Sharp GL5ZV44 Datasheet

PREPARED BY: DATE:

xm /I6 /sq

7-a Usda

APPROVED BY:

Ji”! 1 /t/ PS .

FKL.,+ /

DATE: ELECTRO~C coh4PONENTS GROUP

DEVICE SPECIFICATION FOR

w ISSUE J&16/99

SHARP CORPORATION

SPECIFICATION

SPEC.No.

PAGE

REPRESENTATIVE DIVISION:

Opto-Electronic Devices Division

Light Emitting Diode

MODEL No.

GL5ZV44

1. These specification sheets include materials protected under the copyright of Sharp Corporation (“Sharp”).

Please do not reproduce or cause anyone to reproduce them without Sharp’s consent.

2. When using this product, please observe the absolute maximum ratings and the instructions for use outlined

in these specification sheets, as well as the precautions mentioned below. Sharp assumes no responsibility

for any damage resulting from use of the product which does not comply with the absolute maximum ratings

and the instructions included in these specification sheets, and the precautions mentioned below.

DG99f5040

10 Pages

(Precautions)

(1) This products is designed for use in the following application areas;

* OA equipment * Audio visual equipment * Home appliance

* Telecommunication equipment (Terminal) * Measuring equipment

* Tooling machines * Computers

L

If the use of the product in the above application areas is for equipment listed in paragraphs

(2) or (3). please be sure to observe the precautions given in those respective paragraphs.

(2) Appropriate measures, such as fail-safe design and redundant design considering

the safety design of the overall system and equipment, should be taken to ensure reliability

and safety when this product is used for equipment which demands high reliability and

safety in function and precision, such as ;

* Transportation control and safety equipment (aircraft, train, automobile etc.)

* Traffic signals

* Other safety equipment

L

(3) Please do not use this product for equipment which require extremely high reliability

and safety in function and precision, such as ;

* Space equipment * Telecommunication equipment (for trunk lines)

* Nuclear power control equipment * AMedical equipment

C

(4) Please contact and consult with a Sharp sales representative if there are any questions

regarding interpretation of the above three paragraphs.

3. Please contact and consult with a Sharp sales representative for any questions about this product.

CUSTOMER’S APPROVAL

‘DATE:

BY:

* Gas leakage sensor breakers * Rescue and security equipment

DATE:

PRESENTED BY:

M.Katoh,

Department General Manager of

Engineering DeptJII

Opto-Electronic Devices Division

Electronic Components Group

SHARP CORPORATION

c2-L.i //8/

c%..mJ

I

1

1

099

MODEL No.

GL5ZV44 Snecification

1. Application

‘l”h.k spxi.fication applies to the light emitting dicde &vice Model No. GL5ZV44.

[AlGahP (dicing or scribe/brake type)

Amber LED device]

