Page 1

SERVICE MANUAL

Dolby noise reduction manufactured under license from Dolby

Laboratories Licensing Corporation.

"DOLBY" and the double-D symbol

Laboratories Licensing Corporation.

are trademarks of Dolby

MD-X60H

No.S6849MDX60H//

MD-X60H

• In the interests of user-safety the set should be restored to its original

condition and only parts identical to those specified should be used.

CONTENTS

Page

SAFETY PRECATION FOR SURVICE MANUAL.............................................................................................................. 2

INPORTANT SERVICE NOTES (FOR U.K. ONLY) ...........................................................................................................3

WIRING OF PRIMARILY SUPPLY LEADS (FOR U.K. ONLY)..........................................................................................3

SPECIFICATIONS ............................................................................................................................................................. 4

NAMES OF PARTS ........................................................................................................................................................... 5

OPERATION MANUAL .......................................................................................................................................................8

DISASSEMBLY................................................................................................................................................................ 10

REMOVING AND REINSTALLING THE MAIN PARTS................................................................................................... 14

ADJUSTMENT ................................................................................................................................................................. 17

EXPLANATION OF ERROR DISPLAY.............................................................................................................................27

EEPROM WRITING PROCEDURE ..................................................................................................................................29

RDS OPERATION ............................................................................................................................................................31

NOTES ON SCHEMATIC DIAGRAM .............................................................................................................................. 35

TYPE OF TRANSISTOR AND LED ................................................................................................................................. 35

WIRING DIAGRAM .......................................................................................................................................................... 36

BLOCK DIAGRAM ........................................................................................................................................................... 38

SCHEMATIC DIAGRAM / WIRING SIDE OF P.W.BOARD............................................................................................. 42

WAVEFORMS OF CD CIRCUIT...................................................................................................................................... 69

WAVEFORMS OF MD CIRCUIT ..................................................................................................................................... 70

TROUBLESHOOTING (CD SECTION) ........................................................................................................................... 72

TROUBLESHOOTING (MD SECTION) ........................................................................................................................... 76

FUNCTION TABLE OF IC................................................................................................................................................ 81

REPLACEMENT PARTS LIST/EXPLODED VIEW/PACKING OF THE SET

SHARP CORPORATION

– 1 –

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

MD-X60H

SAFTY ORECAUTION FOR SERVICE MANUAL

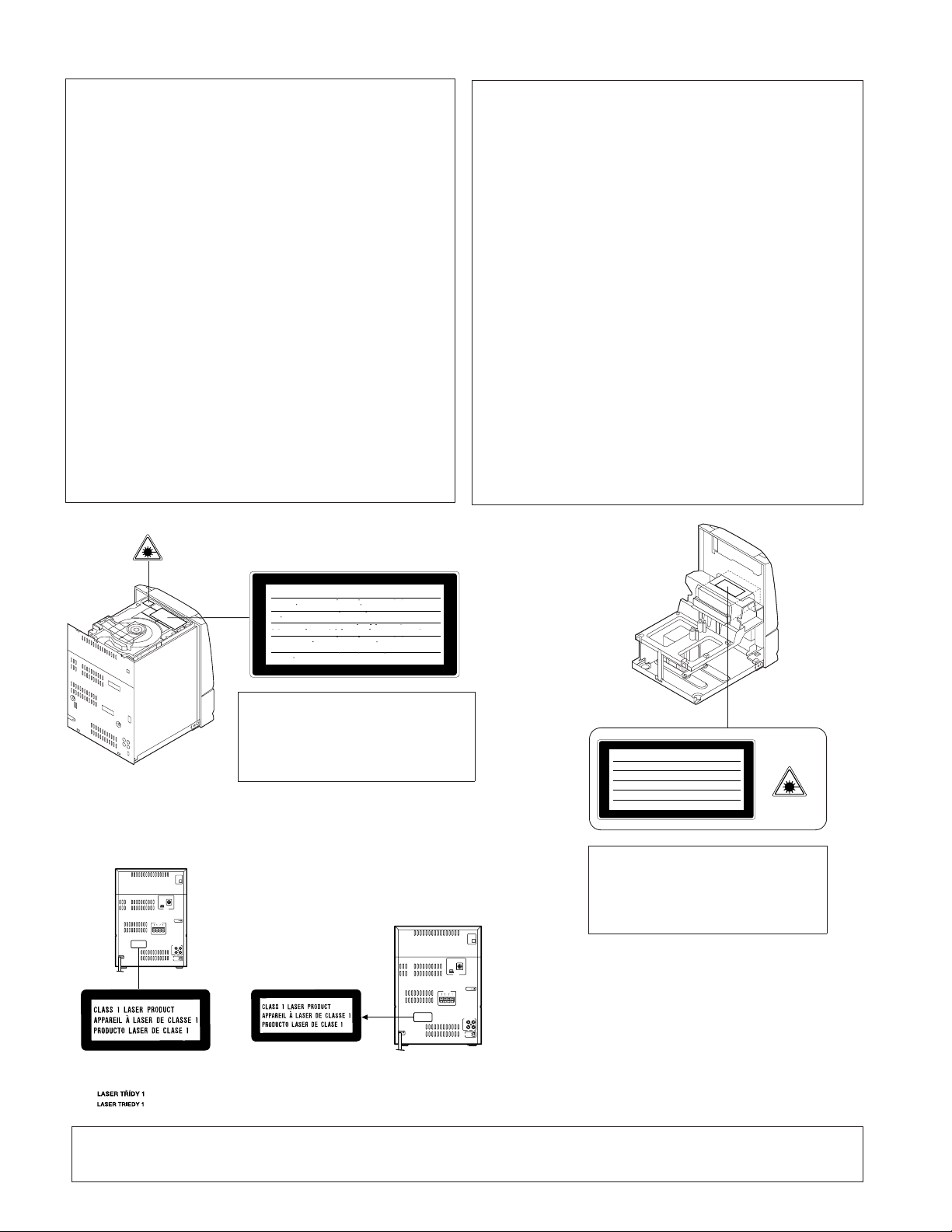

WARNINGS (CD)

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER

POWER OUTPUT IS LESS THAN CLASS 1 BUT THE LASER

COMPONENT IS CAPABLE OF EMITTING RADIATION

EXCEEDING THE LIMIT FOR CLASS 1. THEREFORE IT IS

IMPORTANT THAT THE FOLLOWING PRECAUTIONS ARE

OBSERVED DURING SERVICING TO PROTECT YOUR

EYES AGAINST EXPOSURE TO THE LASER BEAM.

1-WHEN THE CABINET IS REMOVED, THE POWER IS

TURNED ON WITDOUT A COMPACT DISC IN POSITION

AND THE PICK-UP IS ON THE OUTER EDGE THE LASER

WILL LIGHT FOR SEVERAL SECONDS TO DETECT A

DISC. DO NOT LOOK INTO THE PICK-UP LENS.

2-THE LASER POWER OUTPUT OF THE PICK-UP UNIT

AND REPLACEMENT SERVICE PARTS ARE ALL

FACTORY PRE-SET BEFORE SHIPMENT.

DO NOT ATTEMPT TO RE-ADJUST THE LASER PICKUP UNIT DURING REPLACEMENT OR SERVICING.

3-UNDER NO CIRCUMSTANCES STARE INTO THE PICK-

UP LENS AT ANY TIME.

4-CAUTION-USE OF CONTROLS OR ADJUSTMENTS, OR

PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN

HAZARDOUS RADIATION EXPOSURE.

WARNINGS (MD)

The AEL (ACCESSIBLE EMMISSION LEVEL) of the laser

power output is less than class 1 but the laser component is

capable

of emitting radiation exceeding the limit for class 1. Therefore

it is important that the following precautions are observer

during

servicing to protect your eyes against exposure to the laser

beam.

1) When the unit case cover is removed and LOADING SW

(SW 1956) is turned on and then PLAY SW (SW 1954

mechanism PWB) is turned on in a few second.

The laser will light for several second to detect a disk.

2) The laser power output of the pickup unit and replacement

service parts are all factory pre-set before shipment.

Do not attempt to re-adjust the laser pick-up unit during

replacement or servicing.

3) Under no circumstances stare into the pickup lens at any

time.

4) If laser optical unit becomes faulty, replace the complete

laser optical unit.

5) CAUTION-USE of controls or adjustments, or performance

of procedures other than those specified herein may result

in hazardous radiation exposure.

CAUTION-INVISIBLE LASER RADIATION WHEN OPEN. DO NOT STARE INTO

BEAM OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

VARNING-OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD. STIRRA

EJ IN I STRALEN OCH BETRAKTA EJ STRALEN MED OPTISKA INSTRUMENT.

ADVERSEL-USYNLIG LASERSTRALING VED ABNING. SE IKKE IND I

STRALEN-HELLER IKKE MED OPTISKE INSTRUMENTER.

VARO! AVATTAESSA OLET ALTTIINA NAKYMATON LASERSATEILYLLE.

ALA TUIJOTA SATEESEEN ALAKA KATSO SITA OPTISEN LAITTEEN LAPI.

VARNING-OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD.

STIRRA EJ IN I STRALEN OCH BETRAKTA EJ STRALEN GENOM OPTISKT

INSTRUMENT.

ADVERSEL-USYNLIG LASERSTRALING NAR DEKSEL APNES. STIRR IKKE

INN I STRALEN ELLER SE DIREKTE MED OPTISKE INSTRUMENTER.

VAROITUS! LAITTEEN KÄYTTÄMINEN MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA TAVALLA SAATTAA

ALTISTAA KÄYTTÄJÄN TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE.

VARNING - OM APPARATEN ANVÄNDS PÅ ANNAT SÄTT ÄN I

DENNA BRUKSANVISNING SPECIFICERAS. KAN

ANVÄNDAREN UTSÄTTAS FÖR OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN FÖR LASERKLASS 1.

(FOR U.K. ONLY)

CAUTION - INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED

AVOID EXPOSURE TO BEAM .

VARNING - OSYNLIG LASERSTRLNING N R DENNA DEL R PPNAD OCH SPRRAR

R URKOPPLADE. STRLEN R FARLIG.

ADVARSEL - USYNLIG LASERSTRLING N R DEKSEL PNES OG SIKKERHEDSL S

BRYTES. UNNG EKSPONERING FOR STR LEN.

VARO! AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA

NKYM TN LASERS TEILYLLE. L KATSO STEESEN.

VARNING - OSYNLIG LASERSTRLING N R DENNA DEL R PPNAD OCH SPRREN

R URKOPPLAD. BETRAKTA EJ STRLEN.

ADVARSEL - USYNLIG LASERSTRLING VED BNING NR SIKKERHEDSAFBRYDERE

ER UDE AF FUNKTION. UNDG UDSETTELSE FOR STR LING.

VAROITUS! LAITTEEN KÄYTTÄMINEN MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESS A MAINITULLA TAVALLA SAATTAA

ALTISTAA KÄYTTÄJÄN TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE.

VARNING - OM APPARATEN ANVÄNDS PÅ ANNAT SÄTT ÄN I

DENNA BRUKSANVISNING SPECIFICERAS. KAN

ANVÄNDAREN UTSÄTTAS FÖR OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN FÖR LASERKLASS 1.

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

CAUTION

Use the MD/CD component system only in accordance with the instructions given in this manual and do not attempt to interfere with the interlock switch or make any other adjustment as this may result in

exposure to hazardous radiation.

VARO ! Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle lasersäteilylle. Älä katso säteeseen.

VARNING! Osynlig laserstralning när denna del är öppnad och spärren är urkopplad. Betrakta ej strälen.

– 2 –

Page 3

MD-X60H

,,,

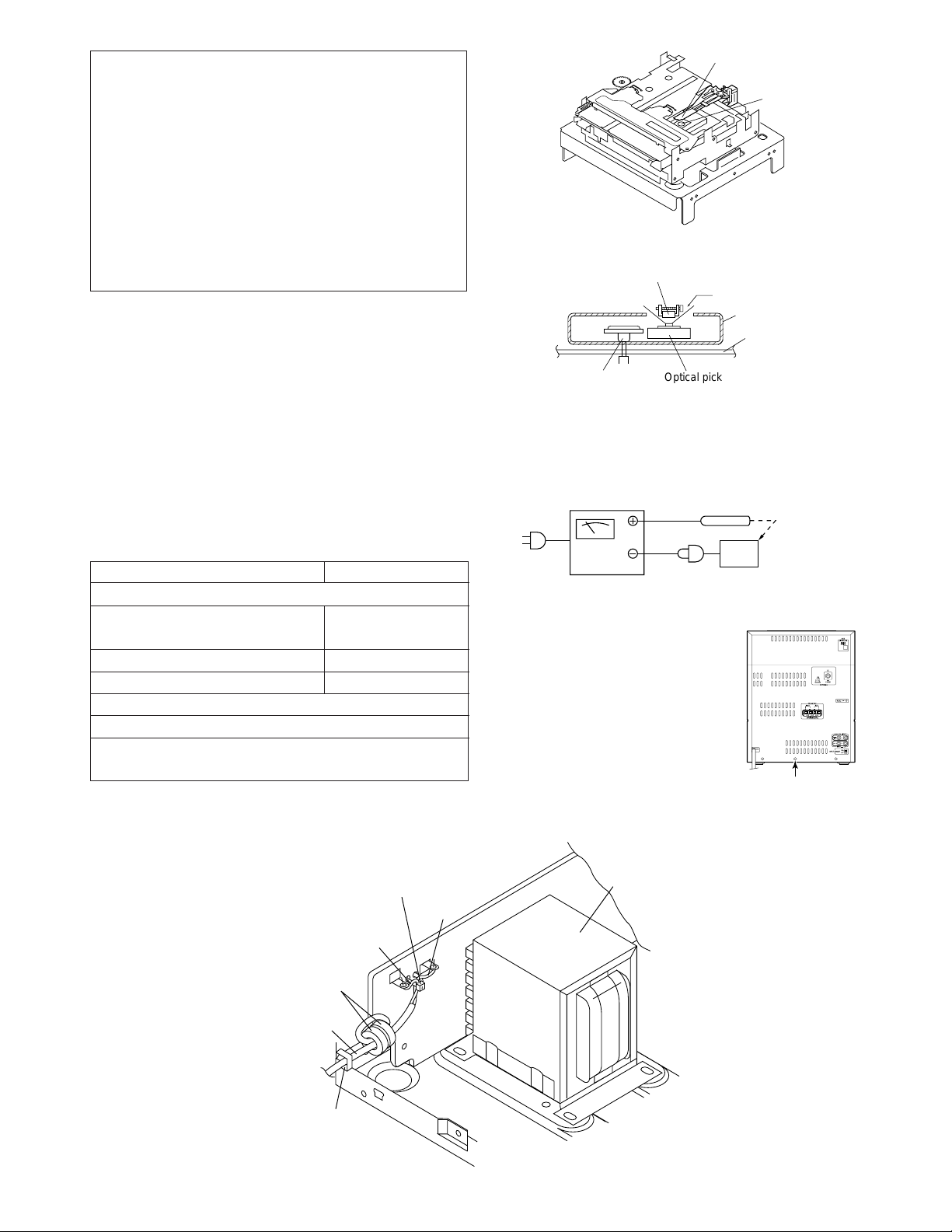

Precaution to be taken when replacing and servicing the

laser pickup.

The following precautions must be observed during servicing

to protect your eyesvagainst exposure to the laser.

Warning of possible eye damage when repairing:

If the AC power plug is connected when the inner cover of

the unit is removed, the laser will light up during focus

access (about 1 second) (Fig. 3-1).

During this operation, the laser will leak from the opening

between the magnetic head and cartridge holder (Fig. 3-2).

In order to protect your eyes, you must not look at the laser

during repair.

Before repairing, be sure to disconnect the AC power plug.

IMPORTANT SERVICE NOTES (FOR U.K. ONLY)

Before returning the unit to the customer after completion of a

repair or adjustment it is necessary for the following withstand

voltage test to be applied to ensure the unit is safe for the

customer to use.

Setting of Withstanding Voltage Tester and set.

Set name

Withstanding Voltage Tester

Test voltage

Set time

Set current (Cutoff current)

Unit

Judgment

OK: The “GOOD” lamp lights.

NG: The “NG” lamp lights and the buzzor sounds.

Set value

4,240 VPEAK

3,000 VRMS

6 secs

4 mA

Spindle Motor

WITHSTANDING

VOLTAGE TESTER

AC

Figure 3-1

Magnet Head

Optical pickup

Figure 3-2

OUT

SHORT-CIRCUT

AC POWER

SUPPLY CORD

Magnetic Head

Optical pickup

Laser Beam

Cartridge Holder

Mechanism

Chassis

PROBE

UNIT

CONNECT THE PROBE

TO GND OF CHASSIS

SCREW

Screw

WIRING OF PRIMARILY SUPPLY LEADS (FOR U.K. ONLY)

Nylon Band 80mm

92LN-BAND 1318A

Brown

Blue

Core

AC Power

Supply Cord

Bushing AC Power

Supply Cord

Figure 3-3

– 3 –

Power

Transformer

Page 4

MD-X60H

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

SPECIFICATIONS

MiniDisc recorder section

Type: MiniDisc recorder

Signal readout: Non-contact, 3-beam semi-conductor laser

Audio channel: Stereo; 2 channels

Frequency response: 20 - 20,000 Hz

Rotation speed: 400 - 900 rpm CLV, Approx

Quantization: 16-bit linear

Filter: 8-times oversampling digital filter

Error correction: ACIRC (Advanced Cross Interleave Reed-

Coding: ATRAC (Adaptive TRansformed Acoustic

Recording method: Magnetic modulation overwrite method

D/A converter: 1-bit D/A converter

Sampling frequency: 44.1 kHz

Wow and flutter: Unmeasurable

Signal/noise ratio: 95 dB (1 kHz)

Dynamic range: 90 dB (1 kHz)

pickup

Monaural; 1 channel

(long-time recording mode)

Solomon Code)

Coding)

(less than 0.001% W. peak)

Compact disc player section

Type: 3-disc multi-play compact disc player

Signal readout: Non-contact, 3-beam semi-conductor laser

Rotation speed: 200 - 500 rpm CLV, Approx.

Error correction: CIRC (Cross Interleave Reed-Solomon

Quantization: 16-bit linear

D/A converter: 1-bit D/A converter

Filter: 8-times oversampling digital filter

Frequency response: 20 - 20,000 Hz

Signal/noise ratio: 95 dB (1 kHz)

Dynamic range: 90 dB (1 kHz)

Wow and flutter: Unmeasurable

pickup

Code)

(less than 0.001% W. peak)

Tuner section

Frequency range: FM; 87.5 - 108 MHz

Sensitivity: FM; 2.5 µV (75 ohms unbalanced)

AM; 522 - 1,620 kHz

AM; 650 µV/m

Cassette deck section

Type: Compact cassette tape

Frequency response: 50 - 14,000 Hz (Normal tape)

50 - 15,000 Hz (CrO

2 tape)

Motor: DC motor with electronic governor × 1

Signal/noise ratio: 50 dB (Recording/Playback, Dolby NR off)

Bias and erasure

system: AC

Tape speed: 4.76 cm/sec. (1-7/8 ips.)

Wow and flutter:

Except for U.K.

U.K. Only

Heads: Record/playback × 1

Dolby NR effect; 10 dB (at over 5 kHz)

0.2 % (DIN 45 511)

0.15 % (WRMS)

Erase × 1

General

Power source: AC 230 V, 50 Hz

Power consumption: 97 W

Output power:

Except for U.K.

U.K. Only

Input terminals: MD IN/AUX (Analogue-1); 500 mV/47 kohms

Output terminals: Auxiliary; 2.0 V/1 kohm

Dimensions: Width; 240 mm (9-1/2")

Weight: 8.6 kg (19.0 lbs.)

PMPO; 340 W (total)

MPO; 170 W (85 W + 85 W)

(DIN 45 324)

RMS; 100 W (50 W + 50 W)

(DIN 45 324)

RMS; 100 W (50 W + 50 W)

(10 % T.H.D.)

Auxiliary (Analogue-2); 500 mV/47 kohms

Auxiliary (Digital); optical

Headphones; 16 - 50 ohms

(recommended; 32 ohms)

Speakers; 6 ohms

Height; 332 mm (13-1/8")

Depth; 325 mm (12-13/16")

Speaker section

Type: 3-way type [150 mm (6") woofer, 65 mm

Maximum input power: 100 W

Rated input power: 50 W

Impedance: 6 ohms

Dimensions: Width; 205 mm (8-1/8")

Weight: 4.2 kg (9.3 lbs.)/each

(2-1/2") tweeter and super tweeter]

Height; 332 mm (13-1/8")

Depth; 323 mm (12-3/4")

Specifications for this model are subject to change without

prior notice.

