Page 1

MD-MS200W/MD-MS200/MD-MS200H

– 1 –

No. S4724MDMS200W

SERVICE MANUAL

CONTENTS

Page

SAFETY PRECAUTION FOR SERVICE MANUAL (MD-MS200H ONLY) ............................................................................ 2

BATTERY DISPOSAL (FOR MD-MS200 ONLY) .................................................................................................................. 3

SPECIFICATIONS ................................................................................................................................................................. 3

NAMES OF PARTS ............................................................................................................................................................... 4

OPERATION MANUAL .......................................................................................................................................................... 4

DISASSEMBLY...................................................................................................................................................................... 7

REMOVING AND REINSTALLING THE MAIN PARTS......................................................................................................... 8

ADJUSTMENT ....................................................................................................................................................................... 9

EXPLANATION OF ERROR DISPLAY................................................................................................................................ 25

NOTES ON SCHEMATIC DIAGRAM .................................................................................................................................. 26

BLOCK DIAGRAM ............................................................................................................................................................... 27

SCHEMATIC DIAGRAM/WIRING SIDE OF P.W.BOARD................................................................................................... 28

WAVEFORMS OF CD CIRCUIT.......................................................................................................................................... 36

TROUBLE SHOOTING ........................................................................................................................................................ 38

FUNCTION TABLE OF IC.................................................................................................................................................... 44

PARTS GUIDE/EXPLODED VIEW

PACKING OF THE SET (MD-MS200 ONLY)

PACKING METHOD (MD-MS200H FOR UK ONLY)

• In the interests of user-safety the set should be restored to its

original condition and only parts identical to those specified should

be used.

MD-MS200W

MD-MS200

MD-MS200H

SHARP CORPORATION

Service Headquarters: 1300 Naperville Drive Romeoville, IL 60441

SHARP ELECTRONICS CORPORATION

Page 2

MD-MS200W/MD-MS200/MD-MS200H

– 2 –

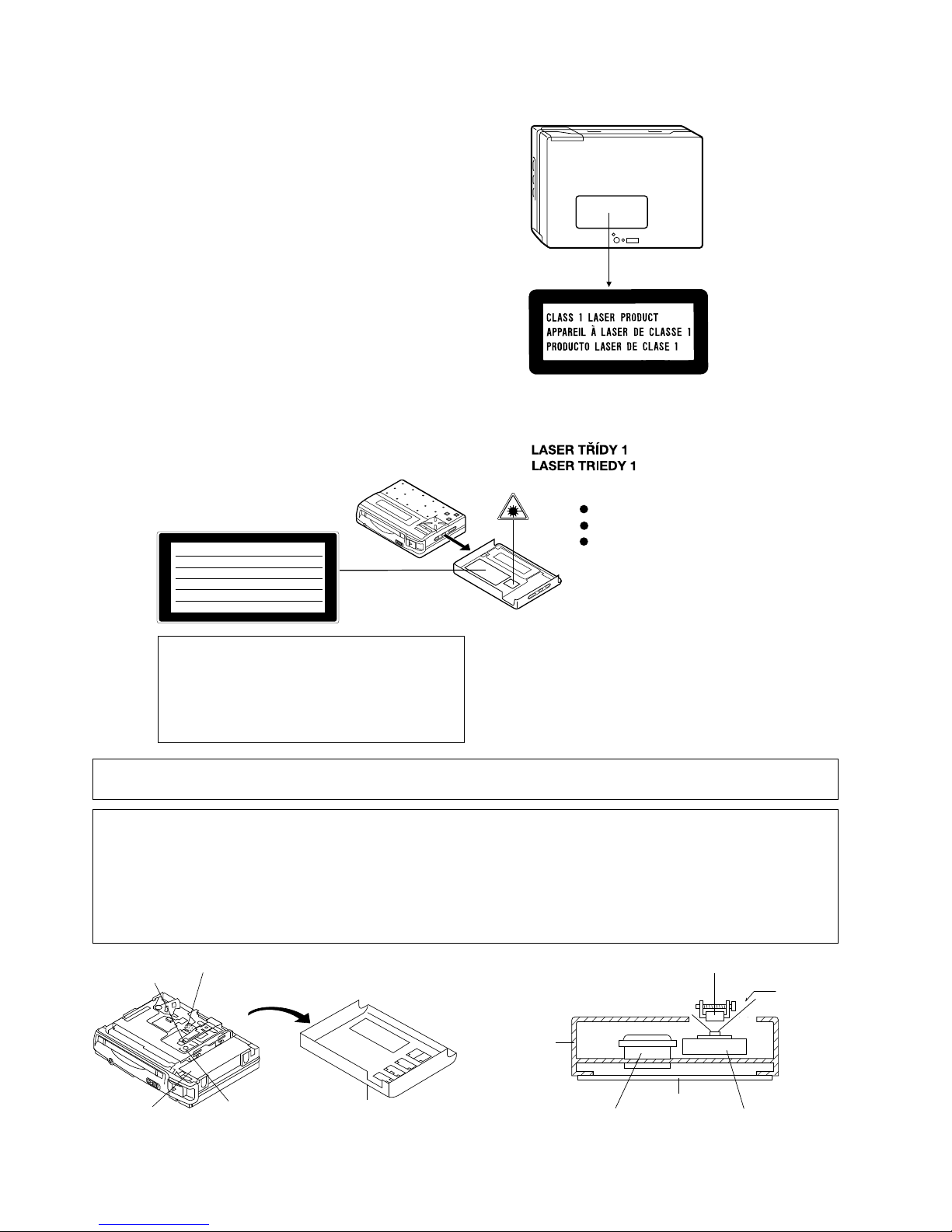

SAFETY PRECAUTION FOR SERVICE MANUAL (MD-MS200H ONLY)

Precaution to be taken when replacing and servicing the

Laser Pickup.

The AEL (Accessible Emission Level) of Laser Power Output for

this model is specified to be lower than Class I Requirements.

However, the following precautions must be observed during

servicing to protect your eyes against exposure to the Laser:-

(1) When the cabinet has been removed, the power is turned

on without a compact disc, and the Pickup is on a

position outer than the lead-in position, the Laser will

light for several seconds to detect a disc. Do not look into

the Pickup Lens.

(2) The Laser Power Output of the Pickup inside the unit and

replacement service parts have already been adjusted

prior to shipping.

(3) No adjustment to the Laser Power should be attempted

when replacing or servicing the Pickup.

(4) Under no circumstances look directly into the Pickup

Lens at any time.

(5) CAUTION - Use of controls or adjustments, or performance

of procedures other than those specified herein may

result in hazardous radiation exposure.

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

Laser Diode Properties

Material: GaAIAs

Wavelength: 785 nm

Pulse time:

Read mode: 0.8 mW Continuous

Write mode: max 10 mW 0.5

min cycle 1.5S

Repetition

VAROITUS! LAITTEEN KÄYTTÄMINEN MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA TAVALLA SAATTAA ALTISTAA

KÄYTTÄJÄN TURVALLISUUSLUOKAN 1 YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE.

VARNING - OM APPARATEN ANVÄNDS PÅ ANNAT SÄTT ÄN I DENNA

BRUKSANVISNING SPECIFICERAS. KAN ANVÄNDAREN UTSÄTTAS

FÖR OSYNLIG LASERSTRÅLNING, SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

CAUTION - INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED

AVOID EXPOSURE TO BEAM .

VARNING - OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH

SPÄRRAR ÄR URKOPPLADE. STRÅLEN ÄR FARLIG.

ADVARSEL - USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS

BRYTES. UNNGÅ EKSPONERING FOR STRÅLEN.

VARO! AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA

NÄKYMÄTÖN LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEN.

VARNING - OSYNLIG LASERSTRÅLING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRREN

ÄR URKOPPLAD. BETRAKTA EJ STRÅLEN.

ADVARSEL - USYNLIG LASERSTRÅLING VED ÅBNING NÅR SIKKERHEDSAFBRYDERE

ER UDE AF FUNKTION. UNDGÅ UDSETTELSE FOR STRÅLING.

VARO! Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle lasersäteilylle. Älä katso säteesee.

VARNING! Osynling laserstralning när denna del är öppnad och sp¨årren är urkopplad. Betrakta ej strälen.

Magnet Head

Lasar Beam

Optical Pick-Up

Main PWB

Disc motor

Mechanism

Chassis

Lift motor

Magnet head

Optical pick-up

Display PWB

Disc cover

Figu re 2-1

Figu re 2-2

Precaution to be taken when replacing and servicing th laser pickup.

The following precautions must be observed during servicing to protect your eyesagainst exposure to the laser.

Warning of possible eye damage when repairing:

If the AC adaptor or batteries are connected when the top housing (disc cover) of the unit is removed, and the PLAY key is

pressed, the laser will light up during docus access (2-3 seconds). (Fig. 2-1)During the operation, the laser will lesk from the

opening between the magnetic head and the mechanical chassis (Fig. 2-2). In order to protect your eyes, you most not look at

the laser durnd repaor. Before repaoring, be sure to disconnect the AC adaptor and remove the batteries.

Page 3

MD-MS200W/MD-MS200/MD-MS200H

– 3 –

BATTERY DISPOSAL (FOR MD-MS200 ONLY)

Contains nickel cadmium (or sealed lead) battery. Must be recycled

or disposed of properly. Remove the battery from the product and

contact federal or state environmental agencies for information on

recycling and disposal options.

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

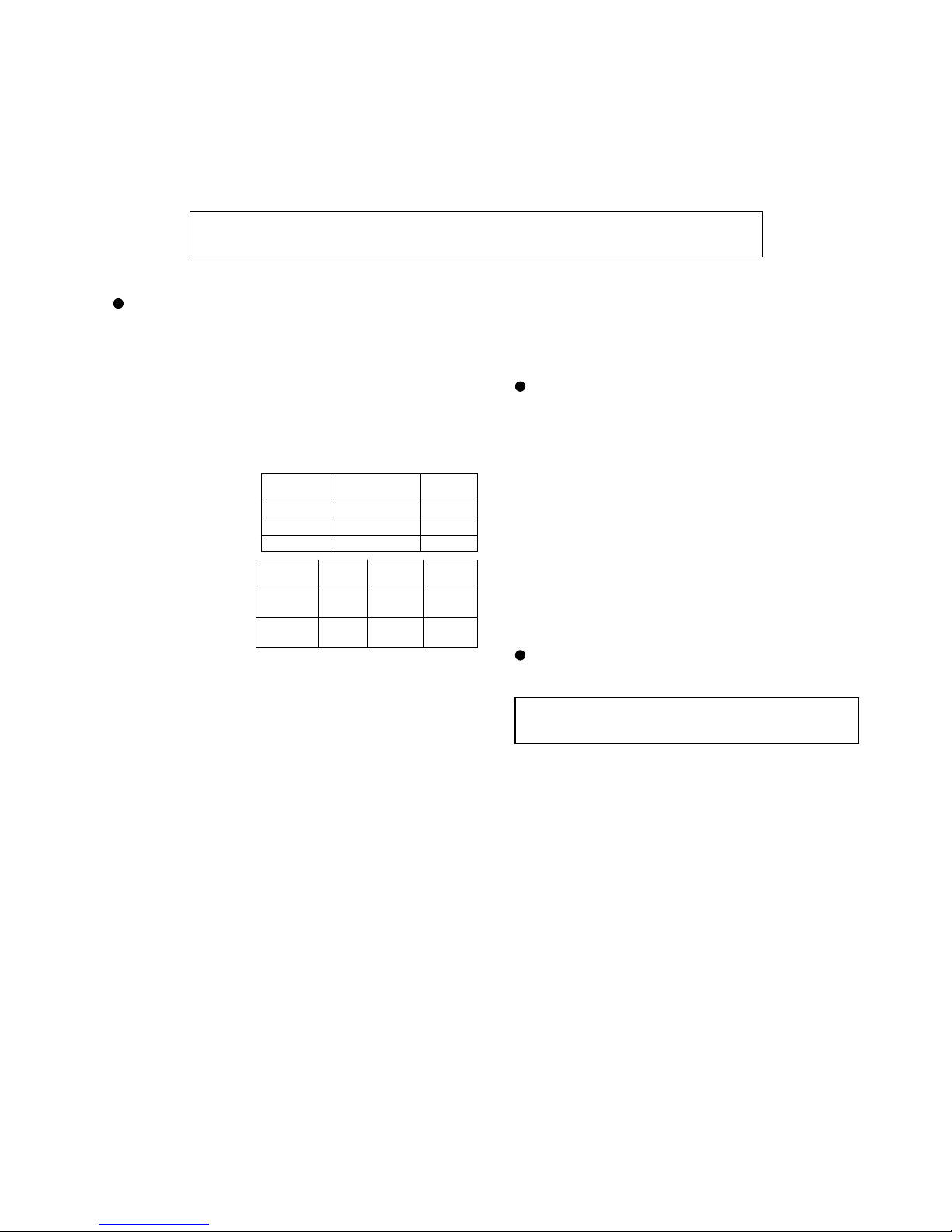

SPECIFICATIONS

General

Power source: DC 3.6 V (rechargeable lithium-ion

battery x 1)

DC 5 V (AC adaptor)

AC 110 - 240V, 50/60 Hz

Power consumption: 0.15 A (AC adaptor)

4 W

Output power: RMS; 20mW (10 mW + 10mW)

(0.2% T.H.D.)

Rechargeable battery Approx. 9.5 hours (continuous play)

performance: Approx. 7.0 hours (continuous

(Fully charged) recording)

Input sensitivity:

Output level:

Dimensions: Width: 4-5/16" (109.2 mm)

Height: 1-7/32" (30.5 mm)

Depth: 3-7/32" (81.3 mm)

Weight: 275 g (0.6 lbs.) with rechargeable

battery

Input jack: Line/Mic/Optical

Output jack: Headphones

MiniDisc Recorder

Type: Portable MiniDisc recorder

Signal readout: Non-contact, semi-coductor laser

pick-up

Audio channels: 2

Frequency response: 20 to 20,000 Hz ± 3 dB

Rotation speed: Approximately 400 to 900 rpm

Error correction: ACIRC (Advanced Cross Interleave

Reed-Solomon Code)

Coding: ATRAC (Adaptive TRansform

Acoustic Coding)

Recording method: Magnetic modulation overwrite

method

A/D,D/A converter: 1-bit

Sampling frequency: 44.1 kHz

Modulation system: EFM (Eight to Fourteen Modulation)

Wow and flutter: Unmeasurable (less than ±0.001%

W.peek)

Headphones

Type: Inner-ear dynamic

Impedance: 16 ohms

Recording

level

Reference input

level

Input

inpedance

MIC H 0.25 mV 10k ohms

MIC L 2.5 mV 10k ohms

LINE 100 mV 20k ohms

Load

impedance

Headphones — 10 mW + 16 ohms

10 mW

LINE 350mV — 50 kohms

(-12dB)

Maximum

output level

Specified

output

Specifications for this model are subject to change without

prior notice.

