GP1A30R

GP1A30R

OPIC Photointerrupter with Encoder

Function

■ Features

1. 2-phase (A, B) digital output

2. Possible to use plastic disk

3. High sensing accuracy

(Disk slit pitch : 0.7mm

)

4. TTL compatible output

5. Compact and light

■ Applications

1. Electronic typewriters, printers

2. Numerical control machines

■ Absolute Maximum Ratings

Parameter

Forward current

*1

Peak forward current

Input

Reverse voltage V

Power dissipation P 100 mW

Supply voltage V

Output

Low level output current

Power dissipation P

Operating temperature T

Storage temperature T

*2

Soldering temperature T

*1 Pulse width <= 100µs, Duty ratio= 0.01

Symbol

I

I

I

F

FM

R

CC

OL

O

opr

stg

sol

(

Ta= 25˚C

Rating Unit

65 mA

1A

6V

7V

20 mA

250 mW

0 to + 70

- 40 to + 80

260 ˚C

*2 For 5 seconds

■ Outline Dimensions

0.1

±

2.0

2- φ

±

0.15

4

9.9

MIN.

10.5

2

1

±

)

(

0.15

0.15

±

(

7.25

2.54

2.0

12.0

7.5

6.4

)

0.8

)

OPIC

±

0.15

±

0.1

(

34

56

1.27

Internal connection diagram

1

2

1 Anode

2 Cathode

3 V

OB

4 - R2.5

0.15

±

1.4

4.4

0.15

MIN.

±

8.0

2.5

)

)

1.27

(

3 -

15.0

* Tolerance:±0.3mm

* ( ): Reference dimensions

8.0

6.0

GP1A30R

±

0.15

20.0

(

Unit : mm

6

5

4

3

OPIC

4 GND

5 V

CC

6 V

OA

4 - R1.3

6.4

11.4

±

)

0.15

*“ OPIC” (Optical IC) is a trademark of the SHARP Corporation.

An OPIC consists of a light-detecting element and signal processing circuit integrated onto a single chip.

˚C

˚C

■ Electro-optical Characteristics

(

Unless otherwise specified, Ta =0 to + 70˚C

Parameter Symbol Conditions MIN. TYP. MAX. Unit

Input

Forward voltage V

Reverse current I

Operating supply voltage V

Output

High level output voltage V

Low level output voltage V

Supply current I

Transfer

charac-

teristics

Duty ratio

Response frequency f

*3 Measured under the condition shown in Measurement Conditions.

*4 In the condition that output A and B are low level.

“ In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that occur in equipment using any of SHARP's devices, shown in catalogs,

data books, etc. Contact SHARP in order to obtain the latest version of the device specification sheets before using any SHARP's device.”

*5

*5

MAX.

Ta= 25˚C, IF= 30mA - 1.2 1.5 V

F

Ta= 25˚C, VR=3V - - 10 µA

R

CC

*3

VCC= 5V, IF= 30mA

OH

IOL= 8mA, VCC= 5V, IF= 30mA*3- 0.1 0.4 V

OL

*3*4

I

CC

D

D

= 30mA, VCC=5V

F

V

= 5V, IF= 30mA,

CC

A

*3

f= 2.5kHz

B

*3

VCC= 5V, IF= 30mA

*5

t

AH

D

= x100, D

AB

t

AP

4.5 5.0 5.5 V

2.4 4.9 - V

- 5 20 mA

20

20

50

50

- - 5 kHz

t

BH

x 100

=

t

BP

80

80

)

