Page 1

PG-C30XU

FINAL PDF

SERVICE MANUAL

S99O4XG-NV5XB

LCD PROJECTOR

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

PG-C30XU

CONTENTS

Page Page

•SPECIFICATIONS.............................................2

•IMPORTANT SERVICE SAFETY NOTES.........3

•NOTE TO SERVICE PERSONNEL...................4

•OPERATION MANUAL......................................7

•REMOVING OF MAJOR PARTS.....................13

•RESETTING THE TOTAL LAMP TIMER.........18

•THE OPTICAL UNIT OUTLINE........................19

•CONVERGENCE AND

FOCUS ADJUSTMENT..................................20

•ELECTRICAL ADJUSTMENT..........................25

•ADJUSTING THE PC BOARD.........................30

•TROUBLE SHOOTING TABLE........................31

•CHASSIS LAYOUT..........................................46

•BLOCK DIAGRAM...........................................48

•OVERALL WIRING DIAGRAM........................50

•DESCRIPTION OF SCHEMATIC DIAGRAM...52

•WAVEFORMS..................................................53

•SCHEMATIC DIAGRAM..................................54

•PRINTED WIRING BOARD ASSEMBLIES.....96

•PARTS LIST

Ë

ELECTRICAL PARTS................................104

Ë

CABINET AND MECHANICAL PARTS......124

Ë

ACCESSORIES PARTS............................130

Ë

PACKING PARTS.......................................130

•PACKING OF THE SET.................................131

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

PG-C30XU

Specifications

Product type

Model

Video system

Display method

LCD panel

Lens

Projection lamp

Contrast ratio

Video input signal

S-video input signal

Horizontal resolution

Audio output

Computer RGB input signal

Pixel clock

Vertical frequency

Horizontal frequency

Computer control signal

Speaker system

Rated voltage

Input current

Rated frequency

Power consumption

Operating temperature

Storage temperature

Cabinet

I/R carrier frequency

Laser pointer of remote control

Dimensions (approx.)

Weight (approx.)

Supplied accessories

Replacement parts

LCD Projector

PG-C30XU

PAL/SECAM/NTSC 3.58/NTSC 4.43/DTV 480P/DTV 720P/DTV 1080I

LCD panel× 3, RGB optical shutter method

Panel size: 0.9" (13.8 [H]× 18.4 [W] mm)

Display method: Translucent TN liquid crystal panel

Drive method: TFT (Thin Film Transistor) Active Matrix panel

No. of dots: 786,432 dots (1,024 [H]× 768 [V])

1-1.3×zoom lens, F1.7-2.0, f = 33-43 mm

200 W NSH lamp

200:1

RCA Connector: VIDEO, composite video, 1.0 Vp-p, sync negative, 75Ωterminated

RCA Connector: AUDIO, 0.5 Vrms more than 22 kΩ(stereo)

4-pin Mini DIN connector

Y (luminance signal): 1.0 Vp-p, sync negative, 75Ωterminated

C (chrominance signal): Burst 0.286 Vp-p, 75Ωterminated

580 TV lines (video input), 700 TV lines (DTV 720P input, Dot by Dot)

2 W (monaural)

PIN MINI D-SUB CONNECTOR (INPUT 1, 2):

15-

RGB separate/composite sync/sync on green type analog input: 0-0.7 Vp-p, positive,

75Ωterminated

TEREO MINIJACK: AUDIO, 0.5 Vrms, more than 22 k

S

ORIZONTAL SYNC. SIGNAL: TTL level (positive/negative) or composite sync (Apple only)

H

ERTICAL SYNC. SIGNAL: Same as above

V

Ω

(stereo)

12-230 MHz

43-200 Hz

15-126 kHz

9-pin Mini DIN male connector (RS-232C Input Port)

3

/32"(8 cm) round

3

AC 110-120/220-240 V

3.0 A/1.5 A

50/60 Hz

300 W

41¡F to 104¡F (+5¡C to +40¡C)

-4¡F to 140¡F (-20¡C to +60¡C)

Plastic

38 kHz

Wave length: 650 nm / Max. output: 1 mW / ClassIILaser Product

1

64

"(W)

/

9

19

/32"(W)×59/32(H)×14

9

49

×

4

64

(H)×1213/64"(D) (229×121×310 mm) (main body only)

/

7

64

"(D) (243.5×134×358.4 mm) (including

/

adjustment feet and projecting parts)

10.6 lbs. (4.8 kg)

Remote control, Two AA size batteries, Power cord (11' 10", 3.6 m), Computer RGB cable

(9' 10", 3 m), Computer audio cable (9' 10", 3 m), PS/2 mouse control cable (3' 3", 1 m),

USB mouse control cable (4' 11", 1.5 m), DIN-D-sub RS-232C cable (6

45

/

64

", 15 cm),

Remote mouse receiver, Extra air filter, Lens cap (attached), CD-ROM, LCD projector

operation manual, LCD projector quick reference, Sharp Advanced Presentation Software

operation manual

Lamp unit (Lamp/cage module) (BQC-PGC30XU/1), Remote control (RRMCG1579CESA),

AA size batteries, Power cord (QACCU5013CEZZ), Computer RGB cable

(QCNW-5304CEZZ), Computer audio cable (QCNW-4870CEZZ), PS/2 mouse control cable

(QCNW-5113CEZZ), USB mouse control cable (QCNW-5680CEZZ), DIN-D-sub RS-232C

cable (QCNW-5288CEZZ), Remote mouse receiver (RUNTK0673CEZZ), Air filter

(PFILD0076CEZZ), Lens cap (GCOVH1307CESB), CD-ROM (UDSKA0019CEN1), LCD

projector operation manual (TINS-7023CEZZ), LCD projector quick reference (TINS-

7025CEZZ), Sharp Advanced Presentation Software operation manual (TINS-7054CEZZ)

This SHARP projector uses LCD (Liquid Crystal Display) panels. These

very sophisticated panels contain 786,432 pixels (×RGB) TFTs (Thin

Film Transistors). As with any high technology electronic equipment

such as large screen TVs, video systems and video cameras, there

are certain acceptable tolerances that the equipment must conform

to.

Specifications are subject to change without notice.

This unit has some inactive TFTs within acceptable tolerances which

may result in illuminated or inactive dots on the picture screen. This

will not affect the picture quality or the life expectancy of the unit.

If you have any questions about this matter, please call toll free 1-888-

GO-SHARP (1-888-467-4277).

U.S.A. ONLY

2

Page 3

PG-C30XU

2

2

IMPORTANT SERVICE SAFETY NOTES

Ë

Service work should be performed only by qualified service technicians who are thoroughly

familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the

chassis and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

» Plug the AC cord directly into a 120-volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

» Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to

0.2 milliamp. AC.) or more is excessive and indicates

a potential shock hazard which must be corrected

before returning the unit to the owner.

AC

VOLTMETER

1.5k ohm (10W)

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in LCD Projector

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in the

original circuit. The use of a substitute replacement parts

which do not have the same safety characteristics as

the factory recommended replacement parts shown in

this service manual, may create shock, fire or other

hazards.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à LCD présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent

pas évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par

l’usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

AVERTISSEMENT:La composante bimétallique dispose du

conducteur primaire dénudé. Faire

attention lors de la manipulation de cette

composante sous tension.

3

Page 4

PG-C30XU

NOTE TO SERVICE

PERSONNEL

UV-RADIATION PRECAUTION

The light source, metal halide lamp, in the LCD

projector emits small amounts of UV-Radiation.

A VOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NOTE POUR LE PERSONNEL

D’ENTRETIEN

PRECAUTION POUR LES RADIATIONS UV

La source de lumière, la lampe métal halide, dans le

projecteur LCD émet de petites quantités de

radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE

DES YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

1. Toujours porter des lunettes de soleil lors d’un

entretien du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du

boîtier de lampe.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type

CLMPF0066CE01 or BQC-PGC30XU/1 rated 85V/

200W.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le

coffret retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du

remplacement de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type.

Type CLMPF0066CE01 or BQC-PGC30XU/1,

caractéristique 85V/200W.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la

lampe avec soin.

4

Page 5

PG-C30XU

5

4

5

5

234567890123456789012345678901212345678901234

UV-RADIATION PRECAUTION (Continued)

23456789012345678901234567890121234567890123

Ë

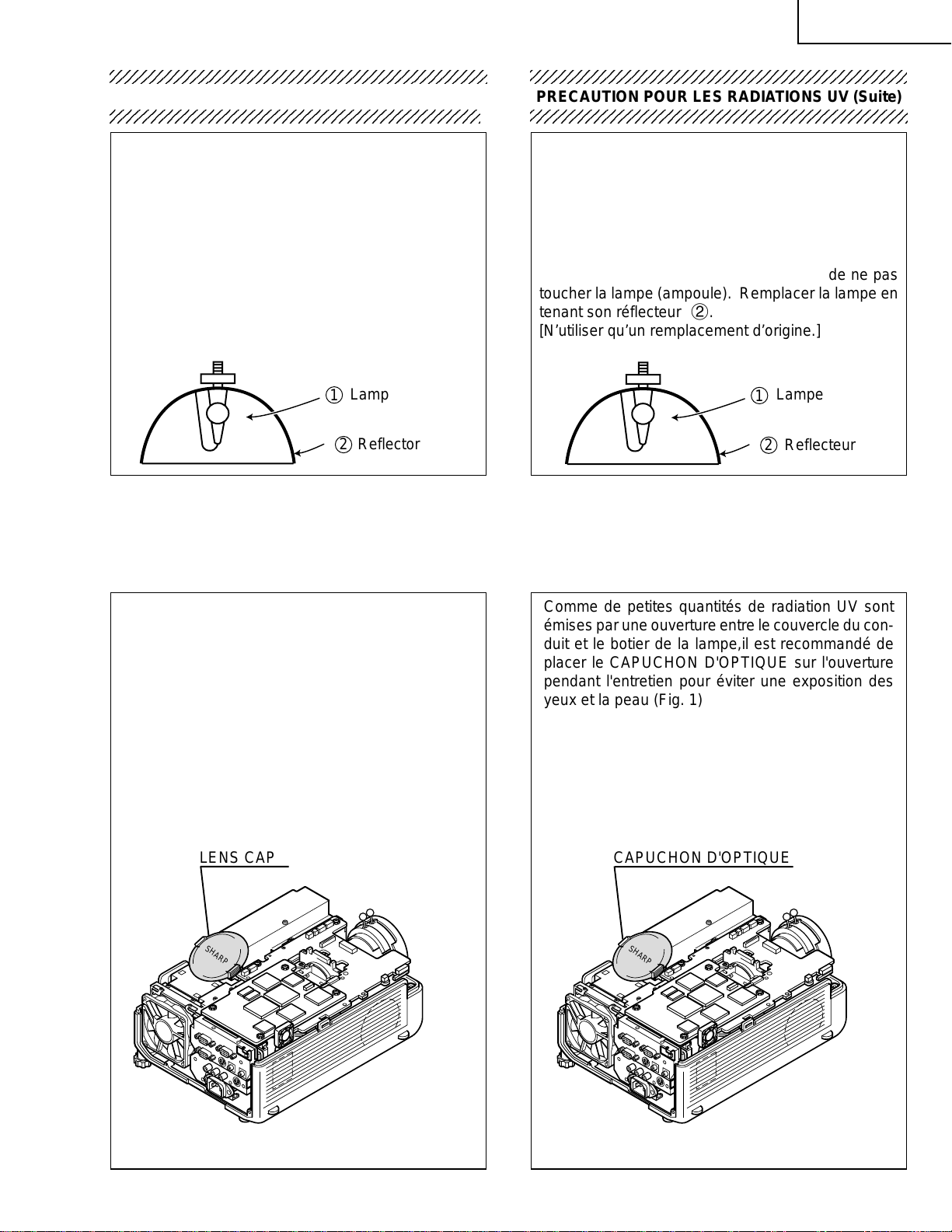

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high voltages

at its start.

234567890123456789012345678901212345678901234

PRECAUTION POUR LES RADIATIONS UV (Suite)

234567890123456789012345678901212345678901234

Ë

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

Lampe

1

Reflecteur

2

DANGER ! –– Ne jamais mettre sous tension sans

la lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

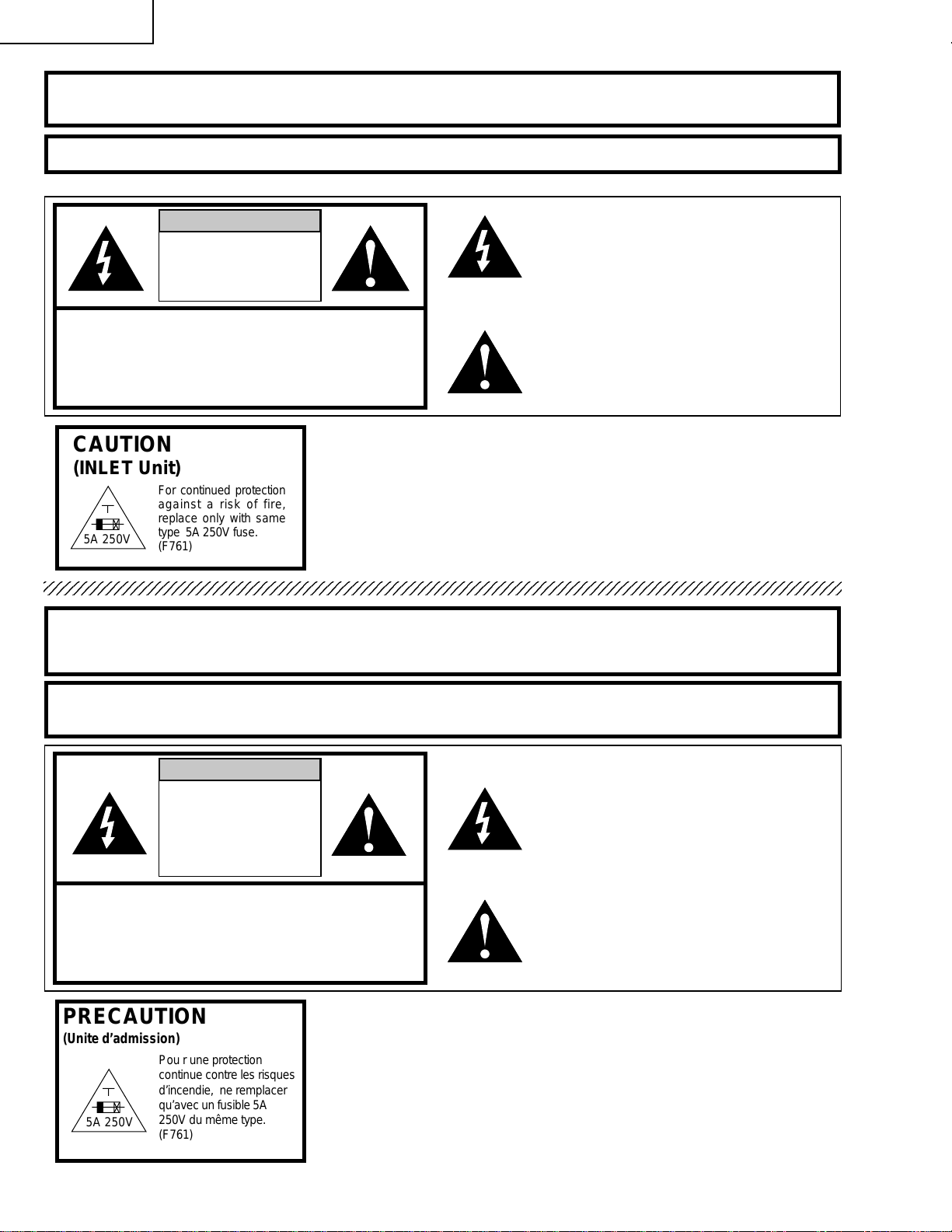

Since small amounts of UV-Radiation are emitted

from an opening between the duct cover and the

lamp housing, it is recommended to place the LENS

CAP on the opening during servicing to avoid eye

and skin exposure (Fig. 1).

Note: Please obtain a lens cap before servicing a

model PG-C30XU that is received without

one.

LENS CAP CAPUCHON D'OPTIQUE

SHARP

Comme de petites quantités de radiation UV sont

émises par une ouverture entre le couvercle du conduit et le botier de la lampe,il est recommandé de

placer le CAPUCHON D'OPTIQUE sur l'ouverture

pendant l'entretien pour éviter une exposition des

yeux et la peau (Fig. 1).

Remarque: Priére de se procurer un capuchon

d'optique acant d'entretien un modéle

PG-C30XU qui est livré sans.

SHARP

Figure 1.

Figure 1.

5

Page 6

PG-C30XU

2

WARNING: High brightness light source. Do not stare into the beam of light, or view directly . Be especially

careful that children do not stare directly into the beam of light.

WARNING: To reduce the risk of fire or electric shock, do not expose this product to rain or moisture.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE CABINET.

NO USER-SERVICEABLE P ARTS EXCEPT LAMP UNIT.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

CAUTION

(INLET Unit)

For continued protection

against a risk of fire,

replace only with same

5A 250V

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

A VERTISSEMENT : Source lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regarder

type 5A 250V fuse.

(F761)

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

AVERTISSEMENT: Afin d’éviter tout risque d’incendie ou d’électrocution, ne pas exposer cet appareil à

la pluie ou à l’humidité.

ATTENTION

RISQUE

D’ELECTROCUTION NE

PASRETIRER LES VIS, A

L’EXCEPTION DES VIS DE

REPARATION UTILISA TEUR

SPECIFIEES

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

ATTENTION: POUR EVITER T OUT RISQUE

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR L’UTILISA TEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR TOUTE REPARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QUALIFIE.

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

PRECAUTION

(Unite d’admission)

Pou r une protection

continue contre les risques

d’incendie, ne remplacer

qu’avec un fusible 5A

5A 250V

250V du même type.