– 4 –

Page 5

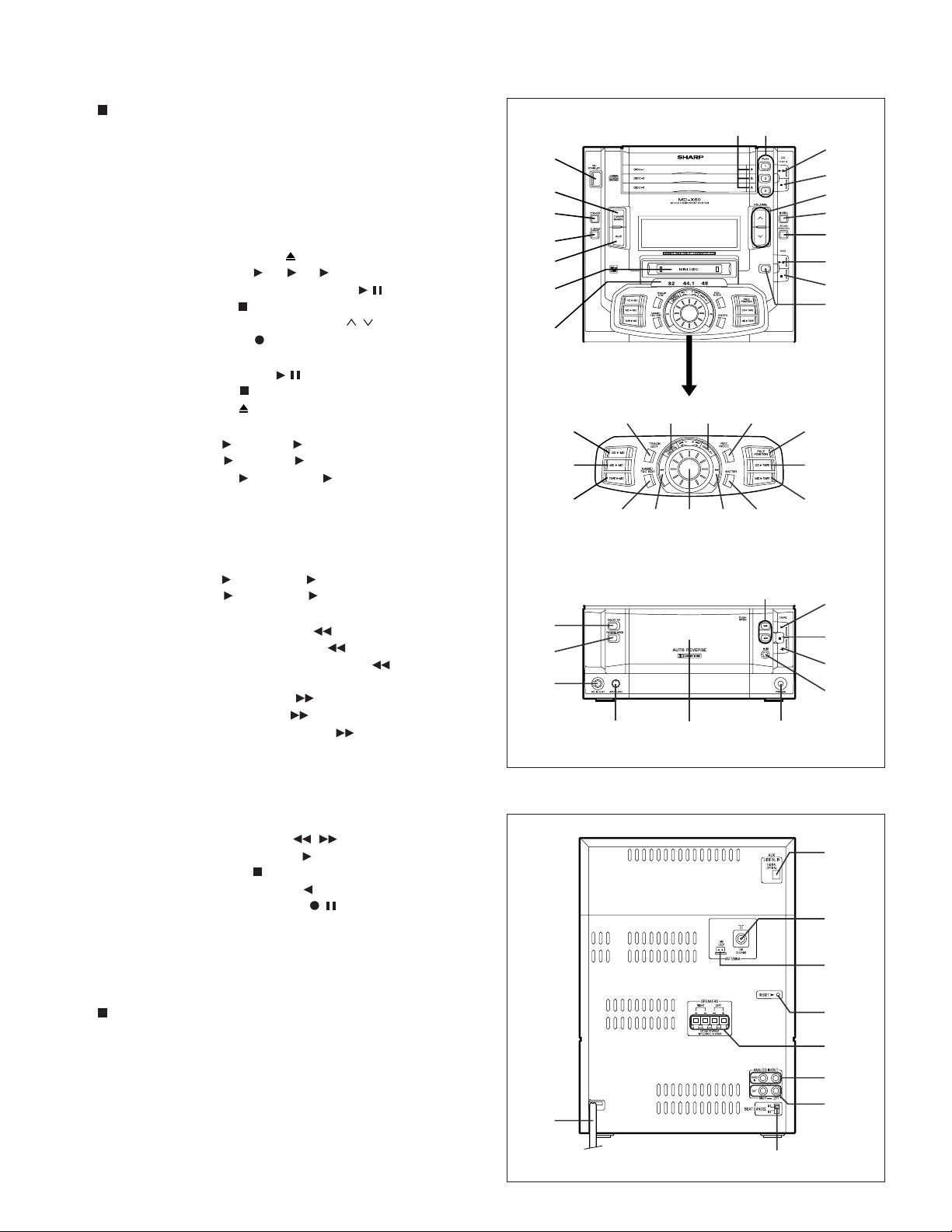

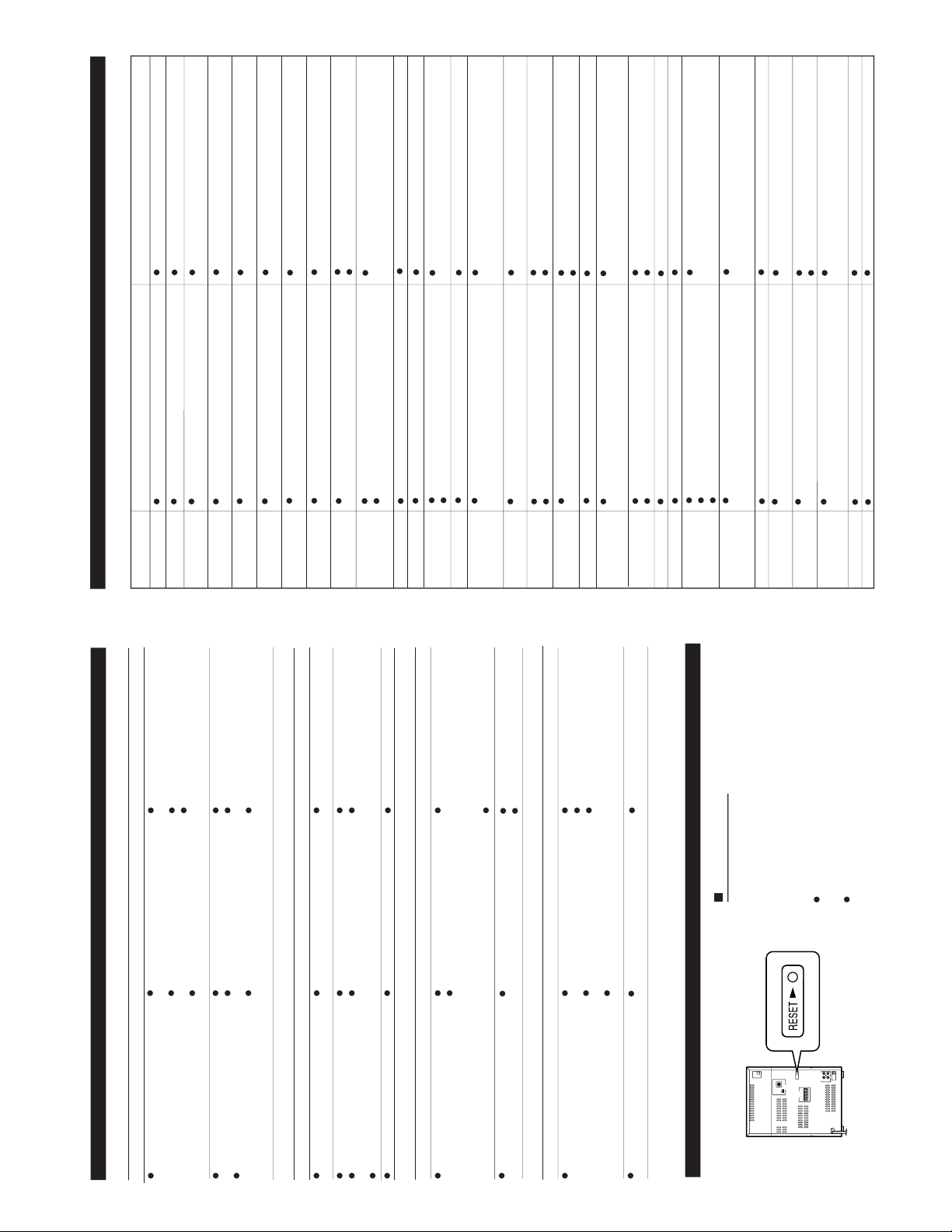

NAMES OF PARTS

MD-X60H

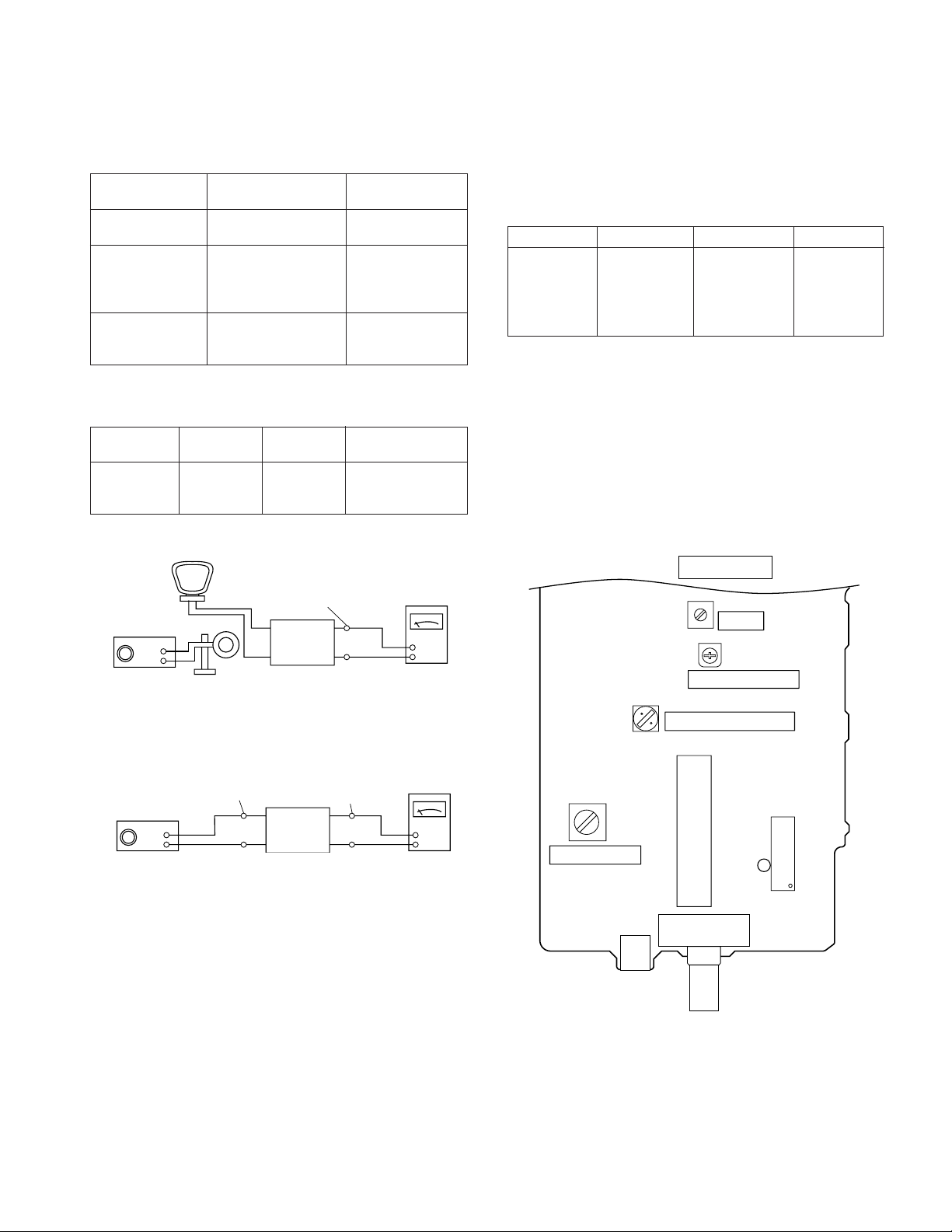

Front panel

11.

On/Stand-by Button: ON/STAND-BY

12.

Tuner Call (Band Select) Button: TUNER (BAND)

13.

Preset Equalizer Button: PRE-EQ

14.

Extra Bass Button: X-BASS

15.

Auxiliary Input (Digital/Analogue) Select Button: AUX

16.

MD Compartment

17.

Sampling Frequency Indicators

18.

(CD) Open/Close Buttons:

19.

(CD) Play Buttons: 1 , 2 , 3

10.

(CD) Play/Pause Button and Indicator:

11.

(CD) Stop Button:

12.

Volume Up/Down Buttons: VOLUME

13.

(MD) Record Button: REC

14.

Sound Synchro Record Button

15.

(MD) Play/Pause Button:

16.

(MD) Stop Button:

17.

(MD) Eject Button:

18.

Edit Button CD MD: CD MD

19.

Edit Button MD MD: MD MD

20.

Edit Button TAPE MD: TAPE MD

21.

(CD/MD) Track Edit Button: TRACK EDIT

22.

Timer/Delete Button: TIMER/DELETE

23.

Display Button: DISPLAY

24.

(MD) Record Mode Button: REC MODE

25.

(MD) Pole Position Button: POLE POSITION

26.

Edit Button CD TAPE: CD TAPE

27.

Edit Button MD TAPE: MD TAPE

28.

(MD) Name/TOC-Edit Button: NAME/TOC EDIT

29.

(TUNER) Tuning Down Button:

3

(CD) Track Down/Review Button:

3

(MD) Track Down/Review/Cursor Button:

30.

Jog Dial

31.

(TUNER) Tuning Up Button:

3

(CD) Track Up/Cue Button:

3

(MD) Track Up/Cue/Cursor Button:

32.

Enter Button: ENTER

1

2

3

4

5

6

7

33

34

35

18

19

20

21 22

28 29

41

30

42

23

31

8

9

10

11

12

13

14

15

16

17

24

25

26

27

32

36

37

38

39

40

43

33.

(TAPE) Dolby NR Button: DOLBY NR

34.

(TAPE) Reverse Mode Button: REVERSE MODE

35.

Edit/Auxiliary 1 (Analogue) Input Socket: MD IN/AUX 1

36.

(TAPE) Fast Wind Buttons:

37.

(TAPE) Forward Play Button:

38.

(TAPE) Stop Button:

39.

(TAPE) Reverse Play Button:

40.

(TAPE) Record Pause Button:

41.

Auxiliary Input Level (Analogue) Control: INPUT LEVEL

42.

Cassette Compartment

43.

Headphone Socket: PHONES

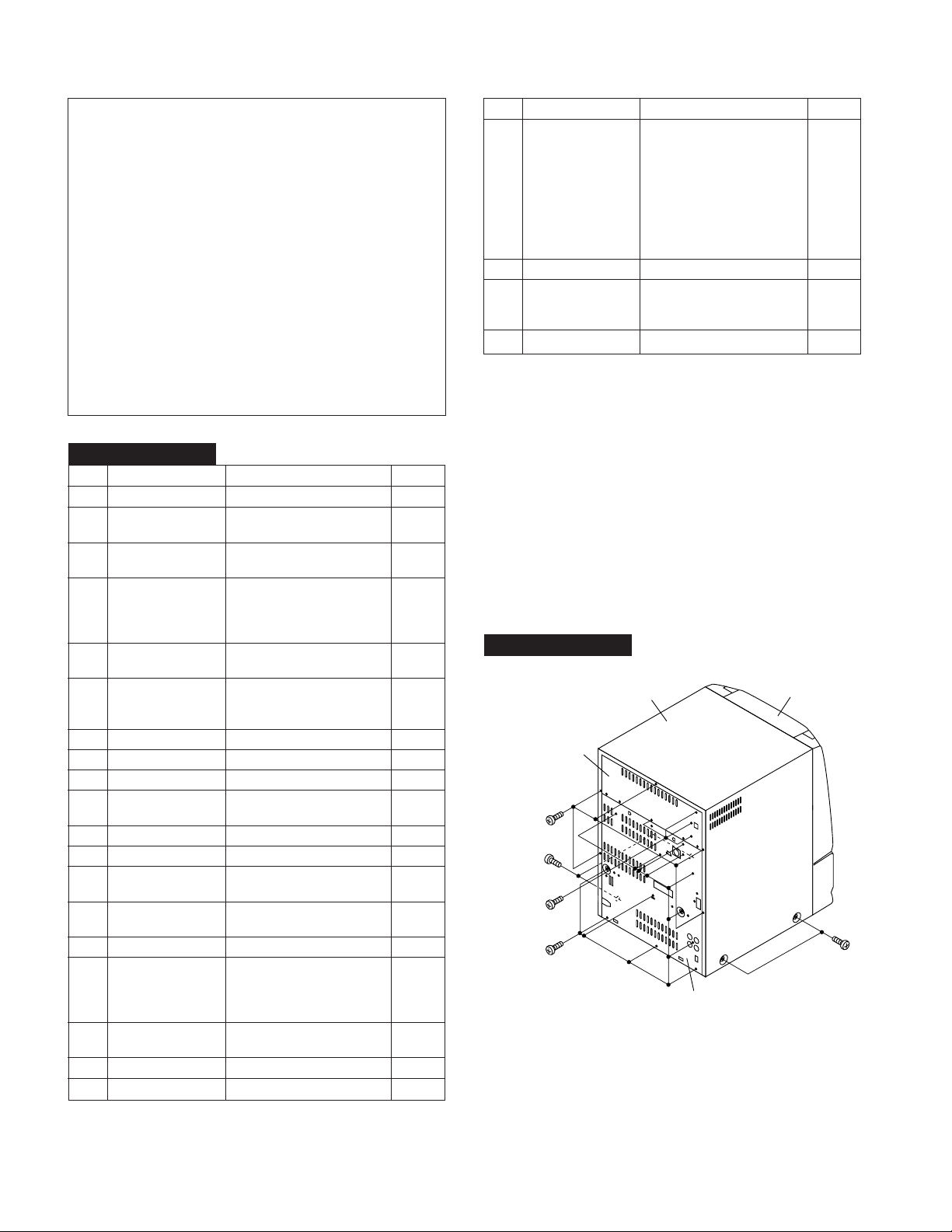

Rear panel

11.

Auxiliary Digital Input Socket (Optical)

12.

FM 75 Ohms Aerial Socket

13.

AM Loop Aerial Socket

14.

Reset Button

15.

Speaker Terminals

16.

AUX 2 (Analogue) Input Sockets

17.

Analogue Output Sockets

18.

Beat Cancel Switch

19.

