SHARP PZ-50HV2, PZ-50HV2E, PZ-50HV2U Service Manual

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

SERVICE MANUAL

SY2U9PZ50HV2E

PLASMA DISPLAY TV

(PANEL UNIT)

PZ-50HV2

PZ-50HV2E

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

PZ-50HV2U

CONTENTS

Page

» IMPORTANT SERVICE SAFETY PRECAUTION... 2

» SPECIFICATIONS .................................................. 4

» SAFETY INFORMATION ........................................ 5

» OPERATION MANUAL ........................................... 8

» DIMENSIONS ....................................................... 11

» REMOVING OF MAJOR PARTS .......................... 12

» ADJUSTMENT PROCEDURES ........................... 16

» TROUBLE DIAGNOSIS ........................................ 35

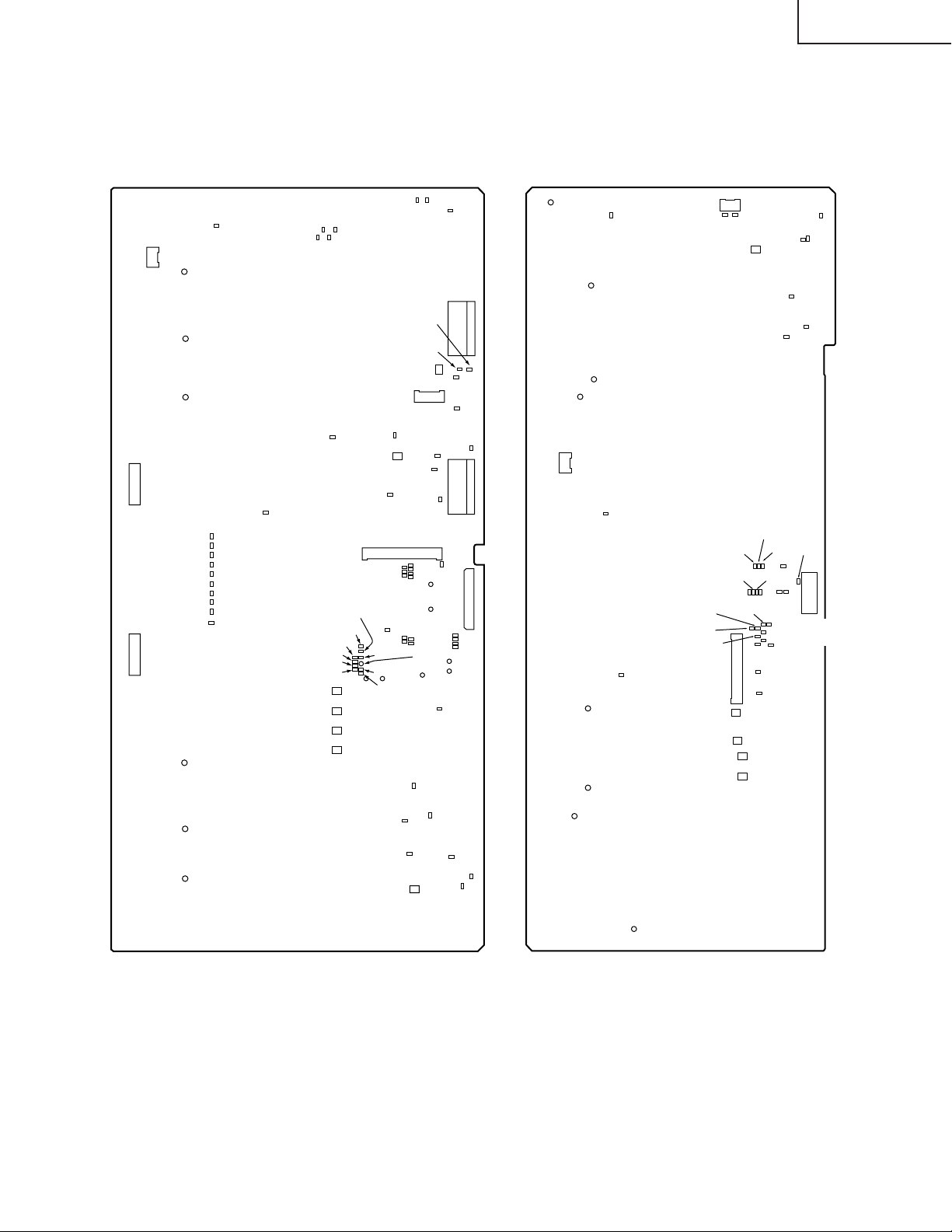

» CHASSIS LA YOUT ............................................... 42

» DESCRIPTION OF MAJOR IC FUNCTIONS ....... 43

» BLOCK DIAGRAM ................................................ 62

» OVERALL WIRING DIAGRAM ............................. 74

» WAVEFORMS....................................................... 78

» SCHEMA TIC DIAGRAM ....................................... 82

» PRINTED WIRING BOARD ASSEMBLIES ........ 178

» PAR TS LIST

Ë ELECTRICAL P ARTS ..................................... 204

Ë CABINET AND MECHANICAL PARTS .......... 231

Ë PACKING PARTS ........................................... 253

» PACKING OF THE SET ...................................... 254

» SPEAKER SYSTEMS......................................... 255

Page

SHARP CORPORATION

This document has been published to be used for after

sales service only.

The contents are subject to change without notice.

PZ-50HV2, PZ-50HV2E

2

2

PZ-50HV2U

IMPORTANT SERVICE SAFETY PRECAUTION

Ë

Service work should be perfomed only by qualified service technicians who are thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

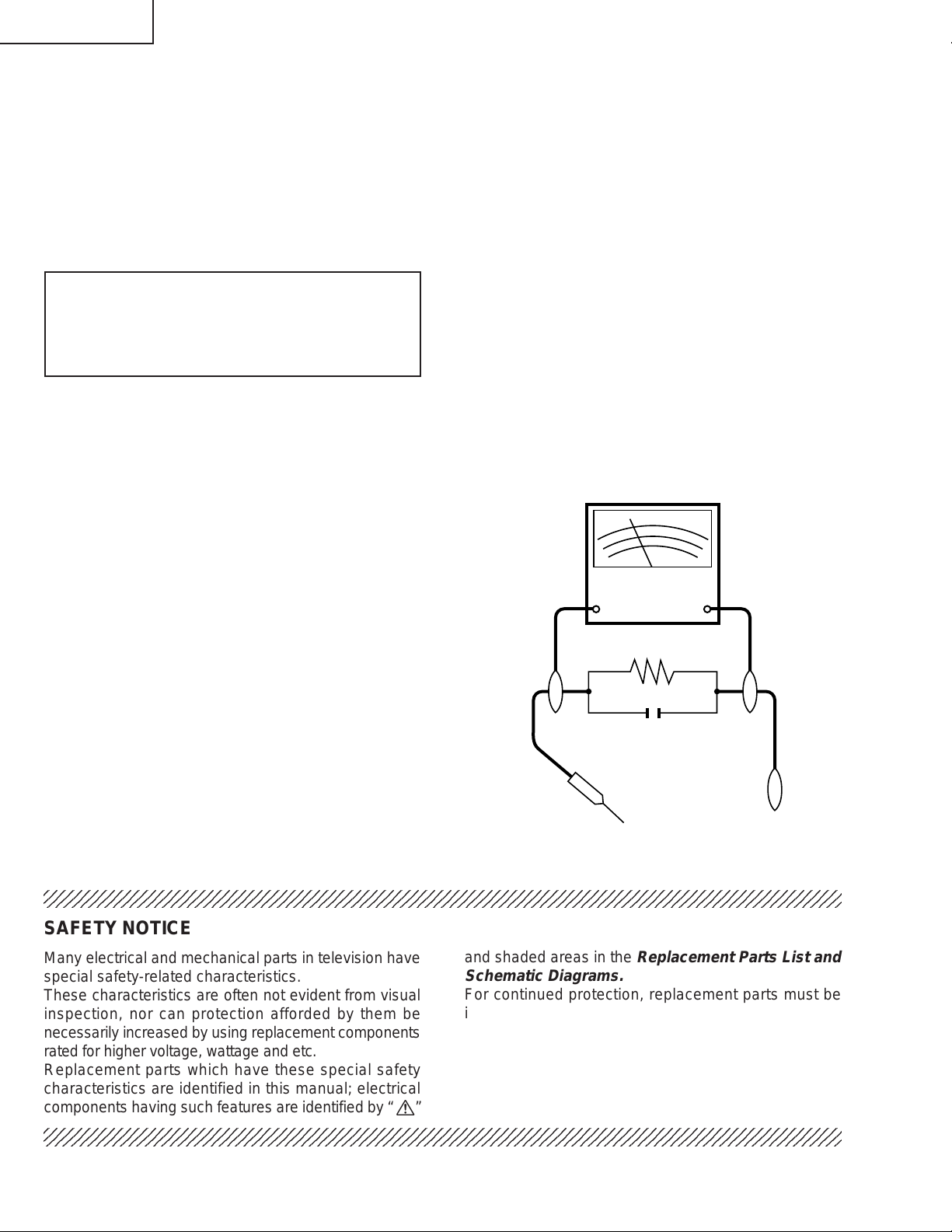

» Use an AC voltmeter having with 5000 ohm per volt,

or higher, sensitivity or measure the AC voltage drop

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

across the resisor.

» Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

CAUTION: FOR CONTINUED PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE. 9GJAEK1071(10A/400V): PZ50HV2E, 9GJAEK1069 (10A/125V): PZ-50HV2U

FUSE.

escutcheon and etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug

connection reversed. (If necessary, a nonpolarized

adaptor plug must be used only for the purpose of

completing these checks.)

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

Any reading of 35V peak (this corresponds to 0.7

milliamp. peak AC.) or more is excessive and

indicates a potential shock hazard which must be

corrected before returning the monitor to the owner.

the following safety checks:

1. Inspect all lead dress to make certain that leads are

not pinched, and check that hardware is not lodged

between the chassis and other metal parts in the

receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators and etc.

DVM

AC SCALE

1.5k ohms.

10W

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

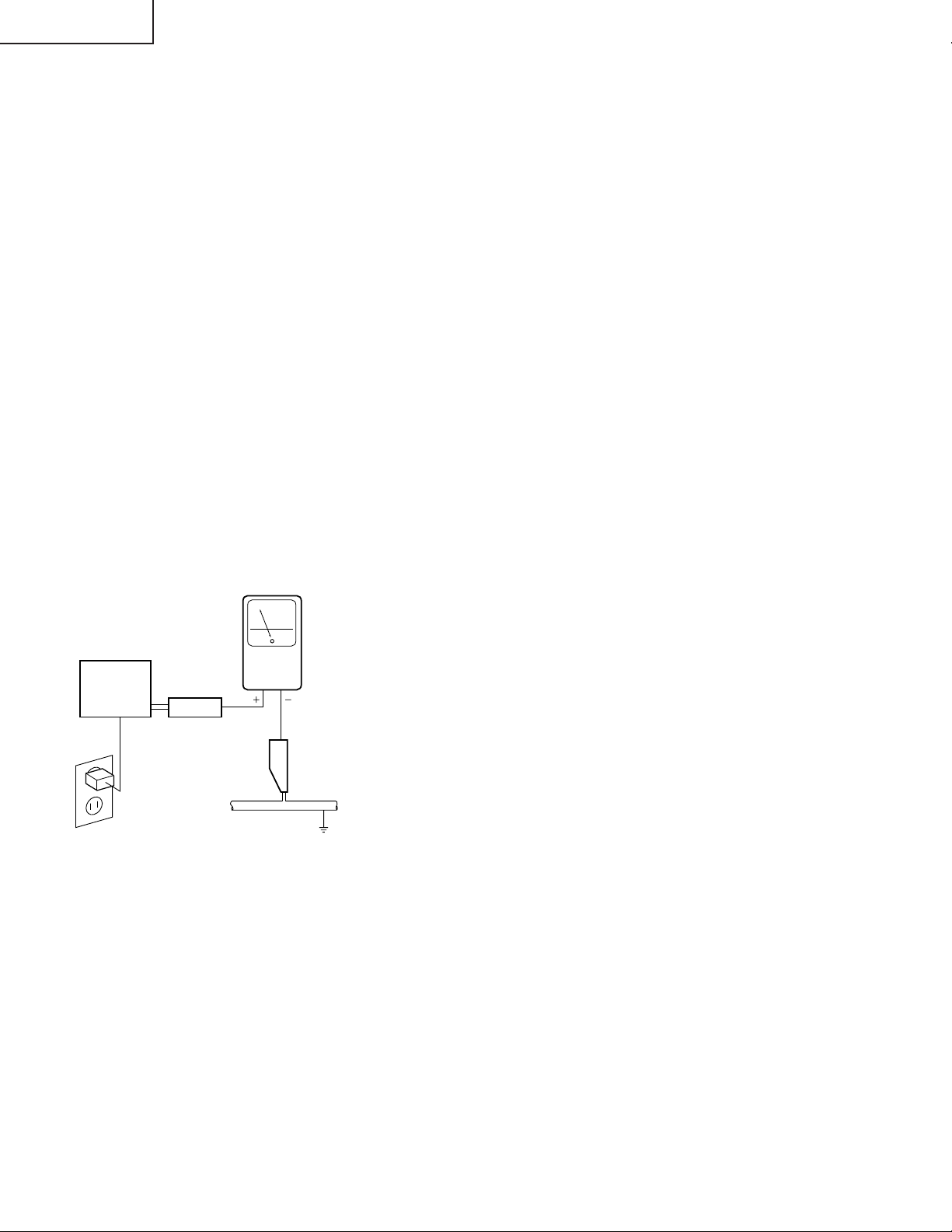

» Plug the AC cord directly into a 110~240 volt AC outlet,

and connect the DC power cable into the receiver's

DC jack. (Do not use an isolation transformer for this

0.15 µF

TEST PROBE

test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series

with all exposed metal cabinet parts and a known

earth ground, such as electrical conduit or electrical

ground connected to an earth ground.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in television have

special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage and etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

and shaded areas in the

Schematic Diagrams.

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of a substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock, fire or other hazards.

components having such features are identified by “ å”

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

Replacement Parts List and

2

PZ-50HV2, PZ-50HV2E

2

2

2

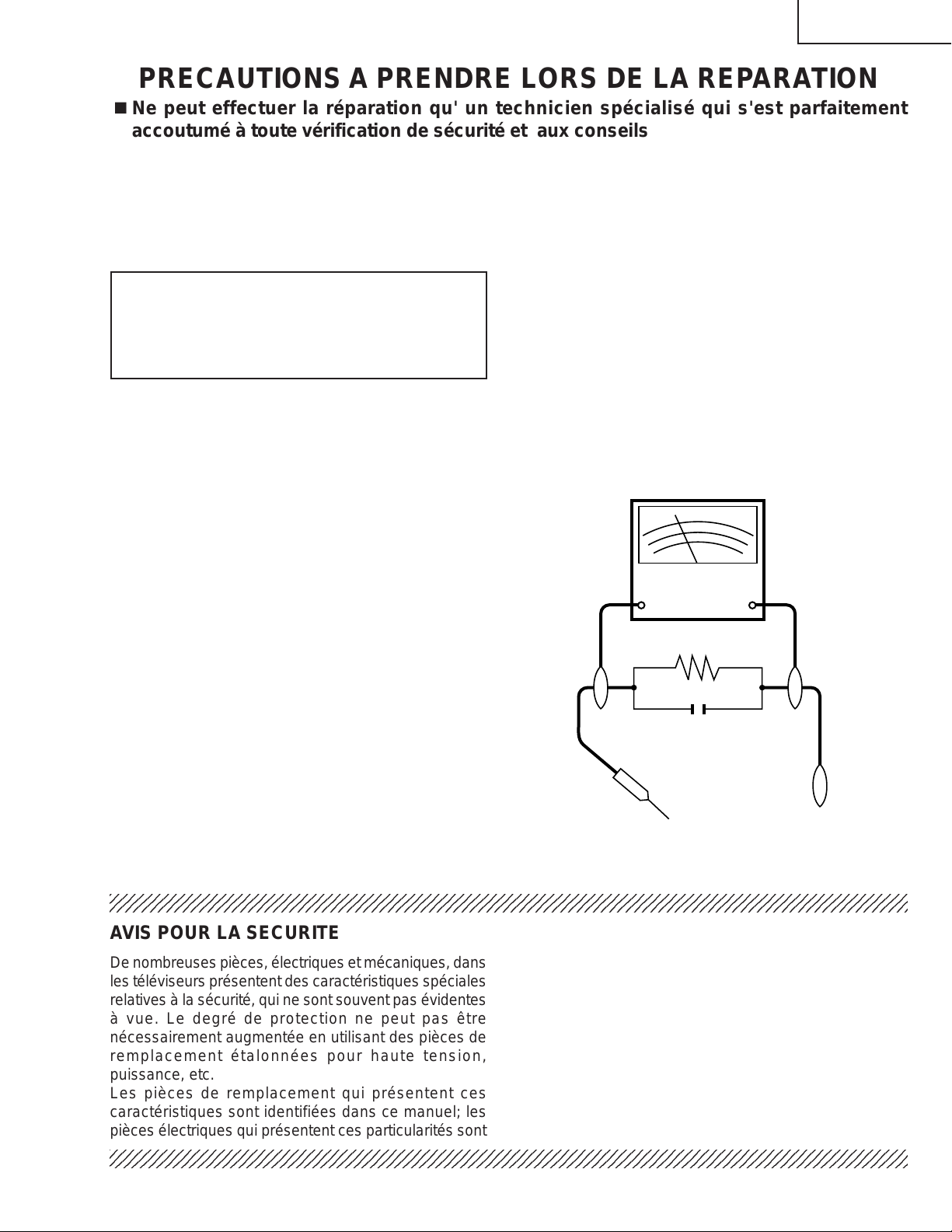

VTVM

ECHELLE CA

1.5k ohm

10W

0.15 µF

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

PZ-50HV2U

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ë

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement

accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

1. N'entreprendre aucune modification de tout circuit.

C'est dangereux.

2. Débrancher le récepteur avant toute réparation.

PRECAUTION

: POUR LA PROTECTION CONTINUE

CONTRE LES RISQUES D'INCENDIE, REMPLACER

LE FUSIBLE PAR UN FUSIBLE DE MEME TYPE

9GJAEK1071(10A/400V): PZ-50HV2E, 9GJAEK1069

(10A/125V): PZ-50HV2U.

