Page 1

TopPage

LC-26/32A37M

SERVICE MANUAL

No. SY8U6LC32A37M

LCD COLOR TELEVISION

LC-26A37M

MODELS

In the interests of user safety (required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified should be used.

LC-32A37M

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRE-

CAUTION............................................................i

PRECAUTIONS FOR USING LEAD-FREE

SOLDER ............................................................ii

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS ......................................... 1-1

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL..................................2-1

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS ................................................3-1

CHAPTER 4. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS ...................4-1

CHAPTER 5. ADJUSTMENT PROCEDURE

[1] ADJUSTMENT PROCEDURE....................... 5-1

CHAPTER 6. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE ......................6-1

CHAPTER 7. BLOCK DIAGRAM/OVERALL WIRING

DIAGRAM

[1] BLOCK DIAGRAM.........................................7-1

[2] OVERALL WIRING DIAGRAM......................7-2

CHAPTER 8. PRINTED WIRING BOARD

[1] MAIN UNIT ....................................................8-1

[2] R/C, LED/KEY UNIT......................................8-5

[3] POWER UNIT................................................8-6

[4] INVERTER UNIT ...........................................8-9

CHAPTER 9. SCHEMATIC DIAGRAM

[1] SCHEMATIC DIAGRAM................................9-1

Parts Guide

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-26/32A37M

LC26A37M

SAFETY PRECAUTION

ServiceManual

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

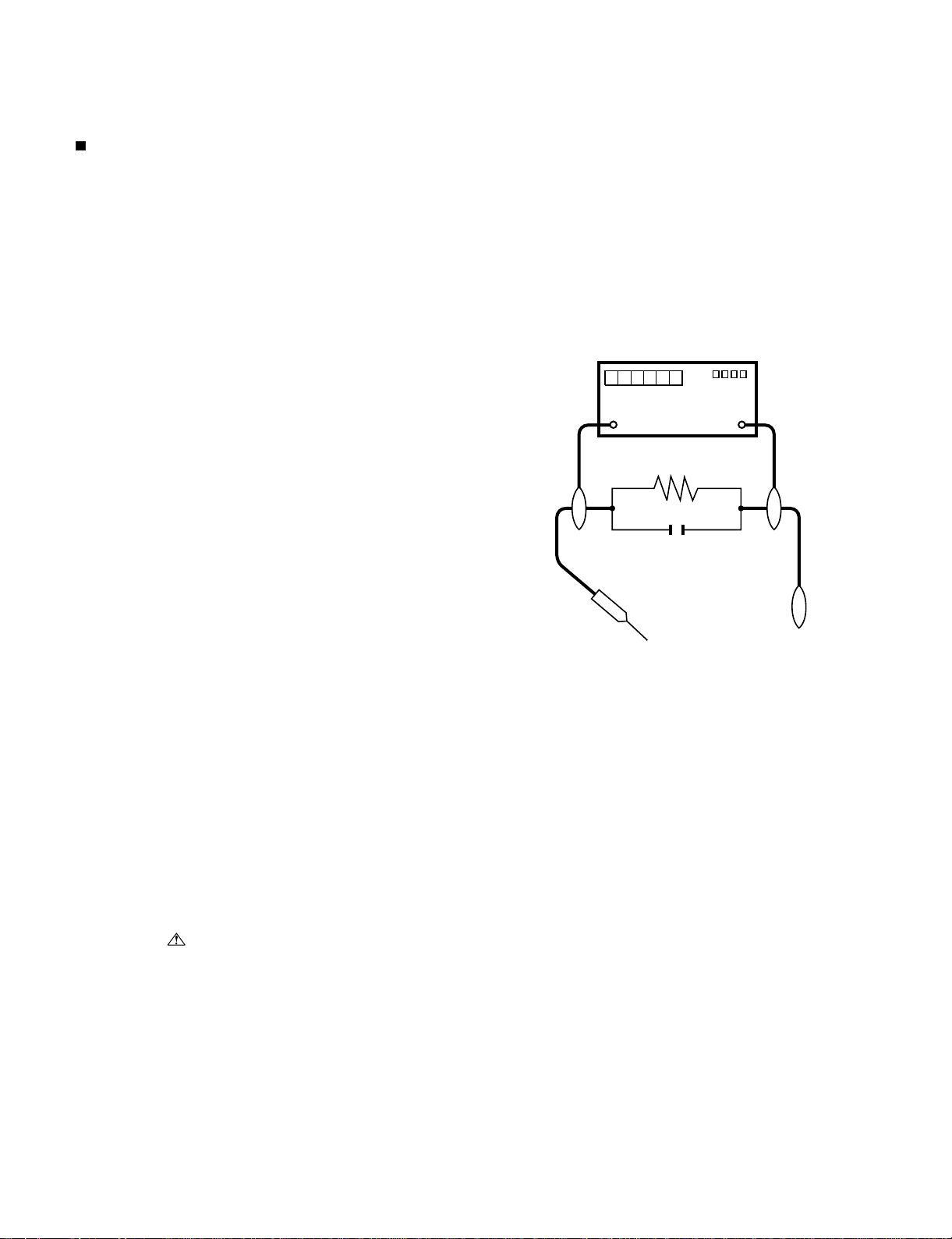

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 110 ~ 240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a non polarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.74 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

DVM

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts

Lists and Schematic Diagrams.

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

i

Page 3

LC-26/32A37M

PRECAUTIONS FOR USING LEAD-FREE SOLDER

Employing lead-free solder

• “All PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals.

The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Indicates lead-free solder of tin, silver and copper.

L F a/a

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g (1roll) BL

ZHNDAi126500E J φ0.6mm 500g (1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg (1roll) BM

ii

Page 4

LC-26/32A37M

LC26A37M

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS

ServiceManual

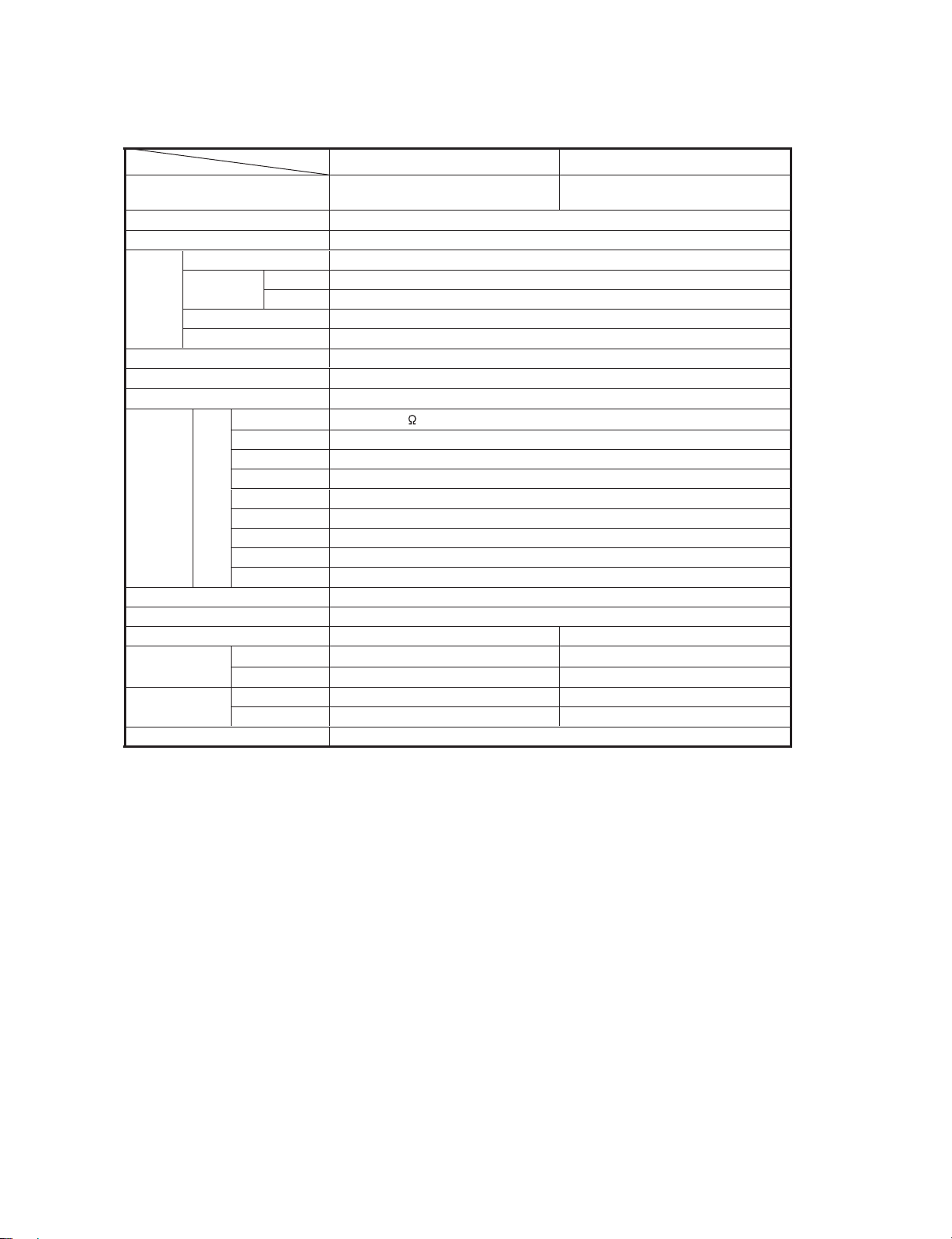

Item

LCD panel

Resolution

Video Colour System PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

TV

Function

Viewing angles H : 176º V : 176º

Audio amplifier

Speakers

Terminals Rear Antenna input

OSD language English/Simplified Chinese/Traditional Chinese/Arabic

Power Requirement AC 110—240 V, 50/60 Hz

Power Consumption 88 W (0.9 W Standby) 97 W (0.9 W Standby)

Dimensions

Weight

Operating Temperature 0°C — 40°C

• As a part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for

product improvement without prior notice. The performance specification figures indicated are nominal values of production

units. There may be some deviations from these values in individual units.

TV-Standard PAL: B/G, D/K, I SECAM: B/G, D/K, K/K

Receiving

Channel

TV-Tuning System Auto Preset 99 ch

STEREO/BILINGUAL NICAM: B/G, I, D/K A2 stereo: B/G

INPUT1

INPUT2

INPUT3

INPUT4

INPUT 5 S-VIDEO in, VIDEO in, AUDIO in

INPUT 6 (PC input)

OUTPUT AUDIO out

RS-232C 9 pin D-sub male connector

without stand

with stand

without stand 7.5 kg 9.5 kg

with stand 9.0 kg 11.0 kg

Model

VHF/UHF 42.75—866.25 MHz

CATV S1—S41ch (including Hyperband)

LC-26A37M LC-32A37M

26" (640 mm) Advanced Super

View & BLACK TFT LCD

1,049,088 pixels (1366 x 768)

10Wx2

10 x 4 cm 2pcs

UHF/VHF 75

HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz, 1080I/60Hz)

HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz, 1080I/60Hz)

AUDIO in, COMPONENT in (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz, 1080I/60Hz)

AUDIO in, COMPONENT in (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz, 1080I/60Hz)

15 pin mini D-sub, AUDIO in (common use with INPUT 1) (Ø 3.5 mm jack)

652 (W) x 445 (H) x 123 (D) mm 788 (W) x 519 (H) x 123 (D) mm

652 (W) x 504 (H) x 235 (D) mm 788 (W) x 575 (H) x 235 (D) mm

DIN type

32" (800 mm) Advanced Super

View & BLACK TFT LCD

1

NTSC: M

1 – 1

Page 5

LC26A37M

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL

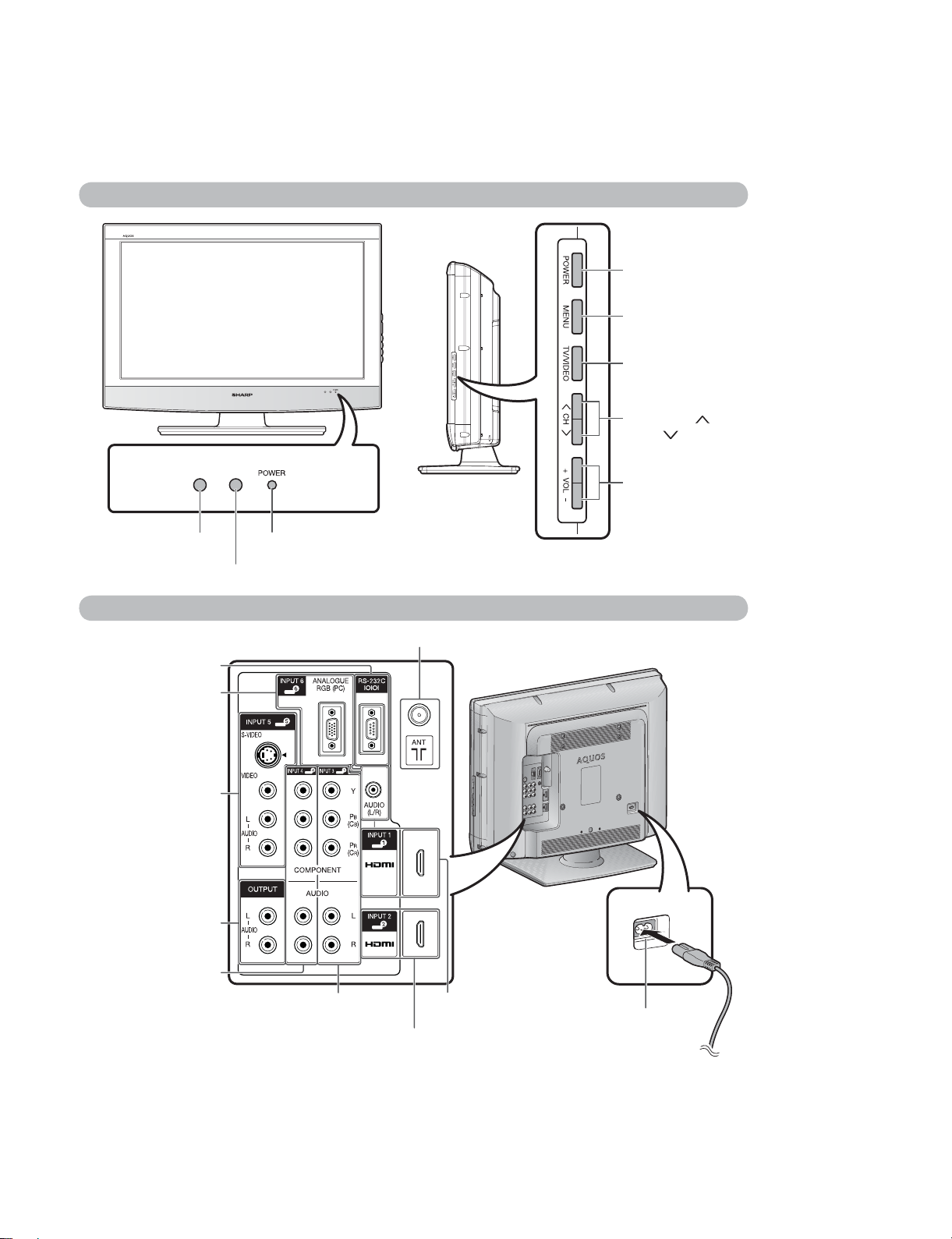

1. Part Names

TV (Front/Side)

LC-26/32A37M

ServiceManual

POWER (On/Off)

button

MENU button

TV/VIDEO button

Channel up( )/

down ( ) buttons

Volume up (+)/

down (-) buttons

Remote control sensor

OPC sensor

TV (Rear)

RS-232C terminal

INPUT 6 (PC) terminals

INPUT 5 terminals

OUTPUT terminals

INPUT 4 terminals

POWER indicator

Antenna input terminal

INPUT 3 terminals

INPUT 2 (HDMI) terminal

INPUT 1 (HDMI)

terminal

2 – 1

AC INPUT terminal

Page 6

LC-26/32A37M

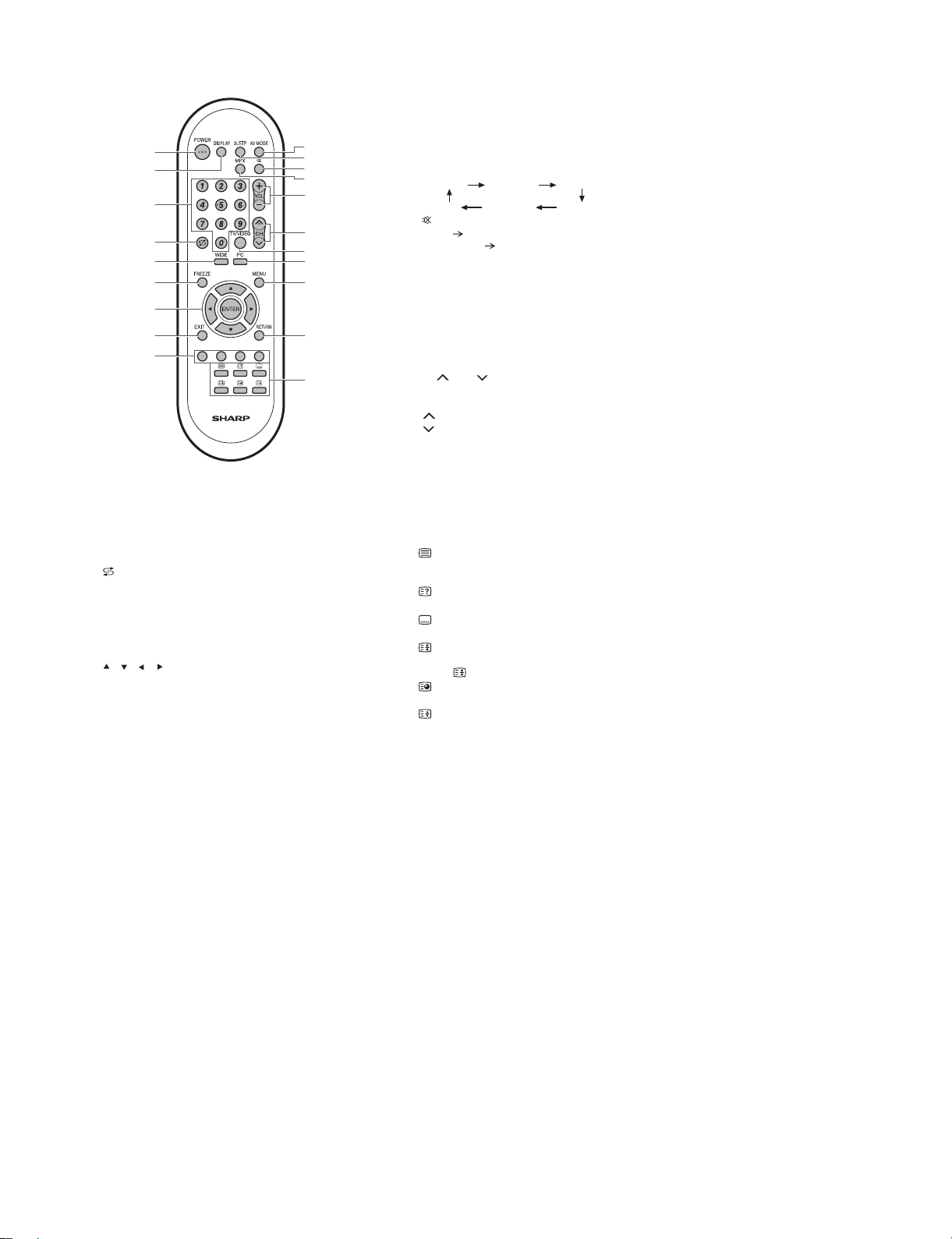

2. Remote Control Unit

1

2

3

4

5

6

7

8

9

1 POWER (STANDBY/ON)

To switch the power on and off.

