Page 1

SERVICE MANUAL

LCD COLOR TELEVISION

#########

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

CONTENTS

SERVICING NOTICES ON CHECKING ..............................................................................

•

HOW TO ORDER PARTS ....................................................................................................

•

IMPORTANT.........................................................................................................................

•

HOTEL MODE FUNCTION ..................................................................................................

•

ABOUT LEAD FREE SOLDER (PbF) ..................................................................................

•

PARENTAL CONTROL - RATING LEVEL ...........................................................................

•

GENERAL SPECIFICATIONS..............................................................................................

•

DISASSEMBLY INSTRUCTIONS ........................................................................................

•

SERVICE MODE LIST..........................................................................................................

•

WHEN REPLACING EEPROM (MEMORY) IC ....................................................................

•

SERVICING FIXTURES AND TOOLS .................................................................................

•

INSTALL FOR WRITING TOOLS.........................................................................................

•

RE-WRITE FOR DIGITAL SOFT FIRMWARE .....................................................................

•

UPDATE FOR VCTP SOFTWARE.......................................................................................

•

UPDATE FOR EEPROM DATA ...........................................................................................

•

ELECTRICAL ADJUSTMENTS ............................................................................................

•

TROUBLESHOOTING GUIDE .............................................................................................

•

BLOCK DIAGRAM................................................................................................................

•

PRINTED CIRCUIT BOARDS ..............................................................................................

•

SCHEMATIC DIAGRAMS ....................................................................................................

•

WAVEFORMS ......................................................................................................................

•

MECHANICAL EXPLODED VIEWS.....................................................................................

•

REPLACEMENT PARTS LIST .............................................................................................

•

LC-26AD5E-BK

Page

A1-1

A1-1

A1-1

A1-2

A1-3

A1-3

A2-1~A2-5

B1-1~B2-2

C-1

C-2

C-3

C-3

C-4~C-7

C-8~C-11

C-12, C-13

D-1~D-7

E-1~E-7

F-1~F-14

G-1~G-10

H-1~H-40

I-1, I-2

J-1~J-3

K1-1~K2-12

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

SERVICING NOTICES ON CHECKING

1. KEEP THE NOTICES

As for the places which need special attentions,

they are indicated with the labels or seals on the

cabinet, chassis and parts. Make sure to keep the

indications and notices in the operation manual.

2. AVOID AN ELECTRIC SHOCK

There is a high voltage part inside. Avoid an

electric shock while the electric current is

flowing.

3. USE THE DESIGNATED PARTS

The parts in this equipment have the specific

characters of incombustibility and withstand

voltage for safety. Therefore, the part which is

replaced should be used the part which has

the same character.

Especially as to the important parts for safety

which is indicated in the circuit diagram or the

table of parts as a mark, the designated

parts must be used.

4. BE CAREFUL WITH THE

LCD PANEL

Avoid a shock to the panel while servicing.

Take enough care to deal with it.

5. PUT PARTS AND WIRES IN THE

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

PERFORM A SAFETY CHECK AFTER

6.

SERVICING

Confirm that the screws, parts and wiring which

were removed in order to service are put in the

original positions, or whether there are the

portions which are deteriorated around the

serviced places serviced or not. Check the

insulation between the antenna terminal or

external metal and the AC cord plug blades.

And be sure the safety of that.

(INSULATION CHECK PROCEDURE)

Unplug the plug from the AC outlet.

1.

Remove the antenna terminal on TV and turn

2.

on the TV.

Insulation resistance between the cord plug

3.

terminals and the eternal exposure metal

[Note 2] should be more than 1M ohm by

using the 500V insulation resistance meter

[Note 1].

If the insulation resistance is less than 1M

4.

ohm, the inspection repair should be

required.

[Note 1]

If you have not the 500V insulation

resistance meter, use a Tester.

[Note 2]

External exposure metal: Antenna terminal

Earphone jack

HOW TO ORDER PARTS

Please include the following informations when you order parts. (Particularly the VERSION LETTER.)

1. MODEL NUMBER and VERSION LETTER

The MODEL NUMBER can be found on the back of each product and the VERSION LETTER can be

found at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

IMPORTANT

When you exchange IC and Transistor with a heat sink, apply silicon grease (YG6260M) on the contact

section of the heat sink. Before applying new silicon grease, remove all the old silicon grease.

(Old grease may cause damage to the IC and Transistor).

A1-1

Page 3

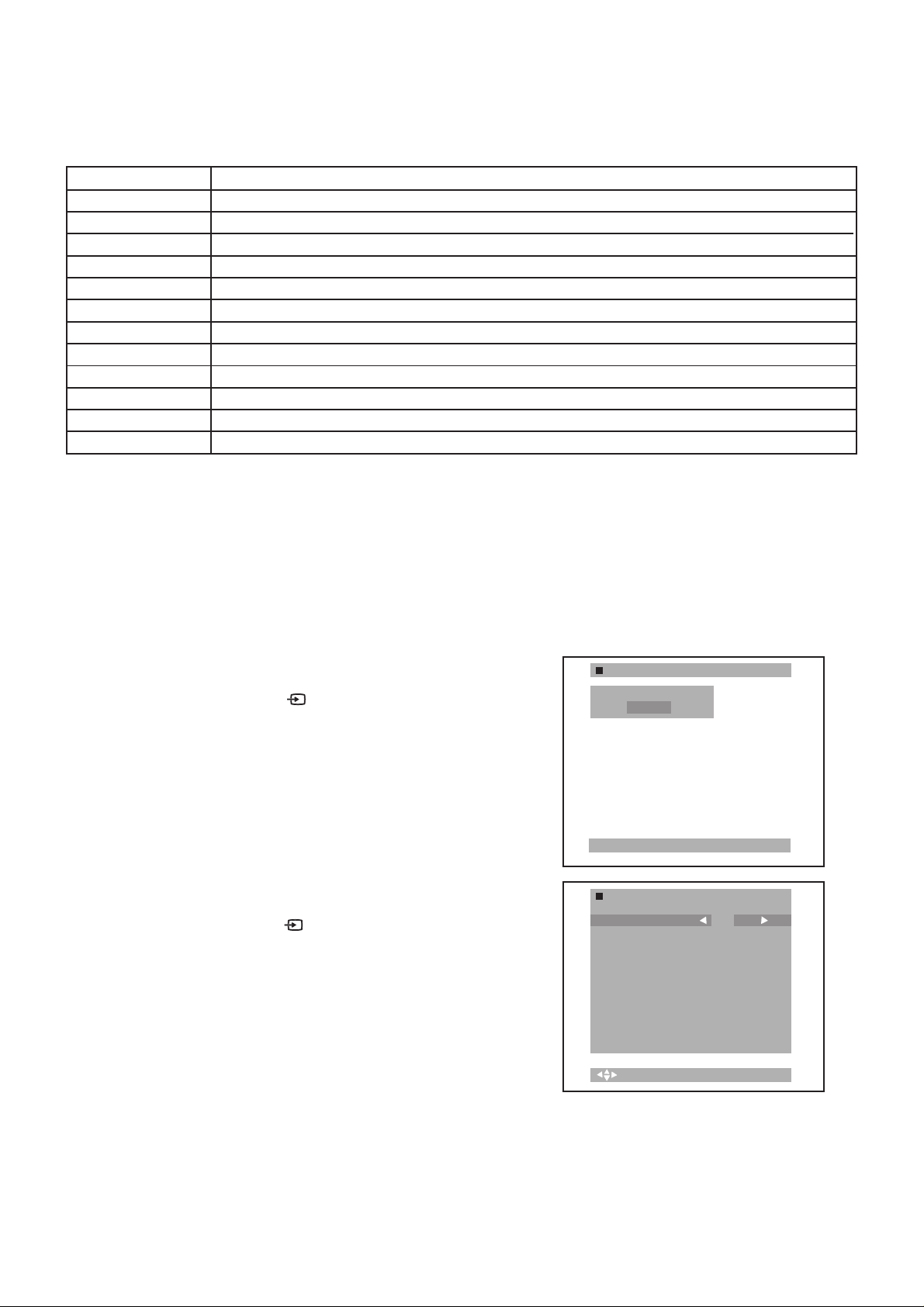

HOTEL MODE FUNCTION

The following can be set by the Hotel mode function.

Setting item

Hotel mode

Power on fixed

Maximum volume

Volume fixed

Volume fix level

RC button

Panel button

Menu button

On screen display

Input mode start

Input mode fixed

Reset

Note 1)

Note 2)

When setting it to “Fixed", the sleep timer setting will turn off.

When setting it to “Fixed", the VOL+/- key operation of a main/ remote control and the MUTE key operation of a

remote control become invalid.

Note 3)

When setting it to “No Respond", the remote control key operation and service mode function in Hotel mode are

effective.

Note 4)

Note 5)

Note 6)

Note 7)

When setting it to “No Respond", the service mode function in Hotel mode are effective.

The sleep timer setting will turn off when setting it to "No", and the audio change using the AUDIO key is invalid.

The Input mode fixed setting becomes effective when the Input mode start setting except for " Normal" setting.

Except the Hotel mode function return initial State.

FUNCTION

ON/OFF setting for Hotel mode function.

Effective/invalid setting of POWER button on the set and remote cotrol. (*Note 1)

Setting of the maximum volume value (0~50).

Effective/invalid setting of volume fix level function. (*Note 2)

Setting of output volume value.

Effective/invalid setting of remote control key operation. (*Note 3)

Effective/invalid setting of main key operation. (*Note 4)

Effective/invalid setting of Menu key operation of set and remote cotrol. (*Note 4)

Display/non-display setting of analog menu, Call, Audio, Program table(CH List) and volume level. (*Note 5)

Setting of input source at power supply On.

During the power on, effective/invalid setting of tuning the channel and input change operation. (*Note 6)

Various settings of the Hotel mode function return initial State. (*Note 7)

To set the Hotel mode, please follow the steps below.

1.

In power off mode, press and hold the ‘VOLUME +’ button on the front panel.

2.

Simultaneously press and hold the ‘ ’ button on the front panel.

3.

Hold both keys for 3 seconds, press the POWER button on the front panel.

4.

The password screen is displayed.

5.

Press it in order of ‘0’, ‘2’ and ‘7’ key of a remote control unit.

Then press the ENTER button.

6.

The Hotel mode setting menu will appear.

7.

Using the LEFT/RIGHT on the remote control, set the Hotel mode to on.

8.

Turn off the power.

The Hotel mode has now been set up.

To release the Hotel mode, please follow the steps below.

In power off mode, press and hold the ‘VOLUME+’ button on the front panel.

1.

Simultaneously press and hold the ‘ ’ button on the front panel.

2.

Hold both keys for 3 seconds, press the POWER button on the front panel.

3.

The password screen is displayed.

4.

Press it in order of ‘0’, ‘2’ and ‘7’ key of a remote control unit.

5.

Then press the ENTER button.

The Hotel mode setting menu will appear.

6.

Using the LEFT/RIGHT on the remote control, set the Hotel mode to off.

7.

Turn off the power.

8.

The Hotel mode has now been cleared.

Hotel Mode

Please input password

- - -

0/9: Set OK: Ener END: Exit

Hotel Mode

Adjust Setting

Hotel mode

Power on fixed

Maximum volume

Volume fixed

Volume fixe level

RC button

Panel button

Menu button

On Screen Display

Input mode start

Input mode fixed

Reset

: Select

Off

Variable

50

Variable

20

Respond

Respond

Respond

Yes

Normal

Variable

Yes

A1-2

Page 4

ABOUT LEAD FREE SOLDER (PbF)

Distinction of PbF PCB:

PCBs (manufactured) using lead free solder will have a PbF printing on the PCB.

(Please refer to figures.)

Caution:

Pb free solder has a higher melting point than standard solder;

•

Typically the melting point is 86°F~104°F(30°C~40°C) higher.

Please use a soldering iron with temperature control and adjust it to 650°F ± 20°F (350°C ± 10°C).

In case of using high temperature soldering iron, please be careful not to heat too long.

Pb free solder will tend to splash when heated too high (about 1100°F/ 600°C).

•

All products with the printed circuit board with PbF printing must be serviced with lead free solder.

•

When soldering or unsoldering, completely remove all of the solder from the pins or solder area,

and be sure to heat the soldering points with the lead free solder until it melts sufficiently.

Recommendations

Recommended lead free solder composition is Sn-3.0Ag-0.5Cu.

PARENTAL CONTROL - RATING LEVEL

4 DIGIT PASSWORD CANCELLATION

If the stored 4 digit password in the Rating Level menu needs to be cancelled, please follow the steps below.

1.

Turn on the power.

2.

Set the VOLUME to minimum.

3.

Press both VOL. DOWN button on the set and Channel button (3) on the remote control for more than 2

seconds.

4.

The 4 digit password has naw been cancelled.

NOTE:

No indications on the screen when the Parental Lock is setting.

Initializing password is 0000.

A1-3

Page 5

GENERAL SPECIFICATIONS

t

0oC

0oC

0oC

+60oC

G-1 TV LCD LCD Size / Visual Size 25.5 inch / 647.7mmV

System LCD Type Color TFT LCD

Color System PAL / SECAM

Speaker 2 Speaker

Sound Output MAX 10W + 10W

NTSC3.58+4.43 /PAL60Hz Yes

G-2 Tuning Broadcasting System Analog

System Tuner and System 1Tuner (Analog+Digital)

Receive CH Destination UK, I.R., CCIR Hyper+France CATV

CH Coverage Analog IreE2~E4, X~Z+2, S1~S10, E5~E12,S11~S41,E21~E69

Intermediate Analog

Frequency Picture(FP) 38.9 / 38.9 / 38.9 / 33.9MHz

Digital

Auto Tuning Method

Preset CH Analog 99

Stereo/Dual TV Sound Nicam/A2 Dual

Tuner Sound Muting Yes

G-3 Power Power Source AC 220-240V AC 50Hz

Power Consumption at AC 155 W at AC 230 V 50 Hz

Stand by (a

Protector Power Fuse Yes

G-4 Regulation Safety 'CE(EN60065:2002), SEMKO HOMOLO

G-5 Temperature Operation

G-6 Operating Humidity 35%RH ~ 75% RH

G-7 OSD Language English, Spanish, German, French, Italian,

G-8 Clock and Sleep Timer Max Time 120 Min

Timer Step 30 Min

On/Off Timer Program(On Timer / Off Timer) -- Program

Wake Up Timer No

Timer Back-up (at Power Off Mode) more than -- Min Sec

Number of Pixels 1366(H) x 768(V)

View Range Left/Right 88/88 degree

Position Front

Size 1.6 x 4.8 inch

Impedance 4 ohm

10%(Typical) ---

Digital

Digital E5~E12, ItaE~G, F1~F6, Rus6~12, E21~E69

Sound(FS)

FP-FS

Digital Carrier 200 / Service 1000

DC ---

w/ EPG Timer 9 W at 230V 50Hz

w/o EPG Timer 1 W at 230V 50Hz

Per Year -- kWh/Year

Radiation CE

X-Radiation ---

Storage

Up/Down 88/88 degree

U.K., I.R., CCIR, FRENCH System

B/G, D/K, I/I, L

DVB-T (OFDM 2k/8k 16QAM/64QAM)

BG / II / DK, L / L' (SECAM VL)

33.4 / 32.9 / 32.4 / 40.4MHz

5.5 / 6.0 / 6.5 / 6.5MHz

36.167MHz

ALL Band (Not C.C.I.R. CH Plan)

at DC --

~ +4

-2

~

Swedish, Dutch, Russian, Portuguese,

Turkish, Greek, Finnish, Polish

A2-1

Page 6

GENERAL SPECIFICATIONS

G-9 Remote Unit RC-MU

Control Glow in Dark Remocon No

G-10 Features Power On Memory Yes

Remocon Format SHARP

Format SHARP

Custom Code 10000 / 10001 / 01111

Power Source Voltage(D.C) 3V

UM size x pcs UM-3 x 2 pcs

Total Keys 43 Keys

Keys Power (Stand By) Yes

TV/Radio Yes

DTV/TV Yes

Backlight No

Mute Yes

1 Yes

2 Yes

3 Yes

4 Yes

5 Yes

6 Yes

7 Yes

8 Yes

9 Yes

Flashback (Quick View) Yes

0 Yes

Input Select Yes

Volume Up Yes

Volume Down Yes

CH Up Yes

CH Down Yes

Screen size Yes

Audio 1/2 Yes

Information Yes

Sleep Yes

Guide Yes

Digital Menu Yes

TEXT / TV Yes

Menu Yes

End Yes

TOP/BOTTOM/FULL Yes

UP Yes

DOWN Yes

LEFT Yes

RIGHT Yes

OK / Channel list / Index Yes

Reveal Yes

HOLD/Freeze Yes

Subtitle Yes

Sub Page Yes

Red Yes

Green Yes

Yellow Yes

Cyan Yes

Auto Shut Off Yes

No Operation Off Yes

Just Clock Function No

Game Position No

DNR Yes

3D

Comb Filter Yes

3D

Auto Set Up (Fast installation) Auto tuning (Analog tuner) Yes

CH sort Yes

ATS Yes

Auto clock (Analog tuner) No

Plug in start Yes

Picture Setting(TV) Picture Preference (AV Mode) Yes

Brightness , Contrast , Color Yes

Tint Yes

Sharpness Yes

Black Stretch Yes

DNR Yes

Color Temperature Yes

Blue Back Yes

Backlight Yes

Film Mode Yes

A2-2

Page 7

GENERAL SPECIFICATIONS

Picture Setting(PC) BRIGHTNESS , CONTRAST Yes

Audio Nicam No

Tuning Auto Tuning Yes

Lock Chaild Lock Yes

Screen Saver

Black Side Panel No

CH Label Yes

T'Text Yes

Wide Mode (AUTO/4:3/FULL SCREEN/16:9/CINEMA/14:9) Yes

HD Zoom No

Picture Scroll (Vertical Position) No

PFC(Power Factor circuit) Yes

Freeze frame Yes (w/o720p, 1080i)

