Page 1

SERVICE MANUAL

R

Page

.

SHARP CORPORATION

COMBINATION LIQUID CRYSTAL

TELEVISION AND DVD/CD PLAYE

S50OPLC26DV20

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

LC-26DV200E

CONTENTS

IMPOTANT WARNING.………………………………………………………………………………………… A1-1

•

SERVICING NOTICES ON CHECKING.………………………………………………………………………A1-2

•

HOW TO ORDER PARTS………………………………………………………………………………………A1-2

•

IMPORTANT………………………………………………………………………………………………………A1-2

•

WHEN REPLACING DVD DECK.………………………………………………………………………………A1-3

•

PREPARATION OF SERVICING………………………………………………………………………………A1-3

•

DISC REMOVAL METHOD AT NO POWER SUPPLY.………………………………………………………A1-4

•

PARENTAL CONTROL-RATING LEVEL.………………………………………………………………….… A1-4

•

ABOUT LEAD FREE SOLDER (PbF).……………………………………………………………..……………A1-5

•

HOTEL MODE FUNCTION………………………………………………………………………………………A1-6

•

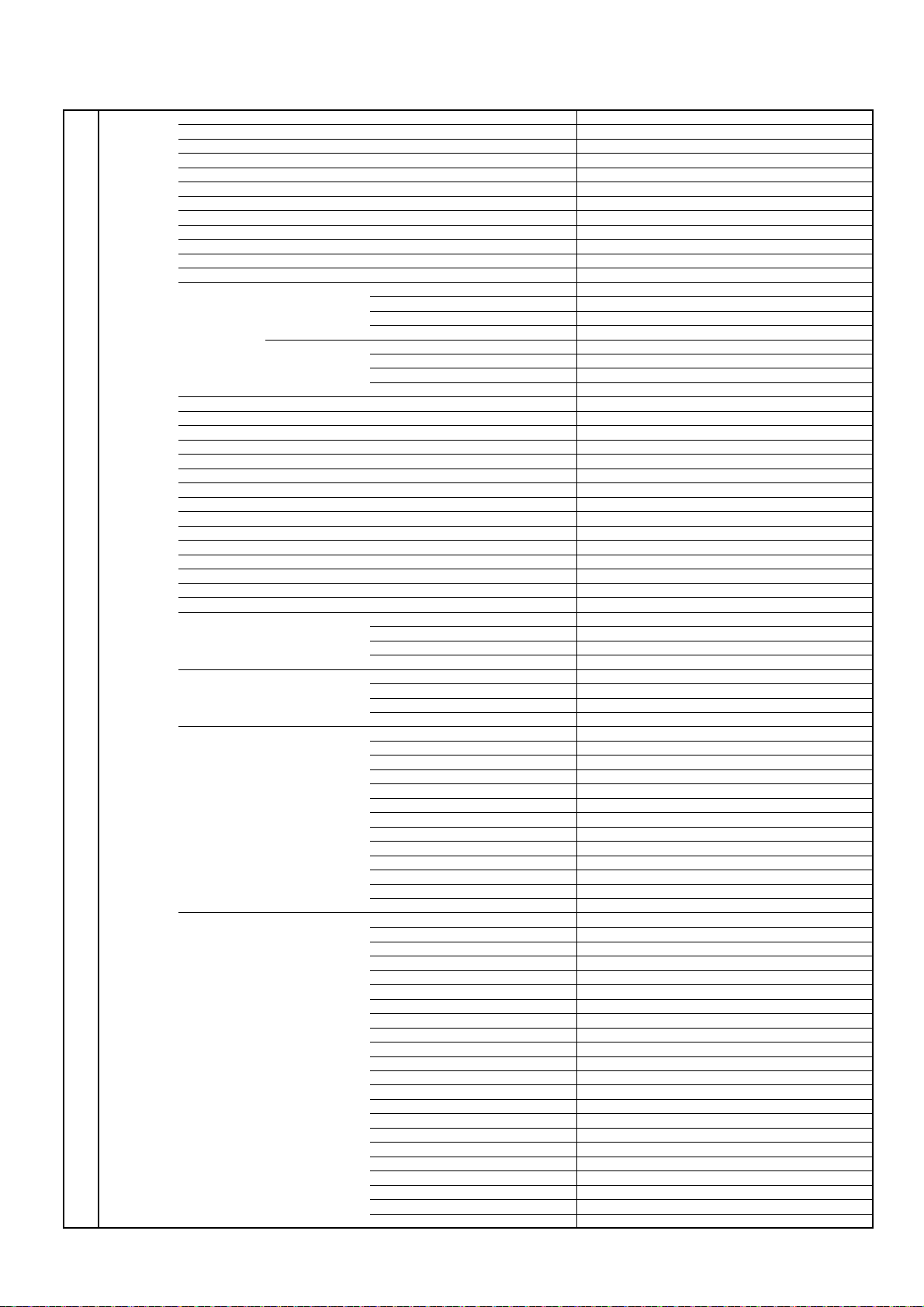

GENERAL SPECIFICATIONS.…………………………………………………………………………………A2-1~A2-7

•

DISASSEMBLY INSTRUCTIONS ………………………………………………………………….……………B1-1~B3-2

•

SERVICE MODE LIST.……………………………………………………………………………………………C-1

•

SERVICING FIXTURES AND TOOLS……………………………………………………………..……………C-2

•

RE-WRITE FOR DVD FIRMWARE………………………………………………………………..……………C-2

•

RE-WRITE FOR DIGITAL SOFT FIRMWARE………………………………………………………………..C-3, C-4

•

PARTS LOCATION GUIDE (WIRING CONNECTION)………………………………………………………D-1

•

TROUBLESHOOTING GUIDE………………………………………………………………………………… E-1~E-9

•

BLOCK DIAGRAM…………………………………………………………………………………..……………F-1~F-12

•

PRINTED CIRCUIT BOARDS……………………………………………………………………….………… G-1~G-11

•

SCHEMATIC DIAGRAMS…………………………………………………………………………..……………H-1~H-50

•

WAVEFORMS……………………………………………………………………………………….……………I-1~I-3

•

MECHANICAL EXPLODED VIEWS……………………………………………………………………… ……J1-1~J1-3

•

DVD DECK EXPLODED VIEWS…………………………………………………………………..……..…… J2-1

•

REPLACEMENT PARTS LIST……………………………………………………………………..……..……K1-1~K3-8

•

Parts marked with " ! " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

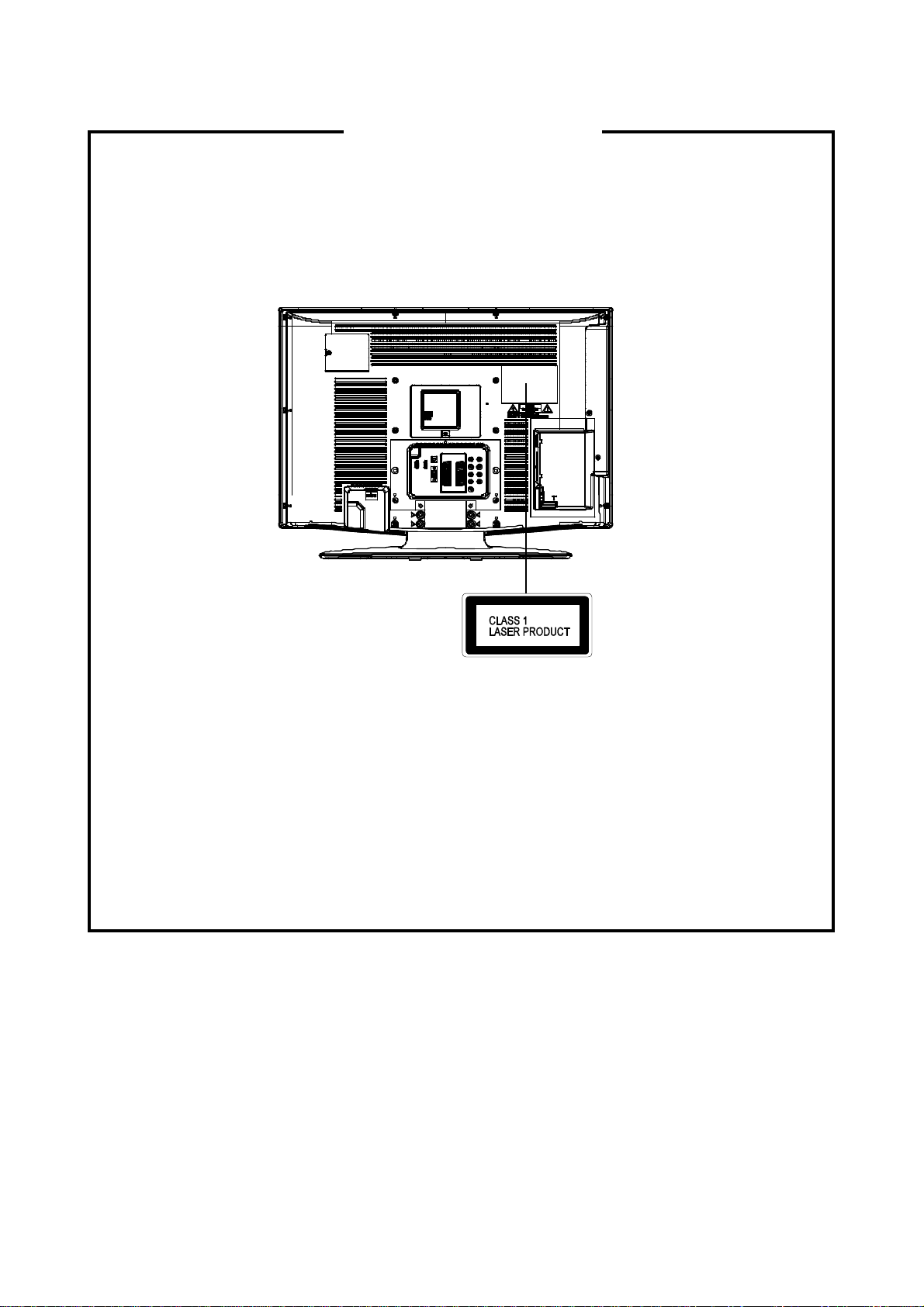

IMPOTANT WARNING

CAUTION:

DVD PLAYER IS A CLASS 1 LASER PRODUCT. HOWEVER THIS PLAYER USES A VISIBLE LASER

BEAM WHICH COULD CAUSE HAZARDOUS RADIATION EXPOSURE IF DIRECTED. BE SURE TO

OPERATE THE PLAYER CORRECTLY AS INSTRUCTED.

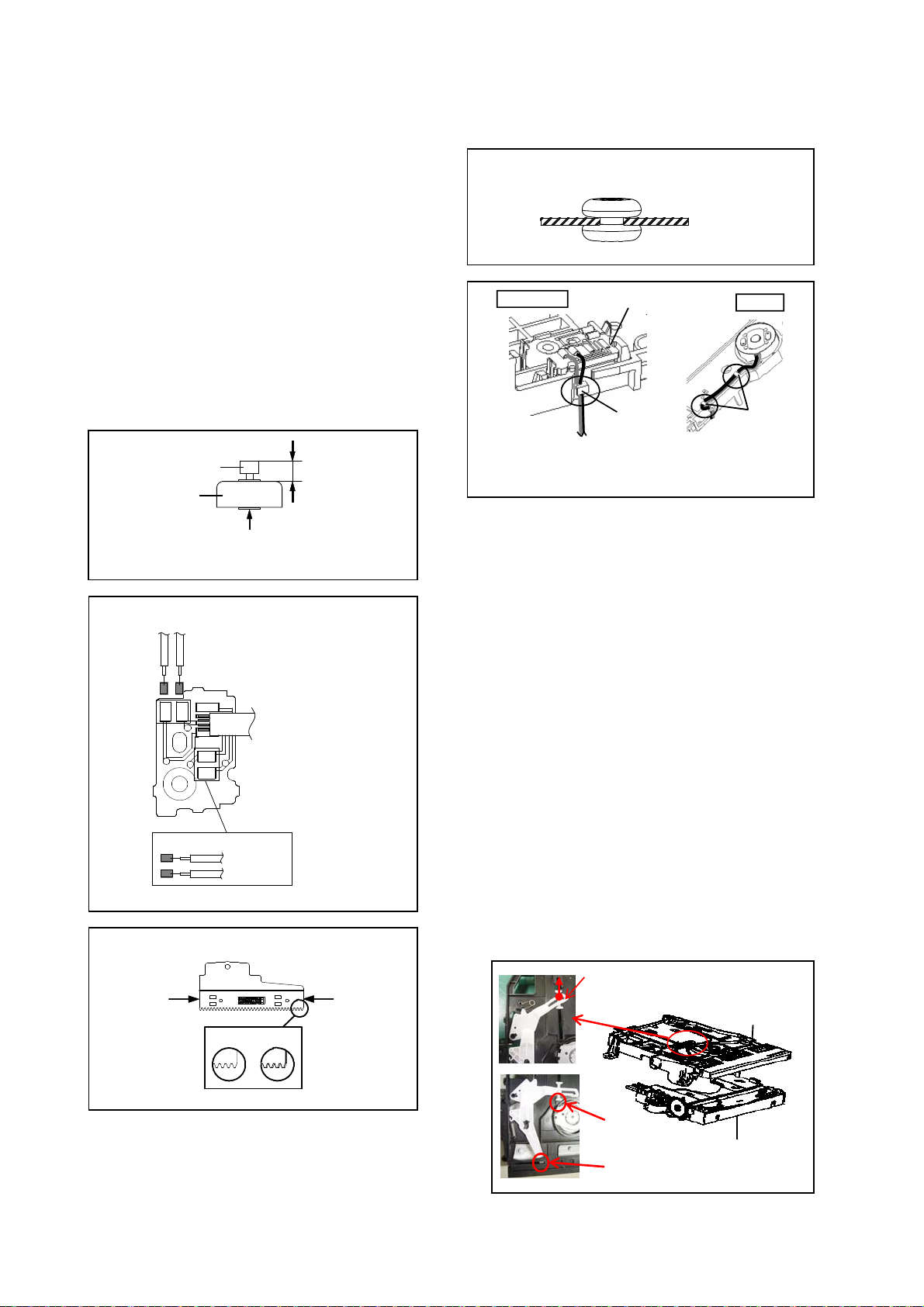

THE FOLLOWING CAUTION LABEL IS LOCATED ON THE REAR PANEL OF THE PLAYER.

(Printed on the Rear Panel)

WHEN THIS PLAYER IS PLUGGED TO THE WALL OUTLET, DO NOT PLACE YOUR EYES CLOSE

TO THE OPENING OF THE DISC TRAY AND OTHER OPENINGS TO LOOK INTO THE INSIDE OF

THIS PLAYER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

DO NOT OPEN COVERS AND DO NOT REPAIR YOURSELF. REFER SERVICING TO QUALIFIED

PERSONNEL.

A1-1

Page 3

SERVICING NOTICES ON CHECKING

4.

BE CAREFUL WITH THE

1. KEEP THE NOTICES 6. PERFORM A SAFETY CHECK AFTER

SERVICING

As for the places which need special attentions,

they are indicated with the labels or seals on the Confirm that the screws, parts and wiring which

cabinet, chassis and parts. Make sure to keep the were removed in order to service are put in the

indications and notices in the operation manual. original positions, or whether there are the

portions which are deteriorated around the

2. AVOID AN ELECTRIC SHOCK

There is a high voltage part inside. Avoid an external metal and the AC cord plug blades.

electric shock while the electric current is And be sure the safety of that.

flowing.

3. USE THE DESIGNATED PARTS

The parts in this equipment have the specific 2. Remove the antenna terminal on TV and turn

characters of incombustibility and withstand on the TV.

voltage for safety. Therefore, the part which is 3. Insulation resistance between the cord plug

replaced should be used the part which has terminals and the eternal exposure metal

the same character.

Especially as to the important parts for safety using the 500V insulation resistance meter

which is indicated in the circuit diagram or the

table of parts as a ! mark, the designated 4. If the insulation resistance is less than 1M

parts must be used. ohm, the inspection repair should be

serviced places serviced or not. Check the

insulation between the antenna terminal or

(INSULATION CHECK PROCEDURE)

1. Unplug the plug from the AC outlet.

[Note 2] should be more than 1M ohm by

[Note 1].

required.

LCD PANEL [Note 1]

If you have not the 500V insulation

Avoid a shock to the panel while servicing. resistance meter, use a Tester.

Take enough care to deal with it.

[Note 2]

5. PUT PARTS AND WIRES IN THE

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

External exposure metal: Antenna terminal

Headphone jack

HOW TO ORDER PARTS

Please include the following informations when you order parts. (Particularly the VERSION LETTER.)

1. MODEL NUMBER and VERSION LETTER

The MODEL NUMBER can be found on the back of each product and the VERSION LETTER can be

found at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

IMPORTANT

When you exchange IC and Transistor with a heat sink, apply silicon grease (YG6260M) on the contact

section of the heat sink. Before applying new silicon grease, remove all the old silicon grease.

(Old grease may cause damage to the IC and Transistor).

