Page 1

SERVICE MANUAL

CODE: 00ZMXM700/S2E

DIGITAL MULTIFUNCTIONAL

SYSTEM

MX-M550N/M550U

MX-M620N/M620U

MODEL

CONTENTS

NOTE FOR SERVICING

[1] PRODUCT OUTLINE . . . . . . . . . . . 1-1

[2] SPECIFICATIONS . . . . . . . . . . . . . 2-1

[3] CONSUMABLE PARTS . . . . . . . . . 3-1

[4] UNPACKING AND INSTALLATION

*

For unpacking and installation, refer to

the installation manual (00ZAR700//I1E).

[5] EXTERNAL VIEW AND INTERNAL

STRUCTURE . . . . . . . . . . . . . . . . . 5-1

[6] ADJUSTMENTS . . . . . . . . . . . . . . . 6-1

[7] SIMULATION . . . . . . . . . . . . . . . . . 7-1

SELF DIAG AND TROUBLE CODE

[8]

[9] MAINTENANCE . . . . . . . . . . . . . . . 9-1

[10] ROM VERSION-UP . . . . . . . . . . . .10- 1

[11] ELECTRICAL SECTION. . . . . . . . . 11- 1

[12] OTHERS. . . . . . . . . . . . . . . . . . . . .12-1

.8-1

MX-M700N/M700U

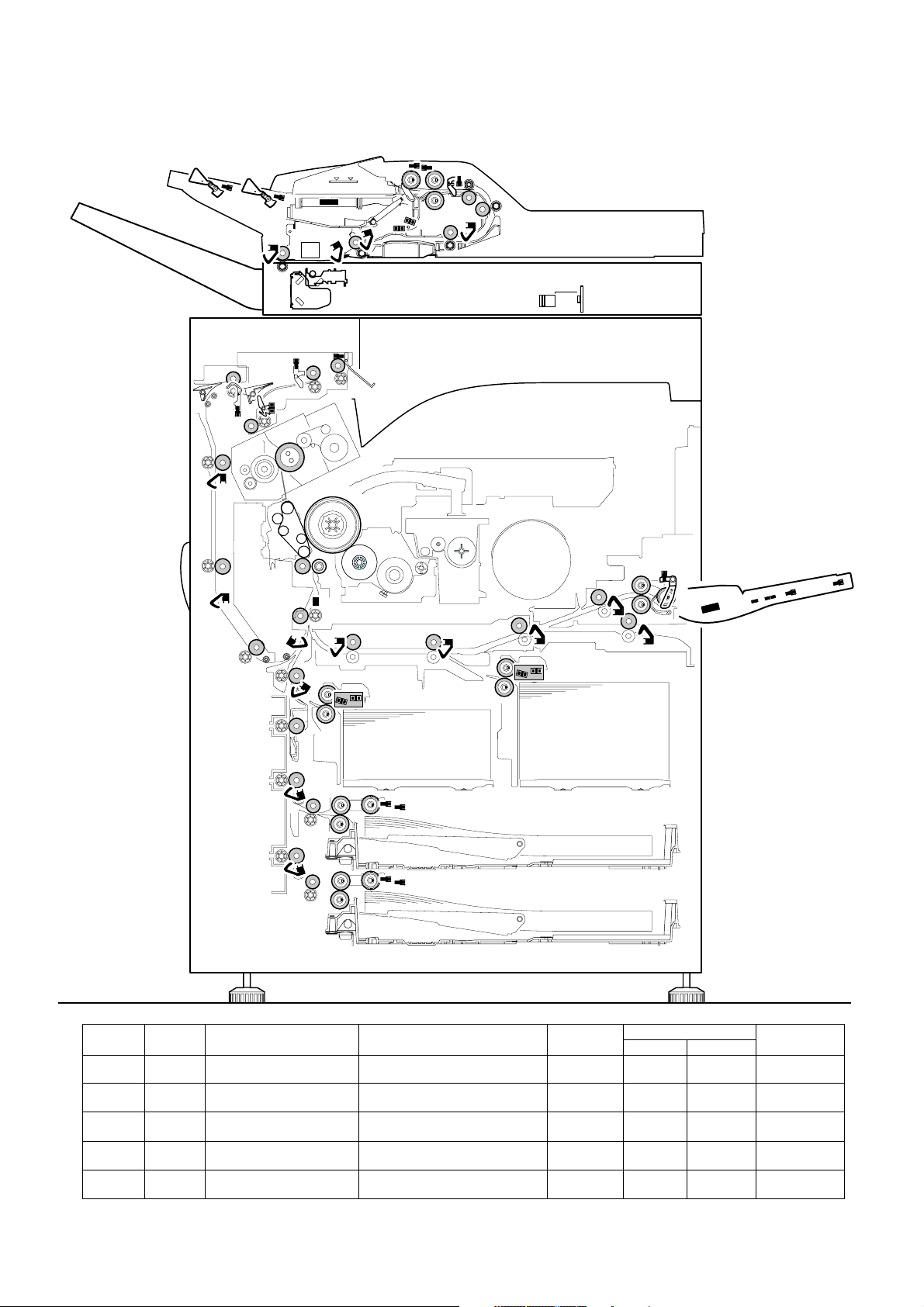

● DETAILS OF EACH SECTION

[A] EXTERNAL OUTFIT . . . . . . . . . . . . A-1

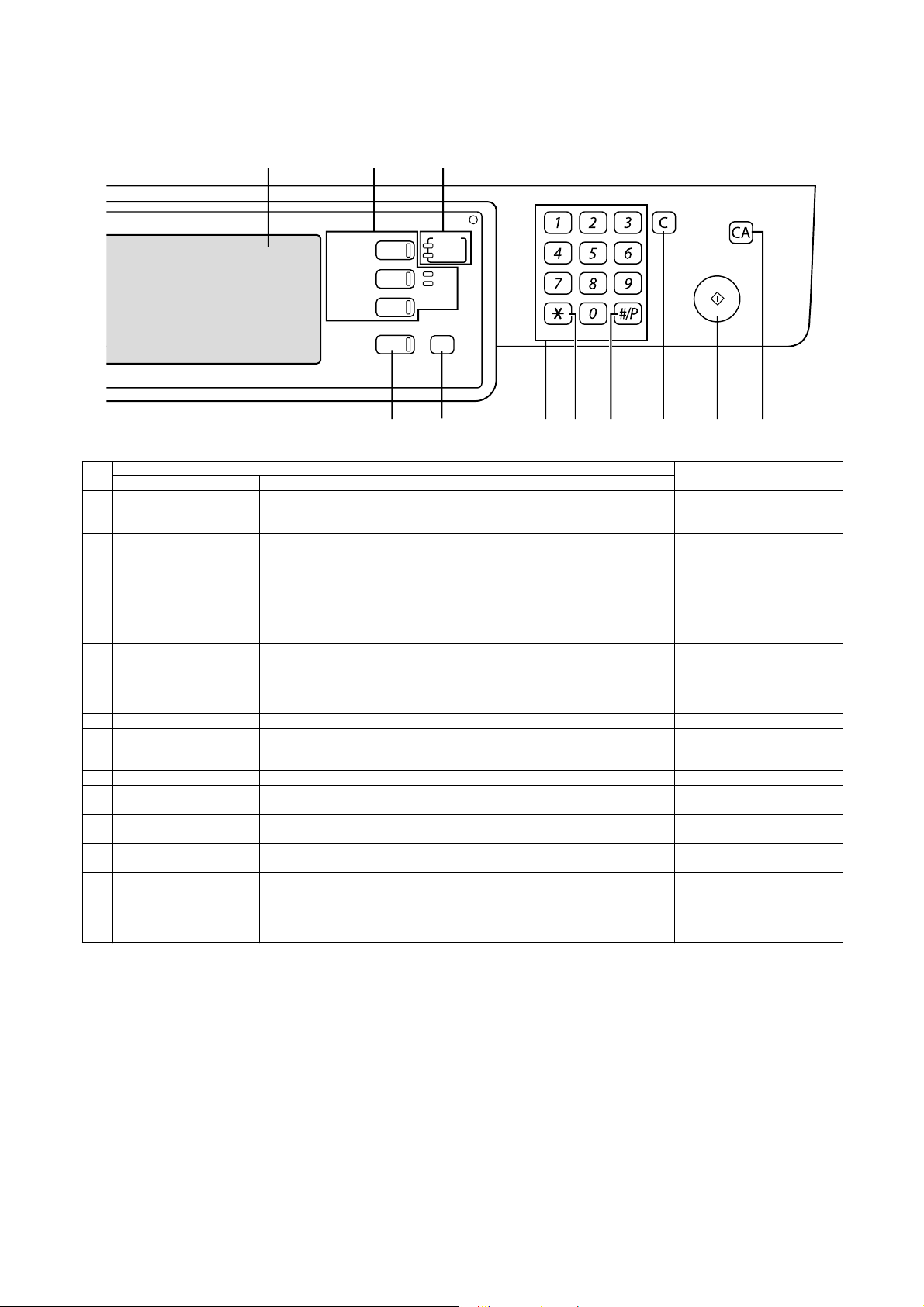

[B] OPERATION PANEL . . . . . . . . . . . B -1

[C] DSPF SECTION . . . . . . . . . . . . . . . C-1

[D] SCANNER SECTION . . . . . . . . . . . D-1

MANUAL PAPER FEED SECTION

[E]

[F] TRAY PAPER FEED SECTION . . . F -1

[G] PAPER TRANSPORT SECTION . . G -1

[H] DUPLEX SECTION . . . . . . . . . . . . H -1

[ i ] LSU SECTION . . . . . . . . . . . . . . . . i -1

[J] PHOTOCONDUCTOR SECTION. . J -1

[K] TONER SUPPLY SECTION . . . . . . K-1

[L] DEVELOPING SECTION . . . . . . . . L -1

[M] TRANSFER SECTION . . . . . . . . . . M-1

[N] FUSING SECTION . . . . . . . . . . . . . N -1

[O] PAPER EXIT SECTION . . . . . . . . . O -1

[P] DRIVE SECTION . . . . . . . . . . . . . . P-1

[Q] PWB SECTION. . . . . . . . . . . . . . . . Q -1

[R] FAN AND FILTER SECTION . . . . . R -1

[S] SENSOR, SWITCH SECTION . . . . S-1

. . E-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

NOTE FOR SERVICING

1. Precautions for servicing . . . . . . . . . . . . . . . . . . . . . . . . i

2. Warning for servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . i

3. Installing site recommendations . . . . . . . . . . . . . . . . . . . i

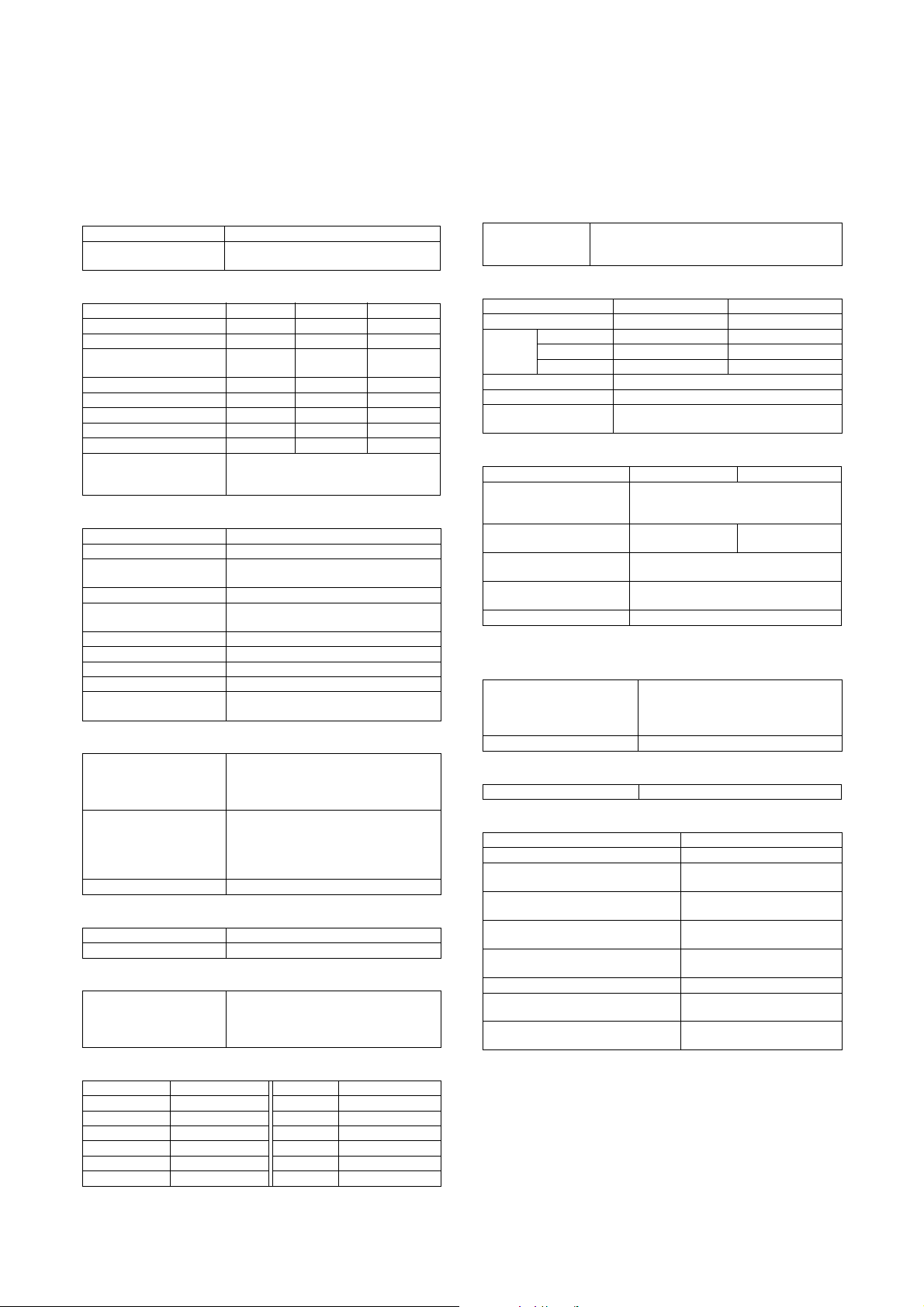

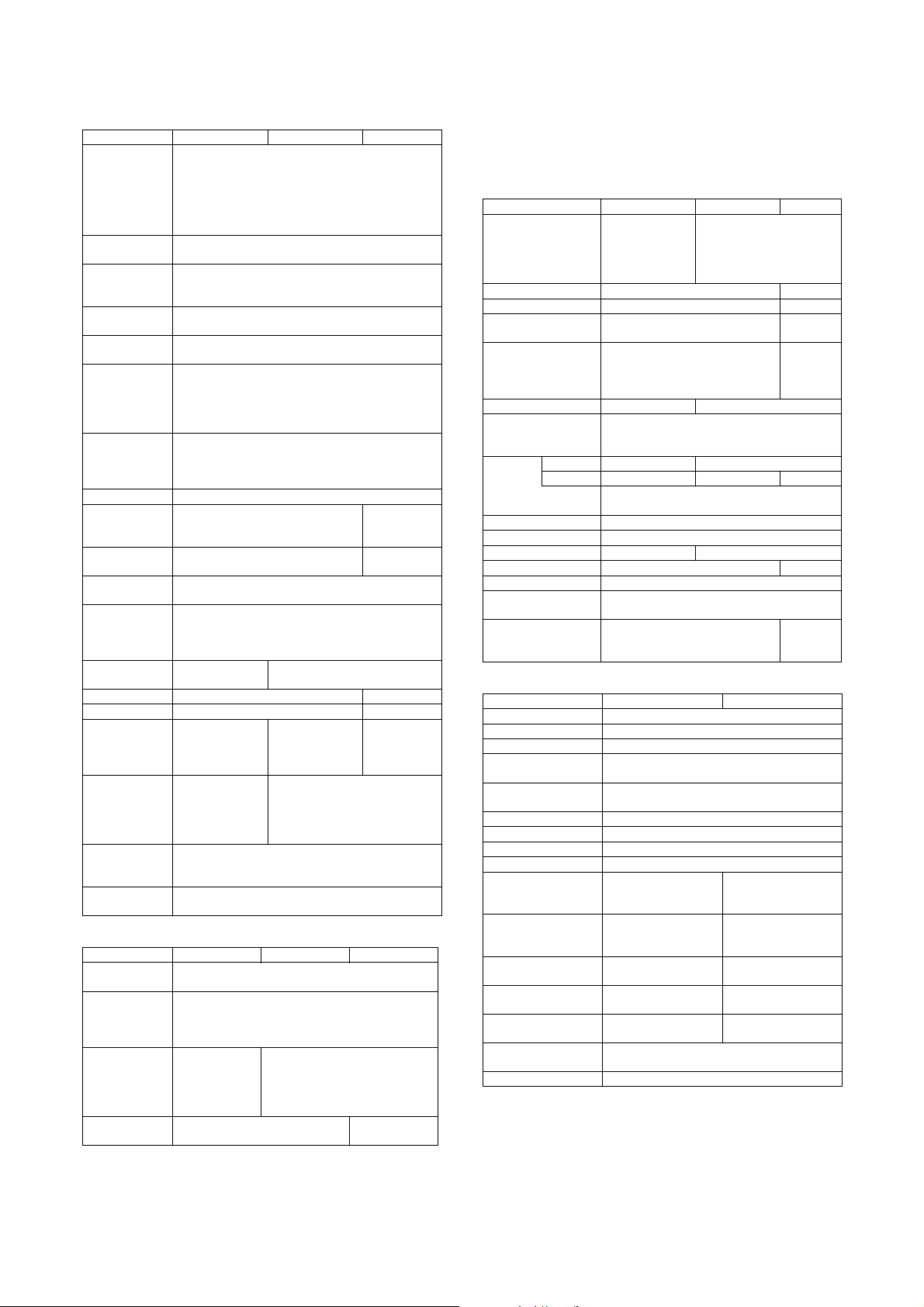

[1] PRODUCT OUTLINE

1. Different points of MX-M550/620/700 series from

AR-M550/620/700 series . . . . . . . . . . . . . . . . . . .

2. Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . .

[2] SPECIFICATIONS

1. Basic specifications . . . . . . . . . . . . . . . . . . . . . . .

2. Functional specifications. . . . . . . . . . . . . . . . . . . .

3. Environmental conditions.. . . . . . . . . . . . . . . . . . .

[3] CONSUMABLE PARTS

1. Supply system table . . . . . . . . . . . . . . . . . . . . . . .

2. Maintenance parts list . . . . . . . . . . . . . . . . . . . . . .

[4] UNPACKING AND INSTALLATION

* For unpacking and installation, refer to the installation man-

ual (00ZAR700//I1E).

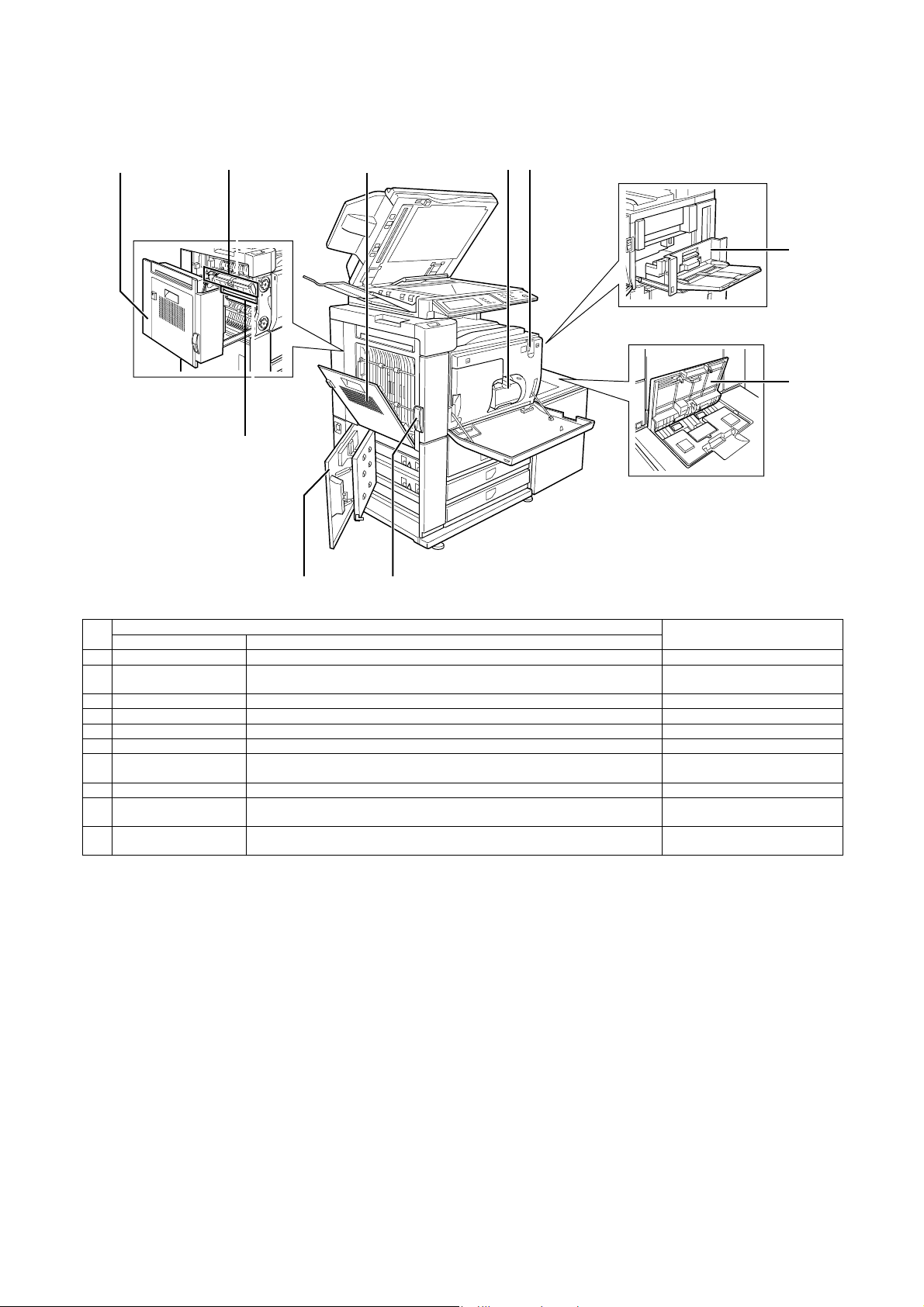

[5] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. Identification of each section and functions . . . . . 5 - 1

[6] ADJUSTMENTS

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Adjustment item list. . . . . . . . . . . . . . . . . . . . . . . .

4. Datails of adjustment . . . . . . . . . . . . . . . . . . . . . .

[7] SIMULATION

1. Adjustment value/Simulation and storage data. . .

2. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. List of simulation codes . . . . . . . . . . . . . . . . . . . .

4. Details of simulation . . . . . . . . . . . . . . . . . . . . . . .

[8] SELF DIAG AND TROUBLE CODE

1. Self diag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Trouble code list . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Details of trouble code . . . . . . . . . . . . . . . . . . . . .

[9] MAINTENANCE

1. Maintenance system table . . . . . . . . . . . . . . . . . .

2. Details of maintenance . . . . . . . . . . . . . . . . . . . . .

3. Other related items . . . . . . . . . . . . . . . . . . . . . . . .

[10] ROM VERSION-UP

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Necessary items for Flash ROM version-up . . . . .

