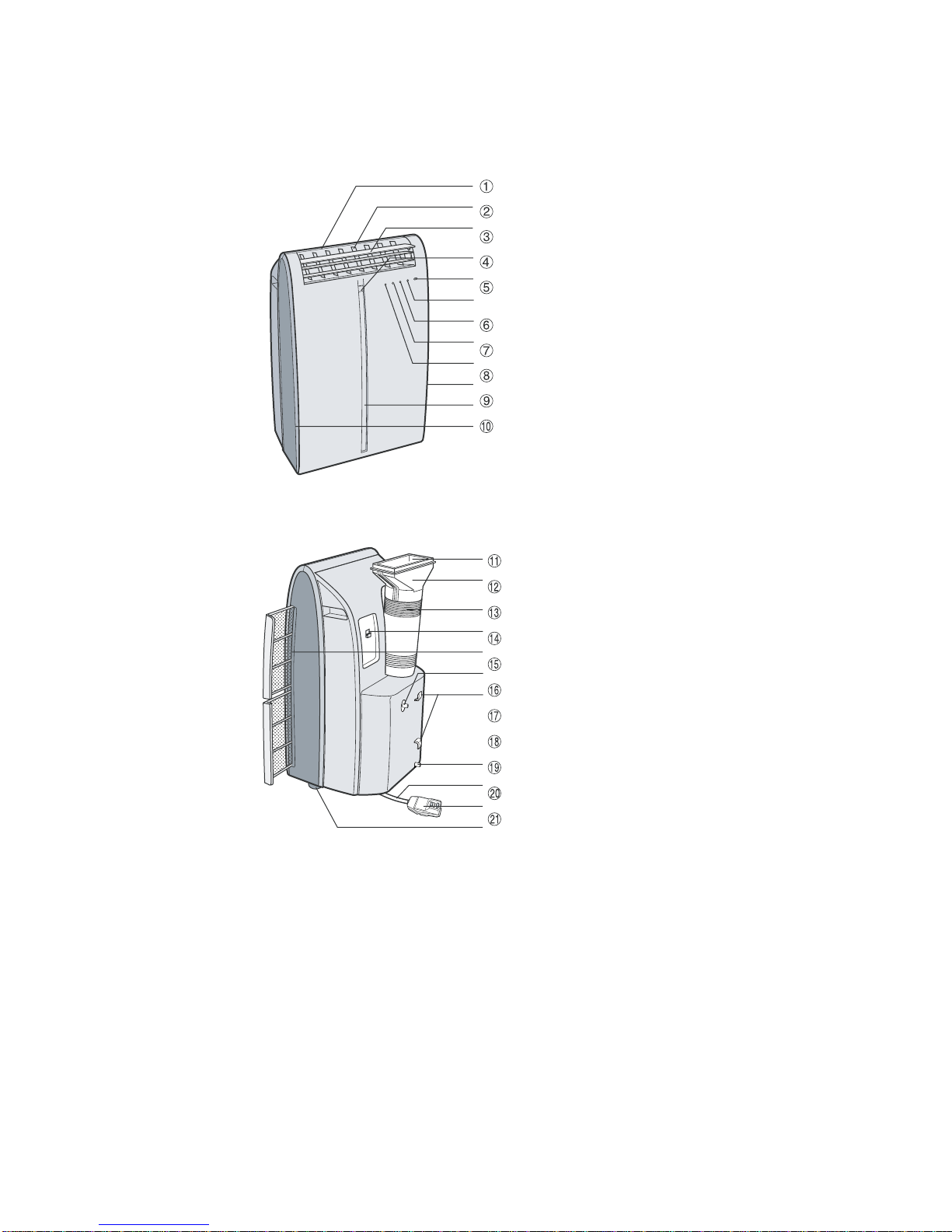

[1] ELECTRONIC CONTROL CIRCUIT DIAGRAM

ALARM

PUMP

FLOAT

CONTROL

)

SWITCH

(

2

2

(XA)

4

123

1

1W

47

R60

240KR55

240KR54

DRAIN

1

)

FLOAT

SWITCH

(

CN13

R701

1 / 2W 470

2

3

PI701

4

432

R59

BCN701

(XA)

1W

47

(XH)

TH2

INDOOR

CN14

PIPE TMEP.

