Page 1

GX-CD30/30C/130/130C

SERVICE MANUAL

GX-CD30

GX-CD30C

GX-CD130

No. S3607GX-CD130

Illustration: GX-CD130

• In the interests of user-safety the set should be restored to its

original condition and only parts identical to those specified

should be used.

GX-CD130C

CONTENTS

IMPORTANT SERVICE NOTES (FOR GX-CD30/130 ONLY) .......................................................................................... 2

SPECIFICATIONS ............................................................................................................................................................. 2

NAMES OF PARTS ........................................................................................................................................................... 3

DISASSEMBLY.................................................................................................................................................................. 4

REMOVING AND REINSTALLING THE MAIN PARTS..................................................................................................... 6

ADJUSTMENT ................................................................................................................................................................... 8

TROUBLESHOOTING (CD SECTION) ........................................................................................................................... 10

NOTES ON SCHEMATIC DIAGRAM .............................................................................................................................. 13

TYPES OF TRANSISTOR ............................................................................................................................................... 13

BLOCK DIAGRAM ........................................................................................................................................................... 14

SCHEMATIC DIAGRAM / WIRING SIDE OF P.W.BOARD............................................................................................. 18

WAVEFORMS OF CD CIRCUIT...................................................................................................................................... 27

FUNCTION TABLE OF IC................................................................................................................................................ 28

PARTS GUIDE/EXPLODED VIEW

PACKING OF THE SET (FOR GX-CD30/130 ONLY)

Page

DIFFERENCE BETWEEN GX-CD30/30C AND GX-CD130/130C

GX-CD30/30C

REMOTE None Used

CONTROL

X-BASS None Used

GX-CD130/130C

SHARP CORPORATION

SHARP ELECTRONICS CORPORATION

Service Headquarters: Sharp Plaza, Mahwah, New Jersey 07430-2135

Page 2

GX-CD30/30C/130/130C

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

IMPORTANT SERVICE NOTES (FOR GX-CD30/130 ONLY)

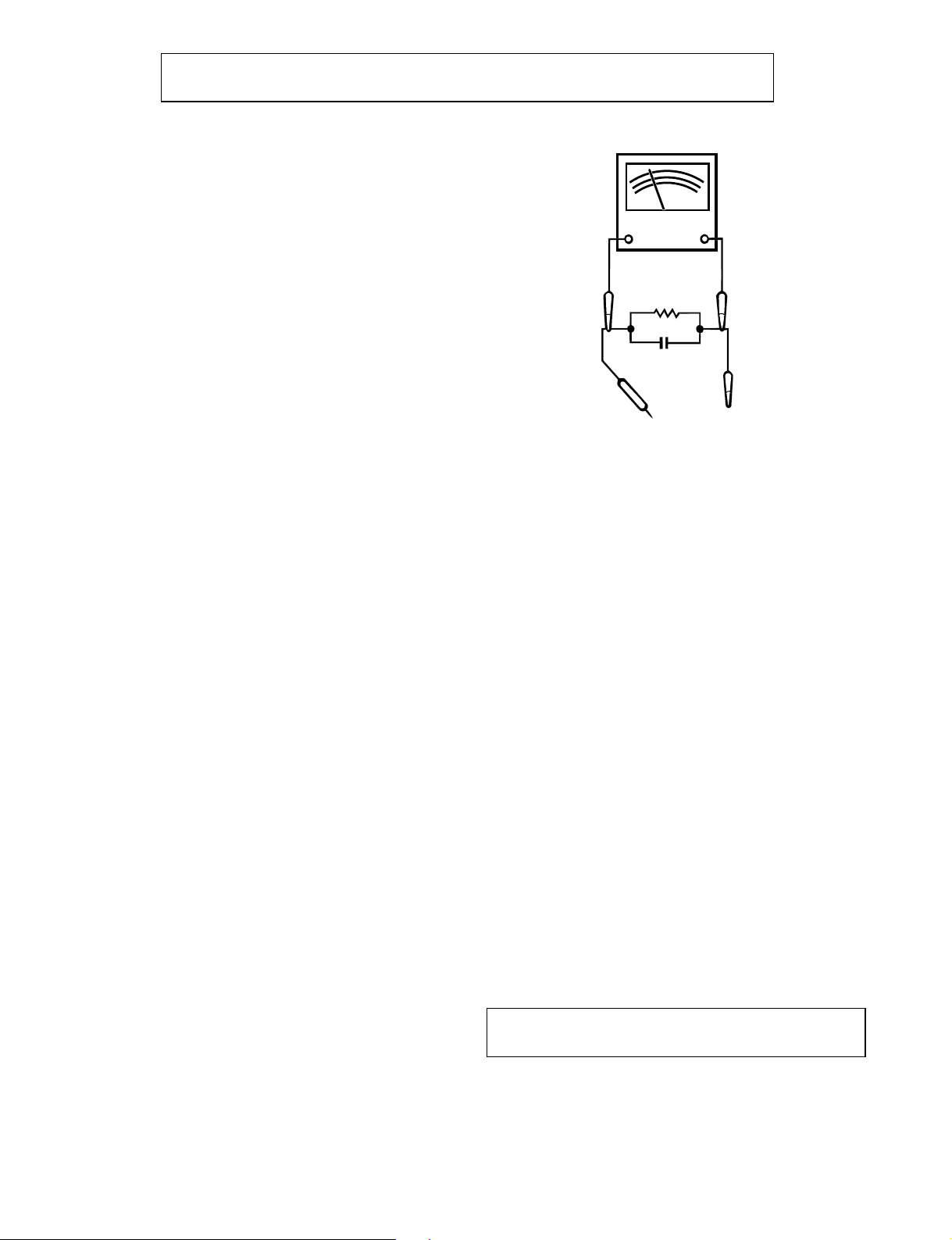

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the user, perform the

following safety checks.

1. Inspect all lead dress to make certain that leads are not

pinched or that hardware is not lodged between the chassis

and other metal parts in the audio product.

2. Inspect all protective devices such as insulating materials,

cabinet, terminal board, adjustment and compartment

covers or shields, mechanical insulators etc.

3. To be sure that no shock hazard exists, check for leakage

current in the following manner.

* Plug the AC line cord directly into a 120 volt AC outlet.

* Using two clip leads, connect a 1.5k ohm, 10 watt resistor

paralleled by a 0.15µF capacitor in series with all exposed

metal cabinet parts and a known earth ground, such as

conduit or electrical ground connected to earth ground.

* Use a VTVM or VOM with 1000 ohm per volt, or higher,

sensitivity to measure the AC voltage drop across the

resistor (See diagram).

* Connect the resistor connection to all exposed metal parts

having a return path to the chassis (antenna, metal cabinet,

screw heads, knobs and control shafts, escutcheon, etc.)

and measure the AC voltage drop across the resistor.

VTVM

AC SCALE

1.5k ohms

10W

0.15 µ F

TO EXPOSED

METAL PARTS

All check must be repeated with the AC line cord plug connection

reversed.

Any reading of 0.3 volt RMS (this corresponds to 0.2 milliamp.

AC.) or more is excessive and indicates a potential shock

hazard which must be corrected before returning the audio

product to the owner.

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

SPECIFICATIONS

●

General

Power source: AC 120V, 60 Hz

DC 12 V [ "D" size (UM/SUM-1, R20

or HP-2) battery x 8]

Power consumption: 25 W

Output power: FTC; 2.5 W minimum RMS per

(30/130) channel into 6 ohms from 100 Hz to

20 kHz with no more than 10 % total

harmonic distortion.

RMS; 3.5 W per channel at 1 kHz,

10 % total harmonic distortion.

(AC operation)

Output power: RMS; 7 W (3.5 W + 3.5 W)

(30C/130C) (AC operation, 10 % T.H.D.)

Output terminal: Headphones; 16 - 50 ohms

(recommended; 32 ohms)

Dimensions: Width; 12" (304 mm)

Height; 9-1/4" (234 mm)

Depth; 8-9/16" (216 mm)

Weight: 7.1 Ibs. (3.2 kg) without batteries

● Radio

Frequency range: FM; 87.6 - 108 MHz

AM; 530 - 1,702 kHz

● Tape recorder

Frequency response: 50 - 14,000 Hz (Normal tape)

Signal/noise ratio: 50 dB (TAPE 1, recording / playback)

55 dB (TAPE 2, playback)

Wow and flitter: 0.25 % (WRMS)

Motor: DC 12 V electric governor

Bias system: AC bias

Erase system: AC erase

● Compact disc player

Disc: Compact disc

Signal readout: Non-contact, 3-beam semi-

conductor laser pickup

Audio channels: 2

Quantization: 16-bit linear

Filter: 4-tims oversampling digital filter

D/A converter: 1-bit D/A converter

Wow and flutter: Unmeasurable

(less than 0.001% W. peak)

● Speaker

Type: 2-way bass-reflex type

Speakers: 4" (10 cm) woofer x 2

Tweeter x 2

Maximum input power: 5 W

Impedance: 6 ohms

Dimensions: Width; 7-5/16" (185 mm)

Height; 8-11/16" (220 mm)

Depth; 5-15/16" (150 mm)

Weight: 2.2 Ibs. (1.0 kg) /each

Specifications for this model are subject to change without

prior notice.

– 2 –

Page 3

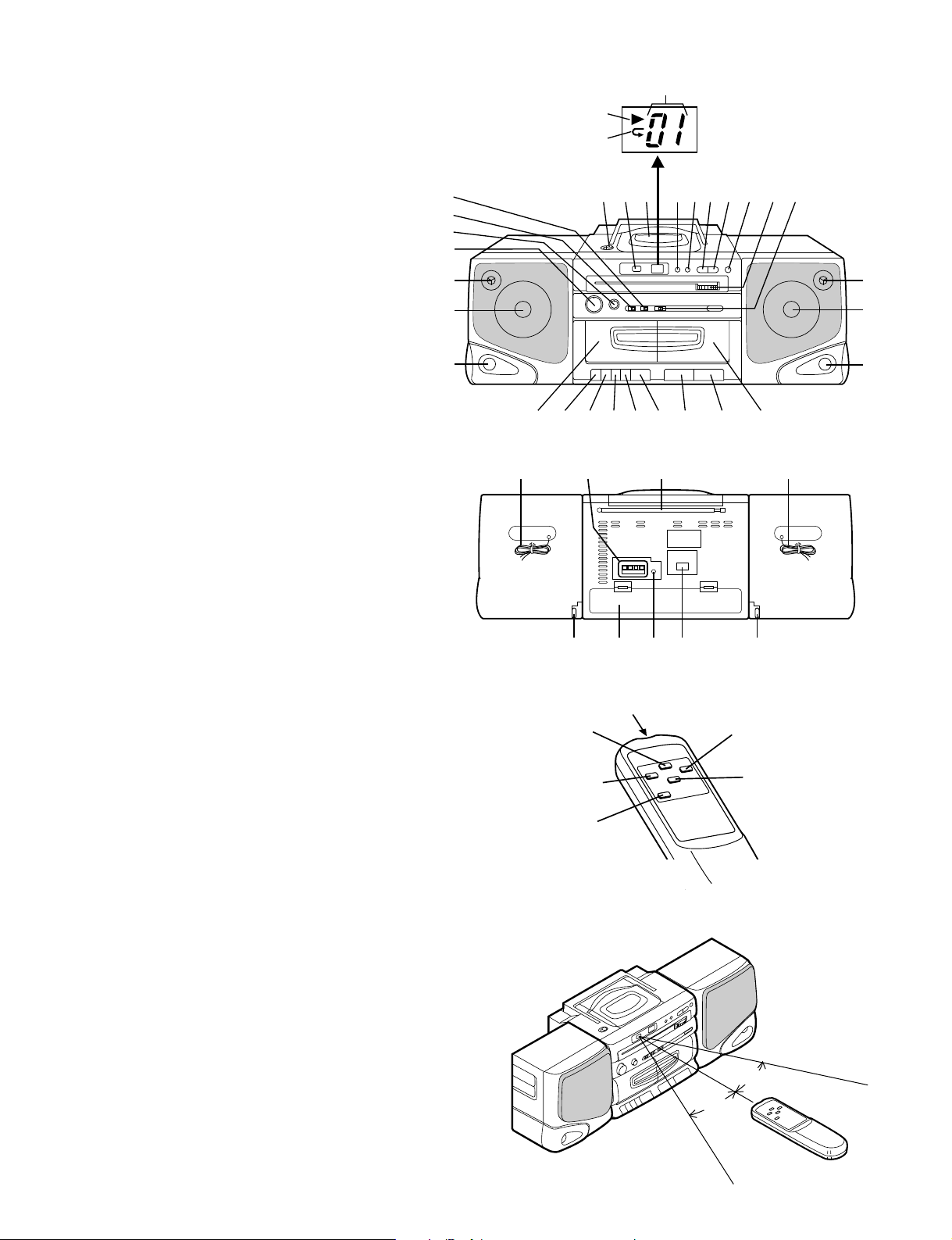

NAMES OF PARTS

25˚

25˚

H Main Unit

1. CD Play Indicator:

2. CD Repeat Indicator:

3. CD Track Number Indicator

4. CD Eject Button:

5. Remote Control Sensor (GX-CD130/130C ONLY)

6. CD compartment

7. (CD) Track Down/Review Button:

