Page 1

MODEL

MX-M550U

MX-M620U

MX-M700U

MX-M550N

MX-M620N

MX-M700N

DIGITAL MULTIFUNCTIONAL

SYSTEM

OPERATION MANUAL

(for general information and copier operation)

Page

PART 1: GENERAL INFORMATION

• BEFORE USING

THE PRODUCT

•

MANAGING THE MACHINE

• PERIPHERAL DEVICES

PART 2: COPIER OPERATION

• MAKING COPIES

• CONVENIENT COPY

FUNCTIONS

•

MACHINE MAINTENANCE

(FOR COPYING)

• DOCUMENT FILING

FUNCTION

•

SPECIFICATIONS

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

Be sure to become thoroughly familiar with this manual to

gain the maximum benefit from the product.

Before installing this product, be sure to read the

installation requirements and cautions sections.

Be sure to keep all operation manuals handy for reference

including this manual, the "Operation manual (for general

information and copier operation)" and operation manuals

for any optional equipment which has been installed.

Page 2

Each instruction also covers the optional units used with these products.

The power switch positions are marked " I " to indicate power "ON" and " " to indicate stand-by.

In the stand-by position, power is being supplied to a drying heater within the paper tray and sensor system in the

printer.

Caution:

For complete electrical disconnection, pull out the main plug.

The socket-outlet shall be installed near the equipment and shall be easily accessible.

FOR YOUR RECORDS ...

To protect against loss or theft, record and retain for reference the machine's serial number located on the back

of the unit.

Model Number

Serial Number

Date of Purchase

Place of Purchase

Authorized Sharp Printer

Service Department Number

WARNING:

FCC Regulations state that any unauthorized changes or modifications to this equipment not expressly approved

by the manufacturer could void the user's authority to operate this equipment.

Note:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

● Reorient or relocate the receiving antenna.

● Increase the separation between the equipment and receiver.

● Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

● Consult the dealer or an experienced radio/TV technician for help.

Shielded interface cables must be used with this equipment to maintain compliance with EMC regulations.

Model Number: MX-M550U/MX-M550N/MX-M620U/MX-M620N/MX-M700U/MX-M700N

MX-M550U J/MX-M620U J/MX-M700U J

Declaration of Conformity

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undersired operation.

Responsible Party: SHARP ELECTRONICS CORPORATION

Sharp Plaza, Mahwah, New Jersey 07430

TEL:1-800-BE-SHARP

Page 3

The Environmental Choice Program guidelines are applied to the products only in Canada. The

products that meet the Environmental Choice Program guidelines carry the logo shown to the left. The

products without the logo may not meet the Environmental Choice Program guidelines.

Trademark acknowledgments

The following trademarks and registered trademarks are used in conjunction with the machine and its peripheral devices and

accessories.

•Microsoft®, Windows®, Windows® 98, Windows® Me, Windows NT® 4.0, Windows® 2000, Windows® XP, Windows® Server

2003 and Internet Explorer

countries.

• PostScript is a registered trademark of Adobe Systems Incorporated.

• Macintosh, Mac OS, AppleTalk, EtherTalk, LaserWriter, and Safari are registered trademarks or trademarks of Apple

Computer, Inc.

• Netscape Navigator is a trademark of Netscape Communications Corporation.

• Adobe, the Adobe logo, Acrobat, the Adobe PDF logo, and Reader are registered trademarks or trademarks of Adobe

Systems Incorporated in the United States and other countries.

• PCL is a registered trademark of the Hewlett-Packard Company.

• IBM, PC/AT, and PowerPC are trademarks of International Business Machines Corporation.

• Sharpdesk is a trademark of Sharp Corporation.

• All other trademarks and copyrights are the property of their respective owners.

Candid and Taffy are trademarks of Monotype Imaging, Inc. registered in the United States Patent and Trademark Office and may

be registered in certain jurisdictions. CG Omega, CG Times, Garamond Antiqua, Garamond Halbfett, Garamond Kursiv,

Garamond and Halbfett Kursiv are trademarks of Monotype Imaging, Inc. and may be registered in certain jurisdictions. Albertus,

Arial, Coronet, Gill Sans, Joanna and Times New Roman are trademarks of The Monotype Corporation registered in the United

States Patent and Trademark Office and may be registered in certain jurisdictions. Avant Garde, ITC Bookman, Lubalin Graph,

Mona Lisa, Zapf Chancery and Zapf Dingbats are trademarks of International Typeface Corporation registered in the United

States Patent and Trademark Office and may be registered in certain jurisdictions. Clarendon, Eurostile, Helvetica, Optima,

Palatino, Stempel Garamond, Times and Univers are trademarks of Heidelberger Druckmaschinen AG, which may be registered

in certain jurisdictions, exclusively licensed through Linotype Library GmbH, a wholly owned subsidiary of Heidelberger

Druckmaschinen AG. Apple Chancery, Chicago, Geneva, Monaco and New York are trademarks of Apple Computer Inc. and may

be registered in certain jurisdictions. HGGothicB, HGMinchoL, HGPGothicB and HGPMinchoL are trademarks of Ricoh Company,

Ltd. and may be registered in some jurisdictions. Wingdings is a registered trademark of Microsoft Corporation in the United States

and other countries. Marigold and Oxford are trademarks of Arthur Baker and may be registered in some jurisdictions. Antique

Olive is a trademark of Marcel Olive and may be registered in certain jurisdictions. Hoefler Text is a trademark of Johnathan

Hoefler and may be registered in some jurisdictions. ITC is a trademark of International Typeface Corporation registered in the

United States Patent and Trademark Office and may be registered in certain jurisdictions. Agfa is a trademark of the Agfa-Gevaert

Group and may be registered in certain jurisdictions. Intellifont, MicroType and UFST are trademarks of Monotype Imaging, Inc.

registered in the United States Patent and Trademark Office and may be registered in certain jurisdictions. Macintosh and

TrueType are trademarks of Apple Computer Inc. registered in the United States Patent and Trademark Office and other countries.

PostScript is a trademark of Adobe Systems Incorporated and may be registered in some jurisdictions. HP, PCL, FontSmart and

LaserJet are trademarks of Hewlett-Packard Company and may be registered in some jurisdictions. The Type 1 processor resident

in Monotype Imaging's UFST product is under license from Electronics For Imaging, Inc. All other trademarks are the property of

their respective owners.

®

are registered trademarks or trademarks of Microsoft Corporation in the U.S.A. and other

Page 4

Page 5

Part 1: General Information

Page 6

Page 7

NOTES

● Considerable care has been taken in preparing this manual. If you have any comments or concerns about the

manual, please contact your nearest SHARP Service Department.

● This product has undergone strict quality control and inspection procedures. In the unlikely event that a defect

or other problem is discovered, please contact your dealer or nearest SHARP Service Department.

● Aside from instances provided for by law, SHARP is not responsible for failures occurring during use of the

product or its options, or failures due to incorrect operation of the product and its options, or other failures, or for

any damage that occurs due to use of the product.

Warranty

While every effort has been made to make this document as accurate and helpful as possible, SHARP Corporation makes

no warranty of any kind with regard to its content. All information included herein is subject to change without notice. SHARP

is not responsible for any loss or damages, direct or indirect, arising from or related to the use of this operation manual.

© Copyright SHARP Corporation 2006. All rights reserved. Reproduction, adaptation or translation without prior

written permission is prohibited, except as allowed under copyright laws.

The display screens, messages, and key names shown in the manual may differ from those on the actual machine

due to product improvements and modifications.

OPERATION MANUALS

The following operation manuals are provided for the machine. Please read the appropriate manuals as needed for

the features you wish to learn about.

● Operation manual (for general information and copier operation) (this manual)

The first half of this manual provides general information about the machine, including safety information, loading

paper, removing misfeeds, and regular maintenance.

The second half of the manual explains how to use the copy and document filing functions.

● Administrator settings guide

The administrator settings are used by the administrator of the machine to configure functions to meet the needs

of your workplace.

This guide explains administrator settings for machine management, copying, and document filing. Administrator

settings for the fax, printer, network scanner and Internet fax functions are explained in the manuals for those

functions.

● Software setup guide

This manual mainly explains how to install and configure the software that allows the machine to be used as a

printer.

● Operation manual (for printer)*

This manual explains the procedures for using the machine as a printer.

● Operation manual (for image send)*

This manual explains the procedures for using the image send feature of the machine, including the network

scanner and Internet fax functions.

To use the network scanner function, the network function of the machine must be in a useable state*

network scanner expansion kit must be installed.

To use the Internet fax function, the network function of the machine must be in a useable state*

scanner expansion kit and the Internet fax expansion kit must be installed.

1

*

The Operation manual (for printer) and the Operation manual (for image send) are provided as PDF files in the

CD-ROM.

These manuals are not provided as printed manuals.

2

*

On the MX-M550U/M620U/M700U, the network expansion kit is required.

1

1

2

and the

2

and the network

0-1

Page 8

INSTALLATION REQUIREMENTS

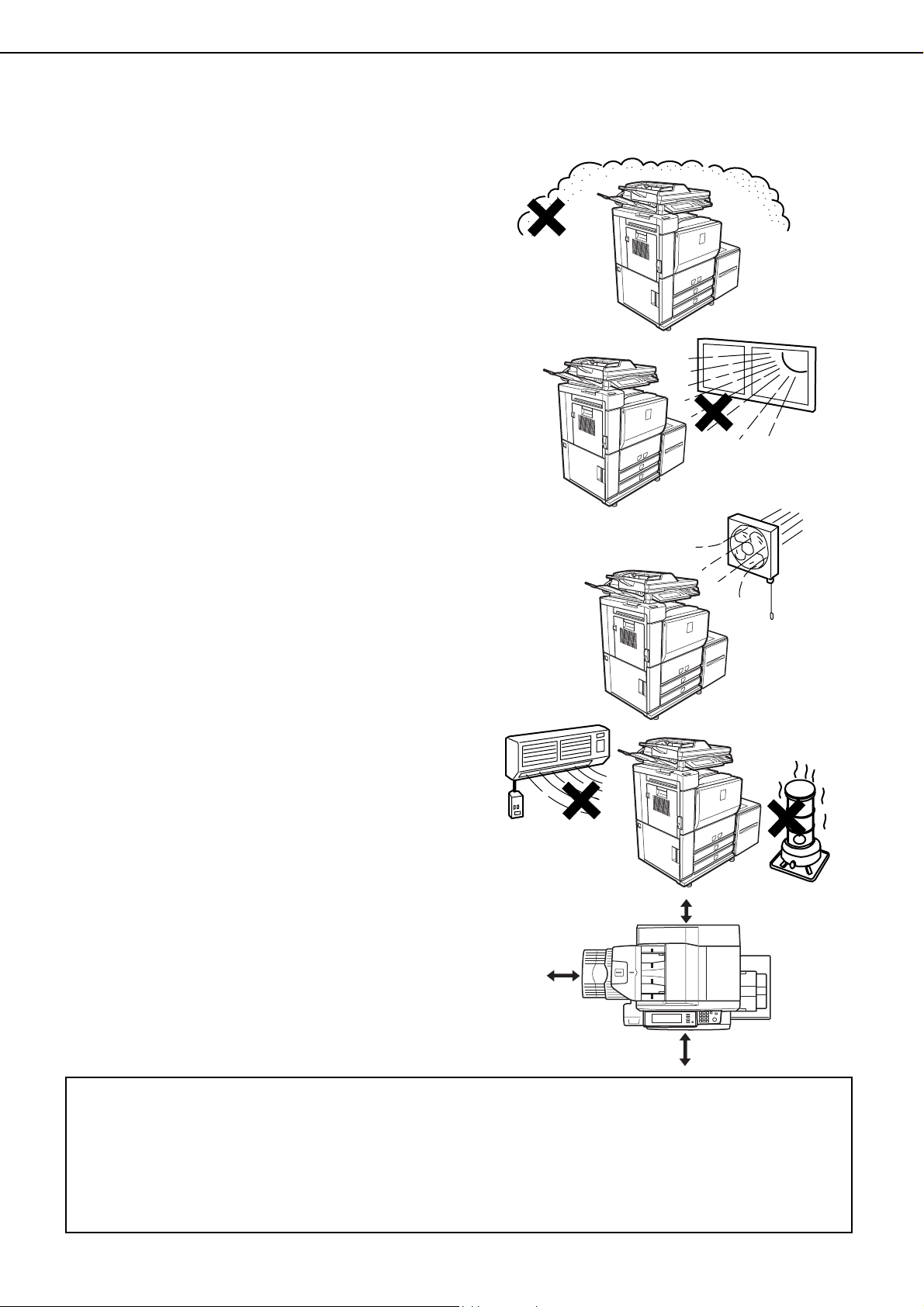

Improper installation may damage this product. Please note the following during initial installation and whenever the

machine is moved.

1.The machine should be installed near an

accessible power outlet for easy connection.

2.Be sure to connect the power cord only to a

power outlet that meets the specified voltage and

current requirements. Also make certain the

outlet is properly grounded.

●For the power supply requirements, see the

name plate on the back of the main unit.

3.Do not install your machine in areas that are:

●damp, humid, or very dusty

●exposed to direct sunlight

●poorly ventilated

●subject to extreme temperature or humidity

changes, e.g., near an air conditioner or heater.

4.Be sure to allow the required space around the

machine for servicing and proper ventilation.

11-13/16"

(30cm)

6-1/8"

(15cm)

23-5/8"

(60cm)

A small amount of ozone is produced within the printer during operation. The emission level is insufficient to cause

any health hazard.

NOTE:

The present recommended long term exposure limit for ozone is 0.1 ppm (0.2 mg/m

weighted average concentration.

However, since the small amount that is emitted may have an objectionable odor, it is advisable to place the copier

in a ventilated area.