4. Flash ROM version-up method. . . . . . . . . . . . . . .

5. Turning OFF the power during the version-up

procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Version-up procedure flowchart . . . . . . . . . . . . . .

[11] ELECTRICAL SECTION

1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Power line chart . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Actual wiring chart . . . . . . . . . . . . . . . . . . . . . . . .

4. Signal name list . . . . . . . . . . . . . . . . . . . . . . . . . .

[12] OTHERS

1. System settings . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Web setting service mode. . . . . . . . . . . . . . . . . . .

3. Paper JAM code . . . . . . . . . . . . . . . . . . . . . . . . . .

1- 1

1- 1

1- 1

1- 4

2- 1

2- 4

2- 11

3- 1

3- 2

6- 1

6- 1

6- 1

6- 2

7- 1

7- 2

7- 4

7- 8

8- 1

8- 4

8- 6

9- 1

9- 4

9- 13

10- 1

10- 2

10- 2

10- 2

10- 5

10- 5

11 - 1

11 - 5

11 - 8

11 - 18

12- 1

12- 8

12- 10

● DETAILS OF EACH SECTION

[A] EXTERNAL OUTFIT . . . . . . . . . . . . . . . . . . . . . . . . .

[B] OPERATION PANEL

1. Electrical and mechanism relation diagram . . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . . .

[C] DSPF SECTION

1. Electrical and mechanism relation diagram . . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . . .

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[D] SCANNER SECTION

1. Electrical and mechanism relation diagram . . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . . .

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[E] MANUAL PAPER FEED SECTION

1. Electrical and mechanism relation diagram . . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . . .

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[F] TRAY PAPER FEED SECTION

1. Electrical and mechanism relation diagram . . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . . .

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[G] PAPER TRANSPORT SECTION

1. Electrical and mechanism relation diagram . . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . . .

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[H] DUPLEX SECTION

1. Electrical and mechanism relation diagram . . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . . .

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[ i] LSU SECTION

1. Electrical and mechanism relation diagram . . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . . .

[J] PHOTOCONDUCTOR SECTION

1. Electrical and mechanism relation diagram . . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . . .

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[K] TONER SUPPLY SECTION

1. Electrical and mechanism relation diagram . . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . . .

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[L] DEVELOPING SECTION

1. Electrical and mechanism relation diagram . . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . . .

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[M] TRANSFER SECTION

1. Electrical and mechanism relation diagram . . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . . .

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A- 1

B- 1

B- 2

B- 2

C- 1

C- 5

C- 6

C-19

D- 1

D- 2

D- 4

D- 11

E- 1

E- 2

E- 2

E- 8

F- 1

F- 5

F- 8

F-17

G- 1

G- 5

G- 5

G-14

H- 1

H- 2

H- 4

H-12

i- 1

i- 2

i- 2

J- 1

J- 3

J- 4

J- 9

K- 1

K- 2

K- 3

K- 4

L- 1

L- 2

L- 2

L- 5

M- 1

M- 2

M- 3

M- 5

Page 3

[N] FUSING SECTION

1. Electrical and mechanism relation diagram . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . .

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[O] PAPER EXIT SECTION

1. Electrical and mechanism relation diagram . . . .

2. Operational descriptions . . . . . . . . . . . . . . . . . . .

3. Disassembly and assembly . . . . . . . . . . . . . . . .

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[P] DRIVE SECTION

1. Disassembly and assembly . . . . . . . . . . . . . . . .

2. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Q] PWB SECTION

1. Disassembly and assembly . . . . . . . . . . . . . . . .

[R] FAN AND FILTER SECTION

1. Disassembly and assembly . . . . . . . . . . . . . . . .

2. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[S] SENSOR, SWITCH SECTION

1. Disassembly and assembly . . . . . . . . . . . . . . . .

CONTENTS

N- 1

N- 2

N- 3

N-12

O- 1

O- 2

O- 2

O- 7

P- 1

P-14

Q- 1

R- 1

R- 6

S- 1

Page 4

MX-M700N

NOTE FOR SERVICING

This Service Manual uses some symbols to assure safe operation.

Please understand the meanings of photographs before servicing.

WARNING: If this WARNING should be ignored, a serious

CAUTION: If this CAUTION should be ignored, an injury or

danger to life or a serious injury could result.

a damage to properties could result.

1. Precautions for servicing

1) When servicing, disconnect the power plug, the printer cable,

the network cable, and the telephone line from the machine,

except when performing the communication test, etc.

It may cause an injury or an electric shock.

2) There is a high temperature area inside the machine. Use an

extreme care when servicing.

It may cause a burn.

3) There is a high voltage section inside the machine which may

cause an electric shock. Be careful when servicing.

4) Do not disassemble the laser unit. Do not insert a reflective

material such as a screwdriver in the laser beam path.

It may damage eyes by reflection of laser beams.

5) When servicing with the machine operating, be careful not to

squeeze you hands by the chain, the belt, the gear, and other

driving sections.

6) Do not leave the machine with the cabinet disassembled.

Do not allow any person other than a serviceman to touch

inside the machine. It may cause an electric shock, a burn, or

an injury.

7) When servicing, do not breathe toner, developer, and ink

excessively. Do not get them in the eyes.

If toner, developer, or ink enters you eyes, wash it away with

water immediately, and consult a doctor if necessary.

8) The machine has got sharp edges inside. Be careful not to

damage fingers when servicing.

9) Do not throw toner or a toner cartridge in a fire. Otherwise,

toner may pop and burn you.

10) When replacing the lithium battery of the PWB, use a specified

one only.

If a battery of different specification is used, it may be broken,

causing breakdown or malfunction of the machine.

11) When carrying a unit with PWB or electronic parts installed to

it, be sure to put it in an anti-static-electricity bag.

It may cause a breakdown or malfunctions.

4) When connecting the grounding wire, never connect it to the

5GTXKEG/CPWCN

following points.

It may cause an explosion, a fire or an electric shock.

• Gas tube

• Lightning conductor

• A water pipe or a water faucet, which is not recognized as a

grounding object by the authorities.

• Grounding wire for telephone line

5) Do not damage, break, or work the power cord.

Do not put heavy objects on the power cable. Do not bend it

forcibly or do not pull it extremely.

It may cause a fire or an electric shock.

6) Keep the power cable away from a heat source.

Do not insert the power plug with dust on it into a power outlet.

It may cause a fire or an electric shock.

7) Do not put a receptacle with water in it or a metal piece which

may drop inside the machine.

It may cause a fire or an electric shock.

8) With wet or oily hands, do not touch the power plug, do not

insert the telephone line jack, do not operate the machine, or

do not perform servicing.

It may cause an electric shock.

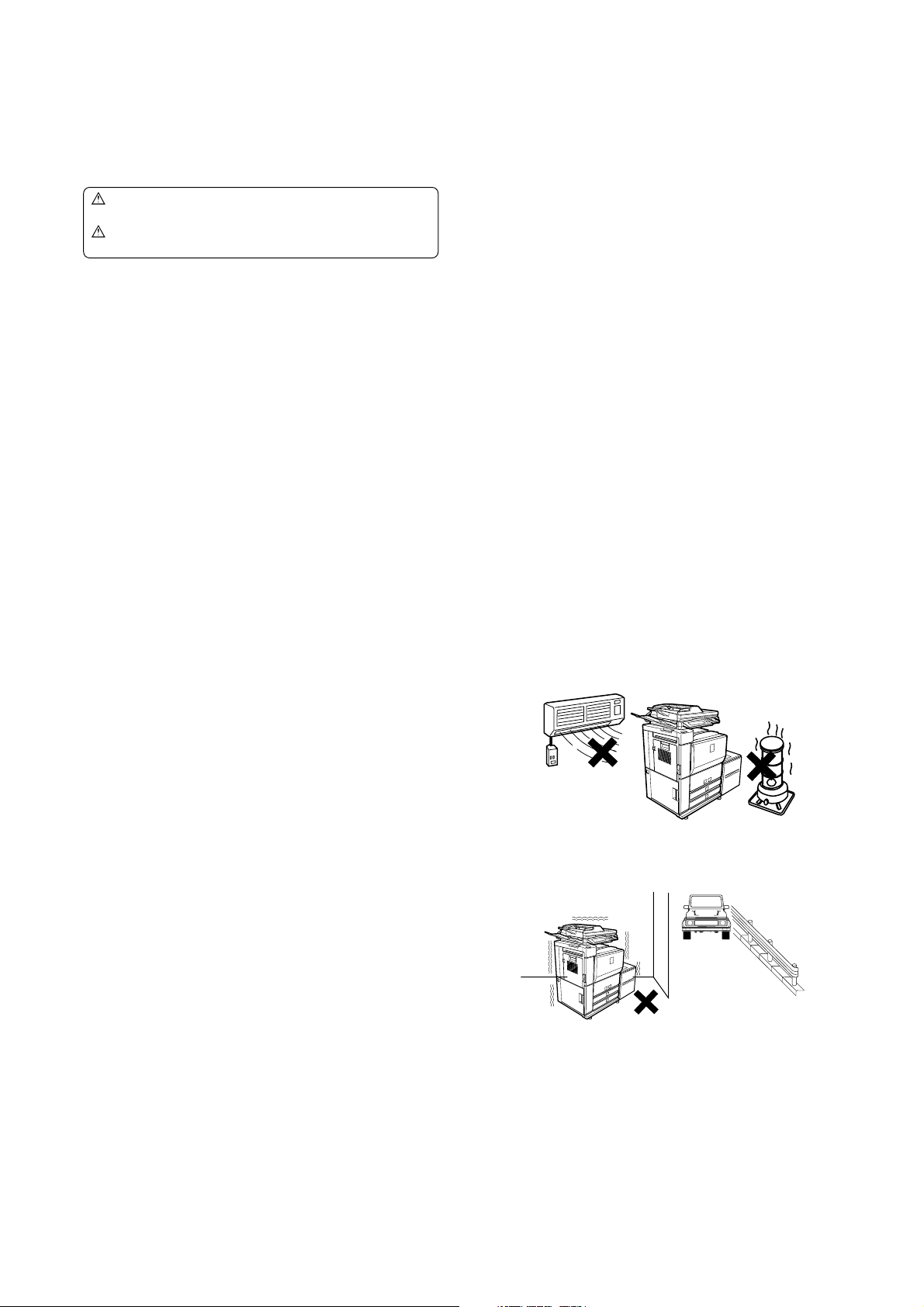

3. Installing site recommendations

Do not install the machine at the following sites.

1) Place of high temperature, high humidity, low tempera-

ture, low humidity, place under an extreme change in temperature and humidity.

Paper may get damp and form dews inside the machine, causing paper jam or copy dirt.

For operating and storing conditions, refer to the specifications

described later.

2) Places of too much vibrations

It may cause a breakdown.

2. Warning for servicing

1) Be sure to connect the power cord only to a power outlet that

meets the specified voltage and current requirements.

Avoid complex wiring, which may lead to a fire or an electric

shock.

It may cause a fire or an electric shock.

2) If there is any abnormality such as a smoke or an abnormal

smell, interrupt the job and disconnect the power plug.

It may cause a fire or an electric shock.

3) Be sure to connect the grounding wire. If an electric leakage

occurs without grounding, a fire or an electric shock may

result.

To protect the machine and the power unit from lightening,

grounding must be made.

MX-M700N NOTE FOR SERVICING - i

Page 5

3) Poorly ventilated areas

An electro-static type copier will produce ozone inside it.

The quantity of ozone produced is designed to a low level so

as not to affect human bodies. However, continuous use of

such a machine may produce a smell of ozone. Install the

machine in a well ventilated place, and ventilate occasionally.

4) Place of direct sunlight.

Plastic parts and ink may be deformed, discolored, or may

undergo qualitative change.

It may cause a breakdown or copy dirt.

7) Place too close to a wall

All machines require clean intake and exhaust of air. If the

intake and exhaust of air are not proper, failure of the machine

will occur.

11-13/16"

(30cm)

6-1/8"

(15cm)

23-5/8"

(60cm)

8) Unstable or uneven surfaces

Placement of the machine will affect performance.

An unstable machine may fall over and cause an injury.

Use the proper optional desk unit. When using the optional

desk, be sure to lock the adjusters and casters.

5) Place which is full of organic gases such as ammonium

The organic photoconductor (OPC) drum used in the machine

may undergo qualitative change due to organic gases such as

ammonium.

Installation of this machine near a diazo-type copier may result

in dirt copy.

6) Place of too much dust

When dust enters the machine, it may affect the operation of

the machine.

MX-M700N NOTE FOR SERVICING - ii

Page 6

MX-M700N

[1] PRODUCT OUTLINE

1. Different points of MX-M550/620/700

series from AR-M550/620/700 series

• Adopted new operation panel with 8.9 inch LCD

• Added web roller and motor for web roller in Fusing section

• Added firmware version-up using USB device by Sim 49-1

• Eliminated parallel port

2. Main Features

A. Single Pass Duplex Scanner

• Max. 76 cpm for duplex scanning

• Best-in-class 150-sheet feeder

B. Security Solution

Data encryption + data clear with random number

• Network security

C. New Toner

• Higher density/Finer particles

D. Inner Output

• Separate copy output pages from printer output pages

E. Enhance the solutions such as document

filing and other features.

F. Design for High Reliability

• Robust frame designed by highly accurate CAE analysis

G. Improved Performance

• Network Tandem Copy/Print

• High-speed Processor

• New high-speed ASIC

H. Fax feature

For replacement of mid/low speed devices (up to area)

I. Large Capacity Finisher

Finisher capacity: 4,000-sheet

(2) Strengthened Frame Structure

5GTXKEG/CPWCN

Highly Rigid Frame

Improved stability with less machine distortion, and both rigidity and

lightweight been achieved.

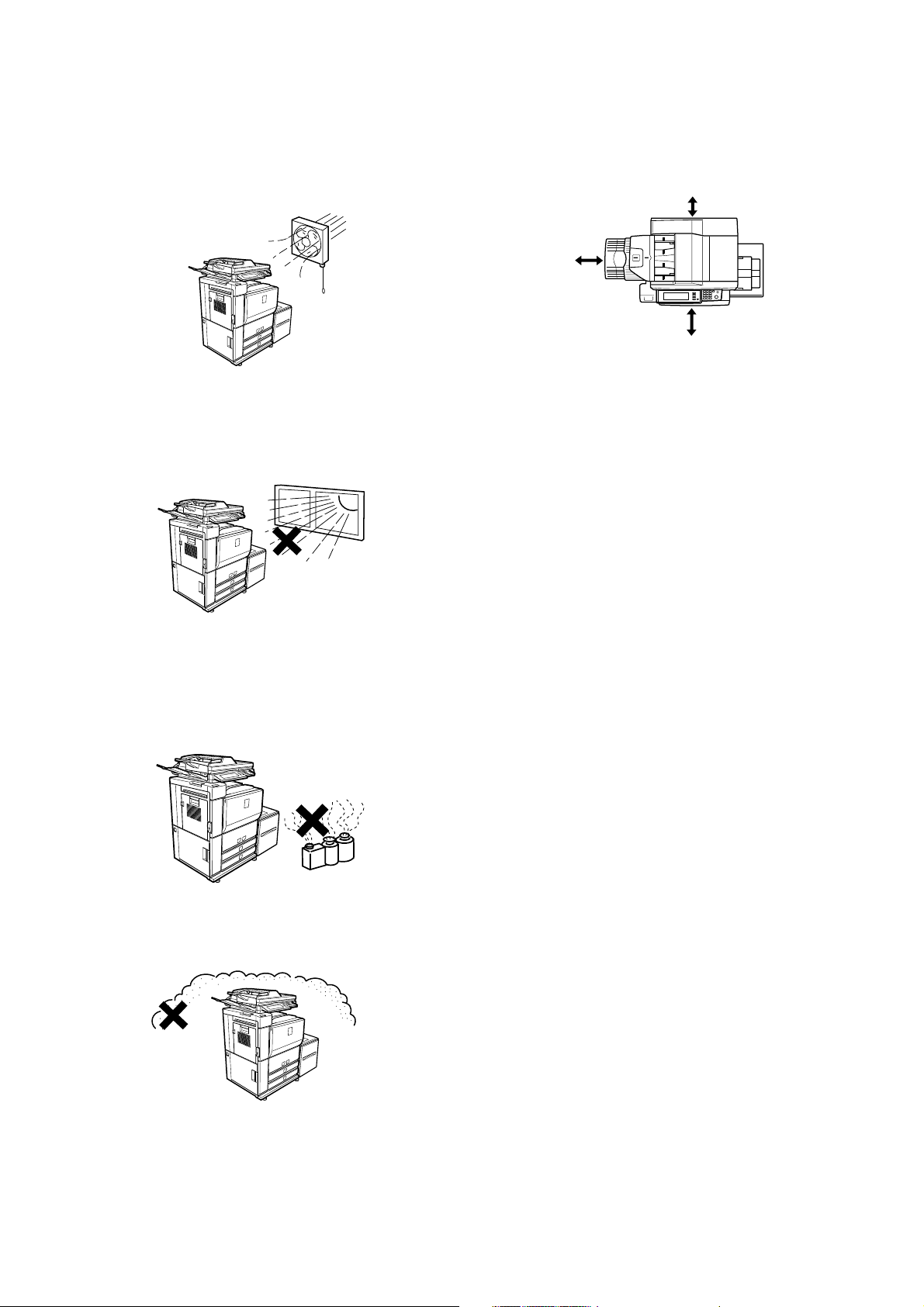

(3) Energy Saving with Unique External Heat Roller

Fusing System

Newly Developed External Heating System

1) High reliability with stabilized fusing ability

2) Shortened warm up time before start copying

3) Achievement of energy efficiency that clears 2006 Rationalization in Energy Use Law

External Heat Roller Fusing System

Thin Steel Fusing

Roller

Low Heat Capacity

Rubber Roller

High Efficiency Heater

External Heating

Roller

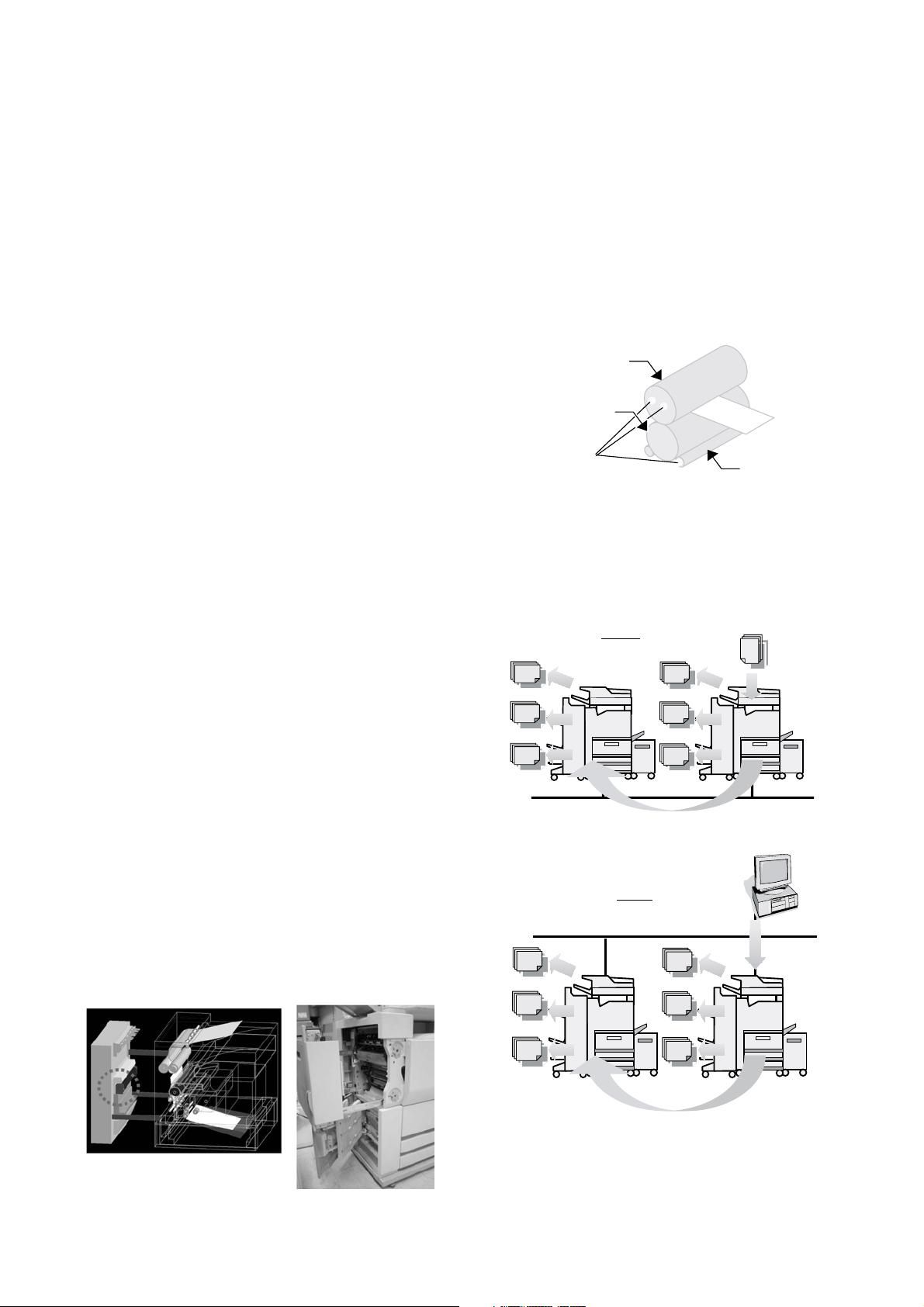

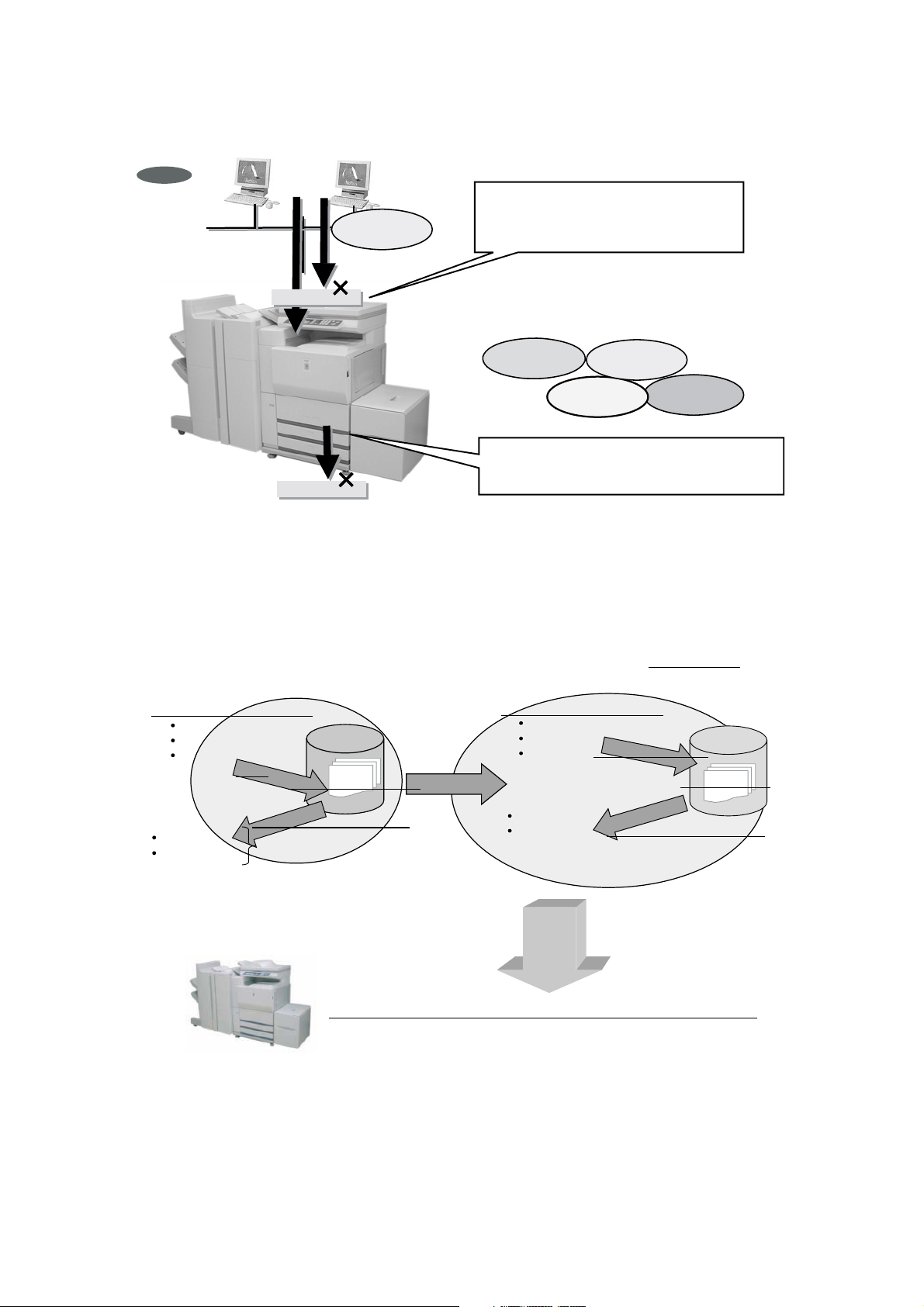

B. Network tandem

With Network tandem function, users can output one job on two

network connected engines. Productivity of large-volume copying/

printing can be dramatically improved by high-speed output of up to

110cpm (55cpm model), 124cpm (62cpm model) and 140cpm

(70cpm model).

