Page 1

QD-101MM

SERVICE MANUAL

SZ545QD-101MM

TFT DISPLAY UNIT

MODEL QD-101MM

• In the interests of user-safety the set should be restored to it's

original condition and only parts identical to those specified be

used.

CONTENTS

1. INTRODUCTION .........................................................................1

2. SPECIFICATIONS.......................................................................2

3. ADJUSTMENT OF PWB.............................................................5

4. CIRCUIT DESCRIPTION.............................................................8

5. TROUBLESHOOTING CHART.................................................21

6. CIRCUIT DIAGRAM & PWB.....................................................38

7. REPLACEMENT PARTS LIST.................................................54

8. ASSEMBLY DRAWINGS .........................................................60

9. INFORMATION..........................................................................64

SHARP CORPORATION

Page 2

1. INTRODUCTION

The QD-101MM is a liquid crystal display monitor.

It employs a high contrast, high response, 10.4-inch TFT liquid crystal display panel,which can

generate a maximum of 16,000,000 different colors. It offers a computer graphic screen which

responds in real time.

Moreover, the built-in composite video circuit and audio circuit can receive video signals of

VCR, laser disc.

Their controls and images can be adjusted with the main-body's buttons referring to the menu

screen.

This monitor also has a speaker to monitor audio signal.

In addition, an external control terminal has been provided to facilitate control of the display

unit's functions.

The power source is an external AC adaptor that provides 12V DC to display monitor unit.

This unit can be used with the following models and signals.

1.Personal computers

1) IBM, PC/XT, PC/AT, PS/2, PS/1, PS/55, Think Pad 700

2) Apple, MACII, MAC+/SE, MACIIcx, MACIIci, MACIIsi, MAC LC,

Power Book 160/180, Quadra

3) AT&T, PC6300WGS

4) SHARP, AX286/386

2.Video adaptors and signals

1) IBM, MDA(720X350)

2) IBM, CGA(640X200)

3) IBM, EGA(640X350)

4) IBM, MCGA(640X400, 640X480)

5) IBM, VGA(640X350, 640X400, 640X480, 720X400)

6) Apple, MACII Video Card (640X480)

7) Apple, MAC LC (640X480, 512X384)

8) Hercules, Graphic Card/Plus/Incolor Card (720X348, 720X350)

9) Composite video signals (PAL/NTSC/SECAM)

1

Page 3

2. SPECIFICATIONS

1.SPECIFICATIONS OF MAIN BODY

1.Display unit :10.4-inch TFT color LCD

(Amolphous silicone active matrix type : a Si TFT)

2.Display color :Approx.16,000,000 colors

3.Display area :211.2(W)X158.4(H)mm

4.Number of pixels :640X(RGB)X480 pixels (pixel = R+G+B dots)

5.Input video signal :TTL level R,G,B,r,g,b, Hsync, Vsync

TTL level R,G,B,I,Hsync, Vsync

TTL level Video, I, Hsync, Vsync

Analog IBM PS/2 type VGA signal

Analog Apple Macintosh II video card signal

Composite / S video signal (NTSC/PAL/SECAM)

6. Input connector :15-pin computer signal input connector (1)

Composite video input connector (1)

S-terminal video signal input connector(1)

Audio input connector (1)

12V DC input socket (1)

7. Switches and others :Power switch

MENU button (1), SELECT button (1),

UP button(1), DOWN button (1), RESET button (1)

8. Adjustment :Color adjustment, Brightness adjustment, Tint adjustment

Contrast adjustment, Audio level adjustment

Image horizontal/vertical position adjustment

Phase adjustment, Frequency adjustment

9. Functions Software reset

Freeze function

Input video signal auto-discrimination function

Menu screen control

Built-in speaker(1W)X1

10. Outside dimensions :280(W)X208(H)X47(D) [mm]

(11.0(W)X8.2(H)X1.9(D) [inches])

11. Weight :Approx. 1.3kg (main body alone)

(Approx.2.86lbs(main body alone))

12. Backlight :Fluorescent lamp

(cold-cathode Fluorescent X1)

2

Page 4

2.SPECIFICATIONS OF INTERFACE

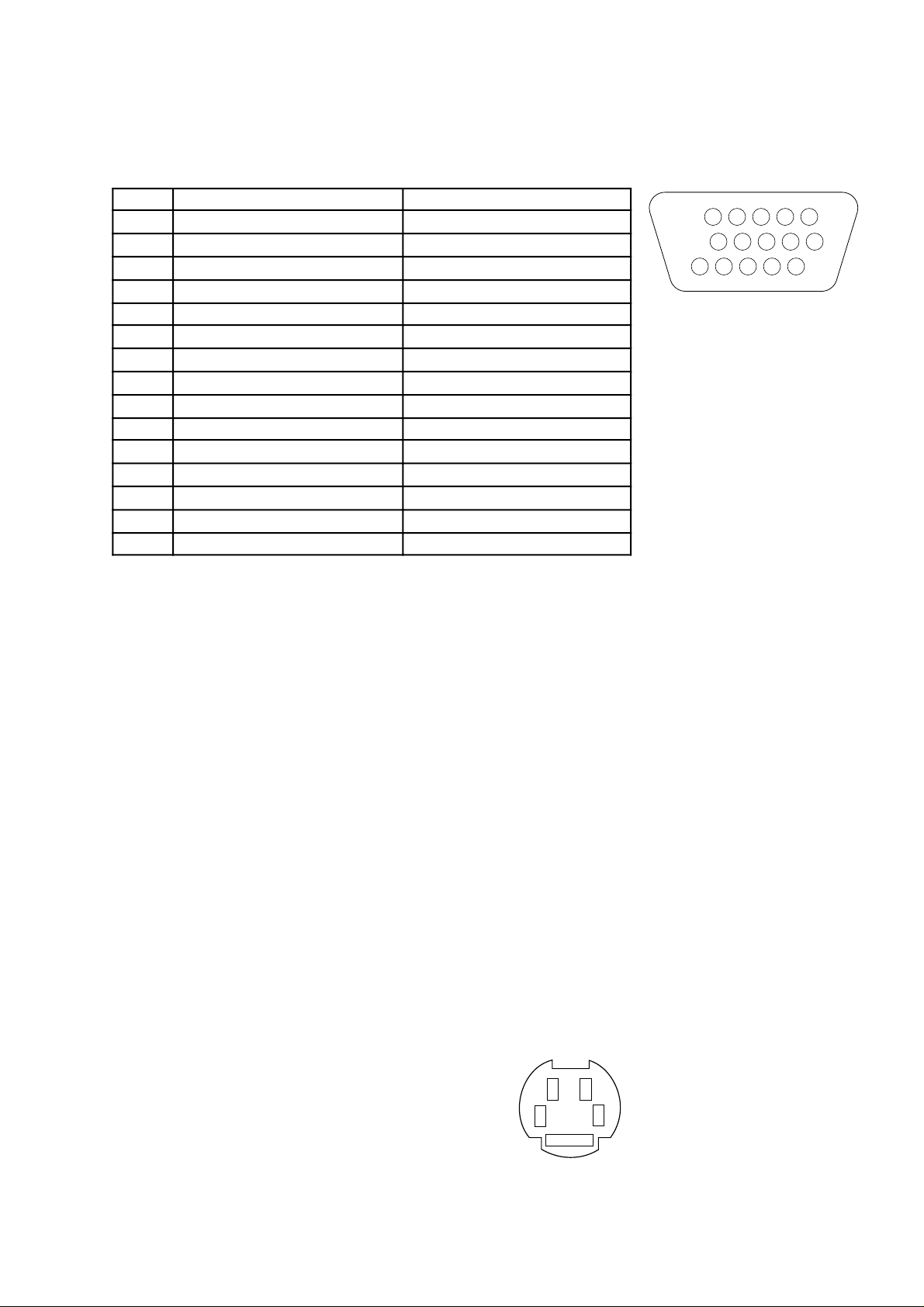

2.1.Computer signal input section

Signal layout

Pin No. Analog Signal Digital Signal

1 Analog Red N.C.

2 Analog Green Digital Green

3 Analog Blue Digital Blue

4 N.C. Digital Secondary Red(r)

5 N.C. Digital Red

6 Analog Red Return Digital Red Return(GND)

7 Analog Green Return Digital Green Return(GND)

8 Analog Blue Return Digital Blue Return(GND)

9 Test 1(Macintosh) N.C.

10 Test 2(GND) Test 2(N.C.)

11 GND GND

12 N.C. Digital Secondary Green(g,I)

13 Hsync/Csync Hsync

14 Vsync Vsync

15 N.C. Digital Secondary Blue(b.Video)

12345

678910

1112131415

Connector :Mini D-Sub 15-pin connector

JST EKHEY-15S-IF3P14-143

(applicable plug housing : JST KEC-15P)

Test 1 :When connecting to Apple Macintosh computer, this terminal must be

grounded.

Test 2 :This terminal must be grounded when inputting analog-type computer

signals.

Leave this terminal open(N.C.) when inputting digital computer signals.

2.2.Composite video signal input section

Connector :Pin jack (EIAJ RC-6703A)

2.3.Audio signal input section

Connector :Pin jack (EIAJ RC-6703A)

2.4.Power input section

Input pin :HEC0470-01-640 [Hoshiden Co., Ltd.] or equivalent

Center pin +

AC adaptor :Accessory AC adaptor DADP-2004PAZZ

Input voltage :DC12V (when main body is loaded)

2.5.S-terminal video signal input section

Signal layout : 1.GND

2.GND

3.Y signal

4

2

3

1

4.C signal

3

Page 5

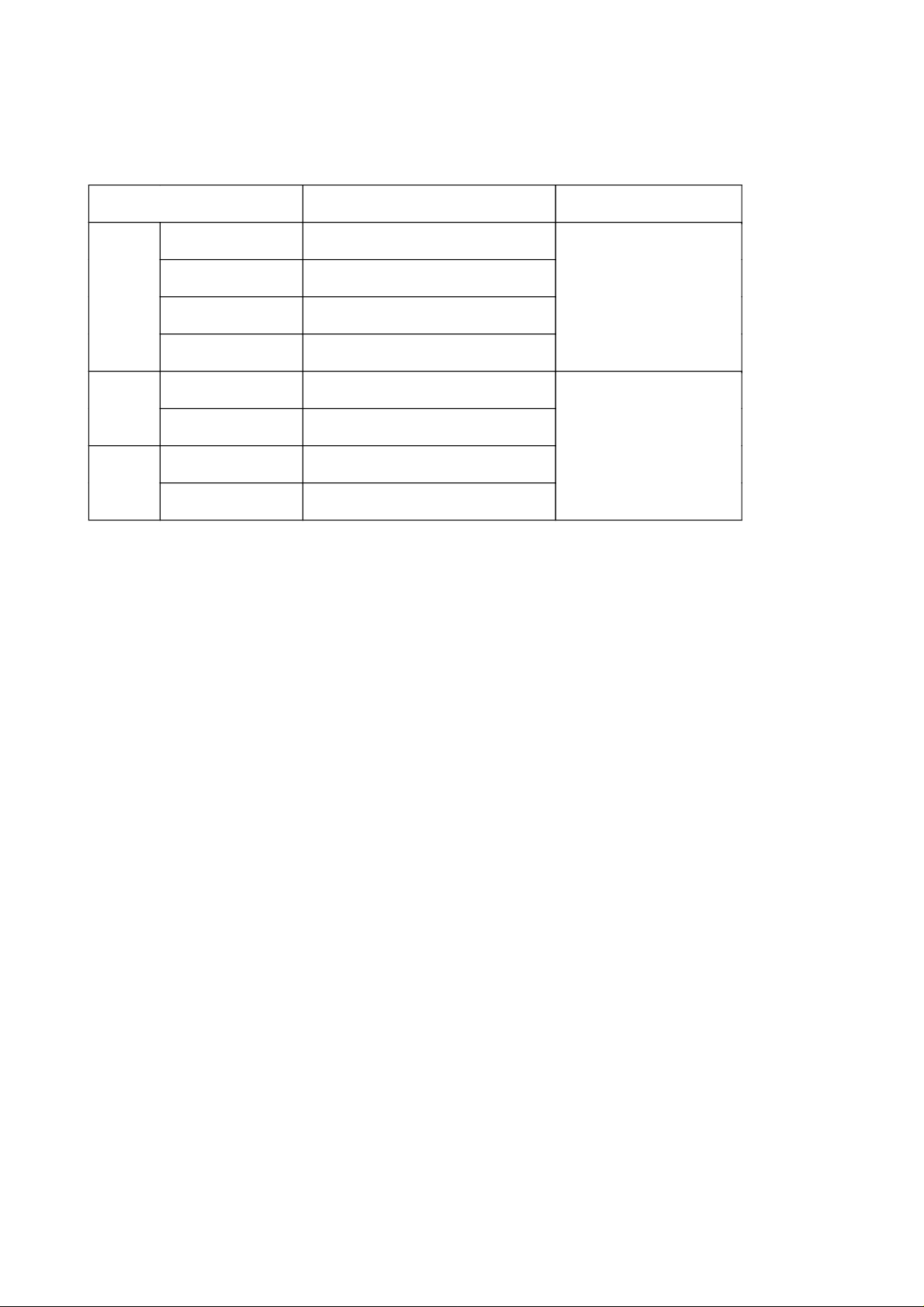

3.SPECIFICATIONS OF ENVIRONMENT

Basically, these environment specifications apply to the main body and its accessories.

Item Specification Remark

Type Single-phase 2-wire type, 1 ground line

Power

Operation

Storage

Frequency 50 / 60 Hz

Input voltage AC 100~240V

Output voltage DC 11.5 ~ 13.8V

Operating temperature 0 ~ 35 °C

Operating humidity 20 ~ 80 %RH

Storage temperature -20 ~ 60 °C

Storage humidity 20 ~ 80 %RH

Special AC adaptor accessory is

used.

Without dew condensation.

Absolute humidity shall be less

than 35 °C / 80 % RH.

4

Page 6

3. ADJUSTMENT OF PWB

The QD-101MM has a Main printed-wiring board (PWB) that needs to be adjusted.

The following paragraphs describe how to adjust the Main PWB. Correct adjustments are

essential for the unit to operate properly. After repair or maintenance, it is necessary to readjust

them. Before adjusting the control block, be sure to verify that the power supply block is

adjusted, and then adjust the control block.

1. ADJUSTMENT OF POWER SUPPLY BLOCK

There are two power voltage adjusting points: VR1 for V

, VR2 for V

CPU

LCD

.

1) Connect the AC adaptor connector plug to J1.

Verify that the output of AC adaptor approximates 12V.

2) Before turning on the power switch, check the conductive pattern on the rear of the

PWB for defects or foreign material that may short the conductive paths.

3) Turn on the power switch SW1 to verify that the LED lights.

4) V

adjustment

CPU

Connect the + lead of DC voltmeter to TP203, and the - lead to TP206.

While turning VR1 with a flat-tipped screwdriver, observe the voltmeter.

Adjust the voltage to 5.15 ±0.05V.

5) VCC voltage check

Connect the + lead of the DC voltmeter to TP202. Verify the voltage of 4.90 to 5.15V.