AC Power Lead

1

2

3

4

5

6

7

9

8

– 5 –

Page 6

MD-X60H

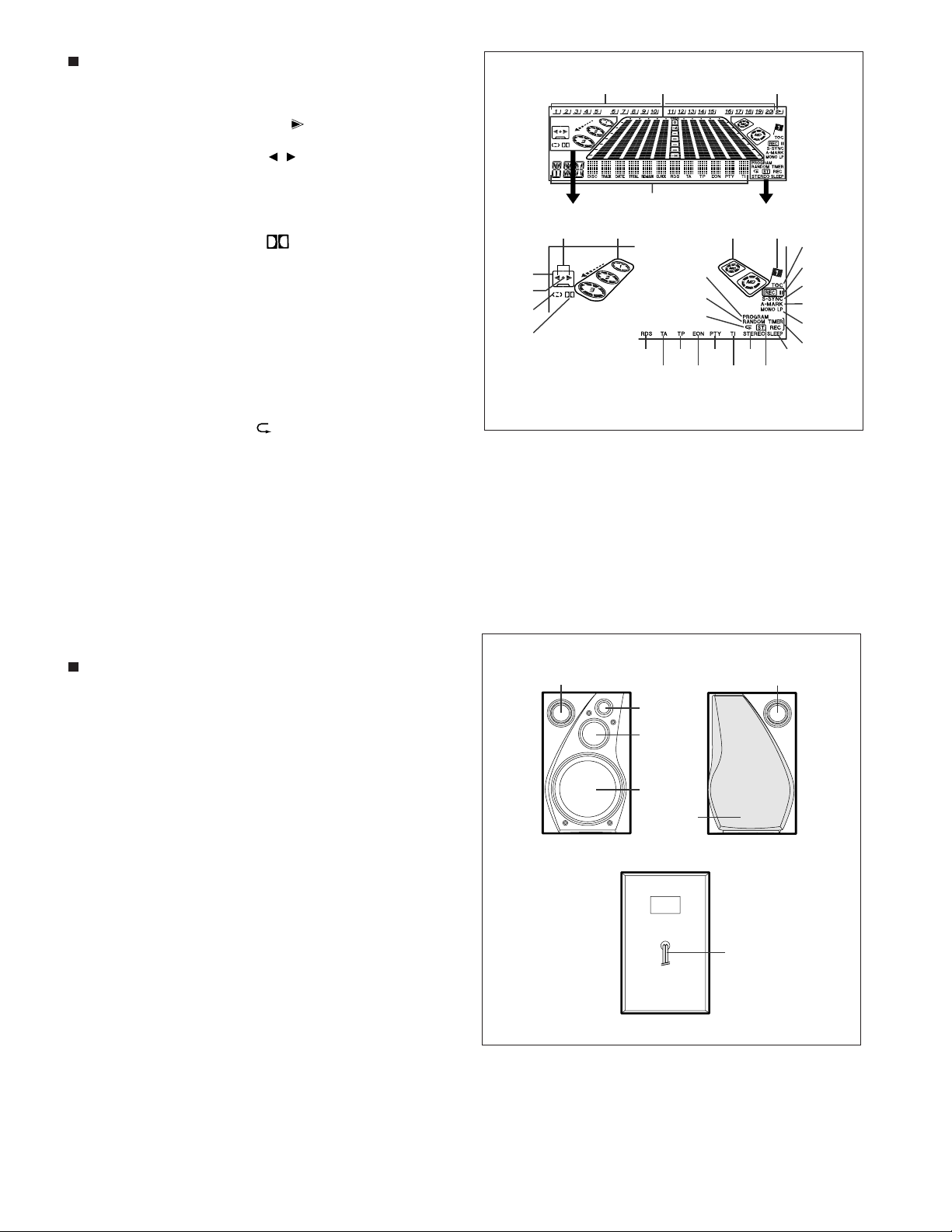

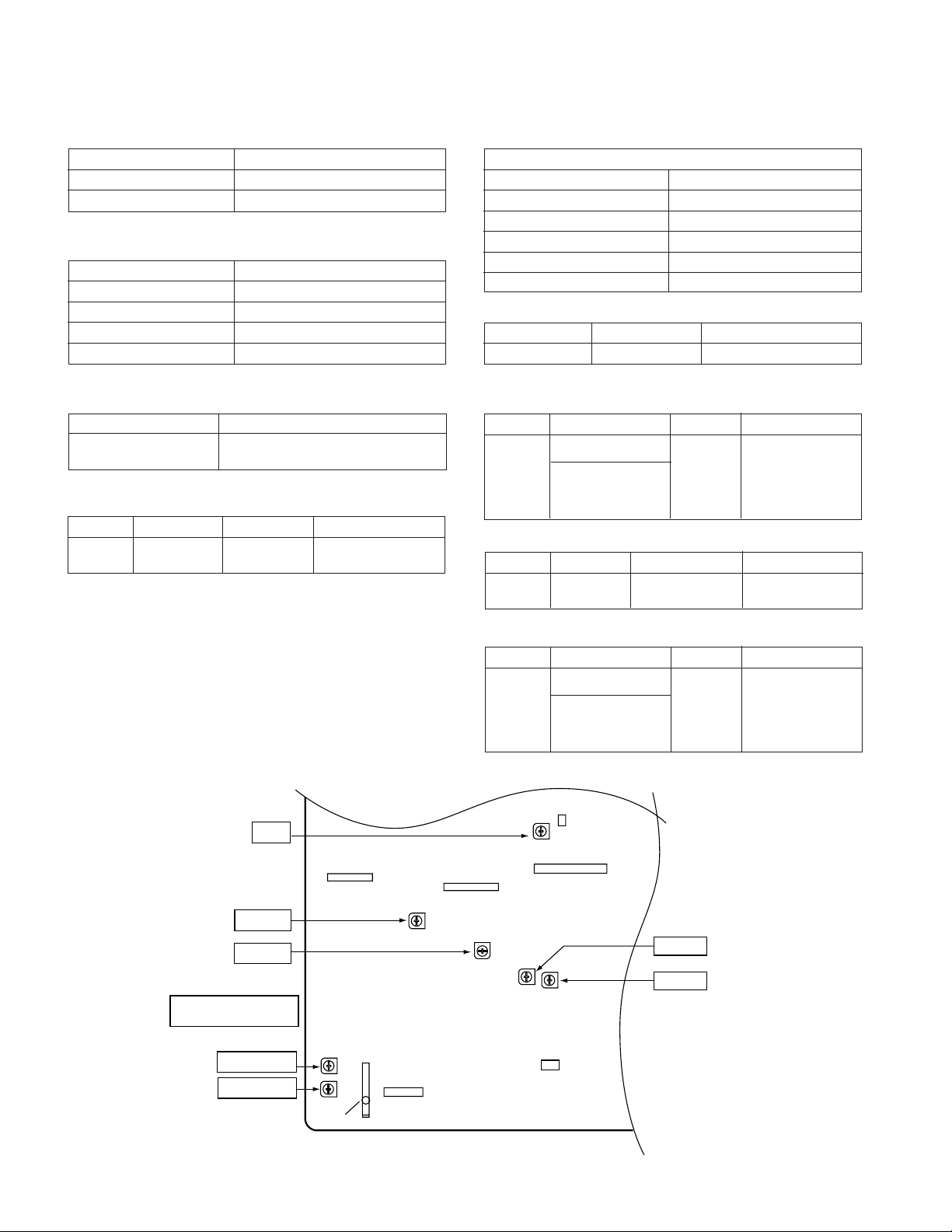

Display window

11. (CD/MD) Music Schedule Indicators

12. Level Meters

13. (CD/MD) More Tracks Indicator:

14. Character Information Display

15. (TAPE) Direction Indicators: /

16. CD Indicator

17. (TAPE) Loading Indicator

18. (TAPE) Recording Indicator

19. (TAPE) Reverse Mode Indicator

10. (TAPE) Dolby NR Indicator:

11. MD Indicator

12. Pole Position Record Indicator

13. (MD) TOC Indicator: TOC

14. (MD) Record Indicator: REC

15. (MD) Sound Synchro Indicator: S.SYNC

16. (MD) Auto Mark Indicator: AUTO MARK

17. (MD) Recording Mode Indicator: MONO LP

18. Timer Play/Timer Record Indicator

19. (CD/MD) Programme Indicator: PROGRAM

20. (CD/MD) Random Play Indicator: RANDOM

21. (CD/MD) Repeat Indicator:

22. RDS Indicator: RDS

23. Traffic Announcement Indicator: TA

24. Traffic Programme Indicator: TP

25. EON Indicator: EON

26. Programme Type Indicator: PTY

27. Traffic Information Indicator: TI

28. FM Stereo Mode Indicator: STEREO

29. FM Stereo Indicator: ST

30. Sleep Indicator: SLEEP

7

8

9

10

1

2

3

4

12

5

6

11

13

19

20

21

14

15

16

17

18

28

22

23

24

25

26

27

30

29

Speaker section

11. Bass Reflex Duct

12. Super Tweeter

13. Tweeter

14. Woofer

15. Speaker Grille

16. Speaker Wire

1

1

2

3

4

5

6

– 6 –

Page 7

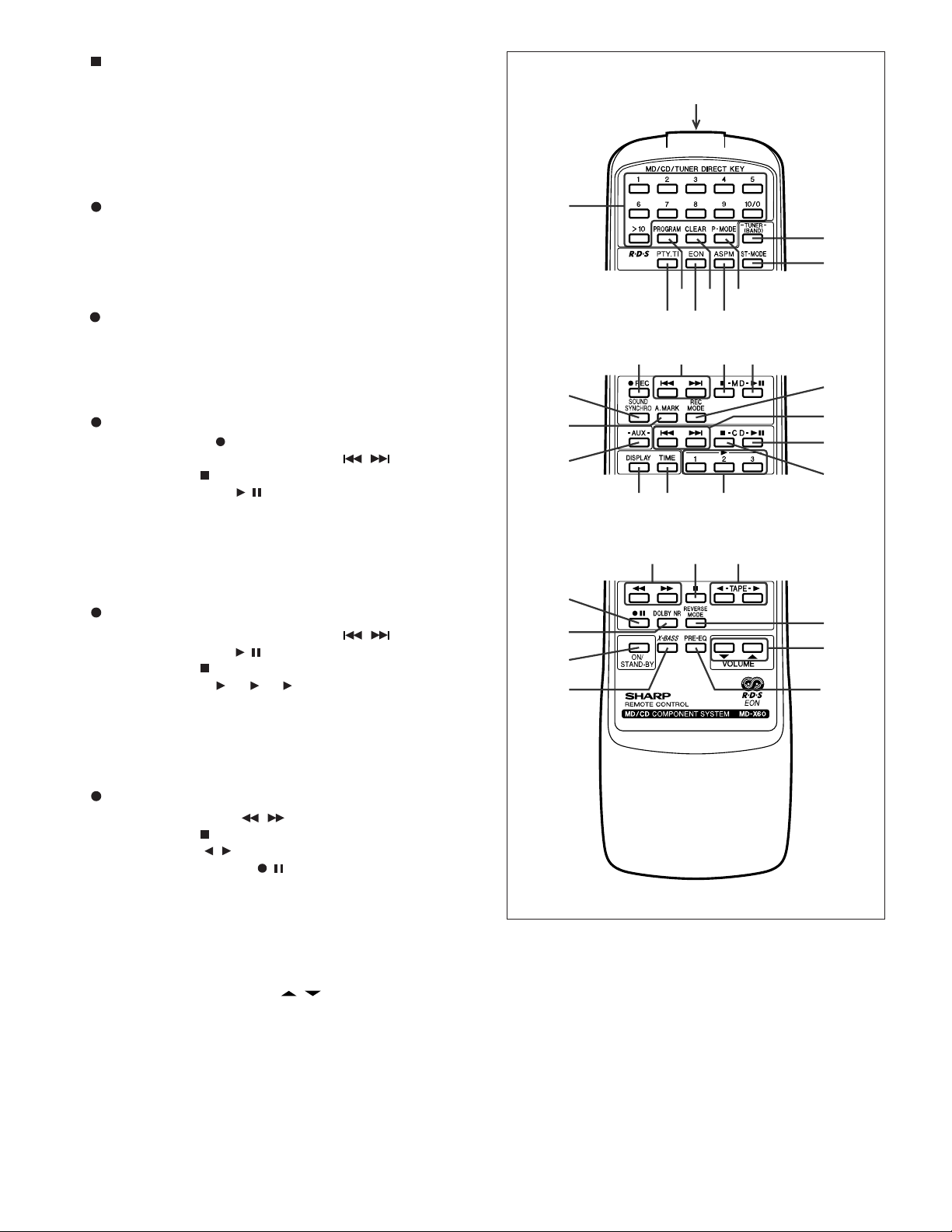

Remote control

11.

Remote Control Transmitter LED

12.

(MD/CD/TUNER) Direct Key

13.

(CD/MD) Programme Button: PROGRAM

14.

(CD/MD) Programme Clear Button: CLEAR

15.

(CD/MD) Play Mode Button: P-MODE

MD-X60H

1

RDS control section

16.

Programme Type/Traffic Information Search Button: PTY. TI

17.

EON Button

18.

ASPM Button

Tuner control section

19.

Tuner Call (Band Select) Button: TUNER/BAND

10.

FM Stereo Mode Button: ST MODE

MD control section

11.

Record Button: REC

12.

Track Up,Cue/Down,Review Buttons: /

13.

Stop Button:

14.

Play/Pause Button:

15.

Sound Synchro Record Button: SOUND SYNCHRO

16.

Auto Mark Button: A.MARK

17.

Record Mode Button: REC MODE

CD control section

18.

Track Up,Cue/Down,Review Buttons: /

19.

Play/Pause Button:

20.

Stop Button:

21.

Play Buttons: 1 , 2 , 3

22.

Auxiliary Input (Digital/Analogue) Select Button: AUX

23.

Display Button: DISPLAY

24.

Time Display Select Button: TIME

15

16

22

28

29

31

32

2

9

10

345

678

11 12 13 14

17

18

19

20

23 24 21

25 26 27

30

33

34

Tape control section

25.

Fast Wind Buttons: /

26.

Stop Button:

27.

Play Buttons: /

28.

Record Pause Button:

29.

Dolby NR Button: DOLBY NR

30.

Reverse Mode Button: REVERSE MODE

31.

On/Stand-by Button: ON/STAND-BY

32.

Extra Bass Button: X-BASS

33.

Volume Up/Down Buttons: /

34.

Pre-programmed Equalizer Button: PRE-EQ

– 7 –

Page 8

MD-X60H

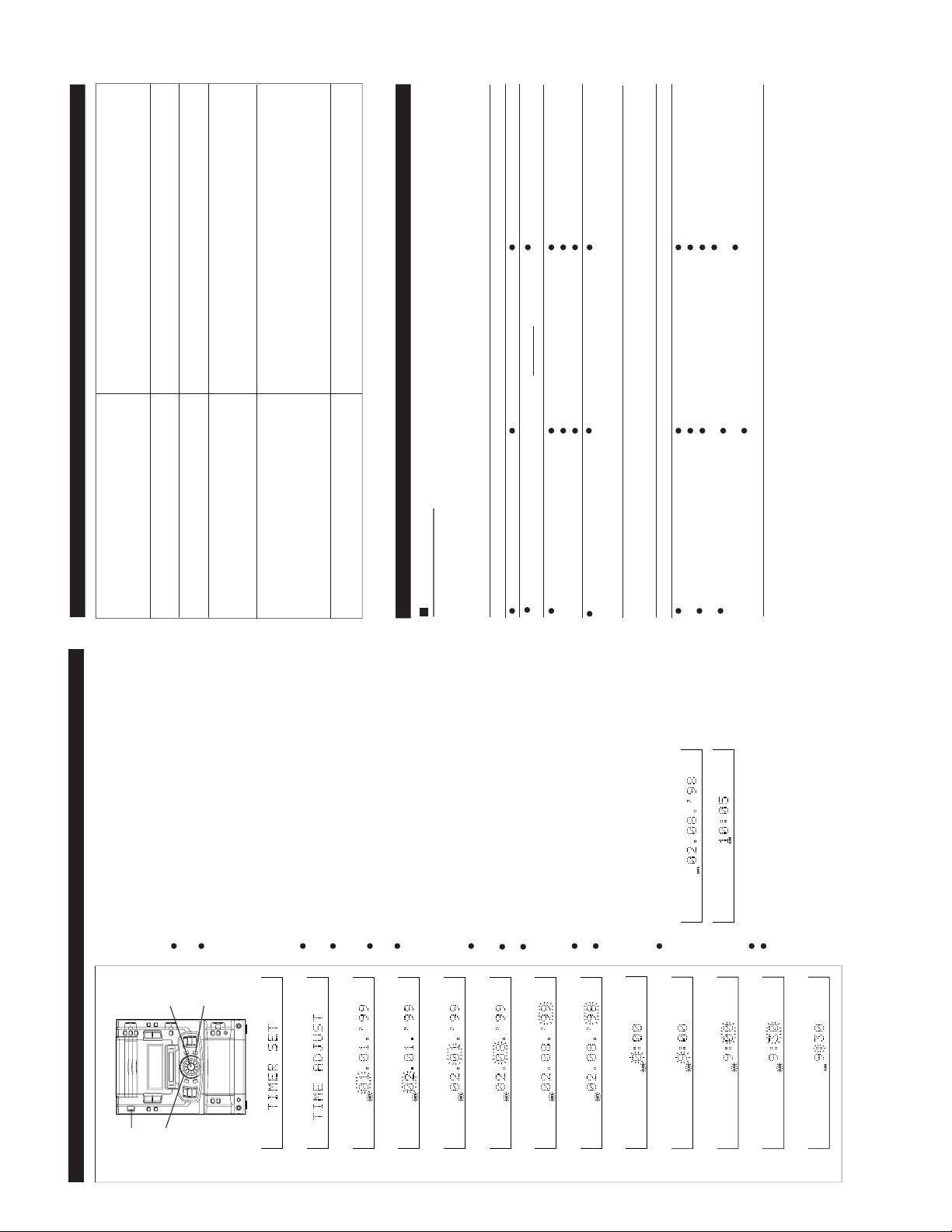

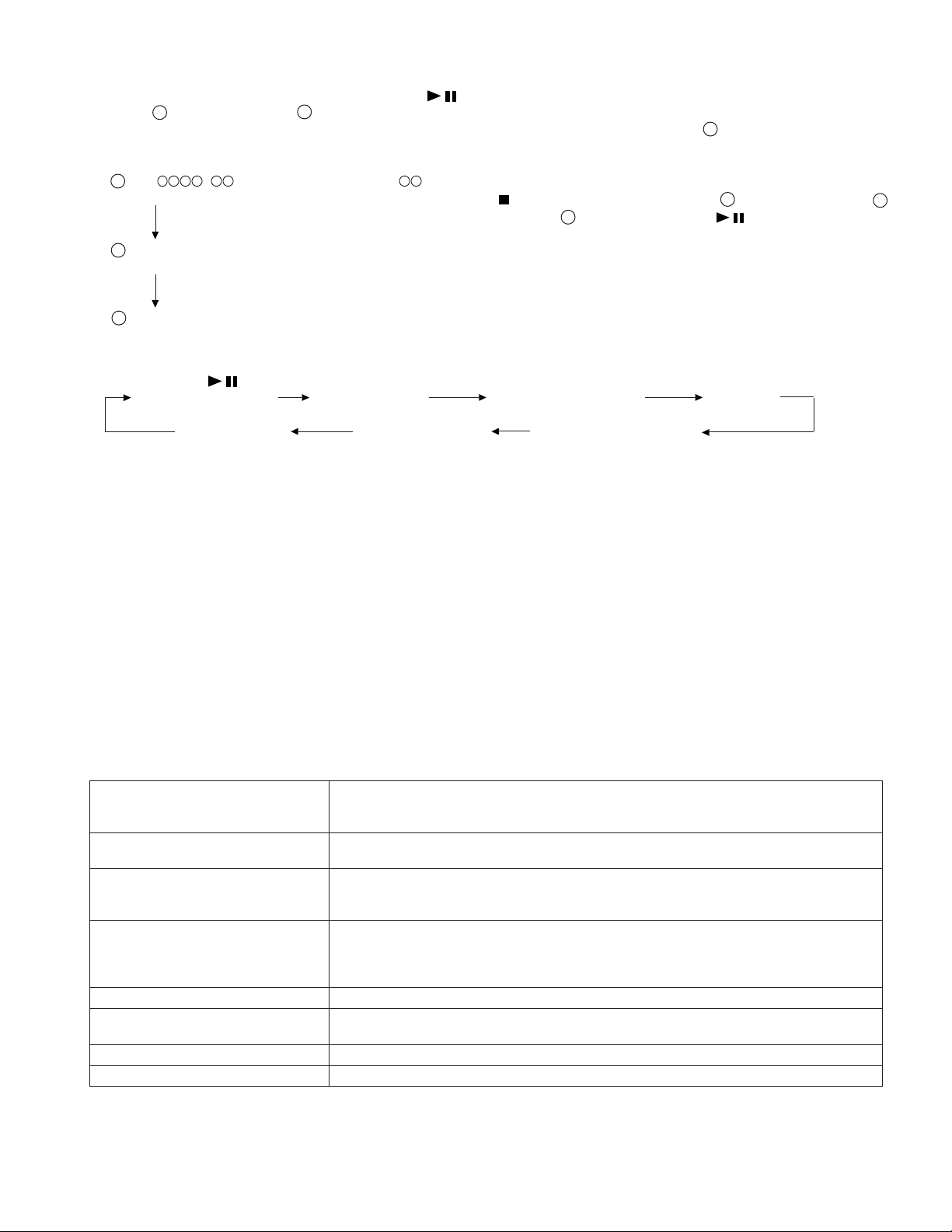

SETTING THE CLOCK

1

Press the ON/STAND-BY button to turn the power on.

2

Press the TIMER/DELETE button.

3

Within 10 seconds, turn the jog dial until "TIME ADJUST" appears.

4

Within 10 seconds, press the ENTER button.

The unit will enter the date setting mode.

5

Adjust the "day" using the jog dial.

When you turn the jog dial by one click position the day will change up or down

by one. When you turn the jog dial continuously, the day will change repeatedly

until the jog dial is released.

6

Press the ENTER button to set the "day".

7

Adjust the "month" using the jog dial.

8

Press the ENTER button to set the "month".

9

Adjust the "year" using the jog dial.

The year 2000 or later is set as follows:

[00] indicates the year 2000.

[01] indicates the year 2001.

The range of dates that can be entered is from January 1, 1997 to December

31, 2099.

10

Press the ENTER button to set the "year".

The unit will enter the time setting mode.

11

Adjust the "hour" using the jog dial.

When you turn the jog dial and let go, the hour will change up or down by one.

When you turn and hold it, the hour will change continuously.

12

Press the ENTER button to set the "hour".

13

Adjust the "minute" using the jog dial.

14

Press the ENTER button to set the "minute".

The clock starts operating from "0" seconds. (Seconds are not displayed.)

ON/

STAND-BY

TIMER /

DELETE

ENTER

2

14

12

13

3

4

5

6

7

8

9

10

11

Notes:

In the event of a power failure or when the AC power lead is disconnected, the

clock setting will be lost. Reset the time.

Whilst recording an MD, you cannot set the date and clock. Be sure to set the

date and clock before recording.

Resetting the date and time:

Once you have set the date and time, "TIME ADJUST" will not be displayed in

step 2. Turn the jog dial to make the date and time appear.

If you don't need to change the settings, just press the ENTER button without

turning the jog dial again.

Checking the date and time:

Press the TIMER/DELETE button. Then turn the jog dial until the date and time

are displayed.

Press the DISPLAY button to switch between the date and the time.

After about 10 seconds, the original display will appear.

Once the date and the time have been set, this unit will normally display the

time when the unit is in the stand-by mode.

To check the date, press the DISPLAY button.

The display will switch between the date and the time each time you press the

button.

(Main unit operation)

Jog dial

Date setting mode

Time setting mode

MINIDISC SYSTEM LIMITATIONS

Even if the maximum recording time of a MiniDisc has not

been reached, "TOC FULL" may be displayed.

Even if the maximum recording time of a MiniDisc has not

been reached, "DISC FULL" may be displayed.

Even if several short tracks are erased, the remaining rec-

ording time may not show an increase.

Two tracks may not be combined in editing.

The total of the recorded time and time remaining on a

disc may not add up to the maximum possible recording

time.

If recorded tracks are fast reversed or fast forwarded, the

sound may skip.

In the MD system, the delimiter of the recording area on an MD is programmed

in a TOC. If partial erasing, recording and editing are repeated several times,

TOC information will fill up, even though the number of tracks has not reached

the limit (255 tracks), and further recording will be impossible. (If you use the all

erase function, this MD can be used from the beginning.)

If there is any flaw on the MiniDisc, that part is automatically excluded from the

space available for recording. Therefore, the recording time becomes shorter.

