Page 1

MODEL:

DX-C310

DX-C311

DX-C380

DX-C381

DIGITAL FULL COLOUR MULTIFUNCTIONAL SYSTEM

Maintenance & Safety GuideMaintenance & Safety GuideMaintenance & Safety Guide

Please read first

Please read this guide first to ensure safe

use of the machine.

Before installing this product, be sure to

read the "TO ENSURE SAFE USE OF THE

MACHINE" and "INSTALLATION

REQUIREMENTS" sections.

TO ENSURE SAFE USE

OF THE MACHINE

INSTALLATION

REQUIREMENTS

Keep this manual close at hand

for reference whenever needed.

SUPPLIES

REPLACING SUPPLIES AND

MAINTENANCE

TROUBLESHOOTING

SPECIFICATIONS

INFORMATION ON DISPOSAL

TO THE ADMINISTRATOR

OF THE MACHINE

Page 2

Caution!

For complete electrical disconnection, pull out the main plug.

The socket-outlet shall be installed near the equipment and shall be easily accessible.

Shielded interface cables must be used with this equipment to maintain compliance

with EMC regulations.

➢➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣

The equipment should be installed near an accessible socket outlet for easy disconnection.

Notice for users in the UK

MAINS

The mains lead of this equipment is already fitted with a mains plug which is either a non-rewireable

(moulded) or a rewireable type. Should the fuse need to be replaced, a BSI or ASTA approved fuse

to BS1362 marked or

be used.

Always refit the fuse cover after replacing the fuse on the moulded plug. Never use the plug without

the fuse cover fitted.

In the unlikely event of the socket outlet in your home not being compatible with the plug supplied

either cut-off the moulded plug (if this type is fitted) or remove by undoing the screws if a rewireable

plug is fitted and fit an appropriate type observing the wiring code below.

DANGER: The fuse should be removed from the cut-off plug and the plug destroyed immediately

and disposed of in a safe manner. Under no circumstances should the cut-off plug be inserted

elsewhere into a 13A socket outlet as a serious electric shock may occur.

To fit an appropriate plug to the mains lead, follow the instructions below:

IMPORTANT: The wires in this mains lead are coloured in accordance with the following code:

As the colours of the wires in this mains lead may not correspond with coloured markings

identifying the terminals in your plug, proceed as follows:

The wire which is coloured GREEN-AND-YELLOW must be connected to the terminal in the plug

which is marked with the letter E, or by the safety earth symbol

and-yellow.

The wire which is coloured BLUE must be connected to the terminal which is marked with the letter

N or coloured black.

The wire which is coloured BROWN must be connected to the terminal which is marked with the

letter L or coloured red.

If you have any doubt, consult a qualified electrician.

WARNING: THIS APPARATUS MUST BE EARTHED.

➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢

PLUG WIRING INSTRUCTIONS

and of the same rating as the one removed from the plug must

GREEN-AND-YELLOW: Earth

BLUE: Neutral

BROWN: Live

Å@, or coloured green or green-

➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣

➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢➣➢

This machine contains the software having modules developed by Independent JPEG

Group.

This product includes Adobe

®

Flash® technology of Adobe Systems Incorporated.

Copyright© 1995-2007 Adobe Macromedia Software LLC. All rights reserved.

Page 3

EMC (this machine and peripheral devices)

Warning:

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

For the users of the fax function

FAX interface cable and Line cable:

These special accessories must be used with the device.

The Declaration of Conformity can be viewed at the following URL address.

http://www.sharp.de/doc/MX-FXX3.pdf

1

Page 4

Contents

TO ENSURE SAFE USE OF THE

MACHINE . . . . . . . . . . . . . . . . . . 4

Cautions . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . 5

Laser information . . . . . . . . . . . . 7

INSTALLATION REQUIREMENTS . . .

SUPPLIES. . . . . . . . . . . . . . . . . 10

Storage of supplies. . . . . . . . . . 10

Supply of spare parts and

consumables . . . . . . . . . . . . . . 11

REPLACING SUPPLIES AND

MAINTENANCE . . . . . . . . . . . . 12

Replacement time for supplies. 12

Supplies . . . . . . . . . . . . . . . . . . 13

Replacing the toner cartridges . 14

Replacing the toner collection

container. . . . . . . . . . . . . . . . . . 19

Replacing the developer cartridge /

drum cartridge. . . . . . . . . . . . . . . . .

Replacing the developer cartridge . .

Colour balance adjustments. . . 31

Replacing the drum cartridge . . 32

Replacing the transfer unit . . . . 35

Replacing the primary transfer

belt unit. . . . . . . . . . . . . . . . . . . 35

Replacing the secondary transfer

roller unit. . . . . . . . . . . . . . . . . . 41

Replacing the fusing unit / ozone

filter. . . . . . . . . . . . . . . . . . . . . . 45

Replacing the fusing unit . . . . . 45

Replacing the ozone filter. . . . . 50

Replacing the staple cartridge

in the finisher . . . . . . . . . . . . . . 52

Regular maintenance . . . . . . . . 55

Cleaning the document glass and

automatic document feeder. . . . .

23

23

55

Cleaning the main charger of the

photoconductive drum . . . . . . . 56

Cleaning and replacing the rollers . .

Cleaning and replacing paper

cassette rollers . . . . . . . . . . . . . 61

8

Cleaning and replacing the

bypass tray rollers . . . . . . . . . . 66

Cleaning and replacing the automatic

document feeder rollers . . . . . . . . . . .

Cleaning the laser unit . . . . . . . 78

Cleaning the PT charger of the

primary transfer belt unit . . . . . . 85

Executing the fusing cleaning

mode. . . . . . . . . . . . . . . . . . . . . 88

TROUBLESHOOTING . . . . . . . 89

When an error code appears . . 89

Checking the status of the machine. .

SPECIFICATIONS . . . . . . . . . . 92

Machine specifications / copier

specifications . . . . . . . . . . . . . . 92

Continuous copying speeds . . . 96

Ambient environment . . . . . . . . 96

Acoustic noise emission

(measurement according to

ISO7779) . . . . . . . . . . . . . . . . . 97

Automatic document feeder

specifications . . . . . . . . . . . . . . 97

Business card feeder specifications. .

500-sheet paper feed unit

specifications . . . . . . . . . . . . . . 98

Finisher specifications . . . . . . . 99

Printer specifications . . . . . . . 101

Network scanner / Internet Fax

specifications . . . . . . . . . . . . . 102

Pull scan function (TWAIN)

specifications . . . . . . . . . . . . . 103

Facsimile specifications . . . . . 104

61

72

91

98

2

Page 5

INFORMATION ON DISPOSAL . .

A. Information on Disposal for

Users (private households) . . 106

B. Information on Disposal for

Business Users. . . . . . . . . . . . 107

Note:

• Considerable care has been taken in preparing this manual. If you have any

comments or concerns about the manual, please contact your dealer or nearest

SHARP Service Department.

• This product has undergone strict quality control and inspection procedures. In the

unlikely event that a defect or other problem is discovered, please contact your

dealer or nearest SHARP Service Department.

• Aside from instances provided for by law, SHARP is not responsible for failures

occurring during the use of the product or its options, or failures due to incorrect

operation of the product and its options, or other failures, or for any damage that

occurs due to use of the product.

106

TO THE ADMINISTRATOR OF

THE MACHINE . . . . . . . . . . . . 110

Factory default passwords . . . 110

Forwarding all transmitted and

received data to the administrator

(document administration function)

For the users of the fax function . .

Trademark acknowledgments . .

. 110

111

112

Products that have earned the ENERGY STAR® are designed to

protect the environment through superior energy efficiency.

The products that meet the ENERGY STAR® guidelines carry the logo shown

above.

The products without the logo may not meet the ENERGY STAR

®

guidelines.

Warranty

While every effort has been made to make this document as accurate and helpful as possible,

SHARP Corporation makes no warranty of any kind with regard to its content. All information

included herein is subject to change without notice. SHARP is not responsible for any loss or

damages, direct or indirect, arising from or related to the use of this operation manual.

©Copyright SHARP Corporation 2008. All rights reserved. Reproduction,

adaptation or translation without prior written permission is prohibited, except as

allowed under copyright laws.

3

Page 6

TO ENSURE SAFE USE OF THE MACHINE

Cautions

• Do not make any modifications to

this machine.

Doing so may result in personal

injury or damage to the machine.

• Do not make copies of anything

which is prohibited from copying

by law.

The following items are normally

prohibited from printing by national

law. Other items may be prohibited

by local law.

●

Money ● Stamps ● Bonds

●

Stocks ● Bank drafts ● Checks

●

Passports ● Driver's licences

• Do not use a flammable spray to

clean the machine.

If gas from the spray comes in

contact with hot electrical

components or the fusing unit inside

the machine, fire or electrical shock

may result.

• Do not place a vessel that

contains water or other liquid on

the machine.

Do not place metal objects on the

machine that may fall into the

machine.

• In the event that a metal object

falls or liquid spills into the

machine, first turn off the

machine's main power switch

and then unplug the power cord.

• If a thunderstorm begins, turn off

the machine's main power switch

and unplug the power cord in

order to prevent electrical shock

and fire due to a lightning strike.

• If you see condensation on the

surface of the machine or on the

display, open the front cover and

right side cover and make sure

there is no condensation on the

inside of the machine. Also

check the area inside the front

cover that is hidden by the toner

collection container.

If condensation has formed inside

the machine, turn off the main

power. Turning on the main power

when condensation has formed

inside the machine may cause a

failure. Leave the cover open until

the condensation evaporates

naturally.

To keep foreign matter from getting

on the primary transfer belt unit or

secondary transfer roller unit while

the right cover is open, place a

cover over the opening.

• Do not plug in or unplug the

power cord with a wet hand.

• The machine emits a slight

amount of electromagnetic

radiation.

If you are using a pacemaker and

notice an abnormal feeling,

distance yourself from the machine.

If necessary, consult a doctor.

4

Page 7

Warnings

• Do not touch the transfer belt

and the transfer roller.

Scratches or smudges on the

transfer belt or transfer roller will

cause dirty prints.

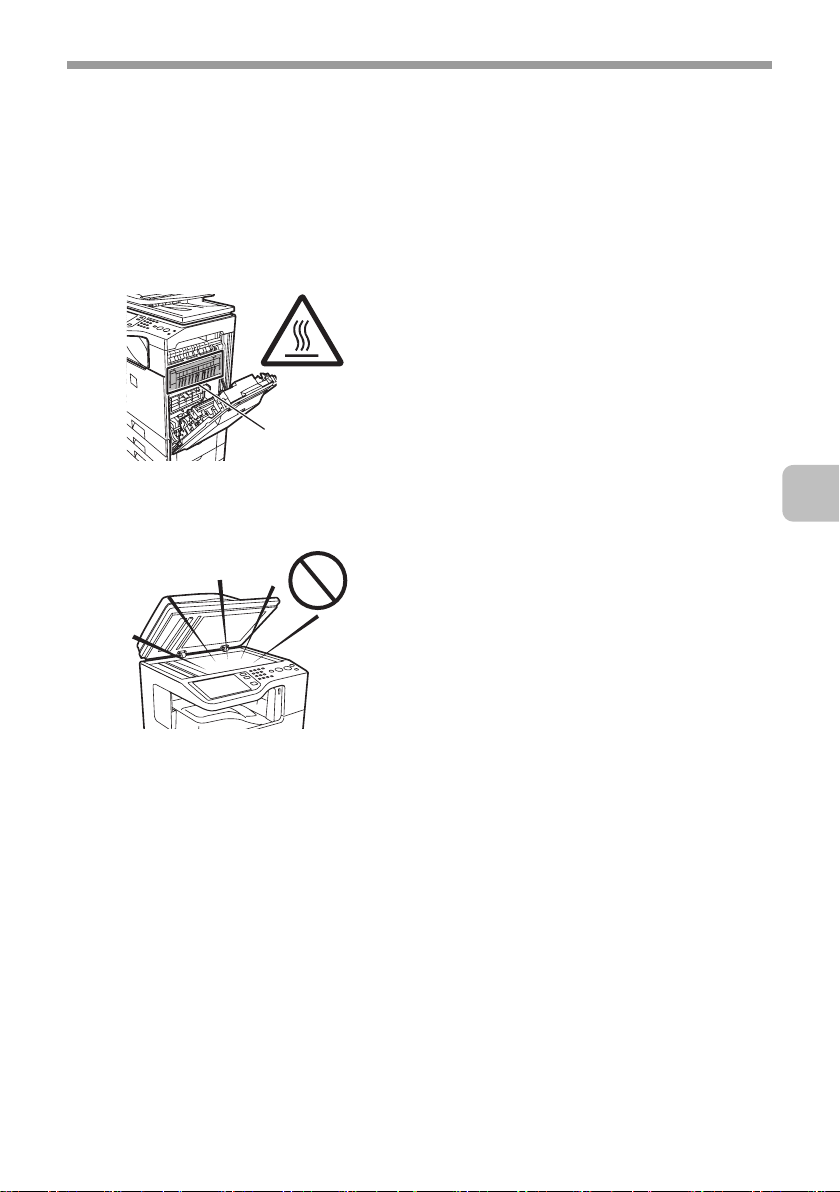

• The fusing unit is extremely hot.

Exercise care in this area.

Fusing unit

• Do not look directly at the light

source.

Doing so may damage your eyes.

TO ENSURE SAFE USE OF THE MACHINE

• Store toner, toner containers

(toner cartridges), and toner

collection containers out of the

reach of children.

• Do not place the machine on a

wobbly, slanted, or unstable

surface.

Install the machine only on a

surface that can withstand the

weight of the machine.

• When unplugging the power

cord, do not grasp and pull on

the cord.

• The machine is heavy.

Firmly grasp the moving handles so

that they do not slip out of your

hands. To prevent injury when

moving the machine, it is

recommended that it be moved by

four or more persons.

• Do not throw toner, a toner

container (toner cartridge), or a

toner collection container into a

fire.

Toner may fly and cause burns.

5

Page 8

TO ENSURE SAFE USE OF THE MACHINE

The machine includes the document filing function, which stores document image data

on the machine's hard drive. Stored documents can be called up and printed or

transmitted as needed. If a hard drive failure occurs, it will no longer be possible to call

up the stored document data. To prevent the loss of important documents in the

unlikely event of a hard drive failure, keep the originals of important documents or store

the original data elsewhere.

With the exception of instances provided for by law, Sharp Corporation bears no

responsibility for any damages or loss due to the loss of stored document data.

"BATTERY DISPOSAL"

THIS PRODUCT CONTAINS A LITHIUM PRIMARY MEMORY BACK-UP BATTERY

THAT MUST BE DISPOSED OF PROPERLY. PLEASE CONTACT YOUR LOCAL

SHARP DEALER OR AUTHORISED SERVICE REPRESENTATIVE FOR

ASSISTANCE IN DISPOSING OF THIS BATTERY.

Each instruction also covers the optional units used with these products.