6) V

adjustment

LCD

Connect the + lead of the DC voltmeter to TP200.

While turning VR2 with a flat-tipped screwdriver, observe the voltmeter.

Adjust the voltage to 5.05 ±0.05V.

7) +10V voltage check

Connect the + lead of the DC voltmeter to TP204. Verify the voltage of 10±0.5V.

2.ADJUSTMENT OF CONTROL BLOCK

2.1.Offset adjustment of computer signal input amplifier

1) Turn off the power, and connect TP10 and TP303 to the DC voltmeter.

(Connect the earth terminal of the probe to TP10.)

2) Input the signal of Fig. 1-B to J2.

3) Turn on the power. Observing the DC voltmeter, adjust the TP303 level to 1.15±0.05V

by turning VR303 with the flat-tipped screwdriver.

2.2.Gain adjustment of computer signal input amplifier

1) Turn off the power, and connect TP303 and TP300 to an oscilloscope.

(Connect the earth terminal of the probe to TP10.)

2) Input the signal of Fig. 1-C to J2.

3) Turn on the power. Observing the oscilloscope, adjust the TP303 level to be equal

to TP300 level by turning VR300 with the flat-tipped screwdriver.

(Output voltage is approx.3.8V at TP300.)

4) Turn off the power, and reconnect the probe from TP303 to TP304.

5) Turn on the power. Observing the oscilloscope, adjust the TP304 level to be equal

to TP300 level by turning VR301 with the flat-tipped screwdriver.

6) Turn off the power, and reconnect the probe from T304 to TP305.

5

Page 7

7) Turn on the power. Observing the oscilloscope, adjust the TP305 level to be equal

to TP300 level by turning VR302 with the flat-tipped screwdriver.

2.3.VCO adjustment

1) Connect the + lead of the DC voltmeter to TP207, and the - lead to TP10.

2) Input the video timing of Fig. 1-A to J2.

3) After turning on the power, leave it as it is for approx. 3 minutes.

Then turn L200 with ceramic driver to adjust the voltage of TP207 to 2.5±0.2V. (*1)

4) Input the video timing of Fig. 1-B or C to J2 .

5) Then turn L201 with ceramic driver to adjust the voltage of TP207 to 4.1±0.05V. (*2)

(*1) Since the voltage of TP207 varies depending on the material of the driver used,

keep the driver away from the core when checking the voltage.

(*2) It is factory-adjusted at the timing of PC9801 640X400 at shipment.

2.4.Audio speaker level adjustment

1) Input the 1KHz, 500mV(RMS) sine wave from an oscillator to the audio signal input

terminal CN502.(The audio signal level should be adjusted when power switch of QD 101MM is on.)

2) Set the volume level to maximum and the audio mute switch to off.

3) Connect an effective value type AC voltmeter to TP502 and adjust the voltage of TP504

to 2.85V(RMS) by turning VR501 with the flat-tipped screw driver.

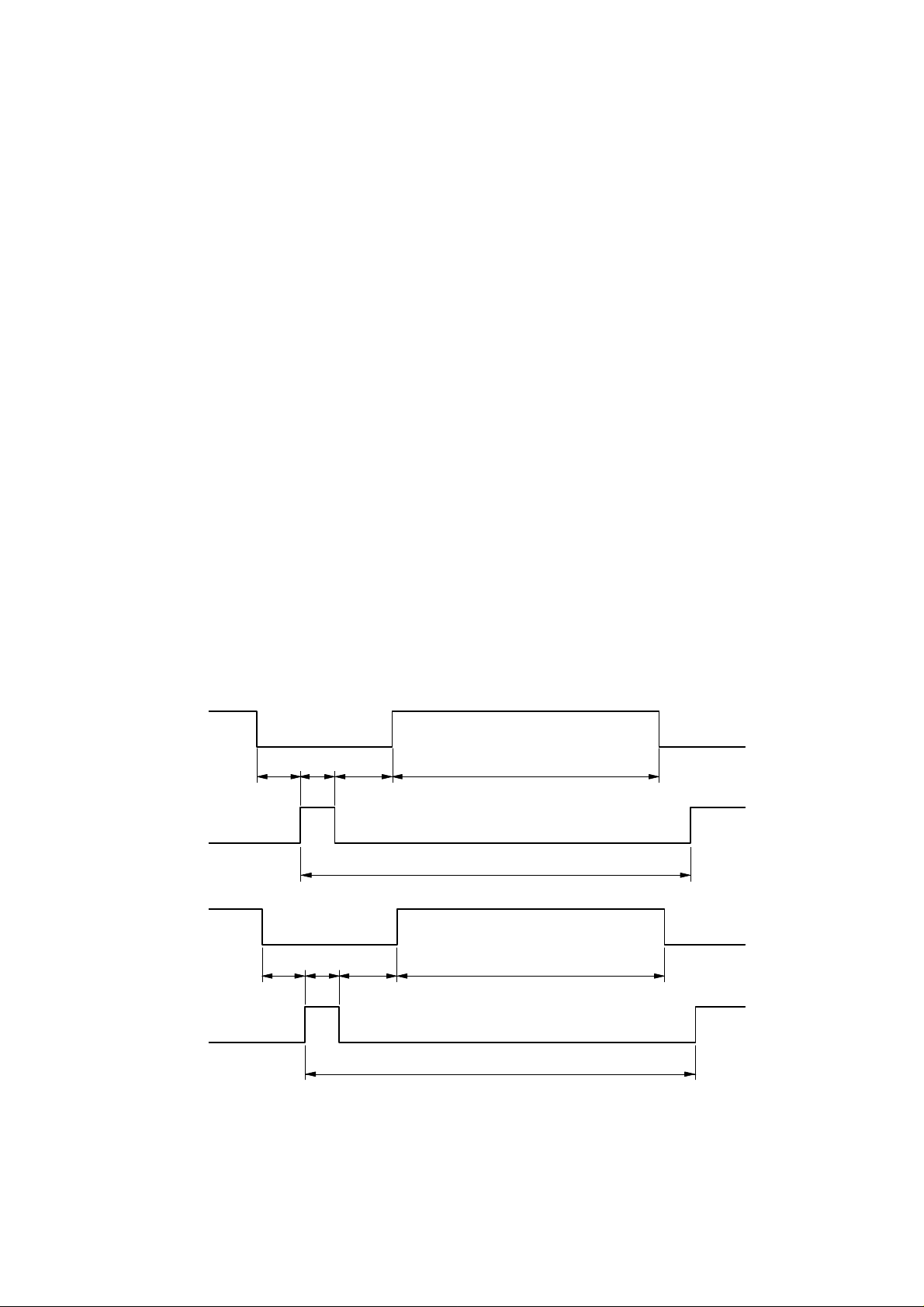

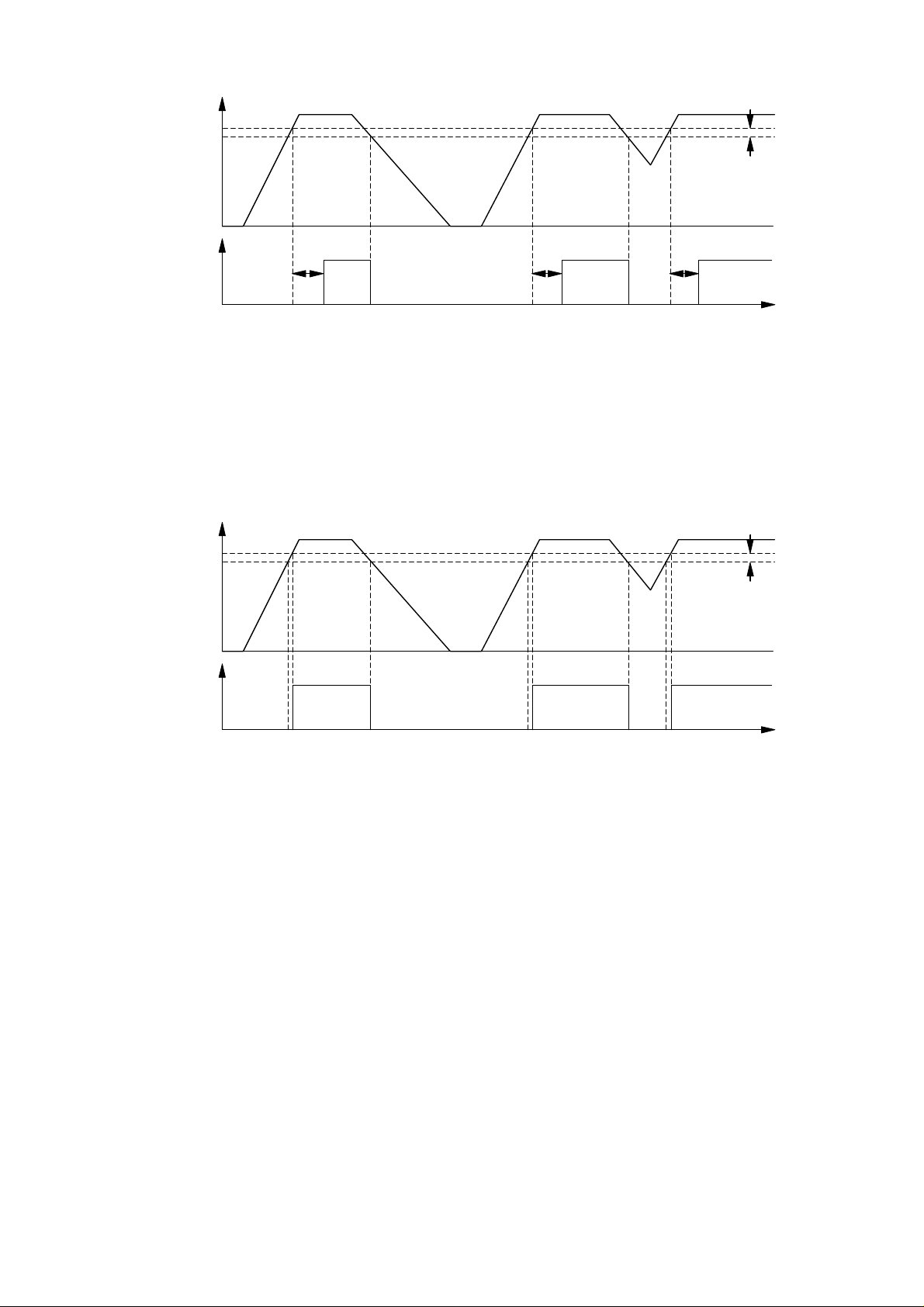

Video

Hsync

Video

Vsync

95 64 113 640dot

1H=912dot=63.696047µs

(1/H=15.699561KHz)

25 3 34 200H

1V=262H=16.688364ms

(1/V=59.92Hz)

Fig. 1-A IBM CGA 200-line 40-character

6

Page 8

Video

Hsync

0V

96

1H=800dot=31.777557µs

Video

Vsync

Video

2

16 96 48

(1/H=31.468881KHz)

0V

1V=525H=16.683217ms

(1/V=59.94Hz)

Fig. 1-B IBM VGA 480-line Black-solid

0.7V

0V

640dot

Hsync

Video

Vsync

1H=800dot=31.777557µs

(1/H=31.468881kHz)

0.7V

0V

11 2 32 480H

1V=525H=16.683217ms

(1/V=59.94Hz)