(F761)

6

Page 7

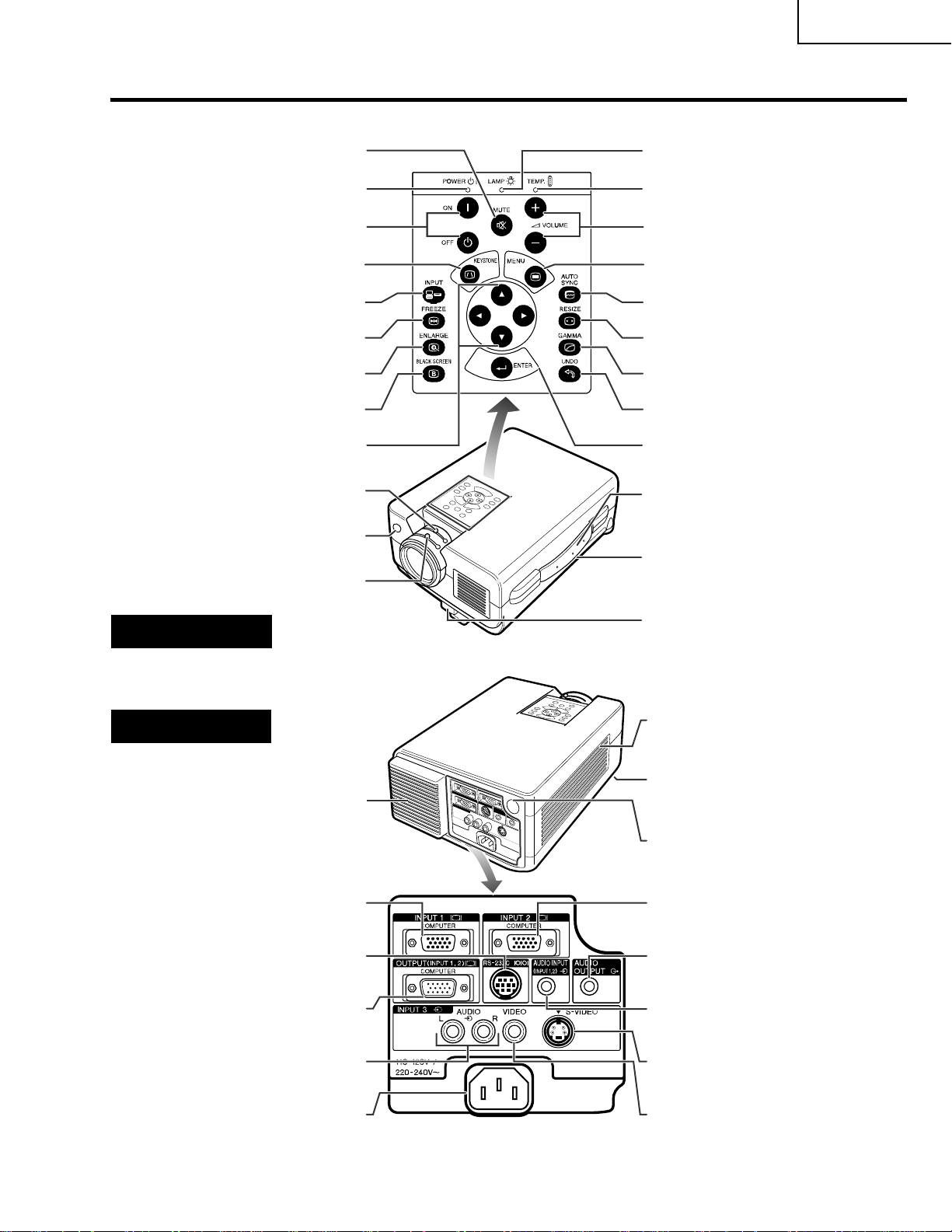

Projector

Foot release

VOLUME buttons (+/–)

MENU button

ENTER button

UNDO button

GAMMA button

RESIZE button

AUTO SYNC button

MUTE button

KEYSTONE button

BLACK SCREEN button

ENLARGE button

FREEZE button

INPUT button

POWER buttons (ON/OFF)

POWER indicator

ADJUSTMENT buttons

(

'/"/\/|

)

TEMPERATURE WARNING

indicator

LAMP REPLACEMENT

indicator

Carrying handle

Zoom knob

Remote control sensor

Kensington Security Standard

connector

Front and Top View

Side and Rear View

INPUT 1 port (HD 15)

Cooling fan(Exhaust vent)

RS-232C port (9-pin Mini DIN)

AUDIO INPUT 3 terminals (RCA)

OUTPUT port for INPUT 1, 2 (HD 15)

Speaker

AC socket

INPUT 2 port (HD 15)

AUDIO OUTPUT terminal

(3.5mm stereo minijack)

AUDIO INPUT terminal

for INPUT 1, 2

(3.5 mm stereo minijack)

S-VIDEO INPUT terminal

(4-pin Mini DIN)

VIDEO INPUT 3 terminal

(RCA)

Focus knob

Remote control sensor

Air filter/Cooling fan (Intake vent)

Location of Controls

PG-C30XU

7

Page 8

PG-C30XU

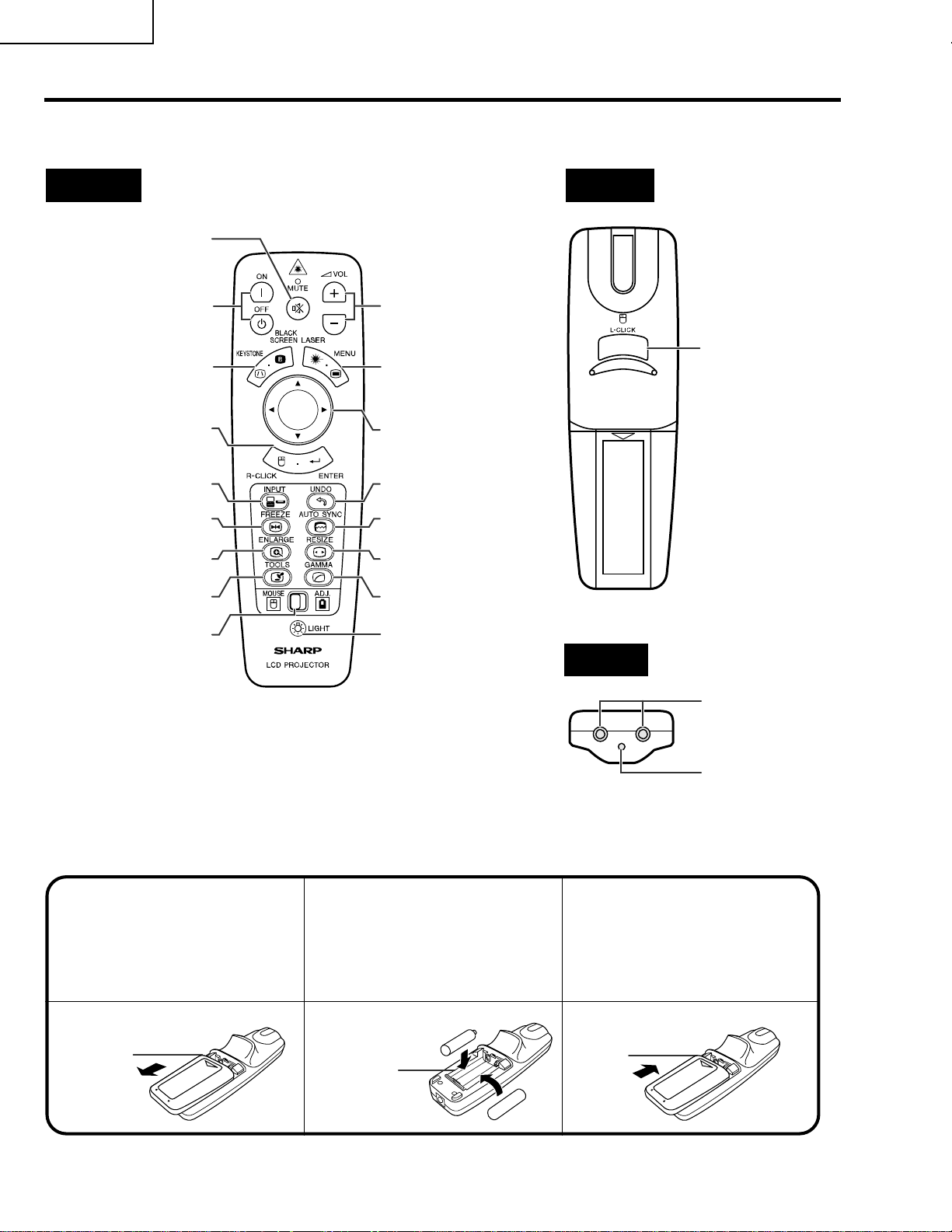

Operating the Wireless Mouse Remote Control

Remote Control

Front View Rear Vie w

MUTE button

POWER buttons

(ON/OFF)

KEYSTONE/BLACK

SCREEN button

RIGHT-CLICK/

ENTER button

INPUT button

FREEZE button

ENLARGE button

TOOLS button

MOUSE/

ADJUSTMENT

switch

VOLUME buttons

(+/–)

LASER POINTER/

MENU button

MOUSE/

ADJUSTMENT

buttons (

UNDO button

AUTO SYNC button

RESIZE button

GAMMA button

BACKLIGHT button

'/"/\/|

LEFT-CLICK

button

)

Top View

Remote control

signal transmitter

Inserting the batteries

Press in on the arrow

mark and slide in the

direction of the arrow to

remove the battery cover.

Battery

cover

Insert two AA size

231

batteries, making sure

their polarities match the

+ and – marks inside

the battery compartment.

Battery

compartment

8

Laser

pointer

window

Insert the side tabs of

the battery cover into

their slots and press the

cover in until it is

properly seated.

Battery

cover

Page 9

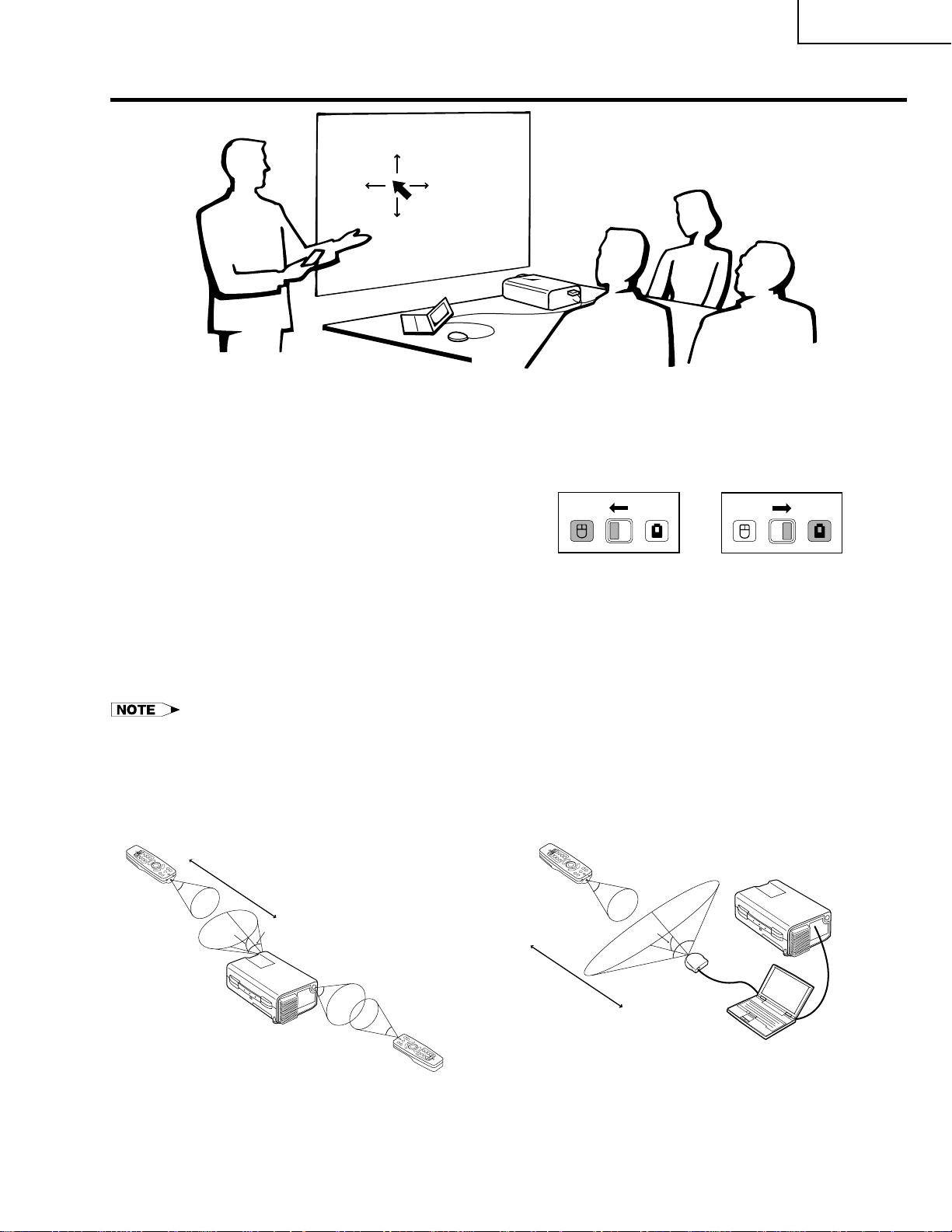

Using the Remote Control as a Wireless Mouse

PG-C30XU

The remote control has the following three functions:

• Projector control

MOUSE/ADJUSTMENT switch

(Remote control)

• Wireless mouse

• Laser pointer

MOUSE

ADJ.

Wireless mouse

Laser pointer

MOUSE

ADJ.

Projector control

Remote Control/Mouse Receiver Positioning

• The remote control can be used to control the projector within the ranges shown below.

• The remote mouse receiver can be used with the remote control to control the mouse functions of a connected

computer within the ranges shown below.

• The signal from the remote control can be reflected off a screen for easy operation. However, the effective distance of the

signal may differ due to the screen material.

Controlling the Projector Using the Wireless Mouse

Remote control

30˚

23' (7 m)

Remote control

30˚

45˚

30˚

13'(4 m)

45˚

30˚

Remote control

30˚

Remote

mouse

receiver

120˚

9

Page 10

PG-C30XU

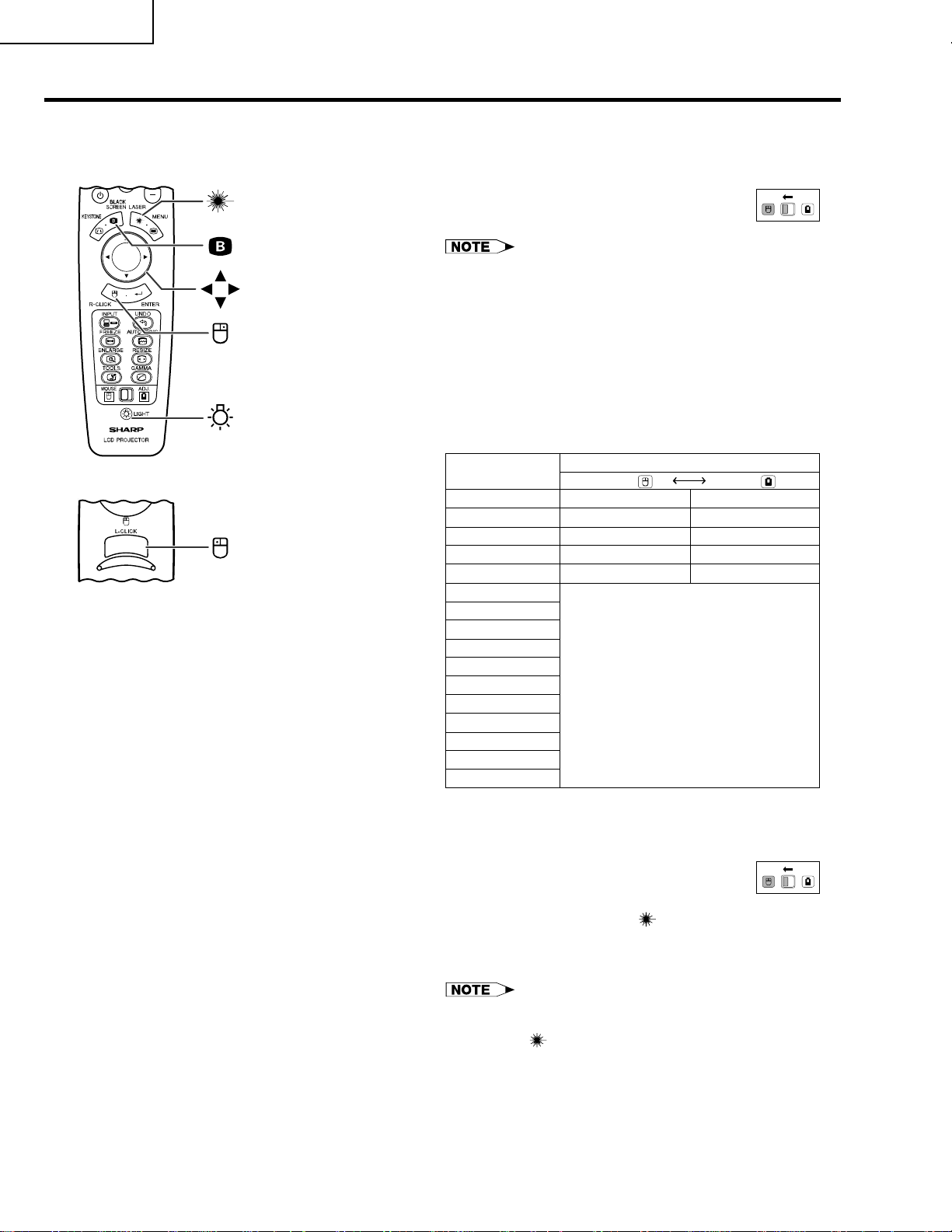

Effective buttons in MOUSE mode

Remote control

(Front view)

LASER POINTER

BLACK SCREEN

MOUSE

RIGHT-CLICK

BACKLIGHT

Remote control

(Rear view)

LEFT-CLICK

Use as a Wireless Mouse

Be sure the supplied remote mouse receiver is

connected to your computer.

(Slide the MOUSE/ADJUSTMENT switch on

the remote control to the MOUSE position.)

• The wireless mouse may not operate correctly if your

computer serial port is not correctly set up. Refer to the

computer’s operation manual for details of setting up/

installing the mouse driver.

• For one-button mouse systems, use either the LEFT-CLICK

or RIGHT-CLICK button.

Using the remote control in a dark room

Press BACKLIGHT, and the buttons will light up. Green

lights refer to mouse operations, and red lights to

projector adjustments.