Page 4

MD-MS200W/MD-MS200/MD-MS200H

– 4 –

OPERATION MANUAL

Rechargeable battery

power

When the rechargeable battery is used for

the first time or when you want to use it

after a long period of disuse, be sure to

charge it fully.

1

Open the rechargeable battery com-

partment cover.

2

Insert the rechargeable battery.

Insert the side with the arrow first.

3

Close the rechargeable battery com-

partment cover.

4

Plug the AC adaptor into the AC

socket, and then insert the plug on the

AC adaptor lead into the DC IN 5V

socket.

5

Press the n OFF button to begin charg-

ing.

“ ” will appear, an d the battery wil l

begin charging.

Battery charging will be complete in 3

hours. When battery chargi ng be gins,

“ ” will be displayed. When the

charging is complete, it will go out.

Notes:

After charging has been completed, the

AC adaptor may be left connected.

(Charging at night.)

The battery will not be charged whilst

the main unit is operating.

If the AC adaptor is removed from the

main unit or from the AC socket whilst

charging, “ ” will not disapp ear for

about 1 minute. This is normal.

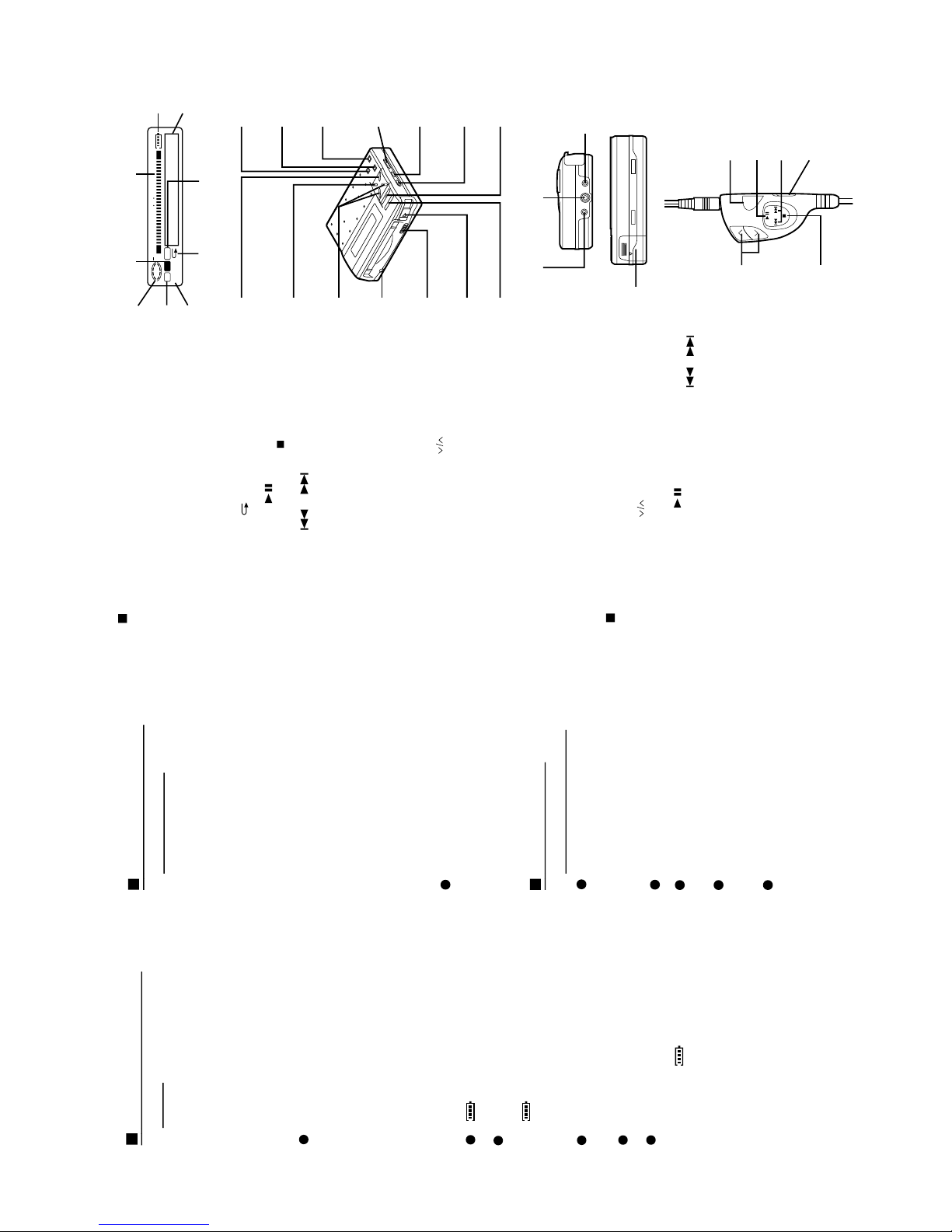

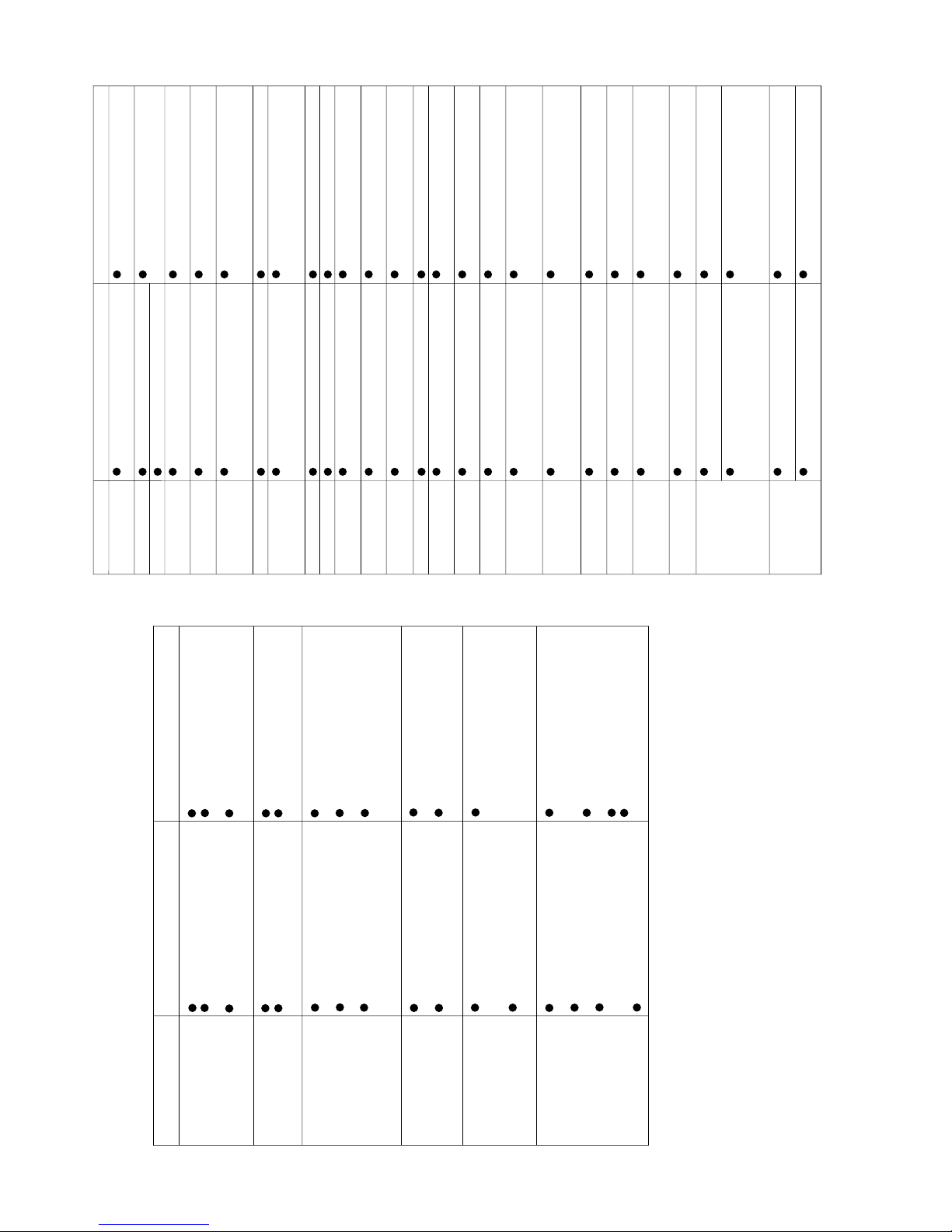

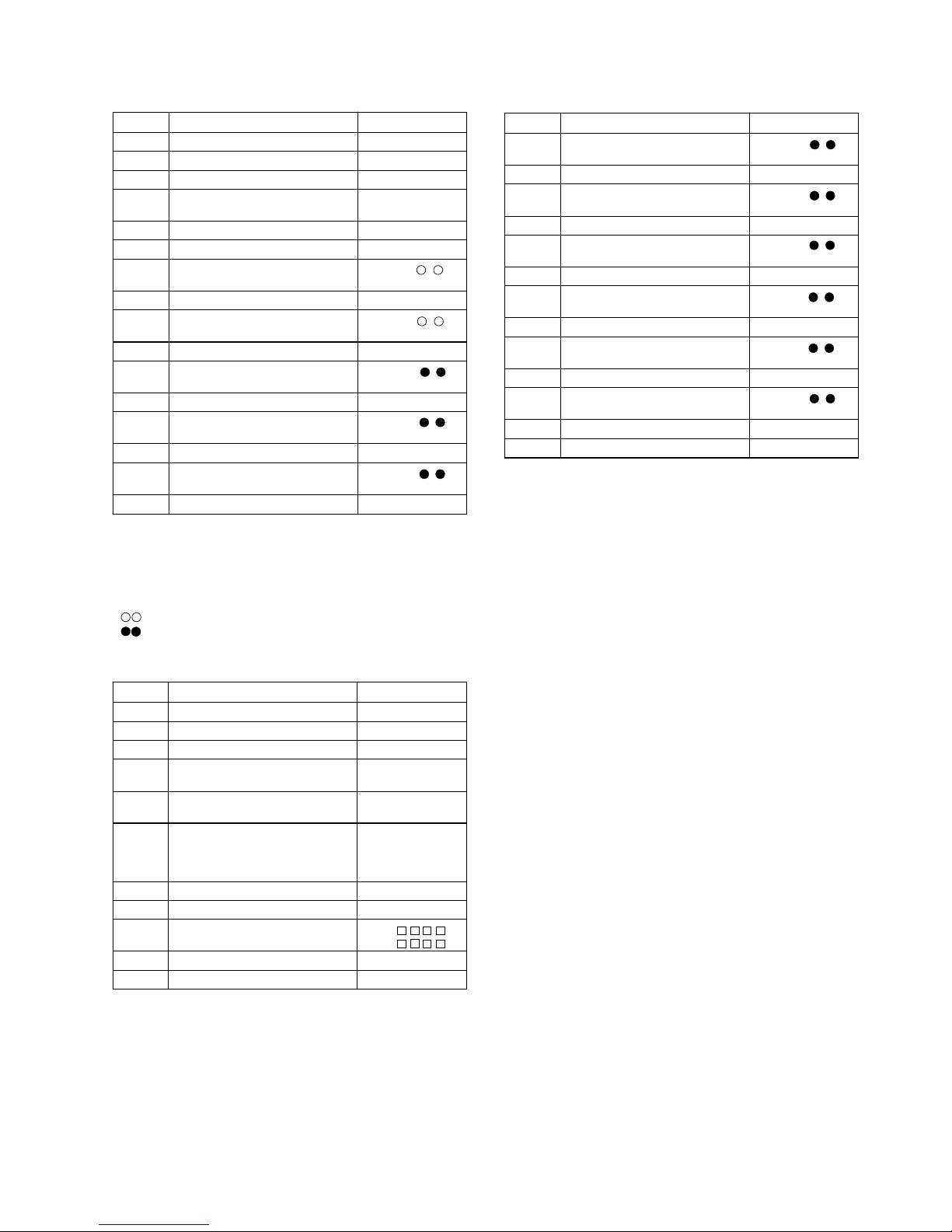

NAME OF PARTS

Main Unit

1. Synchro Recording Indicator

2. Level Meter

3. Battery Indicator

4. Character Information Display

5. Disc Status Indicator

6. TOC Indicator

7. Random Indicator

8. Repeat Indicator:

9. Monaural Long-Play Mode Indicator

10. Play/Pause Button:

11. Stop/Power Off/Charge Button:

12. Fast Reverse/Fast Forward/Recording Level Control/

Cursor Button: /

13. Microphone Input Socket

14. Hold Switch

15. Eject Lever

16. Enter/Synchro/Fast Play Button

17. Character/Symbol Select/Time Button

18. Display/Lowercase Letter Button

19. Record/Track Mark Button

20. Edit/Auto Mark/Time Mark Button

21. Mode/Space Button

22. Extra Bass/Delete Button

23. Volume/Name Select Buttons:

24. 5V DC IN Socket

25. Headphones Socket

26. Optical/Line Input Socket

27. Rechargeable Lithium-Ion Battery Compartment

Remote Control Unit

1. Volume Buttons:

2. Stop/Power Off Button

3. Track Mark/Extra Bass Button

4. Play/Pause Button:

5. Fast Reverse/Fast Forward/Cursor Buttons: /

6. Hold Switch

REC

TOC SYNC MONO

RANDOM

1

dB 40 12 4 0

OVER

12

6

5

7

8

9

3

4

17

18

19

20

21

22

23

10

11

12

13

14

15

16

24 25

26

27

BASS

VOL.

3

4

5

6

1

2

Rechargeable battery

operating time

After charging is complete, the unit can be

used continuously as follows:

Continuous playback:

Approx. 9.5 hours (fully charged, vol-

ume level: VOL 20)

Continuous recording:

Approx. 7 hours (fully charged, anal-

ogue input, volume level: VOL 0)

How to determine the remaining

battery time:

As the battery charge is reduced, the bars

in the indicator will go out one by one.

When the battery is almost completely ex-

hausted, the whole battery indicator will

flash.

At this point you should recharge the bat-

tery.

When the battery has run completely out,

“BATT EMPTY” will be displayed, and the

power will be disconnected automatically.

When the AC adaptor is used, the bat-

tery indicator will light up in the fully

charged condition.

Note:

If the battery indicator is flashing, it will be

impossible to start recording or editing.

Notes about the

rechargeable battery

A rechargeable lithium-ion battery is

the only kind that can be used.

Even if the battery supplied with the

unit is not used, you should charge it at

least once every three months because

of the special quality of this battery.

The rechargeable battery can be

charged approximately 300 times.

