Page 1

PG-A20X

SERVICE MANUAL

SERVICE-ANLEITUNG

S83G3PG-A20XU

LCD PROJECTOR

LCD PROJEKTOR

MODEL

MODELL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. A ußerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

PG-A20X

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

PG-A20X

• SPECIFICATIONS ............................................. 3

• IMPORTANT SERVICE SAFETY

NOTES (for USA)............................................... 4

• NOTE TO SERVICE PERSONNEL ................... 5

• OPERATION MANUAL ...................................... 9

• DIMENSIONS .................................................. 15

• REMOVING OF MAJOR PARTS...................... 16

• RESETTING THE TO TAL LAMP TIMER .......... 20

• THE OPTICAL UNIT OUTLINE ....................... 21

• ELECTRICAL ADJUSTMENT.......................... 23

• TROUBLE SHOOTING TABLE ........................ 31

• CHASSIS LAYOUT........................................... 70

CONTENTS

Page Page

• BLOCK DIAGRAM ........................................... 72

• OVERALL WIRING DIAGRAM......................... 74

• DESCRIPTION OF SCHEMATIC DIAGRAM... 76

• WAVEFORMS .................................................. 77

• SCHEMATIC DIAGRAM .................................. 78

• PRINTED WIRING BOARD ASSEMBLIES ... 105

• PARTS LIST

Ë

ELECTRICAL PARTS............................... 108

Ë

CABINET AND MECHANICAL PARTS .... 118

Ë

ACCESSORIES PARTS ........................... 122

Ë

PACKING PARTS ..................................... 122

• PACKING OF THE SET ................................. 123

Seite Seite

• TECHNISCHE DATEN..................................... 38

• HINWEISE FÜR DAS

WARTUNGSPERSONAL................................. 39

• BEDIENUNGSANLEITUNG............................. 41

• ABMESSUNGEN ............................................. 47

• ENTFERNEN DER HAUPTTEILE ................... 48

• RÜCKSTELLEN DES

LAMPENBETRIEBSZEIT-TIMERS.................. 52

• BESCHREIBUNG DER OPTIK-EINHEIT ........ 53

• ELEKTRISCHE EINSTELLUNG ...................... 55

• FEHLERSUCHTABELLE ................................. 63

• CHASSIS-ANORDNUNG ................................ 70

• BLOCKSCHALTBILD ....................................... 72

INHALT

• GESAMTSCHALTPLAN................................... 74

• BESCHREIBUNG DES SCHEMATISCHEN

• WELLENFORMEN........................................... 77

• SCHEMATISCHER SCHALTPLAN.................. 78

• LEITERPLATTENEINHEITEN ....................... 105

• ERSATZTEILLISTE

• VERPACKEN DES GERÄTS ......................... 123

SCHALTPLANS ............................................... 76

Ë

ELEKTRISCHE BAUTEILE ...................... 108

Ë

GEHÄUSE UND MECHANISCHE

BAUTEILE ................................................ 118

Ë

ZUBEHÖRTEILE...................................... 122

Ë

VERPACKUNGSTEILE ............................ 122

2

Page 3

Specifications

PG-A20X

Product type

Model

Video system

Display method

LCD panel

Standard lens

Projection lamp

Component input signal

(INPUT1)

Horizontal resolution

Computer RGB input signal

(INPUT 1)

S-video input signal

(INPUT 2)

Video input signal

(INPUT 3)

Computer control signal (RS-232C)

Pixel clock

Vertical frequency

Horizontal frequency

Audio input signal

Audio output

Speaker system

Rated voltage

Input current

Rated frequency

Power consumption

Power consumption (standby)

Heat dissipation

Operating temperature

Storage temperature

Cabinet

I/R carrier frequency

Dimensions (approx.)

Weight (approx.)

Supplied accessories

Replacement parts

LCD Projector

PG-A20X

NTSC3.58/NTSC4.43/PAL/PAL-M/PAL-N/PAL-60/SECAM/

DTV480 /DTV480P/DTV540P/DTV580 /DTV580P/DTV720P/DTV1035 /DTV1080

LCD panel 3, RGB optical shutter method

Panel size: 0.79" (20.0 mm) (12 [H] 16 [W] mm)

No. of dots: 786,432 dots (1,024 [H] 768 [V])

1–1.2 zoom lens, F1.7–1.94, f = 26–31 mm

SHP 180 W lamp

15-pin mini D-sub connector

Y: 1.0 Vp-p, sync negative, 75 terminated

: 0.7 Vp-p, 75 terminated

P

B

P

: 0.7 Vp-p, 75 terminated

R

700 TV lines (DTV720P)

15-pin mini D-sub connector

RGB separate/sync on green type analog input: 0–0.7 Vp-p, positive, 75 terminated

HORIZONTAL SYNC. SIGNAL: TTL level (positive/negative)

VERTICAL SYNC. SIGNAL: Same as above

4-pin mini DIN connector

Y (luminance signal): 1.0 Vp-p, sync negative, 75 terminated

C (chrominance signal): Burst 0.286 Vp-p, 75 terminated

RCA connector: VIDEO, composite video, 1.0 Vp-p, sync negative, 75

terminated

9-pin mini DIN connector

12–108 MHz

43–85 Hz

15–70 kHz

ø3.5 mm minijack: AUDIO, 0.5 Vrms, more than 47 k (stereo)

1.0 W (monaural)

2.8 cm round 1

AC 110–240 V

2.3 A

50/60 Hz

240 W (Standard mode)/200 W (Eco mode) with AC 110 V

235 W (Standard mode)/195 W (Eco mode) with AC 240 V

4 W (AC 110 V) – 6 W (AC 240 V)

900 BTU/hour (Standard mode)/750 BTU/hour (Eco mode) with AC 110 V

880 BTU/hour (Standard mode)/730 BTU/hour (Eco mode) with AC 240 V

41°F to 95°F (+5°C to +35°C)

–4°F to 140°F (–20°C to +60°C)

Plastic

38 kHz

45

11

45

11

and projecting parts)

6.4 lbs. (2.9 kg)

Remote control, Two R-6 batteries, Power cord for U.S., Canada, etc. (6', 1.8 m), Power

cord for Europe, except U.K. (6', 1.8 m), Power cord for U.K., Hong Kong and Singapore (6',

1.8 m), Power cord for Australia, New Zealand and Oceania (6', 1.8 m), RGB cable (9'10",

3.0 m), Carrying case, Lens cap (attached), Extra air filter, Projector manual and technical

reference CD-ROM, “QUICK GUIDE” label, Operation manual

Lamp unit (Lamp/cage module) (BQC-PGA20X//1), Remote control (RRMCGA187WJSA),

Two R-6 batteries (“AA” size, UM/SUM-3, HP-7, or similar), Power cord for U.S., Canada etc.

(QACCDA016WJPZ), Power cord for Europe, except U.K. (QACCVA006WJPZ), Power cord

for U.K., Hong Kong and Singapore (QACCBA015WJPZ), Power cord for Australia, New

Zealand and Oceania (QACCLA005WJPZ), RGB cable (QCNWGA012WJPZ), Carrying case

(GCASNA006WJSA), Lens cap (CCAPHA012WJ01), Air filter (PFILDA008WJZZ), Projector

manual and technical reference CD-ROM (UDSKAA037WJZZ), “QUICK GUIDE” label

(TLABZA191WJZZ), Operation manual (TINS-A850WJZZ)

×

×

×

×

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

×

/64" 3 13/64" 9 1/32" (297 (W) 81 (H) 229 (D) mm) (main body only)

×× ××

/64" 3 33/64" 9 1/32" (297 (W) 89 (H) 229 (D) mm) (including adjustment foot

×× ××

III I

As a part of policy of continuous improvement, SHARP reserves the right to make design

and specification changes for product improvement without prior notice. The performance

specification figures indicated are nominal values of production units. There may be

some deviations from these values in individual units.

3

Page 4

PG-A20X

2

2

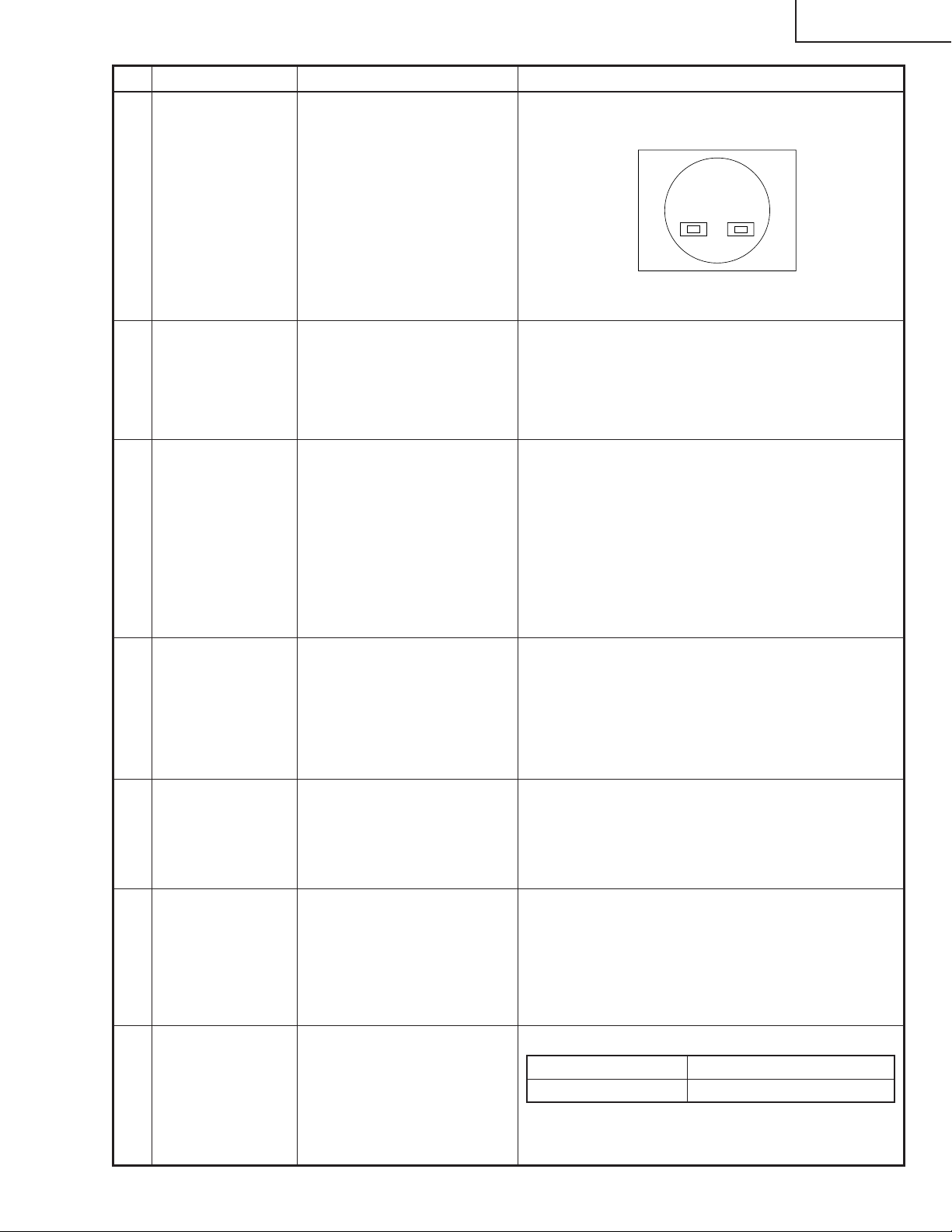

IMPORTANT SERVICE SAFETY NOTES (for USA)

Ë Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the chassis

and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

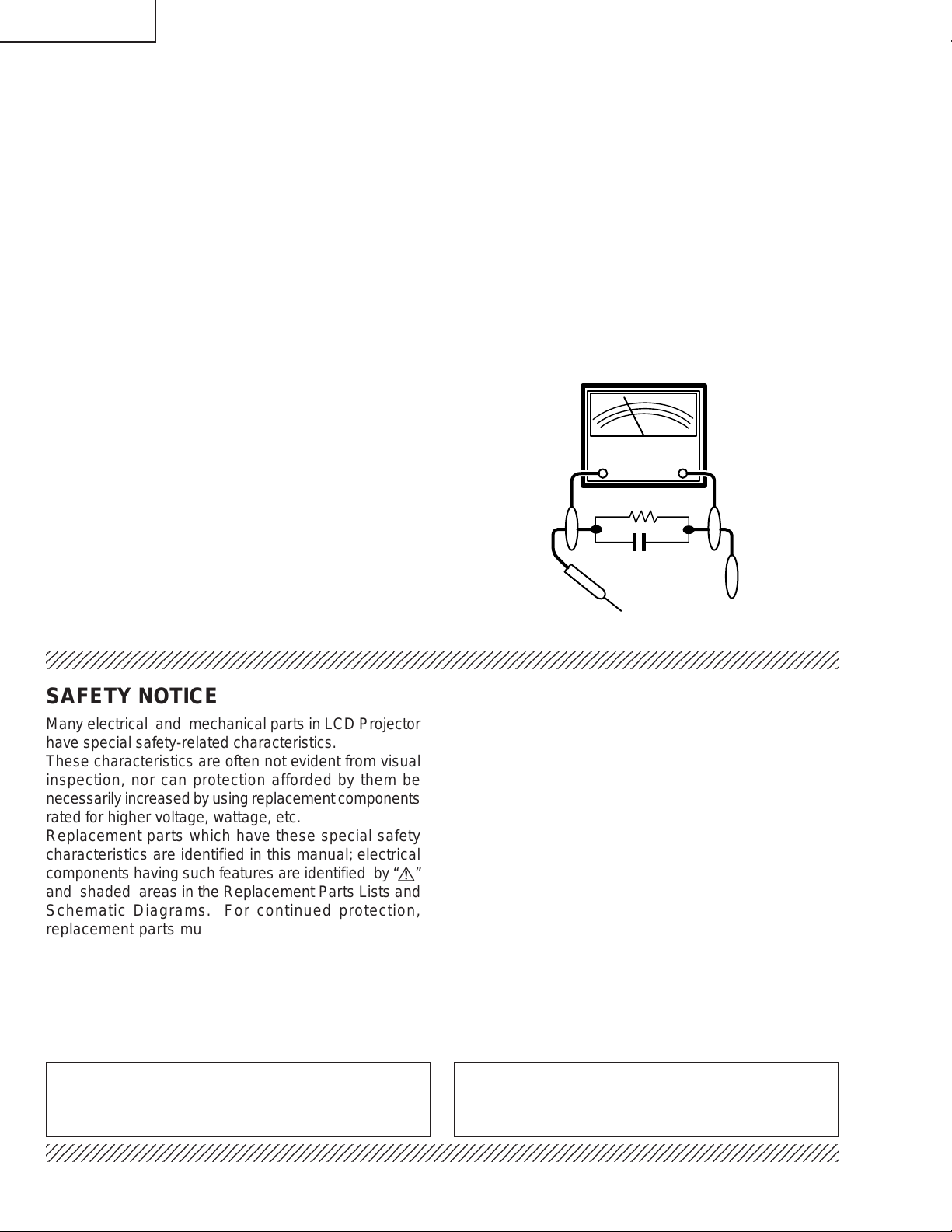

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

» Plug the AC cord directly into a 120-volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

» Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher , sensitivity to measure the A C voltage

drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessar y, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to 0.2

milliamp. AC.) or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the unit to the owner.

AC

VOLTMETER

1.5k ohm (10W)

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in LCD Projector

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in

the original circuit. The use of a substitute replacement

parts which do not have the same safety characteristics

as the factory recommended replacement parts shown

in this service manual, may create shock, fire or other

hazards.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à LCD présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent pas

évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par l’usine,

indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

AVERTISSEMENT:La composante bimétallique dispose du

conducteur primaire dénudé. Faire attention

lors de la manipulation de cette

composante sous tension.