When the remaining recording time of a disc is displayed, short tracks less than

12 seconds long may not be included in the total.

For MiniDiscs on which repeated recording and editing operations were per-

formed, the COMBINE function may not work.

A track recorded from a CD (digital recording) and a track recorded from a radio

or other equipment (analogue recording) cannot be combined.

A cluster (about 2 seconds) is normally the minimum unit of recording. So, even

if a track is less than 2 seconds long, it will use about 2 seconds of space on

the disc. Therefore, the time actually available for recording may be less than

the remaining time displayed.

If there are scratches on discs, those sections will be automatically avoided (no

recording will be placed in those sections). Therefore, the recording time will be

reduced.

An MD which has been recorded or edited repeatedly may skip during fast reverse

or fast forward.

TROUBLESHOOTING

If a problem occurs

If this unit functions abnormally during operation, first check the following items. If the unit continues to function abnormally, or if an abnormality

appears other than listed below, set this unit to the stnad-by mode and disconnect the AC power plug, then consult your SHARP dealer or service

personnel.

General

SYMPTOM

POSSIBLE CAUSE REMEDY

The clock is wrong.

Did a power failure occur?

Try setting it again.

When a button is pressed, the unit does

not respond.

Set this unit to the stand-by mode and then

turn it back on. Then, retry the operation.

No sound is heard.

Is the volume level is set to "0"?

Are the headphones connected?

Are the speaker wires disconnected?

Increase the volume level.

Disconnect the headphones.

Connect the wires securely.

Radios make unusual noise or the picture

on the TV screen is distorted.

When a radio or TV which uses an indoor

aerial is placed near the unit, the picture on

the TV screen may be distorted or the radio

may not function properly.

It is recommended that you use an external

aerial.

CD playback

SYMPTOM

POSSIBLE CAUSE REMEDY

Even though a disc has been loaded, "NO

DISC" or "ERR" is displayed.

Playback stops in the middle of a track, or

playback is not performed properly.

Playback sounds are skipped.

The disc is loaded up-side down.

The disc is very dirty.

The disc which does not satisfy the stand-

ards.

Is the unit located near excessive vibra-

tions?

Has condensation formed inside the unit?

Load the disc with the correct side up.

Clean the disc.

Load the correct disc.

Place the unit on a firm, level surface free

from vibration.

Remove the disc and leave the power

turned on. The unit should function properly

in about 1 hour.

OPERATION MANUALNAMES OF PARTS

– 8 –

Page 9

MD-X60H

(Continued)

MD recording and playback

SYMPTOM

POSSIBLE CAUSE

REMEDY

A recording cannot be made.

Is the MiniDisc protected against accidental

erasure?

Did you try to make recording on a play-

back-only MiniDisc?

Can you see the "TOC FULL" message in

the display?

Slide the accidental erase prevention tab

back to its original position.

Replace it with a recordable disc.

Put in another recordable disc with recor-

ding space on it.

Even though a disc has been loaded, "NO

DISC" or "ERR" is displayed.

Playback sounds are skipped.

The disc is very dirty.

Is the unit located near excessive vibra-

tions?

Has condensation formed inside the unit?

Clean the disc.

Place the unit on a firm, level surface free

from vibration.

Remove the disc and leave the power

turned on. The unit should function properly

in about 1 hour.

Tape recording and playback

SYMPTOM

POSSIBLE CAUSE REMEDY

A recording cannot be made.

Is the tape protected against accidental

erasure?

Cover the accidental erase prevention hole.

Sound is skipped.

Sound in high-frequency range cannot be

reproduced.

Sound quivers.

The tape is damaged.

The capstan and pinch roller are very dirty.

Replace the tape.

Clean the capsten and pinch roller.

The cassette cannot be ejected.

Did a power failure occur?

Wait until the power is supplied.

Radio reception

SYMPTOM

POSSIBLE CAUSE

REMEDY

Radios make unusual noise consecutively.

The unit is placed near the TV or computer.

The aerial direction is not placed properly.

When the unit receives a radio broadcast

near a TV set, a computer or a wordpro-

cessor, it may pick up noise. If this hap-

pens, try to move the unit from the place

where the noise is picked up.

Correct the aerial direction.

The preset channel cannot be recalled.

Did you erase the programmed station?

Preset the channel again.

Redo programming.

Remote control

SYMPTOM

POSSIBLE CAUSE REMEDY

The remote control does not function or

does not operate properly.

The batteries (polarity) are not inserted

properly.

The batteries inside the remote control are

dead.

The remote control is operated from an in-

correct distance or angle.

Insert properly.

Replace the batteries.

Operate it within a range of 0.2 m (8") to

6 m (20') and within an angle of 15° to

either side of centre.

The power cannot be turned on from the

remote control.

Is the AC power lead plugged in?

Connect the AC power lead.

(Continued)

If a problem occurs

If this product is subjected to strong external interference (mechanical

shock, excessive static electricity, abnormal supply voltage due to light-

ning, etc.) or if it is operated incorrectly, it may malfunction or the

display may not function correctly. If such a problem occurs, do the

following:

Connect the AC power lead to the AC socket, and press the RESET

button once on the rear of the main unit.

When the RESET button is pressed, all of the contents in memory

(clock and timer settings, and CD presets) other than the tuner sta-

tions will be erased.

If strange sounds, smells or smoke come out of the unit or if a foreign

object falls into the unit, turn off the power, unplug the AC power

lead from the AC socket, immediately. Contact the shop where you

purchased the unit.

(Continued)

When an error message is displayed, proceed as follows:

Error messages

Meaning

Remedy

BLANK MD

Nothing is recorded.

Replace it with another disc.

Can't COPY

You tried to record from a copy-protected disc.

Replace it with a regular disc that can be copied.

Can't EDIT

A track cannot be edited.

Change the stop position of the track and then try editing

it.

Can't REC

Recording cannot be performed correctly due to vibra-

tion or shock in the unit.

Re-record.

Can't T REC

Timer recording is impossible or there is no available

space on the MD.

Replace it with another disc.

CH ERROR

There is something wrong with the CD changer.

Set this unit to the stand-by mode and then back to on,

and press the button.

CONNECT ERR

Whilst an MD player is being edited on this unit, incorrect

digital signals are input from the portable MD player.

Make sure the cable is connected correctly and that

power is being supplied to the portable MD player.

DEFECT

Since this disc has scratches on it, the recording oper-

ation was skipped.

Replace it with another disc.

Din UNLOCK

Incorrect digital signals are input.

Connect correct digital signals.

Use the analogue input sockets.

DISC ERR

The disc is damaged.

A TOC is not written on the MD or there is something

wrong with data.

Reload the disc or replace it.

DISC FULL

The disc is out of recording space.

Replace the disc with another recordable disc.

EDIT OVER

There is no space to make CD editing on the disc.

Replace it with a disc that has enough time to record.

FOCUS ERROR

A disc has not been loaded.

The disc data cannot be read.

Reload the MiniDisc.

MD ERROR

No operation.

Contact the shop where you purchased the unit.

MECHA ERR∗

(∗:Number or

symbol)

There is a mechanical problem and the disc is not work-

ing properly.

Set this unit to the stand-by mode and press the but-

ton.

NAME FULL

The number of characters for the disc name or track

name exceeds 100.

Shorten the disc or track name.

NO DISC

A disc has not been loaded.

The disc data cannot be read.

Load a disc.

Reload the disc.

NOT AUDIO

The data recorded on this disc is not audio data.

Select another track.

Replace the disc.

PLAYBACK MD

You tried to record on a playback-only disc.

Replace it with another recordable disc.

PROTECT

Trouble is found.

Restart the unit. I f the unit doesn't work, contact a

SHARP Authorised Servicing Dealer or SHARP Auth-

orised Service station.

PROTECTED

The disc is write protected.

The tape is protected against accidental erasure.

Move the write protection tab back to its original position.

Cover the accidental erase prevention hole.

TAPE ERROR

The tape mechanism is defective.

Try pressing the RESET button.

TEMP OVER

The temperature is too high.

Set this unit to the stand-by mode and wait for a while.

TOC ERR∗

(∗:Number or

symbol)

The disc is damaged.

TOC information cannot be read.

MD not specified.

Replace it with another disc.

TOC FULL∗

(∗:Number or

symbol)

There is no space left for recording character information

(track names, disc names, etc.).

Replace it with another recordable disc.

TOC W ERROR

Recording is impossible.

Contact the shop where you purchased the unit.

TRAY ERROR

The CD tray operates incorrectly.

Unplug the AC power lead, plug it back, and then turn

the power on.

U TOC ERR∗

(∗:Symbol)

TOC information recorded on the MD does not match

the MD specifications or it cannot be read.

Replace it with another disc.

Erase all of the track, and try recording.

U TOC W ERR

The TOC information could not be created properly due

to a mechanical shock or to scratches on the disc.

Set this unit to the stand-by mode and try to write the

TOC again.

(Remove any source of shock or vibration whilst writing.)

? DISC

The data contains an error.

Replace it with another disc.

00:00

Music is not being recorded.

Replace the disc with another recordable disc.

– 9 –

Page 10

MD-X60H

DISASSEMBLY

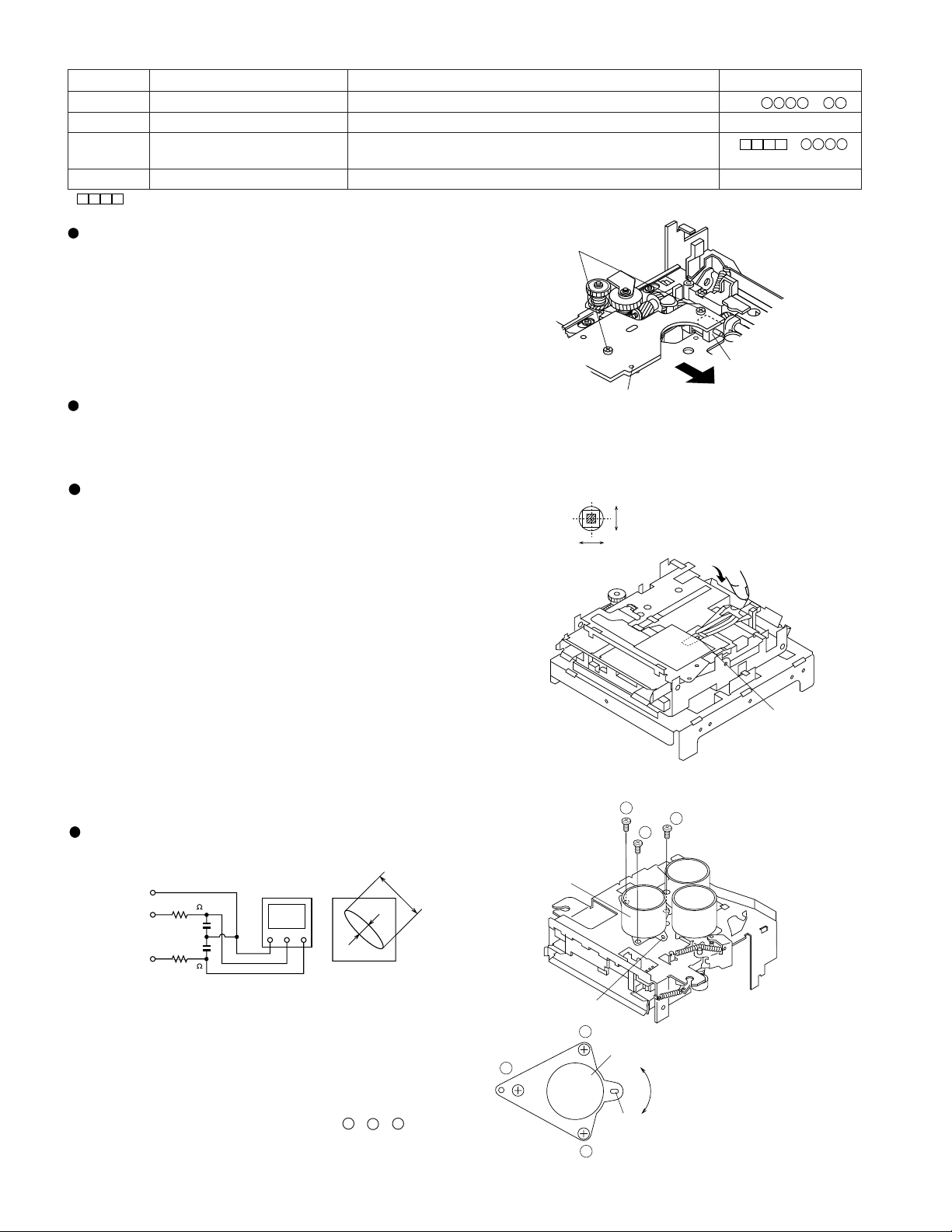

Caution on Disassembly

The disassembling the machine or assembling it after

repair, observe the following instructions so as to ensure

safety and keep its performance.

1. Unload the compact disc, and mini-disc, casette tape

from machine.

2. Be sure to unplug the power cable before starting

disasembly of the machine.

3. When disassembling each section, remove the nylon

band or wire arrangement.

After servicing the unit, be sure to rearrange the leads

where they were before disassembling.

If a screw of improper length is fit to the MD mechanism.

(a screw fit the part to the mechanism chassis of MD

section), it may contact the optical pickup, impeding

normal operation. Hence, due care must be taken.

4. While repairing, pay utmost attention to static electricity

on ICs.

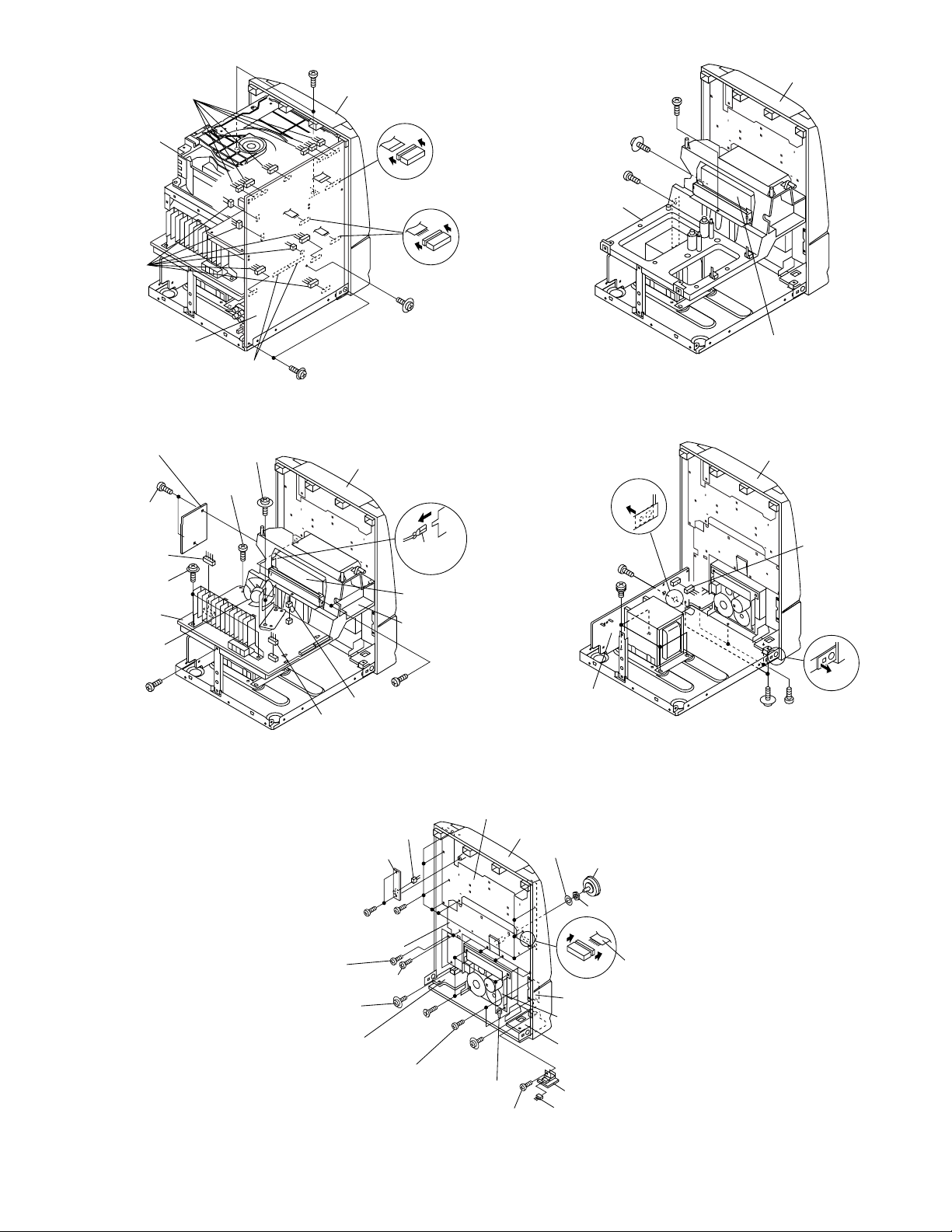

MAIN UNIT

STEP REMOVAL PROCEDURE FIGURE

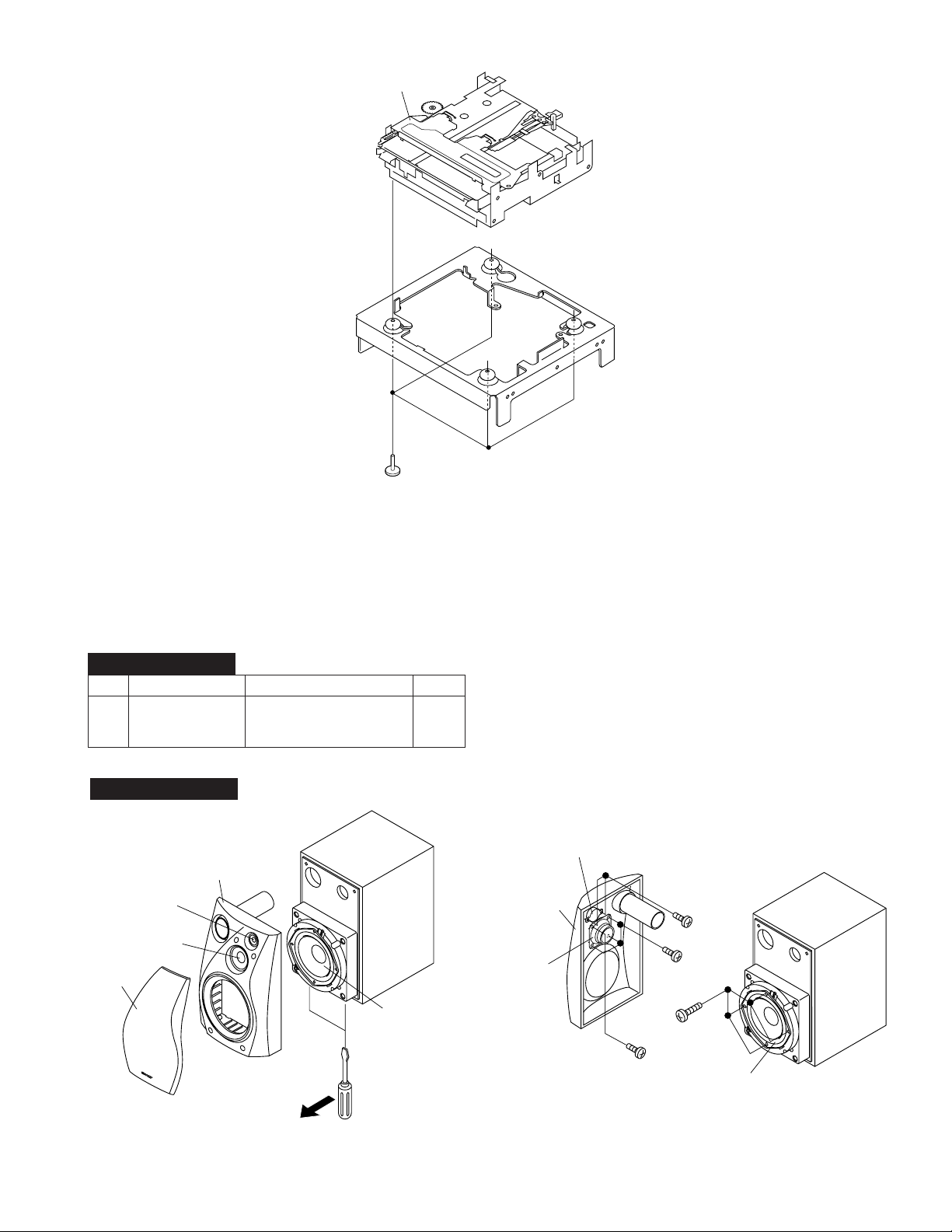

1 Cabinet 1. Screw ................ (A1) x9 10-1

2 Rear Panel 1. Screw ................ (B1) x16 10-1

(Upper,Bottom)

3 CD Changer Block 1. Screw ................ (C1) x6 11-1

4 Main PWB 1. Screw ................ (D1) x3 11-1

5 Fan Motor 1. Socket ............... (E1) x1 11-2

6 Power Amp. PWB 1. Socket ............... (F1) x2 11-2

7 Fuse PWB 1. Screw ................ (G1) x2 11-2

8 MD Holder 1. Screw ................ (H1) x4 11-2,3

9 MD Unit 1. Screw ................ (J1) x2 11-3

10 Front Panel 1. Socket ............... (K1) x1 11-4

11 Power PWB 1. Screw ................ (L1) x5 11-4

12 Tape Mechanism 1. Screw ................ (M1) x4 11-5

13 Tray Switch PWB 1. Screw ................ (N1) x2 11-5

14 Display PWB 1. Screw ................ (P1) x9 11-5

15 Switch A PWB 1. Screw ................ (Q1) x2 11-5

16 Switch B PWB 1. Knob .................. (R1) x1 11-5

17 Jack PWB 1. Socket ............... (S1) x1 11-5

18

MD Input Level PWB

19 Headphone PWB 1. Screw ................ (U1) x1 11-5

2. Screw ................ (C2) x2

2. Socket ............... (D2) x6

3. Flat Cable.......... (D3) x3

4. Socket ............... (D4) x2

2. Screw ................ (E2) x2

2. Lug Wire ............ (F2) x1

3. Screw ................ (F3) x3

2. Screw ................ (K2) x5

2. Socket ............... (N2) x1

2. Flat Cable.......... (P2) x1

2. Nut ..................... (R2) x1

3. Screw ................ (R3) x5

4. Screw ................ (R4) x1

2. Screw ................ (S2) x1

1. Screw ................ (T1) x1 11-5

STEP REMOVAL PROCEDURE FIGURE

20 CD Mechanism 1. Screw ................ (V1) x7 12-1

21 MD Mechanism 1. Screw ................(W1) x8 12-2

22 MD Main PWB 1. Screw ................ (X1) x4 12-3

(Note 1 ) 2. Socket ............... (X2) x5

23 MD Mechanism 1. Screw ................(Y1) x4 13-1

2. Top Bord ........... (V2) x1

3. Disc Holder ....... (V3) x1

4. Disc Tray ........... (V4) x3

5. Screw ................(V5) x3

6. Mechanism Holder

Guide................. (V6) x1

7.