A1-2

Page 4

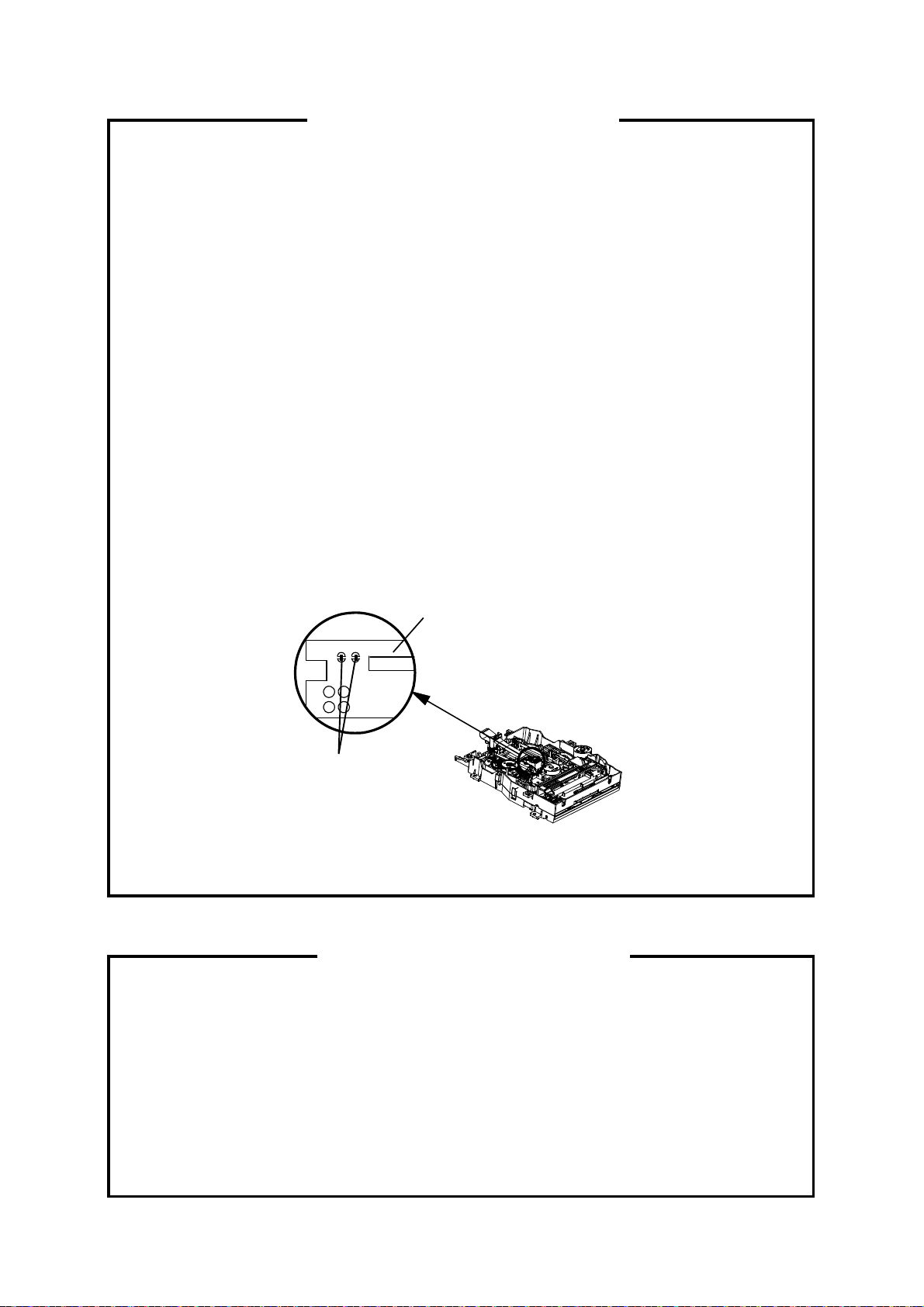

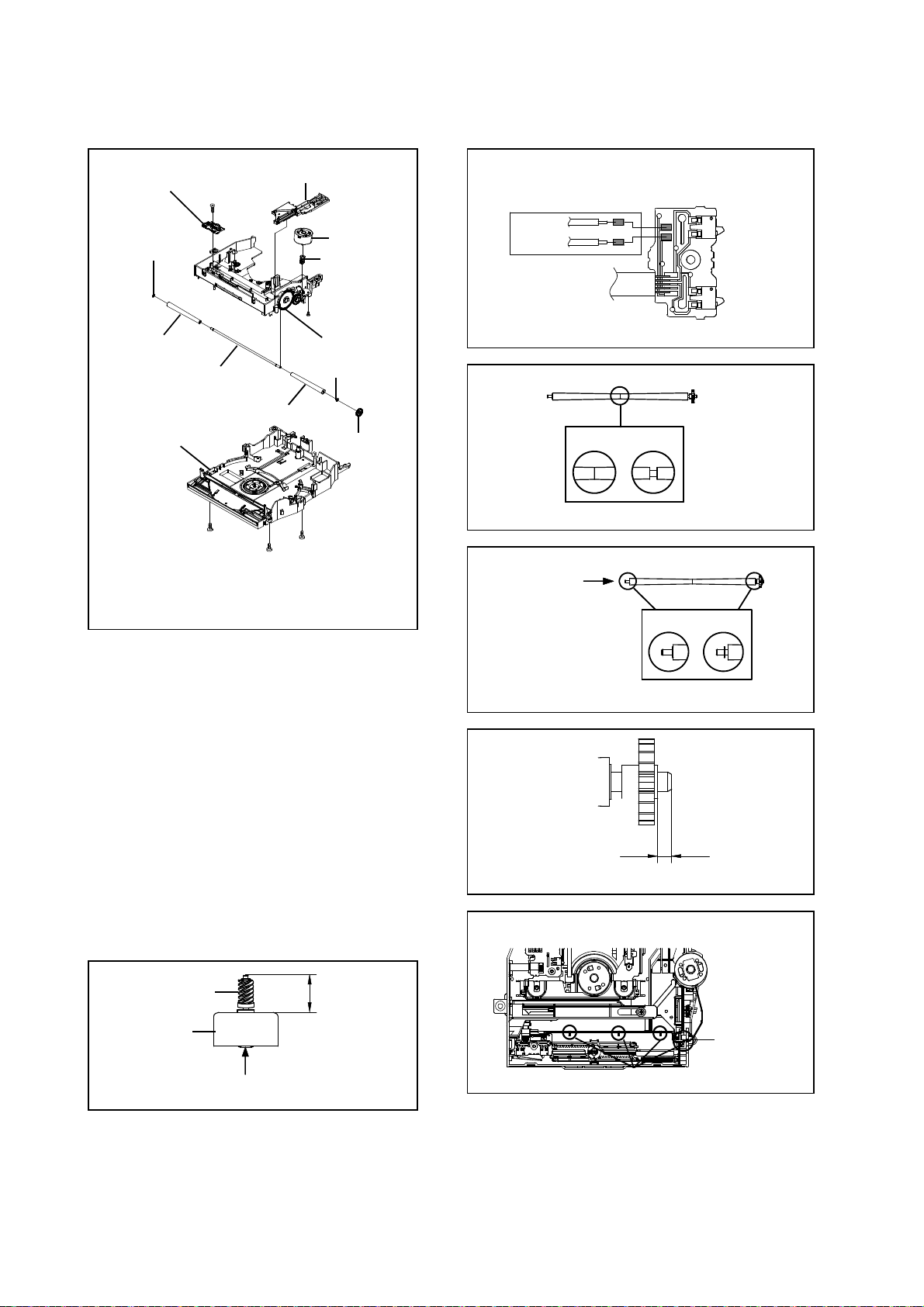

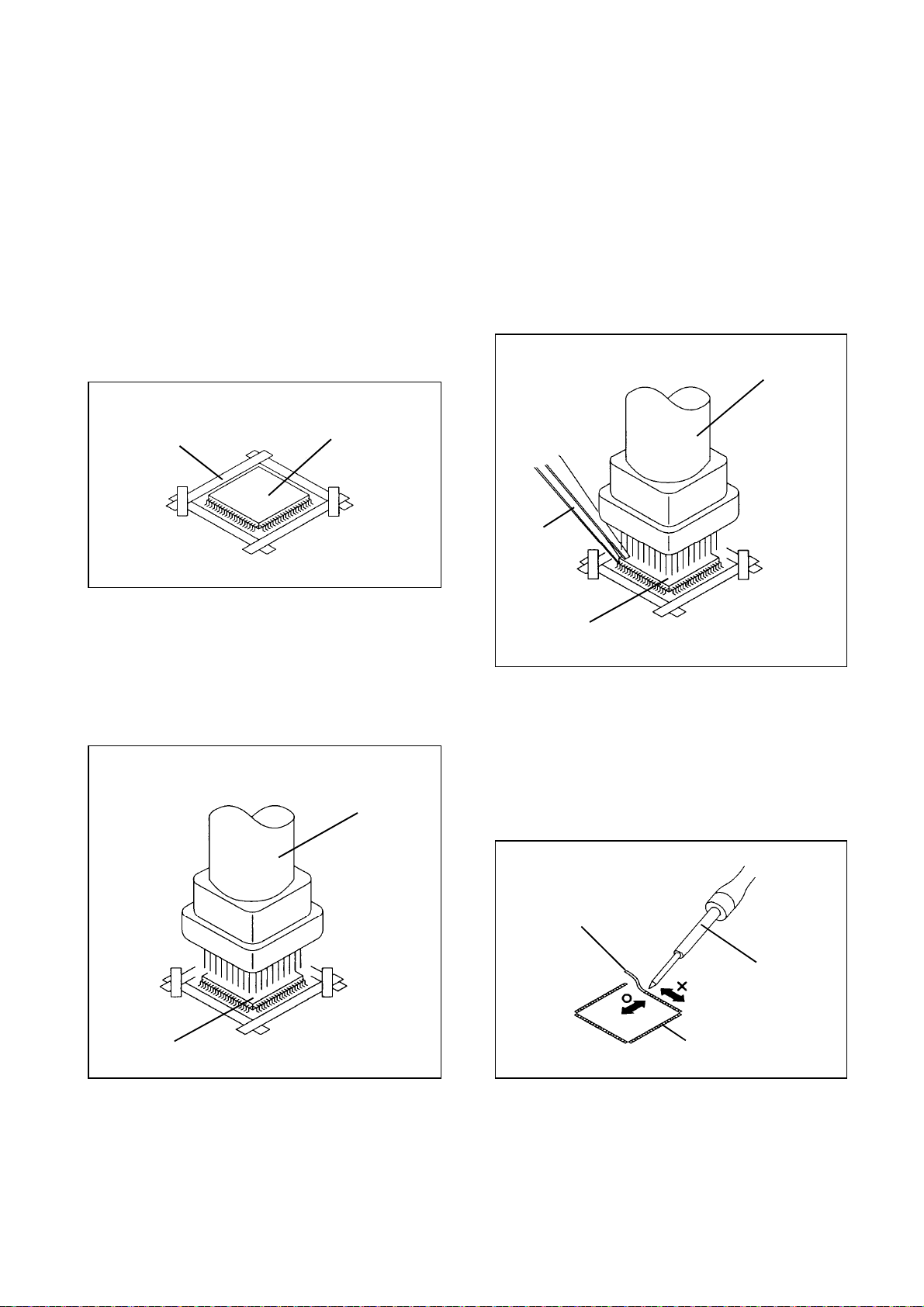

WHEN REPLACING DVD DECK

[ When removing the DVD Deck ]

Before removing Pick Up PCB and DVD MT PCB connector, the short circuit the position shown in Fig. 1

using a soldering iron. If you remove the DVD Deck with no soldering, the Laser may be damaged.

[ When installing the DVD Deck ]

Remove all the soldering on the short circuit position after the connection of Pick Up PCB and DVD

MT PCB connector.

NOTE

• Before your operation, please read “PREPARATION OF SERVICING”.

• Use the Lead Free solder.

• Manual soldering conditions

•

Soldering temperature: 320 ± 20

• Soldering time: Within 3 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

• When Soldering/Removing of solder, use the draw in equipment over the Pick Up Unit to keep the

Flux smoke away from it.

o

C

Pick Up PCB

Short circuit using a

soldering iron.

Fig. 1

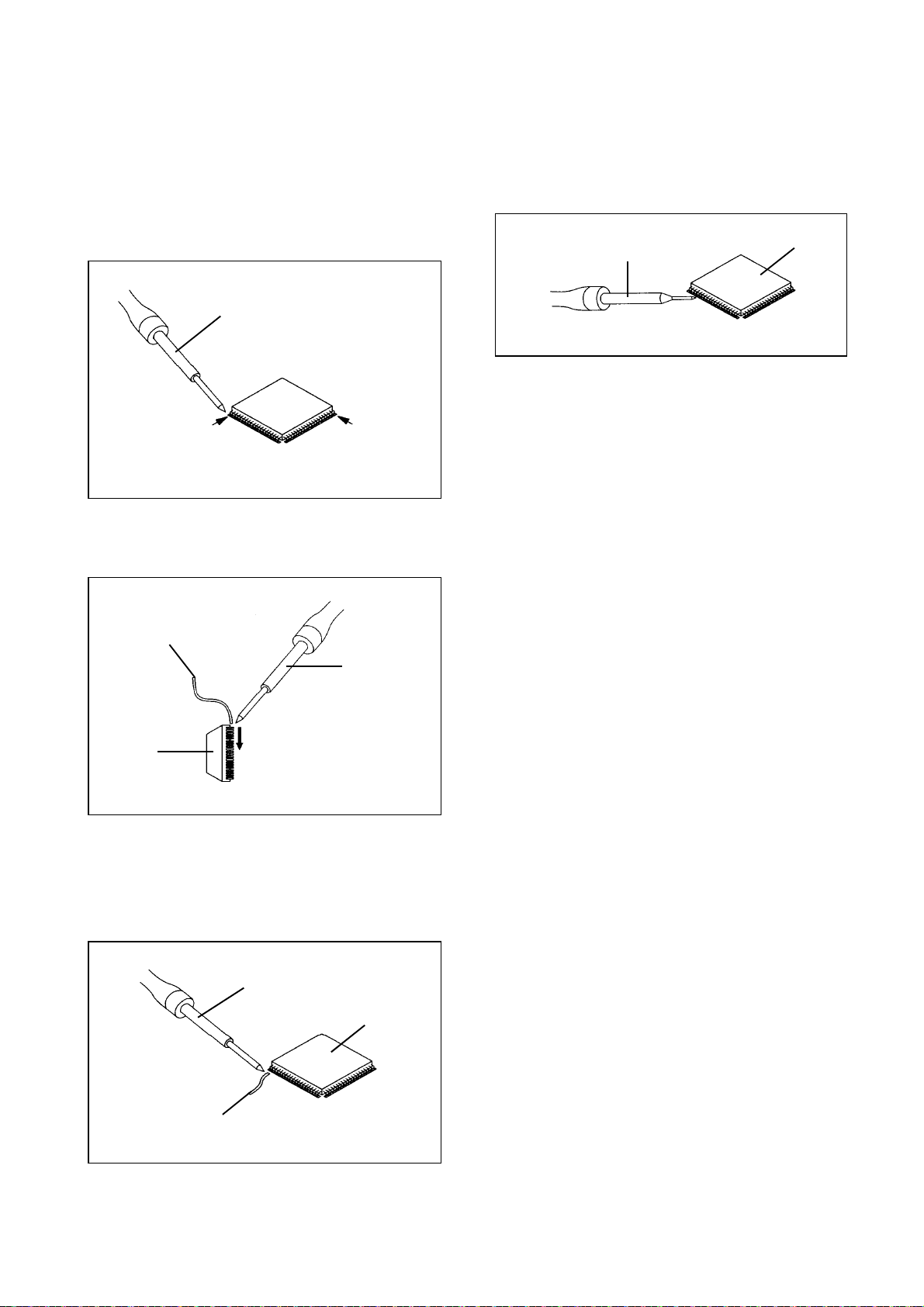

PREPARATION OF SERVICING

The laser diode used for a pickup head may be destroyed with external static electricity.

Moreover, even if it is operating normally after repair, when static electricity discharge is received at the

time of repair, the life of the product may be shortened.

Please perform the following measure against static electricity, be careful of destruction of a laser diode

at the time of repair.

• Place the unit on a workstation equipped to protect against static electricity, such as conductive mat.

• Soldering iron with ground wire or ceramic type is used.

• A worker needs to use a ground conductive wrist strap for body.

A1-3

Page 5

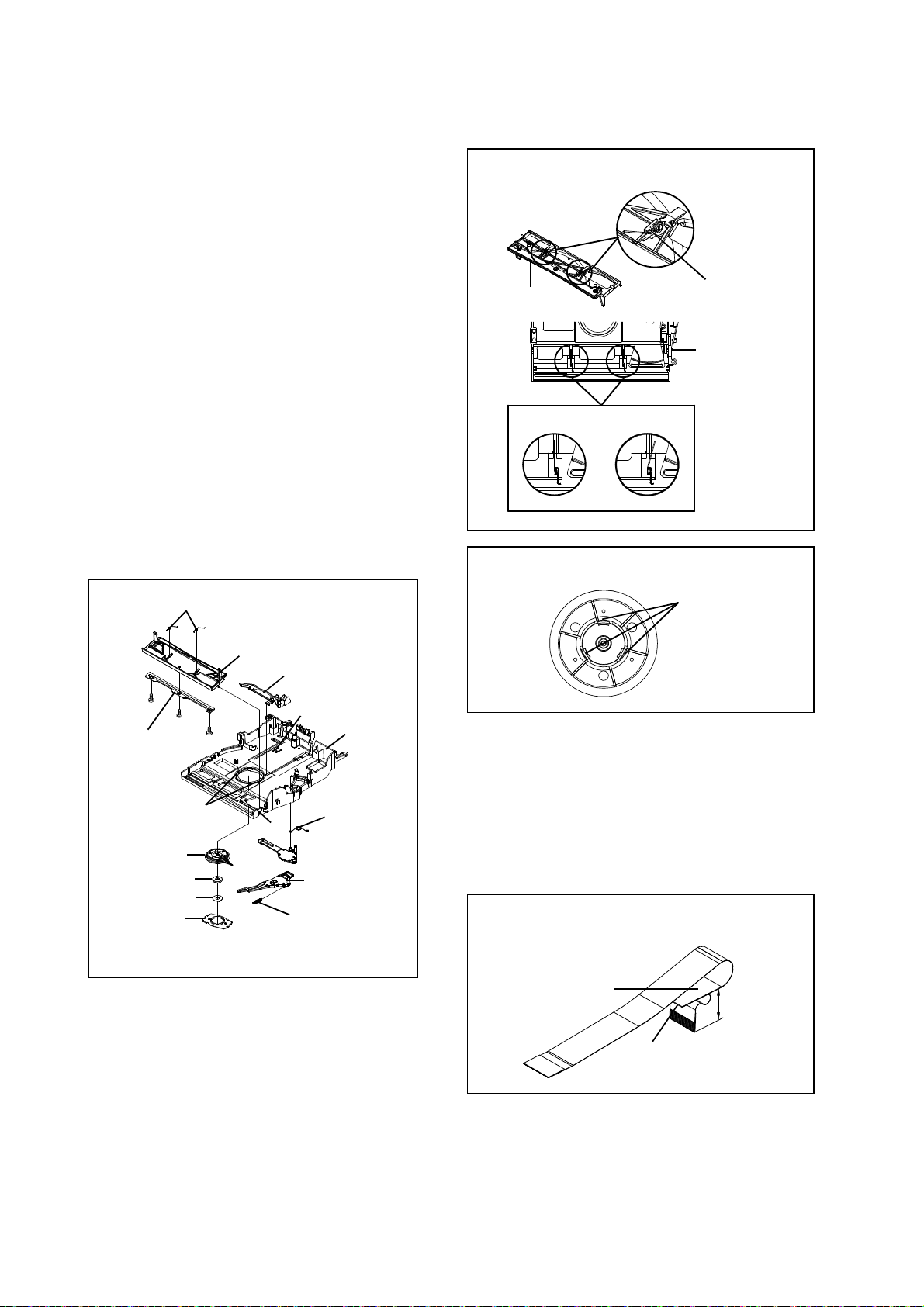

DISC REMOVAL METHOD AT NO POWER SUPPLY

Gear Middle

1. Remove the Stand Ass'y, Front Cabinet Ass'y and LCD Panel.

(Refer to item 1 of the DISASSEMBLY INSTRUCTIONS.)

2.

Slide the Gear Middle toward the arrow direction by hand to release the lock. (Refer to Fig. 1)

3. Take out the Disc from the DVD Deck. Be careful not to scratch on the Disc.

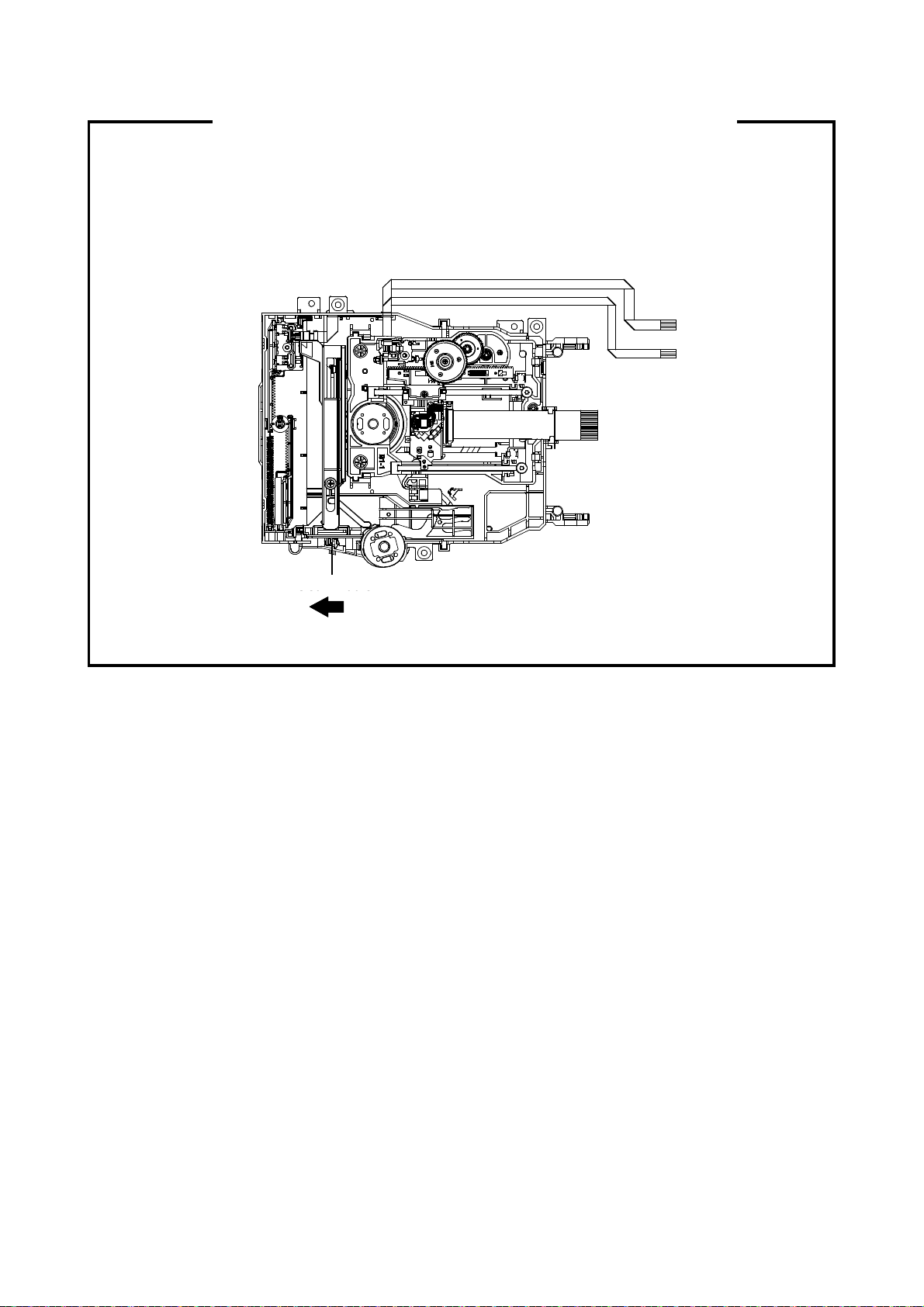

DVD Deck

Fig. 1

PARENTAL CONTROL - RATING LEVEL

4 DIGIT PASSWORD CANCELLATION

If the stored 4 digit password in the Rating Level menu needs to be cancelled, please follow the steps below.

