Page 1

INSTALLATION INSTRUCTION / OPERATION MANUAL

MODEL

KB-0333K

Followed by indicating color: K = black, W = white, S = stainless steel

FORCUSTOMERASSISTANCE.................................... 2

CONSUMERLIMITEDWARRANTY............................... 3

PRODUCTINFORMATIONCARD.................................. 3

IMPORTANTSAFETYINSTRUCTIONS............................ 4

PREPAREHOODLOCATION....................................... 5

PREPARETHEHOOD.......................................... 6 - 8

CONNECTWIRING................................................. 8

INSTALLHOOD..................................................... 9

NON-DUCTEDFILTERS............................................ 9

OPERATING........................................................ 10

FUSE............................................................... 10

CLEANING......................................................... 11

SHARP In s i g h t_M

Page 2

FOR CUSTOMER ASSISTANCE

To aid in reporting this range hood, please record below the model number and serial number located on the unit.

We also suggest you record all the information listed and retain for future reference.

MODELNUMBER

DATEOFPURCHASE

DEALER

SERVICER

/ /

SERIALNUMBER

TELEPHONE

TELEPHONE

TO PHONE:

DIAL

1-800-BE-SHARP (237-4277) for:

SERVICE (for your nearest Sharp Authorized Servicer)

PARTS (for your authorized parts distributor)

DIAL

TO WRITE:

1-800-642-2122 for: Charcoal Filters (model KBK-330)

Sharp Electronics Corporation

Customer Assistance Center

1300 Naperville Drive

Romeoville, IL 60446-1091

Please provide the following information when you write or call: model number, serial number, date of purchase, your

complete mailing address (including zip code), your daytime telephone number (including area code) and description of

the problem.

TO ACCESS INTERNET: www.sharpusa.com

Page 3

CONSUMER LIMITED WARRANTY

SHARP ELECTRONICS CORPORATION warrants to the first consumer purchaser that this Sharp brand product (the

"Product"), when shipped in its original container, will be free from defective workmanship and materials, and agrees that it

will, at its option, either repair the defect or replace the defective Product or part thereof with a new or remanufactured equivalent

at no charge to the purchaser for parts or labor for the period(s) set forth below.

This warranty does not apply to any appearance items of the Product nor to the additional excluded item(s) set forth below nor

to any Product the exterior of which has been damaged or defaced, which has been subjected to misuse, abnormal service or

handling, or which has been altered or modified in design or construction.

In order to enforce the rights under this limited warranty, the purchaser should follow the steps set forth below and provide

proof of purchase to the servicer.

The limited warranty described herein is in addition to whatever implied warranties may be granted to purchasers by law.

ALL IMPLIED WARRANTIES INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR USE

ARE LIMITED TO THE PERIOD(S) FROM THE DATE OF PURCHASE SET FORTH BELOW. Some states do not allow

limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

Neither the sales personnel of the seller nor any other person is authorized to make any warranties other than those described

herein, or to extend the duration of any warranties beyond the time period described herein on behalf of Sharp.

The warranties described herein shall be the sole and exclusive warranties granted by Sharp and shall be the sole and exclusive

remedy available to the purchaser. Correction of defects, in the manner and for the period of time described herein, shall

complete fulfilllneut of all liabilities and responsibilities of Sharp to the purchaser with respect to the Product, and shall constitute

full satisfaction of all claims, whether based on contract, negligence, strict liability or otherwise. In no event shall Sharp be

liable, or in any way responsible, for any damages or defects in the Product which were caused by repairs or attempted repairs

performed by anyone other than an authorized servicer. Nor shall Sharp be liable or in any way responsible for any incident or

consequential economic or property damage. Some states do not allow the exclusion of incidental or consequential damages,

so the above exclusion may not apply to you.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE.

Your product model number &

description

KB-0333K Home Use Range Hood. (Be sure to have this information available when

you need service for your Product.)

Warranty period for this product: One (1)year parts and labor including in-home service.

Additional item(s) excluded from

warranty coverage (if any):

Where to obtain service:

Light Bulbs

From a Sharp Authorized Servicer located in the United States. To find the location

of the nearest Sharp Authorized Servicer, call Sharp toll free at 1-800-BE-SHARP

(1-800-237-4277).

What to do to obtain service: From a Sharp Authorized servicer located in the United States. Be sure to have Proof of

Purchase available. For in-home service, the servicer will come to the unit's location.

If it is necessary to remove the unit for repair, the servicer will reinstall the unit at no

extra charge, provided it was installed according to Sharp's Installation Instructions.

TO OBTAIN SUPPLY, ACCESSORY OR PRODUCT INFORMATION, (!ALL 1-800-BE-SHARP or visit www.shmpusa.com.

SAVE THE PROOF OF PURCHASE AS IT IS NEEDED SHOULD YOUR RANGE HOOD EVER REQUIRE WARRANTY

SERVICE.

PRODUCT INFORMATION CARD

The Product Information Card should be completed within ten days of purchase and returned. We will keep it on file and help

you access the information if needed. This will also enable us to contact you in the unlikely event that any adjustlnents or

modifications are ever required for your range hood.

Page 4

IMPORTANTSAFETYINSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING

FORDOMESTICCOOKINGONLY

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact Sharp at

the address or telephone number listed on page 2 of this

manual.

2. Before servicing or cleaning unit, switch power off at

service panel and lock the service disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a

tag, to the service panel.

3. Installation work and electrical wiring must be done by

a qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction

codes and standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating eqmpment manufacturer s =mdehne and safety

standards such as those published by the National Fire

Protection Association (NFPA), and the American

Society of Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

6. To reduce the risk of fire or electric shock, do not use this

range hood with an additional speed control device.

7. Ducted fans must always be vented to the outdoors.

8. To reduce the risk of fire, use only metal ductwork.

9. Use with approved cord-connection kit only.

10. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE

FIRE:

1. Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

2. Always turn hood ON when cooking at high heat or when

cooking flaming foods.

3. Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate

for the size of the surface element.

• ' o " "

TO REDUCE THE RISK OF INJURY TO PERSONS

IN THE EVENT OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie

sheet or metal tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS. If the flames do

not go out ilmnediately, EVACUATE AND CALL THE

FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN -- You may be

burned.

3. DO NOT USE WATER, including wet dishcloths or

towels - violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and

you already know how to operate it.

B. The fire is small and contained in the area where it

started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on "Kitchen Fire Safety Tips" published by NFPA.

I ,_.-7.,lqtJ[.l ,'I

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or

unbalanced impellers, keep drywall spray, construction

dust, etc. off power unit.

3. For best capture of cooking impurities, your range hood

should be mounted so that the top of the hood is 24-30"

above the cooking surface.

4. Please read specification label on product for further

information and requirements.

Halogen or incandescent bulbs may be hot!

Refer to bulb packaging for further information.

Installer: Leave this manual with the homeowner.

Homeowner: Operating instructions and Cleaning

information are on pages 10-11.

Page 5

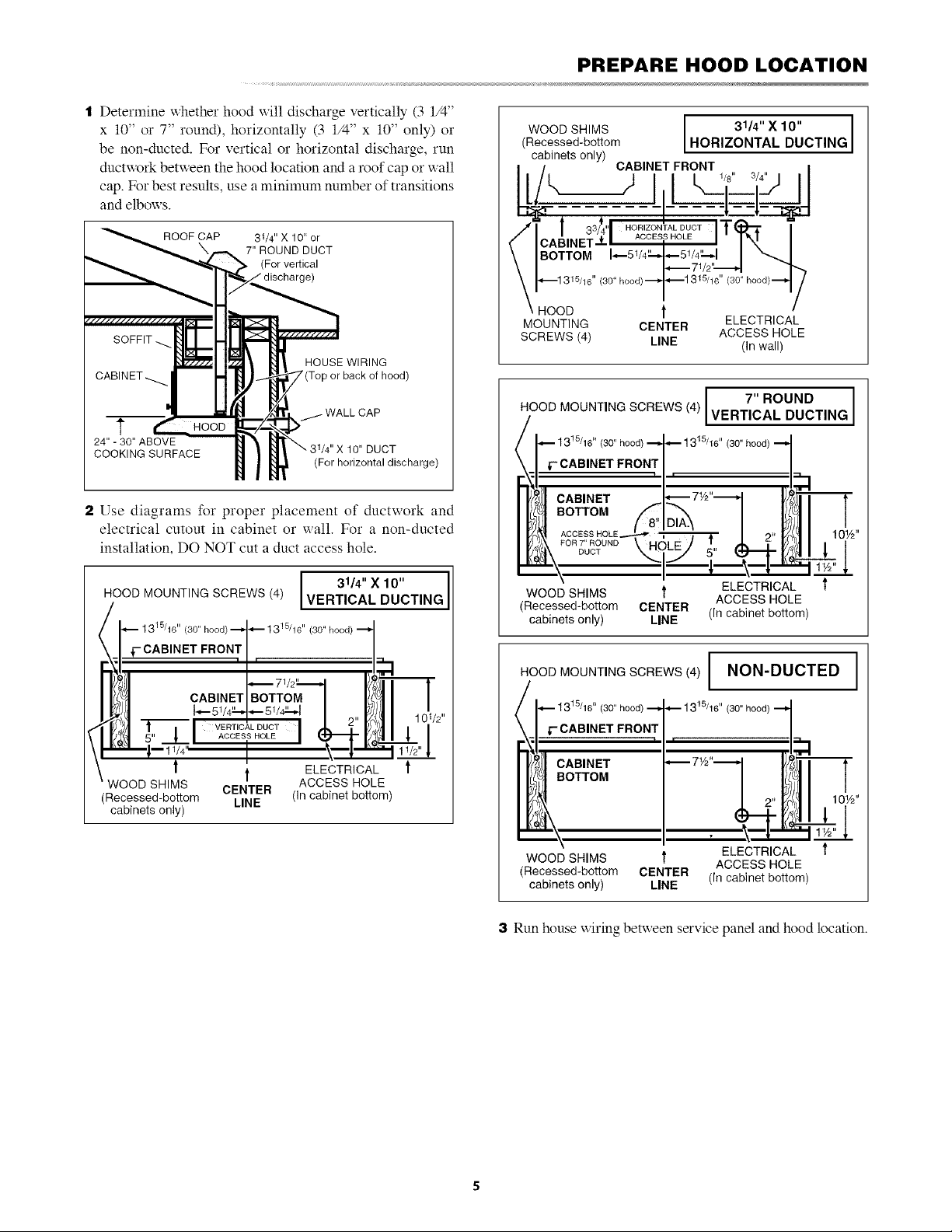

I Determine whether hood will discharge vertically (3 1/4"

x 10" or 7" round), horizontally (3 1/4" x 10" only) or

be non-ducted. For vertical or horizontal discharge, run

ductwork between the hood location and a roof cap or wall

cap. For best results, use a minilnUln nulnber of transitions

and elbows.

