Page 1

SUPPLEMENT ATTACHED

TopPage

LC-32D50U

SERVICE MANUAL

No. S56T2LC32D50U

LCD COLOR TELEVISION

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

LC-32D50U

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRE-

CAUTION............................................................i

PRECAUTIONS A PRENDRE LORS DE

LA REPARATION...............................................ii

Precautions for using lead-free solder ..............iii

CHAPTER 1. Specifications

[1] Specifications.................................................1-1

CHAPTER 2. Operation Manual

[1] Operation Manual...........................................2-1

CHAPTER 3. Dimensions

[1] Dimensions .................................................... 3-1

CHAPTER 4. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS ................... 4-1

CHAPTER 7. MAJOR IC INFORMATIONS

[1] MAJOR IC INFORMATIONS.........................7-1

CHAPTER 8. OVERALL WIRING/BLOCK DIAGRAM

[1] OVERALL WIRING DIAGRAM......................8-1

[2] SYSTEM BLOCK DIAGRAM............ ... ... .... ...8-3

CHAPTER 9. PRINTED WIRING BOARD

[1] PRINTED WIRING BOARD...........................9-1

CHAPTER 10. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIA-

GRAM..........................................................10-1

[2] MAIN Unit....................................................10-2

[3] IF Unit........................................................10-46

[4] LED Unit....................................................10-50

[5] KEY Unit....................................................10-51

[6] POWER SUPPLY Unit...............................10-52

CHAPTER 5. ADJUSTMENT PROCEDURE

[1] ADJUSTMENT PROCEDURE....................... 5-1

CHAPTER 6. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE.......................6-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

PARTS GUIDE

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-32D50U

LC-32D50U

SAFETY PRECAUTION

Service Manual

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CONTINUED PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE.

F701 (8A, 125V)

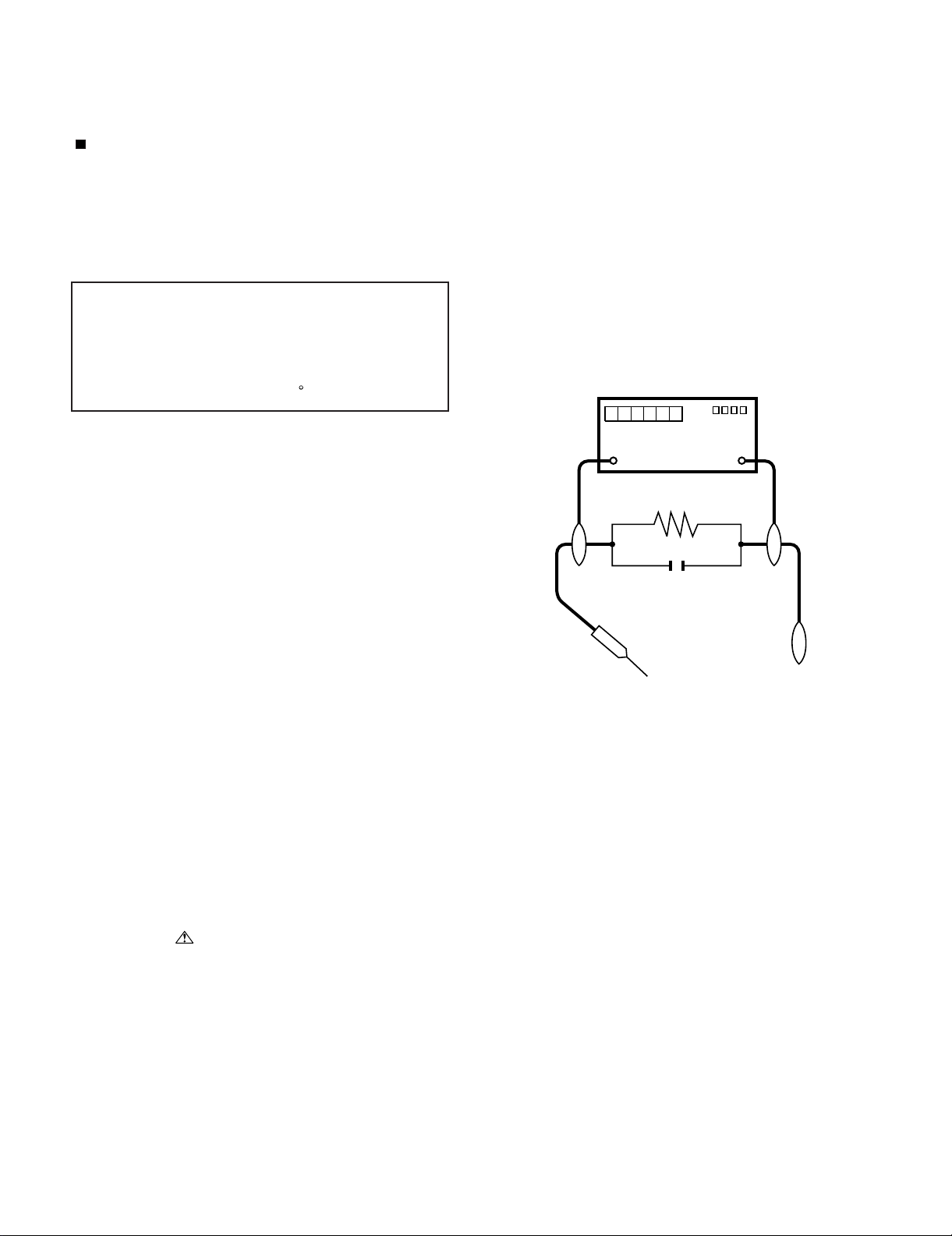

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

F4701, F5701 (3A~, 250V, 115 C)

BEFORE RETURNING THE RECEIVER (Fire &

Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 120 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

TO EXPOSED

METAL PARTS

DVM

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts

List and Schematic Diagrams.

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

i

Page 3

LC-32D50U

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement accoutumé à toute vérification de sécurité et aux

conseils suivants.

AVERTISSEMENT

6. N'entreprendre aucune modification de tout circuit. C'est dangereux.

7. Débrancher le récepteur avant toute réparation.

PRECAUTION: POUR LAPROTECTION CONTINUE

CONTRE LES RISQUES D'INCENDIE,

REMPLACER LE FUSIBLE

F701 (8A, 125V),

F4701, F5701 (3A~, 250V, 115 C)

VERIFICATIONS CONTRE L'INCEN-DIE ET LE

CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, eff ectuer les vérifications suivantes.

8. Inspecter tous les faisceaux de câbles pour s'assurer que les fils ne

soient pas pincés ou qu'un outil ne soit pas placé entre le châssis

et les autres pièces métalliques du récepteur.

9. Inspecter tous les dispositifs de protection comme les boutons de

commande non-métalliques, les isolants, le dos du coffret, les couvercles ou blindages de réglage et de compartiment, les réseaux

de résistancecapacité, les isolateurs mécaniques, etc.

10.S'assurer qu'il n'y ait pas de danger d'électrocution en vérifiant la

fuite de courant, de la facon suivante:

• Brancher le cordon d'alimentation directem-ent à une prise de courant de 120V. (Ne pas utiliser de transformateur d'isolation pour cet

essai).

• A l'aide de deux fils à pinces, brancher une résistance de 1.5 k 10

watts en parallèle avec un condensateur de 0.15 F en série avec

toutes les pièces métalliques exposées du coffret et une terre connue comme une conduite électrique ou une prise de terre branchée

àlaterre.

• Utiliser un voltmètre CA d'une sensibilité d'au moins 5000 /V pour

mesurer la chute de tension en travers de la résistance.

• Toucher avec la sonde d'essai les pièces métalliques exposées qui

présentent une voie de retour au châssis (antenne, coffret métallique, tête des vis, arbres de commande et des boutons, écusson,

etc.) et mesurer la chute de tension CA en-travers de la résistance.

Toutes les vérifications doivent être refaites après avoir inversé la

fiche du cordon d'alimentation. (Si nécessaire, une prise d'adpatation non polarisée peut être utilisée dans le but de terminer ces

vérifications.)

Tous les courants mesurés ne doivent pas dépasser 0.5 mA.

Dans le cas contraire, il y a une possibilité de choc électrique qui

doit être supprimée avant de réndre le recepteur au client.

DVM

ECHELLE CA

1.5k ohm

10W

0.15

µ

SONDE D'ESSAI

F

AUX PIECES

METALLIQUES

EXPOSEES

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

BRANCHER A UNE

TERRE CONNUE

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans les téléviseur

ACL présentent des caractéristiques spéciales relatives à la sécurité,

qui ne sont souvent pas évidentes à vue. Le degré de protection ne

peut pas être nécessairement augmentée en utilisant des pièces de

remplacement étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces caractéristiques sont

identifiées dans ce manuel; les pièces électriques qui présentent ces

particularités sont identifiées par la marque " " et hachurées dans

la liste des pièces de remplacement et les diagrammes schématiques.

Pour assurer la protection, ces pièces doivent être identiques à celles

utilisées dans le circuit d'origine. L'utilisation de pièces qui n'ont pas

les mêmes caractéristiques que les pièces recommandées par l'usine,

indiquées dans ce manuel, peut provoquer des électrocutions, incendies, radiations X ou autres accidents.

////////////////////////////////////////////////////////////////////////////////////////////////////////// /////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

ii

Page 4

LC-32D50U

Precautions for using lead-free solder

Employing lead-free solder

• "PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder , and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Indicates lead-free solder of tin, silver and copper.

L F a/a

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No, Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

iii

Page 5

LC-32D50U

CHAPTER 1. Specifications

Service Manual

[1] Specifications

Item Model: LC-32D50U

LC-32D50U

LCD panel

Number of dots

TV-standard

TV

Function

Receiving

Channel

Audio multiplex

Backlight

Audio out

Terminals

Rear

VHF/UHF

CATV

Digital Terrestrial

Broadcast (8VSB)

Digital cable*

(64/256 QAM)

INPUT1

INPUT2

INPUT3

INPUT4

INPUT5

Air ANTENNA

Cable ANTENNA

32" Advanced Super View & BLACK TFT LCD

3,147,264 dots (1366 x 768 x 3 dots)

American TV Standard ATSC/NTSC System

VHF 2-13ch, UHF 14-69ch

1-135ch (non-scrambled channel only)

2-69ch

1-135ch (non-scrambled channel only)

BTSC System

60,000 hours (at Backlight Standard position)

10W x 2

AV in, COMPONENT in

AV in, S-VIDEO in

HDMI in with HDCP

Audio in, HDMI in with HDCP

Audio in, DVI-I in with HDCP

75 Unbalance, F Type for VHF/UHF/Digital Air in x 1

75 Unbalance, F Type for CATV/Digital Cable in x 1

i.LINK

DIGITAL AUDIO OUTPUT

OUTPUT

OSD language

Power Requirement

Power Consumption

w/o stand

Weight

with stand

Dimension

(WxHxD)

w/o stand

with stand

Accessories

Operating temperature

IEEE1394 x 2 with DTCP (Compatible with DTVLink)

Optical Digital audio output x 1 (PCM/Dolby Digital)

Audio out

English/French/Spanish

AC120V,60Hz

178 W

39.7 lbs./18.0 kg

45.2 lbs./20.5 kg

1

/16x239/32x457/64inch

32

32

1

/

41

25

/

x

16

1

12

/64inch

x

64

Remote control unit(x 1), AC cord (x 1), “AAA” size battery (x 2), Cable clamp (x 1),

Cable tie(x 1), Stand unit (x 1), Operation manual (x 1)

+32°Fto+104°F(0°Cto+40°C)

* Emergency alert messages via Cable are unreceivable.