Button name

LASER POINTER/MENU MENU (RED)

BLACK SCREEN/KEYSTONE

RIGHT-CLICK/ENTER

MOUSE/ADJUSTMENT

LEFT-CLICK

POWER ON/OFF

VOLUME +/–

MUTE

INPUT

UNDO

FREEZE

AUTO SYNC

ENLARGE

RESIZE

TOOLS

GAMMA

Position of MOUSE/ADJUSTMENT switch

MOUSE

LASER POINTER (GREEN)

BLACK SCREEN (GREEN)

RIGHT-CLICK (GREEN)

MOUSE (NOT LIT)

ON (NOT LIT)

KEYSTONE (RED)

ENTER (RED)

ADJUSTMENT (NOT LIT)

ON (RED)

ADJ.

–

MOUSE

ADJ.

Use as a Laser Pointer

(Slide the MOUSE/ADJUSTMENT switch on

the remote control to the MOUSE position.)

Press LASER POINTER (

) to activate the laser

pointer. When the button is released, the light

automatically goes off.

• For safety, the laser pointer automatically goes off after 1

minute of continuous use. To turn it on, release LASER

POINTER ( ) and press again.

10

MOUSE

ADJ.

Page 11

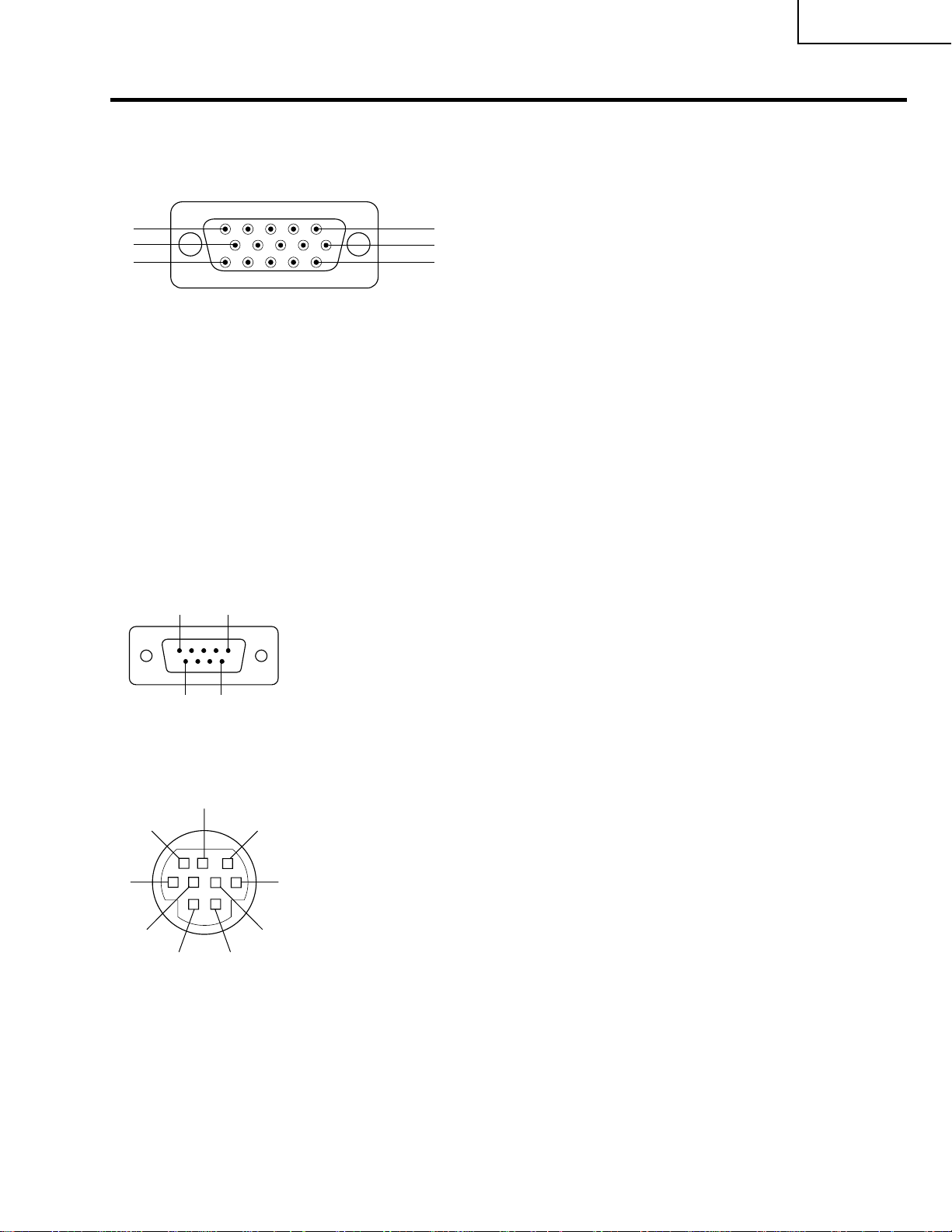

Connection Pin Assignments

Analog Computer 1 and 2 Signal Input Ports: 15-pin mini D-sub female connector

Computer Input

10

15

Analog

1. Video input (red)

2. Video input

(green/sync on green)

5

1

6

11

3. Video input (blue)

4. Reserve input 1

5. Composite sync

6. Earth (red)

7. Earth (green/sync on green)

8. Earth (blue)

Component Input

R

(CR)

1. P

2. Y

3. P

B

4. Not connected

5. Not connected

6. Earth (P

7. Earth (Y)

8. Earth (P

R

)

B

)

9. Not connected

10. GND

11. GND

12. Bi-directional data

13. Horizontal sync signal

14. Vertical sync signal

15. Data clock

9. Not connected

10. Not connected

11. Not connected

12. Not connected

13. Not connected

14. Not connected

15. Not connected

PG-C30XU

RS-232C Port: 9-pin D-sub male connector of the DIN-D-sub RS-232C cable

Pin No.

1

5

9

6

1

2

3

4

5

6

7

8

9

Signal

Name

CD

Receive Data

RD

Send Data

SD

ER

Signal Ground

SG

Data Set Ready

DR

Request to Send

RS

Clear to Send

CS

CI

I/O

Input

Output

Output

Output

Input

RS-232C Terminal: 9-pin Mini DIN connector

8

9

7

6

5

4

21

Pin No.

1

2

3

4

3

5

6

7

8

9

Signal

VCC

EXIR

ERX

ETX

Name

+3.3V (Reserved)

Receive Data

RD

Send Data

SD

Detector of Option Unit

(Reserved)

Signal Ground

SG

IR Receive Signal from

IR Amplifier (Reserved)

Request to Send

RS

Clear to Send

CS

IR Transmit Signal

(Reserved)

I/O

Output

Input

Output

Input

Input

Output

Input

Output

Reference

Not connected

Connected to internal circuit

Connected to internal circuit

Not connected

Connected to internal circuit

Not connected

Connected to internal circuit

Connected to internal circuit

Not connected

Reference

Not connected

Connected to internal circuit

Connected to internal circuit

Not connected

Connected to internal circuit

Not connected

Connected to internal circuit

Connected to internal circuit

Not connected

11

Page 12

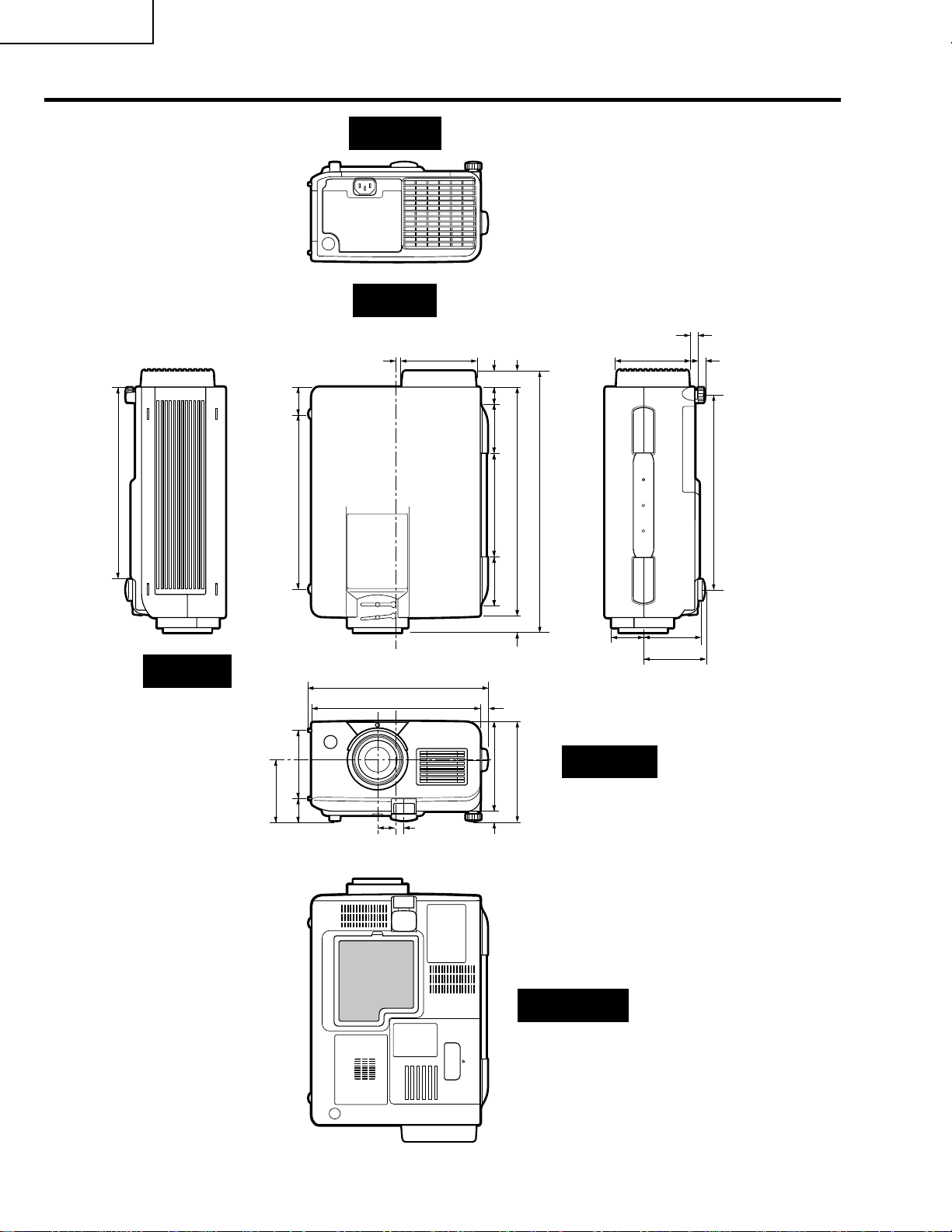

PG-C30XU

Dimensions

Rear View

T op View

(163)

32

/

13

6

Side View

(83)

64

/

17

3

(33.5)

16

/

5

1

(237.5)

32

/

11

9

(93)

32

/

21

3

(30)

16

/

13

1

25

/64 (10)

63

/64 (25)

3

9 19/32 (243.5)

1

/64 (229)

9

7

53

/64 (97.5)

/16 (11)

(27.5)

64

/

5

1

(61)5

32

/

13

2

(142)

32

/

19

(61)4

32

/

13

2

13

/32 (10.5)

(121)

64

/

49

(13)

32

/

17

(23)

32

/

29

(16)

8

/

5

(310)5

64

/

13

12

(134)

32

/

9

(358.4)

64

/

7

14

Front View

11

1

/16 (43)

3 51/64 (96.5)

63

/64 (76)

2

17

3

/64 (83)

23

/64 (9)

23

/64 (9)

(262)

16

/

5

10

12

Bottom View

Units: inches (mm)

Page 13

REMOVING OF MAJOR PARTS

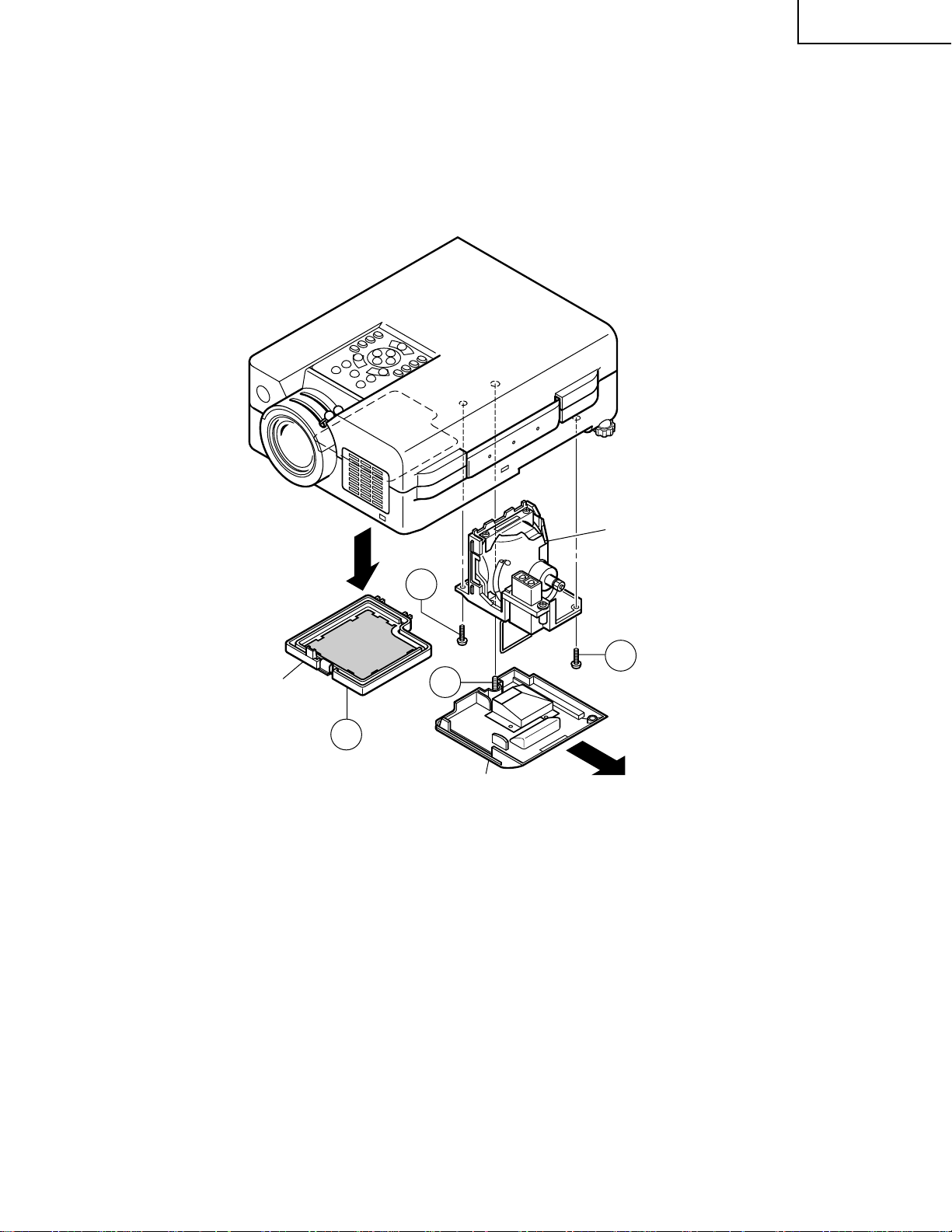

1.Removing the Intake cover and lamp unit

1-1. Detach the Intake cover.

1-2. Loosen the lamp cover screw and draw out the lamp cover in the direction of arrow (toward yourself).

1-3. Remove the two lamp unit lock screws. Detach the lamp unit.

SHARP

PG-C30XU

Intake cover

Note:

When replacing the lamp, make sure

that there is a clearance of over

8mm between the terminal and the

lamp snap-on spring (and other

metallic parts).

Lamp unit

1-3

1-3

1-2

1-1

Lamp cover

13

Page 14

PG-C30XU

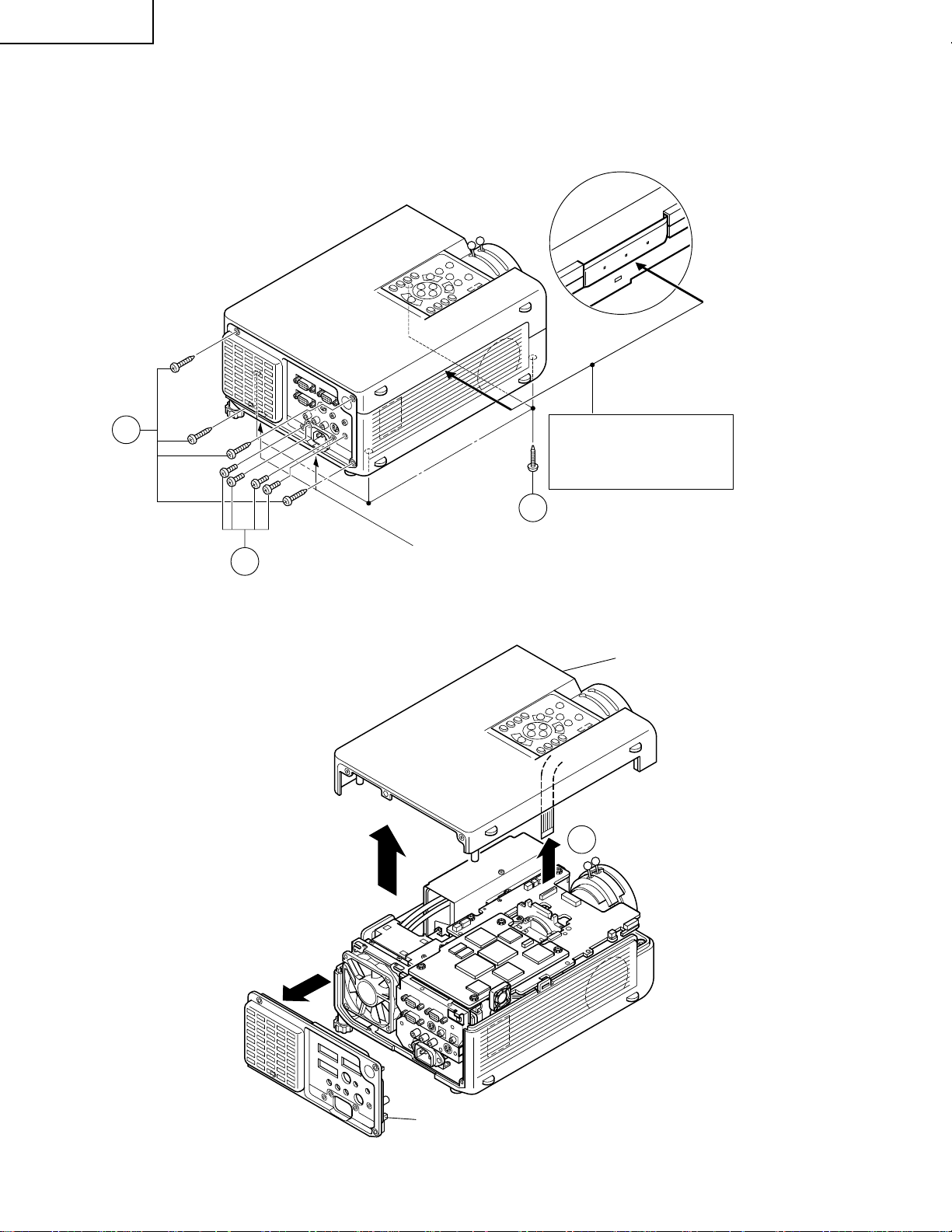

2.Removing the top and rear cabinets

2-1. Remove the four rear cabinet lock screws.