%

%

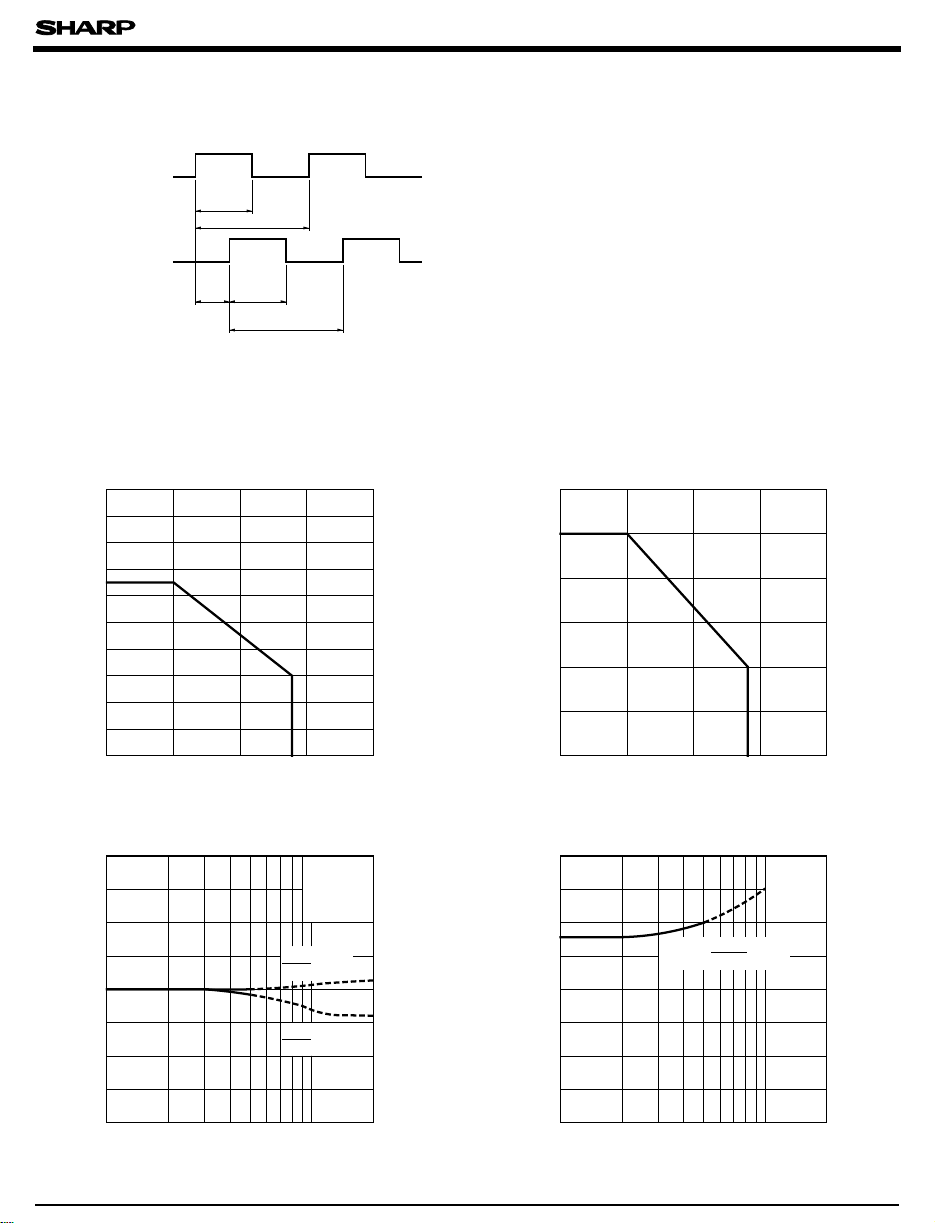

■ Output Waveforms

Output A

)

(V

OA

Output B

)

(V

OB

Rotational direction: Counterclockwise when seen

t

t

AB1

from OPIC light detector

GP1A30R

AH

t

AP

t

BH

t

BP

Fig. 1 Forward Current vs. Ambient Fig. 2 Output Power Dissipation vs.

100

90

80

)

70

mA

(

65

F

60

50

40

30

Forward current I

20

10

0

0

25 50 75 100

Ambient temperature Ta (˚C

70

)

Ambient Temperature Temperature

300

)

250

mW

(

o

200

150

100

Output power dissipation P

50

0

0

Ambient temperature Ta (˚C

70

)

Fig. 3 Duty Ratio vs. Frequency Fig. 4 Phase Difference vs. Frequency

0.9

0.8

0.7

0.6

t

AH

t

AP

V

=5V

CC

= 30mA

I

F

Ta= 25˚C

(

Output A

)

0.5

Duty ratio

0.4

0.3

t

t

BH

BP

(

Output B

)

0.2

0.1

110

25

Frequency f (kHz

)

20

)

deg.

(

AB1

Phase difference θ

130

120

110

100

V

CC

I

= 30mA

F

Ta= 25˚C

t

ABI

=x 360˚

θ

AB1

t

AP

90

80

70

60

50

1

25

Frequency f (kHz

10 20

)

100755025

=5V

GP1A30R

Fig. 5 Duty Ratio vs. Ambient Temperature Fig. 6 Phase Difference vs. Ambient

1.0

0.9

0.8

0.7

0.6

0.5

Duty ratio

0.4

t

AH

(

Output A

t

AP

t

BH

(

Output B

t

BP

=5V

V

CC

= 30mA

I

F

f= 2.5kHz

)

)

0.3

0.2

0.1

0

0

25

50 75 100

Ambient temperature Ta (˚C

)