Do not use any battery other than that

specified. Use of other batteries may

cause malfunctions.

When the operating time is reduced to

about half the normal amount of time,

even after a full charge is performed,

replace the battery with a new one.

When charging or when using the re-

chargeable battery, use it within an am-

bient temperature range of 5 C to

35°

°

C.

Page 5

MD-MS200W/MD-MS200/MD-MS200H

– 5 –

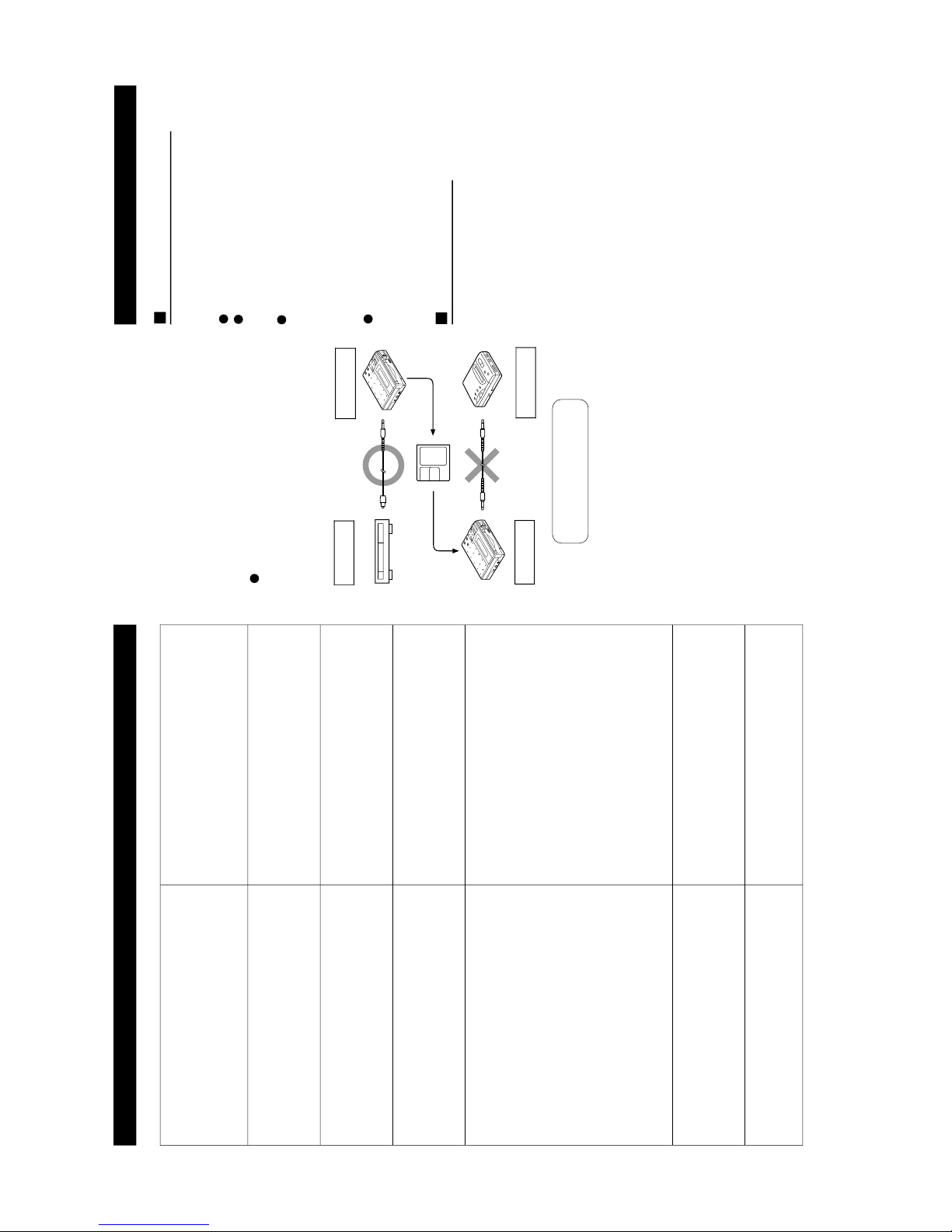

There are cases where digital

recording may be impossible.

In the following cases digital recording is

impossible, even if you are using digital

cables.

When you attempt to make a new digital

recording from a track that was digitally

recorded on a MiniDisc

MiniDiscs are designed so that only

first generation digital copies can

made, further digital copies are

prevented by the SCMS (Serial Copy

Management System).

Moisture condensation

In the following cases, condensation

may form inside the unit.

Shortly after turning on a heater.

When the unit is placed in a room

where there is excessive steam or

moisture.

When the unit is moved from a cool

place to a warm place.

When the unit has condensation inside,

the disc signals cannot be read, and the

product may not function properly.

If this happens, remove the disc. The

condensation should evaporate in ap-

proximately 1 hour. The unit will then

function properly.

If trouble occurs

If strange sounds, smell or smoke come

out of the unit or an object is dropped into

the unit, remove the AC adaptor from the

AC socket and contact an authorised

Sharp service centre.

Note:

When this product is subjected to strong

external interference (mechanical shock,

excessive static electricity, abnormal sup-

ply voltage due to lightning, etc.) or if it is

operated incorrectly, it may malfunction. If

such trouble occurs, proceed as follows:

1. Unplug the AC adaptor from the AC

socket.

2. Remove the rechargeable battery.

3. Leave the unit completely unpowered

for approximately 30 seconds.

4. Reconnect the AC adaptor to the AC

socket and retry the operation.

TROUBLESHOOTING

Recording

Playback

CD player, MD

player, etc.

Digitally recorded MiniDisc

Digital cable

Recording

Playback Digital cable

Analogue recording is

possible.

MINIDISC SYSTEM LIMITATIONS

Even if the maximum recording time of

a MiniDisc has not been reached,

“DISC FULL” or “TOC FULL” may be

displayed.

When the number of tracks used

reaches the limit, regardless of the

remaining recording time, further

recording will be impossible.

(Maximum number of tracks: 254)

Even if the number of tracks and the

recording time have not reached the

limit, “DISC FULL” may be displayed.

If there are scratches on a disc, the

unit will automatically avoid recording

in those areas. The recording time will

be reduced.

Even if several short tracks are

erased, the remaining recording time

may not show an increase.

When the remaining recording time of

a disc is displayed, short tracks less

than 8 seconds long may not be

included in the total.

Two tracks may not be combined in

editing.

For MiniDiscs on which repeated

recording and editing operations were

performed, the COMBINE function

may not work.

The total of the recorded time and

time remaining on a disc may not add

up to the maximum possible recording

time.

A cluster (about 2 seconds) is

normally the minimum unit of

recording. So, even if a track is less

than 2 seconds long, it will use about

2 seconds of space on the disc.

Therefore, the time actually available

for recording may be less than the

remaining time displayed.

If there are scratches on discs, those

sections will be automatically avoided

(no recording will be placed in those

sections). Therefore, the recording

time will be reduced.

When recorded tracks are played back

using the cue and review operations,

some sounds may be skipped.

For MiniDiscs on which repeated

recording and editing were performed,

some sounds may be skipped whilst

cueing and reviewing.

A track number can be created in the

middle of a track.

If there are scratches or dust on a

MiniDisc, the track numbers following

that track will be increased by one.

Page 6

MD-MS200W/MD-MS200/MD-MS200H

– 6 –

Error messages Meaning Remedy

BATT EMPTY

The rechargeable battery run down. Charge the rechargeable battery (or

use the AC adaptor for power.)

BLANK DISC Nothing is recorded. Replace the disc with a recorded

disc.

00Tr 0:00 Music is not being recorded.

Can't COPY

No copy can be made because of

the SCMS copyright system.

Record using the analogue cable.

Can't EDIT

A track cannot be edited. Change the stop position of the

track and then try editing it.

Can't REC

Recording cannot be performed

correctly due to vibration or shock

in the unit.

Re-record or replace it.

Can't WRITE Editing is impossible. Check the number of tracks.

DEFECT

Since this disc has scratches on it,

the recording operation was

skipped.

If the sound you hear is not right,

replace the disc with another

recordable disc.

Din UNLOCK Poor connection of the digital cable. Connect the digital cable securely.

DISC ERROR The disc is damaged. Reload the disc or replace it.

DISC FULL

The disc is out of recording space. Replace it with another recordable

disc.

HOLD

The unit is in the malfunction

prevention state.

Return the HOLD switch to its

original position.

LOCKED

LOCK ERROR

The EJECT lever was moved

during recording or editing.

Turn off the power and remove the

MiniDisc.

NO DISC A disc has not been loaded. Load a disc.

PB DISC

You tried to record on a playback-

only disc.

Replace it with a recordable disc.

POWER ?

Improper power is being supplied. Use one of the specified power

sources.

PROTECTED

The disc is write protected. Move the write protection knob

back to its original position.

SORRY

Since a track number is currently

being located or written to, the unit

cannot accept your command.

Wait for a while and try the

operation again.

SYSTEM ERR

You have come to the conclusion

that the unit is out of order.

To have it repaired, go to the

distributor where you purchased the

unit.

TEMP OVER

The temperature is too high. Turn off the power, and wait for a

while.

TOC ERROR

A large portion of the disc has been

damaged.

Replace it with another recorded

disc.

TOC FULL

There is no space left for recording

character information (track names,

disc names, etc.).

Replace it with another recordable

disc.

Tr. Protect

The track has been protected from

being erased.

Edit the track with the device on

which it was recorded.

UTOC ERROR

A large portion of the disc has been

damaged.

Replace it with another recorded

disc.

There is an error in the recorded

signal.

Replace it with another recordable

disc or use the ALL ERASE function

(page 27), to erase the signal error

and then try recording again.

? DISC

A disc which contains data other

than music was played.

A disc which contains non-music

data cannot be played.

There is an error in the signal from

the disc.

Replace it with another recorded

disc.

Many potential “problems” can be resolved by the owner without calling a service tech-

nician. If something seems to be wrong with this product, check the following before

calling your authorised SHARP dealer or service centre.

PROBLEM CAUSE REMEDY

The unit does not

turn on.

The AC adaptor is disconnected.

The rechargeable battery is

exhausted.

The unit is in the safety mode.

Plug in the AC adaptor.

Recharge the battery.

Move the HOLD switch to turn

off the safety mode.

No sound is heard

from the head-

phones.

The volume is set too low.

The remote control unit or

headphones are not plugged in.

Increase the volume.

Plug the remote control unit or

headphones in securely.

When the operation

buttons are

pressed, the unit

does not respond.

The unit is in the safety mode.

The rechargeable battery is

exhausted.

The remote control unit plug or

headphone plug is not inserted

firmly.

Move the HOLD switch to turn

off the safety mode.

Recharge the battery.

Insert the remote control unit

plug or headphone plug securely.

Some sounds are

skipped.

The rechargeable battery is

exhausted.

The unit is receiving excessive

vibration.

Recharge the battery.

Place the unit in a vibration-free

place.

The MiniDisc cannot

be ejected.

The track number or character

information has not been written

on the disc.

The unit is in the recording or

editing mode.

Press the n OFF button to turn

off the power (which will finish

writing the information on the

disc).

Recording and edi-

ting are impossible.

Is the MiniDisc protected against

accidental erasure?

Is the unit connected properly to

the other equipment?

Is the AC adaptor unplugged or

did a power failure occur whilst

recording or editing?

Is the unit in the safety mode?

Slide the accidental erase

prevention tab back to its original

position.

Connect the unit properly to the

other equipment.

Plug in the AC adaptor.

Move the HOLD switch to turn

off the safety mode.

Page 7

MD-MS200W/MD-MS200/MD-MS200H

– 7 –

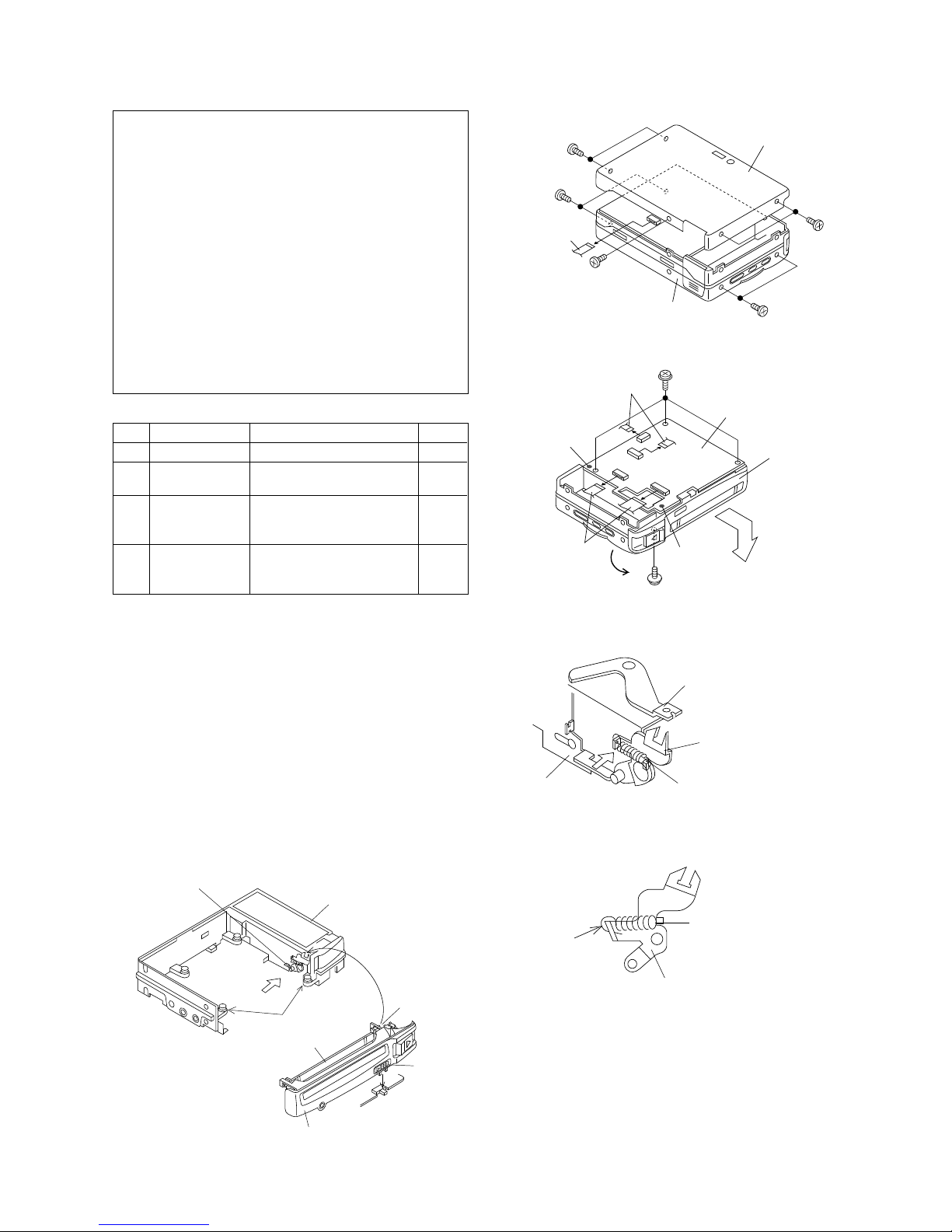

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take the battery and minidisc out of the unit.

