Page 1

TopPage

LC32D44E/S/RU-BK/GY (1st Eddition)

SERVICE MANUAL

No. S38F8LC32D44E

LCD COLOUR TELEVISION

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

LC-32D44E/S/RU-BK/GY

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRE-

CAUTION ............................................................i

PRECAUTIONS A PRENDRE LORS DE

LA REPARATION...............................................ii

PRECAUTIONS FOR USING LEAD-FREE

SOLDER ........................................................... iii

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS ......................................... 1-1

[2] OPERATION MANUAL .................................. 1-2

[3] DIMENSIONS ................................................ 1-5

CHAPTER 2. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS ................... 2-1

CHAPTER 3. ADJUSTMENT

[1] After replacement of any PWB and/or IC for

repair, note the following. ............................... 3-1

[2] SOFTWARE UPDATING................................ 3-1

[3] Entering and exiting the adjustment pro-

cess mode.................................................... 3-18

[4] Remote controller key operation and de-

scription of display in adjustment process

mode. ........................................................... 3-18

[5] Adjustment process mode menu.................. 3-19

[6] Special features............................................ 3-20

[7] Video signal adjustment procedure.............. 3-21

[8] White Balance Adjustment ........................... 3-22

[9] Adjusting procedure by use of [RS-232C]...... 3-23

[10] Initialization to factory settings.....................3-24

[11] Lamp error detection ...................................3-24

[12] Public Mode (Hotel Mode) ...........................3-25

CHAPTER 4. TROUBLE SHOOTING TABLE

[1] TROUBLE SHOOTING TABLE .....................4-1

CHAPTER 5. MAJOR IC INFORMATIONS

[1] MAJOR IC INFORMATIONS .........................5-1

CHAPTER 6. BLOCK DIAGRAM/OVERALL WIRING

[1] BLOCK DIAGRAM.........................................6-1

[2] SYSTEM BLOCK DIAGRAM .........................6-3

[3] OVERALL WIRING DIAGRAM ......................6-4

CHAPTER 7. PRINTED WIRING BOARD ASSEMBLIES

[1] MAIN Unit ...................................................... 7-1

[2] R/C, LED Unit ................................................7-5

[3] MINI AV Unit ..................................................7-6

[4] KEY ...............................................................7-7

CHAPTER 8. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIA-

GRAM............................................................8-1

[2] SCHEMATIC DIAGRAM ................................8-2

Parts Guide

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC32D44E/S/RU-BK/GY (1st Eddition)

LC32D44E-BK

SAFETY PRECAUTION

Service Manual

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION: F O R C O N TI NU E D PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE.

F7101, F7103 (250V 3.15A)

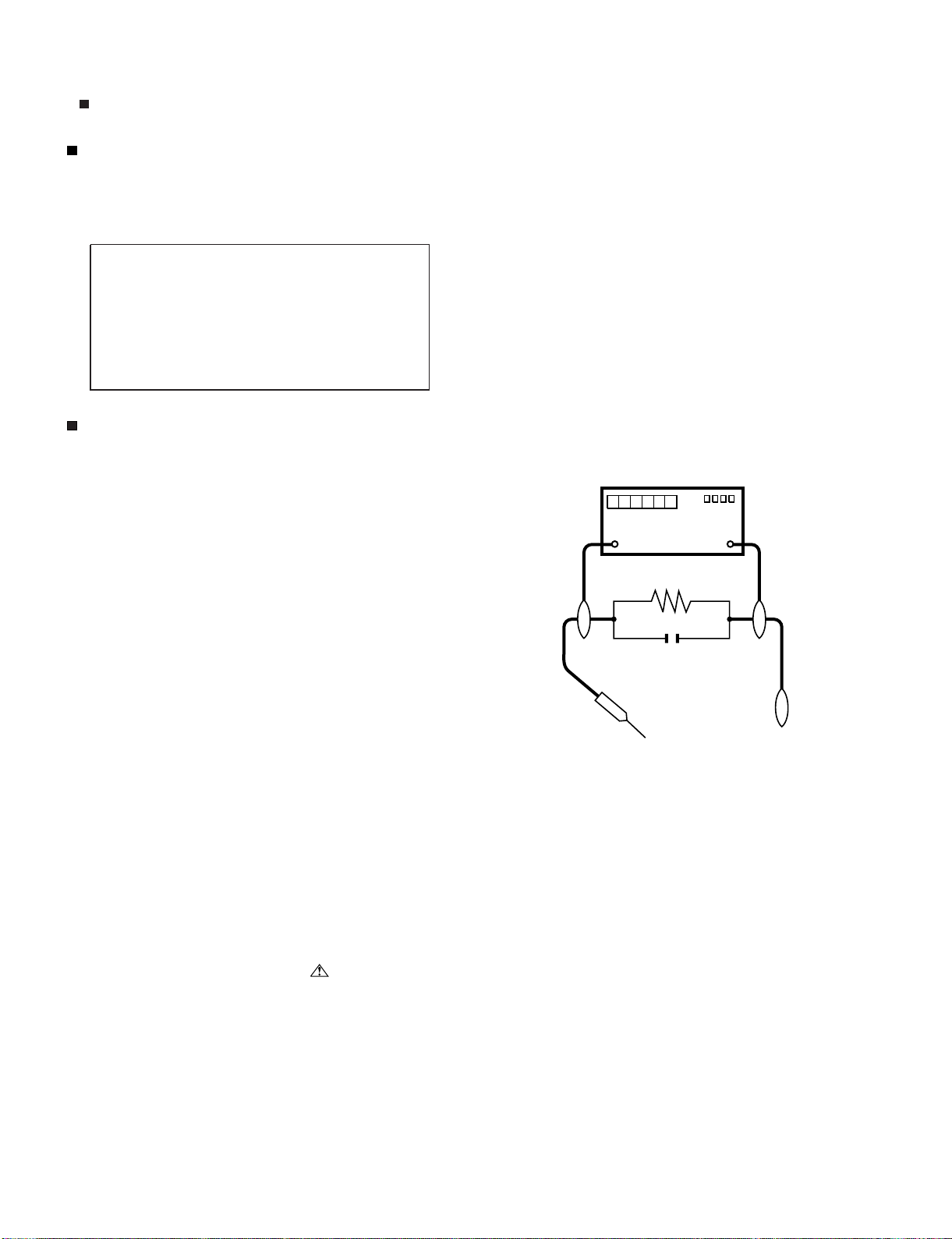

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 1.05 V peak (this corresponds to 0.7 mA peak AC.)

or more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

F7102 (250V 1A)

DVM

AC SCALE

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 220~240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

TO EXPOSED

METAL PARTS

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by “ ” and shaded areas in the Replacement Parts

List and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

i

Page 3

LC32D44E/S/RU-BK/GY (1st Eddition)

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement accoutumé à toute vérification de sécurité et aux

conseils suivants.

•

AVERTISSEMENT

1.

N'entreprendre aucune modification de tout circuit. C'est dangereux.

2.

Débrancher le récepteur avant toute réparation.

PRECAUTION: POUR LA PROTECTION CONTINUE CONTRE LES RISQUES D'INCENDIE,

REMPLACER LE FUSIBLE

F7101, F7103 (250V 3.15A)

F7102 (250V 1A)

VERIFICATIONS CONTRE L'INCEN-DIE ET LE

CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer les vérifications suivantes.

Inspecter tous les faisceaux de câbles pour s'assurer que les fils

3.

ne soient pas pincés ou qu'un outil ne soit pas placé entre le châssis et les autres pièces métalliques du récepteur.

4.

Inspecter tous les dispositifs de protection comme les boutons de

commande non-métalliques, les isolants, le dos du coffret, les couvercles ou blindages de réglage et de compartiment, les réseaux

de résistancecapacité, les isolateurs mécaniques, etc.

5.

S'assurer qu'il n'y ait pas de danger d'électrocution en vérifiant la

fuite de courant, de la facon suivante:

•

Brancher le cordon d'alimentation directem-ent à une prise de courant de 120V. (Ne pas utiliser de transformateur d'isolation pour

cet essai).

A l'aide de deux fils à pinces, brancher une résistance de 1.5 kΩ

10 watts en parallèle avec un condensateur de 0.15µF en série

avec toutes les pièces métalliques exposées du coffret et une terre

connue comme une conduite électrique ou une prise de terre

branchée à la terre.

•

Utiliser un voltmètre CA d'une sensibilité d'au moins 5000Ω/V pour

mesurer la chute de tension en travers de la résistance.

•

Toucher avec la sonde d'essai les pièces métalliques exposées qui

présentent une voie de retour au châssis (antenne, coffret métallique, tête des vis, arbres de commande et des boutons, écusson,

etc.) et mesurer la chute de tension CA en-travers de la résistance.

Toutes les vérifications doivent être refaites après avoir inversé la

fiche du cordon d'alimentation. (Si nécessaire, une prise

d'adpatation non polarisée peut être utilisée dans le but de terminer ces vérifications.)

La tension de pointe mesurèe ne doit pas dépasser 0.75V (correspondante au courant CA de pointe de 0.5mA).

Dans le cas contraire, il y a une possibilité de choc électrique qui

doit être supprimée avant de rendre le récepteur au client.

DVM

ECHELLE CA

1.5k ohm

10W

µ

F

0.15

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

BRANCHER A UNE

TERRE CONNUE

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans les téléviseur ACL présentent des caractéristiques spéciales relatives à la sécurité, qui ne sont souvent pas évidentes à vue. Le degré de protection ne peut pas être nécessairement augmentée en utilisant des

pièces de remplacement étalonnées pour haute tension, puissance,

etc.

Les pièces de remplacement qui présentent ces caractéristiques sont

identifiées dans ce manuel; les pièces électriques qui présentent ces

particularités sont identifiées par la marque " " et hachurées dans la

liste des pièces de remplacement et les diagrammes schématiques.

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Pour assurer la protection, ces pièces doivent être identiques à celles

utilisées dans le circuit d'origine. L'utilisation de pièces qui n'ont pas

les mêmes caractéristiques que les pièces recommandées par l'usine,

indiquées dans ce manuel, peut provoquer des électrocutions, incendies, radiations X ou autres accidents.

ii

Page 4

LC32D44E/S/RU-BK/GY (1st Eddition)

PRECAUTIONS FOR USING LEAD-FREE SOLDER

Employing lead-free solder

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper. Indicates lead-free solder of tin, silver and copper.

