Sharp GXCD-130, GXCD-130-C, GXCD-30, GXCD-30-C Service manual

GX-CD30/30C/130/130C

SERVICE MANUAL

No. S3607GX-CD130

Illustration: GX-CD130

GX-CD30 GX-CD30C GX-CD130 GX-CD130C

• In the interests of user-safety the set should be restored to its original condition and only parts identical to those specified should be used.

CONTENTS |

|

|

Page |

IMPORTANT SERVICE NOTES (FOR GX-CD30/130 ONLY) .......................................................................................... |

2 |

SPECIFICATIONS ............................................................................................................................................................. |

2 |

NAMES OF PARTS ........................................................................................................................................................... |

3 |

DISASSEMBLY .................................................................................................................................................................. |

4 |

REMOVING AND REINSTALLING THE MAIN PARTS ..................................................................................................... |

6 |

ADJUSTMENT ................................................................................................................................................................... |

8 |

TROUBLESHOOTING (CD SECTION) ........................................................................................................................... |

10 |

NOTES ON SCHEMATIC DIAGRAM .............................................................................................................................. |

13 |

TYPES OF TRANSISTOR ............................................................................................................................................... |

13 |

BLOCK DIAGRAM ........................................................................................................................................................... |

14 |

SCHEMATIC DIAGRAM / WIRING SIDE OF P.W.BOARD ............................................................................................. |

18 |

WAVEFORMS OF CD CIRCUIT ...................................................................................................................................... |

27 |

FUNCTION TABLE OF IC ................................................................................................................................................ |

28 |

PARTS GUIDE/EXPLODED VIEW |

|

PACKING OF THE SET (FOR GX-CD30/130 ONLY) |

|

DIFFERENCE BETWEEN GX-CD30/30C AND GX-CD130/130C

|

GX-CD30/30C |

GX-CD130/130C |

|

|

|

REMOTE |

None |

Used |

CONTROL |

|

|

|

|

|

X-BASS |

None |

Used |

|

|

|

SHARP CORPORATION

SHARP ELECTRONICS CORPORATION

Service Headquarters: |

Sharp Plaza, |

Mahwah, New Jersey 07430-2135 |

GX-CD30/30C/130/130C

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER TO THE OPERATION MANUAL.

IMPORTANT SERVICE NOTES (FOR GX-CD30/130 ONLY)

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the user, perform the following safety checks.

1.Inspect all lead dress to make certain that leads are not pinched or that hardware is not lodged between the chassis and other metal parts in the audio product.

2.Inspect all protective devices such as insulating materials, cabinet, terminal board, adjustment and compartment covers or shields, mechanical insulators etc.

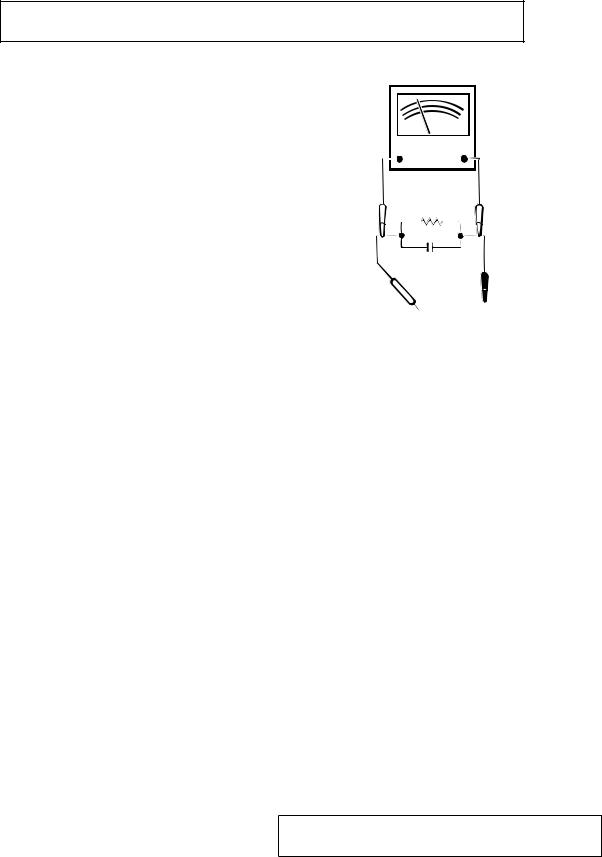

3.To be sure that no shock hazard exists, check for leakage current in the following manner.

*Plug the AC line cord directly into a 120 volt AC outlet.

*Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15μF capacitor in series with all exposed metal cabinet parts and a known earth ground, such as conduit or electrical ground connected to earth ground.

*Use a VTVM or VOM with 1000 ohm per volt, or higher, sensitivity to measure the AC voltage drop across the resistor (See diagram).

*Connect the resistor connection to all exposed metal parts having a return path to the chassis (antenna, metal cabinet, screw heads, knobs and control shafts, escutcheon, etc.) and measure the AC voltage drop across the resistor.

VTVM

AC SCALE

AC SCALE

1.5k ohms

10W

0.15 µ F

TO EXPOSED

TEST PROBE  CONNECT TO

CONNECT TO

METAL PARTS

KNOWN EARTH

GROUND

All check must be repeated with the AC line cord plug connection reversed.

Any reading of 0.3 volt RMS (this corresponds to 0.2 milliamp. AC.) or more is excessive and indicates a potential shock hazard which must be corrected before returning the audio product to the owner.