8. (CD) Track Up/Cue Button:

9. (CD) Stop Button:

10. (CD) Play/Repeat Button:

11. (CD) Pause Button:

12. Tuning Control

13. Power/Function/Band Selector Switch

14. Beat Cancel Switch

15. X-Bass Switch (GX-CD130/130C ONLY)

16. Tone Control

17. Volume Control

18. Tweeter

19. Woofer

20. Bass Reflex Port

21. (TAPE1) Cassette Compartment

22. (TAPE1) Record Button:

23. (TAPE1) Play Button:

24. (TAPE1) Rewind Button:

25. (TAPE1) Fast Forward Button:

26. (TAPE1) Stop Eject Button:

27. (TAPE2) Play Button:

28. (TAPE2) Stop Eject Button:

29. (TAPE2) Cassette Compartment

30. Speaker Terminals

31. FM Telescopic Rod Aerial

32. Speaker Wire

33. Speaker Release Lever

34. Battery Compartment

35. Headphones Socket

36. AC Power Input Socket

H Remote Control (GX-CD130/130C ONLY)

1. Remote Control Transmitter LED

2. (CD) Play/Repeat Button:

3. (CD) Track Down /Review Button:

4. (CD) Pause Button:

5. (CD) Track Up/Cue Button:

6. (CD) Stop Button:

00

0

00

RR

R

RR

77

7

77

5 5

3 3

5 /

3

5 5

3 3

44

22

4 /

2

44

22

HH

H

HH

0R0R

0R

0R0R

66

6

66

II

I

II

00

0

00

33

3

33

22

2

22

H H

7 7

H /

7

H H

7 7

00

0

00

H H

7 7

H /

7

H H

7 7

0R0R

0R

0R0R

5 5

3 3

5 /

3

5 5

3 3

66

6

66

4 4

22

4 /

2

4 4

22

HH

H

HH

14

15

16

17

18

19

20

GX-CD30/30C/130/130C

3

1

2

4 5 6 7 8 9 1011 12 13

21 22 23 24 25 26 27 28 29

32

30 31 32

33 33363534

1

2

3

4

18

19

20

5

6

Notes concerning use:

• Periodically clean the transmitter LED on the remote control

and the sensor on the main unit with a soft cloth.

• Exposing the sensor on the main unit to strong light may

interfere with operation. Change the lighting or the direction

of the unit.

• Keep the remote control away from moisture, excessive

heat, shock, and vibrations.

8" - 20' (0.2 - 6 m)

– 3 –

Page 4

GX-CD30/30C/130/130C

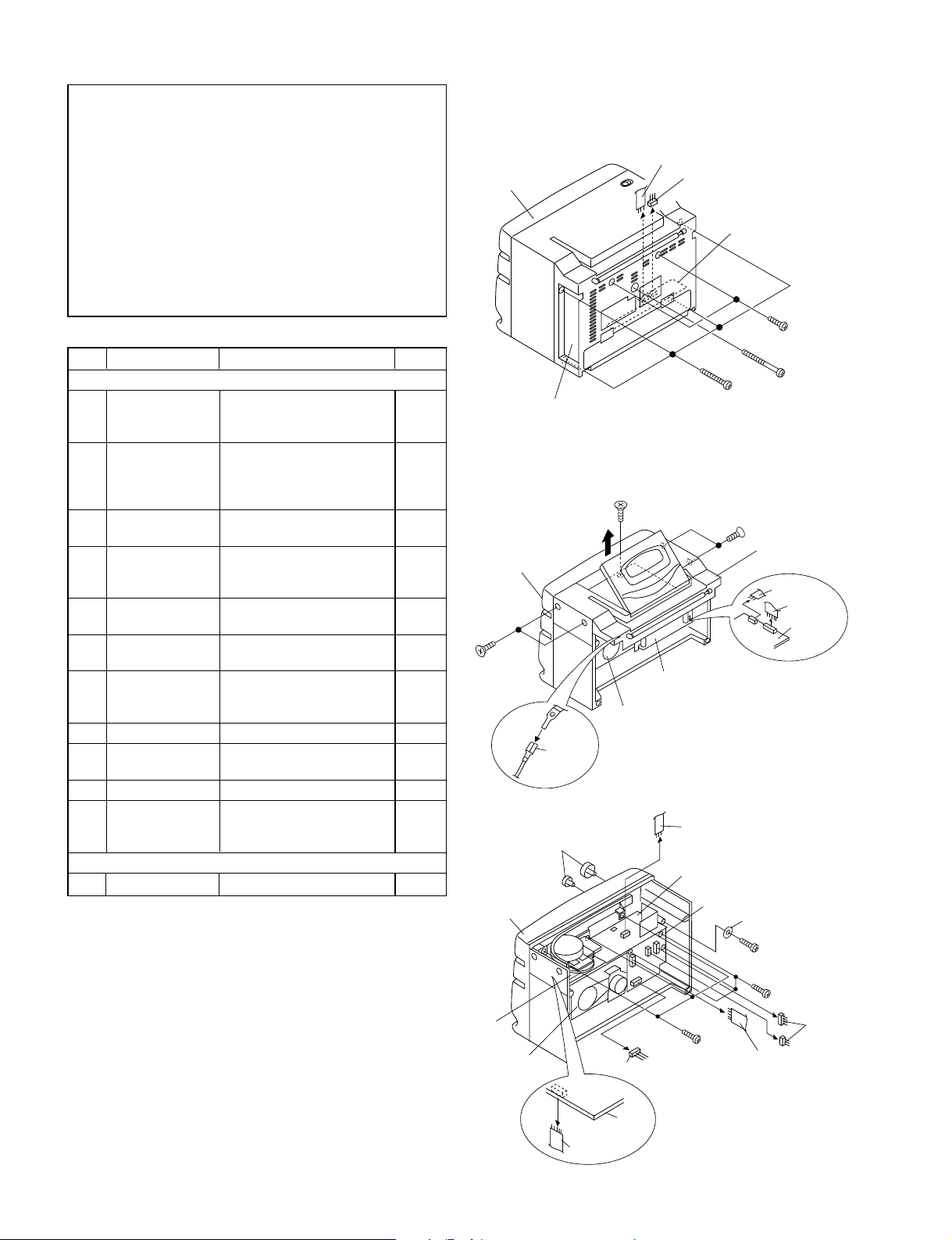

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling the

unit and reassembling it, to keep it safe and ensure excellent

performance:

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need be

removed when disassembling the unit. After servicing the

unit, be sure to rearrange the leads where they were

before disassembling.

4. Take suffcient care on static electricity of integrated

circuits and other circuits when servicing.

