Page 1

Addendum to the Sharp Limited Servicer Maintenance Manual

Including models:

PG-D100U

XG-E1200U

XG-E3000U

XG-E3500U

XG-NV1U

XG-NV2U

XG-NV3XU

XG-NV3XB

XG-NV4SU

XG-NV5XU

XG-NV6XU

XG-NV7XU

XV-C10U

XV-C10U(P)

XV-H37VUA

Ver. 3/00 Volume 1

Page 2

Table of Contents

Subject Page

Convergence

PG-D100U, XG-E1200U, XG-E3000U,

XG-E3500U, XG-NV1U, XG-NV2U,

XG-NV3XU, XG-NV3XB

XG-NV4SU, XG-NV5XU

XG-NV6XU

1-1

1-4

1-7

Lamp Replacement

PG-D100U, XG-NV1U

XG-E1200U, XG-E3000U, XG-E3500U

XG-NV2U, XG-NV3XU, XG-NV3XB

XG-NV4SU, XG-NV5XU

XG-NV6XU

XG-NV7XU

XV-C10U, XV-C10U(P)

2-1

2-3

2-5

2-7

2-9

2-11

2-13

Filter / Cleaning / Replacement

PG-D100U, XG-NV1U

XG-E1200U, XG-E3000U, XG-E3500U

XG-NV2U, XG-NV3XU, XG-NV3XB

XG-NV4SU, XG-NV5XU, XG-NV6XU

XV-C10U, XV-C10U(P)

3-1

3-3

3-5

3-7

3-9

Cleaning the LCD Panels

XV-C10U, XV-C10UP

Note: Because of the difficulty of removing the LCD panels, cleaning the

LCD panels is beyond the scope of the Limited Servicer Program for all

other models included in this addendum.

4-1

Notes:

1. The safety and various description sections must be read in the Main Limited

Servicer Maintenance Manual (part code SM-LCD) before attempting any

procedures outlined in this addendum.

2. The maintenance procedures for the XV-H37VUA, XV-H37VUA(P) are

identical to the XG-E1100U. Therefore, please refer to the Main Limited

Servicer Maintenance Manual when maintaining the XV-H37VUA.

Ver. 3/00 Volume 1

Page 3

HOW TO CONVERGE THE LCD PANELS

For the models XG-NV1U, XG-E1200U, PG-D100U, XG-E3000U,

XG-NV2U, XG-NV3XU, XG-NV3XB, and XG-E3500U

Tools and equipment needed:

• Pattern Generator that can produce a crosshatch pattern (grid pattern)

• Eccentric Cam Adjustment Wrench. (Sharp Part # 9DASPN-XGNV1U)

• L-shaped Hex Wrench (Sharp part # 9EQLNC-XGNV1U)

• Philips Screwdriver

NOTE: Confirm focus before performing the convergence procedure. If pixels are

in focus in one area of the screen and indistinguishable in another area, the

projector is out of focus. The focus alignment procedure is beyond the scope of the

limited maintenance program.

Step Procedure Ref. #

1. Checking

convergence.

Refer to the safety notes on page S-1 of the Main Limited

Servicer Maintenance Manual before attempting to converge

the panels.

1. Connect a pattern generator to the video or RGB (when

applicable ) input terminals.

2. Output a crosshatch signal from the pattern generator.

3. Turn on the projector.

4. Mentally divide the screen into fourths both horizontally

and vertically. Imagine the center four squares as the A zone

and the outer one fourth (all around the outside edge) as the B

zone. Look at the grids to determine if the convergence is off.

You should see only white grid lines on the screen ( a white

line is the product of separate red, green, and blue lines

“added together,” or converged over the same area ). If the

red or blue lines are offset from the green lines ( either

up/down or left/right ), the convergence is off. The green

panel is fixed, so mechanical adjustment isn’t possible. If

any adjustments to the red or blue panels are necessary,

use green as the reference. If the unit is converged to within

one pixel in the A zone and one and a half pixels in the B

zone the unit is converged within specification and adjustment

is not required.

fig. 3-4

(Main

Manual)

Continued on next page

Ver. 3/00 1-1 Sharp Electronics Corporation

Page 4

HOW TO CONVERGE THE LCD PANELS (continued)

Step Procedure Ref. #

2. Removal of

body panels.

3. Adjustment

of the blue

panel.

1. To remove the cabinet, refer to the service manual for the

specific model.

1. Supply the projector with a blue and green crosshatch

signal from the pattern generator (on most video signal

generators, it is possible to remove one or more of the 3

colors making up the crosshatch signal. In this case red

must be removed. To do this refer to the instructions for

the pattern generator).