PREPARE HOOD LOCATION

WOOD SHIMS 31/4" X 10"

(Recessed-bottom HOR ZONTAL DUCT NG

cabinets only)

CABINET FRONT

1/8" 3/4"

ROOF CAP 31/4"X 10" or

7" ROUND DUCT

(For vertical

HOUSE WIRING

7(Top or back of hood)

CAP

t

24" -30" ABOVE

COOKING SURFACE

2 Use diagrams for proper placement of ductwork and

electrical cutout in cabinet or wall. For a non-ducted

installation, DO NOT cut a duct access hole.

HOOD MOUNTING SCREWS (4)

(30"

- CABINET FRONT

CABINET BOTTOM

VERTICAL DUCT

ACCESS HOLE

WOOD SHIMS

(Recessed-bottom

cabinets only)

t ELECTRICAL

CENTER (In cabinet bottom)

LINE

ACCESS HOLE

10" DUCT

(For horizontal discharge)

31/4" X 10"

VERT CAL DUCT NG

101/2''

i I

11/#" l

t

HOOD t ELECTRICAL

MOUNTING CENTER ACCESS HOLE

SCREWS (4) LINE (In wall)

HOOD MOUNTING SCREWS (4 7 ROUND

(30"

DUCT

WOOD SHIMS _' ELECTRICAL

(Recessed-bottom CENTER (In cabinet bottom)

cabinets only) LINE

) VERTICAL DUCTING

ii

ACCESS HOLE

I

HOOD MOUNTING SCREWS (4) I

(3o"

_- CABINET FRONT

CABINET '_

BOTTOM

NON-DUCTED I

10W'

1t/2" _

t

10V2"

WOOD SHIMS 1'

(Recessed-bottom CENTER

cabinets only) LINE

ELECTRICAL

ACCESS HOLE

In cabinet bottom)

3 Run house wiring between service panel and hood location.

Page 6

PREPARE THE HOOD

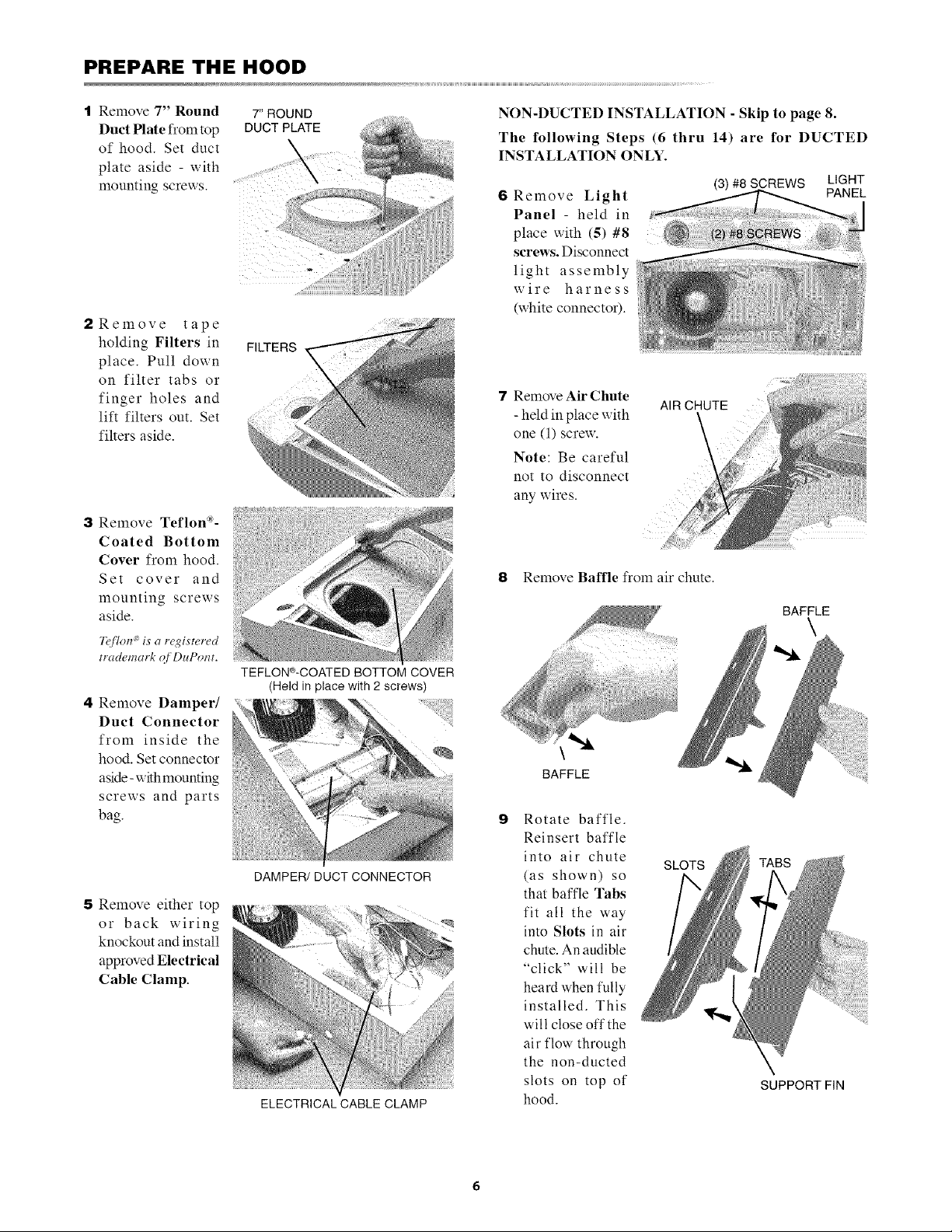

1 Remove 7" Round 7"ROUND

Duct Plate from top DUCTPLATE

of hood. Set duct

plate aside - with

mounting screws.

2Remove tape

holding Filters in

place. Pull down

FILTERS X

on filter tabs or

finger holes and

lift filters out. Set

filters aside.

3 Remove Teflon %

Coated Bottom

Cover froln hood.

Set cover and

mounting screws

aside.

Tq/lon _ is' a regismred

trademark qf DuPont.

TEFLON_)-COATED BOTTOM COVER

(Held in place with 2 screws)

4 Remove Damper/

Duct Connector

from inside the

hood. Set com_ector

aside-with mounting

screws and parts

bag.

DAMPER/DUCTCONNECTOR

5 Remove either top

or back wiring

knockout and install

approved Electrical

Cable Clamp.

ELECTRICAL CABLE CLAMP

NON-DUCTED INSTALLATION - Skip to page 8.

The following Steps (6 thru 14) are for DUCTED

INSTALLATION ONLY.

(3)#8 SCREWS LIGHT

6Remove Light

Panel - held in

place with (5) #8

screws. Disconnect

light assembly

wire harness

(white connector).

i

7 Remove Air Chute

AIR CHUTE

PANEL

- held in place with

one (1) screw.

Note: Be careful

\

not to disconnect

any wires.

8 Remove Baffle from air chute.

BAFFLE

\

BAFFLE

Rotate baffle.

Reinsert baffle

into air chute

(as shown) so

that baffle Tabs

fit all the way

into Slots in air

chute. An audible

"click" will be

heard when fully

installed. This

will close offthe

air flow through

the non-ducted

slots on top of

hood.

