Sharp LH28F160S3HT-L10A Datasheet

®

PRODUCT SPECIFICATIONS

Integrated Circuits Group

LH28F160S3HT-L10A

Flash Memory

16M (2MB × 8/1MB × 16)

(Model No.: LHF16KA7)

Spec No.: EL127111A

Issue Date: August 29, 2000

SHARP

. -

l

Handle this document carefully for it contains material protected by international copyright

law. Any reproduction, full or in part, of this material is prohibited without the express

written permission of the company.

l

When using the products covered herein, please observe the conditions written herein

and the precautions outlined in the following paragraphs. In no event shall the company

be liable for any damages resulting from failure to strictly adhere to these conditions and

precautions.

(1) The products covered herein are designed and manufactured for the following

application areas. When using the products covered herein for the equipment listed

in Paragraph (2), even for the following application areas, be sure to observe the

precautions given in Paragraph (2). Never use the products for the equipment listed

in Paragraph (3).

i *Office electronics

l

instrumentation and measuring equipment

l

Machine tools

aAudiovisual equipment

*Home appliance

l

Communication equipment other than for trunk lines

LHF16KA7

-

(2) Those contemplating using the products covered herein for the following equipment

which demands high reliability, should first contact a sales representative of the

company and then accept responsibility for incorporating into the design fail-safe

operation, redundancy, and other appropriate measures for ensuring reliability and

safety of the equipment and the overall system.

-Control and safety devices for airplanes, trains, automobiles, and other

transportation equipment

*Mainframe computers

l

Tcaff

ic control systems

aGas leak detectors and automatic cutoff devices

*Rescue and security equipment

@Other safety devices and safety equipment, etc.

(3) Do not use the products covered herein for the following equipment which demands

extremely high performance in terms of functionality, reliability, or accuracy.

aAerospace equipment

l

Communications equipment for trunk lines

l

Control equipment for the nuclear power industry

l

Medical equipment related to life support, etc.

(4) Please direct all queries and comments regarding the interpretation of the above

three Paragraphs to a sales representative of the company.

l

Please direct all queries regarding the products covered herein to a sales representative

of the company.

Rev.1.9

SHARP

. -

_-

--

LHF16KA7

CONTENTS

PAGE PAGE

1

I INTRODUCTION

1.1 Product Overview.. .............................................. 3

2 PRINCIPLES OF OPERATION

2.1

Data Protection ................................................... 7

3 BUS OPERATION.. ..................................................

3.1 Read

3.2 O&put

3.3 Standby.. ............................................................. 7

3.4 Deep Power-Down .............................................. 7

3.5 Read Identifier Codes Operation.. ....................... 8

3.6 Query Operation

3.7 Write.. .................................................................. 8

1 COMMAND

4.1 Read Array Command

4.2 Read Identifier Codes Command ...................... 11

4.3 Read Status Register Command.. ..................... 11

4.4 Clear Status Register Command.. .....................

4.5 Query Command

4.51 Block Status Register

4.5.2 CFI Query Identification StAng.. ................... 13

4.5.3 System Interface.lnformation..

4.5.4 Device Geometry

4.5.5 SCS OEM Specific Extended Query Table.. 14

4.6 Block Erase Command.. ....................................

4.7 Full Chip Erase Command

4.8 Word/Byte Write Command.. ............................. 16

4.9 Multi Word/Byte Write Command ...................... 16

4.10 Block Erase Suspend Command.. ................... 17

4.11 (Multi) Word/Byte Write Suspend Command ... 17

4.12 Set Block Lock-Bit Command.. ........................ 18

4.13 Clear Block Lock-Bits Command..

4.14 STS Configuration Command

................................................................... 7

...................................................... 3

................................ 6

Disable

....................................................

.................................................. 8

DEFINITIONS.. ..................................... 8

....................................... 11

............................................... 12

.................................. 12

.....................

Definition ......................... 14

................................ 15

...................

.........................

5 DESIGN CONSIDERATIONS

5.1 Three-Line Output Control

5.2 STS and Block Erase, Full Chip Erase, (Multi)

Word/Byte Write and Block Lock-Bit Configuration

Polling ................................................................ 3c

5.3 Power Supply Decoupling .................................. 3c

5.4 V,, Trace on Printed Circuit Boards..

7

5.5 Vcc,

5.6 Power-Up/Down Protection..

7

5.7 Power Dissipation

6 ELECTRICAL SPECIFICATIONS..

6.1 Absolute Maximum Ratings

6.2 Operating Conditions ......................................... 32

6.2.1 Capacitance ................................................. 32

6.2.2 AC Input/Output Test Conditions..

6.2.3 DC Characteristics ........................................ 34

6.2.4 AC Characteristics - Read-Only Operations .3E

6.2.5 AC Characteristics - Write Operations..

11

13

15

18

19

6.2.6 Alternative CE#-Controlled Writes..

6.2.7 Reset Operations

6.2.8 Block Erase, Full Chip Erase, (Multi)

7 ADDITIONAL INFORMATION ................................ 4E

7.1 Ordering Information .......................................... 46

V,,,, RP# Transitions.. .............................. .31

............................................. .31

Word/Byte Write and Block Lock-Bit

Configuration Performance..

................................

................................ .3C

.............................

........................

.............................. .3i

........................................ .4Z

........................

...............

...............

....... .3E

.............

.3C

.3C

.31

.3i

.3Z

.41

.44

Rev. 1.9

SHAl?P

LHFlGKA7 2

-

LH28F160S3HT-Ll OA

1 GM-BIT (2MBx8/1 MBxl6)

Smart 3 Flash MEMORY

n Smart 3 Technology

- 2.7V or 3.3V Vcc

- 2.7V, 3.3V or SV Vpp

I Common Flash Interface (CFI)

-

Universal & Upgradable Interface

I Scalable Command Set (SCS)

n High Speed Write Performance

-

32 Bytes x 2 plane Page Buffer

-

2.7 @Byte Write Transfer Rate

n High Speed Read Performance

- 1 OOns(3.3V*O.3V), 120ns(2.7\1-3.6V)

I Operating Temperature

- -40°C to +85X

n Enhanced Automated Suspend Options

-

Write Suspend to Read

- Block Erase Suspend to Write

-

Block Erase Suspend to Read

n High-Density Symmetrically-Blocked

Architecture

-

Thirty-two 64K-byte Erasable Blocks

n Enhanced Data Protection Features

- Absolute Protection with VpP=GND

- Flexible Block Locking

- Erase/Write Lockout during Power

Transitions

n Extended Cycling Capability

- 100,000 Block Erase Cycles

- 3.2 Million Block Erase Cycles/Chip

n Low Power Management

- Deep Power-Down Mode

- Automatic Power Savings Mode

Decreases ICC in Static Mode

n Automated Write and Erase

- Command User Interface

- Status Register

n Industry-Standard Packaging

- 56-Lead TSOP

n ETOgTM* V Nonvolatile Flash

Technology

n CMOS Process

(P-type silicon substrate)

I SRAM-Compatible Write Interface

I User-Configurable x8 or x16 Operation

SHARP’s LH28F160S3HT-LlOA Flash memory with Smart 3 technology is a high-density, low-cost, nonvolatile,

*cad/write storage solution for a wide range of applications. Its symmetrically-blocked architecture, flexible voltage

and extended cycling provide for highly flexible component suitable for resident flash arrays, SlMMs and memory

:ards. Its enhanced suspend capabilities provide for an ideal solution for code + data storage applications. For

secure code storage applications, such as networking, where code is either directly executed out of flash or

downloaded to DRAM, the LH28F160S3HT-LlOA offers three levels of protection: absolute protection with V,, at

?ND, selective hardware block locking, or flexible software block locking. These alternatives give designers

Jltimate control of their code security needs.

The LH28F160S3HT-LlOA is conformed to the flash Scalable Command Set (SCS) and the Common Flash

nterface (CFI) specification which enable universal and upgradable interface, enable the highest system/device

data transfer rates and minimize device and system-level implementation costs.

The LH28F160S3HT-LlOA is manufactured on SHARP’s 0.35um

ndustry-standard package: the 56-Lead TSOP ideal for board constrained applications.

‘ETOX is a trademark of Intel Corporation.

n Not designed or rated as radiation

hardened

ETOX TM* V process technology. It come in

Rev. 1.9

SHARP

. -

LHFlGKA7

1 INTRODUCTION

This datasheet contains LH28F160S3HT-Ll OA

specifications. Section 1 provides a flash memory

overview. Sections 2, 3, 4, and 5 describe the

memory organization and functionality. Section 6

covers electrical specifications.