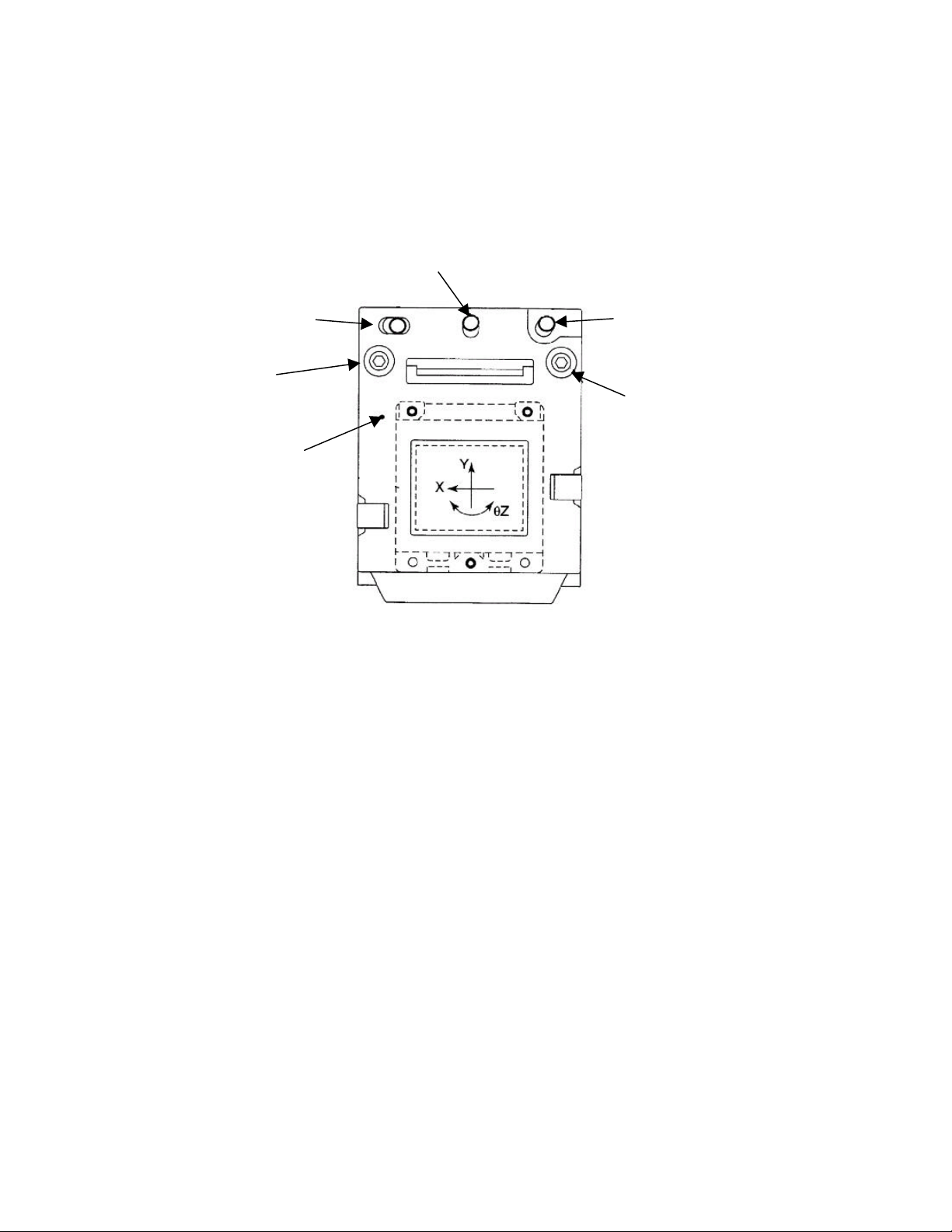

2. Use the L-shaped hex wrench to loosen the two hex screws

labeled “Lock Screw” in fig. 1.

Be sure to leave the lock screws tight enough so that when

an adjustment is made, the panel will stay in that position

until the lock screws are fully tightened after the

completion of all adjustments.

3. Use the eccentric cam wrench to adjust the Y axis (up and

down).

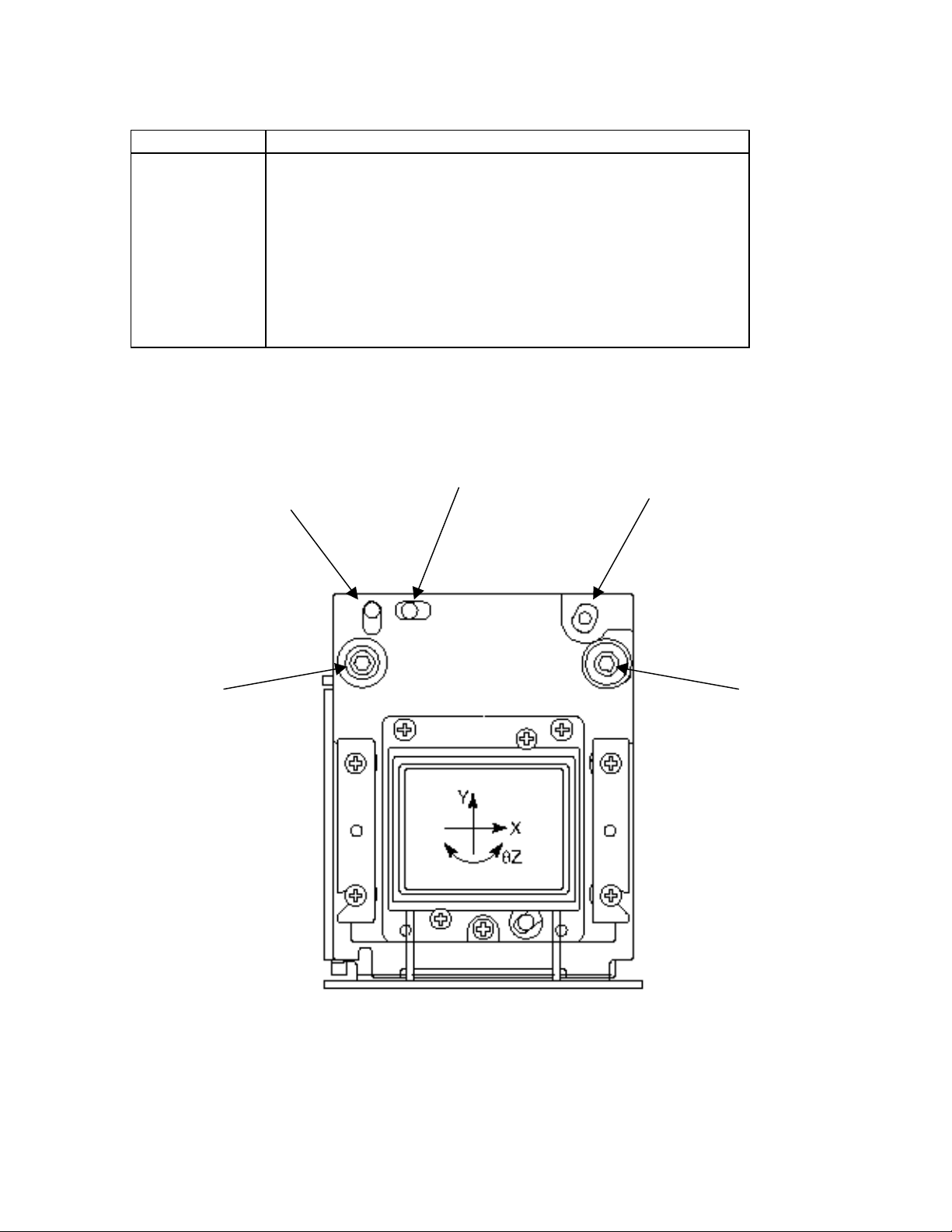

fig. 1

fig. 1

4. Use the eccentric cam wrench to adjust the X axis (side to

side).