SLOTS

SUPPORT FIN

Page 7

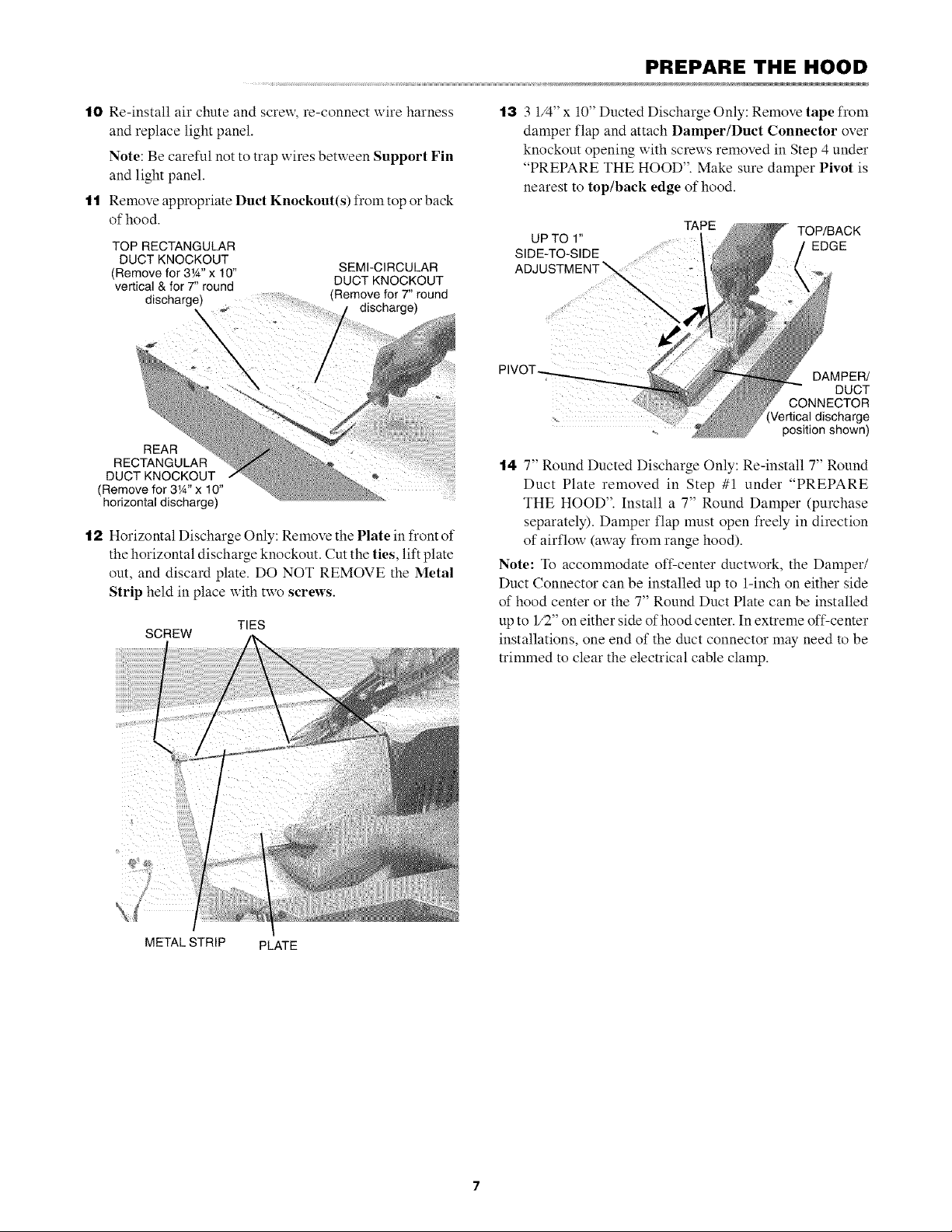

PREPARE THE HOOD

10 Re-install air chute and screw, re-connect wire harness

and replace light panel.

Note: Be careful not to trap wires between Support Fin

and light panel.

11 Remove appropriate Duct Knockout(s) from top or back

of hood.

TOP RECTANGULAR

DUCT KNOCKOUT

(Remove for 31A'' x 10"

vertical & for 7" round

discharge)

REAR

RECTANGULAR

DUCT KNOCKOUT

(Remove for 3W' x 10"

horizontal discharge)

SEMI-CIRCULAR

DUCT KNOCKOUT

tRemove for 7" round

discharge)

12 Horizontal Discharge Only: Remove the Plate in front of

the horizontal discharge knockout. Cut the ties, lift plate

out, and discard plate. DO NOT REMOVE the Metal

Strip held in place with two screws.

SCREW

TIES

13 3 1/4" x 10" Ducted Discharge Only: Remove tape from

damper flap and attach Damper/Duct Connector over

knockout opening with screws removed in Step 4 under

"PREPARE THE HOOD". Make sure damper Pivot is

nearest to top/back edge of hood.

UPTO 1"

SIDE-TO-SIDE / EDGE

. (Vertical discharge

TAPE TOP/BACK

DAMPER/

DUCT

CONNECTOR

position shown)

t4 7" Round Ducted Discharge Only: Re-install 7" Round

Duct Plate removed in Step #1 under "PREPARE

THE HOOD". Install a 7" Round Damper (purchase

separately). Damper flap must open freely in direction

of airflow (away from range hood).

Note: To accommodate oft-center ductwork, the Damper/

Duct Connector can be installed up to 1-inch on either side

of hood center or the 7" Round Duct Plate can be installed

up to 1/2" on either side of hood center. In extreme off-center

installations, one end of the duct connector may need to be

trimmed to clear the electrical cable clamp.

iii(

METAL STRIP PLATE

Page 8

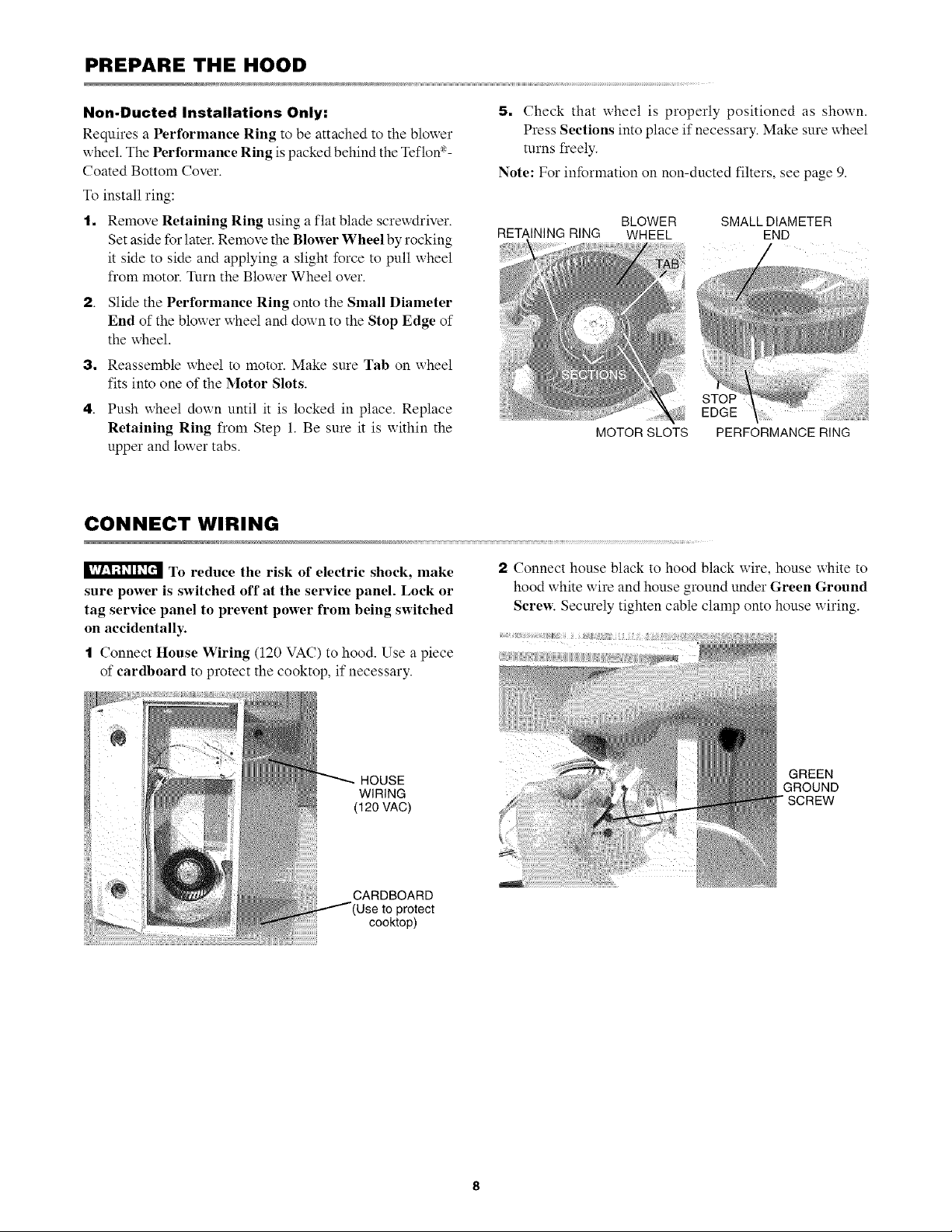

PREPARE THE HOOD

Non-Ducted Installations Only:

Requires a Performance Ring to be attached to the blower

wheel. The Performance Ring is packed behind the Teflon :_-

Coated Bottom Cover.

To install ring:

1, Remove Retaining Ring using a flat blade screwdriver.

Set aside for later. Remove the Blower Wheel by rocking

it side to side and applying a slight force to pull wheel

from motor. Turn the Blower Wheel over.

2. Slide the Performance Ring onto the Small Diameter

End of the blower wheel and down to the Stop Edge of

the wheel.

Reassemble wheel to motor. Make sure Tab on wheel

3m

fits into one of the Motor Slots.

4.

Push wheel down until it is locked in place. Replace

Retaining Ring froln Step 1. Be sure it is within the

upper and lower tabs.

CONNECT WIRING

5. Check that wheel is properly positioned as shown.

Press Sections into place if necessary. Make sure wheel

turns freely.

Note: For information on non-ducted filters, see page 9.

RETAINING RING WHEEL END

BLOWER SMALL DIAMETER

STOF

EDGE

MOTOR SLOTS

PERFORMANCE RING

To reduce the risk of electric shock, make

sure power is switched off at the service panel. Lock or

tag service panel to prevent power from being switched

on accidentally.

1 Connect House Wiring (120 VAC) to hood. Use a piece

of cardboard to protect the cooktop, if necessary.

HOUSE

WIRING

(120 VAC)

CARDBOARD

protect

cooktop)

2 Connect house black to hood black wire, house white to

hood white wire and house ground under Green Ground

Serew. Securely tighten cable clamp onto house wiring.