2. When disassembling the machine, be sure to withdraw

the power plug from the socket in advance.

3. When disassemble the parts, remove the nylon band or

wire holder as necessary.

To assemble after repair, be sure to arrange the wires as

they were.

If a screw of different length is fitted to the MD mecha-

nism (the screw of the part to be fitted to the MD

mechanism chassis), it may contact the optical pickup,

resulting in malfunction.

4. When repairing, pay due attention to electrostatic charges

of IC.

1 Bottom Cover 1. Screw..................... (A1) x5 7-1

2 Disc Cover 1. Screw..................... (B1) x4 7-1

(Note) 2. Flexible PWB......... (B2) x1

3 Main PWB 1. Screw..................... (C1) x3 7-2

2. Flexible PWB......... (C2) x4

3. Soldering ............... (C3) x2

4 Front Cabinet 1. Screw..................... (D1) x1 7-2

2. Remove the front cabinet in

the arrow direction.

REMOVAL

PROCEDURE

STEP

FIGURE

Bottom Cover

(B1) x2

Ø2x2mm

(B1) x2

Ø2x2mm

(A1) x2

Ø2x2mm

(A1) x2

Ø2x2mm

(A1) x1

Ø2x2mm

(B2) x1

Disc Cover

Figu re 7-1

Figure 7-2

Eject knob lever

Eject lever

Lid opening and closing spring

Lid opening and closing spring

Lid opening and closing lever

Engage the spring

at the upper side.

Lid opening and closing lever

<A>

Figure <A>

Figure 7-3

Figure 7-4

Note:

When removing the upper lid, at first turn the operation knob

side in the arrow direction to remove.

Installing the front cabinet (See Fig. 7-3.)

1. Make sure that the lid opening and closing spring has been

engaged at the upper side as shown in Figure < A > .

2. Fit the MD lid right pin into the lid opening and closing lever

to install it.

Note:

• Take care since the antivibration rubber may come off.

• If the main PWB has been installed previously, fit the knob to

the HOLD switch shown in Figure < B > .

• If the mechanism has been installed, the antivibration rubber

may come off from the center cabinet fitting part when the

front part of center cabinet is widened.

(C1) x3

Ø2x2.5mm

(D1) x1

Ø2x2.5mm

(C3) x1

(C2) x2

(C3) x1

Main PWB

Front Cabinet

(C2) x2

Front Cabinet

Lid opening and closing lever

Center Cabinet

<A>

Antivibration rubber

HOLD knob

MD lid

MD lid right pin

SW

<B>

Page 8

MD-MS200W/MD-MS200/MD-MS200H

– 8 –

REMOVING AND REINSTALLING THE MAIN PARTS

Remove the mechanism according to the disassembling methods 1 to 4. (See Page 7.)

How to remove the disc motor (See Fig. 8-1.)

1. Remove the solder joint (A1) x 1 of flex PWB.

2. Remove the screws (A2) x 3 pcs. and remove the disc

motor.

Take care so that the turnrable is not damaged.

Figure 8-4

(A2) x 3

Ø1.4 x 4.5mm

Flexible PWB

solder joint

(A1) x1

Disc Motor

Motor Spacer

Mechanism PWB

Mechanism

Figure 8-1

(B2) x2

Ø1.4x2.2mm

(B1) x2

Remove the solder joint.

Slide Motor

Figure 8-2

Figure 8-3

Shaft (C2) x 1

(C1) x 2

Ø1.4 x 3mm

(C1) x 1

Ø1.4 x 2.5mm

(C1) x 1

Ø2 x4.5mm

Pickup Unit

Magnetic field arm block

Magnetic head

Head intervening flexible PWB

(D1) x1

Ø1.4x2mm

Unsolder

(D2) x2

How to remove the slide motor (See Fig. 8-2.)

1. Remove the solder joint (B1) x 1 of slide motor lead wire.

2. Remove the screw (B2) x 1, and remove the slide motor.

Note:

Take care so that the motor gear is not damaged.

(If the gear is damaged, noise is raised in search mode.)

How to reinstall the optical pickup unit

(See Fig. 8-3.)

1. Remove the screws (C1) x 5 pcs.

2. Remove the magnetic fielt arm block from the pickup, and

move the magnetic field arm block outwards.

Note:

Take due care so that the magnetic head is not damaged.

3. Withdraw a little the slide motor side shaft (C2) x 1 pcs., and

slowly raise the optical pickup.

How to remove the magnetic head

(See Fig. 8-4.)

1. Remove the screw (D1) x 1 pc.

2. Remove the unsolder (D2) x 2 pcs. which connects the

magnetic head and the head hookup flex.

Note:

Mount carefully so as not to damage the magnetic head.

Page 9

MD-MS200W/MD-MS200/MD-MS200H

– 9 –

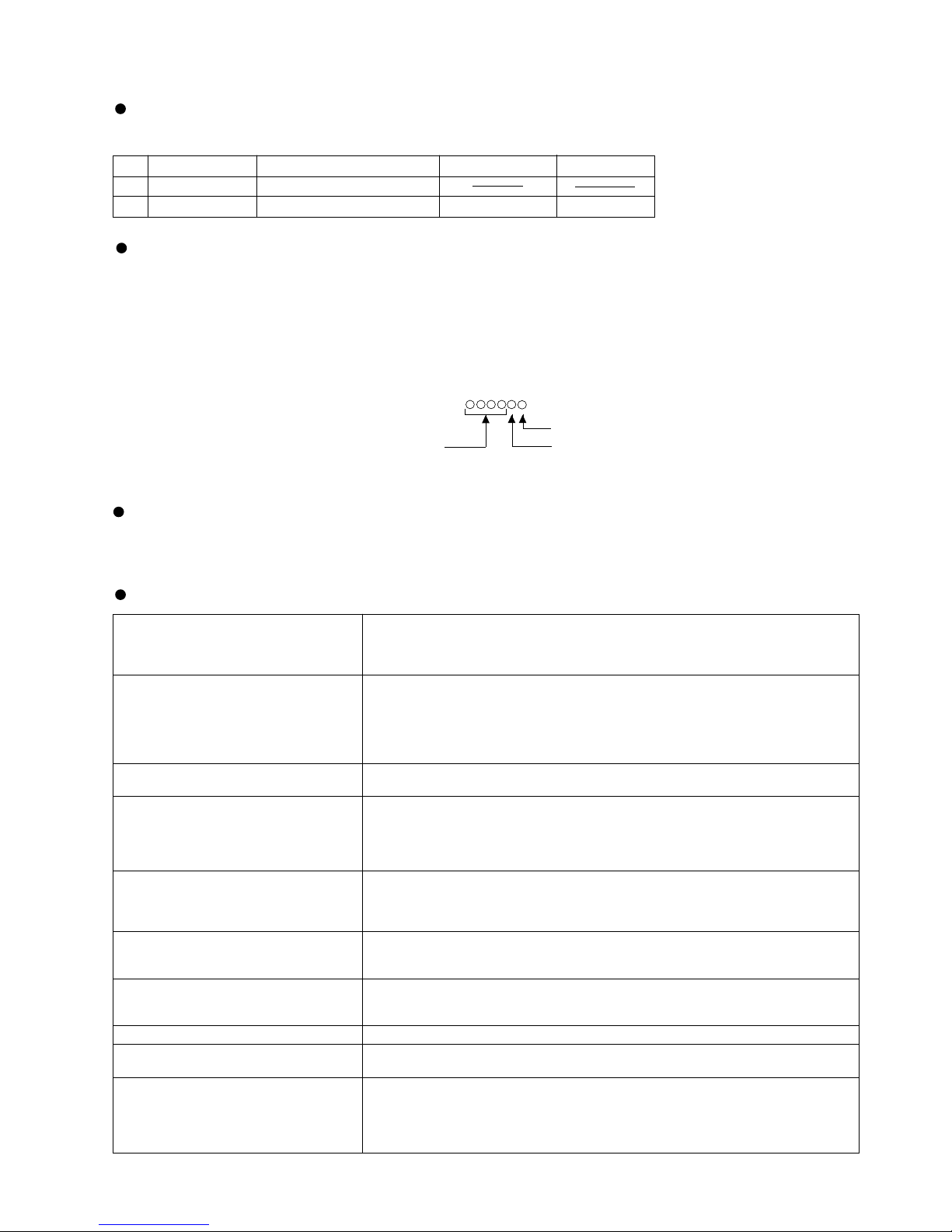

ADJUSTMENT

Test disc

MD adjustment needs two types of disc, namely recording disc (low reflection disc) and playback-only disc (high

reflection disc).

Type

Test disc

Parts No. Price Code

1 High reflection disc ESYA 1014 (SONY)

2 Low reflection disc Recording minidisc UDSKM0001AFZZ AZ

Note: Use the low reflection disc on which music has been recorded.

Microcomputer version

EEPROM version

Destination

Entering the TEST mode

1. Setting at port (in standby state, disc-free state or power nonconnected state)

(1) Set the port as follows.

TEST1 : "Low"

TEST0 : "High"

(2) Press the PLAY button in the standby state (it is allowed to insert the disc or to connect the power supply).

(3) Test Mode STOP [ _ T E S T _ ]

2. Setting by special button operation (in standby state)

(1) Holding down the DISP button and ENTER button, press the PLAY button.

(2) Normal mode setting initialization (BASS setting, VOL setting, etc.)

(3) Indication of microcomputer version for one second [ ]

(4) Whole LCD lighting for 2 seconds

(5) Test Mode STOP [ _ T E S T _ ]

*When the PLAY button is pressed during indication (3) and (4), the process proceeds to (5).

Leaving the TEST mode

(1) Press the STOP button in the TEST mode stop state or version indicating state or whole LCD lighting state.

(2) EEPROM rewrite-enable area updating, adjustment error setting (so as to adjust all the items when the power supply is turned

on in the normal mode)

(3) Change to standby state

Test Mode

1. AUTO Mode • Automatic adjustment is performed. (After adjustment the grating adjustment mode is set.)

• Continuous playback is performed (Error rate indication, jump test).

• The temperature correction is performed only when servo start is performed, but the

posture correction is not performed.

2. MANUAL Mode • Temperature is displayed. (Updating in real time)

• Seeing the displayed measurement value/set value, make manualadjustment to set values

within the allowable range.

• Continuous playback is performed (error rate display, jump test).

• The temperature correction is performed only when servo start is performed, but the

posture correction is not performed.

3. RESULT Mode • Adjustment value is indicted.

• Adjustment value is changed manually. (in servo OFF state).

4. TEST-PLAY Mode • Continuous playback from the specified address is performed.

• 1 line, 10 lines or 400 lines manual jump is performed.

• C1 error rate display (pit section), ADIP error rate display (groove section)

• The temperature correction is performed only when servo start is performed, but the

posture correction is not performed during continuous playback.

5. TEST-REC Mode • Continuous record from the specified address is performed.

• Change of record laser output(servo gain is also changed according to laser output).

• The temperature correction is performed only when servo start is performed, but the

posture correction is not performed during continuous recording.

6. INNER Mode • Determine the position where the INNER switch is turned on.(only high reflection disc).

• The temperature correction is performed only when servo start is performed, but the

posture correction is not performed.

7. NORMAL Mode • The mode is changed from the TEST mode to the normal mode without adjustment.

• In the normal mode the internal operation mode, memory capacity, etc. areindicated.

• In the normal mode both temperature correction and posture correction are performed.

8. Digital input display Mode • Digital input information is displayed.

9. Error data display Mode • Error information is displayed.

• Error information is initialized.

10. E2-PROM setting mode • Factors of digital servo are changed manually. (Each servo is turned on individually.)

• Cut-off frequency of BASS1, BASS2 and BASS3 is selected manually.

• Temperature detection terminal voltage is measured, and the reference value is set.

• Defaults are selected and set.

• Setting of EEPROM protect area is updated. (In case of protect releasing)

Page 10

MD-MS200W/MD-MS200/MD-MS200H

– 10 –

1. AUTO Mode

• When the STOP button is pressed while the AUTO menu

appears or during automatic adjustment, the mode changes to

the TEST mode stop state. At this time the adjustment value is

not output.

• As for operation during continuous playback refer to [Explanation

of TEST-PLAY mode].

• Adjustment NG: If the measurement value of adjustment FEO is

out of range,focus ON failure occurs or adjustment error or TZC

error occurs.

• When the high reflection disc is used, changes as follows.

TEO — FEO — Hf — Hg — Hb — Hf

• When the low reflection disc is used, changes as follows.

TEO — FEO — If — Lg — Lb — Lf — Gl — Gg — Gb — Lf

• Grating adjustment: When the focus servo and spin servo are

ON.

• : Adjustment name

• : Measurement value

• : Set value

• : Address

Operation in each TEST mode

Step No.

Operation and state

Display

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button.

Step 3 AUTO menu. [ A U T O ]

Step 4 PLAY button -->

Slide shift to innermost periphery

Step 5 Automatic adjustment [ ]

Step 6 End of adjustment

Step 7 When adjustment is OK, the

process proceeds to (8).

When adjustment is NG, the

process proceeds to (13).

Step 8 Grating adjustment, adjustment [ A D J . O K ]

value output

Step 9 When the PLAY button is pressed,

the process proceeds to (10).

When the STOP button is pressed,

the process proceeds to (12).

Step 10 Continuous playback (pit section) [ S Q ]

Continuous playback (groove section) [ A P ]

Step 11 STOP button

Step 12 Test mode STOP state [ T E S T ]

Step 13 Adjustment value output [ A D J . N G ]

Step 14 STOP button

Step 15 Test mode STOP state [ T E S T ]

2. MAMUAL Mode

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button

Step 3 AUTO menu [ A U T O ]

Step 4 SKIP UP button x 1 times

(Or SKIP DOWN button x 9 times)

Step 5 MANUAL menu [ M A N U A L ]

Step 6 PLAY button

Step 7 Temperature measurement [ T M P : ]

Step 8 SKIP UP button

Step 9 Tracking error offset measurement [ T E O : ]

Step 10 SKIP UP button

Step 11 Focus error offset measurement [ F E O : ]

Step 12 SKIP UP button—Laser lighting [ L O N : _ _ ]

Step 13 SKIP UP button—

Slide shift to innermost periphery

Step 14-a

Focus gain rough adjustment (high reflection)

[ H f ]

Step 14-b

Focus gain rough adjustment (low reflection)

[ L f ]

Step 15 SKIP UP button

Step 16-a

Pit:Tracking gain adjustment (high reflection)

[ H g ]

Step 16-b

Pit:Tracking gain adjustment (low reflection)

[ L g ]

Step 17 SKIP UP button

Step 18-a Pit: [ H b ]

Tracking balance adjustment (high reflection)

Step 18-b Pit: [ L b ]

Tracking balance adjustment (low reflection)

Step 19 SKIP UP button

Step 20-a Pit: [ H f ]

Focus gain adjustment (high reflection)

Step 20-b Pit: [ L f ]

Focus gain adjustment (low reflection)

Step No.