Fig. 1-C IBM VGA 480-line

7

Page 9

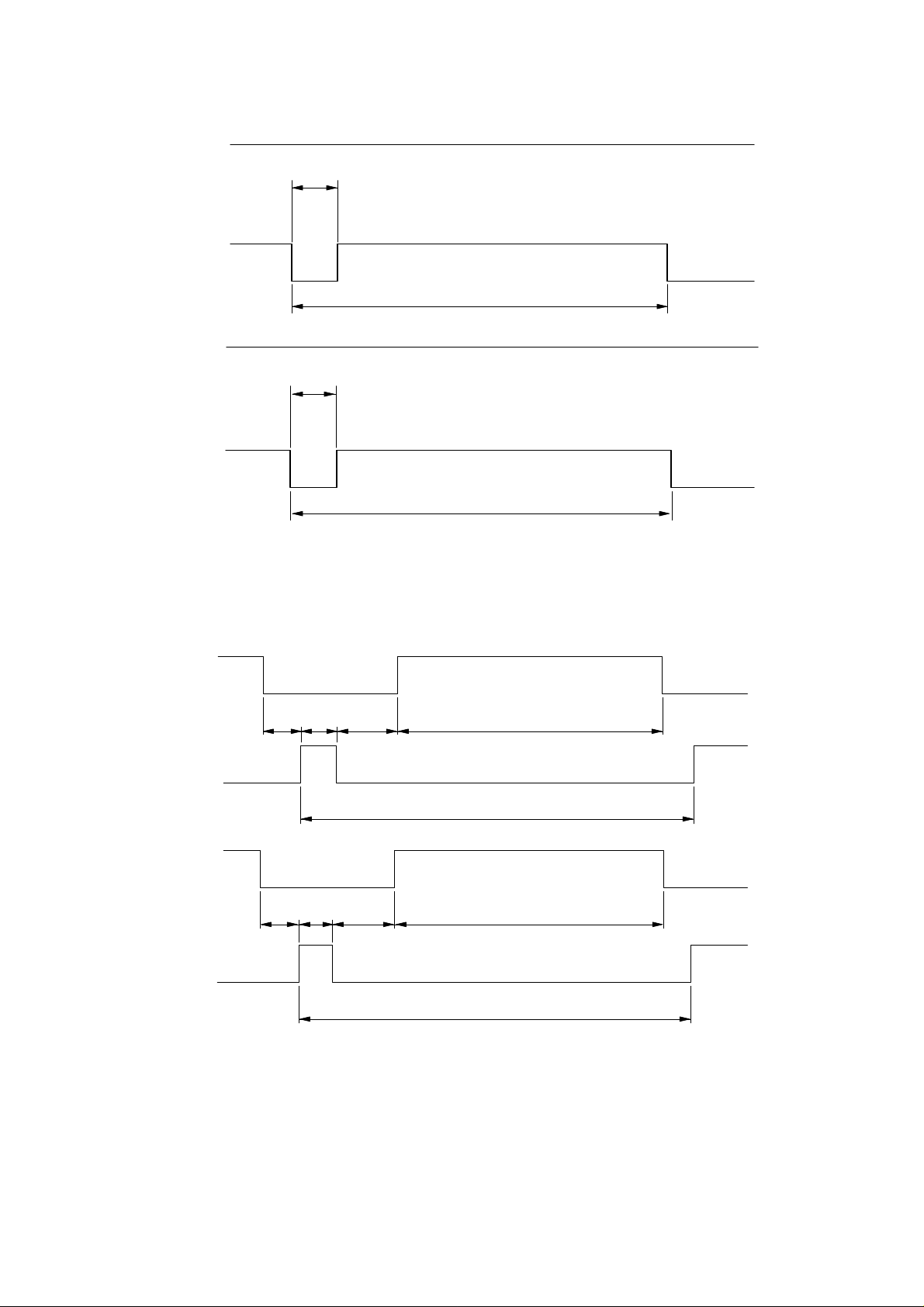

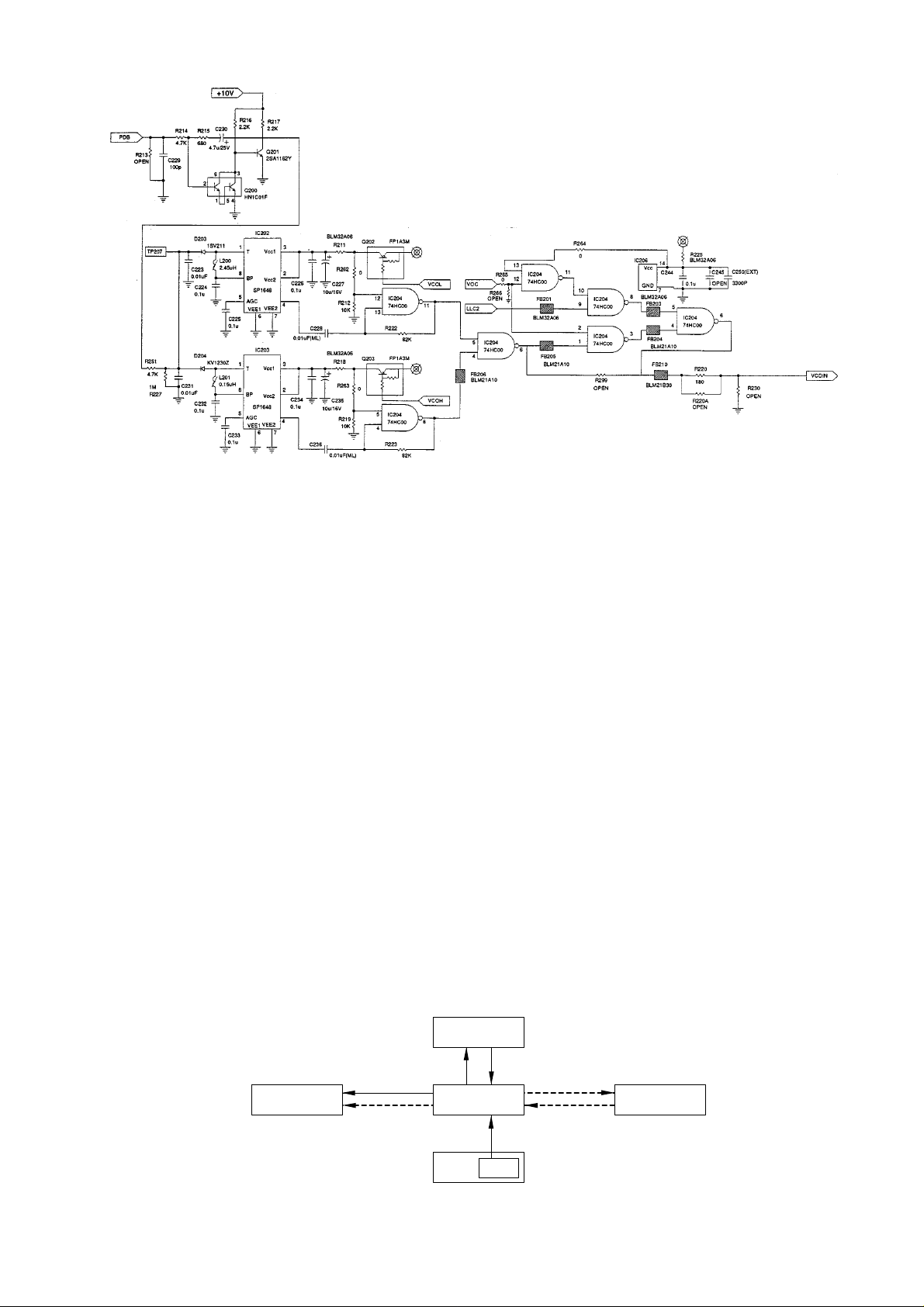

4. CIRCUIT DESCRIPTION

1. GENERAL

Circuit will be described in reference to the QD-101MM block diagram in Fig. 2.

Composite video signal which enters via pin jack connector is converted into the digital RGB

in the composite video input circuit by the control signal from the I2C bus controller. The signal

then enters the signal selector circuit.

Computer analog signal enters via the 15-pin connector and is processed through the computer

analog input circuit and the A/D conversion circuit. The signal is then converted into the digital

RGB signal and enters the signal selector circuit.

Digital video signal from IBM PC EGA or CGA enters via the 15-pin connector is input into the

signal selector circuit.

The signal selected in the signal selector circuit is written into the field memory. The writing

operation into the field memory is controlled by signals which are generated in the IC100 by

HSYNC. VSYNC. Since the LCD control is asynchronous with the computer signal, FRCK.

FRRS is generated in the IC100, and is read out at their timings.

The audio control circuit controls the audio signal input from the audio input terminal, according

to the control signal from IC100. IC400(MPU) controls IC100, IC107 (I2C bus controller) by the

key operation from SW PWB. Since control data from the key is stored into EEPROM, the set

data is memorized even if the power is turned off.

2. COMPUTER SIGNAL INPUT CIRCUIT

In addition to composite video signal, QD-101MM can receive the computer analog RGB signal

and the computer digital RGB signals of MDA, CGA, EGA. These signals enter each input

circuit via the 15-pin connector (J2), pin jack (CN600), and S-terminal(CN601). After they are

converted into the digital signals, they are input to the signal selector or directly to the signal

selector circuit.

Refer to MAIN CIRCUIT No.3.

2.1.Computer digital signal input circuit

The computer digital signal is input to Pins 2, 3, 4, 5, 12 and 15 of J2, and is directly sent to the

signal selector.

EGA outputs the video signal at the 6-bit TTL level. (R, G, B, r, g, b)

CGA outputs the video signal at the 4-bit TTL level. (R, G, B ,I)

MDA outputs the video signal at the 2-bit TTL level. (Mono, Video, I)

As basic, the pins of J2 output the following signals.

Table 1

Connector J2's Pin Number

Signal

12 15 4 2 5 3 14 13 11

EGA g b r G R B Vsync Hsync GND

CGA I x x G R B Vsync Hsync GND

MDA I MONO x x x x Vsync Hsync GND

x:Don`t care or N.C.

8

Page 10

AC

J1

DC INPUT

HV

IC400

MPU

GATE ARRAY IC100

DATA REGISTER

IC108,111

VRAM

FIELD

MEMORY

WRITE

CONTROLLER

TFT COLOR LCD UNIT

MENU

CONTROLLER

MASK

CONTROLLER

COLOR

CONTROLLER

INVERTER PWB

OSC1,2

POWER SUPPLY

+10V VLCD AVCC DVCCVCPU

LCD CONTROLLER

FIELD MEMORY READ CONTROLLER

Fig. 2 QD-101MM Block Diagram

SW

CIRCUIT

IC413,414

2

E PROM

IC107

2

I C BUS

CONTROLLER

IC202,203

IC315~317

IC300~302

A/D

COMPUTER

J2

PDB

VCOIN

PLL

CLK

CONVERSION

CIRCUIT

ANALOG

INPUT

CIRCUIT

RGB SIGNAL

COMPUTER ANALOG

FIELD

MEMORY

IC103~105

SELECTOR

SIGNAL

IC600,601

J2

RGB SIGNAL

COMPUTER DIGITAL

IC308~313

COMPOSITE

VIDEO

INPUT

CIRCUIT

CN600

COMPOSITE

VIDEO SIGNAL

CN601

S-VIDEO

SIGNAL

CN502

SIGNAL

AUDIO INPUT

AUDIO

SP500

COTROL

CIRCUIT

SP

9

Page 11

2.2.Computer analog signal input circuit

IBM computer and APPLE computer output the following analog signals at the load of 75Ω.

Table 2

Computer Analog Signal

R G B

IBM 0.7Vp-p 0.7Vp-p 0.7Vp-p

APPLE 0.7Vp-p

1.0Vp-p

(Synchronization signal

overlapped)

0.7Vp-p

The signals are converted into 8-bit digital signals by the A/D converter(IC315~317).

The computer analog signals are given to Pin 21 of the A/D converter, are divided by 256

between the voltages given to Pin 18(VRT) and Pin 24(VRB), and are digitally converted.

The following table shows the reference voltage which is given to the A/D converter.

Table 3

VRT VRB

Threshold

Level

3.8V(2.8~4.8V)

Adjustment are possible

1.0V

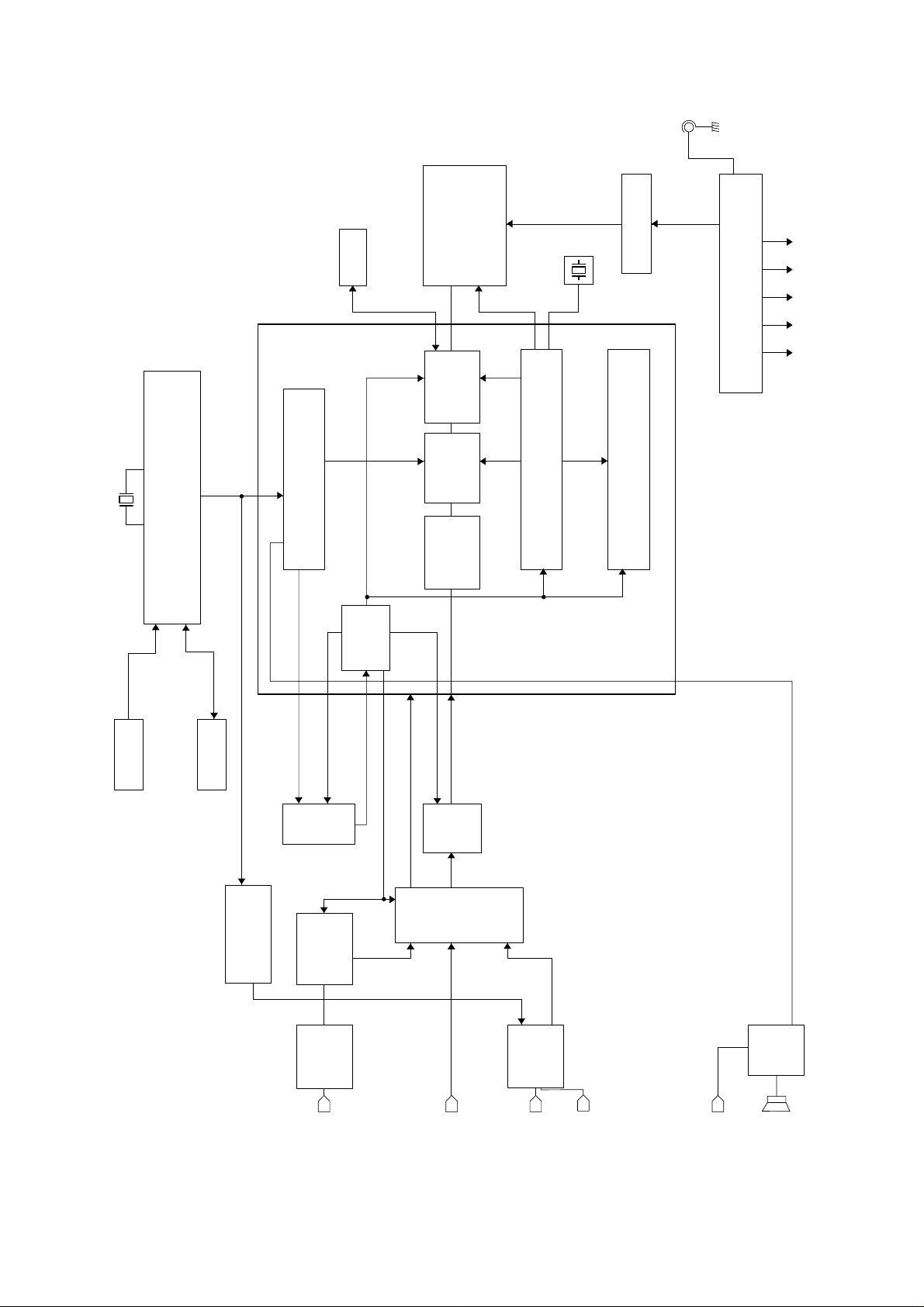

2.3.Threshold level generation circuit

In order to convert the computer and composite analog signal into digital, it is necessary to set

the threshold level on the A/D converter. As shown in Fig. 3, VRT and VRB voltages are set

on the basis of the reference power of ZD1. VRT can be varied by key operation.

As the adjusting method from the main body, the MENU button and SELECT button are used

to display the contrast adjustment in the screen and to allow the set value to be changed with

UP and DOWN selector buttons.

Fig. 3 Threshold Level Generation Circuit

10

Page 12

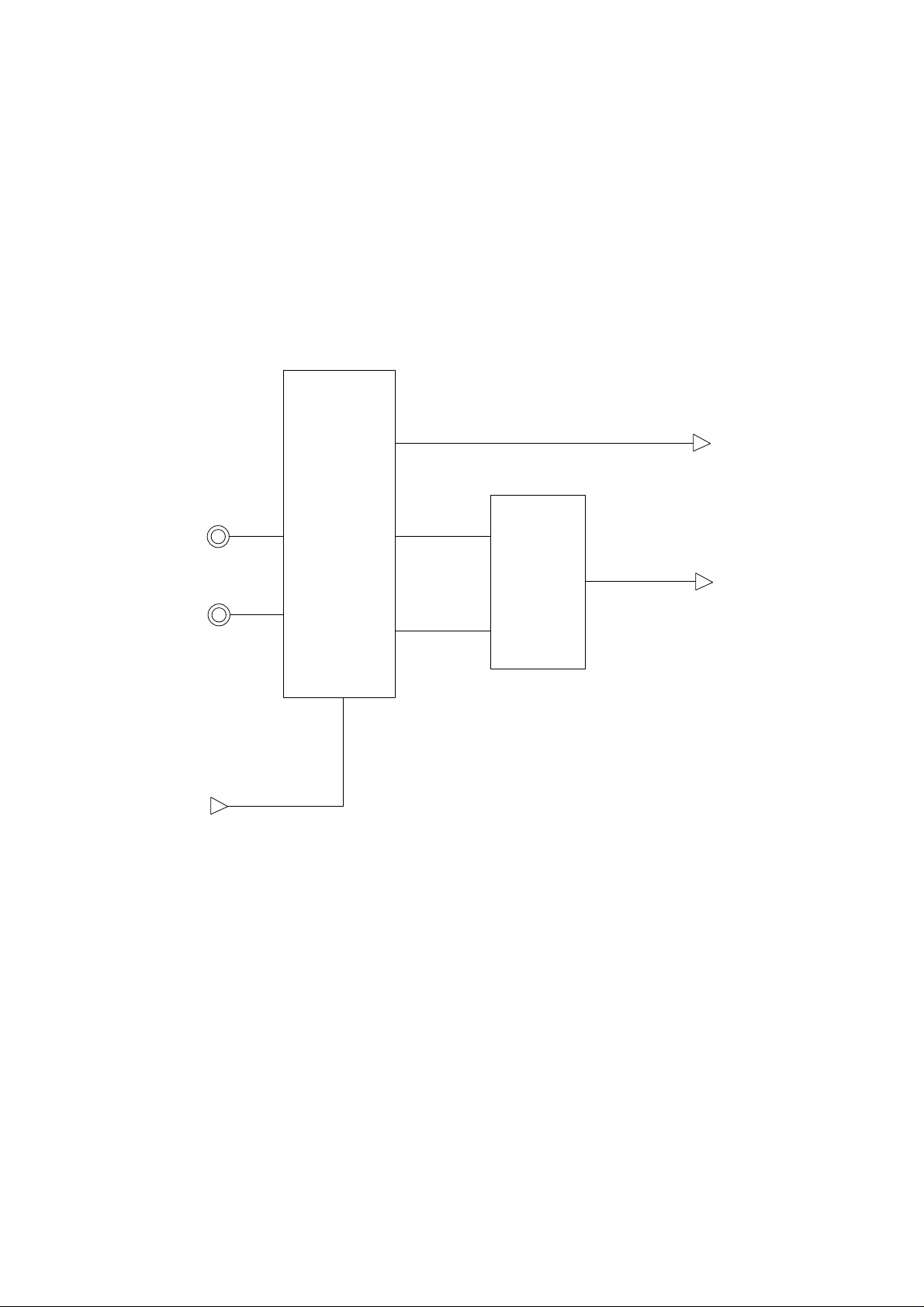

3.VIDEO INPUT CIRCUIT

Fig. 4 shows the block diagram. Circuit diagram is shown in VIDEO CIRCUIT.

