Page 1

SERVICE MANUAL DVD VIDEO PLAYER

DV-A1000U

SERVICE MANUAL

S29C3DV-A1000

D VD VIDEO PLAYER

1. IMPORTANT SAFEGUARDS AND PRECAUTIONS ......................................................................1-1

2. FEATURES .....................................................................................................................................1-3

3. SPECIFICATIONS .......................................................................................................................... 3-1

MODEL DV-A1000U

4. PART NAMES ................................................................................................................................. 4-1

5. MAINTENANCE CHECK ITEMS AND EXECUTION TIME ............................................................ 5-1

6. DISASSEMBLY AND REPLACEMENT OF MAIN PARTS ............................................................. 6-1

7. EXPLANATION OF MECHANISM ..................................................................................................7-1

8. TEST MODE ................................................................................................................................... 8-1

9. TROUBLESHOOTING ....................................................................................................................9-1

10. IC FUNCTION LIST....................................................................................................................... 10-1

11.BLOCK DIAGRAM ......................................................................................................................... 11-1

12. WIRING DIAGRAM .......................................................................................................................12-1

13. SCHEMATIC DIAGRAMS .............................................................................................................13-1

14. PRINTED WIRING BOARD ASSEMBLIES ...................................................................................14-1

15.SEMICONDUCTOR LEAD IDENTIFICATION................................................................................15-1

16. REPLACEMENT PARTS LIST ......................................................................................................16-1

17. PACKING OF THE SET ................................................................................................................ 17-1

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified

be used.

CONTENTS

DV-A1000U

Page

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

DV-A1000U

SSVM

AC SCALE

1.5k ohms.

10W

CONNECT TO

KNOWN EARTH

GROUND

TO EXPOSED

METAL PARTS

0.15 µF

TEST PROBE

0.15 µF

SONDE D'ESSAI

VERS PIECES

METALLIQUES

EXPOSEES

VTVM

ECHELLE CA

1.5KOHMS

10W

CONNECTER A

UNE MASSE DE

TERRE CONNUE

1. IMPORTANT SAFEGUARDS AND PRECAUTIONS

1. IMPORTANT SERVICE NOTES

BEFORE RETURNING THE VIDEO CASSETTE

RECORDER

Before returning the video cassette recorder to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the video cassette

recorder.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields, isolation resistor/capacitor networks, mechanical insulators etc.

3. To be sure that no shock hazard exists, check for

current in the following manner.

● Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

● Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as a water pipe or conduit.

● Use an SSVM or VOM with 1000 ohm per volt, or

higher, sensitivity or measure the AC voltage drop

across the resistor (See Diagram).

● Move the resistor connection to earth exposed metal

part having a return path to the chassis (antenna,

metal cabinet, screw heads, knobs and control shafts,

etc.) and measure the AC voltage drop across the

resistor. Reverse the AC plug on the set and repeat

AC voltage measurements for each exposed part.

Any reading of 0.45V rms (this corresponds to 0.3mA

rms AC.) or more is excessive and indicates a potential shock hazard which must be corrected before

returning the video cassette recorder to the owner.

1. NOTES DE SERVICE IMPORTANTES

AVANT DE RENDRE LE MAGNETOSCOPE

Avant de rendre le magnétoscope à l’utilisateur, effectuer

les vérifications de sécurité suivantes.

1. Vérifier toutes les gaines de fil pour être sûr que les fils

ne sont pas pincés ou que le matériel n’est pas coincé

entre le châssis et les autres pièces métalliques dans le

magnétoscope.

2. Vérifier tous les dispositifs de protection tels que les

boutons de commande non métalliques, les matériaux

d’isolement, le dos du coffret, les couvercles de

compartiment et ajustement ou les boucliers, les

réseaux de résistance / condensateur d’isolement, Ies

isolateurs mécaniques, etc.

3. Pour être sûr qu’il n’y a aucun risque de choc électrique,

vérifier le courant de fuite de la maniére suivante.

● Brancher le cordon d’alimentation secteur directement

dans une prise de courant de 120 volts. (Ne pas utiliser

de transformateur d’isolement pour cet essai).

● Utiliser deux fils à pinces et connecter une résistance

● Utiliser un VTVM ou VOM avec une sensibilité de 1000

● Déposer la connexion de la résistance à toutes les

de 10 watts 1,5 kohm en parallèle avec un condensateur

de 0,15 µF en série avec des pièces du coffret métallique

exposées et une masse de terre connue telle qu’un

tuyau ou un conduit d’eau.

ohms par volt ou plus ou mesurer la chute de tension

CA entre la résistance (voir diagramme).

pièces métalliques exposées ayant un parcours de

retour au châssis (connexions d’antenne, coffret

métallique, tétes de vis, boutons et arbres de commande,

etc.) et mesurer la chute de tension CA entre la résistance.

Inverser la fiche CA (une fiche intermédiaire non polarisée

doit être utilisée à seule fin de faire ces vérifications.) sur

l’appareil et répéter les mesures de tension CA pour

chaque piéce métallique exposée. Toute lecture de

0,45 V rms (ceci correspond à 0,3 mA rms CA) ou plus

est excessive et signale un danger de choc qui doit être

corrigé avant de rendre le magnétoscope à son

utilisateur.

2

1-1

Page 3

WARNING :TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NO T EXPOSE

1.5A 250V

THIS APPLIANCE TO WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC

SHOCK. DO NOT REMOVE COVER. NO

USER·SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

CAUTION

This symbol mark means following.

For continued protection against fire hazard, replace only with same type fuse

F9201 (5A, 125V) or F9101 (1.6A, 125V).

Camcorder

only

DV-A1000U

This symbol warns the user of uninsulated

voltage within the unit that can cause dangerous electric shocks.

This symbol alerts the user that there are

important operating and maintenance instructions in the literature accompanying this unit.

CAUTION

This symbol mark means following.

For continued protection against fire haz-

ard, replace only with same type fuse.

(F1; 1.5A 250V)

AC Adapter

only

ATTENTION:POUR REDUIRE LES RESQUES D'INCENDIE OU DE CHOC ELECTRIQUE,

NE PAS EXPOSER CET APPAREIL A LA PLUIE OU A L'HUMIDITE.

ATTENTION

RISQUE DE CHOC ELECTRIQUE

NE PAS OUVRIR

ATTENTION: AFIN DE REDUIRE LES RISQUES DE

CHOC ELECTRIQUE, NE PAS RETIRER LE

COUVERCLE, AUCUN ORGANE INTERNE

NE PEUT ETRE REPARE PAR

L'UTIUSATEUR, CONFIER L'APPAREIL A

UN DEPANNEUR QUALIFIE.

ATTENTION

Ce symbole signifie que l'on devra utiliser un fusible de même type (F9201

(5A, 125V) or F9101 (1.6A, 125V)) pour

assurer la sécurité.

Camcorder

seulement

Ce symbole signale à l'utilisateur la présence

d'une tension non isolée à l'intérieur de l'appareil

qui peut être la cause de secousses électriques

dangereuses.

Ce symbole avertit l'utilisateur que des instructions importantes relatives à l'utilisation

et àl'entretien se trouvent dans le manuel

accompagnant l'appareil.

ATTENTION

Ce symbole signifie que l'on devra uti-

liser un fusible de même type (F1; 1,5A,

250V) pour assurer la sécurité.

3

1-2

Adaptateur CA

seulement

1,5A 250V

Page 4

DV-A1000U

CLASS 1

LASER PRODUCT

PRODUCT LASER

DE CLASSE 1

2. FEATURES

• High-quality digital images

• High-quality digital sound

• Plays DVD, video CD and CD (Digital Audio) discs

• Built-in Dolby Digital decoder supporting Dolby Pro Logic*

2

digital output capability

• DTS*

• Separate color component output connectors (Y, P

• Built-in amplifier suports 6-channel Dolby Digital (AC-3) surround sound

• Built-in digital output connectors (optical/coaxial)

• Simulated surround sound

• Built-in AM/FM tuner

*1 Manufactured under license from Dolby Laboratories. "Dolby", "Pro Logic" and the double-D symbol are trademarks of Dolby Laboratories.

*2 "DTS" nad "DTS Digital Surround" are trademarks of Digital Theater Systems, Inc.

1

decoding and Virtual Surround

B and PR)

4

1-3

Page 5

3. SPECIFICATIONS

DVD Video Player

Signal System NTSC

Video signal Horizontal resolution: 500 lines

Audio signal 5.1ch output: Front L/R, surround L/R, center and subwoofer

Input/output jack

AUX (input) 1 AUDIO input jacks

AUX (input) 2 S-VIDEO input jacks/VIDEO and AUDIO input jacks

AUX (front panel input) 3 S-VIDEO input jacks/VIDEO and AUDIO input jacks

OUTPUT COMPONENT VIDEO output jack/S-VIDEO output jack/VIDEO•AUDIO output jack/AUDIO

Component color output Y output level: 1 Vp-p (75Ω)

S-video input/output Y input/output level: 1 Vp-p (75Ω)

Video input/output Input/output level: 1 Vp-p (75Ω)

Audio input Input level: 200 mV (47kΩ)

Audio output Output level: 200 mV (1kΩ)

Subwoofer audio output Max. Output level: 6 Vrms (1kΩ)

Digital audio I/F audio output Optical digital output: Optical jack

S/N ratio: more than 60 dB

Output jack: RCA Pin-jack

Output level: 2 Vrms (1kHz, 0 dB) (L/R)

Frequency characteristics:

For DVD linear PCM playback: 4 Hz to 22 kHz (48 kHz sampling)

CD playback:4 Hz to 20 kHz (EIAJ)

S/N ratio: CD: 96 dB (EIAJ)

Dynamic range DVD linear PCM: 96 dB (EIAJ)

CD: 96 dB (EIAJ)

Total harmonic distortion ratio CD: 0.006% (EIAJ)

Pickup:

Wave length: 650 nm

Laser output: Max. 0.7 mW

output jack/subwoofer audio output jack/digital audio output jack (coaxial/optical)

B output level: 0.648 Vp-p (75Ω)/100% Color

P

R output level: 0.648 Vp-p (75Ω)/100% Color

P

Output jack: RCA Pin-jack

C input/output level: 0.286 Vp-p (75Ω)

Input/output jack: S jack

Input/output jack: RCA Pin-jack

Output jack: RCA Pin-jack

Output jack: RCA Pin-jack

Output jack: RCA Pin-jack

Coaxial digital output: RCA Pin-jack

DV-A1000U

4 Hz to 44 kHz (96 kHz sampling)

Amplifier

Rated Output 6ch Power Amplifier

Front L/R 40W/40W (8Ω load, 60 Hz to 20 kHz), T.H.D 0.9%

Center 40W (8Ω load, 60 Hz to 20 kHz), T.H.D 0.9%

Surround L/R 40W/40W (8Ω load, 60 Hz to 20 kHz), T.H.D 0.9%

Subwoofer 40W (8Ω load, 20 Hz to 100 Hz), T.H.D 0.9%

Dynamic Power 45W x 2 channels (8Ω)

Speaker Output Speaker impedance: 8Ω

Tuner

Reception frequency bandwidths FM: 87.5 MHz to 108.0 MHz

AM: 530 kHz to 1710 kHz

Actual sensitivity FM: 14 dBµV

AM: 47 dBµV

S/N ratio FM stereo: 70 dB

FM mono: 75 dB

AM: 53 dB

Antenna FM: Coaxial, 75Ω

AM: Loop antenna

3-1

Page 6

DV-A1000U

Speaker

Front

Type: 2-way magnetically shielded speaker

16 cm (6.3*) woofer

5 cm (2.0*) tweeter

Size 210 mm (8.3*) x 330 mm (13.0*) x 218 mm (8.9*) (W x H x D)

Mass: 3.7 kg (8.2 lbs)

Impedance: 8Ω

Rated input: 40W

Max. permissible input: 80W

Center

Type: 2-way magnetically shielded speaker

13 cm (5.1*) woofer

5 cm (2.0*) tweeter

Size: 400 mm (15.7*) x 165 mm (6.5*) x 163 mm (6.4*) (W x H x D)

Mass: 2.9 kg (6.4 lbs)

Impedance: 8Ω

Rated input: 40W

Max. permissible input: 80W

Rear

Type: 2-way

13 cm (5.1*) woofer

5 cm (2.0*) tweeter

Size: 210 mm (8.3*) x 165 mm (6.5*) x 163 mm (6.4*) (W x H x D)

Mass: 1.6 kg (11.5 lbs)

Impedance: 8Ω

Rated input 40W

Max. permissible: 80W

Sub-woofer

Type: Full range magnetically shielded speaker

16 cm (6.3*) super-woofer

Size: 210 mm (8.3*) x 330 mm (13.0*) x 340 mm (13.4*) (W x H x D)

Mass: 5.2 kg (11.5 lbs)

Imdependence: 8Ω

Rated input: 40W

Max. permissible: 80W

Common Specifications

Specifications are subject to change without notice.

Weight and dimensions are approximate.

Digital Output

· The digital output format (optical or coaxial) used in this DVD player is linear PCM audio sampling at 44.1 kHz or 48 kHz.

Linear PCM sound for DVD video discs sampled at 96 kHz cannot be output digitally.

Check the disc jacket for information on the audio sampling used.

Headphone Max. Output level: 52mW (32Ω)

Output jack: Stereo standard jack

Power supply 120 V AC, 60 Hz

Power consumption 150W (0 W when switched off)

Dimensions 430 mm (16.9*) x 130 mm (5.1*) x 402 mm (15.4*) (W x H x D)

(including attachments)

Weight 9.3 kg (20.5 lbs)

Operating temperature 5°C to 35°C (41°F to 104°F)

Storage temperature -20°C to 55°C (-4°F to 131°F)

3-1. ACCESSORIES

Accessories: S-video cable x 1, Video/audio cable x 1, AC power cord x 1, UM3 battery x 2,

Remote Control Unit x 1, AM loop antenna x 1, Simple FM antenna x 1, FM antenna adaptor x 1,

Speaker cables [2.5 m (8.2 ft)] x 4, Speaker cables [10 m (32.8ft)] x 2, Speakers

3-2

Page 7

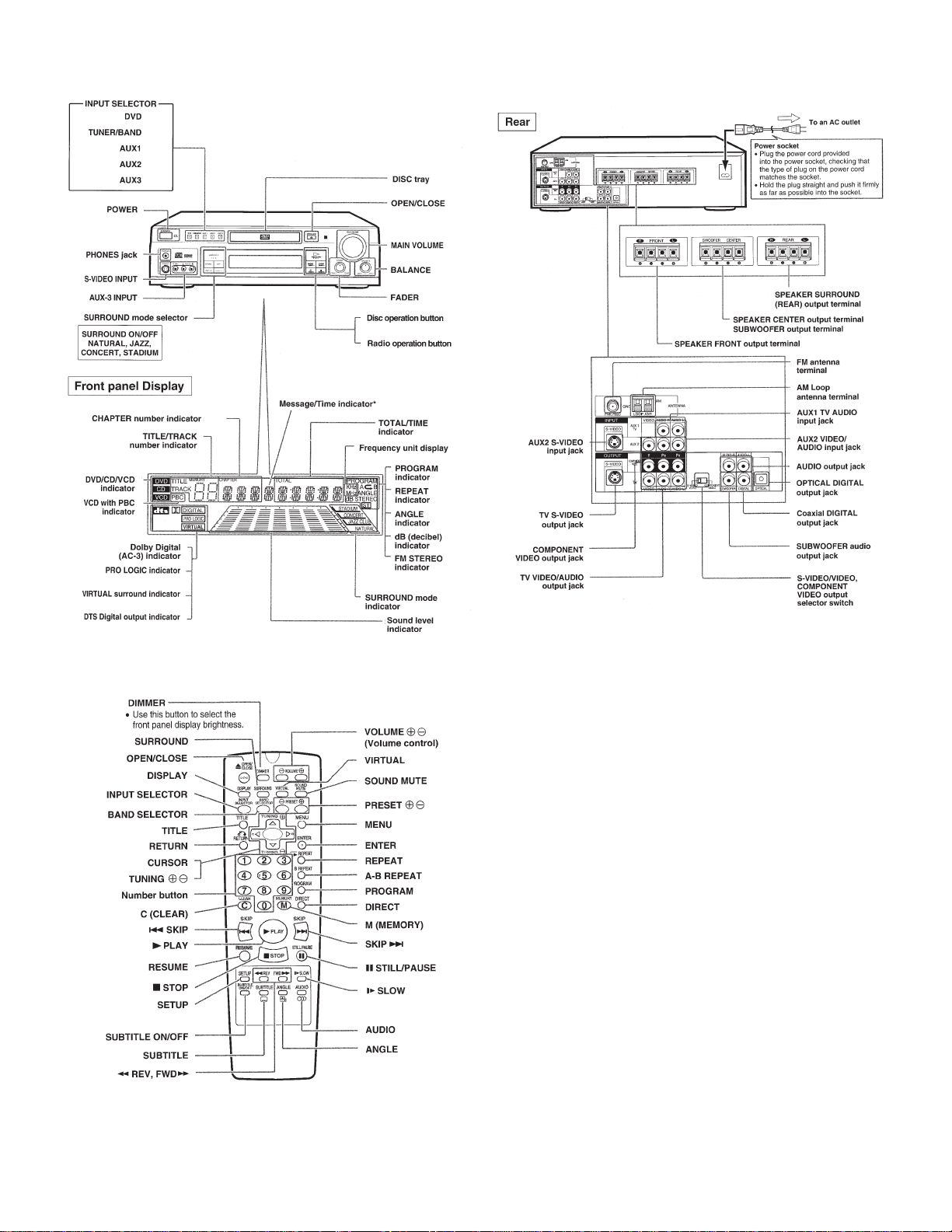

4. PARTS NAME

DV-A1000U

4-1

Page 8

DV-A1000U

5. MAINTENANCE CHECK ITEMS AND EXECUTION TIME

MECHANICAL PARTS REGUIRING PERIODICAL INSPECTION

Use the following table as a guide to maintain the mechanical parts in good operating condition.

Parts

Pickup

Spindle Unit

Sled Motor

Loading Motor

Belt

Note : Part Replacement

: Cleaning

(For cleaning, use a lint-free cloth danpened with pure isopropyl alcohol.)

Maintained

1,000 hrs.

2,000 hrs.

CARES WHEN USING THE PICKUP

1. The laser light having wavelength 650 nm is emitted from the objective lens. BE CAREFUL SO THAT THE LASER

LIGHT DOES NOT ENTER DIRECTLY INTO YOUR EYE.

2. The semiconductor laser may be easily damaged by electrostatic charges. When handling the pickup, take care so that

the electrostatic charge is not generated.

3. The semiconductor laser may be easily damaged by overcurrent. Use the power supply unit which does not give any

spike current when the power is turned on and off.

4. Carefully remove the dust and dirt from the objective lens with the lens blower.

When handling the objective lens, take due care so that it is not contaminated with fingerprint, etc. If the objective lens

is contaminated, impregnate the cleaning paper with a small quantity of solvent (isopropyl alcohol), and gently wipe to

clean.