VERIFICA TIONS CONTRE L'INCEN-DIE ET

LE CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer

les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour s'assurer

que les fils ne soient pas pincés ou qu'un outil ne soit

pas placé entre le châssis et les autres pièces

métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme les

boutons de commande non-métalliques, les isolants,

le dos du coffret, les couvercles ou blindages de réglage

et de compartiment, les réseaux de résistancecapacité, les isolateurs mécaniques, etc.

3. S'assurer qu'il n'y ait pas de danger d'électrocution en

vérifiant la fuite de courant, de la facon suivante:

• Brancher le cordon d'alimentation directem-ent à une

prise de courant de 110-240V. (Ne pas utiliser de

transformateur d'isolation pour cet essai).

• A l'aide de deux fils à pinces, brancher une résistance

de 1.5 kΩ 10 watts en parallèle avec un condensateur

de 0,15µF en série avec toutes les pièces métalliques

exposées du coffret et une terre connue comme une

conduite électrique ou une prise de terre branchée à

la terre.

• Utiliser un voltmètre CA d'une sensibilité d'au moins

5000Ω/V pour mesurer la chute de tension en travers

de la résistance.

• Toucher avec la sonde d'essai les pièces métalliques

exposées qui présentent une voie de retour au châssis

(antenne, coffret métallique, tête des vis, arbres de

commande et des boutons, écusson, etc.) et mesurer

la chute de tension CA en-travers de la résistance.

T outes les vérifications doivent être refaites après avoir

inversé la fiche du cordon d'alimentation. (Si nécessaire,

une prise d'adpatation non polarisée peut être utilisée

dans le but de terminer ces vérifications.)

Tous les courants mesurés ne doivent pas dépasser

0,5 mA.

Dans le cas contraire, il y a une possibilité de choc

électrique qui doit être supprimée avant de rendre le

récepteur au client.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les téléviseurs présentent des caractéristiques spéciales

relatives à la sécurité, qui ne sont souvent pas évidentes

à vue. Le degré de protection ne peut pas être

nécessairement augmentée en utilisant des pièces de

remplacement étalonnées pour haute tension,

puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel; les

pièces électriques qui présentent ces particularités sont

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

identifiées par la marque " å " et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques.

Pour assurer la protection, ces pièces doivent être

identiques à celles utilisées dans le circuit d'origine.

L'utilisation de pièces qui n'ont pas les mêmes

caractéristiques que les pièces recommandées par

l'usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies, radiations X ou autres

accidents.

3

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

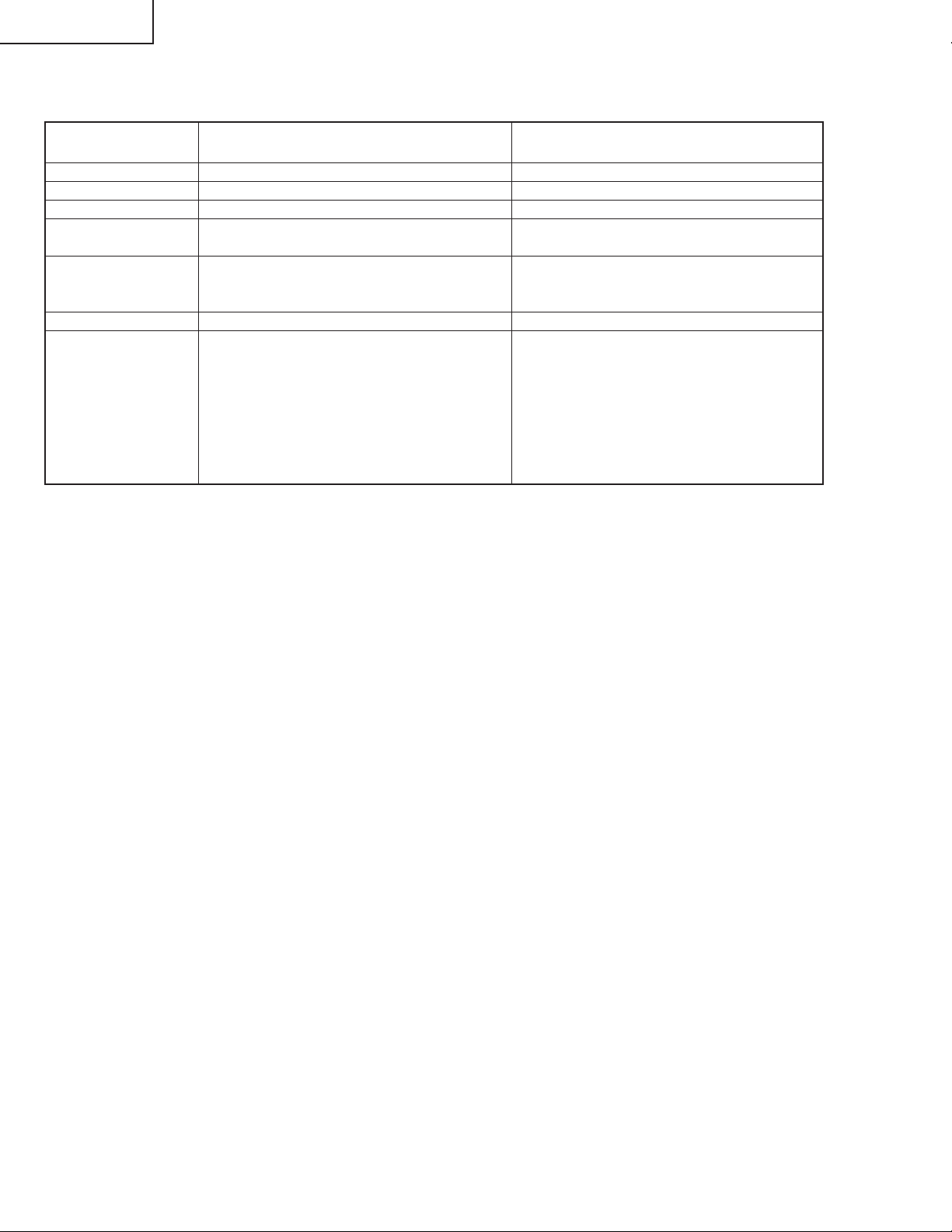

SPECIFICATIONS

Item

Number of Pixels

Audio Amplifier

Surround System

Power requirement

Dimensions

Weight

Accessories

50" Plasma Display TV (Panel Unit),

Model: PZ-50HV2E

2,949,120 dots

12 W + 12 W (10 % distortion)

—

AC 220-240V, 50/60 Hz, 356W

(0.8 W Standby)

1436 (W) × 826 (H) × 428 (D) mm

(with set stand and speakers)

52.0 kg (with set stand and speakers)

Power cord, Cleaning cloth, T wo screws for

preventing the System from falling over, Set

stand securing bracket, Four screws for set stand

securing bracket, System cable clamp, Five

speaker cable clamps, Four speaker brackets,

Hexagon wrench, T wo speaker cables, Two kinds

of screws for speaker brackets, T wo speakers,

Two spacers for speakers

50" Plasma Display TV (Panel Unit),

Model: PZ-50HV2U

2,949,120 dots

12 W + 12 W (10 % distortion)

SRS/FOCUS/SRS + FOCUS

110-240V AC, 50/60 Hz, 371W

(0.8 W Standby)

1436(W) × 826 (H) × 428 (D) mm

(with set stand and speakers)

(56 9/16 (W) × 32 17/32 (H) × 16 7/8 (D) inch)

52 kg (114.6 lbs.)

Power cord, Cleaning cloth, T wo screws for

preventing the System from falling over, Stopper

for set stand, Four screws for set stand, System

cable clamp, Five speaker cable clamps, Four

speaker brackets, Hexagon wrench, T wo speaker

cables, T wo kinds of four screws for speaker

bracket, T wo spacers for speakers, Two speakers

(with set stand and speakers)

4

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PWB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

SAFETY PRECAUTIONS

NOTICE :Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an

isolation transformer should be inserted between the power

line and the set in safety before any service is performed.

2.When replacing a chassis in the set, all the protective

devices must be put back in place, such as barriers,

nonmetallic knobs, adjustment and compartment

covershields, isolation resistor-capacitor, etc.

3. When service is required, observe the original lead dress.

Extra precaution should be taken to assure correct lead

dress in the high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit

diagram should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace

those components that indicate evidence of overheating.

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it

is completely safe to operate without danger of electrical

shock, and be sure that no protective device built into the

set by the manufacture has become defective, or

inadvertently defeated during servicing. Therefore, the

following checks should be performed for the continued

protection of the customer and service technician.

6. Perform the following precautions against unwanted

radiation and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits

the panel face, panel corner, and panel edge (so that the

glass does not break).

• Make sure that the panel vent does not break. (Check

that the cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel.

8. Pay attention to the following.

• Be sure to wire the fan. If the fan does not work, the

temperature will rise and cause the protection circuit to

operate.

• When the front case is removed, infrared ray is radiated

and may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel

are removed because this may cause a high risk of

disturbance to TVs and radios in the surrounding.

5

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

Leakage Current Cold Check

With the AC plug removed from an AC power source, place

a jumper across the two plug prongs. Turn the AC power

switch on. Using an insulation tester (DC 500V), connect one

lead to the jumpered AC plug and touch the other lead to each

exposed metal part (input/output terminals, screwheads,

metal overlays, control shafts, etc.), particularly any exposed

metal part having a return path to the chassis. Exposed metal

parts having a return path to the chassis should have a

minimum resistor reading of 0.3MΩ and a maximum resistor

reading of 5MΩ. Any resistor value below or above this range

indicates an abnormality which requires corrective action.

Exposed metal parts not having a return path to the chassis

will indicate an open circuit.

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not

use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229

equivalent)", measure for current from all exposed metal

parts of the cabinet (input/output terminals, screwheads,

metal overlays, control shaft, etc.), particularly any exposed

metal part having a return path to the chassis, to a known

earth ground (water pipe, conduit, etc.). Any current measured

must not exceed 0.5mA.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in SHARP set have

special safety related characteristics. These are often not

evident from visual inspection nor the protection afforded by

them necessarily can be obtained by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified by

marking with a

this Service Manual.

The use of a substitute replacement component which dose

not have the same safety characteristics as the SHARP

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current SHARP Service

Manual. A subscription to, or additional copies of, SHARP

Service Manual may be obtained at a nominal charge from

SHARP.

å on the schematics and on the parts list in

Reading should

not be above

0.5 mA

Earth ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

Leakage

current

tester

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

6

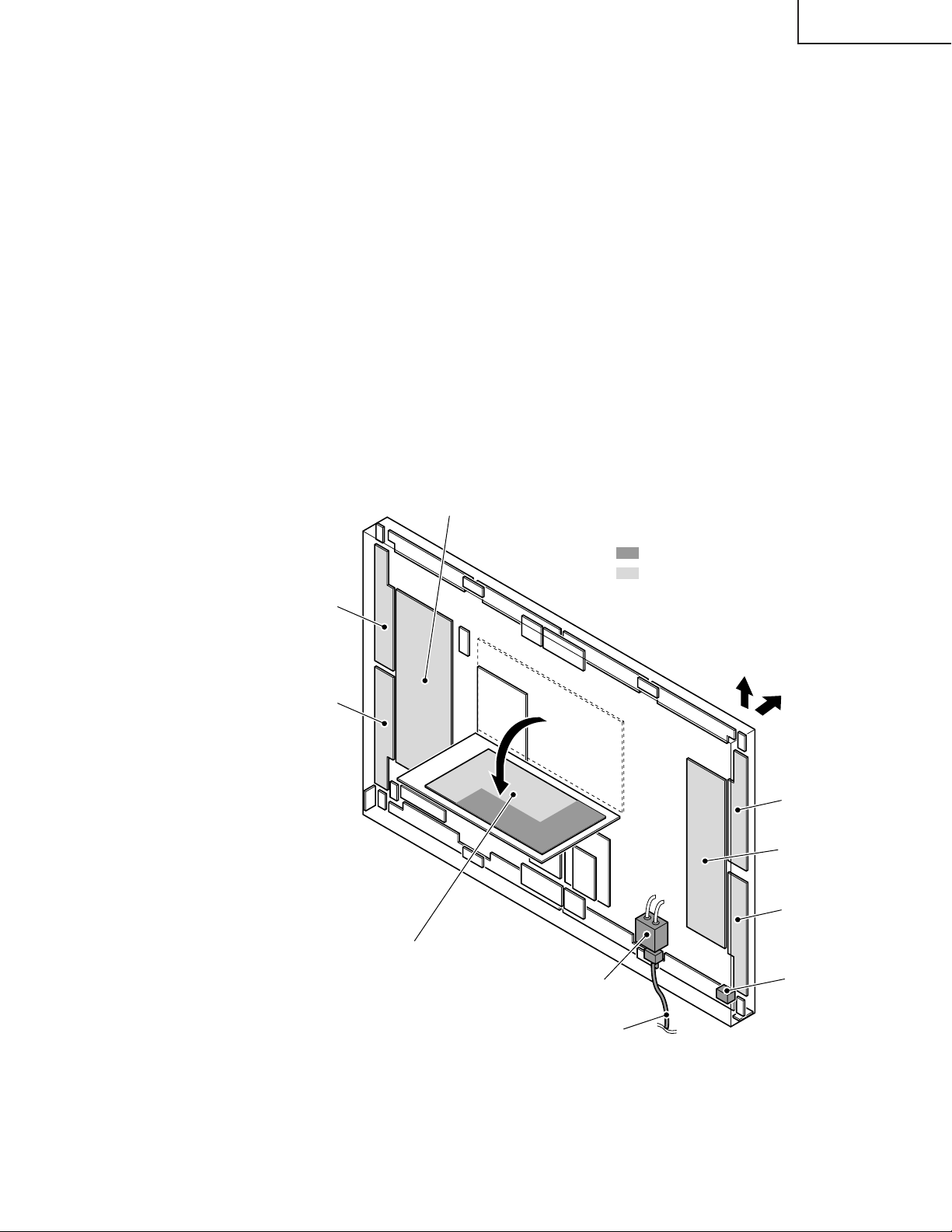

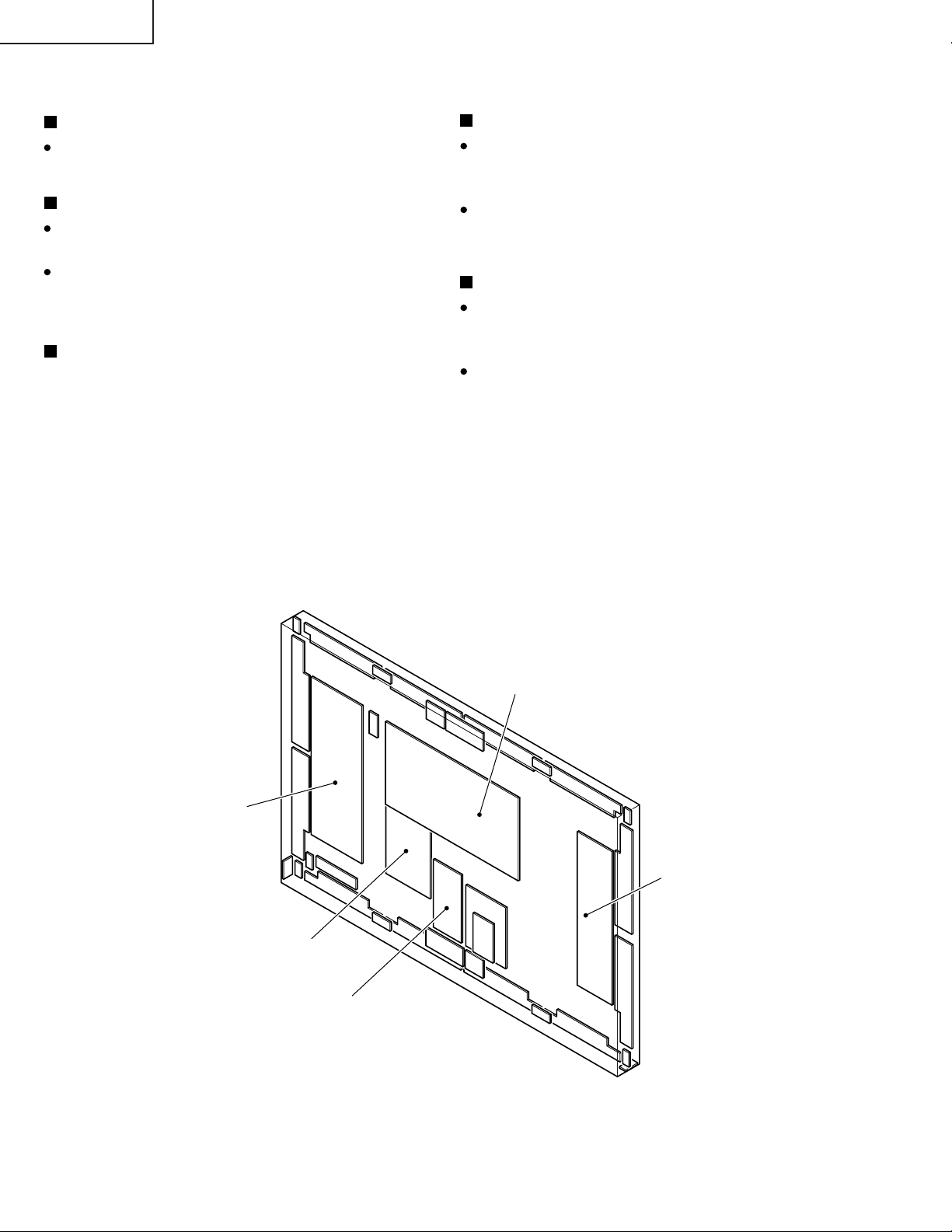

CHARGED SECTION AND HIGH VOLTAGE GENERATING POINT

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

Ë

Charged Section

The places where the commercial AC power is used without

passing through the power supply transformer.

If the places are touched, there is a risk of electric shock. In

addition, the measuring equipment can be damaged if it is

connected to the GND of the charged section and the GND of

the non-charged section while connecting the set directly to

the commercial AC power supply. Therefore, be sure to

connect the set via an insulated transformer and supply the

current.

1. AC Power Cord

2. AC Inlet with Filter

3. Power Switch (S1)

4. Fuse (In the SW POWER SUPPLY Module)

5. STB Transformer and Converter Transformer

(In the SW POWER SUPPLY Module)

6. Other primary side of the SW POWER SUPPLY Module

Y DRIVE

Assy

SCAN (A)

Assy

Ë

High Voltage Generating Point

The places where voltage is 100V or more except for the

charged places described above. If the places are touched,

there is a risk of electric shock.