1. Turn Unit ON.

2. Set the DVD to the Stop Mode.

3. Check that “No disc” is displayed on the screen.

4. Press and hold the “STOP” button on the side panel.

5. Simultaneously press and hold the “7” key on the remote control unit.

6. Hold both keys for more than 2 seconds.

7. The On Screen Display message “PASSWORD CLEAR” will appear.

8. The 4 digit password has now been cleared.

A1-4

Page 6

ABOUT LEAD FREE SOLDER (PbF)

•

Pb free solder will tend to splash when heated too high (about 1100

F/ 600

C).

Distinction of PbF PCB:

PCBs (manufactured) using lead free solder will have a PbF printing on the PCB.

(Please refer to figures.)

Caution:

• Pb free solder has a higher melting point than standard solder;

Typically the melting point is 86oF~104oF(30oC~40oC) higher.

Please use a soldering iron with temperature control and adjust it to 650oF ± 20oF (350oC ± 10oC).

In case of using high temperature soldering iron, please be careful not to heat too long.

o

o

• All products with the printed circuit board with PbF printing must be serviced with lead free solder.

When soldering or unsoldering, completely remove all of the solder from the pins or solder area,

and be sure to heat the soldering points with the lead free solder until it melts sufficiently.

Recommendations

Recommended lead free solder composition is Sn-3.0Ag-0.5Cu.

A1-5

Page 7

HOTEL MODE FUNCTION

RESPOND/

To set the Hotel mode, please follow the steps below.

Press the MENU---> 0027 button on the remote control.

1.

The Hotel mode setting menu will appear.

2.

Using the UP/DOWN button on the remote control,

3.

select the desired mode. Then press the ENTER button.

Using the LEFT/RIGHT button on the remote control,

4.

set the mode to desired setting.

The Hotel mode has now been set up.

5.

To reset the Hotel mode, please follow the steps below.

1. Press the MENU---> 0027button on the remote control.

2. The Hotel mode setting menu will appear.

3. Using the UP/DOWN button on the remote control, select the RESET.

4. Using the LEFT/RIGHT button on the remote control, please select "OK".

Then press the ENTER button.

5. The setting items has now been returned to initial value.

Setting item

Maximum volume

Panel button

Menu button

Input mode start

Channel Number Channel Number tuned when starting this product can be set.

Reset Various settings of the Hotel mode function return initial State.

Note 1) Even if setting it to "No Respond", the service mode function are effective.

Note 2) If setting it to "OFF", it start up in same input source when you turn off the power before.

Setting value

0~100

NO RESPOND

TV/AV/

COMPONENT/

HDMI/PC/DVD/

OFF

All Channel 1

100

RESPOND

OFF

Setting of the maximum volume value.

Effective/invalid setting of main key operation. (*Note 1)

Effective/invalid setting of Menu key operation of set and remote control.

(*Note 1)

Setting of input source at power supply On. (*Note 2)

FUNCTIONInitial value

A1-6

Page 8

GENERAL SPECIFICATIONS

G-1 TV LCD LCD Size / Visual Size 26.01 inch / 660.5mmV

System LCD Type Color TFT LCD

Color System PAL / SECAM

Speaker 2 Speaker

Sound Output MAX 10W + 10W

NTSC3.58+4.43 /PAL60Hz Yes

G-2 DVD System Color System NTSC, PAL

Disc DVD,

Disc Diameter 120 mm , 80 mm

Drive DSM-4

Search speed Fwd 4 step

Slow speed Fwd 4 step

G-3 Tuning Broadcasting System Analog

System Digital

Tuner and System 1Tuner (Analog+Digital)

Receive CH Destination UK, I.R., CCIR Hyper+France CATV

CH Coverage Analog

Intermediate Analog

Frequency Picture(FP) 38.9 / 38.9 / 38.9 / 33.9MHz

Digital

Auto Tuning Method

Preset CH 2000 Service in total of Analog and Digital.

Stereo/Dual TV Sound Nicam/A2 Dual

Tuner Sound Muting Yes

G-4 Signal Video Signal Input Level 1 V p-p/75 ohm

RGB Signal Output Level -Audio Signal Input Level -8.0dBm/50k ohm

G-5 Power Power Source AC 220-240V AC 50Hz

Power Consumption at AC 65 W at AC 230 V 50 Hz

Stand by (at AC) w/ EPG Timer --

Protector Power Fuse Yes

G-6 Regulation Safety

G-7 Temperature Operation

G-8 Operating Humidity Less than 80% RH

Number of Pixels 1366(H) x 768(V)

View Range Left/Right 80/80 degree

Bright Dot n≦0

Zero Bright Dot Ratio --

Position Front

Size 1.6 x 4.8 inch

Impedance 4 ohm

10%(Typical) ---

Rev 4 step

Rev 4 step

Digital E5~E12, ItaD~H2, Fra1~6, Rus6~12, E21~E69

Sound(FS)

FP-FS

Output Level 1 V p-p/75 ohm

S/N Ratio (Weighted) 65dB

Horizontal Resolution at DVD Mode 400 Lines

Output Level at DVD -12.0dBm/1k ohm (-20dBFs 0dBFs=2.0Vrms)

Digital Output Level 0.5 V p-p/75 ohm

S/N Ratio at DVD (Weighted) 85dB

Harmonic Distortion 0.02% (1KHz)

Frequency Response : at DVD 4Hz - 22kHz

DC ---

w/o EPG Timer 0.5 W at AC 230 V 50 Hz

Per Year -- kWh/Year

Radiation CE

X-Radiation ---

Storage

Space Around Unit 100mm (4inch)

Up/Down 80/70 degree

Actual 4, 8, 16, 32 times (DVD)

Actual 4, 8, 16, 32 times (DVD)

Actual 1/16, 1/8, 1/4, 1/2 times

Actual 1/16, 1/8, 1/4, 1/2 times

at TV -8 dBm/1k ohm (0dBm=0.775Vrms)

at Video CD/SVCD 4Hz - 20kHz

at CD 4Hz - 20kHz

at DC --

4, 8, 16, 32 times (CD)

4, 8, 16, 32 times (CD)

U.K.,

DVB-

IreE2~E4, X~Z+2, S1~S10, E5~E12,S11~S41,E21~E69

BG / II

33.4 / 32.9 / 32.4 / 40.4MHz

5.5 / 6.0 / 6.5 / 6.5MHz

36.167MHz

ALL Band (Not C.C.I.R. CH Plan)

CE(EN60065:2002+AMD.11:2008), SEMKO, HOMOLO,

Ukraine Safety

o

C ~ +40oC

+5

o

-20

C ~ +60oC

A2-1

Page 9

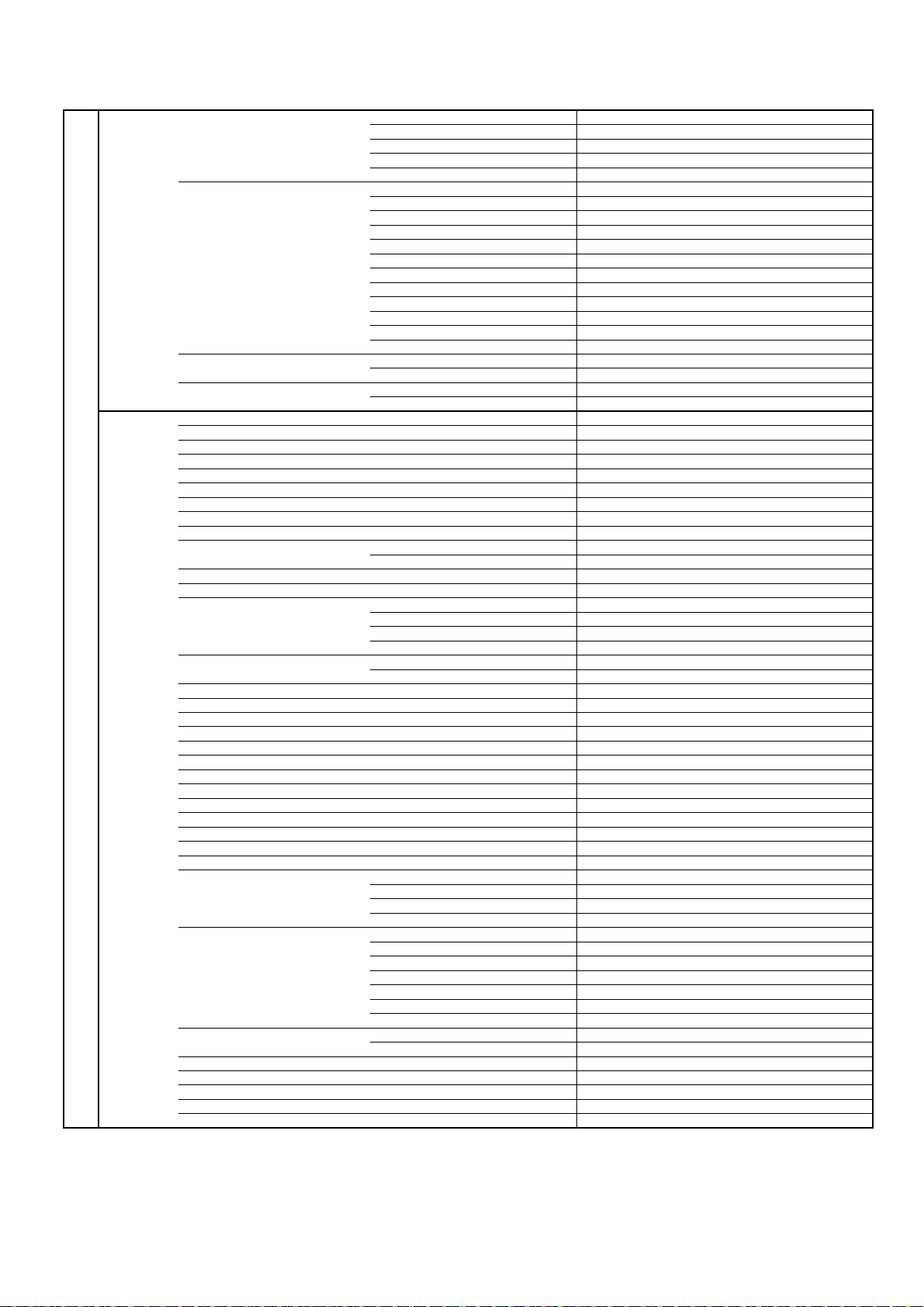

GENERAL SPECIFICATIONS

G-9 OSD Language (TV)

(DVD)

G-10 Clock and Sleep Timer Max Time 120 Min

Timer Step 10 / 20 / 30 / 40 / 50 / 60 / 90 / 120 Min

On/Off Timer Program(On Timer / Off Timer) 1 Program / 1 Program

Timer Back-up (at Power Off Mode) more than -- Min Sec

EPG Timer Events --

G-11 Remote Unit RC-RV

Control Glow in Dark Remocon No

Remocon Format ORION

Format NEC

Custom Code 71-8E h

Power Source Voltage(D.C) 3V

UM size x pcs UM-3 x 2 pcs

Total Keys 47 Keys

Keys Power (Stand By) Yes

Display / (Status) Yes

Analog Menu No

Digital Menu No

Input Select Yes

DTV/ATV Yes

TV/DVD Yes

Eject No

Guide(EPG) Yes

Picture Size Yes

1 Yes

2 Yes

3 Yes

4 Yes

5 Yes

6 Yes

7 Yes

8 Yes

9 Yes

0 Yes

Sleep No

Mute Yes

Volume Up / → No

Volume Down / ← No

Volume Up Yes

Volume Down Yes

CH Down No

CH Up No

Menu / Setup Yes

↑ Yes

↓ Yes

←/Slow- Yes

→/Slow+ Yes

OK / CH List Yes

Return Yes

Freeze No

TV/Radio No

Subtitle Yes

Audio No

Play Yes

Stop Yes

Pause Yes

Quick View Yes

Cancel Yes

DVD Menu Yes

Top Menu Yes

Repeat A-B No

Play Mode Yes

Jump No

Search+ No

Search- No

English, Spanish, German, French, Italian, Swedish

Dutch, Russian, Portuguese, Turkish, Greek, Finnish

Polish, Danish, Norwegian, Hungarian, Czech, Slovak

Estonian, Latvian, Lithuanian, Slovenian, Ukranian

English, Spanish, German, French, Italian, Swedish

Dutch, Russian, Portuguese, Turkish, Greek, Finnish

Polish, Danish, Norwegian, Hungarian, Czech, Slovak

Estonian, Latvian, Lithuanian, Slovenian, Ukranian

A2-2

Page 10

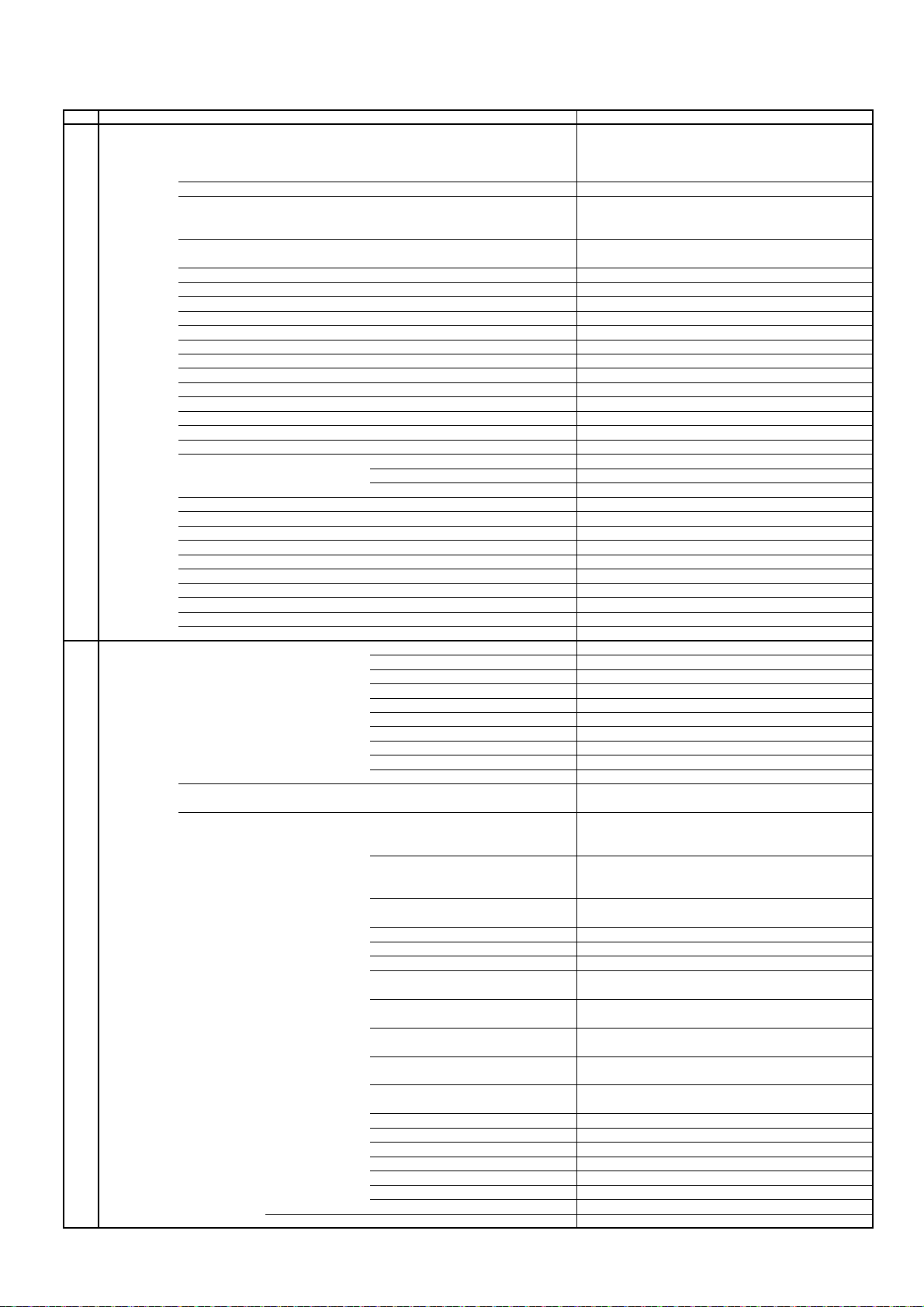

GENERAL SPECIFICATIONS

T'TEXT Keys TEXT / TAP / TV Yes

G-12 Features Power On Memory Yes

Auto Shut Off Yes

Just Clock Function No

Game Position No

DNR Yes

Comb Filter Yes

Auto Set Up (Fast installation) Auto tuning Yes

Picture Setting(TV) Picture Preference Yes

Picture Setting(PC) BRIGHTNESS , CONTRAST Yes (Connected with TV mode setting)

Audio Tone Control (Bass/Treble/Balance) Yes

Tuning Auto Tuning (Analog/Digital) Yes

Lock Panel Lock No

Screen Saver

T'Text Yes

Text and Picture Yes

Wide Mode (AUTO/4:3/16:9/CINEMA/14:9/REAL) Yes

Slow+ / F.T.B No

Audio / F.T.B Yes

Slow- / Hold No

Freeze / Hold Yes

Angle / Reveal Yes

Zoom / Sub Page Yes

Red/Skip- Yes

Green/REV Yes

Yellow/FWD Yes

Cyan/Skip+ Yes

CH Up / Page Up Yes

CH Down / Page Down Yes

3D

3D

CH sort Yes

ATS Yes

Auto clock (Digital tuner) Yes

Plug in start Yes

Brightness , Contrast , Color Yes

Tint Yes

Sharpness Yes

DNR Yes

Color Temperature Yes

Blue Back Yes

Backlight Control Yes

HDMI Mode Yes

DBC (Dynamic Backlight Control) Yes

Film Mode No

HOR POSITION , VER POSITION Yes

PHASE , CLOCK Yes

AUTO ADJUST Yes

RED , GREEN , BLUE Yes

Backlight Yes (Connected with TV mode setting)