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

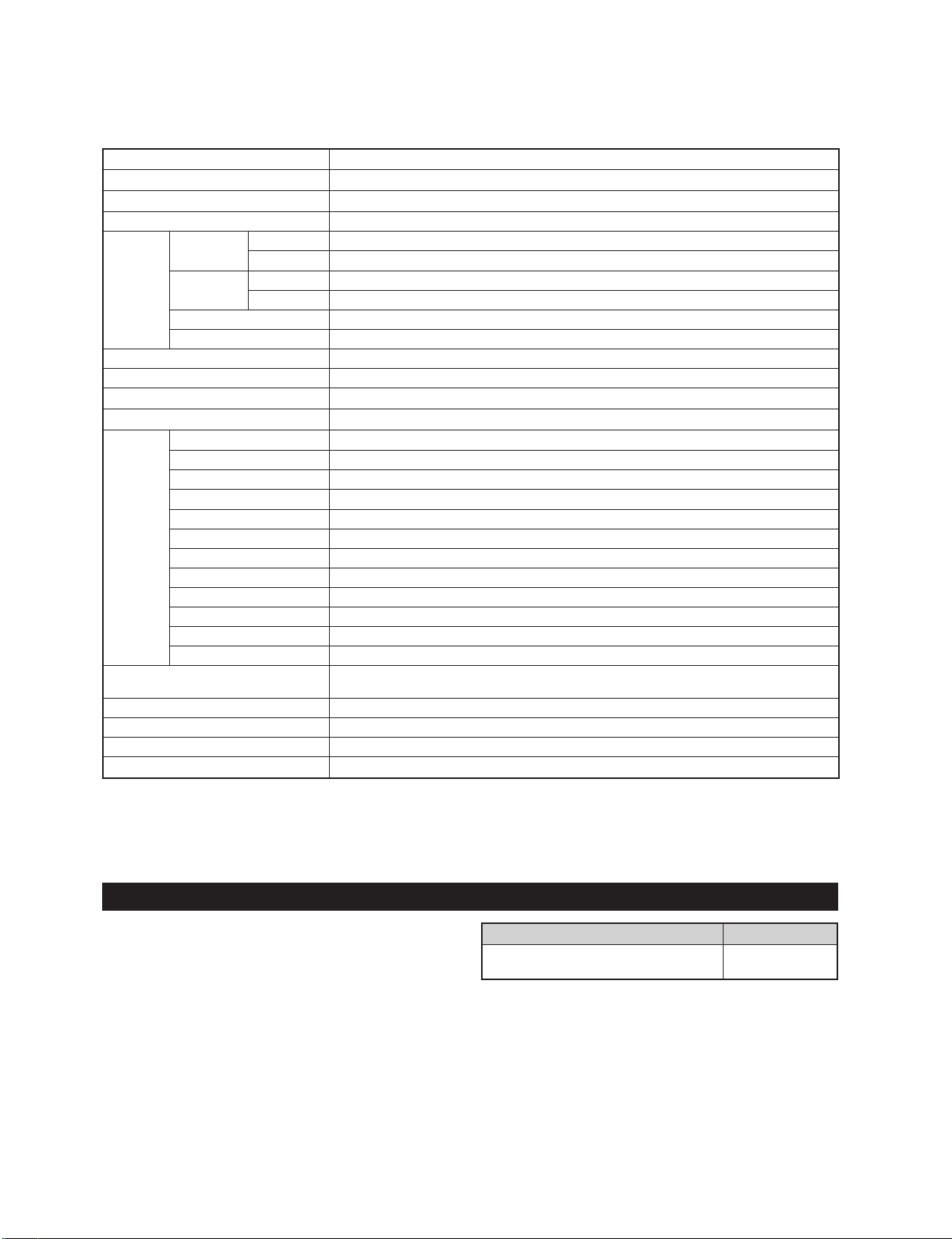

PARTS CODE

ZHNDAi123250E BL J φ0.3mm 250g (1roll)

ZHNDAi126500E BK J φ0.6mm 500g (1roll)

ZHNDAi12801KE BM J φ1.0mm 1kg (1roll)

PRICE

RANK

PART

DELIVERY

DESCRIPTION

iii

Page 5

LC32D44E-BK

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS

LC32D44E/S/RU-BK/GY (1st Eddition)

Service Manual

Item

LCD panel

Resolution

Video Colour System PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

TV

Function

Brightness 450 cd/m2

Viewing angles H : 176° V : 176°

Audio amplifier

Speaker

Terminals Antenna

OSD language English/German/French/Italian/Spanish/Dutch/Swedish/Portuguese/Finnish/Turkish/Greek/

Power Requirement AC 220-240 V,50 Hz

Power Consumption 120 W (0.9 W Standby) (Method IEC60107)

Weight 11.0 kg (Display only), 13.0 kg (Display with stand)

Operating temperature

TV-Standard Analogue CCIR (B/G, I, D/K, L, L’)

Digital DVB-T (2K/8K OFDM)

Receiving

Channel

TV-Tuning System Auto Preset 99 ch, Auto Label, Auto Sort

STEREO/BILINGUAL NICAM/A2

RS-232C 9 pin mini D-sub

EXT 1 SCART (AV input, Y/C input, RGB input, TV output)

EXT 2 SCART (AV input/output, Y/C input, RGB input, AV Link)

EXT 3 S-VIDEO (Y/C input), RCA pin (AV input)

EXT 4 Ø 3.5 mm jack (Audio input), 15 pin mini D-sub (PC)

EXT 5 Audio in, Component in

EXT 6 HDMI, Ø 3.5 mm jack (Audio input)

EXT 7 HDMI

C. I. (Common Interface) EN50221, R206001

OUTPUT RCA pin (Audio)

Headphones Ø 3.5 mm jack (Audio output)

VHF/UHF E2-E69ch, F2-F10ch, I21-I69ch, IR A-IR Jch, (Digital: E5-E69ch)

CATV Hyper-band, S1-S41ch

32" LCD COLOUR TV

32" Advanced Super View & BLACK TFT LCD

1,049,088 pixels (1,366 x 768)

10W x 2

(100mmx35mm)x2

UHF/VHF 75Ω Din type (Analogue & Digital)

Russian/Polish

0°Cto+40°C

• As a part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for

product improvement without prior notice. The performance specification figures indicated are nominal values of production

units. There may be some deviations from these values in individual units.

NOTE

• Refer to inside back cover for dimensional drawings.

Optional accessory

The listed optional accessories are available for the

LCD colour TV. Please purchase them at your nearest

shop.

• Additional optional accessories may be available in near

future. When purchasing, please read the newest catalogue

for compatibility and check the availability.

Wall mount bracket

(LC-32D44E, LC-32D44S)

1 – 1

Part name Part number

AN-37AG5

Page 6

LC32D44E/S/RU-BK/GY (1st Eddition)

[2] OPERATION MANUAL

Remote control unit

1 (Standby/On)

Enter standby mode or turn on the

power.

2AVMODE

Select a video setting.

30–9

Set the channel in TV and DTV mode.

Set the page in Teletext mode.

When Sweden is selected in the

country setting from the Initial

auto installation, DTV channels

are 4-digit. When another

country is selected, DTV channels

are 3-digit.

4 (Flashback)

Press to return to the previous image

in normal viewing mode. (Will not work

while operating in EPG/ESG screen.)

5 (WIDE MODE)

Select the wide mode.

6 (Sound mode)

Select the sound multiplex mode.

(See below.)

7 EPG

DTV: To display EPG (Electronic

Programme Guide) screen.

8 ESG

DTV: To display ESG (Electronic Service

Guide) screen.

9 (Teletext)

Select the TELETEXT mode. (All TV

image, DTV/DATA image, all TEXT

image, TV/TEXT image)

DTV: Select DTV data broadcasting and

TELETEXT.

10 / / / (Cursor)

Select a desired item on the setting

screen.

11 END

Exit the menu screen.

12 (Reveal hidden Teletext)

13 (Freeze/Hold)

Using on the remote control unit

DTV mode:

Press to open the multi audio screen.

Analogue TV mode:

Each time you press , the mode switches as illustrated in the following

tables.

NICAM TV broadcasts selection

Signal Selectable items

Stereo

Bilingual

Monaural

NOTE

• When no signal is input, the sound mode will display “MONO”.

NICAM STEREO, MONO

NICAM CH A, NICAM CH B,

NICAM CH AB, MONO

NICAM MONO, MONO

1

2

3

4

5

6

7

8

9

10

11

12

13

A2 TV broadcasts selection

Signal Selectable items

Stereo

Bilingual

Monaural

STEREO, MONO

CH A, CH B, CH AB

MONO

14 SURROUND

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Switch the surround effects on and off.

15 RADIO

DTV: Switch between RADIO and DTV

mode.

16 (Mute)

Switchthesoundonandoff.

17 DTV

Press to access DTV mode while

watching other input sources, and vice

versa.

(This button will not work if you were

watching DTV immediately before

turning off the TV. In this case first select

any other input source except DTV

using the button.)

18 (+/-) (Volume)

(+) Increase the volume.

(-) Decrease the volume.

19 P ( / )

TV/DTV: Select the channel.

External: Switch to TV or DTV input

mode.

eletext: Move to the next/previous

20 (INPUT SOURCE)

Select an input source.

(TV, DTV, EXT1, EXT2, EXT3, EXT4,

EXT5, EXT6, EXT7)

21 SLEEP

Set the sleep timer on (in units of 30

min. up to max. 2 hr. 30 min) and off.

22 (Display information)

23 DTV MENU

DTV: Display DTV Menu screen.

24 MENU

Display the MENU screen.

25 OK

Execute a command within the menu

screen.

Display the programme list. (Except

external input.)

26 RETURN

Return to the previous menu screen.

27 (Subpage)

28 (Subtitle for Teletext)

TV/External: To turn the subtitles on and

off.

DTV: Display the subtitle selection

screen.

29 Colour (Red/Green/Yellow/Blue)

TELETEXT: Select a page.

DTV: The coloured buttons are used to

select correspondingly to the coloured

items in the menu screen.

1 – 2

Page 7

TV (Front view)

LC32D44E/S/RU-BK/GY (1st Eddition)

TV (Rear view)

-/+) (Volume buttons)

(

(Programme [channel] buttons)

1

Remote control sensor

P (/)

(Standby/On) indicator

(Power button)

MENU button

(Input button)

10

6

7

8

2

9

4 5

3

11

12

1 RS-232C terminal

2 EXT 4 (ANALOGUE RGB/AUDIO)

terminals

3 EXT 5 (COMPONENT) terminals

4 EXT 1 (RGB) terminal

5 EXT 2 (RGB) terminal

NOTE

• Only if you use an active terrestrial antenna, select “On (5V)” under “Supply Voltage”.

6 Antenna input terminal

(DVB-T 5V=/80 mA)

7 OUTPUT (AUDIO) terminals

8 EXT 6 (HDMI/AUDIO) terminals

9 EXT 7 (HDMI) terminal

10 COMMON INTERFACE slot

11 EXT 3 terminals

12 Headphone jack

13 AC INPUT terminal

1 – 3

13

Page 8

LC32D44E/S/RU-BK/GY (1st Eddition)

Appendix

Troubleshooting

Problem Possible Solution

• No power.

• Unit cannot be operated. • External influences such as lightning, static electricity, etc., may cause improper

• Remote control unit does not

operate.

• Picture is cut off. • Is the image position correct?

• Strange colour, light colour, or

dark, or colour misalignment.

• Power is suddenly turned off. • The unit’s internal temperature has increased.

• No picture. • Is connection to other components correct?

• No sound. • Is the volume too low?

• The DTV menu screen is displayed

in monochrome and hard to select

the item.

• The TV sometimes makes a

cracking sound.

• Check if you pressed on the remote control unit.

If the indicator on the TV lights up red, press .

• Is the AC cord disconnected?

• Check if you pressed on the TV.

operation. In this case, operate the unit after first turning the power off, or

unplugging the AC cord and re-plugging it in after 1 or 2 minutes.

• Are batteries inserted with polarity (+, -) aligned?

• Are batteries worn out? (Replace with new batteries.)

• Are you using it under strong or fluorescent lighting?

• Is a fluorescent light illuminated to remote control sensor?

• Are screen mode adjustments (4:3 Mode/WSS) such as picture size made

correctly?

• Adjust the picture tone.

• Is the room too bright? The picture may look dark in a room that is too bright.

• Check the colour system setting.

• Check the HDMI Setup setting.

Remove any objects blocking vent or clean.

• Check the power control setting.

• Is sleep timer set? Press SLEEP on the remote control unit until it sets to Off.

• Is input signal type selected correctly after connection?

• Is the correct input source selected?

• Is non-compatible signal being input?

• Is picture adjustment correct?