This unit automatically switches the circuit corresponding to the composite video signals of

NTSC, PAL and SECAM. The composite video signal and S-Video signal input to the decoder

are first converted into the 8-bit digital Y,UV signal, and is output as the 8-bit digital RGB from

the RGB converter(IC601).

Horizontal sync signal CSHSYNC, vertical sync signal CSVSYNC, ODEV signal and system

clock LLC2 are simultaneously output from the decoder(IC600), and are used in the process

circuit in the rear step.

Controls of brightness, color and tint, and the initial setting of decoder and RGB converter are

sent from MPU by the I2C bus.

38,41

30

COMPOSITE VIDEO

CN600

S-VIDEO

CN601

17,19

21

DECODER

IC600

SAA7110

40

45~50

53~62

CONTROL

29

31

42

32

Y,UV

8bit

16,17,

20~25

63

64

65

26

Y,UV/RGB

CONVERTER

IC601

SAA7192

30~34,37~39

40~47

48~50,53~57

CSHSYNC

CSVSYNC

LLC2

ODEV

RGB 8bit

5,6

2

I C BUS

SDA,SCL

Fig. 4 Composite Video / S-Video Input Circuit Block Diagram

4.AUDIO INPUT CIRCUIT

Fig. 5 shows the block diagram of the audio input circuit. Circuit diagram is shown in AUDIO

CIRCUIT.

The audio signal input to the audio input terminal is inputted to the audio level controller, and

is controlled to the level which corresponds to the volume signal output from MPU.

The output enters the mute switch circuit in the next step, and the audio signal is turned on and

off corresponding to the SMUTE signal which is output from MPU.

11

Page 13

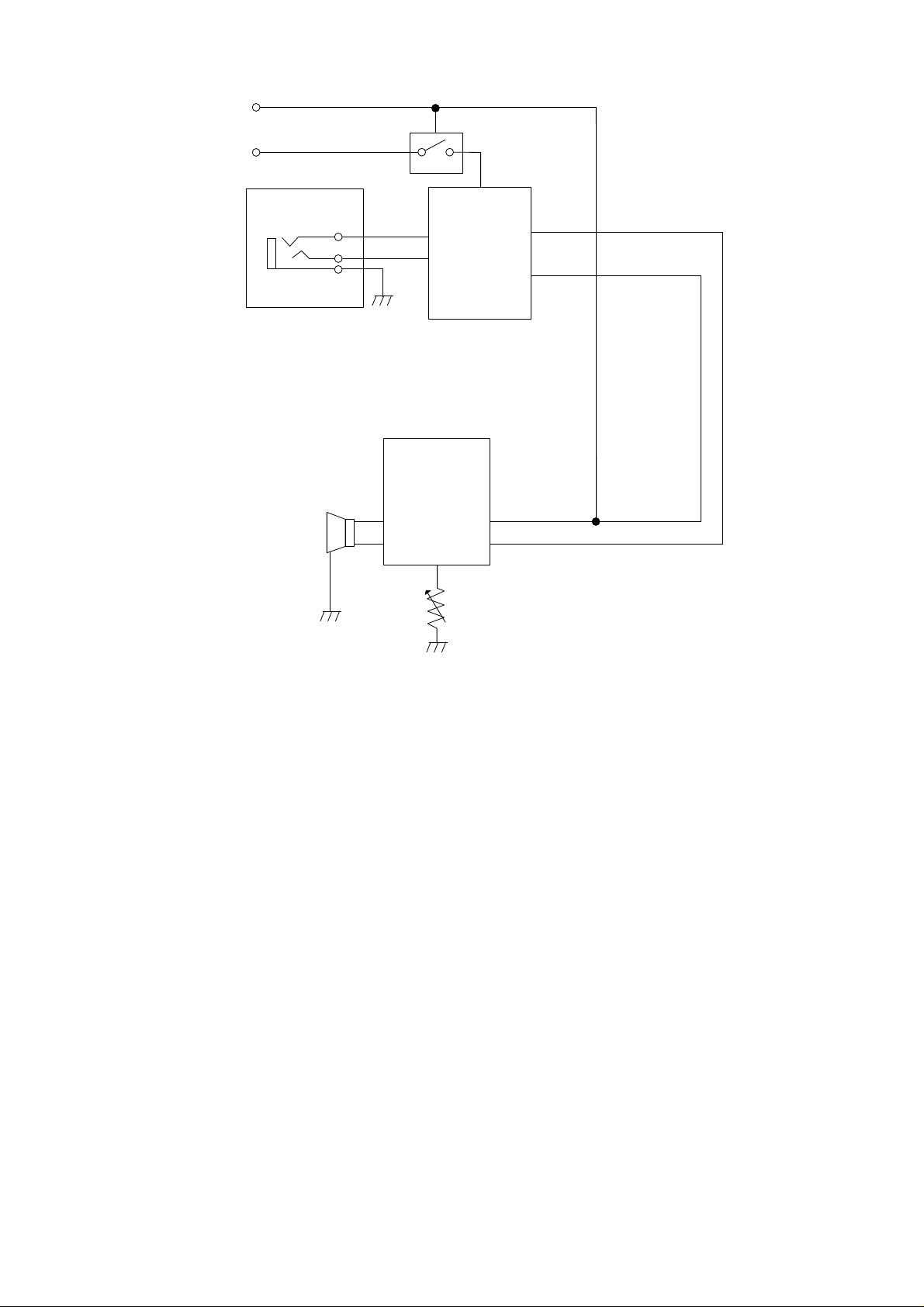

SMUTE

VOLUME

PHONE JACK STEREO INPUT

CN502

SPEAKER

SP500

MUTE SW

1

2

VR501

2

CONTOROLLER

IC503

TDA1905

AMPLIFIER

AUDIO

LEVEL

IC500

TA8184F

4

5

SPEAKER

AMPLIFIER

ADJUST

7

24

Fig. 5 Audio Input Circuit Block Diagram

5. PLL CIRCUIT

The dot clock (VCOIN) is generated by the PLL circuit shown in Fig.6. The dot clock is necessary

to sample the video signal from the computer and change it into the suitable dot data.

Hsync signal from computer enters into IC100. This signal is compared frequency and phase

with the feed-back signal, which is generated from VCOIN by the phase comparator in IC100.

If any error of phase or frequency occurs between Hsync and VCOIN, LOW or HIGH level is

output at PBD of IC100, and when both frequency and phase agree with each other, high

impedance is output.

The output signal from the PDB terminal is converted into a DC voltage by a loop filter and then

controls the VCO.

To select the high band or low band, either VCO is selected according to the signals from No.

120 pin and No. 119 pin of IC100.

12

Page 14

Fig.6 PLL Circuit

6. MEMORY CIRCUIT

BLOCK DIAGRAM is shown in Fig.2.

6.1.Field memory writing

When data sent from the signal selector is written into the field memory(IC103~105), FWCK

(clock slightly later than CLK) generated from the memory controller in IC100 is used.

6.2.Field memory reading

The clock (FRCK) and control signals which are generated in the field memory reading signal

generating circuit in IC100 are used to read data from the field memory.

Reading is asynchronous with writing. In the ordinary mode, data written into the field memory

are color-compensated and are sent to LCD.

In the enlargement mode, the enlargement control signal is sent to the field memory from the

field memory writing/reading signal generating circuit in IC100 to make the enlargement display

possible.

6.3.Menu, message display memory

The menu and message display is stored in the ROM area of IC400(MPU).

When the menu button is first pressed, MPU will write data and address into VRAM (IC108, 111)

via IC100. Moreover, VRAM data is read via IC100.

The data is sent to LCD at the timing of LCD.

LCD

IC108, 111

VRAM

menu and

message data

IC100

display data

ROMMPU

IC103~105

FIELD MEMORY

Fig. 8 Memory Circuit Block Diagram

13

Page 15

7. VARIOUS FUNCTIONS OF IC400(H8/3256 M.P.U)

IC400 is a microcomputer which is provided with a set of 16-bit free running timer and 2

channels of SCI in addition to 48K-byte PROM/2K-byte RAM.

7.1.Key data and various functions

The keys (DOWN, UP, SELECT, MENU, RESET) provided on the main body of QD-101MM

switches and selects the adjustment mode displayed in the LCD screen as well as gives the

direct commands to IC400.

1) DOWN

This key decreases the adjustment items selected by the select key, step by step.

2) UP

Being opposite to DOWN, the key increases the adjustment item, step by step.

3) SELECT

This key is used to select the adjustment mode in the menu screen which is displayed

by the MENU key.

Every push of this key can change the adjustment item, step by step.

4) MENU

This key is used to switch the menu screen.

5) RESET

This key is used to set the initial values of the computer. When this key is pressed,

the adjustment items are all returned to the initial statuses.

7.2.EEPROM control function

The EEPROM(IC413, 414) area is provided to write the timing set values of each computer

when it is connected to QD-101MM. The timing set values are written into EEPROM under the

following four conditions.

1. All resetting

2. Resetting

3. Power turn-off

4. The connected computer is changed.

Here, writing into EEPROM is executed only when the set value is changed.

7.3.Reset circuit

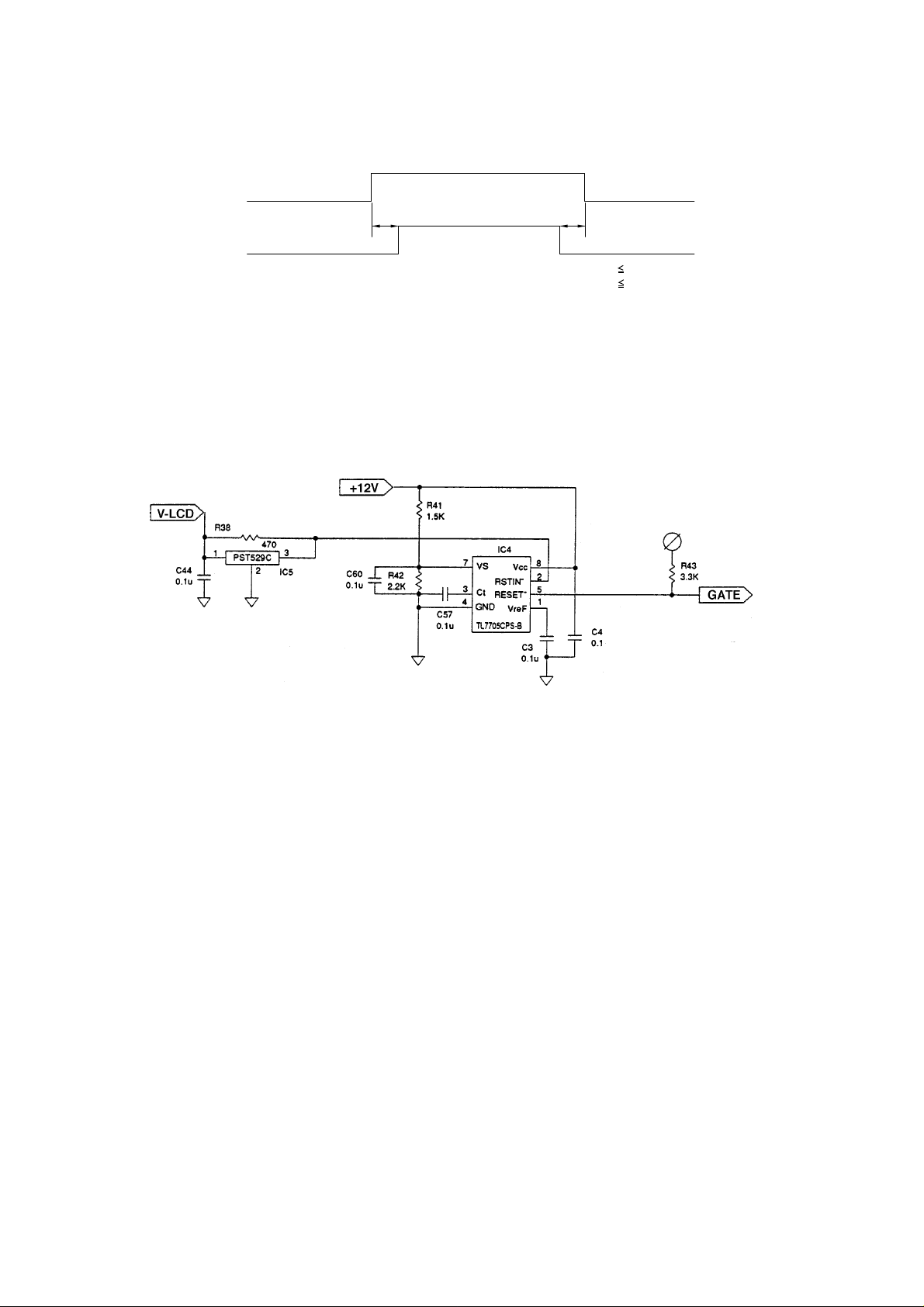

The circuit diagram is shown in MAIN CURCUIT No.4.

IC407(TL7705CPS-B) detects the power voltage, V

and generates the RESET signal. If V

drops below the detection voltage (TYP4.5V) when

CPU

, of IC400 and its surrounding circuit,

CPU

the power is turned off, IC407 shifts the level of the RESET signal to “Low”.

If V

V

rises to exceed the total voltage of the detection voltage VS1 and hysteresis width

CPU

(TYP15mV), IC407 starts charging the timing capacitor(Ct) with a constant current.

HYS1

After (TP0=1.3XCtX10[S]), IC407 shifts the RESET signal to “High” level. (See Fig. 8.)

IC411(S-8054ALB) detects the power voltage VCC to generate the power OFF signal. If V

CC

drops below the detection voltage VS2 (TYP4. 15V) when the power is turned off, IC411 shifts

the power OFF detection level to “Low”.