6

Page 9

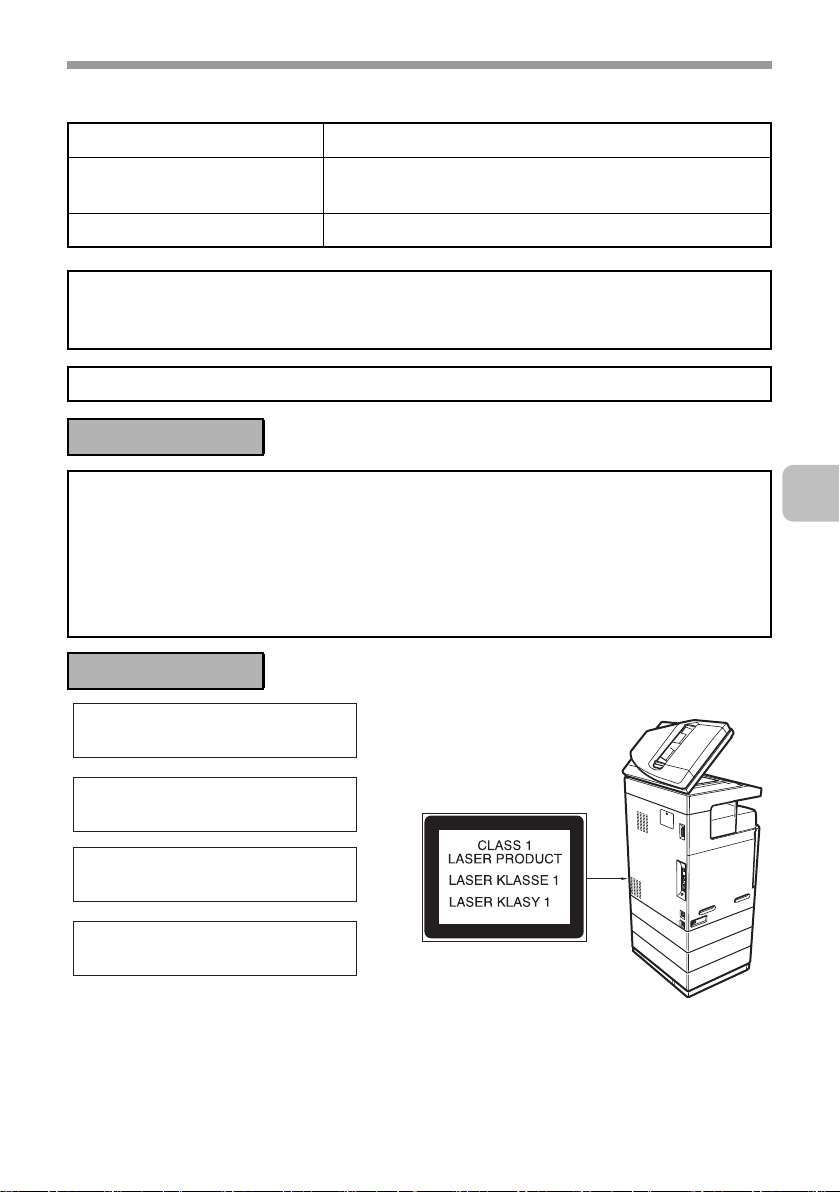

Laser information

Wave length 790 nm ±10 nm

TO ENSURE SAFE USE OF THE MACHINE

Pulse times

(North America and Europe)

Output power Max 0.6 mW (LD1+ LD2)

Caution

Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

This Digital Equipment is CLASS 1 LASER PRODUCT (IEC 60825-1 Edition 1.2-2001)

4.1 µs ±4.1 ns /7 mm

For North America:

SAFETY PRECAUTIONS

This Digital Equipment is rated Class 1 and complies with 21 CFR 1040.10 and

1040.11 of the CDRH standards. This means that the equipment does not produce

hazardous laser radiation. For your safety, observe the precautions below.

• Do not remove the cabinet, operation panel or any other covers.

• The equipment's exterior covers contain several safety interlock switches. Do not

bypass any safety interlock by inserting wedges or other items into switch slots.

For Europe:

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

7

Page 10

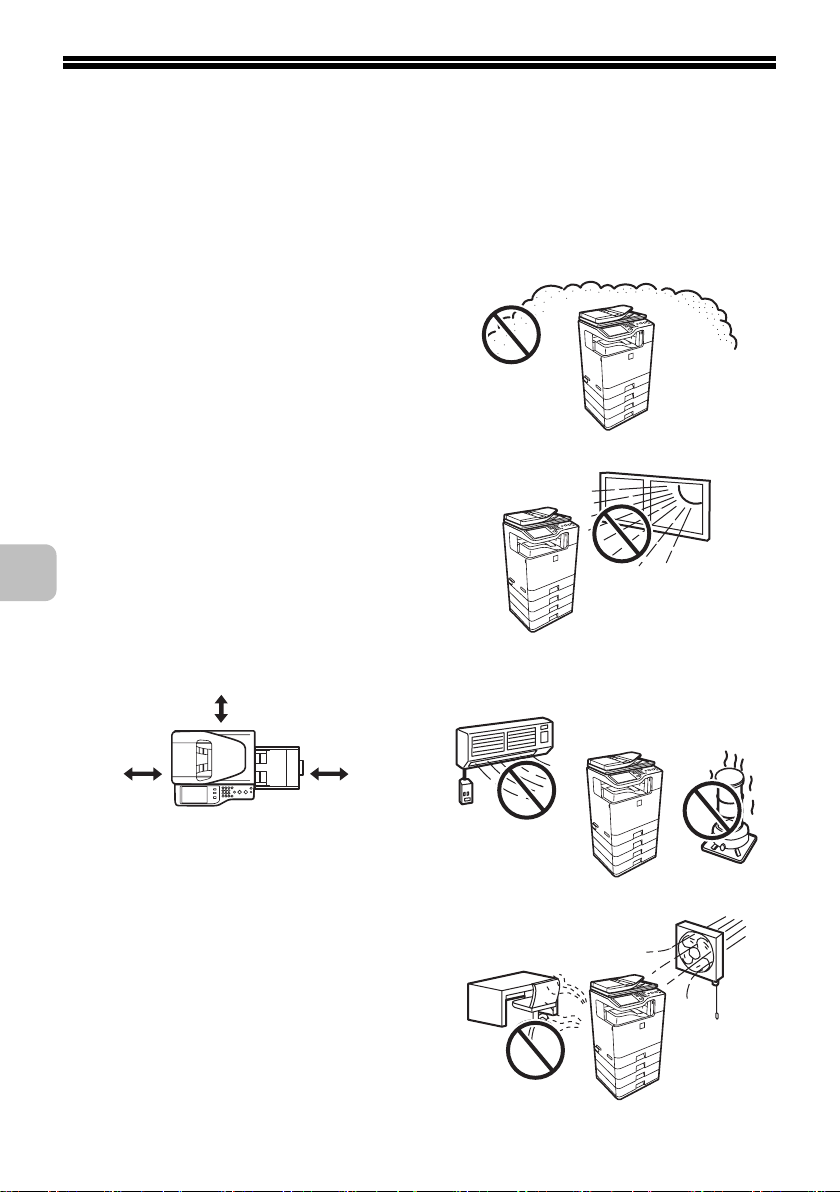

INSTALLATION REQUIREMENTS

Improper installation may damage this product. Please note the following during

initial installation and whenever the machine is moved.

1. The machine should be installed

near an accessible power outlet for

easy connection.

2. Be sure to connect the power cord

only to a power outlet that meets

the specified voltage and current

requirements. Also make certain

the outlet is properly grounded.

• For the power supply

requirements, see the name plate

in the lower left corner of the left

side of the machine.

Connect the machine to a power

outlet which is not used for other

electric appliances. If a lighting

fixture is connected to the same

outlet, the light may flicker.

3. Be sure to allow the required space

around the machine for servicing

and proper ventilation.

30 cm

(11-13/16")

30 cm

(11-13/16")

45 cm

(17-23/32")

6. Do not install the machine in areas

that are:

• damp, humid, or very dusty

• exposed to direct sunlight

z

• subject to extreme temperature

or humidity changes, e.g., near

an air conditioner or heater

4. The machine includes a built-in

hard drive. Do not subject the

machine to shock or vibration. In

particular, never move the machine

while the power is on.

5. The installation surface must be

level and rigid. If the machine is

operated when tilted at an angle,

failure may result.

8

• poorly ventilated.

Page 11

INSTALLATION REQUIREMENTS

CAUTION:

Do not install the machine in a location with poor air circulation.

A small amount of ozone is created inside the machine during printing. The amount of

ozone created is not sufficient to be harmful; however, an unpleasant odor may be

noticed during large copy runs, and thus the machine should be installed in a room with

a ventilation fan or windows that provide sufficient air circulation. (The odor may

occasionally cause headaches.)

* Install the machine so that people are not directly exposed to exhaust from the

machine. If installed near a window, ensure that the machine is not exposed to direct

sunlight.

9

Page 12

SUPPLIES

As you use the machine, it will become necessary to replace supplies such as

paper and toner cartridges.

Be sure to use SHARP-specified supplies, including paper and toner cartridges.

For best copying results, be sure to use only Sharp Genuine

Supplies which are designed, engineered, and tested to

maximize the life and performance of Sharp products. Look for

the Genuine Supplies label on the toner package.

GENUINE SUPPLIES

Storage of supplies

Proper storage

1. Store the supplies in a location that is:

• clean and dry

• at normal temperature with minimal temperature fluctuations

• not exposed to direct sunlight

2. Store paper in the wrapper and lying flat.

3. Paper stored in packages standing up or out of the wrapper may curl or

become damp, resulting in paper misfeeds.

Storing toner cartridges or developer cartridges

Store the box that contains the toner cartridge or developer cartridge

horizontally; do not store it standing up. If the toner cartridge or developer

cartridge is stored standing up, the toner or developer may solidify inside the

cartridge.

Store the toner cartridge or developer cartridge in a location that is cooler than

40°C (104°F). Storage in a hot location may cause the toner or developer in the

cartridge to solidify.

Storing drum cartridges

Store the box that contains the drum cartridge horizontally; do not store it

standing up.

Store the drum cartridge in a location that is cooler than 40°C (104°F). Storage

in a hot location may cause failure.

Staple cartridge

The finisher requires the following staple cartridge:

MX-SCX1 (for finisher)

Approx. 5000 per cartridge x 3 cartridges

10

Page 13

SUPPLIES

Supply of spare parts and consumables

The supply of spare parts for repair of the machine is guaranteed for at least 7

years following the termination of production. Spare parts are those parts of the

machine which may break down within the scope of the ordinary use of the

product, whereas those parts which normally exceed the life of the product are

not to be considered as spare parts. Consumables too, are available for 7 years

following the termination of production.

11

Page 14

REPLACING SUPPLIES AND

MAINTENANCE

This section explains the procedures for replacing supplies such as toner and

staple cartridges and routine maintenance.

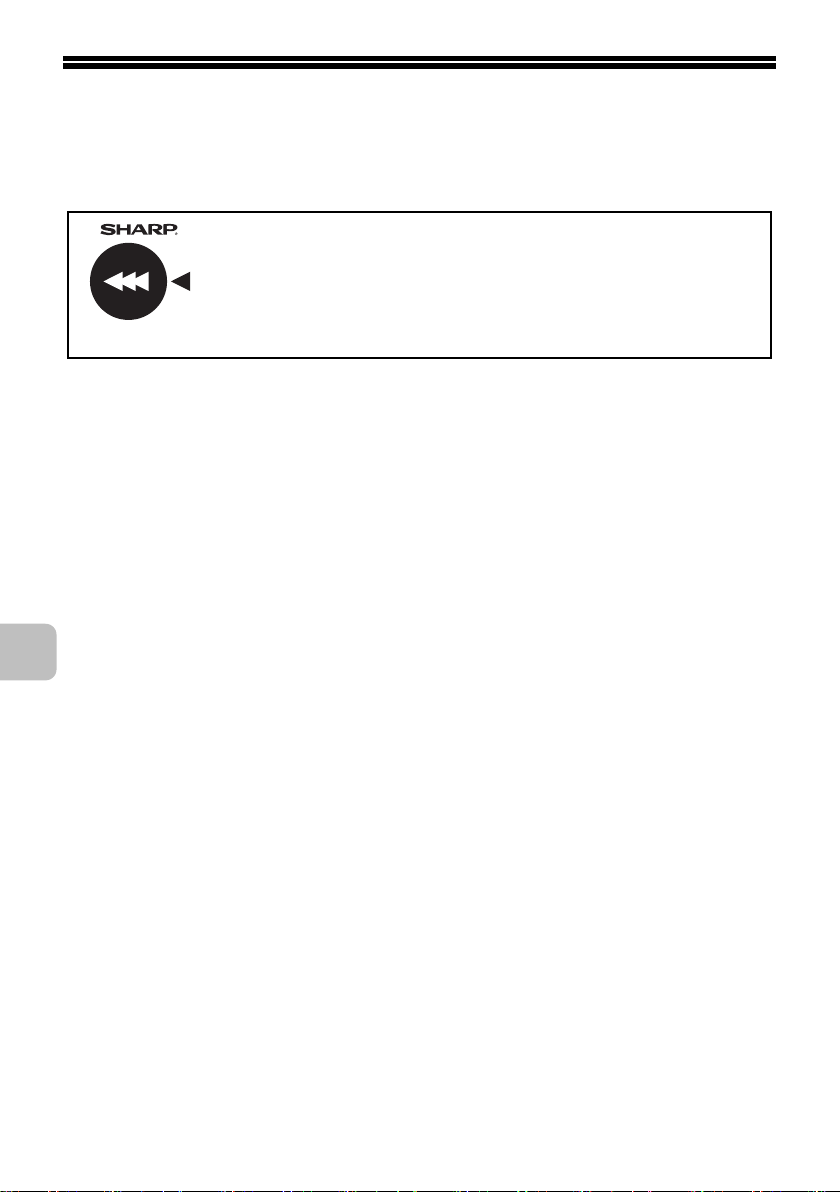

Replacement time for supplies

When it is time to replace a supply item, a message will appear in the display.

Change the supplies.

Toner Cartridge

Developer Cartridge

(1)

(2)

Drum Cartridge

Primary Transfer Belt Unit

Secondary Transfer Roller Unit

Toner Collection Container

The supplies will be needed soon.

Toner Cartridge

Developer Cartridge

Drum Cartridge

Fusing Unit

OK

(1) The item requiring replacement will be indicated.

Replace the item when this message appears.

(3)

(3)

(2) A supply item that will soon require replacement is displayed.

When this message appears, obtain a new item and have it ready for replacement

whenever necessary.

(3) For items such as toner cartridges, developer cartridges, and

drum cartridges that come in different colours, the colour that

is low or has run out is indicated in "( )"

Y

: Yellow, : Magenta, : Cyan, : Black

When a message prompting you to replace a supply item appears, replace the

item promptly.

• You can also check supply replacement times in the Web page.

• Registration is performed in [Device Status] in [Machine Identification] in the

M C

Web page menu.