Mechanism Holder

8. Screw ................(V8) x4

3. Flat Cable.......... (X3) x1

(V7) x1

Cares after repairing

After completion of repair of product set the following shipping

mode to return.

1. Make sure that there is no CD disc, and then press the VOLUP/CD DISC1 PLAY button to turn on the power, and set the

TEST mode.

2. After the indication of TEST END appears, unplug the power

cord. If this test mode is executed, the data stored by the

user in the preset memory are all cleared. It is necessary

tell and obtain the consent of user in advance.

MAIN UNIT

Cabinet

Front Panel

Rear Panel

(Upper)

(A1) x5

ø3 x8mm

(A1) x2

ø3 x8mm

(B1) x4

ø3 x8mm

(B1) x12

ø3 x8mm

(A1) x2

ø3 x8mm

Rear Panel

(Bottom)

Figure 10-1

Note 1: After removing the connector for the optical pickup

from the connector wrap the conductive aluminium foil

around the front end of connector so as to protect the

optical pickup from electrostatic damage.

– 10 –

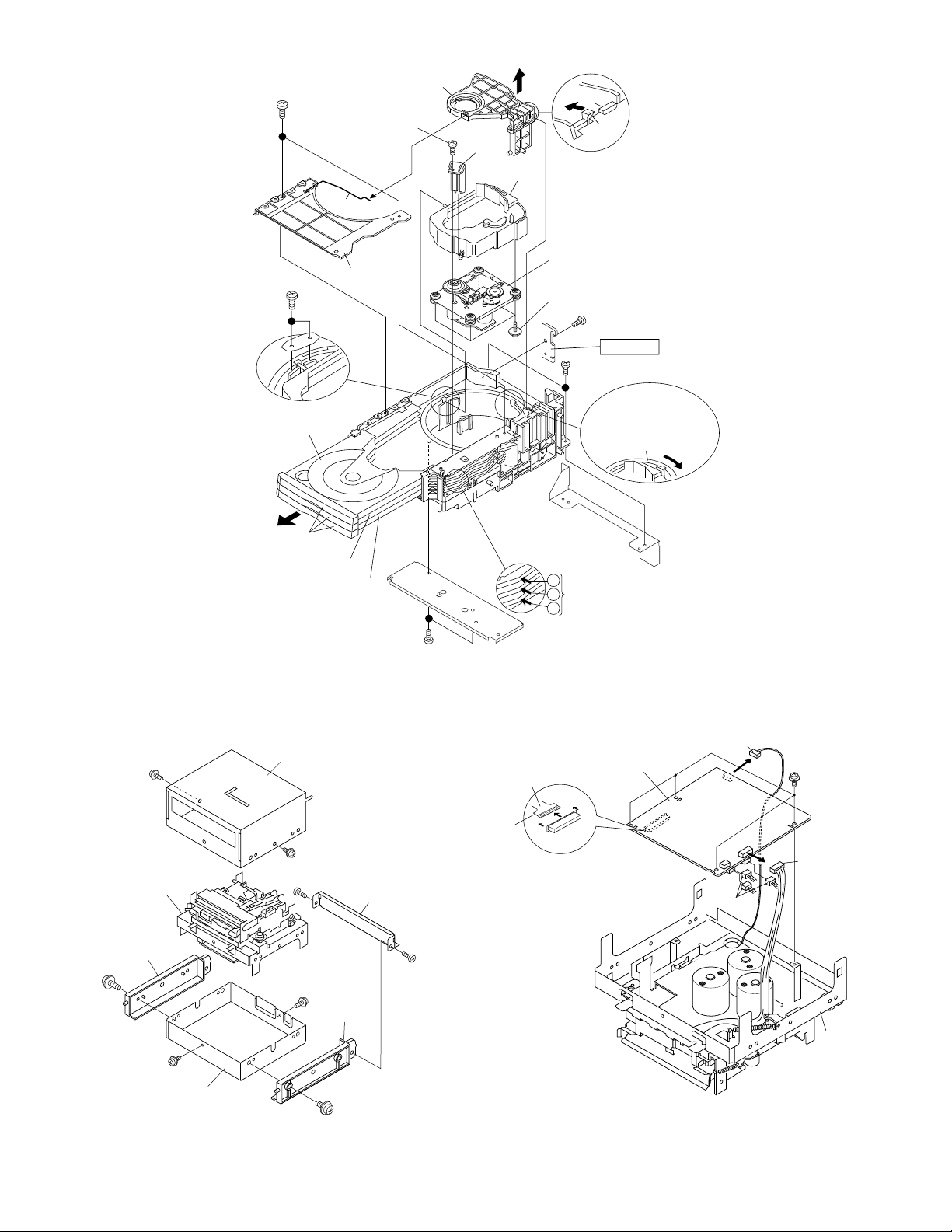

Page 11

CD Chenger

(K1) x1

(L1) x1

ø3 x8mm

(K2) x2

ø3 x10mm

(K2) x3

ø3 x8mm

(L1) x4

ø4 x8mm

Front Panel

Power PWB

Pull

Pull

Block

(C1) x6

(C2) x2

ø3 x10mm

Front Panel

(D3) x1

Pull

Pull

(D3) x2

Pull

(J1) x1

ø1.7 x3mm

(H1) x1

ø3 x10mm

MD Holder

(J1) x1

ø3 x10mm

MD-X60H

Front Panel

(D2) x6

Main PWB

Fuse PWB

(G2) x2

ø3 x10mm

(F1) x1

(F3) x2

ø3 x12mm

Power Amp.

PWB

Fan Motor

(H1) x1

ø3 x10mm

(D4) x2

(E2) x2

ø3 x10mm

(F3) x1

ø3 x10mm

Figure 11-1

(D1) x2

ø3 x10mm

Front Panel

(E1) x1

(F1) x1

Pull

(D1) x1

ø3 x10mm

(F2) x1

Lug wire

MD Unit

MD Holder

(H1) x2

ø3 x10mm

MD Unit

Figure 11-3

Figure 11-2

Tray Switch PWB

Switch B PWB

(R4) x1

ø3 x8mm

Headphone PWB

(N1) x2

ø3 x10mm

(R3) x5

ø3 x10mm

(U1) x1

ø3 x10mm

(N2) x1

(P1) x9

ø3 x10mm

(M1) x4

ø3 x10mm

(Q1) x2

ø3 x10mm

Display PWB

(T1) x1

ø3 x10mm

Lug Wire

Figure 11-5

– 11 –

Front Panel

Washer

(S2) x1

ø3 x10mm

(R1) x1

(R2) x1

Pull

(P2) x1

Pull

Switch A PWB

Tape Mechanism

MD Input Level PWB

Jack PWB

(S1) x1

Figure 11-4

Page 12

MD-X60H

(X3)x1

(X2)x1

(X2)x3

(X2)x1

(X1)x4

ø1.7 x 3mm

MD Main PWB

Pull

(W4) x1

Chassis

Optical pickup

Flexible PWB

(Note 1)

(Note 1) After removing the flexible PWB for optical pickup

from the connector wrap the front end of flexible PWB in

conductive aluminum foil so as to protect the optical pickup

from being damaged electrostatically.

(V1) x2

ø2 x7mm

(V5) x2

ø2 x6mm

Disc Tray 1

Spring

(V2) x1

(V3) x1

(V5) x1

ø2.6 x12mm

(V6) x1

(V7) x1

.

Push

Pawl

CD

Mechanism

(V8) x4

ø2.6 x10mm

(V1) x1

ø3 x10mm

(V1) x2

ø3 x8mm

Turn clockwise the

main cam to raise the

CD mechanism up to

the uppermost position.

PWB-B8

(W1) x 1

ø3 x 10mm

(W1) x 1

ø2 x 4mm

MD Unit

MD Holder

(V4) x3

Disc Tray 2

Disc Tray 3

shield Case(Upper)

(W1) x 1

ø2 x 4mm

(W1) x 1

ø3 x 10mm

(W1) x 1

ø2 x 4mm

MD Holder

(V1) x2

ø3 x10mm

Bracket

(W1) x 1

ø3 x 10mm

Figure 12-1

Press in turns the arrow

1

parts, starting with the

2

uppermost one, to

3

withdraw the disc trays

(W1) x 1

ø2 x 4mm

shield Case(Below)

(W1) x 1

ø3 x 10mm

Figure 12-2

Figure 12-3

– 12 –

Page 13

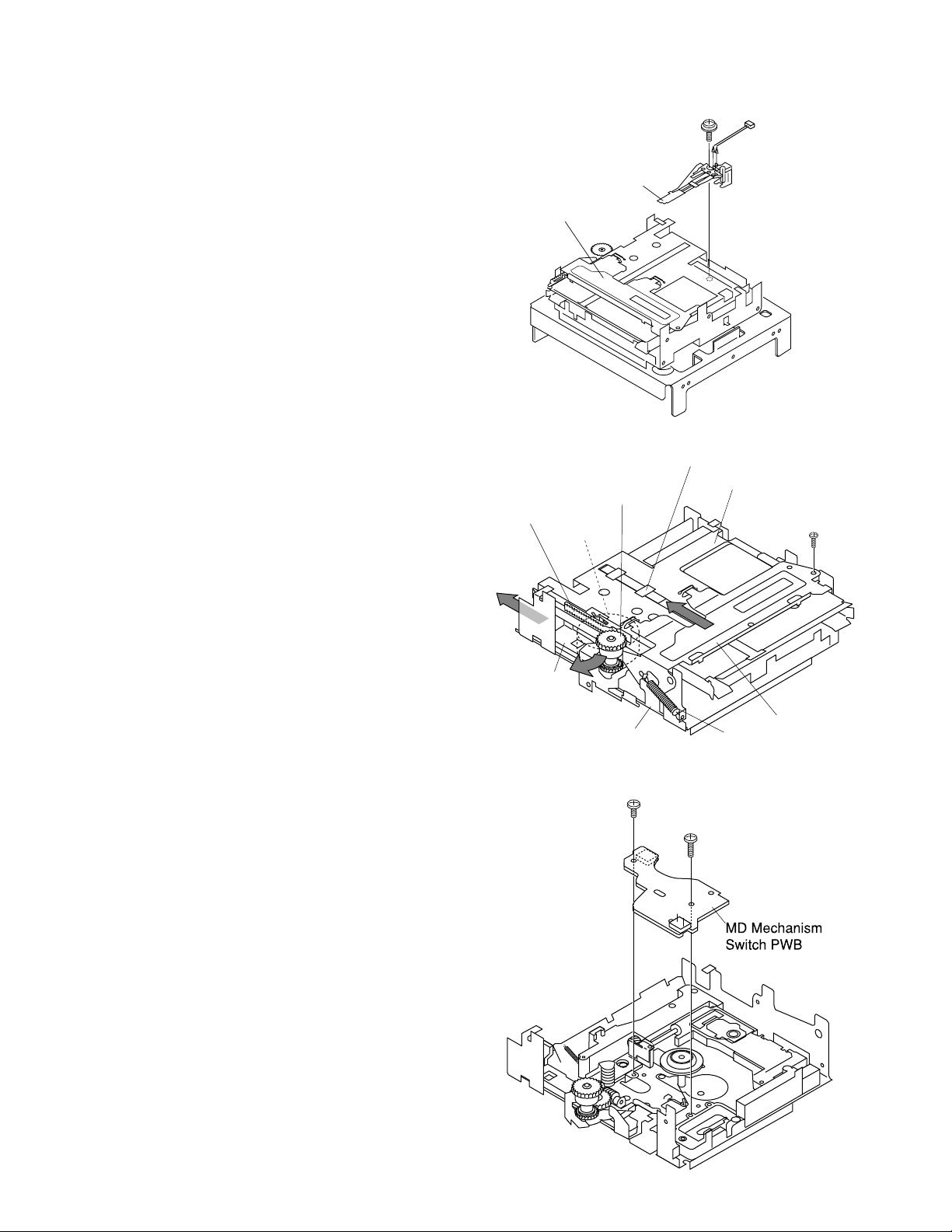

MD Mechanism

MD-X60H

(Y1)x4

ø1.7x8.9mm

Figure 13-1

SPEAKER

STEP REMOVAL PROCEDURE FIGURE

1 Speaker 1. Net ..................... (A1) x1 13-2

2. Front Panel ....... (A2) x1

3. Screw ................(A3) x10 13-3

SPEAKER

Front Panel

( A2 ) x1

Super Tweeter

Super Tweeter

Front Panel

( A3 ) x2

ø3x10mm

Net

( A1 ) x1

Tweeter

Figure 13-2

Woofer

– 13 –

Tweeter

( A3 ) x1

ø3x6mm

( A3 ) x3

ø3x8mm

( A3 ) x4

ø4x16mm

Woofer

Figure 13-3

Page 14

MD-X60H

REMOVING AND REINSTALLING THE MAIN P ARTS

MD MECHANISM SECTION

Perform steps 1 to 9,21 and 23 of the disassembly method to

remove the MD mechanism.(Refering to p.10~13)

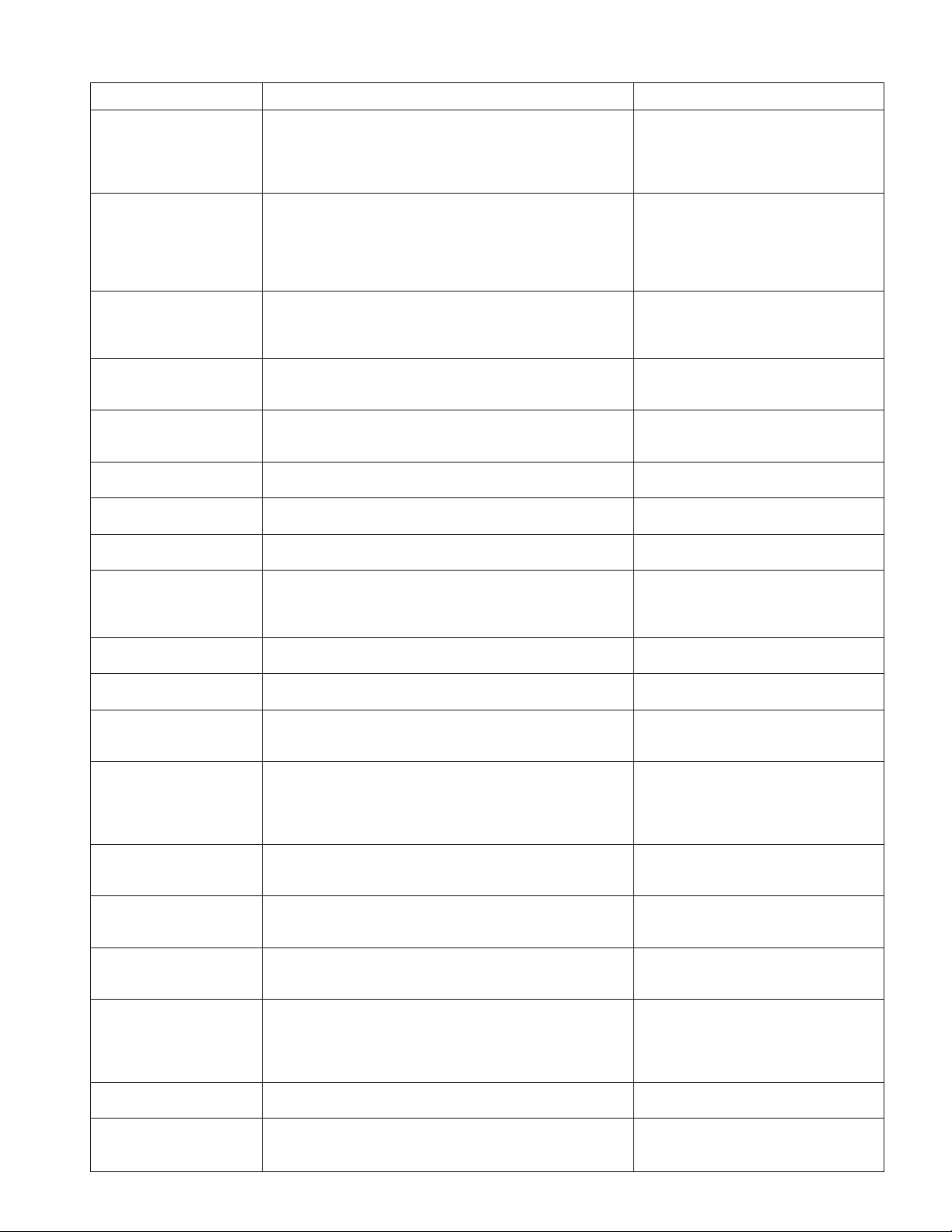

How to remove the magnetic head

(See Fig. 14-1)

1. Remove the screws (A1) x 1 pc.

Caution:

Take utmost care so that the magnetic head is not damaged

when it is mounted.

How to remove the cartridge holder

(See Fig. 14-2)

1. Open the rpller arm lever in the arrow direction, and lower

the clamper lever to the rear side.

2. Apply +5V to the red line side of blue connector of loading

motor, push the rack gear in the arrow direction to move the

cam plate lever until tick is heard.

3. Remove the screw (B1) x1 pc., and the spring (B2) x1 pc.,

fitted to the holder arm, and shift the cartridge holder to the

left side to remove it.

MD Mechanism

Clampa Lever

Loading Motor

Magnetic Head

Figure 14-1

Slider Lever

Roller Arm Lever

(A1)x1

ø1.7x5mm

Cartridge Holder

(B1) x1

Ø1.7x5mm

How to remove the mechanism switch PWB

(See Fig. 14-3)

1. Remove the screws (C1) x 2 pcs., and remove the mechanism

switch PWB.