Front

Cabinet

( A3 ) x1

( A2 ) x1

Power PWB

( A1 ) x2

ø3 x12mm

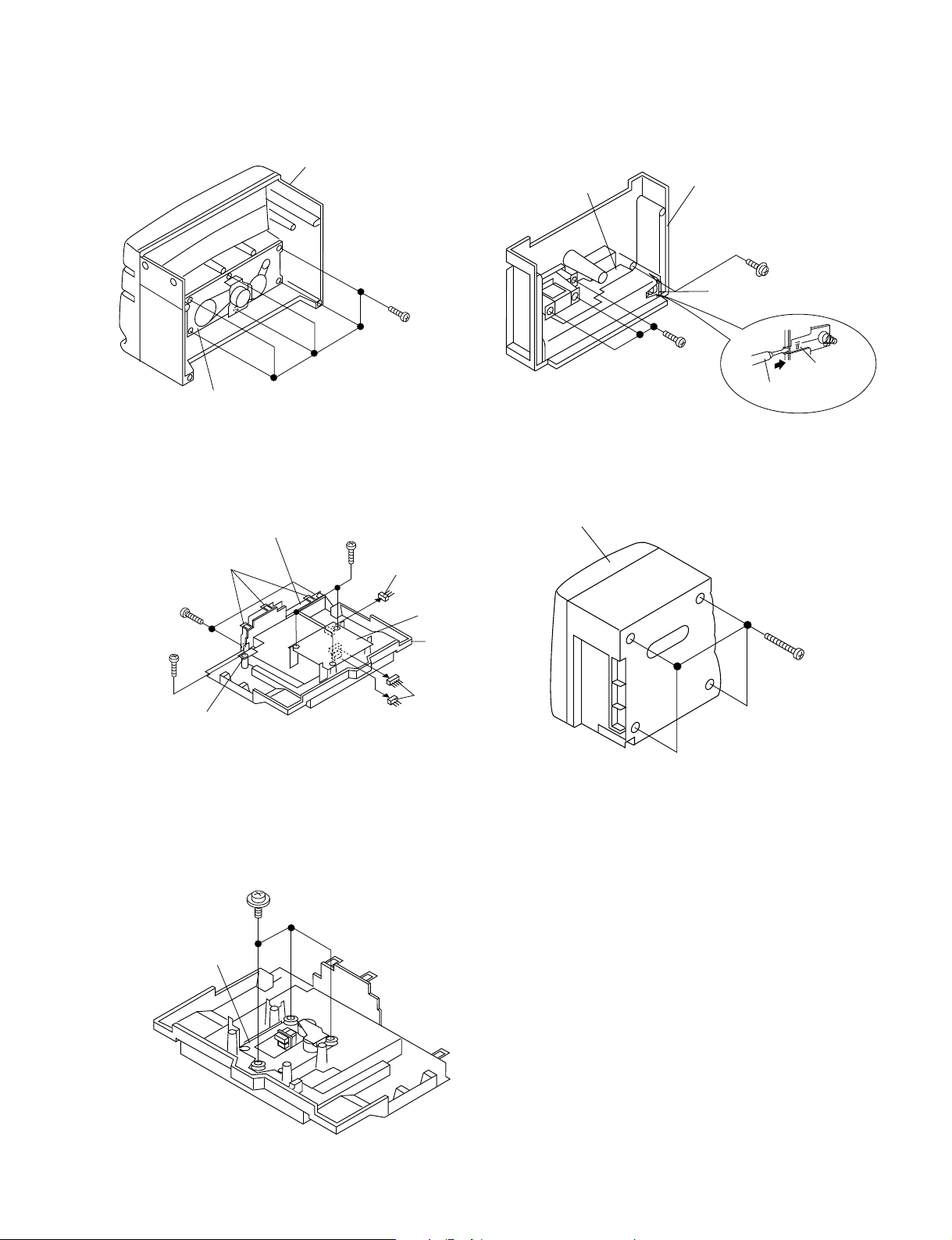

STEP REMOVAL PROCEDURE FIGURE

UNIT

1 Front Cabinet 1. Screw....................(A1) x7 4-1

2. Socket...................(A2) x1

3. Flat Cable ............. (A3) x1

2 Top Cabinet 1. Open the CD lid.

(with CD Block) 2. Screw.................... (B1) x5 4-2

3. Flat Cable ............. (B2) x2 4-2, 4-3

4. Tip.........................(B3) x1 4-2

3 Tuner PWB 1. Screw................... (C1) x3 4-3

(with Tuner Frame) 2. Flat Cable .............(C2) x1

4 Main PWB 1. Screw................... (D1) x1 4-3

2. Knob .................... (D2) x2

3. Flat Cable .............(D3) x1

5 Deck PWB 1. Screw....................(E1) x3 4-3

2. Socket...................(E2) x3

6 Tape Mechanism 1. Open the cassette holder.

2. Screw....................(F1) x6 5-1

7 Display PWB 1. Screw................... (G1) x2 5-2

(with CD control 2. Hook .................... (G2) x3

Button) 3. Flat Cable ............ (G3) x1 4-2

8 Switch PWB 1. Screw................... (H1) x1 5-2

9 CD Servo PWB 1. Screw.................... (J1) x3 5-2

2. Socket................... (J2) x3

10 CD Mechanism 1. Screw....................(K1) x3 5-3

11 Power PWB/ 1. Open the battery lid.

Terminal PWB 2. Screw.................... (L1) x4 5-4

3. Hook ..................... (L2) x1

SPEAKER

1 Front Panel 1. Screw...................(A1) x4 5-5

Front

Cabinet

( B1 ) x2

ø3 x10mm

Front

Cabinet

Rear

Cabinet

( B3 ) x1

( D2 ) x2

OPEN

Figure 4-1

( B1 ) x1

ø3 x8mm

CD Servo PWB

Tape

Mechanism

Figure 4-2

( A1 ) x4

ø3 x20mm

( B1 ) x2

ø3 x10mm

( B2 ) x1

Main PWB

Deck

PWB

( A1 ) x1

ø3 x65mm

Top Cabinet

( B2 ) x1

( G3 ) x1

CD Servo

PWB

Washer

( D1 ) x1

ø3 x10mm

( E1 ) x3

ø3 x10mm

Tuner

PWB

– 4 –

Tape

Mechanism

( C2 ) x1

( E2 ) x1

Tuner

PWB

Figure 4-3

( C1 ) x3

ø3 x10mm

( E2 ) x2

( D3 ) x1

Page 5

Tape

Power PWB

Terminal

PWB

( L1 ) x3

ø3 x10mm

( L1 ) x1

ø3 x10mm

Rear Cabinet

Driver

Push

( L2 ) x1

( A1 ) x4

ø3 x20mm

Front Panel

Mechanism

GX-CD30/30C/130/130C

Front Cabinet

( F1 ) x6

ø3 x10mm

( G1 ) x2

ø3 x10mm

( H1 ) x1

ø3 x12mm

( G2 ) x3

Switch

PWB

( K1 ) x3

ø2.6 x10mm

Figure 5-1

Display

PWB

Figure 5-2

Figure 5-4

( J1 ) x3

ø3 x10mm

( J2 ) x1

CD Servo

PWB

Top Cabinet

( J2 ) x2

Figure 5-5

CD Mechanism

Figure 5-3

– 5 –

Page 6

GX-CD30/30C/130/130C

Pawl

(C1)x2

Play Button

Playback Head

B

B

TAPE 2

TAPE1

Main Belt

(E1)x1

TAPE2

Main Belt

(F1)x1

Main Belt

(F1)x1

Main Belt

(E1)x1

FF/REW Belt

(E2)x1

Flywheel

Flywheel

Motor

Motor

TAPE 1

TAPE 2

REMOVING AND REINSTALLING THE MAIN PARTS

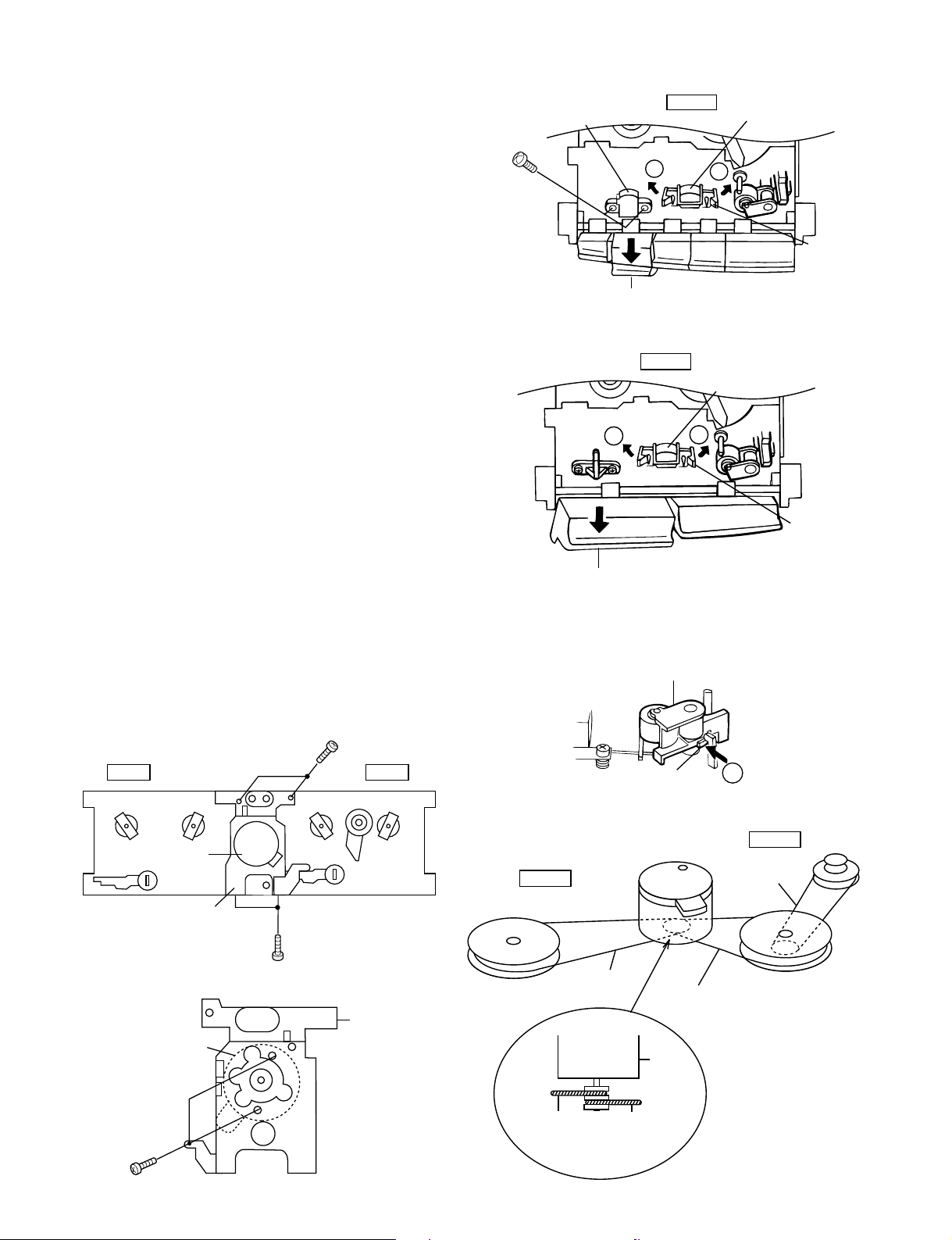

TAPE MECHANISM SECTION

Perform steps 1, 2, 3, 4, 5 and 6 of the disassembly method

to remove the tape mechanism.

How to remove the record/playback and erase

heads (TAPE 1) (See Fig. 6-1.)

1. Carefully bend the record/playback head pawls (A1) x 2

pcs., in the direction of the arrow Â, and remove the record/

playback head upwards.

2. Remove the screws (B1) x 2 pcs., to remove the erase head.

How to remove the playback head (TAPE 2)

(See Fig. 6-2.)

1. Carefully bend the playback head pawls (C1) x 2 pcs., in the

direction of the arrow È, and remove the playback head

upwards.

How to remove the pinch roller (TAPE 1/2)

(See Fig. 6-3.)

1. Carefully bend the pinch roller pawl in the direction of the

arrow Ê, and remove the pinch roller (D1) upwards.

How to remove the belt (TAPE 1) (See Fig. 6-4.)

1. Remove the main belt (E1) x 1 pc., from the motor side.

2. Remove the FF/REW belt (E2) x 1 pc.

How to remove the belt (TAPE 2) (See Fig. 6-4.)

1. Remove the tape 2 main belt (E1) x 1pc., from the motor side.

2. Remove the tape 1 main belt (F1) x 1pc., from the motor side.

( B1 ) x2

ø2 x7mm

Erase Head

Play Button

TAPE 1

A

Figure 6-1

Record/Playback

Head

A

Pawl

(A1)x2

How to remove the motor

(See Figs. 6-5 and 6-6.)

1. Remove the belt.

2. Remove the screws (G1) x 4 pcs., to remove the motor fixture.

3. Remove the screws (G2) x 2 pcs., to remove the motor.

Note:

When mounting the motor, pay attention to the motor mounting

angle.

TAPE2 TAPE1

Motor

Motor

Bracket

Motor

( G1 ) x2

ø2 x4mm

Figure 6-5

( G1 ) x2

ø2 x4mm

Motor

Bracket

Figure 6-2

Pinch Roller

(D1) x 1

Pawl

Figure 6-3

C

( G1 ) x2

ø2.6 x2mm

Figure 6-6

Figure 6-4

– 6 –

Page 7

CD MECHANISM SECTION

Pickup

( F2 ) x2

ø2.6 x6mm

( F1 ) x2

CD Mechanism

CD Cover

Shaft

( F3 ) x1

Gear

( F5 ) x1

Stop Washer

( F4 ) x1

( F1 ) x2

Perform steps 1, 2, 9 and 10 of the disassembly method to

remove the CD mechanism.

How to remove the pickup (See Fig. 7-1.)

1. Remove the hooks (F1) x 4 pcs., to remove the CD cover.

2. Remove the screws (F2) x 2 pcs., to remove the shaft (F3)

x1 pc.

3. Remove the stop washer (F4) x1 pc., to remove the gear

(F5) x 1 pc.

4. Remove the pickup.

GX-CD30/30C/130/130C

Figure 7-1

FITTING OF DIAL POINTER

1. Remove the three screws, and remove the tuner PWB from the tuner frame. (See Fig. 7-2)

2. Turn fully the dial wheel in the  direction. (See Fig. 7-3)

3. Set the dial pointer as shown in Figure 7-2, and mount the tuner PWB.

"0" Point

Tuner

Frame

Dial

Pointer

( 229 )

Screw x3

Tuner PWB

(Top view)

Tuner PWB

(Bottom view)

A

Figure 7-2 Figure 7-3

– 7 –

Page 8

GX-CD30/30C/130/130C

Pin 13 of IC2 Pin 21 of IC2

D

G

S

10 kohm

TO FREQUENCY

COUNTER

FET : 2SK19 or 2SK54

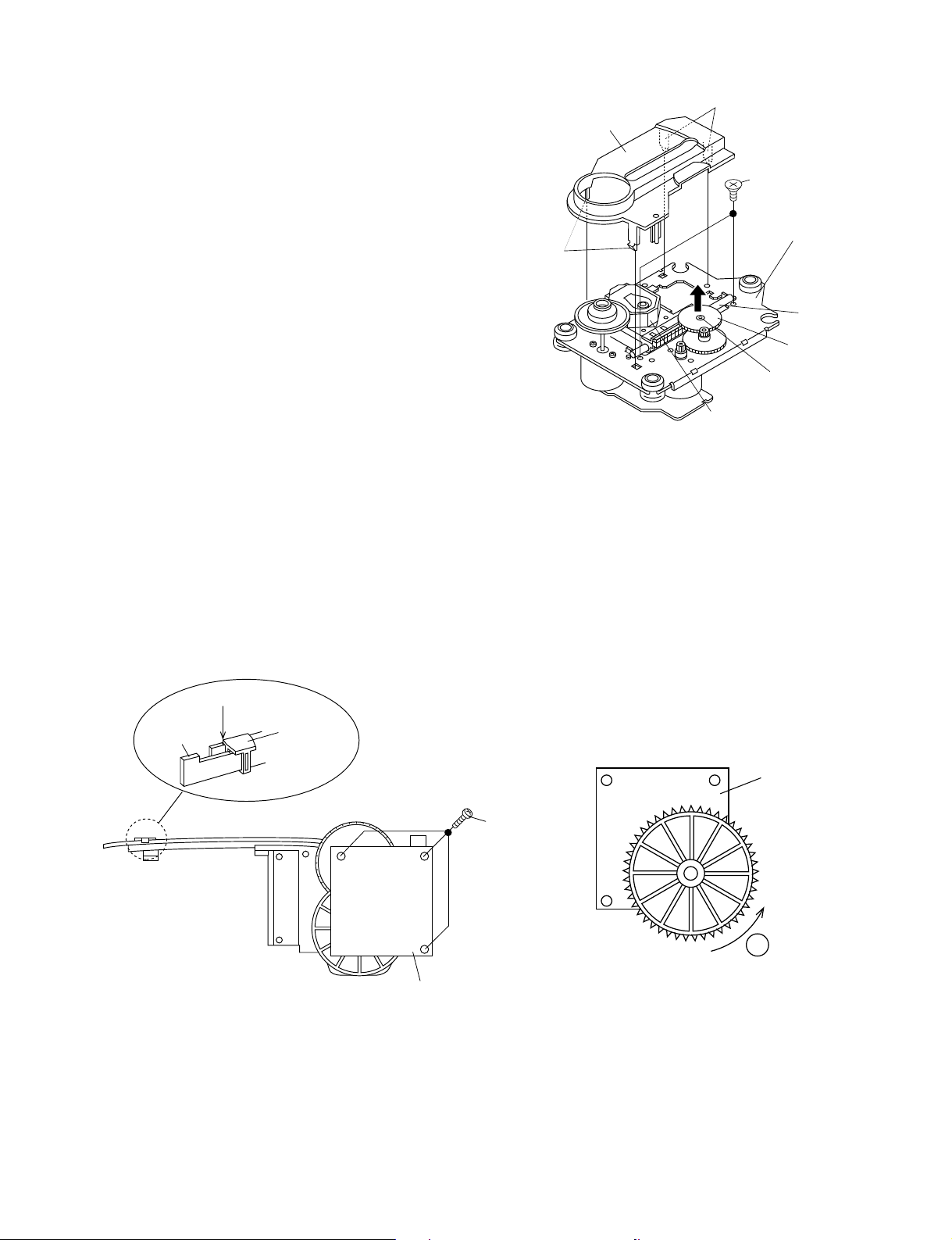

ADJUSTMENT

MECHANISM SECTION

• Driving Force Check

Torque Meter

PLAY: TW-2412 Tape 1: Over 50 g

Tape 2: Over 100 g

• Torque Check

Torque Meter

Play: TW-2111 30 to 60 g.cm 30 to 60 g.cm

Fast Forward: TW-2231 80 to 135 g.cm

Rewind: TW-2231 80 to 135 g.cm

• Tape Speed

Test Tape

Nomal MTT-111 3,000 Speaker

speed ± 30 Hz terminal

Specified

TAPE SECTION

Position of each switch or control

Volume control Max

Beat cancel A

Function/Power switch Tape/Off

• Bias Oscillation Check

Beat cancel A: 82 + 10 kHz / -6 kHz

• Erase Current Check

Resistor for measurement: 1 ohm 50 ± 25 mV

Specified Value

Specified Value

Tape 1 Tape 2

Instrument

Value

B: -2 ± 2 kHz

C: +3 ± 2 kHz

Connection

(Load resistance:

6 ohms)

Specified Value

Specified Value

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

• FM IF/RF

Test Stage

IF T1

Detection T2

Band Coverage fL: L2

Tracking 88.0 MHz: L1

Specified

Value/Adjusting

Point

fH: TC2

108.0 MHz: TC1

• AM IF/RF

Test Stage

IF T3 Input: Antenna

Band Coverage fL: L4 Input: Antenna

Tracking 600 kHz: L3 Socket (Load

Specified

Value/Adjusting

Point

fH: TC4 Output: Headphones

1,400 kHz: TC3 resistance: 32 ohms)

• VCO Frequency

Adjusting Point

VR1 76 kHz ± 200 Hz Pin 13, pin 21 and

Note:

After preparing the test circuit shown in Fig. 8-1, connect the

Pin 13, Pin 21 and ground of the IC2 with the test circuit, and

measure the value. At this time, apply a standard unmodulated

signal input and adjust the VCO.

