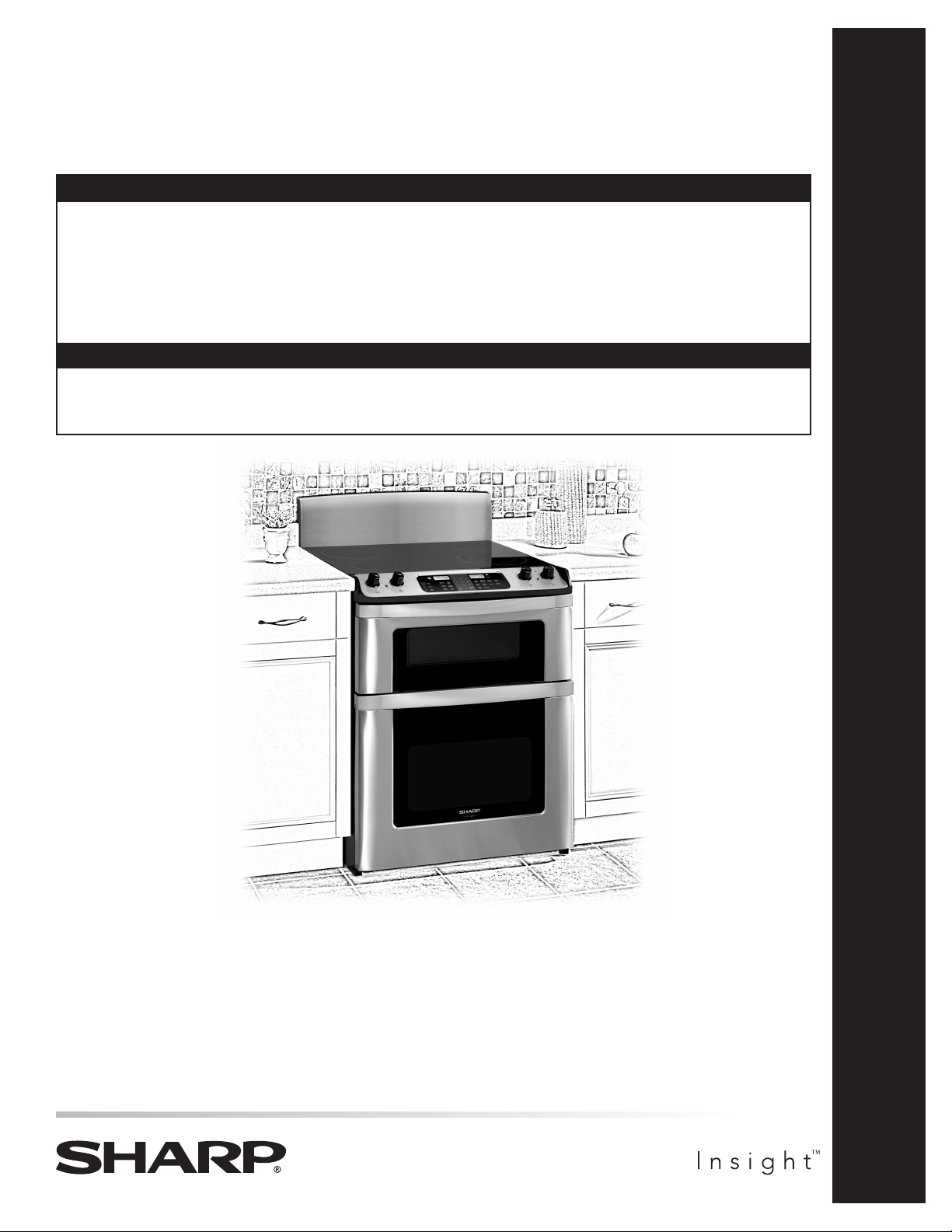

30" Freestanding Range

InstallatIon Manual

sPECIal WaRnInG

InstallatIon anD sERVICE Must BE PERFoRMED BY a QualIFIED InstallER.

IMPoRtant: saVE thIs InstallatIon Manual FoR loCal ElECtRICal

InsPECtoR’s usE.

REaD anD saVE thEsE InstRuCtIons FoR FutuRE REFEREnCE.