HD-Ready Yes

Plug and Play Yes

Reset TV Setting Yes

Scart Spec Scart1 AV in Yes

Scart2 AV in Yes

Digital Text (VBI teletext)

MHEG-5

MHP

EPG (BBC type 8Days Digital tuner only)

OAD (Over Air Download)

Common Interface (Digital tuner only)

Rec Screen Status

Ch sorting based on Ch List (Digital/Germany only)

Rename Carrier (Digital)

Edit Event Timer

Software Update via CI Slot

Preference Language (Audio/Subtitle/Digital Service)(Digital)

Ch Organizer (Fav, Lock, Skip, Go To, Delete, Rename, Move, Move to)

Parental Lock (Digital)

DVB Subtitle (Digital)

Color Temperature Yes

HOR POSITION , VER POSITION Yes

PHASE , CLOCK Yes

AUTO ADJUST No

RED , GREEN , BLUE Yes

Backlight Yes

Power Management Yes

XGA Mode Yes

WXGA INPUT No

WVGA INPUT No

Tone Control (Bass/Treble/Balance) Yes

Loudsp. Sound Yes

Auto Vol Yes

Clear Voice Yes

Surround (Sound wide) Yes

BBE No

SRS WOW (SRS 3D/Focus/Tru Bass) No

Variable Audio Out No

Manual Tuning Yes

CH Allocation Yes

Hotel Lock Yes

Inversion No

Full White No

Screen Saver No

Static Image No

Text type Fastext / Toptext

Text Language English , French, Swedish, Hungarian

Turkish, German, Portuguese, Spanish,

Italian, Greek, Slovakian, Russian, Polish,

Czech, Rumanian, Estonian, Lettish,

Lithuanian, Ukrainian, Croatian, Slovenian,

Latvian

AV out Yes (A.Tuner/D.Tuner)

S-Video in Yes

RGB in Yes

AV out Yes (Monitor)

S-Video in Yes

RGB in Yes

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

A2-3

Page 8

GENERAL SPECIFICATIONS

PC Monitor Input Yes

HDMI Input Yes

Component Input Yes

G-11 Accessories Owner's Manual Language English, German, French, Italian, Dutch, Spanish

Remote Control Unit Yes

Rod Antenna

Loop Antenna (W/ Antenna Change Plug)

U/V Mixer

DC Car Cord (Center+)

Warning Sheet

Circuit Diagram

Antenna Change Plug

Service Facility List

Important Safeguard

Dew/AHC Caution Sheet

Quick Set-up Sheet

Battery Yes

AC Adapter

AC Cord (for AC Adapter)

AC Cord x 2 Yes

AV Cord (2Pin-1Pin)

AQUOS CARE PLAN Yes

HDMI-DVI Cable

Registration Card

300 ohm to 75 ohm Antenna Adapter

Stand Unit Yes

Cable Clamp (x1) Yes

Information Sheet(Protection Sheet) No

Information Sheet(Eco Sheet) Yes(From '07.AUG O/R)

Information Sheet(for G-card and AQUOS CARE PLAN) Yes(Only '07.MAY/JUN oder)

Cleaning Cloth Yes

Gurantee Card Yes

VGA (640x480) Yes (60Hz)

VGA (720x400) No

WVGA (848x480) No

SVGA (800x600) Yes (60Hz)

XGA (1024x768) Yes (60Hz)

WXGA (1280x768) Yes (60Hz)

WXGA (1280x720) No

WXGA (1360x768) Yes (60Hz)

SXGA (1280x1024) No

VGA (640x480)

720x480i (4:3)

720x480i (16:9)

720x480p (4:3)

720x480p (16:9)

720x576i (4:3)

720x576i (16:9)

720x576p (4:3)

720x576p (16:9)

1280x720p

1920x1080i

720x480i (4:3)

720x480i (16:9)

720x480p (4:3)

720x480p (16:9)

720x576i (4:3)

720x576i (16:9)

720x576p (4:3)

720x576p (16:9)

1280x720p

1920x1080i

w/Guarantee Card

Poles Terminal -

Terminal -

UM size x pcs UM-3 x 2 pcs

OEM Brand No

Yes (60Hz)

Yes (60Hz)

Yes (60Hz)

Yes (60Hz)

Yes (60Hz)

Yes (50Hz)

Yes (50Hz)

Yes (50Hz)

Yes (50Hz)

Yes (50/60Hz)

Yes (50/60Hz)

Yes (60Hz)

Yes (60Hz)

Yes (60Hz)

Yes (60Hz)

Yes (50Hz)

Yes (50Hz)

Yes (50Hz)

Yes (50Hz)

Yes (50/60Hz)

Yes (50/60Hz)

Greek, Portuguese, Swedish, Finnish, Danish

Norwegian, Polish, Hungarian, Czech, Slovak, Ukrainian

Estonia, Latvia, Lithuania

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

A2-4

Page 9

GENERAL SPECIFICATIONS

(

G-12 Interface Switch Power (Tact) Yes

Indicator Power/Stand-by/EPG Timer Yes(GREEN / RED / ORANGE)

Terminals Side Video Input 1

Rear Euro Scart (21Pin) No

G-13 Set Size Approx. W x D x H (mm) 663 x 243 x 500

G-14 Weight Net Approx.

G-15 Carton Master Carton

Gift Box Yes

Drop Test Natural Dropping At 1 Corner / 3 Edges / 5 Surfaces

Container Stuffing 514

w/Pallet No

w/Wrapping No

G-16 Material Cabinet Cabinet Front PC+ABS 94V0 NON-HALOGEN

PCB Non-Halogen

G-17 Environment Environmental standard requirement Green procurement of SHARP

Pb- Free Phase3(PHASE3A)

WEEE Yes

System Select No

Main Power SW No

Channel Up/Menu Up Yes

Channel Down/Menu Down Yes

Volume Up/Menu > Yes

Volume Down/Menu < Yes

Input Select/Enter Yes

Menu No

On Timer No

Audio Input 1

S- Input 1 Yes

Video Input 2 No

Audio Input 2 No

S- Input 2 No

Video Output No

Audio Output

Digital Audio Out (Coaxial) No

Other Terminal No

Euro Scart (21Pin)

Component In

Audio Input (Component In use)

PC Monitor Input (D-Sub)

Audio Input

HDMI Input 1

Audio Input (HDMI/DVI In use) PC Monitor Audio Input Alternative

HDMI Input 2

Audio Input (HDMI/DVI In use)

RS-232C

Sub Woofer Output No

Diversity No

Ext Speaker No

DC Jack 12V(Center +) No

VHF/UHF Antenna Input

AC Inlet

Other Terminal Headphone

CI Card Slot Yes

PC Monitor Input (D-Sub) No

Audio Input No

HDMI Input 1 No

Audio Input (HDMI/DVI In use) No

RS-232C No

VHF/UHF Antenna Input No

AC Inlet No

w/o Stand,Handle Approx. W x D x H (mm)

Net w/o Stand,Handle Approx.

Gross Approx.

Content ---Material --

Dimensions W x D x H(mm) -- x -- x --

Description of Origin

Material Double/Brown

Dimensions W x D x H(mm) 762 x 277 x 590

Design As per Buyer's

Description of Origin Yes (Made in Japan)

Height (cm) 40

Cabinet Rear PC+ABS 94V0 NON-HALOGEN

Eyelet Yes

Measures for Whisker Yes

RCA x 1

RCA x 2(L/MONO, R)

RCA x 2(Fixed) (L, R)

2Scart

Yes

RCA x 2(L/MONO, R)

Yes

Mini Pin Jack

Yes

Yes

Mini Pin Jack(d:3.5), STEREO

Yes

DIN Type

Yes

663 x 116 x 451

13.5kg

11.5kg

18.0kg

d: 3.5), STEREO

(29.3lbs)

(25.7lbs)

(38.9lbs)

No

Sets

/--

No

Sets/40' container

No

A2-5

Page 10

DISASSEMBLY INSTRUCTIONS

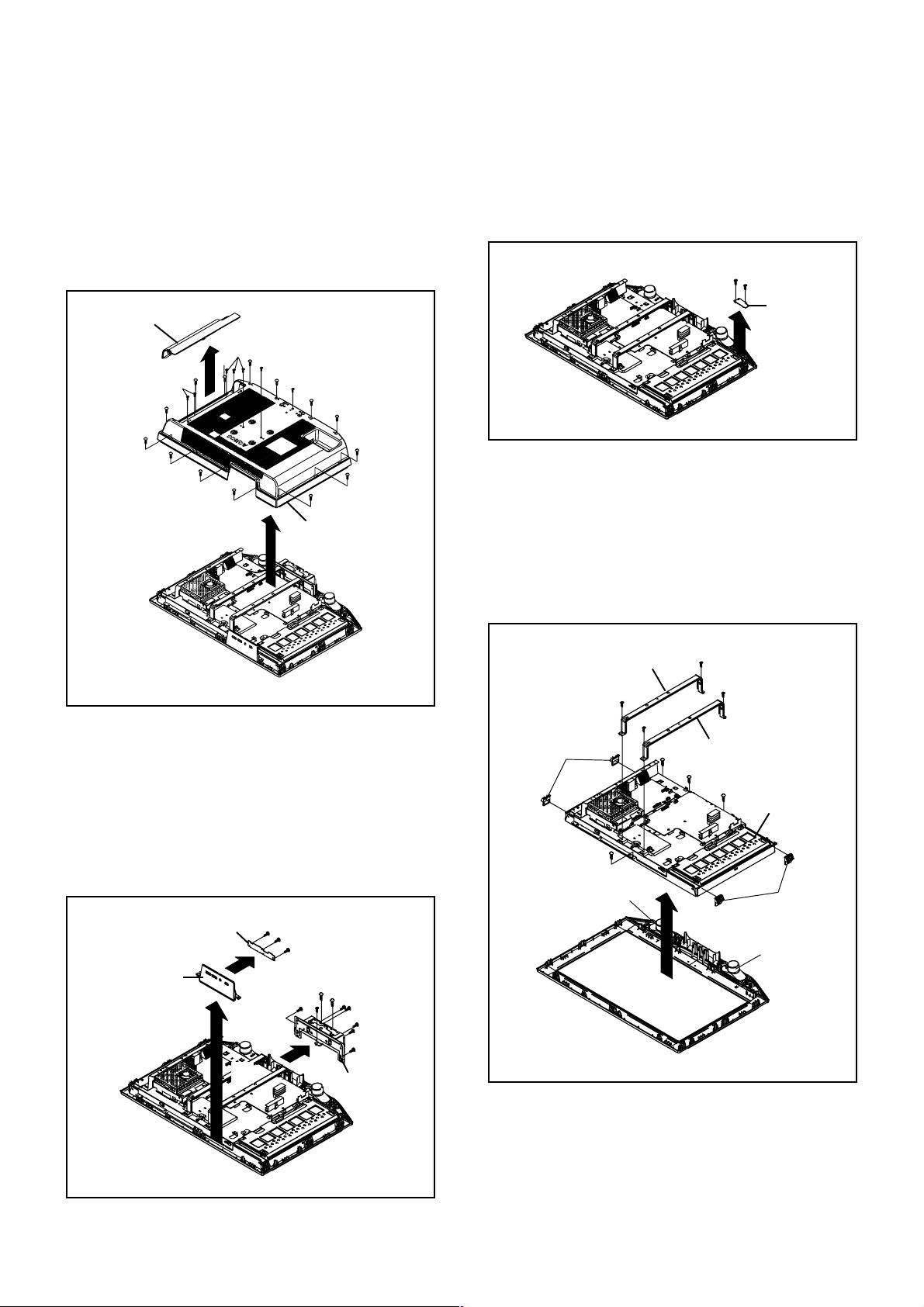

1. REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

1-1: BACK CABINET (Refer to Fig. 1-1)

1.

Remove the Cover Back in the direction of arrow (A).

2.

Remove the 14 screws 1.

3.

Remove the 7 screws 2.

4.

Remove the Back Cabinet in the direction of arrow (B).

Cover Back

2

1

1

(A)

1

2

1

1

1

1

2

1

2

1

1

1

1

Back Cabinet

(B)

1

1

1-3: REMOCON PCB (Refer to Fig. 1-3)

1.

Disconnect the following connector:

(CP2201).

2.

Remove the 2 screws 1.

3.

Remove the Remocon PCB in the direction of arrow.

1

1

Remocon PCB

1-4: LCD BLOCK (Refer to Fig. 1-4)

1.

Disconnect the following connectors:

(CP406 and CP301).

2.

Remove the Speaker Ass'y.

3.

Remove the Holder Panel.

4.

Remove the 4 screws 1.

5.

Remove the LCD Block in the direction of arrow (A).

6.

Remove the 4 screws 2.

7.

Remove the Angle Main.

Fig. 1-3

Fig. 1-1

1-2: OPERATION PCB (Refer to Fig. 1-2)

1.

Disconnect the following connector:

(CP2203).

2.

Remove the Plate Button Ass'y in the direction of arrow (A).

3.

Remove the 3 screws 1.

4.

Remove the Operation PCB in the direction of arrow (B).

5.

Remove the 7 screws 2.

6.

Remove the 2 screws 3.

7.

Remove the Angle Hinge in the direction of arrow (C).

Operation PCB

(B)

Plate Button Ass'y

(A)

1

1

1

3

3

2

2

2

2

2

2

Angle Hinge

2

(C)

Holder Panel

Angle Main

2

1

Speaker Ass'y

2

2

2

Angle Main

1

1

1

LCD Block

Holder Panel

(A)

Speaker Ass'y

Fig. 1-4

Fig. 1-2

B1-1

Page 11

DISASSEMBLY INSTRUCTIONS

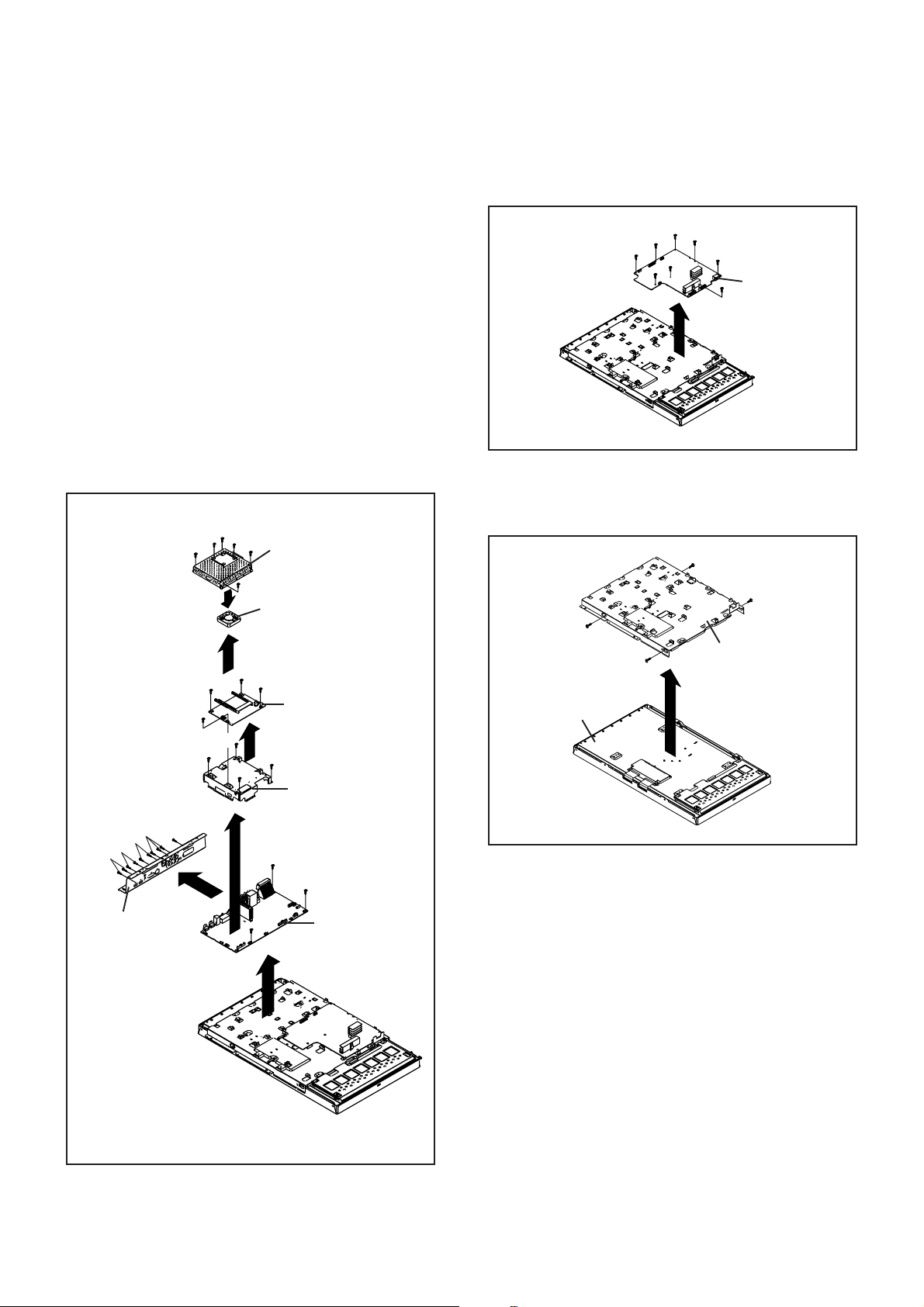

1-5: DIGITAL PCB/ MAIN PCB (Refer to Fig. 1-5)

Remove the 4 screws 1.