4.431kW(25ºC)

TH1

312

6.8KF

R51

C38

10µ

+

10K

R48

10kW(25ºC)

ROOM TMP.

16V

10K

R49

:TESTPOINT

(NOTE)

UNLESS OTHERWISE

SPECIFIED, POWER OF

RESISTOR IS 1 /4W.

RES. No.enclosed by rectangleare

124

124

(WHITE)

CN8

(XH)

5V

12V

CHIP PARTS.

LOUVER

3

3

GND

MOTOR

9

(UPPER)

5

5

(BLACK)

CN9

(XH)

PLASMA

CLUSTER

GR

LED503

(LOWER)

LOUVER

MOTOR

2

3

BCN503

Q6

1

321

BCN1

3

5

4

2

1

3

5

4

2

1

IC6

8

9

IC5

8

TIMER

BL

LED502

820

(PH)

R502

CN501

4

7654321

2.7K

R63

2

Q9

3

470

SSR4

RY1

SSR1

R35

470

1W

SSR2

R34

470

1/2W

SSR3

R33

470

1/2W

1.8K

R32

BZ1

IC7

9

OPERATION

LED501

2.7K

R505

R501

123

1W

R36

TURBO

LED504

1.3K

1W

47

R64

JP14

8

IC501

DRAIN

50V

C502

0.1µ

C501

47µ

+

10V

SW1

SW501

4

5

312

5

4

1W

47

R61

10K

3.3K

10K

R44

R46

R39

JP15

JP16

1

DISPLAY & RECEIVER BOARDUNIT

1

(PH)

CN502

CN12

BCN2

213

3.3K

R42

22K

R41

10K

10K

R43

R45

680

R47

TH3

PIPE TMP.

OUTDOOR

10KF

R52

C39

10µ

+

4.431kW(25ºC)

654

6.8KF

R53

C40

16V

16V

10µ

+

10K

R50

C42

10V

100µ

+

ALARM

SW2

D5

DRAIN

21

C4

3A 125V

D7

)

FLOAT

SWITCH

(

TR1

0.1µ

275V

FUSE1

BLACK

USA

AC115V 60Hz

OUT

RY1

L

OUT

IC2

IN

+

IC3

IN

21

+

C18

+

+

D1 ~ 4

NR1

WHITE

N

POWER

C20

10V

C19

BCN3

(JP68)

25V

7812

C17

SUPPLY

PLUG

100µ

7805

50V

47µ

50V

N

0.1µ

JP9

0.1µ

35V1000µ

C41

35V1000µ

C16

NR2

G

C32

50V

20212223242526272829303132P21

MD1

MD0

RST

MB89538

(PATTERN SIDE)

P43

P42

P41

P44

64636261605958575655545352

(WHITE)

(OUTDOOR)

1

IC4

50V

+

3

50V

L2

C10

SSR2

(BLACK)

THERMAL

PROTECTOR

P64

P63

P62

P61

P60

AVss

AVR

AVcc

P57

P56

P55

P54

P53

P52

P51

P50

MD2

P46

P45

100

0.1µ

275V

1µ

C31

C30

9

8

7

6

5

4

3

2

1

0.01µ

JP1

JP2

JP3

JP4

JP5

0.033µ

1W

CN5

(VH)

0.1µ

19

18

17

16

15

14

13

12

11

10

1000p

0.01µ

R3

HOLE

5

6

7

8

0.1µ

SSR1

(C15)

(XA)

CN7

1K

R11

R10

6.8K

C15

275V

0.01µ

11

3

R29

R27

R25

R23

R21

CLUSTER

NONENONE NONE NONE NONE 13K15K15K15K15K13K15K 13K13K13K

NONE

R29R28R27R26R25R24R23R22R21R20

FANSPEED

FANSPEED

FANSPEED

FANSPEED

FANSPEED

MODEL

JP7

MODEL

AUTO

WIRE

JP2 JP3 JP4JP1 JP6JP5

PWR

SYMBOL

OUTDOOR

L

INDOOR

MH

INDOORINDOOR

INDOOR

TURBO

B

SELECT

A

SELECT

RESTART

TEST

LESS

SWEAT

ON

DEF.

