Page 1

QT-MP3W

SERVICE MANUAL

No. S9632QTMP3W//

PORTABLE CD STEREO SYSTEM

/

CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

[1] Precaution For Using Lead-Free Solder ....... 1-1

[2] Safety Precaution For Service Manual.......... 1-2

[3] Voltage Selection .......................................... 1-2

[4] AC Power Supply Cord and

AC Plug Adaptor ........................................... 1-2

[5] Specifications ................................................ 1-3

[6] Names Of Parts............................................. 1-4

CHAPTER 2. ADJUSTMENTS

[1] Tuner Section................................................ 2-1

[2] Mechanism Section....................................... 2-2

CHAPTER 3. BLOCK DIAGRAM

[1] Block Diagram............................................... 3-1

MODEL

In the Interests of user-safety the set should be restored to

its original condition and only parts identical to those

specified be used.

CHAPTER 5. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] Notes On Schematic Diagram .......................5-1

[2] Types Of Transistor And LED ........................5-1

[3] Schematic Diagram .......................................5-2

[4] Wiring Side Of PWB ....................................5-12

CHAPTER 6. FLOWCHART

[1] Troubleshooting.............................................6-1

CHAPTER 7. OTHERS

[1] Function Table Of IC......................................7-1

[2] LCD Display.................................................7-10

PARTS GUIDE

QT-MP3W

CHAPTER 4. CIRCUIT DESCRIPTION

[1] Waveforms Of CD Servo Circuit ....................4-1

[2] IC Voltage......................................................4-3

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones

for maintaining the safety and performance of the set.

!

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

– 1

Page 2

QT-MP3W

CHAPTER 1.

AudioXL-MP150Service ManualXLMP150Market

[1] Precautions For Using Lead-Free Solder

GENERAL DESCRIPTION

1.Employing lead-free solder

"AUDIO, CONTROL, RECTIFIER, CD, TUNER, TAPE PWB" of this model employs lead-free solder.

The LF symbol indicates lead-free solder, and is attached on the PWB and service manuals. The alphabetical

character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2.Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with

conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 C, were

commend you to use a dedicated soldring bit, if you are not familiar with how to obtain lead-free wire solder or

soldering bit, contact our service station or ser vice branch in your area.

3.Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 C which is higher than the conventional lead

solder by 40 C, and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, since the land may be peeled off or the maximum heat-resistance

temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady

soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corrected. Make sure to turn on

and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit

after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Ref No.

PWB-A1

PWB-A2

PWB-A3

PWB-A4

PWB-B

PWB-C

Parts No.

92LMP300280047

92LMP300380092

92LMP301280047

92LMP300180024

92LMP300980056

92LMP301380047

AUDIO

CONTROL

RECTIFIER

TUNER

CD

TAPE

Description

1 – 1

Page 3

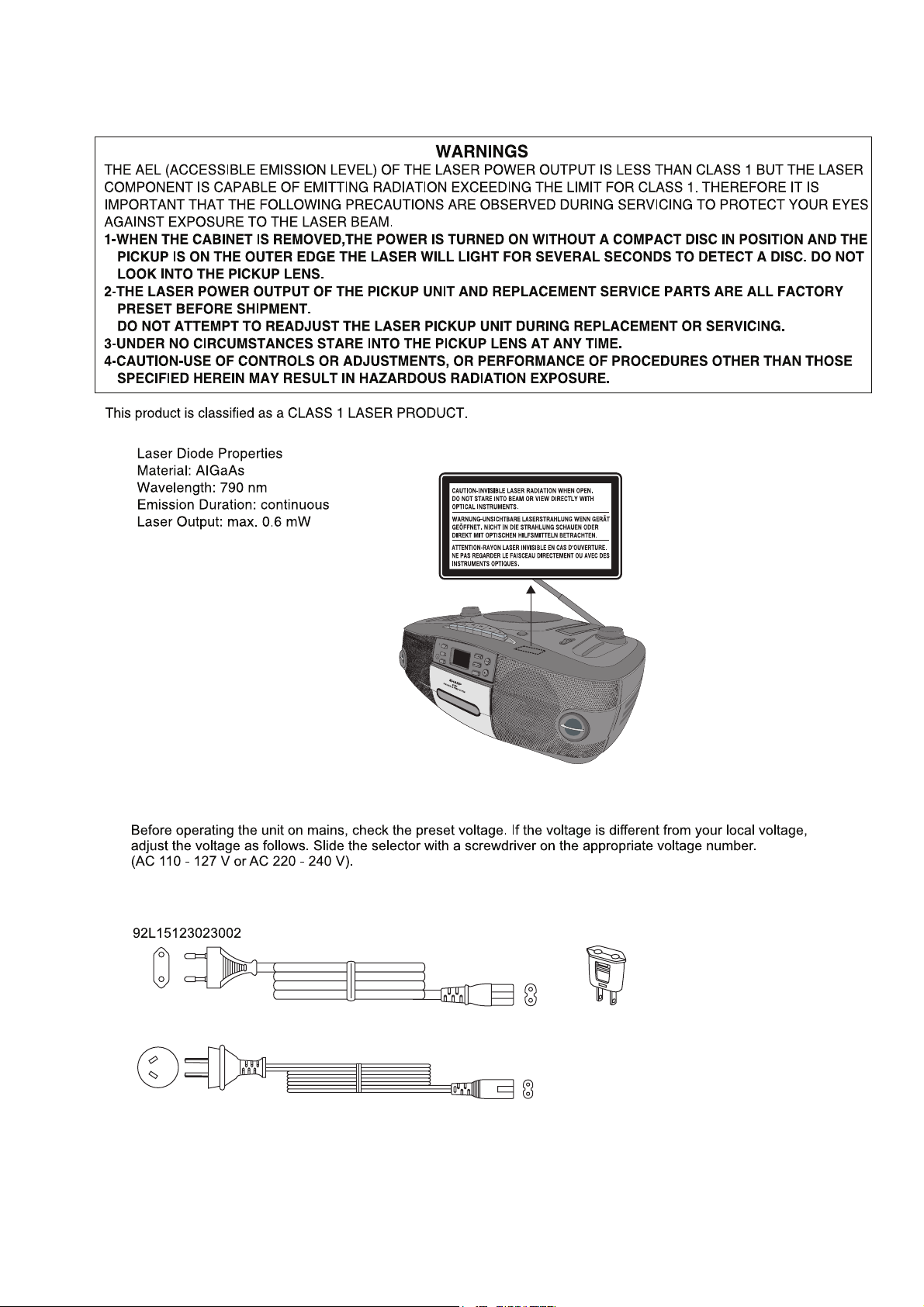

[2] Safety Precaution For Service Manual

Precaution to be taken when replacing and servicing the Laser Pickup.

QT-MP3W

[3] Voltage Selection

[4] AC Power Supply Cord and AC Plug Adaptor

92L15124023002

/

92L15911022019

1 – 2

Page 4

QT-MP3W

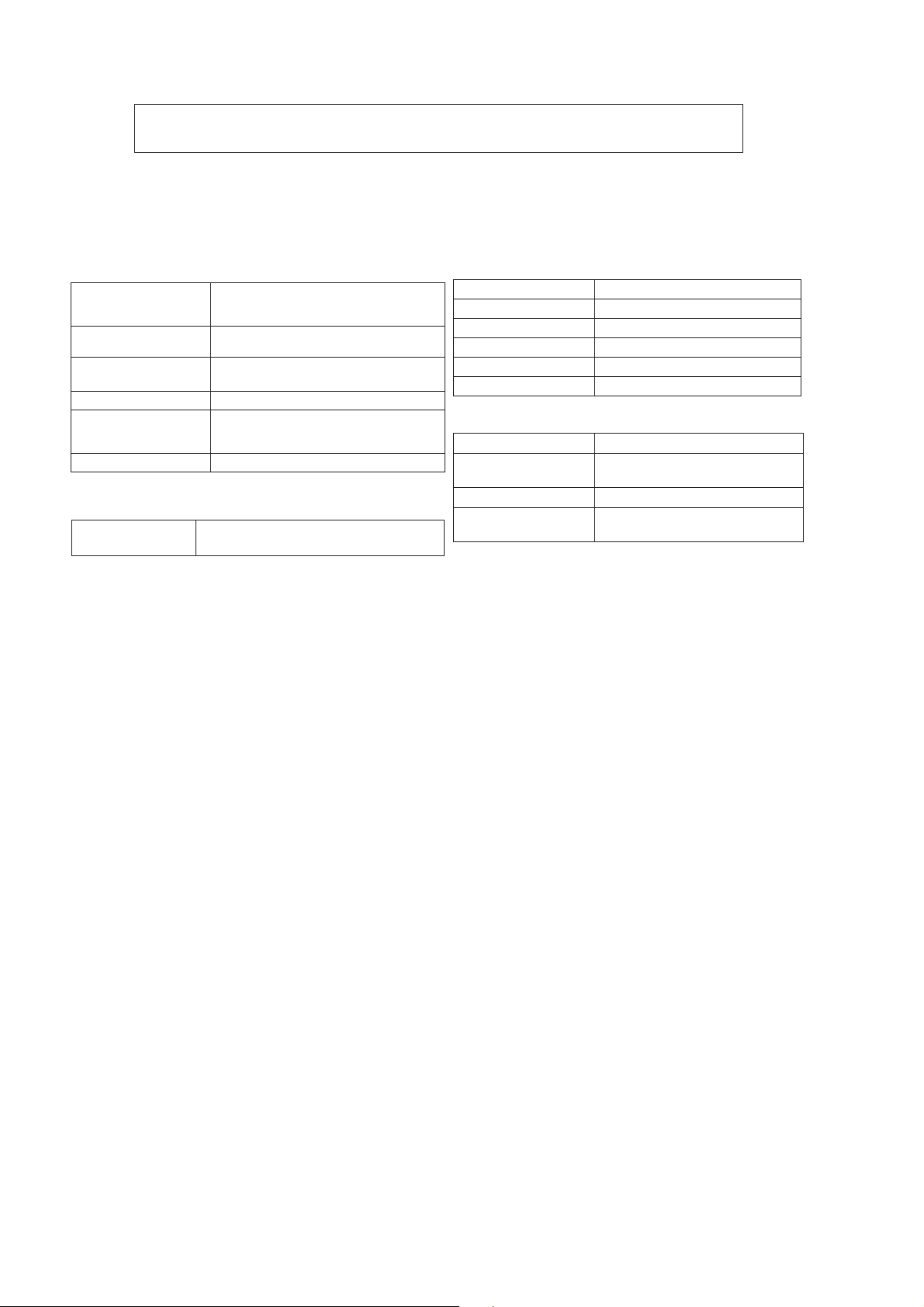

[5] Specifications

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

As part of our policy of continuous improvement, SHARP reserves the right to make design and

specifcation changes for product improvement without prior notice. The performance specification

figures indicated are nominal values of production units .There maybe some deviations from these

values in individual units.

Tape recorder

General

■

Power source

Power

consumption

Output power

Speakers

Dimensions

Weight

Radio

■

Frequency range FM: 88 - 108 MHz

AC 110 - 127/ 220 - 240 V, 50/60 Hz

DC12V ["D" size (UM/SUM-1, R20 or HP-

2) battery x 8]

Power on: 13 W

Power stand-by: 1.4 W

RMS : 4 W (2 W + 2 W)

(DC OPERATION, 10% T.H.D)

9 cm (3-1/2") full range speaker x 2

Width: 410 mm (16-1/8")

Height: 150 mm (6")

Depth: 245 mm (9-1/2")

2.7 kg (5.9 lbs.) without battery

AM: 531 - 1602 kHz

■

Frequency response 80 - 8,000 Hz (Normal tape)

Signal/noise ratio 40 dB

Wow and flutter 0.3% (WRMS)

Motor DC 9 V electric governor

Bias system AC bias

Erase system Magnet erase

CD player

■

Type Compact disc player

Signal readout Non-contact, 3-beam semiconductor

D/A converter 1-bit D/A converter

Frequency

response

laser pickup

60 - 20,000 Hz

1 – 3

Page 5

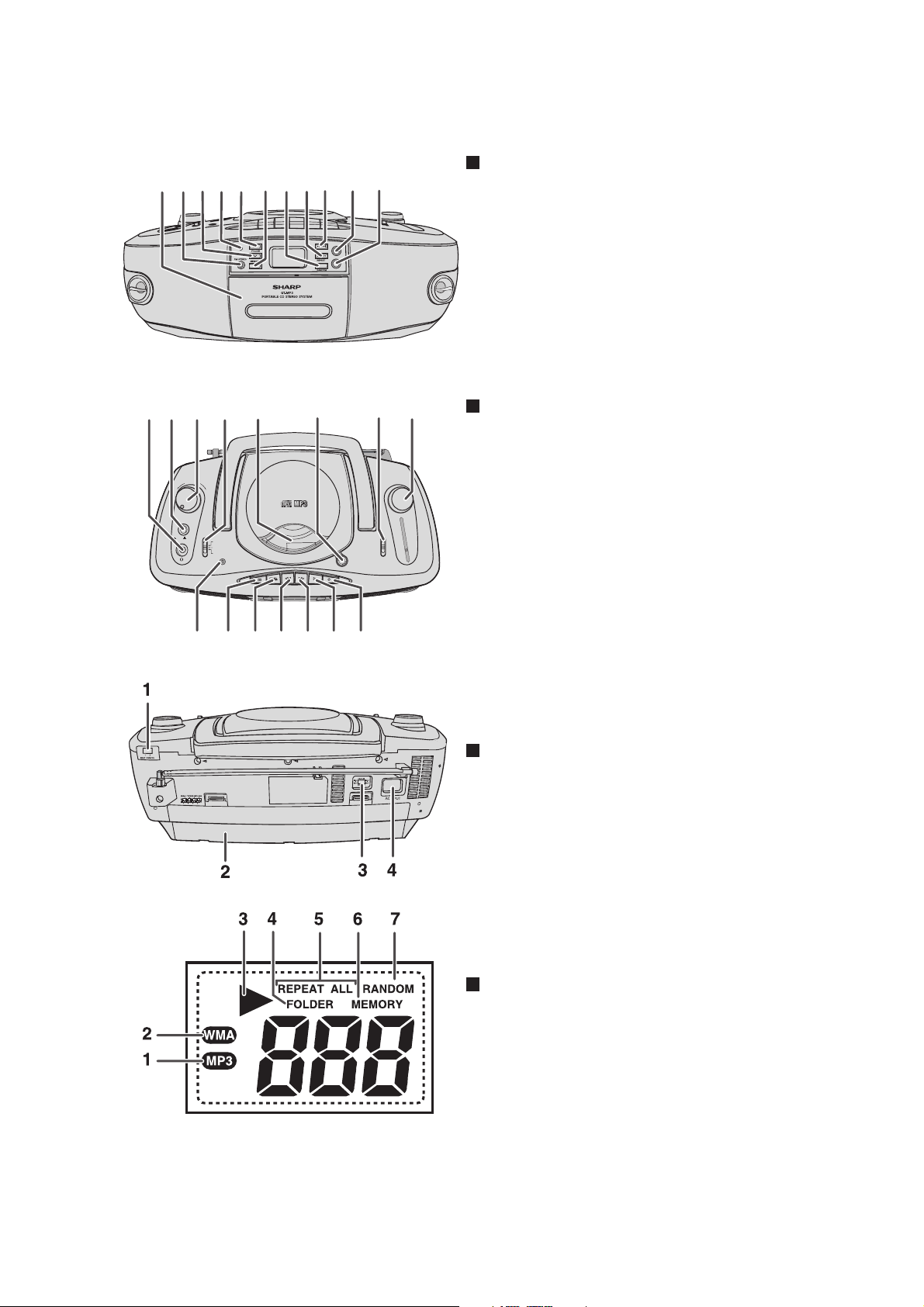

[6] Names Of Parts

r

21 3 4 5 6 7 8 9 10 11

QT-MP3W

Front panel

1. Cassette Compartment

2. FM Stereo Indicator

3. Folder Down Button

ON

/

4. Power on Indicator

5. Folder Up Button

6. Memory Button

7. Repeat/Random Button

8. Fast Reverse/Track Down Button

9. Fast Forward/ Track Up Button

10. Play/Pause Button

11. Stop Button

3

U

M

L

O

E

V

M

IN

MAX

X-BASS

OFFON

TAPE (STAND-BY)

CD

RADIO

FUNCTION

MIC

PAUSE

STOP/EJECT F.FWD REWIND PLAY RECORD

10 11 12 13 14 15

9

6542178

Top panel

1. Headphone Socket

2. X-Bass On/Off Button

3. Volume Control

N

I

G

N

U

T

KHz

Hz

M

1600

08

1

1400

1200

06

1

4

1000

0

1

2

10

800

00

1

00

7

AM

E

S

O

L

C

/

H

S

U

P

N

E

P

O

96

FM

0

60

2

9

0

9

530

8

8

AM

BAND

M

F

4. Function switch

5. CD Compartment

6. CD Door Open Button

7. Tuner Band Selector

8. Tuning Control

9. Build-in Mic

10. Tape Pause Button

11. Tape Stop/Eject Button

12. Tape Fast Forward Button

13. Tape Rewind Button

14. Tape Play Button

15. Tape Record Button

Back Panel

1. FM Stereo/Mono mode/Beat Cancel Selecto

2. Battery Compartment

3. Voltage Selector

4. AC Input Socket

Display

1. MP3 Indicator

2. WMA Indicator

3. Disc Play Indicator

4. Folder Indicator

5. Repeat mode Indicators

6. Memory Indicator

7. Random Indicator

1 – 4

Page 6

QT-MP3W

CHAPTER 2. ADJUSTMENTS

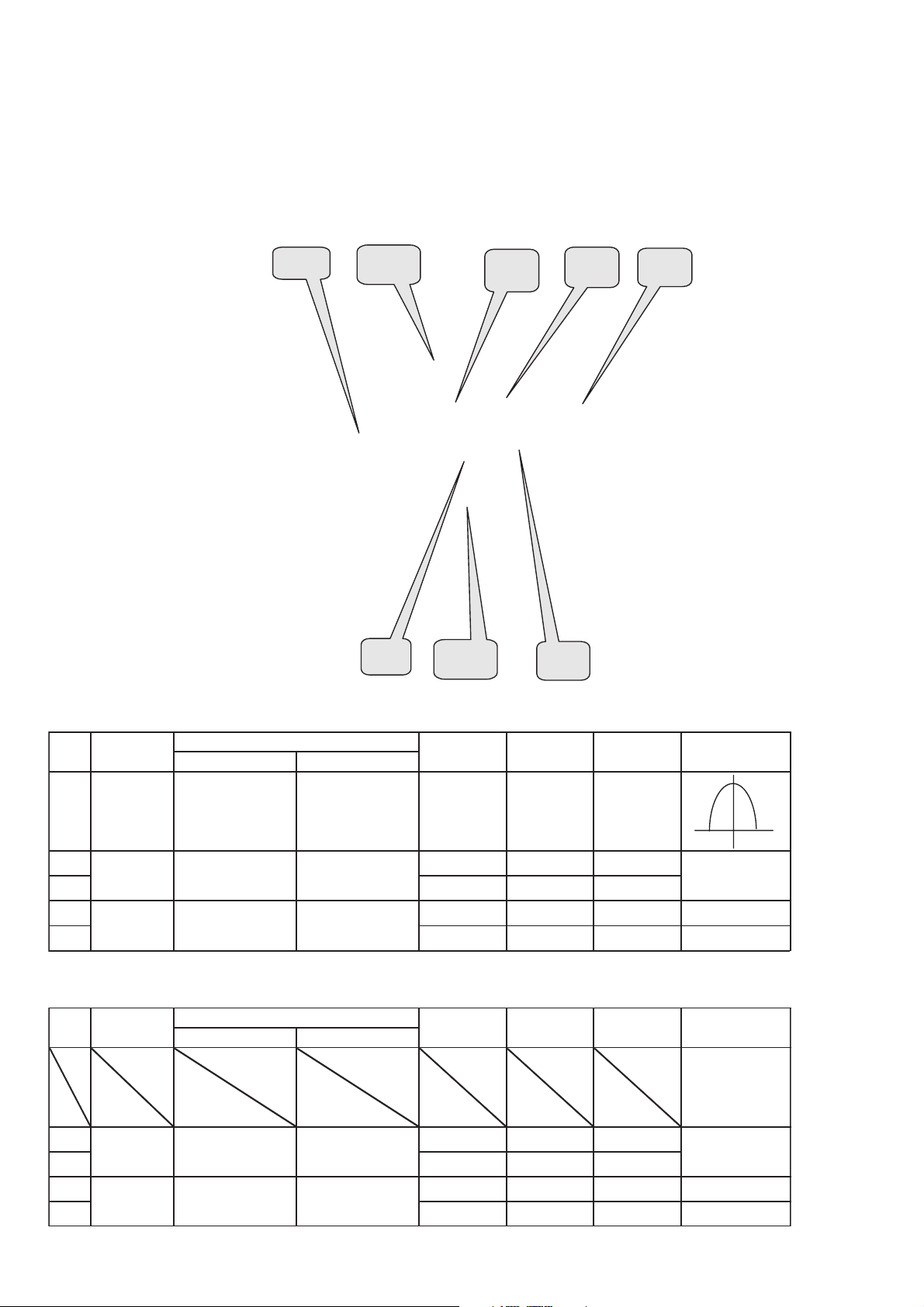

[1] Tuner Section

Use a plastic screw driver for adjustments.

Adjust the intermediate frequency of AM and FM to the frequency of ceramic filter.

Set of unit

Supply voltage

speaker impedance

standard output

Function switch

Parts Location:

DC 12.0V

:

4ohms

:

50 mW

:

RADIO

:

T103

L101

C2

C4

T101

a. AM Adjustment

2

3

4

5

Adjusting

Circuit

IF1

Tuning

coverage

Tracking

Step

b. FM Adjustment

Step

Adjusting

Circuit

C1

L102

C3

Band switch: MW

Connections

Input Output

Closed the output Connect sweep

termial by sweep generator to 465 KHz Low T103

generator, it place

to MW ANT

Connect AM SG to Connect VTVM to

test loop speaker terminals.

Connect AM SG to Connect VTVM to

test loop speaker terminals.

IC101(17) PIN(A)

SG Position of VTVM

Frequency Tuning dial Oscilloscope

522 KHz Low end T101

1620 KHz High end C4

600 KHz 600 KHz MW ANT COIL Max.

1400 KHz 1400 KHz C3 Max.

Adjustment

Band switch: FM FM Dummy antenna: 75 ohms unbalance

Connection

Input Output

SG Position of VTVM

Frequency Tuning dial Oscilloscope

Adjustment

2

3

4

5

Tuning

coverage

Tracking

Connect FM SG to Connect VTVM to

FM.ANT & D101(-) speaker terminals.

Connect FM SG to Connect VTVM to

FM.ANT & D101(-) speaker terminals.