Bk

12

Page 15

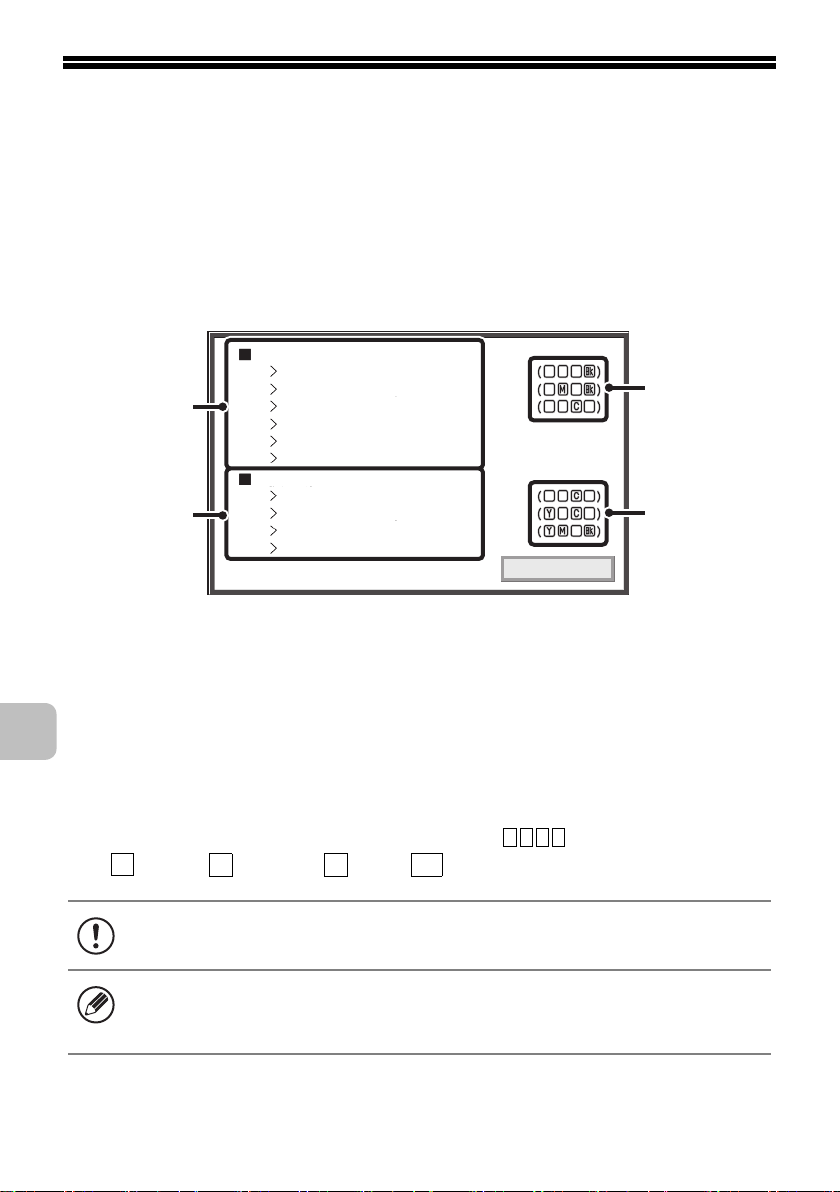

Supplies

REPLACING SUPPLIES AND MAINTENANCE

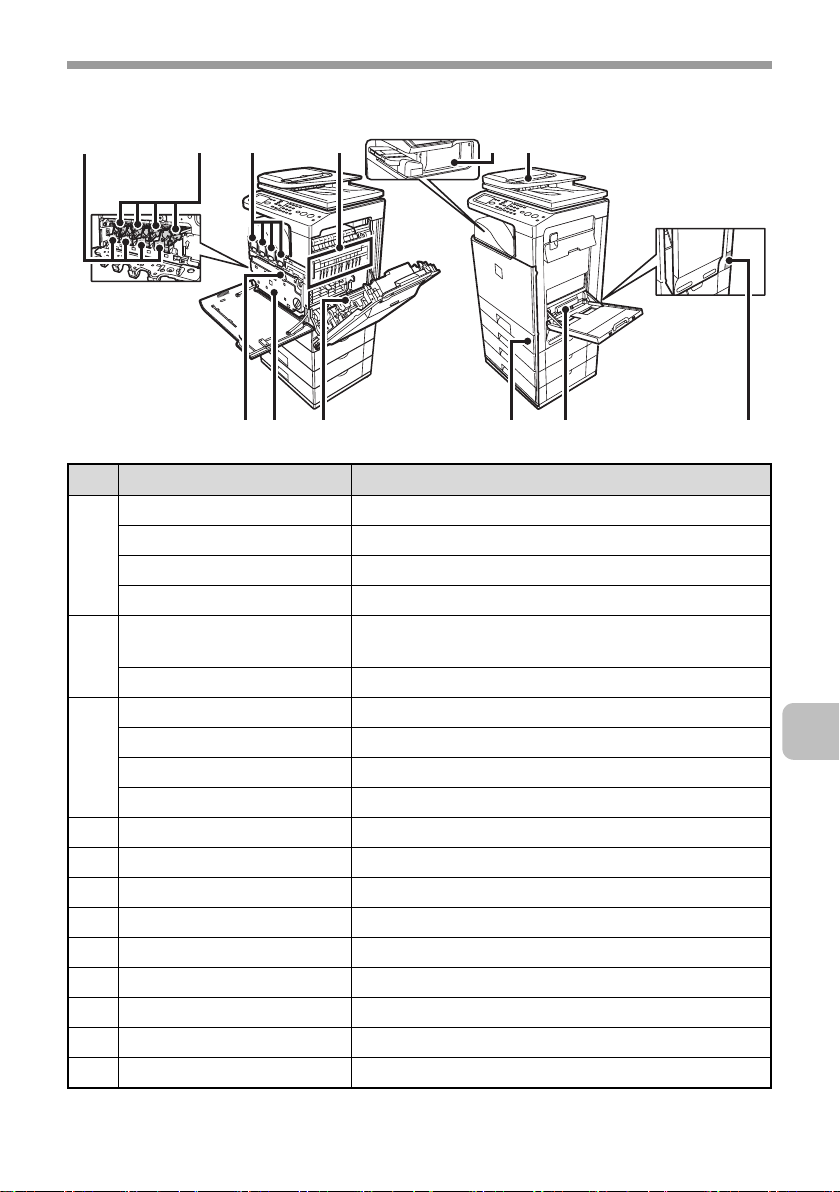

(1)

(3)(2) (4) (5) (6)

(8) (11)(7) (9) (10) (12)

No. Model Name

(1) MX-C40NVB Developer cartridge (black)

MX-C40NVC Developer cartridge (cyan)

MX-C40NVM Developer cartridge (magenta)

MX-C40NVY Developer cartridge (yellow)

(2) MX-C40NRB Drum cartridge (black) (including main charger

cleaner)

MX-C40NRS Drum cartridge (colour)

(3) DX-C40NTB Toner cartridge (black)

DX-C40NTC Toner cartridge (cyan)

DX-C40NTM Toner cartridge (magenta)

DX-C40NTY Toner cartridge (yellow)

(4) MX-C31FU1 Fusing unit (including ozone filter)

(5) MX-SCX1 Staple cartridge

(6) MX-C31DF DF roller kit

(7) MX-C31U1 Primary transfer belt unit

(8) MX-C31HB Toner collection container

(9) MX-C31U2 Secondary transfer roller unit

(10) MX-C31RT Feeding roller kit

(11) MX-C31MR MF feeding roller kit

(12) MX-C31FU1 Ozone filter (included in the fusing unit package)

13

Page 16

REPLACING SUPPLIES AND MAINTENANCE

Replacing the toner cartridges

When it is time to replace a supply item, a message instructing you to replace

the item will appear in the display.

When replacing a toner cartridge, carefully check the indicated colour and

replace the toner cartridge for that colour.

• Do not replace a supply item before the replacement message appears in the

display.

• After using up a cartridge, pack it with the packing case, packing material and

bag that are used for the original cartridge.

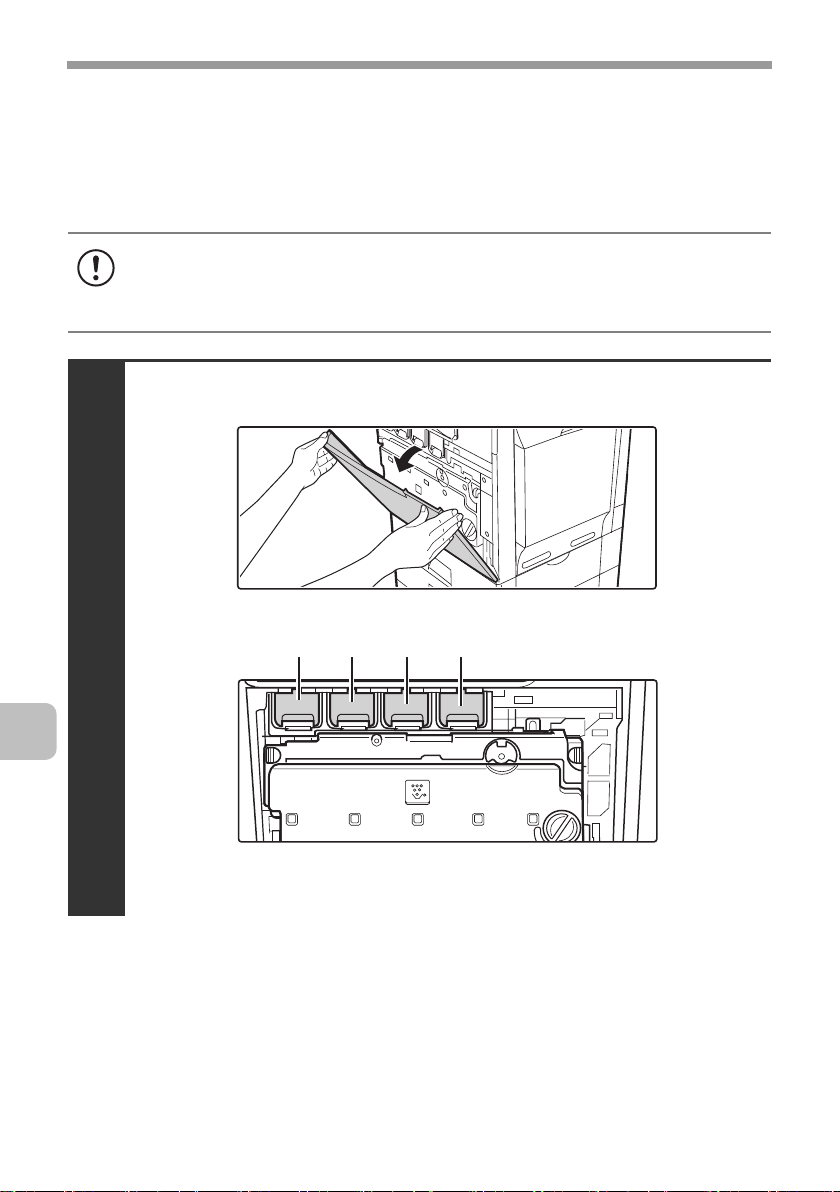

Open the front cover.

Locations of colour toner cartridges

1

(M)(Y) (C) (Bk)

14

(Y): Yellow (M): Magenta

(C): Cyan (Bk): Black

Page 17

REPLACING SUPPLIES AND MAINTENANCE

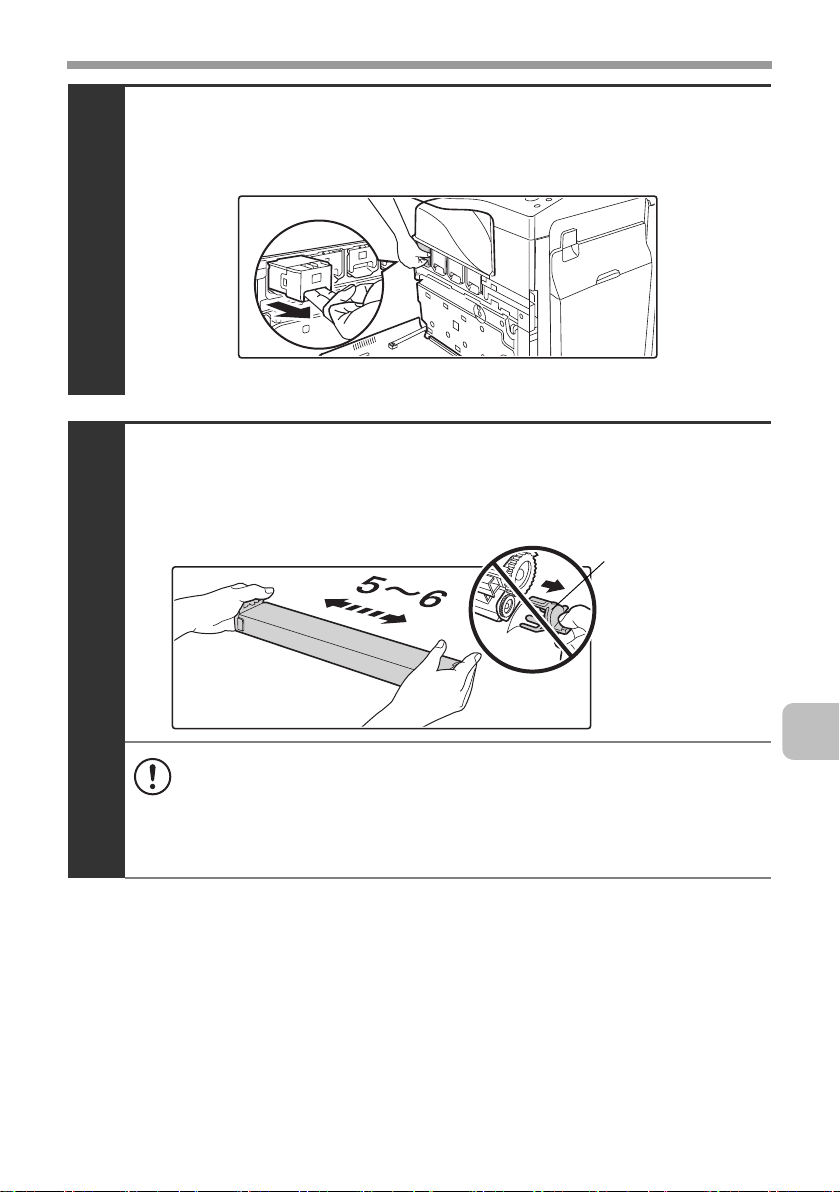

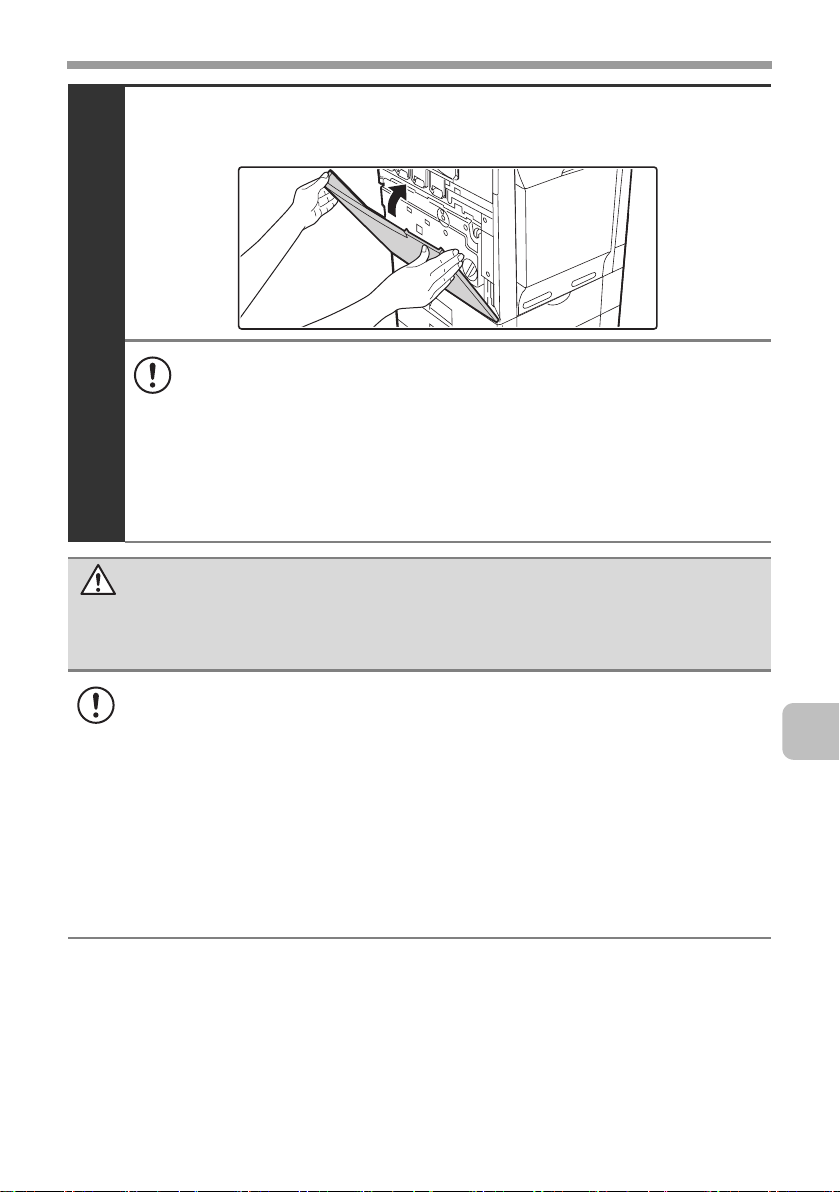

Pull the toner cartridge toward you.