5. Use the eccentric cam wrench to adjust the θZ axis

(tilt).

6. When the blue image is converged within specifications to

the green panel, tighten the two lock screws to secure the

adjustments.

NOTE: Tightening the screws may cause mis-convergence.

If this happens, readjust the affected panel.

fig. 1

fig. 1

fig. 1

Ver. 3/00 1-2 Sharp Electronics Corporation

Page 5

Step Procedure

θ

4. Adjustment

of the red

panel

Y Direction

Adjustment

(Up & Down)

1. Supply the projector with a red and green crosshatch

signal from the pattern generator (turn blue off and red

on).

2. Repeat same adjustment procedure as the blue panel.

Convergence adjustment is complete.

X Direction

Adjustment

(Side To Side)

Direction

Adjustment

(Tilt)

Lock

Screw

Lock

Screw

fig. 1

Ver. 3/00 1-3 Sharp Electronics Corporation

Page 6

HOW TO CONVERGE THE LCD PANELS

For the models XG-NV4SU and XG-NV5XU

Tools and equipment needed:

• Pattern Generator that can produce a crosshatch pattern (grid pattern)

• Eccentric Cam Adjustment Wrench. (Sharp Part # 9DASPN-XGNV1U)

• 2mm Hex Wrench (Sharp part # 9EQLNC-XGNV4U)

• 1.27mm Hex Wrench (available at most hardware stores)

• Philips Screwdriver

NOTE: Confirm focus before convergence procedure. If pixels are in focus in one

area of the screen and indistinguishable in another area, the projector is out of

focus. The focus alignment procedure is beyond the scope of the limited

maintenance program.

Step Procedure Ref. #

1. Checking

convergence.

Refer to the safety notes on page S-1 of the Main Limited

Servicer Maintenance Manual before attempting to converge

the panels.

1. Connect a pattern generator to the video or RGB (when

applicable ) input terminals.

2. Output a crosshatch signal from the pattern generator.

3. Turn on the projector.

4. Mentally divide the screen into fourths both horizontally

and vertically. Imagine the center four squares as the A zone

and the outer one fourth (all around the outside edge) as the B

zone. Look at the grids to determine if the convergence is off.

You should see only white grid lines on the screen ( a white

line is the product of separate red, green, and blue lines

“added together”, or converged over the same area ). If the

red or blue lines are offset from the green lines ( either

up/down or left/right ), the convergence is off. The green

panel is fixed, so mechanical adjustment isn’t possible. If

any adjustments to the red or blue panels are necessary,

use green as the reference. If the unit is converged to within

one pixel in the A zone and one and a half pixels in the B

zone the unit is converged within specification and adjustment

is not required.

Continued on next page.

fig. 3-4

(Main

Manual)

Ver. 3/00 1-4 Sharp Electronics Corporation

Page 7

HOW TO CONVERGE THE LCD PANELS (continued)

Step Procedure Ref. #

2. Removal of

body panels.

3. Adjustment

of the blue

panel.

1. To remove the cabinet, refer to the service manual for the

specific model.

1. Supply the projector with a blue and green crosshatch signal

from the pattern generator (on most video signal generators, it

is possible to remove one or more of the 3 colors making up the

crosshatch signal. In this case red must be removed. To do this,

refer to the instructions for the pattern generator).