DG996040

GL5ZV44

Jun/16/99

PAGE

l/10

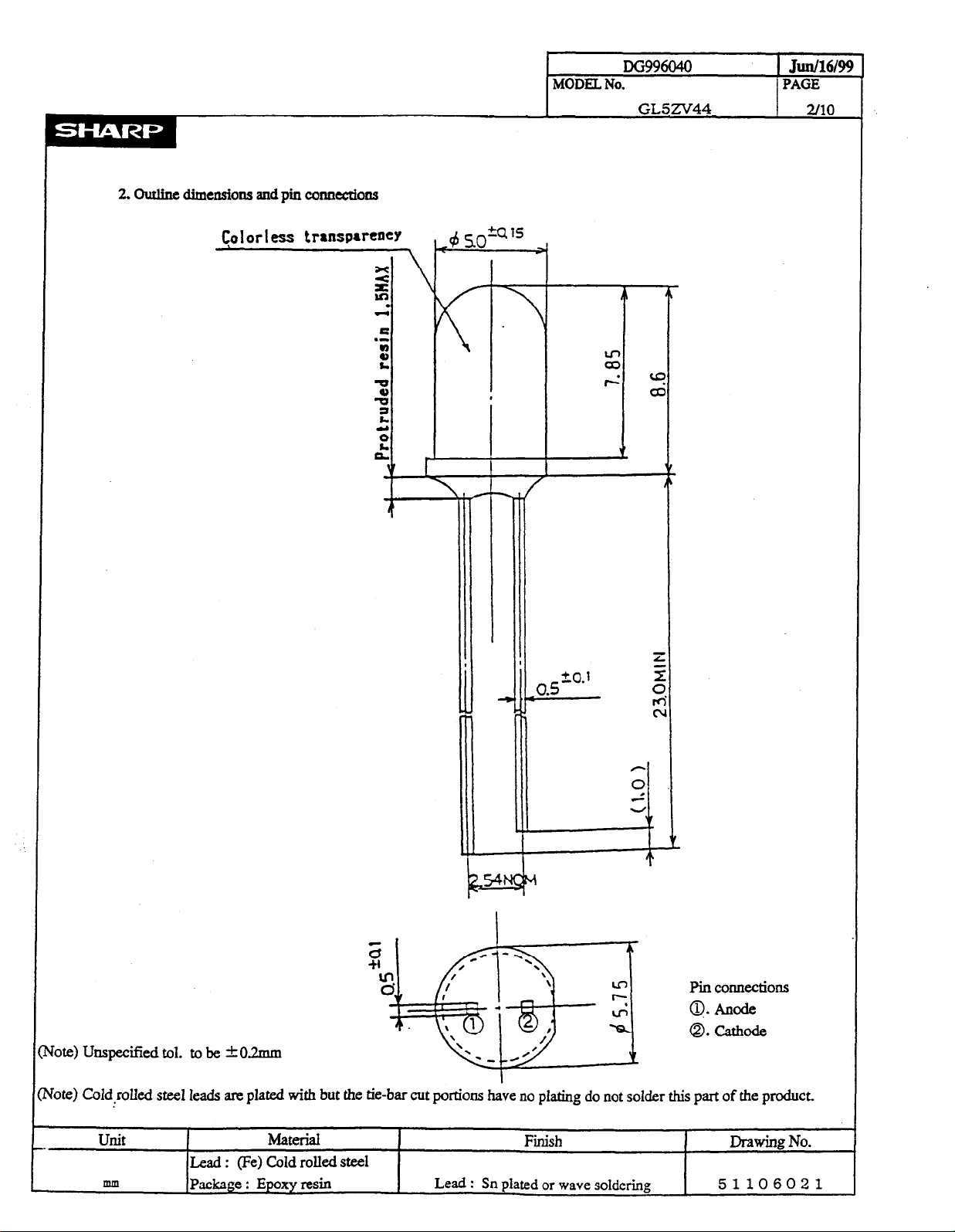

2. Outline dimensions and pin connections

3. Ratings and characteristics

3-l. Absolute maximum ratings

3-2. Electra-optical characteristics

3-3. Derating Curve

3-4. Characteristics Diagram

4. Reliability

4-l. Test items and test conditions

4-2. Measurement items and Failure judgement criteria

5. Incoming inspection

5- 1. Applied standard

5-2. Sampling method and level

5-3. Test items, judgement criteria and classifica of defect

5-4. Test items the surface is be applied for flat type, judgement criteria and classifxa of defect

.,.....................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refer to the attached sheet Page 2.

Refer to the attached sheet Page 3-4.

Refer to the attached sheet Page 5.

Refer to the attached sheet Page 6.

6. Supplement

6-l. Packing

6-2. Luminous intensity rank

6-3. Dominant wavelength rank

6-4. Environment

7 ~ecau~onsforuse.............‘...............’.............’...

7-1. Lead forming method

7-2. Notice of installation

7-3. Soldering Conditions

.7-4. For cleaning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...*

Refer to the attached sheet Page 7-8.

Refer to the attached sheet Page 9- 10.

MODEL No.

I

DG996040

GLSZV44

Jun/l6/W

PAGE

310

‘d

$1

ln

0’

I

9.

kA.bte) Unspecified tol. to be *O&KU

(Note) Cold rolled steel leads are plated with but the tie-bar cut portions have no plating do not solder this part of the product.

unit

mal

Lead : (Fe) Cold rolled steel

Package : Epoxy resin

Matelial

Finish

Lead : Sn plated or wave soldering

Pin connectioIls

Q. Anode

0. cathode

Drawing No.