2 DISPLAY

Display the channel or input information.

30–9

Set the channel.

TELETEXT mode: Set the page.

4 (Flashback)

Press to return to the previous selected channel or

external input mode.

5WIDE

Change the wide image mode.

6 FREEZE

Freeze a motion picture on the screen.

7///(Cursor)

Select a desired item on the setting screen.

ENTER

Execute a command.

8 EXIT

Return to the default screen.

10

11

12

13

14

15

16

17

18

19

20

9 Colour (Red/Green/Yellow/Blue)

TELETEXT mode: Select a page.

10 AV MODE

Select an audio and video setting.

11 SLEEP

Set the Sleep timer.

0hr.30min. 1hr.00min.

Off

12 (Mute)

Press Mutes sound.

Press again Restores sound.

Mute will be cancelled after 30 minutes. However, the TV will

not suddenly output loud sound as the volume level will be set

to 0 automatically. Increase the volume level by pressing VOL +.

13 MPX

Select the sound multiplex mode.

14 VOL + /VOL -

Set the volume.

(+)Increasethevolume.

( - ) Decrease the volume.

15 CH /C H

TV input mode: Select the channel.

TELETEXT mode: Select the page.

( ) Increase the channel number.

( ) Decrease the channel number.

16 TV/VIDEO (INPUT SOURCE)

Select an input source.

17 PC

Directly select the PC terminal.

18 MENU

Display the menu screen.

19 RETURN

MENU mode: Return to the previous menu screen.

20 (TELETEXT)

Select the TELETEXT mode. (all TV image, all TEXT image,

TV/TEXT image)

(Reveal hidden for TELETEXT)

TELETEXT mode: Display hidden characters.

(SUBTITLE for TELETEXT)

To turn the subtitles on and off.

(Hold)

TELETEXT mode: Stop updating Teletext pages automatically.

Press again to release the hold mode.

(Subpage)

Display the Teletext subpage directly.

(Top/Bottom/Full)

TELETEXT mode: Set the area of magnification.

2hr.30min.

1hr.30min.

2hr.00min.

2 – 2

Page 7

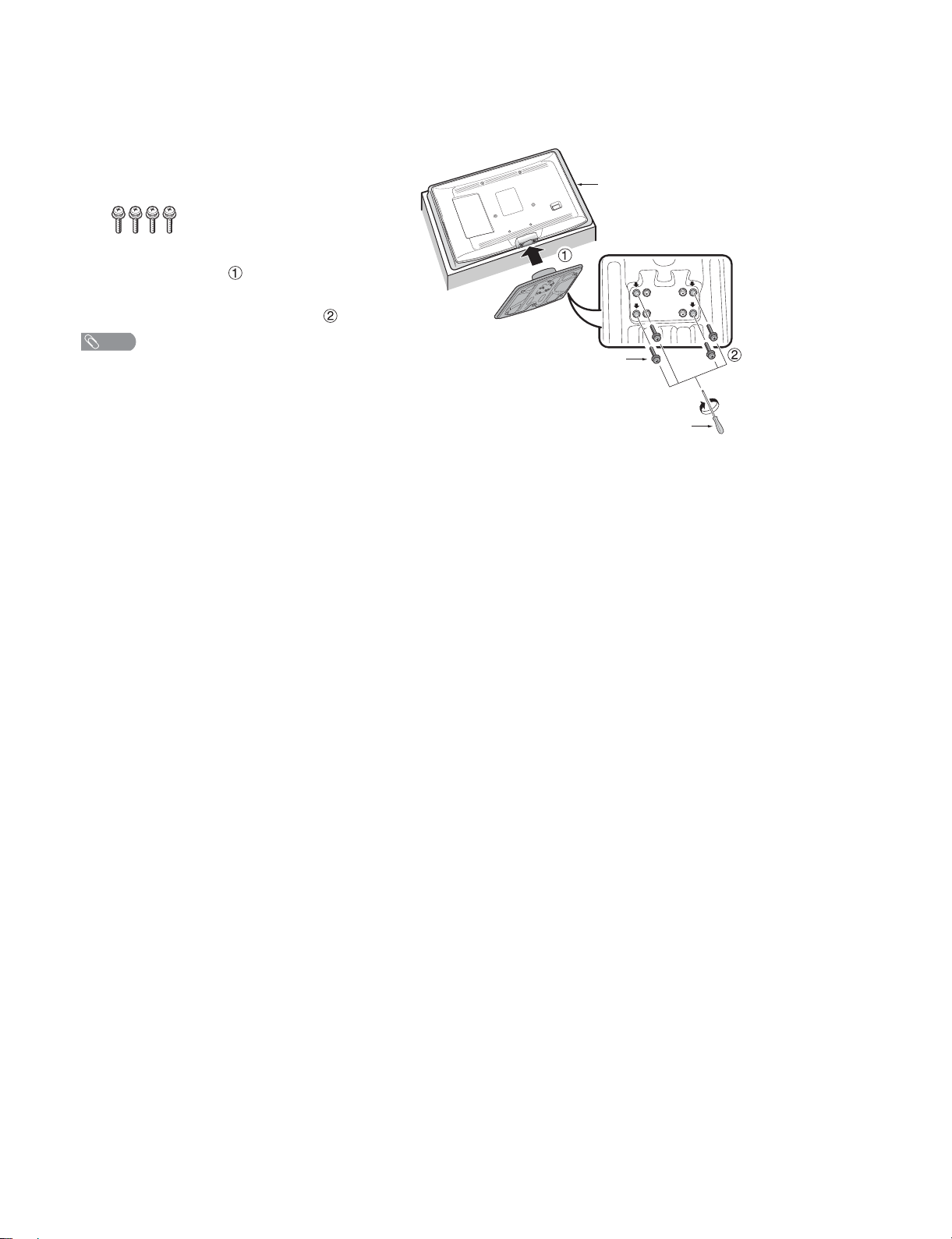

3. Attaching The Stand

• Before attaching (or detaching) the stand, unplug the AC cord from the AC INPUT terminal.

• Before performing work spread cushioning over the base area to lay the TV on. This will prevent it from

being damaged.

Confirm the screws supplied with the TV.

1

Screws (x4)

(used in step 3)

Insert the stand base to the stand post on the

2

bottom of the TV. ( )

Insert and tighten the 4 screws into the 4 holes

3

on the bottom of the stand base.( )

NOTE

• To detach the stand, perform the steps in reverse order.