As part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for product

•

improvement without prior notice. The performance specification figures indicated are nominal values of production units.

There may be some deviations from these values in individual units.

1 – 1

Page 6

LC-32D50U

LC-32D50U

CHAPTER 2. Operation Manual

[1] Operation Manual

HDMI terminal (INPUT 3)

HDMI terminal (INPUT 4)

i.LINK terminals

Service Manual

AIR IN terminal

CABLE IN terminal AC INPUT terminal

RS-232C terminal

Part names

TV (Rear)

Channel buttons

(CH /)

POWER button

INPUT button

/)

(INPUT 5)

DVI terminal

OUTPUT

DIGITAL AUDIO

terminal

DVI AUDIO

terminal

(INPUT 5)

terminals

AUDIO input

INPUT 1 terminals

INPUT 2

(INPUT 4)

terminals

terminals

AUDIO OUTPUT

OPC indicator*POWER

indicator**

OPC sensor*

TV (Front)

Part names

Volume buttons (VOL

2 – 1

Remote control sensor

NOTE

*OPC: Optical Picture Control.

**for TV status indicator.

Page 7

Hex key

LC-32D50U

Long screw

CAUTION

This will prevent it from being damaged.

Attaching the stand

• Before attaching (or detaching) stand, unplug the AC cord from the AC INPUT terminal.

QUICK REFERENCE

• Before performing work spread cushioning over the base area to lay the TV on.

• Attach the stand in the correct direction.

• The “REAR” label should be visible from the back of the TV. Refer to

the figure.

REAR

This side faces the rear.

• Incorrect installation of the stand may result in the TV falling over.

• Be sure to follow the instructions.

3.

1. Confirm the 8 screws supplied with the TV.

Insert the stand into the opening on the bottom of the

1

2

1

Insert and tighten the 4 long screws into the 4 holes on

the rear of the TV.

TV.

2

(used in step 3)

Long screws (x4)

(used in step 2)

Short screws (x4)

2. Attach the two parts of the stand unit to each other using

the 4 short screws and the hex key (supplied with the

product) as shown.

Soft cushion

Short screw

Hex key

NOTE

• To detach the stand, perform the steps in reverse order.

Part names

standby mode.

1 TV POWER: Switches the TV power on or enters

Remote control unit

equipment on and off.

2DISPLAY:Displays the channel information.

3 SOURCE POWER: Turns the power of the external

117

the external equipment.

50–9:Sets the channel.

4 External equipment operational buttons: Operates

6 • (DOT):

7AIR:Receives air signal.

2

18

3

8CABLE:Receives cable signal.

9VOL/:Sets the volume.

10 SURROUND: Selects Surround settings.

11 INFO: Displays the program information screen.

19

4

12 FREEZE: Sets the still image. Press again to return to

normal screen.

13 EXIT: Turns off the menu screen.

14 SLEEP: Sets the sleep timer.

5

15 i.LINK: Displays the i.LINK control panel.

16 AUDIO: Selects the MTS/SAP or the audio mode during

multi-channel audio broadcasts.

SAT, VCR, DVD and AUDIO operation. Indicator lights up

for the current mode.

17 FUNCTION: Switches the remote control for TV, CBL/

21

20

6

7228

* To enter the code registration mode, you need to press

FUNCTION and DISPLAY at the same time.

23

9

control unit will light. The lighting will turn off if no

18 LIGHT : When pressed all buttons on the remote

24

10

2 – 2

operations are performed within about 5 seconds. This

button is used for performing operations in low-light

25

11

situations.

19 VIEW MODE: Selects the screen size.

26

27

12

20 ENT: Jumps to a channel after selecting with the 0–9

buttons.

21 FLASHBACK: Returns to the previous channel or

28

13

external input mode.

22 INPUT: Selects a TV input source. (TV, INPUT 1, INPUT

29

2, INPUT 3, INPUT 4, INPUT 5, i.LINK)

23 CH / : Selects the channel.

30

24 MUTE: Mutes the sound.

25 CH LIST: Displays the channel list screen.

14

31

26 MENU: Displays the menu screen.

27 ////ENTER: Selects a desired item on the

15

screen.

28 RETURN: Returns to the previous menu screen.

16 32

29 FAVORITE CH

A, B, C, D: Selects four preset favorite channels in four

different categories.

While watching, you can toggle the selected channels by

pressing A, B, C and D

30 FAVORITE: Registers favorite channels.

31 CC: Displays captions from a closed-caption source.

32 AV MODE: Selects an audio or video setting. (AV mode:

STANDARD, MOVIE, GAME, USER, DYNAMIC (Fixed),

DYNAMIC. PC mode: STANDARD, MOVIE, GAME,

USER, DYNAMIC (Fixed), DYNAMIC, PC)

NOTE

• When using the remote control unit, point it at the TV.

Page 8

LC-32D50U

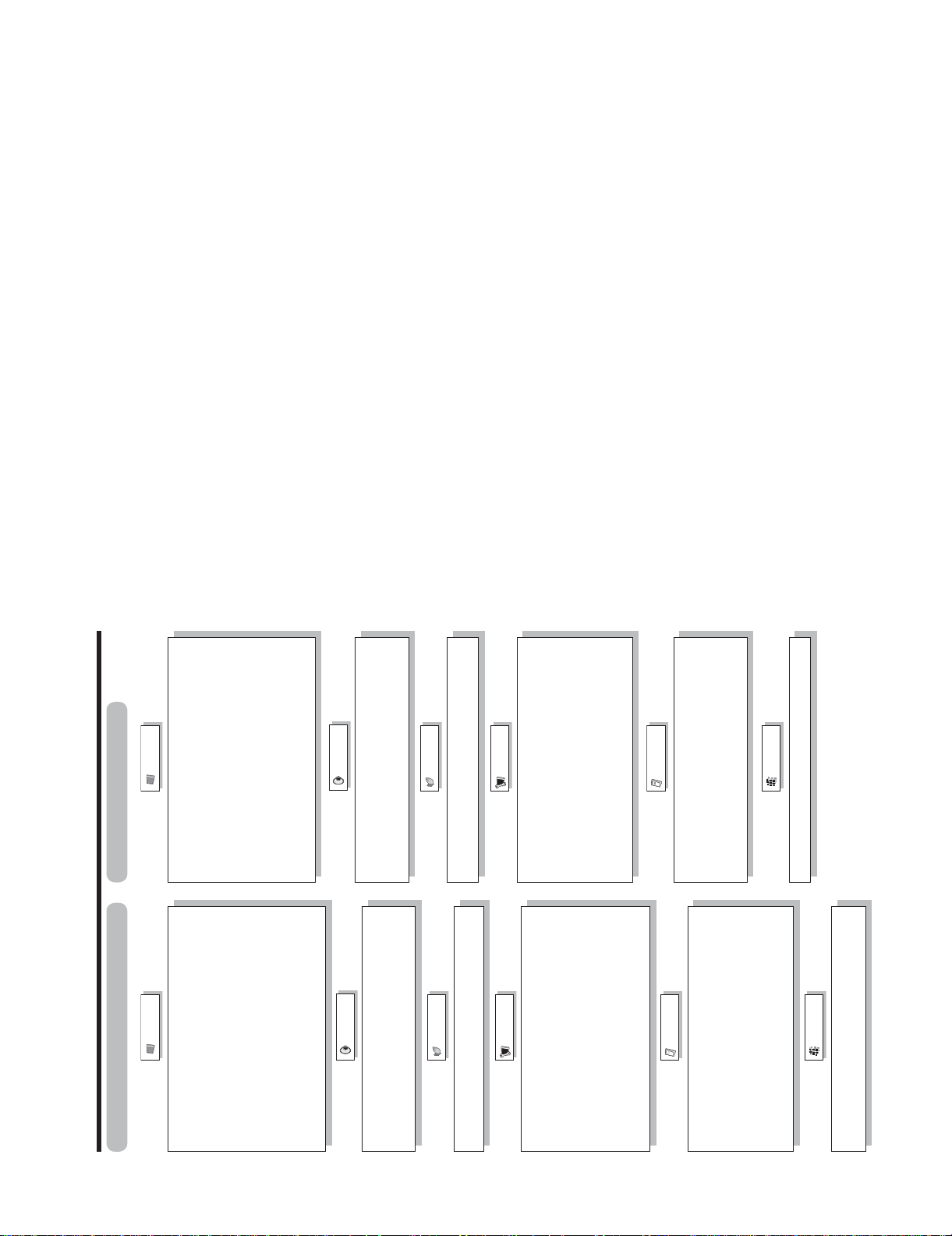

Basic adjustment settings

Picture

Menu items for HDMI/DVI

Picture

Menu items for TV/INPUT 1/INPUT 2

OPC

Backlight

OPC

Backlight

Contrast

Brightness

Color

Contrast

Brightness

Color

Tint

Sharpness

Advanced

Tint

Sharpness

Advanced

Color Temp.

Black

Monochrome

Color Temp.

Black

3D-Y/C

Audio

Film Mode

Range of OPC

Monochrome

Film Mode

Range of OPC

Audio

Treble

Bass

Treble

Balance

Surround

Bass

Balance

Power Control

Surround

Power Control

No Signal Off

No Operation Off

No Signal Off

No Operation Off

2 – 3

Setup

Setup

Input Skip

Input Signal

Auto Sync.

EZ Setup

CH Setup

Antenna Setup-DIGITAL

Input Label

Fine Sync.

Input Skip

Position

Picture Flip

Input Label

Parental CTRL

Standby Mode

Language

Position

Picture Flip

Standby Mode

Reset

Language

Reset

Option

Option

Audio Only

Digital Noise Reduction

Input Select

Audio Only

HDMI Setup

Output Select

Quick Shoot

Digital Noise Reduction

Input Select

Output Select

Quick Shoot

Digital Setup

Color System

Caption Setup

Program Title Display

Favorite CH

i.LINK Setup

Digital Setup

Audio Setup

i.LINK Setup

Page 9

LC-32D50U

CHAPTER 3. Dimensions

[1] Dimensions

243/32(612)

32

1

/16(814)

Service Manual

17

/

4

(115)

LC-32D50U

Unit: inch/(mm)

57

32

/

4

(124)

64

(651)

64

/

41

25

(200)

8

/

7

7

(591)

32

/

9

23

(115)

32

/

17

4

279/16(700.0)

7

7

/8(200)

64

/

35

15

(394.6)

(400)

4

/

3

15

121/64(305)

3 – 1

Page 10

LC-32D50U

LC-32D50U

CHAPTER 4. REMOVING OF MAJOR PARTS

Service Manual

[1] REMOVING OF MAJOR PARTS

1. Remove the SD Card Cover .

2. Remove the 4 lock screws and detach the Stand Base Ass'y.

1

3. Remove the 9 lock screws , 3 lock screws and detach the Rear Cabinet.

2 3

2

SD-Card

Cover

3

1

Rear

Cabinet

Stand Base Ass'y

4 – 1

Page 11

LC-32D50U

4. Remove the 2 lock screws and detach the Stand Assist Angle.

5. Remove the 4 lock screws and detach the Center Angle-L and R.

6. Remove the 3 lock screws and detach the Stand Cover.

7. Remove the 5 lock screws and detach the Stand Fix Angle.

4

5

6

7

5

Center Angel-L

Center Angel-R

5

Stand Fix Angle

Stand Cover

Stand Assist Angle

7

6

4

4 – 2

Page 12

LC-32D50U

8. Disconnect the connectors and , and detach the Speaker L and R.

9. Disconnect the connectors CN7501 and CN7502.

10.Remove the 5 lock screws and detach the MAIN Shield.