WXGA INPUT No

WVGA INPUT No

Surround Yes

Equalizer Yes

Speaker Yes

Stable Sound No

Audio Description Yes

BBE No

SRS WOW (SRS 3D/Focus/Tru Bass) No

Variable Audio Out No

Update Scan (Analog/Digital) Yes

CH Skip (Analog/Digital) Yes

CH Sort (Analog/Digital) Yes

CH Edit (Analog/Digital) Yes

Fine Tuning (Analog) Yes

Channel Lock Yes

Parental Lock (Digital) Yes

Hotel Lock Yes

Inversion No

Full White No

Screen Saver No

Static Image No

Text type Fastext / Toptext

Text Language English, German, Swedish, Finnish, Hungarian,

Italian, French, Portuguese, Spanish, Czech,

Slovak, Polish, Estonian, Lettish, Lithuanian,

Serbian, Croatian, Slovenian, Rumanian, Russian,

Bulgarian, Ukrainian, Turkish, Greek, Hebrew,

Arabic

A2-3

Page 11

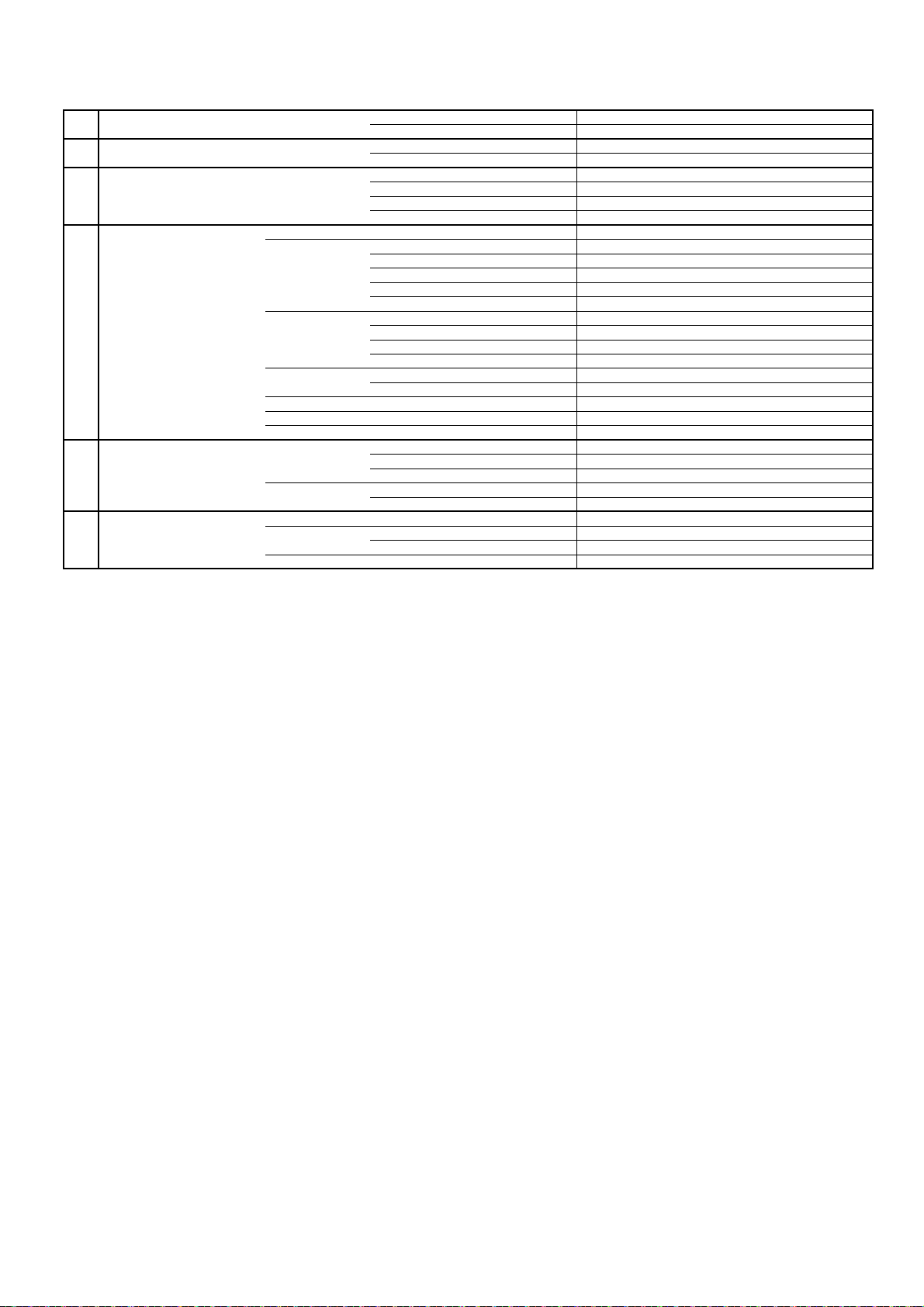

GENERAL SPECIFICATIONS

CH Label Yes

Reset TV Setting Yes

HD Zoom Yes

Picture Scroll (Vertical Position) No

PFC(Power Factor circuit) No

Freeze frame Yes (Tuner Only)

Plug and Play No

Power Management Yes

No Operation Power Off Yes

Hearing Impaired Yes

4:3 Mode (Auto 4:3 Default) Yes

TV Location Yes

Scart Spec Scart1 AV in Yes

Scart2 AV in Yes

Digital Text (VBI teletext)

MHEG-5

MHP

EPG (BBC type 8Days Digital tuner only)

OAD (Over Air Download)

Common Interface (Digital tuner only)

Rec Screen Status

Ch sorting based on Ch List (Digital/Germany only)

Rename Carrier (Digital)

Edit Event Timer

Software Update via CI Slot

Preference Language (Audio/Subtitle/Digital Service)(Digital)

DVB Subtitle (Digital)

Time Setup

Signal Status

Digital Out Dolby Digital Dolby Digital

Decode(Down Mix) Dolby Digital Yes

PC Monitor Input Yes

HDMI Input Yes

AV out Yes (A.Tuner/D.Tuner)

S-Video in Yes

RGB in Yes

AV out Yes (Monitor)

S-Video in Yes

RGB in No

Yes

No

No

Yes

Yes

Yes

No

Yes

No

No

No

Yes

Yes

Yes

Yes

Dolby Digital Plus Dolby Digital

MPEG PCM

HE AAC Dolby Digital

Dolby Digital Plus Yes

MPEG Yes

HE AAC Yes

VGA (640x480) Yes (60Hz)

VGA (720x400) No (Possible to Display)

WVGA (848x480) No

SVGA (800x600) Yes (60Hz)

XGA (1024x768) Yes (60Hz)

WXGA (1280x768) Yes (60Hz)

WXGA (1280x720) Yes (60Hz)

WXGA (1360x768) Yes (60Hz)

SXGA (1280x1024) No (Possible to Display)

WXGA+ (1440x900) No (Possible to Display)

WSXGA+ (1680x1050) No (Possible to Display)

FULL HD (1920x1080) No (Possible to Display)

VGA (640×480) Yes (60Hz)

VGA (720x400) No (Possible to Display)

WVGA (848x480) No

SVGA (800x600) Yes (60Hz)

XGA (1024x768) Yes (60Hz)

WXGA (1280x768) Yes (60Hz)

WXGA (1280x720) Yes (60Hz)

WXGA (1360x768) Yes (60Hz)

SXGA (1280x1024) No (Possible to Display)

WXGA+ (1440x900) No (Possible to Display)

WSXGA+ (1680x1050) No (Possible to Display)

FULL HD (1920x1080) No (Possible to Display)

720×480i (4:3) Yes (60Hz)

720×480i (16:9) Yes (60Hz)

720×480p (4:3) Yes (60Hz)

720×480p (16:9) Yes (60Hz)

720×576i (4:3) Yes (50Hz)

720×576i (16:9) Yes (50Hz)

720×576p (4:3) Yes (50Hz)

720×576p (16:9) Yes (50Hz)

1280×720p Yes (50/60Hz)

A2-4

Page 12

GENERAL SPECIFICATIONS

y

1920×1080i Yes (50/60Hz)

1920×1080p Yes (24/50/60Hz)

CEC(ORION Standard) No

Deep Color No

Component Input Yes

Wall Mount Size W x H(mm) Yes (200 x 100)

Stand Tilt No

Features Parental Lock Yes

(DVD) Auto Power Off No

Video CD Playback Yes

SVCD Playback Yes

MP3 Playback Yes

WMA Playback Yes

JPEG Playback Yes

Fujicolor CD Yes

KODAK Picture CD Yes

Divx Playback Yes

VR Format Pla

USB No

Digital Out Dolby Digital Dolby Digital

Decode(Down Mix) Dolby Digital Yes

Auto Retract Disc No

BNR No

Disc Navigator Yes

E.B.L. (Enhanced Black Level)

Surround No

Screen Saver No

Tray Lock No

One Touch Replay No

CGMS-A in CC XDS No

Audio DAC 192kHz / 24bit

Macrovision Yes (No Video Out)

Closed Caption signal in VBI (DVD Playback) No

Play Mode Yes

Audio Adjust Yes

Video Adjust Yes

TV Screen

Audio Language Yes

Subtitle Language Yes

DVD Menu Language Yes

Subtitle Display Yes

Angle Indicator Yes

ba

xvYCC No

720×480i (4:3) Yes (60Hz)

720×480i (16:9) Yes (60Hz)

720×480p (4:3) Yes (60Hz)

720×480p (16:9) Yes (60Hz)

720×576i (4:3) Yes (50Hz)

720×576i (16:9) Yes (50Hz)

720×576p (4:3) Yes (50Hz)

720×576p (16:9) Yes (50Hz)

1280×720p Yes (50/60Hz)

1920×1080i Yes (50/60Hz)

1920×1080p No (Possible to Display)

Screw Size M4 x 10

Swievel No

DMF Support No

No

MPEG PCM

PCM PCM

DTS Yes

DTS No

No

Equalizer Yes

Dynamic Range Control Yes

Dialog Yes

Sharpness Yes

Brightness Yes

Contrast Yes

Gamma Yes

Hue Yes

Chroma Level Yes

4:3 (Letter Box、Pan Scan) Yes

16:9 (Wide) Yes

A2-5

Page 13

GENERAL SPECIFICATIONS

G-13 Accessories Owner's Manual Language English, Spanish, German, French, Italian, Swedish

w/Guarantee Card No

Remote Control Unit Yes

Rod Antenna No

Poles -

Terminal Loop Antenna (W/ Antenna Change Plug) No

Terminal DVB-T Antenna No

U/V Mixer No

DC Car Cord (Center+) No

Guarantee Card No

Caution Sheet No

Repair Coupon No

AQUOS Care plan No

Warning Sheet No

Circuit Diagram No

Antenna Change Plug No

Service Facility List No

Important Safeguard No

Quick Set-up Sheet Yes(23Language)

Battery Yes

UM size x pcs UM-3 x 2 pcs

OEM Brand No

AC Adapter No

AC Cord (for AC Adapter) No

AC Cord Yes

AV Cord (2Pin-1Pin) No

HDMI-DVI Cable No

Registration Card No

300 ohm to 75 ohm Antenna Adapter No

Stand Screw??? Yes(8pcs,Wrench)

Stand Yes

Frame Stand Yes

G-14 Interface Switch Side Power (Tact) Yes

System Select No

Main Power SW No

Channel Up / Play / Menu Up Yes

Channel Down / Stop / Menu Down Yes

Volume Up/Menu > Yes

Volume Down/Menu < Yes

Input Select/Enter Yes

Menu Yes

Eject Yes

Indicator Power/Stand-by Yes(GREEN / RED)

On Timer No

Terminals Rear Video Input 1

Audio Input 1

S- Input 1 No

Video Input 2 No

Audio Input 2 No

S- Input 2 No

Video Output No

Audio Output No

Digital Audio Out (Coaxial)

Headphone No

Euro Scart (21Pin)

Component In

Audio Input (Component In use)

PC Monitor Input (D-Sub)

Audio Input

HDMI Input 1

Audio Input (HDMI/DVI In use) PC Monitor Audio Input Alternative

HDMI Input 2

Audio Input (HDMI/DVI In use) No

HDMI Input 3 No

Audio Input (HDMI/DVI In use) No

USB(Software Update)

Sub Woofer Output No

Diversity No

Ext Speaker No

DC Jack 12V(Center +) No

AC Inlet

VHF/UHF Antenna Input No

Side CI Card Slot Yes

Dutch, Portuguese, Turkish, Greek, Finnish

Polish, Danish, Norwegian, Hungarian, Czech, Slovak

Estonian, Latvian, Lithuanian, Slovenian, Ukranian

RCA x 1 (AV3)

RCA x 2(L/MONO, R) (AV3)

Yes

2Scart (AV1, AV2)

RCA x 3

RCA x 2(L/MONO, R)

Yes

Mini Pin Jack(φ3.5), STEREO

Yes

Yes

Yes

Yes

A2-6

Page 14

GENERAL SPECIFICATIONS

Headphone Yes

G-15 Set Size Approx. W x D x H (mm) 661 x 243 x 508

G-16 Weight Net Approx. 9.6kg (21.1lbs)

G-17 Carton Master Carton No

Gift Box Yes

Drop Test Natural Dropping At 1 Corner / 3 Edges / 6 Surfaces

Container Stuffing 512 Sets/45' Trailer

w/Pallet No

w/Wrapping No

G-18 Material Cabinet Cabinet Front PC+ABS 94V0 NON-HALOGEN

PCB Non-Halogen No

G-19 Environment Environmental standard requirement Green procurement of SHARP

Pb- Free Phase3(PHASE3A)

WEEE Yes

VHF/UHF Antenna Input DIN Type

w/o Stand,Handle Approx. W x D x H (mm)

Net w/o Stand,Handle Approx. 8.2kg (18.1lbs)

Gross Approx. 13.0kg (28.9lbs)

Gross w/Master Carton (Approx.) --- kg ( --- lbs)

Content ---- Sets

Material -- /--

Dimensions W x D x H(mm) -- x -- x --

Description of Origin No

Material Double/Brown

Dimensions W x D x H(mm) 756 x 265 x 579

Design As per Buyer's

Description of Origin No

Height (cm) 48

Cabinet Rear PS 94V0 NON-DECABROM

Stand PC+ABS 94V0 NON-HALOGEN

Eyelet Yes

Measures for Whisker Yes

661 x 100.5 x 462.5

A2-7

Page 15

S

)

.

g

.

g

DISASSEMBLY INSTRUCTIONS

(

)

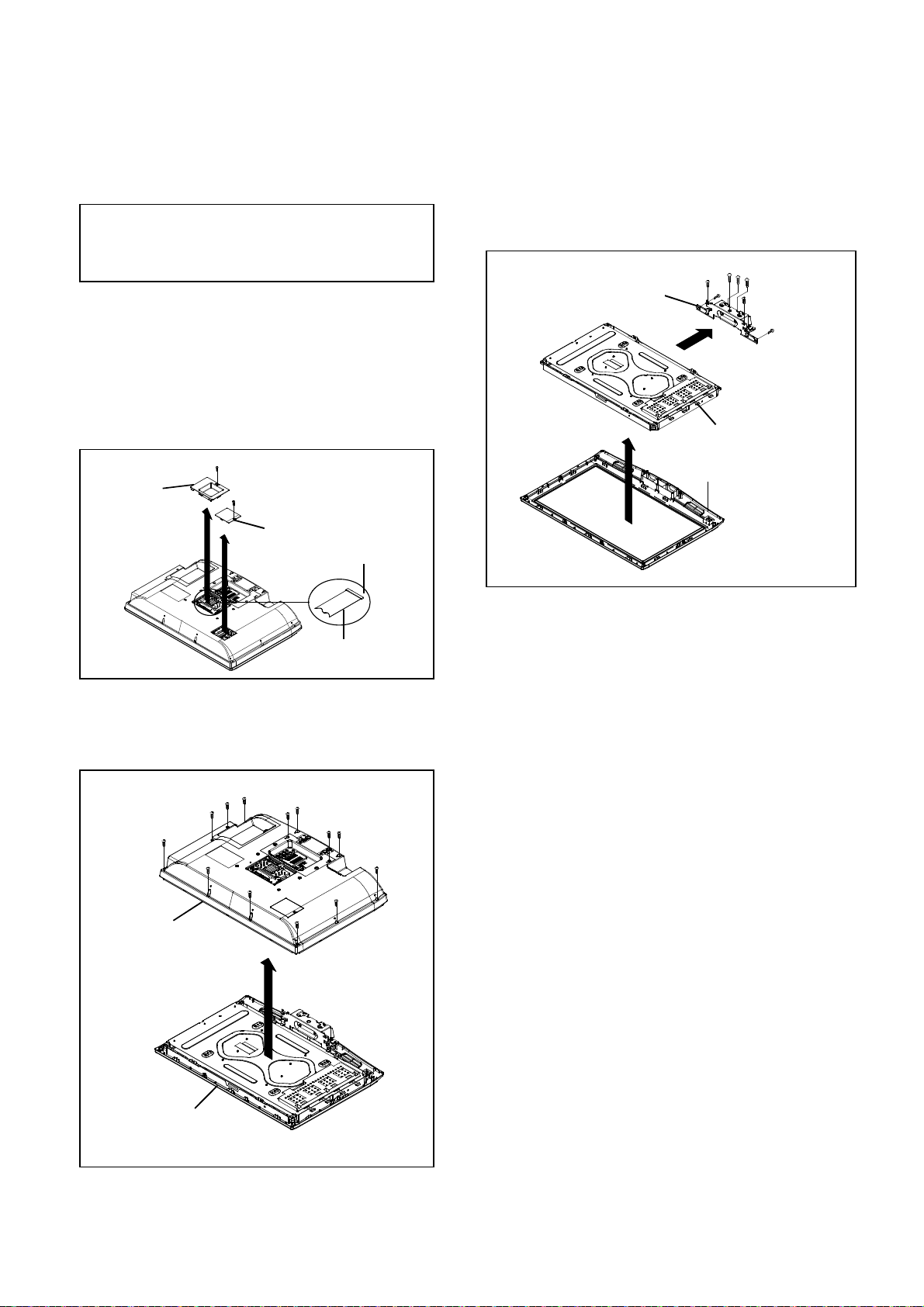

1. REMOVAL OF MECHANICAL PARTS

AND P.C. BOARD

CAUTION

Be careful not to remove the LVDS cable forcibly, because

the LVDS cable may be damaged.

1-1: COVER INVERTER/COVER LVDS (Refer to Fig. 1-1

Remove the screw (1).

1.

Remove the Cover Inverter in the direction of arrow (A)

2.

3.

Disconnect the followin

Remove the screw (2).

4.

Remove the Cover LVDS in the direction of arrow (B)

5.

Release the lock of connector disconnect the followin

6.

connector: (CP2804).

Cover LVDS

(B)

connector: (CP3803).

(2)

(1)

Cover Invertor

(A)

Connector

1-3: LCD BLOCK (Refer to Fig. 1-3)

1.

Remove the 2 screws (1).

Remove the 5 screws (2).

2.

3. Remove the Angle-Hinge in the direction of arrow (A).

4. Remove the LCD Block in the direction of arrow (B).

(2)

(2)

Angle-Hinge

(B)

(2)

LCD Block

Front Cabi Ass'y

(2)

(1)

(2)

(1)

(A)

Fig. 1-3

1-2: BACK CABI ASS'Y

Remove the 13 screws (1).

1.

LVDS CABLE

Refer to Fig. 1-2

Fig. 1-1

2. Remove the Back Cabi Ass'y in the direction of arrow .

(1)

(1)

Back Cabi Ass'y

(1) (1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

Front Cabi Ass'y

Fig. 1-2

B1-1

B1-1

Page 16

)

)

g

(

).

).

pp

g

(B).

(

).