If VCC rises beyond the total voltage of the detection voltage VS2 and hysteresis voltage V

HYS2

(TYP200mV) when the power is turned on, IC411 shifts the power OFF signal to “High” level.

(See Fig. 9.)

14

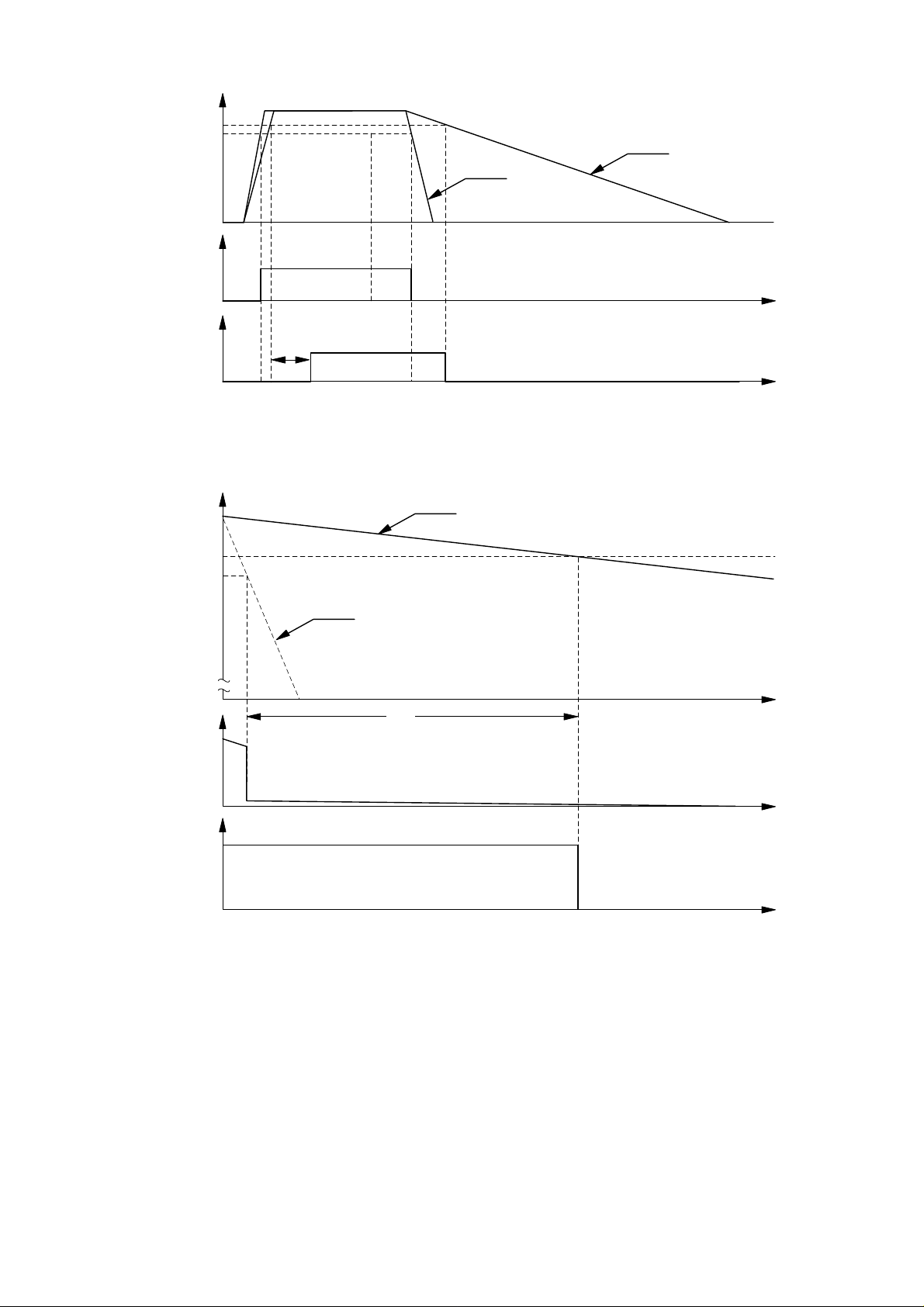

Page 16

VCPU

(4.5V)

RESET

signal

VCC

(4.15V)

V

S1

PO TPO TPO

T

VHYS1

(15mV)

Fig.8

V

S2

VHYS2

(200mV)

POWER OFF

DETECTION

signal

Fig.9

When the power is turned on, V

, VCC and V

LCD

rise. If V

CPU

exceeds VS1+V

CPU

, the RESET

HYS1

signal is shifted to “High” level at the timing shown in Fig. 10. The reset operation of IC400 is

canceled and executes the program.

When the power is turned off, the power OFF detection signal is shifted to “Low” when VCC and

V

drops sharply below VS2.

LCD

On the other hand, Vcpu is backed up by C425 (220mF) so that it can maintain 4.5V for the time

of TW after the trailing edge of the power OFF detection signal. See Fig. 11. (TW is the time

for IC400 to retreat the data to EEPROM.) If V

drops below VS1, the RESET signal level is

CPU

shifted to “Low”, and IC400 starts resetting.

15

Page 17

VS1(VCPU)

S2(VCC)

V

POWER OFF

DETECTION

signal

VCPU

VCC

RESET

5.0V

VS1(4.5V)

4.0V

POWER OFF

DETECTION

signal

TPO

Fig.10

VCPU

V

S2

VCC

TW

RESET

Fig.11

16

Page 18

8. LCD CONTROL CIRCUIT

LCD control signal is slower than the video signal of the computer. While the video signal is

serial data, the LCD display data is given as 4-bit parallel data for each RGB. In order to display

the bit signal of the computer in LCD, it is necessary to store the data of one screen in the

memory and read out the image data of one screen at the drive timing of LCD. To control them,

the field memory is controlled by the memory controller in IC100 as shown in the block diagram

in Fig. 2.

9. LCD UNIT

9.1.Interface signals

3 1

22 20 18 16 14 12 10 8 6 4 2

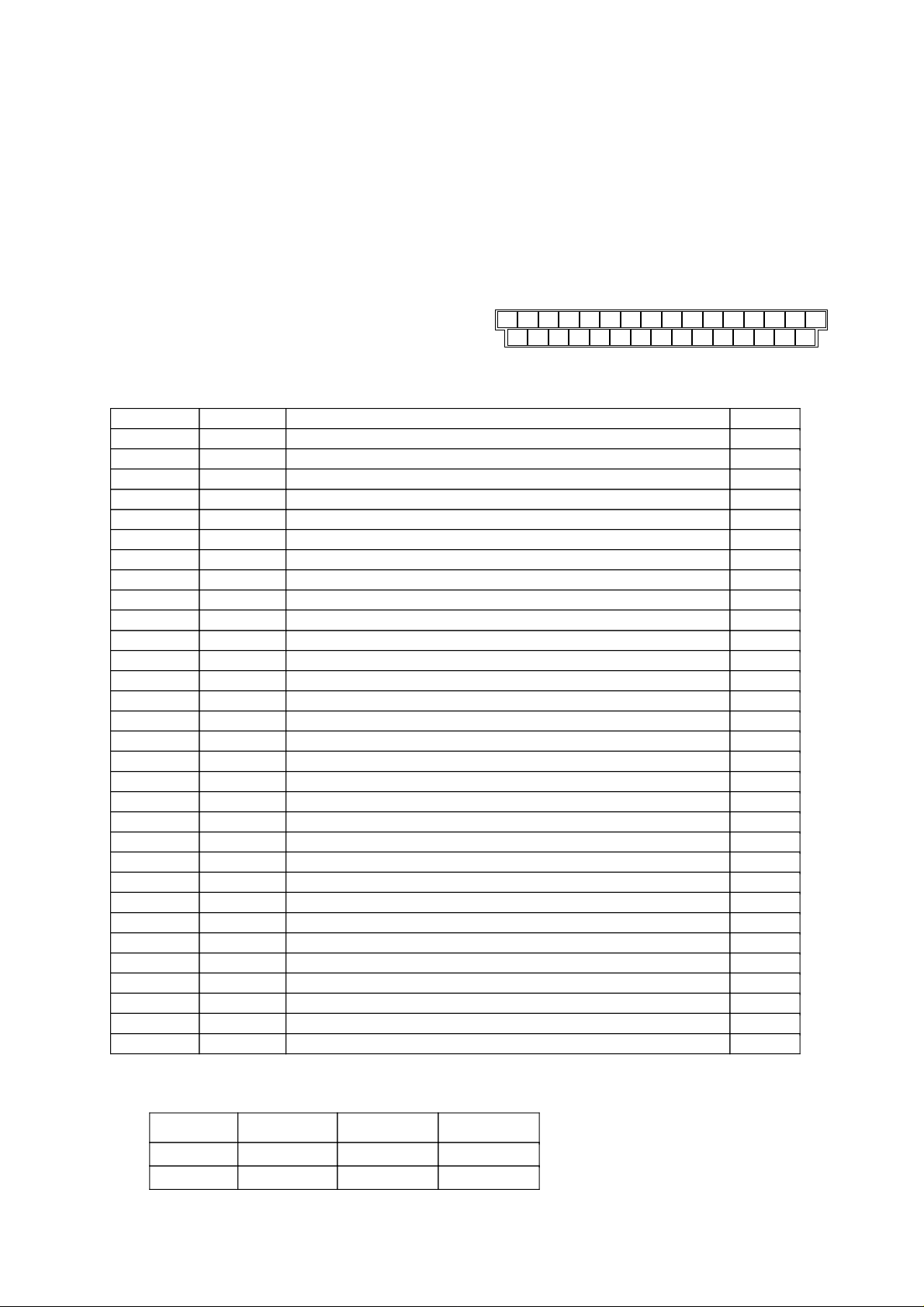

CN1 Pin assignment

Table 4 Pin assignment of LCD unit

Pin Code Function Remark

1 GND

2 CK Sampling clock signal of data

3 Hsymc Horizontally synchronous signal (*1)

4 Vsync Vertically synchronous signal (*1)

5 GND

6 R0 Red data signal(LSB)

7 R1 Red data signal

8 R2 Red data signal

9 R3 Red data signal

10 R4 Red data signal

11 R5 Red data signal(MSB)

12 GND

13 G0 Green data signal(LSB)

14 G1 Green data signal

15 G2 Green data signal

16 G3 Green data signal

17 G4 Green data signal

18 G5 Green data signal(MSB)

19 GND

20 B0 Blue fata signal(LSB)

21 B1 Blue fata signal

22 B2 Blue fata signal

23 B3 Blue fata signal

24 B4 Blue fata signal

25 B5 Blue fata signal(MSB)

26 GND

27 ENAB Data enable signal(Horizontal display position signal) (*2)

28 Vcc +5V power suppry

29 Vcc +5V power suppry

30 TST Open

31 TST Open

24

29 27 25 23 21 19 17 15 13 11 9 7 5

31

30

28 26

The shield case is connected to GND in LCD module.

(*1) The line mode(480 or 400 or 350) can be selected by the polarity of Hsync and Vsync.

Mode 480line 400line 350line

Hsync Negative Negative Positive

Vsync Negative Positive Negative

(*2) Don't use "High".

17

Page 19

9.2.Sequence circuit of LCD panel

In QD-101MM, it is necessary to conform the power ON/OFF sequence of the LCD panel as

shown Fig.12.

LCD

V

T1 T2

Signal

0 T1

0 T2

Fig. 12 Power ON/OFF sequence

Fig. 13 shows the panel sequence generation circuit.

The gate signal which has the same timing as the input signal in Fig. 12 is output by the RESET

IC of IC4 and IC5.

Fig. 13 Panel Sequence Generation Circuit

9.3.Handling the LCD panel

1. The LCD unit is assembled to very high density, do not attempt to disassemble it.

2. The polarizing plate is very easy to scratch, take extra care when handling it.

3. When cleaning the surface of the LCD panel, use absorbent cotton or soft cloth and

carefully wipe the surface.

4. The LCD panel will become discolored or stained if any moisture remains on the surface

for a long period of time.

5. The LCD panel is made of glass. If it is hit by any hard object or is dropped, it may

crack.Handle it very carefully.

6. CMOS LSI which is used in the LCD unit is very sensitive to static electricity. To prevent

damage to the LCD unit from static electricity it is necessary for all service technicians

to use a conductive mat and wrist strap to ground themselves when servicing the unit.

10.POWER CIRCUIT

The AC adaptor which is connected to QD-101MM supplies stable power to the unit, and

generates 5V power (VCC, V

power(12V).

CPU

, V

), VPP power, +10V power and the inverter circuit board

LCD

18

Page 20

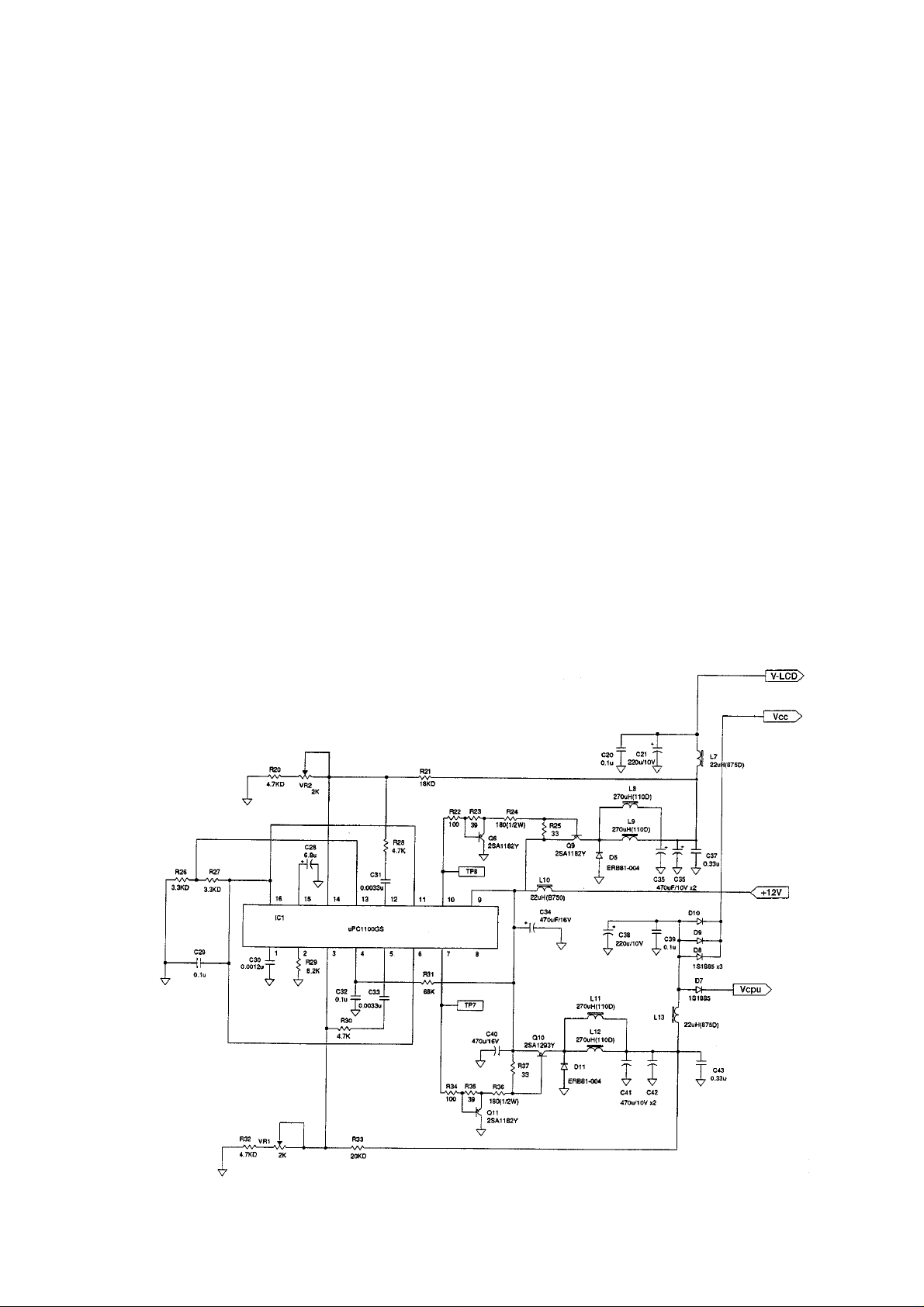

10.1. +5V power (VCC, V

CPU

, V

LCD

)