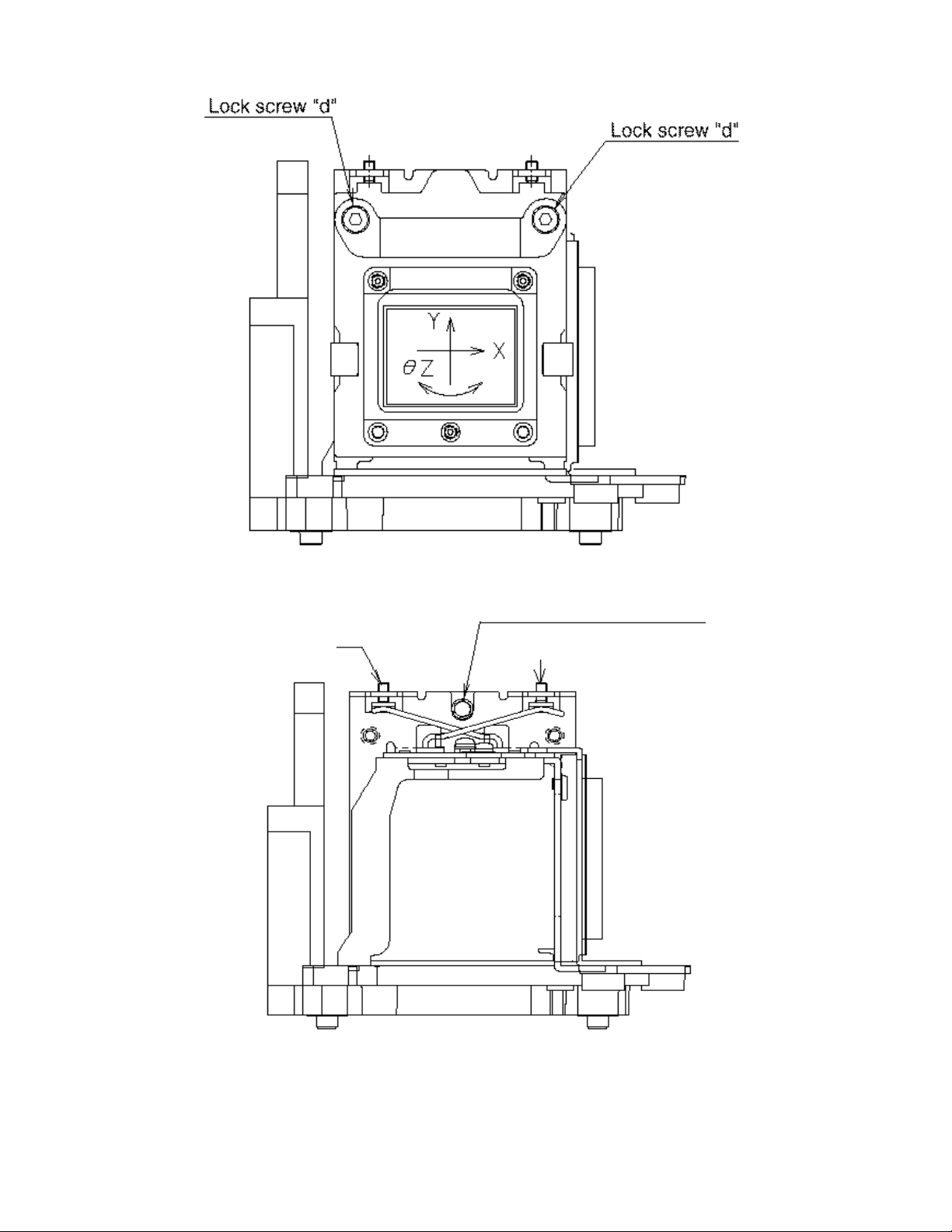

2. Use the 2mm Hex Wrench to loosen the two hex screws labeled

“Lock Screw d” in fig. 2.

Be sure to leave the lock screws tight enough so that when an

adjustment is made, the panel will stay in that position

until the lock screws are fully tightened after the

completion of all adjustments.

3. Use the 1.27mm hex wrench to adjust the Y axis (up and

down).

4. Use the eccentric cam wrench to adjust the X axis (side to

side).

fig. 2-1

fig. 2-1

fig. 2-2

4. Adjustment

of the red panel

5. Use the 1.27mm hex wrench to adjust the θZ axis

(tilt).

6. When the blue image is converged within specifications to

the green panel, tighten the two lock screws to secure the

adjustments.

NOTE: Tightening the screws may cause mis-convergence.

If this happens, readjust the affected panel.

1. Supply the projector with a red and green crosshatch signal

from the pattern generator (turn blue off and red on).

2. Repeat same adjustment procedure as the blue panel.

Convergence adjustment is complete.

fig. 2-2

fig. 2-2

Ver. 3/00 1-5 Sharp Electronics Corporation

Page 8

Y Direction Adj.

(1.27mm Hex)

fig. 2-1

fig. 2-2

Ver. 3/00 1-6 Sharp Electronics Corporation

Page 9

HOW TO CONVERGE THE LCD PANELS

For the model XG-NV6XU

Tools and equipment needed:

• Pattern Generator that can produce a crosshatch pattern (grid pattern)

• Eccentric Cam Adjustment Wrench. (Sharp Part # 9DASPN-XGNV1U)

• 2mm Hex Wrench (Sharp part # 9EQLNC-XGNV1U)

• 1.27mm Hex Wrench (available at most hardware stores)

• Philips Screwdriver

NOTE: Confirm focus before convergence procedure. If pixels are in focus in one

area of the screen and indistinguishable in another area, the projector is out of

focus. The focus alignment procedure is beyond the scope of the limited

maintenance program.

Step Procedure Ref. #

1. Checking

convergence.

Refer to the safety notes on page S-1 of the Main Limited

Servicer Maintenance Manual before attempting to converge

the panels.

1. Connect a pattern generator to the video or RGB (when

applicable ) input terminals.

2. Output a crosshatch signal from the pattern generator.

3. Turn on the projector.

4. Mentally divide the screen into fourths both horizontally

and vertically. Imagine the center four squares as the A zone

and the outer one fourth (all around the outside edge) as the B

zone. Look at the grids to determine if the convergence is off.

You should see only white grid lines on the screen ( a white

line is the product of separate red, green, and blue lines

“added together”, or converged over the same area ). If the

red or blue lines are offset from the green lines ( either

up/down or left/right ), the convergence is off. Do not adjust

the green panel. The green panel is fixed, so mechanical

adjustment isn’t possible. If any adjustments to the red or

blue panels are necessary, use green as the reference. If the

unit is converged to within one pixel in the A zone and one

and a half pixels in the B zone the unit is converged within

specification and adjustment is not required.

fig. 3-4

(Main

Manual)

Ver. 3/00 1-7 Sharp Electronics Corporation

Page 10

Continued on next page.

HOW TO CONVERGE THE LCD PANELS (continued)

Step Procedure Ref. #

2. Removal of

body panels.

3. Adjustment

of the blue

panel.

1. To remove the cabinet, refer to the service manual for the

specific model.

1. Supply the projector with a blue and green crosshatch signal

from the pattern generator (on most video signal generators, it

is possible to remove one or more of the 3 colors making up the

crosshatch signal. In this case red must be removed. To do this,

refer to the instructions for the pattern generator).

2. Use the 2mm hex wrench to loosen the two hex screws labeled

“Lock Screw d” in fig. 2.

Be sure to leave the lock screws tight enough so that when an

adjustment is made, the panel will stay in that position

until the lock screws are fully tightened after the

completion of all adjustments.

1. Use the eccentric cam wrench to adjust the Y axis (up and

down).

3. Use the eccentric cam wrench to adjust the X axis (side to

side).

fig. 2-3

fig. 2-3

fig. 2-3

4. Adjustment

of the red panel

4. Use the eccentric cam wrench to adjust the θZ axis

(tilt).

5. When the blue image is converged within specifications to

the green panel, tighten the two lock screws to secure the

adjustments.

NOTE: Tightening the screws may cause mis-convergence.

If this happens, readjust the affected panel.

1. Supply the projector with a red and green crosshatch signal

from the pattern generator (turn blue off and red on).

2. Repeat same adjustment procedure as the blue panel.

Convergence adjustment is complete.

fig. 2-3

fig. 2-3

Ver. 3/00 1-8 Sharp Electronics Corporation

Page 11

X Direction Adjustment

θ

Lock Screw

Lock Screw

Y Direction Adjustment

"D"

R,B Adjusting Plate

Direction Adjustment

"D"

fig. 2-3

Ver. 3/00 1-9 Sharp Electronics Corporation

Page 12

HOW TO CHANGE THE LAMP ASSEMBLY

For The Models PG-D100U and XG-NV1U

Step Procedure Ref. #

1. Removal of

the old Lamp

Assembly.