Scan original from

Copy

document glass or DSPF

3. Features

A. High reliability

(1) Improved Image Quality/Paper Transport

Full-Grip Path Design

Stable paper feeding realized by rollers that firmly grip paper

Small-Diameter Belt Transfer System

With reduced effect to paper types, drum paper release is stabilized

and transfer efficiency is improved

Easier Paper Jam Fixation with Open Paper Path

Jammed paper on vertical paper path can be easily removed by

opening the left side cover, which shortens time to fix paper jam

MX-M700N PRODUCT OUTLINE 1 – 1

Send print

data from PC

Print

* Users can use the function simply by connecting the engines to

network. This means no Tandem Kit (Connection cable) necessary.

Page 7

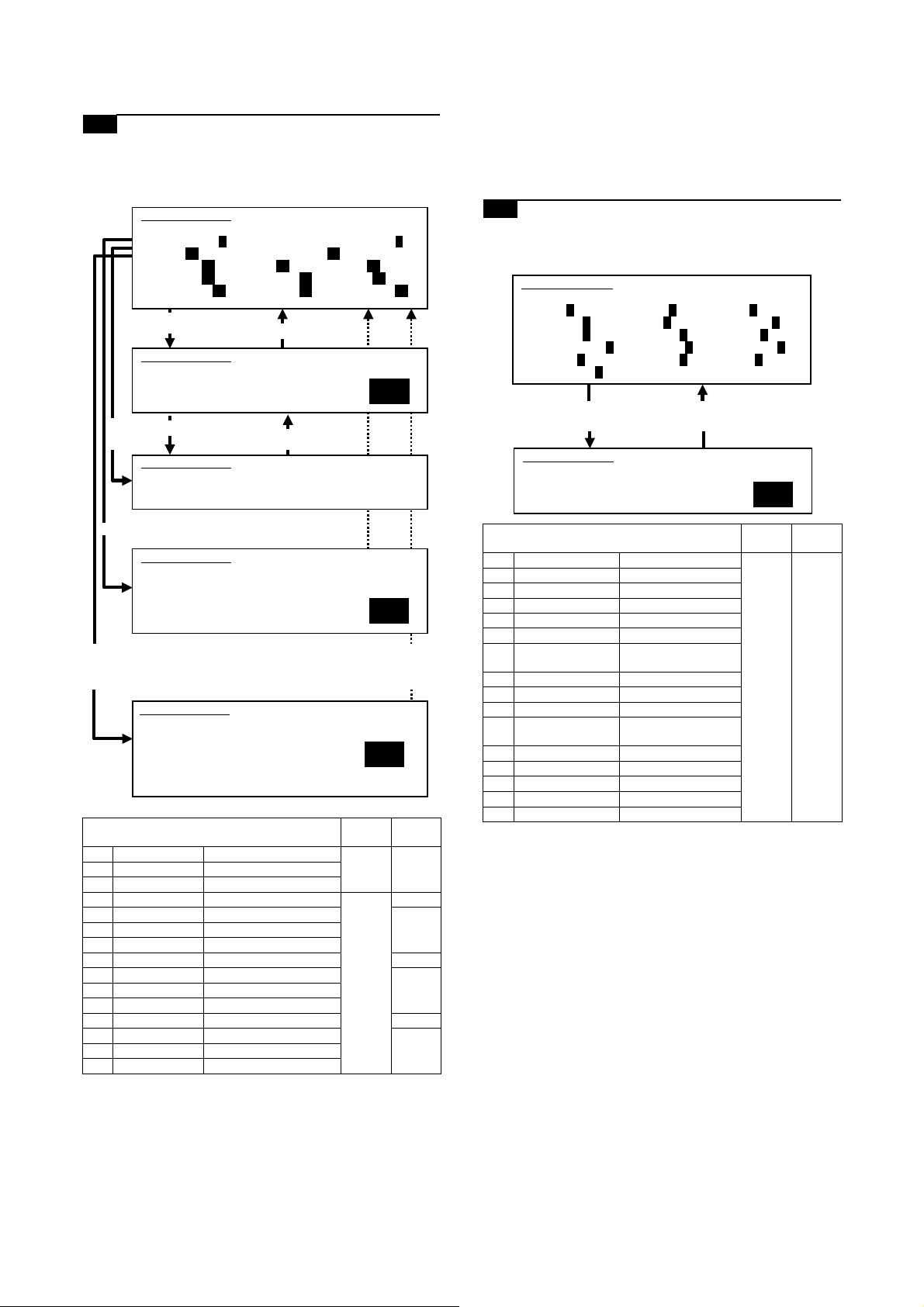

C. 2-Way Security Solution

Document Filing/Quick File

Original data

Print data

Fax data

Install DSK

PIN printing

Password input

Store

Recall (Job settings)

Raw/compressed data

HDD memory

aEncrypted data

Encrypt before storing

Recall (Job settings)

Document Filing/Quick File

Original data

Print data

Fax data

PIN printing

Password input

a

a

HDD memory

ONLY-ONE

Print data

Way-in : Network Security

Allow access of authorized network address only

and prevent unauthorized access from outside.

(Filtering of network address)

(1) Data Security coexisting with Document Filing

Document Filing/Quick File

Original data

Print data

Fax data

PIN printing

Password input

Store

Store

Recall (Job settings)

HDD memory

Raw/compressed dataRaw/compressed data

Install DSK

Copy data

Way-out : HDD Data Clear + Encryption

Data clear by plural writing random number.

Cannot be analyzed even when peeped by encryption.

Print data

Scan data

Fax data

Data SecurityData Security

Document Filing/Quick File

Original data

Print data

Fax data

PIN printing

Password input

Encrypt before storingEncrypt before storing

Recall (Job settings)

HDD memory

Encrypted dat

Encrypted dat

Encrypted dat

Security is assured by encrypting the data to be stored!

Security is assured by encrypting the data to be stored!

MX-M700N PRODUCT OUTLINE 1 – 2

Page 8

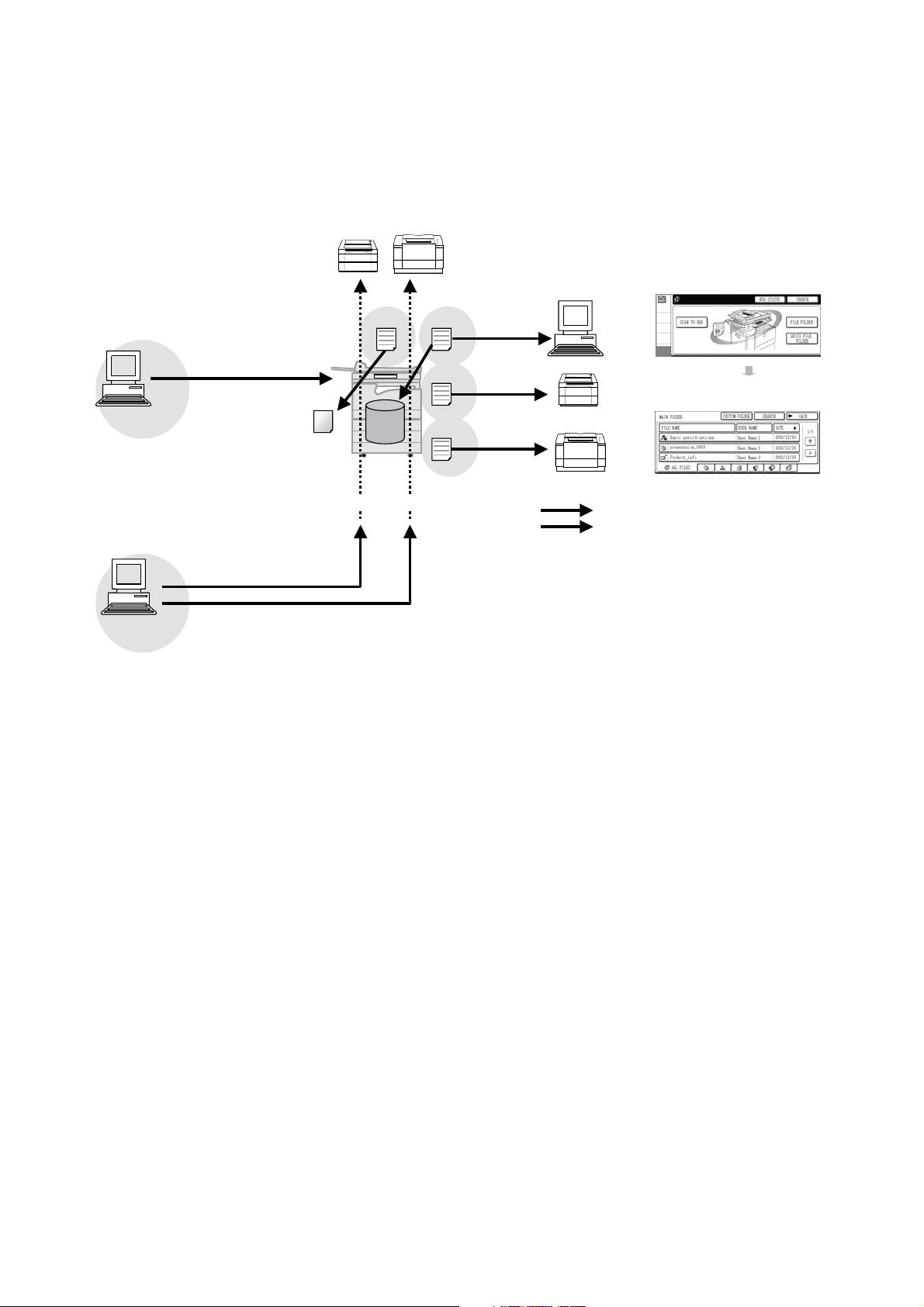

D. Document Filing

>

MX-M550N/U

MX-M620N/U

MX-M620N/U

Document filing is a function that enables users to share and reuse

data stored in the engine's HDD by digitalizing various information

sent/scanned from printer, fax, PC or MFP that are connected by

network.

Print

PC

PC Fax

PC i-Fax

Print data

PC-Fax is like printing

Word data etc. onto fax

paper.

G3 Fax

Fax data

Copy

HDD

MX-M550N/U

MX-M620N/U

MX-M700N/U

i-Fax data

Internet-Fax

Scan

FAX

i-FAX

Telephone line

Network/LAN

Send E-mail

Send

Send E-mail

<Document Filing initial screen>

PC

<List of data stored in Main folder

G3 Fax

Internet Fax

MX-M700N PRODUCT OUTLINE 1 – 3

Page 9

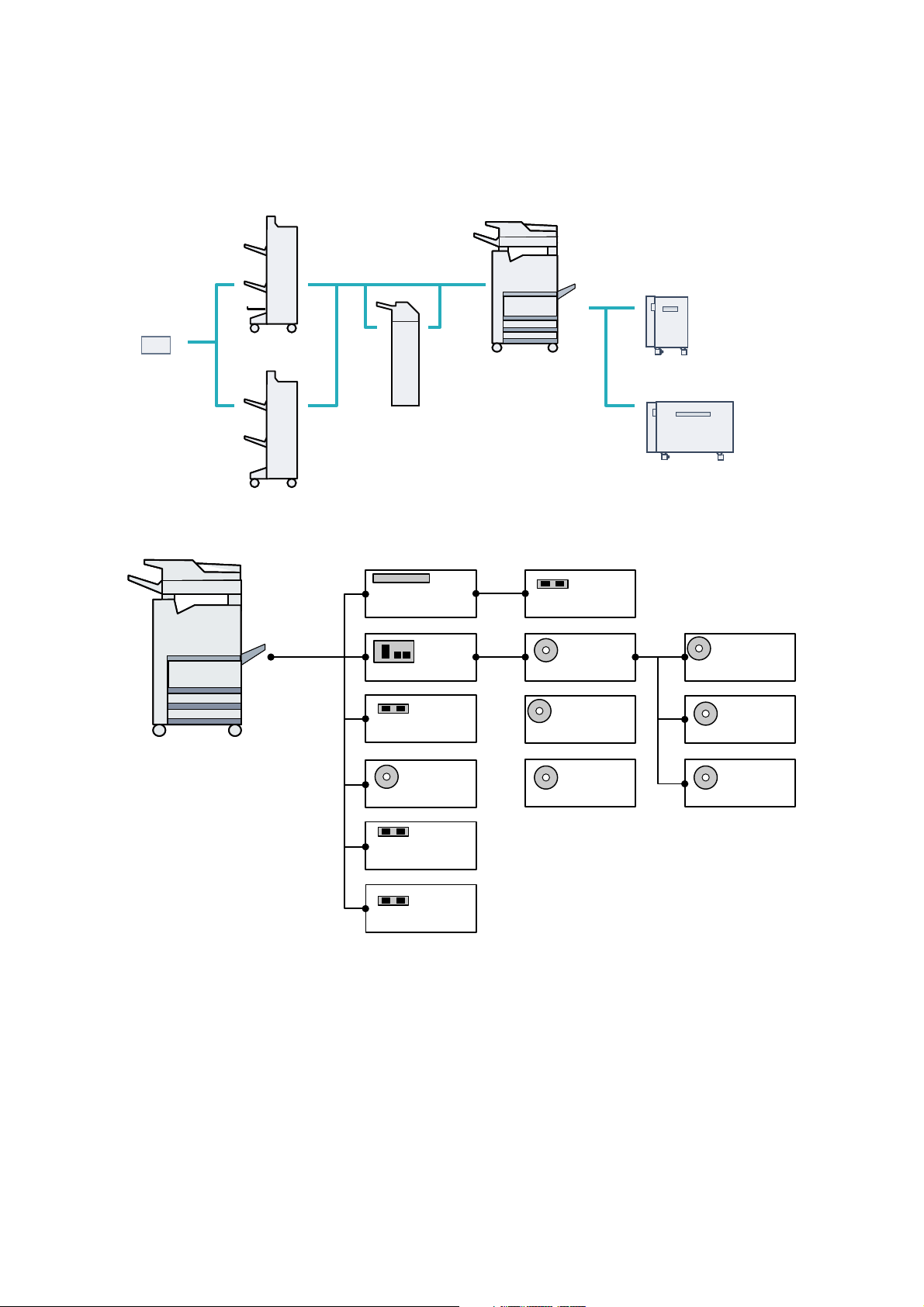

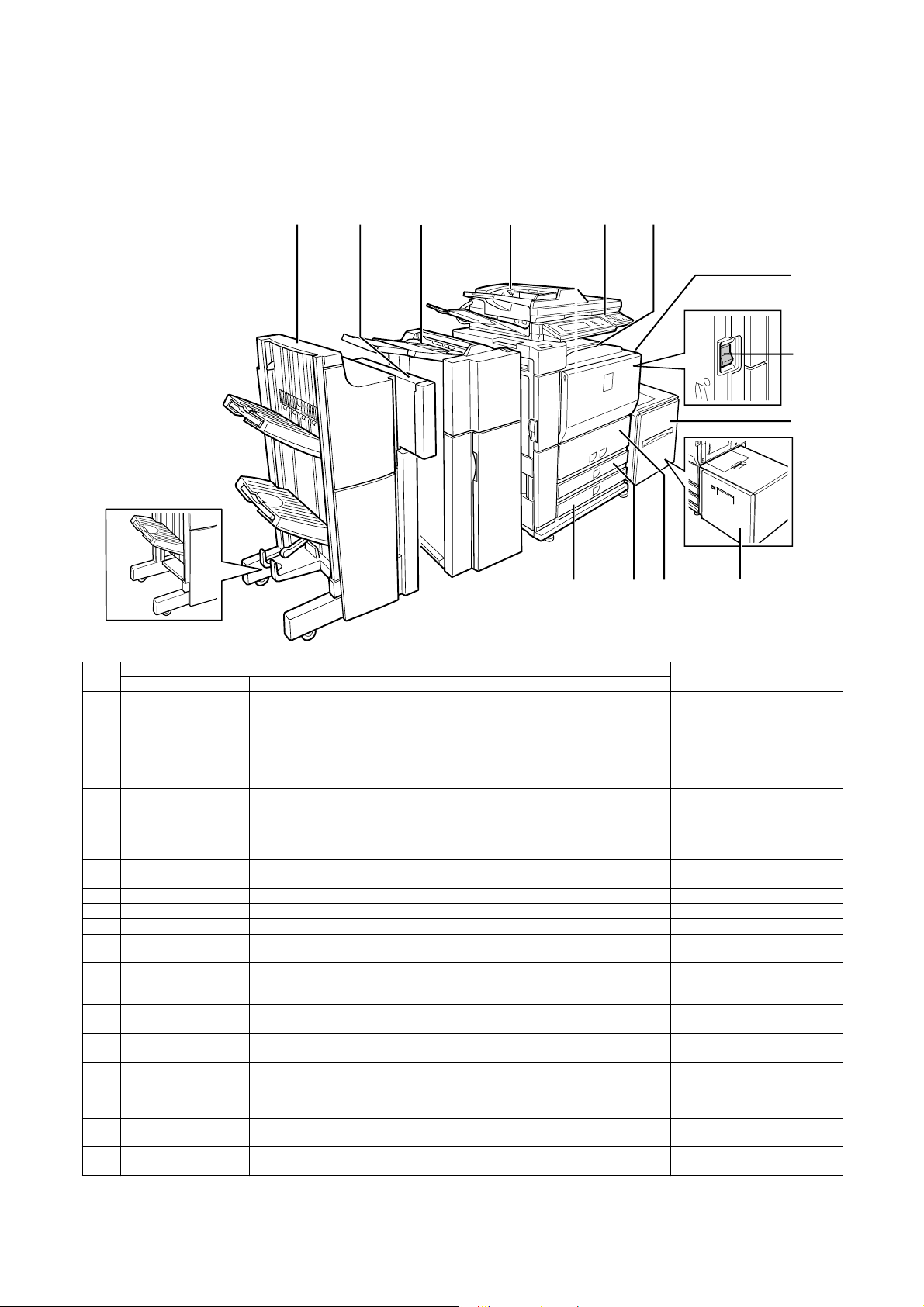

4. CONFIGURATION

A. Main unit and option lineup

(1) Option lineup

Saddle stitch finisher

Punch unit

Finisher

Inserter

55/62/70ppm

A4 LCC

A3 LCC

55/62/70ppm

Printer function

Standard

Facsimile

expansion kit

Network

expansion

kit

Barcode font kit

PS3 expansion kit

256MB expansion

memory board

Data security kit

FAX momory (8MB)