CN80

(XA)

1K

R13

1234

R12

6.8K

874

6

5

R28

R26

0.01µ

0.01µ

0.01µ

0.01µ

0.01µ

16V

16V

C34

C33

50V

C29

0.01µ

0.01µ

0.01µ

16V

16V

16V

JP6

JP7

C26

C27

C28

50V

C25

16V

C24

CAPACITOR

C11

MOTOR

275V

FAN

C

1

3

5

BLACK

RED

BLUE

BLACK

C3

FAN

MOTOR

IC

0.1µ

8µF

250V

16V

16V

16V

C35

C36

3.3K

R16

3.3K

R15

3.3K

R14

2

1

Q5

50V

3

C12

C13

0.1µ

312

D

BLUE

BROWN

GRAY

YELLOW

R24

R22

C37

R20

4

3

2

1

IC8

50V

C22

R6

1W

100

C14

275V

R5

0.033µ

50V

0.1µ

R4

(XH)

2K 2W 2K 2W

(BLACK)

CN6

JP13

JP12

JP11

33

34

35

36

37

38

39

40

NC

41

42

43

44

45

46

47

48

5049NC

51

50V

0.1µ

0.01µ

1

SSR4

DRAIN

(PH)

3

PUMP

1

5V

UI1

(VH)

CN2

(INDOOR)

C23

432

UO1

GND

(CN99)

L1

275V

C6

SSR3

R2

(WHITE)

THERMAL

PROTECTOR

0.033µ

1W

CN3

(VH)

100

0.01µ

HOLE

C7

275V

1

5

3

RED

BLUE

BLACK

FAN

MOTOR

IC

JP10

2

1

Q1

R8

22K

TR1 :

PA031

16V

C21

22K

R7

0.01µ

20K

R9

100

1W

COMPRESSOR

C1

60µF 250V

R1

C5

275V

RUNNING CAPACITOR

SA1

P20

P17

P16

P15

P14

P13

P12

P11

P10

P07

P06

P05

P04

P03

P02

P01

P00

P30

P31

NC

CAPACITOR

MOTOR

FAN

A

BLACKBLACK

6µF

C2

250V

8MHz

OSC1

P22

P23

P24

P25

P26

P27X1X0

Vss

NC

NC

IC1

P40

P37

P36

P35

P34

UI1

UO1

Vcc

2

1

Q4

50V

3

C8

50V

C9

0.1µ

0.1µ

CN4

(XH)

213

B

BLUE

BROWN

GRAY

YELLOW

4 – 1

Page 21

[2] PRINTED WIRING BOARD

CVP09FX

4 – 2

Page 22

CVP09FX

[3] FUNCTION

1. Cool Operation

In the "COOL" mode, the thermostat circuit is controlled by 3 thermostat lines(C1~C3).

When the difference between Room Temper ature and Preset Temperature is in [2]~[4] area, compressor is driving or starts driving. If [1]

area is detected, compressor will stop. And indoor fan speed is set as

following speed.

Room Temperature—Preset Temperature

C1 0.9 / 2.7°F

C2 0 / 0.9°F

C3 -2.7 / -0.9°F

Indoor fan speed

Evaporator Temperature

Lower than D3 DH

Higher than D3 DL

D3 53.6 / 60.8°F

Evaporator Temperature

D3

Customer Setting

AUTO

Room Temperature - Preset Temperature

[4]

C1

C2

C3

Indoor fan speed

Area

[4]

[3] CM

[2]

[1]

Customer Setting

LMHAUTO

CL CM CH

[3]

[2]

[1]

CAH

CAL

2. Dehumidification Operation

In the "Dehumidification" Mode, compressor is controlled by room temperature. If it goes over D1 line and gets into the area [3], or if it lowers

than D2 line and gets into the area [1], compressor will stop.

If the evaporator temperature is lower than D3 line, indoor fan speed

will be DH and if the evaporator temperature is higher than D3 line,

indoor fan speed will be DL when the room temperature is in area [2].

Room Temperature

D1 111.2 / 113.0°F

D2 50.0 / 51.8°F

Room Temperature

[3]

D1

D2

[2]

[1]

3. Fan Operation

In the "Fan" mode, compressor and outdoor fan doesn’t operate.

Indoor fan motor operates as follows.

Indoor fan speed

Customer Setting

LMH

AL AM AH

4. Ventilating Operation

In the "Ventilation" mode, compressor and indoor fan doesn’t operate.

Outdoor fan motor operates as follows.