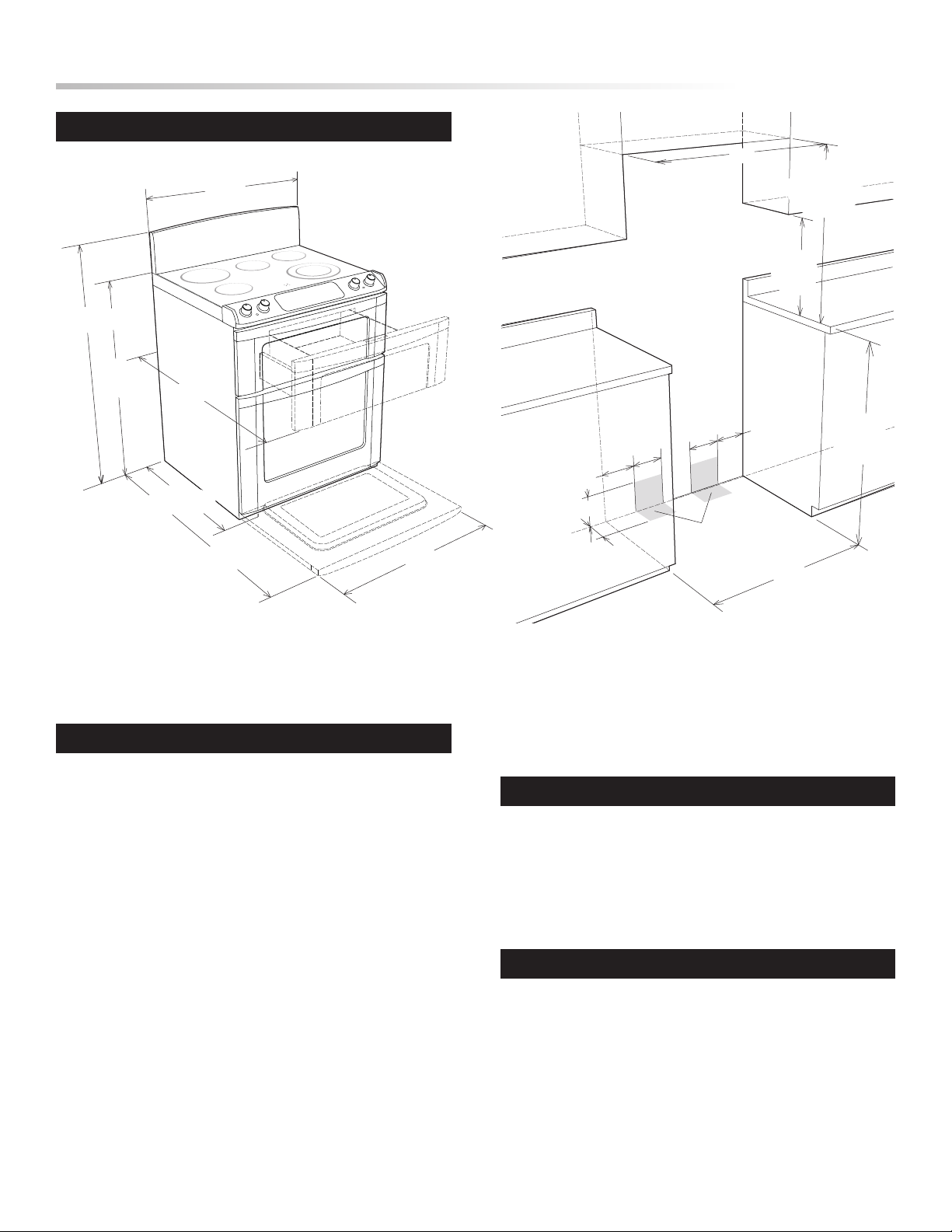

ClEaRanCEs & DIMEnsIons

For SAFETY CONSIDERATIONS do not install a range in any combustible cabinetry which is not in

accord with the stated clearances and dimensions on page 2. See Figures 1 and 2.

ElEctric rangE With MicroWavE DraWEr

RanGE MEasuREMEnts ......................................2

ClEaRanCEs anD DIMEnsIons ..............................2

IMPoRtant notEs .............................................2

unPaCkInG anD ExaMInInG YouR RanGE .................3

IMPoRtant saFEtY InstRuCtIons .........................3

ElECtRICal ConnECtIons ................................ 3-5

MoDEl anD sERIal nuMBER loCatIon ....................4

antI-tIP ..................................................... 6-7

CaRE, ClEanInG anD MaIntEnanCE ......................7

notEs ..... .......................................................8

1

36"

countertop

height

18"

to upper

cabinets

preferred electrical

outlet area

minimum 30"

to bottom of

cabinet over

cooktop

30"

30"

opening width

61/8"

61/8"

73/8"

4"

6"

6"

Maximum

depth of cord,

plug and

receptacle box

is 4" to prevent

interference

with lower

oven.