Soft

cushion

Screw

Screw driver

LC-26/32A37M

2 – 3

Page 8

LC-26/32A37M

LC26A37M

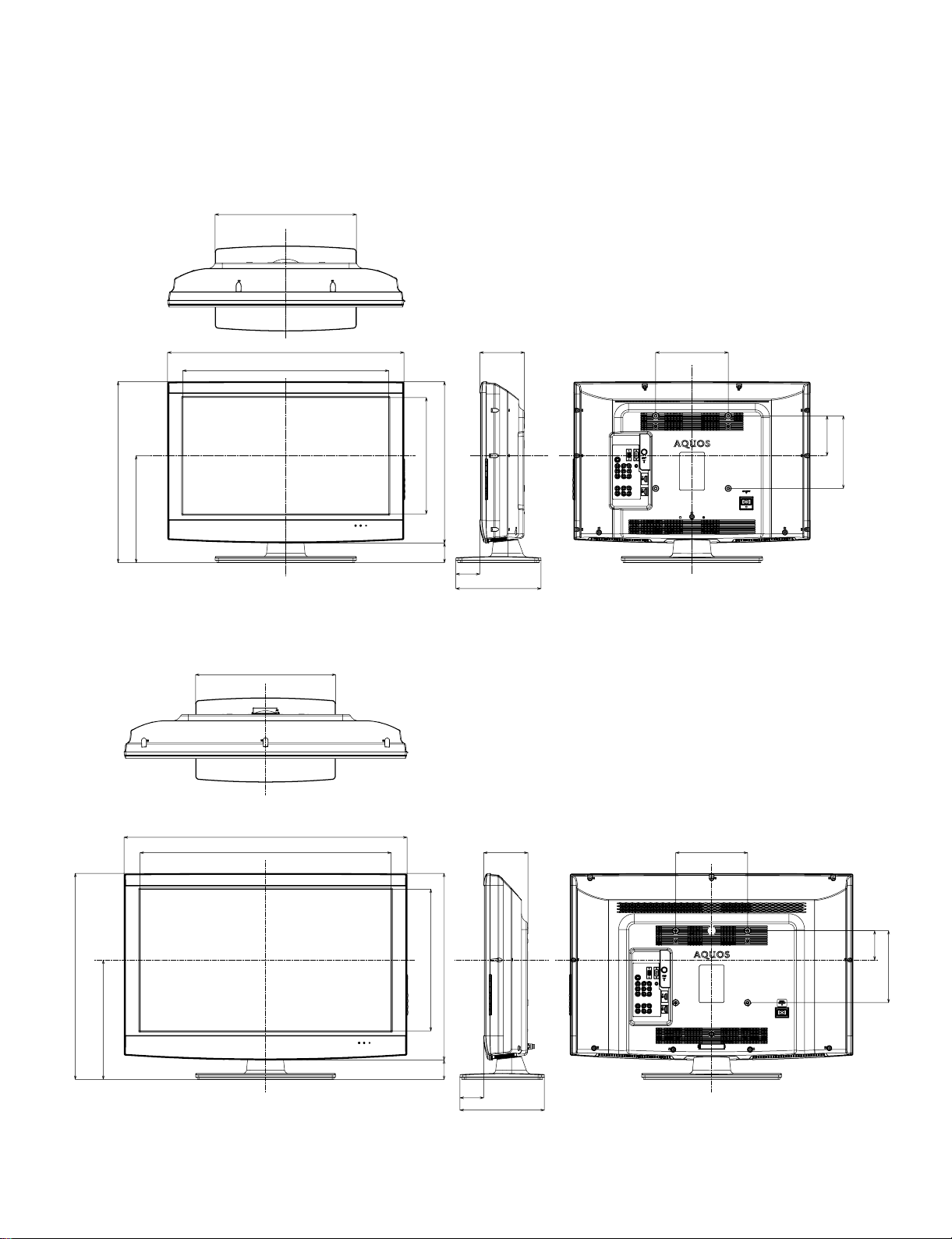

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS

ServiceManual

LC-26A37M

504

299

390

652 123 200

567.9

320.6

445

59

66

235

Unit: mm

110

200

LC-32A37M

575

334

390

788

699.2

393.8

51959

123 200

82

200

66

3 – 1

235

Page 9

LC26A37M

CHAPTER 4. REMOVING OF MAJOR PARTS

ServiceManual

[1] REMOVING OF MAJOR PARTS

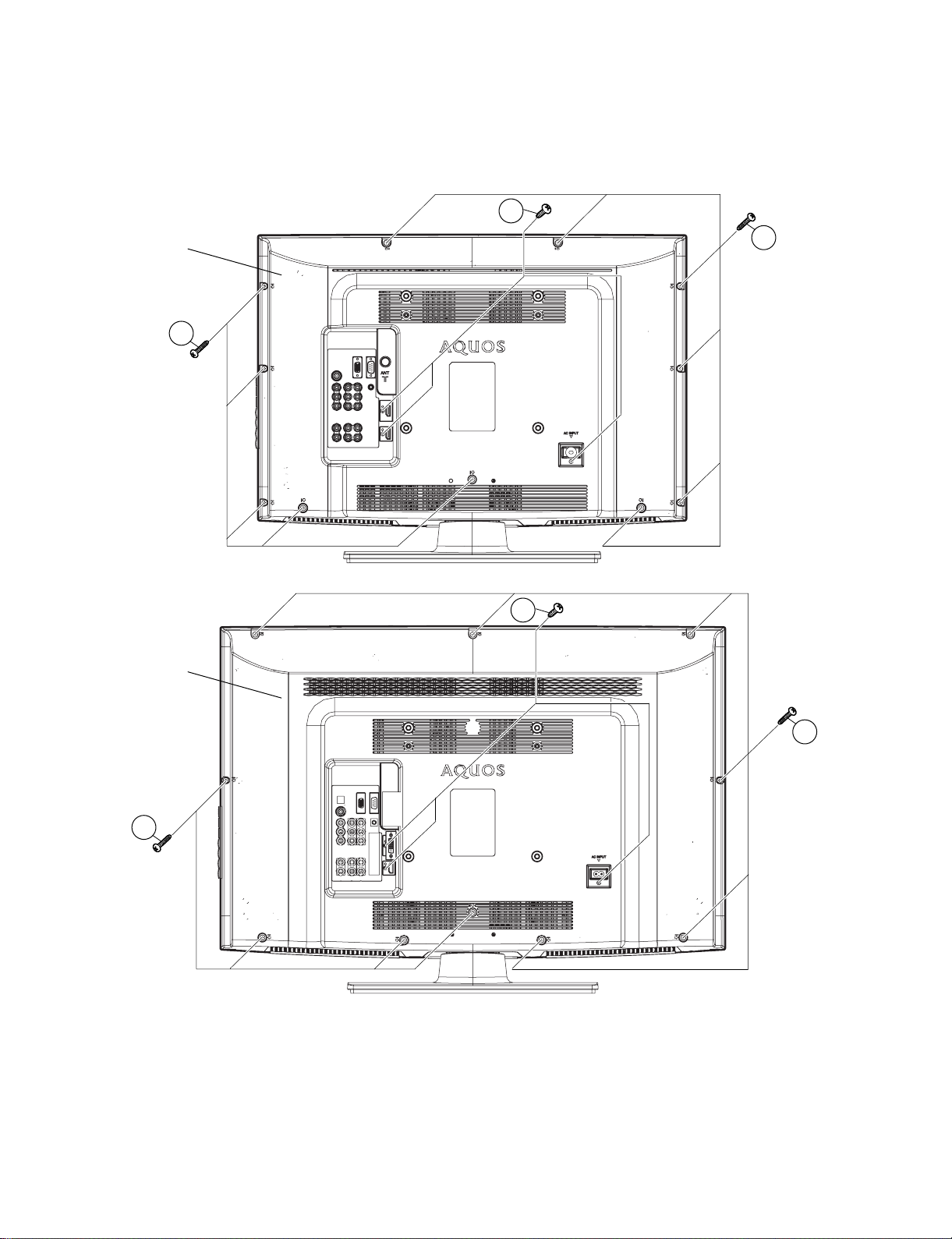

1. REMOVING OF REAR CABINET

1. Remove the 11 (LC-26A37M)/10 (LC-32A37M) screws [1], 3 screws [2] and detach the Rear Cabinet.

LC-26/32A37M

LC-26A37M

Rear Cabinet

LC-32A37M

2

1

1

2

Rear Cabinet

1

1

4 – 1

Page 10

LC-26/32A37M

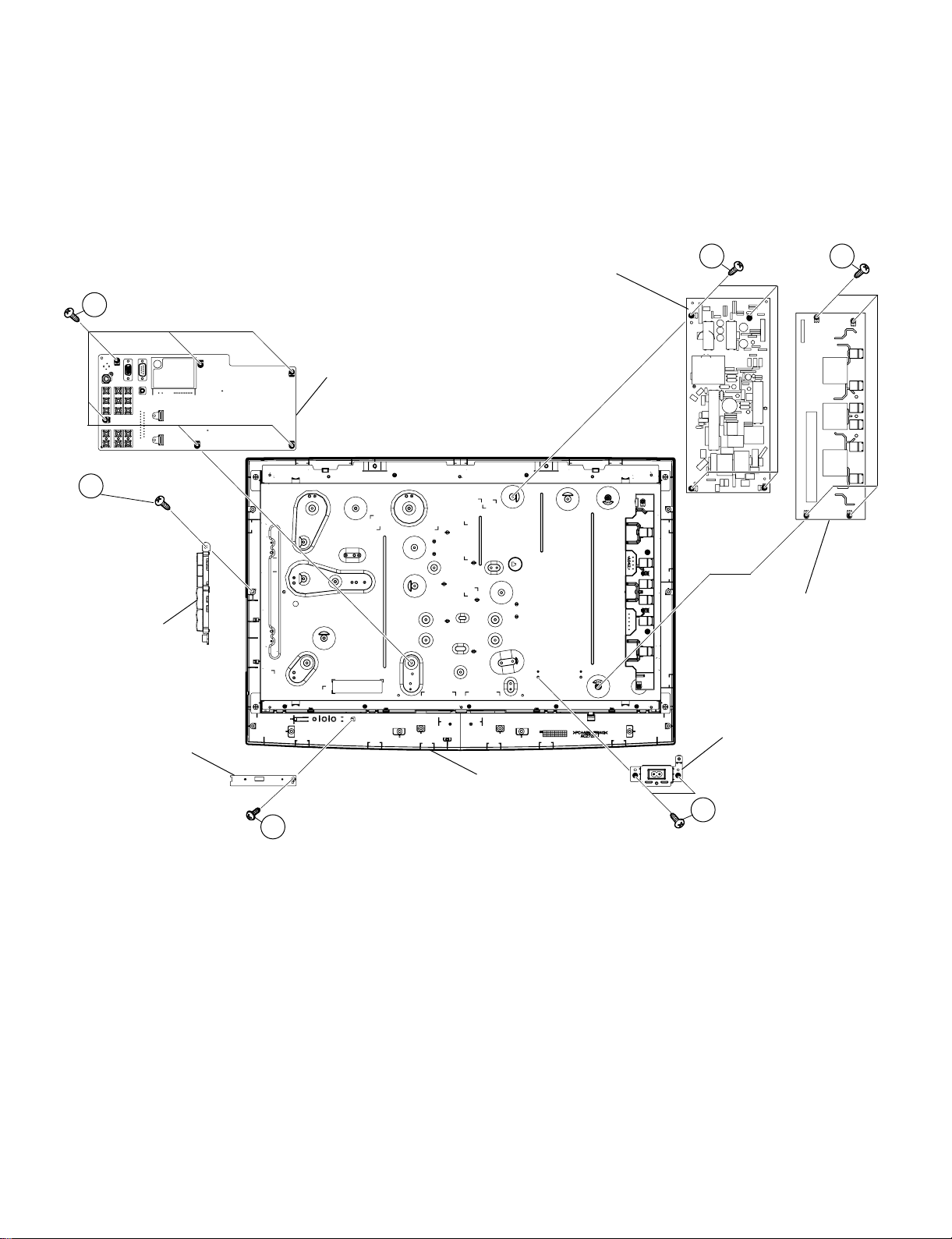

2. REMOVING OF CONNECTORS, SPEAKERS, STAND COVER ASS’Y AND STAND ASS’Y

1. Remove all the connectors from all the PWBs.

2. Remove 2 screws [1] and detach the Speaker-L and Speaker-R.

3. Remove the 4 screws [2], 4 screws [3] and detach the Stand Cover Ass’y.

4. Remove the 4 screws [4] and detach the Stand Ass’y.

POWER PWB Unit

MAIN PWB Unit

KEY PWB Unit

R/C, LED PWB Unit

Speaker-R

3

䬌䎳䎚䎕䎓䎕䬍

䬌䎳䎚䎕䎓䎔䬍 䬌䎦䎱䎚䎖䎓䎕䬍

䬌䎳䎧䬍

䬌䎶䎳䬍

䬌䎳䎚䎓䎓䎔䬍

INVERTER PWB Unit

Speaker-L

䬌䎮䎰䬍

䬌䎵䎤䬍

䬌䎶䎳䬍

䬌䎳䎕䎖䎓䎔䬍

䬌䎳䎛䎕䎓䎔䬍

䬌䎦䎱䎔䬍 䬌䎦䎱䎕䬍

䬌䎳䎛䎕䎓䎕䬍

䬌䎶䎳䬍

1

1

Stand Cover Ass'y

2

3

Stand Ass'y

4

*The shown is LC-26A37M

4 – 2

Page 11

3. REMOVING OF PWB UNITS

1. Remove the 1 screw [1] and detach the R/C, LED PWB Unit.

2. Remove the 6 screws [2] and detach the MAIN PWB Unit.

3. Remove the 4 screws [3] and detach the POWER PWB Unit.

4. Remove the 4 screws [4] and detach the INVERTER PWB Unit.

5. Detach the KEY PWB Unit (LC-26A37M).

Remove the 1 screw [5] and detach the KEY PWB Unit (LC-32A37M).

6. Remove the 2 screws [6] and detach the SW Bracket.

LC-26/32A37M

2

(LC-32A37M only)

5

KEY PWB Unit

MAIN PWB Unit

POWER PWB Unit

3 4

INVERTER PWB Unit

R/C, LED PWB Unit

SW Bracket

Front Cabinet

6

1

*The shown is LC-26A37M

4 – 3

Page 12

LC-26/32A37M

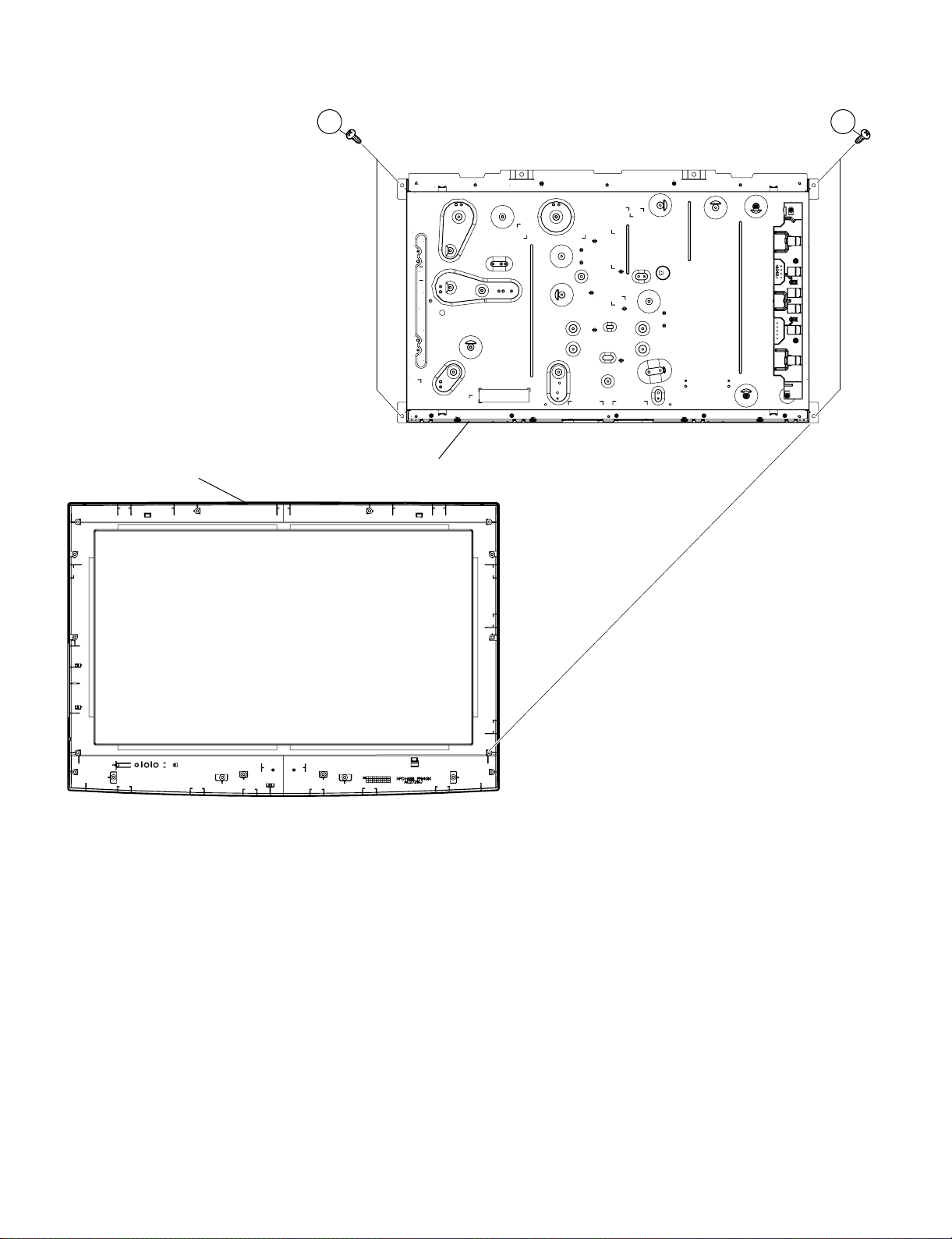

4. REMOVING OF LCD PANEL UNIT

1. Remove the 4 screws [1] and detach the LCD Panel Unit from Front Cabinet.

Front Cabinet LCD Panel Unit

11

4 – 4

*The shown is LC-26A37M

Page 13

LC-26/32A37M

LC26A37M

CHAPTER 5. ADJUSTMENT PROCEDURE

ServiceManual

[1] ADJUSTMENT PROCEDURE

1. Adjustment method after PWB and/or IC replacement due to repair

The unit is set to the optimum at the time of shipment from the factory. If any value should become improper or any adjustment is necessary due to

the part replacement, make an adjustment according to the following procedure.

1. Procure the following units in order to replace the main unit, IC3001and IC1951.

MAIN UNIT: DUNTKF067FM04 (LC-26A37M)

DUNTKF067FM05 (LC-32A37M)

NOTE: [Caution when replacing ICs in the main unit (IC2304/IC1902/IC1922)]

The above ICs are EEPROMs storing the EDID data of HDMI and the monitor microcomputer. Before replacing the relevant part, procure the

following parts in which the data have been rewritten.

IC2304 RH-IXC818WJQZS PC EDID

IC1902 RH-IXC819WJQZS HDMI EDID

IC1922 RH-IXC820WJQZS HDMI EDID

2. After replacing the LCD panel or LCD control PWB, check PANEL_SIZE in the following procedure.

1) Enter the process adjustment mode.

2) Use the cursor keys / and CH / of R/C to select the item [Inch Setting] on the page 2/11.

3) Verify that the panel size is displayed.

4) If the size doesn't match, select the values of the panel size with the Vol +/- keys.

5) After selection in Step 4), press the ENTER key, and it is completed with OK displayed.

3. After replacing the LCD panel, adjust the VCOM in the following procedure.

1) Enter the process adjustment mode.

2) Use the cursor keys / and CH / of R/C to select the item [ VCOM ADJ] on the page 11/11.

3) Press the ENTER key to verify that the adjustment pattern is displayed.

4) Use the +/- keys of VOL of R/C to adjust the flicker in the center of the screen to minimum.

5) When the optimal state is achieved in Step 4, press the ENTER key to turn the pattern to OFF.

5 – 1

Page 14

LC-26/32A37M

2. Entering the adjustment process mode

There are 2 ways as follows:

• After power-on, press “ADJUSTMENT PROCESS” key of the remote control.

• During servicing.

1

While holding down the TV/VIDEO and DOWN keys at the same time, set the Power switch to ON. (“K” standing for inspection process mode is

displayed in the upper left position of the screen.) → Press the Channel DOWN and Volume DOWN keys at the same time. (The adjustment process mode screen appears.)

To cancel it, turn off the power using the Power switch or remote control.

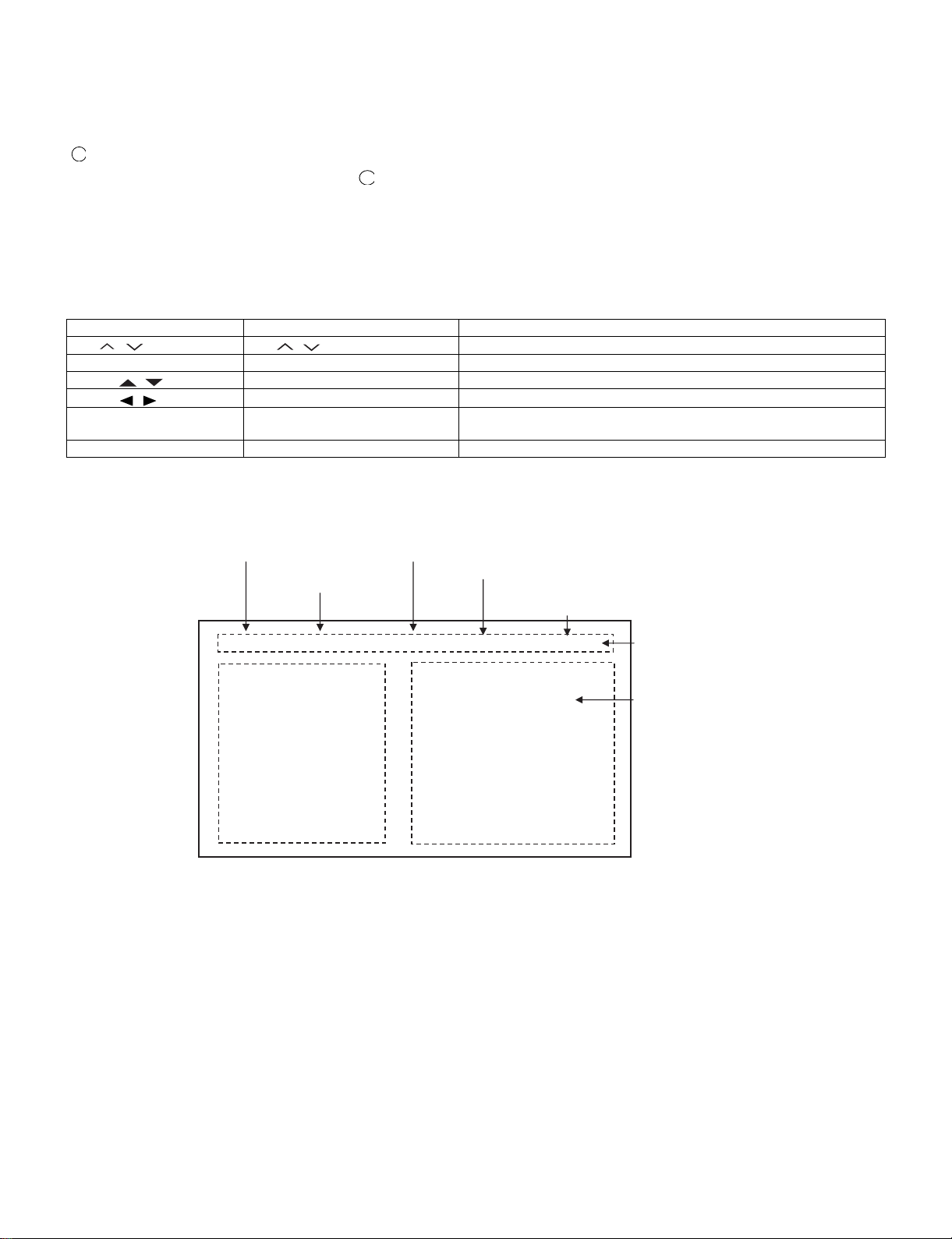

3. Remote controller key operation and description of display in adjustment process mode.

1. key operation

Remote controller key Main unit key Function

CH ( / )

VOL (+ / –) VOL (+ / –) Changing a selected line setting (+1/-1)

Cursor ( / )

Cursor ( / )

TV/INPUT button on remote

controller

OK —————— Executing a function

* Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

CH ( / ) Moving an item (line) by one (UP/DOWN)

—————— Turning a page (PREVIOUS/NEXT)

—————— Changing a selected line setting (+10/-10)

TV/INPUT button Input source switching (toggle switching)

2

(TV→INPUT1→INPUT2→INPUT3→INPUT4→INPUT5→INPUT6)

2. Description of display

(1) Current page/Total pages (3) Currently selected input

(4) Current colour TV system

(2) Current page title

1/11

Main Version

Checsum Value

TCON Version

TEMP SENSOR

NORMAL STANDBY CAUSE

ERROR STANDBY CAUSE

[INFO] TV AUTO XX:ASIA

LEW07 01.XX (XX/XX/XXX)

XX

XX

XX

XX

XX

[1] 0

[2] 0

[3] 0

[4] 0

[5] 0

00H 00M

00H 00M

00H 00M

00H 00M

00H 00M

(5) Inch/Destination

Adjustment process

menu header

(7) Parameters

5 – 2

Page 15

LC-26/32A37M

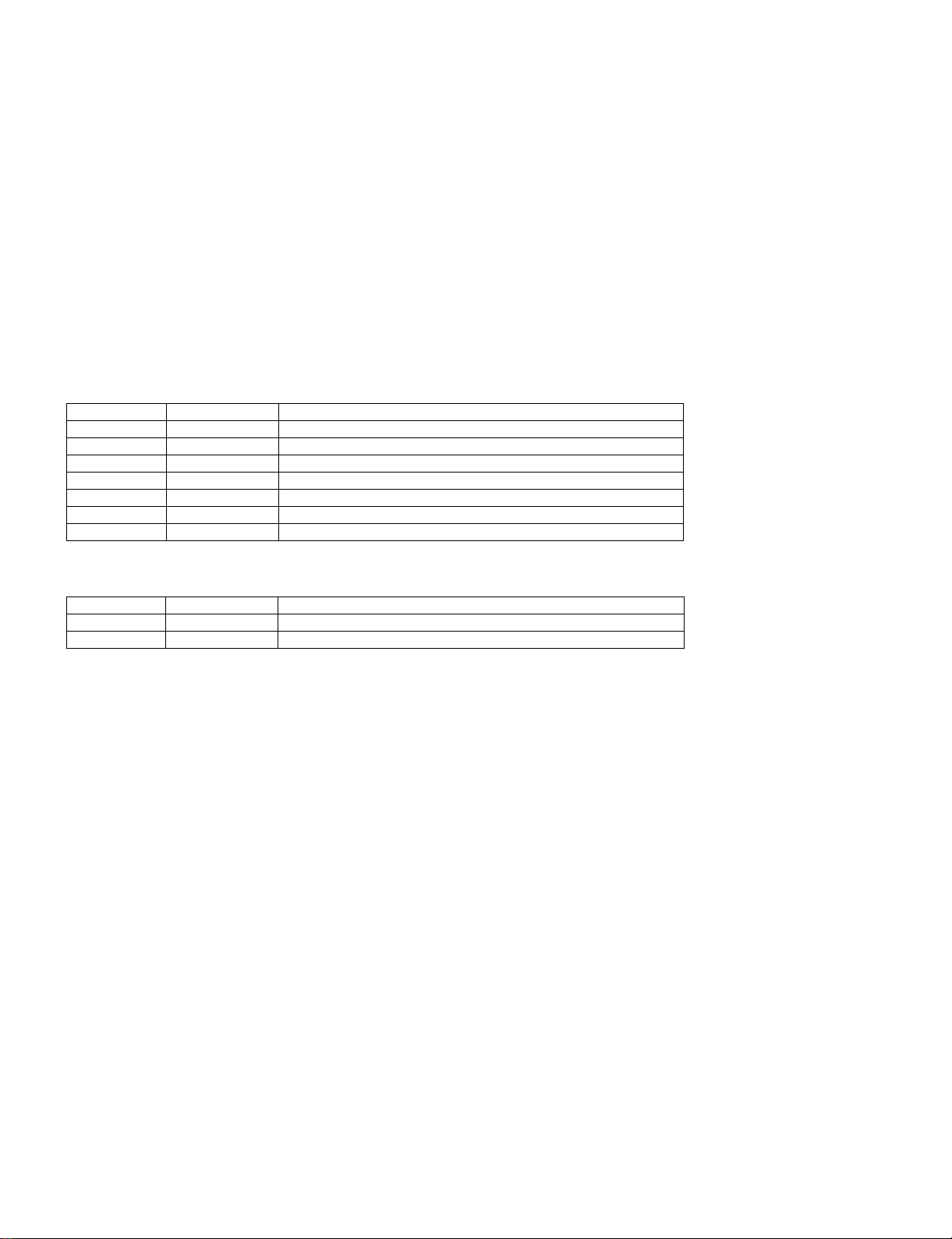

4. Adjustment process mode menu

The character string in brackets [ ] will appear as a page title in the adjustment process menu header.