Fig. 7 Duty Ratio vs. Distance (X direction

0.9

0.8

0.7

0.6

0.5

Duty ratio

0.4

0.3

0.2

0.1

- 1.0

t

AH

(

Output A

t

AP

t

BH

(

Output B

t

BP

- 0.5

Distance X (mm) (Shifting encoder

)

)

VCC=5V

= 30mA

I

F

f= 2.5kHz

Ta= 25˚C

0.5

)

1.00

Fig. 9 Duty Ratio vs. Distance (Y direction

0.9

0.8

0.7

0.6

0.5

Duty ratio

0.4

0.3

0.2

0.1

- 1.0 - 0.5

t

AH

(

Output A

t

AP

t

BH

(

Output B

t

BP

0 0.5 1.0

Distance Y (mm) (Shifting encoder

VCC=5V

= 30mA

I

F

f= 2.5kHz

T

= 25˚C Ta= 25˚C

a

)

)

)

)

)

Temperature

140

130

)

120

deg.

110

(

AB1

100

= x 360˚

θ

AB1

90

80

70

Phase difference θ

60

50

40

0

25

Ambient temperature T

Fig. 8 Phase Difference vs.

Distance (X direction

130

120

)

110

deg.

(

AB1

100

90

t

θ

= x 360˚

AB1

ABI

t

AP

Reference position

80

70

Phase difference θ

60

50

- 1.0 - 0.5

0 0.5 1.0

Distance X (mm) (Shifting encoder

Fig.10 Phase Difference vs.

Distance (Y direction

130

V

=5V

CC

= 30mA

I

F

120

f= 2.5kHz

)

110

deg.

(

100

AB1

90

80

Phase difference θ

70

60

50

- 1.0 - 0.5

Distance Y (mm) (Shifting encoder

θ

GP1A30R

0 0.5 1.0

VCC=5V

I

t

AB1

t

AP

(˚C

a

)

V

I

f= 2.5kHz

Ta= 25˚C

)

t

AB1

= x 360˚

AB1

t

AP

F

f= 2.5kHz

)

F

(+)(-)

= 30mA

=5V

CC

= 30mA

GP1A30R

Disk

)

(+)

Reference

position

(-)

Disk

)

1007550

GP1A30R

Fig.11 Duty Ratio vs. Distance (Z direction

0.9

0.8

0.7

0.6

0.5

Duty ratio

0.4

0.3

0.2

0.1

0

t

AH

t

AP

t

BH

t

BP

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

Distance Z (mm) (Shifting encoder

(

Output A

(

Output B

V

CC

= 30mA

I

F

f= 2.5kHz

Ta= 25˚C

)

)

■ Measurement Conditions

A

3

8

R13.45

Disk center

S

2

18.385

(

GP1A30R

6.4

)

=5V

)

1.4

4-R1.3

)

Fig.12 Phase Difference vs.

Distance (Z direction

130

V

=5V

CC

= 30mA

I

F

120

f= 2.5kHz

)

Ta= 25˚C

110

deg.

(

100

AB1

90

80

70

Phase difference θ

60

50

0

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

Distance Z (mm) (Shifting encoder

θ

= x 360˚

AB1

Z

)

t

AB1

t

AP

(

Detecting side

OPIC

(

Emitting side

)

Disk

)

)

<Basic Design>

RO (distance between the disk center and half point of a slit),

P (slit pitch), S

rupter) will be provided by the following equations.

Slit pitch: P (slit center

RO= x 13.45 (mm)N: number of slits

15

20

120

2x p x R

P=

S

1=RO

Note) When the number of slits is changed, values in parenthesis

are also changed according to the number.

and S2 (installing position of photointer-

1

)

N

O

(mm)

N

- 1.765(mm), S2=S1+ 6.7(mm

)

Disk

φ 31.6, 0.1t

120 slits

S

0.3

20.8

1

(

11.685

11.4

A

9.9

)

■ Precautions for Use

(1) This module is designed to be operated

at I

= 30mA TYP.

F

(2) Fixing torque: MAX. 0.6Nm 6kgf • cm

(

)

3

In order to stabilize power supply line,

connect a by-pass capacitor of more than 0.01µF

between Vcc and GND near the device.

(4) As for other general cautions, refer to

the chapter “Precautions for Use” .

()

P

(Ex.) In the case of

N= 200P/R

200

= x 13.45 (mm

R

O

120

= 22.42mm

2

2 x p x 22.42

r

P=

200

= 0.704mm

1

r

= 22.42- 1.765

S

1

)

(mm)

Enlarged drawing

of A portion

12

7.5

4

Slit pitch : P

= 20.655mm

= 20.655+ 6.7

r1= r

2

S

2

= 27.355mm

Disk center

Loading...

Loading...