Example: Replacing the yellow toner cartridge

2

Take out the new toner cartridge, hold it with both

hands, and shake 5 or 6 times horizontally.

Protective

material

3

• When shaking the toner cartridge, be sure to shake with the protective

material inserted in the cartridge. If you shake the cartridge after

removing the protective material, toner may spill out.

• Shake the toner cartridge only in the horizontal direction. If shaken in

any other direction, toner may collect in one part of the cartridge.

15

Page 18

REPLACING SUPPLIES AND MAINTENANCE

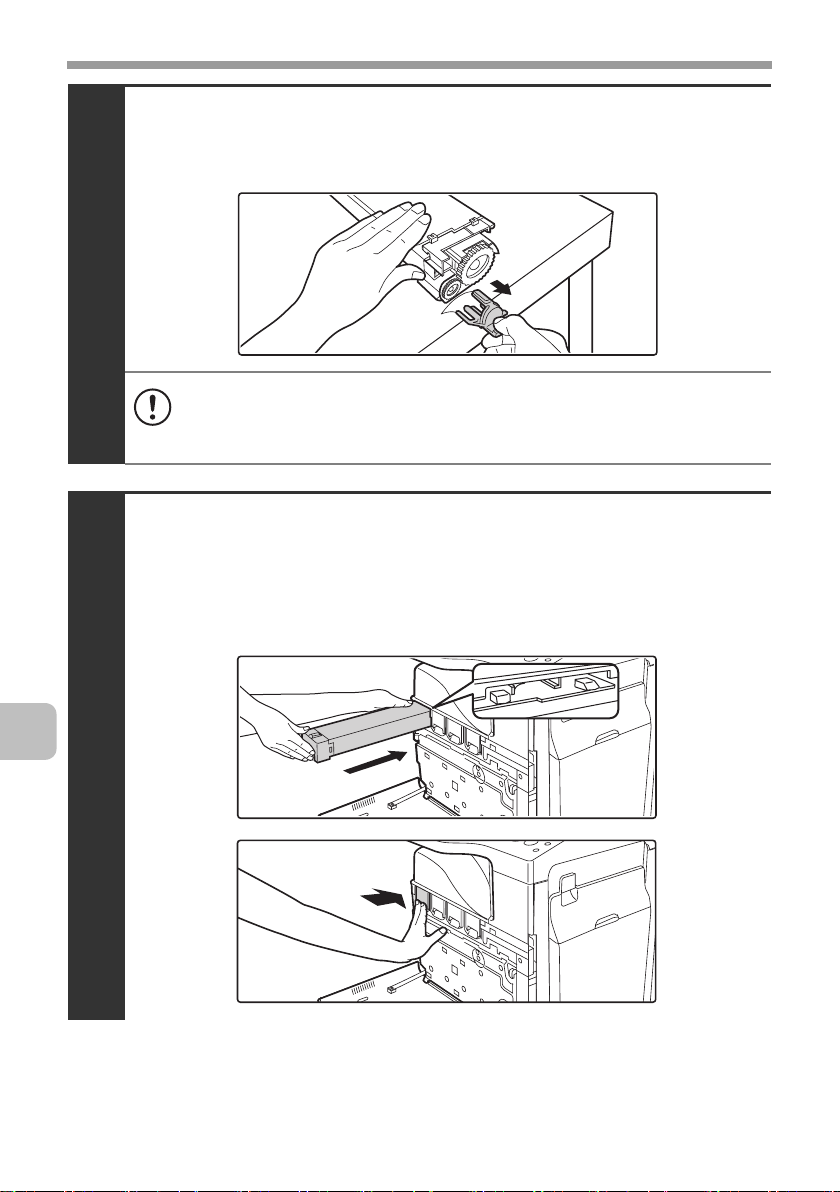

Remove the protective material from the new toner

cartridge.

4

• Hold the toner cartridge firmly while removing the protective material.

• After the protective material has been removed, do not point the toner

cartridge down or shake it. Toner may spill out.

Insert the new toner cartridge horizontally and

push it firmly in.

The shape of the toner cartridge varies by colour. Insert in the same location as

the toner cartridge that was removed.

16

5

Page 19

REPLACING SUPPLIES AND MAINTENANCE

Close the front cover.

6

• Before moving the machine, remove the toner cartridge. Moving the

machine with the toner cartridge installed may cause a failure.

• When the developer cartridge has been removed, do not remove or

insert the toner cartridge. This may cause a failure.

• After the toner cartridge is replaced, the machine automatically enters

image adjustment mode. Image adjustment will not take place if the

cover is not closed.

• Take care that your fingers are not pinched when closing the cover.

Caution

• Do not throw a toner cartridge into a fire. Toner may fly and cause burns.

• Store toner cartridges out of the reach of small children.

• Store the box that contains the toner cartridge horizontally; do not store it

standing up. If the toner cartridge is stored standing up, the toner may solidify

inside the cartridge.

Store the toner in a location that is cooler than 40°C (104°F). Storage in a hot

location may cause the toner in the cartridge to solidify.

• If a toner cartridge other than a SHARP-recommended toner cartridge is

used, the machine may not attain full quality and performance and there is a

risk of damage to the machine. Be sure to use a SHARP-recommended

toner cartridge.

• Place the old toner cartridge in the bag that contained the new toner

cartridge, seal the bag, and place it in the box.

17

Page 20

REPLACING SUPPLIES AND MAINTENANCE

• Keep the used toner cartridge in a plastic bag (do not discard it).

•

To view the approximate amount of

toner remaining, continually touch

the [COPY] key during printing or

when the machine is idle. The

percentage of toner remaining will

appear in the display while the key

is touched. When the percentage

falls to "25-0%", obtain a new toner cartridge and keep it ready for replacement.

When the remaining toner falls to "25-0%", colours in the output may be faint or

partially missing when an original or image with dark colours is copied or

printed.

Total Count B/W:00,000,000

Full Colour:00,000,000

2-colour:00,000,000

Single colour:00,000,000

Toner Quantity [Bk]:100-75%

[C]:100-75%

[M]:100-75%

[Y]:100-75%

18

Page 21

REPLACING SUPPLIES AND MAINTENANCE

Replacing the toner collection container

The toner collection container collects excess toner that is produced during printing.

When it is time to replace a supply item, a message instructing you to replace

the item will appear in the display. Follow the procedure below to replace the

toner collection container. It is also necessary to remove the toner collection

container in order to replace the transfer unit. Refer to the procedure below to

remove the toner collection container when replacing the transfer unit.

• Do not subject the toner collection container to shock. The amount of

collected toner may be incorrectly detected and cause machine failure.

• Do not replace a supply item before the replacement message appears in the

display.

• Toner may spill when the toner collection container is replaced. Before

replacing the toner collection container, take measures such as placing

covers on and around the machine to prevent soiling.

Open the front cover.

1

19

Page 22

REPLACING SUPPLIES AND MAINTENANCE

Release the used toner collection container.

(1) Turn the toner collection container lock lever to the

right until it is horizontal.

2

(2) Tip the toner collection container forward.

Grasp the toner collection container with both hands at the marks on the upper

right and lower left of the container and slowly tip the container toward you.

Mark

Mark

20

Remove the toner collection container.

3

• If the toner collection container is tipped forward too far, it will not be

possible to remove it.

• Do not point the holes down as used toner will spill out.

• Hold the container by both hands and lift it up slowly.

• Do not discard the toner collection container. Place it in a plastic bag

and keep it until it is collected by a service.

Page 23

REPLACING SUPPLIES AND MAINTENANCE

Install the new toner collection container.

Insert the container from above at a slant. (The direction opposite to when you

removed it.)

4

(2)

(1)

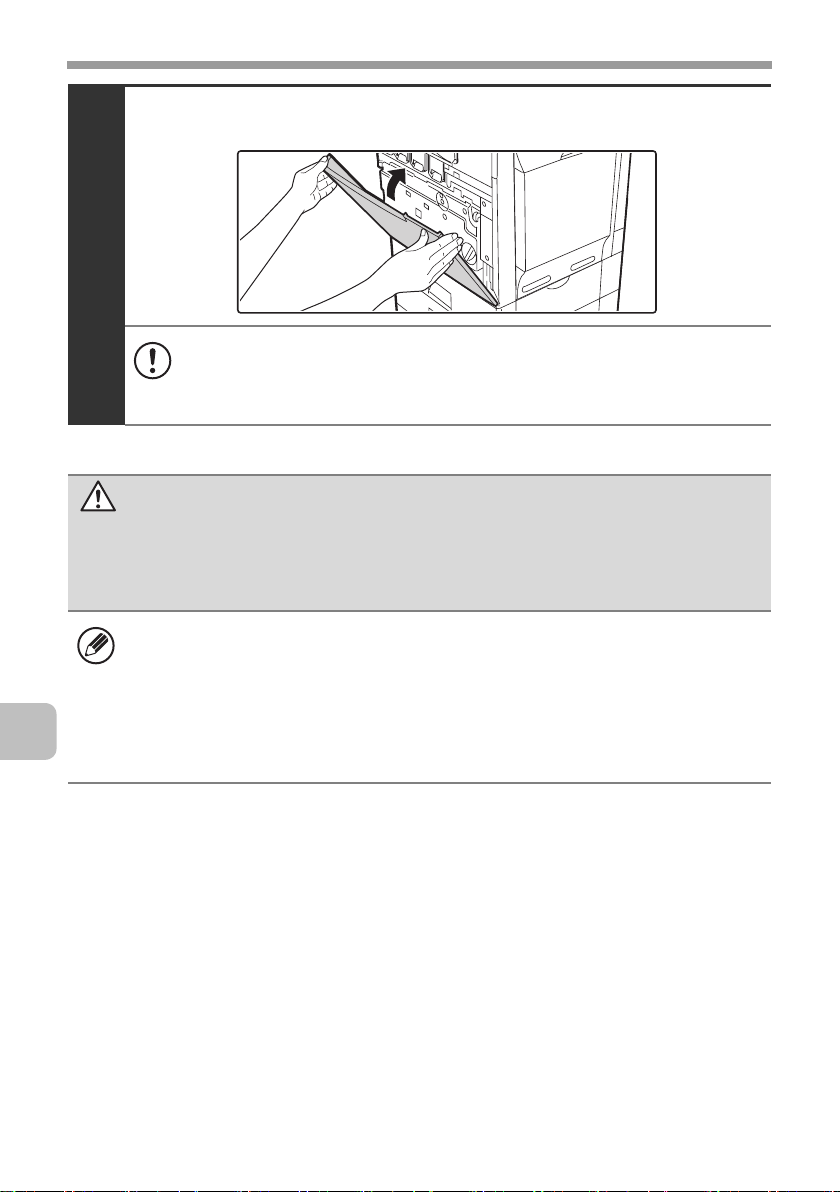

Turn the lock lever on the toner collection

container to the left.

Turn the lock lever to the left until it stops.

5

If the lock lever does not turn, check if the toner collection container is

installed correctly. In particular, make sure that the top left corner of the

toner collection container is correctly in place.

21

Page 24

REPLACING SUPPLIES AND MAINTENANCE

Close the front cover.

6

• If the toner collection container is tipped forward too far, it will not be

possible to remove it.

• Do not point the holes down as used toner will spill out.

• Take care that your fingers are not pinched when closing the cover.

Caution

• Do not throw the toner collection container into a fire. Toner may fly and

cause burns.

• Store the toner collection container out of the reach of small children.

22

• Place the old toner collection container in the bag that contained the new

toner collection container, seal the bag, and place it in the box.

• Toner may spill when the toner collection container is replaced. Take

measures so that there will be no problem if toner spills on the machine,

around the machine, or on your clothes.

• Do not touch the part soiled with toner of the removed toner collection

container. If you accidentally touch the toner, immediately wash your hands.

Page 25

REPLACING SUPPLIES AND MAINTENANCE

Replacing the developer cartridge / drum cartridge

Before replacing the developer cartridge or drum cartridge, turn off the main

power of the machine and wait briefly.

Replacing the developer cartridge

When it is time to replace a supply item, a message instructing you to replace

the item will appear in the display. When replacing a developer cartridge,

carefully check the indicated colour and replace the developer cartridge for that

colour.

It is also necessary to remove the developer cartridge in order to replace the

drum cartridge. Refer to the procedure below to remove the developer cartridge

when replacing the drum cartridge.

Do not replace a supply item before the replacement message appears in the

display.

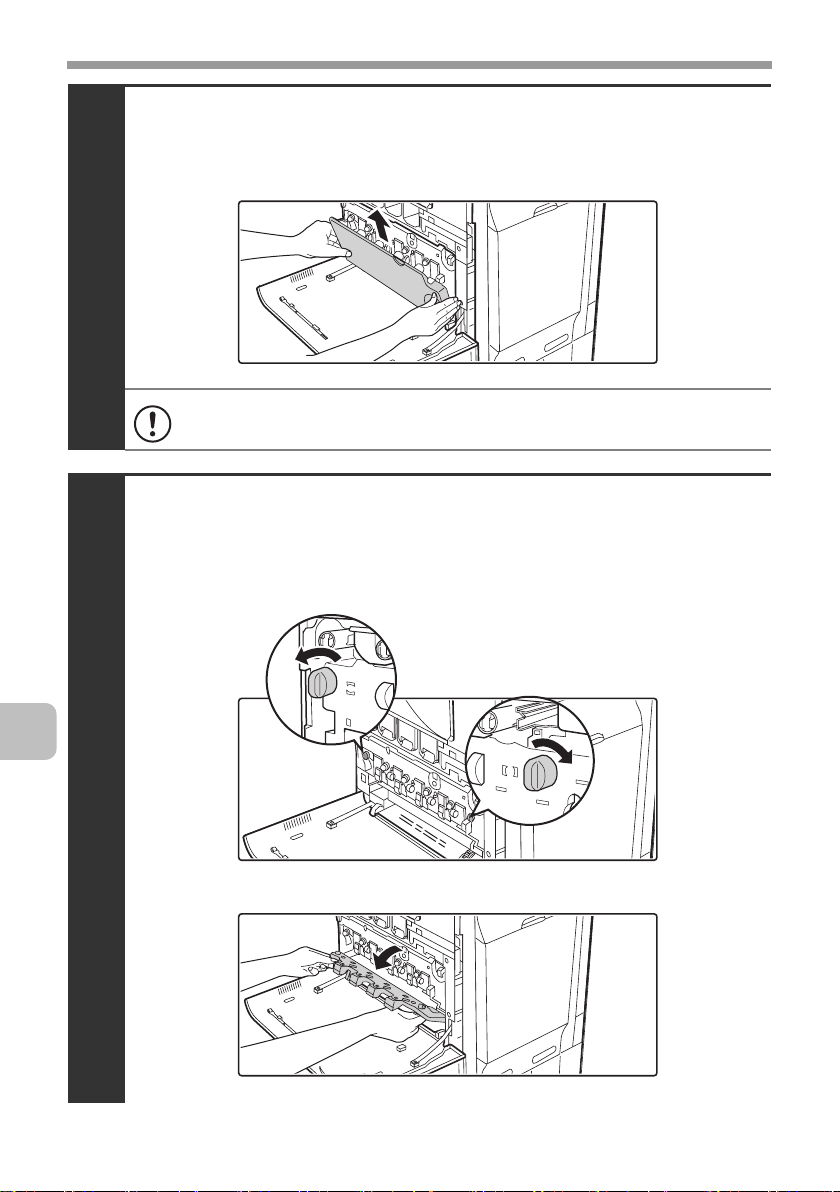

Press the [POWER] key ( ) on the operation panel

to turn off the panel power, and then switch the

main power switch to the off position.