87.35 MHz Low end L102

108.25 MHz High end C1

90.0 MHz 90.0 MHz L101 Max.

106.0 MHz 106.0 MHz C2 Max.

2 – 1

Page 7

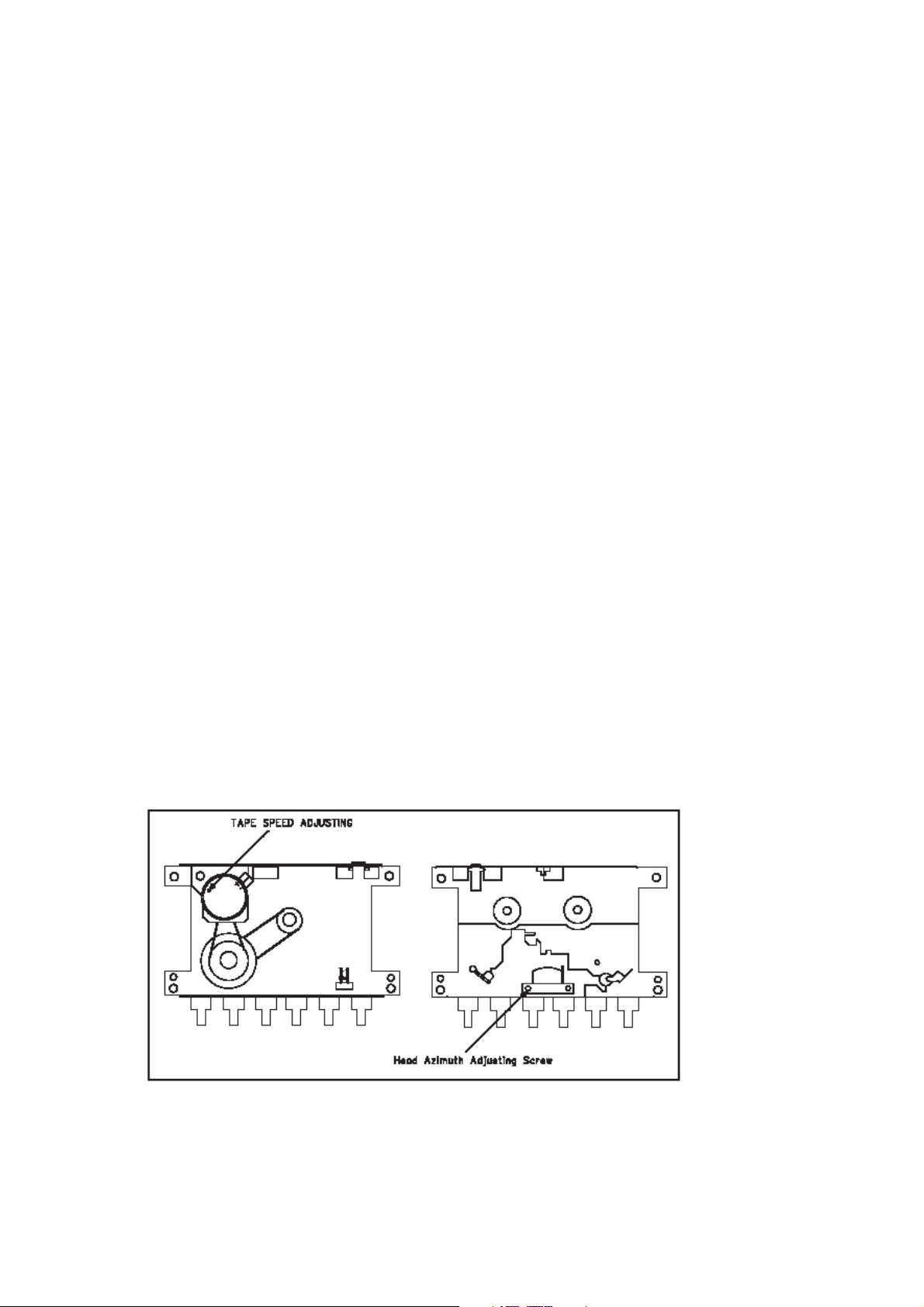

[2] Mechanism Section

1 HEAD AZIMUTH ADJUSTMET

( 1 )Load the test tape TCC-182A 8KHz for azimuth

adjustment.

( 2 )Press the PLAY button.

( 3 )Use a cross-tip screwdriver to turn the screw for azimuth

adjustment so that the left and right output are maximized.

( 4 )Press the STOP button.

( 5 )After completion of the adjustment. Use thread lock (TB-1401B)

to secure the azimuth-adjustment screw.

2 AC BIAS FREQUENCY ADJUSTMENTS

( 1 )Connect frequency counter to CN201 (BS).

( 2 )R/P swith in recording state.

( 3 )Adjusting T201 use a plastic screwdriver, AC bias frepuency; 62+-1KHZ.

QT-MP3W

3 TAPE SPEED ADJUSTMENT

( 1 )Insert the test tape (MTT-111N,3,000 HZ).

( 2 )Press the PLAY button.

( 3 )Use a flat-tip screwdriver to turn the MOTOR VR.

Adjust MOTOR VR so that the frequency counter

become 3,000Hz.

CASSETTE MECHANISM SECTION

CASS DECK

2 – 2

Page 8

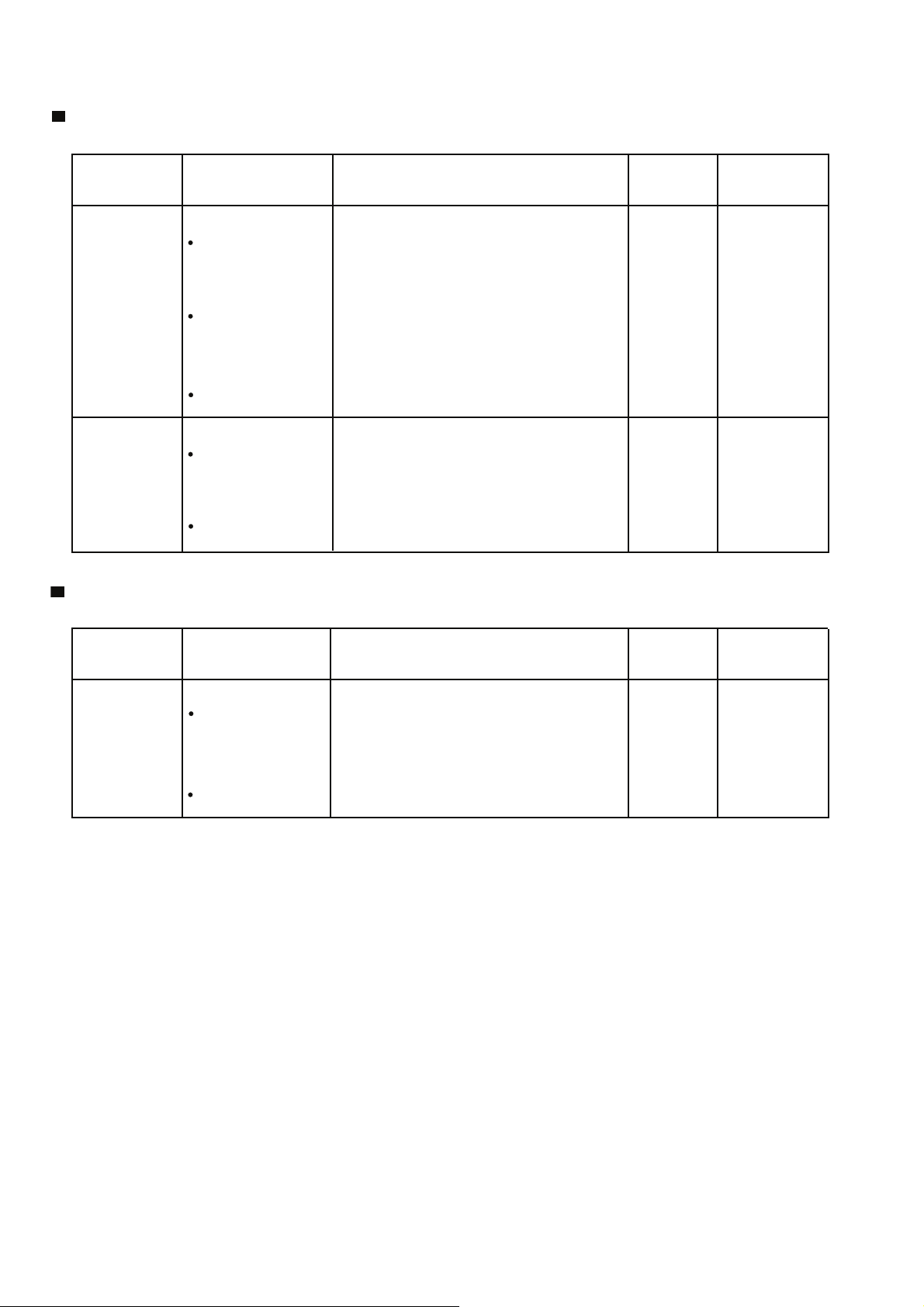

QT-MP3W

Ө

HEAD AZIMUTH ADJUSTING SCREW

Tape recorder section

Items

Confirmation

of head angle

Confirmation Adjust VR401 so that the frequency counter

of tape speed

Reference Values for Confirmation Items

Measurement

conditions

:Test tape

TCC-182A (8KHz)

:Measurement output

terminal

Speaker terminal

Sparker R

(Load resistance:

8Ө

)

Headphone terminal

:Test tape

TCC-112 (3KHz)

:Measurement output

terminal

Headphone terminal

1 Playback the test tape TCC-182A (8KHz) Maximum Adjust the head

left and right output levers become

maximum, After adjustment, lock the head

azimuth at least by half turn.

playing back the test tape TCC-112 (3KHz)

with ending forward winding of the tape.

Measurement method

Standard

Values

output azimuth screw

Tape speed MOTOR VR

of deck

:3,010Hz

+/-15Hz

Adjusting

positions

only

Items

Wow & flutter When the test tape TCC-112 (3KHz) has

Measurement

conditions

:Test tape

TCC-112(3KHz)

:Measurement output

terminal

Headphone terminal

Measurement method

been mechanism at the beginning of

forward wow & flutter should be 0.25% or

less (WRMS).

Standard

Values

0.25% or

less

(WRMS)

Adjusting]

positions

2 – 3

Page 9

Electrical Performance

QT-MP3W

Items

Adjustment of

recording bias

current

(Reference

Value)

Adjustment of

recording and

playback

frequency

characteristics

Measurement

conditions

:Mode

Playback mode

Recording mode

:Test tape

TDK-D60

:Measurement

output terminal

Both recording and

headphone

terminals

:Reference frequency

1KHz and 8KHz

(REF.:- 10dB)

:Test tape

TDK-D60

:Measurement

input terminal

OSC IN

Standard Adjusting

Values

1 With the recording and playback

mechanism, load the test tapes

TDK-D60, and set the mechanism to the

recording and pausing condition in advance.

2 After connecting 100 in series to the

recorder head, measure the bias current

with a valve voltmeter at both of the

terminals.

1 With the recording and playback Output

mechanism, load the test tapes (TDK-D60) deviation

and set the mechanism to the

recording and pausing condition in

advance.

2 While repetitively inputting the reference

frequency signal of 1KHz and 8KHz from

OSC IN, record and playback the tape.

3 While receding and playback the test tape

Lch and Rch so that the output

deviation between 1KHz and 8KHz

becomes -1dB +/-2dB.

TDK-D60

4.5

A

+/-0.5 A

between

1KHz and

8KHz

:-1dB +/-2dB

positions

Reference Values for Electrical Function Confirmation Items

Items

Recording

bias

frequency

Measurement

conditions

Playback

:Test tape

TDK-D60

:Measurement

terminal

BIAS TP on

P.C. board

1 While changing over to and form BIAS 1

and 2, confirm that the frequency is

changed.

2 With the recording and playback

mechanism, load the test tape.

(TDK-D60), and set the mechanism to the

recording and pausing condition in advance.

3 Confirm that the BIAS TP frequency on the

P.C. board is 62KHz +/-6KHz.

Measurement method

Standard Adjusting

Values positions

62KHz T201

+/-6KHz

2 – 4

Page 10

QT-MP3W3

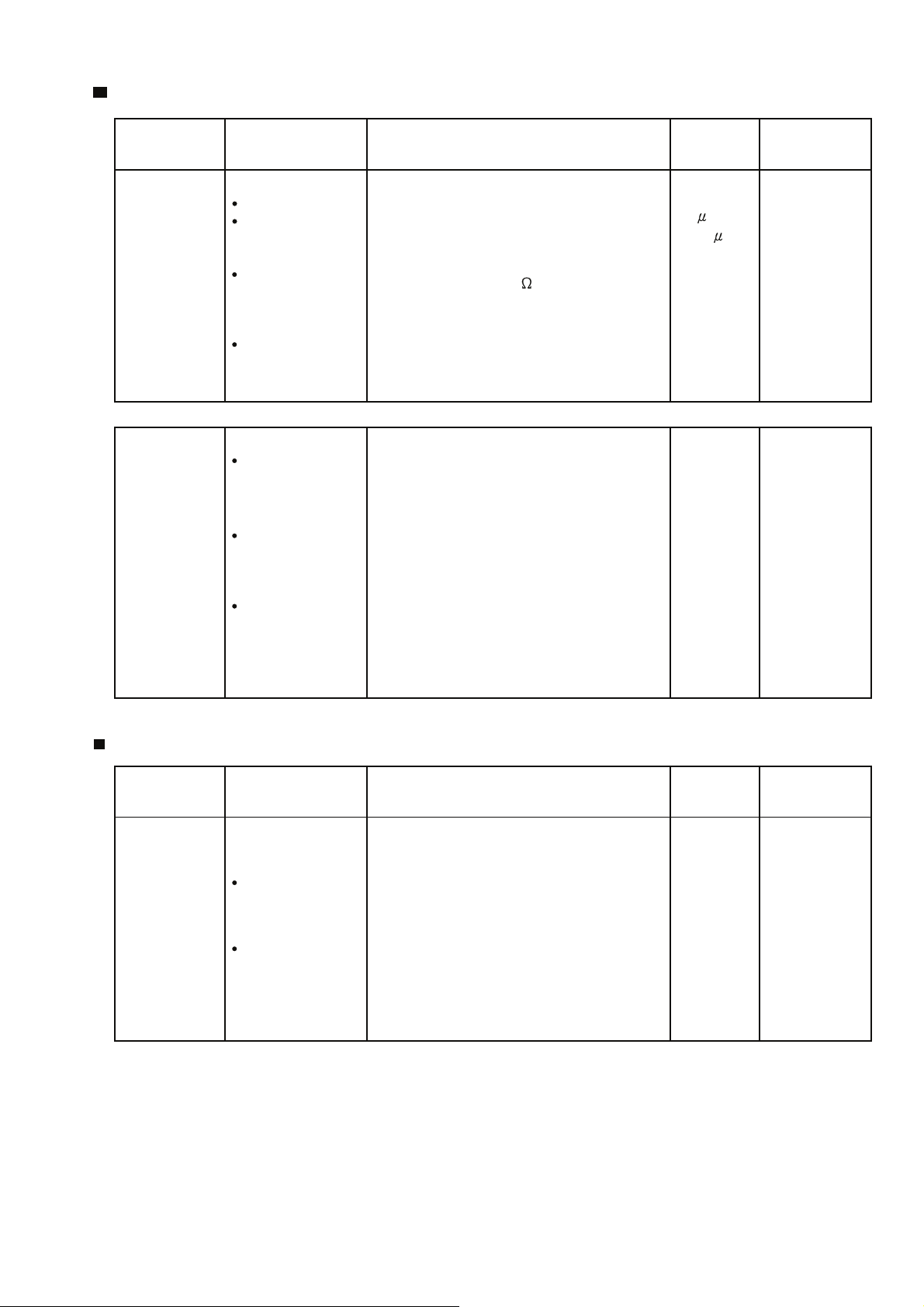

CHAPTER 3. BLOCK DIAGRAM

A

B

C

D

E

F

G

H

1

23456

Figure 1: BLOCK DIAGRAM (1/2)

3 – 1

Page 11

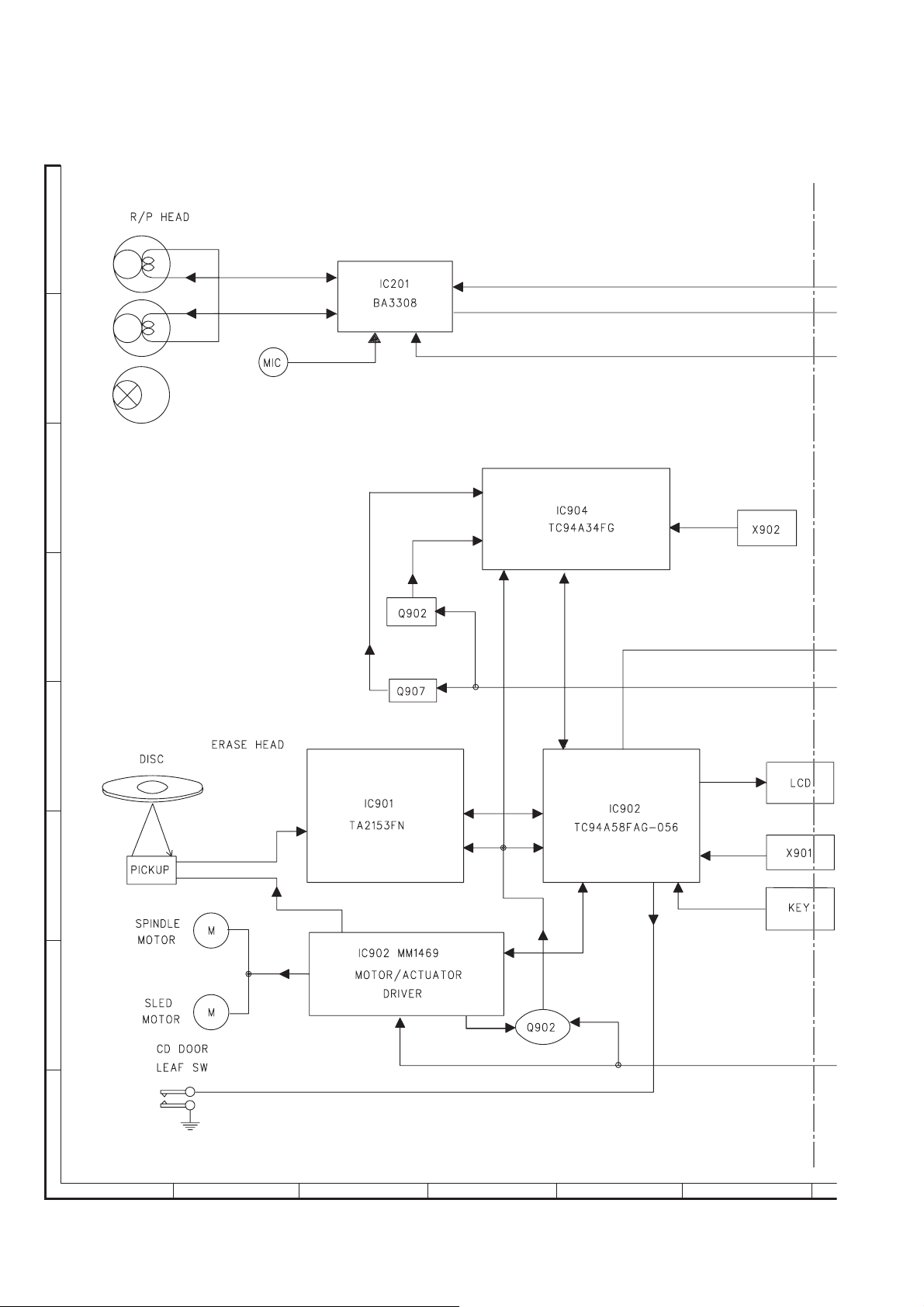

QT-MP3W

7

8 9 10 11 12

Figure 2: BLOCK DIAGRAM (2/2)

3 – 2

Page 12

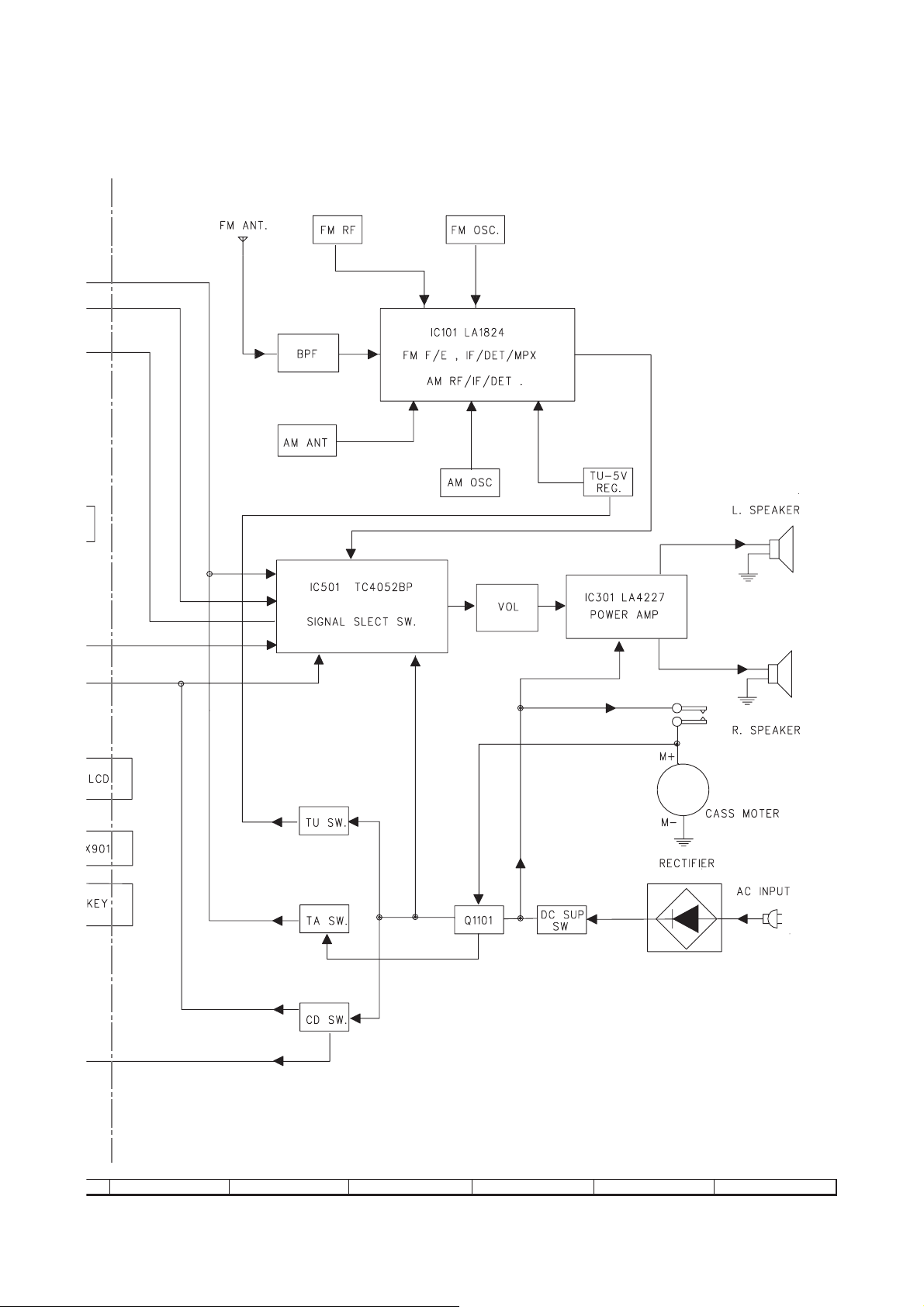

QT-MP3W4

CHAPTER 4.