SPECIFICATIONS

● General |

|

● Compact disc player |

|

Power source: |

AC 120V, 60 Hz |

Disc: |

Compact disc |

|

DC 12 V [ "D" size (UM/SUM-1, R20 |

Signal readout: |

Non-contact, 3-beam semi- |

|

or HP-2) battery x 8] |

|

conductor laser pickup |

Power consumption: |

25 W |

Audio channels: |

2 |

Output power: |

FTC; 2.5 W minimum RMS per |

Quantization: |

16-bit linear |

(30/130) |

channel into 6 ohms from 100 Hz to |

Filter: |

4-tims oversampling digital filter |

|

20 kHz with no more than 10 % total |

D/A converter: |

1-bit D/A converter |

|

harmonic distortion. |

Wow and flutter: |

Unmeasurable |

|

RMS; 3.5 W per channel at 1 kHz, |

|

(less than 0.001% W. peak) |

|

10 % total harmonic distortion. |

● Speaker |

|

|

(AC operation) |

|

|

Output power: |

RMS; 7 W (3.5 W + 3.5 W) |

Type: |

2-way bass-reflex type |

(30C/130C) |

(AC operation, 10 % T.H.D.) |

Speakers: |

4" (10 cm) woofer x 2 |

Output terminal: |

Headphones; 16 - 50 ohms |

|

Tweeter x 2 |

|

(recommended; 32 ohms) |

Maximum input power: |

5 W |

Dimensions: |

Width; 12" (304 mm) |

Impedance: |

6 ohms |

|

Height; 9-1/4" (234 mm) |

Dimensions: |

Width; 7-5/16" (185 mm) |

|

Depth; 8-9/16" (216 mm) |

|

Height; 8-11/16" (220 mm) |

Weight: |

7.1 Ibs. (3.2 kg) without batteries |

|

Depth; 5-15/16" (150 mm) |

● Radio |

|

Weight: |

2.2 Ibs. (1.0 kg) /each |

|

|

|

|

Frequency range: |

FM; 87.6 - 108 MHz |

● Tape recorder |

AM; 530 - 1,702 kHz |

|

|

Frequency response: |

50 - 14,000 Hz (Normal tape) |

Signal/noise ratio: |

50 dB (TAPE 1, recording / playback) |

|

55 dB (TAPE 2, playback) |

Wow and flitter: |

0.25 % (WRMS) |

Motor: |

DC 12 V electric governor |

Bias system: |

AC bias |

Erase system: |

AC erase |

Specifications for this model are subject to change without prior notice.

– 2 –

GX-CD30/30C/130/130C

|

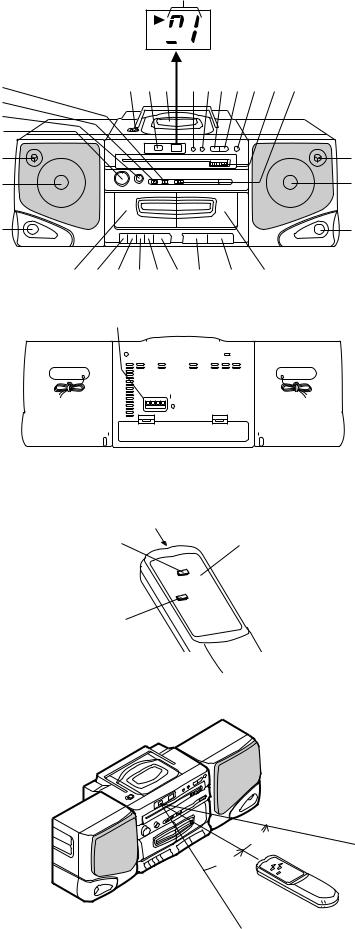

NAMES OF PARTS |

H Main Unit |

3 |

1.CD Play Indicator: 0

2.CD Repeat Indicator: R

3.CD Track Number Indicator

4.CD Eject Button: 7

5.Remote Control Sensor (GX-CD130/130C ONLY)

6. |

CD compartment |

14 |

7. |

(CD) Track Down/Review Button: 5 / 3 |

15 |

8. |

(CD) Track Up/Cue Button: 4 / 2 |

16 |

9. |

(CD) Stop Button: H |

17 |

10. |

(CD) Play/Repeat Button: 0R |

18 |

11. |

(CD) Pause Button: 6 |

|

12. |

Tuning Control |

19 |

13. |

Power/Function/Band Selector Switch |

14.Beat Cancel Switch

15.X-Bass Switch (GX-CD130/130C ONLY)

16. Tone Control |

20 |

17.Volume Control

18.Tweeter

19.Woofer

20.Bass Reflex Port

21.(TAPE1) Cassette Compartment

22.(TAPE1) Record Button: I

23.(TAPE1) Play Button: 0

24.(TAPE1) Rewind Button: 3

25.(TAPE1) Fast Forward Button: 2

26.(TAPE1) Stop Eject Button: H / 7

27.(TAPE2) Play Button: 0

28.(TAPE2) Stop Eject Button: H / 7

29.(TAPE2) Cassette Compartment

30.Speaker Terminals

31.FM Telescopic Rod Aerial

32.Speaker Wire

33.Speaker Release Lever

34.Battery Compartment

35.Headphones Socket

36.AC Power Input Socket

1

2

4 |

5 |

6 |

7 8 9 10 11 12 13 |

18

19

20

21 |

22 23 24 25 26 27 |

28 |

29 |

|

|||||||||||||||||||||||||||

32 |

30 |

|

|

|

31 |

|

|

|

|

|

|

|

|

|

|

32 |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

33 |

34 |

35 36 |

33 |

1

2 |

5 |

H Remote Control (GX-CD130/130C ONLY) |

|

1.Remote Control Transmitter LED

2.(CD) Play/Repeat Button: 0R

3.(CD) Track Down /Review Button: 5 / 3

4.(CD) Pause Button: 6

5.(CD) Track Up/Cue Button: 4 / 2

6.(CD) Stop Button:H

3

6 4

6 4

Notes concerning use:

∙Periodically clean the transmitter LED on the remote control and the sensor on the main unit with a soft cloth.

∙Exposing the sensor on the main unit to strong light may interfere with operation. Change the lighting or the direction of the unit.

∙Keep the remote control away from moisture, excessive heat, shock, and vibrations.

8" - 20' (0.2 - 6 m)