8

10

9

10

Main Shield

SpeakerR

C N 7501

C N 7502

8

9

Speaker L

4 – 3

Page 13

Top Cover Ass`y

Key Unit

LC-32D50U

12

P 2002

11

Coaxial

Cable

S C 1102

SC502

P 2602

P 2601

S C 1101

S C 501

P502

LED Unit

P2603

P9701

P9702

S C 1301

P 2704

P 2703

CN1 CN2

C N 5703

C N 5701

C N 5702

11.Disconnect the connectors, (P2002, P2601, P2602, P2603, P9701, P9702, SC1102, SC1101, SC1301, CN1, CN2, P2703, P502, CN5701,

CN5702, CN5703) and Remover the Coaxial Cable.

12.Remove the 2 lock screws and detach the LED Unit.

13.Remove the KEY Unit and Remove the 3 lock screws from the Top Cover Ass'y

11

12

4 – 4

Page 14

LC-32D50U

14.Remove the 4 lock screws and detach the PWB Ass'y.

15.Remove the 7 lock screws , 2 lock screws and detach the Jack Angle Long.

16.Remove the 5 lock screws and detach the IF Unit.

17.Remove the 6 lock screws and detach the POWER Supply Unit.

18.Remove the 5 lock screws and detach the MAIN Unit.

13

14-1 14-2

15

16

17

17

13

Main Unit

14-1

14-2

14-1

15

16

Power Supply Unit

Chassis

Jack Angle

Long

IF Unit

4 – 5

Page 15

LC-32D50U

19.Remove the 6 lock screws and Remove the 10 lock screws and detach the Center Assist Angle and Rug Angles and LCD Panel Module.

18

19 19 1918 18

Rug Angle

19

Center Assist Angle

19 1918 18

4 – 6

Page 16

LC-32D50U

LC-32D50U

CHAPTER 5. ADJUSTMENT PROCEDURE

Service Manual

[1] ADJUSTMENT PROCEDURE

The adjustment values are set to the optimum conditions at the factory before shipping. If a value should become improper or an adjustment is

required due to part replacement, make an adjustment according to the following procedure.

1. After replacement of any PWB unit and/or IC for repair, please note the following.

• When replacing the following units, make sure to prepare the new units loaded with updated software.

MAIN Unit: DUNTKD640FM13

IF Unit: DUNTKD643FM13

2. Upgrading of each microprocessor software

Caution: Never "POWER OFF" the unit when software upgrade is ongoing.

Otherwise the system may be damaged beyond recovery.

2.1. Software version upgrade

The model employs the following software.

•Main software

• Monitor microprocessor software

The main software and the monitor microprocessor software can be upgraded by using a general-purpose SD memory card.

The followings are the procedures for upgrading, explained separately for each of the main software, the monitor microprocessor software.

2.2. Main software version upgrade

Get ready before you start

• SD memory card of 32MB or higher capacity

• PC running on Windows 98/98SE/ME/2000/XP operating system

• SD memory card reader/writer with USB connectivity.

• SD memory card formatting software

(Downloadable at http://panasonic.jp/support/audio/sd/download/sd_formatter_e.html)

Preparations

To upgrade the main software, it is necessary to get ready the SD card for version upgrade before you start.

Follow the steps below and create the SD card for version upgrade.

1. Insert the SD card into the SD card reader/writer. Start the SD card formatting software. Click [Format].

(When you have the drive options, select the drive where the SD card is inserted before you proceed.)

5 – 1

Page 17

2. When the formatting is over, the following window appears. Click [OK].

3. Click [Exit] to finish the formatting.

NOTE: When you are done, take out the SD card once to make sure it is finished, and then insert it again.

LC-32D50U

4. Copy the binary image file D50UAxxx.SDC (named temporarily) for version upgrade to the root directory (folder) of the SD card drive.

NOTE: In the SD card drive, do not store other folders or unrelated files, or more than one binary image files for version upgrade.

Now the SD card for version upgrade is ready.

How to upgrade the software

5. Shut off the AC power (i.e. unplug the AC cord).

6. Insert the SD card for version upgrade (prepared as above) into the service socket located lower side from center at terminals, above S-VIDEO

terminal in the rear of the unit, in a way that the cut corner of the SD card comes at the upper side.

NOTE: If the SD card is inserted in a wrong way, the card will go deep inside the unit beyond retrieval. Take due care to insert the SD card correctly.

7. Turn on the AC power (i.e. plug in the AC cord).

8. After the unit startup, the system upgrade screen as shown below appears within 20-40 seconds.

SYSTEM UPGRADE

Program

12%

EEPROM

Part Init

U0601051OLD Version

NEW Version U0601241

M150

5 – 2

Page 18

LC-32D50U

9. Even a single failure in the process will trigger the upgrade failure screen as shown below. The word "NG" changes to red for the item failed.

NOTE: In the event of a failure, repeat the upgrading process. If the process repeatedly fails, it is likely that the hardware is troubled.

UPGRADE FAILURE

Program

24%

EEPROM

Part Init

NEW Version U0601241

10.Upon completion of the whole process, the upgrade success screen as shown below appear s. You can check the new software version on this

screen. The version information appears after the upgrade is complete.

UPGRADE SUCCESS

Program

100%

EEPROM

Part Init

NG

NG

U0601051OLD Version

NG

NG

U0601241Main Version

11.Shut off the AC power to the unit (unplug the AC cord), and remove the SD card for version upgrade.

12.Now the software version upgrade is complete.

NOTE: When you are done with the software version upgrade, start the set, go to the top page of the adjustment process screen and check the main

software version information.

5 – 3

Page 19

LC-32D50U

2.3. Monitor microprocessor software version upgrade

NOTE: If "Monitor version" in the process me nu is "2.00M", the monitor microprocessor software can not be rewritten (because IC2002 has been

replaced with the mask type).

Get ready before you begin

Get ready the same items as listed in the "Main software version upgrade".

Preparation

Create the SD card for monitor microprocessor software version upgrade in the same manner as explained in the "Main software version upgrade".

Copy the binary image file M150Mxxx.SDC (named temporarily) for monitor microprocessor software version upgrade to the SD card drive.

How to upgrade the software

1. Shut off the AC power to the unit (i.e. unplug the AC cord).

2. Insert the SD card for version upgrade (prepared as above) into the service socket located lower side from center at terminals, above S-VIDEO

terminal in the rear of the unit, in a way that the cut corner of the SD card comes at the upper side.

NOTE: If the SD card is inserted in a wrong way, the card will go deep inside the unit beyond retrieval. Take due care to insert the SD card correctly.

3. Turn on the AC power (i.e. plug in the AC cord).

CAUTION:The moment this operation is done, the upgrading of the monitor microprocessor software starts. While the upgrade is ongoing,

never power off the unit. Otherwise the upgrade will fail and the s ystem may have a serious damage beyond recov ery (inability

to start).

4. After the unit startup, the system upgrade screen as shown below appears within 10-30 seconds.

MONITOR UPGRADE

Program

12%

1.00OLD Version

NEW Version 1.02

NG

M150

5. A failure in the process will trigger the upgrade failure screen. The word "NG" changes to red for the item failed.

NOTE: In the event of a failure, repeat the upgrading process. If the process repeatedly fails, it is likely that the hardware is troubled.

6. Upon completion of the whole process,the upgrade success screen as sho wn below appears.You can check the new software version on this

screen. The version information appears after the upgrade is complete.

7. Shut off the AC power to the unit (unplug the AC cord), and remove the SD card for version upgrade.

8. Now the software version upgrade is complete.

NOTE: When you are done with the software version upgrade, start the set, go to the top page of the adjustment process screen and check the mon-

itor microprocessor software version information.

2.4. Video signal adjustment procedure

1) Image adjustment

1. Device check

Before adjustment, make sure that the adjusting device and signal source are set for the Sharp LCD US.

Signal generator level adjustment check (Adjustment to the specified level)

• Composite signal : 0.714Vp-p ± 0.02Vp-p (Pedestal to white level)

• 15K component signal : Y level : 0.714Vp-p ± 0.02Vp-p (Pedestal to white level)

PB, PR level : 0.7Vp-p ± 0.02Vp-p

• 33K component signal : Y level : 0.7Vp-p ± 0.02Vp-p (Pedestal to white level)

PB, PR level : 0.7Vp-p ± 0.02Vp-p

• DVI-I (Analog RGB) signal : RGB level : 0.7Vp-p ± 0.02Vp-p (Pedestal to white level)

5 – 4

Page 20

LC-32D50U

2. Entering the adjustment process mode

Adjustment item Adjustment conditions Adjustment procedure

1 Adjustment pro-

cess mode

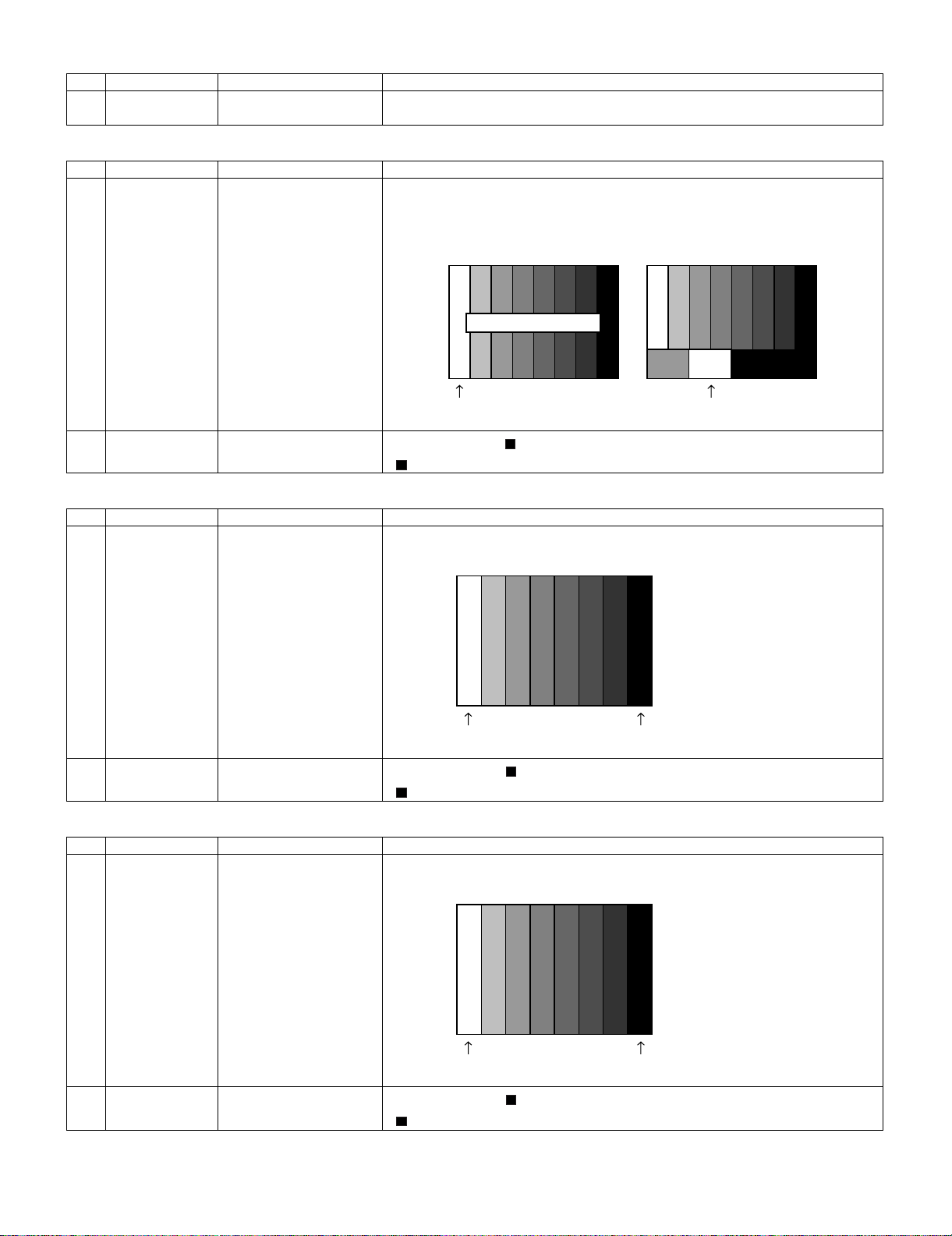

3. N358 composite signal / Tuner adjustment

Adjustment item Adjustment conditions Adjustment procedure

1 Adjustment N358 signal

US-10ch

Enter the process adjustment mode using the process adjustment remote control.