3

) calculated as an 8 hr. time-

0-2

Page 9

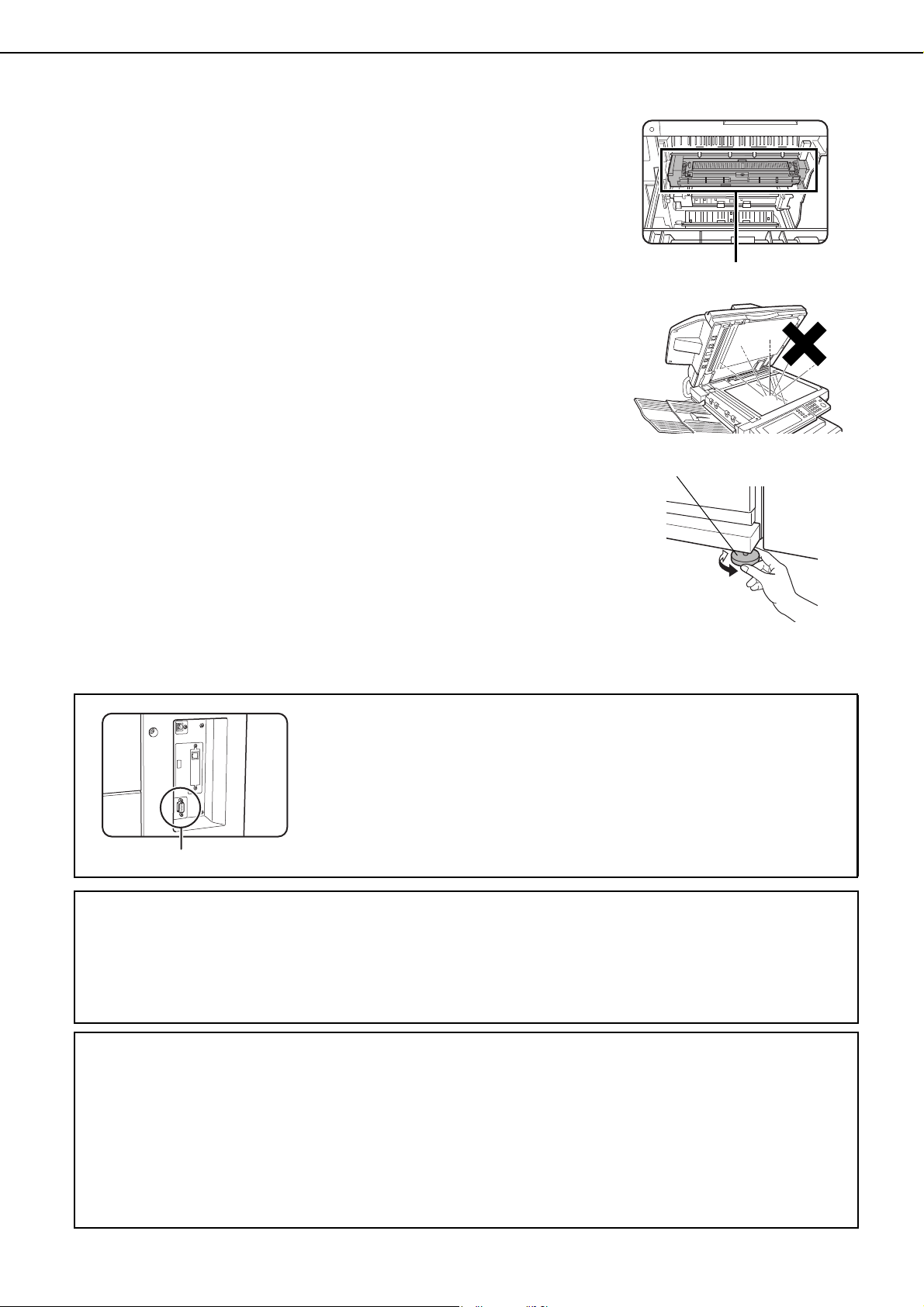

CAUTIONS

1.Do not touch the photoconductive drum. Scratches or smudges on the

drum will cause dirty prints.

2.The fusing unit is extremely hot. Exercise care in this area.

3.Do not look directly at the light source. Doing so may damage your

eyes.

4.Four adjusters are provided on all optional stand/paper drawer units.

These adjusters should be lowered until they contact the floor.

When moving the machine with the optional stand/paper drawer, be

sure to raise the adjusters. Also, unlock the two casters at the front of

the optional stand/paper drawer. After moving the machine, lower the

four adjusters until they reach the floor and lock the two casters.

5.Do not make any modifications to this machine. Doing so may result in

personal injury or damage to the machine.

6.Since this machine is heavy, it is recommended that it be moved by

more than one person to prevent injury.

7.When connecting this machine to a computer, be sure to first turn both

the computer and the machine off.

8.Do not make copies of anything which is prohibited from copying by law.

The following items are normally prohibited from printing by national

law. Other items may be prohibited by local law.

●

Money ● Stamps ● Bonds ● Stocks

●

Bank drafts ● Checks ● Passports ● Driver's licenses

Caution:

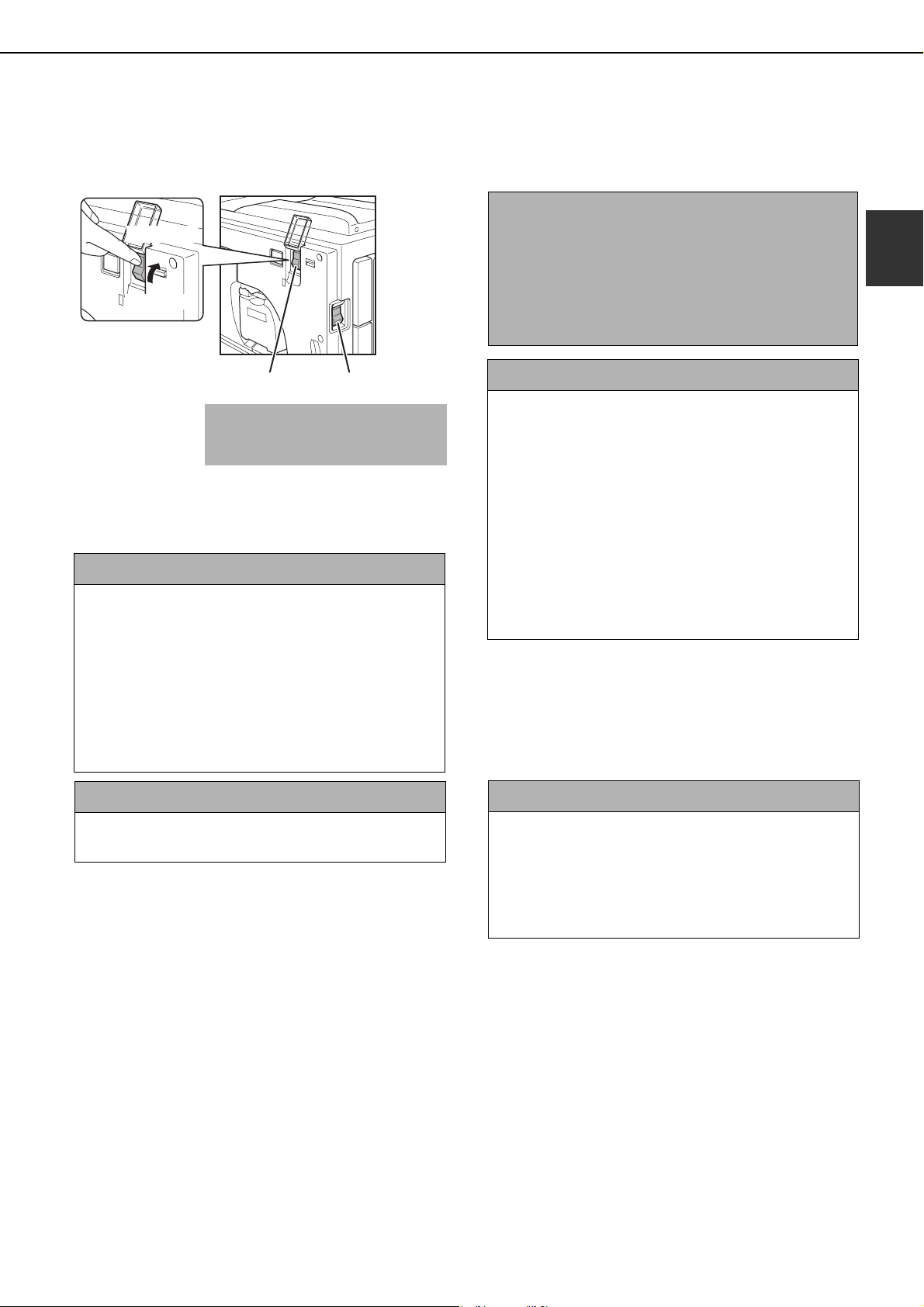

This connector (A) is only intended for service purposes.

Any connection to this terminal may cause malfunctions of the machine.

Fusing unit

Adjuster

Lock

Release

Instruction for service technician:

The cable length for the service terminal has to be less than 118" (3m).

(A)

The machine includes the document filing function, which stores document image data on the machine's hard disk.

Stored documents can be called up and printed or transmitted as needed. If a hard disk failure occurs, it will no

longer be possible to call up the stored document data. To prevent the loss of important documents in the unlikely

event of a hard disk failure, keep the originals of important documents or store the original data elsewhere.

With the exception of instances provided for by law, Sharp Corporation bears no responsibility for any damages

or loss due to the loss of stored document data.

"BATTERY DISPOSAL"

THIS PRODUCT CONTAINS A LITHIUM PRIMARY MEMORY BACK-UP BATTERY THAT MUST BE

DISPOSED OF PROPERLY. PLEASE CONTACT YOUR LOCAL SHARP DEALER OR AUTHORIZED SERVICE

REPRESENTATIVE FOR ASSISTANCE IN DISPOSING OF THIS BATTERY.

This product utilizes tin-lead solder, and a fluorescent lamp containing a small amount of mercury.

Disposal of these materials may be regulated due to environmental considerations.

For disposal or recycling information, please contact your local authorities or the Electronics Industries Alliance:

www.eia.org

0-3

Page 10

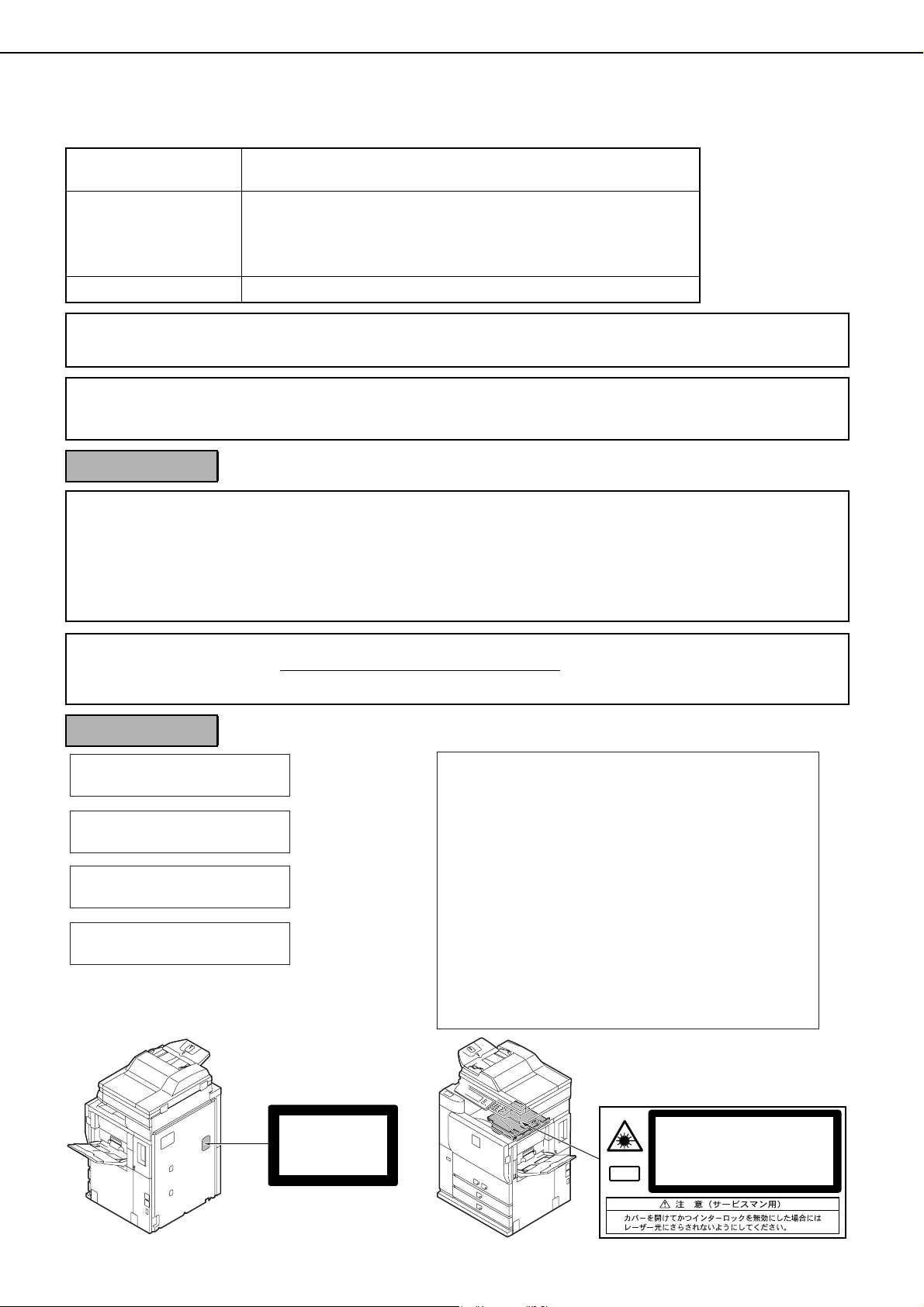

CAUTIONS

Laser Information

Wave length

785 nm

+10 nm

-15 nm

Pulse times North America: 55 cpm / 62 cpm model: (3.1 µs ± 3.1 ns)/7 mm

70 cpm model: (2.7 µs ± 2.7 ns)/7 mm

Europe: 55 cpm / 62 cpm model: (3.7 µs ± 3.7 ns)/7 mm

70 cpm model: (3.2 µs ± 3.2 ns)/7 mm

Output power Max 0.8 mW

At the production line, the output power of the scanner unit is adjusted to 0.8 MILLIWATT PLUS 10 % and is maintained

constant by the operation of the Automatic Power Control (APC).

Caution

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous

radiation exposure.

For North America:

SAFETY PRECAUTIONS

This Digital Equipment is rated Class 1 and complies with 21 CFR 1040.10 and 1040.11 of the CDRH standards. This

means that the equipment does not produce hazardous laser radiation. For your safety, observe the precautions below.

● Do not remove the cabinet, operation panel or any other covers.

● The equipment's exterior covers contain several safety interlock switches. Do not bypass any safety interlock by

inserting wedges or other items into switch slots.

This product utilizes a CR coin Lithium battery which contains a Perchlorate material. Special handling for this material may

apply, California residents, See www.dtsc.ca.gov/hazardouswaste/perchlorate/

Others, consult local environmental officers.

For Europe:

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

INVISIBLE LASER RADIATION

CAUTION

WHEN OPEN INTERLOCKS

DEFEATED. AVOID EXPOSURE

TO BEAM.

VORSICHT

UNSICHTBARE

LASERSTRAHLUNG WENN

ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM

STRAHL AUSSETZEN.

ADVARSEL

USYNLIG LASERSTRÅLNING

VED ÅBNING, NÅR

SIKKERHEDSBRYDERE ER

UDE AF FUNKTION. UNDGÅ

UDSAETTELSE FOR

STRÅLNING.

LAITTEEN KÄYTTÄMINEN

MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA

MAINITULLA TAVALLA SAATTAA

ALTISTAA KÄYTTÄJÄN

TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE.

OM APPARATEN ANVÄNDS PÅ

ANNAT SÄTT ÄN I DENNA

BRUKSANVISNING

SPECIFICERATS, KAN

ANVÄNDAREN UTSÄTTAS FÖR

OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

VAROITUS!

VARNING

0-4

CLASS 1

LASER PRODUCT

LASER KLASSE 1

Laserstrahl

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

CAUTION

UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG ÜBERERÜCKT. NICHT DEM STRAHL AUSSETZEN.

VORSICHT

USYNLIG LASERSTRÅLING VED ÅBNING, NÅR SIKKERHEDSAFBRYDERE ER

UDE AF FUNKTION. UNDGÅ UDSAETTELSE FOR STRÅLNING.

ADVARSEL

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS BRYTES.

UNNGÅ EKSPONERING FOR STRÅLEN.

ADVERSEL

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRRAR ÄR

URKOPPLADE. STRÅLEN ÄR FARLIG. BETRAKTA EJ STRÅLEN.

VARNING

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTÖNTÄ

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VAR O!