INSTALLATION MANUAL

27"

back to front

of doors

45 3/8"

oven door

open

42"

drawer

open

36 1/8"

to cooktop

surface

44 3/8±1/8"

backsplash

29 7/8"

30"

door width

RanGE MEasuREMEnts

Figure 1 contains many range measurements for reference when

planning your kitchen and/or range location.

ClEaRanCEs anD DIMEnsIons

• Provide adequate clearances between the range and adjacent

• Dimensions that are shown in Figure 2 must be used. Given

• Contact surface must be solid and level. Pay special attention

• Check location where the range will be installed for proper

combustible surfaces.

dimensions provide minimum clearance. There needs to be a

30-inch minimum clearance between the top of the cooking

surface and the bottom of unprotected wood or metal cabinets or

a 24-inch minimum when bottom of wood or metal cabinets are

protected by not less than a 1/4-inch ame retardant millboard

covered with not less than no. 29 msg sheet-steel, 0.015-inch

stainless steel, 0.024-inch aluminum or 0.020-inch copper. Note

that the gray shaded area on Figure 2 indicates the location for

the electrical receptacle/connection.

to the oor. Be sure it is solid enough for the weight of the

range. Check that the oor covering is smooth and at and that

it adheres to the sub-oor solidly.

electrical supply.

Figure 2Figure 1

To eliminate the risk of burns or re by reaching over the

cooktop, cabinet storage space located above the cooktop should

be avoided. If cabinet storage is to be provided, the risk can be

reduced by installing a range hood that projects horizontally a

minimum of 5" beyond the bottom of the cabinets.

IMPoRtant notEs to thE InstallER

• Read all of the Installation Manual before installing the

range.

• Remove all packing material from the oven and drawer before

connecting the electrical supply to the range.

• Observe all governing codes and ordinances.

• Be sure to leave these instructions with the consumer.

IMPoRtant notEs to thE ConsuMER

Keep this manual with your Operation Manual for future reference.

• As when using any range generating heat, there are certain

safety precautions you should follow. These are listed in the

Operation Manual. Read all and follow carefully.

• Be sure your range is installed and grounded properly by a

qualied installer or service technician.