1.

Remove the 6 screws 2.

2.

Remove the Plate Jack in the direction of arrow (A).

3.

Disconnect the following connector:

4.

(CP3400).

Remove the 4 screws 3.

5.

Remove the 2 screws 4.

6.

Remove the Shield Digital and Fan Motor in the direc-

7.

tion of arrow (B) and (C).

Disconnect the following connector:

8.

(CP6401).

Remove the 4 screws 5.

9.

Remove the Digital PCB in the direction of arrow (D).

10.

Remove the 4 screws 6.

11.

Remove the Shield Scaler in the direction of arrow (E).

12.

Disconnect the following connector:

13.

(CP3801, CP3802, CP4301, CP4305 and CP7201).

Remove the 3 screws 7.

14.

Remove the Main PCB in the direction of arrow (F).

15.

3

4

4

(C)

6

3

Shield Digital

3

Fan Motor

(B)

5

5

5

Digital PCB

(D)

6

6

6

Shield Scaler

3

5

1-6: POWER PCB (Refer to Fig. 1-6)

1.2.Remove the 8 screws 1.

Remove the Power PCB in the direction of arrow.

1

1

1

1

1

1

1

Power PCB

1

1-7: COVER LCD (Refer to Fig. 1-7)

1.

Remove the 4 screws 1.

2.

Remove the Cover LCD in the direction of arrow.

1

1

1

1

LCD Panel

Cover LCD

Fig. 1-6

2

1

1

Plate Jack

2

2

(A)

(E)

7

7

7

Main PCB

(F)

Fig. 1-7

Fig. 1-5

B1-2

Page 12

DISASSEMBLY INSTRUCTIONS

2.

REMOVAL AND INSTALLATION OF

FLAT PACKAGE IC

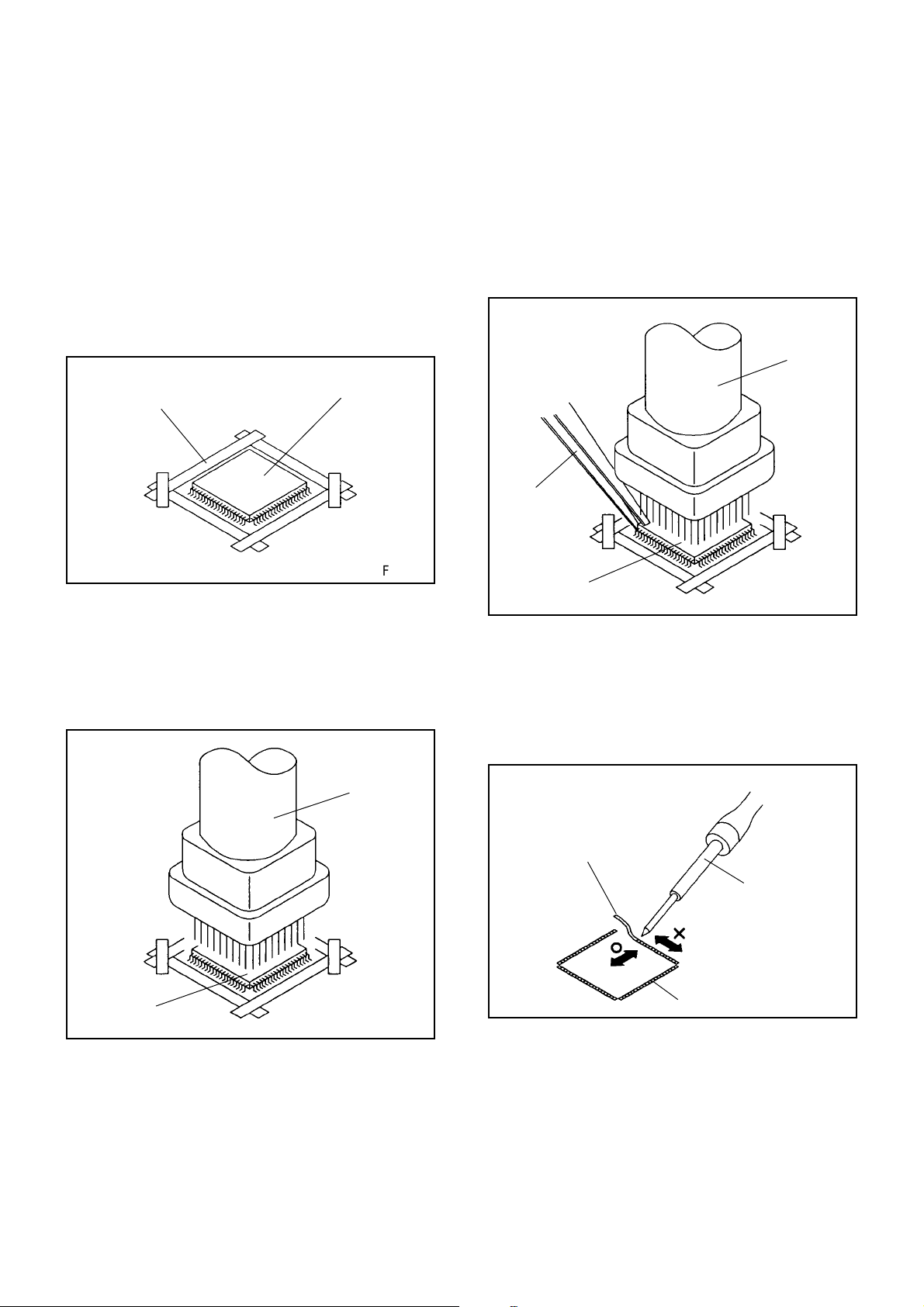

REMOVAL

Put Masking Tape (cotton tape) around the Flat Package

1.

IC to protect other parts from any damage.

(Refer to Fig. 2-1.)

NOTE

Masking is carried out on all the parts located within

10 mm distance from IC leads.

When IC starts moving back and forth easily after

3.

desoldering completely, pickup the corner of the IC

using a tweezers and remove the IC by moving with the

IC desoldering machine. (Refer to Fig. 2-3.)

NOTE

Some ICs on the PCB are affixed with glue, so be

careful not to break or damage the foil of each IC

leads or solder lands under the IC when removing it.

Blower type IC

desoldering

machine

Masking Tape

(Cotton Tape)

Heat the IC leads using a blower type IC desoldering

2.

IC

machine. (Refer to Fig. 2-2.)

NOTE

Do not rotate or move the IC back and forth unit IC

can move back and forth easily after desoldering the

leads completely.

Blower type IC

desoldering machine

Fig. 2-1

Tweezers

IC

Peel off the Masking Tape.4.

Absorb the solder left on the pattern using the Braided

5.

Shield Wire. (Refer to Fig. 2-4.)

NOTE

Do not move the Braided Shield Wire in the vertical

direction towards the IC pattern.

Fig. 2-3

Braided Shield Wire

Soldering Iron

IC

IC pattern

Fig. 2-4

Fig. 2-2

B2-1

Page 13

DISASSEMBLY INSTRUCTIONS

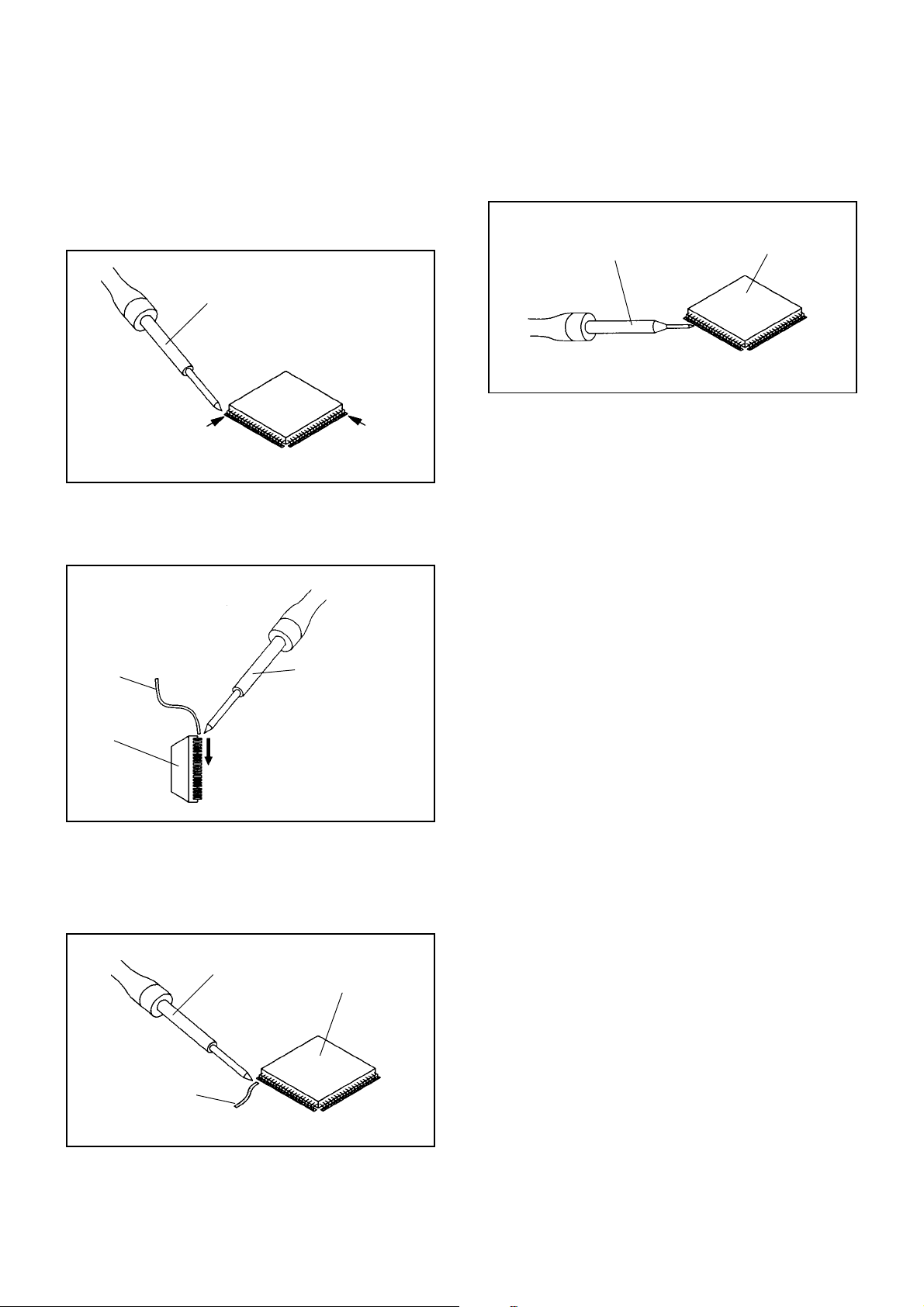

INSTALLATION

Take care of the polarity of new IC and then install the

1.

new IC fitting on the printed circuit pattern. Then solder

each lead on the diagonal positions of IC temporarily.

(Refer to Fig. 2-5.)

Soldering Iron

Solder temporarily

Supply the solder from the upper position of IC leads

2.

sliding to the lower position of the IC leads.

(Refer to Fig. 2-6.)

Solder temporarily

Fig. 2-5

When bridge-soldering between terminals and/or the

4.

soldering amount are not enough, resolder using a Thintip Soldering Iron. (Refer to Fig. 2-8.)

Thin-tip Soldering Iron

IC

Fig. 2-8

Finally, confirm the soldering status on four sides of the

5.

IC using a magnifying glass.

Confirm that no abnormality is found on the soldering

position and installation position of the parts around the

IC. If some abnormality is found, correct by resoldering.

NOTE

When the IC leads are bent during soldering and/or

repairing, do not repair the bending of leads. If the

bending of leads are repaired, the pattern may be

damaged. So, be always sure to replace the IC in this

case.

Soldering IronSolder

IC

Absorb the solder left on the lead using the Braided

3.

Supply soldering

from upper position

to lower position

Shield Wire. (Refer to Fig. 2-7.)

NOTE

Do not absorb the solder to excess.

Soldering Iron

IC

Braided Shield Wire

Fig. 2-6

Fig. 2-7

B2-2

Page 14

SERVICE MODE LIST

This unit is provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter to the SERVICE MODE function, press and hold both buttons simultaneously on the main unit and on the remote

control for more than the standard time in the appropriate condition. (See below chart.)

Set

Condition

POWER ON

POWER ON

DTV mode

POWER ON

POWER ON

Set Key Operations

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

Remocon

Key

1 2 sec.

2

3

6

9

Standard

Time

2 sec.

2 sec.

2 sec.

2 sec.

Initialization of factory TV data.

NOTE:

Check of the SUM DATA, POWER ON total hours, MICON

VERSION and DIGITAL TV MICON FIRMWARE on the screen.

Refer to the "WHEN REPLACING EEPROM (MEMORY) IC".

Releasing of PARENTAL LOCK (DIGITAL).

Refer to the “PARENTAL CONTROL - RATING LEVEL”.

POWER ON total hours are displayed on the screen.

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the "WHEN REPLACING EEPROM (MEMORY) IC".

Display of the Adjustment MENU on the screen.

Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display

Adjustment).

If you set factory initialization, the memories are reset such

as the channel setting, and the POWER ON total hours.

C-1

Page 15

WHEN REPLACING EEPROM (MEMORY) IC

CONFIRMATION OF CHECK SUM, MICON VERSION AND DIGITAL TV MICON FIRMWARE

AND POWER ON TOTAL HOURS

Initial total of MEMORY IC, MICON VERSION, Digital TV MICON Firmware and POWER ON TOTAL HOURS can be

checked on the screen. Total hours are displayed in 16 system of notation.

NOTE:

If you set a factory initialization, the total hours is reset to "0".

Please refer to "CONFIRMATION OF INITIAL DATA" when SUM DATA is not corresponding.

1.

Turn on the POWER, and set to the TV mode.

2.

Set the VOLUME to minimum.

3.

Press both VOL. DOWN button on the set and Channel button (2) on the remote control for more than 2 seconds.

4.

After the confirmation of MICON VERSION and Digital TV MICON Firmware, turn off the power.

ADDRESS and DATA should appear as FIG 1.

NOTE: The each item value might be

different according to each set.

Version

Initial setting data check sum.

AD CONVERTER data check sum.

Main Micon Fimware Version

Sub Micon Fimware Version

Hardware version

Software version

OK

INIT: 3E23

VCT-P: 3479

ANALOG M: DB060_70508A

ANALOG S: DB050_70409B

A.0

CB00C75091

LCD ON: 0000

FIG. 1

Firmware Version

END

POWER ON total hours.

= (16 x 16 x 16 x thousands digit value)

+ (16 x 16 x hundreds digit value)

+ (16 x tens digit value)

+ (ones digit value)

CONFIRMATION OF INITIAL DATA

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to

ensure correct data settings while making reference to INITIAL SETTING TABLE (Attached "INITIAL DATA").

Turn on the POWER, and set to the TV mode.

1.

Set the VOLUME to minimum.

2.

Press both VOL. DOWN button on the set and Channel button (6) on the remote control for more than 2 seconds.

3.

ADDRESS and DATA should appear as FIG 2.

ADDRESS DATA

INIT 0000 00

LDC ON 0000

ANALOG M: DB060_70508A

ANALOG S: DB050_70409B

FIG. 2

ADDRESS is now selected and should "blink". Using the UP/DOWN buton on the remote, step through the ADDRESS

4.

until required ADDRESS to be changed is reached.

Press RIGHT/LEFT button to select DATA. When DATA is selected, it will "blink".

5.

Again, step through the DATA using UP/DOWN button until required DATA value has been selected.

6.

Pressing RIGHT/LEFT button will take you back to ADDRESS for further selection if necessary.

7.

Repeat steps 4 to 6 until all data has been checked.

8.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

9.

After the data input, set to the initializing of shipping.

Turn POWER on.

10.

Press both VOL. DOWN button on the set and Channel button (1) on the remote control for more than 2 seconds.

11.

After the finishing of the initializing of shipping, the unit will turn off automatically.

12.

The unit will now have the correct DATA for the new MEMORY IC.