5. The ozone layer depleting components (ODC) are not used in the production process for the product.

5-1

Page 9

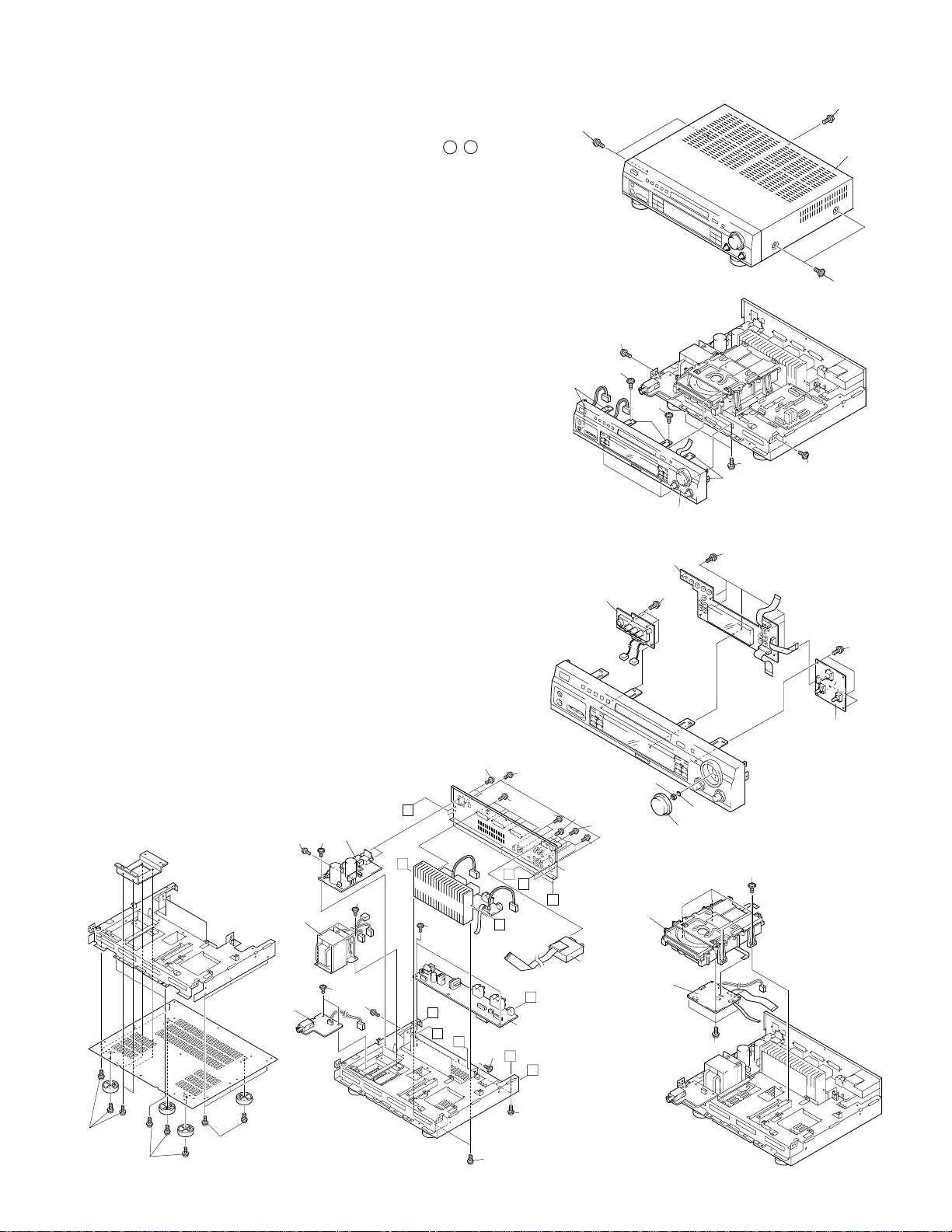

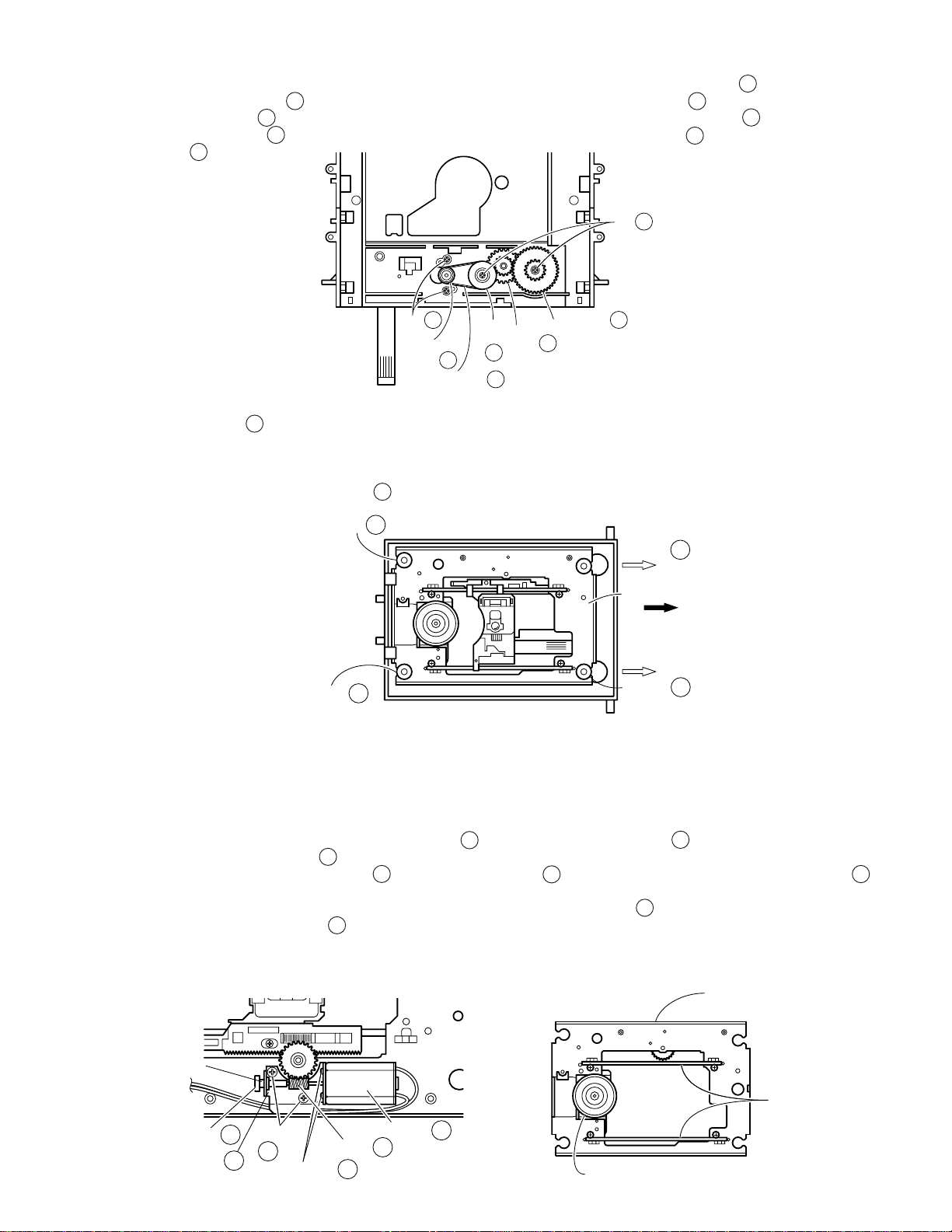

6. DISASSEMBLY AND REPLACEMENT OF MAIN PARTS

6-1. DISASSEMBLY

1. Remove five screws (A), and remove the cabinet.

Note: When assembling it, tighten the screws in order of 1 - 2 .

(Because the set may rise a little by tightening the screws.)

[Figure 1.]

2. Remove the two screws (B) at the lower side of front panel.

3. Remove the two screws (C) of side.

4. Remove the two screws (D) fixing the font panel to the mechanism.

5. Remove both side pawls and lower pawl. [Figure 2.]

6. Remove the PWB fitted to the front panel.

(Front AV PWB (E), 4 pcs., indication display PWB (F), 7 pcs., volume

PWB (G), 3 pcs.)

7. Withdraw the master volume, and remove the VR nut and washer.

[Figure 3.] (At this time the tray decoration plate can be removed.)

8. Remove the four screws (H) for fitting the mechanism unit.

9. Remove the three screws (J) at the lower side of mechanism unit.

(Main PWB) [Figure 4.]

10. Remove the two screws (K) for fitting the headphone PWB.

11. Remove the four screws (L) fitting the transformer.

12. Remove one screw (M) fixing the power PWB, remove the two screws

(N) of AC inlet, remove the screw (P) fixing the transistor, and remove

the spacer hook.

13. Remove the three screws (Q) fixing the FM tuner.

14. Remove the two screws (R) of bottom plate which fix the radiation

plate.Remove the two screws (S).Remove the nine screws(T). Shift the

radiation plate and PWB to this side, remove the terminal from the

terminal block, and lift.

15. Remove the five screws (U) of PWB. Remove the two screws (V) fixing

the terminal PWB.

16. Remove the two screws (W) and three screws (X) fixing the terminal

block. [Figure 5.]

(A) x2 ①

(C)

(D)

Pawl x2

Operate PWB

Front AV PWB

(D)

Pawl

Front Panel

(E) x4

Figure 1

Pawl x2

Figure 2

(F) x7

(B)

DV-A1000U

(A) ②

Top Cabinet

(A) x2 ①

(C)

(G) x3

Volume PWB

17. Remove the sixteen screws (Y). [Figure 6.]

Power PWB

(M)

(P)

Power Transformer

(K) x4

Headphone

PWB

(Y) x8

(Y) x4

(Y) x4

(L) x4

(S)

(N) x2

G

D

(V) x2

G

D

D

Figure 5Figure 6

D

(S)

(R) x2

(W) x2

(T) x6

(U) x2

J

G

J

Terminal PWB

E

G

(X) x3

(Q) x3

Terminal Plate

E

FM Tuner

VR Nut

(T) x3

(U) x3

Mechanism Unit

Washer

Master Volume

Figure 3

(H) x4

Main PWB

(J) x3

Figure 4

6-1

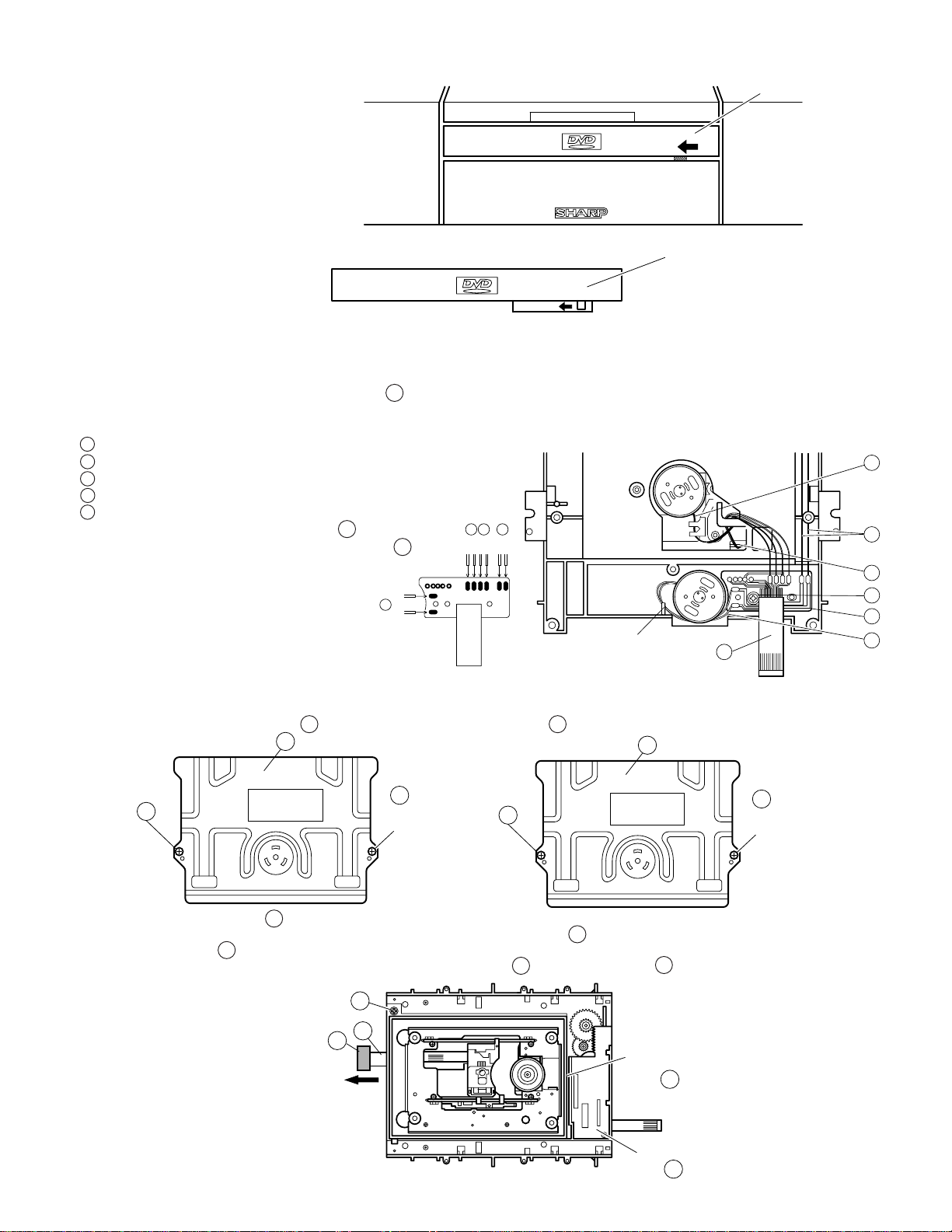

Page 10

DV-A1000U

VIDEO

Tray Decoration Panel

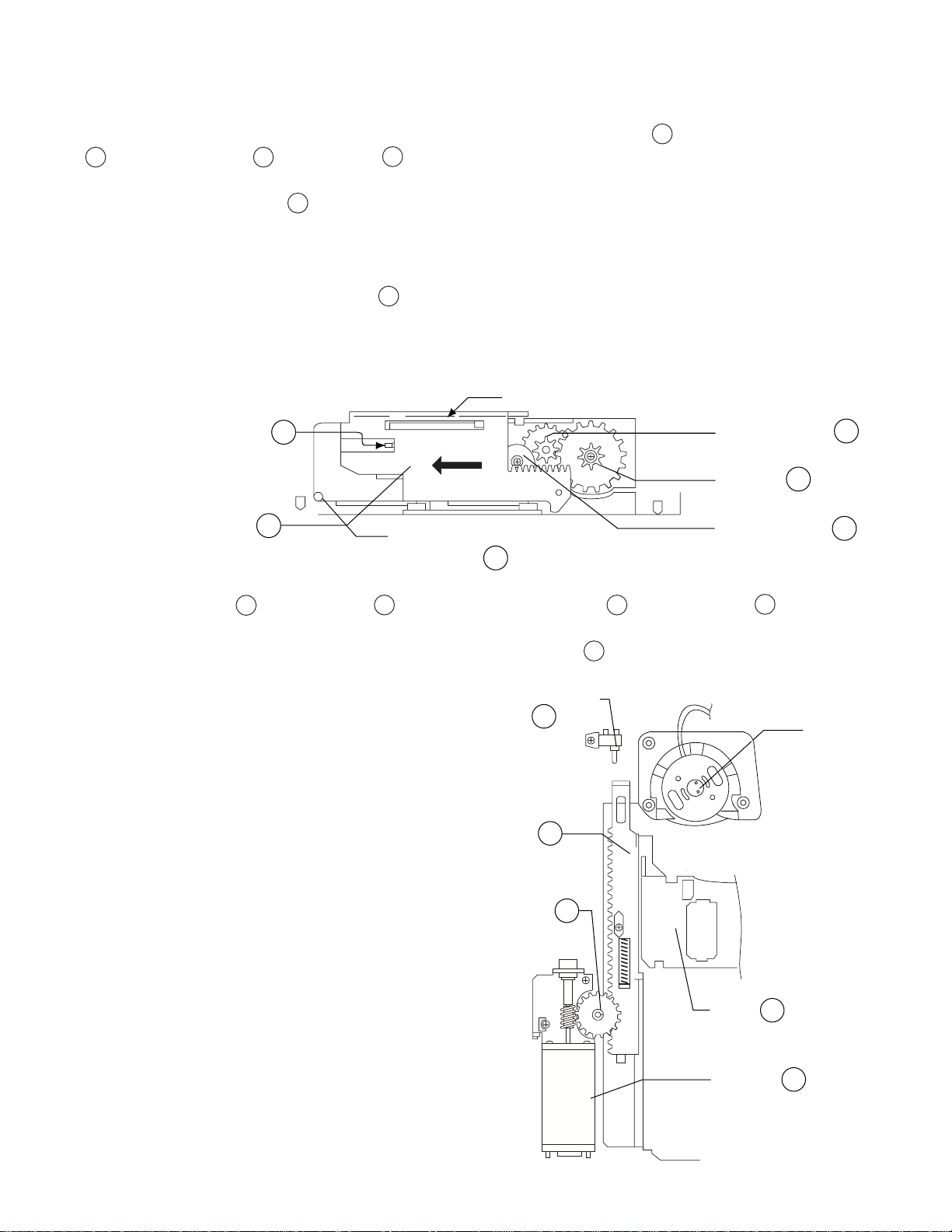

6-2. REPLACEMENT OF MAIN PARTS

<Disassembling and assembling procedure>

· Removing the tray (emergency ejection)

Removing the tray lock (set state)

Insert a thin plate into the hatching part, slowly move the it in the arrow direction so that the tray is moved out a little in the arrow direction.

Note: In this state the tray cannot be removed completely.

Tray Decoration Panel

· Drive Unit State

VIDEO

Slowly move in the arrow direction, using the screwdriver having a fine head.

<Disassembling and assembling the mechanism chassis>

1. Remove the pickup FPC and loading relay FFC A from the main PWB.

Note: Fit the conductive rubber cap to the front end of pickup FPC (short-circuit).

2. Remove the solder joint of loading relay PWB at drive unit rear side.

1 Sled motor lead wire (Yellow·Orange)

2 IN SW lead wire 2 (White)

3

3 Spindle motor lead wire (Red·Black)

4 Loading motor lead wire (Red·Black)

5 Remove each lead wire from the claw.

2

3

3. Remove the relay PWB mounting screw B

(M2.6S + 6S S tight), and remove the relay PWB C .

Brack

4

L motor2

Red

Lmotor2

1

Orange

Yellow

Brown

Brown

Brack

Red

SL motor1

SL motor2

SW

GND

SP1

SP2

Remove the lead wire

A

1

2

B

C

4

4. Disassembling the mechanism chassis moving chassis assembly

(1) Remove the four M2.6 screws A , and remove the clamped top plate B .

B

A

A

P tight screw

with M2.6 washer

A

B

(2) Remove the M2.6 screw C .

(3) Holding aslant upward the mechanism chassis moving chassis assembly D in the arrow direction, remove.

Note: The slide rack E must be moved to the left side as shown in diagram.

Take care so that the lead wires, especially the earth sponge G at the pickup FPC F front end, must not beremoved.

P tight screw with

M2.6 washer

C

F

G

Mechanism chassis moving

chassis assembly

D

Slide rack

E

A

P tight screw

with M2.6 washer

6-2

Page 11

5. Disassembling the loading drive system

Insulator

Insulator

Insulator

Insulator

Mechanism chassis

C

B

B

C

[Item 3 of previous page] Remove the L. relay PWB. (Otherwise the L motor cannot be removed in step 6 .)