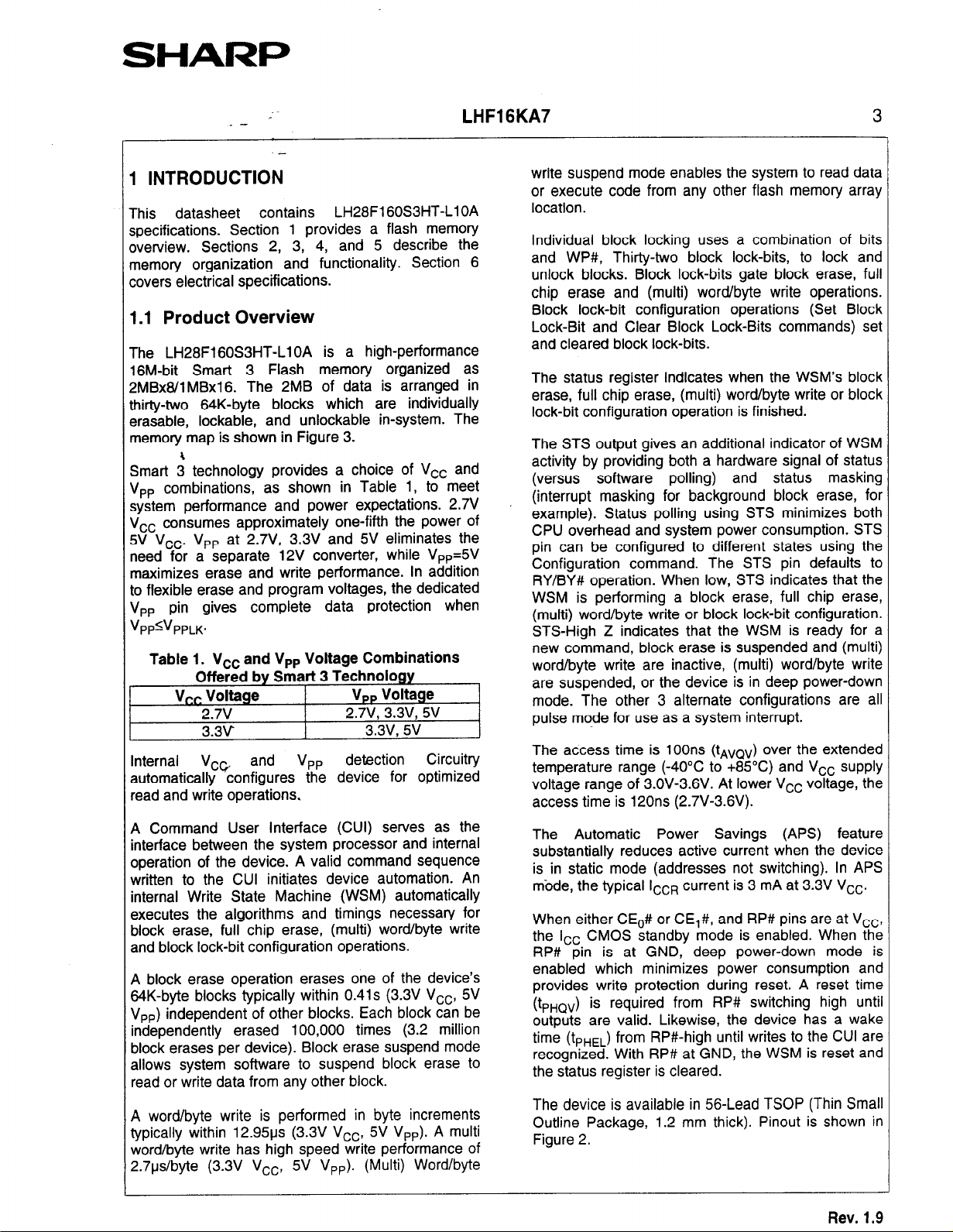

1 .l Product Overview

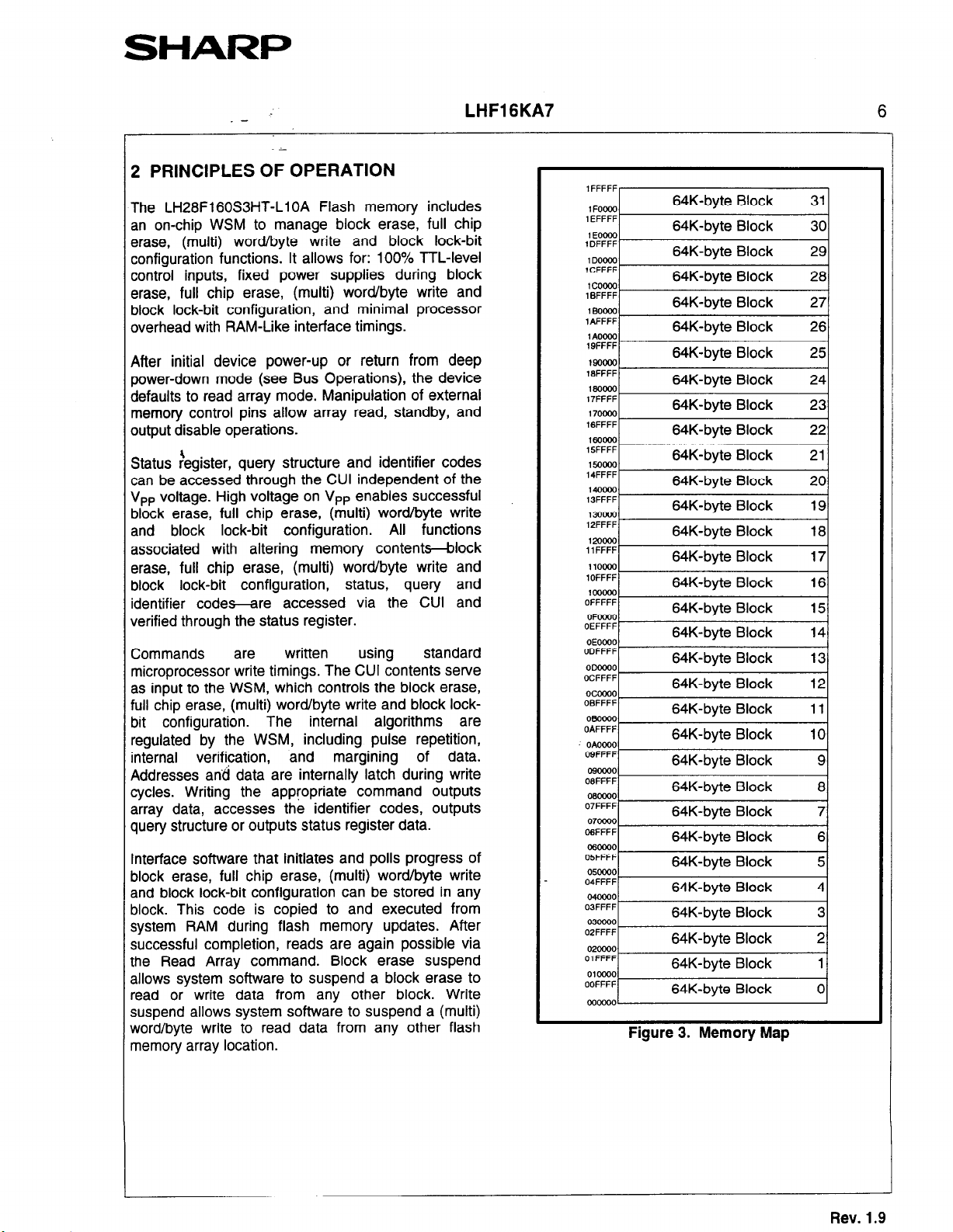

The LH28F160S3HT-Ll OA is a high-performance

16M-bit Smart 3 Flash memory organized as

2MBx80MBxl6. The 2MB of data is arranged in

thirty-two 64K-byte blocks which are individually

erasable, lockable, and unlockable in-system. The

memory map is shown in Figure 3.

Smart 3’ technology provides a choice of V,, and

V,, combinations, as shown in Table 1, to meet

system performance and power expectations. 2.7V

Vc, consumes approximately one-fifth the power of

5V Vc,. V,, at 2.7V, 3.3V and 5V eliminates the

need for a separate 12V converter, while V,,=5V

maximizes erase and write performance. In addition

to flexible erase and program voltages, the dedicated

V,, pin gives complete data protection when

Table 1. Vcc and Vpp Voltage Combinations

Offered by Smart 3 Technology

Vcc Voltage Vpp Voltage

2.7V 2.7V, 3.3V, 5V

3.3v 3.3v, 5v

Internal

automatically configures the device for optimized

read and write operations.

VW

and

VP,

detection Circuitry

3

1

write suspend mode enables the system to read data

or execute code from any other flash memory array

location.

Individual block locking uses a combination of bits

and WP#, Thirty-two block lock-bits, to lock ant

unlock blocks. Block lock-bits gate block erase, full

chip erase and (multi) word/byte write operations.

Block lock-bit configuration operations (Set Block

Lock-Bit and Clear Block Lock-Bits commands) sei

and cleared block lock-bits.

The status register indicates when the WSM’s block

erase, full chip erase, (multi) word/byte write or block

lock-bit configuration operation is finished.

The STS output gives an additional indicator of WSM

activity by providing both a hardware signal of status

(versus software polling) and status maskins

(interrupt masking for background block erase, fol

example). Status polling using STS minimizes bott

CPU overhead and system power consumption. STS

pin can be configured to different states using the

Configuration command. The STS pin defaults tc

RY/BY# operation. When low, STS indicates that the

WSM is performing a block erase, full chip erase

(multi) word/byte write or block lock-bit configuration

STS-High Z indicates that the WSM is ready for a

new command, block erase is suspended and (multi:

word/byte write are inactive, (multi) word/byte write

are suspended, or the device is in deep power-dowr

mode. The other 3 alternate configurations are al

pulse mode for use as a system interrupt.

The access time is 100ns (tAVQv) over the extendec

temperature range (-40°C to +85”C) and Vc, suppI\

voltage range of 3.OV-3.6V. At lower V,, voltage, the

access time is 120ns (2.7V-3.6V).

A Command User Interface (CUI) serves as the

interface between the system processor and internal

operation of the device. A valid command sequence

written to the CUI initiates device automation. An

internal Write State Machine (WSM) automatically

executes the algorithms and timings necessary for

block erase, full chip erase, (multi) word/byte write

and block lock-bit configuration operations.

4 block erase operation erases one of the device’s

%lK-byte blocks typically within 0.41s (3.3V Vcc, 5V

VP,) independent of other blocks. Each block can be

independently erased 100,000 times (3.2 million

olock erases per device). Block erase suspend mode

allows system software to suspend block erase to

read or write data from any other block.

A word/byte write is performed in byte increments

typically within 12.95ps (3.3V V,,, 5V VP,). A multi

word/byte write has high speed write performance of

2.7@byte (3.3V V,,, 5V VP,). (Multi) Word/byte

The Automatic Power Savings (APS) feature

substantially reduces active current when the device

is in static mode (addresses not switching). In APS

m‘ode, the typical I,,, current is 3 mA at 3.3V V,c.

When either CE,# or CE,#, and RP# pins are at V,,

the I,, CMOS standby mode is enabled. When the

RP# pin is at GND, deep power-down mode ic

enabled which minimizes power consumption and

provides write protection during reset. A reset time

(tPHav) is required from RP# switching high until

outputs are valid. Likewise, the device has a wake

time (tPHEL) from RP#-high until writes to the CUI are

recognized. With RP# at GND, the WSM is reset and

the status register is cleared.