2. Installing

the new Lamp

Assembly.

Refer to safety notes on page S-1 in the Main Limited

Servicer Maintenance Manual before attempting to change the

lamp

1. Remove the lamp cover.

2. Remove the screws securing the lamp assembly.

3. Pull the lamp assembly out of the projector.

Safety notes: Be sure to wear Safety Glasses when

removing the lamp. Do not attempt to remove the lamp

assembly until the projector has had an ample amount of

time to cool down.( 1 hour. )

After removing the lamp assembly, do not look at the

actual lamp.

Place the lamp assembly face down. This is necessary

because the metal halide lamp is pressurized and could

explode causing injury.

1. Insert the new assembly by pushing on it until it fits snugly

into the Lamp Well.

2. Install the screws into the same holes as the original lamp

assembly.

fig. 3

fig. 3

fig. 3

fig 3

fig 3

3. Re-install the lamp cover.

fig 3

Note: Be sure the lamp cover is installed correctly or the

projector will not operate due to the safety switch not

being activated.

4. To reset the lamp timer, press and hold down the Enter,

Adjust Down, and Adjust Right Keys, then apply power to the

unit with the Main Power Switch on the side of the projector.

The projector should power on and display “0000H” on the

screen.

Lamp replacement is complete.

Ver. 3/00 2-1 Sharp Electronics Corporation

Page 13

Lamp Cover

Lamp

Assembly

fig. 3

Ver. 3/00 2-2 Sharp Electronics Corporation

Page 14

HOW TO CHANGE THE LAMP ASSEMBLY

For the models XG-E1200U, XG-E3000U, and XG-E3500U

Step Procedure Ref. #

1. Removal of

the old Lamp

Assembly.

2. Installing

the new Lamp

Assembly.

Refer to safety notes on page S-1 in the Main Limited

Servicer Maintenance Manual before attempting to change the

lamp

1. Remove the lamp cover.

2. Remove the screws securing the lamp assembly.

3. Pull the lamp assembly out of the projector.

Safety notes: Be sure to wear Safety Glasses when

removing the lamp. Do not attempt to remove the lamp

assembly until the projector has had an ample amount of

time to cool down.( 1 hour. )

After removing the lamp assembly, do not look at the

actual lamp.

Place the lamp assembly face down. This is necessary

because the metal halide lamp is pressurized and could

explode causing injury.

1. Insert the new assembly by pushing on it until it fits snugly

into the lamp well.

2. Install the screws into the same holes as the original lamp

assembly.

fig. 4

fig. 4

fig. 4

Fig 4

Fig 4

3. Re-install the lamp cover.

Fig 4

Note: Be sure the lamp cover is installed correctly or the

projector will not operate due to the safety switch not

being activated.

3. To reset the lamp timer, press and hold down the Enter,

Adjust Down, and Adjust Right Keys, then apply power to the

unit with the Main Power Switch on the side of the projector.

The projector should power on and display “0000H” on the

screen.

Lamp replacement is complete.

Ver. 3/00 2-3 Sharp Electronics Corporation

Page 15

Lamp

Cover

Lamp

Assembly

fig. 4

Ver. 3/00 2-4 Sharp Electronics Corporation

Page 16

HOW TO CHANGE THE LAMP ASSEMBLY

For the models XG-NV2U, XG-NV3XU, and XG-NV3XB

Step Procedure Ref. #

1. Removal of

the old Lamp

Assembly.

2. Installing

the new Lamp

Assembly.

Refer to safety notes on page S-1 in the Main Limited

Servicer Maintenance Manual before attempting to change the

lamp

1. Remove the lamp cover.

2. Remove the screws securing the lamp assembly.

3. Pull the lamp assembly out of the projector.

Safety notes: Be sure to wear Safety Glasses when

removing the lamp. Do not attempt to remove the lamp

assembly until the projector has had an ample amount of

time to cool down.( 1 hour. )

After removing the lamp assembly, do not look at the

actual lamp.

Place the lamp assembly face down. This is necessary

because the UHP Lamp is pressurized and could explode

causing injury.

1. Insert the new assembly by pushing on it until it fits snugly

into the lamp well.

2. Install the screws into the same holes as the original lamp

assembly.

fig. 5

fig. 5

fig. 5

Fig 5

Fig 5

3. Re-install the lamp cover.

Fig 5

Note: Be sure the lamp cover is installed correctly or the

projector will not operate due to the safety switch not

being activated.

3. To reset the lamp timer, press and hold down the Enter,

Adjust Down, and Adjust Right Keys, then apply power to the

unit with the Main Power Switch on the rear of the projector.

The projector should power on and display “0000H” on the

screen.

Lamp replacement is complete.

Ver. 3/00 2-5 Sharp Electronics Corporation

Page 17

fig. 5

Lamp Cover

Lamp

Assembly

Ver. 3/00 2-6 Sharp Electronics Corporation

Page 18

HOW TO CHANGE THE LAMP ASSEMBLY

For the models XG-NV4SU and XG-NV5XU

Step Procedure Ref. #

1. Removal of

the old Lamp

Assembly.

2. Installing

the new Lamp

Assembly.

Refer to safety notes on page S-1 in the Main Limited

Servicer Maintenance Manual before attempting to change the

lamp

1. Remove the lamp cover.

2. Remove the screws securing the lamp assembly.

3. Pull the lamp assembly out of the projector.

Safety notes: Be sure to wear Safety Glasses when

removing the lamp. Do not attempt to remove the lamp

assembly until the projector has had an ample amount of

time to cool down.( 1 hour. )

After removing the lamp assembly, do not look at the

actual lamp.

Place the lamp assembly face down. This is necessary

because the UHP lamp is pressurized and could explode

causing injury.

1. Insert the new assembly by pushing on it until it fits snugly

into the lamp well.

2. Install the screws into the same holes as the original lamp

assembly.

fig. 6

fig. 6

fig. 6

fig 6

fig 6

3. Re-install the lamp cover.

fig 6

Note: Be sure the lamp cover is installed correctly or the

projector will not operate due to the safety switch not

being activated.