25˚

25˚

25˚

25˚

– 3 –

GX-CD30/30C/130/130C

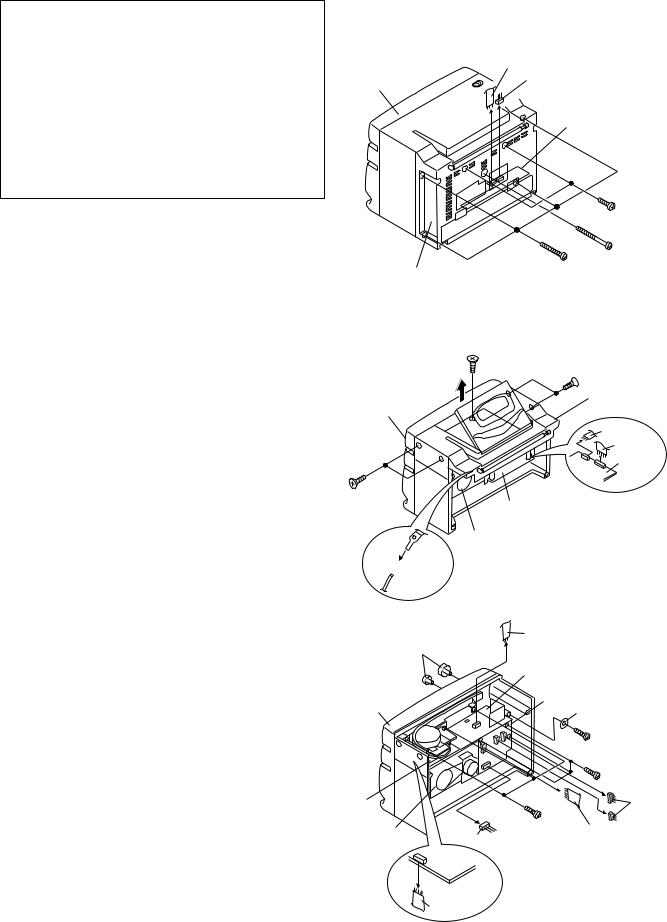

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling the unit and reassembling it, to keep it safe and ensure excellent performance:

1.Take cassette tape and compact disc out of the unit.

2.Be sure to remove the power supply plug from the wall outlet before starting to disassemble the unit.

3.Take off nylon bands or wire holders where they need be removed when disassembling the unit. After servicing the unit, be sure to rearrange the leads where they were before disassembling.

4.Take suffcient care on static electricity of integrated circuits and other circuits when servicing.