1

23

Page 26

REPLACING SUPPLIES AND MAINTENANCE

Open the front cover and remove the toner

collection container.

☞ Replacing the toner collection container (page 19)

2

Do not point the holes down as used toner will spill out.

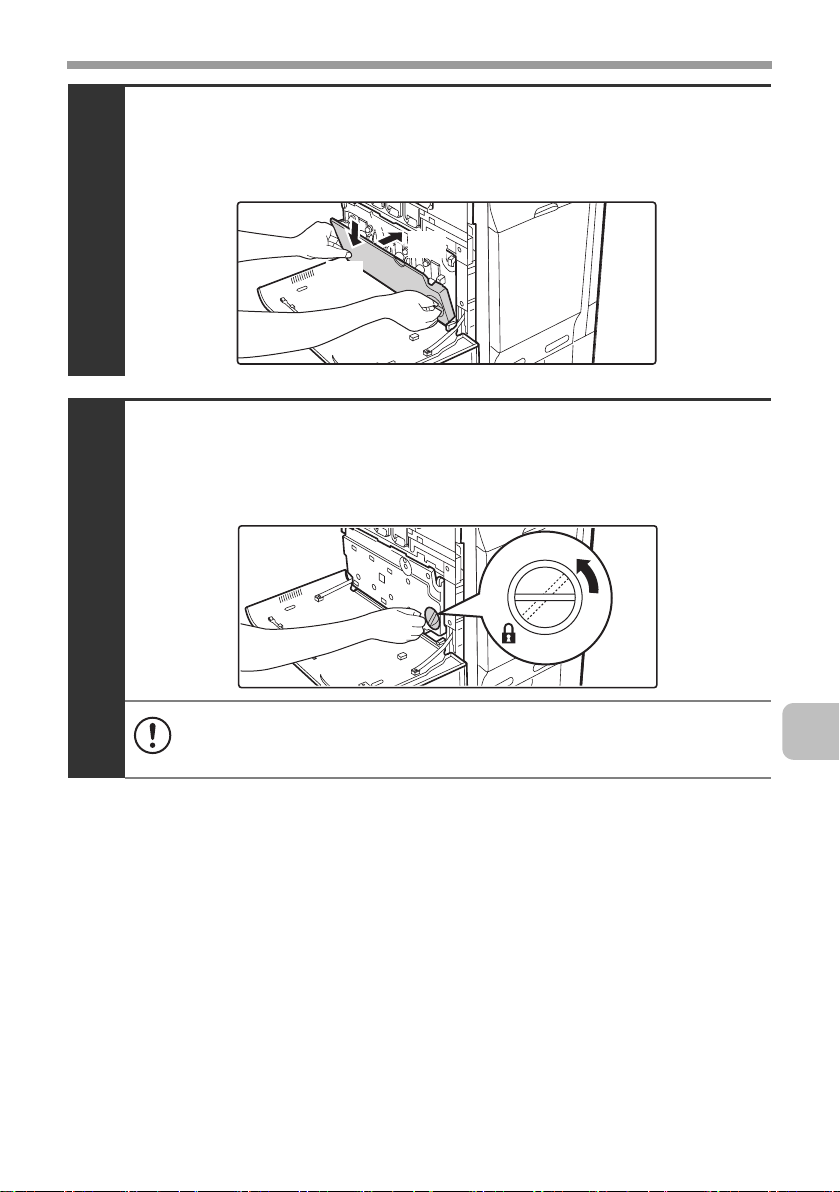

Open the main charger cover.

(1) Turn the main charger cover lock levers in the direction

of an arrow below.

When the lock levers are horizontal, the lock is released.

24

3

(2) Grasp the lock levers and tip the cover forward.

Page 27

REPLACING SUPPLIES AND MAINTENANCE

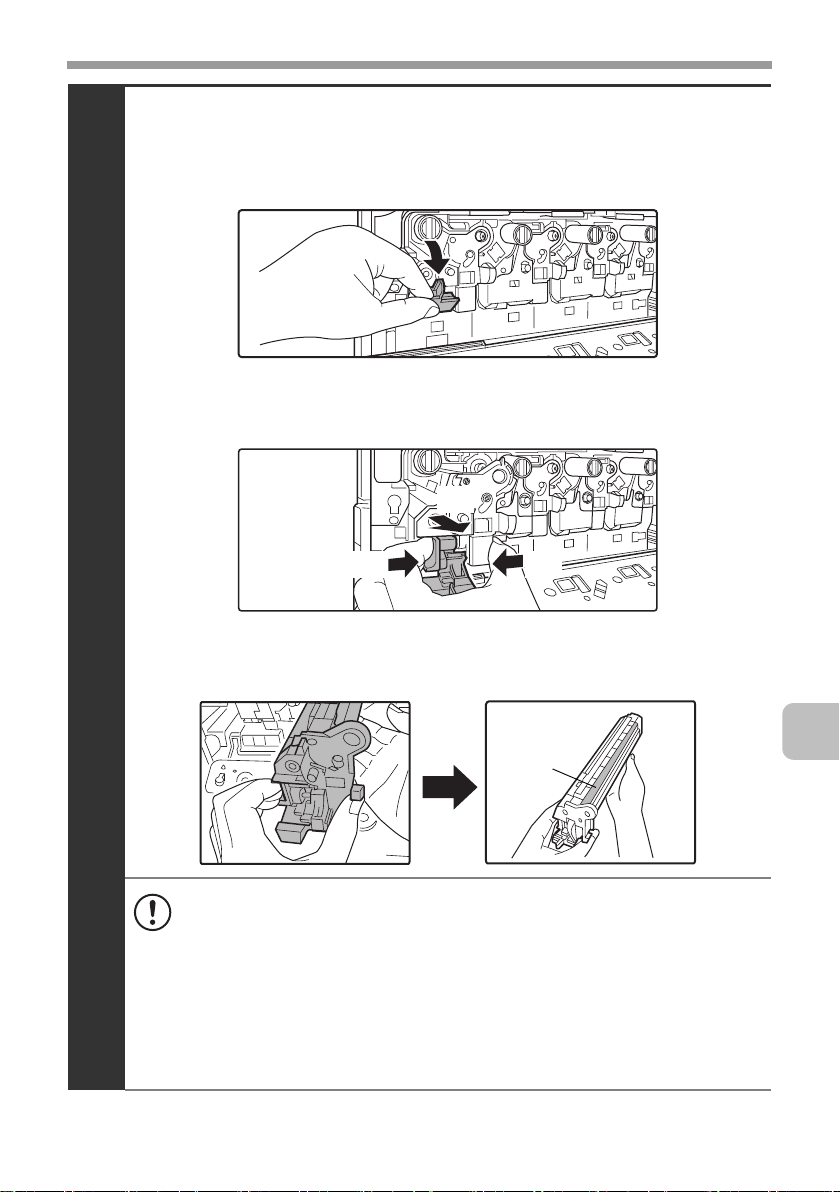

Remove the developer cartridge.

(1) Grasp the developer cartridge lock and pull it forward

and down.

(2) Squeeze the lever on the developer cartridge

(3) Pull the developer cartridge out horizontally.

(3)

(2) (2)

4

(4)

Support the developer cartridge near the middle with your

hand and completely remove the developer cartridge.

Roller

• When removing the developer cartridge, grasp it with both hands at

the middle.

• Try to keep the developer cartridge horizontal as you remove it. If

tipped during removal, developer may spill out.

• There will be toner on the roller area of the removed developer

cartridge. Do not touch the roller area. If you accidentally touch the

toner, immediately wash your hands.

• Place the old developer cartridge in the bag that contained the new

developer cartridge, seal the bag, and place it in the box.

25

Page 28

REPLACING SUPPLIES AND MAINTENANCE

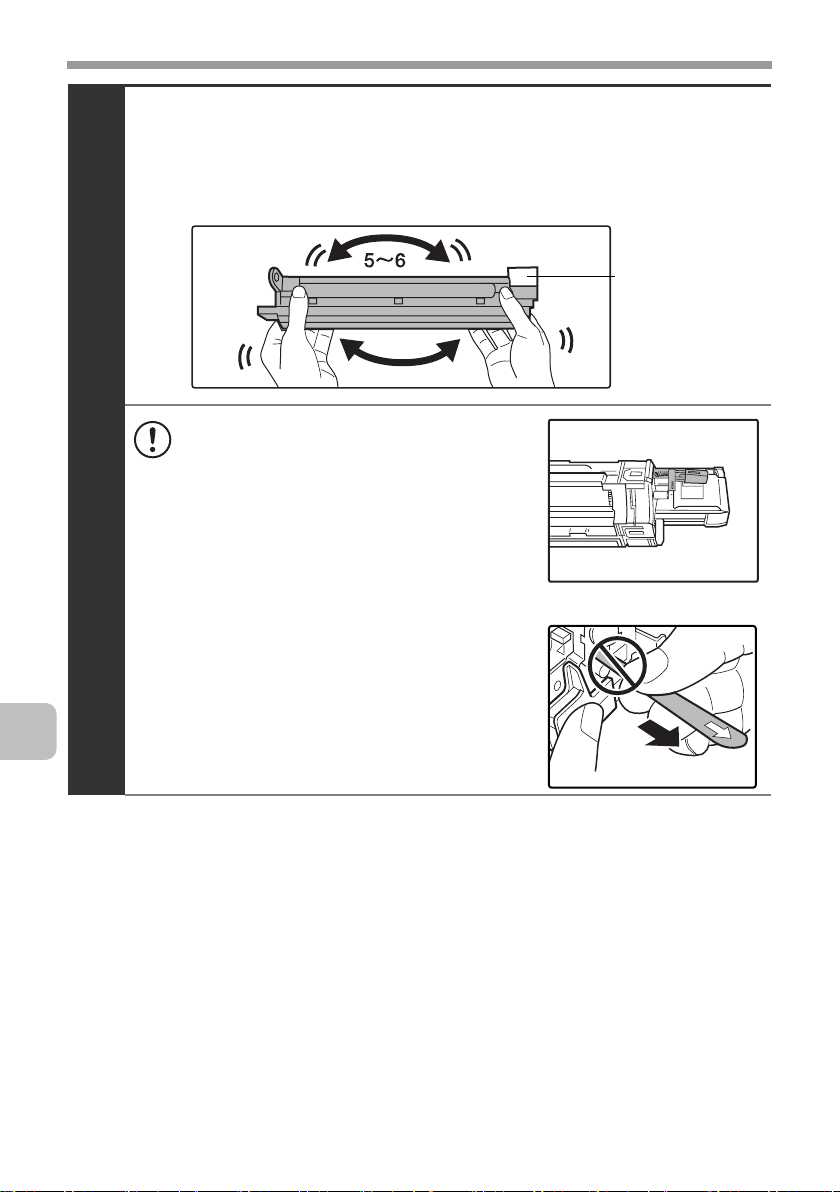

Shake the new developer cartridge 5 or 6 times as shown.

Hold the developer cartridge firmly as shown below and shake forward and

back, left and right.

Remove the protective material after shaking the developer cartridge.

• The part of the developer cartridge

5

shown in the next illustration is easily

deformed or damaged. Do not touch

this part when handling the cartridge.

• Do not touch the roller in the

developer cartridge. If the roller is

accidentally touched, image problems

may result. In that case, replace the

developer cartridge with a new cartridge.

• The seal must not be removed when

shaking the new developer cartridge.

• Take care not to damage the developer

cartridge when shaking it. If damaged,

the developer in the cartridge may leak

out.

Protective

material

26

Page 29

REPLACING SUPPLIES AND MAINTENANCE

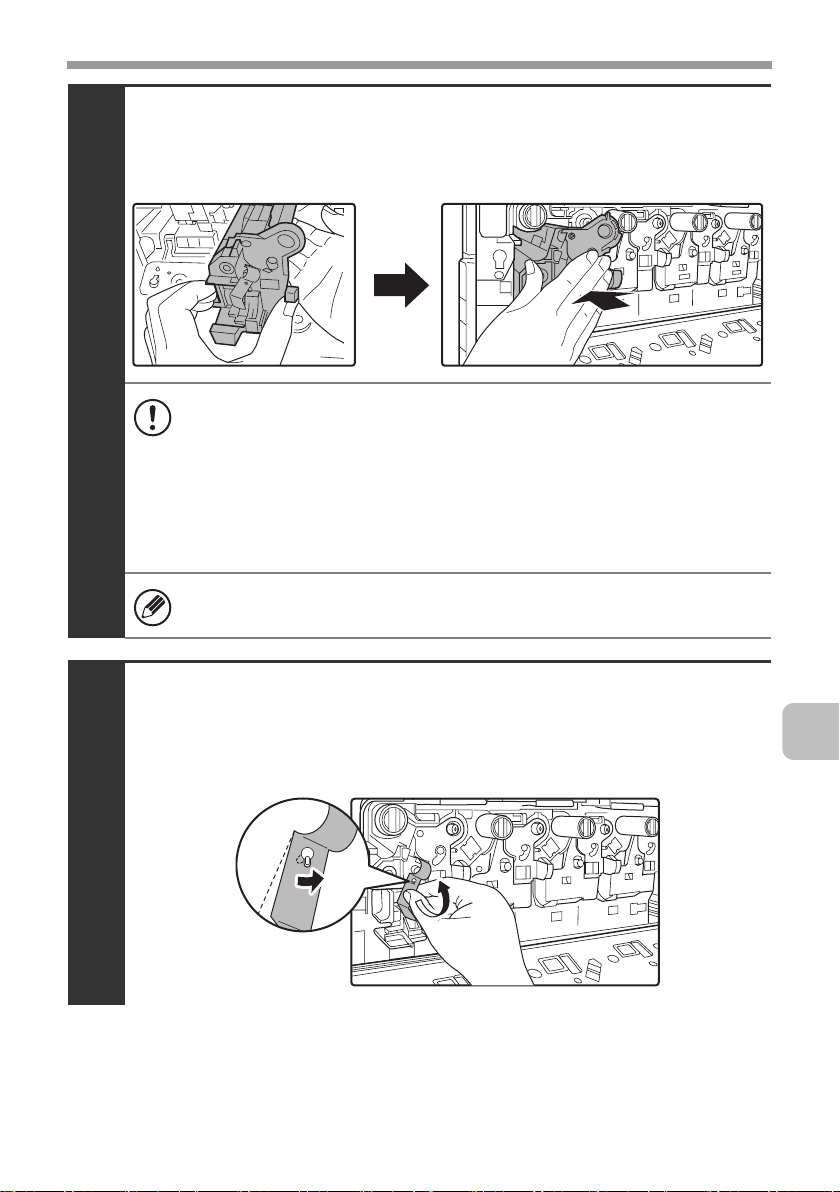

Insert the new developer cartridge horizontally.

Insert the new developer cartridge in the same location as the cartridge that

was removed.