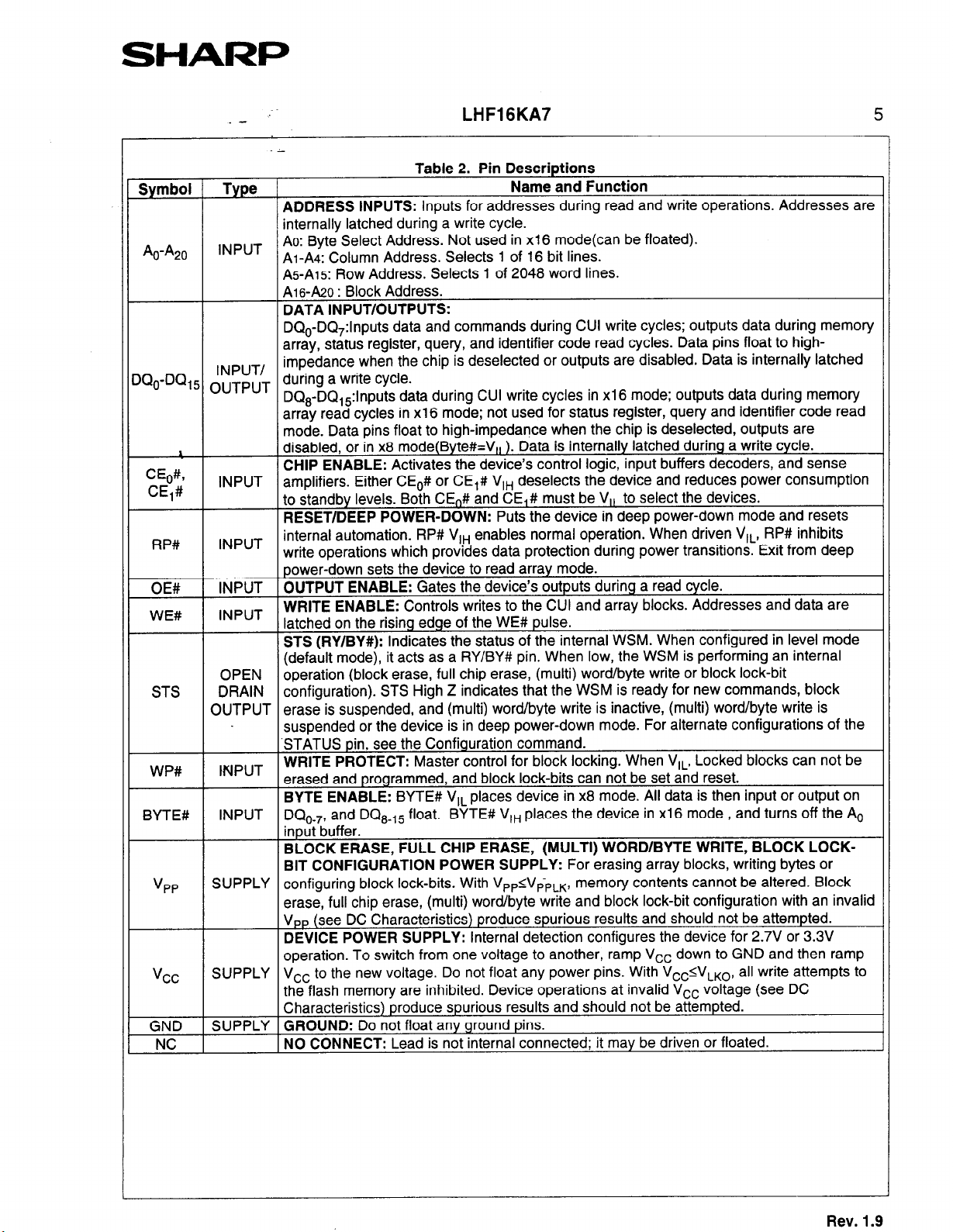

The device is available in 56-Lead TSOP (Thin Small

Outline Package, 1.2 mm thick). Pinout is shown in

Figure 2.

Rev. 1.9

SHARP

LHFlGKA7 4

Comparator

I/ + b

Cl3

WEX

OE%

RP#

WP#

II-4 I

kE,#

./

VCC

CEo#

VPP

RP#

GND

NC

NC

Azo

AIS

Al6

A17

Al6

A15

Al.4

A13

Al2

41

AIO

As

Ae

A7

As

A5

2

A2

AI

:

3

4

5

6

‘7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

d 23

24

25

26

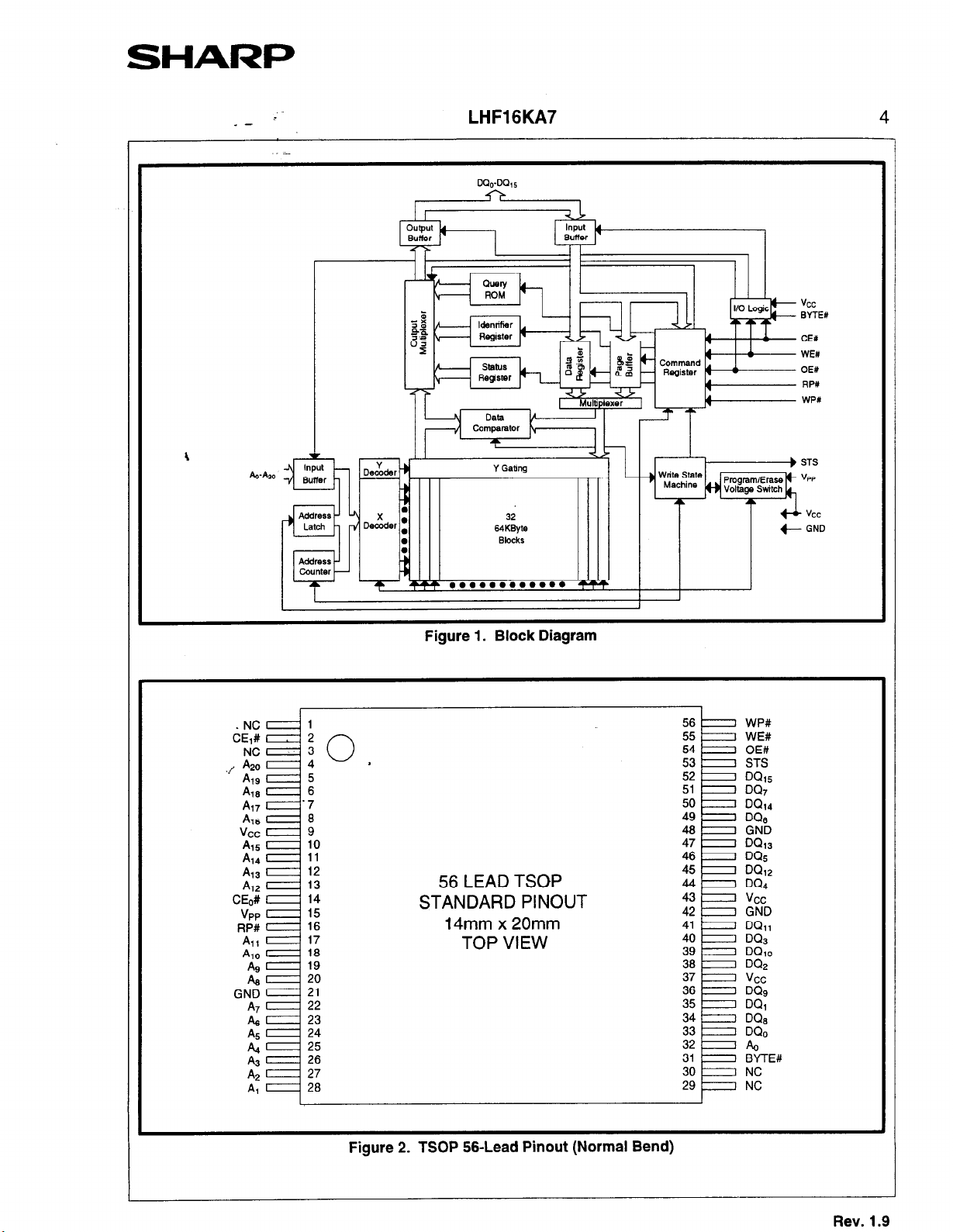

Figure 1. Block Diagram

56 LEAD TSOP

STANDARD PINOUT

14mm x 20mm

TOP VIEW

----G-L

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34 1

33 I

32 I

31 )

30

29

WP#

WE#

OE#

STS

DQ15

z:,

DQ6

GND

DQ13

DQ5

DQ12

DQ4

vcc

GND

DQll

DQ3

DQlo

DQz

vcc

DQP

DQ;

DQe

DQo

A0

BYTE#

NC

NC

Figure 2. TSOP 56-Lead Pinout (Normal Bend)

Rev. 1.9

SHARP

*o-*20

x&)-DC+!

CEO%

CE,#

RP#

OE#

WE#

STS

WP#

BYTE#

“PP

“cc

GND

NC

I

_ -

Type

INPUT

INPUT/

3UTPUT

INPUT

INPUT

INPUT

INPUT

OPEN

DRAIN

OUTPUT

tWPUT

lNPUT

SUPPLY

SUPPLY

SUPPLY

LHF16KA7

-

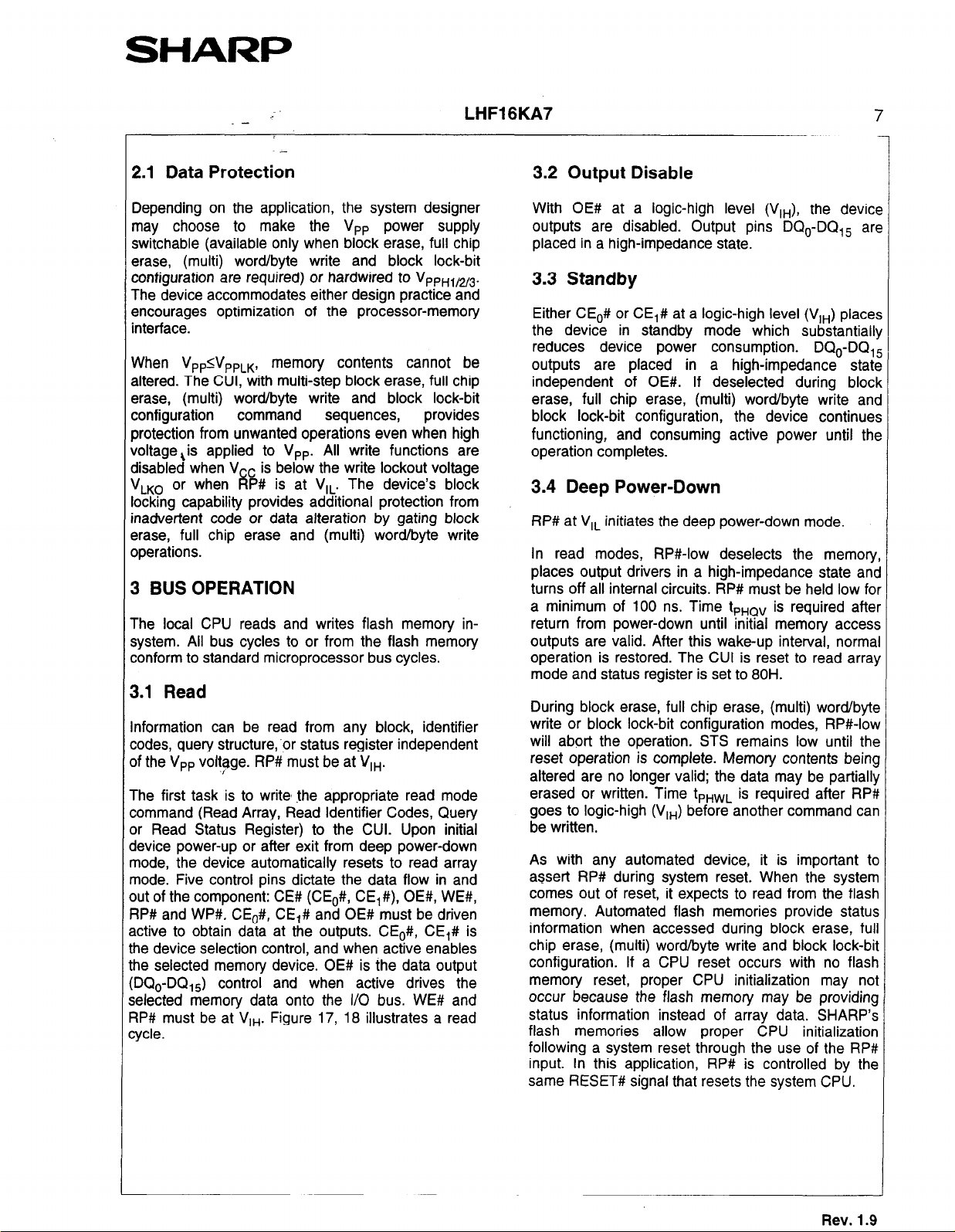

Table 2. Pin Descriptions

T

ADDRESS INPUTS: Inputs for addresses during read and write operations. Addresses are

internally latched during a write cycle.

Ao: Byte Select Address. Not used in x16 mode(can be floated).

AI-AK Column Address. Selects 1 of 16 bit lines.

A+Ai5: Row Address. Selects 1 of 2048 word lines.