Page Line Item Description Remarks (adjustment detail, etc.)

1/11 [INFO]

1 Main Version JraAS XXX(XX/XX/XX) Main microprocessor version

2 Checksum Value XX DTV microprocessor version

3 TCON Version XX DTV micr oprocessor-Loader version

4 TEMP SENSOR xxxxxx

5 NORMAL STANDBY CAUSE RC_STANDBY

6 ERROR STANDBY CAUSE [1] 00H 00M Error standby cause Total operating time before error

[2] 00H 00M

[3] 00H 00M

[4] 00H 00M

[5] 00H 00M

2/11 [INIT]

1 Factory Init [HONG KONG/CHINA/ASIA] Initialization to factory settings execution

2 Inch Setting XX Inch present setting

3 Public Mode OFF/ON HOTEL MODE flag setting

4 Center Acutime xxH xxM Main operating hours

5 RESET OFF/ON Main operating hours reset

6 Backlight Acutime xxH xxM Backlight operating hours

7 RESET OFF/ON Backlight operating hours reset

8 Picture Read Pos X 0-xxx x-axis setting of picture data

9 Picture Read Pos Y 0-xxx y-axis setting of picture data

10 Picture Read ON/OFF Start/stop of picture data

3/11 [PAL.SECAM.N358]

1 RF-AGC ADJ ENTER RF-AGC auto adjustment execution

2 PAL+TUNER ADJ ENTER PAL TUNER auto adjustment execution

3 PAL ADJ ENTER PAL auto adjustment execution

4 TUNER ADJ ENTER TUNER auto adjustment execution

5 CONTRAST SD 32 PAL contrast adjustment

6 SECAM CB OFFSET 1 SECAM offset adjustment

7 SECAM CR OFFSET 1 SECAM offset adjustment

8 TUNER A DAC 32 TUNER DAC adjustment

9 RF AGC 16 RF AGC adjustment

4/11 [COMP 15K]

1 COMP 15K ADJ ENTER COMP15K auto adjustment execution (No use)

2 COMP 15K CONTRAST 40 Contrast adjustment

5/11 [HDTV]

1 HDTV CONTRAST 41 HDTV Contrast adjustment

6/11 [SMPTE]

1 RF-AGC ADJ ENTER RF-AGC auto adjustment execution

2 PAL-AGC ADJ ENTER PAL AGC auto adjustment execution (No use)

3 PAL ADJ ENTER PAL auto adjustment execution

4 TUNER ADJ ENTER TUNER auto adjustment execution

5 CONTRAST SD 30 PAL contrast adjustment

6 SECAM CB OFFSET 1 SECAM offset adjustment

7 SECAM CR OFFSET 1 SECAM offset adjustment

8 TUNER A DAC 36 TUNER DAC adjustment

9 RF AGC 16 RF AGC adjustment

7/11 [M GAMMA INFO]

1 M GAMMA IN 6 928 W/B adjustment, gradation 6 input setting

2 M GAMMA WRITE OFF/ON EEP writing of adjustment values

3 M GAMMA RESET OFF/ON Initialization of adjustment values

8/11 [M GAMMA 1-3]

1 M GAMMA R 2 0 W/B adjustment, gradation 2R adjustment value

2 M GAMMA G 2 0 W/B adjustment, gradation 2G adjustment value

3 M GAMMA B 2 0 W/B adjustment, gradation 2B adjustment value

4 M GAMMA WRITE OFF/ON EEP writing of adjustment values

9/11 [M GAMMA 4-6]

1 M GAMMA R 6 0 W/B adjustment, gradation 6R adjustment value

2 M GAMMA G 6 0 W/B adjustment, gradation 6G adjustment value

3 M GAMMA B 6 0 W/B adjustment, gradation 6B adjustment value

4 M GAMMA WRITE OFF/ON EEP writing of adjustment values

5 – 3

Page 16

LC-26/32A37M

Page Line Item Description Remarks (adjustment detail, etc.)

10/11 [ETC]

1 EEP CLEAR OFF/ON Clear of all adjustment value

2 EEP CLEAR B OFF/ON Clear of adjustment value of B mode

3 STANDBYCAUSE RESET OFF/ON Reset of STANDBY CAUSE

4 AUTO INSTALLATION SW 0/1 1: * * * 0: * * *

5OPTION 0

6 COUNTRY HONG KONG/CHINA/ASIA Destination setting

7 L ERR RESET 0 LAMP ERR RESET Initializatio of L_ERR

8 L ERR STOP 0/1 LAMP ERR Inhibit L_LRR detection

9 I2C-OFF ENTER I2C DATA execution

11/11 [COM-BIAS]

1VCOM ADJ 63

2 TEST PATTERN 0

5. Special features

* ERROR STANDBY CAUSE (Page 1/11)

The total time when the unit enters the standby due to operational error and cause of error are recorded on EEPROM as much as possible.

The values can be used to locate the fault for repair.

* EEP CLEAR (Page10/11)

Clear of process adjustment EEP value.

6. Lamp error detection

1. Function

This LCD colour TV set incorporates a lamp error detection feature that automatically turns off the power for safety under abnormal lamp or lamp

circuit conditions. If by any chance anything is wrong with the lamp or lamp circuit or if the lamp error detection feature is activated for some reason, the following will result.

1) The powe r is interrupted in about 6 seconds after it is turned on.

(The power LED on the front of the TV set turns red from green and keeps blinking in red: ON for 250 ms and OFF for 1 sec.).

2) If the above phenomenon 1) occurs 5 times consecutively, it becomes impossible to turn on the power. (The power LED remained red).

2. Measures

1) Checking with lamp error detection OFF

Enter the adjustment process mode, referring to 1. Entering and exiting the adjustment process mode.

If there is a problem with the lamp or lamp circuit, the lamp will go out. (The power LED is green.)

Then, you can check the operation to see if the lamp and lamp circuit are in trouble.

2) Resetting the lamp error count

After the lamp and lamp circuit are found out of trouble, reset the lamp error count. If a lamp error is detected five consecutive times, the power

cannot be turned on. Using the cursor (UP/DOWN) key, move to the cursor to [LAMP ERROR RESET], Line 8 on adjustment process mode

service page 10/11. With the cursor (LEFT/RIGHT) keys, select the [LAMP ERROR RESET] value. Finally press the cursor (ENTER) ey s to

reset the value to “0”.

Table of contents of adjustment process mode Page 10/11.

[ETC]

EEP CLEAR OFF

EEP CLEAR B OFF

STANDBYCAUSE RESET OFF

AUTO INSTALLATION SW

OPTION

COUNTRY

L ERR RESET

0

0

HONG KONG

0

Resetting to "0"

L ERR STOP 0

I2C-OFF ENTER

5 – 4

Page 17

LC-26/32A37M

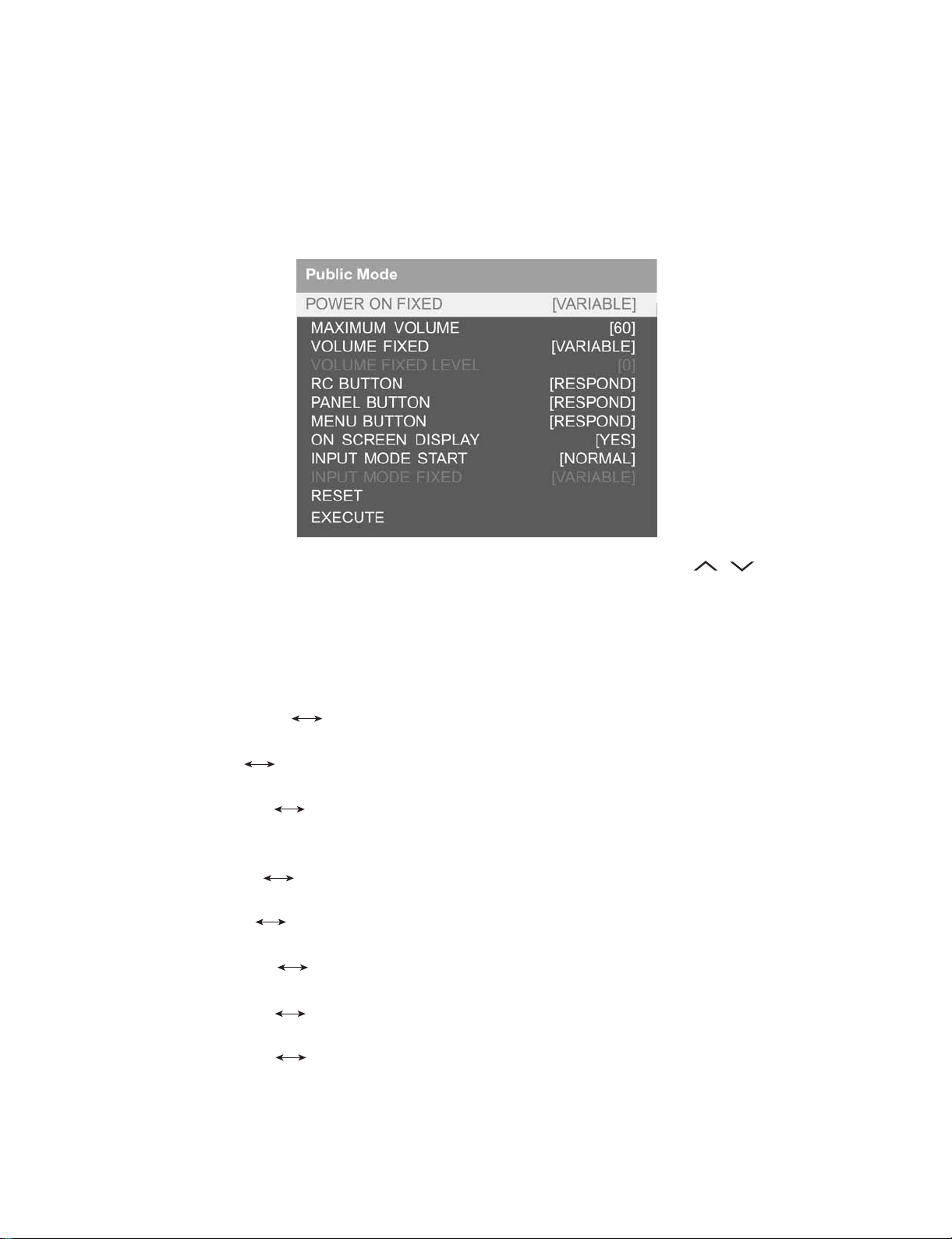

7. Standby Cause Function

This model is equipped with a STANDBY CAUSE FUNCTIONS which stores the cause of why the unit is turned off and displays it on adjustment process mode.

1. NORMAL STANDBY CAUSE

ERROR CODE here indicates cause of standby in normal operation or Function of the Unit.

No display when the unit is turned off with R/C.

Only the latest cause is indicated.

2. ERROR STANDBY CAUSE

ERROR CODE here indicates cause of Error in the unit.

It also indicates accumulated operating times of the unit.

The last five histories are displayed.

1)-5) five histories 1) is the latest.

When there is no error, error code is ‘0’ and no characters appear.

• NORMAL STANDBY CAUSE

Display Code Indication Description

1 RC_STANDBY in the cause of “Remote Controler OFF”

6 NO OPERATION in the cause of “NO OPERATION OFF”

7 NO SIGNAL in the cause of “NO SIGNAL OFF”

8 PC_MODE1 in the cause of “PC(INPUT6) POWER MANAGEMENT MODE1”

9 PC_MODE2 in the cause of “PC(INPUT6) POWER MANAGEMENT MODE2”

a SLEEP_TIMER in the cause of “SLEEP TIMER”

b RS232C in the cause of “RS232C COMMAND (POWR)”

• ERROR STANDBY CAUSE

Display Code Indication Description

1a TEMP_ERROR TEMPERATURE ERROR

1b LAMP_ERROR LAMP ERROR

5 – 5

Page 18

LC-26/32A37M

8. Video signal adjustment procedure

* The adjustment process mode menu is listed in Section 5.

1. Signal check

1) Signal generator level adjustment check (Adjustment to the specified level)

• Composite signal PAL : 0.7Vp-p ± 0.02Vp-p (Pedestal to white level)

• RGB signal : 0.7Vp-p ± 0.02Vp-p

• 15K component signal (50 Hz) : Y level : 0.7Vp-p ± 0.02Vp-p (Pedestal to white level)

: PB, PR level : 0.7Vp-p ± 0.02Vp-p

2. Entering the adjustment process mode

1) Enter the adjustment process mode according to Section 3.

3. RF AGC adjustment

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

PAL

Sprit Field Colour Bar

RF signal UV

[Terminal]

TUNER

• Feed the PAL Sprit Field colour bar signal to TUNER.

Signal level: 55 dB µV +1dB, -1dB (75Ω LOAD)

[E-12CH]

2 Auto adjustment

performance

Adjustment process

Page3

㸡100% white

Bring the cursor on [ RF AGC ADJ] and press [OK]

[***OK***] appears when finished.

5 – 6

Page 19

LC-26/32A37M

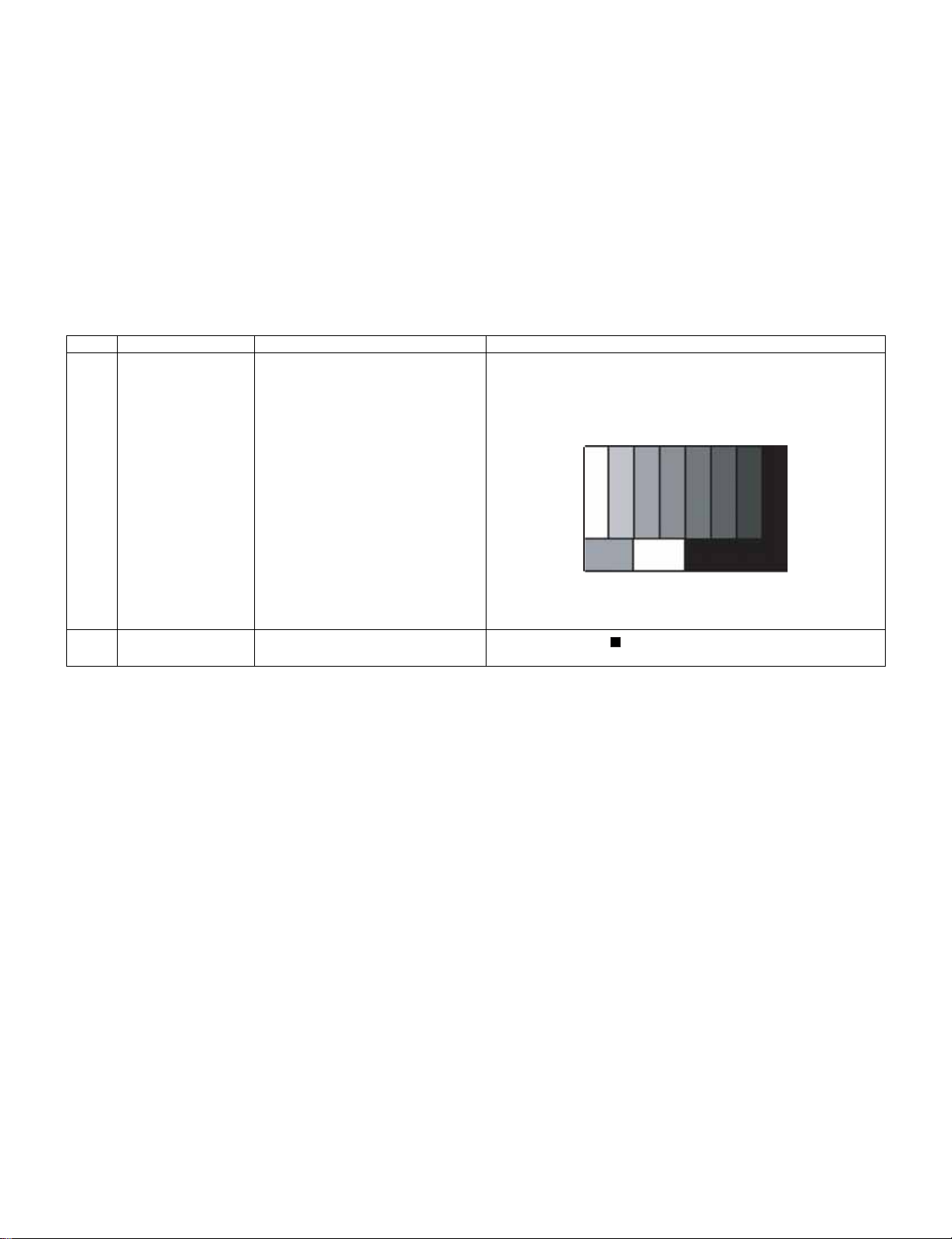

9. White Balance Adjustment

Adjustment gradation values (IN) appear on page 7/11 of process adjustment, and adjustment initial values (offset value) appear on pages 8/11 and

9/11. For white balance adjustment, adjust the offset values on pages 8/11 and 9/11.

[Condition of the unit for inspection] Modulated light: MAX (+8)

[Adjustment reference device] Minolta CA-210

[Adjustment]

Check that the values on page 7/11 of process adjustment are set as below. If not, change them accordingly.