Specified

Value

Instrument

Connection

Input: Pin 1 of IC1

Output: Pin 17 of IC2

Iuput: Antenna

Output: Headphones

Socket (Load

resistance: 32 ohms)

Instrument

Connection

Output: Pin 19 of IC2

Instrument

Connection

ground of IC2

• Playback Amplifier Sensitivity Check

Specified Value

MTT-118 1.8 V ± 3 dB Speaker Terminal

(Load resistance: 6 ohms)

FM

TRACKING

Instrument ConnectionTest Tape

fH

fL

L3

AM BARANTENNA

AM TRACKING fL

Figure 8-2 ADJUSTMENT POINTS

AM TRACKING

fH

TC3

TC1

L1

FM RF

1

IC1

T1

FM IF

TC4

TC2

L2

– 8 –

L4

Figure 8-1 VCO FREQUENCY TEST CIRCUIT

AM BANDfH

fL

COVERAGE

VCO

VR1

T2

FM BANDfL

fH

FM DET

21

1

T3

19

17

IC2

AM IF

13

COVERAGE

Page 9

CD SECTION

3

Since this CD system incorporates the following automatic

adjustment function, when the pickup is replaced, it is necessary

to reajust it.

Since this CD unit does not need adjustment, the combination

of PWB and laser pickup unit is not restricted.

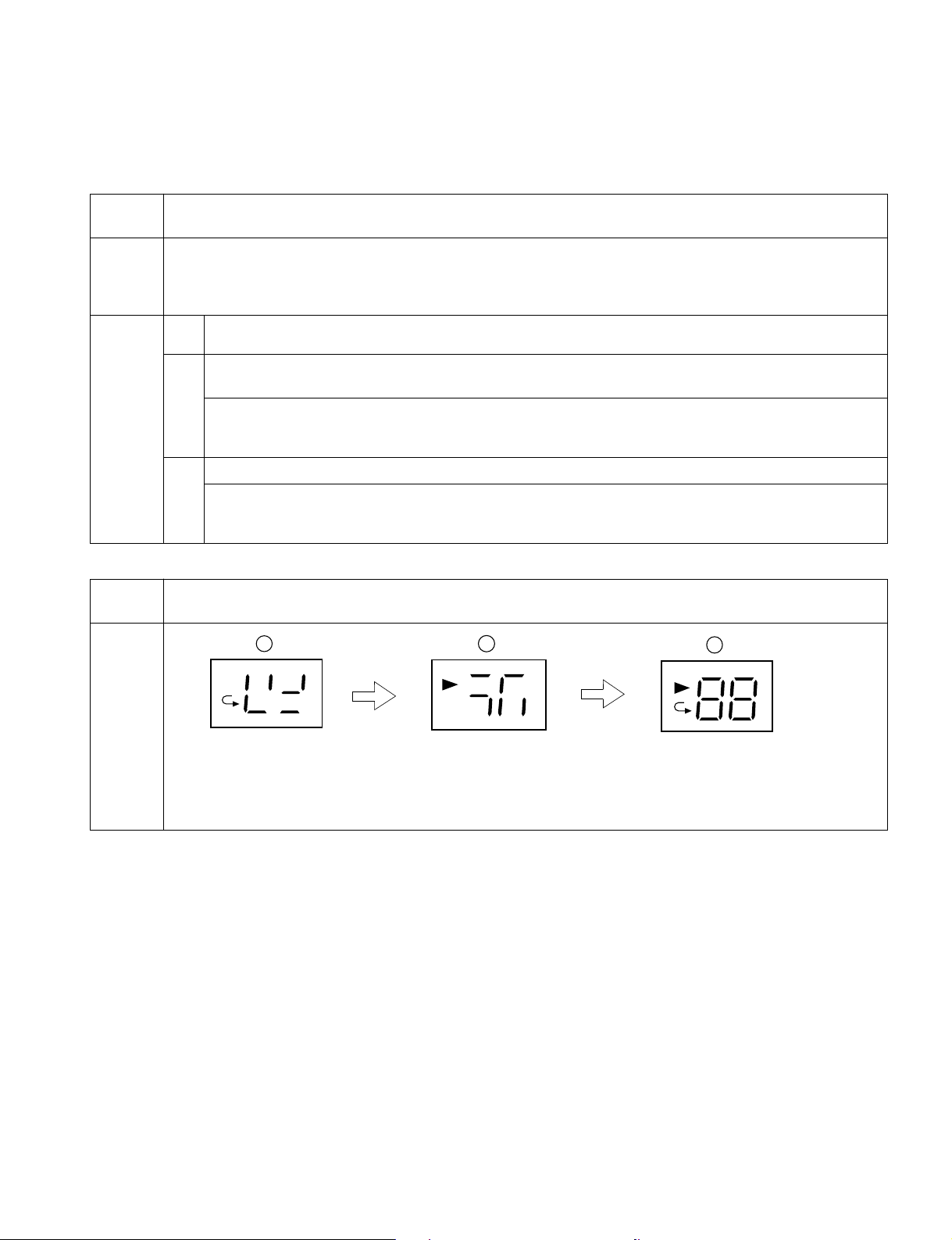

TEST MODE

GX-CD30/30C/130/130C

Start

Note

Operation

LCD MODE

Start

Display

While holding down the "STOP" button, move the FUNCTION/POWER switch to "CD".

Then, release the "STOP" button and, within 0.5 second, press the PAUSE button.

1. When the CD LID switch is in the OFF position, the unit will be able to enter the test mode.

However, playback cannot be performed in this mode.

2. You can only move the pickup.

3. The LCD display should be the same as it is for normal CD operations.

The use of the "UP/CUE" button will move the pickup to the outermost position.

1

The use of the "DOWN/REVIEW" button will move the pickup to the innermost position.

When the "PLAY" button is pressed, the laser will be lit, and when the "STOP" button is pressed, it will be

2

turned off. Playback will also start and stop when these buttons are pressed.

a. If the "PLAY" button is pressed while in the stop mode, the laser will simply be turned on at first.

b. If the laser is lit and the "PLAY" button is pressed again, playback will start from the current pickup position.

c. If the "STOP" button is pressed, playback will stop. When pressed again, the laser will be turned off.

Turning the tracking servo on or off.3

a. Each time the PAUSE button is pressed during playback, the tracking servo will be turned on or off.

(Note: If the PLAY button is pressed while in the stop mode, the tracking servo will automatically be

turned on.)

While holding down the "STOP" button, move the FUNCTION/POWER switch to "CD".

Then, release the "STOP" button and, within 0.5 second, press the PAUSE button.

1

2

1 second

* After the number ➂ has appeared in the display, each time the "UP/CUE" button is pressed, the display will switch

in the following order: ➀, ➁, and then ➂.

1 second

– 9 –

Page 10

GX-CD30/30C/130/130C

TROUBLESHOOTING (CD SECTION)

When the CD does not function

When the CD section does not operate When the objective lens of the optical pickup is dirty,this section may not operate.Clean

the objective lens,and check the playback operation.When this section does not operate even after the above step is taken,check

the following items.

Remove the cabinet and follow the troubleshooting instructions.

"Track skipping and/or no TOC(Table Of Contents) may be caused by build up of dust other foreign matter on the laser pickup lens.

Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned below."

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

• The CD function will not work.

The CD operating keys don't work.

Yes

▼

Check the CD, DPS microcomputer (IC701), power supply, 4.19

MHz and 16.93 MHz clock, and reset terminal.

Yes

▼

Check the waveform of SCK, SO (DATA) and SI (COMM).

Yes

▼

See if the pick-up is in the pick-up in SW702 position.

Yes

▼

If the items mentioned above are OK, check the main

microcomputer IC701.

• The CD operating keys work.

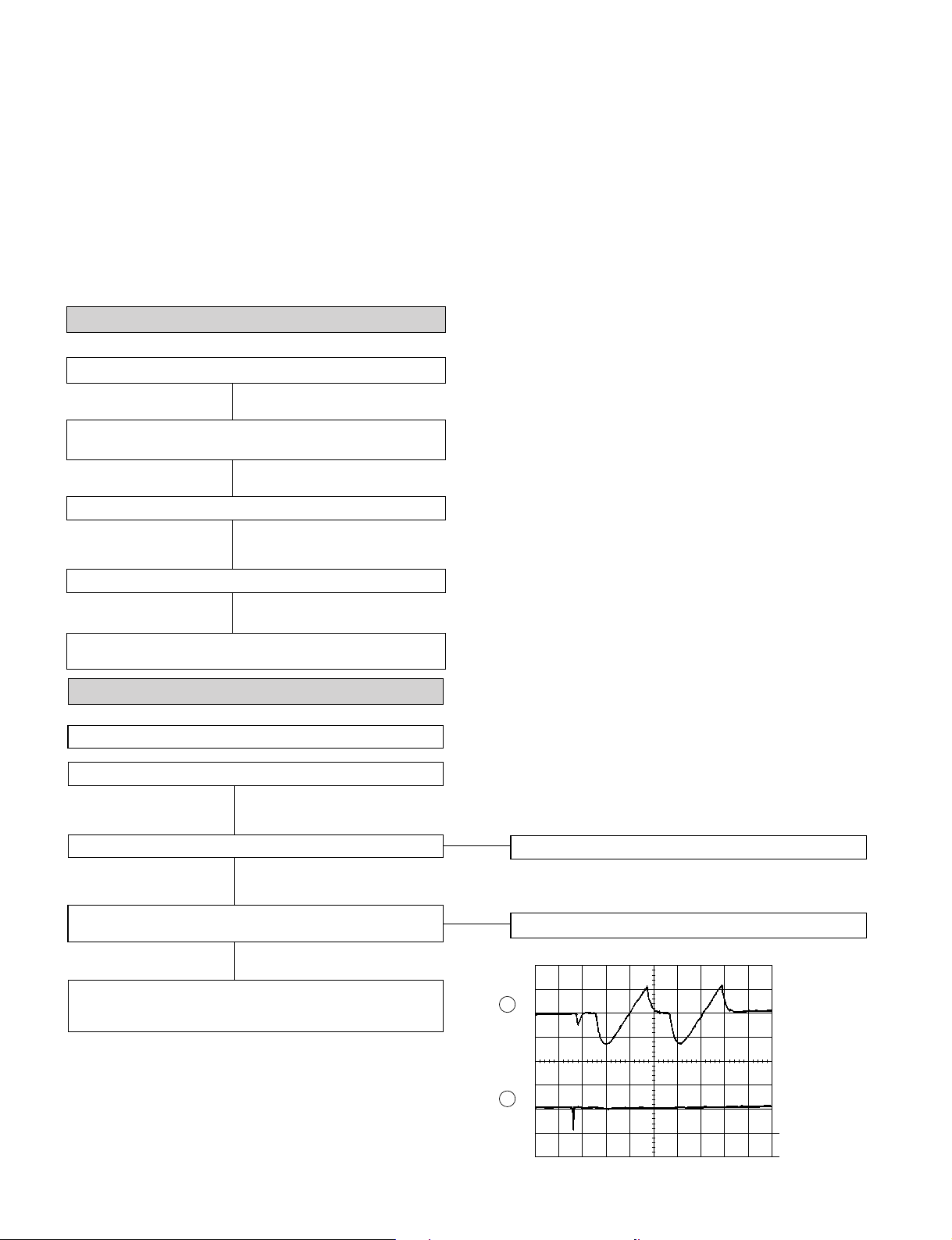

Check the Focus - HF system.

Playback can be performed without a disc.

Yes

▼

Does the pick-up move up and down twice?

