Page 1

LC-22AD1E

SERVICE MANUAL

S14N8LC22AD1E2E

LCD COLOUR TELEVISION

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

CONTENTS

» IMPORTANT SERVICE SAFETY PRECAUTION ................................................................................... 2

» SPECIFICATIONS................................................................................................................................... 4

» OPERATION MANUAL............................................................................................................................ 5

» DIMENSIONS .......................................................................................................................................... 9

» REMOVING OF MAJOR PARTS........................................................................................................... 10

» TROUBLE SHOOTING TABLE ............................................................................................................. 15

» ADJUSTING PROCEDURES ................................................................................................................ 22

» SOFTWARE UPGRADE PROCEDURE DIGITAL BROADCASTING RECEIVER UNIT...................... 36

» MAJOR IC INFORMATIONS ................................................................................................................. 39

» CHASSIS LAYOUT ................................................................................................................................ 56

» BLOCK DIAGRAM................................................................................................................................. 59

» OVERALL WIRING DIAGRAM .............................................................................................................. 62

» DESCRIPTION OF SCHEMATIC DIAGRAM ........................................................................................ 64

» SCHEMATIC DIAGRAM ........................................................................................................................ 65

» PRINTED WIRING BOARD ASSEMBLIES........................................................................................... 94

» PARTS LIST..........................................................................................................................................114

» PACKING OF THE SET....................................................................................................................... 133

LC-22AD1E

Page

SHARP CORPORATION

Page 2

If you need more information on Computer and Electronic Repair, please visit these

in fact

websites to improve yourself.

http://www.fastrepairguide.com

http://www.protech2u.com

http://www.plasma-television-repair.com

http://www.lcd-television-repair.com

Happy Repairing!!

Highly Recommended Repair Ebook:

If you’re a LCD Monitor repairer, then this is the best guide for you.

Why? Because, the author revealed all his LCD Monitor Repairing

secrets for you. I think, with just few Repair tips you learned from

this guide you will get back your investment!

Click Here to read more.

This eBook will show you how to test the electronic component

correctly and accurately. Some of you may say that I don’t

need this eBook because it is too simple! Do you know that,

there is lots of testing electronic components secrets I have learned

from this guide? Do you know how to test a‘TRIAC’ correctly and

accurately? If you answer no then I guess you have to get this

EBook. Click Here to read more.

Are you tired of searching the service manuals to look for the value

of a burnt resistor? If the answer is YES, then this eBook is a ‘must

have’ guide for you. You can save a lot of time and be able to repair

customer’s Electronic equipment with burnt resistors in it.

Click here to read more.

Page 3

LC-22AD1E

2

2

IMPORTANT SERVICE SAFETY PRECAUTION

Ë

Service work should be perfomed only by qualified service technicians who are thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CONTINUED

PROTECTION AGAINST A RISK OF

FIRE REPLACE ONL Y WITH SAME

TYPE F3701 (T2.5AL, 250V), F3702

(T3.15AL, 250V), F6551 (T1.25AL,

250V), F6552 (T1.25AL, 250V),

F6553 (T1.25AL, 250V) AND F6554

(T1.25AL, 250V) FUSE.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks:

1. Inspect all lead dress to make certain that leads are

not pinched, and check that hardware is not lodged

between the chassis and other metal parts in the

receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

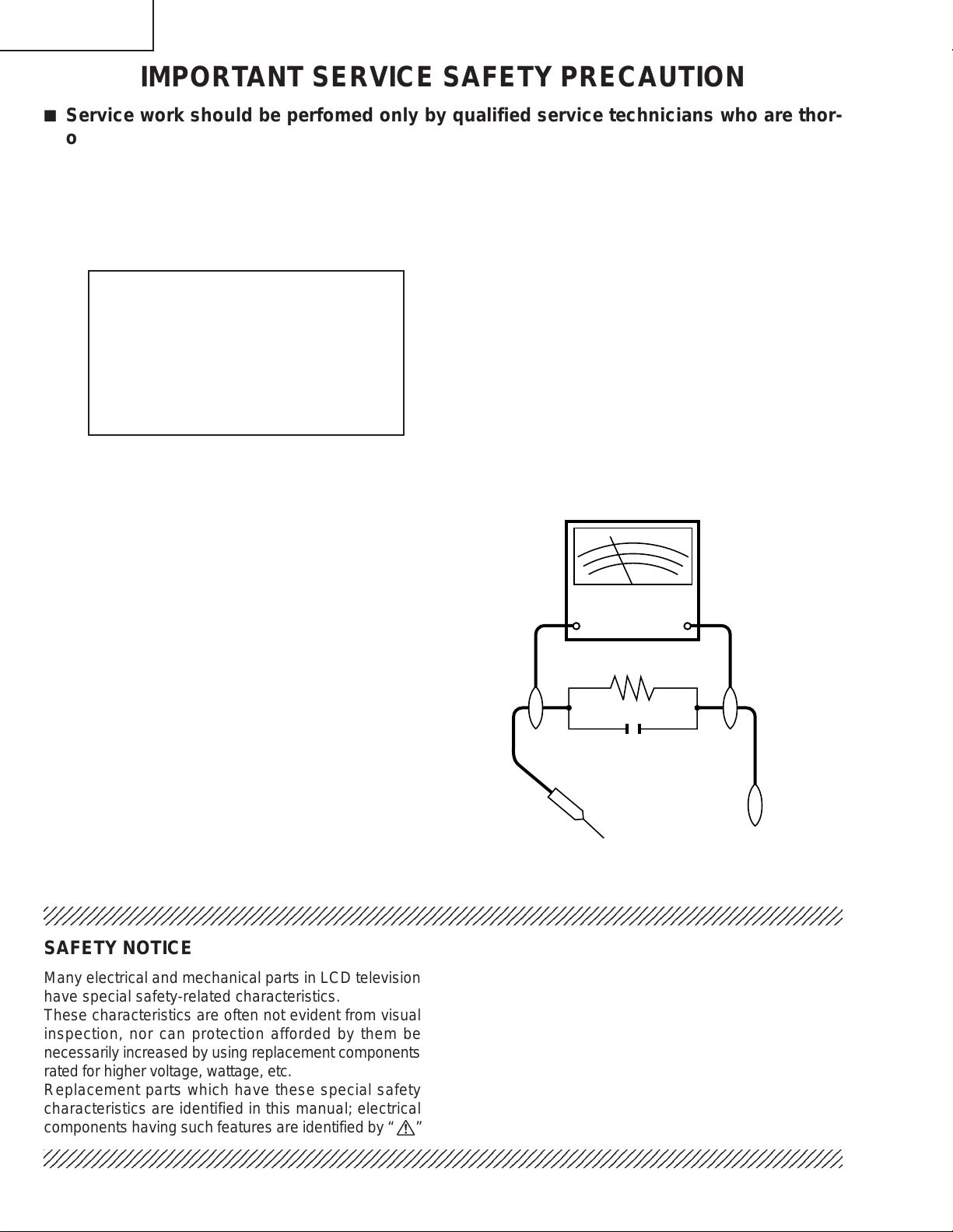

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

• Plug the AC cord directly into a 110~240 volt AC outlet,

and connect the DC power cable into the receiver's

DC jack. (Do not use an isolation transformer for this

test).

• Using two clip leads, connect a 50k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as electrical conduit or electrical ground

connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or

higher, sensitivity or measure the AC voltage drop

across the resisor.

• Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

All checks must be repeated with the AC cord plug

connection reversed. (If necessary, a nonpolarized

adaptor plug must be used only for the purpose of

completing these checks.)

Any reading of 0.75V rms (this corresponds to 0.5

milliamp. rms AC.) or more is excessive and indicates

a potential shock hazard which must be corrected

before returning the monitor to the owner.

DVM

AC SCALE

50k ohm

10W

0.15 F

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in LCD television

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

and shaded areas in the

Schematic Diagrams

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of a substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock, fire or other hazards.

components having such features are identified by “ å”

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

Replacement Parts Lists

.

and

Page 4

LC-22AD1E

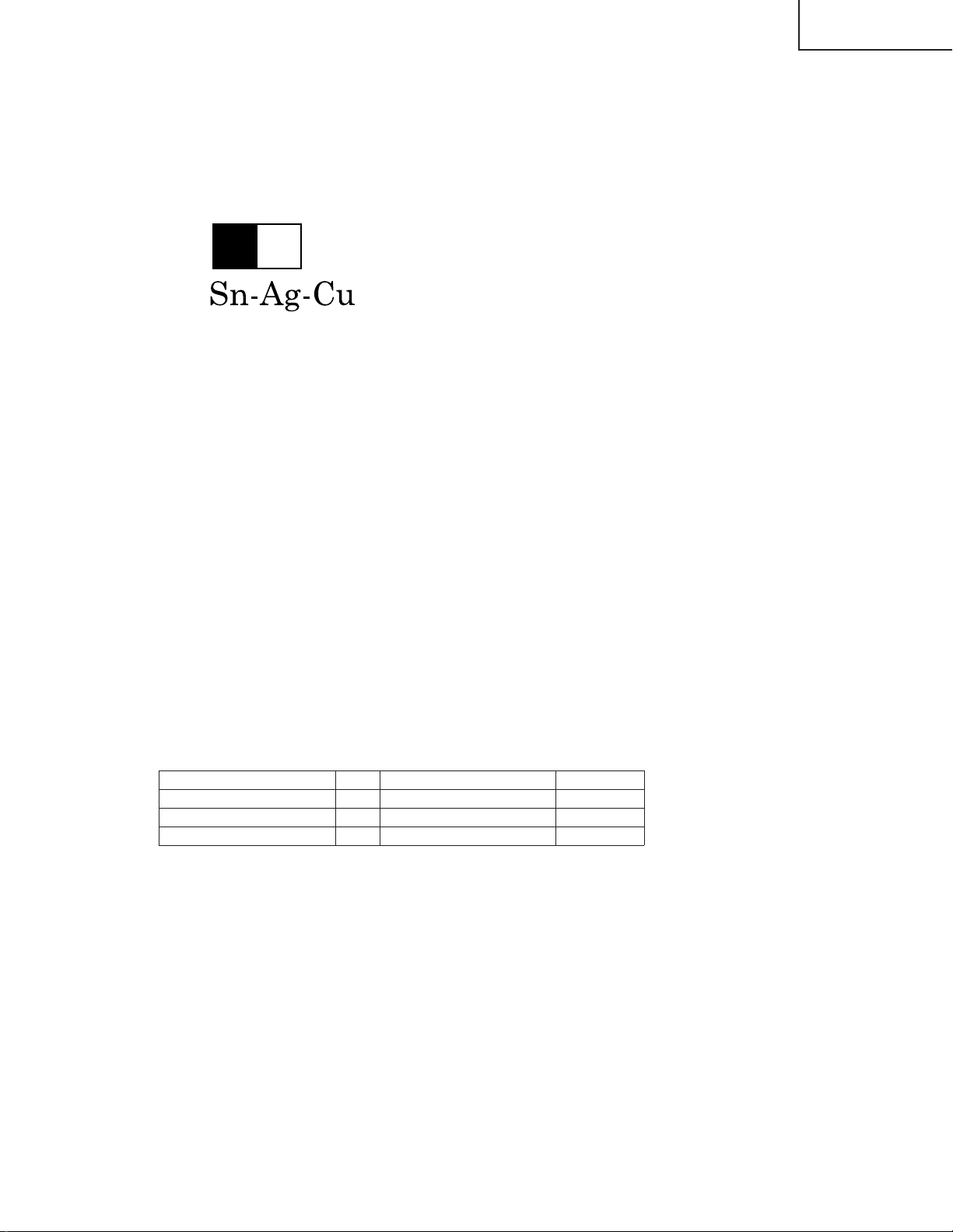

Precautions for using lead-free solder

1 Employing lead-free solder

"Inverter PWB","AV PWB","R/C,LED PWB","EXT-SP TERMINAL PWB","OPEARATION PWB","SP-JACK

PWB","MAIN PWB"of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is

attached on the PWBs and service manuals. The alphabetical character following LF shows the type of leadfree solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40ºC, we recommend

you to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldening

bit, contact our service station or service ranch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead

solder by 40°C, and as it has poor solder wettabillty , you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, Since the land may be peeled off or the maximum heat-resistance

temperature of parts may be excoeded, remove the bit from the PWB as soon as you conurm the steady

soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to tum on

and off the power of the bit as required.

if a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit

after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Becareful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No, ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

3

Page 5

LC-22AD1E

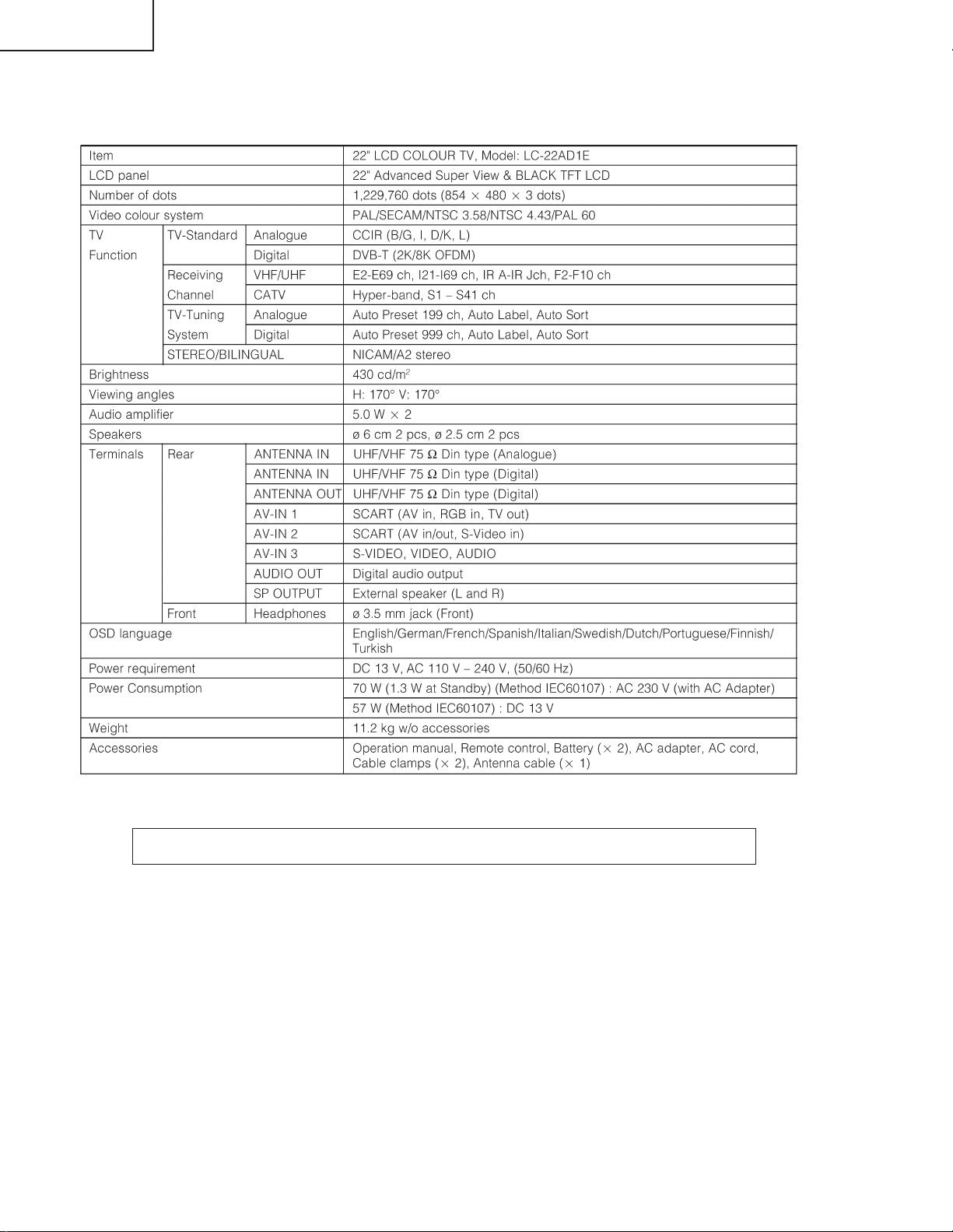

SPECIFICATIONS

Specifications are subject to change without prior notice.