2-2. Remove the four terminal board lock screws off the rear cabinet. Unhook and detach the rear cabinet from

below.

2-3. Remove the four top cabinet lock screws from below.

SHARP

2-1

Press both sides of the bottom

cabinet in the directions of

arrow to undo the hooks. Lift

and detach the top cabinet.

2-3

Hook

2-2

2-4. Slowly lift the top cabinet and disconnect the operation key unit connector (KY). Then take away the top

cabinet.

Top cabinet

(KY)

2-4

Rear cabinet

14

Page 15

PG-C30XU

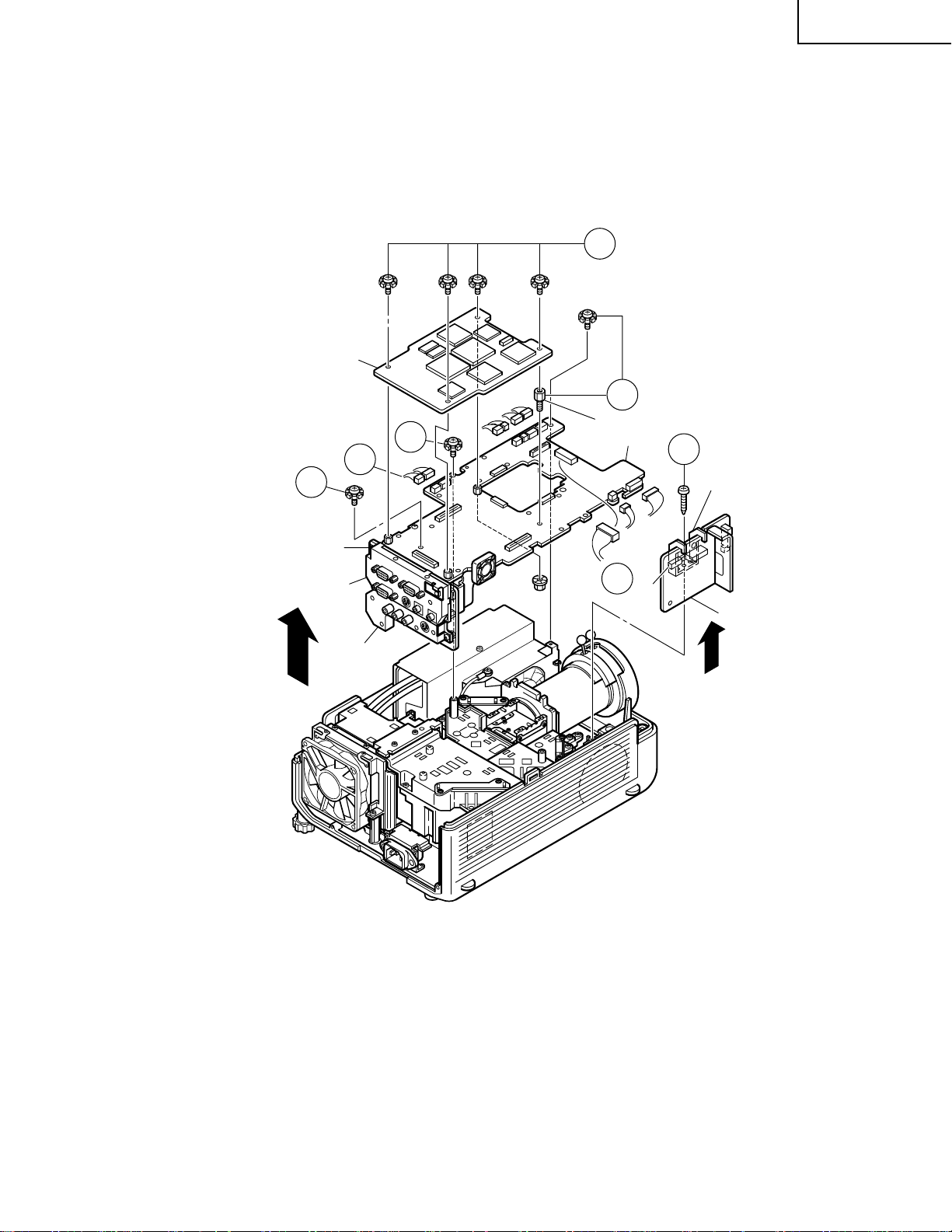

3. Removing the PWB units

3-1. Disconnect the connectors from the output unit.

3-2. Remove the four PC I/F unit lock screws, and take out the PC I/F unit.

3-3. Remove the spacer (stud bolt) and the three screws off the output unit. Lift the output unit, together with the

signal unit, off the position.

3-4. Remove the S-out/REG unit angle lock screw and take out the S-out/REG unit.

3-2

PC I/F Unit

3-3

Signal Unit

PC T erminal Unit

Video Unit

3-1

(FP)

3-3

(FS)

(L)

(Q)

(TP)

(FN)

3-3

Spacer (stud bolt)

Output Unit

(EB)

(EB)

3-1

(F)

(SO)

(SO)

3-4

S-out/REG Unit Angle

(EA)

(SP)

S-out/REG Unit

15

Page 16

PG-C30XU

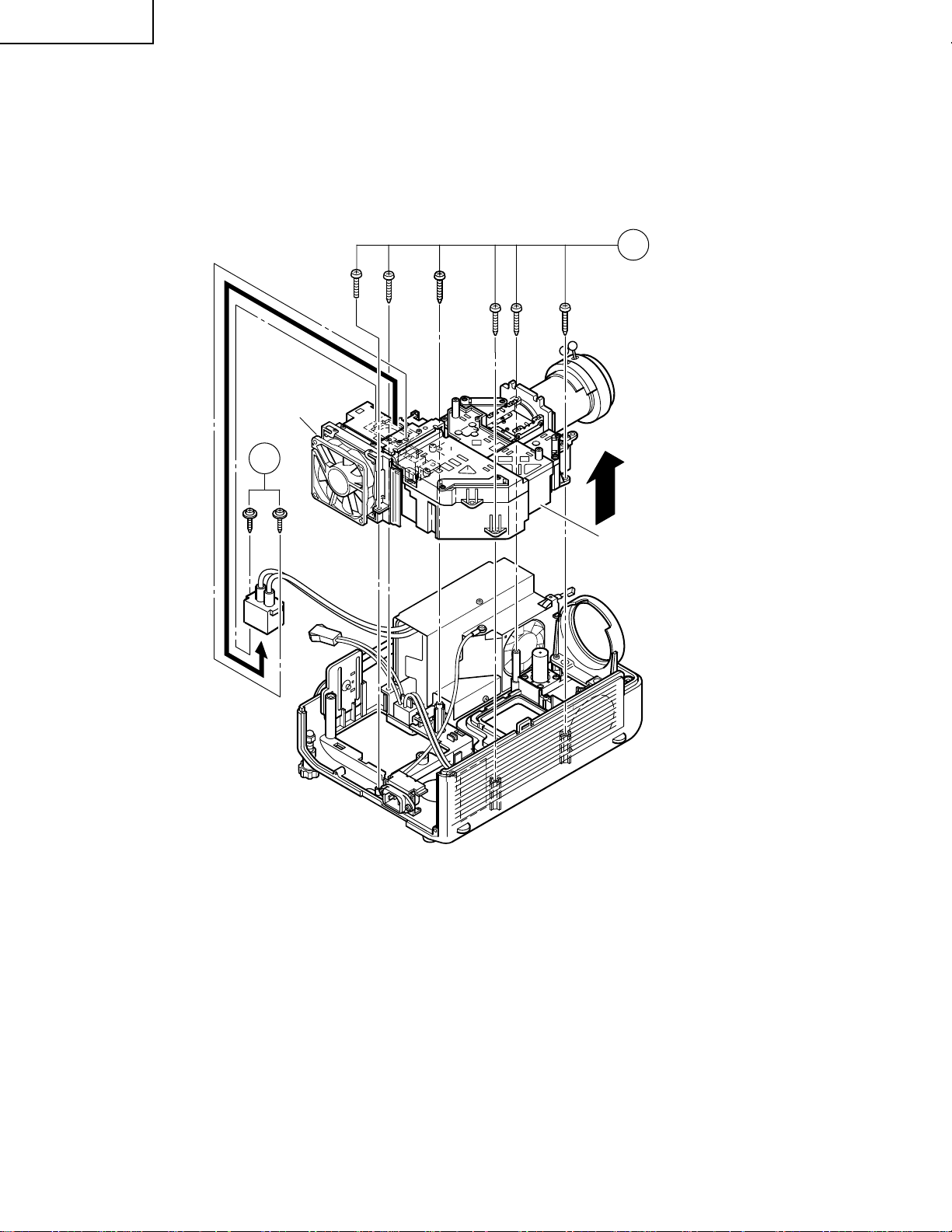

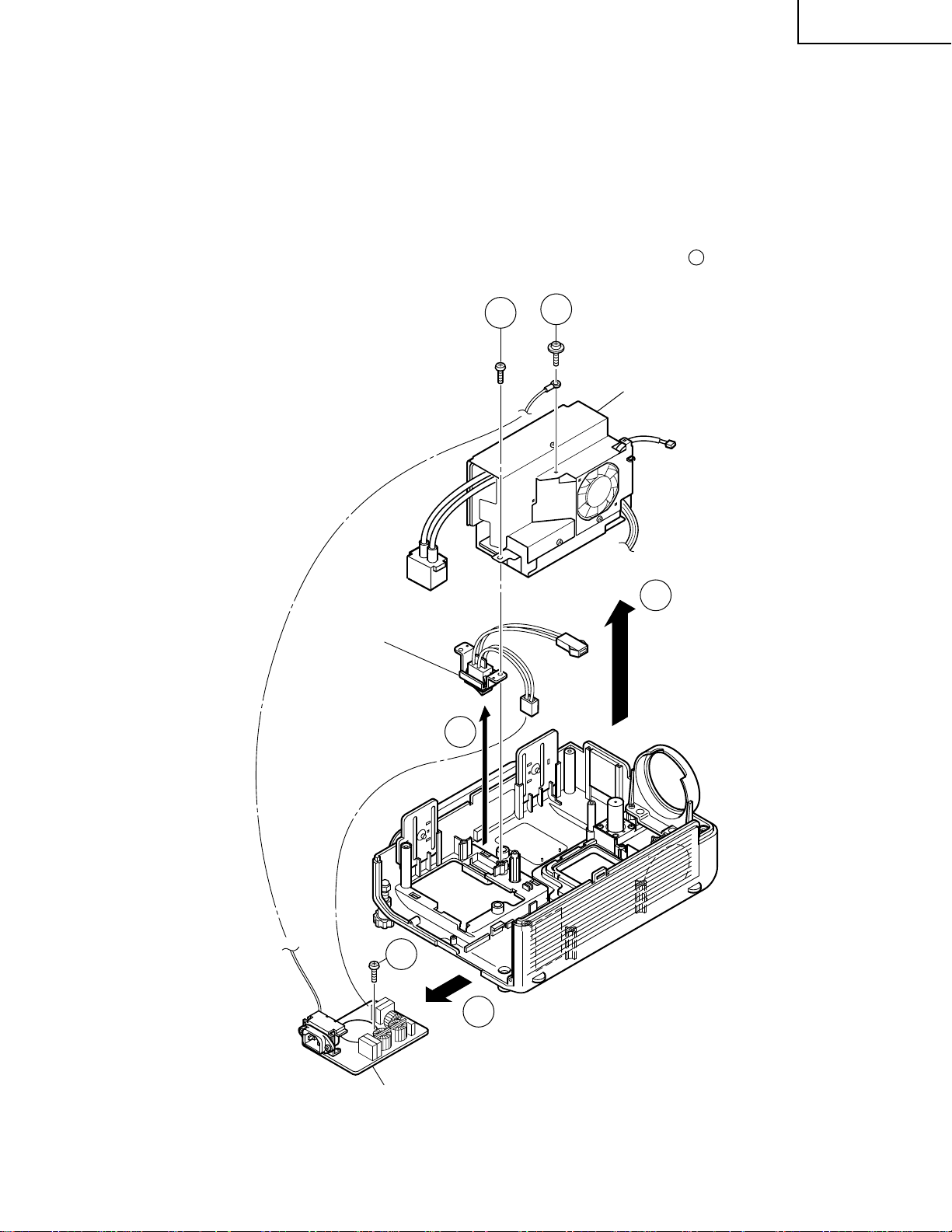

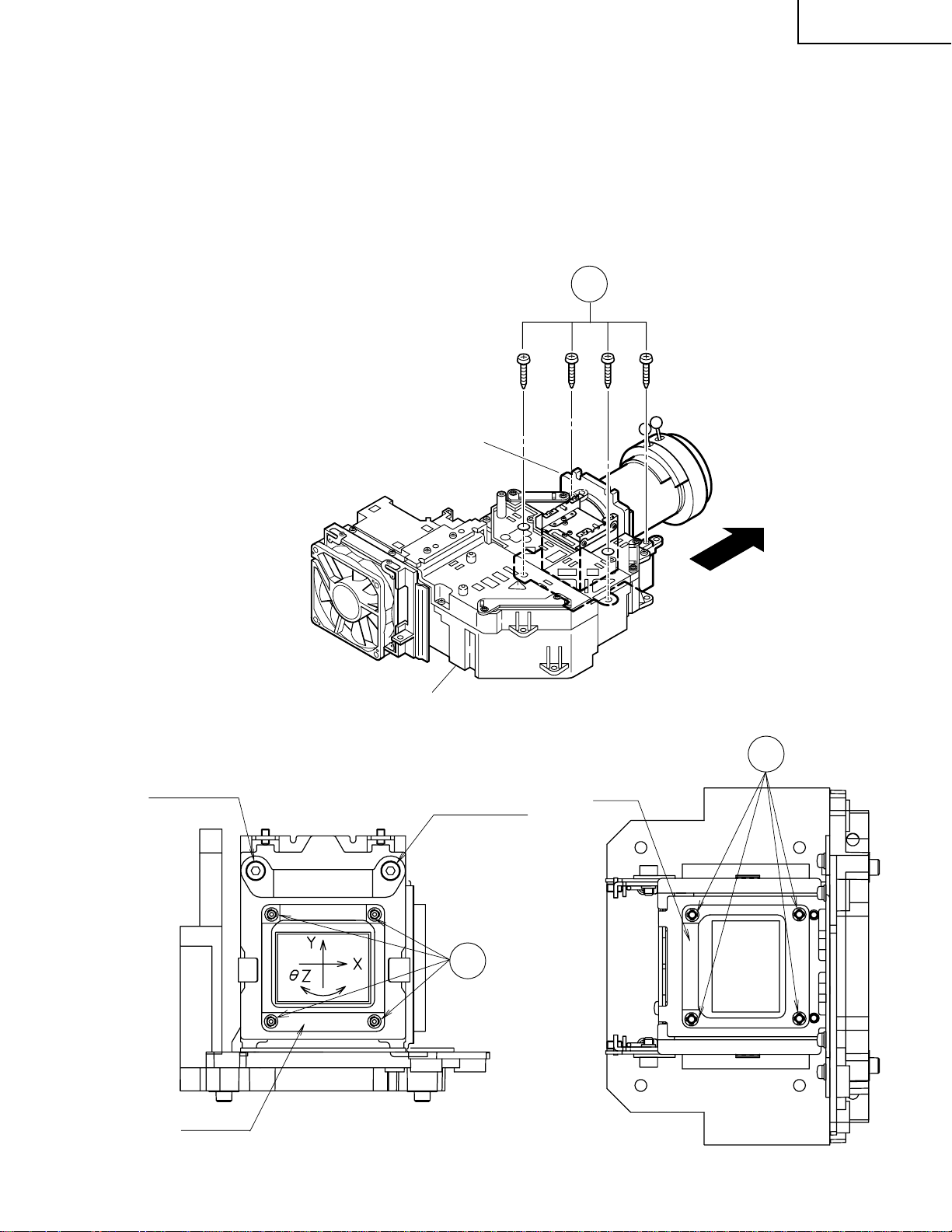

4.Removing the optical mechanism unit

4-1. Remove the six optical mechanism unit lock screws. Lift the unit off the position.

4-2. Remove the two lamp socket holder lock screws and take out the holder.

Duct Fan Unit

4-2

4-1

Optical Mechanism Unit

16

Page 17

5.Removing the Power/Ballast unit assembly

5-1. Remove the Power/Ballast unit assembly lock screw.

5-2. Remove the (FG) lead lock screw.

5-3. Lift the Power/Ballast unit assembly off the position.

6.Removing the ballast unit and inlet unit

6-1. Disconnect the connector (PA) from the inlet unit. Take out the AC power switch.

6-2. Remove the Inlet unit lock screw.

6-3. Pull the inlet unit toward yourself off the position.

Note: Before installing the lamp cover, make sure the AC power switch is at the " " (OFF) position.