A164420

DATA INPUT/OUTPUTS:

DQo-DQ,:lnputs data and commands during CUI write cycles; outputs data during memory

array, status register, query, and identifier code read cycles. Data pins float to highimpedance when the chip is deselected or outputs are disabled. Data is internally latched

during a write cycle.

DQs-DQ15:lnpUtS data during CUI write cycles in x16 mode; outputs data during memory

array read cycles in xl 6 mode; not used for status register, query and identifier code read

mode. Data pins float to high-impedance when the chip is deselected, outputs are

disabled, or in x8 mode(Byte#=V,, ). Data is internally latched during a write cycle.

CHIP ENABLE: Activates the device’s control logic, input buffers decoders, and sense

amplifiers. Either CE,# or CE,# V,, deselects the device and reduces power consumption

to standby levels. Both CE,-# and CE,# must be V,, to select the devices.

RESET/DEEP POWER-DOWN: Puts the device in deep power-down mode and resets

internal automation. RP# V,, enables normal operation. When driven \JIL, RP# inhibits

write operations which provides data protection during power transitions. Exit from deep

power-down sets the device to read array mode.

OUTPUT ENABLE: Gates the device’s outputs during a read cycle.

WRITE ENABLE: Controls writes to the CUI and array blocks. Addresses and data are

latched on the rising edge of the WE# pulse.

STS (RY/BY#): Indicates the status of the internal WSM. When configured in level mode

(default mode), it acts as a RY/BY# pin. When low, the WSM is performing an internal

operation (block erase, full chip erase, (multi) word/byte write or block lock-bit

configuration). STS High Z indicates that the WSM is ready for new commands, block

erase is suspended, and (multi) word/byte write is inactive, (multi) word/byte write is

suspended or the device is in deep power-down mode. For alternate configurations of the

STATUS pin, see the Configuration command.

WRITE PROTECT: Master control for block locking. When V,,, Locked blocks can not be

erased and programmed, and block lock-bits can not be set and reset.

BYTE ENABLE: BYTE# V,, places device in x8 mode. All data is then input or output on

DQO-,, and DQse15 float. BYTE# V,, places the device in x16 mode , and turns off the A,

input buffer.

BLOCK ERASE, FULL CHIP ERASE, (MULTI) WORD/BYTE WRITE, BLOCK LOCK-

BIT CONFIGURATION POWER SUPPLY: For erasing array blocks, writing bytes or

configuring block lock-bits. With V+V+~,K, memory contents cannot be altered. Block

erase, full chip erase, (multi) word/byte write and block lock-bit configuration with an invalid

vpp (see DC Characteristics) produce spurious results and should not be attempted.

DEVICE POWER SUPPLY: Internal detection configures the device for 2.7” or 3.3”

operation. To switch from one voltage to another, ramp V,, down to GND and then ramp

V,, to the new voltage. Do not float any power pins. With V,,IV,,,, all write attempts to

the flash memory are inhibited. Device operations at invalid V,, voltage (see DC

Characteristics) produce spurious results and should not be attempted.

GROUND: Do not float any ground pins.

NO CONNECT: Lead is not internal connected; it may be driven or floated.

: Block Address.

Name and Function

5

I

I

Rev. 1.9

SHARP

. -

r

.i

2 PRINCIPLES OF OPERATION

The LH28F160S3HT-Ll OA Flash memory includes

an on-chip WSM to manage block erase, full chip

erase, (multi) word/byte write and block lock-bit

configuration functions. It allows for: 100% TTL-level

control inputs, fixed power supplies during block

erase, full chip erase, (multi) word/byte write and

block lock-bit configuration, and minimal processor

overhead with RAM-Like interface timings.

After initial device power-up or return from deep

power-down mode (see Bus Operations), the device

defaults to read array mode. Manipulation of external

memory control pins allow array read, standby, and

output disable operations.

Status :egister, query structure and identifier codes

can be accessed through the CUI independent of the

V,, voltage. High voltage on VPP enables successful

block erase, full chip erase, (multi) word/byte write

and block lock-bit configuration. All functions

associated with altering memory contents-block

erase, full chip erase, (multi) word/byte write and

block lock-bit configuration, status, query and

identifier codes-are accessed via the CUI and

verified through the status register.

Commands are

microprocessor write timings. The CUI contents serve

as input to the WSM, which controls the block erase,

full chip erase, (multi) word/byte write and block lockbit configuration. The internal algorithms are

regulated by the WSM, including pulse repetition,

internal verification,

Addresses and data are internally latch during write

cycles. Writing the appropriate command outputs

array data, accesses the identifier codes, outputs

query structure or outputs status register data.

Interface software that initiates and polls progress of

block erase, full chip erase, (multi) word/byte write

and block lock-bit configuration can be stored in any

block. This code is copied to and executed from

system RAM during flash memory updates. After

successful completion, reads are again possible via

the Read Array command. Block erase suspend

allows system software to suspend a block erase to

read or write data from any other block. Write

suspend allows system software to suspend a (multi)

word/byte write to read data from any other flash

memory array location.

written using standard

and margining of data.

LHFlGKA7 6

64K-byte Block

1AFFFF

1 AOOW

ISFFFF

1SOOCKl

1SFFFF

laOW0

17FFFF

17OmO

IGFFFF

160000

15FFFF

15OoM)

14FFFF

14oooo

13FFFF

,-mm

IPFFFF

4~cyyI

1lFFFF

11ocw

1OFFFF

lcmoa

OFFFFF

OFOOOO

OEFFFF

OEOOOO

OIJFFFF

ODoooO

OCFFFF

ocoooo

OBFFFF

OAFFFF

OAOWO

OSFFFF

OSOWO

08FFFF

OKCOO

07FFFF

07wOo

OGFFFF

060000

OBFFFF

nE-n

04FFFF

04OWO

OIFFFF

03Ocm

OZFFFF

OZWOO

01 FFFF

01wo0

OOFFFF

64K-byte Block 26

64K-byte Block 25

64K-byte Block 24

64K-byte Block 23

64K-byte Block 22

64K-byte Block 21

64K-byte Block 20

64K-byte Block 19

64K-byte Block

64K-byte Block 17

64K-byte Block 16

64K-byte Block 15

64K-byte Block 14

64K-byte Block 13

64K-byte Block 12

64K-byte Block 11

64K-byte Block 10

64K-byte Block 9

64K-byte Block 8

64K-byte Block 7

64K-byte Block 6

64K-byte Block 5

64K-byte Block 4

64K-byte Block

64K-bvte Block 0

Figure 3. Memory Map

3’1

‘81

3 64K-byte Block

2 64K-byte Block

1

1

L

Rev. 1.9

SHARP

LHFlGKA7

-

2.1 Data Protection

Depending on the application, the system designer

may choose to make the V,, power supply

switchable (available only when block erase, full chip

erase, (multi) word/byte write and block lock-bit

configuration are required) or hardwired to VPPH1,2/3.

The device accommodates either design practice and

encourages optimization of the processor-memory

interface.

When Vpp~VppLKt

altered. The CUI, with multi-step block erase, full chip

erase, (multi) word/byte write and block lock-bit

configuration command sequences, provides

protection from unwanted operations even when high

voltage,is applied to V,,. All write functions are

disabled when Vcc is below the write lockout voltage

V,,, or when RP# is at V,,. The device’s block

locking capability provides additional protection from

inadvertent code or data alteration by gating block

erase, full chip erase and (multi) word/byte write

operations.

memory contents cannot be

3 BUS OPERATION

The local CPU reads and writes flash memory insystem. All bus cycles to or from the flash memory

conform to standard microprocessor bus cycles.

3.1 Read

Information can be read from any block, identifier

codes, query structure,‘or status register independent

of the V,, voltage. RP# must be at VI,.

The first task is to write the appropriate read mode

command (Read Array, Read Identifier Codes, Query

or Read Status Register) to the CUI. Upon initial

device power-up or after exit from deep power-down

mode, the device automatically resets to read array

mode. Five control pins dictate the data flow in and

out of the component: CE# (CE,#, CE,#), OE#, WE#,

RP# and WP#. CE,#, CE,# and OE# must be driven

active to obtain data at the outputs. CE,#, CE,# is

the device selection control, and when active enables

the selected memory device. OE# is the data output

(DC&-DQ,,) control and when active drives the

selected memory data onto the I/O bus. WE# and

RP# must be at V,,. Figure 17, 18 illustrates a read

cycle.

7

3.2 Output Disable

With OE# at a logic-high level (VI,), the devict

outputs are disabled. Output pins DO,-DQ,, an

placed in a high-impedance state.

3.3 Standby

Either CE,# or CE,# at a logic-high level (V,,) place:

the device in standby mode which substantiall!

reduces device power consumption. DQo-DQ,,

outputs are placed in a high-impedance statt

independent of OE#. If deselected during bloc1

erase, full chip erase, (multi) word/byte write ant

block lock-bit configuration, the device continue:

functioning, and consuming active power until the

operation completes.

3.4 Deep Power-Down

RP# at V,, initiates the deep power-down mode.

In read modes, RP#-low deselects the memory

places output drivers in a high-impedance state ant

turns off all internal circuits. RP# must be held low fol

a minimum of 100 ns. Time t,,crv is required after

return from power-down until initial memory access

outputs are valid. After this wakeup interval, norma

operation is restored. The CUI is reset to read arra)

mode and status register is set to 80H.

During block erase, full chip erase, (multi) word/byte

write or block lock-bit configuration modes, RP#-low

will abort the operation. STS remains low until the

reset operation is complete. Memory contents being

altered are no longer valid; the data may be partially

erased or written. Time tPHWL is required after RP#

goes to logic-high (V,,) before another command can

be written.

As with any automated device, it is important tc

assert RP# during system reset. When the system

comes out of reset, it expects to read from the flash

memory. Automated flash memories provide status

information when accessed during block erase, full

chip erase, (multi) word/byte write and block lock-bit

configuration. If a CPU reset occurs with no flash

memory reset, proper CPU initialization may not

occur because the flash memory may be providing

status information instead of array data. SHARP’s

flash memories allow proper CPU initialization

following a system reset through the use of the RP#

input. In this application, RP# is controlled by the

same RESET# signal that resets the system CPU.