Feed the N358 color bar signal (75% color saturation) to VIDEO 1 input.

Feed the RF signal (by use of US-10ch) to TUNER.

[Video input signal] [US-10CH]

75% color saturation

100% white 100% white

2 Auto adjustment

performance

4. Component 15K signal adjustment

Adjustment item Adjustment conditions Adjustment procedure

1 Adjustment 480i signal Feed the 100% color bar signal to VIDEO 1 component input.

Page 3

Bring the cursor on [ N358 ALL ADJ] and press [ENTER].

[ N358 ALL ADJ FINISH] appears when finished.

480i

100% color bar signal

100% white

2 Auto adjustment

performance

5. Component 33K signal adjustment

Adjustment item Adjustment conditions Adjustment procedure

1 Adjustment 1080i signal Feed the 100% color bar signal to VIDEO 1 component input.

Page 5

Bring the cursor on [ COMP 15K MAIN ADJ] and press [ENTER].

[ COMP 15K MAIN ADJ FINISH] appears when finished.

0% black

2 Auto adjustment

performance

Page 6

1080i

100% color bar signal

100% white

Bring the cursor on [ HDTV ADJ] and press [ENTER].

[ HDTV ADJ FINISH] appears when finished.

0% black

5 – 5

Page 21

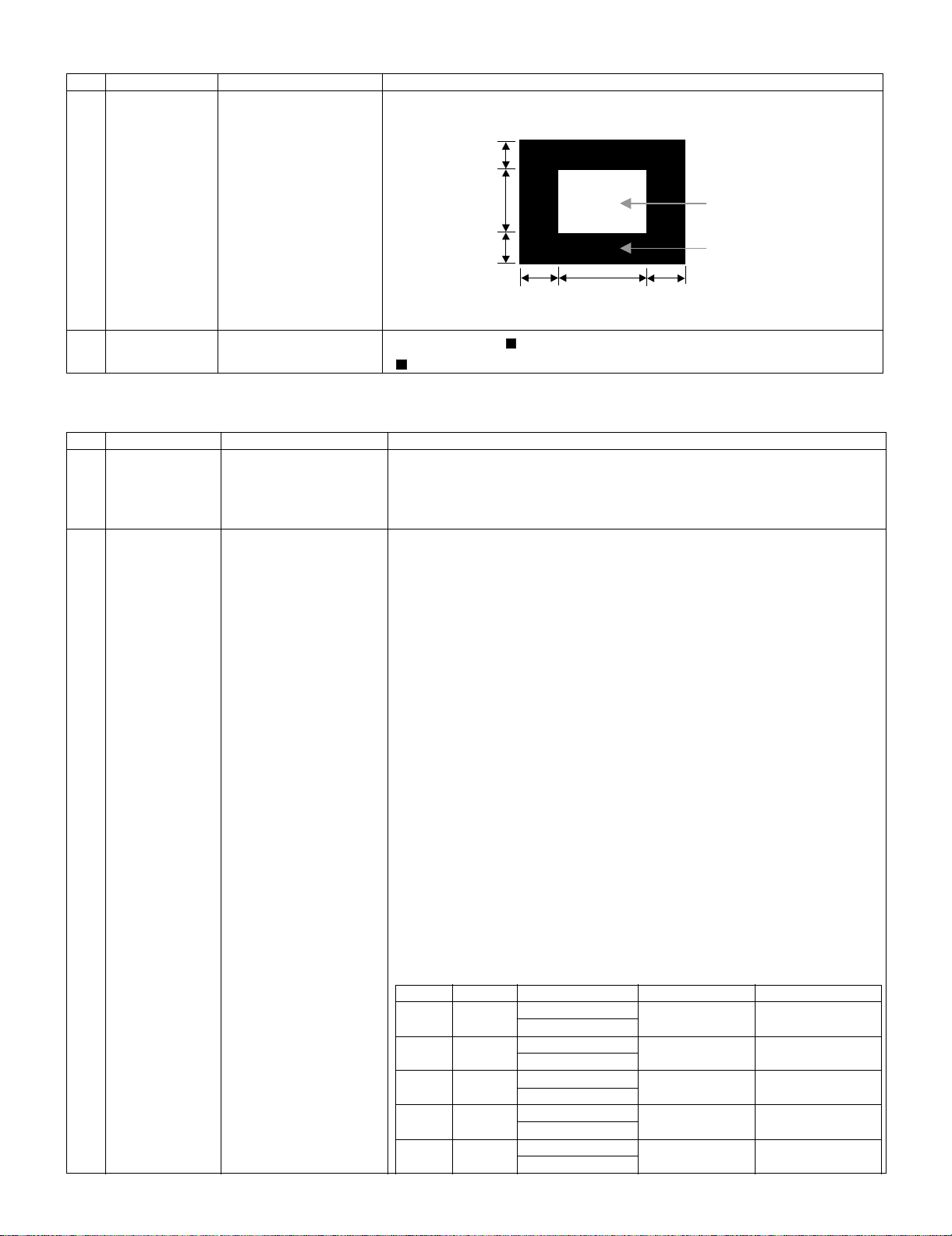

6. DVI-I (analog) signal adjustment

Adjustment item Adjustment conditions Adjustment procedure

1 Adjustment DVI-I (analog)

signal: XGA

(1024 x 768) 60Hz

SYNC:

HV separate

Feed the XGA (100%) white 1/2 window to DVI-I (analog) .

1/4

LC-32D50U

1/2

1/4

1/4

2 Auto adjustment

performance

Bring the cursor on [ DVI ANALOG ADJ] and press [ENTER].

[ DVI ANALOG ADJ OK] appears when finished.

2.5. Adjustment of white balance

1. White balance adjustment

Adjustment item Adjustment conditions Adjustment procedure

1 Setting 1) Apply the following settings to the set.

2 Execution of auto

adjustment

[Command]

Process mode

KRSW0001

KKT10037

Setting

KYOF0000

OSDS0001

SBSL0016

Multipoint adjustment mode

MSET0001

Adjustment value initialization

MSET0004

Point 6

LEV60944

MG6G****

MG6B****

MG6R****

AV MODE: [DYNAMIC]

Backlight: +16

Aging Time: Min. 60 minutes

2) Connect a white balance adjustment jig and the set.

[Adjustment method]

1) Send the “monitor adjustment process” code with the R/C.

2) Set the point 6 to the specified gradation. Set the strongest color as the fixed color

and adjust RGB to the standard value by minus adjustment.

3) Set the point 5 to the specified gradation. Set the correction value of G [(Initial value

of point 5) x (G value of point 6) / (Initial value of point 6)] and adjust RB to the standard value.

4) Set the point 4 to the specified gradation. Set the correction value of G [(Initial value

of point 4) x (G value of point 6) / (Initial value of point 6)] and adjust RB to the standard value.

5) Set the point 3 to the specified gradation. Set the correction value of G [(Initial value

of point 3) x (G value of point 6) / (Initial value of point 6)] and adjust RB to the standard value.

6) Set the point 2 to the specified gradation. Set the correction value of G [(Initial value

of point 2) x (G value of point 6) / (Initial value of point 6)] and adjust RB to the standard value.

7) Set the point 1 to the specified gradation. Set the correction value of G [(Initial value

of point 1) x (G value of point 6) / (Initial value of point 6)] and adjust RB to the standard value.

8) Write the adjustment values with the MSET0003 command and turn off AC power.

* Initial value of each point: Set gradation level x 4

1/2

100% White

0% Black

1/4

Point 5

LEV50800

MG5G****

MG5B****

MG5R****

Point 4 Level Standard value Adjustment spec Test spec

LEV40576 Point 6 944 X=0.272 ±0.0012 ±0.0020

MG4G**** y=0.277

MG4B**** Point 5 800 X=0.272 ±0.0012 ±0.0020

MG4R**** y=0.277

Point 3 y=0.277

LEV30464 Point 3 464 X=0.272 ±0.0012 ±0.0020

MG3G**** y=0.277

MG3B**** Point 2 264 X=0.272 ±0.0012 ±0.0020

MG3R**** y=0.277

[Adjustment values]

•Conform to “Standard set” submitted by Engineering Department.

[LC-32D50U] Teaching set

[Adjustment standard values] Measuring device: [Minolta CA-210 ] technical measuring

device

Point 4 576 X=0.272 ±0.0012 ±0.0020

5 – 6

Page 22

LC-32D50U

Adjustment item Adjustment conditions Adjustment procedure

Point 2 Point 1 200 X=0.272 ±0.0020 ±0.0035

LEV20264 y=0.277

MG2G****

MG2B****

MG2R****

Point 1

LEV10200

MG1G****

MG1B****

MG1R****

Writing

MSET0003

Note

2.6. Key writing

1. EDID writing (Main PWB: QPWBXD640WJZZ DVI input terminal/HDMI input terminal)

Adjustment item Adjustment conditions Adjustment procedure

1 DVI EDID writing File version check 1) Write the EDID data for DVI into IC1505 mounted on the

2 HDMI EDID writ-

ing

Inspection mode

File version check

Test conditions of the set:

2

AV MODE: [DYNAMIC] (Reset)

Monochro: ON

Aging Time: Min. 60 minutes

main PWB with the checker.

TL1514 ••• I2C clock, TL1515 ••• I2C data

TL1516 ••• 5V, TL1517 ••• GND

TL1536••• write protection (H: WP, Low: write enable)

1) Write the EDID data for HDMI into IC1501/IC1502

mounted on the main PWB with the checker.

TL1508/1510••• I2C clock, TL1509/1511••• I2C data

TL1512/1513••• 5V, TL1519/1518••• GND

TL1534/1535••• write protection (H: WP, Low: write

enable)

2) Perform data writing before the checker inspects HDMI.

(If no data has been written, HDMI does not function.)

2. DTCP key writing

Adjustment item Adjustment conditions Adjustment procedure

DTCP key writing

for i.Link

File version check 1) Write the DTCP key into IC8453 mounted on the main

PWB with the checker.

Set TL8453(I2C EXT) to L.

Connect TL8454(SCL)/TL8455(SDA) to the I2C bus.

2) Write the specified data into the specified address (A8).

• Use the second-generation DTCP device key.

• Conform to the internal key management agreement to

manage the DTCP device key.

• Follow [DTCP device key operation check manual] to

check operation.

• For the inspection or production, start in the process

start mode or inspection start mode.

• For details, refer to [Precautions for production].

