GP2L09/GP2L24/GP2L26

GP2L09/GP2L24

Subminiature, High Sensitivity

Photointerrupter

GP2L26

■ Features ■ Applications

1. Compact and thin

GP2L09: Compact DIP, long lead type

GP2L24: Compact DIP type

GP2L26: Flat lead type

2. Optimum detection distance: 0.6 to 0.8mm

3. High sensitivity

: MIN. 0.5mA at IF= 4mA

(I

C

)

4. Visible light cut-off type

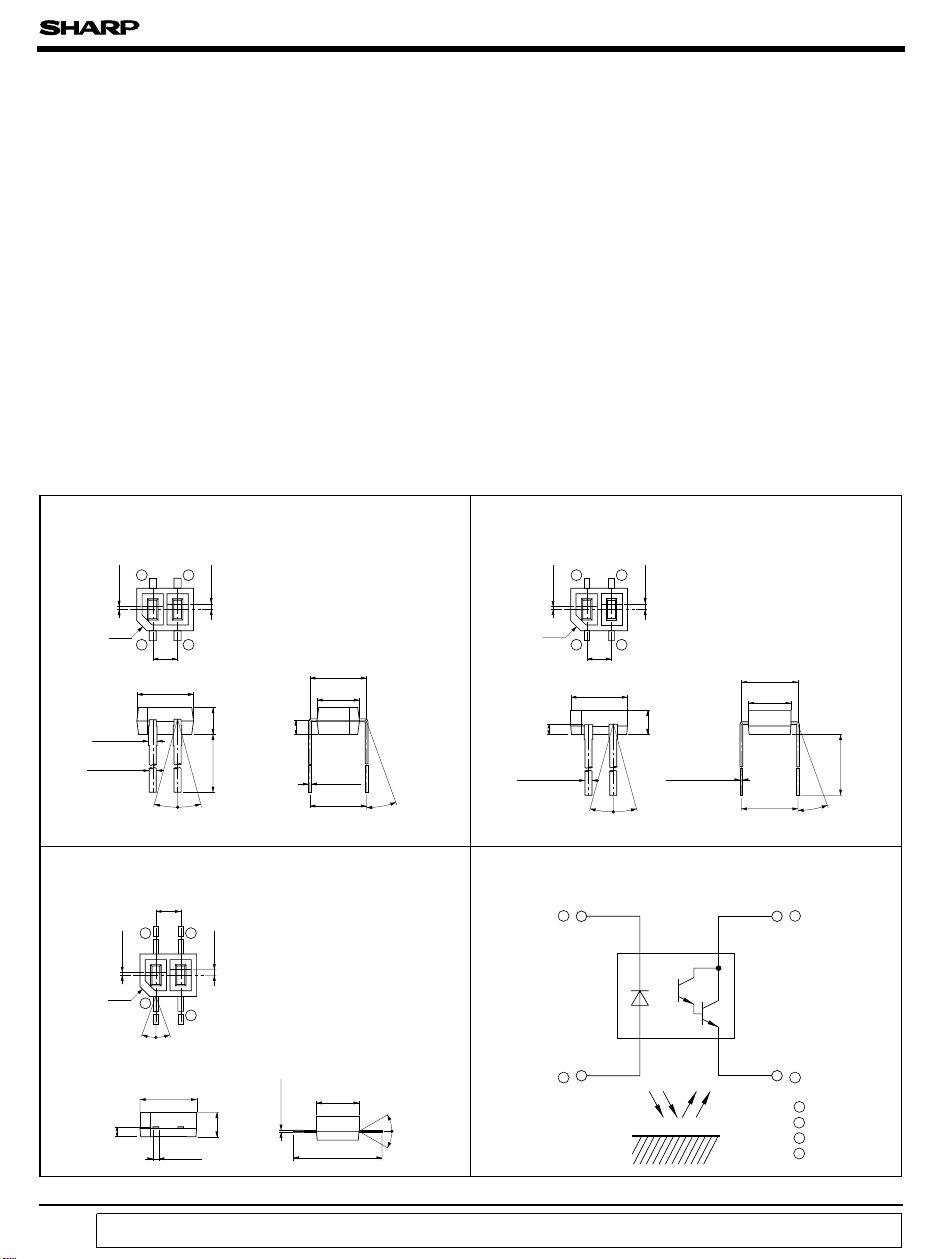

■ Outline Dimensions

GP2L09

+0.2

- 0.1

2

+0.2

- 0.1

Detector center

)

∗

Tolerance:± 0.15mm

0.4

(

( )

∗

: Reference dimensions

∗The dimensions indicated by ❈ refer

to those measured from the lead base.

0.15

0.15

±

1.7

1.0

1.0

±

12.5

Detector center

)

0.4

(

∗Tolerance:± 0.15mm

∗( ): Reference dimensions

2

0.2-0.1

+

0.15

1.7

❈4.0

3.0

0.8

4- 0.2

θ : 0 to 20˚

3.0

13.0

±

0.2

0.2

+ 0.2

- 0.1

+ 0.3

- 0

(

)

4.0

+

0.2

-

0.1

±

1.0

GP2L26

Emitter center

)

0.2

(

C0.7

4-(0.6

+ 0.2

4- 0.5

- 0.1

Emitter center

)

0.2

(

C0.7

0.75

43

1

1.75

+ 0.2

4.0

- 0.1

)

± 15˚

1.75

43

1

± 20˚

4.0

0.4

θ

± 30˚

1. Cassette tape recorders, VCRs

2. Floppy disk drives

3. Various microcomputerized control equip ment

GP2L24

4

Emitter center

)

0.2

(

C0.7

1

1.75

+0.2

4.0

- 0.1

0.75

+0.2

4 - 0.4

- 0.1

±15˚

Internal connection diagram

(

Common to 3 models

4

1

3

2

(

Unit : mm

Detector center

)

∗Tolerance:± 0.15mm

0.4

(

∗( ): Reference dimensions

∗

The dimensions indicated by ❈ refer

to those measured from the lead base.

± 0.2

0.2

❈4.0

+

0.2

3.0

-

0.1

1.7

+ 0.2

4 - 0.15

- 0.1

(

)

4.0

θ

θ:0 to 20˚

)

3

2

1 Anode

2 Emitter

3 Collector

4 Cathode

)

1.0-0

+

3.5

“ In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that occur in equipment using any of SHARP's devices, shown in catalogs,

data books, etc. Contact SHARP in order to obtain the latest version of the device specification sheets before using any SHARP's device.”