GREEN

GROUND

"SCREW

Page 9

INSTALL HOOD

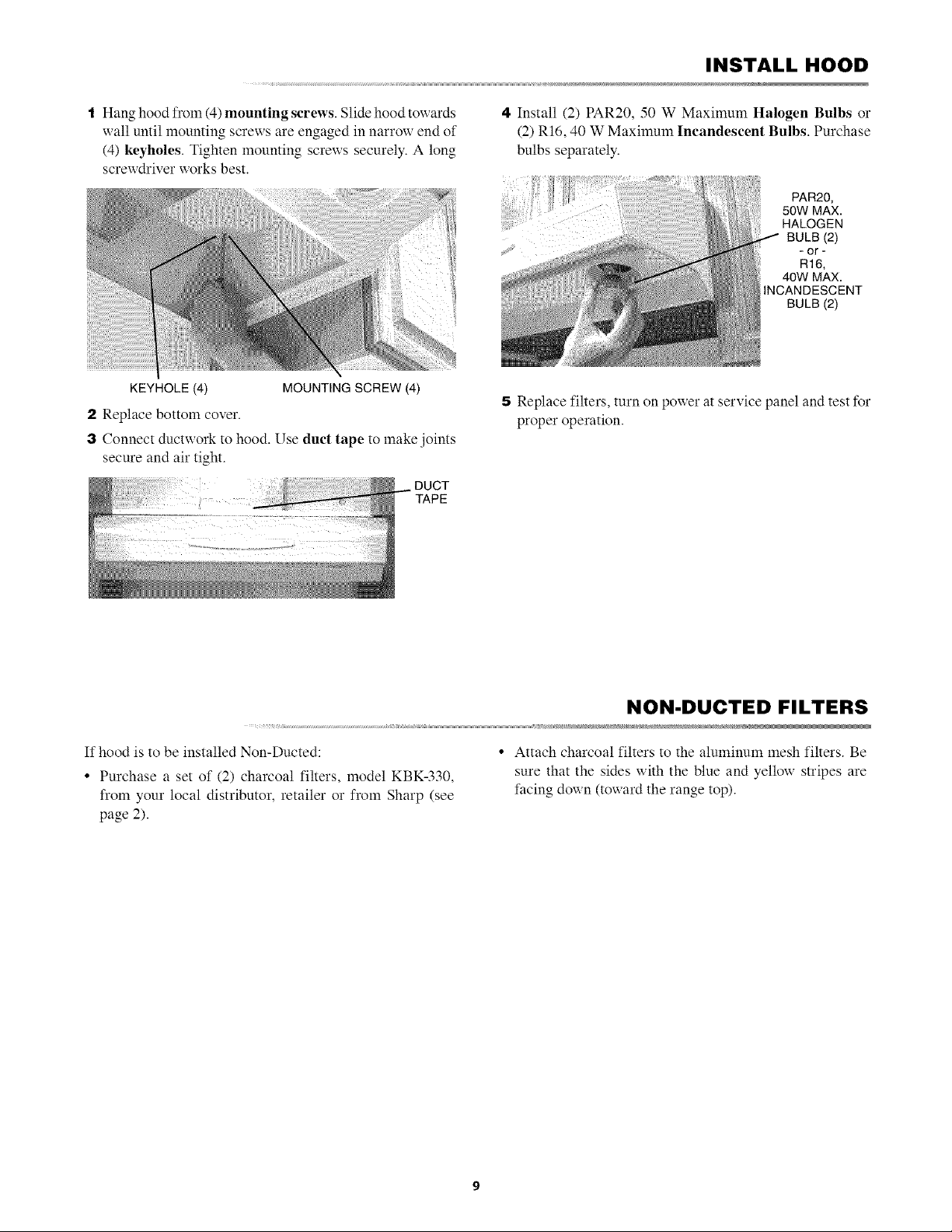

I Hang hood from (4) mounting screws. Slide hood towards

wall until mounting screws are engaged in narrow end of

(4) keyholes. Tighten mounting screws securely. A long

screwdriver works best.

KEYHOLE (4) MOUNTING SCREW (4)

2 Replace bottom cover.

3 Connect ductwork to hood. Use duet tape to make joints

secure and air tight.

DUCT

TAPE

4 Install (2) PAR20, 50 W Maximum Halogen Bulbs or

(2) R16, 40 W Maximum Incandescent Bulbs. Purchase

bulbs separately.

PAR20,

50W MAX.

HALOGEN

BULB (2)

- or-

R16,

40W MAX.

INCANDESCENT

BULB (2)

5 Replace filters, turn on power at service panel and test for

proper operation.

NON-DUCTED FILTERS

If hood is to be installed Non-Ducted: • Attach charcoal filters to the aluminum mesh filters. Be

• Purchase a set of (2) charcoal filters, model KBK-330, sure that the sides with the blue and yellow stripes are

from your local distributor, retailer or from Sharp (see facing down (toward the range top).

page 2).

Page 10

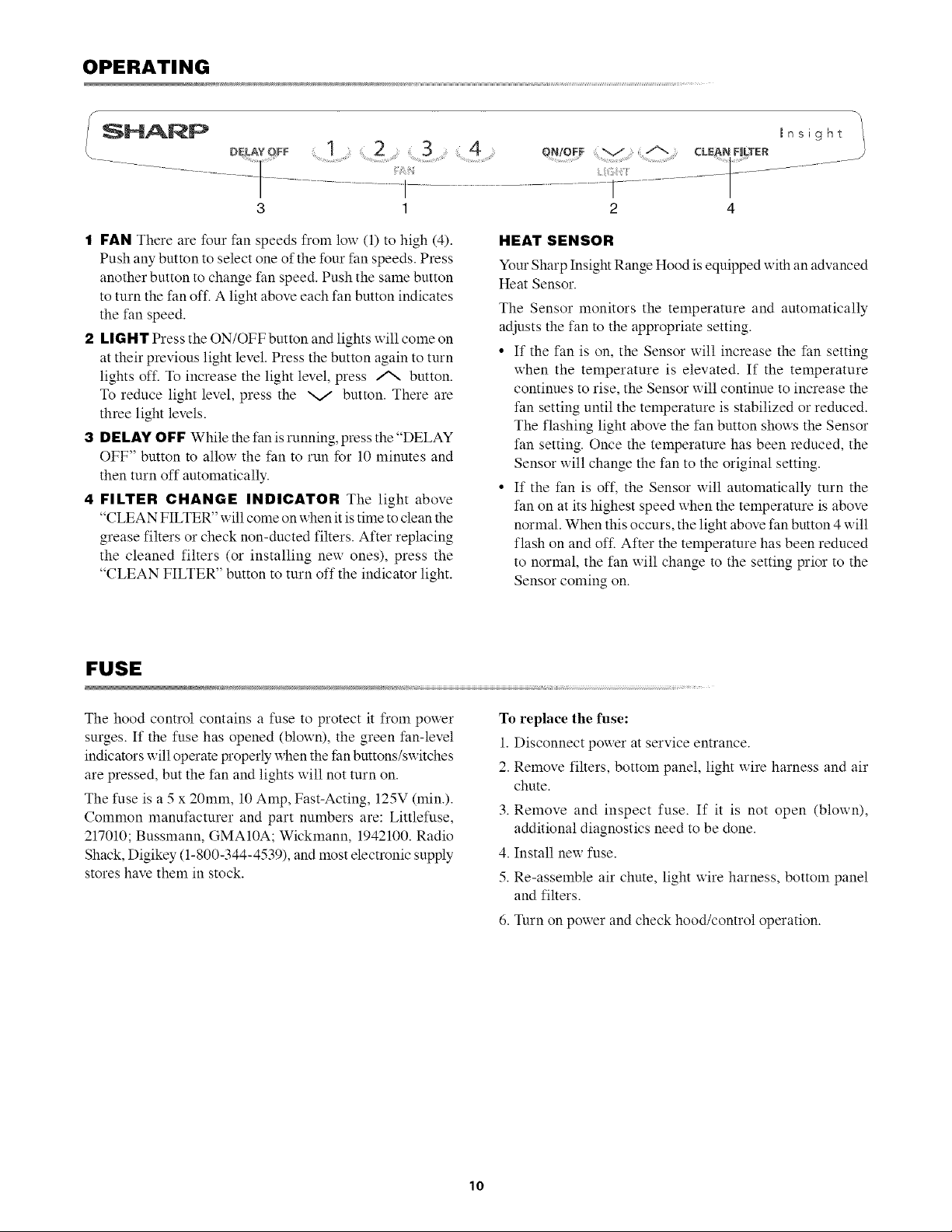

OPERATING

mnsight

3 1

1 FAN There are four fan speeds from low (1) to high (4).

Push any button to select one of the four fan speeds. Press

another button to change fan speed. Push the same button

to turn the fan off. A light above each fan button indicates

the fan speed.

2 LIGHT Press the ON/OFF button and lights will come on

at their previous light level. Press the button again to turn

lights off. To increase the light level, press /_ button.

To reduce light level, press the _/ button. There are

three light levels.

3 DELAY OFF While the fan is running, press the "DELAY

OFF" button to allow the fan to run for 10 minutes and

then turn off automatically.

4 FILTER CHANGE INDICATOR The light above

"(?LEAN FILTER" will come on when it is time to clean the

grease filters or check non-ducted filters. After replacing

the cleaned filters (or installing new ones), press the

"CLEAN FILTER" button to turn off the indicator light.

2 4

HEAT SENSOR

Your Sharp Insight Range Hood is equipped with an advanced

Heat Sensor.

The Sensor monitors the temperature and automatically

adjusts the fan to the appropriate setting.

• If the fan is on, the Sensor will increase the fan setting

when the temperature is elevated. If the temperature

continues to rise, the Sensor will continue to increase the

fan setting until the temperature is stabilized or reduced.

The flashing light above the fan button shows the Sensor

fan setting. Once the temperature has been reduced, the

Sensor will change the fan to the original setting.

• If the fan is off, the Sensor will automatically turn the

fan on at its highest speed when the temperature is above

normal. When this occurs, the light above fan button 4 will

flash on and ofl: After the temperature has been reduced

to normal, the fan will change to the setting prior to the

Sensor coming on.

FUSE

The hood control contains a fuse to protect it from power

surges. If the fuse has opened (blown), the green fan-level

indicators will operate properly when the fan buttons/switches

are pressed, but the fan and lights will not turn on.

The fuse is a 5 x 20mm, 10 Amp, Fast-Acting, 125V (min.).

Common manufacturer and part nulnbers are: Littlefuse,

217010; Bussmann, GMA10A; Wickmann, 1942100. Radio

Shack, Digikey (1-800-344-4539), and most electronic supply

stores have them in stock.

To replace the fuse:

1. Disconnect power at service entrance.

2. Remove filters, bottom panel, light wire harness and air

chute.

3. Remove and inspect fuse. If it is not open (blown),

additional diagnostics need to be done.

4. Install new fuse.

5. Re-assemble air chute, light wire harness, bottom panel

and filters.