4

Page 5

PG-A20X

NOTE TO SERVICE

PERSONNEL

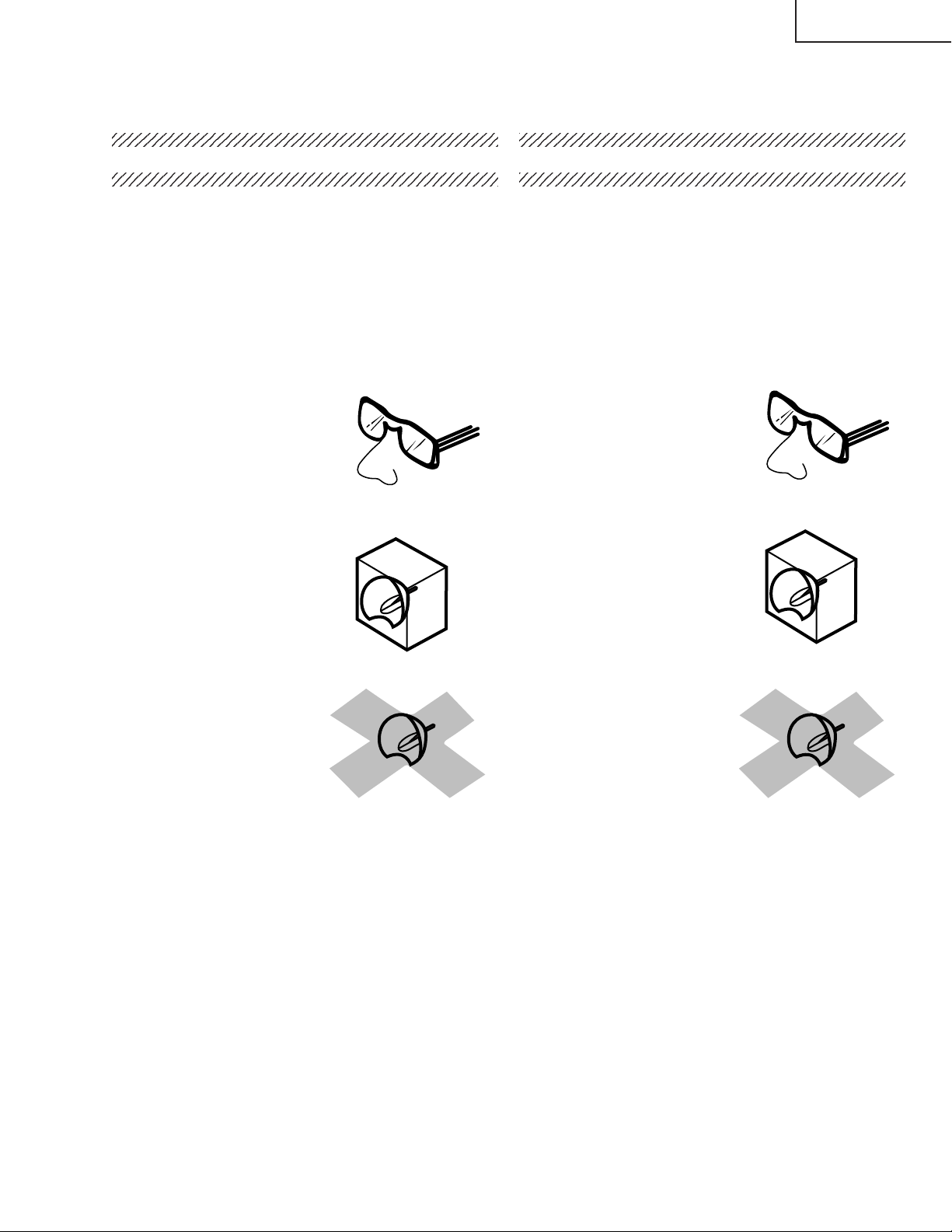

UV-RADIATION PRECAUTION

The light source, UHP lamp, in the LCD projector

emits small amounts of UV-Radiation.

AVOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NO TE POUR LE PERSONNEL

D’ENTRETIEN

PRECAUTION POUR LES RADIATIONS UV

La source de lumière, la lampe UHP, dans le pr ojecteur

LCD émet de petites quantités de radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE DES

YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

1. T oujours porter des lunettes de soleil lors d’un entretien

du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du boîtier

de lampe.

3. Do not operate for more than 2 hours with the enclosure

removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing the

lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type BQCPGA20X//1 rated 110V/180W.

4. The lamp emits small amounts of UV-Radiation, a v oid

direct-eye contact.

5. The medium pressure lamp involves a risk of explosion.

Be sure to follow installation instructions described

below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le coffret

retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. T oujours débrancher la fiche AC lors du remplacement

de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type. Type

BQC-PGA20X//1, caractéristique 110V/180W.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la lampe

avec soin.

5

Page 6

PG-A20X

6

6

6

6

2345678901234567890123456789012123456789012345

UV-RADIATION PRECAUTION (Continued)

2345678901234567890123456789012123456789012345

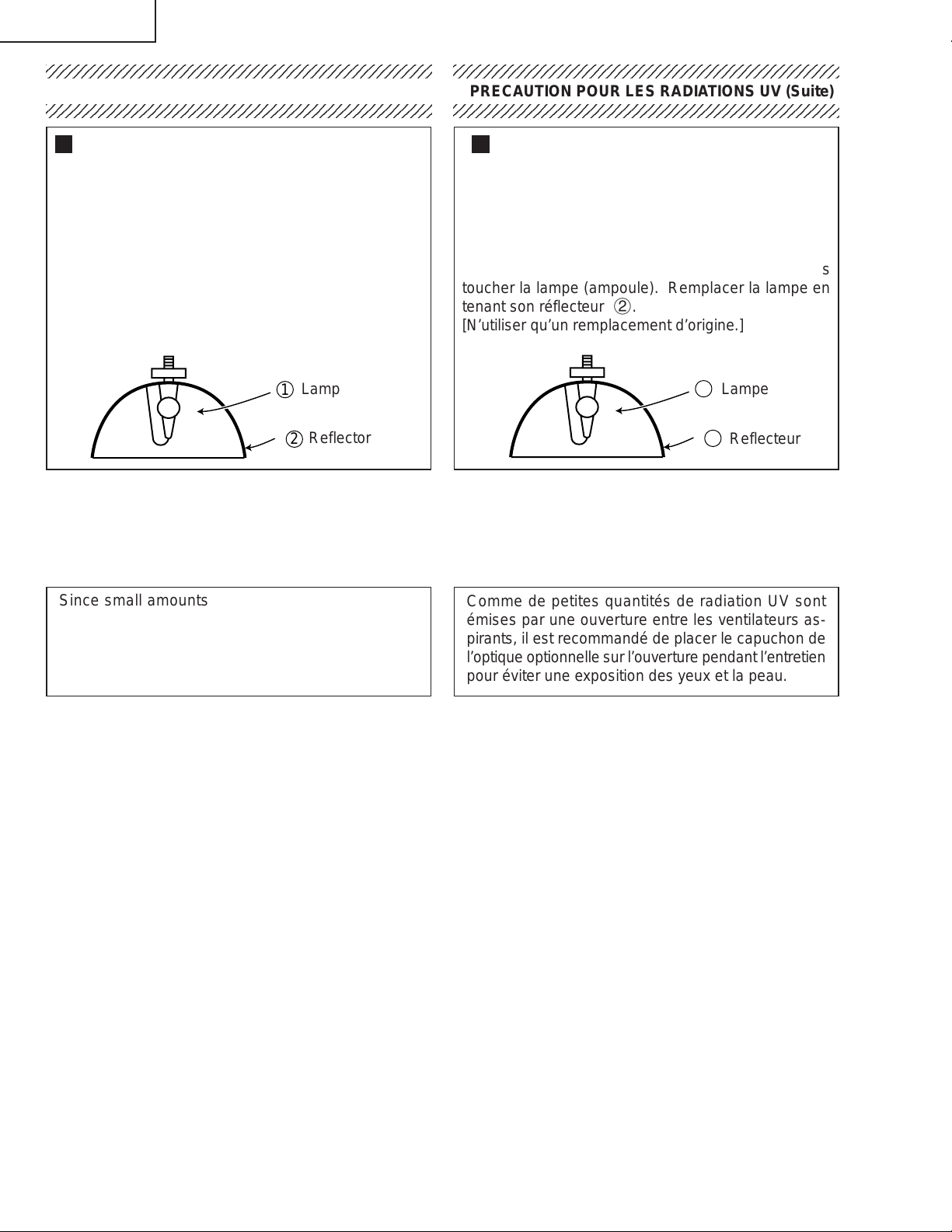

Lamp Replacement

Note:

Since the lamp reaches a very high temperature during

units operation replacement of the lamp should be

done at least one hour after the power has been turned

off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the de vices

since the stabilizer generates high voltages at its start.

2345678901234567890123456789012123456789012345

PRECAUTION POUR LES RADIATIONS UV (Suite)

2345678901234567890123456789012123456789012345

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

1

Lampe

2

Reflecteur

DANGER ! –– Ne jamais mettre sous tension sans la

lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

Since small amounts of UV-radiation are emitted

from an opening between the exhaust fans , it is recommended to place the cap of the optional lens on

the opening during servicing to avoid eye and skin

exposure.

Comme de petites quantités de radiation UV sont

émises par une ouverture entre les ventilateurs aspirants, il est recommandé de placer le capuchon de

l’optique optionnelle sur l’ouverture pendant l’entretien

pour éviter une exposition des yeux et la peau.

6

Page 7

PG-A20X

WARNING: High brightness light source, do not stare into the beam of light, or view directl y . Be especially

careful that children do not stare directly in to the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE CABINET.

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT.

REFER SERVICING T O Q U ALIFIED SER VICE

PERSONNEL.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

CAUTION

(POWER Unit)

6.3A 250V

AVERTISSEMENT: Source lumineuse de grande intensité. Ne pas fix er le faisceau lumineux ou le regarder

For continued

protection against a

risk of fire, replace

only with same type

6.3A, AC250V fuse.

(F701)

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

A VERTISSEMENT : AFIN D’EVITER T OUT RISQ UE D’INCENDIE OU D’ELECTROCUTION, NE PAS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

RISQUE

D’ÉLECTROCUTION. NE

P ASR ETIRER LES VIS Á

L’EXCEPTION DE LA VIS DE

REPARATION UTILISATEUR

SPECIFIEES

ATTENTION: POUR EVITER TOUT RISQUE

D’ELECTR OCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR L ’UTILISA TEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR T OUTE REPARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QU ALIFIE.

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

PRECAUTION

(Unité de PUTSSANCE)

6.3A 250V

Pour une protection

continue contre un

risques d’incendie, ne

remplacer qu’avec un

fusible 6.3A,AC250V

du même type.

(F701)

7

Page 8

PG-A20X

Precautions for using lead-free solder

1 Employing lead-free solder

"PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the

PWBs and service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend y ou

to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit,

contact our service station or service branch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead solder

by 40°C, and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the PWB for

extended period of time. Ho we v er, since the land may be peeled off or the maximum heat-resistance temperature of

parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on

and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is allo yed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

8

Page 9

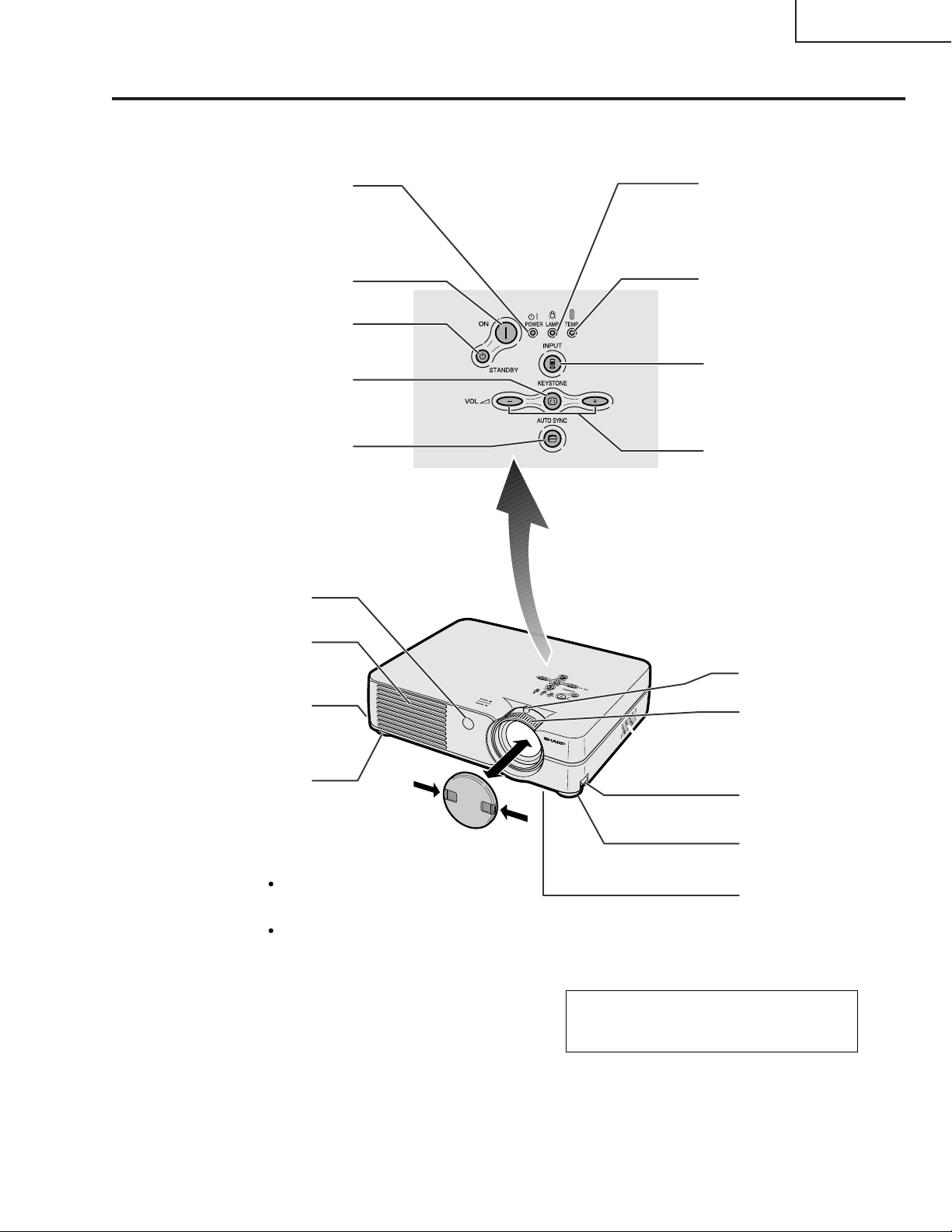

Operation Manual

Projector (Front and Top View)

PG-A20X

Power indicator

Illuminates red when the

projector is in standby.

When the power is turned

on, this indicator will

illuminate green.

ON button

For turning the power on.

STANDBY button

For putting the projector into the

standby mode.

KEYSTONE button

For entering the Keystone

Correction mode.

AUTO SYNC button

For automatically

adjusting images when

connected to a computer.

Remote control

sensor

Lamp indicator

Illuminates green indicating

normal function. Replace

the lamp when the indicator

illuminates red.

Temperature warning

indicator

When the internal

temperature rises, this

indicator will illuminate red.

INPUT button

For switching input mode

1, 2 or 3.

Volume buttons

For adjusting the speaker

sound level or the

Keystone Correction.

Exhaust vent

Foot release

(on the side of

the projector)

Front adjustment foot

Attaching and removing the lens cap

Press on the two buttons of the lens cap

and attach it to the lens, then release the

buttons to lock it in place.

Press on the two buttons of the lens cap

and remove it from the lens.

Zoom knob

Focus ring

Speaker

Foot release

Front adjustment

foot

Air filter/cooling

fan (Intake vent)

(on the bottom of

the projector)

In this operation manual, the illustration and the

screen display are simplified for explanation,

and may differ slightly from actual display.

9

Page 10

PG-A20X

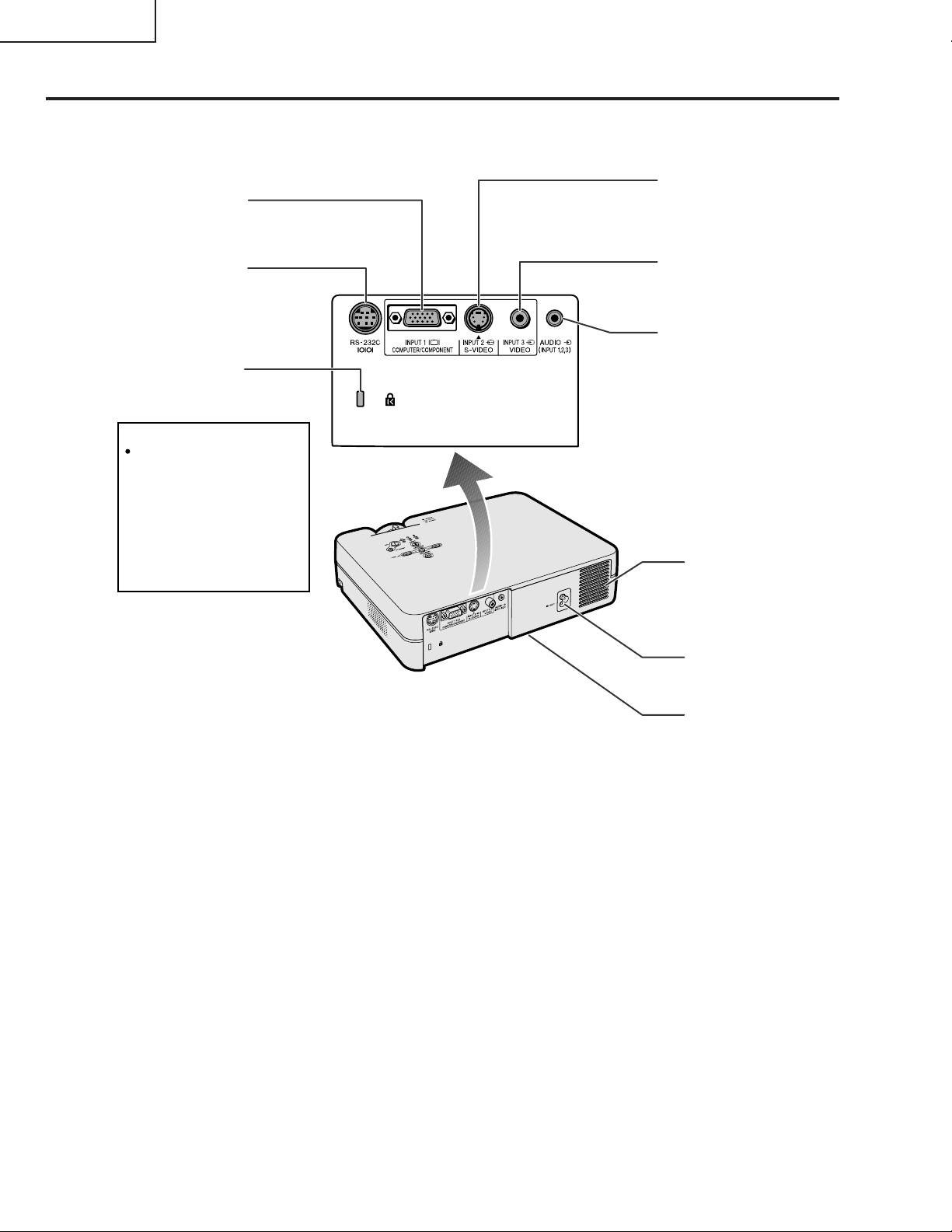

Projector (Rear View)

INPUT 1 terminal

Terminal for

computer RGB and

component signals.