4

Page 6

OPERATION MANUAL

LC-22AD1E

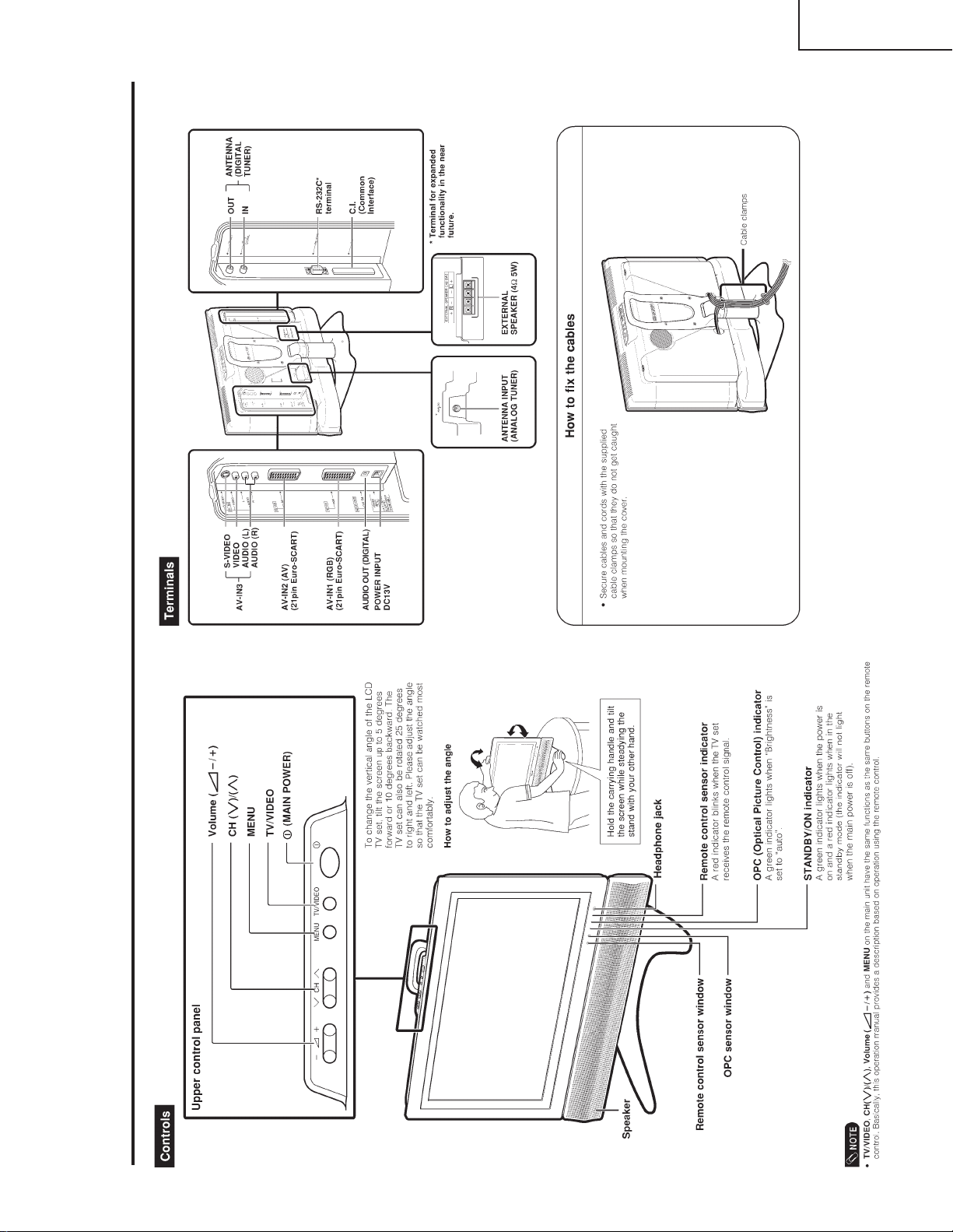

Part name of Main unit

5

Page 7

LC-22AD1E

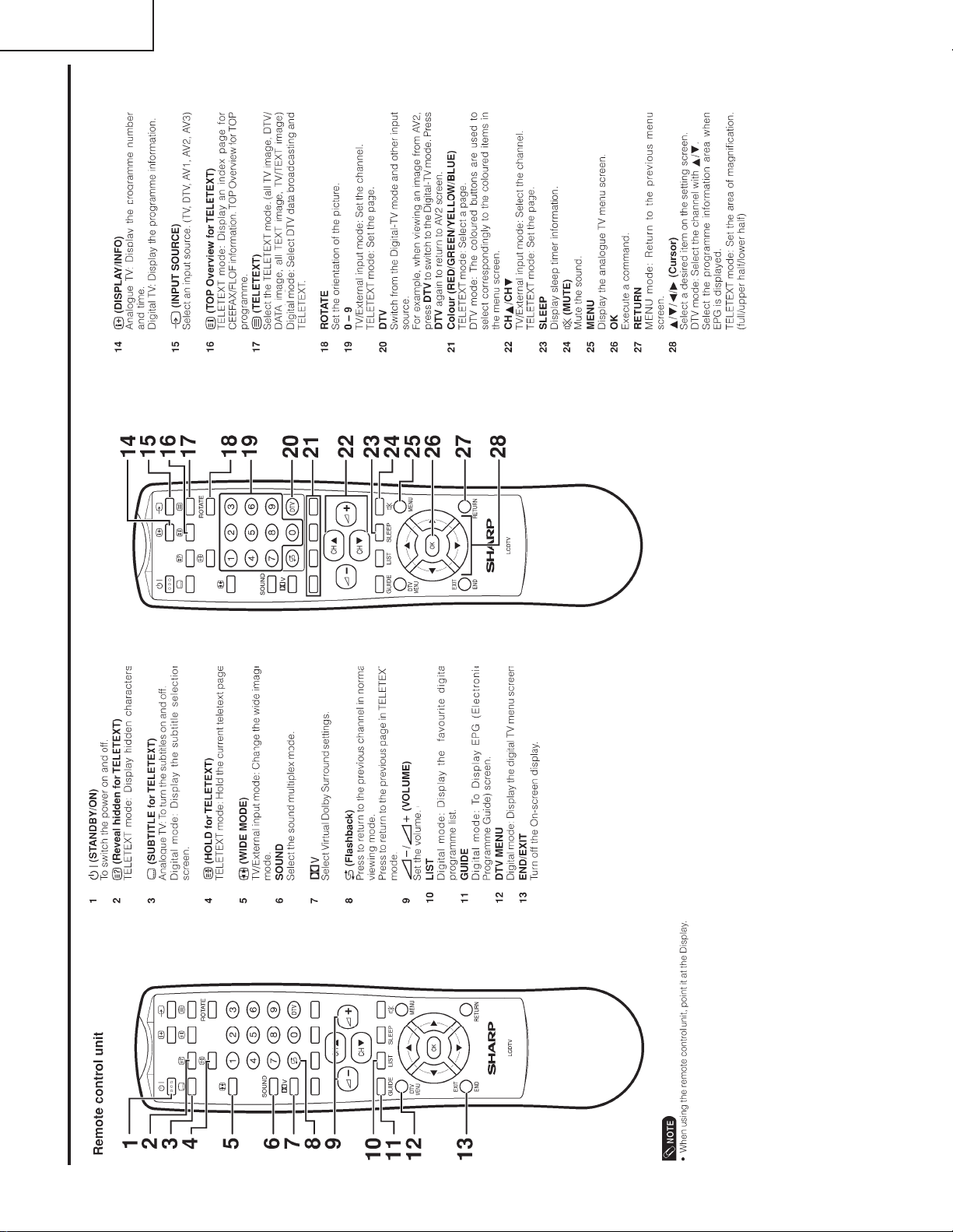

Part name of Remote control unit

6

Page 8

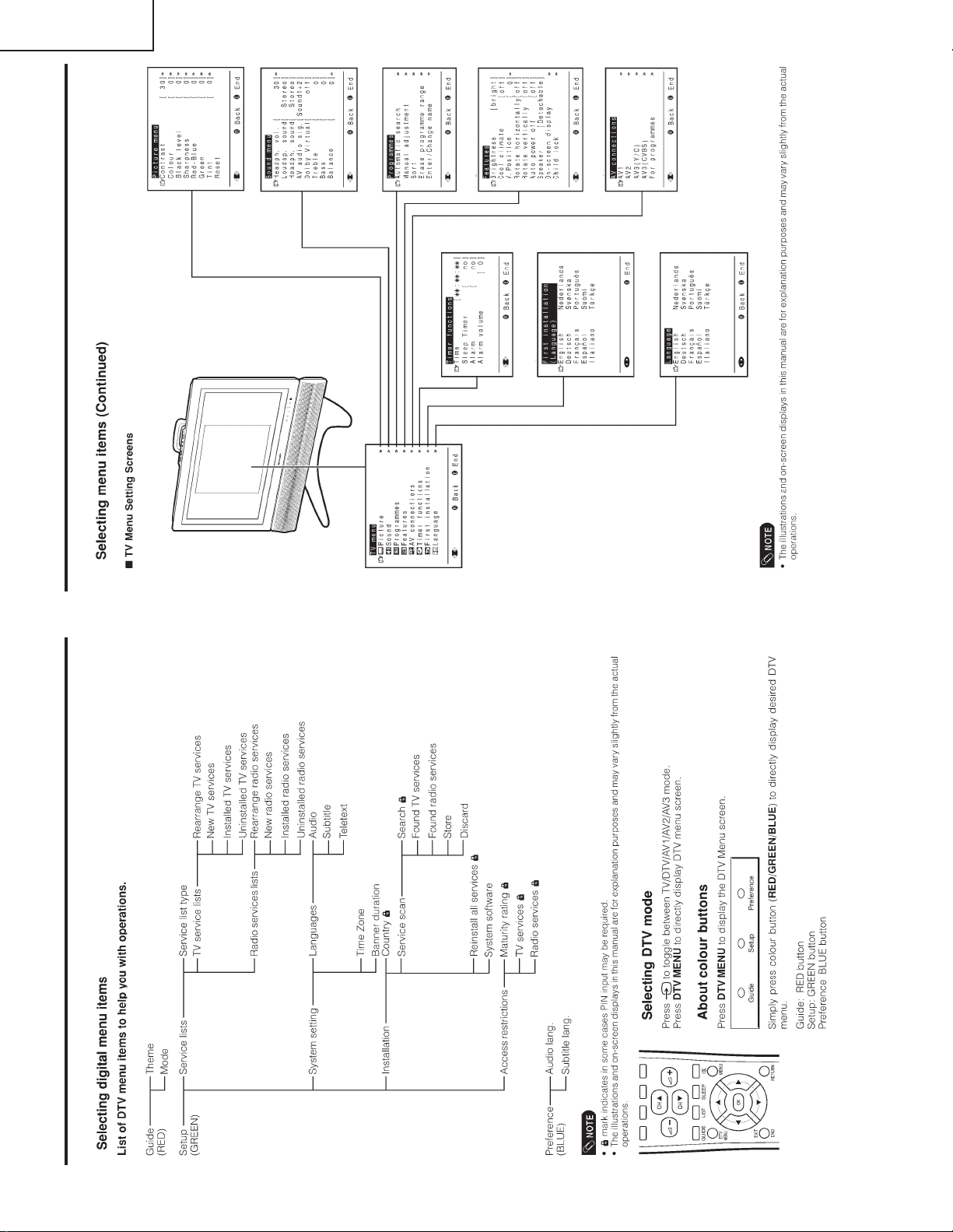

LC-22AD1E

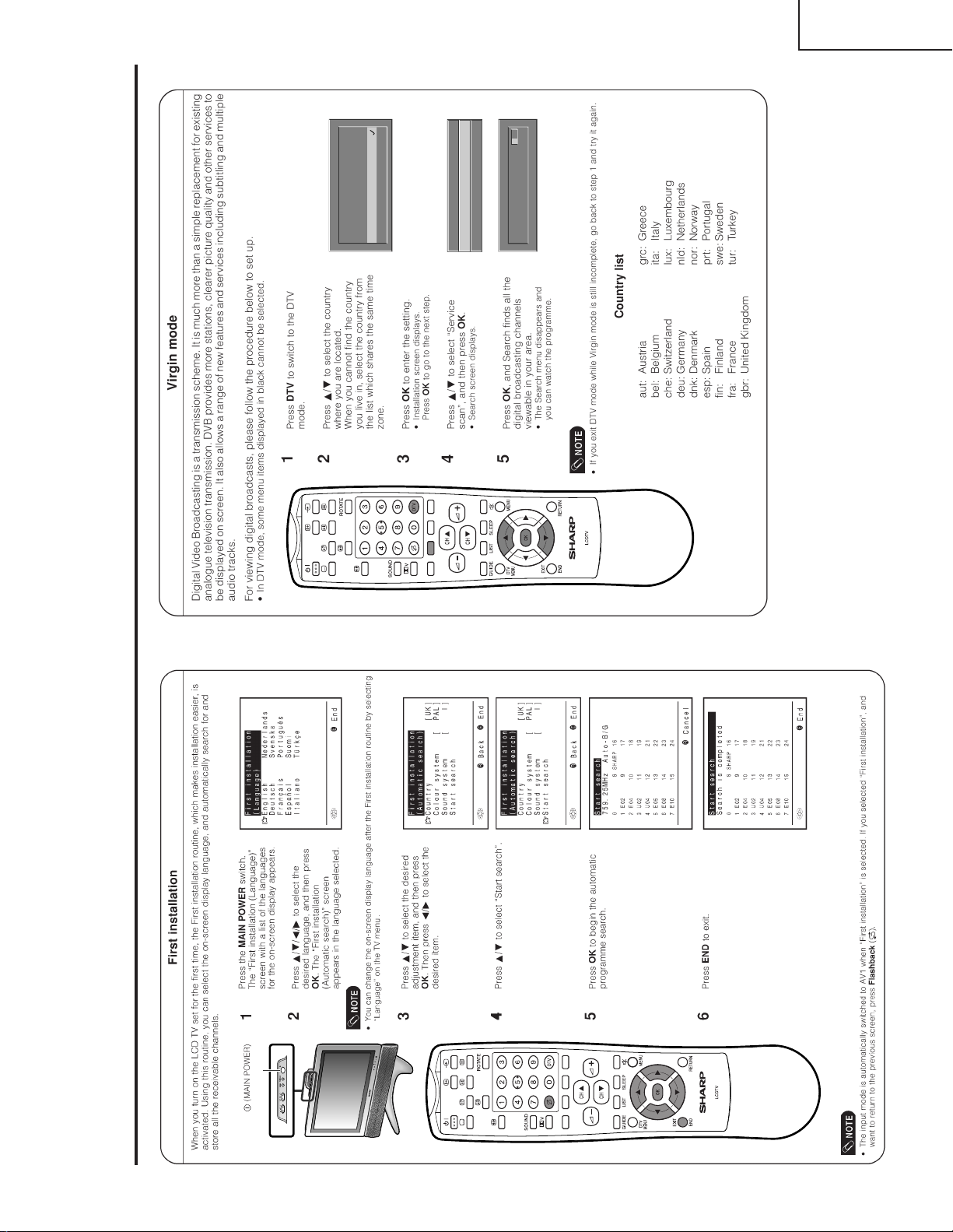

Country

fin

esp

fra

gbr

grc

Search

Country

Service scan

System software

Preparation

7

Page 9

LC-22AD1E

Useful featuresDgital TV features

8

Page 10

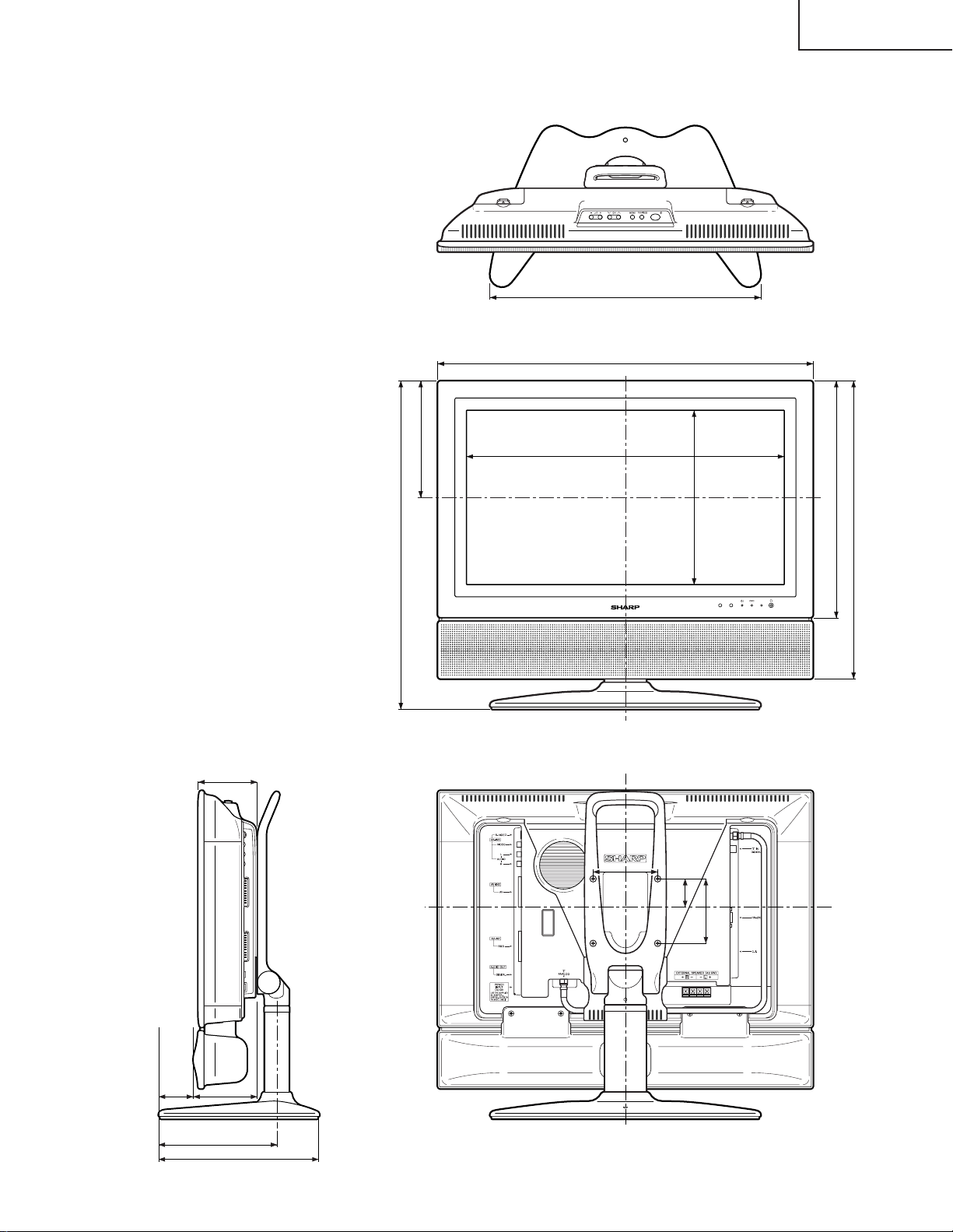

DIMENSIONS

LC-22AD1E

Unit: mm

420

582

91.5

510

180.7

492.6

367

462

270.2

100

43.9

100

53

99

183

250

9

Page 11

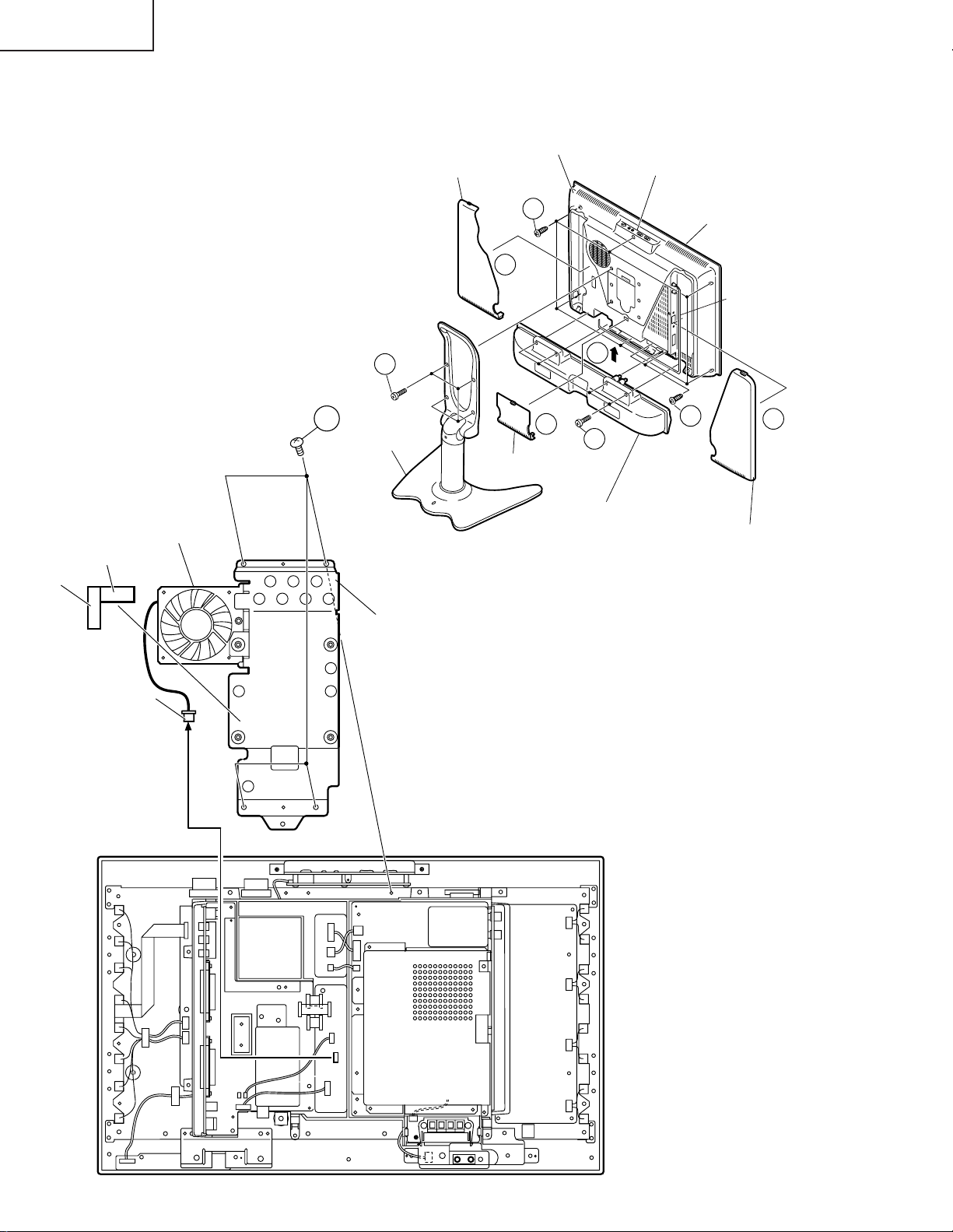

LC-22AD1E

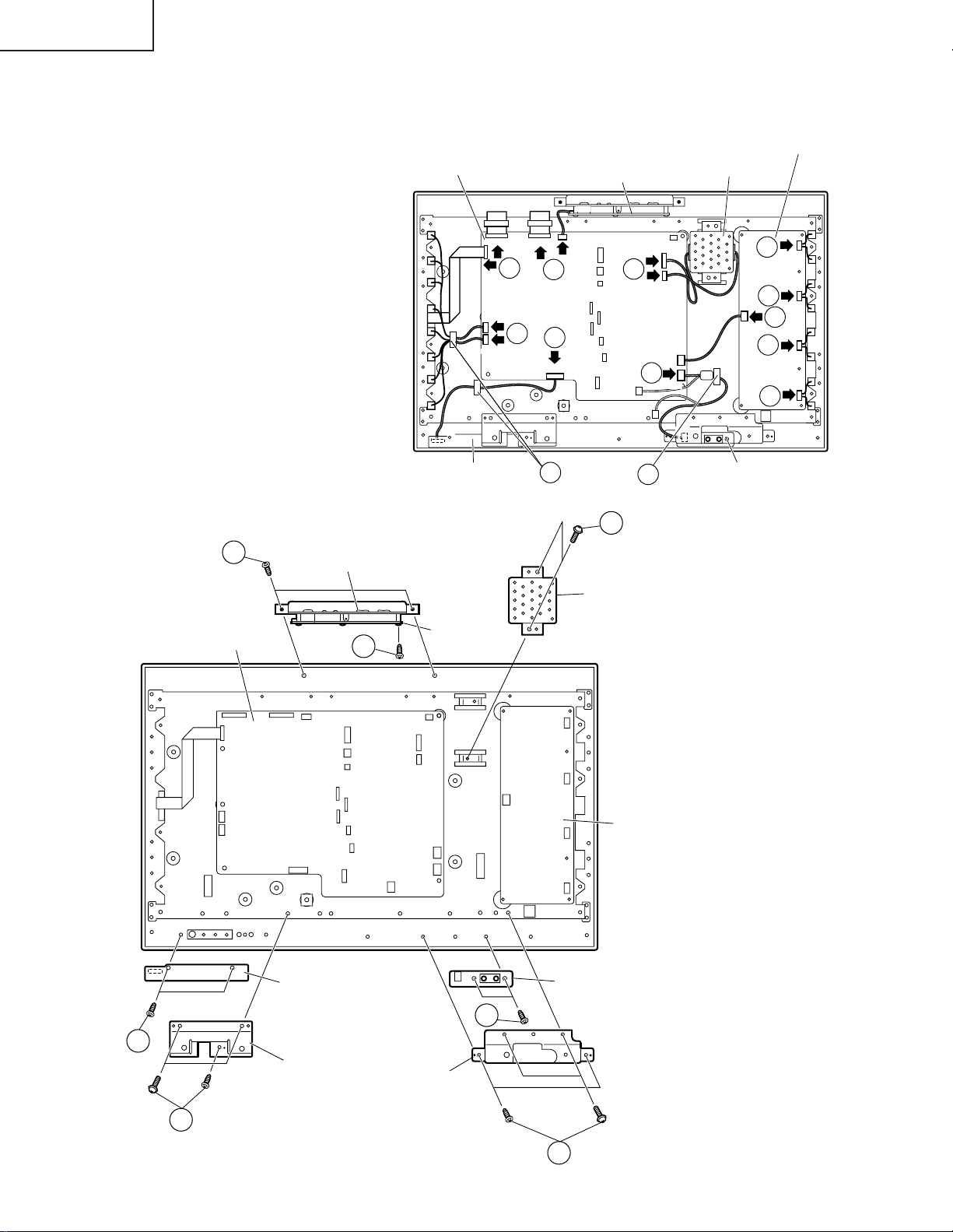

REMOVING OF MAJOR PARTS

1. Remove the 4 stand fixing screws to detach

the stand.

2. Remove the terminal covers (R), (L) and (C).

3. Remove the 2 terminal fixing screws.

4. Remove the 4 speaker fixing screws to detach

the speaker.

5. Remove the 6 cabinet B fixing screws.

6. Open in the direction of the arrow and detach

the cabinet B.

7. Remove the 4 stand reinforcement angle fixing

screws. Remove the connector (MF) to detach

the stand reinforcement angle.

Terminal Cover (R)

2

Cabnet B

5

Control Panel (Top Cover)

Cabnet A

Remove the antenna cable

Shield Tape

Tape

Connector(MF)

Fan

1

7

Stand

Stand Reinforcement Angle

2

Terminal Cover (C)

6

4

Speaker

3

Terminal Cover (L)

2

P3705

10

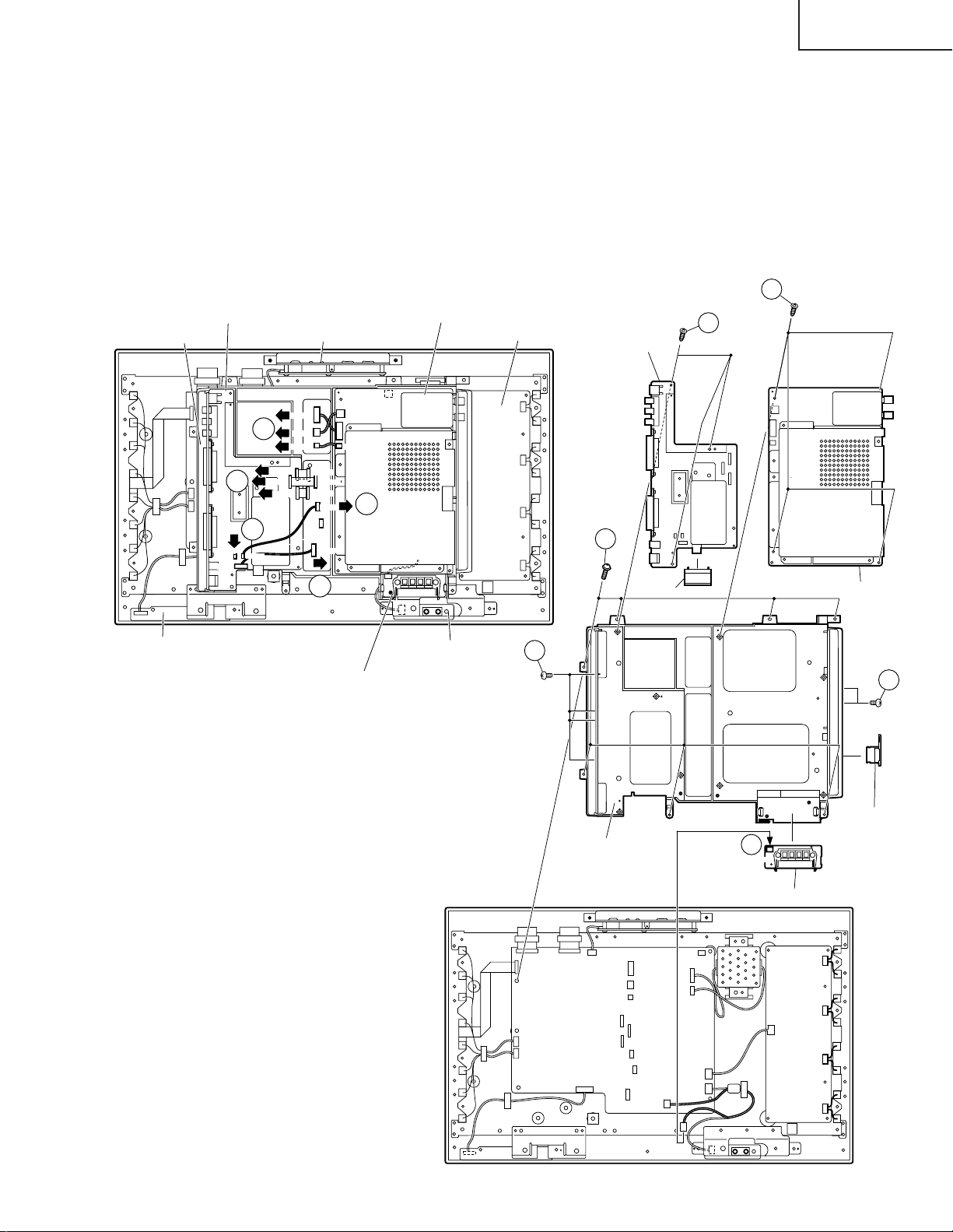

Page 12

LC-22AD1E

8. Remove the tape for fixing the wire.

9. Remove the individual connectors from the AV PWB and EU-DIGITAL PWB.

10. Remove the 4 AV PWB terminal fixing screws.

11. Remove the 2 EU-DIGITAL PWB terminal fixing screws and the PC card cover.

12. Disconnect the connector connecting the EXT-SP TERMINAL PWB and MAIN PWB. Then loosen the PWB

fixing claw to detach the EXT-SP TERMINAL PWB.

13. Remove the 3 AV PQB fixing screws to detach the AV PWB. Then remove the cassis frame cover from the AV

PWB.

14. Remove the 4 EU-DIGITAL PWB fixing screws to detach the EU-DIGITAL PWB.

15. Remove the 7 chassis frame fixing screws to detach the chassis frame.

14

MAIN PWB

R/C, LED PWB

AV PWB

9

MG

P701

OPERATION PWB

SC2503

SC2504

SC2501

P2501

1600

1503

9

SC903

SC904

SC2500

P3704

SC2502

SC905

9

P904

P3703

9

EXT-SP TERMINAL PWB

EU-DIGITAL PWB

MG

9

SP-JACK PWB

INVERTER PWB

10

15

AV PWB

Chassis

Frame Cover

13

EU-DIGITAL PWB

11

11

Chassis Frame

MAIN PWB

P404

PC Card Cover

12

P202

EXT-SP TERMINAL PWB

Page 13

LC-22AD1E

P3404

SC4902

P3503

SC4901

P132

SC1102

P3700

P3701

P3501

P3401

P3402

P3403

P3702

P201

P101

P6555

P6551

P6552

P6553

P6554

MG

17

17

17

17

17

17

17

17

17

17

17

16

16

MAIN PWB

R/C, LED PWB

SP-JACK PWB

OPERATION PWB

1BIT-AMP UNIT

INVERTER UNIT

Wire Holder

Wire Holder