(1) Remove the two M2 screws A . (4) Remove relay gear 2 E .

(2) Remove the tray pinion B . (5) Remove the two M1.7 screws F .

(3) Remove the relay gear 1 C together with the (6) Remove the L motor G (with pulley) downward.

timing belt S D .

M2

A

DV-A1000U

F

M1.7

L.Motor Pully

L.Motor

Timing Belt

Relay

gear2

Tray pininon

E

Relay

gear1

C

G

D

B

6. Disassembling the mechanism chassis from the moving chassis

(1) Remove the insulator B (2 pcs. at the right side in diagram) parallel in the arrow direction.

(At this time it is better to insert the fine head of screw driver at the ID side of insulator and to move in the arrow direction, which

facilitates removal.)

(2) Remove the mechanism chassis in the arrow direction, pulling upward aslant.

At this time take care so that the insulator C (left side, 2 pcs.) is not damaged. (Do not put at once the mechanism chassis

assembly.)

7. Replacing the pickup

After replacement the tilt adjustment with the aid of jitter meter and other special equipment is required. Therefore, it is impossible

to replace on site. (The same as item 9 of next page). Replace as service chassis.

8. Replacing the Sled Motor

(1) At the rear side of chassis remove the two M1.7 screws A , and remove the motor angle B .

(2) Remove the thrust holding screw C (for easier removing wipe off the thread lock).

(3) Remove the two motor fitting screws M1.4 D , and replace the motor E . Motor is replaced in the state while the worm F is

kept press-fitted to the output shaft.

Note: When installing the motor, take care so that the worm does not damage the ANG B hole.

(4) Screw in the thurust holding screw C , adjust the worm front end clearance to 0 to 0.1 mm, and apply screw lock.

9. Replacing the spindlw motor

Since the pickup optical axis and turntable inclination of DVD are adjusted with higher accuracy than of CD/MD, make a replacement

as a mechanism service chassis ass'y (refer to Parts List).

Mechanism chassis

Apply screw-lock

M1.7 Screw

Thurust holding screw

Motor Angle

C

A

B

M1.4 Screw

Worm

D

Sled motor

F

Guide shaft

E

Spindle motor unit

6-3

Page 12

DV-A1000U

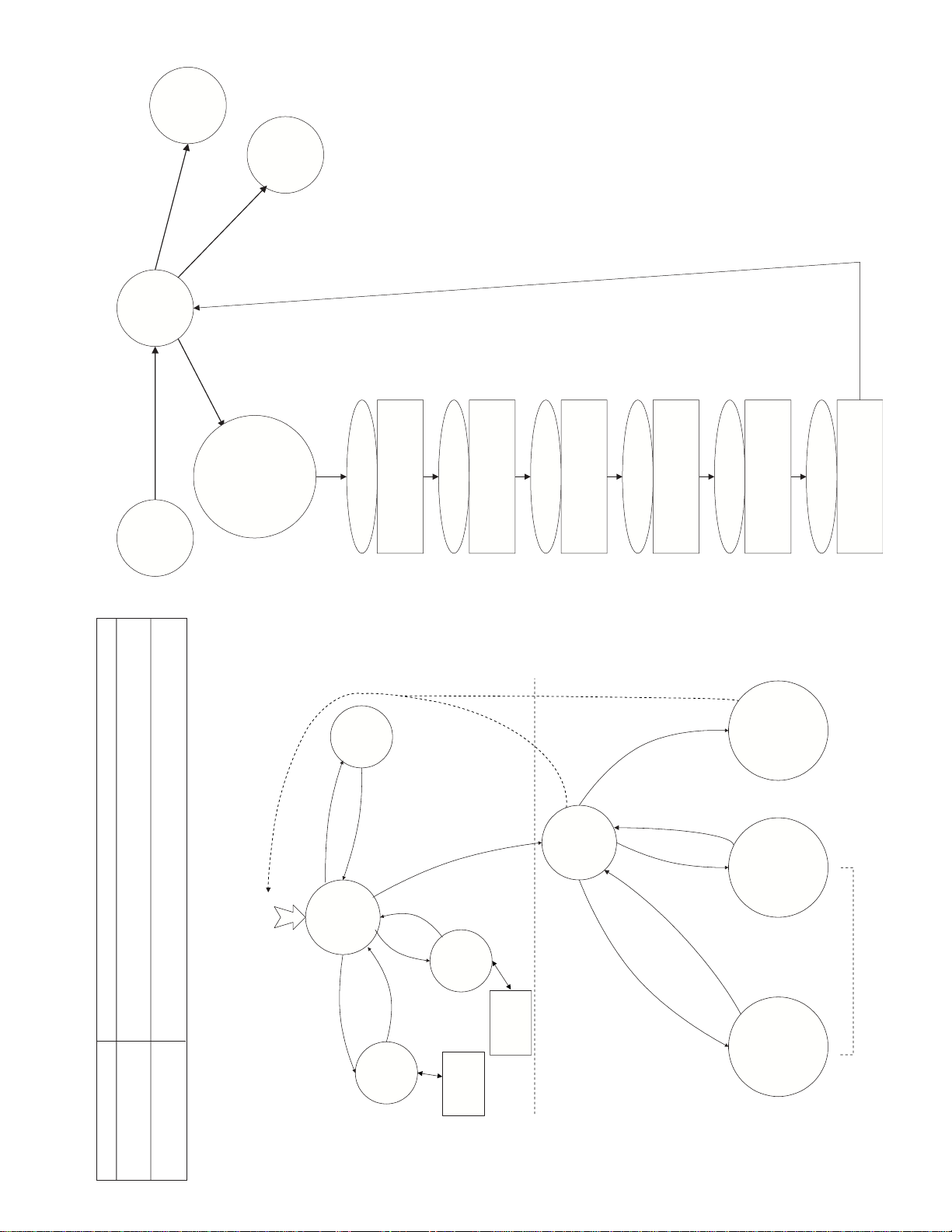

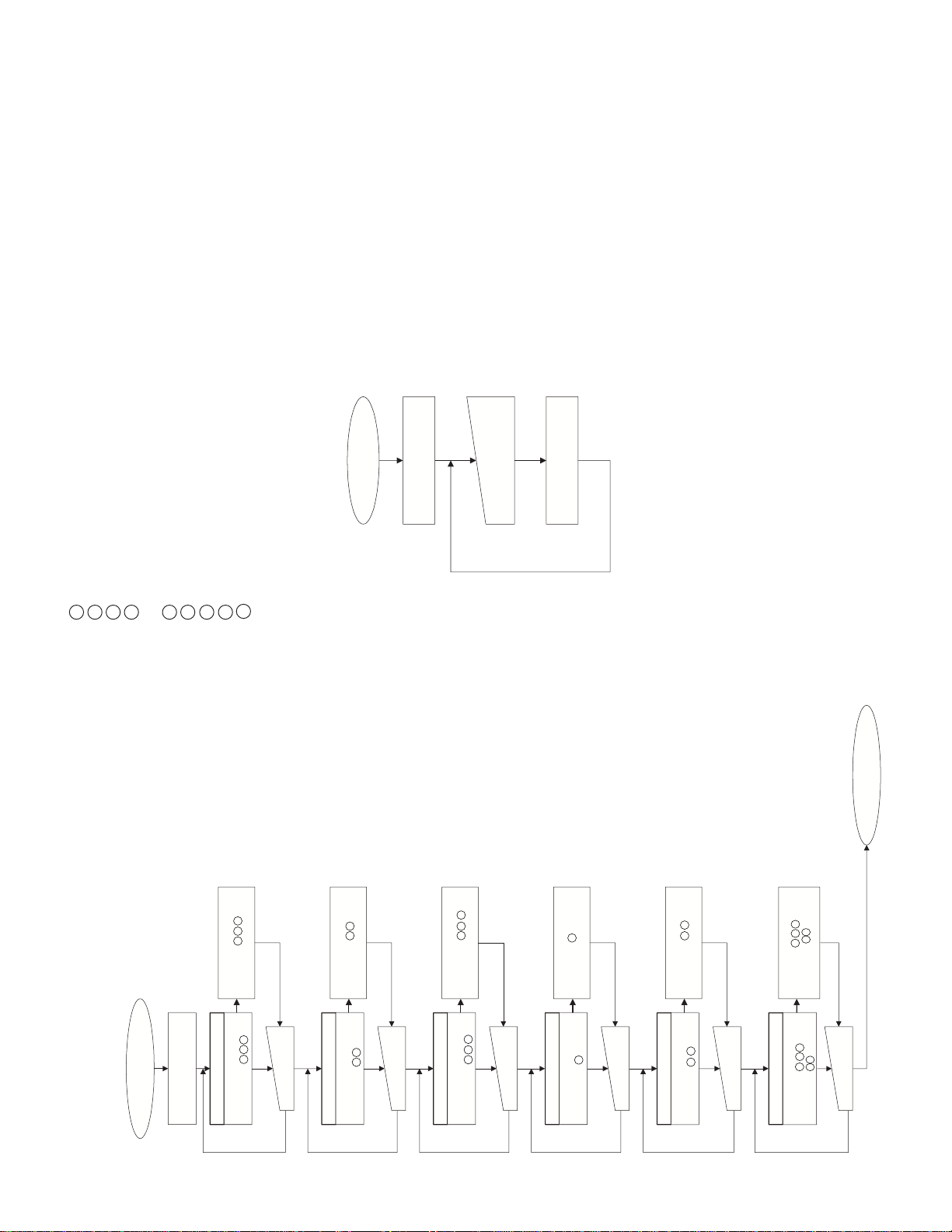

7. EXPLANATION OF MECHANISM

(1)Tray loading mechanism

When the tray loading motor rotates clockwise, motion is transmitted to the slide rack D through the intermediate gear 1

A , intermediate gear 2 B and tray pinion C , resulting in insignificant motion in the arrow direction.

The slide rack is linked with the operating chassis. It lowers the pickup mechanism.

The protrusion of slide rack E is linked with the tray through the groove at the rear side of tray, so that the tray is

pushed ahead a little. When the tray is pushed out, the slide rack is disconnected from the tray pinion, and at the same

time the gear at the rear side of tray is connected with the tray pinion, and the tray is pushed ahead.

When the tray is pushed out fully, the slide rack moves further in the arrow direction through the groove at the rear side

of tray. The tray position detection switch F is turned on, and the tray loading motor stops.

When the tray closes the operation is as follows. If the tray OPEN/CLOSE button or tray is pressed and the detection

switch is turned off, the tray loading motor rotates counterclockwise, so that the tray is retracted. When the detection

switch is turned on again, the tray loading motor stops.

This groove is linked with trhe pawl of

pickup mechanism

Tray position detection switch

Slide rack

F

D

Pawl kinled with the groove at the

rear side of tray

E

Intermediate gear 2

Tray pinion

Intermediate gear 1

C

(2)Pickup feed mechanism

When the sled motor A rotates, the rack C moves through the sled pinion B so that the pickup D is moved to the

internal or external periphery.

When it is moved to the innermost periphery, the position detection switch E is pushed by the rack, so that the position

of pickup is initialized.

(3)Disc rotation mechanism

Pickup

Position detection

switch

E

Spindle motor

The spindle motor is used to rotate.

IC701 is used to control.

When the spindle motor is replaced, replace the

spindle unit.

Rack

C

B

A

Sled pinion

7-1

B

Pickup

Sled motor

D

A

Page 13

DV-A1000U

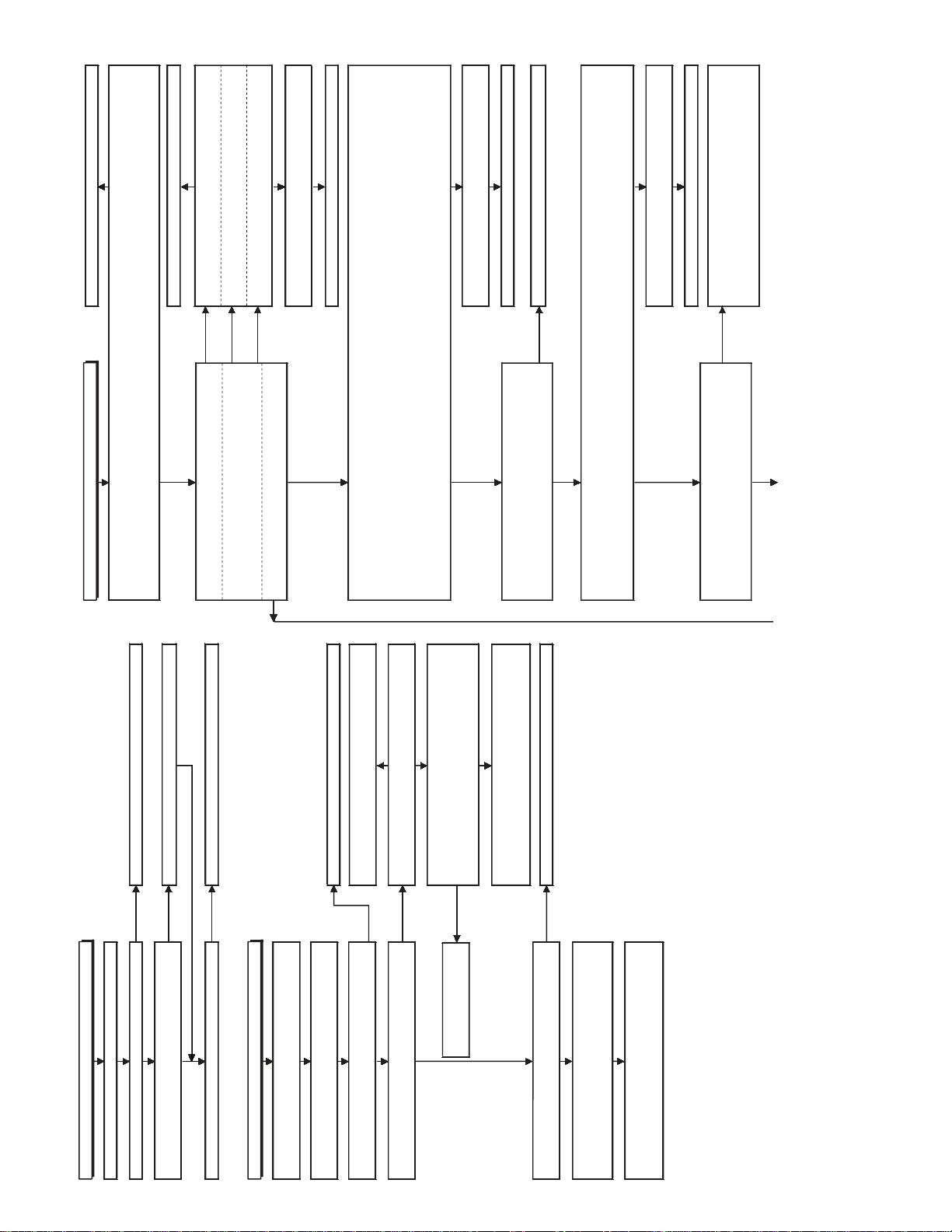

Test Mode Operation

SystemOpe( )

DVDOpe( )

Systest( )

DVD Disc detection

CD Disc

detection

No Disc and

Test 0 (F0h) key

Eject or

error

Eject or

error

Power

Off

Power

Off

Memory Test

Model number

Program version

Region code

microcode version

Dynamic

Test

Tray Open/Close

Sled Move

DVD Servo

CD Servo

Video Test

Initial Screen

Test Pattern

'1' Key

'2' Key

'3' Key

FlashOpe( )

Reset

Start

Flash rewriting key

Static Test

Test0

(F0h)

key

Branching with

ten keys

Test0

Key

Test0

Key

Test0

(F0h)

key

OSD

Adjustment

value display

OSD

Adjustment

value display

Initial resetting

CDOpe( )

Note: For test mode input,

"F0h" = PLAY + Stop

The keys of main body are doubly pressed.

Systest( )

(0xF100)

Dinamic

Test

Video

Test

'1' Key

'2' Key

'3' Key

Transition of test mode status (1)

Memory Test

Last Update display

ErrDisplay0 ErrDisplay1

10000000 ********

(last update)

(last update)

Play Key

System( )

Test0 Key

SystemMode

=

0xF100-0xF1FF

Memory Test

Model number

Program version

Region code

microcode version

Model Number display

(Model Number)

Play Key

Region code display

(Region code)

Play Key

Microcode version

display

(Microcode. Ver)

Play Key

Program Version display

(Program version)

Play Key

Servo version display

(Servo. Ver)

Play Key

ErrDisplay0 ErrDisplay1

10000001 ********

ErrDisplay0 ErrDisplay1

10000002 ********

ErrDisplay0 ErrDisplay1

10000004 ********

ErrDisplay0 ErrDisplay1

10000005 ********

ErrDisplay0 ErrDisplay1

10000003 ********

Memory Test Mode Program version indicaiton.

Video Test Mode Ordinary test pattern indication, and copy guard signal added test

8. TEST MODE

pattern indication are given.

continuous playback, jump test are performed.

Mecha Test Mode Servo system initialization, tray opening and closing, laser, servo,

EXPLANATION OF OPERATION AT THE SYSTEM START

8-1.