RS-232C terminal

For controlling

the projector using a

computer.

Kensington Security

Standard connector

Using the Kensington Lock

This projector has a

Kensington Security Standard connector for use with

a Kensington MicroSaver

Security System. Refer to

the information that came

with the system for instructions on how to use it to secure the projector.

INPUT 2 terminal

Terminal for

connecting video

equipment with an

S-video terminal.

INPUT 3 terminal

Terminal for

connecting video

equipment.

AUDIO INPUT

terminal

Shared audio input

terminal for INPUT

1, 2 and 3.

Intake vent

AC socket

Rear adjustment

foot

(on the bottom of

the projector)

10

Page 11

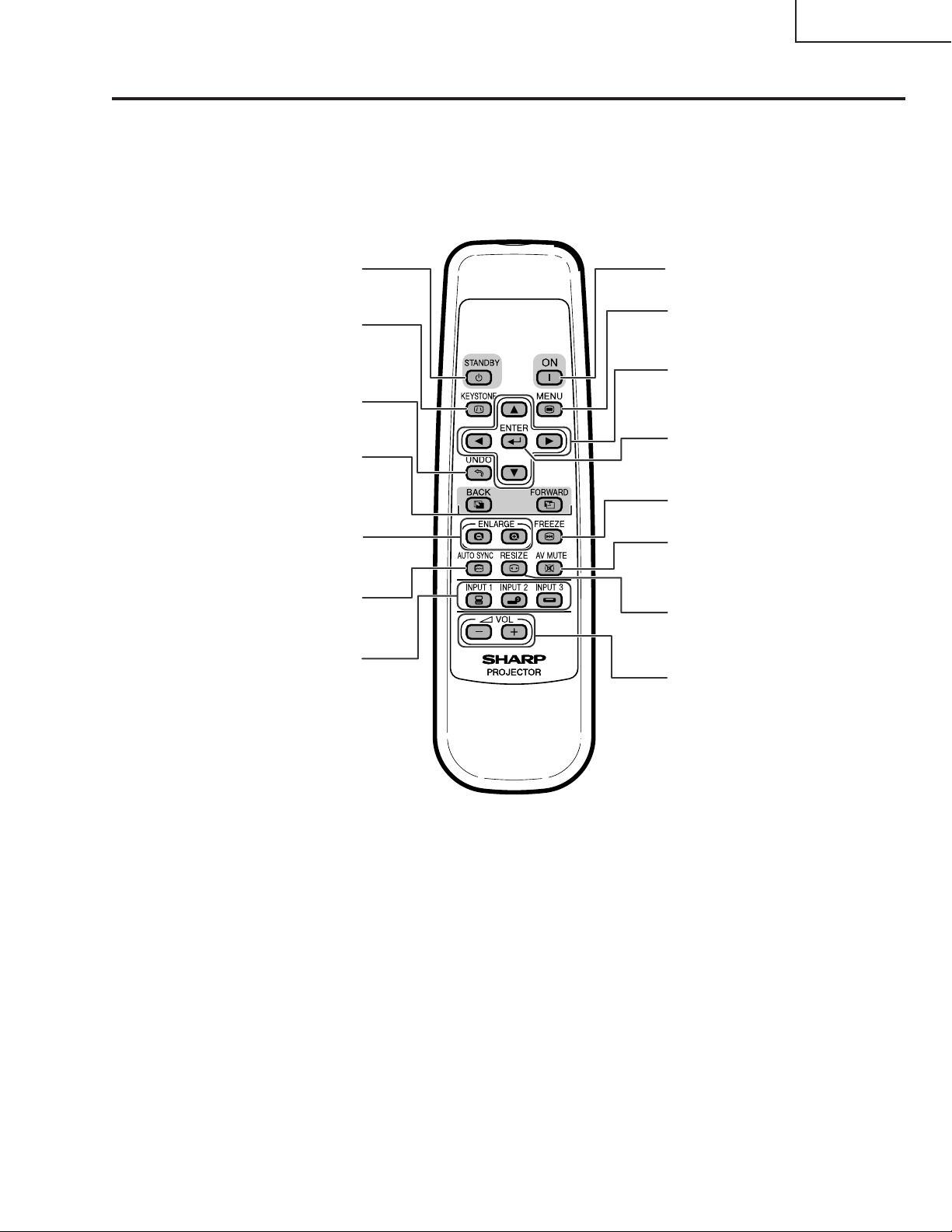

Remote Control (Front View)

PG-A20X

For putting the projector into the

STANDBY button

standby mode.

KEYSTONE button

For entering the Keystone

Correction mode.

UNDO button

For undoing an operation or

returning to the previous display.

FORWARD/BACK buttons

Same function as the [Page Down]

and [Page Up] keys on a computer

keyboard when using the optional

Remote Receiver (AN-MR1EL).

ENLARGE (Enlarge/Reduce)

buttons

For enlarging or reducing part of

the image.

AUTO SYNC button

For automatically adjusting images

when connected to a computer.

INPUT buttons

For switching to the respective

input modes.

ON button

For turning the power on.

MENU button

For displaying adjustment and

setting screens.

Adjustment buttons

(', ", \,|)

For selecting menu items.

ENTER button

For setting items selected or

adjusted on the menu.

FREEZE button

For freezing images.

AV MUTE button

For temporarily displaying the

black screen and turning off the

sound.

RESIZE button

For switching the screen size

(NORMAL, BORDER, etc).

Volume buttons

For adjusting the speaker sound

level.

11

Page 12

PG-A20X

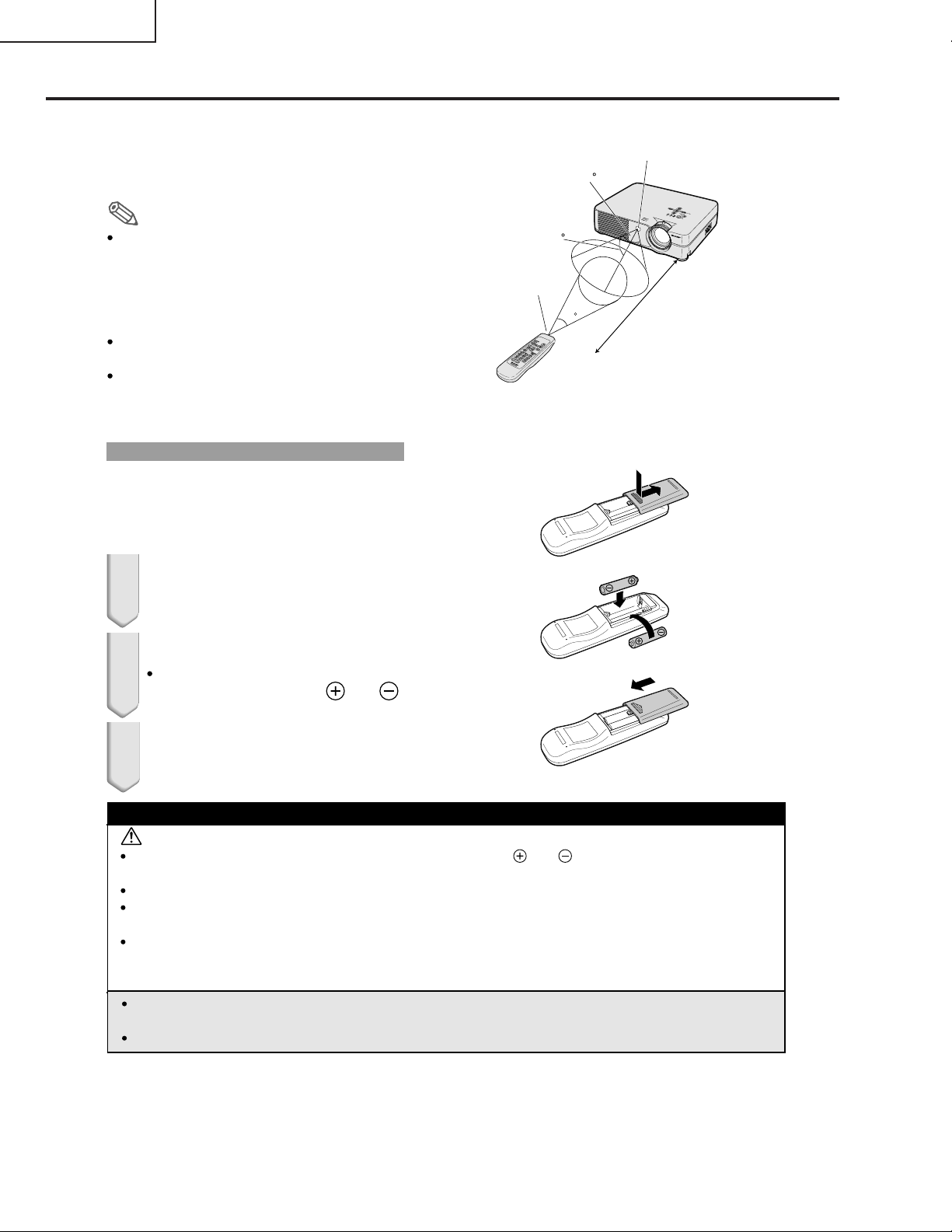

Usable Range

■ The remote control can be used to control

the projector within the ranges shown in

the illustration.

Note

The signal from the remote control can be reflected off a screen for easy operation. However, the effective distance of the signal may

differ depending on the screen material.

When using the remote control:

Be sure not to drop, expose to moisture or high

temperature.

The remote control may malfunction under a

fluorescent lamp. In this case, move the projector away from the fluorescent lamp.

Remote

control

signal

transmitters

Remote control

Remote control sensor

45

30

30

23' (7 m)

Inserting the Batteries

The batteries (two R-6 batteries (“AA” size, UM/

SUM-3, HP-7 or similar)) are supplied in the

package.

1

Press the ▲ mark on the cover

and slide it in the direction of the

arrow.

2

Insert the batteries.

Insert the batteries making sure the polarities correctly match the

marks inside the battery compartment.

3

Attach the cover and slide it until it clicks into place.

Incorrect use of the batteries may cause them to leak or explode. Please follow the precautions below.

Caution

Insert the batteries making sure the polarities correctly match the and marks inside the battery compartment.

Batteries of different types have different properties, therefore do not mix batteries of different types.

Do not mix new and old batteries.

This may shorten the life of new batteries or may cause old batteries to leak.

Remove the batteries from the remote control once they have run out, as leaving them in can cause them to leak.

Battery fluid from leaked batteries is harmful to skin, therefore be sure to first wipe them and then remove them

using a cloth.

and

The batteries included with this projector may run down in a short period, depending on how they are kept. Be

sure to replace them as soon as possible with new batteries.

Remove the batteries from the remote control if you will not be using the remote control for a long time.

12

Page 13

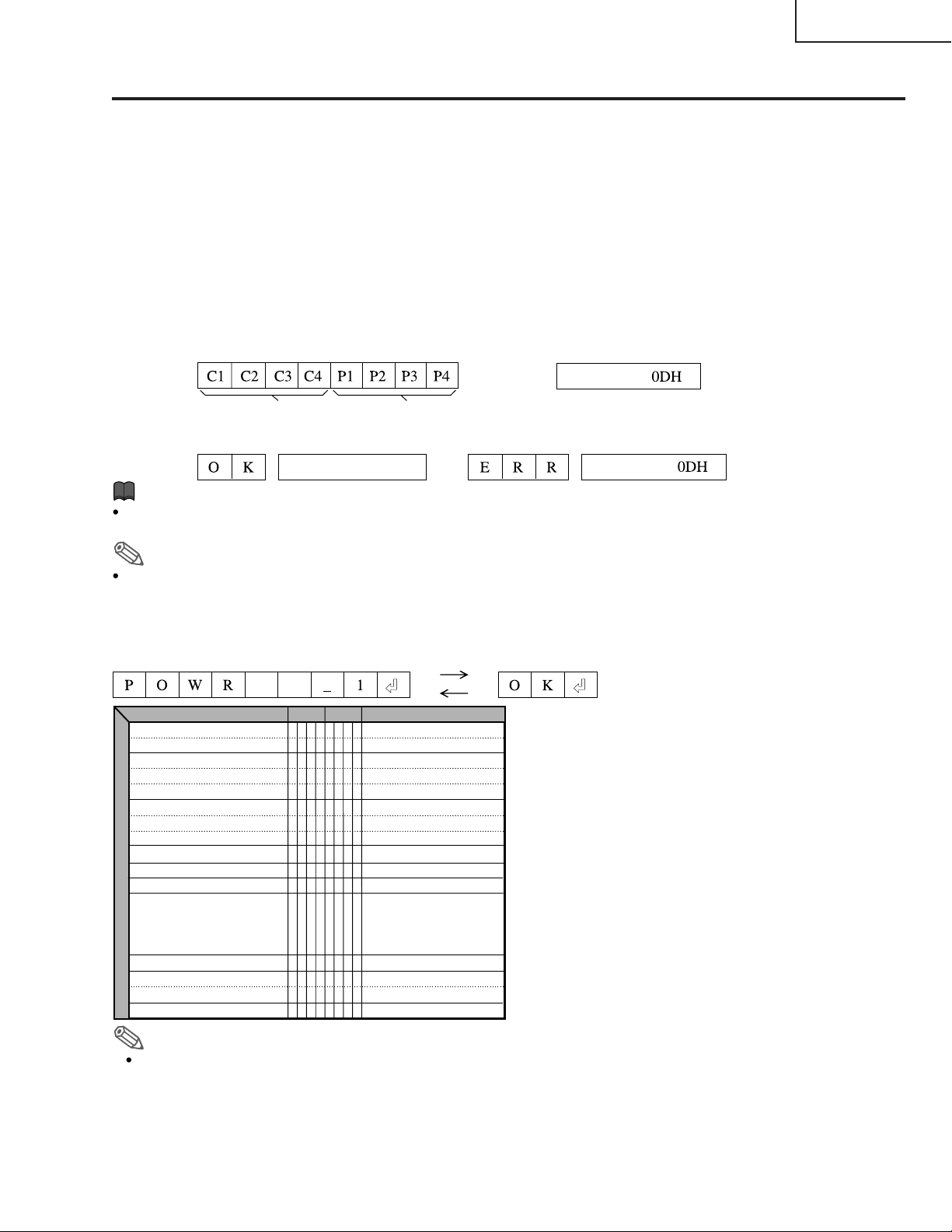

RS-232C Specifications and Command Settings

PC control

A computer can be used to control the projector by connecting an RS-232C serial control cable (cross type,

sold separately) to the projector. (See page 20 for connection.)

Communication conditions

Set the serial port settings of the computer to match that of the table.

Signal format: Conforms to RS-232C standard. Parity bit: None

Baud rate: 9,600 bps Stop bit: 1 bit

Data length: 8 bits Flow control: None

Basic format

Commands from the computer are sent in the following order: command, parameter, and return code. After

the projector processes the command from the computer, it sends a response code to the computer.

Command format

Return code ( )

Command 4-digit Parameter 4-digit

Response code format

Normal response

Return code (

0DH

Info

When more than one code is being sent, send each command only after the response code for the previous

command from the projector is verified.

Problem response (communication error or incorrect command)

)

Return code (

)

PG-A20X

Note

When the projector is put into the standby mode, a message “Shutting Down. Please Wait.” is displayed for

about 20 seconds. At that time, if the “POWR_ _ _1” command is being sent, “ERR” will be returned and this

command is not received.