DISASSEMBLY INSTRUCTIONS

(

)

(E)

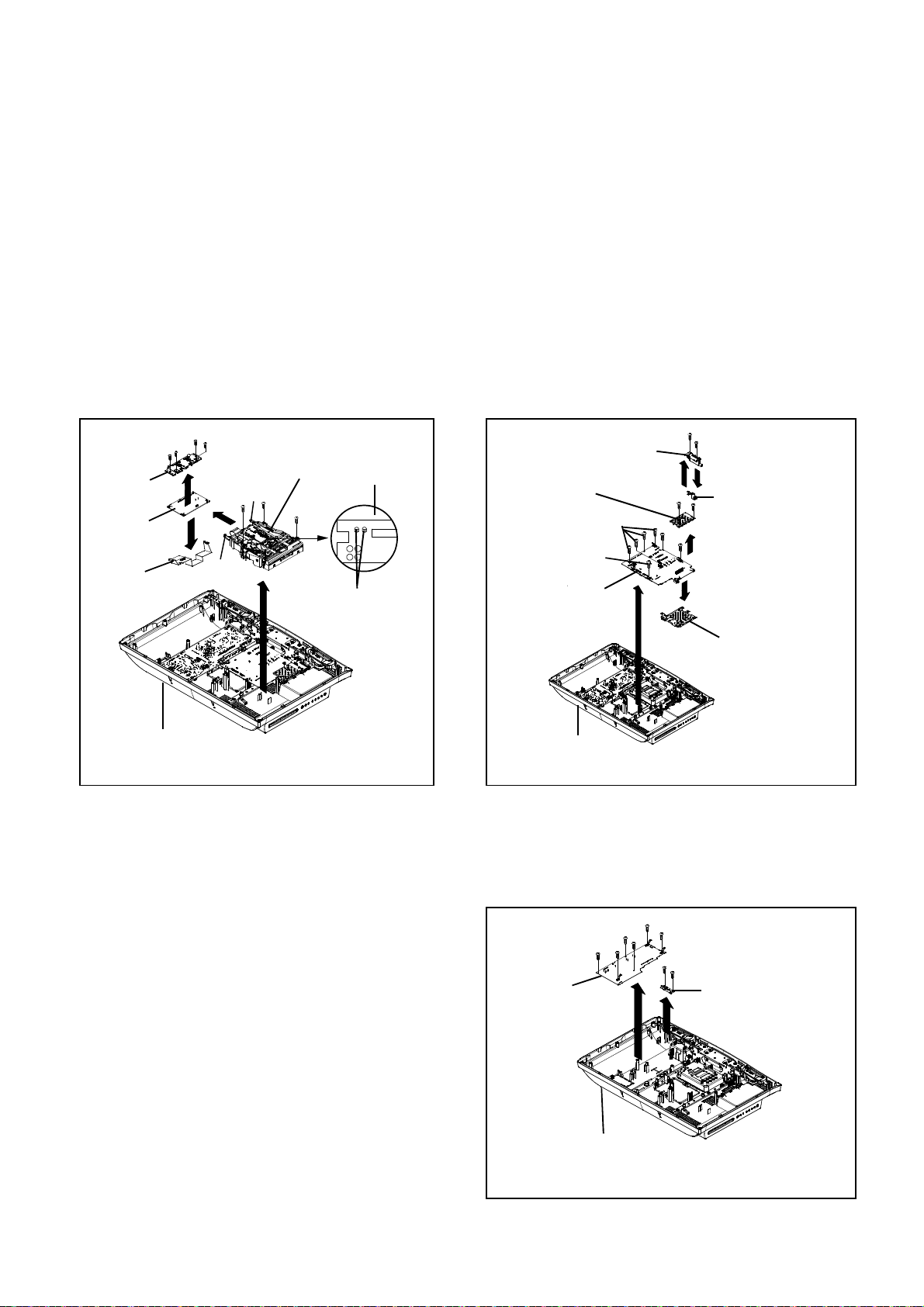

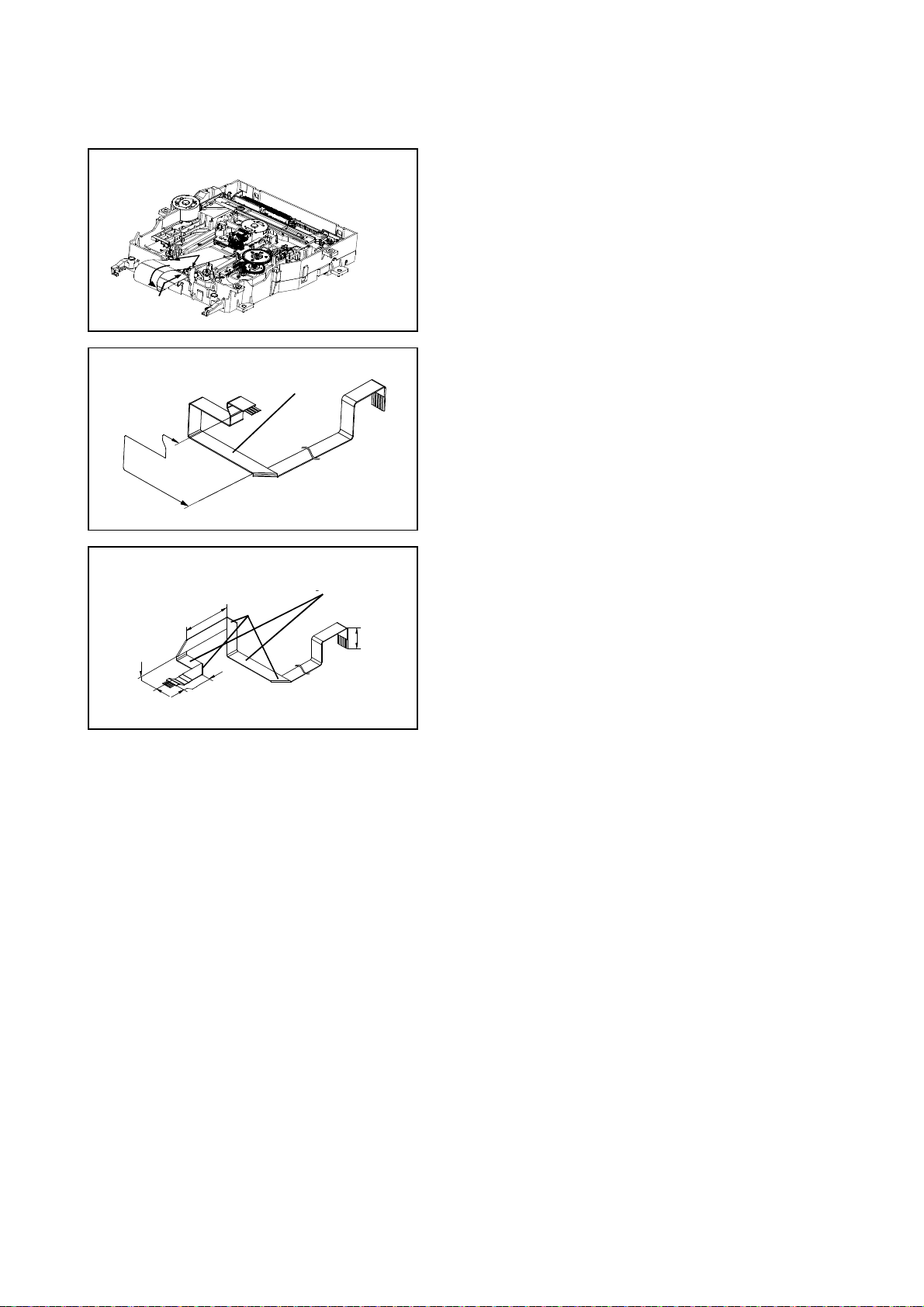

1-4: DVD MT PCB/DVD DECK (Refer to Fig. 1-4

1-5: MAIN PCB/TUNER PCB (Refer to Fig. 1-5

1. Put the Cabinet Back Ass'y on the bottom.

2. Short circuit the position shown in Fig. 1-4 using a 1. Put the Cabinet Back Ass'y on the bottom.

soldering iron. If you remove the DVD Deck with no 2. Remove the 2 screws (1).

soldering, the Laser may be damaged. 3.

Disconnect the followin

connector: (CP5801).

3. Disconnect the following connectors: 4. Remove the Tuner PCB in the direction of arrow (A).

CP2301, CP2302, CP2303, CP8501 and CP8502

5. Remove the Spring Tuner in the direction of arrow (B

4. Remove the 3 screws (1). 6. Remove the 2 screws (2).

5. Remove the DVD DECK Ass'y in the direction of 7. Remove the Shield Digital Bottom Ass'y in the

arrow (A). direction of arrow (C).

6. Remove the 4 screws (2). 8. Remove the 7 screws (3).

7.

Unlock the 2 su

8.

Remove the DVD MT PCB in the direction of arrow

orts (3).

9. Disconnect the followin

connectors:

CP301, CP2201, CP3808, CP3809 and CP4301

9. Remove the Shield LVDS in the direction of arrow (C). 10. Remove the Main PCB in the direction of arrow (D).

10.Remove the Shield LVDS Bottom in the direction of arrow (D). 11. Remove the Shield Digital-Top in the direction of arrow (E).

(3)

(A)

(2)

(3)

(1)

(1)

(B)

Spring Tuner

(2)

(C)

(2)

(2)

Shield LVDS

DVD MT PCB

Shield LVDS Bottom

(D)

(2)

(C)

(B)

(3)

(2)

DVD Deck Ass'y

(3)

(1)

(1)

(A)

Pick Up PCB

(1)

Short circuit using a

Tuner PCB

Shield Digital Bottom Ass'y

(3)

(3)

Main PCB

soldering iron.

(D)

Shield Digital-Top

Back Cabi Ass'y

Fig. 1-4

NOTE 1-6: POWER PCB/REMOCON PCB

Back Cabi Ass'y

Refer to Fig. 1-6

1. Before your operation, please read "PREPARATION 1. Remove the 2 screws (1).

OF SERVICING". 2. Remove the Remocon PCB in the direction of arrow (A).

2. Use the Lead Free solder. 3. Remove the 6 screws (2).

3. Manual soldering conditions 4. Remove the Power PCB in the direction of arrow (B).

•

• Soldering time: Within 4 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

4. When Soldering/Removing of solder, use the drawing

equipment over the Pick Up Unit to keep the Flux

smoke away from it.

5. When installing the DVD Deck, remove all the soldering

on the short circuit position after the connection of Pick

Up PCB and DVD MT PCB connector.

o

(2)

Power PCB

Back Cabi Ass'y

(2)

(2)

(2)

(B)

(2)

(2)

(1)

(1)

(A)

Remocon PCB

Fig. 1-5

Fig. 1-6

B1-2

B1-2

Page 17

DISASSEMBLY INSTRUCTIONS

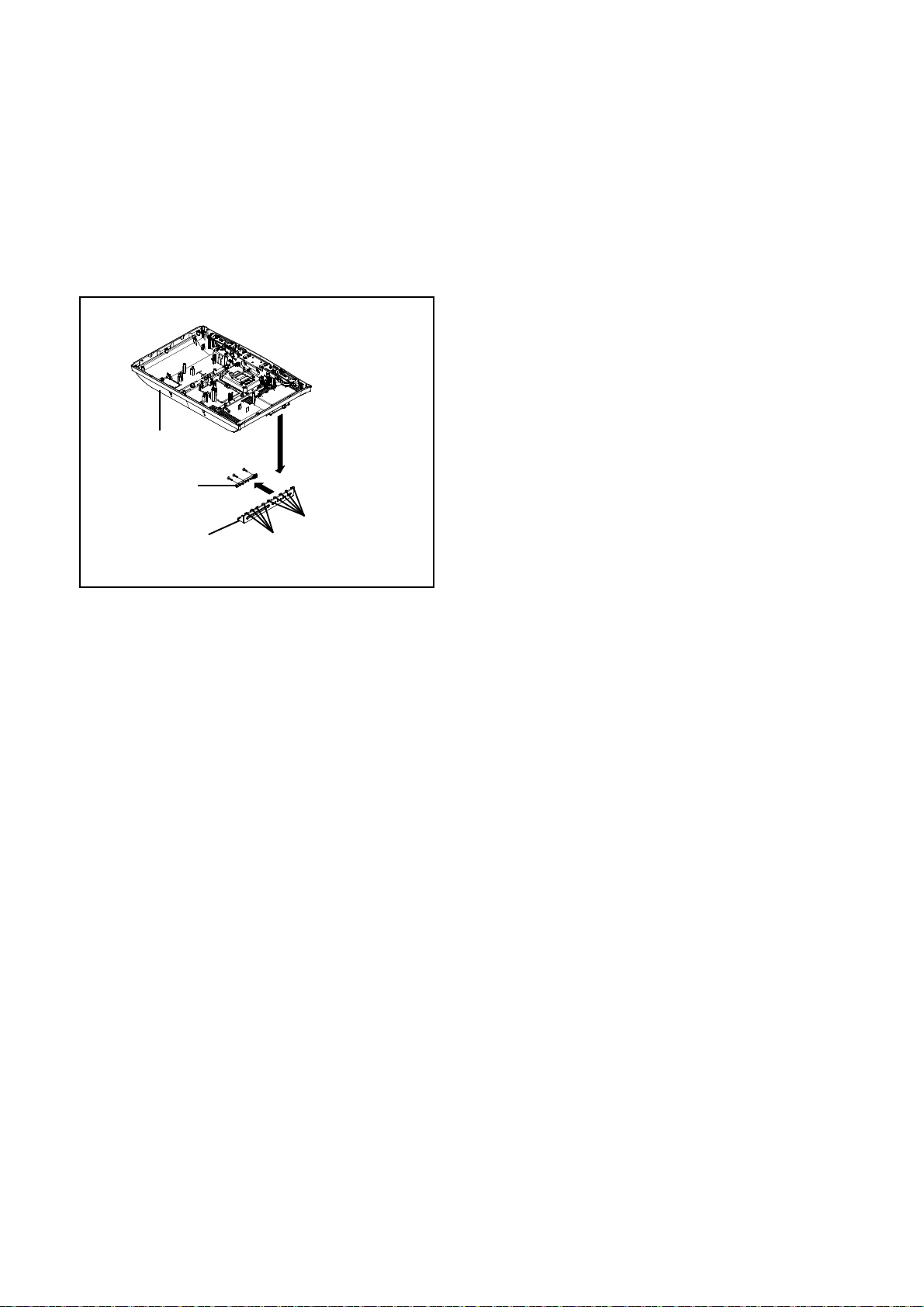

1-7: OPERATION PCB (Refer to Fig. 1-7)

1. Push 9 supports (1).

2. Remove the Panel Side Ass'y in the direction of arrow (A).

3. Remove the 3 screws (2).

4. Remove the Operation PCB in the direction of arrow (B).

Back Cabi Ass'y

Operation PCB

Panel Side Ass'y

(2)

(2)

(2)

(A)

(B)

(1)

(1)

Fig. 1-7

B1-3B1-3

Page 18

S

DISASSEMBLY INSTRUCTIONS

(3)

9.Remove the 2 screws (4)

(

)

(3)

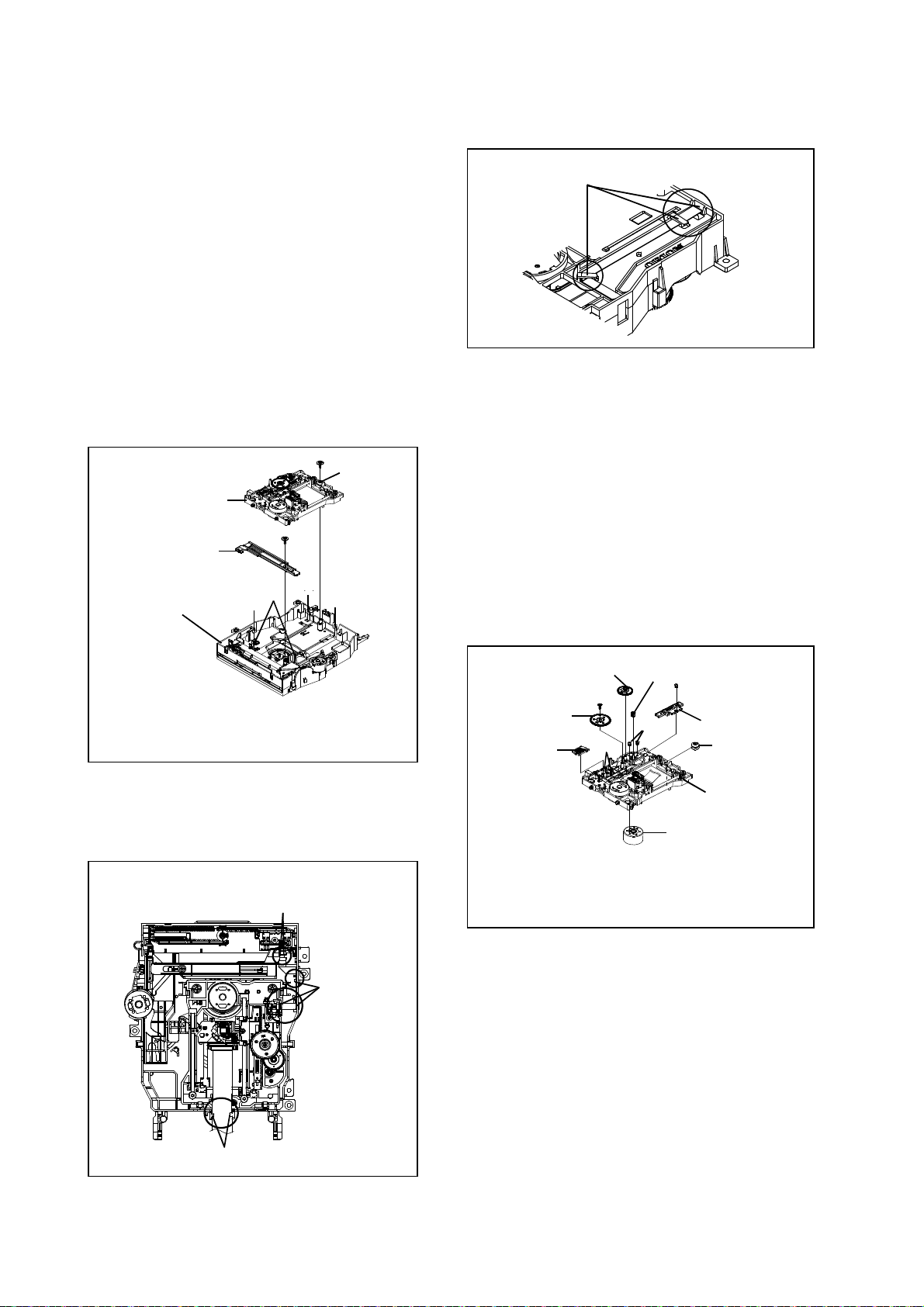

2. REMOVAL OF DVD DECK PART

Check Lock

NOTE

1. Disassemble only the DVD DECK PARTS parts listed

here. Minute adjustments are needed if the

disassembly is done. If the repair is needed except

listed parts, replace the DVD MECHA ASS'Y.

2-1: TRAVERSE ASS'Y/LOADING MOTOR PCB ASS'Y/

PLATE TRVS UD (Refer to Fig. 2-1-A)

1. Remove the screw (1).

2. Remove the screw (2). 2.2: INSULATOR (R)/FEED RACK ASS'Y/

3. Unlock the 5 supports (3). PCB630/GEAR MIDDLE/GEAR FEED/

4. Remove the Insulator (R) from the Loader Ass'y. FEED MOTOR/GEAR MOTOR

5. Remove the Traverse Ass'y and Plate Trvs Ud. (Refer to Fig. 2-2-A)

1. Remove the Insulator (R).

2. Remove the screw (1).

3. Remove the Feed Rack Ass'y.

4. Unlock the 2 supports (2).

5. Remove the PCB630.

6. Remove the screw (3).

7. Remove the Gear Feed.

8. Remove the Gear Middle.

.