Indoor fan speed

Customer Setting

LMH

600[rpm] 900[rpm] 1200[rpm]

5. Indoor Fan Speed

Fan speeds are given by the indoor fan motor, "DL"~"AH" which are

available in the following operation mode.

In the "COOL" or "DRY" mode, indoor fan speed is different by condenser temperature.

Fan Speed Setting [rpm]

DEHUM

COOL

FAN ONLY

DL - AUTO 400 ~ 500

DH - AUTO 500 ~ 600

CL COOL SOFT - 420 ~ 520

CAL - AUTO 500 ~ 600

WET - - 570 ~ 670

CM COOL LOW AUTO 570 ~ 670

CAH - AUTO 650 ~ 750

CH COOL HIGH - 720 ~ 820

AL FAN ONLY - 520

AM FAN ONLY - 640

AH FAN ONLY - 750

6. Overheating protection system

If the condenser temperature goes over 136.4°F during the cooling or

dry operation, outdoor fan speed will rise to prevent the overloading of

the compressor and restrain the rise in high pressure, and If it lowers

than 134.6°F, outdoor fan speed will return.

If the condenser temperature goes over 158.0°F during the cooling or

dry operation, compressor will stop and if it lowers than 149.0°F, compressor will restart after 3 minutes.

4 – 3

Page 23

7. Freeze preventive

When the indoor pipe temperature falls below 32.0°F during cool operation or dry operation, the compressor is turned off. And if the indoor

pipe temperature rises exceeds 39.2°F after 3 minutes, the compressor will restart.

8. Timer

8.1. OFF TIMER

Set the OFF-TIMER.

The unit will turn off automatically according to your setting. Timer

duration can be set by 0.5 hours to maximum 12 hours. Up to 9.5

hours, you can set by 0.5hours increments and from 10 to 12 hours, by

1 hour increment.

CVP09FX

8.3. ONE-HOUR TIMER

When ONE-HOUR timer is set, the unit turns off automatically after

one hour. The one hour timer operation has priority over other time

operation, such as the TIMER ON and TIMER OFF. If the ONE-HOUR

TIMER button is pressed again during operation, the unit will operate

additionally for another one hour.

9. AUX Button

9.1. Test Run

If the "AUX" button on the unit is pressed for 5 seconds or more during

operation, cool test operation starts. The operation LED (red) flickers

during test run. Continuous compressor on operation is performed.

During Test-Run mode, pump is always ON.

8.2. ON TIMER

Set the ON-TIMER.

The unit will turn on automatically according to your setting. Timer

duration can be set by 0.5 hours to maximum 12 hours. Up to 9.5

hours, you can set by 0.5hours increments and from 10 to 12 hours, by

1 hour increment.

9.2. Aux Operation

If the "AUX" button on the unit is pressed during operation OFF, cooling operation starts.

Then setting Temperature will be is automatically set.

During Aux mode, pump will be ON for 1 minute since start.

10. Te st mode

Keep pushing the "AUX." buttons and supply the power, the system

will go to the test mode. In this mode, the output of operation is

switched by pushing the "AUX." button in the unit or the "OI" button in

the remote controller. Normal outputs are shown in "Self Check Mode

Table"

11. Diagnostic program

When indoor fan motor is out of order or compressor lock or abnormal water level occurs, the compressor, indoor fan motor, outdoor fan motor, and

louver are all stopped and the operation LED(red) turns on or off synchronously with the timing of the timer LED. When the thermistor for room te mperature or pipe temperature is open or short state, the operation LED turns on or off synchronously with the timing of the timer LED by pushing continuously for more than 5 seconds "AUX." button during suspension of operation.

Timer LED

Indoor fan motor

ON

OFF

ON

OFF

1sec

1sec

4sec

Outdoor fan motor

Operation LED

Thermistor short state

Thermistor open state

12. Drain Pump

When drainage is accumulated the float switch becomes close condition and the microcomputer detects this for 1 minute and cause to

operate drain pump. If it has passed for 3 minutes since the microcomputer detects an error by photo interrupter circuit, Compressor will stop

and ALL LED will blink.

ON

OFF

ON

OFF

ON

OFF

13. Plasmacluster

Whenever an indoor machine receives the signal of the plasma cluster

from remote control during air conditioner operation, the operation

mode regarding at the plasmacluster changes in the order of the following.