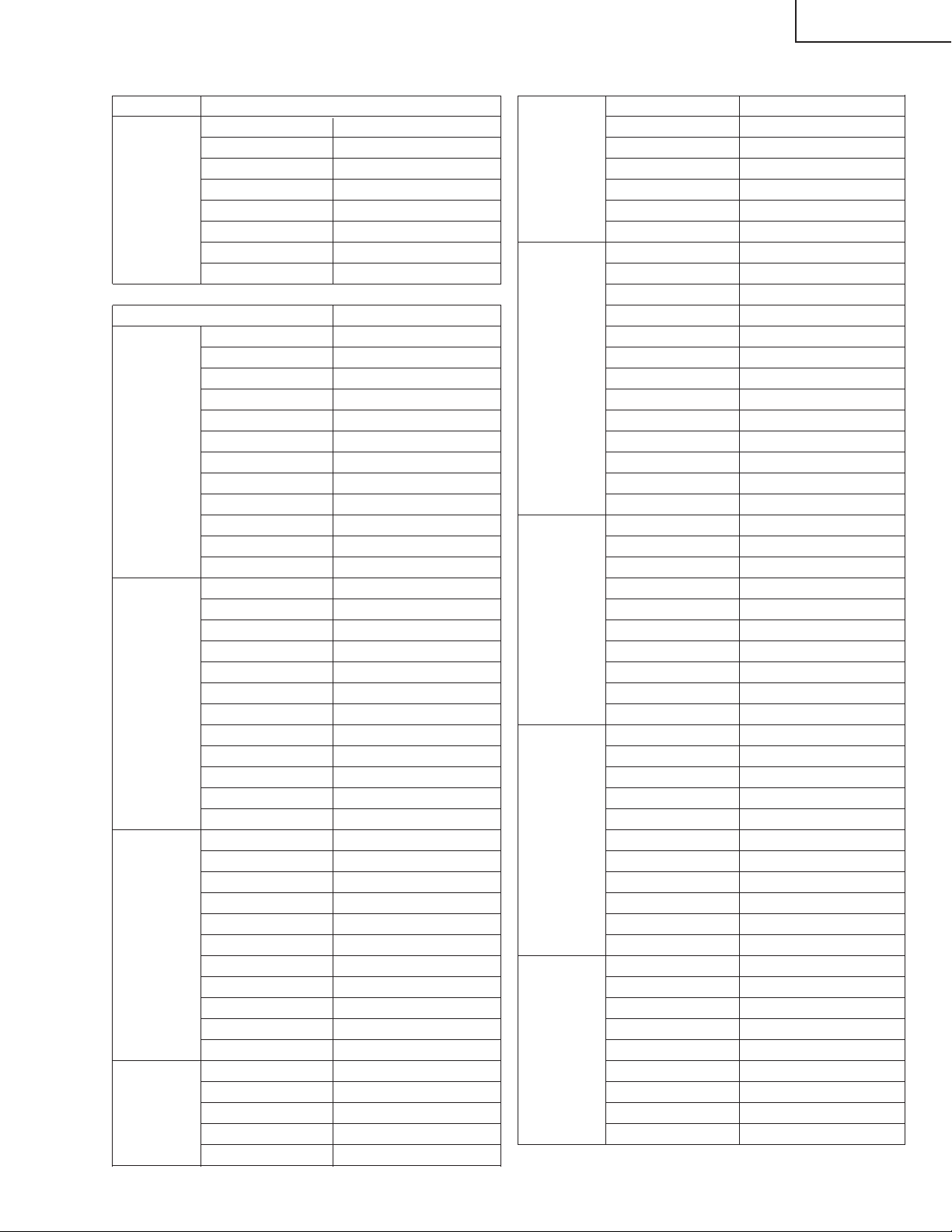

Commands

Example: When turning on the projector, make the following setting.

__

CONTROL CONTENTS

Standby

Power On

INPUT1

INPUT2

INPUT3

INPUT1 SIGNAL TYPE : AUTO

INPUT1 SIGNAL TYPE : RGB

INPUT1 SIGNAL TYPE : COMPONENT

Lamp Usage Time (hour)

Remaining Lamp Life (Percentage)

Lamp Status

Unit Status

BUTTONS & REMOTE CONTROL KEY

Model Name Check

AV Mute Off

AV Mute On

Auto Sync Start

COMMAND

W

O

P

W

O

P

G

R

I

E

V

I

E

V

I

S

A

I

S

A

I

S

A

I

T

L

T

T

L

T

P

L

T

B

A

T

A

N

T

B

M

I

B

M

I

J

D

A

PARAMETER

_

R

_

R

_

B

_

D

_

D

_

I

_

I

_

I

_

T

_

L

_

S

_

N

_

M

_

K

_

K

_

S

RETURN

0

_

_

OK or ERR

1

_

_

OK or ERR

1

_

_

OK or ERR

1

_

_

OK or ERR

2

_

_

OK or ERR

0

_

_

OK or ERR

1

_

_

OK or ERR

2

_

_

OK or ERR

1

_

_

0~9999

1

_

_

0~100

1

_

_

0:Off, 1:On, 2:Retry, 3:Waiting, 4:Lamp Error

1

_

_

0:Normal, 1:Temp High, 2:Fan Err,

4:Filter Cover Err, 8:Lamp Life 5% or less,

16:Lamp Burnt-out, 32:Lamp Not Lit,

64:Temp Abnormally High

1

_

_

PROJECTOR NAME

0

_

_

OK or ERR

1

_

_

OK or ERR

1

_

_

OK or ERR

ProjectorComputer

Note

If an underbar (_) appears in the parameter column, enter a space. If an asterisk (*) appears, enter a

value in the range indicated in brackets under CONTROL CONTENTS.

13

Page 14

PG-A20X

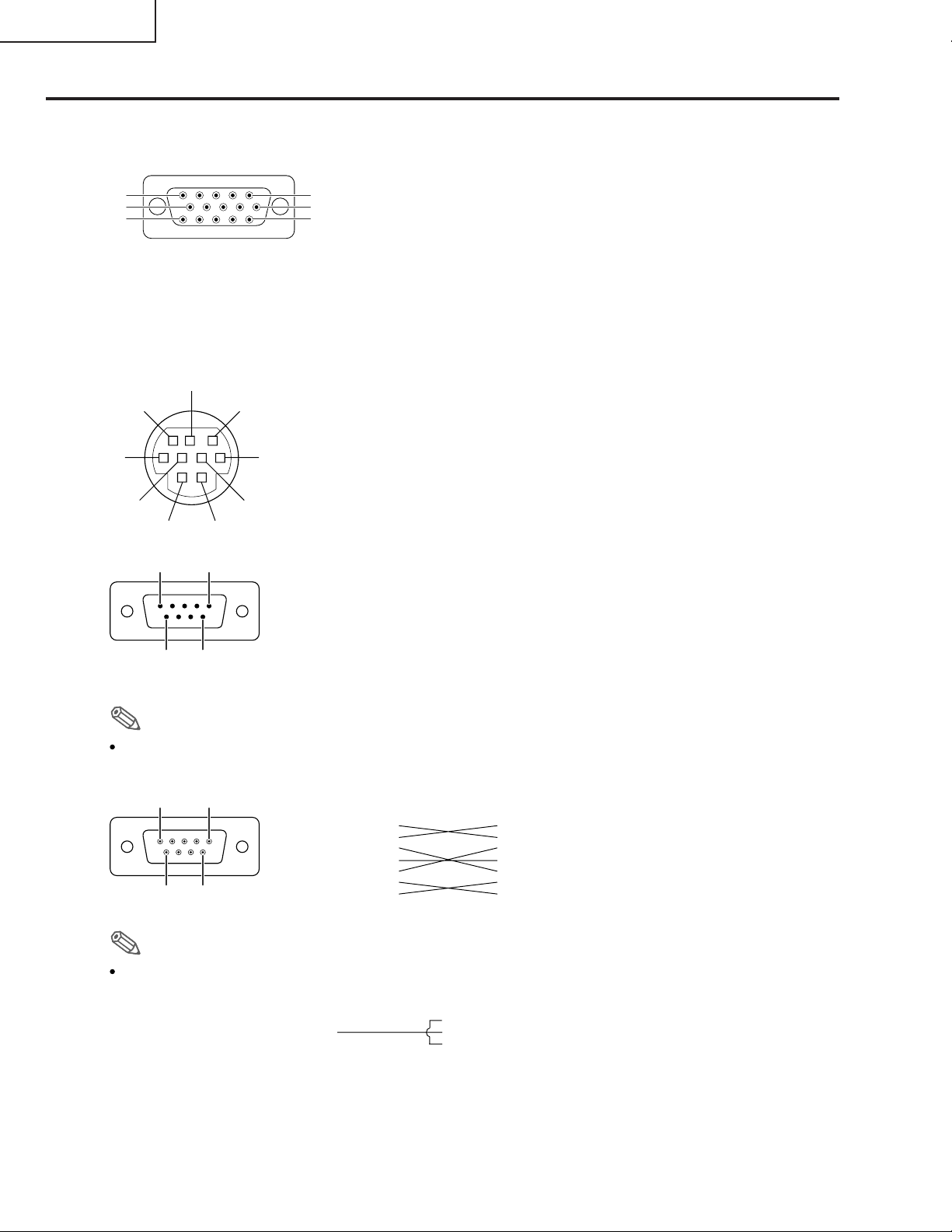

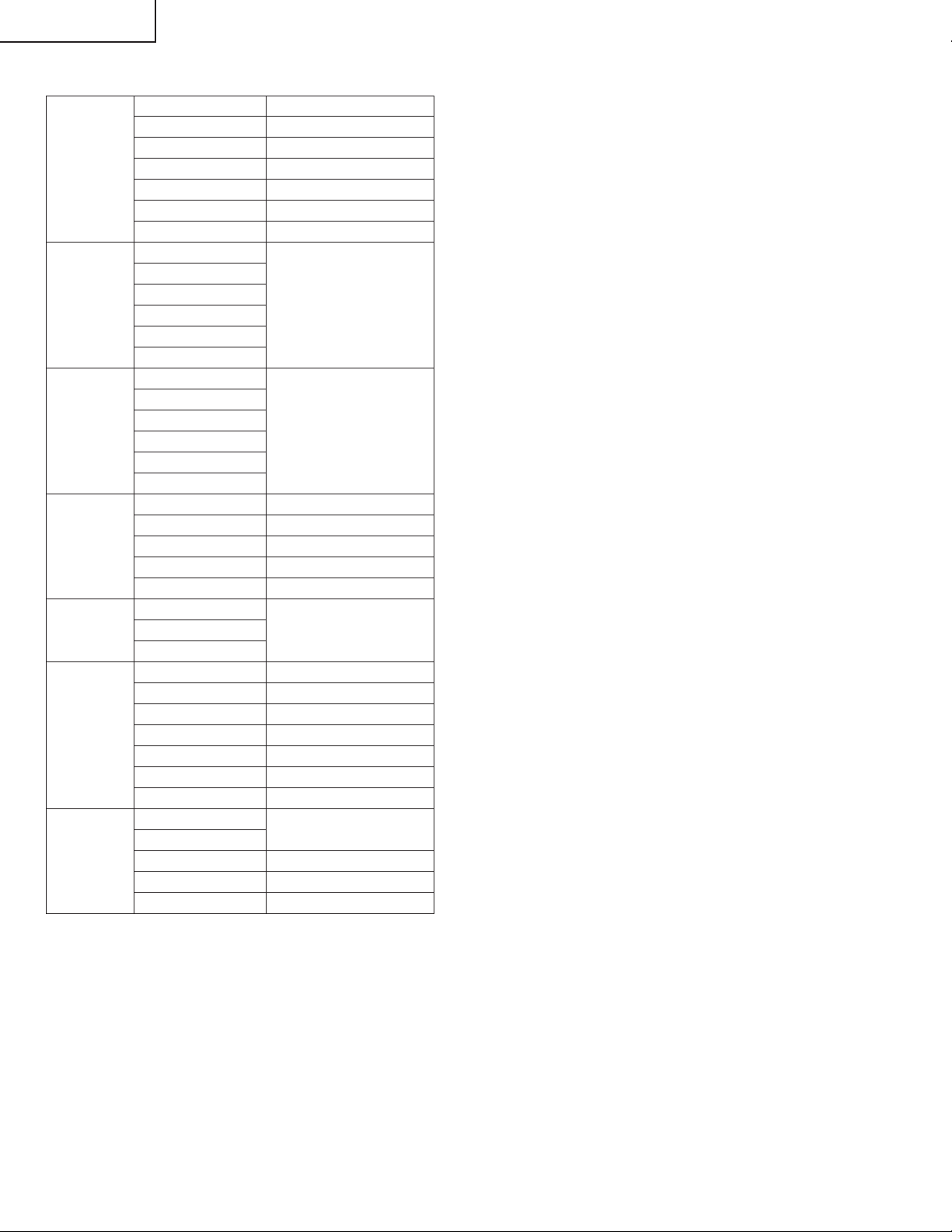

Connection Pin Assignments

INPUT 1 RGB Signal Terminal: 15-pin Mini D-sub female connector

RGB Input

1. Video input (red)

2. Video input (green/sync on green)

3. Video input (blue)

4. Not connected

5. Not connected

6. Earth (red)

7. Earth (green/sync on green)

8. Earth (blue)

9. Not connected

10. GND

11. Not connected

12. Bi-directional data

13. Horizontal sync signal: TTL level

14. Vertical sync signal: TTL level

15. Data clock

10

15

5

1

6

11

RS-232C Terminal:9-pin Mini DIN female connector

8

9

6

5

7

3

4

21

Pin No. Signal Name I/O Reference

1 Not connected

2 RD Receive Data Input Connected to internal circuit

3 SD Send Data Output Connected to internal circuit

4 Not connected

5 SG Signal Ground Connected to internal circuit

6 Not connected

7 RS Connected to Pin 8

8 CS Connected to Pin 7

9 Not connected

9-pin D-sub male connector of the DIN-D-sub RS-232C adaptor

15

69

Pin No. Signal Name I/O Reference

1 Not connected

2 RD Receive Data Input Connected to internal circuit

3 SD Send Data Output Connected to internal circuit

4 Not connected

5 SG Signal Ground Connected to internal circuit

6 Not connected

7 RS Connected to internal circuit

8 CS Connected to internal circuit

9 Not connected

Component Input

1. PR (CR)

2. Y

B

(CB)

3. P

4. Not connected

5. Not connected

6. Earth (P

7. Earth (Y)

8. Earth (P

9. Not connected

10. Not connected

11. Not connected

12. Not connected

13. Not connected

14. Not connected

15. Not connected

)

R

)

B

Note

Pin 8 (CS) and Pin 7 (RS) are short circuited inside the projector.

RS-232C Cable recommended connection: 9-pin D-sub female connector

51

96

Pin No. Signal Pin No. Signal

1CD 1 CD

2RD 2 RD

3SD 3 SD

4ER 4 ER

5SG 5 SG

6DR 6 DR

7RS 7 RS

8CS 8 CS

9CI 9 CI

Note

Depending on the controlling device used , it may be necessary to connect Pin 4 and Pin 6 on the controlling

device (e.g. PC).

Projector

Pin No.

4

5

6

PC

Pin No.