GP2L09/GP2L24/GP2L26

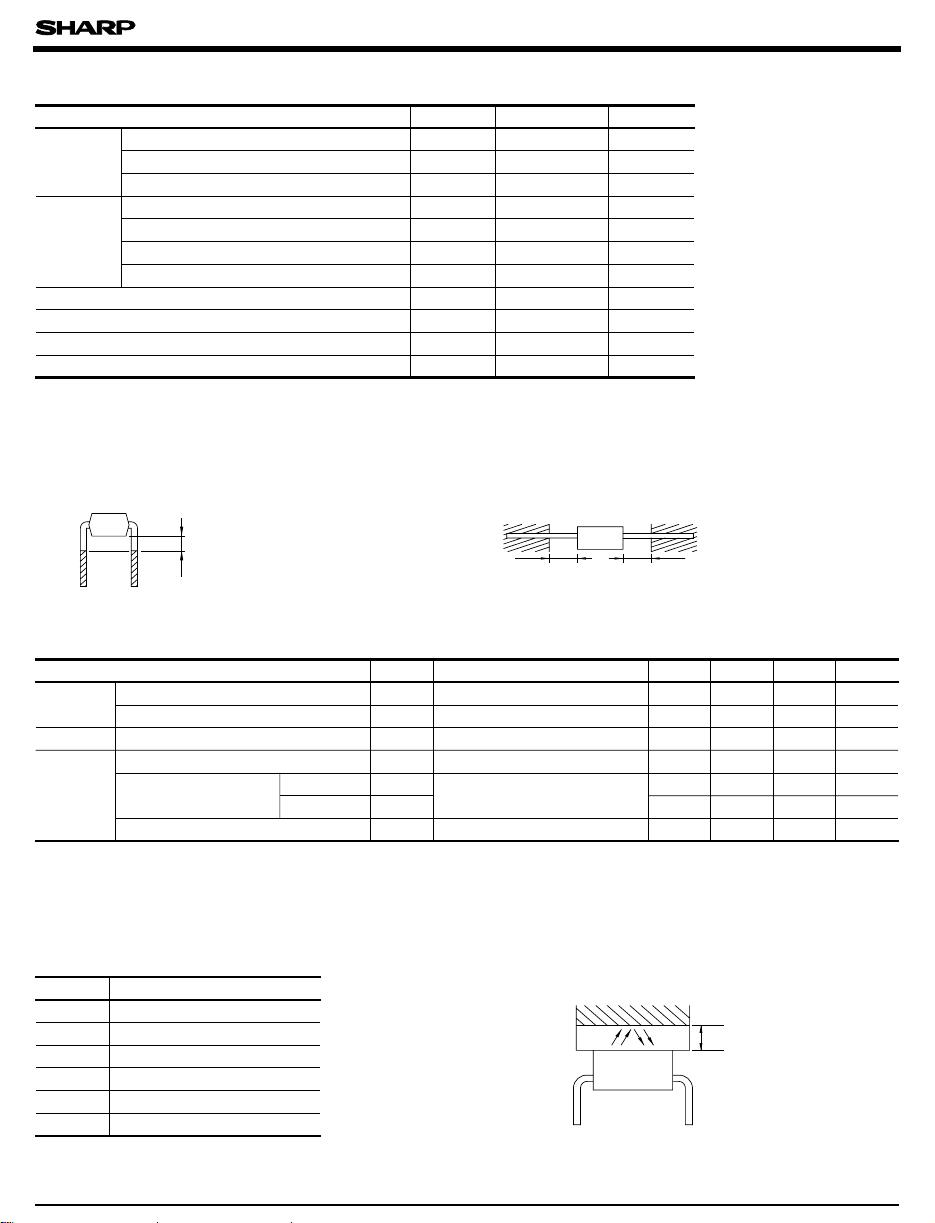

■ Absolute Maximum Ratings

Parameter Symbol Rating Unit

Forward current I

Input

Reverse voltage V

Power dissipation

Collector-emitter voltage V

Output

Emitter-collector voltage V

Collector current I

Collector power dissipation

Total power dissipation P

Operating temperature

Storage temperature T

∗1

Soldering temperature

∗1 Within 5 seconds (Soldering areas for each model are shown below.

GP2L09, GP2L24

Soldering area

The hatched area more than 1mm

away from the lower edge of

package as shown in the drawing

below.

∗2

∗2 GP2L09: 4mm

∗2

1mm

F

R

P75

CEO

ECO

C

P

C

tot

T

opr

stg

T

sol

)

- 25 to + 85 ˚C

- 40 to + 100 ˚C

GP2L26

Soldering area

The hatched area more

than 2.0mm away from

the both edge of package

as shown in the drawing

below.

■ Electro-optical Characteristics

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Input

Forward voltage I

Reverse current I

Output Collector dark current I

∗3

Transfercharacteristics

∗3 The condition and arrangement of the reflective object are shown in the right drawing.