8-1

Page 14

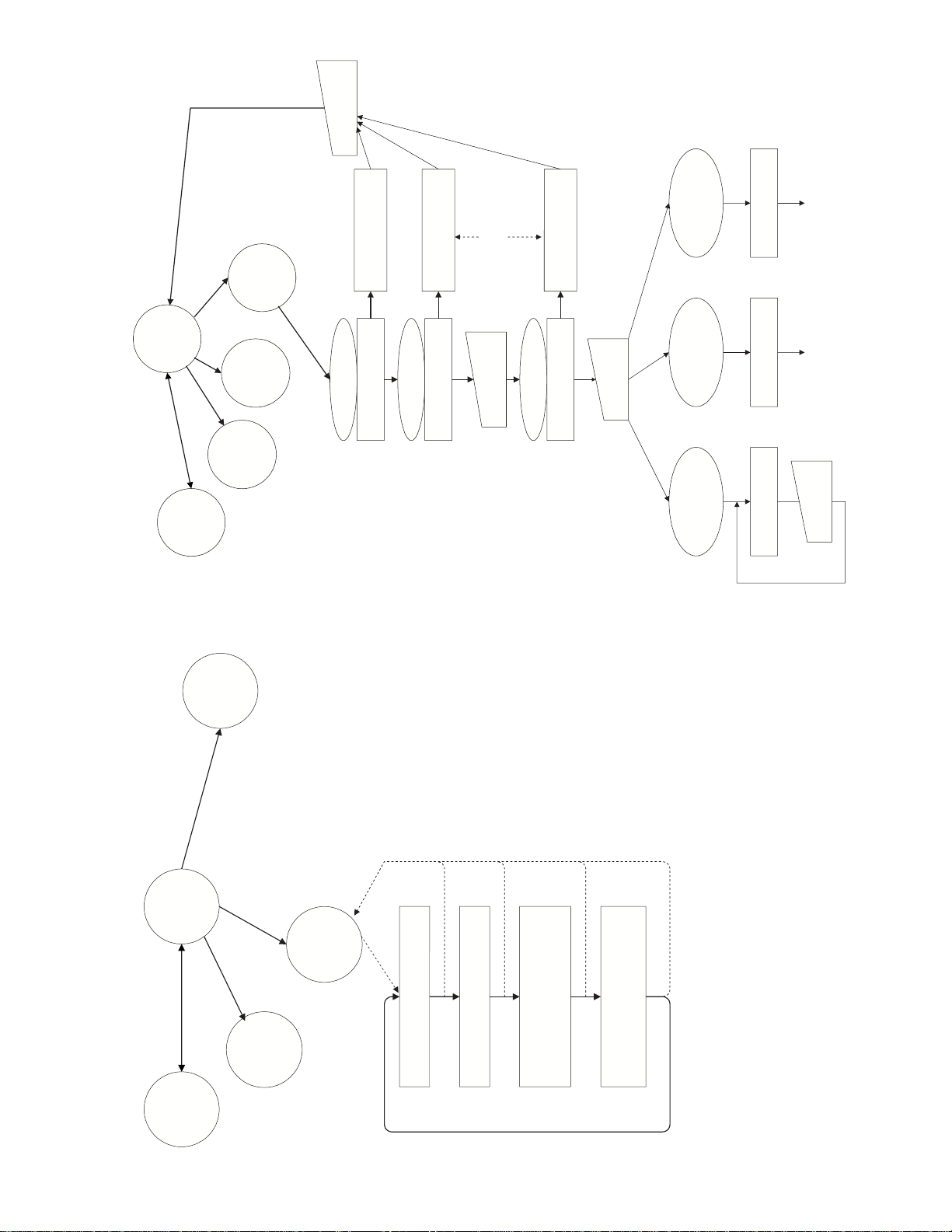

DV-A1000U

SysTest( )

(0xF100)

Memory

Test

Dinamic

Test

'1' Key

'2' Key

'3' Key

System( )

Test0 Key

Video

Test

SystemMode

=

0xF201-0xF204

(1)Test pattern display

20000001 00000000

(2)Copy guard (AGC alone)

20000002 00000000

Play

key

Play

key

Play

key

Play

key

Test0

Key

(3)Copy guard

(AGC + Color stripe 1)

20000003 00000000

(4)Copy guard

(AGC + Color stripe 2)

20000003 00000000

Transition of test mode status (2)

Video Test

In Video Test mode, the color bar test pattern

is first displayed and output, and the display

data mode is changed every entry of PLAY key

as shown in the right. Here, it returns to Sys

Test ( ) if any Test 0 (F0h) key is input in the

test display.

Transition of test mode status (3)

Dinamic Test

Systest( )

(0xF100)

Memory

Test

Dynamic

Test

'1' Key

'2' Key '3' Key

System( )

Test0 Key

Video

Test

SystemMode

=

0xFC00-0xFDFF

Servo Initialize

ErrDisplay0 ErrDisplay1

30000000 00000000

ErrDisplay0 ErrDisplay1

3000E000 EEEEEEEE

(Servo Initial Err)

Tray Eject

ErrDisplay0 ErrDisplay1

30000001 00000000

ErrDisplay0 ErrDisplay1

3000E001 EEEEEEEE

(Tray Eject Err)

Open/Close Key

or hand-push Wait

Tray Load

ErrDisplay0 ErrDisplay1

30000002 00000000

ErrDisplay0 ErrDisplay1

3000E002 EEEEEEEE

(Tray Load Err)

Test0 Key

Wait

SRV Play Test ( )

Continuous replay jump

test mode

'1' or '2'or'3'

Key Wait

SRV Step Test ( )

Step execution mode

Laser Test ( )

Laser Test mode

'1'

'2'

'3'

'1'

Key Wait

Refer to the step

test mode.

Refer to the jump

test mode.

ErrDisplay0 ErrDisplay1

DD000100 00000000

ErrDisplay0 ErrDisplay1

DD000200 00000000

ErrDisplay0 ErrDisplay1

DD000300 00000000

Every input of "1" key, LDON &

the sled moves outward, and the

spindle motor moves also insignificantly.

Note: Tray Err is not

retried in the mode.

8-2

Page 15

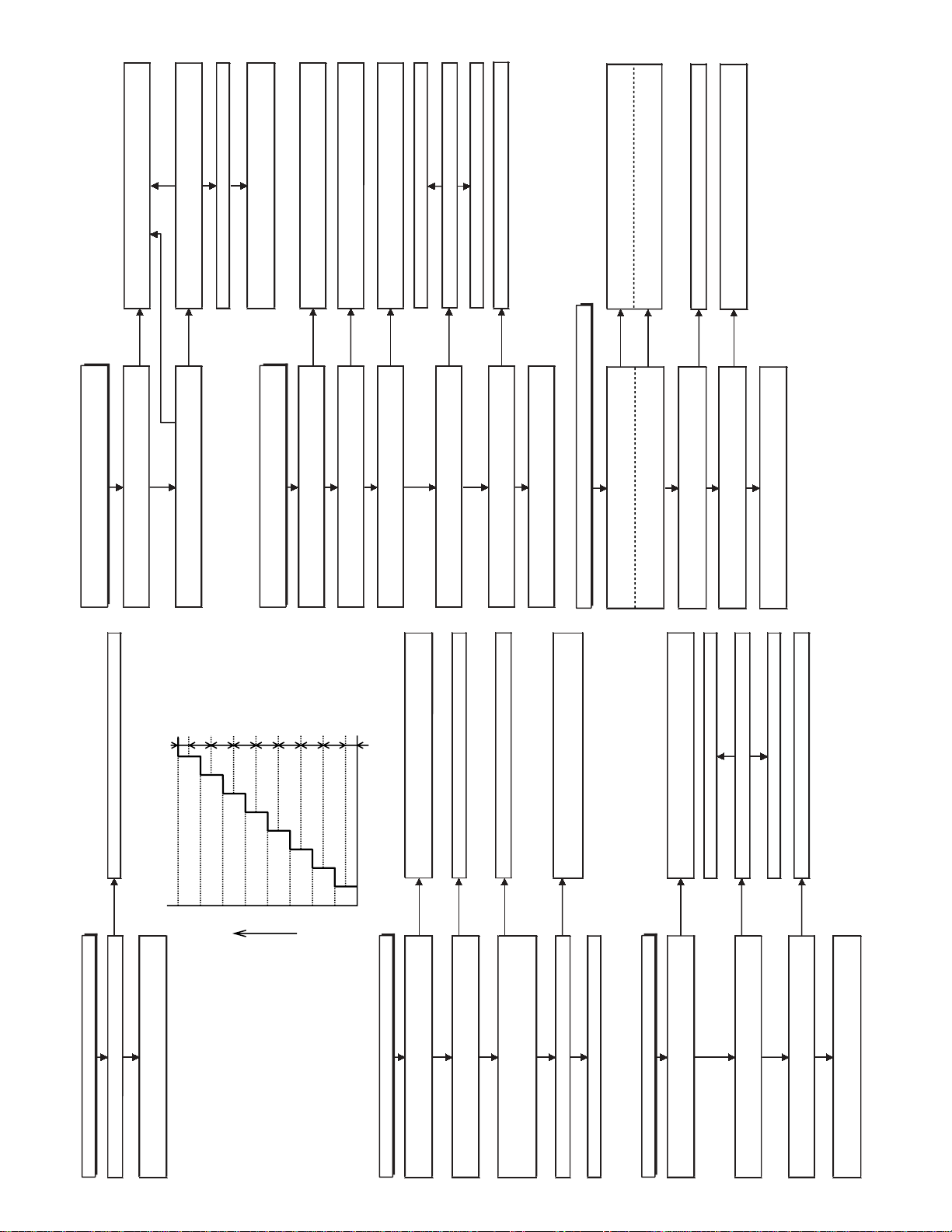

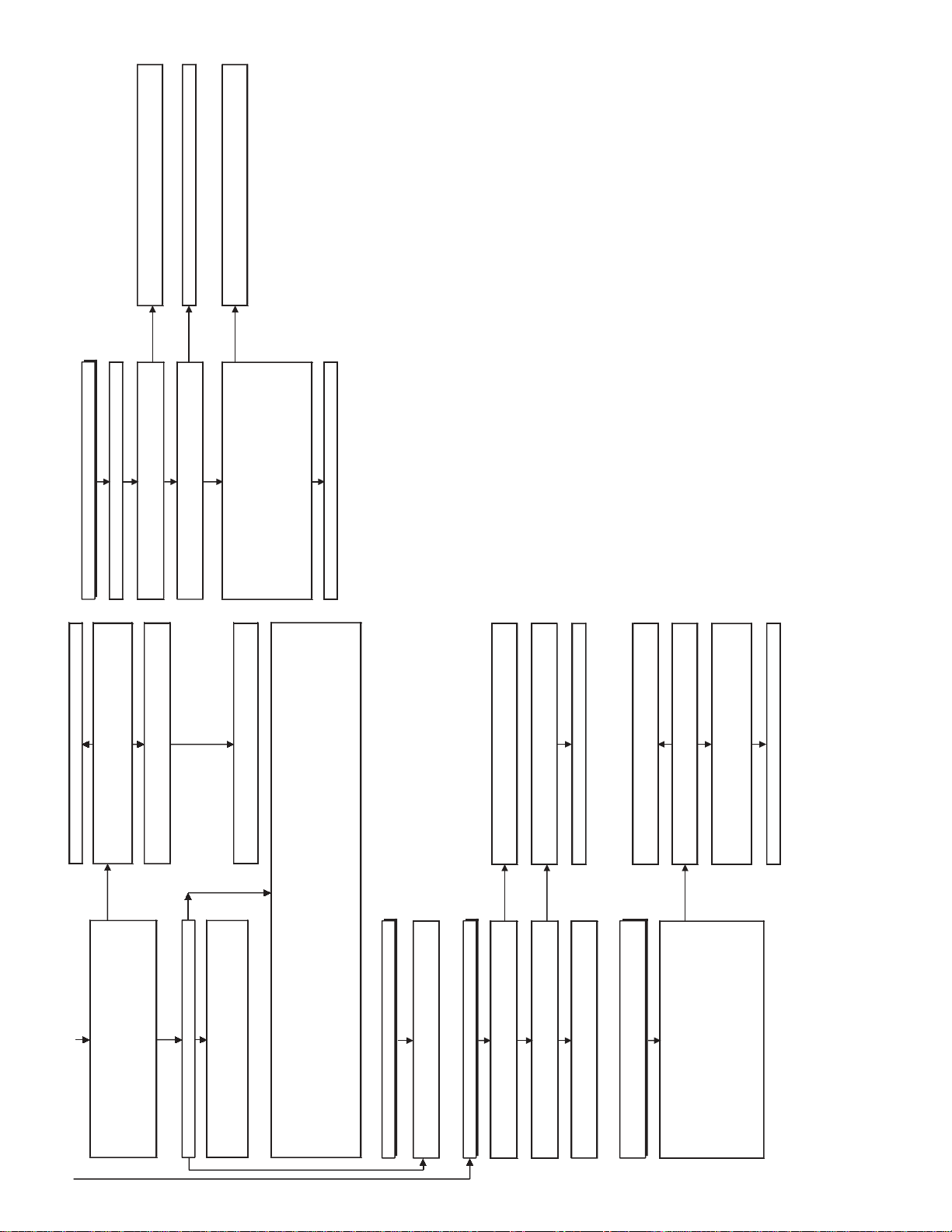

DV-A1000U

SRV Step Test( )

SRV Step Test( )

Step Test Mode

ex. DVD mode

ErrDisplay0 ErrDisplay1

DD000200 00000000

ErrDisplay0 ErrDisplay1

DD000204 7 000000

ErrDisplay0 ErrDisplay1

DD000205 9

11

0000

ErrDisplay0 ErrDisplay1

DD000206

7 4 5 00(CD)

8 5

0000(DVD)

AdjDisplay( )

(0xFF00)

'PLAY'

'STILL'

'PLAY'

'PLAY'

'STILL'

'STILL'

'PLAY'

DDT step 1 operation

ErrDisplay0 ErrDisplay1

DD000201 2 3 4 00

ErrDisplay0 ErrDisplay1

DD00E201 2 3 4 EE

'PLAY' or 'STILL'

'STILL'

ErrDisplay0 ErrDisplay1

DD000202 3 6 0000

'PLAY'

'STILL'

ErrDisplay0 ErrDisplay1

DD000203 4 6

11

00

'PLAY'

'STILL'

DDT step 1 operation

Executed till focus of DDT is turned on.

The numerals shown on Err Display 1

indicate the following adjustment values.

DDT step 2 operation

Track balance adjustment and track

thread on are executed.

DDT step 3 operation

After RF gain is adjusted for a certain

time, the just focus is adjusted.

After end, RF gain adjustment is started

again.

DDT step 4 operation

Focus gain is adjusted.

DDT step 5 operation

Track gain is adjusted.

DDT step 6 operation

On the 2-layer disc, the just focus

adjustment and focus gain adjustment

of layer 1 are done.

On CD, interrupt of SUB-Q is allowed,

TOC is read/set, and mute is turned off.

(for error)

(for error)

(for error)

(for error)

(for error)

(for error)

ErrDisplay0 ErrDisplay1

DD00E202 3 6 00EE

ErrDisplay0 ErrDisplay1

DD00E203 4 6

11

EE

ErrDisplay0 ErrDisplay1

DD00E204 7 0000EE

ErrDisplay0 ErrDisplay1

DD00E205 9

11

00EE

ErrDisplay0 ErrDisplay1

DD00E206

7 4 5

EE(CD)

8 5

00EE(DVD)

DDT step 2 operation

DDT step 3 operation

DDT step 4 operation

DDT step 5 operation

DDT step 6 operation

'PLAY' or 'STILL'

'PLAY' or 'STILL'

'PLAY' or 'STILL'

'PLAY' or 'STILL'

'PLAY' or 'STILL'

Servo adjustment value

Reading-out mode

SRVPlayTest( )

Continuous replay & jump mode

ErrDisplay0 ErrDisplay1

DD000300 ********

SRV Play Test( )

In the continuous replay mode, the current sector

address is displayed on ErrDisplay 1.

Key Wait

TR Jump command publication

In SRV Play Test ( ), key is input and number of TR jumps is specified as follows.

[Next replay] = Layer Jump

* Here, key allocation may be changed.

* Layer jump operation is not guaranteed except during 2-layer DVD test.

Key Name

[1]

[4]

[7]

[Clear]

[2]

[5]

[8]

[Skip(-)]

(Code)

01h

04h

07h

1Fh

02h

05h

08h

2Dh

Jump Number of TRs

-1

-102

-510

-511

-765

-766

-7000

-15000

Key Name

[3]

[6]

[9]

[Memory]

[Repeat]

[A-B]

[Program]

[Skip(+)]

(Code)

02h

06h

09h

1Ch

35h

36h

1Eh

2Eh

Jump Number of TRs

+1

+102

+510

+511

+765

+766

+7000

+15000

2 ........... Focus Offset

3 ........... Track Offset

4 ........... 0-Layer Focus Balance

5 ........... 1-Layer Focus Balance

.............. In case of CD, focus balance after correction.

6 ........... Track Balance

7 ........... 0-Layer Focus Gain

........... RF Gain

8 ........... 1-Layer Focus Gain

9 ........... Track Gain

11

8-3

Page 16

DV-A1000U

DVDOpe( )

(0x4000)

CDOpe( )

(0x1000)

AdjDisplay(*)

(0xFF00)

Test1

(F1h)

key

Test1

(F1h)

key

During stop in DVD/CD/VCD mode,

servo adjustment value reading-out

mode is selected if Test 1 key (F1h)

is input.

(1)Servo version display

F1000001 ********

'PLAY'

In the servo adjustment value reading-out mode,

the focus offset value is first displayed. Every input

of PLAY key, the displayed data is changed as

shown in the left.

After the servo step test, the internal circumference

SW value (ID) display is not defined.

SRV Step Test( )

After measurement is ended in the servo

step test mode,the servo adjustment value

reading-out mode is selected.

'PLAY'

'PLAY'

'PLAY'

'PLAY'

'PLAY'

'PLAY'

'PLAY'

'PLAY'

'PLAY'

If the servo adjustment value reading-out

mode is selected, disc is stopped.

'PLAY'

Argument of AdjDisplay(*)

is char 0:CD/1:DVD.

'PLAY'

(2)Focus offset value display

F1000002 ********

(3)Track offset value display

F1000003 ********

(4)0-layer focus balance value display

F1000004 ********

(5)1-layer focus balance value display

F1000005 ********

(6)Track balance value display

F1000006 ********

(7)0-layer focus gain value display

F1000007 ********

(8)1-layer focus gain value display

F1000008 ********

(9)Track gain value

F1000009 ********

(10)RF amplitude value display

F100000A ********

(11)RF gain value display

F100000B ********

(12)Internal circumference switch ID

value display

F100000C ********

Servo adjustment value

reading-out mode

22 23 24 25 26

9 10111213141516

(In case of CD, 0-Layer focus balance after correction.)

17 18 19 20 21

12345678

(2) 3, 4 .................. 1-layer focus gain

(3) 5, 6 .................. 0-layer focus balance

OSD adjustment value display

1. Press "FOh" key during disc replay. (Multiple press of S. PICTURE and STOP)

2. The following screen is displayed on OSD.

3. OSD display is turned off with "FOh" key.

(1) 1, 2 .................. 0-layer focus gain

(4) 7, 8 .................. 1-layer focus balance

(5) 9, 10 ................ Track offset

(6) 11, 12 .............. Track gain

(7) 13, 14 .............. Track balance

(8) 15, 16 .............. RF gain

Hexadecimal data from (1) to (8).