Network

scanner

expansion kit

Application

communication

module

External

account

module

SHARPDESK

1 (5, 10, 50, 100)

license kit

Application

integration

module kit

Internet FAX

expansion kit

MX-M700N PRODUCT OUTLINE 1 – 4

Page 10

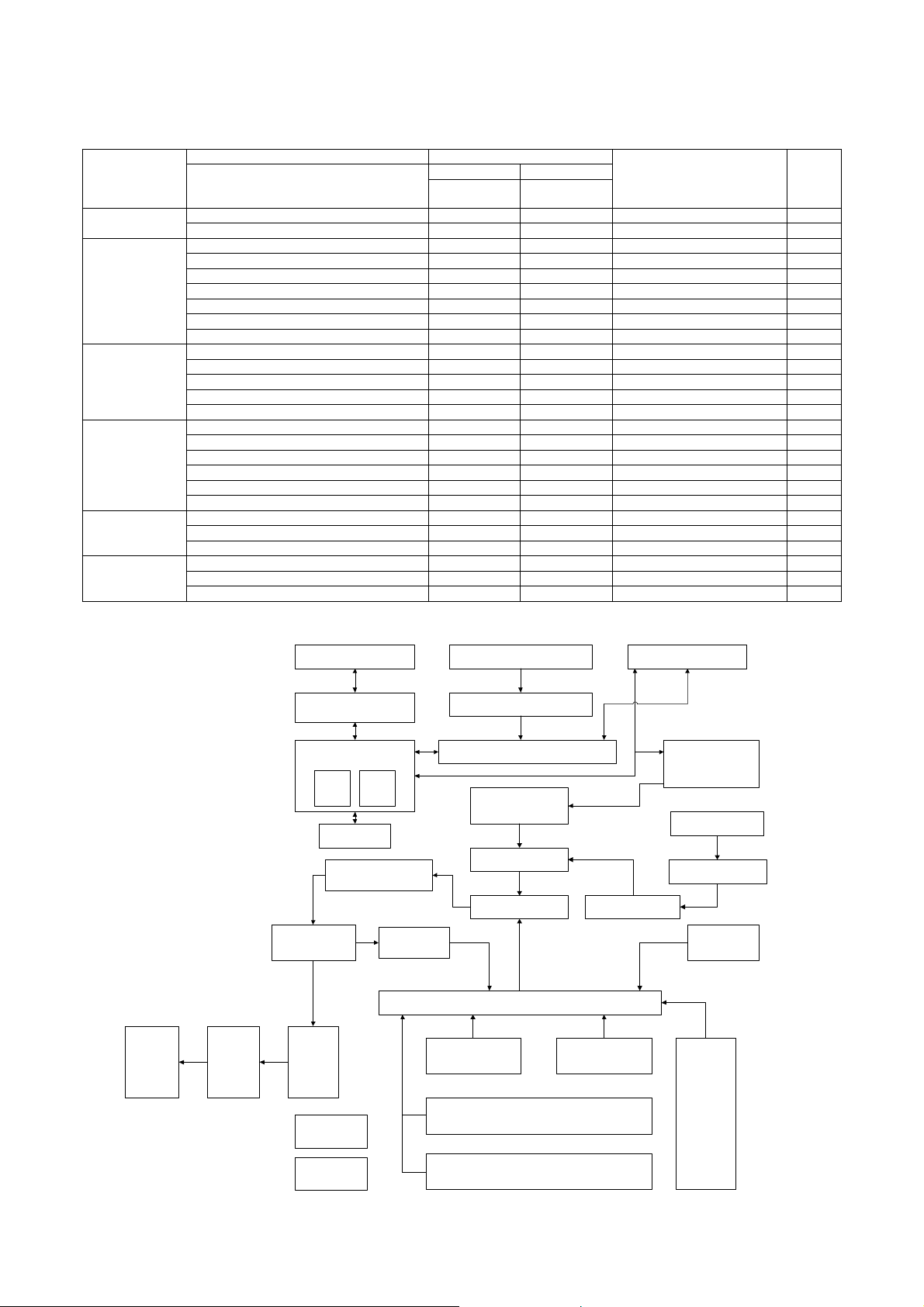

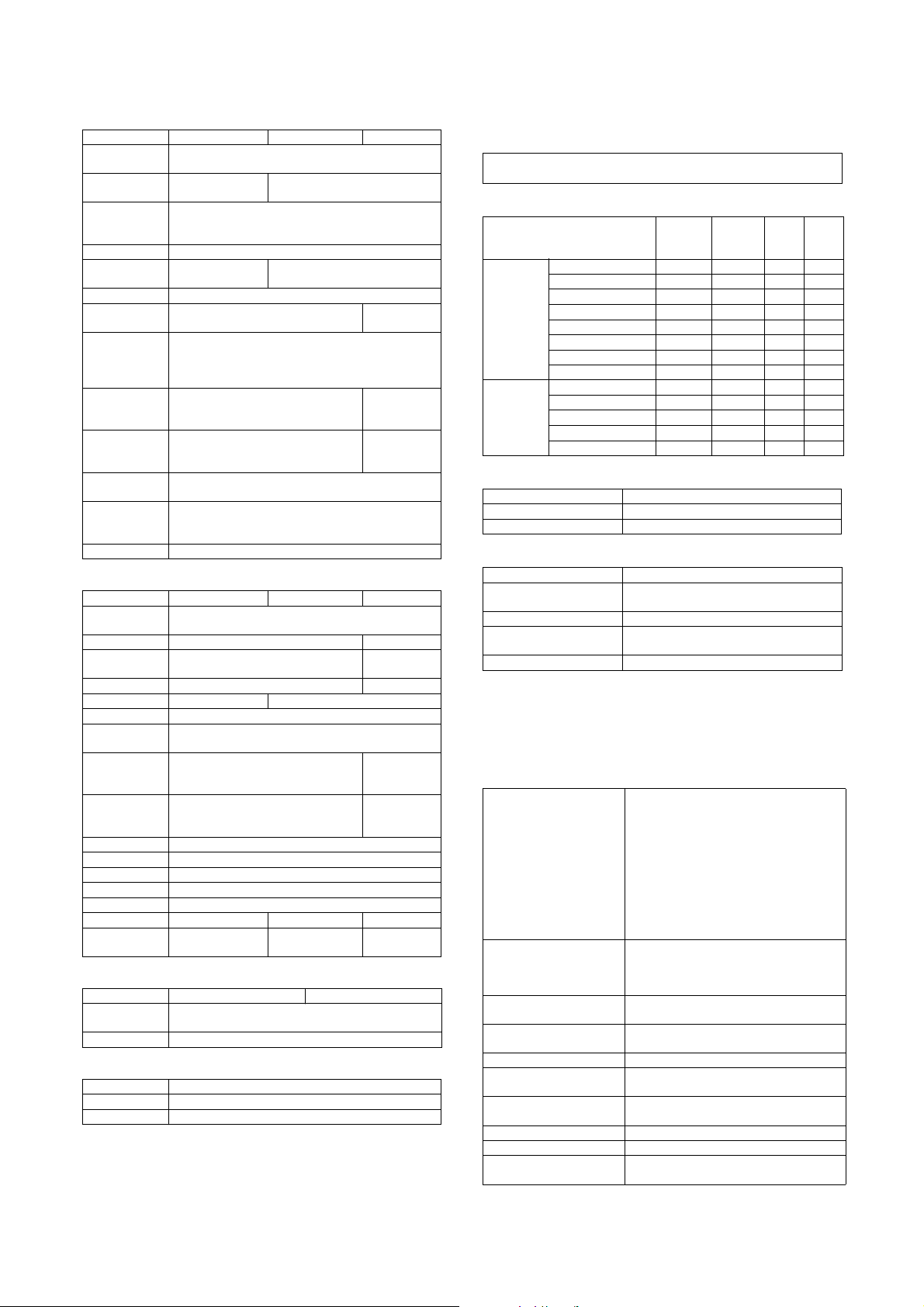

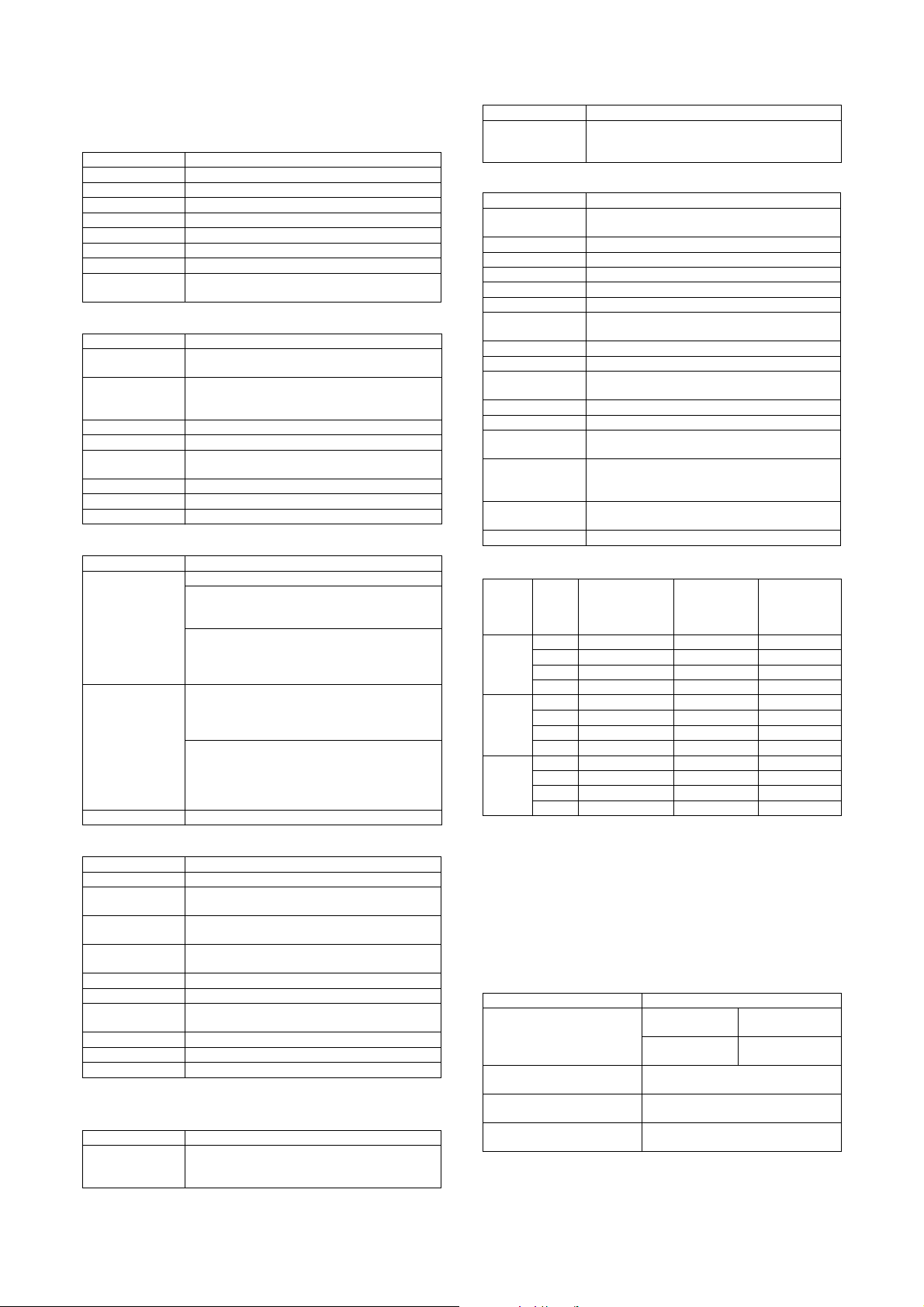

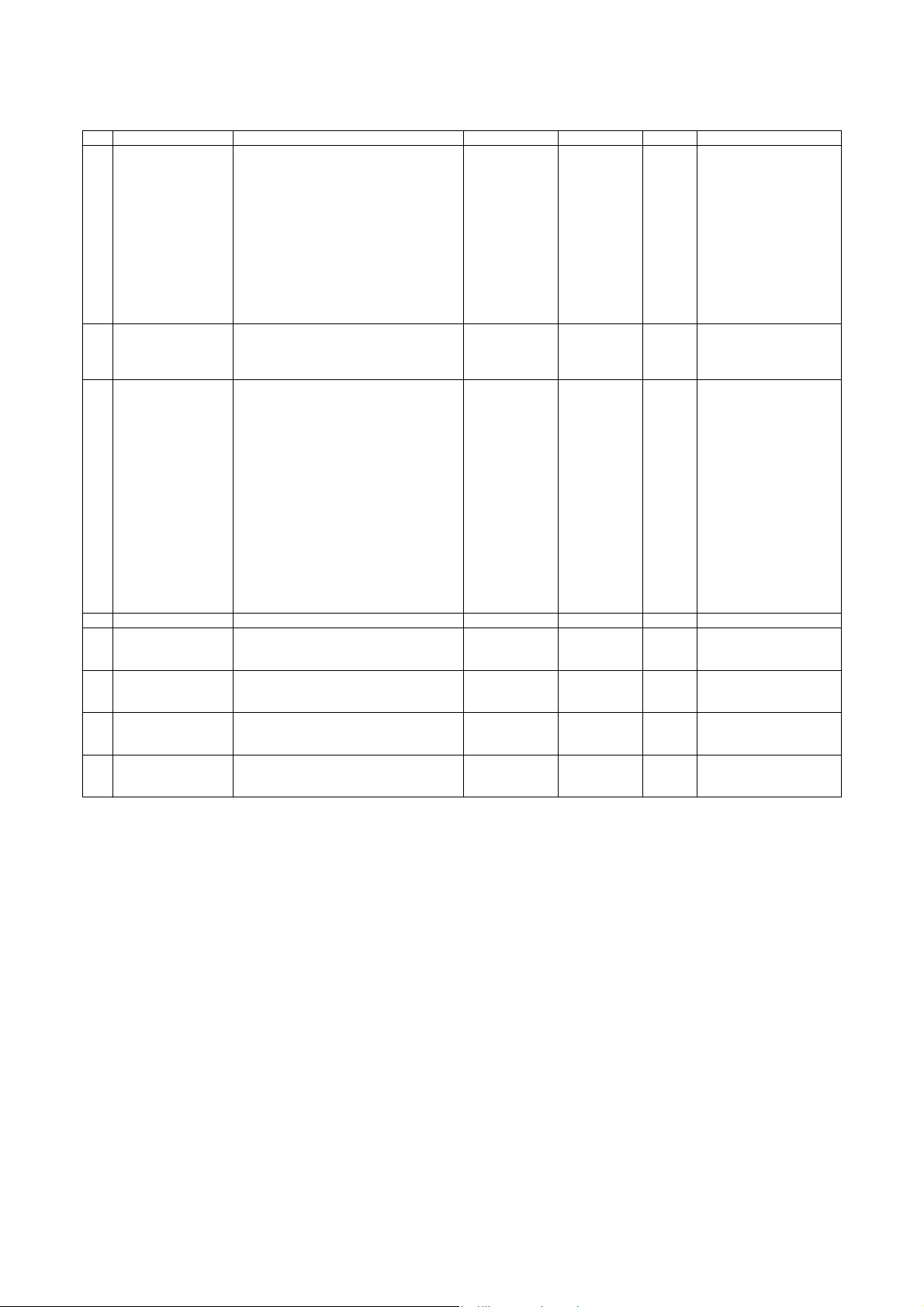

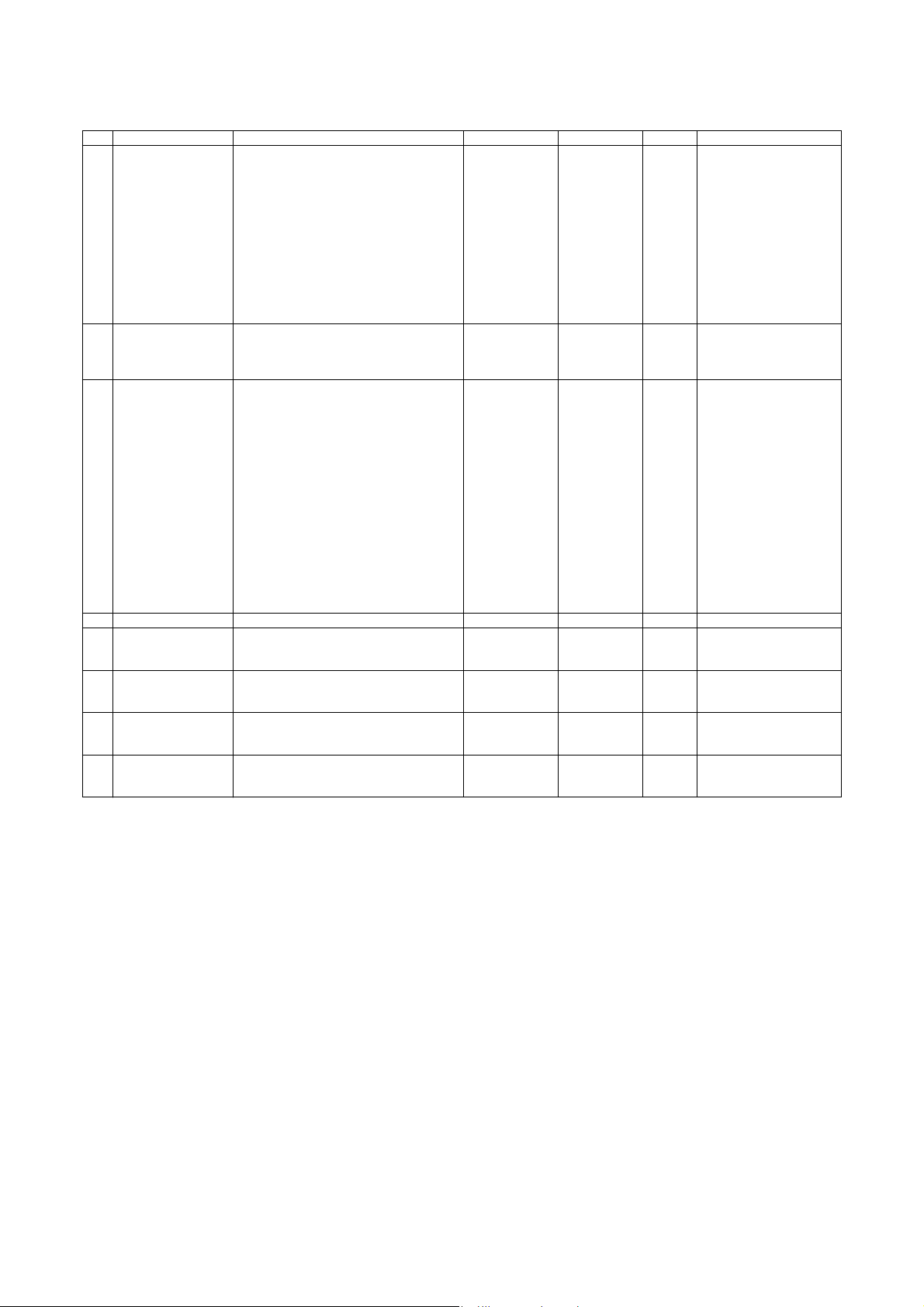

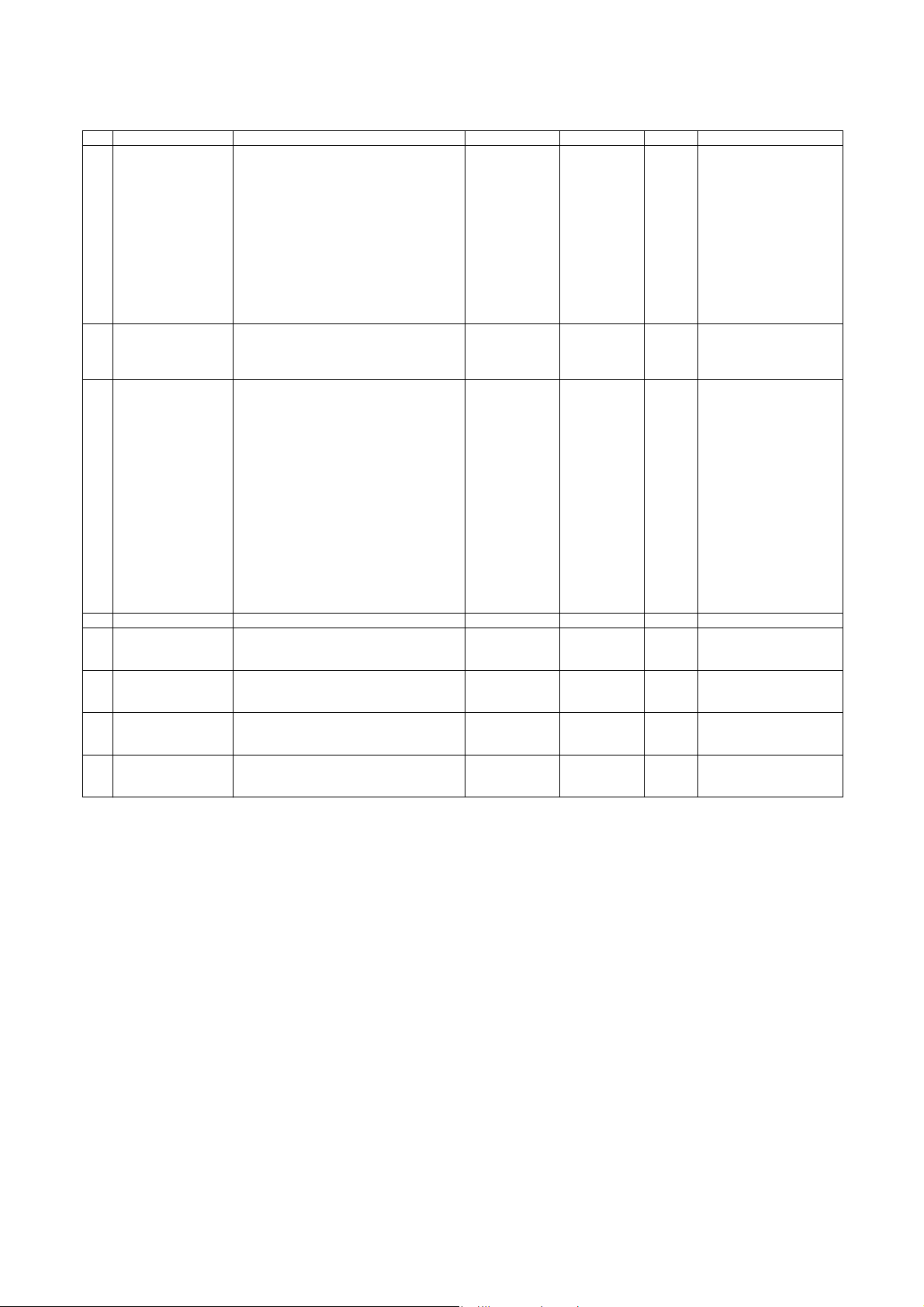

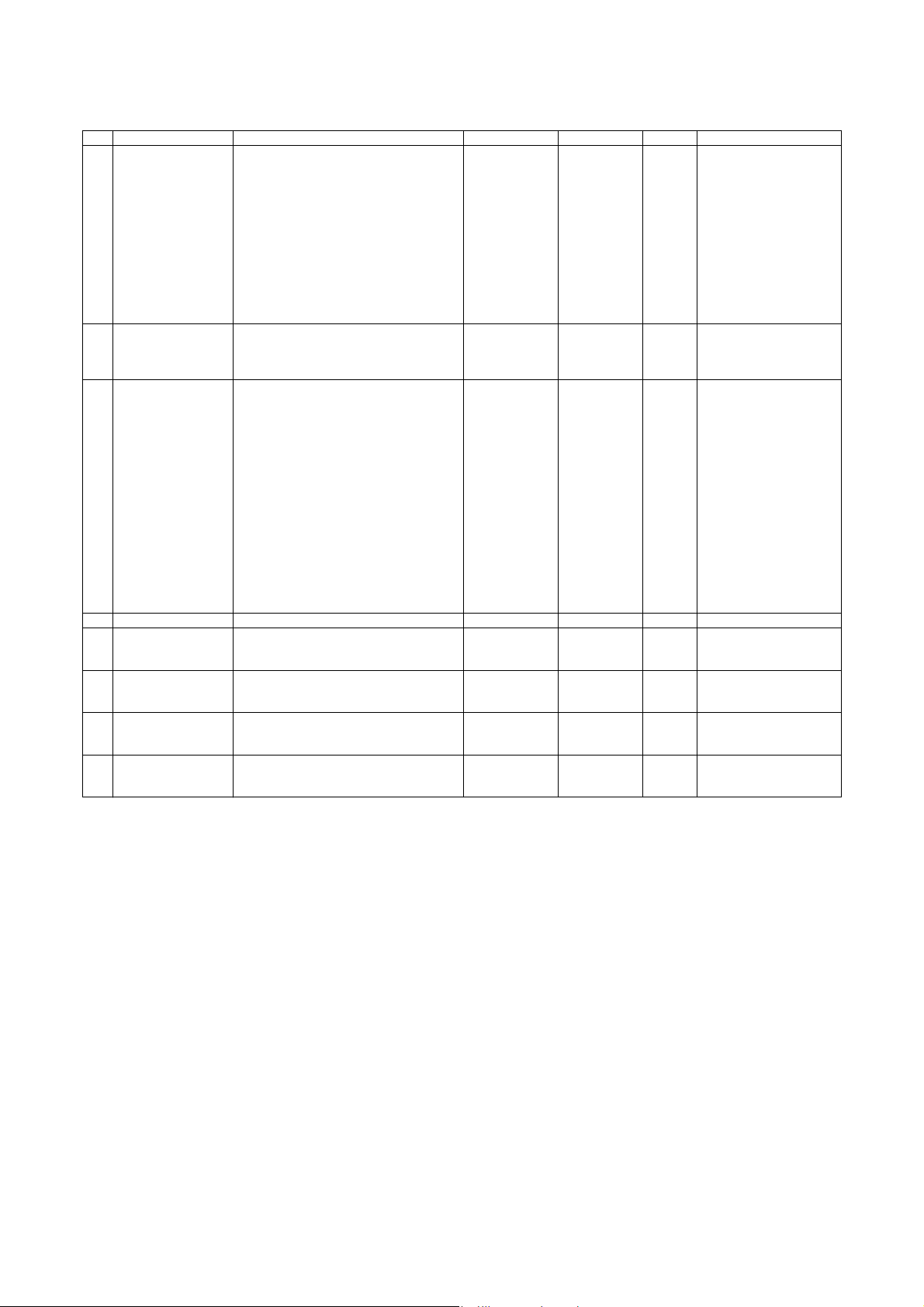

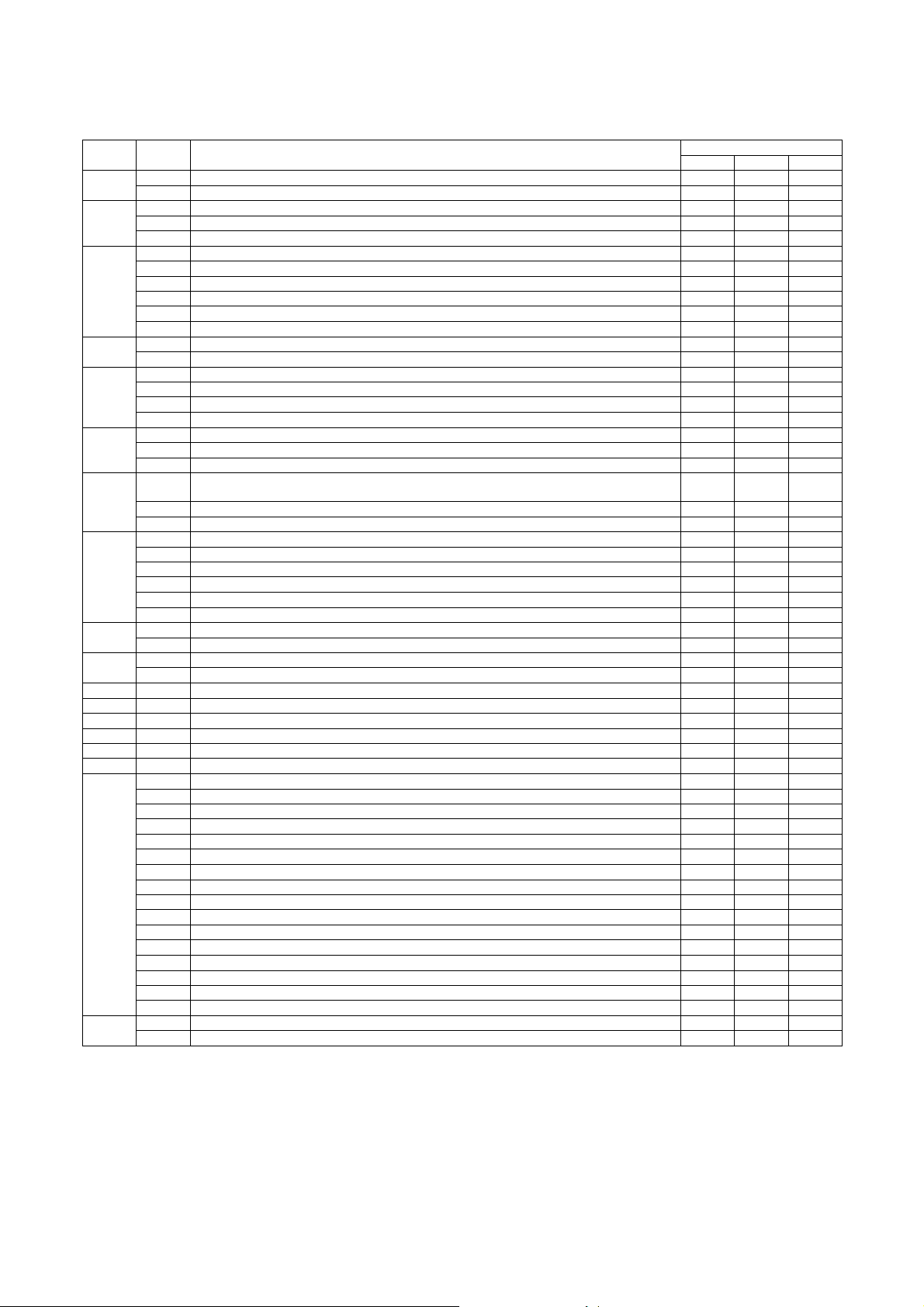

(2) Option combinations

STD: Standard provision OPT: Installable u : Not installable

Option Machine model

Section

Item

Copier model Network printer

MX-M550U/

M620U/M700U

MX-M550N/

M620N/M700N

Paper feed system Large capacity tray (AR-LC6) OPT OPT (A4 / 8.5

Large capacity tray (AR-LC7) OPT OPT (A3 / 11

Remarks

u 11 )

u 17)

Product

Paper exit system Finisher (AR-F15) OPT OPT

Saddle stitch finisher (AR-F16) OPT OPT

Inserter (AR-CF2) OPT OPT

Punch module (AR-PN4A) OPT OPT (2 holes)

Punch module (AR-PN4B) OPT OPT (3 holes)

Punch module (AR-PN4C) OPT OPT (4 holes)

Punch module (AR-PN4D) OPT OPT (4 holes, wide)

Electrical system

(Printer controller)

Printer expansion kit STD STD

Network expantion kit (MX-NBX1) OPT STD Yes

Expansion memory (AR-SM5) OPT OPT (256MB)

PS3 expansion kit (MX-PKX1) OPT OPT Yes

Barcode font kit (AR-PF1) OPT OPT

Software Network scanner expansion kit (MX-NSX1) OPT OPT Yes

Sharpdesk 1 license kit (MX-USX1) OPT OPT

Sharpdesk 5 license kit (MX-USX5) OPT OPT

Sharpdesk 10 license kit (MX-US10) OPT OPT

Sharpdesk 50 license kit (MX-UX50) OPT OPT

Sharpdesk 100 license kit (MX-USA0) OPT OPT

FAX system Internet FAX expansion kit (MX-FWX1) OPT OPT Yes

Facsimile expansion kit (AR-FX8) OPT OPT

FAX expansion memory (8MB) (AR-MM9) OPT OPT

Other options Application integration module kit (MX-AMX1) OPT OPT Yes

Application communication module (MX-AMX2) OPT OPT Yes

External account module (MX-AMX3) OPT OPT Yes

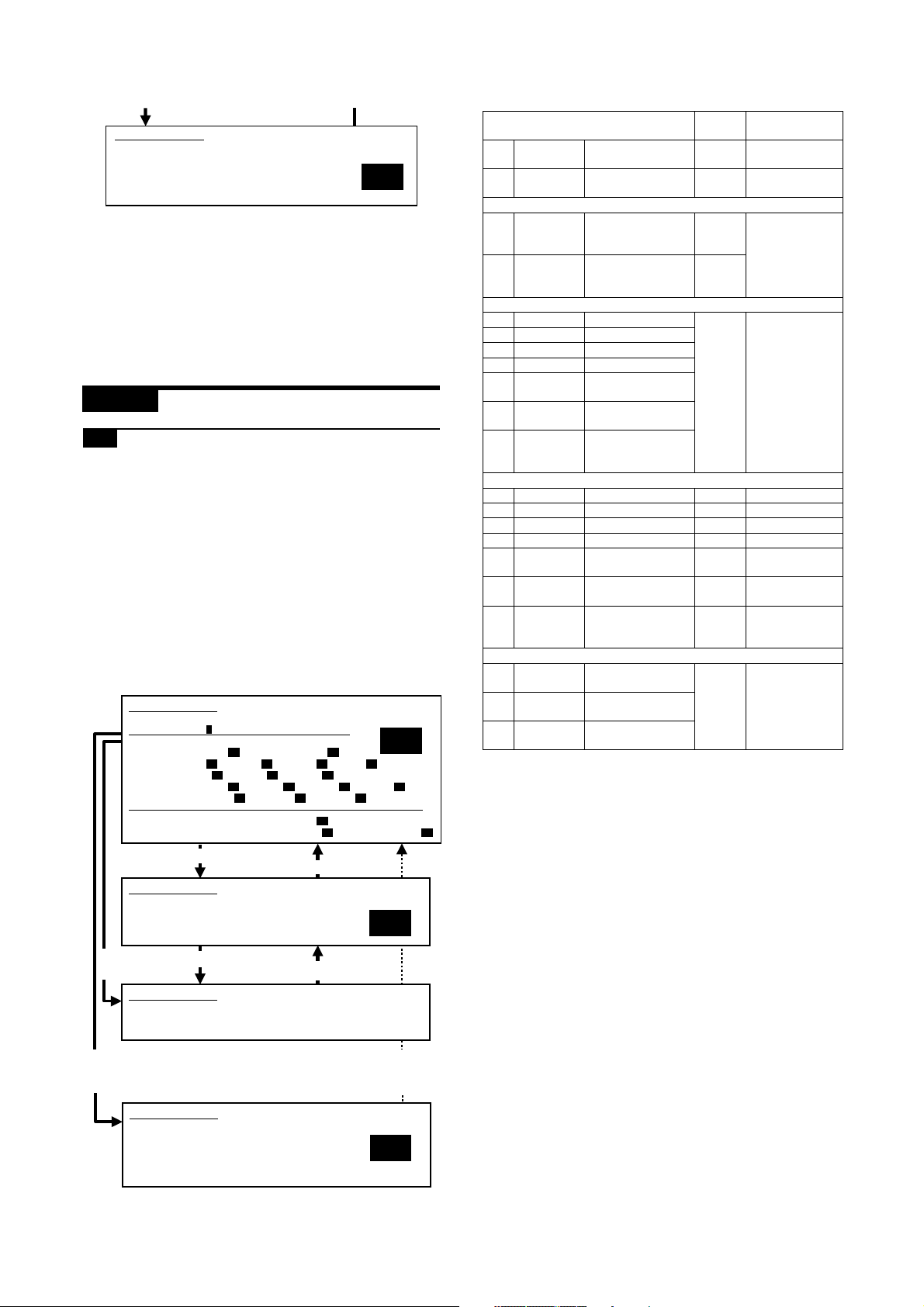

B. Block diagram

key

Finisher

(Option)

Punch Unit

(Option)

Telephone Line

Fax unit (Option)

MFP Control PWB

USB

Port

Paper Exit and switch

back Section

Inserter

(Option)

Network

Port

HDD

Fusing Section

ADU Section

DSPF Unit (CIS)

Image Scanner (reading) Section (CCD)

Scanner Control PWB

Scanner(writing)

(LSU) Section

Drum Section

Developer SectionTransfer Section

Paper Transpor t Section

Paper Feed Tray 1 Paper Feed Tray 2

Operating Section

Engine Control Section

(PCU PWB)

Toner Bottle

Toner Hopper

Manual Paper

Feed Tray

DC Power Unit

AC Power Unit

Paper Feed Tray 3

Paper Feed Tray 4

MX-M700N PRODUCT OUTLINE 1 – 5

Large Capacity

Paper Tray Unit

(Option)

Page 11

MX-M700N

[2] SPECIFICATIONS

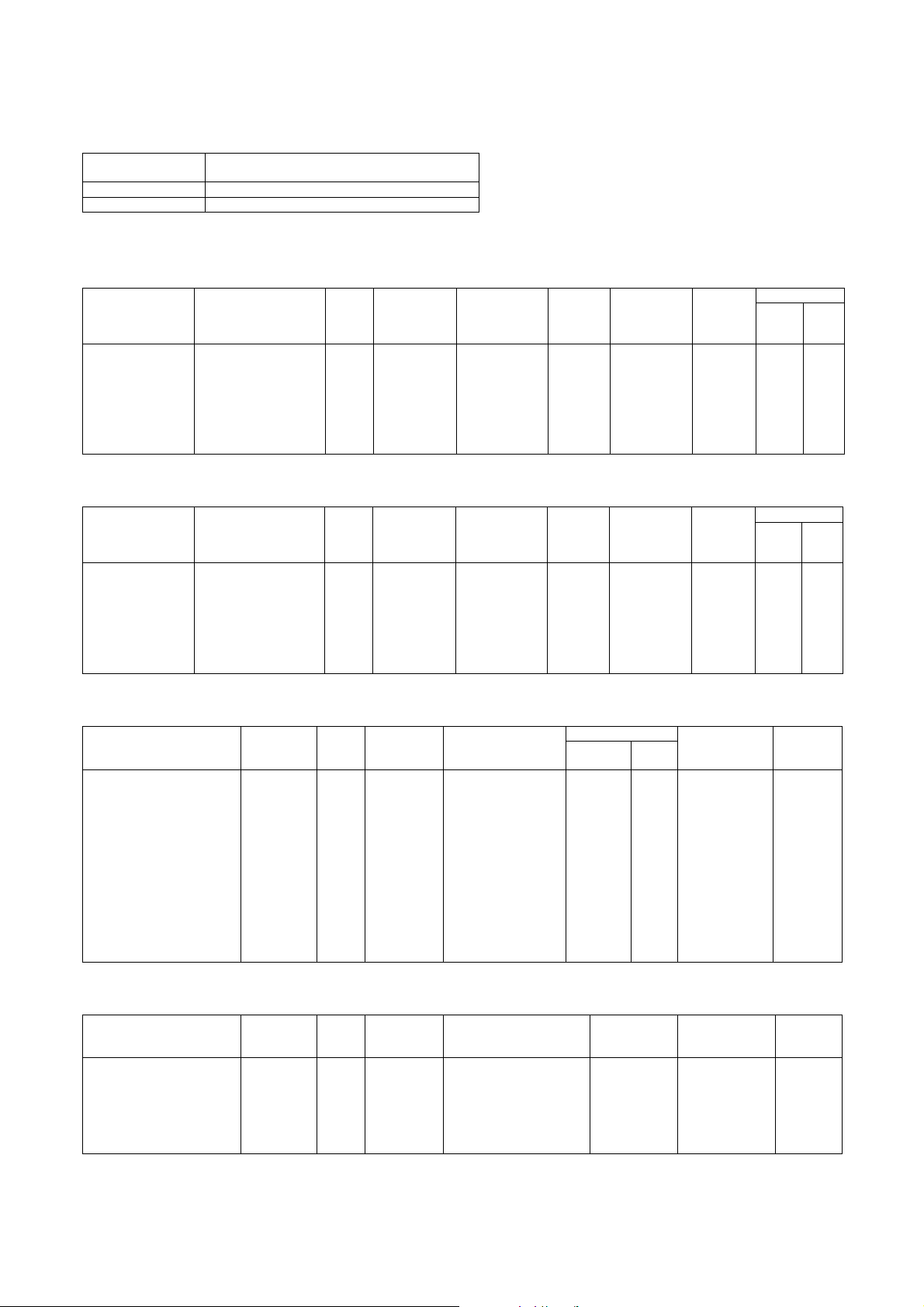

1. Basic specifications

A. Base engine

(1) Type

Type Console

Copy mode Monochrome digital

(2) Engine speed (ppm)

Paper size 55ppm 62ppm 70ppm

A4, 8.5 ✕ 11 55ppm 62ppm 70ppm

A4R, 8.5 ✕ 11R 40ppm 45ppm 48ppm

A5R/5.5 ✕ 8.5R

5.5 ✕ 8.5-R

B5 55ppm 62ppm 70ppm

B5R, 7.25 ✕ 10.5-R 40ppm 45ppm 48ppm

B4/8.5 ✕ 14 35ppm 39ppm 45ppm

A3/11 ✕ 17 30ppm 34ppm 39ppm

Extra 30ppm 34ppm 39ppm

Postcard Since the next paper is fed after completion

(3) Engine composition

Photoconductor kind OPC (Drum diameter: I80mm)