• Is the antenna connected properly?

• Is “On” selected in “Audio Only”?

• Make sure that headphones are not connected.

• Check if you pressed on the remote control unit.

• Check if “Monochrome” is set to “On”. If so, set it to “Off”.

• This is not a malfunction. This happens when the cabinet slightly expands and

contracts according to change in temperature. This does not affect the TV’s

performance.

Cautions regarding use in high and low temperature environments

• When the unit is used in a low temperature space (e.g. room, office), the picture may leave trails or appear slightly

delayed. This is not a malfunction, and the unit will recover when the temperature returns to normal.

• Do not leave the unit in a hot or cold location. Also, do not leave the unit in a location exposed to direct sunlight or near a

heater, as this may cause the cabinet to deform and the LCD panel to malfunction.

Storage temperature: -20°C to +60°C.

IMPORTANT NOTE ON RESETTING THE PIN

We suggest that you remove the following instruction from the operation manual to prevent children from

reading it. As this operation manual is multilingual, we also suggest the same with each language. Keep it in a

safe space for future reference.

1 – 4

Page 9

[3] DIMENSIONS

LC32D44E/S/RU-BK/GY (1st Eddition)

575.0

575,0

523.0

523,0

52.0

52,0

699.2

699,2

776.0

776,0

402.0

402,0

200.0

200,0

393.8

393,8

332.0

332,0

73.9

73,9

94.5

94,5

230.0

230,0

200.0

200,0

110.0

110,0

1 – 5

Page 10

LC32D44E/S/RU-BK/GY (1st Eddition)

LC32D44E-BK

CHAPTER 2. REMOVING OF MAJOR PARTS

Service Manual

[1] REMOVING OF MAJOR PARTS

1. Remove the 4 lock screws and detach the Stand.

2. Remove the 3 lock screws , 6 lock screws , 2 lock screw and detach the Rear Cabinet.

1

2

3

4

Rear Cabinet

2

Front Cabinet

3

4

1

Stand

2 – 1

Page 11

LC32D44E/S/RU-BK/GY (1st Eddition)

3. Remove the 3 lock screws , 2 lock screws , 1 lock screws and detach the Main Shield.

4. Disconnect all the connectors from all the PWBs.

5. Remove the KEY Unit Ass'y .

Operation Button

5A 5B 6

7

6

5B

7

5A

Main Shield

KEY Unit

[KM]

[KM]

[FPC]

[LB]

[PD]

SP-R

[RA]

[LB]

[PD]

[SP]

SP-L

2 – 2

Page 12

LC32D44E/S/RU-BK/GY (1st Eddition)

6. Remove the Speaker (L) , (R) .

7. Remove the 4 lock screws and detach the POWER/INVERTER Unit.

8. Remove the 2 lock screws , and detach the MAIN Unit.

9. Remove the 2 lock screws and detach the MINI AV Unit.

8 9

10

11

12

MINI AV Cover

11

12

Main Unit

MINI AV Unit

10

Power/Inverter Unit

Speaker(R) Speaker(L)

98

2 – 3

Page 13

LC32D44E/S/RU-BK/GY (1st Eddition)

10.Remove the 1 lock screw and detach the Bottom Cover.

11.Remove the 4 lock screws and detach the Stand Fix Angle.

12.Remove the R/C, LED Unit .

13

14

15

15

R/C,LED Unit

14

Stand Fix Angle

Bottom Cover

13

2 – 4

Page 14

LC32D44E/S/RU-BK/GY (1st Eddition)

13.Remove the 6 lock screws and detach the LCD Panel Module.

14.Remove the 2 lock screws and detach the LCD Fix Angle-A.

15.Remove the 2 lock screws and detach the LCD Fix Angle-B.

16.Remove the 8 lock screws and detach the Panel Fix Angle.

16

18

16

17

18

19

LCD Fix Angle-B

16

19

16

19

16

LCD Fix Angle-A

17

LCD Fix Angle-B

18

17

Panel Fix Angle

LCD Fix Angle-A

16

16

2 – 5

Page 15

LC32D44E/S/RU-BK/GY (1st Eddition)

LC32D44E-BK

CHAPTER 3. ADJUSTMENT

Service Manual

[1] After replacement of any PWB and/or IC for repair, note the following.

When replacing the following units, be sure to prepare the new units loaded with updated software.

MAIN-UNIT: DUNTKE449FM02

• Note that an IC into which ROM data is written is available for MAIN-UNIT servicing (see below)

IC1902 RH-iXC448WJZZS EDID (HDMI)

IC1922 RH-iXC447WJZZS EDID (HDMI)

IC2321 RH-iXC206WJQZS EDID (PC)

IC8101 RH-iXC639WJZZS EEPROM

[2] SOFTWARE UPDATING

There are 2 methods to update software in the VCTp: I2C method, RS-232C HyperTerminal and RS-232C Tera Term method.

• RS-232C method is allowed when the TV is working properly and the action should be only software upgrade.

1. RS-232C Method Description (HyperTerminal).

The hardware tools requirement are:

1. A Modem-null (Cross type) DB9 female to DB9 female cable.

2. Make the connections as indicated in the figure:

Computer TV set

TV Set

RS-232C

IOIOI

Before using RS-232C updating method is necessary to configure a Terminal PC software. HyperTerminal has been selected as a Terminal software because it’s include in all Windows versions as an accessory, and you can find it inside “Accessories\Communications” folder. For this reason, please follow carefully the next steps:

1) First time HyperTerminal is used, it’s necessary to configure some settings. Follows next action to configure two connection: low speed

(9600bps) and high speed (115200bps).

2) Create a New Connection file with name “P55_9600bps”.

3) Select a free COM port and select the Port Settings properties as follows:

3 – 1

Page 16

LC32D44E/S/RU-BK/GY (1st Eddition)

4) Click on “File\Properties” menu for selecting the General and ASCII properties as follows:

5) Select “New Connection” in the File Menu.

6) Answer “Yes” to close current connection and “Yes” to save session “P55_9600bps”.

7) Create a new connection with the name “P55_115200bps”.

8) Select a the same COM port used in item 2 and select the Port Settings properties as follows:

9) Select the same General and ASCII properties as item 3.

10)Close HyperTerminal session, answering “Yes” to close current connection and “Yes” to save session “P55_115200bps”.

To start updating session, click over “P55_9600bps” icon that you can find in the “START\All programs\Accessories\ Communications\HyperTerminal\HyperTerminal” folder and follow next procedure:

3 – 2

Page 17

LC32D44E/S/RU-BK/GY (1st Eddition)

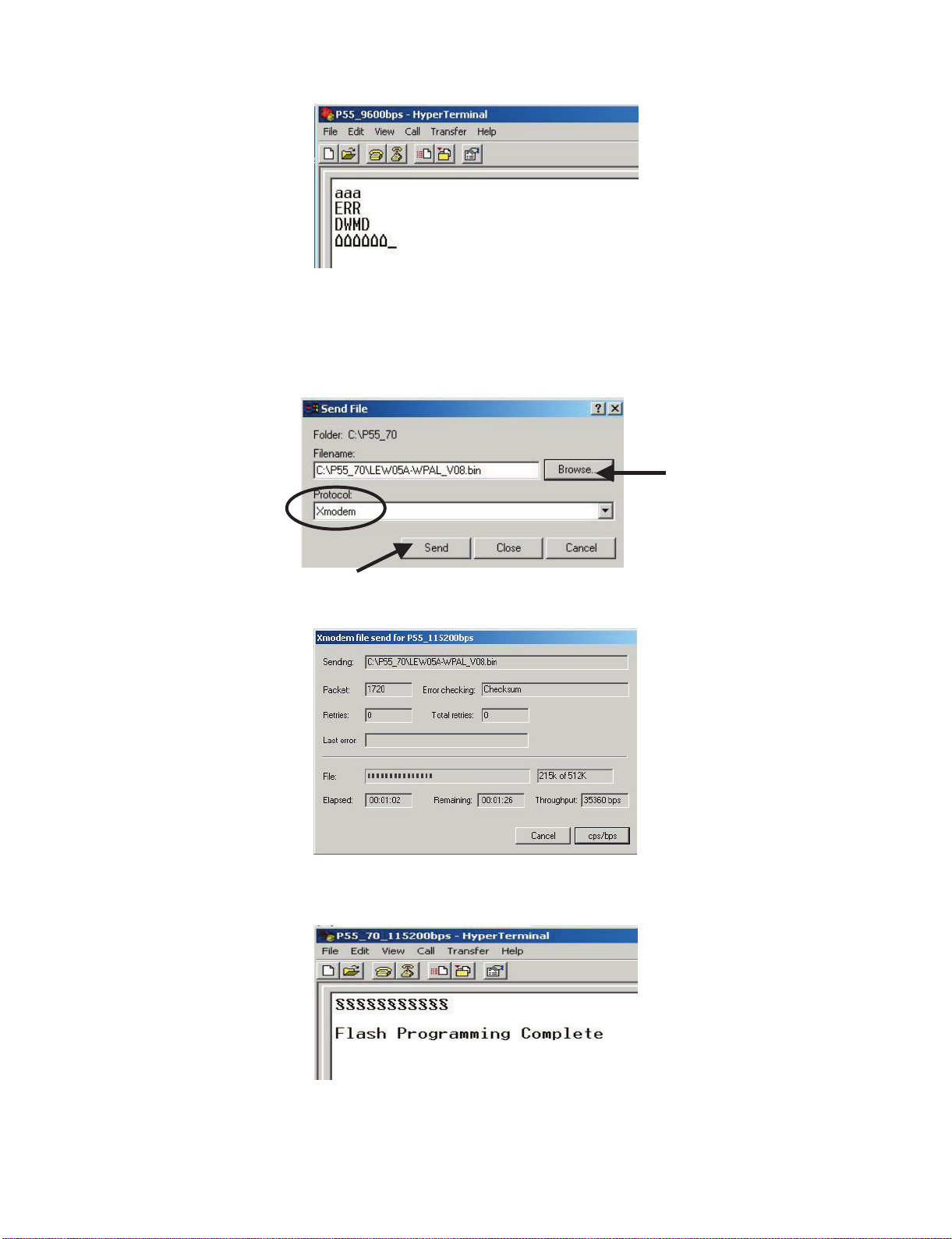

1) Check the connection between TV set and PC, sending a wrong command, as for example: “aaa”. TV set returns an “ERR” label as an syntaxis

ERROR (Not correct order or sequence).

2) Send the command “DWMD” to enter TV set in Download Mode. The TV set answer sending same symbol continuosly. If this symbol character

doesn’t appear, please don’t worry and pass to next step.

3) Close this connection and open “P55_115200bps” connection clicking over the “P55_115200bps” that you can find in “START\All programs\Accessories\ Communications\HyperTerminal\HyperTerminal” folder.

4) Using “Transfer\Send file...” menu, select desired file (.bin format) and the transmission protocol (Xmodem) as show below.

5) After press “Send” button the updating process starts as follows:

6) When flash update process finishes, the “Flash Programming Complete” label appears in the screen, the device automatically go to switch off,

and in a few seconds go to switch on again.

VERY IMPORTANT NOTE:

During the updating time, please don’t use the PC for other purpouses, in order to abolish communication problems between TV set and

PC. If TV set was not updated properly, the TV won’t have the software to startup again, and you must follow the “I2C method” to update

another time the TV set.

3 – 3

Page 18

LC32D44E/S/RU-BK/GY (1st Eddition)

2. RS-232C Method Description (Tera Term)

The hardware tools requirement are:

1. A Modem-null (Cross type) DB9 female to DB9 female cable.

2. Make the connections as indicated in the figure:

Computer TV set

TV Set

Software requirements:

To upgrade VCTp software from RS-232C external connector is necessary to use a Tera Term (Pro) free software.