10. Remove the Gear Motor.

11. Remove the Feed Motor.

Traverse Ass'y

Plate TRVS UD

Loader Sub Ass'y

(3)

(2)

(1)

Insulator (R)

(3)

Fig. 2-1-C

• Screw Torque: 1.0 ± 0.3kgf•cm (screw(1))

• Screw Torque: 3.0 ± 0.3kgf•cm (screw(2))

Fig. 2-1-A

NOTE

1. In case of the Traverse Ass'y installation, hook the wire

on the Loader Ass'y as shown Fig. 2-1-B to Fig. 2-1-C.

Loader Ass'y (Top side)

Check Lock

Check Lock

Gear Middle

(3)

Gear Feed

PCB630

• Screw Torque: 1.3 ± 0.3kgf•cm (Screw (1))

• Screw Torque: 2.5 ± 0.3kgf•cm (Screw (3))

• Screw Torque: 1.0 ± 0.3kgf•cm (Screw (4))

Gear Motor

(4)

(2)

(1)

Feed Rack Ass'y

Insulator (R)

Chassis

Feed Motor

Fig. 2-2-A

Check Lock

Fig. 2-1-B

B2-1

B2-1

Page 19

g

DISASSEMBLY INSTRUCTIONS

NOTE

1. In case of the Gear Motor installation, check if the value

of the Fig. 2-2-B is correct.

2. When installing the wire of the PCB630 install it correctly

as Fig. 2-2-C.

Manual soldering conditions

• Solderin

temperature: 350 ± 5oC

• Soldering time: Within 4 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

3. When installing the Feed Rack Ass'y, push both ends to

align the teeth as shown Fig. 2-2-D. Then install it.

4. In case of the Insulator (R) installation, install correctly as

Fig. 2-2-E.

5. After the assembly of the Traverse Ass'y, hook the wire

on the Traverse Ass'y as shown Fig. 2-2-F.

Gear Motor

7.0 ± 0.1mm

Feed Motor

Safety surface for pressing of the insert.

Fig. 2-2-B

~FEED MOTOR~

YELLOW(2)

• Install wire from (1) to (4) in order.

GREEN(1)

PCB630

Insulator (R)

Traverse Ass'y (Top Side)

Fig. 2-2-E

BOTTOM

• In case of remove FEED MOTOR that has to arrange wire as following

the picture on above.

Traverse Ass'y

Check Hook

UP SIDE

Check Hook

Fig. 2-2-F

2.3: GEAR ROLLER/LUMIRROR WASHER/

ROLLER CONE/SHAFT ROLLER/

LOADING MOTOR PCB/LOADING MOTOR/

GEAR WORM/RACK LEVER (Refer to Fig. 2-3-B)

1. Remove the 3 screws (1).

2. Remove the Chassis Main Ass'y.

3. Remove the Roller Ass'y.

4. Remove the Gear Roller.

5. Remove the Lumirror Washer.

6. Remove the Roller Cone.

7. Remove the Shaft Roller .

8. Remove the screw (2).

9. Remove the Loading Motor PCB Ass'y.

10. Remove the screw (3).

11. Remove the Loading Motor.

12. Remove the Gear Worm.

13. Remove the Rack Lever.

~FEED MOTOR~

BROWN(4)

WHITE(3)

Feed Rack Ass'y Fig. 2-3-A.

Push

(OK) (NG)

Fig. 2-2-C

Push

Fig. 2-2-D

NOTE

1. When Chassis Main Ass'y is removed, it is necessary to

change the position of Lever Disc and Guide Disc.

2. In case of the Chassis Main Ass'y, check position Lever

Disc, Lever Guide and Boss of Rack Disc Sensor as shown

Lever Guide

Frame Main Ass'y

Check Position

Chassis Main Ass'y

Check Boss

B2-2

B2-2

• Remove the Lever Guide in the direction of arrow.

Fig. 2-3-A

Page 20

q

))

DISASSEMBLY INSTRUCTIONS

• Screw Torque: 0.8 ± 0.3kgf•cm (Screw (2))

g

Loading Motor PCB Ass'y

(2)

Lumirror Washer

Roller Cone

Shaft Roller

Frame Main Ass'y

(1)

• Screw Torque: 3.0 ± 0.3kgf•cm (Screw (1))

• Screw Tor

• Screw Torque: 1.0 ± 0.3kgf•cm (Screw (3))

ue: 0.8 ± 0.3kgf•cm (Screw (2

Rack Lever

Roller Cone

(1)

Loading Motor

Gear Worm

(3)

Chassis Main Ass'y

Lumirror Washer

Gear Roller

(1)

Fig. 2-3-B

Loading Motor PCB Ass'y

• Install wire from (1) to (2) in order.

RED(2)

BLACK(1)

Roller Sub Ass'y

(OK) (NG)

Roller Sub Ass'y

Safety surface for

pressing of the insert.

(OK) (NG)

Fig. 2-3-D

Fig. 2-3-E

NOTE

1. In case of the Gear Worm installation, check if the value

of the Fig. 2-3-C is correct.

2. When installing the wire of the Loading Motor PCB Ass'y,

install it correctly as Fig. 2-3-D.

Manual soldering conditions

• Solderin

temperature: 350 ± 5oC

• Soldering time: Within 4 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

3. In case of the Roller Cone installation, install correctly as

Fig. 2-3-E.

4. In case of the Lumirror Washer installation,

install correctly as Fig. 2-3-F.

5. In case of the Gear Roller installation, check if the value

of the Fig. 2-3-G is correct.

6. After the assembly of the Loader Sub Ass'y, hook the wire

on the Loader Sub Ass'y as shown Fig. 2-3-H.

Gear Worm

14.3 + 0, - 0.1mm

Loading Motor

Safety surface for pressing of the insert.

Fig. 2-3-C

Roller Sub Ass'y

1.8 + 0, - 0.1mm

Loader Sub Ass'y

Check Hook

Fig. 2-3-F

Fig. 2-3-G

Check Hook

Fig. 2-3-H

B2-3

B2-3

Page 21

DISASSEMBLY INSTRUCTIONS

2.4: SPRING SHUTTER/PLATE RETAINER/

RETAINER SHUTTER/COVER CLAMPER/

PLATE CLAMPER/MAGNET CLAMPER/

CLAMPER/GUIDE DISC/LEVER DISC/

SPRING LEVER GUIDE/SPRING LEVER DISC/

LEVER DISC (Refer to Fig. 2-4-A)

1. Unlock the support (1).

2. Remove the Retainer Shutter Ass'y.

3. Remove the Spring Shutter.

4. Remove the 3 screws (2).

5. Remove the Plate Retainer.

6. Remove the Retainer Shutter.

7. Unlock the 2 supports (3).

8. Remove the Cover Clamper.

9. Unlock the 3 supports (4).

10. Remove the Plate Clamper.

11. Remove the Magnet Clamper.

12. Remove the Clamper.

13. Unlock the support (5).

14. Remove the Guide Disc.

15. Remove the Lever Guide.

16. Remove the Spring Lever Guide.

17. Remove the Spring Lever Disc.

18. Remove the Lever Disc.

Spring Shutter

Spring Shutter (2pcs)

Retainer Shutter

(OK) (NG)

Check Hook

Clamper Ass'y

Check Hook

Frame Main Ass'y

Fig. 2-4-B

Retainer Shutter

Guide Disc

(2)

(2)

Plate Retainer

Clamper

Magnet Clamper

Plate Clamper

Cover Clamper

• Screw Torque: 0.7 ± 0.3kgf•cm (Screw (2))

(2)

(3)

(4)

(5)

Frame Mian

Spring Lever Guide

(1)

Lever Guide

Lever Disc

Spring Lever Disc

Fig. 2-4-A

NOTE

1. In case of the Retainer Shutter Ass'y installation,

check if the value of the Fig. 2-4-B is correct.

2. In case of the Clamper Ass'y installation,

check if the value of the Fig. 2-4-C is correct.

Fig. 2-4-C

2-5: FFC WIRE HANDLING

1. When installing the FFC, fold it correctly and install it as

shown from Fig. 2-5-A to Fig. 2-5-D.

NOTE

1. Do not make the folding lines except the specified

positions for the FFC.

[ 22 pin FFC ]

Printing Surface

35 ± 1mm

Fold

Fig. 2-5-A

B2-4

B2-4

Page 22

Install the position (A) and (B)

g

(A)

DISASSEMBLY INSTRUCTIONS

(B)

Fig. 2-5-B

[ 4 pin FFC ]

Printing Surface

71 ± 1mm

Fold it by 90°

Fig. 2-5-C

[ 5 pin FFC ]

Printing Surface

25 ± 1mm Fold it by 90°

Fold it by 90° 15 ± 1mm

10 ± 1mm

16 ± 1mm

Fig. 2-5-D

B2-5

B2-5

Page 23

3. REMOVAL AND INSTALLATION OF

desoldering completely, pickup the corner of the IC using

tweezers and remove the IC by moving with the IC

REMOVAL

desoldering machine.

(Refer to Fig. 3-3.)

1.

Put Masking Tape (cotton tape) around the Flat Package

NOTE

IC to protect other parts from any damage.

(Refer to Fig. 3-1.)

Some ICs on the PCB are affixed with glue, so be

careful not to break or damage the foil of each IC

NOTE

leads or solder lands under the IC when removing it.

Masking is carried out on all the parts located within

10 mm distance from IC leads.

DISASSEMBLY INSTRUCTIONS

2.

Heat the IC leads using a blower type IC desoldering

machine.

(Refer to Fig. 3-2.)

NOTE

Do not rotate or move the IC back and forth , until IC

4.

Peel off the Masking Tape.

can move back and forth easily after desoldering the

leads completely.

5.

Absorb the solder left on the pattern using the Braided

Shield Wire.

(Refer to Fig. 3-4.)

NOTE

Do not move the Braided Shield Wire in the vertical

direction towards the IC pattern.

FLAT PACKAGE IC

3. When IC starts moving back and forth easily after

Blower type IC

desoldering machine

Masking Tape

(Cotton Tape)

IC

Tweezers

Fig. 3-1

IC

Fig. 3-3

Blower type IC

desoldering machine

IC

Fig. 3-2

B3-1

B3-1

Braided Shield Wire

Soldering Iron

IC pattern

Fig. 3-4

Page 24

INSTALLATION

4.

When bridge-soldering between terminals and/or the

soldering amount are not enough, resolder using a Thin-

1.

Take care of the polarity of new IC and then install the

tip Soldering Iron.

(Refer to Fig. 3-8.)

new IC fitting on the printed circuit pattern. Then solder

each lead on the diagonal positions of IC temporarily.

(Refer to Fig. 3-5.)

5.

Finally, confirm the soldering status on four sides of the

IC using a magnifying glass.

Confirm that no abnormality is found on the soldering

position and installation position of the parts around the

IC. If some abnormality is found, correct by resoldering.

NOTE

When the IC leads are bent during soldering and/or

2.

Supply the solder from the upper position of IC leads

repairing, do not repair the bending of leads. If the

sliding to the lower position of the IC leads.

bending of leads are repaired, the pattern may be

(Refer to Fig. 3-6.)

damaged. So, always be sure to replace the IC in this

case.

DISASSEMBLY INSTRUCTIONS

Soldering Iron

3.

Absorb the solder left on the lead using the Braided

Shield Wire.

(Refer to Fig. 3-7.)

NOTE

Do not absorb the solder to excess.

Thin-tip Soldering Iron

IC

Fig. 3-8

Solder temporarily

Solder

IC

Solder temporarily

Fig. 3-5

Soldering Iron

Supply soldering

from upper position

to lower position

Fig. 3-6

Soldering Iron

Braided Shield Wire

IC

Fig. 3-7

B3-2

B3-2

Page 25

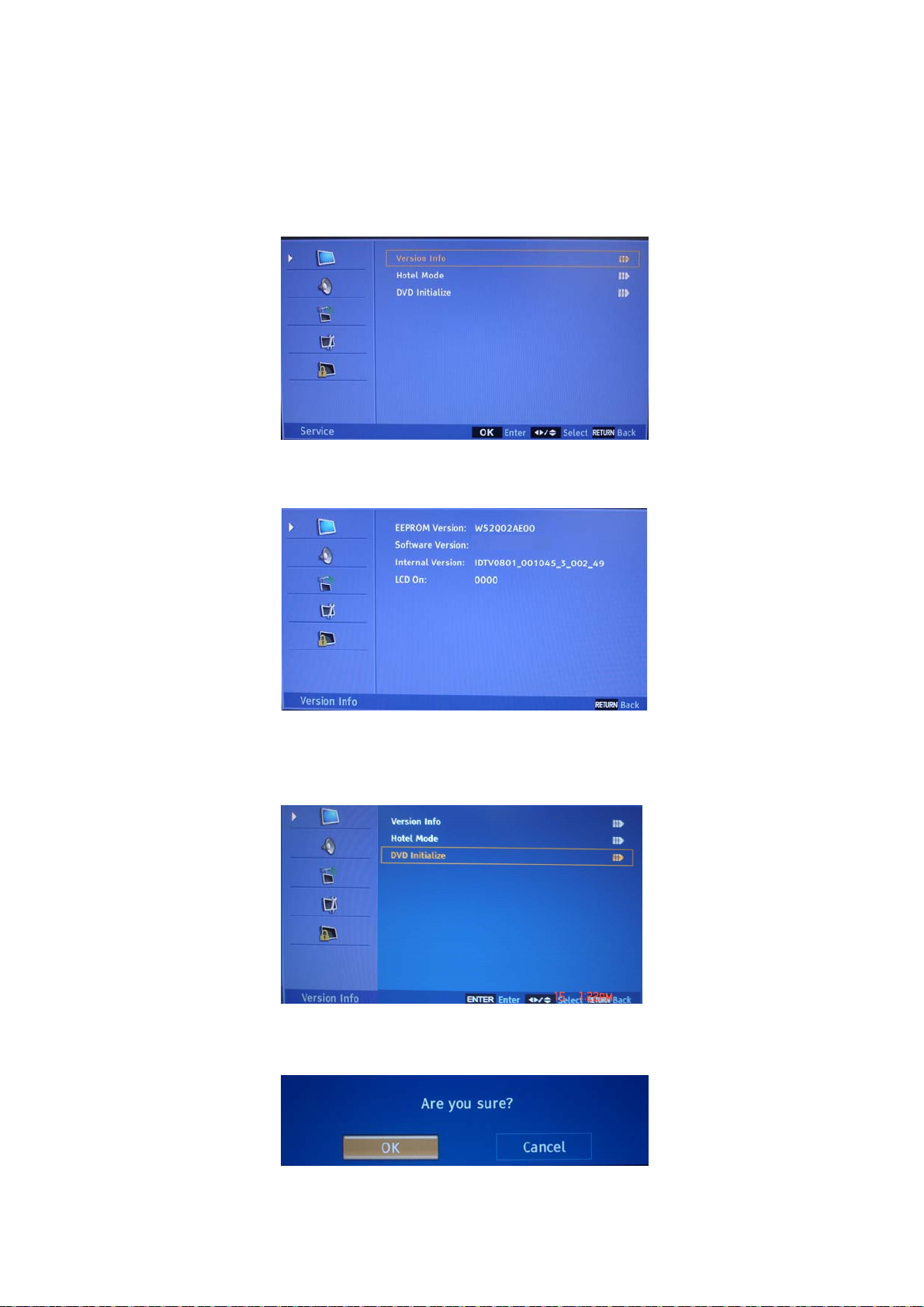

SERVICE MODE LIST

This unit is provided with the following SERVICE MODES so you can repair, examine and adjust easily.

• Do not feel after other MENU.

1. Check of the SUM DATA and MICON VERSION on the screen.

1-1: Press the SETUP/TV MENU ---> 0027 button on the remote control to select "Version Info".

Fig. 1-1

1-2: Press the ENTER button on the remot e control.

CB34M03102

Fig. 1-2

2. DVD Initialize Data.

2-1: Press the SETUP/TV MENU ---> 0027 button on the remote control to select "DVD Initialize".

Fig. 2-1

2-2: Press the ENTER button on the remot e control to select "OK".

Fig. 2-2

C-1

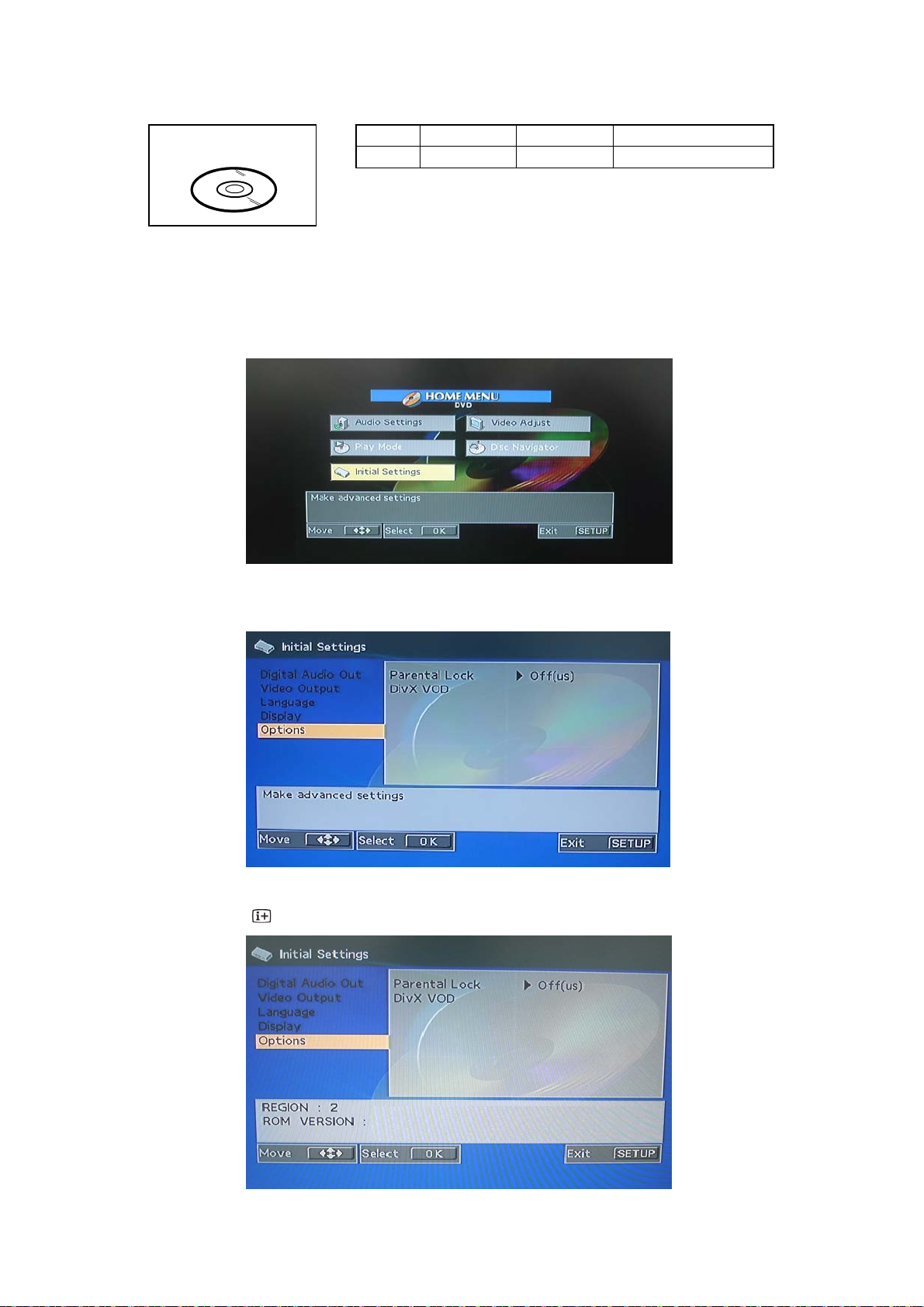

Page 26

SERVICING FIXTURES AND TOOLS

JG176 Up-Date Disc

Ref. No. Part No. Parts Name

JG176 APJG176152 Up-Date Disc

Parts Name

Up-Date of the Firmware

RE-WRITE FOR DVD FIRMWARE

1. Turn on the power, and set the DVD mode.

1-1: Press the SETUP/ TV MENU ---> 0027 button on the remote control to s elect "Initial Settings".