6

• Do not tilt the developer cartridge or insert it in the wrong direction or

orientation. This may damage the developer cartridge or drum

cartridge and cause failure.

• When inserting the developer cartridge, grasp it with both hands at

the middle.

• Do not remove the seal from the developer cartridge until the

cartridge is installed in the machine. If the seal is removed when the

cartridge is not locked, the cartridge may fall out of the machine.

Insert with the arrow on the cartridge aligned with the arrow on the

machine.

Detach the end of the seal from the developer

cartridge.

Align the notch in the seal with the tab on the attachment part and pull up. Be

careful not to completely remove the seal by pulling too hard.

7

27

Page 30

REPLACING SUPPLIES AND MAINTENANCE

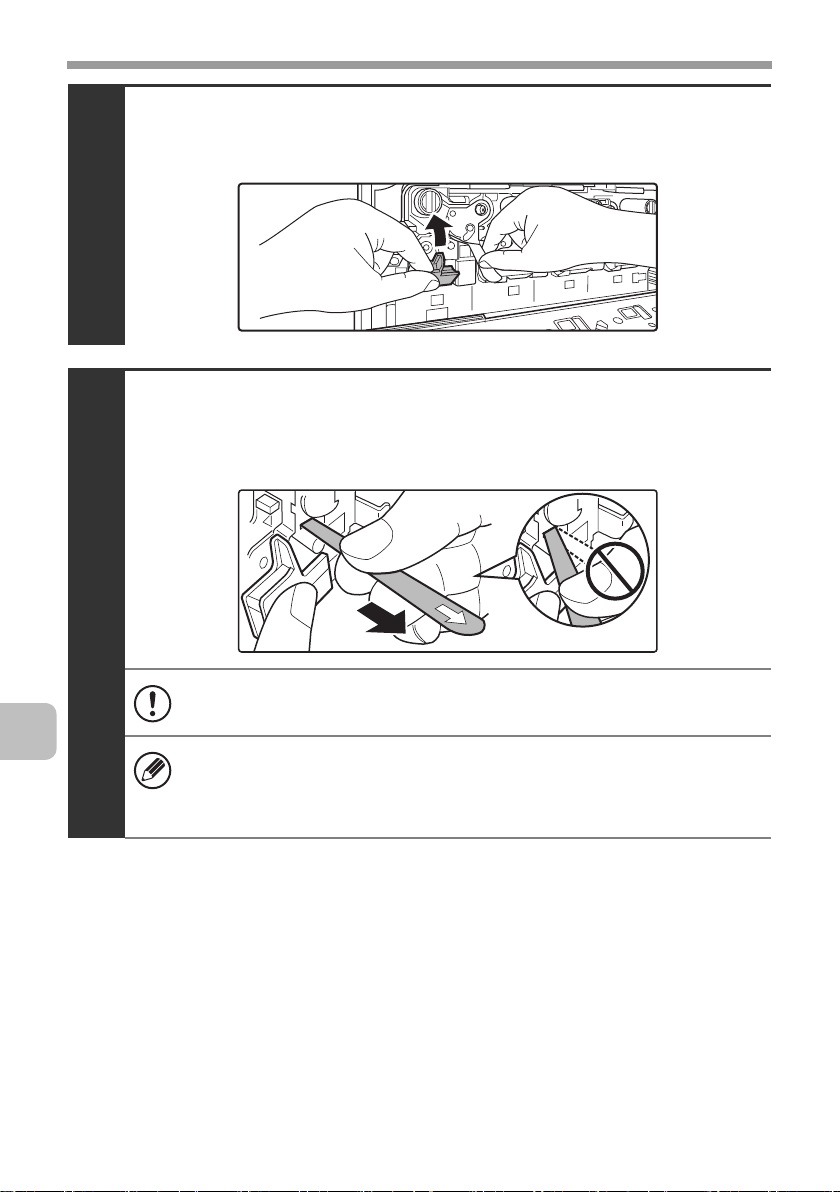

Grasp the developer cartridge lock and replace it

on the machine.

8

Hold the developer cartridge with one hand and

slowly remove the seal with the other hand.

Slowly pull the seal straight and horizontally out.

9

28

If excessive force is used or the seal is pulled out diagonally, it may tear.

There is a mark (red belt) on the end of the seal. After removing the

seal, be sure to verify that the mark (red belt) is on the end of the seal.

If the seal has been cut on the developer cartridge, the cartridge cannot

be used. Replace with a new developer cartridge.

Page 31

REPLACING SUPPLIES AND MAINTENANCE

Close the main charger cover and rotate the lock

levers in the direction of the arrows to lock the cover.

When the lock levers are vertical, the cover is locked.

10

Install the toner collection container.

☞ Replacing the toner collection container (page 19)

11

Close the front cover.

12

Take care that your fingers are not pinched when closing the cover.

(2)

(1)

29

Page 32

REPLACING SUPPLIES AND MAINTENANCE

Turn on the power.

Switch the main power switch "ON" and press the [POWER] key ( ) on the

operation panel to turn on the operation panel power.

When replacement is finished, colour balance adjustments begin automatically.

☞ Colour balance adjustments (page 31)

13

Caution

• Do not throw the developer cartridge into a fire. Toner may fly and cause

burns.

• Store the developer cartridge out of the reach of small children.

• When replacing the developer cartridge, be aware that it may soil your

clothes or the immediate surroundings.

• Do not touch the part soiled with toner of the removed toner collection

container. If you accidentally touch the toner, immediately wash your hands.

30

Page 33

REPLACING SUPPLIES AND MAINTENANCE

Colour balance adjustments

When a supply item is replaced, the machine will automatically perform colour

balance adjustments.

The machine performs colour balance adjustments after the following supply

items are replaced:

• Developer cartridge

• Drum cartridge

• Primary transfer belt unit

• Secondary transfer roller unit

After a supply item is replaced, colour balance adjustments begin.

If the replacement message reappears after you have properly replaced an

item, the machine is unable to detect that the item was replaced. Contact your

dealer or nearest authorised service representative.

During colour balance adjustment, do not open the front cover or right cover,

and do not turn off the power. This may cause degraded image quality.

If there is a problem in the colour balance of the output result after a supply

item is replaced, execute auto colour calibration in the system settings.

To adjust the colour balance of the copy function, see "Copy Function

Settings" - "Colour Adjustments" - "Auto Colour Calibration" in "SYSTEM

SETTINGS" of the Operation Guide.

To adjust the colour balance of the print function, see "Printer Settings" - "Auto

Colour Calibration" in "SYSTEM SETTINGS" of the Operation Guide.

31

Page 34

REPLACING SUPPLIES AND MAINTENANCE

Replacing the drum cartridge

When it is time to replace a supply item, a message instructing you to replace

the item will appear in the display. When replacing a drum cartridge, carefully

check the indicated colour. If black is indicated, replace the drum cartridge for

black. If cyan, magenta, or yellow is indicated, replace the drum cartridge for

colour.

• Do not replace a supply item before the replacement message appears in the

display.

• Do not leave the drum cartridge outside of its package for a long time, and do

not remove cartridge from its package in a location where there is bright

sunlight or bright light. This may cause a failure.

• When you remove a drum cartridge, place it in a dark location and do not

allow light to shine on the cartridge.

Turn off the power and remove the developer cartridge.

For the procedure for removing the developer cartridge, see steps 1 to 4 of

"Replacing the developer cartridge" (page 23).

To remove the drum cartridge, the developer cartridge must first be

removed.

32

1

Drum cartridge alignment

mark on machine

Drum cartridge

Developer cartridge

Page 35

REPLACING SUPPLIES AND MAINTENANCE

Hold down the lever on the drum cartridge with

your finger and pull the drum cartridge toward you.

Place one hand at the middle of the drum cartridge and pull out with both hands.

2

• Do not touch toner on the old drum cartridge. If you accidentally touch

the toner, immediately wash your hands.

• Place the old drum cartridge in the bag that contained the new drum

cartridge, seal the bag, and place it in the box.

33

Page 36

REPLACING SUPPLIES AND MAINTENANCE

Remove the protective material from the drum

cartridge and slowly insert the drum cartridge

along the guides.

Make sure that the mark on the drum cartridge is aligned with the mark

on the machine as you insert the drum cartridge.

3

• To remove the protective material, slowly pull it straight out so that it

does not tear.

When installing the drum cartridge, do not touch or damage the drum.

•

This may cause a failure.

• After removing the protective material, immediately insert the drum

cartridge in the machine. Do not allow the drum cartridge to be directly

exposed to sunlight or electric light.

• Do not tilt the drum cartridge or insert it in the wrong direction or

orientation. This may damage the drum cartridge or cause a failure.

Drum cartridge alignment

mark on machine

Drum cartridge alignment

mark

Right Hand

Drum

Left Hand

34

Make sure that the colours on the new drum cartridge and the insertion

label match.

Replace the developer cartridge and toner

collection container, close the front cover of the

machine, and turn on the power.

For the procedure for replacing the developer cartridge and toner collection

4

container, see steps 6 to 8 and steps 10 to 11 of "Replacing the developer

cartridge" (page 23).

When replacement is finished, colour balance adjustments begin automatically.

☞ Colour balance adjustments (page 31)

Page 37

REPLACING SUPPLIES AND MAINTENANCE

Replacing the transfer unit

When a message appears prompting you to replace the transfer unit, replace the

transfer unit.

The transfer unit consists of the primary transfer belt unit inside the machine and the

secondary transfer roller unit under the right cover.

Replacing the primary transfer belt unit

When it is time to replace a supply item, a message instructing you to replace

the item will appear in the display.

• Do not replace a supply item before the replacement message appears in the

display.

• Install the new primary transfer belt promptly after the primary transfer belt

unit has been removed. Light entering through openings in the machine may

damage the drum cartridges.

Press the [POWER] key ( ) on the operation panel

to turn off the panel power, and then switch the

main power switch to the off position.

1

Caution

After the main power is turned off, the primary transfer belt unit will be

hot. Wait about 5 minutes for the machine to cool.

35

Page 38

REPLACING SUPPLIES AND MAINTENANCE

Open the front cover and remove the toner

collection container.

☞ Replacing the toner collection container (page 19)

2

Do not point the holes down as used toner will spill out.

Securely close the bypass tray and then open the

right cover.

36

3

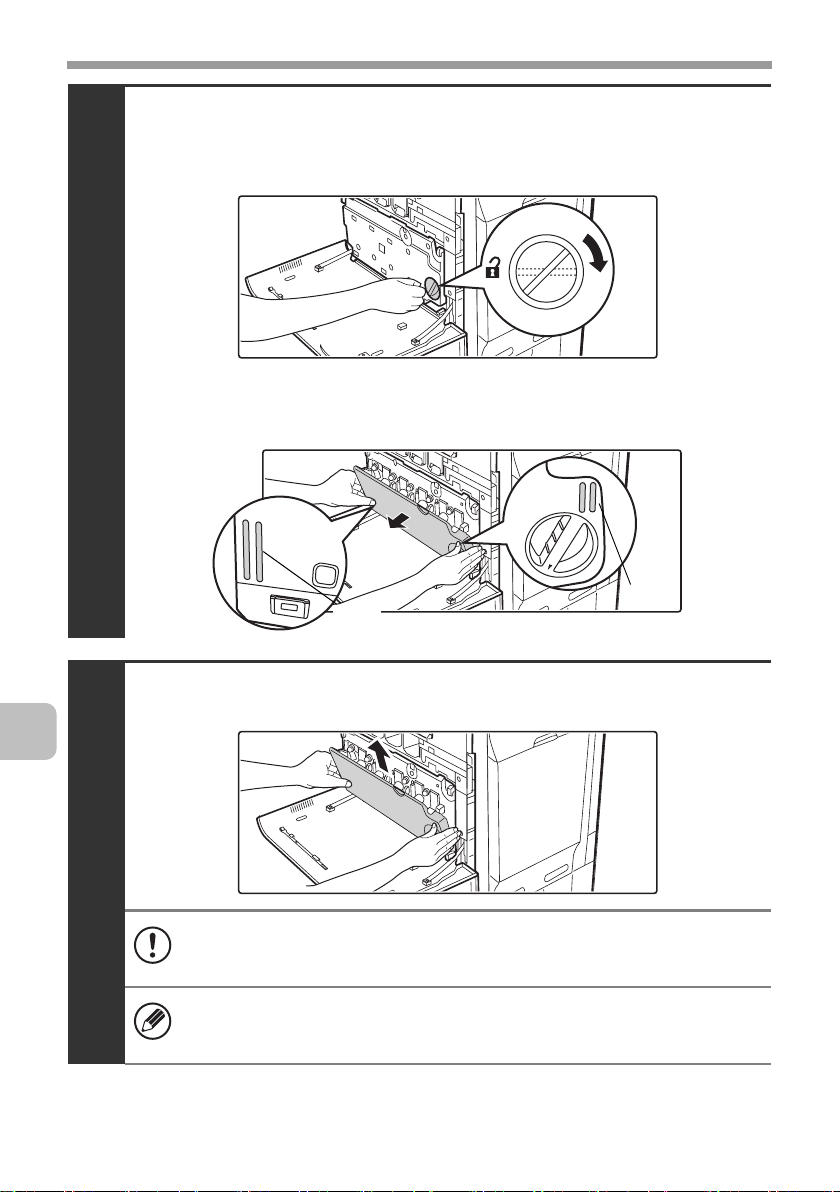

Turn the lock levers in the direction of an arrow

below and release the primary transfer belt unit.

4

Page 39

REPLACING SUPPLIES AND MAINTENANCE

Slowly pull out the primary transfer belt unit.

(1) Grasp the primary transfer unit as shown below and

slowly pull it out.

Transfer belt

Fall prevention

5

lock

(2)

Hold down the fall prevention lock with one hand, grasp the handle

with your other hand, and remove the primary transfer belt unit.

Grip the frame of the primary transfer belt unit with your left hand and hold

down the fall prevention lock on the left side with your left thumb.

Pull the band-shaped green handle on the right side up and grasp it with

your right hand.

Handle

Caution

Always hold the primary transfer belt unit with both hands. Never hold it

with one hand.

•

When installing the primary transfer belt unit, do not touch the transfer belt.

• Do not tilt or turn over the transfer

Hold the middle of the transfer unit firmly and pull the primary transfer

belt unit part way out until the fall prevention lock on the left side of the

unit and the handle on the right side of the unit are visible.

belt

unit. Toner may spill out.

37

Page 40

REPLACING SUPPLIES AND MAINTENANCE

Hold the handle on the left side with your left hand,

the handle on the right side with your right hand,

and lowly insert the transfer unit into the machine.

Handle

6

Transfer belt

Handle

Caution

Always hold the primary transfer belt unit with both hands. Never hold it

with one hand.

• When installing the primary transfer belt unit, do not touch the

transfer belt.

• When installing the primary transfer belt unit, do not touch or damage

the roller or gears. This may cause a failure.

• Do not tilt or turn over the transfer unit. This may cause damage to the

transfer belt or failure when the transfer belt unit is installed.

Turn the lock levers in the direction of an arrow

below and lock the primary transfer belt unit.

38

7

Page 41

REPLACING SUPPLIES AND MAINTENANCE

Close the right cover.

☞ Replacing the toner collection container (page 19)

8

Take care that your fingers are not pinched when closing the cover.

Replace the toner collection container and close

the front cover.

☞ Replacing the toner collection container (page 19)

9

Take care that your fingers are not pinched when closing the cover.

39

Page 42

REPLACING SUPPLIES AND MAINTENANCE

Turn on the power.

Switch the main power switch "ON" and press the [POWER] key ( ) on the

operation panel to turn on the operation panel power.