C-2

Page 16

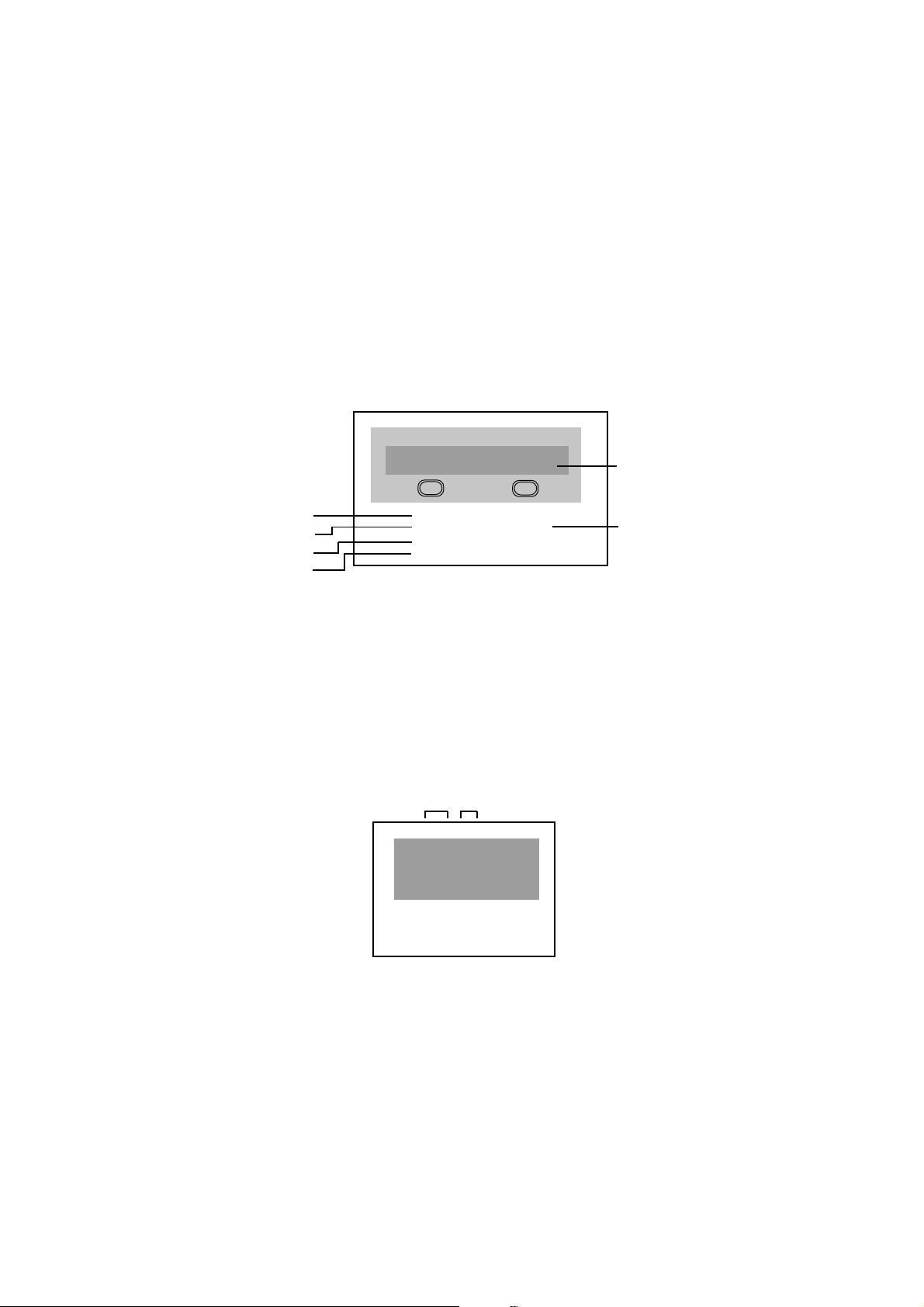

SERVICING FIXTURES AND TOOLS

JG201 Serial Communication

Change JIG

Ref. No.

JG176

JG201

Part No.

APJG176133JG176

APJG212001JG212

APJG201000

JG203 MICON PROGRAM JIG KIT

25-4

Parts Name

EU LCD MICON VER

UP ROM DISC

DTV ROM DISC

EEP ROM DISC

Serial Communication

Change JIG

JG176

JG212

JG204

Up-Date of the VCTP DATA.

Up-Date of the Digital Soft Firmware.APJG176130

Up-Date of the EEPROM DATA.

Connect the set to personal computer.

EU LCD MICON VER UP

ROM DISC

DTV ROM DISC

EEPROM DISC

MICON UPDATE TOOL DISC

Remarks

JG203

JG204

APJG203000

APJG204000

MICON PROGRAM

JIG KIT 25-4

MICON UPDATE TOOL

DISC

INSTALL FOR WRITING TOOLS

1.2.Set the MICON UPDATE TOOL DISC (JG204) to PC.

Install the LPT driver.

NOTE :

It is necessary to install according to the PC.

Windows 95/98 : Setup_LptDrv_v0104_9x.exe

Windows 2000/XP : Setup_LptDrvDev_v020201_XP_2000.exe

Windows NT : Setup_LptDrv_v0104_NT.exe

Connect the set to personal computer.

There is WRITING TOOLS in Disc.

Re-boot the PC.

3.

Install the “Setup_Visual_I2C_v3-2-3b8h.exe”, “Setup_VI2C_for_VCT_Pro_v0101.exe” and “Winupload 4.4.3.exe”.

4.

C-3

Page 17

RE-WRITE FOR DIGITAL SOFT FIRMWARE

Before UPDATE the Digital Soft Firmware, it is necessary to install the WRITING TOOLS into the PC.

For the installation of WRITING TOOL, refer to the "INSTALLING FOR WRITING TOOLS".

Unplug the AC cord, and remove the back cabinet.

1.

Using the Serial Communication Change JIG (JG198) and RS232 Cable, connect the PC terminal and UART

2.

Connector(CP2402) on the DIGITAL PCB Ass'y.

UART Connector(CP2402)

Connect it in order of Digital Pcb Serial Communication Change JIG(JG198) RS232 Cable PC.

Serial Communication Change JIG(JG198)

TO DIGITAL PCB

Insert the AC cord, turn on the power.

3.

Press both VOLUME DOWN button on the set and Channel button (2) on the remote control for 2 seconds.

4.

Confirm that displayed software version.

Set the Standby mode.

5.

Set the DTV ROM DISC(JG176) to PC.

6.

RS232 Cable

TO PC

C-4

Page 18

RE-WRITE FOR DIGITAL SOFT FIRMWARE

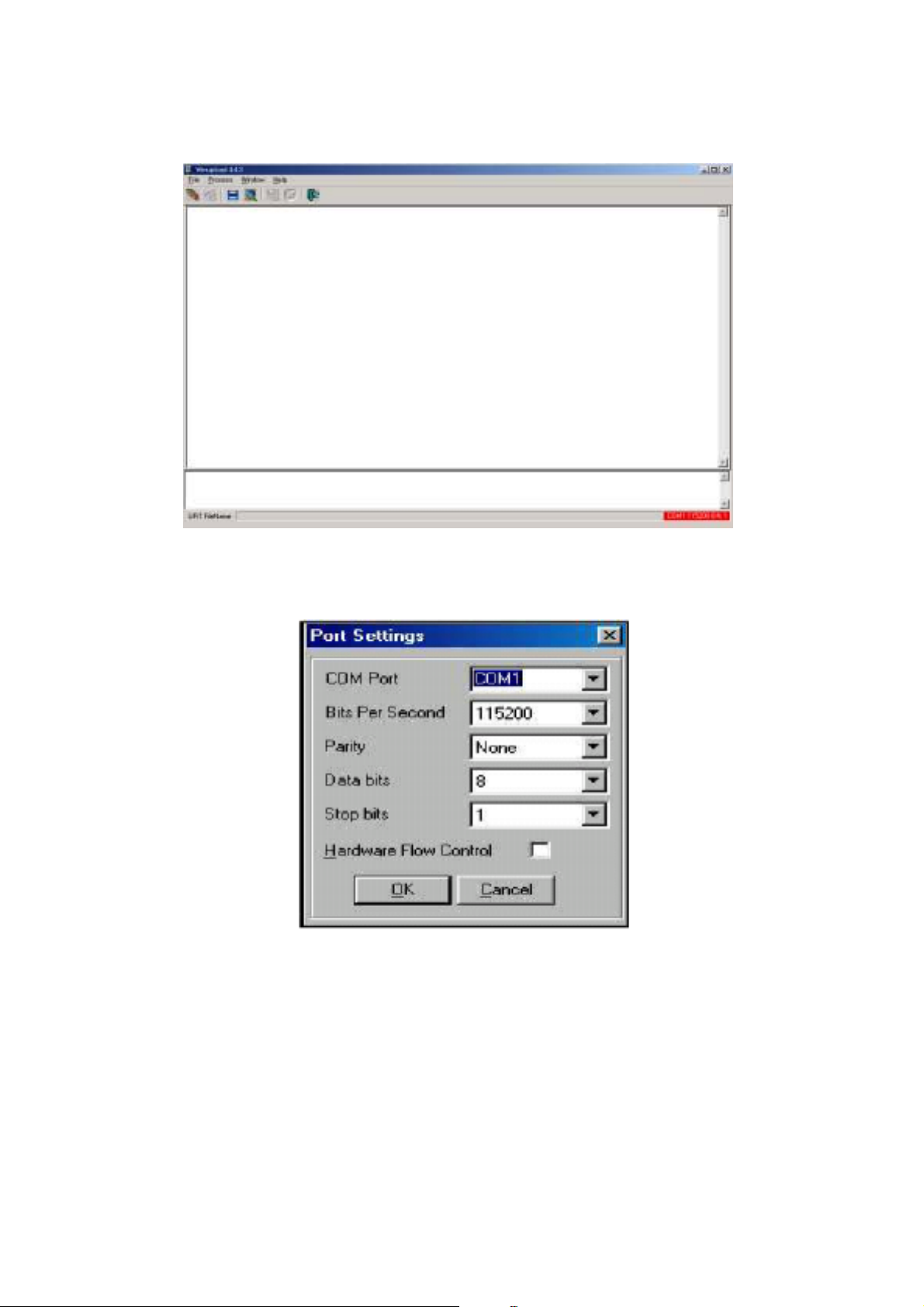

7. Start the "Winupload"(Writing tool).

8. Select the "Port Setting" from Process menu, then please set it as follows.

NOTE: This step is not necessary from next time.

C-5

Page 19

RE-WRITE FOR DIGITAL SOFT FIRMWARE

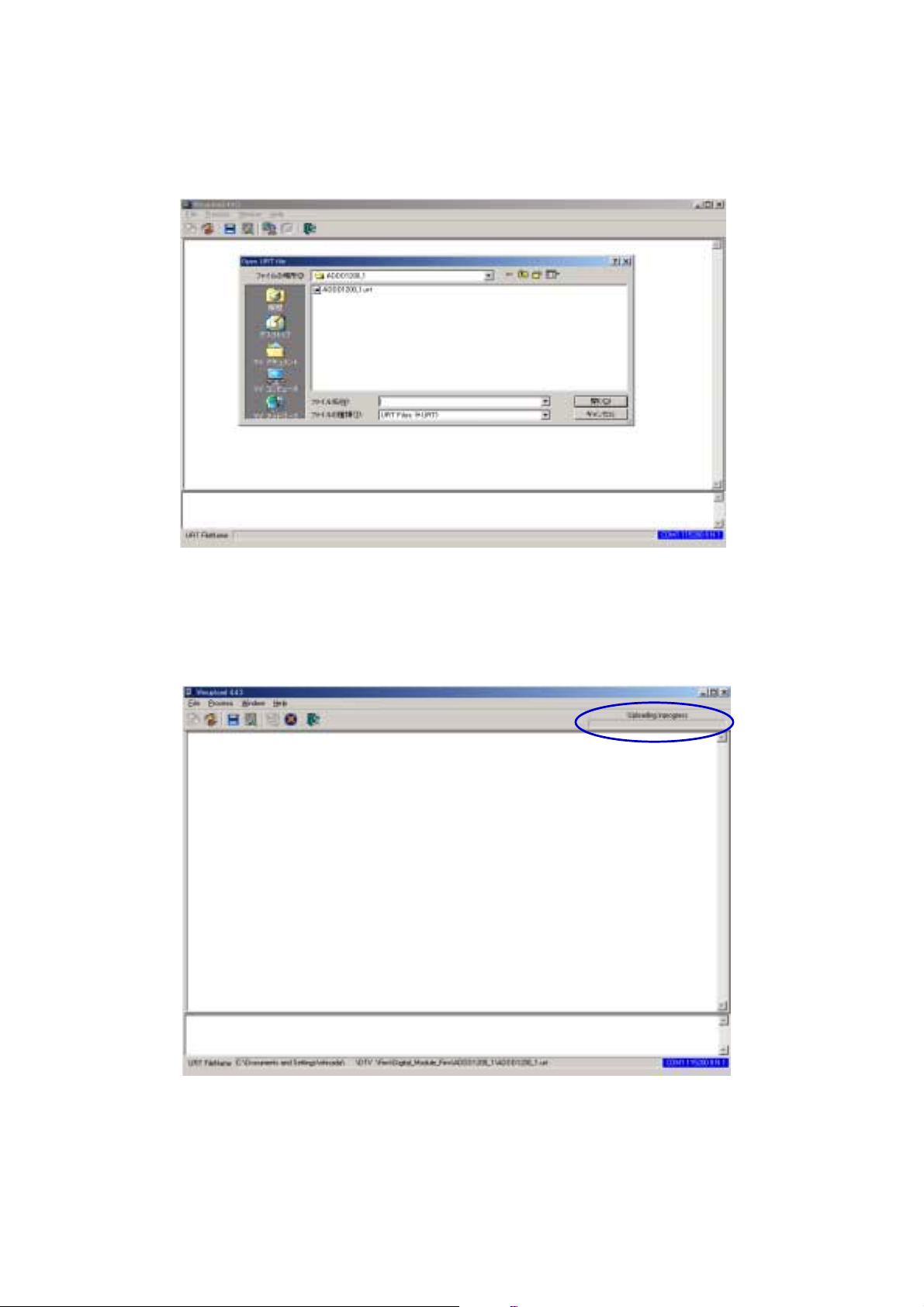

Select the "Connect" from File menu.

9.

Select the "Upload" from Process menu, and select the Software(CB00C75091.urt) in DTV ROM DISC(JG176).

10.

Unplug the AC cord on the set, then plug it in again.

11.

Turn on the power.

12.

The following window will appear, Up-date for Software will start.

"Uploading inprogress" bar will begin to move.

C-6

Page 20

RE-WRITE FOR DIGITAL SOFT FIRMWARE

13.

When the "Uploading inprogress" bar reaches a right edge, the Writing for Digital Soft Firmware will start.

During the writing for Digital Soft Firmware, writing message will appear on the screen.

Finish the writing for Digital Soft Firmware, writing message will disappear.

14.

Unplug the AC cord, and remove the Serial Communication Change JIG(JG198).

15.

Insert the AC cord again.

After the write, set to the initializing of shipping.

16.

Turn on the power.

17.

Press both VOLUME DOWN button on the set and Channel button (1) on the remote control for 2 seconds.

The set will turn into the standby mode.

Check for the Firmware Version

18.

Turn on the power.

19.

Press both VOLUME DOWN button on the set and Channel button (2) on the remote control for 2 seconds.

When the changed version displays, the Re-write will be completed.

20.

Select the "Disconnect" from File menu.