2

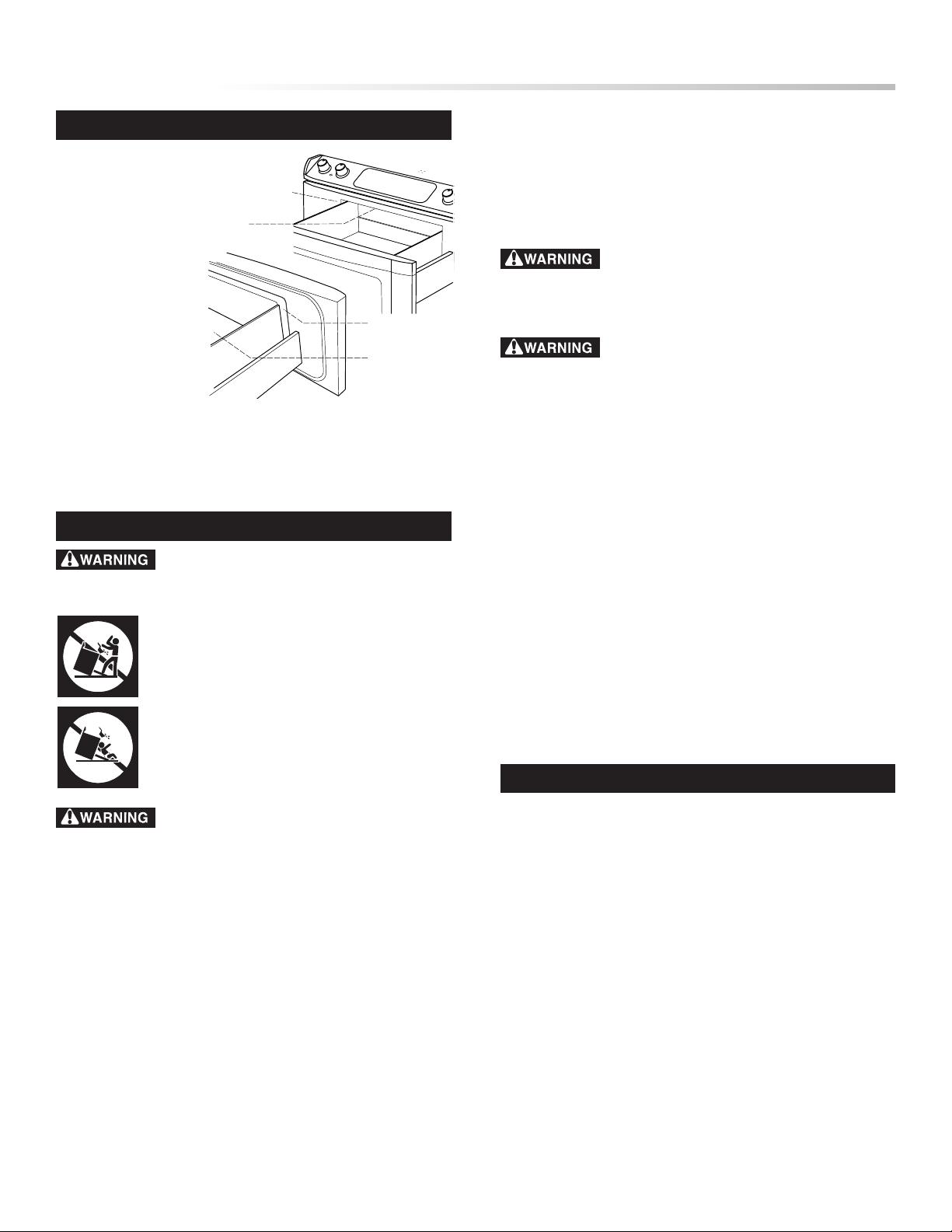

INSTALLATION MANUAL

Sealing Surface

Waveguide

Cover

Sealing Surface

Microwave

Drawer Cavity

unPaCkInG anD ExaMInInG YouR RanGE

1 Remove all packing

m a te r ia l s f r o m

inside the Microwave

Drawer and the oven

cav ity. D O NOT

R E M O V E T H E

W A V E G U I D E

COV ER, wh ich is

located on the top

of the Mi cr owave

Drawer area.

2 Remove the feature

sticker, if there is one.

Check the drawer for

any damage, such as misaligned or bent drawer, damaged drawer

seals and sealing surfaces, broken or loose drawer guides and

dents inside the drawer or on the front side of the drawer. If there

is any damage, do not operate the Microwave Drawer and contact

your dealer or a SHARP AUTHORIZED SERVICER.

IMPoRtant saFEtY InstRuCtIons

If the information in this manual is not followed

exactly, a re or electrical shock may result causing property damage,

personal injury or death.

• ALL RANGES CAN TIP

• INJURY TO PERSONS COULD RESULT

• INSTALL ANTI-TIP BRACKET PACKED

WITH RANGE

• SEE ANTI-TIP BRACKET TEMPLATE

FOR INSTALLATION INSTRUCTIONS

• Before instal ling the range in an area covered with

linoleum or any other synthetic oor covering, make sure

the oor covering can withstand heat at least 90˚F (32.2˚C)

above room temperature without shrinking, warping or

discoloring. Do not install the range over carpeting unless

you place an insulating pad or sheet of 1/4-inch (0.64cm) thick

plywood between the range and carpeting.

Never leave children alone or unattended in the

area where an range is in use. As children grow, teach them the

proper, safe use of all ranges. Never leave the oven door open when

the range is unattended.

Stepping, leaning or sitting on the door or drawer

of this range can result in serious injuries and can also cause damage

to the range.

• Do not store items of interest to children in the cabinets

above the range. Children could be seriously burned climbing

on the range to reach items.

• To eliminate the need to reach over the cooktop, cabinet storage

space above the cooktop should be avoided.

• Do not use the oven as a storage space. This creates a

potentially hazardous situation.

• Never use the range for warming or heating the room.

• Do not store or use gasoline or other ammable vapors and

liquids near this or any other range. Explosions or res could

result.

• Reset all controls to the “off” position after using a

programmable timing operation.

WHEN USING THE SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils before

self-cleaning the oven. Wipe up excess spillage. Follow the

precleaning instructions in the Operation Manual.

ElECtRICal ConnECtIons

be secured by properly installed Anti-Tip bracket packed with

the range.