3. To reset the lamp timer, press and hold down the Enter,

Adjust Down, and Adjust Right Keys, then apply power to the

unit with the Main Power Switch on the rear of the projector.

The projector should power on and display “0000H” on the

screen.

Lamp replacement is complete.

Ver. 3/00 2-7 Sharp Electronics Corporation

Page 19

Lamp Cover

fig. 6

fig. 6

Lamp

Assembly

Ver. 3/00 2-8 Sharp Electronics Corporation

Page 20

HOW TO CHANGE THE LAMP ASSEMBLY

For the model XG-NV6XU

Step Procedure Ref. #

1. Removal of

the old lamp

assembly.

2. Installing

the new lamp

assembly.

Refer to safety notes on page S-1 in the Main Limited

Servicer Maintenance Manual before attempting to change the

lamp

1. Remove the lamp cover.

2. Remove the three screws securing the lamp assembly.

3. Pull the lamp assembly out of the projector.

Safety notes: Be sure to wear Safety Glasses when

removing the lamp. Do not attempt to remove the lamp

assembly until the projector has had an ample amount of

time to cool down.( 1 hour. )

After removing the lamp assembly, do not look at the

actual lamp.

Place the lamp assembly face down. This is necessary

because the UHP lamp is pressurized and could explode

causing injury.

1. Insert the new assembly by pushing on it until it fits snugly

into the lamp well.

2. Install the three screws into the same holes as the original

lamp assembly.

fig. 6-1

fig. 6-1

fig. 6-1

fig 6-1

fig 6-1

3. Re-install the lamp cover.

fig 6-1

Note: Be sure the lamp cover is installed correctly or the

projector will not operate due to the safety switch not

being activated.

3. To reset the lamp timer, press and hold down the Enter,

Adjust Down, and Adjust Right Keys, then press the Power

On Key. The projector should power on and display “0000H”

on the screen.

Lamp replacement is complete.

Ver. 3/00 2-9 Sharp Electronics Corporation

Page 21

Fig. 6

Lamp Unit

Lamp Cover

fig. 6-1

Ver. 3/00 2-10 Sharp Electronics Corporation

Page 22

HOW TO CHANGE THE LAMP ASSEMBLY

For the model XG-NV7XU

Step Procedure Ref. #

1. Removal of

the old Lamp

Assembly.

2. Installing

the new Lamp

Assembly.

Refer to safety notes on page S-1 in the Main Limited

Servicer Maintenance Manual before attempting to change the

lamp

1. Remove the Lamp Cover.

2. Remove the three screws securing the lamp assembly.

3. Pull the lamp assembly out of the projector.

Safety notes: Do not attempt to remove the lamp assembly

until the projector has had an ample amount of time to

cool down.( 1 hour. )

After removing the lamp assembly, do not look at the

actual lamp.

Place the lamp assembly face down. This is necessary

because the UHP lamp is pressurized and could explode

causing injury.

1. Insert the new assembly by pushing on it until it fits snugly

into the lamp well.

2. Install the three screws into the same holes as the original

lamp assembly.

fig. 6-2

fig. 6-2

fig. 6-2

fig 6-2

fig 6-2

3. Re-install the lamp cover.

fig 6-2

Note: Be sure the lamp cover is installed correctly or the

projector will not operate due to the safety switch not

being activated.

3. To reset the lamp timer, press and hold down the Enter,

Adjust Down, and Adjust Right Keys, then press the Power

On Key. The projector should power on and display “0000H”

on the screen.

Lamp replacement is complete.

Ver. 3/00 2-11 Sharp Electronics Corporation

Page 23

Lamp Unit

Lamp Cover

fig. 6-2

Fig. 6-1

Ver. 3/00 2-12 Sharp Electronics Corporation

Page 24

HOW TO CHANGE THE LAMP ASSEMBLY

For the model XV-C10U and XV-C10U(P)

Step Procedure Ref. #

1. Removal of

the old Lamp

Assembly.

2. Installing

the new Lamp

Assembly.

Refer to safety notes on page S-1 in the Main Limited

Servicer Maintenance Manual before attempting to change the

lamp

1. Remove the lamp cover.

2. Remove the two screws securing the lamp assembly.

3. Pull the lamp assembly out of the projector.

Safety notes: Be sure to wear Safety Glasses when

removing the lamp. Do not attempt to remove the lamp

assembly until the projector has had an ample amount of

time to cool down.( 1 hour. )

After removing the lamp assembly, do not look at the

actual lamp.

Place the lamp assembly face down. This is necessary

because the metal halide lamp is pressurized and could

explode causing injury.

1. Insert the new assembly by pushing on it until it fits snugly

into the lamp well.

2. Install the screws into the same holes as the original lamp

assembly.

fig. 7

fig. 7

fig. 7

fig. 7

fig. 7

fig. 7

3. Re-install the lamp cover.

Note: Be sure the lamp cover is installed correctly or the

projector will not operate due to the safety switch not

being activated.

3. To reset the lamp timer, press and hold down the Enter,

Adjust Down, and Adjust Right Keys, then apply power to the

unit with the Main Power Switch on the side of the projector.

The projector should power on and display “0000H” on the

screen.

Lamp replacement is complete.

Ver. 3/00 2-13 Sharp Electronics Corporation

Page 25

Lamp Cage

Cover

Lamp

Assembly

fig. 7

Ver. 3/00 2-14 Sharp Electronics Corporation

Page 26

HOW TO CLEAN OR REPLACE AIR FILTER

For the Models PG-D100U and XG-NV1U

Step Procedure Ref. #

1. Removal of

the Filter

Cover.

2. Removal of

the Filter.

3. Inspecting

the Filter.

4. Cleaning

the Filter.

1. To remove the fan cover, refer to the service manual for the

specific model. The fan cover will either slide out or snap into

place from the unit.

1. Separate the plastic filter cover from the fan cover by

slightly flexing the fixed retaining tabs away from the inner

perimeter of the fan cover, remove filter.