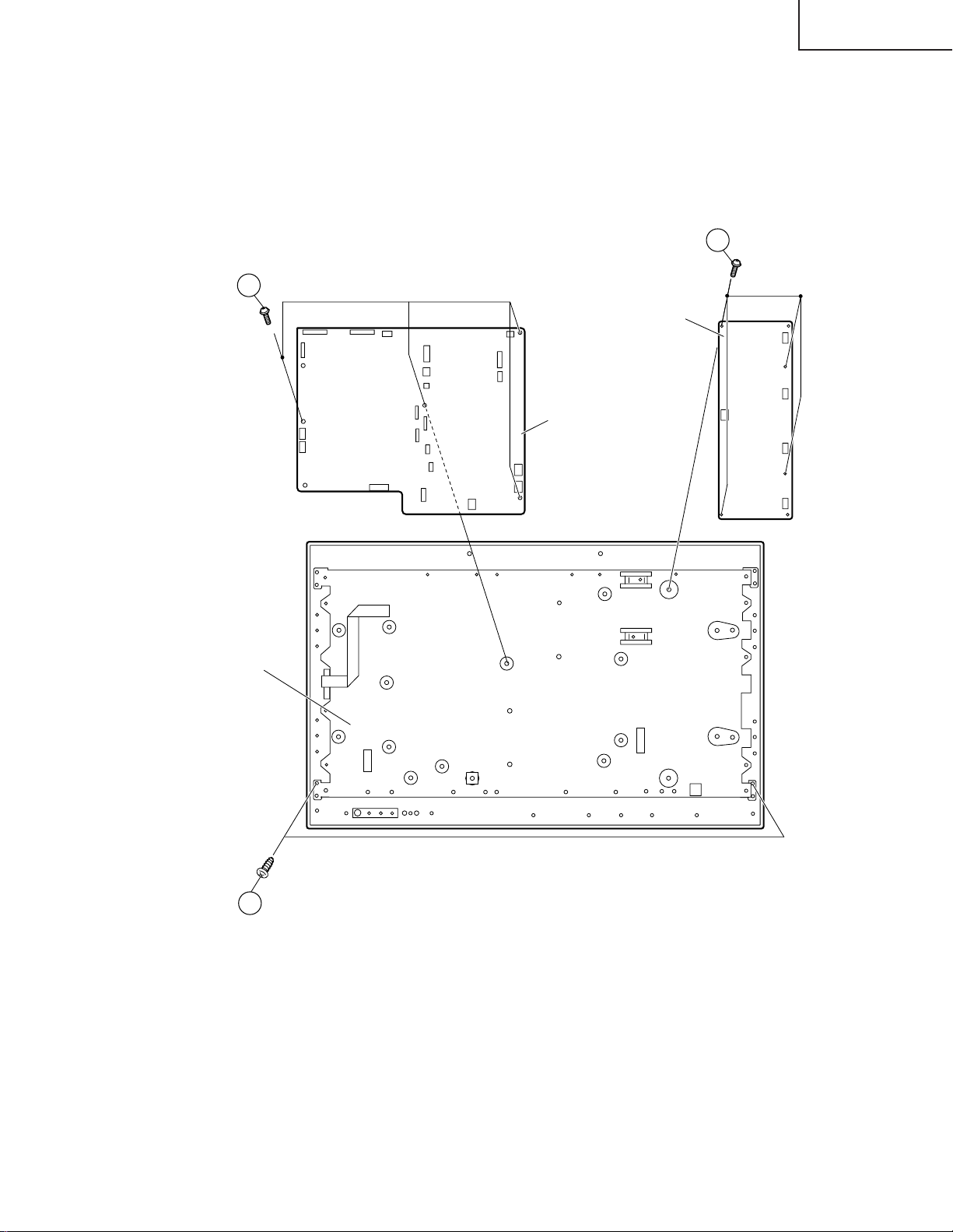

16. Open the wire holder and disconnect the

connection cord.

17. Disconnect each connector from each PWB.

18. Remove the 2 top cover ass’y fixing

screws to take out the top cover ass’y

(OPERATION PWB).

19. Remove the 2 OPERATION PWB fixing

screws from the top cover ass’y to detach

the OPERATION PWB.

20. Remove the 2 1BIT-AMP UNIT fixing

screws to detach the 1 BIT-AMP UNIT.

21. Remove the 3 speaker fixing angle (R) fixing

screws to detach the speaker fixing angle

(R).

22. Remove the 2 R/C, LED PWB fixing screws

to detach the R/C, LED PWB.

23. Remove the 4 speaker fixing angle (L) fixing

screws to detach the speaker fixing angle

(L).

24. Remove the 2 speaker terminal PWB fixing

screws to detach the speaker terminal PWB.

18

MAIN PWB

Top Cover Ass'y

19

20

1BIT-AMP UNIT

OPERATION

PWB

INVERTER PWB

22

21

Speaker Fixing

Angle (R)

R/C, LED PWB SP-JACK PWB

24

Speaker Fixing

Angle (L)

23

12

Page 14

25. Remove the 4 MAIN PWB fixing screws to detach the MAIN PWB.

26. Remove the 4 INVERTER PWB fixing screws to detach the INVERTER PWB.

27. Remove the 2 LCD panel fixing screws to detach the LCD panel unit.

25

INVERTER PWB

MAIN PWB

LC-22AD1E

26

Back Shielding Plate

27

13

Page 15

LC-22AD1E

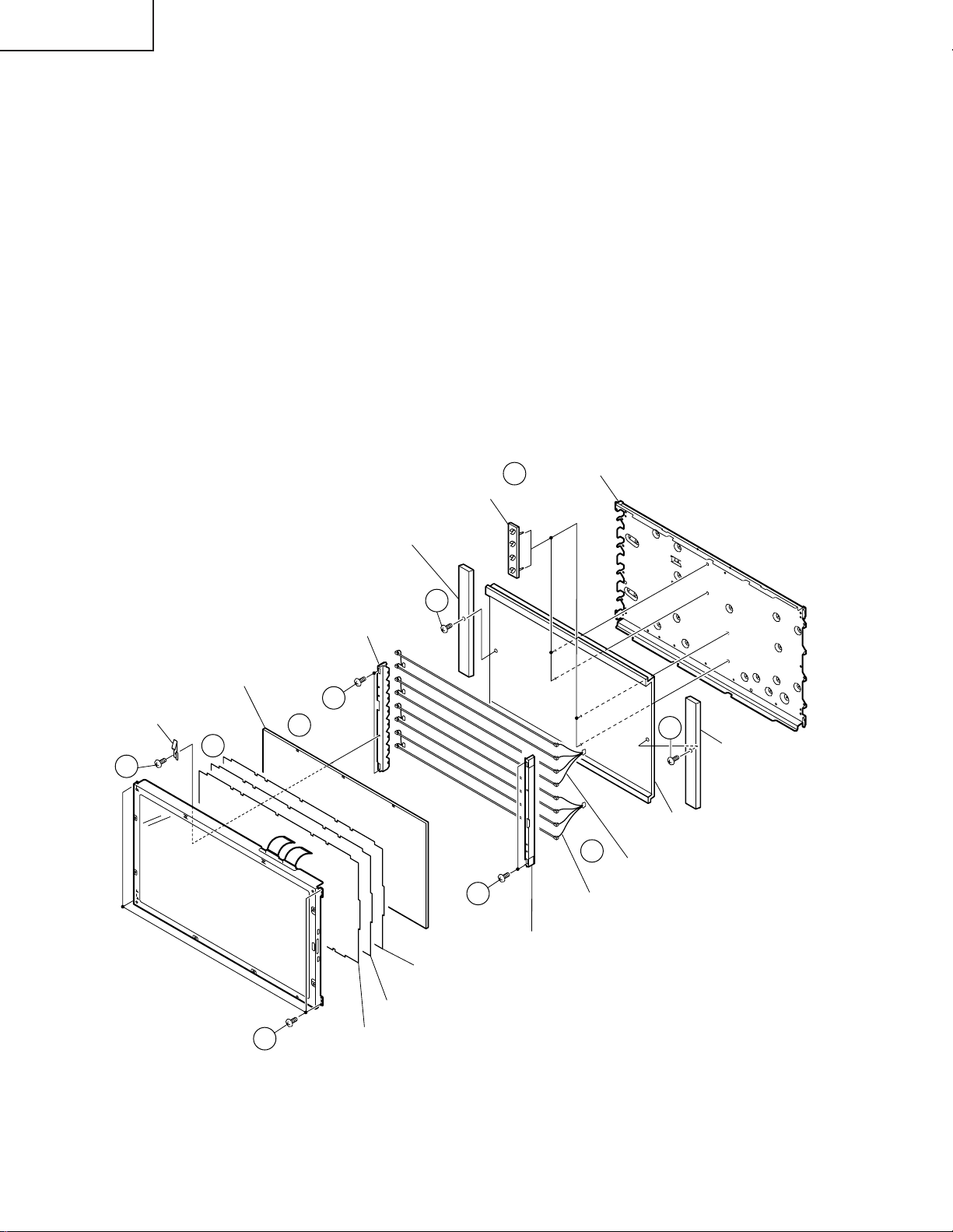

Æ Cautions when handling the LCD panel

1. Work in a clean room (relative humidity: 50% or more).

2. The workers must wear an earth band.

3. Do not expose it to shocks such as drop or vibration.

4. Use an ionizer (within 30 cm).

28. Remove the 4 LCD panel fixing screws to detach the LCD panel unit.

29. Remove the ITO earth fixing angle fixing screw to detach the ITO fixing angle.

30. Detach the reflection/polarization sheet, prism sheet, diffusion sheet, and diffusion plate.

31. Remove each 2 lamp fixing holder (upper) fixing screws to detach the lamp fixing holders (upper).

32. Detach the lamp units A and B.

33. Remove each 1 lamp fixing holder (lower) fixing screws to detach the lamp fixing holders (lower).

34. Detach the 2 lamp clips.

Back Sheilding Plate

(PSLDMA322WJFW)

Lamp Clip

(LHLDZA223WJKA)

34

ITO Earth Spring

(MSPRP1220CEFW)

29

Diffusion Panel

(PCOVU0108CEZZ)

30

22" LCD panel unit

(RLCDTA021WJZZ)

28

Lamp Fixing Holder (Bottom)

(LHLDZA219WJKZ)

Lamp Fixing Holder (Top)

(LHLDZA218WJKZ)

31

30

Prism Sheet

(PSHEPA002WJZZ)

Reflection/Deflection Sheet

(PSHEPA003WJZZ)

33

31

Diffusion Sheet

(PSHEP0294CEZZ)

33

Lamp Fixing Holder

(Bottom)

(LHLDZA219WJKZ)

Reflection Sheet

(PSHEPA112WJZZ)

32

Lamp Unit-A

(KLMP-A022WJZZ)

Lamp Unit-B

(KLMP-A023WJZZ)

Lamp Fixing Holder (Top)

(LHLDZA218WJKZ)

14

Page 16

Yes

No

No

No

No

Yes

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

No picture, No sound

Fluorescent lamp failure to light up

Check all connection of each unit. (Refer to overall wiring diagram.)