Clean mode → OFF

4 – 4

Page 24

CVP09FX

14. SELF-CHECK MODE

LED

STEP

0

1

2

3

4

5

6

7

8

9

10

11

RED YELLOW GREEN BLUE A B C D A B C D

Room Temp Eva Temp Cond Temp Test Input

44.6~107.6°F O 28.4~113.0°F O 28.4~113.0°F O P37 = H O

~44.6°F,

107.6°F~

Power On Start

Select

P44 = H O P45 = H O P46 = H O

P44 = L X P45 = L X P46 = L X

2

E

PROM

OK O P40 = H O OK O

NG X P40 = L X NG X

Photo Interrupter Float SW (L)

P64 = H X P63 = H O OK O

P64 = L O P63 = L X NG X

Photo Interrupter Float SW (L) Sweat

P64 = H X P63 = H O P41 = H O P34 = H O

P64 = L O P63 = L X P41 = L X P34 = L X

Bit7 = 1 O Bit6 = 1 O Bit5 = 1 O Bit4 = 1 O

Bit7 = 0 X Bit6 = 0 X Bit5 = 0 X Bit4 = 0 X

Bit3 = 1 O Bit2 = 1 O Bit1 = 1 O Bit0 = 1 O

Bit3 = 0 X Bit2 = 0 X Bit1 = 0 X Bit0 = 0 X

Bit7 = 0 X Bit6 = 0 X Bit5 = 0 X Bit4 = 0 X

Bit7 = 0 X Bit6 = 0 X Bit5 = 0 X Bit4 = 0 X

Bit7 = 0 X Bit6 = 0 X Bit5 = 0 X Bit4 = 0 X

Bit7 = 0 X Bit6 = 0 X Bit5 = 0 X Bit4 = 0 X

Bit7 = 0 X Bit6 = 0 X Bit5 = 0 X Bit4 = 0 X

~28.4°F,

X

113.0°F~

Function Select A Function Select B

Wireless

2

PROM Version

E

2

PROM Version

E

P53 AD Input

P54 AD Input

P55 AD Input

P56 AD Input

P57 AD Input

~28.4°F,

X

113.0°F~

Cond Fan RPM

Eva Fan RPM

X P37 = L X

Input

Input

Auto Restart

Louver

(Upper Side)

Pump

Eva Fan

Cond Fan

Compressor

Plasmacluster

P.I. Power Supply

XXXXXXXXXXXXXX

X XXOXXXOXOXOXOX

OXOXXX

X OOOX

Select

XXXX

XXOO

XXXX

XXOX

XXXX

XXOX

XXXXXXXXXX CLOSEBit7 = 1 O Bit6 = 1 O Bit5 = 1 O Bit4 = 1 O

XXOXXX CLOSE CLOSEBit7 = 1 O Bit6 = 1 O Bit5 = 1 O Bit4 = 1 O

XOXOXOXO

Speed 1

CL

CM

CH

AL

AM

AH

Mega

OPEN X X X X

Speed 2

OPEN OPEN

Speed 3

XXXXXXXX

Speed 4

XXXXXXXX

VL

XXXXXXXXBit7 = 1 O Bit6 = 1 O Bit5 = 1 O Bit4 = 1 O

VM

XXXXXXXXBit7 = 1 O Bit6 = 1 O Bit5 = 1 O Bit4 = 1 O

VH

XXXXXXXXBit7 = 1 O Bit6 = 1 O Bit5 = 1 O Bit4 = 1 O

VH

Louver

(Lower Side)

4 – 5

Page 25

[4] PERFORMANCE CURVES

NOTE: 1) Use this data only as a guide to check the running condition.

2) The running conditions of this data is as follows.

Remote control setting .......... High cool, 64°F

Drain pump ............................. OFF

Exhaust hose .......................... Shortest

3) This data will be changed by operation conditions such as: a drain pump operation or an exhaust hose configuration.

Especially, pump operation will decrease the line current and the power input value significantly.