The URL of Tera Term home page is:

http://hp.vector.co.jp/authors/VA002416/teraterm.html

(The address may be changed in future)

Tera Term (Pro) supported operating systems:

MS-Windows 95 or upper

MS-Windows NT 3.5 and 4.0 or upper

Note.- For Windows 3.1 use Tera Term version 1.X.

Copy all the distribution files to an empty floppy disk or temporary directory (for example C:\ TEMP).

Run SETUP.EXE and follow the instruction given by it.

After the installation, the distribution? les are no longer needed, you can delete them or may keep them in the floppy disk.

Ho w to us e Tera Te rm Pro :

When the Tera Term (Pro) program is used, it’s necessary to shape some settings. Follows next action to configure the connection:

RS-232C

IOIOI

3 – 4

Page 19

1) Select: Serial→COM X→ O.K.

2) Select: Ter minal

LC32D44E/S/RU-BK/GY (1st Eddition)

3) Choose the same options as the above picture.

3 – 5

Page 20

LC32D44E/S/RU-BK/GY (1st Eddition)

4) Select: Setup → Serial port → O.K. Appear the follow screen:

5) Select follows settings:

Serial port to use: COM x

Baud rate: 9600

Data: 8 bits

Parity: none

Stop: 1 bit

Flow control: none

Enter O.K.

6) Check the connection between TV set and PC, sending a wrong command, as for example: “aaa”. TV set returns an “err” label as an syntaxes

ERROR (Not correct order or sequence).

Send a “DWMD” (capital letters) command to enter TV set in Download Mode.

Change a baud rate to 115200.

Select: Setup → Baud rate → 115200 → O.K.

3 – 6

Page 21

7) Select: File → Transfer → XMODEM → Sent

8) Choose the file for upgrade and click “Open”.

LC32D44E/S/RU-BK/GY (1st Eddition)

9) After select “Open” the upgrade process starts as follows:

3 – 7

Page 22

LC32D44E/S/RU-BK/GY (1st Eddition)

10)When flash update process finishes, the “Flash programming complete” label appear in the screen, the device automatically go to switch off, and

in a few seconds go to switch on again.

VERY IMPORTANT NOTE:

During the updating time, please don’t use the PC for other purposes, in order to abolish communication problems between TV set and PC.

If TV set was not updated properly, the TV won’t have the software to startup again, and you must follow the “I2C method”

another time the TV set.

3. How to update the Digital Board Software.

There are 2 methods to update the Digital Board Software on Flash Memory (IC4251) throught the Digital Processor (IC4001).

• RS-232 Method (From PC trough RS-232C COM port).

• PCMCIA CARD (Compact Flash Memory) Method.

NOTE: The PCMCIA method is only compatible with those PCs running XP Windows Version.

to update

3.1. Jig RS-232 Method Description

• Hardware requirements:

1. A modem null (Cross type) DB9 female to DB9 female cable.

2. Make the connections as in the below figure.

Computer

RS-232C serial control cable

(cross type, commercially available)

TV Set

(CI Terminal)

TV Set

Jig

~

~

RS-232C

IOIOI

• Software requirements:

1. “Winupload” application software on PC.

3 – 8

Page 23

• How to setup the “Winupload” software for the first time:

1. Start “Winupload”. It will appear the following picture.

2. Select the most suitable RS232 Serial Port from “Port Setting” - “Process” Menu.

LC32D44E/S/RU-BK/GY (1st Eddition)

3. Select the following settings from “Port Settings” Menu.

Bits Per Second: 115200

Parity: None

Data bits: 8

Stop bits: 1

Hardware Flow Control: OFF

• Procedure for updating the TV set.

1. Switch off the TV set to be updated, in DTV mode.

2. Start “Winupload”. It will appear the following picture on PC.

3 – 9

Page 24

LC32D44E/S/RU-BK/GY (1st Eddition)

3. Establish connection on Winupload Software.

4. Select “Upload URT file”

5. Select and open the “.urt” data file from data directory

NOTE: Consider the version shown below just an example, may be is not the latest one, and could be different depending on the TV set destination

(market/Country) or model.

6. Switch On the TV Set (previously in DTV Mode). The Uploading Process starts automatically.

3 – 10

Page 25

LC32D44E/S/RU-BK/GY (1st Eddition)

While the TV set is uploading the software, the following information is shown on the TV set screen.

Then, data transfer from PC to TV set finishes when the “Upload progress completed” label appears in the “Winupload” screen. Now, the TV set made

some additional verification (Items #2 to #7). When the full uploading process is finished, in the “Winupload” window appears the label “Preparing to

start application” for a new TV Set, and just now, in the TV screen of the updated set, appears a congratulations label (Item #8).

NOTE: Do not turn off the TV set while the software updating was in progress.

7. Unplug the AC cord.

8. Disconnect the Jig from TV Set.

• Software Version verification procedure.

1. Connect the AC cord and Switch On the TV Set.

2. Select DTV Menu on TV Set. The following On Screen Display will appear.

3. Select “Version”. The updated version can be verified.

NOTE: Consider the version shown above just as example, may be is not the latest one, and could be different depending on the TV set destination

(market/Country) or model.

3 – 11

Page 26

LC32D44E/S/RU-BK/GY (1st Eddition)

4. Software Version Upgrade Using Card

1. Write the software (ATV and DTV) on the PCMCIA CARD by following the procedure described in the separate document, “How to write software

(ATV and DTV) to PCMCIA CARD”.

(* In the document, both ATV and DTV are written; you may write either of them.)

(You can equally use any version after “Storage Media Manager Version 1.3.1”.)

2. Turn off the power.

(* You can select either of the mode ATV or DTV. In this document, ATV is selected.)

3. Insert the PCMCIA CARD with the upper side facing up into the card slot.

(* Do not insert the card with the upper side facing down.)

4. Turn on the power. After a short time, the message, “SYSTEM SOFTWARE UPDATE IN PROGRESS. ...) appears and the software upgrade

starts.

If the ATV software upgrade is necessary, the step proceeds to (5); if unnecessary, the DTV software upgrade starts and the step proceeds to (7).

5. If the ATV software upgrade is necessary, the following display appears and the upgrade starts.

When the status bar reaches 100 %, the ATV upgrade is complete. Then the system restarts from the ATV mode. The step proceeds to (6).

3 – 12

Page 27

LC32D44E/S/RU-BK/GY (1st Eddition)

6. The message, “SYSTEM SOFTWARE UPDATE IN PROGRESS. ...” appears again and the DTV software upgrade starts. Then the step proceeds

to (7).

7. After a short time, the message, “Congratulations! ...” appears. The upgrade is complete.

(Note: You cannot downgrade the ATV software but can downgrade the DTV software.)

3 – 13

Page 28

LC32D44E/S/RU-BK/GY (1st Eddition)