When replacement is finished, colour balance adjustments begin automatically.

☞ Colour balance adjustments (page 31)

10

40

Page 43

REPLACING SUPPLIES AND MAINTENANCE

Replacing the secondary transfer roller unit

When it is time to replace a supply item, a message instructing you to replace

the item will appear in the display.

Do not replace a supply item before the replacement message appears in the

display.

Press the [POWER] key ( ) on the operation panel

to turn off the panel power, and then switch the

main power switch to the off position.

1

Caution

After the main power is turned off, the secondary transfer roller unit will

be hot. Wait about 30 minutes for the machine to cool.

Securely close the bypass tray and then open the

right cover.

2

41

Page 44

REPLACING SUPPLIES AND MAINTENANCE

Press on the locks on the left and right sides of the

secondary transfer roller unit to release the locks.

3

Continue holding the levers firmly and slowly push

them in and down, and lift without changing your

grip to remove the secondary transfer roller.

42

4

Caution

• Always hold the secondary transfer roller unit with both hands. Never

hold it with one hand.

• When holding the secondary transfer roller unit, do not grasp any part

of the unit other than the levers.

Page 45

REPLACING SUPPLIES AND MAINTENANCE

Grasp the left and right levers and align the

secondary transfer roller unit with the installation

guide, and slowly tilt the transfer unit to the right and

down.

Make sure that the marks on the secondary transfer roller unit are aligned

with the marks on the machine as you set the secondary transfer roller unit.

Secondary transfer roller unit

5

Marks

• When installing the secondary transfer roller unit, do not touch or

damage the roller or gears. This may cause a failure.

• Always hold the secondary transfer roller unit with both hands; never

hold it with one hand.

• Do not tilt or turn over the secondary transfer roller unit. The roller or

gears may be damaged when the unit is installed, or a failure may

occur.

43

Page 46

REPLACING SUPPLIES AND MAINTENANCE

Close the right cover.

6

Take care that your fingers are not pinched when closing the cover.

Turn on the power.

Switch the main power switch "ON" and press the [POWER] key ( ) on the

operation panel to turn on the operation panel power.

When replacement is finished, colour balance adjustments begin automatically.

☞ Colour balance adjustments (page 31)

44

7

Page 47

REPLACING SUPPLIES AND MAINTENANCE

Replacing the fusing unit / ozone filter

When a message appears prompting you to replace the fusing unit, replace the

fusing unit. When replacing the fusing unit, replace the ozone filter at the same

time.

Replacing the fusing unit

When it is time to replace a supply item, a message instructing you to replace

the item will appear in the display.

Do not replace a supply item before the replacement message appears in the

display.

Press the [POWER] key ( ) on the operation panel

to turn off the panel power, and then switch the

main power switch to the off position.

1

Caution

After the main power is turned off, the fusing unit will be hot. Wait about

30 minutes for the machine to cool.

45

Page 48

REPLACING SUPPLIES AND MAINTENANCE

Securely close the bypass tray and then open the

right cover.

2

Warning

Do not start immediately after turning off the main power. The fusing

unit is extremely hot and will burn you.

Pull out the left and right levers on the fusing unit.

Fusing area

46

3

Caution

Make sure that the fusing unit has cooled. If still hot, wait until it has cooled.

Page 49

REPLACING SUPPLIES AND MAINTENANCE

Grasp the left and right levers firmly and remove

the fusing unit.

4

Caution

• When holding the fusing unit, insert your index fingers and hold

firmly. Do not grasp any parts other than the levers.

• When removing the fusing unit, remove slowly taking care that your

hands do not contact the inside of the right cover

47

Page 50

REPLACING SUPPLIES AND MAINTENANCE

Grasp the left and right levers on the fusing unit,

align the unit with the installation guides, and

slowly insert the fusing unit into the machine.

The fusing unit will lock into place.

5

• Always hold the fusing unit with both hands. Never hold it with one

hand.

• When holding the fusing unit, do not grasp any parts other than the

left and right levers.

• Do not tilt or turn over the fusing unit.

• Do not open the shutter on the fusing unit. (Do not touch the heat

roller inside the unit.)

48

Return the left and right levers to their original

positions.

6

Page 51

REPLACING SUPPLIES AND MAINTENANCE

Close the right cover.

7

Take care that your fingers are not pinched when closing the cover.

Turn on the power.

Switch the main power switch "ON" and press the [POWER] key ( ) on the

operation panel to turn on the operation panel power.

When replacement is finished, colour balance adjustments begin automatically.

☞ Colour balance adjustments (page 31)

8

49

Page 52

REPLACING SUPPLIES AND MAINTENANCE

Replacing the ozone filter

Replace the ozone filter when you replace the fusing unit. A new ozone filter is

included in the fusing unit box.

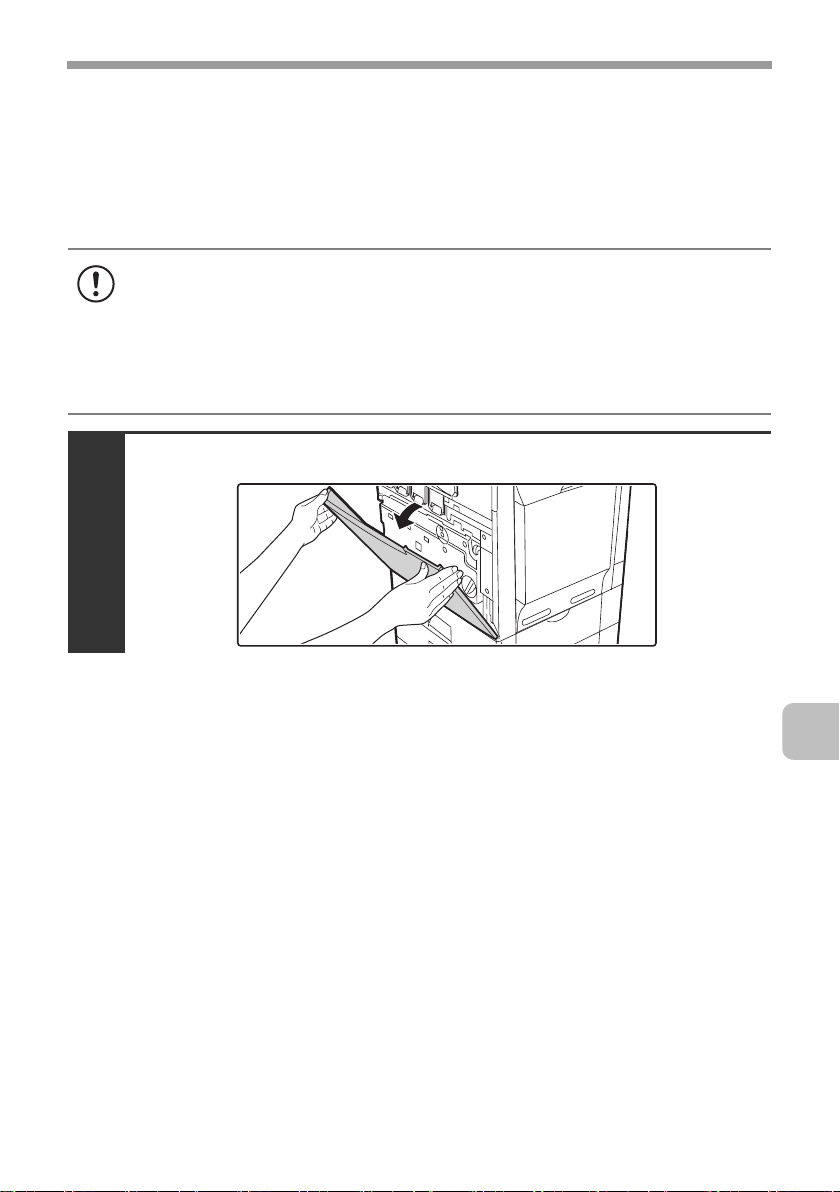

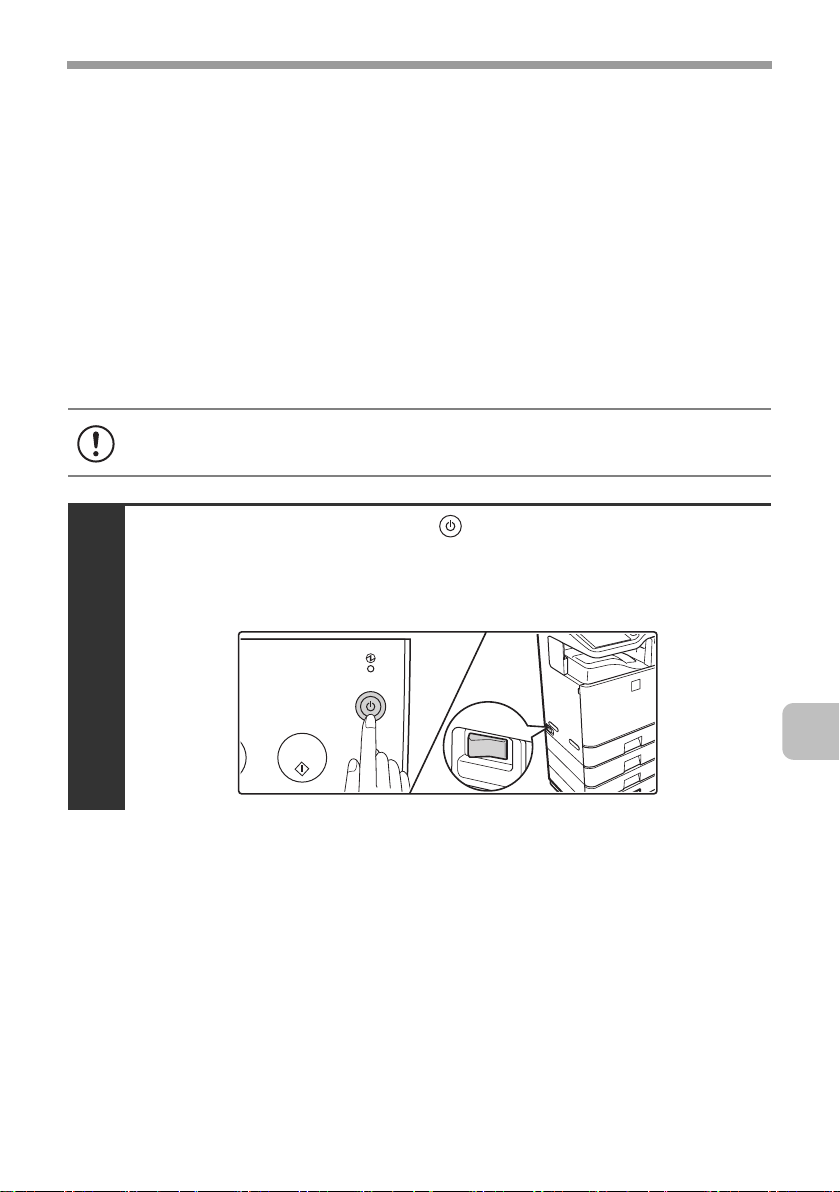

Slide the cover on the right side of the machine

toward the inside to remove it.

1

Remove the ozone filter.

50

2

Install a new ozone filter.

3

Page 53

Attach the cover.

4

REPLACING SUPPLIES AND MAINTENANCE

51

Page 54

REPLACING SUPPLIES AND MAINTENANCE

Replacing the staple cartridge in the finisher

When the staple cartridge runs out of staples, a message will appear in the

operation panel. Follow the procedure below to replace the staple cartridge.

Open the cover.

1

While pressing the lever over to the left, slide the

finisher to the left until it stops.

Gently slide the finisher until it stops

52

2

Lower the staple case release lever and remove

the staple case.

Pull the staple case out to the right.

3

Page 55

REPLACING SUPPLIES AND MAINTENANCE

Remove the empty staple cartridge from the staple case.

Gently grasp the right side of the staple cartridge as shown and lift to the left

and up. The lock will release easily. After the lock releases, continue lifting the

staple cartridge to the left and up to remove it.

4

• Even when a message appears in the operation panel, staples may

occasionally remain in the staple cartridge.

• If staples remain, the lock will not release easily. Forcing the lock to

release may deform the staple case and staple cartridge, causing

failure.

Insert a new staple cartridge into the staple case

as shown.

Push the staple cartridge in until it clicks into place.

5

53

Page 56

REPLACING SUPPLIES AND MAINTENANCE

Replace the staple case.

Push the staple case in until it clicks into place.

6

Slide the finisher back to the right.

Gently slide the finisher back to the right until it locks into its original position.

7

54

Take care that your fingers are not pinched when closing the cover.

Close the cover.

8

Take care that your fingers are not pinched when closing the cover.

Make a test print or copy in staple sort mode to verify that stapling takes place

correctly.

Page 57

REPLACING SUPPLIES AND MAINTENANCE

Regular maintenance

To ensure that the machine continues to provide top quality performance,

periodically clean the machine.

Caution

Do not use a flammable spray to clean the machine. If gas from the spray comes

in contact with hot electrical components or the fusing unit inside the machine,

fire or electrical shock may result.

• Do not use thinner, benzene, or similar volatile cleaning agents to clean the

machine. These may degrade or discolour the housing.

When using the DX-C311/DX-C381,

•

use a soft cloth to gently wipe off dirt

from the area on the operation panel

with a mirror-like finish (shown at

right). If you use a stiff cloth or rub

hard, the surface may be damaged.

The area with a mirror-like finish is

the area that is .

Cleaning the document glass and automatic document feeder

If the document glass or document backplate sheet becomes dirty, the dirt will

appear as dirty spots, coloured lines, or white lines in the scanned image.

Always keep these parts clean.

Wipe the parts with a clean, soft cloth.

If necessary, moisten the cloth with water or a small amount of neutral detergent.

After wiping with the moistened cloth, wipe the parts dry with a clean dry cloth.

Document glass Document backplate sheet

Scanning area

• When wiping dirt off the machine, do not press down hard on the machine.

This may damage or deform the machine.

• If the back of the document glass is dirty, contact your dealer or nearest

authorised service representative.

55

Page 58

REPLACING SUPPLIES AND MAINTENANCE

Scanning area

If coloured lines or white lines appear in images scanned using the automatic

document feeder, clean the scanning area (the thin long glass next to the

document glass).

Cleaning the main charger of the photoconductive drum

If black lines or coloured lines appear even after you have cleaned the document glass

and automatic document feeder, use the charger cleaner to clean the main charger.

A replacement main charger cleaner is included with the drum cartridge (black).

When you replace the drum cartridge (black), replace the main charger cleaner

as well.

Press the [POWER] key ( ) on the operation panel

to turn off the panel power, and then switch the

main power switch to the off position.

1

56

Open the front cover and remove the toner collection

container.

☞ Replacing the toner collection container (page 19)

2

Do not point the holes down as used toner will spill out.

Page 59

REPLACING SUPPLIES AND MAINTENANCE

Release the lock levers and open the main charger

cover.

☞ Replacing the developer cartridge (page 23)

3

Remove the charger cleaner.

(1) Flip down the charger cleaner lock (A) in the direction of

the arrow, and lift the left end of the charger cleaner.

(1)

4

(A)

(2) Move the charger cleaner to the left and pull it out.

(2)

57

Page 60

REPLACING SUPPLIES AND MAINTENANCE

Clean the main charger.

Holes to be cleaned by the charger cleaner are indicated by labels similar to (A).

(A)

(1) Gently push the charger cleaner all the way in.

(2) Gently pull the charger cleaner out.

5

Position of mark

58

(3) Repeat the above (1) to (2) three times.

• Take care not to let the tip of the charger cleaner become soiled by

toner.

• Clean with the mark ( ) on the charger cleaner facing down.