-l

Rev. 1 .Q

_ -

I

--

LHFlGKA7

8

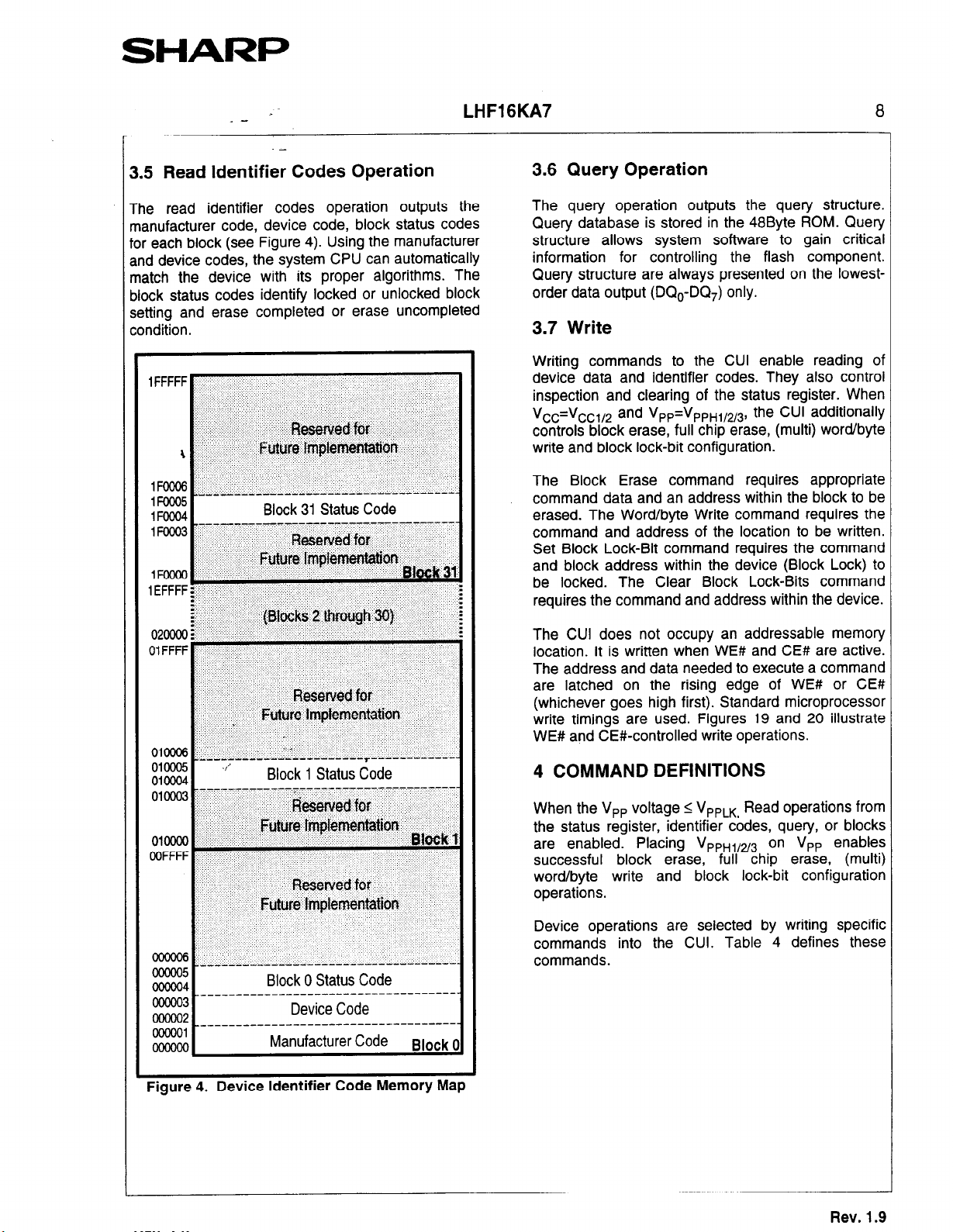

3.5 Read Identifier Codes Operation

The read identifier codes operation outputs the

manufacturer code, device code, block status codes

for each block (see Figure 4). Using the manufacturer

and device codes, the system CPU can automatically

match the device with its proper algorithms. The

block status codes identify locked or unlocked block

setting and erase completed or erase uncompleted

condition.

1FFFFF :.. :

l !", ,: :.

,Fm; .. :.

,K)oo5

IF0004

,Fooo3 T ---,-. ~ _____ --; ____ T-------y---I

,Foooo :,. ., :‘i:

IEFFFF;:. :' . ; : ':,,..

02oooo; ,+ ..: ,, '. ', : .,. :.

OlFFFF ',

o,o(y& (I ” y.,

01ooo5 ./’

010004

010003-

01~ 1. .,: .’ ‘.,

OOFFFF ;. 1.

ooooO6 . .

coo005

OoOcQ4

OOanI3

OOmO2

oooQo1

'.

: :. . . .,.

>

. . . .

..A. 1;; ,, . . .

,., . .

:'.. ;.

;.

iilr-' l_l..d+ - -----------_-------1----

.: ,;.'

'. .' j.: R&&&&, .,:, ': .:' .:

.. Future ~+irnentatt~n '.

Block 31 Status Code

JGxwv~d for

;.

:.

m..

w.

:.

tfutye h$e.merrtiian

: :

: . . '(~ioiks2thi~gl-l~) ;

" : ..,I. ; ,:" "')

: B&;k31

l---l-l---l-~--l’l-l----rll---lll-l---------

___________ --- ______ ---__----------

: .;

Block 1 Status Code

. . ..

i&e&ed~for ,:

:.. .: .f;uture:‘tmplemen~tiQn ..

Block”

Resewed far

Future Implementation

___- -- ____ -- ____ --------_------ -----_____-_____-_______-----------------____________________-----------------

Block 0 Status Code

Device Code

Manufacturer Code

Block (

3.6 Query Operation

The query operation outputs the query structure.

Query database is stored in the 48Byte ROM. Query

structure

information for controlling the flash component.

Query structure are always presented on the lowest-

order data output (DQc-DQ,) only.

allows system software to gain critical

3.7 Write

Writing commands to the CUI enable reading of

device data and identifier codes. They also control

inspection and clearing of the status register. When

Vcc=Vcc1,2 and VPP=VPPHt/2/3, the CUI additionally

controls block erase, full chip erase, (multi) wordlbyte

write and block lock-bit configuration.

The Block Erase command requires appropriate

command data and an address within the block to be

erased. The Word/byte Write command requires the

command and address of the location to be written.

Set Block Lock-Bit command requires the command

and block address within the device (Block Lock) to

be locked. The Clear Block Lock-Bits command

requires the command and address within the device.

The CUI does not occupy an addressable memory

location. It is written when WE# and CE# are active.

The address and data needed to execute a command

are latched on the rising edge of WE# or CE#

(whichever goes high first). Standard microprocessor

write timings are used. Figures 19 and 20 illustrate

WE# and CE#-controlled write operations.

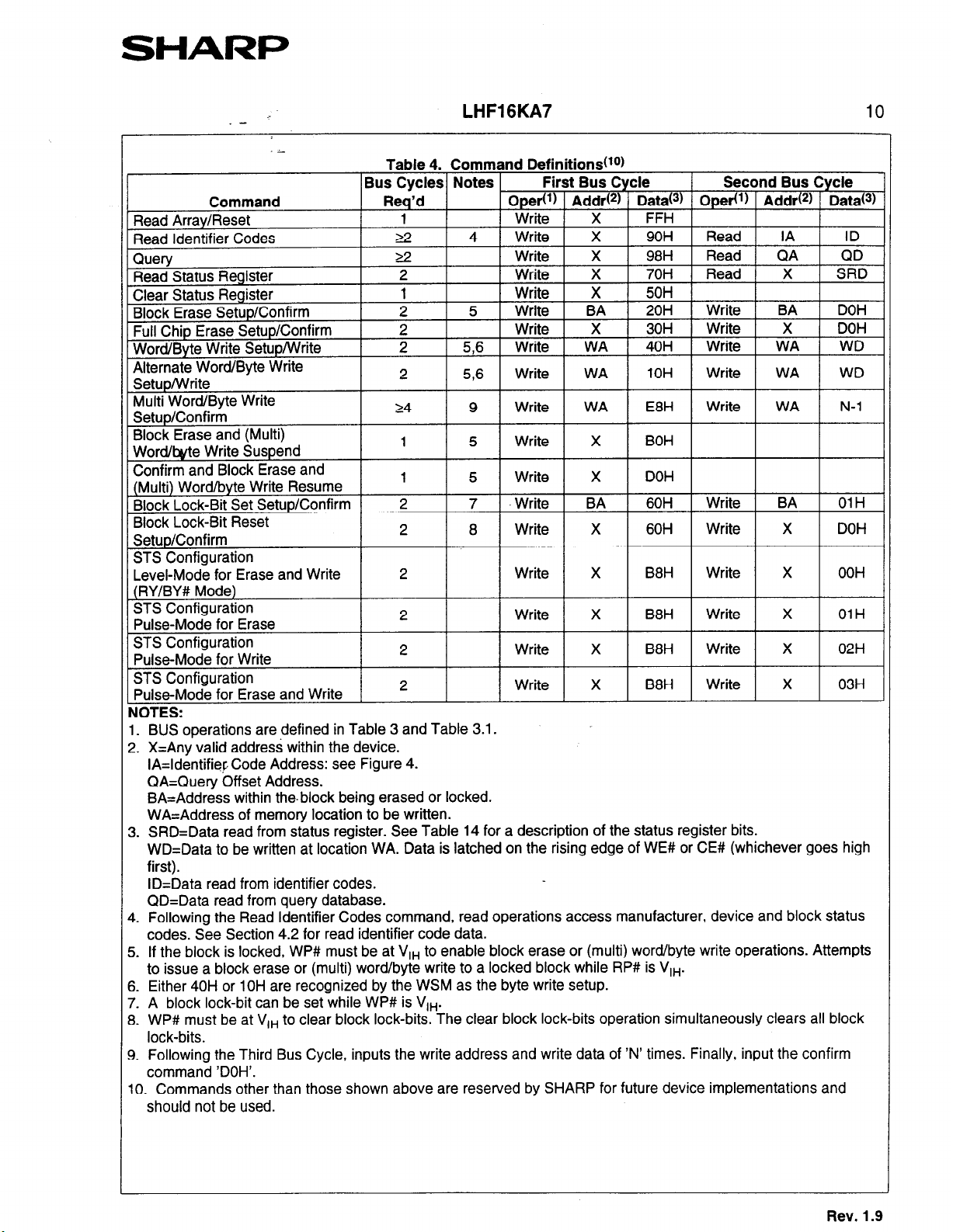

4 COMMAND DEFINITIONS

When the V,, voltage I V,,,,, Read operations from

the status register, identifier codes, query, or blocks

are enabled. Placing V,,,,,us on V,, enables

successful block erase, full chip erase, (multi)

word/byte write and block lock-bit configuration

operations.

Device operations are selected by writing specific

commands into the CUI. Table 4 defines these

commands.