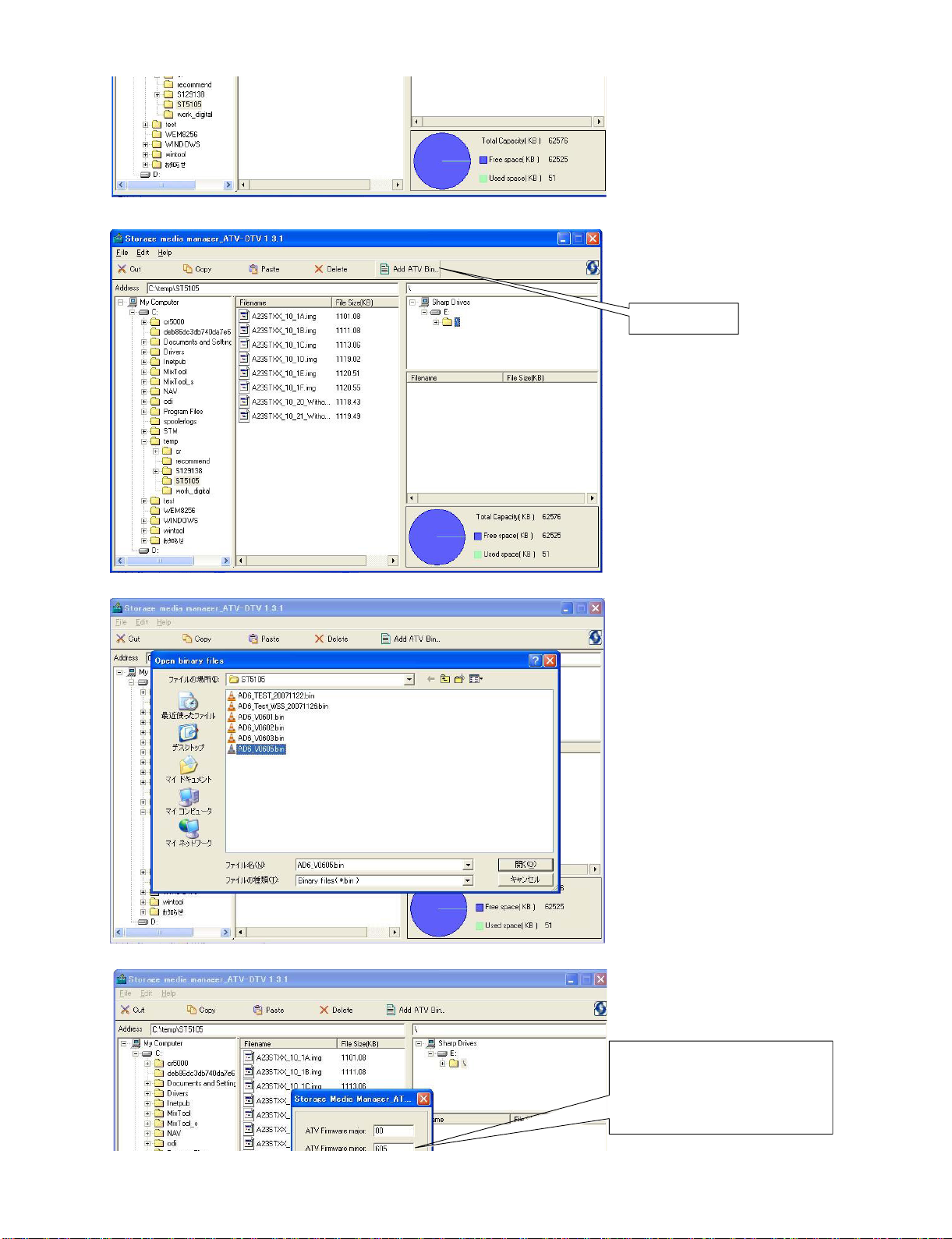

㪟㫆㫎㩷㫋㫆㩷㫎㫉㫀㫋㪼㩷㫊㫆㪽㫋㫎㪸㫉㪼㩿㪘㪫㪭㩷㪸㫅㪻㩷㪛㪫㪭㪀㩷㫋㫆㩷㪧㪚㪤㪚㪠㪘㩷㪚㪘㪩㪛

㪈㪅㪮㪿㪼㫅㩷㫐㫆㫌㩷㫎㫉㫀㫋㪼㩷㫊㪆㫎㩷㪃㩷㫐㫆㫌㩷㫊㪿㫆㫌㫃㪻㩷㫌㫊㪼㩷 㩹㪪㫋㫆㫉㪸㪾㪼㪤㪼㪻㫀㪸㪤㪸

㪉㪅㪪㫋㪸㫉㫋㩷㩹㪪㫋㫆㫉㪸㪾㪼㪤㪼㪻㫀㪸㪤㪸㫅㪸㪾㪼㫉㪶㪘㪫㪭㪄㪛㪫㪭㩷㪈㪅㪊㪅㪈㪅㪼㫏㪼㩹㪅㩿㪛㫀㫊㫇㫃㪸㫐㪼㪻㩷㪸㫊㩷㪽㫆㫃㫃㫆㫎㫊㪅㪀

㫅㪸㪾㪼㫉㪶㪘㪫㪭㪄㪛㪫㪭㩷㪈㪅㪊㪅㪈㪅㪼㫏㪼㩹

㪇㪊㪛㪼㪺㪶㪉㪇㪇㪎

㪮㫉㫀㫋㪼㫅㩷㪹㫐㩷㪢㪼㫅㫋㪸㫉㫆㩷㪪㪼㫐㪸㫄㪸㩿㪪㪟㪘㪩㪧㩷㪡㪸㫇㪸㫅㪀㩷

㪸㫋㩷㫋㪿㪼㩷㪛㫉㫀㫍㪼

㪊㪅㪝㫆㫉㫄

㪋㪅㪚㪿㫆㫆㫊㪼㩷㪽㫆㫃㪻㪼㫉

㪚㫃㫀㪺㫂㩷㫋㪿㪼㩷㫉㫀㪾㪿㫋㩷㪹㫌㫋㫋㫆㫅㩷㪸㫋㩷㪜㪑㩷㪻㫉㫀㫍㪼㩿㪫㪿㪼㩷㪻㫉㫀㫍㪼㩷㫋㪿㪸㫋㩷㫋㪿㪼

㫄㪼㪻㫀㪸㩷㪽㫆㫉㩷㪧㪚㪤㪚㪠㪘㩷㫌㫇㪻㪸㫋㪼㩷䌩䌳㩷䌩䌮䌳䌥䌲䌴䌥䌤㩷㫀㫅㪅㪀㪅

㪘㫅㪻㩷㪃㩷㪺㪿㫆㫆㫊㪼㩷㩹㪝㫆㫉㫄㪸㫋㩷㪛㫉㫀㫍㪼㩹㪅

3 – 14

㪚㪿㫆㫆㫊㪼㩷㫋㪿㫀㫊㩷㪽㫆㫃㪻㪼㫉㪅

Page 29

㪌㪅㪮㫉㫀㫋㪼㩷㪘㪫㪭㩷㫊㫆㪽㫋㫎㪸㫉㪼

㪌㪄㪈㪀㪚㪿㫆㫆㫊㪼㩷㩹㪘㪻㪻㩷㪘㪫㪭㩷㪙㫀㫅㩷㪅㪅㪅㩹

LC32D44E/S/RU-BK/GY (1st Eddition)

㪚㪿㫆㫆㫊㪼㩷㩹㪘㪻㪻㩷㪘㪫㪭

㪙㫀㫅㪅㪅㪅㩹

㪌㪄㪉㪀㪪㪼㫃㪼㪺㫋㩷㫋㪿㪼㩷㪘㪫㪭㩷㫊㫆㪽㫋㫎㪸㫉㪼㪅㩿㪪㫆㫉㫉㫐㩷㪽㫆㫉㩷㪻㫀㫊㫇㫃㪸㫐㪼㪻㩷㪹㫐㩷㪡

㪌㪄㪊㪀㪠㫅㫇㫌㫋㩷㩹㫄㪸㫁㫆㫉㩷㪺㫆㪻㪼㩹㩷㪸㫅㪻㩷㩹㫄㫀㫅㫆㫉㩷㪺㫆㪻㪼㩹㪅

㪸㫇㪸㫅㪼㫊㪼㪅㪀

3 – 15

㪠㫅㫇㫌㫋㩷㫋㪿㪼㩷㩹㫄㪸㫁㫆㫉㩷㪺㫆㪻㪼㩹㩷㪸㫅㪻㩷㩹㫄㫀㫅㫆㫉㩹㩷㪺㫆㪻㪼㪅

㪄㪄㪜㫏㪅㪄㪄㪄

㪮㪿㪼㫅㩷㫐㫆㫌㩷㫎㫆㫌㫃㪻㩷㫃㫀㫂㪼㩷㫋㫆㩷㫎㫉㫀㫋㪼㩷㫊㪆㫎㩷㫍㪼㫉㫊㫀㫆㫅㩷㩹㪇㪅㪍㪇㪌㩹㩷㪃

㫐㫆㫌

㩷㫊㪿㫆㫌㫃㪻㩷㫀㫅㫇㫌㫋㩷㪸㫊㩷㪽㫆㫃㫃㫆㫎㫊㪅

㪘㪫㪭㩷㪝㫀㫉㫄㫎㪸㫉㪼㩷㫄㪸㫁㫆㫉㪑㪇㪇

㪘㪫㪭㩷㪝㫀㫉㫄㫎㪸㫉㪼㩷㫄㫀㫅㫆㫉㪑㪍㪇㪌

㪘㫅㪻㩷㪃㩷㫇㫉㪼㫊㫊㩷㩹㪦㪢㩹㪅

㪄㪄㪄㪄㪄

Page 30

LC32D44E/S/RU-BK/GY (1st Eddition)

㪌㪄㪋㪀㪮㪸㫀㫋㩷㪽㫆㫉㩷㫋㪿㪼㩷㪽㫀㫅㫀㫊㪿㪅

㪌㪄㪌㪀㪘㪫㪭㩷㫊㫆㪽㫋㫎㪸㫉㪼㩷㫎㫉㫀㫋㫀㫅㪾㩷㫀㫊㩷㫊㫌㪺㪺㪼㫊㪼㪻㪅

㪍㪅㪮㫉㫀㫋㪼㩷㪛㪫㪭㩷㫊㫆㪽㫋㫎㪸㫉㪼

㪍㪄㪈㪀㪚㪿㫆㫆㫊㪼㩷㪽㫆㫃㪻㪼㫉㩷㪸㫅

㪻㩷㩹㪻㫉㪸㪾㩷㪸㫅㪻㩷㪻㫉㫆㫇㩹㩷㫋㪿㪼㩷㪛㪫㪭㩷㫊㫆㪽㫋㫎㪸㫉㪼㪅

㪘㪻㪻㪼㪻㩷㫋㪿㪼㩷㪘㪫㪭㩷㫊㫆㪽㫋㫎㪸㫉㪼㪅

3 – 16

Page 31

㪍㪄㪉㪀㪮㪸㫀㫋㩷㪽㫆㫉㩷㫋㪿㪼㩷㪽㫀㫅㫀㫊㪿㪅

㪚㪿㫆㫆㫊㪼㩷㫋㪿㪼㩷㪽㫆㫃㪻㪼㫉㩷㫎㪿㫀㪺㪿㩷㫐㫆㫌

㫊㫋㫆㫉㪼㫊㩷㫋㪿㪼㩷㪛㪫㪭㩷㫊㫆㪽㫋㫎㪸㫉㪼㩷㫋㪿㪸㫋

㫐㫆㫌㩷㫎㪸㫅㫋㩷㫋㫆㩷㫎㫉㫀㫋㪼㩷㫀㫅㪅

LC32D44E/S/RU-BK/GY (1st Eddition)

㪛㫉㪸㪾㩷㩽㩷㪛㫉㫆㫇㩷㫋㪿㪼㩷㪛㪫㪭㩷㫊㫆㪽㫋㫎㪸㫉㪼

㪍㪄㪊㪀㪛㪫㪭㩷㫊㫆㪽㫋㫎㪸㫉㪼㩷㫎㫉㫀㫋㫀㫅㪾㩷㫀㫊㩷㫊㫌㪺㪺㪼㫊㪼㪻㪅

㪎㪀㪚㪿㫆㫆㫊㪼㩷㩹㪝㫀㫃㪼㩹㩷㪄㪄㪕㩷㩹㪜㫏㫀㫋㩹㩷㩿㪽㫀㫅㫀㫊㪿㩷㫋㪿㪼㩷㪪

㪘㪻㪻㪼㪻㩷㫋㪿㪼㩷㪛㪫㪭㩷㫊㫆㪽㫋㫎㪸㫉㪼㪅

㫋㫆㫉㪸㪾㪼㪤㪼㪻㫀㪸㪤㪸㫅㪸㪾㪼㫉㪶㪘㪫㪭㪄㪛㪫㪭㩷㪈㪅㪊㪅㪈㪀

㪝㫀㫅㫀㫊㪿

3 – 17

Page 32

LC32D44E/S/RU-BK/GY (1st Eddition)

[3] Entering and exiting the adjustment process mode

1) Unplug the AC power cord of running TV set to force off the power.

2) While holding down the “VOL (-)” and “INPUT” keys on the set at once, plug in the AC power cord to turn on the power.

The letter appears on the screen.

3) Next, hold down the “VOL (-)” and “P( )” keys on the set at once.

Multiple lines of orange characters appearing on the screen indicate that the set is now in the adjustment Process mode.

If you fail to enter the adjustment process mode (the display is the same as normal startup), retry the procedure.

4) To exit the adjustment process mode after the adjustment is done, unplug the AC power cord to force off the power. (When the power is turned off

with the remote controller, once unplug the AC power cord and plug it in again. In this case, wait 10 seconds or so before plugging.)

Caution: Use due care in handling the information described here lest the users should know how to enter the adjustment process mode.

If the settings are tampered with in this mode, unrecoverable system damage may result.

[4] Remote controller key operation and description of display in adjustment process mode.

1. key operation

Remote controller key Main unit key Function

P ( / )

(+ / –) (+ / –)

Cursor ( / )

Cursor ( / )

Input button on remote

controller

OK —————— Executing a function

* Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

P ( / ) Moving an item (line) by one (UP/DOWN)

Changing a selected line setting (+1/-1)

—————— Turning a page (PREVIOUS/NEXT)

—————— Changing a selected line setting (+10/-10)

Input button

Input source switching (toggle switching)

(TV→DTV→EXT1→EXT2→EXT3→EXT4→EXT5→EXT6)

2. Description of display

(1) Current page/Total pages (3) Currently selected input

1/11

Main Version

Dev Version

Dev Loader Version

Pic Version

TEMP SENSOR

NORMAL STANDBY CAUSE

ERROR STANDBY CAUSE

(4) Current colour TV system

(2) Current page title

(5) Destination

[INFO] TV AUTO XX:EURO

LEW07 01.XX (XX/XX/XXX)

XX

XX

XX

XX

XX

XX

[1] 0

[2] 0

[3] 0

[4] 0

[5] 0

00H 00M

00H 00M

00H 00M

00H 00M

00H 00M

Adjustment process

menu header

(7) Parameters

3 – 18

Page 33

LC32D44E/S/RU-BK/GY (1st Eddition)

[5] Adjustment process mode menu

The character string in brackets [ ] will appear as a page title in the adjustment process menu header.

Page Line Item Description Remarks (adjustment detail, etc.)