M GAMMA IN 2 320 M GAMMA IN 6 928

1) Display the current adjustment status at point 6. (Page 7/11 of process adjustment)

The display for checking the adjustment status is toggled by pressing the “6” button on the remote control.

(Normal OSD display → “6” → display for check (OSD disappears) → “6” →normal OSD display → • • •)

2) Read the value of the luminance meter.

3) Change M GAMMA R6/M GAMMA B6 (Adjustment offset value) on page 9/11 of process adjustment so that the values of the luminance meter

approach x = 0.272 and y = 0.277.

(Basically, G is not changed. If adjustment fails with R and B, change G. When G is lowered, the weaker of R and B must be fixed.)

4) If G is changed in step 3), change the values of M GAMMA G2 on pages 8/11 and 9/11 of process adjustment as follows. When not changed, go

to step5).

Offset value of M GAMMA G2 = (Offset value of M GAMMA G6) * (320/928)

5) Display the adju stment status of the current point 2. (Each time the “2” button on the remo te control is pressed, the adjustment status check display is toggled.)

(Normal OSD display → “2” → Check display (OSD disappears) → “2” → Normal OSD display → • • •)

Change M GAMMA R5/M GAMMA B2 (adjustment offset value) on page 9/11 of process adjustment so that the values of the luminance meter

approach x = 0.272 and y = 0.277.

[Adjustment reference standard value]

Adjustment spec ±0.004 Inspection spec ±0.006 (point 1)

Adjustment spec ±0.002 Inspection spec ±0.004 (Excluding the above-mentioned)

5 – 7

Page 20

LC-26/32A37M

10. Adjusting procedure by us e of [RS- 23 2C ]

1) Get ready the PC with COM port (RS-232C) running on Windows 95/98/ME/2000/XP operating system, as well as the RS-232C cross cable.

2) Start the unit with the RS-232C cable connected.

3) Start the terminal software. (The freeware readily available on the Internet will do.)

4) Make the following settings.

Baud rate 9,600 bps

Data LENGTH 8 bit

Parity bit None

Stop bit 1 bit

Flow control None

5) If the settings are correct, the terminal software indicates "ERR" against pressing of the "ENTER" key.

6) After the settings are done correctly, it is possible to make an adjustment by typing in the command shown in the table below and pressing the

"ENTER" key on the keyboard.

7) Command entry is successful if the terminal software indicates "OK" when the "ENTER" is pressed. If "ERR" is shown, retry to enter the command.

8) Send the process mode switching command to switch from the RS232C operation mode to the process mode.

KRSW0001: "ERR" is returned.

KKT10037: When "OK" is returned, the process mode becomes active. When "ERR", start over from KRSW0001.

9) Send each adjustment command.

RS-232C command list

Command Function Remarks

KYOF0000 Remote control disabled

OSDS0001 OSD display inhibited

SBSL0016 Light control level MAX

MSET0001 Background adjustment start

MSET0004 Initialization of adjustment value

LEV60928 Gradation 6 (928-gradation adjustment)

MG6G **** Adjustment of G of gradation 6 0000 ~4095

MG6R **** Adjustment of R of gradation 6 0000 ~ 4095

MG6B **** Adjustment of B of gradation 6 0000 ~ 4095

LEV20352 Gradation 2 (352-gradation adjustment)

MG2G **** Input of G of 2 Calculated value

MG2R **** Input of R of 2 0000 ~ 4095

MG2B **** Input of B of 2 0000 ~ 4095

MSET0003 Writing of adjustment value

5 – 8

Page 21

11. Initialization to factory settings

LC-26/32A37M

Caution: When the factory settings have been made, all user setting data, including the channel settings, are initialized.

After adjustments, exit the adjustment process mode.

To exit the adjustment process mode, unplug the AC power cord from the outlet to forcibly turn off the power.

When the power is turned off with the remote control, unplug the AC power cord and plug it back in (wait approximately 10 seconds before plugging

in the AC power cord)

(The adjustments done in the adjustment process mode are not initialized.) Keep this in mind when initializing these settings.

Adjustment item Adjustment conditions Adjustment procedure

1 Factory settings Forcibly turn off the power

(See to below caution)

• Enter the adjustment process mode.

• Move the cursor to [Factory Init] on page 2/11.

• Use the R/C key to select a destination [HONG KONG/CHINA/ASIA].

And, press the [OK] key.

• “EXECUTING...” appears and initialization starts.

• After a while, “*** OK ***” appears and the setting is complete.

NOTE: Never turn the power off during initialization.

When performing factory settings (while displaying page 2 of adjustment

process), confirm that the item “Inch Setting” or the panel size displayed

in the upper right corner corresponds to each panel size.

The following settings will be back to their factory ones.

1. User settings

2. Channel data (e.g. broadcast frequencies)

3. Maker option setting

4. Password data

5 – 9

Page 22

LC-26/32A37M

12. Public Mode (Hotel Mode)

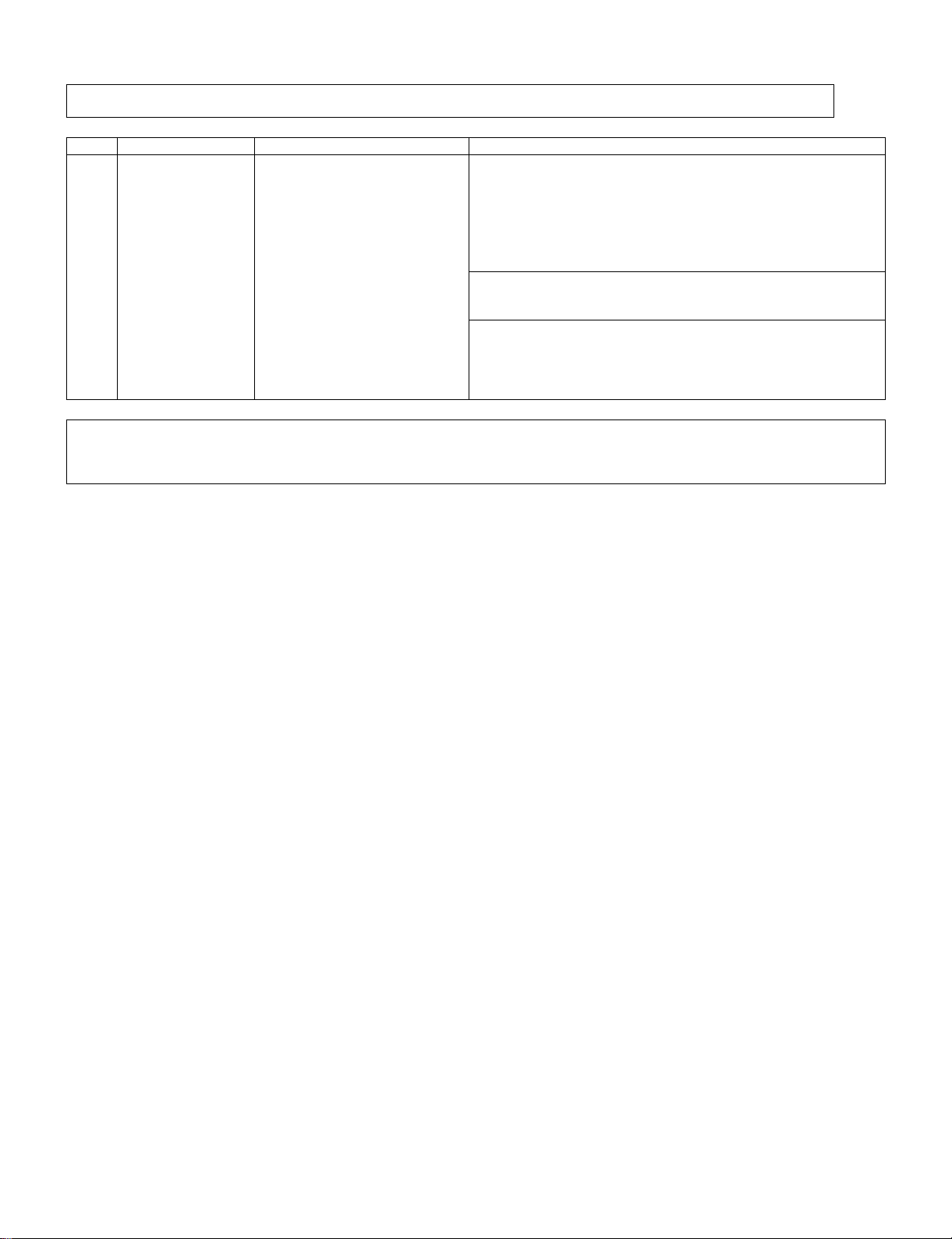

1. How to Enter in the Public Mode (Hotel Mode).

Turn on the power and enter in the Adjustment Process mode as usual.

In the [INIT], Page 2/11 of Service, turns ON the Public Mode option.

Turn off TV by pressing Main Power switch.

While pressing “VOL+” and “INPUT” keys at the same time, press Main Power switch for more than 2 seconds.

Then, when you are asked for the password, enter “027”.

After this sequence the TV will turn on showing the Public Mode setting screen as follows:

Is possible to select each item of function by pressing cursor UP/DOWN keys on the remote control or CH( )( ) keys on the LCD TV.

(Except DTV)

The setting position of each item of functions is made by pressing cursor RIGHT/LEFT keys on the remote control or VOL (+) / (-) keys on the LCD

TV.

Select EXECUTE position after you set all function, and press cursor RIGHT/LEFT keys on the remote control or VOL (+) / (-) keys on the LCD TV

for confirmation.

2. Public Mode Settings.

1) POWER ON FIXED [VARIABLE FIXED]

When it is set to “FIXED” the TV is impossible to be switch off by Main Switch or Remote Control.

2) MAXIMUM VOLUME [0 60]

Is possible to set the maximum volume at limited level.

3) VOLUME FIXED [VARIABLE FIXED]

Is possible to fix the sound volume at limited level.

When “FIXED” is selected the sound volume before limited is fixed.

4) VOLUME FIXED LEVEL [0 60]

If “FIXED” has been selected, is possible to set a fixed volume at the level that is chosen.

5) RC BUTTON [RESPOND NO RESPOND]

If “NO RESPOND” is selected, the remote control keys are inoperative.

6) PANEL BUTTON [RESPOND NO RESPOND]

If “NO RESPOND” has been selected, the set’s keys remain deactivated (Except POWER key).

7) MENU BUTTON [RESPOND NO RESPOND]

If “NO RESPOND” has been selected, “MENU” key, of remote control, is inoperative.

8) ON SCREEN DISPLAY [YES NO]

If “NO” has been selected, the On Screen Display does not appear.

9) INPUT MODE START [NORMAL → TV (X) →DTV→ INPUT1 → INPUT2 → INPUT3 → INPUT4 → INPUT5]

When any other item than “NORMAL” has been selected, the sets will start in a selected input mode at the next power-on.

10)INPUT MODE FIXED [VARIABLE → FIXED]

“FIXED” has been selected, any channels and input modes other than those selected at the start mode cannot be picked up.

5 – 10

Page 23

LC-26/32A37M

11)RESET

Cancel all Public Mode settings. (It returns to the factory settings)

12)EXECUTE

Select this item, and press cursor RIGHT / LEFT keys on the remote control or VOL (+) / (-) keys on the LCD TV for confirmation the functions

settings.

5 – 11

Page 24

LC-26/32A37M

LC26A37M

CHAPTER 6. TROUBLESHOOTING TABLE

ServiceManual

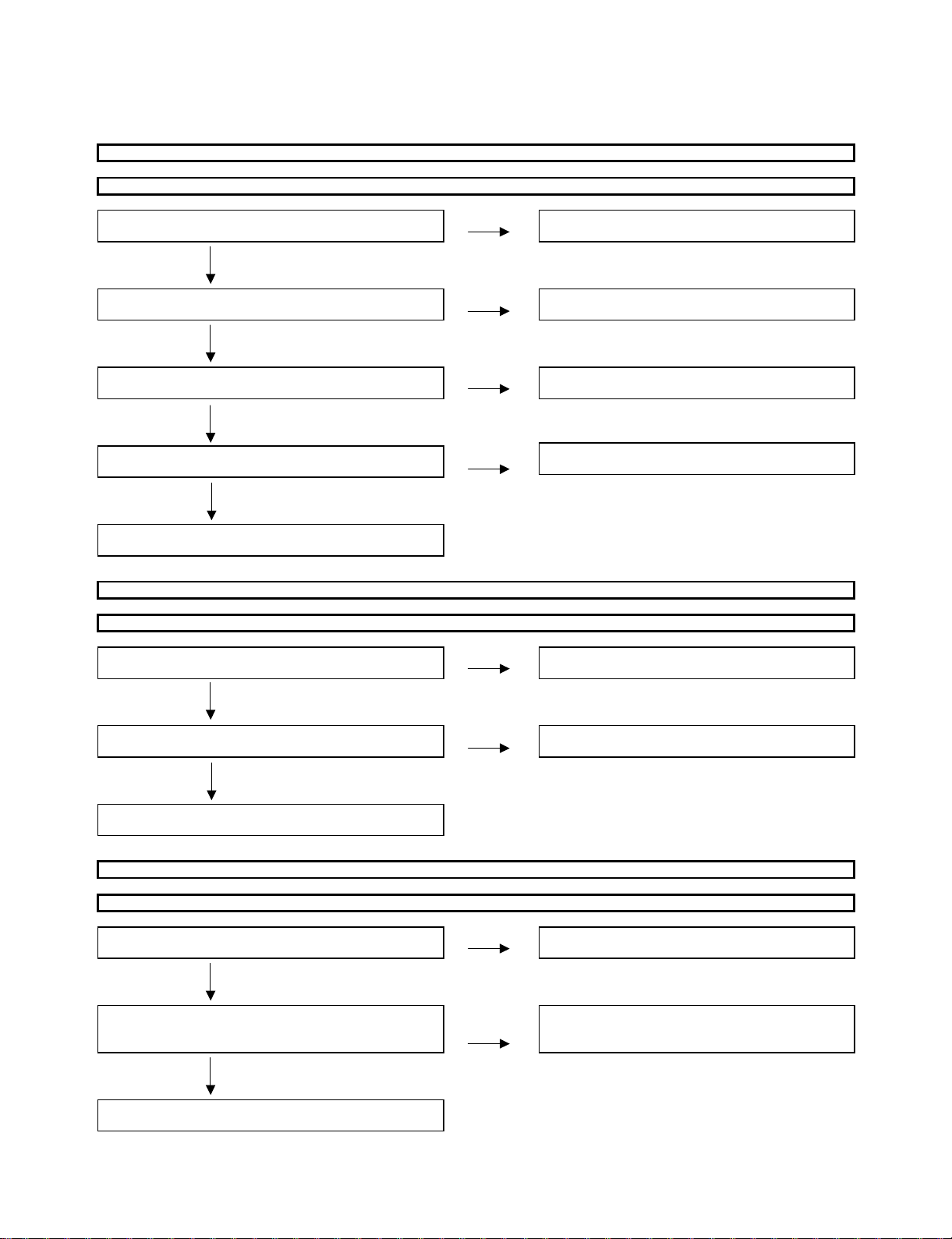

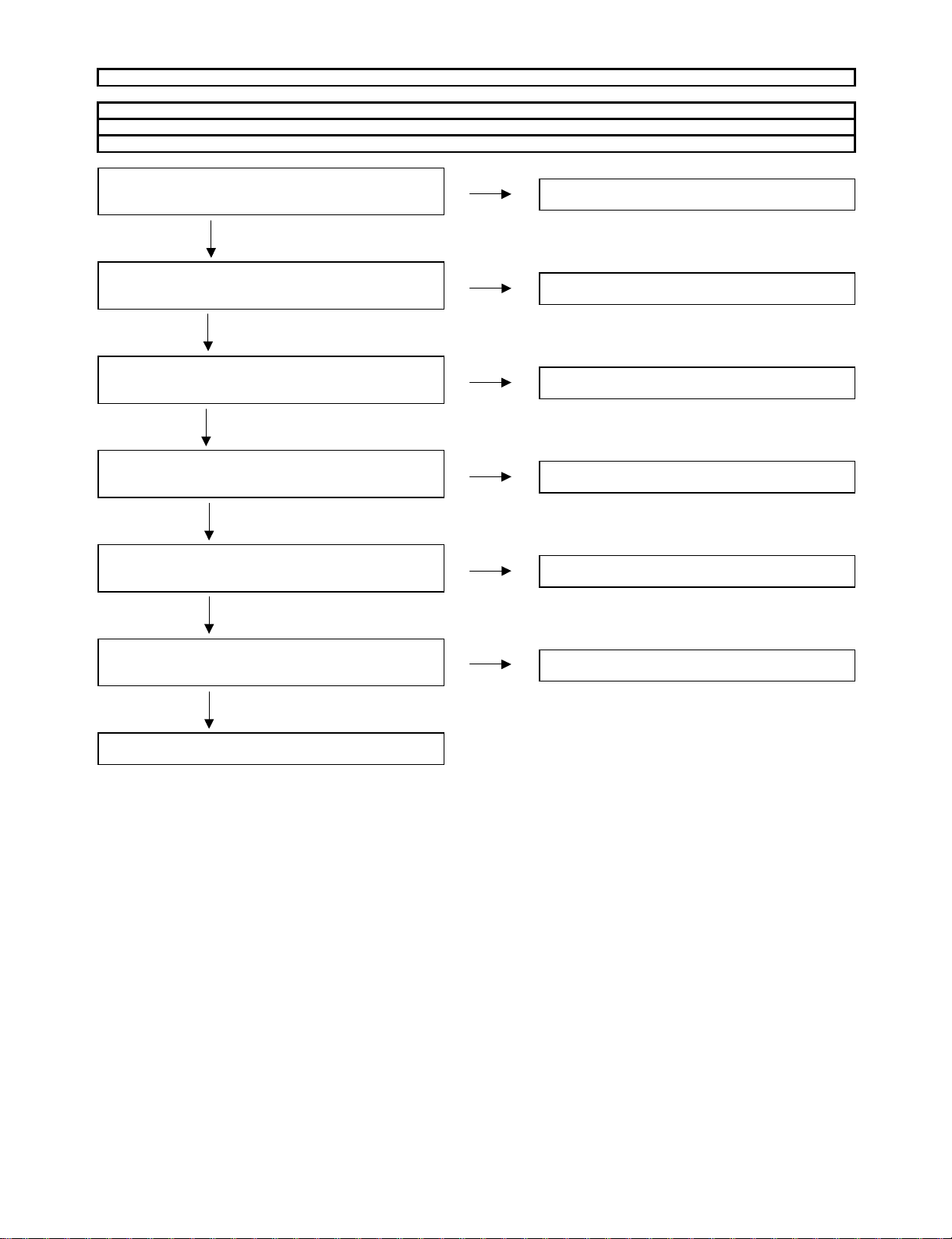

[1] TROUBLESHOOTING TABLE

The sound is not emitted from the speaker though the picture has come out

No sound output in all modes?