4

5

6

14

Page 15

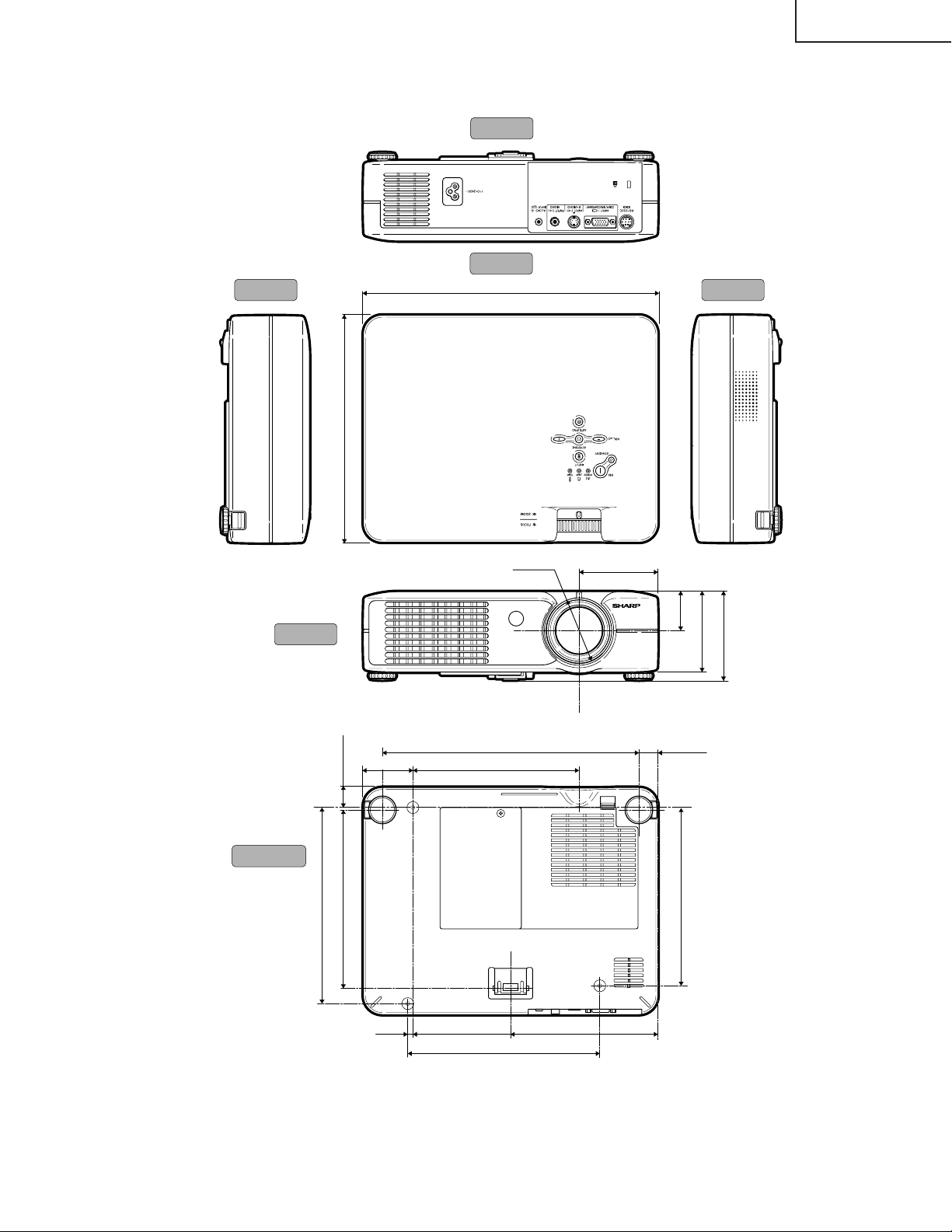

DIMENSIONS

Rear View

Top View

45

11

Side View Side View

(229)

32

/

1

9

/64 (297)

PG-A20X

Front View

Bottom View

(198.5)

64

/

53

7

(19.5)

32

/

25

(180)

32

/

3

7

159/64 (48.5)

13

/64 (5)

M4

9

3

/64 (79.5)

(39.2)

64

/

35

1

49

/64 (19.1)

(180.5)

64

/

7

7

(81)

64

/

13

3

(89)

64

/

33

3

ø 66.4

13

/64 (258.8)

10

21

6

/32 (169)

M4

M4

55

/64 (148.5)

5

11

/16 (195)

7

15

Unit: inches (mm)

Page 16

PG-A20X

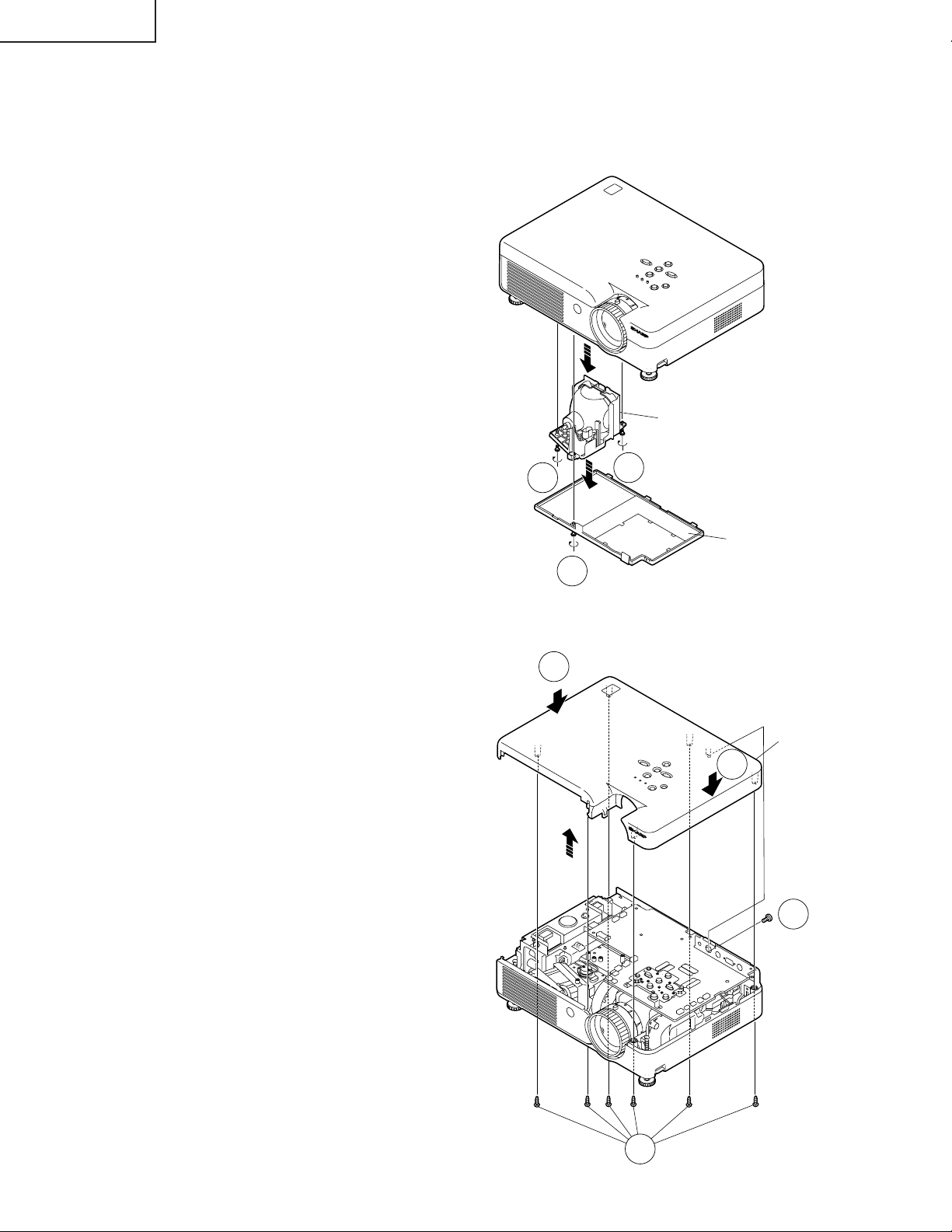

REMOVING OF MAJOR PARTS

1.Removing the lamp unit.

1-1. Loosen a screw and detach the lamp door.

1-2. Loosen the two screws. Hold the lamp unit by the handle and pull it in the direction of allow.

Lamp Unit

2.Removing the top body

2-1. Remove a screw from behind of the set.

2-2. Remove the six lock screws from bottom of the set.

2-3. Remove the two hooks and detach the top body.

1-2

1-2

Lamp Door

1-1

2-3

Top Body

2-3

2-1

16

2-2

Page 17

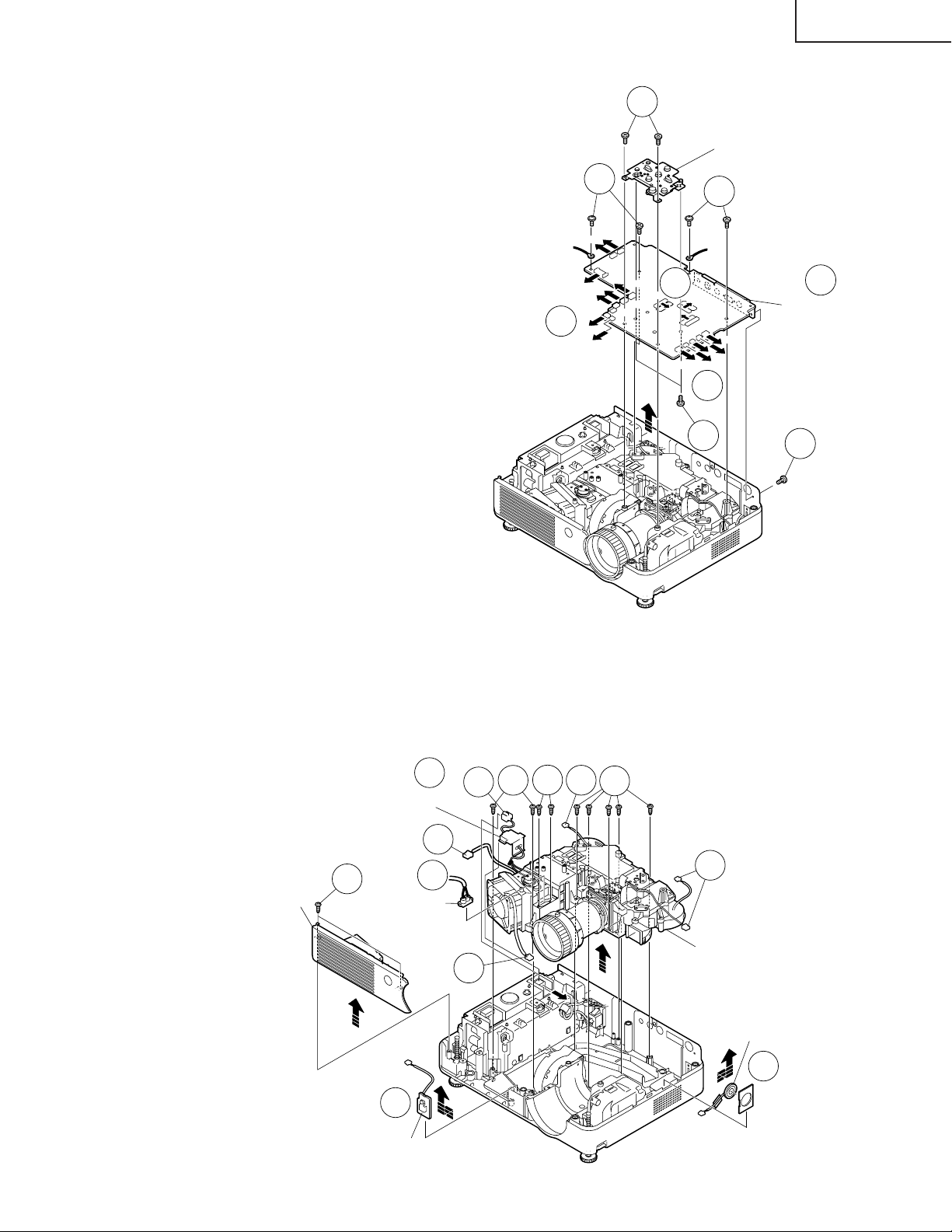

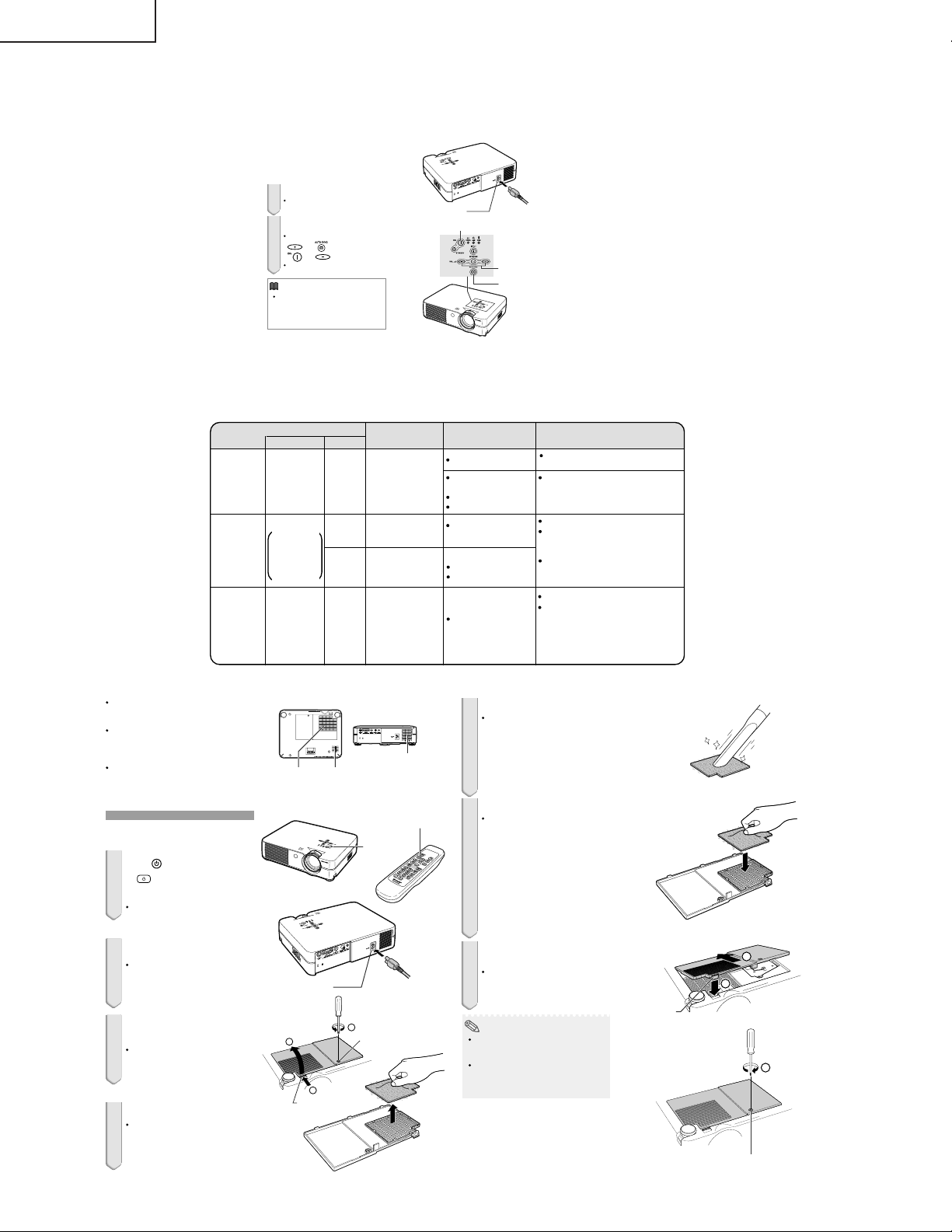

3.Removing the main PWB unit

3-1. Remove the seven screws.

3-2. Remove all the connectors from main PWB.

3-3. Detach the main PWB.

3-4. Remove the two screws and detach the operation

button unit.

[FA]

PG-A20X

3-1

Operation Button

3-1

3-1

[FC]

3-2

[EA]

[TF]

3-2

[BP]

[FD]

[FG]

[RC]

[LF]

[FE]

[TH]

[GP]

[RP]

[FB]

[SP]

[TI]

3-3

MAIN PWB

3-2

3-4

3-1

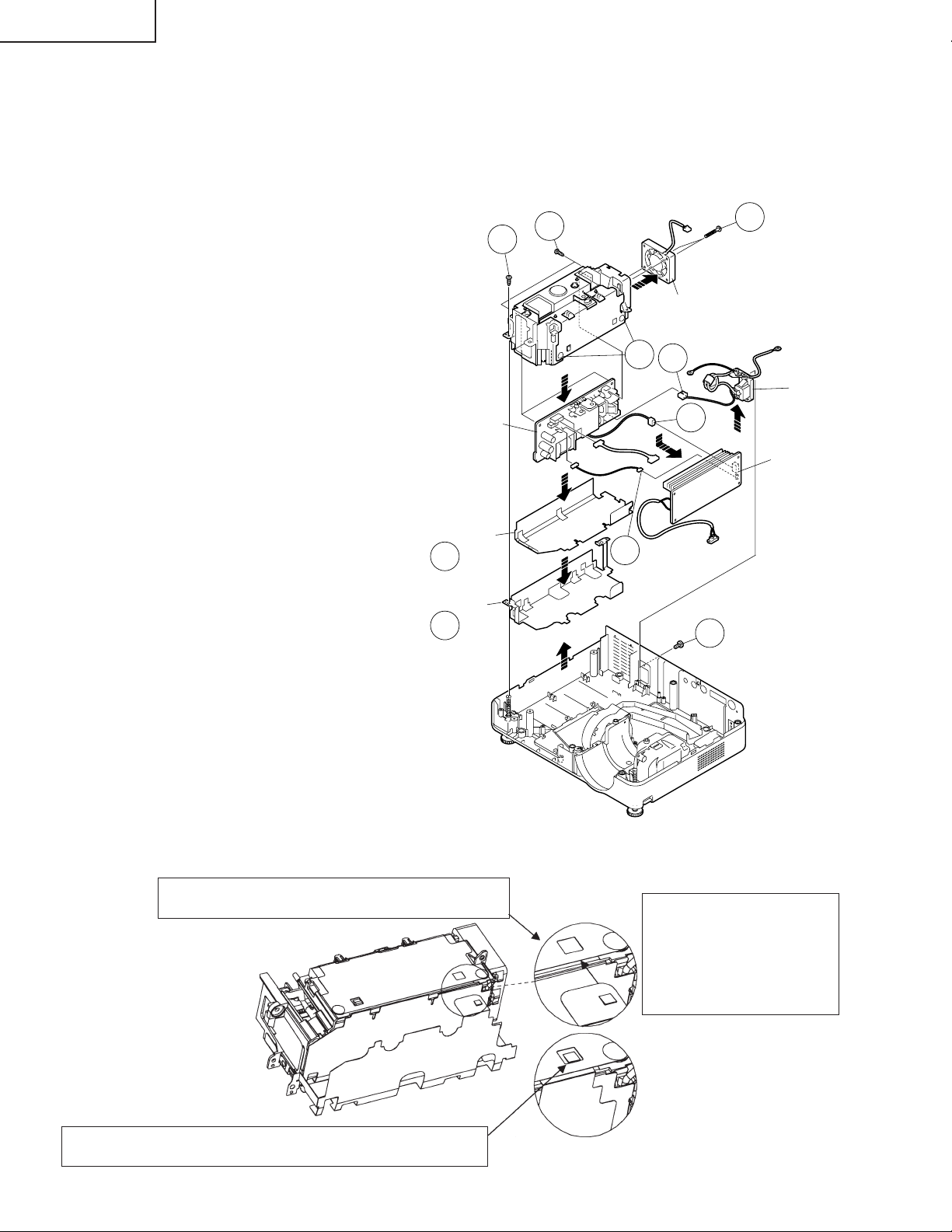

4.Removing the e xhaust co ver, optical mechanism unit, R/C receiver PWB and

speaker

4-1. Remove the two screws and detach the lamp socket.