Page 11

CONTENTS

Page

OPERATION MANUALS ..............................................0-1

INSTALLATION REQUIREMENTS...............................0-2

CAUTIONS...................................................................0-3

● Laser Information .................................................0-4

CONTENTS .................................................................0-5

CHAPTER 1

BEFORE USING THE PRODUCT

INTRODUCTION.......................................................... 1-2

MAIN FEATURES ........................................................1-3

PART NAMES AND FUNCTIONS................................ 1-10

● Exterior .................................................................1-10

● Interior .................................................................. 1-11

● Operation panel....................................................1-13

● Touch panel.......................................................... 1-14

TURNING THE POWER ON AND OFF .......................1-17

AUDITING MODE ........................................................1-18

● Using the machine when the auditing mode is

enabled.................................................................1-18

CHAPTER 2

MANAGING THE MACHINE

LOADING PAPER ........................................................2-2

● Identifying the trays ..............................................2-2

● Loading paper in paper tray 1 - tray 2 ..................2-2

● Changing the paper size in paper tray 1 - tray 2 ..2-3

● Loading paper in paper tray 3 ..............................2-5

● Changing the paper size in paper tray 3 ..............2-5

● Changing the paper size in paper tray 4 ..............2-6

● Loading paper in paper tray 5 (optional large

capacity tray AR-LC6)

● Loading paper in paper tray 5 (optional large

capacity tray AR-LC7)

● Loading paper in the bypass tray .........................2-10

● Specifications of paper trays (Types and sizes of

paper that can be used in the trays).....................2-12

● Setting the paper type and paper size.................. 2-14

● Setting the paper size when a special size is

loaded ..................................................................2-17

SYSTEM SETTINGS ...................................................2-18

● General procedure for system settings ................2-18

● About the settings ................................................ 2-20

REPLACING THE TONER CARTRIDGES .................. 2-21

STORAGE OF SUPPLIES ...........................................2-22

MISFEED REMOVAL ...................................................2-23

● Misfeed removal guidance.................................... 2-23

● Misfeed in the transport area, fusing area, and

exit area................................................................2-24

● Misfeed in the duplex unit.....................................2-25

● Misfeed in the paper feed area.............................2-26

REMOVING AN ORIGINAL MISFEED.........................2-31

● Removing a misfed original from the automatic

document feeder .................................................. 2-31

TROUBLESHOOTING ................................................. 2-32

..................................................

..................................................

2-7

2-8

CHAPTER 3

PERIPHERAL DEVICES

FINISHER AND SADDLE STITCH FINISHER.............3-2

● Part names ...........................................................3-2

● Specifications .......................................................3-2

● Finishing methods ................................................3-4

● Finishing modes and finisher functions ................3-6

● Staple cartridge replacement and staple jam

removal.................................................................3-7

● Removing a misfeed.............................................3-11

● Troubleshooting finisher/saddle stitch finisher

problems...............................................................3-13

INSERTER ...................................................................3-14

● Part names ...........................................................3-14

● Specifications .......................................................3-14

● Loading paper.......................................................3-15

● Manual operation of the inserter...........................3-15

● Misfeed removal ...................................................3-17

● Troubleshooting inserter problems .......................3-18

SHARP OSA.................................................................3-19

APPLICATION COMMUNICATION MODULE (MX-

AMX2)...........................................................................3-19

● Standard application setup...................................3-19

● Selecting a standard application...........................3-19

● Operation in OSA mode .......................................3-20

EXTERNAL ACCOUNT MODULE (MX-AMX3)............3-21

● External account application setup.......................3-21

● Operation in external account mode.....................3-21

CHAPTER 4

MAKING COPIES

AUTOMATIC DOCUMENT FEEDER............................4-2

● Acceptable originals .............................................4-2

PLACING ORIGINALS .................................................4-3

CHECKING THE SIZE OF A PLACED ORIGINAL.......4-5

● Manually setting the scanning size .......................4-5

STORING, DELETING, AND USING ORIGINAL

SIZES ...........................................................................4-6

● Storing or deleting an original size .......................4-6

NORMAL COPYING.....................................................4-7

● Making copies with the automatic document

feeding function ....................................................4-7

● Automatic two-sided copying using the automatic

document feeding function....................................4-10

● Copying from the document glass ........................4-11

● Automatic two-sided copying from the document

glass .....................................................................4-13

ADJUSTING THE EXPOSURE....................................4-14

REDUCTION/ENLARGEMENT/ZOOM........................4-15

● Automatic selection (auto image) .........................4-15

● Manual selection (preset copy ratios/zoom) .........4-16

● XY ZOOM .............................................................4-18

SPECIAL PAPERS .......................................................4-20

0-5

Page 12

CONTENTS

CHAPTER 5

CONVENIENT COPY FUNCTIONS

SPECIAL MODES ........................................................5-2

● General procedure for using special functions .....5-2

● Margin shift ...........................................................5-3

● Erase ....................................................................5-4

● Dual page copy.....................................................5-5

● Pamphlet copy......................................................5-6

● Job build ...............................................................5-8

● Tandem copy ........................................................5-10

● Covers/inserts.......................................................5-12

● Transparency film with insert sheets ....................5-23

● Multi shot ..............................................................5-24

● Book copy.............................................................5-26

● Tab copy ...............................................................5-27

● Card shot

● Mirror image .........................................................5-31

● B/W reverse..........................................................5-31

● Print menu ............................................................5-32

STORING, USING AND DELETING JOB

PROGRAMS.................................................................5-44

● Storing a job program ...........................................5-44

● Calling up a job program ......................................5-45

● Deleting a stored job program ..............................5-45

INTERRUPTING A COPY RUN ...................................5-46

.................................................................

5-29

CHAPTER 8

SPECIFICATIONS

SPECIFICATIONS ....................................................... 8-2

INDEX.......................................................................... 8-4

CHAPTER 6

MACHINE MAINTENANCE (FOR

COPYING)

USER MAINTENANCE ................................................6-2

● Cleaning the document glass and the automatic

document feeder...................................................6-2

TROUBLESHOOTING..................................................6-3

CHAPTER 7

DOCUMENT FILING FUNCTION

OVERVIEW ..................................................................7-2

● Document filing function .......................................7-2

TO USE THE DOCUMENT FILING FUNCTION..........7-4

● A look at the operation panel................................7-4

● Saving files ...........................................................7-4

● Main screen of document filing.............................7-5

● Document filing icons ...........................................7-5

SAVING A DOCUMENT IMAGE FILE..........................7-6

● Quick File..............................................................7-6

● Filing .....................................................................7-7

● Print jobs ..............................................................7-9

● Scan Save ............................................................7-10

CALLING UP AND USING A FILE...............................7-13

● Searching for and calling up a saved file

● Calling up and using a saved file..........................7-15

SYSTEM SETTINGS....................................................7-24

● Creating, editing, and deleting user names and

folders...................................................................7-24

ENTERING CHARACTERS .........................................7-29

TROUBLESHOOTING..................................................7-31

..............

7-13

0-6

Page 13

CHAPTER 1

BEFORE USING THE

PRODUCT

This chapter contains basic information that should be read before using

the product.

Page

INTRODUCTION..................................................................................... 1-2

MAIN FEATURES ................................................................................... 1-3

PART NAMES AND FUNCTIONS........................................................... 1-10

●

Exterior............................................................................................ 1-10

●

Interior............................................................................................. 1-11

●

Operation panel............................................................................... 1-13

●

Touch panel..................................................................................... 1-14

TURNING THE POWER ON AND OFF.................................................. 1-17

AUDITING MODE................................................................................... 1-18

●

Using the machine when the auditing mode is enabled.................. 1-18

1-1

Page 14

INTRODUCTION

Thank you for purchasing a SHARP digital multifunction copier.

Please read this manual before using the machine. In particular, be sure to read "INSTALLATION REQUIREMENTS"

before using the machine.

Please keep this manual close at hand for reference whenever necessary.

This manual provides general information on using the machine, such as routine maintenance and how to load paper

and remove misfeeds. It also explains how to use the copier and document filing functions.

Separate manuals have been provided for the fax function, printer function, and network scanner function.

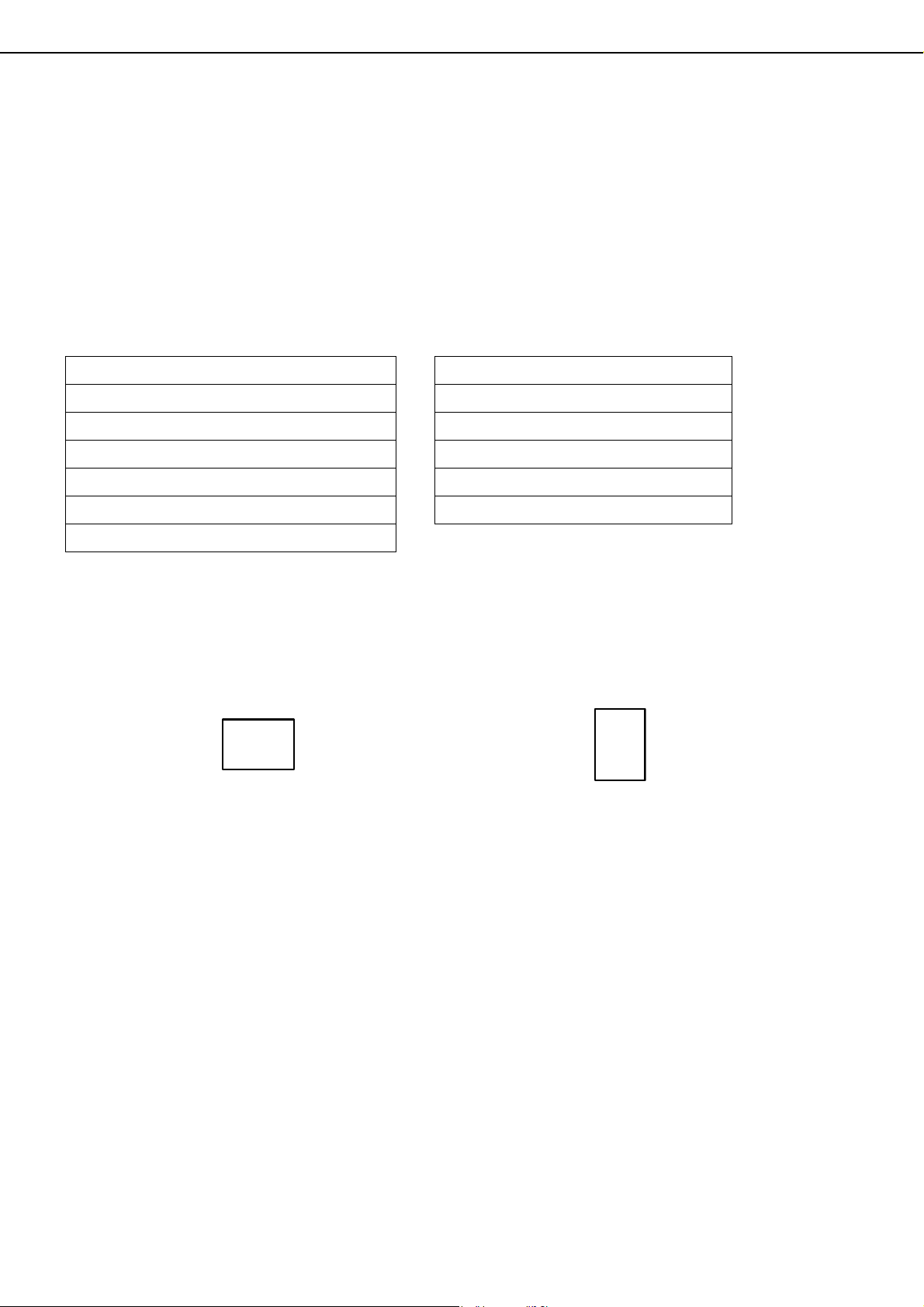

■ Original and paper sizes

This machine allows use of standard sizes in both the inch and AB systems.

These are shown in the tables below.

Sizes in the inch system Sizes in the AB system

11" x 17" (LEDGER) A3

8-1/2" x 14" (LEGAL) B4

8-1/2" x 13" (FOOLSCAP) A4

8-1/2" x 11" (LETTER) B5

7-1/4" x 10-1/2" (EXECUTIVE) A5

5-1/2" x 8-1/2" (INVOICE)

■ The meaning of "R" in original and paper size indications

Some original and paper sizes can be placed in either the portrait or landscape orientations. To differentiate

between landscape and portrait, the landscape orientation size indication will contain an "R". These are indicated

as 8-1/2" x 11"R, 5-1/2" x 8-1/2"R, A4R, B5R, etc. Sizes that can be placed only in the landscape orientation (11"

x 17", 8-1/2" x 14", 8-1/2" x 13", A3, B4) do not contain the "R" in their size indication.

Size indication

with "R"

Landscape

orientation

Size indication

without "R"

Portrait orientation

1-2

Page 15

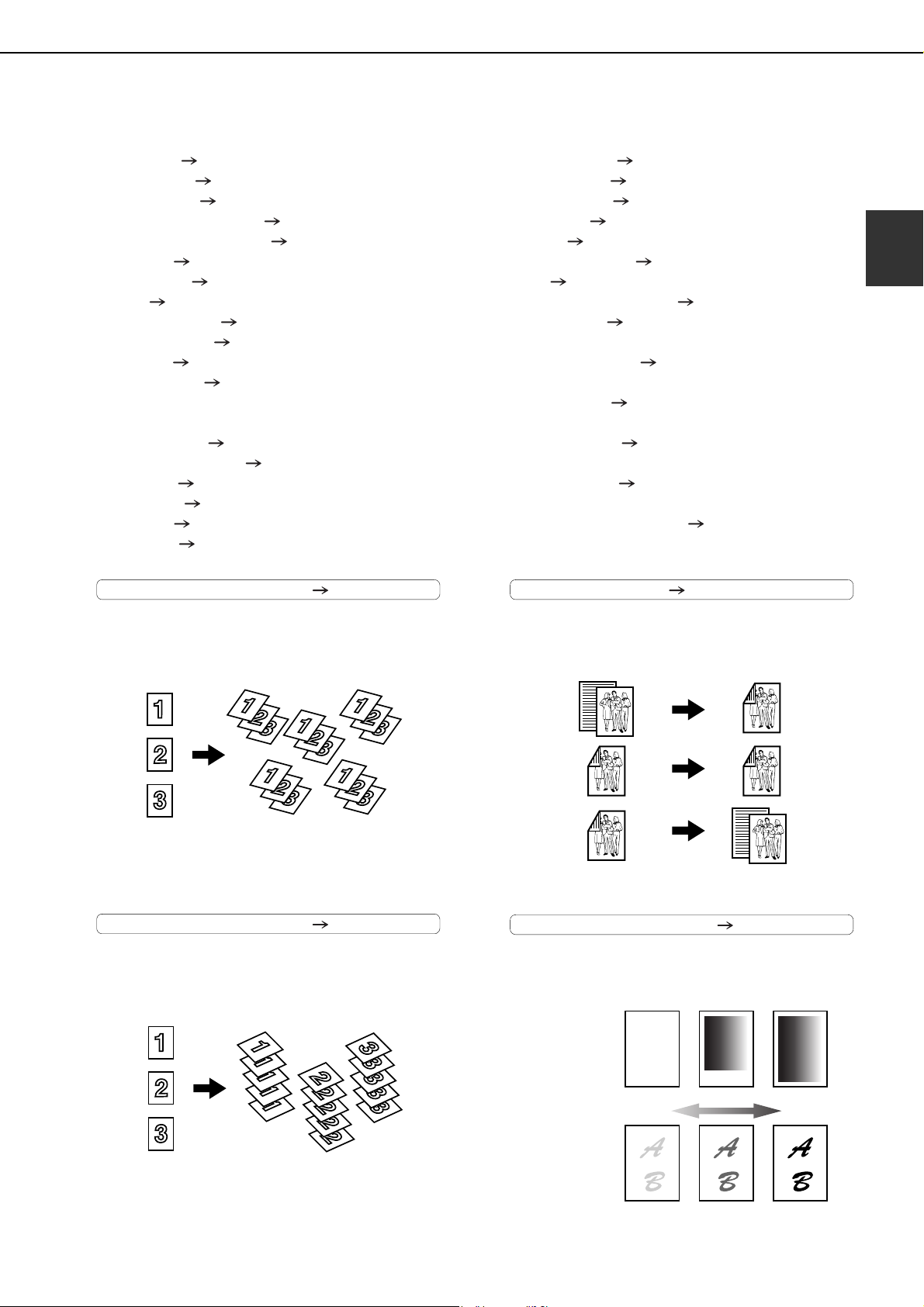

MAIN FEATURES

The digital multifunction copier is capable of performing a variety of functions. This page shows features related to

the copy function.