12.0

70%RH

11.0

10.0

9.0

Line current (A)

8.0

7.0

25ºC

77ºF

Room temperature

30ºC

86ºF

40%RH

CVP09FX

35ºC

95ºF

Power input(W)

temperature

Out let air

1350

1250

1150

1050

950

850

750

30ºC

86ºF

20ºC

68ºF

10ºC

50ºF

25ºC

77ºF

25ºC

77ºF

30ºC

86ºF

Roo m t emp erat ure

30ºC

86ºF

Room t emp erature

70%RH

40%RH

35ºC

95ºF

70%RH

40%RH

35ºC

95ºF

4 – 6

Page 26

CVP09FX

CVP09FX

CHAPTER 5. ATTENTION WHEN REPAIRING

ServiceManual

[1] HOW TO REPAIR REFRIGERATION

Before sealed system work can be preformed a refrigerant recovery EPA and LOCALLY approved certification is required, additionally, EP A

and LOCALLY approved refrigerant recovery equipment is required.

1. Sealed system repair

Sealed system repairs should be properly diagnosed before entering

into a repair of the system.

It is important to follow proper procedures when doing a system repair

for safety reasons and that the repair will result in a restoration of the

system to proper factory standards.

2. Safety reminders

1) Do not heat any system component with an open flame for any reason.

2) Do not solder until you are sure that all refrigerant has been

removed from the system.

3) Do not heat the charging cylinder with an open flame. Use warm

water only and do not exceed 125°F (not too hot to keep your hand

in.)

4) Do not over fill any charging cylinders, as they could explode when

over filled.

5) Use proper wrenches.

6) Use safety goggles when working with refrigerants.

7) Keep a fire extinguisher within easy reach.

8) Watch flame direction when soldering so as not to burn clothing,

wiring or other components.

9) Solder in a well ventilated area. If a high concentration of freon is

present, an open flame will create phosgene gas which can be

harmful.

3. Proper soldering

Joint clearances should be maintained so that the brazing alloy will

flow between the closely mated surfaces rather than forming large fillets.

This films make the strongest joints, capillary attraction also work best

with close tolerance.

The best clearance is between 0.01" to 0.03", the amount of lap will be

approximately 3/8" depending on the swaging tool used.

4. Cleaning tubing

To make a sound, leak tight joint, the brazing alloy when raised to

brazing temperature, must wet and flow freely over the entire surface

of the tubing in the joint area.

To assure this, the tubing surfaces must be free of all dirt, grease, oil

and oxides otherwise the alloy will not wet and flow properly over any

surface with these elements present. Cleaning can be done with an

abrasive cloth or steel wool. Never blow into the tubing because this

will introduce a lot of moisture into the system. Open tubing joints

should be covered if exposed for long periods of time.

EMERY CLOTH

KEEP TUBE IN

DOWNWARD POSITION

Cleaning Tubing.

5. Proper fluxing

Flux is necessary when using silver solder; it is not required when

using silfos on copper to copper joints.

To do a good job the flux should cover the tube surface completely. Be

careful not to introduce any flux inside the tubing.

Fluxing should be done after the tubing is mated together and just

before brazing is done. Do not allow it to dry out.

When brazing, the flux should become entirely liquid and clear, like

water. The temperature will be at 1100°F and only a little more heat will

allow the alloy to flow freely into the joint.

GOOD FIT

PROPER

JOINT FIT

CLEARANCE

0.2mm TO 0.6mm

POOR FIT

Joint Clearance.

5 – 1

10mm

INNER CONE

TORCH STEM

SILVER ALLOY

Directing Torch Flame to Copper Tubing.

Page 27

CVP09FX

HIGH VACUUM PUMP

LARGE DIAMETER

BRAIDED VACUUM

HOSES

HIGH VACUUM

MANIFOLD

DIAL-CHARGE

CHARGING CYLINDER

HIGH SIDE

GAUGE

LOW SIDE

GAUGE

ELECTRIC

VACUUM

GAUGE

TO RELATED SERVICE

VALVE OR PROCESS

TUBES OF THE UNIT.

Hook up for Evacuation

and charging

6. Heating the tubing

Direct the torch flame so that the larger tube receives most of the heat.

Silver solder flows at 1200°F and silfos flows at 1300°F.

Heat all around the tubing.

The flame is composed of two cones, a smaller inner cone (pale blue)

in calor and a much larger outer cone. The hottest part of the flame is

at the tip of the inner cone. The flame should be directed at the joint

with the tip of the cone just touching the surface of the tubing.

Composition of Torch Flame.