No

▼

Does the output waveform of IC801(16)(FD) match that shown in

Fig. 10?

No

▼

Check the IC801(50)(CLK) line, 4MHz.

Check the microcomputer data on pins (51)(CL), (52)(DAT) and

(53)CE.

Yes

Yes

0.5s

0.50 V

IC801 16 FD

0.5s

0.50 V

IC801 15 TD

Focus search OK.

▼

Check the area around IC804-BI801/CNS801.

▼

Focus search

is performed

two times

when play

operation is

done without

disc.

– 10 –

1

2

Figure 10

Page 11

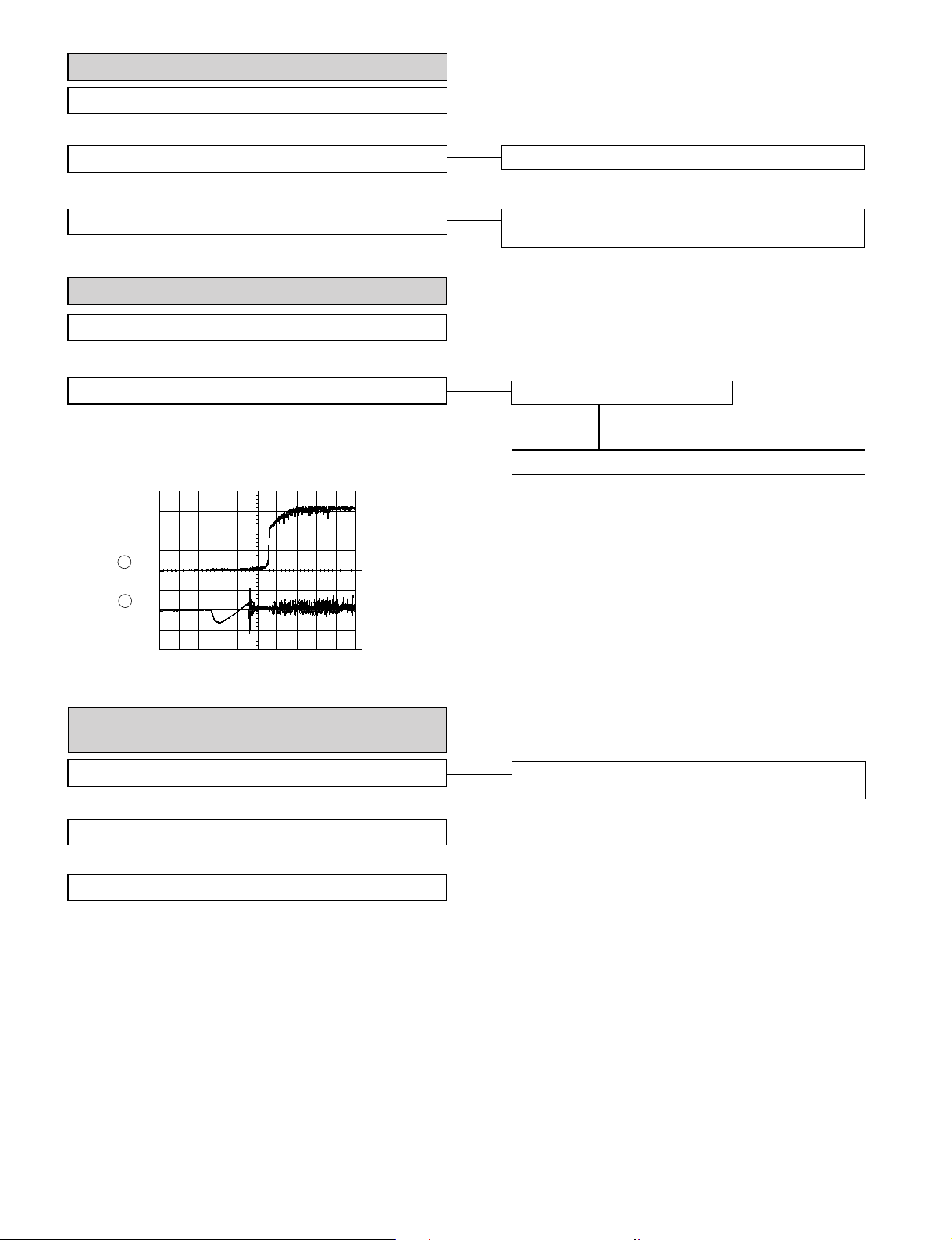

• Playback can only be performed when a disc

3

2

1

4

0.5s

1.00 V

IC801 16 FD

0.5s

10.0 V

IC801 12 CLV+

0.5s

10.0 V

IC801 54 DRF

0.5s

2.00 V

IC801 7 TE

is loaded.

GX-CD30/30C/130/130C

Is the Focus servo active? (Can you hear it working?)

Yes

▼

Does the DRF signal change from "L" to "H"?

Yes

▼

Is HF waveform normal (see the Fig.11-1, 2)?

Yes

▼

Check the tracking system.

HF

0.1V/DIV

0.5µsec/DIV(DC)

(When playing

back the disc)

No

No

No

Check the laser diode driver.

▼

Check the area around IC801(16) - (21) (focus servo circuit).

Yes

If the disc is not turning, the DRF

▼

should not change to "H".

Check the spin

▼

system.

Yes

Level is abnormal.

▼

Check the periphery

▼

of IC801 pins 41 and

42.

Yes

Waveform is unstable.

▼

Check the spin

▼

system.

Waveform in case

of normal playback

Figure 11-1

• Check the tracking system.

Check waveform of IC801 pin 7 (TE).

The waveform shown in Fig. 11-3

▼

appears, and no-disc state appears

soon.

Play is possible in

▼

TEST mode.

Data cannot be read.

▼

Yes

Although IL is possible,

▼

play is impossible.

Yes

5ms

1.00 V

IC801 7 TE

Tracking servo is inoperative.

▼

Yes

Normal jump is impeded, and the

▼

program top cannot be reached.

Yes

Check the VCO-PLL system.

▼

Figure 11-2

Check the periphery of IC801

Yes

4

▼

pin 8 to pin 15, and IC804 to

BI801/CNS801.

Check the periphery of

▼

IC801 pin 14.

Yes

5 ms

5.0 V

IC801 54 DRF

3

Figure 11-3

– 11 –

Page 12

GX-CD30/30C/130/130C

• Checking the spin system.

Play operation is performed without disc.

Yes

▼

The turntable rotates a little.

No

▼

The turntable fails to rotate or rotates at high speed.

• Checking the VCO-PLL system

Play operation is performed when disc exits.

Yes

▼

Although HF waveform is normal, TOC data cannot be read.

Yes

Yes

Yes

The spin driver circuit is normal.

▼

Check the periphery of IC801 pins 23 to 27, pin 39 and pin 40,

▼

IC802 pin 12 and pin 13, IC804 to BI803/CNS803.

Check PDO waveform (Fig. 12).

▼

Error

▼

Check the IC801 pins 43 and 44, IC802 pins 3, 5, 7, 9 and 10.

Stop --> Play

As VCO freque-

0.5s

1.00 V

IC802 3 PDO

0.5s

1.00 V

IC801 16 FD

ncy is locked at

4.32 M Hz,

voltage of PDO

2

rises and stabilizes.

3

Figure 12

• Although HF waveform is normal and the time

indication is normal, no sound is emitted.

Check IC802 pin 48 (EFLG).

Yes

▼

Check IC802 pins 37and 40.

Abnomal

▼

Check the periphery of IC803 (OPAMP).

No

Usually, the number of pulses of flawless disc is 100 pulses/

▼

sec or less.

– 12 –

Page 13

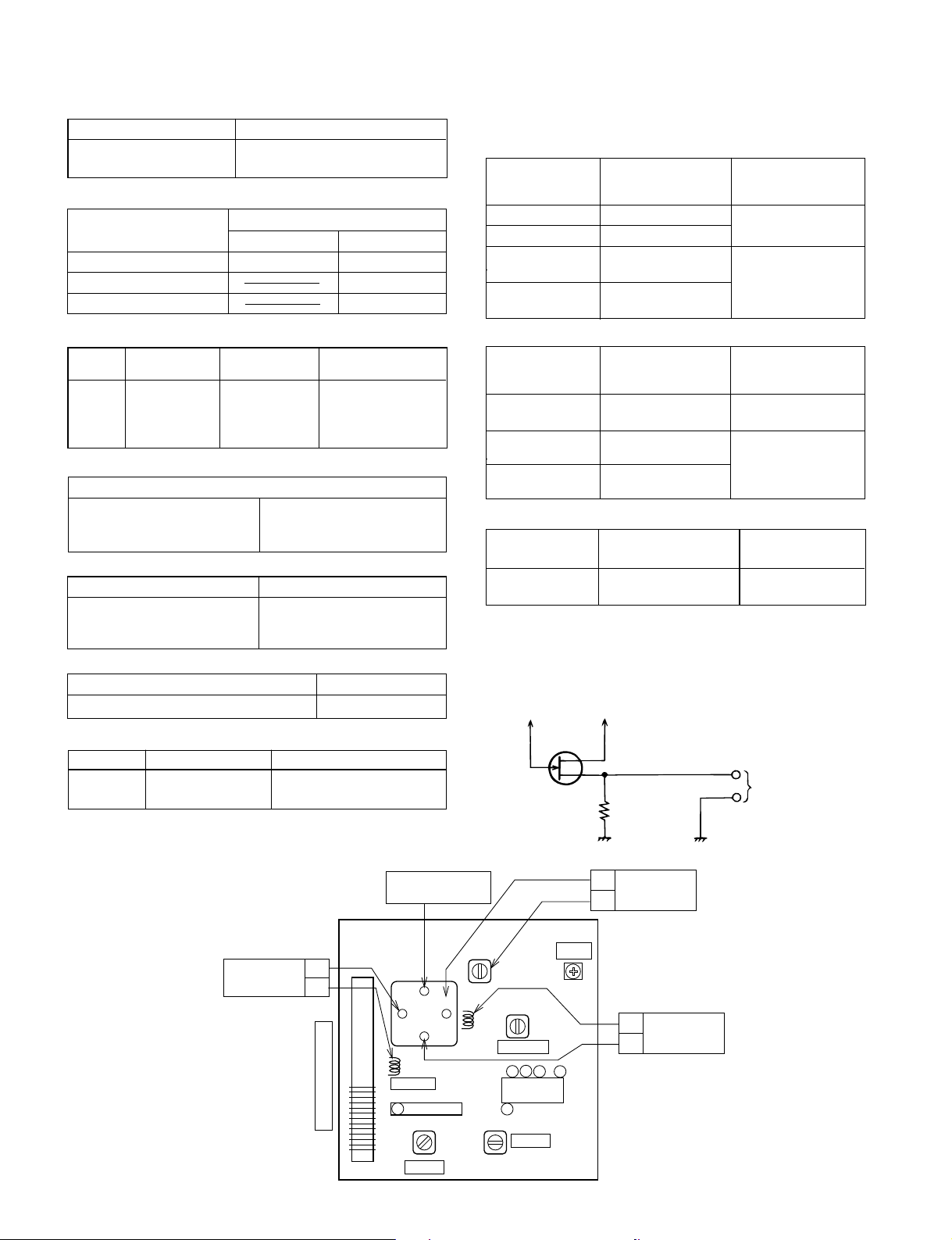

NOTES ON SCHEMATIC DIAGRAM

GX-CD30/30C/130/130C

• Resistor:

To differentiate the units of resistors, the symbol as K and M

are used: the symbol K means 1000 ohm and the symbol M

means 1000 kohm and the resistor without any symbol is an

ohm resistor. The resistor designated "Fusible" is a fuse type

resistor

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means micro-micro-farad and the unit of the capacitor

without such a symbol is microfarad. As to electrolytic capacitor,

the expression “capacitance/withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• The indicated voltage in each section is the one measured by

Digital Multimeter between such a section and the chassis

with no signal given.

REF. NO DESCRIPTION POSITION POSITIONREF. NO DESCRIPTION

SW201 RECODE/PLAYBACK OFF

SW351 BEAT CANCEL A

SW500 X-BASS [130/130C ONLY] OFF

SW501 POWER/FUNCTION OFF

SW605 TAPE 1 MAIN OFF

SW606 TAPE 2 MAIN OFF

SW607 TAPE1/2 SELECTOR OFF

1. Tuner

( ): AM mode

Marking except for ( ): FM mode

2. CD

( ): Play mode

Marking except for ( ): Stop state

3. Deck section

( ): Record mode

Marking except for ( ): Playback mode

Display / Control section:

( ): Active state

Marking except for ( ): CD Function mode at stop state

• Schematic diagram and Wiring Side of P.W.Board for this

model are subject to change for improvement without prior

notice.

• Parts marked with “ î ” ( ) are important for

maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and

performance of the set.