PG-C30XU

AC power switch

(for Lamp replacement)

6-1

5-1

(FG)

5-2

Power/Ballast Unit Ass'y

(TP)

5-3

(BA)

(PA)

(FG)

6-2

(PA)

6-3

Inlet Unit

17

Page 18

PG-C30XU

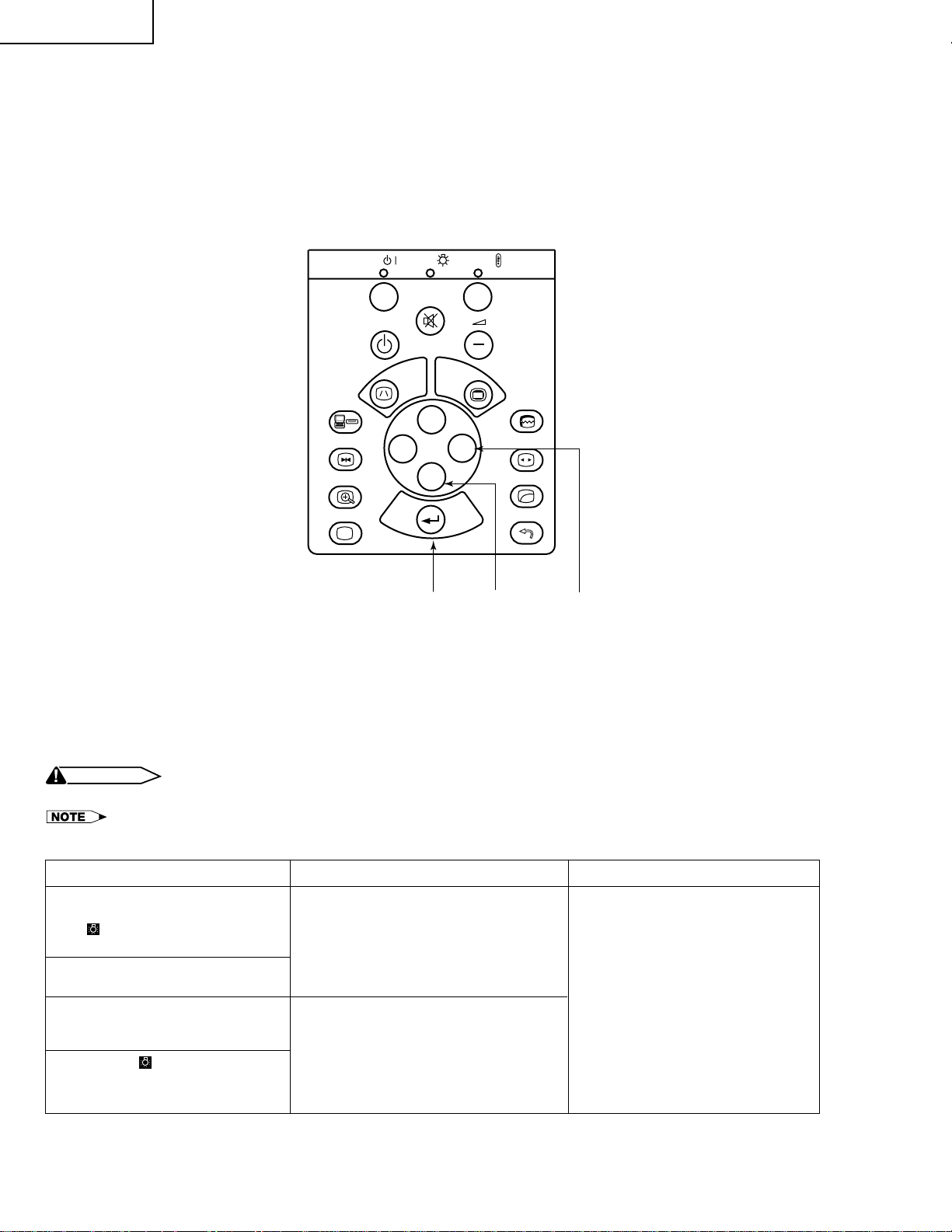

RESETTING THE TOTAL LAMP TIMER

When the lamp has been replaced, reset the total lamp timer in the following steps.

Resetting procedure

1. While holding down the “ENTER”, “ADJ."” and “ADJ.|” keys on the set at the same time, turn on the main

power switch (located side the AC inlet).

2. Now the total lamp timer is reset to zero. “000H” appears on the screen.

POWER

ON

OFF

INPUT

FREEZE

ENLARGE

BLACK SCREEN

B

LAMP

MUTE

I

KEYSTONE

√

ENTER ADJ." ADJ.|

√

MENU

√

ENTER

TEMP.

√

+

VOLUME

AUTO

SYNC

RESIZE

GAMMA

UNDO

Lamp

The lamp in this projector operates for approximately 1,500 cumulative hours, depending on the usage environment. It is recommended that the lamp be replaced after 1,400 cumulative hours of use or when you notice a

significant deterioration of the picture and color quality. The lamp usage time can be checked with the On-screen

Display.

CAUTION

• Intense light hazard. Do not attempt to look into the aperture and lens while the projector is operating.

• As the usage environment can vary significantly, the projector lamp may not operate for 1,500 hours.

Condition

The LAMP REPLACEMENT

indicator lights up red, and "LAMP"

" will flash in yellow in the

and "

lower-left corner of the picture.

A significant deterioration of the

picture and color quality occurs.

The power will automatically turn

off and the projector will enter

standby mode.

"LAMP" and "

" will flash in red in

• Lamp has been used for over 1,400

hours.

• Lamp has been used for over 1,500

hours.

Problem

• Purchase a replacement lamp unit

(lamp cage/module) of the current

type BQC-PGC30XU/1 from your

nearest Authorized Sharp Industrial

LCD Products Dealer or Service

Center.

• Replace the lamp. If you wish, you

may have the lamp replaced at your

nearest Authorized Sharp Industrial

LCD Products Dealer or Service

Center.

the lower-left corner of the picture,

and the power will turn off.

18

Possible Solution

Page 19

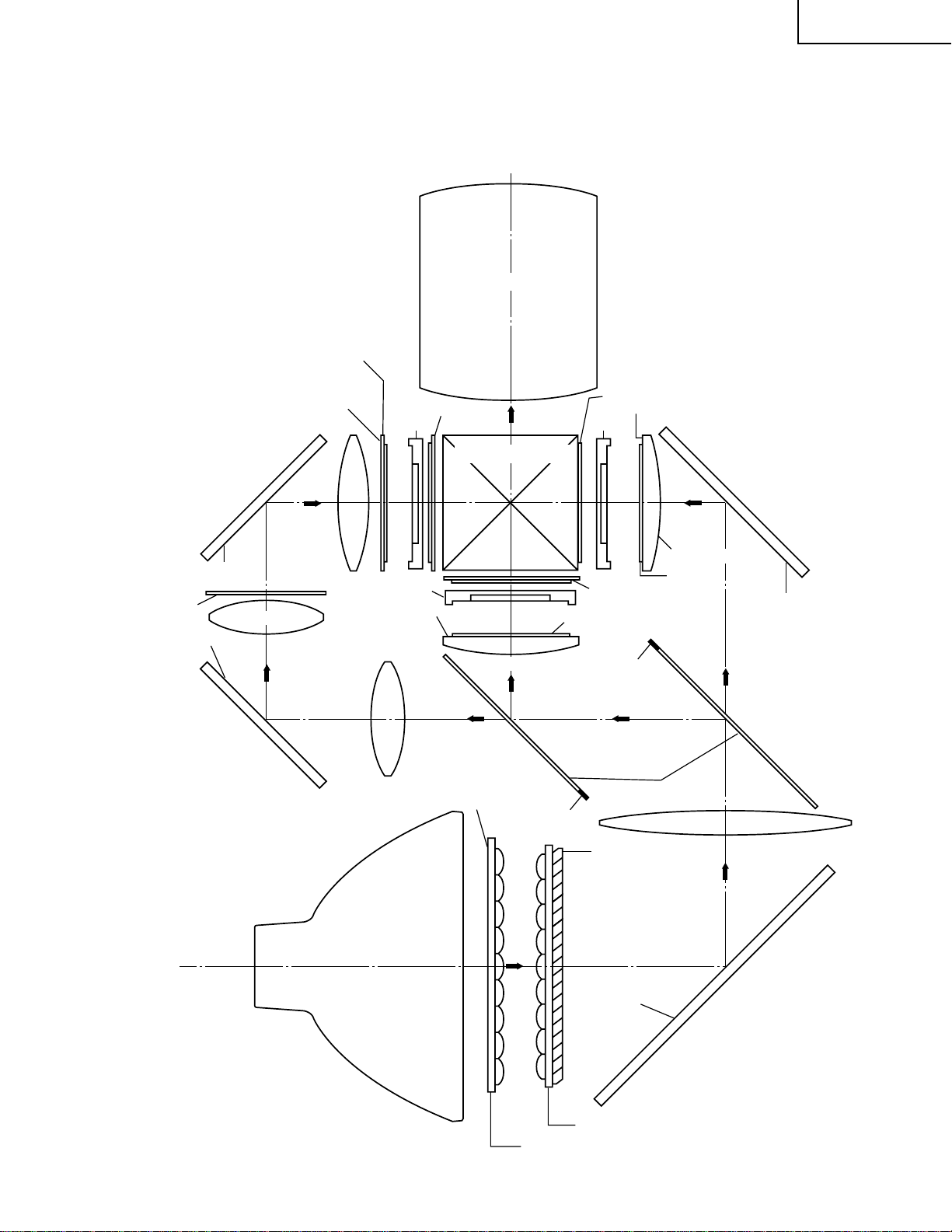

THE OPTICAL UNIT OUTLINE

Layout of the optical system

Note: Layout for positioning the optical system.

Incident polarizing plate B

PG-C30XU

Projection Lens

M4/M6

Dichroic coating

(B reflection)

UV-filter

Dichroic coating

(B reflection)

M4/M6

AR coating

B reflector

Relay lens 2

B reflector

BLUE

RL3

Relay lens 3

Dichroic coating

(G transmission)

RL2

emergent polarizing

B-LCD

G-LCD

CL3

RL1

Relay lens 1

plate B

Cross dichroic prism

Porarizing film

Condenser lens G

GREEN

BLUE

G reflector

M3

UV-IR coating

Marking

emergent polarizing plate R

Dichroic coating (R transmission)

R-LCD

AL-coated mirror R

CL2

Condenser lens R

emergent

polarizing plate G

Marking

(Bottom)

Dichroic coating

Porarizing film

M5

AL-deposited face

(R reflection)

RED

M2

B/G reflector

DC lamp

(Light source)

PBS(polarization

beam splitter)

AL-deposited

face

Fly-eye lens (outgoing light)

Fly-eye lens (incoming light)

19

CL1

M1

AL-coated mirror W

Page 20

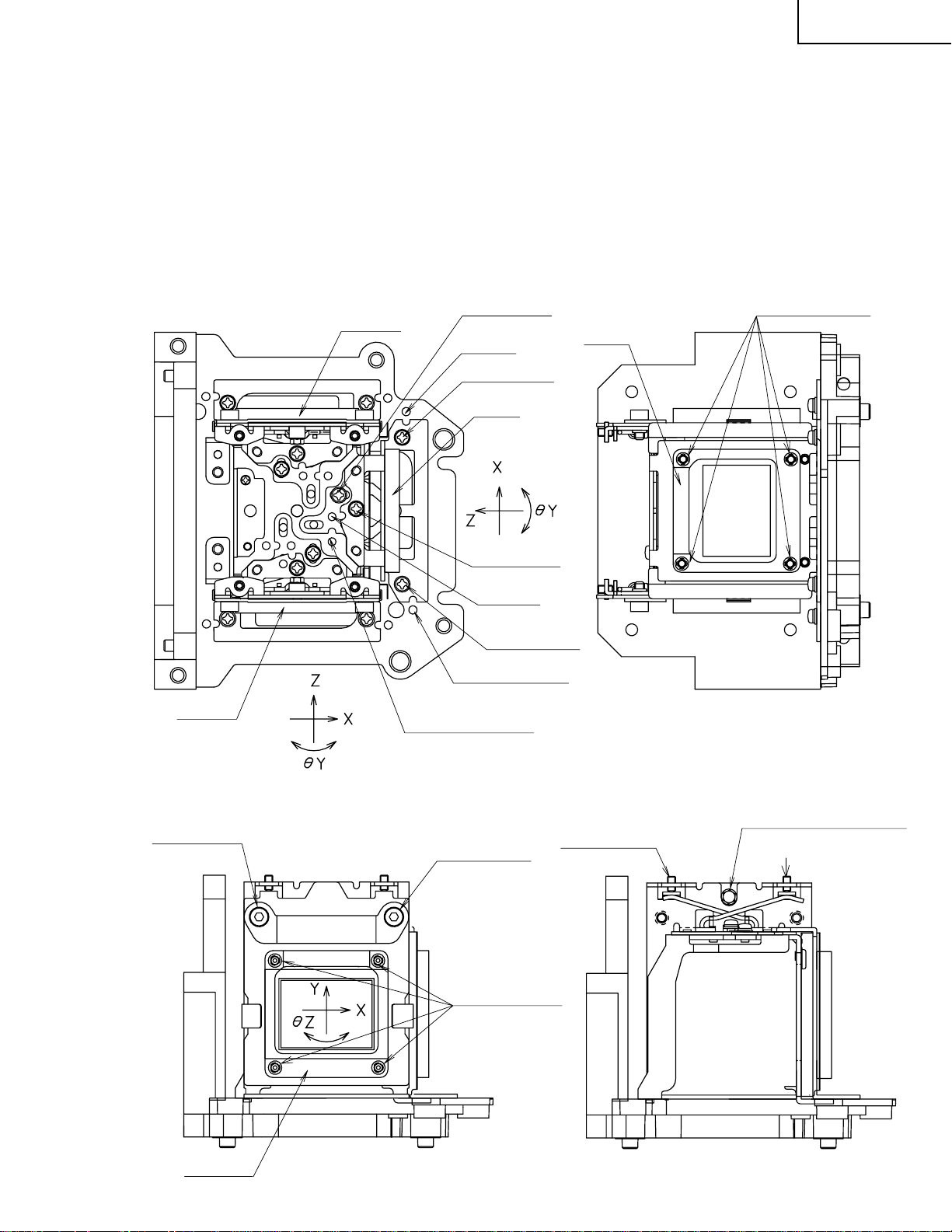

PG-C30XU

CONVERGENCE AND FOCUS ADJUSTMENT

» Start the convergence and focus adjustments with the top panel removed but the power

on. Use the remote control to adjust the image.

Take the following procedures.

1. Focusing the projection lens

(A) Replacing all the 3 LCD panels

1. Before replacing all the 3 LCD panels, project an image on the screen and bring it into focus.

2. Replace the LCD panels with new ones. But until the focus has been completely readjusted, be careful not

to change the projection distance between the set and the screen, nor to move the projection lens focus

and zoom rings.

Note:

If the focus is readjusted with a different positional relation, the relation between the projection distance

and the screen size is affected. In other words, a short-distance image (40 WIDE for example) may get out

of the focus range, or a long-distance image (300 WIDE for example) may come out of the focus.

(B) Replacing 1 or 2 of the 3 LCD panels

1. In adjusting the focus after replacement of one or two LCD panels, project an image on the screen and turn

the projection lens focus ring to get the non-replaced LCD panel into focus.

2. But until the focus has been completely adjusted for the new LCD panels, be careful not to change the

projection distance between the set and the screen, nor to move the projection lens focus and zoom rings.

3. If the projection distance has been changed or the projection lens readjusted, repeat the above steps 1 and

2.

2. Focus adjustment

(A) Adjusting the G-LCD panel(Make this adjustment on the white-only screen.)

1. Adjustment in θX and Z directions .

Loosen the lock screw "a" and insert an eccentric screwdriver into the notch and hole "a". Turn the screwdriver

until the top, center and bottom on the screen get into focus. In adjusting this top-to-bottom focus, tighten

the lock screws "b" and "c" to fix the θY direction adjustment.

First get the right and left halves in balance. Then improve the accuracy while making the adjustment 2

below.

2. Adjustment in θY direction

T emporarily tighten the lock screw "a" and loosen the lock screws "b" and "c". Insert the eccentric screwdriver

into the notch and hole "c" for adjusting in the θY direction on the top of the screen. Insert the eccentric

screwdriver into the notch and hole "b" for adjusting in the θY direction on the bottom of the screen.

3. Repeat the above steps 1 and 2 to finely adjust the focus. Finally tighten up all the lock screws.

Notes :

1 Carefully proceed with the focus adjustment because the adjusting directions are correlated.

2 In adjusting the convergence and focus, do not move the projection lens zoom and focus rings until the end

of all the adjustments.

(B) Adjusting the B-LCD panel (Do the same for the R-LCD panel.)

1. Take the same procedure as for the G-LCD panel focus adjustment. Note that the adjustment range is

wider in the Z direction. If the convergence is quite different between the B-LCD and G-LCD panels,

roughly adjust the convergence first and then the focus.

3. Convergence adjustment

» Use a crosshatch pattern signal for this adjustment.

Make the adjustment just for the G-LCD and the relevant color.

1. Loosen the convergence lock screw "d".

2. Adjustment in Y and θZ directions

Put a hex wrench in the Y and θZ direction adjustment zone.

3. Adjustment in X direction

Put an eccentric cam adjusting wrench in the X direction adjustment zone.

20

Page 21

4. With the G-LCD panel's screen center as refernce, adjust the R-LCD and B-LCD panels.

R-LCD

B-LCD

Lock screw "a"

Lock screw "c"

Notch and

hole "c"

Notch and

hole "b"

Lock screw "c"

G-LCD

G-LCD

Lock screw "b"

Notch and hole "c"

Notch and hole "a"

Lock screw "d"

Lock screw "d"

R.B-LCD panel

mounting screws

(four screws)

R.B-LCD

SIDE VIEW (from inside)

SIDE VIEW (from outside)

TOP VIEW SIDE VIEW

G-LCD panel

mounting screws

Eccentric cam

(Y direction adjustment)

Eccentric cam

(X direction adjustment)

Eccentric cam

(θZ direction adjustment)

(four screws)

5. Finally tighten up the convergence lock screw "d".

Notes :

1 The eccentric cam is used for convergence adjustment.

This means that the cam's turning and the linear movement are not always uniform.

2 This model is not equipped with the LCD image adjustment mechanism. This is because the cross-dichroic

prism is used for image formation. When the LCD panels all get into best focus, the images are almost

completely converged.