Operation and state

Display

Step 21 Step (24) when SKIP UP button,

Step (22) when PLAY button.

Step 22 Pit section continuous playback [ S Q ]

Step 23 When the P-MODE button is pressed,

the process proceeds to (20-a) or (20-b).

Step 24 The high reflection disc is not accepted.

When the low reflection disc is used, the

process proceeds to (25).

Step 25 TOTAL signal level adjustment [ G l ]

Step 26 SKIP UP button

Step 27 Groove: Tracking gain adjustment [ G g ]

Step 28 SKIP UP button

Step 29 Groove: Tracking balance adjustment [ G b ]

Step 30 SKIP UP button

Step 31 Focus gain adjustment [ L f ]

Step 32 PLAY button

Step 33 Groove section continuous playback [ A P ]

Step 34 When the P-MODE button is pressed,

the process to (31).

Step No. Operation and state

Display

• Reversing when the SKIP DOWN button is pressed.

• When the VOL UP button is pressed during adjustment, the set value

increases, and the new set value is output.

• When the VOL DOWN button is pressed during adjustment, the set

value reduces, and the new set value is output.

• When the VOL UP/DOWN button is held down, the setting changes

continuously, one cycle being 100 ms.

• When the STOP button is pressed while the MANUAL menu

appears, or during measurement or adjustment, the mode changes

to the TEST mode stop state.

• As for operation during continuous playback refer to [Explanation of

TEST-PLAY mode].

• : Measurement value

• : Set value

• : Address

• : Temperature code

Page 11

MD-MS200W/MD-MS200/MD-MS200H

– 11 –

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button

Step 3 AUTO menu [ A U T O ]

Step 4 SKIP UP button x 2 times

(Or SKIP DOWN button x 8 times)

Step 5 RESULT menu [ R E S U L T ]

Step 6 PLAY button

Step 7 Indication of measurement value: [ T E O : ]

Tracking error offset

Step 8 SKIP UP button

Step 9 Indication of measurement value: [ F E O : ]

Focus error offset

Step 10 SKIP UP button

Step 11 Indication of measurement value: [ H f _ _ ]

High reflection focus gain

Step 12 SKIP UP button

Step 13 Indication of measurement value: [ H g _ _ ]

High reflection pit tracking gain

Step 14 SKIP UP button

Step 15 Indication of measurement value: [ H b _ _ ]

High reflection pit tracking balance

Step 16 SKIP UP button

Step No.

Operation and state

Display

3. RESULT Mode

Step 17 Indication of measurement value: [ L f _ _ ]

Low reflection focus gain

Step 18 SKIP UP button

Step 19 Indication of measurement value: [ L g _ _ ]

Low reflection tracking gain

Step 20 SKIP UP button

Step 21 Indication of measurement value: [ L b _ _ ]

Low reflection pit tracking balance

Step 22 SKIP UP button

Step 23 Indication of measurement value: [ G l _ _ ]

Low reflection TOTAL signal level

Step 24 SKIP UP button

Step 25 Indication of measurement value: [ G g _ _ ]

Low reflection groove tracking gain

Step 26 SKIP UP button

Step 27 Indication of measurement value: [ G b _ _ ]

Low reflection groove tracking balance

Step 28 STOP button

Step 29 Test mode STOP state [ T E S T ]

Step No.

Operation and state

Display

• Reversing when the SKIP DOWN button is pressed

• When the VOL UP button is pressed during set value indication, the set value increases, and the new set value is stored in RAM.

• When the VOL DOWN button is pressed during set value indication, the set value decreases, and the new set value is stored in RAM.

• When the VOL UP/DOWN button is held down, the setting changes continuously, one cycle being 100 ms.

• When the STOP button is pressed while the RESULT menu appears, or during measurement value or set value indication, the mode

changes to the TEST mode stop state.

• : Measurement value

• : Set value

7. TEST/PLAY Mode

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button

Step 3 AUTO menu [ A U T O ]

Step 4 SKIP UP button x 3times

(Or SKIP DOWN button x 7 times)

Step 5 TEST-PLAY menu [ T _ P L A Y ]

Step 6 When the DISP button is pressed, the

process proceeds to (7).

When the PLAY button is pressed, the

process proceeds to (9).

Step 7 TEST-PLAY mode [ A d 0 0 5 0 ]

Step 8 PLAY button

Step 9 Continuous playback (pit section) [ S Q ]

Continuous playback (groove section) [ A P ]

Step 10 STOP button

Step 11 Test mode STOP state [ T E S T ]

Operation and state

Step No.

Display

Page 12

MD-MS200W/MD-MS200/MD-MS200H

– 12 –

•When the STOP button is pressed while the TEST-PLAY menu appears, or in TEST-PLAY or continuous playback mode, the mode changes

to the TEST mode stop state.

• When the PLAY button is pressed while the TEST-PLAY menu appears,continuous playback is initiated from the current pickup position.

• Whenever the DISP button is pressed in the TEST-PLAY mode, the address changes as follows.

0050 — 03C0 — 0700 — 08A0 — 0050 —

• Whenever the BASS key is pressed in the TEST-PLAY mode, the digit which is changed by the SKIP UP/DOWN button changes as follows.

0050 — 0050 — 0050 — 0050 — 0050 —

• When the SKIP UP button is pressed in the TEST-PLAY mode, the digit of address specified by the BASS button is set to +1h. (0 to F)

• When the SKIP DOWN button is pressed in the TEST-PLAY mode, the digit of address specified by the BASS button is set to -1h. (0 to F)

* When the SKIP UP/DOWN button is held down, the setting changes continuously, one cycle being 100 ms.

• When the BASS button is pressed in the continuous playback mode, the number of jump lines changes as follows.

1 — 10 — 400 — 1

* After the number of jump lines is indicated for one second, the address indication is restored. [ T R _ ]

• When the SKIP UP button is pressed in the continuous playback mode, the specified number of lines is jumped in the FWD direction.

• When the SKIP DOWN button is pressed in the continuous playback mode, the specified number of lines is jumped in the REV direction.

* When the SKIP UP/DOWN button is held down, jump is repeated every approx. 100 ms.

•Whenever the DISP button is pressed in the continuous playback mode, the indication changes as follows.

* Pit section

Continuous playback (SUBQ address indication) [ S Q ]

|

Continuous playback (C1 error indication) [ C E ]

|

Continuous playback (SUBQ address indication) [ S Q ]

* Groove section

Continuous playback (ADIP address indication) [ A P ]

|

Continuous playback (C1 error indication) [ C E ]

|

Continuous playback (ADIP error indication) [ A E ]

|

Continuous playback (ADIP address indication) [ A P ]

• : Address

• : C1 Error rate

• : ADIP Error rate

• : JUMP lines

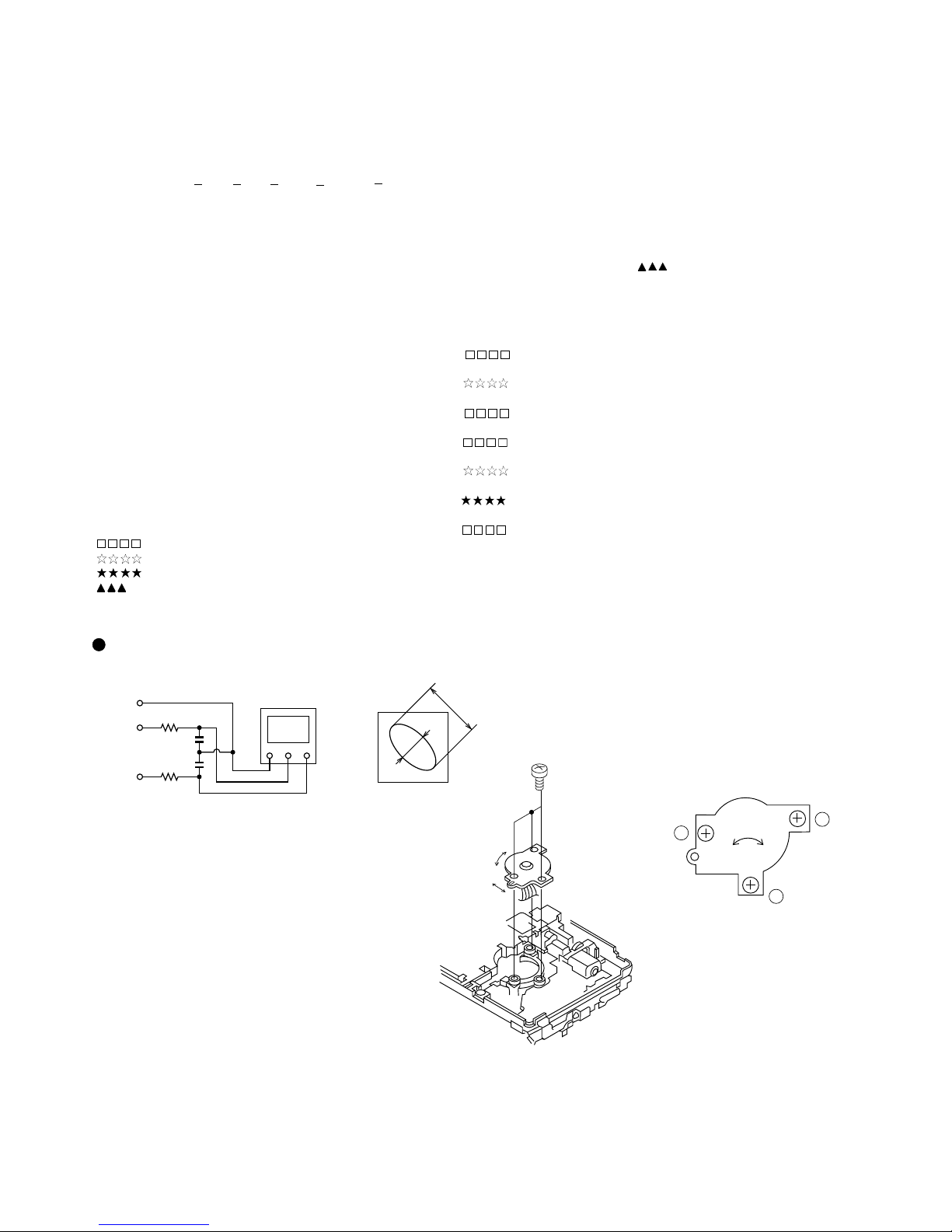

Mechanism Adjustment

1. Optical pickup grating inspecting method

Figure 12-1 OPTICAL PICKUP GRATING DEVIATION

MEASURING METHOD

After the automatic adjustment is performed in the AUTO mode

(test mode) with the aid of high refection MD disc ("COMPLATE" is

displayed), the Lissajous's waveform (x-y) is adjusted.

1. Slightly loosen the 3 screws of spin motor, and make an

adjustment, observing the Lissajous's wavefor.

2. After adjustment tighten the screws in arder of<1> , <2> ,< 3> .

3. It confirms Lissajous's wavwform ripple mark once again.

Figure 12-2

1

3

2

Shifting the spin motor installation

position, check the Lissajous's

waveform.

OSCILLOSCOPE

GND CH1 CH2

XY

TP141

GND

TP132

EOUT

TP133

FOUT

100Kohm

470p

470p

a

b

LISSAJOUS'S WAVEFORM

LESS THAN A:B = 3:1

100Kohm

Page 13

MD-MS200W/MD-MS200/MD-MS200H

– 13 –

5. TEST-REC Mode

Step No.

Setting Method

Display

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button

Step 3 AUTO menu [ A U T O ]

Step 4 SKIP UP button x 4times (Or SKIP DOWN button x 6 times)

Step 5 TEST-REC menu [ T R E C ]

Step 6 When the DISP button is pressed, the process proceeds to (7).

When the PLAY button is pressed, the process proceeds to (9).

Step 7 TEST-REC mode [ A d 0 0 5 0 ]

Step 8 PLAY button

Step 9 Continuous playback mode (groove) [ A P ]

Step 10 STOP button

Step 11 Test mode STOP state [ T E S T ]

• When the STOP button is pressed while the TEST-REC menu appears, or in the TEST-REC mode or continuous record mode, the mode

changes to the TEST mode stop state.

• When the PLAY button is pressed while the TEST-REC menu appears, the continuous record is initiated from the current pickup position.

• Whenever the DISP button is pressed in the TEST-REC mode, the address changes as follows.

0050 — 03C0 — 0700 — 08A0 — 0050 —

• Whenever the BASS button is pressed in the TEST-REC mode, the digit which is changed by the SKIP UP/DOWN button changes as

follows.

0050 — 0050 — 0050 — 0050 — 0050 —

• When the SKIP UP button s pressed in the TEST-REC mode, the digit of address specified by the BASS button is set to +1h.(0 to F)

• When the SKIP DOWN button is pressed in the TEST-REC mode, the digit of address specified by the BASS button is set to -1h. (0 to F)

* When the SKIP UP/DOWN button is held down, the setting changes continuously, one cycle being 100 ms.

• When the VOL UP/DOWN button is pressed in the TEST-REC mode or continuous record mode, the laser record power changes.

(Servo gain changes also according to record power.)

* After the laser record power is indicated for one second, the address indication is restored.

[ R P W ]

• : Address

• : Laser power cord

• Operation is disabled if the premastered disc or disc is in miserase-protected state.

6. INNER Mode

Step No.

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button

Step 3 AUTO menu [ A U T O ]

Step 4 SKIP UP button x 5 times

(Or SKIP DOWN button x 5 times)

Step 5 INNER menu [ I N N E R ]

Setting Method

Display

Step No.

Step 6 PLAY button

Step 7 INNER switch position measurement [ S Q ]

Step 8 STOP button

Step 9 Test mode STOP state [ T E S T ]

Setting Method Display

• When the STOP button is pressed while the INNER menu appears, the mode changes to TEST mode stop state.

• : Address

Page 14

MD-MS200W/MD-MS200/MD-MS200H

– 14 –

7. NORMAL Mode

Step No.

Setting Method

Display

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button

Step 3 AUTO menu [ A U T O ]

Step 4 SKIP UP button x 6times

(Or SKIP DOWN button x 4 times)

Step No.