1/11 [INFO]

1 Main Version LEW07 01XX(XX/XX0/XX) Main microprocessor version

2 Dev Version XX DTV microprocessor version

3 Dev Loader Version XX DTV microprocessor-Loader version

4 Pic Version xxxxxx Pic MICON version

5 TEMP SENSOR xxxxxx

6 NORMAL STANDBY CAUSE RC_STANDBY

7 ERROR STANDBY CAUSE [1] 00H 00M Error standby cause Total operating time before error

[2] 00H 00M

[3] 00H 00M

[4] 00H 00M

[5] 00H 00M

2/11 [INIT]

1 Factory Init [EURO/RUSSIA/SWEDEN] Initialization to factory settings execution

2 Inch Setting XX Inch present setting

3 Public Mode OFF/ON HOTEL MODE flag setting

4 Center Acutime xxH xxM Main operating hours

5 RESET OFF/ON Main operating hours reset

6 Backlight Acutime xxH xxM Backlight operating hours

7 RESET OFF/ON Backlight operating hours reset

8 Picture Read Pos X 0-xxx x-axis setting of picture data

9 Picture Read Pos Y 0-xxx y-axis setting of picture data

10 Picture Read ON/OFF Start/stop of picture data

3/11 [PAL.SECAM.N358]

1 RF-AGC ADJ ENTER RF-AGC auto adjustment execution

2 PAL+TUNER ADJ ENTER PAL TUNER auto adjustment execution

3 PAL ADJ ENTER PAL auto adjustment execution

4 TUNER ADJ ENTER TUNER auto adjustment execution

5 CONTRAST SD 32 PAL contrast adjustment

6 SECAM CB OFFSET 1 SECAM offset adjustment

7 SECAM CR OFFSET 1 SECAM offset adjustment

8 TUNER A DAC 32 TUNER DAC adjustment

9 RF AGC 16 RF AGC adjustment

4/11 [COMP 15K]

1 COMP 15K ADJ ENTER COMP15K auto adjustment execution

2 COMP 15K CONTRAST 40 Contrast adjustment

5/11 [HDTV]

1 HDTV CONTRAST 41 HDTV Contrast adjustment

6/11 [SMPTE]

1 RF-AGC ADJ ENTER RF-AGC auto adjustment execution

2 PAL-AGC ADJ ENTER PAL AGC auto adjustment execution

3 PAL ADJ ENTER PAL auto adjustment execution

4 TUNER ADJ ENTER TUNER auto adjustment execution

5 CONTRAST SD 30 PAL contrast adjustment

6 SECAM CB OFFSET 1 SECAM offset adjustment

7 SECAM CR OFFSET 1 SECAM offset adjustment

8 TUNER A DAC 36 TUNER DAC adjustment

9 RF AGC 16 RF AGC adjustment

7/11 [M GAMMA INFO]

1 M GAMMA IN 1 160 W/B adjustment, gradation 1 input setting

2 M GAMMA IN 2 320 W/B adjustment, gradation 2 input setting

3 M GAMMA IN 3 480 W/B adjustment, gradation 3 input setting

4 M GAMMA IN 4 640 W/B adjustment, gradation 4 input setting

5 M GAMMA IN 5 800 W/B adjustment, gradation 5 input setting

6 M GAMMA IN 6 960 W/B adjustment, gradation 6 input setting

7 M GAMMA WRITE OFF/ON EEP writing of adjustment values

8 M GAMMA RESET OFF/ON Initialization of adjustment values

3 – 19

Page 34

LC32D44E/S/RU-BK/GY (1st Eddition)

Page Line Item Description Remarks (adjustment detail, etc.)

8/11 [M GAMMA 1-3]

1 M GAMMA R 1 0 W/B adjustment, gradation 1R adjustment value

2 M GAMMA G 1 0 W/B adjustment, gradation 1G adjustment value

3 M GAMMA B 1 0 W/B adjustment, gradation 1B adjustment value

4 M GAMMA R 2 0 W/B adjustment, gradation 2R adjustment value

5 M GAMMA G 2 0 W/B adjustment, gradation 2G adjustment value

6 M GAMMA B 2 0 W/B adjustment, gradation 2B adjustment value

7 M GAMMA R 3 0 W/B adjustment, gradation 3R adjustment value

8 M GAMMA G 3 0 W/B adjustment, gradation 3G adjustment value

9 M GAMMA B 3 0 W/B adjustment, gradation 3B adjustment value

10 M GAMMA WRITE OFF/ON EEP writing of adjustment values

9/11 [M GAMMA 4-6]

1 M GAMMA R 4 0 W/B adjustment, gradation 4R adjustment value

2 M GAMMA G 4 0 W/B adjustment, gradation 4G adjustment value

3 M GAMMA B 4 0 W/B adjustment, gradation 4B adjustment value

4 M GAMMA R 5 0 W/B adjustment, gradation 5R adjustment value

5 M GAMMA G 5 0 W/B adjustment, gradation 5G adjustment value

6 M GAMMA B 5 0 W/B adjustment, gradation 5B adjustment value

7 M GAMMA R 6 0 W/B adjustment, gradation 6R adjustment value

8 M GAMMA G 6 0 W/B adjustment, gradation 6G adjustment value

9 M GAMMA B 6 0 W/B adjustment, gradation 6B adjustment value

10 M GAMMA WRITE OFF/ON EEP writing of adjustment values

10/11 [ETC]

1 EEP CLEAR OFF/ON Clear of all adjustment value

2 EEP CLEAR B OFF/ON Clear of adjustment value of B mode

3 STANDBYCAUSE RESET OFF/ON Reset of STANDBY CAUSE

4 AUTO INSTALLATION SW 0/1 1: * * * 0: * * *

5OPTION 0

6 COUNTRY AUTO/EURO/UK Destination setting

7 L ERR RESET 0 LAMP ERR RESET Initializatio of L_ERR

8 L ERR STOP 0/1 LAMP ERR Inhibit L_LRR detection

9 DTV CLR ENTER Clear of DTV setting

10 I2C-OFF ENTER I2C DATA execution

11/11 [COM-BIAS]

1 VCOM ADJ 63 INVERTER drive frequency setting

2 TEST PATTERN 0 INVERTER drive frequency setting

[6] Special features

* ERROR STANDBY CAUSE (Page 1/11)

The total time when the unit enters the standby due to operational error and cause of error are recorded on EEPROM as much as possible.

The values can be used to locate the fault for repair.

* EEP CLEAR (Page10/11)

Clear of process adjustment EEP value.

3 – 20

Page 35

LC32D44E/S/RU-BK/GY (1st Eddition)

[7] Video signal adjustment procedure

* The adjustment process mode menu is listed in Section 5.

1. Signal check

1. Signal generator level adjustment check (Adjustment to the specified level)

• Composite signal PAL : 0.7Vp-p ±0.02Vp-p (Pedestal to white level)

• 15K component signal (50 Hz) : Y level 0.7Vp-p ±0.02Vp-p (Pedestal to white level)

2. Entering the adjustment process mode

1. Enter the adjustment process mode according to Section 3.

3. RF AGC adjustment

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

PB, PR level 0.7Vp-p ±0.02Vp-p

PAL

Sprit Field Colour Bar

RF signal UV

[Terminal]

TUNER

• Feed the PAL Sprit Field colour bar signal to TUNER.

Signal level: 55 dB µV +1dB, -1dB (75Ω LOAD)

[E-12CH]

2 Auto adjustment

performance

Adjustment process

Page3

4. PAL signal & tuner adjustment

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

PAL

Full Field Colour Bar

Composite or RF signal

[Terminal]

EXT1 SCART IN

TUNER

㸡100% white

Bring the cursor on [ RF AGC ADJ] and press [OK]

[***OK***] appears when finished.

• Feed the PAL full field colour bar signal (75% colour saturation) to

EXT1 SCART IN.

• Feed the RF signal (PAL colour bar) to TUNER.

• Make sure the PAL colour bar pattern has the sync level of 7:3 with

the picture level.

㪲VIDEO IN SIGNAL]

㸡100% white

[RF Signal]

㸡100% white

2 Auto adjustment

performance

Adjustment process

Page3

Bring the cursor on [ PAL + TUNER ADJ] and press [OK]

[***OK***] appears when finished.

3 – 21

Page 36

LC32D44E/S/RU-BK/GY (1st Eddition)

5. ADC adjustment (Component 15K)

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

COMP15K, 50Hz

100% Full Field Colour Bar

[Terminal]

EXT5 COMPONENT IN

• Feed the COMPONENT 15K 100% full field colour bar signal

(100% colour saturation) to EXT5 COMPONENT IN.

2 Auto adjustment

performance

Adjustment process

Page4

100% white

Bring the cursor on [ COMP15K ADJ] and press [OK]

[***OK***] appears when finished.

Black

[8] White Balance Adjustment

Adjustment gradation values (IN) appear on page 7/11 of process adjustment, and adjustment initial values (offset value) appear on pages 8/11 and

9/11. For white balance adjustment, adjust the offset values on pages 8/11 and 9/11.

[Condition of the unit for inspection] Modulated light: MAX (+8)

[Adjustment reference device] Minolta CA-210

[Adjustment]

Check that the values on page 7/11 of process adjustment are set as below. If not, change them accordingly.

M GAMMA IN 1 160 M GAMMA IN 2 320

M GAMMA IN 3 480 M GAMMA IN 4 640

M GAMMA IN 5 800 M GAMMA IN 6 960

1) Display the current adjustment status at point 6. (Page 8/11 of process adjustment)

The display for checking the adjustment status is toggled by pressing the “6” button on the remote control.

(Normal OSD display → “6” → display for check (OSD disappears) → “6” →normal OSD display → • • •)

2) Read the value of the luminance meter.

3) Change M GAMMA R6/M GAMMA B6 (Adjustment offset value) on page 9/11 of process adjustment so that the values of the luminance meter

approach x = 0.272 and y = 0.277.

(Basically, G is not changed. If adjustment fails with R and B, change G. When G is lowered, the weaker of R and B must be fixed.)

4) If G is changed in step 3), change the values of M GAMMA G1-M GAMMA G5 on pages 8/11 and 9/11 of process adjustment as follows. When not

changed, go to step5).

Offset value of M GAMMA G1 = (Offset value of M GAMMA G6) * (160/960)

Offset value of M GAMMA G2 = (Offset value of M GAMMA G6) * (320/960)

Offset value of M GAMMA G3 = (Offset value of M GAMMA G6) * (480/960)

Offset value of M GAMMA G4 = (Offset value of M GAMMA G6) * (640/960)

Offset value of M GAMMA G5 = (Offset value of M GAMMA G6) * (800/960)

5) Display the adjustment status of the current point 5. (Each time the “5” button on the remote control is pressed, the adjustment status check display is toggled.)

(Normal OSD display → “5” → Check display (OSD disappears) → “5” → Normal OSD display → • • •)

Change M GAMMA R5/M GAMMA B5 (adjustment offset value) on page 9/11 of process adjustment so that the values of the luminance meter

approach x = 0.272 and y = 0.277.

6) Repeat step 5) for points 4, 3, 2, and 1.

[Adjustment reference standard value]

Adjustment spec ±0.004 Inspection spec ±0.006 (point 1)

Adjustment spec ±0.002 Inspection spec ±0.004 (Excluding the above-mentioned)

3 – 22

Page 37

LC32D44E/S/RU-BK/GY (1st Eddition)

[9] Adjusting procedure by use of [RS-232C]

1) Get ready the PC with COM port (RS-232C) running on Windows 95/98/ME/2000/XP operating system, as well as the RS-232C cross cable.

2) Start the unit with the RS-232C cable connected.

3) Start the terminal software. (The freeware readily available on the Internet will do.)

4) Make the following settings.

Baud rate 9,600 bps

Data LENGTH 8 bit

Parity bit None

Stop bit 1 bit

Flow control None

5) If the settings are correct, the terminal software indicates "ERR" against pressing of the "ENTER" key.

6) After the settings are done correctly, it is possible to make an adjustment by typing in the command shown in the table below and pressing the

"ENTER" key on the keyboard.

7) Command entry is successful if the terminal software indicates "OK" when the "ENTER" is pressed. If "ERR" is shown, retry to enter the command.