5 – 7

Page 23

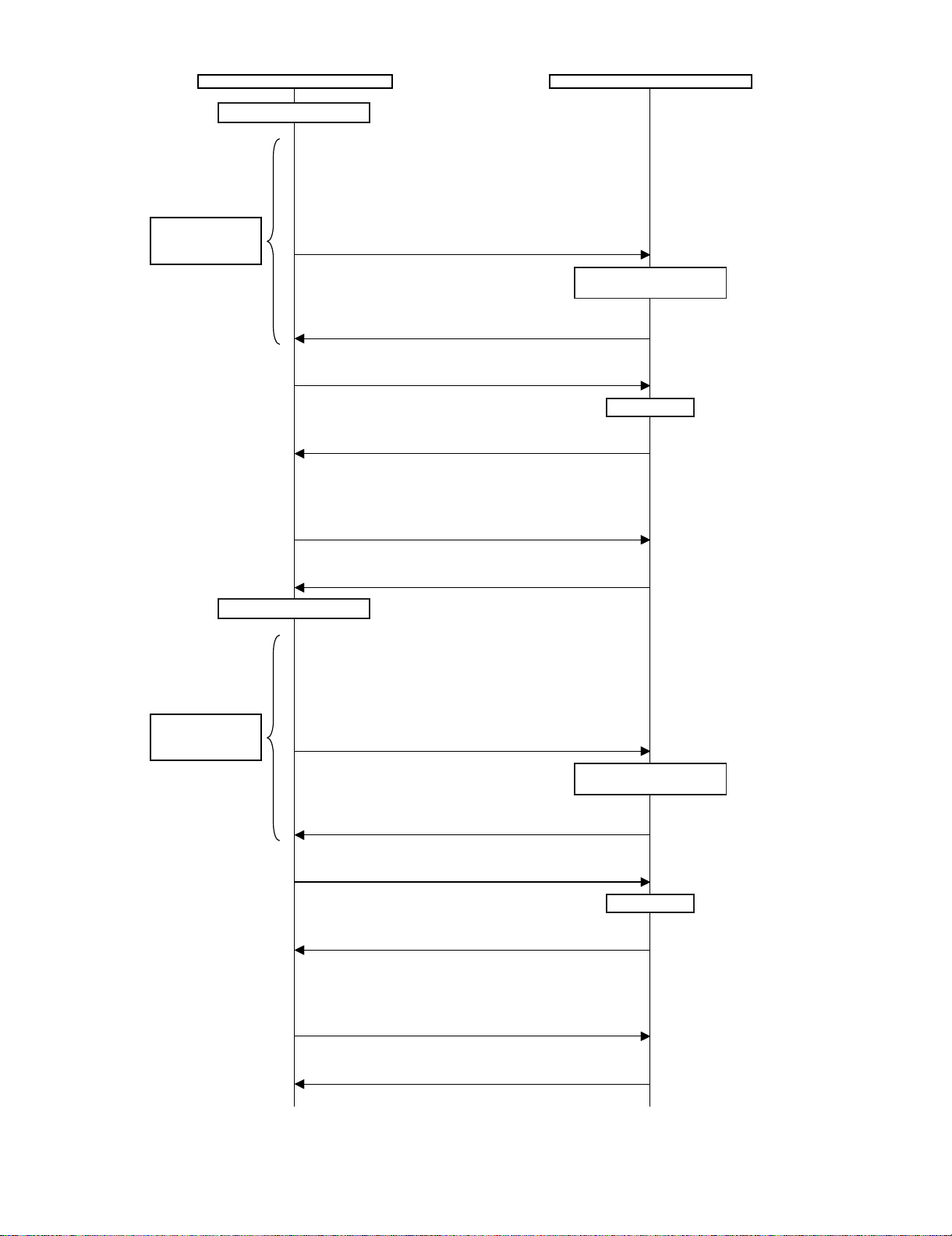

3. Adjustment sequence (adjustment according to the G adjustment value of gradation 6)

* Make sure the adjusting point gradations are correct since they are different for each model.

PC Set

Set the light level to MAX with the light control command

(SBSL0016 for 45).

SBSL0016

Setting is complete.

OK

Multipoint adjustment mode setting

MSET0001

Multipoint adjustment mode is set.

OK

Initialize adjustment values.

MSET0004

Initialization is done.

OK

Adjustment gradation setting (point 6 = 236 gradation adjustment*)

LEV60944

Adjustment values are set.

OK

LC-32D50U

Pattern display

Repeat until RGB

become the target

values.

Adjust RGB to the target xy values.

MG6RXXXX

MG6GXXXX

MG6BXXXX

* XXXX indicates the adjusted values between 0000 and 1023

(4 digit decimal number with zero fill).

* In order to adjust by reducing the value, set the strongest color

as the fixed color.

* The default adjustment value of RGB is the parameter value of

the LEV6 command multiplied by 2.

The adjustment value is

reflected in the image.

Adjustment values are set.

OK

Adjustment gradation setting (point 5 = 200 gradation adjustment*)

LEV50800

Pattern display

Adjustment values are set.

OK

Correction of G value

MG5GXXXX

When G is changed at gradation 6, calculate the ratio of the

change and set the following value to XXXX: (the value set with

LEV5)x2x(theratio).

Adjustment values are set.

OK

5 – 8

Page 24

LC-32D50U

Start measurement

Repeat until RGB

become the target

values.

PC Set

Adjust RB to the target xy values.

MG5RXXXX

MG5BXXXX

* XXXX indicates the adjusted values between 0000 and 1023

(4 digit decimal number with zero fill).

*Gisfixed.

* The default adjustment value of RGB is the parameter value

of the LEV5 command multiplied by 2.

The adjustment value is

reflected in the image.

Adjustment values are set.

OK

Adjustment gradation setting (point 4 = 144 gradation adjustment*)

LEV40576

Pattern display

Adjustment values are set.

OK

Correction of G value

MG4GXXXX

When G is changed at gradation 6, calculate the ratio of the

change and set the following value to XXXX: (the value set with

LEV4)x2x(theratio).

Start measurement

Repeat until RGB

become the target

values.

Adjustment values are set.

OK

Adjust RB to the target xy values.

MG4RXXXX

MG4BXXXX

* XXXX indicates the adjusted values between 0000 and 1023

(4 digit decimal number with zero fill).

*Gisfixed.

* The default adjustment value of RGB is the parameter value of

the LEV4 command multiplied by 2.

The adjustment value is

reflected in the image.

Adjustment values are set.

OK

Adjustment gradation setting (point 3 = 116 gradation adjustment*)

LEV30464

Pattern display

Adjustment values are set.

OK

Correction of G value

MG3GXXXX

When G is changed at gradation 6, calculate the ratio of the

change and set the following value to XXXX: (the value set with

LEV3)x2x(theratio).

Adjustment values are set.

OK

5 – 9

Page 25

Start measurement

Repeat until RGB

become the target

values.

LC-32D50U

PC Set

Adjust RB to the target xy values.

MG3RXXXX

MG3BXXXX

* XXXX indicates the adjusted values between 0000 and 1023

(4 digit decimal number with zero fill).

* G is fixed.

* The default adjustment value of RGB is the parameter value of

the LEV3 command multiplied by 2.

The adjustment value is

reflected in the image.

Adjustment values are set.

OK

Adjustment gradation setting (point 2 = 66 gradation adjustment*)

LEV20264

Pattern display

Adjustment values are set.

OK

Correction of G value

MG2GXXXX

When G is changed at gradation 6, calculate the ratio of the

change and set the following value to XXXX: (the value set with

LEV2)x2x(theratio).

Start measurement

Repeat until RGB

become the target

values.

Adjustment values are set.

OK

Adjust RB to the target xy values.

MG2RXXXX

MG2BXXXX

* XXXX indicates the adjusted values between 0000 and 1023

(4 digit decimal number with zero fill).

* G is fixed.

* The default adjustment value of RGB is the parameter value of

the LEV2 command multiplied by 2.

The adjustment value is

reflected in the image.

Adjustment values are set.

OK

Adjustment gradation setting (point 1 = 50 gradation adjustment*)

LEV10200

Pattern display

Adjustment values are set.

OK

Correction of G value

MG1GXXXX

When G is changed at gradation 6, calculate the ratio of the

change and set the following value to XXXX: (the value set with

LEV1)x2x(theratio).

5 – 10

Adjustment values are set.

OK

Page 26

LC-32D50U

Start measurement

Repeat until RGB

become the target

values.

PC Set

Adjust RB to the target xy values.

MG1RXXXX

MG1BXXXX

* XXXX indicates the adjusted values between 0000 and 1023

(4 digit decimal number with zero fill).

* G is fixed.

* The default adjustment value of RGB is the parameter value of

the LEV1 command multiplied by 2.

The adjustment value is

reflected in the image.

Adjustment values are set.

OK

Writing of adjusted values

MSET0003

Writing is complete.

OK

Deleting adjustment patterns

MSET0000

Deletion is complete.

OK

Completion of adjustment

2.7. Initialization to factory settings

After the shipping setting, pull off the AC cord.

NOTE: Never turn on the power after the shipping setting. If power is turned on, perform the shipping setting again.

Adjustment item Adjustment conditions Adjustment procedure

1 Initialization It turns off with AC power supply. Place the cursor on the [INDUSTRY INIT] row, set "ON" with

[+] or [-] of the [VOL] key, and press the [ENT] key.

Version confirmation screen appears.

[SUCCESS] on a green line indicates that the setting is successfully completed.

(In case of an error, [ERROR] and an error code appear on

a red line.)

Turn off the AC power.