8-4

Page 17

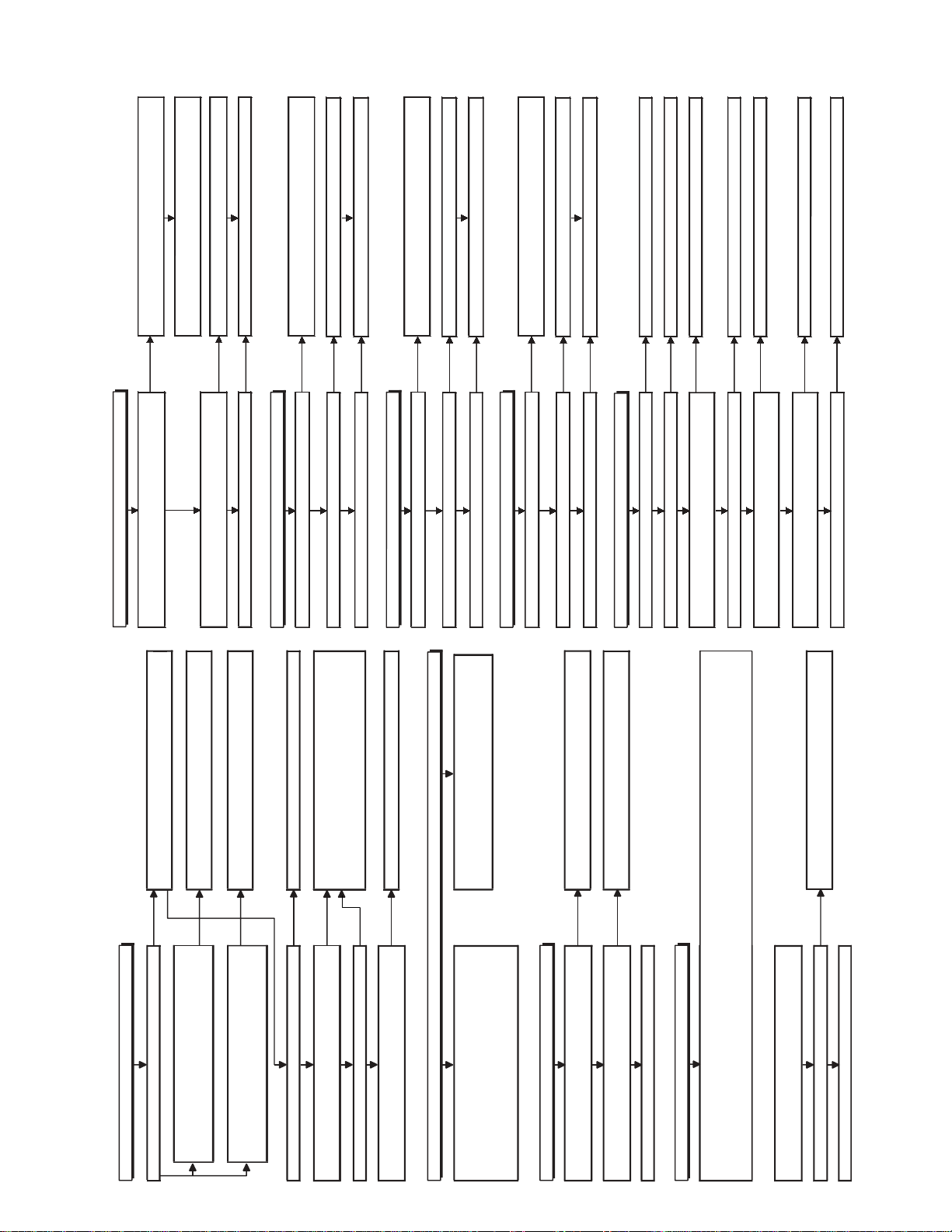

DV-A1000U

Power cannot be supplied.

Check the power transformer primary side circuit.

(T9301,SW9202,AC9201,CN9202,ACCord,etc.)

Yes

Yes

Is fuse (F9201) normal?

Check the audio output power circuit +30.8V,

-30.8V line. (D9201,C9201,C9203,etc.)

Remove the connector CN9203, replace the

fuse (F9201), and turn on power again. Does

fuse (F9201) blow at this time?

The fuse (F9101) is cut.

Check whether there is leaking or short-circuited

part at primary side.(L9103,VR9101,Q9102,Q9104,

D9114,D9115,etc.) If any defect is found in Q9102,

Q9104, D9114 or D9115, replace them at the same

time.

When the output voltage fluctuates.

No

Does the secondary side photocoupler circuit

operate normally?

Check the circuit, and replace part.

(D9115,D9111,D9106-8,Q9101,Q9103,etc.)

Yes

Yes

Replace D9115.

When buzz is heard in the vicinity of power circuit.

(1)

Check for short-circuiting of rectifying diode and circuit in secondary side rectifying circuit.

(D9102-5,D9116,IC9001-2,IC9004,etc.)

(2)Check the audio output power circuit +30.8V, -30.8V line.(D9201,C9201,C9203,etc.)

(3)Check the AV power circuit +12V, -12V line.(D9401,IC9401-2,C9401-9,etc.)

Yes

Remove the connector CN9401, replace the

fuse (F9201), and turn on power again. Does

fuse (F9201) blow at this time?

Check for short-circuiting of rectifying diode and

circuit in secondary side rectifying circuit.

(D9102-5,D9116,etc.)

No

Does the Firstary side photocoupler circuit

operate normally?

Check the circuit, and replace part.

(D9115,D9112-3,etc.)

The power +30.8V, -30.8V for audio output is not

output.NoReplace D9201.

Yes

Is the rectifying diode D9201 normal?

Check the connector CN9203 and power

transformer T9301.

No

No

Is fuse (F9101) normal?

Refer to the flow chart No.2.

Yes

No

Is AT5.3V line voltage normal?

Check whether there is leaking or short-circuited

part in the primary circuit. (Q9102, Q9104, D9114,

D9115, etc.). If any defect is found in Q9102, Q9104,

D9114 or D9115, replace them at the same time.

Yes

Is filament voltage normal (AT 10.5V, AT 7.5,

AT -35V)?

No

Check the rectifying circuit of secondary circuit.

Unplug the power cord, and after several seconds

plug in again. Is normal state recovered at this time?

Yes

No

Check the AV power circuit +12V, -12V line.

(D9401,IC9401-2,C9401-9,etc.)

FLOW CHART NO.1

FLOW CHART NO.2

FLOW CHART NO.3

FLOW CHART NO.4

FLOW CHART NO.5

The fluorescent indicating tube does not light.

No

Is 5V supplied to the pins 16 and 74 of IC5001? Check the D 5V line.

Yes

No

Is approx. 5V applied to the pin 10 of IC5001? Check the RESET(L) line and IC509, IC512.

Yes

No

Is 4.0 MHz oscillation signal observed on the pins

14 and 15 of IC5002?

Check the peripheral circuit of FL5001 and IC5001.

No

Check the main DA, SUM CK, SUB CS signal line

between IC5001 and IC504.

Check IC5001 and IC504 or replace.

Yes

No

Is -36V supplied to the pins 28 of IC5001?

Yes

Yes

No

Is the filament voltage supplied to both ends of

fluorescent indicating tube pins 1, 2, 3, and 60, 61, 62?

Check the peripheral circuit of power circuit and D5006.

Yes

No

Check the periphery of fluorescent indicating tube and main unit.

Check for crack and damage on the fluorescent indicating tube.

The power circuit +12V, -12V for AV is not output.

No

No

Is +15V supplied to the pin 1 of IC9401? Is -15V

supplied to the pin 2 of IC9402?

Are the fuse resistor R9401-2 and rectifying diode

D9401 normal?

Check the connector CN9401 and power

transformer T9301.

Replace IC9401 or IC9402 depending on trouble state.

Yes

Yes

Check for short-circuiting or leak of load circuit.

Yes

Is +12V output to the pin 3 of IC9401?

Is -12V output to the pin 3 of IC9402?

Yes

Check the peripheral circuit of IC9401-2.

Yes

Yes

Analog 5V is not output.

No

Is 7.5V supplied to the pin 1 of IC9002?

Yes

No

Is A 5V output to the pin 2 of IC9002?

No

Check the peripheral circuit of IC9002.

Check for short-circuiting or leak of load circuit.

Yes

Replace IC9002.

Yes

No

Check for short-circuiting or leak of load circuit.

Yes

Replace IC9001.

Check the AT 7.5V line of switching power circuit

secondary side.

AT 8V is not output.

No

Is 10.5V supplied to the pin 1 of IC9001?

Yes

Is AT 8V output to the pin 2 of IC9001?

No

Check the peripheral circuit of IC9001.

Check the AT10.5V line of switching power circuit

secondary side.

Yes

No

Check for short-circuiting or leak of load circuit.

Yes

Replace IC9004.

Digital 5V is not output.

No

Is 5.3V supplied to the pin 1 of IC9004?

Yes

Is D 3.3V output to the pin 2 of IC9004?

No

Check the peripheral circuit of IC9004.

Check the AT5.3V line of switching power circuit

secondary side.

Check the AT -36V line and power circuit.

FLOW CHART NO.6

FLOW CHART NO.7

FLOW CHART NO.8

FLOW CHART NO.9

FLOW CHART NO.10

9. TROUBLESHOOTING

9-1

Page 18

DV-A1000U

The disc is ejected.

(In case of focus error)

Does the optical pickup move up and down after the

disc is removed? (Checking of symptom).

No

The disc is ejected.

Refer to (When the focus servo does not function).

Yes

Yes

No

Is FE signal output to the IC303 pin 21 when the

disc is set?

Is there input signal on the IC303 pins (49, 54), (50,

55), (46, 52), and (47, 53)?

No

Is there output signal on the IC301 pins 18, 17, 16, and 15?

No

Check the connection of optical pickup cable.

If it is normal, replace the optical pickup.

Yes

The disc is ejected.

(When the focus servo does not operate.)

Is FE signal input into the IC707 pin 38?

(Checking of symptom)

No Check the line between the IC303 pin 21 and the

IC707 pin 38.

Yes

Is the focus control signal output to the IC707

pin 43?

No Check the IC707 power source periphery circuit.

If it is normal, replace IC707.

Yes

Is the focus control signal from the IC504 pin 43

input into the IC702 pin 19?

No

Check the focus control signal (FOO) line between

the IC702 and the IC504.

Yes

Check the connection of optical pickup cable.

If it is normal, replace the optical pickup.

Yes

Is the focus control drive voltage output from the

IC702 pins 17 and 18?

Yes

Is the focus control drive voltage applied to the AB

connector pins 4 and 2?

No

Check the line between the IC702 and the AB connector.

No

No

Is 8V voltage applied to the IC702 pin 21?

Yes

Check AT 8V line.

Replace IC702.

The disc is ejected. (When the laser beam does not light.)

No

Is the Q301 (LD POWER ON) drive signal (SEL)

output to the IC707 pin 52?

Is the Q307 (LD POWER CTL) drive signal (LDO1)

output to the IC303 pin 45?(Checking of symptom)

Check the line between the IC707 pin 52 and the

Q301 base through Q304.

Check the line between the IC303 pin 45 and the

Q307 base.

Yes

Is 3.3V voltage applied to the Q301 emitter? Is 5V

voltage applied to the Q307 emitter?

No

Check the D 3.3V (1) line and the A 5V line.

No

Yes

Are 3.3V and 2.3V voltages applied to the AB

connector pin 11 and 9, respectively?

No

Check the line between the Q301 and Q307, AB

connector.

Yes

Check the connection of optical pickup cable.

If it is normal, replace the optical pickup.

FLOW CHART NO.14

FLOW CHART NO.15

FLOW CHART NO.16

The key operation is disabled.

No

Is key switch contact and installation state normal?

Replace Key switch.

Yes

Is the control voltage input normally into the pins

95 and 96 of IC504?

(95Pin→KEY-1, 96Pin→KEY-2)

Operation from the remote control is impossible.

No

Although operation on the deck unit is possible,

operation from the remote control is impossible.

Replace the remote control transmitter

(as necessary).

Yes

No

Is 5V supplied to the terminal of pin 3 of the remote

control receiver?

Check the AT 5V.

Yes

Is the "L" pulse signal generated on the terminal of

pin 1 of receiver when the remote control transmitter

is operated.

No

Replace the remote control receiver.

Replace IC504.

Yes

Yes

Is pulse signal supplied to the pin 32 of IC504?

No

Check the line between the remote control receiver

a the pin 32 of IC504.

The disc tray cannot be opened and closed.

No

Is the signal from the IC504 pins 70 and 69 input

into the IC702 pins 6 and 7?

Check the LD-REV/FWD signal line between the

IC702 and the IC504.

Yes

No

No

Is the loading motor drive voltage output from the

IC702 pins 10 and 11?

Is 8V voltage applied to the IC702 pin 21?

Yes

Is the loading motor drive voltage applied to the

AA connector pins 3 and 2?

No

Check the line between the IC702 and the AA connector.

Yes

Yes

Check for mechanism and gear engagement and

breakage.

Check AT 8V line.

Replace IC702.

OFF

S5006

SURROUND

S5008

JAZZ CLUB

S5009

STADIUM

S5012

STOP

S5013

STILL PAUSE

S5014

SKIP(+)

S5015

KEY-1/KEY-1 INPUT

SKIP(–)

S5016

OPEN/CLOSE

5.0V

4.3V

3.8V

3.1V

2.4V

1.9V

1.3V

0.6V

KEY-1

OFF

S5001

DVD

S5002

TUNER

S5003

AUX-1

S5004

AUX-2

S5005

AUX-3

S5007

NATURAL

S5010

CONCERT

S5011

PLAY

KEY-2

FLOW CHART NO.11

FLOW CHART NO.12

FLOW CHART NO.13

9-2

Page 19

DV-A1000U

Sound is not output in all modes.

Is the audio signal output to the audio output connector of main PWB unit?

Connector CN801 1Pin FRONT-L Connector CN801 5Pin REAR-L

Connector CN801 3Pin FRONT-R Connector CN801 6Pin REAR-R

Connector CN801 7Pin CENTER Connector CN801 8Pin SUB WOOFER

(1)Is the REAR-L/R audio signal output to the pins

8 and 14 of IC6003?

(1) Is the REAR-L/R audio signal output to the pins 6 and 23 of IC6004?

(2)

Is the CENTER audio signal output to the pin 9 of IC6004? Is the SUB WOOFER audiosignal output to the pin 20 of IC6004?

(3) Is the FRONT-L/R audio signal output to the pins 3 and 26 of IC6004?

* Check that the REAR and FRONT L/R audio signal levels shift oppositely to each other when BALANCE VR,

(R8102) is operated.

*Check that the REAR L/R and FRONT L/R audio signal levels shift oppositely to each other when FADER VR,

(R8101) is operated.

* Check that the level of CENTER, SUB WOOFER does not fluctuate.

Check the mute circuit Q6009-10 and mute drive

circuit Q6013-4, A-MUTE(L) line.

Check the mute circuit Q6009-10 and mute drive

circuit Q6007(SUB WOOFER),A-MUTE(L) line.

Is operation of DVD/OTHER SW, (IC6011) and CONFIG.

SW (IC6002) normal? (Refer to the block diagram.)

Are the audio signals of REAR-L, REAR-R, Center

and SUB WOOFER output to the pin 8 of IC6006,

pin 7 of IC6005, pin 7 of IC6006 and pin 8 of

IC6005, respectively?

No

Yes

No

No

No

No

Is signal of CLK, DATA, VOL-STB input into the

pins 14, 15 and 16 of IC6004?

Yes

Yes

Yes

Yes

Check the peripheral circuit of IC6003.

Check the peripheral circuit of IC6001.

Yes

Check the mute circuit Q6004-5 and mute drive

circuit Q6013-4, A-MUTE(L) line.

Yes

No

Check the peripheral circuit of IC6004.

Is signal of CLK, DATA, VOL-STB input into the

pins 14, 15 and 16 of IC6007?

Yes

No

Check the peripheral circuit of IC6007.

Check the peripheral circuit of IC6005 and IC6006.

Replace the main PWB unit.

(2)Is the CENTER audio signal output to the pin 1

of IC6003? Is the SUB WOOFER audiosignal

output to the pin 7 of IC6003?

(3)Is the FRONT-L/R audio signal output to the

pins 8 and 7 of IC6003?

(1) Is the REAR-L/R audio signal output to the pins 6 and 23 of IC6007?

(2)

Is the CENTER audio signal output to the pin 9 of IC6007? Is the SUB WOOFER audiosignal output to the pin 20 of IC6007?

(3) s the FRONT-L/R audio signal output to the pins 3 and 26 of IC6007?

* Check that all the audio signal levels shift simultaneously when MASTER VR, (S8101) is operated.

Yes

Yes

Are the audio signals of REAR-L, REAR-R, Center

and SUB WOOFER output to the pin 8 of IC6008,

pin 7 of IC6010, pin 7 of IC6008 and pin 8 of

IC6010, respectively?

No

Check the peripheral circuit of IC6008 and IC6010.

For FRONT-L/R, SUB WOOFER check the mute

circuit Q6026, Q6025, Q6017 and mute drive circuit

Q6013-4, A-MUTE (L) line.

Yes

FLOW CHART NO.19

Both video and audio do not operate normally.

Set the disc on the disc tray.

Yes

No

Is it possible to hold normally the disc with the chuck?

Check the loading switch.

Yes

No

Is the level of RF signal which is output from the

IC303 pin 28 normal?

Check for contamination of objective lens of optical pickup.

Yes

No

Replace the main PWB unit.

Replace the optical pickup unit.

Image does not appear.

Check the input selection switch mode of front

panel.

Set the input selection switch of front panel to

"DVD" side, and play.

Does the output signal exist on the pins 1 and 8 of

video driver IC, IC2002, IC2003, IC2004?

Does the output signal exist on the pins 4 and 3 of

video driver IC, IC2002, IC2003, IC2004?

Refer to "Flow Chart No.7, Analog 5V is not

output".

Check the peripheral

circuit of IC2051,IC2006.

Check power of AV PWB unit. Is 5V supplied from

the pin 4 of CN9002?

Check the control signal circuit of signal selection

switch IC, IC2051, IC2006.

Is the pin 6 of IC2051, IC2006 in "L" state?

Is the pin 9,10,11 of IC2006 in "L" state?

Check the peripheral circuit of SYSCON(IC504),

SUB CPU(IC5001),HOST I/F(IC512).

Check again the input selection switch of front panel.

Is video signal of 0.5 to 1.0 Vp-p input into the pins

1, 3, and 5 of connector CN2002 of AV PWB unit?

Is the video signal of 1.0 to 2.0 Vp-p output to the

pins 10, 12, 14, 16, 18, and 20 of connector

CN2003 of AV PWB unit?

Check the interval between each output terminal

and the pins 10, 12, 14, 16, 18, and 20 of

connector CN2003 of AV PWB unit.

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

No

Check or replace the main PWB unit.

Check the peripheral circuit of IC2002,IC2003,IC2004.

FLOW CHART NO.17

FLOW CHART NO.18

9-3

Page 20

DV-A1000U

Is sound output to each speaker terminal?

Does the output protection circuit operate?

(1) Does the protection circuit operate through OVER CURRENT DET. (Q6601-6) due to excessive output?

(2) Does the protection circuit operate due to speaker terminal short-circuiting?

(3)

Does the protection circuit operate as a result of overheat detection from the pin 7 terminal of power amplifier IC6601-2?

Check the following parts which compose the output protection circuit.

Q6601-6,Q6607,Q6609-10,C6636,C6639,R6662-4,R6667,RY6601-3,Q6608,Q6611,Q6616,Q6618 and SUB CPU of

IC5001etc.

Yes

No

Is the speaker cable connected correctly to each

speaker terminal?

Is impedance as specified?

Check the peripheral circuit of power amp IC6601

and IC6602.

The headphone audio output is not emitted.

No

Check the periphery of headphone audio output

terminal (J6901).

The line audio output is not emitted.

Is the audio signal L/R input into the pins 1 and 7

of IC6009, respectively?

Check the mute circuit Q6018-9 and mute drive

circuit Q6013-4, A-MUTE(L) line.

Yes

Is the audio signal L/R input into the pins 3 and 6

of IC6009, respectively?

No

Check the line between the pins 15 and 14 of DVD/OTHER

SW, (IC6011) and the pins 3 and 6 of IC6009.

Yes

Check the periphery of lone audio output terminal

(J2101,2104).

Check the peripheral circuit of IC6601 and IC6602.

Yes

The external input sound is not emitted

(the DVD play sound is emitted).

Is the logic control signal AUX-1/2 input into the pins

10 and 9 of IC6702 through Q6702, Q6701 from

SUB CPU IC5001?

Are the following external input audio signals input

into specific input terminal of IC6702?

IC6702 1Pin FRONT AUDIO IN(L)

IC6702 12Pin FRONT AUDIO IN(R)

IC6702 2Pin AUX1 AUDIO IN(L)

IC6702 15Pin AUX1 AUDIO IN(R)

IC6702 5Pin AUX2 AUDIO IN(L)

IC6702 14Pin AUX2 AUDIO IN(R)

Is the selected audio signal L/R output to the pins 3

and 13 of output terminal of IC6702?