1. SW POWER SUPPLY Module .............................. (225V)

2. X DRIVE Assy ....................................... (–300V to 225V)

3. Y DRIVE Assy ....................................................... (355V)

4. SCAN (A) Assy ...................................................... (355V)

5. SCAN (B) Assy ...................................................... (355V)

6. X CONNECTOR (A) Assy ..................... (–300V to 225V)

7. X CONNECTOR (B) Assy ..................... (–300V to 225V)

: Part is Charged Section.

: Part is the High Voltage Generating Points

other than the Charged Section.

SCAN (B)

Assy

∗ Remove the IF Earth Metal beforehand when inclines

the power supply unit as the right figure.

SW POWER SUPPLY

Module

Fig.1 Charged Section and High Voltage Generating Point (Rear View)

AC Inlet with Filter

Power Cord

Top

Front

X CONNECTOR (A)

Assy

X DRIVE

Assy

X CONNECTOR (B)

Assy

Power Switch

(S1)

7

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

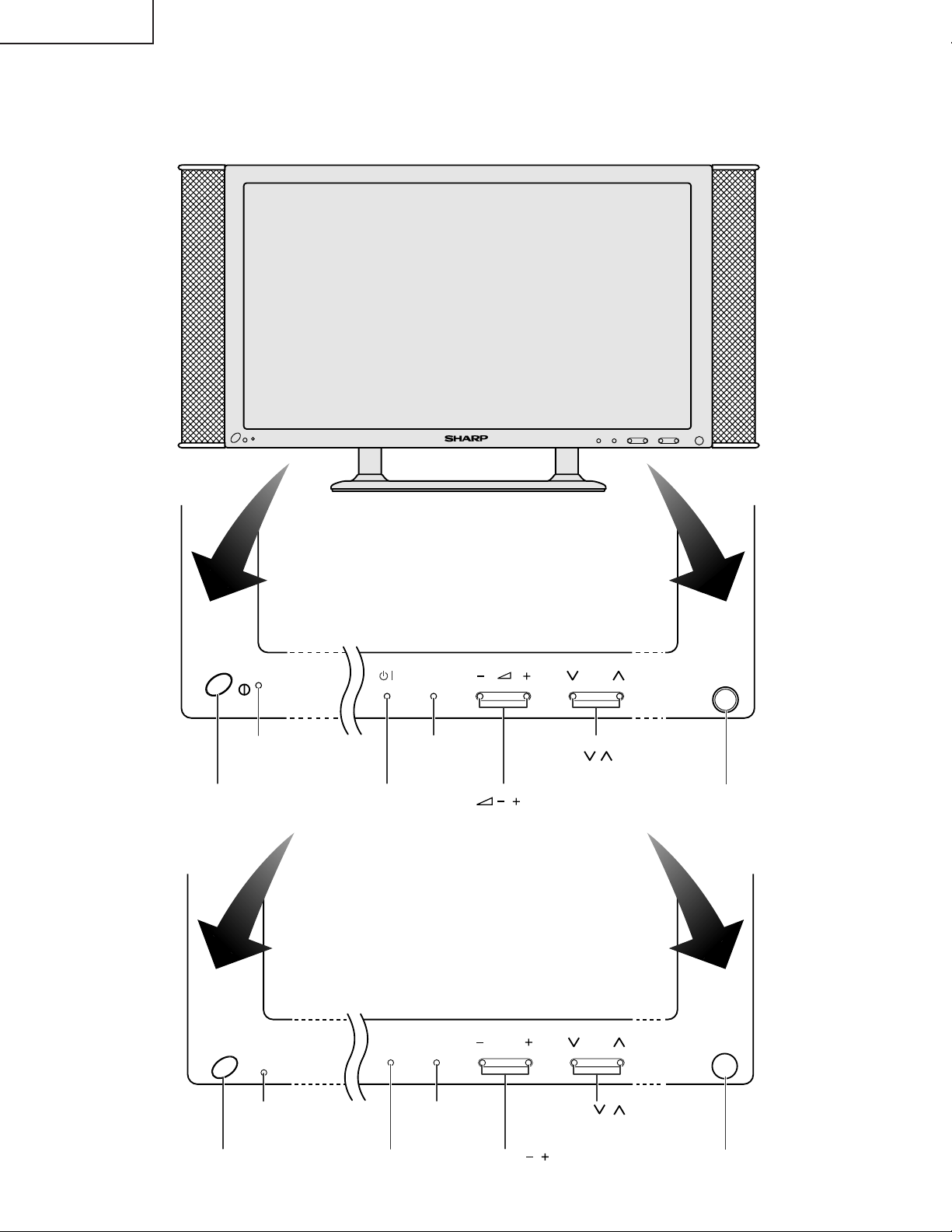

OPERATION MANUAL

Plasma Display TV (Panel Unit)

PZ-50HV2E

MAIN POWER button

PZ-50HV2U

ST

ANDBY/ON indicator

INPUT CH

INPUT button

STANDBY/ON button

VOLUME buttons

(/)

CHANNEL buttons

/

(CH

)

Remote control sensor

MAIN POWER

STANDBY/ON indicator

MAIN POWER button

INPUT button

POWER button

INPUT VOLPOWER

CHANNEL

VOLUME / buttons

CH

/ buttons

Remote control sensor

8

PZ-50HV2, PZ-50HV2E

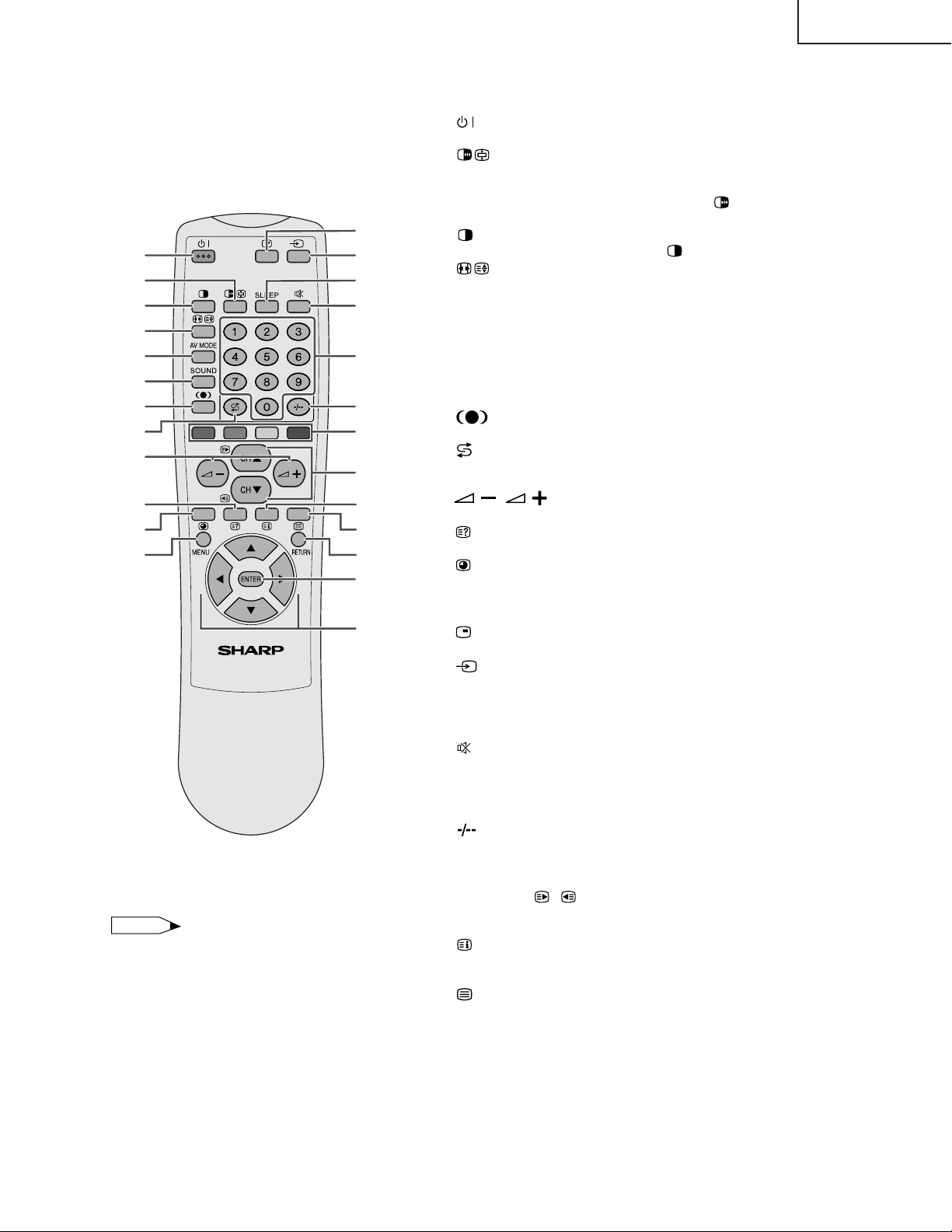

1 (STANDBY/ON)

To switch the power on and off.

2 (FREEZE/HOLD for TELETEXT)

TV/External input mode: Change the still image mode.

TELETEXT mode: Freeze a multi-page on screen while other

pages are automatically updated. Press again to return to the

normal image.

3 (DUAL screen)

Set the dual picture mode. Press again to return to normal view.

4 (WIDE MODE/ T/B/F)*

TV/External input mode: Change the wide image mode.

TELETEXT mode: Set the area of magnification. (full/upper half/

lower half)

5 AV MODE*

Select a video setting. AV MODE (STANDARD, DYNAMIC, MOVIE,

GAME, USER) PC MODE (STANDARD, USER)

6 SOUND

Select the sound multiplex mode.

7 (SRS and FOCUS)

Select SRS and FOCUS Sound System.

8 (FLASHBACK)

Press to return to the previous channel in normal viewing mode.

Press to return to the previous page in TELETEXT mode.

9 / (VOLUME)*

Set the volume.

10 (Reveal hidden for TELETEXT)

TELETEXT mode: Display hidden characters.

11 (SUBPAGE for TELETEXT)

TELETEXT mode: Change the picture mode for sub-page selecting.

12 MENU

Display the Menu screen.

13 (CHANNEL INFORMATION)

Display the channel information and time.

14 (INPUT SOURCE)

Select an input source. (TV, INPUT 1, INPUT 2, INPUT 3, INPUT 4,

PC)

15 SLEEP

Set the SLEEP TIMER.

16 (MUTE)

Mute the sound.

17 0 – 9

TV/External input mode: Set the channel.

TELETEXT mode: Set the page.

18 (Digit for channel select)

Change the digits of the selected TV channel.

19 Colour (RED/GREEN/YELLOW/BLUE)

TELETEXT mode: Select a page.

20 CH /CH (/ )

TV/External input mode: Select the channel.

TELETEXT mode: Set the page.

21 (TOP Overview for TELETEXT)

TELETEXT mode: Display an index page for CEEFAX/FLOF

information. TOP OVER VIEW for TOP programme.

22 (TELETEXT)

Select the TELETEXT mode. (all TV image, all TEXT image, TV/TEXT

image)

23 RETURN

MENU mode: Return to the previous menu screen.

24 ENTER

Execute a command.

Return to the initial image position after moving with ///.

25 /// (Cursor)

Select a desired item on the setting screen.

Move the picture on the screen.

1

2

3

4

5

6

7

8

9

10

11

12

14

15

13

16

17

18

19

20

21

22

23

24

25

Remote control unit

• When using the remote control unit, point it

at the Plasma Display TV (Panel Unit).

* “TV”, “INPUT1”, “INPUT2”, “INPUT3”,

“INPUT4” and “PC” modes can each store

the WIDE mode setting separately.

The same for AV mode and volume.

(PZ-50HV2E)

'

'

"

"\ |

'

"\ |

NOTE

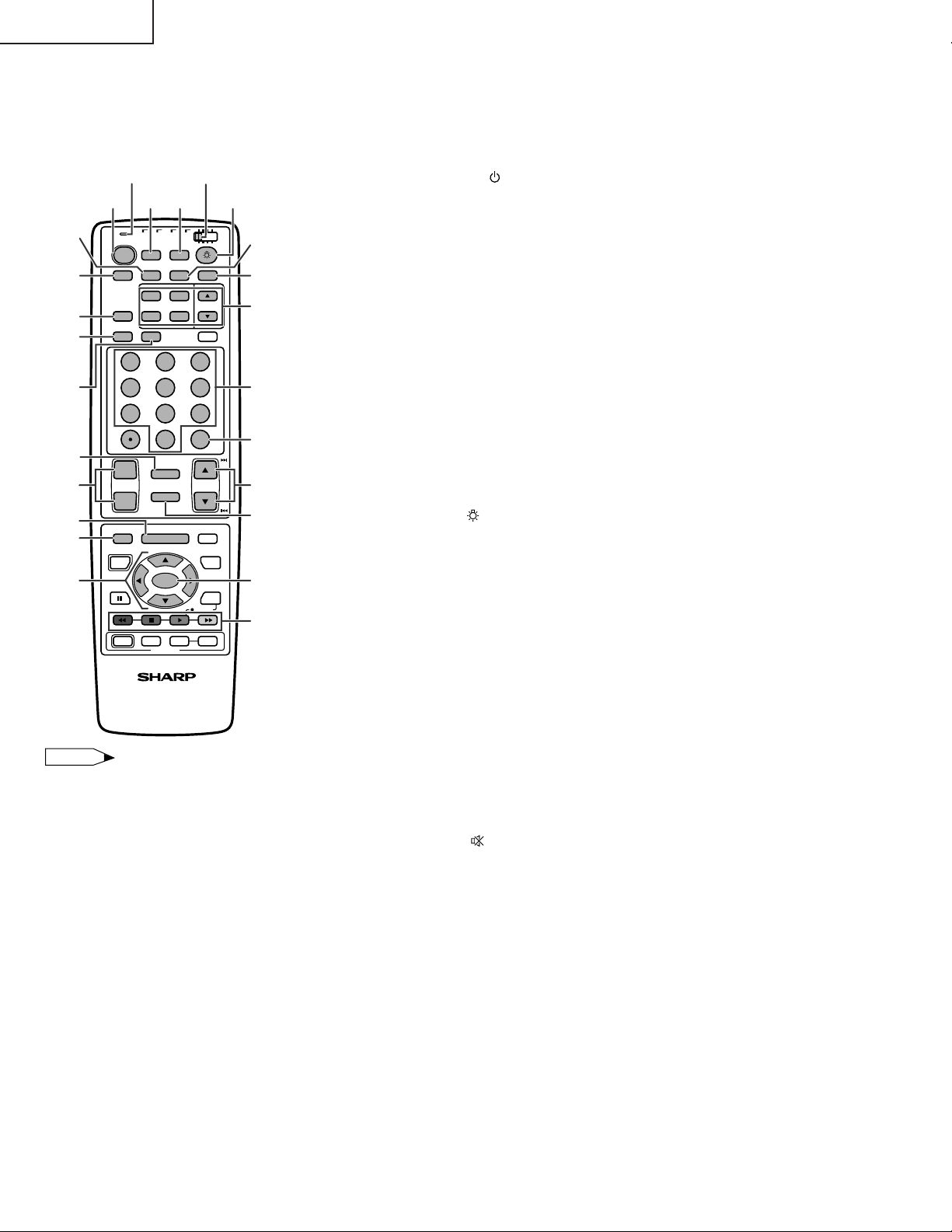

PZ-50HV2U

9

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

Remote control unit

(PZ-50HV2U)

Set the mode switch to TV.

24

12 13

1

2

3

4

5

TV

POWER

AV

MODE

VIEW

MODE

DISPLAY

Mode switch

TV VCRCBL

DVD

/SAT

/LD

/DTV

ANT-A/B

INPUT

FRONT

SURROUND

MTS CC

TWIN

PICTURE

SELECT

SUB TWIN CH

FREEZE

INPUT

SLEEP LEARN

EDIT/

14

15

16

17

123

6

456

18

789

ENT

100

10

11

7

8

9

MENU TV/SAT/DVD

RETURN

SOURCE DTV/SAT

POWER

POWER

0

FLASHBACK

+

VOL CH

MUTE

–

DTV/DVD TOP

MENU

MENU

GUIDE

SET/

ENTER

DTV/SAT

INFO

VCR REC

FAVORITE CH

ABCD

INPUT VOL– VOL+

RECEIVER

19

20

21

22

23

NOTE

• When using the remote control unit, point it at the Plasma

Display TV(Panel Unit).

Press DTV/SAT INFO and | at the same time to begin

•

recording.

1TV : Switch the Plasma Display power on or off.

2 FRONT SURROUND: Set SRS and FOCUS Sound

System mode.

3 AV MODE:Select an audio or video setting.

(AV mode: STANDARD, DYNAMIC,

MOVIE, GAME, USER.

PC mode: STANDARD, USER.)

4 SCREEN MODE: Select the screen size.

5 DISPLAY: Display the channel information.

6 SLEEP: Set the SLEEP timer.

7 CH RETURN: Return to the previous channel.

8 VOL +/– : Set the volume.

9 MENU: Display the menu screen.

10 MENU RETURN: Return to the previous menu screen.

'/"/\/|

11 : Select a desired item on the setting screen.

12 ANT: Select the antenna. (A, B)

13 INPUT: Select an input source of the Plasma Display.

(TV, INPUT 1, INPUT 2, INPUT 3, INPUT 4, PC)

: When pressed all buttons on the remote control unit

14

will light. The lighting will turn off if no operations

are performed within about 5 seconds. This button

is used for performing operations in dark places.

15 MTS: Select the MTS/SAP.

16 CC: Display captions during closed-caption source.

17 Dual picture mode select buttons

TWIN PICTURE: Set the dual picture mode.Press

again to return to normal screen.

FREEZE: Set the still image. Press again to return to

normal screen.

SELECT: Select the active screen.

SUB INPUT: Select an input source of sub screen.

TWIN CH + /– : Select the channel of sub screen.

18 0 – 9: Set the channel.

19 100, CH ENTER: Select the three digit mode. Execute

a command of the channel.(When you select CBL/SA T/

DTV mode, this button operates as CH ENTER function.)

'

20 CH

/": Select the channel.

21 MUTING: Mute the sound.

22 SET/ENTER: Execute a command.

23 FAVORITE CH

A, B, C, D: Select any of four preset channels.

While watching you can toggle the set channels by

pressing A, B, C and D.