4-2. Detach the Power/Ballast holder cover.

4-3. Remove all the connectors from optical mechanism unit.

4-4. Remove the nine screws and take out of the optical mechanism unit and the exhaust cover.

4-5. Detach the R/C receiver PWB.

4-6. Detach the Speaker.

Exhaust

Cover

Power/Ballast

Holder Cover

4-4

4-2

4-3

4-1

Lamp

Socket

4-3

4-4

4-1

4-3

4-4

4-3

4-5

R/C Receiver PWB

4-3

Optical Mechanism Unit

Speaker

4-6

17

Page 18

PG-A20X

AC Inlet

Ballast Unit

Power PWB

Cooling Fan

Bottom Shield

Shield Cover

5-7

5-2

5-6

5-5

5-4

5-5

5-3

5-3

5-5

5-1

5.Removing the AC inlet, power/ballast unit and cooling fan

5-1. Remove a screw from behind of the set.

5-2. Remove a screw and take out of the power/ballast assembly.

5-3. Detach the bottom shield and shield cover.

5-4. Remove a connector and detach the AC inlet.

5-5. Remove the two hooks and take out of the ballast unit from power/ballast case. Remove the all connectors

from power PWB.

5-6. Remove the two screws and detach the power PWB.

5-7. Remove the two screws and cooling fan.

Note: When mounting the shield (bottom) for power supply/ballast (PSLDMA189WJFW) on the power ballast holder

ass'y (CHLDZA135WJ01), make sure that it is inserted into the following place.

Be sure to insert the claw of the bottom shield into

the gap between the upper shield and holder.

* Never insert the claw be-

tween the insulating plate

and holder since the insulating distance to the ballast PWB becomes inadequate.

After assembly, make sure that the claw of the bottom shield

is visible from the square hole on the upper shield.

18

Page 19

PG-A20X

6-1

6-2

6-3

6-5

6-4

6-3

6-3

Intake Duct B

Fan LCD R/G

Leaf Switch

Fan LCD B

6-5

6-3

Spacer B

6.Removing the intake duct assembly

6-1. Remove the two screws and take out of the intake duct assembly.

6-2. Remove a screw and detach the leaf switch.

6-3. Remove a screw and two hooks. Detach the spacer B. Tak e out of the fan LCD R/G-intake duct B assembly.

6-4. Remove a screw and detach the fan LCD R/G.

6-5. Remove the two screws and detach the fan LCD B.

19

Page 20

PG-A20X

RESETTING THE TOT AL LAMP TIMER

● Resetting the total lamp timer

When replacing the lamp, reset the total lamp timer in the procedure below.

Resetting the Lamp Timer

Reset the lamp timer after replacing the lamp.

1

Connect the power cord.

Plug the power cord into the AC socket

of the projector.

2

Reset the lamp timer.

While simultaneously

“LAMP 0000H” is displayed, indicating

that the lamp timer is reset.

Info

Make sure to reset the lamp timer only

when replacing the lamp. If you reset the

lamp timer and continue to use the same

lamp, this may cause the lamp to become

damaged or explode.

holding down

and on the projector, press

and on the projector.

■ The warning lights on the projector indicate problems inside the projector.

■ If a problem occurs, either the temperature warning indicator or the lamp replacement indicator will illumi-

nate red, and the power will turn off. After the power has been turned off, follow the proce-duresgiven

below.

Maintenance indicator

Temperature

warning

indicator

Lamp

indicator

Power

indicator

Normal

Off

Green on

Green

blinks when

the lamp is

warming up

or shutting

down.

Green on/

Red on

Abnormal

Abnormal

Red on/

Standby

Red on

Red on/

Standby

Red blinks

Condition Problem Possible Solution

The internal

temperature is

abnormally high.

Time to change

the lamp

The lamp does

not illuminate.

The power

indicator blinks

in red when the

projector is on.

AC socket

ON button

Blocked air intake

Cooling fan breakdown

Internal circuit failure

Clogged air intake

Remaining lamp life

becomes 5% or less.

Burnt-out lamp

Lamp circuit failure

The filter/lamp unit

cover is open.

Volume

buttons

AUTO SYNC

button

Relocate the projector to an area

with proper ventilation.

Take the projector to your nearest

Sharp Authorized Projector Dealer

or Service Center for repair.

Carefully replace the lamp.

Take the projector to your nearest

Sharp Authorized Projector Dealer

or Service Center for repair.

Please exercise care when

replacing the lamp.

Securely install the cover.

If the power indicator blinks even

when the filter/lamp unit cover is

securely installed, contact your

nearest Sharp Authorized Projector Dealer or Service Center for

advice.

■ Replacing the Air Filter

This projector is equipped with air filters to ensure the optimal operating

condition of the projector.

The air filters should be cleaned every

100 hours of use. Clean the filters more

often when the projector is used in a

dusty or smoky location.

Ask your nearest Sharp Authorized Projector Dealer or Service Center to exchange the filter (PFILDA008WJZZ)

when it is no longer possible to clean.

Cleaning and Replacing

the Air Filter

Press

1

STANDBY

or

put the projector into the

standby mode.

Wait until the cooling fan stops.

2

Disconnect the power cord.

Unplug the power cord from the AC

socket.

3

Remove the filter/lamp unit

cover.

Turn the projector over. Loosen the user

service screw (1) that secures the filter/lamp unit cover. Pressing the tab

(2), remove the filter/lamp unit cover

(3).

4

Remove the air filter.

Pick the air filter up with your fingers and

lift it out of the filter/lamp unit cover.

on the projector

STANDBY

on the remote control to

""

" Bottom view

""

Air filter

AC socket

3

2

Tab

""

" Rear view

""

Air filter

(not removable)

STANDBY

button

1

User service screw

Air filter

(not removable)

STANDBY button

5

Clean the air filter.

Clean the dust off the air filter and cover

with a vacuum cleaner extension hose.

6

Replace the air filter.

Place the air filter underneath the tabs

on the filter/lamp unit cover.

7

Replace the filter/lamp unit

cover.

Align the tab on the filter/lamp unit cover

(1) and place it while pressing the tab

(2) to close it. Then tighten the user

service screw (3) to secure the filter/

lamp unit cover.

Note

Be sure the filter/lamp unit cover is

securely installed. The power will not turn

on unless it is correctly installed.

If dust or dirt has collected inside the rear

and bottom air filters (not removable), clean

the filter with a vacuum cleaner extension

hose.

1

2

Tab

3

20

User service screw

Page 21

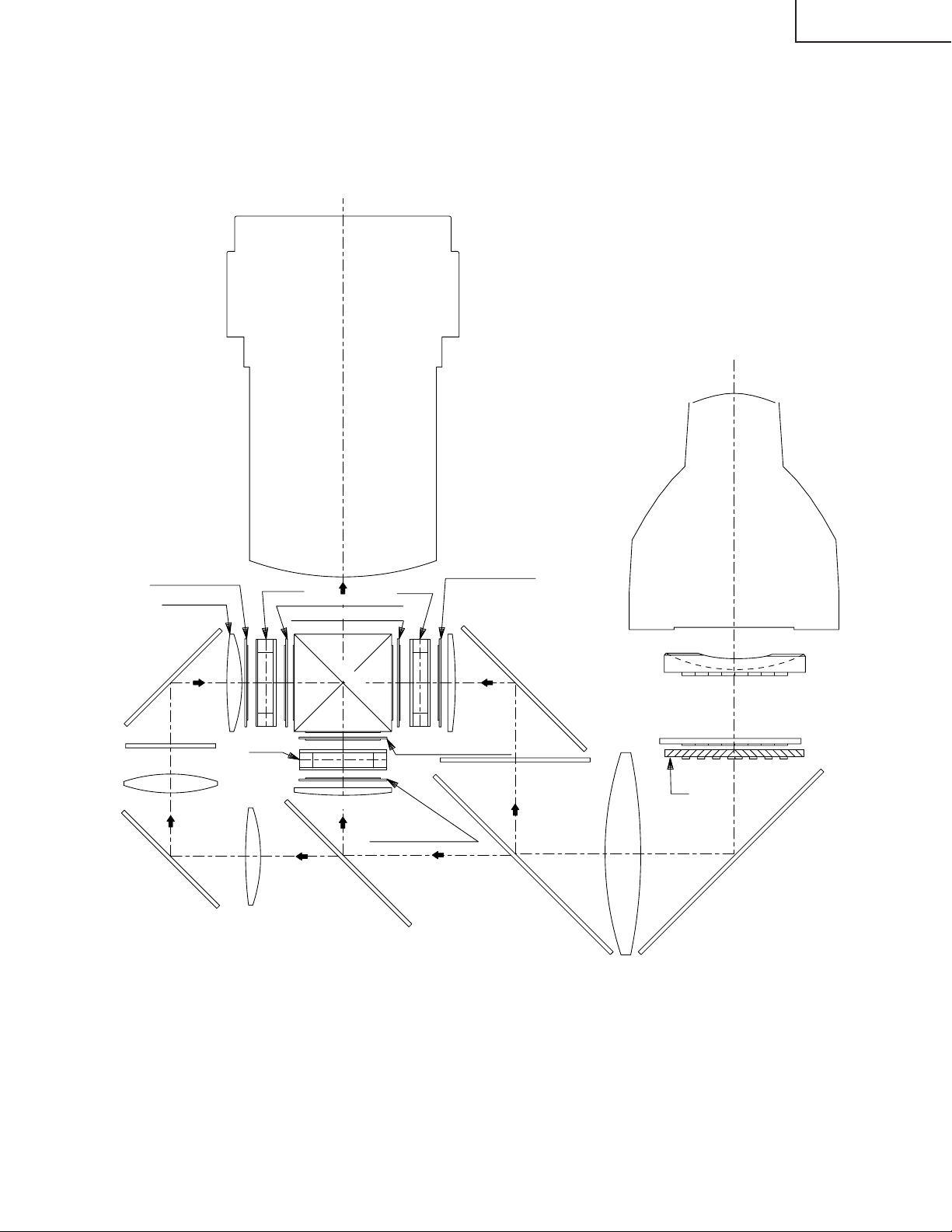

THE OPTICAL UNIT OUTLINE

Layout for proper setup of the optical components and parts (top view)

Projection lens

PG-A20X

Input polariser R

Relay lens 3

Mirror R 2

R dichroic filter

Relay lens 2

Mirror R 1

LCD(R)

LCD(G)

Relay lens 1

Output pre-polariser R

Output pre-polariser B

Cross dichroic prism

Condensing lens G

Green

Input polariser G

Red

G reflector

Input polariser B

LCD(B)

Output pre-polariser G

Green/Red

Condensing lens B

UV reflector

Mirror B

Blue

B reflector

PBS

Condensing lens

LIGHT SOURCE

(LAMP)

Fly-eye lens(Input)

Fly-eye lens(Output)

Mirror R,G,B

21

Page 22

PG-A20X

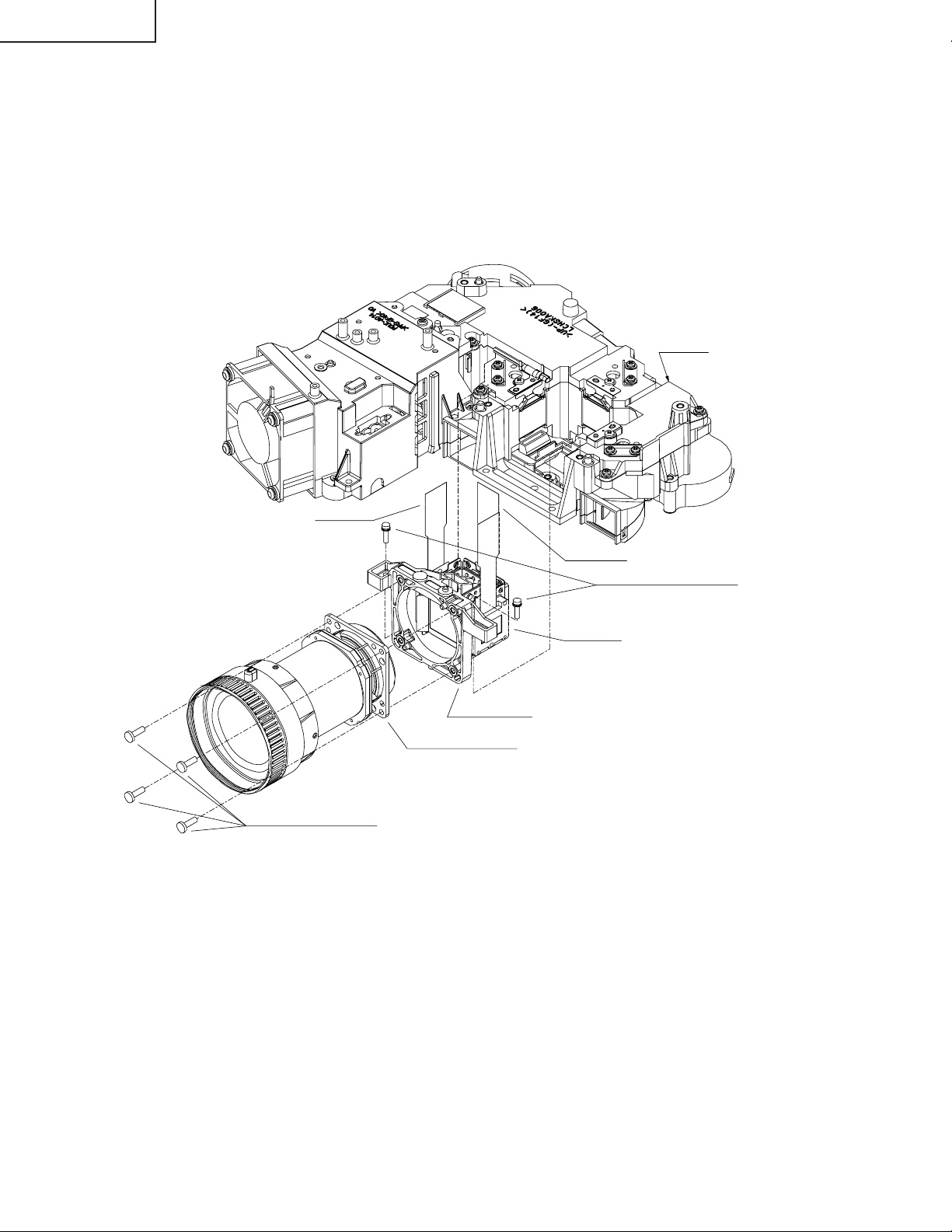

Replacing the prism holder unit

1. Remove the two lock screws, and take the prism holder unit and the projection lens assembly out of the optical

unit.

2. Remove the four lock screws, separate the prism holder unit and the projection lens assembly from each other.

3. Replace the prism holder unit with new one. Take the above steps 1 and 2 in reverse order.

Note: Even if just one of the LCD panels is defective, it is necessary to replace the entire prism holder unit. Do not

replace just the defective LCD panel only.

Optical unit

B-LCD panel

2Projection lens lock screws

G-LCD panel

1Prism holder unit lock screws

R-LCD panel

Prism holder unit

Projection lens assembly

22

Page 23

ELECTRICAL ADJUSTMENT

No. Adjusting point Adjusting conditions Adjusting procedure

PG-A20X

1 EEPROM

initialization

2-1 R/G/B Bright-

ness adjustment

2-2 R/G/B Contrast

adjustment

1. T urn on the power (with the

lamp on) and warm up the

set for 15 minutes.

1. Select the following group

and subjects.

Group : AD

Subject : R-Bright

G-Bright

B-Bright

(Process GAMMA interlock)

2. Feed the XGA 16-step signal with an amplitude level

of 50% (0.35 Vp-p).

1. Select the following group

and subjects.

Group : AD

Subject : R-Contrast

G-Contrast

B-Contrast

(Process GAMMA interlock)

2. Feed the SVGA white signal with an amplitude level

of 96% (0.67 Vp-p).

» Make the following settings.

Press S2002 to call the process mode and execute

"SS2" on SS menu.

1.Watching the screen, adjust the R-, G- and B-Bright

settings so that the second tone (3% level step) on

the black side should have some pixel dropouts and

the bright color zone should become just about a half.

1.Watching the screen, adjust the R-, G- and B-Contrast settings so that because of some pixel dropouts, the bright color zone should become just about

a half.

3 DTV Brightness/

Contrast adjustment

4 DVD Brightness/

Contrast adjustment

1. Feed a 480P component

10-step signal with 100%

amplitude.