Check whether the audio line amplifier IC6701

operates normally.

Check or replace the IC6702

Yes

Yes

Yes

No

No

Yes

heck Flow chart No.1, 4 Power circuit.

Is REAR-L/R and CENTER sound output to the pins 20

and 8 of power amplifier IC6601 and pin 9, respectively?

Is FRONT-L/R and SUB WOOFER sound output to the

pins 20 and 8 of power amplifier IC6602 and pin 9,

respectively?

No

Is the power voltage +28.5V and -28.5V supplied to

the pins 5 and 11 of IC6601-2 and pins 4, 3, 9, and

10, respectively?

Check whether the overcurrent protection circuit

A6613-5, Q6617 operates.

Yes

Yes

FLOW CHART NO.20

FLOW CHART NO.21

FLOW CHART NO.22

Yes

No

No

The tuner sound is not emitted. (External input is good.)

Is FM-AM audio signals output to the pins 6 and 4

of connector CN6010 of AV PWB?

Is the audio signal output to the pins 3 and 1 of

connector CN6704 of rear input amplifier PWB?

Yes

Is the antenna connected correctly?

Yes

Check or replace the tuner pack.

No

Yes

Is 12V,5V voltage replace to the pins 8 and 9

of connector CN6010 of AV PWB?

Check the +12V,AT 5.3V line.

Are the following control signals input into and

output to the connector CN6010 of AV PWB.

Connector CN6010 1Pin ST/TUNED

Connector CN6010 12Pin PLL DA

Connector CN6010 13Pin CLK

Connector CN6010 14Pin DATA

Connector CN6010 15Pin PLL CS

Make sure that the control signal including SUB

CPU IC5001 functions normally.

FLOW CHART NO.23

9-4

Page 21

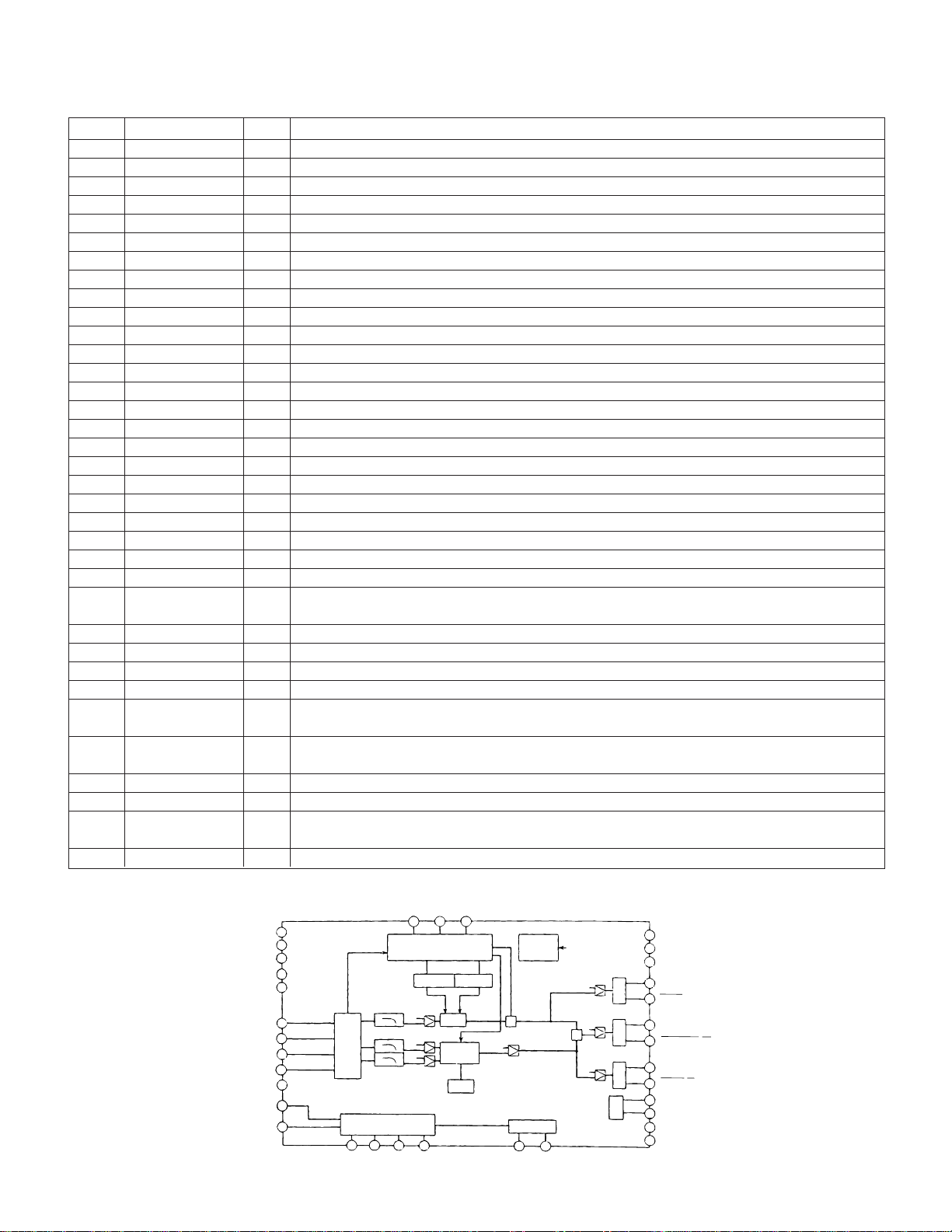

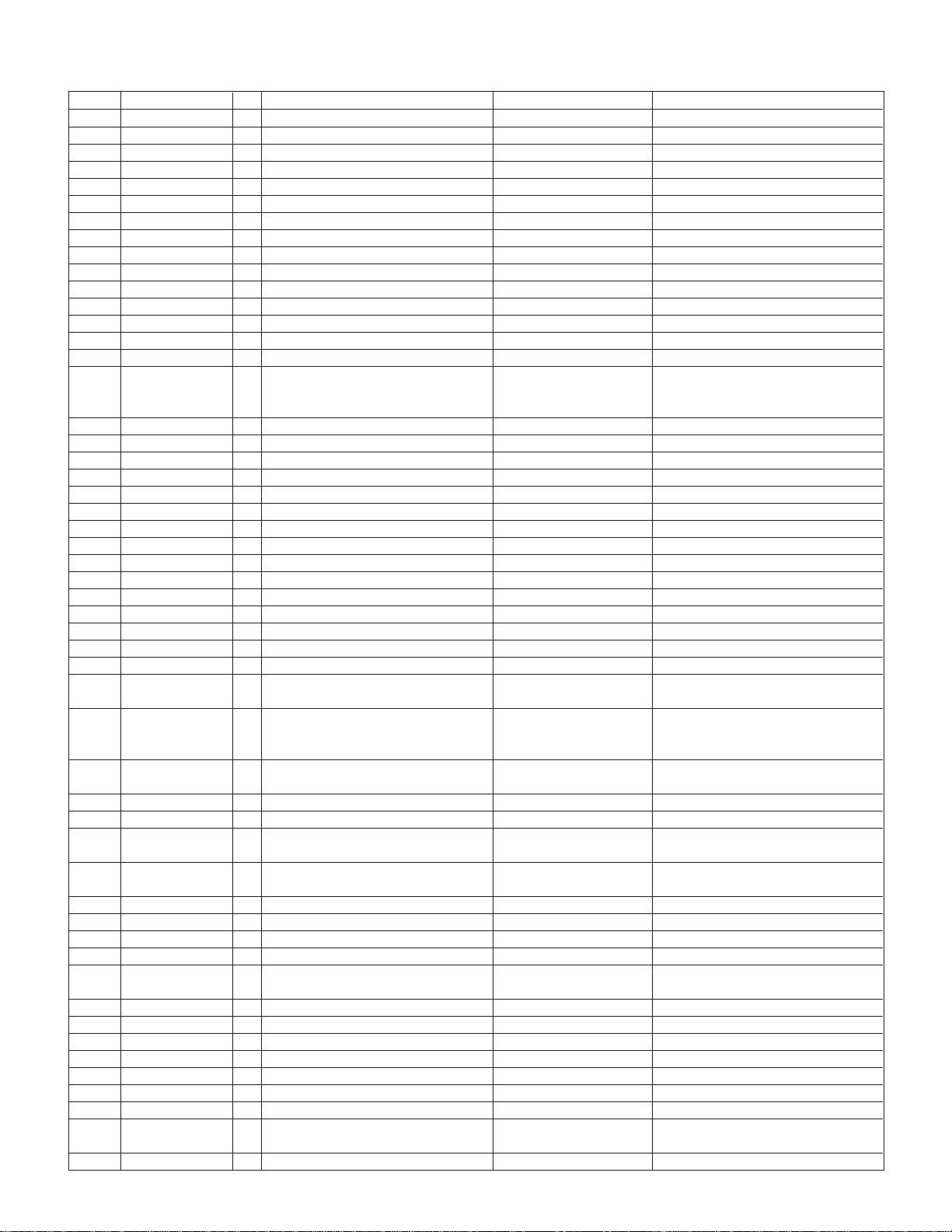

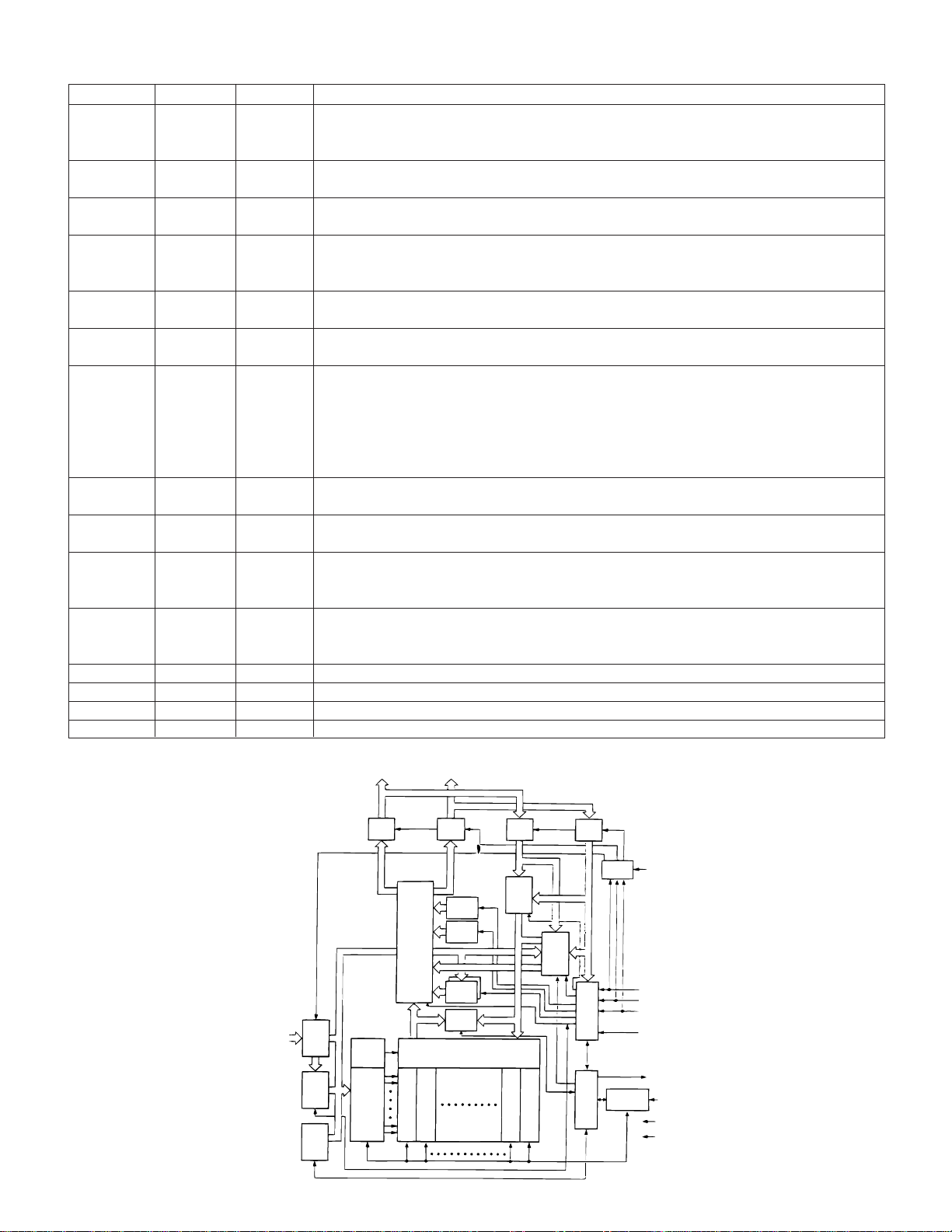

10. IC FUNCTION LIST

10-1. IC201 MC44722A DIGITAL VIDEO DECORDER

Pin No. Terminal name I/O Operation function

1 CVBS/Cb O Analog composite video signal output or Cb signal output current drive (positive)

2 CVBS/Cb O Analog composite video signal output or Cb signal output current drive (negative)

3 CVBS/Cb Vdd Power Supply for CVBS / Cb DAC circuit

4 Y O Analog luminance signal output current drive (positive)

5 Y O Analog luminance signal output current drive (negative)

6 YVdd Power Supply for Y DAC circuit

7 C/Cr O Analog chrominance signal output or Cr signal output current drive (positive)

8 C/Cr O Analog chrominance signal output or Cr signal output current drive (negative)

9 C/CrVdd Power Supply for C/Cr DAC circuit

10 DA Vss Ground for DAC circuit

11 Ibias O Reference current for the 3 DACs

12 DA Vdd Power Supply for DAC circuit

13 VReff Reference full scale voltage for the 3 DACs

14 ChipA I2C chip address select {0 : 42(hex)/43(hex) 1 : 1C(hex)/1D(hex)}

15 TEST I TEST pin (Ground)

16 SO z(O) If SPI mode, serial data output / If I2C mode, connect to ground

17 SDA/SI I/O(I) Serial data input, Open drain output / If SPI mode, serial data input

18 SCL/SCK I Serial clock

19 SEL (I) Connect to Ground / If SPI mode, this pin is chip select

20 DVss Ground for Digital circuit

21 CLOCK I 27MHz clock input

22 DVdd Power Supply for Digital circuit

23 Reset I Reset signal, active LOW

24 PAL/NTSC I NTSC/PAL select. This pin active only Reset time.(NTSC : Low PAL : High)

25-32 DVIN7-0 I 8-bit Multiplexd Y/Cr/Cb 4:2:2 data (ITU Rec656) input (1) or Multiplexd Y data

(ITU-Rec656/601) input in 16-bit input mode (DVIN7 : MSB)

33 TVIN I TEST data input

34 EXT I/O Csync/Frame sync output or external VBI information input

35 F/Vsync I/O Frame sync or Vertical sync input/output

36 Hsync I/O Horizontal sync input/output

37 TP9 I/O MUX switch in 8-bit X 2 Multiplexed Y/Cr/Cb 4:2:2 data (ITU-Rec656) input mode,

or Test data input/output

38-41 TP8-5 I/O 8-bit Multiplexed 4:2:2 data (ITU-Rec656/601) input (2), or Multiplexed Cr/Cb data

(ITU-Rec656/601) input in 16-bit input mode (MSB : TP8), or Test data input/output

42 DVss Ground for Digital circuit

43 DVdd Power Supply for Digital circuit

44-47 TP4-1 I/O 8-bit Multiplexed 4:2:2 data (ITU-Rec656/601) input (2), or Multiplexed Cr/Cb data

(ITU-Rec656/601) input in 16-bit input mode (LSB : TP1), or Test data input/output