CIRCUIT DESCRIPTION

[1] Waveforms Of CD Servo Circuit

< Z1 : 2.5M > < Z1 :1 00K >

IC902 19

1

CH1 10:1

1.00 V/div

DC Full

< Z1 : 2M > < Z1 : 2M >

IC901 24

2

CH1 10:1

2.00 V/div

DC Full

CH 4

Display500ms/div

ONOFF

Position

-0.20div

Coupling

DC1M

Probe

10:1

Offset

0:32 V

Bandwidth

Full

Edge CH4

Auto

0.50 V

100ms/div 1s/div

Freq (C1)

50.00000kHz

Edge CH4

Auto

0.50 V

2

5

1

4

3

IC901 24

IC902 10

IC902 19

IC902 24

IC902 4

CH1 10:1

1.00 V/div

DC Full

CH1 10:1

2.00 V/div

DC Full

Freq(C1) *****

Freq(C1)

FR-A(C4)

CH2 10:1

2.00 V/div

DC Full

40.00000kHz

43.75492kHz

CH3 10:1

2.00 V/div

DC Full

Freq(C2) 50.00000kHz

CH4 10:1

2.00 V/div

DC Full

Edge CH4

Auto

0.50 V

Edge CH4

Auto

0.50 V

20µs/div

MEASURE

Mode

ON

Item Setup

Delay Setup

1Cycle Mode

OFF

Time Range1

1.57000div

Time Range2

1.77000div

CH 4

Display

ONOFF

Position

- 3.00div

Coupling

DC1M

Probe

10:1

Offset

0:82 V

Bandwidth

Full

ON

6

IC901 12

˜

0.2vCH1 A>0.2µs

9

8

7

IC901 21

IC901 22

IC901 23

CH1 10:1

5.00 V/div

DC Full

CH2 10:1

5.00 V/div

DC Full

< Z1 : 25K >

CH3 10:1

5.00 V/div

DC Full

Edge CH4

Auto

0.001 kV

4 – 1

Page 13

QT-MP3W

13

12

11

10

10

3

IC901 31

IC901 33

IC901 32

IC901 43

IC902 4

IC901 64

CH1 10:1

5.00 V/div

DC Full

CH2 10:1

2.00 V/div

DC Full

< Z1 : 2.5M >

CH3 10:1

2.00 V/div

DC Full

< Z1 : 2M >

CH4 10:1

2.00 V/div

DC Full

500ms/div

Edge CH4

Auto

0.50 V

1s/div

Freq (C1)

31.25000kHz

P1sN (C4)

1133

FR-A (C4)

5.891783kHz

Freq (C1)

22.22222kHz

CH1 10:1

2.00 V/div

DC Full

CH1 10:1

2.00 V/div

DC Full

Edge CH4

Auto

0.50 V

4 – 2

Page 14

QT-MP3W

[2] IC Voltage

IC904

TC94A34FG TC94A58FAG

PIN PIN PIN

VOLTAGE VOLTAGEVOLTAGE

NO NO NO NO

1 1.35 33 0.00 1 3.20 1 1.64 33 1.65 1 3.54

2 3.20 34 0.00 2 1.65 2 1.64 34 1.65 2 3.56

3 0.00 35 0.00 3 1.65 3 0.00 35 1.65 3 1.65

4 0.00 36 0.00 4 1.65 4 3.14 36 1.65 4 0.00

5 0.00 37 0.00 5 1.65 5 2.70 37 0.00 5 7.10

6 3.65 38 0.00 6 0.00 6 3.20 38 1.65 6 3.20

7 0.00 39 0.00 7 2.61 7 1.10 39 1.65 7 7.70

8 3.65 40 1.35 8 0.00 8 3.20 40 3.20 8 0.00

9 3.65 41 0.00 9 1.65 9 0.00 41 1.55 9 0.00

10 0.00 42 3.67 10 1.65 10 3.65 42 1.51 10 1.65

11 0.00 43 0.00 11 1.65 11 3.65 43 0.00 11 3.56

12 0.00 44 0.00 12 1.00 12 0.00 44 3.00 12 3.56

13 0.00 45 0.00 13 3.00 13 0.00 45 1.40 13 0.00

14 0.00 46 3.67 14 1.65 14 3.24 46 0.00 14 0.00

15 1.64 47 0.00 15 1.65 15 0.00 47 1.40 15 0.00

16 1.65 48 0.00 16 1.65 16 0.75 48 1.40 16 0.00

17 0.00 49 3.66 17 0.75 17 1.64 49 3.20 17 3.56

18 1.64 50 0.00 18 1.65 18 0.00 50 2.52 18 3.56

19 1.65 51 3.66 19 1.22 19 1.50 51 0.00 19 1.65

20 0.00 52 0.00 20 1.65 20 3.23 52 1.64 20 0.00

21 1.34 53 3.66 21 2.37 21 1.00 53 1.63 21 7.70

22 0.00 54 0.00 22 0.77 22 0.00 54 1.62 22 7.70

23 0.00 55 1.35 23 1.65 23 1.55 55 1.62 23 1.65

24 0.00 56 0.00 24 0.00 24 1.65 56 1.64 24 0.00

25 0.00 57 1.36 25 3.20 57 1.64 25 1.65

26 0.00 58 0.67 26 1.65 58 1.64 26 3.57

27 0.00 59 0.80 27 1.65 59 1.64 27 3.56

28 0.00 60 0.00 28 0.75 60 1.64 28 0.00

29 0.00 61 0.00

30 0.00 62 3.66 NO 30 1.00 62 1.65

31 0.00 63 0.00 1 0.00 31 1.65 63 1.64

32 0.00 64 0.95 2 0.00 32 1.65 64 3.20

PIN

IC901 IC902

TA2157FNG

VOLTAGE

IC501

TC4052BP

PIN

VOLTAGE

3 0.00

4 0.65 NO

5 0.00 1 13.20

6 0.00 2 6.50

7 0.00 3 12.20

8 0.00 4 1.17

9 0.00 5 0.00

10 3.64 6 13.10

11 0.40 7 0.00

12 0.00 8 0.00

13 0.00 9 1.17

14 0.00 10 12.20

15 0.00 11 6.50

16 5.36 12 13.80

1.65 61 1.64

PIN

NO

VOLTAGE

IC903

MM1669A

PIN

NO

IC301

LA4227

PIN

VOLTAGE

VOLTAGE

4 – 3

Page 15

QT-MP3W5

CHAPTER 5. CIRCUIT SCHEMATICS AND PARTS LAYOUT

[1] Notes On Schematic Diagram

•Resistor:

To differentiate the units of resistors, such symbol as

K and M are used: the symbol K means 1000 ohm

and the symbol M means 1000 kohm and the resistor without any symbol is ohm-type resistor.

Besides, the one with “Fusible” is a fuse type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used:

this symbol P means pico-farad and the unit of the

capacitor without such a symbol is microfarad. As to

electrolytic capacitor, the expression “capacitance/

withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board

for this model are subject to change for

improvement without prior notice.

REF. NO DESCRIPTION POSITION

VR301 VOLUME MAX—MIN

SW701 USB ON—OFF

SW702 CD ON—OFF

SW703 Memo / Folder ON—OFF

SW704 Repeat / Random ON—OFF

SW705 Stop ON—OFF

SW706 Play/Pause ON—OFF

SW707 Fast Reverse / Track Down / Folder Down ON—OFF

SW708 Fast Forward / Track Up / Folder Up ON—OFF

• The indicated voltage in each section is the one

measured by Digital Multimeter between such a

section and the chassis with no signal given.

1. In the tuner section,

indicates AM

indicates FM stereo

2. In the audio section, a tape is being played back.

3. In the deck section, a tape is being played back.

( ) indicates the record state.

4. In the rectifier section, a tape is being played

back.

5. In the CD section, the CD is stopped.

• Parts marked with “ “ ( ) are

important for maintaining the safety of the set. Be

sure to replace these parts with specified ones for

maintaining the safety and performance of the set.

[2] Types Of Transistor And LED

FRONT

VIEW

ECB

(S)(G)(D)

(1)(2)(3)

B764

9014C

S8050

9015C

B

(3)

TOP

VIEW

E

(1)

HY3C

HY4C

92L22708030000

92L22708050012

92L22708050001

C

(2)