Fig. 1-1

1-2: Press the ENTER button on the remot e control to select "Options".

Fig. 1-2

1-3: Press the button on the remote control.

AEEUL0304A

Fig. 1-3

C-2

Page 27

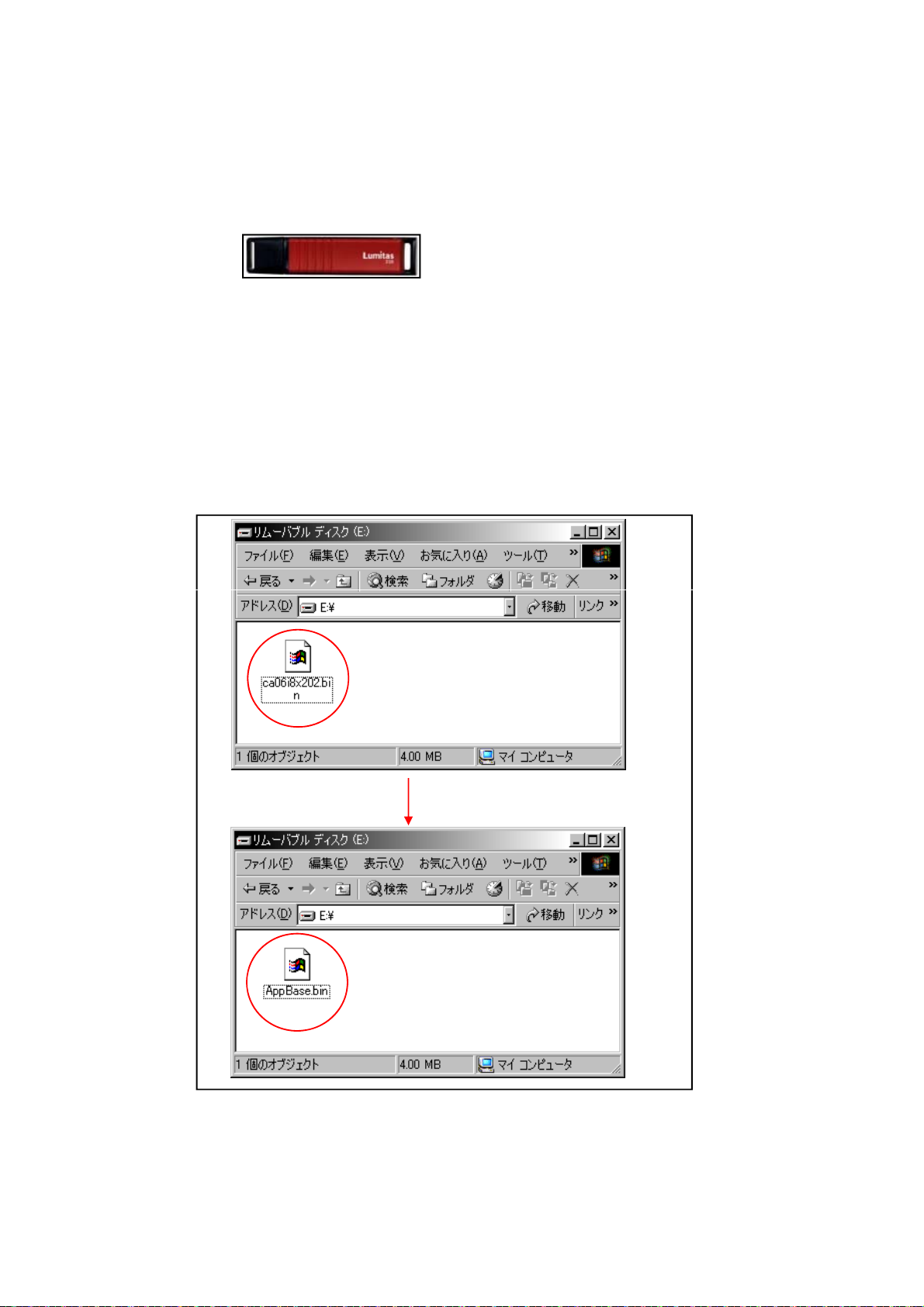

Prepare for USB Memory

p

p

p

.

g

E

y

1 .

1. USB Memory (Figure1) used for Update is connected with PC.

RE-WRITE FOR DIGITAL SOFT FIRMWAR

Figure1:USB Memory

2. The U

3. The software is co

4. The file name of the software co

date software is downloaded.

ied onto USB Memory.

Before file name change:CA**Ixxxxx.bin

↓

After file name change:AppBase.bin

*chan

e the file name by normal-width.

ied onto USB Memory is changed. The following reference

Figure2:Rename for File Name

5. USB Memor

is detached from PC.

C-3

C-3

Page 28

Update procedure

y

p

g

2 .

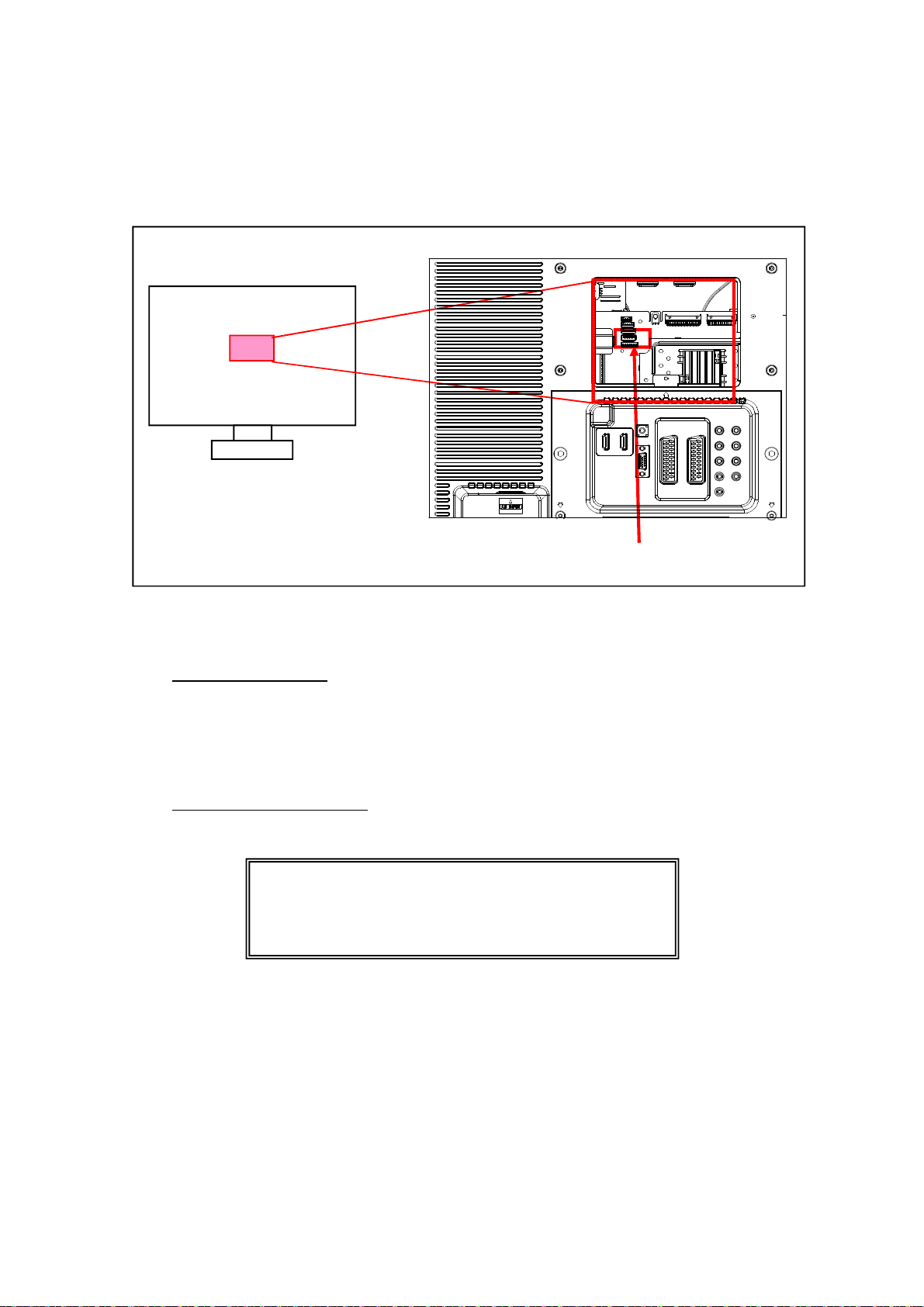

1. Target set is power on. Afterwards, the AC cord is disconnected.

2. The cover of the back of the set is detached.

3. USB Memor

*Refer to "1.Pre

SET (REAR)

that copies software onto the USB connector of the set is insert ed.

are for USB Memory" for the method of copying software onto USB Memory.

USB Connector

Figure3:USB Connector

4. The AC cord of the tar

while updating software.

The key is invalid while updating software.

Attention

Please do not pull out the AC cord while updating software.

When the update is completed

When the update is completed, the checksum screen is displayed in the monitor.

5. The AC cord of the target set is disconnected after the update is complete, and USB Memory is detached.

et set is inserted. The update of software starts.

- Attention The checksum screen is displayed to notify the update completion.

At that time, the version before it updates it is displayed.

It is not a version of the update software.

C-4

Page 29

ELECTRICAL ADJUSTMENTS

3. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE (WIRING CONNECTION)

CD2801

POWER PCB

CP3803

LCD PANEL

DVD DECK

CD3806

CD2302

DVD MT PCB

CP2302

CP2303

CP2301

CD2301

OPERATION PCB

CP2202

CP2804

CP8502

CP8501

CD4201

CD4301

CP4301

J3801

AC IN

CD501

CD3200

CP3808

CP3809

CD3203

OS2201

REMOCON PCB

D-1

CD3203

CP3601

CP3602

CP2201

CD3200

J4208

CP4302

MAIN PCB

J4206

CP4201

J4205

J4204

J4203

J4207

J4301

CP301

CP4200

J4202

SPEAKER

CP5801

CP9600

CP5800

TU5800

TUNER PCB

Page 30

(LCD SECTION)

POWER DOES NOT TURN ON

TROUBLESHOOTING GUIDE

Is F3801 and F3802

broken?

No

Is there voltage at

pin 2 of IC3803 6V?

Yes

Is R3860 broken?

No

Is there voltage at pin

8 of IC3802 19V?

Yes

No

Yes

No

Change F3801 or F3802.

Check IC3803 and peripheral

circuit.

Change R3860.

Check IC3802 and peripheral

circuit.

Yes

Change POWER PCB.

E-1

E-1

Page 31

THE PICTURE APPEARS,

BUT THE AUDIO DOES NOT

APPEARS. (AT RF MODE)

TROUBLESHOOTING GUIDE

Is CD301 connected?

Yes

Is there signal at pins

1 and 4 of CD301?

No

Is there signal at pins 2

and 14 of IC300?

No

Is there signal at pins

17 and 18 of IC4200?

No

Yes

Yes

Yes

Connect CD301.

Change SP301 and SP302.

Check IC300 and peripheral

circuit.

Check IC4200 and

peripheral circuit.

No

Is there signal at pin

16 of TU5800?

No

Change TU5800.

Yes

Check IC800 and

peripheral circuit.

E-2

E-2

Page 32

THE PICTURE DOES NOT

Yes

APPEAR

TROUBLESHOOTING GUIDE

No No

Does backlight shine?

Yes

No

Is CD2801 connected? Connected CD2801.

Yes

Is there voltage at pins

27, 28, 29 and 30 of

CP2804?

Is there signal at pins 6,

7, 9, 10, 12, 13, 15, 16,

18 and 19 of CP2804?

No

Yes

Is there voltage at pins 1,

2, 3, 4 and 5 of CP3803

24V?

Yes

Check Q3012 and

peripheral circuit.

Check IC3802, T3801, D3822

and peripheral circuit.

Change V2801(PANEL).

No

Change DIGITAL PCB.

E-3

E-3

Page 33

THE COLOR DOES NOT

APPEAR

TROUBLESHOOTING GUIDE

Is setting of color

normal?

Yes

Is the color signal

received?

Yes

Is there color signal at

IC800?

Yes

Change DIGITAL PCB.

No

No

No

Adjust the color.

Receive the color signal.

Check IC800 and

peripheral circuit.

E-4

E-4

Page 34

(DVD SECTION)

DOES NOT DISPLAY DVD

PICTURE

TROUBLESHOOTING GUIDE

Does this display

logo picture?

No

Does this have signal

at pins 102 and 103 of

IC4001?

No

Does IC4001 gets

P.CON+3.3V and

P.CON+1.8V?

No

Check P.CON+3.3V and

P.CON+1.8V line.

Yes

Yes

Yes

Check the disc.

Check pins 8 and 10 of

CP8501 and peripheral circuit.

Change IC4001.

E-5

E-5

Page 35

DISC DOES NOT EJECT

TROUBLESHOOTING GUIDE

Does OSD appear

on the screen?

Yes

Does this eject disc at

change DVD DECK?

Yes

Change DVD DECK.

No No

No

Is remote key set

effectively?

Yes

Check pins 33 and 92

of IC4001 and peripheral

circuit.

Does this have signal at

pins 1 and 3 of CP2302?

Yes

Does this have signal at

pins 4 and 5 of CP2302?

Yes

No

No

Check pins B24 and C24

of IC800 and peripheral

circuit.

Check IC4001 and

peripheral circuit.

Change IC2301.

Change IC4001.

E-6

E-6

Page 36

TROUBLESHOOTING GUIDE

DOES NOT PLAY DVD

Does this display

"INCORRECT DISC"?

No

Does this display

reading mark?

Yes

Yes

No

Does CD2001 connect

with CP2301 correctly?

No

Connect CD2001.

Change IC4001.

Yes

Change DVD DECK.

No

Is the voltage between

JG2301 and JG2330

less than 0.3V?

Yes

Does disc rotate?

Yes

Change IC4001.

No

Change DVD DECK.

E-7

E-7

Page 37

TROUBLESHOOTING GUIDE

DOES NOT PLAY CD

Does this display

"INCORRECT DISC"?

No

Does this display

reading mark?

Yes

Yes

No

Does CD2001 connect

with CP2301 correctly?

No

Connect CD2001.

Change IC4001.

Yes

Change DVD DECK.

No

Is the voltage between

JG2301and JG2329

less than 0.3V?

Yes

Does disc rotate?

Yes

Change IC4001.

No

Change DVD DECK.

E-8

E-8

Page 38

NO SOUND DVD/CD ANALOG

AUDIO

TROUBLESHOOTING GUIDE

Does this have signal

at pins 116 and 118

of IC4001?

Yes

Does this have signal at

pins 1 and 7 of IC8501?

Yes

Is CP8501 connected?

Yes

Change DIGITAL PCB.

No

No

No

Change IC4001.

Check pins 1 and 7 of IC8501

and peripheral circuit.

Connect CP8501.

NO SOUND DVD/CD DIGITAL

AUDIO

Does this have signal

at pin1 of CP8501?

No

Does this have signal

at pin 92 of IC4001?

No

Change IC4001.

Yes

Yes

Change DIGITAL PCB.

Check line circuit IC4001

to CP8501.

E-9

E-9

Page 39

DVD BLOCK DIAGRAM

DVD LOADER

RF, A, B, C, D, E, F,TROUT,LIMIT,MDI

1

AUDIO AMP

AL, AR

V

20

Q

2302

,Q

2303

DSM3

OPU

06SD

SPINDLE/

STEPING/

SLED

MOTOR

TRIN

VR(DVD),VR(CD) IOA(DVD-L/CD-H)

T+/-, F+/-,

LOAD+/-,

MOT_SLED+/MOT_SPDL+

MOT_SPDL-

LD_DVD/CD

D

VR_CTL

Q2301

Q2304

Q2305

Motor Driver

IC2301

AM5766

LD DRIVE CTL

SFLASH_CK,SFLASH_CS/DI

DMSO, FMSO, TRSO

FOSO, VIP4, STBY,

TROPEN, TRCLOSE

E

OP+/-

LDO1,LDO2

SFLASH_DO

MPEG/MICON

IC4001

MT1389DE/L-L

B

A

IC8501

NJM4565M(TE1)

ASPDIF

B/PB/SC

G/Y/SY

RESET

XAMUTE

C

AUDIO_L

AUDIO_R

A

TRIN

LCD BLOCK

START_SW

TV_RX/DVD_TX

TV_TX/DVD_RX

SPDIF-134

C_VIDEO

Y_VIDEO

DVD RESET

ZERO

DVD_A_OUT_L

DVD_A_OUT_R

P.CON+3.3V

16M SERIAL FLASH

IC4004

EN25Q16-100HIP

A

DQ0~15

MA0~A11,SDCLK

DWE#, DCAS#, DRAS#,

DBA0/1, DQM0/1

64M SDRAM

IC4005

HY57V641620FTP-7

B

RP131H181D5-T1-F

A

1.8V REG

IC8502

C

D

E

P.CON+12V

P.CON+A5V

MOTOR+6V

A … V+3

B … V+1R8

C … V+12

D … V+5V

E … V+6A

F-1 F-2

Page 40

SC1_AUDIO_OUT_DAC IC7200 WM8521HCGED/RV

21PIN BLOCK DIAGRAM

R_IN

2

SC1_A_IN_R

L_IN

SC1_R_IN

SC1_G_IN

SC1_B_IN

SCART1_FB

FOR_VCR

VIDEO_IN

TUNER_OUT

AV/DVD_INTERFACE/

2

TUNER_OUT

SC1_CVBS_OUT

6

SC1_CVBS_OUT

R_OUT

L_OUT

R_IN

L_IN

SC1_R_IN

FOR_VCR

PANEL_INTERFACE/DDR/TUNER/

VIDEO_IN

MONITOR_OUT

SCART1 AOBCK 4 AOBCK

J4206 RGB-56H AOLRCK 2 AOLRCK

R_OUT 1 6 SC1_A_OUT_R AOSDATA0 3 AOSDATA0

L_OUT 3 10 SC1_A_OUT_L AOMCLK 13 AOMCLK

SCALER_AV/SCALER/FLASH/

PANEL_INTERFACE/DDR/TUNER/

HDMI/COMMON INTERFACE

SCART1

SCART2

J4207 RGB-56H

SCART2

6 SC1_A_IN_L

15 SCART1_R/C1_IN

11 SCART1_G_IN

7 SCART1_B_IN

16 SCART1_FB

8 SCART1_SW

20 SCART1_V_IN

19

TUNER CVBS OUT SW IC4201 MM1502XNRE

ATV/DTV_SW 1 ATV/DTV_SW

ATV_CVBS_OUT 4 ATV_CVBS_OUT

1 SC2_A_OUT_R

3 SC2_A_OUT_L

2 SC2_A_IN_R

6 SC2_A_IN_L

15 SCART2_R/C2_IN

8 SCART2_SW

SOUND AMP/AUDIODAC/

JACK/AUDIO SWITCH

SCALER_AV/SCALER/FLASH/

PANEL_INTERFACE/DDR/TUNER/

HDMI/COMMON INTERFACE

AV/DVD_INTERFACE/

SOUND AMP/AUDIODAC/

JACK/AUDIO SWITCH

SCALER_AV/SCALER/FLASH/

F-3 F-4

20 SCART2_V_IN

19 SC2_CVBS_OUT

HDMI/COMMON INTERFACE

Page 41

CP3200 SOUND+B

REGULATOR2/3 BLOCK DIAGRAM

5V_CI

IC3008

DDRV

IC2402

1

2

3

4 P.CON+9V_MT8292

7

8

SOUND+B

SOUND GND

SW+12V

P.CON+12V SW

Q3003

KTA1664-Y(GP)