24 LED for transmission confirmation

10

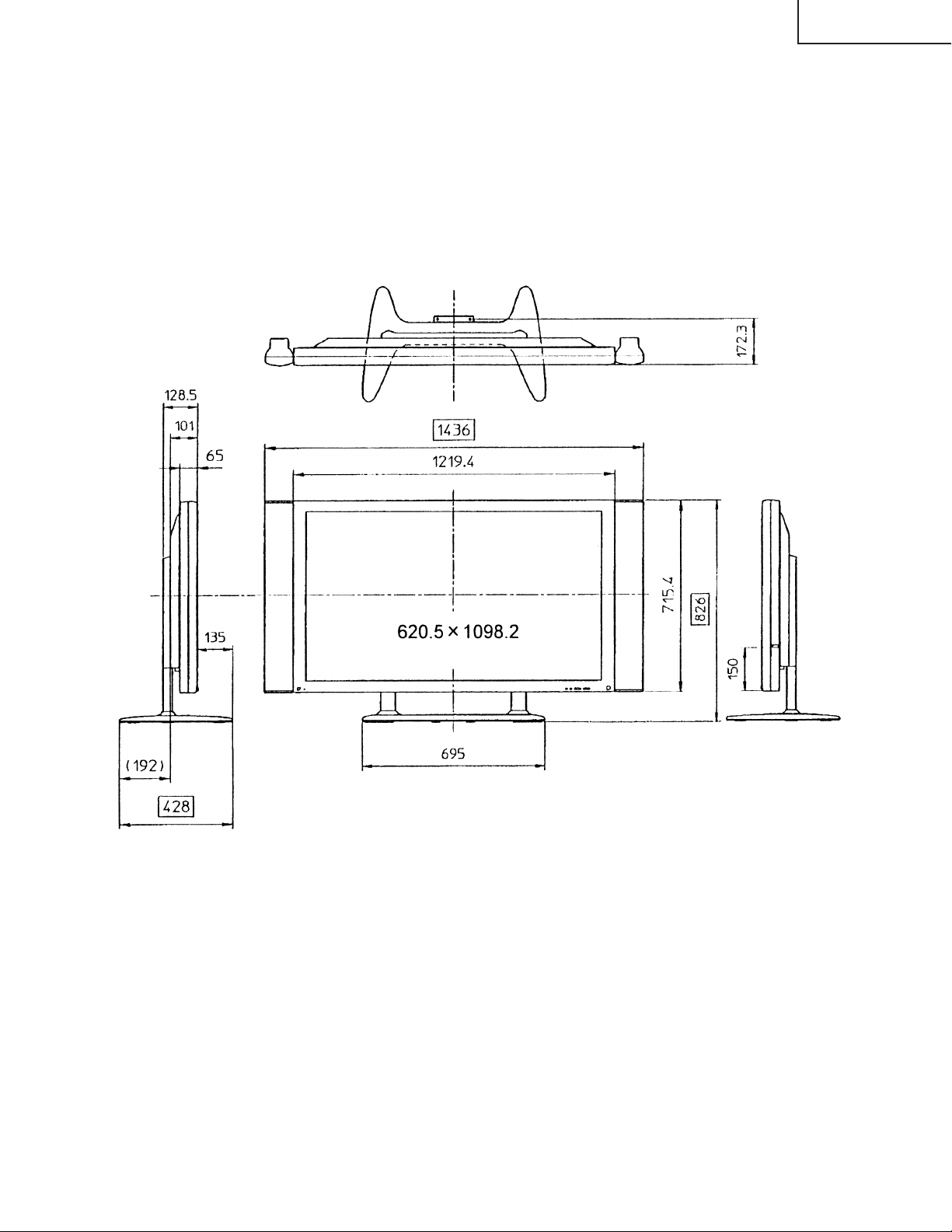

DIMENSIONS

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

11

(Unit : mm)

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

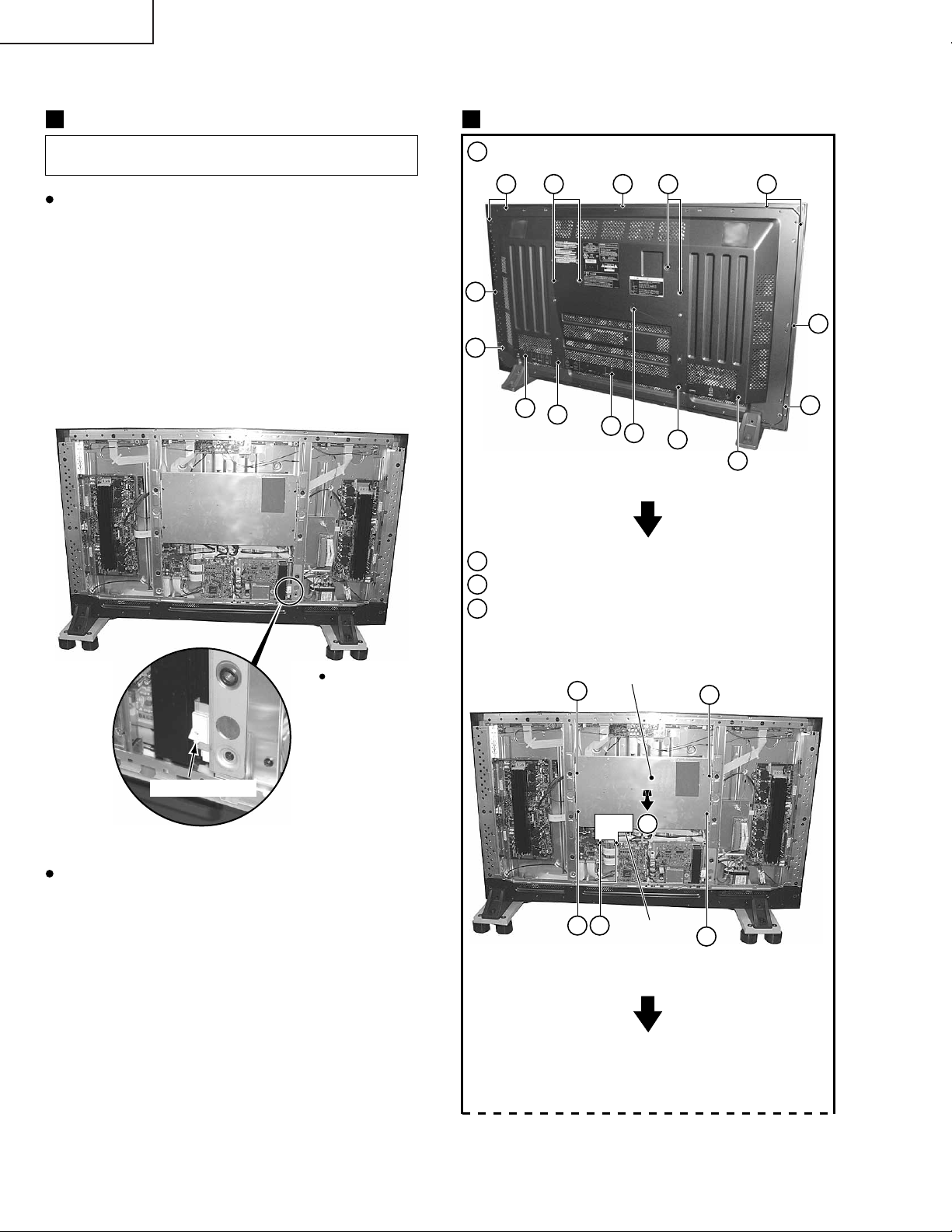

REMOVING OF MAJOR PARTS

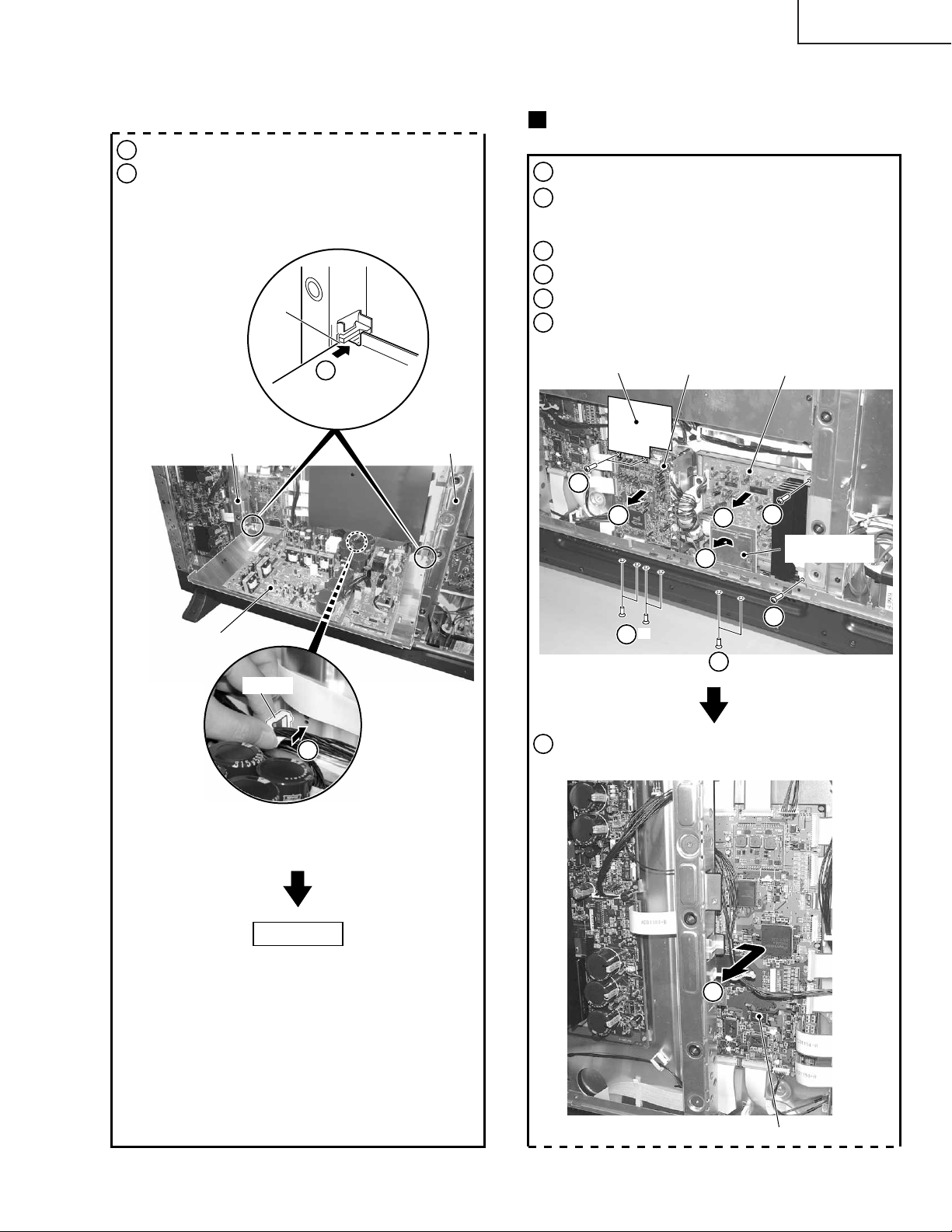

SW Power Supply ModuleAbout detect switch

This unit adopt the "Rear Case opened ! detection" system.

Please work in service as follows by all means.

Outline and caution

Perform video transmission from the AVC System to the

plasma display with digital signal in the PZ-50HV2 series.

Therefore adopt contents protection by HDCP for copyright

protection.

Moreover establish the detect switch which is never turned

on the power when "a rear case of plasma display was

opened carelessly".

Detect switch does not detect at the power supply OFF and

the remote control unit wait state. Please stick this detect

switch with tape before turning on the power in inside

diagnoses of the plasma display. And please remove it not

to forget the tape which stuck after the repair.

Remove the Rear Case (P).(Screws × 19)

1

×2

1

×2

1

1 1

1

1

1

1

1

Remove the IF Earth Metal.(Screws × 2)

2

Remove four screws.

3

Remove the SW Power Supply Module.

4

1

1

×2 ×2

1

1

1

1

Rear View

Detect Switch (S2)

When detect switch has worked by any chance

When detect switch works, LED of red blinks in succession

by a 300msec period.

Press keys in order of "MENU" key, "ENTER" key and

"POWER" key with the remote control unit after sticking the

detect switch with tape or close the rear case beforehand.

This unit activates and it becomes the service factory mode

screen. Afterwards, turn off the power with the remote

control unit.

Perform the normal operation afterward.

SW Power Supply

Module

3

×2

3

2

4

IF Earth

Metal

3

3

12

Insert it and reduce the Clamper.

5

Insert the SW Power Supply Module into the slit

6

of Sub Frame L and R.

Slit

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

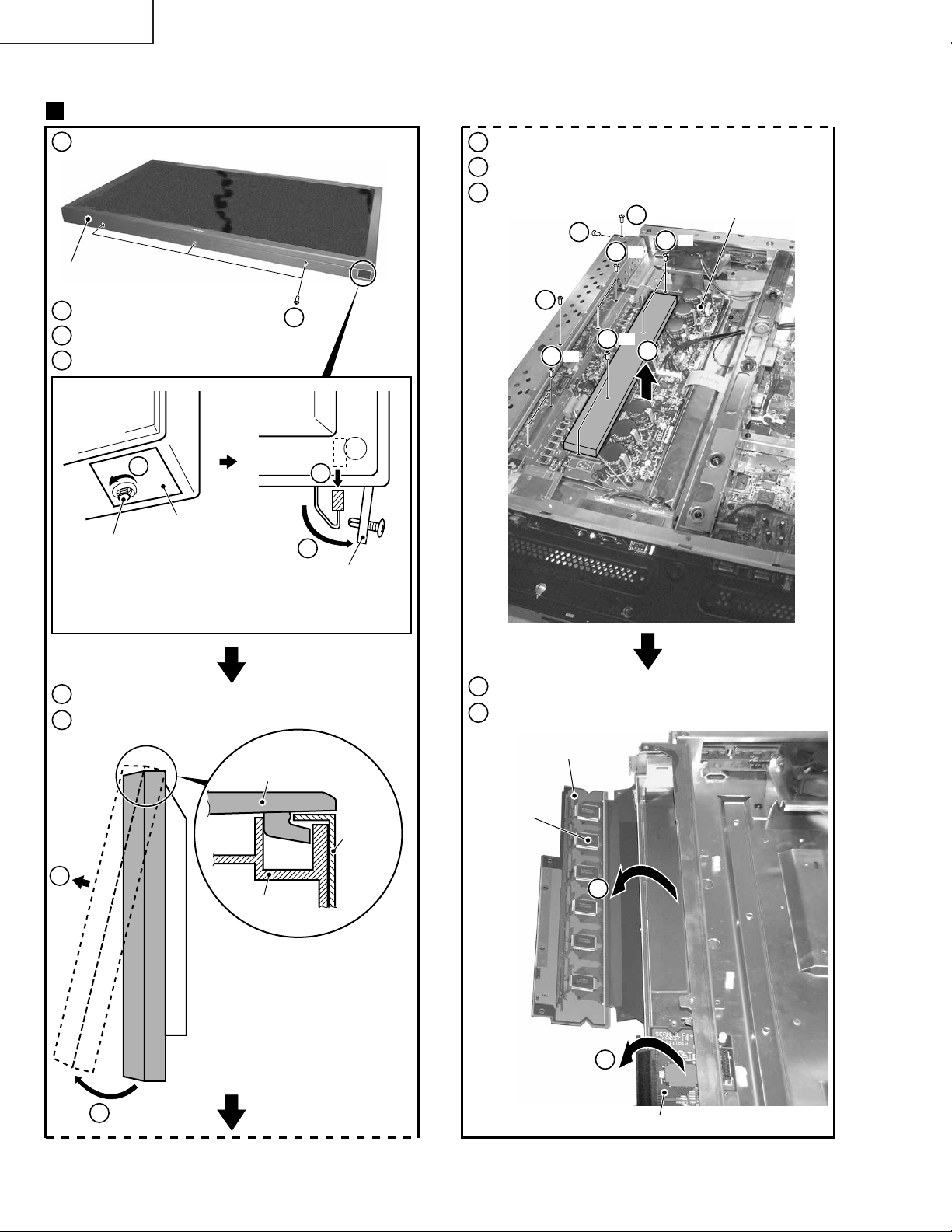

MR INTERFACE, AUDIO AMP SP TERMINAL

and DIGITAL VIDEO Assys

Remove the Rear Case (P). (Screws × 19)

1

Remove the SW Power Supply Module.

2

(Connector, Screws × 4)

Remove the IF Earth Metal (Screws × 2)

3

Remove the MR INTERFACE Assy (Connector, Screws × 4)

4

Remove the SP TERMINAL Assy (Connector, Screws × 2)

5

Remove the AUDIO AMP Assy (Connector, Screws × 2)

6

Sub Frame L

SW Power Supply

Module

Clamper

6

SW Power Supply

Module

5

Sub Frame R

MR INTERFACE

Assy

3

IF Earth

Metal

×2

4

5

×4

4

Remove the DIGITAL VIDEO Assy

7

(Connector,Circuit Board Spacer × 6)

AUDIO AMP Assy

6

6

SP TERMINAL

Assy

6

×2

5

Diagnosis

7

DIGITAL VIDEO Assy

13

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

Y DRIVE, SCAN (A), (B) Assy

Remove the three screws.

1

Front Case 50 (P)

Loosen a rivet.

2

Remove the Lead Cover (P).

3

Pull out a Flexible Cable.

4

2

Lead Cover (P)

Rivet

Turn it not to press the rivet.

(Because when the rivet presses,

fit in once again.)

It is easy to remove when pull out

the Lead Cover (P) with the rivet

before completely removing the rivet.

×3

1

44

3

Lead Cover (P)

Remove the Rear Case (P). (Screws × 19)

7

Remove the Y DRIVE Assy. (Connector, Screws × 8)

8

Remove the Front Chassis V. (Screws × 5)

9

9

9

8

8

×2

Y DRIVE Assy

×2

9

×2

8

×2

8

8

Remove bottom by the fulcrum at the top of Front Case 50 (P).

5

Remove the Front Case 50 (P).

6

Front Case 50 (P)

Rear Case

6

Aluminum

Materials

It is the structure that a hook of

Front Case 50 (P) was put between

with Rear Case and aluminum materials.

5

Reverse the SCAN (A) and SCAN (B) Assemblies.

10

When it is necessary, exchange the ROM.