IC1 in Fig. 14 is a controller for a fixed frequency pulse width modulation(PWM) switching

regulator and has two constant voltage controllers. One controller is used to generate a 5V

power supply(V

CPU,VCC

) from the input power supply VIN(12VDC). The other one is for V

LCD

IC1 has a saw-tooth wave oscillator built in whose oscillating frequency is determined by

capacitor C30 connected to pin 1 and resister R29 connected to pin2. In this circuit

configuration, a saw-tooth wave of approx.75KHz is observed at pin 1 of IC1. Basically this sawtooth wave is compared with a control signal observed at pin5 of IC1. Only while the voltage

of the saw-tooth wave is lower than the control signal voltage, the period between pin 7 of IC1

is "L" becomes longer. As a result the period between external transistor Q11 and Q10 is

conductive becomes longer. The output voltage is fed back to pin 3 of IC1. An error amplifier

in IC1 makes a comparison between the half of the reference voltage and the feed-back signal

to pin 3 and generates a control signal(pin5 of IC1). As explained above the output voltage is

stabilized by the pulse width from pin 7, which is generated by comparing the control signal with

the saw-tooth wave.

V

is adjusted to 5.1V while VCC is 5V. This is done because the load on the VCC is greater than

CPU

the load on V

and the forward voltages of D8, D9, and D10 are higher than that of D7.The

CPU

voltage supplied to pin 6 of IC1 is called a dead time control signal. It controls the maximum

ON period of the output transistor in IC1. The maximum ON period is realized on IC1 by shorting

pin 6 and pin 16.

The saw-tooth wave oscillator of pin 1 of IC1 is used also for the control of this 5V power

supply(V

). The operation of the circuit is similar to that of the other 5V power supply(V

LCD

CPU

and

VCC). The output voltage is fed back to pin 14 of IC1. The control signal is produced using a

voltage generated by dividing the reference voltage inputted to pin 13 of IC1, and the feed back

signal. The output voltage is stabilized by the pulse width from pin 10, which is generated by

comparing the control signal with the saw-tooth wave. V

is adjusted to 5.0V with VR2.

LCD

.

Fig. 14 +5V Power(VCC,V

19

CPU,VLCD

) Circuit

Page 21

10.2. +10V power

Fig. 15 shows the +10V power supply.

+10V is generated from the input power supply of 12V by the 3-terminal regulator of IC7.

Fig.15 +10V Power Circuit

1 1. INVERTER CIRCUIT

The Inverter circuit board supplies the high voltage AC to the cold-cathode fluorescent tube

used as backlight illumination for the TFT panel.

The Inverter circuit is supplied the voltage from CN20 on the Main PWB and it gives to the coldcathode fluorescent tube. The lighting level control can be varied by turning VR50.

(Note)

(1) Inverter circuit is very dengerous because it is outputted the high voltage(max AC1300V).

Make sure that the monitor's power switch is in the OFF position when servicing Inverter

circuit board.

(2) Inverter circuit board can not be replaced. It needs to be replaced when it is failed.

20

Page 22

START

5. TROUBLESHOOTING CHART

Yes

POWER ON

Is the LED

illuminated?

Yes

Is the backlight

illuminated?

Yes

Push the RESET

button.

No

No

Is CN20 12V?

Yes

Is the voltage at the both

side of fuse on the Inverter

circuit board 12V?

Yes

Backlight failure.

No

No

No

Inverter circuit board

failure.

Is power supply voltage

described (*1)?

Yes

1

No

(*1)

TP1 =approx.12V

TP200=approx.5V

TP202=approx.5.1V

TP203=approx.5.15V

TP204=approx.10V

21

Go to Power Source

Circuit Check.

Page 23

Power Source Circuit

Check

POWER OFF

Is the voltage between 1-pin

and 2-pin of J1 approx.12V?

(2-pin is GND)

Yes

POWER ON

Is D2 cathode

approx.12V?

Yes

Is TP203(V

approx.5.15V?

Yes

CPU

)

No

No

No

AC adaptor failure.

F1 failure.

Is D7 anode

approx.5.5V?

No

Yes

D7 failure.

Is TP202(VCC)

approx.5.1V?

Yes

Is TP200(V

approx.5V?

Yes

Is TP204(+10V)

approx.10V?

Yes

Go to Another

Function Check.

LCD

No

)

No

No

Failure of IC7 or their

peripheral parts.

D8,D9,D10 failure.

Disconnect the LCD unit

from CN100.

Is TP200(V

approx.5V?

No

LCD

)

LCD unit failure.

Yes

Failure of IC1 or their

peripheral parts.

22

Page 24

1

Digital Signal Display Check

Input a digital video signal.

(CGA 14.318MHz)

87

Check IC206-6.

Is clock pulse inputted

approx.14.318MHz to

IC100-pin116

(VCOIN)?

Yes

Is proper video signal at

IC100?

Yes

Are J2-pin 9(MAC) and

10(A/D) at a high level?

Yes

No

2

No

No

Disconnect the signal cable

from J2.

IC28 failure.

Signal cable failure.

23

No

Are proper signals outputted

at signal cable-

pin5,2,3,4,12,15

(R,G,B,r,g,b,A/D)?

Yes

Digital Video Signal Input

Circuit failure.

Page 25

2

Is IC100-pin119(PVOL) at a

high level?

Is IC100-pin 120(PVOH) at a

low level?

Yes

Is Q101-collector at a low

level?

Is Q102-collector at a high

level?

Yes

Is TP207 approx.2.5V?

Yes

No

IC100 failure.

No

Q101 or Q102 failure.

No

Can TP207 be adjusted to

approx.2.5V with L200

(LOW BAND)?

Yes

Adjust TP207 to approx.2.5V

with L200.

No

Low band VCO circuit

failure.

24

Page 26

Analog Video Signal

Display Check

Input an analog video

signal.

(VGA,25.175MHz)

7 8

No

No

Check IC206-pin6.

Is clock pulse(25.175MHz)

inputted to IC100-pin 116

(VCOIN)?.

Yes

Disconnect the signal cable

from J2.

Are proper video signals at a

signal cable-pin1,2,3

(A-R,G,B)?

Yes

Is the signal cable-

pin9(MAC) open?

Is the signal cable-pin10

(A/D) GND level?

No

4

Signal cable failure.

Yes

Connect the signal

cable to J2.

Minimize the

CONTRAST.

3

25

Page 27

3

Is TP300(VRT)

approx.2.8V?

Is TP301(VRB)

approx.1V?

Yes

Maximize the

CONTRAST.

Is TP300

approx.4.8V?

Is TP301 approx.1V?

Yes

Push RESET switch to set

the CONTRAST to center.

No

No

Failure of threshold

level setting circuit.

Are amplified video

signals generated from

TP303,304, and 305?

(IC300,301,302

output)?

Yes

Is IC100-

pin108(CSYNCSP) at

a high level?

Yes

Are digitalized video

signals(TTL level) outputted

from pins-1~8 on

IC315,316,317

(A/D converter)?

Yes

No

Adjust again or failure of

IC300,301,302 or their

peripheral circuits.

No

IC100 failure.

No

Failure of IC315,316,317

or peripheral circuits.

IC100(Gate Array) failure.

26

Page 28

4

Is IC100-pin119(PVOL) at a

low level?

Is IC100-pin120(PVOH) at a

high level?

Yes

Is TP207 approx.4.1V?

Yes

Can TP207 be adjusted to

approx.4.1V with L201

(High Band)?

Yes

Adjust TP207 to approx.4.1V with

L201.

No

IC100 failure.

No

No

High band VCO circuit

failure.

27

Page 29

Composite Sync. Signal

Display Check.

Input a composite sync.

signal.

(MAC II type: 30.24MHz)

7 8

Failure of analog

threshold level setting

circuit.

Check IC206-pin6.

Is clock pulse of

approx.30.24MHz inputted to

IC100-pin116

(VCOIN)?

Yes

No

No

Is IC100-pin108 at a

low level?

Yes

Disconnect the signal cable

from J2.

Is signal cable-

pin9(MAC) shorted

to GND?

Is signal cable-pin10

(A/D) GND?

No

Is Hsync inputted to IC100-

pin109?

Is Vsync inputted to IC100-

pin110?

Yes

Is clock pulse of

approx.25.00MHz inputted to

IC100-pin19?

Yes

IC100 failure. OSC1 failure.

No

Failure of signal cable

or input circuit.

No

No

Signal cable failure.

Yes

Is proper level video signal at

signal cable-pin1,2,3?

Yes

Input circuit failure.

28

Page 30

MPU Circuit Check

Press the RESET

switch.

1

2

3

Does IC400-pin7 changed the level

from "L" to "H" after power is turned

Is clock pulse of

approx.7.987MHz at

IC400-pin2?

Yes

on?

Yes

Is IC400-pin5 and pin64 always

high after turning the power on?

Yes

No

No

No

7.987MHz oscillating circuit

failure.

Failure of reset circuit or its

peripheral circuits.

IC400 failure.

Failure of power off detection

circuit or its peripheral circuits.

IC400 failure.

4

Is clock pulse of approx.4MHz

outputted from IC400-pin15?

Yes

Go to Digital Signal

Display Check.

No

IC400 failure.

29

Page 31

LCD Display Circuit Check

Input a digital video signal.

(CGA type; 14.318MHz)

6 7 8

Yes No

Is Hsync inputted to IC100-

pin109?

Is Vsync inputted to IC100-

pin110?

Yes

5

Is clock pulse of

approx.25.00MHz at

IC100-pin19?

Yes

Is clock pulse of

approx.14.318MHz at IC206-

pin6(VCOIN)?

No

Failure of Hsync/ Vsync input circuit

No

OSC1 failure.

5

7 8

or signal cable

Do input signal to IC100-

pin110(Vsync) and output signal

from IC100-pin130(VSC) have the

same frequency?

Yes

Is IC100-pin129(F256HS)

approx.61.326Hz ?

Yes

Are the output levels from

IC100-pin126(HPOL) and

pin127(VPOL) both high?

Yes

6

No

No

No

Failure of IC100 or its

peripheral circuits.

30

Page 32

5

9 10 11

Are signals at IC100-

pin82(LHsync),

83(LVsync),and

79(LCDCK) normal?

Yes

No

No

IC100 failure.

Disconnect the panel.

Are signals at IC100-

pin82,83,and 79

normal?

Yes

Panel failure.

9 10 11

Are digital video signals inputted to

IC100-

pin5,6,95~98(B),3,4,90~93(G),and

1,2,85~88(R)?

Yes

Failure of IC100(Gate Array),

400(MPU),103~105(Field Memory).

No

Video signal input circuit failure.

31

Page 33

6

Is output level from IC100-

pin140(RESET) high?

Yes

Are proper signals at IC100-

pin132~139(KA0~7),

147~154(KD0~7)?

Yes

Is IC100-pin119(PVOL)

at a high level?

Is IC100-pin120(PVOH)

at a low level?

Yes

Is Q102-collector at a

low level?

Is Q101-collector at a

high level?

No

No

Failure of signal line

between IC100 and IC400.

No

IC100 failure.

No

Yes

Failure of VCO circuit or

pattern.

Failure of Q102 or Q101.

32

Page 34

Video Circuit Check

Input NTSC video signal to

CN600.

Are video signals inputted

to IC600-pin21?

Yes

Is a video signal outputted

from TP600?

Yes

Are Hsync or Vsync

outputted from IC600-

pin38 and pin41?

Yes

No

Input cable failure.

Input connector failure.

No

Check IC107 and 400.

No

IC600 failure.

Are digital video signals

outputted from IC601-

pin30~39,40~47,and

48~57?

Yes

Input NTSC and PAL video signal

Is IC400-pin24(XTALSL) "H"

when NTSC is inputted, "L"

when PAL is inputted?

Yes

Failure of

IC417,419,420,418.

No

IC601 failure.

No

IC400 failure.

33

Page 35

Audio Circuit Check

Input a 500mV(RMS) sine-wave to

audio input terminal.

Set the volume to maximize and

mute off.

Is the signal outputted from

IC500-pin7?

Yes

Are the signals outputted from IC507-

pin2 and IC508-pin2?

Does the signals change 0V when mute

off?

Yes

Is the signal inputted to

IC503-pin5?

No

IC500 failure

No

IC507,508 failure.

No

IC503 failure.

Yes

Is 2.85V(RMS) sine-wave

outputted from TP504?

Yes

Check speaker.

No

IC503 failure.