SW702 PICKUP IN OFF

SW761 CD LID OPEN/CLOSE OFF

SW771 CD-PLAY/REPEAT OFF

SW772 CD-STOP OFF

SW773 CD-UP/CUE OFF

SW774 CD-DOWN/REVIEW OFF

SW775 CD-PAUSE OFF

FRONT

VIEW

ECB

(S)(G)(D)

(1) (2) (3)

2SC2001 K

2SD468 C

KRA102 M

KRC102 M

KTA1266 GR

KTC3199 GR

FRONT

VIEW

BCE

2SD2394 F

Figure 13 TYPES OF TRANSISTOR

– 13 –

Page 14

GX-CD30/30C/130/130C

6

5

VCC1

O

2

8

4

D

E

0

LCD771

CD LCD

RX771

REMOTE

SENSOR

31

CD LID

OPEN/CLOSE

SW761

CD

OPERATION

KEY

SW771~SW775

2

321

CFW772

321

PICKUP UNIT

LASER

DRIVER

+

X701

4.19MHz

57

60 41 44 30 33 22 23

~~

K1

SEG1

SEG4

24

27

28

31

34

35

36

COM0

COM3

IC701

IX0105AW

SYSTEM

MICROCOMPUTER

MUTE

7

RES

9

RC IN

SL–

DRF

~~ 1732 14

WRQ

19

XIN

VLC3

VDD

RESET

21

LID

SL+

SL–

XOUT

37

38

25

13

14

20

+5V

(D)

FOCUS COIL

TRACKING COIL

1

2

3

4

30

FIN2

FIN1

E

F

SL–

SL+

15

TO

16

Q805

FD

LA9

SERV

SPO

SLEO

273128

29

IC

SLD

+5V

MUTE

SYNC.IN

321

CNP603

FROM MAIN SECTION

PICKUP IN

SW702

PU-IN SW

M701

SPIN

MOTOR

M702

SLIDE

MOTOR

Figure 14 BLOCK DIAGRAM (1/4)

– 14 –

M

M

19 23 25

10

3

1

2

11

12

FOCUS/TRA

17

/SPIN/SLI

18

26

27

IC80

BA592

DRIV

Page 15

GX-CD30/30C/130/130C

FD

ASER

RIVER

+5V

805

64 62

VCC1

IC801

LA9240M

SERVO AMP.

SLD

SPO

SLEO

27 28 29

+5V

49

Q804

LDO

44

SLI

43

SLC

40

CV+

~

32

JP–

CE

DRF

DAT

CL

CLK

THLD/DEF

50 525351

54

CL, DAT, SELIAL CONTROL

CONSTANT

VOLTAGE

REGULATOR

XL801

16.93MHz

44

XOUT

EFMO

9

10

EFMIN

12

CLV+

13

CLV–

14

15

16

17

18

19

20

SERVO/SIGNAL

V/P

HFL

TES

TOFF

TGL

JP+

RES. CQCK. COIN

JP–

SQOUT. RWC. WRQ

61 58

57

1

45

XIN

IC802

LC78622E

CONTROL

56395538543353

+5V

23

6

VVDD

43

VDD

XVDD

LCHO

42

8

64

63

62

51

37

+7.4V

(CD)

46

32

11

CNP851

1

2

3

4

5

R-CH

GND (A)

L-CH

+7.4V (D)

GND (D)

TO

MAIN

SECTION

19 23 25

IC804

BA5920FP

US/TRACKING

PIN/SLIDE

DRIVER

22

+7.4V

2

5

6

7

8

13

28

Figure 15 BLOCK DIAGRAM (2/4)

– 15 –

Page 16

GX-CD30/30C/130/130C

M

E

M

G

R

S

S

ROD ANTENNA

1

FROM CD

SECTION

TO CD

SECTION

T2 PB HEAD

REC/PB

T1

ERASE

F1

B. P. F

L-CH

R-CH

SELECTOR

L-CH

HEAD

R-CH

HEAD

3

FW851

CNP603

T1/T2

SW607

1

2

3

1

MUTE

SYNC. IN

P.B

P. B

REC

FM FRONT END

RF AMP

2

3

L1

FM RF

R-CH

AUDIO GND

L-CH

CD+7.3V

POWER GND

REC/PB

SW201

C, D, E, F

P. B

REC

SW351

BEAT

CANCEL

IC1

LA1186N

MIX OSC

VCC

69

5

FM

+B

8

L2

FM OSC

P.B

REC

Q351

L351

BIAS

OSC.

23

2

1

19

7

18

7

4

L (T2)

R (T2)

L (T1)

R (T1)

T1/T2

L

R

AM BAR ANT.

POWER/

FUNCTION

SW501-A, B

L

R

L

R

Q252

T1

FM IF

L3

RADIO

CD

TAPE

21

4

15

RECORD/PLAYBACK

1224

13

9

16

REC

LA7345K

PLAYBACK AND

+B2

SW201-B

REC/PB

SW201-A

REC/PB

10.7MHz

IC2

LA1805

FM/AM

IF MPX.

IC201

AMP.

CF2

M601

TAPE

MOTOR

M

AM IF

T3

1

RF

22

REG.

23

3

MPX

OSC

24

TONE

VR532

A, B

VOLTAGE

REGULATO

Q405

+B1

F

L

A

Figure 16 BLOCK DIAGRAM (3/4)

– 16 –

Page 17

SW501-C

POWER/FUNCTION

455kHz A M

CF3

FM DET

T2

TUNER

+B

FM +B

VR1

VCO

GX-CD30/30C/130/130C

MONO

TUNER +B

2

FM-IF

LEVEL-DET.

AM-IF

GND

6

AM OSC

E

2

GE

TOR

TAPE

SW605 T1 MAIN

SW606 T2 MAIN

5

DET.

DET.

AGC

4

L4

SW500

A, B

CD130/130C

ONLY

Q404

RIPPLE

Q401

FILTER

SW501-D

POWER/

FUNCTION

20

VOLUMEX-BASS

POST

AMP.

MUTE

VR531

17

TU

DRIV.

12

A,B

STAND-BY

Q403

19 18

8

+B2

RADIO

SW501-C

POWER/

FUNCTION

CD

MUTING

Q551

Q552

DRIVER

Q554

+B1

PHASE

DET.

DECODER

9

MUTE

TUNER +B

D651~D654

RECTIFIER

15 141316 11

PILOT

DET.

VCO

10

IC501

LA4597

POWER AMP.

L

2

R

6

11

5

[ “D” size (UM/SUM-1,

R20 or HP-2) battery x 8]

TRIG.

ST.

DRIV.

FF FF

ST.

SWIT.

12

10

8

+B1

SPEAKERS

T651

POWER

TRANSFORMER

BATTERY

DC 12V

7

VCC

FF

+

–

–

+

CNP552

130C/30C

21

J551

HEADPHONES

SP3

TWEETER

L-CH

SP1

WOOFER

SP2

WOOFER

R-CH

SP4

TWEETER

SO651

130/30

AC INPUT

AC 120V

60Hz

Figure 17 BLOCK DIAGRAM (4/4)

– 17 –

Page 18

GX-CD30/30C/130/130C

A

R842

22

+B

LASER DRIVER

Q805

KTA1266GR

3V

2.2V

C848

1/50

1.8V

C840

0.33/50

C849

0.022

C839

1/50

C838

0.01

C837

10/16

C835

+B

0.1/50

DEF

REF

+

–

SL–

31 32

0.0033

C820

R826

R871

4.7K

48

NC

TBC

47

THLD

FSC

46

45

DGND

SLI

44

–

+

43

SLC

RFS–

42

C830

41

40

39

38

37

36

35

34

33

R827

220K

R810

2.2P

82K

RFSM

CV+

SLOF

HFL

TES

TOFF

TGL

JP+

SL+

JP–

220K

B

C803

0.1/50

TE

C804

0.001

R804

2.2K

R805

C807

0.1/50

R807

R809

27K

R811

3.3K

6.8K

R806

100

1K

C

C809

0.047

R802

100K

R808

12K

C805

0.033

C806

0.033

C808

0.068

R803

15K

C810

180P

D

R813

R829

1K

R812

15K

33K

R828

R839

1K

22K

E

C811

0.1

R840

22K

VREF

GND

C813

0.1

FIN2

1

FIN1

2

E

3

F

4

TB

5

TE–

6

TE

7

8

9

TH

10

TA

11

TD–

12

TD

13

JP

14

TO

15

FD

16

64 63 62

VCC1

–

REF

+

REF

–

REF

REF

REF

+

–

HIST. COMP

SHOCK;WCOMP

REF

+

–

GEN

REF

REF

+

–

FD–

17

R814

10K

61 60 59 58 57 56 55 54 53 52 51 50 49

PHI

BHI

LDS

LDO

–

+

RF

FE1

–

+

+

REF

VCR

VCR

–

+

–

+

–

+

VCR

BAL

REF

JP

FSC

REF

+

–

TO

GEN

+

–

REF

+

–

FA

FA–

19

18

R815

47K

C814

0.01

WCOMP

GEN

+

–

20

+

–

C812

330P

+

FE

REF

R816

1.5K

TGL1

THDL

THD

REF

+

–

FOF

FE–

21 22 23

R817

VCR

REF

GL

SP

AGND

82K

VCC

VR

LF2

REFI

+

–

REF

+

DEF

–

–

HFL

+

+

DRF

–

IC801

LA9240M

SERVO AMP.

VCC

+

–

REF

+

–

JP

PSTR

REF

S.Q.R

+

–

REF

+

–

SPOF

REF

SPG

SP–

SPI

252624

C816

0.001

R821

56K

10K

R820

C815

R822

0.0047

6.8K

R823

39K

R819

C817

0.47/50

1.2K

FSS

VCC2

+

–

+

–

SPO

27

R824

R830

FEBAL

FOSTA

TOSTA

2FREQ

LASER

FSTA

8/12CM

SLOF

REF

TO

SLEO

28

10K

1K

CL

CE

CLK

DAT

DRF

CLK

CE

CL

DAT

LATCH

P-ON RES

REF

JP–

JP+

RF

CV–

CV+

SLOF

SLOF

OR

SLOF

+

–

+

–

REF

SLD

29 30

C819

47/10

1/50

C818

1.2K

R825

1K

R831

C833

0.001

C845

4.7/50

C821

1/50

R833

5.6K

R832

C850

0.1

R838

33K

C834

0.033

R836

47K

R837

47K

R834

C832

1K

27P

56K

R835

C831

470

HF

0.0027

C822

220P

D802

1SS133

C851

0.022

R849

100K

F

IC801

PIN

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

G

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

VOLTAGE

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

0V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.2V

2.2V

0V

VOLTAGE

NO.

0V

33

5V

34

5V

35

4.8V

36

0V

37

5V

38

0V

39

0V

40

1.5V

41

2.4V

42

2.5V

43

2.5V

44

0V

45

2.5V

46

2.5V

47

0V

48

0V

49

2.4V

50

4.1V

51

52

4.7V

0V

53

0V

54

5V

55

5V

56

2.5V

57

2.5V

58

0.9V

59

0.9V

60

2.1V

61

4.2V

62

0V

63

5V

64

H

IC802

PIN

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

VOLTAGE

0V

0V

1.5V

0V

2V

5V

0.3V

0V

2.5V

2.5V

0V

0V

0V

5V

0V

4.8V

5V

5V

0V

0V

2.5V

0V

5V

0V

0V

0V

0V

0V

0V

5V

2.5V

0V

VOLTAGE

NO.

0V

33

0V

34

5V

35

4.7V

36

2V

37

0V

38

39

0V

40

2V

41

4.7V

0V

5V

2.3V

2V

0V

0.1V

2.2V

0V

2.5V

0V

2.5V

0V

0V

0V

4.1V

4.1V

5V

0V

2.7V

2.4V

0V

0V

0V

P26 6 - F

FW852

TO DISPLAY

PWB

P22 4 - D

FW851

TO MAIN PWB

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

D-GND

PUIN

WRQ

SQOUT

DRF

RWC

COIN

CQCK

RES

CNP852

CNP851

12

5V

11

10

9

8

7

6

SL–

SL+

5

4

3

2

1

5

4

3

2

1

SERVO PWB-D

The numbers 1 to 12 are waveform numbers shown in page 27.