∗4 Without reflective object

Collector current I

Response time

∗4

Leak current I

Rise time t

Fall time t

F

R

CEO

C

r

f

LEAK

IF= 20mA - 1.2 1.4 V

VR=6V - - 10 µA

= 10V, I

V

CE

VCE= 2V, IF= 4mA 0.5 3.0 15.0 mA

V

= 2V, IC= 10mA

CE

= 100Ω , d= 1mm

R

L

IF= 4mA, VCE= 5V - - 5.0

(

Ta= 25˚C

)

50 mA

6V

mW

35 V

6V

50 mA

75 mW

100 mW

260 ˚C

=0

2.0mm

- - 1x 10

2.0mm

F

- 80 400

- 70 400

(

Ta= 25˚C

-6

)

A

µ s

µ s

µA

The ranking of collector current shall be

classified into the following 6 ranks.

(

GP2L09, GP2L24, GP2L26

Rank Collector current IC (mA

∗5

A 0.5 to 1.9

B 1.45 to 5.4

C 4.0 to 15.0

A or B 0.5 to 5.4

B or C 1.45 to 15.0

A, B or C

∗5 GP2L24 and GP2L26 don't

have A rank.

0.5 to 15.0

)

)

Test Condition for Collector Current

Al evaporation

1mm-thick glass

GP2L09/GP2L24/GP2L26

Fig. 1 Forward Current vs.

Ambient Temperature

60

50

)

mA

40

(

F

30

20

Forward current I

10

0

- 25 0 25 50 75 85 100

Ambient temperature Ta (˚C

Fig. 3 Peak Forward Current vs.

Duty Ratio

Pulse width <=100 µ s

-2

10

Ta= 25˚C

10

Duty ratio

2000

)

1000

mA

(

FM

500

200

100

Peak forward current I

50

20

-3

2

10

52525

Fig. 5 Collector Current vs.

Forward Current

25

20

)

mA

(

C

15

10

Collector current I

5

0

2.5 5.0 7.5 10.0 12.50

Forward current IF (mA

Fig. 2 Power Dissipation vs.

Ambient Temperature

120

P

tot

100

)

P, P

80

mW

(

Power dissipation P

)

C

75

60

40

20

0

025-25

Ambient temperature T

50 10075

(˚C

a

85

)

Fig. 4 Forward Current vs.

Forward Voltage

500

200

)

100

mA

(

50

F

20

10

Forward current I

5

2

-1

1

1

0

Ta= 75˚C

50˚C

0.5 1.0 1.5 2.0 2.5 3.0

Forward voltage VF (V

25˚C

)

0˚C

-

25˚C

Fig. 6 Collector Current vs.

Collector-emitter Voltage

V

T

)

=2V

CE

= 25˚C

a

15.0

16

14

)

12

10

8

6

4

2

0

IF= 15mA

2468100

mA

(

C

Collector current I

P

(MAX.

c

10mA

7mA

4mA

2mA

Collector-emitter voltage V

CE

T

= 25˚C

a

)

(V

12

)

GP2L09/GP2L24/GP2L26

Fig. 7 Relative Collector Current vs.

Ambient Temperature

150

125

)

%

(

100

75

50

Relative collector current

25

0

025-25

Ambient temperature Ta (˚C

= 4mA

I

F

V

CE

50 10075

)

Fig. 9-a Response Time vs.

Load Resistance

(

Input

Output

GP2L09

t

r

t

f

t

d

t

s

)

t

d

1000

500

200

)

100

µ s

(

50

20

10

Response time

5

2

1

Input R

D

V

=2V

CE

= 10mA

I

C

T

= 25˚C

a

10 20 50 100 200 500 1000 1 10 100 1000 1000

Load resistance RL (Ω

Test Circuit for Response Time

V

CC

R

L

Output

Fig. 8 Collector Dark Current vs.