34

Page 36

1 IC400-2

1V/div

50ns/div

2 V

CPU...2V/div

IC400-7...2V/div

5ms/div

GND/

GND/

GND/

V

CPU

IC400-7

Fig.16

3 Vcc...2V/div

IC400-5,64

2V/div

10ms/div

4 IC400-15...1V/div

50ns/div

Fig.17

Vcc

GND/

IC400-5,64

GND/

Fig.18

GND/

Fig.19

35

Page 37

5 IC100-19

1V/div

10ns/div

6 IC100-110...2V/div

500ns/div

GND/

Fig.20

7 IC100-110...2V/div

IC206-6...2V/div

50ns/div

GND/

GND/

8 IC100-109...2V/div

IC206-6...2V/div

20ns/div

GND/

Fig.21

IC100-110

IC206-6

Fig.22

IC100-109

GND/

IC206-6

Fig.23

36

Page 38

9 IC100-79

1V/div

5ns/div

10 IC100-82

1V/div

2.5µs/div

IC100-79(LCDCK)

GND/

Fig.24

IC100-82(LHsync)

11 IC100-83

1V/div

2.5ms/div

GND/

Fig.25

IC100-83(LVsync)

GND/

Fig.26

37

Page 39

6. CIRCUIT DIAGRAM & PWB

Fig.27 CIRCUIT DIAGRAM(MAIN CIRCUIT No.1)

38

Page 40

Fig.27 CIRCUIT DIAGRAM(MAIN CIRCUIT No.1)

39

Page 41

Fig.28 CIRCUIT DIAGRAM(MAIN CIRCUIT No.2)

40

Page 42

Fig.28 CIRCUIT DIAGRAM(MAIN CIRCUIT No.2)

41

Page 43

Fig.29 CIRCUIT DIAGRAM(MAIN CIRCUIT No.3)

42

Page 44

Fig.29 CIRCUIT DIAGRAM(MAIN CIRCUIT No.3)

43

Page 45

Fig.30 CIRCUIT DIAGRAM(MAIN CIRCUIT No.4)

44

Page 46

Fig.30 CIRCUIT DIAGRAM(MAIN CIRCUIT No.4)

45

Page 47

Fig.31 CIRCUIT DIAGRAM(POWER CIRCUIT)

46

Page 48

Fig.31 CIRCUIT DIAGRAM(POWER CIRCUIT)

47

Page 49

Fig.32 CIRCUIT DIAGRAM(VIDEO CIRCUIT)

48

Page 50

Fig.32 CIRCUIT DIAGRAM(VIDEO CIRCUIT)

49

Page 51

Fig.33 CIRCUIT DIAGRAM(AUDIO CIRCUIT)

50

Page 52

Fig.33 CIRCUIT DIAGRAM(AUDIO CIRCUIT)

51

Page 53

(FRONT-SIDE)

Fig.34 PWB PATTERN(MAIN PWB)

52

Page 54

(REAR-SIDE)

Fig.34 PWB PATTERN(MAIN PWB)

53

Page 55

7. REPLACEMENT PARTS LIST

"HOW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly,

please furnish the following information.

1.MODEL NUMBER

3.PART NO.

No. REF.No. PART CODE NEW DESCRIPTION QTY PRICE

1. MAIN PWB ASSEMBLY(DPWB-2146YAZZ)

1-1. IC

1 IC1 RH-IX1234PAZZ uPC1100GS(T) 1 AL

2 IC4,407 RH-IX0855PAZZ TL7705CPS-B 2 AK

3 IC5 RH-IX2788YAZZ PST529C 1 AG

4 IC7 RH-IX2936YAZZ uPC24M10HF 1 AH

5 IC22,23 RH-IX0853PAZZ TL712CPS-A 2 AQ

6 IC28 RH-IX2661YAZZ TC74HC04AF EL 1 AD

7 IC100 RH-IX2893YAZZ L7A1322(GATE ARRAY) 1 BF

8 IC101 RH-IX2872YAZZ 74VHC08F 1 AD

IC102,314,405,406,410,

9

421,422,509

RH-IX2650YAZZ TC7S04 8 AC

10 IC103-105 RH-IX2926YAZZ HM530281-20 3 BH

11 IC106 RH-IX2921YAZZ CE16V8(PLD1502) 1 AQ

12 IC107 RH-IX2896YAZZ PCF8584 1 AZ

13 IC108,111 RH-IX2919YAZZ IS62C256-70U 2 AV

14 IC200 RH-IX1233PAZZ TL750L10LP 1 AM

15 IC201 RH-IX2866YAZZ MB88346B 1 AS

16 IC202,203 RH-IX1235PAZZ SP1648(T) 2 AT

17 IC204,206,416 RH-IX1239PAZZ MM74HC00(T) 3 AE

18 IC205 RH-IX1236PAZZ TLC27L9C(T) 1 AR

19 IC300-302 RH-IX2818YAZZ LM1201M 3 AW

20 IC307-313 RH-IX2899YAZZ 74ACT374(SSOP) 7 AQ

21 IC315-317 RH-IX2927YAZZ CXD2302Q 3 BC

22 IC400 RH-IX2979YAZZ N HD6473256F10 1 BF

23 IC401-403 RH-IX2910YAZZ 74HC245 3 AH

24 IC404 RH-IX1922PAZZ TC74HC32AF-EL 1 AD

25 IC409,415,420,512 RH-IX2832YAZZ TC7S08F 4 AC

26 IC411 RH-IX0847PAZZ S-8054ALB-LM-TI 1 AF

27 IC413,414 RH-IX2897YAZZ 35C116 2 AV

28 IC417 RH-IX2917YAZZ TC7S86 1 AE

29 IC418 RH-IX2857YAZZ TC74HC221AF 1 AH

30 IC419 RH-IX1133PAZZ SN74LS74ANS 1 AE

31 IC500 RH-IX2890YAZZ TA8184F 1 AN

32 IC503 RH-IX2892YAZZ TDA1905 1 AL

33 IC507,508 RH-IX2925YAZZ 7S66 2 AF

34 IC600 RH-IX2888YAZZ SAA7110 1 BQ

35 IC601 RH-IX2889YAZZ SAA7192A 1 BQ

1-2. DIODE

1 D2,7-10 VHD1S1885//-1 1S1885 5 AB

2 D3,4 VHDSB05-05CP1 SB05-05CP 2 AC

3 D6,11 VHDERB81-004/ ERB81-004 2 AE

4 D200-202 VHD1SS294//-1 1SS294(A9) 3 AA

5 D203 VHD1SV211//-1 1SV211 1 AB

6 D204 VHDKV1230Z/-1 KV1230Z 1 AH

7 D205,300-302 VHD1SS226//-1 1SS226(C3) 4 AB

8 D502 VHERD10M///-1 RD10M 1 AD

9 D700,800,802 VHD1SS193//-1 1SS193 3 AA

10 D801 VHERD15MB3/-1 ERD15MB3 1 AB

11 DA400,401 VHDHN2D01F/-1 HN2D01F(T) 2 AC

12 ZD1 VHELM385BX/-1 LM385BX 1 AV

2.REF.NO.