6. Turn on power and check hood/control operation.

10

Page 11

CLEANING

To reduce the risk of electric shock, discon-

nect from power supply before cleaning.

Aluminum mesh filters: Clean frequently using hot

water and a mild detergent. Filters are dishwasher safe.

Charcoal filters (additional filters for non-

ducted installations): Clean filter surfaces frequently

with a damp cloth and a mild detergent. DO NOT immerse

filters in water or put in dishwasher. The special "Clean

Sense" feature indicates when the filter is to be replaced.

The blue and yellow stripes will blend to green when it is

time to change the filter. The "Clean Sense" feature works

best when facing toward the cooking surface.

To clean hood: Remove filters. Use a damp cloth and

a mild detergent to wipe all grease-laden surfaces. Do not

use abrasive cloth, steel wool pads or scouring powder on

the Teflon<coated bottom cover or on any painted surface.

Use care when cleaning blower wheel - it must not become

bent or misaligned. DO NOT ALLOW WATER TO ENTER

MOTOR. Make sure all surfaces are completely dry before

re-iustalling filters and restoring power. Motor is permanently

lubricated. Do not oil or disassemble motor.

7k_i_on"is a registered lrademark qf DuPonl.

11

Page 12

- This symbol on the nameplate means the product is listed by Underwriters Laboratories, Inc.

SHARPELECTRONICSCORPORATION• Sharp Plaza, Mahwah, New Jersey 07430-2135

626995B

®

RECYCLEDPAPER

PRINTED IN RSA

Page 13

INSTALLATION INSTRUCTION / OPERATION MANUAL

MODEL

KB-0333K

Followed by indicating color: K = black, W = white, S = stainless steel

FORCUSTOMERASSISTANCE.................................... 2

CONSUMERLIMITEDWARRANTY............................... 3

PRODUCTINFORMATIONCARD.................................. 3

IMPORTANTSAFETYINSTRUCTIONS............................ 4

PREPAREHOODLOCATION....................................... 5

PREPARETHEHOOD.......................................... 6 - 8

CONNECTWIRING................................................. 8

INSTALLHOOD..................................................... 9

NON-DUCTEDFILTERS............................................ 9

OPERATING........................................................ 10

FUSE............................................................... 10

CLEANING......................................................... 11

SHARP In s i g h t_M

Page 14

FOR CUSTOMER ASSISTANCE

To aid in reporting this range hood, please record below the model number and serial number located on the unit.

We also suggest you record all the information listed and retain for future reference.

MODELNUMBER

DATEOFPURCHASE

DEALER

SERVICER

/ /

SERIALNUMBER

TELEPHONE

TELEPHONE

TO PHONE:

DIAL

1-800-BE-SHARP (237-4277) for:

SERVICE (for your nearest Sharp Authorized Servicer)

PARTS (for your authorized parts distributor)

DIAL

TO WRITE:

1-800-642-2122 for: Charcoal Filters (model KBK-330)

Sharp Electronics Corporation

Customer Assistance Center

1300 Naperville Drive

Romeoville, IL 60446-1091

Please provide the following information when you write or call: model number, serial number, date of purchase, your

complete mailing address (including zip code), your daytime telephone number (including area code) and description of

the problem.

TO ACCESS INTERNET: www.sharpusa.com

Page 15

CONSUMER LIMITED WARRANTY

SHARP ELECTRONICS CORPORATION warrants to the first consumer purchaser that this Sharp brand product (the

"Product"), when shipped in its original container, will be free from defective workmanship and materials, and agrees that it

will, at its option, either repair the defect or replace the defective Product or part thereof with a new or remanufactured equivalent

at no charge to the purchaser for parts or labor for the period(s) set forth below.

This warranty does not apply to any appearance items of the Product nor to the additional excluded item(s) set forth below nor

to any Product the exterior of which has been damaged or defaced, which has been subjected to misuse, abnormal service or

handling, or which has been altered or modified in design or construction.

In order to enforce the rights under this limited warranty, the purchaser should follow the steps set forth below and provide

proof of purchase to the servicer.

The limited warranty described herein is in addition to whatever implied warranties may be granted to purchasers by law.

ALL IMPLIED WARRANTIES INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR USE

ARE LIMITED TO THE PERIOD(S) FROM THE DATE OF PURCHASE SET FORTH BELOW. Some states do not allow

limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

Neither the sales personnel of the seller nor any other person is authorized to make any warranties other than those described

herein, or to extend the duration of any warranties beyond the time period described herein on behalf of Sharp.

The warranties described herein shall be the sole and exclusive warranties granted by Sharp and shall be the sole and exclusive

remedy available to the purchaser. Correction of defects, in the manner and for the period of time described herein, shall

complete fulfilllneut of all liabilities and responsibilities of Sharp to the purchaser with respect to the Product, and shall constitute

full satisfaction of all claims, whether based on contract, negligence, strict liability or otherwise. In no event shall Sharp be

liable, or in any way responsible, for any damages or defects in the Product which were caused by repairs or attempted repairs

performed by anyone other than an authorized servicer. Nor shall Sharp be liable or in any way responsible for any incident or

consequential economic or property damage. Some states do not allow the exclusion of incidental or consequential damages,

so the above exclusion may not apply to you.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE.

Your product model number &

description

KB-0333K Home Use Range Hood. (Be sure to have this information available when

you need service for your Product.)

Warranty period for this product: One (1)year parts and labor including in-home service.

Additional item(s) excluded from

warranty coverage (if any):

Where to obtain service:

Light Bulbs

From a Sharp Authorized Servicer located in the United States. To find the location

of the nearest Sharp Authorized Servicer, call Sharp toll free at 1-800-BE-SHARP

(1-800-237-4277).

What to do to obtain service: From a Sharp Authorized servicer located in the United States. Be sure to have Proof of

Purchase available. For in-home service, the servicer will come to the unit's location.

If it is necessary to remove the unit for repair, the servicer will reinstall the unit at no

extra charge, provided it was installed according to Sharp's Installation Instructions.

TO OBTAIN SUPPLY, ACCESSORY OR PRODUCT INFORMATION, (!ALL 1-800-BE-SHARP or visit www.shmpusa.com.

SAVE THE PROOF OF PURCHASE AS IT IS NEEDED SHOULD YOUR RANGE HOOD EVER REQUIRE WARRANTY

SERVICE.

PRODUCT INFORMATION CARD

The Product Information Card should be completed within ten days of purchase and returned. We will keep it on file and help

you access the information if needed. This will also enable us to contact you in the unlikely event that any adjustlnents or

modifications are ever required for your range hood.

Page 16

IMPORTANTSAFETYINSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING

FORDOMESTICCOOKINGONLY

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact Sharp at

the address or telephone number listed on page 2 of this

manual.

2. Before servicing or cleaning unit, switch power off at

service panel and lock the service disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a

tag, to the service panel.

3. Installation work and electrical wiring must be done by

a qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction

codes and standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating eqmpment manufacturer s =mdehne and safety

standards such as those published by the National Fire

Protection Association (NFPA), and the American

Society of Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

6. To reduce the risk of fire or electric shock, do not use this

range hood with an additional speed control device.

7. Ducted fans must always be vented to the outdoors.

8. To reduce the risk of fire, use only metal ductwork.

9. Use with approved cord-connection kit only.

10. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE

FIRE:

1. Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

2. Always turn hood ON when cooking at high heat or when

cooking flaming foods.

3. Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate

for the size of the surface element.

• ' o " "

TO REDUCE THE RISK OF INJURY TO PERSONS

IN THE EVENT OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie

sheet or metal tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS. If the flames do

not go out ilmnediately, EVACUATE AND CALL THE

FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN -- You may be

burned.

3. DO NOT USE WATER, including wet dishcloths or

towels - violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and

you already know how to operate it.

B. The fire is small and contained in the area where it

started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on "Kitchen Fire Safety Tips" published by NFPA.

I ,_.-7.,lqtJ[.l ,'I

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or

unbalanced impellers, keep drywall spray, construction

dust, etc. off power unit.

3. For best capture of cooking impurities, your range hood

should be mounted so that the top of the hood is 24-30"

above the cooking surface.

4. Please read specification label on product for further

information and requirements.

Halogen or incandescent bulbs may be hot!

Refer to bulb packaging for further information.

Installer: Leave this manual with the homeowner.

Homeowner: Operating instructions and Cleaning

information are on pages 10-11.

Page 17

I Determine whether hood will discharge vertically (3 1/4"

x 10" or 7" round), horizontally (3 1/4" x 10" only) or

be non-ducted. For vertical or horizontal discharge, run

ductwork between the hood location and a roof cap or wall

cap. For best results, use a minilnUln nulnber of transitions

and elbows.

PREPARE HOOD LOCATION

WOOD SHIMS 31/4" X 10"

(Recessed-bottom HOR ZONTAL DUCT NG

cabinets only)

CABINET FRONT

1/8" 3/4"

ROOF CAP 31/4"X 10" or

7" ROUND DUCT

(For vertical

HOUSE WIRING

7(Top or back of hood)

CAP

t

24" -30" ABOVE

COOKING SURFACE

2 Use diagrams for proper placement of ductwork and

electrical cutout in cabinet or wall. For a non-ducted

installation, DO NOT cut a duct access hole.

HOOD MOUNTING SCREWS (4)

(30"

- CABINET FRONT

CABINET BOTTOM

VERTICAL DUCT

ACCESS HOLE

WOOD SHIMS

(Recessed-bottom

cabinets only)

t ELECTRICAL

CENTER (In cabinet bottom)

LINE

ACCESS HOLE

10" DUCT

(For horizontal discharge)

31/4" X 10"

VERT CAL DUCT NG

101/2''

i I

11/#" l

t

HOOD t ELECTRICAL

MOUNTING CENTER ACCESS HOLE

SCREWS (4) LINE (In wall)

HOOD MOUNTING SCREWS (4 7 ROUND

(30"

DUCT

WOOD SHIMS _' ELECTRICAL

(Recessed-bottom CENTER (In cabinet bottom)

cabinets only) LINE

) VERTICAL DUCTING

ii

ACCESS HOLE

I

HOOD MOUNTING SCREWS (4) I

(3o"

_- CABINET FRONT

CABINET '_

BOTTOM

NON-DUCTED I

10W'

1t/2" _

t

10V2"

WOOD SHIMS 1'

(Recessed-bottom CENTER

cabinets only) LINE

ELECTRICAL

ACCESS HOLE

In cabinet bottom)

3 Run house wiring between service panel and hood location.

Page 18

PREPARE THE HOOD

1 Remove 7" Round 7"ROUND

Duct Plate from top DUCTPLATE

of hood. Set duct

plate aside - with

mounting screws.