● Sort mode See page 1-3

● Group mode See page 1-3

● 2-sided Copy See page 1-3

● Exposure Adjustments See page 1-3

● Reduction/Enlargement See page 1-4

● XY Zoom See page 1-4

● Margin Shift See page 1-4

● Erase See page 1-4

● Dual Page Copy See page 1-4

● Pamphlet Copy See page 1-4

● Job Build See page 1-5

● Tandem Copy See page 1-5

(When using the MX-M550U, MX-M620U, or

MX-M700U, the network expansion kit is required.)

● Covers/inserts See page 1-5

● Transparency Insert See page 1-5

● Multi Shot See page 1-5

● Book Copy See page 1-5

● Tab Copy See page 1-6

● Card Shot See page 1-6

● Job programs See page 1-6

● Mirror Image See page 1-6

● B/W Reverse See page 1-6

● Date print See page 1-6

● Stamp See page 1-7

● Page numbering See page 1-7

● Text See page 1-7

● Interrupting a copy run See page 1-7

● Offset mode See page 1-7

(When the Finisher or Saddle stitch finisher is installed.)

● Staple sort mode See page 1-7

(When the Finisher or Saddle stitch finisher is installed.)

● Saddle stitch See page 1-8

(When the Saddle stitch finisher is installed.)

● Hole punching See page 1-8

(When the Punch Module is installed.)

● Inserter mode See page 1-8

(When the Inserter is installed.)

● Document filing function See page 1-8

1

Sort See page 4-9

Copies can be collated.

Original

Group See page 4-9

Copies can be grouped by page.

Original Copy

Copy

2-sided Copy See pages 4-10, 4-13

Copy onto both sides of the paper using the document

glass or the automatic document feeder.

Original

Exposure Adjustments See page 4-14

The desired image type for the original can be

selected.

Text Text/Photo Photo

Copy

Resolution

Exposure

ABCDE

ABCDE

DarkerLighter

1-3

Page 16

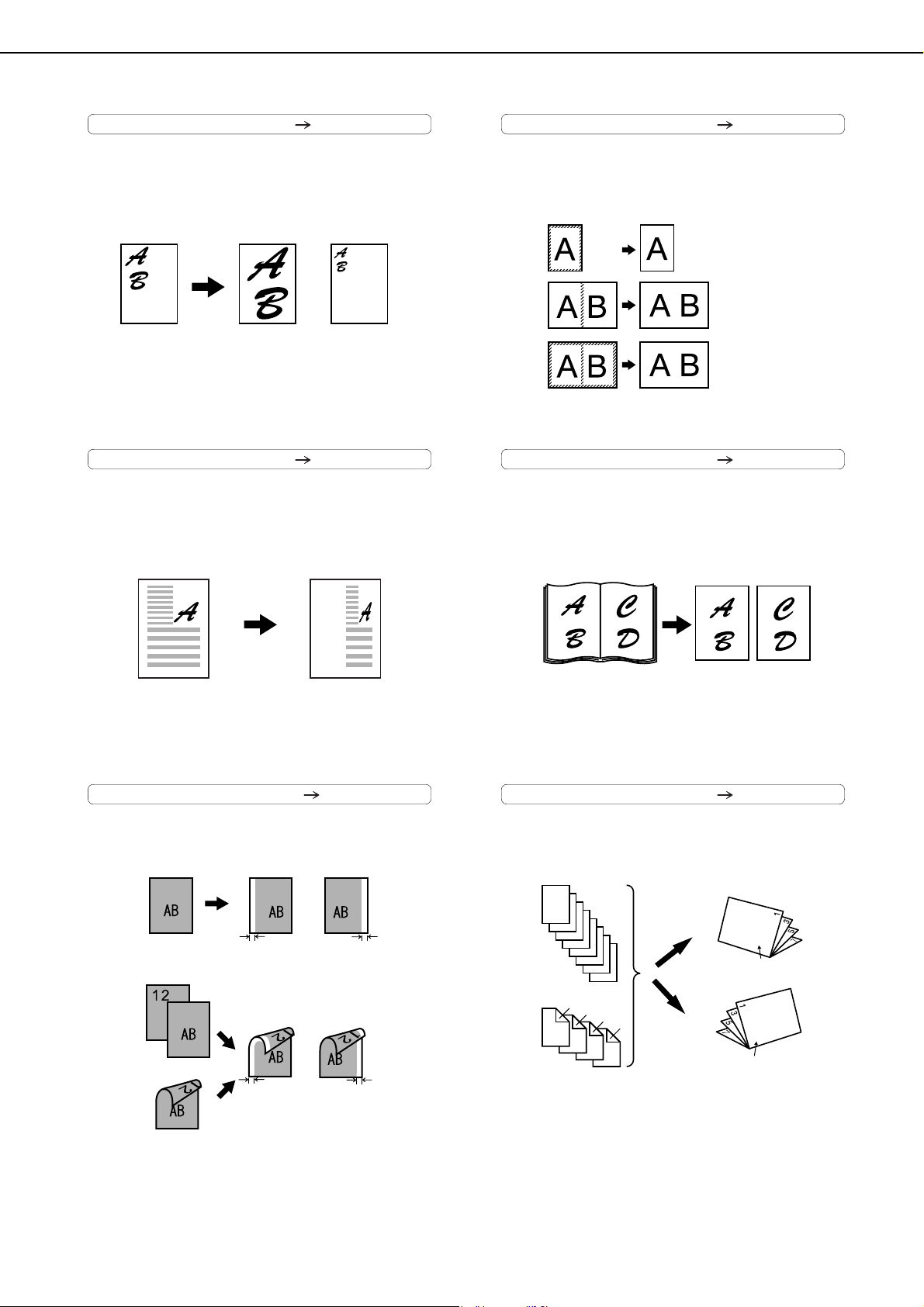

MAIN FEATURES

Reduction / Enlargement See page 4-15

Copies can be enlarged or reduced to the desired

size.

Original

Enlargement Reduction

Copy

XY Zoom See page 4-18

Separate ratio settings can be selected for the

length and width of a copy.

Original Copy

Erase See page 5-4

Shadows that appear around the edges of copies of

books or thick originals can be erased.

Original

Copy

Edge erase

Center erase

Edge+Center

erase

Dual Page Copy See page 5-5

The left and right pages of a book can be

successively copied onto separate sheets.

CopyBook original

Margin Shift See page 5-3

Margins can be added to copies.

One-sided copying

Original

Two-sided copying

Original

Or

Image shifted

to the right

Margin

Image shifted

to the right

Margin

Image shifted

to the left

Margin

Image shifted

to the left

Margin

Pamphlet Copy See page 5-6

One-sided or two-sided pamphlet style copies can

be made.

Originals (one-sided)

1

2

3

4

5

6

7

8

Originals (two-sided)

2

4

6

1

3

5

7

Left binding

8

Right binding

Finished copies are

folded in two.

First page

First page

1-4

Page 17

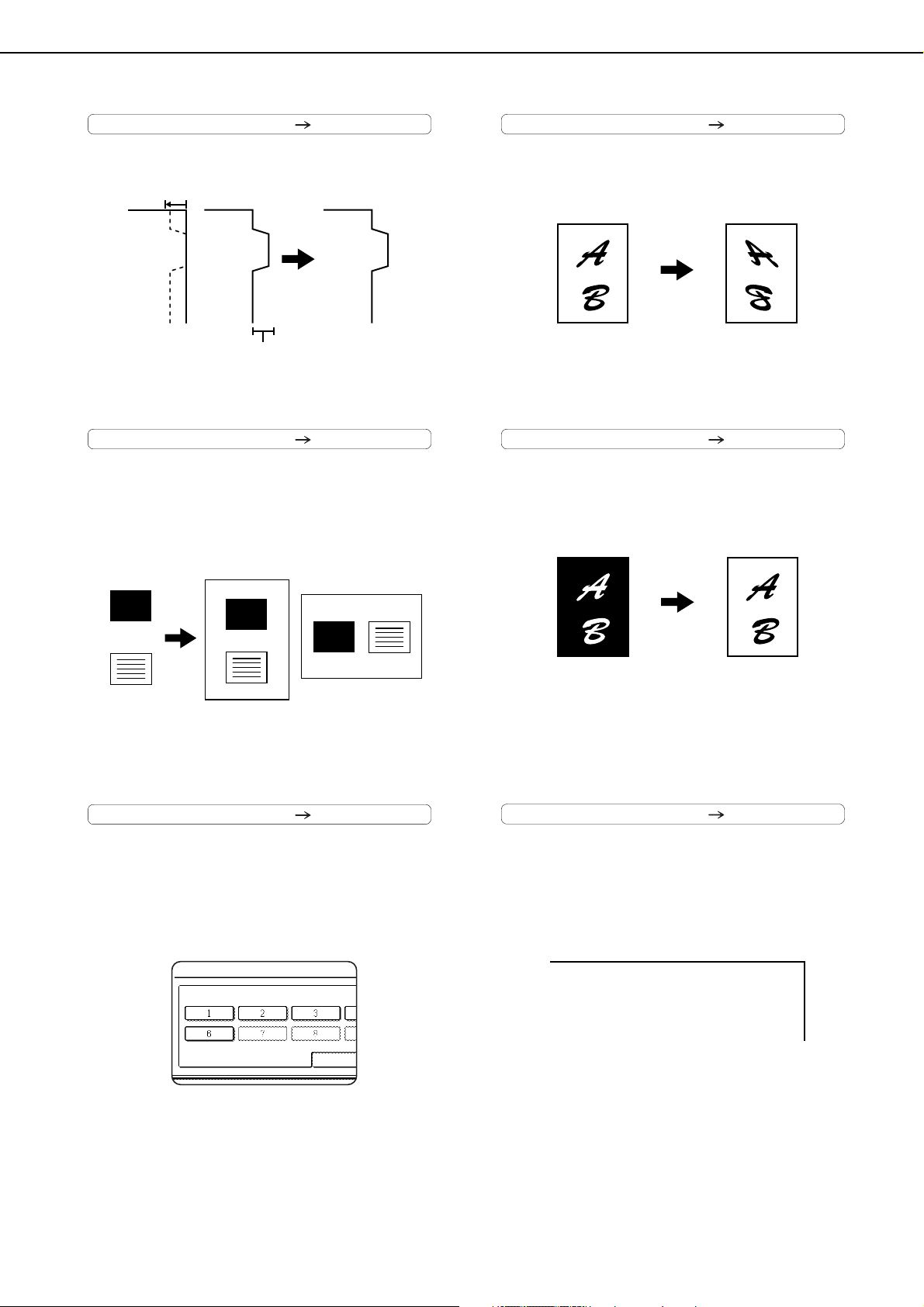

MAIN FEATURES

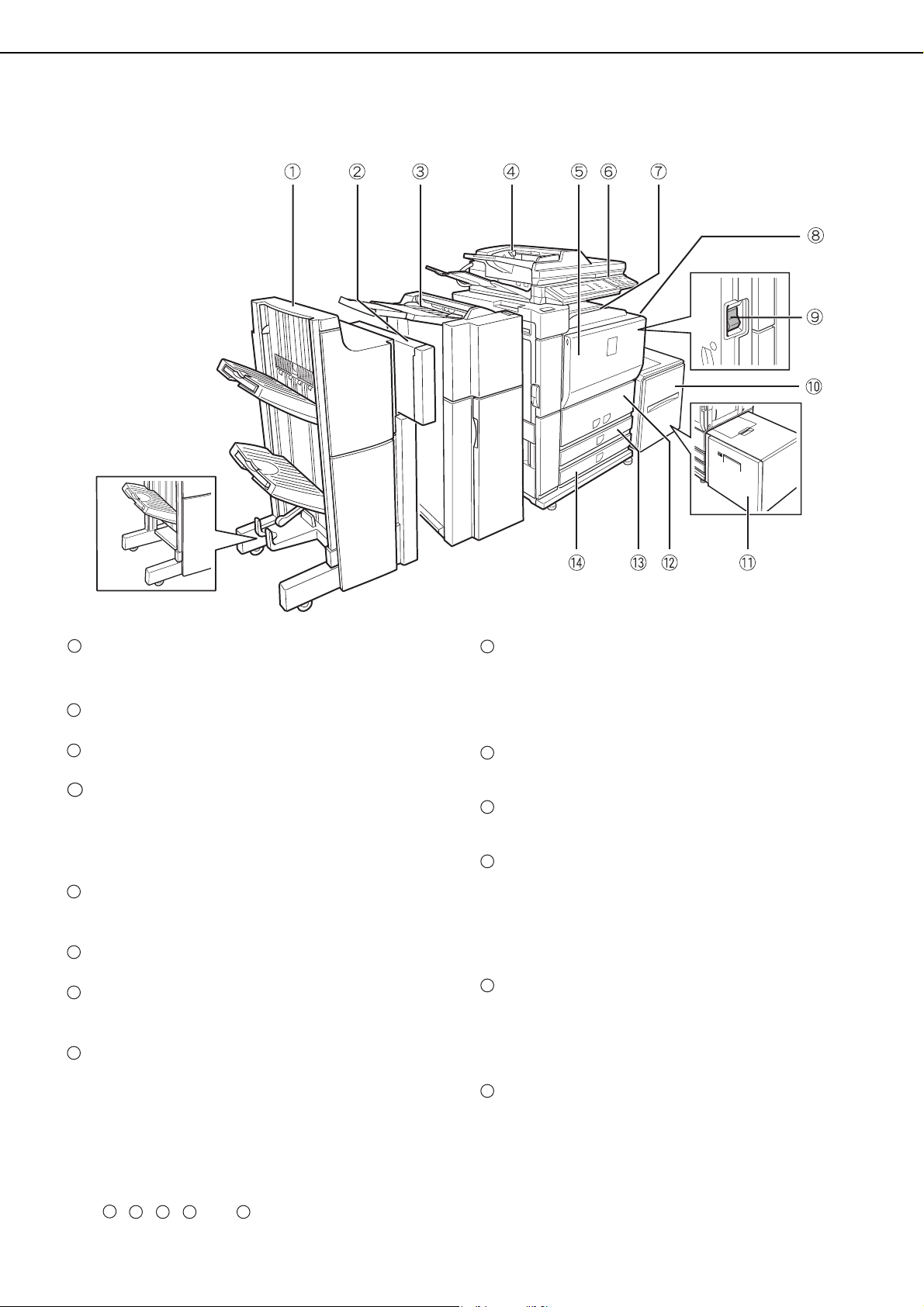

Job Build See page 5-8

When you have a very large number of originals, the

pages can be scanned in sets.