Convergence and Focus Adjustments Mechanism

PG-C30XU

21

Page 22

PG-C30XU

80

2

2

92

5

7.5

0.5

min85

ø5

ø3.5

3.5

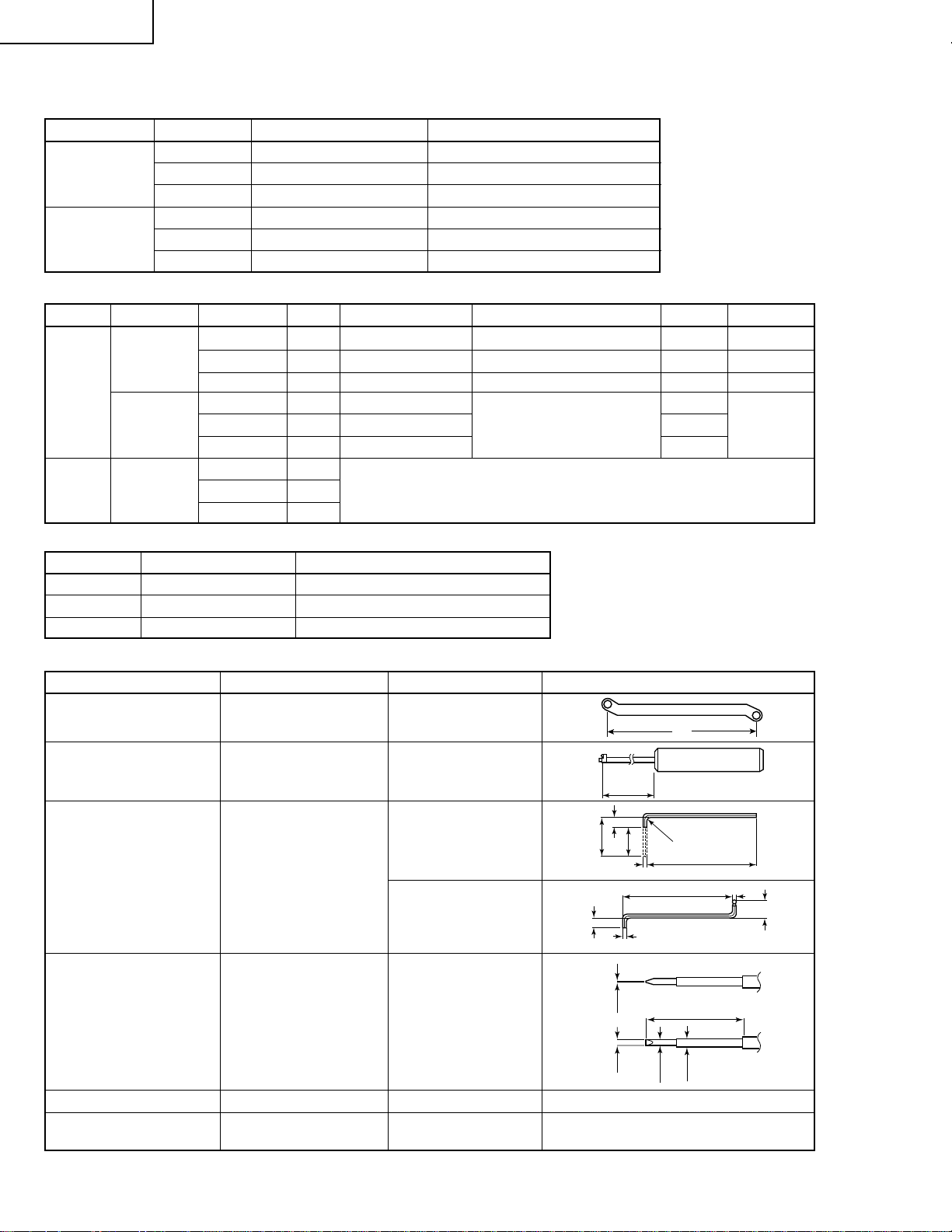

Convergence and Focus Adjustments at a Glance

Adjustment directions

Adjustment Direction Definition Direction of LCD panel

X direction LCD right and left

Convergence Y direction LCD top and bottom

θZ direction Rotation around Z axis LCD turning axis

Z direction LCD optical axis

Focus θX direction Rotation around X axis LCD top-to-bottom flapping

θY direction Rotation around Y axis LCD right-to-left flapping

Convergence and Focus Adjustment for the Optical Mechanism

Color Adjustment Direction

X direction ±0.8mm Eccentric cam Eccentric cam adjusting wrench d Hex wrench

Convergence Y direction ±0.8mm Eccentric cam Eccentric cam adjusting wrench d Hex wrench

R/B θZ direction ±1° Eccentric cam Eccentric cam adjusting wrench d Hex wrench

colors Z direction ±0.8mm

Focus θX direction ±1°

θY direction ±1°

Z direction ±0.2mm

G color Focus θX direction ±1° Same as for R and B colors

θY direction ±1°

Movement

Position Adjusting tool

Notch and hole "a" & "c"

Notch and hole "a" & "c"

Notch and hole "b" & "c"

Eccentric screwdriver, a, c

Bladed screwdriver a, c

Lock screw

b, c

Tightening tool

Phillips

screwdriver,

*Hex wrench

Focus Adjustments the Other Way

Lock screw Position Related direction

a Notch and hole "a" Z and θX directions

b Notch and hole "b" θY direction

c Notch and hole "c" Z, θX and θY directions

Convergence and Focus Adjusting and Tightening Tools

Tool Specific or General Tool code Configuration

Eccentric cam

adjusting wrench

Specific 9DASPN-XGNV1U

Eccentric screwdriver Specific 9DADRiVER-NV4U

100

Hex wrench General (redesigned)

9EQLNC-XGNV1U

5

16

R2

CUT

2

9EQLNC-XGNV4U

Bladed screwdriver General 9EQDRiVER-NV1B

Phillips screwdriver General — For M2.6 pan-head machine screw

*Hex wrench General —

22

1.27mm, preferably use a 70 mm or

longer screwdriver (with a handle).

50

Page 23

PG-C30XU

Replacing the LCD panels

Detach the top panel and the optical mechanism unit in advance.

(1)Remove the four prism holder lock screws. Detach the prism holder from the optical mechanism unit.

(2)Remove the LCD panel lock screws (four each for the R-, G- and B-LCD panels). Detach the LCD panels from the

prism holder.

(3)Mount a new LCD panel in the reverse order of the above steps (1) and (2).

~ Readjust the convergence and focus. Note that the G-LCD panel needs no convergence adjustment and has

a small adjustment range in the Z direction.

1

Prism holder

SIDE VIEW (from inside)

Lock screw "d"

R.B-LCD

Optical Mechanism Unit

Lock screw "d"

2

R.B-LCD panel

mounting screws

SIDE VIEW

G-LCD

G-LCD panel

mounting screws

2

23

Page 24

PG-C30XU

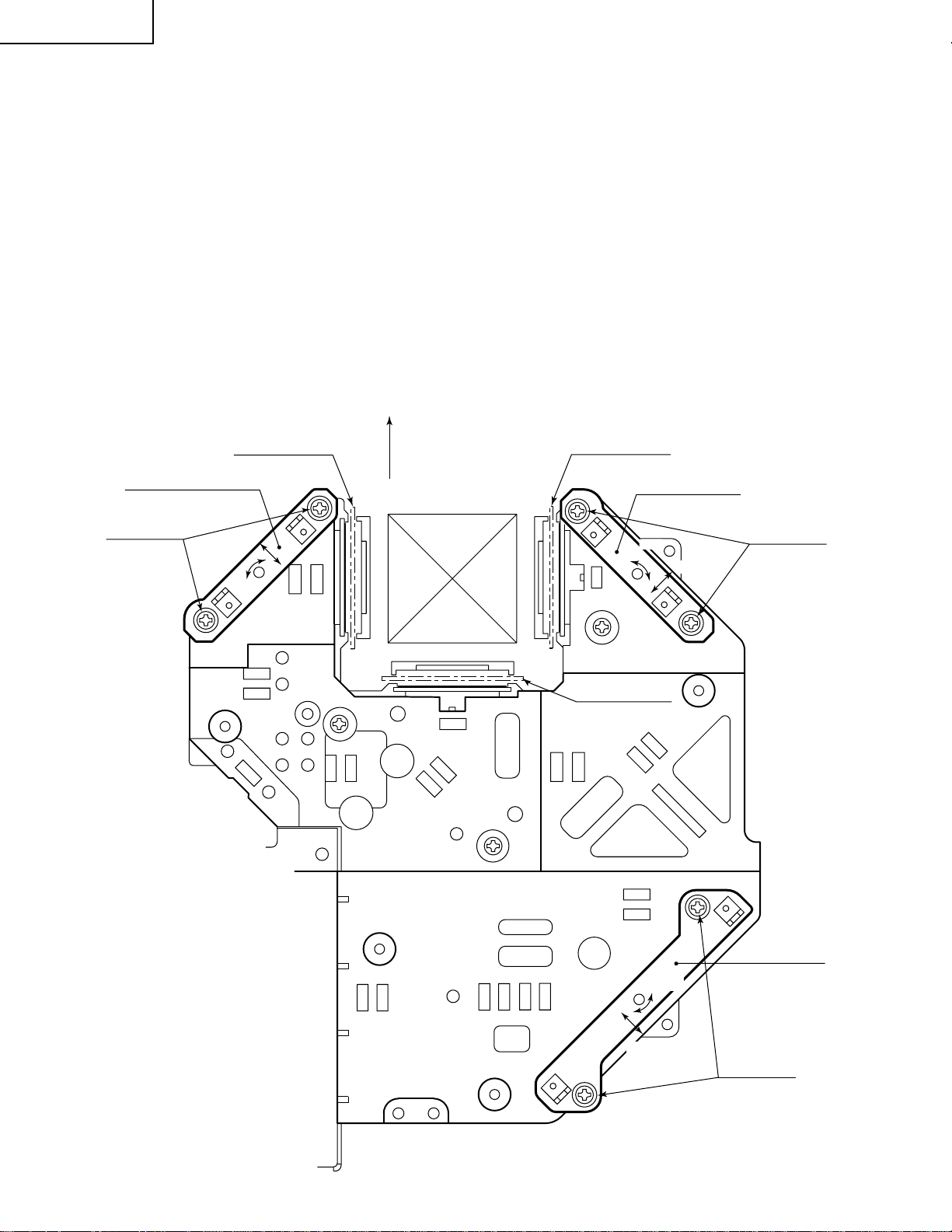

Adjusting the optical axis of the mirrors (M1, M5 and M4/M6)

The optical axis must be readjusted if an eclipse happens with the R. G or B mirrors. Generally speaking,

this adjustment is needed when any of the internal optical components has been replaced.

Adjustment procedure required when any of the panels has been replaced or the convergence has been

adjusted

(1)Disconnect the flat cables of all the LCD panels.

(2)Let the lamp light up.

(3)To adjust the G mirror, shield the R and B mirrors with shielding plates (You can use a business card or the like to

block the light).

(4)Loosen the lock screw of the M1 adjust lever.

(5)Looking at the G image on the screen, turn or slide the M1 adjust lever until the eclipse on the screen disappears.

Tighten up the screw.

(6)T o adjust the R mirror, shield the G and B mirrors and adjust the M5 adjust lever. For the B mirror, shield the R and

G mirrors and adjust the M6 adjust lever.

(Take the same steps 4 and 5 above.)

(7)Remove all the shielding plates to have a white image.

Make sure there is no eclipse.

M4/M6

Lock screws

Shielding plate B

adjust lever

slide

turn

FRONT

Shielding plate R

M5 adjust lever

turn

Shielding plate G

Lock screws

slide

24

M1 adjust lever

turn

slide

Lock screws

Page 25

PG-C30XU

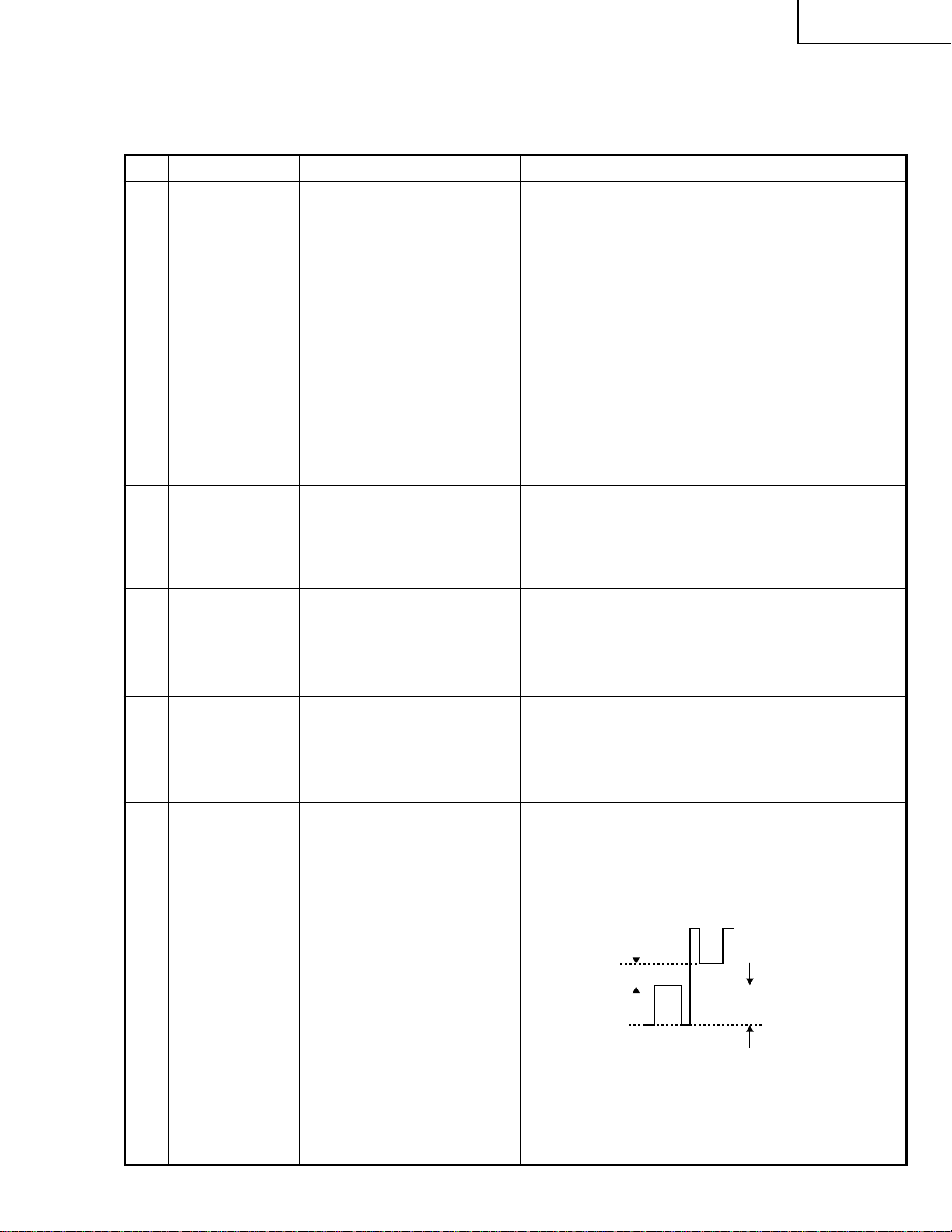

ELECTRICAL ADJUSTMENT

Hook up a signal generator, or a DOSV or Mac personal computer to the projector in order to feed the

signals specified in the Adjusting conditions.

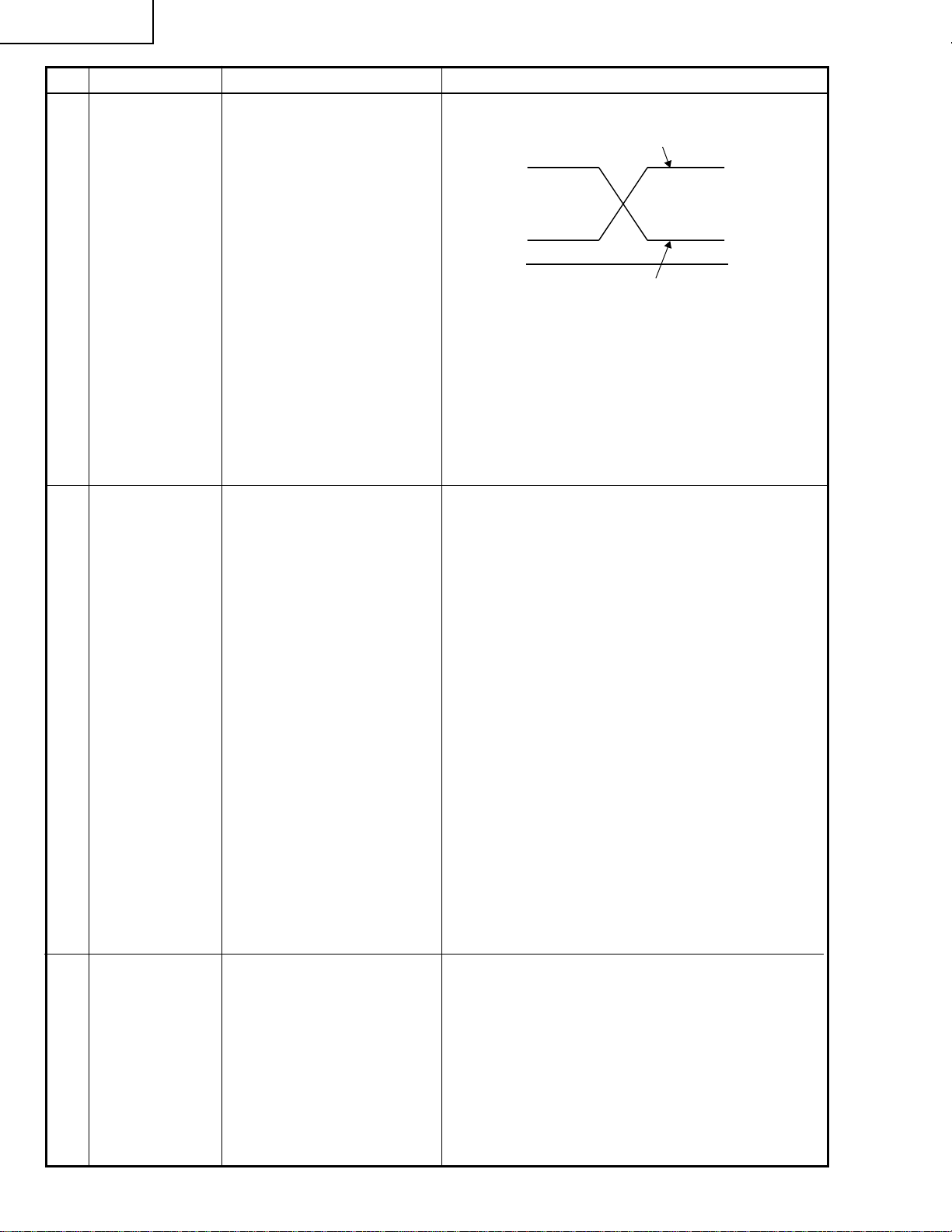

No. Adjusting point Adjusting conditions Adjusting procedure

1 EEPROM

initialization

1. Turn on the power (make

sure the lamp lights up) and

warm up the unit for 15 minutes.