Setting Method

Display

Step 5 NORMAL menu [ N O R M A L ]

Step 6 PLAY button

Step 7 TOC read [

Refer to the

following description.

]

Step 8 Hereafter operation in normal mode

• When the STOP button is pressed while the NORMAl menu appears, the mode changes to the TEST mode stop state.

• Indication during operation

Indication of memory capacity on main unit LCD [ ] + Level meter

: TNO

: Internal mode

: Servo state (#3: Slide, #2: Tracking, #1: Spin, #0: Focus)

: Address

LCD remote control [ ] + TNO indication

: Internal mode

: Servo state (#3: Slide, #2: Tracking, #1: Spin, #0: Focus)

: Address

: Memory capacity (graphic indication)

• Selection of sound volume, BASS, etc. is possible (without indication)

• Recording is also possible.

8. Digital input display mode

Step No.

Setting Method

Display

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button

Step 3 AUTO menu [ A U T O ]

Step 4 SKIP UP button x 7times

(Or SKIP DOWN button x 3 times)

Step 5 Digital input indication menu [ D I N M O N ]

Step 6 PLAY button

Step No.

Setting Method

Display

Step 7 FS code, channel status indication [ C ƒ ƒ ƒƒ ƒƒ ]

Step 8 SKIP UP button

Step 9 U bit indication 1 [ U 1 ]

Step 10 SKIP UP button

Step 11 U bit indication 2 [ U 2 † † ‡ ‡ ]

Step 12 STOP button

Step 13 Test mode STOP state [ T E S T ]

• When the STOP button is pressed while the digital input indication menu appears or during digital input information indication, the mode

changes to the TEST mode stop state.

• In case of analog input or digital input unlocking the indication data is _.

• ƒ ƒ : Control Code

• ƒƒƒƒ : Category code

• : TNO

•

: INDEX

•

† † : TIME(min.)

•

‡ ‡ : TIME(Sec.)

Page 15

MD-MS200W/MD-MS200/MD-MS200H

– 15 –

Step 1 Test mode STOP state [ T E S T ]

Step 2 BASS button

Step 3 AUTO menu [ A U T O ]

Step 4 SKIP UP button x 8times

(Or SKIP DOWN button x 2 times)

Step 5 Error data indication menu [ E D A T A ]

Step 6 PLAY button

Step 7 Indication of error data 0 [ E 0 ]

Step 8 SKIP UP button

Step 9 Indication of error data 1 [ E 1 ]

Step 10 SKIP UP button

Step 11 Indication of error data 2 [ E 2 ]

Step 12 SKIP UP button

Step 13 Indication of error data 3 [ E 3 ]

Step 14 SKIP UP button

Step 15 Indication of error data 4 [ E 4 ]

Step 16 SKIP UP button

Step 17 Indication of error data 5 [ E 5 ]

Step 18 SKIP UP button

Step 19 Indication of error data 6 [ E 6 ]

Step 20 SKIP UP button

Step 21 Indication of error data 7 [ E 7 ]

Step 22 SKIP UP button

Step 23 Indication of error data 8 [ E 8 ]

Step 24 SKIP UP button

Step 25 Indication of error data 9 [ E 9 ]

Step 26 STOP button

Step 27 Test mode STOP state [ T E S T ]

9. Error data display Mode

Step No.

Setting Method

Display

Contents

Error Code

Error data list

11 Automatic adjustment Gain maximum or error

adjustment judgment NG during adjustment retry in TG, FG

adjustment.

12 Automatic adjustment Out of allowable range

13 Automatic adjustment Servo retry error (4 times) during

adjustment

16 Automatic adjustment TZC error in TG, TB adjustment

(TG, TB measurement value does not change.)

17 Automatic adjustment TEO, FEO allowable range error

21 Focus setting disabled

23 Track search time-over

32 P-TOC read disabled

42 U-TOC read disabled

44 U-TOC write disabled

52 Music data write disabled

71 Pickup position initialization error (Inner switch ON failure)

72 EEPROM read error

73 Record head drive disabled (EJECT operation)

82 Overvoltage detection

91 TEMP over

• Reversing when SKIP DOWN button is pressed

• When the STOP button is pressed while the error data indication menu appears or during error data indication, the mode changes to the

TEST mode stop state.

• Error data 0 is the latest error.

• Error which occurred in the TEST mode is also stored in the memory.

• When the DISP button is pressed while the error data indication menu appears, the error data is initialized. [ C L E A R _ ]

•

: Error Code

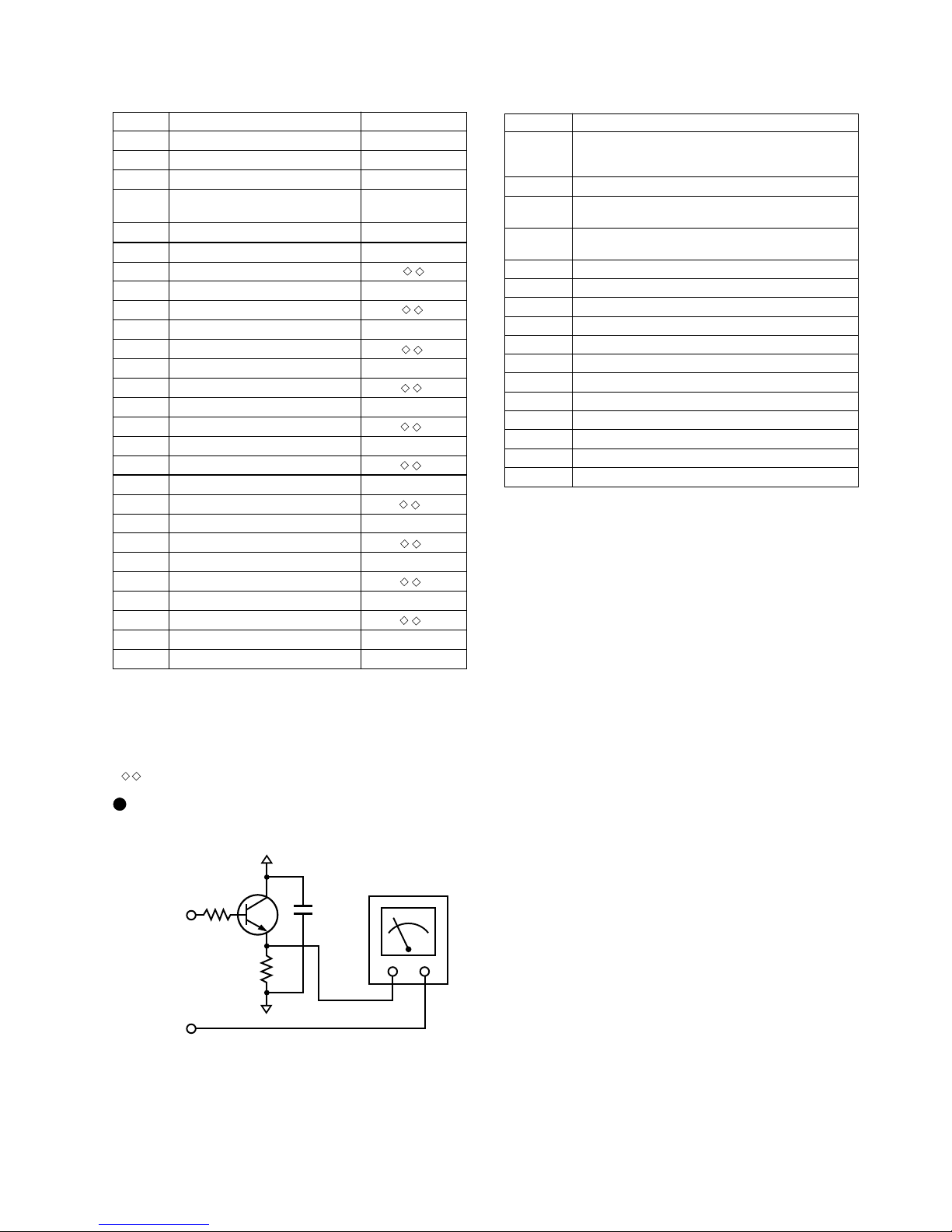

Jitter checking method

JITTER MATER

TP145

(EFM)

0.33

560 ohms

100 ohm

-3V

+3V

Tr: 2SC1815

2SC1740

TP141

(GND)

IC101

7 PIN

IC701 20 PIN

IC701 17 PIN

Figure 15

After automatic adjustment is performed in the AUTO mode (low

reflection MD disc use TEST mode), jitter must be less than 32 ns.

Page 16

MD-MS200W/MD-MS200/MD-MS200H

– 16 –

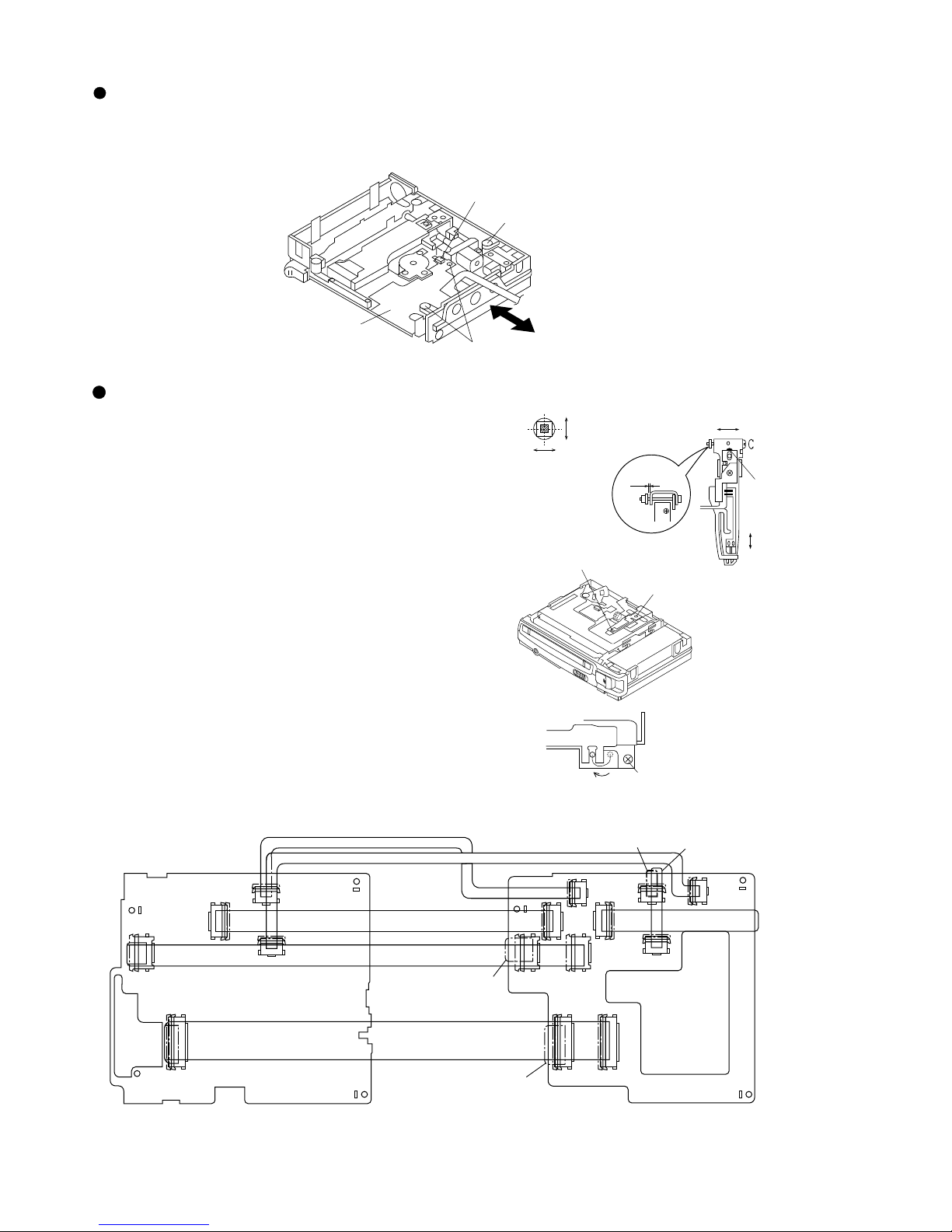

Lead-in switch position adjusting method

Note: Measure the position of lead-in switch in the INNER mode, and fix the position of lead-in switch at SUBQ FF85 to FF02.

After retightening the screw, pressing the mechanism PWB in the arrow direction, measure again the position of lead-in switch. If the

removed screw cannot be fit after position adjustment, fix with two screws.

Lead In Switch

Mechanism PWB

Remove yhe screw when

adjustment is made.

Loosen two screws

Figure 16-1

Adjustment of magnetic head mounting

position

• When the magnetic head and optical pickup have been replaced,

be sure to adjust the mounting position.

• For easier adjustment of mounting position move the optical

pickup to the center position, and then adjust the position.

1. Set the transparent disc 3 for adjustment.(*1)

2. Turn off the power supply, turn the head drive gear by hand to

lower the head.

3. Viewing the set from above, make an adjustment so that the

magnetic head aligns with the optical pickup objective lens.

• Circumferential direction: Slightly loosen the head fixing screw

(A), and shift the magnetic head fitting to align the head with the

pickup abjective lens.

• Radial direction:Turn the magnetic head circumferential adjustment nut (B), and adjust to align the head with the objective lens.

*1: Before setting the disc remove the decoration plate from the

disc lid, and fix it as shown in Figure 16-2.

4. Make sure that there is a clearance as shown in Figure 16-2 and

that the magnetic head moves up and down smoothly.

5. After adjustment apply Screw Lock to the head fixing screw (A)

and adjusted magnetic head radial adjusting screw (B).

Objective

lens

Clearance

Radial Direction

(Align the magnetic head

with the upper end of lens)

Circumferential direction

(Align the magnetic head

approximately with the

lens center)

Circumferential

direction

Radial

Direction

Magnetic

head

(A)

Apply a screw lack for

head fixing.

A

B

Slightly loosen the head

fixing screw.

Lift Motor

The lift pin is moved in the arrow direction

Magnetic head

(B)

Figure 16-2

QCNWK0091AFZZ (13 Pin)

QCNWK0092AFZZ (14Pin)

QCNWK0093AFZZ (26 Pin)

CNS201

CNS402

CNS601

CNS401

CNS101

Extension PWB for servicing

RUNTK0400AFZZ

Pickup Flexible PWB

Flexible PWB

Headdrive flexible PWB

LCD Flexible PWB

Mechanism

Flexible PWB

QCNWK0090AFZZ (7 Pin)

QCNWK0089AFZZ (6 Pin)

Main PWB

Figure 16-3

Page 17

MD-MS200W/MD-MS200/MD-MS200H

– 17 –

(1) Replace E2-PROM.