STEP |

REMOVAL |

|

PROCEDURE |

FIGURE |

|

|

|

|

|

|

|

UNIT |

|

|

|

|

|

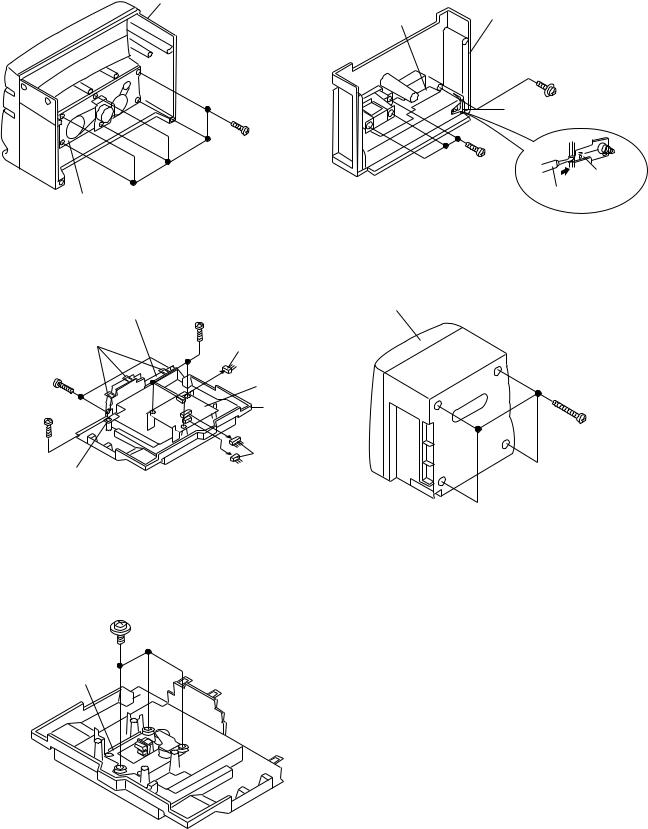

1 |

Front Cabinet |

1. |

Screw .................... |

(A1) x7 |

4-1 |

|

|

2. |

Socket ................... |

(A2) x1 |

|

|

|

3. |

Flat Cable ............. |

(A3) x1 |

|

|

|

|

|

|

|

2 |

Top Cabinet |

1. |

Open the CD lid. |

|

|

|

(with CD Block) |

2. |

Screw .................... |

(B1) x5 |

4-2 |

|

|

3. |

Flat Cable ............. |

(B2) x2 |

4-2, 4-3 |

|

|

4. |

Tip ......................... |

(B3) x1 |

4-2 |

|

|

|

|

|

|

3 |

Tuner PWB |

1. |

Screw ................... |

(C1) x3 |

4-3 |

|

(with Tuner Frame) |

2. |

Flat Cable ............. |

(C2) x1 |

|

|

|

|

|

|

|

4 |

Main PWB |

1. |

Screw ................... |

(D1) x1 |

4-3 |

|

|

2. |

Knob .................... |

(D2) x2 |

|

|

|

3. |

Flat Cable ............. |

(D3) x1 |

|

|

|

|

|

|

|

5 |

Deck PWB |

1. |

Screw .................... |

(E1) x3 |

4-3 |

|

|

2. |

Socket ................... |

(E2) x3 |

|

|

|

|

|

|

|

6 |

Tape Mechanism |

1. |

Open the cassette holder. |

|

|

|

|

2. |

Screw .................... |

(F1) x6 |

5-1 |

|

|

|

|

|

|

7 |

Display PWB |

1. |

Screw ................... |

(G1) x2 |

5-2 |

|

(with CD control |

2. |

Hook .................... |

(G2) x3 |

|

|

Button) |

3. |

Flat Cable ............ |

(G3) x1 |

4-2 |

|

|

|

|

|

|

8 |

Switch PWB |

1. |

Screw ................... |

(H1) x1 |

5-2 |

|

|

|

|

|

|

9 |

CD Servo PWB |

1. |

Screw .................... |

(J1) x3 |

5-2 |

|

|

2. |

Socket ................... |

(J2) x3 |

|

|

|

|

|

|

|

10 |

CD Mechanism |

1. |

Screw .................... |

(K1) x3 |

5-3 |

|

|

|

|

|

|

11 |

Power PWB/ |

1. |

Open the battery lid. |

|

|

|

Terminal PWB |

2. |

Screw .................... |

(L1) x4 |

5-4 |

|

|

3. |

Hook ..................... |

(L2) x1 |

|

|

|

|

|

|

|

SPEAKER |

|

|

|

|

|

|

|

|

|

|

|

1 |

Front Panel |

1. Screw ................... |

(A1) x4 |

5-5 |

|

|

|

|

|

|

|

Front |

( A3 ) x1 |

|

( A2 ) x1 |

||

Cabinet |

||

|

Power PWB

|

|

( A1 ) x2 |

|

|

ø3 x12mm |

|

|

( A1 ) x1 |

|

|

ø3 x65mm |

Rear |

|

( A1 ) x4 |

|

ø3 x20mm |

|

Cabinet |

|

|

|

|

|

|

Figure 4-1 |

|

|

( B1 ) x1 |

|

|

ø3 x8mm |

( B1 ) x2 |

|

|

|

OPEN |

|

ø3 x10mm |

Front |

|

Top Cabinet |

Cabinet |

|

|

|

|

( B2 ) x1 |

|

|

( G3 ) x1 |

|

|

CD Servo |

|

|

PWB |

( B1 ) x2 |

CD Servo PWB |

|

ø3 x10mm |

||

Tape

Mechanism

( B3 ) x1

( B3 ) x1

|

Figure 4-2 |

|

|

|

( B2 ) x1 |

|

|

( D2 ) x2 |

|

|

|

|

Main PWB |

|

|

Front |

Deck |

|

|

Cabinet |

PWB Washer |

||

|

|

( D1 ) x1 |

|

|

|

ø3 x10mm |

|

|

|

( E1 ) x3 |

|

|

|

ø3 x10mm |

|

Tuner |

|

( E2 ) x2 |

|

PWB |

|

||

|

|

||

Tape |

( C1 ) x3 |

( D3 ) x1 |

|

( E2 ) x1 ø3 x10mm |

|||

Mechanism |

|

||

Tuner PWB

Tuner PWB

( C2 ) x1

Figure 4-3

– 4 –

GX-CD30/30C/130/130C

Front Cabinet |

|

Rear Cabinet |

|

|

|

Power PWB |

|

|

|

|

|

|

|

|

( L1 ) x1 |

|

|

|

ø3 x10mm |

|

( F1 ) x6 |

|

Terminal |

|

ø3 x10mm |

|

|

|

|

|

|

|

|

( |

( L2 ) x1 |

|

|

ø3 |

|

|

|

Push |

|

Tape |

|

|

Driver |

|

|

|

|

Mechanism |

|

|

|

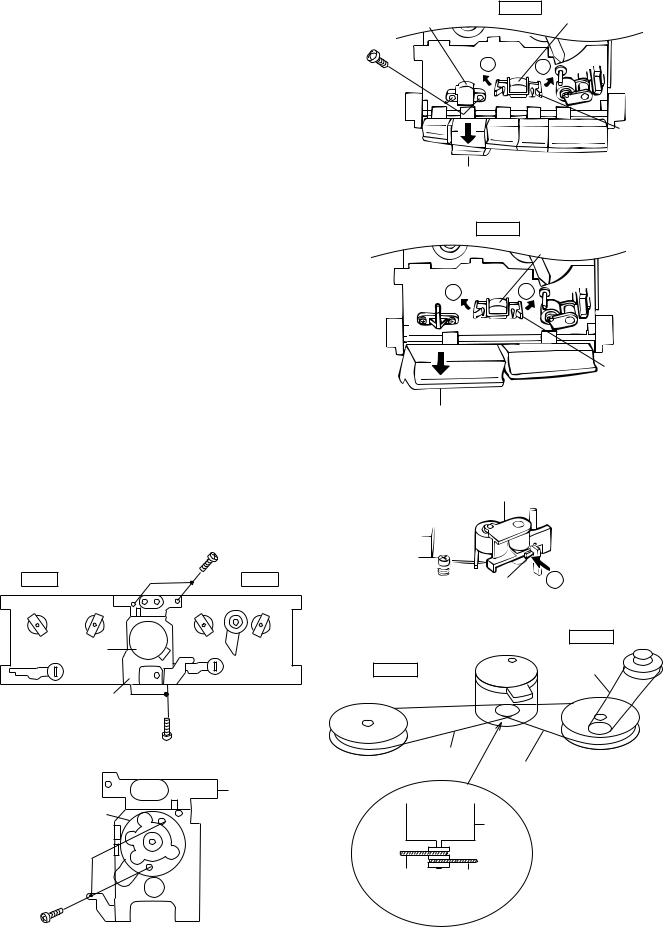

Figure 5-1 |

|

|

Figure 5-4 |

Display |

( J1 ) x3 |

Front Panel |

|

PWB |

ø3 x10mm |

|

|

( G2 ) x3 |

( J2 ) x1 |

|

|

|

|

|

|

( G1 ) x2 |

CD Servo |

|

|

ø3 x10mm |

PWB |

|

|

|

Top Cabinet |

|

|

( H1 ) x1 |

|

|

( A1 ) x4 |

ø3 x12mm |

|

|

|

|

( J2 ) x2 |

|

ø3 x20mm |

Switch |

|

|

|

PWB |

|

|

|

Figure 5-2 |

|

|

Figure 5-5 |

( K1 ) x3 ø2.6 x10mm

CD Mechanism

Figure 5-3

– 5 –

GX-CD30/30C/130/130C

REMOVING AND REINSTALLING THE MAIN PARTS

TAPE MECHANISM SECTION

Perform steps 1, 2, 3, 4, 5 and 6 of the disassembly method to remove the tape mechanism.

How to remove the record/playback and erase heads (TAPE 1) (See Fig. 6-1.)

1.Carefully bend the record/playback head pawls (A1) x 2 pcs., in the direction of the arrow Â, and remove the record/ playback head upwards.

2.Remove the screws (B1) x 2 pcs., to remove the erase head.

How to remove the playback head (TAPE 2) (See Fig. 6-2.)

1.Carefully bend the playback head pawls (C1) x 2 pcs., in the direction of the arrow È, and remove the playback head upwards.

How to remove the pinch roller (TAPE 1/2) (See Fig. 6-3.)

1.Carefully bend the pinch roller pawl in the direction of the arrow Ê, and remove the pinch roller (D1) upwards.

How to remove the belt (TAPE 1) (See Fig. 6-4.)

1.Remove the main belt (E1) x 1 pc., from the motor side.

2.Remove the FF/REW belt (E2) x 1 pc.

How to remove the belt (TAPE 2) (See Fig. 6-4.)

1.Remove the tape 2 main belt (E1) x 1pc., from the motor side.

2.Remove the tape 1 main belt (F1) x 1pc., from the motor side.

How to remove the motor (See Figs. 6-5 and 6-6.)

1.Remove the belt.

2.Remove the screws (G1) x 4 pcs., to remove the motor fixture.

3.Remove the screws (G2) x 2 pcs., to remove the motor.

Note:

When mounting the motor, pay attention to the motor mounting

angle.