Check all the settings microprocessor’s adjust process menu.

Do F3701 and F3702

function?

Remove F3701 and F3702 and

check the load side. Is there

short-circuiting?

Is there short-circuiting of

T3700 primary side periphery,

IC3700, Q3706 and P3703?

Replace F3701 and F3702.

Check T3700’s secondary side

periphery.

Are T3700’s secondary

outputs B31V, B9V, B5V and

B8V normal?

Check T3700’s primary side

periphery.

Check T3700’s primary side

periphery, Q3715 and their

peripheral parts.

Check T3700’s secondary

load.

Does F6551, F6552, F6553

and F6554 function?

Replace F6551, F6552,

F6553 and F6554.

Is the pin(10) of lC4512 in the

"H" state?

Check the OFL line

(Q3700), IC4512 and

their peripheral parts.

Are the Q6564, Q6566,

Q6568 and Q6570 short-

circuiting?

Check Q6564, Q6566,

Q6568, Q6570 and their

peripheral parts.

Is T6551 ~ T6554’s primary

oscillator waveform normal?

Check Q6551, Q6552, Q6554,

Q6555, Q6557, Q6558, Q6560,

Q6561 and connection cable.

Replace the Fluorescent lamp

with new one and check again.

TROUBLE SHOOTING TABLE

LC-22AD1E

15

Page 17

LC-22AD1E

No picture

No picture at

all

No TV, AV1,

AV2 and AV3

output

No TV output

Check all the settings microprocessor’s adjust process menu.

Is in/output of

IC801 normal?

Check lC801

and its

peripheral parts.

Is in/output of

IC4601 normal?

Check IC4601

and its

peripheral parts.

Is in/out of

IC4512 normal?

Check lC4512

and its

peripheral parts.

Check LCD

panel voltages

and waveform.

Is in/output of

lC2521 normal?

Check IC2521

and its

peripheral parts.

Are input at pins

(71), (72) and

(73) of lC801

normal?

Check lC801

and its

peripheral parts.

Are voltages at

pins (6), (7) and

(18) of tuner

normal?

Check the power

line.

Is output at pin

(13) of tuner

normal?

Check tuner and

its peripheral

parts.

Is intput at pin

(23) of IC2521

normal?

Check the its

line.

Check IC2521

and its

peripheral parts.

No DTV output

When input source change as

"TV" and "AV1" to "AV3",

Does the LCD displays

correct video?

Check the

Main2 (power)

part.

Yes

No

Yes

No

Yes

Yes

Is DTV menu displayed when

press "DTV MENU" button?

Yes

Check the power

line. (P3704 &

opposite side)

Check cable

insertion. (SC2500

& opposite side)

Does "Weak or missing signal"

dialogue appears when

antenna cable removes?

Yes

Yes

Yes

Yes

Yes

Yes

Exchange DTV

unit. (Tuner part

problem)

Is any service found by

performing "Reinstall all

services"?

Yes

Check antenna

signal.

Try Software

download via PC

card.

Still no video?

Exchange DTV

unit. (DIgital unit

problem)

No

No

No

No

No

Yes

No

Yes

No

No

Yes

No

Yes

No

TROUBLE SHOOTING TABLE (Continued)

16

Page 18

TROUBLE SHOOTING TABLE (Continued)

No picture

No SCART1

(AV1) output

No SCART2

(AV2) output

No S-Video

(AV3) output

Check all the settings microprocessor’s adjust process menu.

Is output at

pin (17) of

IC2521

normal?

Check the

IC2521 and

its

peripheral

parts.

Check the

IC2522, AV1

line (SC1-

OUT-V) and

their

peripheral

Is input at

pin(27) of

IC2521

normal?

Check the

AV1 line

(SC1-IN-V)

and their

peripheral

parts.

Is output at

pin (13) of

IC2521

normal?

Check the

IC2521 and

its

peripheral

parts.

Check the

IC2523,

(SC2-OUT-V)

and their

peripheral

parts.

Is input at

pins (5) and

(7) of IC2521

normal?

Check the

(SC3-IN-Y)

line, (SC3-

IN-C) line

and their

peripheral

parts.

No line

output

Is input at pin

(70)(72) of

IC801normal?

Check the

(SY-OUT)

line and

their

peripheral

parts.

Yes

No

Yes

No

Yes

Yes

No

No

Is input at pin

(73) of IC801

normal?

Check the

V-PAL line

and their

peripheral

parts.

No

No

No

TELETEXT

output

Is input at

pins (1), (2)

and (3) of

IC801

normal?

Check

IC801 and

its

peripheral

parts.

Yes

Is output at

pins (3), (5)

and (6) of

IC1630

normal?

Yes

Is output at

pins (57) ~

(60) of

IC1601

normal?

Check the

its line.

No

Yes

Is input at pin

(21) of

IC1601

normal?

Check

IC1601,

IC1604 and

their

peripheral

parts.

No

Yes

Check the its

line.

(RMD1/TXD1)

No

Is input at

pin(29) of

IC2521

normal?

Check the

AV2 line

(SC2-IN-V)

and their

peripheral

parts.

Yes

No

LC-22AD1E

17

Page 19

LC-22AD1E

No picture

Becomes dark

Time passes,

becomes dark

Becomes white

Check all the settings microprocessor’s adjust process menu.

Is source GND

normal?

(SC4901,

SC4902)

Check SC4901,

SC4902 and

their peripheral

parts.

Is CSCOM

waveform

normal?

(SC4901 1/2

Pin)

Check IC4706,

IC4702, Q4701

and their

peripheral parts.

Is gate GND

normal?

(SC4501)

Check SC4501

and its

peripheral parts.

Is gate clock

(GCK) normal?

(SC4501 7Pin)

Check FL4505,

R4540 and gate

array peripheral

parts. (IC4512

5Pin)

Is VEE-6V

being

outputted?

(SC4501

16~19Pin)

Check lC4508

and its

peripheral parts.

Is VGH+34V

being outputted?

(SC4501 3/4Pin)

Check lC4507

and its

peripheral parts.

Vertical line

output

Is VSH+3.3V

being

outputted?

(SC4901

8/9Pin)

Check IC4703

and its

peripheral parts.

Yes

No

Yes

No

Yes

No

Yes

No

Is source clock

normal?

(SC4901 47Pin)

Check IC4512

and gate aray

peripheral parts.

Yes

No

Is output of LBR

normal?

(SC4901 10Pin)

Check R4574,

IC4512 and

their peripheral

parts.

No

No

No

Is GSP

waveform

normal?

(SC4501

5/15Pin)

Check FB4512,

FB4515 and

their peripheral

parts. (IC4512

7/3Pin)

Yes

No

No

TROUBLE SHOOTING TABLE (Continued)

18

Page 20

No picture

Colour is

unusual

Picture image

is gloomy

No picture

image

inversion

Check all the settings microprocessor’s adjust process menu.

Is output of R00-

R07 , RE0-RE7

normal?

(SC4902)

Check

FL4506~4509,

R4554, R4661,

R4564, R4662,

and their

peripheral parts.

Is output of

G00-G07, GE0-

GE7 normal?

(SC4901/2)

Check R4569,

R4663, R4577,

R4664,

FL4510~FL4513

and their

peripheral parts.

Is VLS +13V

being

outputted?

Check IC4509,

IC4504 and

their peripheral

parts.

Is in/output of

SPIO and SPOI

normal?

(SC4901

44/45Pin)

Check R4570,

R4571, IC4512

and their

peripheral parts.

Gradation

defect

Is output VL0,

VL64, VL96,

VL128, VL160,

VL192, VL224,

VL256, VH0,

VH64, VH96,

VH128, VH160,

VH192, VH224

and VH256

normal? (SC4902

1~16Pin)

Check IC4701

and its

peripheral parts.

Yes

No No No

No

No

Is output of

B00-B07, BE0-

BE7 normal?

(SC4901)

Check R4580,

R4666, R4579,

R4665,

FL4514~FL4517

and their

peripheral parts.

Yes

No

TROUBLE SHOOTING TABLE (Continued)

LC-22AD1E

19

Page 21

LC-22AD1E

No sound

No sound

from

speakers

No sound

from

headphone

No sound

from external

speaker

Check all the microprocessor’s adjust process menu.

Is pin (60) of

IC3501 at

"H"?

Check

IC3501 and

its

peripheral

parts.

Is pin (43) of

IC3501 at

"L"?

Check Q3508,

P101, P3501

harness and

their

peripheral

parts.

Is pin (70) of

IC3501 at

"H"?

No sound

from SCART1

output line

No sound

from SCART2

output line.

Is output at

pins (36) and

(37) of IC3202

normal?

Is output at

pins (33) and

(34) of IC3202

normal?

Yes

No

Are input and

output of

IC3202 as

specified?

Check

IC3202,

IC3403,

IC3402,

IC3405 and

their

peripheral

parts.

Yes

No

Are output at

pins (1) and

(7) of IC3408

as specified?

Check

IC3408 and

its

peripheral

parts.

Yes

No

Are output

between pins

(2) and (3)

and between

pins (6) and

(7) of P3402

as specified?

Check 1-Bit

amp and

their

peripheral

parts.

Yes

No

Is pin (48) of

IC3501 at

"H"?

Check

Q3401,

RY3401

and their

peripheral

parts.

Yes

No

Check

speakers and

their

peripheral

parts.

Yes

Yes

Yes

No

Is pin (58) of

IC3501 at

"L"?

Check

D3204,

Q3202 and

their

peripheral

parts.

Yes

No

Yes

Yes

Yes

Are input and

output of

IC3203 as

spedfied?

Check

IC3202,

IC3203 and

their

peripheral

parts.

Yes

No

Check the

headphone

and its

peripheral

parts.

No

Check Q3407,

RY3403 and

their

peripheral

parts.

Check

SCART1

periphery

parts.

Check

SCART2

periphery

parts.

No sound

from PHOTO

Audio out.

Is output at

pin (12) of

IC2510

normal?

Check the

"I2S-DA-

OUT" line.

Yes

No

Yes

Check

IC1101 and

its peripheral

parts.

Check the

"TBUS"

line and

their

peripheral

parts.

Is a speaker

setup of

"Speaker"

set as

"External" ?

TROUBLE SHOOTING TABLE (Continued)

20

Page 22

TROUBLE SHOOTING TABLE (Continued)

No sound

TV sound

failure

DTV Sound

failure

Check all the settings microprocessor’s adjust process menu.

Is output at pin

(13) of tuner

(TU1101) as

specified?

Check the tuner

and its

peripheral parts.

Is input at pin (67),

(69) of IC3202 as

specified?

Are TV and INPUT1-4

output the correct sound?

Yes

Yes

No

Yes

Is S/PDIF audio

output working?

Yes

Does "Weak or missing

signal" dialogue

appears when antenna

cable removes?

Yes

Yes

If any service found by

performing "Reinstall all

service" ?

Yes

Try Software download

via PC card.

Exchange DTV unit.

(Digital unit problem)

Yes

Still no sound?

Yes

Yes

Still no sound?

Check the MAIN2

(POWER) part.

Check the S/PDIF line.

(P2502 & opposite side)

Exchange DTV unit.

(Tuner part problem)

Check antenna

signal.

No

Check cable insertion.

(SC2500 & opposite side)

No

No

No

No

Check IC3202,

X3201 and their

peripheral

parts.

Yes

Check Q1101,

Q1102, Q2200,

Q2201, Q2202,

Q2203 and their

peripheral parts.

LC-22AD1E

21

Page 23

LC-22AD1E

ADJUSTING PROCEDURES

The best adjustment is made before shipping. If any position deviation is found or after part replacement is

performed, adjust as follows.

Preparation for adjustments

Use the dedicated AC adaptor or stable DC power supply.

AC adaptor: UADP-A056WJPZ

DC Power supply: 13V 7.0A

1.Adjustment procedure

• +B adjustment (adjustment at 5 V and 13V) → Enter the adjustment process mode.

→ Counter-bias adjustment.→ TAMP (contrast) adjustment. → White balance adjustment at the TV input.

2.Entering the adjustment process mode

•During after-sales service, the “MAIN POWER” key is turned on while pushing the “TV/VIDEO” and “MENU”

keys at the same time. (“K”, indicating the inspection processing mode, will be displayed at the upper left of the

screen.)

→ Next, “CH (Ù)” Key and “ (–)” keys are pushed at the same time. (The adjustment process mode screen

will be brought up.) To exit the adjustment process mode, press the “STANDBY-OFF” or “MAIN POWER-OFF”

key.

3. Key operation in the adjustment process mode

(1) Receiving channel selection

• The receiving channel UP/DOWN is performed with the “CH (ù)/(Ù)” keys.

One push......The UP/DOWN is performed per channel.

Continuous push......The UP/DOWN search is performed until a next receivable station is found.

• Direct channel selection using the 0 - 9 and 100 keys.

(2) Various adjustments

• The adjustment is preformed for each item with the cursor “ (')/(")” keys, cursor “ (Û)/(û)” keys,

“OK” key and “RETURN” key (LCD TV set or remote control).

• The adjustment item makes a toggle operation with the “(")” key input. (Next item)

• If the “(")” key is input while the bottom item is selected, it moves to the top item on the next page.

• When the cursor “(')” key is pressed, the item selected will move up to the previous item.

• When the “ (+)/(–)” keys or the cursor “(Û)/(û)” keys is pressed, the value of the selected item will be

changed up or down.

(3) Item selection

• If the item on the second page of the first layer is not I2C DATA and the “OK” key (the cursor “(Û)/(û)” keys

or the “ (+)/(–)” keys can also be used) is pressed, the top of each first page of the second layer will appear.

• To return from the second layer to the first layer, press the “RETURN” key.

22

Page 24

4. Adjustment

(1) +B adjustment (R3717)

a) Receive the standard colour bar signal.

b) Connect a digital voltage meter to TP3722.

Adjust the voltage to 5.00V±0.02V using R3717 (trimming VR). Specified value: 5.00V±0.02V

Note: Since the reference voltage for all of the supply voltages is 5V, make sure you set the 5.00V

adjustment accurately.

(2) +B adjustment (R4525)

a) Receive the standard colour bar signal.

b) Connect a digital voltage meter to TP4531.

Adjust the voltage to 13.00V±0.05V using R4525 (trimming VR). Specified value: 13.00V±0.05V

Note: Since this is the reference voltage for the power supply for gradation, make sure you perform this

adjustment accurately.

(3) Counter-bias adjustment

• This adjustment minimizes the flicker on the screen.

• To set the COM BIAS shown on the first page of the adjustment

process, perform this adjustment at 50 Hz and 60 Hz,

respectively.

a) Refer to the previous item 2 on page 22 to Entering the

adjustment process mode.

The first page of the adjustment process, shown in the diagram

on the right (Fig. 3-1), will be brought up.

b) Select [G/A] on the second page of the adjustment process

using the cursor “(")” key, and press the “OK” key (Fig. 3-2).

(The second layer item appears.)

• Next, press the cursor ”(")” key twice, to bring up the third

page of the second layer (Fig.3-3).

• Select [G/A TEST PATTERN 1], on the third page.(In this

case, the set value should be [0].)

• Press the cursor “(û)” key repeatedly to set the value to

[14].(In this case, [14] is [dot reverse flicker pattern 2].)

• Press the “RETURN” key and the cursor “(')” key to return

to the first page of the adjustment process.

c) Select [COM BIAS 50] on the first page, using the cursor

“(')/(")” keys.

d) Press the cursor “(Û)/(û)” keys repeatedly. Stop pressing

it when the flicker on the screen is at the lowest level possible.

(In this example, the set value [COM BIAS 50] is [105].)

e) Next, select the first page, [COM BIAS 60], using the cursor

“(')/(")” keys.

Press the cursor “(Û)/(û)” keys repeatedly. Stop pressing

it when the flicker on the screen is at the lowest level possible.

(In this example, the set value [COM BIAS 60] is [108].)

LC-22AD1E

WLD 26 VER 1.000 DTV VER

INCH SIZE 22

MODEL AD1E

ERROR NO RESET 0

1BIT_AMP ERR 0

PUBLIC MODE OFF

COM BIAS 60 100

COM BIAS 50 100

PAL TAMP 20

SECAM TAMP 20

AV AMP 20

TAMP L 160

Y READ VALUE

TAMP M 168

Fig. 3-1

First page of the first layer of the adjustment process

WLD 26 VER 1.000 DTV VER

12C DATA 000000000000

12C DATA WAIT

MSP

VPC

G/A

TUNER

FLI12310

DSP

DOLBY

DELAY

TEXT

OTHERS

Fig. 3-2

Second page of the first layer of the adjustment process

23

Page 25

LC-22AD1E

f) Press the cursor “(")” key and the “OK” key again, and select

[G/A TEST PATTERN 1], on the third page of the [G/A] second

layer on the second page. Then, use the cursor “(Û)/(û)” keys

to return the setting from [14] to [0].

g) Press the “RETURN” key and the “(')/(")” keys to return to

the first page of the adjustment process.

h) To exit the adjustment process mode, press the “STANDBY-

[G/A] : 3

G/A TEST PATTERN1 0

G/A TEST PATTERN2 0

G/A DATA 0000

G/A DATA WAIT

NTSC PWM FREQ 0D2

PAL PWM FREQ 0D2

NTSC PWM DUTY 0

PAL PWM DUTY 0

OFF” or “MAIN POWER-OFF” key.

Fig. 3-3

(4) TAMP adjustment

Third page of the [G/A] second layer

The screen contrast is adjusted.

a) Bring up the pattern shown in Fig. 4-2 using a signal or an RF signal generator that is producing the

standard colour bars.

WHITE

75%

Fig. 4-1

White 75% half-colour bar signal

TAMP adjustment pattern (PAL r = 1.00)

(WHITE 75%)

Fig. 4-2

b) Refer to the item 2 on page 22 to Entering the adjustment process mode.

This will bring up the first page of the adjustment process, shown in Fig. 4-3.

c) There is a [Y] shown on the bottom of the first page. See if the setting is between [160] and [168]. If it is,

it is OK. However, if the value is outside this range, it is necessary to readjust it.

d) Select [PAL TAMP] using the cursor “(')/(")” keys.

e) Press the cursor “(')/(")” keys and adjust the value of [Y] so that it is between [160] and [168].

(In this example, the value of PAL TAMP is [25].)

_______

_______

_______

P AL TAMP 25

SECAM T AMP 20

AV AMP 20

TAMP L 160

Y READ VALUE

TAMP H 168

Fig. 4-3

First page of the adjustment process

_______

_______

_______

P AL TAMP 25

SECAM T AMP 25

_______

_______

Fig. 4-4

First page of the adjustment process

f) Next, select [SECAM TAMP] using the cursor “(')/(")” keys.

• Use the cursor “(Û)/(û)” keys to manually set [SECAM TAMP] to the same value as previously seen

in PAL TAMP, [25] in the example above.

h) Press the “(')/(")” keys to escape.

i) To exit the adjustment process mode, press the “STANDBY-OFF” or “MAIN POWER-OFF” key.

24

Page 26

(5) White balance adjustment

This TV input white balance adjusted.

This adjustment is performed when the LCD is replaced and the white balance must be set.

a) Bring up the pattern shown in Fig. 5-1 on AV1, AV2 or AV3 using a signal generator .