1. User setting

2. Channel data (e.g. broadcast frequencies)

3. Password data

4. Operation time

5. Auto installation flag

6. V-CHIP block setting

5 – 11

Page 27

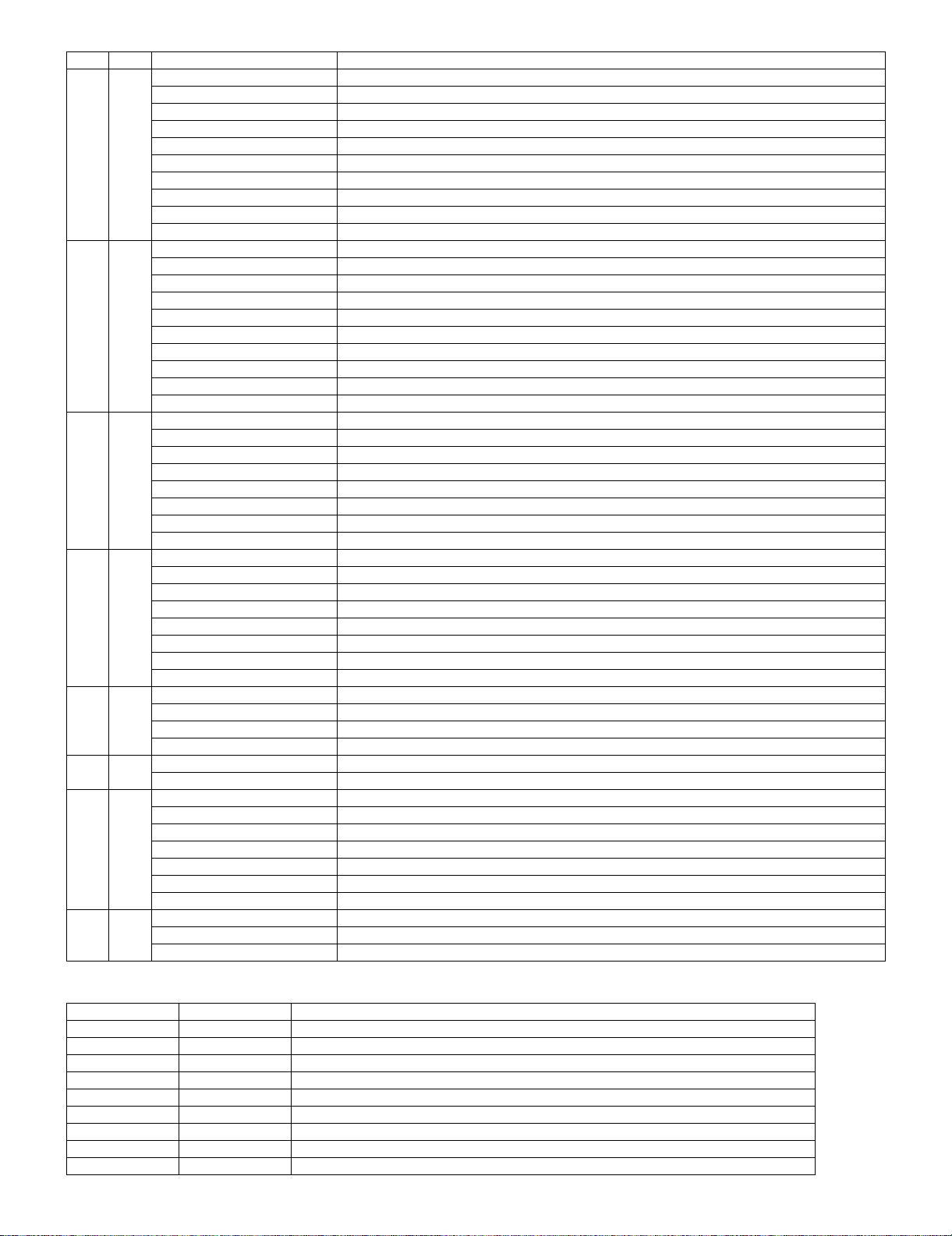

2.8. Menu list in process A mode

Page Line Item

1 MAIN Version Main microcomputer software version

BOOT Version

Monitor Version Monitor microcomputer software version

EQ DATA CHECKSUM Sound parameter checksum

TEMPERATURE Read value of temperature sensor

LAMP ERROR Number of lamp error

NORMAL STANDBY CAUSE Reasons of standby at normal time

ERROR STANDBY CAUSE Reasons of standby in the event of error

2 INDUSTRY INIT(+Cause) Initialization to factory settings(including clearing Sandby Cause data)

INDUSTRY INIT Initialization to factory settings

HOTELMODE Activate/deactivate the hotel mode

Center Acutime Main microcomputer operating time

RESET Reset main microcomputer operating time

Lamp error rest

BacklightAcutime Backlight lighting time

RESET Reset backlight lighting time

LAMP ERROR RESET

VIC XPOS x-coordinate for reading image data

VIC YPOS y-coordinate for reading image data

VIC COLOR Specification of color for reading image data

VIC SIGNAL TYPE Specification of signal for reading image data

VIC READ On/Off of image data read operation

LC-32D50U

3 N358 ALL ADJ Auto adjustment of NTSC and TUNER signals

N358 MAIN ADJ Auto adjustment of NTSC signal

TUNER DAC ADJ Auto adjustment of TUNER

N358 MAIN CONTRAST NTSC contrast adjustment

TUNER A DAC TUNER DAC adjustment

4 TUNER VCHIP TEST(69ch) Execute TUNER TEST

TUNER VCHIP TEST(7ch)

TUNER VCHIP TEST(10ch)

TUNER VCHIP TEST(15ch)

5 COMP15K MAIN ADJ Auto adjustment of component 15k

COMP15K MAIN CONTRAST Component 15k contrast adjustment

6 HDTV ADJ HDTV auto adjustment

CONTRAST HDTV contrast adjustment

Cb GAIN HDTV CB gain adjustment

Cr GAIN HDTV CR gain adjustment

HDTV Y OFFSET HDTV Y offset adjustment

HDTV Cb OFFSET HDTV CB offset adjustment

HDTV Cr OFFSET HDTV CR offset adjustment

7 DVI ANALOG DVI ANALOG adjustment

R CUTOFF R CUTOFF adjustment value

G CUTOFF G CUTOFF adjustment value

B CUTOFF B CUTOFF adjustment value

R DRIVE R DRIVE adjustment value

G DRIVE G DRIVE adjustment value

B DRIVE B DRIVE adjustment value

8 MONITOR GAMMA IN 1 White balance adjustment IN-Point1

MONITOR GAMMA IN 2 White balance adjustment IN-Point2

MONITOR GAMMA IN 3 White balance adjustment IN-Point3

MONITOR GAMMA IN 4 White balance adjustment IN-Point4

MONITOR GAMMA IN 5 White balance adjustment IN-Point5

MONITOR GAMMA IN 6 White balance adjustment IN-Point6

GAMMA WRITE Write adjustment values

GAMMA RESET Reset adjustment values

5 – 12

Page 28

LC-32D50U

Page Line Item

9 MONITOR GAMMA R 1 White balance adjustment OUT R-Point1

MONITOR GAMMA G 1 White balance adjustment OUT G-Point1

MONITOR GAMMA B 1 White balance adjustment OUT B-Point1

MONITOR GAMMA R 2 White balance adjustment OUT R-Point2

MONITOR GAMMA G 2 White balance adjustment OUT G-Point2

MONITOR GAMMA B 2 White balance adjustment OUT B-Point2

MONITOR GAMMA R 3 White balance adjustment OUT R-Point3

MONITOR GAMMA G 3 White balance adjustment OUT G-Point3

MONITOR GAMMA B 3 White balance adjustment OUT B-Point3

GAMMA WRITE Write adjustment values

GAMMA RESET Reset adjustment values

10 MONITOR GAMMA R 4 White balance adjustment OUT R-Point4

MONITOR GAMMA G 4 White balance adjustment OUT G-Point4

MONITOR GAMMA B 4 White balance adjustment OUT B-Point4

MONITOR GAMMA R 5 White balance adjustment OUT R-Point5

MONITOR GAMMA G 5 White balance adjustment OUT G-Point5

MONITOR GAMMA B 5 White balance adjustment OUT B-Point5

MONITOR GAMMA R 6 White balance adjustment OUT R-Point6

MONITOR GAMMA G 6 White balance adjustment OUT G-Point6

MONITOR GAMMA B 6 White balance adjustment OUT B-Point6

GAMMA WRITE Write adjustment values

GAMMA RESET Reset adjustment values

11 AUDIO SELECT Select sound parameter data(ROM/EEP)

INPUT_TRIM_SP

INPUT_TRIM_HP

CLIPPER_LEVEL

ANGLE

MASTER_VOLUME

SCART_PRESCALE

FM_AM_PRESCALE

I2S1_PRESCALE

SCART1_VOLUME

SCART2_VOLUME

12 AIN1_ADC_VOLUME

AIN2_ADC_VOLUME

AIN3_ADC_VOLUME

AIN4_ADC_VOLUME

AIN5_ADC_VOLUME

AIN6_ADC_VOLUME

13 SUB_VOLUME_SURROUND

SUB_VOLUME_FLAT

SUB_VOLUME_EQ

SUB_VOLUME_HP

SUB_VOLUME_HP_CENTER

SP

SUB_VOLUME_CENTERSP_

EQ

SUB_VOLUME_CENTERSP_

FLAT

BBE_HF_ADJUST

BBE_LEVEL

BBE_MACH3_F0

BBE_MACH3_Q

BBE_MACH3_GAIN

14 EQ_MODE

PEQ1_F0

PEQ1_Q

PEQ1_GAIN

PEQ2_F0

PEQ2_Q

5 – 13

Page 29

Page Line Item

14 PEQ2_GAIN

PEQ3_F0

PEQ3_Q

PEQ3_GAIN

PEQ4_F0

PEQ4_Q

PEQ4_GAIN

15 PEQ5_F0

PEQ5_Q

PEQ5_GAIN

EALA_GAIN

16 BRIGHTNESS DA0

BRIGHTNESS DA1

BRIGHTNESS DA2

BRIGHTNESS DA3

BRIGHTNESS DA4

BRIGHTNESS DA5

BRIGHTNESS DA6

BRIGHTNESS DA7

BRIGHTNESS DA8

BRIGHTNESS DA9

BRIGHTNESS DA10

BRIGHTNESS DA11

LC-32D50U

17 BRIGHTNESS DA12

BRIGHTNESS DA13

BRIGHTNESS DA14

BRIGHTNESS DA15

BRIGHTNESS DA16

BRIGHTNESS DA17

BRIGHTNESS DA18

BRIGHTNESS DA19

BRIGHTNESS DA20

BRIGHTNESS DA21

BRIGHTNESS DA22

18 BRIGHTNESS DA23

BRIGHTNESS DA24

BRIGHTNESS DA25

BRIGHTNESS DA26

BRIGHTNESS DA27

BRIGHTNESS DA28

BRIGHTNESS DA29

BRIGHTNESS DA30

BRIGHTNESS DA31

BRIGHTNESS DA32

19 OPC33 ADLEVEL 0

OPC33 ADLEVEL 1

OPC33 ADLEVEL 2

OPC33 ADLEVEL 3

OPC33 ADLEVEL 4

OPC33 ADLEVEL 5

OPC33 ADLEVEL 6

OPC33 ADLEVEL 7

OPC33 ADLEVEL 8

OPC33 ADLEVEL 9

OPC33 ADLEVEL 10

OPC33 ADLEVEL 11

20 OPC33 ADLEVEL 12

OPC33 ADLEVEL 13

5 – 14

Page 30

LC-32D50U

Page Line Item

20 OPC33 ADLEVEL 14

OPC33 ADLEVEL 15

OPC33 ADLEVEL 16

OPC33 ADLEVEL 17

OPC33 ADLEVEL 18

OPC33 ADLEVEL 19

OPC33 ADLEVEL 20

OPC33 ADLEVEL 21

OPC33 ADLEVEL 22

21 OPC33 ADLEVEL 23

OPC33 ADLEVEL 24

OPC33 ADLEVEL 25

OPC33 ADLEVEL 26

OPC33 ADLEVEL 27

OPC33 ADLEVEL 28

OPC33 ADLEVEL 29

OPC33 ADLEVEL 30

OPC33 ADLEVEL 31

22 V6 OS THERMO 1

V6 OS THERMO 2

V6 OS THERMO 3

V6 OS THERMO 4

V6 OS THERMO 5

V6 OS THERMO 6

V6 OS THERMO 7

23 V5 OS THERMO 1

V5 OS THERMO 2

V5 OS THERMO 3

V5 OS THERMO 4

V5 OS THERMO 5

V5 OS THERMO 6

V5 OS THERMO 7

24 MONITOR TIME OUT

MONITOR MAX TEMP

MONITOR STANDBY CAUSE

25 LCD TEST PATTERN

26 KEY LOCK(1217)

KOUTEI AREA ALL CLEAR

A MODE AREA CLEAR

BACKUP AREA CLEAR

B MODE AREA CLEAR

EXECUTION

27 EEP SAVE

EEP RECOVER

STANDBY CAUSE RESET

2.9. Code list for St andby Cause

Code Indication Description

1 RC_STNBY /* Standby set by remote control */

2 E_CCKMVT /* Abnormal voltage of CCKM line detected */

5 OUT_OF_R "/* While a PC display is on, unspecified input continued long time. */"

6 NO_OPERT /* Off caused by no operation */

7 NO_SIGNA /* Off caused by no signal */

8 PC_MODE1 /* Set by the PC power management mode 1 */

9 PC_MODE2 /* Set by the PC power management mode 2 */

A SLEEP_TM /* Set by off timer */

B E_NOMONI /* Incompatible monitor is connected to the AVC center. */

5 – 15

Page 31

Code Indication Description

C OFF_232C /* Set by the command from RS232C */

E AVC_TACT /* Set by the front switch at the AVC center */

F BSBOOKED /* The pre-set time has passed since TV was turned on from standby by the BS timer. */

10 E_AVCFAN /* Fan failure at the AVC center */

11 E_BSSUBM /* Communication failure with the BS sub microcomputer (Not used) */

12 E_CVICIC /* CVIC failure */

13 E_AVCTMP /* Abnormal temperature at the AVC center */

14 E_1BITAU /* 1Bit-AMP failure */

15 E_MONIPW /* Monitor main power failure detected */

16 E_MONITR /* Monitor problem detected */

17 E_FNLOCK /* Fan lock for North America */

40 /* Failure in Digital Standby */

LC-32D50U

5 – 16

Page 32

LC-32D50U

1

LC-32D50U

CHAPTER 6. TROUBLESHOOTING TABLE

Service Manual

[1] TROUBLESHOOTING TABLE

<Power supply>

No power supply (Front LED does not light up) and no power-up even is turned on (Front LED light up to blue)

Is the AC cord connected? NO Connect the AC cord and turn on the power.