150 sheets300 sheets 150 sheets

Tandem Copy See page 5-10

Two machines can be used to run a large copy job

in parallel.

Transparency Insert See page 5-23

Inserts can be automatically inserted between

transparencies.

Originals (1-sided)

Originals (2-sided)

Copy

Insert sheets

Multi Shot See page 5-24

Multiple original pages can be copied onto a

single sheet of paper in a uniform layout.

Originals

(1-sided)

Originals

(2-sided)

Copy

1

100 sets of

copies

*

When using the MX-M550U, MX-M620U, or

50 sets of

copies

50 sets of

copies

MX-M700U, the network expansion kit is required.

Covers/inserts See page 5-12

Front covers, back covers, and inserts can be

added. These can also be copied on.

Originals

Back cover

Front cover

Insert sheets

Book Copy See page 5-26

Books and other bound originals can be copied

pamphlet style.

CopyOriginal

Left binding

First page

Right binding

First page

First page

First page

1-5

Page 18

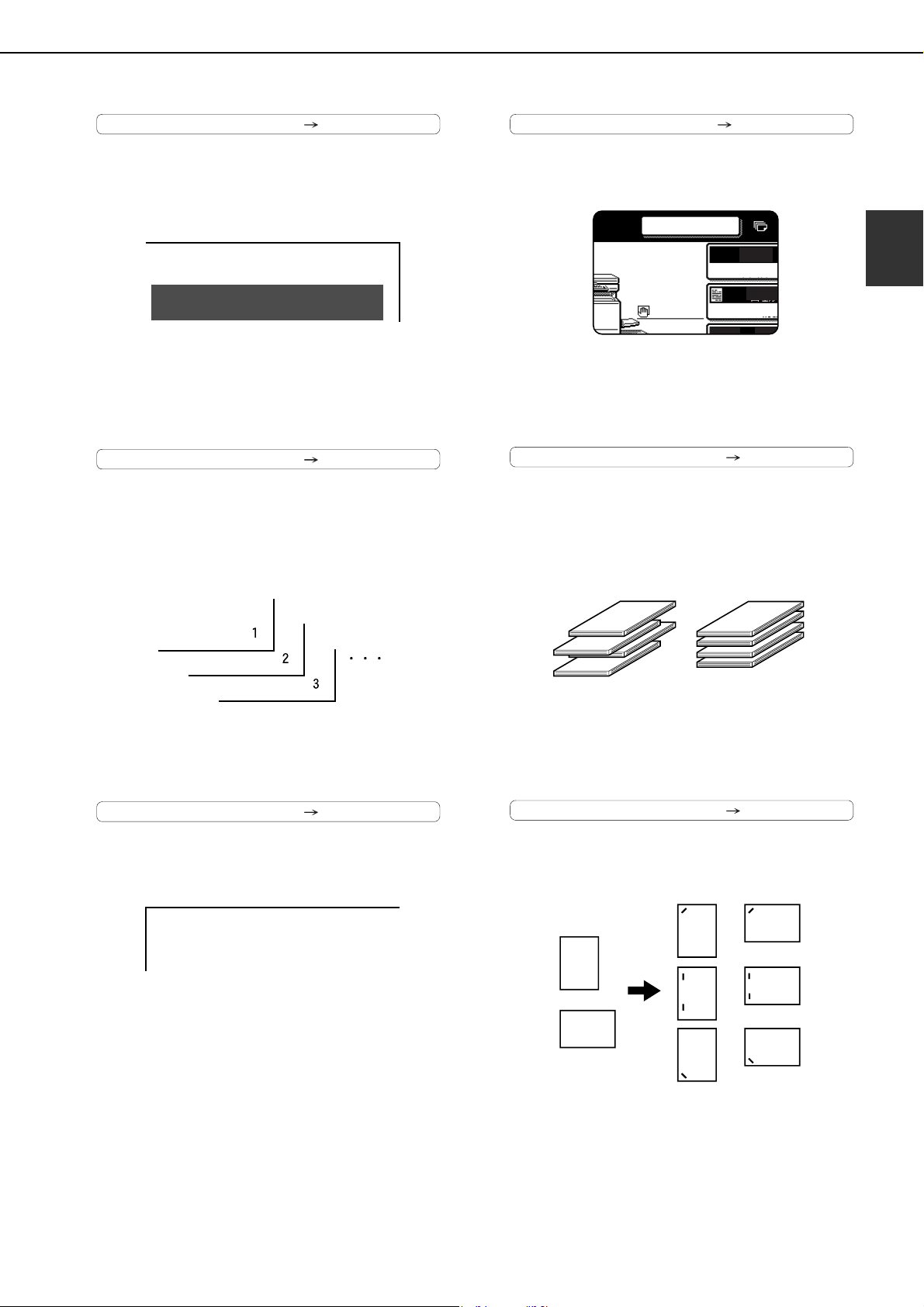

MAIN FEATURES

JOB PROGRAMS

PRESS PROGRAM NUMBER.

RECALL

Tab Copy See page 5-27

Copying is possible on the tabs of tabbed paper.

Original Tab paper Copy

INDEX

Tab width

8-1/2" x 11" : Maximum of 5/8" (17mm)

A4 : Maximum of 51/64" (20mm)

INDEX

Card Shot See page 5-29

The front and back of a card can be copied onto

one sheet of paper.

This function is convenient for making copies for

certification purposes and helps save paper.

Original

Copy

Mirror Image See page 5-31

A mirror image copy can be made.

Original Copy

B/W Reverse See page 5-31

White and black can be inverted on a copy to

produce a negative image.

Original Copy

CARD

Front of

card

Back of

card

CARD

Example:

Portrait

8-1/2" (A4) size

CARD

Example:

Landscape

8-1/2" (A4) size

Job programs See page 5-44

Various steps of a copy operation can be stored

as a program, and up to 10 programs can be

stored. Saving frequently used sets of settings in a

program saves you the trouble of selecting those

settings each time you wish to use them.

Date See page 5-35

The date can be added to copies.

2010/APR/4

1-6

Page 19

MAIN FEATURES

AUTO

AUTO

ORIGINAL

EXPOSUR

INTERRUPT

Stamp See page 5-36

Reverse text can be added to copies ("stamp").

CONFIDENTIAL

Page numbering See page 5-37

Page numbers can be added to copies.

Interrupting a copy run See page 5-46

A copy job in progress can be interrupted for a

rush job.

1

/

8 x11

2

Offset mode See page 3-4

Each set of output can be offset slightly from other

sets for easy separation.

1

Text See page 5-41

Entered text can be added to copies.

Meeting

Offset mode Non-Offset mode

*When the Finisher or Saddle stitch finisher is

installed.

Staple sort mode See page 3-4

Sets of copies can be automatically stapled.

Original

Copy

*When the Finisher or Saddle stitch finisher is

installed.

1-7

Page 20

MAIN FEATURES

Saddle stitch See page 3-5

When a saddle stitch finisher is installed, copies

can be automatically folded in half and stapled at

the fold. (Use with the pamphlet function (see

page 5-6) or book copy function (see page 5-26).)

Saddle stitch binding

67

*When the Saddle stitch finisher is installed.

Hole punching See page 3-5

Copies can be punched to add holes.

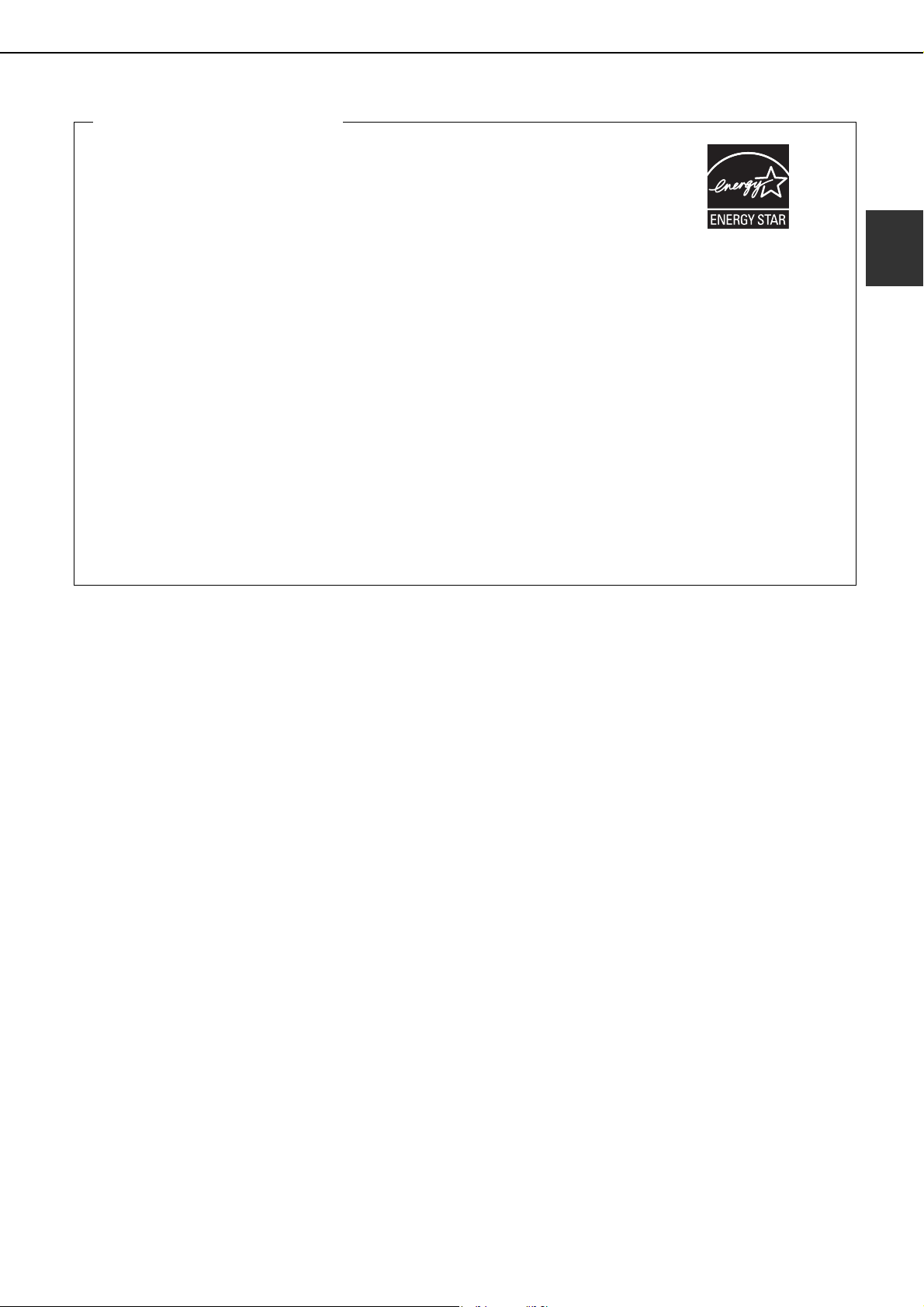

Document filing function See chap. 7

A document image can be stored on the hard disk.

A stored file can easily be called up and printed or

transmitted.

Printed

Document

Image

Save to

machine's

hard disk

HDD

Call up a

saved file to

reuse

Transmitted

Original Punch positions

*When the Punch module is installed.

Inserter mode See page 3-14

Blank or already printed-on sheets of paper can

be added as a cover or an insert without being

printed on. The inserter can be used to feed heavy

sheets of paper that cannot be fed from other

trays.

Original

Copy

1-8

*When the Inserter is installed.

Page 21

MAIN FEATURES

Energy saving features

This product has the following two power reducing modes that conform to the

Energy Star guidelines to help conserve natural resources and reduce

environmental pollution.

Preheat mode

The preheat mode is the first level of power reduction. The power is reduced

to the fuser unit a preset time after the machine has completed a job and no

further machine operations have been performed. The machine can recover

to the ready condition within a short period of time. The preset time to enter

the mode can be set by a administrator settings.

Auto power shut-off mode

The auto power shut-off mode is the second level of power reduction. In this mode power is shut off to the

fusing unit and the touch panel. In this state more energy is saved than in the preheat mode but the time to

recover to the ready condition will be longer. The preset time to enter this mode can be set by a administrator

settings.

When this product is used as a printer, and either of the above modes is active, the mode will be deactivated

automatically by an incoming job and the machine will automatically warm up and start to print when it has

reached the ready temperature.

When this product is configured for multi-function operation, and either of the above modes is active, the mode

will be deactivated as above by an incoming print job. Either mode will also be deactivated by operation of

DOCUMENT FILING, IMAGE SEND or COPY mode key.

Products that have earned

the ENERGY STAR

designed to protect the

environment through

superior energy efficiency.

®

are

1

1-9

Page 22

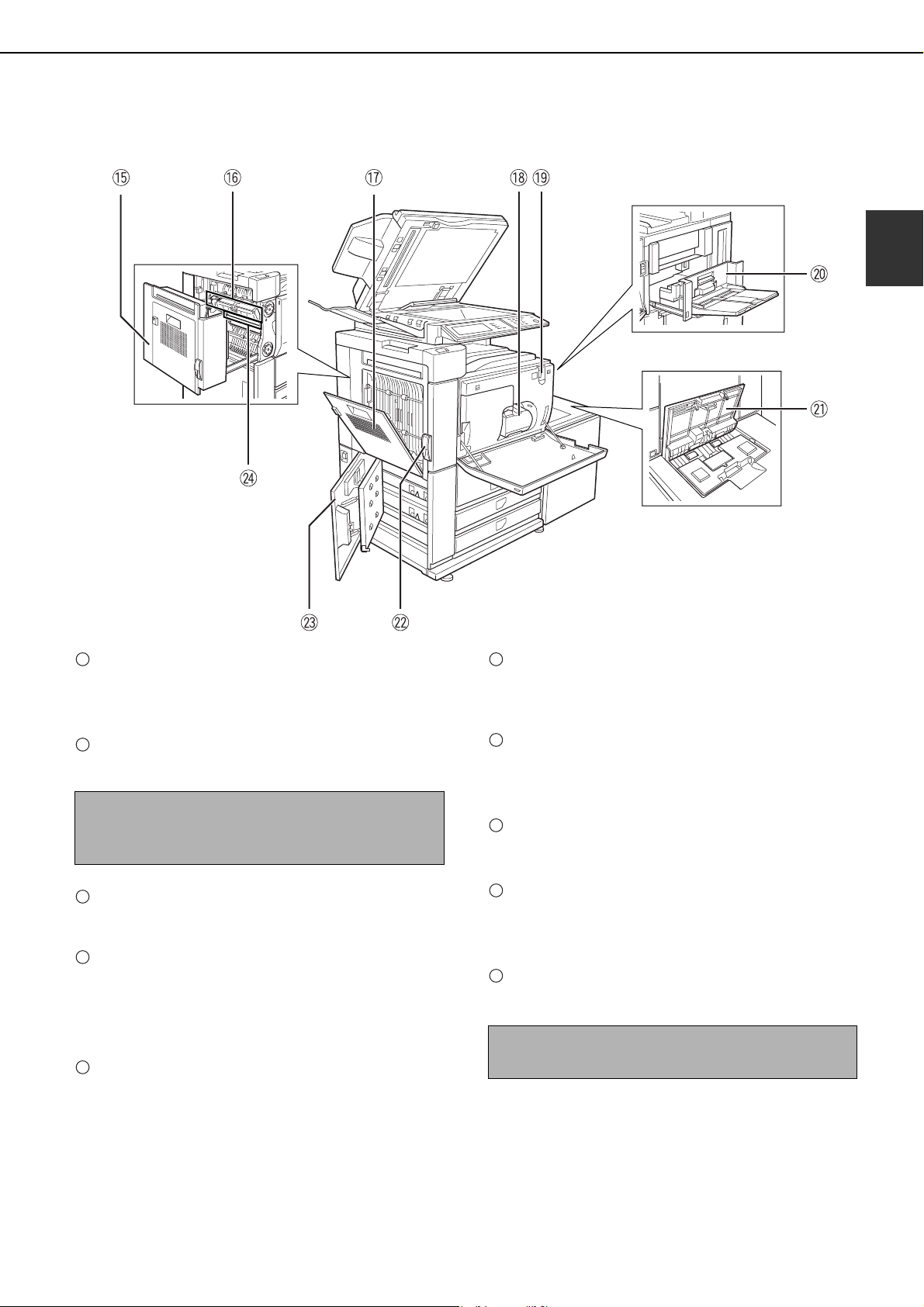

PART NAMES AND FUNCTIONS

Exterior

(AR-F15)

1

Saddle stitch finisher (AR-F16)*1 /

Finisher (AR-F15)

2

Punch module (AR-PN4B)

3

Inserter (AR-CF2)

4

Automatic document feeder (See page 4-2)

*1

(See page 3-2)

*1

(See page 3-2)

*1

(See page 3-14)

This automatically feeds and scans multiple sheet

originals. Both sides of two-sided originals can be

scanned at once.