• This range must be electrically grounded in accordance with

• The installation of ranges designed for manufactured (mobile)

• Make sure the wall coverings and the cabinets around the range

To reduce the risk of tipping the range, it must

local codes, or in their absence, with the National Electrical

Code ANSI/NFPA No. 70—latest edition in United States.

home installation must conform with Manufactured Home

Construction and Safety Standard, title 24CFR, part 3280

[Formerly the Federal Standard for Mobile Home Construction

and Safety, title 24, HUD (part 280)] or when such standard

is not applicable, the Standard for Manufactured Home

Installation 1982 (Manufactured Home Sites, Communities

and Setups), ANSI Z225. 1/NFPA 501A- latest edition, or with

local codes in United States.

can withstand the heat generated by the range.

The installer or consumer is responsible for connecting the power

supply cord to the connection block located behind the back panel

access cover.

This range may be connected by means of permanent “hard wiring”

(exible armored or nonmetallic shielded copper or aluminum cable),

or by means of a power supply cord kit. Only a power supply cord kit

rated at 240 volts or 208 volts and 50 amperes and marked for use

with ranges shall be used. Cord must have either 3 or 4 conductors

to match electric receptacle. The power cord kit is not included so

must be purchase at an appliance store.

For mobile homes, new installations, recreational vehicles or areas

where local codes do not permit grounding through neutral, a 4 conductor power supply cord kit rated at 240 volts or 208 volts minimum,

50 amperes and marked for use with ranges should be used.

Terminals on end of wires must be either closed loop or open-end

spade lugs with upturned ends. Cord must have strain-relief clamp.

The range connection opening should be 1 3/8-inches.

3

INSTALLATION MANUAL

Rating plate

208V

screw

240V

180˚

screw

screw

strain relief clamp

4-wire wall receptacle (14-50R) 3-wire wall receptacle (10-50R)

Risk of re or electrical shock exists if an incorrect size range cord kit is used, or the installation instructions are

not followed precisely and/or a strain relief clamp is not used.

Do not loosen the nuts which secure the factory-installed range wiring to the terminal block while connecting range.

Electrical failure or loss of electrical connection may occur.

ELECTRICAL SHOCK HAZARD

• DISCONNECT POWER TO THE CIRCUIT BREAKER

OR FUSE BOX BEFORE MAKING THE ELECTRICAL

CONNECTION.

• Electrical ground is required on this range.

• Do not connect to the electrical supply until range is permanently

grounded.

• This ra nge must be con nected to a grounded, meta llic,

permanent electrical system or the grounding connector of the

power cord should be connected to the grounding terminal or

wire lead on the range.

• Failure to heed these warnings could result in a re, personal

injury or electrical shock.

3 & 4-WIRE ELECTRICAL WALL RECEPTACLE TYPES &

RECOMMENDED MOUNTING ORIENTATION ON WALL

Figure 5A illustrates 4-wire receptacle required for new and

remodeled installations.

Figure 5B illustrates 3-wire receptacle that is allowed for existing

installations.

Figure 5A

ACCESS TO TERMINAL BLOCK

Figure 5B

Loosen screw on rear access cover and pull down as illustrated in

Figure 6 to access terminal block wiring connection.

MODEL AND SERIAL NUMBER LOCATION

The rating plate, including model and serial number, is located on

the faceplate behind the Microwave Drawer front.

208/240 VOLT CONNECTION INSTRUCTIONS

The range can be set for 208V or 240V. The voltage setting for your

range is pre-set at 240V from the factory. Follow these steps to

change the voltage setting.

1 Locate the voltage switch on the lower back side of the range.

2 Remove the screw and rotate the switch plate 180˚ as indicated

in the Figure 3.

3 Reinsert the switch plate and replace screw as indicated in Figure

4. The voltage setting is indicated by the visible marking.

Figure 3 Figure 4

Figure 6

Figure 7

PoWER CoRD ConnECtIons

4-WIRE CONNECTION INSTRUCTIONS

Before wiring the range, review the suggested power source location

drawing in Figure 2. If connecting to a 4-wire electrical system for a

new branch-circuit or mobile home use a 4-wire connection.

1 Follow the power supply cord kit manufacturer’s Installation

Instructions and install the strain relief clamp on the cord. See

Figure 7.

2 Connect the end connectors for line 1, line 2 and neutral and

tighten securely to the terminal block. See Figure 8.

IMPORTANT

connections which secure the range wiring to the terminal

block. Electrical failure or loss of electrical connection may

occur if these 3 nuts are loosened or removed.

3 You must disconnect the ground strap. Remove the factory

installed ground screw and plate to release the copper ground

strap from the frame of the range. Cut and discard the copper

ground strap and plate. KEEP the ground screw. See Figure 8.