Figure 4. Device Identifier Code Memory Map

Rev. 1.9

SHARP

_- =

LHFlGKA7 9

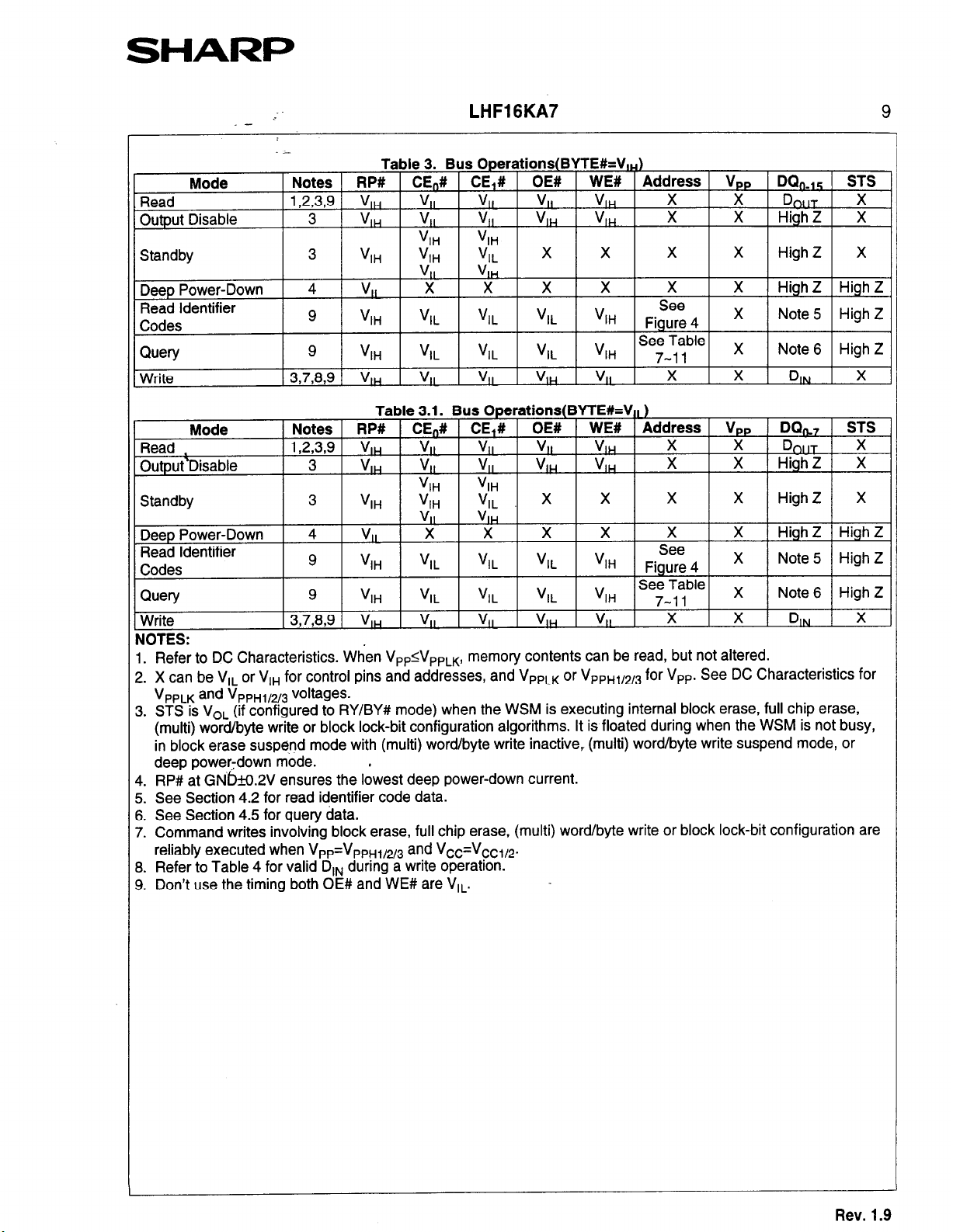

Table 3. Bus Operations(BYTE#=V,Uj

Mode

Read

Output Disable

jeep Power-Down

lead Identifier

Lodes

Query

Write

Deep Power-Down

Read Identifier

Codes

Query

Write

Notes RP#

1,2,3,9 v,w

3 V,H

CE”# CE,# OE# WE#

V,, V,, V,, V,H X X D&r X

V,,

v,,, 11 1

V,, V,w V,H X X High Z X

v

4 V,, X X X X

9

9

I

1

3,7&W

VI, %L

vlH VI, 4, VI,

I I I I I

1 ‘.‘,H 1 VII 1 VII 1 VI’I 1 VII I

VI,

%L 4, 4,

V,w

4 VI, X X X

9

9

‘1, VlL

‘1,

3,7,8,9 VI,,

VI,

VII

VI, YL ‘1,

VI,

VII

VI, vlH

V,H VII

1 Address 1 Vpp 1 DQnm15 1 STS

X X High Z High Z

See Table x

vlH

See

Figure 4

7-11

X

X Note 5 High Z

Note 6 High Z

1 x 1 DIN I x

X X X High Z High Z

See

Figure 4

SeeTable x

7-11

X Note 5 High Z

Note 6 High Z

X X DIN X

NOTES:

1. Refer to DC Characteristics. When V&f,,,,,

memory contents can be read, but not altered.

2. X can be V,, or VrH for control pins and addresses, and VP,,, or VPr+rt/2/s for V,,. See DC Characteristics for

bPLK and VPPH1/~3 voitagese

3. STS is V,, (if configured to RY/BY# mode) when the WSM is executing internal block erase, full chip erase,

(multi) word/byte write or block lock-bit configuration algorithms. It is floated during when the WSM is not busy,

in block erase suspend mode with (multi) word/byte write inactive, (multi) word/byte write suspend mode, or

deep power;down mode.

.

4. RP# at GN&O.2V ensures the lowest deep power-down current.

5. See Section 4.2 for read identifier code data.

6. See Section 4.5 for query data.

7. Command writes involving block erase, full chip erase, (multi) word/byte write or block lock-bit configuration are

reliably executed when

Vpp=VPPH1/2/3

and Vcc=Vcc1~2.

8. Refer to Table 4 for valid D,, during a write operation.

9. Don’t use the timing both OE# and WE# are VI,.

Rev. 1.9

,

SHARP

. -

I

Command

Read Array/Reset

.i

Table 4. Command Definitions(l”)

Bus Cycles Notes First Bus Cycle Second Bus Cycle

Req’d

1 Write ( X 1 FFH

22 4 Write X 90H Read IA

22

2

T

2

2

2

4lternate Word/Byte Write

SetupWrite

Multi Word/Byte Write

Setup/Confirm

Block Erase and (Multi)

Word/byte Write Suspend

Confirm and Block Erase and

(Multi) Word/byte Write Resume

Block Lock-Bit Set Setup/Confirm

Block Lock-Bit Reset

Setup/Confirm

STS Configuration

Level-Mode for Erase and Write

(RY/BY# Mode)

STS Configuration

Pulse-Mode for Erase

STS Configuration

Pulse-Mode for Write

STS Configuration

Pulse-Mode for Erase and Write

NOTES:

1. BUS operations are defined in Table 3 and Table 3.1.

2. X=Any valid address within the device.

IA=ldentifiep Code Address: see Figure 4.

QA=Quety Offset Address.

BA=Address within the. block being erased or locked.

WA=Address of memory location to be written.

3. SRD=Data read from status register. See Table 14 for a description of the status register bits.

WD=Data to be written at location WA. Data is latched on the rising edge of WE# or CE# (whichever goes high

first).

ID=Data read from identifier codes.

QD=Data read from query database.

4. Following the Read Identifier Codes command, read operations access manufacturer, device and block status

codes. See Section 4.2 for read identifier code data.

5. If the block is locked, WP# must be at VI, to enable block erase or (multi) word/byte write operations. Attempts

to issue a block erase or (multi) word/byte write to a locked block while RP# is VI,.

6. Either 40H or 10H are recognized by the WSM as the byte write setup.

7. A block lock-bit can be set while WP# is VI,.

8. WP# must be at VI, to clear block lock-bits. The clear block lock-bits operation simultaneously clears all block

lock-bits.

9. Following the Third Bus Cycle, inputs the write address and write data of ‘N’ times. Finally, input the confirm

command ‘DOH’.

10. Commands other than those shown above are reserved by SHARP for future device implementations and

should not be used.

2

24

1

1 5

2

2 8 Write X

2

2

2 Write X B8H Write X 02H

2 Write X B8H

LHFlGKA7

Oper(‘)

Write X 98H Read QA C

Write X 70H Read X

Write X

5 Write BA

Write X

55

596

Write WA

Write WA 10H

9 Write WA E8H

5 Write X BOH

Write X DOH

7 Write BA 60H

Write X B8H Write X OOH

Write X B8H Write X OlH

1 Add&*) 1 Data13) Ope#) 1 Addr(*) 1 Data13)

_ . .._-

60H Write X DOH

‘D II

Write WA WD

Write WA N-l

Write BA

Write X 03H

OlH

10

I

Rev. 1.9

SHARI=

. -

--

LHF16KA7

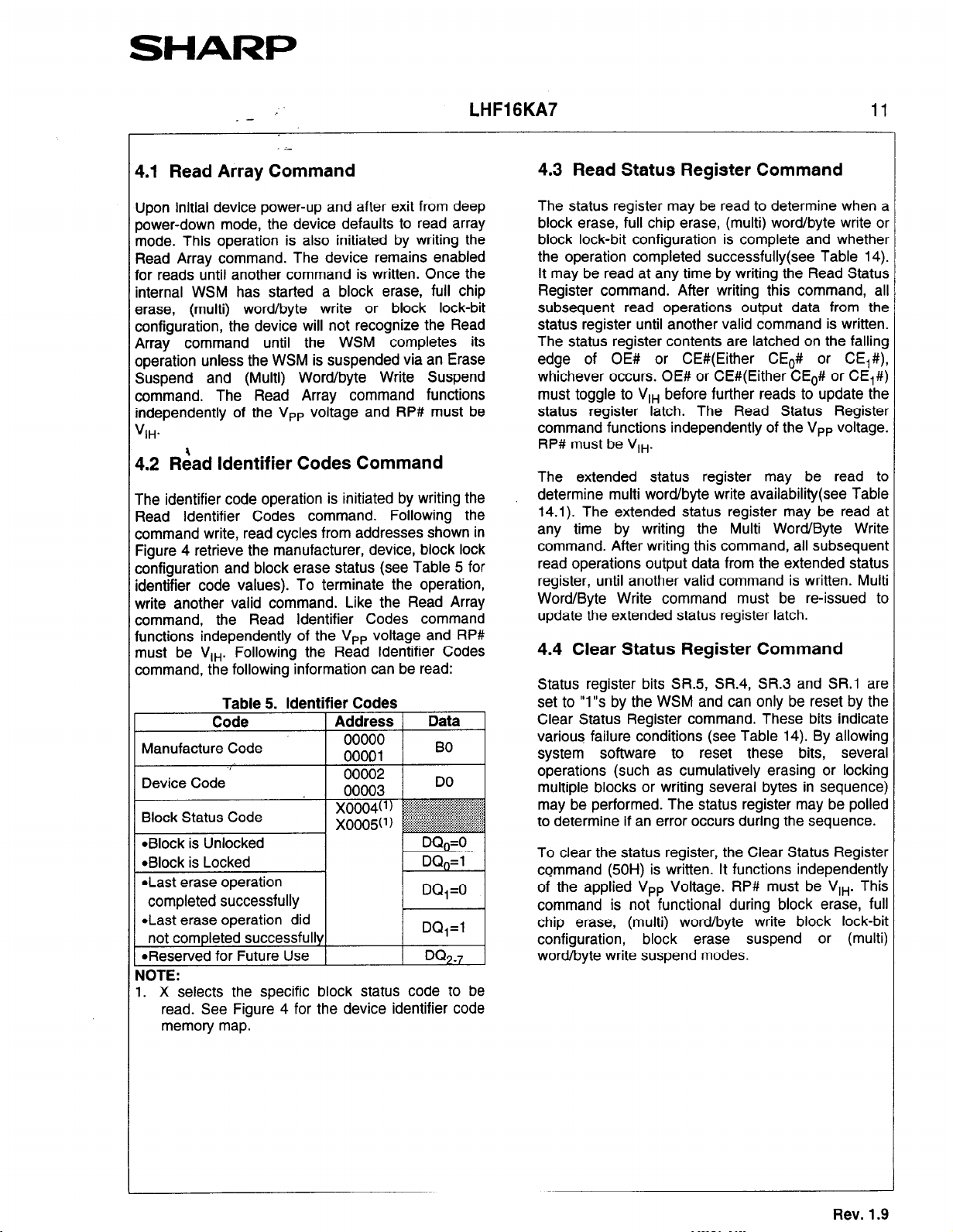

4.1 Read Array Command 4.3 Read Status Register Command

Upon initial device power-up and after exit from deep

power-down mode, the device defaults to read array

mode. This operation is also initiated by writing the

Read Array command. The device remains enabled

for reads until another command is written. Once the

internal WSM has started a block erase, full chip

erase, (multi) word/byte write or block lock-bit

configuration, the device will not recognize the Read

Array command until the WSM completes its

operation unless the WSM is suspended via an Erase

Suspend and (Multi) Word/byte Write Suspend

command. The Read Array command functions

independently of the VP,, voltage and RP# must be

Vi,*

The

status

register may be read to determine when i

block erase, full chip erase, (multi) word/byte write OI

block lock-bit configuration is complete and whethei

the operation completed successfully(see Table 14)