1

2

34 5

Figure 18 SCHEMATIC DIAGRAM (1/5)

CD SIGNAL

5V

DIGITAL GND

PU IN

WRQ

SQOUT

DRF

SL (–)

SL (+)

RWC

CO IN

CQCK

RES

DIGITAL GND

DIGTAL +7.4V

L-CH

AUDIO GND

R-CH

– 18 –

+B

6

Page 19

GX-CD30/30C/130/130C

+B

+B

IC802

LC78622E

SERVO/SIGNAL

CONTOL

R858

C841

680

0.047

C842

0.047

R857

27K

R856

1.2K

TR–

TR+

FO+

FO–

GND

PD

VR

LD

FO+

FO–

TR–

TR+

K

E

A

B

F

CNS801

PICKUP UNIT

CNS802

K

5

5

E

4

4

A

3

3

B

2

2

F

1

1

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

TR–

TR+

FO–

GND

VR

LD

1/16

LD

MON

K

E

A

B

F

C

1M

1M

LT0H30M1

2200P

2200P

FO+

PD

TR+

FO+

FO–

TR–

ACTUATOR

K

B

E

A

F

C847

0.01

DEFI

1

2

TA1

3

PDO

VVSS

4

5

ISET

VVDD

6

7

FR

VSS

8

EFMO

9

EFMIN

10

TEST2

11

CLV+

12

CLV–

13

V/P

14

HFL

15

TES

16

R860

1K

4M

16M

TST11

VCO CLOCK

OSC CONTROL

JP-

JP+

19

56 55

/RES

/CQCK

U-COM

INTERFACE

2K x 8BIT

RAM

ERROR

CORRECT

FLAG

CONTROL

SYNC-DETECT

EFM DEMODULATE

PCK

FSEQ

VDD

64

63 546253

61 60 5951585057

/CS

TEST5

TEST1

SLICE LEVEL

CONTROL

CLV

DIGITAL SERVO

SERVO

COMMAND

TOFF

TGL

COIN

CONT1

24222320 211817

RWC

SQOUT

EXTERNAL

OUTPUT

CONT2

25

WRQ

CONT3

R801

1K

C802

47/10

C801

0.01

+B

52

49

PW

FSX

SBCK

EFLG

SFSY

48

SBSY

CONT4

SUB-CODE

X-TAL

GENERATOR

4FS

DIGITAL

CONT5

EMPH

29 30272826

FILTER

C2F

31

DOUT

1BIT

DAC

DIGITAL

OUT

MUTER

MUTEL

XVSS

XOUT

XVDD

RVDD

RCHO

RVSS

LVSS

LCHO

LVDD

TEST4

32

XIN

NC

NC

TEST3

47

46

+B

+B

C890

100/10

R880

100

XL801

16.93MHz

C868

10/16

C867

10/16

45

44

43

42

41

40

39

38

37

36

35

34

33

R874

100

R873

100

R876

10K

R875

10K

BI802

5

4

3

2

1

1

2

3

4

5

6

7

8

BI801

C870

0.0022

C869

0.0022

DIGITAL GND

+B

AUDIO GND

L-CH

R-CH

C887

0.022

+B

L801

0.82µH

FOCUS/TRACKING/SPIN

3.5V

1

3.5V

2

2.5V

+B+B

C846

330/10

Q804

2SD468 C

+B

7.4V

R877

5.5V

220

R878

10/16

100

ZD801

MTZJ5.6B

+B

SERVO 7.4V

4.9V

REGULATOR

C889

CONSTANT

VOLTAGE

+B

3

2.5V

4

5

0V

6

0V

7

0V

0V

8

2.5V

9

2.5V

10

F+

3.8V

11

F–

3.2V

12

0V

13

14

6.7V

C843

100/10

SLIDE DRIVER

IC804

BA5920FP

+

–

+–

+

+

–+

–

+

+

–

C873

0.01

TR+

TR–

FO–

FO+

M701

C844

330/10

PU-IN

SP+

SP–

SL+

SL–

6

6

5

5

4

4

3

3

2

2

1

1

BI803

0V

28

+

3.5V

27

–

3.5V

26

2.5V

25

–

2.5V

24

2.5V

23

VCC

22

+

–

VCC

21

–

20

19

–

18

17

+

2.9V

16

2.9V

15

+B

7.4V

0V

7.4V

2.5V

2.7V

3.8V

3.2V

CNS803

6

5

4

3

2

1

CNP803

CD MOTOR

SPIN MOTOR

+

M

–

+

M

–

M702

SLIDE MOTOR

SW702

PICKUP IN

PWB-E

+B

NOTES ON SCHEMATIC DIAGRAM can be found on page 13.

78 9101112

Figure 19 SCHEMATIC DIAGRAM (2/5)

– 19 –

Page 20

GX-CD30/30C/130/130C

A

B

SW761

CD LID

C

D

E

OPEN/CLOSE

SWITCH PWB-A5

1

FW772

3

130/130C

ONLY

RX771

R779

30/30C

ONLY

LCD771

R776

C702

SW774

DOWN/ REVIEW

R714

C701

C705

3

2

1

R711

C704

R712

R733

R716

FW772

13

C740

R743

1

2

3

4

5

6

7

8

C741

D741

Q740

3

2

1

D740

R710

R708

R709

35

30

40

45

48

50

IC701

49

55

60

R731

R732

R722

R720

R719

R718

3233

R740

R721

164

5

R728

R723

R713

25

R724

10

R741

R726

R725

R742

DISPLAY PWB-A2

R715

3

R727

R735

FW603

1

12

X701

R734

R730

FW852

20

17

15

16

1

R729

FW603

TO MAIN PWB

CNP603

P25 10 - A

F

G

H

The numbers 1 to 12 are waveform numbers shown in page 27.

1

2

34 5

Figure 20 WIRING OF P.W.BOARD (1/4)

SW773

UP/CUE

SW772

STOP

R772

R774

R773

SW771

PLAY/REPEAT

SW775

PAUSE

– 20 –

R771

6

Page 21

M701

SPIN MOTOR

GX-CD30/30C/130/130C

-

CD MOTOR PWB-E

+

M702

SLIDE MOTOR

COLOR TABLE

BR

RD(R)

OR

YL

GR

BL

VL

GY

WH(W)

BK

PK

-

BROWN

RED

ORANGE

YELLOW

GREEN

BLUE

VIOLET

GRAY

WHITE

BLACK

PINK

SW702

PICKUP IN

CNP803

PICKUP UNIT

+

654321

CNS801

23456781

RDWHGYWHGYWHGY

WH

1 8

CNS803

7 12 10

Q805

C848

R823

C817

33

XL801

R842

R839

R840

32

35

Q804

C873

BI801

BCE

R829

C849

R819

C815

R820

R821

C816

R826

R827

C822

C830

R833

C832

R832

16

17

15

20

25

30

IC802

40

45

50

49

48

1

WH

2

GY

3

WH

4

GY

5

WH

6

BI803

15212228

R810

14

16

RD

IC804

18

178

R824

R825

C889

C844

R874

R878

R877

C818

C867

C868

CNP851

R830

C869

R875

C887

C890

BCE

L801

C843

12345

R822

C819

R831

C820

R880

6

5

4

C846

3

ZD801

R873

C870

R876

CD SERVO PWB-D

R812

C813

R813

R828

R814

C811

R815

C814

R816

C812

17

R817

20

25

32

30

35

33

40

45

48

R834

R837

R835

C831

R856

10

55

101112

5

60

CNP852

9

R857

C842

164

C841

R858

C847

R860

2345678

C807

16

15

IC801

50

C850

1

CNS802

R805

R806

C809

C806

R807

C808

R809

R811

R808

C810

10

5

60

55

49

R871

C804

C805

R804

R802

R803

C803

BI802

164

15

C801

R801

C802

C840

C845

R838

C835

C834

R836

C833

C851

C838

C839

C837

D802

C821

R849

RD

WH

GY

WH

GY

11

9

2

54321

FW851

TO MAIN PWB

P25 12 - B

112

FW852

78 9101112

Figure 21 WIRING OF P.W.BOARD (2/4)

– 21 –

Page 22

GX-CD30/30C/130/130C

W

B. P. F.

ROD

ANT.

A

B

C

D

CNW2

FM RF

C16

0.0047

FM TRACKING

TUNER PWB-B

F1

321

L1

C11

220P

C4

22P

(CH)

C9

0.0047

fHfL

FM FRONT END

RF AMP

1

3

2

1.6V

C2

0.001

TC1

R1

10

C15

0.022

LA1186N

MIX

VCC

5

0V

6.8V

VC1

IC1

OSC

9

6

R2

6.8V

6.8V

33

C5

33P

(CH)

L2

FM

OSC.

R9

22K

C10

0.022

R7

390

+B

C17

0.022

1.4V

7

48

0V

6.2V

C6

15P

(RH)

FM BAND

COVERAGE

FM IF

TC3

TC4

330K

C8

4P

(CH)

TC2

fHfL

T1

AM BAR ANT.

VC3

VC4

C14

0.022

L4

0.022

C39

1.6V

FM IF IN

1.6V

fL

fH

C36

0.022

R6

820K

AM

OSC

321

AM

TRACKING

C37

220/10

STB

CF2

C20

0.022

fH

fL

1.6V

1.6V

RF IN

21

6.1V

(6.4V)

AM

+B

AM MIX

3

(6.3V)

1.6V

AM BAND

COVERAGE

FM DET.

6V

AM IF

C21

0.022

T2

C26

22/16

T3

FM DET

AGC

4

+B

R30

VCO

1.9V

(1.6V)

1415161718192021222324

RCHAM/FM

2.5V

+B+B

C28

VCO

VCO

FW851

0.0015

13

121110

5.1V

(6.6V)

C35

1/50

1.2K

1.2V

(0V)

(1V)

0.8V

LA1805

IF MPX.

VR1

6.8K

R29

15K

MPX VCO

CK 7kKHz

IC2

FM/AM

R-CH

AUDIO GND.

L-CH

CD +7.4V

POW GND

MUTE

SYNC IN

R433

3.3K

+B

FW1

R456

10K

1

2

3

R455

10K

4

5

1

2

3

CNP603

1

2

3

4

5

6

R457

1K

H : MUTE

L : REC

R458

2.2K

R441

CD

FM AUTO

AM

TAPE

SW501-A

FUNCTION

3.3K

2.2K

R434

R442

FUNCTION

SW501-B

CD

FM AUTO

AM

TAPE

+B

+B

+B

1K

C38

0.0022

(0.4V)

AM OUT

GND

6

1.6V

CF3

R27

33K

1.5V

(1.5V)

AM

IN

7

0V

C33

1/50

2134

0.022

C24

470P

C25

C23

0.0082

3.3/50

1.7V

1.5V

(1.7V)

DET

MPX-IN

OUT

TUN

INDSTIND

8

0V

0V

C31

0.022

+B

C34

1/50

+B

FM+B

AM+B

L

R

TUN+B

6

5

TO CD SERVO PWB

CNP851

P18 3 - H

C27

3.3/50

1V

(1.3V)

FM-M/ST

LCH

9

2.5V

C32

0.022

(Ra)

R35

1.8K

TO DISPLAY PWB

FW603

P26 2 - H

C22

R26

3.9K

6.1V

0.4V

(6.4V)

AM IF

5

0.2V

(0.7V)

3

1

2

CNP1

R5

C29

10/16

VC2

R25

120

R3

47

L3

AM OSC.

E

F

G

H

TAPE2

PLAYBACK HEAD

L-CH

R-CH

TAPE1

RECORD/PLAYBACK

HEAD

L-CH

R-CH

ERASE HEAD

CNS201

1

2

3

CNS202

1

2

3

4

5

1

2

3

1

2

3

4

5

CNP201

CNP202

R201

1K (HND)

R202

1K

680P

680P

C201

C202

SW201-D

SW201-C

PRPR

C203

150P

C205

680P

C206

680P

C204

150P

R

P

R

SW201-F SW201-E

R220

27K

8.2K

R222

R231

10K

R205

150P

C211

150P

C213

R203

1K

(0V)

R204

1K

(0V)

P

R232

10K

IC201 : PLAYBACK AND

RECORD/PLAYBACK AMP.

C209

C207

330P

0V

0V

(0V)

24 23 22 21 20 19 18

123

0V

0V

(0V)

C210

C208

330P

330P

150P

C214

C212

150P

150

330P

C228

C217

0.018

C215

22/16

0.6V

0.6V

C216

22/16

C218

0.018

R206

150

470P

(0.6V)

(0.6V)

R219

27K

C219

1/50

C220

1/50

R208

R207

10K

F

CNP602

L

1

L : REC

RP

AUDIO GND

AUDIO +B

SYNC.

TAPE +B

+B

+B

+B

+B

VCC

GND

BC-A

R

2

3

L

4

R

5

6

7

8

9

10

11

R243

56K

8.2K

R221

470P

C227

R241

C239

2.2/50

3V

3V

C240

R351

C354

0.027

(ML)

(3V)

(3V)

47K

R230

R229

10K

2.2/50

10K

12K

C244

22/16

3.7V

IC201

LA7345K

10 12

11

3V

0V

(3V)

C242

0.082

680K

R238

BIAS

OSC.

Q351

R352

2SC2001 K

100K

(7.2V)

0V

0V

(1.1V)

R353

22

(3.7V)

13

(0V)

33/16

C243

0V

(0.4V)

L351

330µH

6V

0V

C356

47/10

C250

C249

100/10

100K

R264

R211

10K

6.8K

0.001

C229

C231

R223

0V

0V

T1 : 0.2V

T2 : 0.8V

(0V)

L:T1

(0V)

57

0V

0V

(0V)

T1 : 0.1V

T2 : 1.2V

R224

C232

C241

10/16

C351

560P

3V

4

3V

R214

R212

6.8K

R213

2.7K

(3V)

(3V)

2.7K

C230

0.001

47

R227

560

R225

17

896

R226

0.6V

(0.6V)

C233

22/16

0.6V

(0.6V)

C234

22/16

560

C237

0.0033

0.047

C235

16 15 14

C236

0.047

0.0033

C238

47

R228

C353

0.0039

0.001

6.8K

(0V)

6.8K

0.001

220/10

R354

47

R355

47

R250

100

SW201-A

P

+B

R254

D251

1SS133

SW201-B

R265

4.7K

R262

4.7K

D203

1SS133

R

R356

47

L : T1

D254

1SS133

3

2

1

22k

Q252

KRC102 M

NOTES ON SCHEMATIC DIAGRAM can be found on page 13.