5

Front cover

Open to replace toner cartridge.

6

Operation panel

7

Center tray (See page 4-9)

Finished sheets are deposited here

8

Bypass tray

Special papers (including transparency film) and

copy paper can be fed from the bypass tray.

9

Power switch (See page 1-17)

Turns the power on and off.

If the power does not come on when the power

switch is turned on, check the main power switch to

see if it is turned on.

10

Tray 5 (Large capacity tray (AR-LC6))

*1

(See page 2-7)

11

Tray 5 (Large capacity tray (AR-LC7))

*1

(See page 2-8)

12

Tray 1-Tray 2

The trays hold paper. Approximately 800 sheets of

standard 8-1/2" x 11" or A4 size paper (20 lbs. (80

2

g/m

)) can be loaded in tray 1, and approximately

1200 sheets of standard 8-1/2" x 11" or A4 size

paper (20 lbs. (80 g/m

13

Tray 3

2

)) can be loaded in tray 2.

Tray 3 holds paper. Approximately 500 sheets of

standard (20 lbs. (80 g/m

2

)) paper can be loaded

in this tray. Tabbed paper and transparencies can

also be loaded.

14

Tray 4

Tray 4 holds paper. Approximately 500 sheets of

standard (20 lbs. (80 g/m

2

)) paper can be loaded

in this tray.

1

*1 , , , and are peripheral devices. For information on these devices, see the explanations of the

2 3

10 11

devices in the manual.

1-10

Page 23

Interior

PART NAMES AND FUNCTIONS

1

15

Duplex unit

Open this cover to remove a misfeed from the

fusing unit area.

16

Fusing unit

Toner images are fused here.

CAUTION

The fusing unit is hot. Take care in removing misfed

paper.

17

Cover of the duplex unit

Open when a misfeed has occurred in duplex unit.

18

Toner cartridge

This holds toner for printing. The toner cartridge

must be replaced when indicated on the operation

panel.

19

Main power switch (See page 1-17)

Keep this switch turned on when the fax option or

Internet fax option is installed.

*2

20

Right side cover

Open when a misfeed has occurred in the bypass

tray or large capacity tray.

21

Upper cover of large capacity tray

Open when a misfeed has occurred in the large

capacity tray.

22

Left side cover release

Push this knob up to open the left side cover.

23

Left cover of paper drawer

Open this cover to remove paper misfed in tray 3 or

tray 4.

24

Photoconductive drum

Images are formed on the photoconductive drum.

NOTE

Do not touch or damage the photoconductive drum.

*2 See page 2-21 for the procedure for installing and replacing the toner cartridge.

1-11

Page 24

PART NAMES AND FUNCTIONS

■ Other optional equipment

●Network expansion kit (MX-NBX1)

This kit is required to add on the network function.

When this expansion kit is installed, the machine

can be used as a network printer.

●Barcode font kit (AR-PF1)

This kit adds bar code fonts to the machine.

● Data security kit (MX-FRX5)

This kit is used to erase electronic data from the

hard disk and memory immediately after a

document is printed or transmitted.

●PS3 expansion kit (MX-PKX1)

This kit provides compatibility of PostScript level 3

to the printer.

●Facsimile expansion kit (AR-FX8)

This kit is required to add fax function.

●Additional fax memory (8 MB) (AR-MM9)

●256MB expansion mamory board (AR-SM5)

This extends the memory of the machine.

●Network scanner expansion kit (MX-NSX1)

This kit is required to add the network scanning

feature.

To add the network scanner function to the

MX-M550U, MX-M620U, or MX-M700U, the

network expansion kit is required.

●Internet fax expansion kit (MX-FWX1)

This kit is required to use the Internet fax function.

To add the Internet fax function, the network

scanner expansion kit is required.

●Application integration module (MX-AMX1)

The application integration module can be

combined with the network scanner function to

append a metadata file to a scanned image file.

●

Application communication module (MX-AMX2)

This allows the machine to be linked over a network

to an external software application.

External account module (MX-AMX3)

●

This is required to use an external account

application on the machine.

Peripheral devices are basically optional, but are incorporated in some models as standard equipment.

1-12

Page 25

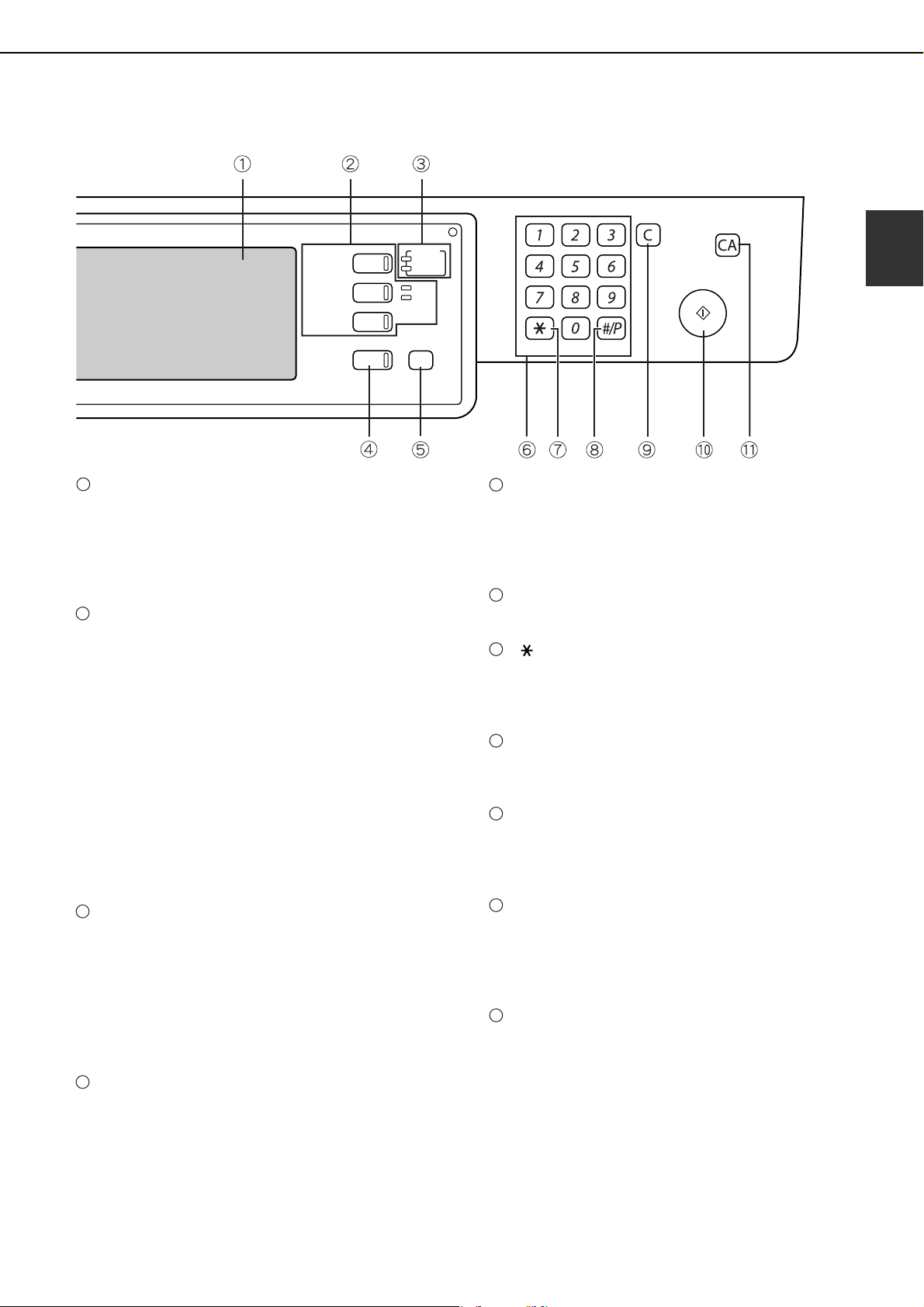

Operation panel

DOCUMENT

FILING

IMAGE SEND

COPY

JOB STATUS

PRINT

READY

DATA

LINE

DATA

SYSTEM

SETTINGS

PART NAMES AND FUNCTIONS

1

LOGOUT

1

Touch panel

The machine status, messages and touch keys are

displayed on the panel. The document filing, copy,

network scanner*

1

, and fax*2, Internet fax*

functions are used by switching to the screen for

the desired function. See the following page.

2

Mode select keys and indicators

Use to change modes and the corresponding

display on the touch panel.

[DOCUMENT FILING] key

Press to select the document filing mode. (See

page 7-5.)

[IMAGE SEND] key/LINE indicator/DATA

indicator

Press to change the display to network scanner

1

mode*

, fax mode*2 or Internet fax mode*3. (See

the "Operation manual (for image send)") and

"Operation manual (for facsimile)".)

[COPY] key

Press to select the copy mode.

3

PRINT mode indicators

READY indicator

Print data can be received when this indicator is

lit.

DATA indicator

Lights up or blinks when print data is being

received. Also lights up or blinks when printing is

being performed.

4

[JOB STATUS] key

Press to display the current job status. (See page

1-15.)

5

[SYSTEM SETTINGS] key

This is used to store, edit, and delete user names

and folder names for the document filing function,

3

and to configure the administrator settings and

printer configuration settings. (See page 7-24)

6

Numeric keys

Use to enter numeric values for various settings.

7

[ ] key ([LOGOUT] key)

This key is used in copy mode, document filing

mode, network scanner mode*

Internet fax mode*

8

[#/P] key

3

.

1

, fax mode*2, and

This is used as a program key when using the copy

function, and to dial when using the fax function*

9

[C] key (Clear key)

2

.

This key is used in copy mode, document filing

mode, network scanner mode*

Internet fax mode*

10

[START] key

3

.

1

, fax mode*2, and

Use this key to start copying in copy mode, scan a

document in network scanner mode*

document for transmission in fax mode*

Internet fax mode*

11

[CA] key (Clear all key)

3

.

1

, or scan a

2

or

This key is used in copy mode, document filing

mode, network scanner mode*

Internet fax mode

*3. Use the key to cancel settings

1

, fax mode*2, and

and perform an operation from the initial machine

state.

*1 When the network scanner option is installed.

*2 When the fax option is installed.

*3 When the Internet fax option is installed.

1-13

Page 26

PART NAMES AND FUNCTIONS

JOB QUEUE

COPY

001

0666211221

003 / 000

003 / 000

010 / 000

SETS / PROG

1/13

COMPLETE

OCK ONTO

0

PRINT ON INSERT SHEETS

PAPER IS FED

FROM INSERTER

YES NO

CANCEL OK

OK

DUAL PAGE

COPY

TANDEM

COPY

8 x11

1

/

2

8 x14

11x17

1

/

2

8 x11

1

/

2

1.

3.

4.

2.

READY TO SCAN FOR COPY.

SPECIAL MODES

ORIGI

2-SIDED COPY

OUTPUT

QUICK FILE

FILE

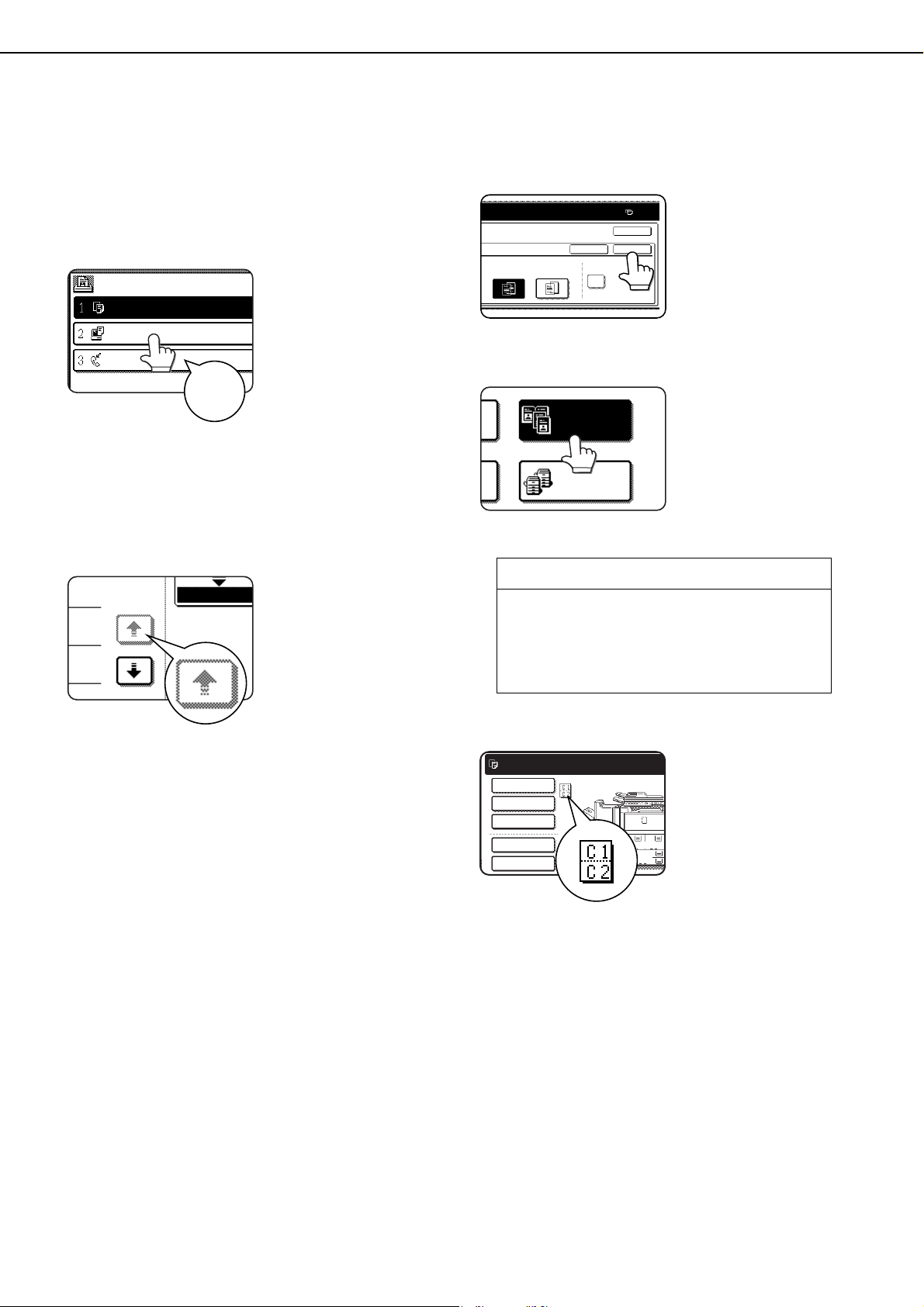

Touch panel

The touch panel screens shown in this manual are

printed images, and may appear different from the

actual screens.