11

SCAN (A) Assy

×6

ROM

10

10

SCAN (B) Assy

14

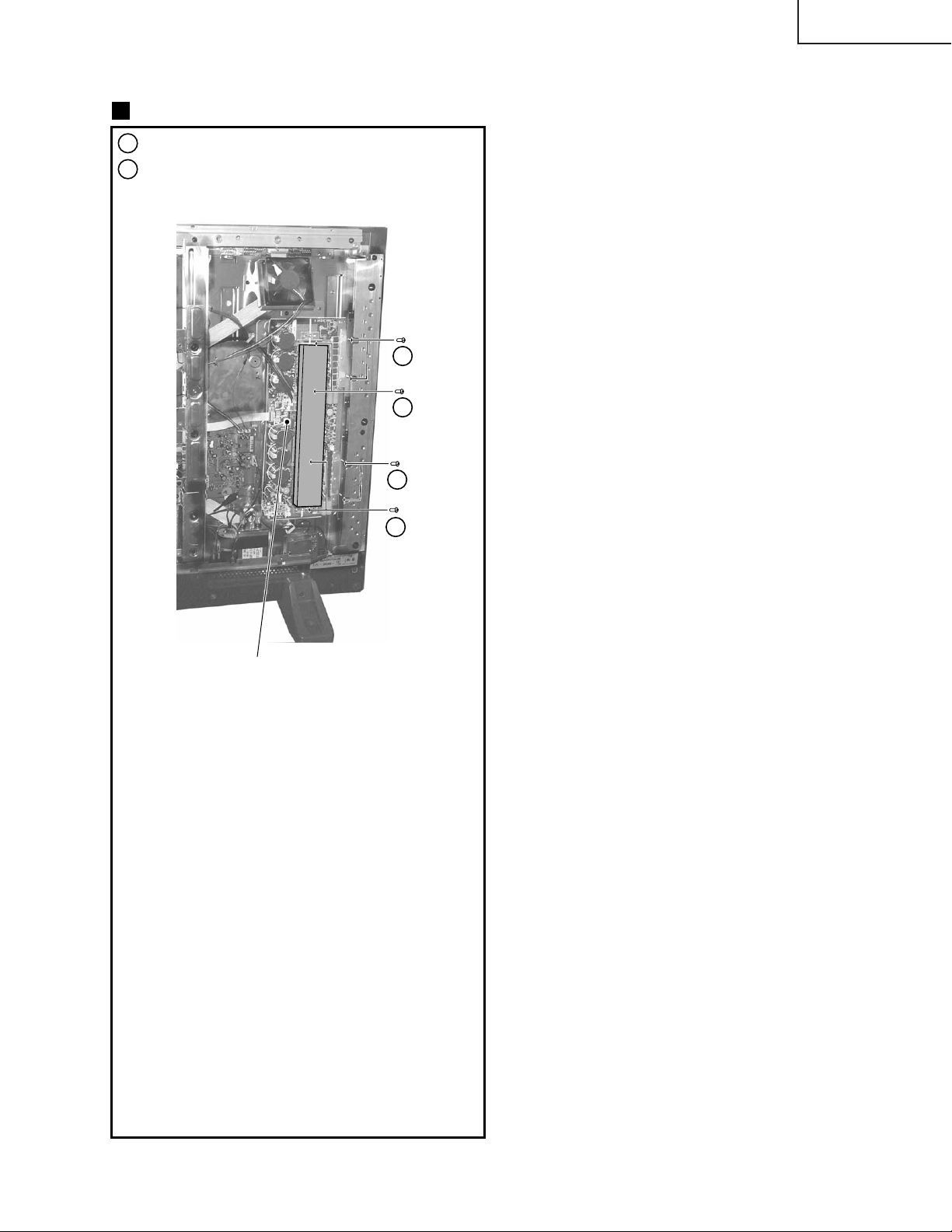

X DRIVE Assy

Remove the Rear Case (P). (Screws × 19)

1

Remove the X DRIVE Assy. (Connector, Screws × 8)

2

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

×2

2

×2

2

X DRIVE Assy

×2

2

×2

2

15

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

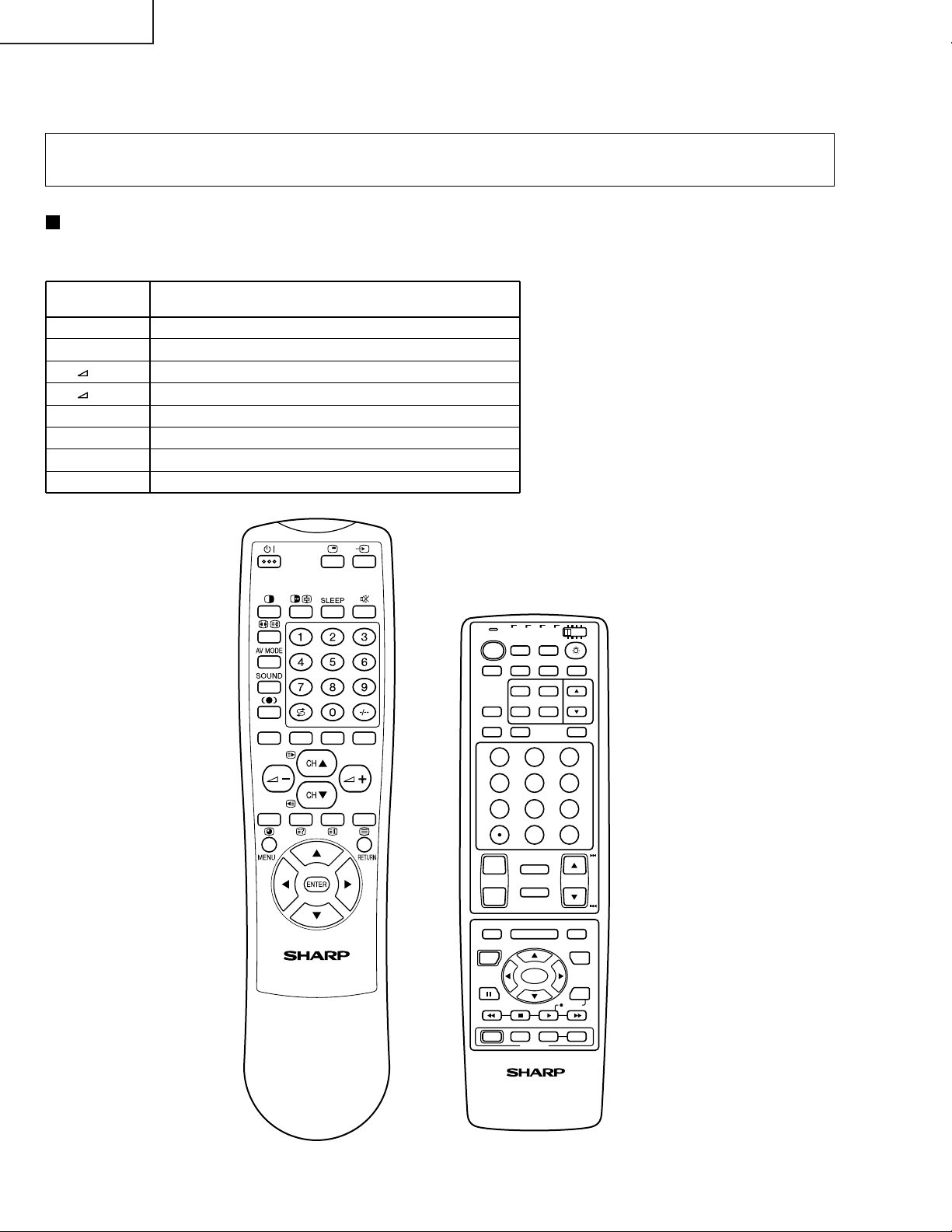

ADJUSTMENT PROCEDURES

SERVICE FACTORY MODE

Service factory mode uses an OSD function of the AVC System.

Perform the adjustment and setting in the state that this unit and Media Receiver are connected by the system.

Plasma display cannot use a factory mode by being simple.

Remote Control Unit Operation in The Service Factory Mode

Operate the service factory mode with the remote control unit of accessory of the AVC System.

Please perform the adjustment by operating the following keys.

Remote

Control Key

CH' key

"

key

CH

VOL + key

VOL – key

'

key

"

key

\

key

|

key

Function

One line moves the selection cursor of the adjustment item up.

One line moves the selection cursor of the adjustment item down.

+1 raises a adjustment value

–1 reduces a adjustment value

Perform page down (previous page)

Perform page up (next page)

–10 reduces a adjustment value

+10 raises a adjustment value

TV

POWER

AV

MODE

VIEW

MODE

DISPLAY

TV VCRCBL

DVD

/SAT

/LD

/DTV

ANT-A/B

INPUT

FRONT

SURROUND

MTS CC

TWIN

PICTURE

SELECT

SUB TWIN CH

FREEZE

INPUT

SLEEP LEARN

EDIT/

Model: PZ-50HV2E

123

456

789

FLASHBACK

+

VOL CH

–

MENU TV/SAT/DVD

RETURN

SOURCE DTV/SAT

POWER

FAVORITE CH

ABCD

POWER

INPUT VOL– VOL+

RECEIVER

Model: PZ-50HV2U

16

MUTE

MENU

SET/

ENTER

ENT

100

0

DTV/DVD TOP

MENU

GUIDE

DTV/SAT

INFO

VCR REC

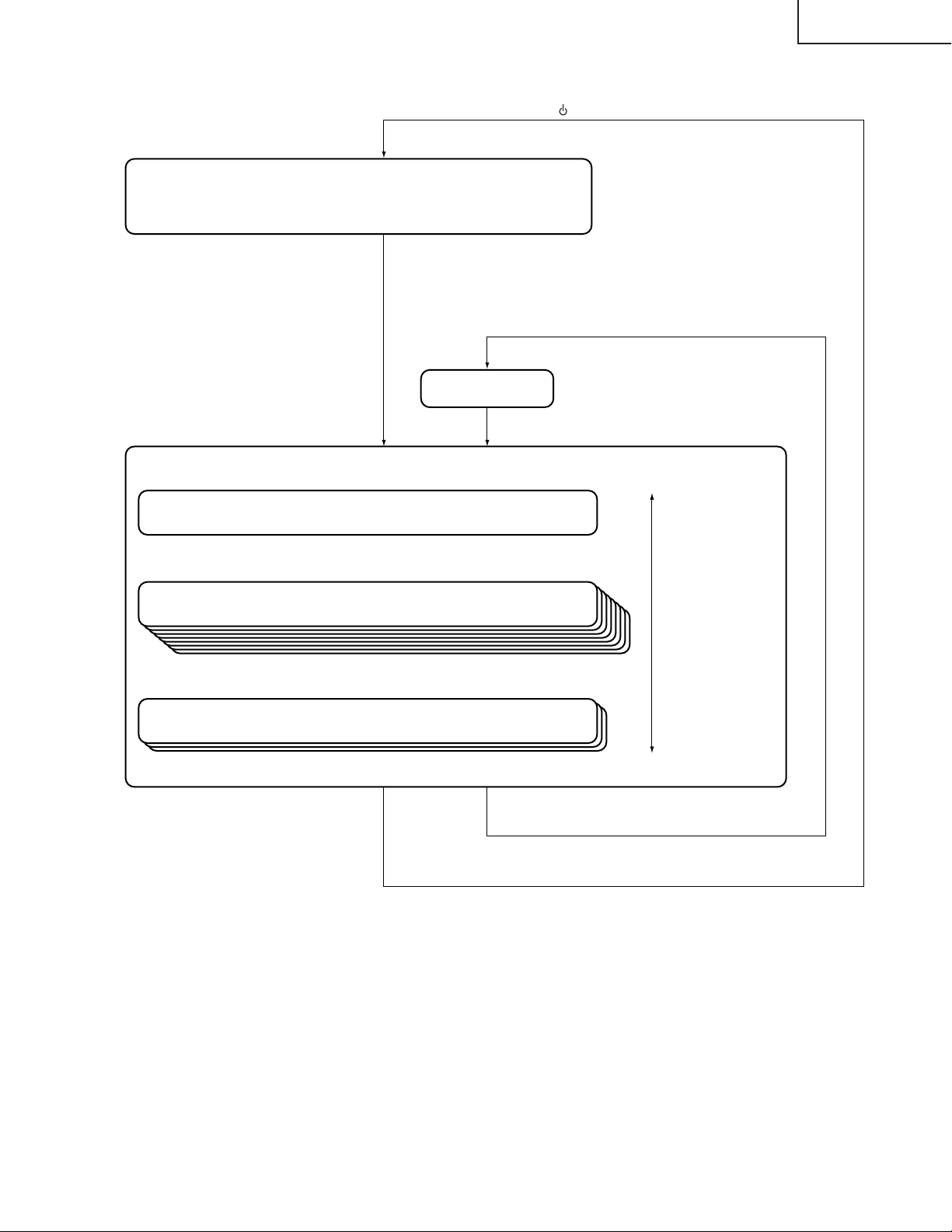

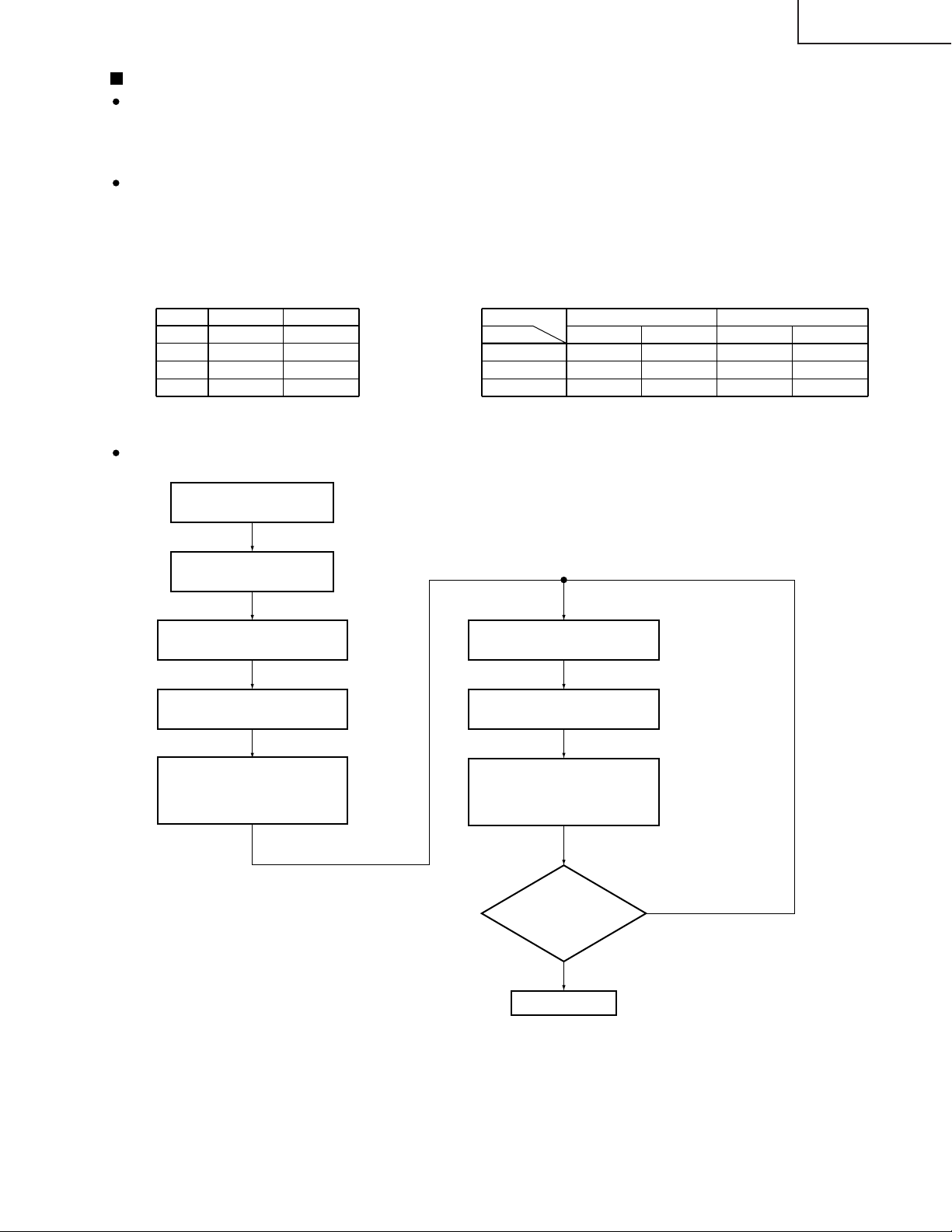

1. How to Enter the Service Factory Mode

Press the " (POWER)" key (POWER OFF)

System standby state

Confirm that the plasma display and the AVC System turned on together and a

system cable is connected properly.

Perform the following operation by the remote control unit for less than 3 seconds.

• Press the "MENU" key

• Press the "ENTER" key

• Press the "0" key

Press the "Factory" key (Note 1)

Image receiving state

Press the "Factory" key (Note 1)

Service Factory Mode

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

Page 1/13

General information of the Plasma Display and AVC System

Page 2/13 to 9/13

Adjustment and setting item of the AVC System

Page 11/13 to 13/13

Switch a page

with "

Adjustment and setting item of the Plasma Display

Note 1: When use the adjustment exclusive use remote control unit with a [AA5F] code.

'

" and """ keys.

∗ : Be careful so that there is the case that page constitution is different.

17

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

2. General Information of the Plasma Display and AVC System

Display example of the first page

1/13

CENTE

RVers

1

2

OSD Ve r s i o n

CV I C Ve r s i on

3

4

TTXP Ve rs i on

5

MON I TOR V e r s i o n

6

PANEL Ve r s i on

7

FLASH Ve rs i on

8

MON I TOR Mo de l

9

Mode l S l eect inMa

Mode l S l eectAV

10

11

Mode l S l eect

12

Senso r e Temp

Cen te r cuAtime

13

14

Mon i t o r Ac ut i me 47 H 4 2 M

15

16

Pu l s e Acut ime 16 4

17

18

ion

MON I TOR

MR M IAN 0021E

MRODS2 0109A//010

W20 0 /109 0 009:12/X200/109 0 079:12/V20

TTX RPG

F6 91 10

-00

-05

01

0

4

0

+

28

OFF

RESET

RESET OFF

RESET OFF

NPIU S1GINoT

025H9//

0/109 0 109:12/

061

H41M16

No. Item Explanation

1 Main software version information of the AVC System

2 OSD version information of the AVC System

IP/resize IC control software version information of the AVC

3

System

Text microcomputer software version information of the

4

AVC System

Module microcomputer software version information of the PDP

5

6 Panel microcomputer version information of the PDP

7 Panel flash ROM version information of the PDP

8 PDP model information

9 AVC System model information

10 AVC System model information

11 PDP destination information

Temperature information of panel temperature sensor on

12

the PDP

13 AVC System accumulation operating time

14 AVC System accumulation operating time reset

15 PDP accumulation operating time

16 PDP accumulation operating time reset

17 PDP accumulation pulse number

18 PDP accumulation pulse number reset

Reference

01: PIONEER 50 inches, 02: PIONEER 43 inches,

11: SHARP 50 inches, 12: SHARP 43 inches

0: All SHARP destinations, Japanese and North America destinations of

PIONEER, 3: European and general destinations of PIONEER

This is internal temperature information. This is not establishment

environment temperature.