7. Dehydrating sealed system

Many servicers feel that since air conditioners run with evaporator temperatures above 33°F, moisture will not present a problem. Nothing is further

from the truth. Oxygen in moisture plus the heat produced during compression will react with the refrigerant oil to produce harmful acids in the system

which will break down motor winding insulation, create sludge and pit comp onent parts, reducing efficiency of the air conditioner and shortening the

life of compressors.

There it becomes mandatory that good dehydrating practices be adhered to at all times.

Proper hook up procedures as shown in Figure 5 must be used in order to pull and good vacuum from the system.

The use of a good vacuum pump is very important so that the boiling point of any water in the system will be lowered to a point where it will vaporize

and be expelled from the system in the form of vapor.

OUTER CONE

HOTTEST PART

OF FLAME

INNER CONE

TORCH STEM

7.1. Type of evacuation methods

1. Piston Type Compressor No good.

System parts must be above 110°F.

2. Rotary Vacuum Pump Disavantages.

Low CFMC. 4 oil gets dirty.

3. Single State Vacuum Pump will not clean oil.

Oil must be changed often.

4. Two Stage Vacuum Pump will reach 50 microns.

First stage is below atmospheric pressure.

Moisture is removed into second stage which works up to atmo-

spheric pressure thus keeping oil clean.

Manometer cannot be read to 1/2 mm. Micron gauge reads from

25,400 microns to 0.

It becomes clear that good equipment and maintained properly must be used in order to remove air and moisture from the system.

When a vacuum of 1,000 to 500 microns is reached, block off the vacuum pump from the system.

This is done by closing the value between the pump and system. If the micron gauge does not increase above 1,000, the system is free of moisture

and no leak exists. If the micron gauge increases to higher levels moisture or a leak exists.

5 – 2

Page 28

CVP09FX

RUNNING CAPACITOR

FAN CAPACITOR

8. Leaks

Several methods are used to detect leaks in systems.

• Electronic Leak Detectors are very sensitive and are able to detect leaks down to 1/2 ounce per year.

A good electronic leak detector is generally far better in locating very small leaks.

• Halide Torch be sure the room is free from refrigerant vapours. Watch the flame for the slightest change in calor.

A very faint green indicates a small leak. The flame will be unmistakably changed to green or purple when large leaks are encountered. To simplify

leak detection pressurize the system to approximately 75 lbs.

Some leaks can be located by a visual inspection of the system components and solder joints and if oil is found at any given location it generally is

a sign that a leak exists at that point due to the fact that flame does carry oil with it travels through the system.

• Soap Bubbles

Liquid detergents can sometimes assist in finding small leaks by brushing detergent on the suspect area and watching for bubbles. Before apply-

ing detergent be sure that the system is pressurized.

Tap line devices are permissible for diagnosis only they are not suitable when evacuat ing the system. After the diag nosis has been made they must

be removed so that the system will be restored to a hermeticly sealed condition.

[2] ELECTRICAL COMPONENT TEST

RUNNING CAPACITOR AND FAN CAPACITOR

NOTE: DISCHARGE THE RUNNING CAPACITOR AND FAN CAPACITOR BEFORE

TOUCHING CAPACITOR OR WIRING.

1) Discharge capacitor by shorting terminals.

2) Take the wires off the capacitor terminals.

3) Set the selector switch of a volt-ohm-meter (or a tester) on the resistance range.

4) Connect the probes to the capacitor terminals and watch the indicator swing.

The indicator does not swing at all ..... Open.

The indicator swings but does not return ..... Shorted.

The indicator swings, then returns a moment later ..... Good.

1. Insulation test

Check the resistance between the terminals and case.

Reading must be more than 10MΩ at DC 500V.

2. Overload relay

Check continuity between terminals with volt-ohm-meter.

3. Insulation test

Check resistance between terminals and the relay case.

Reading must be more than 10MΩ at DC 500V.

4. Compressor

1) Take the wires off compressor terminals.

2) Set selector switch of volt-ohm-meter on the resistance range.

3) Put the probes on the terminals of the compressor and check continuity between each terminal.

5. Insulation test

Check the resistance between the terminals and the copper tube.

Reading must be more than 10MΩ at DC 500V.

5 – 3

Page 29

CVP09FX

CHAPTER 6. TROUBLESHOOTING GUIDE

[1] TROUBLESHOOTING

No cooling

CVP09FX

ServiceManual

Any LED does not turn on

Neither fan nor louver works

The plug was connected

by improper insertion

NO (proper insertion)

Check the Limit SW

for drain water.