(2) Deprive E2-PROM of protection (connect the pins 8 and 2 of IC402).

(3) Refer to the latest E2-PROM data list.

(4) Press the Display/Lower-case Character button, Enter/Synchro button and Play/Pause button to start the test mode.

(5) Version display

[ V e r . ]

E2-PROM version (C ~ Z)

Microcomputer ROM version

(6) The whole LCD lights.

(7) Test mode stop state

[ T E S T ]

(8) Press the Enter/Synchro button.

[ E E P R O M ]

(9) Perform the operation to display "E2-PROM SETTING MODE CHART", compare the E2-PROM DATA LIST with the

display, and set according to the E2-PROM DATA LIST with the VOL UP or VOL DOWN key.

(10)

Set the temperature reference. (Refer to the Temperature Reference Setting Method.)

(11)

Set according to the E2-PROM DATA LIST.

(12)

Press the Stop button.

[ T E S T ]

(13)

Press the Stop button.

(14)

After data is written in E2-PROM, turn off power .

(15)

Restore protection of E2-PROM (Disconnect connection made in Step (2) above).

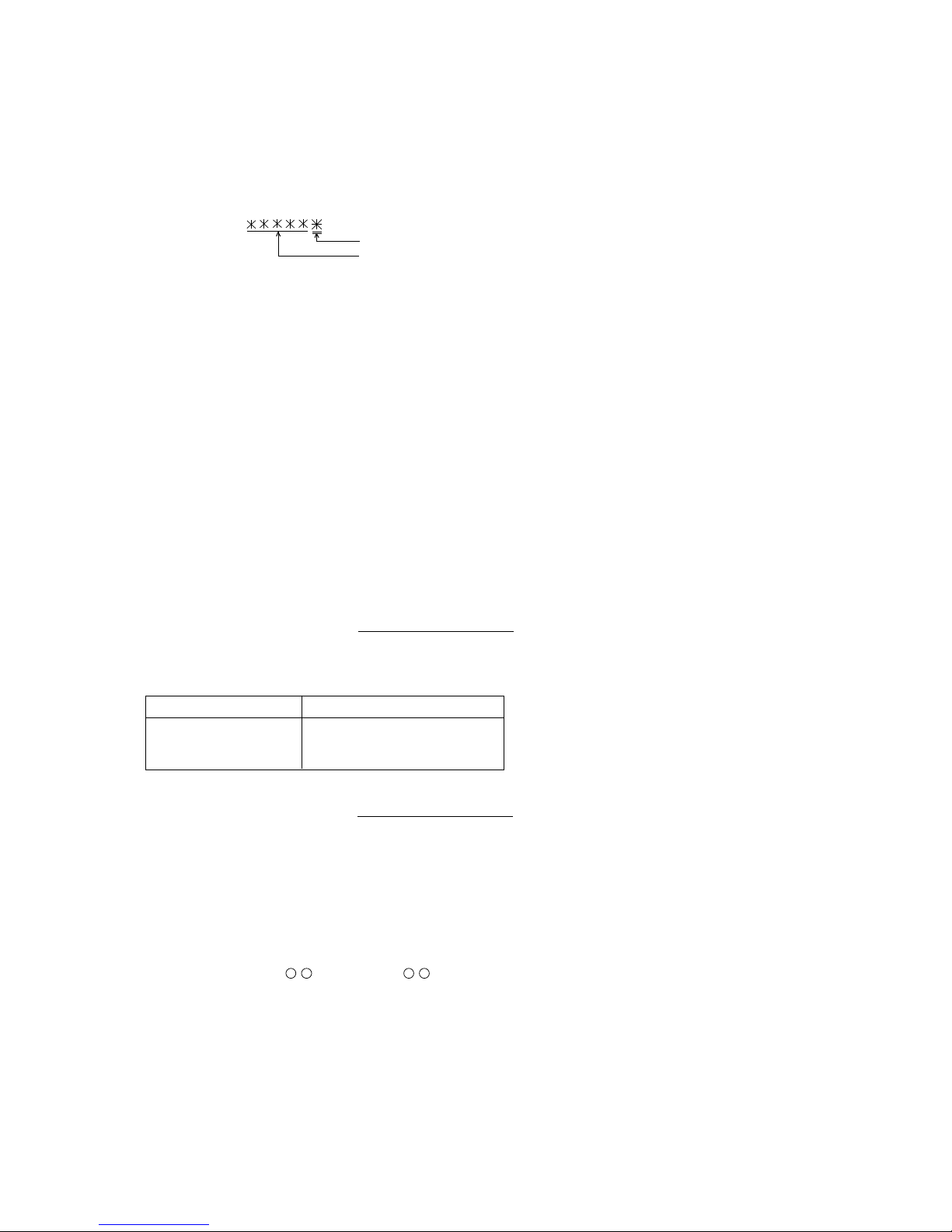

E2-PROM (IC402) writing procedure

1. Procedure to replace E2-PROM and write initial value of microcomputer in E2-PROM

2. Temperature reference setting method (to be performed at room temperature 21 to 29°C)

(1) Test mode stop state

[ T E S T M O D E ]

(2) Measure voltage of TEMP terminal (pin 3, IC401) of microcomputer.

(3) Calculate the temperature reference, using the following formula.

(4) Round down decimal fractions of calculated temperature reference, and convert it to hexadecimal value.

(5) Correct the temperature according to the table below depending on ambient temperature.

Temperature reference =

Measured voltage x 256

2.8

Ambient temperature

Temperature correction

21 - 23 + 1

24 - 26 ± 0

27 - 29 - 1

An example: Environmental temperature is 22°C and set voltage is 1.25V.

Temperature reference =

1.25 x 256

2.8

= 114.286

= 114 (Decimal fraction is rounded down.)

= 72 H (Conversion to hexadecimal value)

(6) Press the BASS button, and press the SKIP DOWN button.

[ E E P R O M ]

(7) Press the PLAY button, and press the SKIP button.

[ T e m p ]

(8) Press the PLAY button.

[ T E M P ] : Temperature reference

(9) Set the temperature standard value to the value obtained above with the VOL UP and VOL DOWN buttons.

(10)

Press the STOP button.

[ T E S T ]

Page 18

MD-MS200W/MD-MS200/MD-MS200H

– 18 –

T B A _ A 8 H

C T 1 _ 1 3 H

C T 2 _ A 8 H

C T 3 _ 0 2 H

C 0 0 _ 0 0 H

C 0 1 _ 9 0 H

C 0 2 _ 8 3 H

C 0 3 _ 0 5 H

C 0 4 _ 1 3 H

C 0 5 _ 0 8 H

C 0 6 _ 2 6 H

C 0 7 _ 2 0 H

C 0 8 _ 8 0 H

C 0 9 _ 0 0 H

C 1 0 _ 1 0 H

C 1 1 _ 0 0 H

C 1 2 _ 1 E H

C 1 3 _ 0 8 H

C 1 4 _ 5 C H

C 1 5 _ 1 D H

C 1 6 _ 1 F H

C 1 7 _ 1 F H

C 1 8 _ 2 0 H

C 1 9 _ 2 3 H

C 2 0 _ 2 4 H

C 2 1 _ 1 D H

C 2 2 _ 1 E H

C 2 3 _ 1 E H

C 2 4 _ 1 F H

C 2 5 _ 2 3 H

C 2 6 _ 2 5 H

C 2 7 _ 3 1 H

C 2 8 _ 2 C H

C 2 9 _ 2 1 H

C 3 0 _ 1 E H

C 3 1 _ 1 4 H

C 3 2 _ 8 5 H

C 3 3 _ 8 6 H

C 3 4 _ 8 5 H

C 3 5 _ 8 7 H

C 3 6 _ 0 5 H

C 3 7 _ C 0 H

C 3 8 _ 0 7 H

C 3 9 _ 7 0 H

C 4 0 _ 0 9 H

C 4 1 _ 4 0 H

C 4 2 _ 0 B H

C 4 3 _ 2 0 H

C 4 4 _ 0 D H

C 4 5 _ 1 0 H

C 4 6 _ 6 5 H

C 4 7 _ 5 0 H

C 4 8 _ 5 0 H

C 4 9 _ 1 5 H

C 5 0 _ D 4 H

E2-PROM DATA LIST

Focus setting

Item display Set values

F G _ _ 6 C H

F F 1 _ 7 0 H

F F 2 _ F 0 H

F F 3 _ F E H

F F 4 _ 0 0 H

F Z H _ E D H

F L n _ F 6 H

F L f _ 7 F H

F P n _ 0 0 H

F P f _ 8 8 H

F L V _ 2 8 H

W T f _ 9 0 H

F S S _ 0 6 H

Item display Set values

S P G _ 1 A H

S P i _ D 0 H

S P m _ A 0 H

S P o _ 6 8 H

S P 1 _ 1 0 H

S P 2 _ 6 0 H

S P 3 _ F 2 H

S P 4 _ F 2 H

S P 5 _ 1 0 H

BASS setting

Item display Set values

B S 1 _ 0 0 H

B S 2 _ 0 0 H

B S 3 _ 0 0 H

TEMP setting

Item display Set values

T M _ _ Calculate values

Tracking setting

Item display Set values

T G _ _ 4 0 H

T F 1 _ E 0 H

T F 2 _ E 8 H

T F S _ 0 0 H

T B o _ 4 0 H

T B t _ 6 0 H

T K o _ 4 8 H

T K t _ 2 8 H

T D o _ 7 5 H

T D t _ 1 A H

S C o _ 0 0 H

S C t _ 4 0 H

S C m _ 5 3 H

D B O _ 0 0 H

C H p _ 1 0 H

C L p _ F 0 H

C H r _ 2 0 H

C L r _ E 0 H

W T m _ 9 0 H

Slide setting

Item display Set values

S L G _ 8 0 H

S L 2 _ 1 C H

S L M _ 7 F H

S L V _ 2 0 H

S K k _ 7 8 H

S K t _ 5 0 H

S K m _ 7 8 H

Control setting

Item display Set values

Item display Set values

Spin setting

Page 19

MD-MS200W/MD-MS200/MD-MS200H

– 19 –

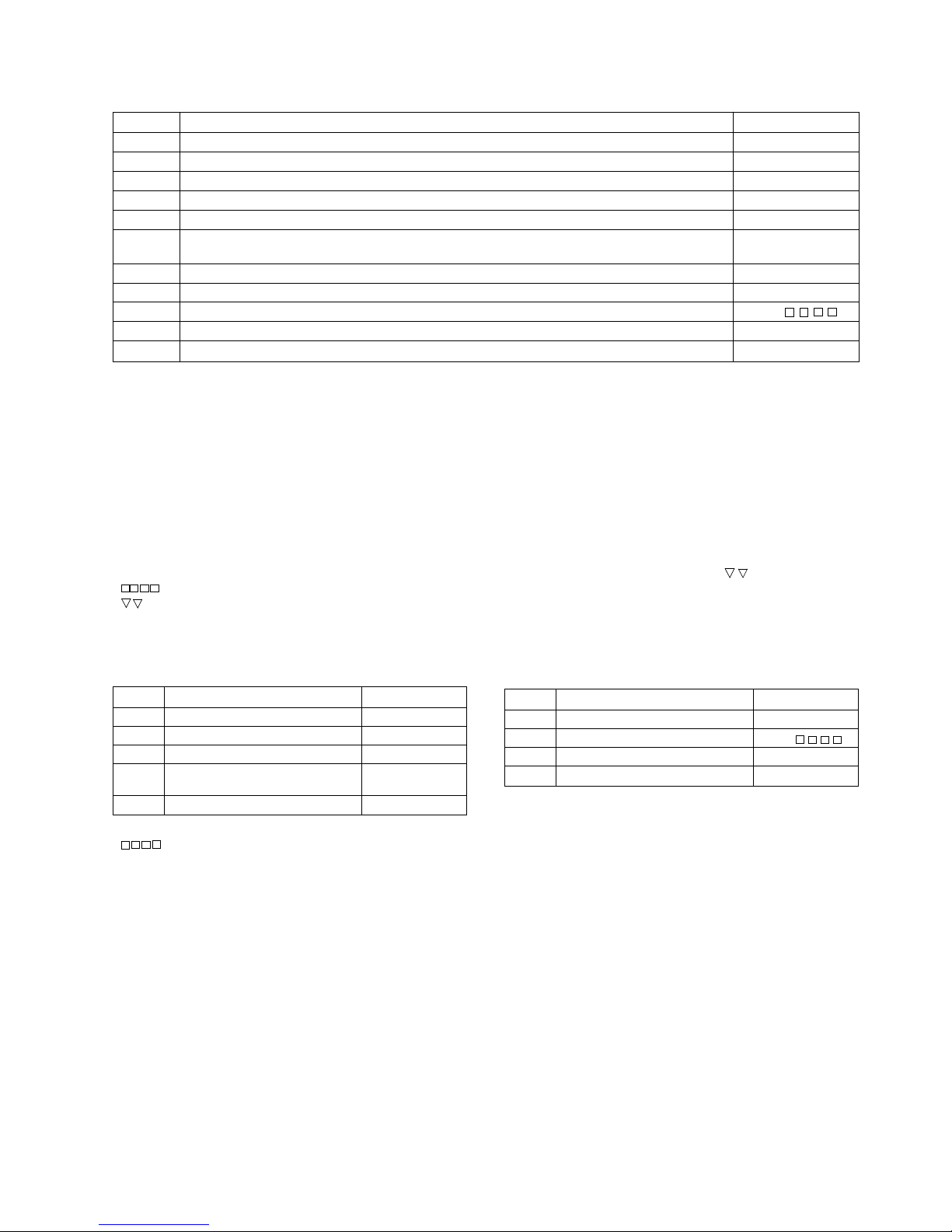

Test Mode Change Chart Test Auto Change Chart

T E S T M O D E

S T O P

BASS

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

T E S T A U T O

M E N U

M A N U A L

A D J U S T

M E N U

R E S U L T

D I S P

M E N U

Continuous

playback

MENU

Continuous

record

MENU

INNER position

measurement

MENU

Normal mode

MENU

Digital input

indication

MENU

Error data

indication

MENU

• When the STOP key is pressed in the specific mode,

the mode changes to the TEST mode stop state.

EEPROM

setting

MENU

T E S T

A U T O

M A N U A L

R E S U L T

T P L A Y

T R E C

I N N E R

N O R M A L

D i n M o n

E D A T A

E E P R O M

PLAY

PLAY

ADJUST

O K

ADJUST

NG

: Adjustment indication

: Address indication

T E S T A U T O

M E N U

Execution of

automatic

adjustment

Adjustment value output

Grating adjustment

Adjustment

value

output

Continuous playback

MODE

• When the STOP key is pressed in the specific mode,

the mode changes to the TEST mode stop state.