[FLI2310] : 2

R CUT OFF 0

G CUT OFF 0

WHITE 70% GRAY 40%

B CUT OFF 0

R DRIVE 100

G DRIVE 100

B DRIVE 100

MOTION THRESH 2F

VE GAIN2 2

NR ON

NR LEVEL 2

LC-22AD1E

White balance adjustment pattern

(PAL signal)

Fig. 5-1

Adjustment process menu [FLI2310]

Screen from the second page of the second layer

Fig. 5-2

b) Refer to the item 2 on page22 to Entering the adjustment process mode.

c) Use the cursor “(')/(")” keys to bring up the second page. Select [FLI2310] using the cursor

“(')/(")” keys, and then press the “OK” key.

You can also press the cursor “(")” key to bring up the second page of the second layer.

• In this case, although the screen from the second page of [FLI2310] is brought up (shown in Fig. 5-2),

make sure the CUT OFF settings for [R], [G], and [B] are [0] and the DRIVE settings for [R], [G], and [B]

are [100].

If they are not [0] and [100], set them.

• Use the cursor “(Û)/(û)” key to set them to [0] and [100].

d) Prepare and install a standard luminance meter (for example, a Minolta CA-110).

e) Use the cursor “(')/(")” keys to bring up the second page. Select “FLI2310”, and then press the

“OK” key. Press the cursor “(")” key to bring up the second page of the second layer.

f) Fig. 5-3 shows the standard adjustment value for the white balance.

g) Adjust the chromaticity of x and y for the six CUT OFF and DRIVE colour items on the screen shown in

Fig.5-2. Use the cursor “(Û)/(û)” keys so that the values shown for White 70% and Gray 40% are the

same as the values shown in Fig. 5-3.

• In this case, each of the set values of R, G, and B is out of [0] or [100].

x y y(ref)

WHITE 70% 0.278 0.283 154

GRAY 40% 0.257 0.264 1.797

Adjustment range ±0.002

Inspection range ±0.003

Fig. 5-3

White balance adjustment values

*1.The adjustment should be performed after a 30-minute aging.

*2.The CUT OFF value should be adjusted within the range of ±0 ~ 25.

The DRIVE value should be adjusted within the range of ±0 ~ 25.

h) To exit the adjustment process mode, press the “STANDBY-OFF” or “MAIN POWER-OFF” key.

25

Page 27

LC-22AD1E

5. Lamp error detection

1) Function description

This LCD colour television has a function (lamp error detection) that turns off the power automatically, for

safety, if a problem occurs with a lamp or a lamp circuit.

If there is a problem with a lamp or a lamp circuit or if a lamp error is detected for some other cause, the

following will occur.

(1)The power is turned off about 15 seconds after the power to the TV is turned on. (The power LED on

the front of the TV will be changed from green to red, and it will flash three times repeatedly.)

(2)If the protective function described in (1) is repeatedly activated five consecutive times, you will not be

able to turn on the power. (The red power LED will flash three times, repeatedly.)

2) Countermeasures

1. Confirmation after the lamp error detection is deactivated

When the power is turned off due to the lamp error detection function as described above, turn off

the [power] while the power LED is red. Then, when the “TV/VIDEO” key and the “MENU” key are

held down and the “MAIN POWER“ key is pressed, the [inspection process] mode will be entered

and “K” will be displayed. Next, press the “ (-)” key and the “(Ù)” key at the same time to

enter the [adjustment mode].

Then, you can check the operation to see if the lamp and lamp circuit are abnormal.

See if [ERROR NO RESET] in the first page of the adjustment is set to 1 or more.

If it is 1 or more, it means that a lamp error has been detected.

2. Resetting the lamp error count

After you have finished checking whether the lamp and lamp circuit are abnormal, reset the lamp error

count.

Select [ERROR NO RESET] in the first page of the adjustment process, and reset it to [0] using the

cursor “(Û)/(û)” keys.

WLD 26 VER 1.000 DTV VER

INCH SIZE 22

MODEL AD1E

ERROR NO RESET 0

1BIT_AMP ERR 0

PUBLIC MODE OFF

COM BIAS 60 100

COM BIAS 50 100

PAL TAMP 20

SECAM TAMP 20

AV AMP 20

TAMP L 160

Y READ VALUE

TAMP H 168

Reset to "0"

Fig. 5-1

First page of the first layer of the adjustment process

26

Page 28

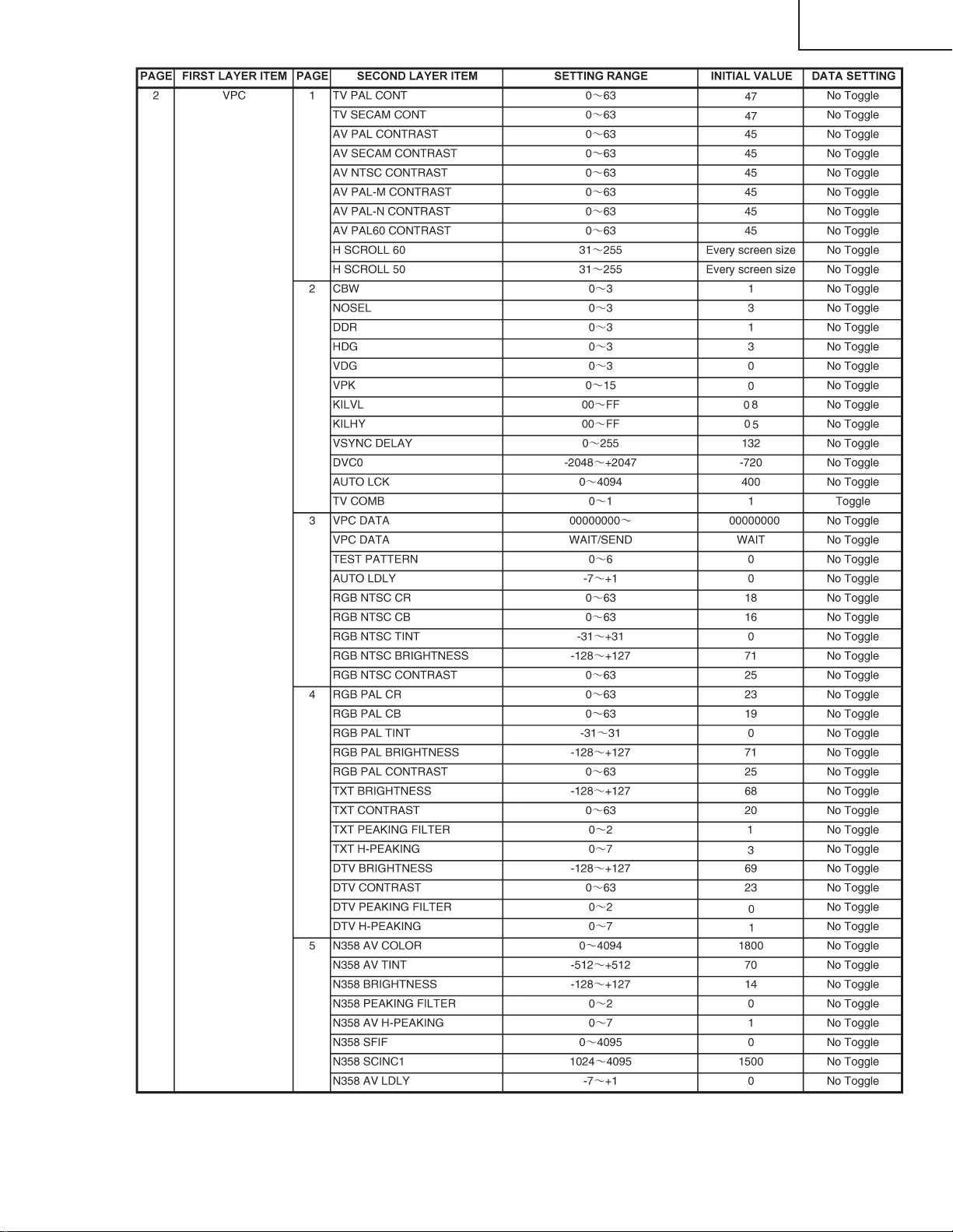

6. Values set at factory shipment

LC-22AD1E

ITEM INITIAL VALUE

LAST CH AV1

LAST POWER OFF

FLASH BACK AV1

Volume 20

Picture

Contrast 30

Colour 0

Black level 0

Sharpness 0

Red-blue 0

Green 0

Tint 0

Sound

Sound via TV

Headph.vol 30

Loudsp. Sound Stereo

Headph. Sound Stereo

AV audio sig. Sound1+2

Maximum volume. 60

Sound wide. off

Treble 0

Bass 0

Balance 0

Speaker Detachable

Programmes

Country (E) Germany

Country (K) UK

Store prog. position 1

Name ALL CH DELETE

Colour System ALL CH PAL

Sound System (E) ALL CH B/G

Sound System (K) ALL CH 1

Skip ALL CH OFF

Features

Brightness bright

Cool climate off

V.Position 0

Rotate horizontally off

Rotate vertically off

Auto power off off

Position buttom

Sound info yes

Time no

Alarm time no

Sleep time no

Child lock All CH Cancel

For all programmes (Child lock)

Password (Child lock) 1234

A V Connections

Signal type(AV1) CVBS

AFC (AV1) Mode1

AFC (AV2(Y/C)) Mode1

AFC (AV2(CVBS)) Mode1

All no

Colour system(AV1) Auto

Colour system(AV2(Y/C))

Colour system(AV2(CVBS))