4 Connect the green ground wire lead with the eyelet to the frame

of the range with the ground screw using the same hole in the

4

DO NOT LOOSEN the factory installed nut

INSTALLATION MANUAL

terminal

block

ground

screw

ground plate

ground strap

line 2

neutral

line 1

ground

screw

ground

screw

ground

wire lead

ground plate

ground

plate

ground strap

line 2

neutral

proper ground

for 4-wire

permanent

G

ro

u

n

d st

ra

p

T

e

rmi

n

a

l b

l

o

ck

Note: Install strain

relief clamp. Center

must always be

attached to the

center terminal on

block.

Connect neutral

here.

Connect line

1 here.

Connect line 2 here.

A user supplied

strain relief clamp

must be installed

at this location. It

requires 13/8"

(3.5 cm) diameter

cord kit hole.

T

e

rmi

n

a

l b

l

o

ck

w

h

i

t

e

g

r

e

e

n

Connect green

insulated copper

ground wire with

ground screw

here.

Cut ground

strap. Discard

ground strap

and ground

plate.

Connect neutral (white

or center) here.

Connect

line 1 here.

Connect line 2 here.

b

l

a

c

k

Note: Install strain

relief clamp. Center or

white wire must always

be attached to the

center terminal on

block.

A user supplied strain

relief clamp must be

installed at this

location. It requires 1

3

/8" (3.5 cm) diameter

cord kit hole.

r

e

d

frame where the ground screw was originally installed. See

Figure 8.

5 Make sure all screws are tightened securely and replace the

rear access cover and secure with screw. See Figure 6.

3-WIRE CONNECTION INSTRUCTIONS

For existing installations ONLY, refer to Figure 9.

1 Follow the power supply cord kit manufacturer’s Installation

Instructions and install the strain relief clamp. See Figure 7.

2 Connect the end connectors for line 1, line 2 and neutral and

tighten securely to the terminal block. See Figure 9.

IMPORTANT

DO NOT LOOSEN the factory installed nut

connections which secure the range wiring to the terminal

block. Electrical failure or loss of electrical connection may

occur if these 3 nuts are loosened or removed.

3 A ground strap is installed on this range which connects the

center terminal of the neutral terminal block to the range

chassis. The ground strap is connected to the range by the

center, lowest screw. See Figure 9. The ground strap must not

be removed unless National, State or Local Codes do not permit

use of a ground strap.

NOTE:

If the ground strap is removed for any reason, a

separate ground wire must be connected to the separate ground

screw attached to the range chassis and to an adequate ground

source.

4 Make sure all connections are tightened securely and replace

the rear access cover and secure with screw. See Figure 6.

4-WIRE CONNECTION

3 & 4-WIRE PERMANENT WIRE CONNECTIONS

3–wire permanent connection – follow steps 1, 2 and 5 below.

4–wire permanent connection – follow all steps below.

Before wiring the range, review the suggested power source location

drawings in Figure 2. If connecting to a 4-wire electrical system:

1 Follow the manufacturer’s Installation Instructions for installing

the strain relief clamp.

2 Strip insulation away from the ends of the permanent wiring

for line 1, line 2 and neutral; also strip ground wire on 4-wire

connections. Tighten all 3 or 4-wire leads to the terminal block.

Follow wire locations shown in Figure 10.

IMPORTANT

DO NOT LOOSEN the factory installed nut

connections which secure the range wiring to the terminal

block. Electrical failure or loss of electrical connection may

occur if these 3 nuts are loosened or removed.

NOTE:

For 3-wire permanent connection skip steps 3 and 4

and continue with step 5.

3 Disconnect the ground strap. Remove the factory installed

ground screw and plate to release the factory installed copper

ground strap from frame of the range. Cut and discard the

copper strap from the terminal block. KEEP the ground screw,

ground plate and go to step 4.

4 Connect the green ground wire lead to the frame of the range

using the ground screw and plate as shown in Figure 11. Be sure

to install using the same hole in the frame where the ground

screw was originally installed.

5 Make sure all connections are tightened securely and replace

the rear access cover and secure with screw. See Figure 6.

NOTE:

Non-terminated eld wire compression connections

must be set at approximately 90 in./lb.