51106021

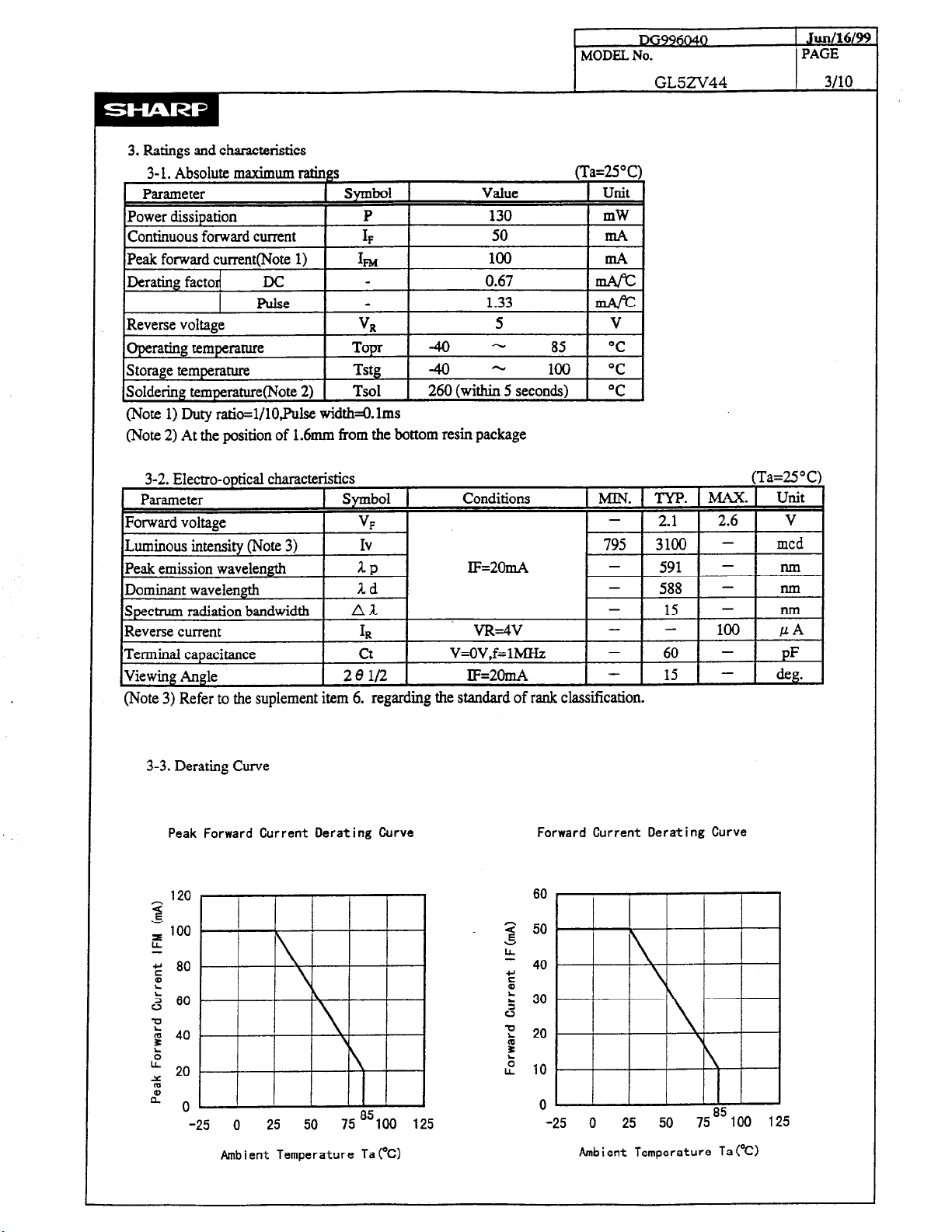

3. Ratings and characteristics

(Note 1) Duty ratio=1/1O,Pulse width=&lms

(Note 2) At the position of 1.6mm from the bottom resin package

J?G996040

I Jun/16/99

1 PAGE

GL5ZV44 I 3/10

(Note 3) Refer to the suplement item 6. regarding the standard of rank classification.

3-3. Derating Curve

Peak Forward Current Derating Curve

120

3

h 100

g 80

z

2 60

2

g 40

b

: 20

?Y

Lz

01 ’ ’

-25 0 25 50 75 85100 125

Ambient Temperature Ta(“CI

I

I

Forward Current Derating Curve

Ambient Temperature TarC)

Loading...

Loading...