Turn the display to [ON] by pressing the "VOL +" key, then it becomes [0H]

when pressing the "ENTER" key.

Turn the display to [ON] by pressing the "VOL +" key, then it becomes [0H]

when pressing the "ENTER" key.

Real accumulation pulse number becomes "indicated value *10,000,000 pulse".

Turn the display to [ON] by pressing the "VOL +" key, then it becomes [0]

when pressing the "ENTER" key.

∗

: Be careful so that there is the case that page constitution is different.

18

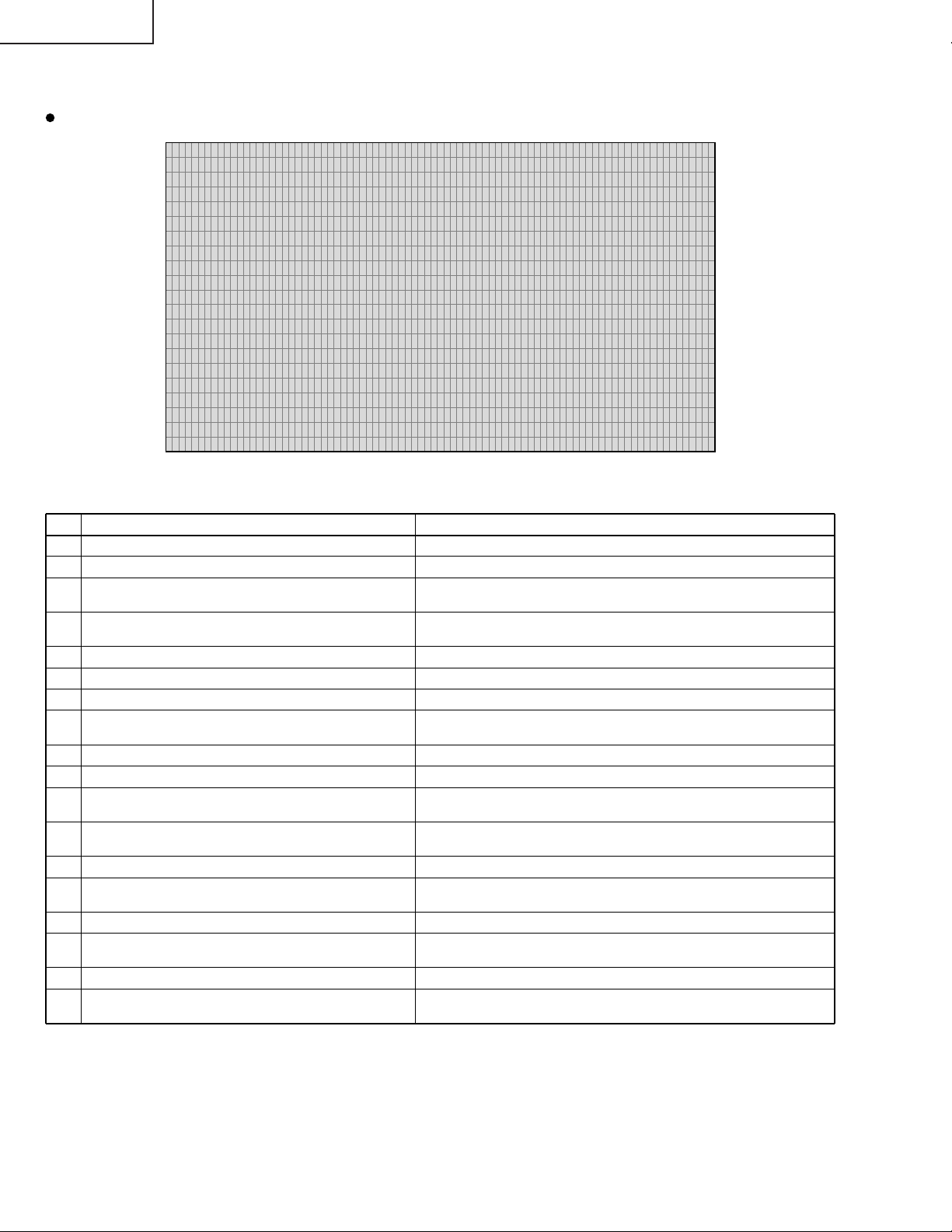

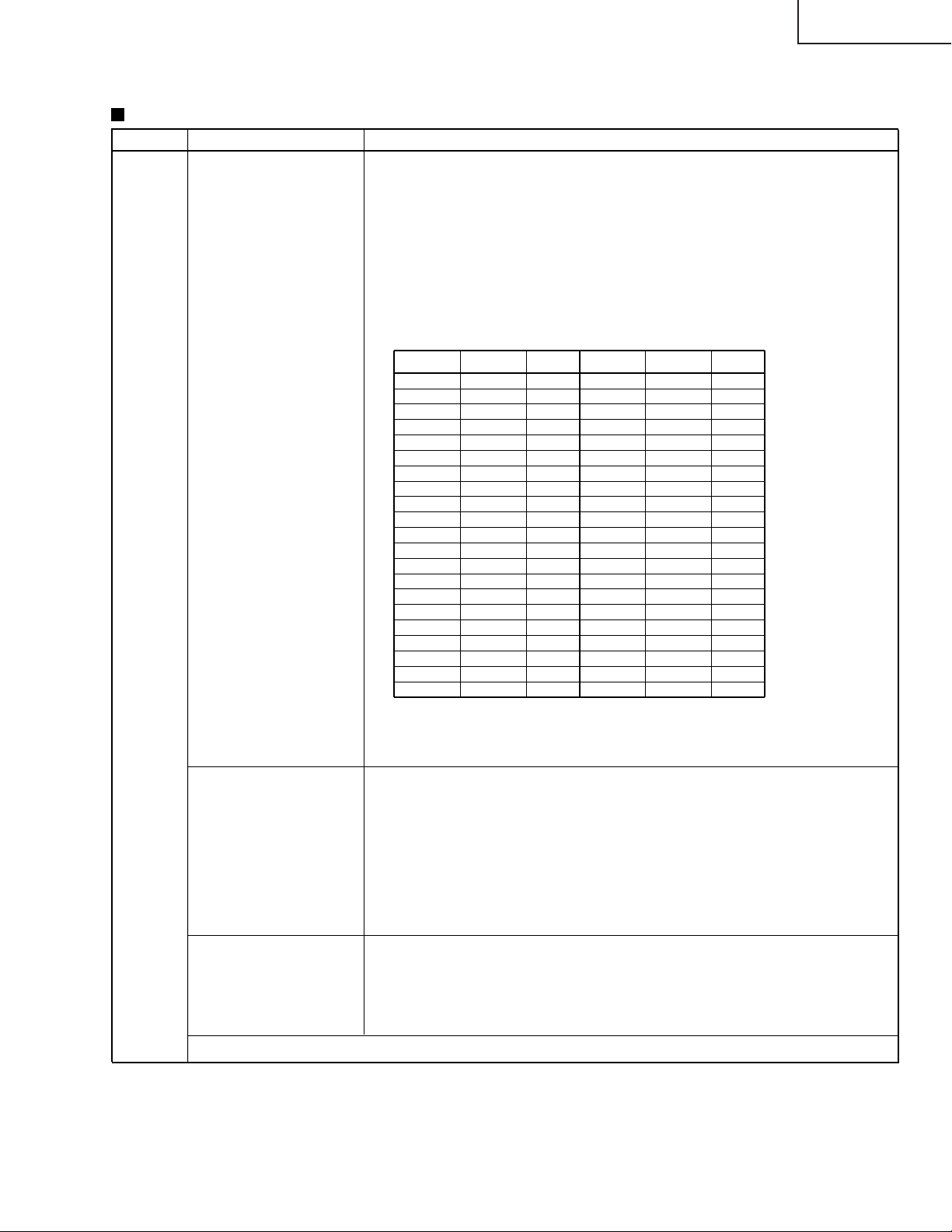

3. Adjustment and Setting Item of the Plasma Display

Display example of the eleventh page

11/13 PUT1NoSIGNI

MNTR

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

V50 02WB

MNTR V6 0 0 1WB

MNTR PC 0 1WB

MNTR R H 25 5IGH1

MNTR G H 2 5 5IGH1

MNTR B H 25 4IGH1

MNTR R L 5 1 0OW1

MNTR G L 5 0 9OW1

MNTR B L 5 1 2OW1

MNTR R H 25 5IGH2

MNTR G H 2 5 5IGH2

MNTR B H 25 4IGH2

MNTR R L 5 1 0OW2

MNTR G L 5 1 1OW2

MNTR B L 5 1 2OW2

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

No. Item Adjustable Range Shipping Setting Storage Place

PDP_W/B table selection at VIDEO 50Hz

1

PDP_W/B table selection at VIDEO 60Hz

2

PDP_W/B table selection at PC

3

RED_GAIN of PDP_W/B table 1

4

GREEN_GAIN of PDP_W/B table 1

5

BLUE_GAIN of PDP_W/B table 1

6

RED_OFS of PDP_W/B table 1

7

GREEN_OFS of PDP_W/B table 1

8

BLUE_OFS of PDP_W/B table 1

9

RED_GAIN of PDP_W/B table 2

10

GREEN_GAIN of PDP_W/B table 2

11

BLUE_GAIN of PDP_W/B table 2

12

RED_OFS of PDP_W/B table 2

13

GREEN_OFS of PDP_W/B table 2

14

BLUE_OFS of PDP_W/B table 2

15

1 or 2

1 or 2

1 or 2

0 to 255

0 to 255

0 to 255

0 to 999

0 to 999

0 to 999

0 to 255

0 to 255

0 to 255

0 to 999

0 to 999

0 to 999

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Caution in the PDP W/B (No.4 to 15) adjustment:

Adjustment value is reflected without relation in input signal during adjustment to the actual PDP.

For example, when operate a adjustment value of [MNTR HIGH1] during PAL input, switch to the adjustment value operation of W/B table 1

while displaying PAL in the actual PDP.

This is temporary.

After adjustment, it becomes the W/B table 2 operation in the PAL input after restarted in the normal mode. It becomes an operation of the W/B

table 1 adjustment value after adjustment in the NTSC input.

As for the above example, table selection (No. 1 and 2) becomes the shipping setting.

2

1

1

PDP

PDP

PDP

PDP

PDP

PDP

PDP

PDP

PDP

PDP

PDP

PDP

PDP

PDP

PDP

∗ : Be careful so that there is the case that page constitution is different.

19

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

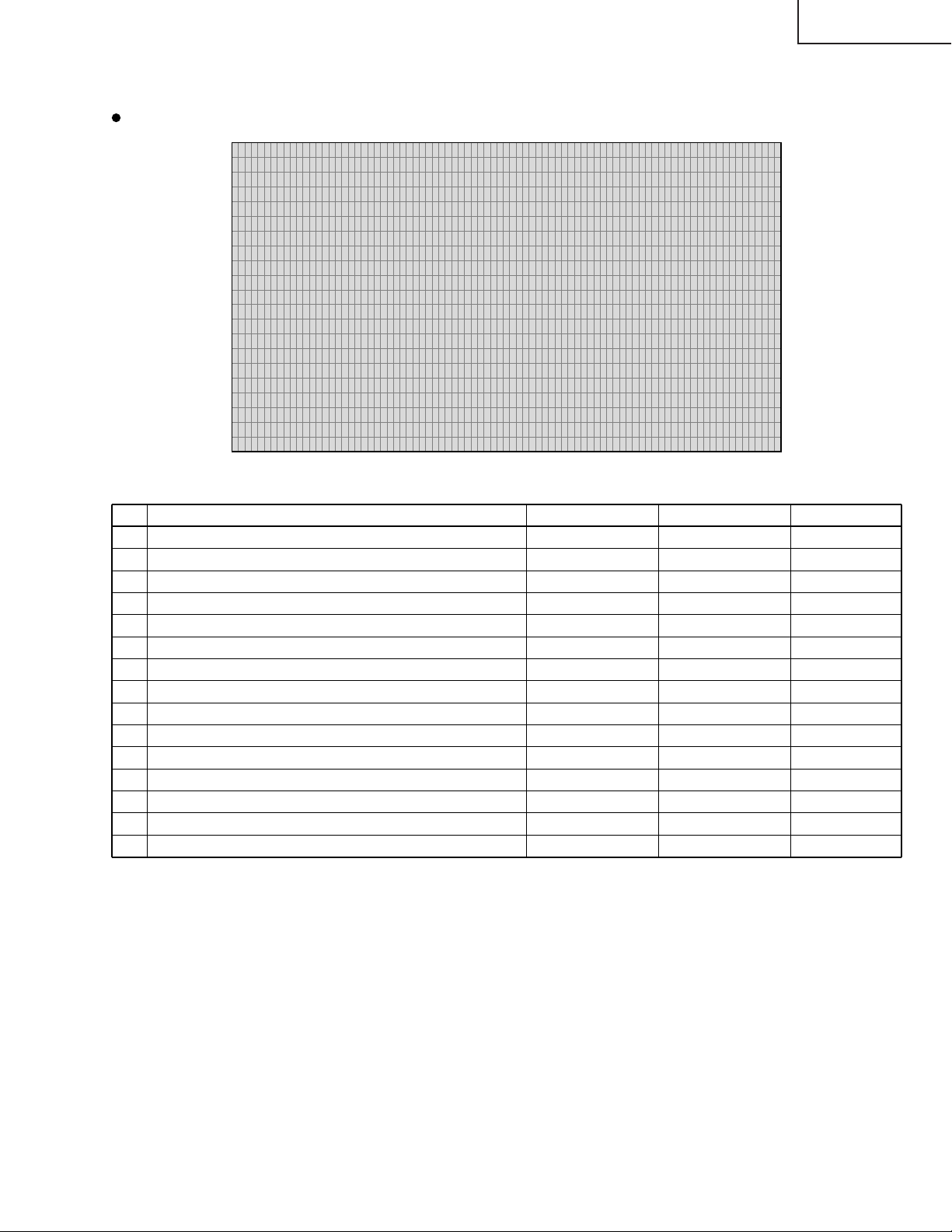

Display example of the twelfth page

21/13 PUT1NoSIGNI

ABL V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

IDE 11860 PCO

ABL V I DE 1 2 250O

VOF ADJ 13 1S

VSU ADJ 12 8S

XSU ADJ 08SB

XSU ADJ 08SG

YSU ADJ 08SB

YSU ADJ 08SG

No. Item Adjustable Range Shipping Setting Storage Place

1 Electric power setting at the PC, VIDEO 60Hz 0 to 255

2 Electric power setting at VIDEO 50Hz 0 to 255

3 VOFS voltage setting 0 to 255

4 VSUS voltage setting 0 to 255

5 SUS_B timing setting of X drive 0 to 15

6 SUS_G timing setting of X drive 0 to 15

7 SUS_B timing setting of Y drive 0 to 15

8 SUS_G timing setting of Y drive 0 to 15

Adjustment item of this page is related in damage of the set when mistakes adjustment. When adjustment is needed, be enough

careful to adjustment.

Caution in the electric power setting (No. 1 and 2) adjustment:

Adjustment value is reflected without relation in input signal during adjustment to the actual PDP.

For example, when operate a adjustment value of [ABL VIDEO 60 PC] during PAL input, switch to the adjustment value operation of [ABL

VIDEO 60 PC] while displaying PAL in the actual PDP. This is temporary.

After adjustment, it becomes the [ABL VIDEO 50] operation in the PAL input after restarted in the normal mode. It becomes an operation of the

[ABL VIDEO 60PC] adjustment value after adjustment in the NTSC input.

∗

: Be careful so that there is the case that page constitution is different.

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

Factory adjustment value

PDP

PDP

PDP

PDP

PDP

PDP

PDP

PDP

20

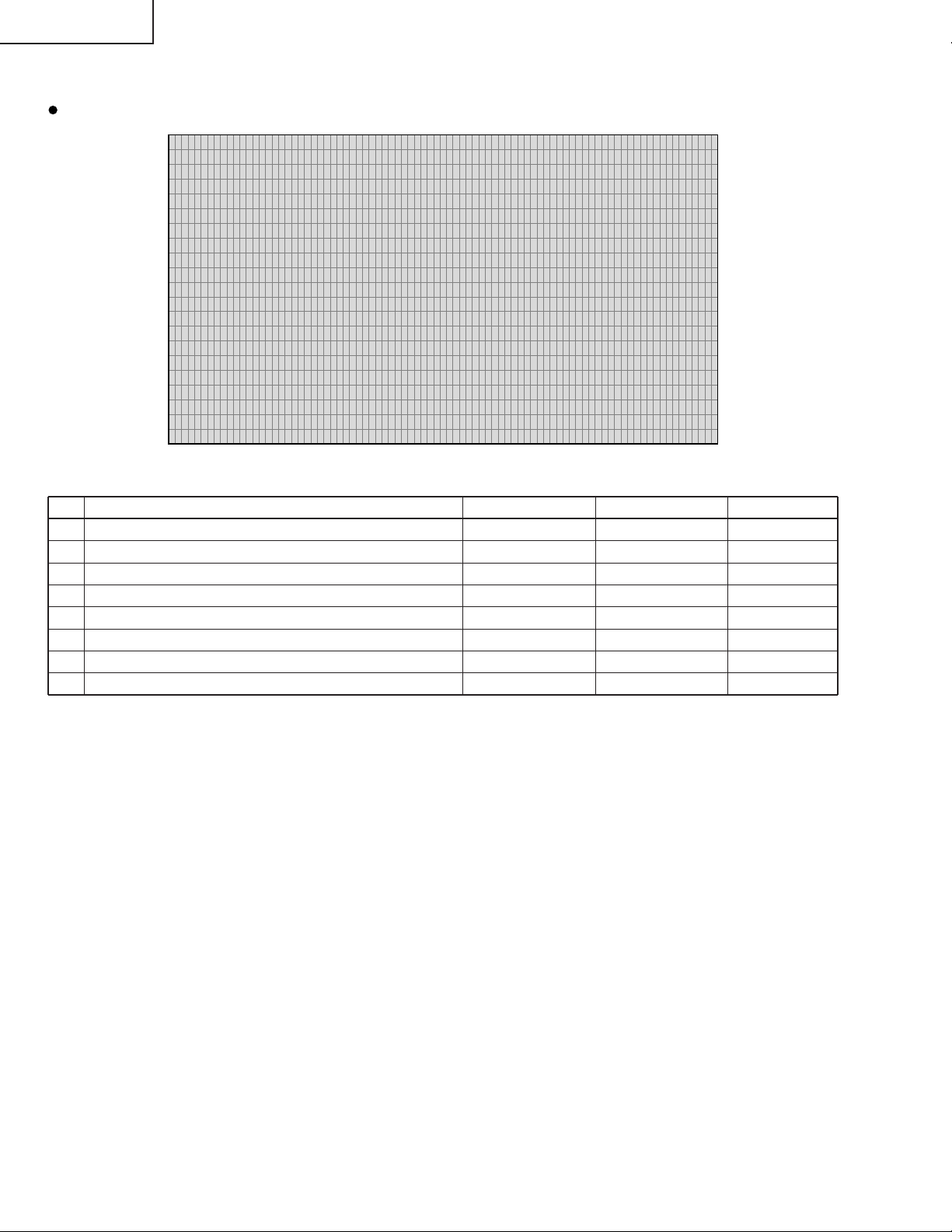

Display example of the thirteenth page

21/13 PUT1NoSIGNI

VIPCDDEEO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

DR 00VE MOI

I

NEGAT

VEI

ENHAN ECBR I GHT

FREQMASK

V

PATTE NR

FULL MASK

DEDR VE MO

DEMO

MASK

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

03

OFF

OFF

50

OFF

OFF

No. Item Adjustable Range Shipping Setting Storage Place

1 Drive mode selection at VIDEO 0 to 5 0 PDP

2 Drive mode selection at PC 0 to 5 3 PDP

3 Negative positive inversion mode OFF/ON OFF PDP

4 Bright enhance OFF/ON OFF None

5 Refresh rate at mask signal generation 50/60/70 – None

6 Pattern mask signal generation OFF/ OFF PDP

7 Full mask signal generation OFF/ OFF PDP

Caution in the mask (generation test signal screen in the PDP inside) signal generation:

• A pattern mask and a full mask can use only either.