Is the audio signal output of pins (28/L) and (27/R) of

IC3001 (MAIN_MICON) normal?

YES

Is the audio signal input to pin (3/L) and (7/R) of

IC2701 (AMP)?

YES

Is MUTE circuit [MUTE_SP_LINE,RESET_N_LINE]

normal? (Q2701, etc.)

YES

Is the audio signal output of pins (3,4)(L-Ch) and

(6,7)(R-ch) of P2701 (AOUDIO-CONNECTOR) normal ?

NO

NO

NO

NO

Check IC3001 and its peripheral circuits

Check the line between IC3001 and IC2701

Check the MUTE_SP_LINE and RESET_N_LINE

Check IC2701 and its peripheral circuits

YES

Check Speaker (right and left) and wire harness

No sound (during the reception of TV (Analog) broadcasting)

Does not the sound go out through the picture has come out when UHF/VHF is receive?

Is the SIF signal output from pin (14) of TUNER

(TU201) replace as required

YES

Is the SIF signal sent to pins (31) of IC3001

(MAIN_MICON)?

YES

Refer to" No sound output in all modes".

No sound from external input devices (1)

Does not the sound of the audio signal input to INPUT1 / INPUT2 (HDMI) go out?

Is the picture of the signal input from INPUT1/

INPUT2 displayed? to (INPUT1/INPUT2) go out?

NO

NO

NO

Check the tuner and its peripheral circuits

Check line between TU201 and IC3001

Refer to " Does not the picture of the HDMI signal input

YES

Is the HDMI_SCK/WS/SD0 audio output from pin (86)

, (85),(84) of IC1915 (HDMI RECEIVER) to pin (39), MICON) and their peripheral circuits

(40), (38) of IC3001 (MAIN_MICON)?

YES

Refer to "No sound output in all modes".

NO

Check the line between IC1915 and IC3001 (MAIN

6 – 1

Page 25

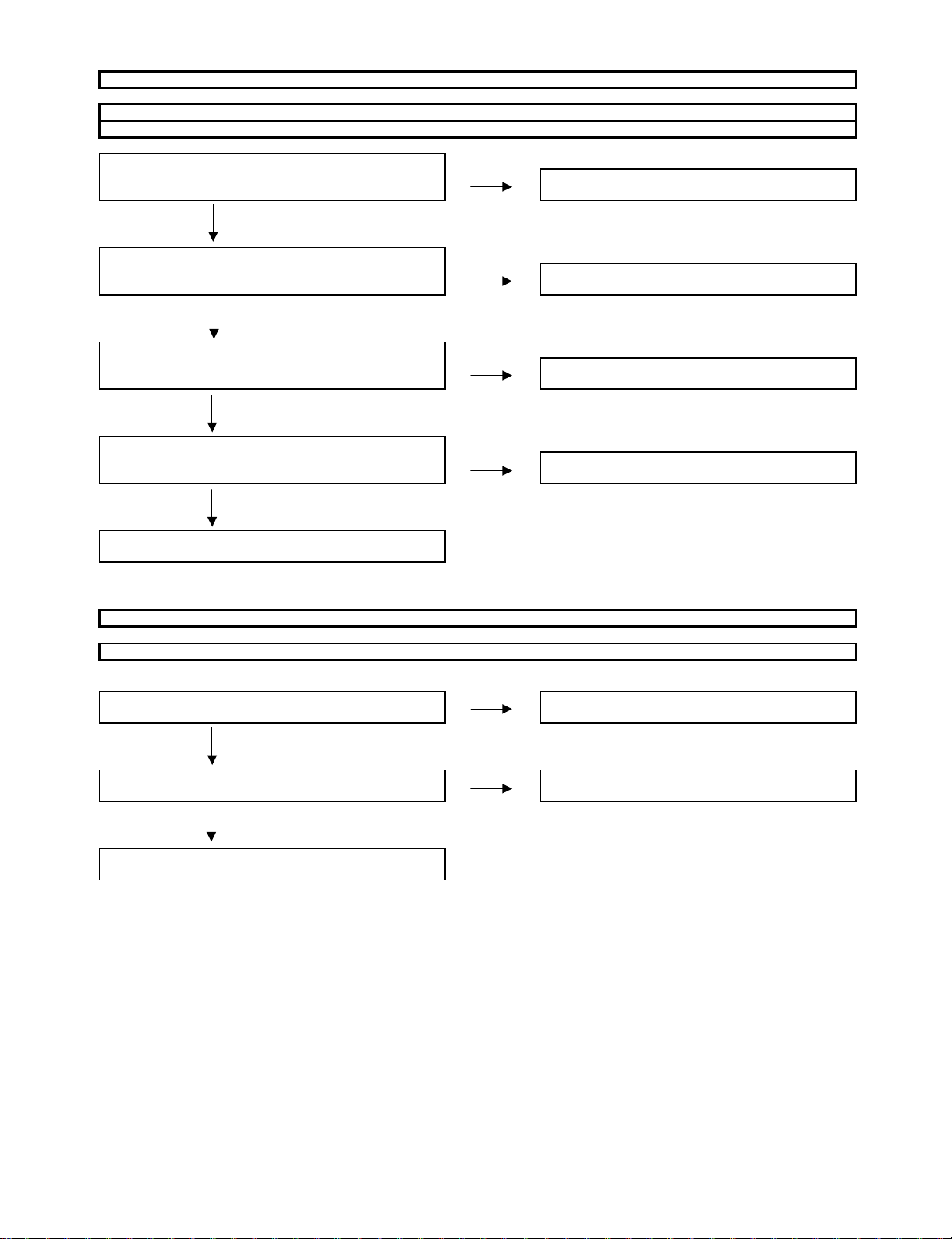

No sound from external input devices (2)

Does not the sound of the audio signal input to INPUT5 (J504) go out?

Does not the sound of the audio signal input to INPUT3 (J507) go out?

Does not the sound of the audio signal input to INPUT4 (J501) go out?

LC-26/32A37M

J504

Is the audio signal properly sent to pin (5) (AIN3L) and

(3) (AIN3_R) of (CVBS_IN) J504?

YES

J507

Is the audio signal properly sent to pin (5) (AIN1_L) and

(3) (AIN1_R) of (COMP1_AUDIO_IN) J507?

YES

J501

Is the audio signal properly sent to pin (5) (AIN2_L) and

(3) (AIN2_R) of (COMP2_AUDIO_IN) J501?

YES

J504

Is the audio signal properly sent to pin (14) (AIN3_L) and

(15) (AIN3_R) of IC3001 (MAIN_MICON)?

YES

J507

Is the audio signal properly sent to pin (10) (AIN1_L) and

(9) (AIN1_R) of IC3001(MAIN_MICON)?

YES

NO

Check the setting of an external input device

that connects of J504

NO

Check the setting of an external input device

that connects of J507

NO

Check the setting of an external input device

that connects of J501

NO

Check the line between J504 and IC3001

(MAIN_MICON)

NO

Check the line between J501 and IC3001

(MAIN_MICON)

J501

Is the audio signal properly sent to pin (12) (AIN2_L) and

(11) (AIN2_R) of IC3001(MAIN_MICON)?

YES

Refer to "No Sound output in all modes"

NO

Check the line between J501 and IC3001

(MAIN_MICON)

6 – 2

Page 26

LC-26/32A37M

No sound from external input devices (3)

Does not the sound of the audio signal input to INPUT3 (J506) go out?

Does not the sound of the audio signal input to INPUT4 (J503) go out?

J506

Is the audio signal properly sent to pin (5) (VIN15_L) and

(7) (VIN17_R) of (COMP_1_IN) J506? that connects of J506

YES

J503

Is the audio signal properly sent to pin (5) (VIN11_L) and

(7) (VIN13_R) of (COMP_2_IN) J503? that connects of J503

YES

J506

Is the audio signal properly sent to pin (178) (VIN15_L) and

(176) (VIN17_R) of IC3001(MAIN_MICON)? (MAIN_MICON)

YES

J503

Is the audio signal properly sent to pin (181) (VIN11_L) and

(179) (VIN13_R) of IC3001(MAIN_MICON)? (MAIN_MICON)

YES

Refer to "No Sound output in all modes"

NO

Check the setting of an external input device

NO

Check the setting of an external input device

NO

Check the line between J506 and IC3001

NO

check the line between J503 and IC3001

The Audio Signal not output (5)

No audio signal output from AUDIO_OUTPUT terminal.

Is audio signal output to pin (4/R-ch) and (2/L-ch) of audio

output terminal J502

YES

Is audio signal sent to pins (25) (AOUT_R) and

(26) (AOUT_L)of IS3001 (MAIN_MICON)? (MAIN_MICON)

YES

Check IC3001 (MAIN_MICON) and its peripheral circuit

NO

Check the connection of J502 and external devices.

NO

Check the line between J502 and IC3001

6 – 3

Page 27

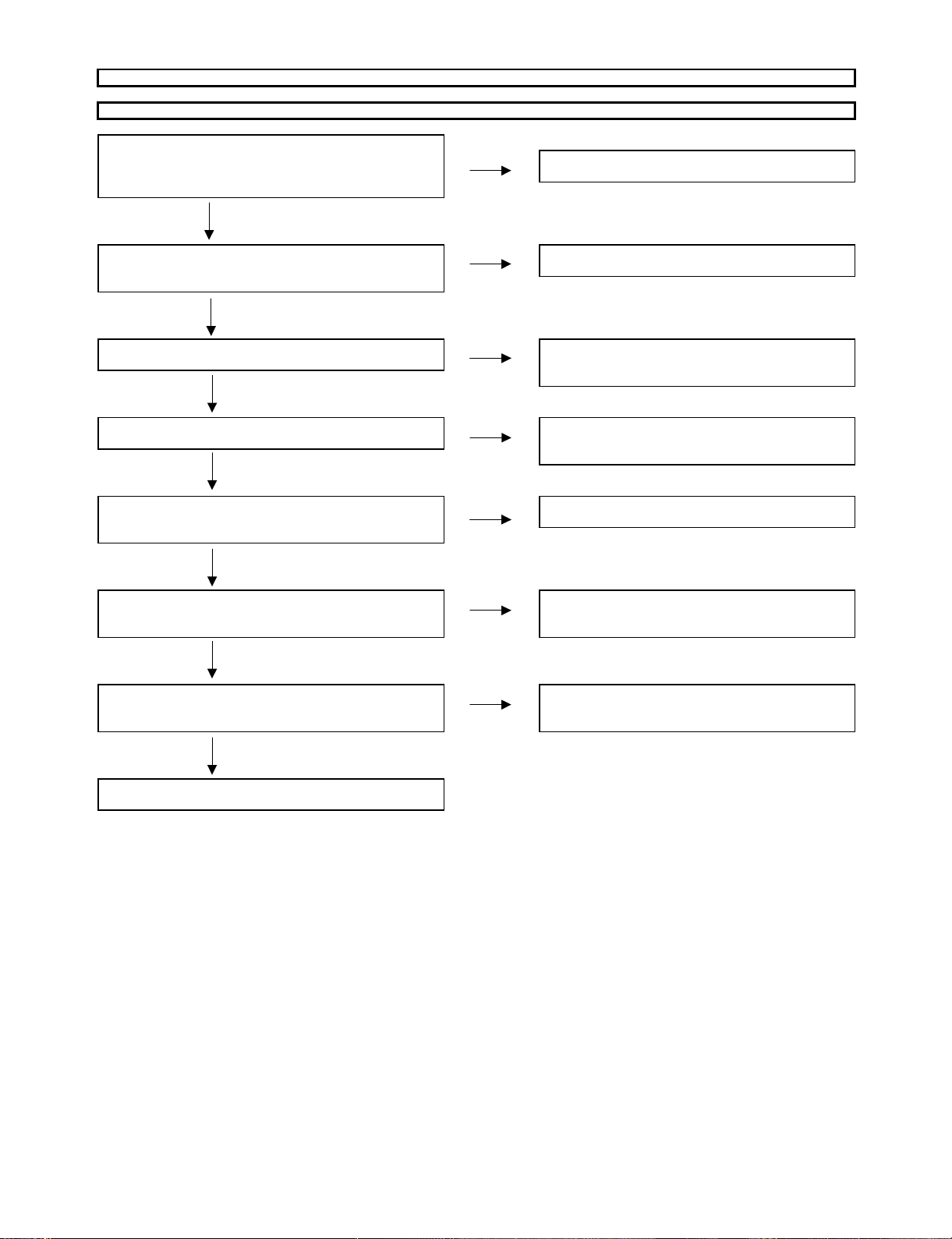

No picture on the display (1)

The picture doesn't appear in all modes.

LC-26/32A37M

Is the LVDS signal output from IC3001(MAIN_MICON)?

LVDS0_P/N(140/141), LVDS1_P/N(137/138),

LVDS2_P/N(134/135), LVDS3_P/N(128/129),

LVDS4_P/N(125/126), LVDS_CP/CN(131/132)

YES

Is the LVDS signal input to IC8103(LCD_CONTROL)?

A0+/-(165/164), A1+/-(167/166), A2+/-(169/168), and IC8103

A3+/-(189/188), A4+/-(191/190), ACK+/-(187/186)

YES

Is the control signal of LCD controller normal?

YES

Is VCC_3.3V, VCC_2.5V or VCC_1.5V supplied

to IC8103? _POWER_SUPPLY) and the peripheral

YES

Are the video signals BR/BG/BB (0_P/M-3_PM), FR/

FG/FB(0_P/M-3_M/P) and the CLK signals (BCLK_P/

M, FCLK_P/M) output from IC8103?

YES

Are BR/BG/BB(0_P/M-3_P/M), BCLK(P/M) input to

connector SC8201 and FR/FG/FB(0_P/M-03_P/M),

FCLK(P/M) input to connector SC8202?

NO

NO

NO

NO

NO

NO

Check IC3001 and its peripheral control circuits.

Check the line between IC3001 (MAIN_MICON)

Check the control signal R/L_LINE, U/D_OUT_LINE

FRAME_LINE, BANK_SEL_LINE, TEMP1/2/3_LINE

QS_EN_LINE, etc.

Check if IC8402(MULTI_CHANNEL_SYSTEM

power supply circuit are normal.

Check IC8103 and its peripheral circuits.

Check the line between IC8103 and CN8201/CN8202

YES

Are the gradiation signals (VH/VL_247, 191, 159, 63,

31, 0) normal sent from IC8201( GLAY_LEVEL peripheral circuits and IC8103 is normal.

_GENERATION) to CN8201/CN8202? (Each line of DAC_CLK/DATA/LATCH)

YES

Check the connectors CN8201/CN8202 and LCD Panel

NO

Check IC8201 and the communication between its

6 – 4

Page 28

LC-26/32A37M

No picture on the display (2)

Does not the picture come out when UHF/VHF is received?

Is the video signals (VIN1) output form pin (17)

of TUNER (TU201)? named TU201 and IC3001 (MAIN_MICON)

YES

Is the video signal (VIN1) sent to pin (191) of IC3001

(MAIN_MICON)?

YES

Refer to "The picture doesn't appear in all modes."

No picture on the display (3)

Does not the picture of the composite video signal input go out?

Is CVBS signal output from pin (8) in input terminal

J504 to pin (188) IC3001 (MAIN_MICON)?

NO

NO

NO

Check whether I2C is normal accessed between

Check the line between TU201 and IC3001

Check the line between J504 and IC3001

YES

Refer to "The picture doesn't appear in all modes"

No picture on the display (4)

Does not the picture of the Y/C video signal (S-video) go out?

Is Y/C signal input from pin (3)/Y and (4)/C of input

terminal J 505

YES

Is Y/C signal output from pin (3)/Y and (4)/C connect

to pin (184)/VIN7 and (187)/VIN6 of IC3001 (MAIN_MICON) (MAIN_MICON)

YES

Is the Y/C video signal detection function SV1JSW signal

from pin (6) of the input terminal J505 normal?

YES

Is the SV1JSW signal input to pin (201) of IC3001

(MAIN_MICON)?

NO

NO

NO

NO

Check the S_IN (J505) line and its peripheral circuits

Check the line between J505 and IC3001

Check J505 or peripheral circuits.