48 TP0 I/O For test (should be ground)

DV-A1000U

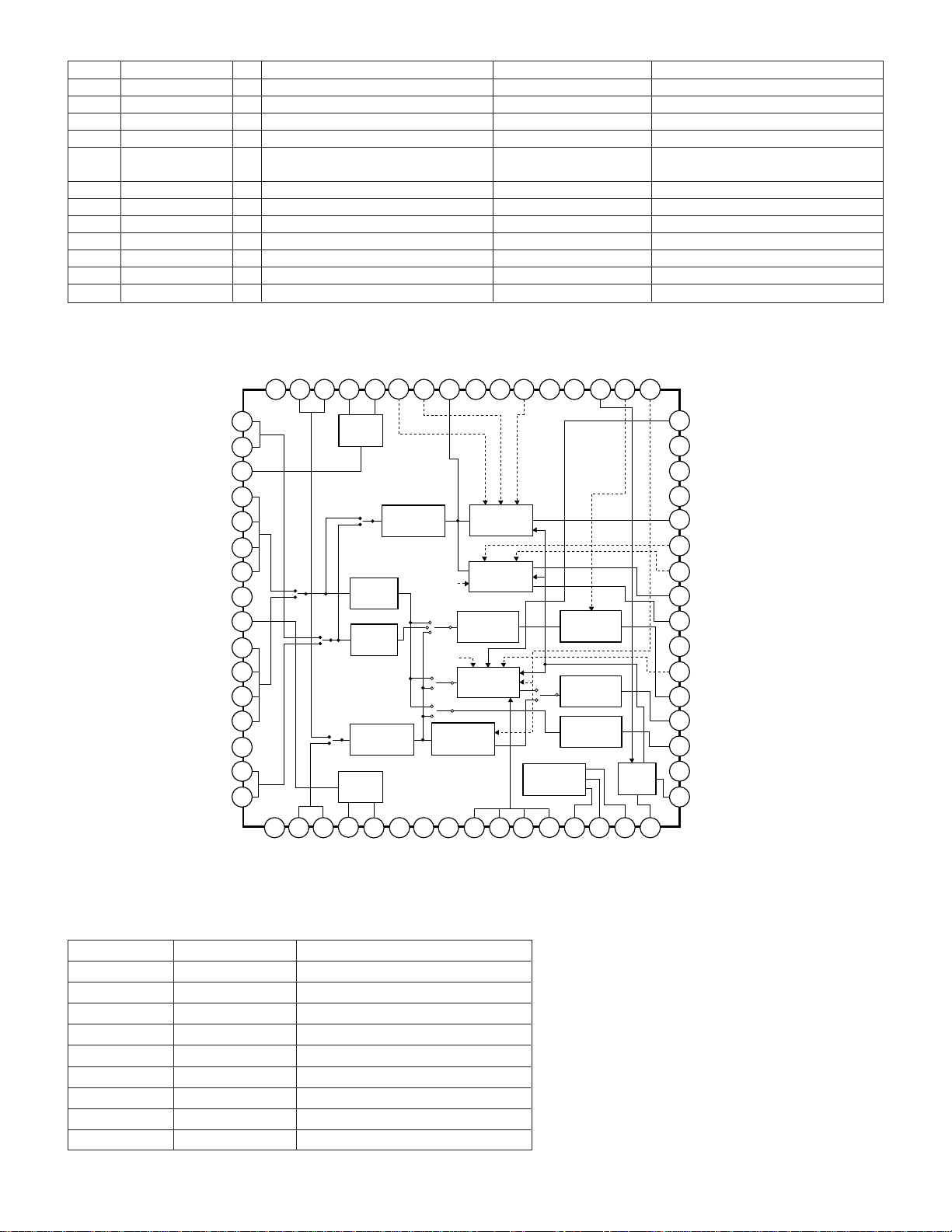

• Block Diagram

ChipA

DVdd

DVdd

DVss

DVss

DVIN

TP0~7

TVIN

TP9

clock

Reset

PAL/NTSC

14

43

22

20

42

DVIN0~7

32~25

48~44 41~39

33

37

21

23

24

H, V

Y

demux

C

C

b

r

16

12C/SPI

17 18 19

SO

SDA/SI

EXT

34 35 36

Sync_generator

CGM5_gen

0

0

0

SEL

ACL/SCK

F/Vsync

off_set

Modulator

10-1

Hsync

BG

CC_gen

6

DAC

DAC

DAC

BIAS

YVdd

3

CVBS/CbVDD

9

C/CrVdd

4

YOUT

YOUT

5

1

CVBSOUT/Cb

2

CVBSOUT/Cb

7

COUT/Cr

COUT/Cr

8

13

VReff

11

Ibias

12

DAVdd

10

DAVss

copy

bus

protection

0

+

0

TEST

15

TEST

TP0~9

0

+

0

MC44722/3

Page 22

DV-A1000U

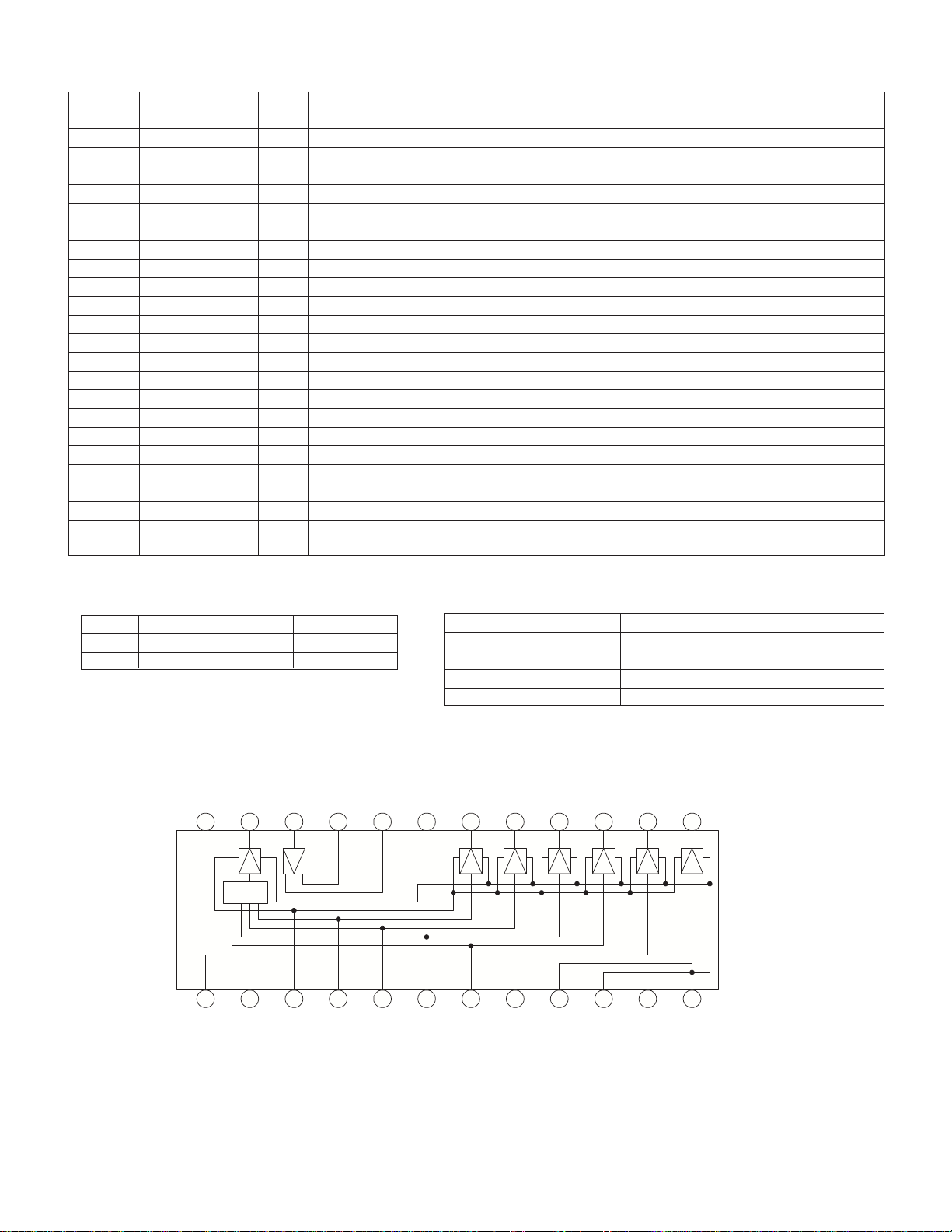

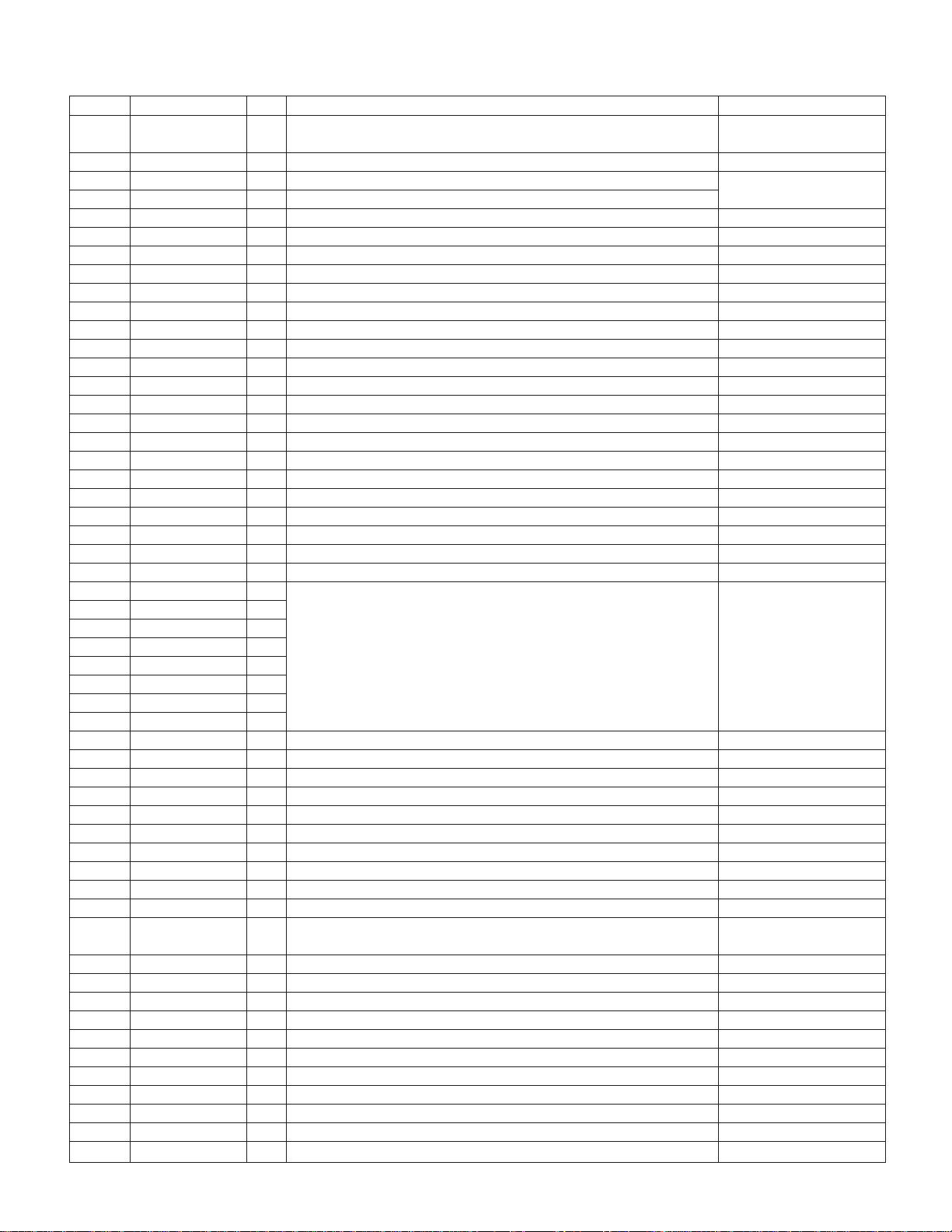

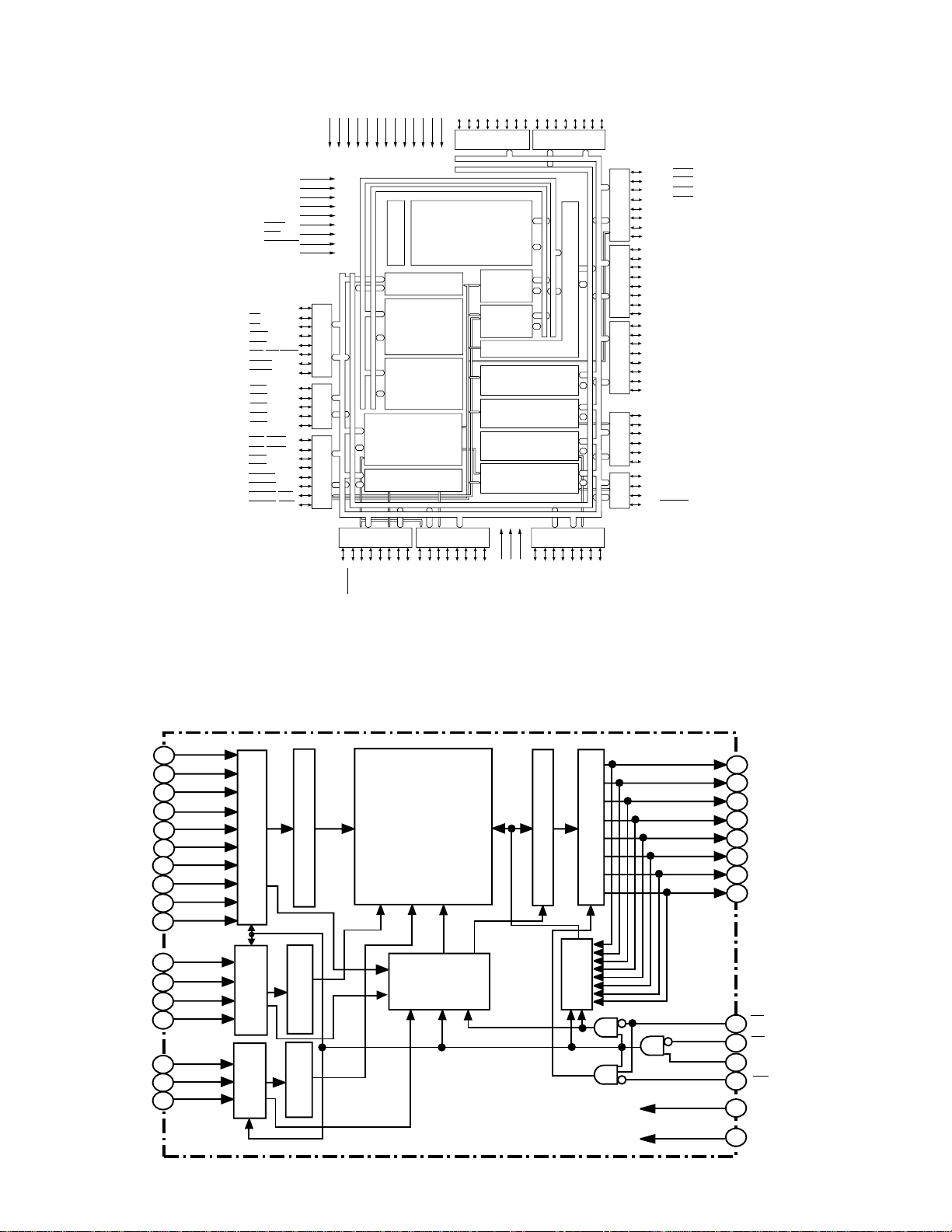

10-2. IC301 IX1461GE RF PRE AMP.