1. Inspect the filter for signs of dirt and debris.

2. Hold the filter to the light and ensure that some light passes

through the filter. If some light passes, continue to step 4. If

all light is restricted, proceed to step 5.

1. To clean the filter, vacuum it with a brush attachment.

Note: Do not just brush the filter, as particles of debris

will just be worked into the filter deeper.

fig. 8

fig. 8

fig. 8

5. Replacing

the Filter.

1. If the filter has been subjected to a harsh environment that

caused the filter to become sticky or embedded with particles

fig. 8

that cannot be removed with a vacuum, replace it.

2. Install the new or cleaned filter into the fan cover, re-attach

the filter cover, and re-connect the fan cover to the projector.

Note: The filter must be properly replaced before the

projector can be operated. A safety switch is mounted in

the projector. It is activated by the filter or the fan cover.

If the switch is not activated, the lamp will not light.

Filter replacement is complete.

Ver. 3/00 3-1 Sharp Electronics Corporation

Page 27

POWER indicator goes

cover.

into position.

off.

Unplug the power cord.

Press the arrow mark on

the air filter cover and pull

straight out.

Grasp the air filter between

your fingers and lift it out

of the filter cover.

Clean the dust off the air

filter and cover with a

vacuum cleaner.

Place the filter underneath the

tabs on the filter frame.

Return the air filter to its

original position in the filter

fig. 8

Insert the two tabs on the

end of the filter cover into

the filter cover opening

and press the filter cover

Ver. 3/00 3-2 Sharp Electronics Corporation

Page 28

HOW TO CLEAN OR REPLACE AIR FILTER

For the Models XG-E1200U, XG-E3000U, and XG-E3500U

Step Procedure Ref. #

1. Removal of

the Filter

Cover.

2. Removal of

the Filter.

3. Inspecting

the Filter.

4. Cleaning

the Filter.

1. To remove the fan cover, refer to the service manual for the

specific model. The fan cover will either slide out or snap into

place from the unit.

1. Separate the plastic filter cover from the fan cover by

slightly flexing the fixed retaining tabs away from the inner

perimeter of the fan cover, remove filter.

1. Inspect the filter for signs of dirt and debris.

2. Hold the filter to the light and ensure that some light passes

through the filter. If some light passes, continue to step 4. If

all light is restricted, proceed to step 5.

1. To clean the filter, vacuum it with a brush attachment.

Note: Do not just brush the filter, as particles of debris

will just be worked into the filter deeper.

fig. 9

fig. 9

fig. 9

fig. 9

5. Replacing

the Filter.

1. If the filter has been subjected to a harsh environment that

caused the filter to become sticky or embedded with particles

fig. 9

that cannot be removed with a vacuum, replace it.

2. Install the new or cleaned filter into the fan cover, re-attach

the filter cover, and re-connect the fan cover to the projector.

Note: The filter must be properly replaced before the

projector can be operated. A safety switch is mounted in

the projector. It is activated by the filter or the fan cover.

If the switch is not activated, the lamp will not light.

Filter replacement is complete.

Ver. 3/00 3-3 Sharp Electronics Corporation

Page 29

•

The air filter should be cleaned every 100 hours of use. Clean the

Unplug the power cord.

your fingers and lift it out of

the filter cover.

hose.

correctly installed.

•

AIR FILTER (Not removable)

filter more often when the projector is used in a dusty or smoky

location.

• Have your nearest Authorized Sharp Industrial LCD Products Dealer

or Service Center exchange the filter (PFILD0055CEZZ) when it is no

longer possible to clean it.

Press the tab in the direction

of the arrow and lift open

Turn off the MAIN POWER

switch.

POWER indicator goes off.

Clean the dust off the air

filter and cover with a

vacuum cleaner extension

NOTE:

• Be sure the AIR FILTER COVER is securely installed. The power cannot be turned on unless it is

Place the filter underneath

the tabs on the filter frame.

Return the air filter to its

original position in the filter

cover opening.

Grasp the air filter between

Insert the tab on the end of

the filter cover into the filter

cover opening and press the

filter cover into position.

Ver. 3/00 3-4 Sharp Electronics Corporation

The side air filter cannot be removed.

• If dust or dirt has collected inside the filter, clean the

filter with a vacuum cleaner extension hose.

fig. 9

Page 30

HOW TO CLEAN OR REPLACE AIR FILTER

For the Models XG-NV2U, XG-NV3XU, and XG-NV3XB

Step Procedure Ref. #

1. Removal of

the Filter

Cover.

2. Removal of

the Filter.

3. Inspecting

the Filter.

4. Cleaning

the Filter.

1. To remove the fan cover, refer to the service manual for the

specific model. The fan cover will either slide out or snap into

place from the unit.

1. Separate the plastic filter cover from the fan cover by

slightly flexing the fixed retaining tabs away from the inner

perimeter of the fan cover, remove filter.

1. Inspect the filter for signs of dirt and debris.

2. Hold the filter to the light and ensure that some light passes

through the filter. If some light passes, continue to step 4. If

all light is restricted, proceed to step 5.

1. To clean the filter, vacuum it with a brush attachment.

Note: Do not just brush the filter, as particles of debris

will just be worked into the filter deeper.

fig. 10

fig. 10

fig. 10

fig. 10

5. Replacing

the Filter.

1. If the filter has been subjected to a harsh environment that

caused the filter to become sticky or embedded with particles

fig. 10

that cannot be removed with a vacuum, replace it.

2. Install the new or cleaned filter into the fan cover, re-attach

the filter cover, and re-connect the fan cover to the projector.

Note: The filter must be properly replaced before the

projector can be operated. A safety switch is mounted in

the projector. It is activated by the filter or the fan cover.

If the switch is not activated, the lamp will not light.

Filter replacement is complete.

Ver. 3/00 3-5 Sharp Electronics Corporation

Page 31

•

The air filter should be cleaned every 100 hours of use. Clean

when it is no longer possible to clean it.

filter cover.

hose.

the filter more often when the projector is used in a dusty or

smoky location.

• Have your nearest Authorized Sharp Industrial LCD Products

Dealer or Service Center exchange the filter (PFILD0059CEZZ)

POWER indicator goes

off. Unplug the power

cord.