FRONT

VIEW

TOP VIEW

1N4001

1N4148

5 – 1

Page 16

QT-MP3W

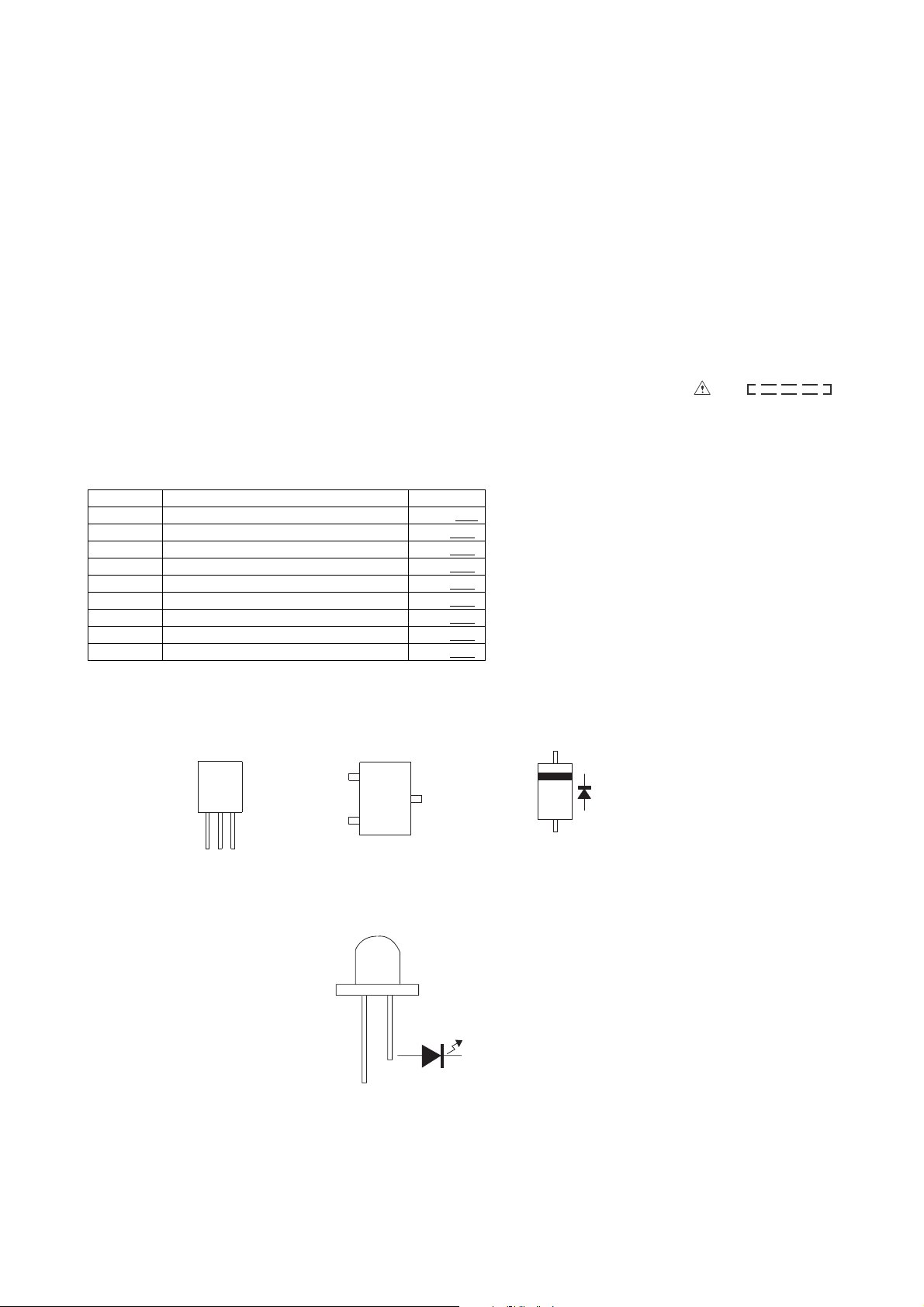

[3] Schematic Diagram

A

B

C

D

E

F

G

H

1

23456

Figure 5-1: TUNER SCHEMATIC DIAGRAM

5 – 2

Page 17

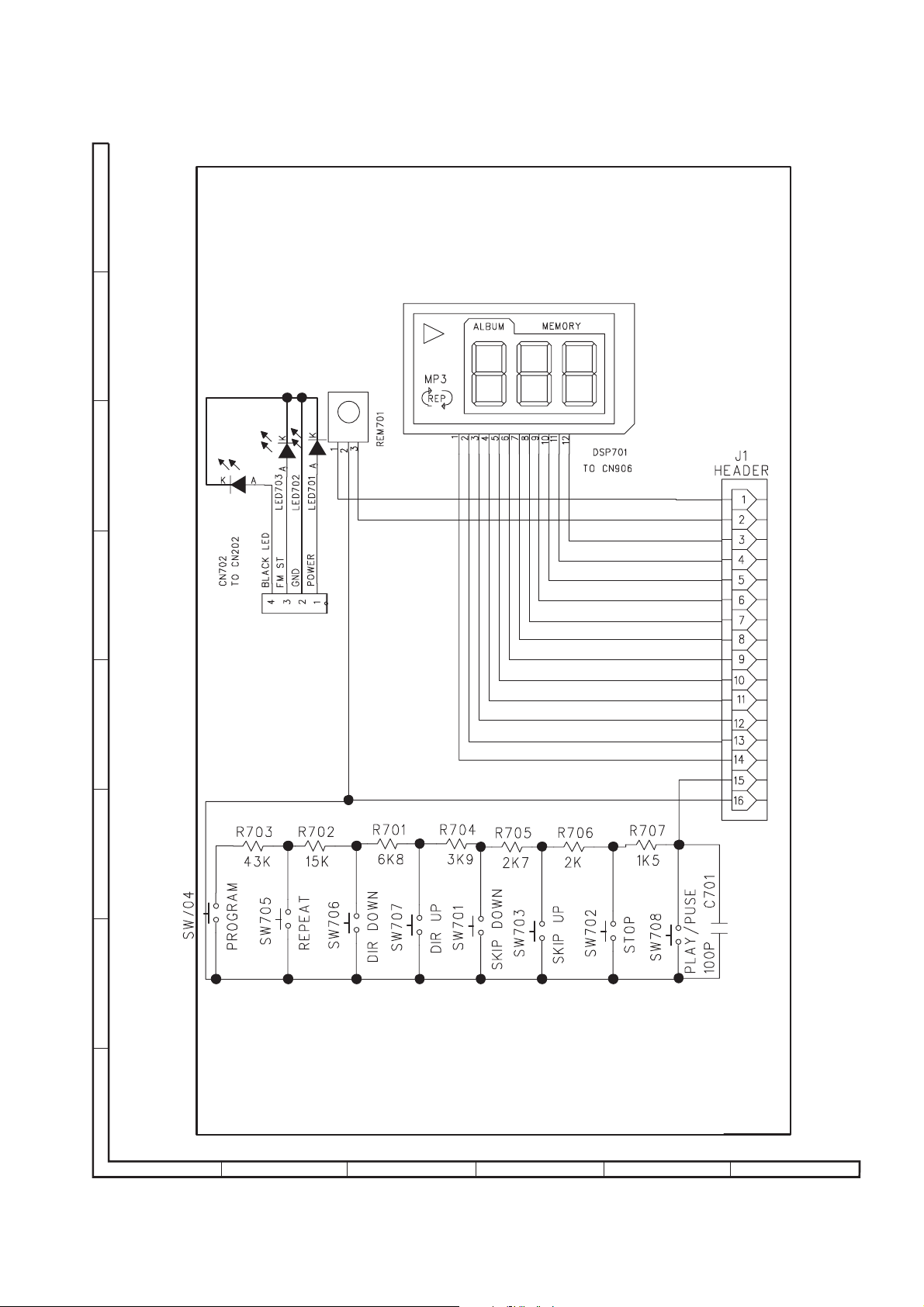

QT-MP3W

A

B

C

D

E

F

G

H

1

23456

Figure 5-2: DISPLAY SCHEMATIC DIAGRAM

5 – 3

Page 18

QT-MP3W

A

B

C

D

E

F

G

H

1

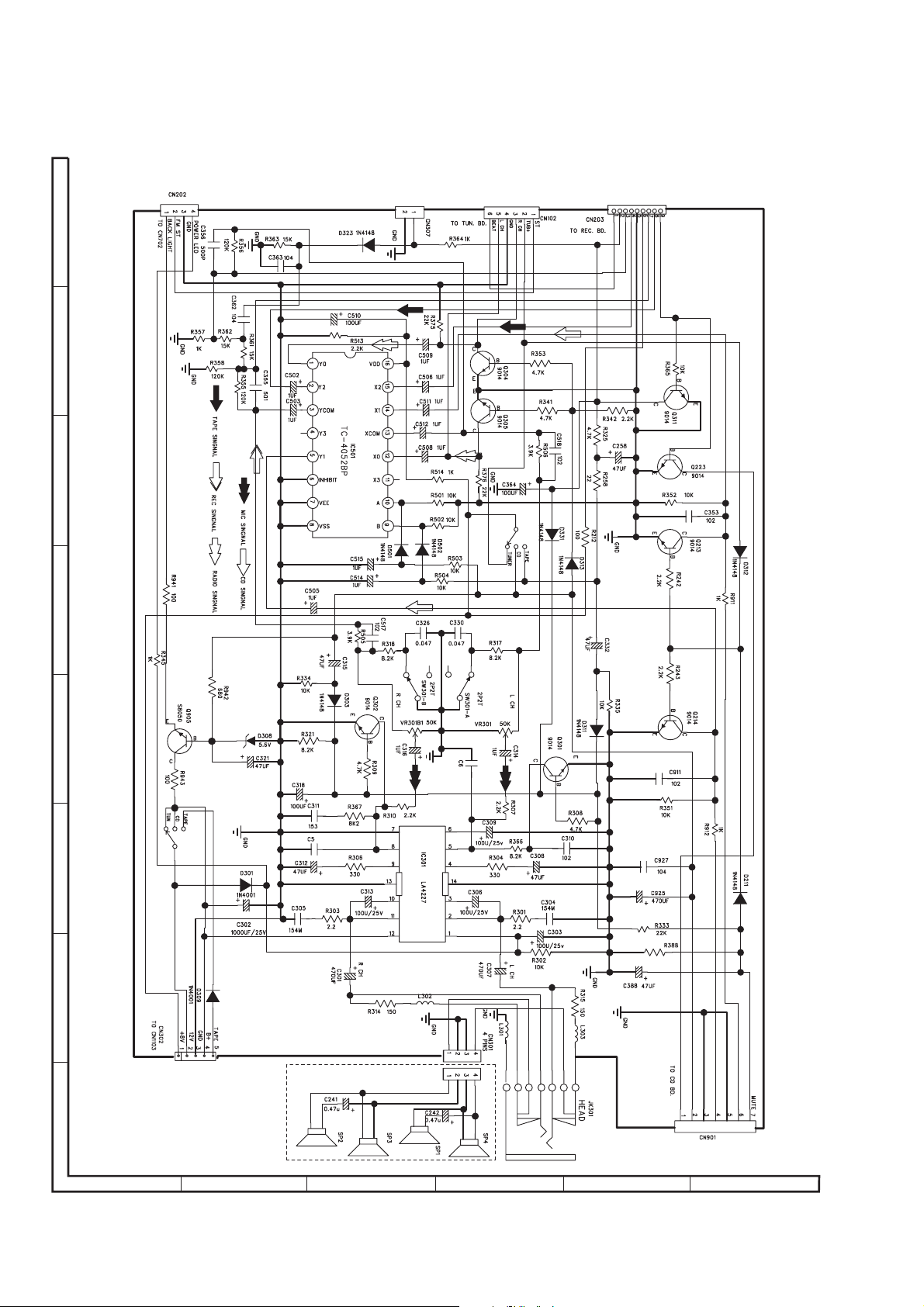

23456

Figure 5-3: AUDIO SCHEMATIC DIAGRAM

5 – 4

Page 19

QT-MP3W

A

B

C

D

E

F

G

H

1

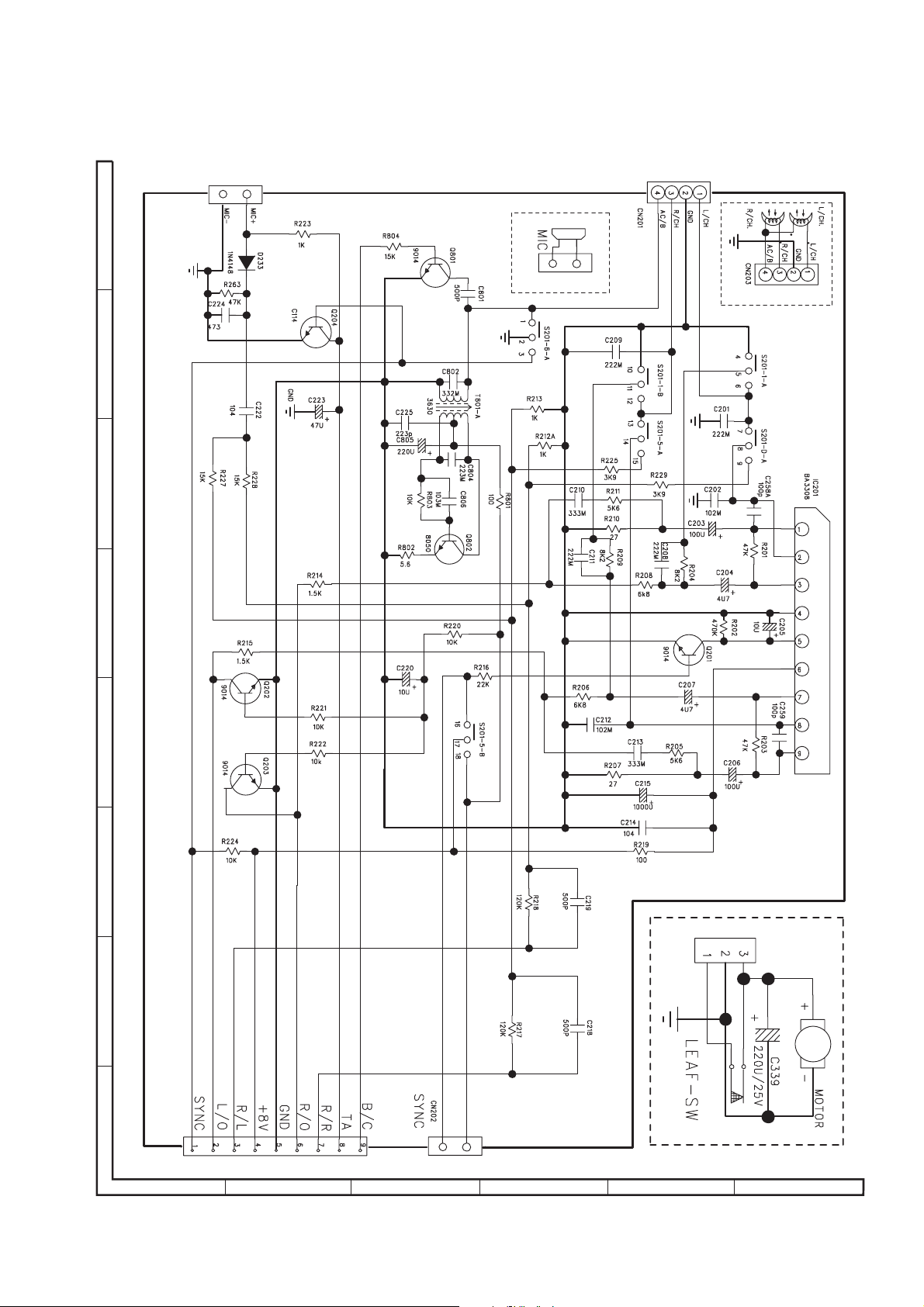

23456

Figure 5-4: TAPE SCHEMATIC DIAGRAM

5 – 5

Page 20

QT-MP3W

A

B

C

D

E

F

G

H

1

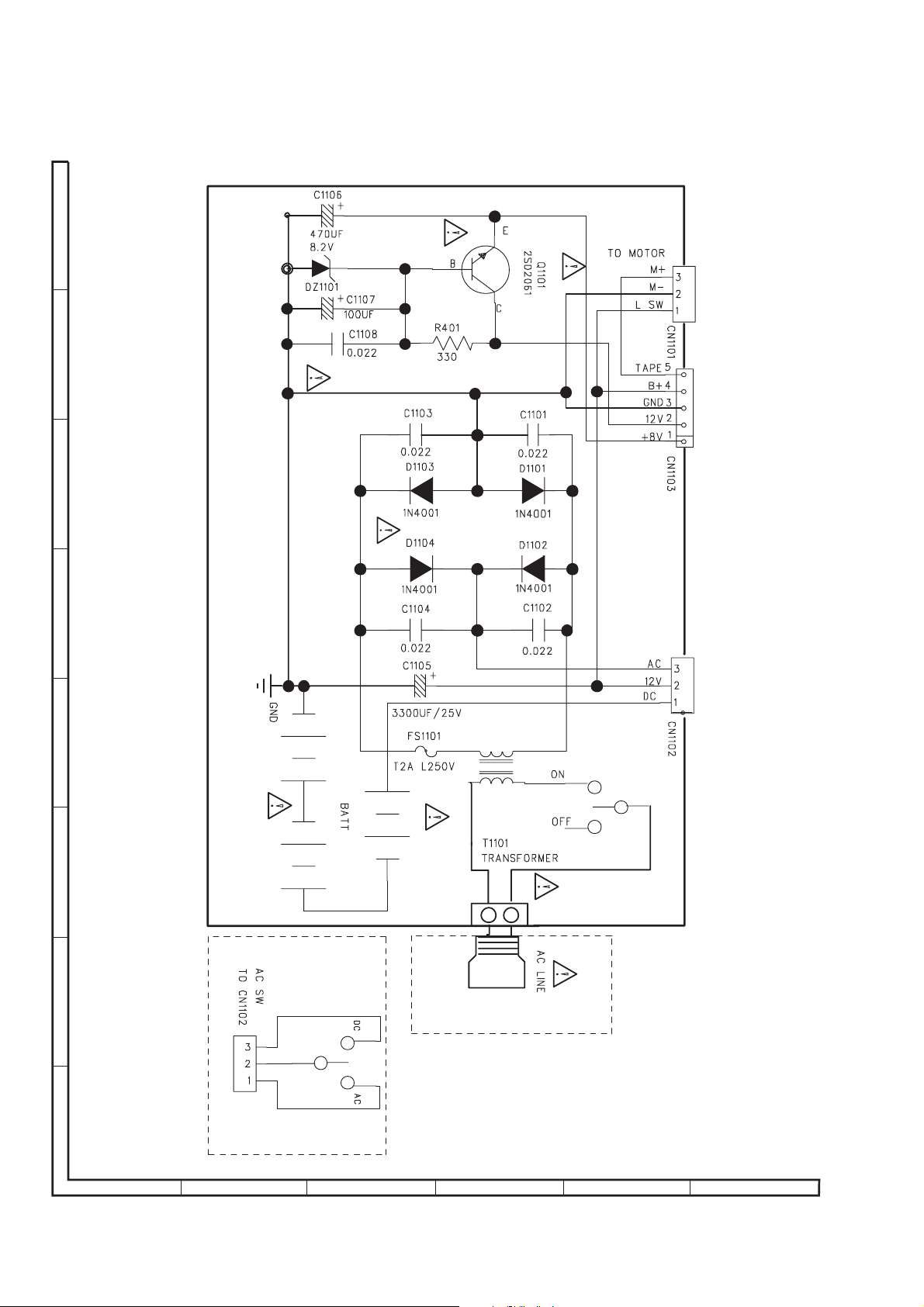

23456

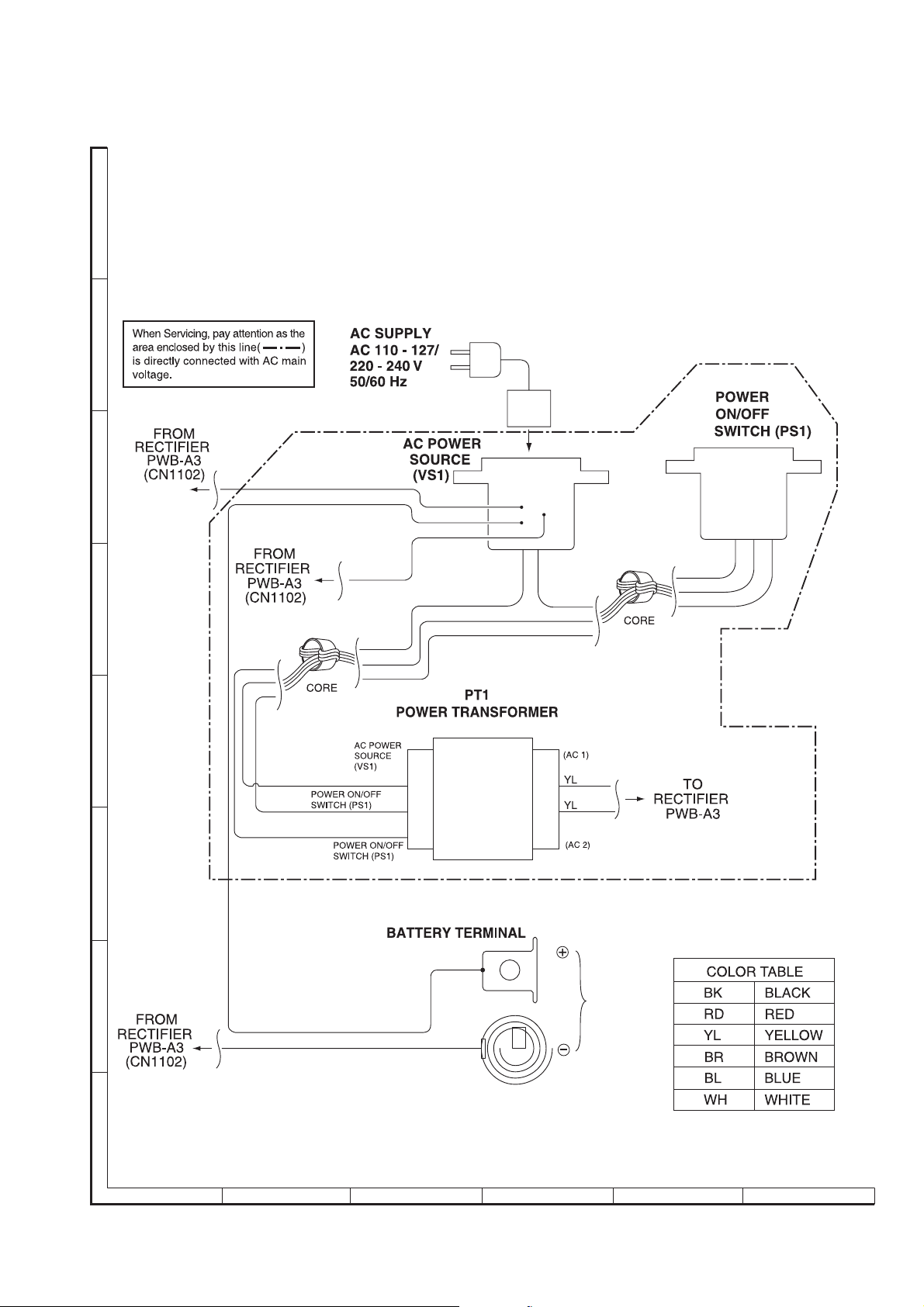

Figure 5-5: POWER SCHEMATIC DIAGRAM

5 – 6

Page 21

-MEMO-

QT-MP3W

5 – 7

Page 22

QT-MP3W

A

B

C

D

E

F

G

H

1

23456

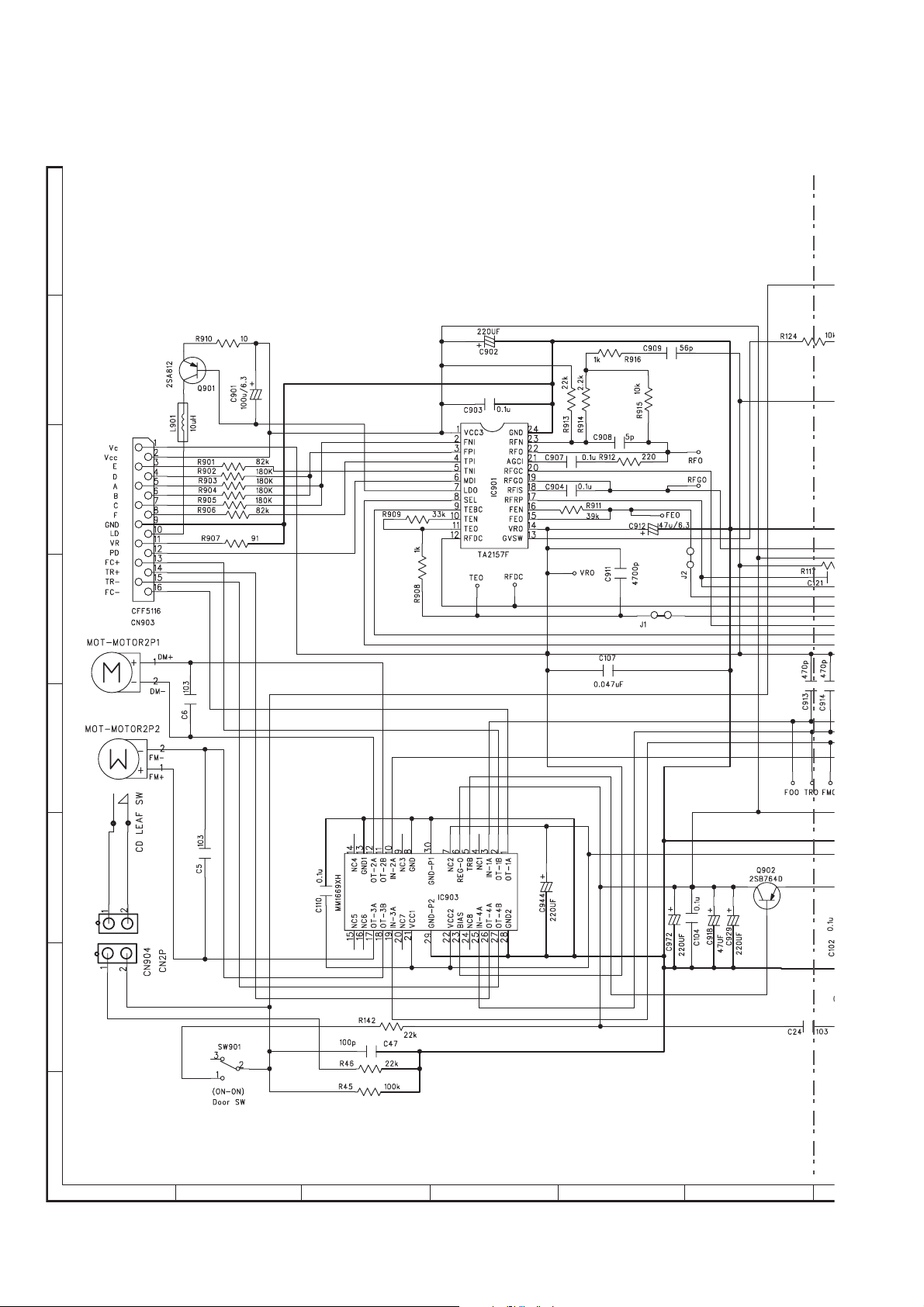

Figure 5-6: CD SCHEMATIC DIAGRAM (1/4)

5 – 8

Page 23

QT-MP3W

7

8 9 10 11 12

Figure 5-7: CD SCHEMATIC DIAGRAM (2/4)

5 – 9

Page 24

QT-MP3W

A

B

C

D

E

F

G

H

1

23456

Figure 5-8: CD SCHEMATIC DIAGRAM (3/4)

5 – 10

Page 25

QT-MP3W

7

8 9 10 11 12

Figure 5-9: CD SCHEMATIC DIAGRAM (4/4)

5 – 11

Page 26

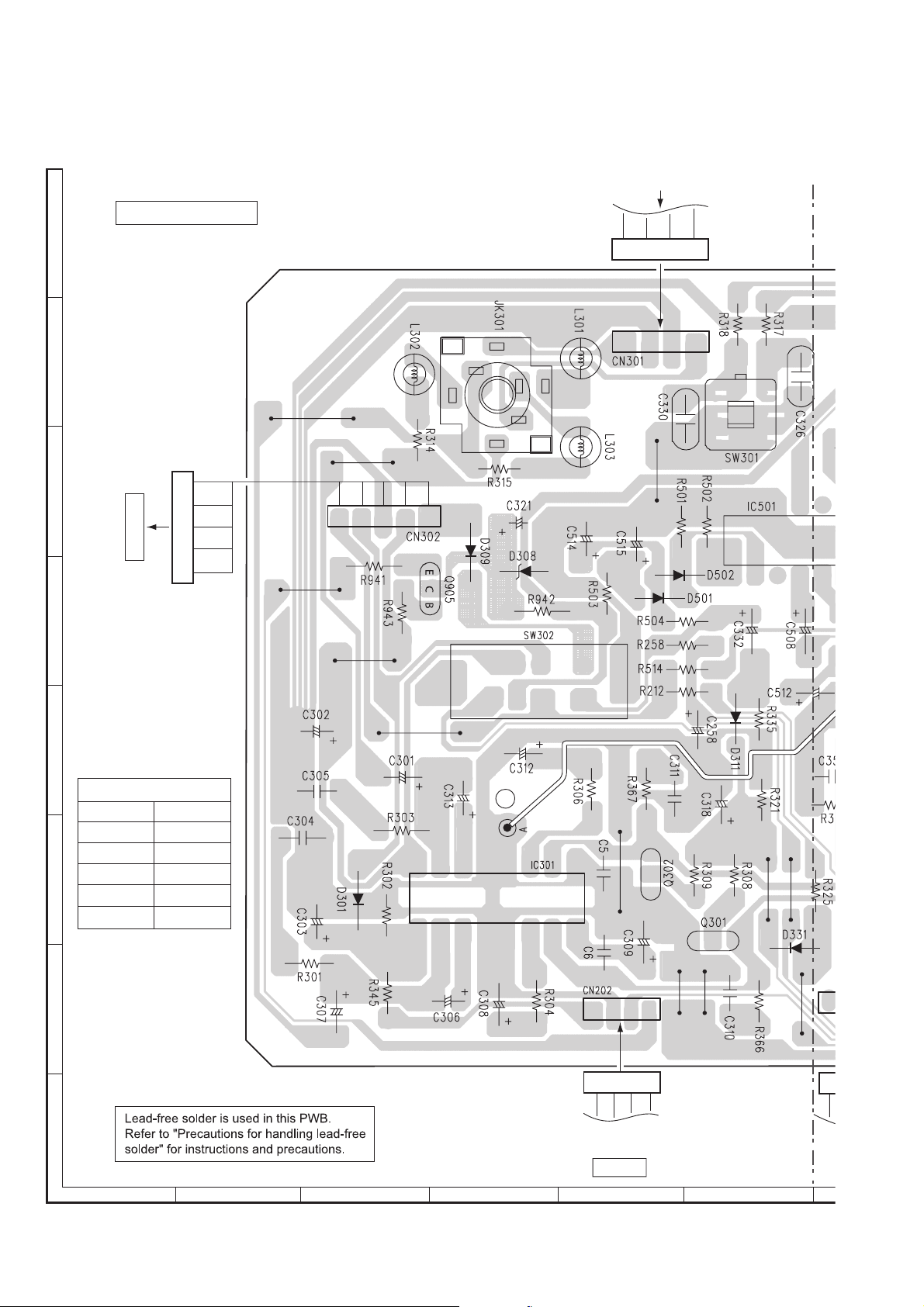

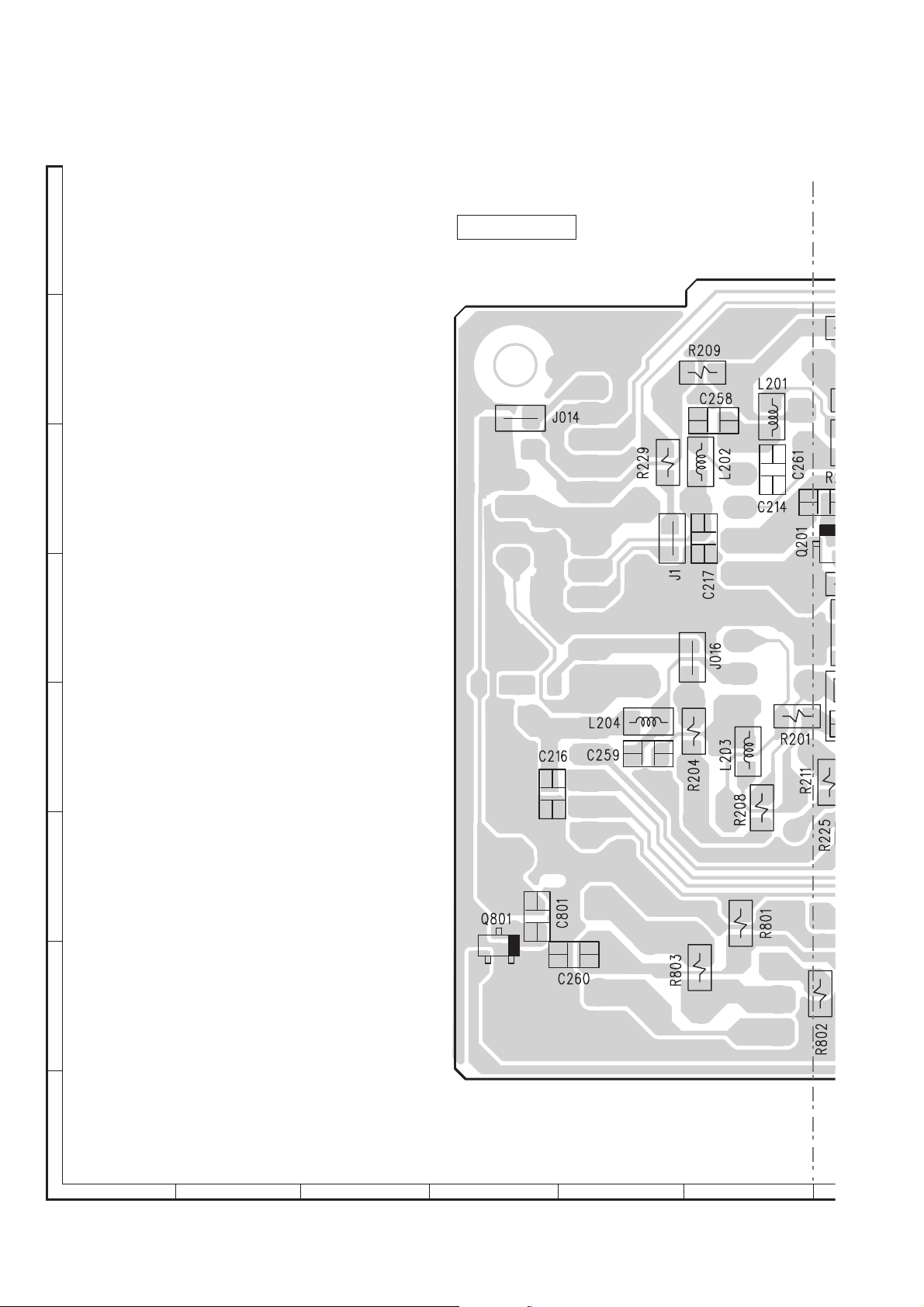

QT-MP3W55

[4] Wiring Side Of PWB

AUDIO PWB-A1

A

B

C

103

TO

CN1

RECTIFIER PWB-A3

2345

1

GY

GY

GY

GY

OR

GY

GY

GY

GY

OR

12345

FROM SPEAKER UNIT

BK

BR

BK

RD

1234

1234

D

E

COLOR TABLE

GY GRAY

OR ORANGE

RD RED

BR BROWN

F

BK BLACK

WH WHITE

G

CNS302

WIR 1

BCE

BCE

1234

1

1234

CNS702

GYGYGY

OR

H

FROM

CONTROL PWB-A2

1

OR

CN702

1

23456

Figure 5-10: WIRING SIDE OF AUDIO PWB (TOP VIEW) (1/2)

5 – 12

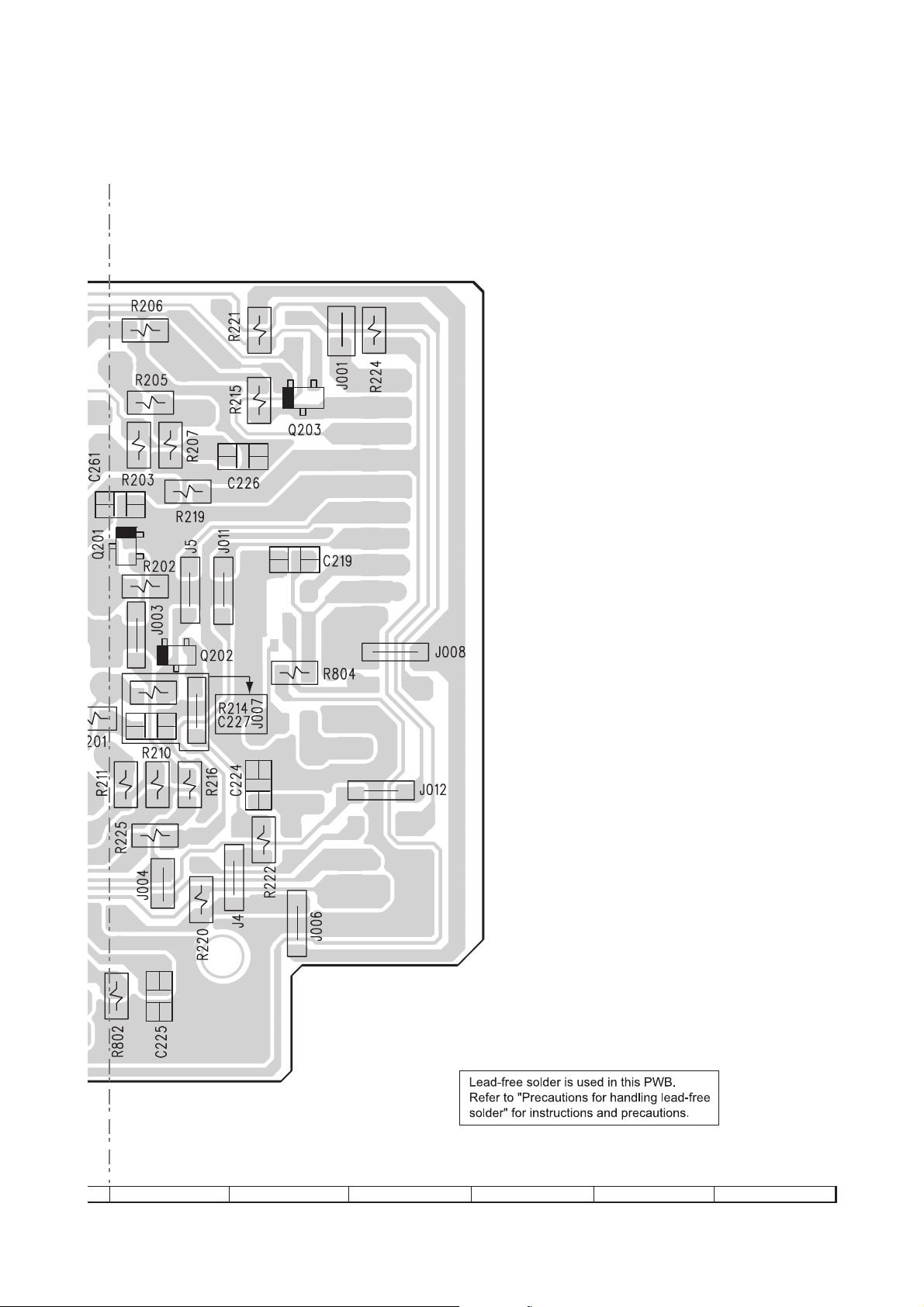

Page 27

WIR 1

GYGYGYGYGY

1234567

GY

OR

CORE

BCE

GY

GY

GY

GY

GY

GY

OR

QT-MP3W

TO

CD PWB-B

CN902

1234567

CNS901

12345678910

12345678910

GYGYGYGYGYGYGYGYGY

OR

TO TAPE PWB-C

CN202

7

8 9 10 11 12

21

BCE

654321

CNS203

21

BK WH

GYGYGYGYGY

CNS307

OR

BCE

TO MIC INPUT

Figure 5-11: WIRING SIDE OF AUDIO PWB (TOP VIEW) (2/2)