Copying method Electronic photo (Laser)

Developing system Dry, 2-component magnetic brush

Charging system Charged saw-tooth method

Transfer system Static electricity transfer

Cleaning system Counter blade

Fusing system Heat roller

Fused cleaning system WEB cleaning method

Toner supply method Toner supply by the front cover open

Waste toner disposal Toner cartridge collection

(4) Engine resolution

Resolution (Writing) Copy : 600 ✕ 600dpi

Smoothing Copy: None

Gradation [Writing] 2 gradations

(5) Warmup

After turned on 120 seconds or less

Pre-heat YES

(6) Jam recovery time

Jam recovery time Approx. 30 sec. (After leaving the machine

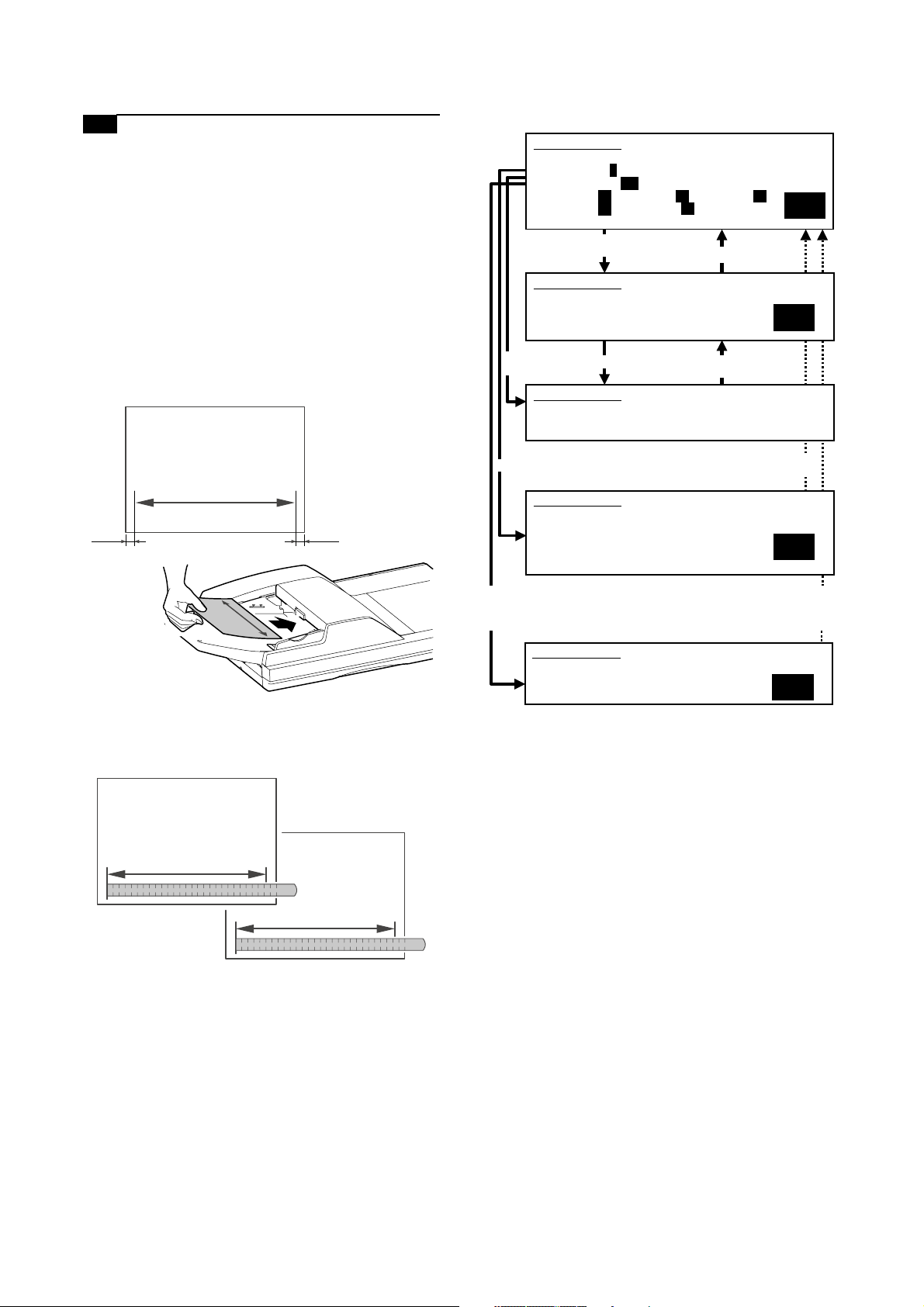

(7) Printable area

(Electronic photo graphic)

40ppm 45ppm 48ppm

of paper exit outside the machine, it

depends on the machine composition.

development

(Transfer belt method)

(No toner recycling system)

Printer:

PCL: 600 ✕ 600dpi, 300 ✕ 300dpi

PS : 600 ✕ 600dpi

Printer:

Model of 55/62 sheets:

Equivalent to1200dpi ✕ 600dpi (PCL/PS)

Model of 70 sheets : None

with the side cover open for 60sec, in the

standard condition and the polygon stop

conditions.)

5GTXKEG/CPWCN

(8) Image defect

a. Void area/Image loss

Void area/Image

loss

(9) Power source

Voltage 100 to 127V 200 to 240V

Current 55 ppm 16A 8A

62 ppm 16A 8A

70 ppm 16A 8A

Frequency 50/60Hz

Power source code Dedicated outlet

Power switch 2 switches (Primary switch: in the front cover;

(10) Power consumption

Low power consumption

mode

Maximum rated power

consumption

Reset time from low power

mode

Power consumption in the

off mode

Shift time to off mode 90 min.

* : With full options

(11) Dimensions

Outer dimensions 728 ✕ 679 ✕ 1050mm

Footprint 728 (W) ✕ 679 (D) mm

(12) Weight

Main unit Approx. 185kg / 408lbs

(13) Dimensions occupied by Machine

Main unit 1264 ✕ 679 ✕ 119 2 mm

Main unit + A4-LCC installed 1340 ✕ 679 ✕ 119 2m m

Main unit + finisher/

Saddle finisher installed

Main unit + A4-LCC + finisher/

Saddle finisher installed

Main unit + Inserter + Finisher/

Saddle finisher

Main unit + A4-LCC + Inserter +

Finisher/Saddle finisher installed

Main unit + A3-LCC installed 1660 ✕ 679 ✕ 119 2m m

Main unit + A3-LCC + finisher/

Saddle finisher installed

Main unit + A3-LCC + inserter +

finisher/ Saddle finisher installed

Lead edge: 40mm or less

Rear edge: 4.0mm or less

FR total : 8.0mm or less

100V series 200V series

Seconday switch: on side of the main unit)

100V series 200V series

55 ppm : max. 261.75W

6 2 p p m : ma x . 2 88 . 7 W

7 0 p p m : m a x . 3 1 9 . 5 W

1.80KW (*) 1.84KW (*)

30 sec.

95W or less

(Height: Floor to Glass surface)

728 ✕ 679 ✕ 1192m m

(Height: Floor to SPF top)

1797 ✕ 679 ✕ 1192 mm

1873 ✕ 679 ✕ 1192 mm

2079 ✕ 679 ✕ 1192 mm

2155 ✕ 679 ✕ 1192 mm

2193 ✕ 679 ✕ 1192 mm

2475 ✕ 679 ✕ 1192 mm

A3 289 ✕ 412mm 11 ✕ 17 271 ✕ 424mm

B4 242 ✕ 356mm 8.5 ✕ 14 208 ✕ 348mm

A4 202 ✕ 289mm 8.5 ✕ 13 208 ✕ 322mm

B5 174 ✕ 249mm 8.5 ✕ 11 208 ✕ 271mm

A5 140 ✕ 202mm 5.5 ✕ 8.5 132 ✕ 208mm

7.25

✕ 10.5 183 ✕ 259mm 8K 262 ✕ 382mm

Postcard 92 ✕ 140mm 16K 187 ✕ 262mm

MX-M700N SPECIFICATIONS 2 – 1

Page 12

B. Paper feed, paper transport, and paper exit section

(1) [Paper feed section]

Type 4-stage paper feed tray

(Parallel LCC + 2 tray + Multi manual paper feed)

Paper feed method Paper is fed from the above by the front loading system.