Therefore, turn a full mask to OFF when uses a pattern mask. Also turn a pattern mask to OFF when uses a full mask.

• A pattern mask and a full mask are test signal screens occurring together in the PDP inside. Therefore, in the mask signal generation, it

cannot confirm video inputting from OSD and the outside.

When release mask setting or change of each setting or perform the confirmation of the adjustment or external input signal, perform key

operation of the main unit button or the remote control unit.

When operated something, stop the generation of the mask signal just after that for two seconds. Therefore, modification and adjustment of

each setting and confirmation of the external input signal are possible.

∗ : Be careful so that there is the case that page constitution is different.

21

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

ADJUSTMENT REQUIRED WHEN THE SET IS REPAIRED OR REPLACED

SW POWER SUPPLY Module

When replaced

No adjustment required.

DIGITAL VIDEO Assy

When repaired

No adjustment required.

When replaced

• Remove IC1204 (24LC04(1) SN-TBB) from the former

PC Board to replace, and install it to the new PC Board.

MR INTERFACE Assy

• Set slide SW according to page 244.

Y DRIVE Assy

When repaired

1. VOFS/VH/IC5V voltage adjustment

2. Timing adjustment of pulse module

When replaced

1. SUSB ground timing adjustment

2. Panel white balance adjustment

X DRIVE Assy

When repaired

1. VRN voltage adjustment

2. Timing adjustment of pulse module

When replaced

1. SUSB ground timing adjustment

2. Panel white balance adjustment

Y DRIVE

Assy

DIGITAL VIDEO

Assy

SW POWER SUPPLY

Module

X DRIVE

Assy

MR INTERFACE

Assy

Fig. 1 PC Board Location (rear side view)

22

ADJUSTMENT

VOFS/VH/IC5V Voltage Adjustment

Input Signal

Adjusting Point

VOFS (Offset voltage) adjustment

Method 1

1. Write down a adjustment value of VOFS ADJ in the factory mode.

2. Set this adjustment value to center (128).

3. Adjust VR2701 so that the voltage between K2701 (VOFS) and K2703 (SUS GND) becomes

45V.

4. Return it to the value that wrote down a adjustment value of V-OFFSET in step 1.

Method 2

1. Read the adjustment value of VOFS ADJ in the factory mode.

2. Adjust VR2701 so that the voltage between K2710 (VOFS) and K2703 (SUS GND) becomes

following voltage ± 0.5V.

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

Adjusting Method

White 100%

VR2701 (VOFS)

(Y DRIVE Assy)

VR2703 (VH)

(Y DRIVE Assy)

Input

Command

VOF000 0.4 25 VOF134 2.599212598 45.94488

VOF006 0.4984375 25.9375 VOF141 2.71496063 47.04724

VOF013 0.61328125 27.03125 VOF147 2.814173228 47.99213

VOF019 0.71171875 27.96875 VOF153 2.913385827 48.93701

VOF026 0.8265625 29.0625 VOF160 3.029133858 50.03937

VOF032 0.925 30 VOF166 3.128346457 50.98425

VOF038 1.0234375 30.9375 VOF172 3.227559055 51.92913

VOF045 1.13828125 32.03125 VOF179 3.343307087 53.0315

VOF051 1.23671875 32.96875 VOF185 3.442519685 53.97638

VOF058 1.3515625 34.0625 VOF191 3.541732283 54.92126

VOF064 1.45 35 VOF198 3.657480315 56.02362

VOF070 1.5484375 35.9375 VOF204 3.756692913 56.9685

VOF077 1.66328125 37.03125 VOF211 3.872440945 58.07087

VOF083 1.76171875 37.96875 VOF217 3.971653543 59.01575

VOF090 1.8765625 39.0625 VOF223 4.070866142 59.96063

VOF096 1.975 40 VOF230 4.186614173 61.06299

VOF102 2.0734375 40.9375 VOF236 4.285826772 62.00787

VOF109 2.18828125 42.03125 VOF242 4.38503937 62.95276

VOF115 2.28671875 42.96875 VOF249 4.500787402 64.05512

VOF122 2.4015625 44.0625 VOF255 4.6 65

VOF128 2.5 45

DAC

Output

Setting

Voltage

Input

Command

DAC

Output

Setting

Voltage

The symptom is case of mis-adjustment

If the VOFS Voltage adjustment is not performed properly, dots like blinking luminance points

appear. If deviated greatly from the right adjustment point, panel will light white.

VH (voltage for scan IC) Adjustment

Adjust so that the voltage between K2716 (VH) and K2720 (PSUS) becomes 103V ± 0.5V.

PSUS (=GNDH) is a floating GND and the electric potential is different from that of chassis

GND. Be sure not to short-circuit PSUS (=GNDH) and another GND, because that may

damage the unit.

The symptom is case of mis-adjustment

If the VH adjustment is not performed properly, dots like blinking luminance points appear. If

deviated greatly from the right adjustment point, panel will light white.

IC5V Adjustment

Adjust so that the voltage between K2707 (IC5V) and K2720 (PSUS) becomes 5.0V ± 0.1V.

VR2702 (IC5V)

(Y DRIVE Assy)

PSUS (=GNDH) is a floating GND and the electric potential is different from that of chassis

GND. Be sure not to short-circuit PSUS (=GNDH) and another GND, because that may

damage the unit.

Note : Be sure to measure between specified test points.

23

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

Sustain Pulse Waveform Adjustment

Input Signal

REF_DIG mode

White 100%

in Factory mode

XSUSB ADJ

YSUSB ADJ

VRN Voltage Adjustment

Input Signal

Adjusting Point Adjusting Method

X-SUS-B, Y-SUS-B Adjustment

Set to the indicated value with the remote control unit.

(Refer to "Timing adjustment of control signal of X and Y Drive Assys".)

Adjusting Point Adjusting Method

White 100%

VR3701 (VRN)

(X DRIVE Assy)

VRN (minus reset voltage adjustment)

Adjust so that the voltage between K3707 (VRN) and K3702 (SUS-GND) becomes

-300V ± 1.0V.

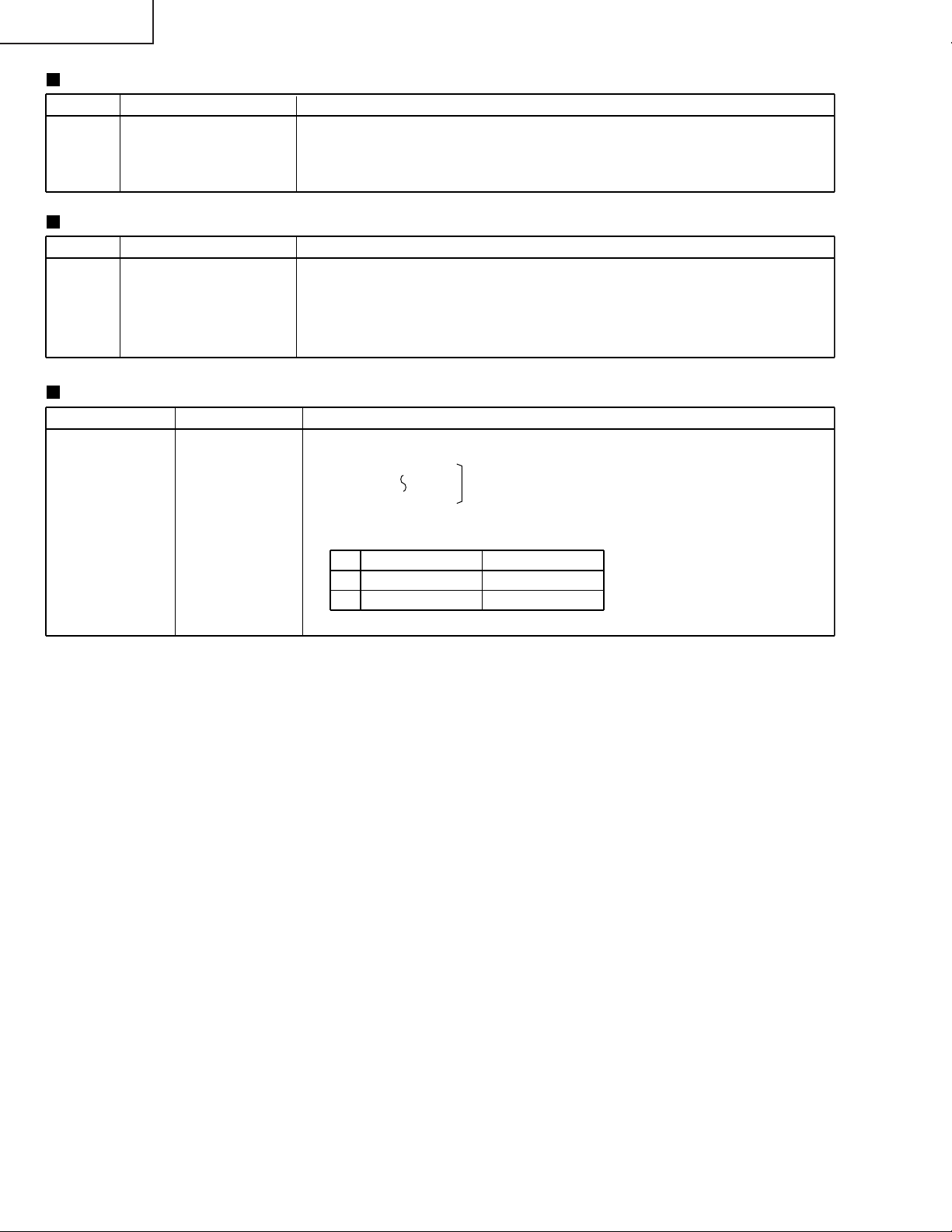

Panel White Balance Adjustment

Input Signal

∗

When perform the various adjustment by RS-232C control, execute a "DM0" command (release the limit of pulse number)

beforehand.

After the adjustment completion, execute a "DM 3" command (Limit of pulse number: 64%, shipping state) by all means.

Adjusting Point Adjusting Method

Adjust the parameter in the OFFSET-DIGITAL of factory mode as follows;

In this time, dispay uses the mask (MASK04) of factory mode.

PANEL R-HIGH

PANEL B-LOW

Reference : Adjustment values using the Media color-difference meter (CA-100)

MASK Left Side

x295

y306

MASK Right Side

291

300

24

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

Timing Adjustment of X and Y DRIVE Assys Control Signal

Purpose

• Pulse module loads in DRIVE Assy as one of heat measures of DRIVE Assy. Adjust the drive timing of the pulse module

driving parallel with VR.

• Pulse module has each peculiar delay time. Readjustment is necessary when replaced the pulse module in the X and

Y DRIVE Assys.

Adjustment Method

CR delay circuit is each inserted on signal path of four control signals (SUS-U, SUS-B, SUS-D, SUS-G) driving

the pulse module.

Quantity of delay can adjust pulse module of one side with VR.

Adjust VR while measuring a waveform of the pulse module, and match a timing.

Adjustment VR Test pin for adjustment and measurment

X DRIVE Y DRIVE

SUS-U VR3203 VR2204

SUS-D VR3202 VR2203

SUS-B VR3201 VR2202

SUS-G VR3200 VR2201

Adjustment Procedure

Pulse Module X DRIVE Y DRIVE

Upper Lower Upper Lower

SUSOUT K3105 K3106 K2212 K2203

SUS-U K3200 K3204 K2220 K2224

SUS-D K3108 K3205 K2207 K2225

Power ON

Black Mask Screen

Display a SUSOUT waveform

Coarse adjustment of

SUS-U, SUS-B, SUS-G

Display a SUS-D waveform

SUS-D adjustment

Adjust the waveform to 20-25ns.

Display a SUS-U waveform

SUS-U adjustment

Adjust the waveform to 20-25ns.

Power OFF

Adjust VR resistance value

of SUS-B and SUS-G to match

VR resistance value of SUS-D

within ± 2Ω.

Measuring points of waveform

are refered to next page.

SUS-D readjustment

Adjust the waveform to 20-25ns.

SUS-U readjustment

Adjust the waveform to 20-25ns.

Adjust VR resistance value

of SUS-B and SUS-G to match

VR resistance value of SUS-D

within ± 2Ω.

Power ON and

display a SUS-D waveform

Display a SUS-U waveform

Power OFF

Power ON and display a SUSOUT

waveform

Compare waveform,

and do harmonize

almost?

No

As for this adjustment, adjustment with set state is difficult.

Therefore replace it every Assy when replacing the pulse module.

Yes

Adjustment end

25

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

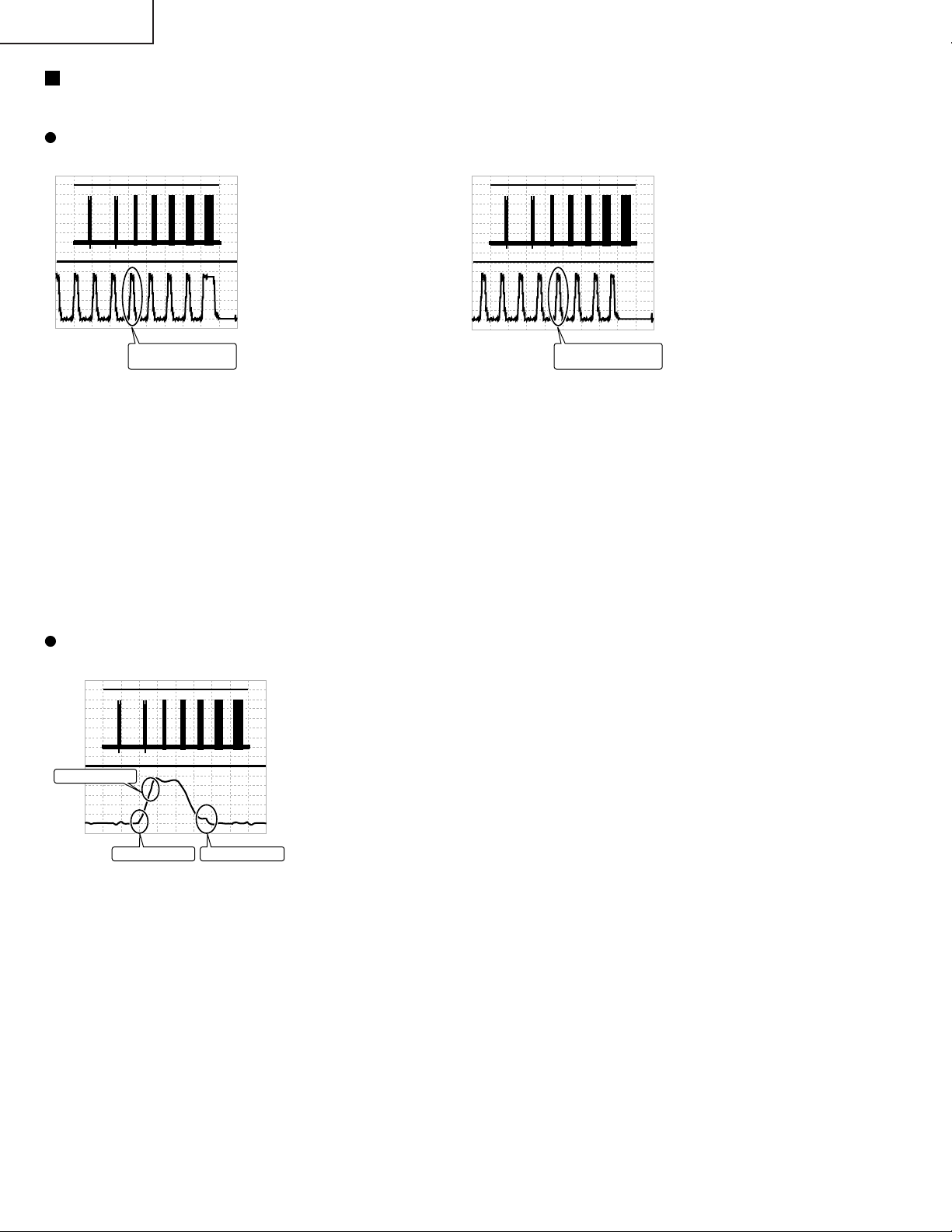

Measuring Waveform of Pulse Module Timing Adjustment

Timing adjustment of the pulse module control signal adjusts with the sustain pulse of eighth pulse (X DRIVE) and

the ninth pulse (Y DRIVE) from the back of 6SF.

Measuring point of waveform

Y DRIVE SUSOUT waveform X DRIVE SUSOUT waveform

1SF 2SF 3SF 4SF 5SF 6SF 7SF

1ms/div

Magnify 6SF block

CH1 : Y SUSOUT Under (K2203), 50V/div

CH2 : Y SUSOUT Upper (K2212), 50V/div

CH4 : YPR-U1 (K2038)- Trigger, 5V/div

5µs/div

Use this sustain pulse

and adjust.