5 – 13

BCE

GY

GY

GY

GY

GY

GY

TO

654321

CNS102

CN101

TUNER PWB-A4

Page 28

QT-MP3W

A

B

C

CONTROL PWB-A2

321

OR

GY

GY

GY

1234

1234

TO

AUDIO PWB-A1

CN202

CNS702

COLOR TABLE

121110

D

987654321

OR ORANGE

GY GRAY

E

F

14 161210

1113 15

8642

161

161

CN901

FROM

CD PWB-B

G

13579

FFC703

H

1

23456

Figure 5-12: WIRING SIDE OF CONTROL PWB

5 – 14

Page 29

-MEMO-

QT-MP3W

5 – 15

Page 30

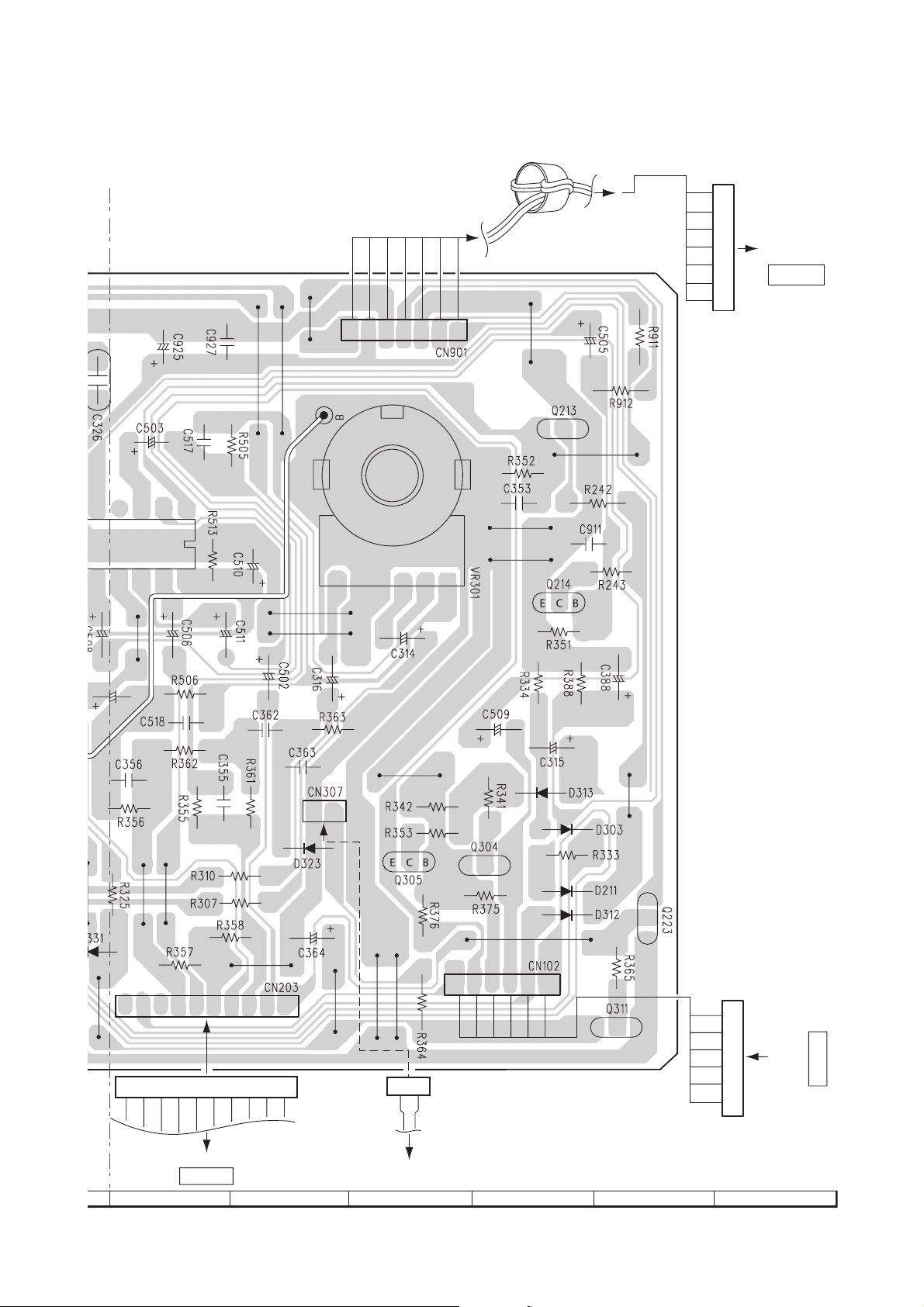

QT-MP3W

A

B

C

D

RECTIFIER PWB-A3

OR

GY

GY

FROM

AUDIO PWB-A1

FROM

CN302

GY

GY

WH

BK

RD

CNS302CNS1101

12345

123

12345

CNS1102

YL

AC POWER SOURCE (VS1)

123

1 2 3

WH

RD

1 2 3

BA TTER Y TERMINAL

FROM

&

( )

TAPE MOTOR

E

YL

(PT1)

FROM

F

YL

POWER TRANSFORMER

COLOR TABLE

BK BLACK

OR ORANGE

G

RD RED

WH WHITE

GY GRAY

YL YELLOW

H

1

23456

Figure 5-13: WIRING SIDE OF RECTIFIER PWB (1/2)

5 – 16

Page 31

QT-MP3W

A

B

C

RD

RD

YL

BK BL

BL BR RD

D

E

BK

BR

RD

F

RD

G

WH

DC

VOLTAGE

12 V

H

1

23456

Figure 5-14: WIRING SIDE OF RECTIFIER PWB (2/2)

5 – 17

Page 32

QT-MP3W

A

TUNER PWB-A4

A

TO

BAR ANTENNA

B

TO

BAR ANTENNA

RD

B

C

WH

D

E

F

G

H

1

23456

Figure 5-15: WIRING SIDE OF TUNER PWB (TOP VIEW) (1/2)

5 – 18

Page 33

QT-MP3W

TO

BAR ANTENNA

BK

TO

BAR ANTENNA

GR

2324 22 21 20 19 18 17 16 15 14 13

1234567891011

12

321

COLOR TABLE

GY GRAY

OR ORANGE

GR GREEN

BK BLACK

WH WHITE

RD RED

BCE

GYGYGY

GY

OR

FROM

AUDIO PWB-A1

CN102

124563

CNS102

124563

GY

7

8 9 10 11 12

Figure 5-16: WIRING SIDE OF TUNER PWB (TOP VIEW) (2/2)

5 – 19

Page 34

QT-MP3W

A

B

C

TUNER PWB-A4

D

E

F

G

H

1

23456

Figure 5-17: WIRING SIDE OF TUNER PWB (BOTTOM VIEW) (1/2)

5 – 20

Page 35

COLOR TABLE

WH WHITE

RD RED

BK BLACK

GR GREEN

WH RD BK GR

LUG 1

BAR ANTENNA

BR2

QT-MP3W

BR1

RA1

TO

TUNER PWB-A4

(Please see at top side

page 6-20 & 6-21)

ROD ANTENNA

7

8 9 10 11 12

Figure 5-18: WIRING SIDE OF TUNER PWB (BOTTOM VIEW) (2/2)

5 – 21

Page 36

QT-MP3W

A

B

C

D

CD PWB-B

EBC

EBC

COLOR TABLE

BR BROWN

E

RD RED

GY GRAY

OR ORANGE

FROM

CD DOOR

F

G

H

LEAF SWITCH

BR

RD

12

12

2468

1357 9

FROM

10 12 14 16

11 13 15

161

CONTROL PWB-A2

1

23456

Figure 5-19: WIRING SIDE OF CD PWB (TOP VIEW) (1/2)

5 – 22

Page 37

QT-MP3W

EBC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

123456 7

1 2 3 4 5 6 CNS901

GY

GY

GY

GY

GY

GY

7

OR

FROM

CD PICK-UP

UNIT

FROM

AUDIO PWB-A1

CN901

7

8 9 10 11 12

Figure 5-20: WIRING SIDE OF CD PWB (TOP VIEW) (2/2)

5 – 23

Page 38

QT-MP3W

A

B

C

CD PWB-B

D

1

E

F

G

H

1

23456

Figure 5-21: WIRING SIDE OF CD PWB (BOTTOM VIEW) (1/2)

5 – 24

Page 39

QT-MP3W

IC902

IC904

7

89101112

Figure 5-22: WIRING SIDE OF CD PWB (BOTTOM VIEW) (2/2)

5 – 25

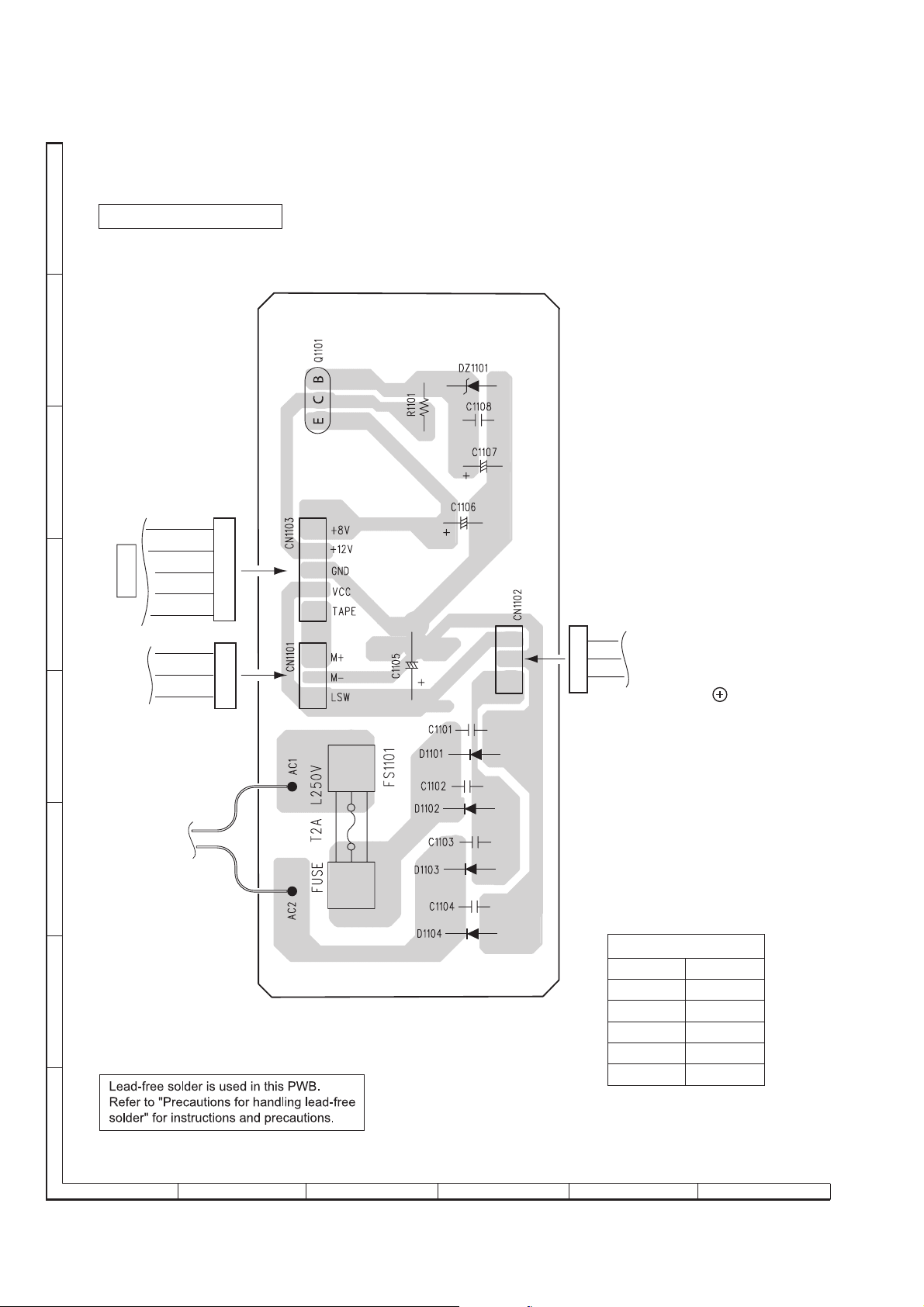

Page 40

QT-MP3W

A

B

C

TO

CN304

AUDIO PWB-A1

D

CNS304

GY

12345678910

GY

GY

GY

GY

GY

GY

GY

GY

OR

CNS202

12345678910

TAPE PWB-C

12345678910

CN202

E

F

G

EBC

Lead-free solder indication

Lead-free solder is used in the TAPE PWB.

Refer to "Precautions for handling lead-free solder" for

H

instructions

1

and precautions.

23456

Figure 5-23: WIRING SIDE OF TAPE PWB (TOP VIEW) (1/2)

5 – 26

Page 41

QT-MP3W

123456789

CNS201-A

1234

1234

YL

WH

BK

RD

TO

TAPE HEAD

COLOR TABLE

BK BLACK

WH WHITE

RD RED

EBC

7

8 9 10 11 12

Figure 5-24: WIRING SIDE OF TAPE PWB (TOP VIEW) (2/2)

OR ORANGE

YL YELLOW

GY GRAY

5 – 27

Page 42

QT-MP3W

A

B

C

D

TAPE PWB-C

E

F

G

H

1

23456

Figure 5-25: WIRING SIDE OF TAPE PWB (BOTTOM VIEW) (1/2)

5 – 28

Page 43

QT-MP3W

7

8 9 10 11 12

Figure 5-26: WIRING SIDE OF TAPE PWB (BOTTOM VIEW) (2/2)

5 – 29

Page 44

A

B

C

D

E

F

G

H

1

2 3 4 5 6

QT-MP3W

TAPE PWB-C

TO

CN203

12

34

RD

BK

WH

YL

RD

BL

TAPE PLAY

SWITCH

CNS203

TAPE MECHANISM

TAPE MOTOR

WH

1

BK

2

RD

WH

CAPACITOR

(220 µF/25 V)

BL

BK

3

CNS201

TO

TAPE PWB-C

CN201

COLOR TABLE

BK BLACK

WH WHITE

RD RED

YL YELLOW

BL BLUE

Figure 5-27: WIRING SIDE OF TAPE MECHANISM

5 – 30

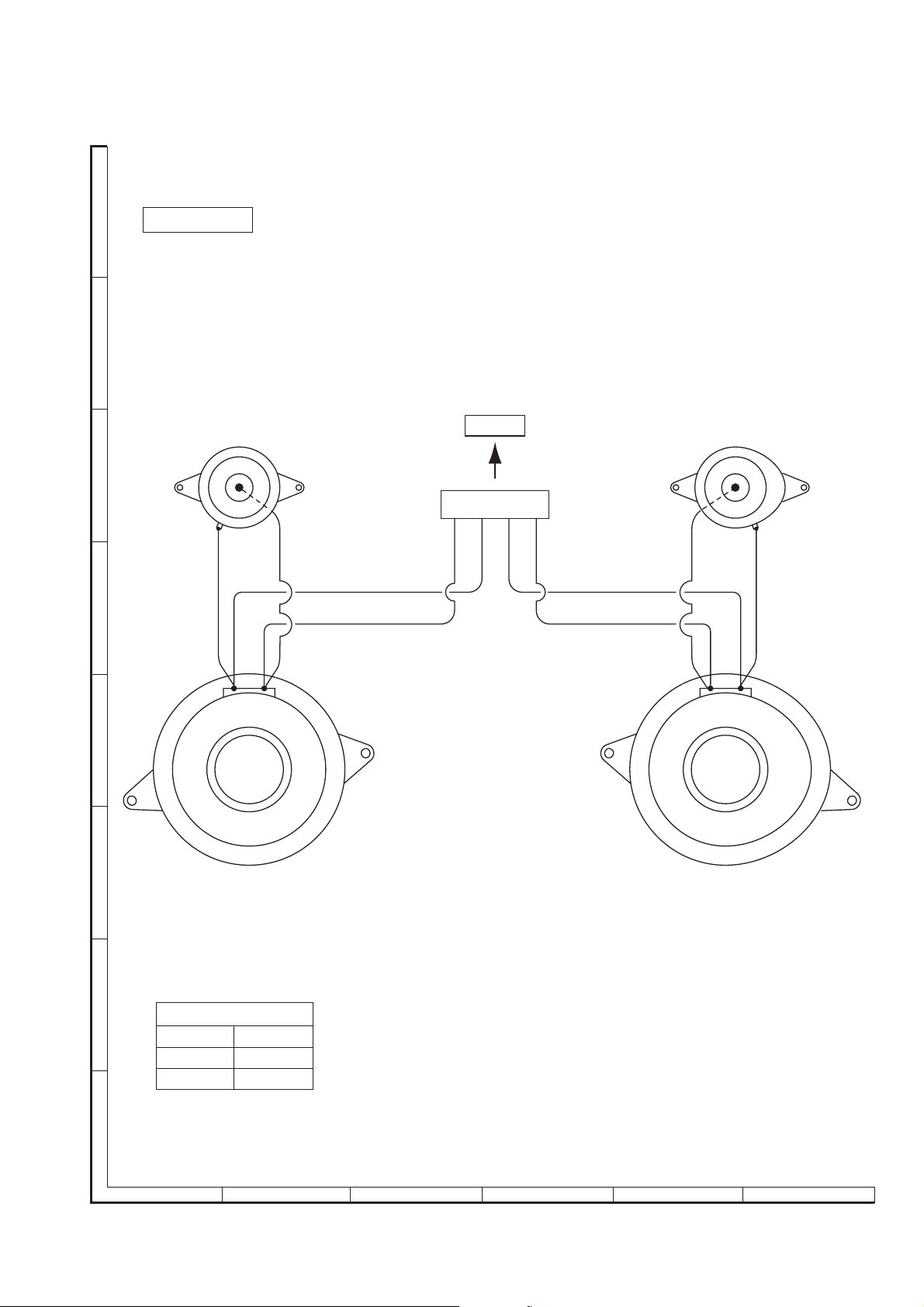

Page 45

QT-MP3W

A

B

SPEAKER

R-CH

TO

L-CH

AUDIO PWB-A1

TWEETER

C

CN301

TWEETER

1234

BK RD

BK

D

BR

BR

BK

BK

RD

BK

BR

BKRD

BK BK

E

F

RD RD

WOOFERWOOFER

G

COLOR TABLE

BK BLACK

BR BROWN

RD RED

H

1

23456

Figure 5-28: WIRING SIDE OF SPEAKER

5 – 31

Page 46

QT-MP3W

CHAPTER 6. FLOWCHART

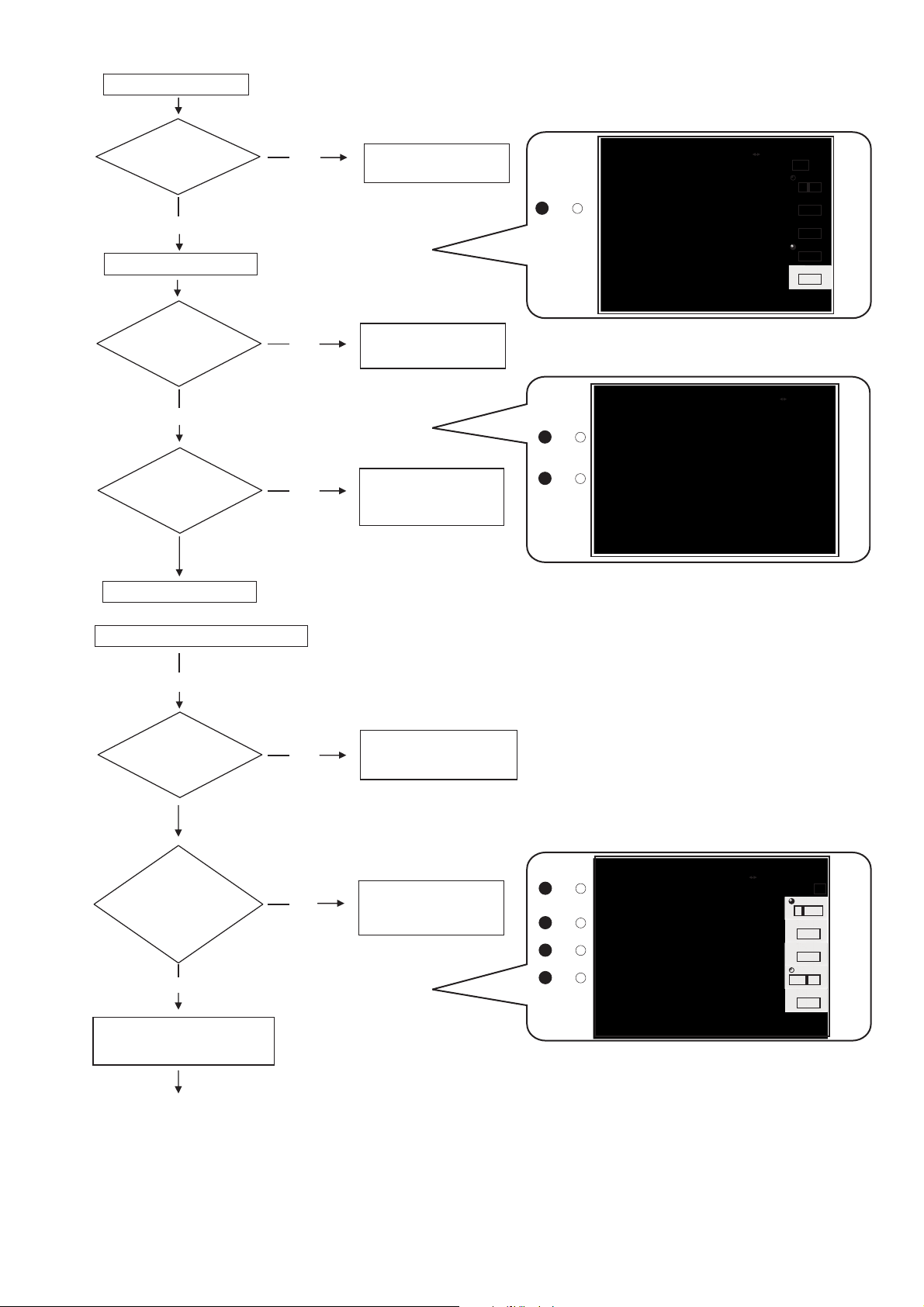

[1] Troubleshooting

1. When the CD does not function

The CD section may not operate when the objective lens of the optical pickup is dirty. Clean the objective lens, and

check the playback operation. When this section does not opera te even af ter the abo ve step is t aken , check the fo llowing items.

Remove the cabinet and follow the trouble shooting instructions.

"Track skipping and/or no T OC (Table Of Conte nts) may be ca used by build up of du st other foreig n matter on the laser

pickup lens. Before attempting any adjustmen t make certain that the lens is clean. If not, clean it as mentioned below."

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

Parts code

1. CD optical pickup Lens cleaner disc UDSKA0004AFZZ

HOW TO USE

1.

Using the brush in the cleaner cap, apply 1 or 2 drops of the cleaning fluid to the

brush on the CD cleaner disc which has the mark next to it.

2.

Place the CD cleaner disc onto the CD disc tray with the brush side down, then

press the play button.

3.

You will hear music for about 20 seconds and the CD player will automatically stop.

If it still play continuously, press the stop button.

CAUTION

The CD lens cleaner should be effective for 30-50 operations, however if the

brushes become worn out earlier then please replace the cleaner disc.

If the CD cleaner brushes become very wet then wipe off any excess fluid with a soft

cloth.

Do not drink the cleaner fluid or allow it contact with the eyes. In the event of this

happening then drink and / or rinse with clean water and seek medical advice.

The CD cleaner disc must not be used on car CD players or on computer CD-ROM

drives.

All rights reserved. Unauthorized duplicating, broadcasting and renting this product

is prohibited by law.

2. When a CD cannot be played

Cleaning fluid

Cleaner disc

2.1. Pressing the CD operation key is accepted, but playback does not occur.

1) Focus-RF system check

2) Tracking system check

3) Spin system check

4) Others

6 – 1

Page 47

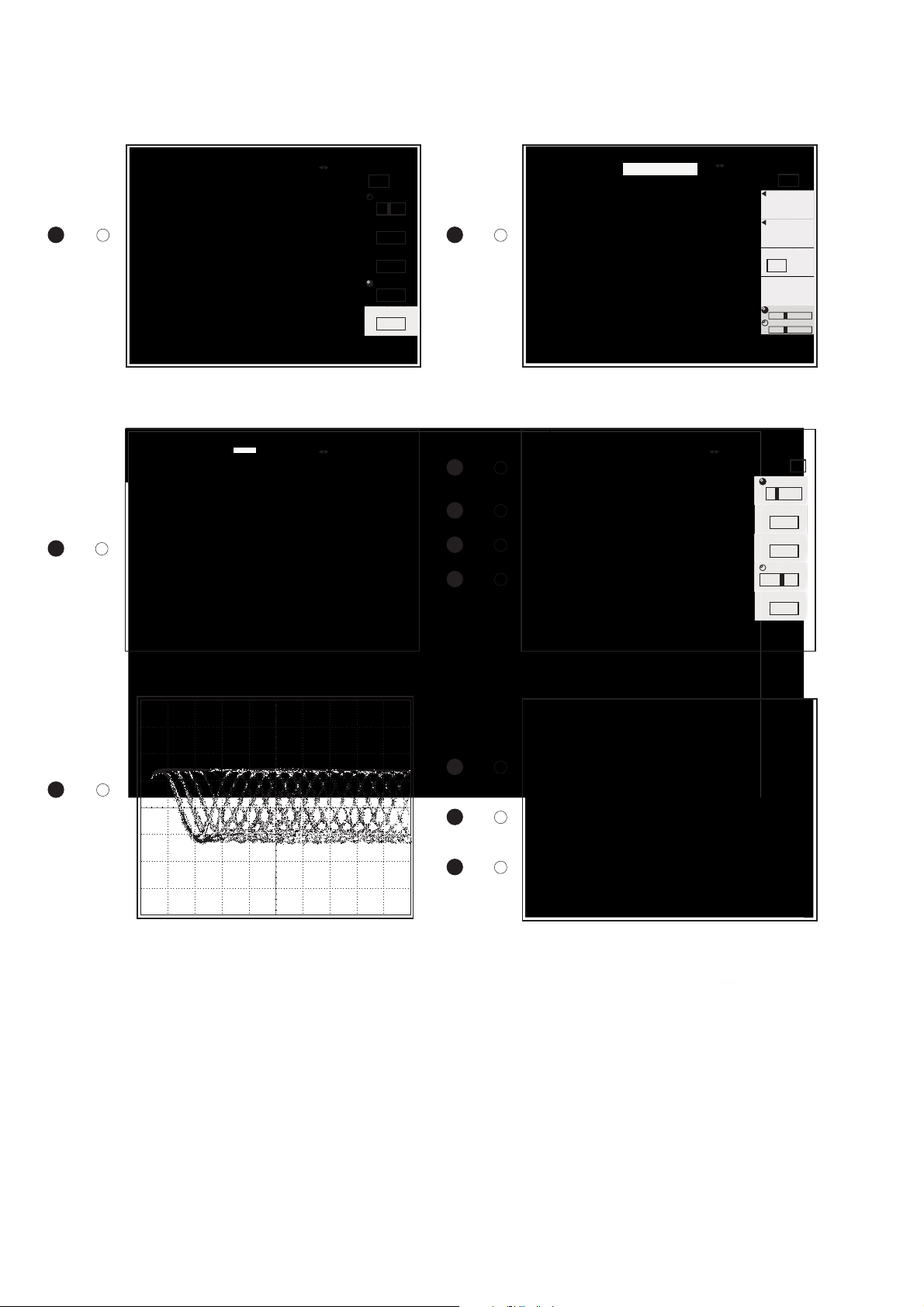

SC9641 reposit to 600MS

g

2

g

o

QT-MP3W

Confirm SLDGE

reposit or not?