Ambient Temperature

-4

10

5

=5V

10

)

A

(

10

CEO

10

10

10

Collector dark current I

-10

10

-11

10

-5

5

-6

5

-7

5

-8

5

-9

5

5

-25 0

VCE= 10V

25 10050 75

Ambient temperature Ta (˚C

)

Fig. 9-b Response Time vs.

Load Resistance

)(

)

µ s

(

1000

500

200

100

50

VCE=2V

I

= 10mA

C

= 25˚C

T

a

GP2L24/GP2L26

t

r

t

f

20

10

t

d

5

Response time

2

t

s

1

0.5

0.2

0.1

Load resistance R

)

(Ω

L

)

Fig.10 Relative Collector Current vs.

Distance between Sensor and

Al Evaporation Glass

100

80

)

%

(

60

10%

90%

t

s

t

t

r

f

40

Relative collector current

20

IF= 4mA

=2V

V

CE

= 25˚C

T

a

0

012 45

Distance between sensor and Al evaporation glass

3

d (mm

)

GP2L09/GP2L24/GP2L26

Fig.11 Relative Collector Current vs.

Card Moving Distance(1

100

80

)

%

(

60

40

Relative collector current

20

0

-1 1 3 5

024

Card moving distance L(mm)

)

= 4mA

I

F

V

=2V

CE

d= 1mm

= 25˚C

T

a

6

7 531-1

Test Condition for Distance & Detecting

Position Characteristics

Lmm

)

d

GP2L24

d

Correspond to Fig.12

Test condition

= 4mA

I

F

V

CE

d = 1mm

OMS card

White

+

L=0

/

= 2V

)

(EX.: GP2L24

Correspond to Fig.10

Correspond to Fig.11

Test condition

I

= 4mA

F

VCE= 2V

d = 1mm

d

OMS card

White

+

L= 0

Al evaporation

Black

-

Fig.14 Frequency Response (GP2L24 GP2L26 Fig.15 Spectral Sensitivity (Detecting Side

Fig.12 Relative Collector Current vs.

Card Moving Distance(2

100

)

80

%

(

60

40

Relative collector current

20

0

Card moving distance L(mm)

Fig.13 Frequency Response

0

)

dB

(

-5

3

5

10

RL=1kΩ

2

Frequency f (Hz

Black

Lmm

-

-10

Voltage gain Av

-15

-20

2

2

10

)

IF= 4mA

V

=2V

CE

d= 1mm

= 25˚C

T

a

420-2

VCE=2V

I

=10mA

C

T

= 25˚C

a

5

10

10Ω

5

)

2

(

GP2L09

100Ω

4

2

5

10

)

6

)

5

0

)

dB

(

-5

-10

Voltage gain Av

-15

-20

2

10

=1kΩ

R

L

3

10

Frequency f (kHz

IF= 10mA

V

=2V

CE

T

= 25˚C

a

100Ω

4

10

10Ω

5

10

)

6

10

100

80

)

%

(

60

40

Relative sensitivity

20

0

600 700 800 900 1000 1200

Wavelength λ (nm

Ta= 25˚C

)

1100

GP2L09/GP2L24/GP2L26

■ Precautions for Use

(1)

In order to stabilize power supply line, connect a by-pass capacitor of more than 0.01µF bet-

ween Vcc and GND near the device.

(2)

In this product, the PWB is fixed with a resin cover, and cleaning solvent may remain inside

the case; therefore, dip cleaning or ultrasonic cleaning are prohibited.

(3)

Remove dust or stains, using an air blower or a soft cloth moistened in cleaning solvent.

However, do not perform the above cleaning using a soft cloth with cleaning solvent in the

marking portion.

In this case, use only the following type of cleaning solvent used for wiping off:

Ethyl alcohol, Methyl alcohol, Isopropyl alcohol, Freon TE, Freon TF, Diflon solvent S3-E

When the cleaning solvents except for specified materials are used, please consult us.

(4)

As for other general cautions, refer to the chapter “ Precautions for Use ”.

Loading...

Loading...