Dehumidification heater Service parts

(2) Paper feed tray of the main unit

a. Tray1 (Left tray in the parallel LCC)

Allowable

paper type and

weight for

paper feed

Plain paper:

60 to 105g/m

(16 to 28lbs)

Allowable

paper type and

weight for

paper feed

Plain paper:

60 to 105g/m

(16 to 28lbs)

Paper size

AB (Europe, SCA):

A4, 8.5 ✕ 11

Paper size change

method

Paper

type

setting

Size setting by user YES Inch: 8.5 ✕ 11

Paper size

setting when

shipping

AB: A4

AB (Other):

A4, 8.5 ✕ 11

Inch: 8.5 ✕ 11, A4

(Supported by the

guide change and

the software setting)

* Time required from tray insertion to empty detection when paper is empty.

b. Tray2 (Right tray in the parallel LCC)

Paper size

AB (Europe, SCA):

A4, 8.5 ✕ 11

AB (Other):

A4, B5, 8.5 ✕ 11

Inch: 8.5 ✕ 11, A4

(Supported by the

guide change and

the software setting)

Paper size change

method

A4: User can change

8.5 ✕ 11:

User can change

B5:

Size setting by

serviceman (B5 available

through bolt fixing and

setting by serviceman)

Paper

type

setting

YES Inch: 8.5 ✕ 11

Paper size

setting when

shipping

AB: A4

(16K is not

supported)

* : Time required from tray insertion to empty detection when paper is empty.

c. Tray3 (multi-purpose tray)

2

2

Paper

capacity

(Standard

paper)

800

sheets

2

(80g/m

Paper

capacity

(Standard

paper)

1200

sheets

(80g/m2)

Paper type

Normal paper,

printed paper,

recycled

)

paper,

letterhead,

punched

paper, color

paper

Paper type

Normal paper,

printed paper,

recycled

paper,

letterhead,

punched

paper, color

paper

Paper

remaining

detection

Enable

(Paper

empty and

3 steps)

Paper

remaining

detection

Enable

(Paper

empty and

3 steps)

Tray lift ti me

Up Down

Within

12sec

(*)

Tray lift time

Up Down

Within

12sec

(*)

Free

fall

Free

fall

Paper size

Auto AB: A3, B4, A4, A4R, B5,

B5R, A5R, 8.5 ✕ 13

Auto inch: 11 ✕ 17, 8.5 ✕ 14,

8.5 ✕ 11, 8.5 ✕ 11R,

Paper size

change

method

Guide

adjustment

by user

Paper

type

setting

Paper size

setting when

shipping

YES Shipped with

the paper

guide width at

Max.

7.25 ✕ 10.5R, 5.5 ✕ 8.5R

Manual: 8K, 16K, 16KR

Special size

:[Vertical]

139 to 297mm (5.5 to 11-5/8)

[Horizontal]

139 to 431mm (5.5 to 17)

(Tab paper is of A4; limited to

tab width 12mm to 20mm/8.5 ✕

11; tab width 6.1mm to 17mm.)

2

* 105g/m

or above, A4/8.5 ✕ 11 or less. For 128g/m2 or above, horizontal feed only.

d. Tray 4 (500 sheets paper feed tray)

Paper size

Auto AB: A3, B4, A4, A4R, B5,

B5R, 8.5 ✕ 13

Auto inch: 11 ✕ 17, 8.5 ✕ 14,

8.5 ✕ 11, 8.5 ✕ 11R,

7.25 ✕ 10.5R

Manual: 8K, 16K, 16KR

Custom size: None

2

* 1: 105g/m

or above, A4/8.5 ✕ 11 or less. For 128g/m2 or above, horizontal feed only.

Paper size

change

method

Guide

adjustment

by user

Paper

type

setting

Paper size

setting when

shipping

YES Shipped with

the paper

guide width at

Max.

* 2: For multi copy and back surface copy, single feed only.

Allowable paper type

and weight for paper

feed

Plain paper:

60 to 105g/m

2

(16 to 28lbs)

Thick paper:

106 to 128g/m

(29 to 34lbs)

176g/m

Cover

205g/m

2

(65lbs)

2

2

(110lbs) Index(*)

Allowable paper type and

weight for paper feed

Plain paper:

60 to 105g/m

Thick paper:

106 to 128g/m

176g/m

205g/m

2

(16 to 28lbs)

2

(29 to 34lbs)

2

(65lbs) Cover

2

(110lbs)Index

(*1),(*2)

Paper capacity

Normal

paper

500 sheets

2

(80g/m

)

Paper capacity

(Standard

paper)

500 sheets

(80g/m

2

)

OHP

40

sheets

Paper type

Normal paper,

printed paper,

recycled paper,

letterhead,

punched paper,

color paper,

label paper,

thick paper, OHP,

tab paper

Paper type

Normal paper,

recycled paper,

printed paper,

letterhead,

punched paper,

color paper,

thick paper

Paper

remaining

detection

Enable

(Paper

empty and

3 steps)

Paper

empty

detection

Enable

(Paper

empty and

3 steps)

MX-M700N SPECIFICATIONS 2 – 2

Page 13

(3) Bypass tray

Paper size

Auto AB: A3, B4, A4, A4R, B5,

B5R, A5R, 8.5 ✕ 13, Postcard

Auto inch: 11 ✕ 17, 8.5 ✕ 14,

8.5 ✕ 13, 8.5 ✕ 11, 8.5 ✕ 11R ,

7.25 ✕ 10.5R, 5.5 ✕ 8.5R

Manual: 8K, 16K, 16KR

Custom size:

[Vertical]

100 to 297mm (3.9 to 11-5/8)

Paper size

change

method

Guide

adjustment by

user

Paper

Allowable paper type and weight

type

setting

YES Thin paper:

52 to 59g/m

(single feed only)

Plain paper:

60 to 105g/m

Thick paper:

106 to 128g/m

176g/m

205g/m

for paper feed

2

(14 to 15lbs)

2

(16 to 28lbs)

2

(29 to 34lbs)

2

(65 - lbs) Cover

2

(110lbs) Index (*)

Paper capacity

(Standard paper)

Plain paper:

100 sheets

(standard paper:

2

80g/m

)

Postcard: 20 sheets

OHP: 20 sheets

[Horizontal]

139 to 432mm (5.5 to 17)

* 105g/m2 or above, A4/8.5 ✕ 11 or less. For 128g/m2 or above, horizontal feed only.

(4) Duplex (5) Paper exit size / type

System Non stack system

Paper size A3, B4, A4, A4R, B5, B5R, A5R, 8K, 16K,

16KR, 11 ✕ 17, 8.5 ✕ 14, 8.5 ✕ 13.4, 8.5 ✕ 13,

8.5 ✕ 11, 8. 5 ✕ 11R , 8 .5 ✕ 5.5R, 7.25 ✕ 10.5R

Type and weight of

paper which can be

passed

Plain paper: 60 to 105g/m

Thick paper: 106 to 128g/m

176g/m

205g/m

2

(16 to 28lbs)

2

(29 to 34lbs)

2

(65 - lbs) Cover

2

(110lbs) Index

Paper type Plain paper, printed paper, recycled paper,

letterhead, punched paper, color paper, thick

paper

Paper exit position/

Main unit top surface face-down paper exit

system

Paper exit capacity 250 sheets (80g/m

Paper exit paper size/kind All kinds of paper which can be fed

Remaining paper

None

detection

Paper exit paper full

Provided

detection

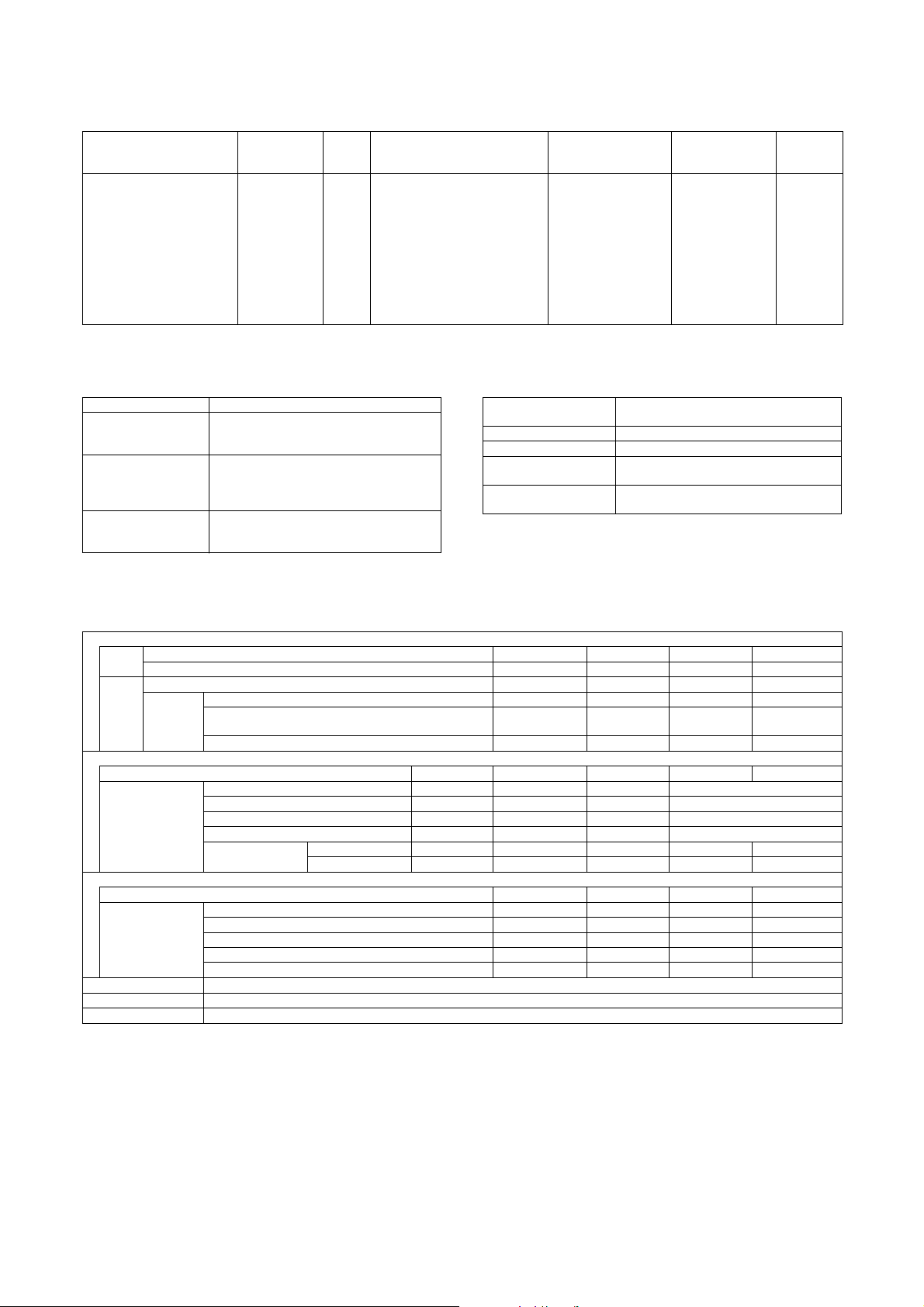

C. Scanner section

(1) Resolution/Gradation

Paper type

Normal paper,

recycled paper,

printed paper,

punched paper,

color paper,

letterhead, thin

paper, label paper,

thick paper, OHP,

tab paper (tab width

20mm or less),

Postcard

2

paper)

Paper

empty

detection

YES

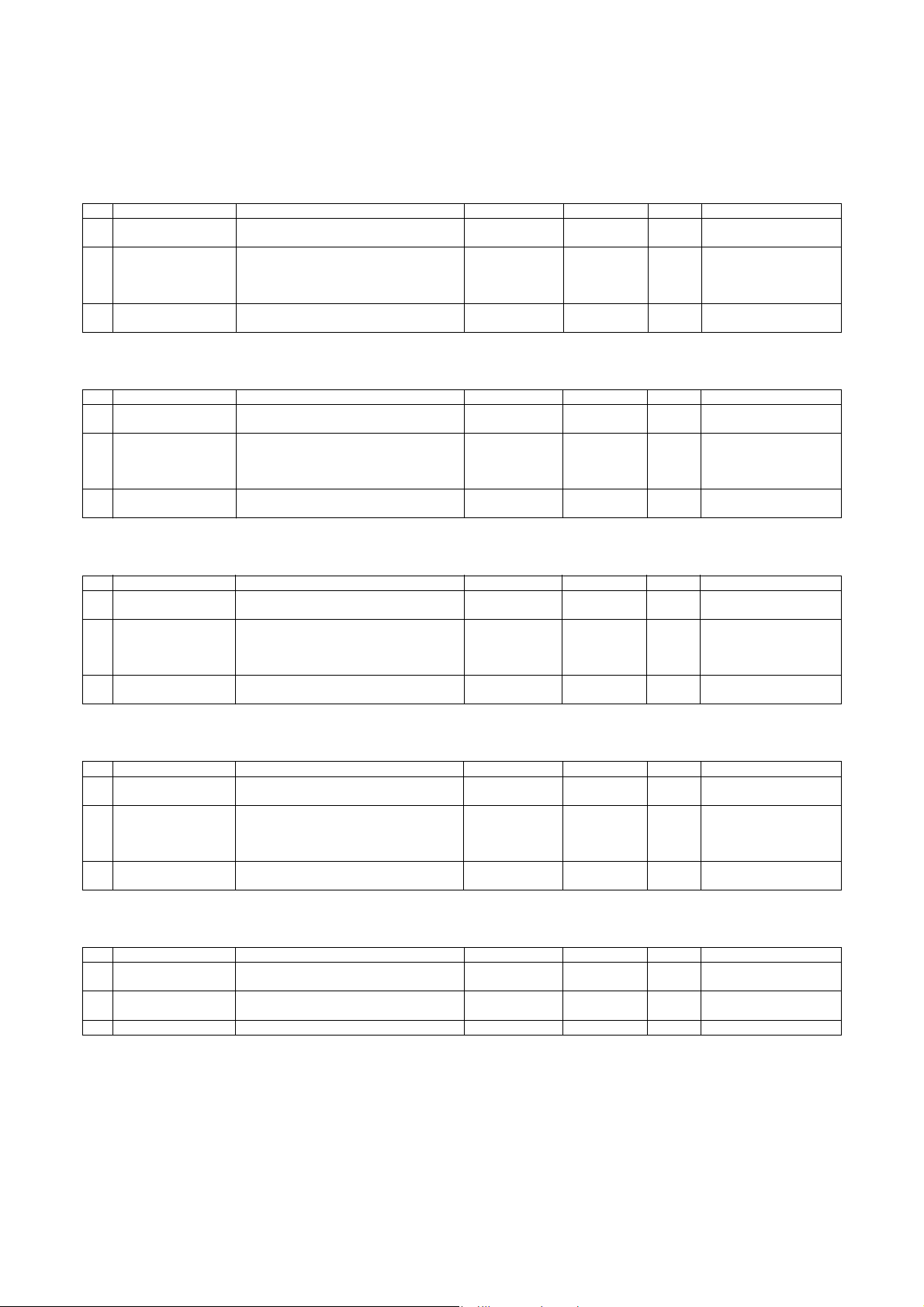

copy mode

Platen Magnification ratio 25 to 99 Normal ratio 101 to 171 172 to 400

Scan resolution (dpi) 600 ✕ 600 600 ✕ 600 600 ✕ 600 600 ✕ (600 ✕ 2)

DSPF Magnification ratio 25 to 99 Normal ratio 101 to 117 118 to 200

Scan

resolution

(dpi)

When in single copy 600 ✕ 367 600 ✕ 367 600 ✕ 367 600 ✕ 600

SPF duplex (front) CCD 600 ✕ 600 600 ✕ 600

600x

(600 ✕ 2)

SPF duplex (back) CIS 600 ✕ 300 600 ✕ 300 600 ✕ 600 600 ✕ 600

When in the Fax send mode and the scanner FAX broadcast mode

Select mode Standard Fine text Super fine test Ultra fine text 600dpi send (*)

Input and send

resolution (dpi)

Input resolution: OC 600 ✕ 600 600 ✕ 600 600 ✕ 600 600 ✕ 600

Input resolution: DSPF simplex 600 ✕ 367 600 ✕ 367 600 ✕ 367 600 ✕ 367

Input resolution: DSPF duplex (front) CCD 600 ✕ 600 600 ✕ 600 600 ✕ 600 600 ✕ 600

Input resolution: DSPF duplex (back) CIS 600 ✕ 300 600 ✕ 300 600 ✕ 300 600 ✕ 300

Transmission

resolution

FAX 20 3.2 ✕ 97.8 203.2 ✕ 195.6 203.2 ✕ 391 406.4 ✕ 391 —

Internet FAX 200 ✕ 100 200

✕ 200 200 ✕ 400 400 ✕ 400 600 ✕ 600

Scanner mode

Select mode 200 ✕ 200 300 ✕ 300 400 ✕ 400 600 ✕ 600

Input and send

resolution (dpi)

Input resolution: OC 600 ✕ 600 600 ✕ 600 600 ✕ 600 600 ✕ 600

Input resolution: DSPF simplex 600 ✕ 367 600 ✕ 367 600 ✕ 367 600 ✕ 367

Input resolution: DSPF duplex (front) CCD 600 ✕ 600 600 ✕ 600 600 ✕ 600 600 ✕ 600

Input resolution: DSPF duplex (back) CIS 600 ✕ 300 600 ✕ 300 600 ✕ 300 600 ✕ 300

Transmission resolution 200 ✕ 200 300 ✕ 300 400 ✕ 400 600 ✕ 600

Exposure lamp None-electrode xenon lamp (Front), LED (Back)

Scanning 256 gradations (8bit)

Printing 2 gradations (1bit)

* Except for FAX sending

600x

(600 ✕ 2)

MX-M700N SPECIFICATIONS 2 – 3

Page 14

(2) Document table

2. Functional specifications

Scanning area 297 ✕ 431.8mm

Original

standard

position

Detection Provided

detection size Automatic detection

Manual

detection size

setting

Dehumidificati

on heater

(Scanner

section)

Left bottom reference

(Supported by changeover of the software destination of

one kind of the detection unit.)

Inch series-1 11 ✕ 17, 8.5 ✕ 14, 8.5 ✕ 11, 8. 5 ✕ 11R ,

5.5 ✕ 8.5

Inch series-2 11 ✕ 17, 8.5 ✕ 13, 8.5 ✕ 11, 8. 5 ✕ 11R ,

5.5 ✕ 8.5

AB series-1 A3, B4, A4, A4R, B5, B5R, A5

AB series-2 A3, A4, A4R, B5, B5R, A5, 216 ✕ 330

AB series-3 B4, A4, A4R, A5, 8K, 16K, 16KR

Manual setting fixed size input:

Min. : 64 ✕ 64 to Max.297 ✕ 432mm

Provided

Service parts

(3) Automatic document feeder

Type DSPF: Duplex surface scan and feed unit

Scan speed When in single copy When in duplex copy

Original standard

position

Document size Automatic detection

Document weight 50 to 128g/m

Max. loading

capacity of

documents

Copy 65 sheets/min

Scanner 59 sheets/min

Internet

(600 ✕ 300 dpi, 1bit)

Fax 46 sheets/min

FAX

(Normal text, 1bit)

(200 ✕ 200dpi, 1bit)

46 sheets/min

(200 ✕ 100dpi, 1bit)

Center reference

Inch series-1:

11 ✕ 17, 8.5 ✕ 14, 8.5 ✕ 11, 8 .5 ✕ 11 R, 8.5 ✕ 5.5,

A4

Inch series-2 :

11 ✕ 17, 8.5 ✕ 13, 8.5 ✕ 11, 8.5 ✕ 11R, 8 .5 ✕ 5.5,

A4

AB series-1/-2:

A3, B4, A4, A4R, B5, B5R, A5, 8.5 ✕ 11, 8.5 ✕ 13

AB series-3 :

8K, A4, A4R, B4, 16K, 16KR, A5, 8.5 ✕ 13

Mix paper feed (Same series, same width paper)

enabled

Manual setting Min. 64 ✕ 64 to Max.297 ✕ 432mm

(Scan position: Center reference)

2

14 to 34lbs, 65 lbs Cover (Equivalent of 176g/m2),

110 lbs Index (Equivalent of 205g/m

Max. 150 sheets (80g/m

76 pages/min

(600 ✕ 300dpi, 1bit)

48 sheets/min

(Normal text, 1bit)

67 sheets/min

(200 ✕ 200dpi, 1bit)

48 sheets/min

(200 ✕ 100dpi, 1bit)

2

2

) or Max. 19.5mm

)

D. Fuser section

(1) Type

System Heat roller pressure system

A. Copy functions

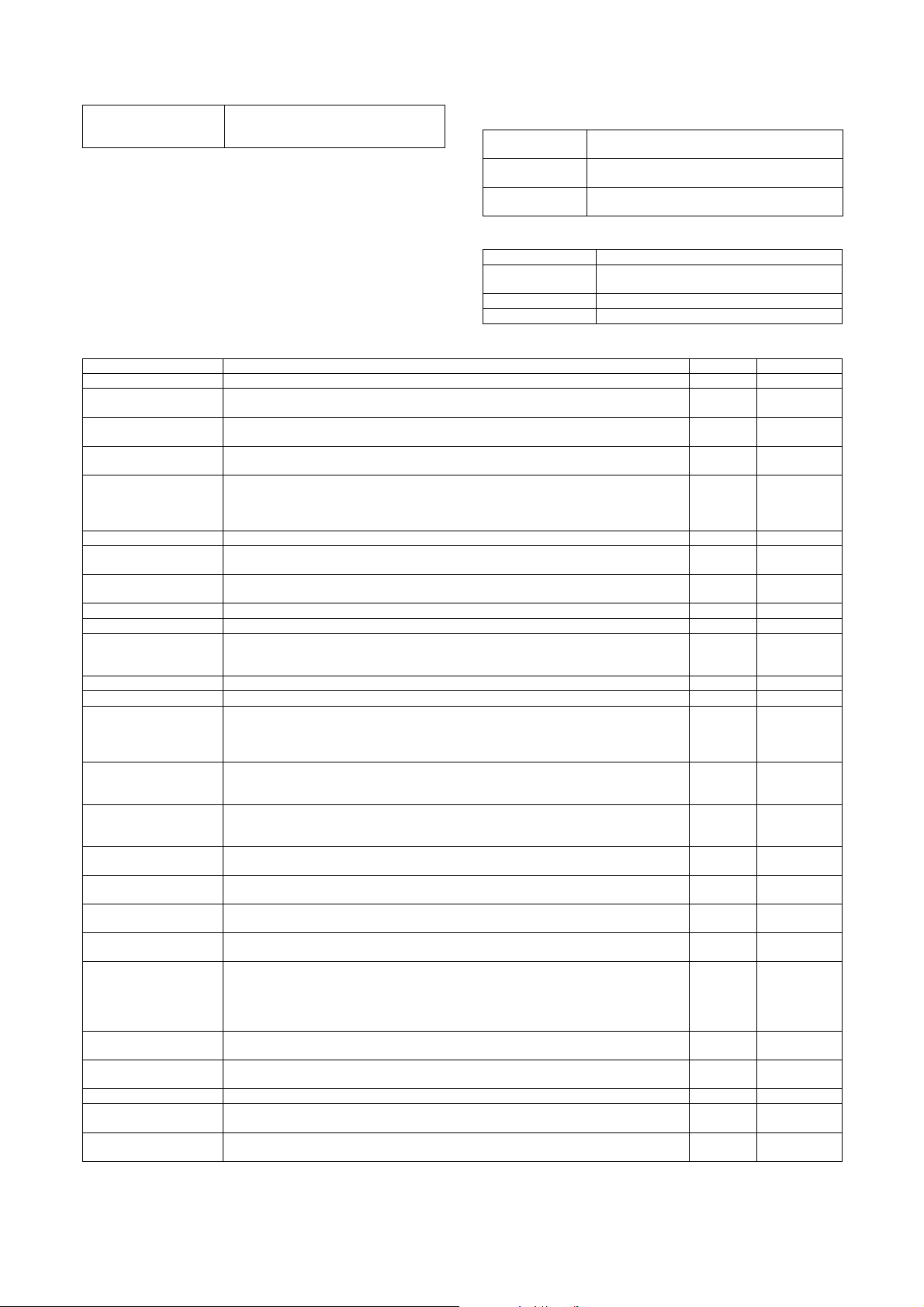

(1) Copy speed (Continuous copy speed) (cpm)

a. Tray 1 to 4, LCC (Reduction/Normal/Enlargement)

Copy mode Paper size 55ppm 62ppm 70ppm

Original table

mode

(2) First copy time

Original Cover

/DSPF

Original Cover 4.0 seconds or less 3.5 seconds or less

DSPF 6.2 seconds or less 5.7 seconds or less

* Measurement conditions: Feeding A4/8.5 ✕11 paper from the

main unit tray. Polygon in rotation.