AV control voltage no

RGB on-screen display

For decoder connected to AV1

Sound from AV1 Dec

Timer functions

Time --:--:- Switch off no

Alarm timer no

Alarm volume 0

Language (E) Deutch

Language (K) English

WIDE MODE Panorama

WSS(Auto) Panorama

Character set (TEXT) West Europe

•ADJUSTMENT PROCESS

MODEL (E) AD1E

MODEL (K) AD1K

ERROR NO RESET 0

1BIT_AMP ERR 0

PUBLIC MODE OFF

Auto

Auto

no

All CH Cancel

27

Page 29

LC-22AD1E

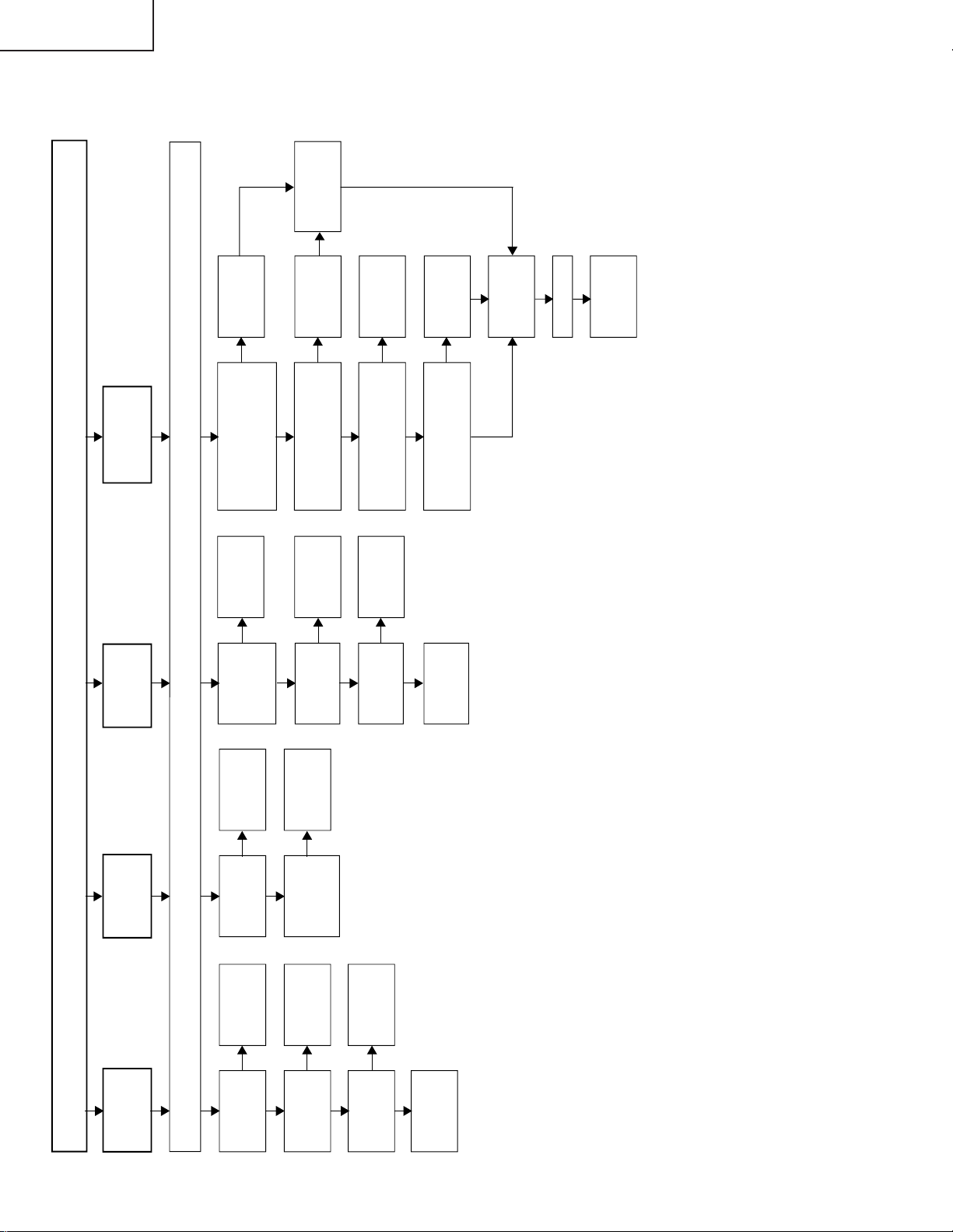

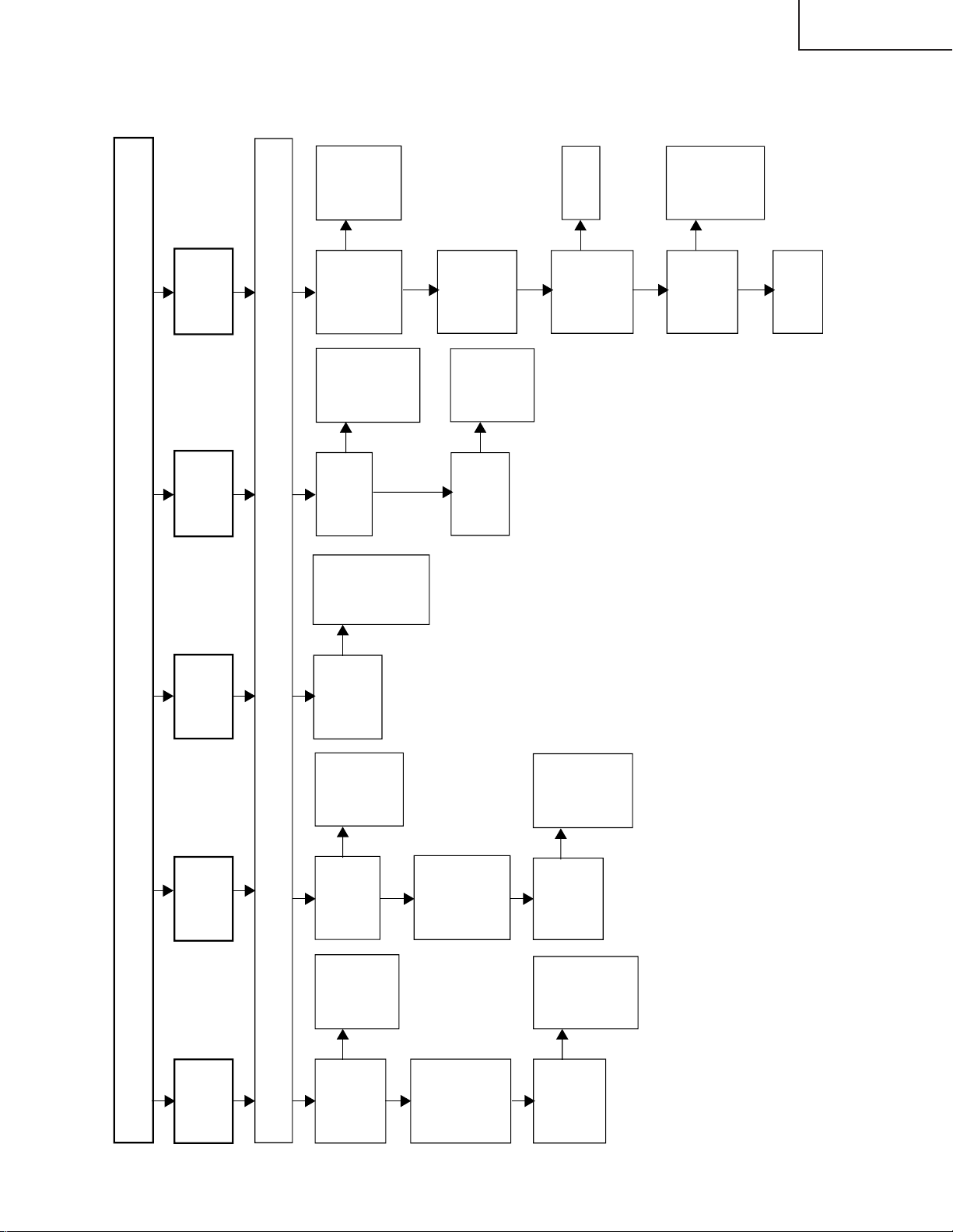

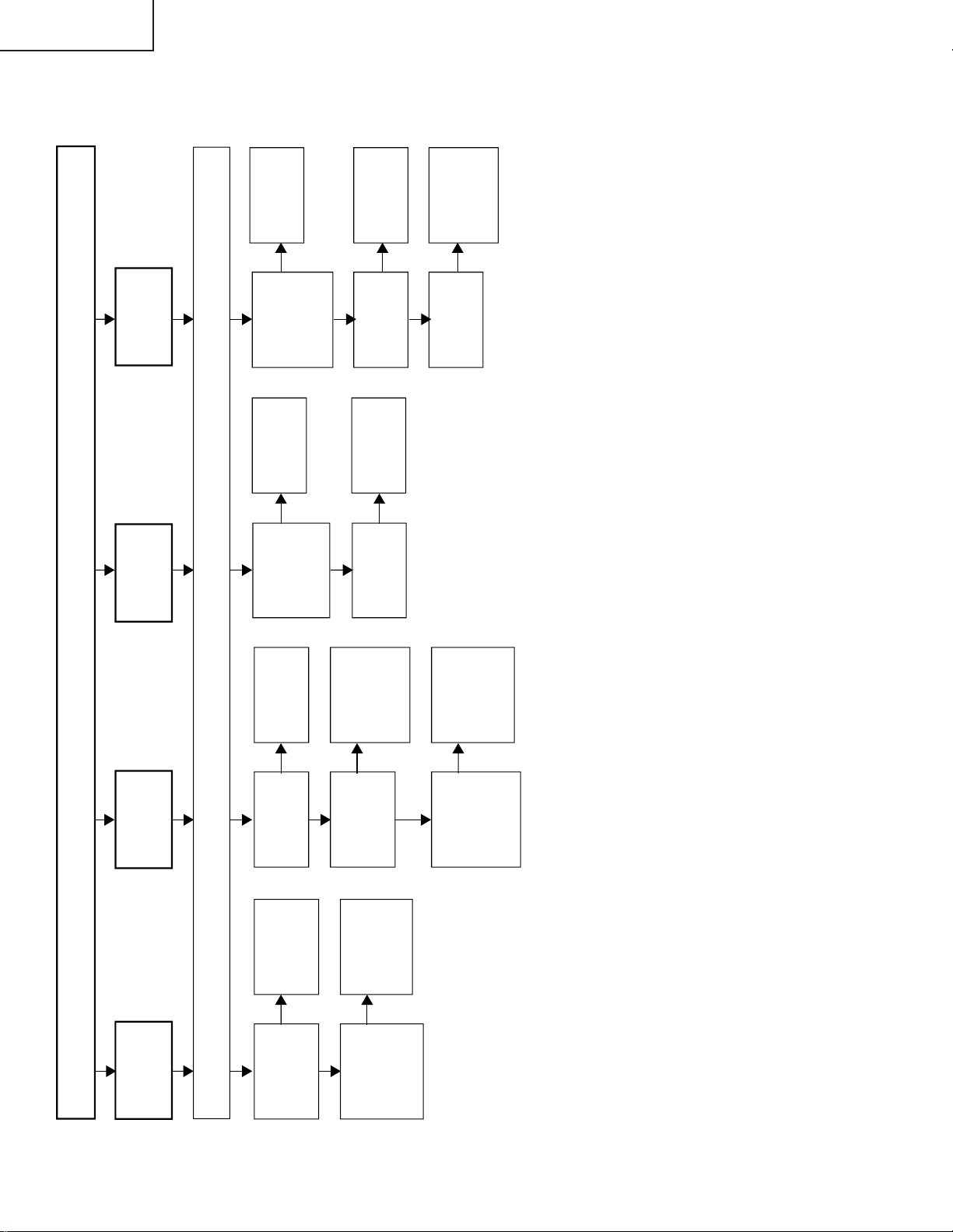

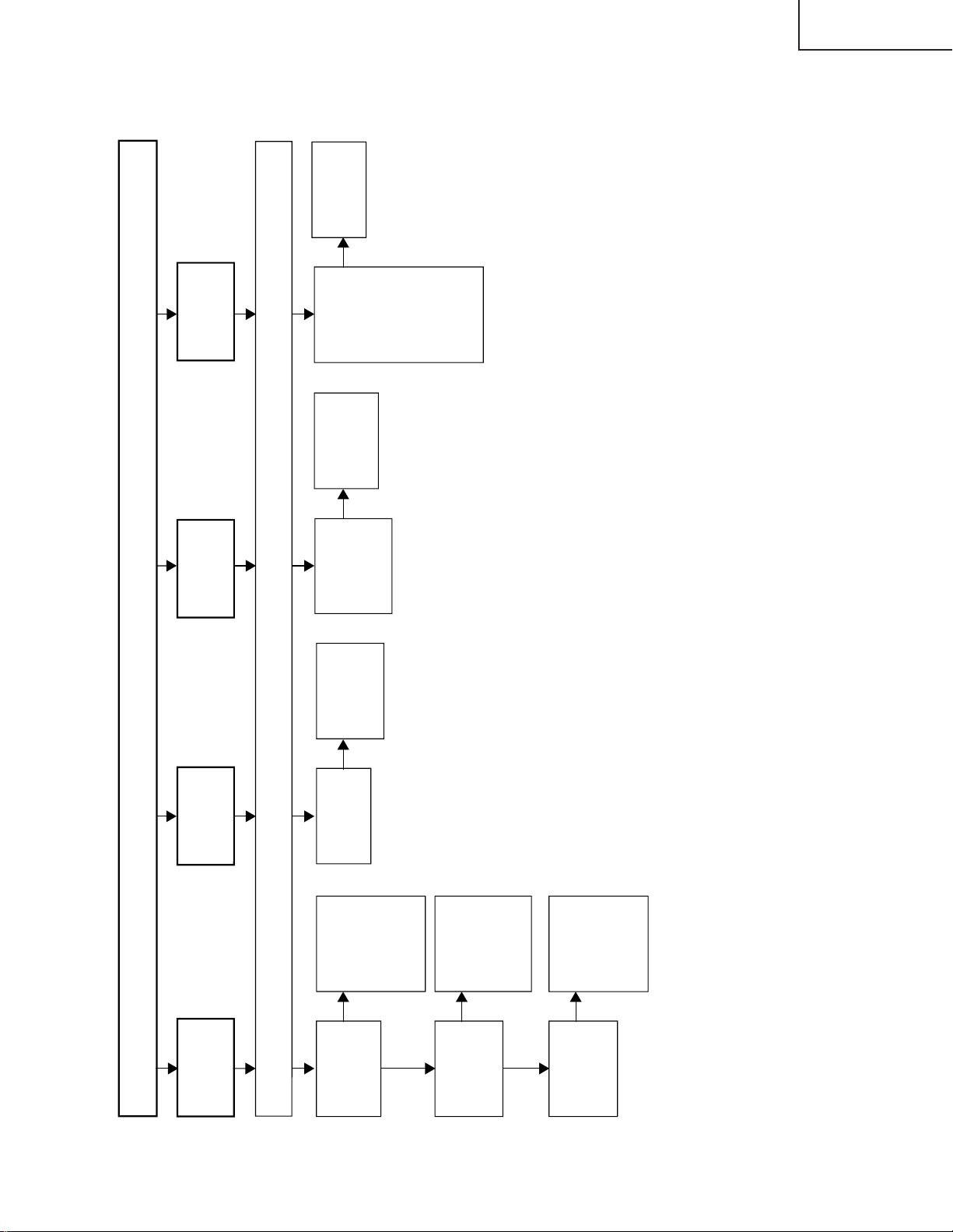

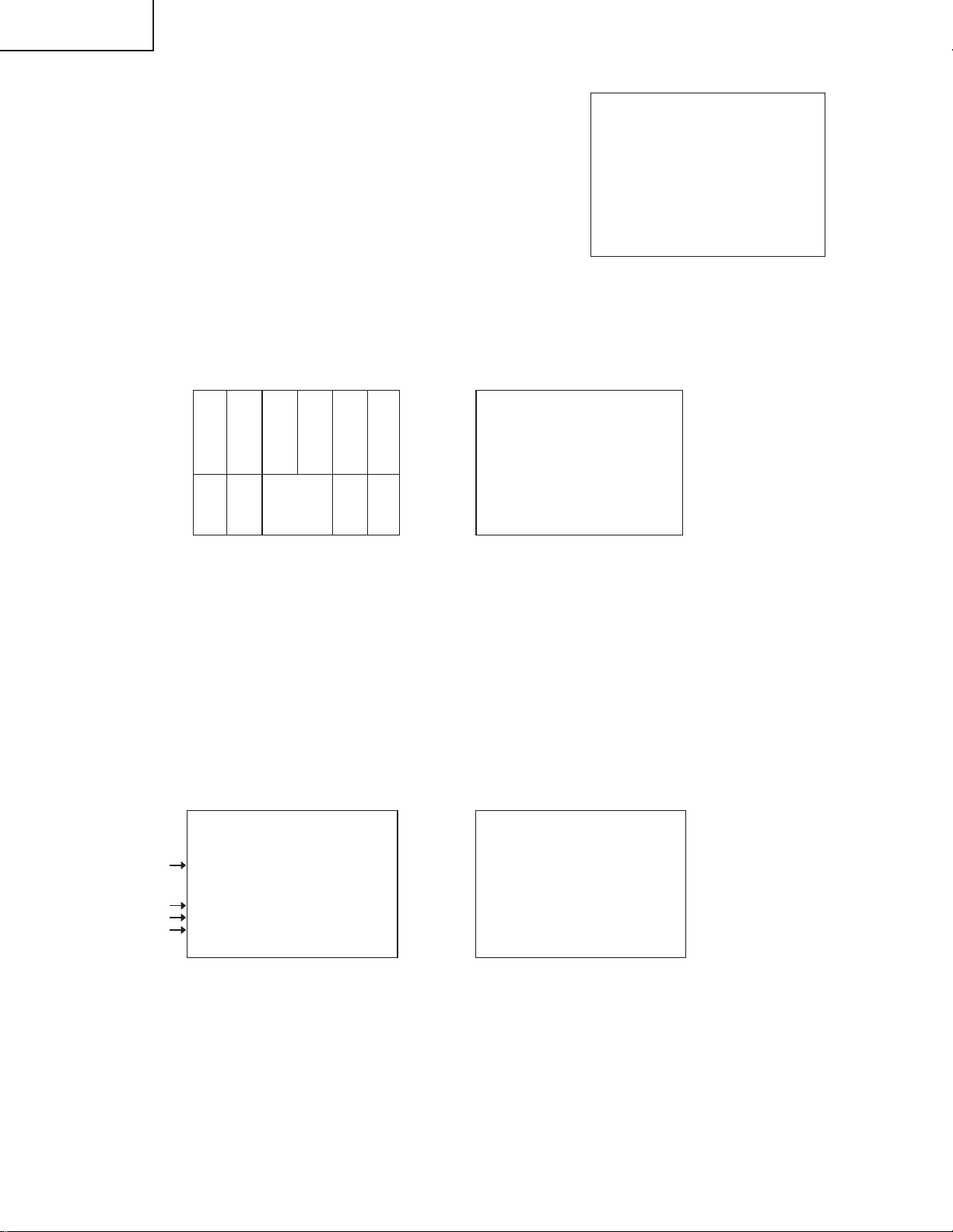

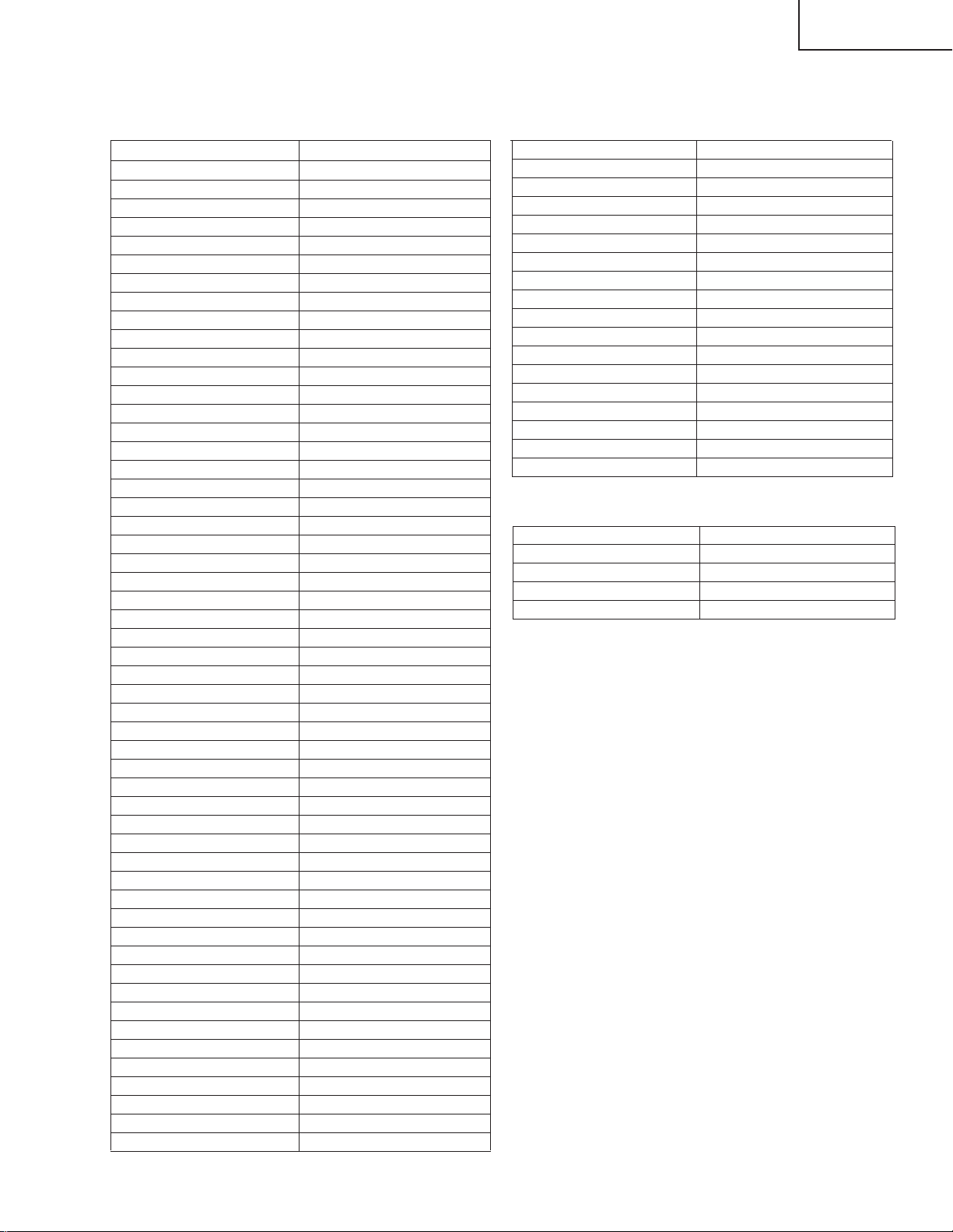

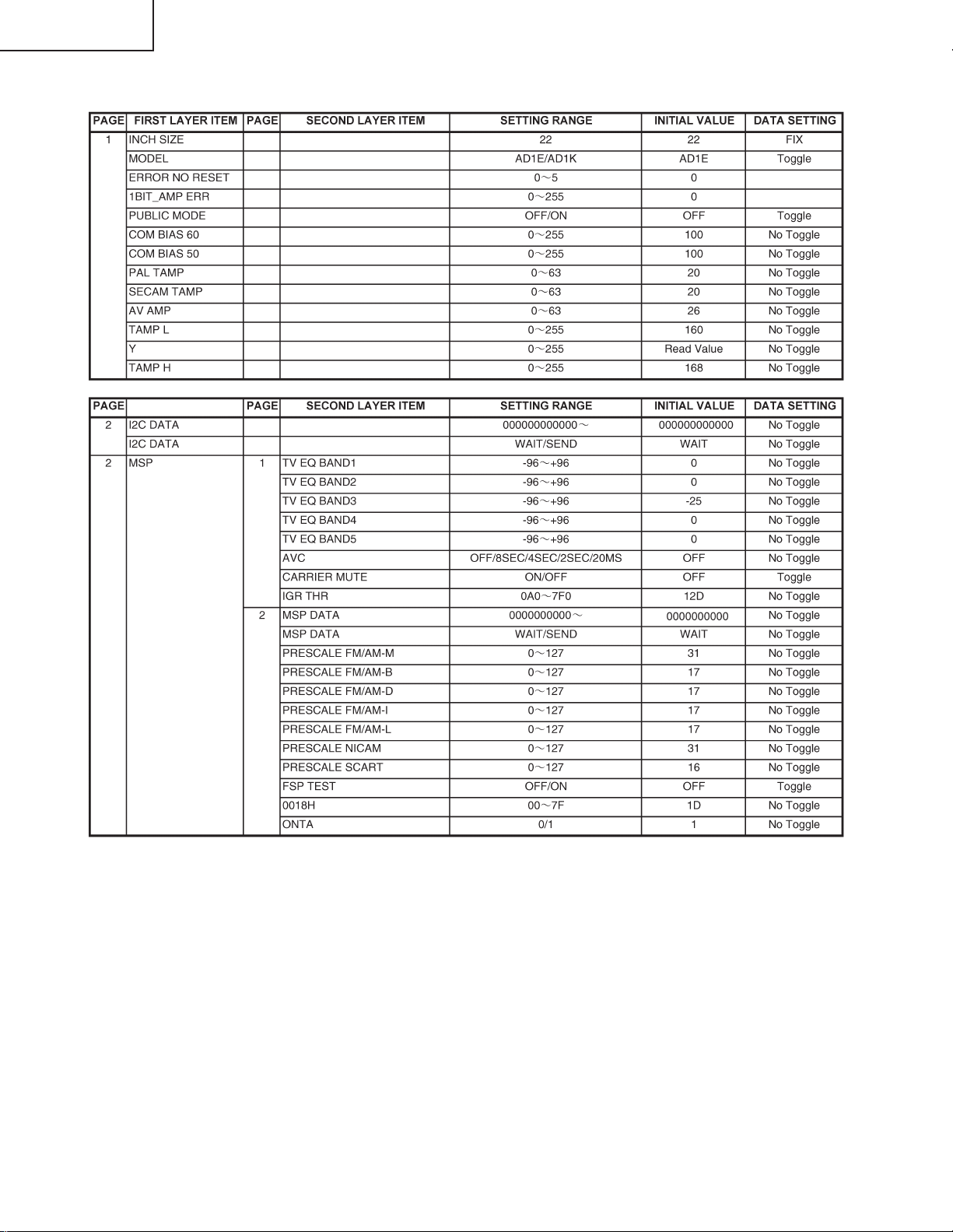

7. ADJUSTMENT PROCESS MODE MENU LIST

28

Page 30

LC-22AD1E

29

Page 31

LC-22AD1E

30

Page 32

LC-22AD1E

31

Page 33

LC-22AD1E

32

Page 34

LC-22AD1E

33

Page 35

LC-22AD1E

34

Page 36

LC-22AD1E

35

Page 37

LC-22AD1E

Software Upgrade Procedure for Digital Broadcasting

Receiver Unit

1. Applicable Models

• LC22AD1E/K

2. Equipment Required

• PC card-sized flash memory card: 1

The following Compact Flash cards and PCMCIA Compact Flash card adapters are available.

Support the following Compact Flash card PCMCIA Compact Flash card adapters.

Manufacture Product Number Description

Sandisk SDCFB-32-768 32MB Compact Flash card

Sandisk SDCFB-64-768 32MB Compact Flash card

Kingston CF/32 32MB Compact Flash card

Kingston CF/64 64MB Compact Flash card

Integral 32MB Compact Flash card

Integral 64MB Compact Flash card

Sandisk SDCF-38 PCMCIA Compact Flash card adapter

MicroTech CFA PCMCIA Compact Flash card adapter

Integral PCMCIA Compact Flash card adapter

3. Preparation

1. Copy the software to download from your Windows computer to the flash card.

Open Explorer.exe on your Windows computer and copy “FCL.IMG” and “IBOP.IMG” in the “Ver1.xx” folder

(xx stands for the version of the software to download) to the top directory of the flash card.

* Distribution method of the software will be informed to you separately.

2. Check the version of the software to be upgraded, if possible.

The version of the software installed on the unit can be checked by following these menu options: DTV

menu -> Setup -> Installations -> Software version.

3. Switch the image source to “DTV” and turn off the power.

4. Procedure

Upgrade the “Digital Broadcasting Receiver Unit Software”.

Case A: When the versions differ between the installed software and software to download

1. Make sure that the power of the unit is turned off, and insert the flash memory card into the CI slot.

2. Turn on the power.

Download starts automatically.

* Do not turn off the power until the download is complete about 2 minutes.

There is no information appears on screen while downloading.

When the download is complete, the digital broadcasting receiver unit resets itself and reboots automatically.

After it is reset, the display blacks out for approximately 10 seconds, then the information banner appears.

* If an error message appears, refer to “Troubleshooting”.

3. Check the software version.

Follow these menu options: DTV menu -> Setup -> Installations -> Software version.

Check that the version matches with the one you wanted to download.

4. Turn off the power and remove the flash memory card from the CI slot.

36

Page 38

LC-22AD1E

Case B: When the versions are the same between the installed software and software to download

1. Disconnect the antenna cable from the unit.

2. Make sure that the power of the unit is turned off, and insert the flash memory card into the CI slot.

3. Turn on the power.

4. Download the software manually as follows:

• Use the buttons on the main unit or remote control to display the process mode screen.

• Set “IBO PROG UPDATE” to “ON” and press the “OK” button.

Download starts.

* Do not turn off the power until the download is complete about 2 minutes.

There is no information appears on screen while downloading.

When the download is complete, the digital broadcasting receiver unit resets itself and reboots automatically.

After it is reset, the display blacks out for approximately 10 seconds, then the information banner appears.

* If an error message appears, refer to “Troubleshooting”.

• Use the buttons on the main unit or remote control to exit the process mode screen.

5. Check the software version.

Follow these menu options: DTV menu -> Setup -> Installations -> Software version.

Check that the version matches with the one you wanted to download.

6. Turn off the power and remove the flash memory card from the CI slot.

Case C: When the version of the installed software cannot be confirmed

If the digital broadcasting receiver unit does not activate properly or enters the download mode immediately after

it is activated, perform the following procedure.

1. Disconnect the antenna cable from the unit.

2. Make sure that the power of the unit is turned off, and insert the flash memory card into the CI slot.

3. Turn on the power.

Download starts automatically.

* Do not turn off the power until the download is complete about 2 minutes.

There is no information appears on screen while downloading.