Exhaust some water

from the lower outlet.

At first only about 500mL

Water was exhaust. YES YES Check the diagnostic program.

NO

Check the power supply

The wall socket output

under 100V.

Or when the product is

powered on, the voltage is

drop down under 100V.

NO

115V(over 100V)

YES

Some LED turn on.

YES

Some fan or louver

work.

YES YES Check the diagnostic program.

Insert the plug properly.

YES If you use the power supply equipment, check the current capacity of it.

Check the diagnostic program.

Refer to the page(4-4).

Check the display&

detector unit.

Check the operation of

the product.

Any LED does not turn on

NO

Check the operation of

the product.

Any LED does not turn on

Check the indoor wiring capacity.

This product needs more than 15A

Some LED turn on.

Some LED turn on.

Refer to the page(4-4).

EX. For the house fuse, the circuit breaker on the distributing board and

the wires(wire diameter), check the capacity of the current.

NG

Exchange the proper part or equipment.

Refer to the page(4-4).

A

Checking for LCDI

Pull the LCDI out from the wall socket. And remove the LCDI from product.

Push the reset button on the LCDI.(If the LCDI is tripped itself before, you must push the reset button to bring back the common state.)

Put the LCDI into the wall socket.(Check the output of the power supply cord) under 100V NG(out of order)

Push the test button on the LCDI.

(If the LCDI is tripped itself by this action, the LCDI is working normally.) The LCDI did NOT trip. The output is 115V( over 100V.)

Push the reset button on the LCDI to bring back the common state. The LCDI output voltage is 0V .

115V( over 100V)

--

115V

>0V NG(out of order)

--

0V

>115V( or receptacle output voltage) NG(out of order)

While the reset button is pushed ,the power supply cord output is 0V.

OK

When you release the button, the output will be 115V.

6 – 1

Page 30

CVP09FX

A

Check the LCDI

(the power supply cord)

Exhaust water from the lower outlet.

All of them.

Open the panels, and check the power cord output voltage.

Check the voltage between white wire at R-capasitor under 100V

and black wire at main relay(IN) on PWB.

The voltage is under 100V

115V (over 100V) Check the output voltage between white and black wires. Set the product

115V(over 100V)

you must check the insulation Change the power supply cord with LCDI

resistance of compressor. Check the leak current

Push the reset button on the LCDI.

Remove the power supply cord from the product.

Check the power supply cord with LCDI only.

Refer to the page(6-1).

OK NG

under 100V

Check the operation of

the product.

Any LED does not turn on

Check the PWB

(the control board)

The fuse on PWB is short.

short

Measure the insulation

resistance of compressor.

OK(over 10M )

Measure the insulation

resistance of indoor fan motor.

OK(over 10M )

Measure the insulation

resistance of outdoor fan motor.

OK(over 10M )

Can the Compressor operate ?

can operate

YES Check the diagnostic program.

Some LED turn on.

Change the fuse on PWB.

The fuse was open.

And check the cause of over current.

Check the operation of

the product.

Any LED does not turn on

NG(under 10M )

Change the compressor.

NG(under 10M )

Change the indoor fan motor.

NG(under 10M )

Change the outdoor fan motor.

can't operate

Change the compressor.

Refer to the page(4-4).

YES

Some LED turn on.

Check the diagnostic program.

Refer to the page(4-4).

Check the voltage.

The voltage 14V and -12V don't output.

The voltage -5V doesn't output.

Check the operation of

the product.

Any LED does not turn on

Complete the checking

proper output

proper output

proper output(-5V)

EX. Transformer secondary voltage14V, -12V and -5V.

improper output

Check the conduction between 1pin and 6pin of BCN3.

(short or open)

Repair the connection of BCN3 and their

lead wires and the connected limit SW.

YES

Some LED turn on.

Check the diagnostic program.

Refer to the page(4-4).

open

6 – 2

Change the PWB ass'y.

short

Page 31

No cooling

(Fan operate but the

compressor doesn't operate.)

CVP09FX

Measure the power

supply voltage at

receptacle.

120V(over 100V)

I

s it sufficient current

capacity of power

equipment ?

Is it small wiring for power

supply equipment ?

sufficient