( G1 ) x2 ø2 x4mm

TAPE2 |

TAPE1 |

Erase Head |

TAPE 1 |

Record/Playback |

|

||

|

Head |

|

|

|

|

A |

A |

|

( B1 ) x2 |

|

|

ø2 x7mm |

|

|

|

|

Pawl |

|

|

(A1)x2 |

Play Button |

|

|

Figure 6-1 |

|

|

TAPE 2 |

|

|

|

Playback Head |

|

B |

B |

|

Pawl (C1)x2

Play Button

Figure 6-2

Pinch Roller (D1) x 1

Pawl C

|

|

|

|

|

Figure 6-3 |

|

|

|

|

|

TAPE 1 |

|

Motor |

|

|

|

Motor |

|

|

|

|

|

FF/REW Belt |

|

|

TAPE 2 |

|

|

(E2)x1 |

|

Motor |

|

|

|

|

|

Bracket |

|

|

|

|

|

|

( G1 ) x2 |

|

|

|

|

|

ø2 x4mm |

|

|

|

|

Figure 6-5 |

Flywheel |

Main Belt |

Flywheel |

|

|

(F1)x1 |

||||

|

|

Main Belt |

|||

|

|

|

|||

|

|

Motor |

|

|

(E1)x1 |

|

|

Bracket |

|

|

|

|

Motor |

|

|

|

|

|

|

|

|

|

Motor |

( G1 ) x2 |

|

TAPE2 |

|

TAPE1 |

|

|

Main Belt |

Main Belt |

|||

ø2.6 x2mm |

|

(F1)x1 |

|

(E1)x1 |

|

|

Figure 6-6 |

|

|

|

Figure 6-4 |

– 6 –

|

GX-CD30/30C/130/130C |

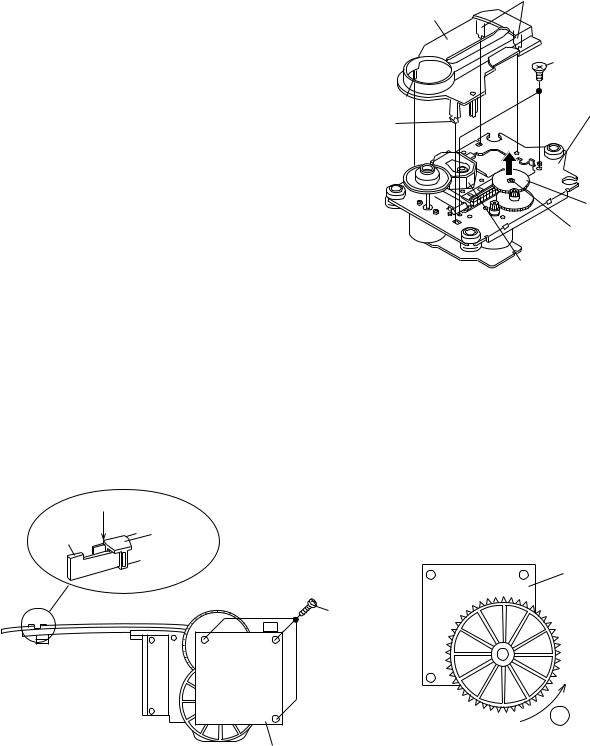

CD MECHANISM SECTION |

|

Perform steps 1, 2, 9 and 10 of the disassembly method to |

|

remove the CD mechanism. |

( F1 ) x2 |

How to remove the pickup (See Fig. 7-1.) |

CD Cover |

|

1.Remove the hooks (F1) x 4 pcs., to remove the CD cover.

2.Remove the screws (F2) x 2 pcs., to remove the shaft (F3) x1 pc.

3.Remove the stop washer (F4) x1 pc., to remove the gear (F5) x 1 pc.

4.Remove the pickup.

( F2 ) x2 ø2.6 x6mm

CD Mechanism

( F1 ) x2

Shaft

Shaft

( F3 ) x1

Gear

( F5 ) x1

Stop Washer ( F4 ) x1

Pickup

Figure 7-1

FITTING OF DIAL POINTER

1.Remove the three screws, and remove the tuner PWB from the tuner frame. (See Fig. 7-2)

2.Turn fully the dial wheel in the  direction. (See Fig. 7-3)

3.Set the dial pointer as shown in Figure 7-2, and mount the tuner PWB.

|

"0" Point |

|

Tuner |

Dial |

|

Frame |

||

Pointer |

||

|

( 229 ) |

Screw x3 |

Tuner PWB (Bottom view)

A

Tuner PWB

(Top view)

Figure 7-2 |

Figure 7-3 |

– 7 –

GX-CD30/30C/130/130C

ADJUSTMENT

MECHANISM SECTION

• Driving Force Check

Torque Meter |

Specified Value |

|

|

PLAY: TW-2412 |

Tape 1: Over 50 g |

|

Tape 2: Over 100 g |

|

|

• Torque Check

Torque Meter |

|

Specified Value |

||

|

|

|

|

|

|

Tape 1 |

Tape 2 |

||

|

|

|||

|

|

|

|

|

Play: TW-2111 |

30 to 60 g.cm |

30 to 60 g.cm |

||

|

|

|

|

|

Fast Forward: TW-2231 |

|

|

|

80 to 135 g.cm |

|

|

|

||

|

|

|

|

|

Rewind: TW-2231 |

|

|

|

80 to 135 g.cm |

|

|

|

||

|

|

|

|

|

• Tape Speed |

|

|

|

|

|

Test Tape |

Specified |

Instrument |

|

|

Value |

Connection |

|

|

|

|

Nomal |

MTT-111 |

3,000 |

Speaker |

speed |

|

± 30 Hz |

terminal |

|

|

|

(Load resistance: |

|

|

|

6 ohms) |

|

|

|

|

TAPE SECTION

Position of each switch or control |

|||||

|

|

|

|

|

|

Volume control |

|

Max |

|||

Beat cancel |

|

|

A |

||

Function/Power switch |

|

Tape/Off |

|||

|

|

|

|

|

|

• Bias Oscillation Check |

|||||

|

|

|

|

Specified Value |

|

|

|

|

|

|

|

Beat cancel |

|

|

A: 82 + 10 kHz / -6 kHz |

||

|

|

|

B: -2 ± 2 kHz |

||

|

|

|

C: +3 ± 2 kHz |

||

|

|

|

|

|

|

• Erase Current Check |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Specified Value |