Clean the dust off the air

filter and cover with a

vacuum cleaner extension

Press the tab in the direction

of the arrow and lift open the

Place the filter underneath the

tabs on the filter frame.

Return the air filter to its

original position in the filter

cover opening.

Grasp the air filter between

your fingers and lift out the

filter cover.

Insert the tab on the end of

the cover into the filter cover

opening and press the filter

cover into position.

Ver. 3/00 3-6 Sharp Electronics Corporation

fig. 10

Page 32

HOW TO CLEAN OR REPLACE AIR FILTER

For the Models XG-NV4SU, XG-NV5XU and XG-NV6XU

Step Procedure Ref. #

1. Removal of

the Filter

Cover.

2. Removal of

the Filter.

3. Inspecting

the Filter.

4. Cleaning

the Filter.

1. To remove the fan cover, refer to the service manual for the

specific model. The fan cover will either slide out or snap into

place from the unit.

1. Separate the plastic filter cover from the fan cover by

slightly flexing the fixed retaining tabs away from the inner

perimeter of the fan cover, remove filter.

1. Inspect the filter for signs of dirt and debris.

2. Hold the filter to the light and ensure that some light passes

through the filter. If some light passes, continue to step 4. If

all light is restricted, proceed to step 5.

1. To clean the filter, vacuum it with a brush attachment.

Note: Do not just brush the filter, as particles of debris

will just be worked into the filter deeper.

fig. 11

fig. 11

fig. 11

fig. 11

5. Replacing

the Filter.

1. If the filter has been subjected to a harsh environment that

caused the filter to become sticky or embedded with particles

fig. 11

that cannot be removed with a vacuum, replace it.

2. Install the new or cleaned filter into the fan cover, re-attach

the filter cover, and re-connect the fan cover to the projector.

Note: The filter must be properly replaced before the

projector can be operated. A safety switch is mounted in

the projector. It is activated by the filter or the fan cover.

If the switch is not activated, the lamp will not light.

Filter replacement is complete.

Ver. 3/00 3-7 Sharp Electronics Corporation

Page 33

POWER indicator goes

cord.

off. Unplug the power

Press the tab in the direction

of the arrow and lift open the

filter cover.

Grasp the air filter between

your fingers and lift out the

filter cover.

Clean the dust off the air

filter and cover with a

vacuum cleaner extension

hose.

Place the filter underneath the

tabs on the filter frame.

Return the air filter to its

original position in the filter

cover opening.

fig. 11

Insert the tab on the end of

the cover into the filter cover

opening and press the filter

cover into position.

Ver. 3/00 3-8 Sharp Electronics Corporation

Page 34

HOW TO CLEAN OR REPLACE AIR FILTER

For the Model XV-C10U and XV-C10U(P)

Step Procedure Ref. #

1. Removal of

the Filter

Cover.

2. Removal of

the Filter.

3. Inspecting

the Filter.

4. Cleaning

the Filter.

1. To remove the fan cover, refer to the service manual for the

specific model. The fan cover will either slide out or snap into

place from the unit.

1. Separate the plastic filter cover from the fan cover by

slightly flexing the fixed retaining tabs away from the inner

perimeter of the fan cover, remove filter.

1. Inspect the filter for signs of dirt and debris.

2. Hold the filter to the light and ensure that some light passes

through the filter. If some light passes, continue to step 4. If

all light is restricted, proceed to step 5.

1. To clean the filter, vacuum it with a brush attachment.

Note: Do not just brush the filter, as particles of debris

will just be worked into the filter deeper.

fig. 12

fig. 12

fig. 12

fig. 12

5. Replacing

the Filter.

1. If the Filter has been subjected to a harsh environment that

caused the filter to become sticky or embedded with particles

fig. 12

that cannot be removed with a vacuum, replace it.

2. Install the new or cleaned filter into the fan cover, re-attach

the filter cover, and re-connect the fan cover to the projector.

Note: The filter must be properly replaced before the

projector can be operated. A safety switch is mounted in

the projector. It is activated by the filter or the fan cover.

If the switch is not activated, the lamp will not light.

Filter replacement is complete.

Ver. 3/00 3-9 Sharp Electronics Corporation

Page 35

Remove Filter

Clean

From Fan

Cover & And

Fan

Cover

fig. 12

Ver. 3/00 3-10 Sharp Electronics Corporation

Page 36

HOW TO CLEAN THE LCD PANELS

For the Model XV-C10U

Tools and equipment needed:

• Philips screw driver

• Dry lens cleaning tissue, bleached cotton cloth, or lens brush

Step Procedure Ref. #

Refer to safety notes on page S-1 in the Main Limited

1. Removing

the necessary

Body Panels.

Servicer Maintenance Manual before attempting to clean the

panels.

1. To remove the Body Panel, first remove the Upper Cabinet

Body to gain access to the components. ( Refer to the specific

service manual.)

2. Removing

the LCD

Panel

3. Clean the

LCD Panel.

4. Reassemble

1. Remove wire connector (LD) from the control unit.

2. Remove the panel cover screw.

Remove the LCD panel by pulling the Panel slowly upward.

1. Use a dry cotton based lens cleaning tissue, bleached cotton

cloth, or lens brush to dab any large pieces of dust or debris

from the LCD panel

Note: Do not use any cleaning solutions as they may

damage the panel. Dust is easily removed with a dry lens

cleaning tissue, bleached cotton cloth, or lens brush.

1. Reinstall the LCD Panel Assembly into the projector,

securing the screw.

2. After the panel is cleaned always check the results

immediately after the procedure. Any time the panel is

exposed, it may pickup additional dust or debris. To check

the results, input the appropriate raster signal ( an all red,

green, or blue signal ) from a signal generator to the video

or RGB input. Inspect the projected image for any more

dust or debris. If dust is present, repeat steps 2 and 3. If

this procedure is done in a dusty environment, it may take

a few cleanings before a dust free image is present.

fig. 13

fig. 13

End of procedure.

Ver. 3/00 4-1 Sharp Electronics Corporation

Page 37

fig. 13

Ver. 3/00 4-2 Sharp Electronics Corporation

Loading...

Loading...