YES

Start playback without Disc

Confirm Pick up

raise up down

focus aging

YES

Judge focus open

or close

?

Servohead inspect no disc

NO

NO

NO

Check SLED output and

drive circuit, see Figure 1

Checking FOC drive

information,see Fi

ure

Inspect the informationo of

LDON and the laser control

cricuit of SA9618

1

10

3

U902 19

U902 4

U901 64

CH1 10:1

1.00 V/div

DC Full

CH1 10:1

2.00 V/div

DC Full

CH1 10:1

2.00 V/div

DC Full

< Z1 : 2.5M >

< Z1 : 2M >

Edge CH4

Auto

0.50 V

Edge CH4

Auto

0.50 V

1s/div

CH 4

Display500ms/div

Position

-0.20div

Coupling

DC1M

Probe

10:1

Offset

0:32 V

Bandwidth

Full

Freq (C1)

22.22222kHz

ONOFF

Put disc and then re-start playback

YES

Whether disc is

stepped-up

playback

Whether the 56pin

information of SC9641

raise chan

e from high t

low

YES

Have lock track.under regular

condition, can find every drive

wave(figure-3)

NO

NO

Whether focus is regular or

not, inspect focus reposit

Track raise change and can

not block the original track,

inspect track

CH 4

1s/div

Display

Position

- 3.00div

Coupling

DC1M

Probe

10:1

Offset

0:82 V

Bandwidth

Full

ONOFF

CH3 10:1

2.00 V/div

DC Full

< Z1 : 2M >

Freq(C2) 50.00000kHz

Edge CH4

CH4 10:1

Auto

2.00 V/div

0.50 V

DC Full

U902 10

5

U902 19

1

U902 24

4

U902 4

3

Freq(C1)

40.00000kHz

FR-A(C4)

CH2 10:1

2.00 V/div

DC Full

43.75492kHz

CH1 10:1

2.00 V/div

DC Full

6 – 2

Page 48

QT-MP3W

g

Whether RF waveform is ok (ftgure4)

YES

Check whether

disc is good

YES

Confirm output

whether have noise

or wrong song

NO

Servo system ok

NO

YES

Check circuit of SA9618 of

RF

Confirm Disc

format whether

CDDA or not

YES

6

U901 12

NO

NO

˜

0.2vCH1 A>0.2µs

Whether 56pin

output raise any high

voltage impulse or

not

YES

C2 cannot rectify when raise

many wrong data under

Disc, as a result, which

readin

exist any wrong songs. Please

check Disc and whether Pickup is aging or not.

Confirm pin no. 24 output

is square wave of 88.2K is

stabil or not

YES

C2 cannot rectify if many

many wrong data during

read the Disc, cause wrong

song selected. Please

check Disc and whether

Pick-up is aging or not.

Confirm pin no.24 output

shows high voltage

impulse or not.

YES

6 – 3

Page 49

CHAPTER 7. OTHERS

[1] Function Table Of IC

U712 92L31012161601 : SDRAM (M12L161A)

QT-MP3W

V

DQ0

DQ1

VSS0

DQ2

DQ3

VDD0

DQ4

DQ5

VSS0

DQ6

DQ7

VDD0

LDQM

WE

CAS

RAS

A10/AP

VDD

DD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

CS

18

BA

19

20

A0

21

A1

22

A2

23

A3

24

25

VSS

50

49

DQ15

48

DQ14

VSS0

47

46

DQ13

DQ12

45

44

VDD0

DQ11

43

42

DQ10

VSS0

41

DQ9

40

DQ8

39

VDD0

38

N.C/RPU

37

UDQM

36

CLK

35

CKE

34

N.C

33

A9

32

A8

31

A7

30

A6

29

A5

28

A4

27

VSS

26

I/O Control

CLK

ADD

Address Register

LCKE

LRAS

CLK

Bank Select

Refresh Counter

Row Buffer

Row Decoder

Data Input Register

Sense AMP

512 x 16

512 x 16

LCBR

LRAS

Col. Buffer

Column Decoder

Latency & Burst Length

Programming Register

LCBR LWE

CKE L(U)DQM

CS

LCAS

LWCBR

WERAS CAS

LWE

LDQM

Output Buffer

DQi

LDQM

Figure 7-1 BLOCK DIAGRAM OF IC

7 – 1

Page 50

QT-MP3W77

U710 92L31000250110 : CPU ( TS2501 ) ( 1/4 )

GPIO_D21

GPIO_D20

GPIO_D19

GPIO_D18

GPIO_D17

GPIO_D16

GPIO_D15

PKG1

VSSI_ADC

VDDI_ADC

VBBA_ADC

VSSA_ADC

ADIN4

ADIN2

ADIN0

VDDA_ADC

VBBA_PLL

VSSA_PLL

XFILT

VDDA_PLL

VDDIO

XOUT

XIN

READY

nRESET

VDD_OSC

XTOUT

XTIN

DAI/GPIO_B25

DAO/GPIO_B24

MCLK/GPIO_B23

VSSIO

VSSIO

MODE1

TDI

TMS

TCK

TDO

nTRST

SDO0/GPIO_A0

SCK0/GPIO_A1

SFRM0/GPIO_A2

SDI0/GPIO_A3

SDO1/GPIO_A4

VDDI

VSSI

SCK1/GPIO_A5

VDDIO

SFRM1/GPIO_A5

SDI1/GPIO_A7

SDO2/GPIO_A8

SCK2/GPIO_A9

SFRM2/GPIO_A10

SD12/GPIO_A11

VDDI

VSSI

EXINT0/GPIO_A12

EXINT1/GPIO_A13

EXINT2/GPIO_A14

EXINT3/GPIO_A15

XDD

XD1

XD2

XD3

96959493929190898887868584838281807978777675747372177069686766

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

124

126

127

128

12345678910111213141516171819202122232425262728293031

Ts2501

65

VDD-USB

64

LRCK/GPIO_B22

63

BCLK/GPIO_B21

62

UT_RX/IDE_nCS/GPIO_59

61

UT_TX/GPIO_88

60

nOE

59

nWE

58

ND_nWE/GPIO_B7

57

SD_CKE/GPIO_B0

56

VSSI

55

USBH_CN/GPIO_B29

54

USBH_DP/GPIO_B28

53

USB_DN/GPIO_B27

52

USB_DP/GPIO_B26

51

nCS3/nOE3/GPIO_B5

50

nCS/nOE2/GPIO_B4

49

nCS1/nOE1/GPIO_B3

48

nCS0/nOE0/GPIO_B2

47

SD_nCS/GPIO_B1

46

VSSIO

45

SD_CLK/GPO

44

XA21/DQM0

43

XA20/DQM1

42

VDD1

41

XA19

40

XA18

39

XA17/CLE

38

XA16/nRAS/ALE

37

XA15/nCAS

36

XA14/BA1

35

XA13/BA0

34

VDDIO

33

32

XD4

VSSIO

XD5

XD6

XD7

XA0

XD8

VSSI

VDDI

XD9

XD11

XD10

XD12

XD13

XD14

XD15

VDDIO

XA1

Figure 7-2 BLOCK DIAGRAM OF IC

7 – 2

XA2

XA3

XA4

XA5

XA6

VDDI

VSS1

XA7

XA8

XA9

1

XA1

XA10

XA12

VSSIO

Page 51

U710 92L31000250110 : CPU ( TS2501 ) ( 2/4 )

USB_DP/GPIO_B[28], USB_DN/GPIO_B[27]

USBH_DP/GPIO_B[28], USBH_DN/GPIO_B[29]

QT-MP3W77

DQM[0:1] / XA[21:20]

DQS[1:0] / XA[19:18]

ND_CLE / XA[17]

D_ALE / SD_nRAS / XA[16]

SD_nCAS / XA[15]

SD_BA[1:0] / XA[14:13]

XA[12:0]

XD[15:0]

nOE. nWE. nCS[3:0]

SD_nCS, SD_CKE

SD_CLK

ND_nWE

IDE_nCS1

READY

TDI. TMS. TCK

nTRST , TDO

GPIO_D[21:15]

GPIO_A[3:0]

Boot ROM

(4KB)

SRAM

(64KB)

Ext. Memory

Interface

AHB Wrapper

ARM940T

JTAG

Video Input

Interface

USB1.1

Host/Device

ECC

Generation

APB

Bridge

AHB Arbiter

DMA

(2-channel)

DAI (12S)

for

CODEC

&

CD-DSP

Pll &

CLK Generator

Timers/

Counters

Interrupt

Controller

GSIO

GPIO

UART/IrDA

12C

ADC

XIN, XOUT

XTIN, XTOUT

XFILT

TCO2/GPIO_A[11]

TCO5/GPIO_A[8]

TCO1/GPIO_A[7]

TCO4/GPIO_A[4]

TCO0/GPIO_A[3]

TCO3/GPIO_A[0]

EXINT[3:0] /

GPIO_A[15:12]

GPIO_A[11:0]

GPIO_A[15:0]

GPIO_B[20:21]

GPIO_B[9:7]

GPIO_B[5:0]

GPIO_D[17:15]

UT TX/GPIO_B[8]

UT RX/GPIO_B[8]

GPIO_A[11:10]

GPIO_A[9:8]

GPIO_D[17:16]

ADIN0

ADIN1

ADIN4

DAO / GPIO_B[24]

MCLK / GPIO_B[23]

BCLK / GPIO_B[21]

LRCKO / GPIO_B[22]

DAI / GPIO_B[25]

GPIO_A[3] / CDAI

GPIO_A[2] / CLRCK

GPIO_A[1] / CBCLK

Figure 7-3 BLOCK DIAGRAM OF IC

7 – 3

Page 52

QT-MP3W

U710 92L31000250110 : CPU ( TS2501 ) ( 3/4 )

PIN DESCRIPTION

Signal Name Shared Signal Pin # Type Description-TS2501

External Memory Interface Pins

SD_CKE GPIO_B[0] 56 I/O SDRAM Clock Enable signal. Active high. / GPIO_B[0]

SD_CLK GPO 44 I/O SDRAM Clock / GPO. SD_CLK can be used as a general purpose output.

SD_nCS SD_nCLK/

GPIO_B[1]

XA[21:20] DQM[0:1] 43:42 I/O External Bus Address Bit [21:20] / Data I/O Mask 0, 1

XA[19:18] DQS[1:0] 40:39 I/O External Bus Address Bit [19:18] / DDR SDRAM / GPIO_B[1]

XA[17] ND_CLE 38 I/O External Bus Address Bit [17] / CLE for NAND Flash

XA[16] SD_nRAS 37 I/O External Bus Address Bit [16] / SDRAM RAS signal / ALE for NAND Flash

XA[15] SD_nCAS 36 I/O External Bus Address Bit [15] / SDRAM CAS signal

XA[14] SD_BA[1] 35 I/O External Bus Address Bit [14] / SDRAM Bank Address 1

XA[13] SD_BA[0] 34 I/O External Bus Address Bit [13] / SDRAM Bank Address 0

XA[12:7] 31:26 I/O External Bus Address Bit [12:0]

XA[6:0] 23:17

XA[15:9] 15:9 I/O External Bus Address Bit [15:0]

XA[8:4] 6:2

XA[3:0] 128:125

NCS[3:0] ND_nOE[3:0] /

GPIO_B[5:2]

ND_nWE GPIO_B[7] 57 I/O NAND Flash WE. Active low. / GPIO_B[7]

nWE 58 I/O Static Memory Write Enable signal. Active low.

nOE 59 I/O Static Memory Write Output Enable signal. Active low.

READY 73 I Ready information from external device.

GPIO_B[0] SD_CKE 56 I/O GPIO[0] / SDRAM clock control

GPIO_D[21:18]FGPIO[14:11] /

CISD[7:4]

GPIO_D[17] FGPIO[10] / SCL

/ CISHS

GPIO_D[16] FGPIO[9] / SDA /

CISVS

GPIO_D[15] FGPIO[9] /

CISCLK

ADIN_0 - 82 AI General purpose multi-channel ADC input 0

ADIN_2 - 83 AI General purpose multi-channel ADC input 2

ADIN_4 - 84 AI General purpose multi-channel ADC input 4

XIN - 74 I Main Crystal Oscillator Input for PLL. 12MHz Crystal must be used if USB

XOUT - 75 O Main Crystal Oscillator Output for PLL

XFILT - 78 AO PLL filter output

XTIN - 69 I Sub Crystal Oscillator Input. 32.768kHz is recommended. Input voltage must

XTOUT - 70 O Sub Crystal Oscillator Output

MODE1 - 98 I Mode Setting Input 1. Pull-down for normal operation.

PKG1 - 89 I Package ID1. Pull-up for normal operation.

nRESET - 72 I System Reset. Active low.

TDI - 99 I JTAG serial data input for ARM940T

TMS - 100 I JTAG test mode select for ARM940T

TCK - 101 I JTAG test clock for ARM940T

TDO - 102 I/O JTAG serial data output for ARM940T. External pull-up resistor is required to

nTRST - 103 I JTAG reset signal for ARM940T. Active low.

VDDIO - 112

VDD_USB - 64 PWR Power for USB I/O (3.3V)

46 I/O Chip select signal for SDRAM, Active low / Inverted SD_CLK for DDR SDRAM

50:47 I/O External Bus Chip Select [3:0] / NAND Flash Output Enable [3:0] /

96:93 I/O GPIO_D[21:18] / Fast GPIO bits 14 ~ 11 / Camera Interface Data Inputs

92 I/O GPIO_D[17] / Fast GPIO bit 10 / 12C SCL / Camera Interface Hsync.

91 I/O GPIO_D[16] / Fast GPIO bit 9 / 12C SDA / Camera Interface Vsync.

90 I/O GPIO_D[15] / Fast GPIO bit 8 / Camera Interface Clock

PWR Digital Power for I/O (1.8V ~ 3.3V)

76

33

16

Refer to section “MEMORY CONTROLLER”.

(MCFG register Bit[3] and Bit [1])

/ GPIO_B[1]

GPIO_B[5:2]

SDRAM / Inverted Clock for DDR SDRAM.

3 ~ 0. Internal pull-up resistors are enabled at reset. GPIO_D[19:18] are

disabled in TS250IT(N.C).

ADC Input Pins

Clock Pins

Boot Mode is required. Input voltage must not exceed VDD_OSC

(1.95V max).

not exceed VDD_OSC (1.95V max).

Mode Control Pins

JTAG Interface Pins

prevent floating during normal operation.

Power Pins

7 – 4

Page 53

U710 92L31000250110 : CPU ( TS2501 ) ( 4/4 )

Signal Name Shared Signal Pin # Type Description-TS2501

VDD_OSC - 71 PWR Digital Power for Oscillators (1.8V)

VDDI - 119

109

41

24

7

VDDI_ADC - 87 PWR Digital Power for ADC (1.8V)

VDDA_ADC - 81 PWR Analog Power for ADC (3.3V)

VDDA_PLL - 77 PWR Analog & Digital Power for PLL (1.8V)

VSSIO - 97

65

45

32

1

VSSI - 120

110

55

25

8

VSSI_ADC - 88 GND Digital Ground for ADC

VBBA_ADC - 86 GND Analog Ground for ADC

VSSA_ADC - 85 GND Analog Ground for ADC

VBBA_PLL - 80 GND Analog Ground for PLL

VSSA_PLL - 79 GND Analog Ground for PLL

PWR Digital Power for Internal Core (1.8V)

GND Digital Ground for I/O

GND Digital Ground for Internal

QT-MP3W

7 – 5

Page 54

QT-MP3W77

U711 92L31003980031 : FLASH MEMORY ( SST39VF800A )

A15

A14

A13

A12

A11

A10

WE#

A18

A17

NC

NC

NC

NC

NC

NC

1

2

3

4

5

A9

A8

A7

A6

A5

A4

A3

A2

A1

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

SST39LF / VF800A

X-Decoder

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

SuperFlash

Memory

A16

NC

V

SS

DQ15

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

DD

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

0E#

V

SS

CE#

A0

Memory Address

Address Buffer & Latches

Y-Decoder

CE#

OE#

Control Logic

I/O Buffers and Data Latches

WE#

DQ

Figure 7-4 BLOCK DIAGRAM OF IC

PIN DESCRIPTION

Symbol Pin Name Functions

1

-

A Address Inputs To provide memory addresses. During Sector-Erase address lines will select theA

MSDD0

DQ Data Input/output To ouput data during Read cycles and receive input data during Write cycles.

DQ

-

15 0

sector. During Block-Erase address lines will select the block.

Data is internally latched during a Write cycle.

-

AA

MS 15

The outputs are in tri-state when OE# or CE# is high.

CE# Chip Enable To activate the device when CE# is low.

OE# Output Enable To gate the data output buffers.

WE# Write Enable To control the Write operations.

V Power Supply To provide power supply voltage:

3.0-3.6V for SST39LF200A/400A/800A

2.7-3.6V for SST39VF200A/400A/800A

V Ground

SS

NC No Connection Unconnected pins.

1.

A Most significant address=

MS

A for SST39LF/VF200A,=MSA

16

for SST39LF/VF400A, andA

17

for SST39LF/VF800AA

18

-

AA

MS 11

-

15DQO

7 – 6

Page 55

U901 92L31000964110 : CD SERVO ( SC9641 )

R

VREF

VDD0

VSS0

VDDA

RESET

D

C

A

RAD

FOC

SLED

VSSP

BCLK

MOTO

VDDP

V

GND

TRAY_SW

SLED_SW

LDON

48

47 46 45 44 43 42

49

CR

50

CL

L

51

52

53

54

55

56

NC

57

58

59

DD

60

61

62

63

64

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

B

VDDA1

VAAA1

TESR

IO.0

IO.1

IO.2

IO.3

IO.4

41 40 39 38 37 36 35 34 33

IO.5

SC9641

E

F

VCOM

Vadc

Idata

RFIN

RFREF

IO.6

lr

IO.7

VSSA2

ACK

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

VDDA2

QT-MP3W

STB

DATA

CL16

MCLK_IN

NC

DATA_IN

SCLK_IN

WCLK_IN

ERR

DATA_OUT

SCLK_OUT

WCLK_OUT

MUTE

MODE

CROUT

CRIN

B

C

D

E

F

VCOM

Vadc

Idata

RFIN

RFREF

MOTO

LDON

CRIN

CROUT

IO.0

SLED

FOC

RAD

4A

3

Analog

5

6

8

7

9

10

11

12

13

lr

14

58

64

17

18

and

Digital

Conversion

Digital Signal

Processor

Decode

Clock

control

30

Servo signal

Processor

CL 16

IO.1

IO.2

IO.3

IO.4

IO.5

Microcomputer

Connector

Audio D/A

Conversion

51 50 49 48 47

L

R

CL

CR

IO.6

IO.7

4140393837363534545352

VREF

33

32

31

43

42

62

63

21

22

23

24

29

25

26

27

ACK

STB

DATA

RESET

TEST

TRAY_SW

SLED_SW

WCLK_OUT

SCLK_OUT

DATA_OUT

ERR

MCLK_IN

WCLK_IN

SCLK_IN

DATA_IN

Figure 7-5 BLOCK DIAGRAM OF IC

7 – 7

Page 56

QT-MP3W777

U902 92L31000925910 : MOTOR DRIVER ( SC9259 )

VOTK2

GND3

VITK2

VOTK1

VREF

VITK1

CC2

V

FIN (GND)

CC1

V

VISL

LD CTL

VOSL1

VOSL2

VOLD1

VOLD2

21 20 19 18 17 16 1528 27 26 25 24 23 22

SA9259

1 2 3 4 5 6 7 8 9 10 11 12 13 14

FIN (GND)

GND1

VILD1

VISP

VOSP2

VOSP1

GND2

VILD2

VOFC2

VOFC1

VIFC2

VIFC1

REB

REO

MUTE

28 27 26 25 24 23 22 21 20 19 18 17 16 15

LEVER CONVERSION

BUFFER

10K

+

10K

LEVER CONVERSION

BUFFER

LEVER CONVERSION

BUFFER

TSD

10K

+

10K

+

+

+

LEVER CONVERSION

BUFFER

10K

10K

Voltage Regulatory

+

10K

2.5V

10K

50K

MUTE

10K

50K

10K

+

LEVER CONVERSION

BUFFER

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Figure 7-6 BLOCK DIAGRAM OF IC

7 – 8

Page 57

U903 92L31000961810 : CD RF ( SA9618 )