Pin No. Terminal name I/O Operation function

1 EIN I RF signal input. Input of RF signal output of optical pickup.

2 GND1 – Ground

3 S/Dsel I Single layer/dual layer selection signal input.

4 AIN I RF signal input. Input of RF signal output of optical pickup.

5 BIN I RF signal input. Input of RF signal output of optical pickup.

6 CIN I RF signal input. Input of RF signal output of optical pickup.

7 DIN I RF signal input. Input of RF signal output of optical pickup.

8 VrefIN I Reference voltage input. (2.1V)

9 FIN I RF signal input. Input of RF signal output of optical pickup.

10 GAINsel1 I Amp gain selection input 1.

11 VCC1 – Power terminal. (5.0V)

12 GAINsel2 I Amp gain selection input 2.

13 FOUT O RF signal output. Input RF signal is current-voltage-converted and output.

14 EOUT O RF signal output. Input RF signal is current-voltage-converted and output.

15 DOUT O RF signal output. Input RF signal is current-voltage-converted and output.

16 COUT O RF signal output. Input RF signal is current-voltage-converted and output.

17 BOUT O RF signal output. Input RF signal is current-voltage-converted and output.

18 AOUT O RF signal output. Input RF signal is current-voltage-converted and output.

19 VCC2 – Power terminal. (5.0V)

20 RFPOUT O Data read signal output. The same phase as MIXIN.

21 RFNOUT O Data read signal output. Reverse phase with respect to MIXIN.

22 MIXIN I Data read signal input.

23 MIXOUT O Data read signal output.

24 GND2 – Ground

• Mode selection table

Single layer/dual layer selection

Layer S/DSEL (Terminal 3) Amp gain

Single L, OPEN 0dB

Dual H +10dB

• Block Diagram

GND2

MIXOUT

MIXIN

24 23 22 21 20 19 18 17 16 15 14 13

MIX

1 98765432 10 1211

EIN

GND1

S/Dsel

RFNOUT

AIN

RFPOUT

BIN

Amp. gain selection

GAINsel1 (Terminal 10) GAINsel2 (Terminal 12) Amp gain

L L +6dB

H, OPEN L -2dB

L H, OPEN +2dB

H, OPEN H, OPEN -6dB

VCC2

CIN

AOUT

DIN

BOUT

VrefIN

COUT

FIN

DOUT

GAINsel1

EOUT

VCC1

FOUT

GAINsel2

10-2

Page 23

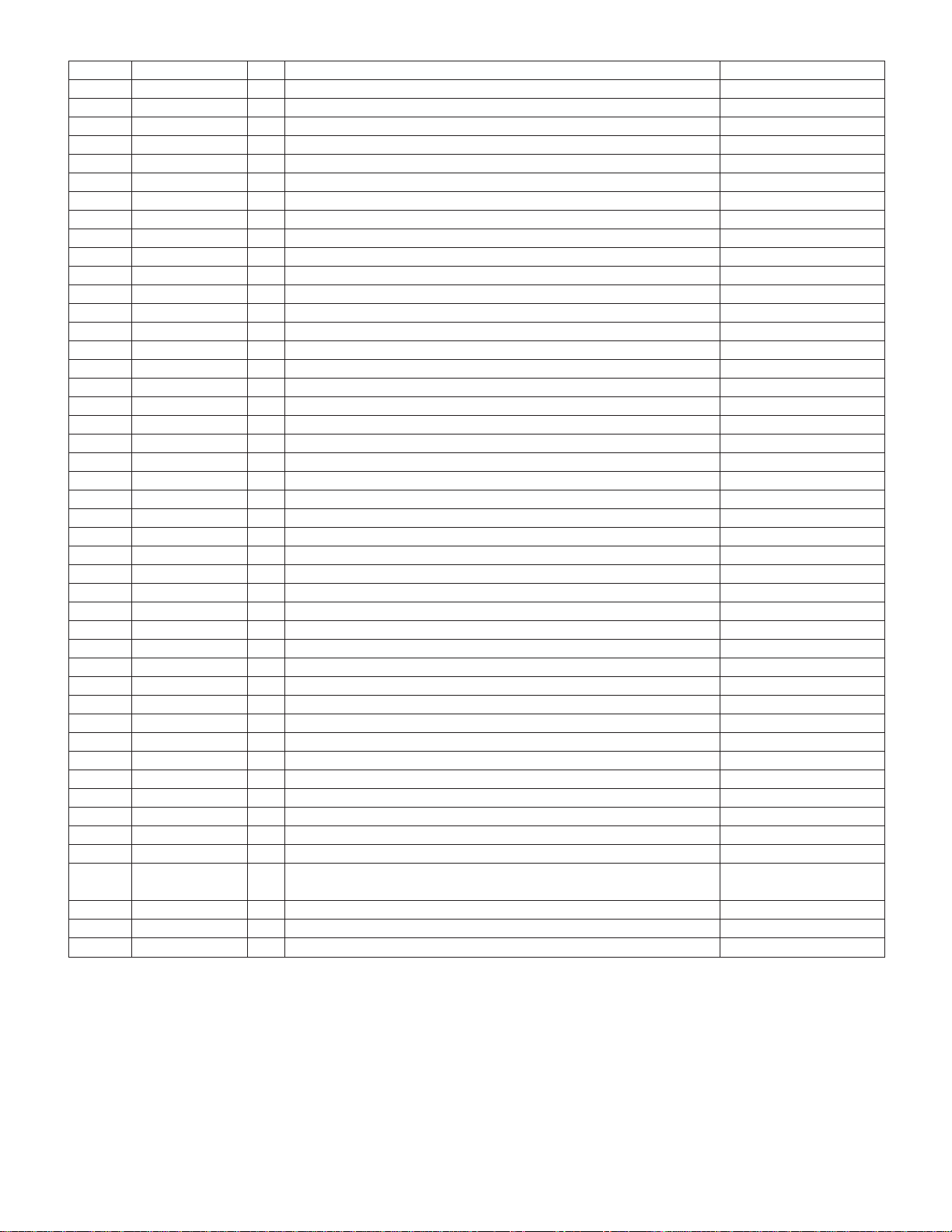

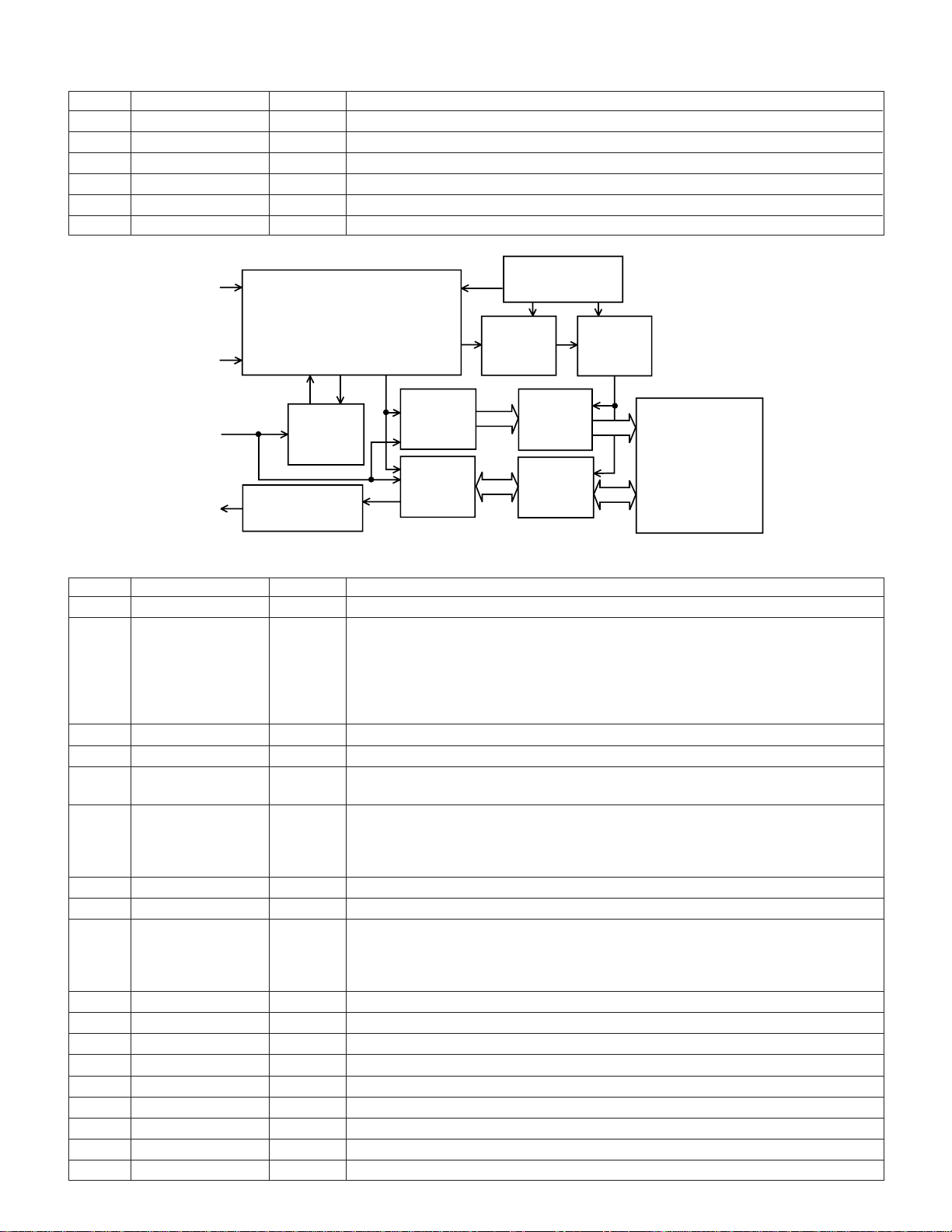

10-3. IC303 IX1517GE RF SIGNAL PROCESSOR

DV-A1000U

Pin No. Terminal name I/O Operation function

1 GND – GND terminal. –

2 P2TP I TE+input (CD) VrA

3 P2TN I TE–input (CD) VrA

4 LDO2 O Drive ouput –

5 MDI2 I Monitor input –

6 VrA O Analog VREF 2.1[V]

7 VrD O Digital VREF – Vdd 1/2

8 Vdd I Power terminal 4.2V (3.3V)

9 DPAC – DPD AC combination capacity 1 –

10 DPBD – DPD AC combination capacity 2 –

11 DPD1 – DPD integral capacity 1 –

12 DPD2 – DPD integral capacity 2 –

13 SCB I Control line (Bit clock) 2.2[V]

14 SCL I Control line (Latch signal) 2.2[V]

15 SCD I Control line (Sirial Data) 2.2[V]

16 VRCK I Reference clock input 2.3[V] When frequency is increased, the

17 VCKF –

18 VccP – Power terminal –

19 LVL O Servo addition output Vrd x (1/2)

20 TEO O TE output VrD

21 FEO O FE output VrD

22 DFTN I DPD difect – Low DPD output: Mute

23 VccS – Power terminal (servo) –

24 RPZ O RF ripple center voltage VrD

25 RPO O RF ripple output VrD

26 RPB O RF ripple bottom –

27 RPP O RF ripple peak –

28 RFO O Equalizing RF output 2.3[V]

29 NC – NC terminal – To be connected to GND

30 NC – NC terminal – To be connected to GND

31 VccR – Power terminal (RF) –

32 DPDB I Pit depth adjustment VrD When D PDB is raised, the A/B

33 TEB I TE balance VrD When TEB is raised, the TP side

34 FEB I FE balance VrD When FEB is raised, the A+C (FP)

35 PSC I VRCK frequency division ON/OFF – High: Frequency division OFF

36 Vcc2 – Power terminal –

37 NC – NC terminal VrD To be connected to VrD, or to GND

38 EQD I Group delay correction VrD When EQD is raised, the group

39 GND2 – GND terminal. –

40 RFDC – DC feedback capacity –

41 RFA O RF total addition output 2.2[V]

42 EQB I Boost adjustment VrD

43 EQF I Frequency adjustment VrD When EQF is raised, shift to the

44 MDI1 I Monitor input –

45 LDO1 O Drive output –

46 P1TN I TE–input (DVD) VrA

47 P1TP I TE+input (DVD) VrA

48 NC – NC terminal – To be connected to GND

49 P1FN I FE–input (DVD) VrA

50 P1TP I FE+input (DVD) VrA

51 LDP1 I APC polarity 1 – Positive polarity when this terminal

52 P1DI I D input (DVD)

Capacity for time constant adjustment

Terminal DC Voltage(TYP.)

–

Remarks

filters excepting the servo LPF are

shifted to high frequency side.

side delay increases.

gain increases and the A+C side

delay increases.

side gain increases.

through C

delay increases at the right side.

When EQB is raised, the boost increases.

high frequency side occurs.

is connected to Vcc.

10-3

Page 24

DV-A1000U

Pin No. Terminal name I/O Operation function

Terminal DC Voltage(TYP.)

Remarks

53 P1CI I C input (DVD) VrA

54 P1BI I B input (DVD) VrA

55 P1AI I A input (DVD) VrA

56 GNDR – GND terminal (RF) –

57 LDP2 I APC polarity 2 – Positive polarity when this terminal

is connected to Vcc.

58 P2AI I A input (CD) VrA

59 P2BI I B input (CD) VrA

60 P2CI I C input (CD) VrA

61 P2DI I D input (CD) VrA

62 GNDS – GND terminal (Servo) –

63 P2FP I FE+input (CD) VrA

64 P2FN I FE–input (CD) VrA

• Block Diagram

NC

P1TP

P1TN

LDO1

MDI1

EQF

EQB

RFA

RFDC

GND2

P1FN

P1FP

LDP1

P1DI

P1CI

P1BI

P1AI

GNDR

LDP2

P2AI

P2BI

P2CI

P2DI

GNDS

P2FP

P2FN

EQDNCVcc2

48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33

49

APC1

50

51

52

53

sel-RF

R-gain

Adjust

EQ

54

55

56

57

58

59

60

61

62

63

64

sel-PD

sel-PD

sel-PD

F-gain

Adjust

F-gain

Adjust

sel-DPD

T-gain

Adjust

APC2

RF Ripple

sel-IC

sel-FE

FE creation

sel-TE

DPDTE

creation

sel-LVL

3BTE creation

creation

mode-TE

B U S

PSC

FE-gain

Adjust

TE-gain

Adjust

Level detect

FEB

Time

constant

adjustment

TEB

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

DPDB

VccR

NC

NC

RFO

RPP

RPB

RPO

RPZ

VccS

DFTN

FEO

TEO

LVL

LccP

VCKF

12345678910111213141516

GND

P2TP

P2TN

LDO2

MDI2

10-4. IC401 IX1484GE 4M DRAM

Terminal

10~13,16~20,9 A0~A8,A9R Address input

8 RAS Row address strobe

23 CAS Column address strobe

1~5,24~27 DQ1~DQ8 Data input/Data output

22 OE Output enable

7 WE Light enable

1 Vcc Power (5V)

28 Vss Ground (0V)

21 NC Not connected

Terminal name Function

VrA

VrD

Vdd

10-4

DPAC

DPBD

DPD1

DPD2

SCB

SCL

SCD

SRCK

Page 25

10-5. IC402 IX1474GE DEM/ECC (DVD)

Pin No. Terminal name I/O Operation function Remarks

1 DPCK1 I Signal processing reference clock input. 0.5-3.3Vp-p Feedback

resistor built in.

2 DVDD3 – Digital power. (3.3V) For logic cell

3 SVCK1 I Servo reference clock input. (Oscillation circuit input terminal) 3.3V-I/F Feedback

4 SVCK0 O Servo reference clock output. (Oscillation circuit input terminal) resistor built in.

5 DVSS – Digital power. (0V) For logic cell

6 DVDD2 – Digital power. (3.3V) For logic cell

7 N.C. – User use prohibited. Open

8 HDWT I MPU write signal. TTL level

9 HDRD I MPU read signal. TTL level

10 HCEN I MPU chip selection. TTL level

11 HD0 I/O MPU data bus. TTL level

12 HD1 I/O MPU data bus. TTL level

13 HD2 I/O MPU data bus. TTL level

14 HD3 I/O MPU data bus. TTL level

15 HD4 I/O MPU data bus. TTL level

16 HD5 I/O MPU data bus. TTL level

17 HD6 I/O MPU data bus. TTL level

18 HD7 I/O MPU data bus. TTL level

19 DVSS – Digital power. (0V) For I/O cell

20 DVDD5 – Digital power. (5V) For I/O cell

21 HINT O MPU interruption signal. (Occurrence of interruption = “L”) OPEN DRAIN

22 HA0 I MPU address bus. TTL level

23 HA1 I MPU address bus. TTL level

24 PLCK I/O Read channel clock input/output terminal.

25 ED0 – User use is prohibited (N.C.) since it is for shipping adjustment. Open

26 ED1 –

27 ED2 –

28 ED3 –

29 ED4 –

30 ED5 –

31 ED6 –

32 ED7 –

33 TEST I For shipping adjustment. Set to “L”

34 PDON O PLL phase error signal output. (Negative polarity)

35 PDOP O PLL phase error signal output. (Positive polarity)

36 RLLD O RLL detection result output.

37 LPFN I PLL loop filter amp. reverse input.

38 LPFO O PLL loop filter amp. output.

39 VCOF O VCO filter terminal.

40 SLCO O Built-in comparator reference voltage output terminal.

41 AVSS – Analog power. (0V)

42 AVR O Non-PLL system analog reference potential. (1.65V)

43 VRC – Resistance division point potential. (For analog reference

potential generation: 1.65)

44 PVR O PLL system analog reference potential. (1.65V)

45 AVDD – Analog power. (3.3V)

46 RVR2 – 2nd reference voltage. (For capacitor connection)

47 RVDD – Exclusive-use power terminal. (3.3V)

48 RFIN I RF signal input.

49 RVSS – Exclusive-use power terminal. (0V)

50 RVR1 – 1nd reference voltage. (For capacitor connection)

51 DVR I DMO reference potential. (1.65V recommended)

52 DMO O Disc equalizer output for DVD. (Triple value PWM + HiZ)

53 RASN O External RAM row address selection. (Negative logic)

54 CASN O External RAM row address selection. (Negative logic)

DV-A1000U

10-5

Page 26

DV-A1000U

Pin No. Terminal name I/O Operation function Remarks

55 MOEN O External RAM output permission signal.

56 MWEN O External RAM read/write selection.

57 DVSS – Digital power. (0V) For logic cell

58 DVDD3 – Digital power. (3.3V) For logic cell

59 MA9 O External RAM address bus.

60 MA8 O External RAM address bus.

61 MA7 O External RAM address bus.

62 MA6 O External RAM address bus.

63 MA5 O External RAM address bus.

64 MA4 O External RAM address bus.

65 MA3 O External RAM address bus.

66 MA2 O External RAM address bus.

67 MA1 O External RAM address bus.

68 MA0 O External RAM address bus.

69 DVSS – Digital power. (0V) For I/O cell

70 DVDD5 – Digital power. (5V) For I/O cell

71 MD7 I/O External RAM data bus. TTL level

72 MD6 I/O External RAM data bus. TTL level

73 MD5 I/O External RAM data bus. TTL level

74 MD4 I/O External RAM data bus. TTL level

75 MD3 I/O External RAM data bus. TTL level

76 MD2 I/O External RAM data bus. TTL level

77 MD1 I/O External RAM data bus. TTL level

78 MD0 I/O External RAM data bus. TTL level

79 SD7 O MPEG data output.

80 SD6 O MPEG data output.

81 SD5 O MPEG data output.

82 SD4 O MPEG data output.

83 DVSS – Digital power. (0V) For logic cell

84 DVDD3 – Digital power. (3.3V) For logic cell

85 SD3 O MPEG data output.

86 SD2 O MPEG data output.

87 SD1 O MPEG data output.

88 SD0 O MPEG data output.

89 SERR O MPEG data reliability flag. (Data error: “L”)

90 SBGN O MPEG output sector sync signal. (Sector top: “L”)

91 SENB O MPEG data effective flag. (Effective state: “L”)

92 SDCK O MPEG data transfer clock.

93 DVSS – Digital power. (0V) For logic cell

94 SREQ I MPEG data request flag. (Request state: “L”) TTL level

95 RSTN I Hard reset input. (Reset state: “L”)

96 DVDD3 – Digital power. (3.3V) For logic cell

97 STDA O Operation state monitor data. Common with PWM.

(Output synchronizing with SDCK fall)

98 STCK O Operation state monitor sync signal. (Data top bit: “L”) Common with PWM.

99 UPWM O General-use PWM output. 4mA, 5V-I/F

100 DVSS – Digital power. (0V) For logic cell

10-6

Page 27

DV-A1000U

ID

Register

CSR

ESRs

DQ

8-15

DQ

0-7

OUTPUT MULTIPLEXER

Program Erase

Voltage Switch

BYTE#

CUIWSM

16-KBYTE

Block 31

16-KBYTE

Block 30

16-KBYTE

Block 1

16-KBYTE

Block 0

CE#

OE#

WE#

RP#

RY/BY#

V

PP

V

CC

GND

Y GATING/SENSING

X-DECODER

Y-DECODER

Input

Buffer

ADDRESS

QUEUE

LATCHES

ADDRESS

COUNTER

A

-1.0~17

Output

Buffer

Output

Buffer

Input

Buffer

Input

Buffer

I/O Logic

DATA

QUEUE

REGISTER

Register

Data

Comparator

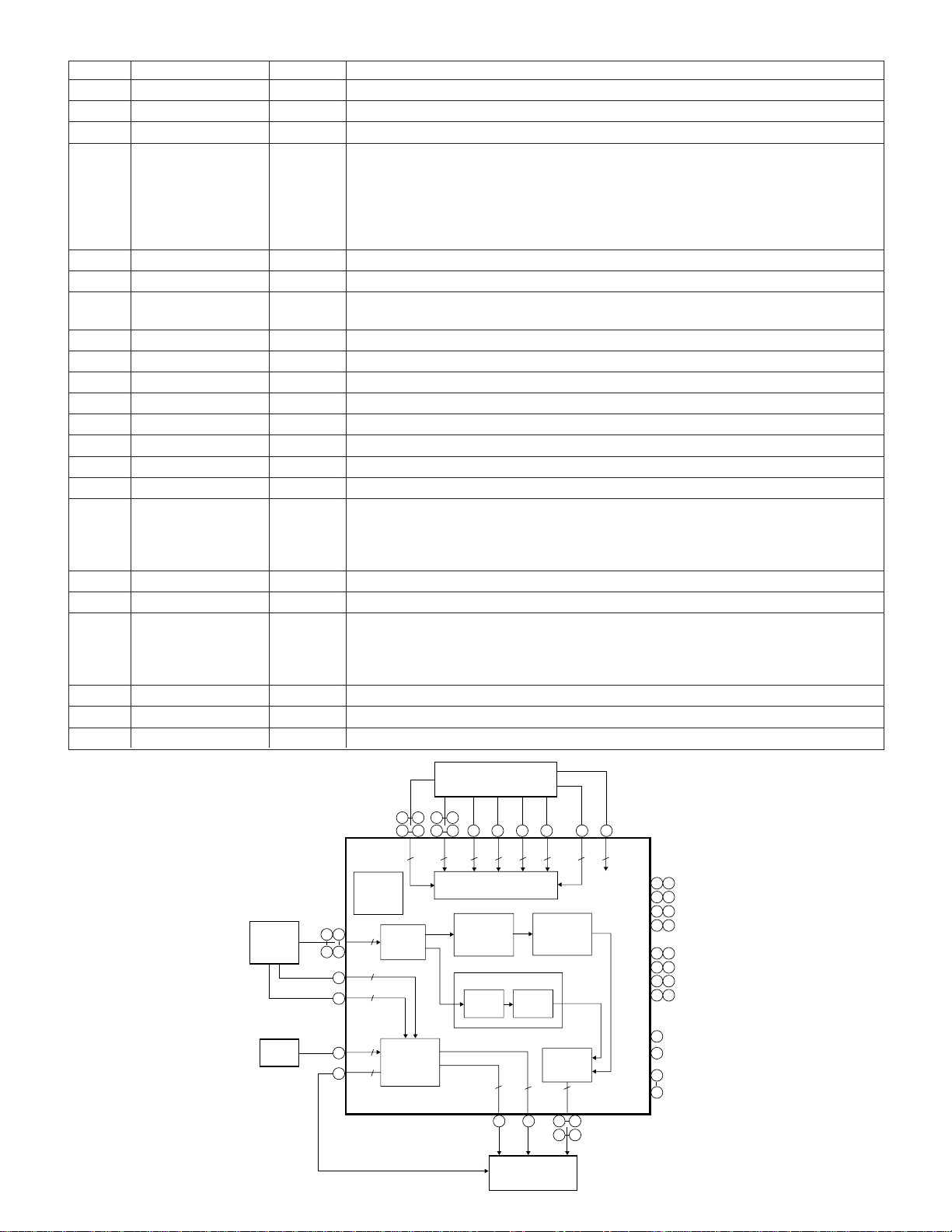

10-6. IC501 IX1518GE FLASH

Terminal Symbol Type Name and function

Byte selection address: When the device is in the x8 mode, the low or high order byte is

45 DQ

25~18,

8~4 latched during data wiring operation.

3~1,

48,17 during data writing, erasing and lock block operation.

A

A

13-A17

15/A-1

0-A12

29, 31, 33 Low order byte data input/output: Command user interface writing cycle data and command

35, 38, 40, DQ

-DQ7Input/Output

0

42, 44 disable: Float state

30, 32, 34, 36,

39, 41, 43, 45

DQ8-DQ15Input/Output

26 CE# Input

12 RP# Input

28 OE# Input

11 WE# Input

15 RY/BY# Output

47 BYTE# Input the DQ

13 Vpp Wr ite/erase power supply: 5.0 ± 0.5V is applied during writing/erasing.

37 Vcc Device power supply: 5.0 ± 0.5V

27, 46 GND Ground

9, 10, 14, 16 NC Nonconnection

Input selected. It is not used in the x16 mode.

(If BYTE# is high, DQ15/A-1 input circuit does not operate.)

Input

Input

Word selection address: Selection of one word of 16k byte block. These addresses are

Block selection address: Selection of 1/32 erase block. These addresses are latched

input. Various data read memory identifier and status data output Chip nonselection or output

High order byte data input/output: The function is the same as that of low order byte data

input/output. Operative only in x16 mode. x8 mode: Float state DQ15/A-1 is address.