Lack Gear

Cam Plate Lever

Figure 14-2

(C1)x1

Ø1.7x3mm

Holder Arm

(B2) x1

(C1)x1

Ø1.7x9.5mm

– 14 –

Figure 14-3

Page 15

MD-X60H

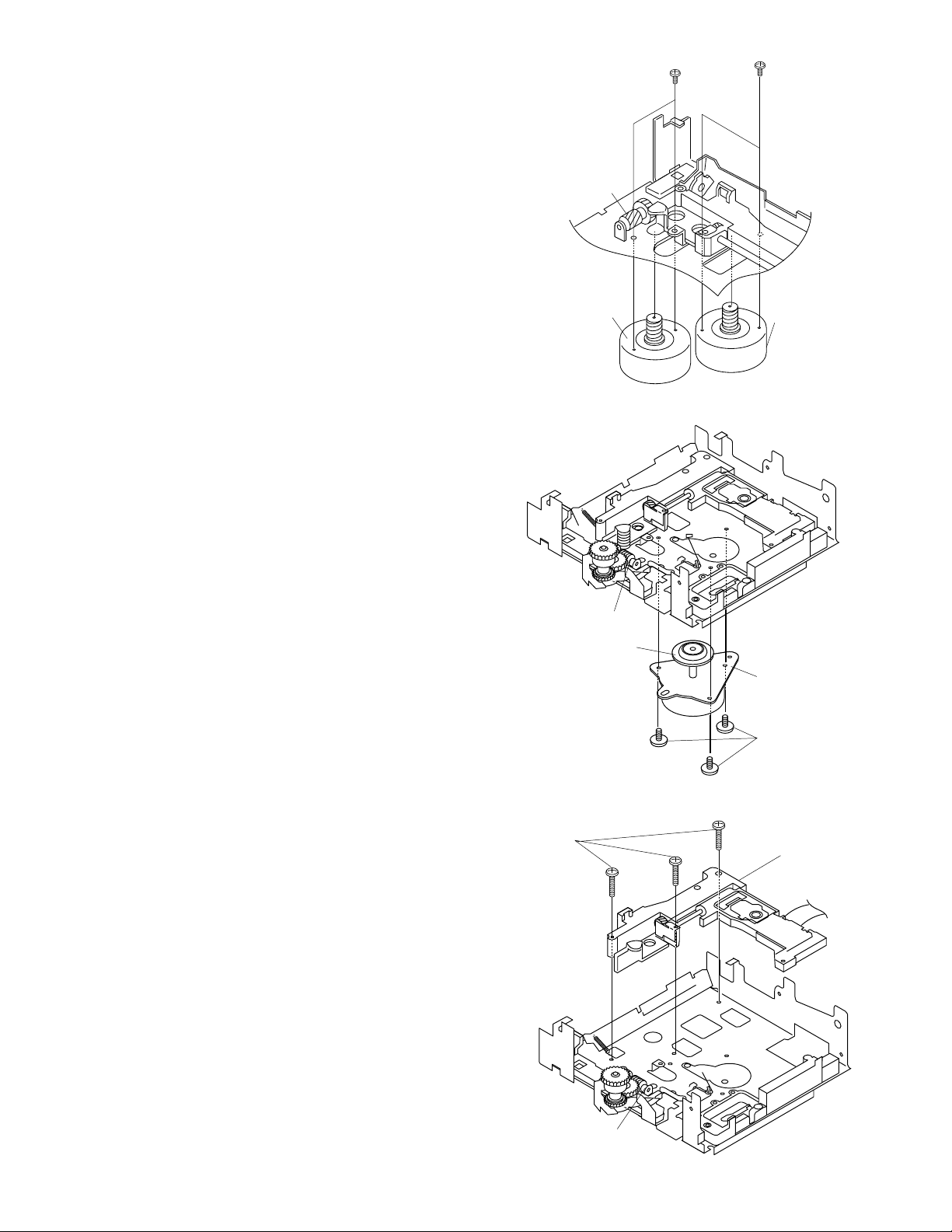

How to remove the sled motor/loading motor

(See Fig. 15-1)

1. Remove the screws (D1) x 4 pcs., and remove the sled

motor/loading motor.

Caution:

Be careful so that the gear is not damaged.

(The damaged gear emits noise during searching.)

How to remove the spindle motor

(See Fig. 15-2)

1. Remove the screws (E1) x 3 pcs., and remove the spidle

motor.

(D1)x2

Ø1.7x2mm

Gear

Loading

Motor

(D1)x2

Ø1.7x2mm

Sled

Motor

Figure 15-1

Caution:

Be careful so that the turntable is not damaged.

How to remove the optical pickup

(See Fig. 15-3)

1. Remove the screws (F1) x 3 pcs.

Caution:

Be careful so that the gear is not damaged.

(The damaged gear emits noise during searching.)

Gear

Turntable

Spindle Motor

(E1)x3

Ø1.7x2.5mm

Figure 15-2

(F1)x3

Ø1.7x9.5mm

Optical Pickup

– 15 –

Gear

Figure 15-3

Page 16

MD-X60H

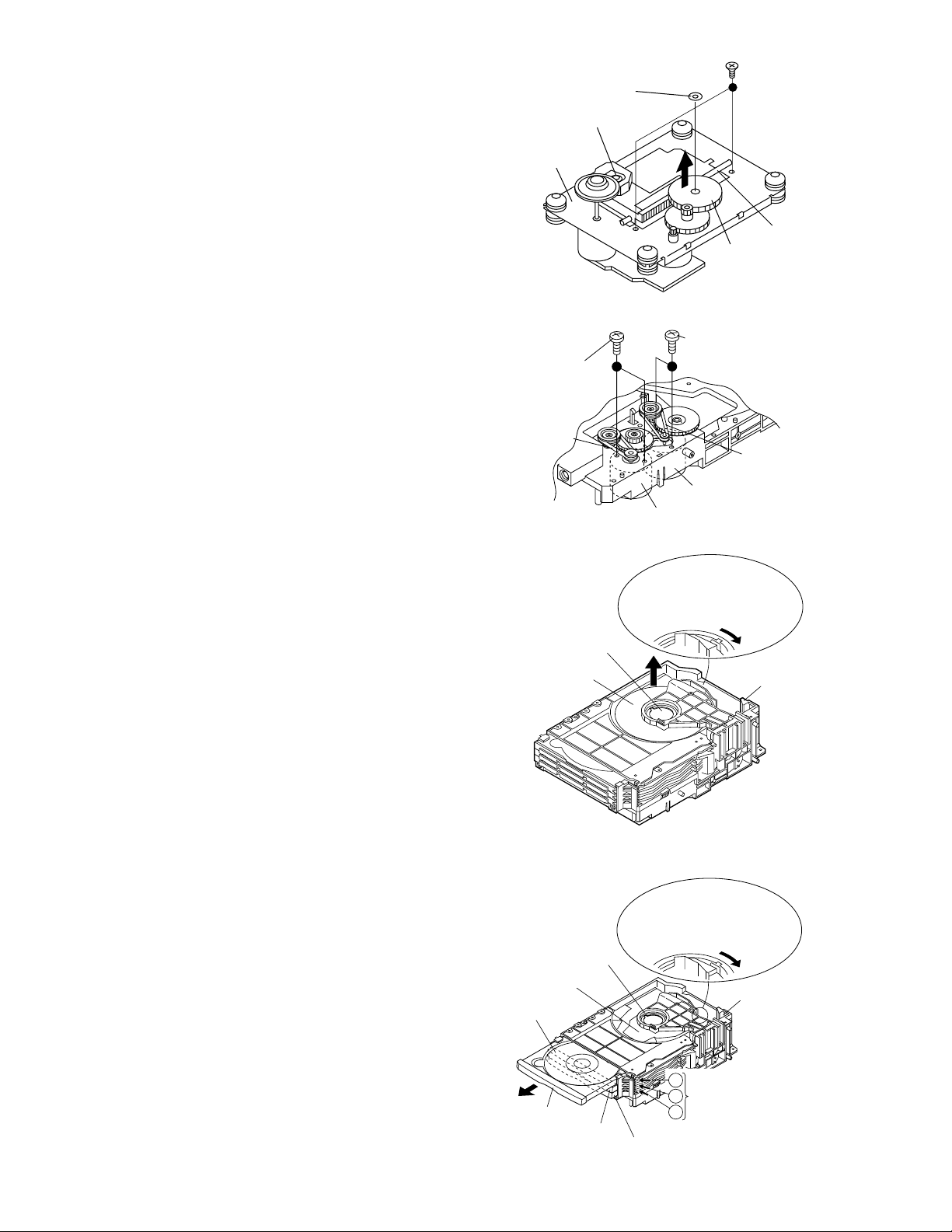

CD MECHANISM SECTION

For the procedure to remove the CD mechanism from the

main unit, refer to Disassembling Procedure, Steps 1~3, and

20. (p.10~12).

How to Remove the optical pickup

(See Fig. 16-1.)

1. Remove the screws (A1)x 2 pcs., to remove shaft (A2)x 1

pc.

2. Remove stop washer (A3)x 1 pc., to remove gear (A4)x 1 pc.

3. Remove the optical pickup.

Note:

After disconnecting the optical pickup connector wrap the

front end of connector in conductive aluminum foil so as to

prevent damage to the optical pickup by static electricity.

How to Remove the tray motor/main cam motor

(See Fig. 16-2.)

1. Remove the CD changer section by the method described

in page 8, and disassemble as shown in the figure.

2. Remove the belts (B1)x 2 pcs., from the motor side.

3. Remove the screws (B2)x 4 pcs.

4. Remove the tray motor and main cam motor.

Stop Washer

(A3) x1

Pickup

CD

Mechanism

(B2) x2

ø2.6 x4mm

Belt

(B1) x1

(A1) x2

ø2.6 x5mm

Figure 16-1

(B2) x2

ø2.6 x4mm

Main Cam

Motor

Tray Motor

Figure 16-2

Gear

(A4) x1

Belt

(B1) x1

Shaft

(A2) x1

How to remove the CD disc

(When CD is in playback state)

(See Fig. 16-3.)

1. Remove the cabinet and front panel.

2. Disassemble as shown in the figure so that the CD disc of

CD changer becomes visible.

3. Remove the CD disc as shown in the figure.

How to remove the CD disc

(When CD exists in the tray)

(See Fig. 16-4.)

1. Remove the cabinet and front panel.

2. Disassemble as shown in the figure so that the CD disc of

CD changer can be taken out.

3. Remove the CD disc from the tray as shown in the figure.

Turn the main cam clockwise,

and raise the CD mechanism

and disc holder up to

uppermost position.

Disc Holder

CD Disc

(When CD is in playback state.)

Figure 16-3

Turn the main cam clockwise,

and raise the CD mechanism

and disc holder up to

Disc Holder

CD Mechanism

CD Disc

uppermost position.

CD Changer

Block

CD Changer

Block

– 16 –

Disc Tray 1

Disc Tray

Press in turns the arrow

1

parts, starting with the

2

uppermost one, to

3

2

Disc Tray

withdraw the disc trays

3

(When CD exists in the tray.)

Figure 16-4

Page 17

ADJUSTMENT

TUNER SECTION

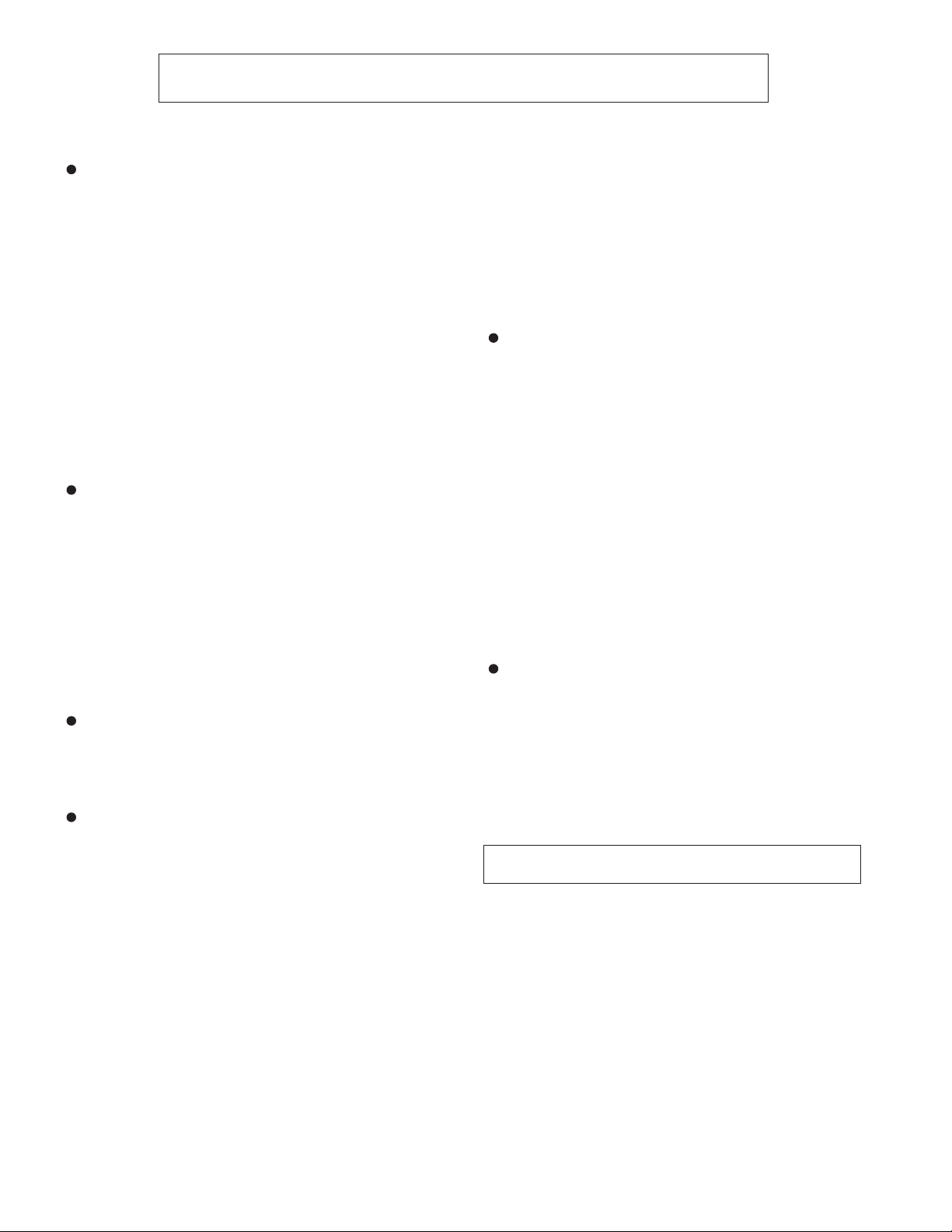

fL: Low-range frequency

fH: High-renge frequency

• AM adjustment and confirmation

AM signal oscillator Frequency 400 Hz, 30%, AM modulation

Adjusting item Adjusting object

IF Adjust the indication of Set IF wafeform

T351 set to 1,620 kHz.

Frequency cover fL: T306 (522 kHz) fL: 1.1 ± 0.1 V

(VT line voltage of Adjust the indication fH: 7.3 ± 1.3 V

of pin 20 of IC302) of set to 522 kHz. (Only confirmation)

fH: (1,620 kHz)

Tracking fL: T302 (990 kHz) Set the output of

Adjusting

method

450 kHz to maximum.

speaker terminal

to maximum.

MD-X60H

• TEST mode setting method

Holding down the ENTER button and TUNER (BAND) button,

turn on the power. Frequency is set in the memory (initial

setting) as shown in Table 17. Call the setting with the

PRESET button to use it for tuner circuit adjustment or

confirmation.

Preset No. Frequency

P01 87.50 MHz P06 522 kHz

P02 108.00 MHz P07 1,620 kHz

P03 90.00 MHz P08 603 kHz

P04 106.00 MHz P09 1,404 kHz

P05 98.00 MHz P10 990 kHz

Table 17 Initial setting of memory

Preset No. Frequency

• FM mute level adjustment

FM signal oscillator Frequency 400 Hz, 22.5 kHz

Frequency Adjusting

98 MHz 30 dB VR351 Input: SO301

FM signal oscillator

Adjusting

method

AM Loop Antenna

Loop Antenna

object

IF : Speaker Terminal

Freqency cover: IC302,Pin 20

UNIT

Adjusting object

Output: Speaker

Terminal

GND

Figure 17-1 AM IF

SO301

FM signal oscillator

UNIT

Speaker

Terminal

Figure 17-2 FM Mute Level

Electronic

voltmeter

Electronic

voltmeter

• Erasing the registered broadcast station

Holding down TRACK EDIT and ENTER in power-off state,

press POWER.

All the registered stations are erased.

Note:

Even when the RESET switch provided at the rear side of this

model, is pressed, the preset of tuner is not cleared.

TUNER PWB

T351

AM IF

VR351

FM Mute Level

T306

AM Band Coverge

T302

FE301

AM Tracking

1213

IC302

20

1

– 17 –

CNP301

SO301

Antenna Terminal

Figure 17-3 Adjustment Point

Page 18

MD-X60H

TAPE SECTION

Adjusting the mechanism

Driving Force Check

Torque Meter Specified Value

Play:TW-2412 120 g or more

Reverse Play:TW-2422 120 g or more

Checking the playback/FF/rewinding torque

Torque Meter Specified Value

Play:TW-2111 25 to 65 g.cm

Reverse Play:TW-2121 25 t o 6 5 g.cm

Fast forward:TW-2231 60 to 130 g.cm

Rewind:TW-2231 60 to 130 g.cm

Adjusting the record / playback head azimuth

Test Tape

MTT-114 Output: L:TP102 pin 3

Tape Speed

Test Tape

MTT-111 VR107 3,000±30Hz L:TP102 pin 3

* Raise the cassette holder cover and remove it, and then

adjust the azimuth.

Adjusting Point

Instrument Connection

R:TP102 pin 1

Specified Value

Instrument Connection

R:TP102 pin 1

Adjusting the deck circuit

Position of each swich or control

VOLUME MAX

FUNCTION TAPE

TAPE NORMAL

DOLBY NR OFF

REVERSE MODE NORMAL

BEAT SW A

Checking the bias oscillation Frequency

Adjusting Point Specified Value

- 102±7kHz TP101(IC102 pin 3)

Adjusting the record/playback frequency

Test Tape

UR-121 L:VR101 10mV Output

Adjusting Point

Record level control

R:VR102 L:TP102 pin 3

Adjusting the playback amplifier sensitivity

Test Tape

Adjusting Point

MTT-150 L:VR103 Standard:300mV L:TP102 pin 3

R:VR104 R:TP102 pin 1

Specified Value

Instrument Connection

Specified Value

10mV Input:AUX

Instrument Connection

(10kHz)

R:TP102 pin 1

Instrument Connection

TAPE

SPEED

R-CH

PLAY SENS.

L-CH

PLAY SENS.

MAIN PWB

L-CH

REC FREQUENCY

R-CH

REC FREQUENCY

VR101

VR102

TP101

CNP930

IC102

3

VR104

CNP101

Adjusting the record/playback sensitivity

Test Tape

UR-121 L:VR105 100mV Output

VR107

CNP102

VR103

VR105

Adjusting Point

Record level control

Specified Value

100mV Input:AUX

R:VR106 L:TP102 pin 3

CNP103

CNP920

L-CH

REC SENS.

R-CH

VR106

TP102

2

1

3

Pin 1 : R

Pin 3 : L

REC SENS.