When the download is complete, the digital broadcasting receiver unit resets itself and reboots automatically.

After it is reset, the display blacks out for approximately 10 seconds, then the information banner appears.

* If an error message appears, refer to “Troubleshooting”.

4. Check the software version.

Follow these menu options: DTV menu -> Setup -> Installations -> Software version.

Check that the version matches with the one you wanted to download.

5. Turn off the power and remove the flash memory card from the CI slot.

This is the end of the download process.

Notes:

• Download takes about 2 minutes. Once the download starts, never turn off the power until the unit is reset

automatically, or error message appears.

• After the download process is complete, perform the search operation from the menu, if necessary.

Especially for Case C in “Procedure”, search (or Reinstall all services) should be performed as there is a high

possibility that the service list has disappeared.

37

Page 39

LC-22AD1E

5. T roubleshooting

Error message may appear when the download is not completed properly.

Case A: Card identification failed

The unit failed to detect the card. Loose insertion or poor contact may be the cause. Follow the procedure

below.

1. Turn off the power of the unit.

2. Remove the flash memory card from the CI slot.

• Check whether the Compact Flash card is inserted fully.

• Check that the used Compact Flash card or adapter is listed in the table under “Equipment Required”.

3. Re-insert the flash memory card into the CI slot.

•Ensure that the card is inserted fully into the slot.

4. Download the software again according to the above “Procedure”.

Case B: Software compatibility error

The software copied to the flash memory card is inappropriate. Copy failure or version incompatibility may be

the cause.

1. Turn off the power of the unit.

2. Remove the flash memory card form the CI slot.

3. Insert the flash memory card into your Windows computer and copy the files again.

• Check the versions of the files to copy.

• Check that the files are copied to the top directory of the flash card.

• Ensure that both files are copied.

4. Re-insert the flash memory card into the CI slot.

• Ensure that the card is inserted fully into the slot.

5. Download the software again according to the above “Procedure”.

38

Page 40

Major IC Informations

1. IC2510 (A385WJ) S/PDIF

This is an audio signal encoder IC that converts signals to the S/PDIF format.

The output signal of this IC is optically connected to an external digital adio device,allowing you to enjoy

digital sound on an LCD TV.

2. IC3202 (A416WJ) MSP

This is an audio signal processing IC called a Multi-Standard Sound Processor.

This IC not only processes the audio signal of all standard analog TV broadcasts worldwide, it also

incorporates the NICAM digital sound standard.

3. IC3301 (CXA2040A) VIDEO-SW

This is an I2S BUS-compliant, 5-input, 3-output video switch.

This switch is used to select the digital tuner output, analog tuner output, composite video input, and Sterminal input.

4. IC1603 (6258308X) 2Mb-SRAM

This is a 256K x 8 bit CMOS static RAM.

This IC is used to store TELTEXT signals (which are broadcast simultaneously) in the memory.

These signals are output by a command from the TELTEXT micon as necessary.

LC-22AD1E

5. IC1602 (A134WJ) 4M-FLASH

This IC is a 4Mb dual operation flash memory.

It incorporates a TELTEXT micon program, and it outputs data on a command from the TELTEXT micon.

6. IC1601 (SDA5550M) TELETEXT (LC-22AA1M ONLY)

The SDA5550M is a single chip teletext decoder for decoding World System teletext data as well as Video

Programming System (VPS), Program Delivery Control (PDC), and Wide Screen Signaling (WSS) data

used for PAL plus transmissions (line23).

7. IC3501 (IXA904WJ) MICRO PROCESSOR

This is a 16-bit single chip microcomputer that uses a high-performance silicon gate CMOS process. Although

this microcomputer uses high-functionality commands, it has a high-command efficiency. It has a 1Mbyte

address space and it has the ability to carry out instructions at high speed. It also incorporates an OSD and

a data slicer. This microcomputer supports Closed Captions (an official teletext broadcast standard for

hearing-impaired people) and ID1 (525p compliant).

8. IC801 (VPC3230D) VPC

This IC is an I2S BUS-compliant video processor.

This IC works as a 4H comb filter, Y/C separator, PAL/NTSC/SECAM color decoder, PIP processor, etc. Its

results are output as an 8-bit Y-OUT/CrCb-OUT signal which is supplied to a scaler.

9. IC4601 (FLI2310) SCALER

This IC is an I2S BUS-compliant scaler IC.

The FLI2310 is a highly integrated digital video format converter for DTV and DVD applications using

patented deinterlacing and post-processing algorithms from Faroudja Laboratories, coupled with highly

flexible scaling, a wide variety of aspect ratio conversions, and other special video enhancing features to

produce the highest quality image.

10. IC4603/IC4516 (A312WJ) 64M-SDRAM

This IC is a 64Mb (2M x 32bit) synchronous DRAM memory.

This IC is used to control the progressive converter,format converter (image conversion), noise reducer on

the scaler (IC4601) and LCD control IC (IC4512), and Quick Shoot. Video signal is stored when correcting

the Quick Shooting image quality.

39

Page 41

LC-22AD1E

11. IC4512 (IXA595) QS-LCD-CONTROL

This is an LCD control IC for OS driving control that handles three-wire serial communication with the

MICON (IC3501).

It outputs a control signal for driving the liquid crystal panel.

Additionally, it has a Quick shoot image quality correction function (including control of the temperature)

and an OSD MIX function.

12. IC4701 (A706WJ) GRAY-LEVEL

This IC is a gradation reference power supply for a TFT liquid crystal display. It incorporates a gradation

output buffer amplifier (18 circuits), a COM buffer amplifier, and a REF amplifier (reference power supply).

13. IC3405 (NJU26150) SOUND DSP

This IC is a 24-bit digital audio processor.

It downloads the program stored in the E2PROM IC3407 to the built-in PRAM and then executes it.

Audio data input and output are performed through an I2S serial host interface. There are three data inputs

and three data outputs.

14. IC3406 (NJU26106) VIRTUAL DOLBY

This is the Virtual Dolby Surround IC, manufactured under license from Dolby Laboratories.

Audio data input and output are performed through an I2S serial host interface.

15. IC3203 (BH3543F) HP-AMP

This is the dual headphone output amplifier IC.

It incorporates a POP noise prevention circuit and a thermal shut down circuit (150°C) that work if an eror

occurs when turning the power on or off.

16. IC1623 (BA7046F) SYNC-SEP

This IC incorporates a video synchronous separation circuit, a vertical synchronous separation circuit,

a horizontal oscillation circuit, and a phase-comparison circuit. When a video signal is input, a composite

synchronous signal (SYNC), a vertical synchronous signal (VD), and a horizontal synchronous signal (HD)

are produced.

This IC has both synchronous separation and AFC (Auto Frequency Control) functions.

40

Page 42

LC-22AD1E

Pin functions of S/PDIF IC (IC2510) RH-iXA385WJZZ

RH-iXA385WJZZQ (ASSY:IC2510)

S/PDIF

BLOCK DIAGRAM

41

Page 43

LC-22AD1E

Pin functions of MSP IC (IC3202) RH-iXA416WJZZ

RH-iXA416WJZZQ (ASSY:IC3202)

MSP (Muti Standard Sound Processor)

BLOCK DIAGRAM

42

Page 44

LC-22AD1E

Pin functions of VIDEO SW IC (IC3301) VHiCXA2040A-1Q

VHiCXA2040-1Q (ASSY:IC3301)

VIDEO SW

BLOCK DIAGRAM

43

Page 45

LC-22AD1E

RH-iXA134WJN5 (ASSY:IC1602)

4M-FRASH

BLOCK DIAGRAM

Pin functions of FRASH MEMORY IC (IC1602) RH-iXA134WJN5

VHi162S8308X-1Q (ASSY:IC1603)

2M-SRAM

BLOCK DIAGRAM

Pin functions of 2M-SRAM IC (IC1603) VHi162S8308X-1Q

44

Page 46

LC-22AD1E

Pin functions of TELETEXT IC (IC1601) VHiSDA5550M-1

VHiSDA5550M-1 (ASSY:IC1601)

TELETEXT CPU

BLOCK DIAGRAM

45

Page 47

LC-22AD1E

46

Page 48

LC-22AD1E

Pin functions of MICRO PROCESSOR IC (IC3501) RH-iXA799WJN1QRH-iXA799WJN1Q (ASSY:IC3501)

MICRO PROCESSOR

BLOCK DIAGRAM

47

Page 49

LC-22AD1E

48

Page 50

LC-22AD1E

Pin functions of VPC IC (IC801) VH-iVPC3230D1EQ

VHiVPC3230D1EQ (ASSY:IC801)

VPC (Video Processor)

BLOCK DIAGRAM

49

Page 51

LC-22AD1E

VHiFLi2310/-1Q (ASSY:IC4601)

SCALER (Digital Video Format Converter)

BLOCK DIAGRAM

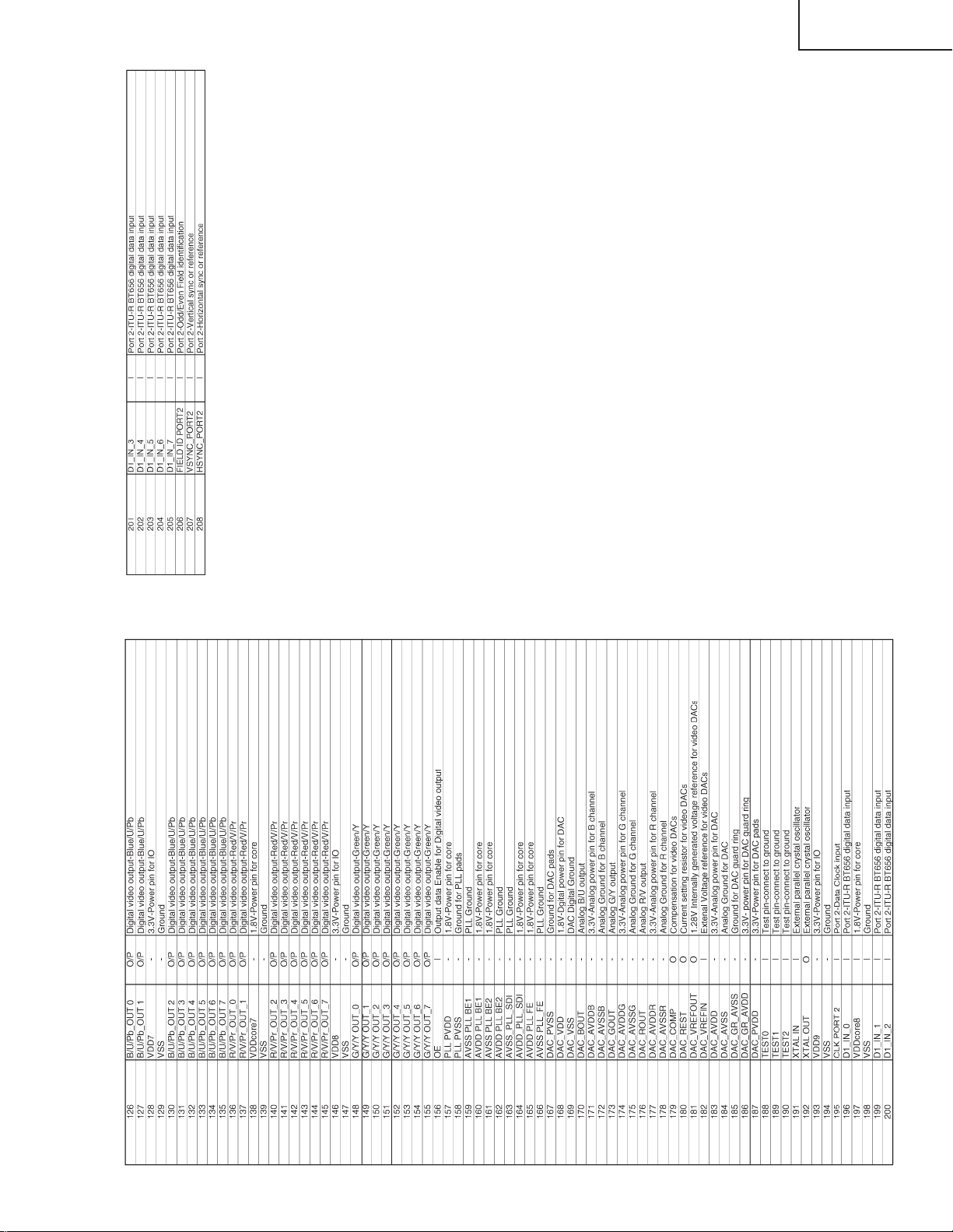

Pin functions of SCALER IC (IC4601) VHiFLi2310/-1Q

50

Page 52

LC-22AD1E

51

Page 53

LC-22AD1E

Pin functions of 64M-SDRAM IC (IC4516) RH-iXA312WJN1Q

RH-iXA312WJN1Q (ASSY:IC4516)

64M-SDRAM

BLOCK DIAGRAM

52

Page 54

LC-22AD1E

Pin functions of QS-LCD CONTROL IC (IC4512) RH-iXA595WJN1Q

53

Page 55

LC-22AD1E

Pin functions of GRAY-LEVEL IC (IC4701) RH-iXA706WJZZQ

RH-iXA706WJZZQ (ASSY:IC4701)

GRAY-LEVEL

BLOCK DIAGRAM

54

Page 56

LC-22AD1E

VHiNJU26106-1Q (ASSY:IC3406)

VIRTUAL DOLBY

BLOCK DIAGRAM

Pin functions of VIRTUAL DOLBY IC (IC3406) VH-iNJU26106-1Q

VHiNJU26150-1Q (ASSY:IC3405)