Trigger : 2msec delay

• Perform adjustment of waveform with a black mask screen.

• It is easy to adjust when turned field AB offset to OFF (RS-232C

command: OCN) in adjustment.

Note:

• Sampling rate of oscilloscope sets it more than 500MS/s in order

to perform ns order adjustment.

• Collecting calibration of probe before adjustment by all means.

• Connect GND of probe measuring waveform to SUSGND terminal

by all means.

• Precise waveform is not displayed, and an adjustment gap may

occur that does not collect GND properly.

1SF 2SF 3SF 4SF 5SF 6SF 7SF

1ms/div

Magnify 6SF block

CH1 : X SUSOUT Under (K3106), 50V/div

CH2 : X SUSOUT Upper (K3105), 50V/div

CH4 : YPR-U1 (K2038)- Trigger, 5V/div

5µs/div

Use this sustain pulse

and adjust.

Trigger : 2msec delay

When took waveform be each drive Assy unit, measure it at the

fourth sustain pulse from the back except for a large width sustain

pulse.

Therefore, when measured both waveform of the X and Y drives

together, it becomes the sustain pulse of 8 and 9 pulses from the

back.

Waveform coarse adjustment

Measure the SUSOUT waveform

1ms/div

Magnify the adjustment waveform

Adjust with SUS-B

500ns/div

Adjust with SUS-U Adjust with SUS-G

When there is a gap with waveform of CH1 / CH2 of the part which

enclosed in the following circle, adjust required VR to overlap the

waveform.

CH1 : Y SUSOUT Under (K2203), 50V/div

CH2 : Y SUSOUT Upper (K2212), 50V/div

CH4 : YPR-U1 (K2038)- Trigger, 5V/div

Trigger : 2msec delay

26

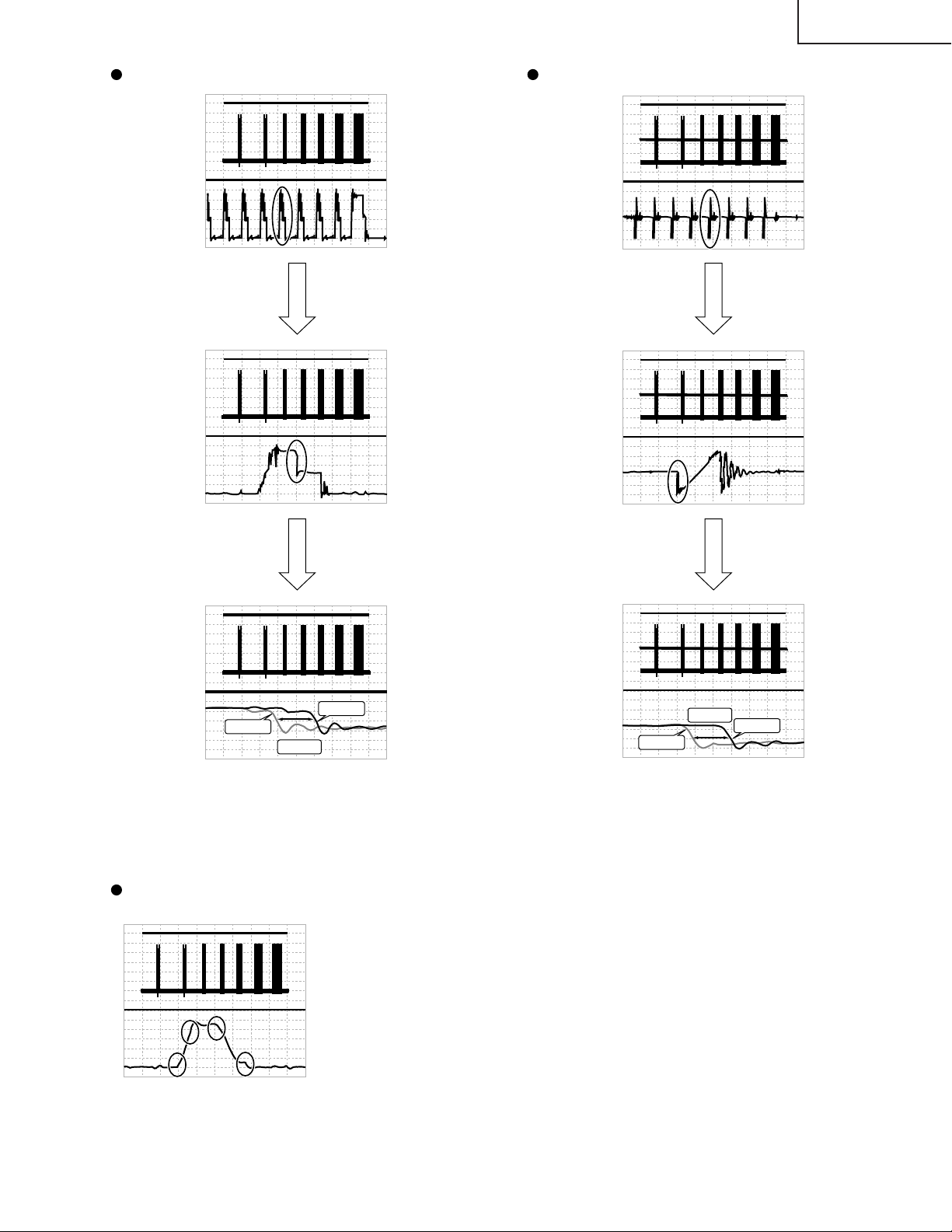

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

SUS-D Adjustment (Y DRIVE)

1ms/div

Magnify 6SF block

5µs/div

1ms/div

Magnify 6SF block

500ns/div

SUS-U Adjustment (Y DRIVE)

1ms/div

Magnify 6SF block

5µs/div

Magnification Magnification

1ms/div

Magnify 6SF block

200ns/div

Magnification

1ms/div

Magnify 6SF block

Upper PM

Lower PM

10ns/div

CH1 : Y SUS-D Under (K2225), 50V/div

CH2 : Y SUS-D Upper (K2207), 50V/div

CH4 : YPR-U1 (K2038)- Trigger, 5V/div

Trigger : 2msec delay

20 - 25ns

Caution:

Not absolutely mistaking upper

and lower of waveform.

Waveform Confirmation in Adjustment completion

Measure the SUSOUT waveform

1ms/div

Magnify the adjustment waveform

CH1 : Y SUSOUT Under (K2203), 50V/div

CH2 : Y SUSOUT Upper (K2212), 50V/div

CH4 : YPR-U1 (K2038)- Trigger, 5V/div

500ns/div

Trigger : 2msec delay

Magnification

1ms/div

Magnify 6SF block

20 - 25ns

Upper PM

Lower PM

10ns/div

CH1 : Y SUS-U Under (K2224), 50V/div

CH2 : Y SUS-U Upper (K2220), 50V/div

CH4 : YPR-U1 (K2038)- Trigger, 5V/div

Trigger : 2msec delay

Confirm it to waveform of CH1 / CH2 of the part which enclosed in

the following circle whether there is not a large gap.

(A gap of the quantity that shifts 20nS and adjusted remains.)

When adjust in the power supply ON state, change so that the

quantity of gap that adjusted by temperature-rise of the pulse

module becomes small.

Therefore, perform high power OFF (RS-232C command: DRF)

except measurement time of waveform when adjusts, and

adjustment error by temperature-rise does not occur.

27

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

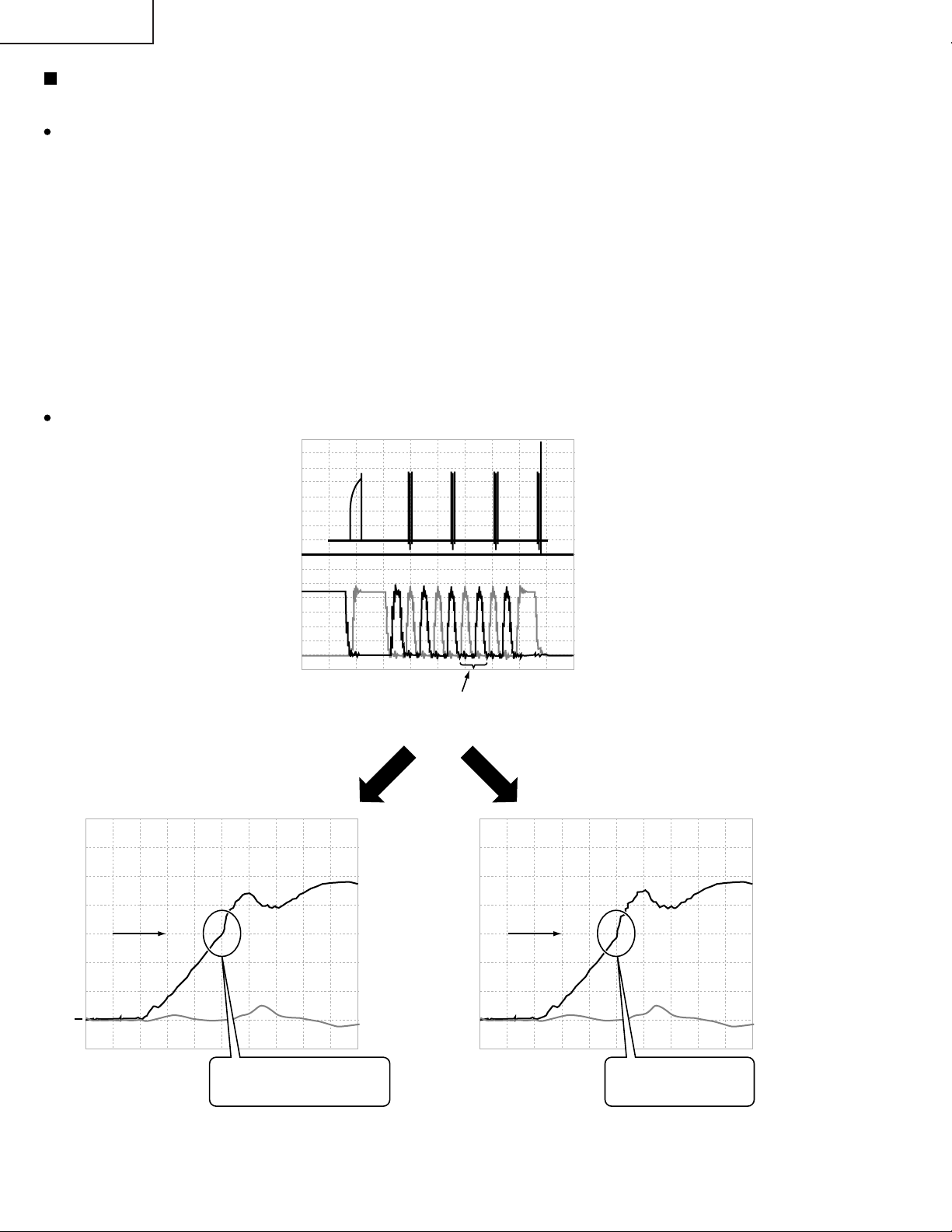

SUS-B Ground Timing Adjustment

It is necessary to readjust this adjustment when replaced the X or Y DRIVE Assy and the pulse module.

Measurement point and method

Measurement point of waveform of X and Y DRIVE Assy in timing adjustment is test pin of SUSOUT of the pulse module of

bottom of the main unit.

X DRIVE Assy : K3106 Y DRIVE Assy : K2203

Measurement screen : White mask

The measurement is easy to perform when turns field AB alternation to OFF. (RS-232C command: OCN)

Measure a sustain pulse of the fourth pulse (X DRIVE) and the fifth pulse (Y DRIVE) from the back of the fourth FS, and

adjust. In the start section of this sustain pulse, waveform has inflection point with the timing when SUS-B becomes ON.

Adjust so that the voltage of this inflection point is the nearest to 150V and do not become less than 150V.

Adjustment parameter

X DRIVE: XSUSB (RS-232C command : XSB)

Y DRIVE: YSUSB (RS-232C command : YSB)

Note:

• Connect GND of probe measuring waveform to SUSGND terminal by all means.

• Precise waveform is not displayed, and an adjustment gap may occur that does not collect GND properly.

Waveform in the measurement

Rst

1ms/div

Magnify 4SF block

XXXXXXY YYYY Y

5µs/div

Magnify the fourth pulse sustain pulse (XSUSOUT waveform) from the back of the above waveform.

1SF 2SF 3SF 4SF

CH1 : Y SUSOUT (K2203), 50V/div

CH2 : X SUSOUT (K3106), 50V/div

CH4 : YPR-U1 (K2038)- Trigger, 5V/div

Trigger : 2msec delay

Measure a waveform of this section and adjust.

NG

OK

100msec/div

100msec/div

GND

150V Line

50V/div

This broken section moves by

changing the adjustment

parameter.

150V Line

50V/div

Become less than 150V.

→ NG

28

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

Y DRIVE Assy X DRIVE Assy

K2720

K2227

(SUS_D)

K2226

(SUS_U)

K2212

(SUSOUTB)

K2225

(SUS_D)

K2224

(SUS_U)

K2203

(SUSOUTA)

K2218

(1/2 VSUS)

K2011

K2010

K2013

K2009

K2005

K2003

K2002

K2001

K2004

K2205

K2215

(SUS_B)

K2214

(SUS_G)

K2211

K2039 (YSUS_MSK)

K2037 (YSUS_G)

K2028 (YSUS_U)

VR2204

(SUS_U_ADJ)

VR2203

(SUS_D_ADJ)

VR2201

(SUS_G_ADJ)

(SUS_U)

K2216

(SUS_D)

K2222

(YPR_U2)

K2053

(SOFT_D)

K2041 (OFS)

K2217

VR2701

K2021

(PN MUTE)

VR2202

(SUS_B_ADJ)

K2716

(VH)

(YDC_DC_PD)

(VH_ADJ)

K2703

(SUSGND)

K2710

(VOFS)

K2050

K2048

K2046

K2012

K2040

(YCP_MSK)

K2029

(YSUS_D)

K2027

(YSUS_B)

K2704

(VF-)

K2701

(VF+)

(IC5V_ADJ)

K2715

K2718

(VH UVP)

VR2703

K2702

(VSUS)

K2709

K2712

(VOFSUVP)

K2045

K2049

K2047

K2044

K2038

(YPR_U1)

K2024

(DGND)

(DEW_DET)

K2707

(IC5V)

VR2702

(PSUS)

K2717

(VH CONT)

K2719

(VH OVP)

K2708

(VOFS)

K2705

(SUSGND)

K2221

(+15V)

K2043

(DGND)

K2008

(DGND)

K2007

(DGND)

K2006

(+5V)

K2101

K2714

(GNDHS)

K2706

(+14V)

K2711

(-8V)

K2713

(IC5V UVP)

K3214

(SUSGND)

K3205

(SUS_D)

K3204

(SUS_U)

K3106

(SUSOUT_B)

K3102

(XNR_PD)

K3203

(1/2VSUS)

K3108

(SUS_D)

K3200

(SUS_U)

K3105

(SUSOUTA)

K3213

(1/2VSUS)

(SUSGND)

K3201

K3707

(VRN)

(PN_MUTE)

K3015

(XSUS-MSK)

K3014

(XNR-D1)

K3012

(XSUS-D)

VR3203

(SUS-U)

VR3202

(SUS-D)

(SUS. GND)

VR3701

(VRN. ADJ)

K3029

K3008

K3010

(XNR-U)

K3017

(XCP-MSK)

(XSUS-B)

VR3200

(SUS-G)

K3702

K3030

K3021

K3022

K3003

K3103

(VCP_PD)

K3104

(+5V)

VR3201

(SUS-B)

(VSUS)

K3708

(VRN_OVP)

K3706

(X DC-DC PD)

K3705

VRN UVP)

K3701

K3703

(SUS. GND)

K3704

(VRN. CNT)

K3009

K3006

K3011

K3007

K3025

K3018 (XNR-D2)

K3013 (XSUS-G)

K3004 (XSUS-U)

K3001

(+5V)

Adjusting Points

29

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

COMMAND

RS-232C Command

As for PZ-50HV2 system, the 232C control of the panel control item is possible by a single state.

However, the following exclusive use communication jig is necessary.

∗

Be careful so that can not use a DSUB 9-pin in the rear panel of the AVC System.

Connection

DVI (Video line):

Input optional video from the

signal source with the DVI

output.

Input timing is as follows.

DVI input timing

XGA60 (VESA conformity)

CLK 65MHz

H total 1344 clk

H disp 1024 clk

H sync 136 clk

H BP 160 clk

V total 806 line

V disp 768 line

V sync 6 line

V BP 29 line

fH 48.363 kHz

fV 60.004 Hz

Communication baudrate

38400 bps is fixed.

PDP rear view

AC-DC adapter

(9V or 12V output)

Communication line:

Connect a system cable.

Exclusive use

communication jig

PC for control

Connect to DSUB 9-pin

DSUB 9-pin straight cable

Jig Schematic Diagram

CN1

AKP1201

R4

100

R5

100

R8

CN2

AKB1099

R

L

GND

G_JIGU10

CN4

AKP1205

CN5

B3B-PH-SM3-TBB

9V

NC

D1FS4-TRB

GND

D1

100

9.3V

C7

D2

D1FS4-TRB

47/16

V_JIGU10

IC1

DS14C232CM-TBB

C1

1

1/50

2

3

C2

4

1/50

5

1/50

C3

C8

6

7

8

1/50

100k

C6

R14

0.1

16

C1+

VCC

V+

GND

15

14

C1-

DOUT1

C2+

RIN1

13

C2-

ROUT1

12

V-

DIN1

11

10

DOUT2

DIN2

9

RIN2

ROUT2

C4

0.1

100k

R15

G_JIGU10

IC2

PQ05DZ51-TLB

NC

VIN VO

GND

2.2k

R11

2.2k

R12

47/16

C5

10k

10k

R16

R17

VC

0.1

47/16

C9

C10

G_JIGU10

R6

100

R7

100

R9

0

R13

0

R10

R1

1k

CN3

0

R2

AKP1194

SP_L

20

10

GND

19

9

SRST

18

GND

SP_R

GND

8

17

7

16

6

15

5

14

4

13

3

12

2

11

1

FLASH_W

SR_UP

0

SR_DOWN

TXD0_M

SP_L

CSEN1

CSEN2

CCKM

GND

SMPOW

SP_R

SENCE

GND

RXD0_M

0

R3

30

Loading...

Loading...