VTH

QT-MP3W

V

1

16

DD

5

4

PD2

VREF

VREF

6K

VREF

10K

10K

LD

MON

PD1

PD2

GND

NC

+

VREF

+

+

VREF

++++

6P

8K

6P

8K

2K

2K

2

3

4

5

6

7

8

2K

2K

15

LDON

14

AGC

RFRC

13

RFI

12

11

10

RFO

RFM

9

NC

SA9618/SA9618A

30K

30K

+ +

VREF

VREF

RFM

RFO

DD

V

7

10

11

16

12

14

1

3

RFI

54K

AGC

VTH

VREF

MON

VREF

Mode

SW

3.4K

10K

1.24V

55K

+

VL

12K

+

Figure 7-7 BLOCK DIAGRAM OF IC

10K

10K

+

55K

55K

RFRC

GND

LD

LDON

NC

NC

13

6

2

15

8

9

7 – 9

Page 58

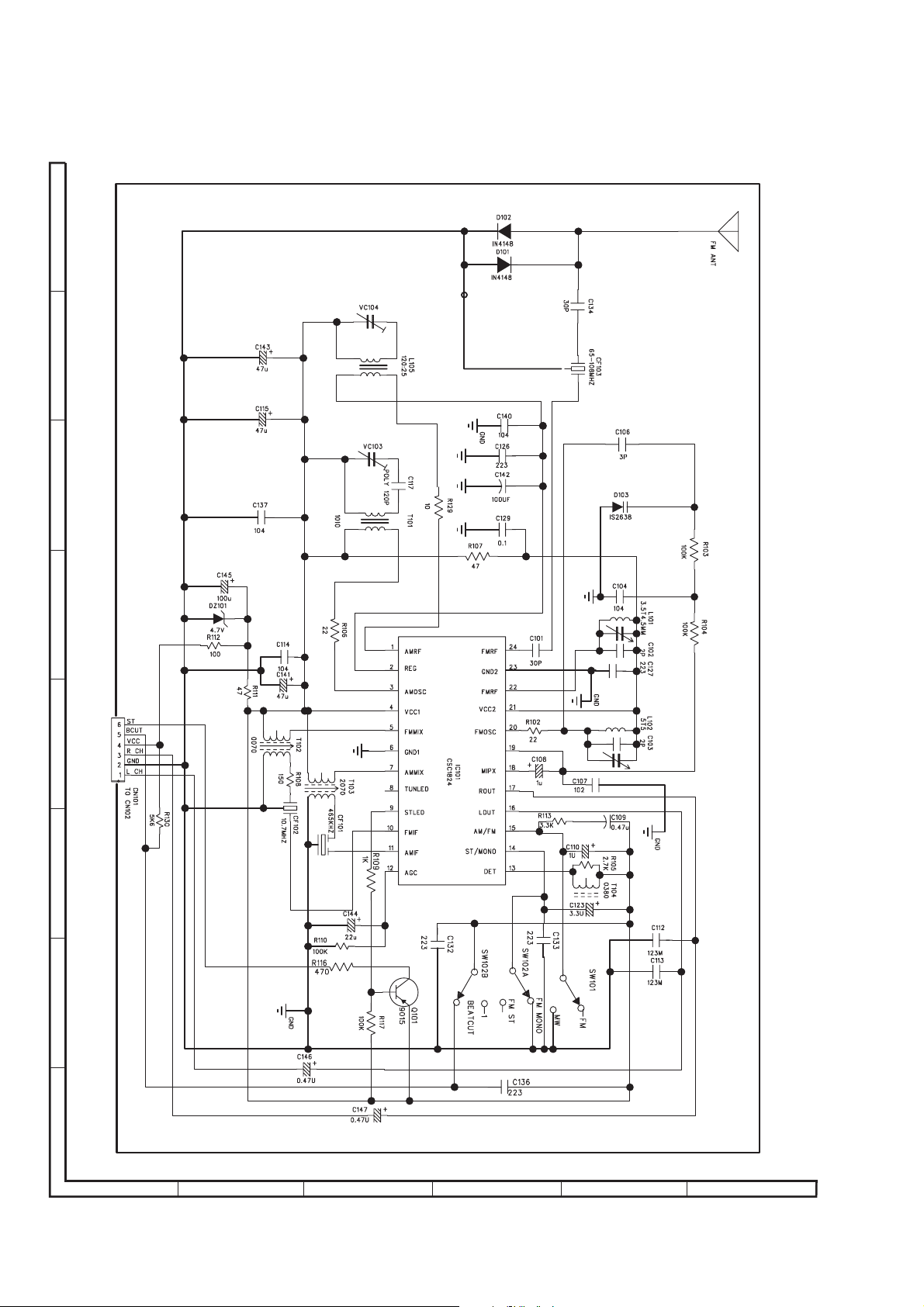

QT-MP3W

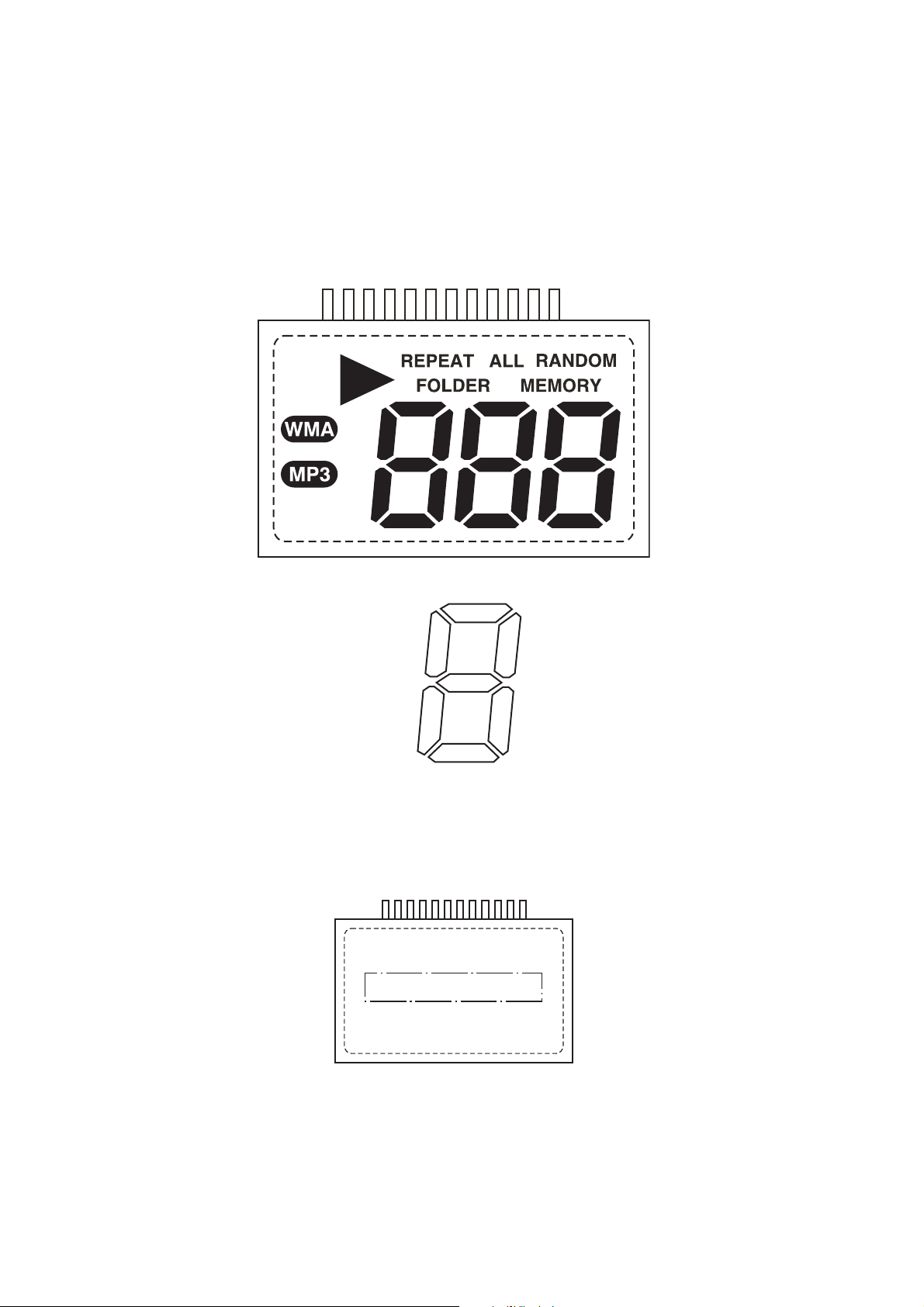

[2] LCD Display

DSP701 92L22020382621

GRID ASSIGNMENT

COM1

COM2

COM3

COM4

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

1

SEG8

12

OUTER DIMENSIONS

A

BF

G

CE

D

12 1

PATTERN AREA

7 – 10

Page 59

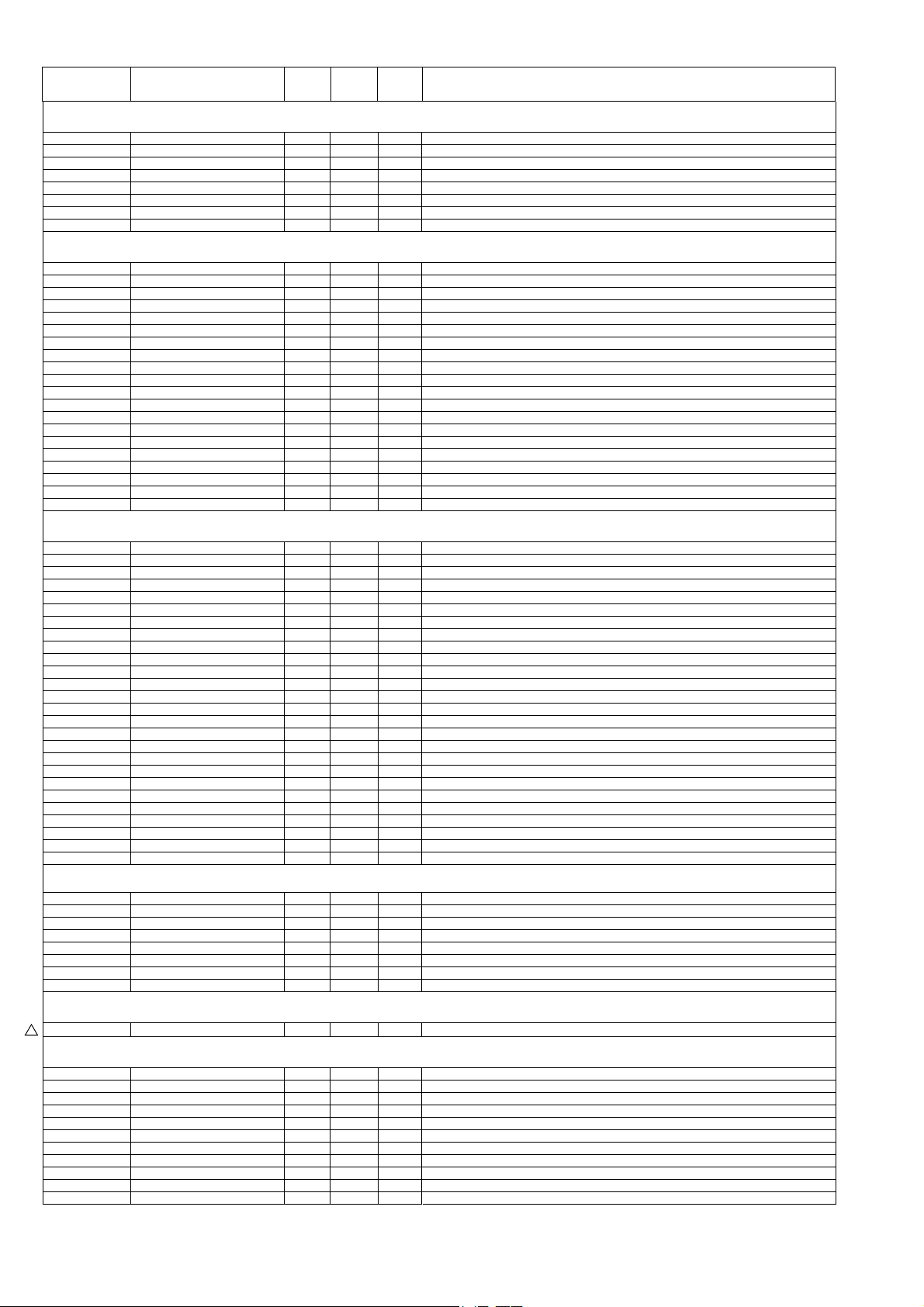

PARTS GUIDE

PORTABLE CD STEREO SYSTEM

QT-MP3W

[1] INTEGRATED CIRCUITS

[2] TRANSISTORS

[3] DIODES

[4] FILTERS

[5] TRANSFORMERS

CONTENTS

[8] CAPACITORS

[9] RESISTORS

[10] OTHER CIRCUITRY PARTS

[11] CABINET PARTS

[12] ACCESSORIES/PACKING PARTS

MODEL

QT-MP3W

[6] COILS

[7] VIBRATORS/CRYSTALS

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

!

SHARP CORPORATION

[13] P.W.B. ASSEMBLY

(Not Replacement Item)

[14] OTHER SERVICE PARTS

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 60

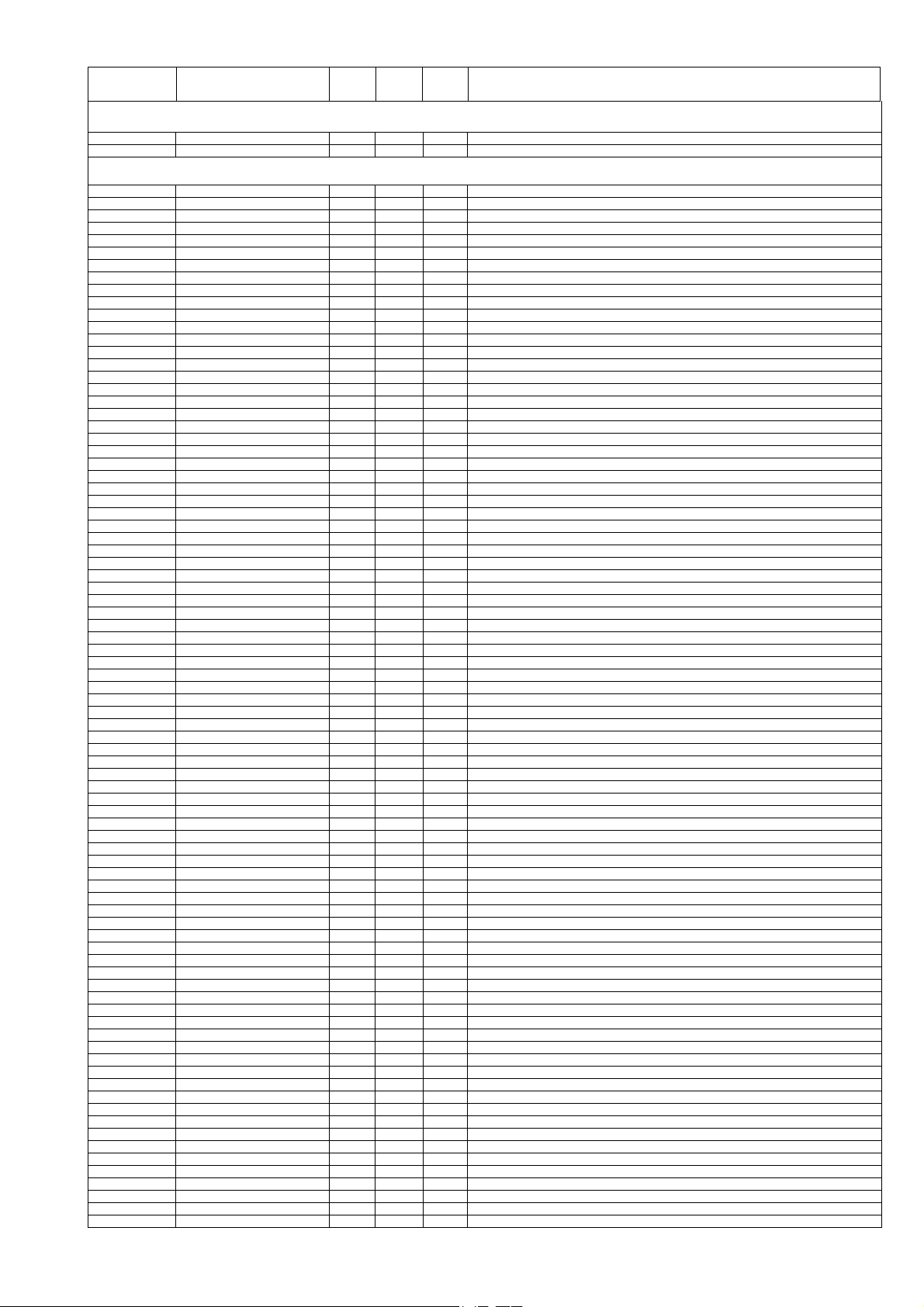

QT-MP3W

NO. PARTS CODE

PRICE

RANK

[1] INTEGRATED CIRCUITS

IC101 92L21000182400 AM CSC-1824

IC201 92L21000330800 AH BA-3308

IC301 92L21000422700 AN LA-4227

IC501 92L21000405200 AH TC4052

IC901 92L31000215747 AL TA2157

IC902 92L31094580600 AT TC94A58FAG061

IC903 92L31000166968 AK MM1669XH

IC904 92L31094340002 BC TC94A34FG

[2] TRANSISTORS

Q101 92L20700901530 AB 9015C

Q201 92L30700901430 AB 9014C

Q202 92L30700901430 AB 9014C

Q203 92L30700901430 AB 9014C

Q213 92L20700901430 AB 9014C

Q214 92L20700901430 AB 9014C

Q223 92L20700901430 AB 9014C

Q301 92L20700901430 AB 9014C

Q302 92L20700901430 AB 9014C

Q304 92L20700901430 AB 9014C

Q305 92L20700901430 AB 9014C

Q311 92L20700901430 AB 9014C

Q801 92L30700901430 AB 9014C

Q802 92L20700805030 AC 8050C/D

Q901 92L30700081200 AC 2SA-812

Q902 92L20719076440 AE 2SB-764

Q903 92L20700805030 AC 8050C/D

Q904 92L20700805030 AC 8050C/D

Q905 92L20700805030 AC 8050C/D

Q1101 92L20718206100 AH 2SD-2061E

[3] DIODES

D101 92L20610414800 AB IN-4148

D102 92L20610414800 AB IN-4148

D103 92L20610263800 AC IS-2638

D211 92L20610414800 AB IN-4148

D301 92L20630400100 AB IN-4001

D303 92L20610414800 AB IN-4148

D308 92L20620005602 AC ZENER 5.6V ( 1/2W )

D309 92L20630400100 AB IN-4001

D311 92L20610414800 AB IN-4148

D312 92L20610414800 AB IN-4148

D323 92L20610414800 AB IN-4148

D331 92L20610414800 AB IN-4148

D333 92L20610414800 AB IN-4148

D901 92L20620002402 ZENER 2.4V ( 1/2W )

D902 92L20620003902 ZENER 3.9V ( 1/2W )

D903 92L20620004302 AB ZENER 4.3V ( 1/2W )

D1101 92L20630400100 AB IN-4001

D1102 92L20630400100 AB IN-4001

D1103 92L20630400100 AB IN-4001

D1104 92L20630400100 AB IN-4001

DZ101 92L20620005102 AC ZENER 5.1V ( 1/2W )

DZ1101 92L20620008202 AC ZENER 8.2V ( 1/2W )

LED701 92L22708030000 AC LED ROUND TYPE 3mm RED

LED702 92L22708030000 AC LED ROUND TYPE 3mm RED

LED703 92L22708050012 AG LED ROUND 5mm 53B3SC08 SUPER

LED704 92L22708050001 AC LED ROUND TYPE 3mm RED

[4] FILTERS

CF101 92L20834653000 AC 450 KHz 3 PINS

CF102 92L20801073018 AD Ceramic Filter,10.7Mhz

CF103 92L20887010850 AD Band Pass Filter

T101 92L20918101010 AD Intermediate.Frequency,1010 RED 10mm

T102 92L20915007010 AD Intermediate.Frequency,0070 ORANGE 10mm

T103 92L20925207010 AD Intermediate.Frequency,2070 YELLOW 10mm

T104 92L20916038010 AD Intermediate.Frequency,0380 PINK 10mm

T801 92L20922363010 AE Intermediate.Frequency,3630 BLACK 10mm

[5] TRANSFORMER

!

PT1 92L15230236918 AY POWER ( MAIN )

[6] COILS

L3 92L32612010312 AC Inductor 10uH

L101 92L21303504570 AA FM COIL 3.5T 4.5x0.7 mm

L102 92L21302504570 AA FM COIL 2.5T 4.5x0.7 mm

L301 92L22104503014 AB FERRITE BEAD 4.5x3x1.4mm

L302 92L22104503014 AB FERRITE BEAD 4.5x3x1.4mm

L303 92L22104503014 AB FERRITE BEAD 4.5x3x1.4mm

L304 92L22104503014 AB FERRITE BEAD 4.5x3x1.4mm

L901 92L32612010312 AC Inductor 10uH

L902 92L32612010312 AC Inductor 10uH

L903 92L32612010312 AC Inductor 10uH

L904 92L22600260000 AD CHOKE COIL 26uH

NEW

MARK

PART

RANK

DESCRIPTION

1

Page 61

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

RANK

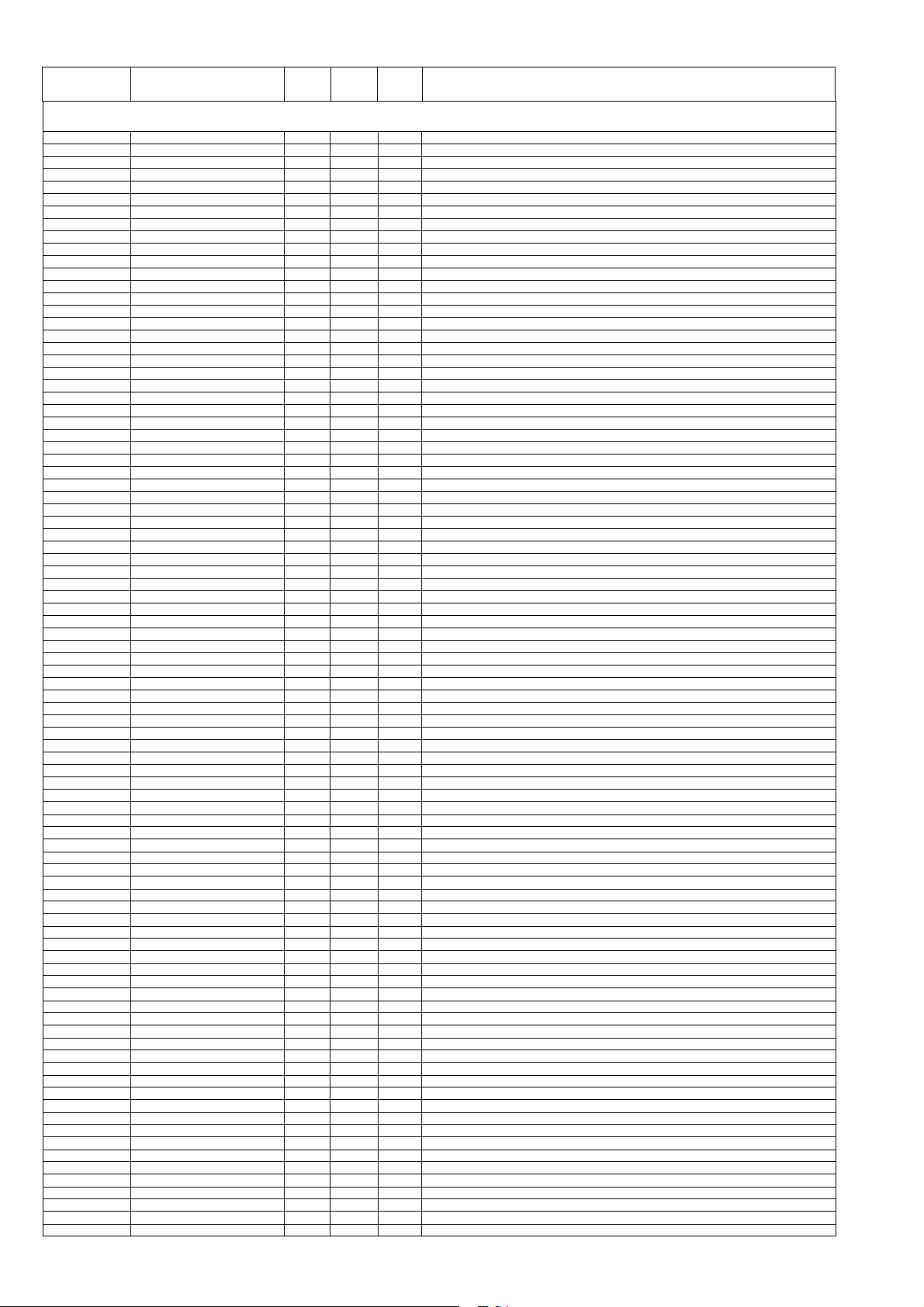

[7] VIBRATORS/CRYSTALS

X901 92L22916934402 AF CRYSTAL 16.9344MHz

X902 92L22916934402 AF CRYSTAL 16.9344MHz

[8] CAPACITORS

C1 92L00406476216 AB 47 UF/16V,Electrolytic [Use in Tuner PWB]

C1 92L30233103150 0.01 UF/50V [Use in CD PWB]

C2 92L00303153850 0.015 UF/50V [Use in Tuner PWB]

C2 92L30233103150 0.01 UF/50V [Use in CD PWB]

C3 92L30233103150 0.01 UF/50V

C4 92L30233103150 0.01 UF/50V

C5 92L30233103150 0.01 UF/50V

C6 92L30233103150 0.01 UF/50V

C7 92L30234104850 0.1 UF/50V

C8 92L30232222150 0.0022 UF/50V

C9 92L30234104850 0.1 UF/50V

C10 92L30233103150 0.01 UF/50V

C11 92L30222222150 0.0022 UF/50V

C12 92L30231101150 100 PF/50V

C13 92L30230220550 AA 22 PF/50V

C14 92L30234104850 0.1 UF/50V

C15 92L30230220550 AA 22 PF/50V

C16 92L30231101150 100 PF/50V

C18 92L30234104850 0.1 UF/50V

C19 92L30234104850 0.1 UF/50V

C20 92L30234104850 0.1 UF/50V

C21 92L30234104850 0.1 UF/50V

C22 92L30231101150 100 PF/50V

C23 92L30233103150 0.01 UF/50V

C24 92L30233103150 0.01 UF/50V

C25 92L30233103150 0.01 UF/50V

C26 92L30234104850 0.1 UF/50V

C27 92L30234104850 0.1 UF/50V

C30 92L30233103150 0.01 UF/50V

C31 92L30233103150 0.01 UF/50V

C47 92L30231101150 100 PF/50V

C50 92L30234104850 0.1 UF/50V

C52 92L30233103150 0.01 UF/50V

C101 92L00390300150 AB 30 PF/50V

C102 92L00390200150 AB 20 PF/50V [Use in Tuner PWB]