Instrument Connection

(1kHz)

R:TP102 pin 1

Figure 18 Adjustment Point

– 18 –

Page 19

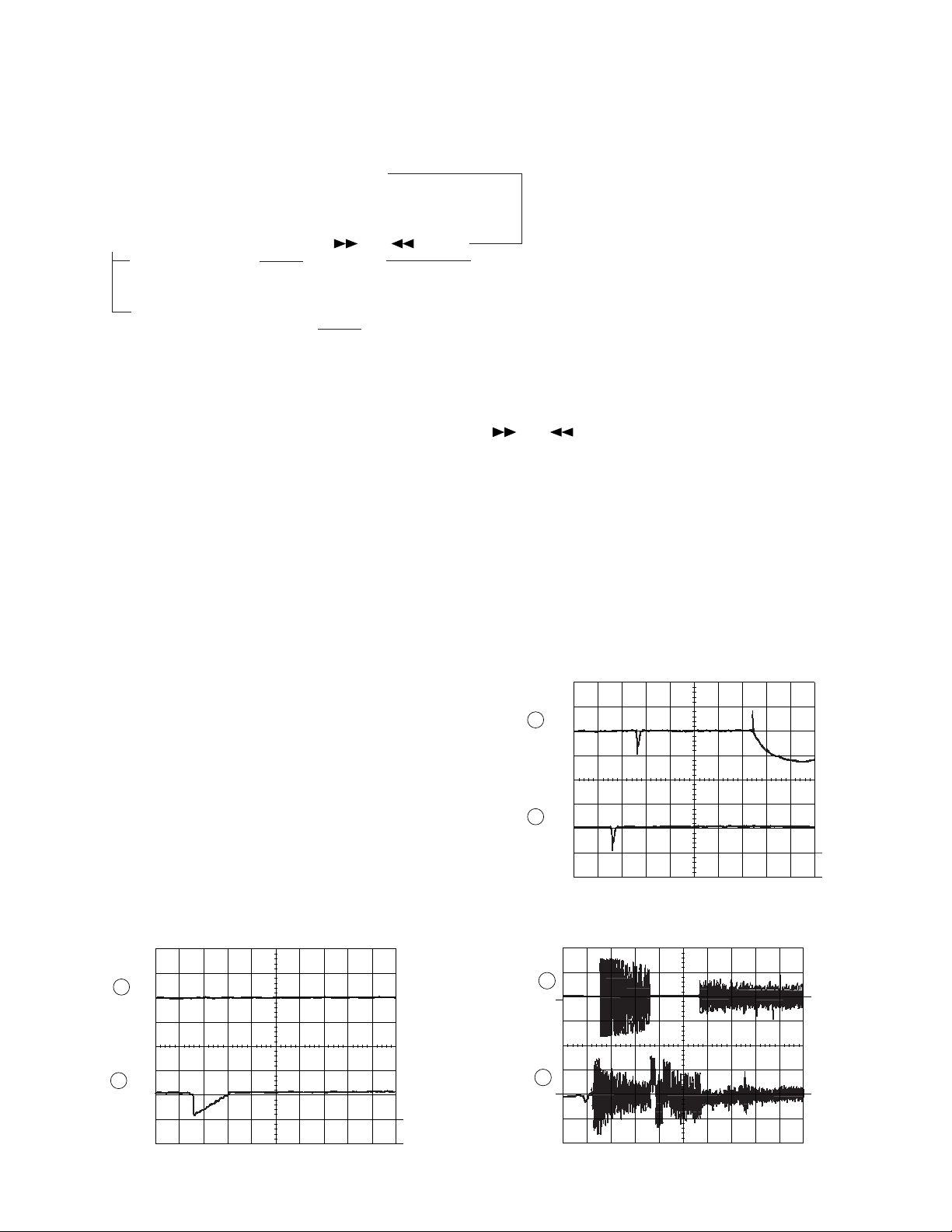

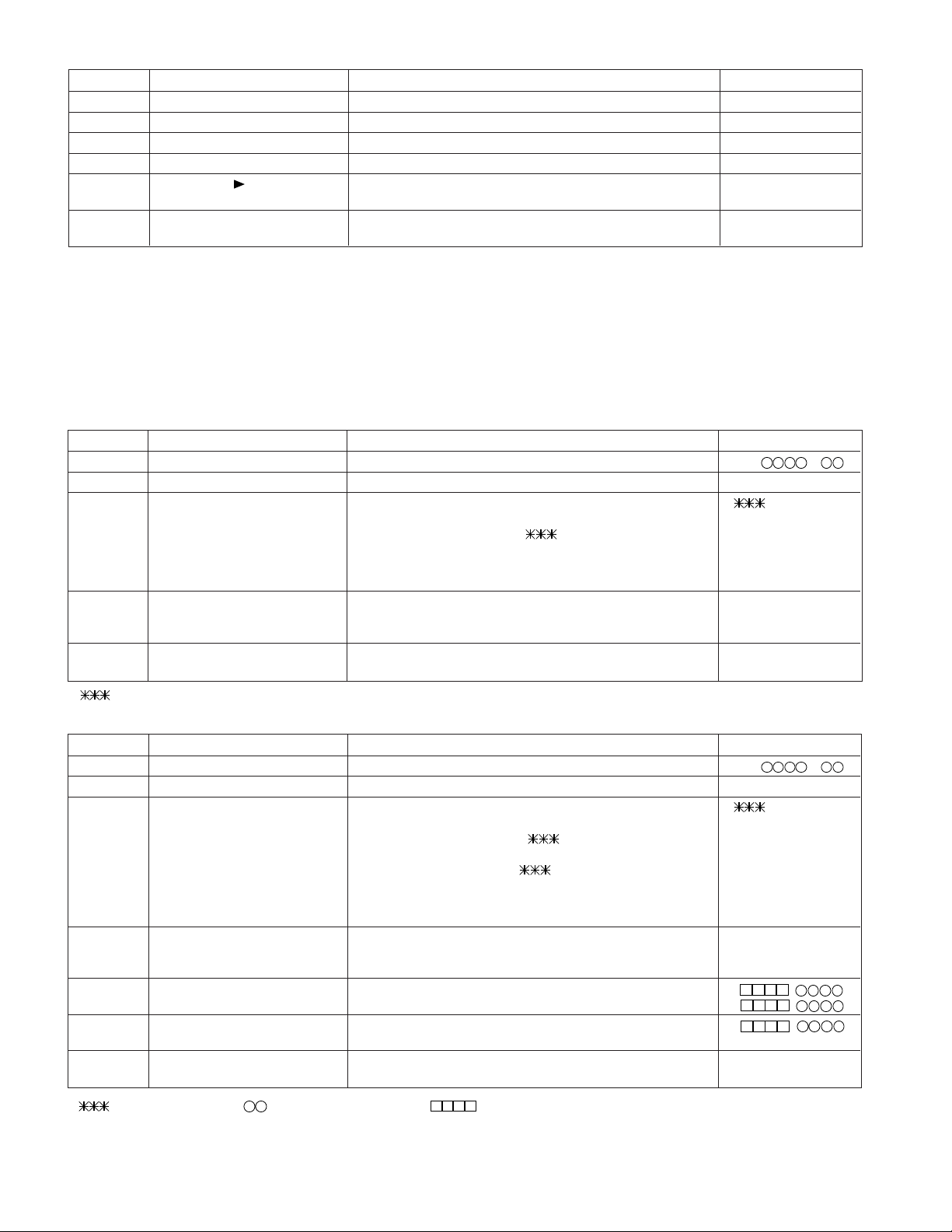

CD TEST MODE

CD test mode setting

Any one of test mode can be set by pressing several buttons as follows.

Holding down VOL-UP and CD DISC 3 PLAY, turn on POWER. TEST: CD operation test

Test Mode

Function - CD TEST mode

Setting of Test mode

Indication of CD TEST mode

OPEN/CLOSE operation is manual operation.

The pickup can be moved with the (

) or ( ) button.

<CD MD EDIT> <TRACK> <CD-STOP>

Tracking on the spot. Tracking on the spot. STOP

SERVO ON PLAY SERVO OFF PLAY

<PLAY> button input - TOC. Initialization performed, and the ordinary PLAY is performed.

Press the <STOP> button. Stop

If the following button is pressed during PLAY, it is possible to specify directly any Track No.

<Disc 1 PLAY> button: Track 4

<Disc 2 PLAY> button: Track 9

<Disc 3 PLAY> button: Track 15

Note:

Only in STOP state it is possible to slide the pickup with the (

Cancel method: POWER OFF

Initialization is not performed.

) or ( ) button.

MD-X60H

CD SECTION

Since this CD system incorporates the following automatic adjusting function, when the pickup is replaced, it is not necessary

to the readjust it .

Since this CD unit does not need adjustment, the combination of PWB and laser pickup unit is not restricted.

Automatic adjustment items

1. Focus Offset (Fig. 19-1)

2. Tracking Offset (Fig. 19-2)

3. E/F Balance (Tracking Error Balance) (Fig. 19-3)

4. R/F level AGC function (HF level: Constant)

5. RF level automatic follow-up of the tracking gain

This automatic adjustment is performed each time a disc

is changed. Therefore, each disc is played back using

the optimal settings.

10ms

0.50 V

IC1 20 FE

Enlarged

View

0.1s

0.50 V

IC1 20 FE

0.1s

0.50 V

IC1 7 TE

200 ms

1V/diV

IC 1 15

TO

Figure 19-1

FOCUS

OFF-SET

ADJUST

TRACKING

OFF-SET

ADJUST

1

2

TRACKING/

ERROR

BARANCE

1

ADJUST

10ms

0.50 V

IC1 7 TE

Figure 19-2

TRACKING

OFF-SET

ADJUST

1

2

– 19 –

200 ms

1V/diV

IC 1 7

TE

2

Figure 19-3

Page 20

MD-X60H

MD SECTION

When the combination of mechanism/pickup and PWB was changed , set the TEST mode to perform the AUTO preliminary

adjustment and AUTO adjustment, write the adjustment data in EEPROM.

When EEPROM was replaced, set the TEST mode,write the EEPROM set data (p29,p30) and then perform the preliminary

adjustment and AUTO adjustment, write adjustment data in EEPROM.

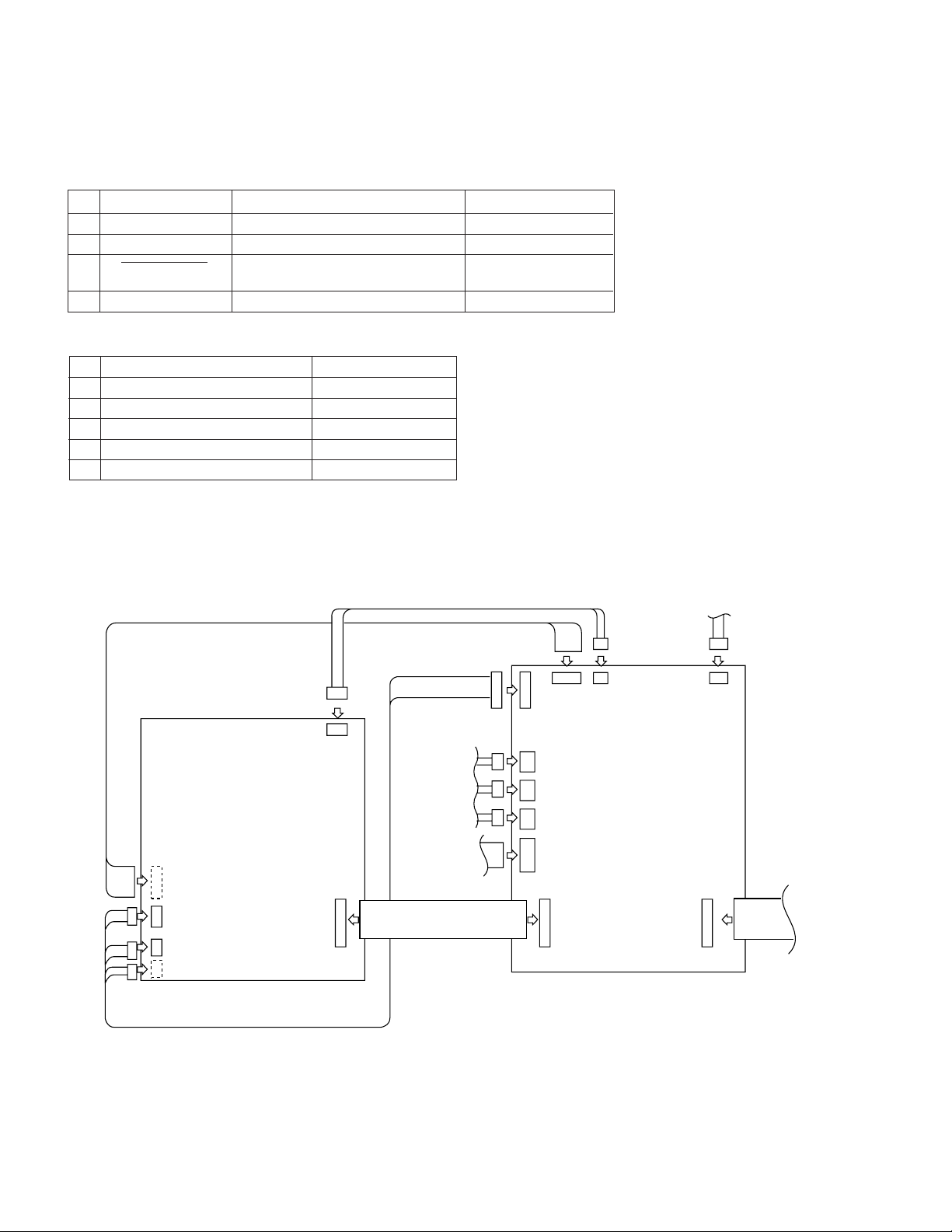

1. Preparation for adjustment

Test disc

Type Test disc

1 High reflection disc TGYS1 (SONY) [for Playback] RRCDT0101AFZZ

2 Low reflection disc Recording minidisc UDSKM0001AFZZ

3 Head Adjusting transparent RRCDT0103AFZZ

[TEAC Test MD]

4 Low reflection disc Pre-adjustment disc 88GMMD-318

Extension Cable (See Fig. 19)

Type Part No.

1 Extension PWB for servicing RUNTK0457AFZZ

2 Extension Connector (2 Pin) QCNWK0059AFZZ

3 Extension Connector (6 Pin) QCNWK0107AFZZ

4 Extension Cable (5 Pin) QCNWK0109AFZZ

5 Extension Cable (28 Pin) QCNWK0108AFZZ

Part No.

5Pin extension flat cable

QCNWK0109AFZZ

CN1601(Bottom side)

CN1602

CN1603

CN1604(Bottom side)

MD MAIN PWB

6P-2P extension connector

QCNWK0107AFZZ

CN1252

CN1101

2Pin extension connector

QCNWK0059AFZZ

From

motor

From mechanism switch

PWB

28Pin extension

flat cable

QCNWK0108AFZZ

From Magnetic Head

From Optical

Pickup Unit

Extension PWB for service

(RUNTK0457AFZZ)

Fit the extension PWB for service to the mechanism

Figure 20 Conection of Extention Cable

– 20 –

Page 21

2. Test mode

Test mode setting method

1. Holding down the POLE POSITION button and MD

(State A is changed to state B .)

2. Insert the playback disc 1 (high reflection disc) or recording disc 2 (low reflection disc). (State C is set.)

Thus, the test mode state is set.

(PLAY/PAUSE) button, press the POWER button.

MD-X60H

A tsm

TEST STOP state (When the MD

e : TEST MODE represents version of MD microcomputer.

(STOP) button is ressed in the C state, the indication A

is restored. To restore C again, press the CD

(PLAY/ PAUSE)

button.)

B EJECT

TEST

C AUT YOBI

TEST

Entering the specific mode

Whenever the CD

AUTO pre-adjustment AUTO adjustment RESULT Pre-adjustment

(PLAY/PAUSE) button is pressed, the mode is changed.

RESULT

EEPROM setting MANUAL adjustment MANUAL pre-adjustment

Cancel of TEST mode

When the ENTER button is pressed, data is written in EEPROM, and then the TEST mode is canceled. (Mode where automatic

adjustment is not performed)

To restore the usual state once reset.

When the data of EEPROM was changed or the preliminary adjustment was performed again, be sure to press the ENTER

button to write data in the EEPROM.

(Data is written in the EEPROM by pressing the ENTER button.)

* Be sure to ascertain "COMPLETION" by pressing the MD PLAY button in the AUTO preliminary adjustment mode before

pressing the ENTER button.

• Test Mode

1. EJECT mode • TEMP setting (of EEPROM setting)

• CONTROL setting (of EEPROM setting)

• Setting of laser power (record/playback power)

2. AUTO pre-adjustment mode • Automatic pre-adjustment is performed. (After adjustment the grating adjustment mode is set.)

• The adjustment value is output with the aid of system controller interface.

3. AUTO adjustment mode • Automatic adjustment is performed.

• The adjustment value is output with the aid of system controller interface.

• Continuous playback is performed. (Error rate indication, jump test)

• RESULT sub-mode •

• RESULT mode (final adjustment)

• MANUAL pre-adjustment mode

• MANUAL adjustment mode

4. EEPROM setting mode • Various coefficients of digital servo are changed manually.

5. TEST-PLAY mode • Continuous playback from the specified address is performed.

6. TEST-REC mode • Continuous recording from the specified address is performed.

7. INNER mode • The position where the INNER switch is turned on is measured.

Because the data of ROM is rewritten in this mode, set malfunction may occur. Therefore do

not set this mode since it is not necessary for the service.

• C1 error rate measurement, ADIP error rate measurement.

– 21 –

Page 22

MD-X60H

1. EJECT mode

Step No.

Step 1 Testmode EJECT state [ _ _ E J E C T _ _ _ ]

Step 2 Press oncethe CD STOP button. Max. power output state [ x p w _ _ _ _ _ _ _ ]

Step 3 Press once the CD STOP button. Record power output state [ r p w _ _ _ _ _ _ _ ]

Step 4 Press once the CD STOP button. Playback power output state [ p p w _ _ _ _ _ _ _ ]

Step 5 Press the CD MD EDIT button. TEMP setting of EEPROM setting

Step 6 Press the TRACK EDIT button. CONTROL setting of EEPROM setting

Confirmation of pickup laser power

It is possible to confirm in the record/playback mode with the aid of laser power meter. However, since the laser power meter

measurement is characterized with dispersion, obtained data are used only for confirmation.

Reference data (at room temperature 25°C)

Playback: 0.72±0.1 mV

Record: 5±1 mV

Note: Never see directly the laser light. Otherwise your eyes are injured.

2. AUTO pre-adjustment mode (Low reflection disc only)

With the pre-adjustment disc (MMD-318)

Step No. Setting Method Display

Step 1 Testmode STOP state [ t s m e ]

Step 2 Press once the CD PLAY button. AUTO pre-adjustment menu [ _ A U T _ Y O B I _ ]

Step 3 Press once the MD PLAY button. The slide moves to the innermost periphery, and automatic [ : _ _ _ _ _ _ ]

End of adjustment If adjustment is OK, Step 4.

Step 4 Grating adjustment, [ _ C O M P L E T E _ ]

adjustment value output

Press once the MD STOP button. STEP 2

Step 5 Adjustment value output [ C a n ' t _ A D J . ]

Press once the MD STOP button. STEP 2 AUTO pre-adjustment menu

• : Adjustment name

Setting Method

Remarks Display

(Refer to TEMP setting of EEPROM)

(Refer to CONTROL setting of EEPROM)

Remarks

pre-adjustment is started.

• During automatic adjustment changes as follows.

HAo→ • • • • • • • • • →LAO

If adjustment is NG, Step 5.

3. AUTO adjustment mode

Step No. Setting Method Remarks Display

Step 1 Testmode STOP state [ t s m e ]

Step 2

Step 3 Press once the MD PLAY button. The slide moves to the innermost periphery, and automatic [ : _ _ _ _ _ _ ]

Step 4 Adjustment value output For grating adjustment [ _ C O M P L E T E _ ]

Step 5 Continuous playback (pit section) Comfirmation of CI error [ s c ]

Step 6 Press the CD STOP button. Comfirmation of ADP error [ a a ]

Step 7 Adjustment value output [ C a n ' t _ A D J . ]

Press the CD PLAY button two times.

End of adjustment If adjustment is OK, Step 4.

Press the MD PLAY button. STEP 5

Press the MD STOP button. STEP 2

Continuous playback (groove section)

Press the MD STOP button. STEP 2 AUTO adjustment menu

Press the MD STOP button. STEP 2 AUTO adjustment menu

AUTO adjustment menu [ A U T O _ A J S T _ ]

adjustment is started.

• In case of high reflection disc changes as follows.

PEG→HAG

•In case of low reflection disc changes as follows.

PEG→LAG→GCG→GEG→LAG

If adjustment is NG, Step 7.

[ a c ]

• : Adjustment name, : Measurement value, : Address

– 22 –

Page 23

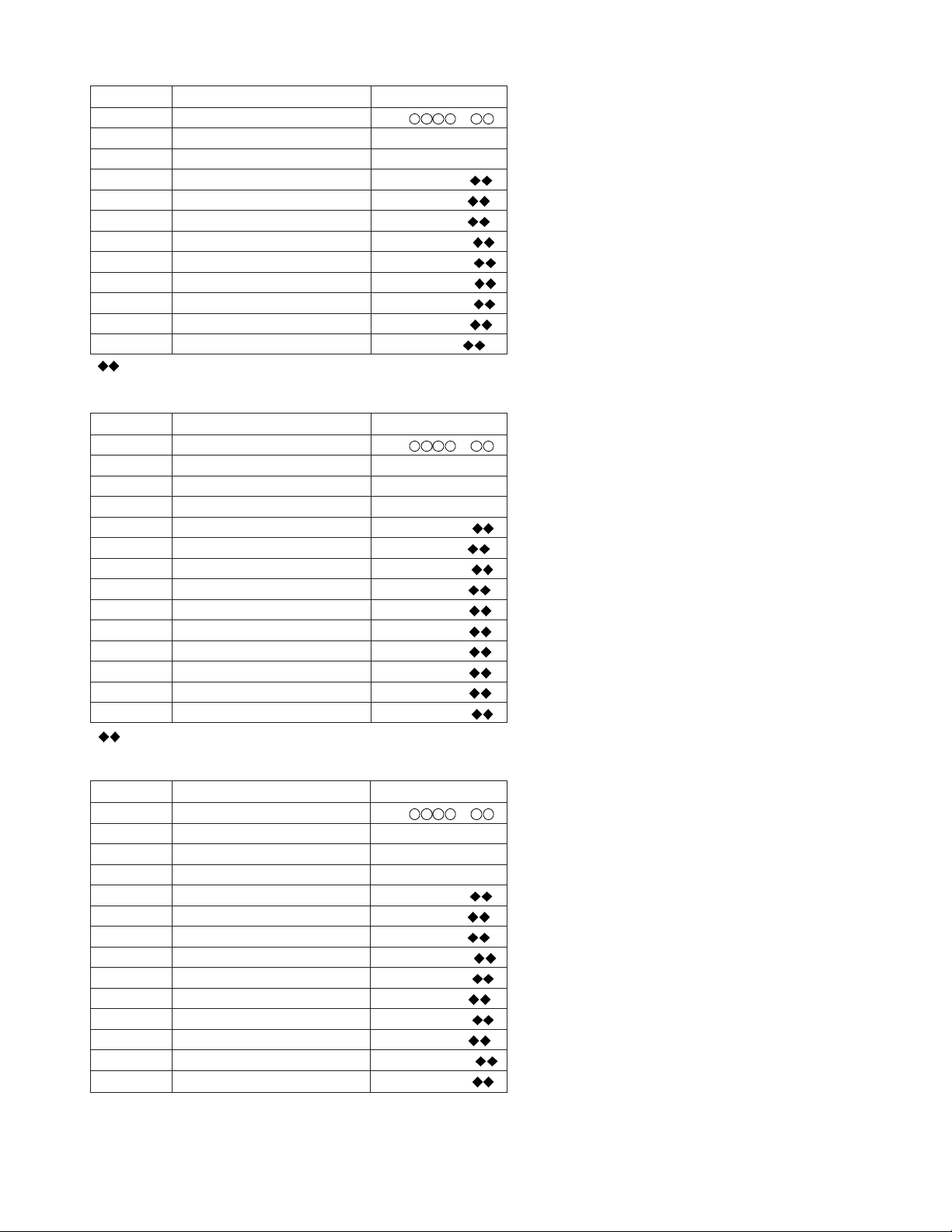

4. EEPROM setting mode

a) Focus setting

Step No.