C-7

Page 21

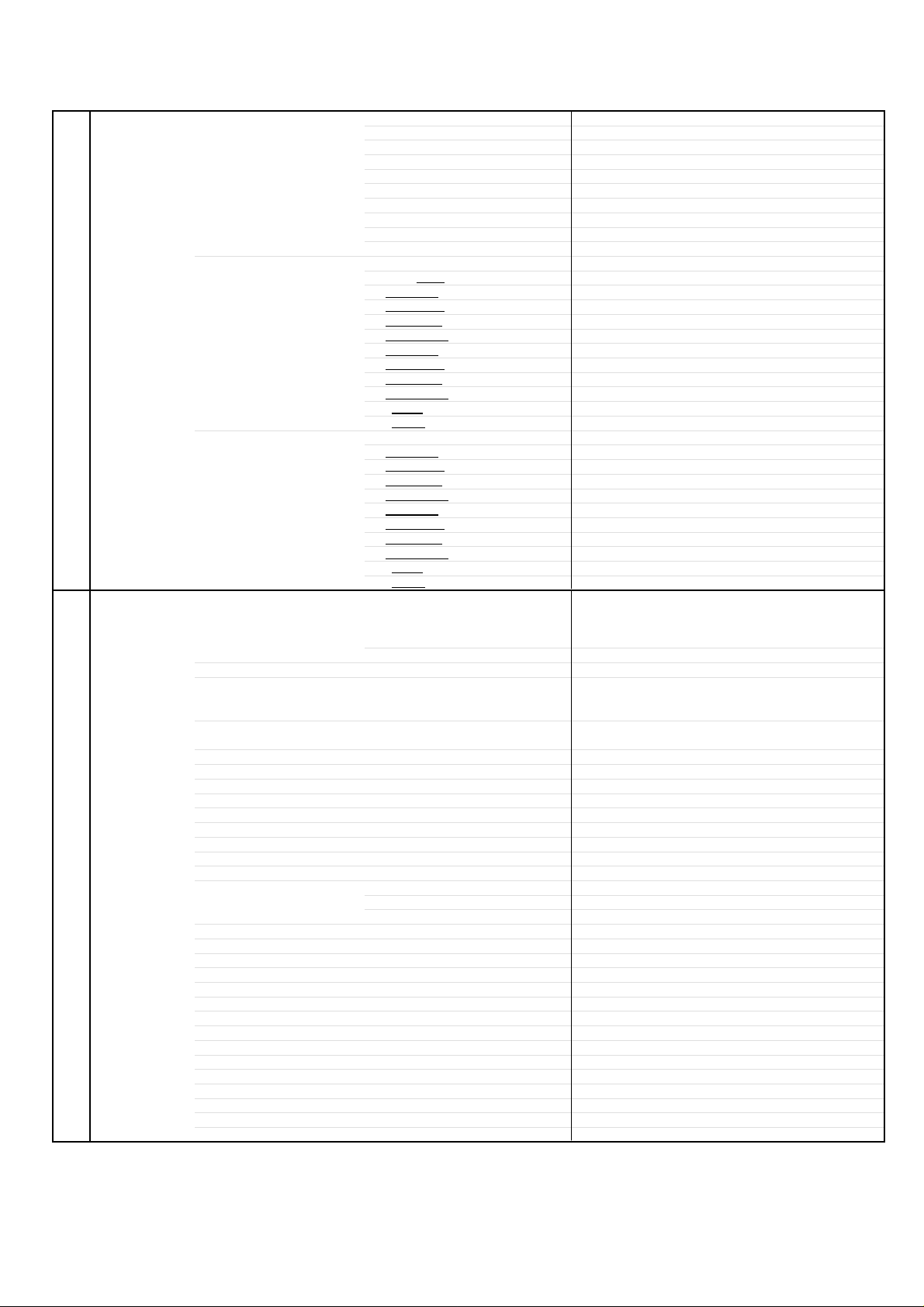

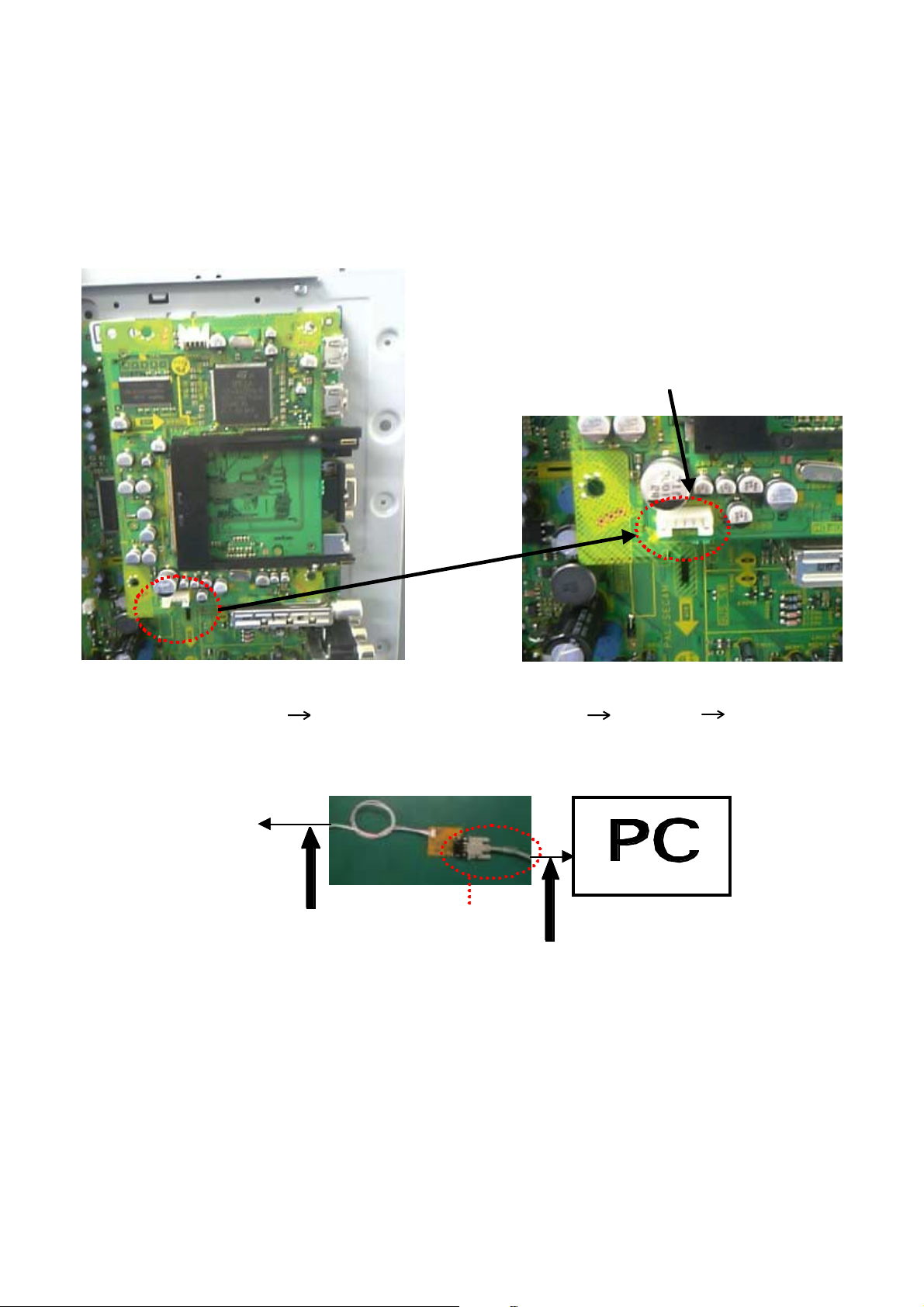

UPDATE FOR VCTP SOFTWARE

Before Update the VCTP Software, it is necessary to install the WRITING TOOLS into the PC.

For the installation of WRITING TOOLS, refer to the "INSTALL FOR WRITING TOOLS".

1.

Unplug the AC cord, and remove the back cabinet.

2.

Short circuit the 1 pin and 2 pin of CP802 on the Main PCB.

3.

Insert the AC cord.

4.

Remove the short circuit 1 pin and 2 pin of CP802 on the Main PCB.

5.

Set the EU LCD MICON VER UP ROM DISC (JG176) to PC.

6.

Start the "VCTP" (Writing Tools).

7.

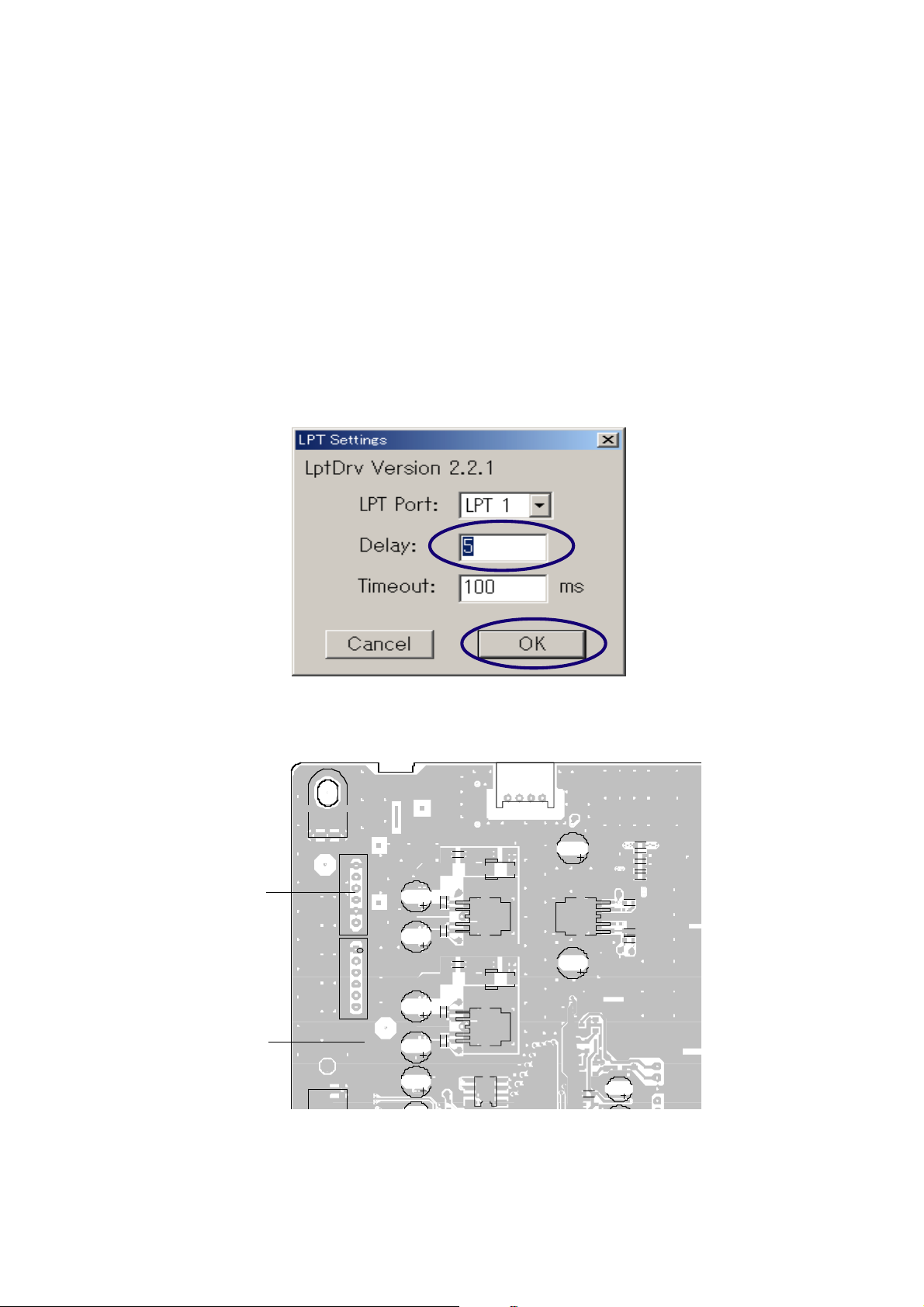

Select the "LPT Preferences" from File/Preferences menu, then input "5" to the value of "Delay", and press "OK".

NOTE: This step is not necessary from next time.

Using the MICON PROGRAM JIG KIT 25-4 (JG203), connect the PC Terminal and 1~4 pin of CP802 on the

8.

Main PCB (JG203(Red line) =1 pin of CP802).

CP4305

SH4304

C818

C837

R3701

C3627

R3704

B3609

C3638

C3635

C3639

CP802

Main PCB

CP802

CP101

C3228

C3232

C3227

C3231

C801

R3213

R3216

R3215R3210

W815

W811

IC3203

IC3204

IC801

C3659

D3205

IC3601

C3615

D3204

C-8

Page 22

UPDATE FOR VCTP SOFTWARE

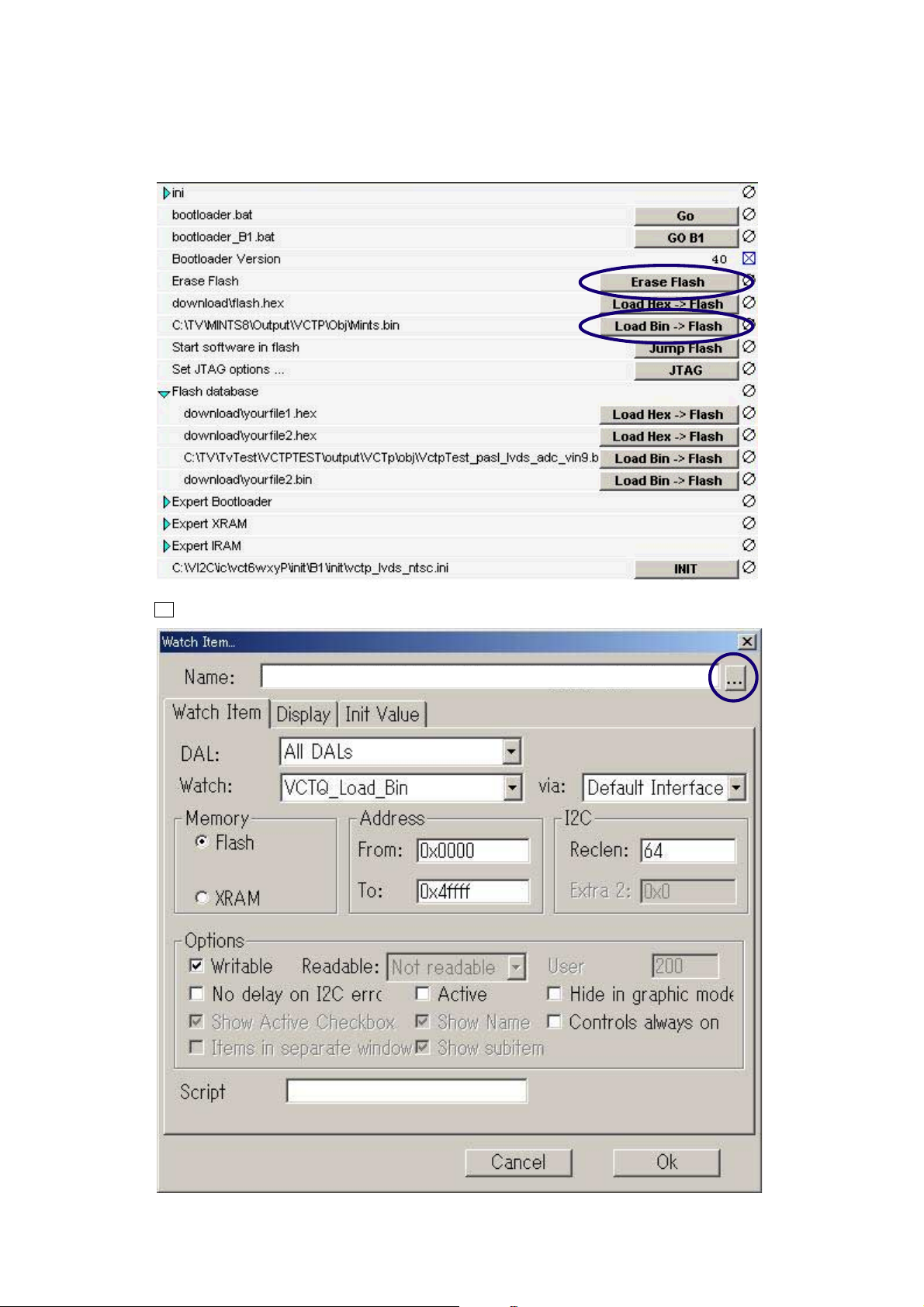

Press the “TVT”.

9.

Remove the check of “Bootloader Version”, and check it again.

10.

NOTE :

When the number of the side of the check box becomes 40, you can proceed to next step.

If the number doesn’t become 40, check the connection and try again from step 1.

C-9

Page 23

UPDATE FOR VCTP SOFTWARE

Press the “Erase Flash”.

11.

Then, press the “Load Bin -> Flash” twice.

Press the , and select the writing Firmware.

12.

...

C-10

Page 24

UPDATE FOR VCTP SOFTWARE

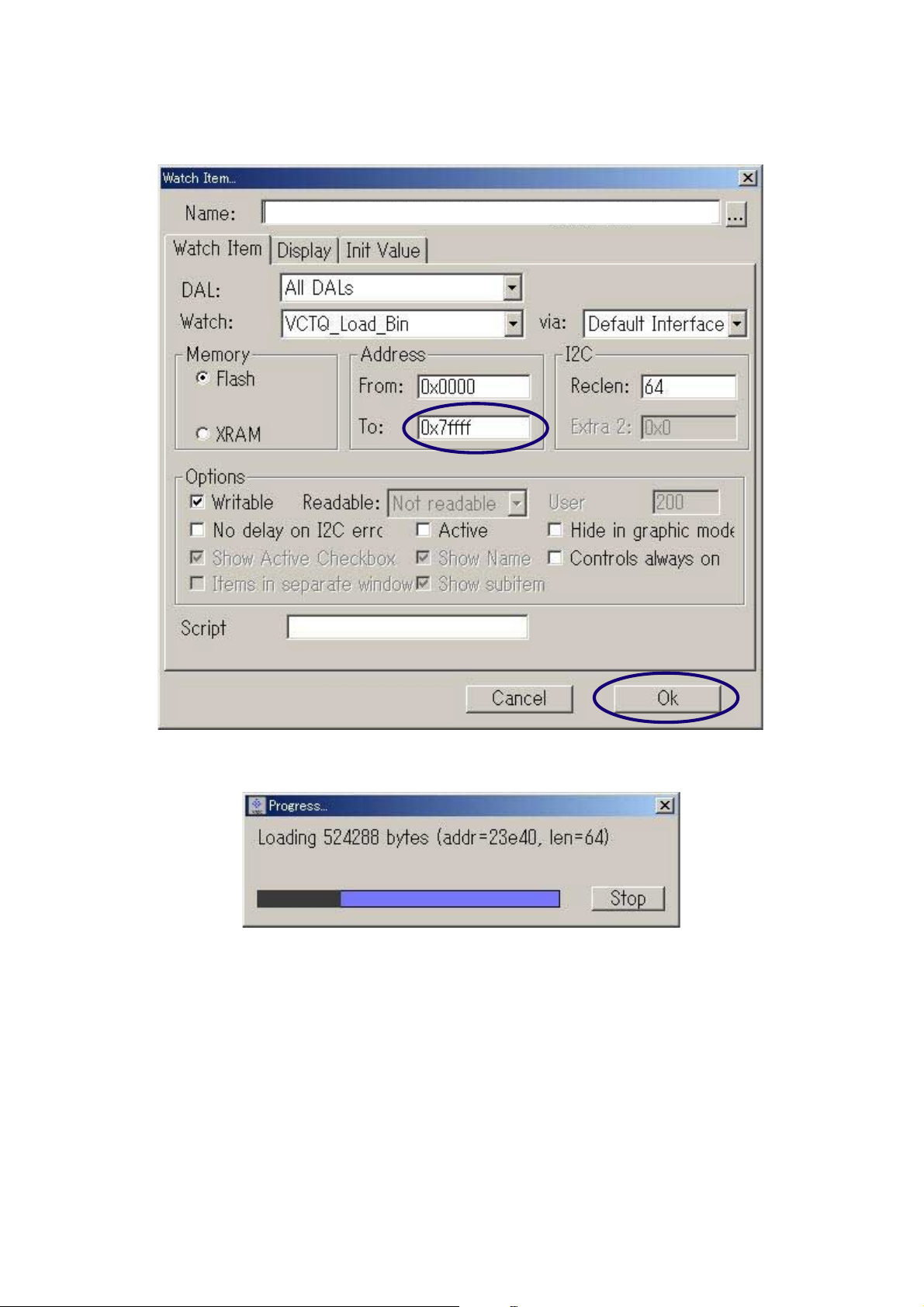

Select the “Address", then input the ”0x7ffff", and press the “OK”.