|

|

|

|

|

|

Resistor for measurement: 1 ohm |

|

|

50 ± 25 mV |

||

|

|

|

|

||

• Playback Amplifier Sensitivity Check |

|||||

|

|

|

|

||

Test Tape |

Specified Value |

|

Instrument Connection |

||

|

|

|

|

||

MTT-118 |

1.8 V ± 3 dB |

|

Speaker Terminal |

||

|

|

|

|

(Load resistance: 6 ohms) |

|

|

|

|

|

|

|

TUNER SECTION

fL: Low-range frequency fH: High-range frequency

• FM IF/RF

Test Stage |

Specified |

Instrument |

|

|

Value/Adjusting |

Connection |

|

|

Point |

|

|

IF |

T1 |

Input: Pin 1 of IC1 |

|

|

|

Output: Pin 17 of IC2 |

|

Detection |

T2 |

||

|

|||

|

|

|

|

Band Coverage |

fL: L2 |

Iuput: Antenna |

|

|

fH: TC2 |

Output: Headphones |

|

|

|

Socket (Load |

|

Tracking |

88.0 MHz: L1 |

||

resistance: 32 ohms) |

|||

|

108.0 MHz: TC1 |

||

|

|

||

|

|

|

• AM IF/RF

Test Stage |

Specified |

Instrument |

|

Value/Adjusting |

Connection |

|

Point |

|

IF |

T3 |

Input: Antenna |

|

|

Output: Pin 19 of IC2 |

|

|

|

Band Coverage |

fL: L4 |

Input: Antenna |

|

fH: TC4 |

Output: Headphones |

Tracking |

600 kHz: L3 |

Socket (Load |

|

1,400 kHz: TC3 |

resistance: 32 ohms) |

|

|

|

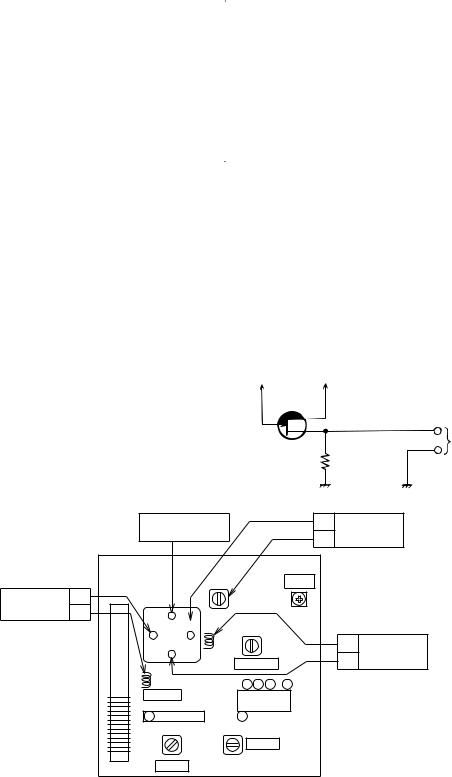

• VCO Frequency |

|

|

Adjusting Point |

Specified |

Instrument |

|

Value |

Connection |

|

|

|

VR1 |

76 kHz ± 200 Hz |

Pin 13, pin 21 and |

|

|

ground of IC2 |

|

|

|

Note:

After preparing the test circuit shown in Fig. 8-1, connect the Pin 13, Pin 21 and ground of the IC2 with the test circuit, and measure the value. At this time, apply a standard unmodulated signal input and adjust the VCO.

Pin 13 of IC2 Pin 21 of IC2

FET : 2SK19 or 2SK54

G  D

D

S |

TO FREQUENCY |

|

COUNTER |

|

10 kohm |

FM fH

TRACKING fL

L3 BARANTENNA |

|

TRACKING fL |

|

AM |

AM |

Figure 8-1 VCO FREQUENCY TEST CIRCUIT

AM TRACKING |

|

fH AM BAND |

|||

fH |

|

|

|

fL |

COVERAGE |

|

|

|

|

||

|

|

L4 |

|

VCO |

|

TC3 |

TC4 |

L2 |

T2 |

VR1 |

|

|

|

|

|||

|

|

|

|

|

|

TC1 |

TC2 |

|

|

|

fL FM BAND |

|

|

|

|

||

|

|

FM DET |

|

fH COVERAGE |

|

|

|

|

|

||

L1 |

|

|

21 19 17 |

13 |

|

FM RF |

|

|

|||

|

IC2 |

|

|

||

|

|

|

|

|

|

1 |

|

|

1 |

|

|

IC1 |

|

|

|

|

|

T1 |

|

|

AM IF |

|

|

FM IF |

|

T3 |

|

|

|

|

|

|

|

||

Figure 8-2 ADJUSTMENT POINTS

– 8 –

GX-CD30/30C/130/130C

CD SECTION

Since this CD system incorporates the following automatic adjustment function, when the pickup is replaced, it is necessary to reajust it.

Since this CD unit does not need adjustment, the combination of PWB and laser pickup unit is not restricted.

TEST MODE

Start |

While holding down the "STOP" button, move the FUNCTION/POWER switch to "CD". |

|

Then, release the "STOP" button and, within 0.5 second, press the PAUSE button. |

||

|

||

|

|

|

Note |

1. When the CD LID switch is in the OFF position, the unit will be able to enter the test mode. |

|

However, playback cannot be performed in this mode. |

||

|

2.You can only move the pickup.

3.The LCD display should be the same as it is for normal CD operations.

Operation |

1 |

The use of the "UP/CUE" button will move the pickup to the outermost position. |

|

The use of the "DOWN/REVIEW" button will move the pickup to the innermost position. |

|||

|

|

||

|

|

|

|

|

2 |

When the "PLAY" button is pressed, the laser will be lit, and when the "STOP" button is pressed, it will be |

|

|

turned off. Playback will also start and stop when these buttons are pressed. |

||

|

|

a.If the "PLAY" button is pressed while in the stop mode, the laser will simply be turned on at first.

b.If the laser is lit and the "PLAY" button is pressed again, playback will start from the current pickup position.

c.If the "STOP" button is pressed, playback will stop. When pressed again, the laser will be turned off.

3Turning the tracking servo on or off.

a. Each time the PAUSE button is pressed during playback, the tracking servo will be turned on or off. (Note: If the PLAY button is pressed while in the stop mode, the tracking servo will automatically be turned on.)