YES

Are the harness and FFC connected properly? NO Connect the harness and FFC properly.

YES

Are F701 normal?

YES

Is the voltage of C4701/C4702/C4703 approx.

160V?

NO

NO Check if VZ701, R701, R702, R703 and DS4701 are normal.

If the fuse is blown when turning on the power after replacing F701, replace

VZ701, DS4701, F4701/F4702, F5701, Q4701/Q4702, Q5701, IC4701 and

IC5701, then recheck.

YES

Is BU5V supplied? NO

Do the primary side and secondary side of T5701 oscillate normally?

YES

Are F5702, D5705, IC5706 and D5717 out

of order?

Are there defective parts on the

primary side? Is the output on the

NO

secondary side short-circuited?

YES

Are UR6V/UR10V/UR13V supplied? NO Does PS_ON (pin 1 of CN5702) become High (approx. 3.3V)?

YES

Check the regulator circuit of UR6V, rectifier

circuit of UR13V and DC/DC circuit of

Is the unit set to STANDBY

MODE2? Is the main unit normal?

NO

UR10V.

YES

Is 24V supplied? NO Do the primary side and secondary side of T4701 oscillate normally?

YES NO

Are D4705/D4706 out of order? Are there defective parts on the

primary side? Is the output on the

secondary side short-circuited?

YES

Is PNL5V supplied? NO Does PNL_POW (pin 4 of CN5702) become High (approx. 3.3V)?

YES

Check the DC/DC circuit of PNL5V? Is the main unit normal?

Turn on the power again, and check if the unit

works normally.

Remarks

State of the set

STDBY

MODE1 High High 5V 6V 10V 13V 5V 24V

MODE2LowLow5V-----

PS_ON

(CN5702 )

1

PNL_POW

(CN5702 )

4 5

BU5V

(CN5702 )

UR6V

(CN5701 )

1

UR10V

(CN5701 )

7

UR13V

(CN5701 )

11

(CN5701 )

PNL5V

3

(CN5703 )

24V

Power ON High High 5V 6V 10V 13V 5V 24V

6 – 1

Page 33

No audio output during UHF/VHF reception

Is Video output during UHF/VHF reception normal? NO Check the tuner and RF-SW (UNT 501)

YES

Is SIF output from the tuner (TU1101_Pin3) normal? NO Check the tuner and peripheral circuits.

YES

Is input signal fed to pin 21 (SOUNDIF 1) of IC1401 (SIF Demodulator) normal?

YES

Are audio signals from pins 29 and 30 (SC2_OUTL/R) of IC1401

to pins 51 and 52 of IC1403 (CODEC) normal?

YES

Are audio outputs (A-OUT_L/R) of pins 38 and 39 of IC1403 nor-

mal?

YES

Is audio input from pins 38 and 39 of IC1403 to pins 11 and 15 of

IC2701(STEREO_AMP) normal?

NO Check the filter circuits (Q1144 and Q1102-3) and peripheral cir-

cuits.

NO Check between pins 29 and 30 (SC2_OUTL/R) of IC1401 and

pins 51 and 52 of IC1403 (CODEC).

NO Are the LRCK, BICK, SDTO and SDTI signals sent from IC1403

to IC1406 (DSP) normally?

YES

Check IC1403 and peripheral circuits.

NO Check the circuits between pins 38 and 39 of IC1403 and pins 1 1

and 15 of IC2701. (MUTE circuits: Q1306-8)

LC-32D50U

YES

Is audio output from IC2701 normal? NO Check IC2701 and peripheral circuits.

YES

Is the speaker switching circuit (T2701)

YES

Check the connector (P2703) of AV_UNIT and around the speakers.

No monitor audio output

Is monitor audio output set to "Variable"? YES Reset monitor audio output to "Fixed".

NO

Are audio output pins 40 and 41 of IC1403 (CODEC) normal? NO Check IC1403 and peripheral circuits.

YES

Are audio output pins 7 and 1 of IC1407 (Buffer_AMP) normal? NO Check IC1407 and peripheral circuits.

YES

Check between IC1407 and MONITOR OUTPUT terminal (pins

10 and 16 of J502).

6 – 2

Page 34

LC-32D50U

No audio output from external input

<<INPUT-1>>

Is L-ch audio signal fed from pin 12 of input terminal J501 to pin 53 of IC1403?

Is R-ch audio signal fed from pin 18 of input terminal J501 to pin 54 of IC1403?

<<INPUT-2>>

Is L-ch audio signal fed from pin 10 of input terminal J501 to pin 57 of IC1403?

Is R-ch audio signal fed from pin 16 of input terminal J501 to pin 58 of IC1403?

<<HDMI>> [INPUT-3/INPUT4 (Digital audio mode)]

Is digital audio signal (HDMI_SPDIF) fed from pin 70 of IC1508 to pin 2 of IC1401?

<<HDMI>> [INPUT-4 (Analog audio mode)]

Is L-ch audio signal fed from pin 3 of input terminal J1501 to pin 59 of IC1403?

Is R-ch audio signal fed from pin 2 of input terminal J1501 to pin 60 of IC1403?

<<INPUT-5>>

Is L-ch audio signal fed from pin 2 of input terminal J1502 to pin 55 of IC1403?

Is R-ch audio signal fed from pin3 of input terminal J1502 to pin 56 of IC1403?

YES

No audio output during digital broadcasting reception

Are the I2S signals MCLK, SCLK, LRCK, and DATA sent

from pins N22, N19, N21 and M20 of IC8101 (PH1) normally?

NO

Check around IC8101 PH1.

YES

Are input signals of pins 24 (MCLK), 11 (SCLK), 10

(LRCK), 32 (DATA) of IC1403 normal?

YES

Are audio signals from pins 29 and 30 (SC2_OUTL/R) of IC1401

to pins 51 and 52 of IC1403 (CODEC) normal?

YES

Are audio outputs (A-OUT_L/R) of pins 38 and 39 of IC1403 normal?

YES

Is audio input from pins 38 and 39 of IC1403 to pins 11 and 15 of

IC2701(STEREO_AMP) normal?

YES

Is audio output from IC2701 normal? NO Check IC2701 and per ipheral circuits.

YES

Is the speaker switching circuit (T2701)

NO Check the circuits between pins N22, N19, N21 and M20 of

IC8101 PH1 and pins 24, 11, 10 and 32 of IC1403.

NO Check between pins 29 and 30 (SC2_OUTL/R) of IC1401 and

pins 51 and 52 of IC1403 (CODEC).

NO Are the LRCK, BICK, SDTO and SDTI signals sent from IC1403

to IC1406 (DSP) normally?

YES

Check IC1403 and peripheral circuits.

NO Check the circuits between pins 38 and 39 of IC1403 and pins 1 1

and 15 of IC2701. (MUTE circuits: Q1306-8)

YES

Check the connector (P2703) of AV_UNIT and around the speakers.

6 – 3

Page 35

LC-32D50U

<Composite video signal input> No video output (1)

No video output from external input <<INPUT-1>> Select INPUT-1 and the input signal on the input switching menu

screen.

Is INPUT-1 selected on the input switching menu screen? NO When INPUT-1 cannot be selected since the characters INPUT-1

on the menu screen are gray.

Is the video signal detection function normal?

YES

Is video signal fed to pin 65 of IC501 (AV SWITCH)? NO Check between pin 4 of J501 and pin 65 of IC501.

YES

Is video signal sent to pin 60 of IC501? NO Check IC501 (AV SWITCH) and peripheral circuits.

YES

Is video signal sent to pin 2 of IF_UNIT connector (FC_SC501)? NO Check between IC501 and SC501. (Q501, Q502, etc.)

Check between pin 5 of J501 and pin 70 of IC501.

YES

Is video signal fed to pin 2 of MAIN_UNIT connector

(FC_SC1101)?

YES

Is video signal fed to pin 242 of IC3301 (Trident) via L.P.F. composed of Q2201 and Q2207?

YES

Are digital video (LVDS) signals sent from pins 28-31 and 34-37

of IC3301?

YES

Check LCD_CONTROL PWB.

NO Check the board-to-board cable "FC".

NO Check between IC501 and IC3301. (Q2201, Q2207, etc.)

NO Check IC3301 and peripheral circuits.

6 – 4

Page 36

LC-32D50U

<Composite video signal/S-video signal input> No video output (2)

No video output from external input <<INPUT-2>> Select INPUT-2 and the input signal on the input switching menu

screen.

Is INPUT-2 selected on the input switching menu screen? NO When INPUT-2 cannot be selected since the characters INPUT-3

on the menu

Is the video signal detection function normal?Check between pin

2 of J501and pin 2 of IC501.

Is the S-video signal detection function normal?Check between

YES

Is signal fed to each input terminal of IC501 (AV SWITCH)?

<Composite video signal input>

Is video signal fed to pin 3 of IC501?

NO Check between pin 1 of J501 and pin 3 of IC501.

pin 6 of J503 and pin 6 of IC501.

<S-video signal input>

Are Y and C signals fed to pins 5 and 7 of IC501 respectively?

YES

<Composite video signal input>

Is video signal sent to pin 60 of IC501?

<S-video signal input>

Are Y and C signals sent to pins 60 and 59 of IC501 respectively?

YES

<Composite video signal input>

Is video signal sent to pin 2 of IF_UNIT connector (FC_SC501)?

<S-video signal input>

Are Y and C signals sent to pins 2 and 4 of IF_UNIT connector

(FC_SC501) respectively?

YES

<Composite video signal input>

Is video signal fed to pin 2 of MAIN_UNIT connector

(FC_SC1101)?

<S-video signal input>

Are Y and C signals fed to pins 2 and 4 of MAIN_UNIT connector

(FD_SC1101) respectively?

YES

<Composite video signal input>

Is video signal fed to pin 242 of IC3301 (Trident) via L.P.F. com-

posed of Q2201 and Q2207?

<S-video signal input>

Are Y and C signals fed to pins 242 and 231 of IC3301 (Trident)

via L.P.F. composed of Q2201 and Q2207 and via L.P.F. composed of Q2205 and Q2209 respectively?

NO Check between pins 3 and 4 of J503 and pins 5 and 7 of IC501.

NO Check IC501 (AV SWITCH) and peripheral circuits.

NO Check between IC501 and SC501. (Q501, Q502, Q503, Q504,

etc.)

NO Check the board-to-board cable "FC".

NO Check between SC1101and IC3301. (Q2201, Q2207, etc.)/

(Q2205, Q2209, etc.)

YES

Are digital video (LVDS) signals sent from pins 28-31 and 34-37

of IC3301?