C102 92L30234104850 0.1 UF/50V [Use in CD PWB]

C103 92L00390240150 24 PF/50V

C104 92L00304104850 AB 0.1 UF/50V [Use in Tuner PWB]

C104 92L30234104850 0.1 UF/50V [Use in CD PWB]

C105 92L30234104850 0.1 UF/50V

C106 92L00390010150 AB 1 PF/50V

C107 92L00302102850 AB 0.001 UF/50V [Use in Tuner PWB]

C107 92L30233473150 AB 0.047 UF/50V [Use in CD PWB]

C108 92L00405105250 AB 1 UF/50V,Electrolytic

C109 92L00404104250 0.1 UF/50V,Electrolyti c

C110 92L00304104850 AB 0.1 UF/50V [Use in Tuner PWB]

C110 92L30234104850 0.1 UF/50V [Use in CD PWB]

C112 92L00503123199 0.012 UF/100V

C113 92L00503123199 0.012 UF/100V

C114 92L00304104850 AB 0.1 UF/50V

C115 92L00406476216 AB

117 9

C

C121 92L30233333150 0.033 UF/50V

C123 92L00405335250 AB 3.3 UF/50V,Electrolytic [Use in Tuner PWB]

C123 92L30233103150 0.01 UF/50V [Use in CD PWB]

C126 92L00303223850 AB 0.022 UF/50V

C127 92L00303223850 AB 0.022 UF/50V [Use in Tuner PWB]

C127 92L30233153150 0.015 UF/50V [Use in CD PWB]

C128 92L30230470550 AA 47 PF/50V

C129 92L00304104850 AB 0.1 UF/50V

C130 92L30233103150 0.01 UF/50V

C131 92L30232272150 0.0027 UF/50V

C133 92L00303223850 AB 0.022 UF/50V

C134 92L00390300150 AB 30 PF/50V

C135 92L00303223850 AB 0.022 UF/50V [Use in Tuner PWB]

C135 92L30232272150 0.0027 UF/50V [Use in CD PWB]

C136 92L00303223850 AB 0.022 UF/50V

C137 92L00304104850 AB 0.1 UF/50V [Use in Tuner PWB]

C137 92L30233473150 AB 0.047 UF/50V [Use in CD PWB]

C138 92L00304104850 AB 0.1 UF/50V [Use in Tuner PWB]

C138 92L30233473150 AB 0.047 UF/50V [Use in CD PWB]

C139 92L30233473150 AB 0.047 UF/50V

C140 92L00304104850 AB 0.1 UF/50V [Use in Tuner PWB]

C140 92L30230150550 15 PF/50V [Use in CD PWB]

C141 92L00406476216 AB 47 UF/16V,Electrolytic [Use in Tuner PWB]

C141 92L30230150550 15 PF/50V [Use in CD PWB]

C142 92L00407107216 AB 100 UF/16V,Electrolytic

C143 92L00406476216 AB 47 UF/16V,Electrolytic

C144 92L00406226216 AB 22 UF/16V,Electrolytic

C145 92L00407107216 AB 100 UF/16V,Electrolytic

C146 92L00404474250 AB 0.47 UF/50V,Electrolytic

C147 92L00404474250 AB 0.47 UF/50V,Electrolytic

C154 92L00304104850 AB 0.1 UF/50V

C155 92L00304104850 AB 0.1 UF/50V [Use in Tuner PWB]

2L20501125005 AC 120 PF/50V

47 UF/16V,Electrolytic

QT-MP3W

DESCRIPTION

2

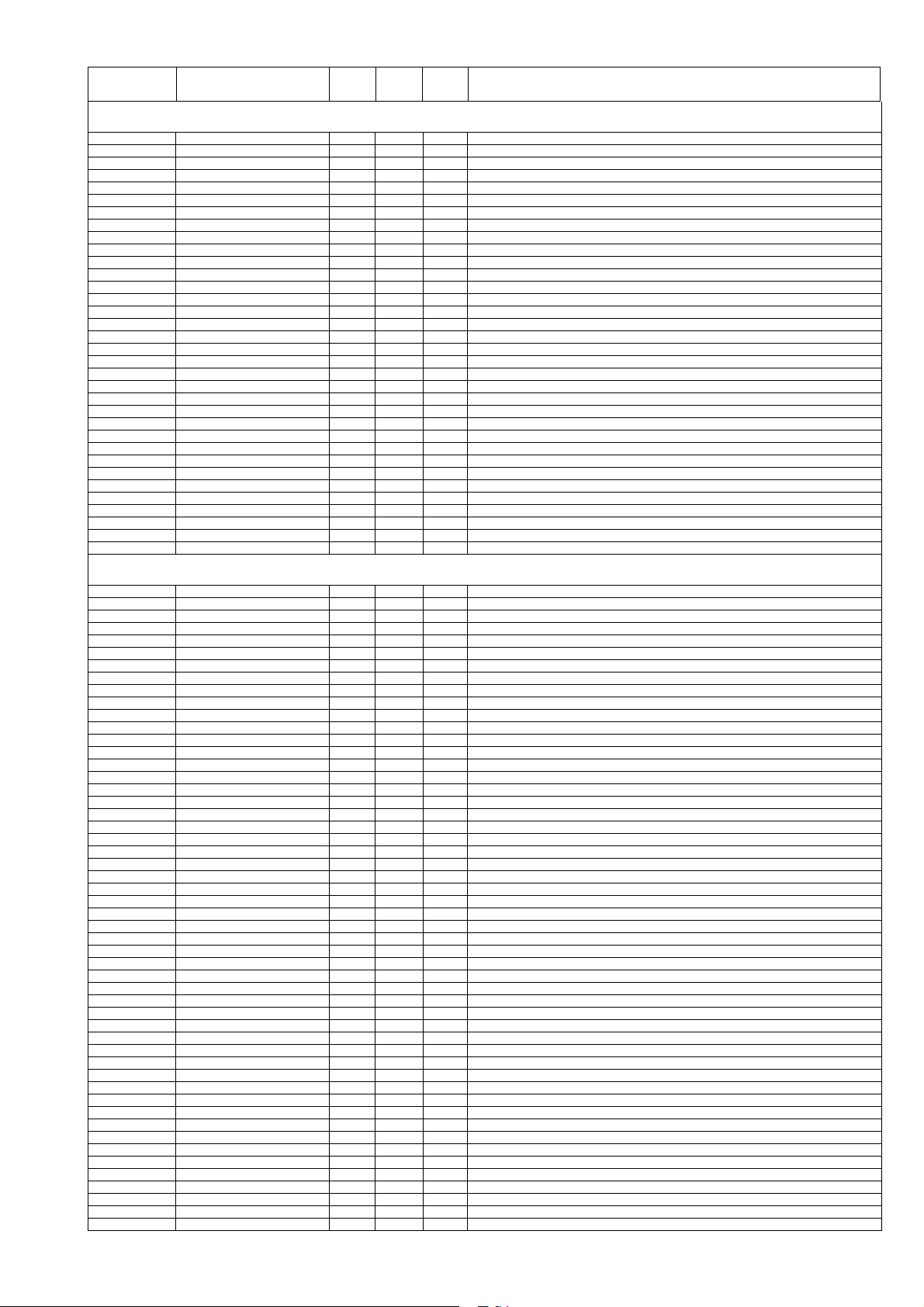

Page 62

QT-MP3W

NO. PARTS CODE

PRICE

RANK

[8] CAPACITORS

C155 92L30232272150 0.0027 UF/50V [Use in CD PWB]

C201 92L00502222199 AB 0.0022 UF/100V

C202 92L00502102199 AB 0.001 UF/100V

C203 92L00417107210 AB 100 UF/10V,Electrolytic

C204 92L00425475250 AB 4.7 UF/50V,Electrolytic

C205 92L00416106216 AB 10 UF/16V,Electrolytic

C206 92L00417107210 AB 100 UF/10V,Electrolytic

C207 92L00425475250 AB 4.7 UF/50V,Electrolytic

C208 92L00502222199 AB 0.0022 UF/100V

C209 92L00502222199 AB 0.0022 UF/100V

C210 92L00503333199 AB 0.033 UF/100V

C211 92L00502222199 AB 0.0022 UF/100V

C212 92L00502102199 AB 0.001 UF/100V

C213 92L00503333199 AB

C214 92

C215 92L00408108210 AC 1000 UF/10V,Electrolytic

C216 92L30220070150 AB 7 PF/50V

C217 92L30220070150 AB 7 PF/50V

C219 92L30223103550 AB 0.01UF/50V

C220 92L00416106216

C225 92L30223223550

C226 92L30220070150 AB 7 PF/50V

C227 92L30220070150 AB 7 PF/50V

C258 92L00406476216 AB 47 UF/16V,Electrolytic [Use in Audio PWB]

C258 92L30221101550 AB 100 PF/50V [Use in Tape PWB]

C259 92L30221101550 AB 100 PF/50V

C260 92L30223223550

C301 92L00407477210 AC 470 UF/10V,Electrolytic

C302 92L00408108225 AE 1000 UF/25V,Electrolytic

C303 92L00407107225 AC 100 UF/25V,Electrolytic

C304 92L00504154199 AC 0.15 UF/100V

C305 92L00504154199 AC 0.15 UF/100V

C306 92L00407107225 AC 100 UF/25V,Electrolytic

C307 92L00407477210 AC 470 UF/10V,Electrolytic

C308 92L00406476216 AB 47 UF/16V,Electrolytic

C309 92L00407107225 AC 100 UF/25V,Electrolytic

C310 92L00303153850 0.015 UF/50V

C311 92L00303153850 0.015 UF/50V

C312 92L00406476216 AB 47 UF/16V,Electrolytic

C313 92L00407107225 AC 100 UF/25V,Electrolytic

C314 92L00405105250 AB 1 UF/50V,Electrolytic

C315 92L00406476216 AB 47 UF/16V,Electrolytic

C316 92L00405105250 AB 1 UF/50V,Electrolytic

C318 92L00405475250 AB 4.7 UF/50V,Electrolytic

C321 92L00406476216 AB 47 UF/16V,Electrolytic

C326 92L00503473199 AC 0.047 UF/100V

C330 92L00503473199 AC 0.047 UF/100V

C332 92L00406476216 AB 47 UF/16V,Electrolytic

C353 92L00302472850 AA 0.0047 UF/50V

C355 92L00301501150 AB 500 PF/50V

C356 92L00301501150 AB 500 PF/50V

C362 92L00304104850 AB

C363 92L00303473850 AB 0.047 UF/50V

C364 92L00406476216 AB 47 UF/16V,Electrolytic

C388 92L00407477216 AC 470 UF/16V,Electrolytic

C502 92L00405105250 AB 1 UF/50V,Electrolytic

C503 92L00405105250 AB 1 UF/50V,Electrolytic

C505 92L00405105250 AB 1 UF/50V,Electrolytic

C506 92L00405105250 AB 1 UF/50V,Electrolytic

C508 92L00405105250 AB 1 UF/50V,Electrolytic

C509 92L00405105250 AB 1 UF/50V,Electrolytic

C510 92L00407107216 AB 100 UF/16V,Electrolytic

C511 92L00405105250 AB 1 UF/50V,Electrolytic

C512 92L00405105250 AB 1 UF/50V,Electrolytic

C514 92L00405105250 AB 1 UF/50V,Electrolytic

C515 92L00405105250 AB 1 UF/50V,Electrolytic

C517 92L00302102850 AB 0.001 UF/50V

C518 92L00302102850 AB 0.001 UF/50V

C701 92L00301101150 AB 100 PF/50V

C801 92L30221501550 AB 500 PF/50V

C803 92L00502332199 AB 0.0033 UF/100V

C804 92L00503223199 AB 0.022 UF/100V

C805 92L00417227210 AC 220 UF/10V,Electrolytic

C806 92L00503103199 AB 0.01 UF/100V

C901 92L00427107263 100 UF/6.3V,Electrolytic

C902 92L00407227210 AB 220 UF/10V,Electrolytic

C903 92L30234104850 0.1 UF/50V

C904 92L30234104850 0.1 UF/50V

C905 92L30233103150 0.01 UF/50V

C906 92L30233473150 AB 0.047 UF/50V

C907 92L30234104850 0.1 UF/50V

C908 92L30230050550 5 PF/50V

C909 92L30230560550 56 PF/50V

C910 92L30233333150 0.033 UF/50V

C911 92L00302472850 AA 0.0047 UF/50V [Use in Audio PWB]

C911 92L30232472150 AA 0.0047 UF/50V [Use in CD PWB]

C912 92L00406476210 47 UF/10V,Electrolytic

C913 92L30231471150 470 PF/50V

C914 92L30231471150 470 PF/50V

L30224104250 AA 0.1UF/50V

NEW

PART

MARK

AB 10 UF/16V

AB

AB

RANK

0.033 UF/100V

0.022 UF/50V

0.022 UF/50V

0.1UF/50V

3

,Electrolytic

DESCRIPTION

Page 63

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PART

RANK

[8] CAPACITORS

C915 92L00427107263 100 UF/6.3V,Electrolytic

C916 92L00427107263 100 UF/6.3V,Electrolytic

C917 92L00406476210 47 UF/10V,Electrolytic

C918 92L00406476210 47 UF/10V,Electrolytic

C919 92L00427107263 100 UF/6.3V,Electrolytic

C920 92L00427107263 100 UF/6.3V,Electrolytic

C921 92L00406226210 22 UF/10V,Electrolytic

C922 92L00425105250 1 UF/50V,Electrolytic

C923 92L00407227210 AB 220 UF/10V,Electrolytic

C924 92L00406476210 47 UF/10V,Electrolytic

C925 92L00407477225 470 UF/25V,Electrolytic [Use in Audio PWB]

C925 92L00425335250 3.3 UF/50V,Electrolytic [Use in CD PWB]

C926 92L00425335250 3.3 UF/50V,Electrolyti c

C927 92L00304104850 AB 0.1UF/50V [Use in Audio PWB]

C927 92L00407477210 AC 470 UF/10V,Electrolytic [Use in CD PWB]

C928 92L00427107210 100 UF/10V,Electrolytic

C929 92L00407227210 AB 220 UF/10V,Electrolytic

C930 92L00407477210 AC 470 UF/10V,Electrolytic

C931 92L00427107263 100 UF/6.3V,Electrolytic

C932 92L00427107263 100 UF/6.3V,Electrolytic

C933 92L00427107263 100 UF/6.3V,Electrolytic

C934 92L00427107263 100 UF/6.3V,Electrolytic

C944 92L00407227210 AB 220 UF/10V,Electrolytic

C972 92L00407227210 AB 220 UF/10V,Electrolytic

C987 92L00407477210 AC 470 UF/10V,Electrolytic

C1101 92L00303223850 AB 0.022 UF/50V

C1102 92L00303223850 AB 0.022 UF/50V

C1103 92L00303223850 AB 0.022 UF/50V

C1104 92L00303223850 AB 0.022 UF/50V

C1105 92L00408338225 AH 3300 UF/25V,Electrolytic

C1106 92L00407477225 470 UF/25V,Electrolytic

C1107 92L00407107225 AC 100 UF/25V,Electrolytic

C1108 92L00303223850 AB 0.022 UF/50V

CM1 92L00407227225 AC 220 UF/25V,Electrolytic

[9] RESISTORS

D313 92L00102682518 AA 6.8 KOHM 1/8W

J1 92L30120000518 AA 0 OHM 1/8W

J4 92L30110000514 AA 0 OHM 1/4W

J5 92L30110000514 AA 0 OHM 1/4W

J001 92L30120000518 AA 0 OHM 1/8W

J003 92L30110000514 AA 0 OHM 1/4W

J004 92L30120000518 AA 0 OHM 1/8W

J006 92L30110000514 AA 0 OHM 1/4W

J007 92L30110000514 AA 0 OHM 1/4W

J008 92L30110000514 AA 0 OHM 1/4W

J011 92L30110000514 AA 0 OHM 1/4W

J012 92L30110000514 AA 0 OHM 1/4W

J014 92L30120000518 AA 0 OHM 1/8W

J016 92L30120000518 AA 0 OHM 1/8W

L201 92L30120000518 AA 0 OHM 1/8W

L202 92L30120000518 AA 0 OHM 1/8W

L203 92L30120000518 AA 0 OHM 1/8W

L204 92L30120000518 AA 0 OHM 1/8W

R2 92L30133103516 AA 10 KOHM 1/16W

R3 92L30135225516 22 MOHM 1/16W

R4 92L30133103516 AA 10 KOHM 1/16W

R5 92L30133103516 AA 10 KOHM 1/16W

R9 92L30131101516 AA 0 OHM 1/16W

R10 92L30131101516 AA 0 OHM 1/16W

R11 92L30110000514 AA 0 OHM 1/4W

R12 92L30131221516 AA 220 OHM 1/16W

R13 92L30130000516 AA 0 OHM 1/16W

R14 92L30131101516 AA 0 OHM 1/16W

R15 92L30110000514 AA 0 OHM 1/4W

R16 92L30110000514 AA 0 OHM 1/4W

R24 92L30131271516 270 OHM 1/16W

R31 92L30132122516 AA 1.2 KOHM 1/16W

R33 92L30131221516 AA 220 OHM 1/16W

R45 92L30134104516 AA 100 KOHM 1/16W

R46 92L30133223516 AA 22 KOHM 1/16W

R47 92L30133103516 AA 10 KOHM 1/16W

R48 92L30133123516 AA 12 KOHM 1/16W

R49 92L30132222516 AA 2.2 KOHM 1/16W

R50 92L30132222516 AA 2.2 KOHM 1/16W

R102 92L001001005018 AA 10 OHM 1/8W

R103 92L00104104518 AA 100 KOHM 1/8W

R104 92L00104104518 AA 100 KOHM 1/8W

R105 92L00102272518 AA 2.7 KOHM 1/8W

R106 92L00100220518 AA 22 OHM 1/8W

R107 92L00100470518 AA 47 OHM 1/8W

R108 92L00101151518 AA 150 OHM 1/8W

R109 92L00102102518 AA 1 KOHM 1/8W

R110 92L00104104518 AA 100 KOHM 1/8W

R111 92L00100470518 AA 47 OHM 1/8W

R112 92L00101101518 AA 100 OHM 1/8W

R113 92L00102332518 AA

116 9

R

2L30133103516 AA 10 KOHM 1/16W [Use in CD PWB]

3.3 KOHM 1/8W

4

QT-MP3W

DESCRIPTION

Page 64

QT-MP3W

NO. PARTS CODE

PRICE

RANK

[9] RESISTORS

R116 92L00101471518 AA 470 OHM 1/8W [Use in Tuner PWB]

R117 92L00104104518 AA 100 KOHM 1/8W [Use in Tuner PWB]

R117 92L30133103516 AA 10 KOHM 1/16W [Use in CD PWB]

R118 92L30133153516 AA 15 KOHM 1/16W

R119 92L30135225516 22 MOHM 1/16W

R120 92L30134474516 AA 470 KOHM 1/16W

R121 92L30133473516 AA 47 KOHM 1/16W

R122 92L30132562516 5.6 KOHM 1/16W

R124 92L30133103516 AA 10 KOHM 1/16W

R126 92L30132562516 5.6 KOHM 1/16W

R127 92L30133103516 AA 10 KOHM 1/16W

R128 92L30130000516 AA 0 OHM 1/16W

R129 92L001001005018 AA 10 OHM 1/8W

R130 92L00102562518 AA 5.6 KOHM 1/8W

R133 92L30131221516 AA 220 OHM 1/16W

R134 92L30133103516 AA 10 KOHM 1/16W

R136 92L30133103516 AA 10 KOHM 1/16W

R138 92L30133103516 AA 10 KOHM 1/16W

R139 92L30132472516 AA 4.7 KOHM 1/16W

R140 92L30132392516 AA 3.9 KOHM 1/16W

R141 92L30132392516 AA 3.9 KOHM 1/16W

R142 92L30133223516 AA 22 KOHM 1/16W

R145 92L30132222516 AA 2.2 KOHM 1/16W

R149 92L30130000516 AA 0 OHM 1/16W

R201 92L30123473518 AA 47 KOHM 1/8W

R202 92L30124474518 AA 470 KOHM 1/8W

R203 92L30123473518 AA 47 KOHM 1/8W

R204 92L30122822518 AA 8.2 KOHM 1/8W

R205 92L30122562518 AA 5.6 KOHM 1/8W

R206 92L30122682518 AA 6.8 KOHM 1/8W

R207 92L30120270518 AA 27 OHM 1/8W

R208 92L30122682518 AA 6.8 KOHM 1/8W

R209 92L30122822518 AA 8.2 KOHM 1/8W

R210 92L30120270518 AA 27 OHM 1/8W

R211 92L30122562518 AA 5.6 KOHM 1/8W

R212 92L00101101518 AA 100 OHM 1/8W

R214 92L30122152518 AA 1.5 KOHM 1/8W

R215 92L30122152518 AA 1.5 KOHM 1/8W

R216 92L30123223518 AA 22 KOHM 1/8W

R219 92L30121101518 AA 100 OHM 1/8W

R220 92L30123103518 AA 10 KOHM 1/8W

R221 92L30123103518 AA 10 KOHM 1/8W

R222 92L30123103518 AA 10 KOHM 1/8W

R224 92L30122102518 AA 1 KOHM 1/8W

R225 92L30122392518 AA 3.9 KOHM 1/8W

R229 92L30122392518 AA 3.9 KOHM 1/8W

R242 92L00102222518 AA 2.2 KOHM 1/8W

R243 92L00102222518 AA 2.2 KOHM 1/8W

R258 92L00100220518 AA 22 OHM 1/8W

R301 92L00100022518 AA 2.2 OHM 1/8W

R302 92L00103103518 AA

03 92

R3

R304 92L00101121518 AA 120 OHM 1/8W

R306 92L00101121518 AA 120 OHM 1/8W

R307 92L00102222518 AA 2.2 KOHM 1/8W

R308 92L00102472518 AA 4.7 KOHM 1/8W

R309 92L00102472518 AA 4.7 KOHM 1/8W

R310 92L00102222518 AA 2.2 KOHM 1/8W

R314 92L00101151518 AA 150 OHM 1/8W

R315 92L00101151518 AA 150 OHM 1/8W

R317 92L00102472518 AA 4.7 KOHM 1/8W

R318 92L00102472518 AA 4.7 KOHM 1/8W

R321 92L00102822518 AA 8.2 KOHM 1/8W

R325 92L00102682518 AA 6.8 KOHM 1/8W

R334 92L00103103518 AA 10 KOHM 1/8W

R335 92L00103103518 AA 10 KOHM 1/8W

R341 92L00102472518 AA 4.7 KOHM 1/8W

R342 92L00102272518 AA 2.7 KOHM 1/8W

R345 92L00102102518 AA 1 KOHM 1/8W

R351 92L00103103518 AA 10 KOHM 1/8W

R352 92L00103103518 AA 10 KOHM 1/8W

R353 92L00102472518 AA 4.7 KOHM 1/8W

R355 92L00104124518 AA 120 KOHM 1/8W

R356 92L00104124518 AA 120 KOHM 1/8W

R357 92L00102102518 AA 1 KOHM 1/8W

R358 92L00102102518 AA 1 KOHM 1/8W

R361 92L00103153518 AA 15 KOHM 1/8W

R362 92L00103153518 AA 15 KOHM 1/8W

R363 92L00103473518 AA 47 KOHM 1/8W

R364 92L00102102518 AA 1 KOHM 1/8W

R365 92L00103103518 AA 10 KOHM 1/8W

R366 92L00102822518 AA 8.2 KOHM 1/8W

R367 92L00102822518 AA 8.2 KOHM 1/8W

R501 92L00103103518 AA 10 KOHM 1/8W

R502 92L00103103518 AA 10 KOHM 1/8W

R503 92L00103103518 AA 10 KOHM 1/8W

R504 92L00103103518 AA 10 KOHM 1/8W

R505 92L00102472518 AA 4.7 KOHM 1/8W

R506 92L00102472518 AA 4.7 KOHM 1/8W

L00100022518 AA 2.2 OHM 1/8W

NEW

MARK

PART

RANK

10 KOHM 1/8W

5

DESCRIPTION

Page 65

NO. PARTS CODE

PRICE

RANK

NEW