Figure 8

3-WIRE CONNECTION

Figure 9

FOR 3 & 4-WIRE PERMANENT CONNECTIONS

Figure 10

4-WIRE PERMANENT CONNECTION ONLY

Figure 11

5

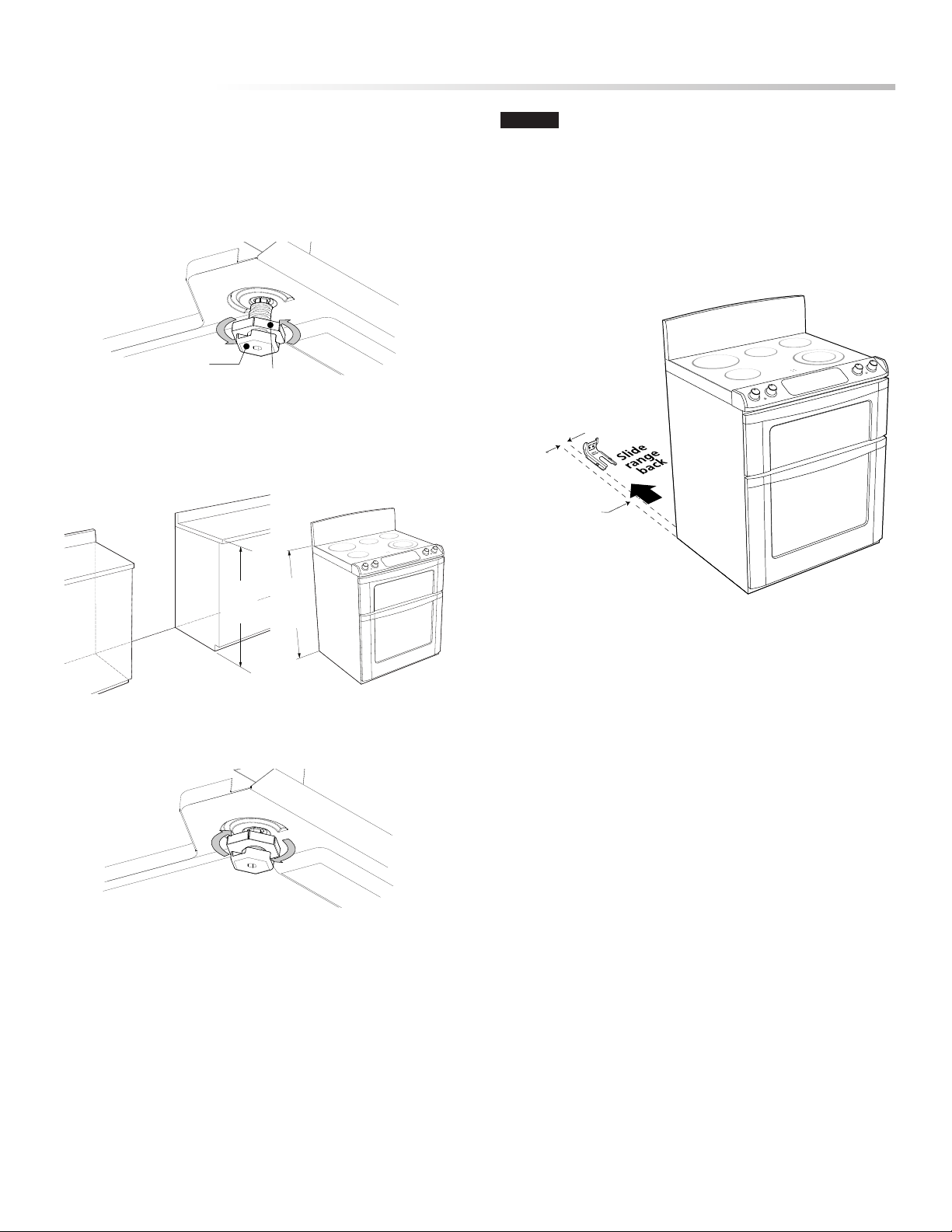

FASTEN BRACKET (WALL OR FLOOR MOUNTING)

FASTEN BRACKET (FLOOR MOUNTING ONLY)

floor mount

floor mount

Anti-Tip bracket

Anti-Tip bracket

wall

wall mount

wall plate

more than

11/4"

max 11/4"

leveling leg

leveling leg

The edge of the template

should be aligned with the left

or right edge of the range.

15"

15"

INSTALLATION MANUAL

13 3/8" from the center of

the wall opening to the edge

of the backet.

133/8"

133/8"

antI-tIP

NORMAL INSTALLATION STEPS

ANTI-TIP BRACKET INSTALLATION INSTRUCTIONS

IMPORTANT SAFETY WARNING

To reduce the risk of tipping of the range, the range must be secured

to the oor by properly installed Anti-Tip bracket and screws packed

with the range. Failure to install the Anti-Tip bracket will allow the

range to tip over if excessive weight is placed on an open door or if

a child climbs upon it. Serious injury might result from spilled hot

liquids or from the range itself.