(3) Job speed

a. BLI standards

S to S 50.1cpm (91%) 56.4cpm (91%) 63.0cpm (90%)

S to D 49.0cpm (89%) 53.3cpm (86%) 58.8cpm (84%)

D to D 51.7cpm (94%) 57.0cpm (92%) 63.0cpm (90%)

* S to S: A4/8 ✕ 11 documents 10 sheets, copy 5 sets

* S to D: A4/8 ✕ 11 documents 10 sheets, copy 5 sets

* D to D: A4/8 ✕ 11 documents 10 sheets (20 pages), copy 5 sets

(4) Continuous copy

Multi max. quantity 999 sheets

(5) Resolution

Scan resolution 600 ✕ 600dpi

Writing resolution 600 ✕ 600dpi

(6) Copy document

Document size Max. A3

Document type Sheet/Book original

(7) Copy magnification ratio

Copy magnification

ratio

Zoom 25 to 400% (25 to 200% for DSPF)

Preset magnification

ratio

(8) Density, copy image quality processing

Exposure mode Binary: Text (auto/manual), Text/Photo, photo,

Number of manual

steps

Toner save mode Provided

A4, 8.5 ✕ 11 55 62 70

A4R, 8.5 ✕ 11R 404548

A5R/5.5 ✕ 8.5R,

5.5 ✕ 8.5-R

B5 55 62 70

B5R, 7.25 ✕ 10.5-R 40 45 48

B4/8.5 ✕ 14 35 39 45

A3/11 ✕ 17 30 34 39

Extra 303439

Postcard Since the next paper is fed after

55ppm 62ppm 70ppm

55ppm 62ppm 70ppm

AB series: 25%, 50%, 70%, 81%, 86%, 100%,

Inch series: 25%, 50%, 64%, 77%, 100%,

4

auto

9 steps

40 45 48

completion of paper exit outside

the machine, it depends on the

machine composition.

115%, 122%, 141%, 200%, 400%

121%, 129%, 200%, 400%

MX-M700N SPECIFICATIONS 2 – 4

Page 15

(9) Paper size

Paper

type

AB

series

Inch

series 8.5 ✕ 5.5 11 ✕ 17

Standard size

Min. Max.

A6 (A6R)

Postcard

(10) Copy functions

Function

(Special

function)

Automatic paper selection Yes

Automatic magnification

ratio selection

Vertical/horizontal

independent

magnification ratio

Paper type select Yes

Auto tray switching Yes

Rotation copy Yes

Electronic sort Yes

Rotation sort Yes (Europe, SCA, Dealer area)

Job reservation Yes (99 items)

Program call/register Yes (10 items)

Document filing Yes

Preheat function Yes

Auto power shut off

function

User management (Dept.

management)

Process control Yes

Indefinite document size

input

Indefinite paper size input Yes (Tray 3/manual paper feed)

Mixed document feeder Yes (MIX only)

Binding margin Yes (Left/Right)

Border erase/Center

erase

2 in 1 Yes

Tandem copy Yes

Cover/Insert paper/Tab

insert paper

OHP insert paper Yes

Tab copy Yes

2in1/4in1 Yes (Centering provided)

Card shot Yes (Centering provided)

Center binding Yes (Centering provided)

Book copy Yes

Duplex copy system

switch

Large volume document

mode

Black-white reversion Yes (except UK)

Mirror image Yes

Date print Yes

Stam p Yes

Page print Yes

Character print Yes

Standard size

A3, B4, A4, A4R, B5, B5R, A5R,

A3

8K, 16K, 16KR, Postcard

11 ✕ 17, 8.5 ✕ 14, 8.5 ✕ 13,

8.5 ✕ 11, 8.5 ✕ 11 R,

7.25 ✕ 10.5R, 5.5 ✕ 8.5R

(Conditions set up

by system setting)

(Conditions set up

by system setting)

Yes (500 users)

(Border/Center/Border+Center)

(Network interface is required)

Yes (Max. 10000 sheets)

Magnification ratio/ Density/

Paper can be changed for every

bundle.

Yes

Yes

Yes

Yes

Yes

Yes

Yes

B. Image send function

(1) Mode

Scanner Scan to E-mail

Fax Fax

Internet

Fax

* Conforming to PC-FAX/PC-internet fax

(2) Image send function (Push from the main unit)

a. Support system

Corresponding

server/protocol

SMTP, POP3 and FTP support SSL. (Web support)

b. Support image

File format TIFF, PDF TIFF-FX (TIFF-F) —

Compression

system

c. Image process

half tone

reproduction

Density

adjustment

Image quality

selection

Resolution

(depends on

file format/

transmission

method)

Scan to Desktop

(Scan data send without depending on the IP address under

the DHPC environment)

Scan to FTP

Scan to Folder (SMB)

Scan to e-mail with Meta

Scan to Desktop with Meta

Scan to FTP with Meta

Scan to SMB with Meta

Fax to E-mail (inbound Routing)

Fax to FTP/Desktop/SMB/E-mail (Document Admin)

Internet Fax (Supported full mode)

Internet Fax to E-mail (inbound routing)

Internet Fax to FTP/Desktop/SMB/E-mail

(Document Admin) (*)

Item Scanner Internet Fax

Item Scanner Internet Fax Fax

Item Scanner Internet Fax Fax

SMTP

FTP(TCP/IP)

SMB

•Noncompression

•G3

(1-dimensional)

= MH (Modified

Huffman)

•G4

= MMR

(Modified MR)

Equivalent of 256 steps

Auto + 5 steps

Half tone ON/OFF

200 ✕ 200dpi Standard

300 ✕ 300 dpi Super fine

400 ✕ 400 dpi Ultra fine

600 ✕ 600 dpi 600 ✕ 600dpi —

POP server

SMTP server

ESMTP server

MH, MMR MH, MR,

(200 ✕ 100dpi)

(middle tone not

allowed)

Fine

(200 ✕ 200dpi)

(200 ✕ 400dpi)

(400 ✕ 400dpi)

MMR, JBIG

Standard

(203.2

✕ 97.8dpi)

(middle tone

not allowed)

Fine

(203.2

✕ 195.6dpi)

Super fine

(203.2

✕ 391dpi)

Ultra fine

(406.4

✕ 391dpi)

MX-M700N SPECIFICATIONS 2 – 5

Page 16

d. Address specification

Item Scanner Internet Fax Fax

Address

specification

Setting of

default address

Number of Onetouch address

key registration

Inbound Routing

List

Inbound routing

addresses

Sender Number/

Address

Registration

(Inbound

Routing)

Number of

Group (1 key)

address

registtation

Program 8 items

Direct address

input

Chain dial

Resend Call up nearest address which are specified as a single

Shortcut for

address

selection (quick

key)

CC/BCC

sending

Item name Selective/direct entry from the list —

File name Selective/direct entry from the list —

Return mail

address

Sender name Yes (Selective

Transmission

message

(message body)

Mail footer

preset

Specified by one-touch, group, or direct address input.

Input from the soft keyboard (Scanner/Internet FAX)

Input the 10-key (Fax)

Selection from LDAP server

Resend

Quick

No

Max. total 999 items (of which 200 items can be

assigned to FTP, desktop and/or SMB)

50 items

1000 items

500 items

Number of Group (1 key) address registration : Max.

500 items

Input from the soft keyboard Entry by 10-

—

destination

Use the 10-key to call up registered numbers of

addresses.

Yes —

(1 default

—

from the list/direct

entry from the list/

selection from

LDAP server)

address fixed as

sender name)

—

—

key, # key, *

key

Yes (pause

key)

(1 default

address fixed

as sender

name)

No

e. Multiple address specification

Item Scanner Internet Fax Fax

Address

specification

No. of

registration

items of direct

address input *

Broadcast send Yes

Sequential send

request

Specification by one-touch/group/direct address input.

*

Group, interface broadcasting total max: 5,000 items

(Broadcast

send is disabled

for FTP/

Desktop/SMB)

—Yes

Ye s

* Direct address input: 10-key other than one-touch, and soft key-

board input

• When broadcasting including FAX, the resolution is that of FAX.

• When broadcasting of the internet FAX and the scanner, the resolution is that of the internet FAX.

• The compression type when broadcasting depends on the conforming of the system setting.

f. Send function

Item Scanner Internet Fax Fax

Memory transmission —

Onhook — Yes

Quick online send — Yes

Direct transmission — Only in

Automatic reduction

send

Rotation send Yes (Manual) Yes (Auto)

Zoom send Yes (Zooming of standard size to standard size

Recall

mode

Book document send Yes

Long document send Yes (Max.800mm)

File division send Yes —

Send size limit Yes —

Stamp function Yes

No. of registration

items of senders

Address Confirmation

Function (Prevention

of mis-send)

Error — Yes

Busy — — Yes

When the upper

limit value is set,

memory send is

performed.

—

only. (There are combinations that cannot be

rotated.))

The conditions of recall number and time can be

set with the system setting.

Max. 999 items

—

Ye s

Onhook

Ye s

(A3oB4,

A3oA4,

B4oA4

Ye s

(Soft

switch)

g. Receive function

Item Internet Fax Fax

Automatic reception Yes

Manual reception Yes

Memory reception Yes

Fixed size reduction

reception

Specified size zoom

reception

Rotation reception Yes

Division reception Yes (Conditions are set by the system.)

Duplex reception Yes (Conditions are set by the system.)

2 in 1 reception —

Domain/Address

specification receive

enable

Domain/Address

specification receive

disable

Certain rejection

number setting

External telephone

connection remote

Answering telephone

connection

Transfer function when

output is disable

Automatic boot mode Yes

Yes (50 items) —

Yes (50 items) —

—Yes

—

—

Yes

—

(50 items)

Ye s

No

(PAT countermeasure)

Yes

MX-M700N SPECIFICATIONS 2 – 6

Page 17

h. Report/list function

Item Scanner Internet Fax Fax

Communication

record table

Communication

result table

Address/

Telephone

number table

Group table Yes

Sender table Yes (Sender

Program table Yes

Memory box

table

Memory

contents clear

notification

table

Receivable/

rejection

number list

Receivable/

Rejection

address list

Transfer-toemail table list

Transfer-toadministrator

list

Web setting list Yes

NO Yes

registration table)

(May be outputted in case of an error.)

Yes

Yes

Yes (Described on the system

setting list.)

—

—

—Yes

Yes —

Yes

Yes

Yes (FAX

mode only)

i. Other functions

Item Scanner Internet Fax Fax

Time

specification

Poling receive — Yes

Bulletin board

send

Cover function — NO

Sender print — Yes

Page division Yes

Page

connection

Confidential

data (Remote

machine)

Relay

broadcast

indication

Send message NO

Edge erase Yes

Center erase Yes

2 in 1 Yes

Card shot Yes

Send to PC — PC-iFAX PC-FAX

Linearrized

PDF

Corresponds by

Net Scan Tool

Yes

—Yes

NO

—

—

——

Ye s

(F code

system)

Ye s

(F code

system)

j. Record size

Item Internet Fax Fax

Max. record

width

Record size A3 to A5/11 x 17 to 5.5 x 8.5

293mm

k. F code communication

Item Fax

Sub address Yes (Max. 20 digits)

Pass code Yes (Max. 20 digits)

C. Printer function

(1) Platform

• IBM PC/AT compatible machine

•Macintosh

(2) Support OS

OS

Windows 98 Yes Yes Yes No

Me Ye s Ye s Ye s No

NT 4.0 SP5 or later Yes Yes Yes No

2000 Yes Yes Yes No

XP Yes Yes Ye s N o

Server2003 Yes Yes Yes No

Server2003 x64 No No No Yes

XP x64 No No No Yes

Mac 9.0 to 9.2.2 No No Yes No

X 10.1.5 No No Yes No

X 10.2.8 No No Yes No

X 10.3.9 No No Yes No

X 10.4 - X 10.4.7 No No Yes No

Custom

PCL5e/6

SPDL2

(3) Command system

Command system

PCL5e, PCL6 compatible Standard

PS3 compatible Option (PS expansion kit)

(4) Built-in fonts

Bitmap fonts 1 kind of font

PCL5 Latin font 80 PCL Latin fonts (SPDL)

PCL Kanji font Option (2 ACT Fonts)

PS Latin font 136 Type 1 Latin fonts

Bar code font Option

Standard built-in fonts

Auxiliary to the PS expansion kit

• The printing system is provided with one bitmap font compatible

with HP and 80 European outline fonts for PCL.

• In addition to this, when the PS expansion kit is installed, it is provided with 136 European outline fonts for PS and 5 Japanese

outline fonts.

(5) Support print channel

Support print channel NetWare environment PSERVER/RPRINT

USB USB 1.1:

For NetWare environment

PSERVER/RPRINT

LPR UNIX LPR/LPD command-compatible print

IPP Print channel in compliance with IPP1.0

PAP: EtherTalk

(AppleTalk)

FTP Function to print receive data by use of the

NetBEUI Microsoft NetBEUI compatible print channel

Port9100 Supports 9100 TCP port (Raw Port).

WEB Submit Print This channel is used to set and print directly

LPR

IPP

PAP : EtherTalk (AppleTalk)

FTP

FTP Pull Print

NetBEUI

Raw Port (Port 9100)

USB 2.0

HTTP (WEB Submit Print)

POP3 (E-mail To Print)

Windows98/98SE/Me/2000/XP only

USB 2.0:

Windows 2000/XP only

Print channel in PSERVER/PRINT mode to

be used in netware environment

channel

Print channel used in the Macintosh

environment

builtin FTP server.

the files on the network by Web Page.

Custom

PS

PPD GPD

MX-M700N SPECIFICATIONS 2 – 7

Page 18

E-mail To Print This channel is used to print only an

attached file directly when an E-mail with an

attached file is received.

• IPP, and HTTP supports SSL.

(6) Command compatibility

PCL5e compatible PCL5e is aimed to provide compatibility with HP

PCL6 compatible PCL6 is aimed to provide compatibility with HP

PostScript

compatible

LaserJet 4050.

LaserJet 4050.

PostScript is aimed to provide compatibility with

Adobe PostScript.

(7) Environment setting

Setting item Outline

Default setting Basic setting of printing such as the number of

PCL setting PCL symbol setting and font setting

PS setting Setting of print enable/disable in a PS error

copies and printing direction.

(8) Print function

Functions Content PCL6/5e PS (OPTION)

Multiple Pamphlet Two or more center bindings are collected into one. Yes Yes

Barcode font Compatible with JetCAPS BarDIMM emulation.

Network tandem print Two main units are connected in network and printing can be made by the linkage of the two main

Windows Cluster Print Even if one Windows server is down, the mirror server will execute the interrupted print job

PDF/TIFF direct print PDF/TIFF files can be printed without the printer drivers.

E-Mail To Print When an e-mail with an attached file is received, only the attached file is printed directly. Yes Yes

PULL print from front panel The FTP server is checked from the front panel and only the specified file is pull-printed (direct

USB PULL print The FTP server is checked from the front panel and only the specified file is pull-printed (direct

SMB PULL print The file folder on the network is checked from the front panel, and the specified file is pull-printed. No No

FTP PUSH print Data are transferred from the client PC to the MFP server, and direct print is executed. Yes Yes

Print by setting the file on

the Web Page.

[Web Submit Print]

ROPM One RIP process allows to print two or more copies. Yes Yes

Conforming to multi access RIP process can be executed during printing. Printing can be executed during scanning. Yes Yes

Setting of the paper

direction for duplex print of

letterhead paper and

punched paper

Manual specification type/

Size detection enable

setting

Management of setting

environment under the

terminal server control

Driver delivery function The administrator can distribute the driver to each client by PAU4.

Form overlay The form is downloaded to the main unit in advance, and only the data are sent to the main unit,

Conforming to Planet Press Supports the Objectif Lune PlanetPress (which performs mapping between the downloaded form

Management of blind Web

Page by the password

Bonjour for

Macintosh environment

Document control print The pattern is printed on paper.

Missing-prevention

marking

Layout print The layout supported for various print purposes can be made. No No

No-line binding To prevent against bulge at the end when binding pages, center binding is executed for small lot of

Chapter division A white sheet is automatically inserted so that the head page of each chapter comes on the odd

True type font for barcode usable in PCL5e.

unit.

instead of the down server.

(1) Print of an attached file of an e-mail

(2) Print from the FTP server

(3) Print from the setting file on the Web page

print).

print).

A file on the network is set on the Web page, and direct print is executed.

For letterhead and punching sheet which has attribute of front and back, duplex print can be made

in the proper front and back and proper page sequence.

When the set value of the manual tray type on the main unit differs from that on the driver side, the

set value of the printer driver has priority over the set value on the main unit and printing is made. Yes Yes

Under the meta-frame environment (under the auto print create environment), the print setting of

each client is saved. (In order to avoid the trouble of having to set at every login.) Yes

where data are loaded into the form to be printed.

and the variable data in the printer).

In order to block access to the address of a blind Web Page.

The technology developed by Apple for detecting and connecting peripheral devices on the

network automatically

Without setting by the user, the computer, the peripheral devices, and the software can be

dynamically connected in netw ork.

(OS X 10.3 and later)

(When the data security kit is installed)

The paper edge is marked in order to judge paper missing.

pages.

(or even) page.

Yes

(5e only)

Yes Yes

Yes

Yes

(PDF is No)

Yes Yes

No No

Yes Yes

Yes Yes

Yes

Yes

(5e only)

No

Yes Yes

No Yes

No No

No No

No No

No No

(Windows only)

(Windows only)

(Windows only)

(Windows only)

No

Yes

Yes

Yes

Yes

Yes

Yes

MX-M700N SPECIFICATIONS 2 – 8

Page 19

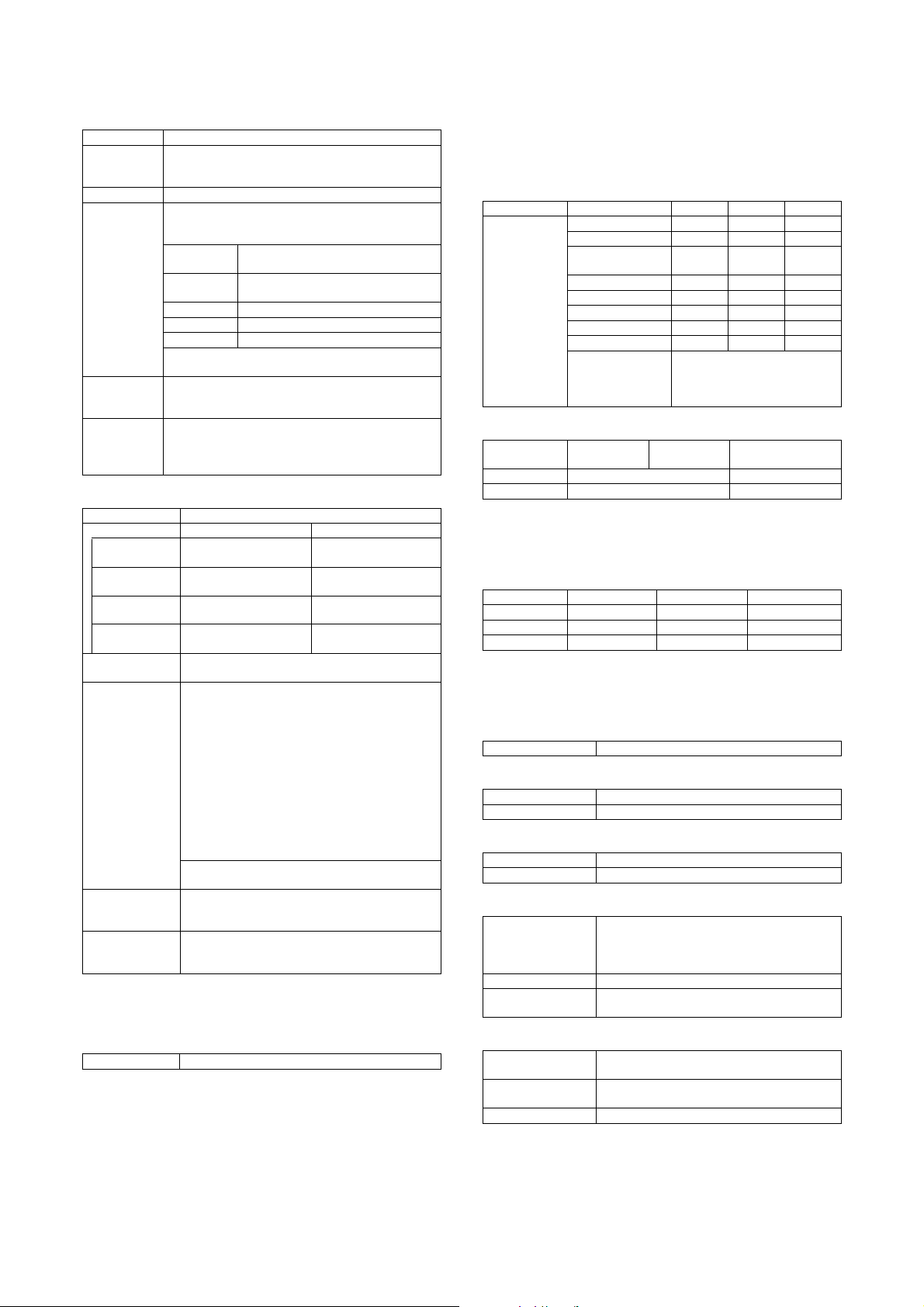

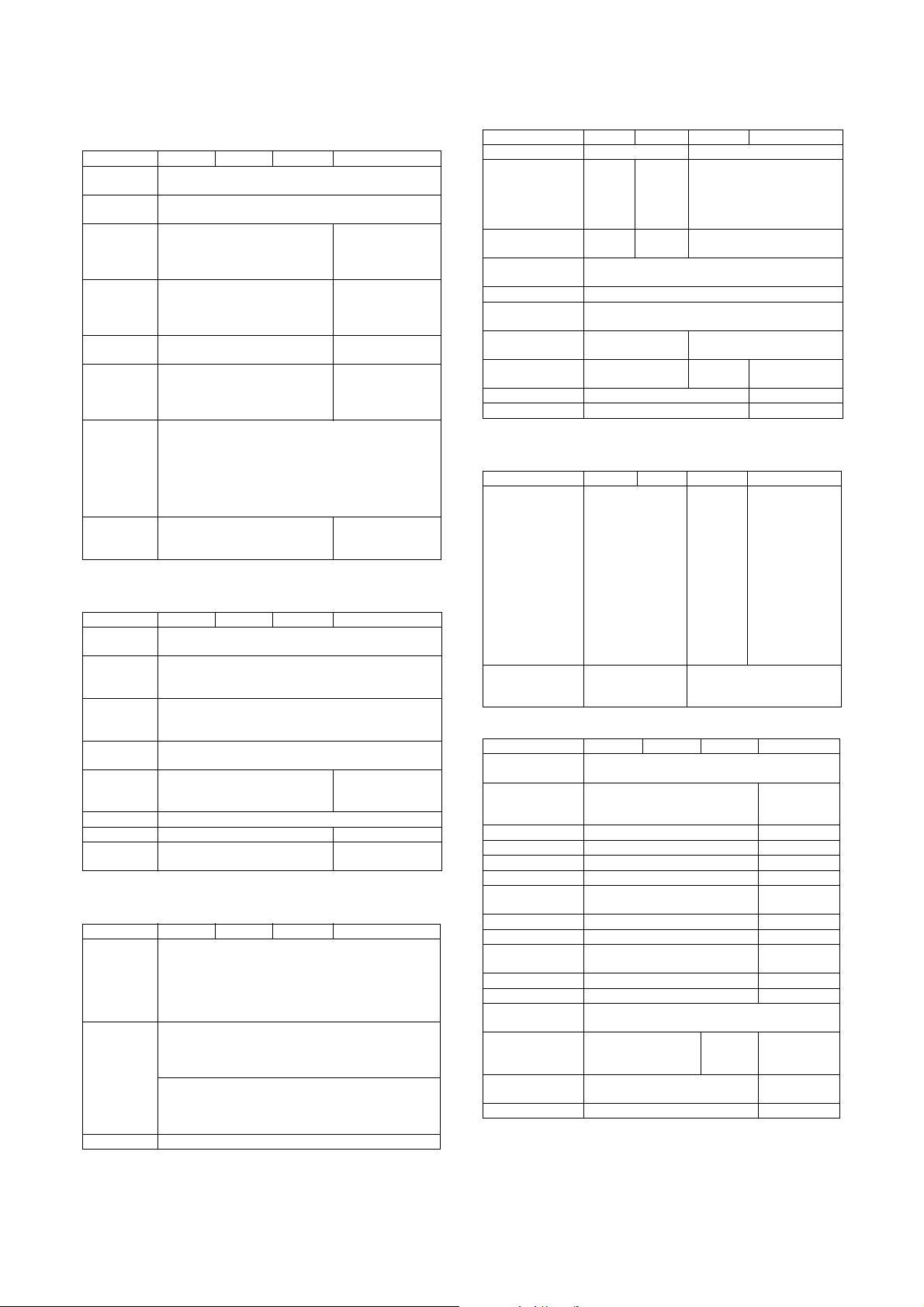

(9) Windows driver function

a. Frequently used functions

Functions PCL5e PCL6 PS PPD (*)