13.

Press the “Load Bin -> Flash”.

14.

The following window will appear, then writing will start. After the finishing of the writing, window will close.

Finish the writing, unplug the AC cord, and remove the MICON PROGRAM JIG KIT 25-4 (JG203).

15.

Insert the AC cord again, turn on the power.

16.

Press both VOL. DOWN button on the set and Channel button (2) on the remote control for 2 seconds.

17.

Confirm that displayed version agreement with writing.

18.

C-11

Page 25

UPDATE FOR EEPROM DATA

Before Update the EEPROM data, it is necessary to install the WRITING TOOLS into the PC.

For the installation of WRITING TOOLS, refer to the "INSTALL FOR WRITING TOOLS".

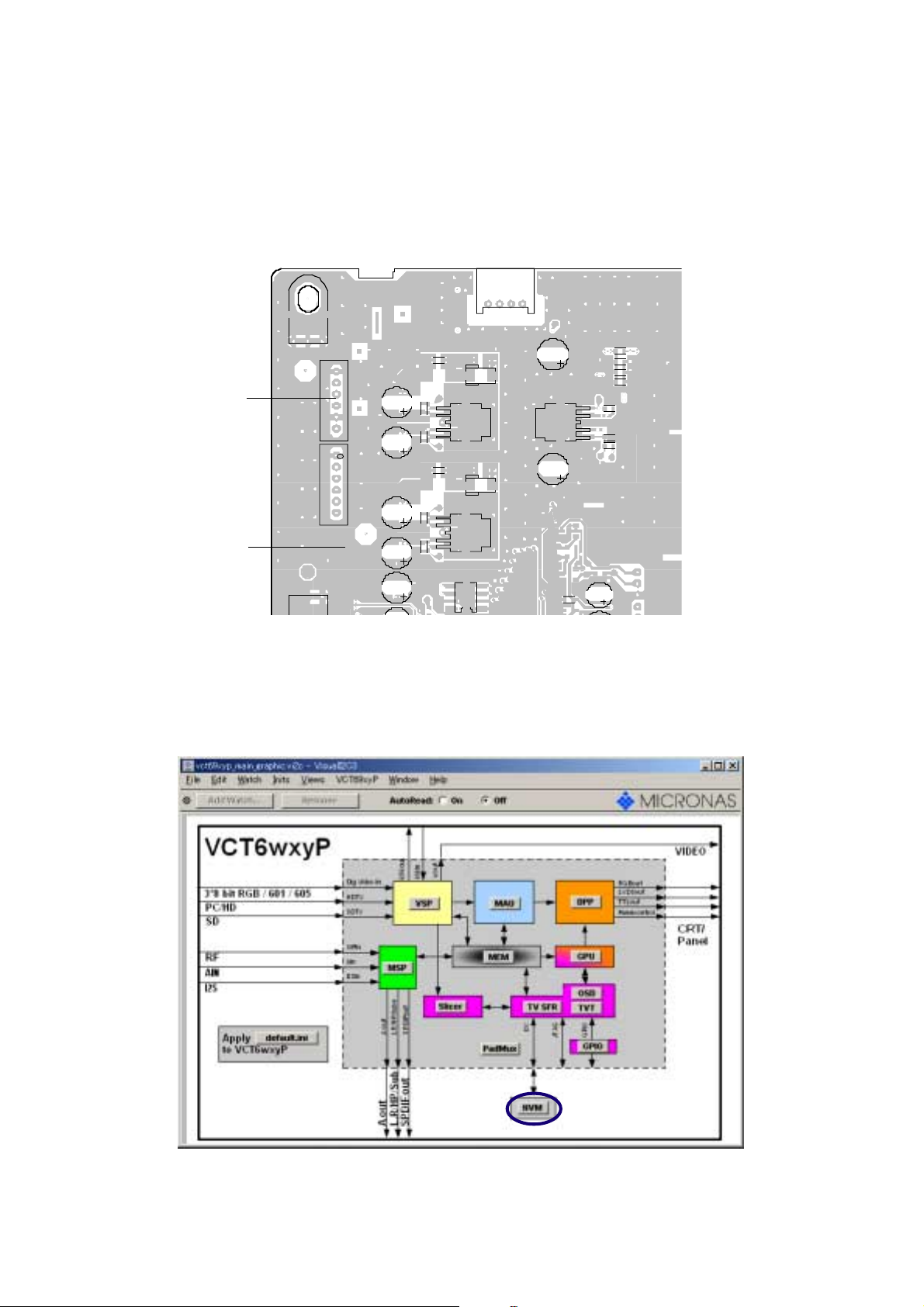

Set to the standby mode, and remove the back cabinet.

1.

Using the MICON PROGRAM JIG KIT 25-4 (JG203), connect the PC Terminal and Pin 1-4 of CP802 on the

2.

Main PCB (JG203(Red line) =1 pin of CP802).

CP4305

SH4304

CP802

CP802

CP101

Main PCB

Set the EU LCD MICON VER UP ROM DISC (JG176) to PC.

3.

Start the "VCTP" (Writing Tools).

4.

Press the "NVM".

5.

C3228

C3232

C3227

C3231

C801

R3213

R3216

R3215R3210

W815

W811

IC3203

IC3204

IC801

D3205

D3204

C3659

C3615

IC3601

C818

C837

R3701

C3627

R3704

B3609

C3638

C3635

C3639

C-12

Page 26

UPDATE FOR EEPROM DATA

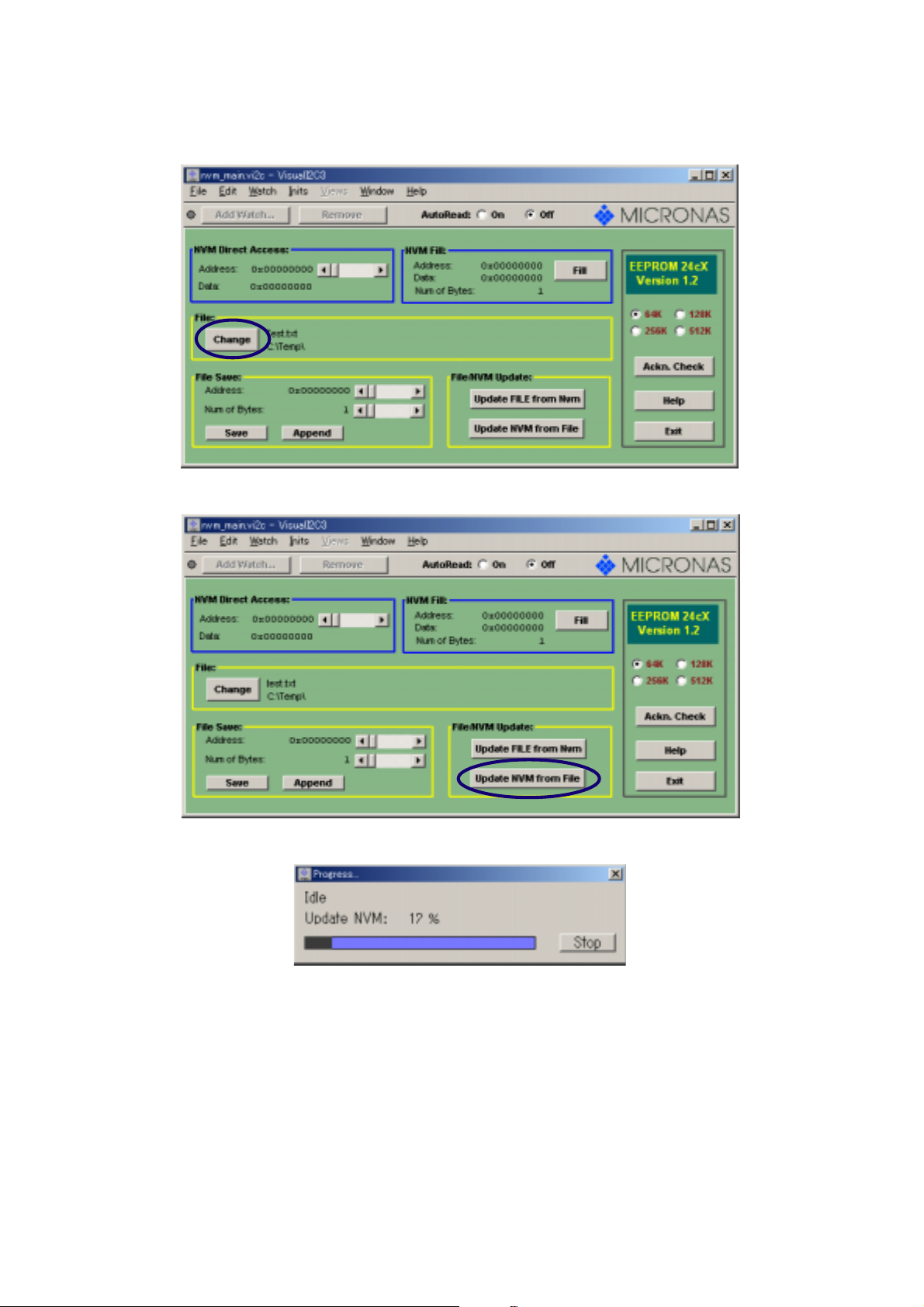

Press the "Change", and select the writing EEPROM data file (TEXT file).

6.

Press the "Update NVM from File".

7.

The following window will appear, writing will start. After the finishing of the writing, the window will close.8.

Finish the writing, unplug the AC cord, and remove the MICON PROGRAM JIG KIT 25-4 (JG203).

9.

Insert the AC cord again, turn on the power.

10.

Press both VOL. DOWN button on the set and Channel button (2) on the remote control for 2 seconds.

11.

Confirm that displayed version agreement with writing.

12.

C-13

Page 27

ELECTRICAL ADJUSTMENTS

1. ADJUSTMENT PROCEDURE

Read and perform these adjustments when repairing the

circuits or replacing electrical parts or PCB assemblies.

CAUTION

Use an isolation transformer when performing any

•

service on this chassis.

When removing a PCB or related component, after

•

unfastening or changing a wire, be sure to put the wire

back in its original position.

When you exchange IC and Transistor with a heat sink,

•

apply silicon grease (YG6260M) on the contact section of

the heat sink. Before applying new silicon grease,

remove all the old silicon grease. (Old grease may cause

damages to the IC and Transistor).

Prepare the following measurement tools for electrical

adjustments.

1. Patterm Generator

On-Screen Display Adjustment

1.2.Set the VOLUME to minimum.

Press the VOL. DOWN button on the set and the

channel button (9) on the remote control for more than

2 seconds to display adjustment mode on the screen as

shown in Fig. 1-1.

PAL

Function

3.

Use the Channel UP/DOWN button or Channel button

01 OSD H POSI 28

(0-9) on the remote control to select the options shown

in Fig. 1-2.

Press the MENU button on the remote control to end the

4.

adjustments.

5.

To display the adjustment screen for TUNER, EXT1,

EXT2, EXT3, Component, HDMI1, HDMI2 and PC

mode, press the button on the remote control.

Press the VOL.DOWN button on the set and the channel

(9) on the remote control for more than 2 seconds.

TUNER

Full

Step No.

Fig. 1

FUNCTION

NO.

H POSI OSD

01

V POSI OSD

02

R DRIVE(M)

03

R CUT OFF(M)

04

G DRIVE(M)

05

G CUT OFF(M)

06

B DRIVE(M)

07

B CUT OFF(M)

08

R DRIVE(H)

09

R CUT OFF(H)

10

G DRIVE(H)

11

G CUT OFF(H)

12

B DRIVE(H)

13

B CUT OFF(H)

14

R DRIVE(L)

15

R CUT OFF(L)

16

G DRIVE(L)

17

G CUT OFF(L)

18

B DRIVE(L)

19

B CUT OFF(L)

20

H POSI

21

H POSI MAX

22

NO.

FUNCTION

23

H POSI MIN

24

V POSI

25

V POSI MAX

26

V POSI MIN

27

BAKLIGHT CENT

28

BAKLIGHT MAX

29

BAKLIGHT MIN

30

BRIGHT CENTER

31

BRIGHT MAX

32

BRIGHT MIN

33

TINT CENTER

34

CONTRAST CENTER

35

CONTRAST MAX

36

CONTRAST MIN

37

CONTRAST 50

38

COLOR CENTER

39

COLOR MAX

40

COLOR MIN

41

TEXT H POSI

42

TEXT V POSI

43

DAC VCOM

Fig. 1-2

2. BASIC ADJUSTMENTS

2-1: WHITE BALANCE

1.

Place the set in Aging Test for more than 15 minutes.

2.

Receive the gray scale pattern from the Pattern

Generator.

3.

Press the button on the remote control to set to the

AV mode.

4.

Using the remote control, set the brightness and contrast

to normal position.

5.

Activate the adjustment mode display of Fig. 1-2 and

press the channel button (03) on the remote control to

select “R DRIVE (N)”.

6.

Press the UP/DOWN button on the remote control to

select the “R CUTOFF (N)”, “B DRIVE (N)”, “B CUTOFF

(N)”, “R DRIVE (C)”, “R CUTOFF (C)”, “B DRIVE (C)”, “B

CUTOFF (C)”, “R DRIVE (W)”, “R CUTOFF (W)”, “B

DRIVE (W)” and “B CUTOFF (W)”.

7.

Adjust the RIGHT/LEFT button on the remote control to

whiten the R CUTOFF (N), B DRIVE (N), B CUTOFF (N),

R DRIVE (C), R CUTOFF (C), B DRIVE (C), B CUTOFF

(C), R DRIVE (W), R CUTOFF (W), B DRIVE (W) and B

CUTOFF (W) at each step tone sections equally.

8.

Perform the above adjustments 5 and 6 until the white

color is looked like a white.

D-1

Page 28

ELECTRICAL ADJUSTMENTS

2-2: CONTRAST

Place the set in Aging Test for more than 15 minutes.

1.

Receive the color bar pattern. (RF Input)

2.

Using the remote control, set the brightness and

3.

contrast to normal position.

Press the LEFT/RIGTH button on the remote control

4.

until the contrast step No. becomes "50"

Check if the picture is normal.

5.

Receive the color bar pattern. (VIDEO1 Input)

6.

Using the remote control, set the brightness and

7.

contrast to normal position.

Press the button on the remote control to set to

8.

the EXT1 mode.

Press the LEFT/RIGTH button on the remote control

9.

until the contrast step No. becomes "38".

Check if the picture is normal.

10.

Receive the color bar pattern. (VIDEO2 Input)

11.

Using the remote control, set the brightness and

12.

contrast to normal position.

Press the button on the remote control to set to

13.

the EXT2 mode.

Press the LEFT/RIGTH button on the remote control

14.

until the contrast step No. becomes "38".

Receive the color bar pattern. (VIDEO3 Input)

15.

Using the remote control, set the brightness and

16.

contrast to normal position.

Press the button on the remote control to set to

17.

the EXT3 mode.

Press the LEFT/RIGTH button on the remote control

18.

until the contrast step No. becomes "38".

Receive the color bar pattern. (AV RGB Input)

19.

Using the remote control, set the brightness and

20.

contrast to normal position.

Press the button on the remote control to set to

21.

the Component mode.

Press the LEFT/RIGTH button on the remote control

22.

until the contrast step No. becomes "38".

Receive the color bar pattern. (S-VIDEO Input)

23.

Using the remote control, set the brightness and

24.

contrast to normal position.

Press the button on the remote control to set to

25.

the HDMI mode.