If range is ever moved to a different location, the Anti-Tip bracket

must also be moved and installed with the range. Instructions are

provided for installation in wood or cement fastened to either the oor

or wall. When installed to the wall, make sure that screws completely

penetrate dry wall and are secured in wood or metal. When fastening

to the oor or wall, be sure that screws do not penetrate electrical

wiring or plumbing.

1 LOCATE THE BRACKET - USING THE TEMPLATE

The bracket may be located on either the left or right side of the

range. Refer to gure 12b to locate the bracket if template is not

available.

Mark the oor or wall where left or right side of the range will be

located. If rear of range is against the wall or no further than 1

1

/4-inches from wall when installed, you may use the wall or oor

mount method. See Figure 13. If molding is installed and does not

allow the bracket to t ush against the wall, remove molding or

mount bracket to the oor. For wall mount, locate the bracket by

placing the back edge of the template against the rear wall and the

side edge of template on the mark made referencing the side of the

range. Place bracket on top of template and mark location of the

screw holes in wall. If rear of range is further than 1 1/4-inches from

the wall when installed, attach bracket to the oor. See Figure 14. For

oor mount, locate the bracket by placing back edge of the template

where the rear of the range will be located. Mark the location of the

screw holes, shown in template.

2 DRILL PILOT HOLES AND FASTEN BRACKET

Drill a 1/8-inch pilot hole where screws are to be located. If bracket

is to be mounted to the wall, drill pilot hole at an approximate 20

degree downward angle. If bracket is to be mounted to masonry or

ceramic oors, drill a 5/32-inch pilot hole 1 3/4-inches deep. The

screws provided may be used in wood or concrete material. Use a

5

/16-inch nut-driver or at head screwdriver to secure the bracket

in place.

Figure 12A

Figure 12B

Figure 13

Figure 14

6

INSTALLATION MANUAL

(X")

floor to top

of cooktop

glass

(Y")

floor to

top of

countertop

Range Slide

15/8" to edge

of bracket

3 LEVEL AND POSITION RANGE

• Measure from the countertop to the oor height to determine

the height that the back of the range needs to be set at.

• Loosen legs and lock nuts to set level of the range. (Note that

the lock nuts are only on the rear feet). See Figure 15.

Range Leg

Figure 15

• Adjust the back leveling legs with an adjustable wrench or pliers.

Measure from the oor to the top of the cooktop glass (X) and

adjust the legs to match the measurement (Y) taken from the

cutout. See Figure 16.

Lock Nut

(Rear leg only)

NOTE:

A minimum clearance of 1/8-inch is required between

the bottom of the range and the leveling leg to allow room for the

bracket. Use a level to check your adjustments. Plug range into

properly prepared electrical receptacle or if hard wired, check that

it was completed properly. Check oor condition for evenness and

stability. Slide range back into position. See Figure 18.

Visually check that rear leveling leg is inserted into and fully secured

by the Anti-Tip bracket by looking underneath the range with a

ashlight and carefully attempt to tilt it forward.

Figure 16

• After leveling, tighten the lock nuts on the rear to prevent the

feet from turning when sliding into position. See Figure 17.

Figure 17

Figure 18

7

INSTALLATION MANUAL

CaRE, ClEanInG anD MaIntEnanCE

Refer to the Operation Manual for cleaning instructions. If removing

the range is necessary for cleaning or maintenance, disconnect the

electrical power supply. If the electrical supply is inaccessible, lift

the unit slightly at the front and pull out away from the wall. Pull

only as far as necessary to disconnect the electrical supply. Finish

removing the unit for servicing and cleaning. Reinstall in reverse

order making sure to level the range and check electrical connections.

See pages 2 and 3 for proper anchoring instructions.

BEFoRE You Call FoR sERVICE

Read the BEFORE YOU CALL and operating instruction sections

in your Operation Manual. It may save you time and expense. The

list includes common occurrences that are not the result of defective

workmanship or materials in this range.

Refer to your Operation Manual for our service address. Sharp's

toll-free telephone number is 1-800-BE-SHARP (1-800-237-4277).

Please call or write if you have inquiries about your range product

and/or need to order parts.

NOTE:

seconds after plugged in.

Please do not open or close the lower oven door for 30

T IN S EB 4 3 8M R R1

SHARP ELECTRONICS CORPORATION

Sh arp Plaza, Mahwah , New Jersey 07430- 21 35

PRIn tED In usa

Loading...

Loading...