2Remove tape

holding Filters in

place. Pull down

FILTERS X

on filter tabs or

finger holes and

lift filters out. Set

filters aside.

3 Remove Teflon %

Coated Bottom

Cover froln hood.

Set cover and

mounting screws

aside.

Tq/lon _ is' a regismred

trademark qf DuPont.

TEFLON_)-COATED BOTTOM COVER

(Held in place with 2 screws)

4 Remove Damper/

Duct Connector

from inside the

hood. Set com_ector

aside-with mounting

screws and parts

bag.

DAMPER/DUCTCONNECTOR

5 Remove either top

or back wiring

knockout and install

approved Electrical

Cable Clamp.

ELECTRICAL CABLE CLAMP

NON-DUCTED INSTALLATION - Skip to page 8.

The following Steps (6 thru 14) are for DUCTED

INSTALLATION ONLY.

(3)#8 SCREWS LIGHT

6Remove Light

Panel - held in

place with (5) #8

screws. Disconnect

light assembly

wire harness

(white connector).

i

7 Remove Air Chute

AIR CHUTE

PANEL

- held in place with

one (1) screw.

Note: Be careful

\

not to disconnect

any wires.

8 Remove Baffle from air chute.

BAFFLE

\

BAFFLE

Rotate baffle.

Reinsert baffle

into air chute

(as shown) so

that baffle Tabs

fit all the way

into Slots in air

chute. An audible

"click" will be

heard when fully

installed. This

will close offthe

air flow through

the non-ducted

slots on top of

hood.

SLOTS

SUPPORT FIN

Page 19

PREPARE THE HOOD

10 Re-install air chute and screw, re-connect wire harness

and replace light panel.

Note: Be careful not to trap wires between Support Fin

and light panel.

11 Remove appropriate Duct Knockout(s) from top or back

of hood.

TOP RECTANGULAR

DUCT KNOCKOUT

(Remove for 31A'' x 10"

vertical & for 7" round

discharge)

REAR

RECTANGULAR

DUCT KNOCKOUT

(Remove for 3W' x 10"

horizontal discharge)

SEMI-CIRCULAR

DUCT KNOCKOUT

tRemove for 7" round

discharge)

12 Horizontal Discharge Only: Remove the Plate in front of

the horizontal discharge knockout. Cut the ties, lift plate

out, and discard plate. DO NOT REMOVE the Metal

Strip held in place with two screws.

SCREW

TIES

13 3 1/4" x 10" Ducted Discharge Only: Remove tape from

damper flap and attach Damper/Duct Connector over

knockout opening with screws removed in Step 4 under

"PREPARE THE HOOD". Make sure damper Pivot is

nearest to top/back edge of hood.

UPTO 1"

SIDE-TO-SIDE / EDGE

. (Vertical discharge

TAPE TOP/BACK

DAMPER/

DUCT

CONNECTOR

position shown)

t4 7" Round Ducted Discharge Only: Re-install 7" Round

Duct Plate removed in Step #1 under "PREPARE

THE HOOD". Install a 7" Round Damper (purchase

separately). Damper flap must open freely in direction

of airflow (away from range hood).

Note: To accommodate oft-center ductwork, the Damper/

Duct Connector can be installed up to 1-inch on either side

of hood center or the 7" Round Duct Plate can be installed

up to 1/2" on either side of hood center. In extreme off-center

installations, one end of the duct connector may need to be

trimmed to clear the electrical cable clamp.

iii(

METAL STRIP PLATE

Page 20

PREPARE THE HOOD

Non-Ducted Installations Only:

Requires a Performance Ring to be attached to the blower

wheel. The Performance Ring is packed behind the Teflon :_-

Coated Bottom Cover.

To install ring:

1, Remove Retaining Ring using a flat blade screwdriver.

Set aside for later. Remove the Blower Wheel by rocking

it side to side and applying a slight force to pull wheel

from motor. Turn the Blower Wheel over.

2. Slide the Performance Ring onto the Small Diameter

End of the blower wheel and down to the Stop Edge of

the wheel.

Reassemble wheel to motor. Make sure Tab on wheel

3m

fits into one of the Motor Slots.

4.

Push wheel down until it is locked in place. Replace

Retaining Ring froln Step 1. Be sure it is within the

upper and lower tabs.

CONNECT WIRING

5. Check that wheel is properly positioned as shown.

Press Sections into place if necessary. Make sure wheel

turns freely.

Note: For information on non-ducted filters, see page 9.

RETAINING RING WHEEL END

BLOWER SMALL DIAMETER

STOF

EDGE

MOTOR SLOTS

PERFORMANCE RING

To reduce the risk of electric shock, make

sure power is switched off at the service panel. Lock or

tag service panel to prevent power from being switched

on accidentally.

1 Connect House Wiring (120 VAC) to hood. Use a piece

of cardboard to protect the cooktop, if necessary.

HOUSE

WIRING

(120 VAC)

CARDBOARD

protect

cooktop)

2 Connect house black to hood black wire, house white to

hood white wire and house ground under Green Ground

Serew. Securely tighten cable clamp onto house wiring.

GREEN

GROUND

"SCREW

Page 21

INSTALL HOOD

I Hang hood from (4) mounting screws. Slide hood towards

wall until mounting screws are engaged in narrow end of

(4) keyholes. Tighten mounting screws securely. A long

screwdriver works best.

KEYHOLE (4) MOUNTING SCREW (4)

2 Replace bottom cover.

3 Connect ductwork to hood. Use duet tape to make joints

secure and air tight.

DUCT

TAPE

4 Install (2) PAR20, 50 W Maximum Halogen Bulbs or

(2) R16, 40 W Maximum Incandescent Bulbs. Purchase

bulbs separately.

PAR20,

50W MAX.

HALOGEN

BULB (2)

- or-

R16,

40W MAX.

INCANDESCENT

BULB (2)

5 Replace filters, turn on power at service panel and test for

proper operation.

NON-DUCTED FILTERS

If hood is to be installed Non-Ducted: • Attach charcoal filters to the aluminum mesh filters. Be

• Purchase a set of (2) charcoal filters, model KBK-330, sure that the sides with the blue and yellow stripes are

from your local distributor, retailer or from Sharp (see facing down (toward the range top).

page 2).

Page 22

OPERATING

mnsight

3 1

1 FAN There are four fan speeds from low (1) to high (4).

Push any button to select one of the four fan speeds. Press

another button to change fan speed. Push the same button

to turn the fan off. A light above each fan button indicates

the fan speed.

2 LIGHT Press the ON/OFF button and lights will come on

at their previous light level. Press the button again to turn

lights off. To increase the light level, press /_ button.

To reduce light level, press the _/ button. There are

three light levels.

3 DELAY OFF While the fan is running, press the "DELAY

OFF" button to allow the fan to run for 10 minutes and

then turn off automatically.

4 FILTER CHANGE INDICATOR The light above

"(?LEAN FILTER" will come on when it is time to clean the

grease filters or check non-ducted filters. After replacing

the cleaned filters (or installing new ones), press the

"CLEAN FILTER" button to turn off the indicator light.

2 4

HEAT SENSOR

Your Sharp Insight Range Hood is equipped with an advanced

Heat Sensor.

The Sensor monitors the temperature and automatically

adjusts the fan to the appropriate setting.

• If the fan is on, the Sensor will increase the fan setting

when the temperature is elevated. If the temperature

continues to rise, the Sensor will continue to increase the

fan setting until the temperature is stabilized or reduced.

The flashing light above the fan button shows the Sensor

fan setting. Once the temperature has been reduced, the

Sensor will change the fan to the original setting.

• If the fan is off, the Sensor will automatically turn the

fan on at its highest speed when the temperature is above

normal. When this occurs, the light above fan button 4 will

flash on and ofl: After the temperature has been reduced

to normal, the fan will change to the setting prior to the

Sensor coming on.

FUSE

The hood control contains a fuse to protect it from power

surges. If the fuse has opened (blown), the green fan-level

indicators will operate properly when the fan buttons/switches

are pressed, but the fan and lights will not turn on.

The fuse is a 5 x 20mm, 10 Amp, Fast-Acting, 125V (min.).

Common manufacturer and part nulnbers are: Littlefuse,

217010; Bussmann, GMA10A; Wickmann, 1942100. Radio

Shack, Digikey (1-800-344-4539), and most electronic supply

stores have them in stock.

To replace the fuse:

1. Disconnect power at service entrance.

2. Remove filters, bottom panel, light wire harness and air

chute.

3. Remove and inspect fuse. If it is not open (blown),

additional diagnostics need to be done.

4. Install new fuse.

5. Re-assemble air chute, light wire harness, bottom panel

and filters.

6. Turn on power and check hood/control operation.

10

Page 23

CLEANING

To reduce the risk of electric shock, discon-

nect from power supply before cleaning.

Aluminum mesh filters: Clean frequently using hot

water and a mild detergent. Filters are dishwasher safe.

Charcoal filters (additional filters for non-

ducted installations): Clean filter surfaces frequently

with a damp cloth and a mild detergent. DO NOT immerse

filters in water or put in dishwasher. The special "Clean

Sense" feature indicates when the filter is to be replaced.

The blue and yellow stripes will blend to green when it is

time to change the filter. The "Clean Sense" feature works

best when facing toward the cooking surface.

To clean hood: Remove filters. Use a damp cloth and

a mild detergent to wipe all grease-laden surfaces. Do not

use abrasive cloth, steel wool pads or scouring powder on

the Teflon<coated bottom cover or on any painted surface.