Press the LEFT/RIGTH button on the remote control

26.

until the contrast step No. becomes "38".

Check if the picture is normal.

27.

D-2

Page 29

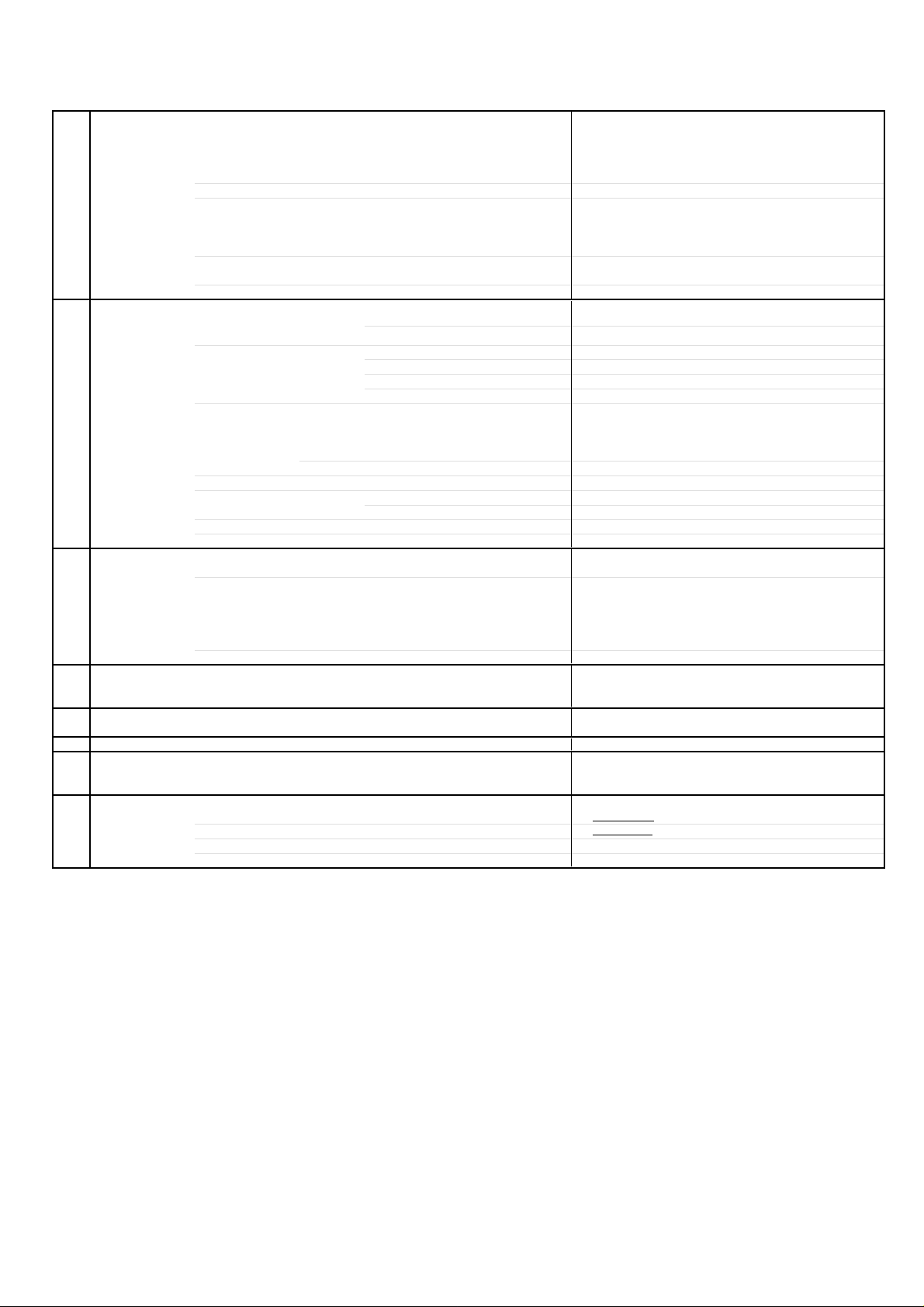

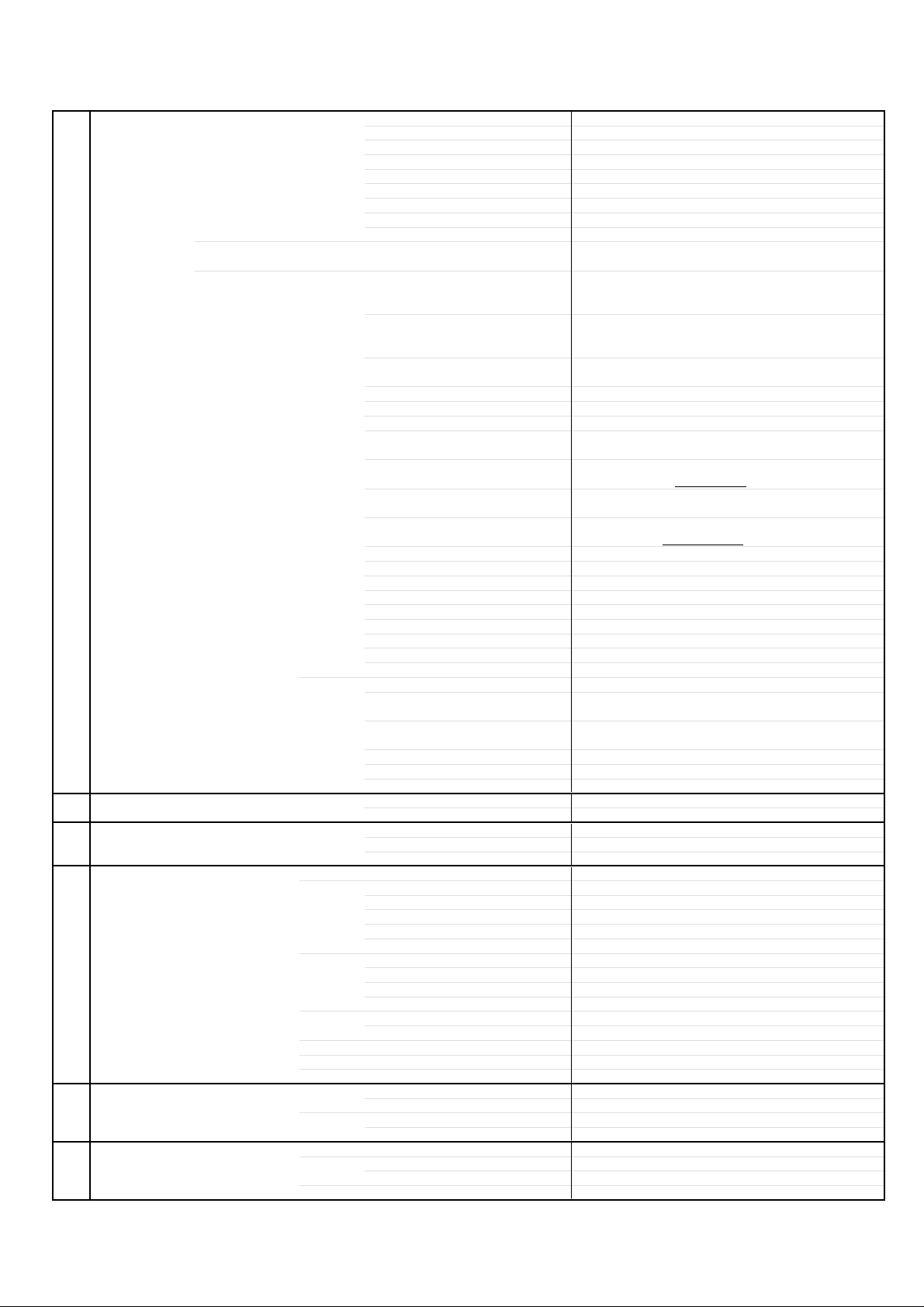

2-3: Confirmation of Fixed Value (Step No.)

p

Please check if the fixed values of each of the adjustment item is set correctly referring below. (TUNER/AV/CS/HDMI/PC)

ELECTRICAL ADJUSTMENTS

AV CS (NTSC) CS (PAL) HDMI (NTSC) HDMI (PAL)

CVBS S(Y/C) RGB 480i 480p 720p 1080i 576i 576p 720p 1080i 480i 480p VGA 720p 1080i 576i 576p 720p 1080i 640x480 800x600 1024x768 1280x768 1360x768

NO. FUNCTION Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No.

1 OSD H POSI 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26

2 OSD V POSI 77777777777777777777777 7 7 77

3 R DRIVE (M) 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850

4 R CUTOFF(M) 000000000000000000000-- - - -0

5 G DRIVE(M) ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ

6 G CUTOFF (M) ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ - - - - - ADJ

7 B DRIVE (M) ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ

8 B CUTOFF (M) ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ - - - - - ADJ

9 R DRIVE (H) 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 - - - - - 850

10 R CUTOFF (H) 000000000000000000000- - - - -0

11 G DRIVE (H) ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ - - - - - ADJ

12 G CUTOFF (H) ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ - - - - - ADJ

13 B DRIVE (H) ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ - - - - - ADJ

14 B CUTOFF (H) ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ - - - - - ADJ

15 R DRIVE (L) 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 850 - - - - - 850

16 R CUTOFF (L) 000000000000000000000- - - - -0

17 G DRIVE (L) ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ - - - - - ADJ

18 G CUTOFF (L) ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ - - - - - ADJ

19 B DRIVE (L) ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ - - - - - ADJ

20 B CUTOFF (L) ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ - - - - - ADJ

21 H POSI 50 Hz (4:3) 642 642 642 642 - - - - 608 284 - - - - - - - 76 5 - - - - - - - 578

H POSI 50 Hz (4:3) OTHER 640 640 640 642 - - - - 608 284 307 256 - - - - - 76 5 138 38 - - - - - 578

H POSI 60 Hz (4:3)

H POSI CENTER (PC)

H POSI 60 Hz (4:3) OTHER 586 586 586 582 560 266 306 256 - - - - 52 5 5 92 33 - - - - 129 191 279 - - 545

22 H POSI MAX (PC) - - - - - - - - - - - - - - - - - - - - - 299 291 379 358 444 23 H POSI MIN (PC) - - - - - - - - - - - - - - - - - - - - - 29 91 179 158 244 -

V POSI 50Hz FULL SCREEN/Cinima OTHER

24

V POSI 50Hz FULL SCREEN - - - - - - - - - - - - - - - - - - - - - - - - - - 0

V POSI 50Hz Cinema - - - - - - - - - - - - - - - - - - - - - - - - - - 0

V POSI 60Hz FULL SCREEN/Cinima OTHER

V POSI CENTER (PC)

V POSI 60Hz FULL SCREEN - - - - - - - - - - - - - - - - - - - - - 0 - - - - -

V POSI 60Hz Cinema - - - - - - - - - - - - - - - - - - - - - 0 - - - - 25 V POSI MAX - - - - - - - - - - - - - - - - - - - - - 51 51 51 51 51 26 V POSI MIN - - - - - - - - - - - - - - - - - - - - - 1 1 1 1 1 27 BAKLIGHT CENTER 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96 96

28 BAKLIGHT MAX 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223 223

29 BAKLIGHT MIN 00000000000000000000000 0 0 0 0

30 BRIGHT CENTER ####8888888815151515151515151515151515152

31 BRIGHT MAX ####5050505050505050505050505050505050505050505050

32 BRIGHT MIN ####-64-64-64-64-64-64-64-64-64-64-64-64-64-64-64-64-64-64-64-64-64-64-64

33 TINT CENTER ####00000000000000000000 0 00

34 CONTRAST CENTER ####ADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJ

35 CONTRAST MAX ####ADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJ

36 CONTRAST MIN ####1818181818181818181818181818181818181818181818

37 CONTRAST 50 ####ADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJADJ

38 COLOR CENTER ####4141414141414141414141414141414141363636363632

39 COLOR MAX ####6060606060606060606060606060606060606060606060

40 COLOR MIN ####0000000000000000000 0 0 00

41 TEXT H POSI 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150 150

42 TEXT V POSI 00000000000000000000000 0 0 00

43 DAC VCOM 000000000000 000000000000 0 00

584 584 584 582 560 266 - - - - - - 52 5 5 - - - - - - 129 191 279 258 344 554

25252523 - - - -25502219 - - - - -13372319 - - - - -25

19 19 19 17 19 41 21 18 - - - - 8 27 27 21 18 - - - - 26 26 26 23 23 -

PC

DTVTUNER

NOTE: For the ste

D-3 D-4

no. with # mark, please adjust it according to the 2-4.

Page 30

ELECTRICAL ADJUSTMENT

S

2-4: Confirmation of Fixed Value (Step No.)

Please check if the fixed values of each of the adjustment item is set correctly referring below. (A-TU/AV1, AV2(CVBS)/AV3(CVBS)/AV2 S(Y/C)/AV3 S(Y/C)/AV1(RGB)

AV1(SCART1), AV2(SCART2)

A-TU

PAL50

NO. FUNCTION Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No. Step No.

PAL60 SECAM

PAL50

PAL60 SECAM NTSC3.58 NTSC4.43

CVBS

PAL50

PAL60 SECAM NTSC3.58 NTSC4.43

AV3(RCA)

CVBS

PAL50

AV2(SCART2)

576i

S(Y/C)

PAL60 SECAM NTSC3.58 NTSC4.43

480i576i 480i

PAL50

AV3(RCA)

S(Y/C)

576i 480i

PAL60 SECAM NTSC3.58 NTSC4.43

PAL50

AV1(SCART1)

576i

RGB

PAL60 SECAM NTSC3.58 NTSC4.43

480i576i 480i

30 BRIGHT CENTER 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20

31 BRIGHT MAX 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50

32 BRIGHT MIN -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64 -64

33 TINT CENTER 000000 0 0 000 0 0 000 0 0 000 0 0 000 0 0

34 CONTRAST CENTER ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ

35 CONTRAST MAX ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ

36 CONTRAST MIN 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18

37 CONTRAST 40 ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ ADJ

38 COLOR CENTER 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40

39 COLOR MAX 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60

40 COLOR MIN 000000 0 0 000 0 0 000 0 0 000 0 0 000 0 0

D-5 D-6

Page 31

ELECTRICAL ADJUSTMENTS

3. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE (WIRING CONNECTION)

LCD PANEL

OPERATION PCB

POWER PCB

CP406

CD403

CP2203

CD2202

CP411

FAN

CD7200

CD3400

CP7201

CP3400

CP3801

DIGITAL PCB

CP3001

CP6401

CP4305

CP3603

CP3601

CP6001

TU6002

CP4202

J4203

J4204

J4205

J4301

CP4302

CP102

J401

AC IN

CD3805

D-7

CP412

CP3802

CP301

CD301

SPEAKER

CP2201

REMOCON PCB

J4206

CP4301

MAIN PCB

CD2201

OS2201

Page 32

POWER DOES NOT TUNER ON

TROUBLESHOOTING GUIDE

Is F401 broken?

No

Is there voltage at pin

10 of IC401 at 18.9V?

Yes

Is there voltage at pin

4 of IC402 at 15.1V?

Yes

Change MAIN PCB.

Yes

No

No

Change F401.

Check IC401 and peripheral

circuit.

Check IC402 and peripheral

circuit. Or change IC402.

E-1

Page 33

THE PICTURE DOES NOT

APPEAR (1)

TROUBLESHOOTING GUIDE

Is CD7204 connected?

Yes

Is there signal

at CP7201 ?

Yes

Check IC803.

Or change SCALER PCB.

No

No

Connected CD7204.

Change CP7201.

E-2

Page 34

THE PICTURE DOES NOT

APPEAR (2)

TROUBLESHOOTING GUIDE

Is there signal at at

IC4205 ?

Yes

Check IC803 and

peripheral circuit.

No

Check IC4205 and

peripheral circuit.

E-3

Page 35

THE PICTURE DOES NOT

APPEAR. (DIGITAL)

TROUBLESHOOTING GUIDE

Does an error

message display it?

Yes

Is there signal at pins

2 and 3 of CP2402?

Yes

Check SUB POWER PCB.

No

No

Change DIGITAL TUNER

MODULE.

Change DIGITAL TUNER

MODULE.

E-4

Page 36

THE COLOR DOES NOT

APPEAR

TROUBLESHOOTING GUIDE

Is setting of color

normal?

Yes

Is the color signal

received?

Yes

Check IC803 and peripheral

circuit.

No

Change the setting of color.

No

Receive the color signal.

E-5

Page 37

ON SCREEN DISPLAY DOES

NOT APPEAR

TROUBLSHOOTING GUIDDE

Is there signal at

pins 2, 4 of IC101?

Yes

Is there color signal

at pins 83 and 84 of

IC803 ?

Yes

Change MAIN PCB.

No

No

Check IC101 and

peripheral circuit.

Check IC803 and peripheral

circuit.

E-6

Page 38

THE SCREEN HAS A VERTICAL

g

LINE OR A HORIZONTAL LINE.

TROUBLESHOOTING GUIDE

Is there a normal

waveform at pins 184,

187 and 190 of IC803?

Yes

Chan

e IC803.

No

Change V2301.