Step 1 Testmode STOP state [ t s m e ]

Step 2

Step 3 Press once the MD PLAY button. [ _ _ F o c u s _ _ _ ]

Step 4 Press once the MD PLAY button. [ F G _ _ _ _ _ _ ]

Step 5 Press once the CD PLAY button. [ F F 1 _ _ _ _ _ ]

Step 6 Press once the CD PLAY button. [ F F 2 _ _ _ _ _ ]

Step 7 Press once the CD PLAY button. [ F Z H L E V _ _ ]

Step 8 Press once the CD PLAY button. [ F O K L E V n _ ]

Step 9 Press once the CD PLAY button. [ F O K L E V f _ ]

Step 10 Press once the CD PLAY button. [ F O K L P F n _ ]

Step 11 Press once the CD PLAY button. [ F O K L P F f _ ]

Step 12 Press once the CD PLAY button. [ W A I T f_ _ _ ]

: Setting value

•

Press the CD PLAY button seventimes.

Setting Method Display

[E E P R O M _ S E T]

b) Spindle setting

Step No.

Step 1 Testmode STOP state [ t s m e ]

Step 2

Step 3 Press once the MD PLAY button. [ _ _ F o c u s _ _ _ ]

Step 4 Press once the CD PLAY button. [ _ S p i n d l e _ _ ]

Step 5 Press once the MD PLAY button. [ S P G _ _ _ _ _ ]

Step 6 Press once the CD PLAY button. [ S P G _ i n _ _ ]

Step 7 Press once the CD PLAY button. [ S P G _ m i d _ ]

Step 8 Press once the CD PLAY button. [ S P G _ o u t _ ]

Step 9 Press once the CD PLAY button. [ S P 1 _ _ _ _ _ ]

Step 10 Press once the CD PLAY button. [ S P 2 _ _ _ _ _ ]

Step 11 Press once the CD PLAY button. [ S P 3 _ _ _ _ _ ]

Step 12 Press once the CD PLAY button. [ S P 4 _ _ _ _ _ ]

Step 13 Press once the CD PLAY button. [ S P 5 _ _ _ _ _ ]

Step 14 Press once the CD PLAY button. [ S P D L I M _ _ ]

• : Setting value

Press the CD PLAY button seven times.

Setting Method

Display

[E E P R O M _ S E T]

MD-X60H

c) Tracking setting

Step No.

Step 1 Testmode STOP state [ t s m e ]

Step 2

Step 3 Press once the MD PLAY button. [ _ _ F o c u s _ _ _ ]

Step 4

Step 5 Press once the MD PLAY button. [ T G _ _ _ _ _ _ ]

Step 6 Press once the CD PLAY button. [ T F 1 _ _ _ _ _ ]

Step 7 Press once the CD PLAY button. [ T F 2 _ _ _ _ _ ]

Step 8 Press once the CD PLAY button. [ S V C N T 4 _ _ ]

Step 9 Press once the CD PLAY button. [ T R B L V 0 _ _ ]

Step 10 Press once the CD PLAY button. [ T R B L V t _ _ ]

Step 11 Press once the CD PLAY button. [ T R K L V 0 _ _ ]

Step 12 Press once the CD PLAY button. [ T R K L V t _ _ ]

Step 13 Press once the CD PLAY button. [ T D P W o _ _ _ ]

Step 14 Press once the CD PLAY button. [ T D P W t _ _ _ ]

Press the CD PLAY button seven times.

Press the CD PLAY button two times.

Setting Method Display

[E E P R O M _ S E T]

[ _ T r a c k i n g _ ]

– 23 –

Page 24

MD-X60H

c) Tracking setting

Step No. Setting Method

Step 15 Press once the CD PLAY button. [ S L C T 0 _ _ _ ]

Step 16 Press once the CD PLAY button. [ S L C T t _ _ _ ]

Step 17 Press once the CD PLAY button. [ S L C T m _ _ ]

Step 18 Press once the CD PLAY button. [ T C R S C 1 P _ ]

Step 19 Press once the CD PLAY button. [ C O T L V P _ ]

Step 20 Press once the CD PLAY button. [ C O T L V r _ ]

Step 21 Press once the CD PLAY button. [ W A I T m_ _ _ ]

: Setting value

•

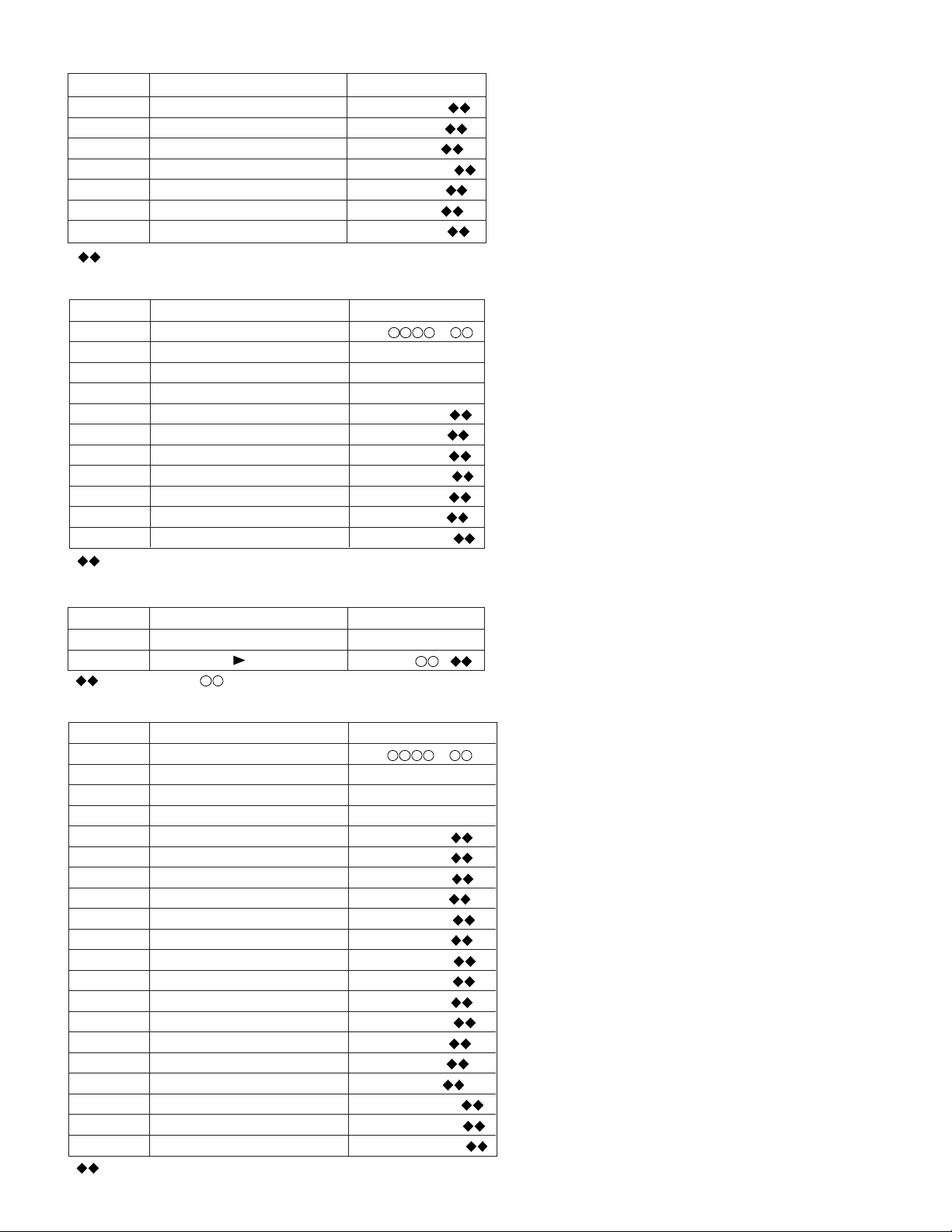

d) Slide setting

Step No.

Step 1 Testmode STOP state [ t s m e ]

Step 2

Step 3 Press once the MD PLAY button. [ _ _ F o c u s _ _ _ ]

Step 4

Step 5 Press once the MD PLAY button. [ S L G _ _ _ _ _ ]

Step 6 Press once the CD PLAY button. [ S L 2 _ _ _ _ _ ]

Step 7 Press once the CD PLAY button. [ S L D L I M _ _ ]

Step 8 Press once the CD PLAY button. [ S L D L E V _ _ ]

Step 9 Press once the CD PLAY button. [ S L K L V k _ _ ]

Step 10 Press once the CD PLAY button. [ S L K L V t _ _ ]

Step 11 Press once the CD PLAY button. [ S L K L V m _ _ ]

•

: Setting value

Setting Method

Press the CD PLAY button seven times.

Press the CD PLAY button three times.

Display

Display

[E E P R O M _ S E T]

[ _ _ _ S l e d _ _ _ ]

e) TEMP setting

Step No.

Step 1

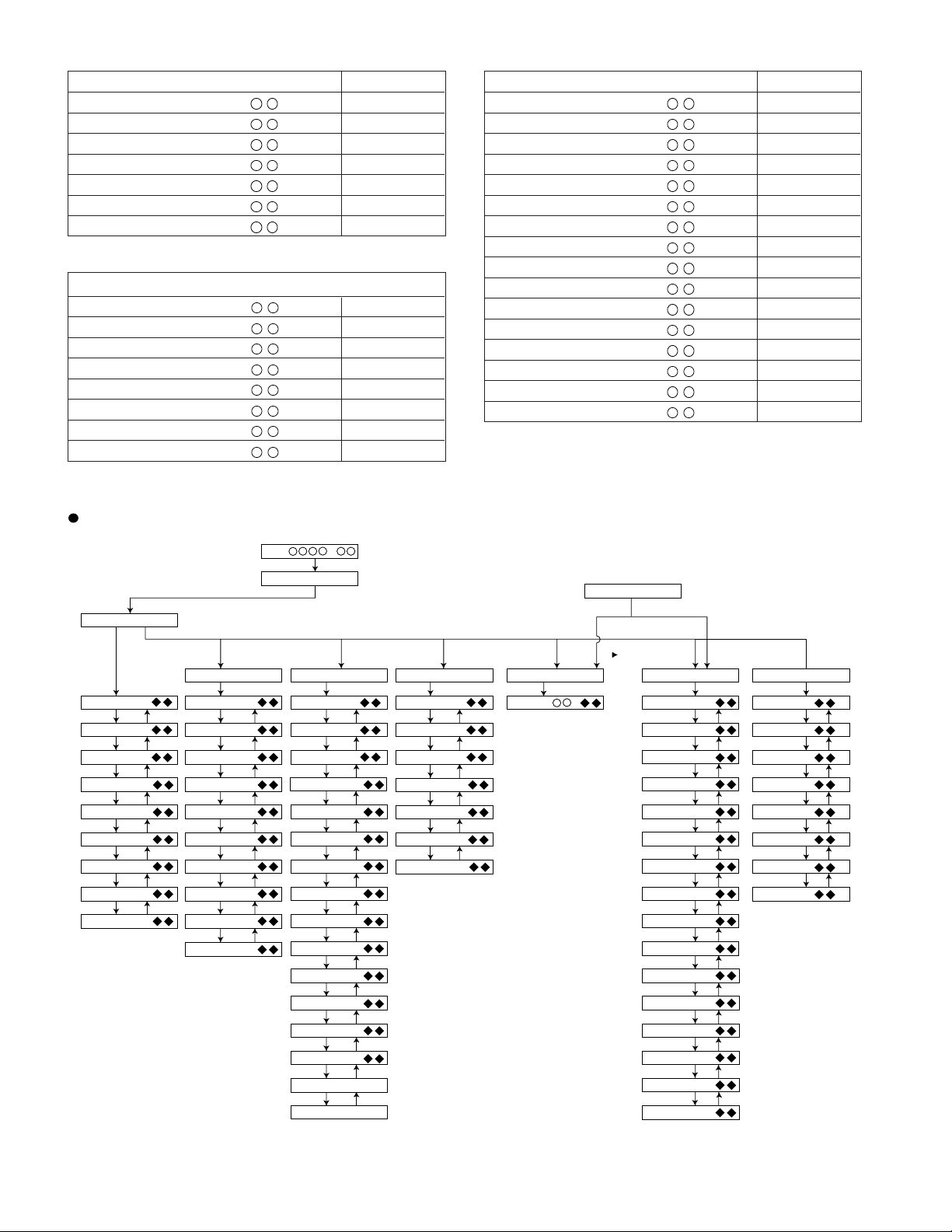

Step 2 Press the CD MD EDIT button. [ T E M P _ _ ]

• : Setting value, : Measurement value

EJECT state (or mechanism-less state)

Setting Method

Display

[ _ _ E J E C T _ _ _ ]

f) CONTROL setting

Step No. Setting Method Display

Step 1 Testmode STOP state [ t s m e ]

Step 2

Step 3 Press once the MD PLAY button. [ _ _ F o c u s _ _ _ ]

Step 4

Step 5 Press once the MD PLAY button. [ C O N T R L 1_ ]

Step 6 Press once the CD PLAY button. [ C O N T R L 2_ ]

Step 7 Press once the CD PLAY button. [ S P K L E V m_ ]

Step 8 Press once the CD PLAY button. [ A D J T T M_ _ ]

Step 9 Press once the CD PLAY button. [ H D E Q A D_ _ ]

Step 10 Press once the CD PLAY button. [ L D E Q A D_ _ ]

Step 11 Press once the CD PLAY button. [ G D E Q A D_ _ ]

Step 12 Press once the CD PLAY button. [ H D E Q B C_ _ ]

Step 13 Press once the CD PLAY button. [ L D E Q B C_ _ ]

Step 14 Press once the CD PLAY button. [ G D E Q B C_ _ ]

Step 15 Press once the CD PLAY button. [ H A L S G_ _ _ ]

Step 16 Press once the CD PLAY button. [ L A L S G_ _ _ ]

Step 17 Press once the CD PLAY button. [ G A L S G _ _ ]

Step 18 Press once the CD PLAY button. [ H A L S O F S_ _ ]

Step 19 Press once the CD PLAY button. [ L A L S O F S _ _ ]

Step 20 Press once the CD PLAY button. [ G A L S O F S _ _ ]

• : Setting value

Press the CD PLAY button seven times.

Press the CD PLAY button five times.

[E E P R O M _ S E T]

[ _ C o n t r o l _ _ ]

– 24 –

Page 25

MD-X60H

G) ADJUST setting

Step No. Setting Method

Step 1 Testmode STOP state [ t s m e ]

Step 2

Step 3 Press once the MD PLAY button. [ _ _ F o c u s _ _ _ ]

Step 4

Step 5 Press once the MD PLAY button. [ C O K _ _ _ _ _ ]

Step 6 Press once the CD PLAY button. [ F A T _ _ _ _ _ ]

Step 7 Press once the CD PLAY button. [ T A T _ _ _ _ _ ]

Step 8 Press once the CD PLAY button. [ C A T _ _ _ _ _ ]

Step 9 Press once the CD PLAY button. [ F A B _ _ _ _ _ _ ]

Step 10 Press once the CD PLAY button. [ S T R _ _ _ _ _ _ ]

Step 11 Press once the CD PLAY button. [ S F S _ _ _ _ _ _ ]

Step 12 Press once the CD PLAY button. [ S T C _ _ _ _ _ _ ]

: Setting value

•

Press the CD PLAY button seven times.

Press the CD PLAY button six times.

5. TEST-PLAY mode

(For comfirmation of the playback ability at the named address.)

Step No.

Step 1 Testmode STOP state [ t s m e ]

Step 2 Press the CD MD EDIT button. TEST-PLAY menu [ T E S T _ P L A Y _ ]

Step 3 Press once the CD STOP button. ADRES setting (Target address initial value is indicated) [ A D R E S _ 0 0 5 0 ]

Press once the MD PLAY button.

Step 4 Continuous playback (pit section) (Address + C1 error indication) [s c ]

Continuous playback (groove section)

Step 5 Press once the CD STOP button. (Address + ADIP error indication) [a a ]

Continuous playback (groove section)

Step 6 Press once the MD STOP button. TEST-PLAY menu [ T E S T _ P L A Y _ ]

• If the MD STOP button is pressed while the TEST-PLAY menu is displayed, TEST mode STOP state is set.

• If the MD PLAY button is pressed while the TEST-PLAY menu is displayed, continuous playback is started from the current pickup position.

• Whenever the CD

0 0 5 0 → 0 3 C 0 → 0 7 0 0 → 0 8 A 0 → 0 0 5 0 → …………

• Whenever the CD STOP button is pressed in the address setting mode, the digit which is changed with - / + changes as follows.

0 0 5 0 → 0 0 5 0 → 0 0 5 0 → 0 0 5 0 → …………

• The digit of address which has been specified with - / + and CD STOP button in the address setting mode is set to +01H/-01H.(0~F)

* If the - / + button is held down, the setting changes continuously with 100 ms cycle.

Setting Method

MD EDIT button is pressed in the address setting mode, the address changes as follows.

Display

[E E P R O M _ S E T]

[ A D J U S T _ _ _ ]

Remarks

(Address + C1 error indication) [a c ]

Display

6. TEST-REC mode

With recording mini disk (For comfirmation of the playback ability at the named address.)

Step No. Setting Method Remarks Display

Step 1 Testmode STOP state [ t s m e ]

Step 2 Press the CD MD EDIT button. TEST-REC menu [ T E S T _ R E C _ _ ]

Step 3 Press once the CD STOP button. ADRES setting (indication of address initial value) [ a 0 0 5 0 _ p w ]

Step 4 Press once the MD PLAY button.

Step 5 Press once the MD STOP button. TEST-REC menu [ T E S T _ R E C _ _ ]

• If the MD STOP button is pressed while the TEST-PLAY menu is displayed, TEST mode STOP state is set.

• If the MD PLAY button is pressed while the TEST-REC menu is displayed, continuous record is started from the current pickup position.

• Whenever the CD MD EDIT button is pressed in the address setting mode, the address changes as follows.

0 0 5 0 → 0 3 C 0 → 0 7 0 0 → 0 8 A 0 → 0 0 5 0 → …………

• Whenever the CD STOP button is pressed in the address setting mode, the digit which is changed with - / + changes as follows.

0 0 5 0 → 0 0 5 0 → 0 0 5 0 → 0 0 5 0 → …………

• The digit of address which has been specified with - / + and CD STOP button in the address setting mode is set to +01H/-01H.(0~F)

* If the - / + button is held down, the setting changes continuously with 100 ms cycle.

• Be sure to remove since excessive raising results in breakage of the pickup.

While searching, set the search output to "H". To start continuous play,

return it to "L".

Continuous recording

[ a p w ]

– 25 –

Page 26

MD-X60H

7. INNER mode

Step No.

Step 1 Testmode STOP state [ t s m e ]

Step 2 Press the TRACK EDIT button. INNER menu [ _ _ I N N E R _ _ ]

Step 3 Press once the MD PLAY button. INNER switch position measurement [s c ]

Step 4 Press once the MD STOP button. INNER menu [ _ _ I N N E R _ _ ]

• : Adress

Setting Method

Remarks Display

(SUBQ address and C1 error are also indicated.)

Lead-in switch position measurement mode

Insert High reflection test disk (TGYS1)

Note: Adjust the lead-in switch position to FF85 to FFD2.

1. Loosen the screw (A) x 2 pcs. which fix the mechanism switch

PWB.

2. Retighten the screw, pressing the mechanism switch PWB in

the arrow direction, and then measure the lead-in switch

position again.

After position adjustment fix with the two screws (A). (See Fig. 26-1.)

Note: After tightening the two screws on the PWB apply Screw Lock.

Forced rotation of loading motor

While the display indication is test mode STOP state or EJECT state,

the loading motor can be forcibly rotated by press theVOL UP/DOWN

button.

Adjustment of magnetic head mounting position

When the magnetic head and optical pickup have been replaced, be

sure to adjust the mounting position.

For easier adjustment of mounting position move the optical pickup

to the center position, and then adjust the position.

1. Set the adjusting transparent disc 3.

2. Lower the magnetic head up-shift arm with your finger, and raise

the magnetic head.

3. Viewing the set from above, make an adjustment so that the

magnetic head aligns with the optical pickup objective lens.

4. Make sure that there is a clearance as shown in Figure 26-2 and

the magnetic head moves up and down smoothly.

Loosen the

two screws (A).

Mechanism Switch PWB

Magnetic head

Objective lens

Circumferential direction

Lead In Switch

Figure 26-1

Radial direction

Push

Mechanism Adjustment

1. Optical pickup grating inspecting method

43 Pin of IC1101

GND (TP1131)

26 Pin of IC1101

EOUT (TP1133)