» Make the following settings:

Press S5001 to call up the process mode and

execute S2 in the SSS menu. Now the system,

with the PC board not included, is initialized. Do

not execute S1 because otherwise the PC board

will be initialized.

To adjust the PC board, follow the instruction in

"Adjusting the PC board". (See page 31)

2 3.3V power

supply

adjustment

3 2.5V power

supply

adjustment

4 R drive 1. Feed the 100% red-only

5 B drive 1. Feed the 100% blue-only

6 G drive 1. Feed the 100% green-only

1. Turn on the power.

2. Connect the digital voltmeter to TP1446.

1. Turn on the power.

2. Connect the digital voltmeter to TP1447.

signal. Make the following

choice.

Group : A/D

Subject : R-D

signal. Make the following

choice.

Group : A/D

Subject : B-D

signal. Make the following

choice.

Group : A/D

Subject : G-D

» Adjust R1649 so that the voltmeter should read

3.43 ±0.03 Vp-p.

» Adjust R1652 so that the voltmeter should read

2.60 ±0.05 Vp-p.

» Using the control switches or the remote controller

buttons, adjust the data so that the signal becomes bit-less (noise).

» Using the control switches or the remote controller

buttons, adjust the data so that the signal becomes bit-less (noise).

» Using the control switches or the remote controller

buttons, adjust the data so that the signal becomes bit-less (noise).

7 RGB 1 system

black level

signal amplitude

(odd-numbered)

1. Make the following choice:

Group : OUTPUT 1

Subject : G1-BLK

G1-GAIN

For red, choose the sub-

jects R1-BLK and R1-

GAIN.

For blue, choose the subjects B1-BLK and B1-GAIN.

2. Connect the oscilloscope to

TP1101 for red.

TP1201 for green

TP1301 for blue

» Choose the subject G1-GAIN and adjust the sig-

nal amplitude to 3.3 ±0.1 Vp-p using the control

switches or the remote controller buttons.

» Next,choose the subject G-BLK and adjust the

white to white level to 2.6 ±0.1V DC.

(Adjust to 2.6V

DC for red and

blue.)

» Adjust the signal's amplitude and white to white

level to 3.3 ± 0.1Vp-p and 2.6 ± 0.1V DC, respectively, for red and blue.

2.6V

3.3Vp-p

(Adjust to 3.3Vp-p

for green and blue.)

25

Page 26

PG-C30XU

No. Adjusting point Adjusting conditions Adjusting procedure

8 P SIGNAL 1. Connect the oscilloscope to

TP1701 for red.

TP1702 for green

TP1703 for blue.

2. Make the following choice:

Group : OUTPUT 2

Subject : PSIG-H

: PSIG-L

9 Panel ghost

adjustment

1. Project the XGA60Hz ghost

test pattern (black charac-

ters in bold on the halftone

RGB background).

Group: OUTPUT3

2. GCK-PHASE adjustment

Make sure the setting is

fixed at 8 (initial value).

3. EN-WIDTH adjustment

Make sure the setting is

fixed at 8 (initial value).

4. ENR-PHASE adjustment

(R-LCD ghost adjustment)

5. ENG-PHASE adjustment

(G-LCD ghost adjustment)

6. ENB-PHASE adjustment

(B-LCD ghost adjustment)

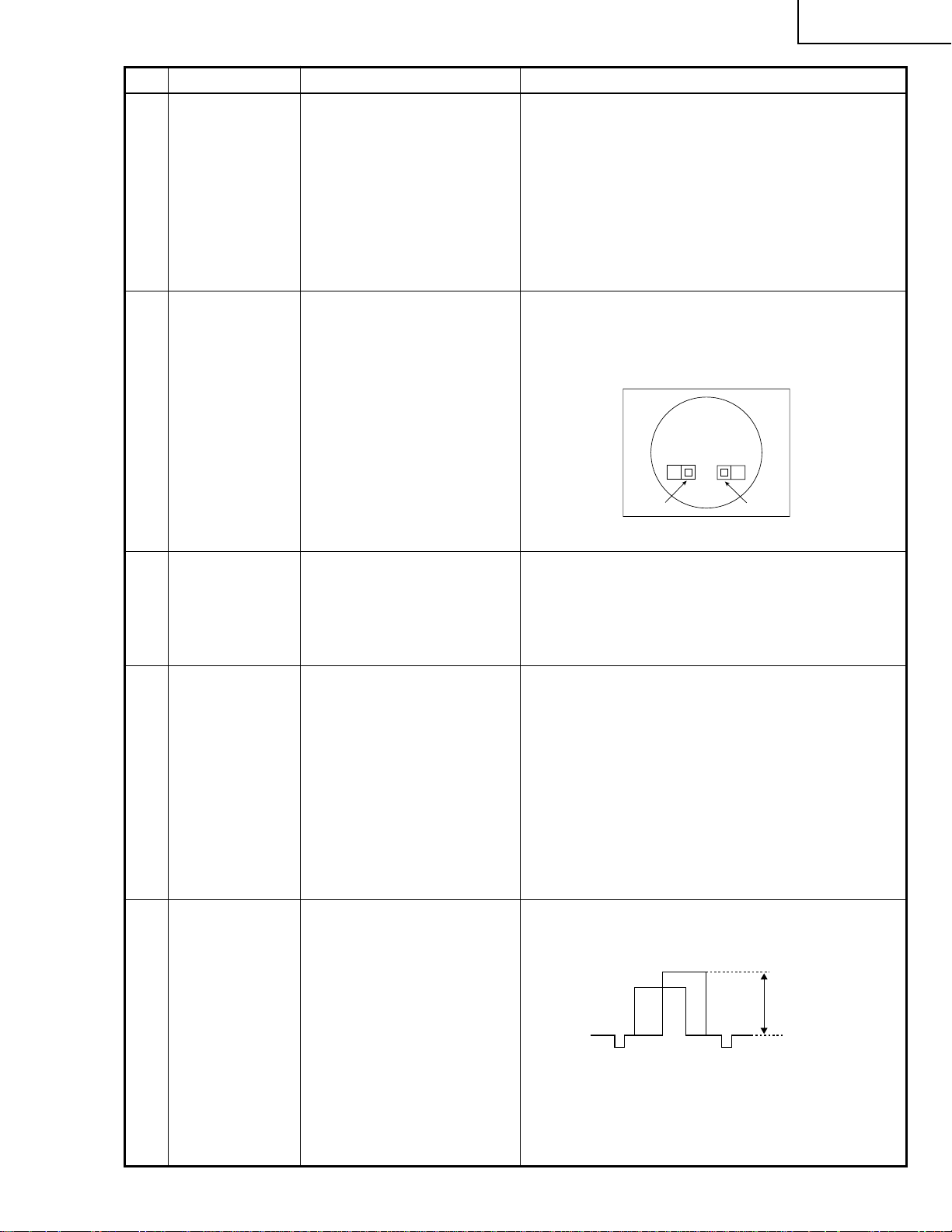

» Adjust the PSIG waveform to the one shown below.

(Adjust with PSIG-H.)

PSIG

7.3±0.2V DC

2.0V DC

GND

(Adjust with PSIG-L.)

» For the green and blue colors, make sure their wave-

forms are similar to that of the red color.

» Make sure the pin stripe of every 12 dot doesn't ap-

pear at 10 steps signal of side nays.

(Appearing white pin stripe or black one, adjust the

PSIG-H.)

» ENR-PHASE adjustment (R-LCD ghost adjust-

ment)

1 Increase the setting until a ghost image (see

Note) becomes visible at the left of the back

characters on the R half-tone background.

2 Lower the setting point by point until the left-

hand ghost image (1 above) disappears.

3 Further lower the setting by one point.

» ENG-PHASE adjustment (G-LCD ghost adjust-

ment)

Adjust the G ghost image by following the same

procedures described under step 1 above.

» ENB-PHASE adjustment (B-LCD ghost adjust-

ment)

Adjust the B ghost image by following the same

procedures described under step 1 above.

Note: Left-hand ghost image: Characters are shown

double 12 dots left from the real characters.

Reference: This adjustment is made because the

EPSON LCD panel may have 1- or 2point differences due to lot-by-lot

variations.

10 Sample-and-

hold pulse

phase

RCK-PHASE

GCK-PHASE

BCK-PHASE

1. Feed the XGA mode 75-Hz

black signal.

2. Make the following choice:

Group : OUTPUT 3

Subject : SH-PHASE

(Have the standard level at

2.)

Fix the RCK-, GCK- and

BCK-PHASE settings all to

8.

» Using the control switches or the remote controller

buttons, make sure that the “OUTPUT 3” characters are not blurry and there is no ghost image. If

such blur or ghost occurs, finely adjust the setting

in the range of 7~9.

26

Page 27

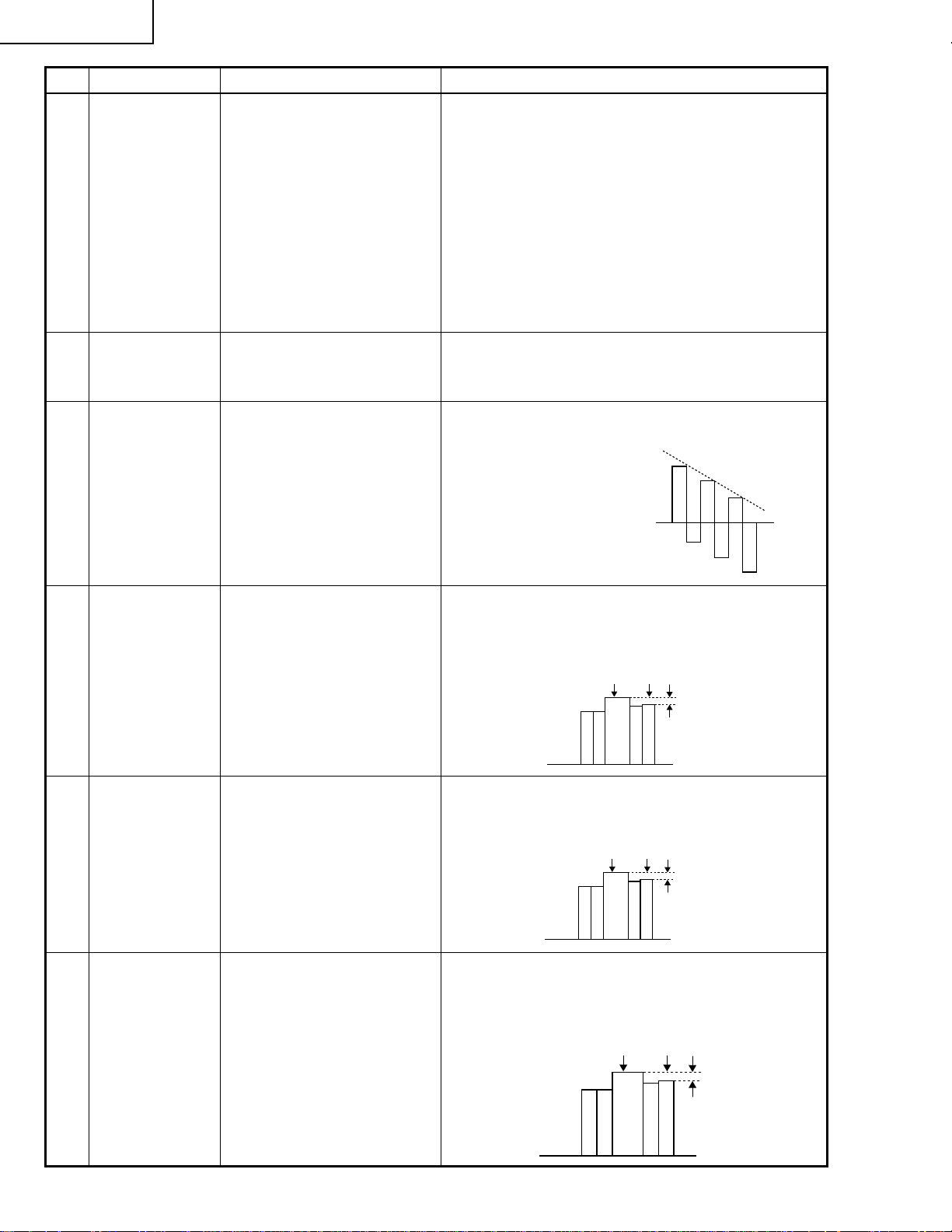

No. Adjusting point Adjusting conditions Adjusting procedure

PG-C30XU

11 RGB counter-

voltage

adjustment

12 RGB gradation

regeneration

adjustment

1. Feed the black-and-red

(25%) stripe signal (XGA).

2. Make the following choice:

Group : OUTPUT 3

Subject : RC (R)

and

Group : OUTPUT 3

Subject : RC-INV (R)

1. Feed the green-only

SMPTE pattern signal

(XGA).

Group : OUTPUT 1

Subject : G1-BLK

» Using the control switches or the remote controller

buttons, adjust the data in order to minimize the

flicker.

» Make the same adjustment for BC (B), GC (G),

RC-INV (B) and RC-INV (G).

» See if the image is equally adjusted at the center

and both sides of the screen. If not, readjust the

setting to have the image equal at right and left.

» Adjust the G-BLK data until the gradation of the

portion 1 (95% and 100% white) shown below

can be slightly recognized. Make sure also that

the gradation of the portion 2 (0% and 5% black)

is visible.

2

1

13 RGB white

balance

14 Horizontal

center

15 Video picture

adjustment

1. Feed the 32-step gray scale

signal (XGA).

Group : OUTPUT 1

Subject : R1-BLK (R)

B1-BLK (B)

1. Feed the NTSC monoscope pattern signal.

2. Group : VIDEO 2

Subject : N358-DLY (4)

N443-DLY (0)

PAL-DLY (3)

SECAM-DLY (0)

Make sure the settings are

as above.

3. Group : VIDEO 1

Subject : NTSC-H

1. Feed the split color bar signal.

Group : VIDEO 1

Subject : PICTURE

2. Connect the oscilloscope

between pin (2) of P801

and GND.

» Choose the subjects R1-BLK and B1-BLK and

adjust the black balance of the gradation.

» Using the control switches or the remote controller

buttons, adjust the data to have the same

overscan.

» Using the control switches or the remote controller

buttons, adjust the black-to-white (100%) level

difference to 2.0 ±0.02 Vp-p.

2.0Vp-p

27

Page 28

PG-C30XU

100% White Red

No. Adjusting point Adjusting conditions Adjusting procedure

16 Video

brightness

adjustment

1. Feed the baseband (split

color bar) signal. (The ONAIR signal is not accepted

because of its too much

noise.)

Group : VIDEO 2

Subject :

VROS/VGOS/VBOS

2. Press the control switch or

the remote control’s mute

button (to set the gamma

correction to the process

setting).

17 V ideo AGC 1.

Feed the split color bar signal.

Group : VIDEO 1

Subject : AGC

18 Tint 1. Feed the split color bar sig-

nal.

Group : VIDEO 1

Subject : TINT

2. Connect the oscilloscope to

pin (4) of P801.

» Using the control switches or the remote controller

buttons, adjust the setting until the black signal

becomes bit-less.

» Using the control switches or the remote controller

buttons, adjust the setting until the white signal

becomes bit-less.

» Using the control switches or the remote controller

buttons, adjust the data to have the -(B-Y) waveform downhill straight.

» After adjusting, adjust the value

of TINT up 3 point.

19 NTSC color

saturation level

20 PAL color

saturation level

21 SECAM color

saturation level

1. Feed the split color bar signal.

Group : VIDEO 1

Subject : N-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

1. Feed the PAL color bar signal.

Group : VIDEO 1

Subject : P-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

1. Feed the SECAM color bar

signal.

Group : VIDEO 1

Subject : S-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

» Using the control switches or the remote controller

buttons, adjust the difference between the 100%

white portion and the red portion to 0.00 ±0.05 Vp-p.

(same as 100% white)

» Using the control switches or the remote controller

buttons, adjust the difference between the 100%

white portion and the red portion to 0.2 ±0.05 Vp-p.

100% White Red

» Using the control switches or the remote controller

buttons, adjust the data to have a level difference

of 0.2 ±0.05 Vp-p between the 100% white portion

and the red portion.

100% White Red

28

Page 29

No. Adjusting point Adjusting conditions Adjusting procedure

PG-C30XU

22 Video input

panel signal

amplitude

adjustment

23 Video white

balance

24 DTV white

balance

1. Feed the NTSC 10-step

signal.

2. Select the following group

and subject.

Group: VIDEO2

Subject: R1-GAIN

B1-GAIN

3. Connect the synchroscope

to TP1101 (R) and TP1201

(G).

4. For the blue color, connect

the synchroscope to

TP1301 (B) and TP1201

(G).

1. Feed the NTSC monoscope pattern signal

Group : VIDEO 2

Subject : R1-BLK

B1-BLK

1. Feed the monoscope pattern signal.

2. Group: DTV

Subject: CR-OFFSET

CB-OFFSET

» Select R1-GAIN and adjust the setting so that the

R and G signals have the same amplitude.

» For the blue color, adjust the setting the same

way.

» Using the control switches or the remote controller

buttons, adjust so that the entire screen looks

evenly colorless.

» Using the control switches or the remote controller

buttons, adjust so that the entire screen looks

evenly colorless.