■ Using the touch panel

[Example 1]

Items on the touch panel

are easily selectable by

touching the key

associated with the item

with a finger. Selection

Beep

tone

Also, the key area for the item will be highlighted

for visual confirmation.

* If a grayed out key is touched, a double beep will

sound.

[Example 2]

of an item will be

accompanied with a

beep tone* to confirm

the item was selected.

Keys which are grayed

out on any screen are

not selectable.

■ Selecting a function

[Example 1]

If a key is highlighted in a

setting screen at the

time the screen appears,

the [OK] key can be

pressed to store the

selection without further

operation.

[Example 2]

A function in the special

functions screen is

selected by touching the

key so that it is

highlighted. To cancel

the selection, touch the

highlighted key once

again.

Copier feature

● Dual page copy

● Job build

● Tandem copy

● Mirror image

● B/W Reverse

The confirmation beeps can be disabled using

"Keys touch sound" in the administrator settings.

(See page 10 of the administrator settings guide.)

[Example 3]

A corresponding icon

representing the feature

will appear on the touch

key and on the main

screen of the mode

selected. If this icon is

touched, the setting

screen of the function (or

a menu screen) will

appear, allowing the settings to be checked or

adjusted and the function to be canceled easily.

1-14

Page 27

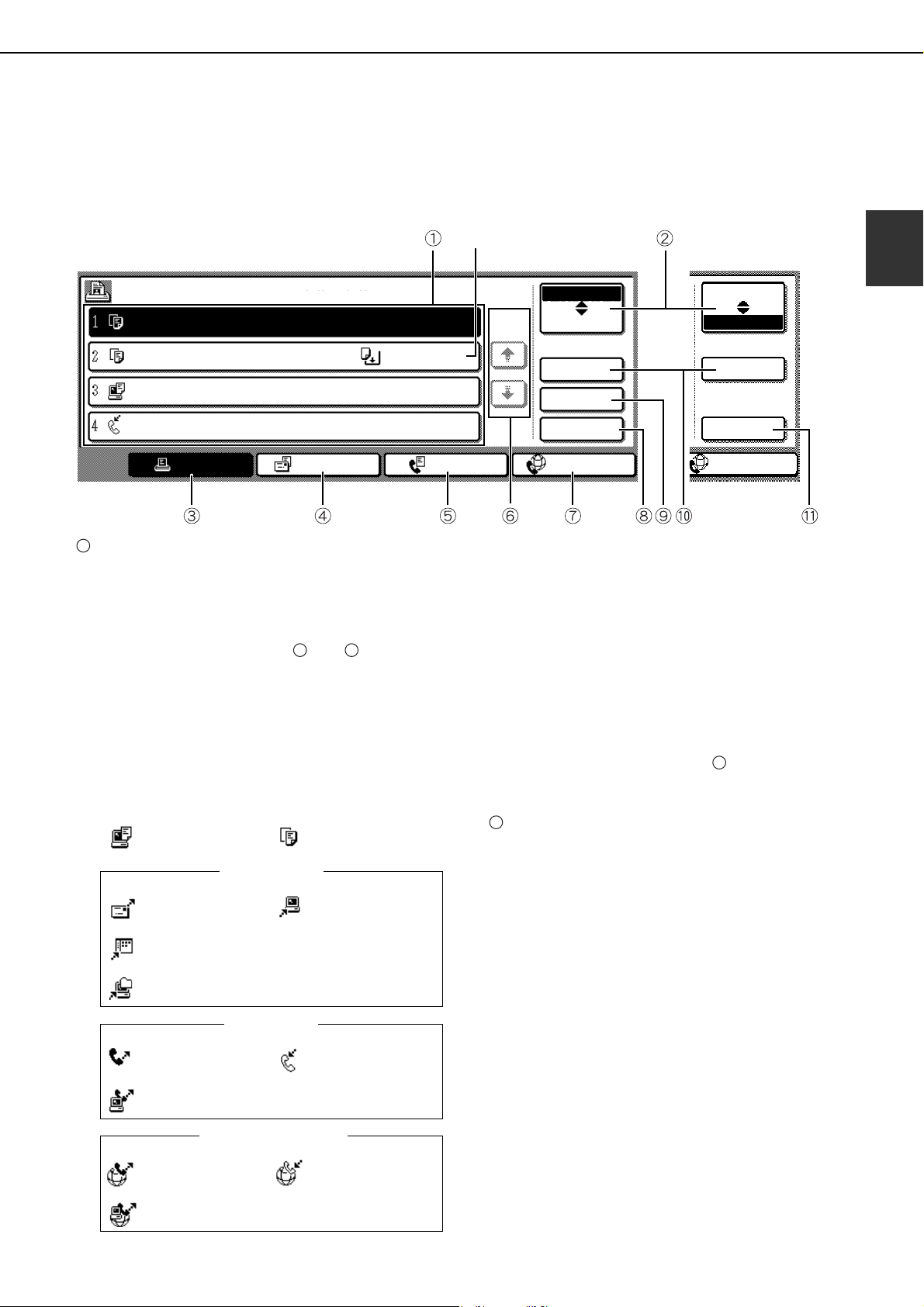

PART NAMES AND FUNCTIONS

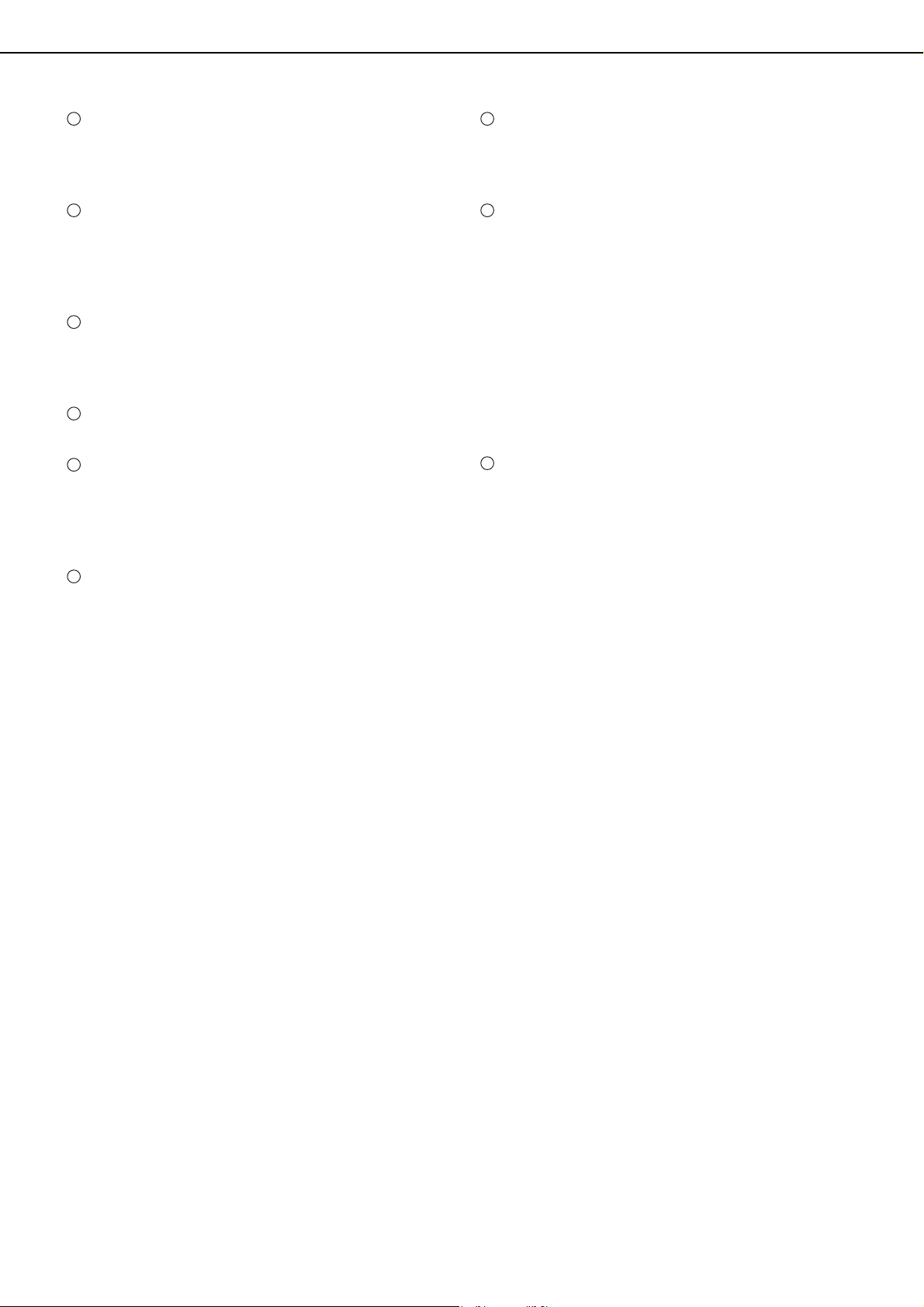

■ Job status screen (common to print, scan, fax and Internet fax)

This screen is displayed when the [JOB STATUS] key on the operation panel is pressed.

This screen can be used to display the "JOB QUEUE" (showing stored jobs and the current job) or the

"COMPLETE" job list (showing finished jobs). This screen is used to check jobs, move a job to the top of the JOB

QUEUE, or delete a job.

"JOB QUEUE" screen

1

Job list

JOB QUEUE

COPY

COPY

Suzuki

066211221

PRINT JOB

SETS / PROGRESS

020 / 001

020 / 000

020 / 000

002 / 000

SCAN TO

STATUS

COPYING

PAPER EMPTY

WAITING

WAITING

The displayed jobs in the job list are themselves

operation keys. To cancel printing or to give a job

the highest print priority, touch the relevant job key

to select the job and execute the desired operation

using the keys described in and .

8 9

This shows the current job and the jobs waiting to

be run. The icons to the left of the jobs in the

queue show the job mode. The document filing

reprint job icon is highlighted.

Note that the icon does not become highlighted

during retransmission of a fax/image transmission

job.

*1

FAX JOB

"COMPLETE"

job screen

JOB QUEUE

COMPLETE

DETAIL

CALL

INTERNET-FAX

1/1

JOB QUEUE

COMPLETE

DETAIL

PRIORITY

STOP/DELETE

INTERNET-FAX

*1 "PAPER EMPTY" in the job status display

When a job status display indicates "PAPER

EMPTY", the specified paper size for the job is not

loaded in any of the trays.

In this case, the job will be suspended until the

required paper is loaded. Other stored jobs will be

printed (if possible) until the required paper is loaded.

(Other jobs will not be printed if the paper runs out

during printing.) If you need to change the paper size

because the specified paper size is not available,

touch the current job key to select it and then touch

the [DETAIL] key described in .

10

1

Print mode Copy mode

SCAN mode

Scan to e-mail job

Scan to FTP job

Scan to Desktop job

Scan to Network folder job

Fax mode

Fax send job Fax reception job

PC-Fax send job

Internet Fax mode

i-Fax send job

i-Fax reception job

PC-Internet Fax send job

2

Mode select key

This switches the job list display between "JOB

QUEUE" and "COMPLETE".

"JOB QUEUE": Shows stored jobs and the job in

progress.

"COMPLETE": Shows finished jobs.

Files saved using the "FILE" and "QUICK FILE"

functions and finished broadcast transmission

jobs appear as keys in the finished job screen.

The "FILE" or "QUICK FILE" job keys in the

finished job screen can be touched, followed by

the [CALL] key, to call up a finished job and print

or transmit it. A finished broadcast transmission

job key can be touched followed by the [DETAIL]

key to check the result of the transmission.

1-15

Page 28

PART NAMES AND FUNCTIONS

3

[PRINT JOB] key

This displays the print job list of print mode

(copying, printing, fax reception, Internet fax

reception, and self printing).

4

[SCAN TO] key

This displays the transmission status and finished

jobs of scan mode (Scan to e-mail, Scan to FTP,

Scan to Desktop, and Scan to Network Folder)

when the network scanner option is installed.

5

[FAX JOB] key

This displays the transmission/reception status

and finished jobs of fax mode (fax and PC-Fax)

when the fax option is installed.

6

Display switching keys

Use to switch the page of the displayed job list.

7

[INTERNET-FAX] key

This displays the transmission/reception status

and finished jobs of Internet fax mode and PC

Internet fax mode when the Internet fax option is

installed.

8

[STOP/DELETE] key

Use to cancel or delete the current job or delete

the selected reserved job. Note that printing of

received faxes and received Internet faxes cannot

be canceled or deleted.

9

[PRIORITY] key

A stored job in the "JOB QUEUE" job list can be

printed ahead of all other stored jobs by selecting

the job and then touching this key.

10

[DETAIL] key

This shows detailed information on the selected

job.

Files saved using the "FILE" and "QUICK

FILE" functions and finished broadcast

transmission jobs

appear as keys in the finished

job screen. A Quick File in the finished job screen

or the [Filing] key can be touched, followed by the

[CALL] key, to call up a finished job and print or

transmit it. A finished broadcast transmission job

key can be touched followed by the [DETAIL] key to

check the result of the transmission.

11

[CALL] key

When this key is touched after selecting a job in

the COMPLETE job status screen (a job stored

using the FILE or QUICK FILE keys of the

document filing function), the "JOB SETTINGS"

menu screen appears to let you resend or reprint

the finished job. (See "Document filing function"

on page 7-2.)

1-16

Page 29

TURNING THE POWER ON AND OFF

The machine has two power switches. The main power switch can be found at the upper right after the front cover

is opened. The power switch is located at the upper left of the right side of the machine.

The two switches are normally used as follows:

CAUTION

"ON" position

"OFF" position

Before turning off the main power switch, make sure

that the communication and data lights are not

blinking on the operation panel. Turning off the main

power switch or unplugging the power cord while the

lights are blinking may damage the hard disk and

cause the data being stored or received to be lost.

1

Main power switch

Main power switch: Normally kept in the ON position.

(Be sure to keep ON when using the

fax function.)

Power switch : Turn to ON position before using

the machine.

Turn OFF at night when the

machine is not used.

Main power switch ON, Power switch ON

The copy, printer, fax*, Internet fax*, network

scanner*, and document filing functions can be

used. If the machine is not used for a certain interval

after turning on the power switch, the machine will

automatically enter a reduced power consumption

state (preheat mode or auto power shut-off mode

(see page 1-9)).

* The required options must be installed to use

these functions.

Main power switch OFF, Power switch ON

Power switch

Main power switch ON, Power switch OFF

Set the switches in this way at night or at other times

when the machine is not being used. The touch

panel cannot be used, however, the following

functions will remain operational:

When the fax option is installed:

Automatic fax reception, timer transmission

(automatic transmission at a specified time), and

transmission when a polling request is received from

another machine (remote transmission, relay

broadcast transmission)

When the Internet fax option is installed:

Automatic Internet fax reception

Main power switch OFF, Power switch OFF

The copy, printer, fax, Internet fax, network scanner,

and document filing functions cannot be used.