Use care when cleaning blower wheel - it must not become

bent or misaligned. DO NOT ALLOW WATER TO ENTER

MOTOR. Make sure all surfaces are completely dry before

re-iustalling filters and restoring power. Motor is permanently

lubricated. Do not oil or disassemble motor.

7k_i_on"is a registered lrademark qf DuPonl.

11

Page 24

- This symbol on the nameplate means the product is listed by Underwriters Laboratories, Inc.

SHARPELECTRONICSCORPORATION• Sharp Plaza, Mahwah, New Jersey 07430-2135

626995B

®

RECYCLEDPAPER

PRINTED IN RSA

Page 25

INSTALLATION INSTRUCTION / OPERATION MANUAL

MODEL

KB-0333K

Followed by indicating color: K = black, W = white, S = stainless steel

FORCUSTOMERASSISTANCE.................................... 2

CONSUMERLIMITEDWARRANTY............................... 3

PRODUCTINFORMATIONCARD.................................. 3

IMPORTANTSAFETYINSTRUCTIONS............................ 4

PREPAREHOODLOCATION....................................... 5

PREPARETHEHOOD.......................................... 6 - 8

CONNECTWIRING................................................. 8

INSTALLHOOD..................................................... 9

NON-DUCTEDFILTERS............................................ 9

OPERATING........................................................ 10

FUSE............................................................... 10

CLEANING......................................................... 11

SHARP In s i g h t_M

Page 26

FOR CUSTOMER ASSISTANCE

To aid in reporting this range hood, please record below the model number and serial number located on the unit.

We also suggest you record all the information listed and retain for future reference.

MODELNUMBER

DATEOFPURCHASE

DEALER

SERVICER

/ /

SERIALNUMBER

TELEPHONE

TELEPHONE

TO PHONE:

DIAL

1-800-BE-SHARP (237-4277) for:

SERVICE (for your nearest Sharp Authorized Servicer)

PARTS (for your authorized parts distributor)

DIAL

TO WRITE:

1-800-642-2122 for: Charcoal Filters (model KBK-330)

Sharp Electronics Corporation

Customer Assistance Center

1300 Naperville Drive

Romeoville, IL 60446-1091

Please provide the following information when you write or call: model number, serial number, date of purchase, your

complete mailing address (including zip code), your daytime telephone number (including area code) and description of

the problem.

TO ACCESS INTERNET: www.sharpusa.com

Page 27

CONSUMER LIMITED WARRANTY

SHARP ELECTRONICS CORPORATION warrants to the first consumer purchaser that this Sharp brand product (the

"Product"), when shipped in its original container, will be free from defective workmanship and materials, and agrees that it

will, at its option, either repair the defect or replace the defective Product or part thereof with a new or remanufactured equivalent

at no charge to the purchaser for parts or labor for the period(s) set forth below.

This warranty does not apply to any appearance items of the Product nor to the additional excluded item(s) set forth below nor

to any Product the exterior of which has been damaged or defaced, which has been subjected to misuse, abnormal service or

handling, or which has been altered or modified in design or construction.

In order to enforce the rights under this limited warranty, the purchaser should follow the steps set forth below and provide

proof of purchase to the servicer.

The limited warranty described herein is in addition to whatever implied warranties may be granted to purchasers by law.

ALL IMPLIED WARRANTIES INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR USE

ARE LIMITED TO THE PERIOD(S) FROM THE DATE OF PURCHASE SET FORTH BELOW. Some states do not allow

limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

Neither the sales personnel of the seller nor any other person is authorized to make any warranties other than those described

herein, or to extend the duration of any warranties beyond the time period described herein on behalf of Sharp.

The warranties described herein shall be the sole and exclusive warranties granted by Sharp and shall be the sole and exclusive

remedy available to the purchaser. Correction of defects, in the manner and for the period of time described herein, shall

complete fulfilllneut of all liabilities and responsibilities of Sharp to the purchaser with respect to the Product, and shall constitute

full satisfaction of all claims, whether based on contract, negligence, strict liability or otherwise. In no event shall Sharp be

liable, or in any way responsible, for any damages or defects in the Product which were caused by repairs or attempted repairs

performed by anyone other than an authorized servicer. Nor shall Sharp be liable or in any way responsible for any incident or

consequential economic or property damage. Some states do not allow the exclusion of incidental or consequential damages,

so the above exclusion may not apply to you.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE.

Your product model number &

description

KB-0333K Home Use Range Hood. (Be sure to have this information available when

you need service for your Product.)

Warranty period for this product: One (1)year parts and labor including in-home service.

Additional item(s) excluded from

warranty coverage (if any):

Where to obtain service:

Light Bulbs

From a Sharp Authorized Servicer located in the United States. To find the location

of the nearest Sharp Authorized Servicer, call Sharp toll free at 1-800-BE-SHARP

(1-800-237-4277).

What to do to obtain service: From a Sharp Authorized servicer located in the United States. Be sure to have Proof of

Purchase available. For in-home service, the servicer will come to the unit's location.

If it is necessary to remove the unit for repair, the servicer will reinstall the unit at no

extra charge, provided it was installed according to Sharp's Installation Instructions.

TO OBTAIN SUPPLY, ACCESSORY OR PRODUCT INFORMATION, (!ALL 1-800-BE-SHARP or visit www.shmpusa.com.

SAVE THE PROOF OF PURCHASE AS IT IS NEEDED SHOULD YOUR RANGE HOOD EVER REQUIRE WARRANTY

SERVICE.

PRODUCT INFORMATION CARD

The Product Information Card should be completed within ten days of purchase and returned. We will keep it on file and help

you access the information if needed. This will also enable us to contact you in the unlikely event that any adjustlnents or

modifications are ever required for your range hood.

Page 28

IMPORTANTSAFETYINSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING

FORDOMESTICCOOKINGONLY

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact Sharp at

the address or telephone number listed on page 2 of this

manual.

2. Before servicing or cleaning unit, switch power off at

service panel and lock the service disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a

tag, to the service panel.

3. Installation work and electrical wiring must be done by

a qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction

codes and standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating eqmpment manufacturer s =mdehne and safety

standards such as those published by the National Fire

Protection Association (NFPA), and the American

Society of Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

6. To reduce the risk of fire or electric shock, do not use this

range hood with an additional speed control device.

7. Ducted fans must always be vented to the outdoors.

8. To reduce the risk of fire, use only metal ductwork.

9. Use with approved cord-connection kit only.

10. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE

FIRE:

1. Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

2. Always turn hood ON when cooking at high heat or when

cooking flaming foods.

3. Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate

for the size of the surface element.

• ' o " "

TO REDUCE THE RISK OF INJURY TO PERSONS

IN THE EVENT OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie

sheet or metal tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS. If the flames do

not go out ilmnediately, EVACUATE AND CALL THE

FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN -- You may be

burned.

3. DO NOT USE WATER, including wet dishcloths or

towels - violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and

you already know how to operate it.

B. The fire is small and contained in the area where it

started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on "Kitchen Fire Safety Tips" published by NFPA.

I ,_.-7.,lqtJ[.l ,'I

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or

unbalanced impellers, keep drywall spray, construction

dust, etc. off power unit.

3. For best capture of cooking impurities, your range hood

should be mounted so that the top of the hood is 24-30"

above the cooking surface.

4. Please read specification label on product for further

information and requirements.

Halogen or incandescent bulbs may be hot!

Refer to bulb packaging for further information.

Installer: Leave this manual with the homeowner.

Homeowner: Operating instructions and Cleaning

information are on pages 10-11.

Page 29

I Determine whether hood will discharge vertically (3 1/4"

x 10" or 7" round), horizontally (3 1/4" x 10" only) or

be non-ducted. For vertical or horizontal discharge, run

ductwork between the hood location and a roof cap or wall

cap. For best results, use a minilnUln nulnber of transitions

and elbows.

PREPARE HOOD LOCATION

WOOD SHIMS 31/4" X 10"

(Recessed-bottom HOR ZONTAL DUCT NG

cabinets only)

CABINET FRONT

1/8" 3/4"

ROOF CAP 31/4"X 10" or

7" ROUND DUCT

(For vertical

HOUSE WIRING

7(Top or back of hood)

CAP

t

24" -30" ABOVE

COOKING SURFACE

2 Use diagrams for proper placement of ductwork and

electrical cutout in cabinet or wall. For a non-ducted

installation, DO NOT cut a duct access hole.

HOOD MOUNTING SCREWS (4)

(30"

- CABINET FRONT

CABINET BOTTOM

VERTICAL DUCT

ACCESS HOLE

WOOD SHIMS

(Recessed-bottom

cabinets only)

t ELECTRICAL

CENTER (In cabinet bottom)

LINE

ACCESS HOLE

10" DUCT

(For horizontal discharge)

31/4" X 10"

VERT CAL DUCT NG

101/2''

i I

11/#" l

t

HOOD t ELECTRICAL

MOUNTING CENTER ACCESS HOLE

SCREWS (4) LINE (In wall)

HOOD MOUNTING SCREWS (4 7 ROUND

(30"

DUCT

WOOD SHIMS _' ELECTRICAL

(Recessed-bottom CENTER (In cabinet bottom)

cabinets only) LINE

) VERTICAL DUCTING

ii

ACCESS HOLE

I

HOOD MOUNTING SCREWS (4) I

(3o"

_- CABINET FRONT

CABINET '_

BOTTOM

NON-DUCTED I

10W'

1t/2" _

t

10V2"

WOOD SHIMS 1'

(Recessed-bottom CENTER

cabinets only) LINE

ELECTRICAL

ACCESS HOLE

In cabinet bottom)

3 Run house wiring between service panel and hood location.

Page 30

PREPARE THE HOOD

1 Remove 7" Round 7"ROUND

Duct Plate from top DUCTPLATE

of hood. Set duct

plate aside - with

mounting screws.

2Remove tape

holding Filters in

place. Pull down

FILTERS X

on filter tabs or

finger holes and

lift filters out. Set

filters aside.