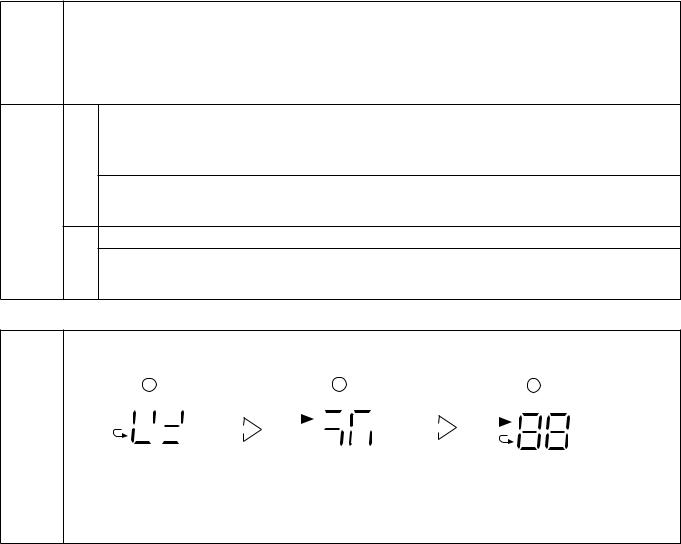

LCD MODE

Start |

While holding down the "STOP" button, move the FUNCTION/POWER switch to "CD". |

|||||||||||

Then, release the "STOP" button and, within 0.5 second, press the PAUSE button. |

|

|

||||||||||

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Display |

1 |

|

2 |

|

|

|

|

3 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 second |

1 second |

*After the number has appeared in the display, each time the "UP/CUE" button is pressed, the display will switch in the following order: , , and then .

– 9 –

GX-CD30/30C/130/130C

TROUBLESHOOTING (CD SECTION)

When the CD does not function

When the CD section does not operate When the objective lens of the optical pickup is dirty,this section may not operate.Clean the objective lens,and check the playback operation.When this section does not operate even after the above step is taken,check the following items.

Remove the cabinet and follow the troubleshooting instructions.

"Track skipping and/or no TOC(Table Of Contents) may be caused by build up of dust other foreign matter on the laser pickup lens. Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned below."

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

• The CD function will not work.

The CD operating keys don't work.

Yes

▼

Check the CD, DPS microcomputer (IC701), power supply, 4.19

MHz and 16.93 MHz clock, and reset terminal.

Yes

▼

Check the waveform of SCK, SO (DATA) and SI (COMM).

Yes

▼

See if the pick-up is in the pick-up in SW702 position.

Yes

▼

If the items mentioned above are OK, check the main microcomputer IC701.

• The CD operating keys work.

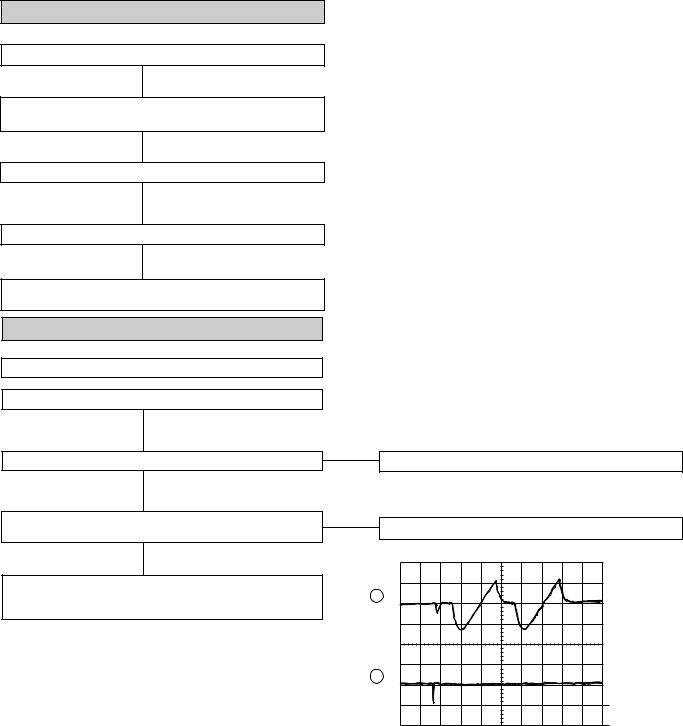

Check the Focus - HF system.

Playback can be performed without a disc.

Yes

▼

Does the pick-up move up and down twice?

No

▼

Does the output waveform of IC801(16)(FD) match that shown in Fig. 10?

No

▼

Check the IC801(50)(CLK) line, 4MHz.

Check the microcomputer data on pins (51)(CL), (52)(DAT) and (53)CE.

▼ |

Focus search OK. |

Yes

▼ |

Check the area around IC804-BI801/CNS801. |

Yes

0.5s |

Focus search |

|

is performed |

||

0.50 V |

||

two times |

||

IC801 16 FD |

||

when play |

||

|

||

|

operation is |

|

|

done without |

|

|

disc. |

|

0.5s |

|

|

0.50 V |

|

|

IC801 15 TD |

|

|

|

1 |

|

|

2 |

Figure 10

– 10 –

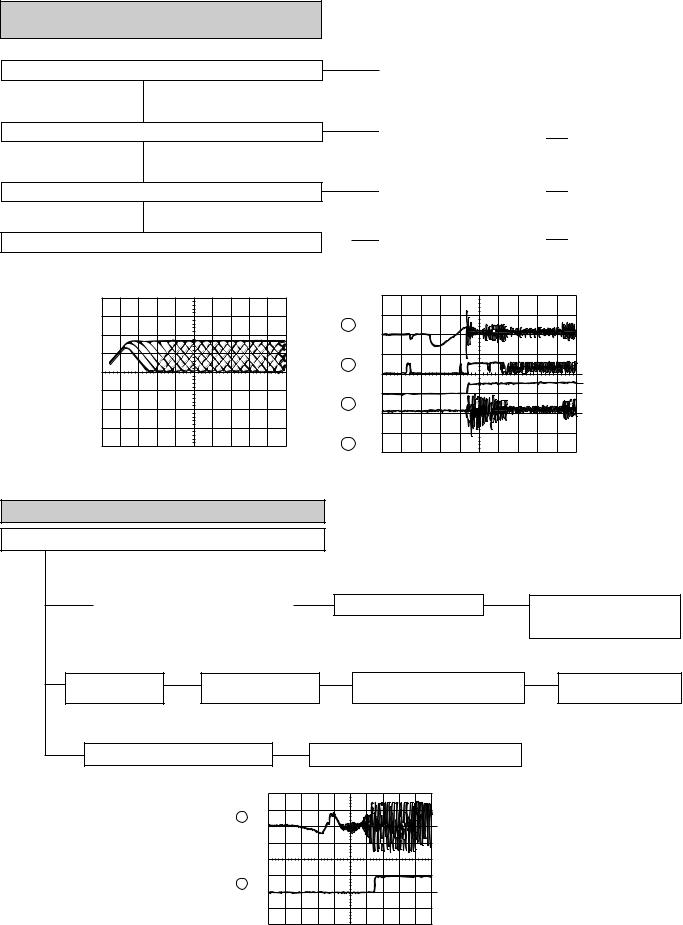

•Playback can only be performed when a disc is loaded.