• Do not use the charger cleaner for any purpose other than cleaning

the main charger.

Page 61

REPLACING SUPPLIES AND MAINTENANCE

Repeat step 5 with each of the other main chargers.

6

Main charger

There are a total of 4 places to be cleaned in the machine as shown.

Replace the charger cleaner in its original position.

Insert the tip of the charger cleaner in toward the right and then press down on

the end of the charger cleaner. The charger cleaner will lock into place.

7

(2)

(1)

Close the main charger cover and rotate the lock

levers in the direction of the arrows to lock the cover.

☞ Replacing the developer cartridge (page 23)

8

59

Page 62

REPLACING SUPPLIES AND MAINTENANCE

Install the toner collection container.

☞ Replacing the toner collection container (page 19)

9

(1)

(2)

Close the front cover.

10

Turn on the power.

Switch the main power switch "ON" and press the [POWER] key ( ) on the

operation panel to turn on the operation panel power.

11

60

Page 63

REPLACING SUPPLIES AND MAINTENANCE

Cleaning and replacing the rollers

To clean the rollers of the paper cassettes, bypass tray, and automatic

document feeder, the rollers must be removed. An old roller should be replaced

as it will cause paper misfeeds and dirty output. The procedures for cleaning

and replacing rollers are explained below.

Warning

Do not use a flammable spray to clean the machine. If gas from the spray

comes in contact with hot electrical components or the fusing unit inside the

machine, fire or electrical shock may result.

• Do not use thinner, benzene, or similar volatile cleaning agents to clean the

machine. These may degrade or discolour the housing.

• It is recommended that you wear thin gloves (that do not interfere with work)

when handling the rollers. If you do not wear gloves, wash your hands well to

remove all oil before handling the rollers.

• When cleaning or replacing rollers, be careful of protruding parts on the

inside of the machine.

Cleaning and replacing paper cassette rollers

If you find that paper from a paper cassette misfeeds or is soiled by the rollers,

remove the rollers and clean them. If misfeeds or soiling continue to occur,

replace the rollers.

Press the [POWER] key ( ) on the operation panel

to turn off the panel power, and then switch the

main power switch to the off position.

1

61

Page 64

REPLACING SUPPLIES AND MAINTENANCE

(2)

After pulling the paper cassette all the way out, lift

the cassette up and out.

2

All cassettes can be removed in a similar way.

Remove three rollers that are at the right back in the cassette.

To remove roller (1), first remove roller (2).

To remove roller (2), grasp the end of the roller with part (A) pulled down and

pull the roller straight out. Do not remove part (B); leave it in position.

(1)

62

3

(B)

(2)

(A)

• Do not insert your hand into any place other than the installation

position of each roller.

• Do not touch the surface of the rollers if your hands are dirty.

Grasp each roller and slowly pull out.

Grasp this part of the roller with your

fingers and pull the roller out.

Page 65

REPLACING SUPPLIES AND MAINTENANCE

To clean the removed rollers, wipe each roller with

a clean cloth.

Caution

When cleaning the rollers, be careful not to injure your hands.

4

Do not touch the surface of the rollers if your hands are dirty.

• When you replace rollers, go to the next step.

• If the dirt is difficult to remove, moisten the cloth with water or a

neutral detergent and then wipe the roller dry with a clean, dry cloth

until no moisture remains.

63

Page 66

REPLACING SUPPLIES AND MAINTENANCE

Install the rollers in their respective positions.

Make sure that the roller numbers match the numbers on the machine in the

illustration below, and install the rollers. Install roller (1) before installing roller (2).

To install roller (2), grasp the end of the roller with part (A) pulled down and

insert the roller.

Make sure the rollers click into place. If a roller does not click into place, rotate

it slightly to find the correct position.

5

(3)

(B)

(1)

(2)

(A)

(1) (2) (3)

\

Front

Rear

• Do not insert your hand into any place other than the installation

position of each roller.

• Do not touch the surface of the rollers if your hands are dirty.

• Do not apply force to (B). This may cause failure.

64

Keep the used rollers in a plastic bag (do not discard it). A plastic bag is

contained in a new roller package.

Page 67

REPLACING SUPPLIES AND MAINTENANCE

Replace the paper cassette.

6

With the far side of the cassette tilted slightly down and the near side

slightly up, place the cassette on the rails, level the cassette, and then

push it in.

Turn on the power.

Switch the main power switch "ON" and press the [POWER] key ( ) on the

operation panel to turn on the operation panel power.

7

After turning on the power, make sure that an error message regarding

replacement of the rollers does not appear.

65

Page 68

REPLACING SUPPLIES AND MAINTENANCE

Cleaning and replacing the bypass tray rollers

If you find that paper fed from the bypass tray misfeeds or is soiled by the roller,

remove and clean the roller. If misfeeds or soiling continue to occur, replace the

roller.

Before starting, remove the paper from the bypass tray.

Press the [POWER] key ( ) on the operation panel

to turn off the panel power, and then switch the

main power switch to the off position.

1

Remove the roller cover from the bypass tray.

Place your fingers behind the marks on the roller cover and pull straight

toward you. Pull alternately on the left and right side of the roller cover.

66

Marks

2

• To obtain sufficient space when removing the roller cover, open the

guides on the bypass tray to their maximum width.

• Do not apply force to (A). This may cause

failure.

Page 69

REPLACING SUPPLIES AND MAINTENANCE

To clean the rollers, wipe each roller with a clean cloth.

3

Caution

When cleaning the rollers, be careful not to injure your hands.

Do not touch the surface of the roller if your hands are dirty.

• When you replace roller, go to the next step.

• If the dirt is difficult to remove, moisten the cloth with a small amount

of water or neutral detergent, and then wipe with a clean, dry cloth

until no moisture remains.

Move the knobs on the left and right sides of the

roller to the specified positions.

4

Move the knobs until they click into place.

67

Page 70

REPLACING SUPPLIES AND MAINTENANCE

Move the fixtures on the left and right sides of the

roller to the positions of the knobs.

5

Move the feed roller to the left and remove it.

Move the roller until it is completely separated from the shaft pin.

6

68

Do not insert your hand into any place other than the location of the

roller.

Remove the pad under the roller.

7

Do not insert your hand into any place other than the installation position

of pad.

Keep the used pad in a plastic bag (do not discard it). A plastic bag is

contained in a new pad package.

Page 71

REPLACING SUPPLIES AND MAINTENANCE

Attach a new pad and install the feed roller.

Align the roller with the shaft pin and attach the roller.

8

• Do not touch the surface of the roller and pad if your hands are dirty.

• Do not insert your hand into any place other than the location of the

roller and pad.

Keep the used roller in a plastic bag (do not discard it). A plastic bag is

contained in a new roller package.

69

Page 72

REPLACING SUPPLIES AND MAINTENANCE

Return the roller fixtures and knobs to their

original positions.

9

Attach the roller cover on the bypass tray.

Press the cover onto the bypass tray so that it locks into place.

70

10

Page 73

REPLACING SUPPLIES AND MAINTENANCE

Turn on the power.

Switch the main power switch "ON" and press the [POWER] key ( ) on the

operation panel to turn on the operation panel power.

11

71

Page 74

REPLACING SUPPLIES AND MAINTENANCE

Cleaning and replacing the automatic document

feeder rollers

If you find that originals fed through the automatic document feeder misfeed or

are soiled by the rollers, remove the rollers and clean them. If misfeeds or

soiling continue to occur, replace the rollers.

Before starting, remove any originals from the automatic document feeder.

Press the [POWER] key ( ) on the operation panel

to turn off the panel power, and then switch the

main power switch to the off position.

1

72

Open the document conveyor cover on the

automatic document feeder.

2

Page 75

REPLACING SUPPLIES AND MAINTENANCE

Lift up the knob that holds the roller shaft.

3

Remove the roller with the shaft.

(1) Pull down the release lever.

(2) Remove the shaft rotating the roller cover upward and

4

remove the shaft.

(3)

(2)

If the roller cover is not pointing straight up when the shaft is removed, a

failure may occur.

(1)

73

Page 76

REPLACING SUPPLIES AND MAINTENANCE

To clean the removed rollers, wipe each roller with

a clean cloth.

Rotate the shaft as you wipe so that the entire roller is wiped.

5

Caution

When cleaning the rollers, be careful not to injure your hands.

• Do not touch the surface of the roller if your hands are dirty.

• The shaft can only be rotated in one direction. Do not force the shaft

to rotate.

• If the dirt is difficult to remove, moisten the cloth with water or a

neutral detergent and then wipe the roller dry with a clean, dry cloth

until no moisture remains and go to the step 10.

• When you replace roller, go to the next step.

74

Release the left or right hooks that hold the pad

and remove the pad.

6

• When the hooks are released, the pad will spring up. Lift the pad up

from that position to remove it.

• Keep the used pad in a plastic bag (do not discard it). A plastic bag is

contained in a new roller package.

Page 77

REPLACING SUPPLIES AND MAINTENANCE

Attach the pad.

(1) Align the protrusion on the pad with the spring on the

automatic document feeder.

(2) Push the pad into the automatic document feeder.

7

The hooks lock onto the pad and secure it.

Do not touch the surface of the pad if your hands are dirty.

75

Page 78

REPLACING SUPPLIES AND MAINTENANCE

With the roller cover pointing up, insert the shaft

into the hole in the automatic document feeder,

and rotate the shaft to return the roller to its

original position.

If the shaft does not fit into place, rotate it slightly to find the correct position.

(1)

(2)

8

Caution

When cleaning the rollers, be careful not to injure your hands.

When cleaning or replacing roller, make sure your hands are clean

before touching the surface of the roller.

Lower the knob that secures the roller.

9

(3)

(A)

76

Page 79

REPLACING SUPPLIES AND MAINTENANCE

Close the document conveyor cover on the

automatic document feeder.

10

• When cleaning or replacing roller, make sure your hands are clean

before touching the surface of the roller.

• Take care that your fingers are not pinched when closing the cover.

Turn on the power.

Switch the main power switch "ON" and press the [POWER] key ( ) on the

operation panel to turn on the operation panel power.

11

77

Page 80

REPLACING SUPPLIES AND MAINTENANCE

Cleaning the laser unit

When the laser unit inside the machine becomes dirty, line patterns (coloured

lines) may form in the printed image. Follow the steps below to clean the laser

unit.

Identifying lines (coloured lines) caused by a dirty laser unit

• Coloured lines always appear in the same place. (The lines are never black.)

• The coloured lines are parallel to the direction of paper feeding.

Direction of

paper feeding

Coloured line

• Coloured lines appear not only on copies but also on print jobs from a

computer. (The same lines appear on both copies and print jobs.)

Press the [POWER] key ( ) on the operation panel

to turn off the panel power, and then switch the

main power switch to the off position.

78

1

Page 81

REPLACING SUPPLIES AND MAINTENANCE

Open the front cover and remove the toner

collection container.

☞ Replacing the toner collection container (page 19)

2

Do not point the holes down as used toner will spill out.

Remove the cleaning tool for the writing unit from

the front cover.

3

79

Page 82

REPLACING SUPPLIES AND MAINTENANCE

Make sure that the cleaner at the tip of the cleaning

tool is not dirty.

4

If the cleaner is dirty, remove the cleaner and replace it with a clean

one. For the procedure for replacing the cleaner, see steps 5 through 7.

If the cleaner is not dirty, go to step 8.

Cleaner

Pull out the replacement cleaner from the toner

collection container.

5

80

Page 83

REPLACING SUPPLIES AND MAINTENANCE

Remove the dirty cleaner.

Firmly grasp the tool close to where the cleaner is attached.

Use your other hand to press down on the hook that secures the cleaner and

remove the cleaner.

6

Return the removed cleaner to the toner collection container.

Attach the new cleaner to the cleaning tool.

Firmly grasp the tool close to where the cleaner is attached.

Use your other hand to press down on the hook that secures the cleaner and

remove the cleaner.

7

Make sure that the cleaner is firmly attached to the cleaning tool.

81

Page 84

REPLACING SUPPLIES AND MAINTENANCE

Clean the laser unit.

(1) Point the cleaner down and slowly insert the tool into

the hole that you wish to clean.

The parts of the writing unit that require cleaning are indicated by labels

similar to (A).

(2) Insert the cleaning tool all the way into the hole and

then pull it back out.

8

Pull the cleaning tool out until you feel the tip of the tool leave the

cleaning surface of the laser unit.

(A)

82

(3) Repeat step (2) two or three times and then remove the

cleaning tool.

Page 85

REPLACING SUPPLIES AND MAINTENANCE

Repeat step 8 to clean all holes in the laser unit.

9

Holes to be cleaned

There are a total of 4 holes to be cleaned in the laser unit.

If the cleaner becomes dirty during cleaning, replace with a new

cleaner. For the procedure for replacing the cleaner, see steps 5 to 7.

Replace the cleaning tool.

10

Install the toner collection container.

☞ Replacing the toner collection container (page 19)

11

(1)

(2)

83

Page 86

REPLACING SUPPLIES AND MAINTENANCE

Close the front cover.

12

Take care that your fingers are not pinched when closing the cover.

Turn on the power.

Switch the main power switch "ON" and press the [POWER] key ( ) on the

operation panel to turn on the operation panel power.

13

84

Page 87

REPLACING SUPPLIES AND MAINTENANCE

Cleaning the PT charger of the primary transfer belt unit

If black or coloured lines still remain after the document glass / automatic

document feeder and main charger have been cleaned, use the PT charger

cleaner to clean the PT charger.

Press the [POWER] key ( ) on the operation panel

to turn off the panel power, and then switch the

main power switch to the off position.

1

Open the front cover and remove the toner

collection container.

☞ Replacing the toner collection container (page 19)

2

Do not point the holes down as used toner will spill out.

85

Page 88

REPLACING SUPPLIES AND MAINTENANCE

Clean the PT charger.

(1) Slowly pull the PT charger cleaner out until you feel a

slight resistance.

3

(2) Slowly push the PT charger cleaner back in.

(3) Repeat the above (1) to (2) three times.

86

Install the toner collection container.

☞ Replacing the toner collection container (page 19)

4

(1)

(2)

Page 89

REPLACING SUPPLIES AND MAINTENANCE

Close the front cover.

5

Take care that your fingers are not pinched when closing the cover.

Turn on the power.

Switch the main power switch "ON" and press the [POWER] key ( ) on the

operation panel to turn on the operation panel power.

6

87

Page 90

REPLACING SUPPLIES AND MAINTENANCE

Executing the fusing cleaning mode

If the printed image is dirty as shown in the following illustration, the fusing unit

may be dirty.

• The dirt will appear at fixed intervals.

• The dirt will appear horizontally (perpendicular to the direction of feeding of

the paper).

Direction of

paper feeding

Dirt

Press the [SYSTEM SETTINGS] key on the

1

operation panel.

Select the [Device Control] key.

2

88

Select the [Other Setting] key.

3

Select the [Execute] key of the "Fusing Cleaning

4

Mode".

Page 91

TROUBLESHOOTING

This section explains what to do when an error code* appears in the display.

* An error code is a code that appears when a problem has occurred in the machine.

Error code

Alphabet

Numbers

Code:xx-xx.

Please refer to operation manual.

When an error code appears

Check if the displayed error code is in the table below. "xx" in the table

represents two numeric digits.

Error codes

F3-xx H4-xx U1-xx PF-xx

H3-xx H5-xx U2-xx

If the displayed error code is in the table, write down the error code and contact

your dealer or nearest authorised service representative.

If an error code that is not in the above table appears, turn the machine power

off and then on.

To turn on the power again, follow the procedure below.

When the power is turned off, data that was being processed may be lost.