YES

Check LCD_CONTROL PWB.

NO Check IC3301 and peripheral circuits.

6 – 5

Page 37

LC-32D50U

No video output during digital broadcasting reception

Is video signal sent to output terminal pin 4 of tuner (TU1101)? NO Check or replace the tuner's peripheral circuits.

YES

Is video signal fed to pin 7 of IC1103 (LEVEL ADJ)? NO Is control signal for level adjustment fed from pin 1 of IC1104 to

YES

Is video signal fed to pin 244 of IC3301 (Trident) via L.P.F. composed of Q2204 and Q2208?

YES

Are digital video (LVDS) signals sent from pins 28-31 and 34-37

of IC3301?

YES

Check LCD_CONTROL PWB.

NO Check IC3301 and peripheral circuits.

pin 6 of IC1103?

NO

Check or replace IC1104 (CONTROL) and peripheral circuits.

NO

Check between IC1103 and IC3301. (Q2204 ,Q2208, etc.)

6 – 6

Page 38

LC-32D50U

<Component video signal input> No video output (3)

No video output from external input <<INPUT-1>>

Is INPUT-1 selected on the input switching menu screen? NO Select INPUT-1 and the input signal on the input switching menu

screen.

When INPUT-1 cannot be selected since the characters INPUT-1

on the menu screen are gray.

Is the component video signal detection function normal? Check

between pin 8 of J501 and pin 38 of IC501.

YES

Are component video signals fed to pins 21, 23 and 25 (Y, PB

and PR) of IC501(AV SWITCH)?

YES

Are Y, PB and PR signals sent to pins 60, 59 and 58 of IC501

respectively?

YES

Are component video signals sent to pins 2, 4 and 6 of IF_UNIT

connector (FC_SC501)?

NO Check between J1501 and each input pin of IC501.

NO Check IC501 and peripheral circuits.

NO Check between IC501 and SC501. (Q501-Q506, etc.)

YES

Are component video signals fed to pins 2, 4 and 6 of

MAIN_UNIT connector (FC_SC1101)?

YES

Are Y, Pb and Pr signals fed to pins 246, 232 and 225 of IC3301

(Trident) respectively?

YES

Are digital video (LVDS) signals sent from pins 28-31 and 34-37

of IC3301?

YES

Check LCD_CONTROL PWB.

NO Check the board-to-board cable "FC".

NO Check between SC1101 and IC3301. (Q2202, Q2203, Q2206,

etc.)

NO Check IC3301 and peripheral circuits.

6 – 7

Page 39

No video output from HDMI input (INPUT3)

LC-32D50U

INPUT3

Are signals fed from HDMI (SC1501) connector to input terminals

H_RX0± (pins 51 and 52), H_RX1± (pins 54 and 55), H_RX2±

(pins 57 and 58) and H_RXC± (pins 48 and 49) of IC1507

(TMDS_SW)?

YES

Are signals fed from IC1507 (TMDS_SW) to input terminals

H_RX0± (pins 54 and 55), H_RX1± (pins 58 and 59), H_RX2±

(pins 61 and 62) and H_RXC± (pins 50 and 51) of IC1508

(HDCP_LSI)?

YES

Are R/G/B and CLK/H/V/Data Enable signals sent from pins 9296, 99-105,108-111, 114-117, 121-124, 119 and 127-129 of

IC1508(HDCP_LSI)?

YES

Are digital video (LVDS) signals sent from pins 28-31 and 34-37

of IC3301(Trident)?

NO

NO Check IC1507 (TMDS_SW) and peripheral circuits.

NO Check IC1508 (HDCP_LSI) and peripheral circuits.

NO Check peripheral circuits of IC3301.

Is IC1501 (E

device and is DDC_I2C_CLOCK/DATA data read out?

Check the setting of HDMI device.

For INPUT4, pin 21 is Low and pin 22 is High.

For INPUT5, pins 21 and 22 are Low and pin

2

PROM) accessed with I2C when connecting HDMI

Check IC1501 and peripheral circuits.

Are cables connected securely?

YES

NO

YES

Check LCD_CONTROL PWB.

When using an old HDMI transmission device, some video formats cannot be selected or no sound is heard. Since this model conforms to the latest

HDMI standard, the HDMI transmission device does not recognize the data of the latest version correctly. It is necessary to upgrade its firmware.

Download the latest firmware from the website of each manufacturer, or contact the customer service center of each manufacturer.

6 – 8

Page 40

LC-32D50U

No video output from HDMI input (INPUT4)

INPUT4

Are signals fed from HDMI (SC1502) connector to input terminals

H_RX0± (pins 70 and 71), H_RX1± (pins 73 and 74, H_RX2±

(pins 76 and 77) and H_RXC± (pins 67 and 68) of IC1507

(TMDS_SW)?

YES

Are signals fed from IC1507 (TMDS_SW) to input terminals

H_RX0± (pins 54 and 55), H_RX1± (pins 58 and 59), H_RX2±

(pins 61 and 62) and H_RXC± (pins 50 and 51) of IC1508

(HDCP_LSI)?

YES

Are R/G/B and CLK/H/V/Data Enable signals sent from pins 9296, 99-105,108-111, 114-117, 121-124, 119 and 127-129 of

IC1508 (HDCP_LSI)?

YES

Are digital video (LVDS) signals sent from pins 28-31 and 34-37

of IC3301 (Trident)?

NO

NO Check IC1507 (TMDS_SW) and peripheral circuits.

NO Check IC1508 (HDCP_LSI) and peripheral circuits.

NO Check peripheral circuits of IC3301.

Is IC1502 (E

device and is DDC_I2C _CLOCK/DATA data read out?

Check the setting of HDMI device.

For INPUT4, pin 21 is Low and pin 22 is High.

For INPUT5, pins 21 and 22 are Low and pin

2

PROM) accessed with I2C when connecting HDMI

NO

Check IC1502 and peripheral circuits.

Are cables connected securely?

YES

YES

Check LCD_CONTROL PWB.

When using an old HDMI transmission device, some video formats cannot be selected or no sound is heard. Since this model conforms to the latest

HDMI standard, the HDMI transmission device does not recognize the data of the latest version correctly. It is necessary to upgrade its firmware.

Download the latest firmware from the website of each manufacturer, or contact the customer service center of each manufacturer.

6 – 9

Page 41

LC-32D50U

No video output from DVI input (INPUT 5)

DIGITAL mode Analog mode

Are signals fed from DVI (SC1503) connector to input terminals H_RX0± (pins 8 and

9), H_RX1± (pins 11 and 12), H_RX2±

(pins 14 and 15) of IC1507 (TMDS-SW)?

YES

Are signals fed from IC1507 (TMDS_SW) to input terminals H_RX0± (pins 54 and 55), H_RX1± (pins 58 and 59),

H_RX2± (pins 61 and 62) and H_RXC± (pins 50 and 51)

of IC1508 (HDCP_LSI)?

YES

Are R/G/B and CLK/H/V/Data Enable signals sent from

pins 92-96, 99-105,108-111, 114-117, 121-124, 119 and

127-129 of IC1508(HDCP_LSI)?

NO IS IC1505 (E2PROM) accessed with I2C

when connecting HDMI device and is

DDC_I2C_CLOCK/DATA data read out?

YES

NO

Check IC1505 and peripheral circuits.Are cable connected

securely?

Check the setting of DVI Device. Check LCD_C ONTROL PWB.

NO Check IC1507 (TMDS_SW) and peripheral circuits.For INPUT4, pin 21

is Low and pin 22 is High.For INPUT5, pins 21 and 22 are Low and pin

NO Check IC1508 (HDCP_LSI) and peripheral circuits.

Are signal fed from pins 25, 26, 27 (Analog-R/G/B), and 28, 8 (H Sync/V Sync) of

input terminal (SC1503) to pins 226, 248,

233, 10, 11 of IC3301 (Video PROCESSOR)?

YES

NO

Check peripheral circuits of

IC3301.

YES

Are digital video (LVDS) signals sent from pins 28-31 and

34-37 of IC3301 (Trident)?

YES

Check LCD_CONTROL PWB.

When using an old HDMI transmission device, some video formats cannot be selected or no sound is heard. Since this model conforms to the latest

HDMI standard, the HDMI transmission device does not recognize the data of the latest version correctly. It is necessary to upgrade its firmware.

Download the latest firmware from the website of each manufacturer, or contact the customer service center of each manufacturer.

[ FRONT-END SECTION]

Digital broadcasting cannot be received.

Are US_TS_CLK/PKTSYNC/DATA signal supplied to pin (51), (59), (66) of

IC8601 respectively?

YES NO

Check the IC8101 and its peripheral circuits.

NO Are IF_OUT_P/N signal send from

NO Check peripheral circuits of IC3301.

pin (20), (21) of TU1101 respectively?

Check the TU1101.

YES Check IC8601 and its peripheral cir-

cuits.

6 – 10

Page 42

LC-32D50U

1sec

250ms

LED flashing timing chart for error notification

1) Red power LED Remarks

Pins are monitor microprocessor pins.

L_FL_ERR (pin 73): Abnormal L. Confirmed after 5 consecutive detections at 1 second intervals (detected only when the backlight is on).

H: On

Error type Power red LED operation (1 cycle)

Note that after five detection counts, the lamp cannot be activated except in the monitoring process. (For the first time, only the inverter is reset, and error OFF is not activated)

Accumulated counts are cleared to 0 when the corresponding setting in the process A is made, when the power is turned on with [CH_DOWN] and [VOL_UP] on the unit down or after continuous illumination for 3 minutes.

Refer to "Power failure details".

L: Off

H: On

Lamp failure

Flashes once: Fast

L: Off

Power failure

Flashes twice

Refer to "Communication failure details".

Communication line failure or main CPU communication failure > Check debug statements for the main CPU.

H: On

communication failure

with main CPU

L: Off

Flashes 3 times

VSYNC (pin 48) failure (uninput). Trident_IC operation failure.

H: On

Vsync

Trident failure

Detected during operation (interruption)

If the panel temperature is 60°C or more for 15 seconds or more in a row, CAUTION appears on the OSD of AVC (flashes in red in the lower right screen).

If the panel temperature is 60°C or more for 25 seconds or more in a row, error standby is activated.

L: Off

H: On

Flashes 4 times

Monitor temperature failure

(MONITOR MAX TEMP on process A mode: Change of temperature failure AD value): Thermistor

Remarks

L: Off

Flashes 5 times

2) Power failure details (Power LED flashes twice and OPC LED flashes)

Pins are monitor microprocessor pins unless otherwise specified.

AC_DET (pin 31): Abnormal (L), DET_10V (pin 63). Main converter 13V/UR10V is not applied.

H: On

Error type Power red LED operation (1 cycle)

13V/UR10V failure

PS_ON

6 – 11

If error is detected during operation, error standby is activated by polling.

If error is detected during operation, the power is turned on again by interrupt handling (instantaneous blackout processing).

DET_3V3 (pin 64): Abnormal (L). Main power 3.3V is not applied.

L: Off

H: On

L: Off

Flashes once

Main 3.3V failure

Flashes twice

EU_POW

DET_6V (pin 27): Abnormal 㧔L). UR6V is not applied.

H: On

UR6V failure

D_POW

DET_D3V3 (pin 62): Abnormal 㧔L). Digital 3.3V is not applied.

If error is detected during operation, error standby is activated by polling.

L: Off

H: On

Flashes 3 times

D_POW

If error is detected during operation, error standby is activated by polling.

L: Off

Digital 3.3V failure

Flashes 4 times

Main microprocessor detection error (FAN error, 1bitAMP error, etc.㧕