A U T O

A D J . N G

A D J . O K

S Q

A P

Page 20

MD-MS200W/MD-MS200/MD-MS200H

– 20 –

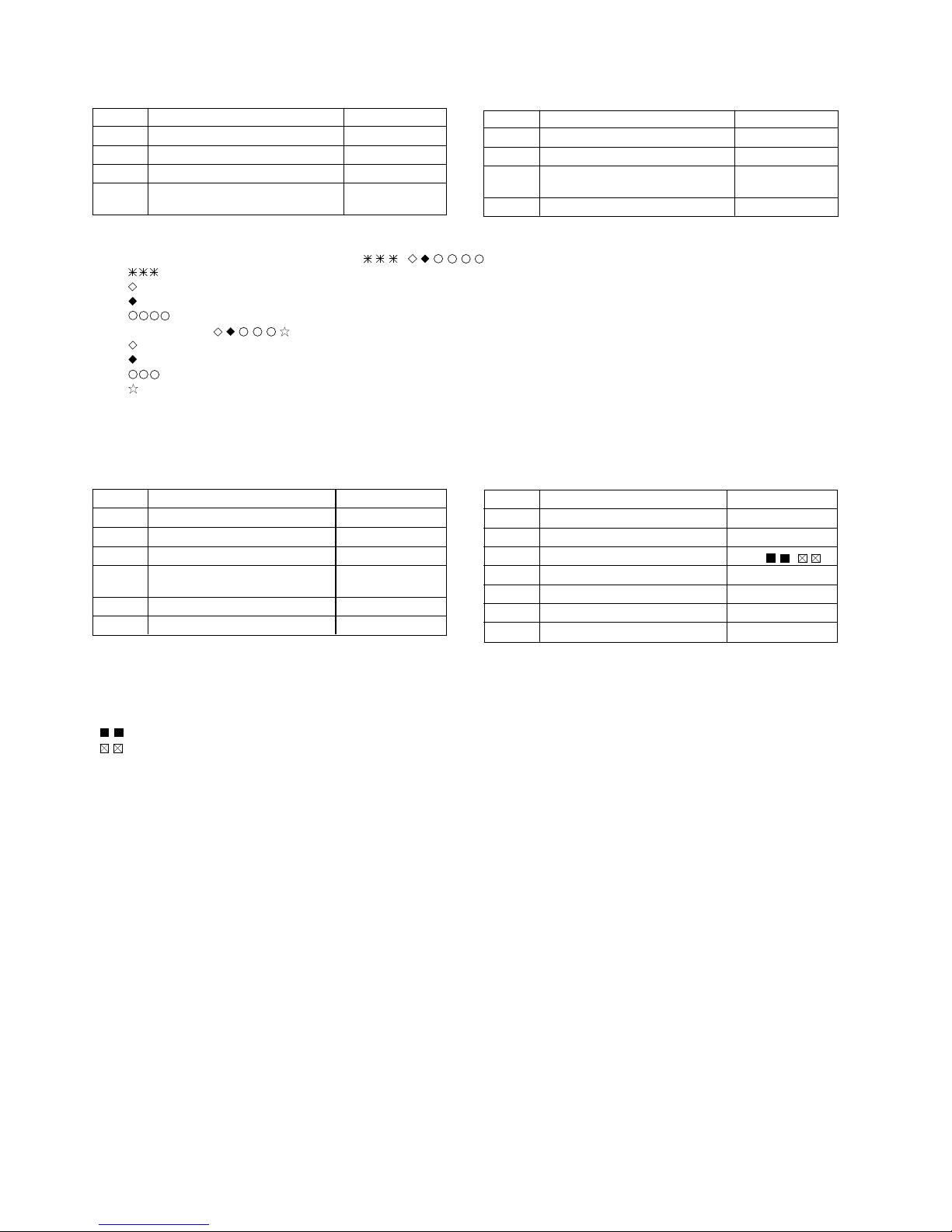

Manual Adjustment Change Chart Result Indication Change Chart

MANUAL ADJUST

MENU

PLAY

PLAY

P-MODE

PLAY

P-MODE

SKIP DOWN

SKIP DOWN

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP DOWN

BASS

2 sec.

BASS

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP UP

SKIP DOWN

SKIP UP

SKIP DOWN

Temperature

measurement

Tracking Error Offset

measurement

Focus Error Offset

measurement

Laser ON

Record power laser ON

Pit section continuous playback

Groove section continuous playback

FG rough

adjustment

FG fine adjustment

FG fine adjustment

: measurement value

: Adjustment value

: Addres

Pit section

TG adjustment

Pit section

TB adjustment

TOTAL signal

adjustment

• When the STOP key is pressed in the specified mode, the mode changes tothe TEST mode stop state.

Groove section

TG adjustment

Groove section

TB adjustment

M A N U A L

T M P :

T E O :

F E O :

L O N :

h f

l f

H g

L g

H b

L b

H f

L f

G l

R P W :

S Q

A P

G g

G b

L f

RESULT DISP

MENU

PLAY

SKIP DOWN

SKIP DOWN

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP UP

SKIP DOWN

SKIP UP

SKIP DOWN

Temperature

measurement value

Tracking error offset

measurement value

Focus error offset

measurement value

High reflection

FG set value

High reflection pit

section TG set value

Low reflection groove

section TB set value

High reflection pit

section TB set value

• When the STOP key is pressed in the specified mode, the mode changes tothe TEST mode stop state.

Low reflection groove

section TOTAL

set value

Low reflection groove

section TG set value

R E S U L T

T M P :

T E O

F E O

H f

H g

Low reflection

FG set value

L f

Low reflection

TG set value

L g

H b

Low reflection

TB set value

L b

G l

G g

G b

: measurement value

: Adjustment value

Page 21

MD-MS200W/MD-MS200/MD-MS200H

– 21 –

Continuous Playback Change Chart Inner Position Measurement Change Chart

Continuous

playback menu

DISP

PLAY

PLAY

PLAY

PLAY

PLAY

Start address

indication 1

Start address

indication 2

Start address

indication 3

Start address

indication 4

: Address

• When the STOP key is pressed in the specified mode, the mode changes to the TEST mode stop state.

• When the SKIP UP/DOWN key is pressed in the start address indication state, the address of specific

digit changes.

• When the BASS key is pressed in the start address indication state, the digit of address which is changed

by the SKIP UP/DOWN key is changed.

T P L A Y

A D 0 0 5 0

A D 0 3 C 0

A D 0 7 0 0

A D 0 8 A 0

S Q

A P

DISPDISP

DISP

DISP

Continuous playback

Continuous

record menu

DISP

PLAY

PLAY

PLAY

PLAY

PLAY

Start address

indication 1

Start address

indication 2

Start address

indication 3

Start address

indication 4

DISPDISP

DISP

DISP

Continuous record

A P

• When the STOP key is pressed in the specified mode, the mode changes to the TEST mode stop state.

• When the SKIP UP/DOWN key is pressed in the start address indication state, the address of specific digit changes.

• When the BASS key is pressed in the start address indication state, the digit of address which is changed by the

SKIP UP/DOWN key is changed.

• When the VOL UP/DOWN key is pressed in the start address indication state or continuous record state,

the record laser power changes.

T R E C

A D 0 0 5 0

A D 0 3 C 0

A D 0 7 0 0

A D 0 8 A 0

: Address

Continuous Record Change Chart

Digital input

indication menu

FS code

C bit data indication

U bit 1 data

indication

U bit 2 data

indication

: FS Code

: Control Code

: Category Code

:TNO

: INDEX

: TIME (min)

: TIME (sec)

• When the STOP key is pressed in the specified mode, the mode changes to the

TEST mode stop state.

D i n M o n

U 1

U 2

C

PLAY

SKIP DOWN

SKIP DOWN

SKIP UP

SKIP UP

Inner position

measurement menu

PLAY

Position

measurement

• When the STOP key is pressed in the specified mode, the mode changes to the

TEST mode stop state.

I N N E R

S Q

Normal Mode Change Chart

Normal mode

change menu

Normal mode

• When the STOP key is pressed in the specified mode, the mode changes to the

TEST mode stop state.

N O R M A L

# # # # # #

PLAY

Digital Input Indication Change Chart

Page 22

MD-MS200W/MD-MS200/MD-MS200H

– 22 –

Error Data Indication Change Chart EEPROM Setting Change Chart

Error data

indication menu

PLAY

DISP

SKIP DOWN

SKIP DOWN

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

Error data

0 indication

Error data

1 indication

Error data

2 indication

Error data

3 indication

Error data

4 indication

Error data

5 indication

Error data

6 indication

Error data

7 indication

Error data

8 indication

Error data

9 indication

: Error Code

After 2 seconds

• When the STOP key is pressed in the specified mode, the mode changes to the TEST mode stop state.

E D A T A

E 0

C L E A R

E 1

E 2

E 3

E 4

E 5

E 6

E 7

E 8

E 9

EEPROM

setting menu

PLAY

SKIP DOWN

SKIP DOWN

SKIP UP

SKIP DOWN

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

FOCUS

setting menu

SPIN

setting menu

TRACKING

setting menu

SLIDE

setting menu

BASS

setting menu

TEMP

setting menu

CONTROL

setting menu

• When the STOP key is pressed in the specified mode, the mode changes to the TEST mode stop state.

E E P R O M

F o c u s

S p i n

T r a c k

S l e d

B a s s

T e m p

C T R L

Page 23

MD-MS200W/MD-MS200/MD-MS200H

– 23 –

EEPROM Slide Setting Change Chart

EEPROM TEMP Setting Change Chart

EEPROM BASS Setting Change Chart

BASS setting menu

PLAY

• When the STOP key is pressed in the specified mode, the mode changes to the TEST mode stop state.

B A S S

B S 1

SKIP UP

SKIP UP

SKIP DOWN

SKIP DOWN

B S 2

B S 3

: measurement value

TEMP setting menu

PLAY

: Normal setting value

: Temperature code

• When the STOP key is pressed in the specified mode, the mode changes to the TEST mode stop state.

T E M P

T M

Slide setting menu

PLAY

: measurement value

• When the STOP key is pressed in the specified mode, the mode changes to the TEST mode stop state.

S l e d

S L G

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

S L 2

S L M

S L V

S K k

S K t

S L m

Control setting

menu

PLAY

C 0 2 ~ C 4 8

• When the STOP key is pressed in the specified mode, the mode changes to the TEST mode stop state.

C T R L

C 0 0

SKIP UP

SKIP UP

SKIP UP

SKIP DOWN

SKIP DOWN

SKIP DOWN

C 0 1

C 4 9

C 5 0

: measurement value

EEPROM Control Setting Change Chart

Page 24

MD-MS200W/MD-MS200/MD-MS200H

– 24 –

EEPROM Focus Setting Change Chart

EEPROM Spin Setting Change Chart EEPROM Tracking Setting Change Chart

Focus setting

menu

PLAY

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

• When the STOP key is pressed in the specified mode, the mode changes tothe TEST mode stop state.

F o c u s

F G

SKIP UP SKIP DOWN

F F 1

F F 2

F F 3

F F 4

F Z H

F L n

F L f

F P n

F P f

F L V

W T f

F S S

: measurement value

Spin setting

menu

PLAY

• When the STOP key is pressed in the specified mode, the mode changes tothe TEST mode stop state.

S p i n

S P G

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

S P i

S P m

S P o

S P 1

S P 2

S P 3

S P 4

S P 5

: measurement value

Tracking setting

menu

PLAY

• When the STOP key is pressed in the specified mode, the mode changes tothe TEST mode stop state.

T r a c k

T G

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP UP

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

SKIP DOWN

T F 1

T F 2

T F S

T B o

T B t

T K o

T K t

T D o

T D t

S C o

SC t

D B O

C H p

C L p

C H r

C L r

W T m

: measurement value

Page 25

MD-MS200W/MD-MS200/MD-MS200H

– 25 –

Can't REC • Defect occurred 10 times successively during REC-PLAY. • Check that disc is free from flaws, dust,

• During REC-PLAY, the break that full, high temperature fingerprint, black spots, etc. Check for

memory taped occurred. significant disalignment and runout of disc.

• When reads it, and impossibility tries it again, and an

address doesn't hire you in REC state repeatedly for 20

seconds either.

Can't COPY • The following judgment was made based on the channel • Record, using the analog cable.

status of digital signal which was input from D-IN during

REC-PAUSE or REC-PLAY significant disalignment and

runout of disc.

(1) Other than audio uses

(2) Other than home-uses

(3) SCNS revealed that copy is impossible.

Din UNLOCK • The following result occurred when the digital signal was • Check for troubles in D-IN signal line.

input from D-IN during REC-PAUSE or RECD-PLAY.

(1) PLL of digital IN was unlocked.

TOC FULL • The domain that music turn and character information • Replace disc with another record/playback

(title of a musical composition, disk names) was registered disc having a sufficient area to write UTOC.

during REC-PLAY.

UTOC ERROR • UTOC recorded in the disc could not be read. • Record, using the analog cable.

• Data of UTOC 0 to 4 was looped. • UTOC data has error. Replace disc with

another disc

? DISC • "MINI" data of system ID written with ASCII code in TOC is • The disc is nonstandard disc. Replace disc

not correct. with another disc, and check.

• The disc type written in TOC is not for premastered MD,

recording MD or hybrid MD.

DISC FULL • When an attempt to set REC-PAUSE was made, there was • Replace the disc with another record disc

no record-enable area in the disc. having record-enable area.

PB DISC • An attempt to set REC-PAUSE or to edit was made on the • Replace the playback-only disc with record

playback-only disc. disc.

PROTECTED • An attempt to record or edit was made on the record/ • Release the safety lug, and try again.

playback disc whose safety lug has been set to careless

protected. Redo on another track.

TR. PROTECT • An attempt was made to edit the write-protected track • The track which you want to edit is write-

according to information written in UTOC. erase preventing position.

TOC FULL • When an attempt to enter REC-PAUSE or DIVIDE mode or • Replace disc with another record/playback

to write the character information was made, the UTOC disc having a sufficient area to write UTOC.

writing area was full of data.

Can't EDIT • The specific editing conditions were not satisfied in editing. • Operation procedure is not proper. Redo,

following the correct operation procedure.

TEMP OVER • Because any abnormality occurred, temperature in a set • It checks it by troubleshooting.

(MD unit) became too high. • It uses it at a place of high temperature, and

is there not it?

DISC ERROR • Data weren't right or didn't just understand it as a result • Data has error or the disc has flaw. Replace

of having read data. the disc.

• Abnormality occurred during a record of music data, and

wasn't able to do a record justly.

TOC ERROR • An attempt to read TOC was made, but it could not be read. • Because it isn't in MD standard, TOC

• It was going to read TOC, but wasn't able to read it. information recorded in DISC tries to turn it