1

2

34 5

Figure 22 SCHEMATIC DIAGRAM (3/5)

– 22 –

6

Page 23

MAIN PWB-A1

GX-CD30/30C/130/130C

D

AUTO

M

PE

SW501-A

FUNCTION

FUNCTION

SW501-B

D

UTO

AM

APE

P602

L

R

ND

L

R

+B

NC.

+B

CC

ND

10

C-A

(130/130C ONLY)

R561

2.7K

C509

0.027

TONE

VR532-A

50K (A)

TONE

VR532-B

50K (A)

C510

0.027

R562

2.7K

R461

68

FW602

1

2

3

4

5

6

7

8

9

11

1

2

3

4

5

6

7

8

9

10

11

AB

SW351

BEAT

CANCEL

C561

0.027

SW500-A

X-BASS

SW500-B

X-BASS

C562

0.027

+B

+B

+B

+B

+B

+B

R517

R518

C567

0.0027

VOLUME

C568

0.0027

D405

1SS133

CD

FM AUTO

AM

TAPE

CD: 7.3V

C565

0.1/50

R565

2.7K

R566

2.7K

C566

0.1/50

VR531-B

R579

10K

FUNCTION

SW501-C

C401

0.022

Q403

KRC102 M

312

0V

0V

VR531-A

20K (B)

20K (B)

VOLUME

+B

CD: 0V

7.7V

(8V)

ON

OFF

22K

22K

OFF

ON

+B

+B

+B

D406

1SS133

D575

1SS133

RIPPLE

FILTER

Q401

2SD468 C

7.3V

7.9V

C402

C406

330/16

R571

1K

R572

1K

KTC3199 GR

11.8V

R402

100/10

CD: 7.3V

MUTING

Q551

KTC3199 GR

0V

0V

R573

0V

R575

100K

C586

0.47/50

0V

0V

R574

0V

Q552

MUTING

R570

STAND-BY

C589

2.2/50

R401

4.7

560

VOLTAGE

REGULATOR

Q405

2SD2394 F

0V

C407

10/16

4.7K

4.7K

1K

Q554

KRA102 M

12V

0V

2

3

11.4V

2

7.9V

KRA102 M

220/25

1

11.4V

Q404

C569

1/50

C575

C570

C573

100/10

1/50

C404

1

C574

1SS133

0.01

7.9V

CD:4.2V

3

C571

0.001

100/10

D572

1SS133

D573

D574

1SS133

C588

100/25

POWER AMP.

IC501

LA4597

0V

2

1.2V

1

0V

4

1.2V

7

11.2V

3

0V

6

C572

5

0.001

11.3V

D501

1SS133

R576

1K

R403

270

D401

RD8.2JB1

R410

1.5

(1/2W)

R601

2.7

5.8V

10.3V

10.3V

5.8V

8

12V

C576

0.022

FUNCTION

SW501-D

CD

FM AUTO

AM

TAPE

+B

12

13

11

10

100/10

9

C579

0V

C580

100/10

C583

1000/10

C581

0.1

(ML)

R581

1

3.3

2

3

R582

4

3.3

C582

FW652

0.1

(ML)

C584

1000/10

+B

C57

4700

or 25V

BI651

+B

1

2

+B

+B

+B

CNS651

1

2

1

2

3

4

1

2

CNP652

CNP651

R577

120

R578

120

CNP552

SPEAKERS

0.01

0.01

0.01

0.01

RL104A

RL104A

RL104A

RL104A

D651-D658:

C651-C654:

D651

D652

C651

D653

D654

C654

31

FW651

31

FM SIGNAL

AM SIGNAL

PLAYBACK SIGNAL

RECORD SIGNAL

CD SIGNAL

J551

HEADPHONES

+

–

–

+

POWER TRANSFORMER

C652

C653

BATTERY 12V

[ “D” size (UM/SUM-1,

R20 or HP-2) battery x 8 ]

SP3

TWEETER

L-CH

SP1

WOOFER

SP2

WOOFER

R-CH

SP4

TWEETER

130C/30C

T651

AC SOCKET

AC 120V

60Hz

T.F

130/30

POWER PWB-A3

TERMINAL PWB-A4

SO651

+B

+B

–

TAPE

+

M

+B

+B

C393

0.022

MECHA GND

8

7

6

5

4

3

2

1

CNP204

8

7

6

5

4

3

2

1

CNS204

TAPE MECHANISM

M601

SW608

T1/T2

MUTE

SW605

MAIN

T1

SW606

MAIN

T2

78 9101112

Figure 23 SCHEMATIC DIAGRAM (4/5)

– 23 –

Page 24

GX-CD30/30C/130/130C

C34

123456

CNP1

T1

FM IF

C33

11 12

C32

C31

10

123

C26

R9

23

1

CF3AM IF

C15

C10

123

IC1

C20

89

7

6

5

4

3

2

1

C24

C22

C39

23456789

1

CF2

R5

R1

C16

T3

C21

R3

R25

C17

R7

C2

F1

A

B

C

TUNER PWB-B

C35

R29

R30

C38

C11C36

TC2TC1

VC3 VC4

L3

AM BAR ANTENNA

R35

VR1

ROD ANNTENA (236)

COLOR TABLE

BR

L4

(233)

TC4TC3

CNW2

RD(R)

OR

YL

GR

BL

VL

GY

WH(W)

BK

PK

BROWN

RED

ORANGE

YELLOW

GREEN

BLUE

VIOLET

GRAY

WHITE

BLACK

PINK

C27

C28

IC2

13

C25

14

15

R27

16

17

18

C23

19

20

21

T2

22

R26

23

24

R6

FM DET

C29

C37

C14

C5

R2

C9

L1

L2

C6

C8

C4

VC1 VC2

BK

D

T651

POWER TRANSFORMER

D653

C653

E

T.F

D654

F

13

FW651

BATTERT

SPRING

(249)

G

BATTERY DC 12V

["D" size (UM/SUM-1,R20 or

HP-2) battery X 8]

C652

C654

D651

12

CNP651

D652

C651

SO651

AC INPUT

AC 120V 60Hz

4321

CNP652

3

FW651

1

R577

J551

J551

HEADPHONES

R578

POWER PWB-A3

L-CH R-CH

CNP552

SPEAKERS

BATTERT

TERMINAL PWB-A4

SPRING

(204)

H

1

2

34 5

6

Figure 24 WIRING OF P.W.BOARD (3/4)

– 24 –

Page 25

GX-CD30/30C/130/130C

CNS651

FW652

FW1

VR531 VR532

VOLUME

MAXMIN

C567

R571

R572

C576

C570C569

C571

1

2

R565

A

B

C568

R566

C579

IC501

13

12

11

10

C580

9

8

7

6

C575

5

4

3

2

1

C573

R574

R575

C572

R582

C582

C581

C565

C566

C574

D501

ECB

Q552

ECB

R573

R581

D572

D573

R576

R570

Q405

C586

SW500

X-BASS

R561

R562

D575

C577

P20 6 - D

TO DISP PWB

TO DISP PWB

FW603

ONOFF

A

B

R579

123

CNP603

C584

BI651

12

SW351

BEAT CANCEL

11

FW602

R601

C583

FW652

4

SW501

R455

FUNCTION

AM FM AUTO

CDTAPE

ONOFF

POWER

1

6

R461

C401

Q401

D405

D406

CFW1

D

C

P21 9 - G

CNP851

TO CD SERVO

PWB

ECB

A

B

R458

1

R457

R441

1

R433

R434

R456

Q403

C404

Q404

123

C402

123

R402

AB

R442

5

FW851

R401

D401

1

R403

[130/130C ONLY]

TONE

HIGHLOW

R518

130/130C

ONLY

B

Q554

C407

C510

123

C509

130/130C ONLY

C561

C562

130/130C

ONLY

C588

C589

R410

R517

A

D574

C406

ECB

Q551

MAIN PWB-A1

RD

GY

FW602

RECORD/PLAYBACK

SW606

TAPE2

MAIN

(47)

HEAD

SW605

TAPE1

MAIN

BKWHPK

TAPE1

SW607

TAPE1/ 2

SELECTOR

TAPE2

PLAYBACK HEAD

(47)

WHPK

ERASE HEAD

(13)

BK

WH

BRGY

TAPE MOTOR

GY

BK

SW601

DECK PWB-C

C230

R208

R214

C231

R227

L351

C239

D203

R223

C235

IC201

C354

C241

C233

R225

R220

C236

R228

R222

C232

R224

C234

10 11

15

181920212223

16

17

C244

C237

R221

R219

C227

R230

C228

C238

R226

C242

C240

12

R264

13

C249

14

C250

R241

CNP204

R243

R250

R238

C243

R232

D251

11

10

9

8

7

CNP602

6

5

4

3

2

1

R265

C393

12345678

C218

R206

R212C210

C220

C216

R204

C212

C208

C356

3

2

1

R211

CNP201

C207

R229

R352

C209

Q351

C215

C202

C211

C219

R207

C229

B

C

E

C214

123456789

C213

24

R213

R262

R353

CNS201

PK

3

BK

2

WH

1

CNS202

PK

5

BK

4

WH

3

BK

2

WH

1

+-

CNS601

GY

8

VL

7

BL

6

GR

5

YL

4

OR

3

RD

2

BR

1

D254

Q252

R356

5

4

3

2

CNP202

1

C351

C204

R254

3

2

1

R355

C203

C353

F

E

D

C

B

A

R354

REC.

R351

P.B.

C206

C205

R205

SW201

R202

C201

R201

R203

C217

R231

78 9101112

Figure 25 WIRING OF P.W.BOARD (4/4)

– 25 –

Page 26

GX-CD30/30C/130/130C

DISPLAY PWB-A2

R771

A

LCD771

4

8

B

567

C

SEG13

SEG12

SEG11

SEG10

SEG9

SEG8

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

P00

P01

P02

SEG14

POWER-IN

MTCONT2

P03

P10

R735

49

50

51

TR1 LED

TR2 LED

MTCONT1

52

53

54

55

56

57

58

59

60

61

62

63

64

D

E

F

G

3.9K

R772

2.7K

R773

1.8K

R774

1.5K

123

10K

R776

+B

0.022

C702

C701

0.022

AIN7

VLC1

VLC2

COM0

COM1

SEG15

SEG16

IX0105AW

SYSTEM

MICROCOMPUTER

STB (VOL)

POWER-ON

CK (VOL)

DATA (VOL)

P11

P12

P13D0D1

4321

5

VLC3

COM2

COM3

LIDSW

REMCON

IC701

MUTE

RES

SYNC-OUT

CQCK

RWC

COIN

D2D3D4D5D6D7D8D9D10

10 11 12 13 14 15 16

9876

R720

R719

R718

R722

1K

R716

10K

MUTE

SYNC. IN

12

3

R710

10K

R711

2.7K

343536373839404142434445464748

AIN6

AIN5

SYNC-IN

TORAY2

TORAY1

SIMUKE

SQOUT

SL–

SL+

R718~

R725: 15K

R723

R725

SW774

DOWN/

REVIEW

SW773

UP/CUE

SW775

PAUSE

SW771

PLAY/

REPEAT

SW772

STOP

R709

1K

K1

K2

POWER

33

P33

P40

P32

P31

INT2 P30

VREF

AVSS

XCIN

XCOUT

VDD

VSS

XOUT

XIN

RESET

P23

PU-IN

P22

WRQ

P21

DRF

P20

SRS2

SRS1

R726 1K

R728 1K

R729 1K

R731 1K

R732 1K

R733 1K

R708

1K

R712

1K

32

31

30

29

28

27

26

25

24

23

R713

22

1K

21

20

19

18

17

R734

1K R730

R724

R721

REMOTE

SENSOR

12

R779

47

R714

10K

C704

100/10

C705

0.022

X701

4.19MHz

R727

1K

1K

+B

R741

3.3K

D740

1SS133

KRC102 M

2

R740

4.7K

RX771

3

+B

R715

15K

Q740

3

1

D741

1SS133

130/130C

ONLY

R742

1K

C741

3.3/50

R743

100K

+B

SL (–)

SL (+)

+B

C740

+B

0.01

SWITCH

PWB-A5

FW772

1

3

12

11

10

1

3

OPEN/CLOSE

PIN

VOLTAGE

NO.

0V

1

0V

2

0V

3

4

0V

5

0V

6

0V

7

3.9V

8

0V

9

5V

10

4.1V

11

4.1V

12

0V

0V

13

0V

14

0.4V

15

0.4V

16

0V

17

0V

18

0V

19

0V

20

5V

21

2.5V

22

2.5V

23

0V

24

5V

25

5V

26

0V

27

0V