8) Send the process mode switching command to switch from the RS232C operation mode to the process mode.

KRSW0001: "ERR" is returned.

KKT10037: When "OK" is returned, the process mode becomes active. When "ERR", start over from KRSW0001.

9) Send each adjustment command.

RS-232C command list

Command Function Remarks

KYOF0000 Remote control disabled

OSDS0001 OSD display inhibited

SBSL0016 Light control level MAX

MSET0001 Background adjustment start

MSET0004 Initialization of adjustment value

LEV60928 Gradation 6 (928-gradation adjustment)

MG6G **** Adjustment of G of gradation 6 0000 ~4095

MG6R **** Adjustment of R of gradation 6 0000 ~ 4095

MG6B **** Adjustment of B of gradation 6 0000 ~ 4095

LEV50800 Gradation 5 (800-gradation adjustment)

MG5G **** Input of G of gradation 5 Calculated value

MG5R **** Input of R of gradation 5 0000 ~4095

MG5B **** Input of B of gradation 5 0000 ~ 4095

LEV40656 Gradation 4 (656-gradation adjustment)

MG4G **** Input of G of 4 Calculated value

MG4R **** Input of R of 4 0000 ~4095

MG4B **** Input of B of 4 0000 ~ 4095

LEV30528 Gradation 3 (528-gradation adjustment)

MG3G **** Input of G of 3

MG3R**** Input of R of 3 0000 ~ 4095

MG3B **** Input of B of 3 0000 ~ 4095

LEV20352 Gradation 2 (352-gradation adjustment) Calculated value

MG2G **** Input of G of 2 0000 ~ 4095

MG2R **** Input of R of 2 0000 ~ 4095

MG2B **** Input of B of 2 0000 ~ 4095

LEV10184 Gradation 1(176-gradation adjustment)

MG1G **** Input of G of 1 Calculated value

MG1R **** Input of R of 1 0000 ~ 4095

MG1B **** Input of B of 1 0000 ~ 4095

MSET0003 Writing of adjustment value

3 – 23

Page 38

LC32D44E/S/RU-BK/GY (1st Eddition)

[10] Initialization to factory settings

Caution: When the factory settings have been made, all user setting data, including the channel settings, are initialized.

After adjustments, exit the adjustment process mode.

To exit the adjustment process mode, unplug the AC power cord from the outlet to forcibly turn off the power.

When the power is turned off with the remote control, unplug the AC power cord and plug it back in (wait approximately 10 seconds before plugging

in the AC power cord)

(The adjustments done in the adjustment process mode are not initialized.) Keep this in mind when initializing these settings.

Adjustment item Adjustment conditions Adjustment procedure

1 Factory settings Forcibly turn off the power

(See to below caution)

• Enter the adjustment process mode.

• Move the cursor to [Factory Init] on page 2/11.

• Use the R/C key to select a destination [EURO/RUSSIA/

SWEDEN]. And, press the [OK] key.

• “EXECUTING...” appears and initialization starts.

• After a while, “*** OK ***” appears and the setting is complete.

NOTE: Never turn the power off during initialization.

When performing factory settings (while displaying page 2 of adjustment

process), confirm that the item “Inch Setting” or the panel size displayed

in the upper right corner corresponds to each panel size.

The following settings will be back to their factory ones.

1. User settings

2. Channel data (e.g. broadcast frequencies)

3. Maker option setting

4. Password data

[11] Lamp error detection

1. Function description

This LCD colour television has a function (lamp error detection) to be turned OFF automatically for safety when the lamp or lamp circuit is abnormal

If the lamp or lamp circuit is abnormal, or some other errors happen, and the lamp error detection is executed, the following occur.

1- The main unit of television is turned OFF 5 seconds after it is turned ON. (The power LED on the front side of TV turns from green to red.)

2 - If the situation “1” happens 5 times sequentially, the power is turned on (relay is turned ON).

However, the backlight is not turned on, and then the relay is turned OFF after 5 to 6 seconds. (The power LED turns from green to red.)

2. Countermeasures

When television is turned OFF by the lamp error detection mentioned above, it enters the adjustment process with the power LED red. Entering the

adjustment process turns OFF the error detection and turns ON TV. This enables the operation check to detect errors in the lamp or lamp circuit

Check whether “L ERROR RESET” on point 7, page 10/11 of the adjustment process is 1 or more. If it is 1 or more, it indicates the lamp error detection was executed. After confirming that the lamp or lamp circuit is normal, reset the lamp error counter pushing “OK” in the R/C. After resetting

counter the label “***OK***” appears on Screen.

3. Reset standby cause error list

After confirming that the lamp error counter has been erased, select “STAND BY CAUSE RESET” on point 3, page 10/11 of the adjustment process

and select ON using the right cursor. For execute press “OK” in the R/C and the label “***OK***” appears on Screen.

3 – 24

Page 39

LC32D44E/S/RU-BK/GY (1st Eddition)

[12] Public Mode (Hotel Mode)

1. How to Enter in the Public Mode (Hotel Mode).

Turn on the power and enter in the Adjustment Process mode as usual.

In the [INIT], Page 2/11 of Service, turns ON the Public Mode option.

Turn off TV by pressing Main Power switch.

While pressing “VOL+” and “INPUT” keys at the same time, press Main Power switch for more than 2 seconds.

Then, when you are asked for the password, enter “027”.

After this sequence the TV will turn on showing the Public Mode setting screen as follows:

Is possible to select each item of function by pressing cursor UP/DOWN keys on the remote control or CH( )( ) keys on the LCD TV. (Except

DTV)

The setting position of each item of functions is made by pressing cursor RIGHT/LEFT keys on the remote control or VOL (+) / (-) keys on the LCD

TV.

Select EXECUTE position after you set all function, and press cursor RIGHT/LEFT keys on the remote control or VOL (+) / (-) keys on the LCD TV for

confirmation.

2. Public Mode Settings.

1. POWER ON FIXED [VARIABLE FIXED]

When it is set to “FIXED” the TV is impossible to be switch off by Main Switch or Remote Control.

2. MAXIMUM VOLUME [0 60]

Is possible to set the maximum volume at limited level.

3. VOLUME FIXED [VARIABLE FIXED]

Is possible to fix the sound volume at limited level.

When “FIXED” is selected the sound volume before limited is fixed.

4. VOLUME FIXED LEVEL [0 60]

If “FIXED” has been selected, is possible to set a fixed volume at the level that is chosen.

5. RC BUTTON [RESPOND NO RESPOND]

If “NO RESPOND” is selected, the remote control keys are inoperative.

6. PANEL BUTTON [RESPOND NO RESPOND]

If “NO RESPOND” has been selected, the set’s keys remain deactivated (Except POWER key).

7. MENU BUTTON [RESPOND NO RESPOND]

If “NO RESPOND” has been selected, “MENU” key, of remote control, is inoperative.

8. ON SCREEN DISPLAY [YES NO]

If “NO” has been selected, the On Screen Display does not appear.

9. INPUT MODE START [NORMAL → TV (X) →DTV→ INPUT1 → INPUT2 → INPUT3 → INPUT4 → INPUT5]

When any other item than “NORMAL” has been selected, the sets will start in a selected input mode at the next power-on.

10.INPUT MODE FIXED [VARIABLE → FIXED]

“FIXED” has been selected, any channels and input modes other than those selected at the start mode cannot be picked up.

3 – 25

Page 40

LC32D44E/S/RU-BK/GY (1st Eddition)

11.RESET

Cancel all Public Mode settings. (It returns to the factory settings)

12.EXECUTE

Select this item, and press cursor RIGHT / LEFT keys on the remote control or VOL (+) / (-) keys on the LCD TV for confirmation the functions settings.

3 – 26

Page 41

LC32D44E-BK

CHAPTER 4. TROUBLE SHOOTING TABLE

Service Manual

[1] TROUBLE SHOOTING TABLE

No power supply (Front LED does not light up) and no power-up even if turned on (Front LED light up).

LC32D44E/S/RU-BK/GY (1st Eddition)

Is the wire harness in the unit properly connected?

YES

Are F7101 and F7103 normal?

YES

Is F7102 normal?

YES

Is BU5V supplied from PIN(11) of connector CN7201

when the power switch is turned on?

YES

Is the PS_ON signal sent to PIN(10) of connector CN7201

when turning on the power switch and does RL7101 normally work?

NO

NO

NO

NO

NO

Reconnect and recheck the wire harness.

Are L7101-2, L7110, C7104-5, VA7103, D7101, etc. faulty? Check if

the peripheral circuits are short-circuited.

Are T7101, D7104, TH7101, C7118, etc.faulty? Check if the peripheral circuits are short-circuited.

Check the peripheral circuits on the primary side of IC7101, T7101,

etc. and the secondary side of D7222, D7215, L7206, PC7104, etc.

Check the peripheral circuits such as PS_ON circuits of Q7207,

PC7103, RL7101, etc.

YES

Is a DC voltage of approx. 400V applied to both ends of

C7129?

YES

Is 13V supplied from PIN(1-4) of connector CN7201 when

the power switch is turned on?

YES

Is 60V supplied when the power switch is turned on?

NO Does the PFC circuit normally work?

NO Check the primary side of T7102-3, Q7111-6, etc., the secondary side

NO

(Check IC7102, L7103, L7104, D7106, D7108, TH7102, Q7104-5,

Q7117, etc. and the peripheral circuits.)

of D7203, etc., the peripheral circuits and the protection circuits of

D7205, D7208, PC7102, etc.

Check the secondary side of D7201, the protection circuits of D7206,

D7207, D7209, PC7102, etc. and the peripheral circuits.

4 – 1

Page 42

LC32D44E/S/RU-BK/GY (1st Eddition)

The backlight does not light

Are all fluorescent lamps on?

NO

Is F7501 normal?

YES

Is 60V applied to both ends of C7501?

YES

Is a voltage of 13V applied to PIN(20) of IC7501?

YES

Is the STB_ON/OFF signal supplied from PIN(2) of

CN7502?

YES

Is each control signal of connector CN7502 normally function?

PIN(3) OFL (PWM light control signal input) OFL (PWM light control signal input)/H: Lamp ON, L: Lamp OFF

PIN(5) ERR (Error output) ERR (Error output)/H: Normal, L: Error

PIN(7) REG2 (Light control method identification)

PIN(9) ADIM (Tube current setting)

NO

NO

NO

NO

NO Check the STB signal line on the MAIN_UNIT side and the peripheral

NO Check each control circuit.

Check each fluorescent lamp, and replace if defective.

(CN7503-12, etc.)

Check if the peripheral circuits are short-circuited or parts are faulty.

(Q7501, Q7503, etc.)

Refer to "No power supply (Front LED does not light up)" and "No

power-up even if turned on (Front LED light up)".

Check the 13V line and the peripheral circuits.

circuits.

(P2303/CN7502, etc.)

REG2 (Light control method identification)/H: External PWM input, L:

Analog voltage input

ADIM (Tube current setting)/H: Tube current 12mA, L: Tube current

8.5mA

YES

Is [0] displayed as the number of [LAMP_ERROR] in the

process mode?

YES

Is the drive output signal sent from PIN(16) and (15) of

IC7501?

YES

Does the drive output circuit normally work?

YES

Does the secondary side of T7501-5 normally work?

YES

Check if the feedback circuit is normal.

(D7501-5, D7507-11, D7513-17, etc.)

NO

NO

NO

NO

Reset the number of [LAMP_ERROR] to the default value in the process mode.

Check IC7501and the peripheral circuits.

Are Q7509-10, Q7501-4, etc. faulty? Check the peripheral circuits.