Is the Focus servo active? (Can you hear it working?)

Yes

▼

Does the DRF signal change from "L" to "H"?

Yes

▼

Is HF waveform normal (see the Fig.11-1, 2)?

Yes

▼

Check the tracking system.

GX-CD30/30C/130/130C

|

▼ |

Check the laser diode driver. |

|

|

||

No |

Check the area around IC801(16) - (21) (focus servo circuit). |

|||||

|

|

|

|

|||

|

|

|

|

Yes |

|

|

|

▼ |

If the disc is not turning, the DRF |

▼ |

Check the spin |

||

No |

should not change to "H". |

system. |

||||

|

||||||

No |

|

|

Yes |

|

||

|

|

|

Check the periphery |

|||

Level is abnormal. |

|

▼ |

||||

|

▼ |

|

of IC801 pins 41 and |

|||

|

|

|||||

|

|

|

|

|

||

|

|

|

|

|

42. |

|

|

|

|

|

Yes |

|

|

|

▼ |

Waveform is unstable. |

|

▼ |

Check the spin |

|

|

||||||

|

|

|

|

|

system. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

HF |

0.5s |

|

|

Waveform in case |

0.1V/DIV |

1.00 V |

|

|

of normal play- |

0.5µsec/DIV(DC) |

IC801 16 FD |

back |

||

(When playing |

0.5s |

|

|

|

back the disc) |

|

|

|

|

10.0 V |

|

|

|

|

|

|

|

|

|

|

IC801 12 CLV+ |

2 |

||

|

|

|

|

|

|

0.5s |

|

|

1 |

|

|

|

3 |

|

|

10.0 V |

|

|

|

|

|

|

|

|

|

IC801 54 DRF |

4 |

||

|

|

|

|

|

|

0.5s |

|

|

|

|

2.00 V |

|

|

|

|

IC801 |

7 |

TE |

|

Figure 11-1 |

|

|

|

Figure 11-2 |

• Check the tracking system.

Check waveform of IC801 pin 7 (TE).

▼ |

The waveform shown in Fig. 11-3 |

Yes |

|

appears, and no-disc state appears |

|

|

soon. |

|

|

|

|

▼

Tracking servo is inoperative.

Yes

▼

Check the periphery of IC801 pin 8 to pin 15, and IC804 to

BI801/CNS801.

▼

Play is possible in |

Yes |

TEST mode. |

▼

Although IL is possible, play is impossible.

▼

Yes

Normal jump is impeded, and the program top cannot be reached.

▼

Yes

Check the periphery of

IC801 pin 14.

▼

Data cannot be read.

▼

Yes

Check the VCO-PLL system.

5ms

1.00 V

IC801 7 TE

4

5 ms

5.0 V

IC801 54 DRF

3

Figure 11-3

– 11 –

GX-CD30/30C/130/130C

• Checking the spin system.

Play operation is performed without disc.

Yes

▼

The turntable rotates a little.

No

▼

The turntable fails to rotate or rotates at high speed.

▼ Yes

▼ Yes

The spin driver circuit is normal.

Check the periphery of IC801 pins 23 to 27, pin 39 and pin 40, IC802 pin 12 and pin 13, IC804 to BI803/CNS803.

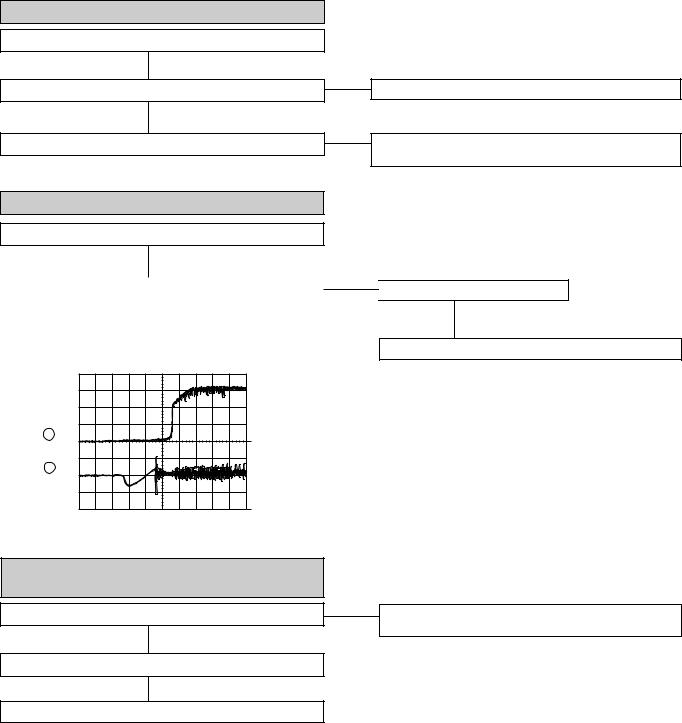

• Checking the VCO-PLL system

Play operation is performed when disc exits.

Yes |

|

|

▼ |

|

|

Although HF waveform is normal, TOC data cannot be read. |

▼ |

|

|

Yes |

|

|

|

0.5s

1.00 V

IC802 3 PDO

0.5s

1.00 V

IC801 16 FD

2

3

Stop --> Play

As VCO frequency is locked at 4.32 M Hz, voltage of PDO rises and stabilizes.

Check PDO waveform (Fig. 12).

Error

▼

Check the IC801 pins 43 and 44, IC802 pins 3, 5, 7, 9 and 10.

Figure 12

• Although HF waveform is normal and the time indication is normal, no sound is emitted.

Check IC802 pin 48 (EFLG).

No

Yes

▼

Check IC802 pins 37and 40.

Abnomal

▼

Check the periphery of IC803 (OPAMP).

▼

Usually, the number of pulses of flawless disc is 100 pulses/ sec or less.

– 12 –

Loading...

Loading...