3 Remove Teflon %

Coated Bottom

Cover froln hood.

Set cover and

mounting screws

aside.

Tq/lon _ is' a regismred

trademark qf DuPont.

TEFLON_)-COATED BOTTOM COVER

(Held in place with 2 screws)

4 Remove Damper/

Duct Connector

from inside the

hood. Set com_ector

aside-with mounting

screws and parts

bag.

DAMPER/DUCTCONNECTOR

5 Remove either top

or back wiring

knockout and install

approved Electrical

Cable Clamp.

ELECTRICAL CABLE CLAMP

NON-DUCTED INSTALLATION - Skip to page 8.

The following Steps (6 thru 14) are for DUCTED

INSTALLATION ONLY.

(3)#8 SCREWS LIGHT

6Remove Light

Panel - held in

place with (5) #8

screws. Disconnect

light assembly

wire harness

(white connector).

i

7 Remove Air Chute

AIR CHUTE

PANEL

- held in place with

one (1) screw.

Note: Be careful

\

not to disconnect

any wires.

8 Remove Baffle from air chute.

BAFFLE

\

BAFFLE

Rotate baffle.

Reinsert baffle

into air chute

(as shown) so

that baffle Tabs

fit all the way

into Slots in air

chute. An audible

"click" will be

heard when fully

installed. This

will close offthe

air flow through

the non-ducted

slots on top of

hood.

SLOTS

SUPPORT FIN

Page 31

PREPARE THE HOOD

10 Re-install air chute and screw, re-connect wire harness

and replace light panel.

Note: Be careful not to trap wires between Support Fin

and light panel.

11 Remove appropriate Duct Knockout(s) from top or back

of hood.

TOP RECTANGULAR

DUCT KNOCKOUT

(Remove for 31A'' x 10"

vertical & for 7" round

discharge)

REAR

RECTANGULAR

DUCT KNOCKOUT

(Remove for 3W' x 10"

horizontal discharge)

SEMI-CIRCULAR

DUCT KNOCKOUT

tRemove for 7" round

discharge)

12 Horizontal Discharge Only: Remove the Plate in front of

the horizontal discharge knockout. Cut the ties, lift plate

out, and discard plate. DO NOT REMOVE the Metal

Strip held in place with two screws.

SCREW

TIES

13 3 1/4" x 10" Ducted Discharge Only: Remove tape from

damper flap and attach Damper/Duct Connector over

knockout opening with screws removed in Step 4 under

"PREPARE THE HOOD". Make sure damper Pivot is

nearest to top/back edge of hood.

UPTO 1"

SIDE-TO-SIDE / EDGE

. (Vertical discharge

TAPE TOP/BACK

DAMPER/

DUCT

CONNECTOR

position shown)

t4 7" Round Ducted Discharge Only: Re-install 7" Round

Duct Plate removed in Step #1 under "PREPARE

THE HOOD". Install a 7" Round Damper (purchase

separately). Damper flap must open freely in direction

of airflow (away from range hood).

Note: To accommodate oft-center ductwork, the Damper/

Duct Connector can be installed up to 1-inch on either side

of hood center or the 7" Round Duct Plate can be installed

up to 1/2" on either side of hood center. In extreme off-center

installations, one end of the duct connector may need to be

trimmed to clear the electrical cable clamp.

iii(

METAL STRIP PLATE

Page 32

PREPARE THE HOOD

Non-Ducted Installations Only:

Requires a Performance Ring to be attached to the blower

wheel. The Performance Ring is packed behind the Teflon :_-

Coated Bottom Cover.

To install ring:

1, Remove Retaining Ring using a flat blade screwdriver.

Set aside for later. Remove the Blower Wheel by rocking

it side to side and applying a slight force to pull wheel

from motor. Turn the Blower Wheel over.

2. Slide the Performance Ring onto the Small Diameter

End of the blower wheel and down to the Stop Edge of

the wheel.

Reassemble wheel to motor. Make sure Tab on wheel

3m

fits into one of the Motor Slots.

4.

Push wheel down until it is locked in place. Replace

Retaining Ring froln Step 1. Be sure it is within the

upper and lower tabs.

CONNECT WIRING

5. Check that wheel is properly positioned as shown.

Press Sections into place if necessary. Make sure wheel

turns freely.

Note: For information on non-ducted filters, see page 9.

RETAINING RING WHEEL END

BLOWER SMALL DIAMETER

STOF

EDGE

MOTOR SLOTS

PERFORMANCE RING

To reduce the risk of electric shock, make

sure power is switched off at the service panel. Lock or

tag service panel to prevent power from being switched

on accidentally.

1 Connect House Wiring (120 VAC) to hood. Use a piece

of cardboard to protect the cooktop, if necessary.

HOUSE

WIRING

(120 VAC)

CARDBOARD

protect

cooktop)

2 Connect house black to hood black wire, house white to

hood white wire and house ground under Green Ground

Serew. Securely tighten cable clamp onto house wiring.

GREEN

GROUND

"SCREW

Page 33

INSTALL HOOD

I Hang hood from (4) mounting screws. Slide hood towards

wall until mounting screws are engaged in narrow end of

(4) keyholes. Tighten mounting screws securely. A long

screwdriver works best.

KEYHOLE (4) MOUNTING SCREW (4)

2 Replace bottom cover.

3 Connect ductwork to hood. Use duet tape to make joints

secure and air tight.

DUCT

TAPE

4 Install (2) PAR20, 50 W Maximum Halogen Bulbs or

(2) R16, 40 W Maximum Incandescent Bulbs. Purchase

bulbs separately.

PAR20,

50W MAX.

HALOGEN

BULB (2)

- or-

R16,

40W MAX.

INCANDESCENT

BULB (2)

5 Replace filters, turn on power at service panel and test for

proper operation.

NON-DUCTED FILTERS

If hood is to be installed Non-Ducted: • Attach charcoal filters to the aluminum mesh filters. Be

• Purchase a set of (2) charcoal filters, model KBK-330, sure that the sides with the blue and yellow stripes are

from your local distributor, retailer or from Sharp (see facing down (toward the range top).

page 2).

Page 34

OPERATING

mnsight

3 1

1 FAN There are four fan speeds from low (1) to high (4).

Push any button to select one of the four fan speeds. Press

another button to change fan speed. Push the same button

to turn the fan off. A light above each fan button indicates

the fan speed.

2 LIGHT Press the ON/OFF button and lights will come on

at their previous light level. Press the button again to turn

lights off. To increase the light level, press /_ button.

To reduce light level, press the _/ button. There are

three light levels.

3 DELAY OFF While the fan is running, press the "DELAY

OFF" button to allow the fan to run for 10 minutes and

then turn off automatically.

4 FILTER CHANGE INDICATOR The light above

"(?LEAN FILTER" will come on when it is time to clean the

grease filters or check non-ducted filters. After replacing

the cleaned filters (or installing new ones), press the

"CLEAN FILTER" button to turn off the indicator light.

2 4

HEAT SENSOR

Your Sharp Insight Range Hood is equipped with an advanced

Heat Sensor.

The Sensor monitors the temperature and automatically

adjusts the fan to the appropriate setting.

• If the fan is on, the Sensor will increase the fan setting

when the temperature is elevated. If the temperature

continues to rise, the Sensor will continue to increase the

fan setting until the temperature is stabilized or reduced.

The flashing light above the fan button shows the Sensor

fan setting. Once the temperature has been reduced, the

Sensor will change the fan to the original setting.

• If the fan is off, the Sensor will automatically turn the

fan on at its highest speed when the temperature is above

normal. When this occurs, the light above fan button 4 will

flash on and ofl: After the temperature has been reduced

to normal, the fan will change to the setting prior to the

Sensor coming on.

FUSE

The hood control contains a fuse to protect it from power

surges. If the fuse has opened (blown), the green fan-level

indicators will operate properly when the fan buttons/switches

are pressed, but the fan and lights will not turn on.

The fuse is a 5 x 20mm, 10 Amp, Fast-Acting, 125V (min.).

Common manufacturer and part nulnbers are: Littlefuse,

217010; Bussmann, GMA10A; Wickmann, 1942100. Radio

Shack, Digikey (1-800-344-4539), and most electronic supply

stores have them in stock.

To replace the fuse:

1. Disconnect power at service entrance.

2. Remove filters, bottom panel, light wire harness and air

chute.

3. Remove and inspect fuse. If it is not open (blown),

additional diagnostics need to be done.

4. Install new fuse.

5. Re-assemble air chute, light wire harness, bottom panel

and filters.

6. Turn on power and check hood/control operation.

10

Page 35

CLEANING

To reduce the risk of electric shock, discon-

nect from power supply before cleaning.

Aluminum mesh filters: Clean frequently using hot

water and a mild detergent. Filters are dishwasher safe.

Charcoal filters (additional filters for non-

ducted installations): Clean filter surfaces frequently

with a damp cloth and a mild detergent. DO NOT immerse

filters in water or put in dishwasher. The special "Clean

Sense" feature indicates when the filter is to be replaced.

The blue and yellow stripes will blend to green when it is

time to change the filter. The "Clean Sense" feature works

best when facing toward the cooking surface.

To clean hood: Remove filters. Use a damp cloth and

a mild detergent to wipe all grease-laden surfaces. Do not

use abrasive cloth, steel wool pads or scouring powder on

the Teflon<coated bottom cover or on any painted surface.

Use care when cleaning blower wheel - it must not become

bent or misaligned. DO NOT ALLOW WATER TO ENTER

MOTOR. Make sure all surfaces are completely dry before

re-iustalling filters and restoring power. Motor is permanently

lubricated. Do not oil or disassemble motor.

7k_i_on"is a registered lrademark qf DuPonl.

11

Page 36

- This symbol on the nameplate means the product is listed by Underwriters Laboratories, Inc.

SHARPELECTRONICSCORPORATION• Sharp Plaza, Mahwah, New Jersey 07430-2135

626995B

®

RECYCLEDPAPER

PRINTED IN RSA

Loading...

Loading...