SOUND DSP

BLOCK DIAGRAM

Pin functions of SOUND DSP IC (IC3405) VH-iNJU26150-1Q

55

Page 57

LC-22AD1E

LC-22AD1E

CHASSIS LAYOUT

J

I

H

G

MAIN Unit

OPERATION Unit

INVERTER Unit

F

E

D

C

EXT -SP TERMINAL Unit

B

R/C, LED Unit

SP-JACK Unit

A

12345678910

11 12 13 14 15 16 17 18 19

56-57

20

Page 58

LC-22AD1E

H

G

F

AV Unit

E

D

C

B

A

654321

58

Page 59

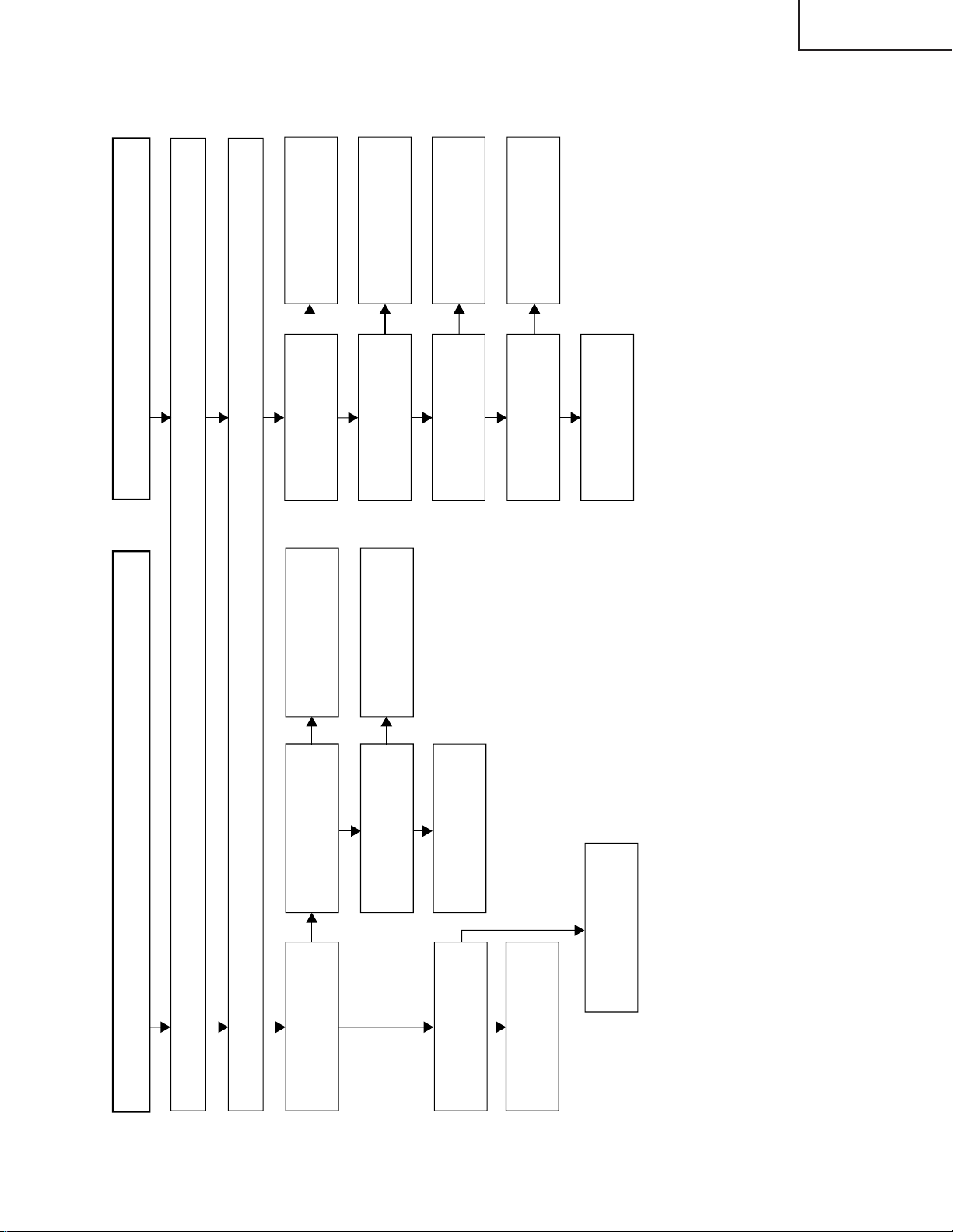

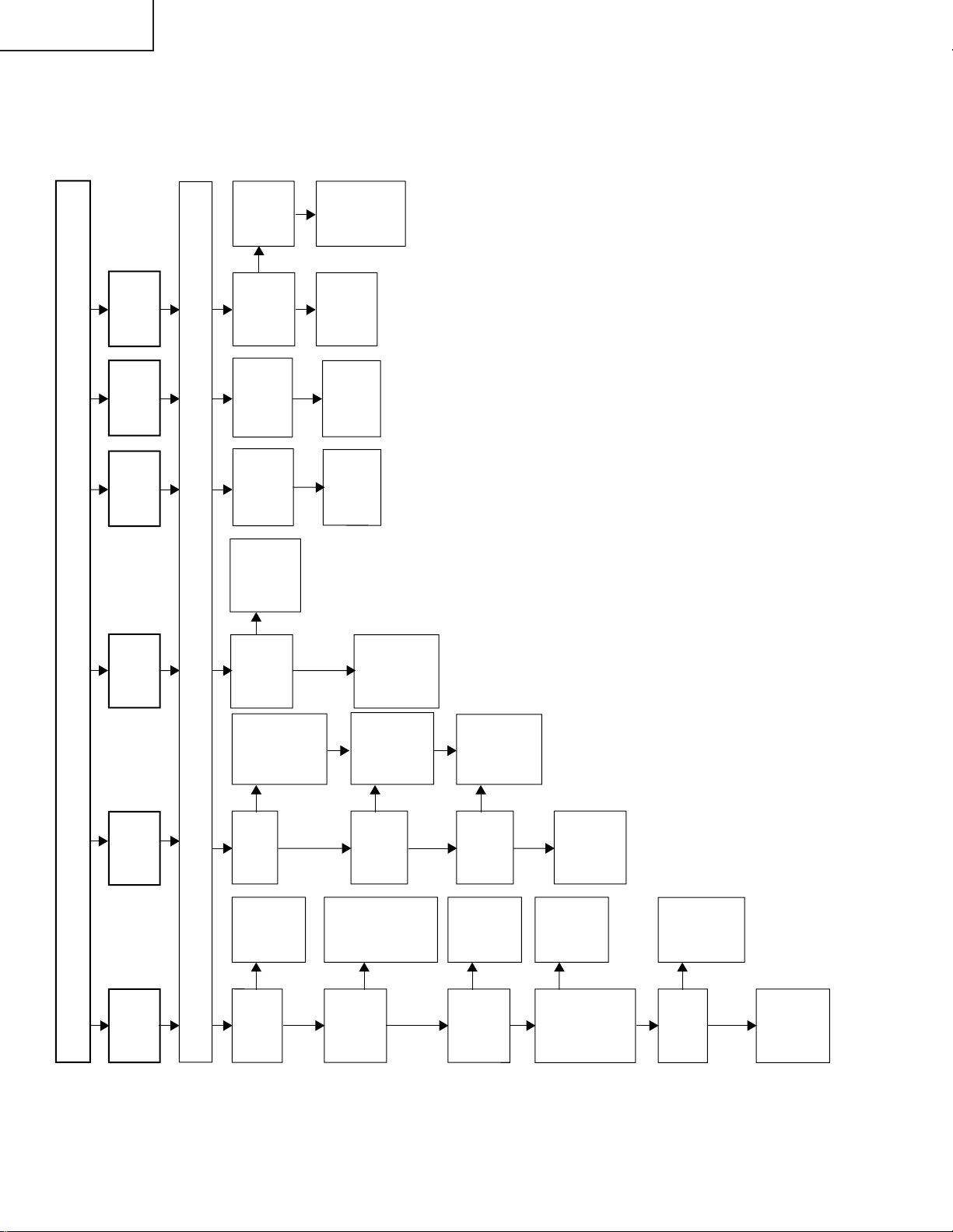

BLOCK DIAGRAM 1/2

LC-22AD1E

H

POWER-SOURCE BLOCK DIAGRAM

G

F

E

D

C

B

A

59

654321

Page 60

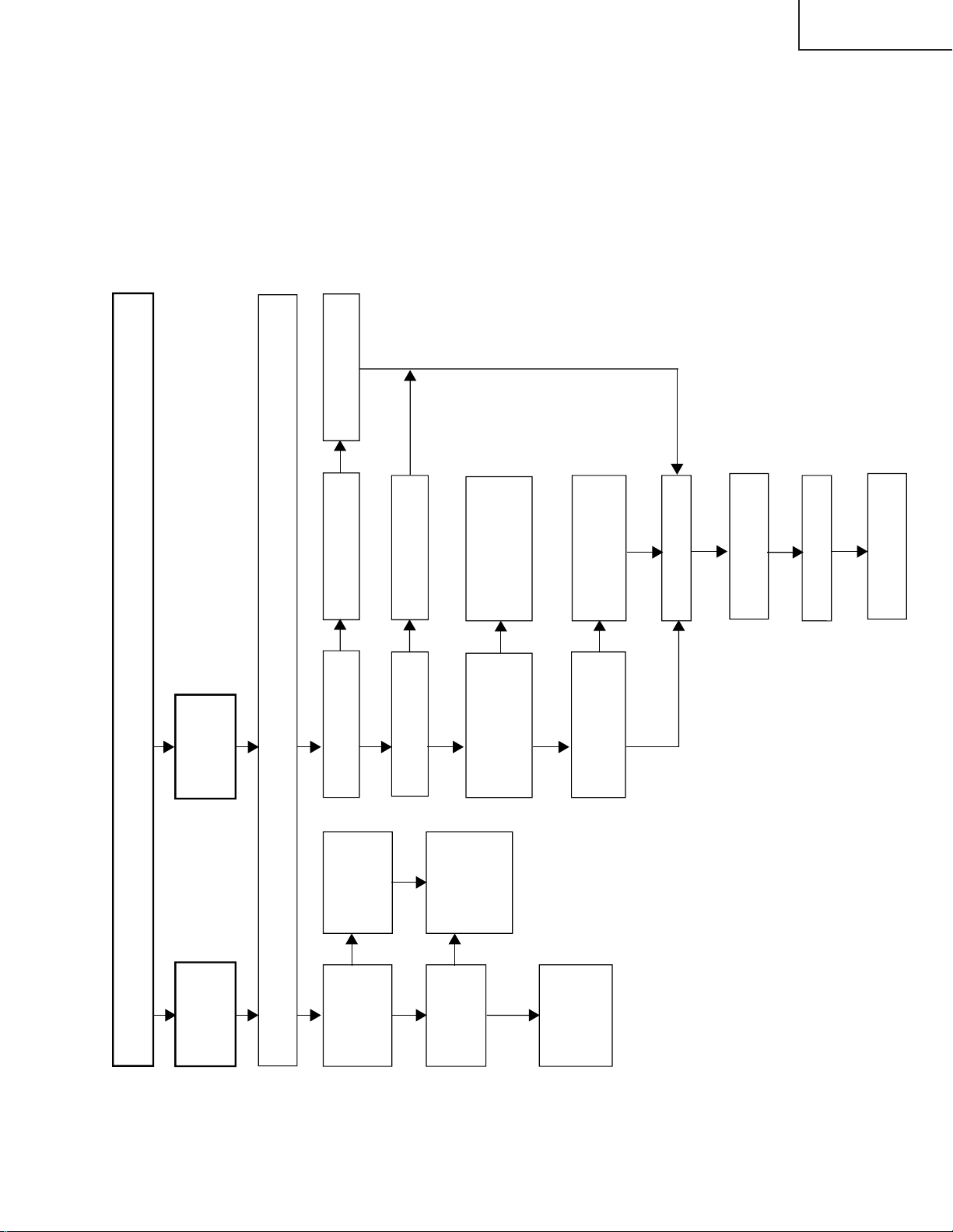

LC-22AD1E

LC-22AD1E

BLOCK DIAGRAM 2/2

SYSYTEM BLOCK DIAGRAM

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

60-61

Page 61

LC-22AD1E

LC-22AD1E

OVERALL WIRING DIAGRAM

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

62-63

Page 62

LC-22AD1E

DESCRIPTION OF SCHEMATIC DIAGRAM

VOLTAGE MEASUREMENT CONDITION:

1. The voltages at test points are measured on

exclusive AC adaptor and the stable supply voltage

of AC 120V. Signals are fed by a color bar signal

generator for servicing purpose and the above

voltages are measured with a 20k ohm/V tester.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/16W, unless otherwise noted.

4. All resistors are Carbon type, unless otherwise

noted.

C : Solid

S : Oxide Film T : Special

N : Metal Coating

CAPACITOR

1. All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2. All capacitors are 50V, unless otherwise noted.

3. All capacitors are Ceramic type, unless otherwise

noted.

(ML): Mylar (TA): Tantalum

(PF): Polypro Film (ST): Styrol

W

: Cement

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å” ( ) ARE

IMPORTANT FOR MAINTAINING THE SAFETY OF

THE SET. BE SURE TO REPLACE THESE PARTS

WITH SPECIFIED ONES FOR MAINTAINING THE

SAFETY AND PERFORMANCE OF THE SET.

64

Page 63

SCHEMATIC DIAGRAM

Ë

INVERTER Unit

H

G

F

LC-22AD1E

E

D

C

B

A

654321

65

Page 64

LC-22AD1E

LC-22AD1E

Ë

AV Unit

J

I

H

G

F

E

D

C

B

A

12345678910

66-67

11 12 13 14 15 16 17 18 19

20

Page 65

LC-22AD1E

Ë

R/C,LED Unit

H

G

F

E

D

C

B

A

87109654321

68

Page 66

LC-22AD1E

Ë

OPERATION Unit

H

G

F

E

D

C

B

A

654321

69

Page 67

LC-22AD1E

Ë

H

G

F

EXT -SP TERMINAL Unit

E

D

C

B

A

87109654321

70

Page 68

LC-22AD1E

Ë

SP-JACK Unit

H

G

F

E

D

C

B

A

654321

71

Page 69

LC-22AD1E

LC-22AD1E

Ë

MAIN Unit - A UDIO 1/11

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

72-73

Page 70

LC-22AD1E

LC-22AD1E

Ë

MAIN Unit - PO WER 2/11

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

74-75

Page 71

LC-22AD1E

LC-22AD1E

Ë

MAIN Unit - TELETEXT 3/11

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

76-77

Page 72

LC-22AD1E

LC-22AD1E

Ë

MAIN Unit - MICON 4/11

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

78-79

Page 73

LC-22AD1E

LC-22AD1E

Ë

MAIN Unit - VPC 5/11

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

80-81

Page 74

LC-22AD1E

LC-22AD1E

Ë

MAIN Unit - SCALER 6/11

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

82-83

Page 75

LC-22AD1E

LC-22AD1E

Ë

MAIN Unit - QS-CONTROL 7/11

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

84-85

Page 76

LC-22AD1E

LC-22AD1E

Ë

MAIN Unit - GRAY-LEVEL 8/11

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

86-87

Page 77

LC-22AD1E

LC-22AD1E

Ë

MAIN Unit - PANEL 9/11

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

88-89

Page 78

LC-22AD1E

LC-22AD1E

Ë

MAIN Unit - 1BIT-CONTROL 10/11

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

90-91

Page 79

LC-22AD1E

LC-22AD1E

Ë

MAIN Unit - CTRL-SW 11/11

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

92-93

Page 80

LC-22AD1E

C6580 D6554

R6566

R6565

Q6562

C6579

R6564

R6563

L6558

C6582

C6578 C6577

Q6561

Q6560

C6575

T6558

T6557

FDC1

P6554

P6553

T6555

T6556

Q6558

Q6557

C6569

C6570

L6556

R6560

R6559

C6571Q6559

D6553

R6561 R6562

C6572

FH6557 FH6558

FH6554

P706

R6557

C6564

Q6556

D6552 R6558

C6574

R6555

C6562 C6563

FH6556

Q6555

Q6554

R6556

C6567

C6561

FH6555

T6553

Z2

P6552

Z1

T6554

C6551

C6560

C6566

L6554

C6556

R6553

D6551 R6554

FH6553 FH6552 FH6551

L6552

C6558

Q6553

R6551

C6555 C6554

R6552

Q6552

Q6551

C6553

T6552

T6551

P6551

LC-22AD1E

PRINTED WIRING BOARD ASSEMBLIES

J

I

H

G

F

INVERTER Unit (Side-A)

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

INVERTER Unit (Chip Parts Side-A)

94-95

Page 81

LC-22AD1E

LC-22AD1E

AV Unit (Side-A)

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

96-97

Page 82

LC-22AD1E

IC1101IC1101

J701J701

C1106C1106

R1111R1111

FB702FB702

FB701FB701

C1107C1107

L701L701

L1101L1101

FB703FB703

P1107P1107

P701P701

FB704FB704

C1123C1123

L1102L1102

C1125C1125

P1108P1108

C1127C1127

R1110R1110

R1141R1141

C1130C1130

TU1101TU1101

C1124C1124

C1129C1129

L1103L1103

P702P702

C1113C1113

D1120D1120

C1135C1135

D1112D1112 D1111D1111

D1117D1117 D1118D1118 D1119D1119

P1104P1104

C1133C1133 C1134C1134 C1136C1136

D1125D1125

R1135R1135

R1127R1127

R1128R1128

FB1106FB1106

R1124R1124

C1117C1117 C1118C1118 R1139R1139 C1119C1119

D1110D1110

R1130R1130 R1129R1129 C1120C1120 R1138R1138 R1132R1132 R1134R1134

R1126R1126

R1137R1137

R1136R1136

R1125R1125

SC1101SC1101

R1133R1133

R1131R1131

C1114C1114 C1115C1115 R1113R1113 R1112R1112 D1122D1122

R1119R1119 R1120R1120 C1109C1109 C1108C1108

C1137C1137

R1115R1115

C1110C1110

C1111C1111

R1114R1114

FB1105FB1105

D1123D1123

C1140C1140

C1121C1121

D1109D1109

C1138C1138

C1139C1139

D1124D1124

C1116C1116

D1115D1115

D1116D1116

D1113D1113

D1114D1114

D1121D1121

TP1109TP1109

TP1108TP1108

TP1106TP1106

TP1104TP1104

TP1102TP1102

TP1110TP1110

TP1107TP1107

TP1105TP1105

TP1103TP1103

TP1101TP1101

C1103C1103

D1103D1103

C1101C1101

D1101D1101

R1140R1140

SC1104SC1104

R1146R1146

C1126C1126

R1145R1145

R1142R1142

R1144R1144

R1147R1147

SC1105SC1105

C1128C1128

R1143R1143

Q1102Q1102 Q1101Q1101

SC1103SC1103

P1106P1106

D1107D1107

C1105C1105

D1106D1106

R1116R1116 R1149R1149

R1121R1121

D1108D1108

D1105D1105

R1117R1117

R1123R1123

C1112C1112

R1118R1118

R1122R1122

SC1102SC1102

J1101J1101

J1104J1104

C1132C1132 C1131C1131

D1104D1104

R1105R1105

FB1103FB1103

FB1102FB1102

R1108R1108 R1106R1106

R1102R1102

FB1101FB1101

FB1104FB1104

R1148R1148

R1109R1109 C1104C1104 R1107R1107

R1101R1101

C1100C1100

R1104R1104

D1102D1102

C1102C1102

P1105P1105

R1103R1103

LC-22AD1E

AV Unit(Chip Parts Side-A)

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

98-99

Page 83

LC-22AD1E

LC-22AD1E

AV Unit (Side-B)

J

I

H

G

F

E

D

C

B

A

12345678910

100-101

11 12 13 14 15 16 17 18 19

20

Page 84

LC-22AD1E

H

G

F

R/C, LED Unit (Side-A)

E

R/C, LED Unit (Side-B)

D

RMC101RMC101

SLD1SLD1

R101R101

C101C101

C106C106

C

P101P101

C105C105

J101J101

Q106Q106

D104D104

R113R113

R114R114

R115R115

R111

R112

R110

R108

R106

D103D103

Q105Q105

Q103Q103

R107R107

R109R109

D101D101

Q102Q102

R104R104

D102D102

C103C103

Q104Q104

R105R105

Q101Q101

R103R103

R102R102

C102C102

IC101IC101

C104C104

RC, LED Unit(Chip Parts Side-B)

B

A

654321

102

Page 85

LC-22AD1E

H

G

OPERATION Unit (Side-A)

F

E

OPERATION Unit (Side-B)

D

S135S135

R133R133

S134S134

R132R132

S133S133

S132S132

R131R131

S131S131

C

P132P132

S136S136

D132D132

D131D131

R134R134

S137S137

OPERATION Unit (Chip Parts Side-B)

B

A

654321

103

Page 86

LC-22AD1E

H

G

F

E

EXT-SP TERMINAL Unit (Side-A)

D

C

EXT-SP TERMINAL Unit (Side-B)

B

A

87109654321

104

Page 87

LC-22AD1E

H

G

F

E

SP-JACK Unit (Side-A)

D

SP-JACK Unit (Side-B)

C

B

A

654321

105

Page 88

LC-22AD1E

LC-22AD1E

MAIN Unit (Side-A)

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

106-107

Page 89

LC-22AD1E

LC-22AD1E

MAIN Unit (Side-B)

J

I

H

G

F

E

D

C

B

A

12345678910

108-109

11 12 13 14 15 16 17 18 19

20

Page 90

LC-22AD1E

LC-22AD1E

MAIN Unit (Chip Parts Side-A)

J

SC4902SC4902

C4901C4901

C4912C4912

FB4902FB4902

R4580R4580

R4666R4666

R4579R4579

FL4515FL4515

FL4516FL4516

IC4512IC4512

R4665R4665

FL4517FL4517

C4551C4551

FL4514FL4514

I

SC4501SC4501

R4501R4501

FL4512FL4512 FL4513FL4513

R4577R4577 R4664R4664

H

FL4506FL4506 FL4507FL4507 FL4508FL4508 FL4509FL4509 FL4510FL4510 FL4511FL4511

R4554R4554 R4661R4661 R4564R4564 R4662R4662 R4569R4569 R4663R4663

C4561C4561

C4537C4537

P4502P4502

G

F

P4501P4501

E

P3201P3201 P3504P3504

R4567R4567

IC4514IC4514

R4561R4561

Q4502Q4502D4501D4501

D4502D4502

R4504R4504

Q4501Q4501

C4505C4505

Q4504Q4504 R4668R4668

R4502R4502

R4505R4505

Q4503Q4503

L4501L4501

R4503R4503

C4506C4506

C4507C4507

R3702R3702

R3733R3733

D

R3701R3701

P3701P3701 P3700P3700

R3700R3700

R4779R4779

R4778R4778

R3730R3730 R3732R3732

R4782R4782

R4781R4781

C4560C4560

C4569C4569

C4568C4568

IC4502IC4502

IC4501IC4501

IC4513IC4513

R4551R4551

R4556R4556

R4508R4508

FL4501FL4501

C4501C4501 C4504C4504

FL4502FL4502

R4784R4784

R4791R4791

C4751C4751

R4790R4790

R4794R4794

R4793R4793

R4792R4792

C4519C4519

R4667R4667

Q4505Q4505 R4509R4509

R4529R4529

D4508D4508

R4519R4519

Q4506Q4506

R4528R4528

D4507D4507

R4516R4516

C4503C4503

C4511C4511

FB4501FB4501

R4511R4511

C4509C4509

L4504L4504

C4518C4518

C4513C4513

C4510C4510

D4504D4504

C4502C4502

C4512C4512

FB4502FB4502

L4505L4505

C4709C4709

D4704D4704

R4767R4767

R4766R4766

R4756R4756 R4757R4757

R4761R4761 R4762R4762

C4737C4737

R4777R4777

C4752C4752

R4786R4786

IC4701IC4701

R4785R4785

C4750C4750

C4749C4749R4780R4780

R4789R4789

C4748C4748

R4788R4788

C4747C4747

R4787R4787

R4758R4758 C4736C4736

R4763R4763 C4738C4738

R4768R4768 C4740C4740

R4771R4771 C4744C4744

R4774R4774 C4746C4746

R4590R4590

R4532R4532

R4540R4540

R4537R4537

FL4503FL4503

FL4505FL4505

C4566C4566

C4562C4562

C4563C4563

C4528C4528

C4567C4567

FB4503FB4503

IC4510IC4510

IC4503IC4503

R4523R4523

R4527R4527

L4509L4509

C4526C4526

L4503L4503

D4505D4505

L4507L4507

C4516C4516

IC4507IC4507

R4515R4515

C4517C4517

R4514R4514

R4507R4507

R4510R4510

C4525C4525

L4508L4508

IC4508IC4508

L4502L4502

R4518R4518

C4514C4514

IC4504IC4504

D4503D4503

C4508C4508

C4706C4706

C4757C4757

R4748R4748

R4747R4747

R4731R4731

R4740R4740

R4732R4732

R4736R4736

C4724C4724

R4720R4720

R4725R4725

R4726R4726

C4720C4720

R4715R4715

R4727R4727

C4719C4719

R4714R4714 C4712C4712

R4713R4713 C4714C4714

R4733R4733 C4721C4721

R4741R4741 C4727C4727

R4749R4749 C4731C4731

R4753R4753 C4734C4734

R4737R4737 C4725C4725

R4744R4744 C4728C4728

C4544C4544

C4545C4545

FB4508FB4508

FB4507FB4507

C4547C4547

R4578R4578

R4576R4576

C4540C4540

C4534C4534

C4532C4532

C4531C4531

FL4504FL4504

IC4515IC4515

C4542C4542

D4506D4506

C4522C4522

R4524R4524

C4520

C4524C4524

C4520

R4525R4525 R4526R4526

R4506R4506

R4530R4530

IC4509IC4509

C4521C4521R4521R4521 C4523C4523

C

B

SC4901SC4901

C4908C4908

C4911C4911

C4909C4909

C4910C4910

FL4902FL4902

C4543C4543

FL4524FL4524

R4522R4522

FL4521FL4521

C4611C4611

C4558C4558

L4506L4506

C3534C3534

R3622R3622

R3532R3532

R3533R3533

C3535C3535

R3660R3660

C3519C3519