E-7

Page 39

A

A

TUNER/SCART1/SCART2/RCA AUDIO OUT BLOCK DIAGRA

M

TU6002 TUNER

AGC 4 RF_AGC

SCL 9 IC6001 BUS_SW

SDA 10 15

CVBS 15

IF AGC 18

DIF1 19 DIF1

DIF2 20 DIF2

SCL F_SCL

SDA F_SDA

14

D_TUNER_SCL

D_TUNER_SDA

SCALER/

SUBMICON

IC4201 TUNER_OUT_CVBS_SW

6 TU_TUNER_CVBS_IN D_TUNER_CVBS_IN 4 D_TUNER_CVBS

2 OUT

J4206 SW_CVBS_(TU/D_TU)

SCART 1

R_OUT

L_OUT

L_IN

R_IN

21-B_IN

21-G_IN

21-R_IN

(21-C_IN)

21-Y_IN

FOR_VCR

1 SC1_A_OUT_R

3 SC1_A_OUT_L

2

6

7 8 SCART1_B_IN SW_SCART_R/C_OUT 3 SW_SCART_R/C

11 11 SCART1_G_IN SW_SCART_G_OUT 5 SW_SCART_G

15 16 SCART1_R_IN SW_SCART_B_OUT 6 SW_SCART_B

16 1 SCART2_R/C_IN

8 14 SCART2_G_IN

TUNER OUT 19

VIDEO IN

R_OUT

L_OUT

20 IC4203 SCART1/2_AUDIO_Lch_SW

22 SC2_A_OUT(SCALER IC803 21pin) 6 SC1_A_IN_L

24 SC2_A_OUT(SCALER IC803 22pin)

1 F_SCL

13 F_SDA

2 D_TUNER_SCL

12 D_TUNER_SDA

IF_AGC

SCART1_Y_IN

IC4204 SCART1/2_RGB_SW

9 SCART2_B_IN

SCART1_SW

4 SC2_A_IN_L A_L_OUT 2 SW_A_L

SCALER/SUB

MICON

SOUNDAMP/

HEADPHONE

JACK/COMPONENT

SCART2

L_IN

R_IN

21-B_IN

21-G_IN

21-R_IN

(21-C_IN)

21-Y_IN(FB)

FOR_VCR

MONITOR OUT

VIDEO IN

23 IC4202 SCART1/2_AUDIO_Rch_SW

27 4 SC2_A_IN_R

28

32 IC4206 SCART1/2_VIDEO_SW

36 4 SCART2_V_IN V_OUT2 SW_SCART_CVBS/Y

37 SCART2_FB(Y_IN)

29 SCART2_SW

40 SC2_CVBS_OUT

41

J4204 AV_AUDIO_OUT/S-TERMINAL_JACK

6 SC1_A_IN_R

6 SCART1_V_IN

_R_OUT2 SW_A_R

S_JACK_C/ S_JACK_Y

CVBS_IN

VIDEO_A_L

VIDEO_A_R

AUDIO_OUT_JACK_L

UDIO_OUT_JACK_R

SCALER/

SUBMICON

F-1 F-2

Page 40

A

A

POWER/REGULATOR BLOCK DIAGRA

M

CP3801

SOUND+B 1 SOUND+B

SOUND+B 2

IC3801 REG

SW+12V 8 P.CON+9V

SW+12V 9

AT+5V 14 AT+5V

AT+5V 15

P.CON+5V 20 P.CON+5V

P.CON+5V 21

SW+3.3V 22 SW+3.3V

SW+3.3V 23

SW+12V

Q3805/Q3804 SW_TR

P.CON+12V_DTV

Q3202

IC3203

AT+3.3V

IC3205 5V_REG

P.CON+5V

D3804

IC3203 REG

T+1.8V_1

IC3204 REG

T+1.8V_2

Q3806 SW

P.CON+5VDTV

IC3201 3.3V_REG

HDMI+3.3V

Q3205 SW

HDMI5V

HDMI_VNREG+5V

F-3 F-4

Page 41

D

D

SOUND AMP/

HEADPHONE

JACK/

COMPONENT

CP3802

LCD+B 8

LCD+B 9

DTV_H

DTV_LPM_CTL_H

LPM_INT

DTV_RESET

DTV_TX/RX

DTV_TX/RX

D_TUNER_AUDIO_L

D_TUNER_AUDIO_R

SW_Y/D_Y

SW_PB/D_PB

SW_PR/D_DR

AUDIO_OUT_JACK_L/R

VIDEO_A_L/R

SCALER/SUB MICON BLOCK DIAGRAM

CP7201 LCD PANEL

LVDS+/-

10 106 91/92 102 88 87 128 SW_A1_R

9 129 SW_A1_L

131 ~ 135 VGA-R/G/B

137 ~ 141 SDA/SCL

179~181

CP4301 REMOCON_PCB

REMOCON

25/26 89

EPG_LED 100

13/14 STAND_BY_LED 117

V2301

HDMI/D-SUB

TUNER/

SCART1/

SCART2/ RCA

AUDIO OUT

S_JACK_Y/C

AW_CVBS(TU/D_TU)

SC1_A_OUT_R

SC2_A_OUT_L

SCART1_Y_IN

SC2_A_OUT_R

SC2_A_OUT_L

SW_SCART_R/C

SW_SCART_G

SW_SCART_B

SW_A_R

SW_A_L

SW_SCART_CVBS/Y

SCART2_FB(Y_IN)

SC2_CVBS_OUT

SCART1_SW

SCART2_SW

RF AGC

HP_IN

184/ 187

191 79 X801

23 78 20.25MHz

24 CP4304 OPERATION_PCB

20 KEY_A/B 159/160

21

178

176

177

48 ~73

11 DEN/DCLK IC801 256K EEPROM

12 DRI0~7/DGI0~7/DBI0~7 84 5 SDA

189 83 6 SCL

183 195 8 38 39 40

1

IC802 SYSTEM RESET

IC101 SUB MICON R5F21244SNFP IC105 RESET

8 HDMI I2S

42

43

9

41

X101 16MHz

11 Q101/Q102

25 F.SDA 4

F.SCL 2

23 24

M24256-BWNM6TP

DEN/DCLK

DRI0〜7/DGI0〜7/DBI0〜7

HDMI/D-SUB

RS232_RXD RS232_TXD

IC102

CP102

DIN-901B

RS232_RX

RS232_TX

SOUND AMP/

HEADPHONE

JACK/

COMPONENT

F-5 F-6

F.SDA

F.SCL

2

3

ISL83220ECVZ-T

911

8

13

Page 42

_

_

HDMI/D-SUB BLOCK DIAGRAM

SW_A1_R

SW_A_L

IC4304 VGA-R/VGA-G

J4301 AUDIO_MINI_PIN_JACK YUV/DVI_Rch_SW VGA-B

PC/DVI1_A_IN_R SDA/SCL

DVI2_A_R H-SYNC

V-SYNC

PC/DVI1_A_IN_L DEN/DCLK

DVI2_A_L DRI0~7/DGI0~7/DBI0~7

HDMI_I2S

IC4303 IC3605 HDMI_I/F SiI9025CTU

J4202 AUDIO_IN_JACK YUV/DVI_Lch_SW 110~144

YUV_A_R

YUV_A_L Q4303

COAXIAL

SCALER/ SUB

MICON

SOUND

AMP/HEADPHONE

JACK/COMPONENT

CP4302 D-SUB

D_TUNER_SPDIF IC3606 SIGNAL IC3609

CONNECTOR VGA-R

VGA-G Q4304 96

VGA-B

SDA DDHS

SCL

VS

VGA

VGA_HS 94

DDVS

31 39, 40, 43, 44, 58, 59, 62, 63

32 47, 48, 51, 52 66, 67, 70, 71 29 30

DIGITAL

DIGITAL SIGNAL

2K EEPROM 2K EEPROM

BR24L02F-WE2 BR24L02F-WE2

15 15

16 16

HDMI CONNECTOR HDMI CONNECTOR

CP3601 CP3603

97

X3602 28.322MHz

IC3601 1.8V_REG

HDMI+5V

POWER/

REGULATOR

F-7 F-8

Page 43

SOUND AMP/HEADPHONE JACK/COMPONENT JACK BLOCK DIAGRA

M

J4203 COMPONENT_JACK

IC4205 D.TUNER/YUV_SW

8

11

Y_IN 16 3 SW_Y/D_Y

PR_IN 5 SW_PB/D_PB

PB_IN 1 6 SW_PR/D_PD

9 DTV_LPM_CTL_H

14 D_TUNER_AUDIO_L

D_TUNER_AUDIO_R

DTV_TX/RX

DTV_RESET

LPM_INT

SP_AUDIO_OUT_L

SP_AUDIO_OUT_R

DTV_H

AUDIO_MUTE

HP_MUTE

CP6001 (FROM/TO DIGITAL_PCB) HP_IN

A_OUT_L 1

A_OUT_R 2

3 IC301 SOUND_AMP

9

CVBS 5 2

TVTX 6 SP_L+/- CP301 SPEAKER

5

TVRX 8

SP_R+/RESET 10

Y11 14

D.TUNER YUV

U13

SCALER/ SUB

MICON

V15

DTV-H 7

SPDIF 23

SCL/SDA 21/25

DIF1 27

DIF2 29 IC300 HEAD_PHONE_AMP J4205 HEAD_PHONE_JACK

IF_AGC 30

TUNER/SCART1

/SCART2/RCA

AUDIOOUT

IF_AGC

DIF2 4

DIF1

D_TUNER_SCL

D_TUNER_SDA

D_TUNER_CVBS

318

19

2

D_TUNER_SPDIF

HDMI/D-SUB

F-9 F-10

Page 44

DIGITAL BLOCK DIAGRA

M

Digital IF+/-

12C

C, D, F

OFDM

STV0362

IC4001

Flash ROM

Update

CP2402

DDR

256Mbit

IC2403

MEPGTS

12C

TXR

E

EEPROM64K

M24C4WMN6TP

IC2409

GG

Common Interface

(PCMCIA)

CP3001/3002

B

A, B, E

STM5105

IC2401

MPEG

AUDIO L+LAUDIO R+R-

FLASH

16Mbit

IC240

AUDIO

OPEAMP

TSH73CD

IC6406

30pinBOARD

to BOARD

E

CONNECTOR

125622330K3

CP6403

1.AOUTR

2.AOUTL

5.CVBS

6.TVTX

8.TVRX

9.POWER CTL

10.RESET

11. Y

13. U

15 .V

17. 12V

18. 5V

20.22.24. 3.8V

A. 1.2V

B. 2.5V

C. 1.0V

D. 2.5V

E. 3.3V

F. 3.3V

7.DTV_H

3.LPM_INT

21.25. SCLT/SDAT

27.29 IF+/-

30. IF_AGC

REG

IC6401.6402

IC6405.6407

REG

IC6403

IC6404

F-11 F-12

Page 45

POWER BLOCK DIAGRAM

3

542

3

5

813

4

32A

3

A

3

2

4

+

8

2

3

7

+

A

3

564

8

719

C IN

CD3805

J401

1

RERAY

RY401

LKS329_A60

POWER SW

Vcc Q1

10 18

F401

P.GND

L401

4

21

D408

4

3

2

L402

1

1

4

2

POWER SW

IC402

D Vcc FB

C405

D425

D427

D430

D431

L403

Vdd

1

1

1

1

CP411__11 SYS_POWER_H

TRANSFORMER

T402

1

C424

SW

D457 SR240-

REGULATOR

IC404 KIA431A-AT

IC410

PS2561AL1-1-V(W)

SW

Q416

IC406+Q410

RSS050P03

DC-DC

D462 SR240-F

L1015

CP411__20, 21 P.CON5V

CP411__16 POWER FAIL

CP411__14,15 AT+5V

CP412__1 DTV_H

CP411__22, 23 SW+3.3V

1

TRANSFORMER

T401

1

1

1

1

1

12V Reg

Q422

KTB1151

DC-DC

IC407

LA5779

CP411__1,2. SOUND+B

CP406__1,2,3,4,5. +24V

CP411__8,9. SW+12V

CP412__8,9. LCD+B

CP412__6. PANEL_POWER_H

F-13 F-14

Page 46

PRINTED CIRCUIT BOARDS

MAIN (TOP SIDE)

SH4301

CP301

B302

B303

B4306

Q4309 Q4305

C4277

Q4205 Q4210

L4205

Q4204 Q4208

L4203

SH4307

B301

B304

CP4301_1

B4309

B4307

C4358

C4359

D4305

Q4308 Q4310

R4327

L4219

L4223

IC4202 IC4203

D4212

D4214

R4287

L4204

L4211

L4202

L4206

B4318

W819

R4335

D4258

W912

R4268

D4255

C4374

R4264

C4379

L4224L4232

C4285

D4215

W826

D4213

R4276

R4261

R335

R4300

R4267

C384

C376

C4381

Q4218

C334

L4212

R333

R4346

W806

D4218

L4217

D4256

R4284

Q4217

L4207

W841

IC4204

C4281

W888

R4234

W851

C4377

C4241

R4218

L302_1

L300_1

R4290

C4220

W850

J4206

C326

C333

W843

R4227

CP3802

R4349

C4265

D4216

C4230

W849

IC3201

D4220

R4225

R4242

R4254

D4259

C4380

C4233

W883

R316

D4247

C330

D4241

W864

C4238

R4272

C308

C324C323

IC300

R3212 R3238

C3211 R3211

L4225

R4355

C4218

C3213

D3202

C317

R3205C3212

L4221

C379

C373 R334C381

C322

C378

C380C370R332

C372

C316

C318

C4250

C4217

C315

R309

C337

R303

C314

C4363

IC301

R307

C4283_1

W873

B4210

B4212

B307

R301

C310

L4214

R4201

B4209

B4213

J4205

W925

C366R330C368

C365

C307

C300

C319

R331

W886

C320

C4242

B4211

W889

R317

R315

C4227

C4216

IC4201

C363

Q321

Q302

Q3806

R4352

R4353

C4294

R4228

B4205

B306

C4222

B4214

Q300

Q301

R302

R306

L4230

L4213

C4239

R4304

L4208

R3815

R325

Q4221

C4295

W876

R311

R3816

L4227

CP3801

Q3807

L4226

C4293

C3804

R4298

J4204

R4313

C4290

R4306

R4230

IC3801

W835

C4300

C4297_1

IC4205

D3210

D4223

L4233

L4231

C4299

C4288_1

Q3805

C3802

C3815

C4296

C4385

Q3804

R3813

IC4206

C4383

C4289

R3814

C4384

R4351

D3209

C3241

D3804

D4222

C4287_1

Q3802

L3201

C4229

Q3206

R6019

B4200

J4203

B3801

R6017

D6001

Q3205

R3224

C3219

R6016

Q6005

R3223

R6018

C3218

C3201

Q4207

Q4209

R6012

R6022

C6010

R3808

R3202

R6013

R4232

J4202

R3203

R4229

IC6001

CP3400

R3801

R3805

IC3202

Q3202

L3202_1

CMF111A

W878

W848

W879

C6014 C6006

B6003

IC3205

TU6002

C3216

C3238

L3203

C3240

CP6001

C6003_2

SH4306

SH4302

R811

C857

R855

R868

R857

R862

R859

R863

C803

R864

R860

R865

R861

R104

C126

C124

IC102

W896

CP102

C819

C827

C838

C820

C828

C839

C892

C127

R813

C824

C834

C825

C835

R866

C826

X101

R814

R129

R103

R112

R818

C893

R128

R102

B7201

R810

R7205

R819

W829

C7201

R807

157

1 53

R820

R821

C849

C854

C847

C851

C856

C848

C853

C852

R115R116

1

40

IC101

14 27

R114

C112

C106

R126

D4221

R4328

R823

C858

R4354

R824

CP7201

NR802NR801

IC803

R825

R118

R119

R120

B4305

R4321

R826

C4333

IC4301

C859

Q101

R4315

R827

C867

Q102

CP4302

R828

R4320

W809

C861

R4312

R833

W813

C120

105

R834

C862

B4303

R4314

C822

R816

W814

C830

R867

R890R889

R887

R888

R852 R853 R845

R7207

R7206

C885

B817

C863

C840

R850

C116

IC105

C119

D107

C4328_1

R4309B4304

R878

W818

C884

C806

L4305

R4329

R839

R840

C864

R108

C4356

Q4306Q4303

X801

C4355

R4334

R842

R846

C4353

R4337

B4302

D804

IC802

C842

IC4303 IC4304

R4319

R4317

B4315

C831

C4348R4347

J4301

SH4303

C804

R815

C821

W893

C4339C4337

C4350

R4318

IC801

R3688

C818

C4347

B4301

C837

C801

R4343

C4336

R3695

R3716

B4314

R3636

R3715

C3654

R3614

R3613

C3722

C3227

C3231

R3215 R3210

IC3203 IC3204

NR3602

NR3601

C3637

C3606

R3711

Q3602

C3643

R3635

D3601

L3601

D3603

R3601

CP3601

CP101

C3232

R3213R3216

W811

D3204

IC3601

C3615

R3704

C3627

NR3605NR3606

C3703

NR3603

NR3604

1

37 73

C3607

L3603

L3602

L3604

R3633

IC3605

C3605

Q3601

R3632

C3642

R3621

R3670

D3602

C3633

109

R3610

CP802

C3228

R3701

D3627

C3702

D3626

C3639

C3618

L3608

CP3603

D3205

C3635