Number of

copies

Print

direction

Duplex print Simplex print, duplex print

Center

binding

Binding

direction

N-up 2/4/6/8/9/16 WindowsNT 4.0: —

N-up

direction

N-up frame

line Yes/No

* For printing, the PS driver bundled in Windows is required.

b. Paper feed system

Functions PCL5e PCL6 PS PPD (*)

Paper size A3/B4/A4/B5/A5/Postcard/Ledger/Legal/Foolscap/Letter/

Paper type Normal paper, letterhead, printed paper, punched paper,

User

definition

type

Paper feed

system

Cover paper/

Back cover

page

Cover paper Yes

Insert paper Yes —

OHP insert

paper

* For printing, the PS driver bundled in Windows is required.

c. Paper exit method

Functions PCL5e PCL6 PS PPD (*)

Paper exit

destination

setting

Staple Finisher

Offset Yes (every time)

* For printing, the PS driver bundled in Windows is required.

1 to 999

Vertical/Horizontal

(Left/Upper/Right binding)

Invoice on Letter, Letter on Ledger,

A5 on A4, A4 on A3, B5 on B4,

Letter on Letter, Ledger on Ledger,

A4 on A4, A3 on A3, B4 on B4

Left/Upper/Right Long side/Short

[2-Up]:

Left to Right / Right to Left

[4, 6, 8, 9, 16-Up]:

Right, and Down /

Down, and Right

Left, and Down /

Down, and Left

Executive/Invoice/8K/16K

recycled paper, color paper, label sheet, thick paper, OHP,

tab pape r

7 types

Auto paper feed, Tray 1/2/3/4/5, manual feed

Yes/No Setting of Duplex/Simplex/

No print —

No/Yes (White paper)

Yes (Printed paper)

• Center tray

• Finisher o Tray 1

• Finisher oTray 2

• Saddle stitch finisher oTra y 1

• Saddle stitch finisher oTra y 2

• Saddle stitch finisher o Saddle stitch tray

• No staple

• 1 position

• 2 positions

Saddle stitch finisher

• No staple

• 1 position

• 2 positions

Simplex print,

duplex print (Long

side/Short side

binding)

Windows2000, XP:

Yes

Other OS: No

side

Windows2000, XP:

2/4/6/9/16 Other

OS: 2/4

Yes

(Always prints

border line)

—

d. Image quality

Function PCL5e PCL6 PS PPD (*)

Resolution 600/300dpi 600dpi

Halftone

Graphic mode

selection

Smoothing 55/62ppm: Yes

Toner save Yes/No

Ultra fine photo 55/62ppm: Yes

Black-white

reversion

Mirror image

Zoom — 25 to 400%

Fit page Yes/No —

Raster

HP-GL2

70ppm : No

70ppm : No

(55ppm/

62ppm)

—

Yes/No

(70ppm)

Raster

vector

—Yes/No

—

Screen Frequency 8.0 to

360.0 in 0.1 steps

Screen angle 0.0 to 360.0 in

0.1 steps

—

Horizontal

/Vertical

—

Horizontal

* For printing, the PS driver bundled in Windows is required.

e. Font

Function PCL5e PCL6 PS PPD (*)

Usable built-in

fonts

Download system

which can be

selected

80 fonts

Category 3 and 4

In font chapter

Bitmap, TrueType,

Graphics

136 fonts

Category

1In font

chapter

5 Japanese fonts

Category

2 In font

chapter

Bit map, Ty pe 1, Tr ueType

(For Windows

NT4.0)

Traditional 35

Latin fonts

Category 1 In

font chapter

(For Other OS)

136 Latin fonts

Category 1 In

font chapter 5

Japanese fonts

Category 2 In

font chapter

f. Other functions

Function PCL5e PCL6 PS PPD (*)

Units composition

setting

Waterm ark

Overlay Yes —

Print hold Yes —

Job retention Yes —

Sample print Yes —

Print department

management

User setting Yes —

Option auto setting Yes —

Job complete

notification

Tandem print Yes

Carbon print Yes —

Enlargement

continuous copy

Vertical/horizontal

independent

magnification ratio

Cover insertion

+center binding

Document filing Yes —

—Yes—

Yes

Yes

Yes —

Yes —

—

Yes —

(Limitations on

functions)

Yes

* For printing, the PS driver bundled in Windows is required.

MX-M700N SPECIFICATIONS 2 – 9

Page 20

(10) Windows PPD, Macintosh PPD driver funciton

a. Frequently used functions

Functions Macintosh PPD

Number of copies 1 to 999

Print direction Vertical/Horizontal

Duplex print Simplex print, duplex print (Left/Upper binding)

Center binding Yes

Binding direction Long side/Short side

N-up 2/4/6/8/16

N-up direction Z / Reverse Z/N / Reverse N

N-up frame line None / Single Hairline / Single Thinline / Double

b. Paper feed system

Functions Macintosh PPD

Paper size A3, B4, A4, B5, A5, Postcard, Ledger, Legal,

Paper type Normal paper, letterhead, printed paper, punched

User definition type 7 types

Paper feed system Auto paper feed, Tray 1/2/3/4/5, manual feed

Cover paper/Back

cover page

Cover paper Yes

Insert paper NO

OHP insert paper No/Yes (White paper), Yes (Printed paper)

c. Paper exit method

Function Macintosh

Paper exit

destination setting

Staple Finisher

Offset Yes (every time)

d. Image quality

Function Macintosh

Resolution 600dpi

Halftone (55ppm/62ppm) Yes/No

Graphic mode

selection

Smoothing (55ppm/62ppm) : Yes/No

Toner save Yes/No

Ultra fine photo —

Black-white

reversion

Mirror image Horizontal/Vertical

Zoom 25 to 400%

Fit page No

e. Font

Function Macintosh

Usable built-in

fonts

Hairline / Double Thinline

Foolscap, Letter, Executive, Invoice, 8K, 16K

paper, recycled paper, color paper, label sheet, thick

paper, OHP, tab paper

Yes / No

Top tray

Finisher

Tray 1

Tray 2

Saddle stitch finisher

Tray 1

Tray 2

Saddle stitch tray

• No staple

• 1 position

• 2 positions

Saddle stitch finisher

• No staple

• 1 position

• 2 positions

• Saddle stitch

(70ppm) —

—

(70ppm) : —

Yes / No

Traditional 35 PS Latin fonts

Category 1 In font chapter

5 fonts Category 2 In font chapter

Function Macintosh

Download system

which can be

selected

Yes (Mac OS9.x.x - LaserWriter)

f. Other functions

Function Macintosh

Units composition

setting

Waterm ark Yes

Overlay No

Print hold Yes

Job retention Yes (PIN code input enable)

Sample print Yes

Print department

management

User setting —

Option auto setting Yes

Job complete

notification

Tandem print Yes

Carbon print Yes

Enlargement

continuous copy

Vertical/horizontal

independent

magnification ratio

Cover insertion

+center binding

Document filing —

Yes

Yes

—

—

—

—

(11) Print performance

Model

55ppm PCL6 16.2 sec 33.7 sec 10.5 sec

62ppm PCL6 13.8 sec 31.4 sec 12.8 sec

70ppm PCL6 14.6 sec 31.1 sec 11.9 sec

* Measurement conditions

(Windows) (Macintosh)

PC: Pentium III 1GHz 128MB PC: PowerPC G3 700MHz 256MB

OS: Windows XP Professional

Driver setting: Default

Software: Microsoft Office XP

PDL

type

PCL5e 15.4 sec 32.4 sec 13.0 sec

PS 15.8 sec 50.0 sec 13.9 sec

ppd 14.1 sec 37.1 sec 11.6 sec

PCL5e 15.4 sec 31.5 sec 12.7 sec

PS 15.6 sec 49.9 sec 13.9 sec

ppd 13.4 sec 41.3 sec 12.2 sec

PCL5e 15.4 sec 30.5 sec 13.3 sec

PS 14.6 sec 49.2 sec 13.4 sec

ppd 14.3 sec 37.0 sec 11.0 sec

Word:

script.doc (eng.)

A total of

9 pages

Excel:

xl8garly.xls

A total of

20 pages

PowerPoint:

Pw4051.ppt

A total of

6 pages

D. Document filing function

(1) Basic function

Document filing capacity 16GB

Fixed folder Standard folder/

Number of pages for one file Conforms to the large volume document

Number of folders which can

be formed in the user folder

Number of users which can be

registered

User folder

Temporary folder

mode. (Within the HD capacity)

Max. 500 folders

Max. 500 users

Max. 20000 pages

or 3000 files

Max. 10000 pages

or 1000 files

MX-M700N SPECIFICATIONS 2 – 10

Page 21

2

: '07 Nov 15

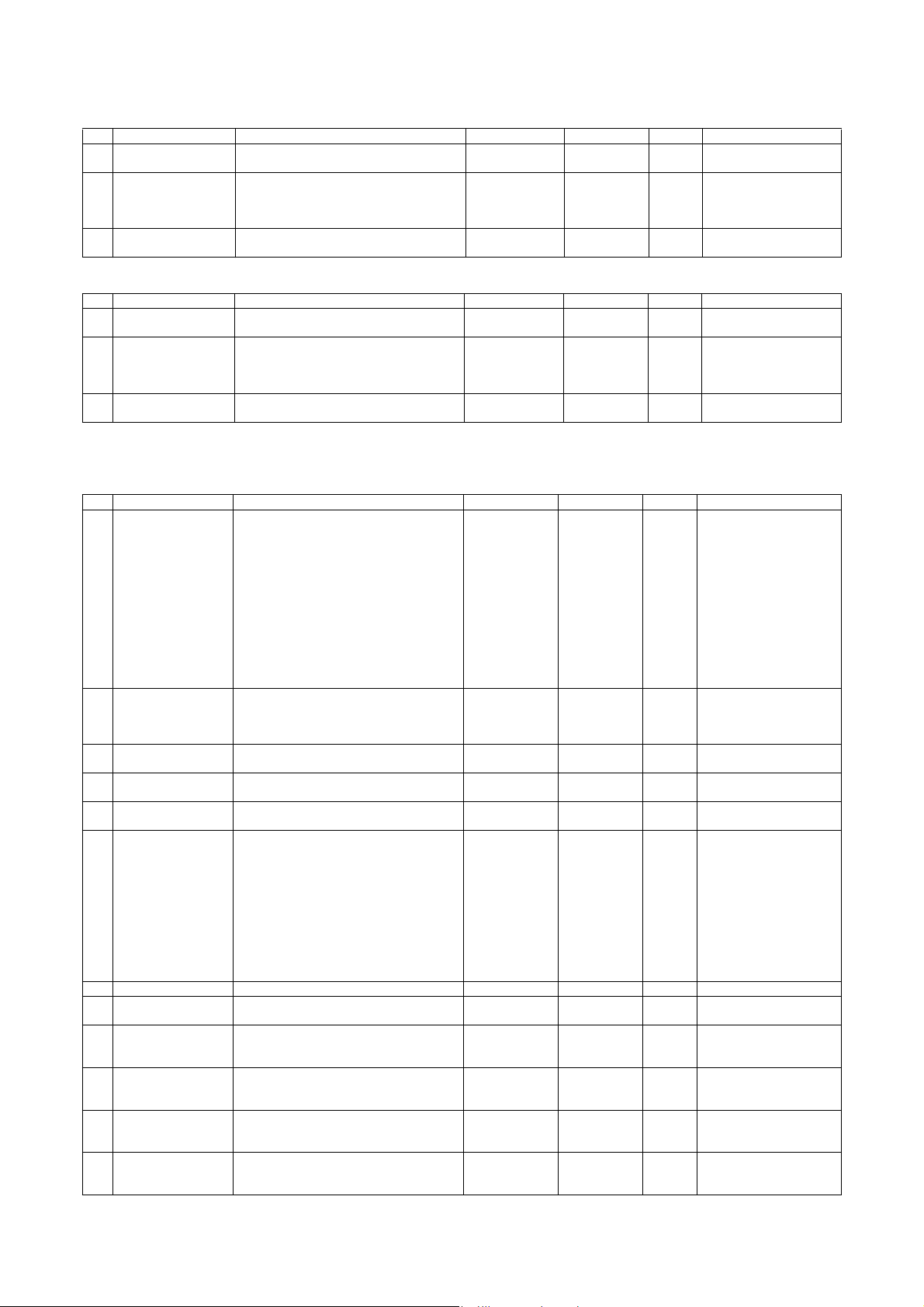

(2) Data operation by each function

Each folder in the

standard folder/

Job

Copy Yes Yes Yes No

Printer Yes Yes Yes No

Direct print (FTP pull) No No Yes No

Direct print (FTP push) No No Yes No

Direct print (e-mail) Yes No Yes No

Direct print (Web) No No Yes No

Scan send Yes No Yes No

Scan to HDD Yes Yes No No

FAX receive NoNoNoNo

FAX send Yes No Yes No

Internet FAX receive No No No No

Internet FAX send Yes No Yes No

PC-Fax/PC-INternet Fax

transmisson

Data input Yes Yes Yes No

user folder

Storage

sharing

Storage

of

Yes Ye s Yes N o

of

Confiden-

tial

Temporary folder

Storage

sharing

Storage

of

Confiden-

E. Safety and environmental standards

(1) Safety standards

2

Item

Safety

standards

Environmental

standards

(EMC)

Line

standards

(When

the FAX

expansion

board is

installed.)

North

America

UL60950-1,

CSA C22.2

No.60950-1

-03,

21CFR

(Laser)

FCC Part 15

Class B,

ICES-003

Class B

FCC Part 68,

ICCS-03

Standard

Europe

(Western/

North)

EN60950-1,

IEC60950-1,

IEC60825-1

(Laser)

EN55022

Class B,

CISPR22

Class B,

EN61000-3-2,

EN61000-3-3,

EN55024

TS103021 or

TBR21,

EG201120,

EG201121

Australia

IEC60950-1,

IEC60825-1

(Laser)

AS/NZS

CISPR22

Class B

(EN 55022

Class B)

AS/ACIF

S0002,

AS/NZS

60950

China /

Tai wa n

GB9254

Class B,

GB17625.1,

GB/T17618,

CNS13438

Class B

GB/T3382.1,

GB/T3382.2,

YD/T514,

YD/T589,

YD/T703,

YD/T965,

YD/T993,

PSTN01

tial

of

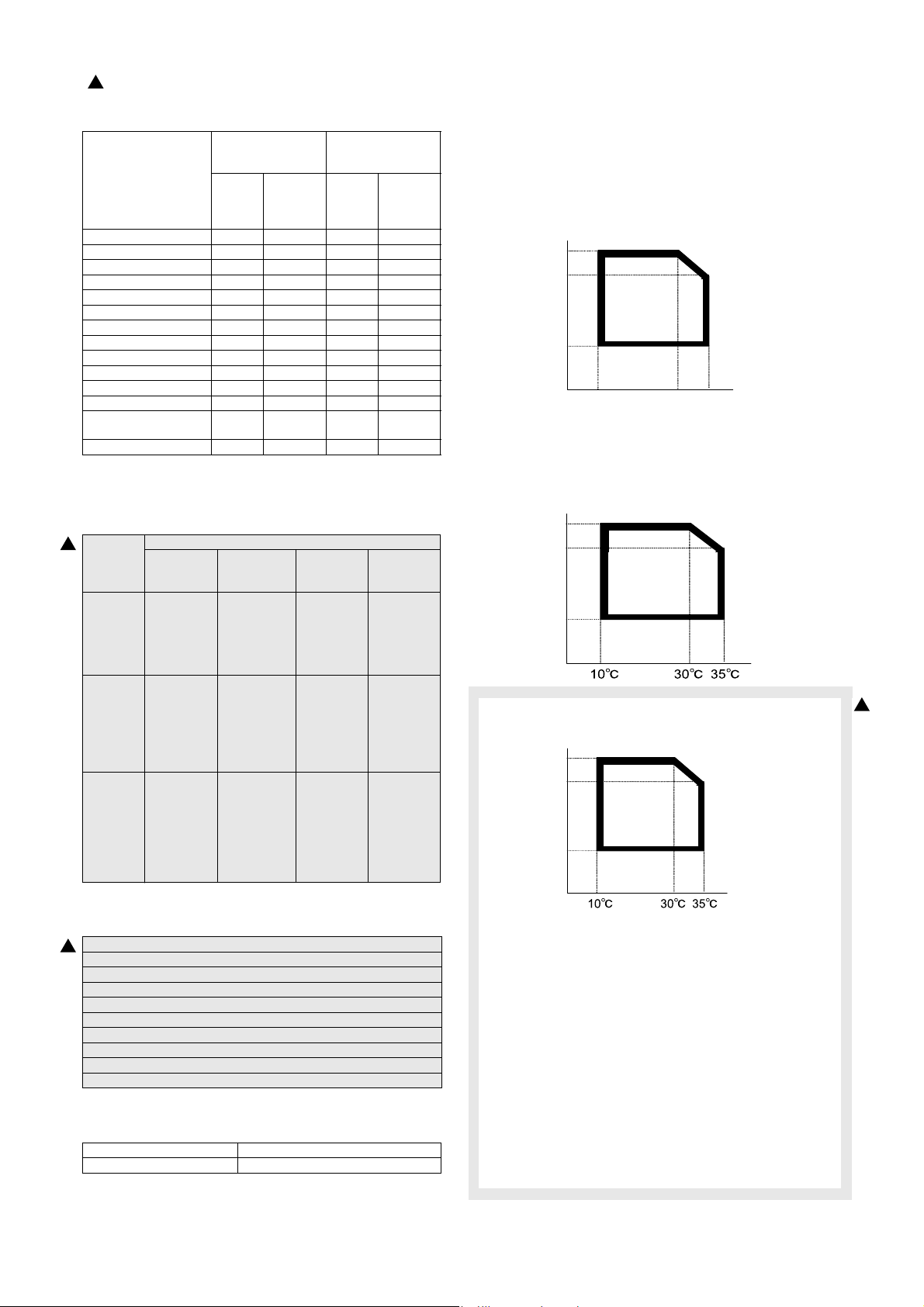

3. Environmental conditions

A. Environmental conditions for use of the main

Temperature: 10°C to 35°C

Humidity: 20 to 85% RH

Air pressure: 590 to 1013hPa (height: 0 to 2000m)

(Humidity)

85%

60%

20%

10 30 35

B. Environmental conditions for transit of the

main unit

–20°C to 45°C (No condensation)

Humidity (RH)

85%

60%

20%

C. Operating environmental conditions (Supply)

Humidity (RH)

85%

60%

20%

(Temperature)

2

(2) Environmental standards

2

International Energy Star Program MFP (EPA)

Environmental Choice Program (ECP)

WEEE (The machine shipped for Europe only)

Standard

Nordic swan

European ROHS regulations

Taiwan battery

(3) Noise

Operating 7.3B or less

Standby (Standby mode) 5.5B or less

D. Ambient conditions for transporting

–20qC to 45qC (No condensation)

E. Environmental conditions for storing

unopened consumable parts

–10qC to 40qC (No condensation)

F. Standard storage period of unopened

consumable parts

1) Photoconductor drum

36 months from the production month

2) Toner/Developer

24 months from the production month

MX-M700N SPECIFICATIONS 2 – 11

Page 22

MX-M700N

[3] CONSUMABLE PARTS

5GTXKEG/CPWCN

1. Supply system table

A. U.S.A, Canada, South and Central America

No. Part name Content Life Model name Packing Remark

1 Toner cartridge (Black) Toner cartridge (Black)

(Toner; Net weight 1815g) With IC chip

2 Developer (Black) Developer (Black)

(Developer; Net weight 725g)

3 Drum OPC drum x 1 62/70ppm: 300k

B. Europe affiliates (Including East Europe, Russia)/Australia/New Zealand/UK

No. Part name Content Life Model name Packing Remark

1 Toner cartridge (Black) Toner cartridge (Black)

(Toner; Net weight 1815g) With IC chip

2 Developer (Black) Developer (Black)

(Developer; Net weight 725g)

3 Drum OPC drum x 1 62/70ppm: 300k

x 10 830k (83k x 10) AR-621MTA 1 * Life setting by A4 6%

x 10 62/70ppm: 1500k

(150k x 2bags x 5)

55ppm: 1250k

(125k x 2bags x 5)

55ppm: 250k

x 10 830k (83k x 10) AR-621LT 1 * Life setting by A4 6%

x 10 62/70ppm: 1500k

(150k x 2bags x 5)

55ppm: 1250k

(125k x 2bags x 5)

55ppm: 250k

AR-620MD 1 Two bags needed.

AR-620DR 10

AR-620LD 1 Two bags needed.

AR-620DM 10