Check the line between J505 and IC3001

YES

Is Y/C signal sent to pins (184)/Y and (187)/C

of IC 3001 (MAIN_MICON)? (MAIN_MICON)

YES

Refer to "The picture doesn't appear in all modes"

NO

Check the line between J505 nad IC3001

6 – 5

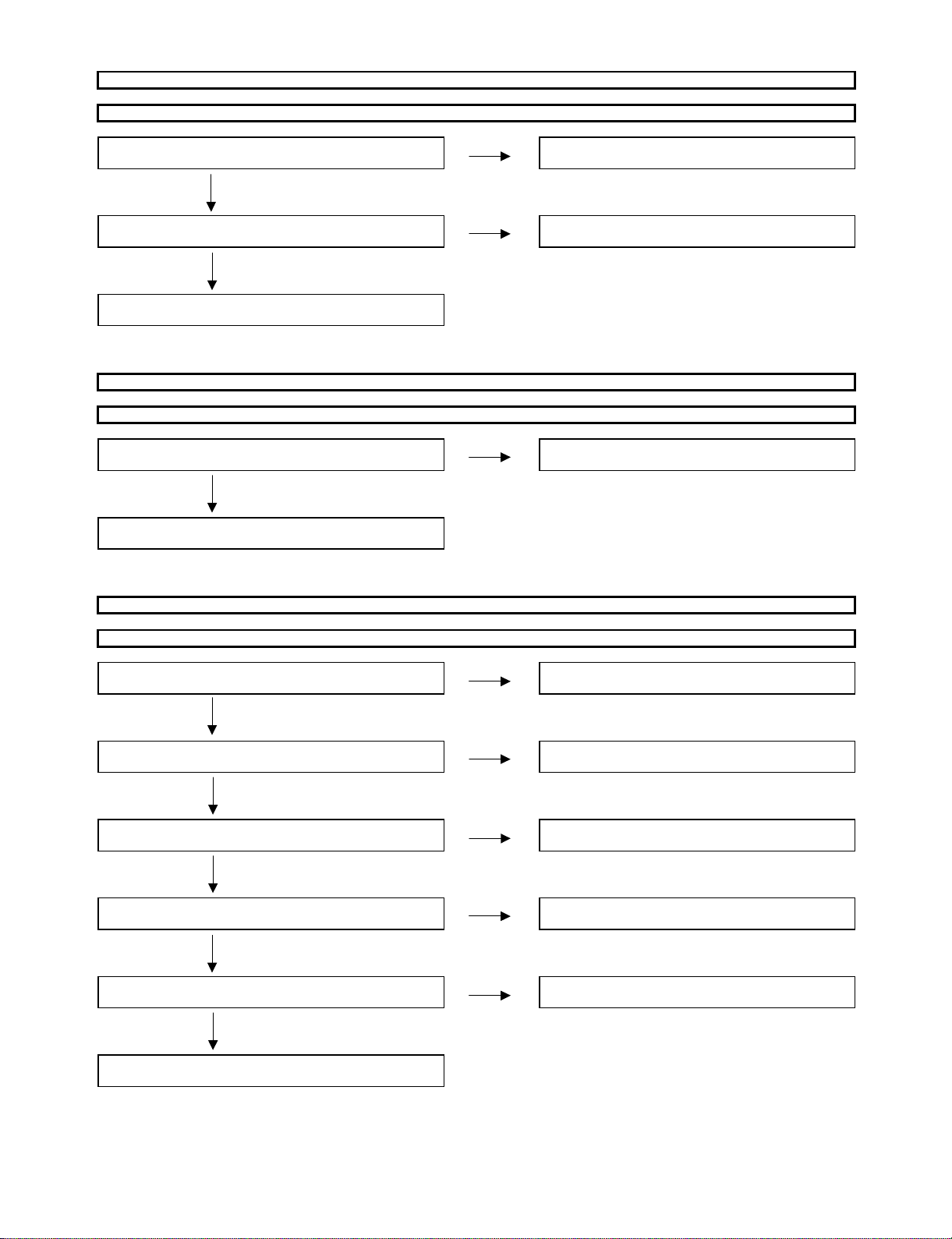

Page 29

No picture on the display (5)

Does not the picture of the DVI(ANALOG) video signal input INPUT6 (15pin-D-SUB) terminal go out?

Are the video signal and the synchonized signal input from

pin (1,2,3)/(R,G,B),(13 and 14)/(V,H) of input devices

terminal D-SUB (SC2301)

YES

Is EDID data pin (6)/SCl and (5)/SDA of IC2304

(EEPROM) accessed, and is it read from pin (15), (12) of EDID data of IC2304

of a DVI terminal SC2301

YES

Are the video signal and the synchronized signal input

from pin (174, 173,172)/(R,G,B), pin (171,47)/(H,V) of

IC3001 (MAIN_MICON)?

YES

Refer to "The picture doesn't appear in all modes"

NO

NO

NO

Check the connection and setup with the external DVI

Is access possible ui the re-writing or exchange

NO

Check the circumference circuit of SC2301 and IC2304

Check the line between SC2301 and IC3001

LC-26/32A37M

No picture on the display (6)

Does not the picture of the component video signal input INPUT3 (J506) go out?

Does not the picture of the component video signal input INPUT4 (J503) go out?

Is COMPONENT video signal input to pin (3)/Y, (5)/Pb

(7)/Pr of the input J506? device.

YES

Is COMPONENT video signal input to pin (3)/Y, (5)/Pb

(7)/Pr of the input J503? device.

YES

Is COMPONENT video signal input (J506) into pin (177),

(176) and (175) of IC3001 (MAIN_MICON).

YES

Is COMPONENT video signal input (J503) into pin (180),

(179) and (181) of IC3001 (MAIN_MICON).

YES

Refer to "The picture doesn't appear in all modes"

NO

NO

NO

NO

Check the connection of J506 and the external input

Check the connection of J503 and the external input

Check the line between J506 and IC3001

Check the line between J503 and IC3001

6 – 6

Page 30

LC-26/32A37M

No picture on the display (7)

Does not the picture of the HDMI signal input to INPUT1 (SC1901) / INPUT2 (SC1921) go out?

Is the HDMI detection function output from pin (19) of Check the line between SC1901 and IC3001

the HDMI terminal (SC1901) normal? (MAIN_MICON) of pin (205)

NO

Is the HDMI detection function output from pin (19) of Check the line between SC1921 and IC3001

the HDMI terminal (SC1921) normal? (MAIN_MICON) of pin (203)

Check the connection and setup with the

external HDMI Devices

YES

Is EDID data pin (6)/SCL, pin (5)/SDA of NO Is access possible in the re-writing or exchange of

IC1902 (EEPROM) accessed, and is it read from pin EDID data of IC1902

(15), (16) of a HDMI terminal SC1901

NO

Check the circumference circuit of SC1901, IC1902 and

IC1915 (HDMI_RECEIVER)

Is EDID data pin (6)/SCL, pin (5)/SDA of NO Is access possible in the re-writing or exchange of

IC1922 (EEPROM) accessed, and is it read from pin EDID data of IC1922

(15), (16) of a HDMI terminal SC1901

NO

Check the circumference circuit of SC1901, IC1902 and

YES IC1915 (HDMI_RECEIVER)

Is TMDS signal input pin(59,58)/TMDS2_CLKP/N NO Check the line between SC1901 and IC1951

(63,62)/TMDS2_D0P/N, (67,66)/TMDS2_D1P/N

(71,70)/TMDS2_D2P/N of IC1951 from SC1901

Is TMDS signal input pin(40,39)/TMDS2_CLKP/N NO Check the line between SC1921 and IC1951

(44,43)/TMDS2_D0P/N, (48,47)/TMDS2_D1P/N

(52,51)/TMDS2_D2P/N of IC1951 from SC1921

YES

Is each signal output fron DINR[0:7], DING[0:7] NO Is the control signal of IC1951 and IC3001

DINB[0:7], pin(2,3)/HDMI_H/V, (1)/DINEN, (121)/ (MAIN_MICON) normal? (HDMI_RST etc.)

DINCK, of IC1951?

YES

Is each signal of DINR[0:7], DING[0:7], DINB[0:7], pin (171,47)/HDMI_HV, (48)/DINEN, (49)/DINCK of IC3001 (MAIN_MICON) input?

YES NO

Refer to "The picture doesn't appear in all modes." Check the line between IC1951 and IC3001

(IC1941 etc.)