25 Setup 1. Group: VIDEO1

Subject: SET UP B

SET UP C

26 Automatic color

correction

27 Color system

performance

check

28 Video system

performance

check

29 Audio system

performance

check

1. Using the color correction

system (ccdc), apply automatic color correction.

1. Receive the color bar signal.

1. Receive the monoscope

pattern signal.

» Make sure the settings are 11 for SET UP B and 2

for SET UP C.

» Make sure there is no noticeable color irregularity

left on the screen.

» In the process mode and select L1. Check the color

and tint.

» In the process mode and select L2. Check the pic-

ture, brightness and sharpness.

» In the process mode nad select L3. Check the bass,

treble.

29

Page 30

PG-C30XU

No. Adjusting point Adjusting conditions Adjusting procedure

30 RGB

performance

check

31 Off-timer

performance

check

32 Thermistor

performance

check

33 Automatic

synchronization

34 Keystone

correction

performance

check

1. Receive the RGB signal. » In the process mode and select L4. Check the picture, brightness, red, blue, clock, phase, horizontal

position, and vertical position.

» In the process mode and select OFF. Make sure that

the off-timer starts with “5” (minutes), counts down

each minute in 1 second, and turns off the set at “0”.

1. Heat the thermistor using a

» Make sure the “TEMP” is displayed.

dryer.

1. Receive the PHASE check

pattern signal.

» Call the VGA/SVGA/XGA/SXGA mode and make

sure that the clock, phase, horizontal and vertical

positions can be automatically adjusted.

» Make sure the keystone correction functions well.

» Make the following settings.35 Factory settings

Process

adjustment

S4 “Factory setting 4”

Remote controller

setting

30

Page 31

PG-C30XU

ADJUSTING THE PC BOARD (CPCi-0047CE01. PC I/F Unit)

1. Setting the oscilloscope

Set the range to DC 1 V/div and 5µs/div.

2. Connecting the PC interface

1) Connect the PC interface to the projector. Make surethe CON2 (P8404), CON3 (P8502) and CON4

(P8405)connectors are all tight in position.

2) Connect the cable between the computer’s ANALOG OUTPUTterminal and the DSUB (INPUT1 on the

projector)connector.

3) Set the projector’s input selector to the RGB1position.

4) Set the signal generator to the XGA mode (1024 x 768, 60Hz, 32-tone scale). Keep the output amplitude at

700mVp-p.

5) Turn on the power.

3. Adjusting the levels and checking the tones

1) Press the S5001 switch to call up the process mode.

2) Enter 8 for the SH-PHASE setting on the OUTPUT3 menu.

(Adjust to get the on-screen display characters clearand crisp.)

(A/D menu adjustment)

3) R-BRIGHT adjustment: Feed the black signal and adjust the R-BRIGHT setting on the A/D menu screen until

the bitless state.

4) G-BRIGHT adjustment: Feed the black signal and adjust the G-BRIGHT setting on the A/D menu screen until

the bitless state.

5) B-BRIGHT adjustment: Feed the black signal and adjust the B-BRIGHT setting on the A/D menu screen until

the bitless state.

6) R-D adjustment: Feed the white signal and adjust the R-D setting on the A/D menu screen until the bitless

state.

7) G-D adjustment: Feed the white signal and adjust the G-D setting on the A/D menu screen until the bitless

state.

8) B-D adjustment: Feed the white signal and adjust the B-D setting on the A/D menu screen until the bitless

state.

4. DTV adjustment

1) Feed the 480P Y signal to INPUT1. Keep the R (Pr) and B (Pb) without signal input.

2) G-BRIGHT adjustment: Make this setting the same as the G-BRIGHT setting on the A/D menu screen.

3) CR-OFFSET adjustment: Feed the 56% white signal and adjust the CR-OFFSET setting on the DTV menu

screen until the bitless state.

4) CB-OFFSET adjustment: Feed the 56% white signal and adjust the CB-OFFSET setting on the DTV menu

screen until the bitless state.

5) G-BRIGHT correct adjustment = Adjust the value of G-BRIGHT up 6 point.

6) Press SW5101 and exit from the process mode.

31

Page 32

PG-C30XU

Servicing precautions

(1) If the convergence gets out of spec in servicing the set, call the process mode and select the following

group and subjects.

Group: NOKO

Subject: R-CNV-H, R-CNV-V

G-CNV-H, G-CNV-V

B-CNV-H, B-CNV-V

(H and V are for horizontal and vertical adjustments, respectively.)

Adjust the above settings to the range of 0 to 4.

(2) When entering the process mode, select the following group and subjects too.

Group: VIDEO1

Subject: SET-UP B

SET-UP C

Make sure the SET-UP B and SET-UP C settings are 11 and 2, respectively. To exit from the process mode,

be sure to take either of the following ways: Go to the subject SET-UP 1 and quit the mode, or select Group:

SSS and Subject: S4 and quit the mode.

32

Page 33

TROUBLE SHOOTING TABLE

Checking the PWB performance

PG-C30XU

Video input in trouble

Go to "Checking the video unit

circuit".

RGB input in trouble

Feed test pattern signal from

PC.

Is specified cable connected

between PC and projector?

Yes

Is supply voltage as specified?

Yes

Does image appear?

Yes

Go to "Trouble shooting table

for PC I/F unit ".

Through-output in trouble

Through-output circuit in

trouble.

No

Use specified cable.

No

Power circuit in trouble.

No

Check the connectors, starting

from the PC input circuit.

Remote control in trouble

Go to "Checking the remote

control".

33

Page 34

PG-C30XU

TROUBLE SHOOTING TABLE (Continued)

Checking the video system

Is the lamp on?

Is specified voltage fed to EA

connectors?

Are there signal inputs at pins (3) and

(29) of P402?

Are there signal outputs at pins (3)

and (6) of IC816?

Yes

Go to "Checking IC801

(RGB signal output circuit)".

No

Yes

No

Yes

No

Yes

No

Check IC816, IC806 and

their peripheral circuits as

well as switching circuit.

Go to "Lamp fails to light-up".

Check the power circuit and its parts.

Are there signals at pin (4) of IC401

and pin (4) of IC402?

Yes

Check the video unit circuit

(IC6004 and its peripheral

circuits).

No

Check the oscillation circuit

of IC401 and IC402, and

their peripheral circuits.

Checking the video unit circuit

Is there video signal output at pin (7)

of IC6001?

Yes

Is there video signal input at IC6004?

Yes

Are there signal outputs at pins (6)

and (8) of IC6004?

Yes

Check the low-pass and buffer circuits

of Q6002 thru Q6008. Is the signal as

specified?

Yes

Go to "Checking IC801 (RGB signal

output circuit)".

No

Check the IC6001 selector switch,

terminal voltage and input circuit.

No

Check the low-pass and buffer

circuits of Q6009 thru Q6015.

No

Check IC6004 and its peripheral

circuits (bias).

No

Check Q6002 thru Q6008 and their

peripheral circuits.

34

Page 35

TROUBLE SHOOTING TABLE (Continued)

Checking IC801 (RGB signal output circuit)

PG-C30XU

No

Are there RGB output waveforms at

pins (31), (32) and (33) of IC801?

Go to "No color or unusual tone", "No

Y signal" or "Out of sync".

Are there output waveforms at the

emitters of Q1501, Q1502 and

Q1503?

Are there output waveforms at the

emitter of Q1505, Q1506 and Q1507?

Go to "Trouble shooting table for PC

I/F unit".

Yes

Yes

Yes

Checking the chroma and Y signals of IC801

No

Check the data transfer and other

performance at pins (17) and (18) of

video IC801.

No

Check Q1501 thru Q1503, SC1501

and their peripheral circuits.

No

Check IC1501, Q1505 thru Q1507

and their peripheral circuits.

(RGB signal output)

Are there signal inputs at pins (12)

(Y signal) and (19)(chroma signal) of

P402?

Yes

Are there output waveforms at pins

(3)(chroma signal) and (6)

(Y signal)of IC816?

Yes

Are there signal inputs at pins (20)

(chroma signal) and (21) (Y signal)

of IC801?

Yes

Go to "Checking IC801 (RGB

signal output circuit)".

No

Go to "Checking the video unit

circuit".

No

Check the IC816 switching and their

peripheral circuits. If there is no signal

at pins (9) and (1) of IC816, check 3-D

noise reduction circuit (IC806).

No

Check IC801 and its peripheral

circuits.

Check IC806 (3-D noise reduction

circuit) and its peripheral circuits.

35

Page 36

PG-C30XU

TROUBLE SHOOTING TABLE (Continued)

Checking IC806 (3-D noise reduction circuit)

and its peripheral circuits

Are there signal inputs at pins (40)

(Y signal) and (45)(chroma signal) of

IC806?

Yes

Are there signal outputs at pins (55)

(Y signal) and (51)(chroma signal) of

IC806?

Yes

Are there signal outputs at the

emitters of Q817 (Y signal) and Q910

(chroma signal)?

Yes

Check IC816 and IC801 (RGB signal

output circuit).

No

Check the buffer circuit of Q814 thru

Q816 as well as Q903 thru Q906.

No

Check IC806, IC807 (memory) and

their peripheral circuits.

No

Check the low-pass circuit around

Q817, Q907 and Q910.

No color or unusual tone (NTSC, PAL)

Is there chroma signal input at pin

(20) of IC801?

Yes

Are there signal outputs at pins

(46)(R-Y) and (45)(B-Y) of IC801?

Yes

No

Go back to the signal processing

block.

No

Check the oscillation of X801 and

X802, and their peripheral circuits.

Check IC803, IC814 and their

peripheral circuits.

36

Page 37

TROUBLE SHOOTING TABLE (Continued)

No or unusual Y signal

PG-C30XU

Is there Y signal input at pin (21) of

IC801?

Yes

Is there Y signal output at pin (40) of

IC801?

Yes

Is there Y signal output at pin (17) of

IC803?

Yes

Check IC803 and its peripheral

circuits.

No

Go back to the signal processing

block.

No

Check IC801 and its peripheral

circuits.

No

Check IC803 and its peripheral

circuits as well as IC805 (AGC).

No or unusual horizontal sync

Is there horizontal sync pulse output

at pin (56) of IC801?

Yes

Is there horizontal sync pulse output

at pin (9) of IC603?

Yes

No

Check IC801 and its peripheral

circuits.

No

Check the pulse shaping circuit of

IC602 and IC603.

Check IC604 and its peripheral

circuits, and go to "Trouble shooting

table for PC I/F unit".

No or unusual vertical sync

Is there vertical sync pulse output at

pin (4) of IC801?

Yes

Check IC604 and its peripheral

circuits, and go to "Trouble shooting

table for PC I/F unit".

No

Check IC801 and its peripheral

circuits.

37

Page 38

PG-C30XU

TROUBLE SHOOTING TABLE (Continued)

Checking the output PWB unit

If there is no signal at SC1501

and SC1502, go to the video

system block.

If there is no signal at SC1404

and SC1405, go to "Trouble

shooting table for PC I/F unit".

Are there signal inputs at

SC1404, SC1405, SC1501 and

SC1502?

Are voltages applied to EA

connectors and SC5502?

Yes

Are there signal outputs at

pins (14) ,(16) and (18) of

IC1401 ?

Yes

Are there signal inputs at pin

(47) of IC1101, IC1201 and

IC1301?

Yes

Are there signal outputs at pins

(17), (19), (21), (28), (30) and

(32) of IC1101, IC1201 and

IC1301?

Yes

NoNo

If there is no signal at EA

connector or SC5502, go to

Checking the power unitblock.

No

Check IC1401 and their

peripheral circuits.

No

Check IC1401 and their

peripheral circuits.

No

Check IC1101,IC1201,IC1301

and their peripheral circuits.

If there is no signal input at

pins (1) and (31) of SC1101,

SC1102 and SC1103, check

the switching circuit and

amplifier circuit of IC1101,

IC1201, IC1301, IC1102,

IC1202, IC1302 and their

peripheral circuits.

Are there signal outputs at pins

(17), (19), (21), (28), (30) and

(32) of IC1102, IC1202 and

IC1302?

Yes

No

Are there signal inputs at

SC1101, SC1201 and

SC1301?

Check the R, G and B panels.

Yes

Yes

No

Check IC1102,IC1202,IC1302

and their peripheral circuits.

No

If there is no signal input at

pins (15) and (30) of

SC1101, SC1102 and

SC1103, check IC1409

and their peripheral

circuits.

Check IC1106, IC1206,

IC1306, IC1408 and their

peripheral circuits.

38

Page 39

TROUBLE SHOOTING TABLE (Continued)

No audio output

PG-C30XU

Are there audio signal inputs at pin

(2) of IC1411?

Are there audio signal outputs at pin

(2) of P5508?

Are there audio signal outputs at pin

(6) of IC7301?

If the voltage at pin (2) of IC7301 is

not as specified, check Q5501,

Q5502 and their peripheral circuits.

No

Yes

No

Yes

No

Yes

Check IC7301 and its peripheral

circuits, and the SP connectors and

speakers.

Checkig the Power Unit

Check the input, the switching circuit

of IC3303 and IC3304, and their

peripheral circuit,SC3001,SC1502,etc.

Check the IC1411 control voltage,and

its peripheral circuits.

Check IC7301 and its peripheral

circuits.

Which output voltage line fails?

6.7V

Replace ICP751.

Replace TF701.

There is no voltage output at

EA connector.

Yes

Is there any other output

voltage failure?

Is EA connector disconnected

or loose?

Is AC voltage (85-264V)

applied across the PA

connector?

Yes

Is TF701 open?

Is R706 open?

Yes

No

No

Yes

No

Yes

Reconnect the EA connector.

No

Replace F701 or Check

Bimetal SW.

No

Replace R700. Replace Power

unit.

39

Page 40

PG-C30XU

TROUBLE SHOOTING TABLE (Continued)

Power on

Is the right input selected?

Yes

Are the PC, video and LCP cables as

specified and properly connected?

Yes

With the contrast control at maximum,

does the image appear?

No

Is the voltage at CON3 (P8502)

connector as specified?

Yes

Hook up a personal computer.

Does the image appear?

No

Select the right input with remote

control.

No

Use the right cables or reconnect the

cables.

Yes

Readjust the video system.

No

Power circuit faulty.

No

Is the image as specified?

A

Is the image’s color as specified?

Does the on-screen display function?

Does the remote control function?

End

Yes

Yes

Yes

Yes

Yes

Go to "Checking the clock circuit and

its peripheral circuits".

No

Check the sync signal circuit and its

peripheral circuits.

No

Check the video circuit and its

peripheral circuits.

No

Go to "Checking the OSD circuit and

its peripheral circuits".

No

Go to "Checking the remote control".

40

Page 41

Is the lamp out of socket?

Yes

Reconnect the

lamp into socket.

TROUBLE SHOOTING TABLE (Continued)

Lamp fails to light-up

Turn on the power switch. Is

Yes

discharging sound heard from

the lamp?

No

No

No

Check the power circuit.

Replace the

lamp.

Is the ballast cooling fan

running?

Yes

PG-C30XU

Replace the ballast.

Is DC 360V voltage applied

between PL connector pins?

Yes

Is 2V or higher voltage applied

between pins (1) and (2) of

ballast’s D connector?

Is D connector disconnected?

Yes

Reconnect the

connector into socket.

No

Yes

No

No

Check the

microcomputer circuit.

41

Page 42

PG-C30XU

Checking the clock circuit and its peripheral circuits

TROUBLE SHOOTING TABLE FOR PC I/F UNIT-1

Is X8001 (6MHz) oscillating?

Yes

Is X8003 (1.84MHz) oscillating?

Yes

Is X8004 (22.165MHz) oscillating?

Yes

Is X8005 (16.25MHz) oscillating?

Yes

Does pin (162) of IC8001 function?

Yes

Are there signals at pins (100) and

(101) of IC8606?

No

Is there signal at TL8616?

No

Is there signal at TL8615?

No

Go to "Checking the Sync Signal

Circuit and Its Peripherals."

No

No

No

No

No

Yes

Yes

Yes

X8001 or its peripheral part faulty.

X8003 or its peripheral part faulty.

X8004 or its peripheral part faulty.

X8005 or its peripheral part faulty.

IC8001 or its peripheral circuit faulty.

IC8004 or its peripheral parts

defective.

IC8025 or its peripheral parts

defective.

IC8609 or its peripheral parts

defective.

No

Is the sync signal of split type?

Yes

Are there signals at TP8004 and

TP8005?

Yes

No

Is the sync signal of Sync On Green

type?

Yes

Is there signal at TL8606?

Yes

Does the input have a below-XGA

resolution or is it video signal?

Yes

Are there signals at TL8034 and

TL8035?

Yes Yes

Are there signals at TL8043, TL8041

and TL8042?

E

Are there signals at TL8057 and

TL8058?

Are there signals at pins (19), (20),

(21), (32), (36) and (40) of P8405?

Go to "Checking the PLL Circuit and

its Peripherals."

Yes

Yes

Yes

No

No

No

No No

No

No

No

Output PWB defective.

IC8606 or its peripheral parts

defective.

IC8025 or its peripheral parts

defective.

IC8020 or its peripheral parts

defective.

IC8029 or its peripheral parts

defective.

IC8609 or its peripheral parts

defective.

Are there signals at TPL8023,

TL8024 and TL8025?

E

42

Page 43

TROUBLE SHOOTING TABLE FOR PC I/F UNIT-2

Checking the PLL circuit and its peripheral circuits

PG-C30XU

Are there signals at pin(111) of

IC8606 and TL8606?

Yes

Are there signals at pins (100) and

(101) of IC8606?

Yes

Check the video circuit and its

peripheral circuits.

Is image as specified at resolution

above XGA level?

Yes

Is image as specified at resolution

below XGA level?

Yes

Hook up a video system. Is the

display as specified?

Yes

A

No

IC8025 or its peripheral circuit faulty.

No

IC8606 or its peripheral circuit faulty.

No

Check the S-XGA video circuit and

its peripheral circuits.

No

Check the VGA video circuit and its

peripheral circuits.

No

Check the video system’s video

circuit and its peripheral circuits.

43

Page 44

PG-C30XU

TROUBLE SHOOTING TABLE FOR PC I/F UNIT-3

Checking the SXGA's red video

circuit and its

peripheral circuits

Is there signal at pin (139) of IC8606?

Yes

Are there signals at pins (21), (22),

(24) thru (28) and (34) thru (41) of

IC8606?

Yes