2. Select the following group

and subjects.

Group : DTV

Subject : Bright

Contrast

(Process GAMMA interlock)

1. Feed a 480PI component

10-step signal with 100%

amplitude.

2. Select the following group

and subjects.

Group : DVD

Subject : Bright

Contrast

(Process GAMMA interlock)

1. Check the setting value.

Contrast (White Level): 2

Bright (Black Level): 12

1. Check the setting value.

Contrast (White Level): 1

Bright (Black Level): 13

23

Page 24

PG-A20X

No. Adjusting point Adjusting conditions Adjusting procedure

5 Video Bright-

ness/Contrast

adjustment

6 PSIG adjust-

ment

1. Feed an NTSC composite

video 10-step signal (no

setup) with 100% amplitude.

2. Select the following group

and subjects.

Group : VIDEO

Subject : Bright

Contrast

(Process GAMMA interlock)

1. Select the following group

and subjects.

Group : OUTPUT2

Subject : PSIG-H

PSIG-L

2. Check the fixed value.

PSIG-H: 90

PSIG-L: 16

1. Check the setting value.

Contrast (White Level): 0

Bright (Black Level): 13

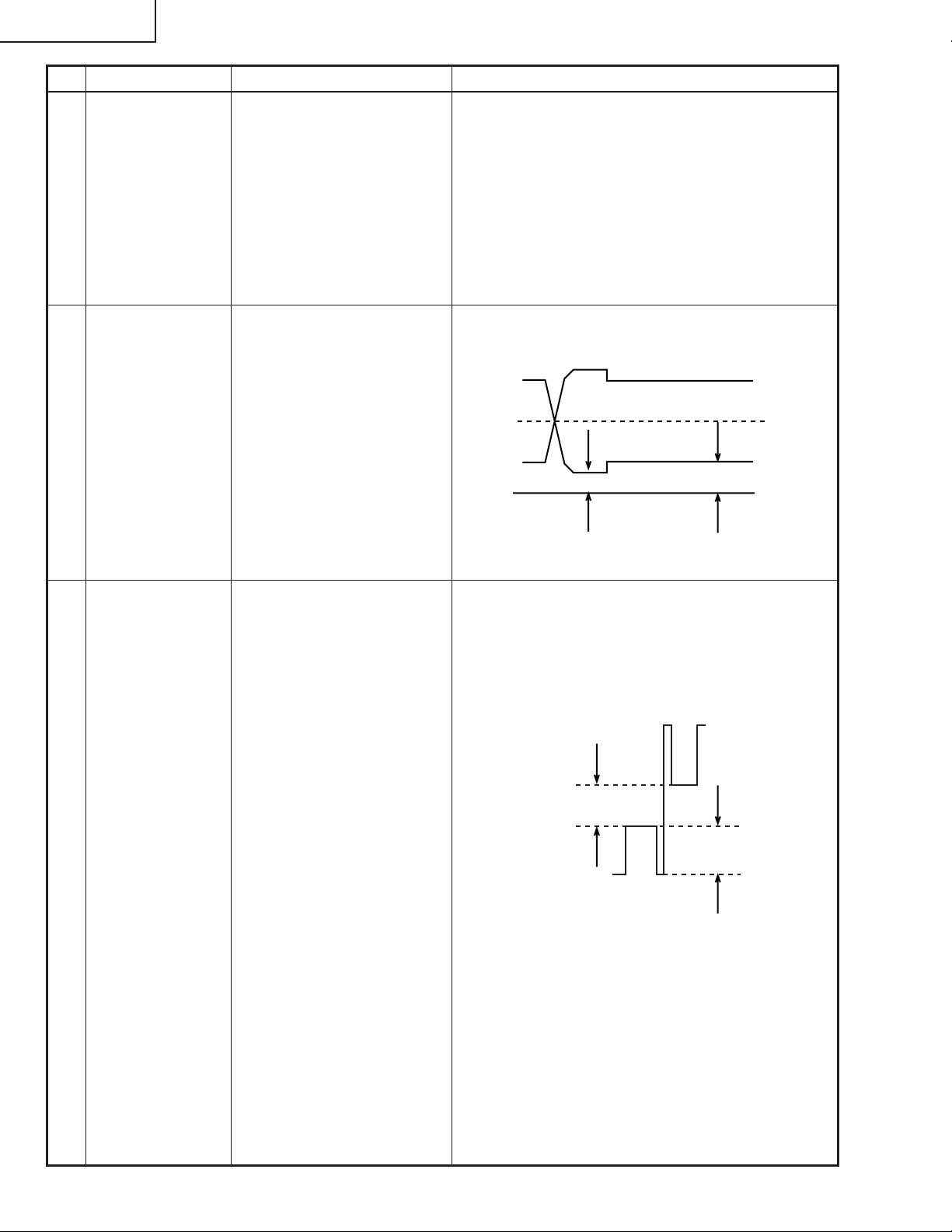

1. Feed the XGA signal and adjust to make the following PSIG wavef orm. (TP1101, TP1201 and TP1301)

PSIG

2.5V DC

Adjust with PSIG-L

5.6V DC

Adjust with PSIG-H

GND

7 R/G/B Black

Level Signal

Amplitude

adjustment

1. Select the following group

and subjects.

Group : OUTPUT1

Subject :

On Green adjustment

G1-BLK

G1-GAIN

On Red Adjustment

R1-BLK

R1-GAIN

On Blue Adjustment

B1-BLK

B1-GAIN

2. Make sure the process adjustment color bags appear

onscreen.

3. Connect a oscilloscope to

pin(2) of P1301 for the G

setting.

4. Connect the oscilloscope to

pin(1) of P1301 and pin(3)

of P1301 for the R and B

settings, respectively.

1. Select G1-GAIN. Using the set's control switch or

the remote controller's button, adjust the signal amplitude to 4.05 Vp-p ± 0.05 V.

2. Now select G1-BLK. Using the set's control switch

or the remote controller's button, adjust the whiteto-white level to 1.70 Vp-p ± 0.05 V.

3. Do the same for the R and B settings.

White-to-White

Amplitude

24

Page 25

No. Adjusting point Adjusting conditions Adjusting procedure

PG-A20X

8 RGB

countervoltage

adjustment

9 Chiral phase

selection of LCD

panel

10 RGB white

balance adjustment

1. Feed the counter voltage

adjustment signal. (SVGA)

2. Select the following group

and subjects.

Group : OUTPUT3

Subject : RC (R)

GC (G)

BC (B)

1. Group : OUTPUT3

Subject : OPT-MECH

1. Feed the RGB 50% gray

signal. (SVGA)

2. Select the following group

and subjects.

Group : OUTPUT1

Subject : R1-BLK(R)

B1-BLK(B)

1. Using the remote controller’s button, adjust the

setting so that the flickering be minimum.

2. Adjust the setting so that the image comes to the

center of the screen.

1. Adjust the GR and GL panel settings to 0 and 1,

respectively.

1. Adjust the R1-BLK and B1-BLK(B) settings so that

the chromaticity based on CL200 becomes as

follows (8500K). x=291±5 y=320±5

11 sRGB adjust-

ment

12 Video white

balance

adjustment

13 DVD white

balance

adjustment

1. Feed the RGB 50% gray

signal. (SVGA)

2. Select the following group

and subjects.

Group : OUTPUT1

Subject : S-R1-BLK

S-B1-BLK

1. Feed the NTSC 40% gray

signal.

2. Select the following group

and subjects.

Group : VIDEO

Subject : CB-OFFSET

CR-OFFSET

1. Feed the 480I component

40% gray signal.

2. Select the following group

and subjects.

Group : DVD

Subject : CB-OFFSET

CR-OFFSET

1. Adjust the R1-BLK and B1-BLK(B) settings so that

the chromaticity based on CL200 becomes as

follows (6500K). x=313±5 y=334±5

1. Make sure the CB-OFFSET and CR-OFFSET

settings are 7.

1. Make sure the CB-OFFSET and CR-OFFSET

settings are 7.

14 DTV white

balance

adjustment

1. Select the following group

and subjects.

Group : DTV

Subject : CB-OFFSET

CR-OFFSET

1. Make sure the CB-OFFSET and CR-OFFSET

settings are 7.

25

Page 26

PG-A20X

No. Adjusting point Adjusting conditions Adjusting procedure

15 Automatic color

irregularity

correction

16 Video Tint

adjustment

17 Video Color

saturation

adjustment

18 Video

sharpness

adjustment

1. Apply the automatic color

correction using the automatic color irregularity correction system.

1. Select the following group

and subject.

Gro u p : VIDEO

Subject : N-Tint

P-Tint

S-Tint

1. Select the following group

and subject.

Gro u p : VIDEO

Subject : N-Color

P-Color

S-Color

1. SGroup: VIDEO

Subject: Sharpness

1. Make sure that no remarkable uneven color remains

on the screen.

1. Check the fixed value.

N-Tint : 5

P-Tint : 5

S-Tint : 5

1. Check the fixed value.

N-Color : 5

P-Color : 5

S-Color : 5

1. Check the preset value.

Sharpness: 3

19 DTV Tint

adjustment

20 DTV Color

saturation

adjustment

21 DVD Tint adjust-

ment

22 DVD Color

saturation

adjustment

23 Sample hold

pulse phase

checking

1. Select the following group

and subject.

Group : DTV

Subject : Tint

1. Select the following group

and subject.

Group : DTV

Subject : Color

1. Select the following group

and subject.

Group : DVD

Subject : Tint

1. Select the following group

and subject.

Group : DVD

Subject : Color

1. Feed the XGA 75-Hz black

signal.

2. Select the following group

and subjects.

Group : OUTPUT3

Subject : GCK-PHASE

1. Check the fixed value.

Tint : 5

1. Check the fixed value.

Color : 8

1. Check the fixed value.

Tint : 5

1. Check the fixed value.

Color : 5

1. Check the fixed value.

Fixed V alue : 8

26

Page 27

No. Adjusting point Adjusting conditions Adjusting procedure

No. Adjusting point Adjusting conditions Adjusting procedure

PG-A20X

24 RGB tone

reproduction

adjustment

25 White balance

checking

26 Automatic

keystone

initialization

1. Feed the SMPTE pattern

signal.

1. Use the adjustment conditions in the item 9 for RGB

input and item 10 for sRGB

input.

Group : LINE

Subject : Calibration

1. Make sure the 100% and 95% white as well as the

0% and 5% black gradations are visible.

Check that there is no deviation of white balance with

the monitor.

Select Calibration in the process mode. Place the set

on a level surf ace. Press the ENTER key on the remote

controller. The calibration setting becomes 1 first, and

then both the calibration and K-sensor settings become

0.

Make sure that the K-sensor setting alone will change

to 0-3 or 128-131.

27 Off-timer per-

formance

performance

checking

29 Auto sync

performance

checking

30 Delivery set-

tings

1. Heat the thermistor with a

hair dryer.

1. Feed the phase check pattern signal.

1. Select OFF from the process mode.

Make sure the off-timer starts with 5 minutes

onscreen and count one minute in one second.

And then indication is 0 minute, the power supply

of the set is cut off.

1. Make sure that the temperature is indicated.28 Thermistor

1. In the VGA, SVGA and XGA modes, make sure the

Clock, Phase, H-Pos and V-Pos settings can be automatically adjusted.

1. Make the following settings.

Process adjustment Remote control adjustment

S3 Factory setting at 3

27

Page 28

PG-A20X

1. Calling and quitting the process mode with the control keys on this model.

1-1. Calling and quitting

With no menu onscreen, press the "UP", "UP", "DOWN", "DOWN", "RIGHT", "LEFT" and "ENTER" keys, in this

order, on the remote controller (Type A10, or C50/45 and P25/20 series remote controllers).

1-2. Others

Press the S2002 process key (toggle) on the main PWB to call and quit the process menu.

2. Resetting the lamp timer for this model

2-1. Resetting procedure

While holding down the Vol+ and AUTOSYNC keys, press the POWER ON and Vol- keys. The "LAMP 000H"

indicator appears for 60 seconds after the power is turned on.2-1. Resetting procedure

While holding down the Vol+ and AUTOSYNC keys, press the POWER ON and Vol- keys. The "LAMP 000H"

indicator appears for 60 seconds after the power is turned on.

Power On

Power Off

Keystone

Volume Down

Input Select

Volume Up

Auto Sync

3. Forced disabling of the Anti-Seft of this model

3-1. Disabling procedure

With Anti-Seft input window onscreen, press the "MENU", "ENTER", "ENTER", "MENU", "UNDO", "UNDO" and

"MENU" keys, in this order, on the remote controller.

4. Forced disabling of the password of this model

4-1. Disabling procedure

In whatever state, press the "ON", "+", "–", "ON", "+", "–" and "INPUT" keys in this order.

Power On

Power Off

Keystone

Volume Down

Input Select

Volume Up

Auto Sync

28

Page 29

Process menu1

PG-A20X

Adjustment Process Menu

First layer DTV Pedestal

DVD VERSION

VIDEO SS

AD TEMP

OUTPUT1 PATTERN

OUTPUT2 LAMP

OUTPUT3 LINE

VIDEO1 EXIT

second layer Initial Value

DTV Contrast 2

Tint 5

Color 8

Sharpness 1

CTI-Level 1

LTI-Level 0

CB-Offset 7

CR-Offset 7

Bright 12

B-DRIVE 41

R-DRIVE 41

EXIT

DVD Contrast 1

Tint 5

Color 5

Sharpness 3

CTI-Level 1

LTI-Level 0

CB-Offset 7

CR-Offset 7

Bright 13

B-DRIVE 41

R-DRIVE 41

EXIT

VIDEO Contrast 0

N-Tint 5

P-Tint 5

S-Tint 5

N-Color 5

P-Color 5

S-Color 5

Sharpness 3

CTI-Level 1

LTI-Level 0

CB-Offset 7

VIDEO CR-Offset 7

Bright 13

B-DRIVE 41

R-DRIVE 41

EXIT

AD R-Bright 63

G-Bright 63

B-Bright 63

R-Contrast 172

G-Contrast 172

B-Contrast 172

EXIT

OUTPUT1 R1-BLK 200

R1-GAIN 166

G1-BLK 200

G1-GAIN 166

B1-BLK 200

B1-GAIN 166

S-R1-BLK 200

S-R1-GAIN 166

S-G1-BLK 200

S-G1-GAIN 166

S-B1-BLK 200

S-B1-GAIN 166

EXIT

OUTPUT2 PSIG-H 90

PSIG-L 16

VCENTER 34

VS-ON 0

VS-POS 0

VS-DAT 0

VS-GDAT1 64

VS-GDAT2 128

VS-GDAT3 192

EXIT

OUTPUT3 RC 90

GC 90

BC 90

GCK-PHASE 8

CC 0

OPT-MECH 0

DFT-SET 1

R-HPC-DAT 321

G-HPC-DAT 321

B-HPC-DAT 321

EXIT

VIDEO1 N-Contrast 14

P-Contrast 14

S-Contrast 15

Color 17

NT3.58 Delay 1

NT4.43 Delay 1

PAL Delay 1

SECAM Delay 3

EXIT

29

Page 30

PG-A20X

Process menu2

Pedestal R-Bright -10

G-Bright -10

B-Bright -10

R-Contrast +10

G-Contrast +10

B-Contrast +10

EXIT

VERSION Build

Boot Code

Config

Rom Code

GUI

EXIT

SS SS2

SS3 EU

SS4 US

SS5 JPN

SS6 CHIN

EXIT

TEMP Temp1 Parameter of sensor 1

Temp2 Parameter of sensor 2

Temp3 No Use

Temp4 No Use

EXIT

PATTERN Cross Hatch

Color Bar

EXIT

LAMP Current Time Current time of use

History1 One earlier

History2 Two earlier

History3 Three earlie

History4 Four earlier

TOTAL TIME Total operating hours

EXIT

LINE OFF

LED CHECK

Calibration 0

K-Sensor

EXIT

30

Page 31

TROUBLE SHOOTING TABLE

Checking the basic

performance

PG-A20X

Is the POWER LED on or

flickering in red or green?

YES

Is the set turned on by the

set’s or remote controller’s

power key?

YES

Is the cooling fan

running? Is the lamp on?

YES

Is the user menu

displayed?

YES

Go to "Checking the RGB

signal"

NO

Go to "Checking the

power unit"

NO

Go to "Checking the

microcomputer

peripherals".

NO

Go to "Checking the lamp

light-up"

NO

Go to "Checking the RGB

sync".

Go to "Checking the

video system".

End

31

Page 32

PG-A20X

Checking the power unit

Are the connectors CN701,

CN702 and CN751

inserted completely?

YES

Is the bimetal switch off?

YES

Is there AC voltage (110240V) applied across

C701?

YES

Disconnect the CN751

connector. Is there 6V

output at pins (3) and (4)?

YES

Check the MAIN PWB for

short-circuit.

NO

Insert the connectors

CN701, CN702 and

CN751 tightly?

NO

Replace the bimetal

NO

Replace F701.

NO

Check Q702 for damage.

Replace as required.