4.DESCRIPTION

54

Page 56

No. REF.No. PART CODE NEW DESCRIPTION QTY PRICE

1-3. TRANSISTER

1 Q8,11 VS2SA1182-Y-1 2SA1182-Y 2 AB

2 Q9,10 VS2SA1293Y/1E 2SA1293Y 2 AG

3 Q101,102,500 VS2SC3913//-1 2SC3913-TB 3 AB

4 Q200 VSHN1C01FY/-1 HN1C01F-Y(T) 1 AB

5 Q201,702 VS2SA1162SY-1 2SA1162-SY 2 AA

6 Q202,203 VSFP1A3M///-1 FP1A3M(T) 2 AC

7 Q204 VS2SA1204RY-1 2SA1204RY 1 AC

8 Q205 VS2SC2884PY-1 2SC2884PY 1 AC

9 Q701 VSDTC-144WK-1 N DTC144WK 1 AC

10 Q800,801 VS2SC2712LY-1 2SC2712 LY 2 AA

1-4. COIL

1 L7,10,13 RCILZ3877PAZZ RCR-875D 22MH 3 AE

2 L8,9,11,12 RCILZ3878PAZZ RCR-110D 270MH 4 AF

3 L14 RCILZ2109YAZZ RCH-664 100MH 1 AD

4 L200 RCILZ3875PAZZ 7KTLT 2.45MH 1 AD

5 L201 RCILZ2135YAZZ 7KTLT 0.15UH 1 AE

6 L600,601,603 RCILZ2133YAZZ NW5650(10MH) 3 AH

7 L602 VP-VD100K0000 LEM4532 10MH 1 AC

8 L800 RTRNZ0035PAZZ FILTER-COIL 1 AE

1-5. FILTER

1 FL100 RMPT-2062YAZZ ACF321825-470 1 AE

2 FL102 RFILN2002YAZZ NFM840R01G101 1 AD

3 FL200,201,203-206 RFILN0163PAZZ NFM61R10T102 6 AE

4 FL800 RCILZ2110YAZZ PLT1R53C 1 AH

5 FL801 RCORF0058PAZZ BNX002-01 1 AD

1-6. CORE

1 FB100-119 RCORF2024YAZZ BLM11A12 20 AC

2 FB120,130,300,301 RCORF2044YAZZ N BLM21A50 4 AC

3 FB122,L202,203 RCORF2011YAZZ BLM41A04 3 AE

FB123,124,126,132,13

4

4,302-304

5 FB125 RCORF2023YAZZ MMZ2012S181A 1 AB

6 FB127 RCORF2038YAZZ N BLM11B30 1 AC

7 FB131 VRN-CY1JQ561D (CY)1/16W-560D 1 AA

8 FB133 RCORF2010YAZZ BLM21A05 1 AE

9 FB202 RCORF2033YAZZ BLM21B30 1 AC

10 FB204-206 RCORF2027YAZZ BLM21A10 3 AC

1-7. OSCILLATOR

1 OSC1 RCRS-2123YAZZ DSO751S 25.175 1 AV

2 OSC2 RCRS-2124YAZZ DSO751S 21.000 1 AT

3 XTL400 RCRS-2129YAZZ AT-51 7.9872MHZ 1 AS

4 XTL600 RCRS-2127YAZZ 9922 520 30004 1 AL

1-8. LED

1 LED1 RH-PX2157YAZZ N LED(RED)TLR206 1 AC

1-9. RELAY

1 RL1 RRLY-2124YAZZ RELAY JY-12H-K 1 AM

2 RL2 RRLYU0090PAZZ A-12W-K 1 AT

1-10. VR

1 VR1,2 RVR-M2276YAZZ RVG4M08(2KORM) 2 AF

2 VR50,51 RVR-M2294YAZZ N RK08H-50K 2 AH

3 VR300-302 RVR-M0216PAZZ VR ST-4 5K 3 AG

4 VR303 RVR-M2285YAZZ ST-4A 1K 1 AG

5 VR501 RVR-M2290YAZZ ST-4A 20K 1 AH

1-11. FUSE, FUSE HOLDER

1 F1 QFS-F0003PAZZ FUSE 2A/125V 1 AD

2 QFSHA2008YAZZ 85PE1850 2 AA

RCORF2030YAZZ BLM11B20 8 AC

55

Page 57

No. REF.No. PART CODE NEW DESCRIPTION QTY PRICE

1-12. JUMPER, JACK, CONNECTOR

1 JAG1.JDG1 QJUM-3001CEFW N 5M/M-JUMPER 2 AB

2 J1 QSOCZ0115PAZZ DC JACK 1 AC

3 J2 QPLGJ2731YAZZ D-SUB 15P 1 AX

4 CN20 QPLGJ2755YAZZ N DF13-5P-1.25DSA 1 AD

5 CN100 QCNCW0034KAZZ N IL-FPR-33S-VF 1 AK

6 CN201 QCNCW0050PAZZ DF3A-2P-2DSA 1 AA

7 CN400 QPLGJ2702YAZZ 53047-1110 1 AD

8 CN401,501 QPLGZ0370PAZZ B2B-PH-K-S 2 AB

9 CN402 QPLGJ2701YAZZ DF13-6P-1.25DSA 1 AC

10 CN403 QPLGJ2754YAZZ N 53048-1110 1 AE

11 CN502 QSOCZ2042YAZZ N JPJ1125-01-030 1 AG

12 CN504 QPLGJ2725YAZZ 53047-1210 1 AE

13 CN600 QSOCZ2041YAZZ JPJ1125-01-040 1 AF

14 CN601 QSOCZ2032YAZZ TCS7931-14-401 1 AH

1-13. SWITCH

1 S1,2,3,4,5 QSW-P0089PAZZ SKHHLQ 5 AC

2 SW1 QSW-P2102YAZZ N SPPJ6-N2-W 1 AG

1-14. RESISTER

1 R20,32,713 VRN-TV2AQ472D (TV)1/10W-4.7KD 3 AA

2 R21 VRN-TV2AQ183D (TV)1/10W-18KD 1 AA

3 R23,35 VRS-TW2AD390J (TW)1/10W-39J 2 AA

4 R22,34,532,702 VRS-TW2AD101J (TW)1/10W-100J 4 AA

5 R24,36 VRS-TW2HD181J (TW)1/2W-180J 2 AA

6 R25,37 VRS-TW2AD330J (TW)1/10W-33J 2 AA

7 R26,27 VRN-TV2AQ332D (TV)1/10W-3.3KD 2 AA

8 R28,30 VRS-TW2AD472J (TW)1/10W-4.7KJ 2 AA

9 R29 VRS-TW2AD822J (TW)1/10W-8.2KJ 1 AA

10 R31 VRS-TW2AD683J (TW)1/10W-68KJ 1 AA

11 R33 VRN-TV2AQ203D (TV)1/10W-20KD 1 AA

12 R38 VRS-TW2AD471J (TW)1/10W-470J 1 AA

13 R41 VRS-TW2AD152J (TW)1/10W-1.5KJ 1 AA

14 R42 VRS-TW2AD222J (TW)1/10W-2.2KJ 1 AA

15 R43,611,710,711 VRS-TW2AD332J (TW)1/10W-3.3KJ 4 AA

R100,104,105,107,108,

112,122,228,260265,269,606-608,900-

16

903,FB128,129,135,38

4,600602,JP30,101,200,202

R109,110,203205,209,212,219,352357,400-402,404-

17

406,409,410,412424,431,433-436

R114,364-

18

376,509,604,605,704,7

08,709,803

19 R120,380,381 VRS-CY1JD471J (CY)1/16W-470J 3 AA

20 R123 VRS-CY1JD221J (CY)1/16W-220J 1 AA

21 R124 VRS-CY1JD151J (CY)1/16W-150J 1 AA

22 R127,382 VRS-CY1JD121J (CY)1/16W-120J 2 AA

23 R200 VRN-CY1JQ681D (CY)1/16W-680D 1 AA

24 R201 VRN-CY1JQ912D (CY)1/16W-9.1KD 1 AA

25 R202 VRN-CY1JR104D (CY)1/16W-100KD 1 AA

26 R206 VRN-CY1JQ392D (CY)1/16W-3.9KD 1 AA

27 R207 VRN-CY1JQ911D (CY)1/16W-910D 1 AA

VRS-CY1JD0000 (CY) 0 33 AA

VRS-CY1JD103J (CY)1/16W-10KJ 40 AA

VRS-TW2AD0000 (TW) 0 21 AA

56

Page 58

No. REF.No. PART CODE NEW DESCRIPTION QTY PRICE

28 R208 VRN-CY1JS680D (CY)1/16W-68D 1 AA

R211,218,224,225,FB2

29

01,203

30 R214,251,426-429,602 VRS-CY1JD472J (CY)1/16W-4.7KJ 7 AA

31 R215,403 VRS-CY1JD681J (CY)1/16W-680J 2 AA

32 R216,217 VRS-CY1JD222J (CY)1/16W-2.2KJ 2 AA

33 R220 VRN-CY1JQ181D (CY)1/16W-180D 1 AA

34 R221 VRN-CY1JR334D (CY)1/16W-330KD 1 AA

35 R222,223 VRS-CY1JD823J (CY)1/16W-82KJ 2 AA

36 R227 VRS-TW2AD105J (TW)1/10W-1MJ 1 AA

R303,311,319,516,555,

37

557

R304,312,320,502,503,

38

506,507

39 R305,313,321 VRS-TW2AD221J (TW)1/10W-220J 3 AA

40 R306,314,322 VRN-TV2AS510D (TV)1/10W-51D 3 AA

41 R307,315,323 VRN-TV2AQ271D (TV)1/10W-270D 3 AA

42 R308,316,324 VRN-TV2AQ331D (TV)1/10W-330D 3 AA

43 R309,317,325,715 VRN-TV2AQ222D (TV)1/10W-2.2KD 4 AA

44 R310,318,326 VRN-TV2AQ272D (TV)1/10W-2.7KD 3 AA

45 R327 VRN-TV2AQ822D (TV)1/10W-8.2KD 1 AA

46 R328 VRN-TV2AQ391D (TV)1/10W-390D 1 AA

47 R358-363 VRS-CY1JD331J (CY)1/16W-330J 6 AA

48 R383 VRS-CY1JD101J (CY)1/16W-100J 1 AA

49 R408 VRN-CY1JQ333D (CY)1/16W-33KD 1 AA

50 R411 VRN-CY1JR304D (CY)1/16W-300KD 1 AA

51 R450 VRS-CY1JD223J (CY)1/16W-22KJ 1 AA

52 R501,540,552 VRN-TV2AQ473D (TV)1/10W-47KD 3 AA

53 R512 VRN-TV2AQ104D (TV)1/10W-100KD 1 AA

54 R520 VRS-TW2AD102J (TW)1/10W-1KJ 1 AA

55 R521,522 VRS-TW2HD150J (TW)1/2W-15J 2 AB

56 R530 VRN-TV2AQ562D (TV)1/10W-5.6KD 1 AA

R531,535,701,703,712,

57

714,800,801

58 R533 VRS-TW2ED1R0J (TW)1/4W-1J 1 AB

59 R534 VRS-TW2AD153J (TW)1/10W-15KJ 1 AA

60 R556 VRS-CY1JD332J (CY)1/16W-3.3KJ 1 AA

61 R600,609,610,705-707 VRN-TV2AS750D (TV)1/10W-75D 6 AA

62 R700 VRS-TW2AD272J (TW)1/10W-2.7KJ 1 AA

63 R716 VRS-TW2AD561J (TW)1/10W-560J 1 AA

1-15. CAPACITOR

C3,4,13,20,29,32,39,44

1

,45,48,57,60,701-704

2 C21,38 VCEAPZ1AC227M (UR)220uF/10V 2 AC

3 C28 VCEAPL1EN685M (WF)6.8uF/25V 1 AD

4 C30 VCKYTV1HB122K B/1200pF/K/50V 1 AA

5 C31,33 VCKYTV1HB332K B/3300pF/K/50V 2 AA

6 C34,40 VCEAPZ1CC477M (UR)470uF/16V 2 AC

7 C35,36,41,42 VCEAPZ1AC477M (UR)470uF/10V 4 AD

8 C37,43 VCKYTQ1EF334Z F/0.33uF/Z/25V 2 AB

9 C46,47 VCEAPZ1CC107M (UR)100uF/ 16V 2 AC

10 C100-119,165,372 VCCCCY1H3270J CH/ 27pF/J/50V 22 AA

11 C120,160 VCCCCY1H3120J CH/12pF/J/50V 2 AB

RCORF2028YAZZ BLM32A06 6 AA

VRN-CY1JQ103D (CY)1/16W-10KD 6 AA

VRN-CY1JQ223D (CY)1/16W-22KD 7 AA

VRS-TW2AD103J (TW)1/10W-10KJ 8 AA

VCKYTV1EF104Z F/0.1uF/Z/25V 16 AA

57

Page 59

No. REF.No. PART CODE NEW DESCRIPTION QTY PRICE

C121,124,129142,145,147,149,151,1

52,154,158,208,209,21

1214,216,217,219,221,2

22,224-226,232234,237,244,251,260,3

03-307,309-315,317-

12

323,325,326,345348,350-353,355358,363-370,400403,406415,423,424,426,427,4

30432,434,435,531,540,5

44,

558-560,563,600,609617,619-625,627,628

C122,125128,220,227,235,246,2

52,300-

13

302,344,349,354,504,5

06,509,513,524,532,53

5,802

14 C123,250,374-376 VCKYBT1CX332M X/3300pF/M/16V 5 AB

C143,144,223,231,404,

15

405,507,601,630,631

C146,148,150,155,157,

16

505,700

17 C164 VCCCCY1H33R0C CH/3pF/C/50V 1 AB

C200,201,203-

18

206,308,316,324,536

19 C218 VCEAPS1CC226M (WX)22uF/16V 1 AC

20 C228,236 RC-QZS103AFYK 0.01uF/K/50V 2 AF

21 C229,550 VCCCCY1H3101J CH/100pF/J/50V 2 AA

22 C230 VCEAPH1EC475M (WX)4.7uF/ 25V 1 AC

23 C238,239,332-338 VCKYCY1HB102K B/1000pF/K/50V 9 AA

24 C253 VCKYBT1HF104Z F/0.1uF/Z/50V 1 AC

25 C422 VCEAPS1AC226M (WX)22uF/ 10V 1 AC

26 C425 RC-EZ2622YAZZ FS 0.22F/5.5V 1 AK

27 C428,429 VCCCCY1H3180J CH/18pF/J/50V 2 AA

28 C502 VCKYTV1HB822K B/8200pF/K/50V 1 AA

29 C503 VCKYTQ1CR334K R/0.33uF/K/16V 1 AB

30 C517 VCEAPF1CC106M (WP)10uF/16V 1 AC

31 C528,533,538,539 VCKYTQ1CB224M B/0.22uF/M/16V 4 AC

32 C530 VCEAPP1CM337M (UX)330uF/16V 1 AE

33 C534 VCEAPZ1CC337M UR 330uF/16V 1 AE

34 C537 VCEAPH1VC225M (WX)2.2uF/35V 1 AC

35 C603 VCCCTV1H3102J CH/1000pF/J/50V 1 AA

36 C604,605 VCCCCY1H3100D CH/10pF/D/50V 2 AA

37 C618,626,629 VCEAPL1AN476M (WF)47uF/ 10V 3 AD

38 C705 VCCCCY1H3181J CH/180pF/J/50V 1 AB

39 C800,C801 RC-QZS473AFYK 0.047uF/K/50V 2 AF

2. INVERTER UNIT(DUNT-2126YAZZ)

1 F1 QFS-L0004PAZZ N 451001 FUSE(FOR INVERTER) 1 AG

3. CABINET PARTS

1 No.3-1 DUNTL2125YAZZ N LCD UNIT(LCD-LQ10D365) 1 EH

VCKYCY1EF104Z F/0.1uF/Z/25V 134 AA

VCEAPH1CC106M (WX)10uF/16V 24 AC

VCKYCY1HB103K B /0.01uF/K/50V 10 AA

VCKYTQ1CF105Z F/1uF/Z/16V 7 AC

VCEAPS1CC476M (WX)47uF/16V 10 AC

58

Page 60

No. REF.No. PART CODE NEW DESCRIPTION QTY PRICE

2 No.3-2 GCABA2055YASA N FRONT CABINET(CABNET A) 1 BB

3 No.3-3 GCABB2056YASA N REAR CABINET(CABINET B) 1 BC

4 No.3-4 DANGK2063YASA N STAND ARM ASSEMBLY 1 BA

5 No.3-5 GCOVH2037YASA N STAND ARM COVER 1 AF

6 No.3-6 JBTN-2098YASA N KEY BLOCK 1 AH

7 No.3-7 JKNB-2016YAZZ N VR KNOB 2 AF

8 No.3-8 LANGK2064YASA N CONNECTOR ANGLE 1 AQ

9 No.3-9 LANGK2065YASA N SHIELD BOARD A 1 AH

10 No.3-10 LANGK2066YASA N SHIELD BOARD B 1 AH

11 No.3-11 QCNCM2534YAZZ CABLE FOR SWITCH PWB 1 AL

12 No.3-12 QCNCM2579YAZZ N CABLE FOR INVERTER 1 AN

13 No.3-13 VSPRA01P-038B SPEAKER ASSEMBLY 1 AX

14 No.3-14 LX-BZ0312PAZZ SCREW(FOR D-SUB15P) 2 AE

15 No.3-15 XBBSD30P06000 SCREW 3B+6S 12 AA

16 No.3-16 XYBSD20P06000 SCREW 2B+6S 2 AA

17 No.3-17 XYBSD30P06000 SCREW 3B+6S 5 AA

18 No.3-18 XYBSD30P08000 SCREW 3B+8S 8 AA

19 No.3-19 XYSUW30P08000 SCREW 1 AA

20 No.3-20 LX-BZ0269PAZZ SCREW 2 AA

21 No.3-21 XYPSD26P20000 N SCREW 2.6B+20S 2 AA

22 No.3-22 PCUS-2092YAZZ N CUSHION 1 AM

23 No.3-23 PCUS-2093YAZZ N CUSHION 1 AH

24 No.3-24 PCUS-2099YAZZ N CUSHION 1 AH

25 No.3-25 PCUS-2100YAZZ N CUSHION 1 AK

26 No.3-26 PCUS-2101YAZZ N CUSHION 1 AG

27 No.3-27 PCUS-2056YAZZ CUSHION 2 AH

28 No.3-28 PSHEG2131YAZZ N INSULATION SHEET 1 AH

29 No.3-29 PCUS-2113YAZZ N CUSHION 2 AM

30 No.3-30 RV-KX2070YAZZS N BACK LIGHT 1 BN

31 No.3-31 DFUNP0008PAZZ N FAN MOTOR 1 BB

32 No.3-32 RCORF2014YAZZ CORE FOR INVERTER CABLE 1 AN

33 No.3-33 RCORF2017YAZZ CORE FOR SWITCH CABLE 1 AM

34 No.3-34 PCUS-2107YAZZ N CUSHION 1 AM

35 No.3-35 PCUS-2108YAZZ N CUSHION 1 AM

36 No.3-36 PCUS-2109YAZZ N CUSHION 1 AM

37 No.3-37 PCUS-2112YAZZ N CUSHION 1 AM

38 No.3-38 PCUS-2111YAZZ N CUSHION 2 AM

39 No.3-39 PSLDM2004YAZZ N SHELTER SHEET 1 AM

40 No.3-40 PCUS-2110YAZZ N CUSHION 1 AM

4. OTHERS

1 DADP-2004YAZZ AC ADAPTOR 1 BU

2 DACCV2005YAZZ AC CORD 1 AZ

3 TINSL2134YAZZ N OPERATION MANUAL 1 BC

4 TLABZ2119YAZZ CAUTION LABEL 1 AD

5 DSOCZ0070PAZZ VGA CABLE 1 BN

6 DSOCZ0071PAZZ MAC CABLE 1 BN

7 RCORF2013YAZZ CORE FOR AC ADAPTOR 2 AP

5. PWB ASSEMBLY

1 No.5-1 DPWB-2146YAZZ N MAIN PWB ASSEMBLY 1 DW

2 No.5-2 DPWB-2147YAZZ N FPC CABLE ASSEMBLY 1 BK

3 No.5-3 DUNT-2126YAZZ N INVERTER UNIT 1 BF

Because parts marked with " " is indispensable for the machine safety

maintenance and operation, it must be replaced with the product specification.

59

Page 61

3-16

5-3

3-16

8. ASSEMBLY DRAWINGS

3-2

3-37

3-32

3-12

3-29

3-7

3-40

3-20

5-2

3-25

3-15

3-24

3-15

3-17

3-11

3-15

3-33

3-23

3-17

3-28

3-1

3-9

3-15

3-21

3-31

3-15

3-22

3-35

3-15

3-26

3-10

3-27

3-38

3-17

3-15

3-34

3-8

3-15

3-25

5-1

3-17

3-36

3-39

3-14

3-6

3-17

3-13

3-18

3-15

3-19

60

3-18

3-3

3-18

3-18

3-4

3-15

3-5

3-18

QD-101MM CABINET PARTS

Page 62

PACKING CASE

ACCESSORIES

CASE

SHARP

Color LCD Monitor

OPERATION MANUAL

QD-101MM

OPERATION MANUAL

PACKING ADD

QD-101MM

AC ADAPTOR

VGA SIGNAL CABLE

MAC SIGNAL CABLE

PACKING ADD

AC CODE

PROTECTER

QD-101MM PACKING OF THE SET

61

Page 63

14

6

15

3

13

13

2

20

19

16

21

16

7

7

18

17

4

16

16

5

21

4

26

27

7

10

11

12

7

9

11

8

23

25

24

30

1

6

1

1

31

30

29

28

22

21

QD-101MM DISASSEMBLY AND REASSEMBLY

62

1

Page 64

CAUTIONCAUTION

CAUTION

*Turn off the power before removing the Inverter PWB(DUNT-2126YAZZ)

or Backlight(RV-KX2070YAZZS) because high voltage is applied.

*You should remove the LCD unit(DUNTL2125YAZZ) after removing the

Inverter PWB(DUNT-2126YAZZ).

<Disassembling method>

Please disassemble the QD-101MM according to the following procedure.

(1)Remove four rear cabinet screws.

(2)Disconnect the FPC cable from the LCD panel.

(3)Disconnect the Inverter PWB connector from the Inverter PWB.

(4)Disconnect the speaker connector and fan motor connector from the Main PWB.

(5)Disconnect the Switch PWB connector from the Switch PWB.

(6)Separate the rear cabinet from the front cabinet.

(7)Remove four Main PWB screws.

(8)Remove two D-sub connector screws.

(9)Remove the Main PWB.

(10)Remove the shield board(B).

(11)Remove two connector angle screws.

(12)Remove the connector angle.

(13)Remove two Inverter PWB screws.

(14)Disconnect the Backlight connector from the Inveter PWB.

(15)Remove the Inverter PWB.

(16)Remove four shield board(A) screws.

(17)Remove the shield board(A).

(18)Remove the LCD panel.

(19)Remove the Backlight screws.

(20)Pull out the Backlight.

(21)Remove three Switch PWB screws.

(22)Remove the Switch PWB.

(23)Remove the Key block.

(24)Remove four speaker screws.

(25)Remove the speaker.

(26)Remove two fan motor screws.

(27)Remove the fan motor.

(28)Remove the stand arm cover screws.

(29)Remove the stand arm cover.

(30)Remove four stand arm assembly screws.

(31)Remove the stand arm assembly.

63

Page 65

9. INFORMATION

There are some special modifications made to the MAIN PWB.

Applied serial number is shown below.

From 5AG00011 to 5AG00453 for SEEG.

1. The Diode(VHD1SS226//-) is mounted between the pattern for CN201 and the pattern for

12V-line. (CN201: Connector for Fan motor)

[MAIN PWB(FRONT SIDE)]

CN201

12V line

Strip the pattern

Pattern cut

2. Between CN20 pin 1 and CN20 pin 2 is soldered.

The insulation sheet is added on the following position.

Soldering

Hot melt

[MAIN PWB(BACK SIDE)]

CN20(Solder side)

Soldering

pin2

pin1

JP10

JP20

Soldering

Diode(D205) is added.

(VHD1SS226//-1)

Insulation sheet is added.

64

Page 66

PRINTED IN GERMANY

Loading...

Loading...