Is T7501-5, etc. faulty? Check the peripheral circuits.

4 – 2

Page 43

No sound output in all modes.?

LC32D44E/S/RU-BK/GY (1st Eddition)

The sound is not emitted from the speaker though the picture has come out.

Is the audio signal output of pins (28/L) and (27/R) of

IC3001 (MAIN_MICON) normal?

YES

Is audio signal input to pin(5/L), pin(9/R) of IC2701(AMP)?

YES

Is MUTE circuit [MUTE_SP_LINE, RESET_N_LINE] normal?

YES

Is the audio signal output of pins (3, 4) (L-ch) and (2, 1)

(R-ch) of P2701(AOUDIO-CONNECTOR) normal?

YES

Check Speaker (right and left) and wire harness.

No sound (during the reception of TV(ANALOG) broadcasting)

NO

NO

NO

NO

Check IC3001 and its peripheral circuits.

Check the line between IC3001 and IC2701.

Check the MUTE_SP_LINE and RESET_N_LINE.

(Q2701, etc.)

Check IC2701 and its peripheral circuits.

Does not the sound go out though the picture has come out when UHF/VHF is received?

Is the SIF signal output from pin (4) of TUNER (TU201)?

YES

Is the SIF signal sent to pins (31) of IC3001

(MAIN_MICON)?

YES

Refer to “No sound output in all modes”.

NO

NO

Check the tuner and its peripheral circuits.

Replace as required.

Check the line between TU201 and IC3001.

4 – 3

Page 44

LC32D44E/S/RU-BK/GY (1st Eddition)

No sound (during the reception of TV(DIGITAL) broadcasting)

Does not the sound go out though the picture has come out when DTV is received?

Is the audio signal output from PIN(24,25)/ LETFT_M/P,

PIN(28,29)/ RIGH_M/P of IC4001(SETTOP_BOX_DECODER).

YES

Is the audio signal input to PIN(6,5)/ LETFT_M/P, (2,3)/

RIGH_M/P of IC4005(OP-AMP)?

YES

Is the audio signal sent from PIN(7)/ AIN1L, (1)/AIN1R of

IC4005 to PIN(10), PIN(9) of IC3001 (MAIN_MICON)?

Refer to “No sound output in all modes”.

Does not the sound of the audio signal input to EXT1(SCART1) go out?

Does not the sound of the audio signal input to EXT2(SCART2) go out?

EXT1

Is the audio signal properly sent to pins (6) (AIN3_L) and

(2) (AIN3_R) of SCART1(SC1102)?

EXT2

Is the audio signal properly sent to pins (6) (AIN2_L) and

(2) (AIN2_R) of SCART2(SC1101)?

YES

No sound from external input devices (1)

NO

NO

NO

NO

NO

Check IC4001 and its peripheral circuits.

Check the line between IC4001 and IC4005.

Check the line between IC4005 and IC3001.

Check the setting of an external input device that connects of

SC1102.

Check the setting of an external input device that connects of

SC1101.

YES

EXT1

Is the audio signal properly sent to pins (14) (AIN3_L) and

(13) (AIN3_R) of IC3001(MAIN_MICON)?

EXT2

Is the audio signal properly sent to pins (12) (AIN2_L) and

(11) (AIN2_R) of IC3001(MAIN_MICON)?

YES

Refer to “No sound output in all modes”.

NO

Check the line between SC1102 and IC3001.

NO

Check the line between SC1101 and IC3001.

4 – 4

Page 45

No sound from external input devices (2)

Does not the sound of the audio signal input to EXT3 go out?

MINI AV UNIT:

Is audio signal output from pin(5/IN3L), (4/IN3R) of input

terminal J1002 to pin(8), (6) of connector SC1001?

MAIN UNIT: YES

Is audio signal input to pin(8/IN3L), (6/IN3R) of connector

P1001?

YES

Is audio signal input to pin(1/IN3L), (6/IN3R) of IC1301

(AUDIO_SELECTOR)?

YES

Is the audio signal sent to pin (15/AIN4L), (11/AIN4R) of

IC1301?

NO

NO

NO

NO

LC32D44E/S/RU-BK/GY (1st Eddition)

Check connection of between from J1002 to SC1001 and the external input device.

Check the connector(SC1001/ P1001).

Check the line between P1001 and IC1301.

Check IC1301 and its peripheral circuits.

YES

Is audio signal input from pin (15/AIN4L), (11/AIN4R) of IC1301 to pin (16, 15) of IC3001 (MAIN_MICON)?

YES NO

Refer to “No sound output in all modes” Check the line between IC1301 and IC3001.

No sound from external input devices (3)

Does not the sound of the audio signal input to EXT4 go

out?

Is audio signal sent from pin(2/L) and (3/R) of input terminal J1301 to pin(5) and (8) of IC1301

(AUDIO_SELECTOR)?

YES

Does not the sound of the audio signal input to EXT6(Analog) go

out?

Whether "Analog" has selected it in the Audio setup of the HDMI

option is checked.

Is audio signal sent from pin(2/L) and (3/R) of input terminal J1302

to pin(3) and (7) of IC1301(AUDIO_SELECTOR)?

NO NO

Check the connection between J1301 and the peripheral

circuit, the external input devices.

Is the audio signal sent to pin (15/AIN4L), (11/AIN4R) of

IC1301?

Check the connection between J1302 and the peripheral circuit, the

external input devices.

NO

Check IC1301 and its peripheral circuits.

4 – 5

Page 46

LC32D44E/S/RU-BK/GY (1st Eddition)

YES

Is audio signal input from pin (15/AIN4L), (11/AIN4R) of IC1301 to pin (16, 15) of IC3001 (MAIN_MICON)?

YES NO

Refer to “No sound output in all modes” Check the line between IC1301 and IC3001.

No sound from external input devices (4)

Does not the sound of the audio signal input to EXT5 go out?

Is audio signal output from pin(2/COMP_AL), (4/

COMP_AR) of input terminal J1303 to pin(13), (9) of

IC1301 (AUDIO_SELECTOR)?

YES

Is the audio signal sent to pin (15/AIN4L), (11/AIN4R) of

IC1301?

YES

Is audio signal input from pin (15/AIN4L), (11/AIN4R) of IC1301 to pin (16, 15) of IC3001 (MAIN_MICON)?

YES NO

Refer to “No sound output in all modes” Check the line between IC1301 and IC3001.

No sound from external input devices (5)

Does not the sound of the audio signal input to EXT6/7(HDMI) go out?

Is picture of the signal input from EXT6/7 displayed?

NO

NO

NO

Check connection of between from J1303 to IC1301 and the external

input device.

Check IC1301 and its peripheral circuits.

Refer to “Does not the picture of the HDMI signal input to EXT6/7 go

out?”.

YES

Is the HDMI_SCK/ WS/ SD0 audio signal output from

pin(86), (85), (84) of IC1951 (HDMI RECEIVER) to pin(39),

(40), (38) of IC3001 (MAIN_MICON)?

YES

Refer to “No sound output in all modes”.

NO

Check the line between IC1951 and IC3001, and their peripheral circuits.

4 – 6

Page 47

No audio signal output from SCART1 terminal.

LC32D44E/S/RU-BK/GY (1st Eddition)

The audio signal is not output (1)

Is audio signal sent to pins (3/L-ch) and (1/R-ch) of

SCART1(SC1102)?

NO

Is S-MUTE-LINE [pin(62) of IC2302(SUB_MICON)] at H?

NO

Is audio signal sent to pins (24/L-ch) and (23/R-ch) of

IC3001(MAIN_MICON)?

NO

Check IC3001 and its peripheral circuits.

No audio signal output from SCART2 terminal.

Is audio signal sent to pins (3/L-ch) and (1/R-ch) of

SCART2(SC1101)?

YES

YES

YES

The audio signal is not output (2)

YES

Check the connection to SCART1 and external devices.

Check the peripheral circuits of IC2302 and S-MUTE_LINE.

(Q1101, etc.)

Check the line between SC1102 and IC3001.

(Q1106, Q1105, etc.)

Check the connection to SCART2 and external devices.

NO

Is S2-MUTE-LINE [pin(63) of IC2302(SUB_MICON)] at H?

NO

Is audio signal sent to pins (22/L-ch) and (21/R-ch) of

IC3001(MAIN_MICON)?

NO

Check IC3001 and its peripheral circuits.

YES

YES

Check the peripheral circuits of IC2302 and S2-MUTE_LINE.

(Q1102, etc.)

Check the line between SC1101 and IC3001.

(Q1108, Q1107, etc.)

4 – 7

Page 48

LC32D44E/S/RU-BK/GY (1st Eddition)

NO

No audio signal output from AUDIO_OUTPUT terminal.

The audio signal is not output (3)

Is audio signal output to pin(2/L-ch), (4/R-ch) of audio output terminal J1304?

NO

Is S-MUTE-LINE [pin(62) of IC2302(SUB_MICON)] at H?

NO

Is audio signal sent to pins (22/L-ch) and (21/R-ch) of

IC3001(MAIN_MICON)?

NO

Check IC3001 and its peripheral circuits.

No sound from HEDPHONE_OUTPUT terminal.

Is the HP_PLUG signal input into pin (208) of

MAIN_UNIT's IC3001 (MAIN_MICON) from pin (6) of a

headphone terminal (J1003)?

YES

YES

YES

The audio signal is not output (6)

NO

Check the connection to J1304 and external devices.

Check the peripheral circuits of IC2302 and S-MUTE_LINE.

(Q1303, etc.)

Check the line between J1304 and IC3001.

(Q1302, Q1301, etc.)

Check the line between J1003 and IC3001.

(SC1001/P1001, IC3001, etc.)

YES

Is the audio signal output to pin(2/L-ch) pin(3/R-ch) of

headphone terminal J1003?

NO

Is the audio signal input into pin (3) and (1) of connector

SC1001 from pin(3/L-ch),(1/R-ch) of connector P1001?

NO

Is HP-MUTE-LINE [pin(40) of IC2302(SUB_MICON)] at

H?

NO

Is audio signal sent to pins (26/L-ch) and (25/R-ch) of

IC3001(MAIN_MICON)?

NO

Check IC3001 and its peripheral circuits.

YES

YES

YES

YES

Check HEAD-PHONE (J1003) or peripheral circuits.

Check the line between P1001 and J1003.

(SC1001/P1001, etc.)

Check the peripheral circuits of IC2302 and HP-MUTE_LINE.

(Q1001, etc.)

Check the line between P1001 and IC3001.

(IC1102, etc.)

4 – 8

Page 49

No picture on the display (1)

The picture doesn't appear in all modes.

LC32D44E/S/RU-BK/GY (1st Eddition)

Is the LVDS signal output from IC3001

(MAIN_MICON)?

LVDS0_P/N(140/141), LVDS1_P/N(137/138),

LVDS2_P/N(134/135), LVDS3_P/N(128/129),

LVDS4_P/N(125/126), LVDS_CP/CN(131/132).

YES

Is the LVDS signal input to IC8103 (LCD_CONTROL)?

A0+/-(165/164), A1+/-(167/166), A2+/-(169/168), A3+/(189/188), A4+/-(191/190), ACK+/-(187/186)

YES

Is the control signal of LCD controller normal?

YES

Is VCC_3.3V, VCC_2.5V or VCC_1.5V supplied to

IC8103?

YES

Are the video signals BR/BG/BB (0_P/M-3_P/M), FR/

FG/FB (0_P/M-3_M/P) and the CLK signals (BCLK_P/

M, FCLK_P/M) output from IC8103?

NO

Check IC3001 and its peripheral control circuits.

NO