32

Page 33

Checking the

microprocessor

peripherals

PG-A20X

Is a voltage of about 3.3V

DC applied to pins (3) and

(5) of IC1703?

YES

Is about DC 2.5V applied

between pins (5) and (8) of

IC1704?

YES

Is about DC 2.5V applied

between pins (4) and (3) of

IC8009?

YES

NO

NO

NO

Check IC1703 and its

peripheral circuits, or IC1702

and its peripheral circuits.

Check IC1704 and its

peripheral circuits.

Is the lamp access lid

open? Is the P2006 (LF)

tight in the socket?

YES

Fully close the lamp access

lid. Or insert the P2006 (LF)

tightly in the socket.

NO

Check IC8009 and its

peripheral circuits.

Is there 133-MHz clock

output at pin (6) of IC8010?

Is there 75-MHz clock

output at pin (6) of IC8011?

YES

Is there about DC3V

applied at pin (21) of

IC2002? Do the D0 thru D7

signals appear as pulse

signals on the oscilloscope

screen?

YES

Check IC2002 and its

peripheral circuits.

Check IC8202, IC8203,

IC2601 and their

peripheral circuits.

NO

Check IC8010, IC8011 and

their peripheral circuits.

NO

See if the fan is running as

specified. Or check IC8003

and its peripheral circuits.

33

Page 34

PG-A20X

Checking the lamp

light-up

Is the lamp socket

disconnected?

NO

Are DC350-400V voltages

applied between the pins

of CN703?

YES

Are the CN751 and

CN752 harnesses tight in

position in the power unit

and ballast unit as well?

Are these harnesses free

of damage?

YES

Are there 3V (High level)

and 1V applied at pins (1)

and (13), respectively, of

CN751 in the power unit?

YES

YES

Reconnect the lamp

socket tightly.

NO

Go to "Checking the

power unit".

NO

Reconnect the CN751

and CN752 harnesses

tight enough. Or replace

these harnesses.

NO

Go to "Checking the

microcomputer

peripherals".

Replace the ballast unit.

Checking the RGB

sync

Are there signal inputted

into pins (2)

of IC5002, IC5015?

YES

Are there signal inputted

into pins (30),

(31) of IC6004?

NO

Check RGB terminal and

its peripheral circuits

NO

Check IC6001 and its

peripheral circuits.

34

Page 35

Checking the RGB signal

Are the RGB signals

outputted from

pin (9), (7) and (4) of

IC3104? gradation signals?

NO

PG-A20X

YES

Check IC3104 and its

peripheral circuits.

Are their RIN2-RIN9,

GIN2-GIN9, BIN2-BIN9

signals inputted into

IC2601?

YES

Are their signals inputted

into pins(37)-(46) of IC1101,

IC1201 and IC1301?

NO

Are their signals inputted

into pins (5)-(10) of

SC1101, SC1301 and into

pins (23)-(28) of SC1201?

YES

Are there input signals at

pins (3) of SC1101 and

SC1301 and pin

(30) of SC1201?

NO

NO

Check IC8003 and its

peripheral circuits.

YES

Check IC2601 and its

peripheral circuits.

NO

Check IC1101, IC1201,

IC1301 and their peripheral

circuits.

YES

Check IC1101, IC1201,

IC1301 and their

peripheral circuits.

Are there input signals at

pins (2) and (31) of

SC1101, SC1201 and

SC1301?

YES

Check the connection

of LCD panels.

And when video signal and

OSD are also not

disaplayed, replace the

LCD panels.

NO

Check IC1103 and its

peripheral circuits.

35

Page 36

PG-A20X

No colour or unusual

tone(NTSC, PAL)

Are there RGB outputs at

pins (23)(R-Y), (22)(B-Y) of

IC3105?

YES

Check C3126 and C3124.

No or unusual Y signal

Are there RGB outputs at

pins (21)(Y) of IC3105?

YES

Check C3121.

Checking IC3102 (RGB

signal output circuit)

NO

Check IC3105 and its

peripheral circuits.

NO

Check IC3506 and its

peripheral circuits.

Are there signal outputs at

pins (66)(R-Y), (68)(B-Y),

(69)(Y) of IC3102 ?

YES

Are there RGB outputs

waveforms at pins(35),

(37) and (39) of IC3102 ?

YES

Are there output

waveforms at the emitters

of Q3110, Q3111 and

Q3112?

NO

Go to "No colour or unusual

tone", "No Y signal" or "Out

of sync"

NO

Check the data transfer and

other performance at pins

(55) and (56) of IC3102.

NO

Check Q3110 thru Q3112

and their peripheral circuits.

36

Page 37

Checking the S-video

system

PG-A20X

Is the lamp on ?

YES

Is the specified voltage EA

connectors?

YES

Is the video signal inputted

into the pins(43) and (44)

of IC3105?

YES

Go to "Checking IC3102"

Checking the video

system

Is the lamp on ?

YES

NO

Go to "Lamp light-up".

NO

Check power circuit and its

parts.

NO

Check the video terminal

and its peripheral circuits.

NO

Go to "Lamp light-up".

Is the specified voltage EA

connectors?

YES

Is the video signal inputted

into the pin(7) of IC3506?

YES

Is the video signal

outputted from the pins(25)

and (27) of IC3506?

YES

Is the signal inputted into

the pins(39) and (41) of

IC3105?

YES

Check IC3105 and its

peripheral circuits.

NO

Check power circuit and its

peripheral parts.

NO

Check the video terminal

and its peripheral circuits.

NO

Check IC3506 and its

peripheral circuits.

NO

Check Q3501, Q3502 and

their peripheral circuits.

NO

Check IC1103 and its

peripheral circuits.

37

Page 38

PG-A20X

Technische Daten

Produkttyp

Videosystem

Anzeigeverfahren

LCD-Panel

Standard-Objektiv

Projektionslampe

Komponenten-Eingangssignale

(INPUT 1)

Horizontale Auflösung

Computer-RGB-Eingangssignal

(INPUT 1)

S-Videoeingangssignal

(INPUT 2)

Videoeingangssignal

(INPUT 3)

Computer-Steuerungssignal (RS-232C)

Pixeltakt

Vertikale Frequenz

Horizontale Frequenz

Audioeingangssignal

Audioausgang

Lautsprechersystem

Nennspannung

Eingangsstrom

Nennfrequenz

Leistungsaufnahme

Leistungsaufnahme

(Bereitschaft)

Wärmeableitung

Betriebstemperatur

Lagertemperatur

Gehäuse

I/R-Trägerfrequenz

Abmessungen (ca.)

Gewicht (ca.)

Mitgeliefertes Zubehör

Ersatzteile

LCD-Projektor

PG-A20X

Modell

NTSC3.58/NTSC4.43/PAL/PAL-M/PAL-N/PAL-60/SECAM/

DTV480 /DTV480P/DTV540P/DTV580 /DTV580P/DTV720P/DTV1035 /DTV1080

LCD-Panel 3, optische RGB-Verschlussmethode

Panel-Größe: 0,79 tum (20,0 mm) (12 [H] 16 [B] mm)

Anzahl der Bildpunkte: 786.432 Bildpunkte (1.024 [H] 768 [V])

×

1–1,2 Zoom-Objektiv, F1,7–1,94, f = 26–31 mm

SHP 180 W-Lampe

15-Pin-Mini-D-Sub-Anschluss

Y: 1,0 Vp-p, negatives Sync., 75 terminiert

: 0,7 Vp-p, 75 terminiert

P

B

: 0,7 Vp-p, 75 terminiert

P

R

700 Fernsehzeilen (DTV 720P)

15-Pin-Mini-D-Sub-Anschluss

RGB getrennt/Sync. auf Grün-Typ analoger Eingang: 0-0,7 Vp-p, positiv, 75 terminiert

HORIZONTALES SYNC.-SIGNAL: TTL-Pegel (positiv/negativ)

VERTIKALES SYNC.-SIGNAL: Wie oben

4-pin-Mini-DIN-Anschluss

Y (Luminanzsignal): 1,0 Vp-p, negatives Sync., 75 terminiert

C (Chrominanzsignal): Stoß 0,286 Vp-p, 75 terminiert

RCA-Anschluss: VIDEO, Verbund-Video, 1,0 Vp-p, negatives Sync., 75 terminiert

9-Pin-Mini-DIN-Stecker

12-108 MHz

43-85 Hz

15-70 kHz

ø 3,5 mm-Minibuchse: AUDIO, 0,5 Vrms, mehr als 47 k (Stereo)

1,0 W (Mono)

2,8 cm rund 1

110-240 V Wechselstromspannung

2,3 A

50/60 Hz

240 W (Standard-Modus)/200 W (Eco-Modus) bei AC 110 V

235 W (Standard-Modus)/195 W (Eco-Modus) bei AC 240 V

4 W (bei AC 110 V)-6 W (bei AC 240 V)

900 BTU/Stunde (Standard-Modus)/750 BTU/stunde (Eco-Modues) bei AC 110 V

880 BTU/Stunde (Standard-Modus)/730 BTU/stunde (Eco-Modues) bei AC 240 V

°°° °

41 F bis 95 F (+5 C bis +35 C)

°°°°

– 4 F bis 140 F (–20 C bis +60 C)

Plastik

38 kHz

45

/64" 3 13/64" 9 1/32" (297 (B) 81 (H) 229 (T) mm) (nur Hauptgerät)

11

45

/64" 3 33/64" 9 1/32" (297 (B) 89 (H) 229 (T) mm) (einschließlich Einstellfüße und

11

Projektionsteile)

6,4 lbs. (2,9 kg)

Fernbedienung, zwei R6-Batterien, Netzkabel für USA, Kanada usw. (6', 1,8 m), Netzkabel für Europa, außer

Großbritannien (6', 1,8 m), Netzkabel für Großbritannien, Hongkong und Singapur (6', 1,8 m), Netzkabel für Australien,

Neuseeland und Ozeanien (6', 1,8 m), RGB-Kabel (9' 10", 3,0 m), Tragetasche, Objektivkappe (befestigt), zusätzlicher

Luftfilter, Projektorhandbuch- und technische Referenz-CD-ROM, “QUICK GUIDE (Schnellanleitung)”-Aufkleber,

Bedienungsanleitung

Lampeneinheit (Lampen-/Gehäusemodul) (BQC-PGA20X//1), Fernbedienung (RRMCGA187WJSA), zwei R 6-Batterien

(“AA”, UM/SUM-3, HP-7 oder entsprechend), Netzkabel für USA, Kanada usw. (QACCDA016WJPZ), Netzkabel für

Europa, außer Großbritannien (QACCVA006WJPZ), Netzkabel für Großbritannien, Hongkong und Singapur

(QACCBA015WJPZ), Netzkabel für Australien, Neuseeland und Ozeanien (QACCLA005WJPZ),RGB-Kable

(QCNWGA012WJPZ), Tragetasche (GCASNA006WJSA), Objektivkappe (CCAPHA012WJ01), Luftfilter

(PFILDA008WJZZ), Projektorhandbuch- und- technische Referenz-CD-ROM (UDSKAA037WJZZ), “QUICK GUIDE

(Schnellanleitung)”-Aufkleber (TLABZA191WJZZ), Bedienungsanleitung (TINS-A850WJZZ)

II II

×

×

×

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

×

×× ××

×× ××

Bedingt durch fortlaufende technische Verbesserungen behält sich SHARP das Recht vor, das Design

und die Spezifikationen ohne vorherige Ankündigung ändern zu können. Die angegebenen

Leistungswerte stellen die Nennwerte einer in Serienherstellung produzierten Einheit dar. Geringe

Abweichungen bei einzelnen Geräten sind möglich.

38

Page 39

HINWEISE FÜR DAS

6

6

WARTUNGSPERSONAL

2345678901234567890123456789012123456789012345

ACHTUNG: UV-STRAHLUNG

2345678901234567890123456789012123456789012345

Die Beleuchtungsquelle des LCD-Projektors, eine

UHP-Lampe, emittiert eine geringe Menge

UV-Strahlung.

DIREKTE BESTRAHLUNG AUF AUGEN

UND HAUT MUSS VERMIEDEN WERDEN.

Zur Gewährleistung der Sicherheit muß folgendes

beachtet werden:

1. Bei Arbeiten am Projektor bei eingeschalteter

Lampe und abgenommenem oberen Gehäuse muß

unbedingt eine Sonnenbrille getragen werden.

PG-A20X

Auswechseln der Lampe

Hinweis:

Da die Lampe während des Betriebs sehr heiß wird, sollte

die Lampe erst ausgewechselt werden, nachdem das

Gerät mindestens eine Stunde ausgeschaltet war , damit

die Lampe ausreichend abkühlen kann.

Beim Installieren der neuen Lampe muß darauf

geachtet werden, die Lampe selbst (Glaskolben)

nicht zu berühren. Vielmehr muß die Lampe am

Reflektor 2 gehalten werden.

[Es darf nur ein Original-Ersatzteil verwendet

werden.]

Lampe

1

Reflektor

2

2. Die Lampe darf nicht außerhalb des

Lampengehäuses eingeschaltet werden.

3. Betrieb für länger als 2 Stunden bei

abgenommenem Gehäuse ist nicht zulässig.

Zur Beachtung bei UV-Strahlung

und Mitteldruck-Lampen

1. Vor dem A uswechseln der Lampe m uß der Netzstecker

gezogen werden.

2. Vor Durchführung von Wartungsarbeiten muß das

Gerät eine Stunde abkühlen.

3. Die Lampe darf nur gegen eine der gleichen Art

ausgewechselt werden. Typ BQC-PGA20X//1,

bemessen für 110 V/180 W.

4. Die Lampe gibt eine geringe UV-Strahlung ab, daher

muß direkter Augenkontakt vermieden werden.

5. Die Mitteldruck-Lampe weist ein Explosionsrisiko auf.

Daher mü ssen die nachstehenden

Installationsanweisungen beachtet werden, und die

Lampe muß vorsichtig behandelt werden.

GEFAHR! — Niemals die Spannungsversorgung

einschalten, ohne daß eine Lampe vorhanden ist, um

elektrische Schläge und Schäden am Gerät zu

vermeiden, da der Stabilisator anfangs hohe

Spannungen erzeugt.

Da eine geringe Menge UV-Strahlung an der Öffnung

zwischen den Lüftern austritt, wird empfohlen, während

der Wartungsarbeiten die Abdeckkappe des Zusatzobjektivs an dieser Öffnung anzubringen, um Augen

und Haut vor den UV-Strahlen zu schützen.

39

Page 40

PG-A20X

Vorsichtsmaßregeln für bleifreien Lötzinn

1 Verwendung von bleifreiem Lötzinn

Bei den Platinen für dieses Modells wird bleifreies Lot verwendet. Das Symbol LF kennzeichnet bleifreies Lot und

findet sich an den Platinen und in den W artungshandbüchern. Der Buchstabe hinter LF bezieht sich auf die Art des

bleifreien Lots.

Beispiel:

L Fa

Zeigt bleifreien Lötzinn aus Zinn, Silber und Kupfer an.

2 Bei Reparatur der mit bleifreiem Lötzinn gelöteten Platine immer bleifreien Lötzinn verwenden. Reparatur mit

herkömmlichem Lötzinn kann zu Schäden oder Unfällen aufgrund von Rissen führen.

Da der Schmelzpunkt bleifreien Lvtzinns (Sn-Ag-Cu) um 40°C höher als der von Bleidraht-Lötzinn ist, empfehlen

wir die Verwendung einer speziellen Lötspitze. Wenn Fragen über den Beschaffung leitfreien Lötzinns oder spezieller

Lötspitzen bestehen, wenden Sie sich an unsere Kundendienstvertretung in Ihrem Gebiet.

3Löten

Da der Schmelzpunkt bleifreien Lötzinns (Sn-Ag-Cu) etwa 220°C beträgt, was um 40°C höher als der von b leihaltigem

Lötzinn ist, und außerdem schlechte Löt-Benetzbarkeit aufweist, kann es erforderlich werden, die Lötspitz e längere

Zeit in Kontakt mit der Platine zu halten. Da die Lötlauge abfliessen kann oder der maximale Hitzewiderstand von

Teilen überschritten werden kann, die Lötspitze sofort von der Platine nehmen, sobald eine gute Lötung erzielt ist.

Bleifreier Lötzinn enth_lt mehr Zinn, und das Ende der Lötspitze kann leicht angegriffen werden. Immer sicherstellen,

dass der Lötkolben nur bei Bedarf eingeschaltet wird.

Wenn ein anderer Typ von Lötzinn an der Lötspitze haften bleibt, verschmilzt er mit dem bleifreien Lötzinn. Die

Lötspitze nach jeder Verwendung reinigen.

Wenn die Lötspitze bei der Verwendung geschwärzt wird, die Spitze mit Stahlwolle oder feinem Sandpapier

abschmirgeln.

Immer beim Austausch von Teilen v orsichtig sein, und die Polaritätsanzeige auf der Platinenbeschriftung beachten.

Bleifreier Lötzinn zur Wartung

Teile-Nr. ★ Beschreibung Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1 Rolle BM

40

Page 41

Bedienungsanleitung

Projektor (Vorderansicht- und Draufsicht)

PG-A20X

Netz-Anzeige

Leuchtet rot, wenn sich der