6 – 7

Page 31

LC26A37M

CHAPTER 7. BLOCK DIAGRAM/OVERALL WIRING DIAGRAM

[1] BLOCK DIAGRAM

BL

LC-26/32A37M

ServiceManual

LCD

Panel

INV

block

POWER

block

13.5V

ON/OFF

OPC

10W x 2

MAIN

HDMI

HDMI

AMP

YDA148

LR

LR

PC

HDMI-Rx

SII9025

24bit

D-in

AOUT1

AOUT2 /AIN5

AIN4

AIN3

AIN2

AIN1

㪪㫆㫌㫅㪻㩷

㫄㫌㫃㫋㫀㫇㫃㪼㫏

S-IF

Flash

1MB

FONT

ROM

1024 letter

VIN 19-21 VIN 11-13

RGB

VIN 15-17

YPbPr

T-CON

䌖䌃䌔䌐䋭䌐䌲䌯

YPbPr

CVBS

LVDS

CVBS

VIN 6,7,9

Y/C

VIN 3

8051

3D-IP

3D-NR

3D-Y/C

VOUT 1

L

LED_R

E

LED_G

D

R/C

LED

IR

U

N

LED_OPC

OPC

I

䌓䌬䌯䌷

䌁/䌄

KEY

EEPROM

Buffer

CN

8KByte

BR24L64F

I2C_BUS

VIN 1VIN5 VIN2

CVBS

OPC

IR PASS

TC7W00U

RS232CTxRx

ISL83220

RS232C

T

K

E

Y

U

N

I

T

Option

CH+

CHVol䋫

VolMENU

INPUT

POWER

L R

Tuner

SAW

LR䋨COMP䋩

S-IF

Demodulation

Y

Pb

Pr

7 – 1

L

R

Pb

LR䋨COMP䋩

Y

Pr

L

R

LR䋨CVBS䋩

CVBS

L R

(ctrl䋩

RESET

V

VS

L R

LR䋨CVBS/䌓䋩

CVBS

䋨TUNER䋩

D/A_SEL

D_POW

ANT_POW

SIO

AGC

AFT

GPIO

I2C

Page 32

LC-26/32A37M

[2] OVERALL WIRING DIAGRAM

7 – 2

Page 33

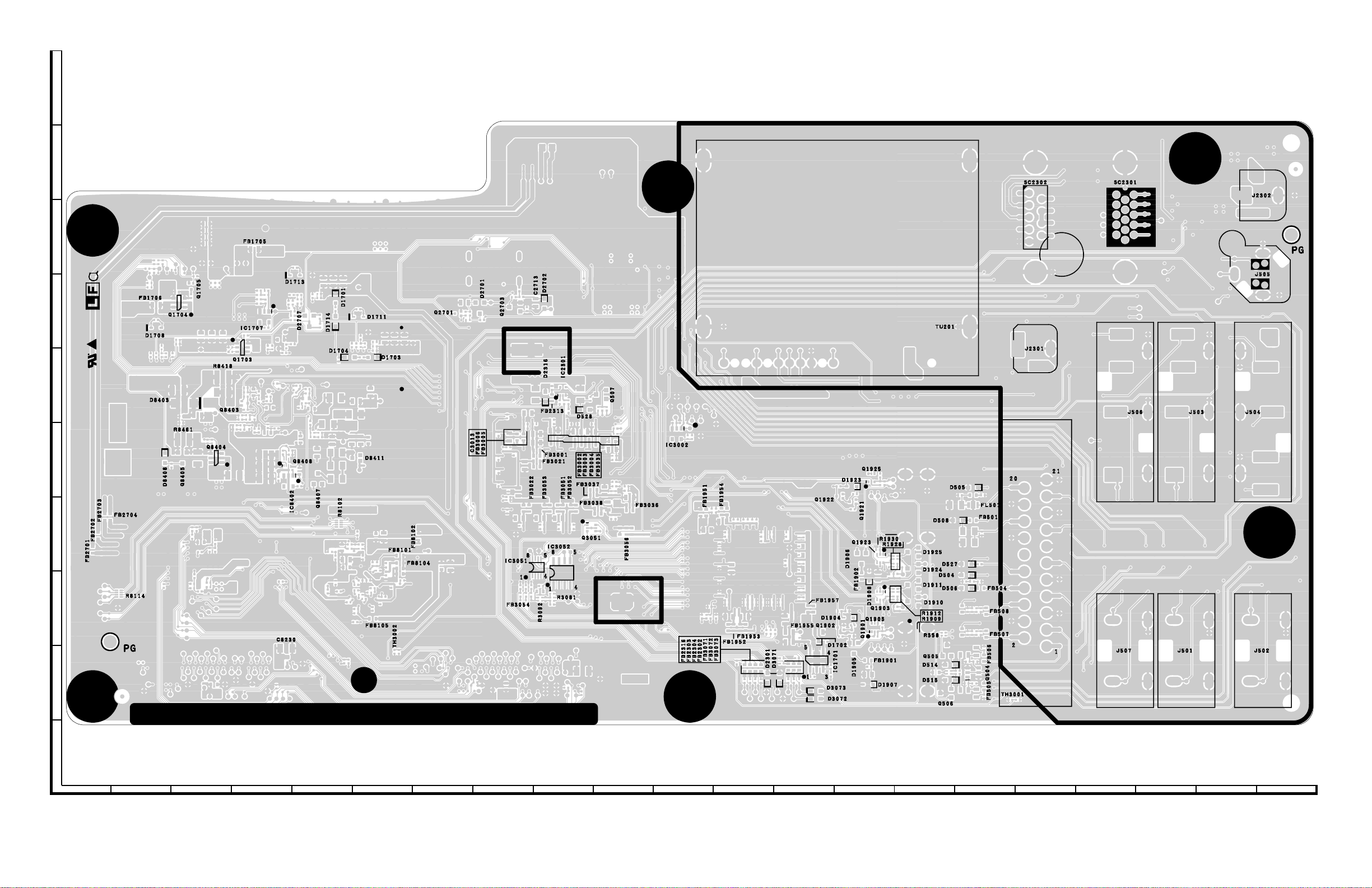

LC26A37M

CHAPTER 8. PRINTED WIRING BOARD

[1] MAIN UNIT

MAIN Unit Side-A

J

I

H

LC-26/32A37M

ServiceManual

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

8 – 1

Page 34

LC-26/32A37M

MAIN Unit Chip Side-A

J

R2336R2337

I

D2319

H

G

D521

R549

C573

F

E

R575

R514

C521

Q501

C517

R525

R513

R512

Q503

C522

LUG1701

R518

R526

C525

R576

R520

Q502

C526

C524

D

R516

D2318

D2317

C555

D516

C554

D517

D518

R554

C553

FL509

R543

C556

FB509

R578

C557

R545

R544

C564

C565

R547

R546

C559

R579

FB510

C558

R521

C2317

C560

D520

C520

C562

C563

R523

R2315

C2319

R571

C581

C2320

FL510

FL511

IC2302

C502

FB502

LUG1706

C2318

R2334

C2321

R548

FL507

R532

C534

C537

R504

R503

R2314

R2331

R2330

R2335

R2311

C2322

R2316

R2317

C561

R2321

C2323

C572

IC2303

D519

FL508

R536

C541

D511D512

C507 C508

C514

R505

R506

D507

FB503

C501

R508

FB2311

D2310

FB2310

D2308

D2312

D2306

FB2308

D2304

R2320

R507

C515

FB2309

C532

D509

R2322

D2313

C570

C575

FB511

Q2303

FL513

R552

C567

R563

R567

R2333

D523

C577

R565

C579

D525

D522

C574

FB512

FL514

R553

C568

R562

R566

C

B

IC2304

C576

R564

C578

C569

D526

VA2302

R2312

R2313

VA2301

D524

D513

C552

C544

C519

C511

C512

C513

FL512

C566

C533

FL506

C529

R550

C527

D510

R509

FL502

R519

FL503

D501

D502

FL504

R522

R524

FL505

D503

FL2303

R2308

FL2302

R2307

FL2301

R2306

D2302

R551

R531

R577

L501

IC501

R515

C504

C505

C506

D2311

C2312

FB2306

FB2307

D2305

C571

C545

C2310C2311

D2303

C2325

D2309

FB2315

R2324

R2325

R2703

FB2312

R2302

D2307

FB2305

C2324 R1745

FB2314

R2323

R2326

C2327

R2327

C2326

R2328

C2331

D2314

C2330

D2315

C206

C201

SC1921

SC1901

C202

R214

Q1906

C1922

C1906

L202

D1922

D1921

IC1922

IC1902

D1903

D1902

C207

R3010

R209

R213

C208

R210

Q203

R206

R215

R1976

C2004

C2002

R1761

C203

FB1956

Q1701

R205

C204

R1759

R1760

R208

R211

R1926

R212

Q202

R1907

C1753

C1752

C2302 C2303

P2301

R3056

R1971

C1993

R207

C209

C1995

FB2301

C205

IC1951

C1974

C1973

R1965

FL1901

C1977

R1966

C1971

C1972

R1963

R1964

R1962

R1960

IC1941

P3091

R1951

C210

C1941

R1957

R1956

R1955

R1954

R1953

R1952

LUG1704

Q2704

R2720

C2707

R2722

R2719

C2747

C2731

C2743

C2744

C2745

C2749

R2724

R2701

L2705

C2742

R2725

C2750

C2751

C3036

D2708

C2753

C2752

C2760

IC2702

C2762

C2758

C2756

C2754

P2702

C2764

C2755

C2763

C2761

R2726R2727

R2738

C2757

D2709

L2706

R2735

R2733

R2734

C2759

P3081

R2736

C3054

R3094

C2720

D2705

C2732

R3093

X3051

C2736

C2740

C2728

C2735

IC3001

C2721

D2706

C3055

C2726

C2738

R3054

P2701

L2704

L2701

C2723

C2737

C2741

R8104

C2739

R8120

R2728

R2721

C2727

C2724

C2718

C2714

R2723

C2708

R2706

R2737

C2765

C2705

C3083

R3003

IC2701

C2715

C2711

Q2702

C2701

R8130R8131R8132R8134R8135

R2730

C2729

C2712

C2709

C2702

R3009

R3013

R3016

R3018

R2729

C2706

C2704

R2732

R2711

C2730

R2716

C2725

C2717

R2715

R2731

C8232

L2703

L2702

FL8101

R8121

R8115

R8266

D2703

C2722

C2733

C2734

FB8106

C8102

IC8102

C2719

R2702

C8229

D2704

L1702

C8228

R8149

R8142

R8143

R8263

C2746

C2748

D1710

R8246

R8146

R8147

C8417

R8145

R8425

D8401

C8406

C8405

C8103

IC8103

IC1704

C8467

C8129

R8463

R8462

L1703

C8468

C2710

L8401

R8405

R8404

C1735

C1741

C1737

C1733

C8404

R8108

R8408

R8406

D8404

Q8406

C8456

R8401

C1734

FB1702

C8407

C8408

D1712

R8243

D8402

C8415

R8410

C8423

C8450

C8449

R8118

C2716

R1737

C8451

R8245

D8407

D8406

IC8101

R8248

C8418

R8244

IC1706

C8225C8226

C8234

R8427

C8420

C8101

R8148

R8472

C8444

C8443

R8105

R2704

IC8404

R8439

C8434

R8441

R8106

C1751

C1744

D1709

R8428

R8437 R8438

IC1703

R8237

C1746

C8428

R8250

R8435

C8460

C8461

C8208

R8249

R8210

R8215

R8213

R8242

C1742

D8405

C8433

C8466

R8225

C8212

R1736

R8414

IC8202

R8433

R8222

C8213

FB1703

C1725

R8419

R8421

R8420

C8438

D8410

L8402

R8211

R8218

R8217

R8103

C1747

R1735

C8203

C8223

R8101

C8441

C8206

C8222

FB1704

R1747

L8403

CN8201CN8202

R8403

R1746

L1701

D8409

IC8201

D1706

P1701

R8458

C8453

C8454

C8458

R8207

R8202

R1703

R8220

R8201

C8219

R1749

C8238

C8239

R8122R8123R8124R8125R8127R8128R8129

D1707

D1705

R8204

R8208

R8212

R8214

R8219

R8221

R8206

R8226

R8228

R8233

C8204

C8207

C8209

C8215

C8211

C8214

C8210

C8216

C8217

R1748

C1750

C1721

IC1702

R1750

R8265

C1729

FB1701

C1720

C1724

C2766

C2767

C2768

C2769

C8202

C8218

LUG1705

P2703

P8102

LUG1702LUG1703

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

8 – 2

Page 35

MAIN Unit Side-B

J

I

H

G

LC-26/32A37M

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

8 – 3

Page 36

LC-26/32A37M

MAIN Unit Chip Side-B

J

I

H

G

R1751

C1748

R1753

R1733

C1705

C1716

R1752

FB1706

C1715

D1708

R1728

C1722

C1712

R1715

R1762

R1713

C1749

R1710

R1739

Q1704

R1709

R1708

Q1705

R1738

C1702

C1711

R1742

R1743

R1741

R1740

C1710

C1709

R1706

R1705

Q1703

R1707

FB1705

R1758

R1757

R1756

R1754

C1743

R1734

R1755

IC1707

C1745

C1728

R1716

C1719

R1727

C1740

R1725

C1736

C1738

R1732

R2718

R2739

R1722

C1739

D1713

R1730

R1729

C1718

D2707

R1721

R1720

R1719

R2705

R2740

C1727

C1726

D1701

R1744

D1714

R1701

C1723

D1704

C1732

R1718

C1731

D1711

C1730

R1724

R1702

R1723

R1714

R1712

R1711

D1703

C1713

C1717

C1714

Q2701

C2703

R2707

R2708

R2709

D2701

R2710

R2712

Q2703

R2717

R2713

R2714

C2713

D2702

R8418

D8408

R8223

R8460

C8410

R8430

C8409

D8403

R8461

Q8405

R8216

F

E

FB2703

FB2704

FB2702

D

FB2701

R8114

R8205

C8205

R8241

C8221

R8240

R8417

C8447

R8203

R8238

R8239

C8201

C8455

R8236

R8224

R8232

R8459

R8235

C8220

Q8404

C8439

R8449

R8450

C8459

R8453

R8454

C

B

C8224

C8440

R8447

R8429

C8422

R8409

Q8403

R8432

C8448

R8455

R8444

C8445

R8456

C8435

R8452

R8451

R8442

C8437

C8462

C8465

C8463

C8442

R8446

C8446

R8448

R8431

R8445

C8235

R8467

R8474

R8469

C8230

Q8408

IC8402

R8471

R8470

R8468

R8413

R8411

C8413

C8424

C8464

C8457

C8411

R8416

R8415

R8412

C8402

R8424

C8421

R8422

R8426

R8423

C8452

Q8407

R8113

C8131

C8432

C8401

R8464

R8465

R8466

R8116

C8126

R8102

C8122

R8119

R8247

C8135

C8132

C8125

R8110

R8111

R8264

C8412

C8430

C8130

C8403

D8411

R8107

C8117

C8123

C8128

C8127

C8429

R8109

R8112

C8118

C8124

C8107

C8121

R8402

R8440

C8112

C8116

C8109

C8115

C8120

FB8105

C8137

C8110

C8108

C8119

C8139

C8114

C8106

C8105

C8113

C8111

FB8101

FB8104

R8117

C8133

TH3002

C3048

C8104

FB8102

C8134

C8141

C8233

C3014

C3021 C3022

C3017

R3006

R3004

C3023

R3007

C3024

C8227

C3013

FB3006

C3047

C3018

C3026

C2301

R2332

IC2301

D2316

FB2313

R2301

R2303

R2304

C3016

C3003

FB3001

R3095

FB3021

R3023

C3057

IC3051

C3060

FB3054

R3092

FB3053

C3020

C3052

C3009

R3030

C3081

R3081

C3082

C3005

FB3002

R3020

R3028

C3058

C3056

C3027

IC3052

R3011

C3032C3033R8407

FB3051

C8237

C3010

C3011 C3012

C3006

C3034

FB3005

C3025

FB3022

R3024

C3051

R3075

R3076

R3074

R3071

R3072

R3073

FB3052

C3059

C3053

C3007

FB3003

R3021

R3029

R574

C8236

D528

C8231

R530

C3015

C3008

FB3004

R3022

R3026

FB3037

Q3051

Q507

R3012

FB3038

R3027

R568

C3045

R533

C3046

FB3035

C3038

C3043

C3028

R3002

R3001

C3031

C3037

C3039

C3040 C3041

C3029

C3030

C3044

FB3056

R3017

C3042

FB3036

R3025

R3031

C3004

IC3002

C3035

C3001

C3002

FB1951

R1972

R1961

C1969

C1952

C1907

C1960

R1958

C1908

R1959

FB1954

C1978

C1958

C1955C1956C1957

C1954

R1975

C1968

C1970

C1966

C1967

C1959

C1965

C1964

C1961 C1962

FB1952

FB1953

R1973

R2309

C1975

C1976

C1979

R1974

R2305

FB2316

C2304

C1980

FB2303

C2308

C1982

C1983

C1981

C1984

FB2302

FB2304

C2306

C2309

C1989

C1987

C1988

C1985

C1986

R1968

D2301

C1991

C1990

C1994

C1992

R1969

R1970

C1996

C1997

C3075

C3076

D3071

C1998

C1999

C2011

C2012

C1963

FB1955

C2001

C2000

C1701

FB3071

C3073

C2018

C2014C2015C2016

C2009C2010

C2008

C2006

C1703

C3074

FB3072

FB3073

C3071

C3072

C2017

C2013

C2007

C2005

FB1957

D1702

C1704

R1977

D3073

D3072

C1708

IC1701

C1707

C1706

R1704

R1924

Q1922

R1905

R1906

Q1902

C1905

D1904

D1923

Q1921

R1925

R1904

Q1901

D1905

R1921

D1906

FB1902

Q1925

D1908

FB1901

C1903

C1901

D1907

Q1905

R1914

R1922

R1932

C1921

Q1923

C1902

Q1903

R1923

R1902

R1903

C1904

R1930

R1928

R1933

R1912

R1909

R1915

D1924D1925

D1911

D1910

C580

R558

Q506

Q505

D514

R542

D515

R511

C516

D508

R541

R510

R517

D527

D504

R501 R502

D506

C548

R537

C549

R538

C550

C535

C536

C551

D505

C509

FL501

FB501

C542 C543

R539

Q504

R540

R534

R535

R527 R528

C518

R529

C510

FB504

C538

C539

C503

C530 C531

FB505FB506

FB507FB508

C3019

TH3001

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

8 – 4

Page 37

[2] R/C, LED/KEY UNIT

R/C, LED Unit Side-A R/C, LED Unit Side-B

J

I

R/C, LED Unit Chip Side-A R/C, LED Unit Chip Side-B

H

LC-26/32A37M

G

F

E

D

KEY Unit

C106

C105

C104

IC101

D116

R135

R136

D103

R105

R110

R104

R108

R109

R107

Q102Q103

R137

Q104

R117

R102

Q105

R106

R138

P101

R132

R101

C102D101

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

8 – 5

Page 38

LC-26/32A37M

[3] POWER UNIT

POWER Unit Side-A

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

8 – 6

Page 39

POWER Unit Side-B

J

I

H

G

LC-26/32A37M

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

8 – 7

Page 40

LC-26/32A37M

POWER Unit Chip Side-B

J

I

H

TL7002

G

TL7003

TL7004

F

E

TL7205

R7235

R7230

D7220

R7223

C7224

Q7205

D7218

R7243

R7236

TL7217

TL7212

C7217

C7230

TL7207

TL7214

TL7220 TL7209 TL7210

R7239

R7266

R7241

TL7215

R7240

R7234

R7237

RJ1

TL7206TL7208

TL7213TL7211

R7273

D7233D7232

Q7210

R7276

TL7219

R7279 R7278

R7277

R7233

R7259 R7224

R7229

TL7216

D7228

C7219

D7219

R7242

R7245

D7231

D7230

R7260

R7244

R7232

D7221

TL7221

R7246

R7124

D7103

C7107

D7105

TL7103

C7115

C7101

D7106

FB7106

R7133

FB7101

IC7101

D7110

R7102

C7105

TL7105

R7103

C7109

R7101

C7102

FB7105

R7110

R7112

TL7106

TL7107

TL7102

C7211

TL7101

R7206

R7207

C7203

D7205

D7216

FB7201

C7231

R7261

R7208

Q7203

D7209

D7229

R7219

TL7201

D7207

R7231

D7223

C7206

R7257

C7215

D7204

R7238

Q7208

D7225

D7203 D7226

Q7201

R7209

RJ2

R7264

R7212

R7265 R7258

R7269

TL7203

R7129

R7131

R7135

R7111

R7114

R7123

TL70012

TL70013TL70014TL7001

TL70011

R7128

R7127

R7126

R7125

C7106

R7136

R7117

R7130

D7108

Q7104

Q7102

R7134

R7263

D7208

D7222

R7262

Q7206

C7229

R7249

TL7204

C7204

Q7202

R7222

R7213

Q7207

R7225

R7226

Q7209

R7227

C7214

R7228

C7226

R7248

D7114

RJ3

TL7218

R7247

R7250

R7251

TL7202

R7256

R7255

D7210

R7271

R7221 R7268

R7220 R7267 D7211

D

R7204

C

R7205

R7203

R7202

R7106

R7201

TL7108

TL7111 TL7112

R7107 R7105

R7109 R7108

B

A

123456789

Q7101

R7120

D7109

R7121 R7118

R7281 R7280

R7253 R7252

D7107

TL7104

FB7107 R7116 R7119 R7115

R7132

R7254

TL7224

TL7222

TL7223

LF1

C7225

10 11 12 13 14 15 16 17 18 19 20 21

8 – 8

Page 41

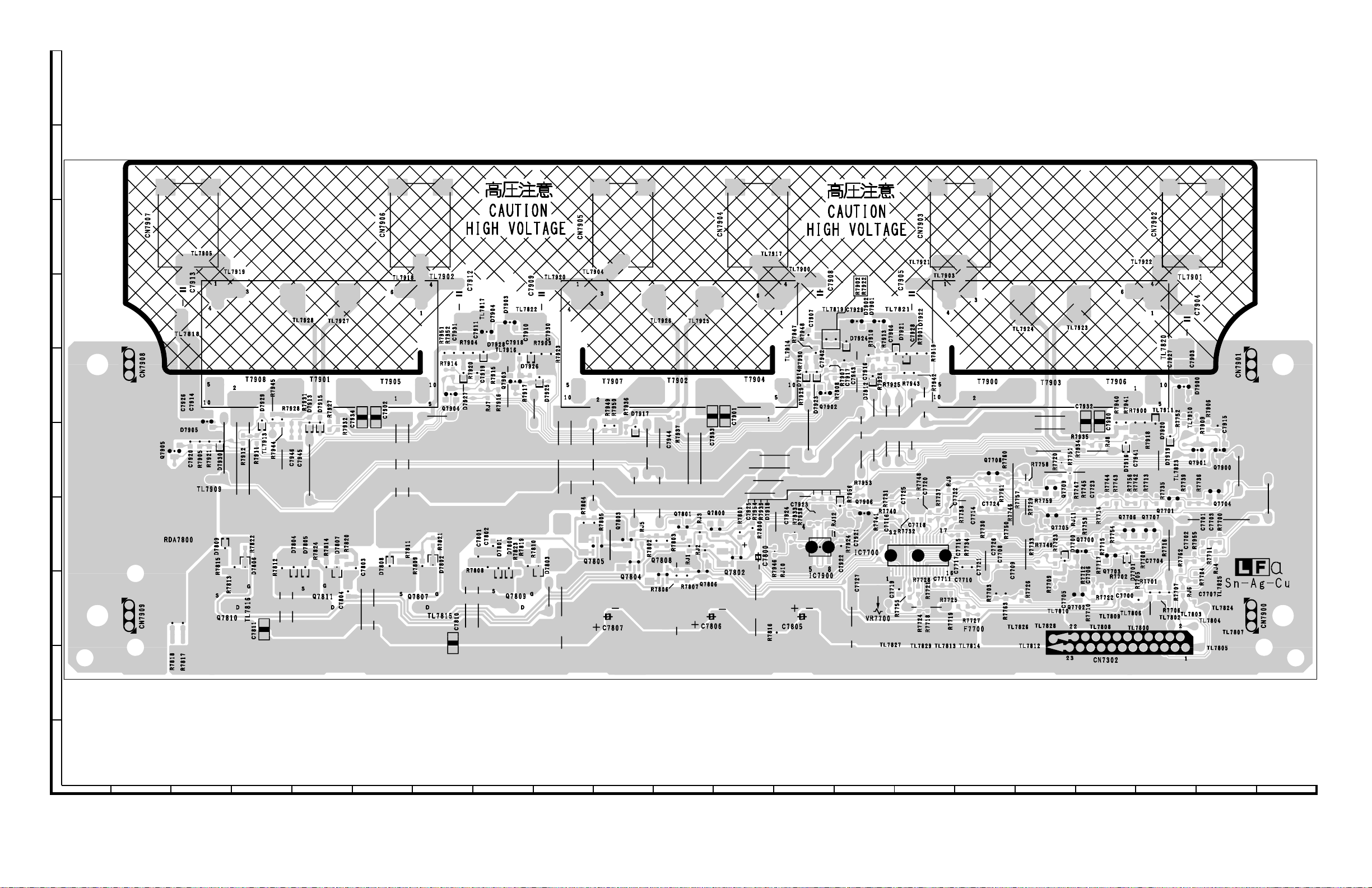

[4] INVERTER UNIT

INVERTER Unit Side-A (LC-26A37M)

J

I

H

G

LC-26/32A37M

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

8 – 9

Page 42

LC-26/32A37M

INVERTER Unit Chip Side-B (LC-26A37M)

J

I

H

G

C7914

C7926

R7921

R7905

R7915

C7920

Q7904

D7809

R7912

R7815

R7911

R7813

D7930

R7944

R7822

D7929

R7945

D7806

C7810

R7812

D7804

D7805

R7824

R7814

C7946

D7913

R7928

C7945

R7927

R7820

D7807

R7931

C7803

C7804

RJ33

R7932

C7943

D7915

R7925

RJ32

R7926

D7912

R7811

R7821

D7808

R7809

D7802

C7801 C7802

C7811

D7905

Q7905

C7919

F

R7914

E

C7808

C7809

D

R7817

R7818

R7808

C7934

C7902

D7801

R7904

D7800

R7920

R7952

C7911

R7823

D7928

R7951

R7819

R7810

C7931

D7927

D7904

C7918

R7917

R7916

D7803

RJ26

RJ29

Q7903

Q7902

Q7804

D7903

C7917

C7910

D7926

D7925

R7907

R7908

R7923

R7903

R7803

R7950

C7944

C7930

R7802

R7949

R7936

D7917

Q7801

R7937

RJ19

RJ20

R7806

R7807

Q7808

Q7806

RJ24

RJ22

RJ21

R7816

C7933

C7901

Q7802

RJ27

R7801

R7800

Q7800

R7804

R7946

R7805

D7923

C7923

R7933

C7929

R7947

R7938

C7924

R7902

Q7805

R7922

R7948

RJ18

C7907

IC7900

D7924

RJ17

Q7803

D7902

C7925

RJ16

R7924

C7922

R7954

C7916

C7921

R7741

D7901

R7953

Q7906

RJ15

R7910

C7727

D7922

R7913

R7939

R7956

C7716

D7918

R7718

R7901

D7921

R7740

R7724

C7906

R7919

R7732

RJ14

C7928

R7943

C7718

C7719

R7942

R7755

IC7700

R7728

R7731

C7720

RJ13

R7737

RJ12

R7721

C7722

R7719

R7761

C7711

R7738

C7715

R7725

R7734

R7727

Q7705

C7725

C7721

C7710

R7747

R7748

C7717

R7722

C7714

RJ11

C7708

R7730

C7709

C7723

RJ10

RJ9

R7703

R7745

C7726

Q7708

R7746

R7750

R7763

C7724

C7932

C7900

R7760

R7757

R7729

R7758

R7749

R7759

R7733

R7723

Q7700

D7700

Q7709

R7714

R7709

R7712

C7705

R7715

R7754

Q7703

D7920

R7940 R7941

R7900

C7942

R7929

R7934

R7935

Q7706 Q7707

R7708

D7701

R7726

R7701

R7705

D7914

C7704

R7706

C7903

R7918

R7930

R7751

C7927

D7916

R7720

RJ6

R7716

Q7702

R7707

RJ8

C7941

RJ5

R7717

D7900

RJ7

D7919

R7735

C7706

R7710

R7753

R7756

R7744

R7702

C7915

R7752

Q7900

R7909

R7906

Q7901

R7742

Q7701

R7736

R7739

R7713

R7743

Q7704

RJ4

RJ3

C7700

C7702

R7955

R7711

RJ2

C7701

C7703

R7700

R7704

RJ1

R7762

C7707

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

8 – 10

Page 43

INVERTER Unit Side-A (LC-32A37M)

J

I

H

G

LC-26/32A37M

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

8 – 11

Page 44

LC-26/32A37M

INVERTER Unit Side-B (LC-32A37M)

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

8 – 12

Page 45

INVERTER Unit Chip Side-B (LC-32A37M)

J

I

H

LC-26/32A37M

G

D7903

D7800

Q7903

C7918

R7823

R7917

R7819

R7810