It may be read at any time by writing the Read Statu:

Register command. After writing this command, al

subsequent read operations output data from the

status register until another valid command is written

The status register contents are latched on the fallins

edge of OE# or CE#(Either CE,# or CE,#)

whichever occurs. OE# or CE#(Either CE,# or CE,#:

must toggle to ‘Jr, before further reads to update the

status register latch. The Read Status Register

command functions independently of the V,, voltage

RP# must be VI,.

4.2 F&ad Identifier Codes Command

The extended status register may be read tc

The identifier code operation is initiated by writing the

Read Identifier Codes command. Following the

command write, read cycles from addresses shown in

Figure 4 retrieve the manufacturer, device, block lock

configuration and block erase status (see Table 5 for

identifier code values). To terminate the operation,

write another valid command. Like the Read Array

command, the Read Identifier Codes command

functions independently of the V,, voltage and RP#

must be V,,. Following the Read Identifier Codes

command, the following information can be read:

Table 5. Identifier Codes

Code

Manufacture Code

./

Device Code

Block Status Code

*Block is Unlocked

l Block is Locked

*Last erase operation

completed successfully

@Last erase operation did

not completed successfully

OReserved for Future Use

NOTE:

1. X selects the specific block status code to be

read. See Figure 4 for the device identifier code

memory map.

Address

00000

00001

00002

00003

x0004(’ )

x0005(‘) ~

1 / DQ,=O 1

Data

BO

DC&,=0

DQc= 1

DQ,=l

DQyw7

determine multi word/byte write availability(see Table

14.1). The extended status register may be read a

any time by writing the Multi Word/Byte Write

command. After writing this command, all subsequen

read operations output data from the extended statuz

register, until another valid command is written. Mult

Word/Byte Write command must be re-issued tc

update the extended status register latch.

4.4 Clear Status Register Command

Status register bits SR.5, SR.4, SR.3 and SR.l are

set to “1”s by the WSM and can only be reset by the

Clear Status Register command. These bits indicate

various failure conditions (see Table 14). By allowins

system software to reset these bits, severa

operations (such as cumulatively erasing or lockinc

multiple blocks or writing several bytes in sequence:

may be performed. The status register may be pollee

to determine if an error occurs during the sequence.

To clear the status register, the Clear Status Register

command (50H) is written. It functions independently

of the applied V,, Voltage. RP# must be VI,. This

command is not functional during block erase, ful

chip erase, (multi) word/byte write block lock-bii

configuration, block erase suspend or (multi:

word/byte write suspend modes.

11

Rev. 1.9

SHARP

. -

--

LHFlGKA7

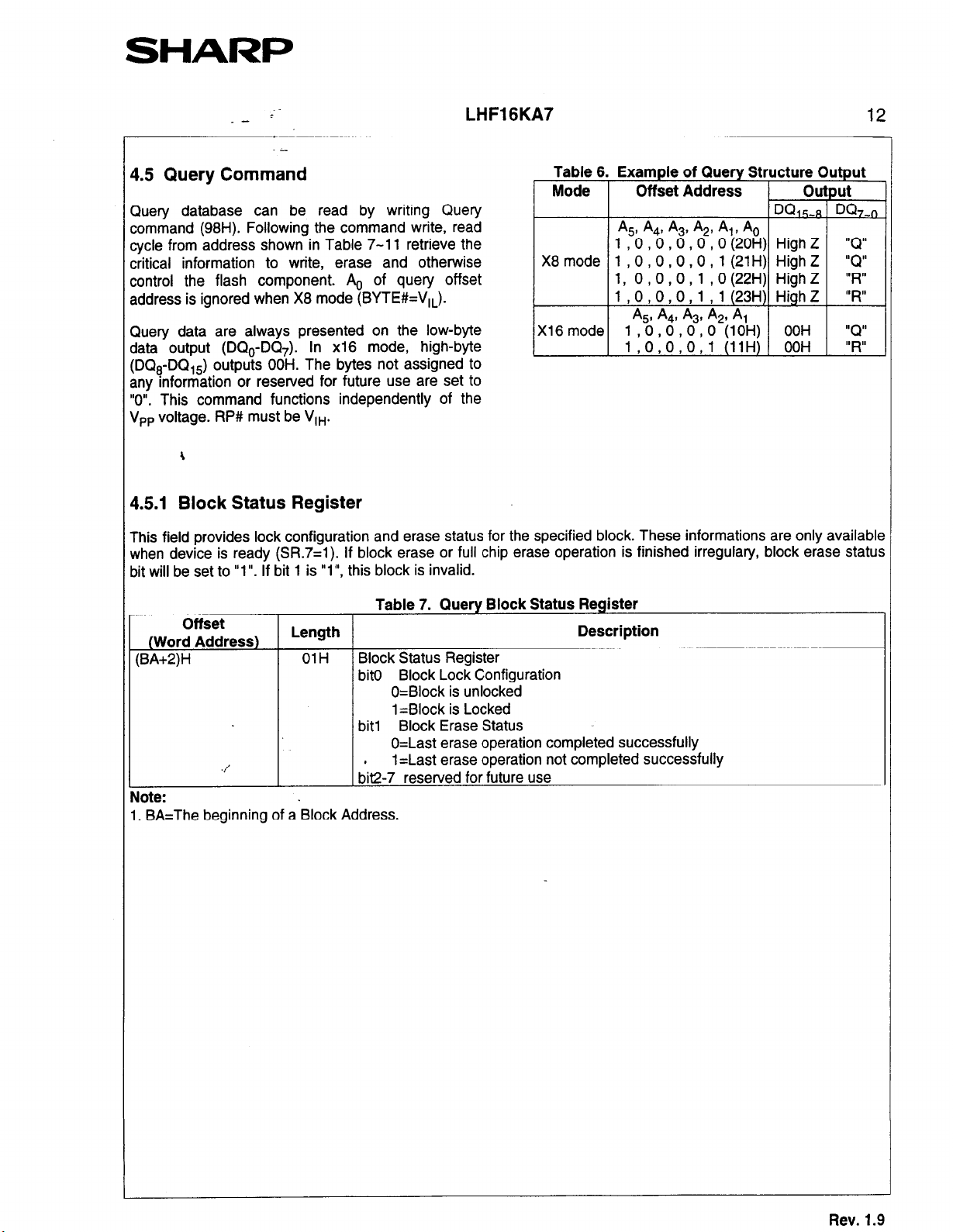

1.5 Query Command

=luery database can be read by writing Query

:ommand (98H). Following the command write, read

ycle from address shown in Table 7-l 1 retrieve the

xitical information to write, erase and otherwise

:ontrol the flash component. A, of query offset

address is ignored when X8 mode (BYTE#=V,L).

;luery data are always presented on the low-byte

jata output (DC&-D&). In x16 mode, high-byte

;DQs-DQ,s) outputs OOH. The bytes not assigned to

any information or reserved for future use are set to

‘0”. This command functions independently of the

Jpp voltage. RP# must be V,,.

Table 6. Example of Query Structure (

Mode Off set Address

A,, A,, A,, A,, A,, A,

1 , 0 , 0 , 0 (0 , 0 (20H) High Z

X8 mode 1 , 0 , 0 , 0 , 0 , 1 (21H) High Z

1, O,O,O,l ,0(22H) HighZ

1 , 0 , 0 , 0 , 1 , 1 (23H) High Z

A,, A,, A,, A,, A,

X16mode 1 ,O,O,O,O (10H) OOH

l,O,O,O,l (11H) OOH

ou

DQ%8

12

But

DQm-,

"Q"

"Q"

“R”

“R”

“Q”

“R”

1.5.1 Block Status Register

This field provides lock configuration and erase status for the specified block. These informations are only available

Nhen device is ready (SR.7=1). If block erase or full chip erase operation is finished irregulary, block erase status

lit will be set to “1”. If bit 1 is “l”, this block is invalid.

Table 7. Query Block Status Register

Offset

(Word Address)

(BA+2)H

v’

Uote:

I. BA=The beginning of a Block Address.

Length

OlH Block Status Register

bit0 Block Lock Configuration

O=Block is unlocked

1 =Block is Locked

bit1 Block Erase Status

O=Last erase operation completed successfully

1 =Last erase operation not completed successfully

t&2-7 reserved for future use

Description

Rev. 1.9

SHARP

_ -

LHFlGKA7

13

--

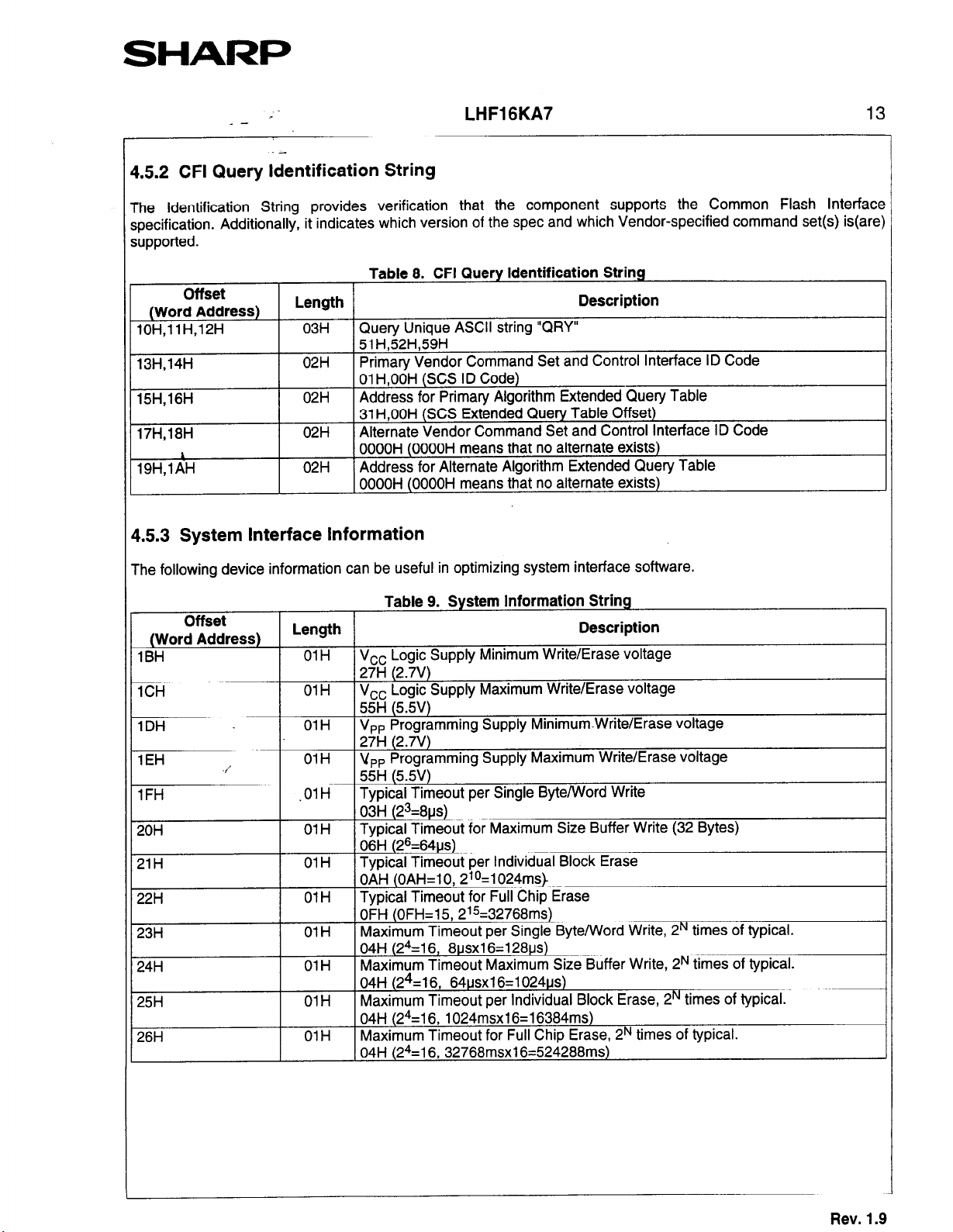

IS.2

CFI Query Identification String

‘he identification String provides verification that the component supports the Common Flash Interface

specification. Additionally, it indicates which version of the spec and which Vendor-specified command set(s) is(are)

upported.

Table 8. CFI Query Identification String

Offset

(Word Address)

lOH,l lH,12H

13H,14H

15H.16H

17H,18H

i

lSH,lAH

Length

03H Query Unique ASCII string “QRY”

51 H,52H,59H

02H

02H Address for Primary Algorithm Extended Query Table

02H

02H

Primary Vendor Command Set and Control Interface ID Code

01 H,OOH (SCS ID Code)

31 H,OOH (SCS Extended Query Table Offset)

Alternate Vendor Command Set and Control Interface ID Code

OOOOH (OOOOH means that no alternate exists)

Address for Alternate Algorithm Extended Query Table

1 OOOOH (OOOOH means that no alternate exists)

Description

1.53 System Interface Information

The following device information can be useful in optimizing system interface software.

Table 9. System Information String

Offset

(Word Address)

1BH

1CH

1DH OlH

1EH

1FH

20H

21H

22H

23H

24H

25H OlH

26H OlH Maximum Timeout for Full Chip Erase, 2N times of typical.

./’

Length

OlH

OlH V,, Logic Supply Maximum Write/Erase voltage

OlH

.OlH Typical Timeout per Single Byte/Word Write

1 01 H 1 Typical Timeout for Maximum Size Buffer Write (32

OlH Typical Timeout per Individual Block Erase

OlH Typical Timeout for Full Chip Erase

OlH Maximum Timeout per Single Byte/Word Write, 2N times of typical.

1 01

Voc Logic Supply Minimum Write/Erase voltage

27H (2.7V)

55H (5.5V)

V,, Programming Supply Minimum.Write/Erase voltage

27H (2.7V)

Up,, Programming Supply Maximum Write/Erase voltage

55H (5.5V)

I03H (23=8us)

06H (26=64us)

OAH (OAH=lO 21°=1024ms)

OFH (OFH=15, 215=32768ms)

I04H (24=1 6, 8usxl6=128us)

H

1 Maximum Timeout Maximum Size Buffer Write, 2N times of

04H (24=1 6, 64usxl6=1024us)

Maximum Timeout per Individual Block Erase, 2N times of typical.

04H (24=1 6,1024msxl6=16384ms)

I04H (24=1 6,32768msxl6=524288ms)

Description

Bytes)

_

typiCal.

Rev. 1.9

SHARI=

_ -

/

LHFlGKA7 14

.i

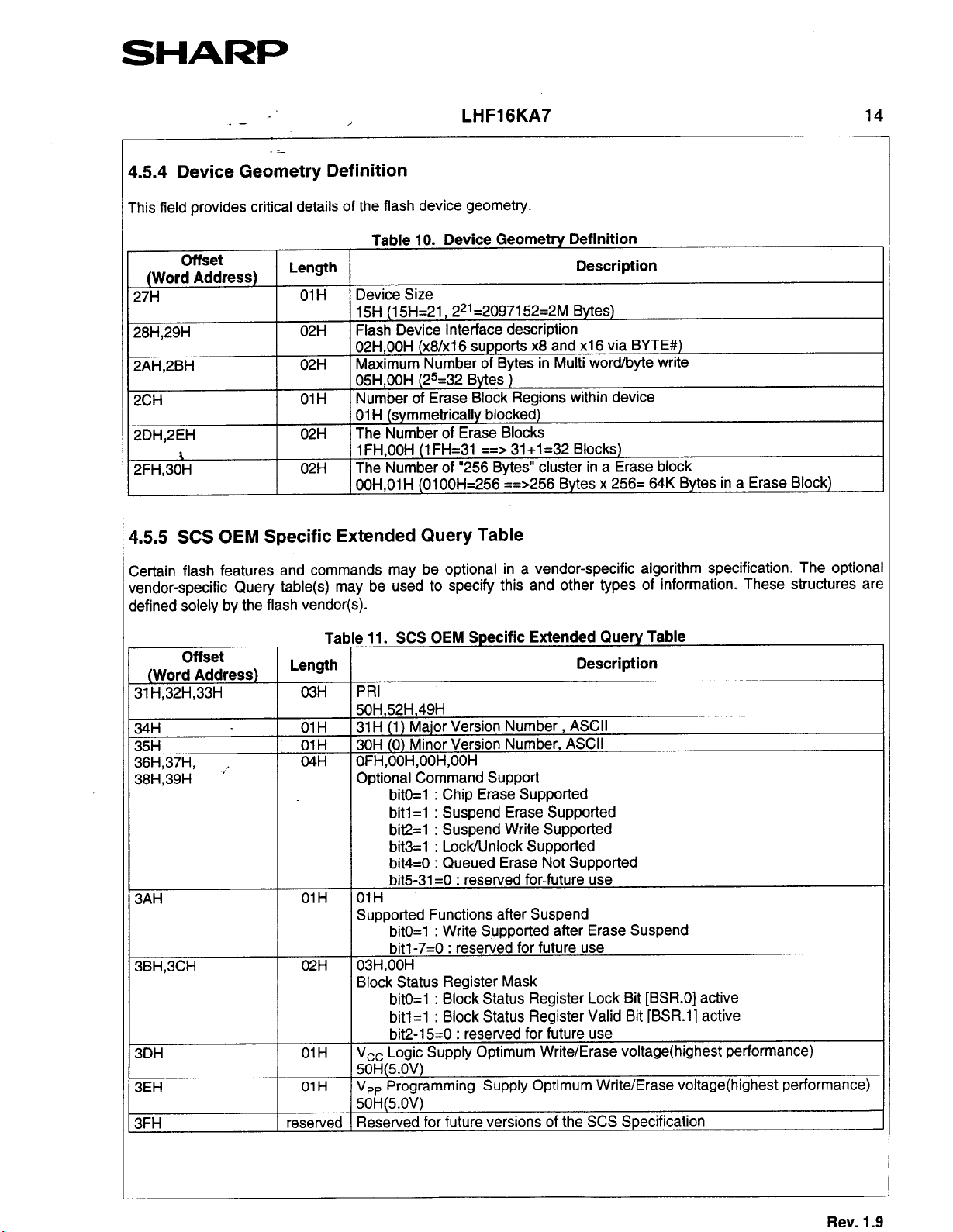

1.5.4 Device Geometry Definition

rhis field provides critical details of the flash device geometry.

Table 10. Device Geometry Definition

Offset

(Word Address)

27H

28H,29H

2AH,2BH

2CH

2DH,2EH

\

2FH,30H

Length

OlH Device Size

15H (15H=21,221=20971 52=2M Bytes)

02H

02H

01H

02H

02H

Flash Device Interface description

02H,OOH (x8/x16 supports x8 and xl 6 via BYTE#)

Maximum Number of Bytes in Multi word/byte write

05H,OOH (2s=32 Bytes )

Number of Erase Block Regions within device

01 H (symmetrically blocked)

The Number of Erase Blocks

1 FH,OOH (1 FH=31 ==> 31+1=32 Blocks)

The Number of “256 Bytes” cluster in a Erase block

, OOH,OlH (OlOOH=256 ==>256 Bytes x 256= 64K Bytes in a Erase Block)

1.5.5 SCS OEM Specific Extended Query Table

Description

Zertain flash features and commands may be optional in a vendor-specific algorithm specification. The optional

rendor-specific Query table(s) may be used to specify this and other types of information. These structures are

defined solely by the flash vendor(s).

Tat

e 11. SCS OEM Specific Extended Query Table

Offset

(Word Address)

31 H,32H,33H

38H,39H ”

3AH

3BH,3CH

3DH

3EH

3FH

Length

03H

OlH

OlH

04H OFH,OOH,OOH,OOH

OlH

02H

OlH

OlH

reserved

PRI

50H,52H,49H

31 H (1) Major Version Number , ASCII

30H (0) Minor Version Number, ASCII

Optional Command Support

bitO=l : Chip Erase Supported

bit1 =l : Suspend Erase Supported

bit2=1 : Suspend Write Supported

bit3=1 : Lock/Unlock Supported

bit4=0 : Queued Erase Not Supported

bit531 =O : reserved for-future use

OlH

Supported Functions after Suspend

bitO=l : Write Supported after Erase Suspend

bit1 -7=O : reserved for future use

03H,OOH

Block Status Register Mask

bitO=l : Block Status Register Lock Bit [BSR.O] active

bitl=l : Block Status Register Valid Bit [BSR.l] active

bit2-15=0 : reserved for future use

V,, Logic Supply Optimum Write/Erase voltage(highest performance)

50H@.OV)

Vpp Programming Supply Optimum Write/Erase voltage(highest performance)

56i-l(5.OV)

deserved for future versions of the SCS Specification

Description

Rev. 1.9

Loading...

Loading...