The copy, printer, fax, Internet fax, network scanner,

and document filing functions cannot be used.

Turn both switches off and unplug the power cord if

you suspect a machine failure, if there is a bad

thunderstorm nearby, or when you are moving the

machine.

1-17

Page 30

AUDITING MODE

LOGOUT

LOGOUT

Auditing mode can be enabled to keep track of the number of pages printed and transmitted (scanned) by each

account (up to 500 accounts can be established). The page counts can be viewed and totaled as needed.

<This mode is enabled in the administrator settings separately for the copy, printer, fax, Internet fax, network scanner,

and document filing functions (page 7 of the administrator settings guide)>

Using the machine when the auditing mode is enabled

The procedure for making copies when auditing mode has been enabled for the copy function is explained below.

NOTES

●

When auditing mode is enabled for document filing and fax/image transmission, a message will appear asking you

to enter your account number each time you switch to the main screen of one of those functions in the touch panel.

Enter your account number in the same way as for copy mode, and then begin the scanning procedure.

● When the account counter is turned on for the printer function, you must enter your account number in the

setting screen of the printer driver on your computer in order to print.

When the account counter is turned on, the right

message appears on the touch panel.

When the above screen appears, enter your 5-digit account number and then begin the copying procedure.

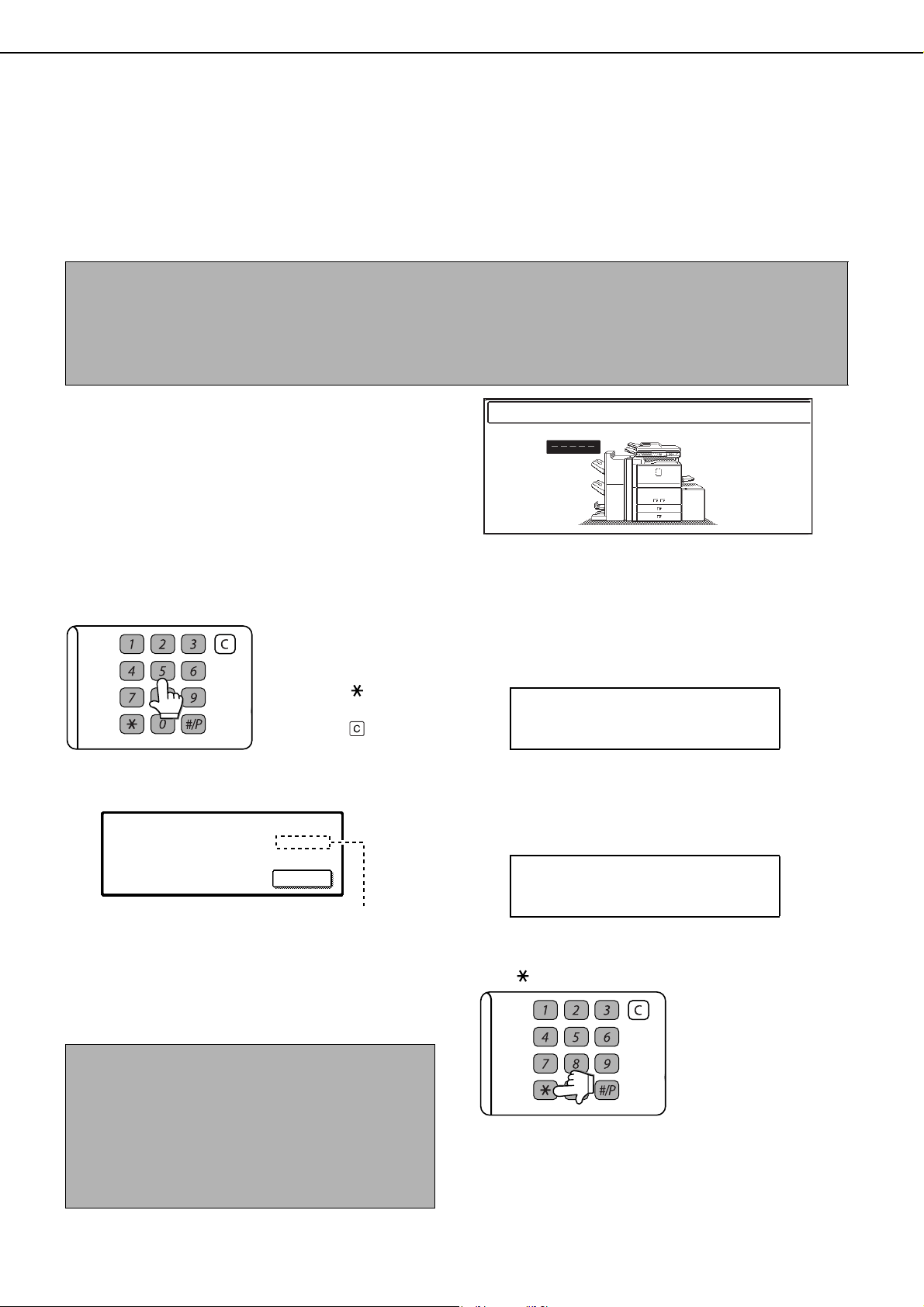

Enter your account number (5 digits) with

1

the numeric keys.

As you enter your

account number, the

hyphens (-) change to

asterisks ( ). If you

enter an incorrect digit,

press the key and

re-enter the correct digit.

When a correct account number is entered, the

following message will appear.

ACCOUNT STATUS :MADE /REMAINING

COPIES :00,123,000/00,012,456

ENTER YOUR ACCOUNT NUMBER.

Follow the appropriate steps to perform

2

the copy job.

When copying is begun, the following message

will appear.

READY TO SCAN FOR COPY.

PRESS [LOGOUT] WHEN FINISHED.

To perform an interrupt copy job (page 5-46),

touch the [INTERRUPT] key and then enter your

account number as explained in step 1. The

following message will appear.

OK

If a limit has been set in the administrator settings

for the number of copies that can be made by the

account, the remaining number that can be made

is displayed.

Check the number in the display and touch the

[OK] key.

NOTE

If "ACCOUNT NUMBER SECURITY" is enabled in the

administrator settings and an incorrect account

number is entered three times in a row, "PLEASE SEE

YOUR ADMINISTRATOR FOR ASSISTANCE." will

appear (page 8 of the administrator settings guide).

Operation is not possible while this message

appears (about one minute).

1-18

COPY INTERRUPT MODE.

READY TO SCAN FOR COPY.

When the copy job is finished, press the

3

[ ] key ([LOGOUT] key)

Page 31

CHAPTER 2

MANAGING THE MACHINE

This chapter explains how to load paper, replace the toner cartridge, and

remove paper misfeeds. It also contains information about supplies.

Page

LOADING PAPER ................................................................................... 2-2

●

Identifying the trays......................................................................... 2-2

●

Loading paper in paper tray 1 - tray 2 ............................................. 2-2

●

Changing the paper size in paper tray 1 - tray 2 ............................. 2-3

●

Loading paper in paper tray 3 ......................................................... 2-5

●

Changing the paper size in paper tray 3 ......................................... 2-5

●

Changing the paper size in paper tray 4 ......................................... 2-6

●

Loading paper in paper tray 5 (optional large capacity tray AR-LC6)

●

Loading paper in paper tray 5 (optional large capacity tray AR-LC7)

●

Loading paper in the bypass tray.................................................... 2-10

●

Specifications of paper trays (Types and sizes of paper that can be

used in the trays)............................................................................. 2-12

●

Setting the paper type and paper size ............................................ 2-14

●

Setting the paper size when a special size is loaded...................... 2-17

SYSTEM SETTINGS .............................................................................. 2-18

●

General procedure for system settings ........................................... 2-18

●

About the settings ........................................................................... 2-20

REPLACING THE TONER CARTRIDGES ............................................. 2-21

STORAGE OF SUPPLIES ...................................................................... 2-22

MISFEED REMOVAL.............................................................................. 2-23

●

Misfeed removal guidance .............................................................. 2-23

●

Misfeed in the transport area, fusing area, and exit area................ 2-24

●

Misfeed in the duplex unit................................................................ 2-25

●

Misfeed in the paper feed area........................................................ 2-26

REMOVING AN ORIGINAL MISFEED ................................................... 2-31

●

Removing a misfed original from the automatic document feeder .. 2-31

TROUBLESHOOTING ............................................................................ 2-32

... 2-7

... 2-8

2-1

Page 32

LOADING PAPER

If the paper runs out during printing, a message will appear in the display.

Follow the procedure below to load paper.

Identifying the trays

The trays are identified using numbers as shown below.

For the types and sizes of paper that can be used in each tray, see page 2-12.

1

Tray 1

This is the left large capacity tray.

2

Tray 3

3

Tray 4

4

Tray 2

This is the right large capacity tray.

5

Tray 5

This is an optional large capacity tray.

6

Bypass tray

NOTES

● Do not use curled or folded paper. Doing so may cause a misfeed.

● Do not place heavy objects or press hard on any tray which is pulled out.

● Do not place objects on the large-capacity tray. This may damage the tray or interfere with operation.

● Load paper with the print side face up. However, when the paper type is set to "PRE-PRINTED" or "LETTER

HEAD", load the paper face down*.

* If the two-sided function is disabled using "DISABLING OF DUPLEX" in the administrator settings (page 11

of the administrator settings guide), load the paper face up.

Loading paper in paper tray 1 - tray 2

8-1/2" x 11" or A4 size paper can be loaded in tray 1 and tray 2. These are parallel large-capacity trays that allow a

total of approximately 2000 sheets of SHARP standard paper (20lbs. (80g/m

the paper size of tray 1 or tray 2, see "Changing the paper size in paper tray 1 - tray 2" on the next page.

Pull out paper tray 1-tray 2.

1

Gently pull the tray out

until it stops.

Load paper in the left and right trays.

2

2

)) to be loaded. If you wish to change

Indicator line

Indicator line

Lift the paper guide and

load paper in tray 1.*

Approximately 800 sheets

of SHARP standard paper

(20lbs.(80g/m2))

loaded.

Be sure to return the

paper guide to its

original position after

loading the paper.

Load paper in tray 2.*

Approximately 1200

sheets of SHARP

standard paper

(80g/m

2

))

can be loaded.

1

can be

1

(20lbs.

2-2

*1 The paper stack must not be higher than the indicator line.

Page 33

LOADING PAPER

Gently push tray 1-tray 2 into the machine.

3

Push the tray firmly all

the way into the

machine.

Set the paper type.

4

If the paper size was changed from an inch size to an

AB size, or from an AB size to an inch size, or if the

paper type was changed, be sure to change the

appropriate settings as explained in "Setting the

paper type and paper size" (See page 2-14).

Loading paper in paper tray 1/tray 2 is now

5

complete.

Changing the paper size in paper tray 1 - tray 2

To change the paper size of tray 1 - tray 2, follow the steps below.

This section only explains how to change the paper size. For the procedures for opening/closing the tray and loading

paper, see "Loading paper in paper tray 1 - tray 2" (page 2-2).

Remove the paper size guide.

1

Tray 1 Tray 2

Adjust the paper size guide to the paper

2

size to be used.

(A)

LT

A4

(B)

A4

LT

2

Hook

With the base of the tray pressed all the way down,

hold down the hook at the bottom on the paper

size guide and pull the paper size guide up slightly.

NOTES

● Do not place heavy objects on the tray or press

down on the tray.

● Before changing the paper size of tray 1, raise the

paper guide.

Paper guide

Paper sizes are inscribed at the slot (A) on the

bottom of the tray and at the hole (B) at the top of

the paper size guide. ("LT" indicates 8-1/2" x 11"

size.)

Align the bottom of the paper size guide with the

slot, and align the hole at the top with the locking

tab.

NOTES

● When attaching the paper size guide, make sure

that the top and bottom of the guide are aligned to

the same paper size.

● If the top and bottom of the paper size guide are not

aligned to the same paper size, skewed feeding

and misfeeds will result.

2-3

Page 34

LOADING PAPER

Push in the paper guide so that it locks

3

into place.

Push the paper size guide in until the hook at the

bottom locks into place. (You will hear a "click"

when the hook locks.) Move the paper size guide

slightly to verify that it has locked into place.

Repeat steps 1 to 3 to adjust the far paper

4

guide to the paper size to be used.

Set the paper type and paper size.

5

For the procedure for configuring these settings,

see "Setting the paper type and paper size" (page

2-14).

An incorrect paper type or paper size setting may

cause automatic selection of the wrong type or

size of paper, and result in a misfeed or otherwise

prevent printing.

Be sure to adjust the far paper guide to the same

size as the near paper guide.

NOTES

● When removing and attaching the far paper size

guide, take care not to hit the front cover of the

machine.

● Adjust both the front and back guides. If only one

guide is adjusted, skewed feeding and misfeeds

may result.

2-4

Page 35

LOADING PAPER

Loading paper in paper tray 3

Approximately 500 sheets of standard paper (20lbs. (80g/m2)) from 11" x 17" to 5-1/2" x 8-1/2"R size (A3 to A5R) can

be loaded in tray 3. Special papers such as tabbed paper and transparency film can also be loaded. For information

on what special papers can be used, see "Specifications of paper trays (Types and sizes of paper that can be used

in the trays)" on page 2-12. To load tabbed paper or transparency film, see "Loading tabbed paper" or "Loading

transparency film" on the next page.

Pull out paper tray 3.

1

Gently pull the tray out

until it stops.

Load paper into the tray.

2

The paper stack must not

be higher than the

indicator line (no more

than 500 sheets of

SHARP standard paper

(20lbs. (80g/m2)

To change the paper

size, see "Changing the paper size in paper tray 3"

below.

).

Gently push tray 3 into the machine.

3

Set the paper type.

4

If the paper size was changed from an inch size to

an AB size, or from an AB size to an inch size, or if

the paper type was changed, be sure to change the

appropriate settings as explained in "Setting the

paper type and paper size" (see page 2-14).

Loading paper in paper tray 3 is now

5

complete.

Changing the paper size in paper tray 3

Pull out paper tray 3.

1

If paper remains in the tray, remove it.

Gently push tray 3 into the machine.

4

Push the tray firmly all the way into the machine.

Push the tray firmly all

the way into the

machine.

2

Adjust the guide plates A and B by

2

squeezing their lock levers and sliding

them to the paper size to be loaded.

The guide plates A and

B are slidable. Adjust

them to the paper size to

be loaded while

squeezing their lock

levers.

Load paper into the tray.

3

Set the paper type of the paper that was

5

loaded in tray 3.

Be sure to change the appropriate settings as

explained in "Setting the paper type and paper size"

(see page 2-14).

If you changed the paper size, be sure to change

the paper size setting. An incorrect paper size

setting will cause the wrong paper to be

automatically selected and may prevent printing or

cause misfeeds.

Changing the paper size in paper tray 3 is

6

now complete.

2-5

Page 36

LOADING PAPER

■ Loading tabbed paper

When using tabbed paper, follow the steps below to attach the special guide to the divider plate at the bottom

edge of the tabbed paper. (Tabbed paper cannot be used in tray 4.)

Take out the tabbed paper guide.

1

The guide is stored

inside the left side of the

machine as shown.

Be sure to replace the

guide when you have

finished using it.

Pull out the tray and attach the guide.

2

Slide the divider plate to

the position of the

bottom edge of the

tabbed paper and attach

the guide so that it

covers the divider plate.

Place the tabbed paper in the tray.

3

Place the tabbed paper

with the print side face

up.

[Example]

Make sure that the positions of the tabs correspond