P.CON+9V REG

IC3007

R1190S090B-E2-F

SOUND GND

P.CON+12V

14

15

AT+6V

LCD+B SW

Q3012 TPC6108

AT+2.5V REG

IC3006

RP131H251D-T1-F

TUNER+5V REG

IC3013

RP131H501D-T1-F

AT+3.3V REG

IC3003

RP131H331D-T1-F

P.CON+1.8V REG

IC3004

RP131H181D-T1-F

DC/DC 3.3V

IC3005

LV5809MX

USB+5V REG

IC3009

RP131H501D-T1-F

CI CARD+5V REG

RP131H501D-T1-F

P.CON+1.25V REG

IC3002

BD7820FP-E2

DC/DC 1.1V

IC3010

LV5809MX

1.8V_REGULATOR

LCD+B

SW+6V

P.CON+2.5V

5V_USB

P.CON+5V_TUNER

AT+3.3V

P.CON+1.25V

P.CON+1.8V

P.CON+1.1V_CORE

P.CON+3.3V

CP3203 HDMI+5V

2

P.CON+5V P.CON+5V

3

8 RLY_H RLY_H

9 POWER_ON_H SYS_POWER_H

10 LIGHT_CTL LIGHT_CONTROL

11 INVERTER_H LIGHT_POWER_H

12 POWER_FAIL POWER_FAIL

F-5 F-6

PQ035ZN1HZPH

D3613 SS160

SCALER_AV/SCALER/FLASH/

PANEL_INTERFACE/DDR/TUNER/

HDMI/COMMON INTERFACE

Page 42

RESET IC806 PST3229NR

SCALER_AV/SCALER/FLASH/PANEL_INTERFACE/DDR/TUNER/HDMI/COMMON INTERFACE BLOCK DIAGRAM

TU_SCL

TMDS_CLK+/-,CLK_SH,DATA0+/- ~2,DATA1/2_SH

HDMI PORT2

AT24C02BN-SH-T

DDC_SDA

AOBCK

TMDS_CLK+/-,CLK_SH,DATA0+/- ~2,DATA1/2_SH

CP2804 A2006WR0-2X15P

LIGHT_POWER_H

DDR2 SDRAM

DVD_A_R

HDMI PORT1 TUNER

CP3601 TU5800 TDTW-S126D

1A0300030

TU_SDA

15 DDC_SCL

16 DDC_SDA TINP,TINM,SIFN,SIFP,IF_AGC

EEP_ROM IC

IC3600

CP3602 ATV_CVBS_OUT

1A0300030 AOLRCK

AOSDATA0

15 DDC_SCL AOMCLK

16

SCART1_G,B_IN

EEP_ROM IC SCART1_R/C1_IN 21PIN

IC3601 SCART2_R/C2_IN

EEPROM 32K AT24C02BN-SH-T SCART1_FB

IC804 AT24C32CN-SH-T SCART1,2_SW

0SDA0 SCART1,2_V_IN

0SCL0 SC1_CVBS_OUT

SC2_CVBS_OUT

ATV/DTV_SW

LCD PANEL SCALER

V2801 V315B6-L01 IC800 RLY_H

MT5362CHG SYS_POWER_H REGULATOR1/2

LVDS CONNECTOR LIGHT_CONTROL

LCD_TXOUT0+/- ~3,CLKOUT+/-

Z PANELPOWER_H

LVDS CABLE

CD2801

CHRU2502

CVBS_IN

Y/PB/PR_IN

ADCOUTL,R

AL0O,AR0O

AL1O,AR1O

AL2O,AR2O

IC802 MRCAS#,MRODT,MRRAS#,MRWE#,MRCS# SPDIF_OUT

H5PS5162FFR-S5C RDQ0~15,RDQS0,0#,1,1#,RDQM0,1 VGA-R,G,B

MRA0~12,MRBA0,1,CLK0,0#,MRCKE VGA-HS,VS

KEY-A,B

REMOCON_IN

DDR2 SDRAM GREEN,RED_LED

IC803 MRCAS#,MRODT,MRRAS#,MRWE#,MRCS# DVD_A_L

H5PS5162FFR-S5C RDQ16~31,RDQS2,2#,3,3#,RDQM2,3 DVD_A_R

MRA0~12,MRBA0,1,CLK1,1#,MRCKE

CP4201

SERIAL FLASH

IC2403 AT26DF081A-SU

CI CONNECTOR

CP9600

19_5028_068_531_899+

CI_A0~A14,CI_D0~D7,CI_INDATA0~7

CI_OUTDATA0~7,CI_IREQ#

CI_IOIS16#,CE2#,INSYNC

CI_RESET,WAIT#,REG#,INVALID,INCLKA

CI_OUTVALID,CI_OUTSYNC

POCE0#

IC CARD INTERFACE IC

IC9600

MT8295AE

TS_VALID_IN,CLK_IN

TS_DO_IN,SYNC_IN

TS0INCLK,TS0INSYNC

TS0INVALID,TS0INDATA0

Nor_ FLASH_128 Mbit

PARB#,POCE1#,PACLE,PAALE IC2401 HY27US08561A-TP

POWE#,PDD0~7

4

DVD_A_L

6

1

SPDIF-134

DVD/BD_RST

7

DVD_Y

8

DVD_C

10

DISC_IN_DET

11

13

DVD_BD_TX

14

DVD_BD_RX

PDD0,PDD1,POOE#

AV/DVD_INTERFACE/

SOUND AMP/AUDIODAC/

JACK/AUDIO SWITCH

F-7 F-8

Page 43

CVBS_AV_IN

AV/DVD_INTERFACE/SOUND AMP/AUDIO DAC/JACK/AUDIO SWITCH BLOCK DIAGRAM

SP_AUDIO_OUT_L,R

SC1_A_IN_L

J4204

RCA-341H(2)NI-06

CVBS_IN

VIDEO_A_L,R

Y/PB/PR_IN

COMPONENT_VIDEO_IN

J4203

RCA-341H(NI)-09 AUDIO_SW_IC

IC4200 MT8292N

COMPONENT_AUDIO_IN

J4202 ADCOUTL,R

RCA-228(3)NI-02 YUV_A_L,R AL0O

AR0O

AL1O

HEADPHONE JACK AR1O

J4205 AR1O

PJ-317-02 HP_A_L,R AR2O

DVD_A_L

DVD_A_R

HDMI/PC AUDIO IN

J4208

PJ-364H PC/DVI1_A_IN_L,R SC2_A_OUT_R

SC2_A_OUT_L

SC2_A_IN_R 21PIN

SPEAKER SOUND AMP SC2_A_IN_L

SP301,302 S0412F03 IC300 TDA8932BT/N2,118 SC1_A_IN_R

SCALER_AV/SCALER/FLASH/

PANEL_INTERFACE/DDR/TUNER/

HDMI/COMMON INTERFACE

ZZZZZZ

COAXIAL

J4301

RCA-101HT(OR)

SPDIF_OUT

DB15ds

CP4302

WD-00021-R

1 VGA-R VGA-R

2 VGA-G VGA-G

3 VGA-B VGA-B

13 VGAHS VGA-HS

14 VGAVS VGA-VS

OPERATION PCB

POWER CP2202 CP4301

CH DOWN 2 KEY_A 3 KEY_A KEY_A

MENU 3 KEY_B 2 KEY_B KEY_B

CH UP

VOL UP

VOL DOWN

INPUT

REMOCON PCB

REMOCON PCB CP2201 C

1 REMOCON_IN 1 REMOCON_IN REMOCON_IN

4 STANDBY_LED 4 STANDBY_LED RED_LED

5 POWER_ON_LED 5 POWER_ON_LED GREEN_LED

P4200

SCALER_AV/SCALER/FLASH/

PANEL_INTERFACE/DDR/TUNER/

HDMI/COMMON INTERFACE

F-9 F-10

Page 44

TRANSFORMER

POWER BLOCK DIAGRAM

AC IN

132

4

2

TRANSFORMER

1

3

4

FB

Vdd

D

3825

RYL_H

P.CON+

5

V_A

POWER_ON_H

P.CON+

6

V[DVD]

FB

SOUND GND

IC

3808 PS2561AL1

-

DVD_POWER_H

POWER+

3.3

V[DVD]

CD3801

J3801

F3802

F3801

POWER CTL

IC3802 MCZ5230NA-7101

Vsen

GND

Vc1

VGH

P.GND

VS

VGL

OPC

1

2

5

8

16

11

15

12

9

L3801

SW REG CTL IC

IC3803 VIPER28LN

VCC SW

Q3802

KTA1281_Y

D3803

T3802 81190141

C3805

7

5

3

2

7 8

POWER SW

IC3810

3

42

PS2561AL1-1-V(W)

14

2

FEED BACK

1V(W)

POWER SW.

Q3805

STF10NK50Z

POWER SW.

Q3806

STF10NK50Z

4

3

TRANSFORMER

T3801 8728002H

2

1

2

5

11

13

15

REGULATOR

IC3804 KIA431A-AT

13

8

7

10

9

D3824

POWER FAIL SWITCH

KTA1504S_Y_RTK

5V REG

IC3805 S-1170B50UC-OUJTFG

4

1

5

MOTER+6V SW

IC3806 SI3443BDV-T1-E3

5

4

3

SOFT SWITCH

Q3907

KTC3875S_Y_RTK

Q3813

KTA1271_Y

Q3814

KTC3198

D3821

D3819

Q3809

Q3812

KRC101S-RTK

AT +6V

POWER FAIL

GND

SOUND +B

SW +12V

FEED BACK

IC3809

14

13

D3822

INV SW +24V

PS2561AL1-1-V(W)

14

23

REGULATOR

IC3801 KIA431A-AT

1

3

2

DVD+3.3V DC/DC CONVERTER

IC3807 LV5893M

2

7

3

F-11 F-12

Page 45

PRINTED CIRCUIT BOARDS

DVD MT (TOP SIDE) DVD MT (BOTTOM SIDE)

CP8501

C8529

CP8502

B4003

C8530

B4008

C8535

C8539

C4043

B8502

B8504

C8521

R8525

B8501

B8503

C8524

C8525

R8522

C8520

R8523

R8526

C4123

C4015

C8534

C8538

C8519

R8516

C8518

IC8501

C

8

5

C8522

C4122

C8523

C8532

C8536

R8519

R8509

R8510

1

7

R8513

R4004

R

8

5

R4052

R4006

C4075_1

CP2302

C

P

2

3

0

3

R2309

C4044

B4012

97

C2335

C2308

C2333

C2334

B2341

B2342

R2310

C2311

C2330

Q2301

Q2303

R2307

R2302

Q2305 Q2304

C4038

C4063

C4013 C4045

C4059

IC4001

R2311

IC2301

R2308

C2321

R2301

Q2302

R2306

R4056

C4047

R2317

C2305

C2306

C2319

C2331

C2320

C2303

C2328

C2304

C2327

C2301

CP2301

SH8501

PAL/NTSC

C4058

C4088

C4036

C4008

C4001

C4006

1

C4033

3365

C4003

C4029

R4014

R4039

C4005

C4020

X4001

R4024

W808

R4015

R4016

R4019

C4007

C4037

C4019

C2325

C4089

C4090

R4002

MPEG

C2332

R2312

R2313

R8507

R8501

R8502

R8503

C8511

C8512

R8506

R8505

C4041

R4027

C2322

R2342

C8540

C8513

C8056

D2302

D2301

IC8502

R4057

NR4002

R2344

R2341

C8502

R2325

C2323

R4031

R4050

W818 W809

B4010

W814

C4073

4

R2328

C8501

D4001

L8501

C8514

W810

C8516

C4064

C4074

C4071

R4066

C2307

R2316

R2319

R2326

R4009

C8503

C4066

C2329

C4023

R4062

R4045

R4055

R4059

C8504

R4046

C8531_2

C8533

Q8507

Q8506

R8504

R8515

C8507

1

1

G-1

C4050

DMJ120B

R4026C4055 C4054 C4053_1 C4052

R4020

IC4005

C4049_1

R4054

C4012

R4043

IC4004

R4018

R4034

R4042

C4101

C4102

R4017

DMJ120B

SH8502

C4048_1

C4057

C4060

R4005

C4062

R4047

R4044

R4053

C4072

C4076

R4007

R4040

G-2

Page 46

PRINTED CIRCUIT BOARDS

MAIN/TUNER (TOP SIDE)

W877

C301

W831

L301

R309

SOUND AMP

CI

IC3004

C3031

C3057

W946

B9603

IC3008

C3042

C9600

C3041

D302

R308

C330

W981

IC300

2

CP5801

W834

CEJ569A

PAL

C300_1

L300

TU5800

B5805

C5833

C5851

TUNER

C351C352

W988

C354

C9613

C353

C4404

C4397

CP9600

C3001

C3014

C5826

C3013

R5801

R5802

C5825

C5824

R5805

R5806

CP5800

R4284

R4275

R4270

R4278R4300

C4267C4269

Q4214

B4231

B4232

Q4215

R4279

R4286

R4271

R4340 R4339

R3040

IC3013

SH5801

J4205

SH3205 SH3206

SH3204

R3017

R3045 R3008

Q3001

C3061

R3007

D3001

C3065

L3003

C2499

C2498

IC2401

R2401

R2400

W815

R4297

R4299

C5816

C5817

C4285

C4287

C4332

B4226

C4305

C7202

C7203

D4222

W924

R7202

R7201

C7207

C7206

W830

C2808

C2809

R5803 C5812

C858

C856

C860

X800

R845

D822

C814

R814

R857

B809

SH3200

C3068

R804

W835

W840

W806

W847

C869

C809

R813

C800

Q3005

IC3006

C3039C3040

R3047

R3038

C3046

R3006

C802

R815

SCALER

J4204

J4301

C4222

CP4200

C2854

R2412

C2465

CMJ158A

Q4216

C4304

R4209

C4375

R4238

D4224

CP2804

C2437

NR2804

C2442

C2413

R2455

R2404

A1

NR2400

NR2403

R2413

R2410

R2411

AF1 AF26

R859

R853

R854

C2440

C2411

C4299

W975

D4223

C4259

L4200

W866

B4212

C4387

R4218

D4249

B4207

R4207

B4204

B4210

C4390

R4229

R4220

R4250

R4251

W982

C4249

C4242

D4216

D4217

NR2805

C2810

B2802

C868

B805

R805

Q800

R860

NR2806

HS800

R9626

R861

A26

IC800

R832

R847

W963

W803

C824

R869

C5811

C5802

C817

C807

C805

R837

R839

R811

C871

C5806

C801

C811

C870

C813

R818

C816 R834

W825

B808

C2406

B2401

R812

B2800

B2801

C2407

W989

C822

C5801

C862

B5804

C845

C886

R844

R808

R810

D824

C910R840

C911

C810

C872

C815

B810

R831

R809

R836

R823

D825

D823

B807

2

PAL

C831

R851

IC806

J4203

J4207

B4209

B4206

C4389

C4388

J4202

R4272

R4274

D4248

D4247

D4220

R828

R829

CP803

CP800

CP804

W965

W990

C3201

C3275

W822

C3259

W966

W920

W922

C3025

R3016

R3014

Q3002

CD3200

C3204

W947C3203

CD3203

B3005

D3613

L3001

L3000

D3002

C3016

IC3003

C3048

L3602L3603

CP3602

R3009

C3010

R3058

B801

R3019

R2417

R2418

C2404

C2400

C2495

R3026

POWER

CP3601

L3600

L3601

Q3004

C3044

C3026

R3029

C3027

R2854

R2853

Q3012

R3030

R866

R865

C2412

C2483

R1

C2467

C2472

C2457

C2459

W820

C2468

C2450

R2419

C2409

C2410

R2416

R2415

J4208

W905

CP4302

IC802

R9

R2456

C2466

C2482

C2478

C2473

C2475

C2486

C2470

C2493

C2491

R1

IC803

R9

R2457

R4291

C4324

B4301

R4318

C4409

B4302

C4325

R4217

C4405

R4317

C2893

C2851

B2805

C2448

C2441C2436

A1

A9

A1

A9

R4296

R4295

R4294

R4293

R4292

C4203

C4206

C4376

IC4201

C4377

C4308

R4214

C4208

R4240

Q4201

R4328

C4229

J4206

HDMI

B4203

R4219

B4205

R4223

R4254

R4255

CP4301

B4312

B4322

B4326

C4372

C4364

C4301

B4306

R4263

R4285

B4225

C4408

Q4219

C4407

W862

Q4220

C3053

R3049

R2402

C919

W872

R4362

R4280

W870

B4223

C4402

R4213

C4239

R4212

C4210

B4219

W940

D301

Q301Q307Q308

CP4201

W852

C4399

MICON

R878

R4304

R4306

R4308

R4319

C4370

C4371

C4291

C4373

C4294

C4295

C4297

C4296

29

15

C4303

IC4200

C4334

43

1

C4362

C4357

W811

C7201

C7205

C7204

D4221

C7200

W925R7200

IC7200

Q4203

R4205

Q4204

Q4202

R4200

C355

C356

B308

B307

CP301

C302

R876

R3031

C3029

C4300

C4359

B4233

C4336

W919

C357

C358

B306

B302

R3039

G-3

G-4

Page 47

PRINTED CIRCUIT BOARDS

MAIN/TUNER (BOTTOM SIDE)

W883

W884

W886

W885

W845

W846

R5804

CEJ569A

R5813

C5829

C5821

B4218

R4231

C4262

R4277

B4217

C4264

R4236

Q4222

R4241

NR9600

R9601

R9600

R9622

C9615

R9608

R9611

R9614

R9609

C9617

X9600

C9616

C9619

C9618

C9609

R9607

C9606

B9605

C9607

C9608

R9624

1

C9604 C9635

R9606

C9638

B9602

C9614

C9610

B9601

C9622 C9625

C9621

IC9600

C9636C9605

C9601

B9604

B9600

C9624

6597

33

C9627

C9623

C9634

C9620

R303

R359

R305

C318

R360

R332

R328

C334

W961

R322

C322

C329

R323

C323

W987

W876

R336

R9605

C9637

R9603C9603

R9604

R9625

C9632

R9616

R9618

C9629

C9628

C9612

C9611

R9621

R9620

C9631

C9630

C9633

R9615

R9613

R9623

R9617

R9612

R9602

C9602

Q300

W916

W854

C335

B301

C333

C341

C344

C345

B300

R334

C349

W915

C324

C360

R329

C338

C347

R5807

R325

C319

C328

C325

R326

C326

C332

C359

R301

C340

C346

C348

R335

R337

C350

C5827

Q5800

R5808

R5809

R306R307

C343

C339

W959

C853

W953

C5828

W841

R5810

W903

C3051

C3064

R4261

Q4212

W980

R2403

W801

C4350

IC3007

W800

R822

R824

W843

R821

R825

R4307

R4313

C4292

C4290

D4241

C4302

D4240

C4354

C4348

C4293

C4347

C4339

B4237

D4236

R4264

C4337

B4230

C4344

C3006

R877

R856

R801

R875

C3004

C3005

C4310

W868

IC804

C4356

R3005

R3048

C3052

C3050

IC3010

D3011

C2497

R4298

R4303

R4305

C4288

C4286

C4289

R4326

R4325

R4323

C4391

D4233

C4214

B7200

W850

R4368

C3012

C3054

C3011

R3037

R3052

R3050R3051

C3055

IC2403

R4210

W983

C4266

C4282

C4313

B4253

R4265

C4392

B4208

B4228

R4363

D4239

R4267

IC3002

W952

R3022

W842

R4230

C4318

R803

C857

C838

C859

C812

R4336

R4226

C4306

D4237

R4266

B4213

C4394

C4227

CMJ158A

C3074

R802

C864

C835

B803

C836

C851

B5803

C5800

R816

C5803

B821

B5802

C5819

C850

B3600

C3613

C819

D818

D812

D802

D803

C873

C806R820

D820

R835

B4214

R4337

B4216

R4221

C4307

R4338

B4200

C4200